Patents

Literature

43results about How to "Electret effect is good" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

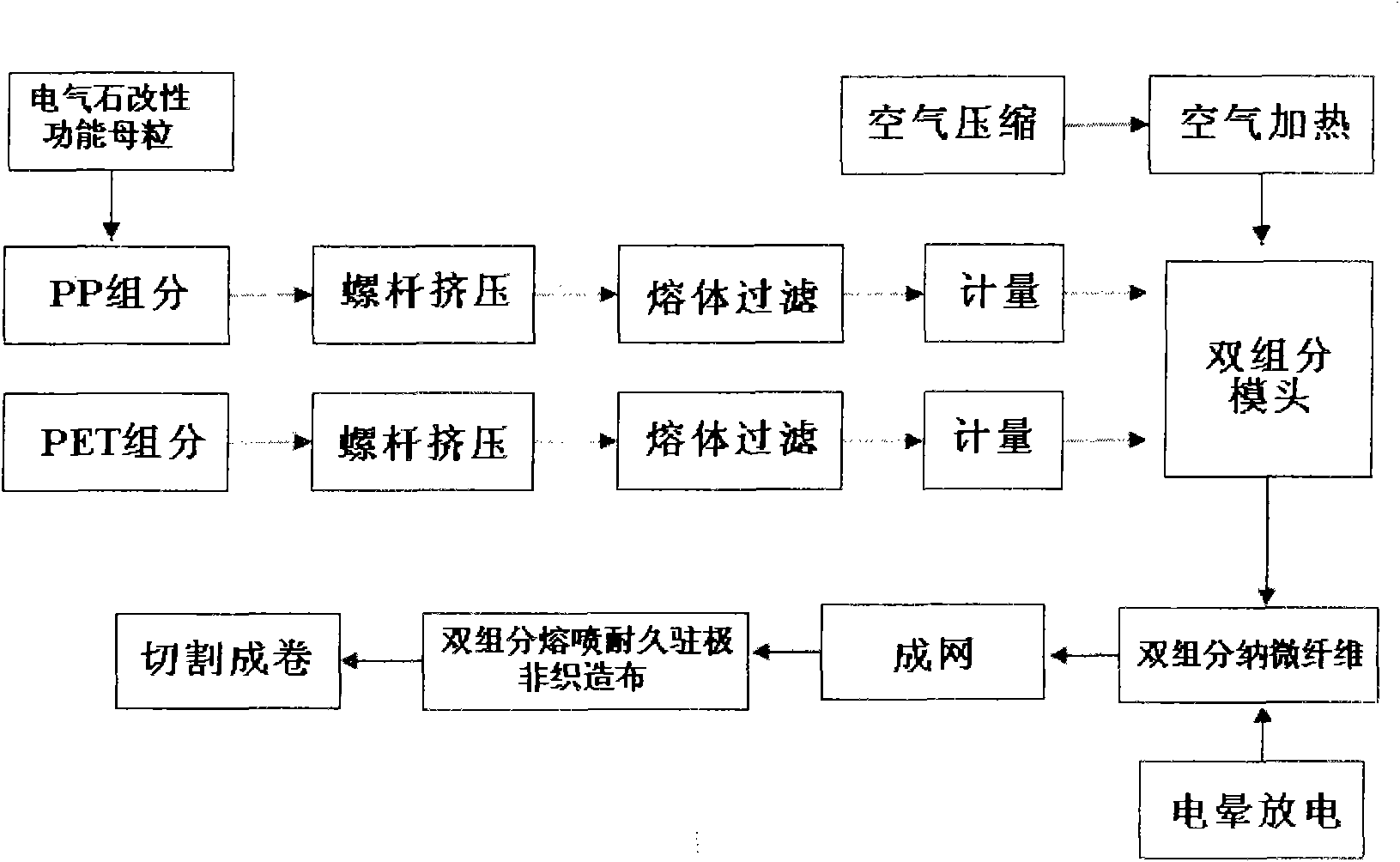

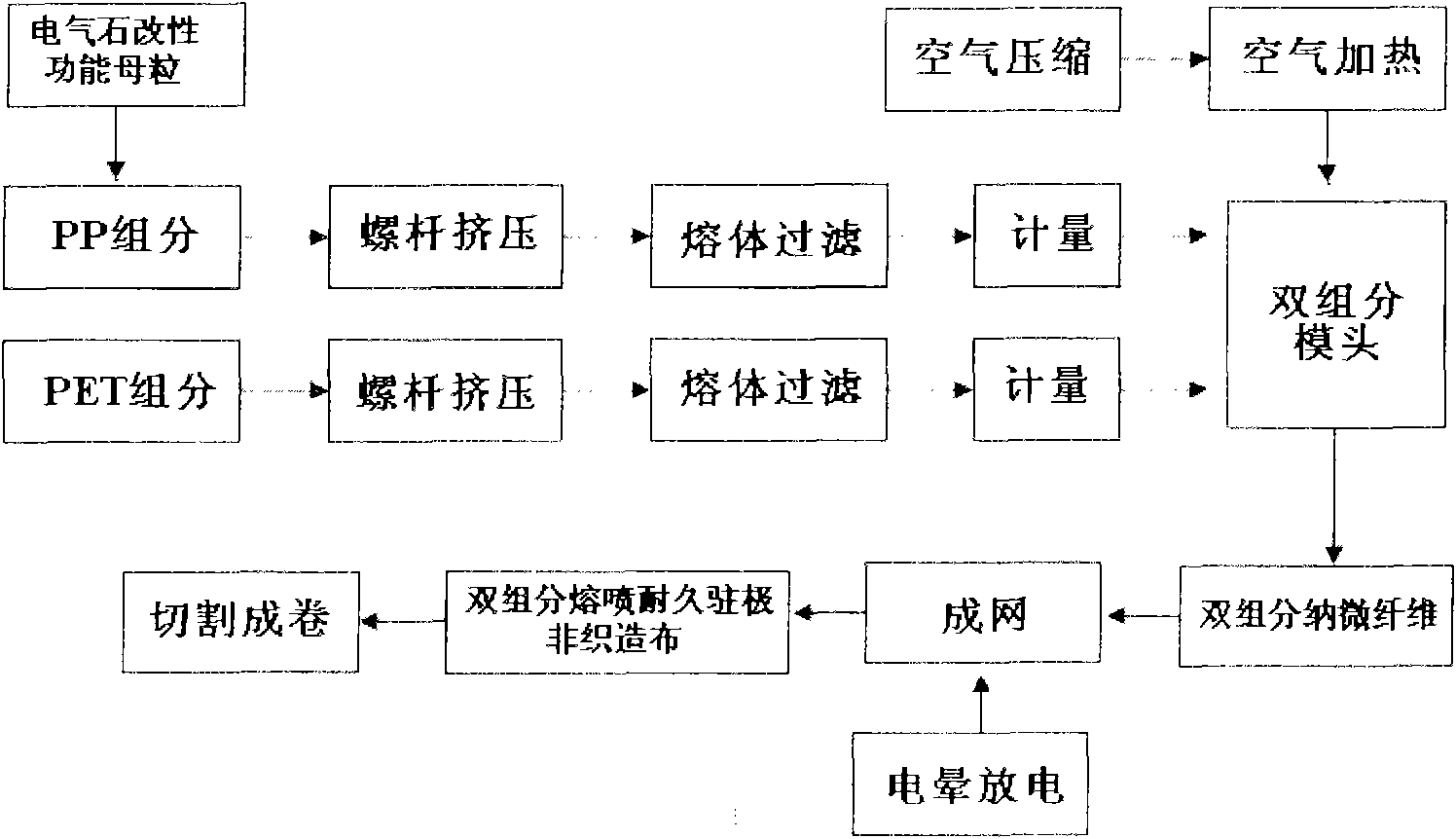

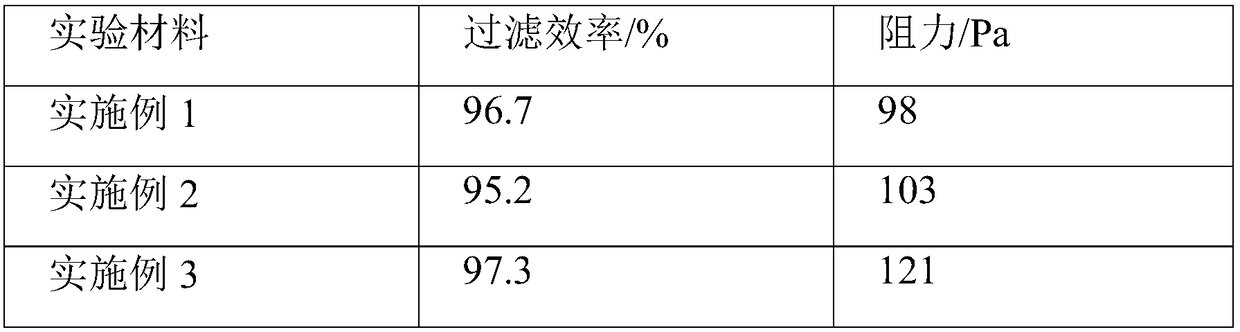

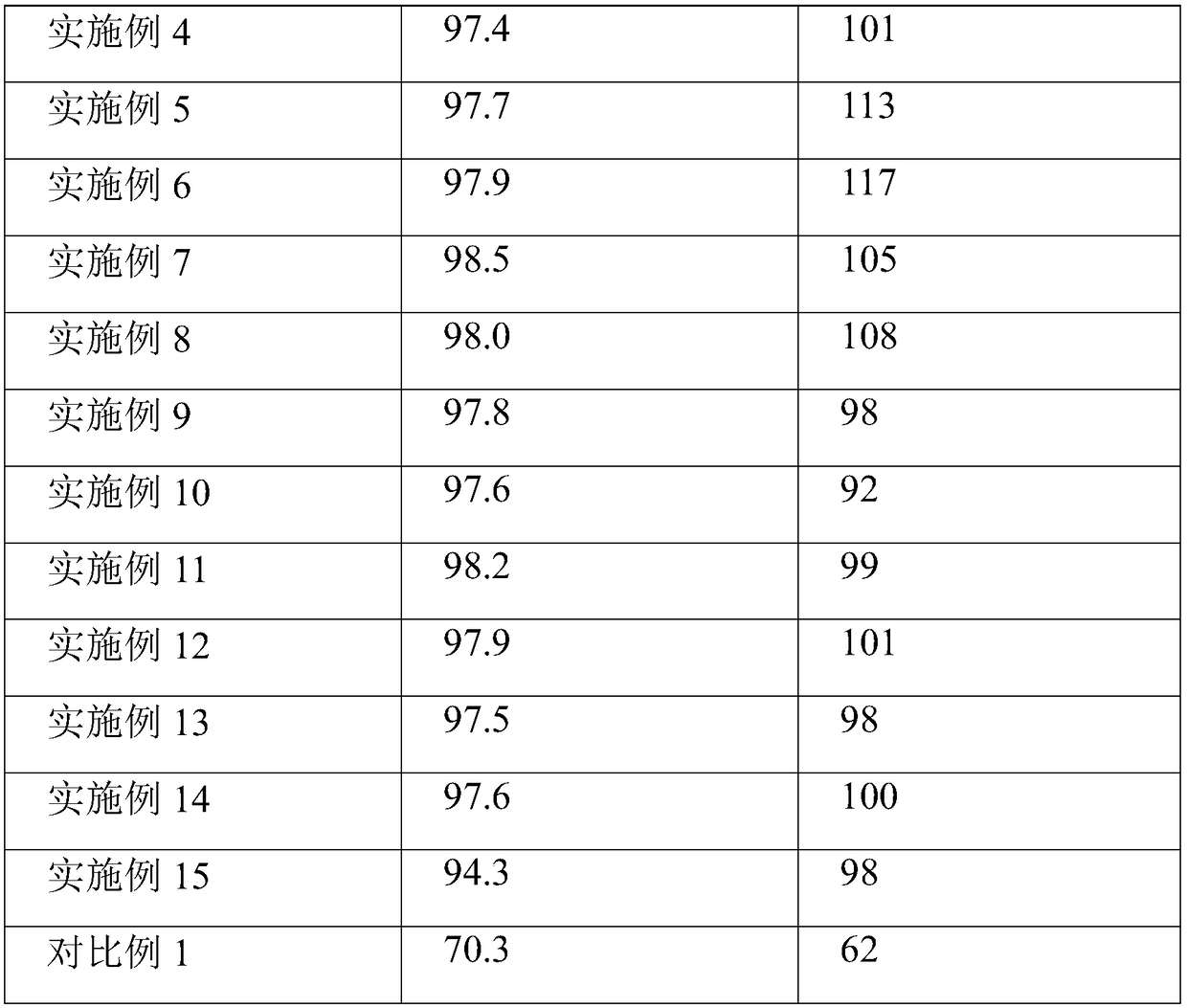

Double-component melt-blown durable electret non-woven fabric and manufacturing method thereof

InactiveCN101591837ASoft touchImprove breathabilityElectroconductive/antistatic filament manufactureArtificial filament physical treatmentFiltrationThermal insulation

The invention relates to a double-component melt-blown durable electret non-woven fabric and a manufacturing method thereof. The non-woven fabric consists of tourmaline modified polypropylene / polyethylene glycol adipate (tourmaline modified PP / PET) parallel double-component melt-blown nano microfiber; and the fiber has the following components in percentage by mass: 20 to 80 percent of tourmaline modified PP, and 80 to 20 percent of PET. The method for manufacturing the non-woven fabric adopts the components in percentage by mass and the process steps of: (1) performing drying pre-treatment on the PET first; (2) then preparing a double-component melt-blown non-woven fabric by tourmaline modified PP / PET melt-blown composite spinning technology; and (3) finally obtaining the double-component melt-blown durable electret non-woven fabric by performing high-voltage corona discharge electret treatment on the non-woven fabric. The non-woven fabric can be used for durable high-efficiency filtration materials, and can also be applied to thermal insulation materials, antibacterial medical materials, oil absorption materials and the like.

Owner:TIANJIN POLYTECHNIC UNIV

Polypropylene electret master batch material, method for preparing same and application of polypropylene electret master batch material

The invention belongs to the technical field of high-polymer materials, and particularly relates to a polypropylene (PP) electret master batch material, a method for preparing the same and applicationof the polypropylene electret master batch material. The PP electret master batch material is mainly prepared from components including, by weight, 50-100 parts of polypropylene, 8-50 parts of electret agents, 0-3 parts of compatibilizers, 0.05-0.35 part of antioxidants and 0-3 parts of anti-aging agents. The components are molten and granulated to obtain the polypropylene electret master batch material. The polypropylene electret master batch material, the method and the application have the advantages that resin and auxiliaries are uniformly mixed with one another in melt blending modes, accordingly, obvious electret effects can be realized by melt-blow non-woven materials produced from the polypropylene electret master batch material prepared by the aid of the method, the melt-blow non-woven materials are high in filter efficiency and low in filter resistance, and the like.

