Fluorosilicone rubber composition and cured product thereof

A technology of fluorosilicone rubber and composition, which is applied in the field of fluorosilicone rubber composition and can solve the problems of inability to obtain heat-resistant fluorosilicone rubber and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

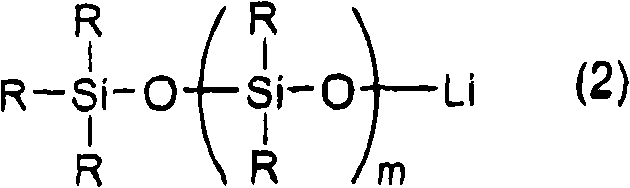

Method used

Image

Examples

preparation example Construction

[0074] [Preparation of composition]

[0075] The fluorosilicone rubber composition of the present invention can be obtained by uniformly mixing the above-mentioned components (A)-(D), and Add any other ingredients as desired. These ingredients can all be mixed at the same time, or can be added to the mixture at different times.

[0076] [Molding and curing method]

[0077] The method for molding and curing the fluorosilicone rubber composition of the present invention is not particularly limited, for example, the composition of the present invention can be molded using typical rubber molding methods such as compression molding (compression molding), transfer molding (transfer molding) , injection molding, extrusion molding (extrusion molding) or calender molding (calendar molding) molded into a desired shape and then cured, either at room temperature or by heating at a temperature of about 80-180°C, thereby forming a rubber molding such as a turbine Air supply hose, O-ring ...

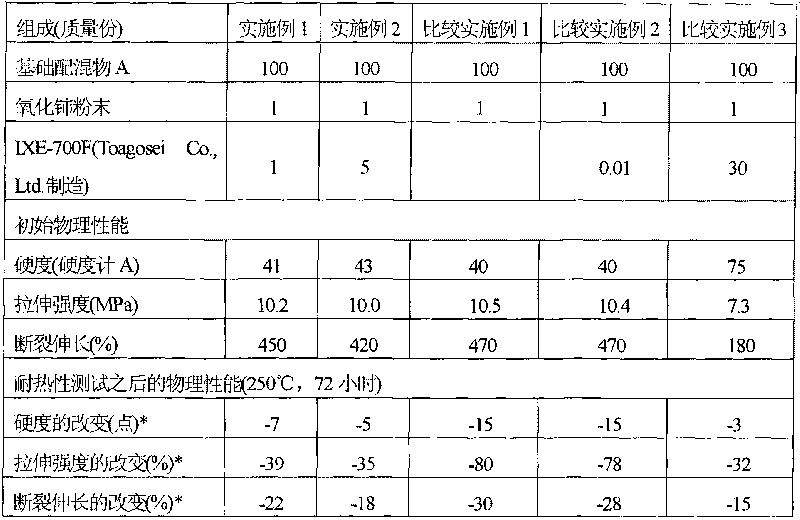

Embodiment 1-2, comparative Embodiment 1-3

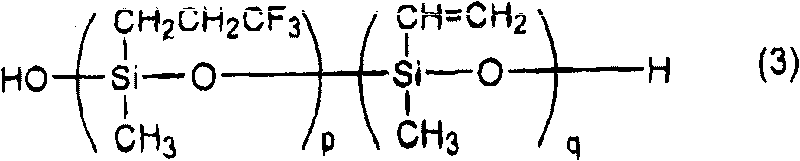

[0081] - Preparation of base compound A

[0082] First, Base Compound A was prepared using the method described below. That is, 100 parts by mass of an organopolysiloxane represented by the following formula (3) existing in a colloidal state at room temperature (25° C.), 20 parts by mass of dry silica A (product name: Aerosil (registered trademark) 200, manufactured by NipponAerosil Co., Ltd) and 4 parts by mass of diphenylsilanediol as a dispersant were uniformly mixed together, then heated at 150° C. for 4 hours, and the mixture was masticated and Plasticized, resulting in base compound A.

[0083]

[0084] (where p+q (that is, the degree of polymerization) is about 4,000, and q / (p+q) (that is, the ratio of vinyl-containing siloxane units to all siloxane units) is 0.15±0.05 moles %.)

[0085] - Preparation of composition

[0086] Subsequently, cerium oxide powder having an average particle size of 1 μm and a hydrotalcite-based inorganic anion exchanger IXE-700F (produ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com