Melt spinning non-woven material and production method and application thereof

A non-woven material, melt spinning technology, applied in the field of materials, can solve problems such as restricting applications, and achieve the effects of improving fluffy performance, enhancing fluffiness, and long ash absorption time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. In this example, a plurality of unwinding devices with controllable tension are used; and a double-die melt blown equipment with a width of 1.6m, and the first die is used; and an ultrasonic bonding equipment with a width of 1.6m; and Constant tension winding device.

[0035] 2. The grammage of the high bulky nonwoven material obtained in this example is 100g / m 2 .

[0036] 3. In this example, the upper protection or support layer and the lower protection or support layer of the high-lofty nonwoven material are selected with a grammage of 10g / m 2 spunbond nonwovens.

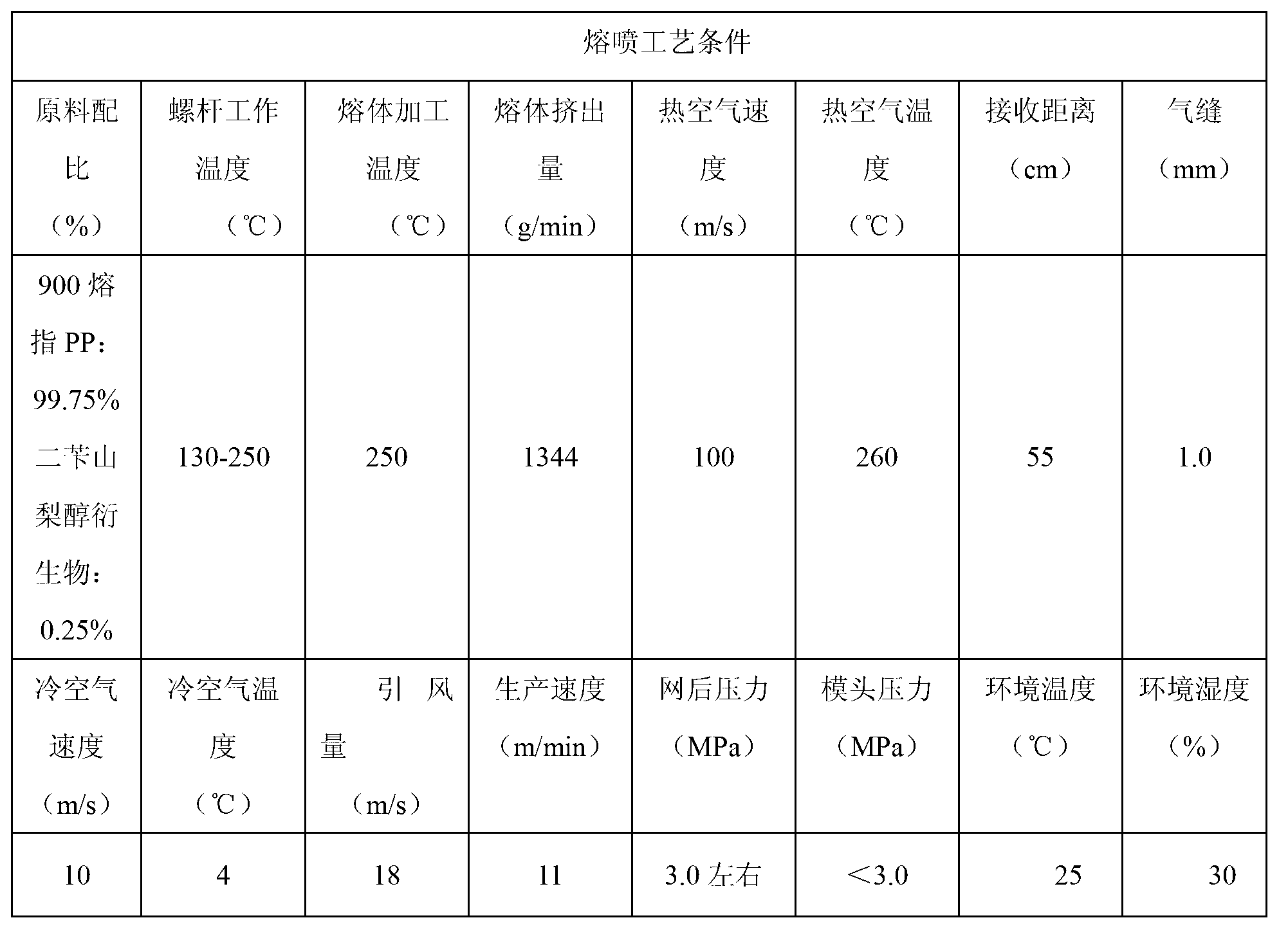

[0037] 4. In this embodiment, the melt-spun nonwoven material is obtained through the process control of the melt-spinning equipment, and the specific process conditions are as follows figure 1 .

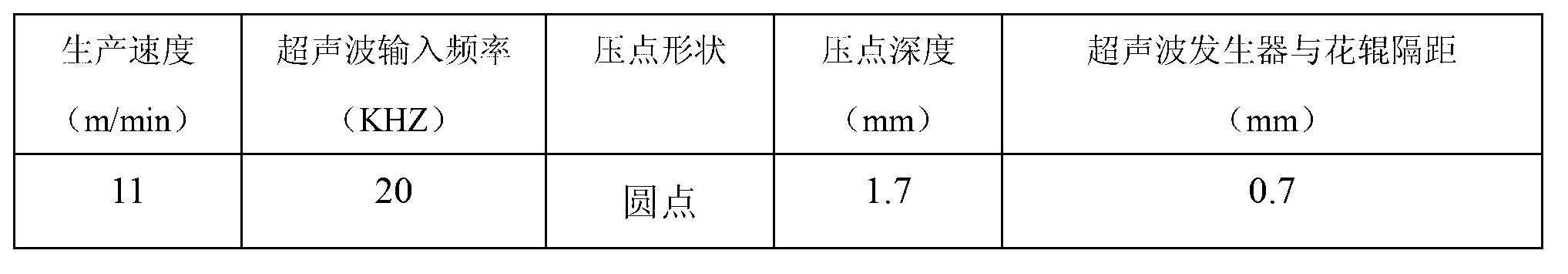

[0038] 5. In this example, the ultrasonic bonding process is used to achieve the bonding between the materials of each layer. The specific process conditions are as follows figure 2 .

[0039] 6. In this...

Embodiment 2

[0042] 1. In this example, multiple unwinding devices with controllable tension are used; and a double-die melt blown equipment with a width of 1.6m, and the first die head and the second die head are used; and an ultrasonic wave with a width of 1.6m bonding equipment; and constant tension rewinding devices.

[0043] 2. The grammage of the high bulky nonwoven material obtained in this example is 105g / m 2 .

[0044] 3. In this example, the upper protection or support layer and the lower protection or support layer of the high-lofty nonwoven material are selected with a grammage of 10g / m 2 spunbond nonwovens.

[0045] 4. In this embodiment, the high-loft layer of the high-loft nonwoven material is obtained through the process control of the melt-spinning equipment, and the specific process conditions are as follows Figure 4 .

[0046] 5. In this example, the ultrasonic bonding process is used to achieve the bonding between the materials of each layer. The specific process c...

