Patents

Literature

273 results about "Anion exchanger" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition of anion exchanger. : an anion-exchange agent that can exchange its anion with the anion or anions of a solution passed through it or that can adsorb anions in the form of acids especially : an insoluble basic synthetic organic resin usually containing amine groups or quaternary ammonium groups.

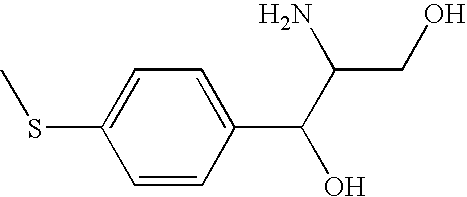

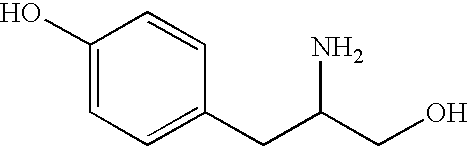

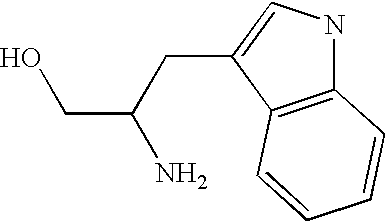

Process for chromatographic separation of peptides and nucleic acid, and new high affinity ion exchange matrix

InactiveUS6090288ACation exchanger materialsComponent separationChromatographic separationTransferrin

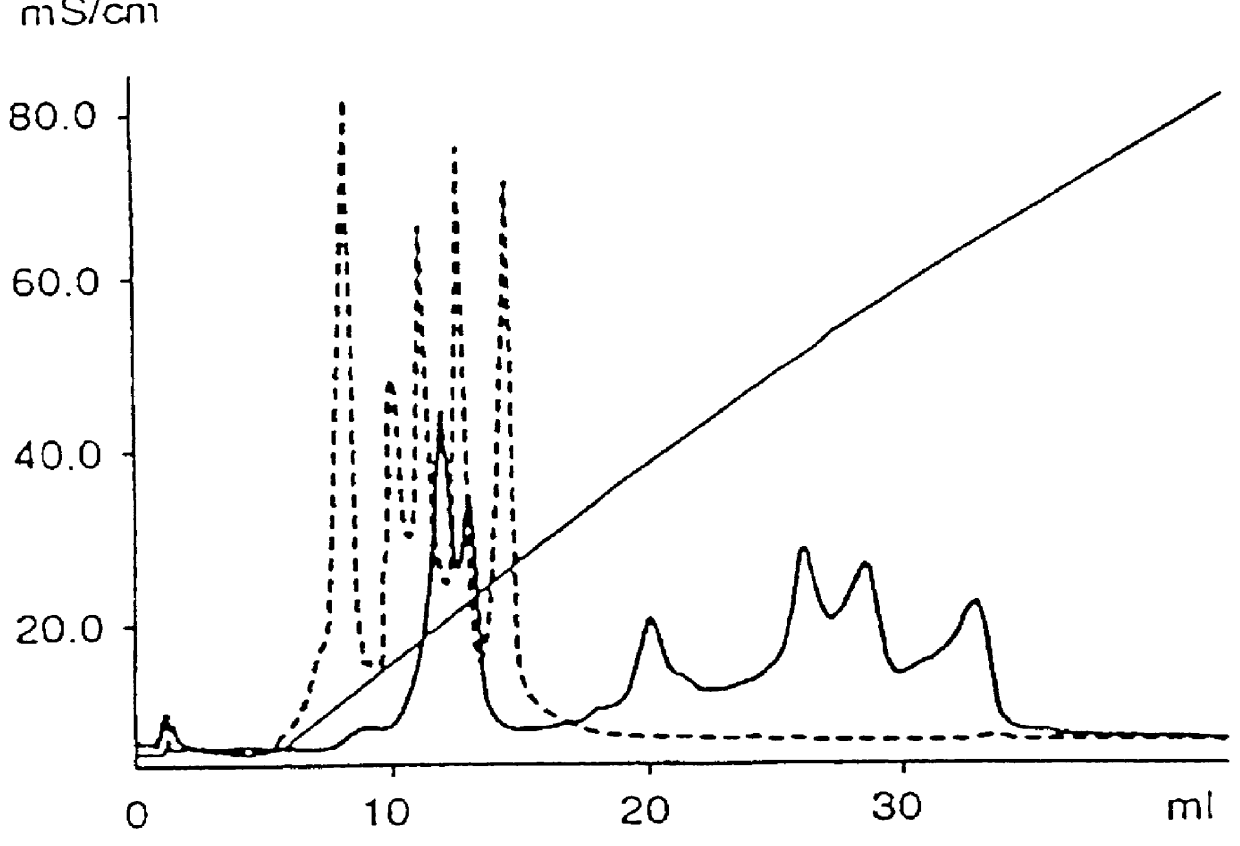

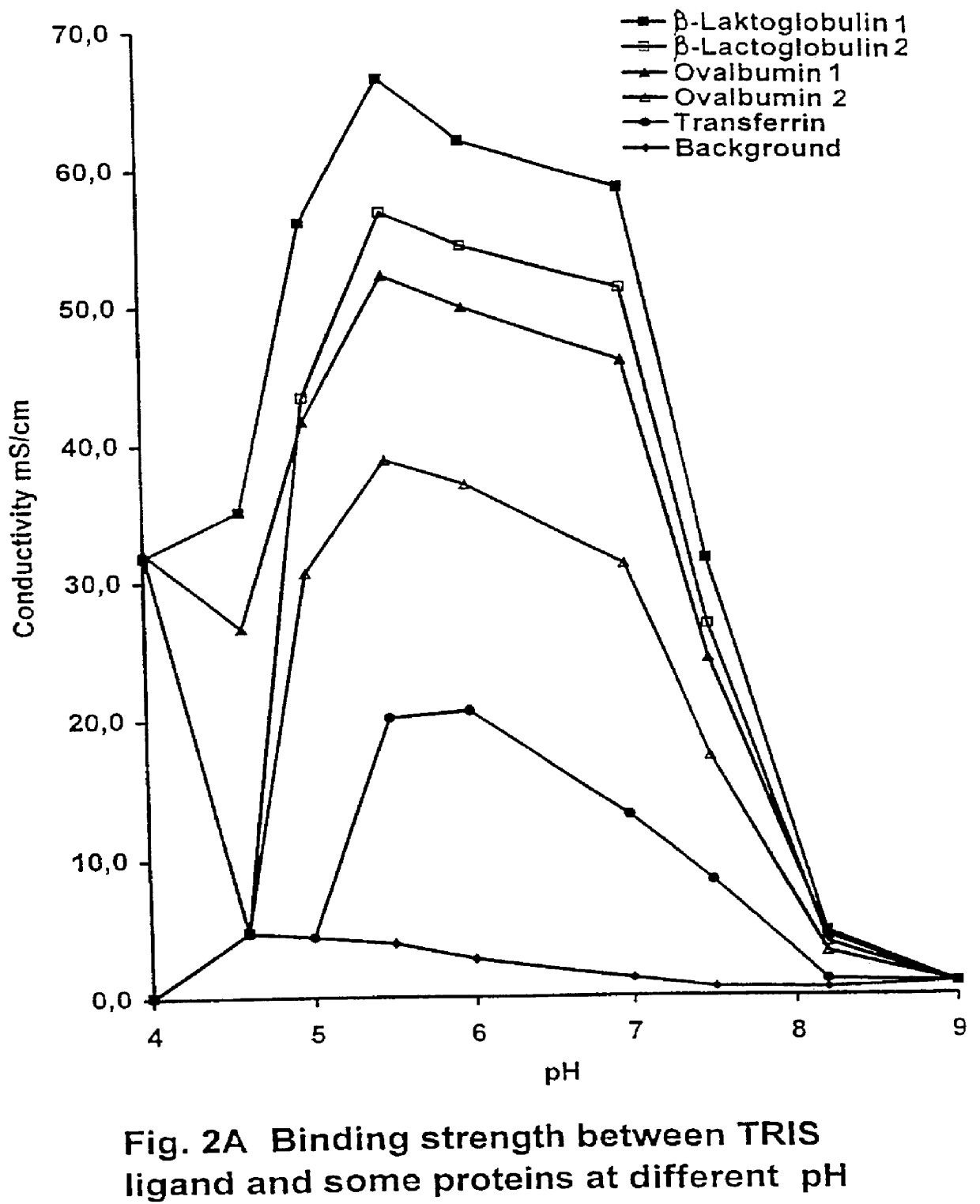

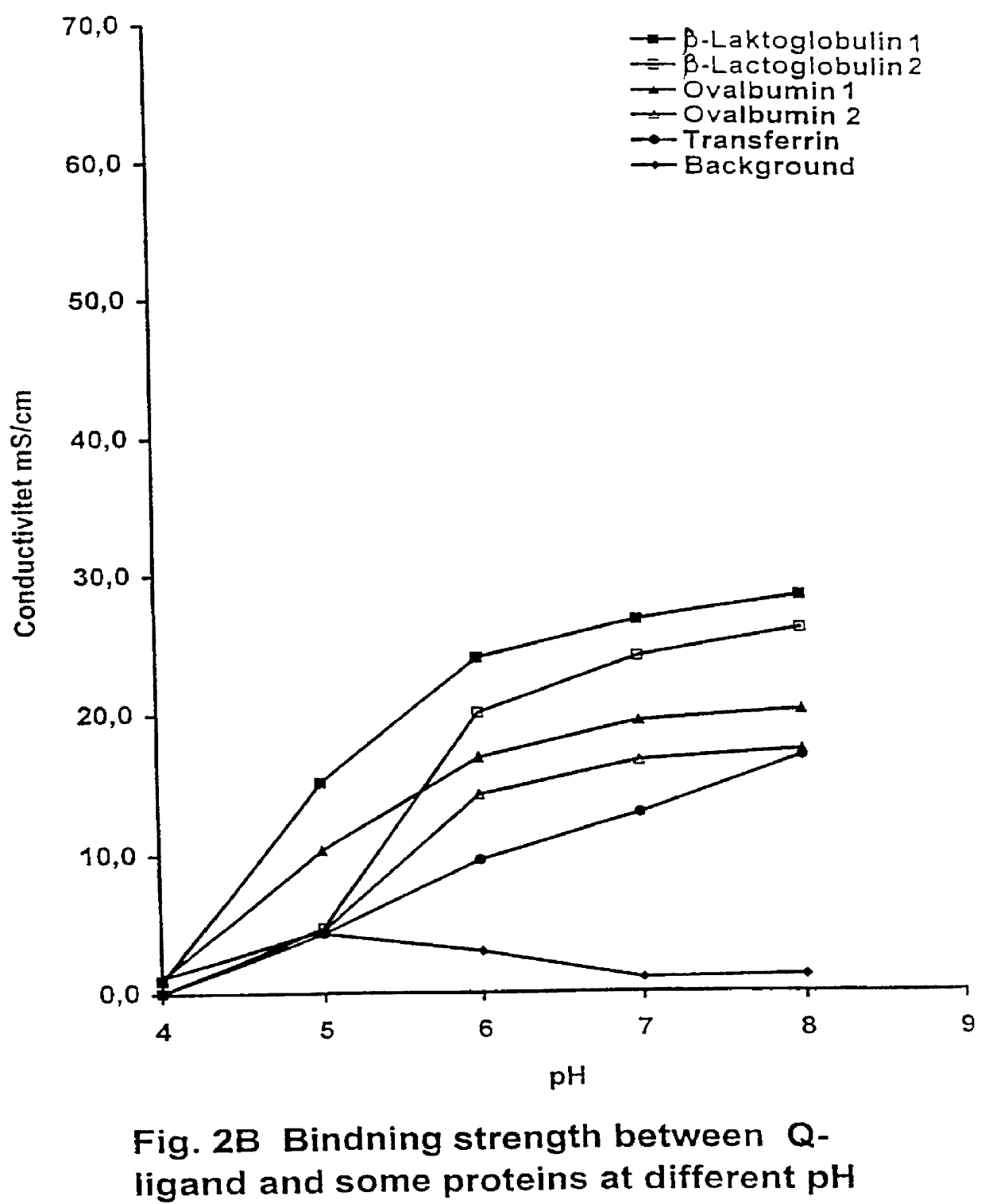

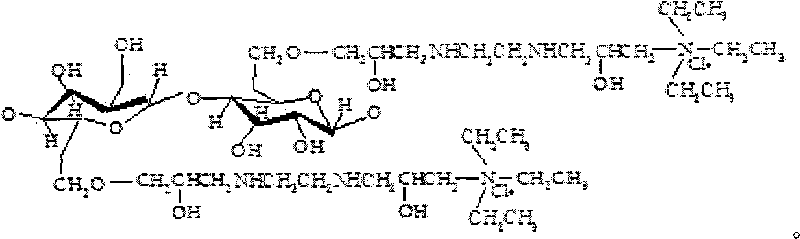

PCT No. PCT / SE97 / 00237 Sec. 371 Date Dec. 29, 1998 Sec. 102(e) Date Dec. 29, 1998 PCT Filed Feb. 14, 1997 PCT Pub. No. WO97 / 29825 PCT Pub. Date Aug. 21, 1997Process for separating off a peptide or a nucleic acid by an anion exchanger (I) characterized in that a) the anion exchanger (I) exhibits ligands, which (i) contain a primary, secondary or tertiary amino group and (ii) are covalently bound to an organic polymer (matrix), b) there on a carbon atom at a distance of 2 or 3 atoms away from an amino nitrogen in the ligands is a hydroxyl group or a primary, secondary or tertiary amino group, and c) the maximum elution ionic strength in the pH range 2-14 for at least one of the proteins transferrin, ovalbumin 1, ovalbumin 2, beta -lactoglobulin 1 and beta -lactoglobulin 2 on the anion exchanger is higher than the elution ionic strength required for a quaternary comparative ion exchanger.

Owner:GE HEALTHCARE BIOPROCESS R&D

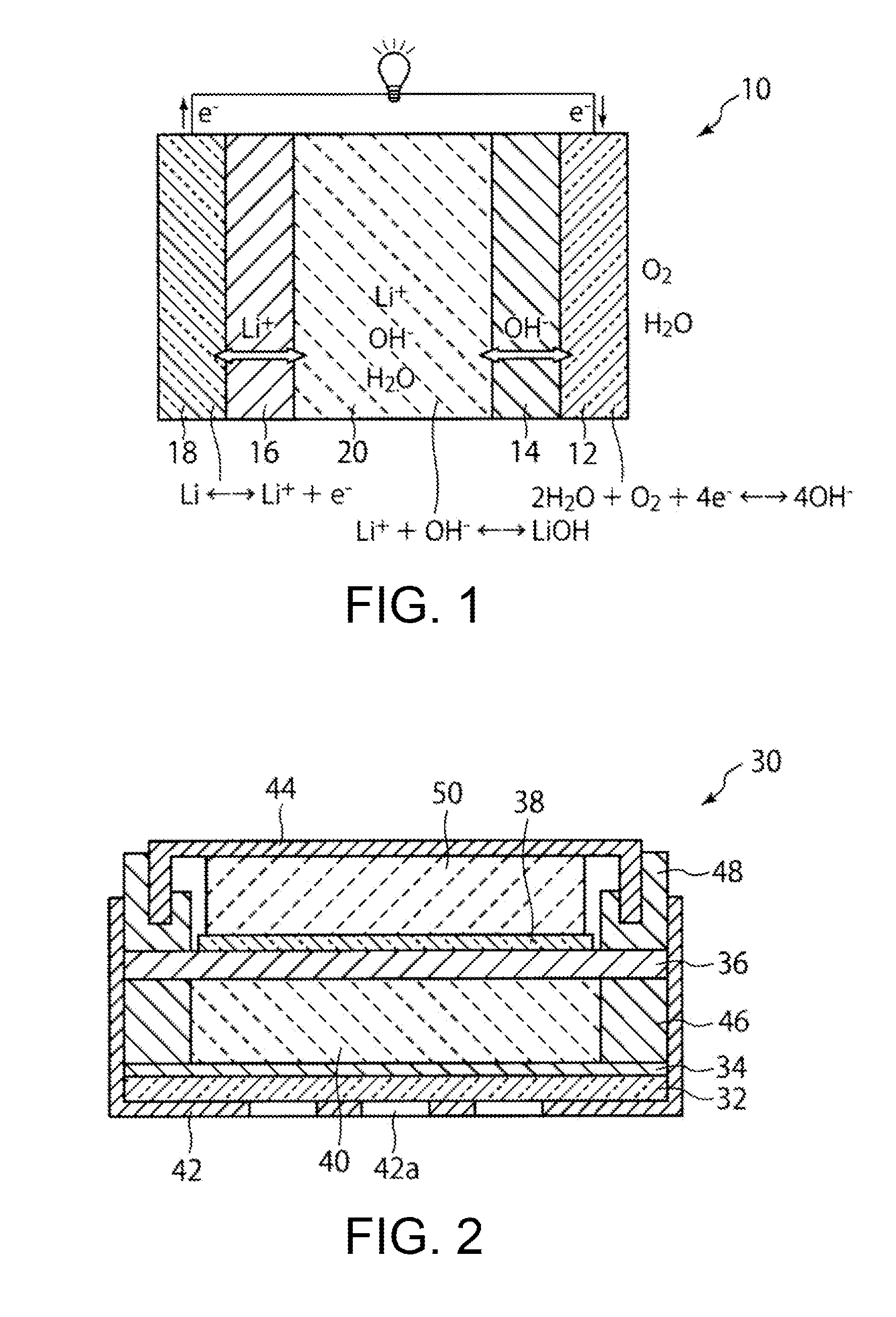

Lithium air secondary battery

ActiveUS20150024292A1Solve the blockageSolution to short lifeSolid electrolytesFuel and secondary cellsLithiumEngineering

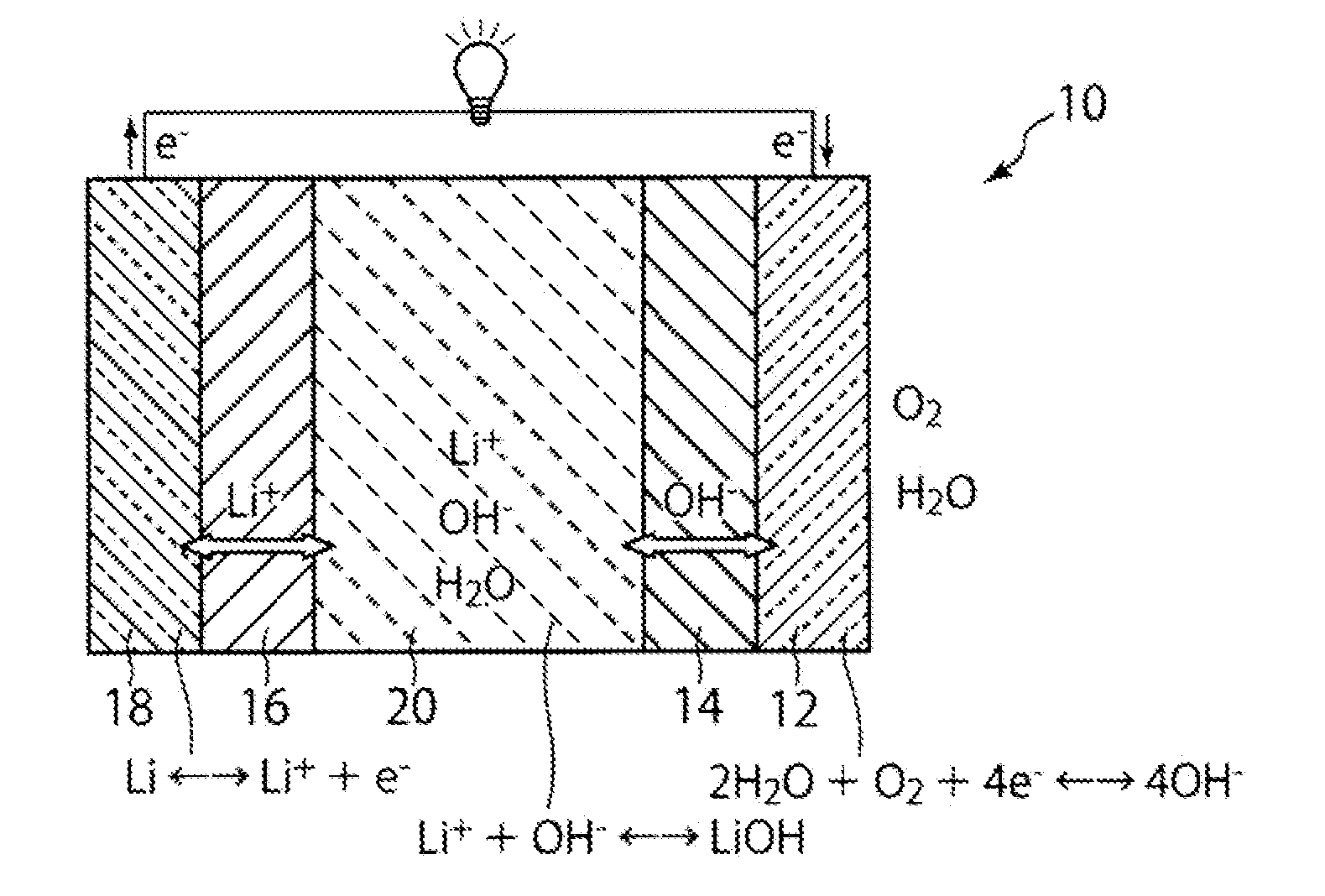

The present invention provides a lithium-air secondary battery that is capable of effectively preventing deterioration of an alkaline electrolytic solution, air electrode, and negative electrode and has a long life and high long-term reliability. The lithium-air secondary battery comprises an air electrode 12 functioning as a positive electrode, an anion exchanger 14 provided in close contact with one side of the air electrode and composed of a hydroxide-ion conductive inorganic solid electrolyte, a separator 16 provided away from the anion exchanger and composed of a lithium-ion conductive inorganic solid electrolyte, a negative electrode 18 provided so as to be capable of supplying and receiving lithium ions to and from the separator and comprising lithium, and an alkaline electrolytic solution 20 filled between the anion exchanger and the separator.

Owner:NGK INSULATORS LTD

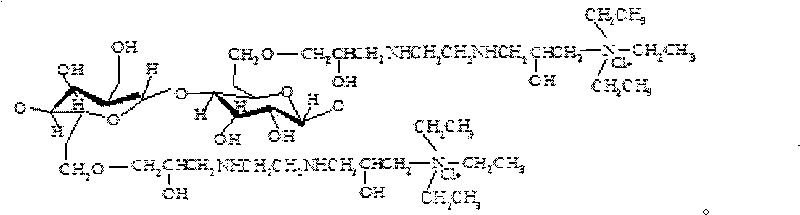

Method for anion-exchange adsorption and anion-exchangers

InactiveUS6702943B1Reduced ligand contentSolve insufficient capacityIon-exchanger regenerationOrganic anion exchangersHydrogenDesorption

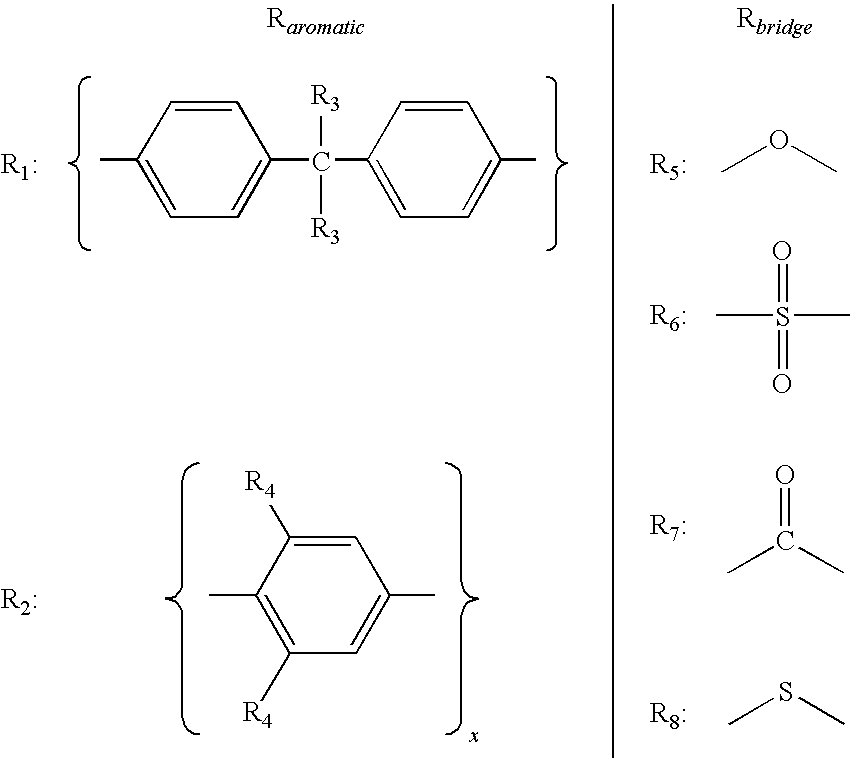

A method for the removal of a substance carrying a negative charge and being present in an aqueous liquid (I). The method comprises the steps of: (i) contacting the liquid with a matrix carrying a plurality of ligands comprising a positively charged structure and a hydrophobic structure, and (ii) desorbing the substance. The characterizing feature is that (I) each of said ligands together with a spacer has the formula: -SP-[Ar-R1-N<+>(R2R3R4)] where (A) [Ar-R1-N<+>(R2R3R4)] represents a ligand a) Ar is an aromatic ring, b) R1 is [(L)nR'1]m where n and m are integers selected amongst zero or 1; L is amino nitrogen, ether oxygen or thioether sulphur; R'1 is a linker selected among 1) hydrocarbon groups; 2) -C(=NH)-; c) R2-4 are selected among hydrogen and alkyls; (B) SP is a spacer providing a carbon or a heteroatom directly attached to Ar-R1-N<+>(R2R3R4); (C)-represents that SP replaces a hydrogen in (Ar-R1-N<+>(R2R3R4); (D)-represents binding to the matrix; and (II) desorption. There is also described (a) anion-exchangers having high breakthrough capacities, (b) a screening method and (c) a desalting protocol.

