Double-component melt-blown durable electret non-woven fabric and manufacturing method thereof

A two-component, woven fabric technology, applied in the field of non-woven fabrics, to achieve high temperature resistance, excellent electret durability, and high filtration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

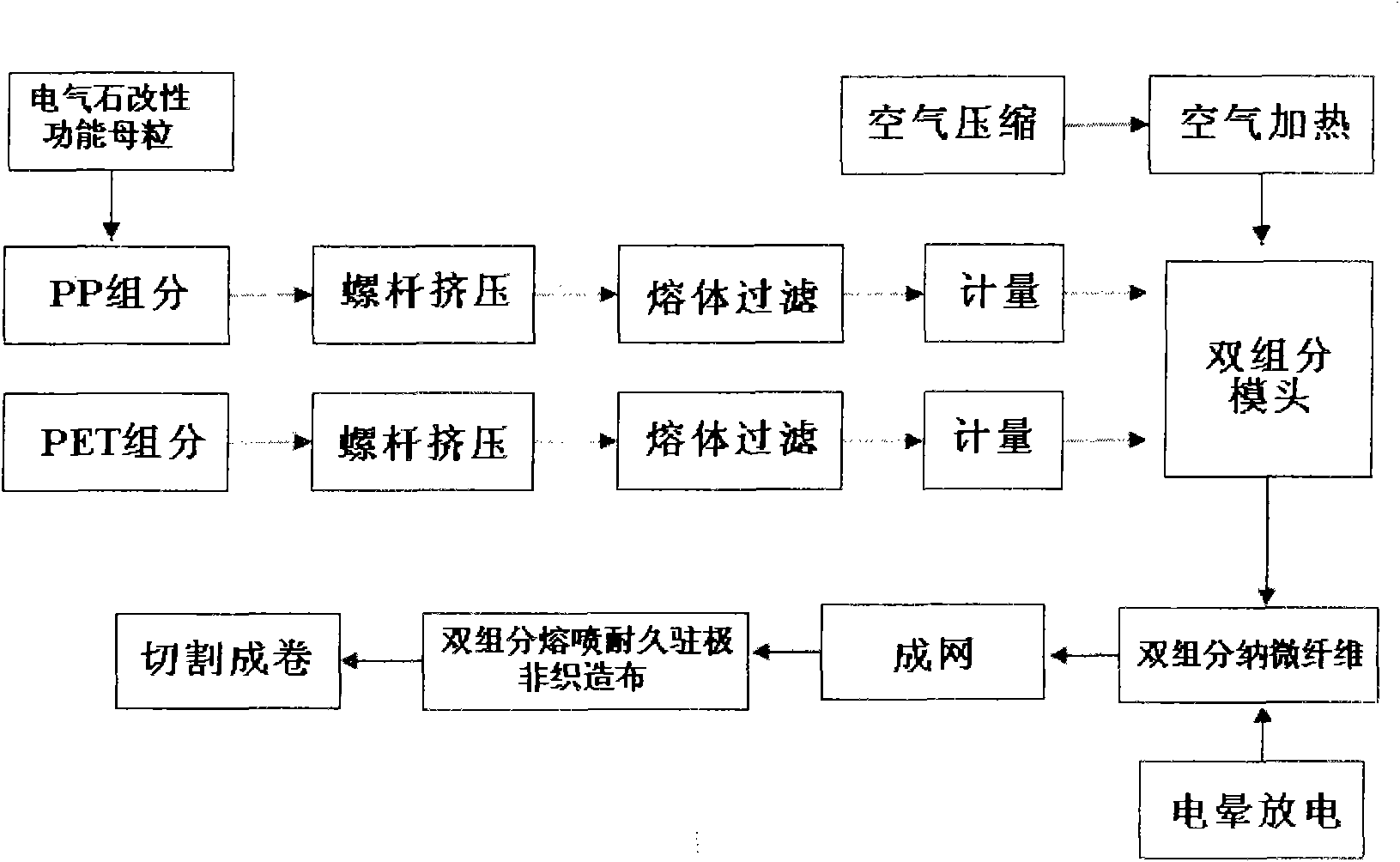

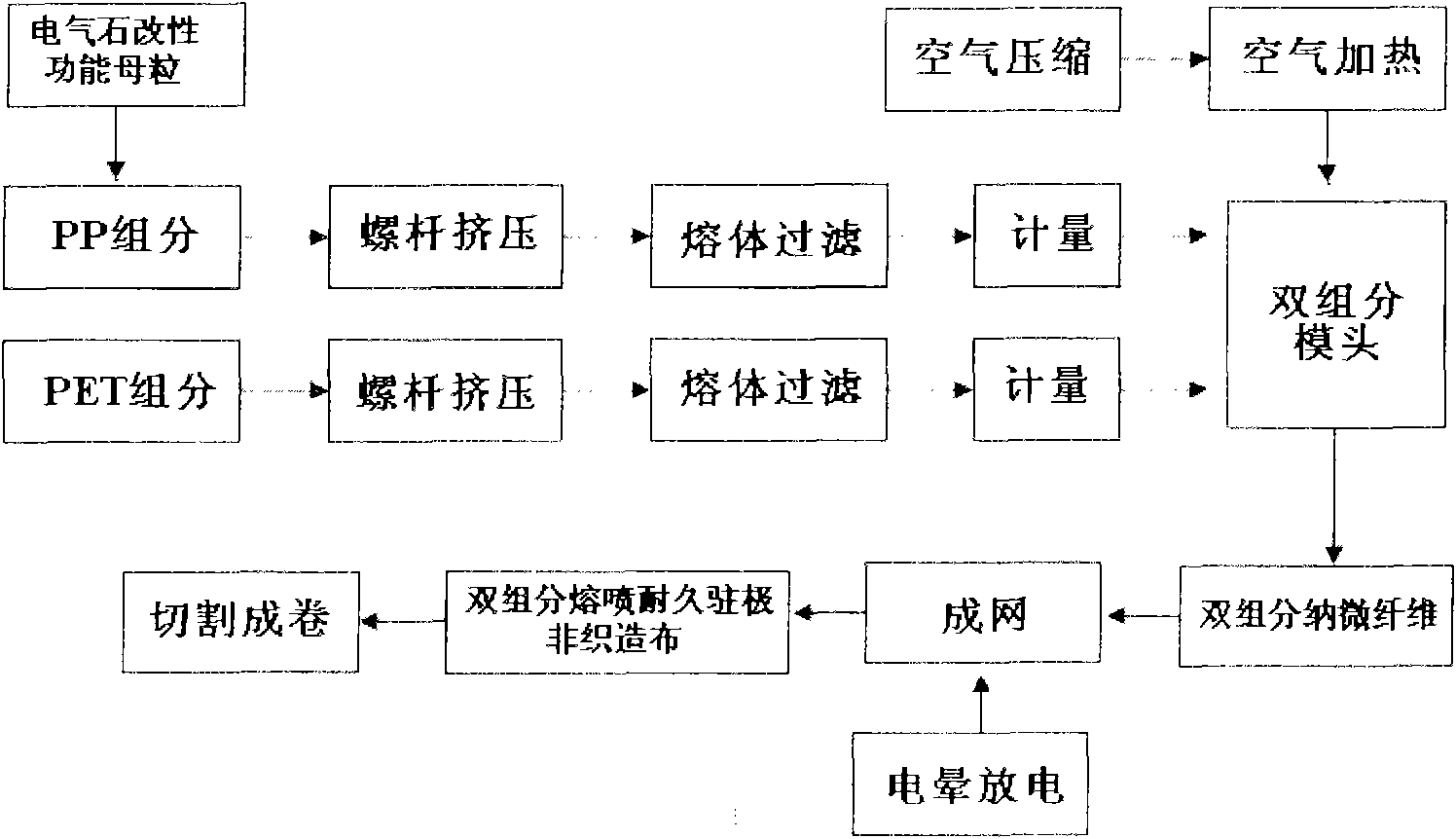

Method used

Image

Examples

Embodiment 1

[0042] (1) Pretreatment: first put the 80 parts of PET component slices into a fluidized bed pre-crystallizer, pre-crystallize at 160°C for 1.5 hours, then send them into a filling dryer, and dry at 160°C for 8 hours;

[0043] (2) Manufacture of melt-blown nonwovens: Mix 2 parts of modified functional masterbatch containing 20% tourmaline and 18 parts of pure PP resin in a high-speed mixer and feed them directly into another screw extruder. Melt at 250, and then pass through the melt filter and metering pump into the same melt blown die head; under the protection of nitrogen, feed the pretreated PET component into one of the screw extruders under the protection of nitrogen. Melt and extrude at 270°C, and then pass through a melt filter and a metering pump into the melt-blown die; the two melts meet at the melt-blown die at a ratio of 20 / 80, and then pass through the spinneret hole of the melt-blown die Under the action of hot air blowing at 300°C on both sides, a side-by-sid...

Embodiment 2

[0046] (1) Pretreatment: first put the 60 parts of PET component slices into a fluidized bed pre-crystallizer, pre-crystallize at 165°C for 1 hour, then send them into a filling dryer, and dry at 165°C for 6 hours;

