Ethylene binary copolymer, polyethylene melt-blown material and preparation method

An ethylene binary copolymer and polyethylene technology, which is applied in rayon manufacturing, textile and papermaking, single-component polyolefin rayon, etc., can solve the problems of poor compatibility, low graft rate, low molecular weight, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] (1) Preparation of ethylene binary copolymer:

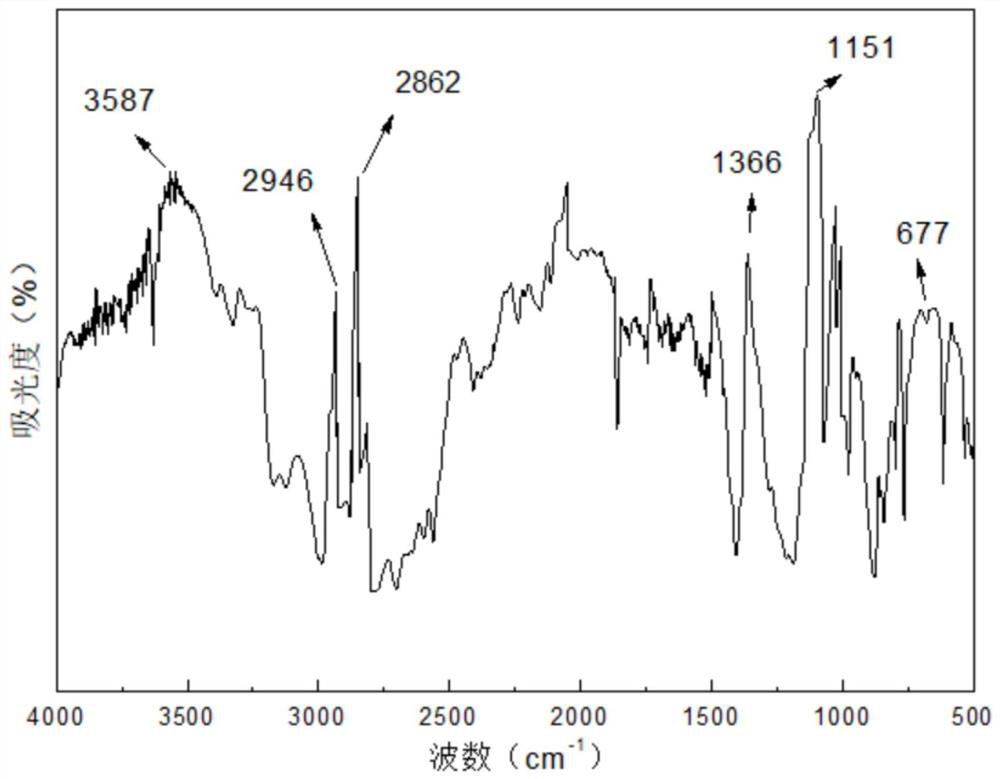

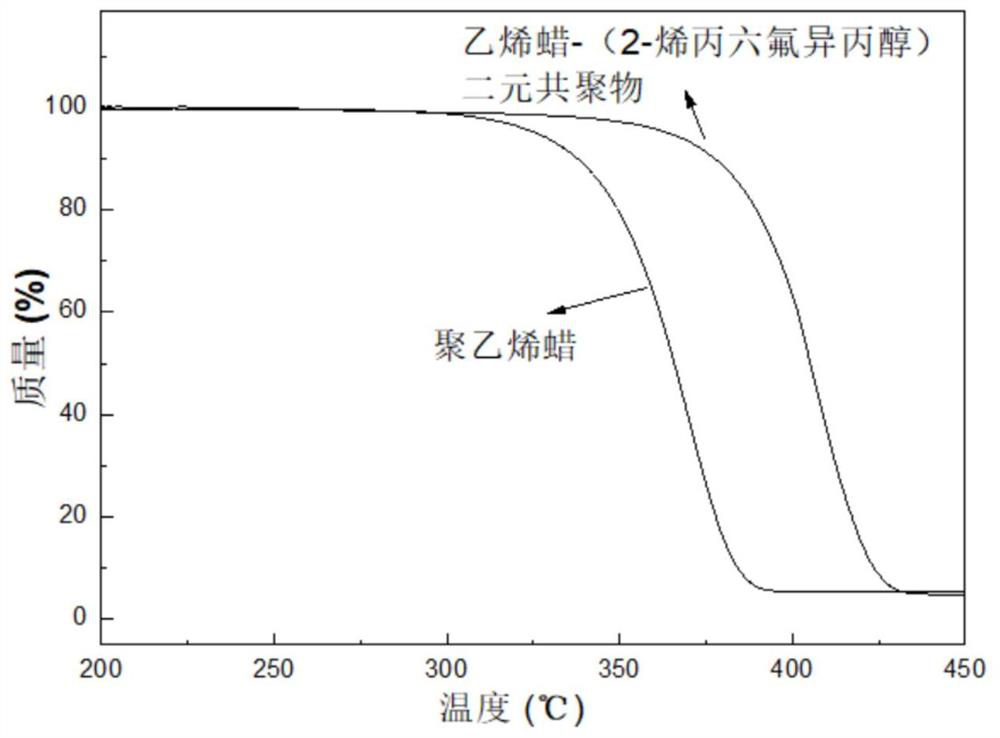

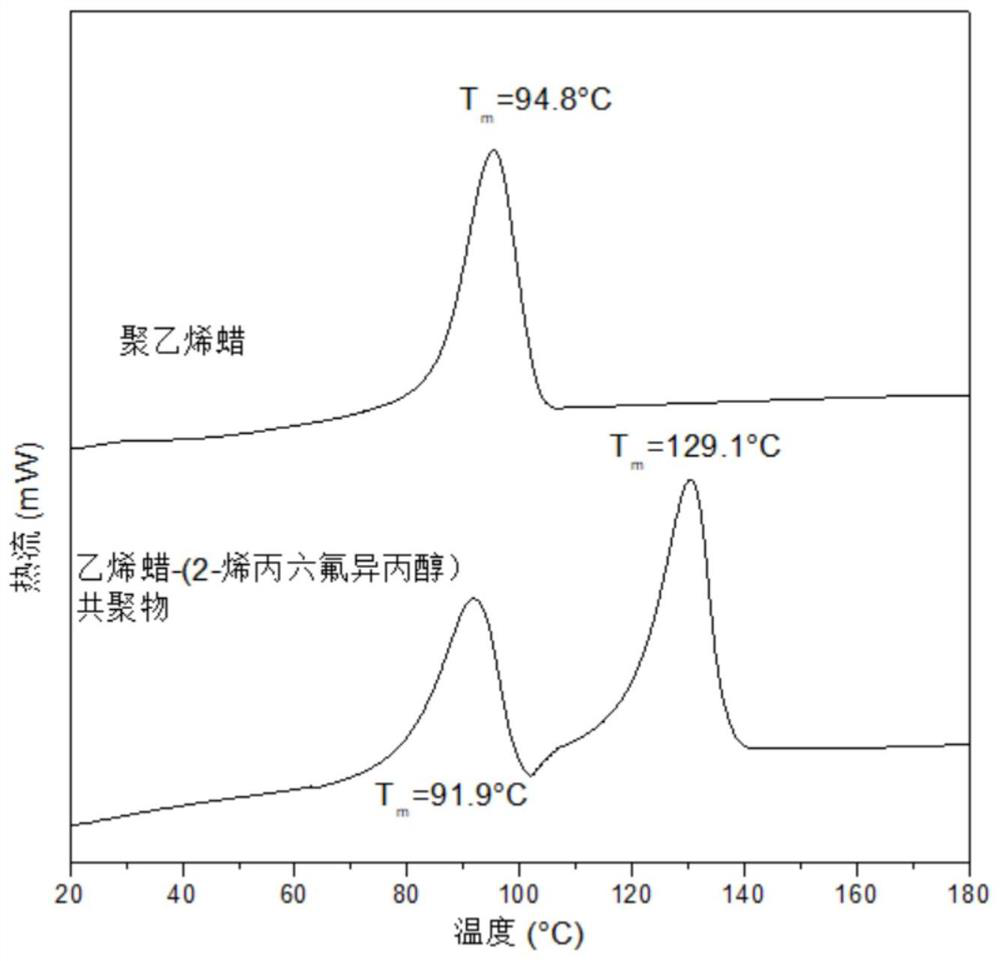

[0043] Weigh polyethylene wax, 2-allyl hexafluoroisopropanol, initiator and antioxidant according to the mass ratio of 100:80:1:0.5, add them to the high-speed mixer in sequence, stir evenly at high speed and pour into the twin-screw extruder , set the temperature in the six zones of the extruder head to 90°C, 95°C, 95°C, 95°C, 95°C, and 90°C, melt extrusion, water cooling, dry pelletizing, and obtain ethylene wax-(2-ene Hexafluoroisopropanol) binary copolymer, that is, ethylene binary copolymer.

[0044] (2) Preparation of polyethylene meltblown material:

[0045] Weigh the prepared ethylene binary copolymer, polyethylene, anti-aging agent, and tourmaline at a mass ratio of 2:100:0.2:0.5. After mixing evenly, melt and extrude it in a twin-screw extruder. The temperature of the melting section is 170 -190°C to obtain polyethylene melt-blown material;

[0046] (3) Preparation of polyethylene melt-blown cloth:

[0047] T...

Embodiment 2

[0052] According to the preparation process of Example 1, the mass ratio of ethylene binary copolymer to polyethylene, anti-aging agent and tourmaline in step (2) is changed to 1: 100: 0.2: 0.5, and the ratio of other raw materials and the preparation process are unchanged. A polyethylene melt-blown nonwoven fabric was obtained.

Embodiment 3

[0054] According to the preparation process of Example 1, the mass ratio of polyethylene binary copolymer to polyethylene, anti-aging agent, and tourmaline in step (2) is changed to 0.5:100:0.2:0.5, and the ratio of other raw materials and the preparation process remain unchanged. , to obtain polyethylene melt-blown non-woven fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Maximum decomposition temperature | aaaaa | aaaaa |

| Maximum decomposition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com