Patents

Literature

42470results about How to "High mechanical strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

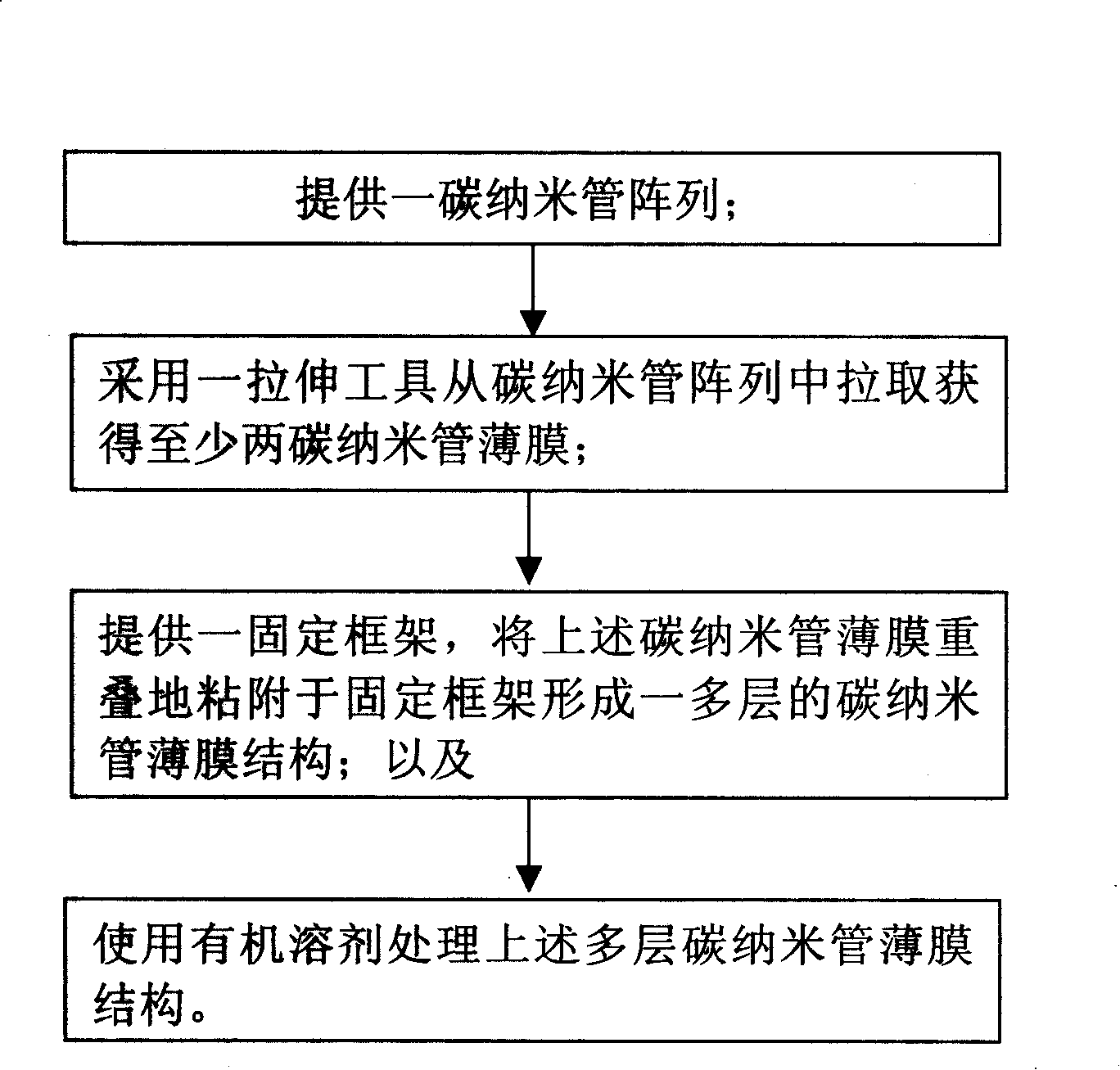

Carbon nano-tube thin film structure and preparation method thereof

ActiveCN101239712ASmall surface to volume ratioNon stickyMaterial nanotechnologyLamination ancillary operationsOrganic solventFixed frame

The present invention provides a preparing method of carbon nanotube film structure, including following steps: providing a carbon nanotube array; adopting a pulling tool to acquire at least two carbon nanotube films from the carbon nanotube array; providing a fixed frame, forming a multiple-layer carbon nanotube film structure by overlap adhereing the carbon nanotube film in the fixed frame; and treating the multiple-layer carbon nanotube film by an organic solvent. The carbon nanotube film structure prepared by the method includes at least two layers overlapped and cross-over installed carbon nanotube film, which includes multiple carbon nanotube bundle end to end and arranged in the direction, the multiple-layer carbon nanotube film further includes millipore crosswise formed by multiple carbon nanotube bundles.

