Patents

Literature

553results about How to "Improve interception effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Layer-by-layer self-assembling oxidized graphene nano-filtration membrane and preparation method thereof

ActiveCN103706264AImprove permeabilityImprove interception effectSemi-permeable membranesFiltration membraneGraphene nanoribbons

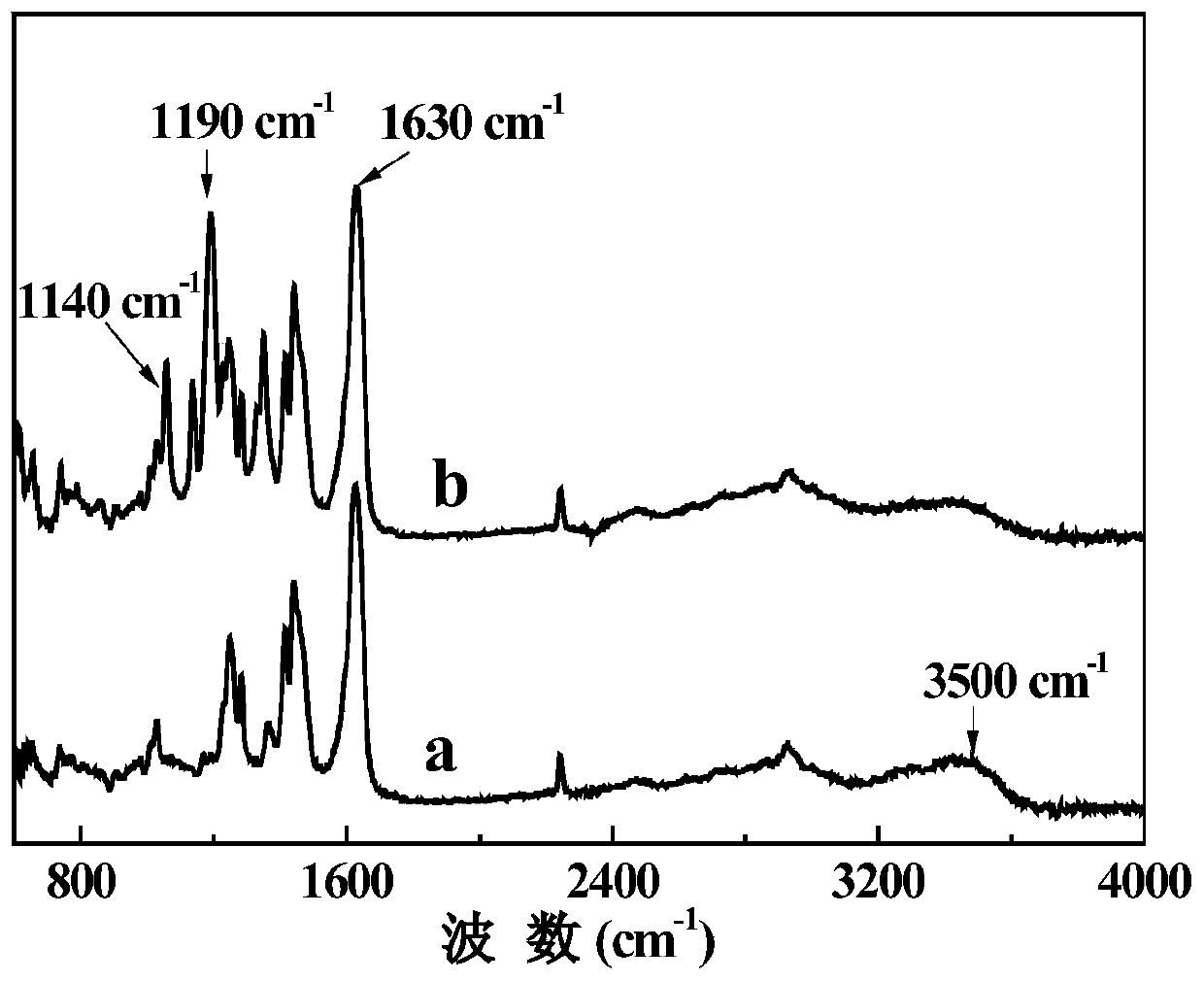

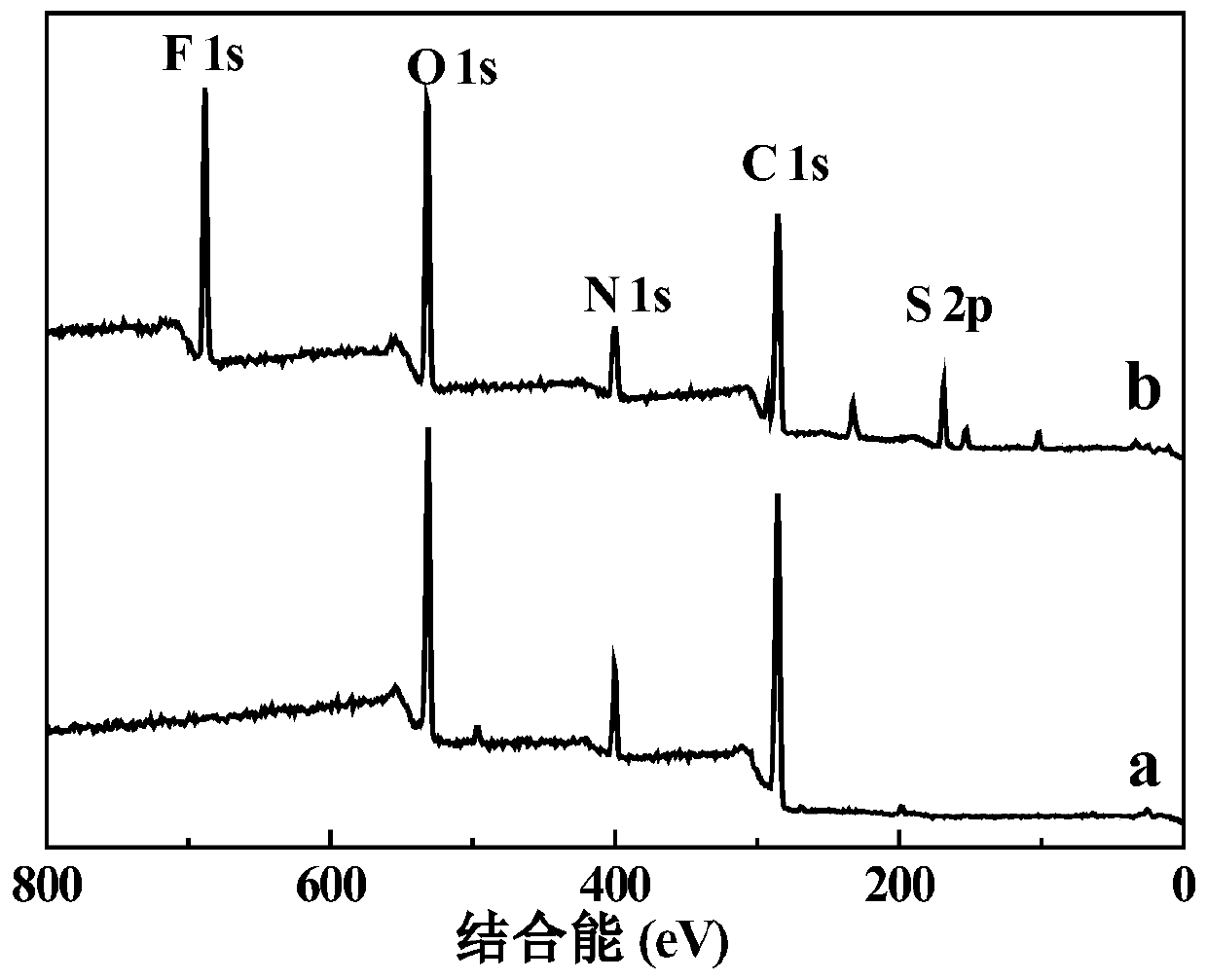

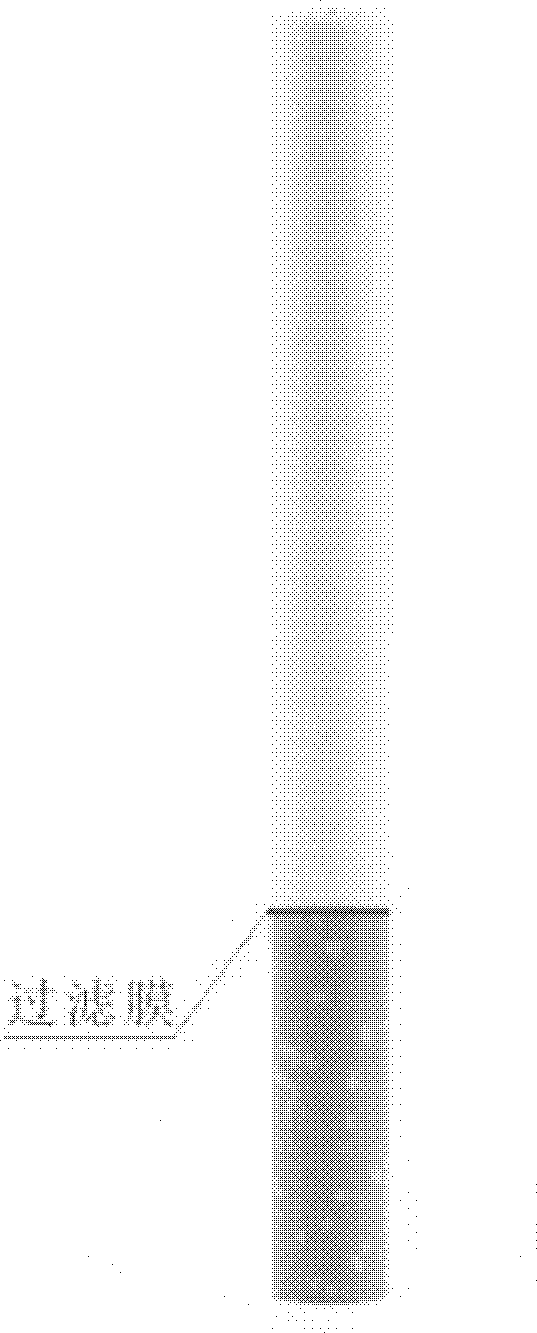

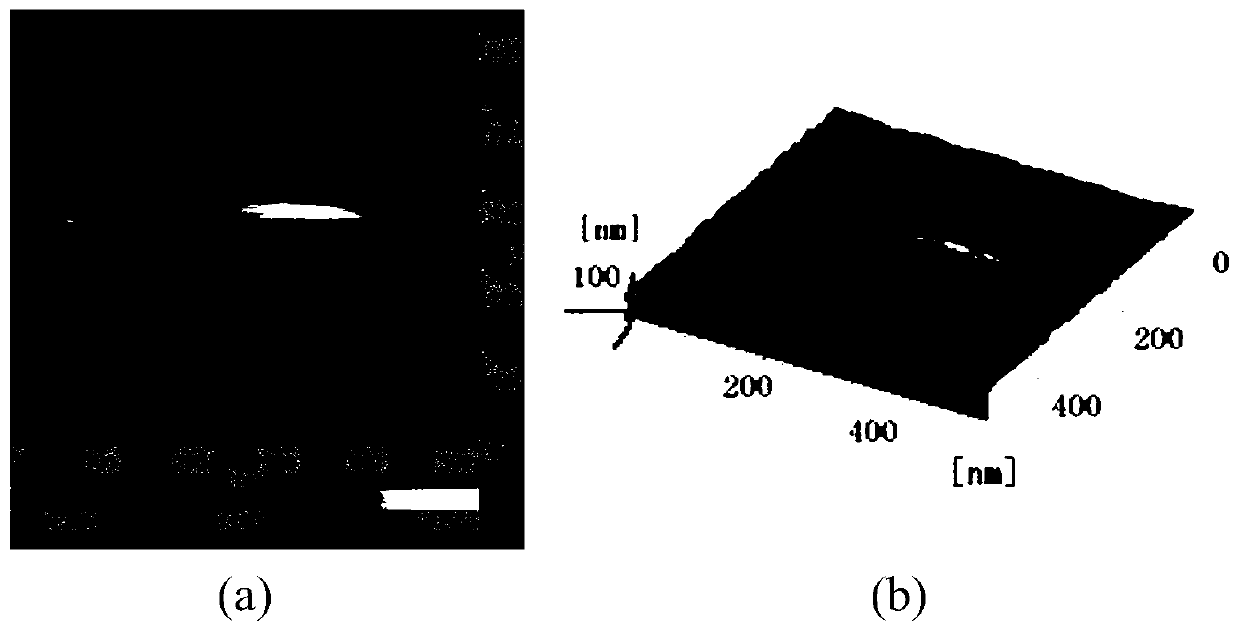

The invention relates to a layer-by-layer self-assembling oxidized graphene nano-filtration membrane and a preparation method of the layer-by-layer self-assembling oxidized graphene nano-filtration membrane, which belongs to the technical field of the preparation of a nano-filtration membrane. The layer-by-layer self-assembling oxidized graphene nano-filtration membrane comprises a supporting layer and a functional layer, wherein the functional layer is in a layered structure which is different from the compact structure of the traditional nano-filtration membrane functional layer. The preparation method comprises the following steps of (I) preparing an oxidized graphene solution through a hummers method; and (II) preparing an oxidized graphne nano-filtration membrane through a layer-by-layer self-assembling method. The oxidized graphene nano-filtration membrane is prepared through the layer-by-layer self-assembling method, a water passage is formed between the oxidized graphene lamellas, the distance of the oxidized graphene layer has a good interception effect for ions, the hydrophilia can be improved through the oxygen-containing functional groups on the surface of the oxidized graphene layer, so that the membrane is good in permeability and interception property. By utilizing the layer-by-layer self-assembling method, the high requirement of the traditional nano-filtration membrane preparation process on the condition can be avoided, the process is simple, the condition is easily controlled, and the application prospect is wide.

Owner:OCEAN UNIV OF CHINA

Membrane adsorbent for removing heavy metal ions from drinking water effectively and preparation method thereof

ActiveCN101961648AImprove adsorption capacityImprove interception effectOther chemical processesWater contaminantsPolymer resinSorbent

The invention relates to a membrane adsorbent for removing heavy metal ions and a preparation method thereof, in particular to a method for preparing a membrane adsorbent for removing heavy metal ions from water by utilizing the process of membrane filtration. Casting membrane liquid for preparing the membrane adsorbent comprises the following components in percentage by mass: 70 / 30 to 20 / 80 percent of polymer / resin, 4 to 30 percent of additive and 30 to 75 percent of solvent, wherein the concentration sum of the polymer and the resin is between 20 and 55 percent, and the sum of components is 100 percent. According to the formula of the invention, the method of the membrane adsorbent comprises the following steps of: 1, preparing the casting membrane liquid; 2, preparing a membrane; and 3, performing aftertreatment. The surface of the membrane adsorbent has an opening structure, so the membrane adsorbent has the excellent adsorption function, can be used as filtering and adsorbing media, and is particularly suitable for removing the heavy metal ions from the water.

Owner:安徽森诺膜技术有限公司

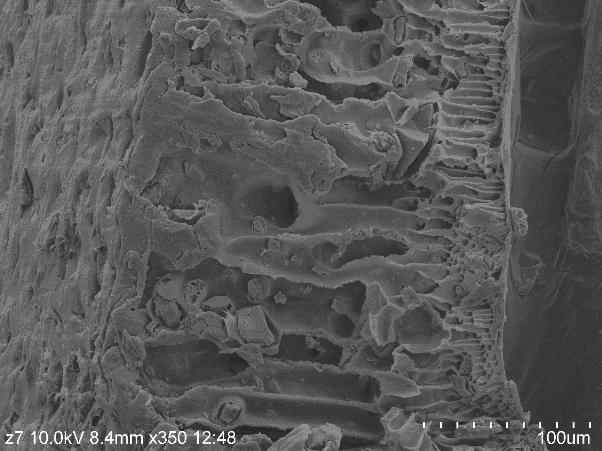

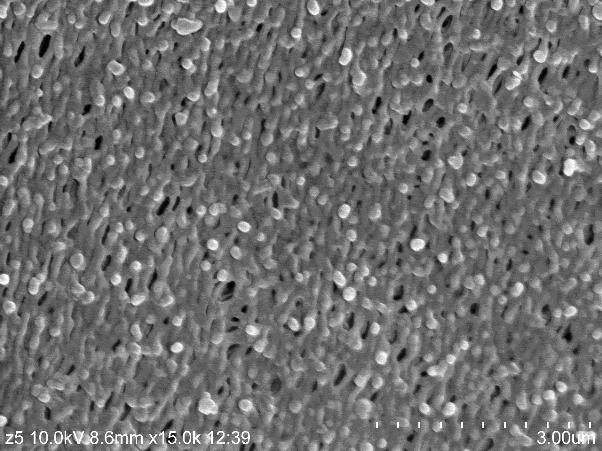

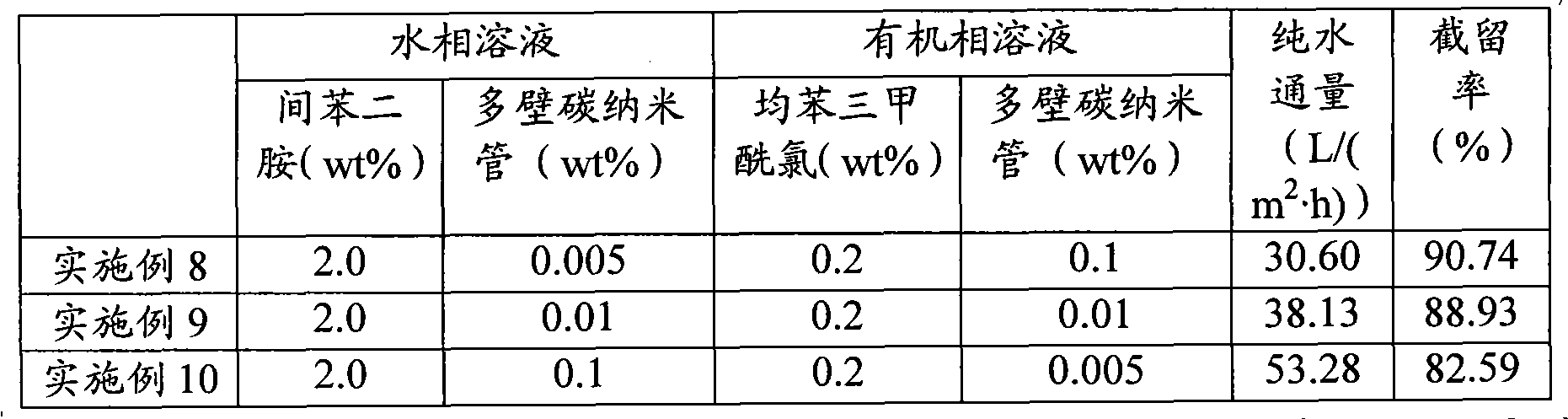

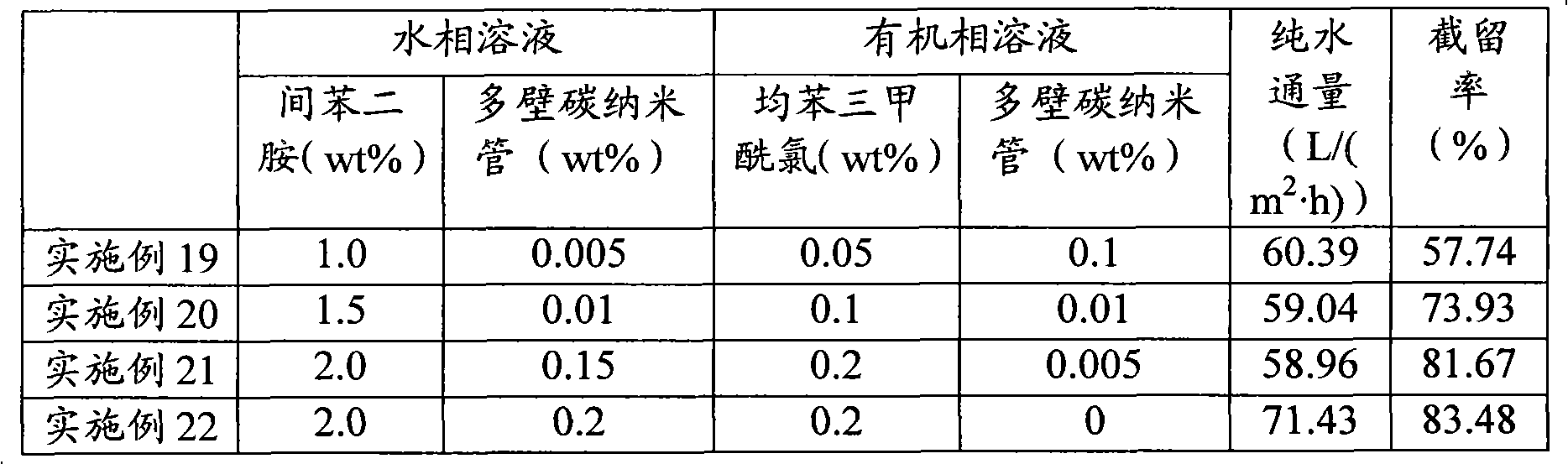

Hybridized composite reverse osmosis membrane containing carbon nano tubes and preparation method thereof

The invention discloses a hybridized composite reverse osmosis membrane containing carbon nano tubes and a preparation method thereof. The preparation method comprises the following steps of: adding the carbon nano tubes to a monomer solution for synthesizing a polyamide membrane; and preparing the hybridized composite reverse osmosis membrane containing the carbon nano tubes through an immersion method. The hybridized reverse osmosis composite membrane keeps the retention rate of a reverse osmosis membrane and also greatly increases the flux of the membrane by utilizing unique microcellular structures and good water channel action of the carbon nano tubes, and finally the reverse osmosis membrane with high flux and retention rate is prepared.

