Patents

Literature

430 results about "Polyvinyls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Surface-functionalized mesoporous carbon materials

ActiveUS9249241B2Effectively and efficiently functionalizedPractical and cost-effective for large scale productionProcess efficiency improvementPolyvinyl polymerSolvent

A functionalized mesoporous carbon composition comprising a mesoporous carbon scaffold having mesopores in which polyvinyl polymer grafts are covalently attached, wherein said mesopores have a size of at least 2 nm and up to 50 nm. Also described is a method for producing the functionalized mesoporous composition, wherein a reaction medium comprising a precursor mesoporous carbon, vinyl monomer, initiator, and solvent is subjected to sonication of sufficient power to result in grafting and polymerization of the vinyl monomer into mesopores of the precursor mesoporous carbon. Also described are methods for using the functionalized mesoporous carbon, particularly in extracting metal ions from metal-containing solutions.

Owner:UT BATTELLE LLC

Crosslinkable flame retardant wire and cable compositions having improved abrasion resistance

Moisture curable flame retardant wire and cable formulations having improved abrasion resistance are provided. The compositions are comprised of a high density silane-containing polyethylene base resin which can be a blend of a bimodal HDPE and ethylene-silane copolymer or silane-grafted bimodal HDPE in combination with a flame retardant and silanol condensation catalyst.

Owner:EQUSR CHEM LP

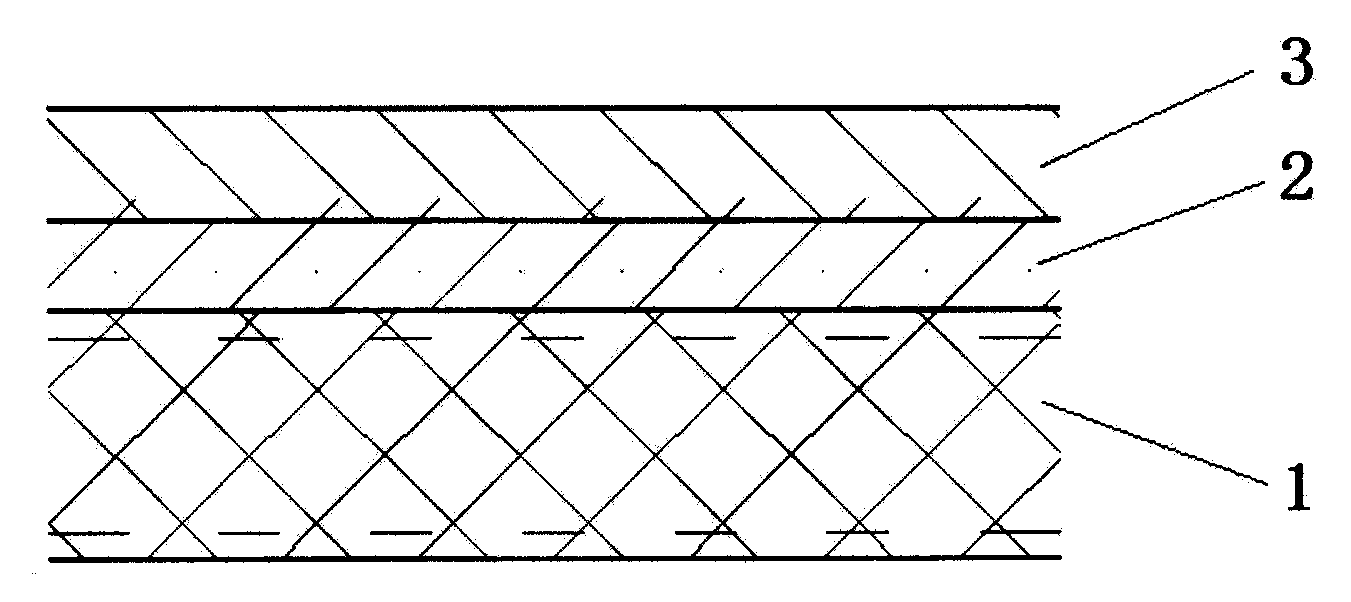

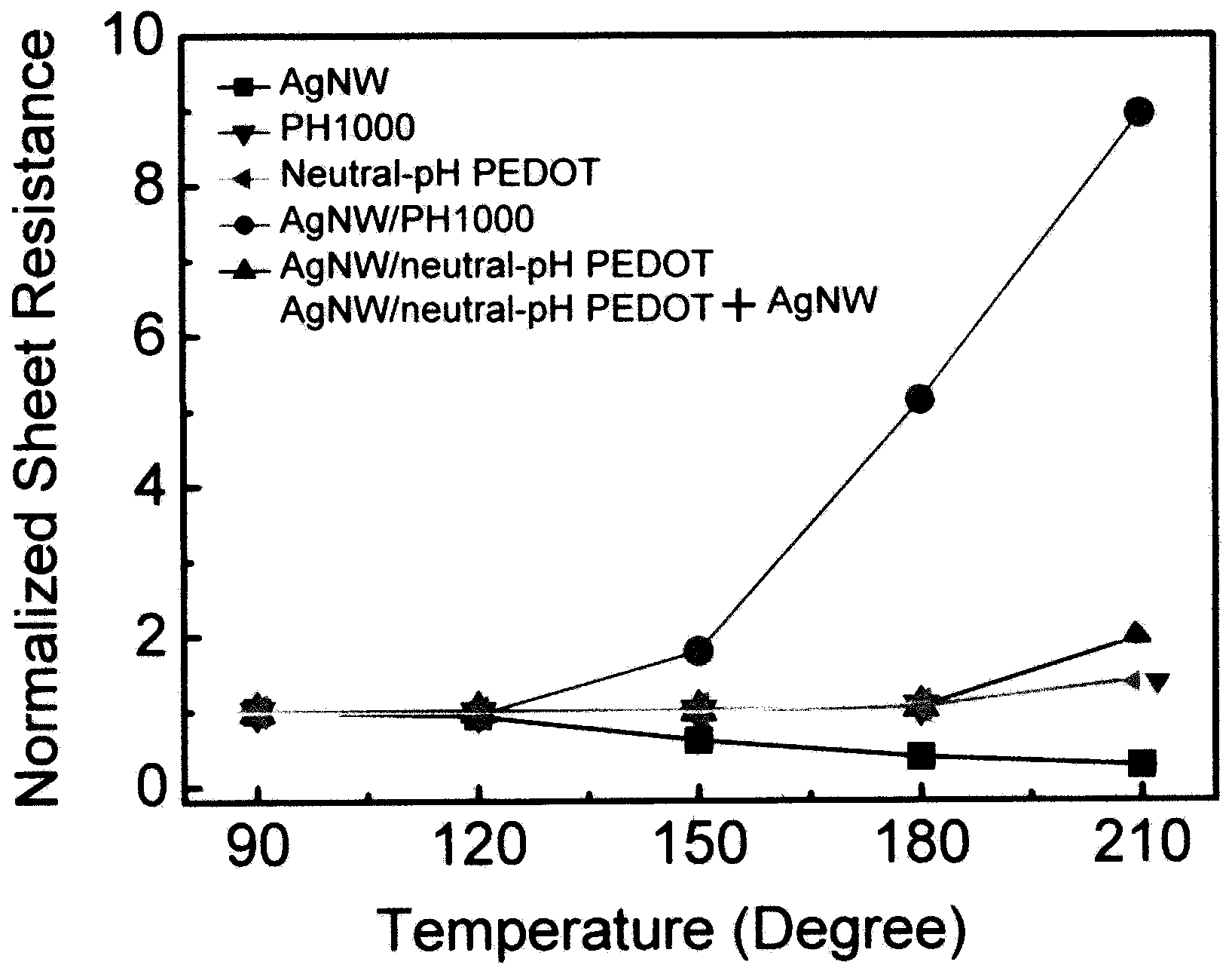

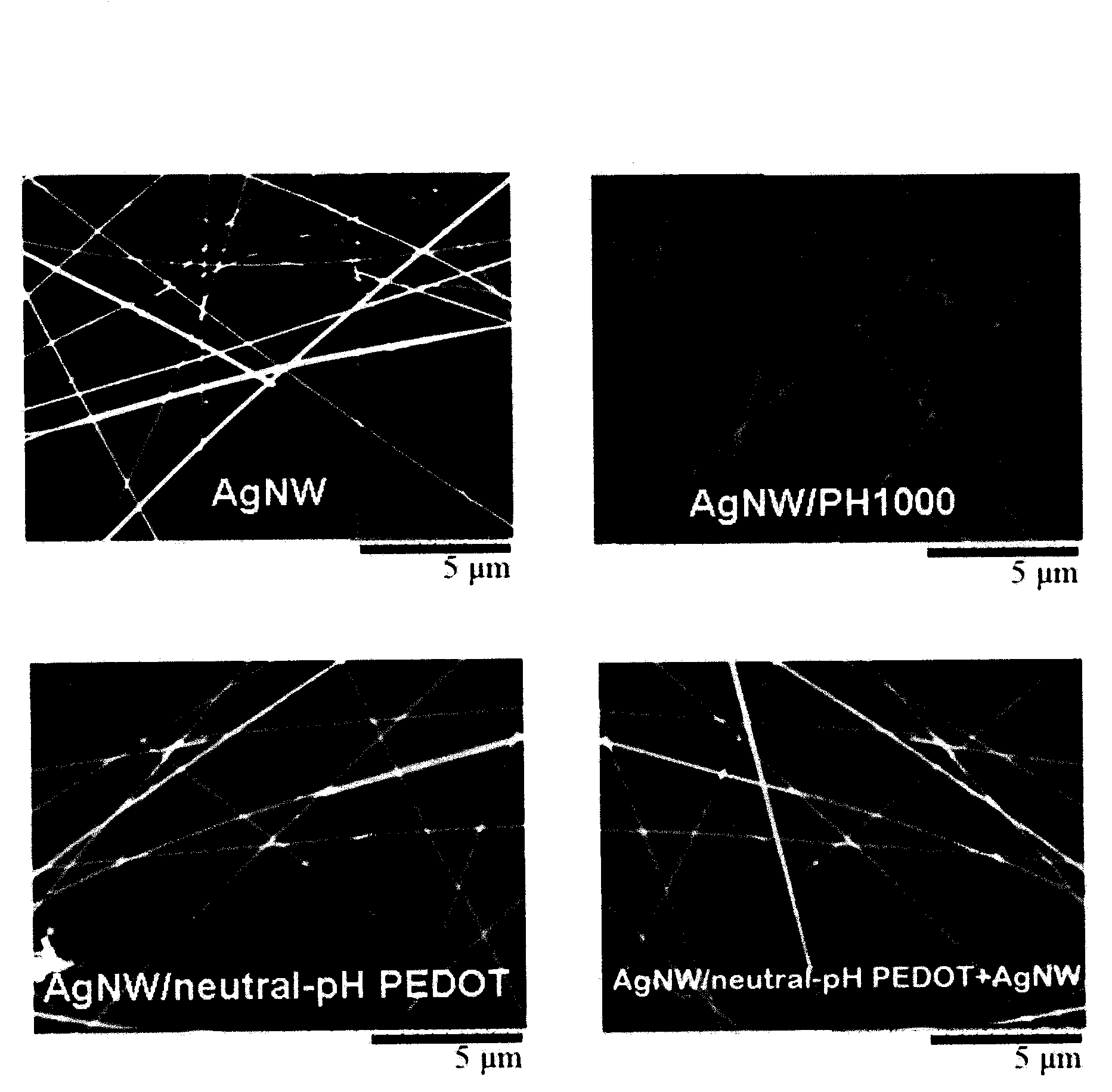

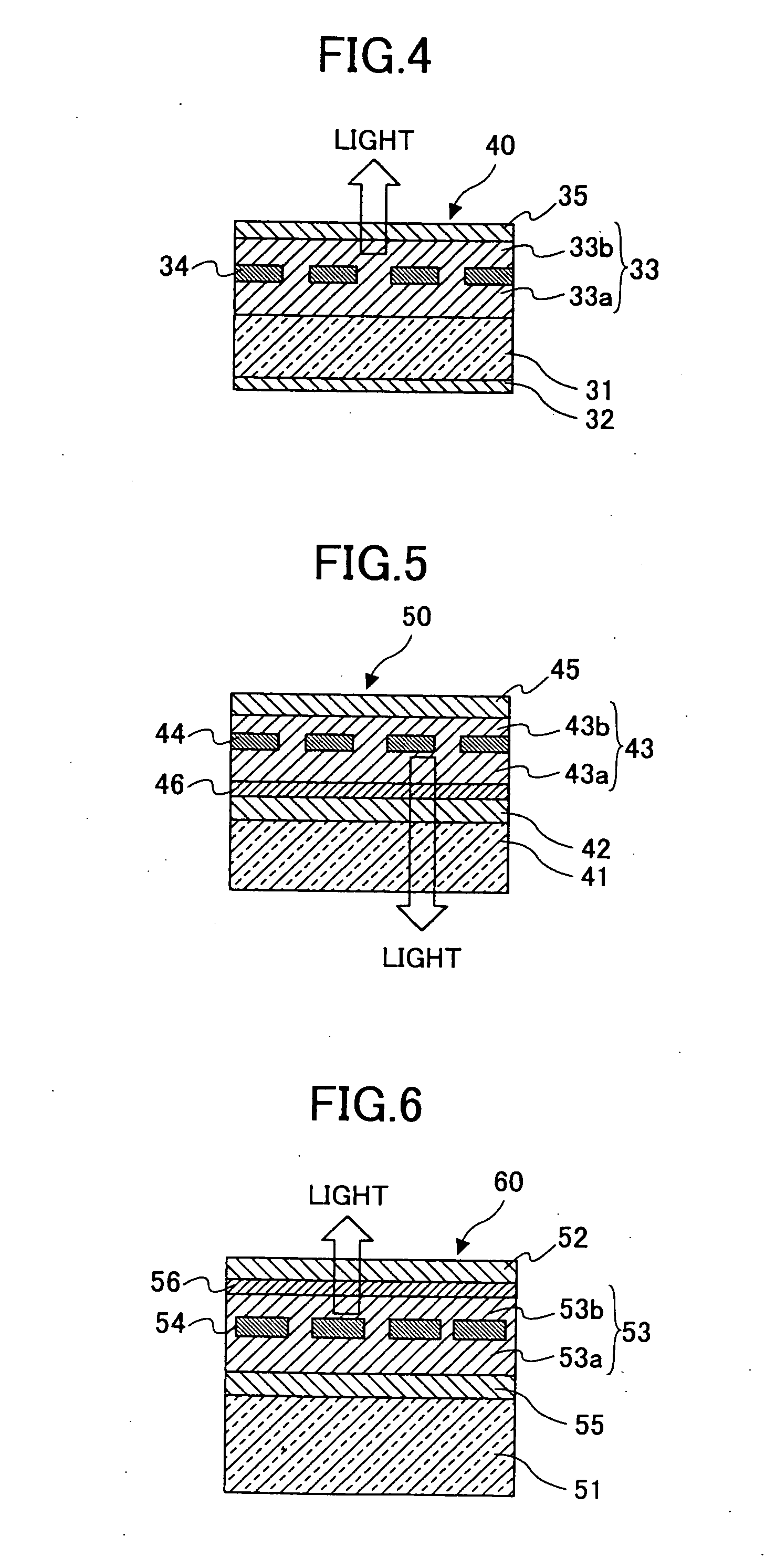

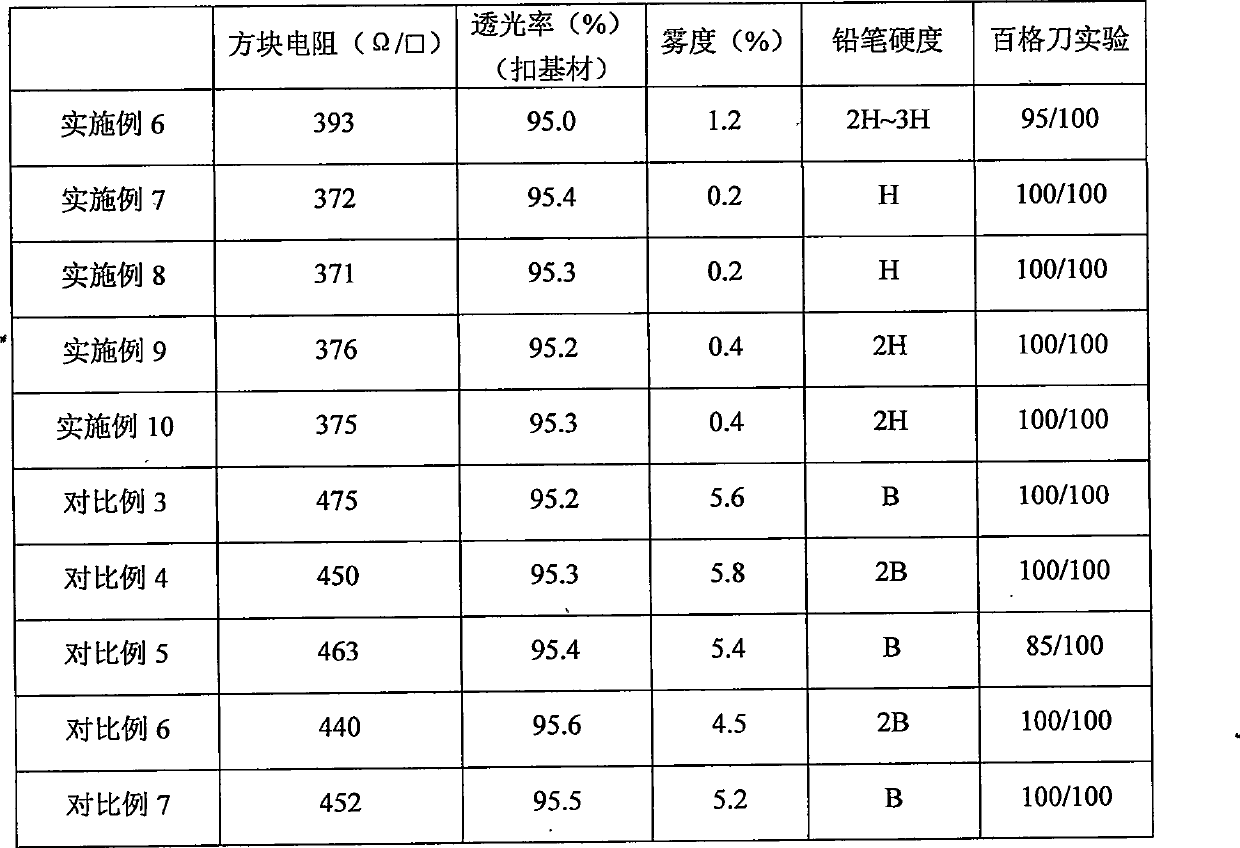

Stable PEDOT/PSS conducting layer electrode and preparing method thereof

ActiveCN104183303AImprove conductivityGood light transmissionConductive layers on insulating-supportsSolid-state devicesOrganic solar cellPower flow

The invention discloses a method for preparing a stable transparent electrode provided with a neutral PEDOT / PSS conducting layer. The transparent electrode comprises a transparent base material layer and the conducting layer covering the transparent base material layer, wherein the conducting layer comprises a coated first silver nanowire conducting layer part and a second neutral PEDOT / PSS macromolecule conducting layer part or a macromolecule conducting layer part formed by mixing neutral PEDOT / PSS with silver nanowires, and the PEDOT / PSS macromolecule conducting layer part is made of neutral PEDOT / PSS conductive ink. The preparing method comprises the steps that 3,4-EDOT is polymerized into PEDOT / PSS dispersion liquid in the presence of PSS, alkaline additives are added to regulate the PH, neutral PEDOT / PSS dispersion liquid is obtained after the ink strength is high enough through the seasoning technology, and at least one kind of organic functional auxiliaries is added to the neutral PEDOT / PSS dispersion liquid to obtain the stable transparent electrode. The transparent electrode prepared with the method has the advantages of being high in conductivity, high in light permeability, simple in preparing technology, resistant to weather and current stability and the like and can be applied to the fields such as organic solar cells, organic light emitting diodes and touch display screens.

