Patents

Literature

3270 results about "Oil absorption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

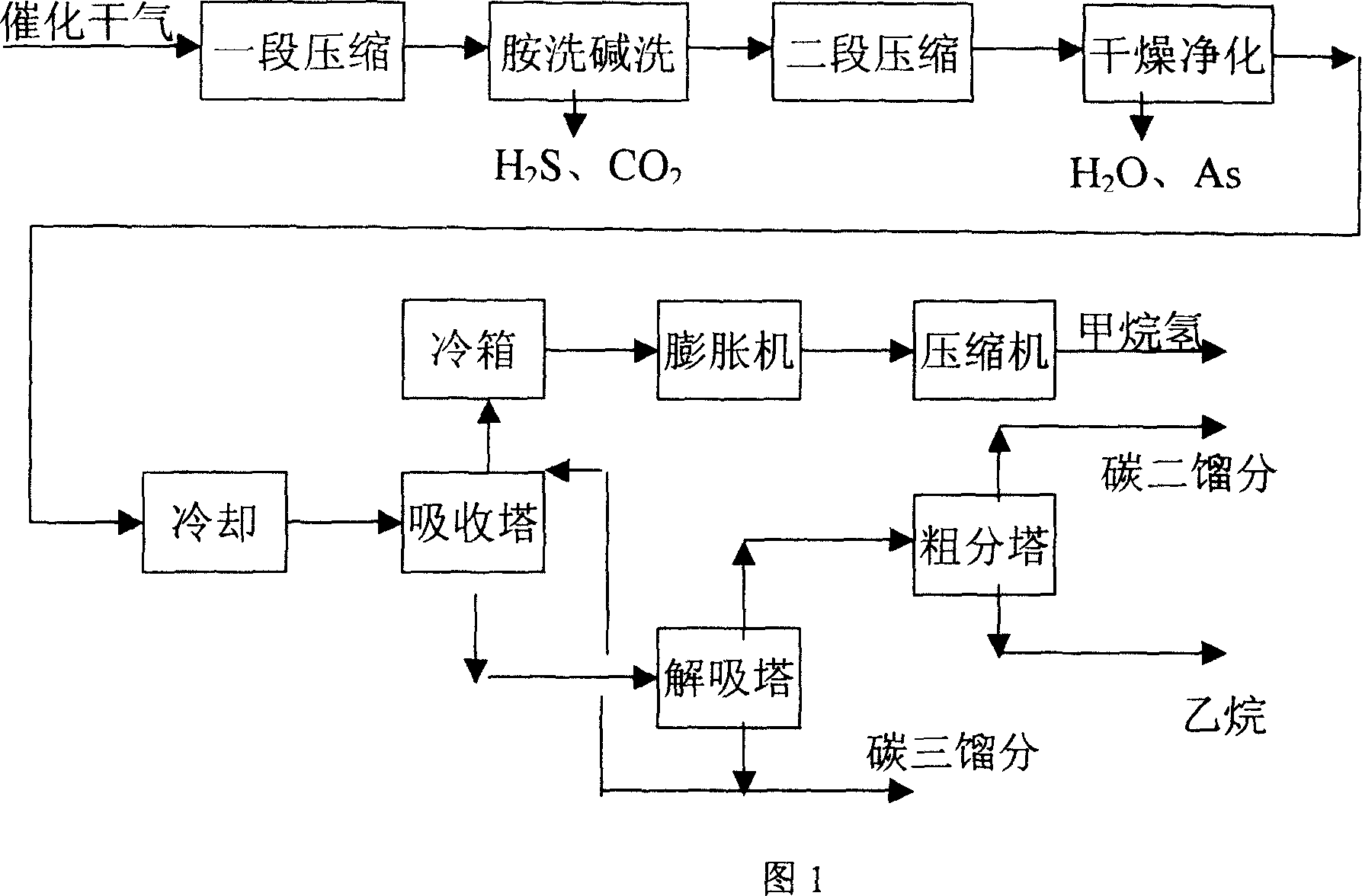

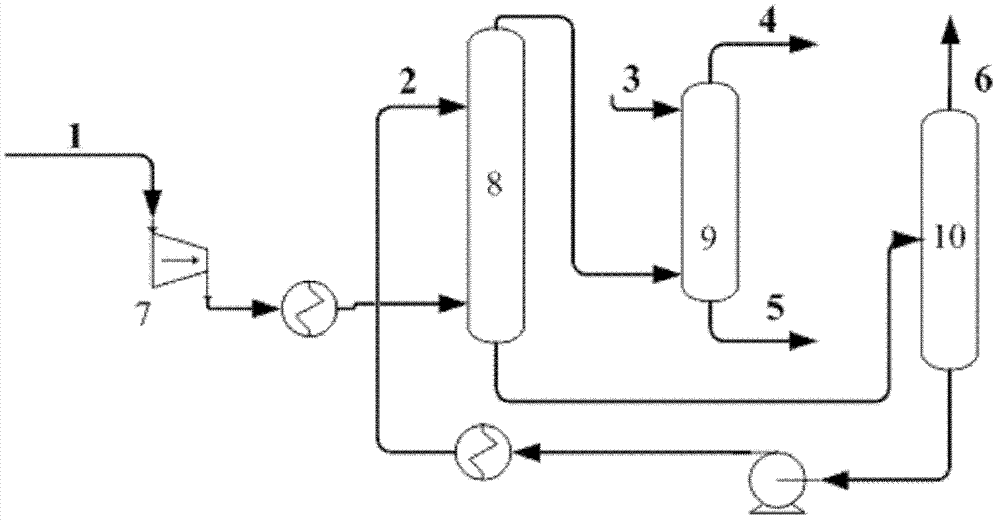

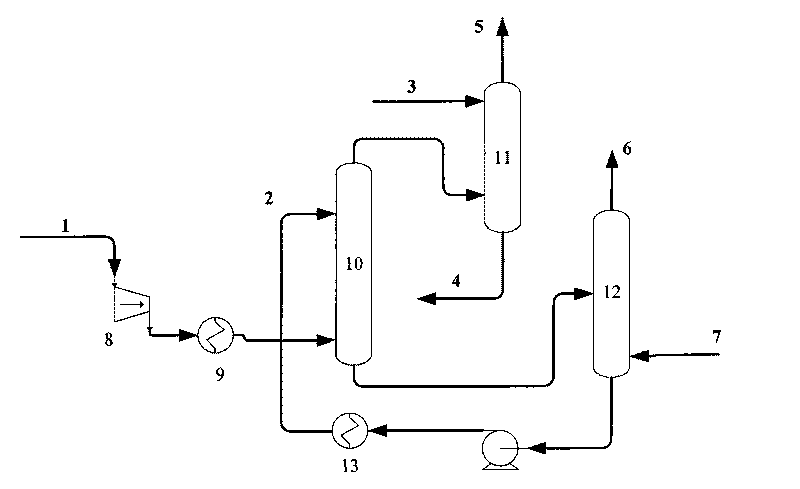

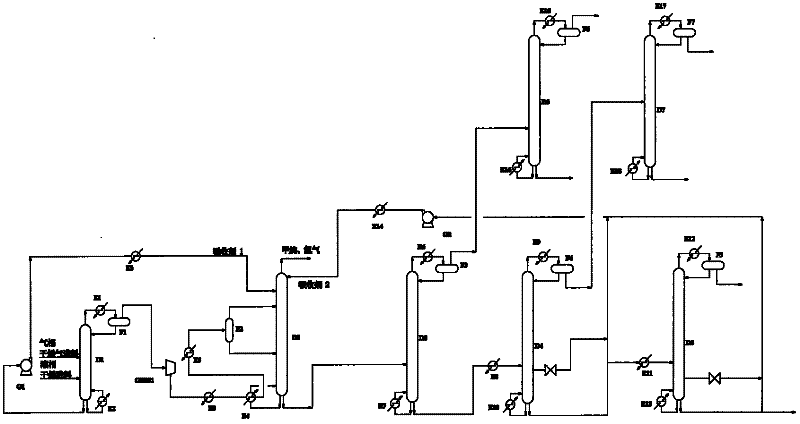

Method for separating plant catalytic dry gas by employing middle-cool-oil absorption process

InactiveCN101063048AEasy to getLow costOrganic chemistryEthylene productionProduct gasEnergy consumption

The invention discloses a separating refinery catalytic dry gas method with middle cold oil absorptive method in separating refinery catalytic dry gas technical domain, which comprises the following steps: compressing; stripping acid gas; drying; purifying; absorbing; desorbing; reclaiming cold energy; crude-separating. This invention possesses cheap cost, low lost, simple operation, little investment and low energy consumption, which can get C2 fraction and ethane.

Owner:CHINA PETROLEUM & CHEM CORP +1

Cable semiconducting shields

A semiconducting composition comprising (i) an olefinic polymer and (ii) about 25 to about 45 percent by weight, based on the weight of the composition, of a carbon black having the following properties: (a) a particle size of at least about 29 nanometers; (b) a tint strength of less than about 100 percent; (c) a loss of volatiles at 950 degrees C in a nitrogen atmosphere of less than about 1 weight percent based on the weight of the carbon black; (d) a DBP oil absorption of about 80 to about 300 cubic centimeters per 100 grams; (e) a nitrogen surface adsorption area of about 30 to about 300 square meters per gram or an iodine adsorption number of about 30 to about 300 grams per kilogram; (f) a CTAB surface area of about 30 to about 150 square meters per gram; and (g) a ratio of property (e) to property (f) of greater than about 1.1.

Owner:UNION CARBIDE CHEM & PLASTICS TECH CORP

Micronized perlite filler product

ActiveUS20060075930A1High blue lightness brightnessLow oil absorptionCoatingsPlastic filmFiller - product

Micronized perlite filler product, methods of producing the micronized expanded perlite products, and methods of use thereof are provided. The micronized expanded perlite product has, for example, a small median particle size (for example, less than 11 microns), a high blue light brightness (for example, higher than 84) and low oil absorption (for example, less than 70 percent in volume). The micronized expanded perlite product may be used in a variety of applications such as anti-block filler in plastic films and reinforcement filler in polymers.

Owner:IMERYS USA INC

Preparation method of ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption

InactiveCN103756006ASolve the defect of strong hydrophilicityLow densityCoatingsEnvironmental resistanceCellulose

The invention discloses a preparation method of an ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption, and relates to a preparation method of cellulose aerogel. The method disclosed by the invention aims to solve the problem that existing cellulose aerogel which is lower in oil absorption multiplying power and strong in hydrophilicity is not suitable for oil-water separating materials. The method comprises the following steps: I, preparing cellulose aqueous liquor; II, preparing a nano fibrillated cellulose aqueous dispersion liquid; III, preparing a strongly gelatinous nano fibrillated cellulose aqueous dispersion liquid; IV, freezing and drying; and V, carrying out hydrophobic modification to obtain the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption. The preparation method of the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption is simple in preparation process, wide in source of raw materials, low in cost and environment-friendly and green. The invention relates to the preparation method of the ultralight and hydrophobic nano fibrillated cellulose aerogel with high oil absorption.