Owner:联泓(江苏)新材料研究院有限公司

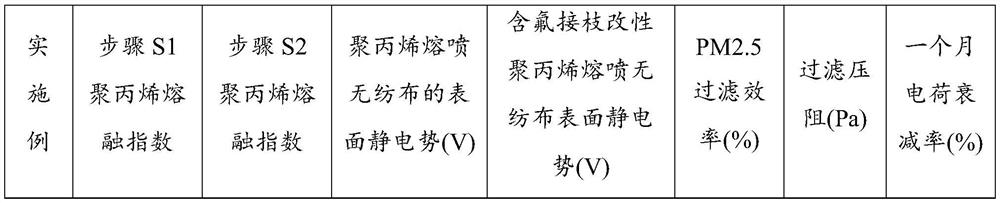

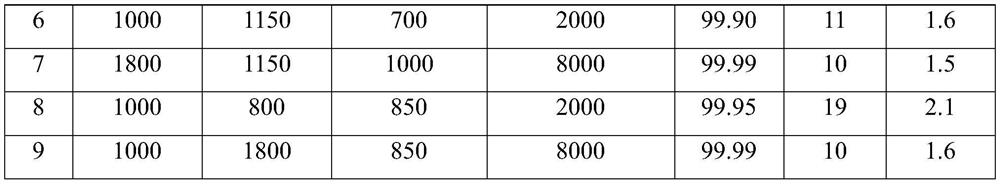

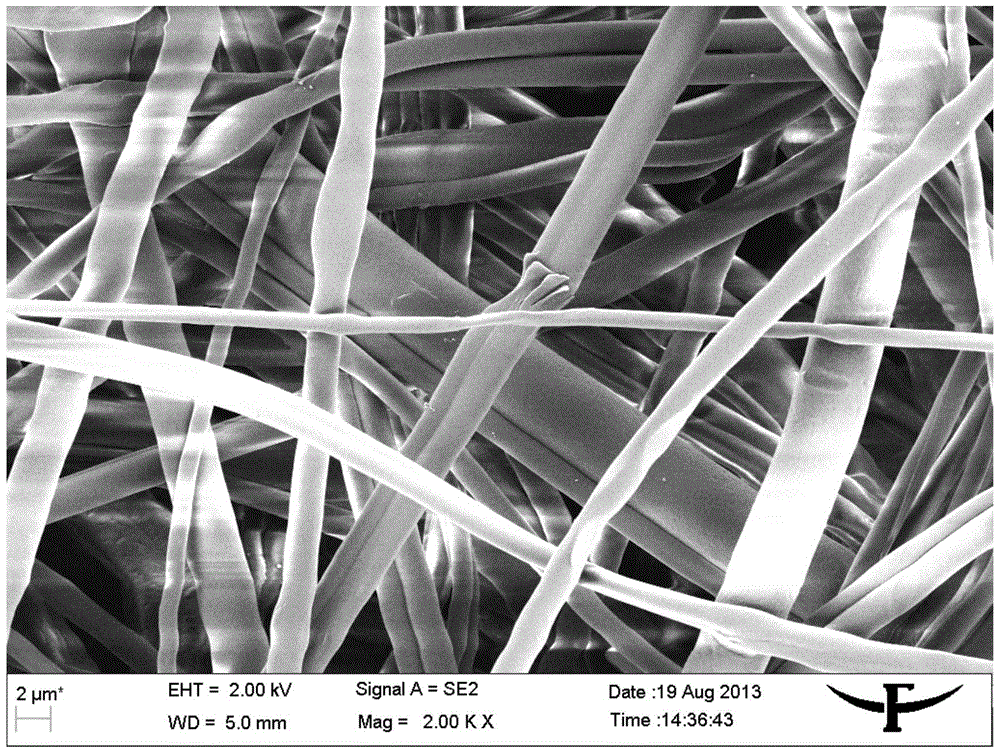

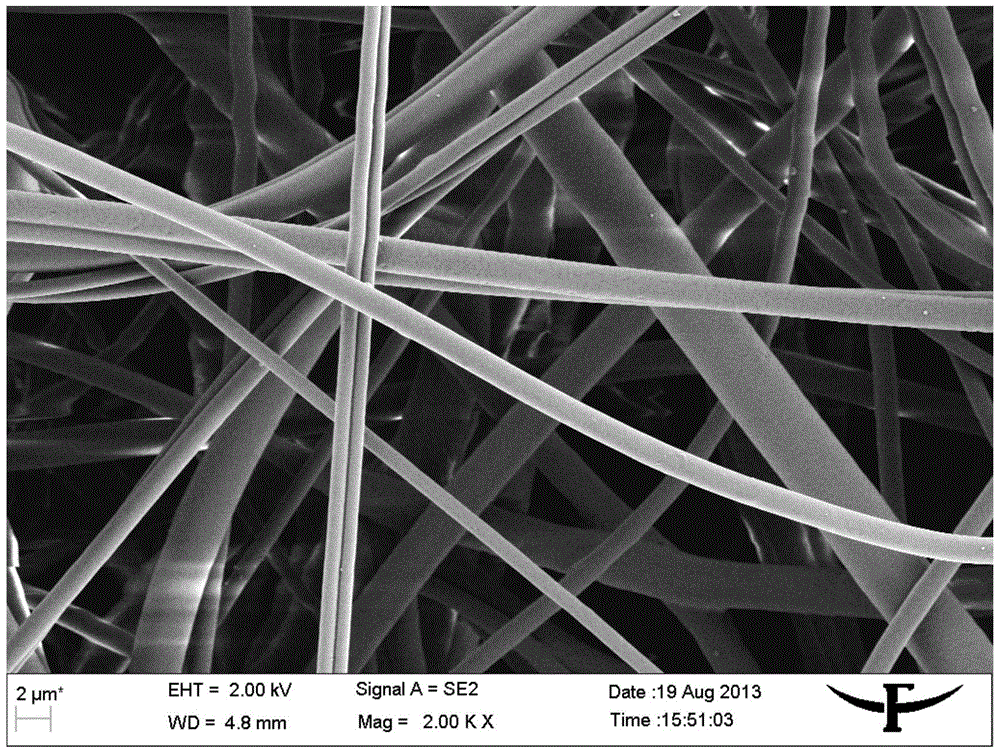

Melt-blow non-woven material capable of effectively filtering PM 2.5 particles, preparation method and production device

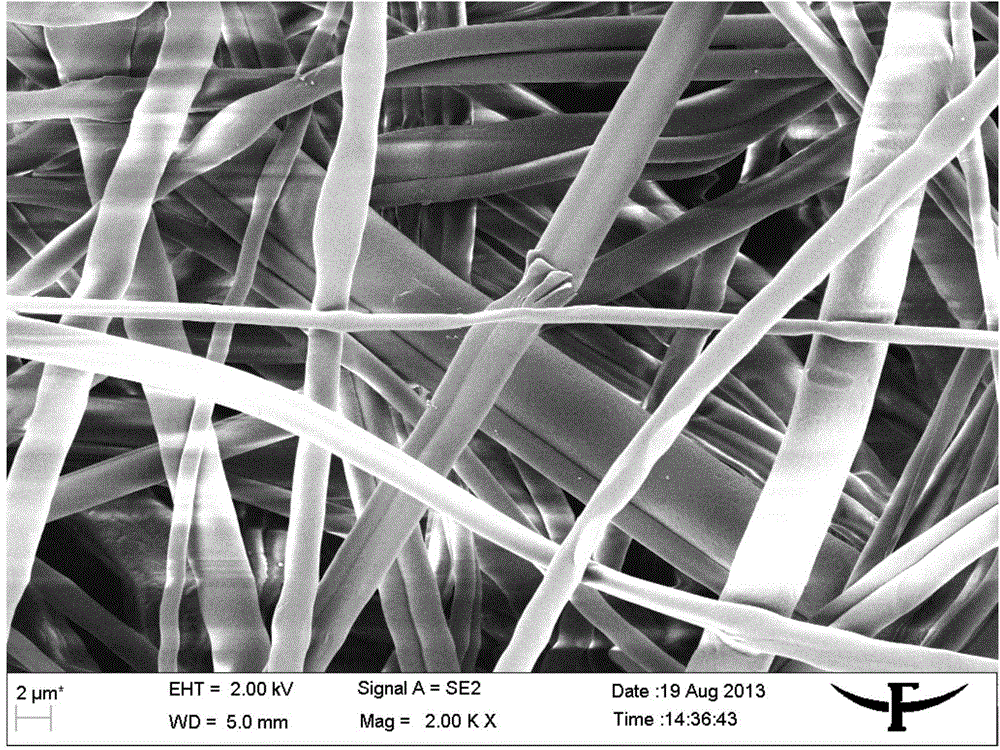

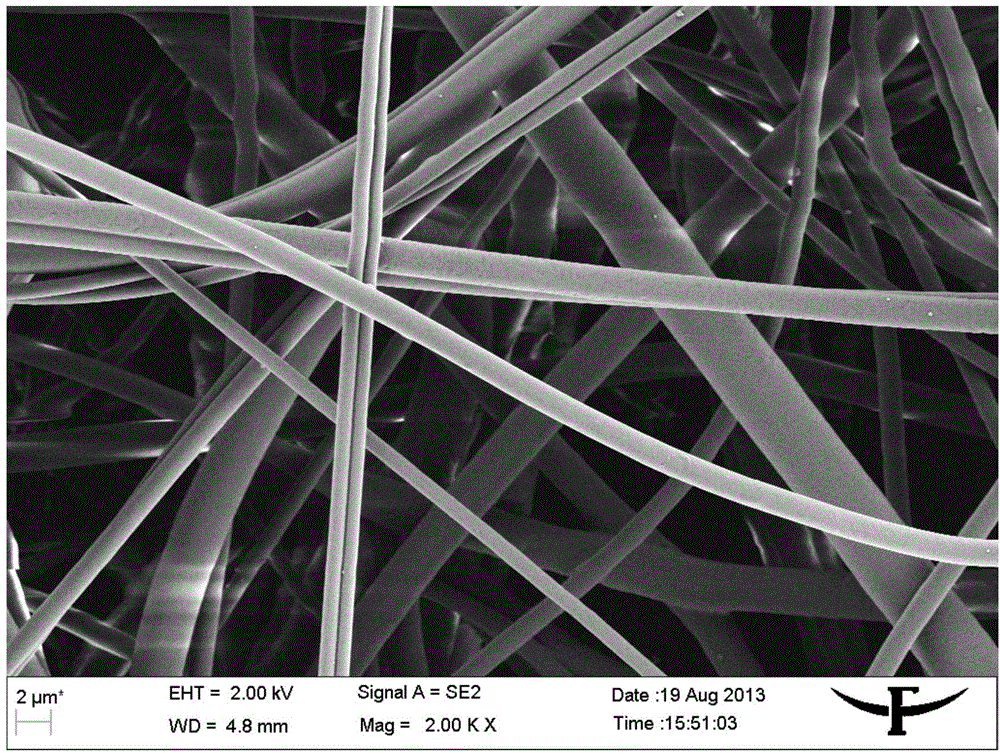

ActiveCN104153119AHigh filtration efficiencyImprove dust collection effectHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentPorosityEngineering

The invention discloses a melt-blow non-woven material capable of effectively filtering PM 2.5 particles, a preparation method and a production device. The melt-blow non-woven material comprises, by weight percentage, 93-97 parts of polypropylene, 3-6 parts of electret master batch and 0.1-1 part of polyvinylidene fluoride. According to the melt-blow non-woven material capable of effectively filtering PM 2.5 particles, the polypropylene, the electret master batch and the polyvinylidene fluoride are compounded, the obtained melt-blow non-woven material is characterized by high porosity, the fiber diameter of smaller than two micrometers, large clogging capacity, high filtering efficiency and low resistance, an electret is good in charge storage performance after electret processing, the charge keeping rate can be above two years, and the electret can be used in a high-temperature and high-humidity environment. The product is environmentally friendly and free of pollution, has the advantages of being long in service life and wide in use range, and is particularly suitable for removing PM 2.5 particles in the air.

Owner:DO FLUORIDE CHEM CO LTD

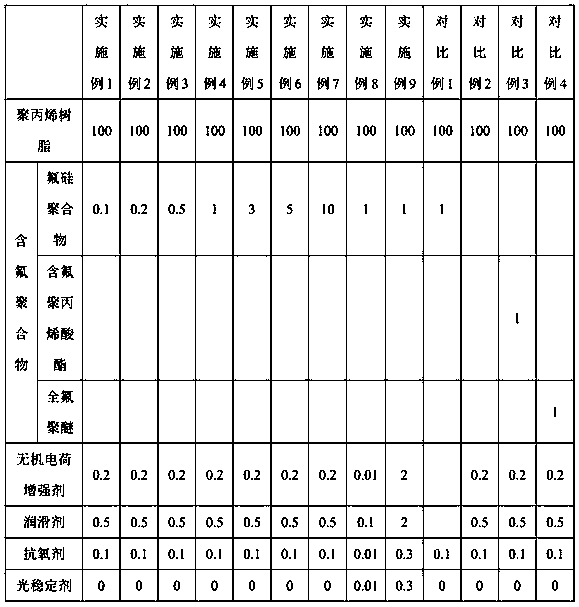

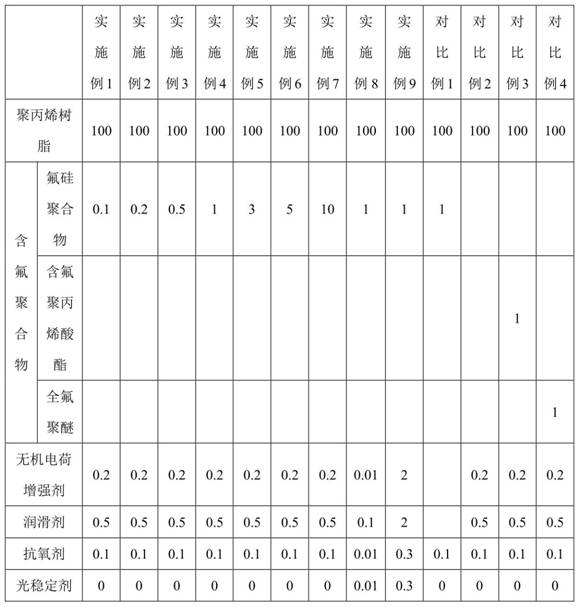

Long-acting melt-blown polypropylene composite electret material for mask melt-blown cloth and preparation method of long-acting melt-blown polypropylene composite electret material

ActiveCN111423663ALow melting pointEvenly dispersedUltrasonic/sonic fibre treatmentNon-woven fabricsPolypropylene compositesBackbone chain

The invention discloses a long-acting melt-blown polypropylene composite electret material for mask melt-blown cloth and a preparation method of the long-acting melt-blown polypropylene composite electret material. The long-acting melt-blown polypropylene composite electret material comprises the following components in parts by weight: 100 parts of polypropylene resin, 0.1 to 10 parts of a fluorosilicone polymer, 0.01 to 2 parts of an inorganic charge enhancer, 0.1 to 2 parts of a lubricant, and 0.01 to 0.3 part of an antioxidant, wherein the fluorosilicone polymer is fluorine-containing polysiloxane taking a silicon-oxygen bond as a main chain and fluoroalkyl as a side chain. In the long-acting melt-blown polypropylene composite electret material for mask melt-blown cloth, a silicon-oxygen main chain of the fluorosilicone polymer is smooth, increase of the charge injection depth can be facilitated, a fluoroalkyl side chain promotes charge capture, meanwhile, dipole directional arrangement is generated, a main chain can be masked, a cloth cover is endowed with good hydrophobicity, the material has a good electret effect, and the long-term effect of the material is effectively improved. Moreover, the fluorosilicone polymer is low in melting point and is uniformly dispersed, so that the melt-blown polypropylene composite electret material is relatively simple to process and form.