Owner:上海欧依有机光电材料有限公司

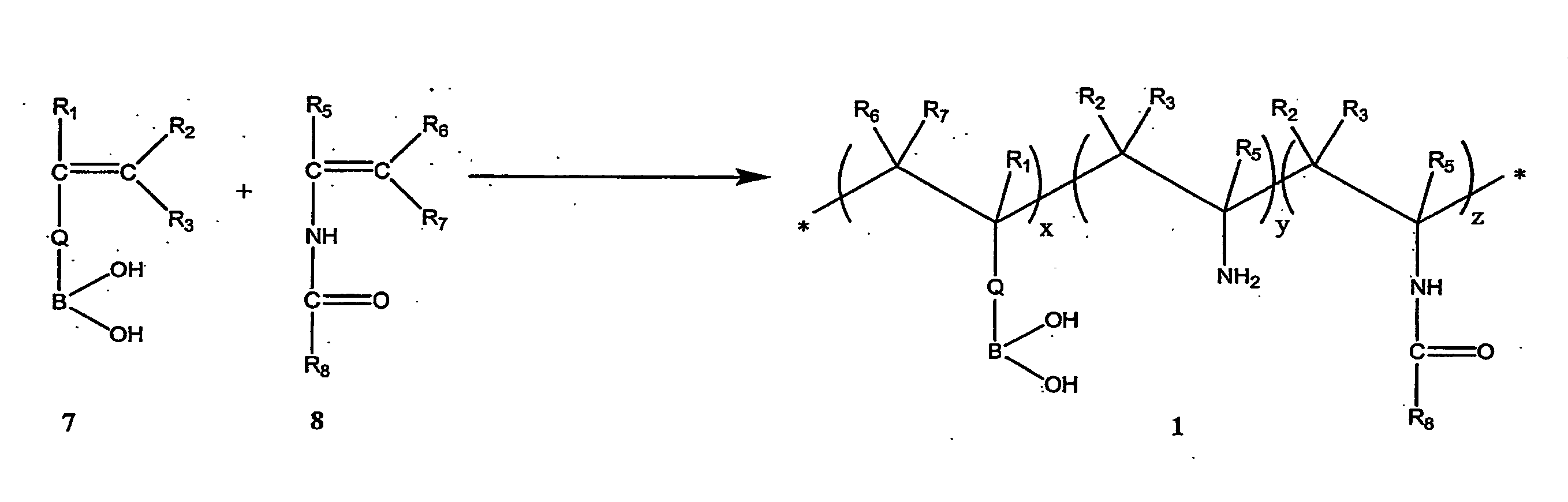

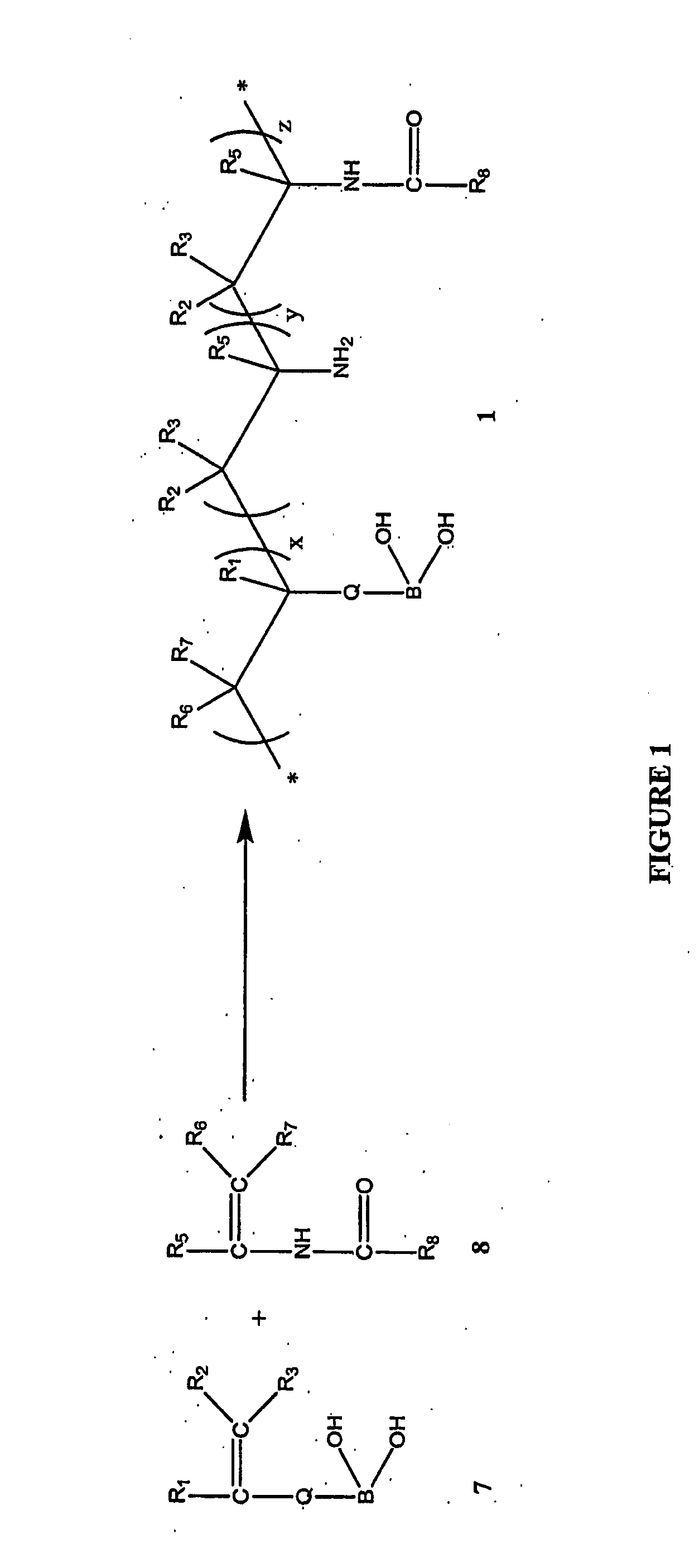

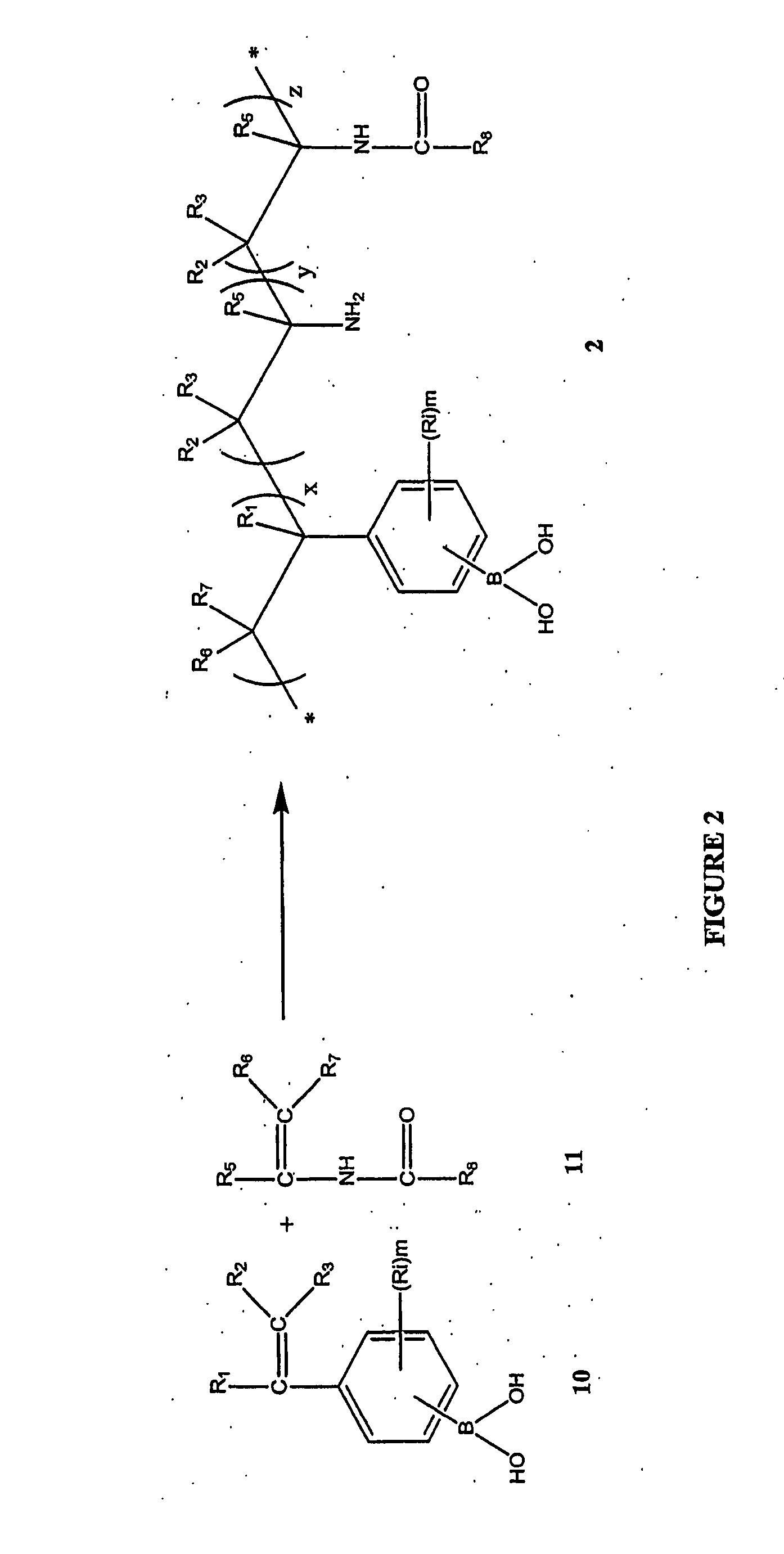

Polymeric Boronic Acid Derivatives and Their use for Papermaking

ActiveUS20080099172A1Improve featuresNatural cellulose pulp/paperSpecial paperAcid derivativePapermaking

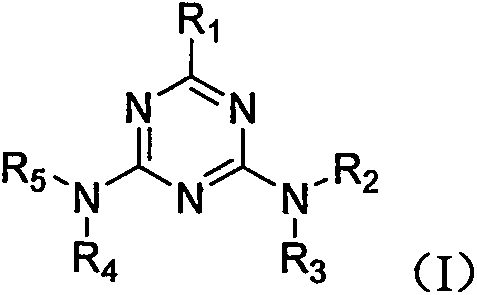

Polymeric compounds of formula I comprising boronic acid are provided. These polymeric compounds are prepared either by grafting boronic acid containing compounds (e.g. 4-carboxyphenylboronic acid) to hydrolysed poly(N-vinylformamide) or hydrolysing copolymer(s) obtained by copolymerizing vinyl group containing boronic acid monomers (e.g. -vinylphenyl boronic acid) and N-vinylformamide. These polymeric compounds are used in increasing the wet strength of paper in paper-making processes. Formula (I).

Owner:SOLENIS TECH CAYMAN

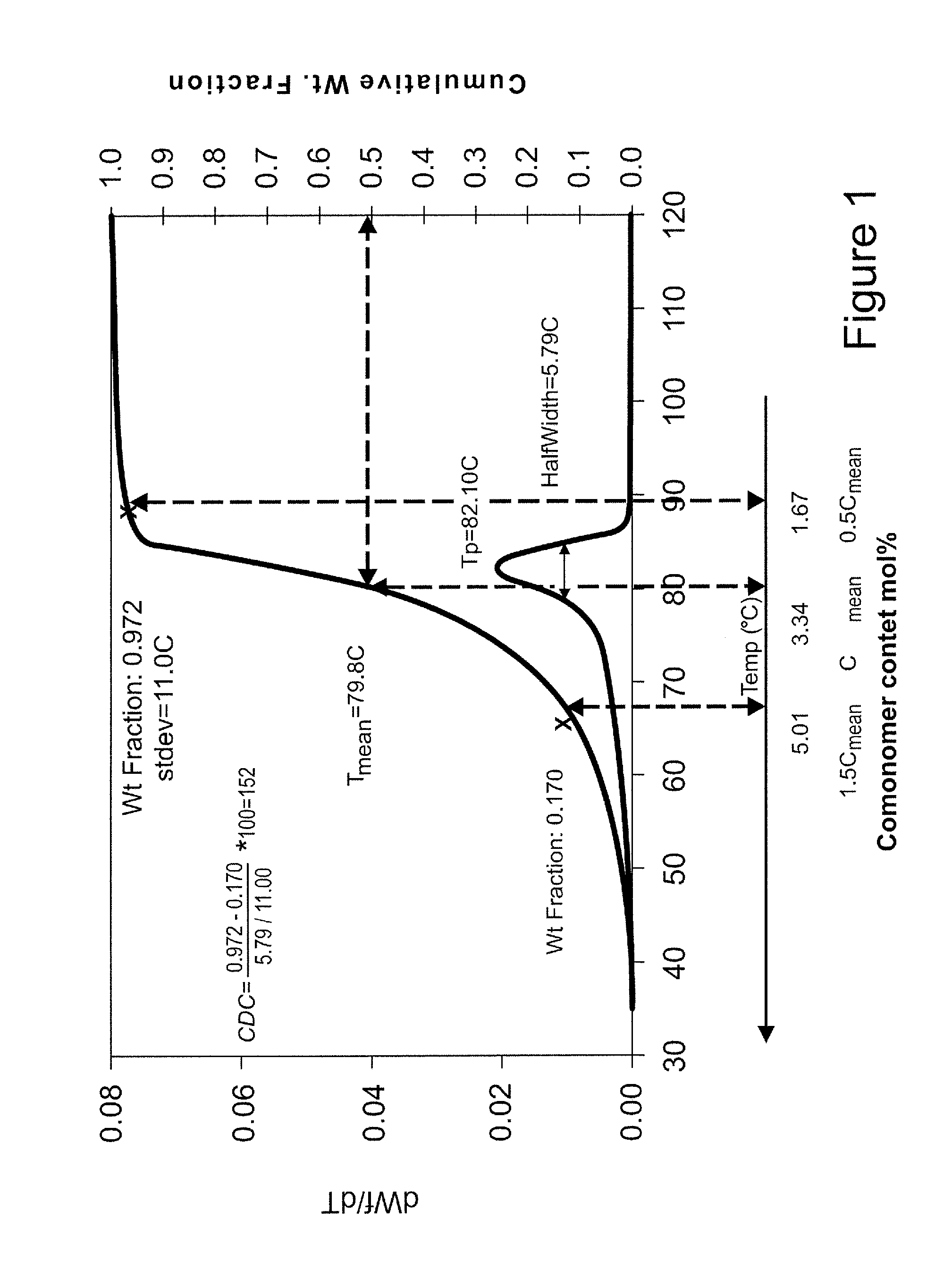

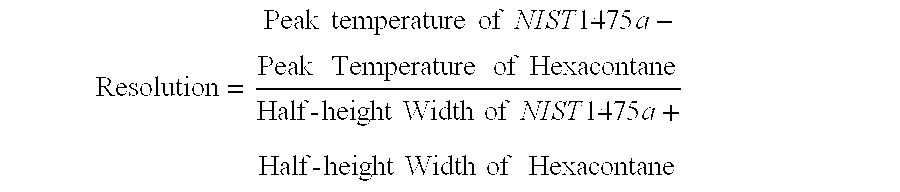

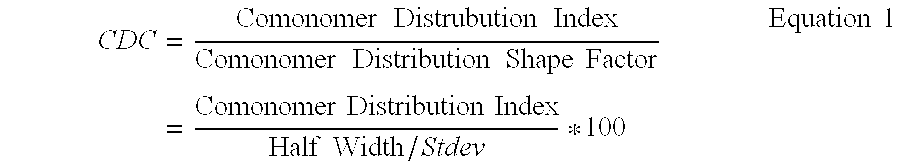

Bicomponent fiber

ActiveUS20110165470A1Good flexibilityGood touchFilament/thread formingAnimal housingPolymer scienceNonwoven fabric

The present invention relates to a new bicomponent fiber, a nonwoven fabric comprising said new bicomponent fiber and sanitary articles made therefrom. The bicomponent fiber contains a polyethylene-based resin forming at least part of the surface of the fiber longitudinally continuously and is characterized by a Co-monomer Distribution Constant greater than about 45, a recrystallization temperature between 85° C. and 110° C., a tan delta value at 0.1 rad / sec from about 15 to 50, and a complex viscosity at 0.1 rad / second of 1400 Pa.sec or less. The nonwoven fabric comprising the new bicomponent fiber according to the instant invention are not only excellent in softness, but also high in strength, and can be produced in commercial volumes at lower costs due to higher thoughputs and requiring less energy.

Owner:TREVIRA GMBH & CO KG

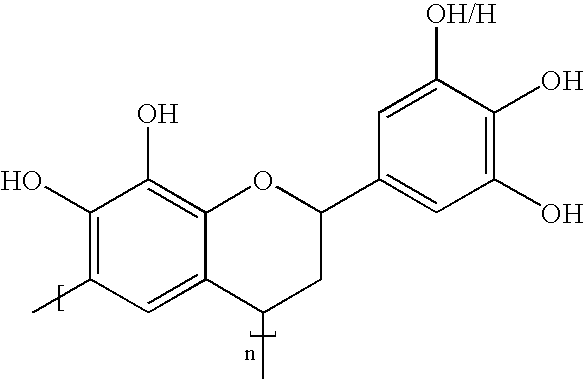

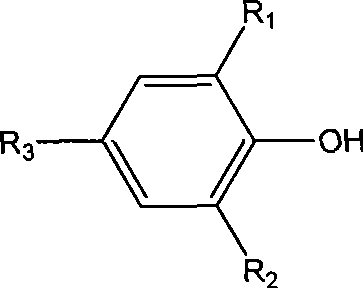

Polyacetal resin composition and process for producing the same

ActiveUS7186766B2Improve thermal stabilityQuality improvementSuture equipmentsOrganic chemistryPhenolPolymer chemistry

About 0.001 to 1 part by weight of a phenol component (B1) and / or about 0.001 to 10 parts by weight of an amino acid (B2) are added relative to 100 parts by weight of a polyacetal resin (A) to prepare a polyacetal resin composition. The phenol component (B1) may be a novolak phenol-series resin, a phenol aralkyl-series resin, a polyvinyl phenol-series resin, a polyhydric phenol, a polyphenol, a catechin compound, or a lignin. The amino acid (B2) may be an α-amino acid, a β-amino acid, a γ-amino acid, a δ-amino acid, or a derivative of an amino acid. The polyacetal resin composition may further contain an antioxidant, a heat stabilizer, a processing stabilizer, a weather (light)-resistant stabilizer, or a coloring agent. The polyacetal resin composition ensures marked inhibition of formaldehyde emission.

Owner:POLYPLASTICS CO LTD

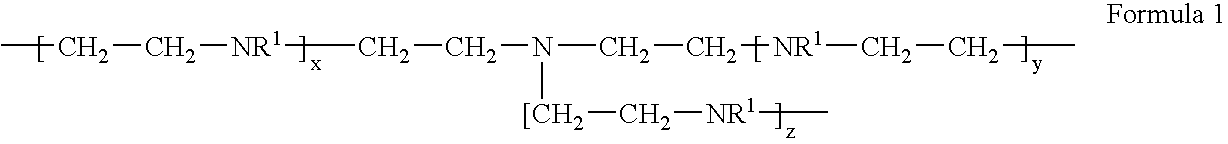

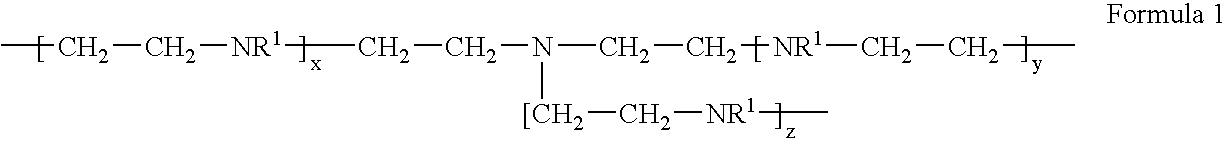

Polymeric chelant and coagulant to treat metal-containing wastewater

The present invention is directed to the use of a combination of a polymeric chelant and coagulant to treat metal containing wastewater. More particularly, the invention is directed at removing copper from CMP wastewater. The composition includes a combination of (a) a polymeric chelant derived from a polyamine selected from the group consisting of diethylenetriamine (DETA), triethylenetetraamine (TETA), tertraethylenepentaamine (TEPA), poly[vinylamine], and branched or linear poly[ethylenimine] (PEI); and (b) a water soluble or dispersible copolymer of a tannin and a cationic monomer selected from the group consisting of methyl chloride or dimethyl sulfate quaternary salt of dimethyl aminoethyl acrylate, diethylaminoethyl acrylate, dimethylaminoethyl methacrylate, diethylaminoethyl methacrylate, dimethylaminopropyl methacrylamide, dimethylaminopropyl acrylamide, and diallyl dimethyl ammonium chloride.