Owner:NORTHEAST FORESTRY UNIVERSITY

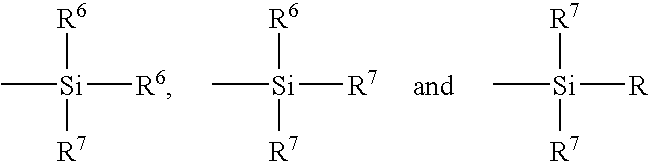

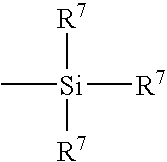

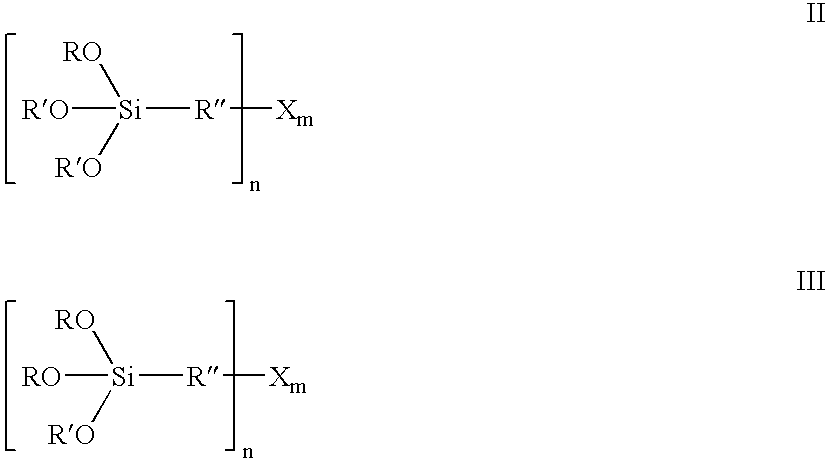

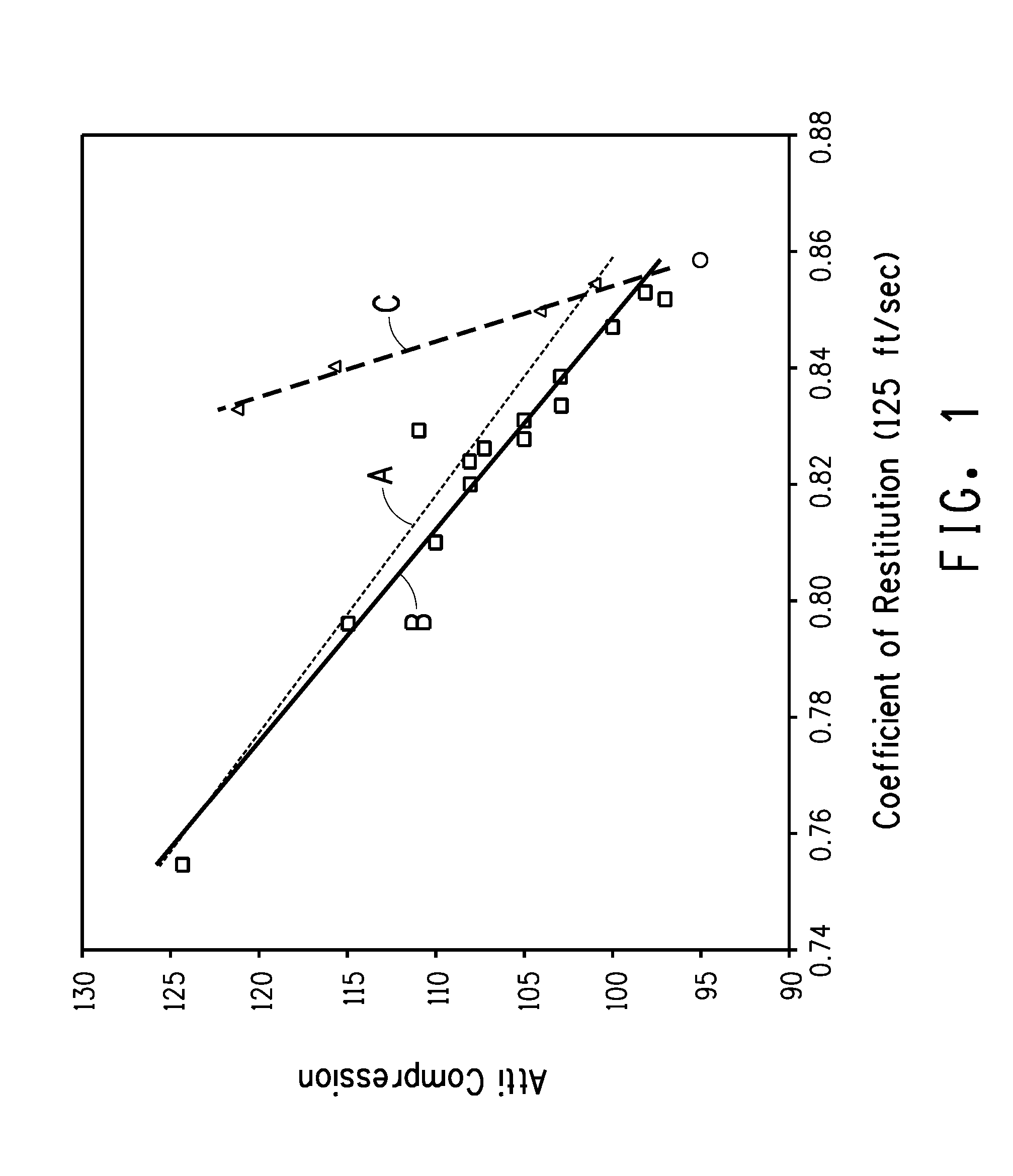

Pneumatic tire

The invention is directed to a pneumatic tire having a tread including a vulcanizable rubber composition including, expressed as parts by weight per 100 parts by weight of elastomer (phr),(A) 60 to 95 phr of solution-polymerized styrene-butadiene rubber with a bound styrene content of from 20 to 30 percent by weight, a vinyl 1,2 content of from 50 to 70 percent by weight based on the butadiene content, and a Tg of from about −40° C. to about −20° C.;(B) 5 to 15 phr of cis-1,4 polybutadiene having a Tg of from −95° C. to −105° C.;(C) 10 to 20 phr of 3,4-polyisoprene;(D) 30 to 70 phr of processing oil;(E) 10 to 30 phr of carbon black having an Iodine absorption ranging from 192 to 212 g / kg according to ASTM D-1510 and an oil absorption ranging from 126 to 142 cc / 100 g according to ASTM D-2414;(F) 90 to 110 phr of silica;(G) 0.5 to 20 phr of a sulfur containing organosilicon compound; and(H) 10 to 20 phr of resin.

Owner:THE GOODYEAR TIRE & RUBBER CO

Hydrogenation catalyst of diesel production at most amount and production thereof

A maximum hydrogen catalyst of diesel oil and its production are disclosed. The catalyst consists of amorphous silica aluminum, modified beta molecular sieve, aluminum oxide, VIB family and VIII family metals. Modified beta molecular sieve has high silicon and crystallinity, small crystal grain and acidity. It has good cyclanes selective loop open and alkane isomerization. Its advantages include higher heavy oil hydrogen crack activity and middle oil selectivity, better diesel oil absorption and lower filtering point, and it improves density, colloidal matter, iodine value and color.

Owner:CHINA PETROLEUM & CHEM CORP +1

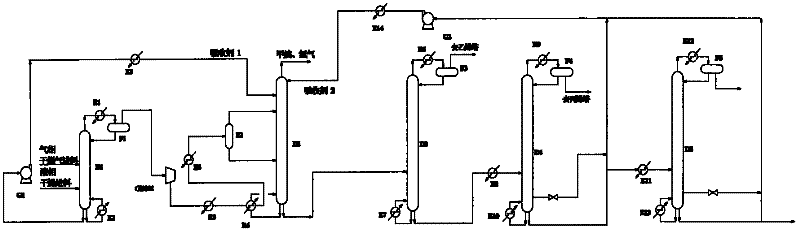

Device and method for separating refinery dry gas through oil absorption

InactiveCN103087772AEasy to getLow costGaseous mixture working upAbsorption purification/separationDesorptionGasoline

The invention discloses a device and a method for separating refinery dry gas through oil absorption. The device comprises a C4 absorption tower and a C4 desorption tower. A gasoline absorption tower is arranged after the C4 absorption tower. A top outlet of the C4 absorption tower is connected to the lower part of the gasoline absorption tower. The bottom and the top of the gasoline absorption tower respectively communicate with the outside world. The method comprises the steps that: catalytic dry gas is subjected to compression and cooling, and is delivered into the C4 absorption tower and is absorbed by using a C4 absorption agent; the tower kettle material of the C4 absorption tower is delivered into the C4 desorption tower; the tower kettle material of the C4 desorption tower is delivered back to the C4 absorption tower; tower top gas of the C4 absorption tower is delivered into the gasoline absorption tower and is absorbed by a gasoline absorption agent. According to the invention, no equipment such as ethylene cooling machine, expansion machine, or cold box is needed, such that investment and energy consumption are reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

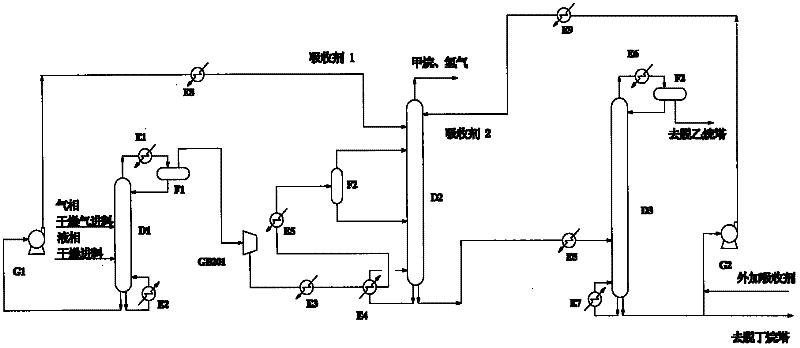

Method for refining catalysis drying gas by using oil absorption extraction

The invention discloses a method for refining catalysis drying gas by using oil absorption extraction. The method comprises the steps of using the carbon five-hydrocarbon containing pentane as absorbent, absorbing the C2 distillate and more important components in the compressed and cooled catalysis drying gas in a main absorbing tower, sending the matter in the main absorbing tower to a desorbing tower, and recycling the C2 concentrated gas from the top of the desorbing tower. The method of the invention has high absorbing temperature and needs no ethylene, propylene cooling compressor and de-compressor so the energy consumption is less, the investment is low and the operation is simple.