[0047] (2) Manufacture of melt-blown nonwovens: mix 5 parts of modified functional masterbatch containing 20% tourmaline with 35% pure PP resin in a high-speed mixer and directly feed it into another screw extruder, at 260 It is melted at ℃, and then sent to the same melt-blown die head through a melt filter and a metering pump; under the protection of nitrogen, the pretreated PET component is fed into one of the screw extruders under the protection of nitrogen. Melt and extrude at 280°C, and then pass through a melt filter and a metering pump into the melt-blown die; the two melts meet at the melt-blown die in a ratio of 40 / 60, and then pass through the spinneret hole of the melt-blown die Under the blowing of hot air at 290°C on both sides, a side-by-side two-...

Embodiment 3

[0050] (1) Pretreatment: first put the 40 parts of PET component slices into a fluidized bed pre-crystallizer, pre-crystallize at 170°C for 0.5 hours, then send them into a filling dryer, and dry at 170°C for 4 hours;

[0051](2) Manufacture of melt-blown nonwovens: Mix 15 parts of modified functional masterbatch containing 20% tourmaline with 45 parts of pure PP resin in a high-speed mixer and directly feed it into another screw extruder. It is melted at ℃, and then sent to the same melt-blown die head through a melt filter and a metering pump; under the protection of nitrogen, the pretreated PET component is fed into one of the screw extruders under the protection of nitrogen. Melt and extrude at 280°C, and then pass through the melt filter and metering pump into the melt-blown die head; the two melts meet at the melt-blown die head at a ratio of 60 / 40, and then flow through the spinneret hole of the melt-blown die head Under the blowing of hot air at 280°C on both sides, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com