Owner:GENERAL ELECTRIC CO

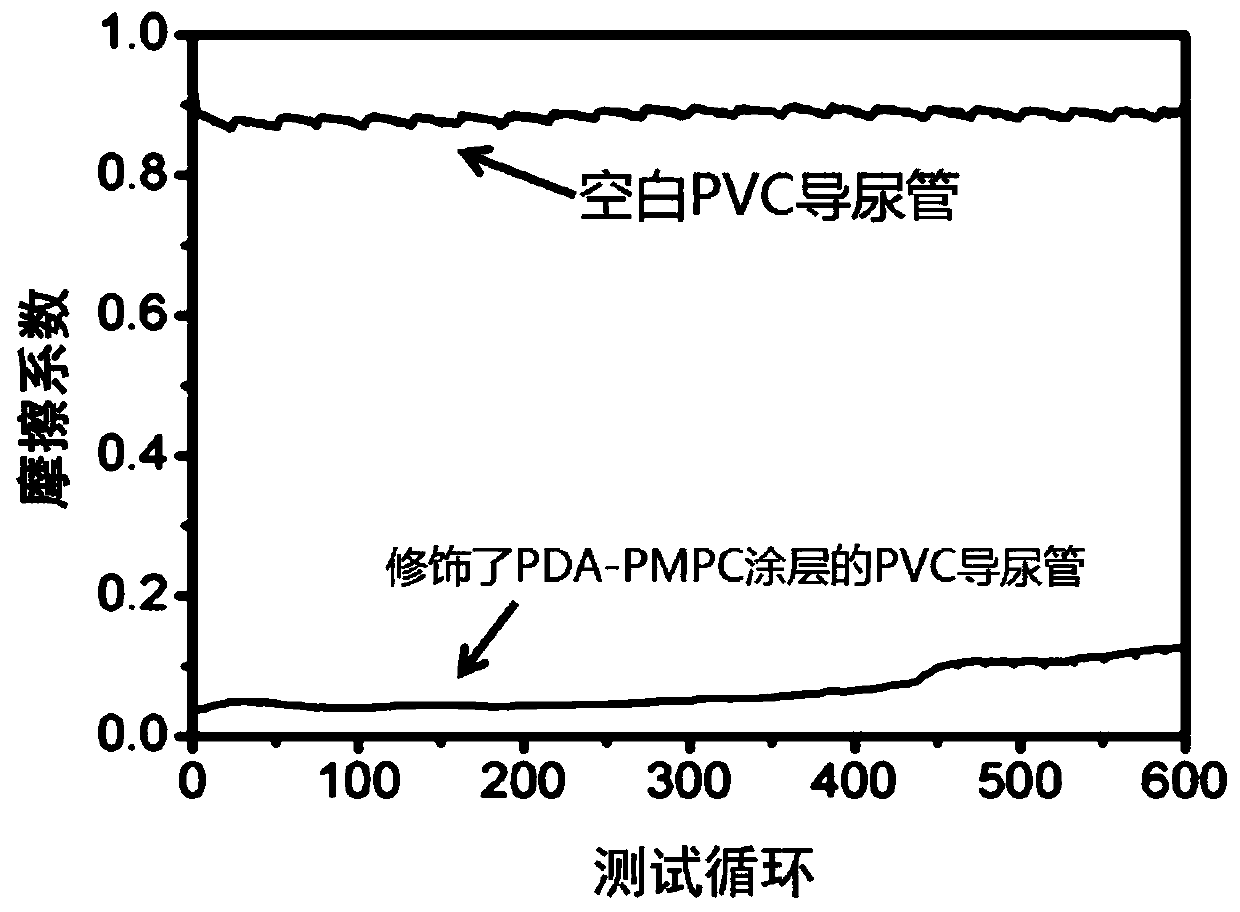

Biomaterial modified with hydrophilic lubrication coating on surface and preparation method of biomaterial

ActiveCN109912826AStable water lubrication performanceSimple componentsCoatingsUltravioletLubrication

The invention provides a biomaterial modified with a hydrophilic lubrication coating on the surface and a preparation method of the biomaterial and belongs to the technical field of surface and interface modification of biological medical device materials. The preparation method comprises the following materials: mixing a vinyl active monomer, dopamine hydrochloride and a tris buffer solution to form a precursor solution; immersing a to-be-modified biological base material into the precursor solution for performing polymerization reaction. The dopamine in the biomaterial disclosed by the invention is subjected to oxidation self-crosslinking polymerization under the aerobic condition; meanwhile, the dopamine produces free radical in the oxidation self-crosslinking process; the generated free radical initiates free radical polymerization of the vinyl active monomer on the surface of the biological base material to form a coating; as wet adhesion effect of the dopamine enables the coatingto be well adhered to the surface of the biological base material, a binding force of the coating and the biological base material is better; means such as ultraviolet or heating is not needed in theprocess, so that the cost is low; as polyvinyl active monomer contains a large amount of hydrophilic groups, the biomaterial shows stable water lubrication performance.

Owner:YANTAI ZHONGKE RES INST OF ADVANCED MATERIALS & GREEN CHEM ENG

Mixed bed ion exchange resin system and method of preparation

InactiveUS6060526AEasy to measureSatisfied levelIon-exchange column/bed processesCation exchanger materialsPolyelectrolyteIon exchange

A method for preparing non-agglomerating mixed bed ion exchange resin systems without affecting the ion exchange kinetics of the anion exchange resin component of the mixed bed system is disclosed. Pretreatment of the anion exchange resin component with a sulfonated poly(vinylaromatic) polyelectrolyte is particularly effective in providing non-agglomerated mixed bed systems without affecting ion exchange kinetics. Treatment levels of 10 to 800 milligrams per liter of anion exchange resin with sulfonated poly(vinylaromatic) polyelectrolyte having number average molecular weight from 5,000 to 1,000,000 are particularly preferred.

Owner:ROHM & HAAS CO

Mother stock of polyvinyl carbon nanotube anti-static composite material and anti-static composite material based on mother stock

InactiveCN1670070AGood antistatic propertiesComprehensive mechanical propertiesAntistatic MaterialsMaleic anhydride

The invention relates to an anti-static modified material with carbon nanotubes (CNTs) predominantly and a process which is a thermal oxidation treatment with acid together with a ball grinding surface treatment to CNTs and comprises: adding maleic anhydride grafted polyethylene, coupling agents and EPT rubber to prepare the high concentration masterbatch of CNTs / PE anti-static composite material by solution blending and melt blending methods, mixturing the said masterbatch with common PE in a finite proportion to melt blend and prill, then getting the final CNTs / PE anti-static composite material. The electrical surface resistivity and volume resistivity can reach the operating requirements of the anti-static material when the content of CNTs is only 0.3 wt % in the CNTs / PE anti-static composite material in the invention.

Owner:EAST CHINA UNIV OF SCI & TECH

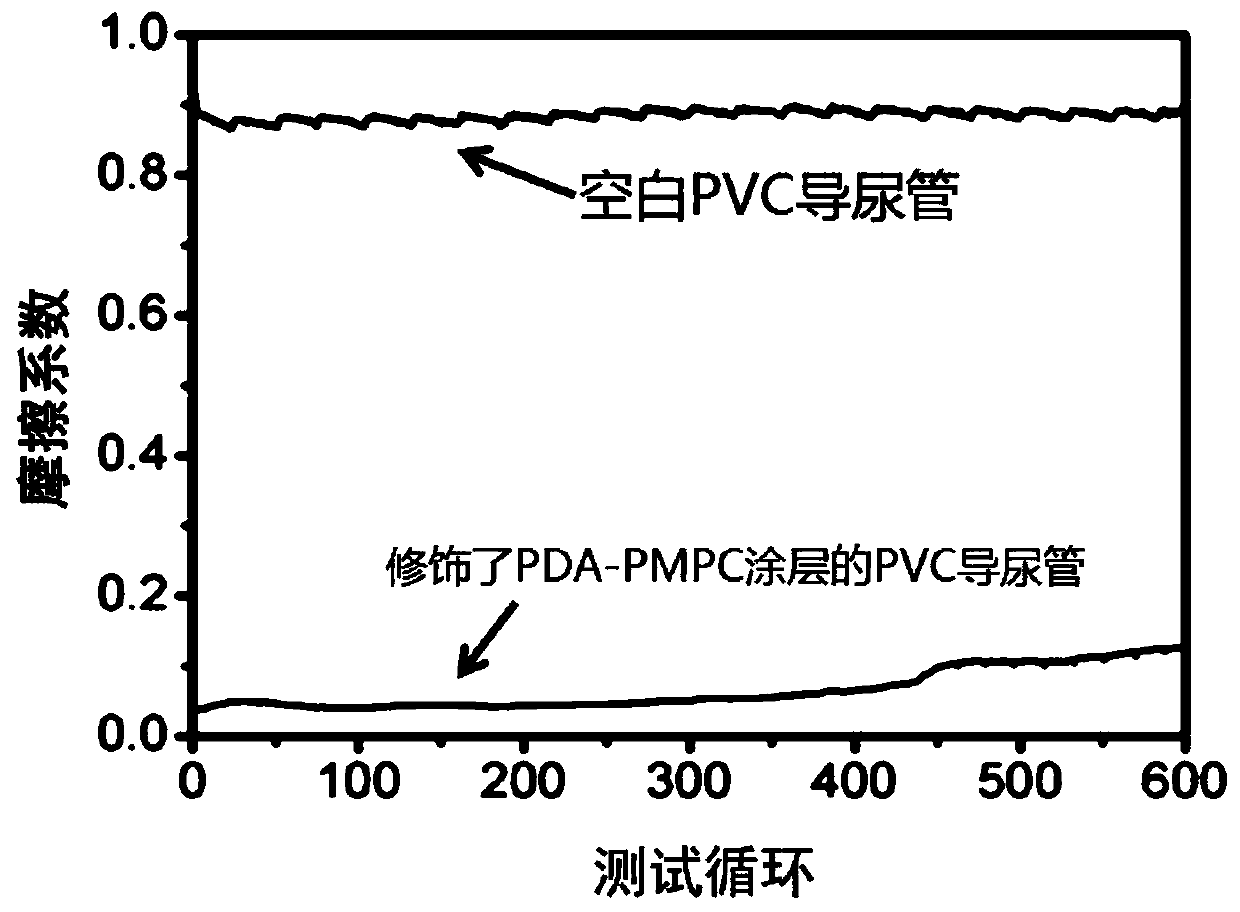

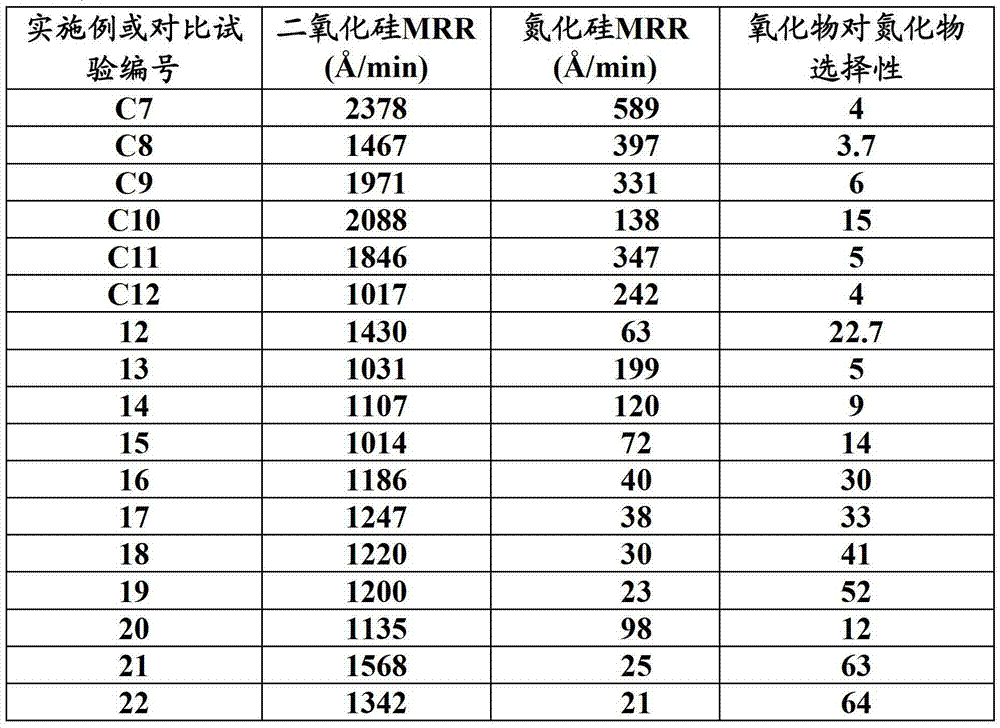

Compositions and methods for selective polishing of silicon nitride materials

ActiveUS20120264304A1Other chemical processesSemiconductor/solid-state device manufacturingParticulatesPolymer

The present invention provides an acidic aqueous polishing composition suitable for polishing a silicon nitride-containing substrate in a chemical-mechanical polishing (CMP) process. The composition, at point of use, comprises about 0.01 to about 2 percent by weight of a particulate calcined ceria abrasive, about 10 to about 1000 ppm of at least one cationic polymer, optionally, about 10 to about 2000 ppm of a polyoxyalkylene polymer; and an aqueous carrier therefor. The at least one cationic polymer is selected from a poly(vinylpyridine) polymer and a combination of a poly(vinylpyridine) polymer and a quaternary ammonium-substituted polymer. Methods of polishing substrates and of selectively removing silicon nitride from a substrate in preference to removal of polysilicon using the compositions are also provided.

Owner:CMC MATERIALS INC

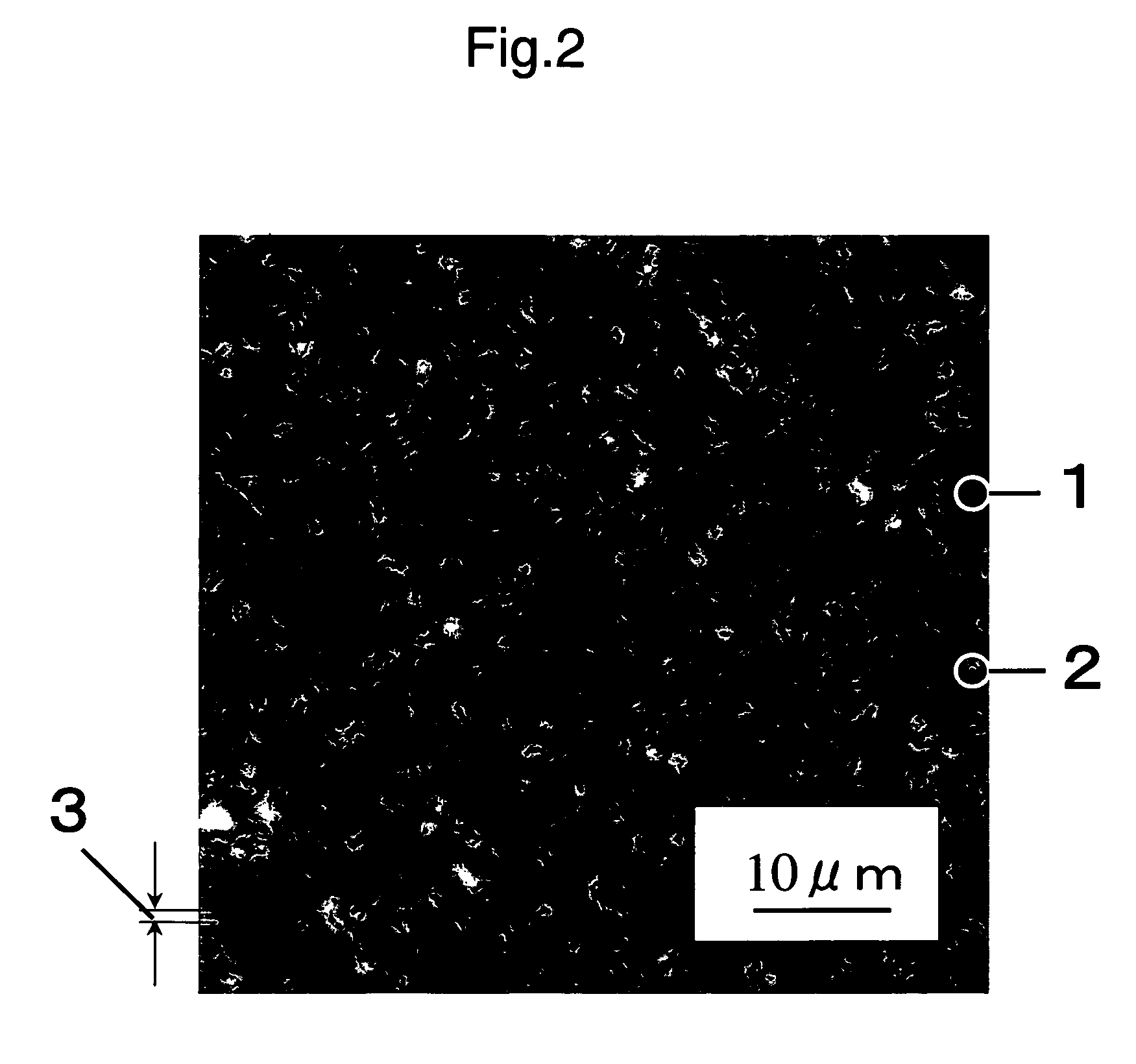

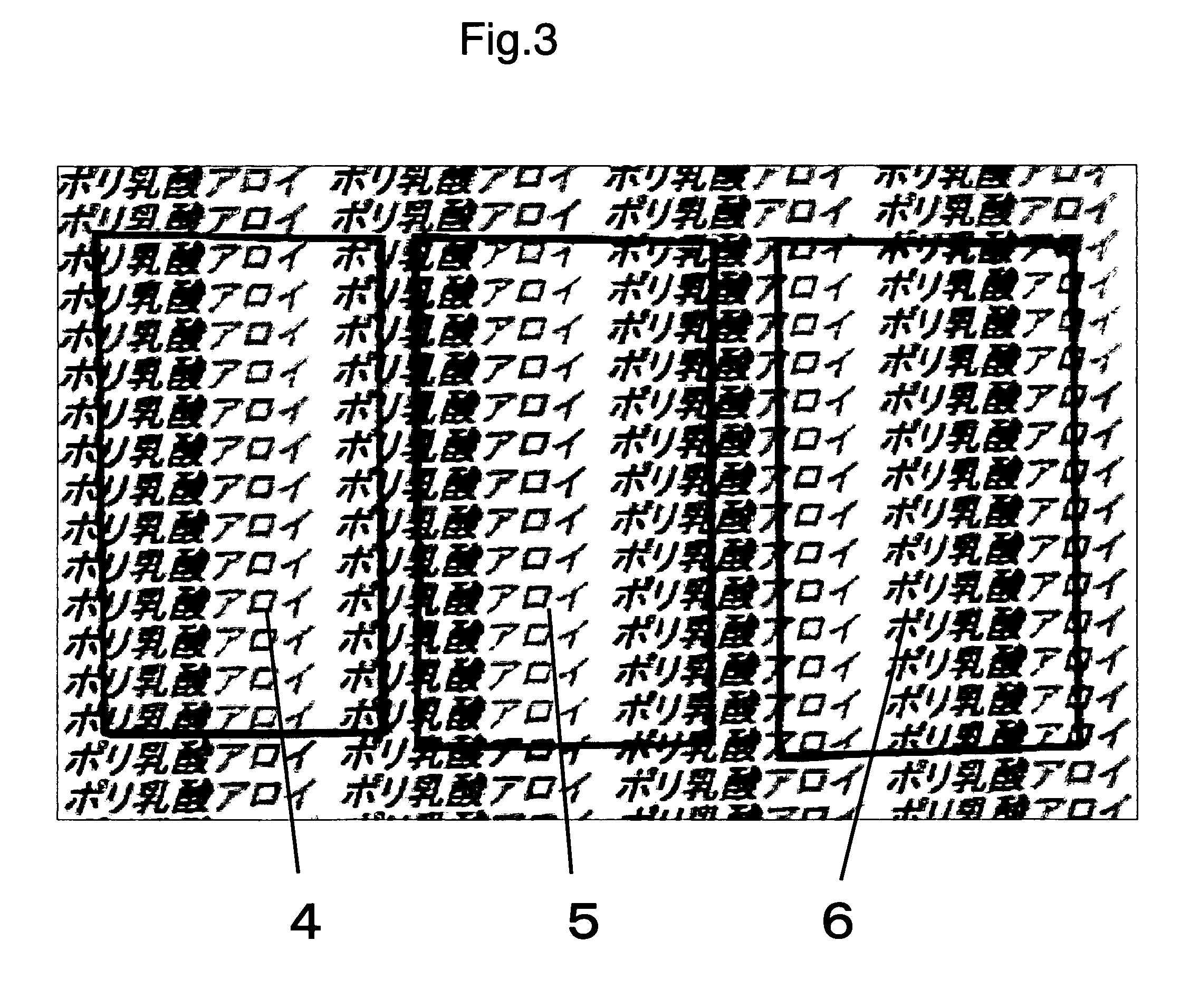

Polylactic acid resin composition, process for producing the same, biaxially stretched polylactic acid film, and molded articles thereof

A resin composition contains poly(lactic acid) and a cellulosic ester, a resin composition excellent in transparency, mechanical properties, and thermostability; a biaxially drawn film containing poly(lactic acid) and at least one compound selected from cellulosic esters, poly(meth)acrylates, and polyvinyl compounds having a glass transition temperature of 60° C. or higher; and a biaxially drawn film excellent in transparency, mechanical properties, and thermostability. The resin composition is obtained by melt-kneading a poly(lactic acid) polymer with a weight average molecular weight of 50,000 or higher and a cellulosic ester; a resin composition excellent in transparency and having luminous transmittance of 40% or higher for visible light with 400 nm; a molded article and a film made of the resin composition; a poly(lactic acid) biaxially drawn film containing a poly(lactic acid) polymer with a weight average molecular weight of 50,000 or higher and at least one compound selected from cellulosic esters, poly(meth)acrylates, and polyvinyl compounds having a glass transition temperature of 60° C. or higher; a poly(lactic acid) biaxially drawn film excellent in transparency and having film haze of 10% or lower.