Owner:CHINA PETROLEUM & CHEM CORP +1

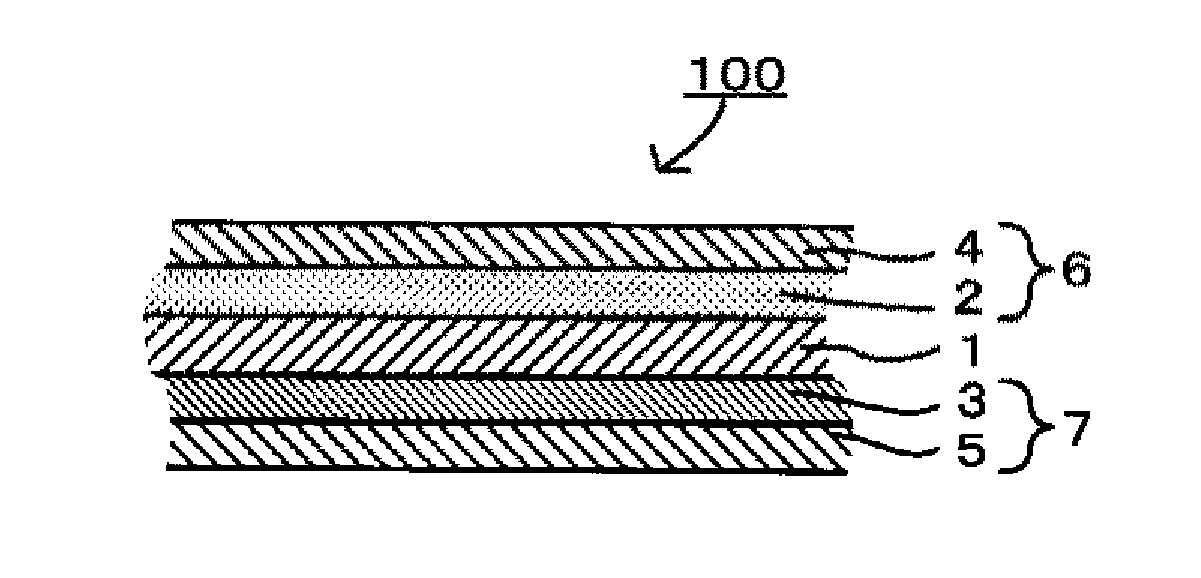

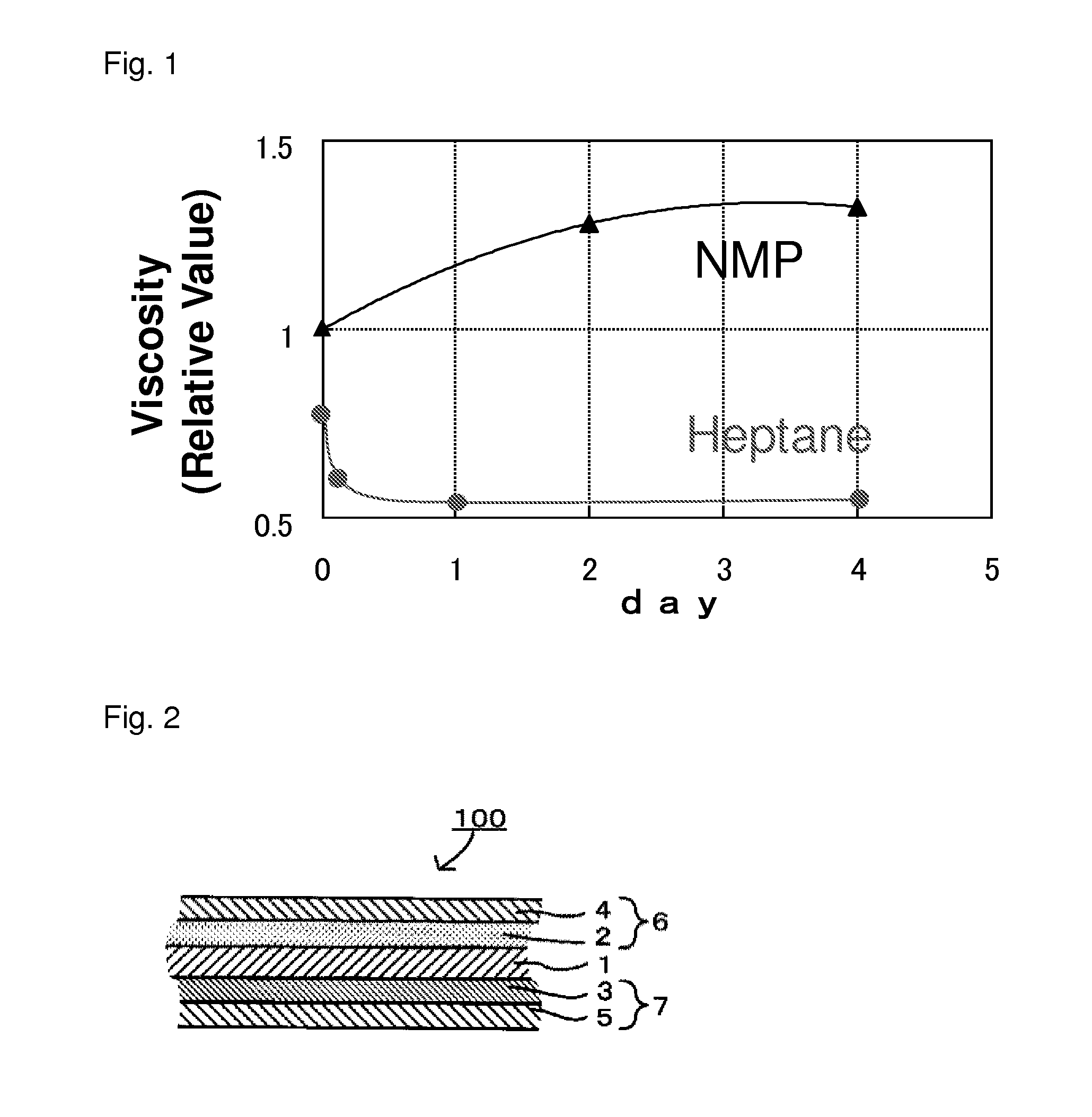

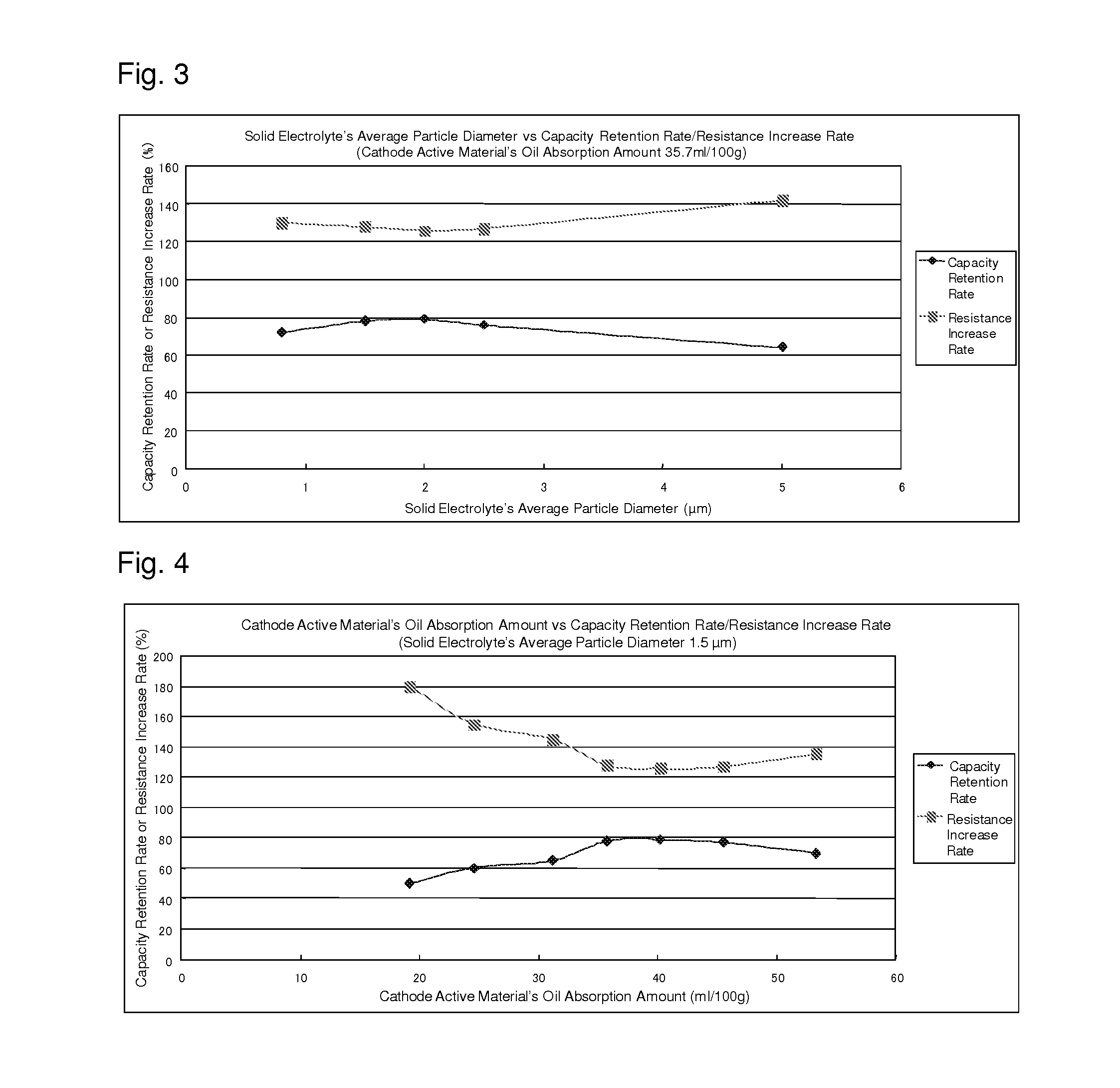

Cathode for secondary batteries, method for producing cathode for secondary batteries, and all-solid-state secondary battery

ActiveUS20150325844A1High capacity retentionSolid electrolytesFinal product manufactureAll solid stateEngineering

To provide: a cathode for secondary batteries, which has a high capacity retention rate; a method for producing a cathode for secondary batteries; and an all-solid-state secondary battery comprising the cathode. This object has been achieved providing by a cathode for secondary batteries, which is characterized by comprising a cathode active material layer containing at least a cathode active material and a solid electrolyte, wherein the cathode active material has an oil absorption amount of 35 to 50 ml per 100 g; wherein the solid electrolyte has an average particle diameter of 1.5 to 2.5 μm; and wherein the cathode active material layer is formed by mixing the cathode active material and the solid electrolyte in the absence of solvent and pressure-forming the resulting mixture.

Owner:TOYOTA JIDOSHA KK

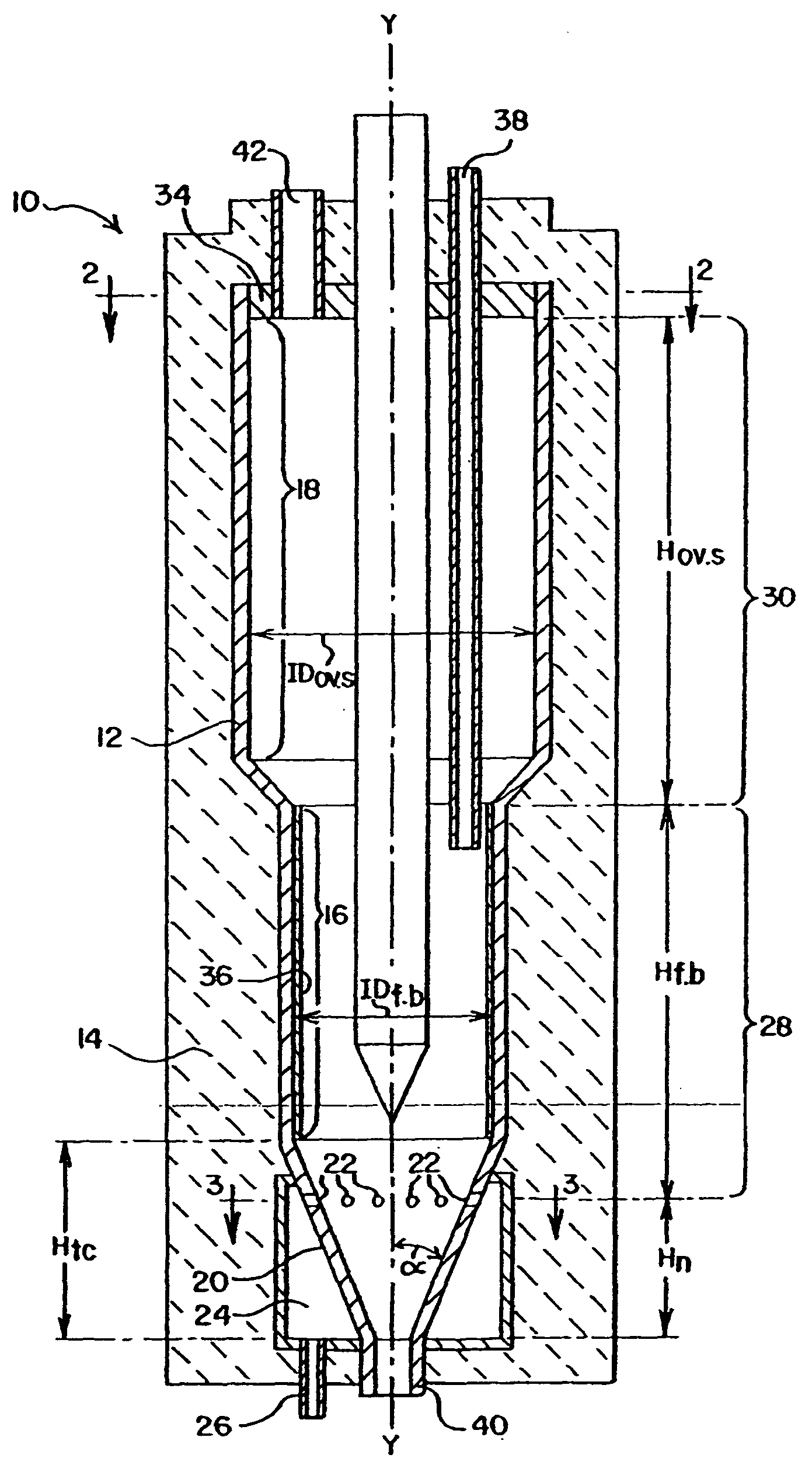

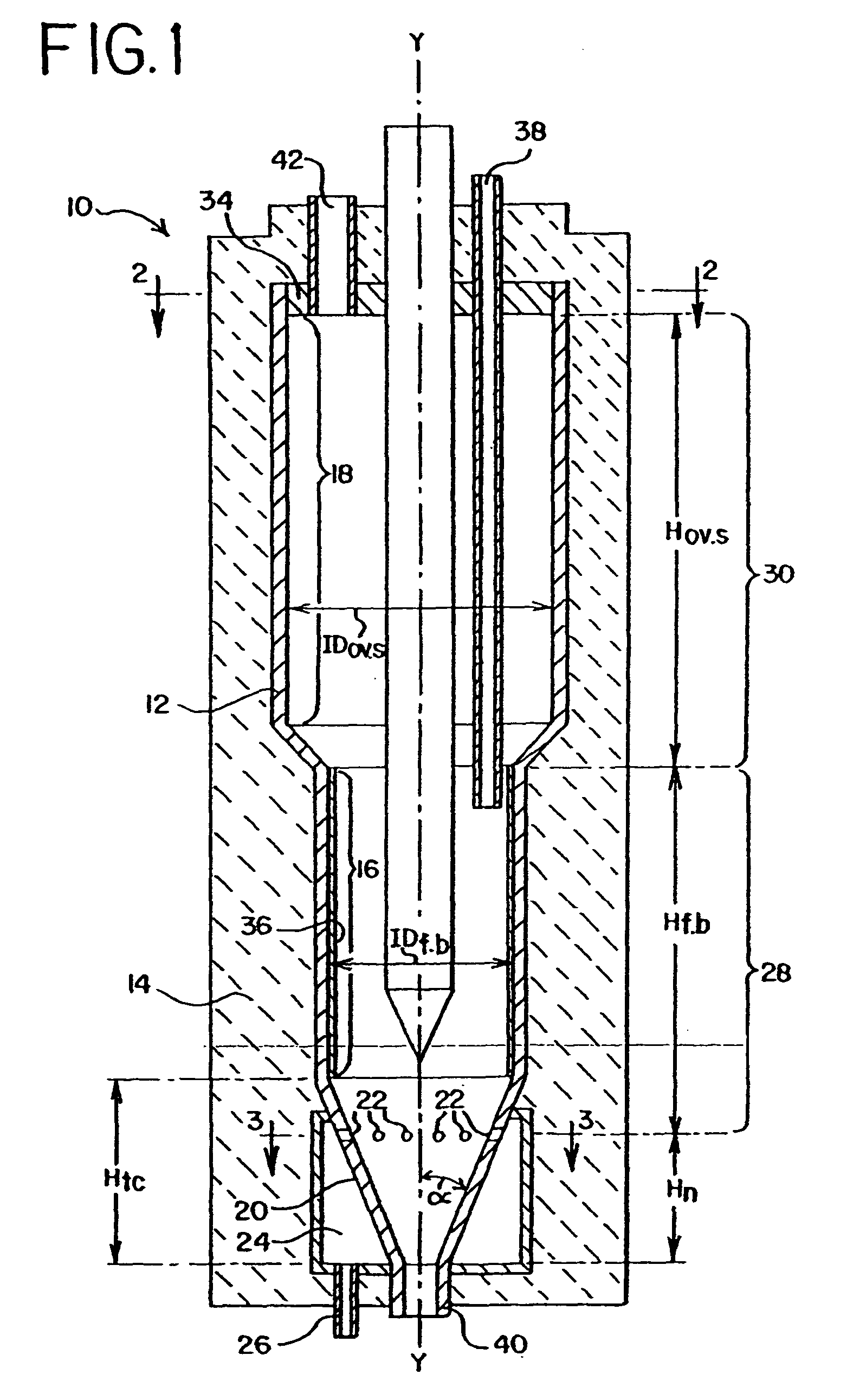

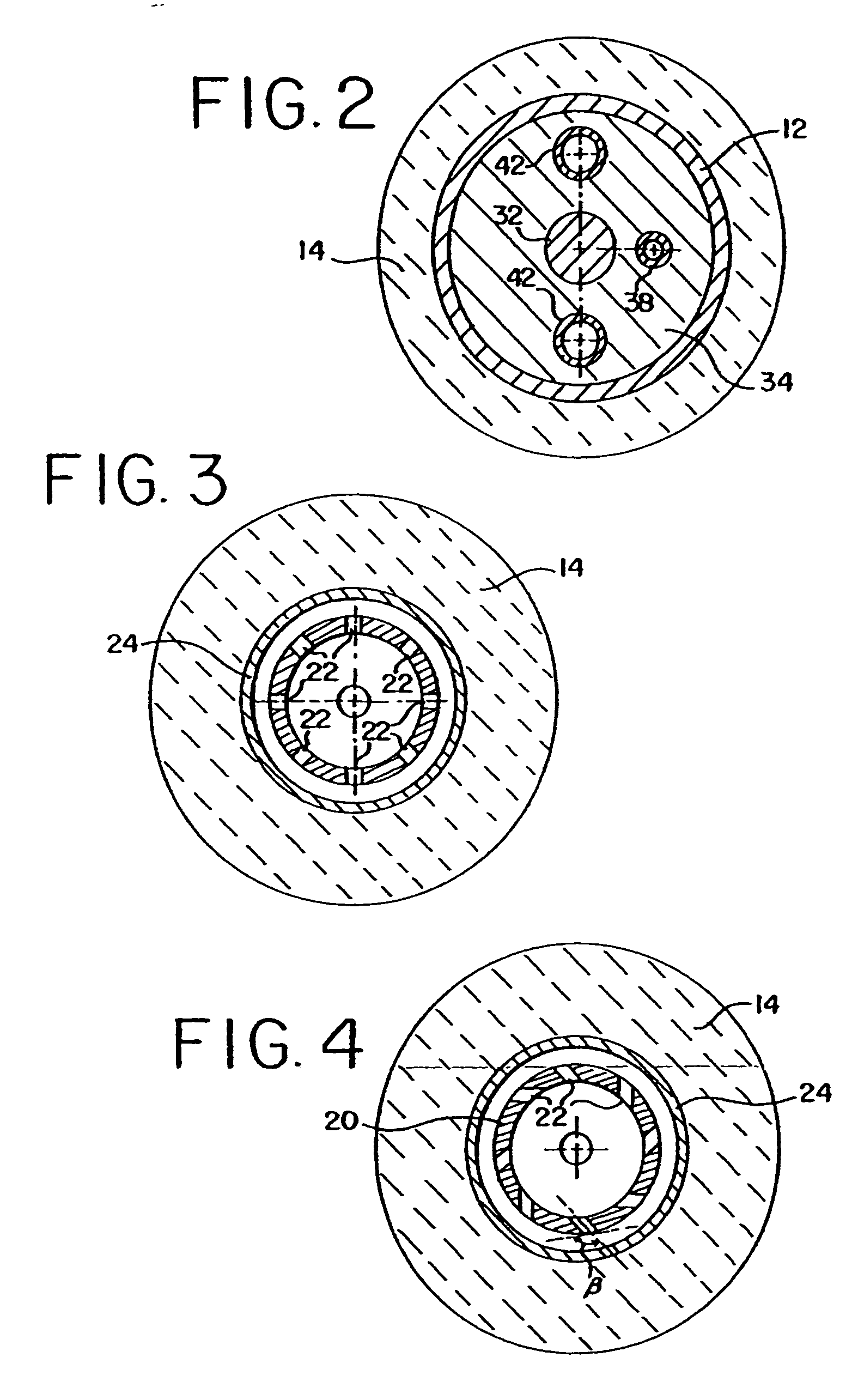

Thermally modified carbon blacks for various type applications and a process for producing same