Owner:CYTIVA BIOPROCESS R&D AB

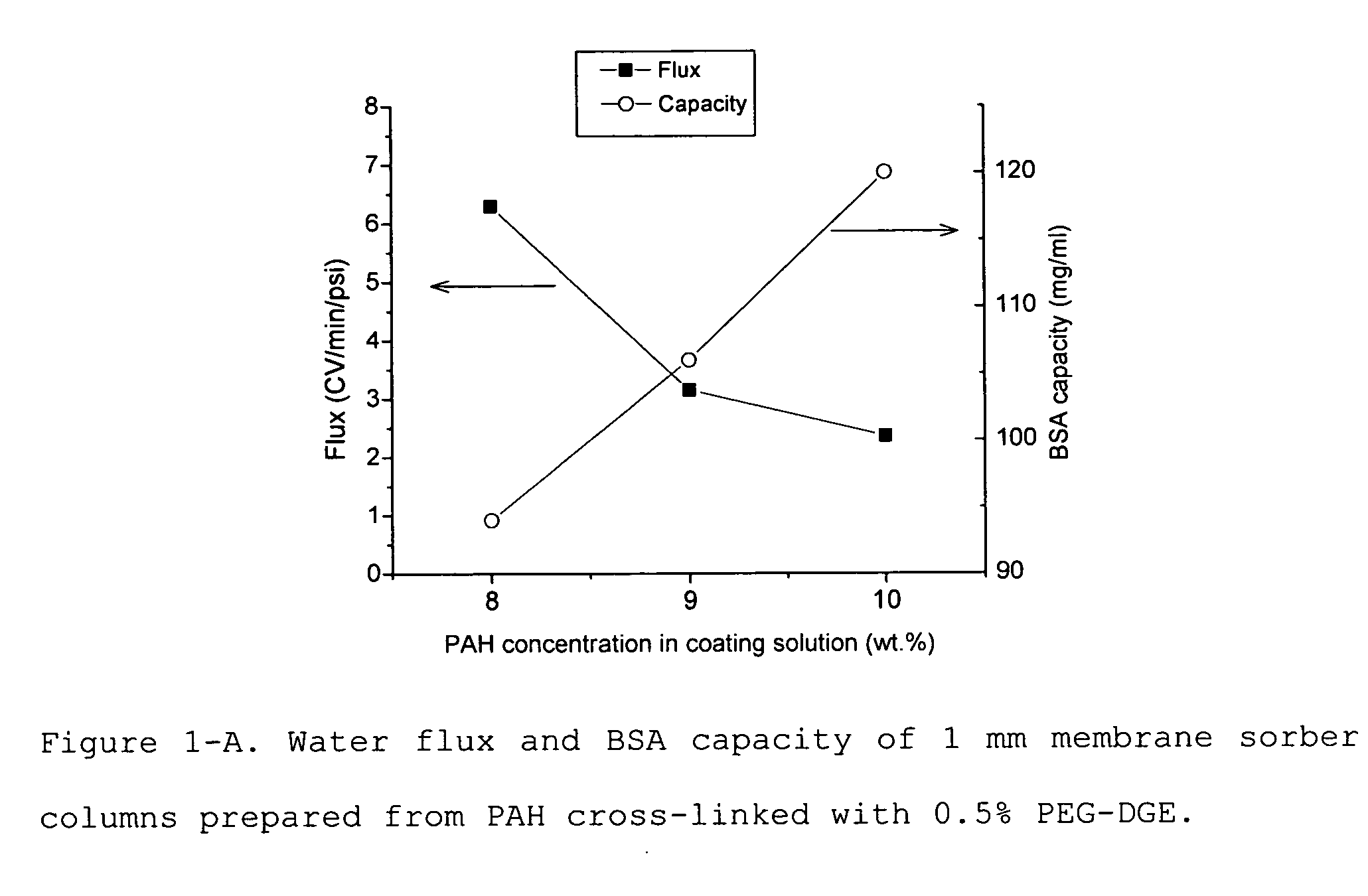

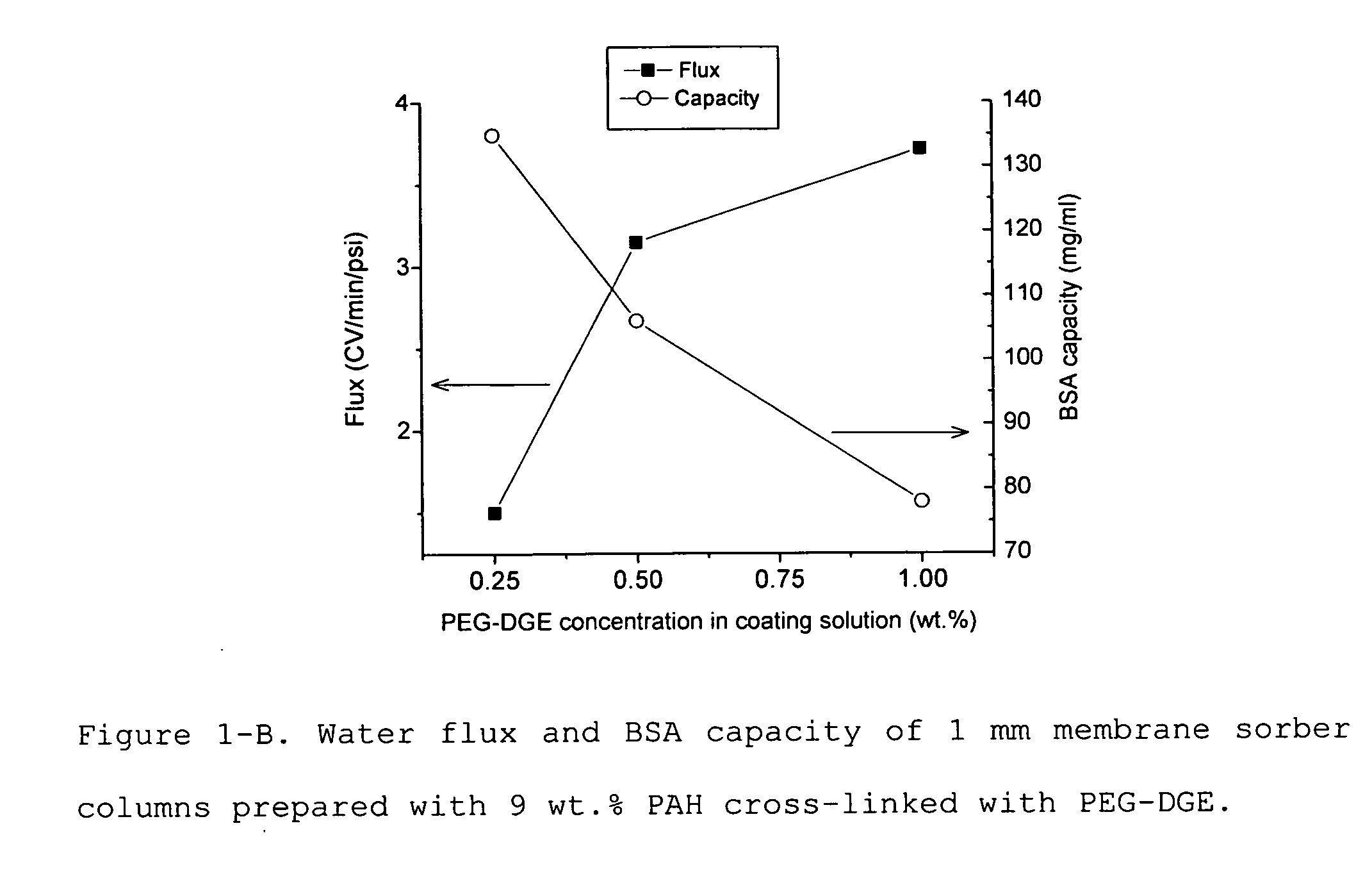

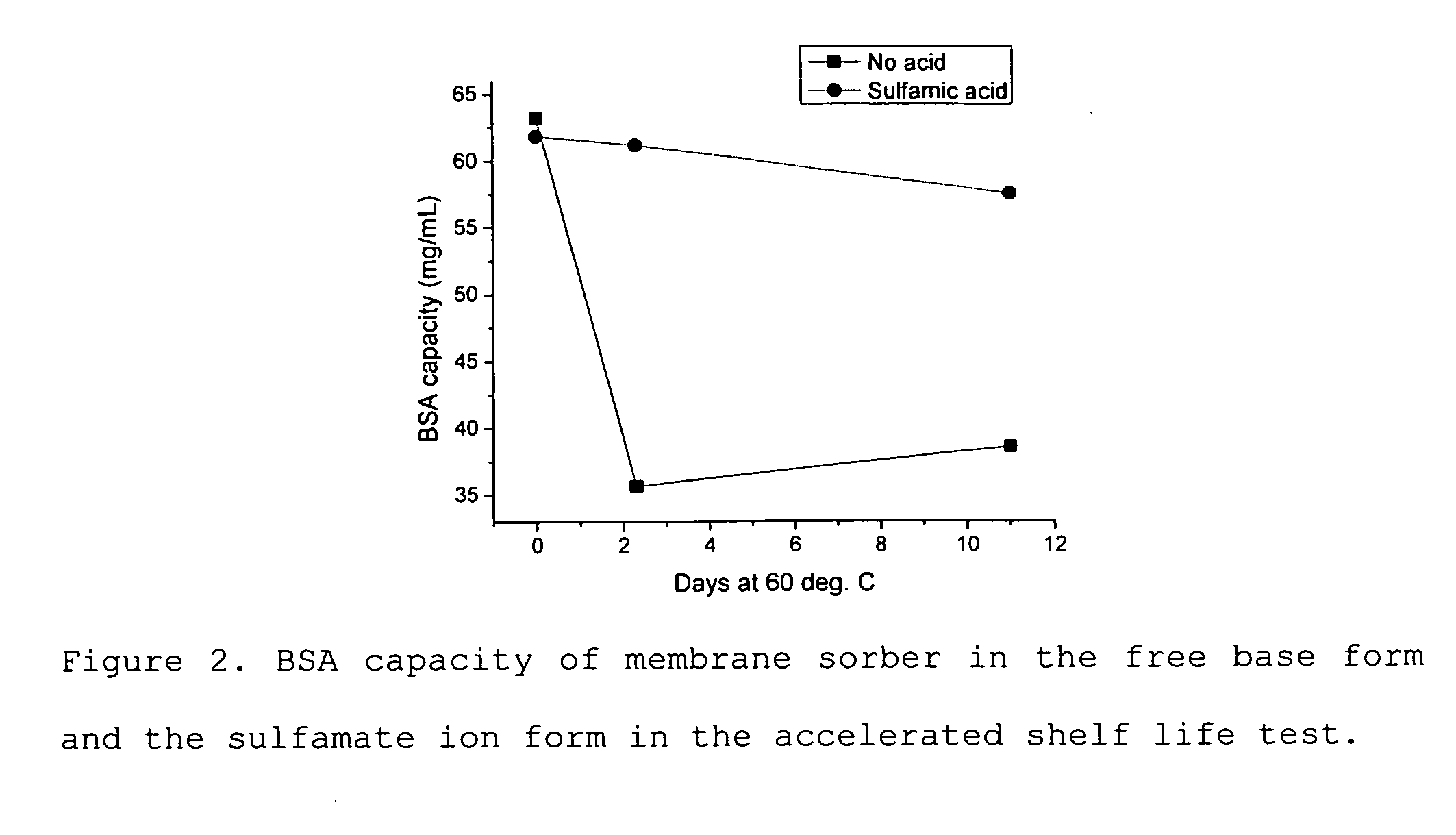

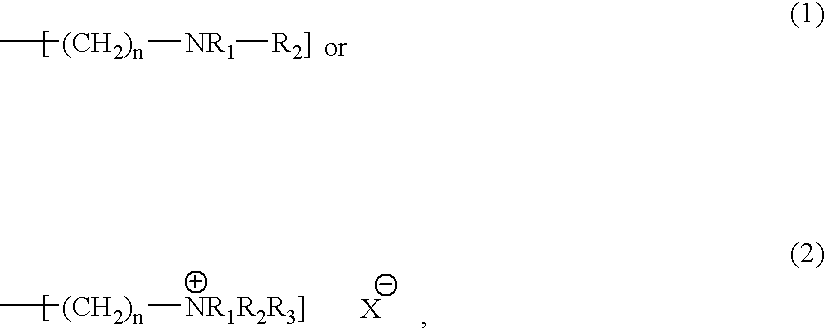

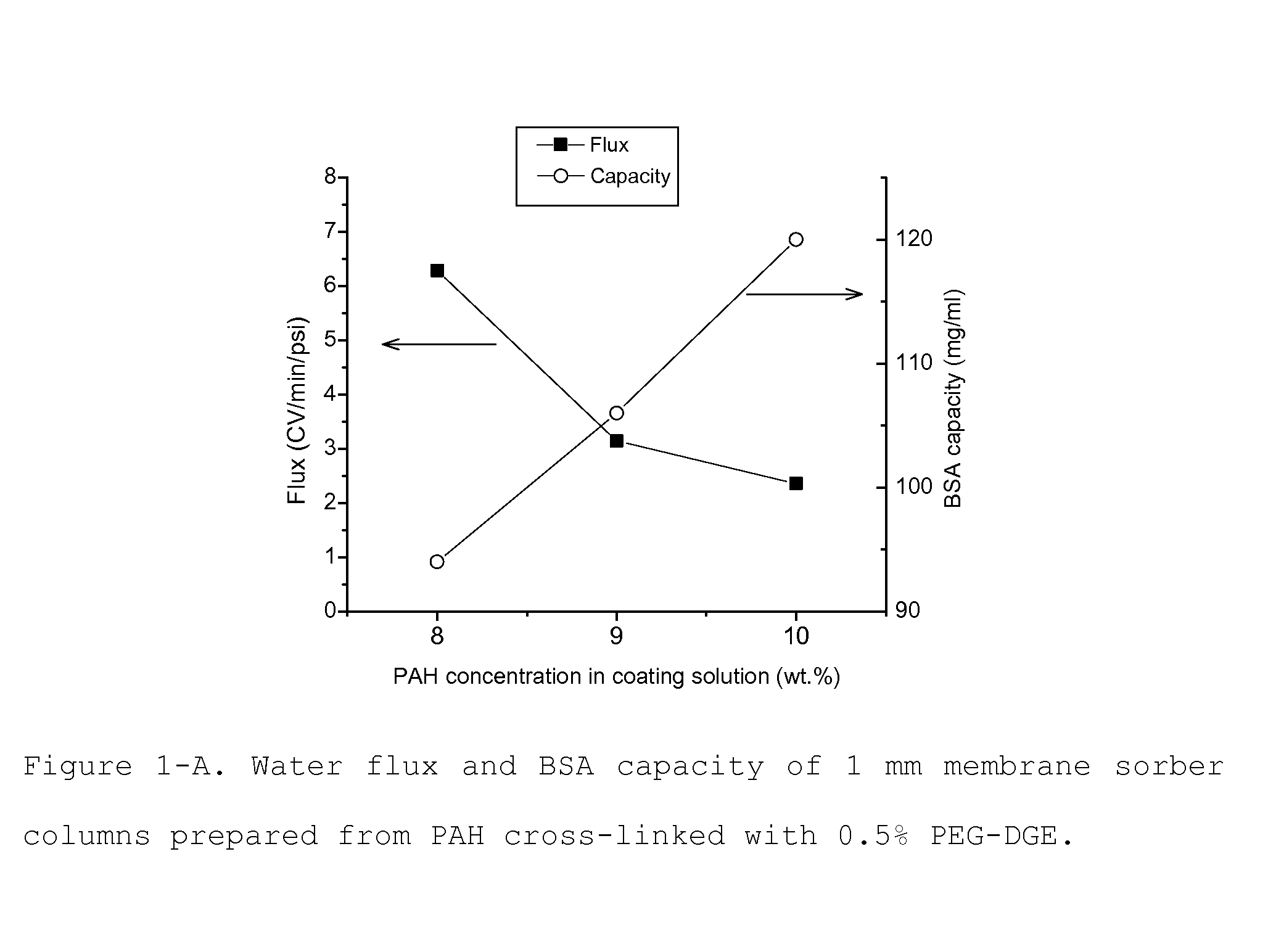

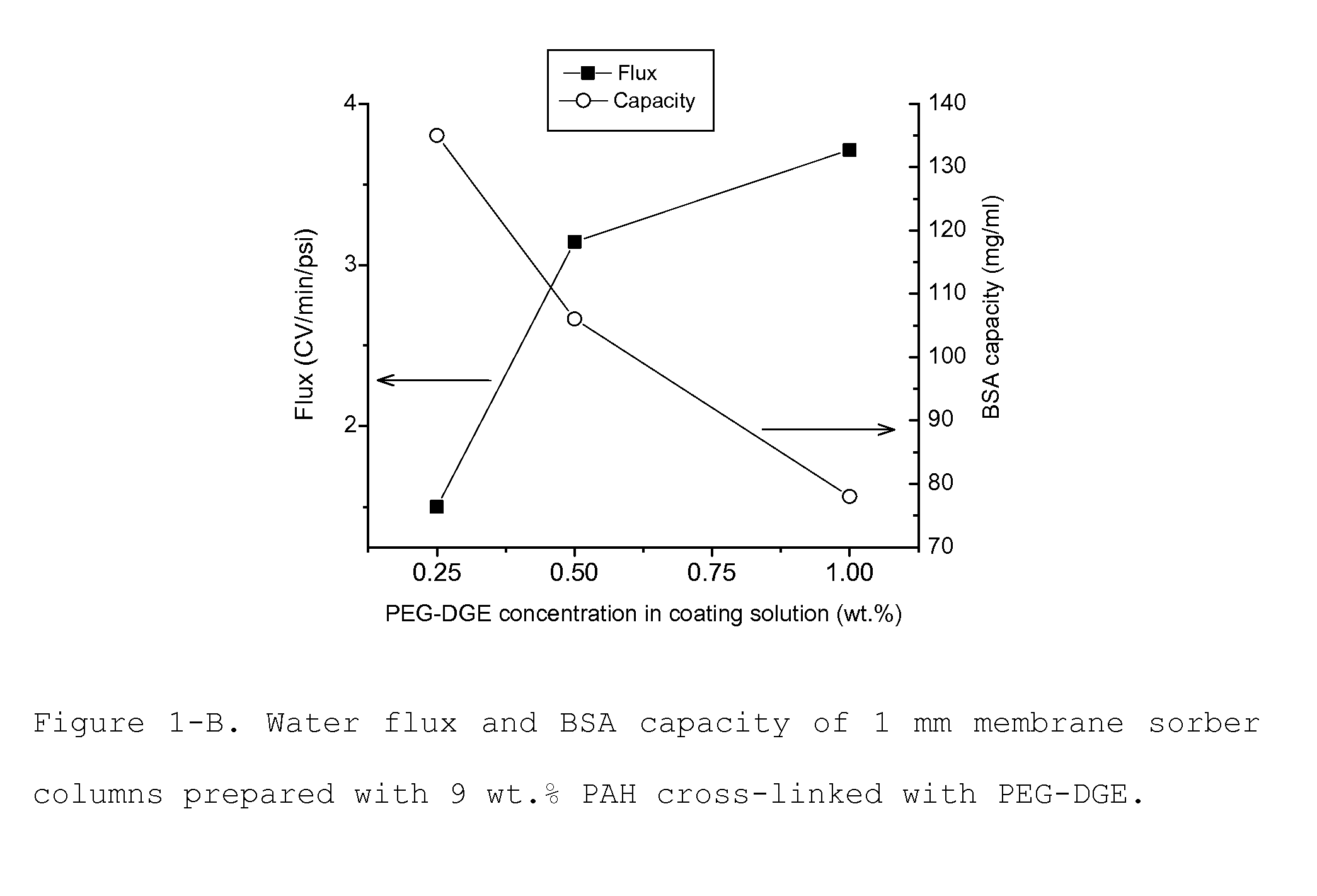

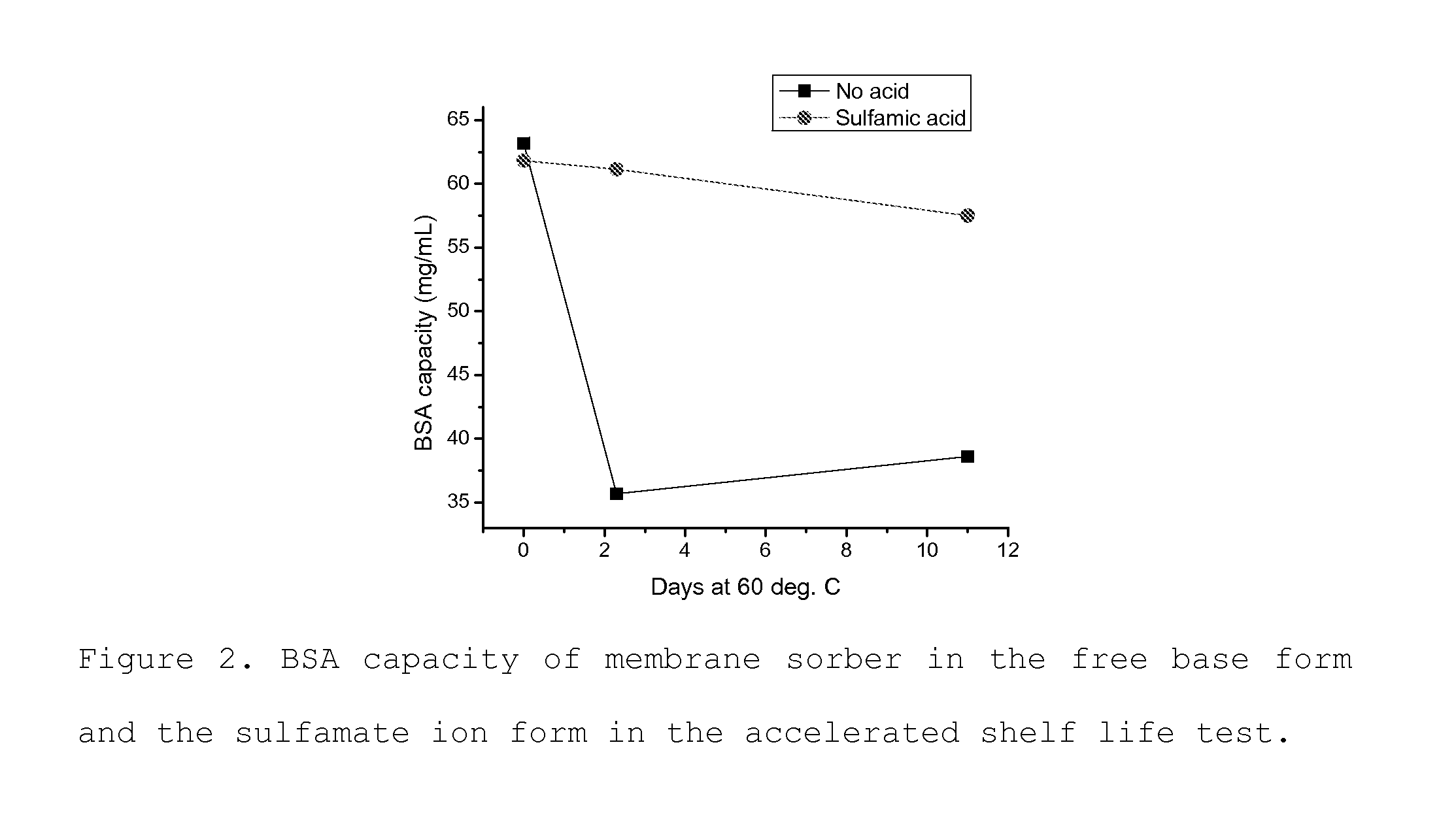

Media for membrane ion exchange chromatography based on polymeric primary amines, sorption device containing that media, and chromatography scheme and purification method using the same

ActiveUS20090050566A1Improve bindingGood removal effectCation exchanger materialsIon-exchanger regenerationPurification methodsSorbent

Media and devices, such as anion exchangers including such media, wherein the media is a membrane having a surface coated with a polymer such as a polyallylamine. The resulting membrane offers stronger binding of protein impurities and superior removal of host cell proteins from biological samples than conventional ligands based on quaternary ammonium salts, including trimethylammonium ligands. Also described is a chromatography scheme and method for purifying monoclonal antibodies, wherein the anion exchange sorber is placed downstream of an affinity column (such as Protein A or Protein G affinity column) and optionally one or more polishing devices such as cationic exchange columns. Little or no dilution of the cation exchanger pool (or affinity column exchange pool where no cation exchanger is used) is necessary to lower the conductivity of the sample. The sorber functions well to strongly bind host cell proteins and other impurities in biological samples even at high conductivities and pH.