Owner:ZHEJIANG UNIV

Preparation method and application of separation film with nano composite cortical layer

ActiveCN102908906AImprove throughputImprove interception effectSemi-permeable membranesDesalinationNanofiltration

The invention provides a preparation method and application of a separation film with a nano composite cortical layer. The separation film comprises a non-woven fabric layer, two porous support layers and a desalination layer, and is characterized in that the lower layer of the two porous support layers is a porous body layer containing polymers and / or nano particles, and the upper layer of the two porous support layers is a porous cortical containing polymers and nano particles. The preparation method includes coating the upper layer and the lower layer of the non-woven base material by means of a double-layer coating technology. An ultrafilter support layer of the composite separation film prepared by the preparation method is good in surface evenness, hight water flux is kept in the meantime of keeping higher cutoff rate, and the separation film can be directly used as an ultrafiltration film or can be used as a basic porous support layer to further prepare a composite forward osmosis, reverse osmosis and nanofiltration film. The preparation method can be applied to preparing the reverse osmosis film and the nanofiltration film which are good in performance, and a composite ultrafiltration film with low molecular weight cutoff.

Owner:VONTRON TECH CO LTD

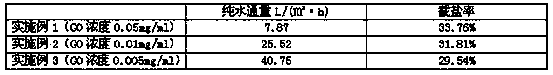

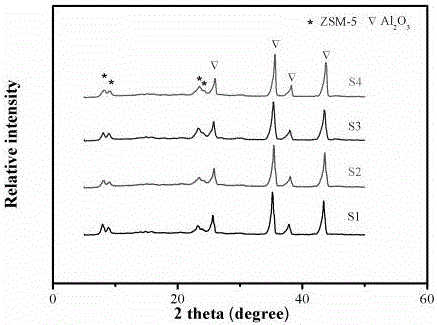

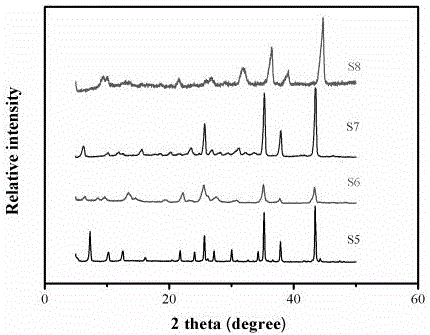

Preparation method and application of hierarchical porous molecular sieve membrane

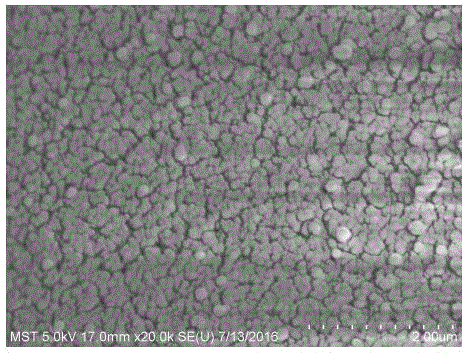

ActiveCN106378013AIncreased pure water fluxImprove interception effectSemi-permeable membranesMembranesMolecular sieveSynthesis methods

The invention relates to a preparation method and application of a hierarchical porous molecular sieve membrane. A mesoporous structure guiding agent is added to limit the growth of a molecular sieve crystal, and is subjected to self-assembly in a crystallization process of the molecular sieve crystal, so as to generate a mesoporous structure. The hierarchical porous molecular sieve membrane is synthesized by using a seed crystal inducing secondary nucleation mechanism and a hydrothermal one-step synthesis method; synthesis conditions are mild and controllable, the simplicity in preparation and good repeatability are realized, energy consumption is reduced, and the cost is reduced. The hierarchical porous molecular sieve membrane prepared by adopting the method shows good retention performance, and the retention molecular weight is controllable between 200 and 500000 Da. The method for preparing the hierarchical porous molecular sieve membrane, provided by the invention, can be used for synthesizing the hierarchical porous molecular sieve membrane with other micropore skeleton structures, and has high cost performance and a broad industrial production prospect; the application of the preparation method also can be popularized to the field of catalysis.

Owner:NANJING TECH UNIV

Preparation method for polydopamine-modified polyamide composite forward osmosis membrane

InactiveCN105169970AIncrease water fluxTightly boundSemi-permeable membranesGeneral water supply conservationChemistryPolyamide

The invention relates to a preparation method for a polydopamine-modified polyamide composite forward osmosis membrane. The preparation method comprises the following steps: (1) a supporting layer is prepared; (2) the surface of the supporting layer is modified by polydopamine coating; (3) a polyamide separation layer is prepared on the surface of the modified supporting layer, and thereby the polydopamine-modified polyamide composite forward osmosis membrane is obtained. The polydopamine-modified polyamide composite forward osmosis membrane prepared by the preparation method has the advantages of hydrophilcity, large pure water permeation flux and small reverse salt diffusion flux, and is applicable to the field of water treatment such as sea water desalination.

Owner:WUHAN UNIV

Method for preparing nanofiltration membrane by adopting layer-by-layer self-assembly method

ActiveCN105169962APore Size ControlImprove interception effectSemi-permeable membranesPolymer scienceFruit juice

The invention discloses a method for preparing a nanofiltration membrane by adopting a layer-by-layer self-assembly method, and relates to a preparation method of a nanofiltration membrane, aiming at solving the problems that a nanofiltration membrane prepared by adopting an existing method cannot have both good interception performance and high water flux. The method comprises the following steps: preparing a polyacrylonitrile solution, preparing a polyacrylonitrile basilar membrane, preparing a treated polyacrylonitrile basilar membrane, assembling a layer of polyethlenimine, assembling a layer of graphene oxide, and reassembling polyethlenimine and graphene oxide, thus obtaining the nanofiltration membrane. According to the method disclosed by the invention, a layer-by-layer self-assembly method is adopted, polyethlenimine and graphene oxide are adopted for modifying a PAN membrane, so that the hydrophilia and the pore size of the surface of the membrane are effectively adjusted; because the membrane is relatively thin, relatively large flux can be obtained, and the obtained nanofiltration membrane has good interception performance. The method can be applied to the fields of antibiotics separating, fruit juice concentrating and seawater desalting.

Owner:HARBIN INST OF TECH

Ionic liquid modified positively charged composite nanofiltration membrane and preparation method thereof

ActiveCN110026091AImprove interception effectReduce retentionMembranesSemi-permeable membranesHigh magnesiumPolyamide

The invention discloses an ionic liquid modified positively charged composite nanofiltration membrane and a preparation method thereof. The preparation method comprises the following steps: on a supporting bottom film, firstly, carrying out interfacial polymerization on polyamine and polyacyl chloride to form a primary polyamide layer, and then carrying out an amidation reaction on acyl chloride groups remaining on the surface of the primary polyamide layer and amino functionalized ionic liquid to prepare the composite film. The preparation method comprises the following steps: (1) preparing apolyamine aqueous phase solution and a polyacyl chloride organic phase solution; (2) carrying out interfacial polymerization on the surface of the bottom film to prepare a primary polyamide nanofiltration membrane; and (3) reacting the amino-functionalized ionic liquid solution with acyl chloride groups on the surface of the primary polyamide layer, and carrying out heat treatment to obtain the positively charged composite nanofiltration membrane. By changing the charge property of the composite membrane, lithium resources in the salt lake brine with a high magnesium-lithium ratio can be effectively extracted, the magnesium-lithium separation factor of the composite membrane is lower than 0.15, and the flux is 40-50L / m<2>h. The method has the advantages that the preparation method is simple, and the method has a good industrial application prospect in the aspect of salt lake lithium extraction.

Owner:TSINGHUA UNIV

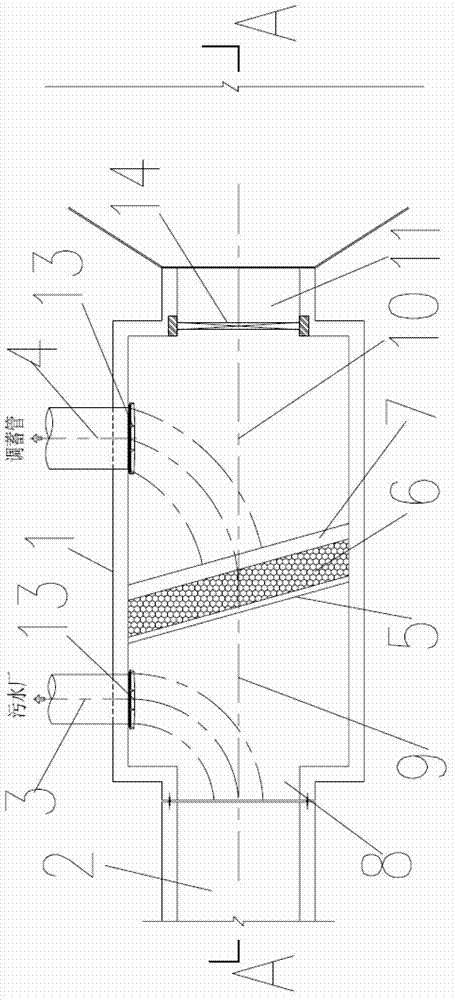

Dry weather flow and initial rainwater multifunctional catch basin for combined network

The invention discloses a dry weather flow and initial rainwater multifunctional catch basin for a combined network. The dry weather flow and initial rainwater multifunctional catch basin for the combined network comprises a basin body. The basin body is provided with an interceptor sewer extending to a sewage plant, an initial rainwater interceptor extending to a regulation and storage pipe, a water outlet communicated with a river channel, and a water inlet communicated with a combining pipe. The catch basin further comprises a filter layer disposed in the basin body. The filter layer is disposed between the water inlet and the water outlet so that a water inlet area close to one side of the water inlet and a water outlet area close to one side of the water outlet form in the basin body. The filter layer comprises a stop board disposed on the upper portion of the basin body, an overflow weir disposed on the lower portion of the basin body and a filter net disposed between the stop board and the overflow weir. The stop board is provided with through holes. The dry weather flow and initial rainwater multifunctional catch basin for the combined network has the advantages that the multifunctional catch basin is convenient to implement, the filter layer can be cleaned automatically, intercepting effect is improved, service life of the catch basin is prolonged, and river channel pollution is reduced.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