InactiveUS20050063892A1Oxidation resistance can be improvedReduced metal and ash contentPigmenting treatmentMaterial nanotechnologyModified carbonOxidation resistant

An electro thermal fluidized bed furnace is adapted to be used in a process for continuously heat treating of fine particulate matter, such as carbon black material, by continuously introducing a non-reactive fluidizing gas through the nozzles of the furnace at a pre-determined rate, continuously introducing untreated carbon black material through the feed pipe of the furnace at a predetermined rate so that it forms a fluidized bed, energizing the electrode so as to heat the fluidized bed, and continuously collecting the treated carbon black from the discharge pipe. The carbon black collected from the discharge pipe exhibits properties of having the PAHs and sulfur removed, the carbon black has been graphitized, the moisture pick-up by the carbon black has been eliminated and the carbon black is more oxidation resistant, Furthermore, the resultant furnace carbon backs have a particle size of 7-100 nm and an oil absorption number of 50-300 ml / 100 g., while the thermal blacks have a particle size of 200-500 nm and an oil absorption number of less than 50 ml / 100 g. All of these properties result in thermally modified carbon blacks having such properties and of such purity so as to provide improved performance properties in food contact type applications, moisture cured polymer systems, zinc-carbon dry cell battery applications, and semi-conductive wire and cable applications.

Owner:COLUMBIAN CHEM CO +1

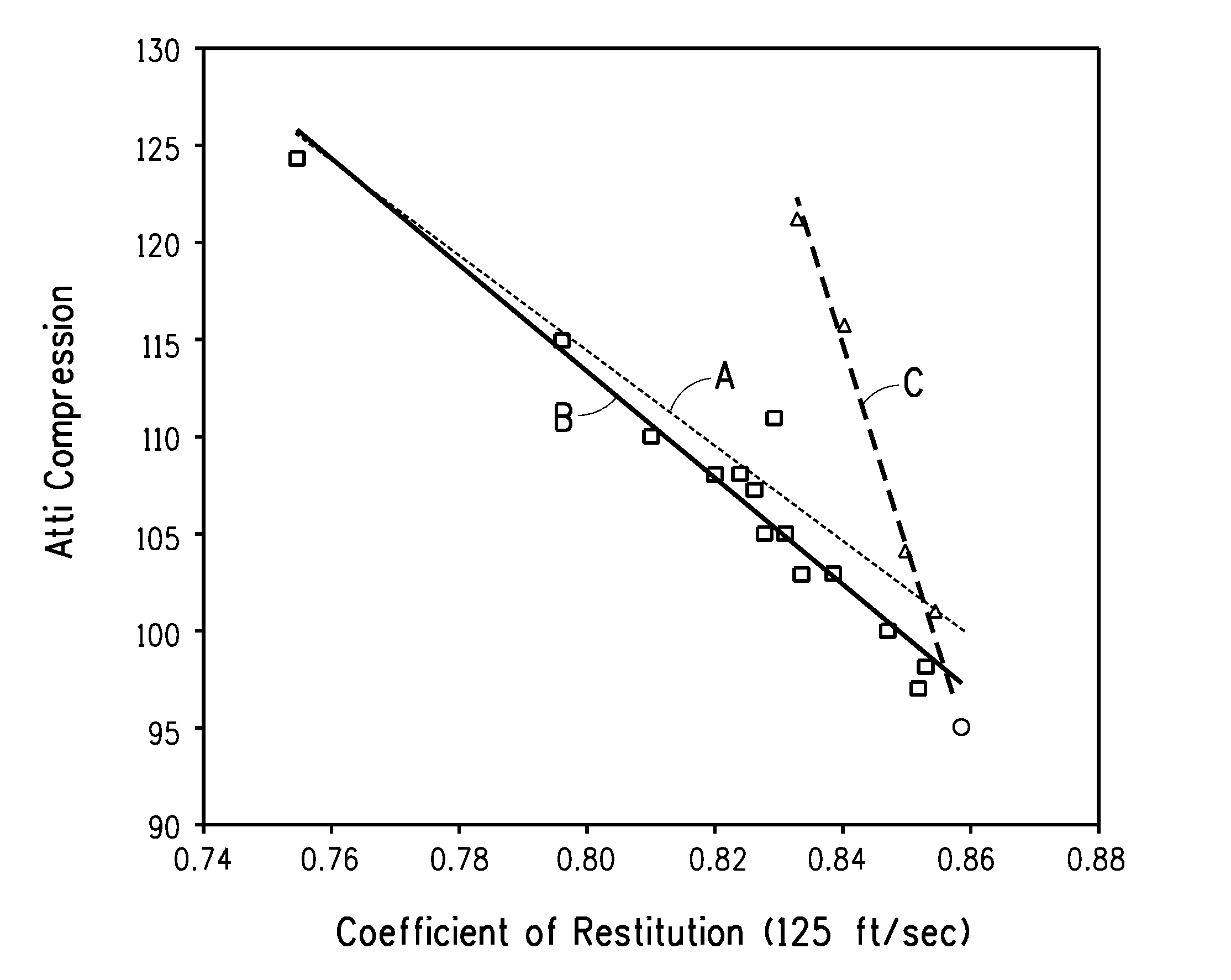

Compositions of organic acid modified ionomers filled with silica

Disclosed is a composition comprising, or produced from, an organic acid-modified ionomer and silica filler having oil absorption greater than 100 g oil / 100 g silica. Also disclosed are articles produced from the composition such as golf balls.

Owner:DOW GLOBAL TECH LLC

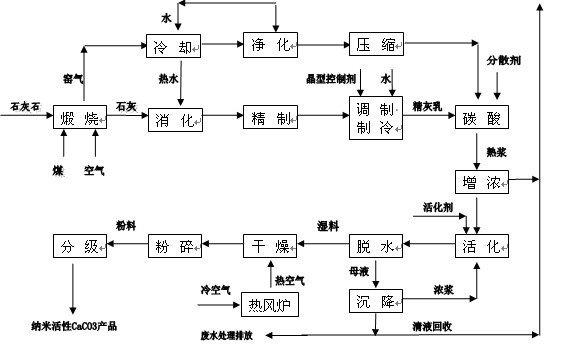

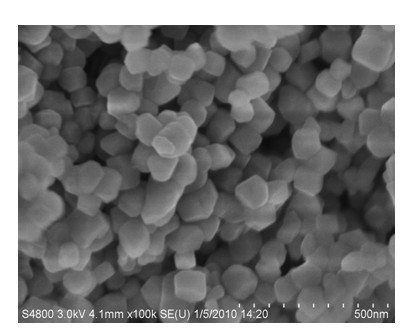

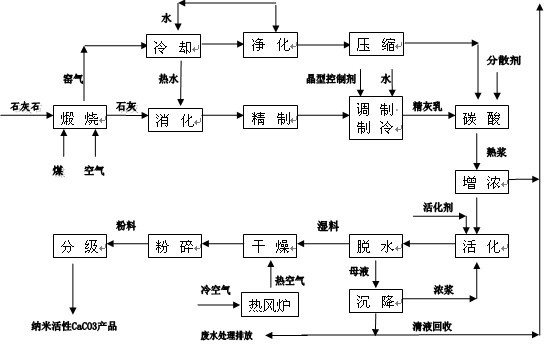

Preparation method of nano-calcium carbonate SCC-2 special for silicone sealant

InactiveCN102491397AProcessability can be optimizedEasy to processCalcium/strontium/barium carbonatesNanotechnologyDispersitySlurry

The invention discloses a preparation method of nano-calcium carbonate SCC-2 special for a silicone sealant, belonging to the technical field of inorganic chemical industry. According to an adopted technical scheme, the method comprises the following steps of: calcining limestone, crushing to obtain CaO; digesting, refining and aging the CaO in a hot state in the ratio of 1:4.8 of CaO to H2O; adding 1 percent of white granulated sugar crystal form control agent for undergoing a carbonation reaction to obtain CaCO3 slurry; performing activation surface treatment; and dehydrating, drying, crushing and degrading to obtain a nano-active CaCO3 product of 60-100 nanometers. The crystal form, size, regularity, oil absorption value and pH value of CaCO3 are controlled, so that 'hard aggregation' among particles is avoided from a surface modification production process, and the product has low oil absorption value and high bulk specific weight and has high dispersity in polymers.

Owner:广东嘉维化工实业有限公司

Plugging material used for oil base drilling fluid, and preparation method thereof

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Method for preparing seaweed cellulose aerogel oil absorption material

ActiveCN103980530AEnsure thoroughnessFast oil absorptionOther chemical processesCelluloseUltimate tensile strength

The invention discloses a method for preparing a seaweed cellulose aerogel oil absorption material and relates to a method for preparing an oil absorption material. The method comprises the following steps: I, purifying seaweed cellulose; II, preparing seaweed nano cellulose microfibril in a mechanical colloid milling mode; III, preparing seaweed cellulose aerogel; and IV, performing hydrophobic modification on the seaweed cellulose aerogel. The seaweed cellulose aerogel oil absorption material prepared by using the method is natural and pollution-free and has the advantages of high oil absorption efficiency, , good strength, simple secondary treatment and the like, and is an important development direction of novel aerogel oil absorption materials.

Owner:HARBIN INST OF TECH

Method for preparing three-dimensional graphene through doping of nanoparticles

The present invention discloses a method for preparing three-dimensional graphene through doping of nanoparticles. The technical scheme comprises that: graphite is adopted as a base material to prepare graphene oxide lamella, nanoparticles are attached on the graphene oxide lamella, and the three-dimensional graphene is formed through self-assembly between the graphene oxide lamella. According to the present invention, the reaction temperature and the graphene oxide solution concentration are adjusted to form the opened-cell and closed-cell (different densities) three-dimensional graphene; and the prepared three-dimensional graphene can be widely used in the fields of supercapacitors, oil absorption, seawater desalination and the like.

Owner:慧迈材料科技(广东)有限公司

Preparation method of foamed porous graphene/polypyrrole composite oil absorption material

InactiveCN102617853AEasy to operateMild reaction conditionsOther chemical processesPotassium persulfatePorous graphene

The invention relates to a preparation method of a foamed porous graphene / polypyrrole composite oil absorption material, belonging to the technical fields of environmental protection and composite materials. The method is characterized by comprising the following steps: carrying out KH570 functionalization on graphite oxide prepared from graphite; carrying out ultrasonic treatment on the functionalized graphite oxide product to obtain a graphene oxide aqueous solution with a certain concentration, adding certain amounts of pyrrole, styrene or butyl methacrylate or lauryl methacrylate and an initiator (ammonium persulfate or potassium persulfate); carrying out thermostatic reaction in a hydrothermal reaction kettle for 10 hours, thereby obtaining a black solid; and carrying out freeze-drying on the black solid to obtain the foamed porous graphene / polypyrrole composite oil absorption material in a three-dimensional structure. The graphene / polypyrrole composite oil absorption material ina three-dimensional structure is prepared by a chemical process, so the material has hydrophobicity and large specific area of the graphene, can contain abundant oil molecules, and has high oil adsorbability. The preparation method is simple to operate, and has the advantage of mild reaction conditions.

Owner:DALIAN UNIV OF TECH

Hydrophobic chitosan-silicon dioxide composite aerogel and preparation method and oil absorption application thereof

The invention discloses hydrophobic chitosan-silicon dioxide composite aerogel and a preparation method and oil absorption application of the hydrophobic chitosan-silicon dioxide composite aerogel. The preparation method comprises the steps that a silicon source precursor is added into chitosan liquid and subjected to hydrolysis and condensation polymerization gradually to form viscous composite sol, wherein a large number of hydroxyl radicals and amino radicals in chitosan provide a large quantity of active sites, and the active sites serve as a supporting framework to participate in forming of a whole gel network structure; the composite sol is subjected to further ageing, the network structure is stabilized, and then composite gel is obtained; the composite gel is dried, solvents in the gel is removed, and then chitosan-silicon dioxide composite aerogel is obtained; the chitosan-silicon dioxide composite aerogel is subjected to hydrophobic modification through the vapor deposition method, modifying agent steam deposits on the surface of the chitosan-silicon dioxide composite aerogel at a constant temperature, and finally the hydrophobic chitosan-silicon dioxide composite aerogel is obtained. The preparation process is simple, raw materials are easy to get, and the prepared composite aerogel is low in density and high in porosity and has good hydrophobicity and lipophilicity and efficient oil absorption capacity.

Owner:TIANJIN UNIV

Silica-coated alkaline earth metal carbonate pigment

InactiveUS6136085AMaintenance economyMaintain ecological advantageCalcium/strontium/barium carbonatesPigmenting treatmentParticulatesAlkaline earth metal

A method for forming a silica coating on at least a portion of the surface of alkaline earth metal carbonate particulates in aqueous suspension and the silica-coated alkaline earth metal carbonate so produced are claimed. The claimed method consists of allowing soluble silicate ions in the aqueous phase to slowly react with the alkaline earth metal carbonate surface to form silica micro-particulates on the surface. This silica coating confers upon the composition unique properties among which are pronounced thixotropic behavior when incorporated into an aqueous suspension and increased oil absorption when dry. The pigment produced by this method is especially suited for use as a filler in paper.