Owner:TORAY IND INC

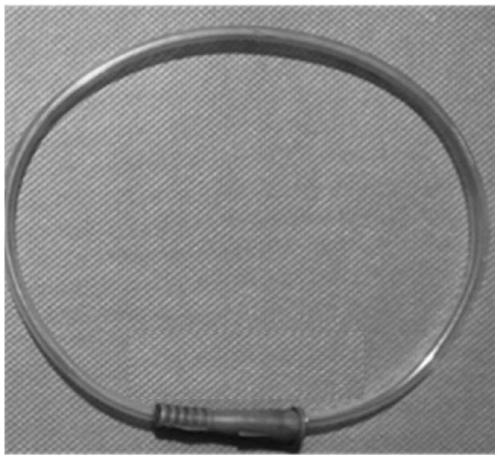

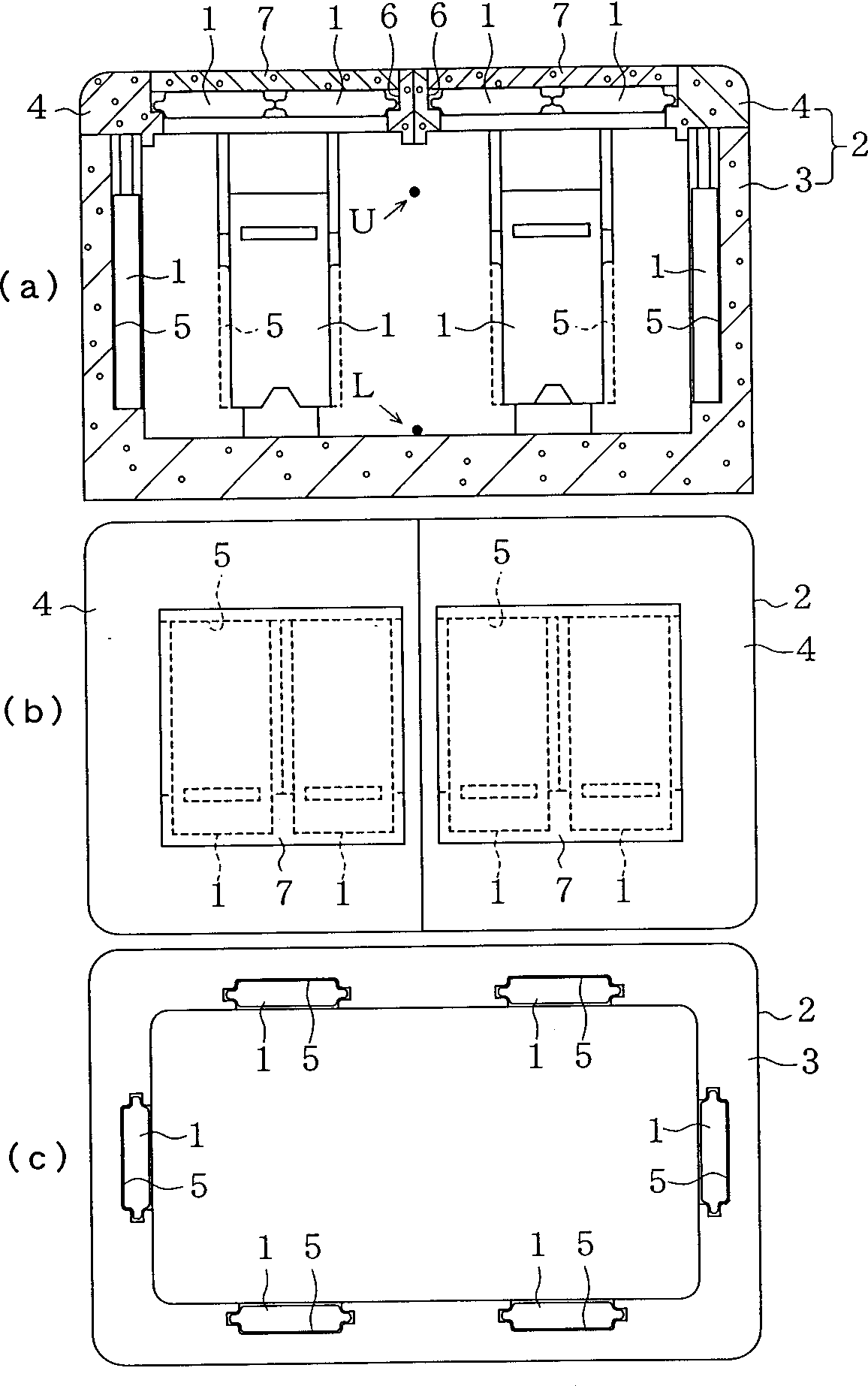

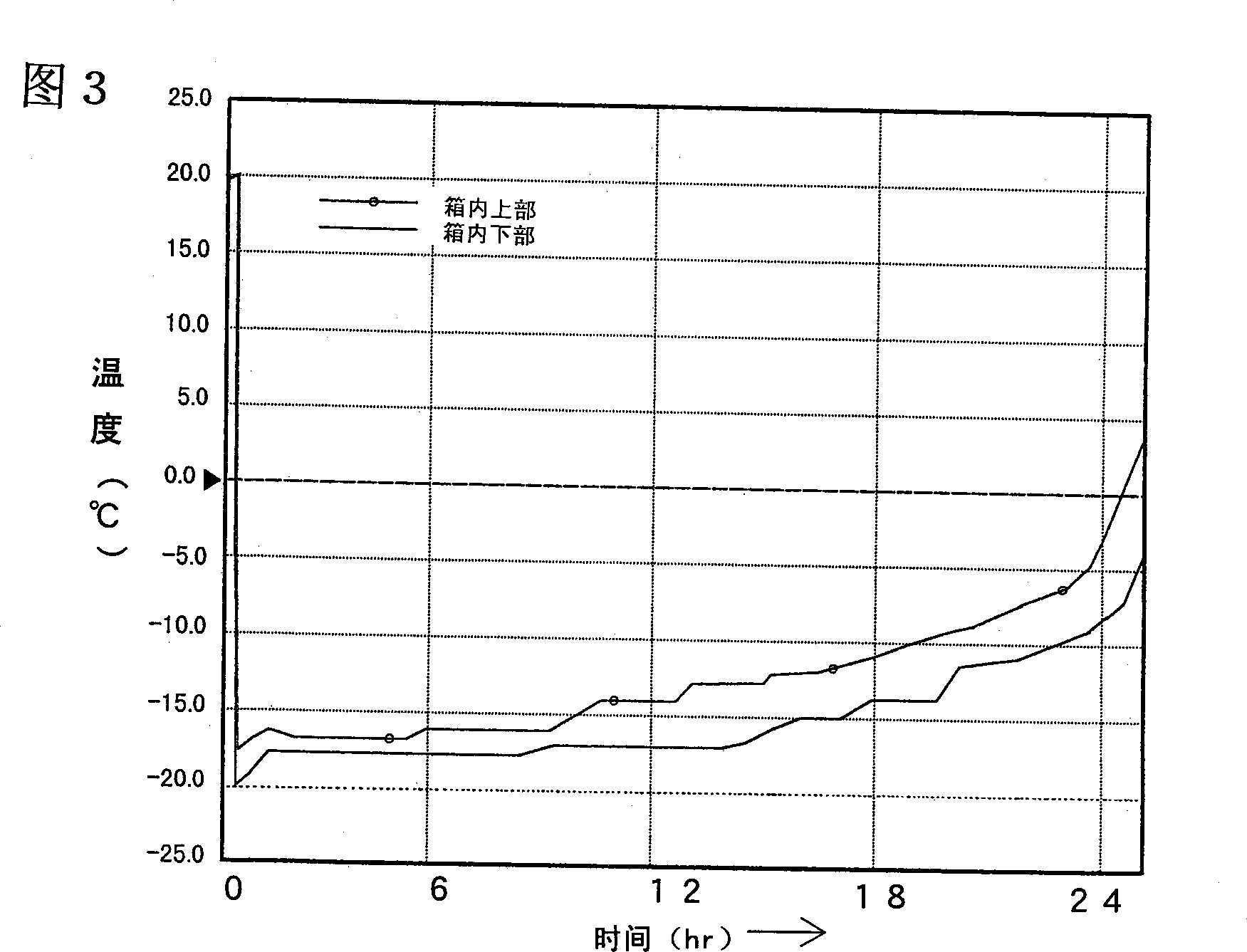

Cold-storage material, cold-storage pack, and cold-reserving box

InactiveCN1343241ALong storage timeSuitable for long-term cold transportationDomestic cooling apparatusLighting and heating apparatusThermodynamicsAqueous solution

A cold-storage material obtained by adding 4 parts by weight of poly(N-vinylacetamide) as a cold-storage-prolonging agent to 100 parts by weight of 20 wt.% aqueous sodium chloride solution and adding thereto sodium borate as a supercooling inhibitor in an amount of 3 parts by weight per 100 parts by weight of the aqueous solution was packed into a pack (1) and cooled in a refrigerator to solidify it. This pack (1) containing the cold-storage material was placed in a cold-reserving box (2), which was examined for temperature change. As a result, it was ascertained that the cold-storage retention time was prolonged. Thus, a cold-storage material can be provided which has a prolonged cold-storage retention time and is suitable for use in cold reservation for long-term transportation, storage, display, etc.

Owner:水谷 耕治 +1

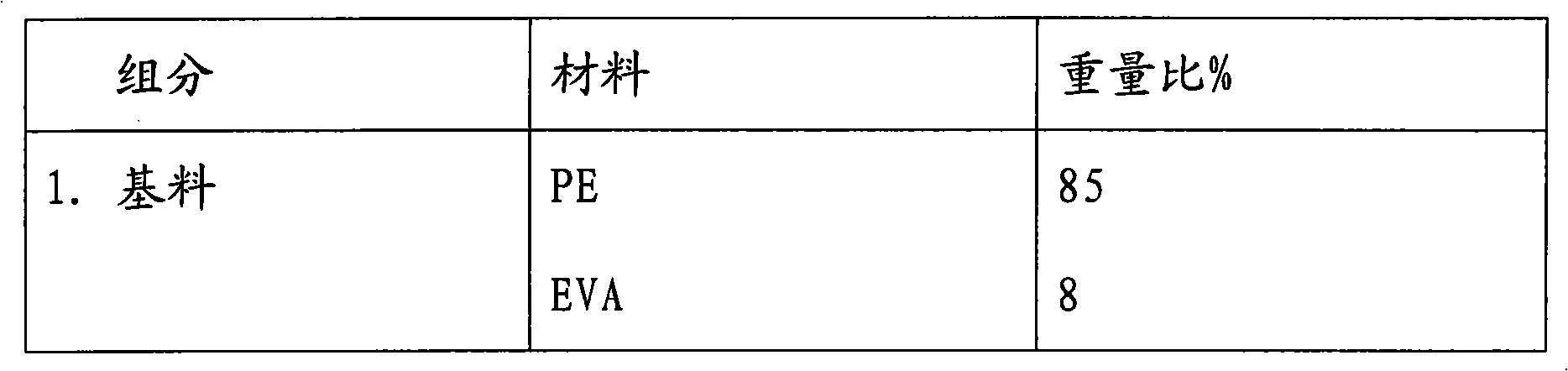

Sheath material for optical fiber cable, and production process thereof

InactiveCN102807693AMeet the use requirementsImprove performanceFibre mechanical structuresPolymer sciencePolyolefin

The present invention relates to a sheath material for an optical fiber cable, and a production process thereof. The sheath material comprises, by weight, 85-95% of a polyolefin base material, 2.35-2.85% of carbon black, 0.5-1% of an antioxidant, and 0.8-1% of an additive, wherein the polyolefin base material comprises a polyethylene base material and a modifier, and the additive comprises a fluorine-containing rheological agent PPA, a lubricant, a plastic brightening agent and a softener. During production, carbon black is made into a masterbatch; PPA is made into a masterbatch by using a polyethylene base material; the carbon black masterbatch, the PPA masterbatch, an antioxidant, a plastic brightening agent and a softener are mixed; the mixed material is added to EVA to mix; the resulting mixture is added to polyethylene to mix, and then mastication extrusion is performed through a plastic extruder. According to the present invention, high and medium density polyethylene is adopted as a base material for the optical fiber cable sheath, such that a chemical performance is stable; and various auxiliary materials are added to the polyethylene base material, such that performances of the optical fiber cable sheath are improved, and various use requirements of the optical fiber cables are met.