Owner:TSINGHUA UNIV +1

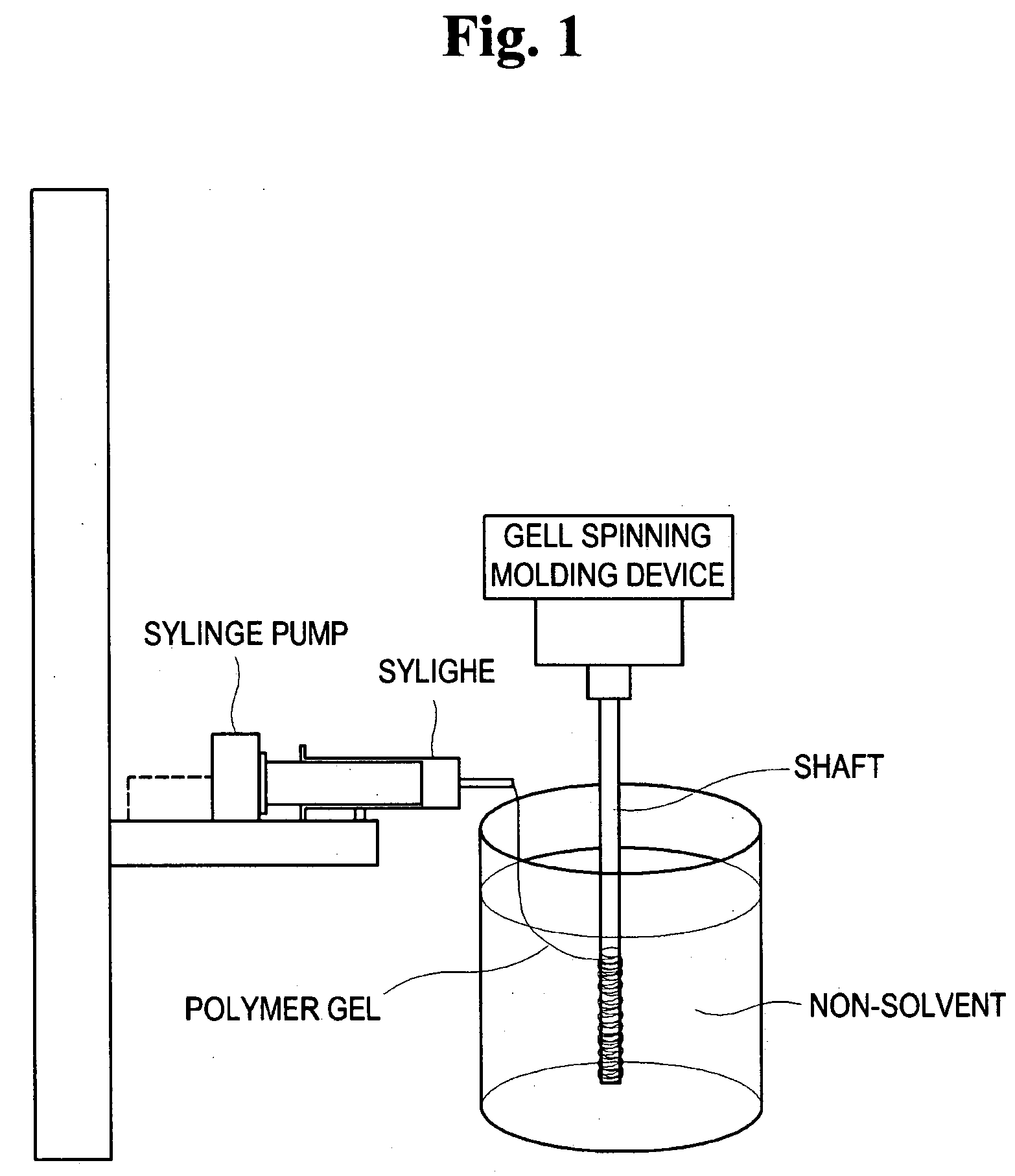

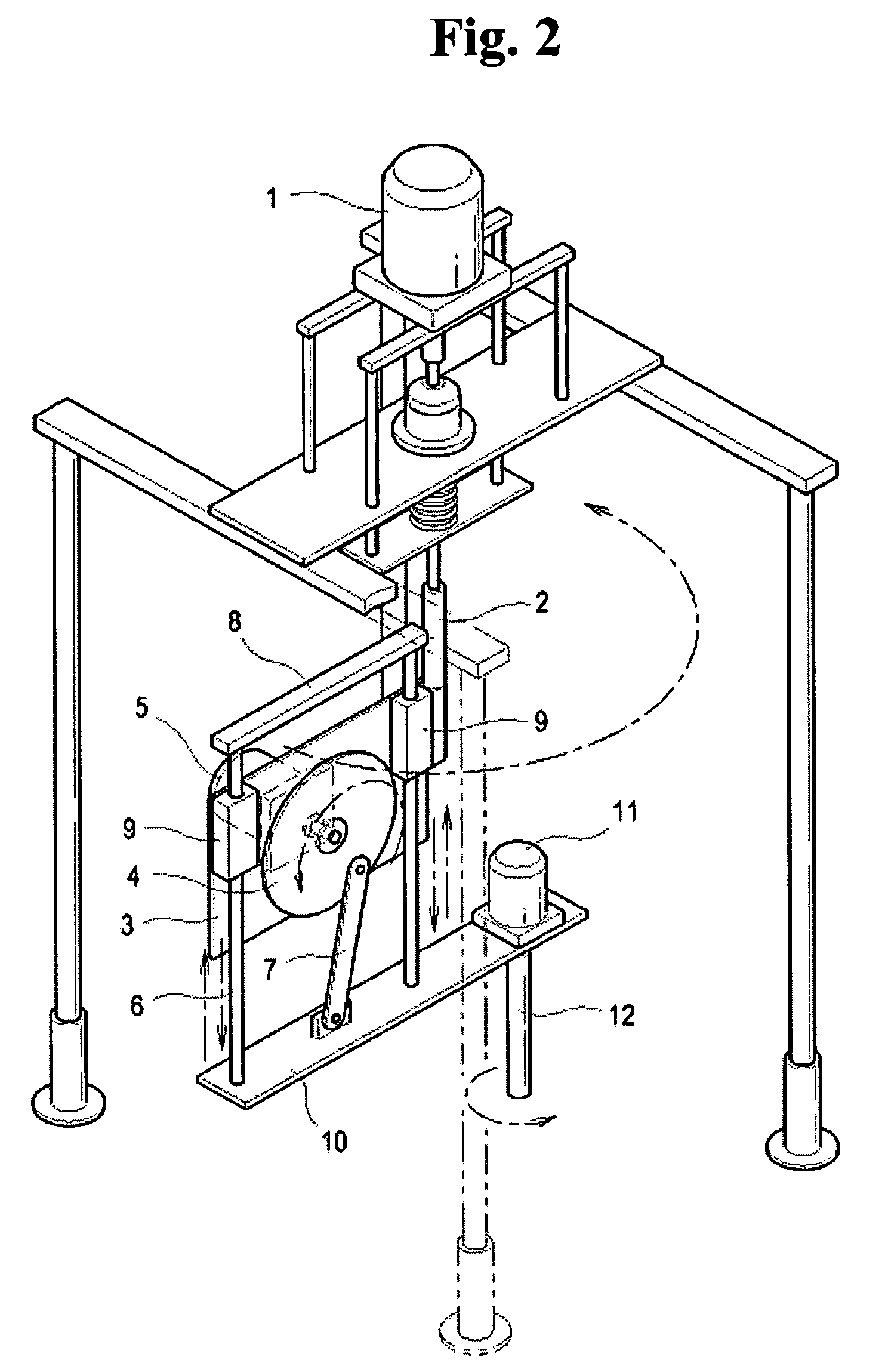

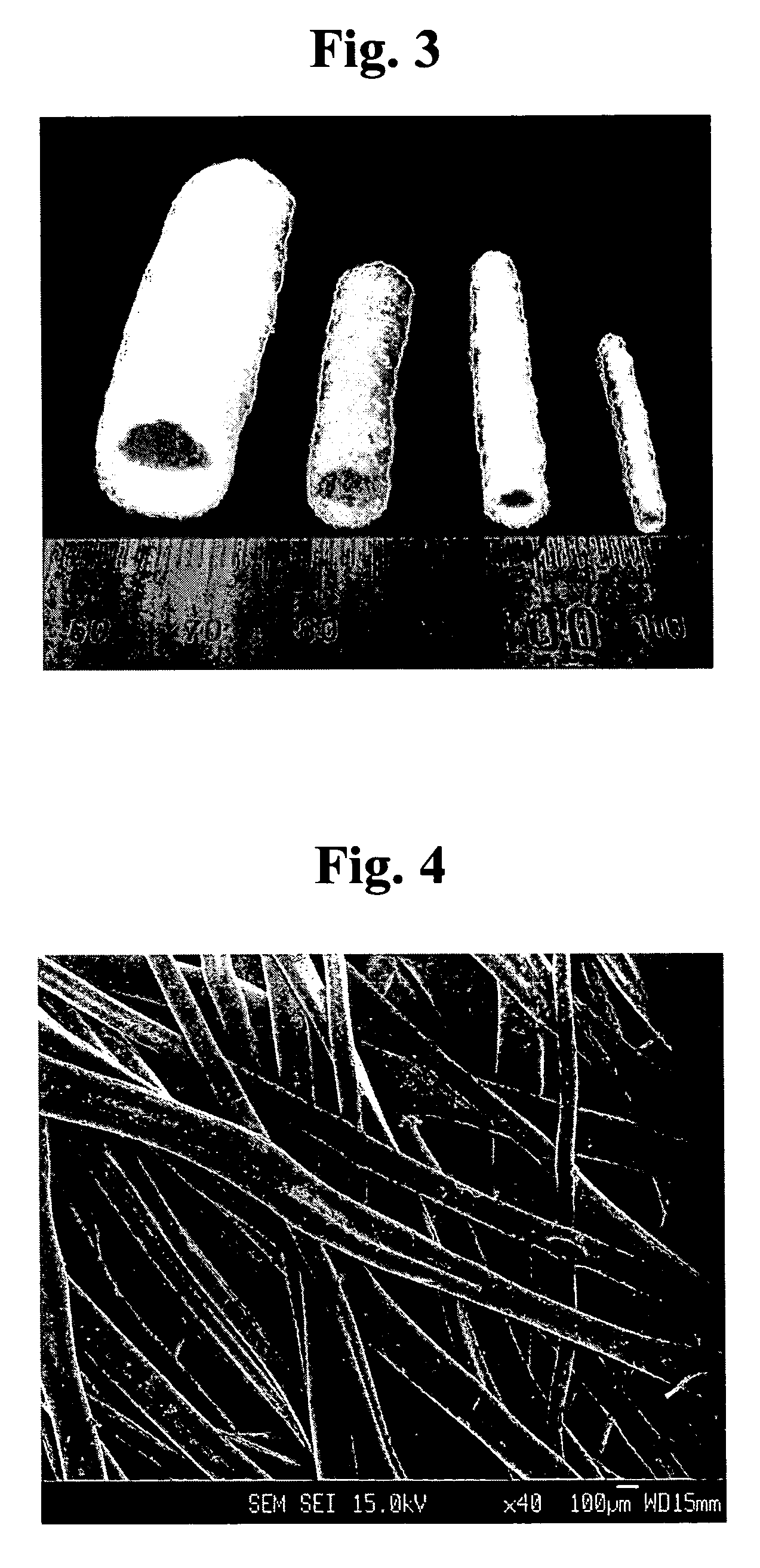

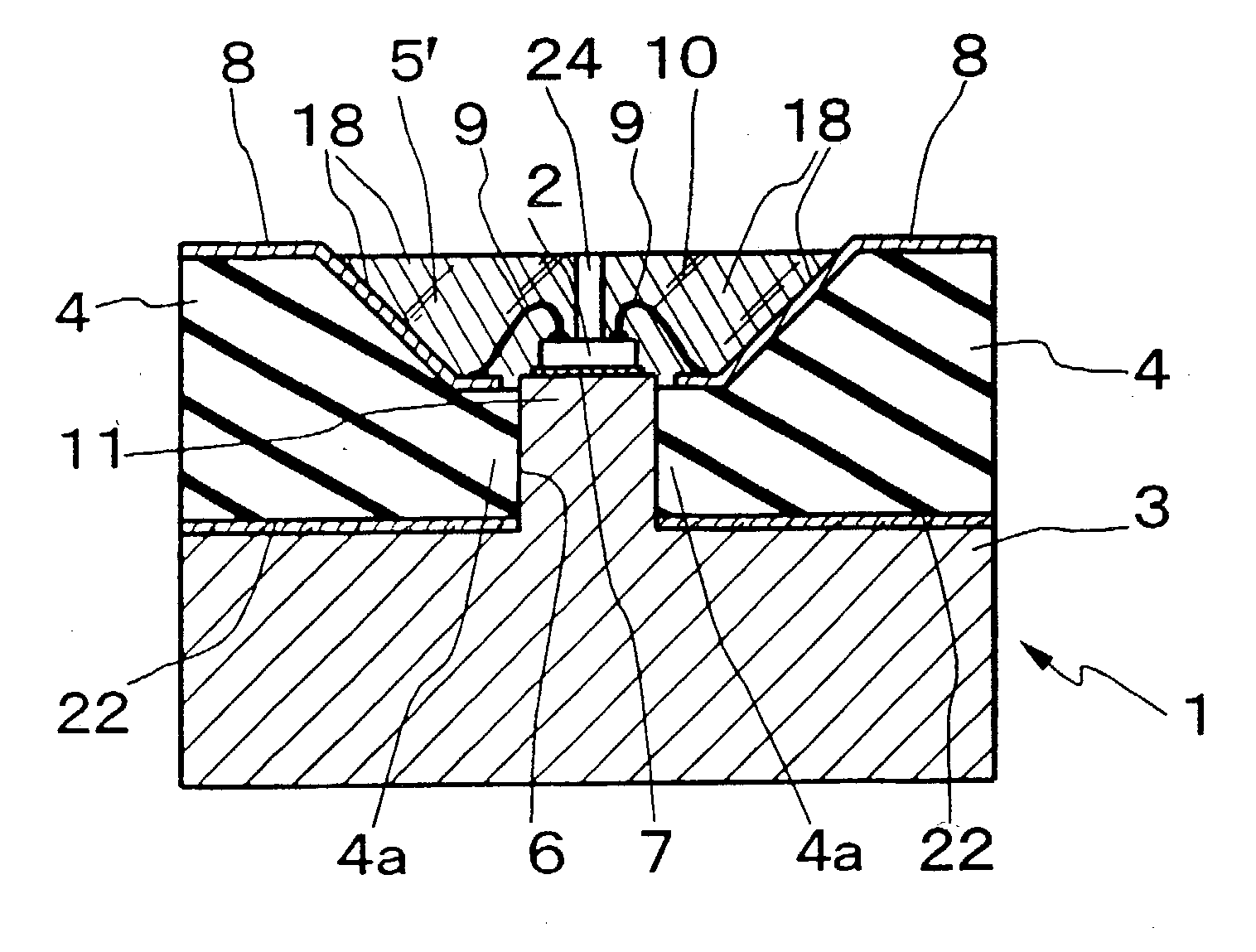

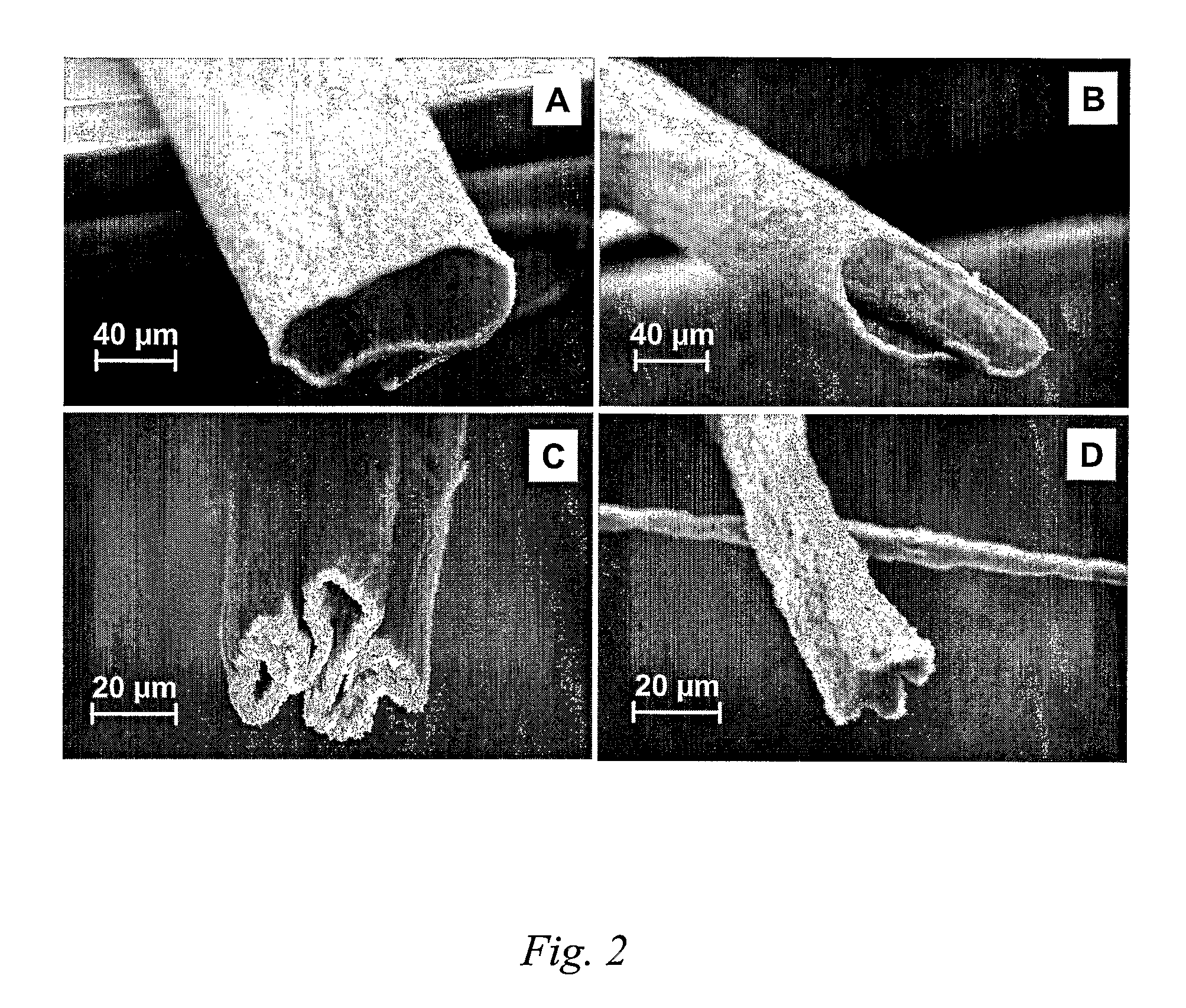

Method for preparing porous polymer scaffold for tissue engineering using gel spinning molding technique

InactiveUS20070009570A1Uniform pore sizeImprove interconnectivitySuture equipmentsCeramic shaping apparatusPolymer scienceSpinning

The present invention relates to a method of preparing a porous polymer scaffold for tissue engineering using a gel spinning molding technique. The method of the present invention can prepare a porous polymer scaffold having a uniform pore size, high interconnectivity between pores and mechanical strength, as well as high cell seeding and proliferation efficiencies, which can be effectively used in tissue engineering applications. Further, the method of the present invention can easily mold a porous polymer scaffold in various types such as a tube type favorable for regeneration of blood vessels, esophagus, nerves and the like, as well as a sheet type favorable for regeneration of skins, muscles and the like, by regulating the shape and size of a template shaft.