Owner:CHEM PROD CORP

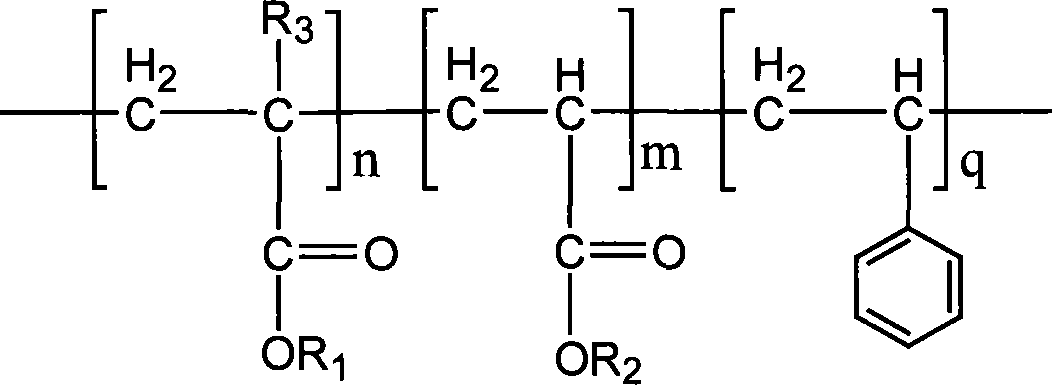

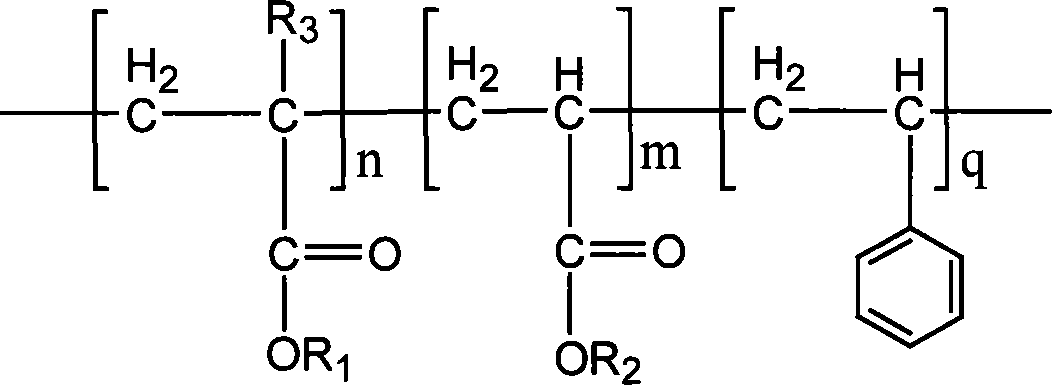

High oil absorption resin and synthetic method thereof

The invention discloses a high oil absorbing resin, and a process for preparation comprises utilizing short-chain ester of (metyl group) acrylic acid, long-chain ester of acrylic acid and styrene monomer to be monomers, adding dispersing agent and surface active agent, and getting through suspension polymerization and random copolymerization under the condition of the existence of cross linker and initiating agent. The process for synthesizing has lithe time consumption, which can be industrialized, and high oil absorbing resin which is got has high oil absorbing efficiency, fast oil absorbing speed, and which can be recycled to be repeatedly used.

Owner:SUZHOU TIMELYBLUE ENVIRONMENTAL TECH

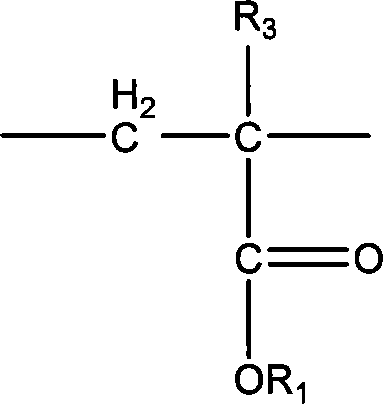

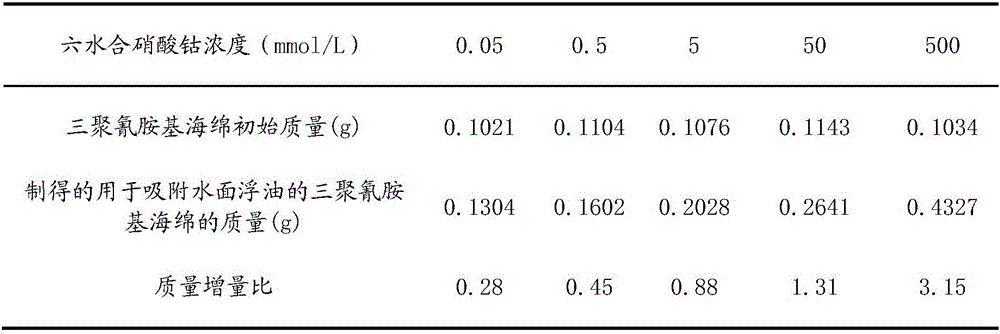

Melamine-based sponge for absorbing oil slick and preparation method

InactiveCN105949498AEasy to prepareMild reaction conditionsFatty/oily/floating substances removal devicesOther chemical processesAlcoholRoom temperature

The invention relates to melamine-based sponge for absorbing oil slick and a preparation method thereof. The preparation method includes the following steps of pretreatment: putting melamine-based sponge in absolute ethyl alcohol and deionized water for ultrasonic cleaning prior to drying; roughening: putting the pretreated melamine-based sponge in cobalt compound water solution, adding oxidant solution into cobalt compound water solution with stirring at room temperature, and after reaction, taking out and drying the melamine-based sponge; hydrophobic modification: soaking the roughened melamine-based sponge into hydrophobic modified reagent with stirring; after soaking, taking out the soaked melamine-based sponge prior to drying to obtain the melamine-based sponge for absorbing oil slick. The melamine-based sponge for absorbing oil slick is simple preparation method, mild in reaction condition, easily available in raw material, low in cost, high in oil absorption rate and good in reusability.

Owner:BEIJING FORESTRY UNIVERSITY

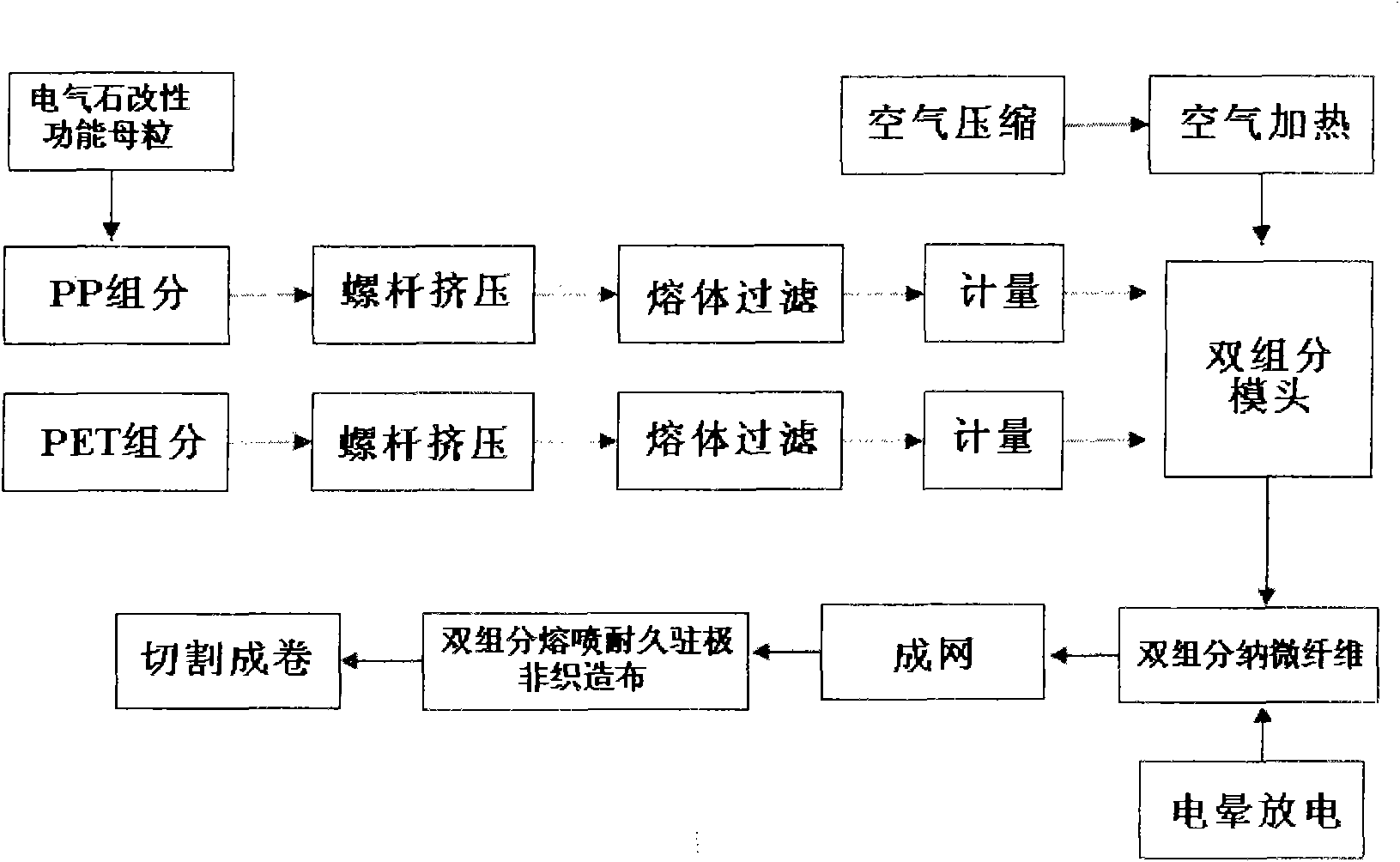

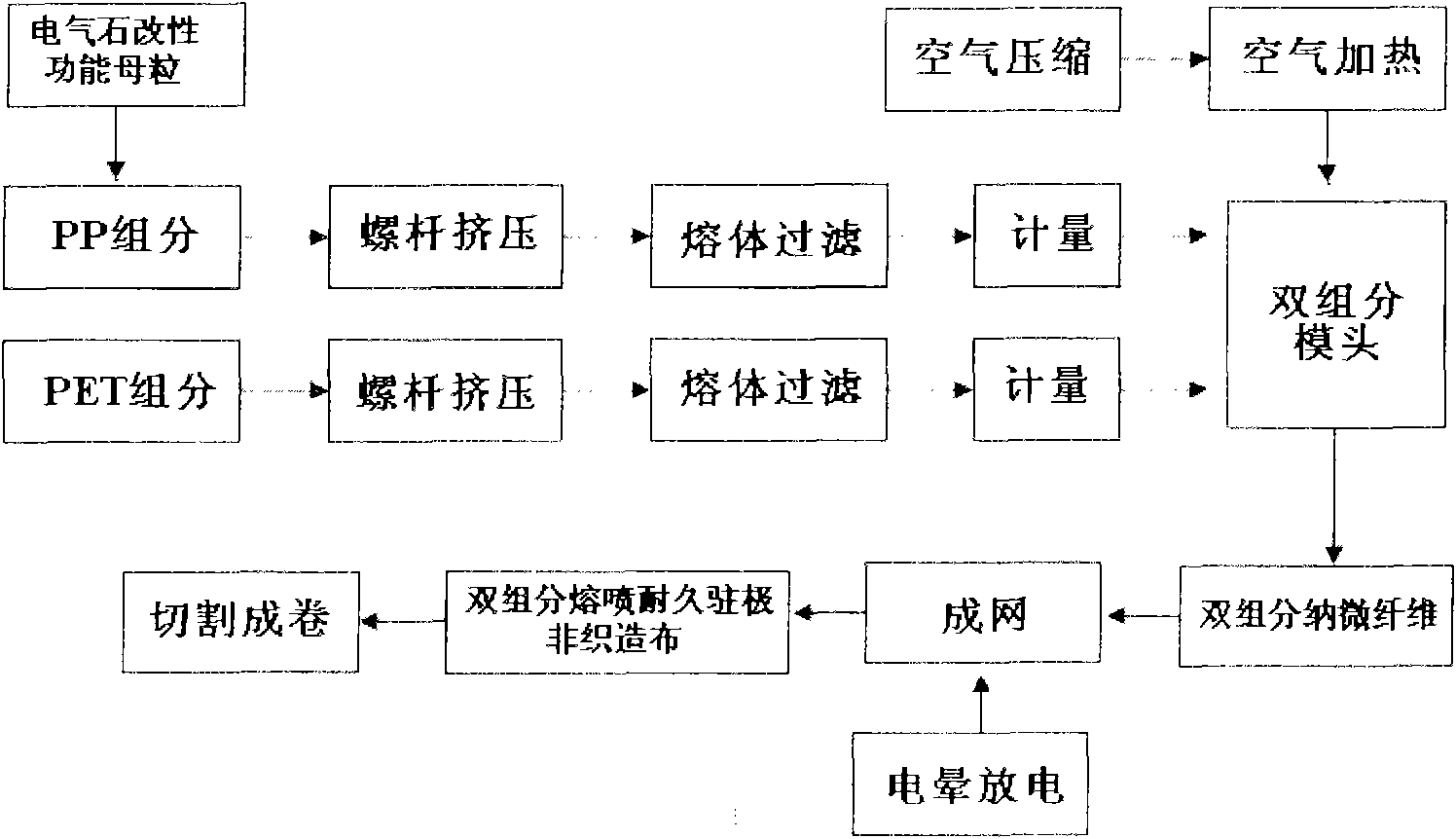

Double-component melt-blown durable electret non-woven fabric and manufacturing method thereof

InactiveCN101591837ASoft touchImprove breathabilityElectroconductive/antistatic filament manufactureArtificial filament physical treatmentFiltrationThermal insulation

The invention relates to a double-component melt-blown durable electret non-woven fabric and a manufacturing method thereof. The non-woven fabric consists of tourmaline modified polypropylene / polyethylene glycol adipate (tourmaline modified PP / PET) parallel double-component melt-blown nano microfiber; and the fiber has the following components in percentage by mass: 20 to 80 percent of tourmaline modified PP, and 80 to 20 percent of PET. The method for manufacturing the non-woven fabric adopts the components in percentage by mass and the process steps of: (1) performing drying pre-treatment on the PET first; (2) then preparing a double-component melt-blown non-woven fabric by tourmaline modified PP / PET melt-blown composite spinning technology; and (3) finally obtaining the double-component melt-blown durable electret non-woven fabric by performing high-voltage corona discharge electret treatment on the non-woven fabric. The non-woven fabric can be used for durable high-efficiency filtration materials, and can also be applied to thermal insulation materials, antibacterial medical materials, oil absorption materials and the like.