Owner:MILLIPORE CORP

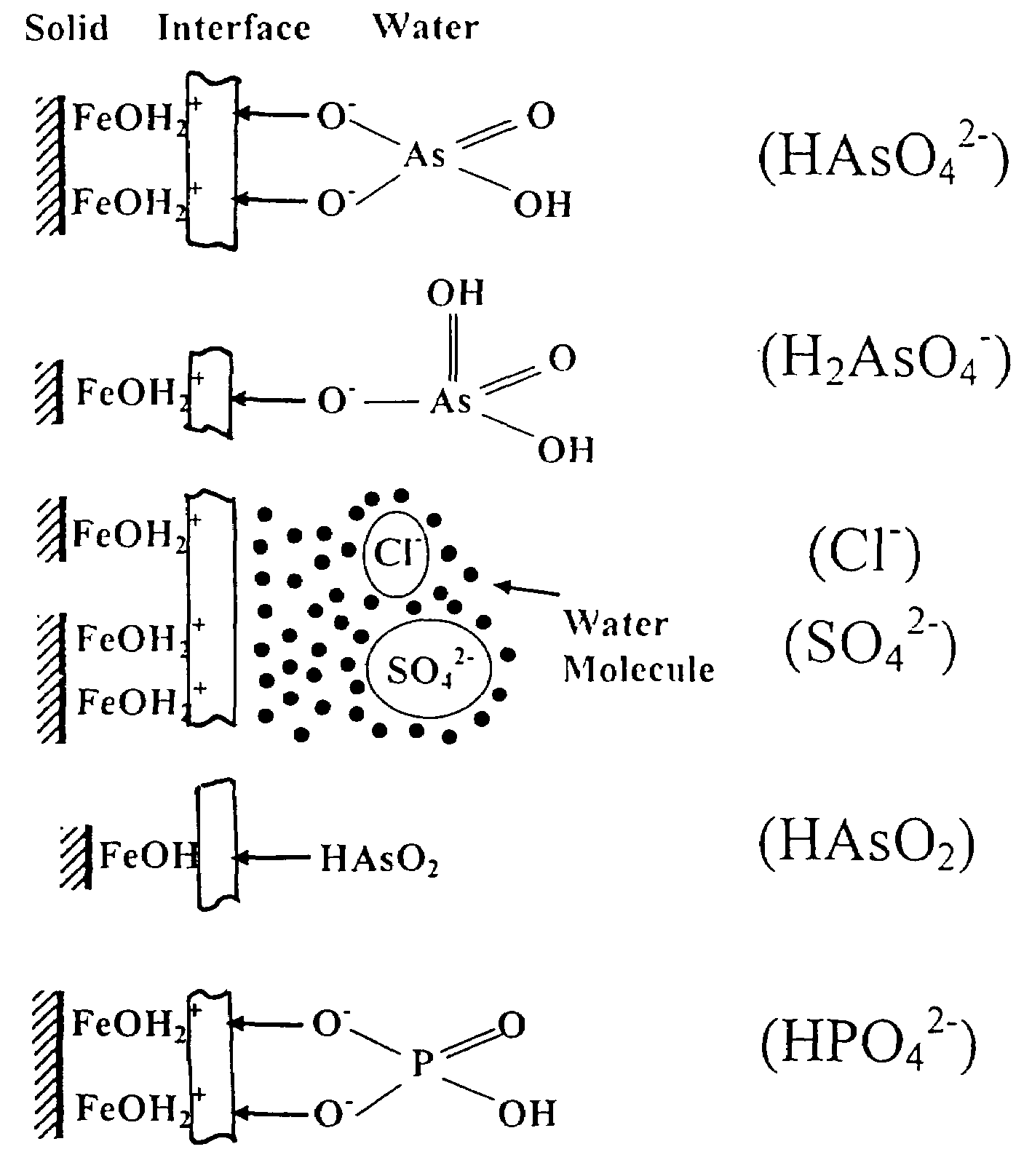

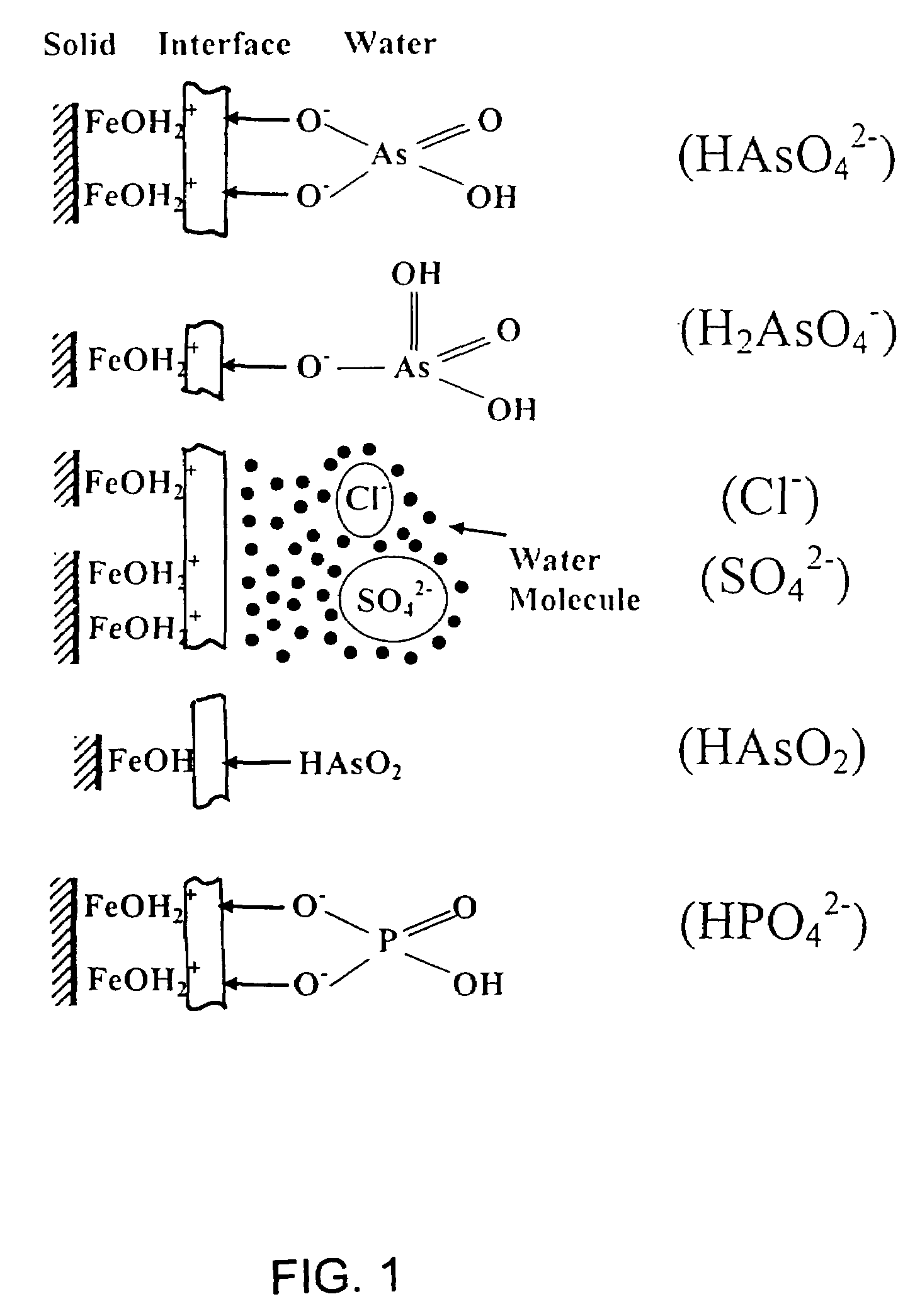

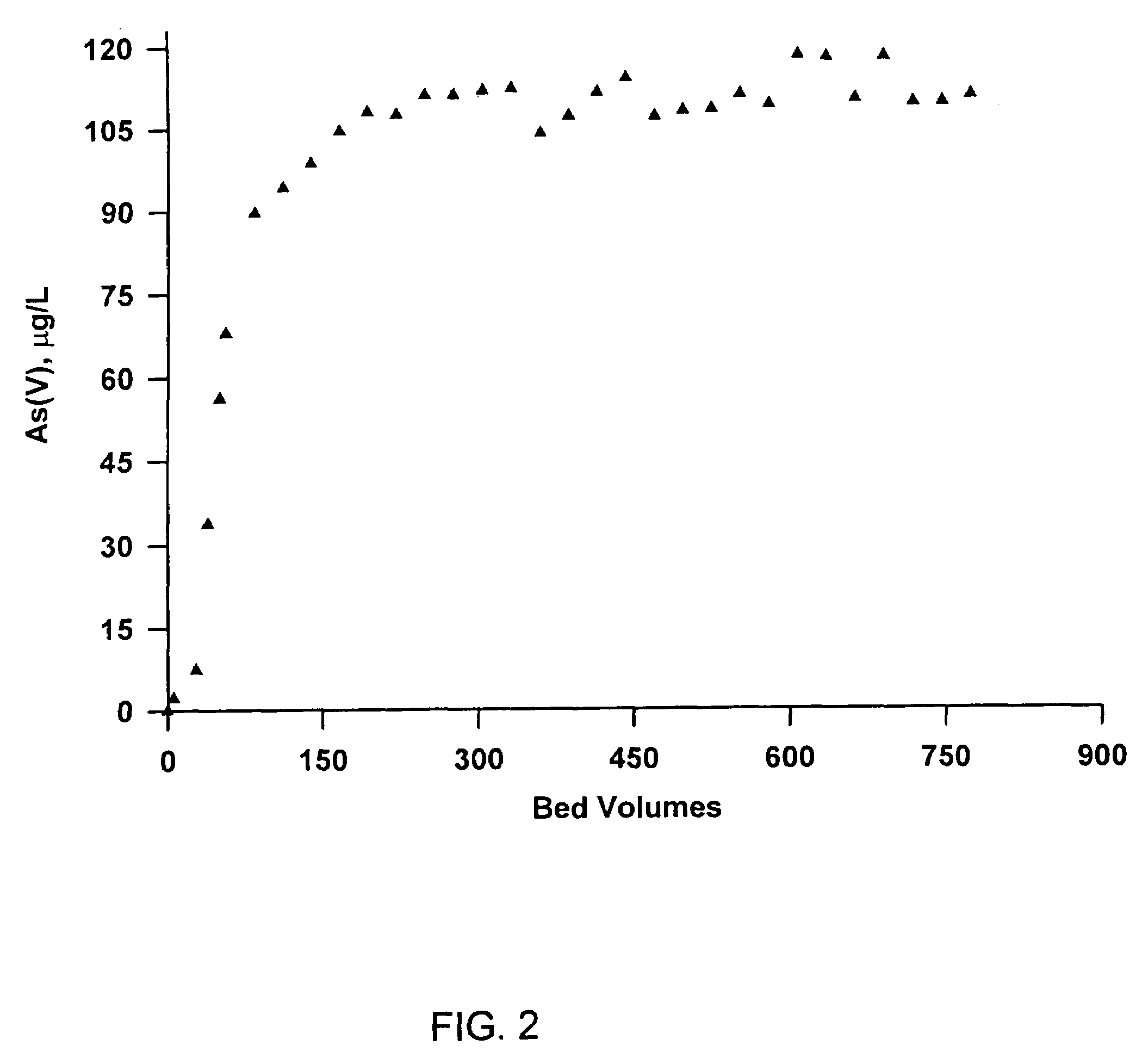

Hybrid anion exchanger for selective removal of contaminating ligands from fluids and method of manufacture thereof

ActiveUS7291578B2Improve material performanceImprove physical strengthOther chemical processesWater contaminantsPhosphateIon-exchange resin

Owner:ARUP K SENGUPTA

Process for preparing monodisperse anion exchangers

The present invention relates to a process for preparing novel, monodisperse anion exchangers by(a) reacting monomer droplets made from monovinylaromatic compounds and polyvinylaromatic compounds, and optional porogens and / or initiators,(b) amidomethylating the resultant monodisperse, crosslinked bead polymers with phthalimide derivatives,(c) converting the amidomethylated bead polymers to aminomethylated bead polymers, and(d) alkylating the aminomethylated bead polymers.

Owner:LANXESS DEUTDCHLAND GMBH

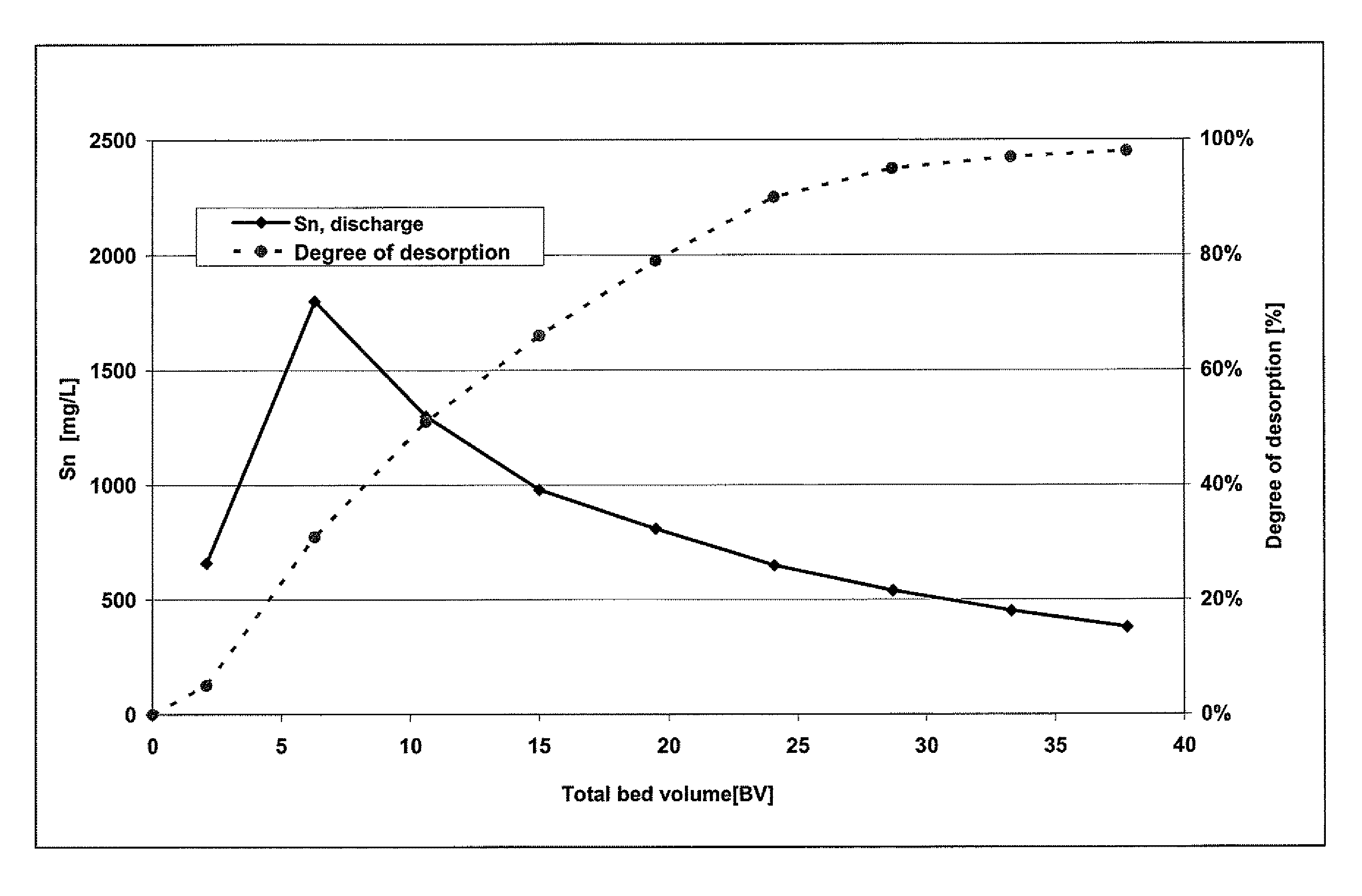

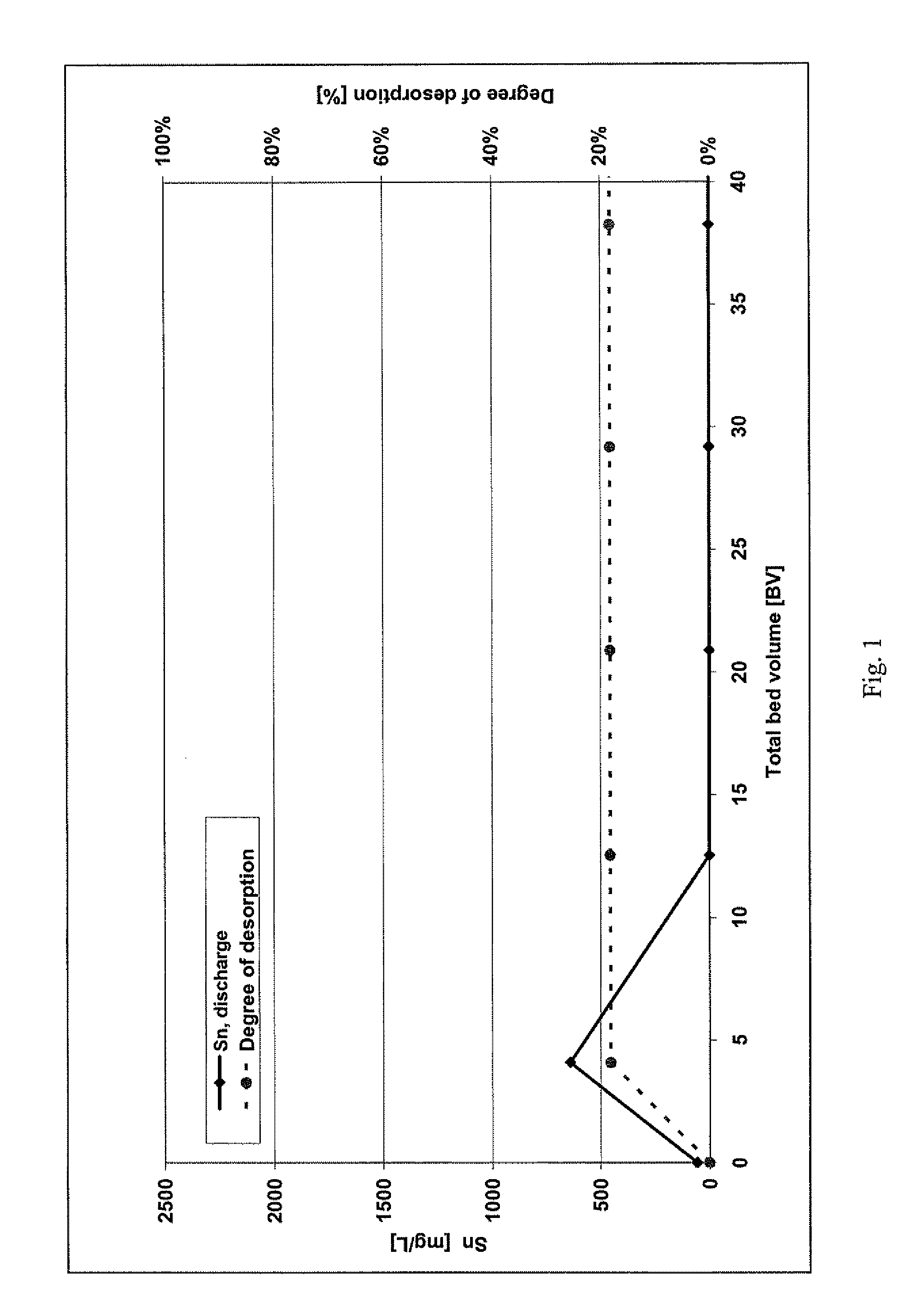

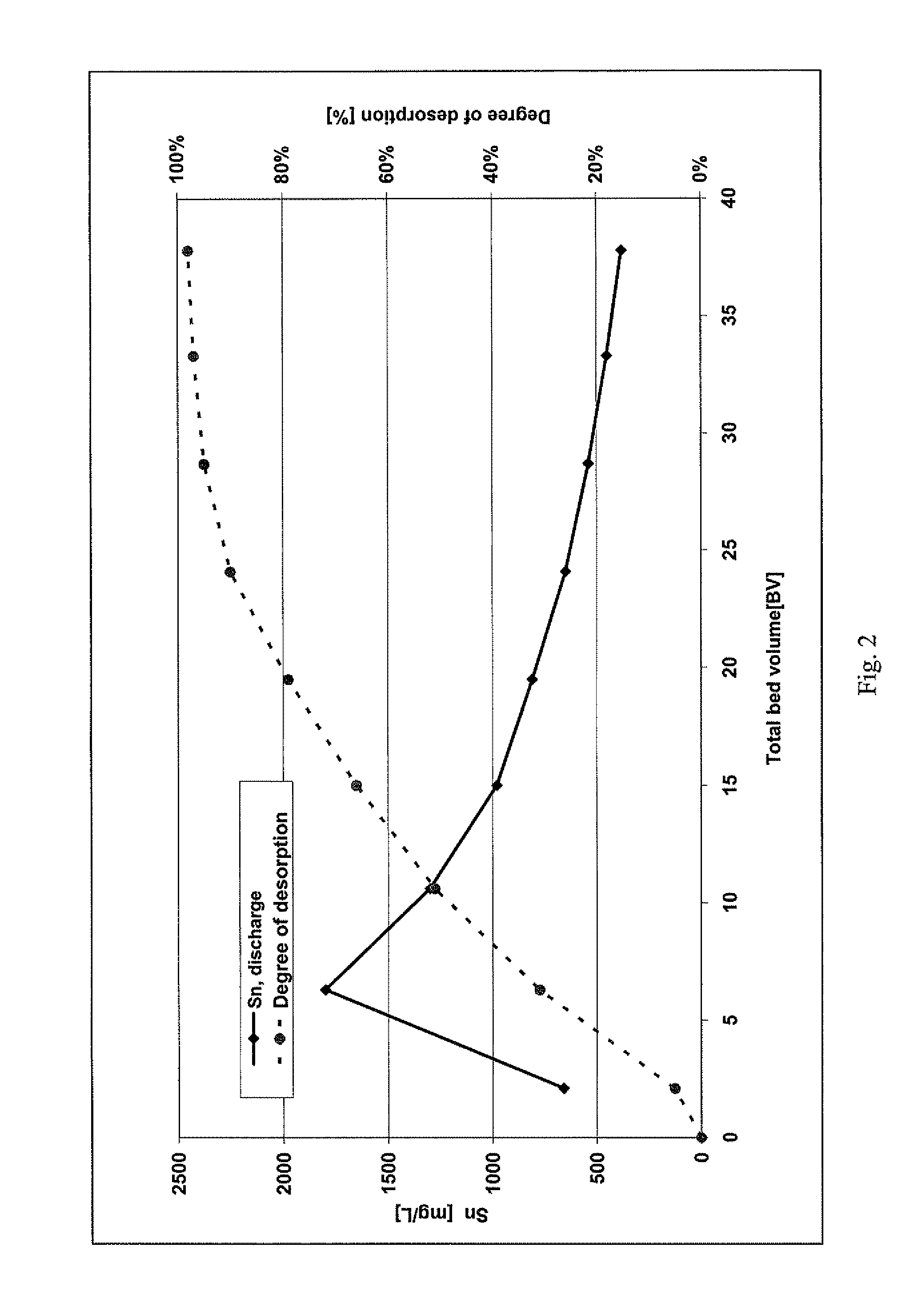

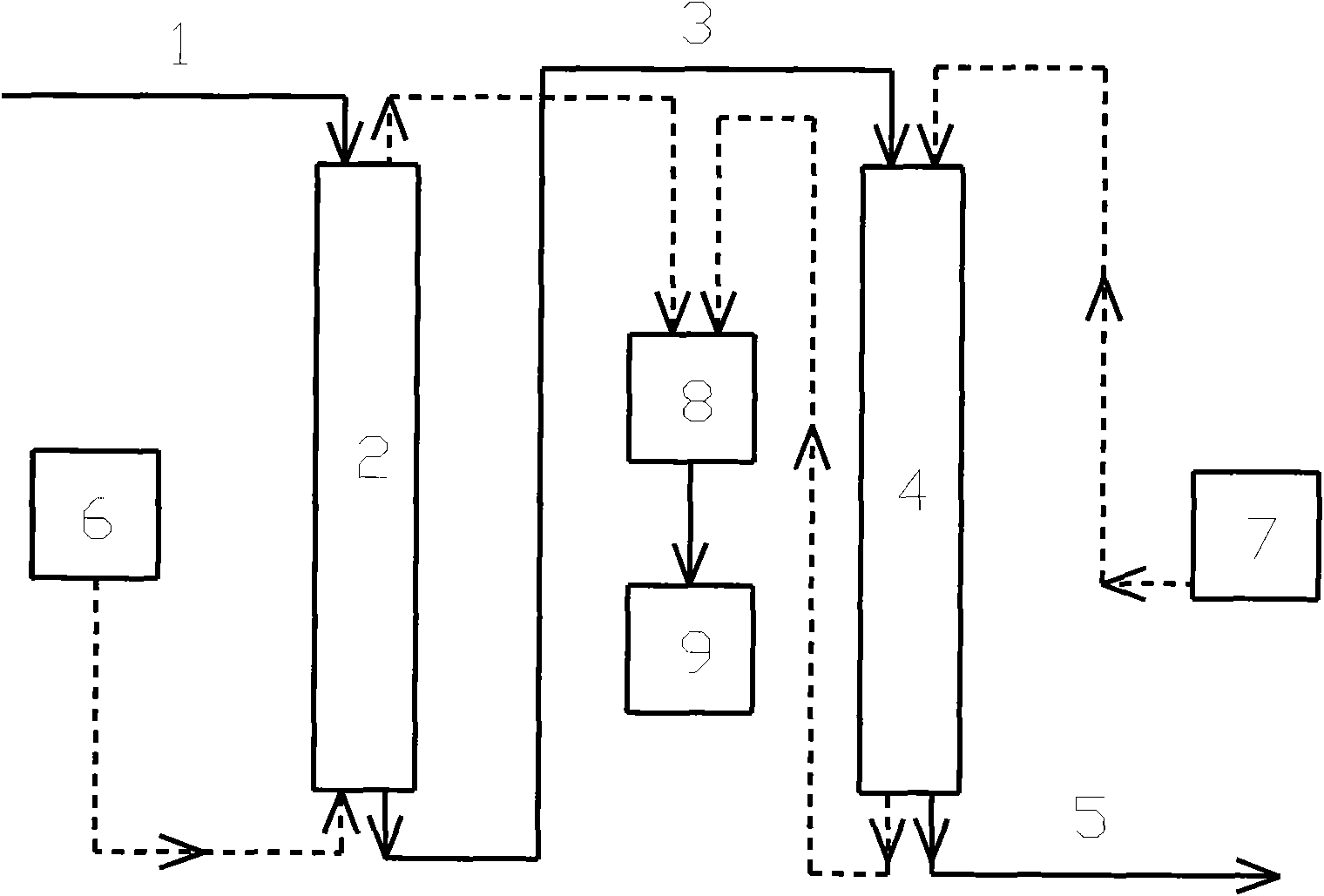

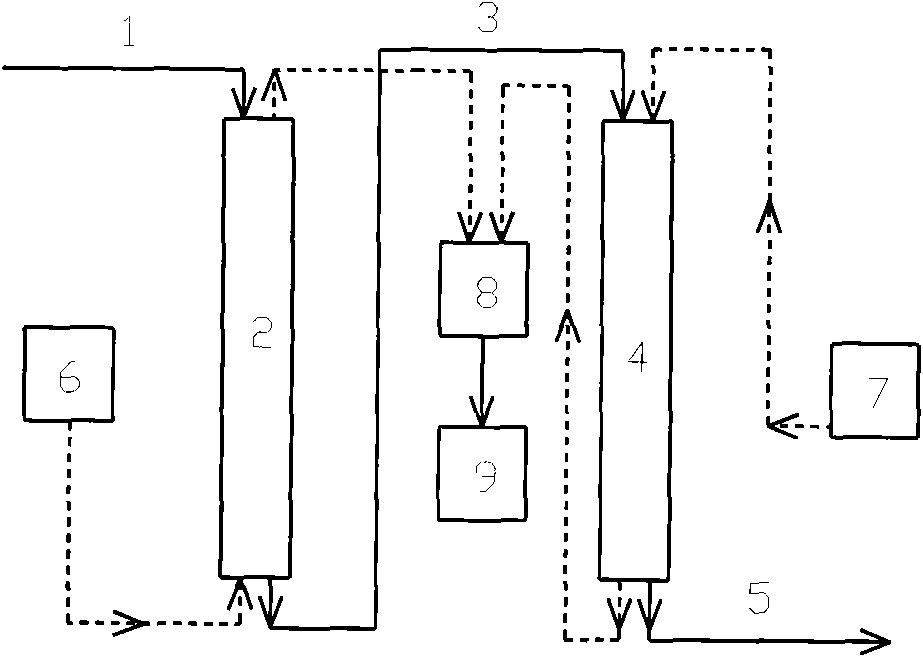

Processes for the regeneration of an anion exchanger loaded with hexachlorostannate

InactiveUS20090020478A1Ion-exchanger regenerationWater/sewage treatment by ion-exchangeRadiochemistryAnion exchanger

Processes comprising: providing an anion exchanger at least partially loaded with hexachlorostannate; and contacting the at least partially loaded anion exchanger with a 1 to 10 wt. % hydrochloric acid solution to regenerate the anion exchanger.