Owner:JIANGSU NANFANG COMM TECH

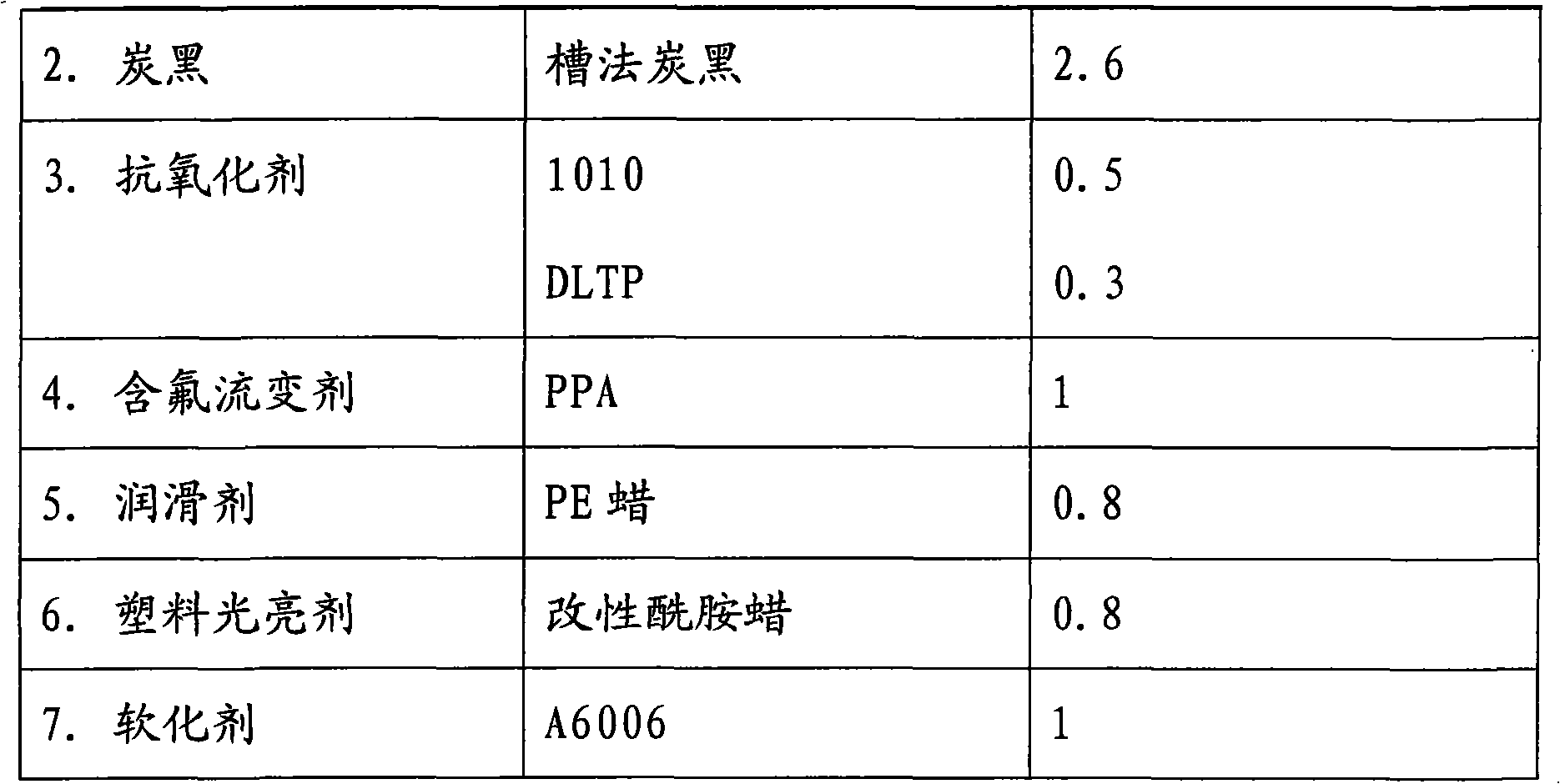

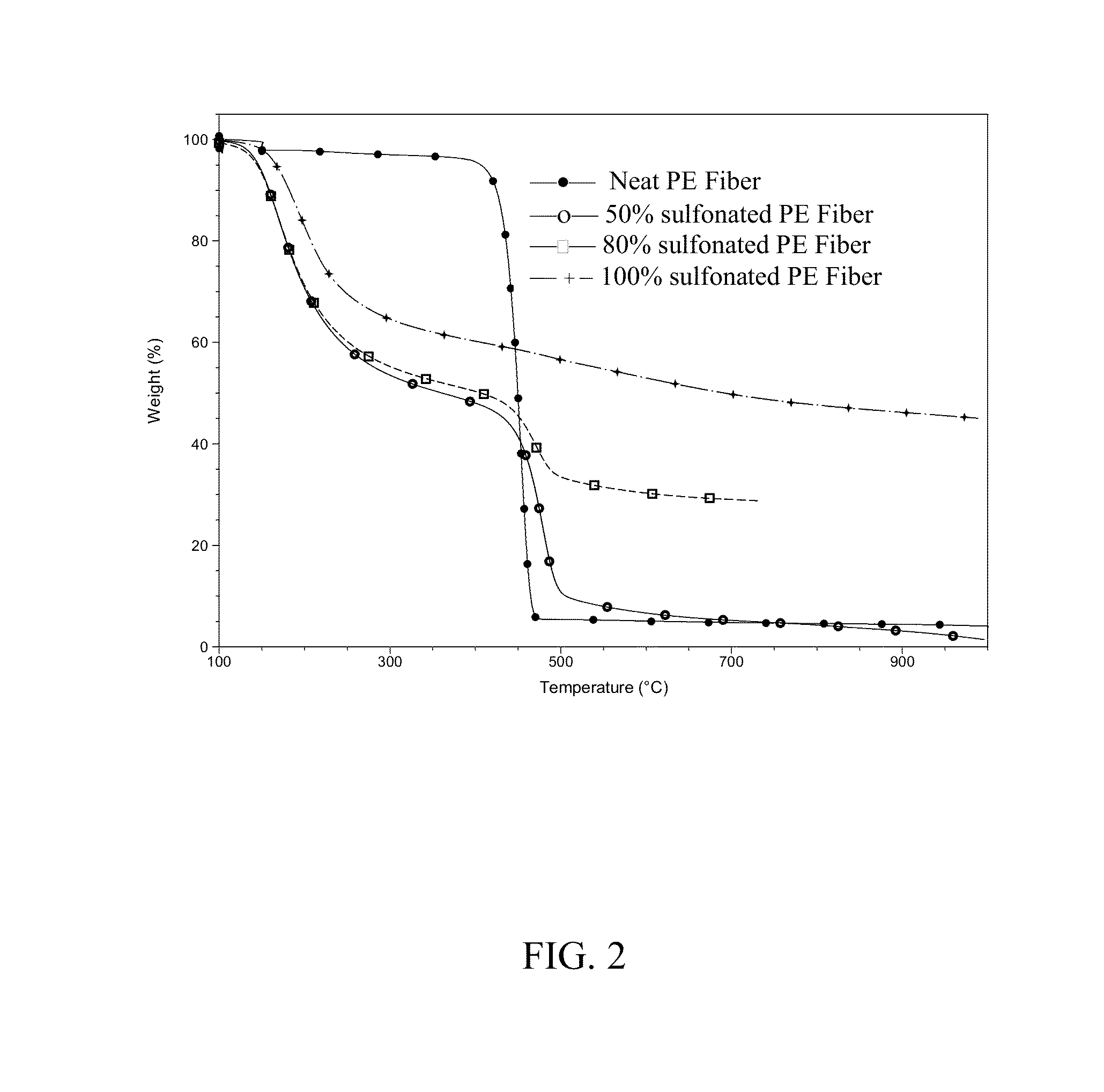

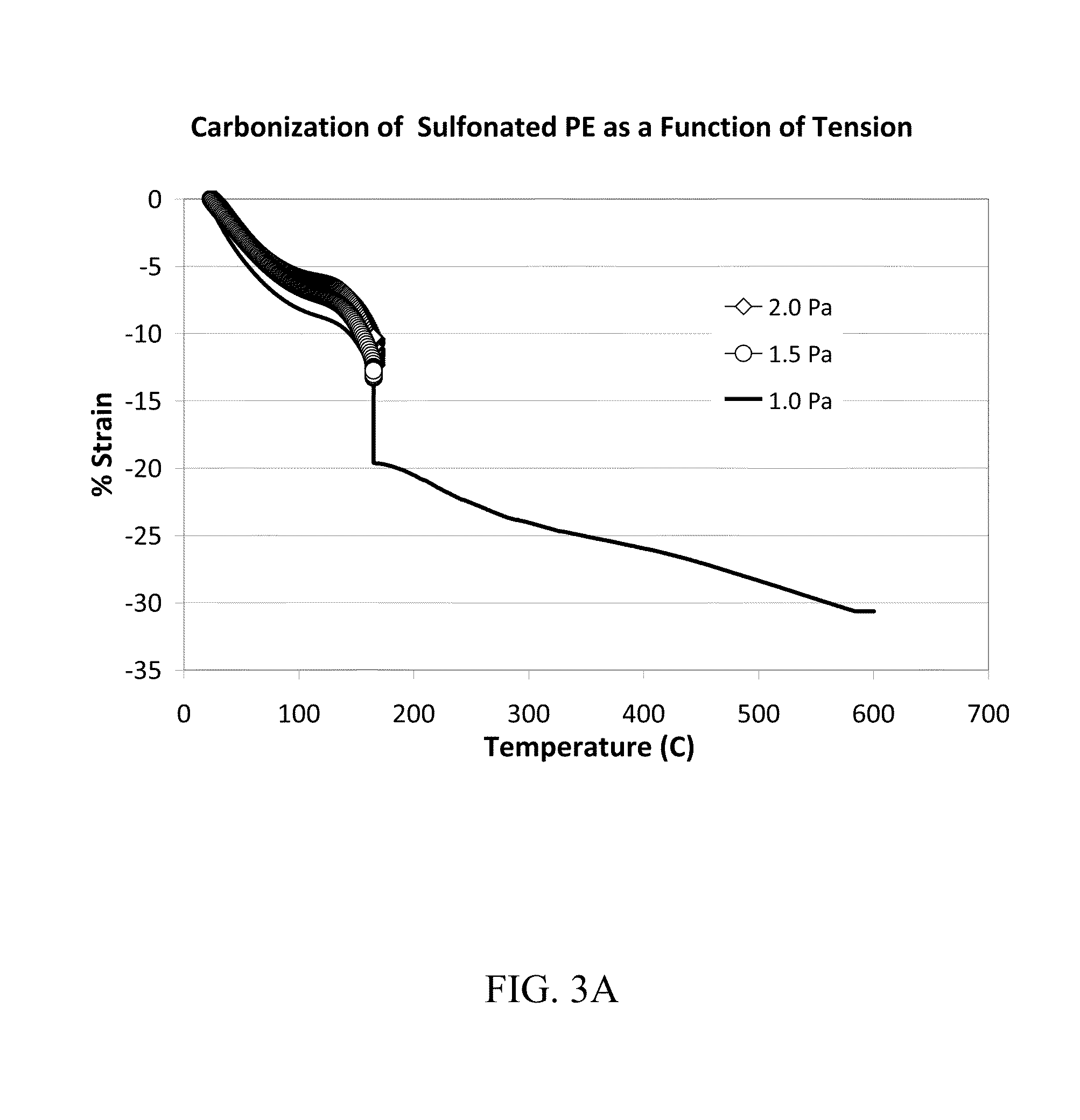

Controlled chemical stabilization of polyvinyl precursor fiber, and high strength carbon fiber produced therefrom

ActiveUS20140306364A1Improved strength and modulusHigh degree of orderFibre chemical featuresCarbonsing ragsFiberPolymer science

Method for the preparation of carbon fiber, which comprises: (i) immersing functionalized polyvinyl precursor fiber into a liquid solution having a boiling point of at least 60° C.; (ii) heating the liquid solution to a first temperature of at least 25° C. at which the functionalized precursor fiber engages in an elimination-addition equilibrium while a tension of at least 0.1 MPa is applied to the fiber; (iii) gradually raising the first temperature to a final temperature that is at least 20° C. above the first temperature and up to the boiling point of the liquid solution for sufficient time to convert the functionalized precursor fiber to a pre-carbonized fiber; and (iv) subjecting the pre-carbonized fiber produced according to step (iii) to high temperature carbonization conditions to produce the final carbon fiber. Articles and devices containing the fibers, including woven and non-woven mats or paper forms of the fibers, are also described.

Owner:UT BATTELLE LLC

Polymerization of fluoropolymers using non-fluorinated surfactants

ActiveUS8697822B2Organic-compounds/hydrides/coordination-complexes catalystsFibre treatmentFluoropolymerALLYL SUCROSE

Owner:ARKEMA INC

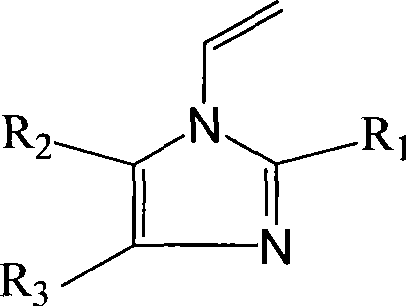

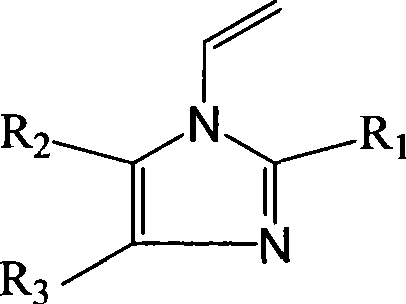

Metallic ion-polyvinyl imidazol complex catalyst and preparation method and application thereof

InactiveCN101544755AIncrease local concentrationSolve the problem of low catalytic efficiencyEthylene HomopolymersWater soluble

The invention discloses a metallic ion-polyvinyl imidazole complex catalyst, which is a complex of a metallic ion and a polyvinyl imidazole ligand, wherein the molar ratio of imidazole groups to the metallic ion is 0.5 to 300; the metallic ion is a copper ion or manganese ion; and the polyvinyl imidazole ligand is a homopolymer of a N-vinyl imidazole monomer or copolymer of the N-vinyl imidazole monomer and another one or various water-soluble monomers and has a weight average molecular weight of 10<3> to 10<7>. The polyvinyl imidazole ligand has a large number of imidazole groups and can significantly increase the local concentration of the catalyst in a reaction medium after the complexation with the metallic ion, so the catalyst has greatly improved catalytic efficiency, achieves high PPO yield with a very small dosage when used in the preparation of PPO in a water medium, and solves the problem of the low catalytic efficiency of the prior polyphenylether catalyst prepared in the water medium.

Owner:ZHEJIANG UNIV

Label stock with improved die-cutting performance

The present invention concerns label stock comprising a laminate of face stock, a pressure sensitive adhesive layer and a release liner, wherein the pressure sensitive adhesive layer comprises (a) at least one block copolymer, comprising at least two terminal blocks of poly(vinyl aromatic compound) and at least one midblock of a randomly copolymerized mixture of isoprene (1) and butadiene (B) used in a weight ratio of (1):(B) of 35:65 to 80:20, said midblock having a single glass transition temperature Tg of at most determined according to ASTM E-1 356-98), (b) at least one diblock copolymer, comprising one block of poly(vinyl aromatic compound) and one block of polymerized butadiene and / or isoprene; (c) a tackifying resin; and (d) optionally a plasticizer wherein component (a) is a thermoplastic elastomer, component (b) comprises from 30 to 85% by weight of the mixture of components (a) and (b), and wherein on 100 parts by weight of the mixture of components (a) and (b), from 20 to 450 parts by weight component (c) is used.

Owner:KRATON POLYMERS US LLC

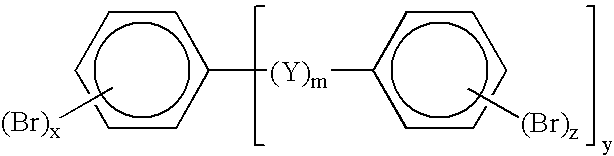

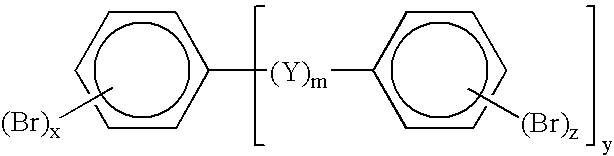

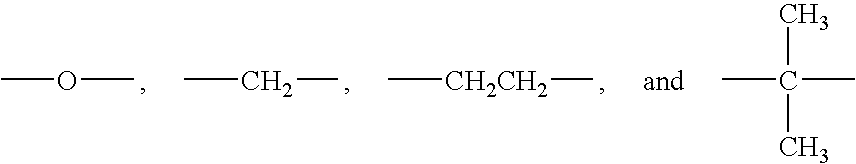

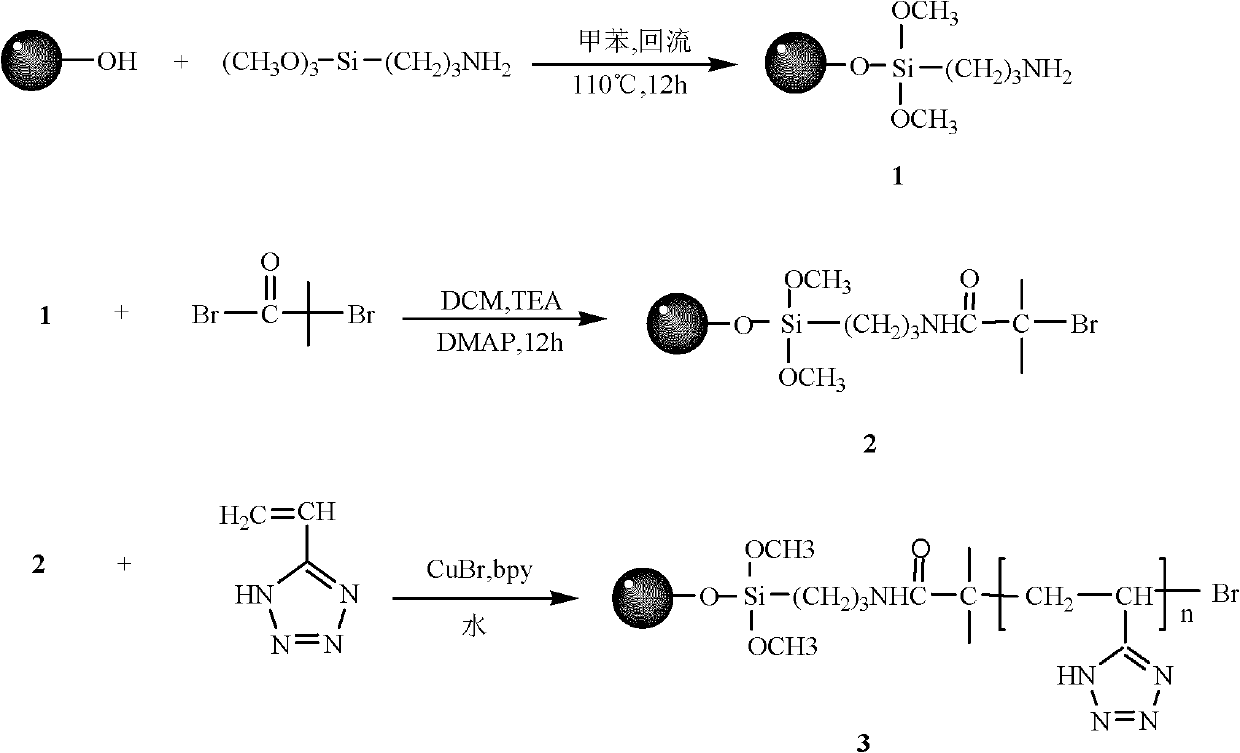

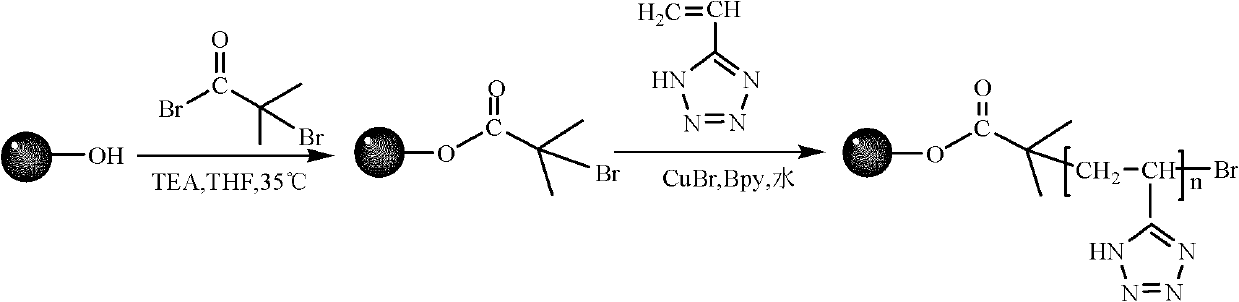

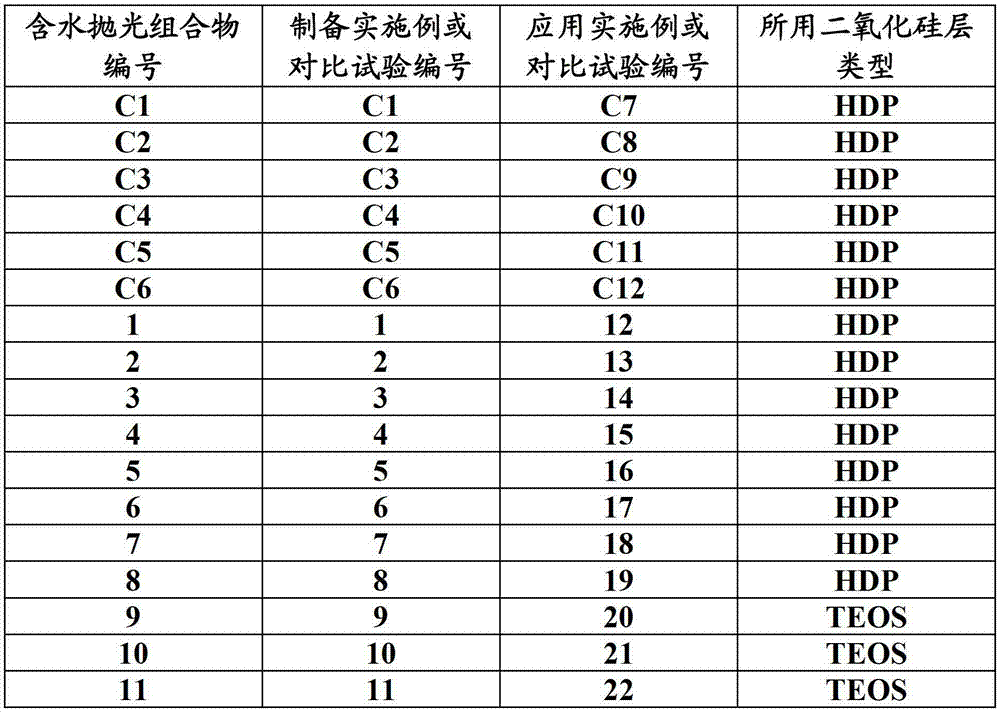

Polyvinyl tetrazole separation medium, preparation method and application thereof

InactiveCN101837284AImprove adsorption capacityQuality improvementIon-exchange process apparatusOther chemical processesTetrazoleMicrosphere

The invention discloses a polyvinyl tetrazole separation medium and a preparation method thereof. The polyvinyl tetrazole separation medium has a structurally general formula shown in the specification. The separation medium of the invention can be obtained by modifying polyvinyl tetrazole on the surfaces of silica gel, agarose or polystyrene microspheres. The separation medium of the invention has double functions of separating an ion-exchange chromatograph and a metal-chelating chromatograph. The medium is used for the ion-exchange separation chromatograph and the metal-chelating chromatograph of a protein, and has the characteristics of high protein adsorption capacity, quality, activity, and recovery rate.