Owner:TIANJIN POLYTECHNIC UNIV

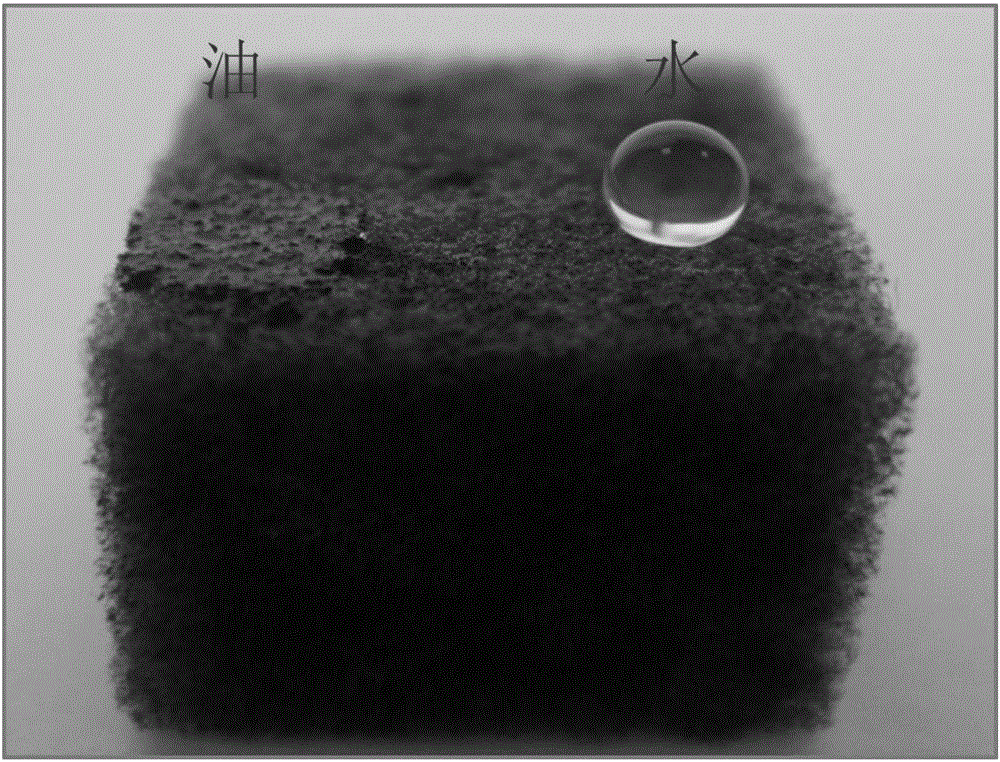

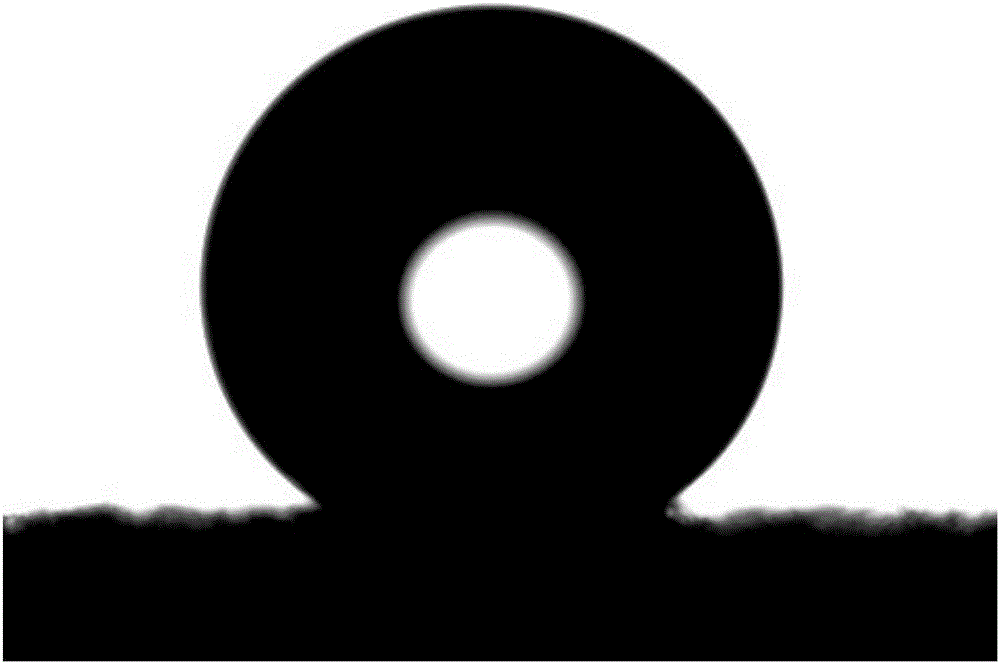

Super-hydrophobic reduced graphene oxide/sponge composite material and preparation method thereof

InactiveCN105754144ASimple preparation processShort response timeOther chemical processesEthylenediamineMicrowave

The invention discloses a super-hydrophobic reduced graphene oxide / sponge composite material and a preparation method thereof. The method includes: employing a microwave-ultrasonic wave method and using ethylenediamine as the reducing agent to reduce graphene oxide into reduced graphene oxide, and under the action of hole and other sound waves, dispersing and attaching the reduced graphene oxide to a commodity sponge, thus obtaining the super-hydrophobic reduced graphene oxide / sponge composite material. The method provided by the invention has the characteristics of simple operation, low cost, short reaction time, high efficiency and low energy consumption, and is beneficial to industrial mass production. The reduced graphene oxide / sponge composite material prepared by the method provided by the invention has excellent hydrophobic and oil absorption properties, large adsorption capacity and good stability, and can be used as a selective adsorbent for oily wastewater treatment.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

Process flow for separating low-carbon hydrocarbons and separating gas during production of olefins (M-OS/MTO) from methanol

ActiveCN102503757ALess investmentReduce energy consumptionDistillation purification/separationEthylene productionOlefiant gasAbsorption effect

The invention provides a non-cryogenic oil absorption separation method for a mixture of low-carbon hydrocarbons, which is used for separating the mixture of the hydrocarbons from gas during production of olefins from methanol. Methane / hydrogen can be separated from heavy components, namely C2 and above by absorbing fractions of the C2 and above by adopting two or more strands of absorbing agents. According to the method disclosed by the invention, an absorbing agent separating tower is increased before a demethanization tower, one strand of material flow, which is separated from the tower is taken as a main absorbing agent of the demethanization tower for absorbing the C2 and C3, the strand of the absorbing agent is the mixture of the fractions, which is from the former system and needs to be separated, and circulation is not required. The second strand of the absorbing agent of the demethanization tower is from a system including a depropanization tower and a debutanization tower, and the absorption effect is further enhanced. Compared with the prior art, the method can greatly reduce the using quantity of the circulating absorbing agents; moreover, the multiple strands of the absorbing agents are adopted, equipment investment and energy consumption are significantly reduced, the recovery rate of ethylene and propylene is further improved; and furthermore, the flow is simple, the operation cost is low, and the operation is safe and reliable.