Owner:BAYER MATERIALSCIENCE AG

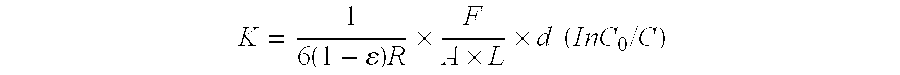

Process for treating nitrogen-containing wastewater by ion exchange and reclaiming ammonium nitrate

InactiveCN101891316AAchieve reuseFlexible operation and managementAmmonium nitratesWater/sewage treatment by ion-exchangeHigh concentrationStrong acids

The invention discloses a process for treating nitrogen-containing wastewater by ion exchange and reclaiming ammonium nitrate, and belongs to the technical field of environmental protection and wastewater treatment. The process is characterized in that: a strong acid cation exchanger and a weak alkali anion exchanger are connected in series to realize denitrification of the nitrogen-containing wastewater of a nitrogen fertilizer plant; the process is used for treating the high-concentration ammonia nitrogen and median-concentration nitrate nitrogen containing wastewater of the nitrogen fertilizer plant; strong acid cation exchange resin and weak alkali anion exchange resin are regenerated by adopting nitric acid and aqueous ammonia respectively; and the regenerated waste liquid ammonium nitrate is evaporated and concentrated to reclaim the ammonium nitrate. Compared with the traditional wastewater denitrification method, the process can remove ammonia nitrogen and nitrate nitrogen from the wastewater at the same time, reclaim the ammonium nitrate and recycle production water, does not produce secondary pollution, reclaims products from the pollutants, has obvious environmental benefit and economic benefit, and is a new path for treating the high-concentration ammonia nitrogen and median-concentration nitrate nitrogen containing wastewater of the nitrogen fertilizer plant.

Owner:TAIYUAN UNIV OF TECH

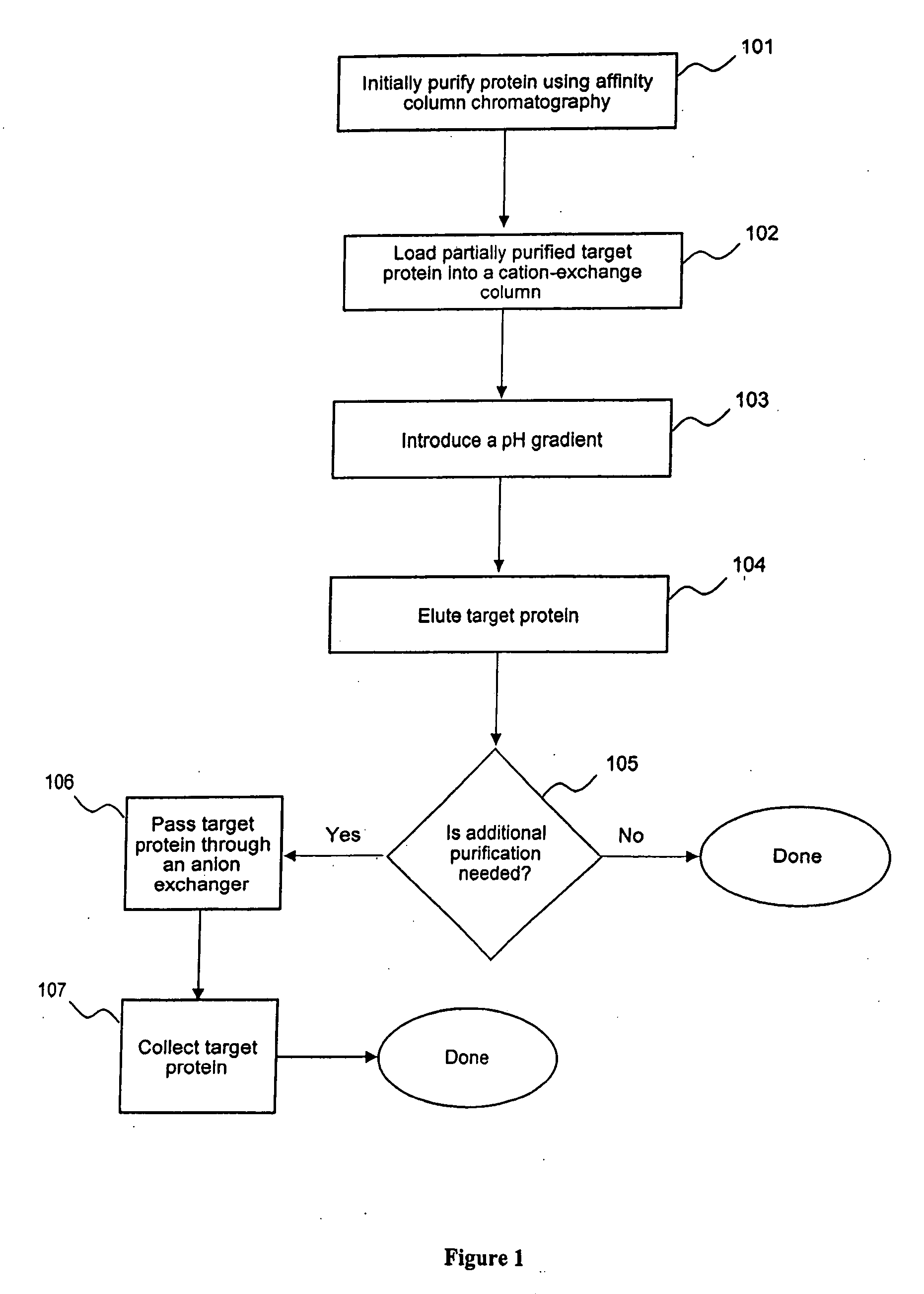

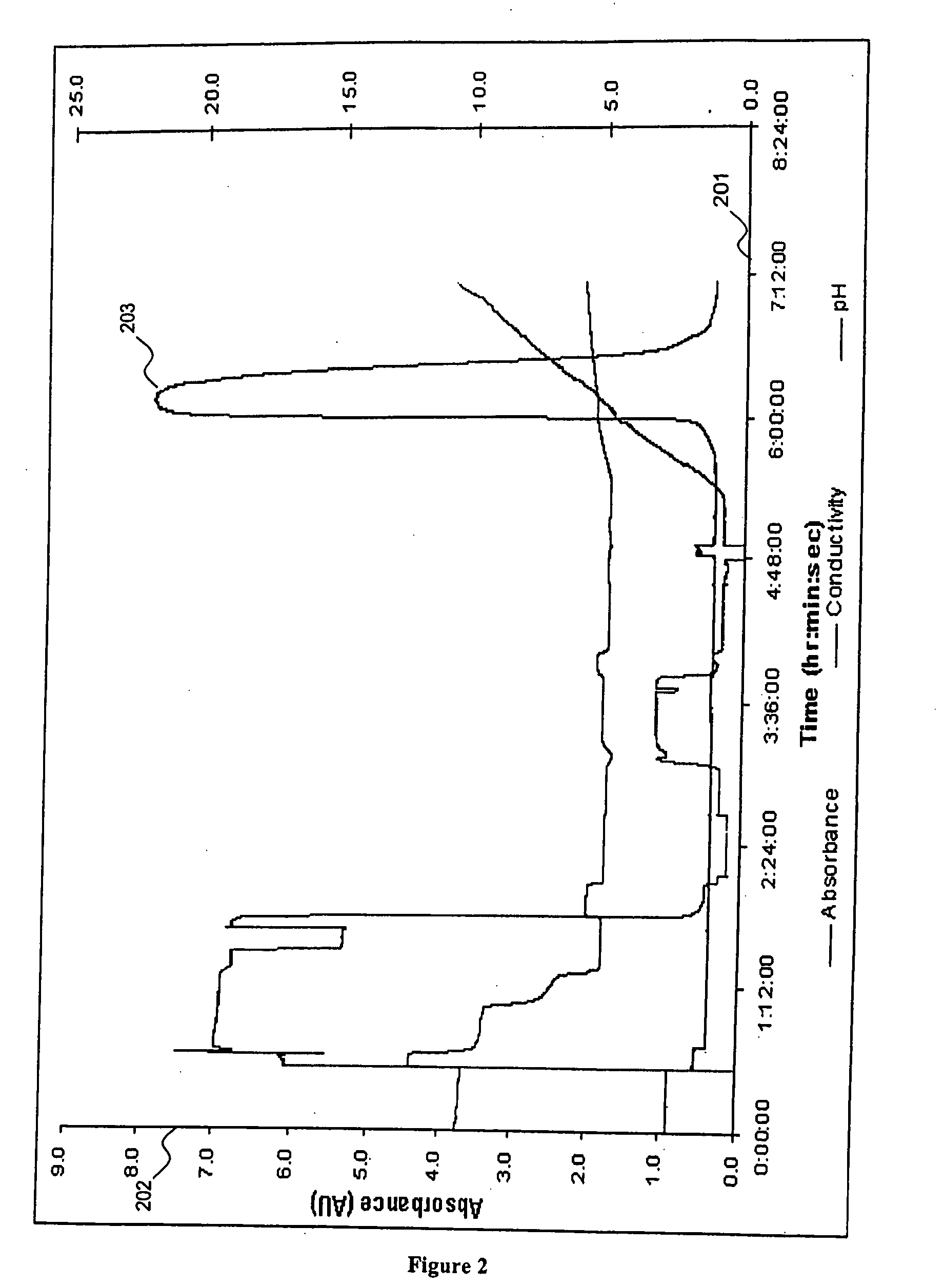

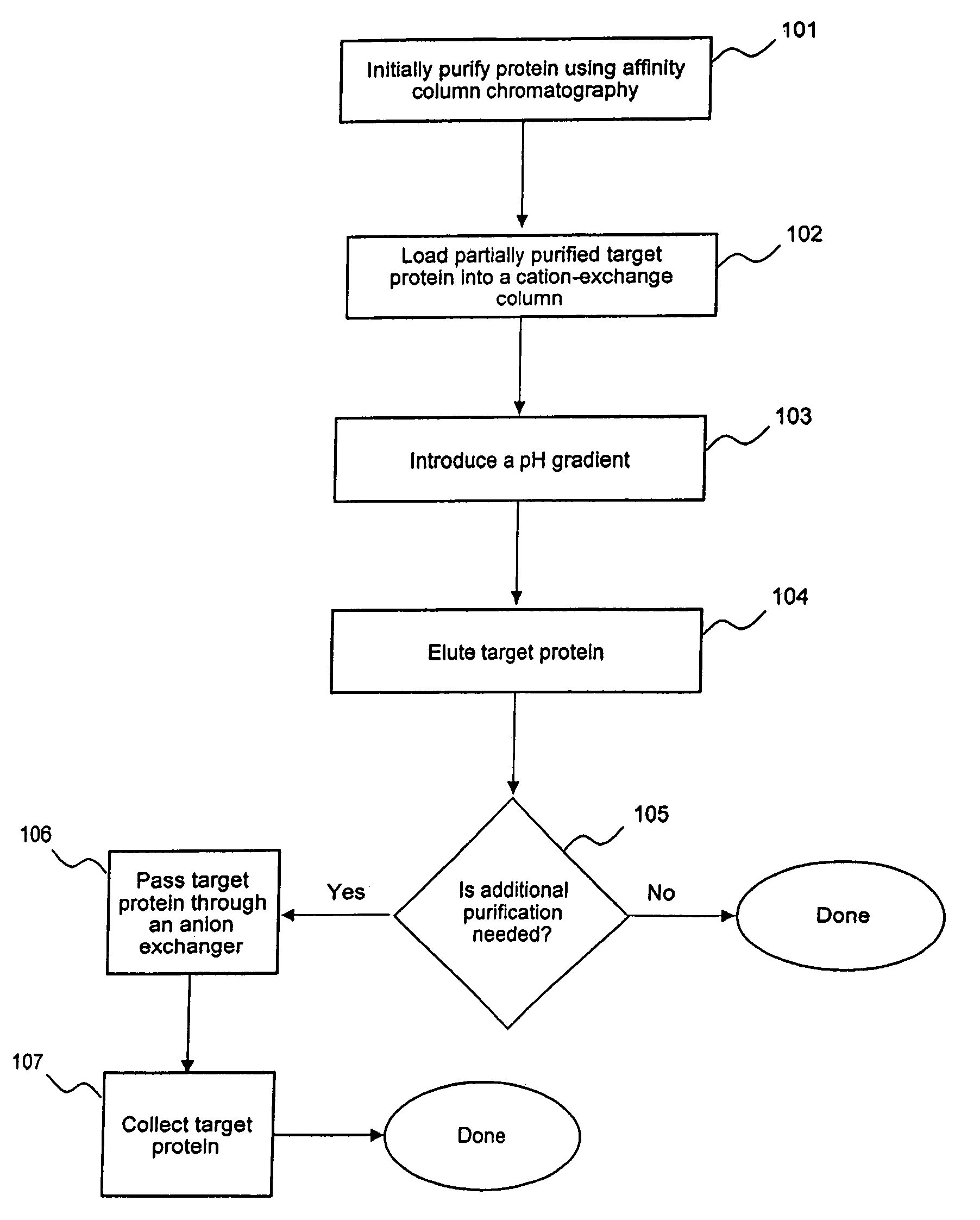

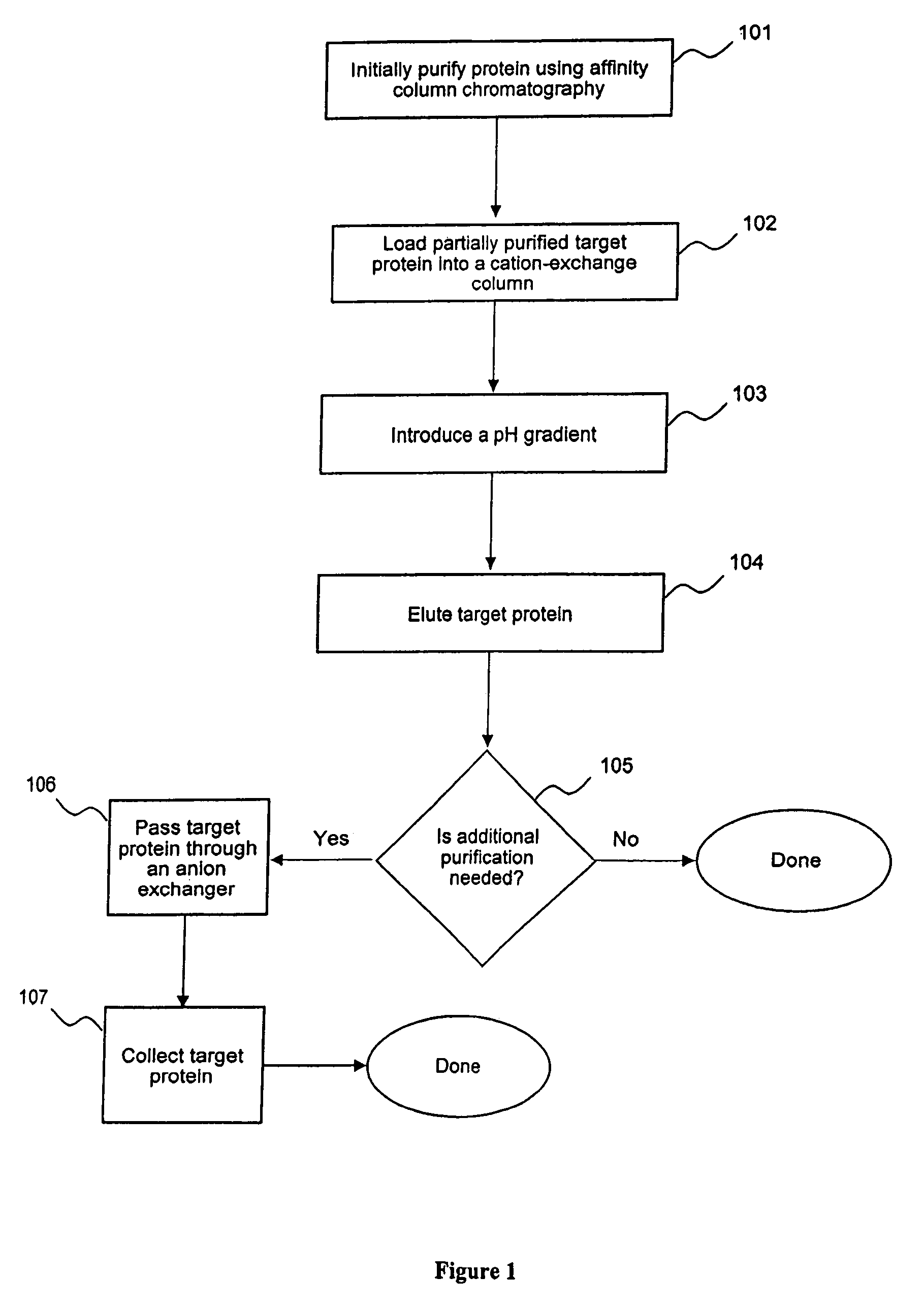

Polishing steps used in multi-step protein purification processes

ActiveUS20070167612A1Component separationSolid sorbent liquid separationFiltrationProtein purification

Various embodiments of the present invention are directed to multi-step systems and methods for target-molecule purification that employ column-chromatography-based and / or membrane-filtration-based polishing steps. In one described embodiment of the present invention, a target-protein-containing eluate having a high residual salt concentration is collected from a first chromatography column prepared with an affinity-chromatography resin, loaded onto a second chromatography column prepared with a cation-exchange resin, and eluted from the second cation-exchange column using a buffer in which a time-dependent pH gradient is established. In another described embodiment of the present invention, a partially purified target-protein-containing eluate is collected from a chromatography column and further purified by passing the target-protein-containing eluate through a salt-tolerant anion exchanger.

Owner:AMGEN INC

Media For Membrane Ion Exchange Chromatography Based On Polymeric Primary Amines, Sorption Device Containing That Media, And Chromatography Scheme And Purification Method Using The Same

InactiveUS20100200507A1Improve bindingGood removal effectIon-exchange process apparatusIon-exchanger regenerationPurification methodsSorbent

Media and devices, such as anion exchangers including such media, wherein the media is a membrane having a surface coated with a polymer such as a polyallylamine. The resulting membrane offers stronger binding of protein impurities and superior removal of host cell proteins from biological samples than conventional ligands based on quaternary ammonium salts, including trimethylammonium ligands. Also described is a chromatography scheme and method for purifying monoclonal antibodies, wherein the anion exchange sorber is placed downstream of an affinity column (such as Protein A or Protein G affinity column) and optionally one or more polishing devices such as cationic exchange columns. Little or no dilution of the cation exchanger pool (or affinity column exchange pool where no cation exchanger is used) is necessary to lower the conductivity of the sample. The sorber functions well to strongly bind host cell proteins and other impurities in biological samples even at high conductivities and pH.

Owner:MILLIPORE CORP

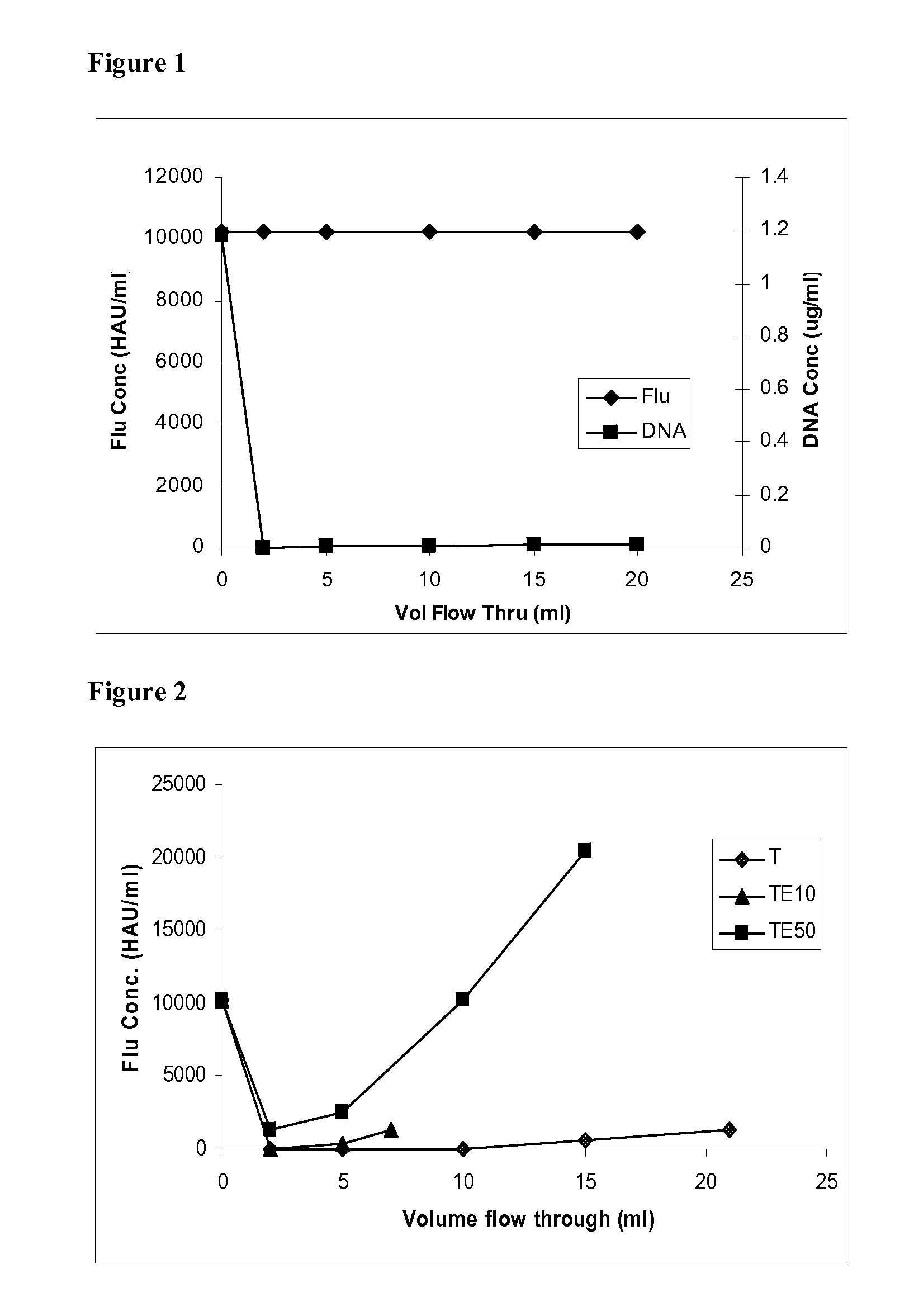

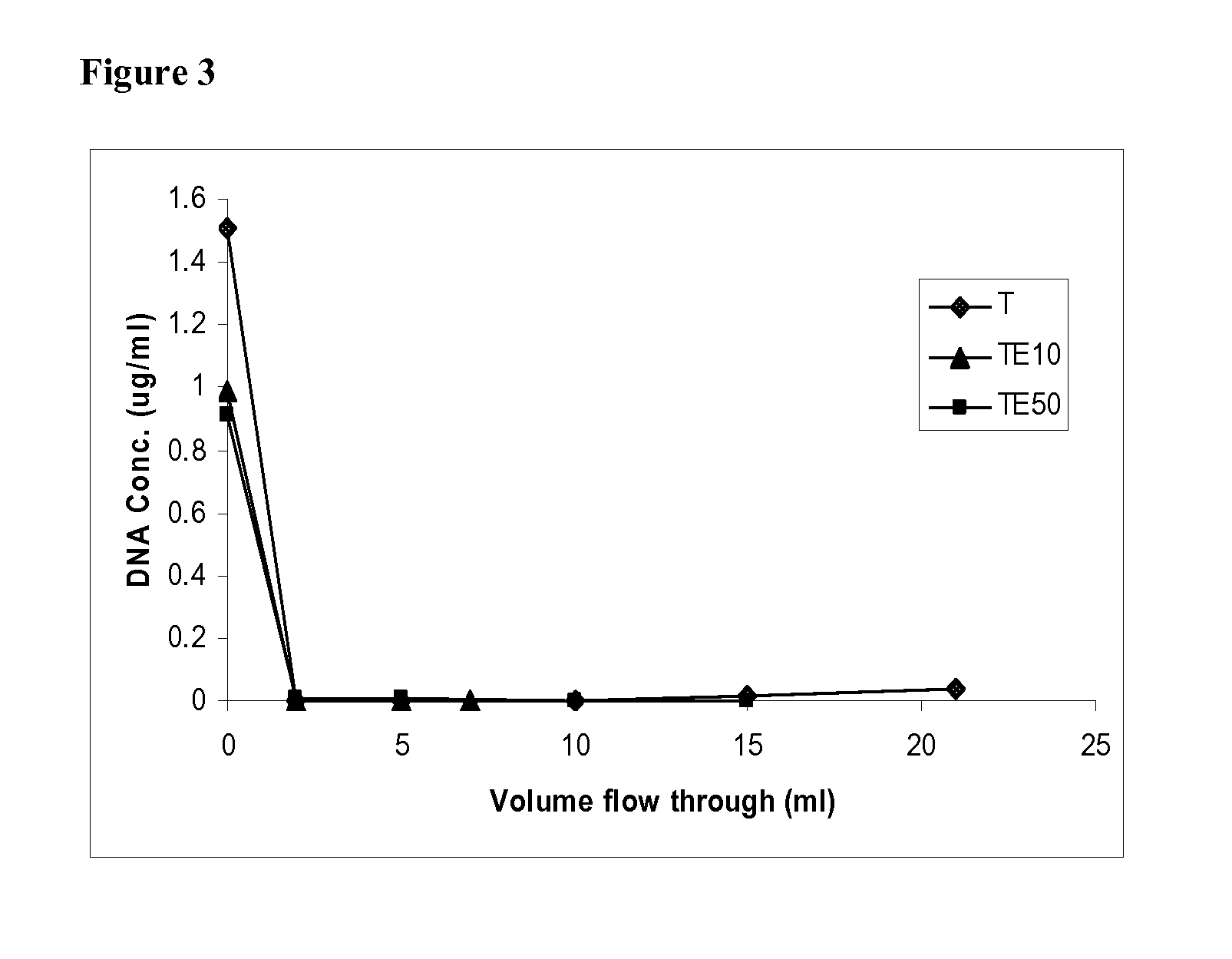

Separation Of Virus And/Or Protein From Nucleic Acids By Primary Amines

InactiveUS20120077249A1Significant and effective capacityIon-exchange process apparatusSsRNA viruses negative-senseAmine ligandsVirus

