Forward-osmosis organic-inorganic composite membrane and preparation method thereof

An inorganic composite membrane and forward osmosis technology, which is applied in the field of membrane separation, can solve the problem that the flux of forward osmosis is not greatly improved, and achieve the effect of improving water flux, solving susceptibility to microbial contamination, and having wide application potential.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

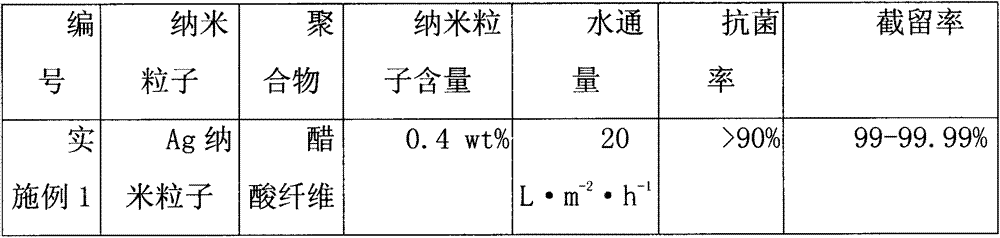

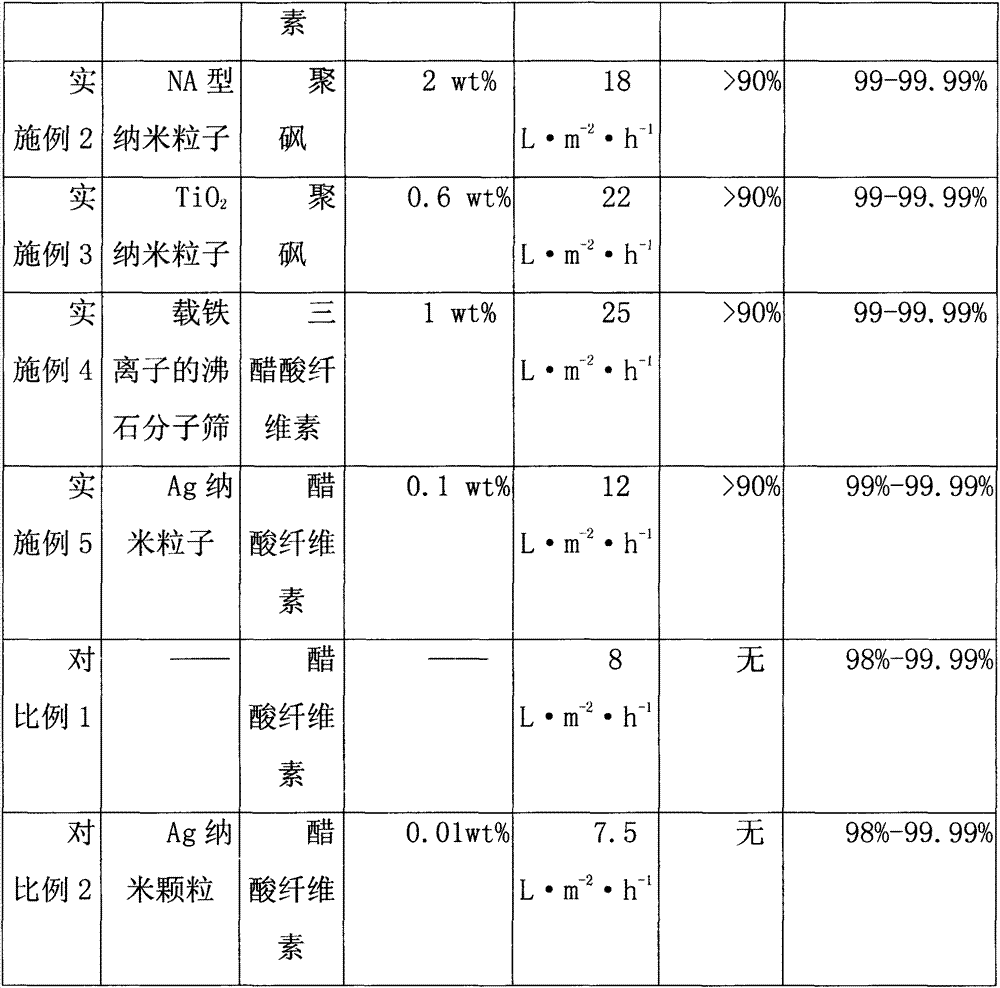

Embodiment 1

[0033] Forward osmosis organic-inorganic composite membrane and preparation method thereof:

[0034] Adopt cellulose acetate as polymer, add 12g cellulose acetate and 0.4gAg nanoparticle (particle size is 1.5μm) in 87.6g1,4-dioxane solvent, stir and dissolve to form the Ag nanoparticle that content is 0.4wt% The casting solution is used to form a gel in a gel bath, and the prepared membrane is washed with deionized water to remove residual organic solvents to obtain a forward osmosis organic-inorganic composite membrane, which is stored in deionized water for later use.

[0035] After testing, the flux of the forward osmosis organic-inorganic composite membrane prepared in this example is 20L m -2 h -1 , The rejection rate is above 99%.

[0036] The prepared forward osmosis organic-inorganic composite membrane and the membrane without nanoparticles were subjected to microbial contamination experiments under the same conditions. Escherichia coli microorganisms were added to ...

Embodiment 2

[0038] Forward osmosis organic-inorganic composite membrane and preparation method thereof:

[0039] Take by weighing 16g polysulfone polymer, be dissolved in 84g by the mixed solvent that N,N-dimethylacetamide and Polyethylene Glycol 400 form (the ratio of the two is 76:8), be made into polymer concentration and be 18% polysulfone solution. Add 2g of silver-loaded NaA zeolite molecular sieve nanoparticles (particle size: 1.5 μm) with a hexahedral shape to the prepared polysulfone solution, and disperse in ultrasonic for 30 min to prepare NaA type zeolite molecular sieve nanoparticles containing 2wt% silver. Particle casting solution, coating the casting solution on the low-density non-woven support layer, using a scraper with a certain thickness to scrape the film, putting it into a gel bath to form a gel film, using m-phenylenediamine and homophenylene Triformyl chloride was subjected to an interfacial polymerization reaction on the formed membrane (reacted at 110° C. for 3...

Embodiment 3

[0043] Forward osmosis organic-inorganic composite membrane and preparation method thereof:

[0044] Take by weighing 18g polysulfone polymer, 0.6g spherical TiO2 nanoparticle (particle diameter is 2 μ m), be dissolved in the mixed solvent that 82g is made up of N, N-dimethylacetamide and Polyethylene Glycol 400 (both ratios is 72:10), and the casting solution with polysulfone concentration of 18wt% and TiO2 nanoparticle concentration of 0.6wt% was prepared. Coat the casting solution on the low-density non-woven support layer, use a scraper with a certain thickness to scrape the film, put it in a gel bath to form a gel film, and obtain a forward osmosis organic-inorganic composite film, which is stored in deionized water spare.

[0045]After testing, the water flux of the forward osmosis organic-inorganic composite membrane prepared in this example is 22L m -2 h -1 , The rejection rate is above 99%.

[0046] Microbial contamination experiments were carried out on the prepa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com