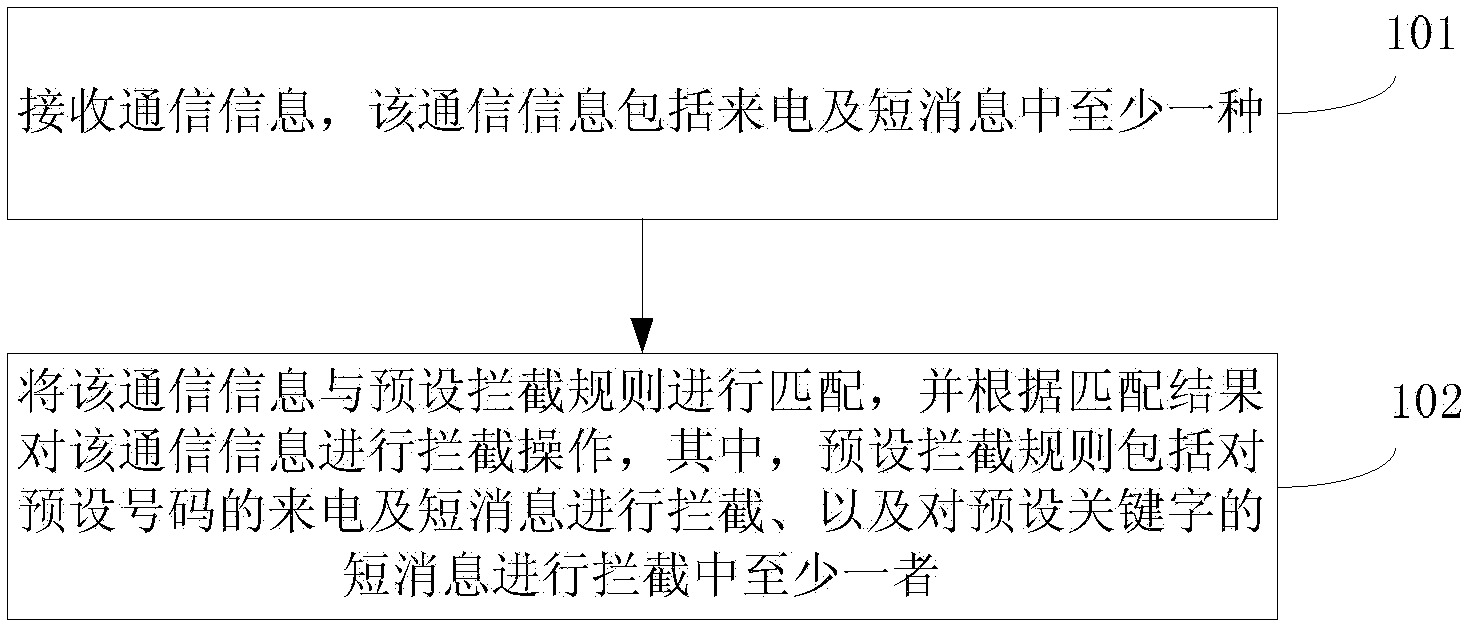

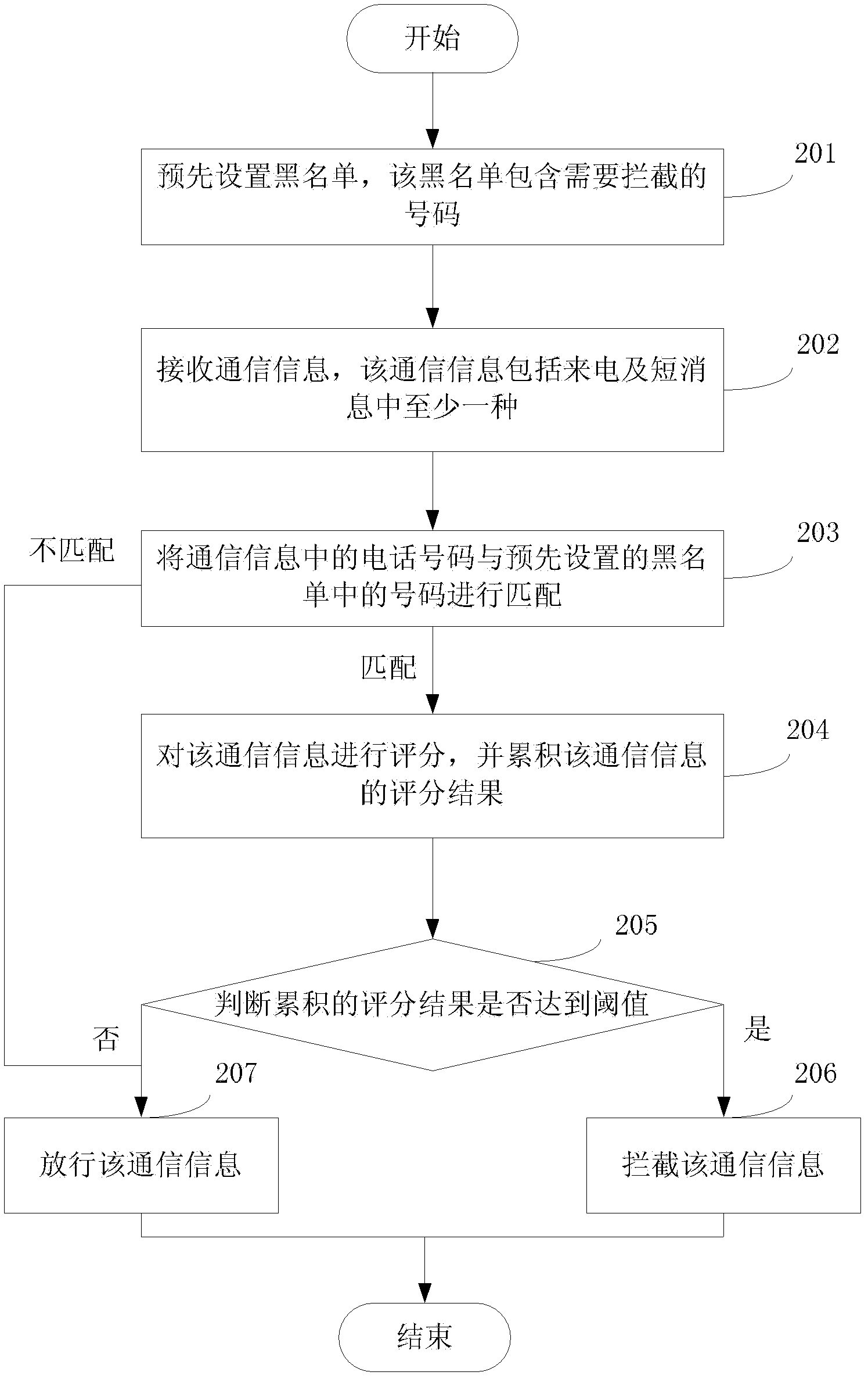

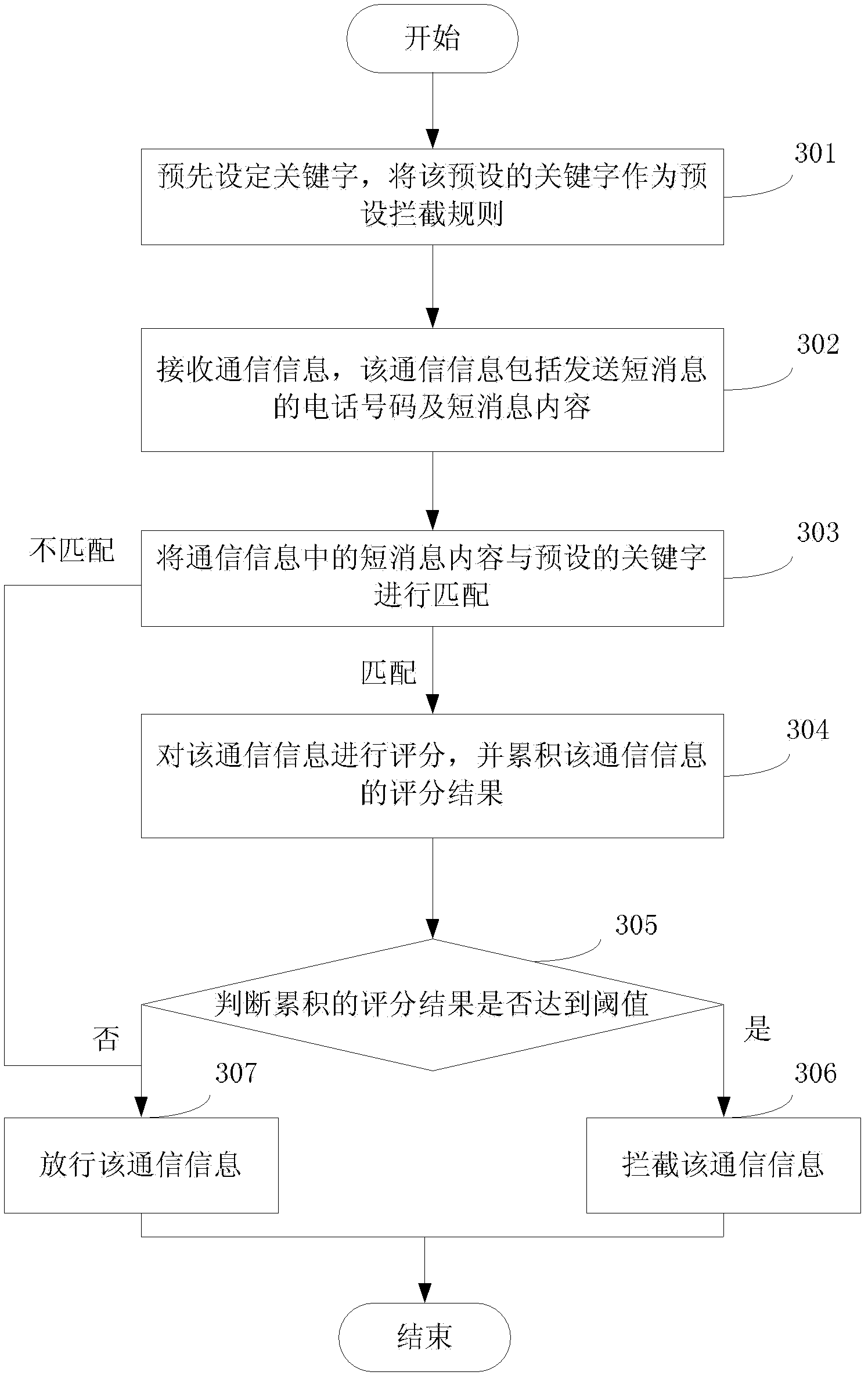

Method and device of intelligent intercept

InactiveCN103152738AImprove convenienceImprove interception effectSecurity arrangementSoftwareComputer science

The invention discloses a method and a device of an intelligent intercept and belongs to the technical field of information handling. The method comprises that communication information can be received and the communication information comprises at least one of incoming telegrams and short messages; the communication information can be matched with pre-installing intercept rules and the communication information can be in an intercept operation according to matched results, wherein the pre-installing intercept rules comprise one of the two operations that incoming telegrams preinstalled with numbers and short messages can be intercepted and the short messages pre-installed with key words can be intercepted without installing extra other security soft wares. Therefore, convenience property and intercepting effects of a high intelligent interception can be improved. Furthermore, pretreatment can be carried out over the communication information can be implemented in pretreatment and then the communication information can be matched with the pre-installing intercept rules so as to enable the matched results to be more accurate. Therefore, intercepting effects can be further improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Method for preparing hydrophilic low catching molecular composite ultrafiltering membrane

InactiveCN101053779AImprove hydrophilicityLow molecular weight cut offSemi-permeable membranesPolyelectrolyteSurface structure

The invention relates to a method for preparing a hydrophilic low retain molecular weight composite ultrafiltration membrane. The invention uses polysulfone or polyethersulfone as membrane material to prepare water repellent ultrafiltration membrane-substrate membrane with high retain molecular weight by transfer method; and based on this, the polyelectrolyte multilayer film is assembled on the ultrafiltration membrane-substrate membrane as a composite layer using layers static self-assembly technology to get the hydrophilic low retain molecular weight composite ultrafiltration membrane. The said composite ultrafiltration membrane preparation method in the invention is characterized in low cost and simple process. The surface of the composite ultrafiltration membrane prepared by the said method in the invention is electriferous, electrical property is controlled, and the surface structure is controlled. The invention has good retain performance to the low molecular weight solute, and also has better anti pollution performance.

Owner:SHANGHAI UNIV

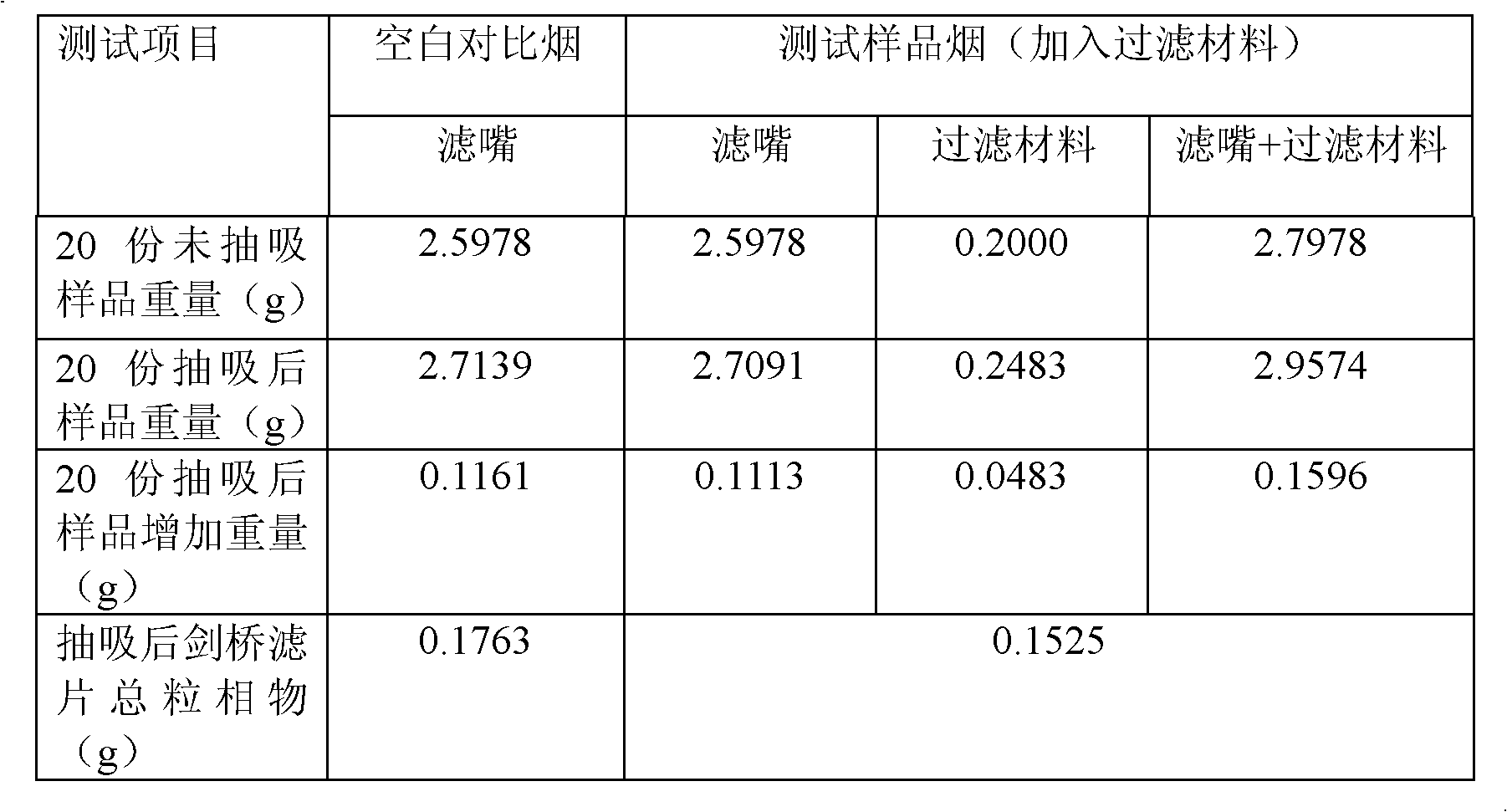

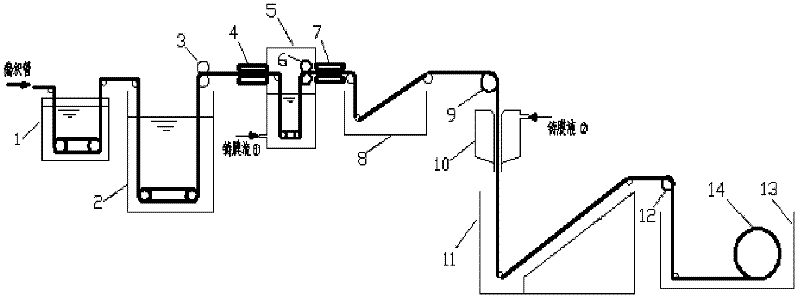

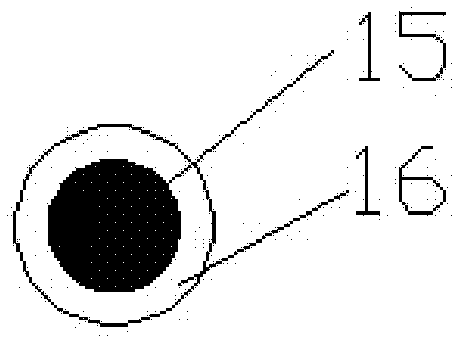

Preparation method for cigarette filter tip adopting electrostatically spun cellulose acetate membrane

InactiveCN102423141AEasy to cutEasy to sampleCigarette manufactureCellulose diacetateElectrospinning

The invention relates to a preparation method for a cigarette filter tip adopting an electrostatically spun cellulose acetate membrane, and the method includes the following steps: (1) cellulose diacetate is dissolved in the mixture of acetone and dimethylacetylamide, electrostatic spinning is carried out, and thereby the nano cellulose acetate membrane is obtained; (2) cellulose acetate tows in a cigarette are pulled out, the nano cellulose acetate membrane is laid between the filter tip and the cigarette along the cross-sectional direction of the filter tip, the cellulose acetate tows which are originally pulled out are then put into the cigarette, the part of the filter tip, which exceeds connecting paper, is cut off, and thereby the improved cigarette filter tip is fabricated. The preparation method uses the electrostatic spinning technology to fabricate the nano cellulose acetate membrane and adds the nano cellulose acetate membrane into the cigarette filter tip, the nano cellulose acetate membrane not only can be perfectly combined with the cigarette filter tip, but also can enhance the harmful gas-filtering performance of the cigarette filter tip, meanwhile, the preparation method is easy to operate, the efficiency is relatively high, and the cigarette filter tip can remarkably reduce the contents of various harmful components, and has a good market prospect.

Owner:DONGHUA UNIV +1

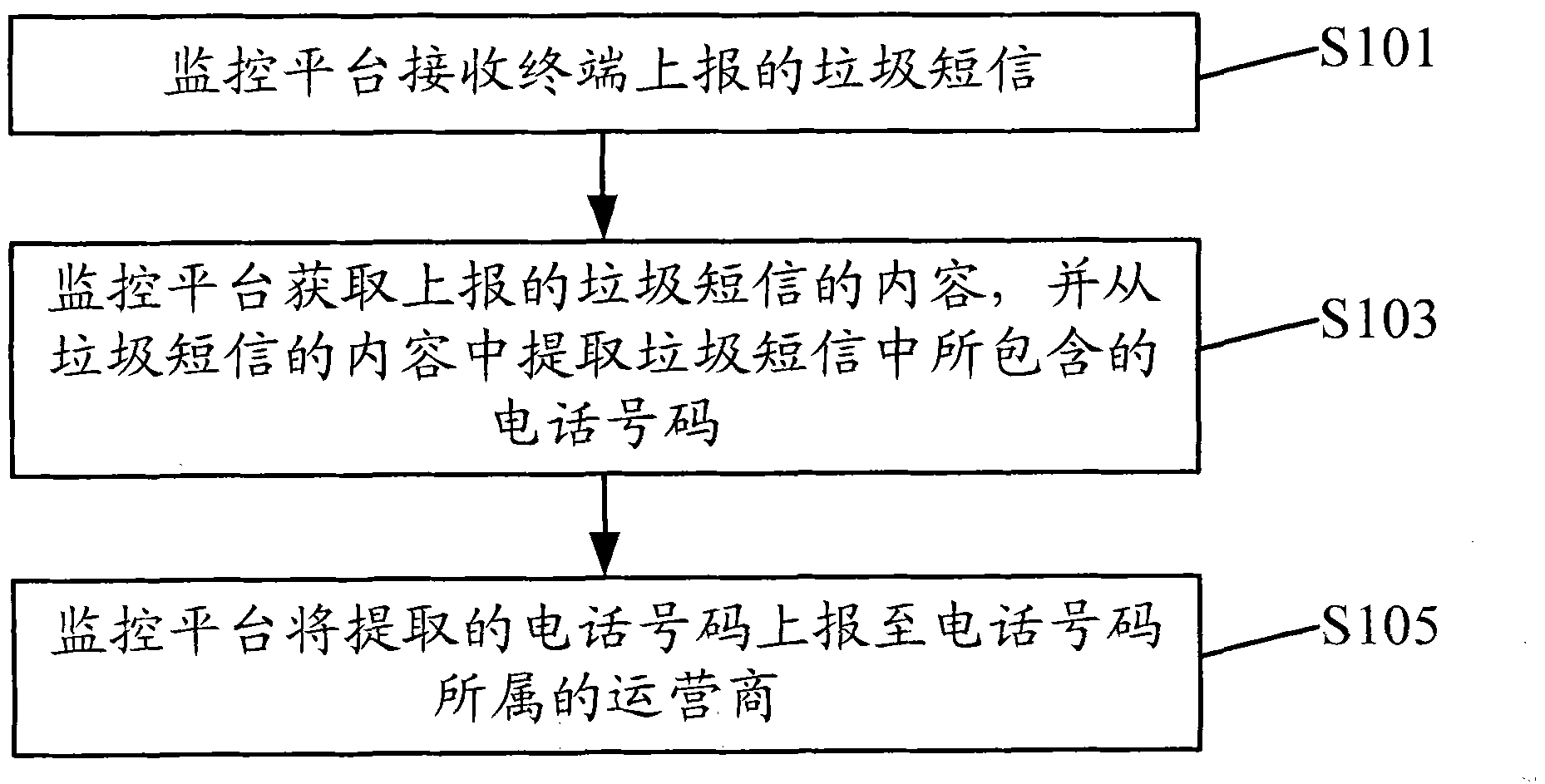

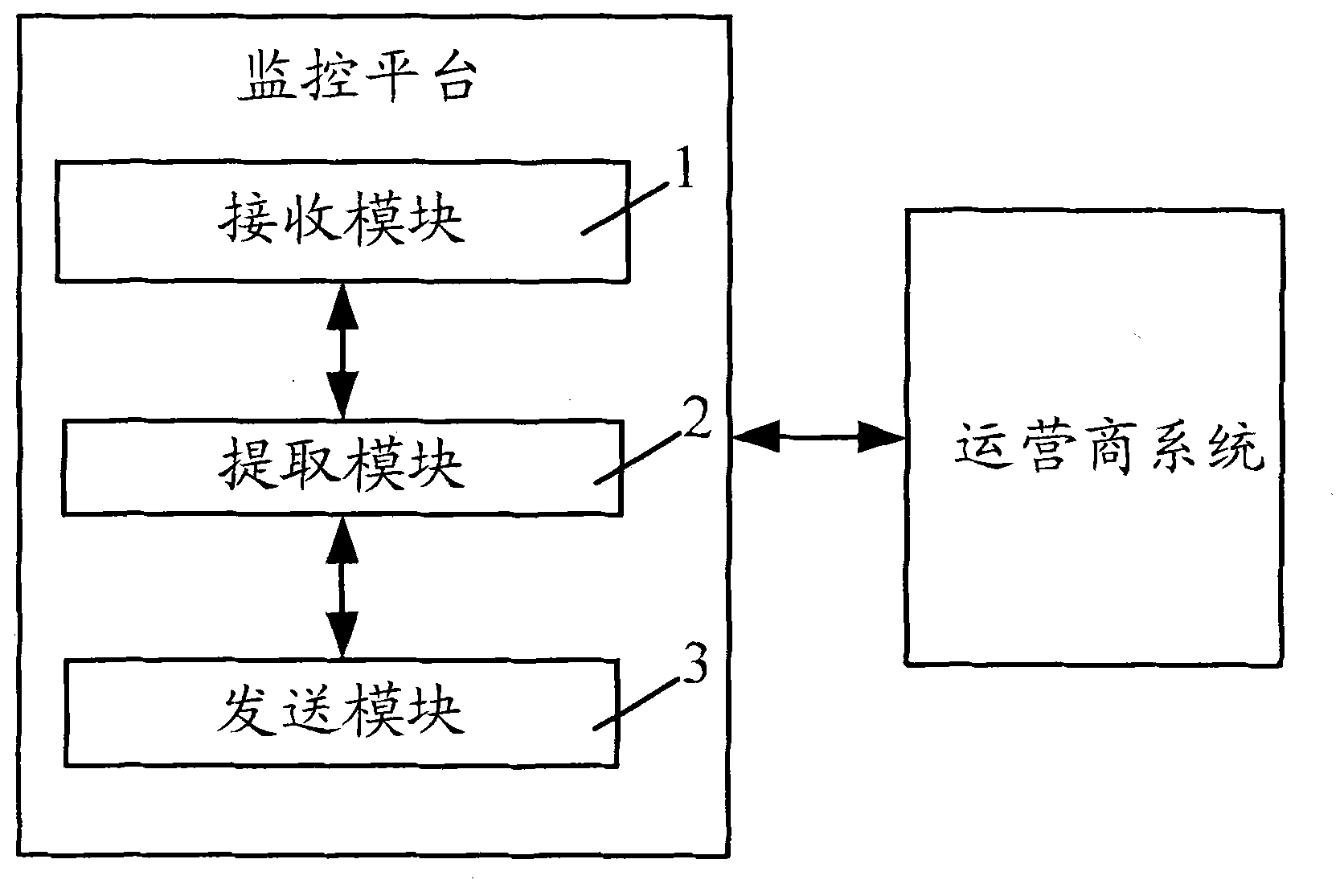

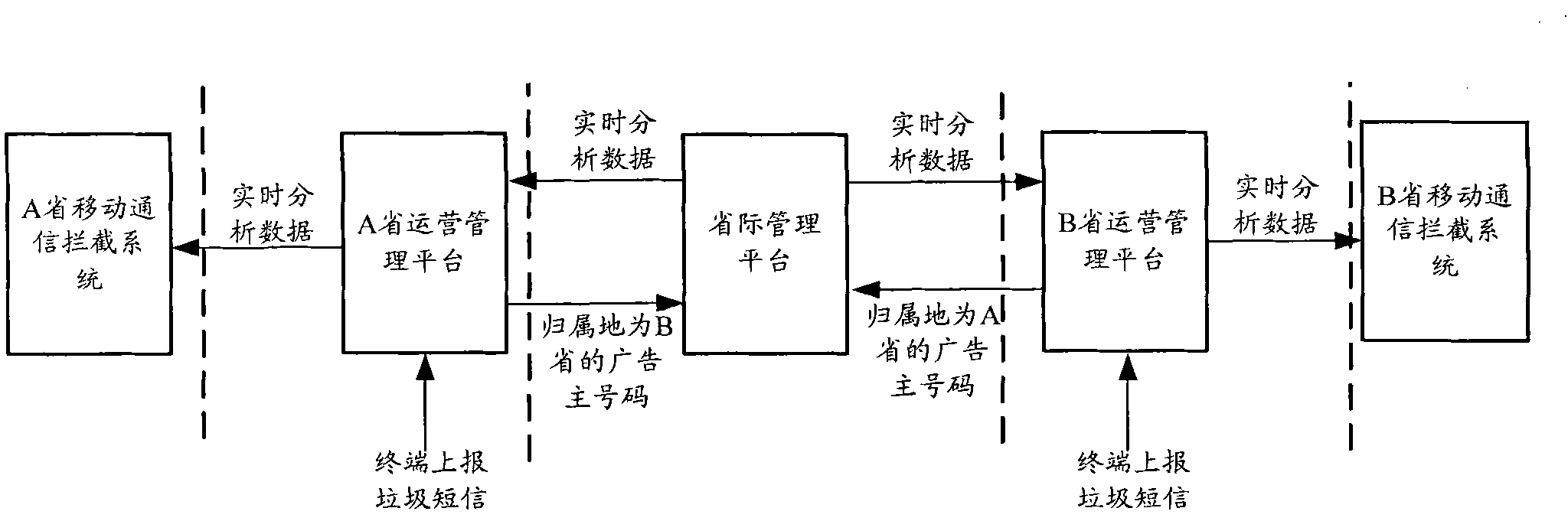

Method and system for processing spam

InactiveCN102088697AImprove performance and accuracyAvoid manual operationSecurity arrangementTelecommunicationsMaterial resources

The invention discloses a method and a system for processing spam. The method comprises the following steps: a monitoring platform receives the spam reported by a terminal; the monitoring platform acquires the content of the reported SMS spam and extracts a telephone number contained in the spam from the content of the spam; and the monitoring platform reports the extracted telephone number to an operator to which the telephone number belongs. By means of the method, the number (can be regarded as a main advertising number) contained in the content of the spam is extracted and reported to the operator; and the number of a contact person in the spam such as the advertising spam is always fixed, thus being beneficial for the operator to carry out interception or other processing from the source of the spam, improving interception effect and accuracy of the spam, avoiding a large amount of manual operation, and saving manpower and material resources.