Owner:MILLIPORE CORP

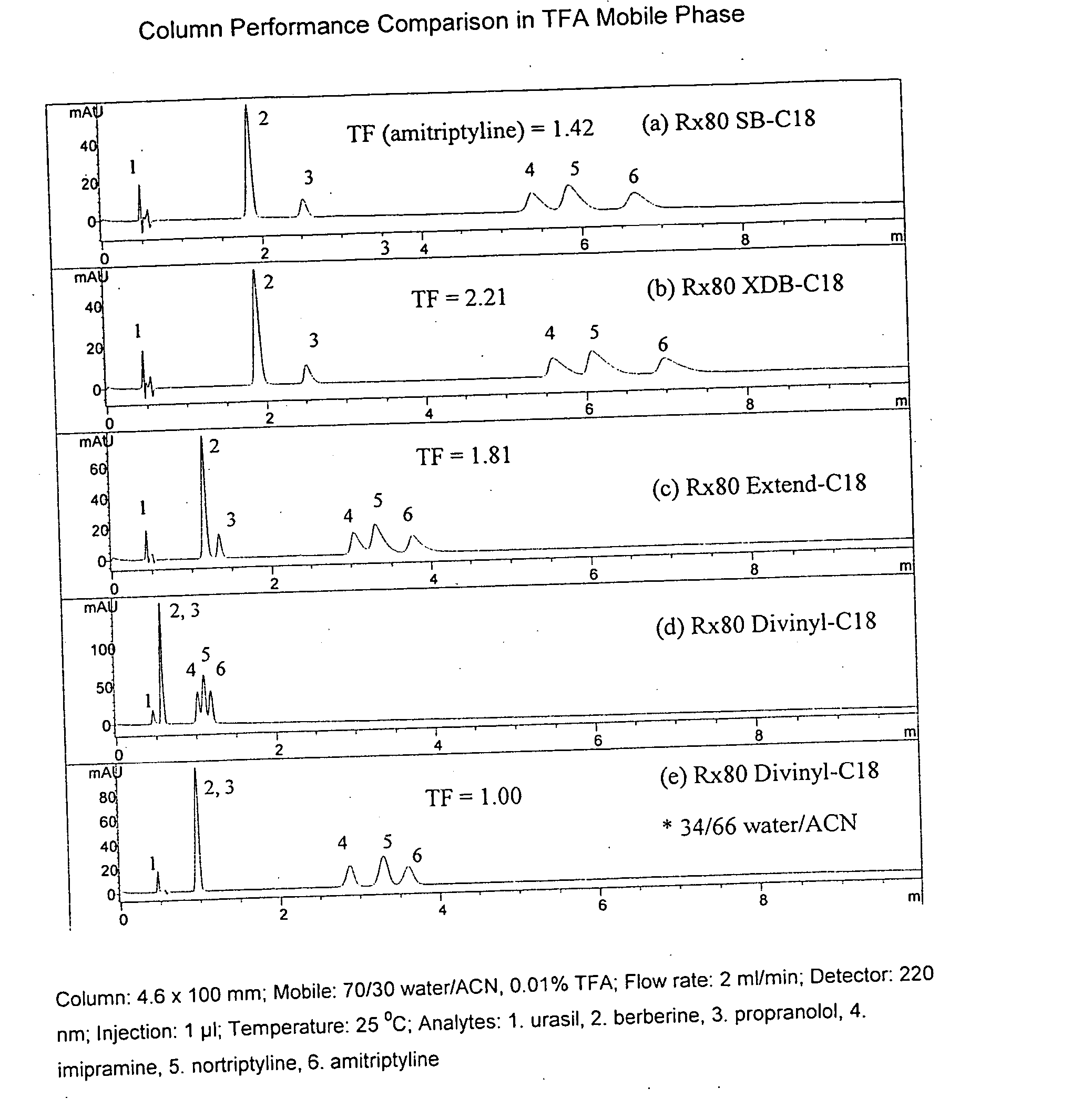

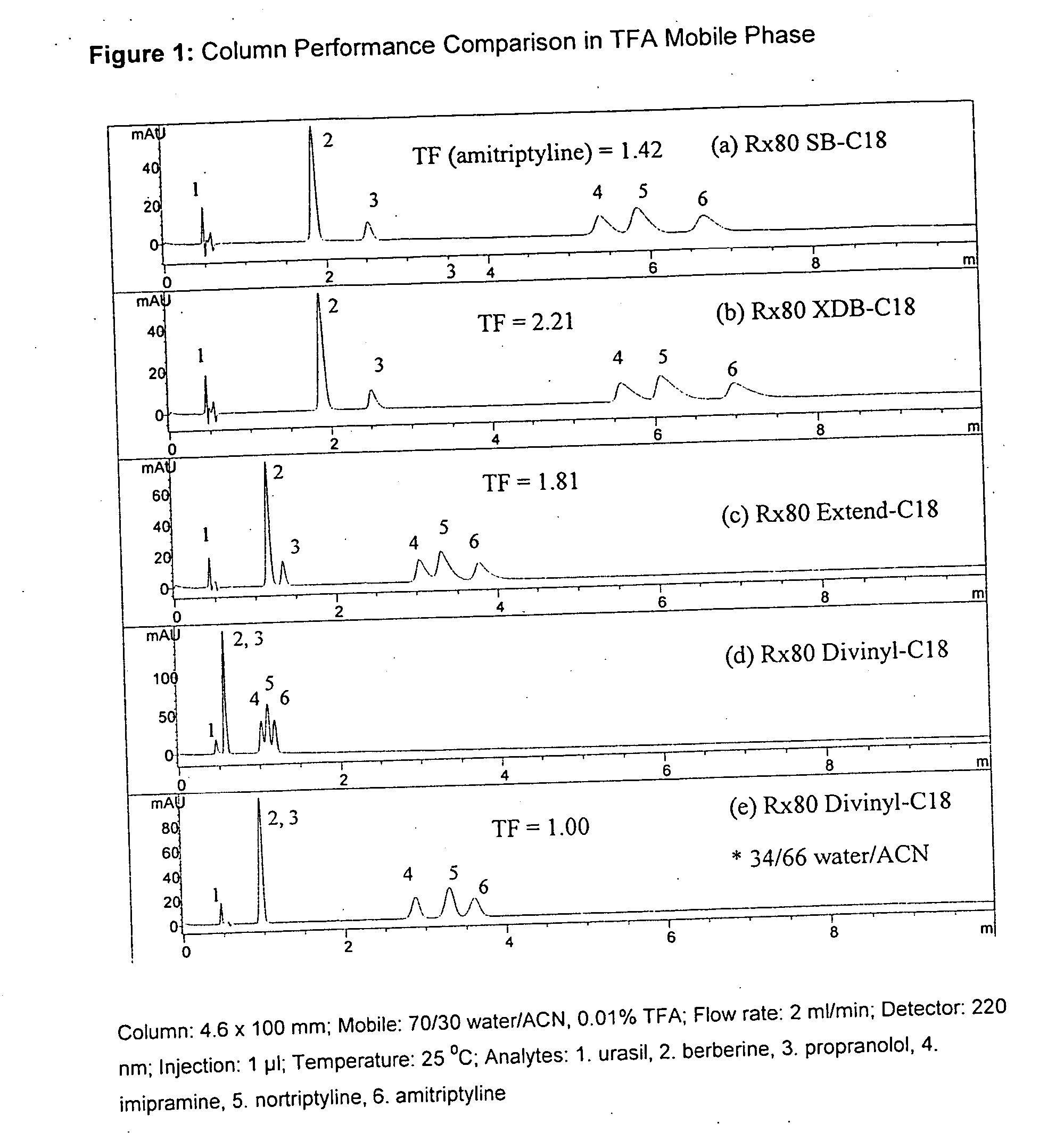

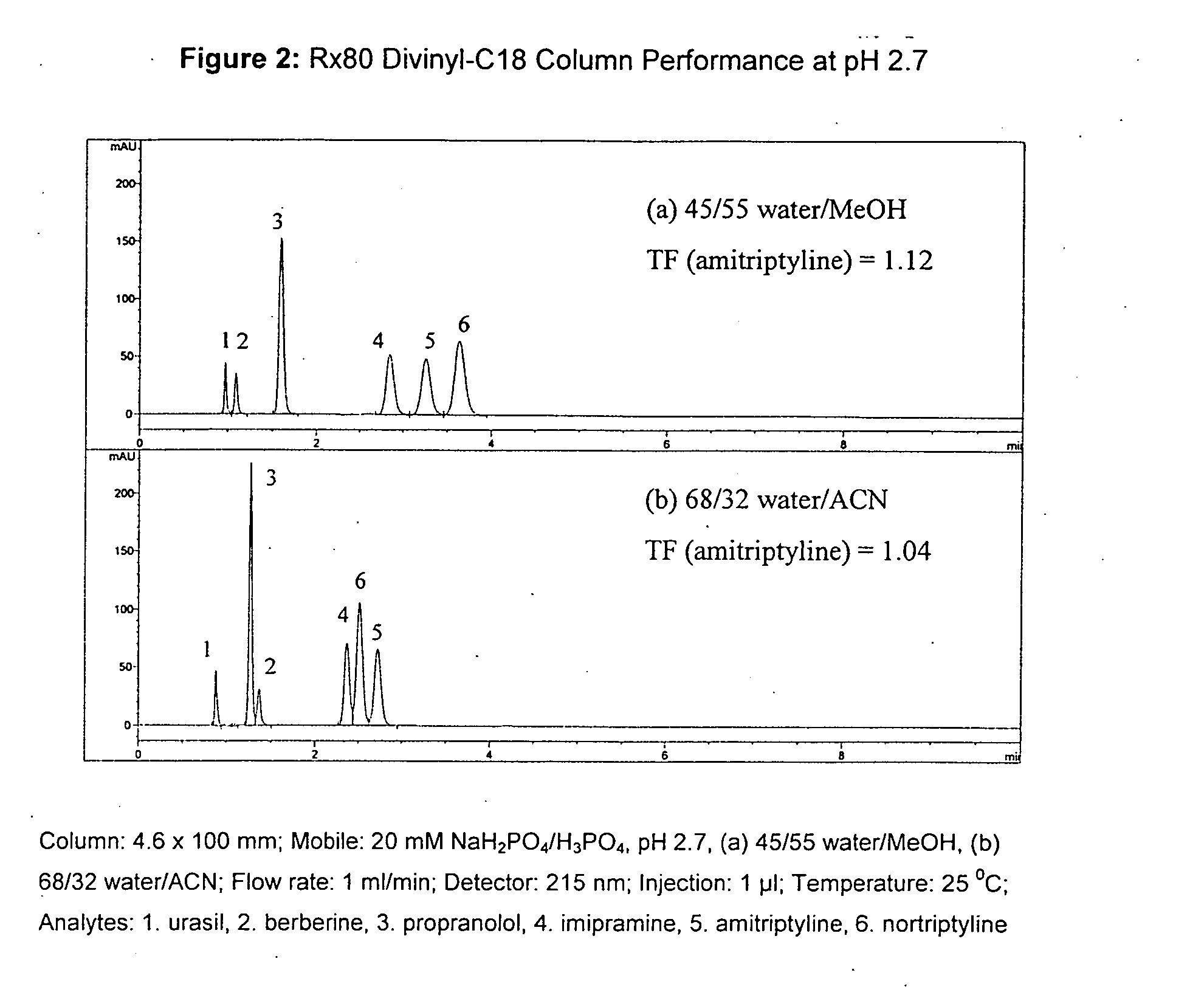

Novel stationary phases for use in high-performance liquid chromatography

InactiveUS20050242038A1Ion-exchange process apparatusChromatographic cation exchangersArylStationary phase

The invention provides novel materials for chromatography and chromatography columns. The invention provides a monofunctional silane chemically bonded to a substrate, the monofunctional silane has two groups, R, and R′, the monofunctional silane being of the form: where the R groups are independently selected from the group consisting of alkenyl, alkynyl, and phenyl, R′ is selected form the group consisting of alkyl, substituted alkyl, alkenyl, substituted alkenyl, aryl, substituted aryl, alkylamine, amide, ether, alcohol, cabamate, ester, an anion exchanger, and a cation exchange. Methods for manufacture and design of the columns are also provided and disclosed.

Owner:AGILENT TECH INC

Polishing steps used in multi-step protein purification processes

Various embodiments of the present invention are directed to multi-step systems and methods for target-molecule purification that employ column-chromatography-based and / or membrane-filtration-based polishing steps. In one described embodiment of the present invention, a target-protein-containing eluate having a high residual salt concentration is collected from a first chromatography column prepared with an affinity-chromatography resin, loaded onto a second chromatography column prepared with a cation-exchange resin, and eluted from the second cation-exchange column using a buffer in which a time-dependent pH gradient is established. In another described embodiment of the present invention, a partially purified target-protein-containing eluate is collected from a chromatography column and further purified by passing the target-protein-containing eluate through a salt-tolerant anion exchanger.

Owner:AMGEN INC

Nucleic acid purification method

ActiveUS20080076910A1Promote recoveryEfficient elutionSugar derivativesSolid sorbent liquid separationSupport matrixPurification methods

The invention provides an improved method for the purification of nucleic acid molecules, which method comprises generating a cellular lysate containing the nucleic acid; contacting the lysate with an anion exchanger bound to a solid support matrix under conditions such that the anion exchanger binds the nucleic acid; followed by eluting the nucleic acid from the anion exchanger with an aqueous mobile phase comprising an elution solution; and desalting the eluted nucleic acid such that it is suitable for downstream applications. The improvement of the method includes adding in the elution solution a composition such that the pH of the aqueous mobile phase is between about pH 9 and about pH 13, wherein the presence of the composition in the elution solution provides an increase in nucleic acid recovery, as compared with the recovery in the absence of the composition.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