Owner:KINGFA SCI & TECH CO LTD +1

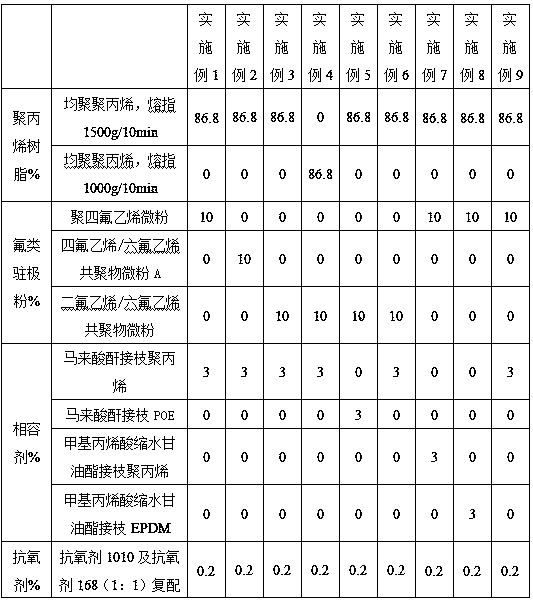

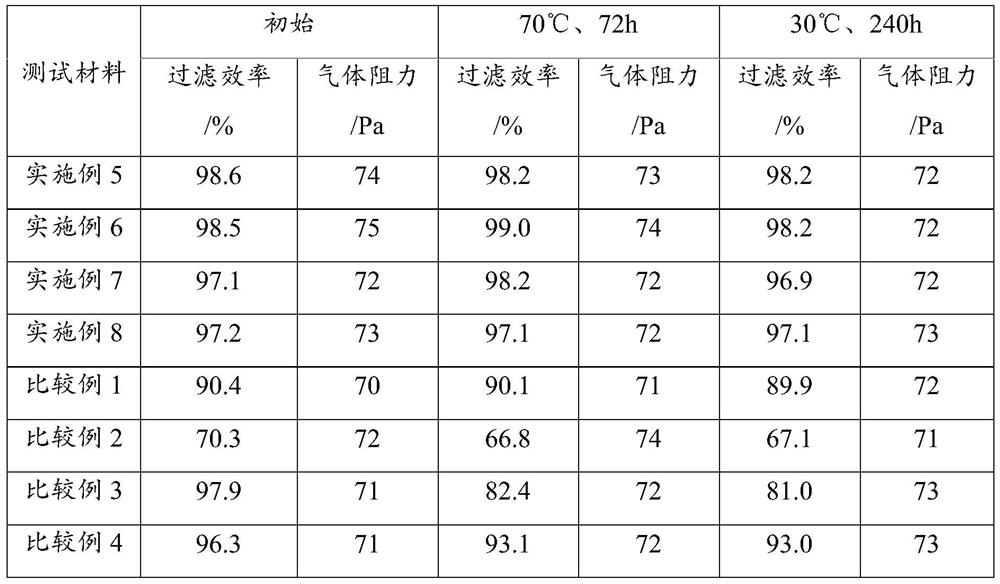

Special organic electret master batch for melt-blown non-woven fabric applied to mask and preparation method thereof, and melt-blown non-woven fabric prepared from special organic electret master batch

ActiveCN111560140AEvenly dispersedOvercome the possibility of precipitation due to electret powderNon-woven fabricsMonocomponent polyolefin artificial filamentElastomerPolymer science

The invention discloses a special organic electret master batch for a melt-blown non-woven fabric applied to a mask and a preparation method thereof, and the melt-blown non-woven fabric prepared fromthe special organic electret master batch. The special organic electret master batch for the melt-blown non-woven fabric applied to the mask is prepared from the following components in percentage byweight: 80-90% of polypropylene resin, 2-10% of fluorine electret powder, 1-10% of a compatilizer and 0.05%-0.5% of a processing aid, wherein the average particle size of the fluorine electret powderis 0.05-3 [mu] m, the compatilizer is a maleic anhydride-grafted olefin copolymer / elastomer or glycidyl methacrylate grafted olefin copolymer / elastomer; and the melt index of the polypropylene resin is not lower than 1000 g / 10 min, and the length-diameter ratio of a screw for preparing the organic electret master batch special for the melt-blown non-woven fabric is larger than or equal to 40: 1. According to the special organic electret master batch for the melt-blown non-woven fabric, the phenomenon that an existing electret master batch is prone to being blocked due to separation of electretpowder in the production process of the melt-blown non-woven fabric applied to masks is overcome, fluorine electret powder can be better dispersed evenly, and good electret effect is still achieved under the condition of a small adding amount.

Owner:KINGFA SCI & TECH CO LTD +1

Polypropylene electret master batch, preparation method thereof and polypropylene melt-blown non-woven fabric

ActiveCN111875886AImprove liquidityStable melt indexTextile/flexible product manufactureNon-woven fabricsLong chain fatty acidPolymer science

The invention relates to the technical field of high polymer materials, in particular to a polypropylene electret master batch, a preparation method thereof, and a polypropylene melt-blown non-woven fabric. The polypropylene electret master batch comprises the following components in parts by weight: 70-90 parts of polypropylene resin, 10-30 parts of an electret agent, 2-5 parts of a nucleating agent, 1-3 parts of a compatilizer, 3-5 parts of a lubricant and 0.5-2 parts of an antioxidant; wherein the electret comprises any one or more of zinc salt, magnesium salt and aluminum salt of long-chain fatty acid with the carbon atom number of 14-22. The preparation method comprises the following steps: uniformly mixing the components in proportion to obtain a premix, and granulating the premix. The polypropylene electret master batch obtained through cooperation of the components has high fluidity, the volatile components and the melt index of the polypropylene electret master batch are morestable, the electret effect of the polypropylene melt-blown non-woven fabric produced by the electret master batch can be effectively improved, the electret effect is stable, the filtering efficiencyis improved, and the filtering resistance is reduced.

Owner:GUANGZHOU LUSHAN NEW MATERIALS +2

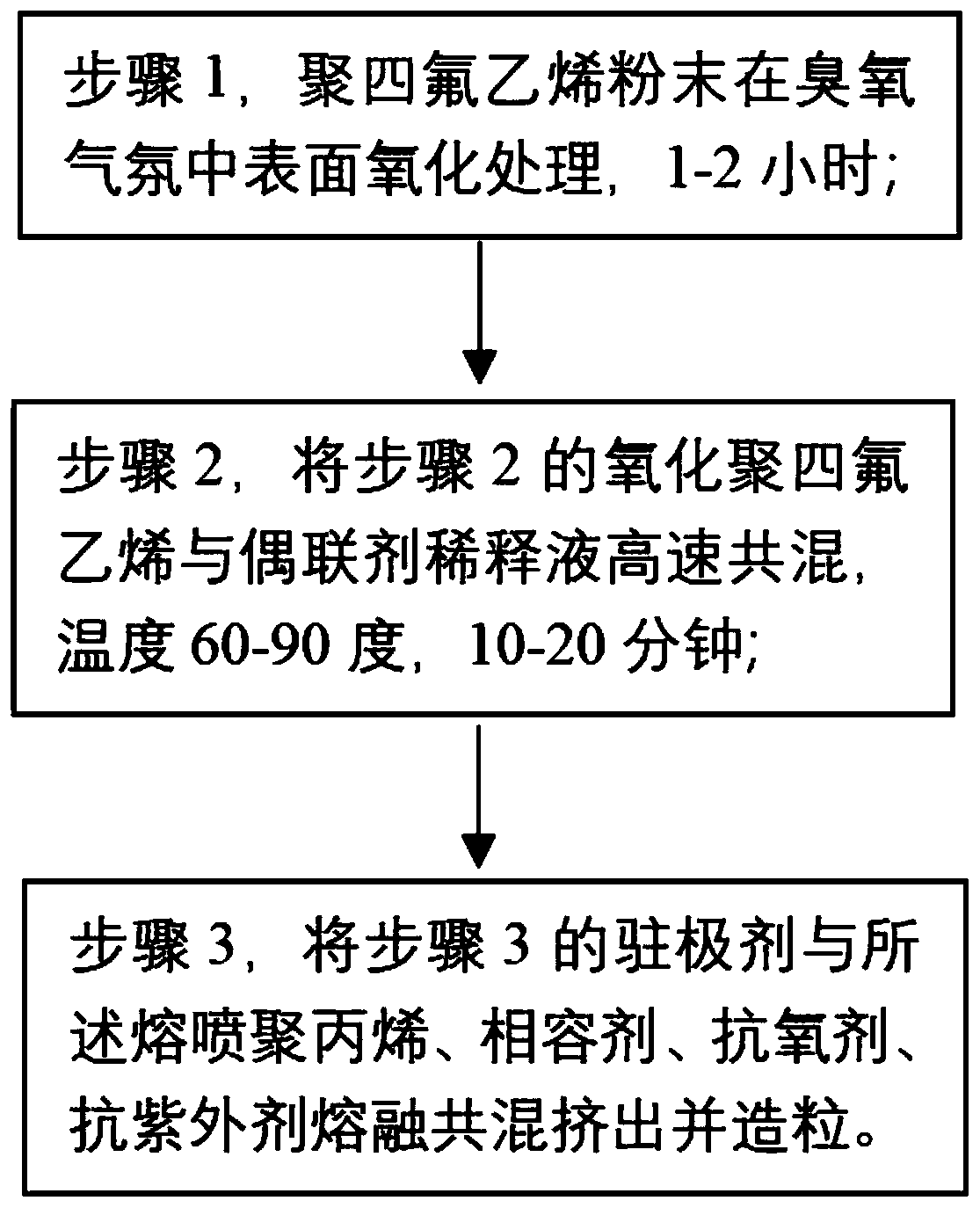

Melt-blown polypropylene electret master batch and preparation method thereof

InactiveCN111303539AElectret effect is goodImprove filtration efficiencyMonocomponent polyolefin artificial filamentArtifical filament manufacturePolymer scienceAntioxidant

The invention discloses a melt-blown polypropylene electret master batch which comprises the following components in parts by weight: 45-100 parts of polypropylene, 5-70 parts of an electret, 1-5 parts of a compatilizer, 0.01-1 part of an antioxidant, and 0.01-5 parts of an anti-ultraviolet agent. The invention also discloses a preparation method of the melt-blown polypropylene master batch material. The master batch has the following beneficial effects: polytetrafluoroethylene subjected to oxidation by ozone and surface modification by a coupling agent is used as an electret, polypropylene resin and corresponding auxiliaries are mixed in a melt blending granulation mode to obtain a melt-blown polypropylene electret master batch material, and a non-woven fabric fiber product produced fromthe master batch and a pure polypropylene raw material has the advantages of being obvious in electret effect, high in filtering efficiency, small in wind resistance and the like. The melt-blown polypropylene electret master batch and the preparation method thereof have the advantages of simplicity, quickness and cheapness, and are suitable for large-scale batch production.

Owner:中山市鸿盛新材料有限公司

Energy increasing additive added multi-layer melt-blown composite filter material and preparation method thereof

ActiveCN106076000AImprove filtration efficiencySmall filter resistanceGas treatmentDispersed particle filtrationUltrasound attenuationSurface layer

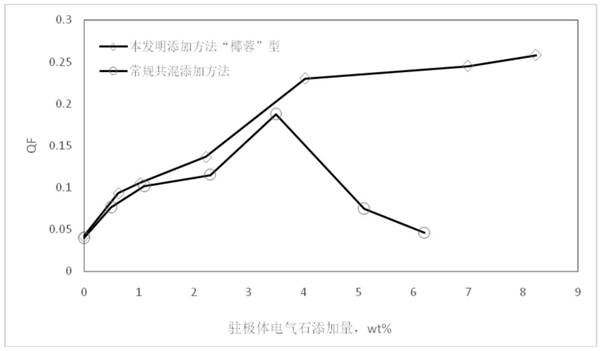

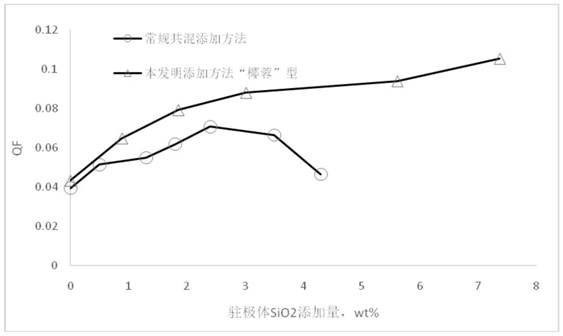

The invention relates to an energy increasing additive added multi-layer melt-blown composite filter material and a preparation method thereof. The multi-layer melt-blown composite filter material comprises a dust surface layer melt-blown material, a middle layer melt-blown material and a fine filtration layer melt-blown material and is prepared by steps: subjecting raw materials to melt blowing in a melt blowing device to form the dust surface layer melt-blown material, the middle layer melt-blown material and the fine filtration layer melt-blown material sequentially, compounding, and performing corona electret treatment to obtain the energy increasing additive added multi-layer melt-blown composite filter material. The energy increasing additive added multi-layer melt-blown composite filter material is simple in process route, low in implementation cost and easy in industrial popularization; on the one hand, due to a gradient structure, material bulkiness can be improved, and filtration efficiency attenuation can be decelerated while filtration efficiency is improved.

Owner:浙江圣蓝新材科技有限公司

Needled/melt-blown/spunbond composite filter material and preparation method thereof

ActiveCN110772889ASmall filter resistanceDelay the rise of filter resistanceDispersed particle filtrationMembrane filtersComposite filterFilter material

The invention belongs to the technical field of air filter materials, and discloses a needled / melt-blown / spunbond composite filter material and a preparation method thereof. The preparation method comprises the steps that modified polypropylene master-batches are mixed with polypropylene slices, and then mixed granules are obtained; the mixed granules are made into a polypropylene fiber net, and needling reinforcement is conducted to obtain a dust-facing layer needled material; a fine filter layer melt-blown material is prepared from the mixed granules; polypropylene slices are made into a polypropylene fiber net, and hot-rolling reinforcement is conducted to obtain a supporting layer spunbond material; and the dust-facing layer needled material, the fine filter layer melt-blown material and the supporting layer spunbond material are placed on an electret condensing device to be subjected to electret condensing simultaneously, and online compositing is conducted through electrostatic attraction to obtain the needled / melt-blown / spunbond composite filter material. The composite filter material prepared by the preparation method can reduce filtration resistance and delay rising of thefiltration resistance in the loading filtration process to intercept small-particle-size particles, and the filtration efficiency and stability are higher.