Embodiment 3

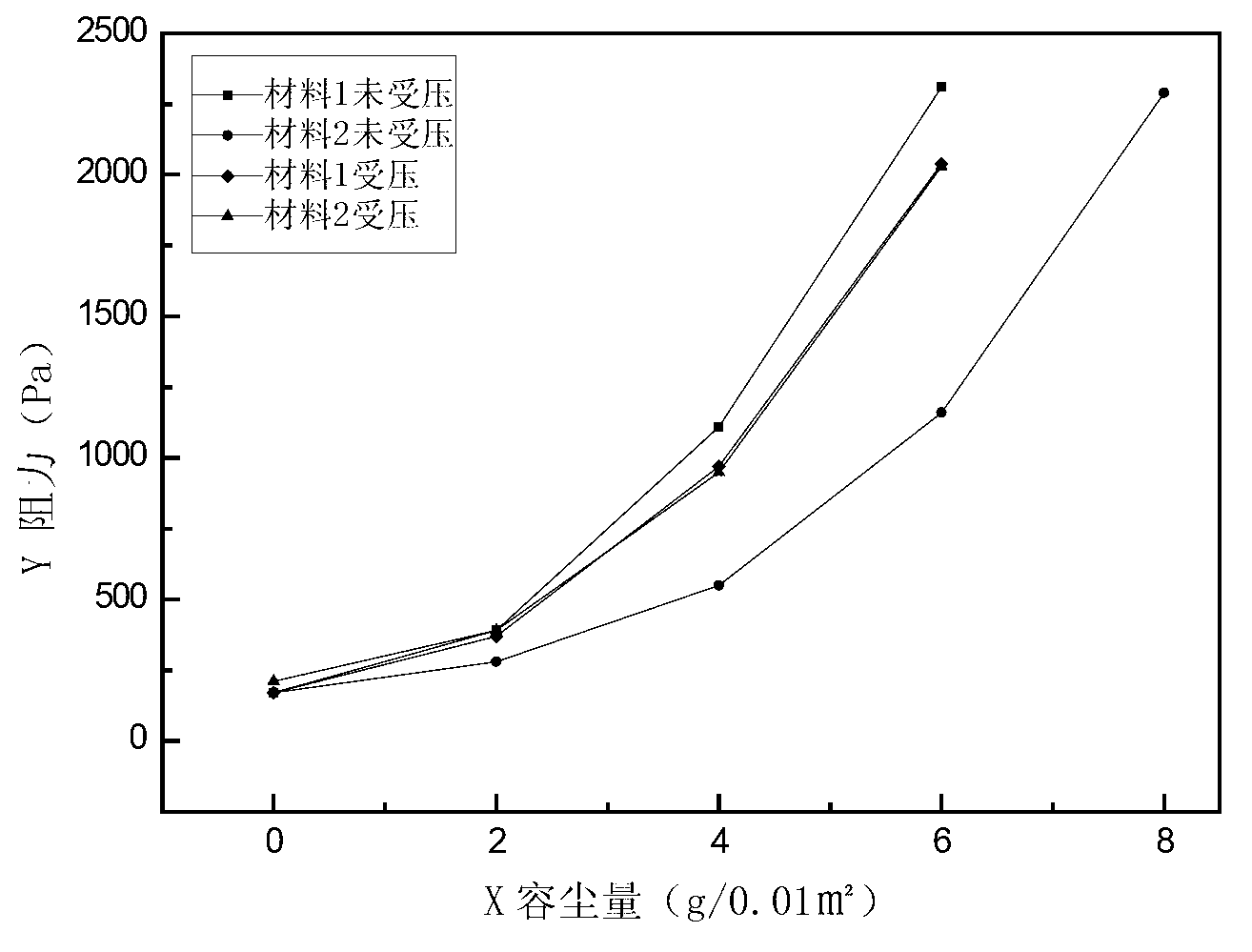

[0050] The vacuum cleaner filter bag obtained by the above process, the obtained suction power change schematic table is as follows Figure 8 Shown: where:

[0051] (1) The three bag filters in the example are of the same size (310mm×260mm), and the ironing process is ultrasonic welding;

[0052] (2) The suction power test in the example is a foreign brand machine, and the whole machine test is carried out under the same test conditions;

[0053] (3) This example shows the change trend of the suction power of the three material combinations during the process of sucking ashes to 500g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Basis weight | aaaaa | aaaaa |

| Basis weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com