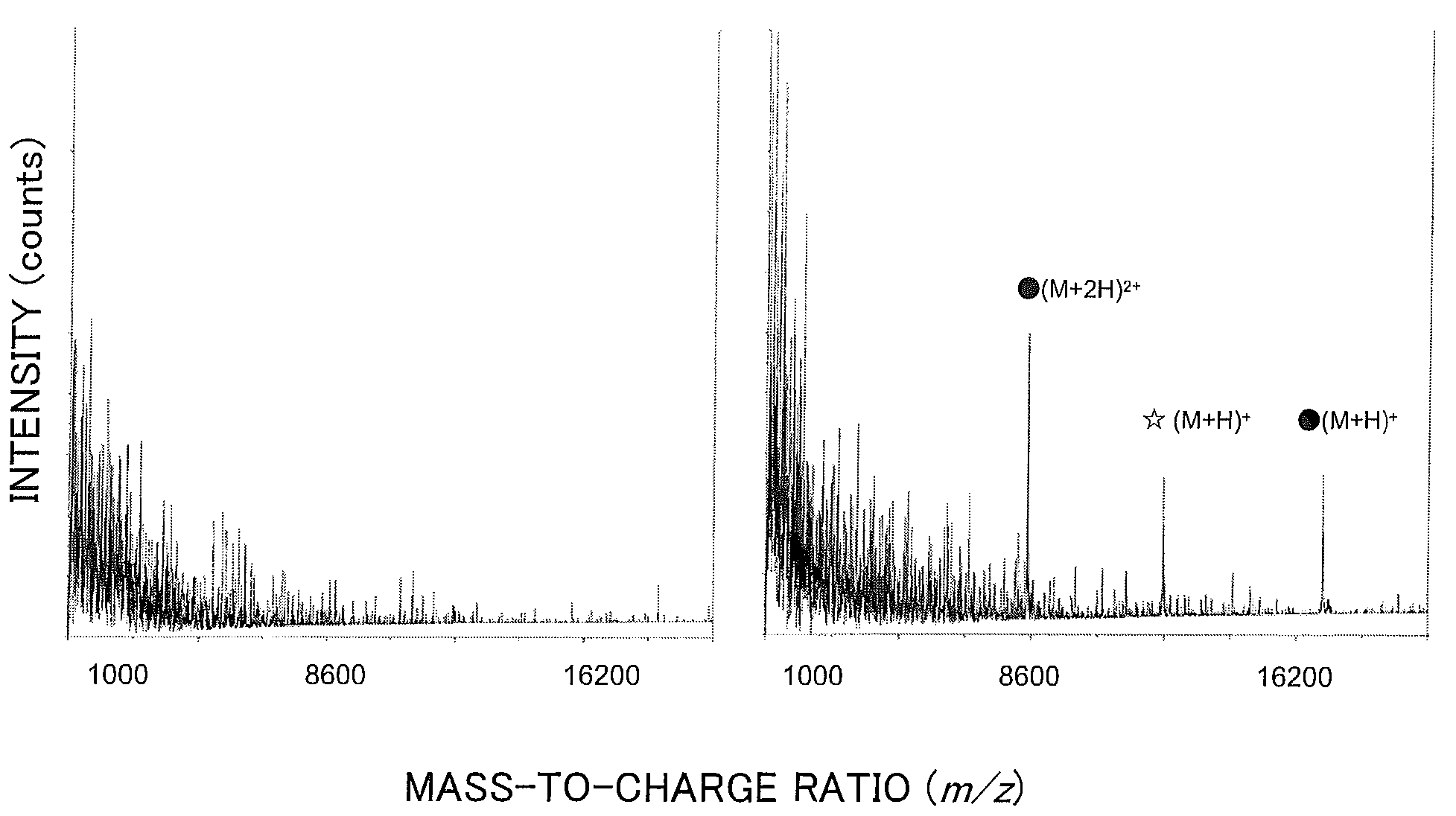

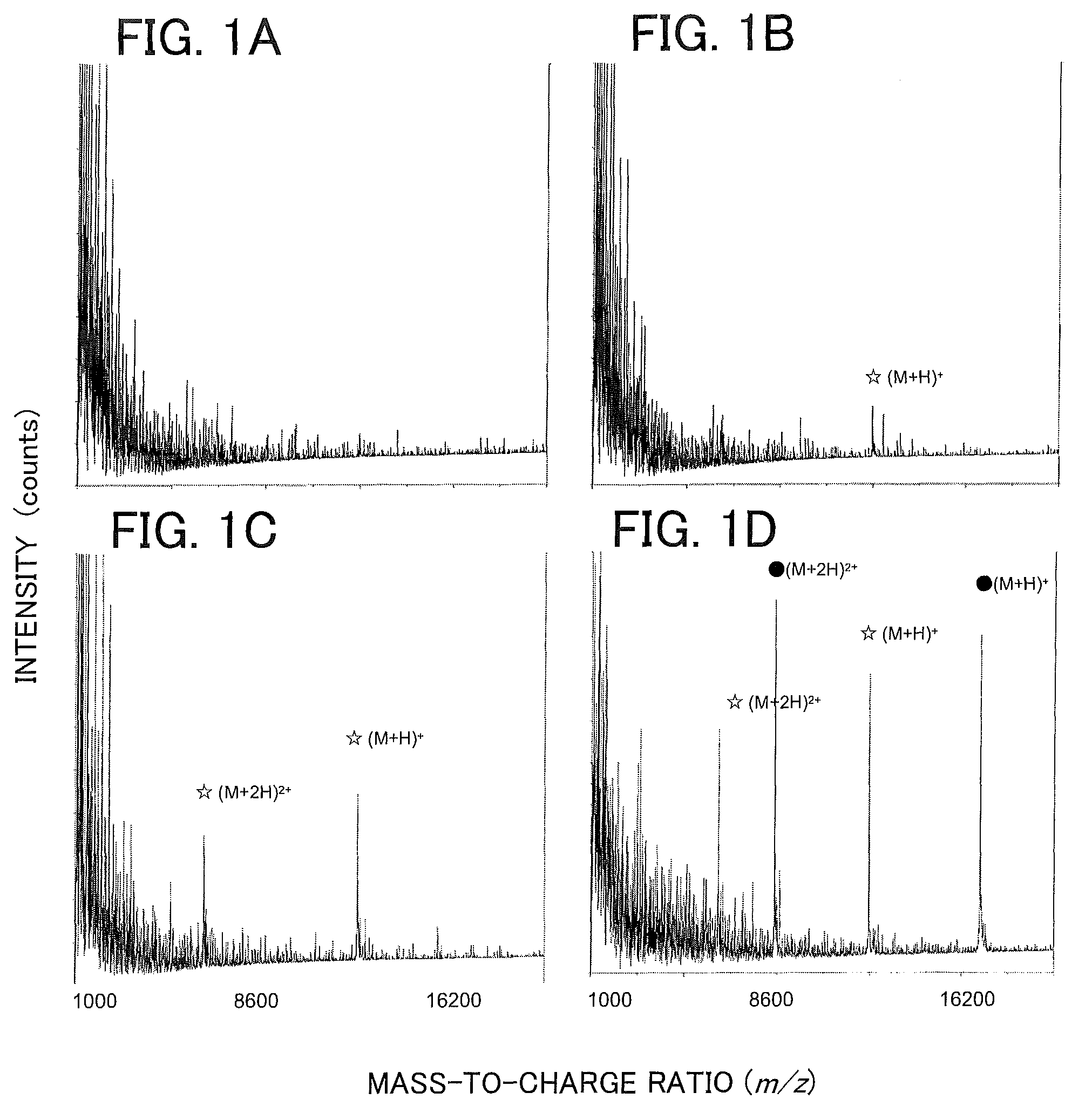

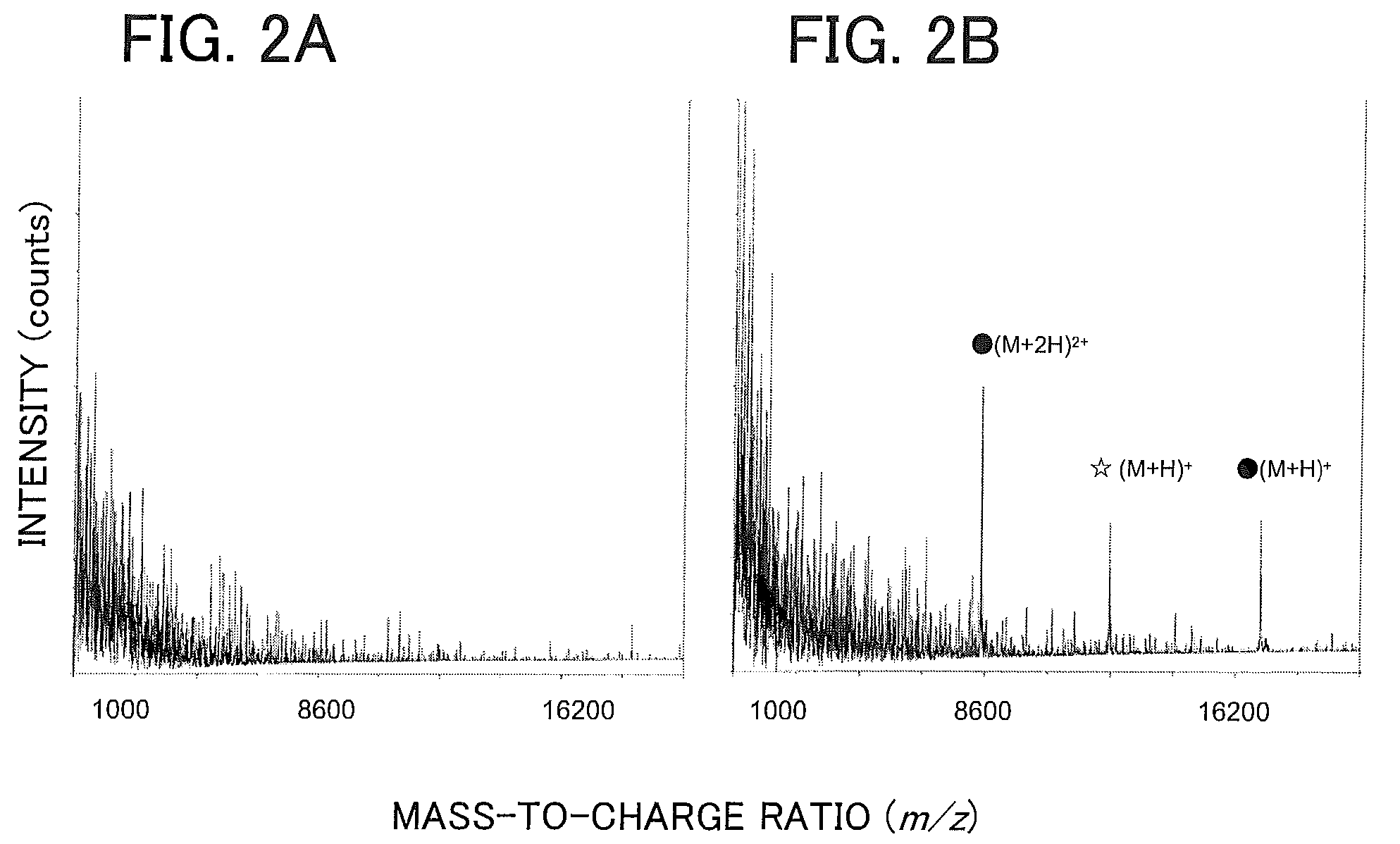

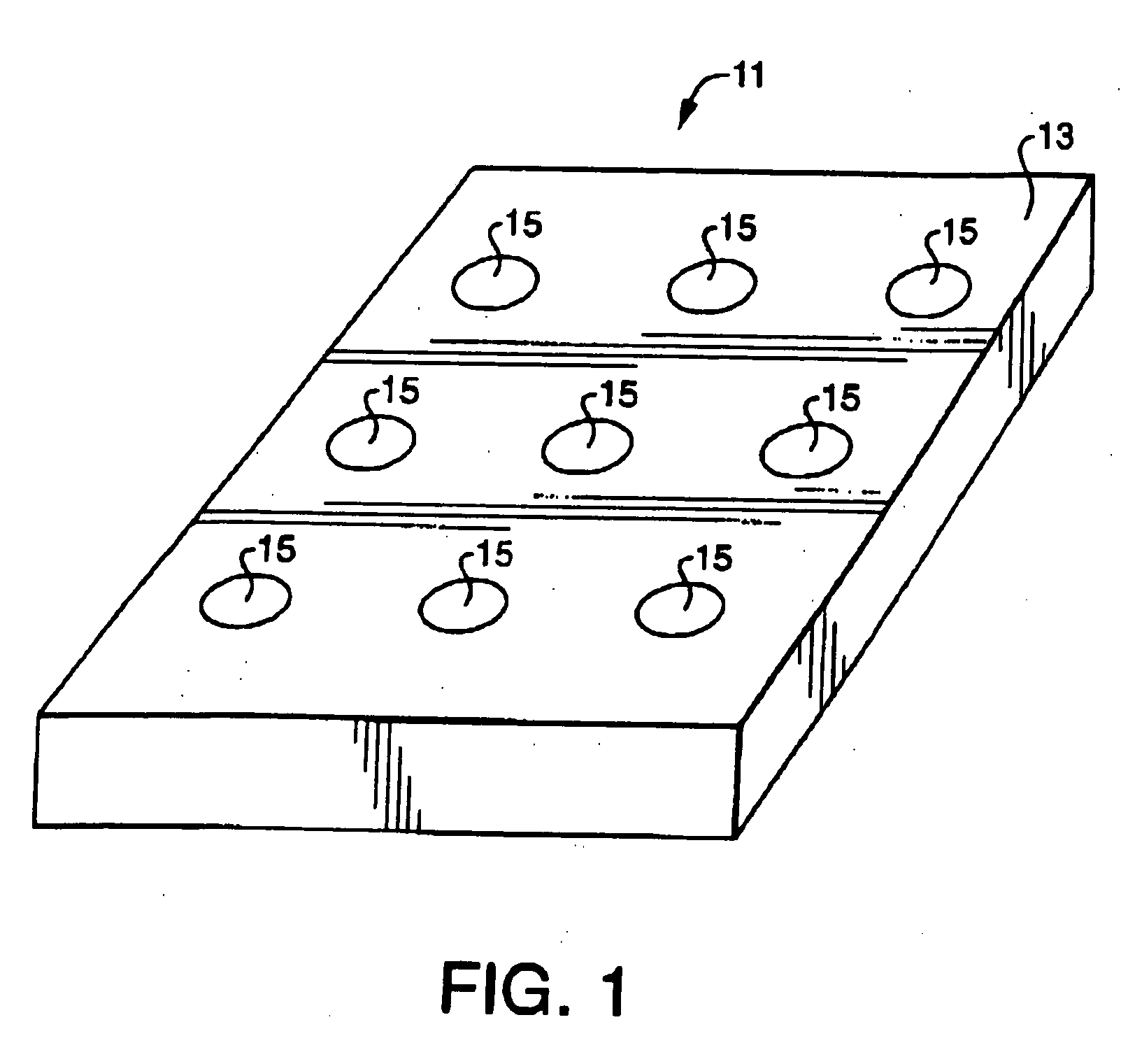

Methods of preparing samples for MALDI mass spectrometry and reagent compositions for the same

InactiveUS7928367B2Quality improvementQuick measurementParticle separator tubesIsotope separationMicroparticleMaldi ms

A simple and efficient method of preparing a sample in the measurement according to matrix-assisted laser desorption / ionization mass spectrometry (MALDI-MS) capable of inhibiting any ion suppression by impurities, such as inorganic salts and surfactants, contained in the sample. An analyte and matrix molecules are co-crystallized in the presence of porous microparticles. Preferably, this co-crystallization is carried out by bringing the analyte, matrix molecules and porous microparticles into contact with each other on a target plate and thereafter drying the mixture. The porous microparticles consist of an ion exchanger having an average particle diameter of not more than 50 μm, preferably a strongly basic anion exchanger.

Owner:RIKEN

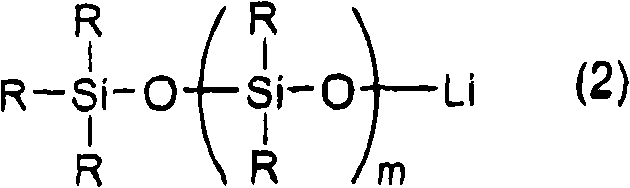

Fluorosilicone rubber composition and cured product thereof

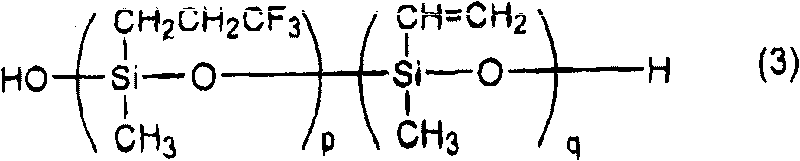

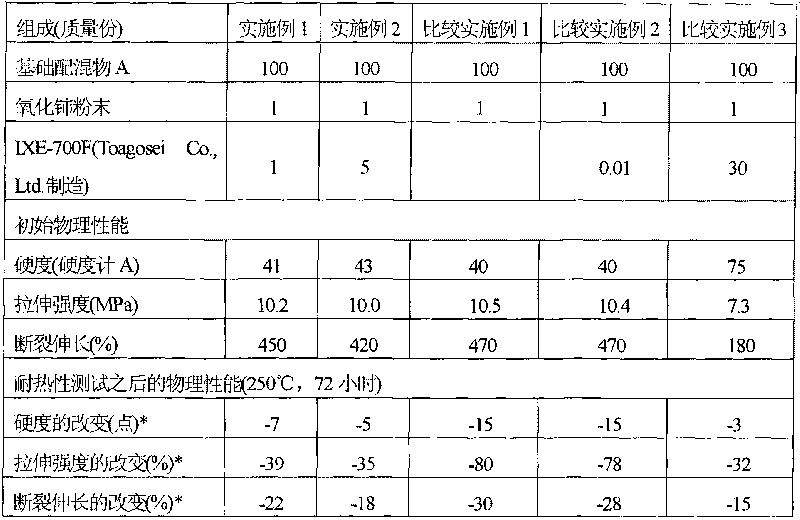

InactiveCN101724274AImprove heat resistanceThin material handlingAliphatic unsaturated hydrocarbonPolymer science

A fluorosilicone rubber composition including: (A) an organopolysiloxane containing trifluoropropyl groups and monovalent aliphatic unsaturated hydrocarbon groups, with a viscosity at 25 DEG C of not less than 10,000 mPas, represented by a specific average composition formula, in an amount of 100 parts by mass, (B) a silica-based filler, in an amount of 2 to 100 parts by mass, (C) a hydrotalcite-based inorganic anion exchanger, in an amount of 0.1 to 20 parts by mass, and (D) a curing agent, in an effective amount. Also disclosed is a cured product obtained by curing the composition. The composition forms a molded item that exhibits minimal deterioration in physical properties even when exposed to heat at temperatures of 200 DEG C or higher.

Owner:SHIN ETSU CHEM IND CO LTD

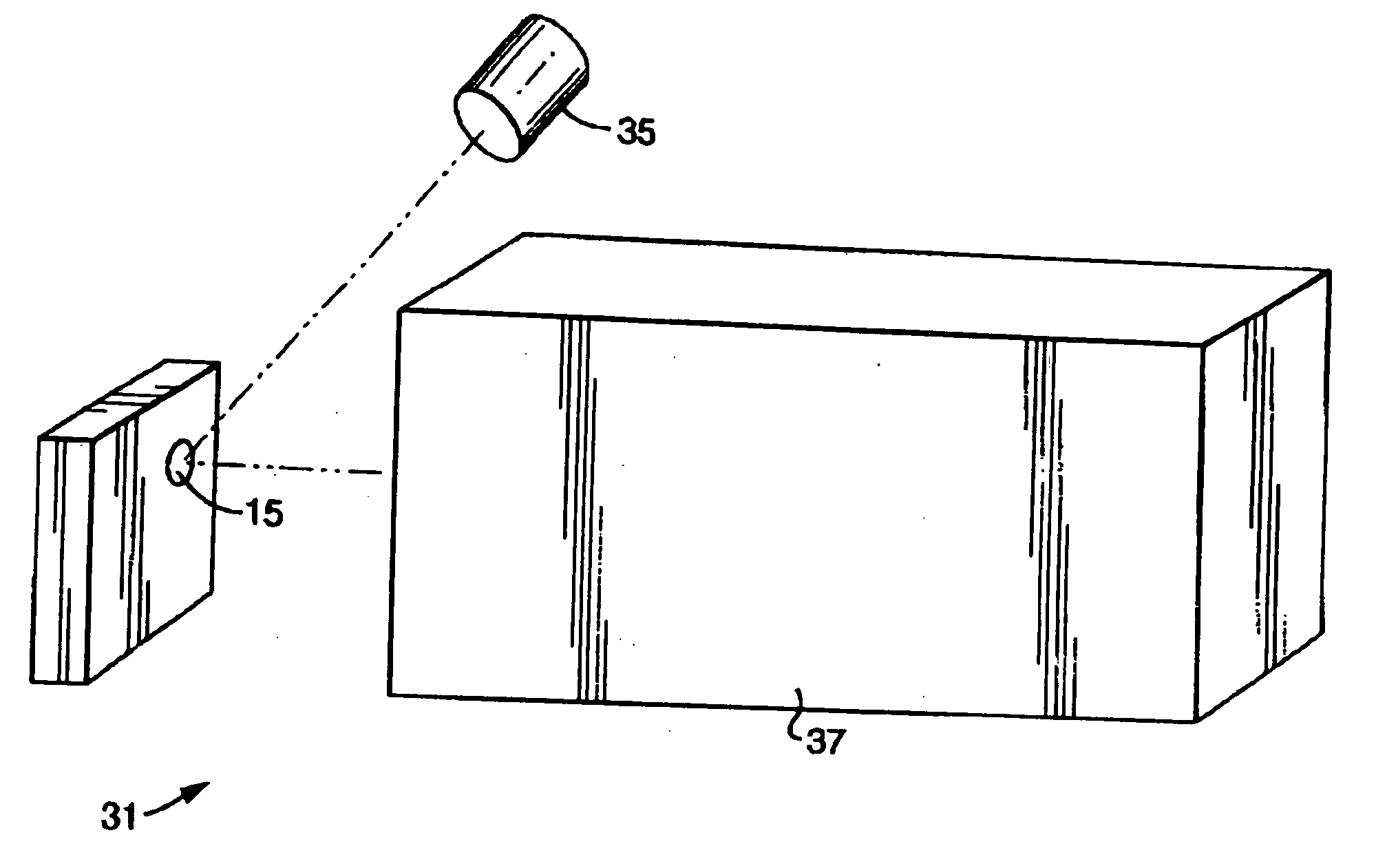

Methods, compositions and devices for performing ionization desorption on silicon derivatives

InactiveUS20060157648A1Consistent resultElectrolysis componentsWithdrawing sample devicesCarbamateDesorption

Embodiments of the present invention are directed to a substrate for performing ionization desorption on porous silicon, methods for performing such ionization desorption and methods of making substrates. One embodiment directed to a substrate for performing ionization desorption on silicon comprises a substrate having a surface having a formula of: As used above, X is H or Y, where at least at least twenty five mole percent of X is Y and Y is hydroxyl, or —O—R1 or O—SiR1,R2,R3 wherein R1,R2, and R3 are selected from the group consisting C1 to C6 straight, cyclic, or branched alkyl, aryl, or alkoxy group, a hydroxyl group, or a siloxane group, and R6 may be a C1 to C36 straight, cyclic, or branched alkyl (e.g., C18, cyanopropyl), aryl, or alkoxy group, where the groups of R6 are unsubstituted or substituted with one or more moieties such as halogen, cyano, amino, diol, nitro, ether, carbonyl, epoxide, sulfonyl, cation exchanger, anion exchanger, carbamate, amide, urea, peptide, protein, carbohydrate, and nucleic acid functionalities. The letter “n” represents an integer from 1 to infinity and any vacant valences are silicon atoms, hydrogen or impurities.

Owner:WATERS INVESTMENTS

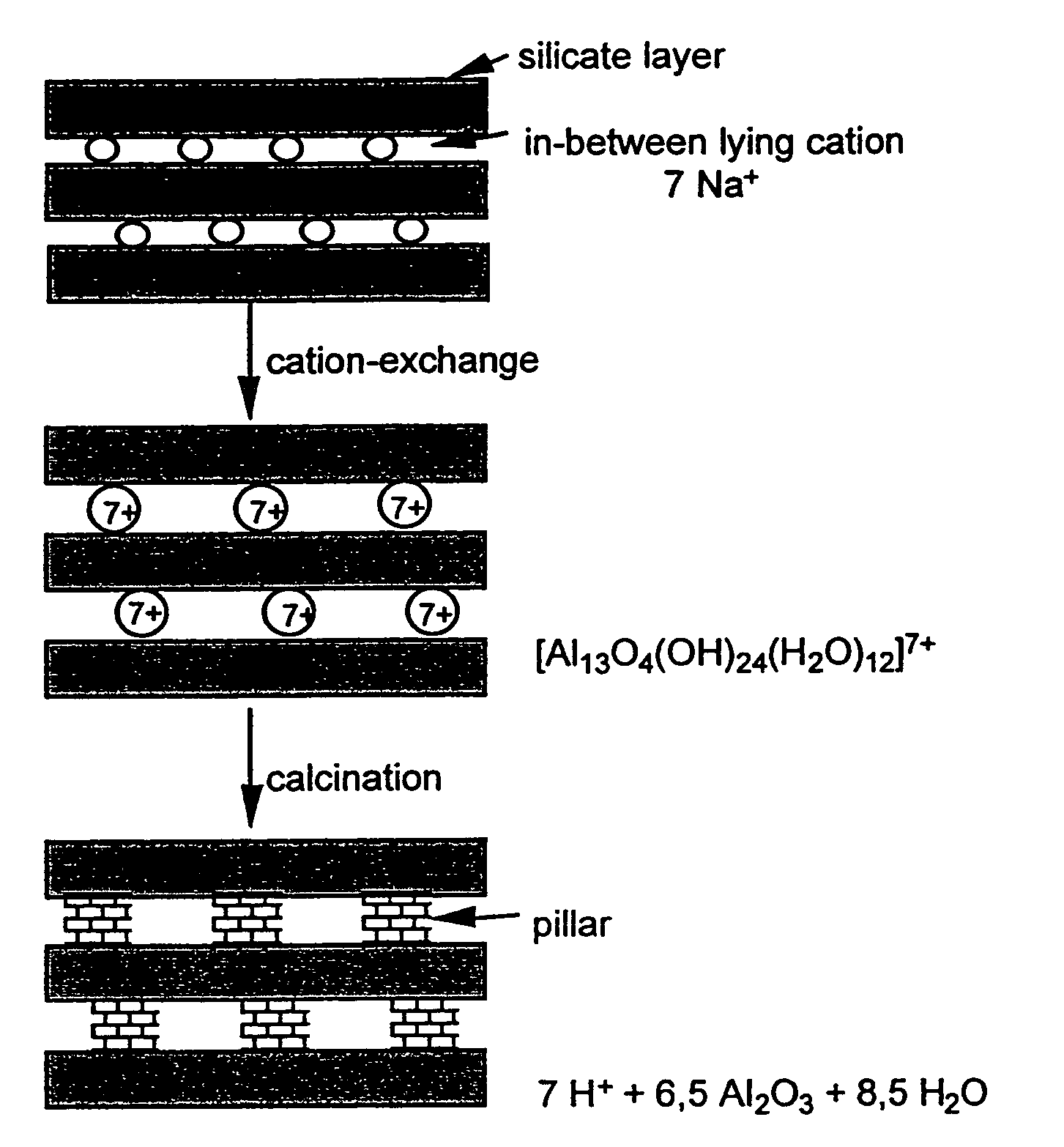

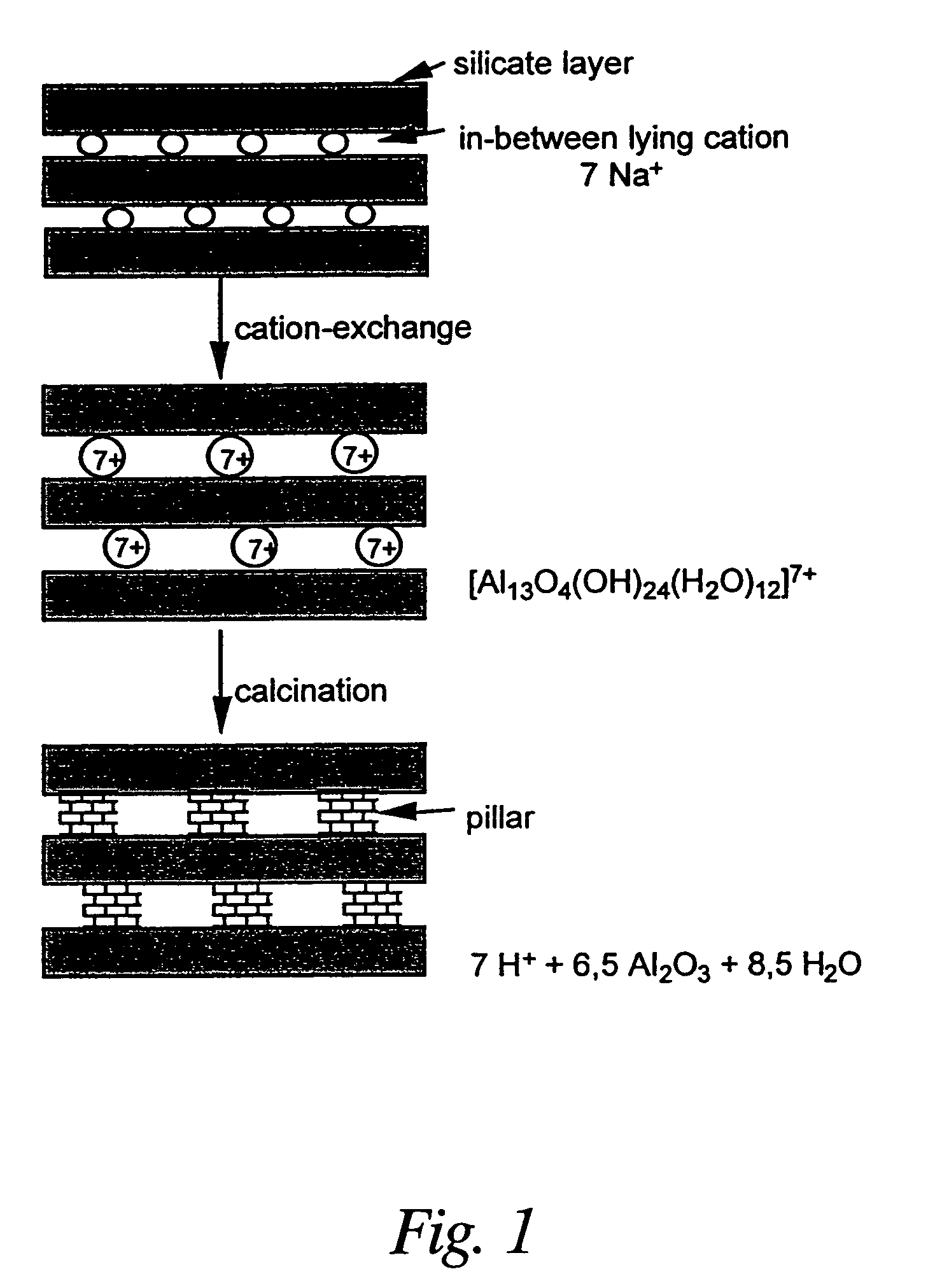

Composites and composite membranes

The invention relates to a composite or a composite membrane consisting of an ionomer and of an inorganic optionally functionalized phyllosilicate. The isomer can be: (a) a cation exchange polymer; (b) an anion exchange polymer; (c) a polymer containing both anion exchanger groupings as well as cation exchanger groupings on the polymer chain; or (d) a blend consisting of (a) and (b), whereby the mixture ratio can range from 100% (a) to 100% (b). The blend can be ionically and even covalently cross-linked. The inorganic constituents can be selected from the group consisting of phyllosilicates or tectosilicates.

Owner:THOMAS HARING & RIMA HARING

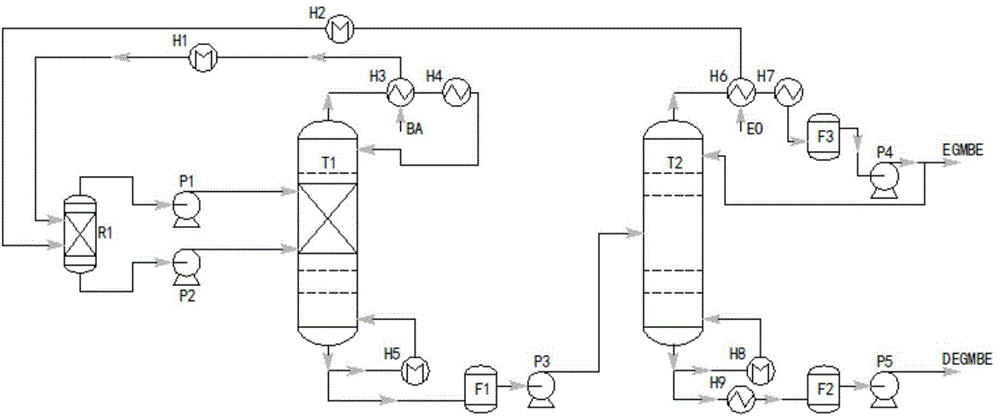

Device and processing method for synthesis of ethylene glycol monobutyl ether through reactive distillation

ActiveCN104788294AEther separation/purificationChemical industryDiethylene glycol monobutyl etherReboiler

The invention provides a device and technological process for synthesis of ethylene glycol monobutyl ether through reactive distillation. The device comprises a reactor, a reactive distillation tower, a treating tower, a condenser, a reboiler, a heat exchanger, a return tank, a kettle outlet tank, a pump and a pipeline. In the technological process, the reactive distillation tower is combined with the reactor and the treating tower. Acidic cation exchange resin or alkali anion exchanger is selected for being used as a catalyst. Preheated ethylene oxide and butanol enter into a reactor for reaction, and unreacted materials pumped into the reactive distillation tower react or are rectified on a tower plate or a filling material on the section; materials flowing down after passing through the reaction section are rectified through a stripping section; total reflux is conducted at the tower top of the reactive distillation tower; materials discharged from the tower kettle of the reactive distillation tower are pressurized to enter into the treating tower for rectification; the ethylene glycol monobutyl ether with the purity higher than 99.9 percent is obtained from the tower top of the treating tower, the yield is greater than 97 percent, and the diethylene glycol monobutyl ether is obtained from the tower kettle of the rectification tower. The device solves the problems that ethylene glycol monobutyl ether produced intermittently is not stable in product quality, the yield is relatively low, the loss of the catalyst is high, and sewage treatment is difficult.