Owner:NANTONG UNIVERSITY

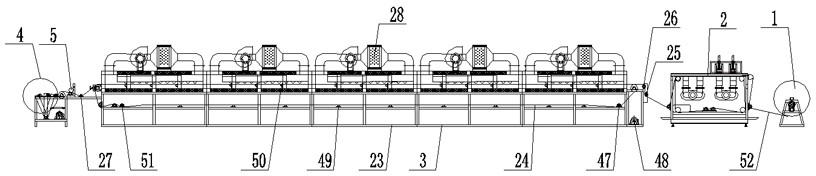

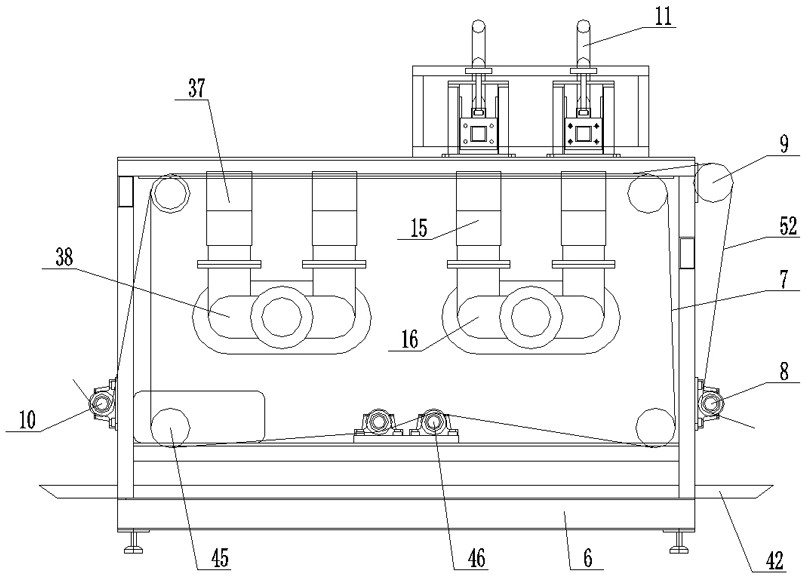

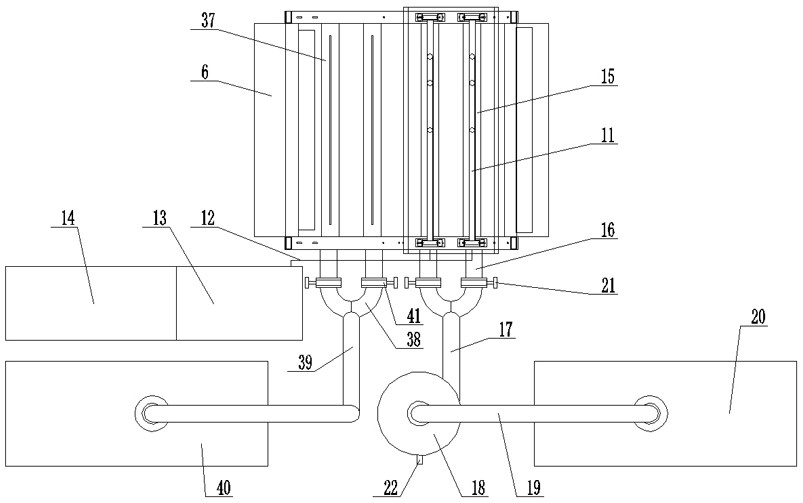

Melt-blown cloth spunlace production line

PendingCN111809312AImprove filtering effectImprove breathabilityDrying solid materials with heatDispersed particle separationStructural engineeringWater pipe

The invention discloses a melt-blown cloth spunlace production line, comprising an unwinding device arranged at the front end, wherein a spunlace device is arranged at the rear end of the unwinding device; a multi-stage drying device is arranged at the rear end of the spunlace device; an automatic winding device is arranged at the rear end of the multi-stage drying device; a longitudinal slittingcutter group is arranged between the automatic winding device and the multi-stage drying device; the spunlace device structurally comprises a first rack, a first conveying belt is arranged in the first rack through a first transmission mechanism; a first front supporting roller is arranged at the front end of the first rack. A cloth feeding roller is arranged at the position, at the upper end of the first front supporting roller, of the first rack, a first rear supporting roller is arranged at the rear end of the first rack, and two sets of longitudinal spunlace nozzles are arranged at the upper end of the first rack and connected with a water outlet of a water pump through a water pipe.

Owner:JIANGSU KUNTAI MACHINERY

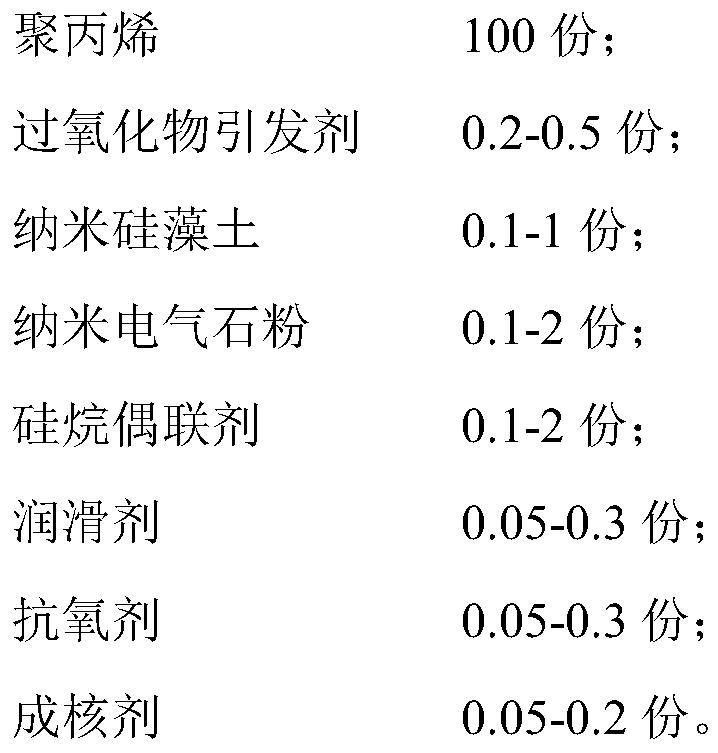

Melt-blown polypropylene material with long-acting filtering function and preparation method and application thereof

ActiveCN112481726ACapable of retaining solid particlesIncreased electronegativityNon-woven fabricsMonocomponent polyolefin artificial filamentPolymer scienceOrganosolv

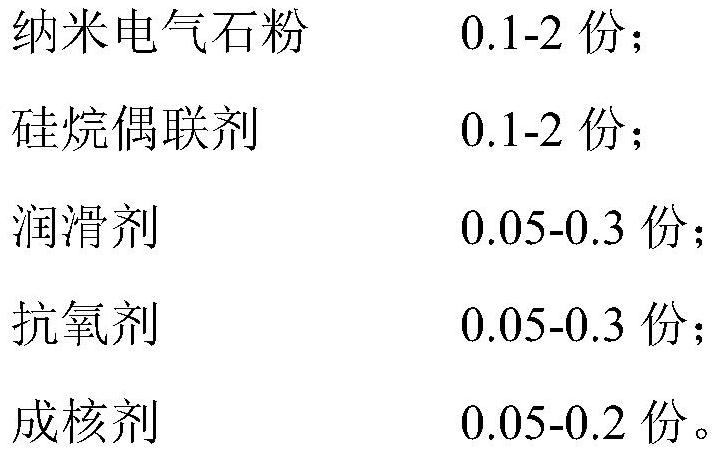

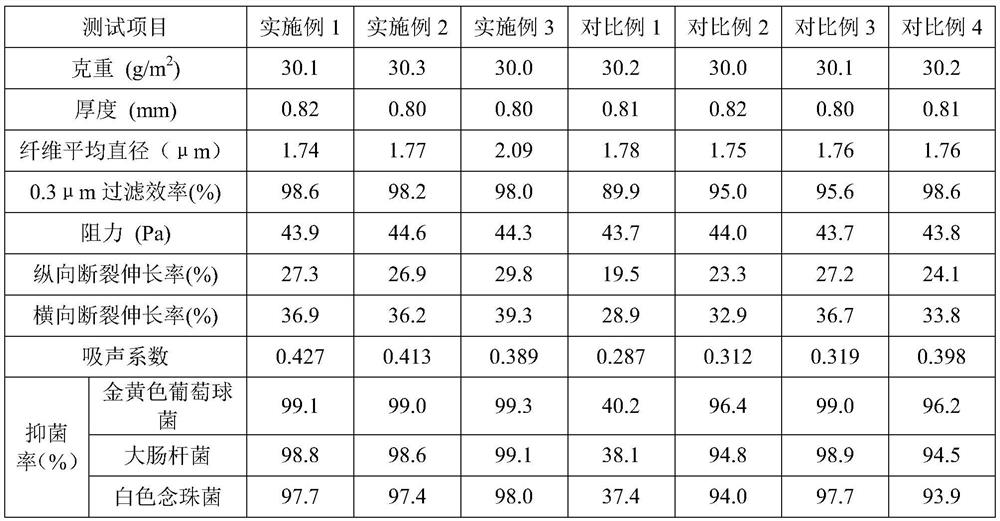

The invention belongs to the field of high polymer materials, and particularly relates to a melt-blown polypropylene material with a long-acting filtering function and a preparation method and application of the melt-blown polypropylene material. The melt-blown polypropylene material comprises the following components in parts by weight: 100 parts of polypropylene; 0.2-0.5 part of a peroxide initiator; 0.1-1 part of nano diatomite; 0.1-2 parts of nano tourmaline powder; 0.1-2 parts of a silane coupling agent; 0.05-0.3 part of a lubricating agent; 0.05-0.3 part of an antioxidant; and 0.05-0.2 part of a nucleating agent. The nano tourmaline powder is conveyed into pores of the nano diatomite to form the nano composite material through organic solvent infiltration and ultrasonic treatment bymeans of electronegativity and a multi-stage open pore structure of the nano tourmaline powder, so that the problem that electronegativity of melt-blown cloth taking the tourmaline powder as an electret declines due to long-term exposure in air is reduced, the electrostatic adsorption capacity and the long-acting filtering function can be effectively improved, the process is simple, and batch production is facilitated.

Owner:SHANDONG INOV POLYURETHANE

Preparation method of antibacterial mildew-proof filter cotton

ActiveCN113244695AHas broad-spectrum antibacterial propertiesGood antibacterial and antifungal effectDispersed particle filtrationFibre typesSpinningUltraviolet irradiation

The invention discloses a preparation method of antibacterial mildew-proof filter cotton. The preparation method comprises the following steps: (1) preparation of azido-modified nanometer titanium dioxide; (2) preparation of modified PET master batches: uniformly mixing PET slices with the azido-modified nanometer titanium dioxide, and conducting extruding and granulating to obtain the modified PET master batches; (3) melt-blowing: uniformly mixing the modified PET master batches and electret master batches, carrying out extruding and melting, feeding a formed melt to a spinning assembly for spinning, and forming fine fibers under the traction action of hot air; (4) ultraviolet irradiation: performing ultraviolet irradiation on the obtained fine fibers to obtain porous fibers; and (5) forming: carrying out web forming, electret formation and rolling on the porous fibers to obtain the antibacterial mildew-proof filter cotton. The azido-modified nanometer titanium dioxide is added into PET fibers, so the antibacterial property, the filtering property and the mechanical property of the filter cotton can be effectively improved.