Owner:NORTHWEST UNIV(CN)

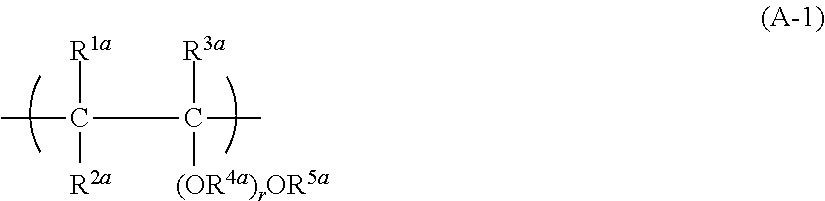

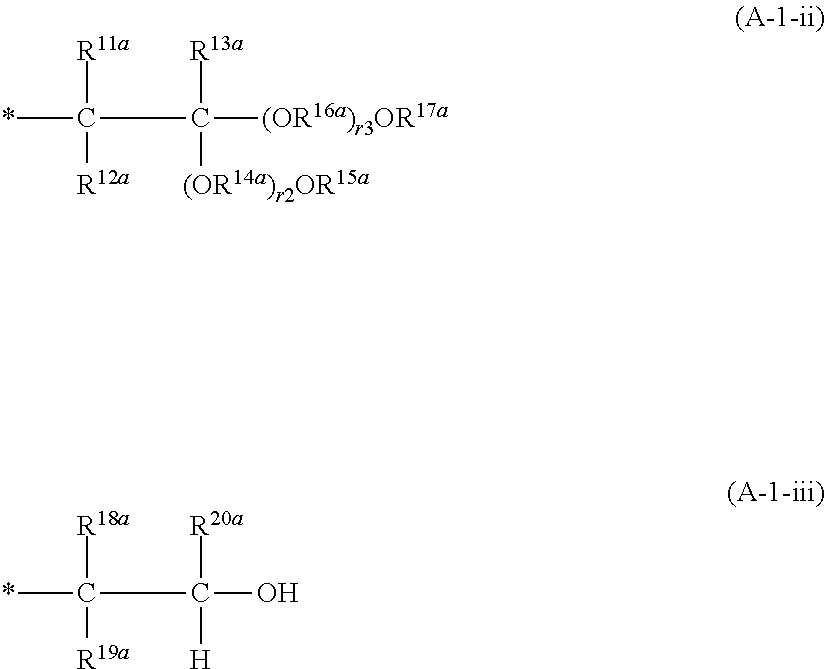

Aqueous polishing composition and process for chemically mechanically polishing substrates for electrical, mechanical and optical devices

InactiveCN103097476AGood choiceOther chemical processesSemiconductor/solid-state device manufacturingWater dispersibleAlcohol

An aqueous polishing composition having a pH of 3 to 11 and comprising (A) abrasive particles which are positively charged when dispersed in an aqueous medium free from component (B) and of a pH of 3 to 9 as evidenced by the electrophoretic mobility; (B) anionic phosphate dispersing agents; and (C) a polyhydric alcohol component selected from the group consisting of (c1) water-soluble and water-dispersible, aliphatic and cycloaliphatic, monomeric, dimeric and oligomeric polyols having at least 4 hydroxy groups; (c2) a mixture consisting of (c21) water-soluble and water-dispersible, aliphatic and cycloaliphatic polyols having at least 2 hydroxy groups; and (c22) water-soluble or water-dispersible polymers selected from linear and branched alkylene oxide homopolymers and copolymers (c221 ); and linear and branched, aliphatic and cycloaliphatic poly(N-vinylamide) homopolymers and copolymers (c222); and (c3) mixtures of (c1) and (c2); and a process for polishing substrates for electrical, mechanical and optical devices.

Owner:BASF AG

Glyoxalation of vinylamide polymer

ActiveCN101553508AImprove performanceNon-fibrous pulp additionPaper/cardboardCellulosePolymer science

The present invention is directed to a method for preparing a cellulose reactive adduct of polyvinylamide and a composition resulting from the method. The preparation of the cellulose reactive adduct is carried out close to a Critical Concentration defined herein. When the reaction is run close to this Critical Concentration, the risk of gelation is minimized, consumed glyoxal is maximized, and shelf live is enhanced. Additionally, the glyoxalated vinylamides of the present invention impart improved wet and dry strengthening efficiency to paper and paperboard when compared to adducts disclosedin previously described art.

Owner:BASF AG

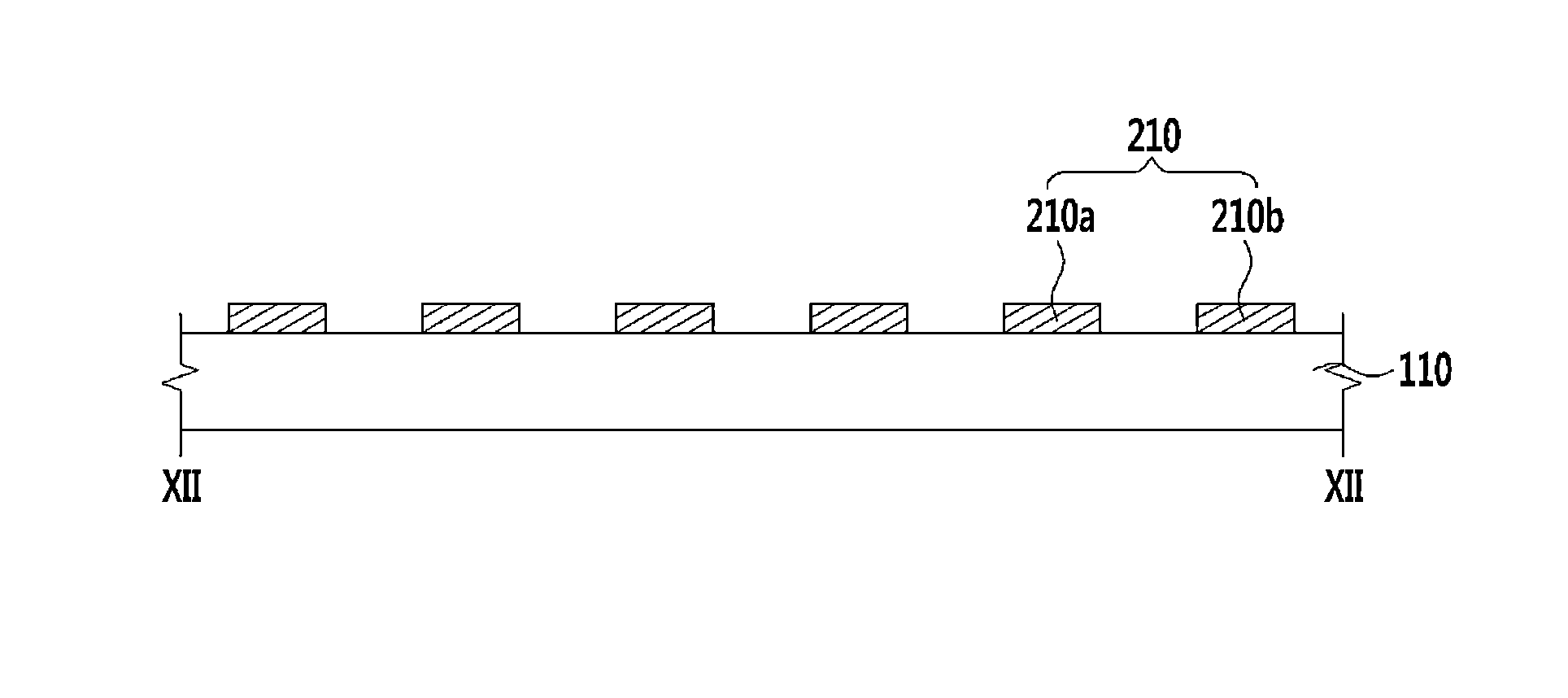

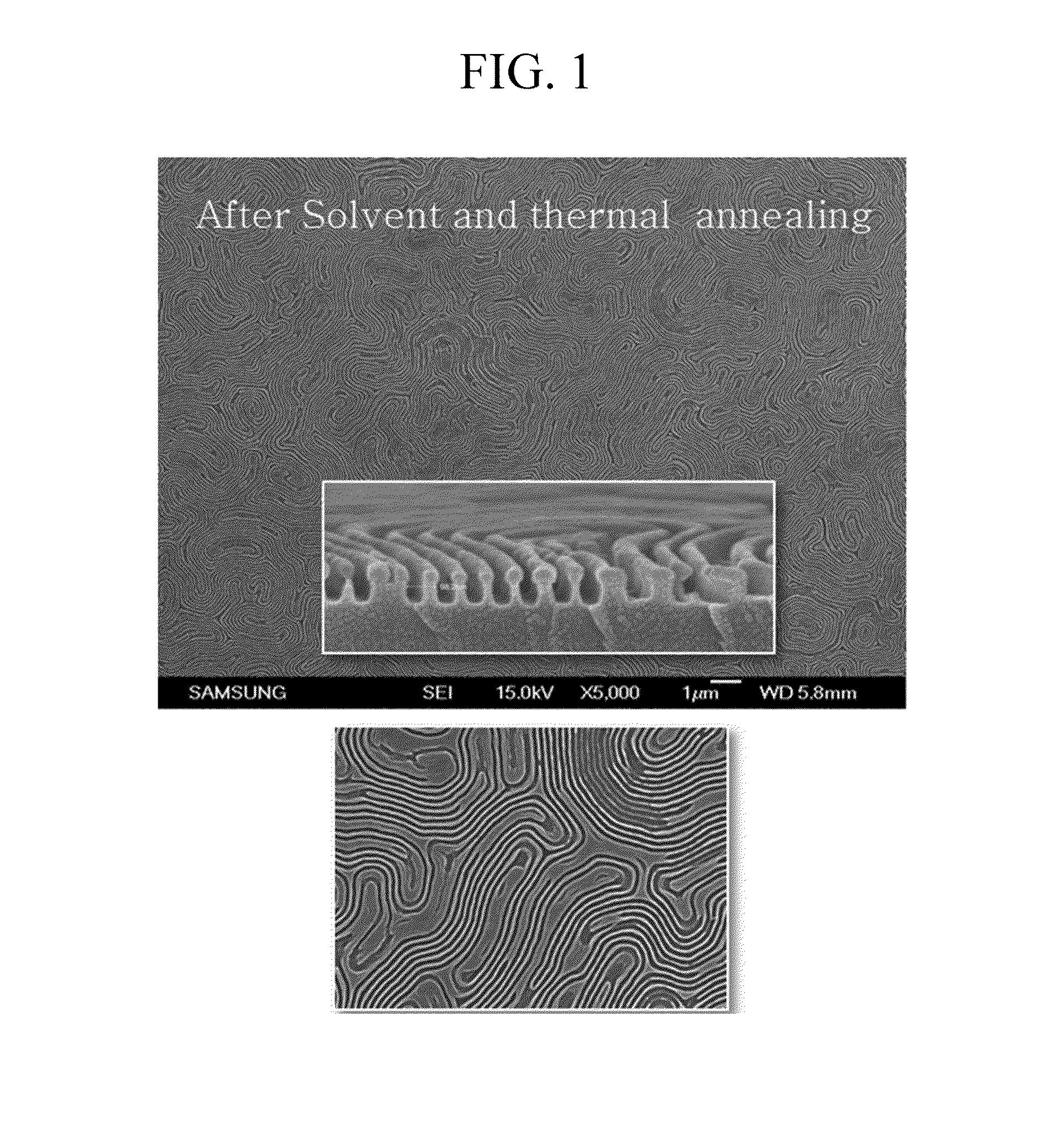

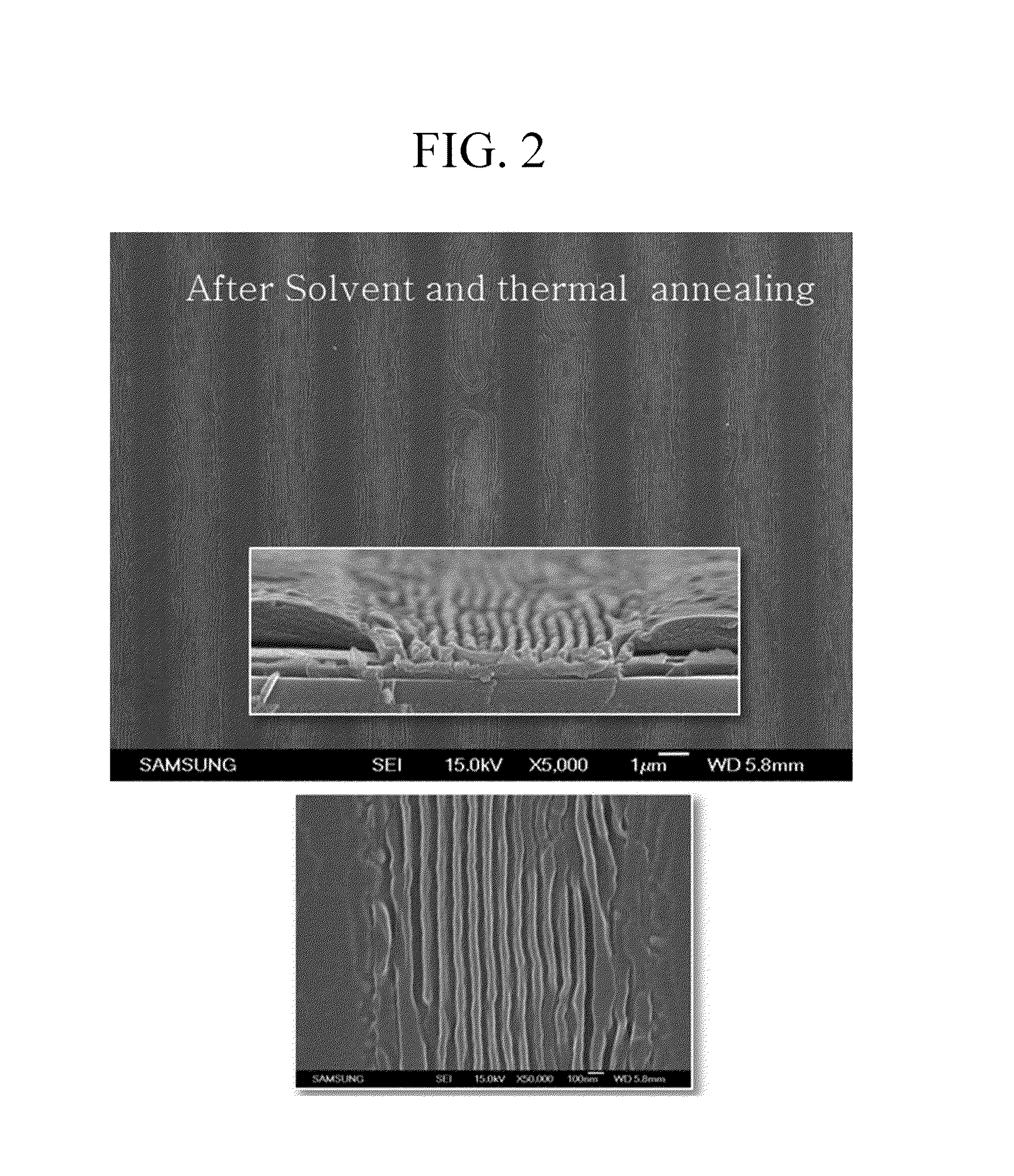

Block copolymer, method of forming the same, and method of forming pattern

ActiveUS20140197132A1Increase separation speedAvoid processing timeDecorative surface effectsFootwearPolyethylene oxideHydrogen

A block copolymer is provided. The block copolymer according to an exemplary embodiment includes a first block represented by Chemical Formula 1 and a second block represented by Chemical Formula 2:wherein COM1 and COM2 are independently selected from a polystyrene moiety, polymethylmethacrylate moiety, polyethylene oxide moiety, polyvinylpyridine moiety, polydimethylsiloxane moiety, polyferrocenyldimethylsilane moiety, and polyisoprene moiety, R1 is hydrogen or an alkyl group with 1 to 10 carbon atoms, Ph is a phenyl group, a is 1 to 50, R2 is hydrogen or an alkyl group with 1 to 10 carbon atoms, and b is 1 to 50.

Owner:SAMSUNG DISPLAY CO LTD +2

Multilayer sheet, encapsulant for solar cell element, and solar cell module

InactiveUS20110272026A1Increased durabilityHigh strengthSynthetic resin layered productsVehicle componentsSolar cellSealant

A multilayer sheet including an (A) layer containing an ethylene type zinc ionomer as a main component and a silane coupling agent, and a (B) layer containing a polyethylene-based copolymer with a melting point of 90° C. or higher as a main component and a silane coupling agent having a content ratio with respect to the resin material that is lower than a content ratio of the silane coupling agent with respect to resin material in the (A) layer, wherein the total thickness of the (A) layer and the (B) layer is from 0.1 to 2 mm. Such multilayer sheet may be superior in adhesive strength, durability and heat resistance, and obtained at a suppressed cost.

Owner:MITSUI LTD

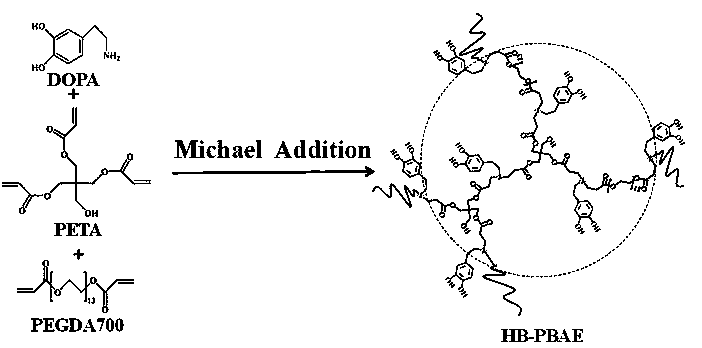

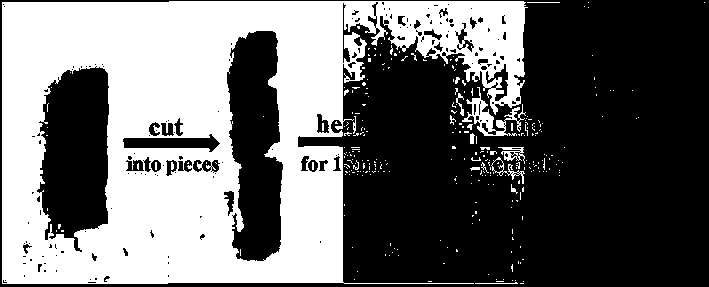

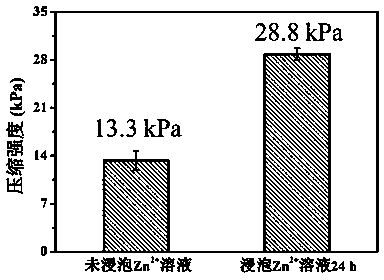

Response type medical gel as well as preparation method and application thereof

ActiveCN107626002AAdhesion can be regulatedSurgical adhesivesBandagesSurgical operationPolymer science

The invention provides response type medical gel. Particularly, a functional hyperbranched polymer monomer (HB-PBAE) is synthesized by virtue of Michael addition reaction of dopamine (DOPA), polyethylene glycol diacrylate (PEGDA700) and pentaerythritol triacrylate (PETA); and gel is formed by virtue of a mixed solution of HB-PBAE, polyvinyl imidazol (PVI) and gelatin (Geln) under the action of aniron ion (Fe<3+> solution). The gel has the properties of softness and viscidity in the primary formation period, and the viscidity is obviously reduced after the gel is soaked in a zinc ion (Zn<2+> solution). Hydrogel provided by the invention has syringeability, can be taken as a sealing agent or a wound surface dressing for surgical operations and is used for smearing the wound surface of a tissue, so that the adverse leakage of liquid or gas is avoided; and the viscidity of the gel has ion responsitivity, so that the secondary injury in a dressing change process can be reduced, and the pain of the wound surface can be alleviated.

Owner:HANGZHOU YAHUI BIOTECH CO LTD

Refrigerator oil composition, and refrigeration device

InactiveUS20170166831A1Improve compatibilityImprove thermal stabilityCompressorCompression machines with non-reversible cycleEngineeringCopolymer

Provided is a refrigerator oil composition for a refrigerant containing an unsaturated fluorinated compound having a carbon-carbon unsaturated bond, which is represented by a general formula (I): C2FpR4-p, wherein R each independently represents a hydrogen atom, a chlorine atom, a bromine atom, or an iodine atom, and p represents an integer of 1 to 3. The composition contains a base oil (P) including one or more kinds selected from polyvinyl ethers, polyalkylene glycols, copolymers of a poly(oxy)alkylene glycol or a monoether thereof and polyvinyl ethers, and a polyol ester. The kinematic viscosity at 100° C. of the base oil (P) is 2.00 to 50.00 mm2 / s, and the hydroxyl value thereof is 5.0 mgKOH / g or less. The refrigerator oil composition is excellent in compatibility with a refrigerant containing an unsaturated fluorinated compound having 2 carbon atoms and having a specific atom, and is also excellent in thermal stability.