Owner:BEIJING HUAZHONG FUSION TECH

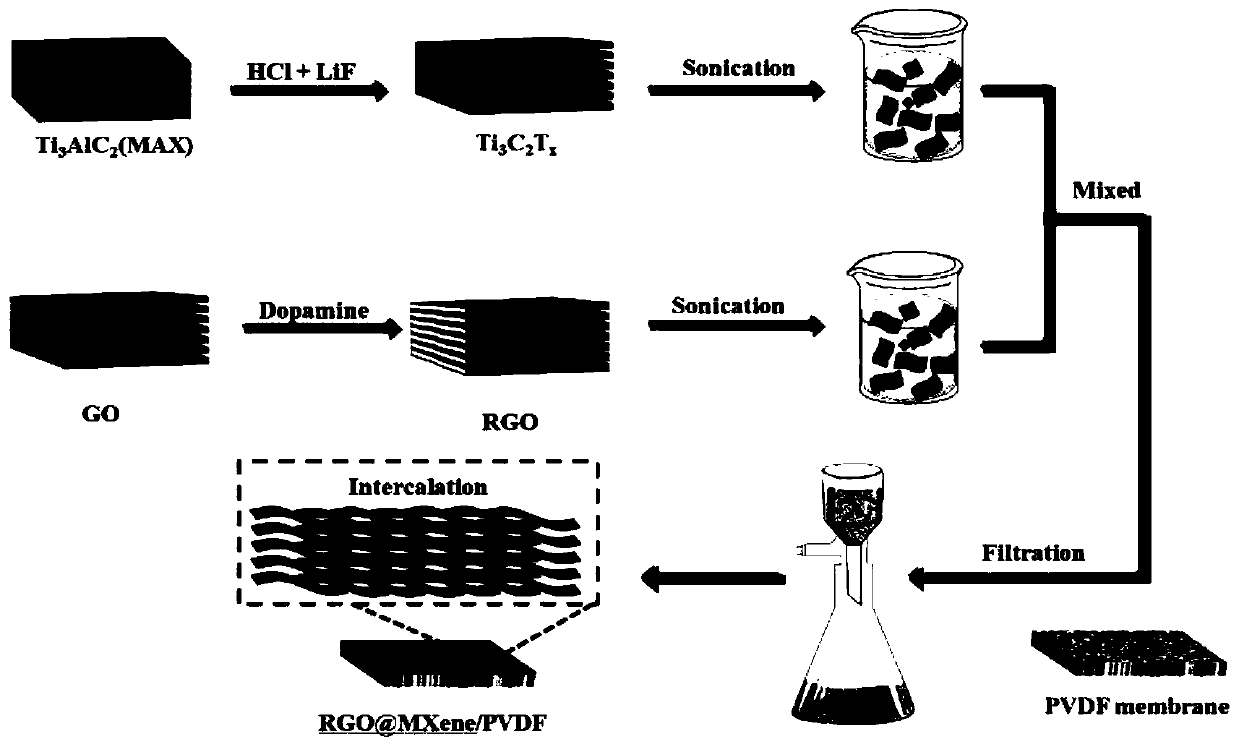

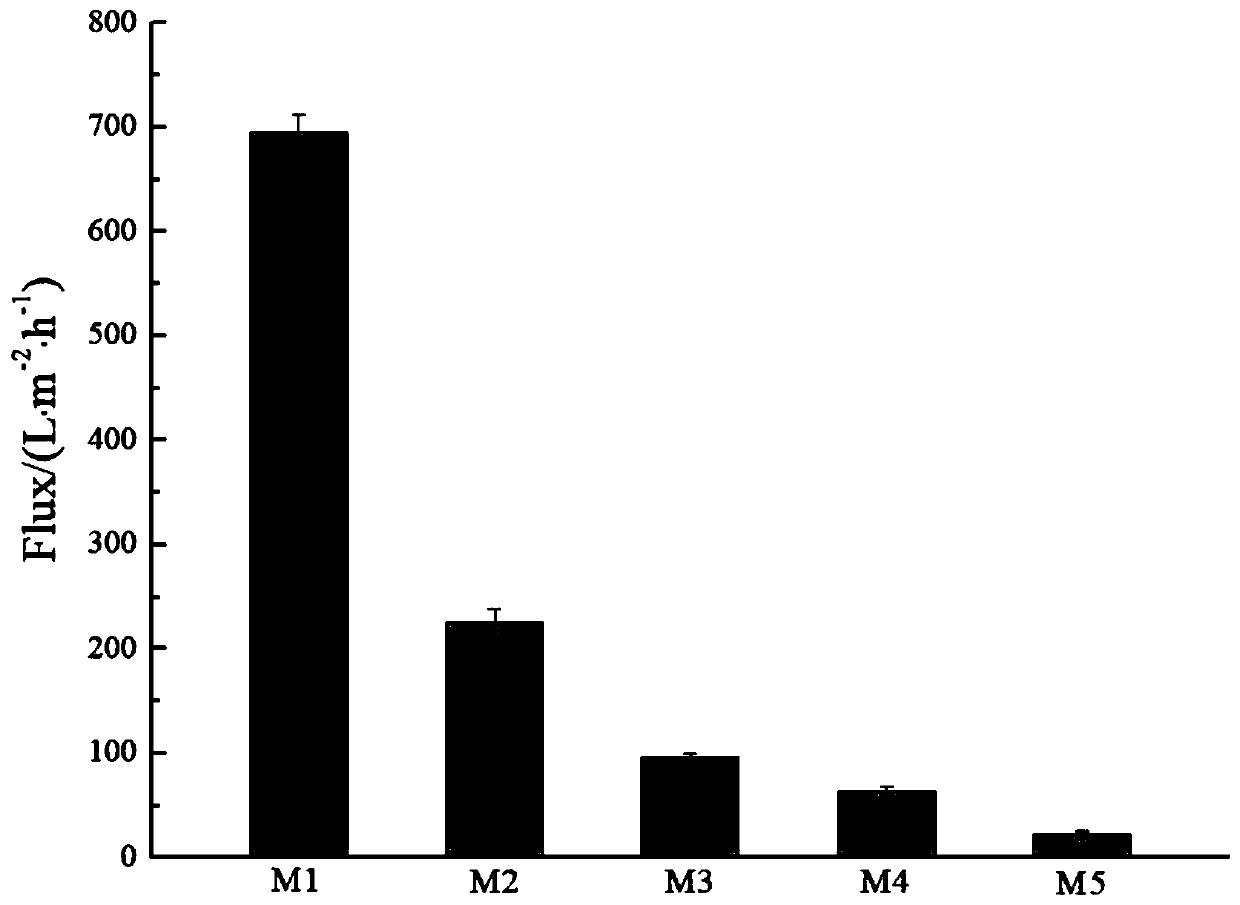

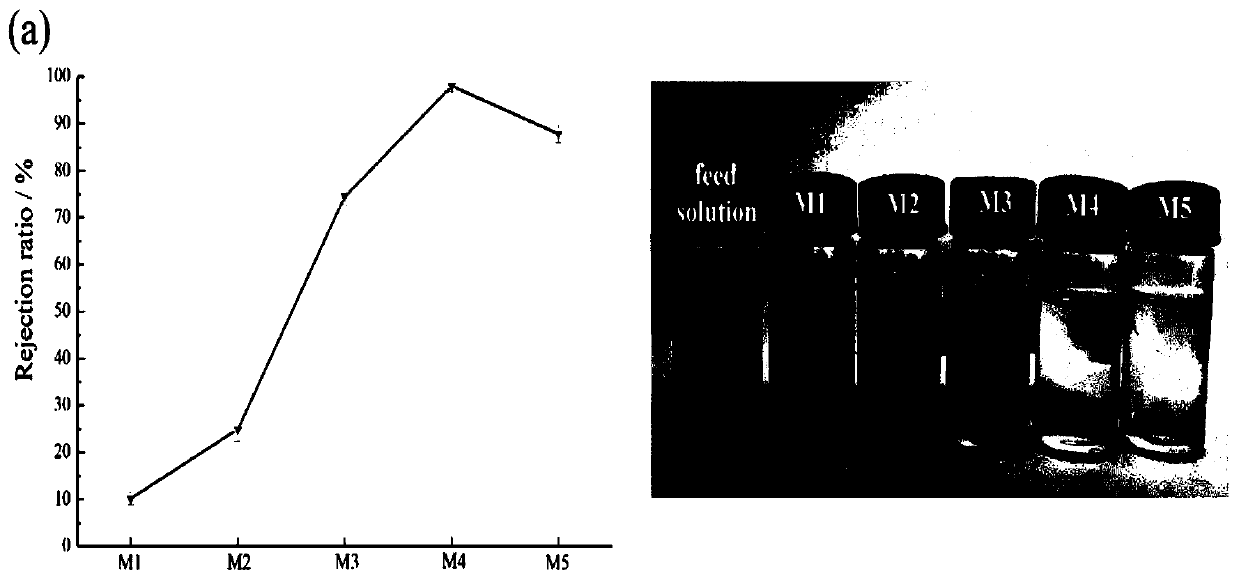

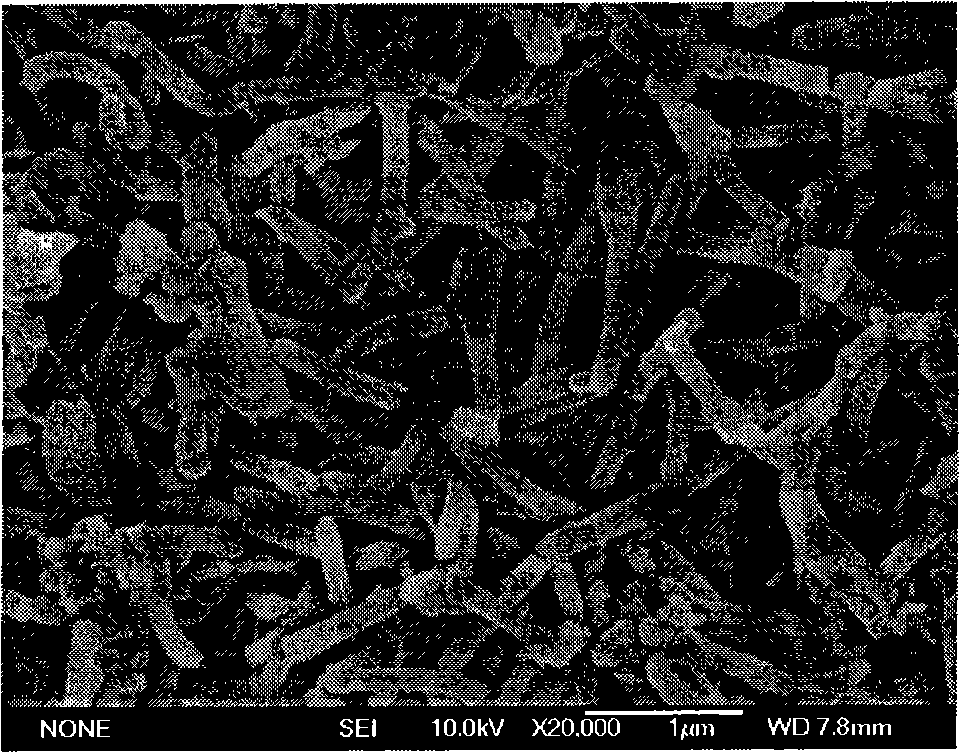

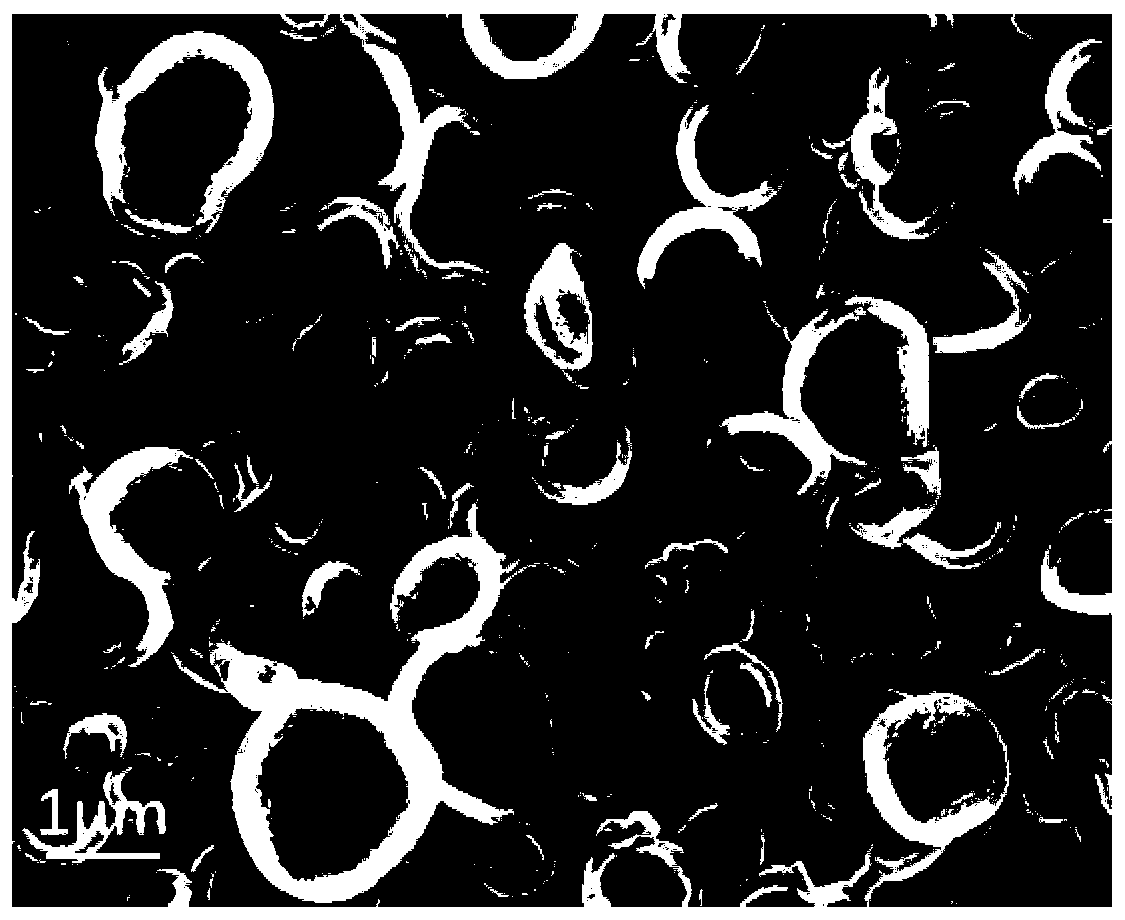

Novel RGO/MXene composite film and preparation method thereof

ActiveCN110975655AImprove permeabilityEasy to separateSemi-permeable membranesMembranesComposite filmIndustrial waste water

The invention discloses a novel RGO / MXene composite film and a preparation method thereof, and the method comprises the following steps: carrying out reduction processing on GO through DA to prepare RGO; stripping MAX by using a LiF and HCl mixed solution to obtain a two-dimensional MXene material with a clear lamellar structure; ultrasonically mixing an MXene dispersion solution and an RGO dispersion solution, constructing the RGO / MXene composite film on a PVDF film substrate in a vacuum filtration manner, and applying the RGO / MXene composite film to processing of industrial wastewater. According to the method, the synergistic film-forming mechanism and the separation mechanism of the RGO and the MXene are explored in detail, and some reference significance is provided for further widening the application range of the MXene and developing and constructing more novel high-performance film materials. From the perspective of improvement of the structure of the film material, the processing efficiency and the recyclability of the film are improved, and finally the practical purpose of reducing the industrial wastewater processing cost is achieved.

Owner:CHENGDU QINHUAN TECH CO LTD

Modified polyvinyl chloride alloy ultra-filtration membrane and preparation method of hollow fiber ultra-filtration membrane

InactiveCN102151491AImprove hydrophilicityEasy to prepareSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisSolventMethacrylic acid copolymer

The invention relates to a modified polyvinyl chloride alloy ultra-filtration membrane and a preparation method of a modified polyvinyl chloride alloy hollow fiber ultra-filtration membrane. The modifier in membrane preparation solution is a macromolecular modifier, the main component in the macromolecular modifier is methyl methacrylate-methacrylic acid copolymer, the macromolecular modifier can also contain a certain amount of methyl methacrylate, and the finished membrane is modified by using the synergetic effect of the methyl methacrylate-methacrylic acid copolymer and the methyl methacrylate; and the membrane preparation solution consists of the following components in part by mass: 8 to 17 parts of polyvinyl chloride, 1 to 8 parts of macromolecular modifier, 4 to 18 parts of pore forming agent, 57 to 87 parts of solvent, and 0.2 to 1 part of stabilizing agent. The tensile strength, the elongation at break, the hydrophilic property and the surface flatness of the ultra-filtration membrane, particularly the hollow fiber ultra-filtration membrane prepared by adopting the membrane preparation solution and using a dry-wet method are greatly improved; the ultra-filtration membrane has high pollution resistance and pure water flux; and the adopted main materials have wide source and low cost, the membrane preparation cost is greatly reduced, and large-scale popularization and application of the ultra-filtration membrane in the water treatment industry are favorable.