Owner:杭州诗蓝过滤科技有限公司

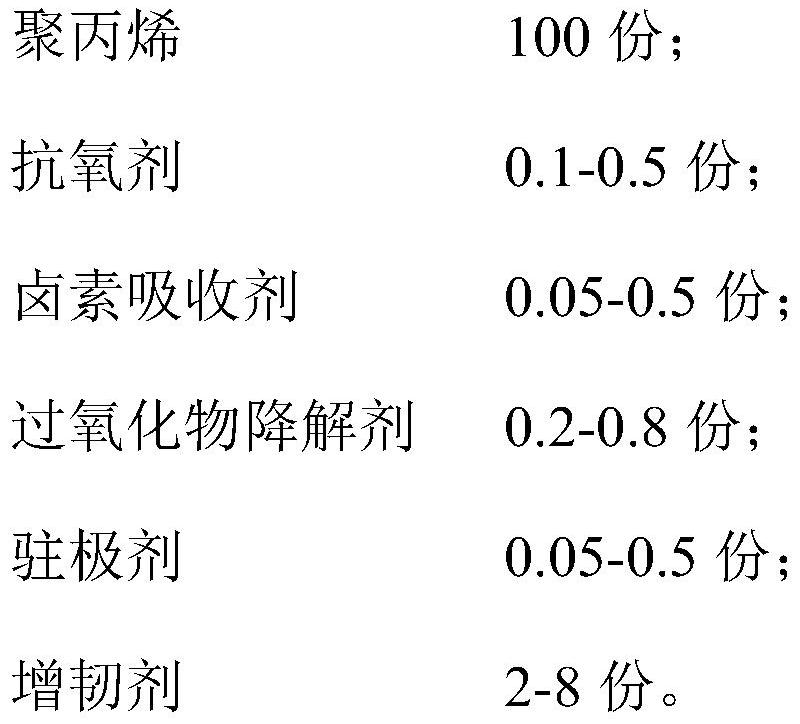

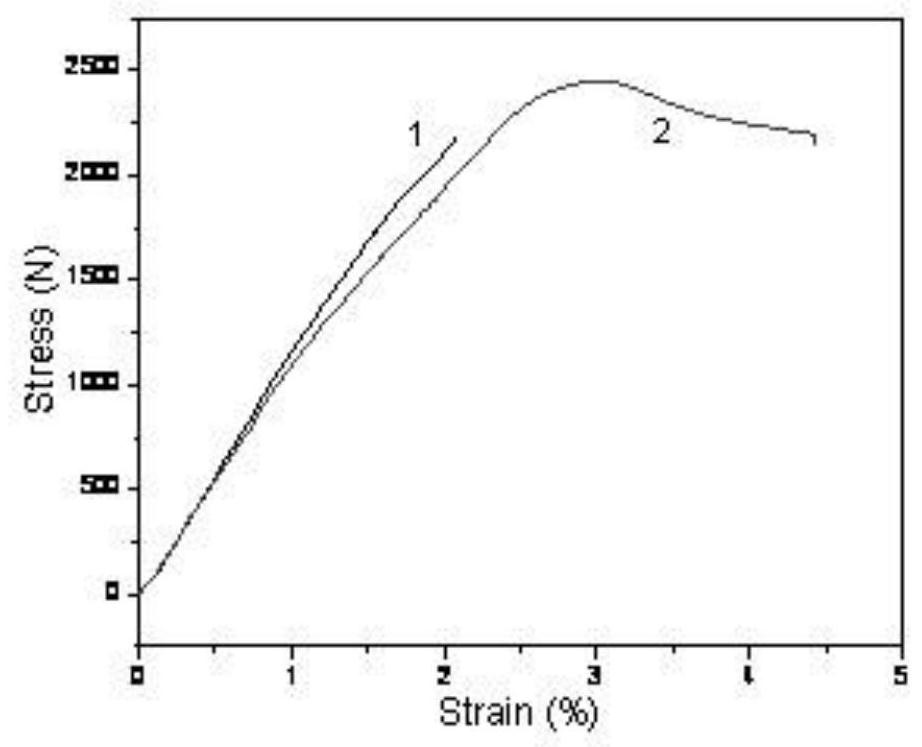

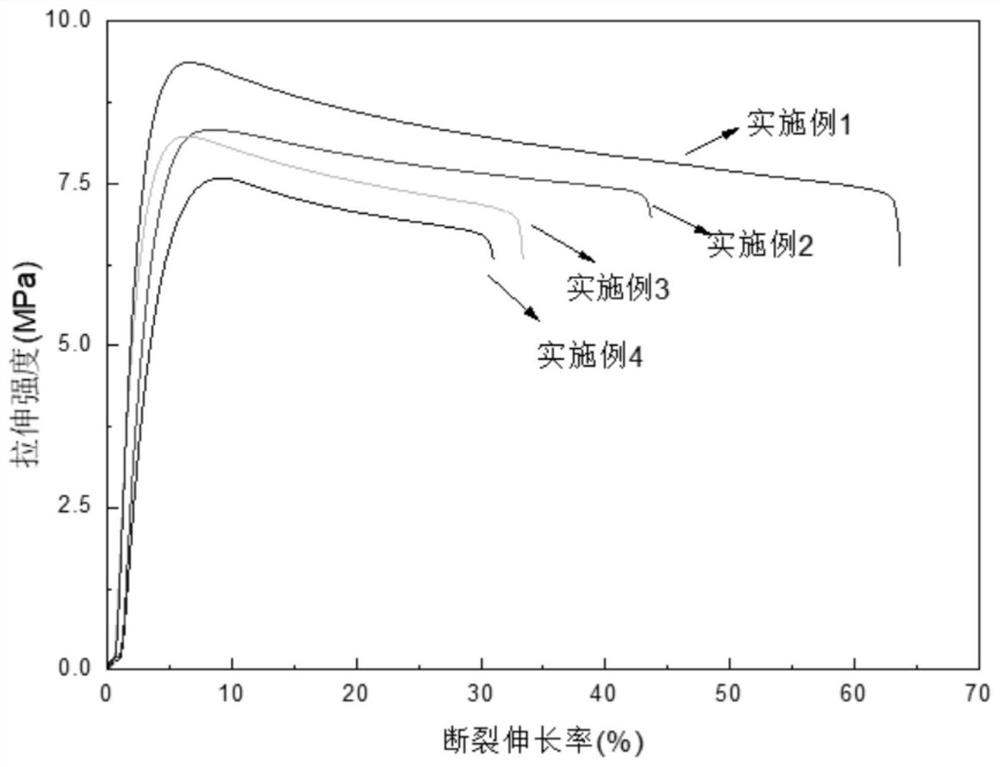

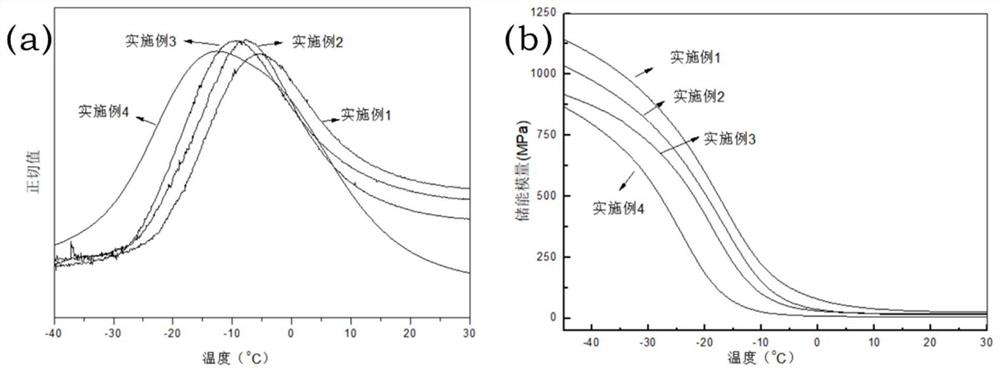

Low-odor, high-toughness and high-electret polypropylene melt-blown material and preparation method thereof

PendingCN112194850ANarrow molecular weight distributionSmall smellFilament-forming treatmentPolymer scienceAnoxomer

The invention discloses a low-odor, high-toughness and high-electret polypropylene melt-blown material and a preparation method thereof. The low-odor, high-toughness and high-electret polypropylene melt-blown material comprises 100 parts of polypropylene, 0.1-0.5 part of an antioxidant, 0.05-0.5 part of a halogen absorbent, 0.2-0.8 part of a peroxide degradation agent, 0.05-0.5 part of an electretagent and 2-8 parts of a flexibilizer. The invention also provides a preparation method of the low-odor, high-toughness and high-electret polypropylene melt-blown material. The polypropylene melt-blown material provided by the invention has the characteristic of low odor, and the melt-blown cloth prepared from the melt-blown material has good toughness and electret effect.

Owner:ZHEJIANG JAVA SPECIALTY CHEM CO LTD

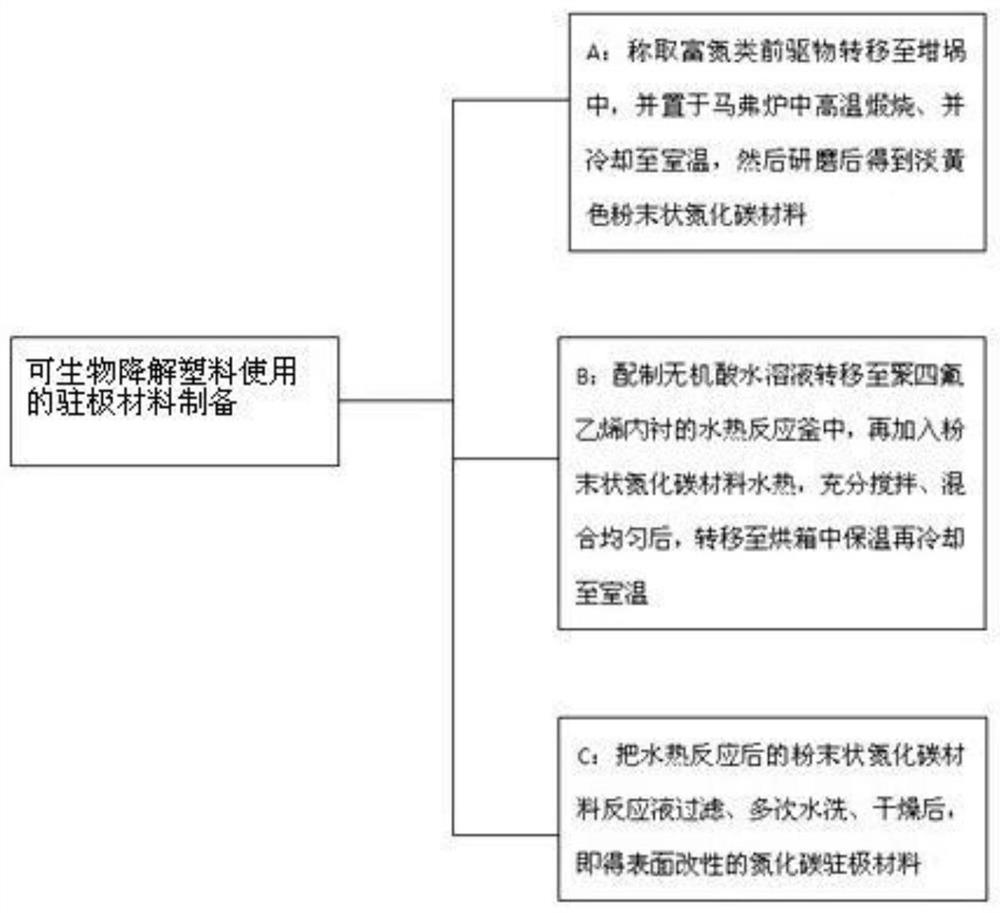

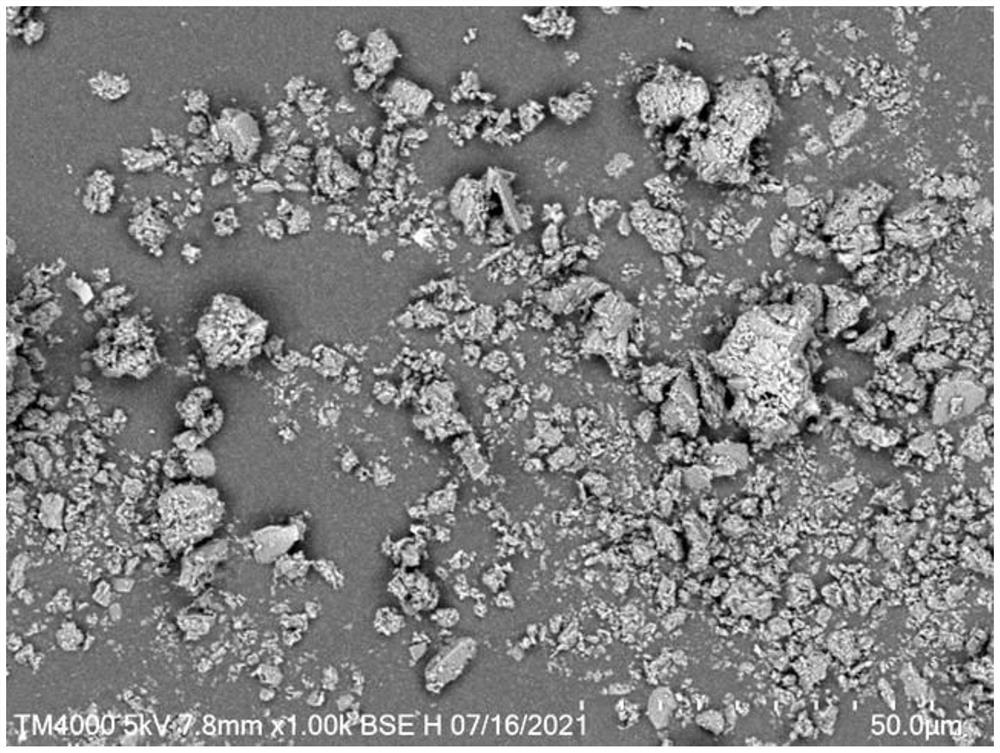

Preparation and application method of electret material for biodegradable plastic

ActiveCN113699616AIncrease the number ofGood dispersionNon-woven fabricsMonocomponent polyesters artificial filamentModified carbonCarbon nitride

The invention discloses preparation of an electret material for biodegradable plastic. Carbon nitride and inorganic acid are used as raw materials. The process for preparing the electret material comprises the following steps of A, preparing a carbon nitride material; B, preparing an inorganic acid aqueous solution, stirring and mixing the inorganic acid aqueous solution and the carbon nitride material uniformly, transferring a mixture into a drying oven, preserving heat, and cooling to room temperature; and C, filtering a carbon nitride material reaction liquid, performing washing with water for multiple times, and performing drying to obtain the surface-modified carbon nitride electret material. The application method of the electret material for the biodegradable plastic comprises the following steps of A, preparing surface-acidified carbon nitride electret master batch; and B, mixing the electret master batch and the biodegradable plastic in proportion to generate melt-blown cloth. According to the invention, the electret material is prevented from being separated out from the biodegradable plastic during melt-blowing, the cost is low, the electret material can effectively store electrostatic charge and prolong the retention time of the charge in the melt-blown cloth, a relatively high electret effect can be achieved with a small amount of the electret material, and the filtering efficiency can be effectively improved by terminal application.

Owner:大韩道恩高分子材料(上海)有限公司

A kind of multi-layer melt-blown composite filter material adding energy-enhancing additive and its preparation method

ActiveCN106076000BImprove filtration efficiencySmall filter resistanceGas treatmentDispersed particle filtrationUltrasound attenuationSurface layer

The invention relates to an energy increasing additive added multi-layer melt-blown composite filter material and a preparation method thereof. The multi-layer melt-blown composite filter material comprises a dust surface layer melt-blown material, a middle layer melt-blown material and a fine filtration layer melt-blown material and is prepared by steps: subjecting raw materials to melt blowing in a melt blowing device to form the dust surface layer melt-blown material, the middle layer melt-blown material and the fine filtration layer melt-blown material sequentially, compounding, and performing corona electret treatment to obtain the energy increasing additive added multi-layer melt-blown composite filter material. The energy increasing additive added multi-layer melt-blown composite filter material is simple in process route, low in implementation cost and easy in industrial popularization; on the one hand, due to a gradient structure, material bulkiness can be improved, and filtration efficiency attenuation can be decelerated while filtration efficiency is improved.

Owner:浙江圣蓝新材科技有限公司

Aromatic melt-blown non-woven fabric having low ventilation resistance, planar mask with melt-blown non-woven fabric and manufacturing method of planar mask

InactiveCN112080859AImprove filtering effectIncrease contentNon-woven fabricsProtective garmentLinear low-density polyethylenePolymer science

The invention discloses an aromatic melt-blown non-woven fabric having low ventilation resistance, a planar mask with the melt-blown non-woven fabric and a manufacturing method of the planar mask. Theplanar mask is prepared from the following raw materials in parts by weight of 80-90 parts of polypropylene melt-blown non-woven fabric slices, 10-13 parts of maleic anhydride grafted polypropylene,5-7 parts of metallocene catalyzed linear low-density polyethylene, 1.8-2.2 parts of mesoporous silica, 2.5-3 parts of nano bismuth stearate, 1.5-1.8 parts of 3-[3-(benzotriazole-2-yl)-5-tert-butyl-4-hydroxyphenyl] methyl propionate, 3-3.8 parts of 2,6-dimethylphenylphthalimide, 2-2.5 parts of oleamide and 0.6-0.9 part of erucamide. The aromatic melt-blown non-woven fabric having low ventilation resistance is good in filtering effect and excellent in electret charge storage performance, the filtering efficiency of the non-woven fabric is still good after the non-woven fabric is stored for 3 months under the high-temperature and high-humidity conditions, and the prepared planar mask is good in filtering effect and good in protection effect. The mask is good in air permeability, low in ventilation resistance, and not liable to cause discomfort such as oxygen deficit when being worn.

Owner:怡佳(福建)卫生用品股份有限公司

Antibacterial polylactic acid melt-blown non-woven fabric

InactiveCN112647154AIncrease the rate of crystallizationHigh crystallinityConjugated synthetic polymer artificial filamentsNon-woven fabricsPolymer scienceButanedioic acid

The invention discloses an antibacterial polylactic acid melt-blown non-woven fabric. The antibacterial polylactic acid melt-blown non-woven fabric is prepared from the following raw materials in parts by weight: 80-85 parts of polylactic acid, 15-20 parts of polybutylene succinate, 0.5-1 part of a nucleating agent and 3-5 parts of a toughening agent. Through mutual cooperation of all the substances, the toughness and crystallinity of polylactic acid are improved, so that the antibacterial polylactic acid melt-blown non-woven fabric is easy to process and good in filtering performance; and in addition, the antibacterial polylactic acid melt-blown non-woven fabric is easy to degrade, does not pollute the environment and has certain antibacterial performance.

Owner:临泉县圣茂纺织品有限公司

A kind of environment-friendly air filter non-woven fabric and its production process and application

ActiveCN112853619BImprove charging effectElectret effect is goodUltrasonic/sonic fibre treatmentGrip property fibresAir filtrationPolymer science

The invention provides an environment-friendly production process of non-woven fabric for air filtration, which belongs to the technical field of air filtration. Polypropylene, electret masterbatch and polymer electret are evenly mixed, and the prepared mixture is fed into a screw for extrusion. machine, the screw extruder is melted and extruded to form a melt, and the melt is sprayed out through a spinneret to form fibers, and the fibers are drawn by hot air at constant temperature and pressure to form melt-blown cloth on the mesh curtain, and then sequentially After infrared radiation heat treatment, high-pressure electret treatment and cooling treatment, the air filter non-woven fabric is wound up, and the electret masterbatch is composed of polypropylene, few-layer graphene nanosheets, antioxidant, compatibilizer, nucleating The composition of the agent; the few-layer graphene nanosheets are prepared by chemical vapor deposition with magnesium oxide microcrystals with a face-centered cubic structure as a substrate and a template, and the electret masterbatch improves the degree of electretization of the fiber, At the same time, the storage stability of the charge is improved, thereby improving the filtration performance.