Owner:TIANJIN PULAI CHEM TECH

Process for separating proteins fibrinogen, factor XIII and biological glue from a solubilized plasma fraction and for preparing lyophilised concentrates of said proteins

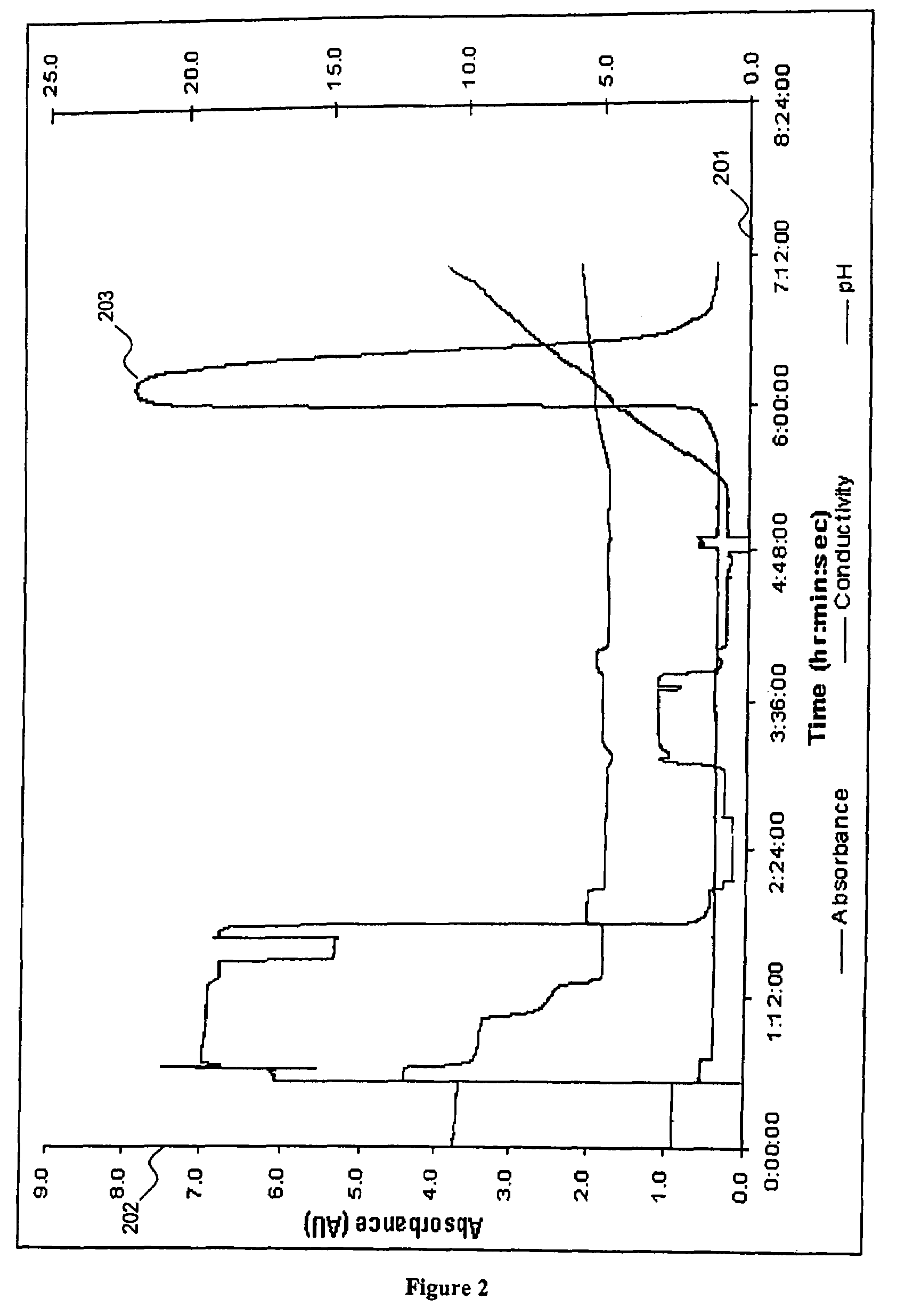

ActiveUS20080207878A1Simple and rapid and low cost processEasy to optimizeFibrinogenPeptide/protein ingredientsFreeze-dryingBlood plasma

Process for separating proteins fibrinogen, Factor XIII and biological glue from a solubilized plasma fraction and for preparing lyophilised concentrates of said proteinsSummaryThe invention is related to a process for separating proteins fibrinogen, Factor XIII and biological glue from a solubilized plasma fraction and for preparing freeze-dried concentrates of said proteins comprising the steps of:chromatographic purification comprising the steps of loading an anion exchanger of weak base type with the said solubilized fraction, previously equilibrated with a buffer of a predetermined ionic strength of an alkaline pH, which allows to retain the biological glue, elution of the biological glue by increasing the ionic strength of the said buffer, andseparation of FXIII from fibrinogen by addition to at least one part of the biological glue eluate of at least one chemical agent precipitating the FXIII, and recovery of the resulting purified fibrinogen containing supernatant solution, anddiafiltration of the fibrinogen, biological glue and resolubilized FXIII solutions, followed by a freeze-drying of said solutions. It is also related to freeze-dried concentrates of the said proteins capable to be obtained by carrying out the process.

Owner:LABE FR DU FRACTIONNEMENT & DES BIOTECH SA

Method for purifying L-cysteine

ActiveUS9120729B2Reduce impurityPurify L-cysteine effectivelyOrganic compound preparationAmino-carboxyl compound preparationStrong acidsFermentation broth

The invention relates to a method for producing a purified solution containing L-cysteine from a fermentation broth containing L-cysteine. In said method, the fermentation broth containing L-cysteine, at a pH value from pH 6 to 9, is brought in contact with a basic anion exchanger, wherein the L-cysteine bonds to the anion exchanger. The anion exchanger is then rinsed with a first washing solution, and the bonded L-cysteine is removed from the anion exchanger by means of an acid and transferred into an eluate. Said eluate, having a pH≦4, is brought in contact with an acidic cation exchanger, wherein the L-cysteine bonds to the cation exchanger. The cation exchanger is rinsed with a second washing solution, and the bonded L-cysteine is removed from the cation exchanger by means of a strong acid.

Owner:WACKER CHEM GMBH

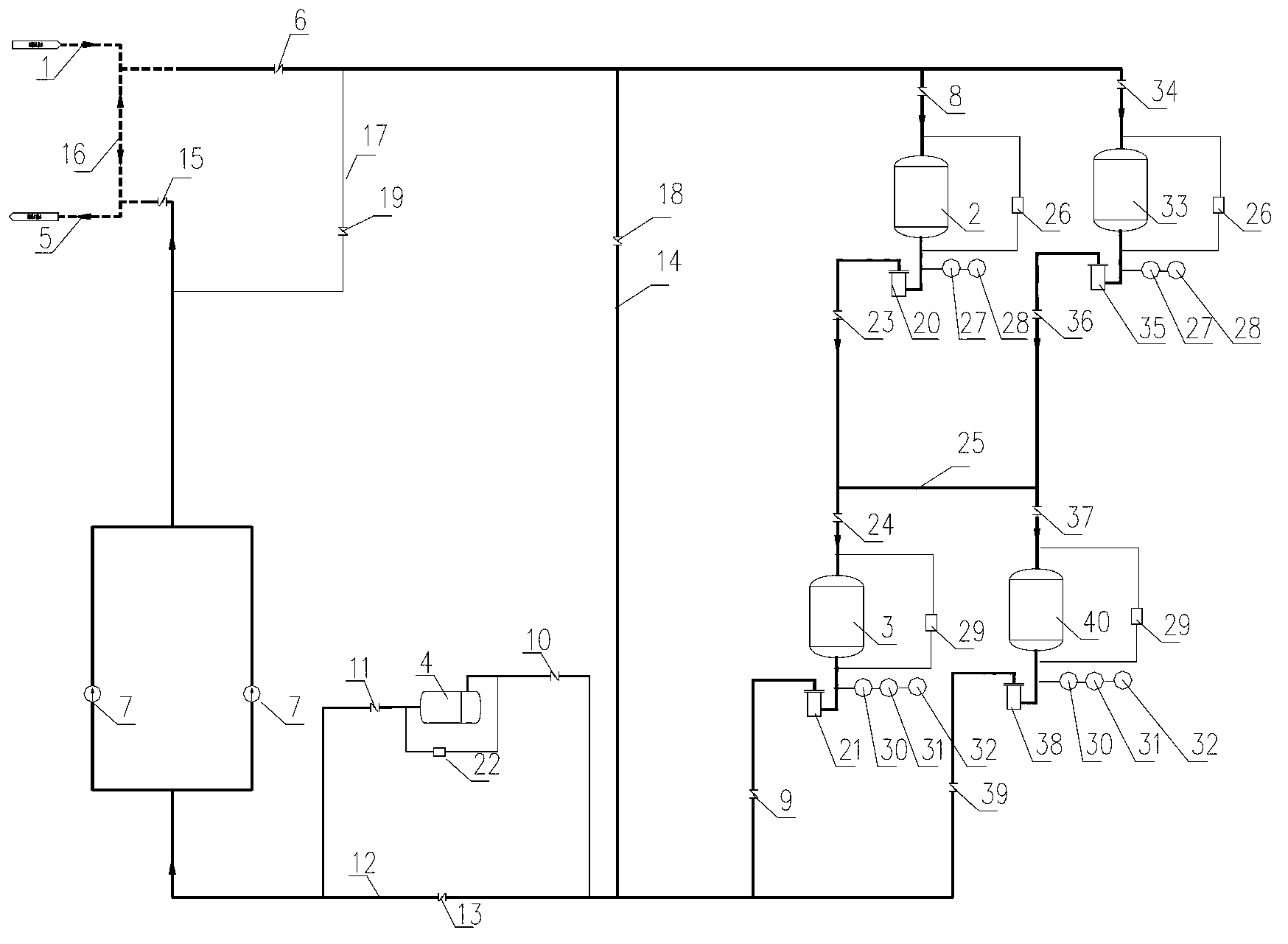

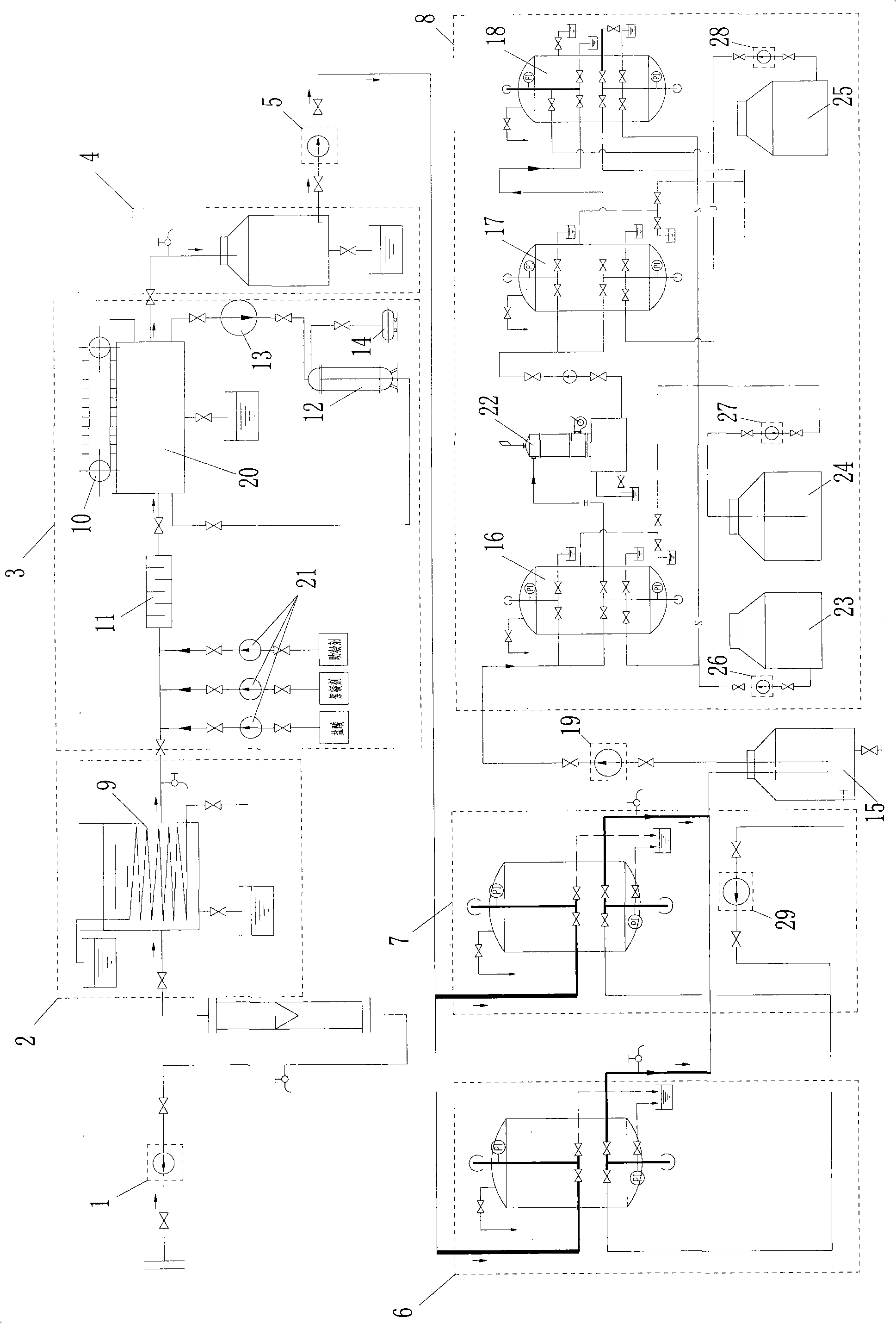

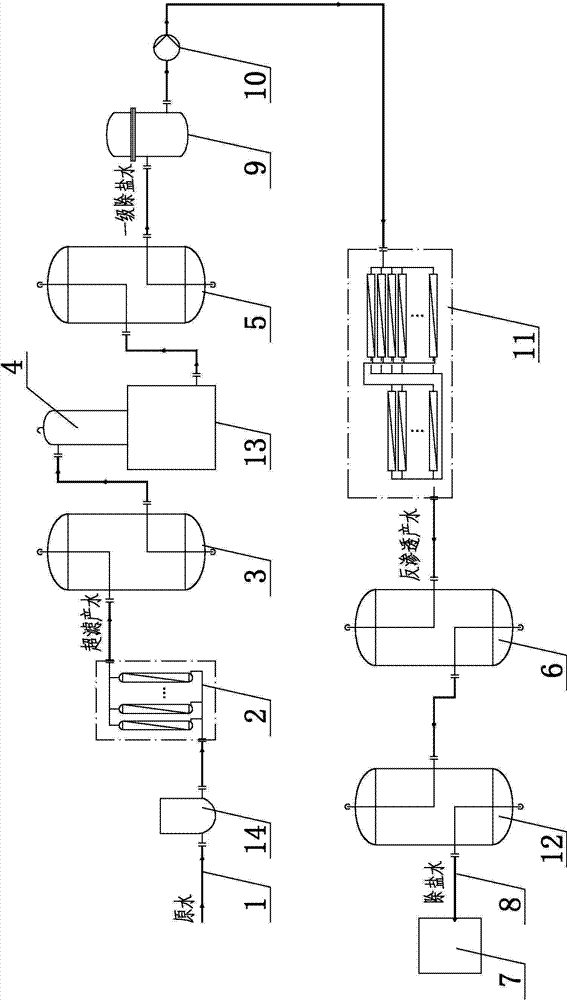

System and method for fine treatment of condensation water

ActiveCN103265131ATo meet the high demands of water qualityQuickly put into operationWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentWater resourcesHandling system

The invention discloses a system and method for fine treatment of condensation water. The system comprises a pipeline inlet, a cation exchanger, a cation-anion exchanger, a filter, a booster pump and a pipeline outlet which are connected in series in sequence through connecting pipelines; a valve 1 and a valve 3 are arranged between the pipeline inlet and the cation exchanger; a valve 4 and a valve 6 are arranged between the cation-anion exchanger and the filter; a valve 7 is arranged between the filter and the booster pump; a valve 8 is arranged on the connecting pipeline between the booster pump and the pipeline outlet; and the pipeline inlet is communicated with the pipeline outlet through a valveless bypass. According to the system and the method, metal corrosion products and suspended solids can be effectively removed, ion exchange resin can be protected, the condition for putting the ion exchangers into operation can be met as soon as possible, the time for flushing the pipelines is shortened, and the waste of water resources is reduced; and tiny resin particles can be effectively captured after the ion exchangers are normally operated, so that the operation safety of two thermal devices is kept.

Owner:CHINA HUADIAN ENG

Nucleic acid purification method

ActiveUS20080076912A1Promote recoveryEfficient elutionSugar derivativesDNA preparationPurification methodsSupport matrix

The invention provides an improved method for the purification of nucleic acid molecules, which method comprises generating a cellular lysate containing the nucleic acid; contacting the lysate with an anion exchanger bound to a solid support matrix under conditions such that the anion exchanger binds the nucleic acid; followed by eluting the nucleic acid from the anion exchanger with an aqueous mobile phase comprising an elution solution; and desalting the eluted nucleic acid such that it is suitable for downstream applications. The improvement of the method includes providing the anion exchanger in a packed column, wherein the column is packed using a salt solution containing an antimicrobial agent. In addition, the salt solution has a salt concentration similar to that of the lysate, such that the column does not need equilibration prior to sample loading.

Owner:GLOBAL LIFE SCI SOLUTIONS USA LLC

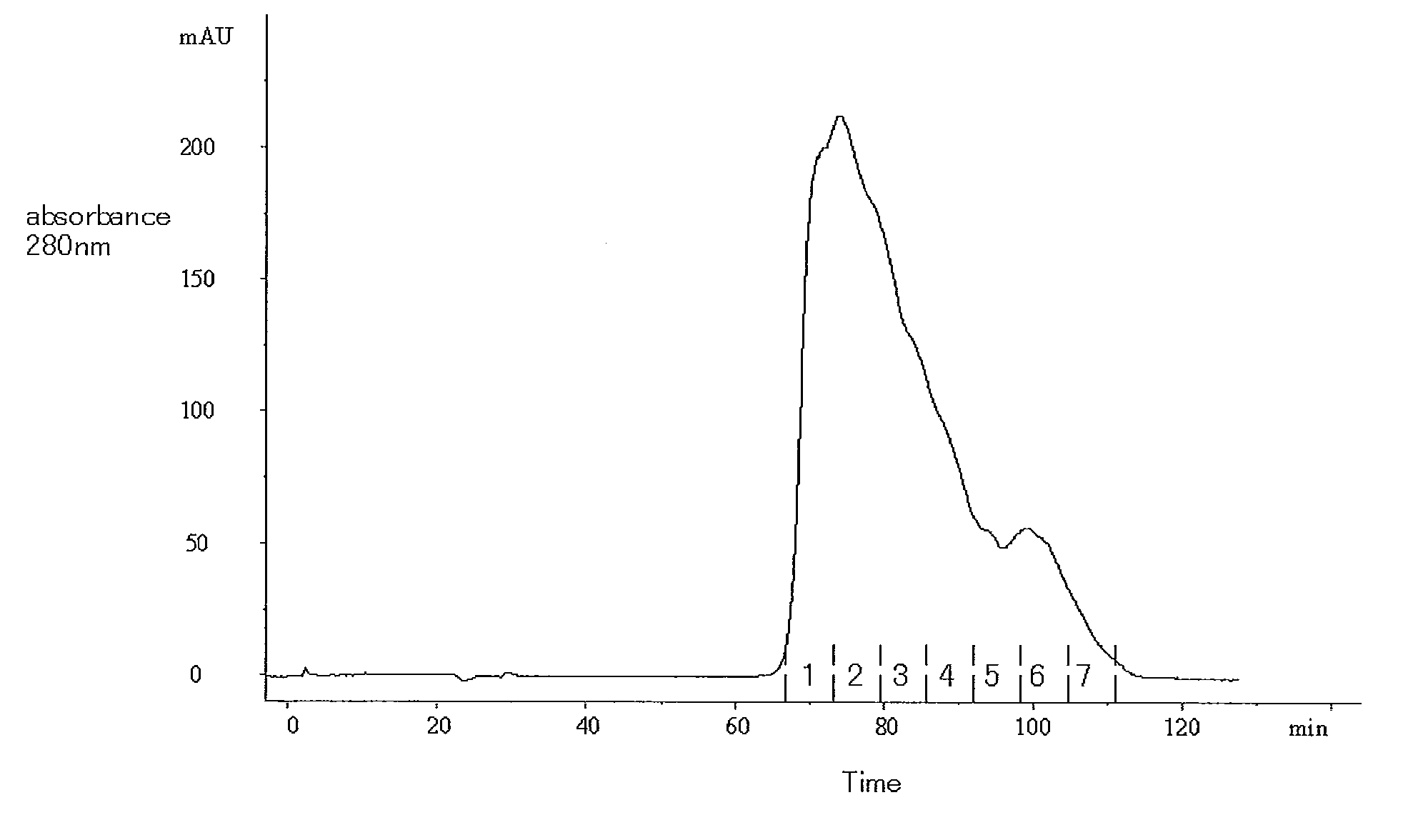

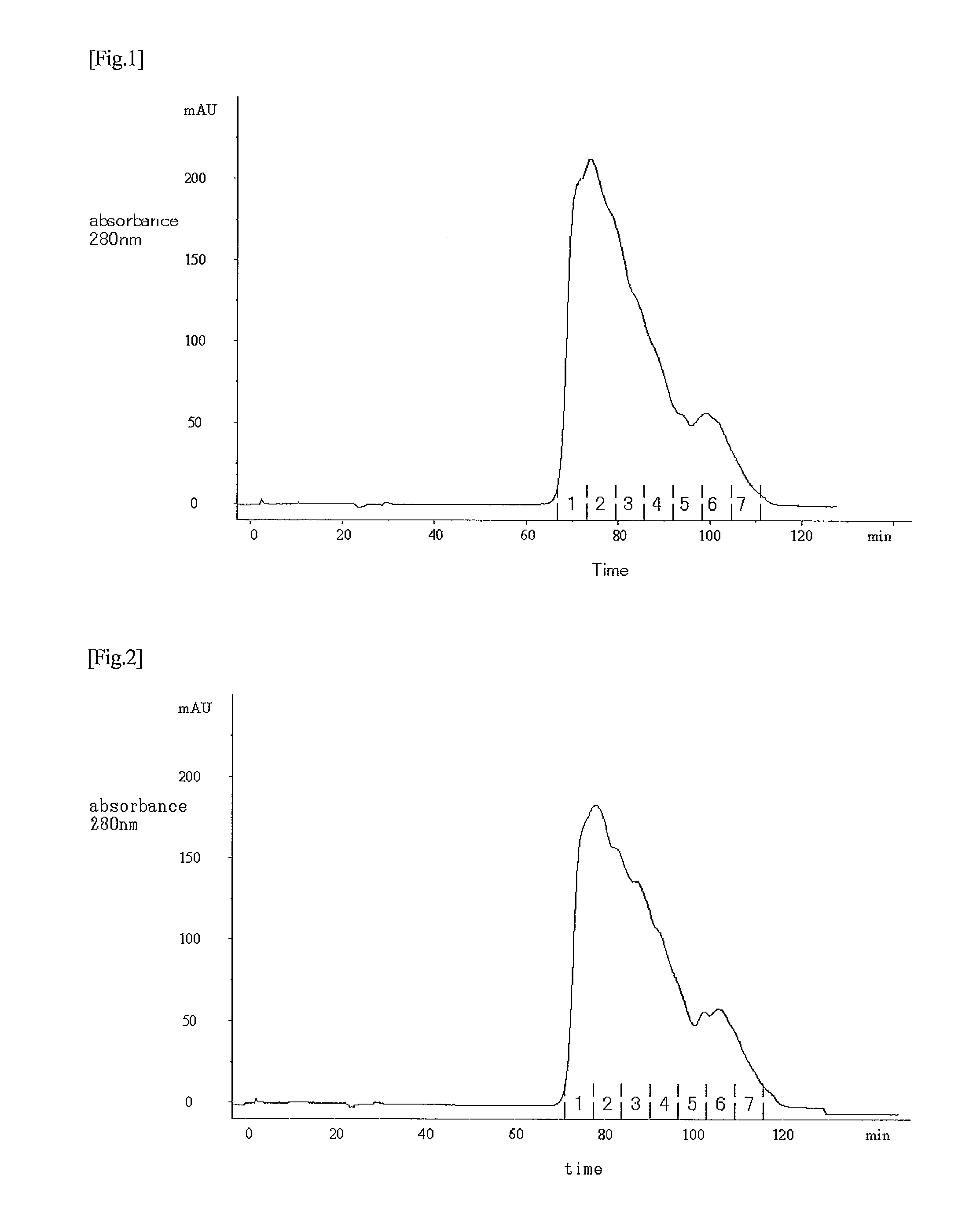

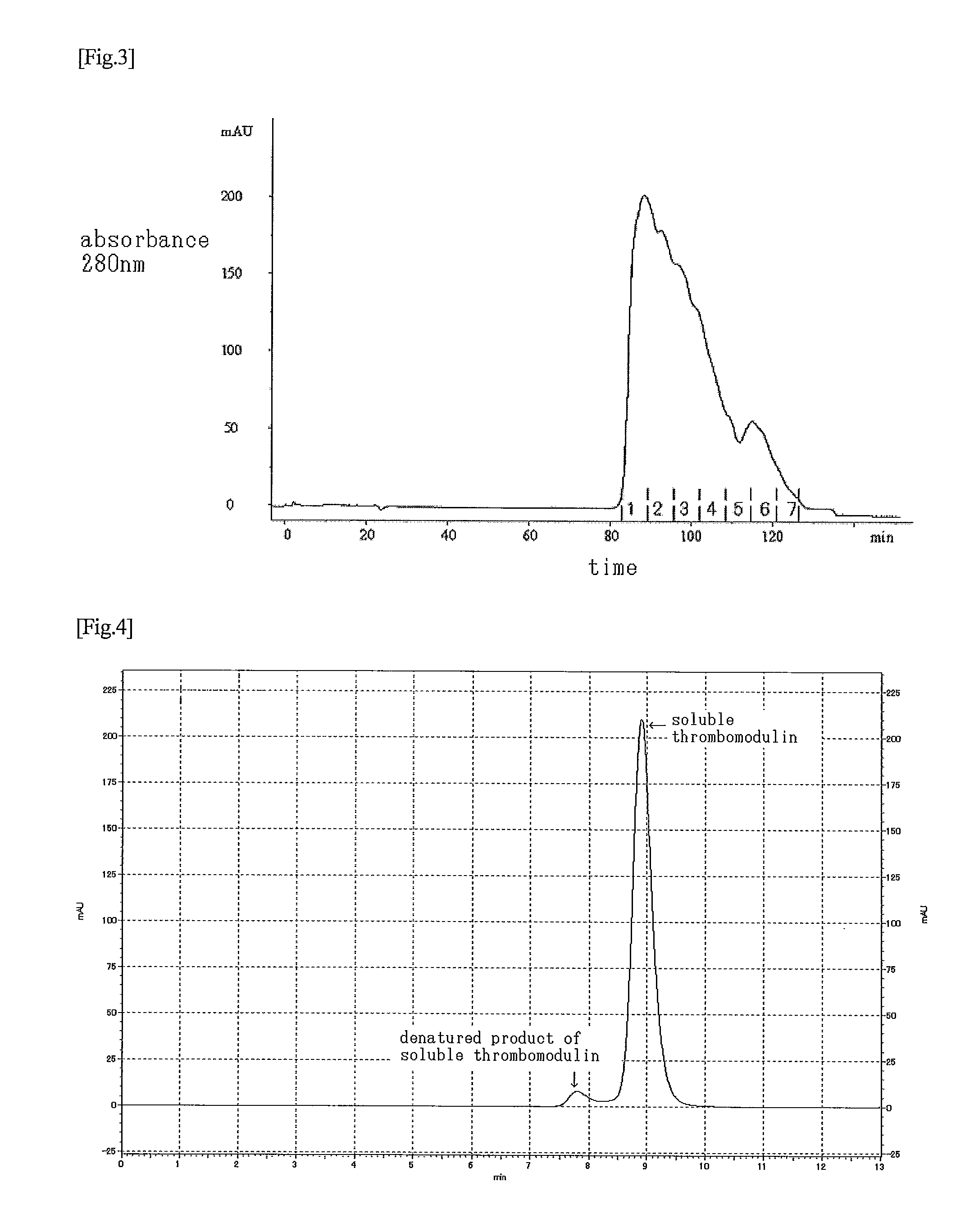

Method for producing high-purity soluble thrombomodulin

ActiveUS20100145020A1Improve productivityPeptide/protein ingredientsThrombomodulinThrombusBiochemistry