Owner:刘镇江

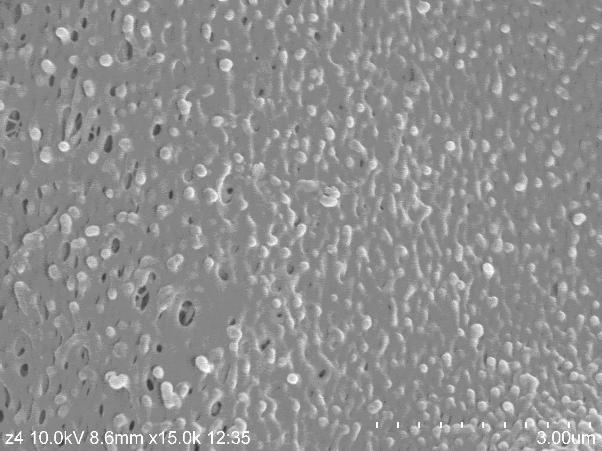

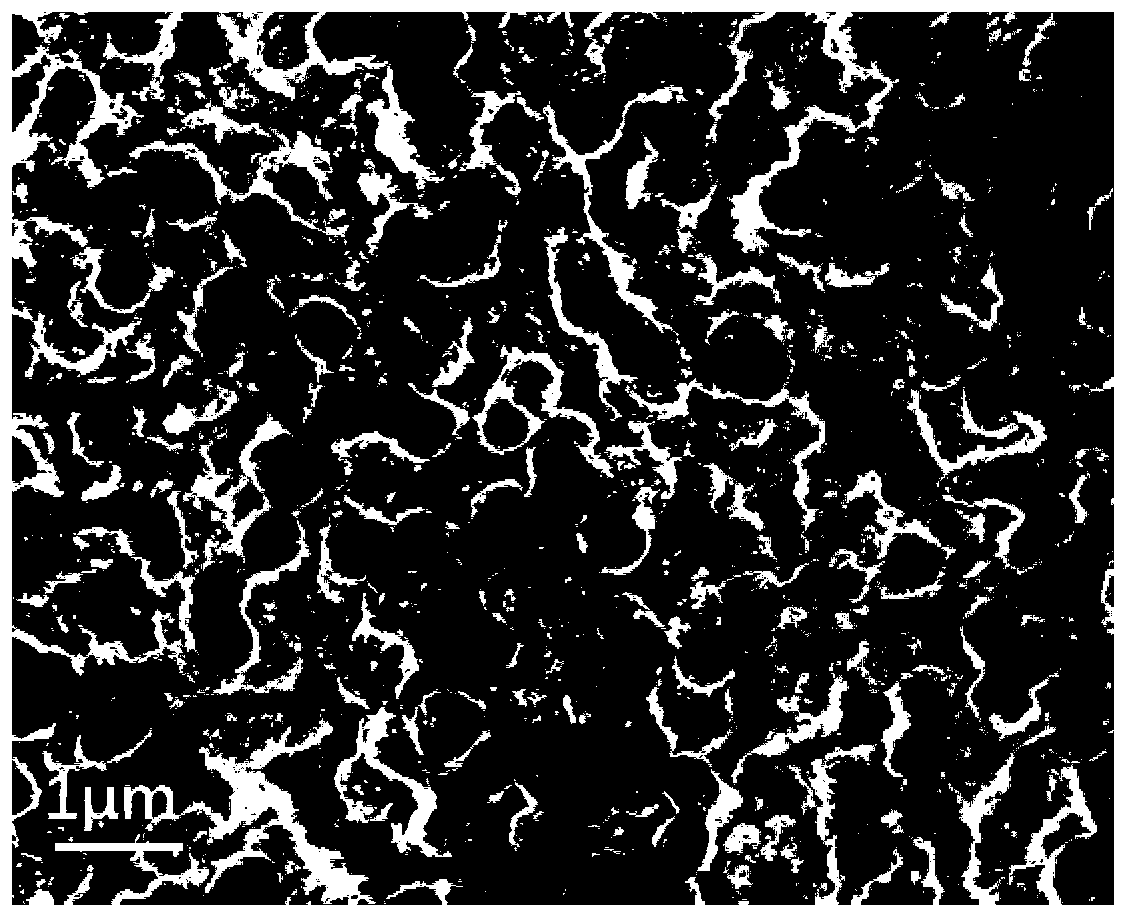

In-situ polymerization process for preparing polyaniline composite hyperfiltration membrane

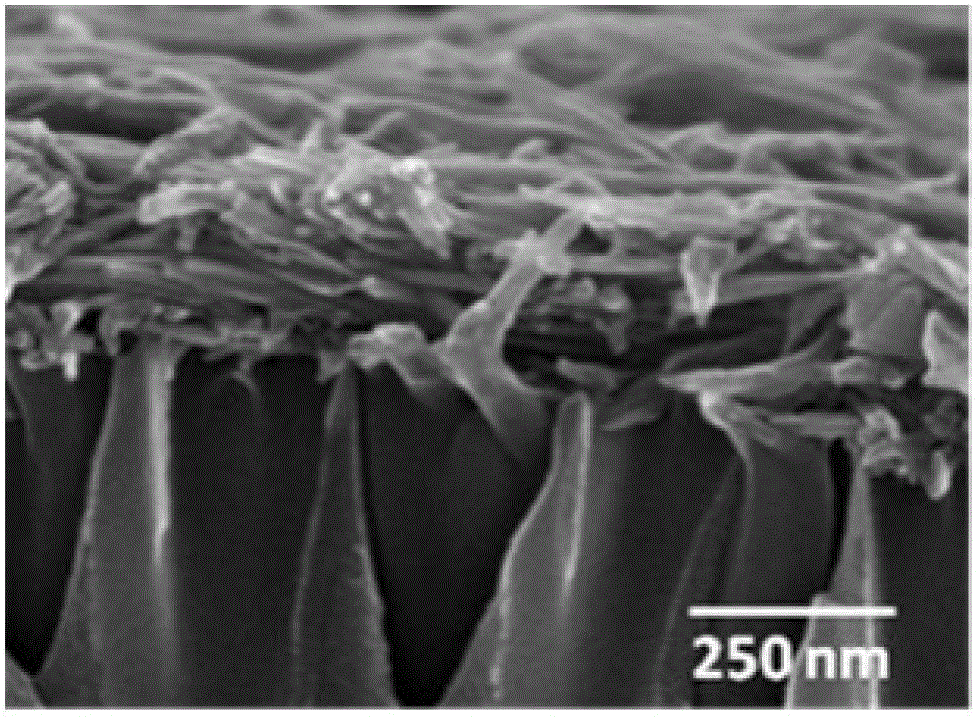

InactiveCN101274221AImprove interception effectImprove hydrophilicitySemi-permeable membranesComposite filmFiltration

The invention discloses a method for preparing poly-aniline composite ultra-filtration film by in-situ polymerization, belonging to the preparation technique of ultra-filtration composite film. The method process comprises that under the temperature of 20 to 25 DEG C, citric acid, camphor sulfonic acid or hydrochloric acid is added into dodecyl benzene sulfonic acid sodium solution; after the pH value of the solution is adjusted, aniline is added into the solution; after the solution is uniformly mixed, polysulfone membrane is then added into the solution and the solution is then mixed for 4 to 6 hours under the temperature of 20 to 25 DEG C and then for 2 hours under the temperature of 0 to 5 DEG C; water solution of ammonium persulfate with a certain quantity is then added into the solution, and the solution is then mixed for a plurality of minutes under the temperature of 0 to 5 DEG C to complete the reaction. The finished poly-aniline composite ultra-filtration film is gained by a series of cleaning of the prepared poly-aniline composite ultra-filtration film. The method of the invention is simple and has easy operation; the surface of the prepared poly-aniline composite ultra-filtration film is densely and uniformly covered by nano-fibre-shaped polyaniline; the interception performance and the hydrophilicity performance of the poly-aniline composite ultra-filtration film are greatly improved compared with basic films and can be adjusted by controlling the film preparation reaction time.

Owner:TIANJIN UNIV

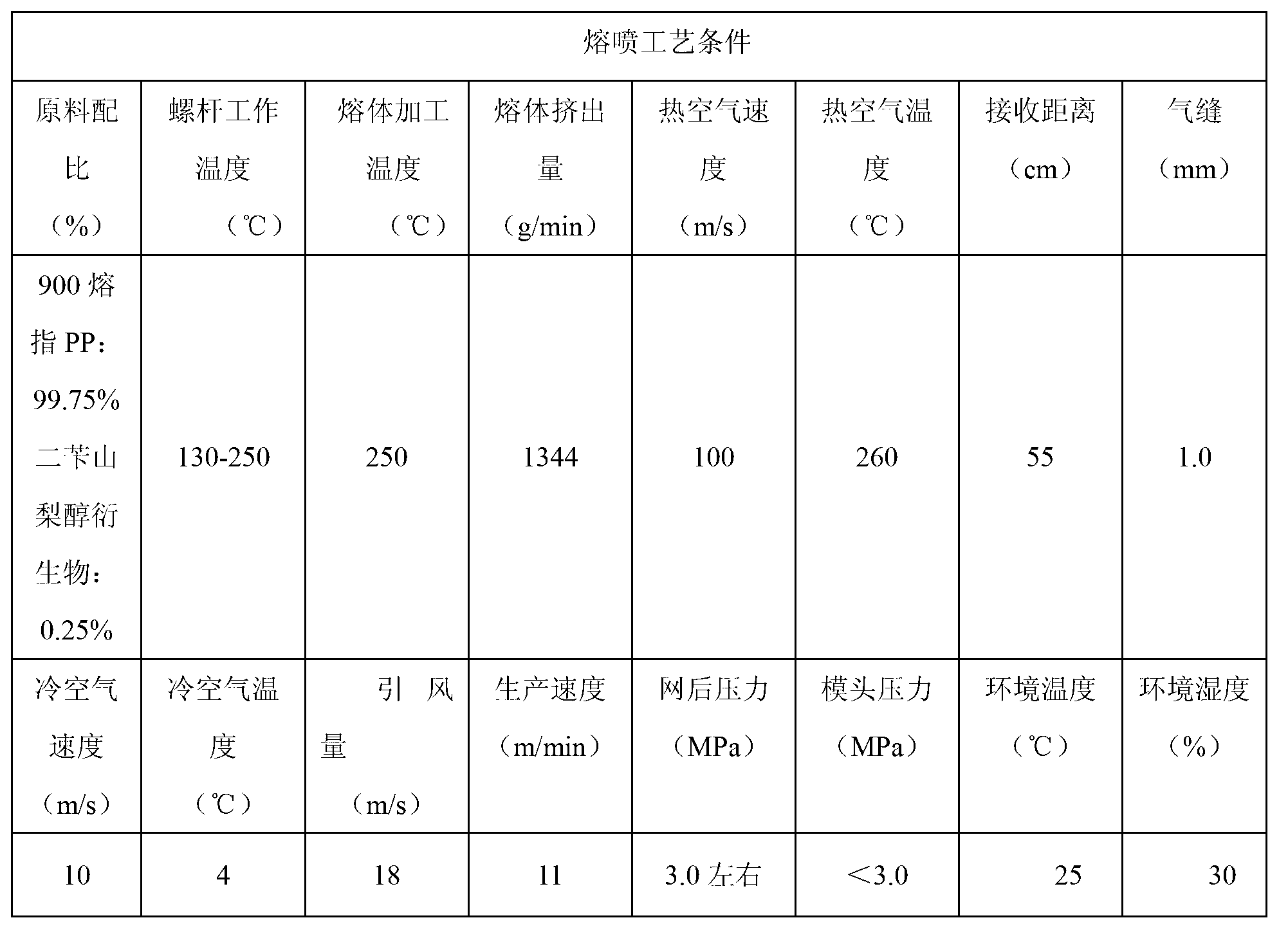

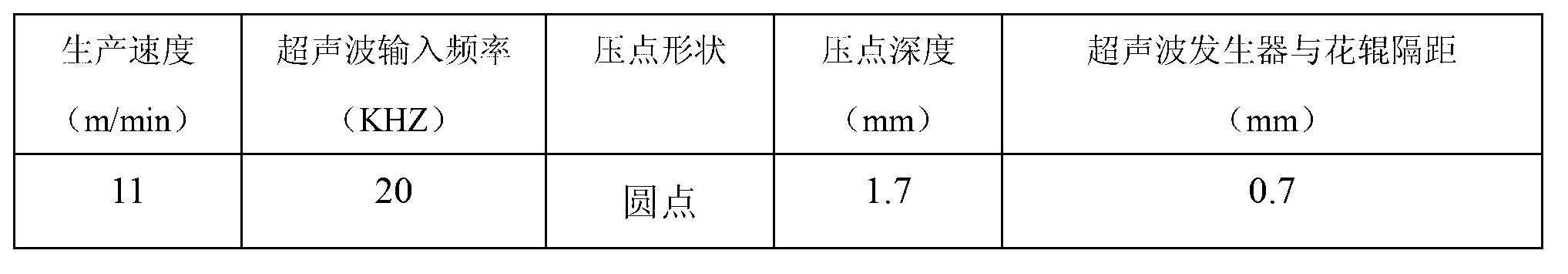

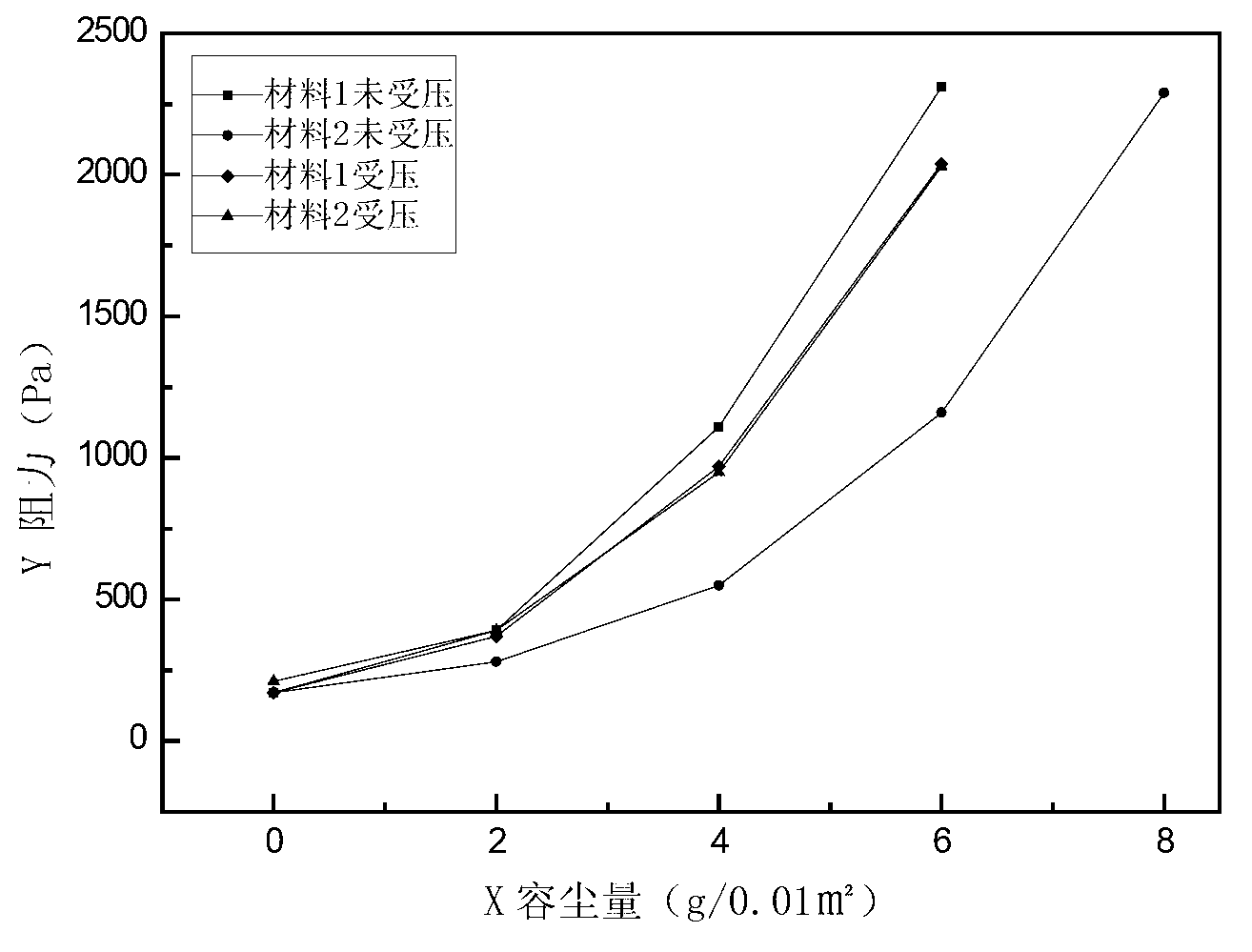

Melt spinning non-woven material and production method and application thereof

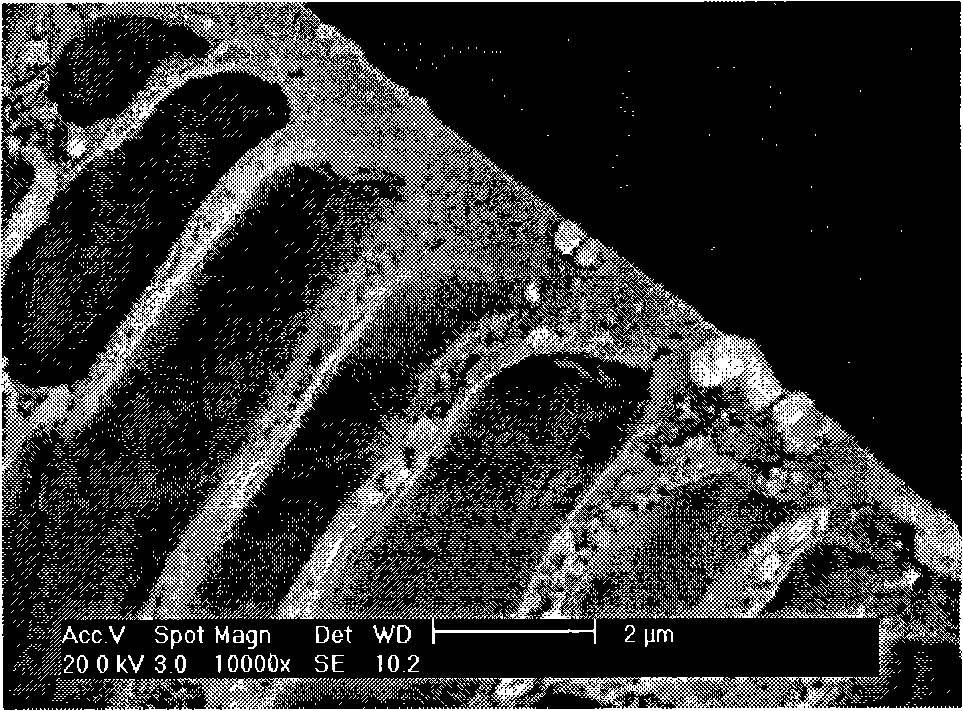

InactiveCN103046231AImprove interception effectSmall pressure lossSuction filtersLayered productsCrude fibrePolymer science

A melt spinning non-woven material is characterized in that the weight of the non-woven material weights 35 to 500 g / m<2> and being obtained by a polymer slice being directly melting to spin and the spine being weaved into webs. The melt spinning non-woven material consists of superfine fibers and crude fibers, the crude fibers are used as a framework and the superfine fibers are filled into the framework to form a fiber web to form a thickness matching structure. The fiber web has one layer or more, and when the layer number of the fiber web is more than one, a thickness increasing or gradient structure is formed through a multilayer structure. By means of the optimization of raw materials and process, the melt spinning non-woven material and a production method and an application of the melt spinning non-woven material can control a fiber web structure of the melt spinning non woven material: the distribution of fiber finenesses is controlled in a reasonable range, the fiber web has a large amount of superfine fibers and a certain amount of crude fibers; the crude fibers being used as a framework and the superfine fibers being filled into the framework improve the fluffiness of the material, and the material can still maintain some recovery capability when in use; and the fiber web forms a structure with some gradients.