Owner:SINOPEC SHANGHAI ENG +1

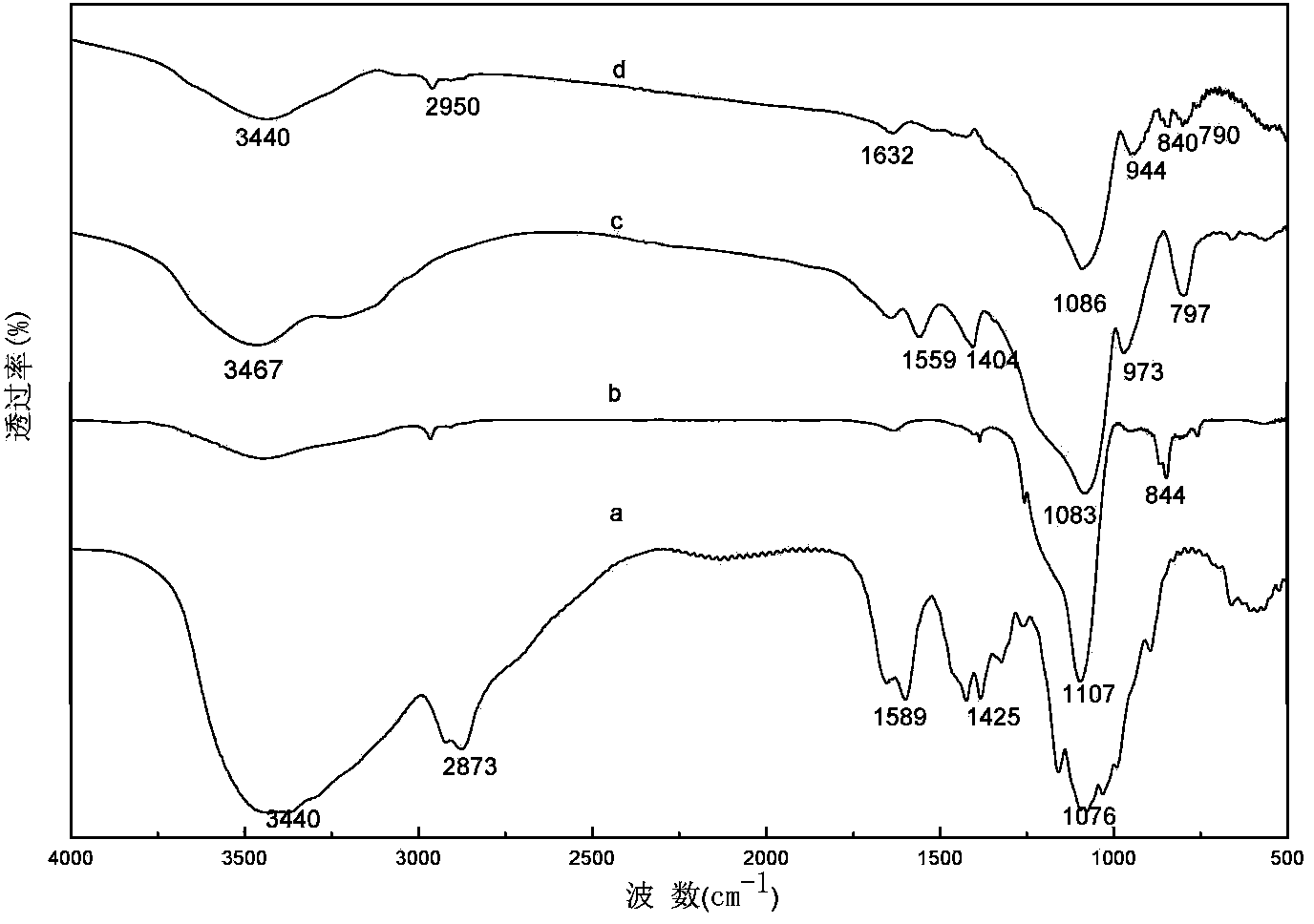

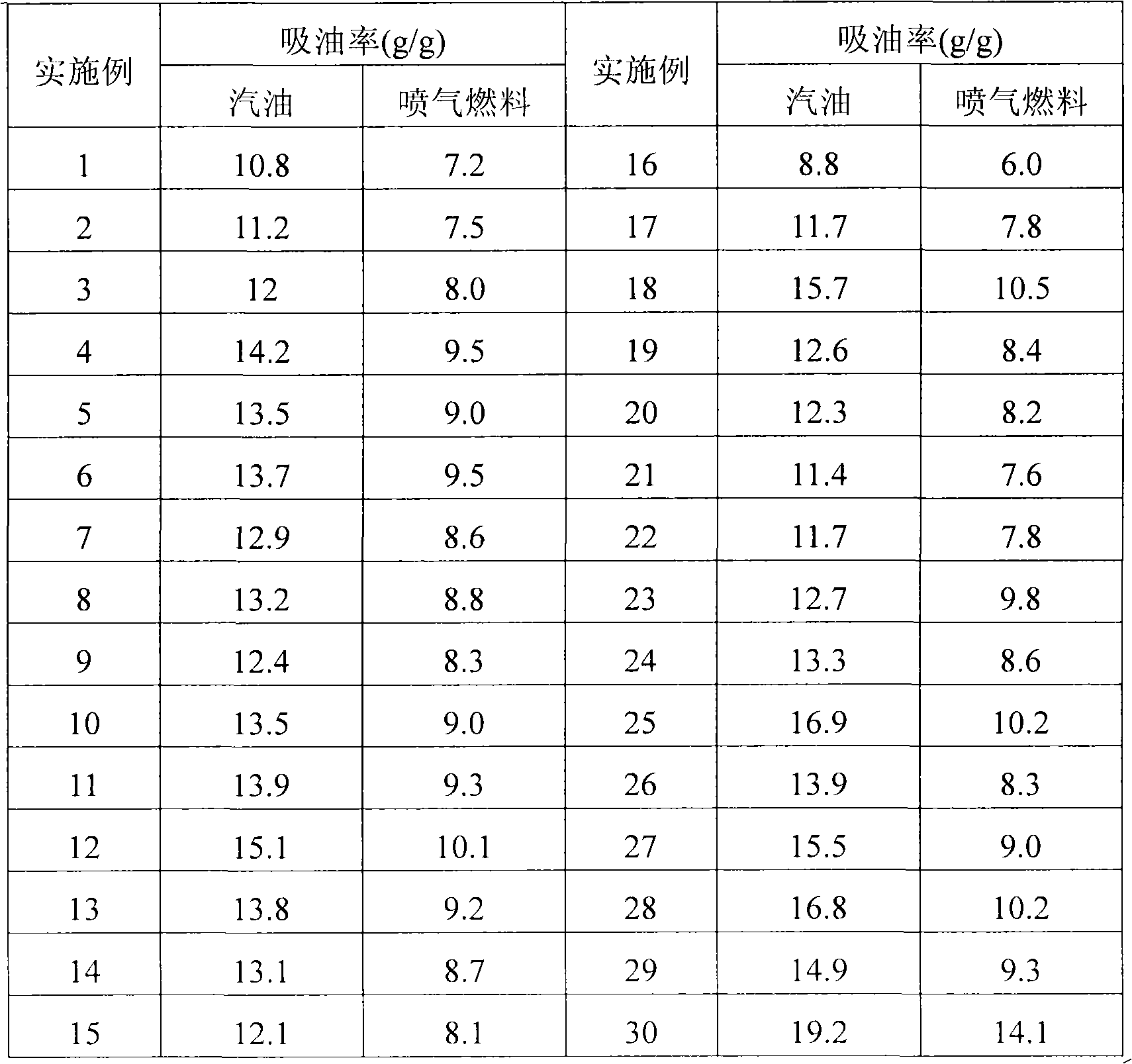

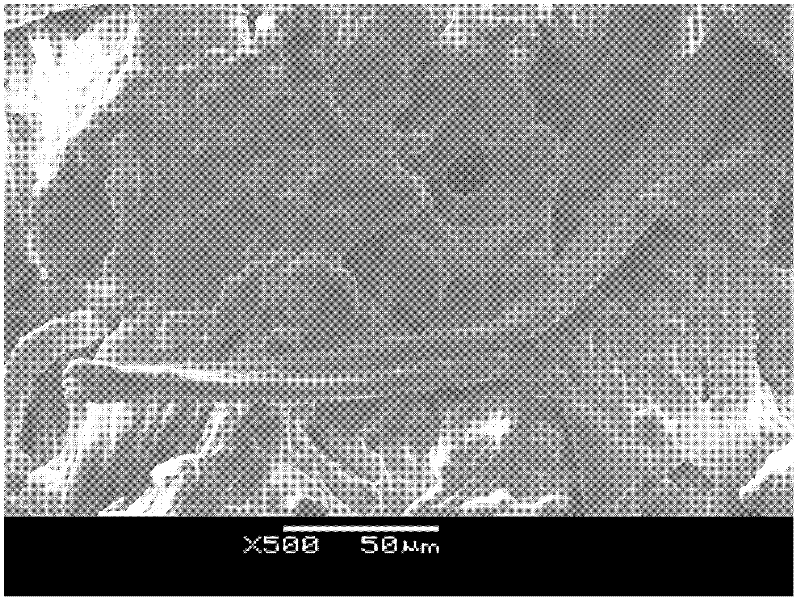

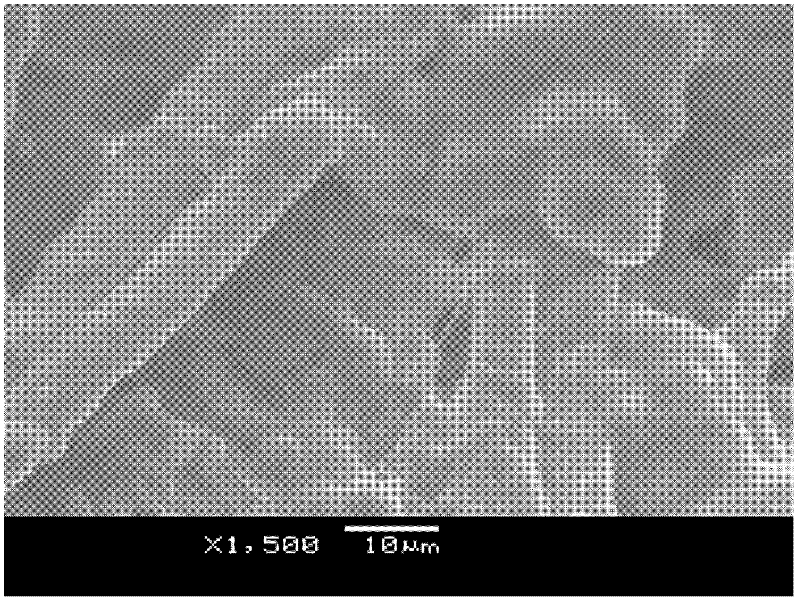

Porous high oil absorption resin and preparation method thereof

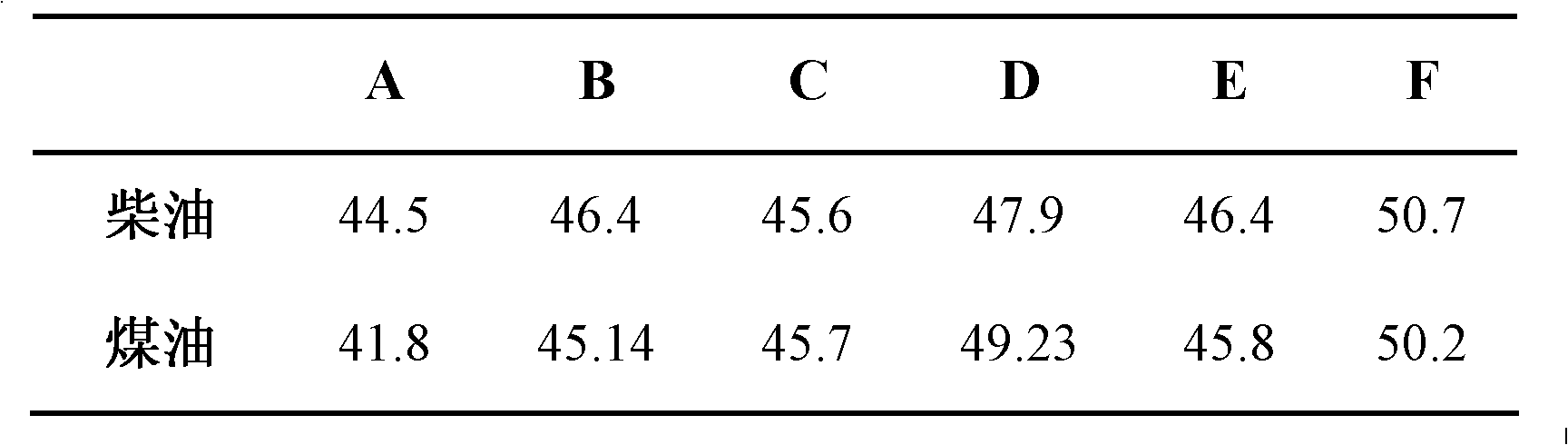

InactiveCN101891860AOther chemical processesAlkali metal oxides/hydroxidesSolution polymerizationJet fuel

The invention relates to a porous high oil absorption resin and a preparation method thereof. The preparation method reasonably proportions raw materials and performs suspension polymerization on the proportioned raw materials to prepare the porous high oil absorption resin, and comprises steps of dispersing, mixing, charging, suspension polymerization, extracting and conventional post-processing. The porous high oil absorption resin has high oil absorptivity, particularly for jet fuel.

Owner:PLA AIR FORCE OIL MATERIAL RES INST

High oil absorption resin and its synthesis method

InactiveCN1442438AHigh oil absorptionCompliance with emission requirementsCalcium biphosphateSynthesis methods

A high-oil-absorbency resin is prepared from acrylate as monomer, ethanediol acrylate as cross-linking agent, gel or cellulose as disperser, active calcium phosphate as co-disperser, and azo or oganic peroxide as trigger through suspension polymerizing. Its granularity is 0.3-2 mm and has high oil absorbency (up to 37 times).

Owner:PETROCHINA CO LTD

Method for preparing oil absorption material by adopting straws as base materials

InactiveCN102344531AEfficient recyclingHigh oil absorptionOther chemical processesChemical recyclingCross-linkOil retention

The invention relates to a method for preparing an oil absorption material by adopting straws as base materials, which comprises the following steps of: grinding crop straws (maize straws, wheat straws, sorghum straws and the like) into block shapes; adding sodium hydroxide solution or dilute sulphuric acid solution; reflowing and stewing for 10min under the action of microwave, or reflowing in anormal pressure reactor for 3h; filtering, rinsing and drying to obtain straw powder; adding the straw powder into water; warning up under the protection of nitrogen; adding an initiating agent, a reaction monomer and a cross-linking agent; stirring and reacting; and filtering and drying to obtain the oil absorption material. According to the invention, the straws of agricultural solid residues are utilized as the base materials, suspension polymerization is adopted, and graft copolymerization is carried out on acrylic ester or styrene and the like, so that the biodegradable oil absorption material is prepared. The oil absorption material not only has the biodegradability of the straws, but also has the high oil absorption performance of long-chain acrylic ester, so that not only can the production cost be greatly reduced and the solid waste be effectively utilized, but also the density is low, and the effects of oil absorption and oil retention are good due to a special porous structure of the raw straw materials.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Oral care products comprising calcium metasilicates

Disclosed is an oral care composition comprising a calcium metasilicate having an aspect ratio (average major axial diameter / average minor axial diameter) of from about 1:1 to about 2.5:, and an oil absorption of from about 20 ml / 100 g to about 220 ml / 100 g. Also disclosed is an oral care composition comprising: a calcium metasilicate having an aspect ratio (average major axial diameter / average minor axial diameter) of from about 1:1 to about 2.5:, and an oil absorption of from about 20 ml / 100 g to about 220 ml / 100 g, a disintegration aid, an organoleptic enhancing agent, and an abrasive.

Owner:EVONIK OPERATIONS GMBH

High-cleaning/low abrasive silica and materials and dentifrice containing such materials

InactiveUS20060110338A1Desirable abrasiveGood thickening effectPigmenting treatmentCosmetic preparationsSilica gelSilicon dioxide