Owner:IDEMITSU KOSAN CO LTD

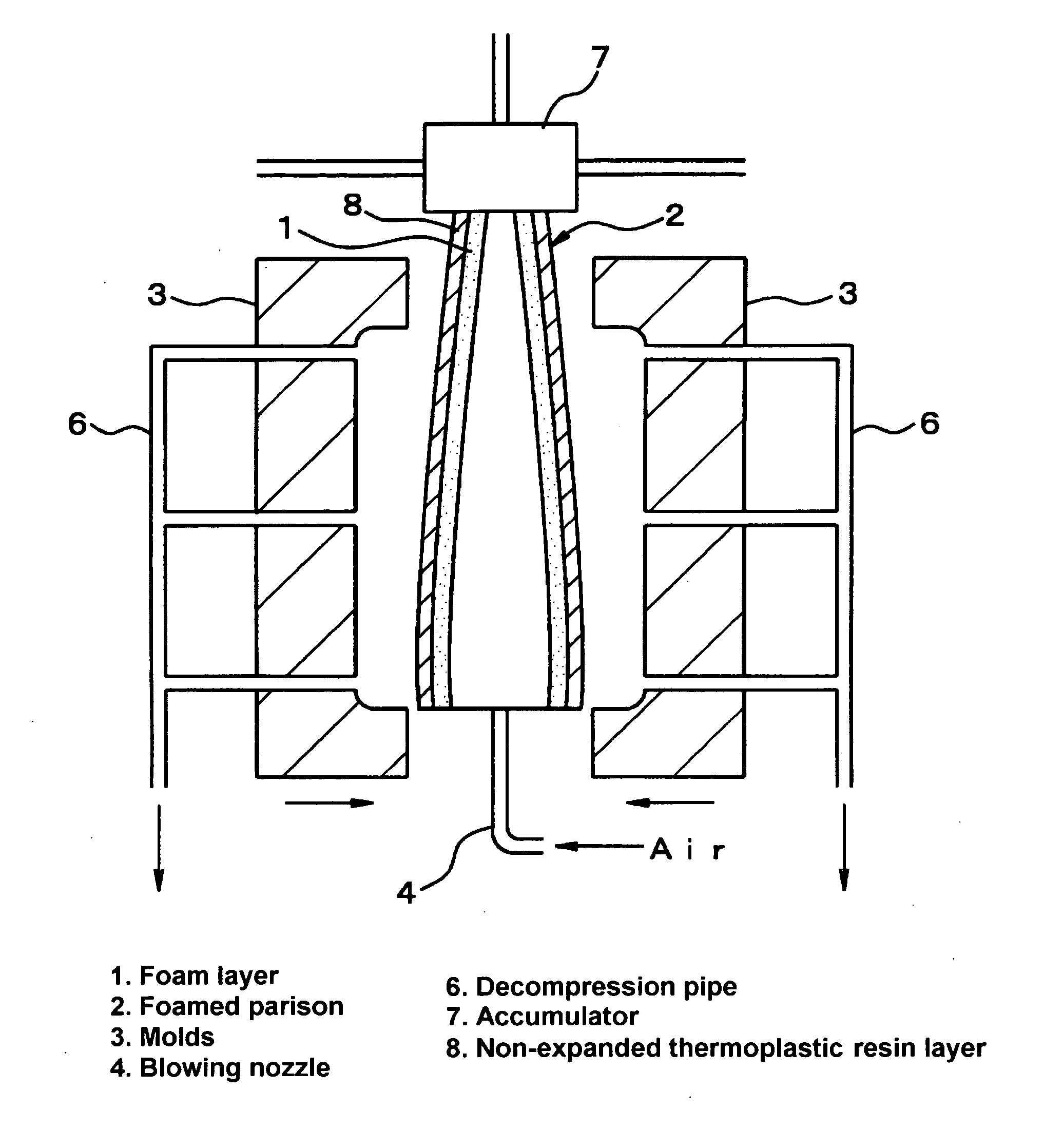

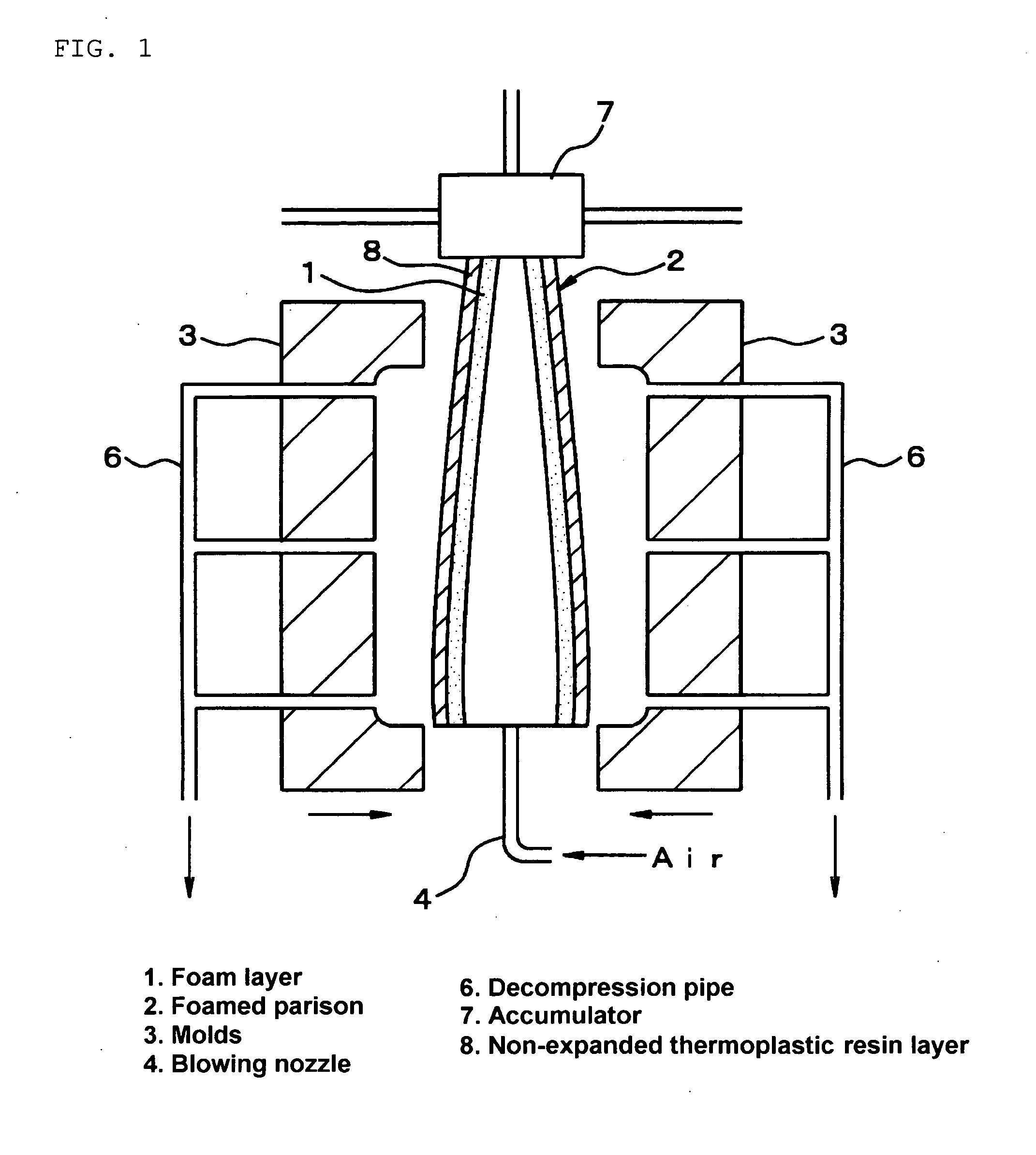

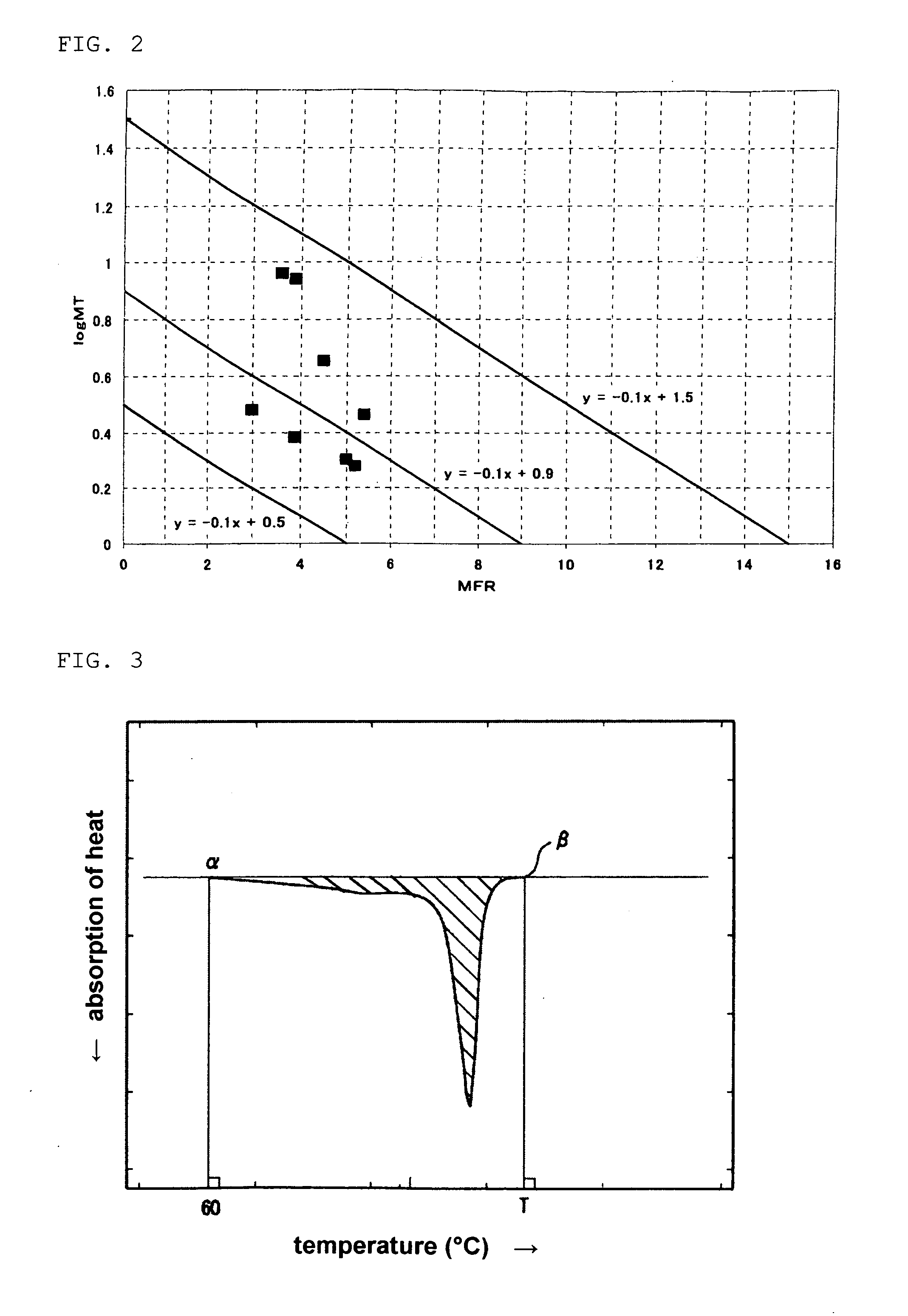

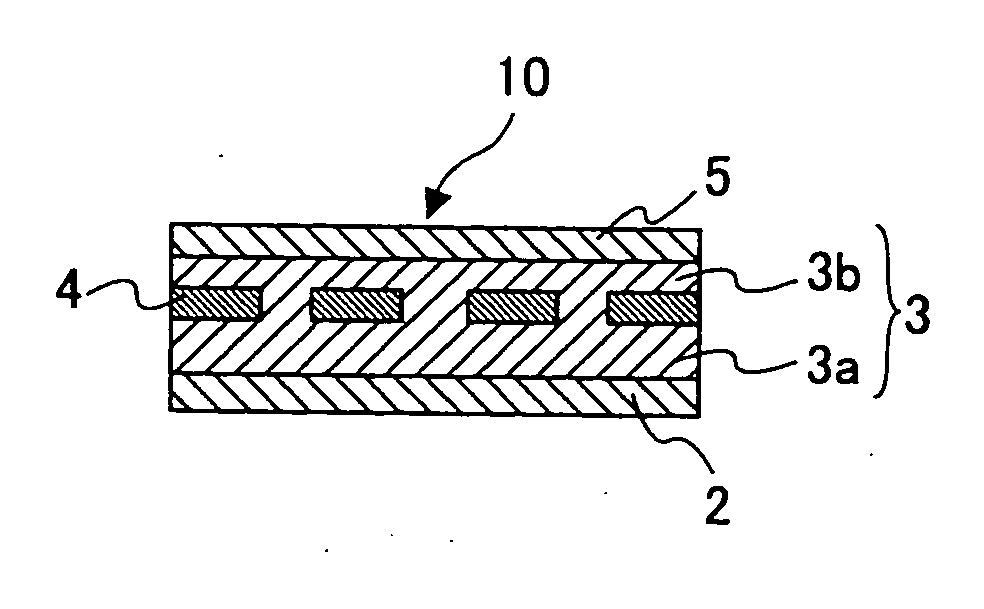

Polyethylene-based resin foamed blow molded article

InactiveUS20100279087A1High expansion rateSatisfactory mechanical propertyLayered productsDomestic articlesBlow moldingApparent density

A polyethylene resin foamed blow molded article obtained by extruding a foamable resin melt to form a foamed parison, subsequently inserting the foamed parison in a mold, and blow molding the foamed parison,the foamed blow molded article having a foam layer having an apparent density of 0.1 g / cm3 or more to less than 0.7-g / cm3,wherein the resin composing the foam layer is:a polyethylene resin having a density of 0.935-g / cm3 or more,a melt tension of 0.7-cN or more at 190° C.,a melt flow rate (MFR) of 1 g / 10 min or more as measured at 190° C. under a load of 2.16-kg, andan one-quarter isothermal crystallization time of 40 seconds or longer, which is defined as the time required that an exothermic calorific value due to isothermal crystallization by measurement condition (I) becomes equal to one-quarter of a total endothermic calorific value by measurement condition (II).

Owner:JSP CORP

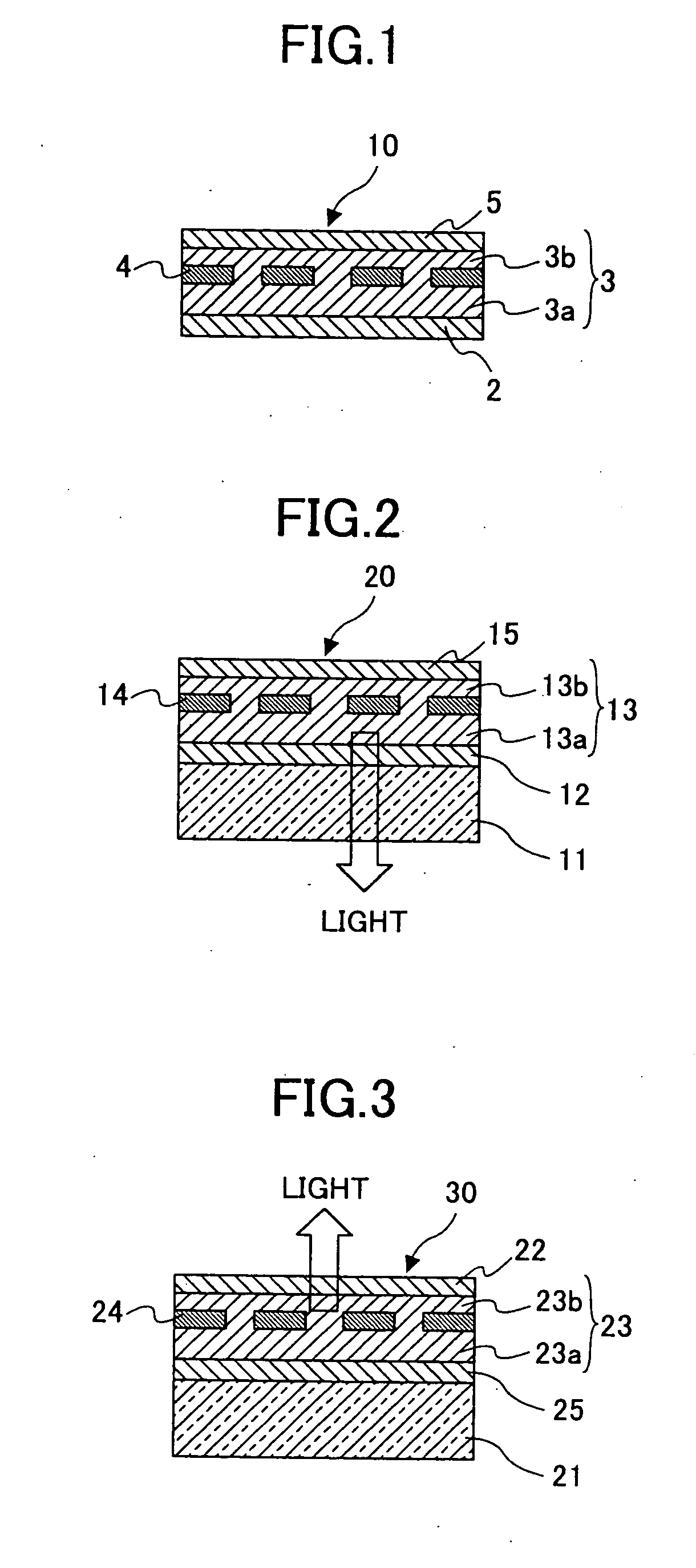

Organic transistor

InactiveUS20060243971A1High luminous efficiencyLow costElectroluminescent light sourcesSolid-state devicesVinyl carbazolePhthalocyanine

An organic transistor is capable of emitting light at high luminescence efficiency, operating at high speed, handling large electric power, and can be manufactured at low cost. The organic transistor includes an organic semiconductor layer between a source electrode and a drain electrode, and gate electrodes shaped like a comb or a mesh, which are provided at intervals approximately in the central part of the organic semiconductor layer approximately parallel to the source electrode and the drain electrode. The organic semiconductor layer consists of an electric field luminescent organic semiconductor material such as compounds of naphthalene, anthracene, tetracene, pentacene, hexacene, a phthalocyanine system compound, an azo system compound, a perylene system compound, a triphenylmethane compound, a stilbene compound, poly N-vinyl carbazole, and poly vinyl pyrene.

Owner:RICOH KK

Preparation method of PEDOT/PSS conductive ink and coating

The invention relates to a preparation method of PEDOT / PSS conductive ink and a coating. The preparation process of the conductive ink comprises the following steps: adding a thickener into an acidic PEDOT / PSS dispersion solution or a neutralized PEDOT / PSS dispersion solution to achieve the viscosity required by the ink; polymerizing 3, 4-ethylenedioxythiophene (EDOT) in the presence of polystyrenesulfonate (PSS) to form PEDOT / PSS, adding an alkaline additive to regulate the pH value to near neutral, achieving the use viscosity by an aging process, removing inorganic salts, thus obtaining the PEDOT / PSS dispersion solution with the neutral ink viscosity, then adding at least one condensate and / or non-aqueous solvent type polyester solution formed by guanamine and at least one carbonyl compound into the dispersion solution with the viscosity of the ink as an adhesive and mixing other functional additives to obtain the PEDOT / PSS conductive ink. The PEDOT / PSS conductive coating can be obtained by coating with the conductive ink, wherein the neutral PEDOT / PSS conductive coating is stable and has optimal performances.