It is an object of the present invention to obtain a soluble thrombomodulin substantially not containing a denatured product of soluble thrombomodulin that may be generated under acidic conditions. The present invention provides a method for producing soluble thrombomodulin substantially not containing a denatured product of the soluble thrombomodulin that may be generated under acidic conditions, from a soluble thrombomodulin-containing material that contains or is suspected to contain the denatured product of the soluble thrombomodulin, which comprises; a step of subjecting the soluble thrombomodulin-containing material to an anion exchanger or hydroxyapatite; and a step of carrying out linear gradient elution, stepwise gradient elution, or gradient elution in which linear gradient elution is combined with stepwise gradient elution under separation conditions in which the denatured product of the soluble thrombomodulin can be separated, wherein said gradient is a gradient of salt concentration, so as to obtain an elution fraction containing soluble thrombomodulin that does not substantially contain the denatured product of the soluble thrombomodulin, either (a) after the position of a fraction has previously been confirmed, or (b) while confirming the elution fraction.

Owner:ASAHI KASEI PHARMA

Process for preparing fluoropolymer dispersions

A process to substantially remove fluorinated anionic surfactants from fluoropolymer dispersions comprising the following steps: a) addition to the fluoropolymer dispersion of one or more non fluorinated surfactants; b) contact of the dispersion with an anionic exchanger; c) separation of the dispersion from the anionic exchanger and recovery of the dispersion substantially fluorinated anionic surfactant free.

Owner:SOLVAY SOLEXIS

Method for recovering activity of ion exchanger and agent for use in recovering activity of anion exchanger

InactiveUS20050029087A1Deionization capacityNegatively chargedElectrolysis componentsVolume/mass flow measurementAmmonium compoundsIon-exchange membranes

A performance-lowered ion exchanger hard to recover in performance by the conventional regeneration (ion exchange resin, ion exchange membrane, or the like) is endowed with the same electric charge as the electric charge of the ion exchanger. A performance-lowered ion exchanger hard to recover in performance by the conventional regeneration owing to adsorption thereon of a charged substance is endowed with an electric charge opposite to that of the charged substance. According to the foregoing operations, the ion exchangers are recovered in performance. At least one compound selected from among organic amine compounds and organic ammonium compounds, which are capable of being endowed with an electric charge through dissociation thereof in solution, is preferably used as a rejuvenation agent for an anion exchanger.

Owner:ORGANO CORP

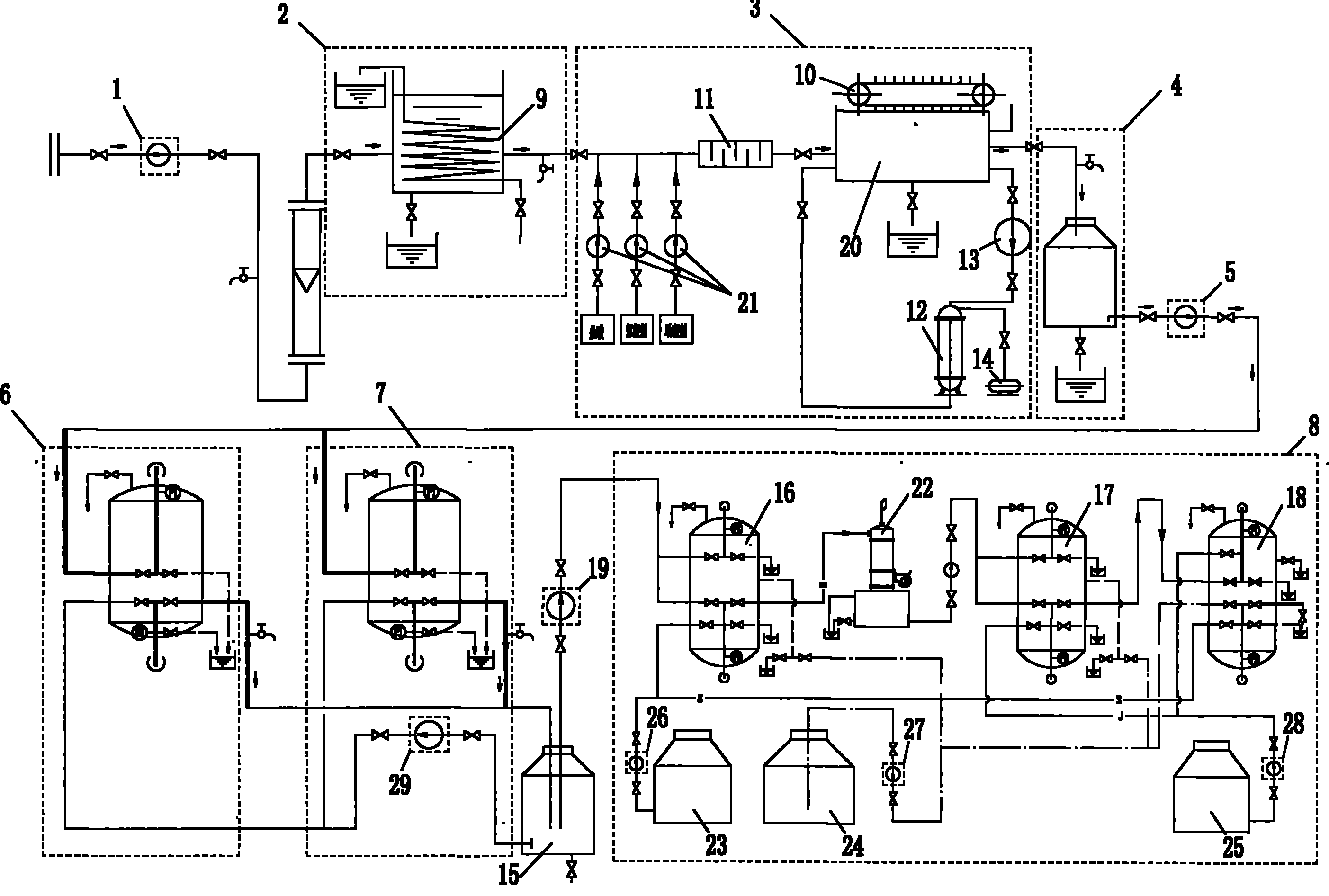

Water treatment method and device using aluminum oxide secondary condensation water as make-up water of power plant

InactiveCN101774716AEasy to handleAvoid pollutionWater/sewage treatment by ion-exchangeMultistage water/sewage treatmentHigh pressureIon-exchange resin

The invention discloses a water treatment method and device using aluminum oxide secondary condensation water as make-up water of power plant. The water treatment method comprises the following steps: reducing the temperature of secondary condensation water from an aluminium oxide factory, degrading pollutants, flocculating, performing floatation, filtering and performing ion exchange, wherein after a floatation device is used for primary aluminum removal, a two-medium mechanical filter is used to remove residual aluminum; the mechanical filter adopts anthracite coal and quartz sand as filter materials and is used to remove most of aluminium in water passing through the floatation device so that the content of aluminium in water meets the standard that the content of aluminium is less than 0.3 mg / L and the problem that when the content of aluminium is too high, the subsequent ion exchange resin is polluted, is avoided. The filtered water of which aluminium content is less than 0.3 mg / L enters a cation exchanger, a carbon dioxide remover, an anion exchanger and a mixed ion exchanger in turn, the effluent can be used as the make-up water of a high-pressure boiler, and water processed by the device completely meets the make-up water standard of the high-pressure boiler.

Owner:SHAANXI DATANG ENERGY SAVING TECH

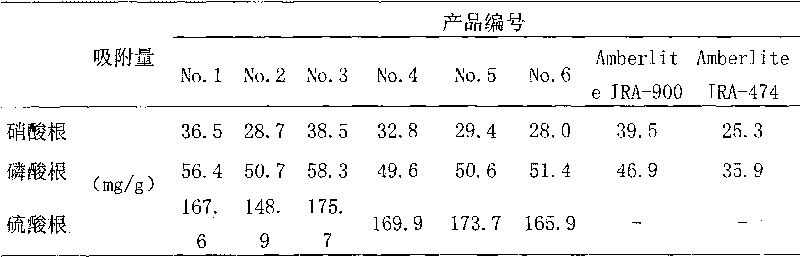

Anion-exchange agent prepared by using fermented straws, preparation method thereof and use thereof

InactiveCN101698157ASimple production processIncrease productivitySugar derivativesAnion exchanger materialsEpoxyTherapeutic effect

The invention discloses an anion-exchange agent prepared by using fermented straws and a preparation method thereof. The anion-exchange agent is brown or red brown solid powder in appearance, the Zeta electric potential is 10 to 40mv, the nitrogen content is 2.0 to 6.0 percent and the pH value of aqueous solution of the anion-exchange agent is 4 to 6; and the anion-exchange agent is prepared by using fermented straws, epoxy chloropropane and triethylamine or dimethylamine as raw materials and using amide as a crosslinker. The preparation method prepares the anion-exchange agent by using the fermented straws, the epoxy chloropropane and the triethylamine or dimethylamine as raw materials and using the amide as the crosslinker, has the characteristics of simple production process, high production efficiency, economy and the like and is suitable to be used for large-scale production. The prepared anion-exchange agent has the advantages of secondary pollution prevention, high product stability, desirable absorption effect, wide application range, low cost, large-scale production and use and the like. The anion-exchange agent can be widely used in waste water treatment with excellent treatment effect.

Owner:SHANDONG UNIV

System and method for manufacturing demineralized water

InactiveCN103496806AEfficient removalReduce pollution indexWater contaminantsMultistage water/sewage treatmentReverse osmosisHigh pressure

The invention discloses a system and a method for manufacturing demineralized water. The system comprises an industrial water inlet, a pretreatment device, a cation exchanger, a carbon remover, an anion exchanger, a primary mixed bed, a demineralized water tank and a demineralized water outlet which are sequentially connected with one another by pipelines; a primary demineralized water tank, a reverse osmosis water feeding pump, a cartridge filter, a high-pressure pump, a reverse osmosis device, a reverse osmosis water manufacturing tank and a fresh water pump are sequentially arranged on the connecting pipeline between the anion exchanger and the primary mixed bed; a polishing mixed bed is arranged on the connecting pipeline between the primary mixed bed and the demineralized water outlet. The system and the method have the advantages that suspension, colloid, organic matters and cation and anion impurities in water can be removed, and total organic carbon in the water further can be effectively removed, so that power generation sets can safely and stably run for a long time.

Owner:CHINA HUADIAN ENG +1

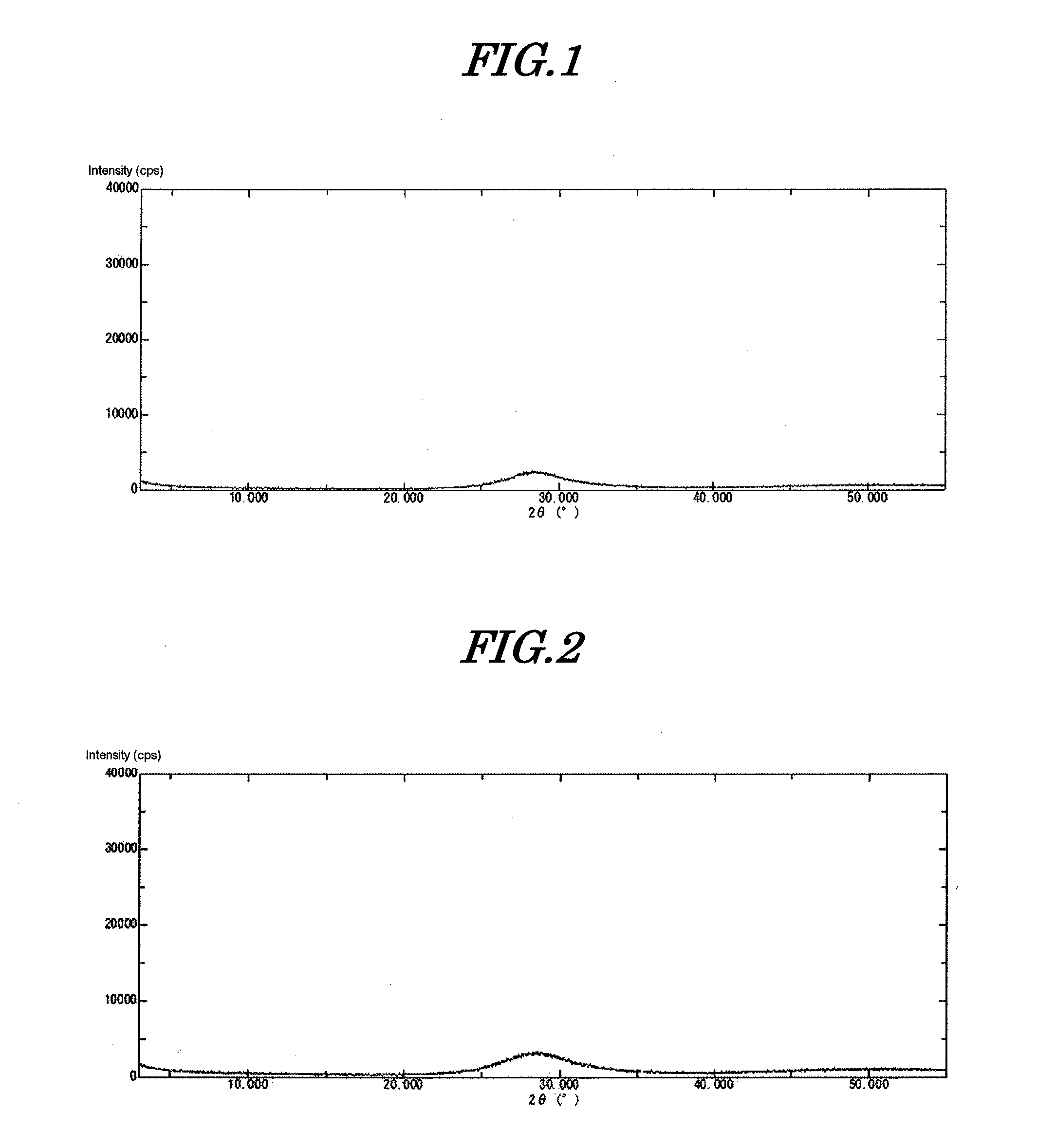

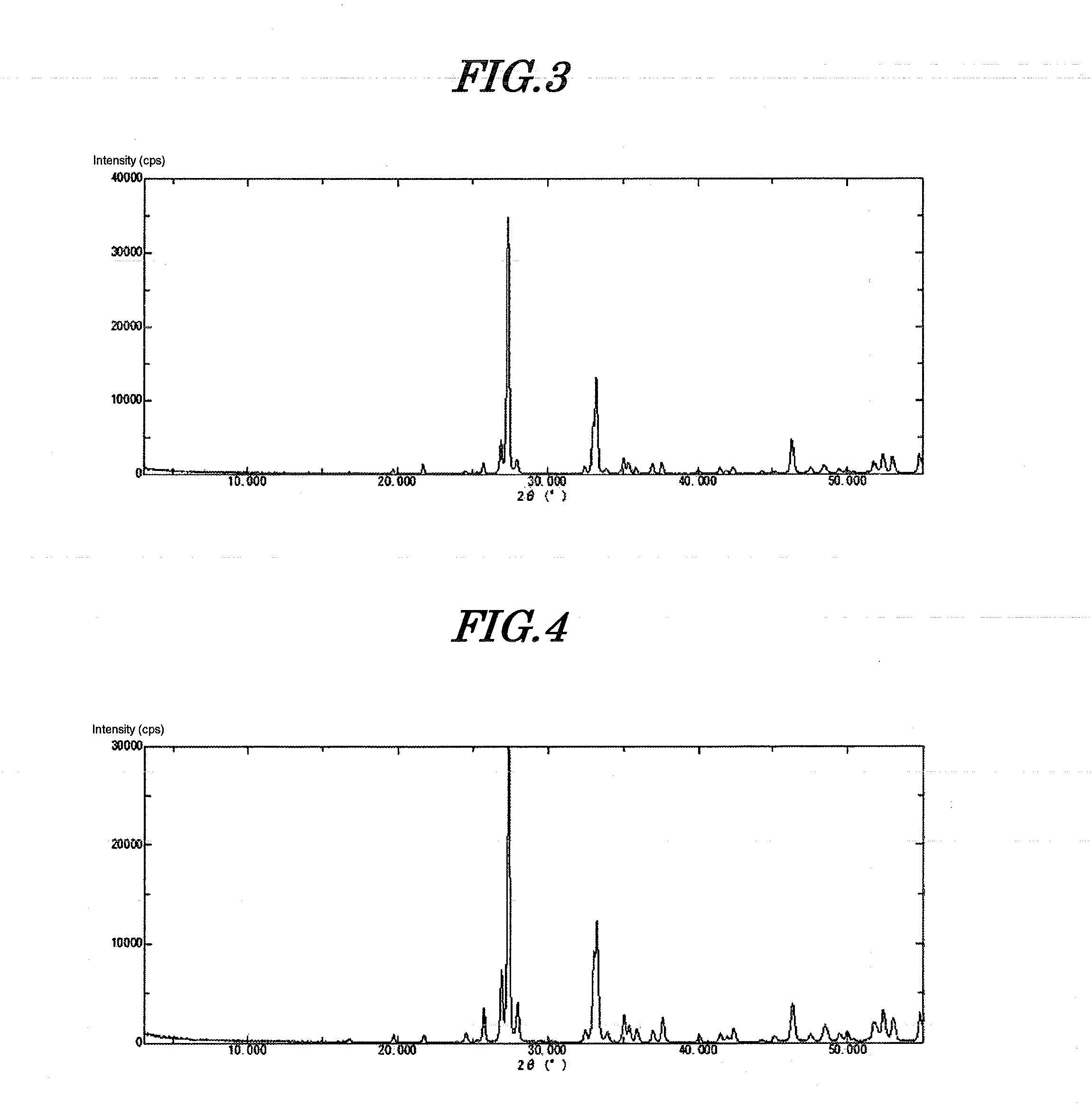

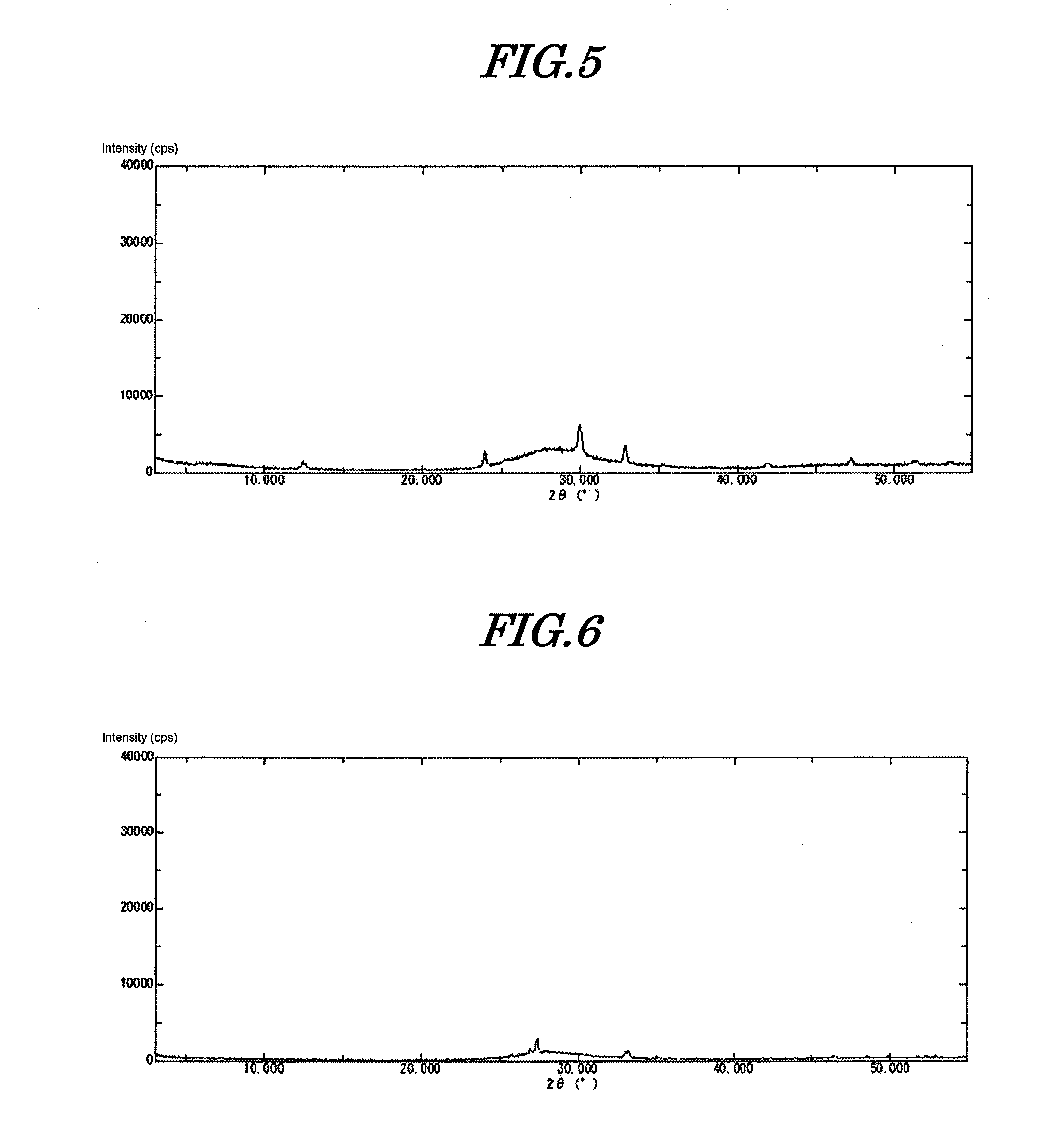

Amorphous inorganic anion exchanger, resin composition for electronic component sealing, and process for producing amorphous bismuth compound

ActiveUS20150321189A1High ion exchange capacityImprove abilitiesCation exchanger materialsNon-macromolecular adhesive additivesBismuth compoundElectron microscope

The object is to provide an amorphous inorganic anion exchanger having excellent anion exchangeability and suppressed corrosivity toward metals and to provide a production process that can produce an amorphous bismuth compound having excellent anion exchangeability and suppressed corrosivity toward metals.The amorphous inorganic anion exchanger of the present invention is represented by Formula (1) and has an average primary particle size observed with an electron microscope of at least 1 nm but no greater than 500 nm and an NO3 content of no greater than 1 wt % of the whole.The process for producing an amorphous bismuth compound of the present invention includes a precipitate formation step of forming a precipitate by subjecting an acidic aqueous solution containing trivalent Bi ions to a temperature in the range of higher than 0° C. but less than 20° C. and a pH of at least 12, the amorphous bismuth compound thus obtained being represented by Formula (1) and having an NO3 content of no greater than 1 wt %.BiO(OH) (1)

Owner:TOAGOSEI CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com