Owner:KOREA INST OF SCI & TECH

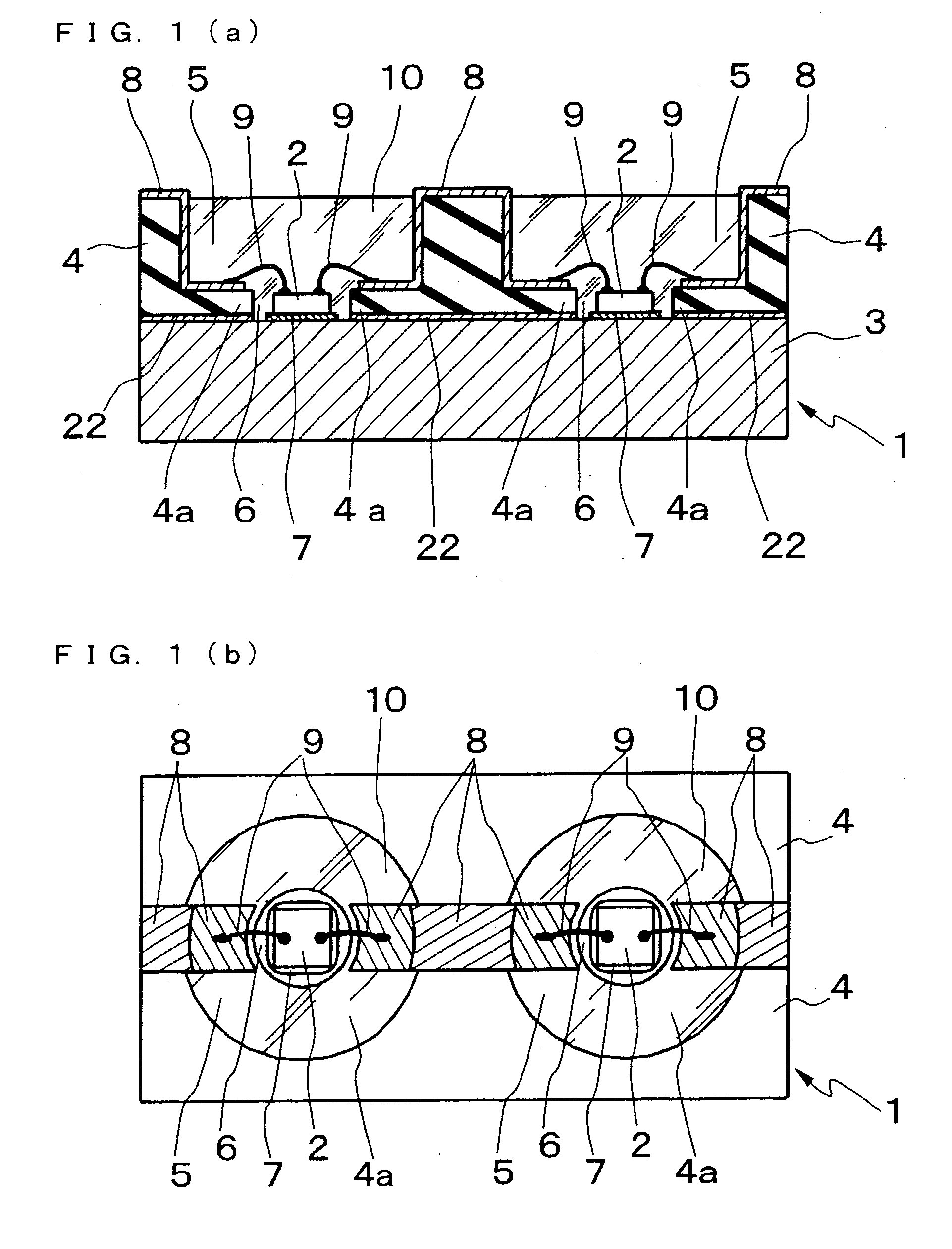

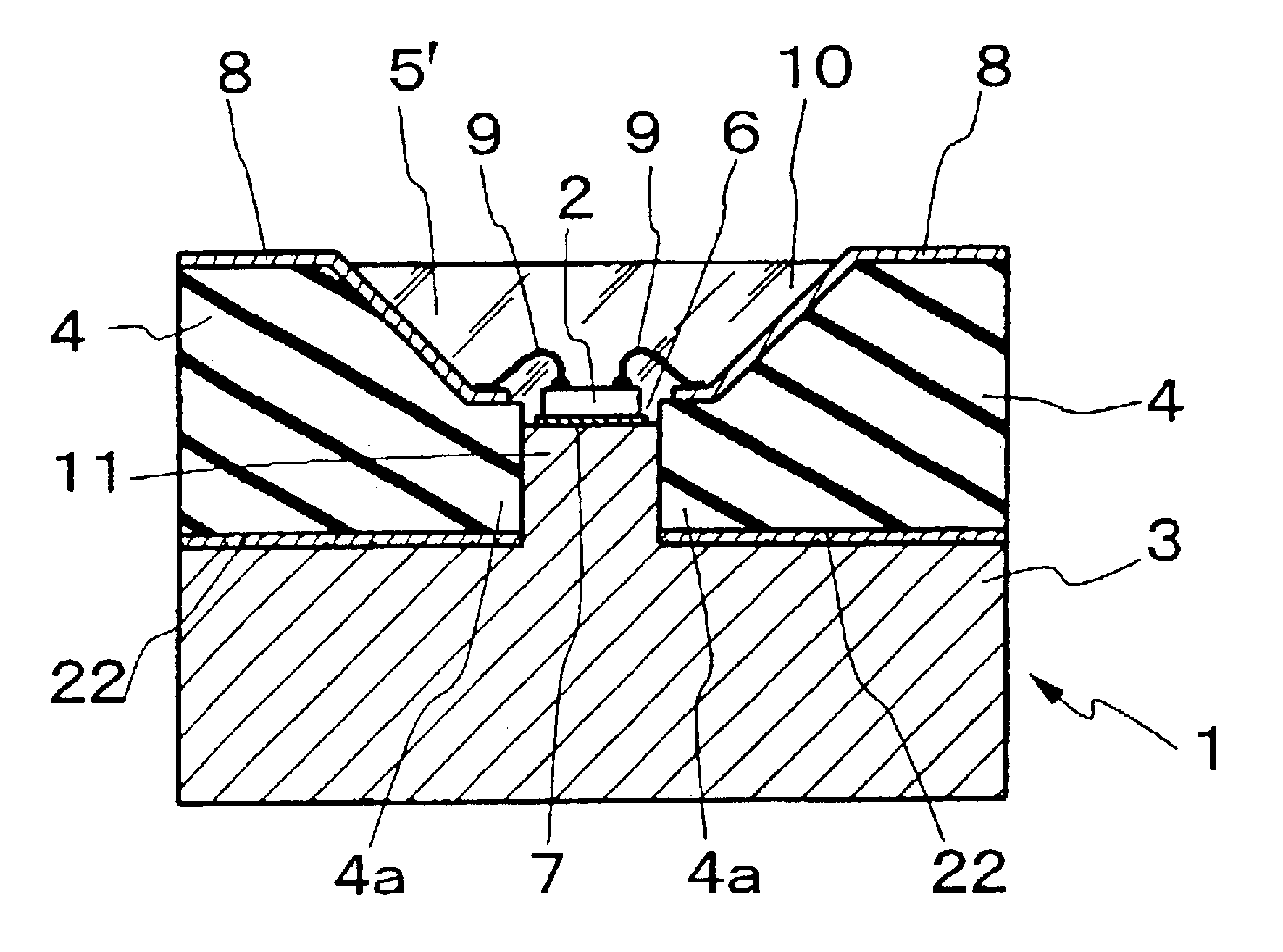

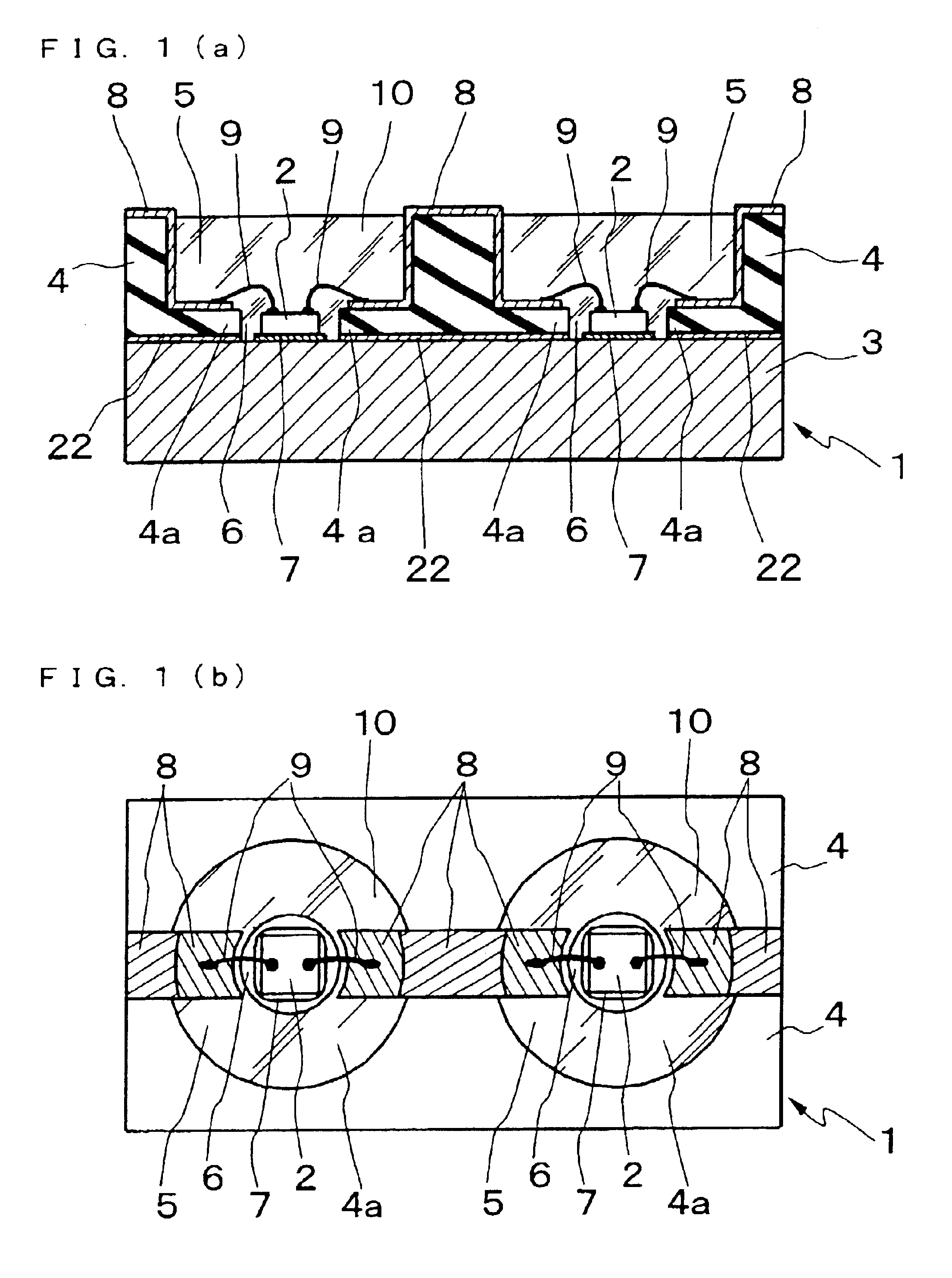

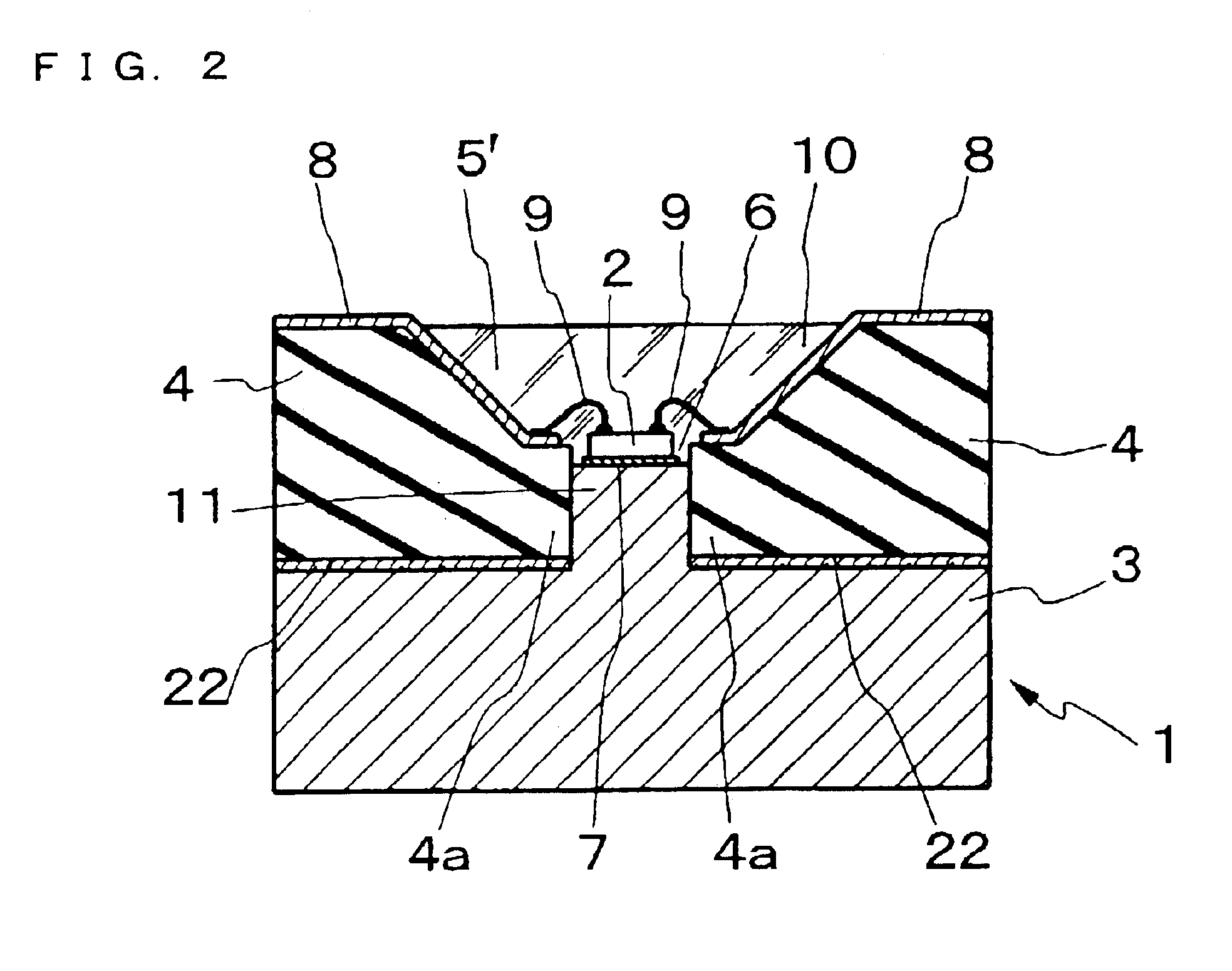

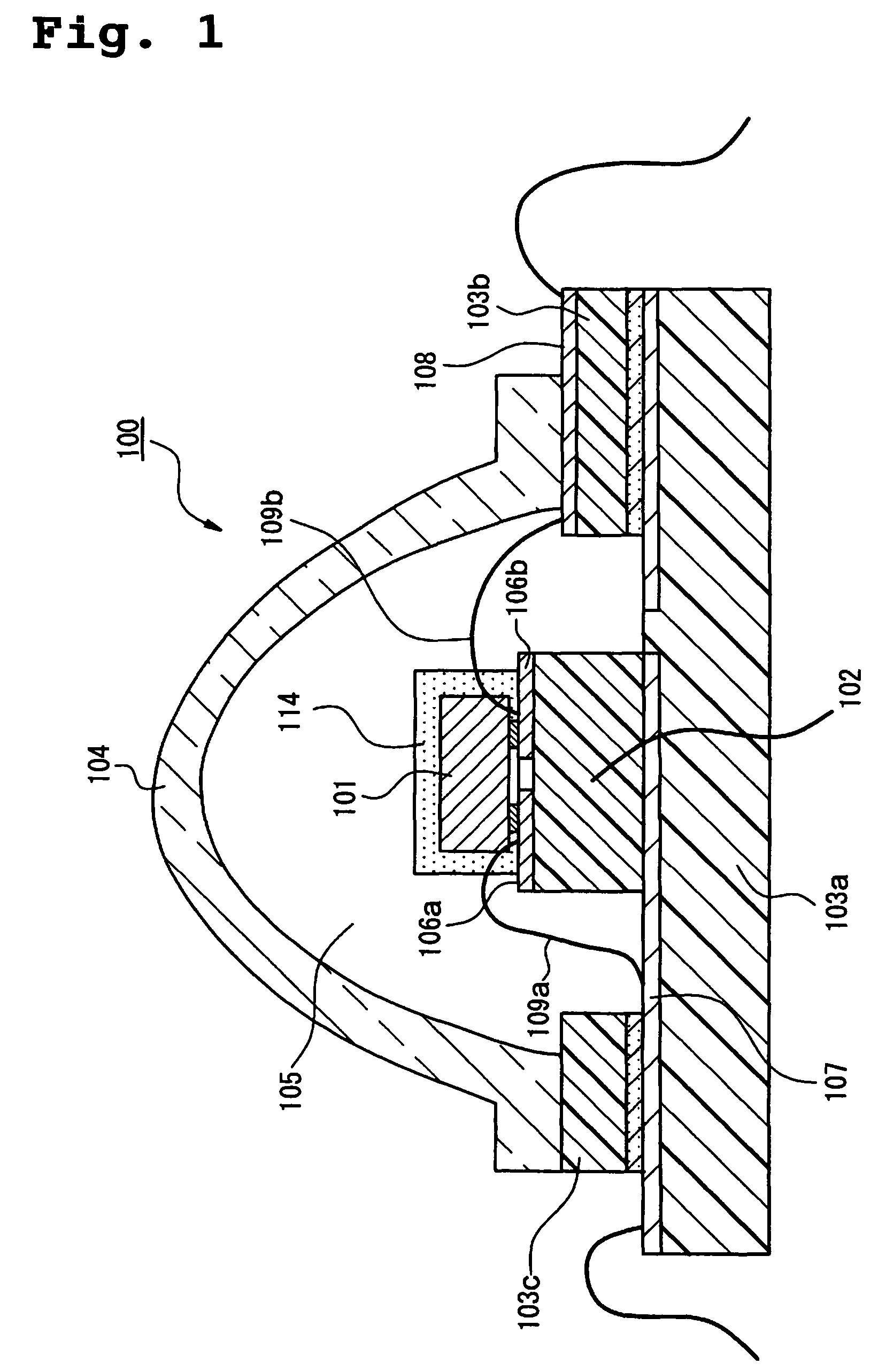

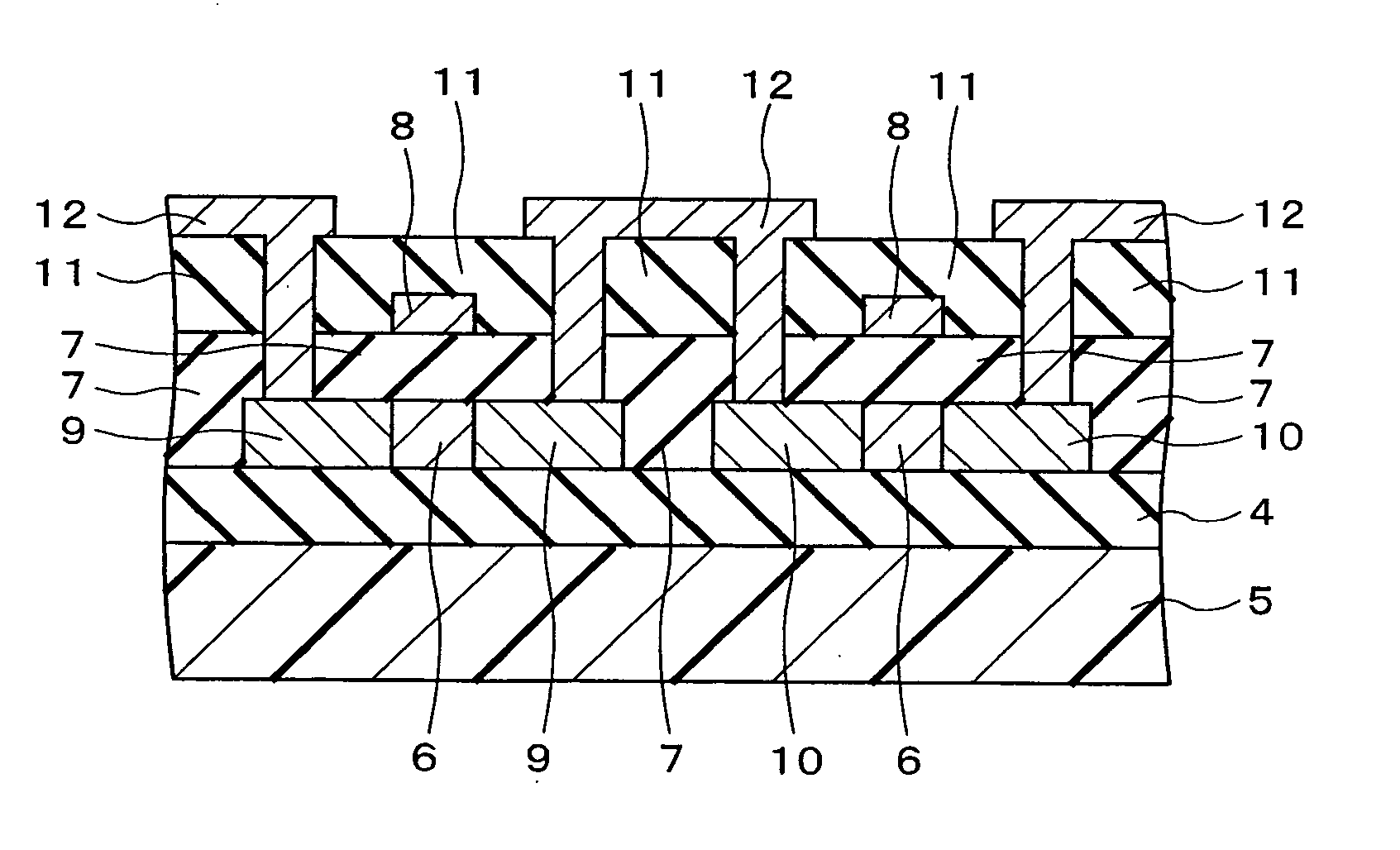

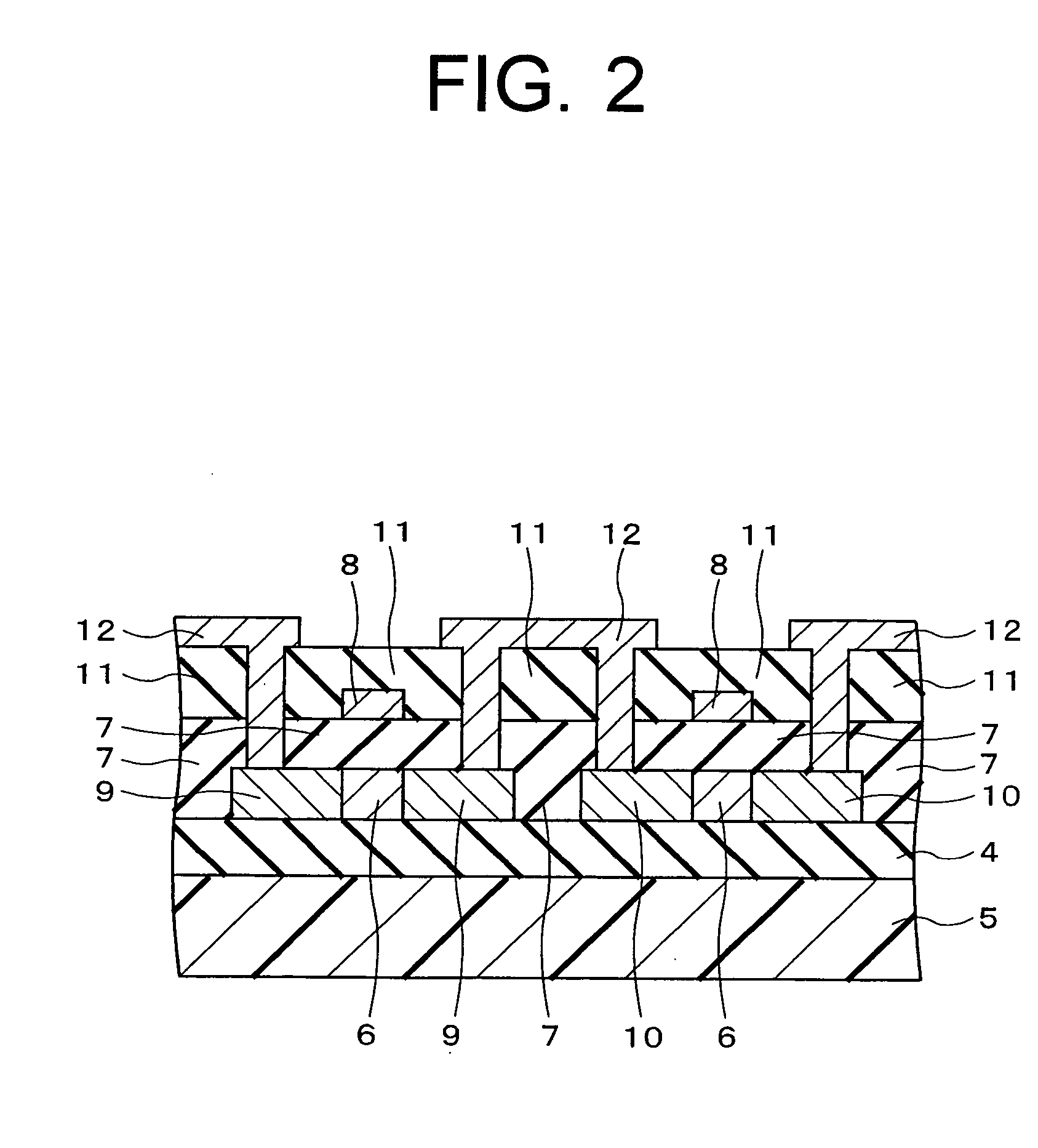

Light source device using led, and method of producing same

InactiveUS20030189830A1Easy to controlImprove powerLighting heating/cooling arrangementsSolid-state devicesLight emissionOperating life

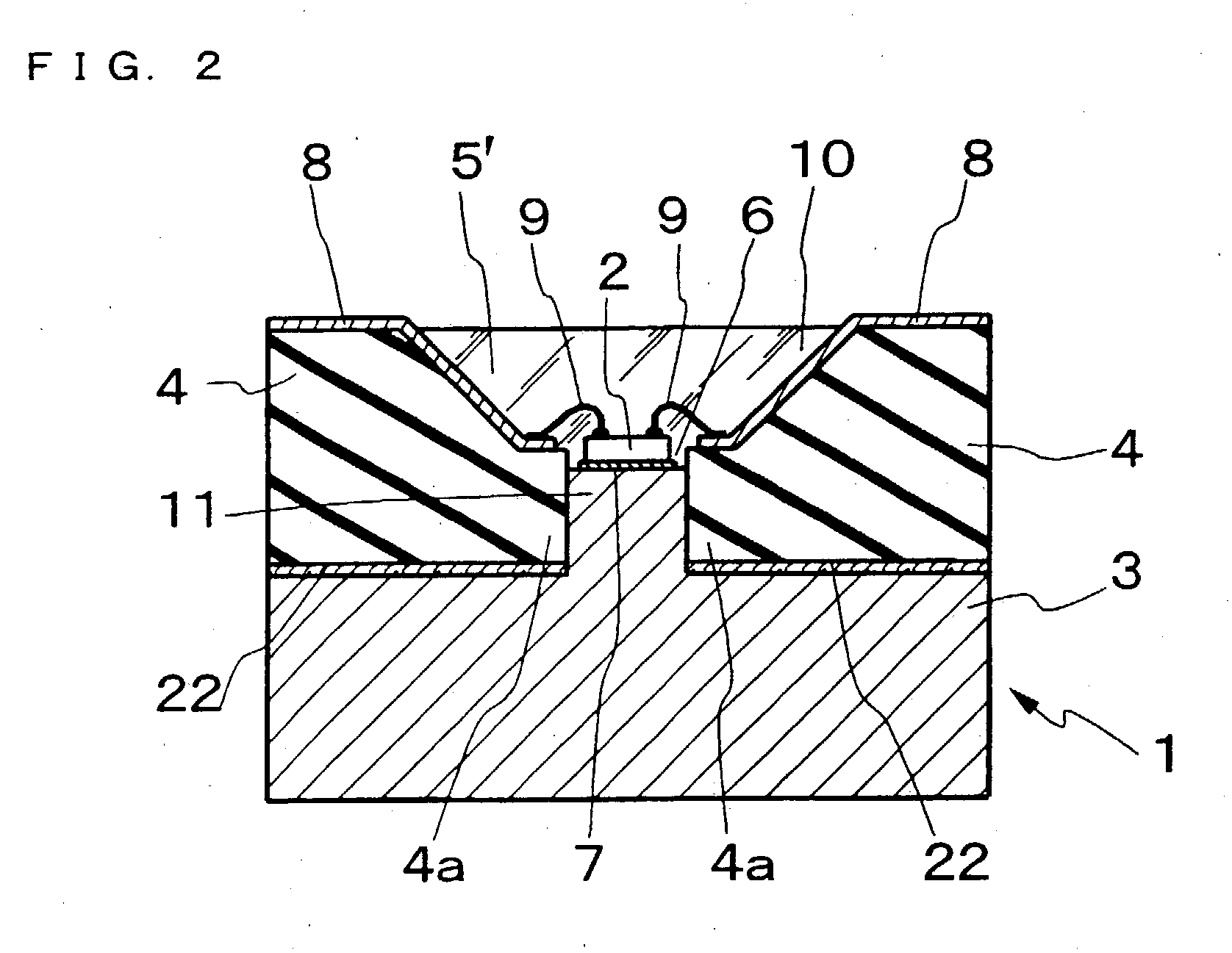

A light source apparatus which is improved in the efficiency of light emission thus to increase the operating life and the mechanical strength and a method of producing the same are provided. The light source apparatus 1 comprises a radiator plate 3 having thermally conductive properties, an insulating member 4 coupled to at least one side of the radiator plate 3 and having a through hole 6 provided in the side thereof facing the radiator plate 3, an LED chip 2 installed and thermally coupled to an exposed portion of the radiator plate 3 facing the through hole 6, an extension 4a inwardly projecting at the hole 6 from the radiator plate 3 end of the insulating member 4, a wiring pattern 8 provided on the insulating member 4 and electrically isolated by the insulating member 4 from the radiator plate 3, bonding wires 9 electrically connecting between portions of the wiring pattern 8 extended to the extension 4a and the electrodes of the LED chip 2, and a light-transmissive sealing material 10 filled in the through hole 6 for entirely encapsulating the LED chip 2 and the bonding wires 9.