Owner:ZHEJIANG ZHAOHUI FILTRATION TECH

Carboxylic oxidized graphene and method for modifying organic release film by means of same

ActiveCN105921031AEasy to chargeImprove hydrophilicityMembranesSemi-permeable membranesSolubilityChemical reaction

The invention discloses a carboxylic oxidized graphene preparing method and a method for modifying a release film by means of carboxylic oxidized graphene. According to the carboxylic oxidized graphene preparing method, oxidized graphene solution is used as the raw material, amino acid serves as the carboxylation reagent, the ph value of a reaction system is adjusted to be alkaline, heating reaction is conducted for a while, then natural cooling and dialysis are conducted in sequence to remove foreign ions, and then carboxylic oxidized graphene solution is obtained. When the carboxylic oxidized graphene solution is used for modifying a functional layer of the organic release film, carboxylic oxidized graphene is used as a modifier, and the surface functional layer of the organic release film is modified through chemical blending modification, interfacial polymerization modification, surface graft modification or self-assembly modification. Oxidized graphene with higher carboxyl functional group content can be obtained, higher hydrophilia, solubility, electric charge property and chemical reactivity of oxidized graphene can be realized through higher carboxyl content, and then the release film has higher permeability, entrapment property and hydrophilia.

Owner:高学理

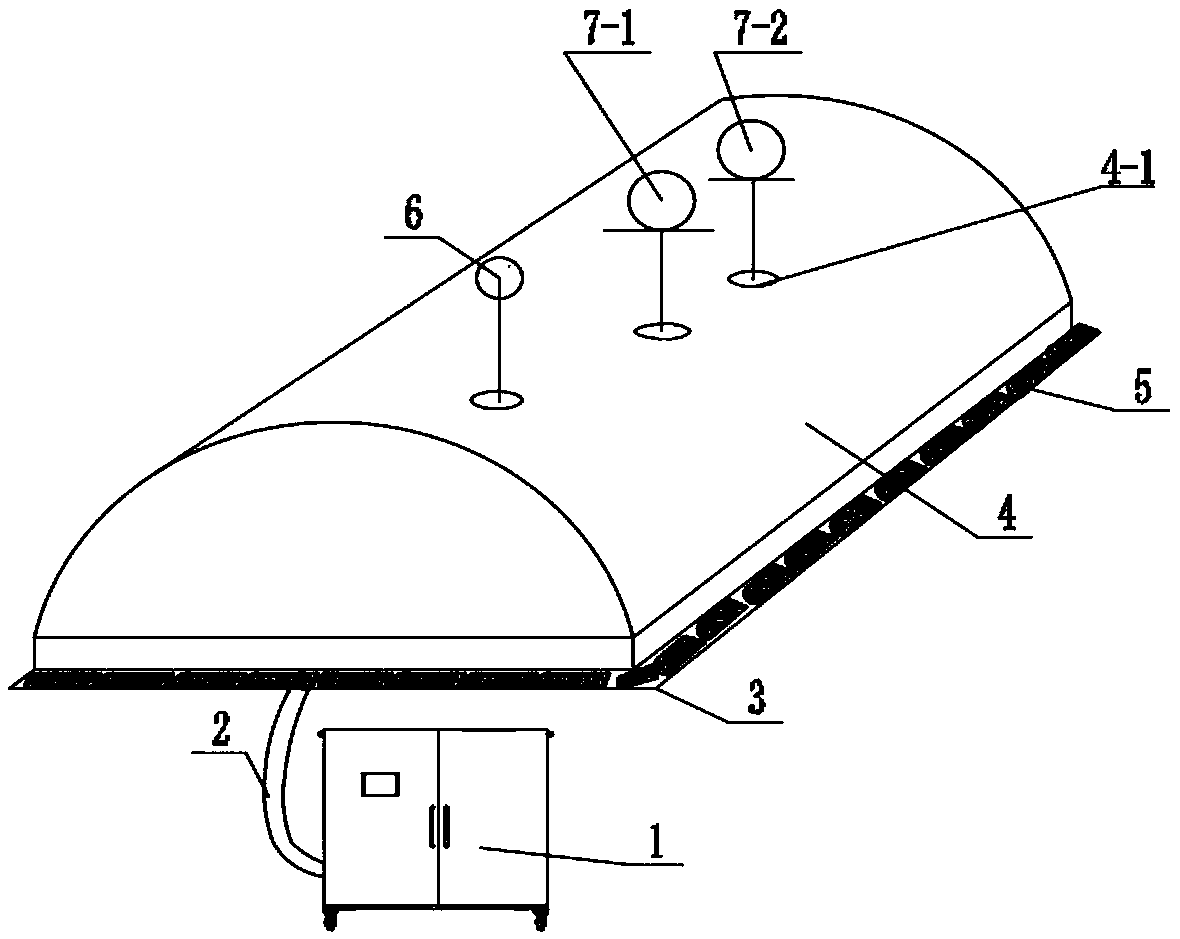

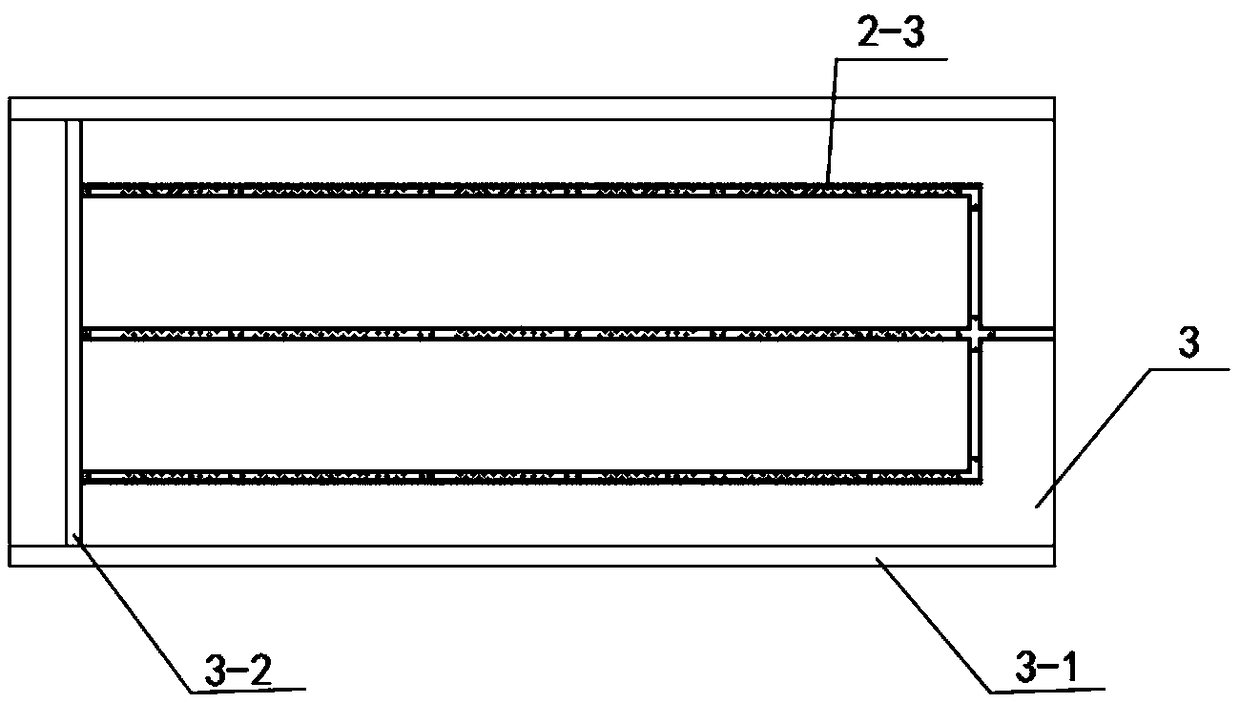

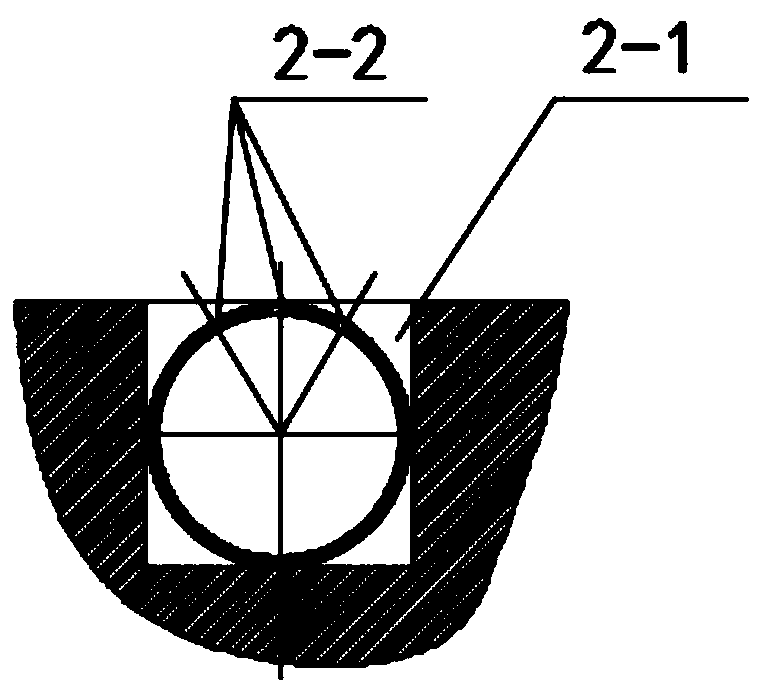

Nano membrane aerobic composting device for livestock manure

ActiveCN109160829AAvoid secondary pollutionReduce shipping costsClimate change adaptationExcrement fertilisersLivestock manureHazardous substance

The invention relates to a nano membrane aerobic composting device for livestock manure. The device comprises a host, a supply duct, an anti-seepage layer, a composite nano membrane, a sealing device,a multi-point temperature sensor, a moisture content sensor and an oxygen concentration sensor. The device is outstanding in environmental protection, involves composting between open and closed aerobic composting, and is suitable for treating the livestock manure in situ or near a farm to avoid secondary pollution caused by transfer; the composite nano membrane effectively blocks the emission ofharmful substances such as odor, pathogenic bacteria and aerosol, the environmental condition in the membrane is efficiently controlled to form an internal environment suitable for microbial life metabolism, and the composting fermentation process is effectively controlled through a feedback regulation mechanism, so that the livestock manure is composted more thoroughly and the cost is lower. Thedevice has simple requirements for sites, does not need to build a factory building, can be used in the open air, is easy to operate, automatic in operation and unmanned, and can be monitored and controlled remotely to save labor and time.

Owner:领先生物农业股份有限公司

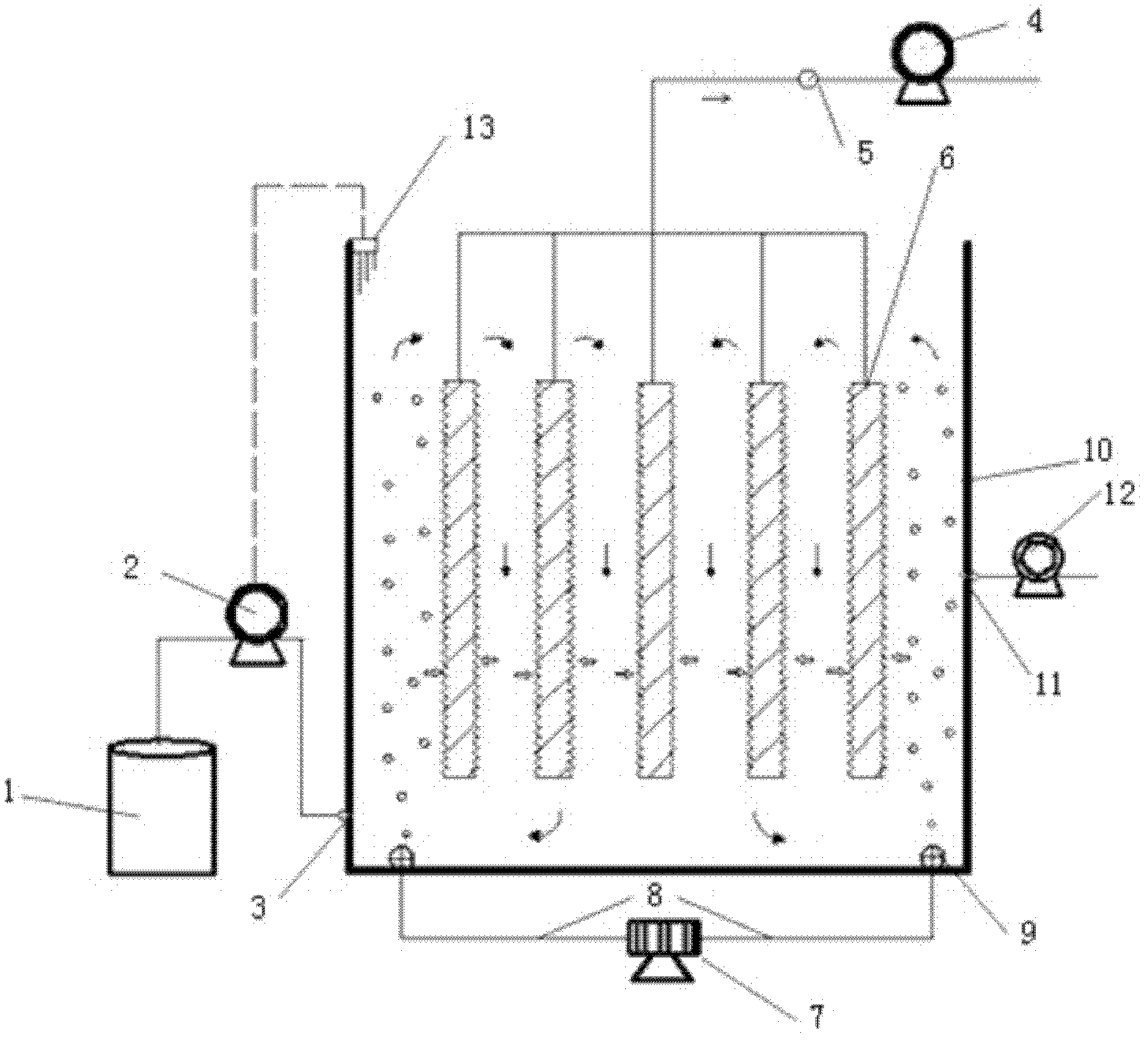

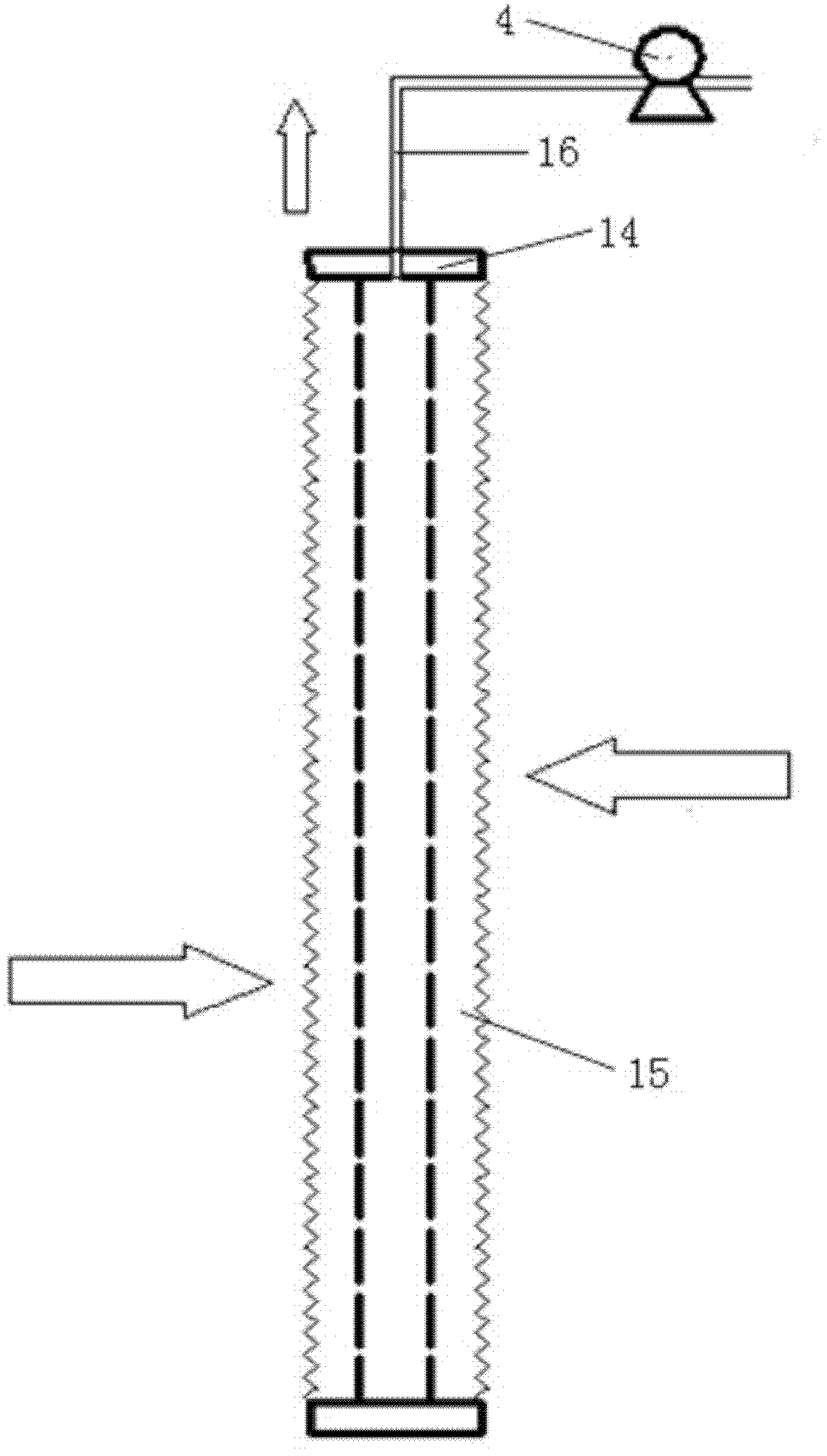

Biological membrane-activated sludge composite membrane bioreactor for denitrification and water treatment method using same

ActiveCN102557255AAchieve nitrificationThe process of achieving denitrificationTreatment with aerobic and anaerobic processesSustainable biological treatmentActivated sludgeWater treatment

The invention discloses a biological membrane-activated sludge composite membrane bioreactor. The composite membrane bioreactor utilizes non-woven fabric as a biological membrane carrier and a filter medium to perform coupling action with suspended sludge, thus finally achieving the purpose of high-efficient denitrification. The composite membrane bioreactor comprises a water inlet pipeline communicated with a reaction tank, a water outlet pipeline and a sludge discharge pipeline, wherein a plurality of membrane components and microporous aeration pipes are arranged in the reaction tank. Each membrane component consists of a support plate and non-woven fabric and is connected with a water outlet pump, and the membrane components consisting of the non-woven fabric can play functions of both the biological membrane carrier and the membrane filter. The composite membrane bioreactor disclosed by the invention can not only remove organic matters and nitrogen in sewage with high efficiency, but also realize high mass transfer efficiency, and further has the advantages of compact process structure, capability of saving the adding amount of alkalinity, capability of saving operation cost and the like.