Owner:DONGGUAN CHUNXIA IND CO LTD

Ethylene binary copolymer, polyethylene melt-blown material and preparation method

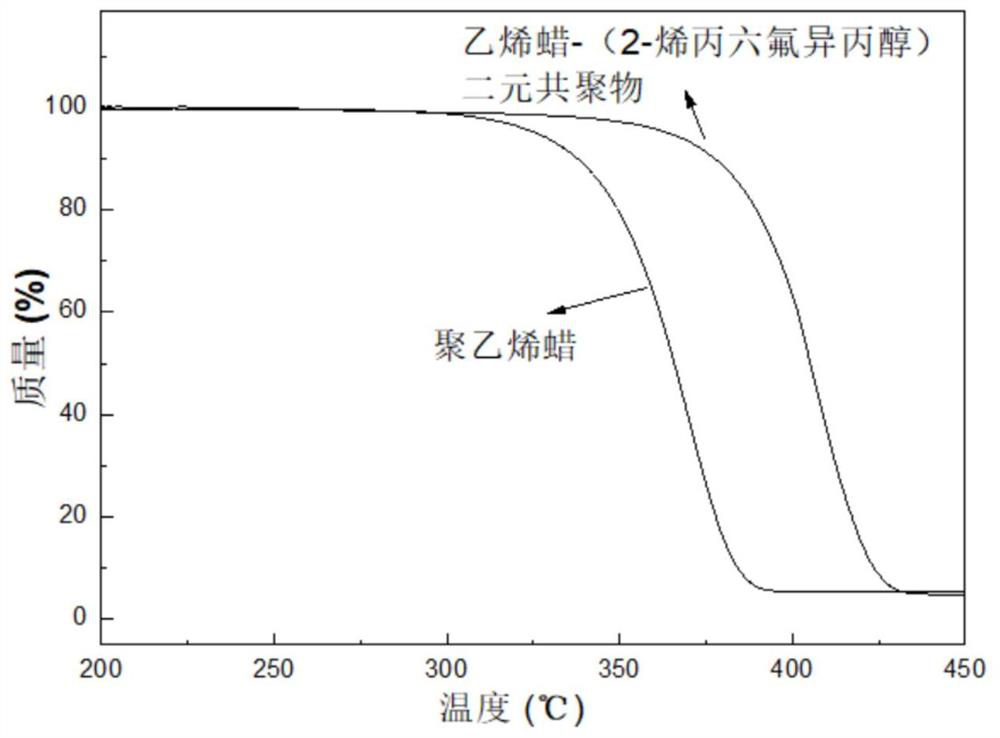

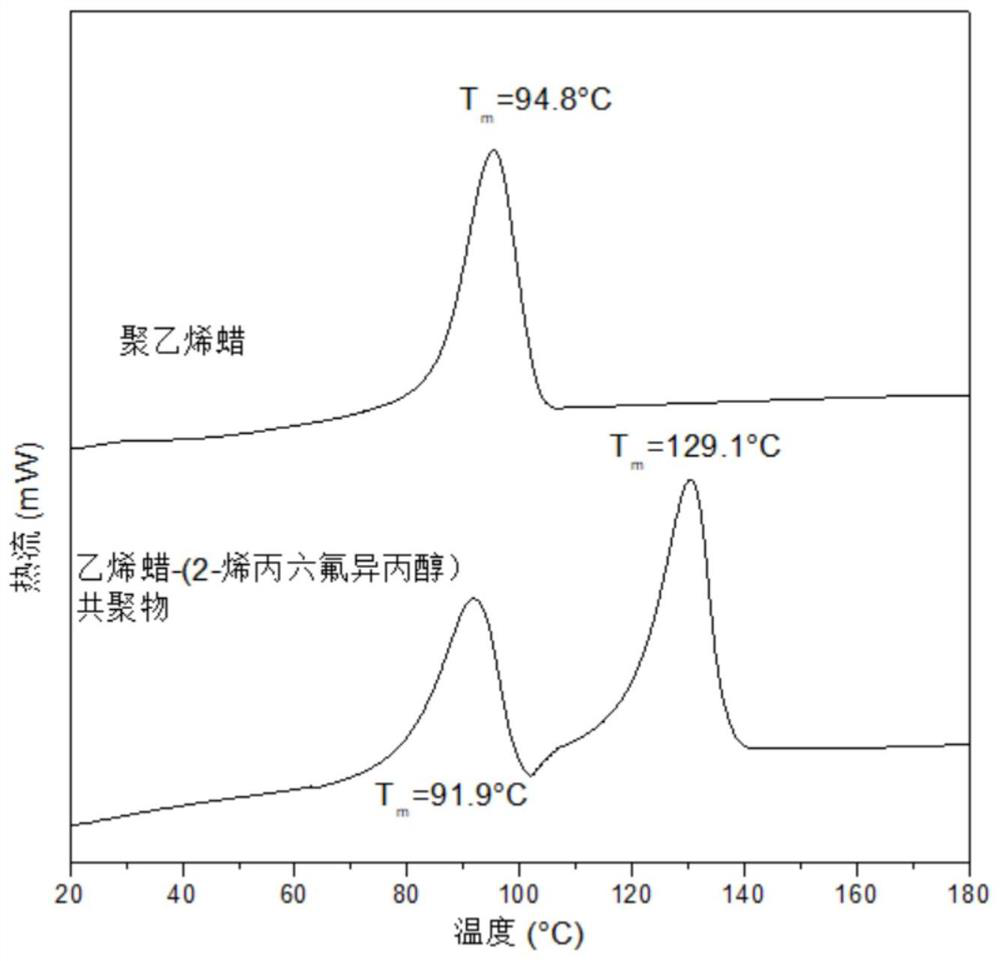

ActiveCN112724320ASolve processing difficultiesMelting pointNon-woven fabricsMonocomponent polyolefin artificial filamentPolymer scienceCopolymer

The invention relates to a high-molecular electret material, in particular to an ethylene binary copolymer, a polyethylene melt-blown material and a preparation method. The ethylene binary copolymer is a binary polymer of ethylene wax and 2-allylhexafluoroisopropanol, and has the shownstructural formula . The preparation method comprises the following steps: mixing the polyethylene wax and the 2-allylhexafluoroisopropanol under the effect of the initiator and the antioxidant, and reacting, melting and extruding to obtain the product. The copolymer can be used as a compatilizer to improve the compatibility between polyethylene / inorganic electrets, and a large amount of fluorine element contained in poly (2-allylhexafluoroisopropanol) can play an organic electret role in a polyethylene melt-blown material and improve the thermal stability of the polyethylene melt-blown material. After the ethylene binary copolymer is added into the polyethylene-based composite material, the effects of capacity increase, electret and aging resistance improvement can be achieved, and the ethylene binary copolymer has a wide potential application prospect in polyethylene melt-blown materials.

Owner:TAIZHOU UNIV

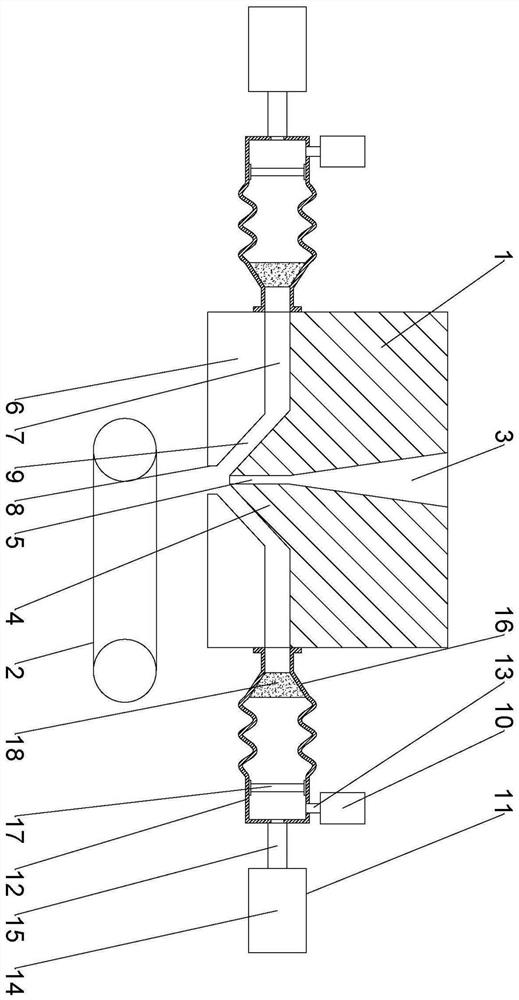

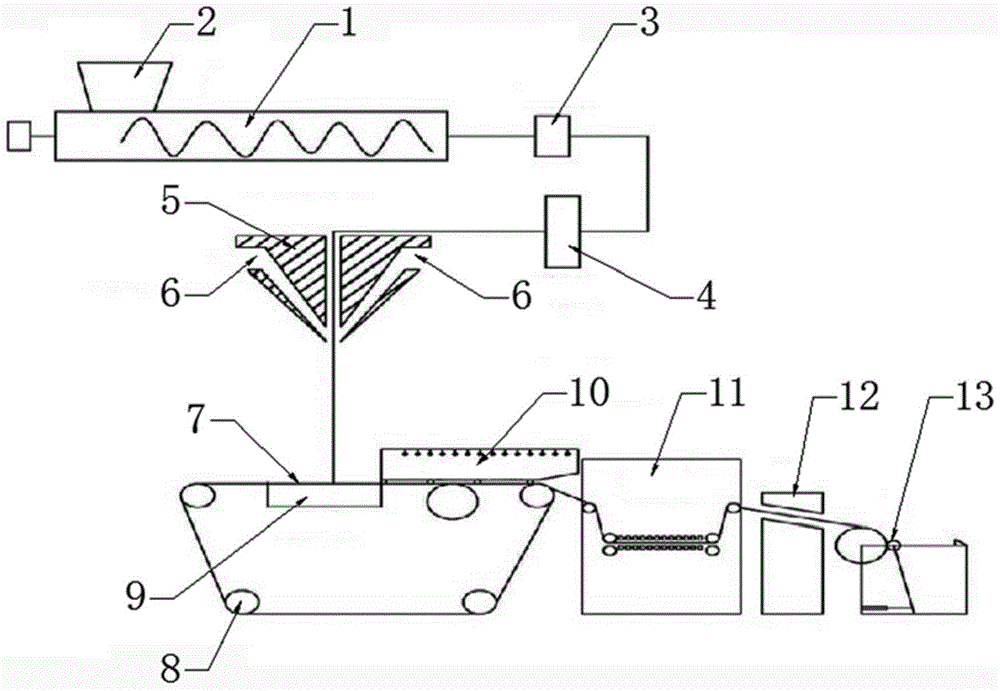

Melt-blown non-woven fabric electret adding device and adding method

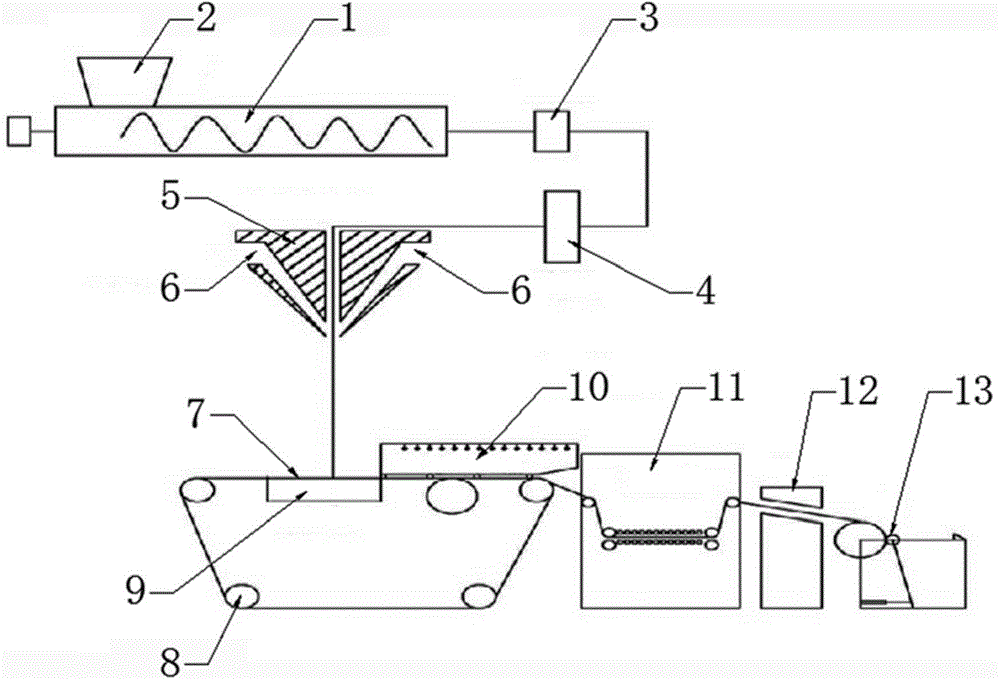

PendingCN111876902ALarge adjustment rangeWon't blockSpinning head liquid feederMelt spinning methodsEngineeringNonwoven fabric

The invention discloses a melt-blown non-woven fabric electret adding device and adding method. The melt-blown non-woven fabric electret adding device comprises a spinneret plate and a receiving device, wherein a melt channel is formed in the spinneret plate, a triangular block is arranged on the spinneret plate, the bottom edge of the triangular block is fixedly connected with the spinneret plate, and a spinneret hole is formed in the triangular block and communicates with the melt channel; air knives are arranged on the left side and the right side of the triangular block and distributed ina bilateral symmetry mode with the spinneret orifice as the center, a drafting airflow channel is formed between the top of each air knife and the spinneret plate, one side of each air knife is closeto the triangular block, an air outlet is formed in the side close to the triangular block, and the other side of each air knife is far away from the triangular block; an air gap is formed between oneside close to the triangular block, of each air knife and the side of the triangular block; and one end of the drafting airflow channel communicates with the spinneret orifice through the air gap, anaerosol generator and a hot airflow device are arranged at the other end of the drafting airflow channel, the receiving device is located under the spinneret orifice and the air knives, and the spinneret plate is located over the air knives. The spinneret plate has the beneficial effect that the spinneret hole cannot be blocked.

Owner:ZHEJIANG CHENWEI ENVIRONMENTAL TECH CO LTD

A long-lasting melt-blown polypropylene composite electret material for mask melt-blown cloth and preparation method thereof

ActiveCN111423663BLow melting pointEvenly dispersedUltrasonic/sonic fibre treatmentNon-woven fabricsPolypropylene compositesBackbone chain

Owner:KINGFA SCI & TECH CO LTD +1

Completely biodegradable filter material and preparation method thereof

ActiveCN112295314ASolve efficiency problemsSolve the strength problemMembrane filtersFiltration separationPlant fibreMedical waste

The invention provides a completely biodegradable filter material and a preparation method thereof. The preparation method comprises the steps of 1, adding a retention agent and an electret into paperpulp to prepare a wet paper web, wherein the paper web is quantified to range from 10 g / m<2> to 30 g / m<2>; (2) spunlacing the wet paper web obtained in the step (1) onto a spunlace polylactic acid non-woven fabric to obtain a plant fiber-polylactic acid non-woven fabric filtering base material; (3) carrying out skin-friendly treatment on the filtering base material in the step (2), so as to enable the filtering material to have good wearing comfort; and (4) carrying out electret treatment on the filtering base material obtained by the skin-friendly treatment, so as to enable the surface of the filtering material to have relatively high electrostatic potential, so as to obtain the completely biodegradable filtering material with high filtering efficiency. The obtained filtering material has excellent wearing comfort, good mechanical usability and good electret stability. The performance requirement of the filtering material is met, and meanwhile, a large amount of medical wastes causedby large-scale use of the disposable mask are avoided.

