Preparation method of PEDOT/PSS conductive ink and coating

A conductive ink, ink viscosity technology, applied in ink, home appliances, applications, etc., can solve problems such as insufficient stability, limited compatibility, and increased haze

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

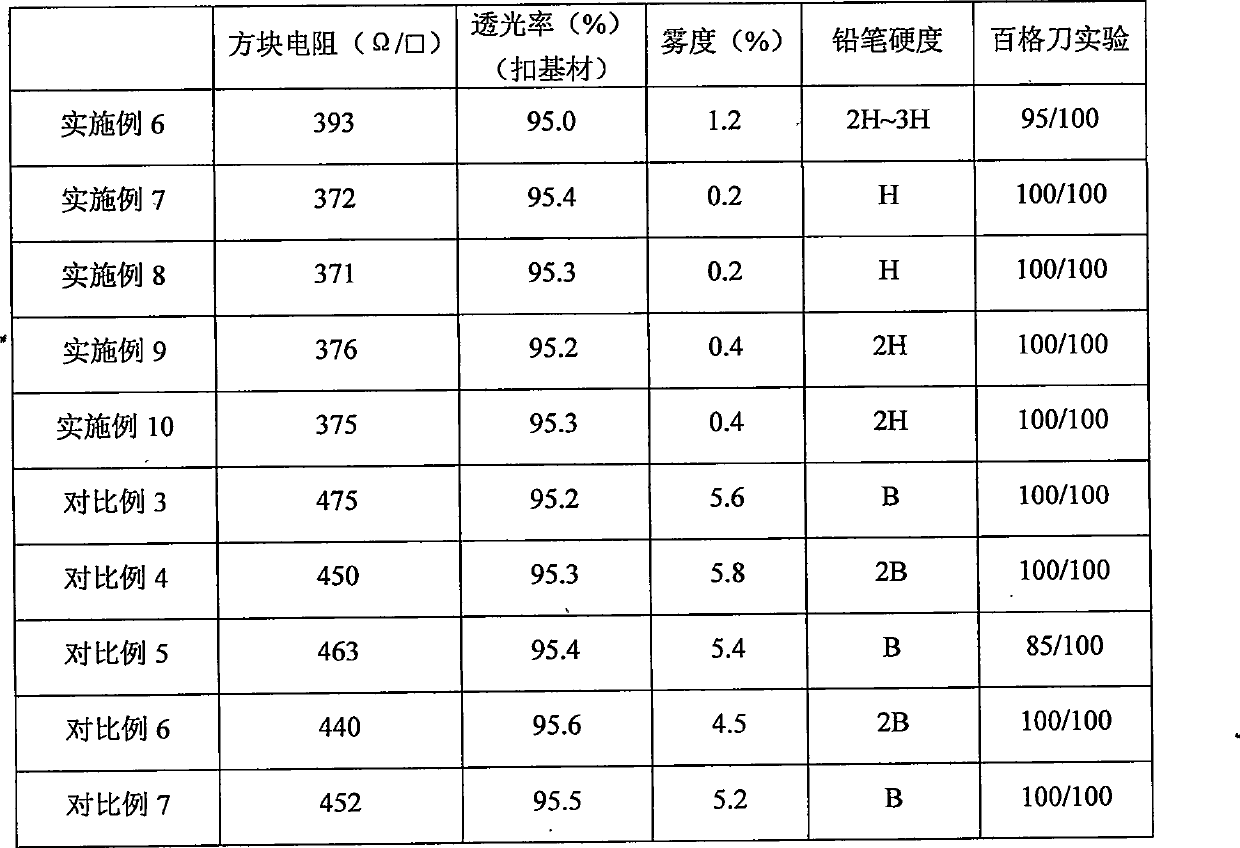

Examples

Embodiment 1

[0041] After the PEDOT / PSS polymerization reaction is over, stop the reaction. Add 2-amino-2-methyl-1-propanol, monitor and adjust the pH value to nearly neutral through a pH meter, and age for 0.5 hours. The mixture was transferred to a beaker, and 50 ml of cation exchanger (Lewatit S100H, Lanxess AG) and 29 ml of anion exchanger (Lewatit MP62, Lanxess AG) were added to remove inorganic salts. After the mixture was stirred for 6 hours, the exchanger was filtered out, and the viscosity was tested by a rotary viscometer;

Embodiment 2

[0043] After the PEDOT / PSS polymerization reaction is over, stop the reaction. 0.2 g of triethyl phosphate was added, and then 2-amino-2-methyl-1-propanol was added, and the pH value was adjusted to nearly neutral by monitoring with a pH meter, and aged for 0.5 hours. According to the same method in Example 1, after carrying out the anion-positive resin exchange treatment, the rotational viscometer tests the viscosity;

Embodiment 3

[0045] After the PEDOT / PSS polymerization reaction is completed, stop the reaction, add 2-amino-2-methyl-1-propanol, monitor and adjust the pH value to nearly neutral through pH meter, and age for 1 hour. According to the same method in Example 1, after carrying out the anion-positive resin exchange treatment, the rotational viscometer tests the viscosity;

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com