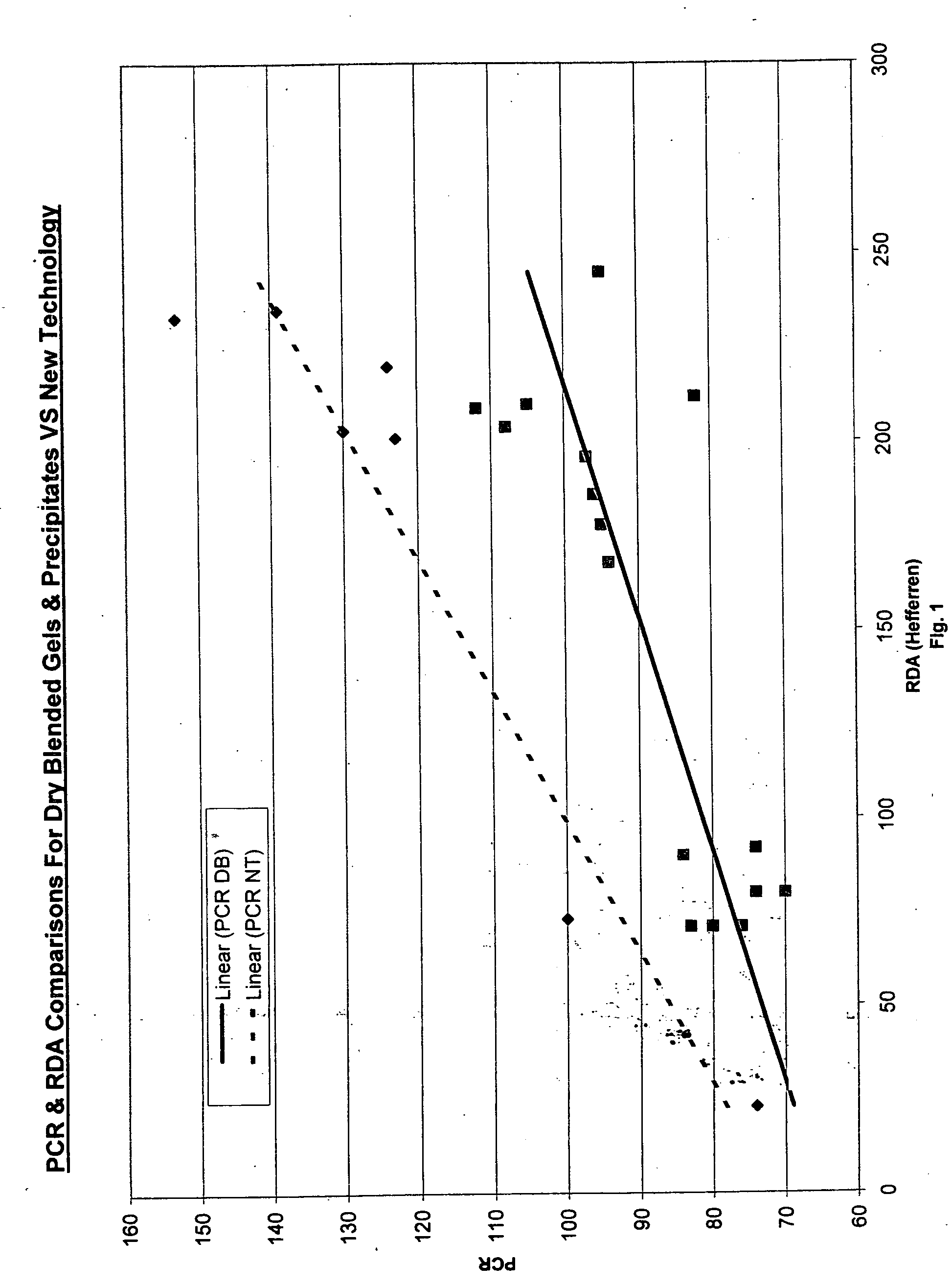

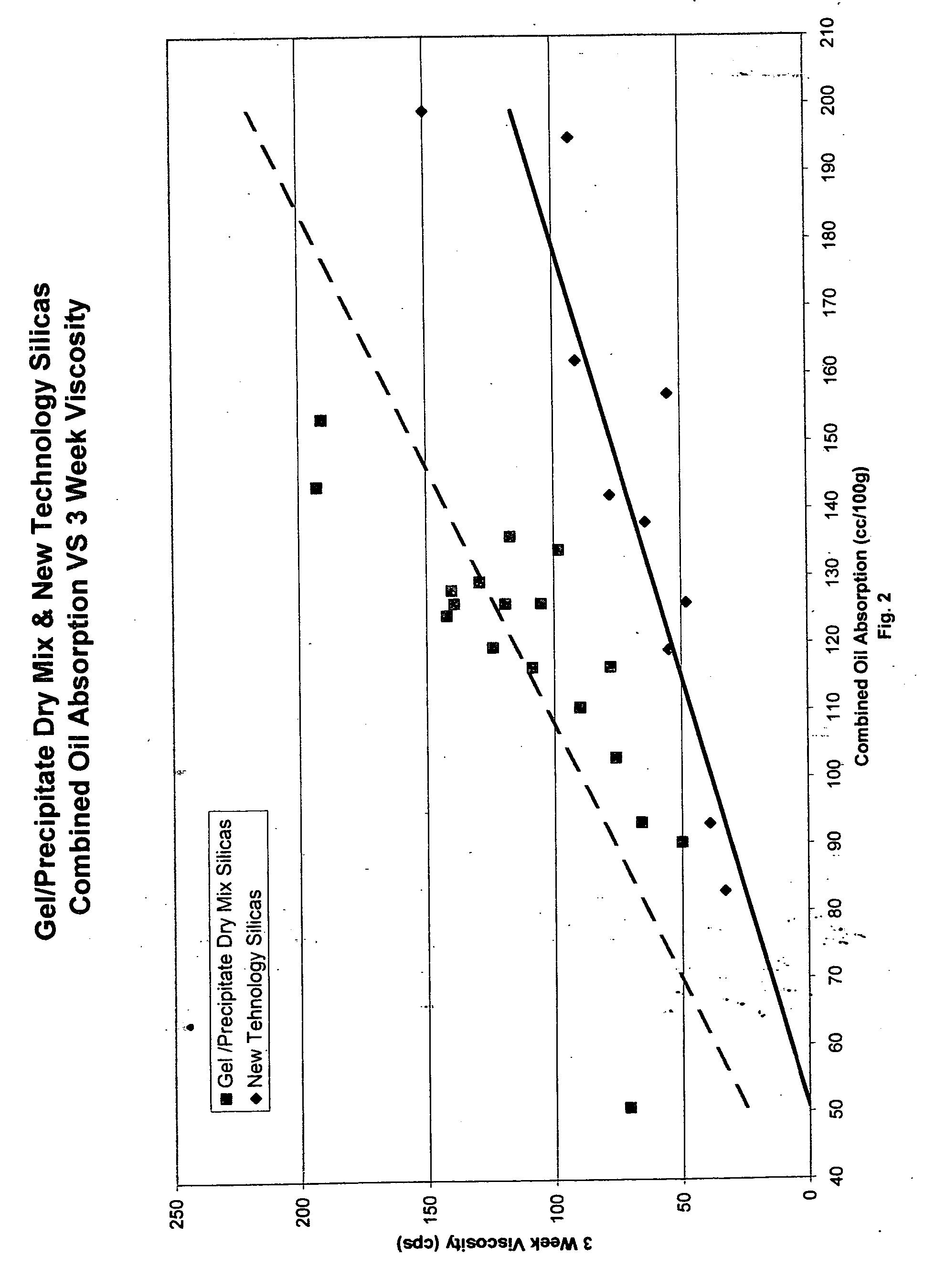

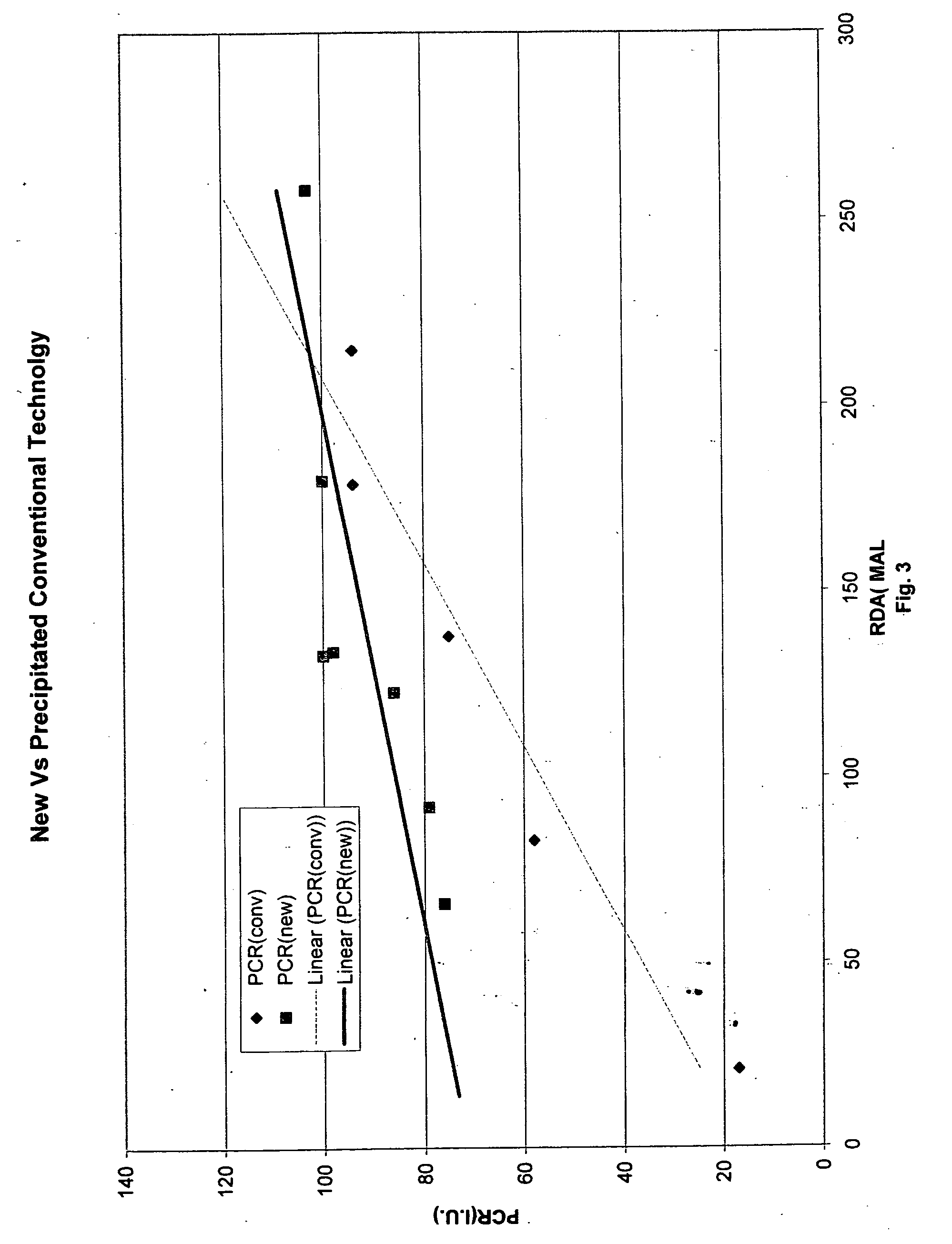

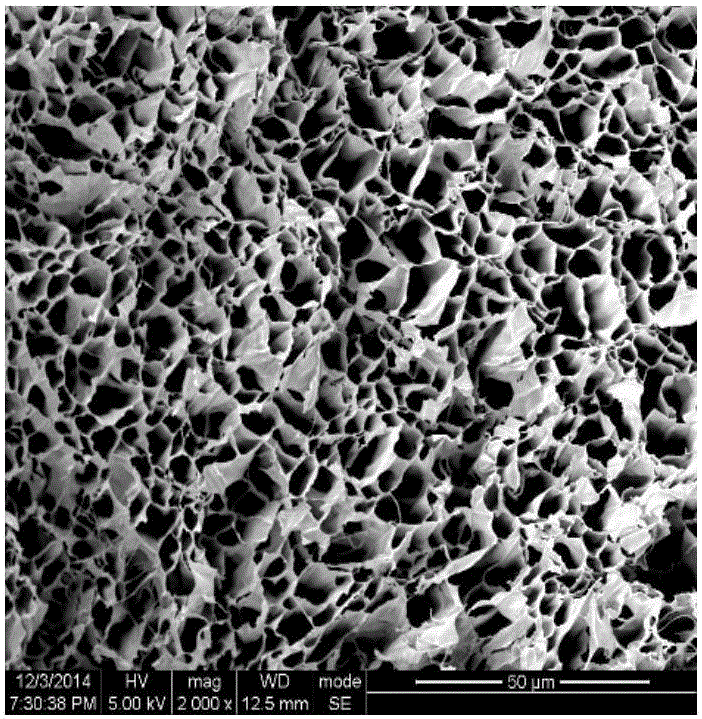

Unique abrasive and / or thickening materials that are in situ generated compositions of precipitated silicas and silica gels are provided. Such compositions exhibit different beneficial characteristics depending on the structure of the composite in situ generated material. With low structured composites (as measured via linseed oil absorption levels from 40 to 100 ml oil absorbed / 100 g composite), simultaneously high pellicle film cleaning properties and moderate dentin abrasion levels are possible in order to accord the user a dentifrice that effectively cleans tooth surfaces without detrimentally abrading such surfaces. Increased amounts of high structure composite materials tend to accord greater viscosity build and thickening benefits together with such desirable abrasion and cleaning properties, albeit to a lesser extent than for the low structure types. Thus, mid-range cleaning materials will exhibit oil absorption levels from an excess of 100 to 150, and high thickening / low abrasion composite exhibit oil absorption properties in excess of 150. Such an in situ, simultaneously produced precipitated silica / silica gel combination provides such unexpectedly effective low abrasion and high cleaning capability and different thickening characteristics as compared to physical mixtures of such components. Encompassed within this invention is a unique method for making such gel / precipitated silica composite materials for such a purpose, as well as the different materials within the structure ranges described above and dentifrices comprising such.

Owner:J M HUBER CORP

High oil absorption polyurethane foam and preparation method thereof

ActiveCN101987884AHigh oil absorptionFast oil absorptionOther chemical processesChemical recyclingChlorobenzeneKerosene

The invention relates to a high oil absorption polyurethane foam which comprises the following components in parts by weight: 20 to 40 parts of isocyanate, 35 to 60 parts of polyol, 0.5 to 3 parts of catalyst, 0.5 to 3 parts of foam stabilizer, 5 to 10 parts of foaming agent, 2 to 10 parts of opening agent,5 to 20 parts of flame retardant, 5 to 15 parts of silicon rubber spherical micro powder and 0.5 to 2 parts of coupling agent. The preparation method comprises the following technology steps of weighing, prepolymerization, dispersing, polymerization foaming reaction, curing and peeling at room temperature and cutting. The high oil absorption polyurethane foam can be used for the absorption and recycle of various oil products (crude oil, engine oil, diesel fuel, gasoline, kerosene and the like) on water surfaces, ground or surfaces of other objects, and various oil soluble organic compounds (benzene, methylbenzene, dimethylbenzene, chloroform, nitrobenzene, chlorobenzene and the like). The invention has the advantages of simple technology and low cost, obviously improves the dispersing effect of the silicon rubber spherical micro powder in a polymerization system by using ultrasonic technique, and greatly increase the oil absorption quantity and oil absorption rate of the polyurethane foam by adding the silicon rubber spherical micro powder.

Owner:CHINA BLUESTAR CHENGRAND CO LTD +1

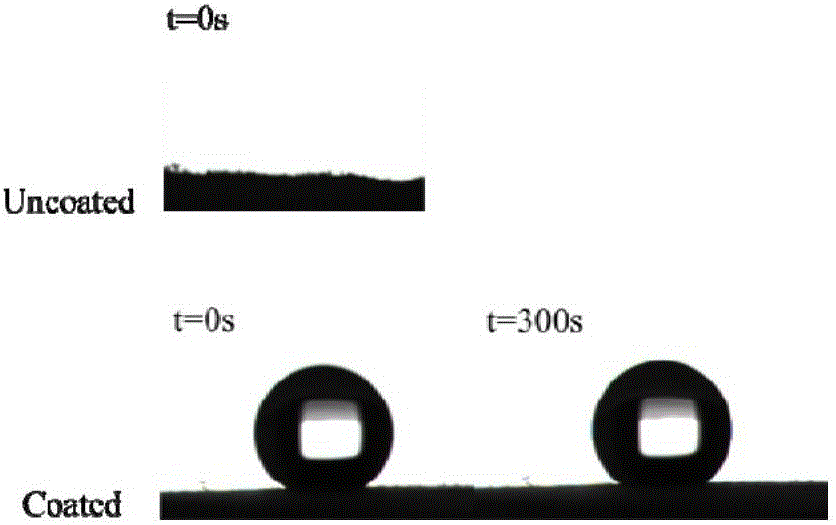

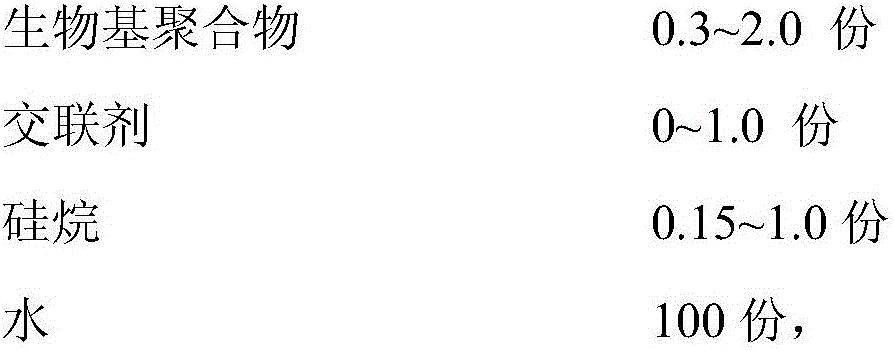

Biology base polymer aerogel oil absorption material and preparation method thereof

The invention discloses a biology base polymer aerogel oil absorption material. The oil absorption material is prepared by the following steps: at first, crosslinking biology base polymers by a crosslinking agent, to obtain a precursor liquid, then freeze-drying the precursor liquid to obtain aerogel, and finally grafting silane onto the aerogel surface to obtain the hydrophobic biology base polymer aerogel oil absorption material. The density of the oil absorption material is 3.8 to 23.1 kg / m3. The water contact angle is at least 117.8 degrees. The adsorption capacities on gasoline, paraffin oil, chloroform, and crude oil are 30.5-109.0 g / g, 33.2-131.2 g / g, 58.2-163.0 g / g, and 24.7-95.8 g / g. After 50 times of gasoline adsorption-extrusion circulation, the retention rate of adsorption capacity is 43 to 99%. The disclosed aerogel oil absorption material has the advantages of large oil absorption capacity and high oil absorption efficiency. Moreover, the oil absorption material can be repeatedly used by simply extruding the oil absorption material, while a high retention rate of adsorption capacity can be maintained. At the same time, the raw material sources are wide, the raw materials are cheap and easily available, the preparation is simple, the technology is matured, the method is environment-friendly, and the requirements of sustainable development can be met.

Owner:SICHUAN UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com