Owner:SIGNIFY HLDG BV

SiCOH dielectric

InactiveUS20070173071A1Improve cohesive strengthReduce brittlenessSemiconductor/solid-state device detailsSolid-state devicesDielectricDevice material

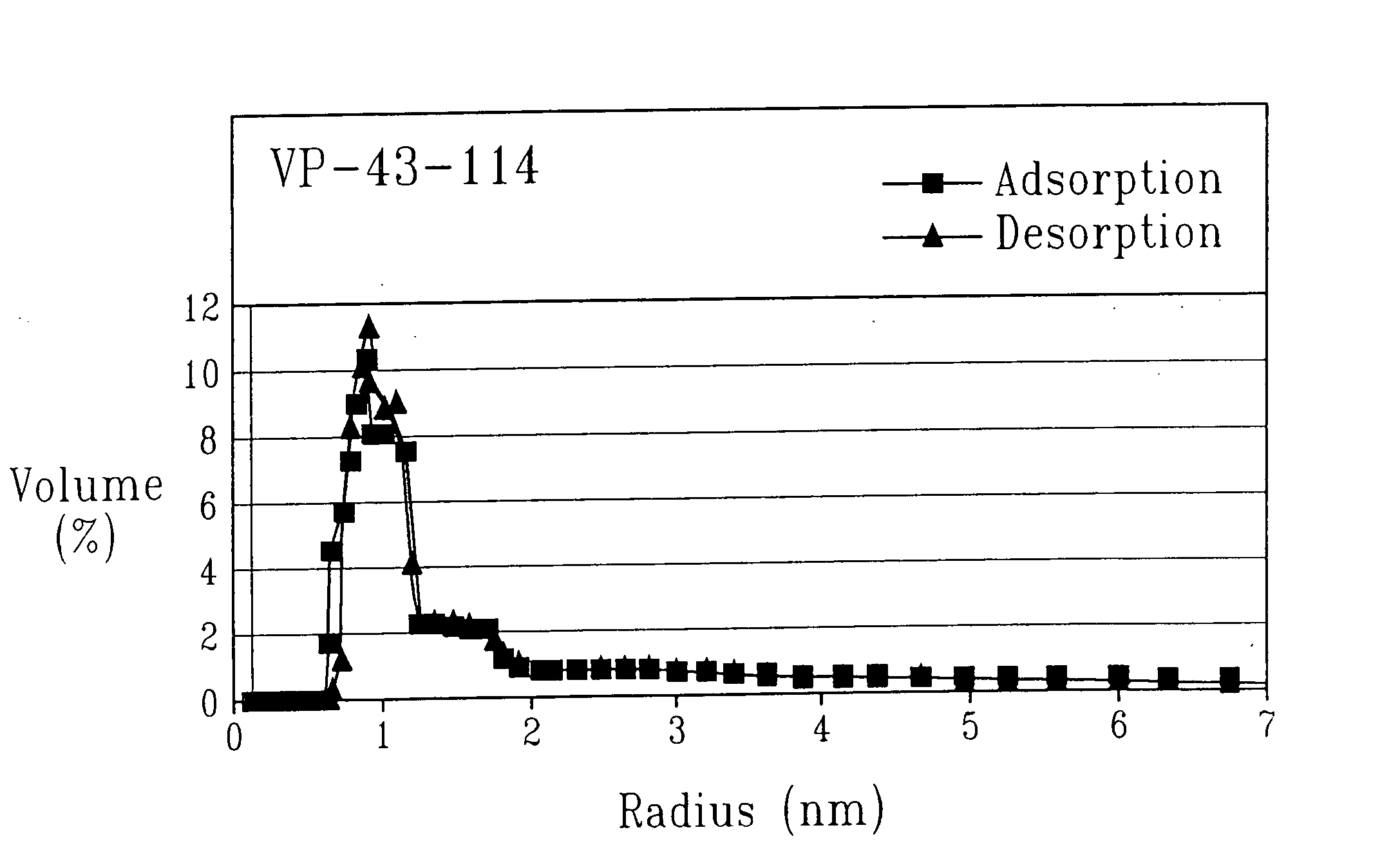

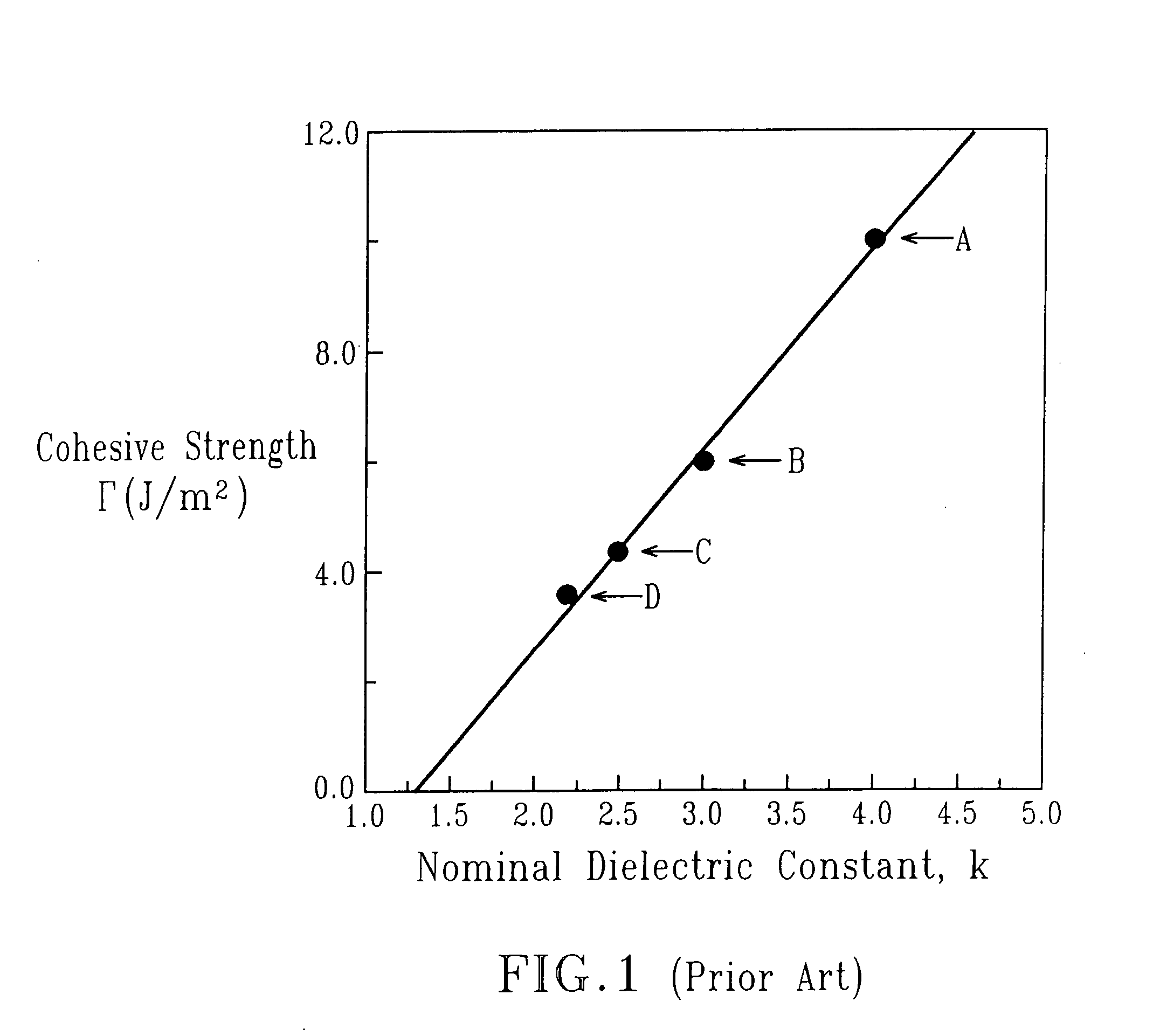

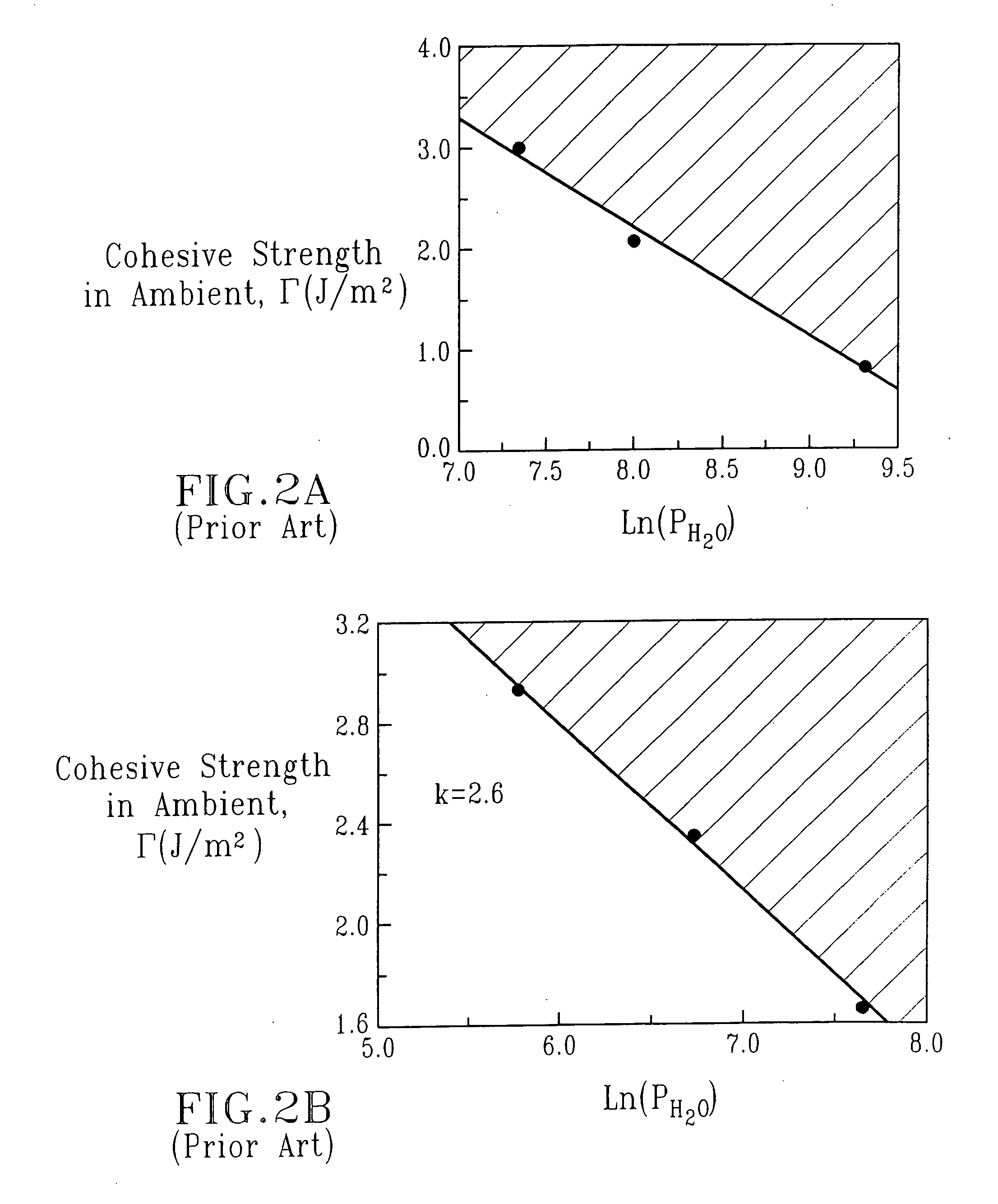

A porous composite material useful in semiconductor device manufacturing, in which the diameter (or characteristic dimension) of the pores and the pore size distribution (PSD) is controlled in a nanoscale manner and which exhibits improved cohesive strength (or equivalently, improved fracture