Owner:广州宏诚检测有限公司

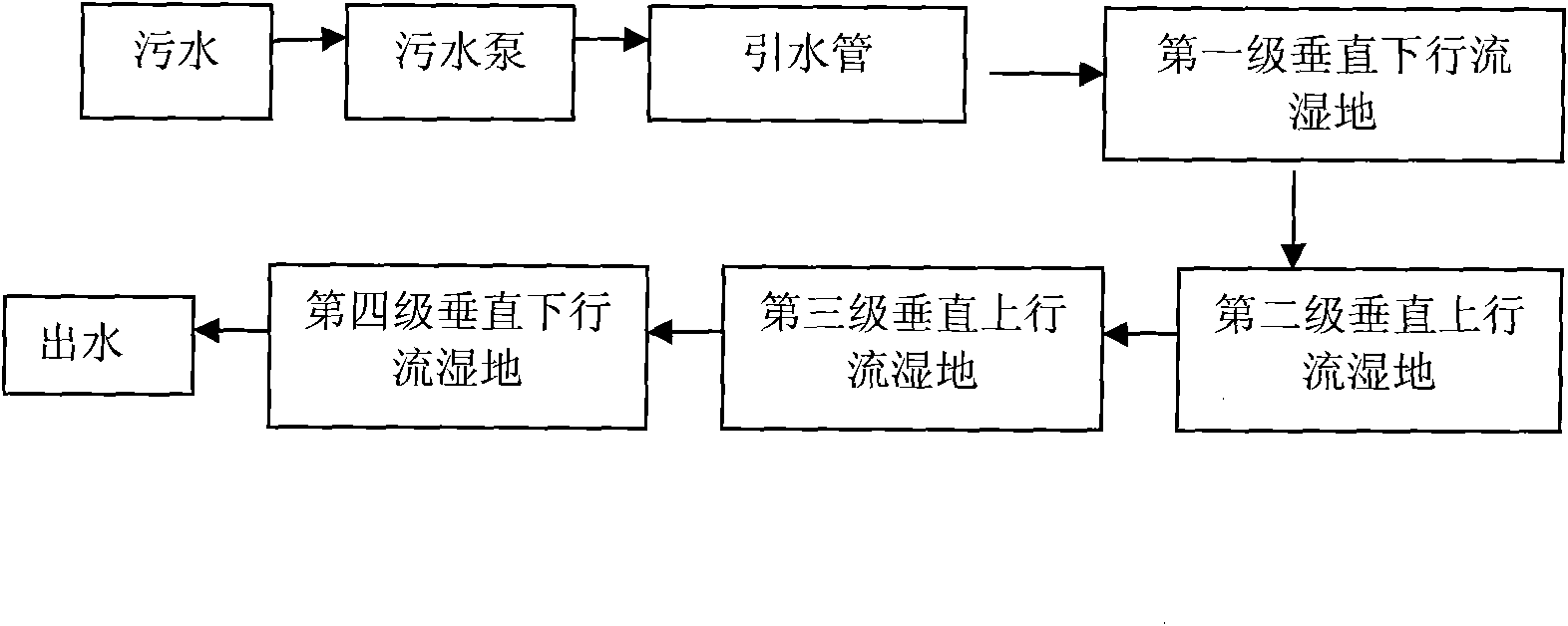

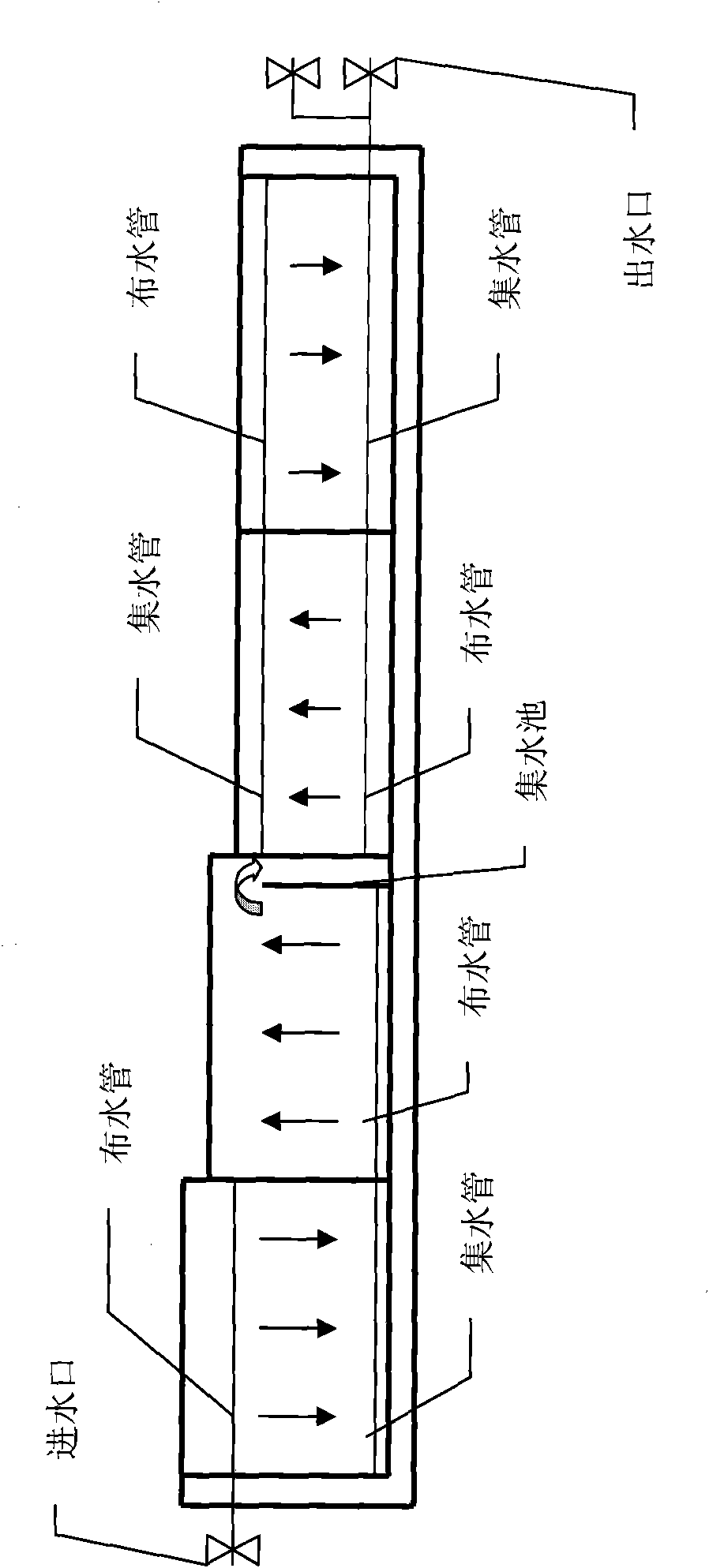

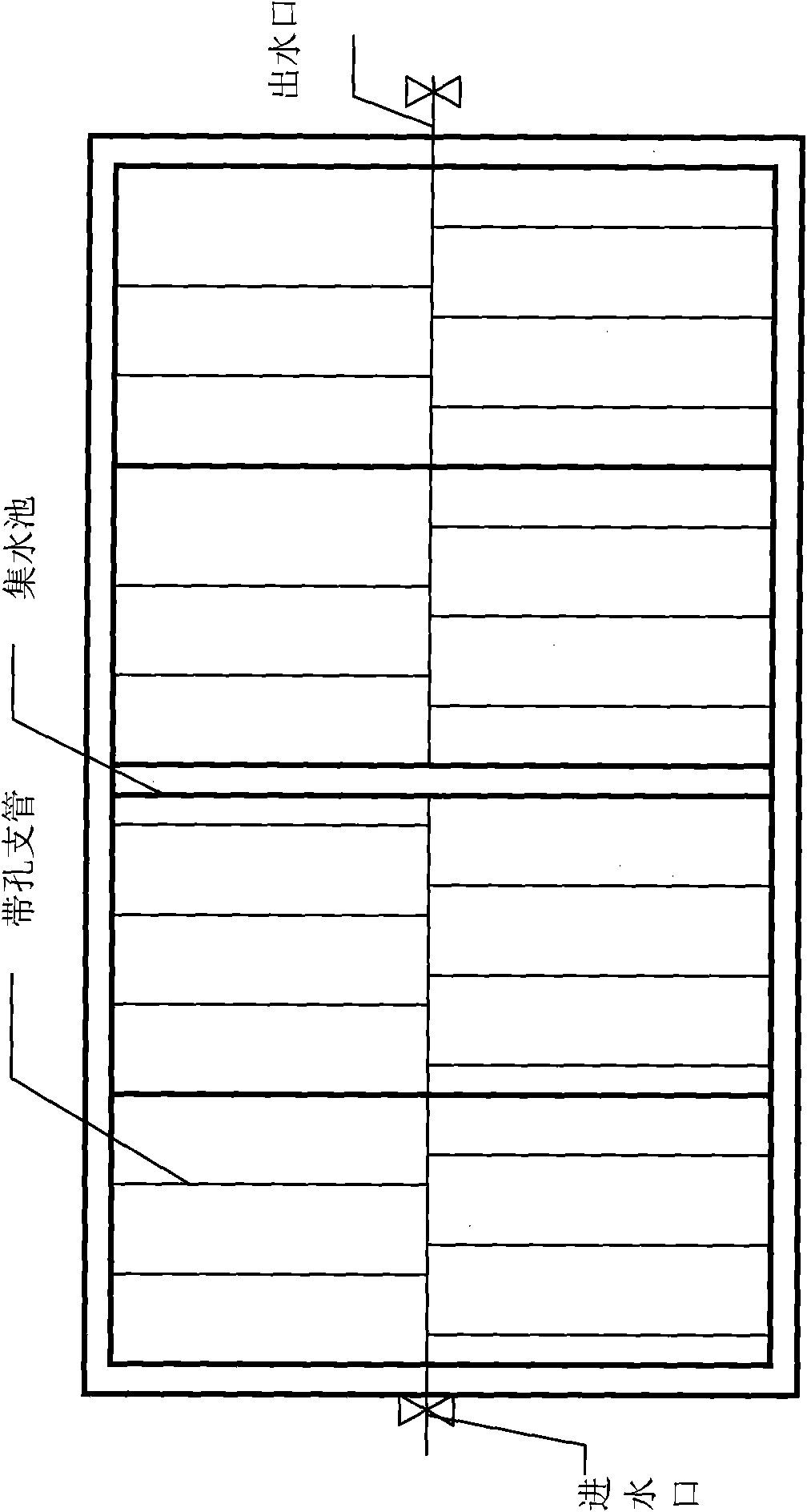

Method for processing sewage by multilevel vertical-current compound manual wetting ground and processing system thereof

InactiveCN101671096AGood removal effectFully contactedTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentConstructed wetlandPhosphor

The invention discloses a method for processing sewage of a multilevel vertical-current compound manual wetting ground system and a processing system thereof. The method comprises the steps of addinga vertical downstream and a vertical upstream wetting ground processes based on the compound vertical downstream-upstream manual wetting ground process, and treating the sewage by a four-level serialvertical current manual wetting ground process. The vertical-current manual wetting ground comprises a bed, a water distributing pipe and a treating medium. The sewage is uniformly distributed into the wetting ground by the water distributing pipe through a first-level vertical downstream manual wetting ground and the processed sewage is processed in a fourth-level vertical downstream manual wetting ground by orderly passing through a second and a third-level vertical upstream manual wetting ground units. The invention has low processing cost, occupies small area and can obviously remove nitrogen and phosphor.

Owner:东莞市华清净水技术有限公司 +1

Preparation method of composite forward osmosis membrane

ActiveCN103962015AImprove salt interception rateHigh water fluxSemi-permeable membranesWater channelCellulose acetate

The invention provides a preparation method of a composite forward osmosis membrane. A nanotube and cellulose triacetate are combined, the nanotube has a good water channel, the transferring speed of water molecules in the forward osmosis membrane is increased, the water flux in a forward osmosis process is greatly improved, the saline ion interception capability is improved, and the salt intercepting rate of the forward osmosis membrane is improved due to the special cavity structure of the nanotube. The invention also provides the composite forward osmosis membrane prepared by the method. The composite forward osmosis membrane has high water flux and high salt intercepting rate.

Owner:ETERNAL GUANGDONG TECH ELECTRIC CO LTD

Method for preparing loose nanofiltration membrane based on interfacial polymerization

ActiveCN110180402AImprove hydrophilicityImprove structural stabilitySemi-permeable membranesMembranesNanoparticlePolyamide

The invention discloses a method for preparing a loose nanofiltration membrane based on interfacial polymerization. The method comprises the following steps: preparing a polymer casting solution, dispersing nanoparticles in an aqueous phase monomer and an oil phase monomer, and preparing a flat plate support membrane; immersing the flat plate support membrane in the water phase monomer, then pouring the oil phase monomer into the aqueous phase monomer, and loading a nano membrane onto the surface of the flat plate support membrane after the two phase monomers are subjected to an interfacial polymerization reaction. The composite nanofiltration membrane prepared by the method has a loose structure on the surface; nano materials are embedded into a polyamide nano thin layer during the interfacial polymerization reaction; on the one hand, the hydrophilicity of the surface of the membrane can be improved; on the other hand, in the process of polycondensation, polyamide is simultaneously grown around the materials in the direction perpendicular to the nano materials to form such a sandwich structure; upper and lower polyamide layers can protect the nano materials from being damaged under high operating pressure; the structure of the polyamide nano membrane is regulated; meanwhile, the structural stability, permeability and retention property of the nanofiltration membrane are improved.

Owner:TSINGHUA UNIV

Composite nanofiltration film and preparation method thereof

ActiveCN110917897ABacteriostaticEnvironmentally friendlySemi-permeable membranesUltrafiltrationSurface modification

The invention provides a composite nanofiltration film and a preparation method thereof, the composite nanofiltration film comprises an ultrafiltration base film and a surface active layer, and the surface active layer comprises a reaction product of chitosan quaternary ammonium salt, beta-cyclodextrin and a cross-linking agent. The method for preparing the composite nanofiltration film comprisesthe following steps: (1) treating the ultrafiltration base film by using a surface active layer solution; and (2) forming a surface active layer. The composite nanofiltration film is prepared by adopting a blending or surface modification matched crosslinking or interfacial polymerization method, the conditions are controllable, the operation is simple, the subsequent heat treatment conditions areadjustable, the continuous production can be realized, and the industrial prospect is realized. The composite nanofiltration film provided by the invention has the advantages of good hydrophilicity,high water flux, good pollution resistance, good interception performance on heavy metal ions, environment-friendly material, low cost, no toxicity and certain antibacterial performance.

Owner:中化(宁波)润沃膜科技有限公司

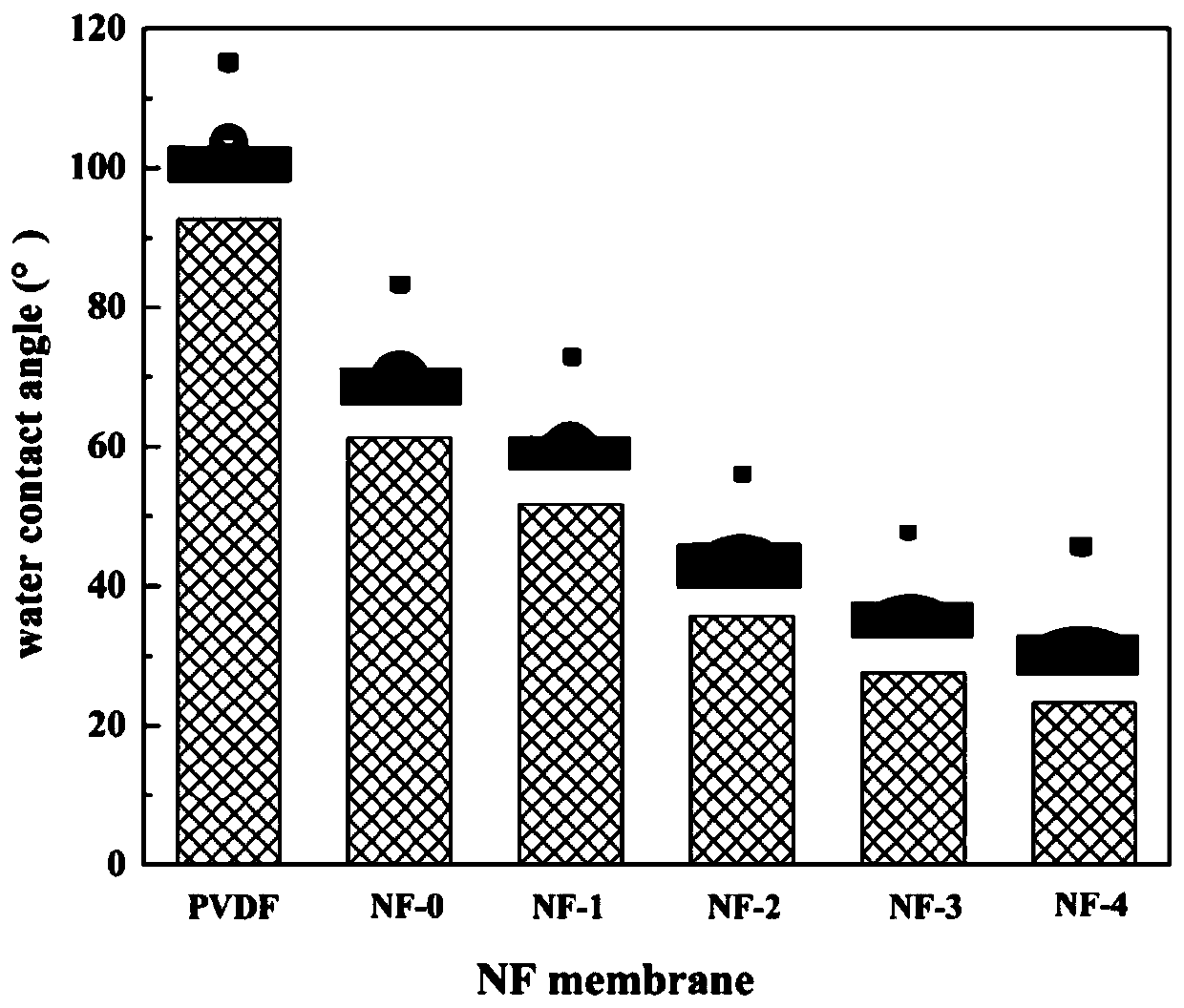

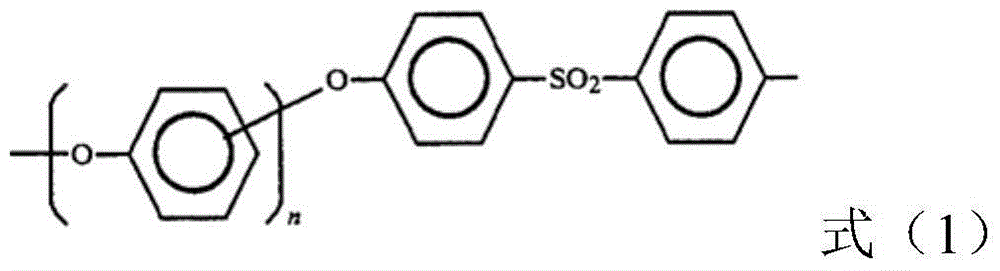

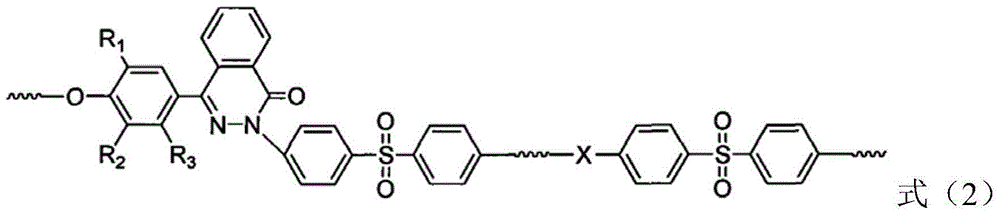

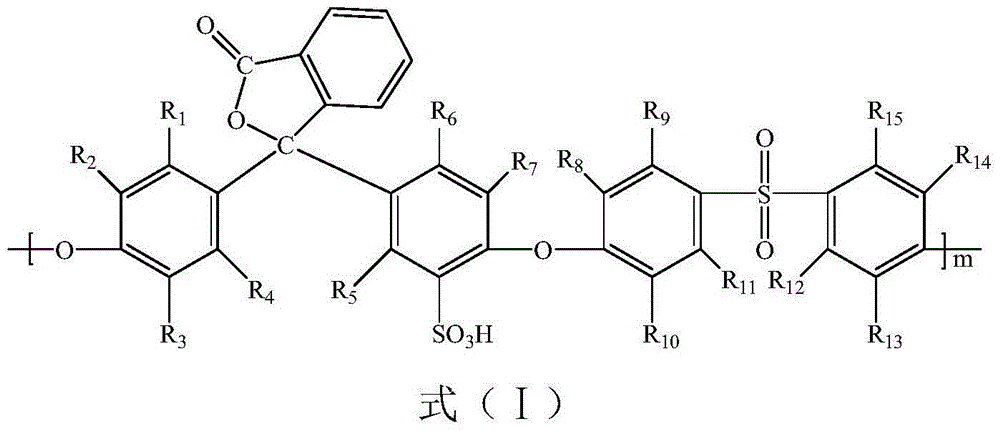

Nanofiltration membrane as well as preparation method and application thereof

ActiveCN104548970AImprove performanceIncrease water fluxSemi-permeable membranesGeneral water supply conservationEtherAnionic polymers