Owner:QILU UNIV OF TECH +1

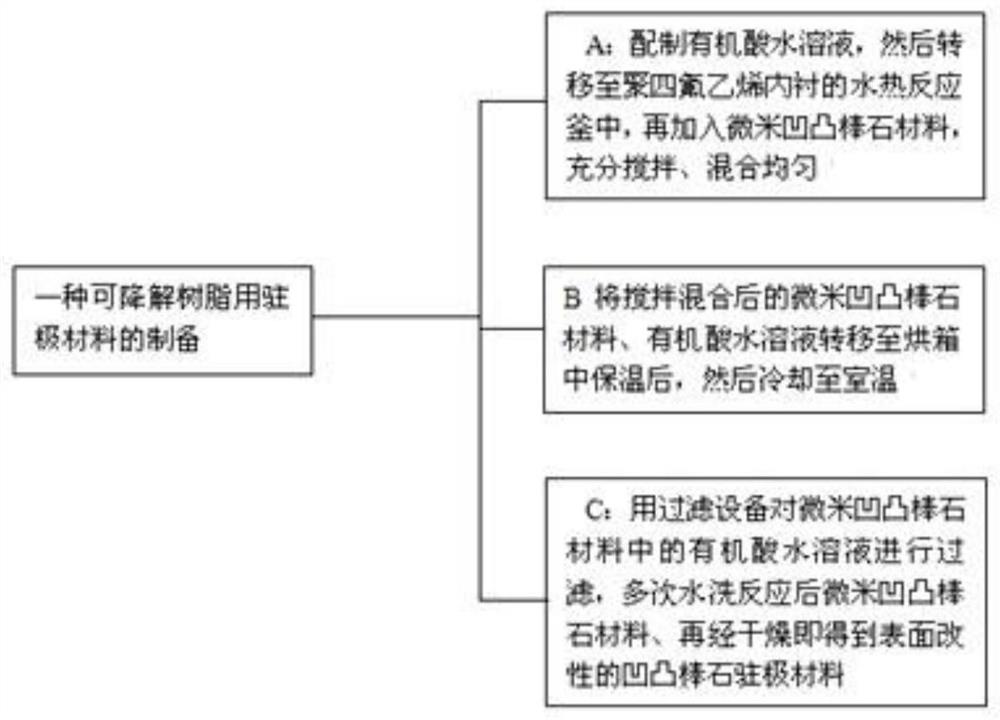

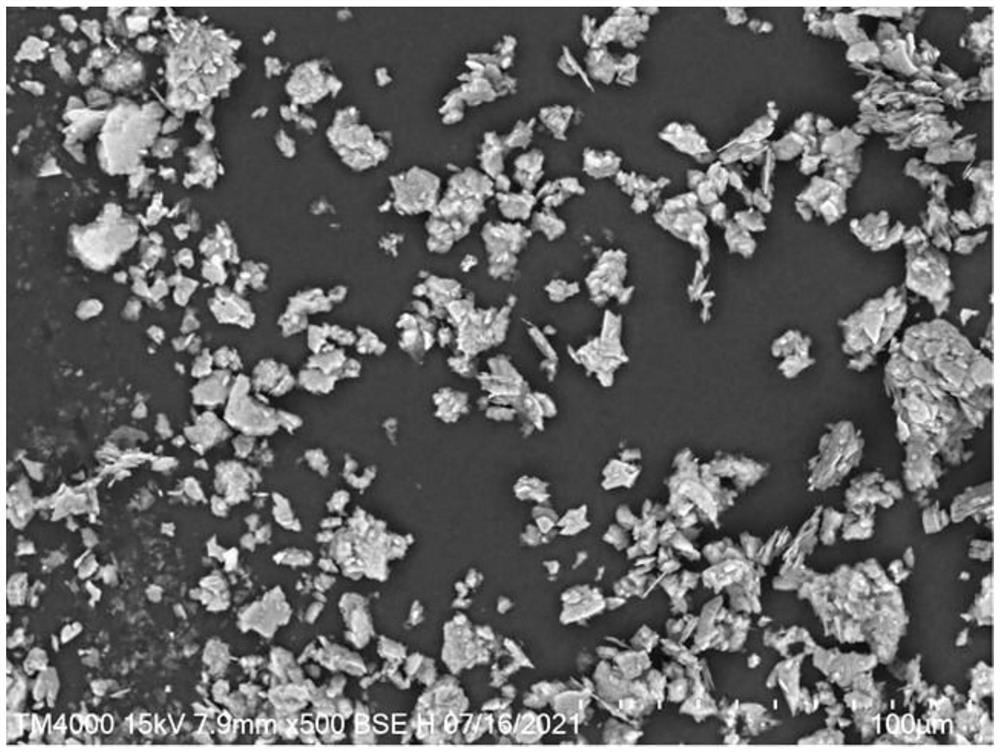

Preparation and application method of electret material for degradable resin

PendingCN113862818AAvoid cloggingEfficient storageNon-woven fabricsMonocomponent polyesters artificial filamentPolymer sciencePolymer chemistry

The invention relates to preparation of an electret material for degradable resin. The preparation of the electret material adopts micron attapulgite and an organic acid aqueous solution as raw materials. The preparation process of the electret material is as follows: A: preparing the organic acid aqueous solution, then adding the micron attapulgite material, fully stirring and uniformly mixing; B, transferring into a drying oven for heat preservation, and then cooling to room temperature; and C, filtering to obtain the surface modified attapulgite electret material. The invention discloses an application method of the electret material for the degradable resin. The application method comprises the following steps of A, preparing surface-modified attapulgite electret master batches; and B, mixing the electret master batches with biodegradable plastic serving as a melt-blown cloth production raw material in proportion to obtain a melt-blown cloth finished product containing the electret master batches. According to the preparation and application method of the electret material for the degradable resin provided by the invention, during production and melt-blowing, a die head of an extruder can be prevented from being blocked, electrostatic charges can be effectively stored, the retention time of the charges in melt-blowing cloth can be prolonged, a relatively high electret effect can be achieved by using a small amount of the material, and the filtering efficiency can be effectively improved by terminal application. On the basis, the electret material for the degradable resin provided by the invention has a good application prospect.

Owner:大韩道恩高分子材料(上海)有限公司

Low-temperature plasma mask sterilization and repair electret machine and method

PendingCN111405740AAlleviate supply tensionFast and portable processingDrying gas arrangementsLavatory sanitoryEngineeringNonwoven fabric