Owner:上海欧依有机光电材料有限公司

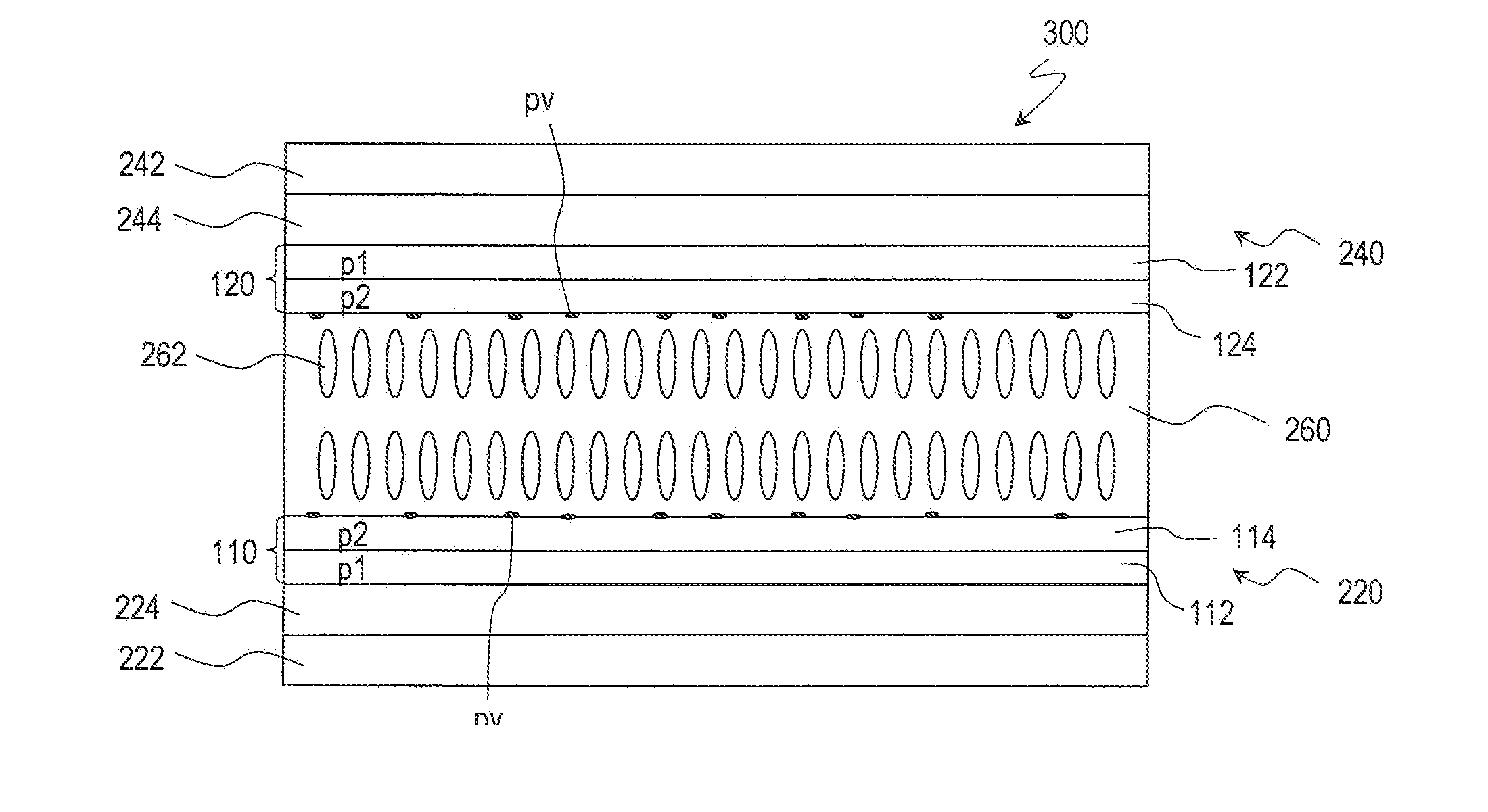

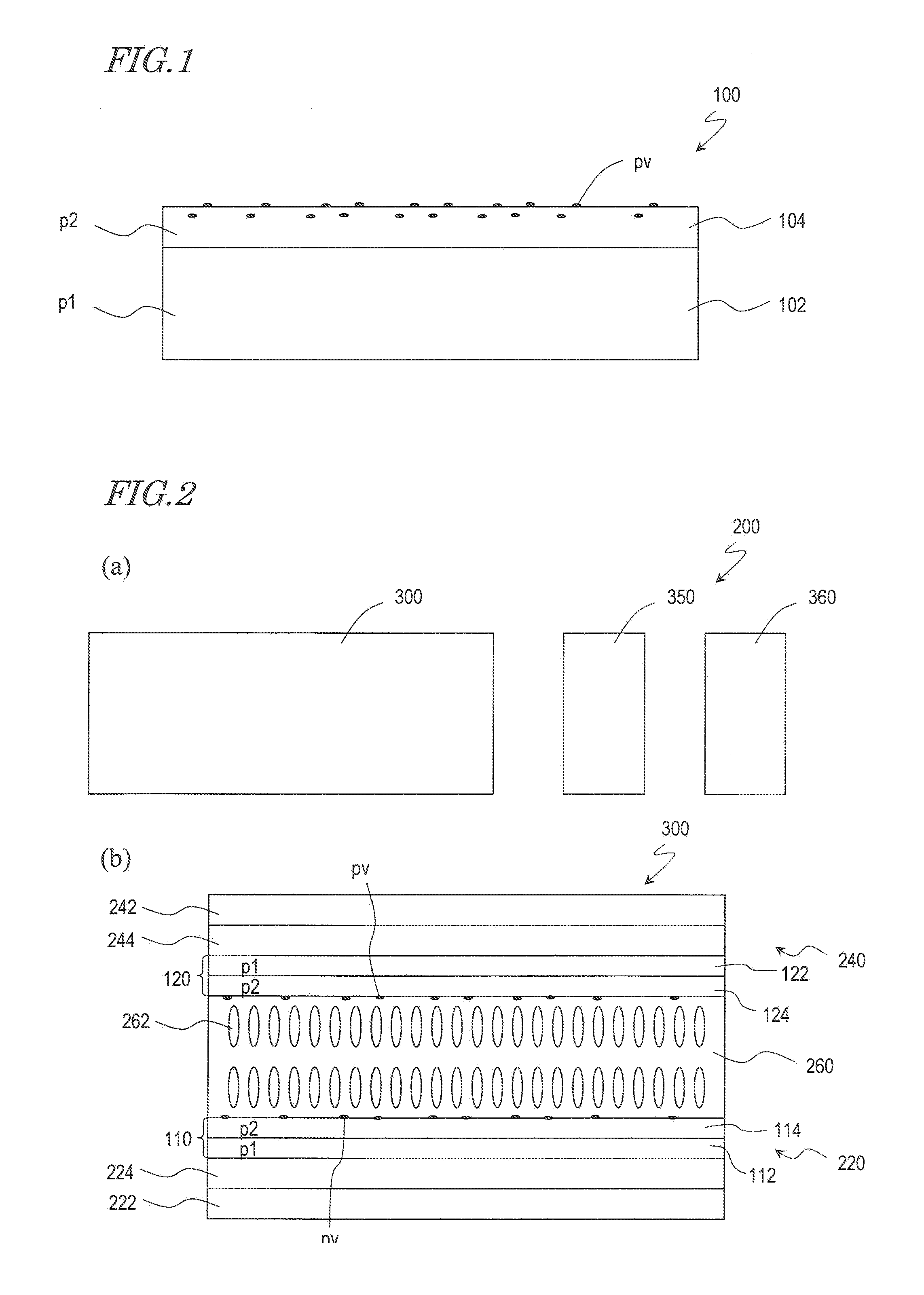

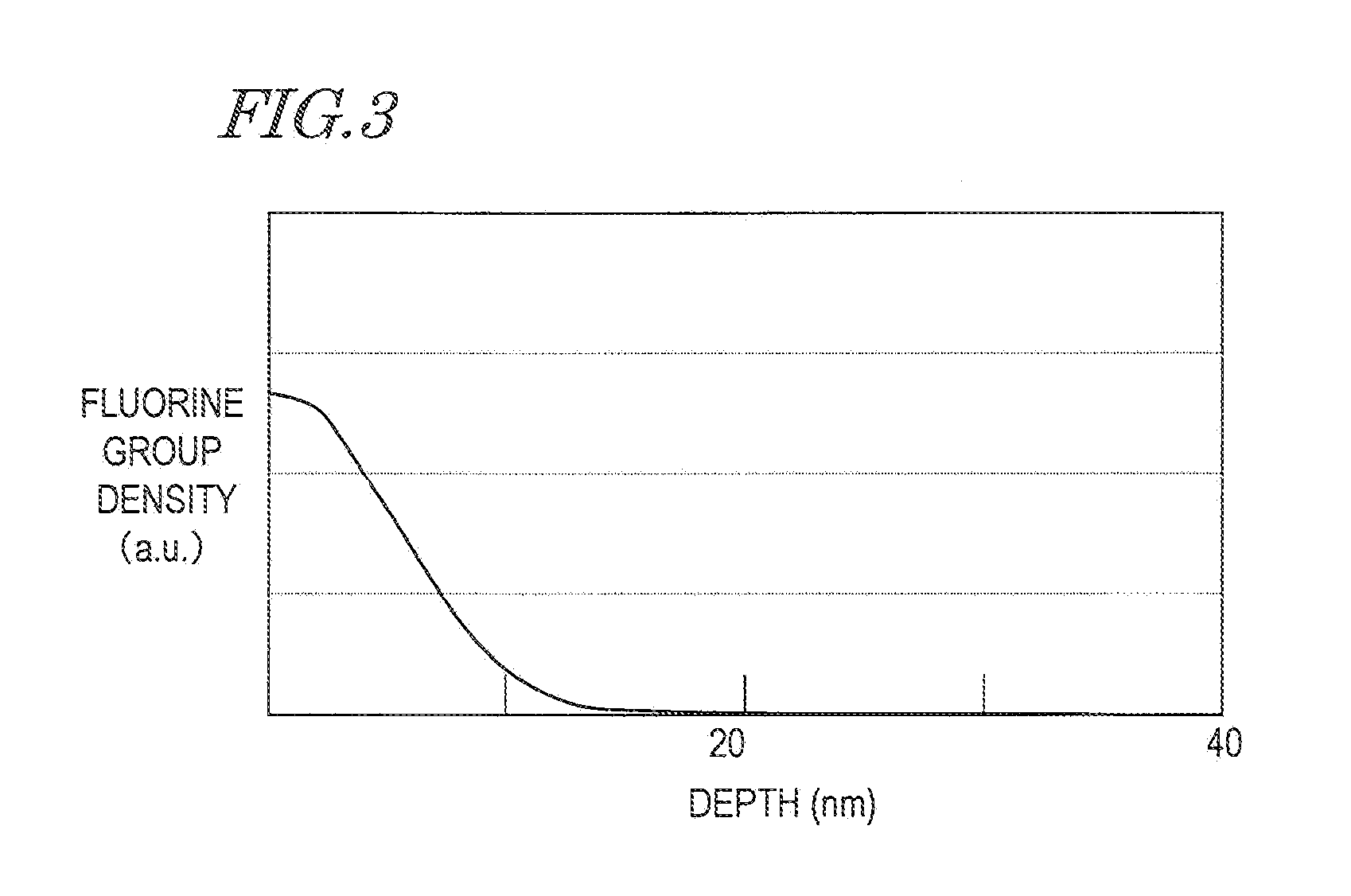

Alignment film material comprising polyimide and a vinyl-type monomer, alignment film comprising polyimide and polyvinyl compound, method of forming the alignment film, and liquid crystal display having the same

An alignment film material according to the present invention includes: a precursor of a first polyimide (p1); a second polyimide (p2) and a precursor thereof; and a vinyl-type monomer. The vinyl-type monomer is represented by general formula (1) P1-A1-(Z1-A2)n-P2 (in general formula (1), P1 and P2 are, independently, acrylate, methacrylate, acrylamide or methacrylamide; A1 and A2 represent, independently, 1,4-phenylene, 1,4-cyclohexane or 2,5-thiophene, or naphthalene-2,6-diyl or anthracene-2,7-diyl; at least one of A1 and A2 is substituted by at least one fluorine group; and Z1 is a —COO— group, a —OCO— group, a —O— group, a —CONH— group or a single bond, where n is 0 or 1).

Owner:MERCK PATENT GMBH

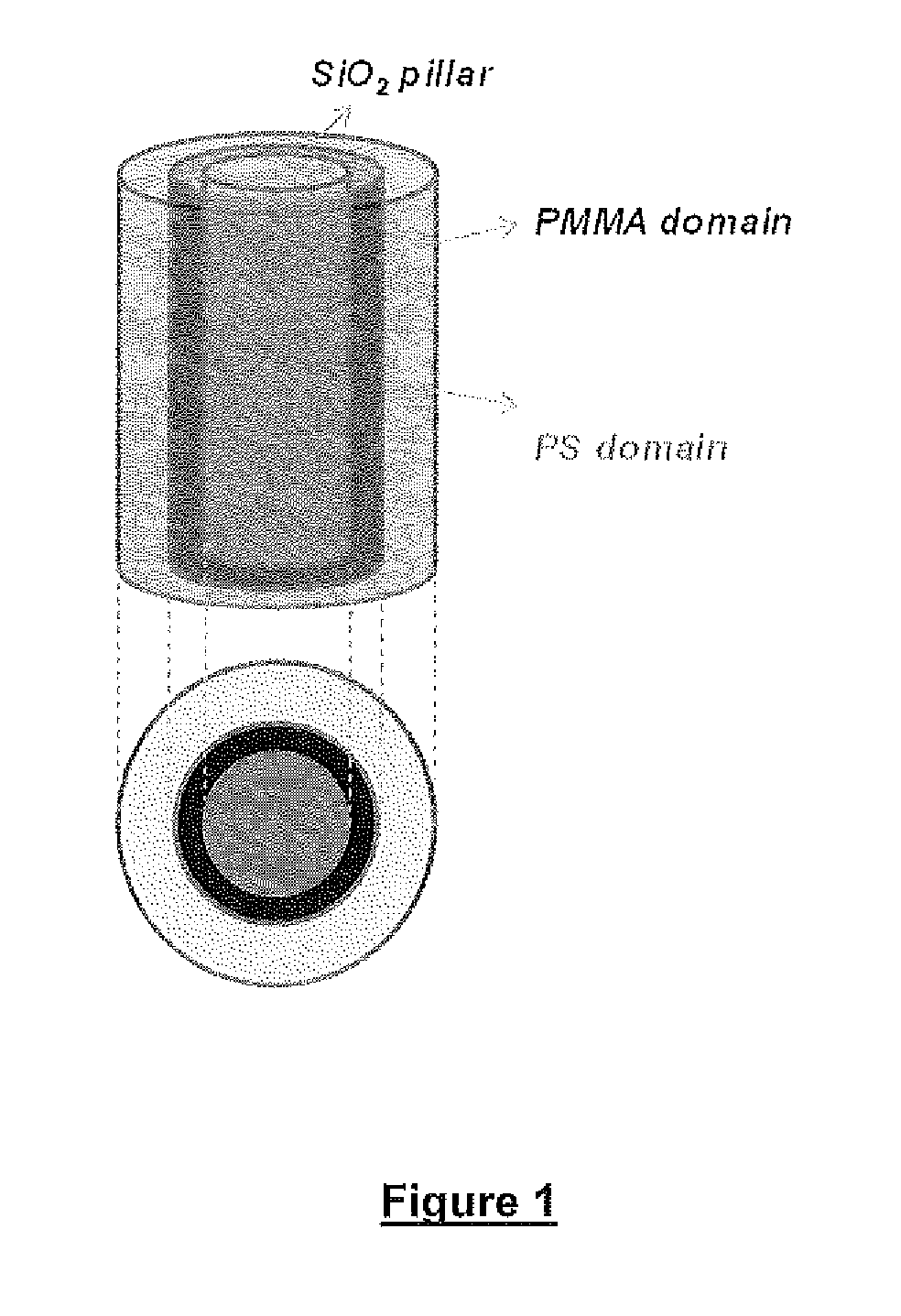

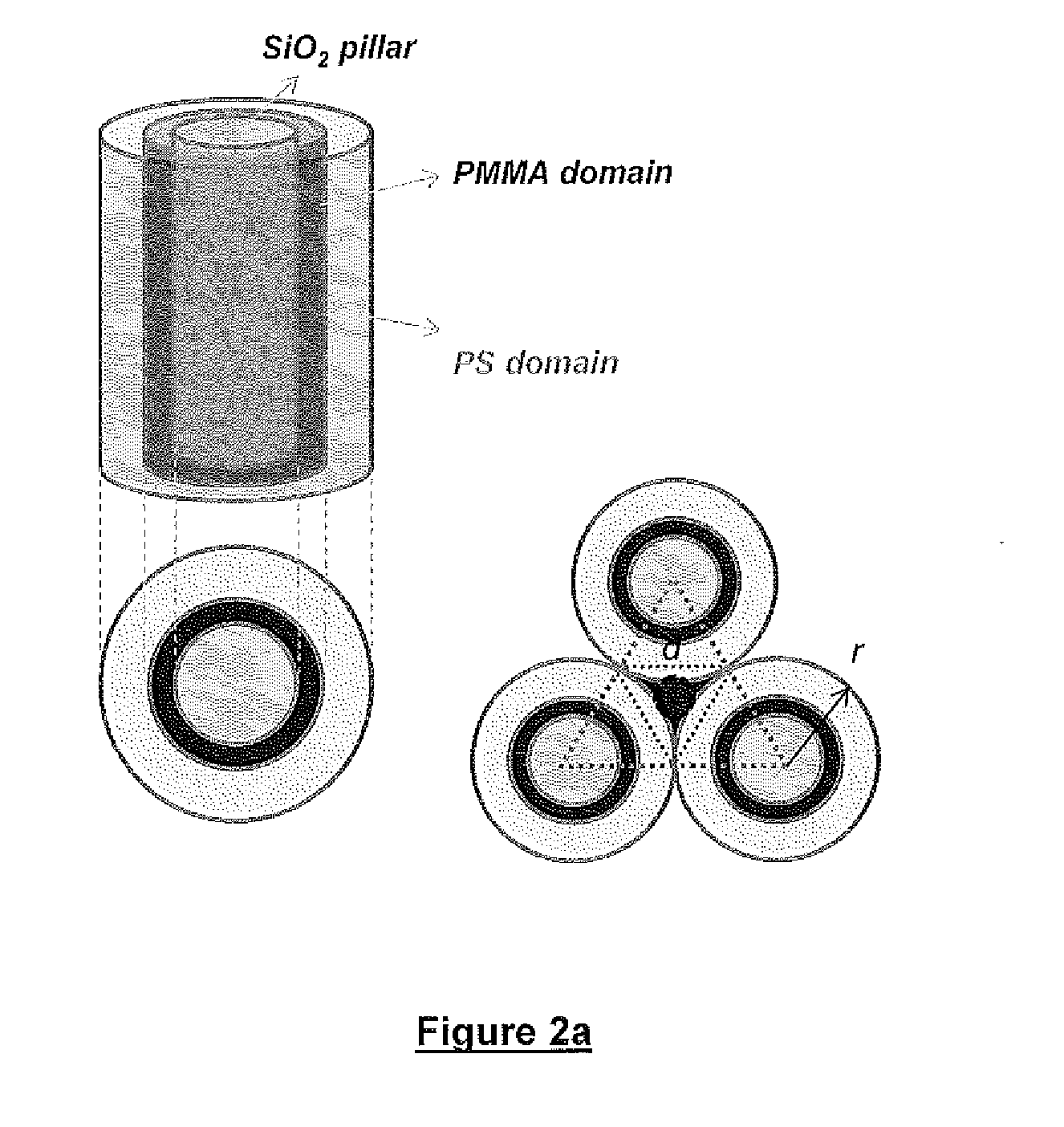

Defect reduction methods and composition for via formation in directed self-assembly patterning

InactiveUS20160122580A1Inhibition formationBetter grafting of the hydroxyl terminated polyhydroxystyreneElectric discharge tubesFilm/foil adhesivesArylHydrophobic polymer

The present invention relates to a two novel processes, “Dual Coating Process and Single Coating Process,” for forming an array of via's by employing a graphoepitaxy approach, where an array of pillars the surface of the pillars has been modified by the formation of a hydrophobic poly(vinyl aryl) brush at the surface of the pillars. The present invention also relates to a composition comprising a poly(vinyl aryl) hydrophopic polymer brush precursor terminated at one chain end with a reactive functional group, a diblock copolymer comprising an etch resistant hydrophobic block and a highly etchable hydrophilic block, a thermal acid generator and a solvent.

Owner:AZ ELECTRONICS MATERIALS LUXEMBOURG R L

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com