The invention provides a nanofiltration membrane, a preparation method of the nanofiltration membrane, and an application of the nanofiltration membrane prepared with the method in the water treatment field. The nanofiltration membrane comprises an electronegative support layer and at least one separation layer located on the surface of the support layer, wherein the separation layers comprise polycationic layers and polyanionic layers which are sequentially laminated; the polycationic layers are contacted with the support layer; or the nanofiltration membrane comprises an electropositive support layer and at least one separation layer located on the surface of the support layer; the separation layers comprise polyanionic layers and polycationic layers which are sequentially laminated; the polyanionic layers are contacted with the support layer; and an anionic polymer in each polyanionic layer is sulfonated poly ether sulfone with the structure as shown as Formula (I) and / or Formula (II) as shown in the specification. The nanofiltration membrane has excellent desalinization ratio, water permeability and acid-alkali corrosion resistance, and has a good industrial application prospect.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing braided tube/polymer composite hollow fibrous membrane by thermal induced method

ActiveCN102553463AReduce binding resistanceExtended service lifeSemi-permeable membranesFiberHigh flux

The invention discloses a method for preparing braided tube / polymer composite hollow fibrous membrane by a thermal induced method. The method comprises the following steps of: preparing membrane-casting liquid 1 and membrane-casting liquid 2; dipping a polyethylene glycol terephthalate (PET) braided tube in a boiling NaOH solution with certain concentration to remove oil stains remained on the braided tube; modifying the braided tube of a supporting layer with a modifier; coating the high-molecular polymer membrane-casting liquid 1 onto the filament surface of the braided tube by a one-time dipping and one-time rolling method, thermoforming the round tube, and curing the tube in a gel bath; uniformly coating the membrane-casting liquid 2 on the outer surface of the membrane-laminated fibrous braided tube with spinning equipment, and curing composite filaments in cooling liquid; and displacing a diluent from a formed membrane with an extracting agent, and rinsing the membrane filamentsto obtain the braided tube / polymer composite hollow fibrous membrane. The braided tube / polymer composite hollow fibrous membrane prepared by the method has the characteristics of high flux, strength and interception and high-pressure backwash resistance; and moreover, the supporting layer and the coating layer are difficult to separate.

Owner:SUZHOU CNPT SOURCETECH ENVIRONMENTAL TECH

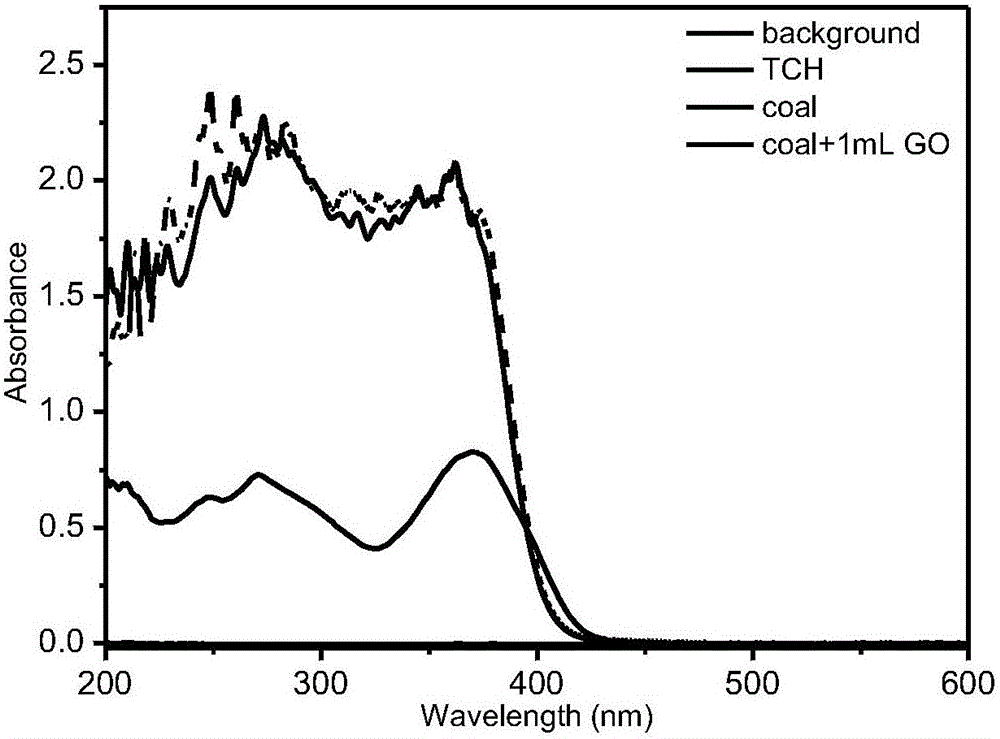

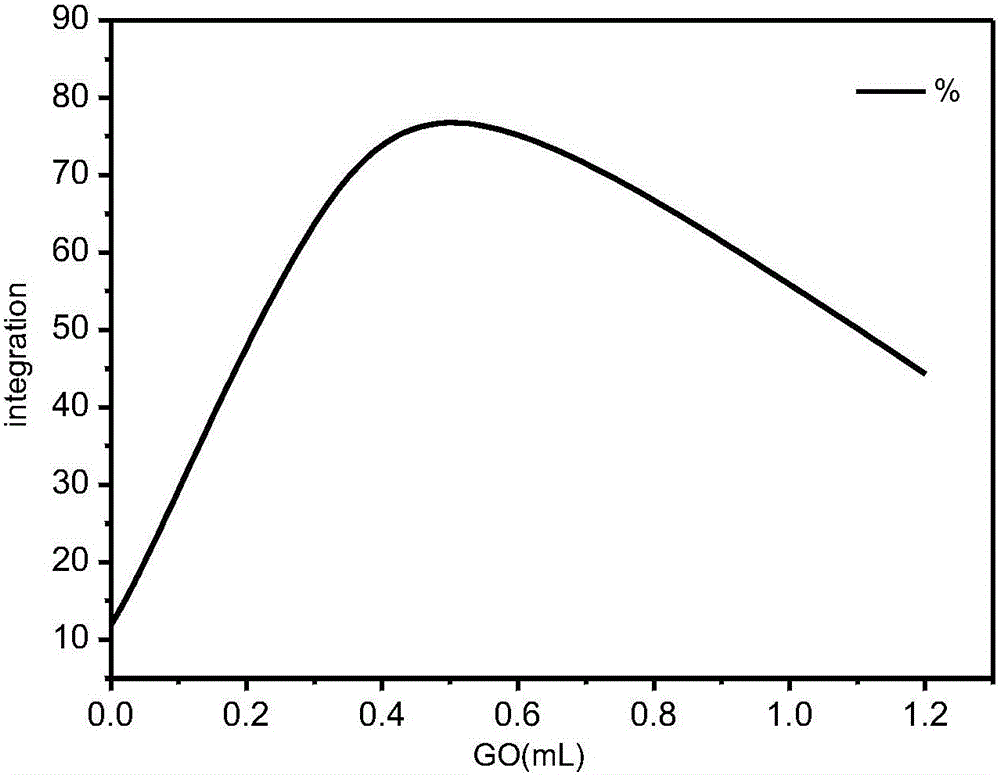

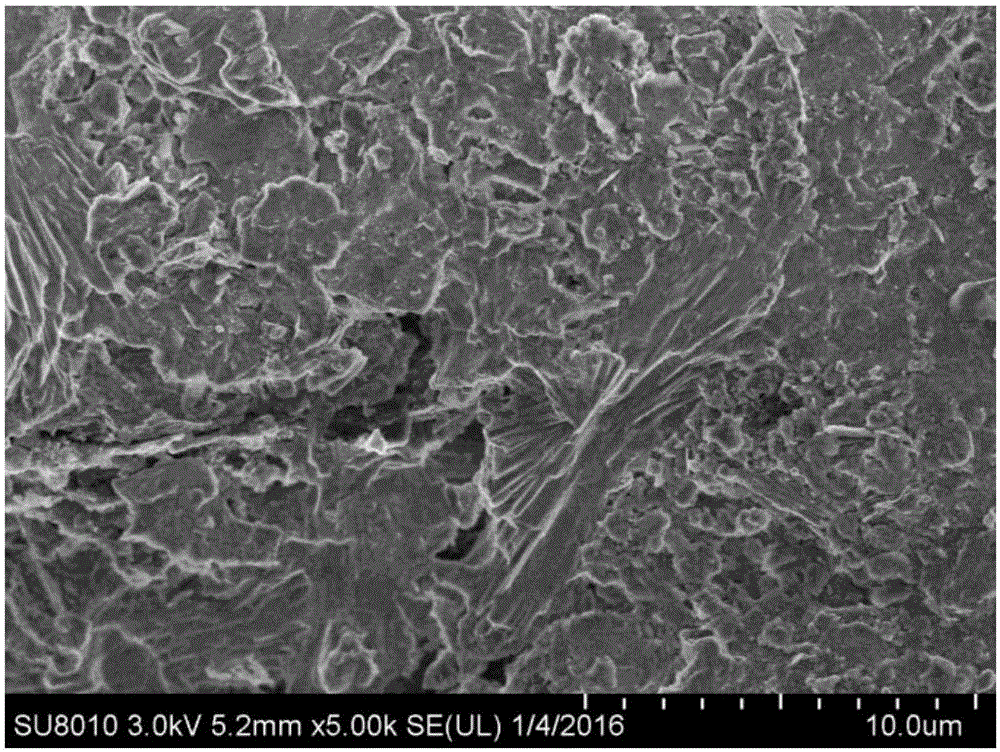

Graphene carbon filtering material and preparation method thereof

InactiveCN105709498AImprove interception effectImprove filtering effectOther chemical processesMembrane filtersActive carbonCarbon filtering

The invention discloses a graphene carbon filtering material and a preparation method thereof. The material includes fruit shell active carbon granules, wherein 1% of graphene oxide is contained in gaps at bottoms of active carbon. The method includes the following steps of weighing granular and columnar active carbon, adding graphene oxide dispersion liquid after drying according to the mass ratio of 250:1, stirring for 30 minutes, conducting ultrasonic treatment for 30 minutes, and drying after repeatedly conducting stirring and ultrasonic treatment twice. By means of the filtering material, antibiotics in drinking water can be effectively removed, and the efficient filtering material is provided for current water treatment, especially the purification of drinking water.

Owner:XUZHOU SHENLAN NEW MATERIAL TECH CO LTD

Preparation method of dual-purpose filter material for dedusting and decomposing dioxins

The invention discloses a preparation method for double action filtering material capable of dedusting and decomposing dioxin. The material comprises the following five-layer structure: a first layer is a dust receiving layer formed by polytetrafluoroethylene fibers through carding process; a second layer is a buffer layer formed by fine denier polytetrafluoroethylene fiber through preneedling processing; a polytetrafluoroethylene film carrying a catalyst is processed into reticular structure fibers by a film splitting method, and a plurality of films are laminated to form a catalysis layer which is a third layer; a fourth layer is a Teflon base cloth reinforced layer; and the four layers are laminated, then the dust receiving layer is laminated on the base cloth reinforced layer, and finally the material is formed through needling processing. The material can be widely applied to the dedusting and dioxin decomposition of high temperature off gas. Compared with the prior art, the preparation method has the advantages of simple and feasible process, low processing cost, and lower requirements on the equipment; and simultaneously the preparation method removes the defects of great fiber loss and a great drag force for the filtering material.

Owner:ZHEJIANG SCI-TECH UNIV

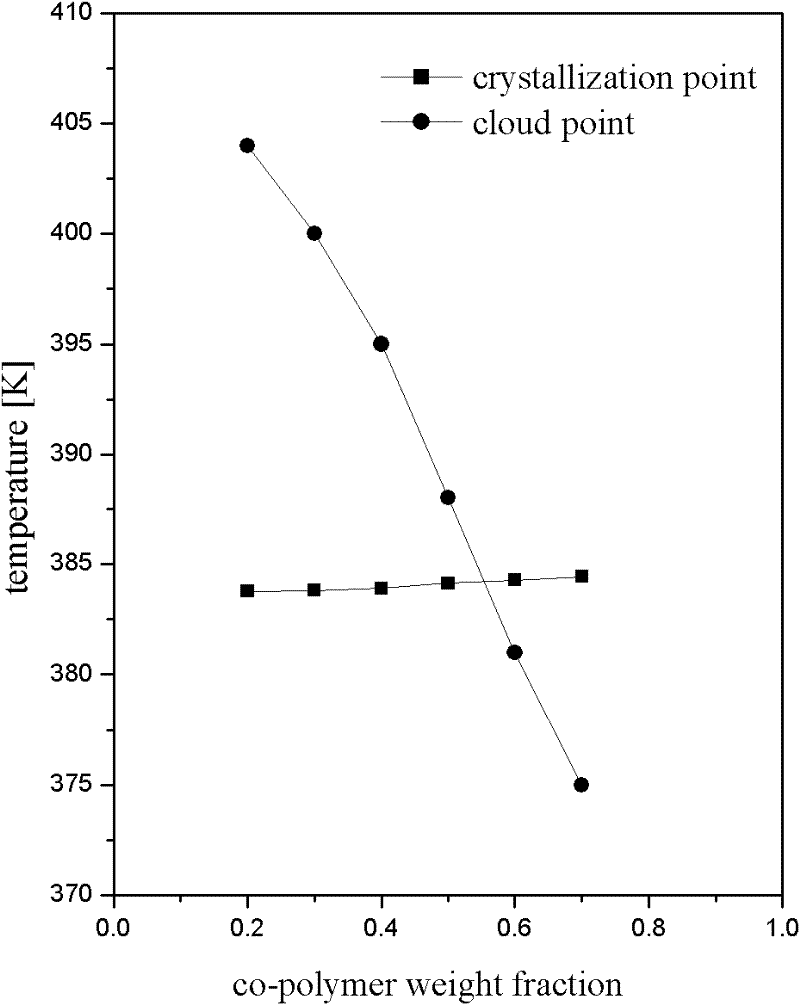

Forward-osmosis film and preparation method thereof

The invention provides a forward-osmosis film and a preparation method thereof. The forward-osmosis film comprises a support layer, the support layer is a superfilter film, oxidized graphene, and 0-2nd generation polyamide-amide blend. The forward-osmosis film is high in water flux, graphene layers are not easy to shed among layers and from the superfilter film as interlayer distance among oxidized graphene layers is constant, and distance among the oxidized graphene layers can be adjusted. Meanwhile, the forward-osmosis film has high cutoff performance for negative and positive ions in the solution, and the overall cutoff performance of the film is optimized.

Owner:HEILONGJIANG BAYI AGRICULTURAL UNIVERSITY

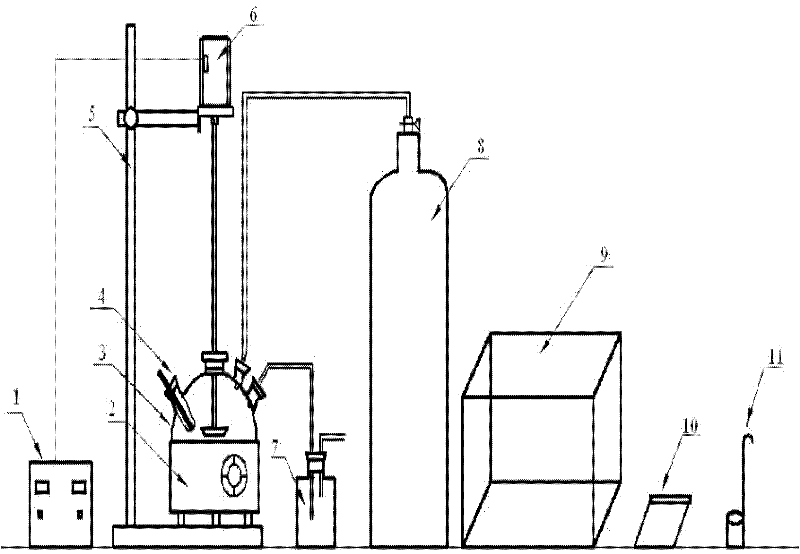

Method for preparing hydrophobic microporous membrane and membrane prepared by method

The invention relates to a method for preparing hydrophobic microporous membrane and a membrane prepared by the method. The method comprises the following step of successfully preparing an ethylene-propylene copolymerization hydrophobic microporous membrane from polypropylene (iPP) and high-density polyethylene (HDPE) serving as membrane materials by taking soybean oil as a diluting agent, adipic acid as a nucleating agent and normal hexane as an extracting agent through a titerless infected-cells preservation and scale-up (TIPS) method. The invention develops a high-efficiency membrane preparing process, which comprises the following steps of: ensuring that the temperature of casting solution is between 190 and 200 DEG C, controlling the scraper temperature to be about 210DEG C, and ensuring that the temperature of a quenching water bath is 20DEG C; and determining that a flat membrane forming mass ratio of the polypropylene to the polyethylene is 4:1-7:1 and the optimal membrane forming mass ratio is 6:1, and determining that the concentration range of the copolymer for membrane formation is 25 to 38 weight percent on the basis. The method is suitable for preparing flat membranes, hollow fibrous membranes, tubular membranes and the like; and the prepared membranes have the advantages of high hydrophobic property, low price, good performance and high chemical stability.

Owner:TIANJIN UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com