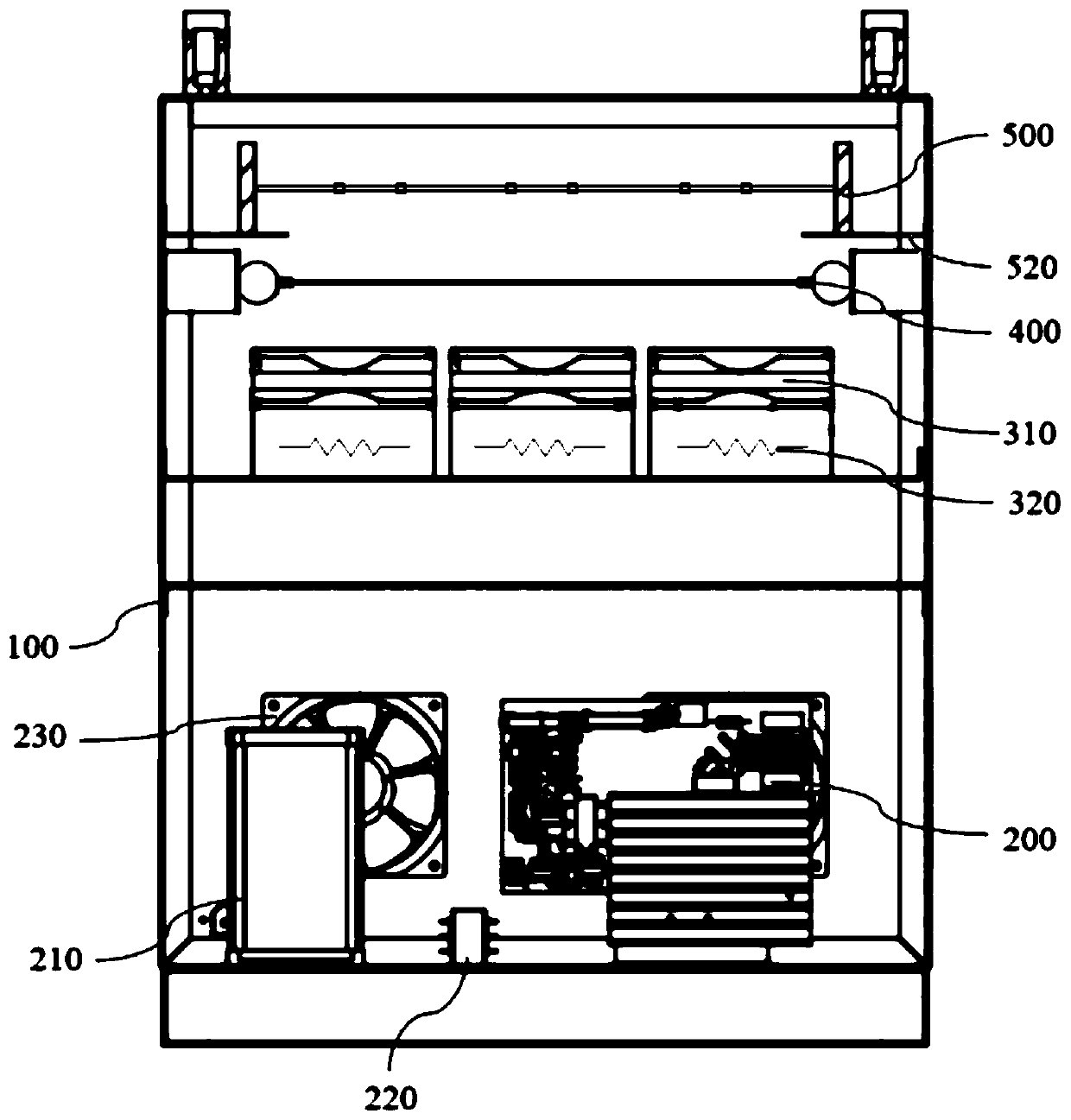

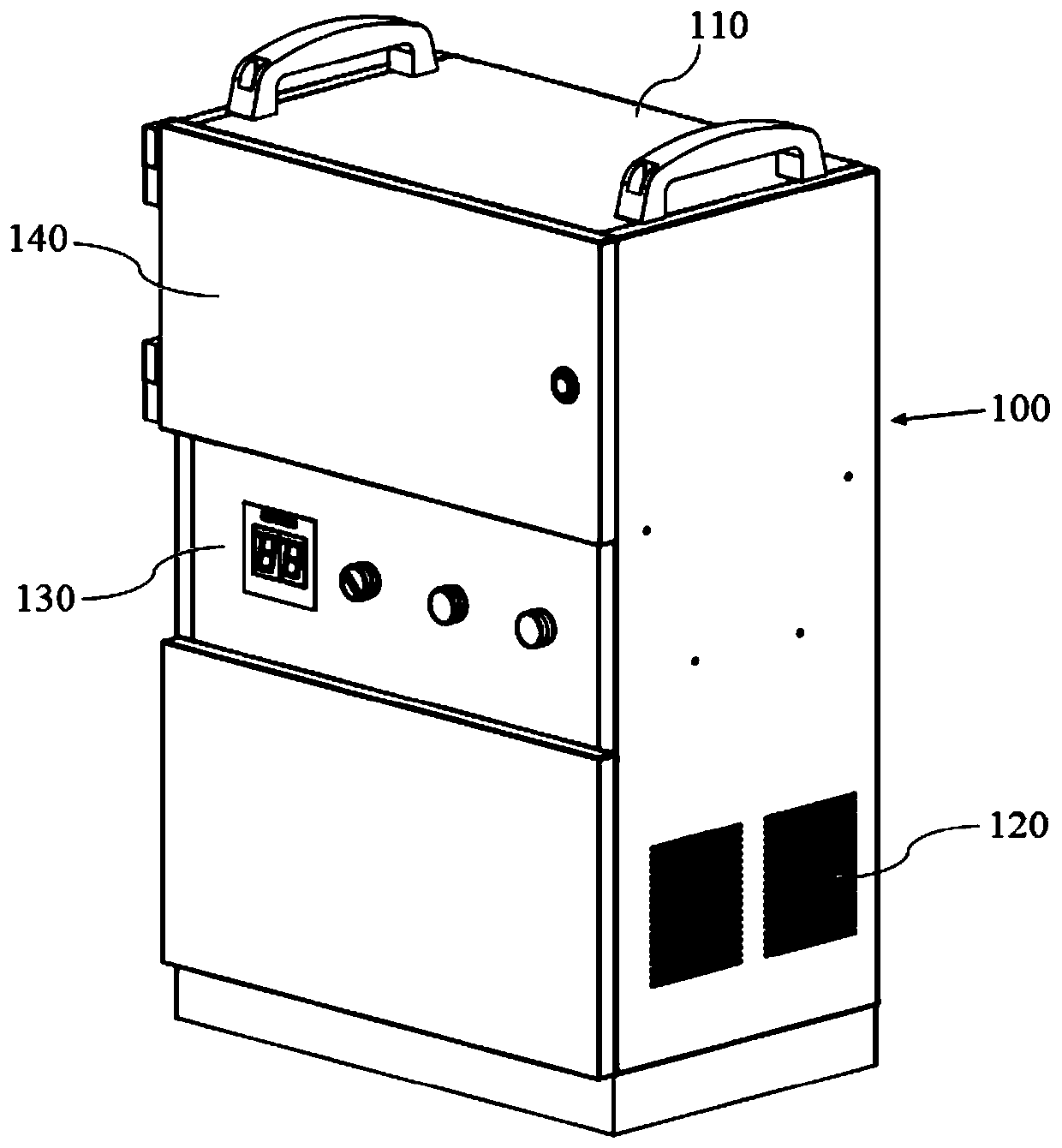

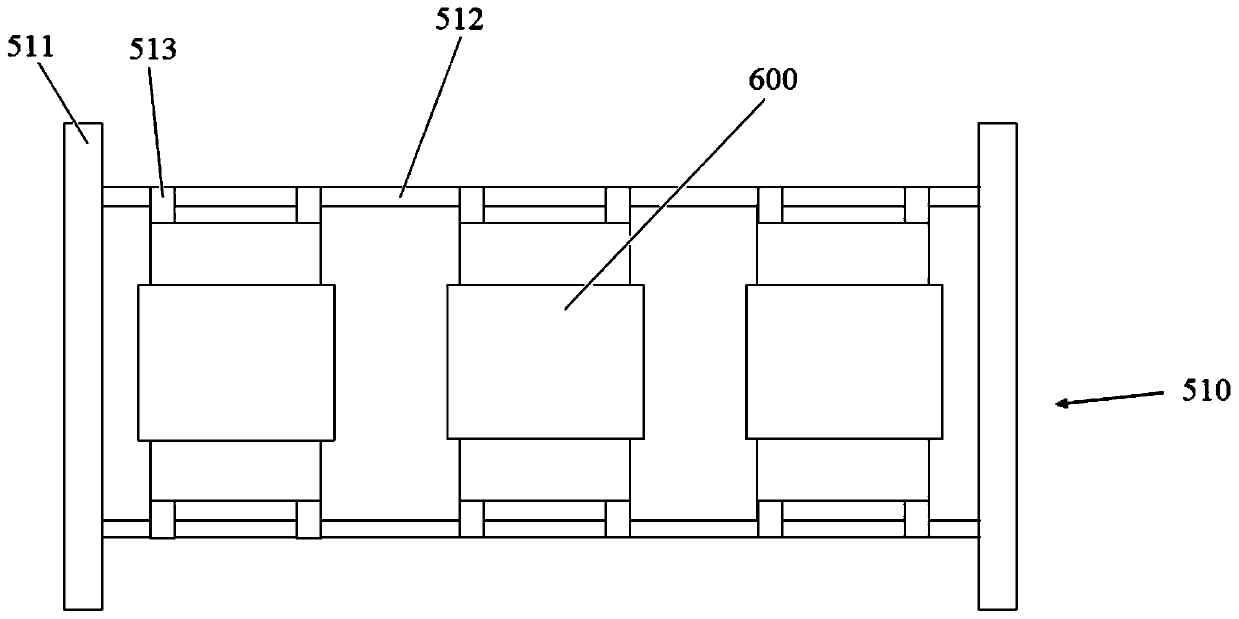

The invention discloses a low-temperature plasma mask sterilization and repair electret machine and method, and belongs to the technical field of medical mask sterilization and repair. The machine comprises a shell. A power supply, a blowing device, a plasma electret device and a mask fixing device are arranged in the shell. The mask fixing device is positioned above a dielectric barrier dischargedevice. An electric field generated by the plasma electret device is used for treating the surface of a to-be-treated mask, and the charged adsorption capacity of the mask can be improved. Electret treatment is performed on a non-woven fabric material, meanwhile, plasma active particles generated in the electric field are quickly adsorbed by the material, the sterilization effect can be continuously achieved after the plasma active particles are adsorbed, and the mask is free of peculiar smells. Efficient sterilization, disinfection and regeneration can be conducted on a mask used for a shorttime, mask supply tension is relieved, pollution is reduced, and meanwhile quick and portable treatment of a small number of small masks is achieved.

Owner:NANJING SUMAN PLASMA TECH CO LTD

Radiation-resistant PP electret melt-blown material and preparation process thereof

PendingCN114044973AGood flexibilityDoes not affect filtration efficiencyConjugated synthetic polymer artificial filamentsArtifical filament manufactureUv absorbancePolymer science

The invention relates to the technical field of melt-blown material preparation, and particularly discloses an irradiation-resistant PP (polypropylene) electret melt-blown material and a preparation process thereof. The melt-blown material is prepared from the following components in parts by weight: 80 to 100 parts of polypropylene resin, 10 to 20 parts of polylactic acid, 2 to 8 parts of electret master batch, 0.2 to 0.6 part of an antibacterial agent, 0.01 to 0.05 part of a nucleating agent, 1 to 4 parts of an antioxidant, 0.2 to 0.8 part of a lubricating agent, 0.1 to 0.5 part of an ultraviolet absorbent and 0.01 to 0.08 part of a light stabilizer, wherein the electret master batch is prepared from the following components in parts by weight: 50 to 80 parts of homo-polypropylene resin, 10 to 15 parts of modified nano silicon dioxide, 12 to 18 parts of modified nano white carbon black, 1 to 5 parts of an accelerant Tac and 1 to 9 parts of an electret agent. The defects in the prior art are overcome, the flexibility of the polypropylene melt-blown material is improved by adding the polylactic acid into the polypropylene resin, the filtering efficiency of the polypropylene melt-blown material is not influenced, the reaction is thorough, the molecular weight distribution is narrow, and the melt index is uniform.

Owner:中核同辐(长春)辐射技术有限公司 +1

A kind of highly compatible polypropylene electret masterbatch, its preparation method and melt-blown cloth

ActiveCN112708198BGood compatibilityHigh tensile strengthNon-woven fabricsMonocomponent polyolefin artificial filamentPolymer scienceMagnesium stearate

The invention relates to the technical field of polymer materials, and discloses a highly compatible polypropylene electret masterbatch, a preparation method thereof and a melt-blown cloth. 0.5: 0.05-0.2 polypropylene, polyvinylidene fluoride, ethylene-chlorotrifluoroethylene copolymer, tourmaline, magnesium stearate. Ethylene-chlorotrifluoroethylene copolymer and magnesium stearate are used as compatibilizers to improve the compatibility between polypropylene, polyvinylidene fluoride and tourmaline, and ethylene-chlorotrifluoroethylene copolymer plays a role in the formula Compatibilization, electret and strengthening and toughening; magnesium stearate plays three functions of compatibilization, lubrication and electret in the formula, so that the final obtained polypropylene melt-blown material has good compatibility, stable storage charge, and filtration High efficiency and broad application prospects.

Owner:TAIZHOU UNIV

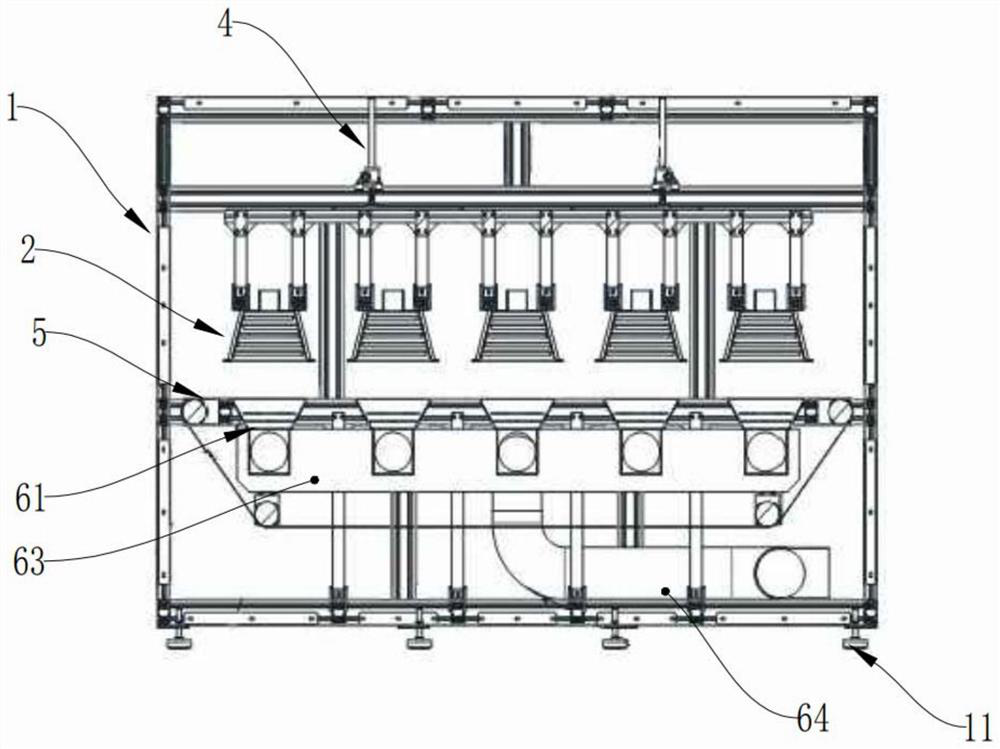

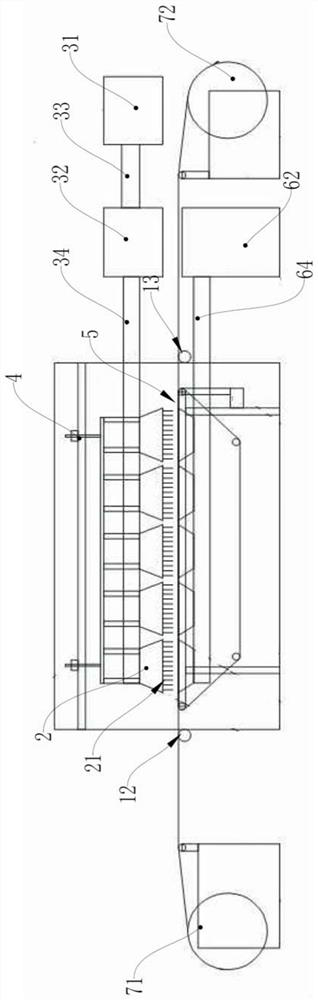

Plasma hot air electret equipment

PendingCN112064333AUniform and stable electretIncrease productivityUltrasonic/sonic fibre treatmentEngineeringAcoustics

The invention discloses plasma hot air electret equipment, and belongs to the field of electret equipment. The plasma hot air electret equipment comprises a rack, a hot air device, a lifting platform,a conveying device and a plurality of electret nozzle groups, the lifting platform, the conveying device and the electret nozzle groups are arranged on the rack, the multiple electret nozzle groups are arranged at the movable end of the lifting platform, and the fixed end of the lifting platform is connected to the rack. The conveying device is arranged under the electret nozzle groups, a plurality of electret micropore needles are arranged at the bottom of each electret nozzle group, and each electret micropore needle is communicated with the output end of the hot air device. The distances between the electret nozzle groups and the conveying device are adjusted through the lifting platform, so that the distances between the electret micropore needles and a base material is adjusted, andthe applicability to the plasma hot air electret of the base material can be improved. The plasma hot air electret time is prolonged, and the electret quality of a base material is improved.

Owner:FOSHAN QINGZI PRECISION MEASUREMENT & CONTROL TECH +1

Multifunctional composite melt blown nonwoven fabric and preparation method thereof

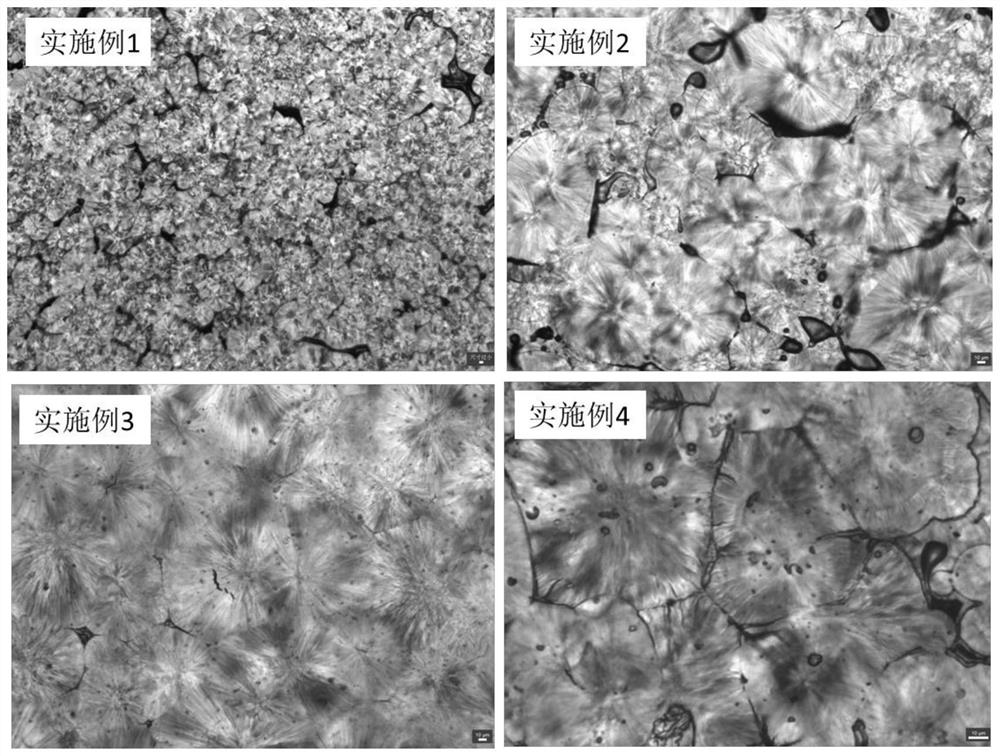

ActiveCN112779673BInhibition attenuationDecrease decay rateMonocomponent polypropylene artificial filamentNon-woven fabricsAir filtrationPolymer science

The invention provides a multifunctional composite melt blown nonwoven fabric and a preparation method thereof. Firstly, the principle of polypropylene modification reaction extrusion is used to mix the initiator, fluorine-containing olefin monomer and polypropylene according to a certain mass ratio, and then undergo melt grafting modification through a twin-screw extruder to prepare a high-strength Flowable modified polypropylene material. Then melt-blown grade polypropylene and modified polypropylene are subjected to double-layer melt-blown spinning and composite web laying to prepare a multifunctional composite melt-blown nonwoven fabric. The invention combines conventional polypropylene non-woven fabric with fluorine-containing graft modified polypropylene non-woven fabric through double-layer melt blown to obtain gradient electret filter material. The electret effect and charge stability are improved by adjusting the chain segment composition of the fluorine-containing graft-modified polypropylene. The non-woven fabric prepared by the invention has the advantages of good electrostatic electret effect, high air filtration efficiency, low pressure resistance and the like.

Owner:WUHAN TEXTILE UNIV

A kind of multi-layer spunmelt electret filter material containing energizer and preparation method thereof

ActiveCN105944455BHigh strengthFluffy soft structureSynthetic resin layered productsFiltration separationFilter materialMelt spinning

The invention relates to a multilayered sun-melt electret filtering material containing an energy increasing auxiliary agent and a preparation method thereof. The raw material of the filtering material comprises a plurality of layers of fiber nets; the plurality of layers of fiber nets form a stacked structure and sequentially comprise a spun-bonded fiber net and a pre-needled fiber net or the spun-bonded fiber net, the pre-needled fiber net and the spun-bonded fiber net. The preparation method comprises: after stacking the plurality of layers of fiber nets, carrying out needling reinforcing treatment, baking treatment and corona electret treatment in sequence. The energy increasing auxiliary agent and a specific composite structure are added into the material, so that the product disclosed by the invention has the characteristics of high filtering efficiency, low filtering resistance, long service life and the like.

Owner:DONGHUA UNIV

A kind of high-efficiency filter PM2.5 melt-blown non-woven material and preparation method thereof

ActiveCN104153119BHigh filtration efficiencyImprove dust collection effectHeating/cooling textile fabricsUltrasonic/sonic fibre treatmentPorosityHigh humidity

The invention discloses a melt-blow non-woven material capable of effectively filtering PM 2.5 particles, a preparation method and a production device. The melt-blow non-woven material comprises, by weight percentage, 93-97 parts of polypropylene, 3-6 parts of electret master batch and 0.1-1 part of polyvinylidene fluoride. According to the melt-blow non-woven material capable of effectively filtering PM 2.5 particles, the polypropylene, the electret master batch and the polyvinylidene fluoride are compounded, the obtained melt-blow non-woven material is characterized by high porosity, the fiber diameter of smaller than two micrometers, large clogging capacity, high filtering efficiency and low resistance, an electret is good in charge storage performance after electret processing, the charge keeping rate can be above two years, and the electret can be used in a high-temperature and high-humidity environment. The product is environmentally friendly and free of pollution, has the advantages of being long in service life and wide in use range, and is particularly suitable for removing PM 2.5 particles in the air.

Owner:DO FLUORIDE CHEM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com