toughness or reduced brittleness), and increased resistance to water degradation of properties such as stress-corrosion cracking, Cu ingress, and other critical properties is provided. The porous composite material is fabricating utilizing at least one bifunctional organic porogen as a precursor compound

Owner:INTEL CORP

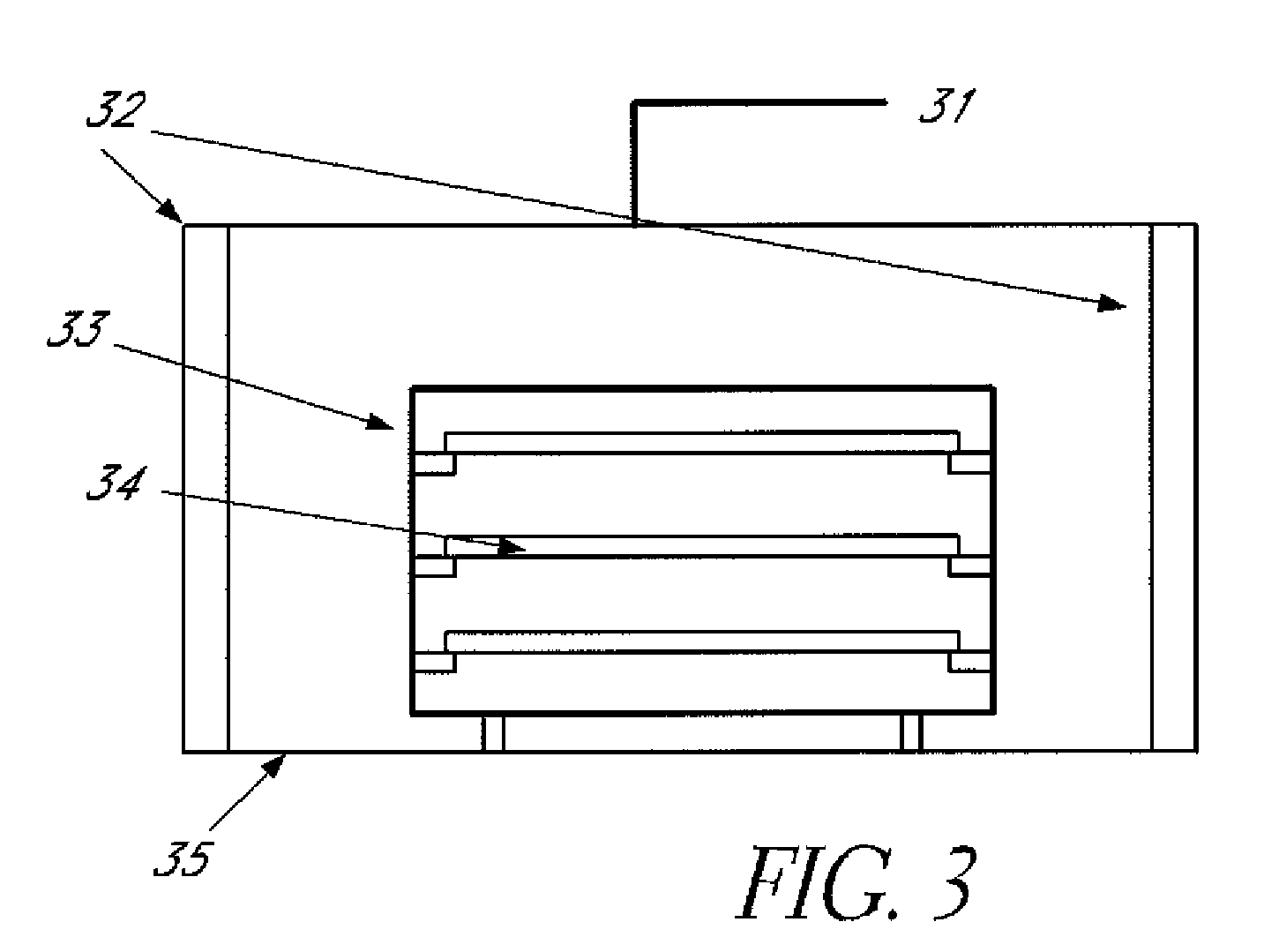

Method for forming dielectric film using siloxane-silazane mixture

ActiveUS8003174B2High densityHigh strengthPretreated surfacesSemiconductor/solid-state device manufacturingSilazaneMetallurgy

Owner:ASM JAPAN

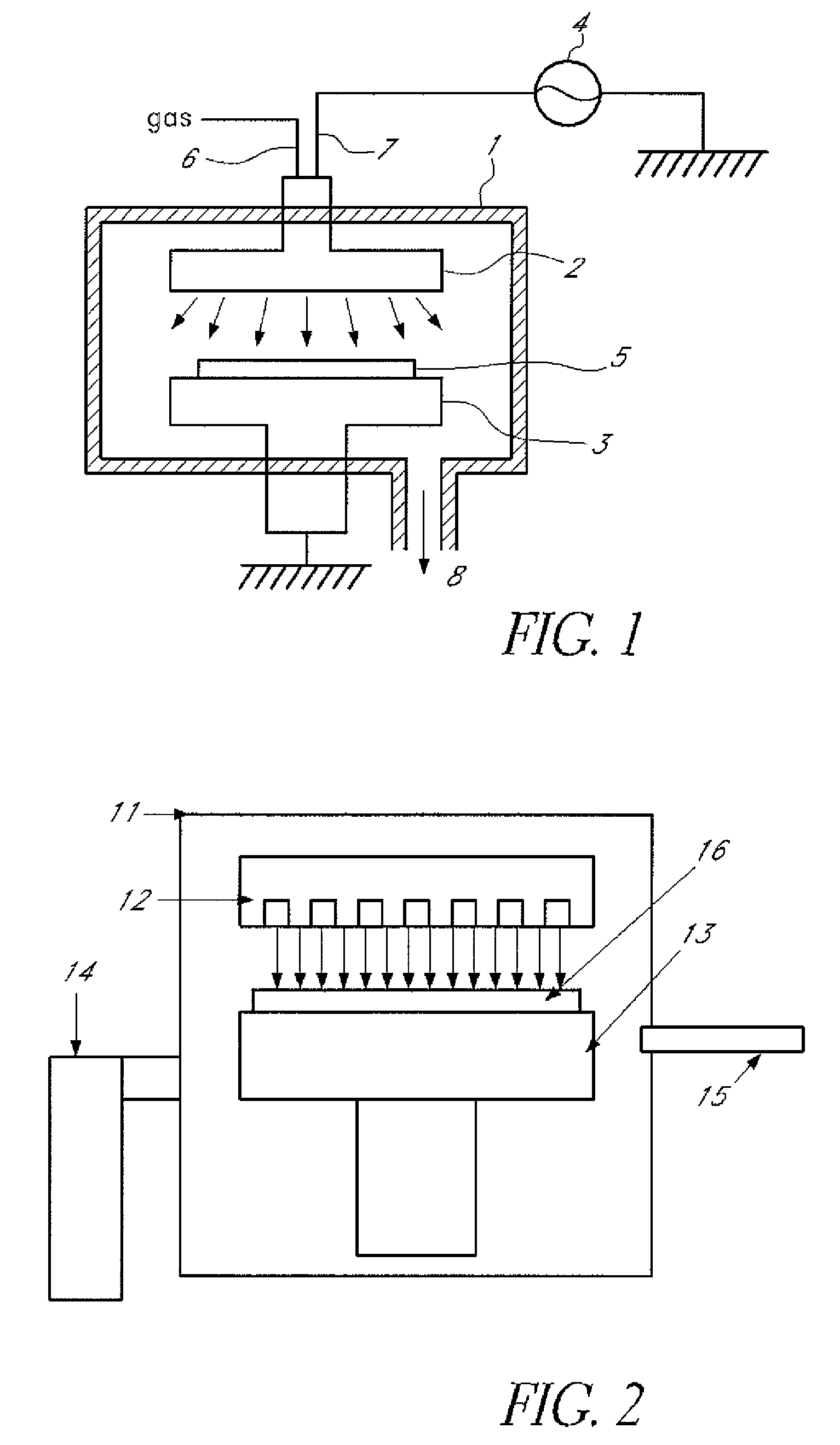

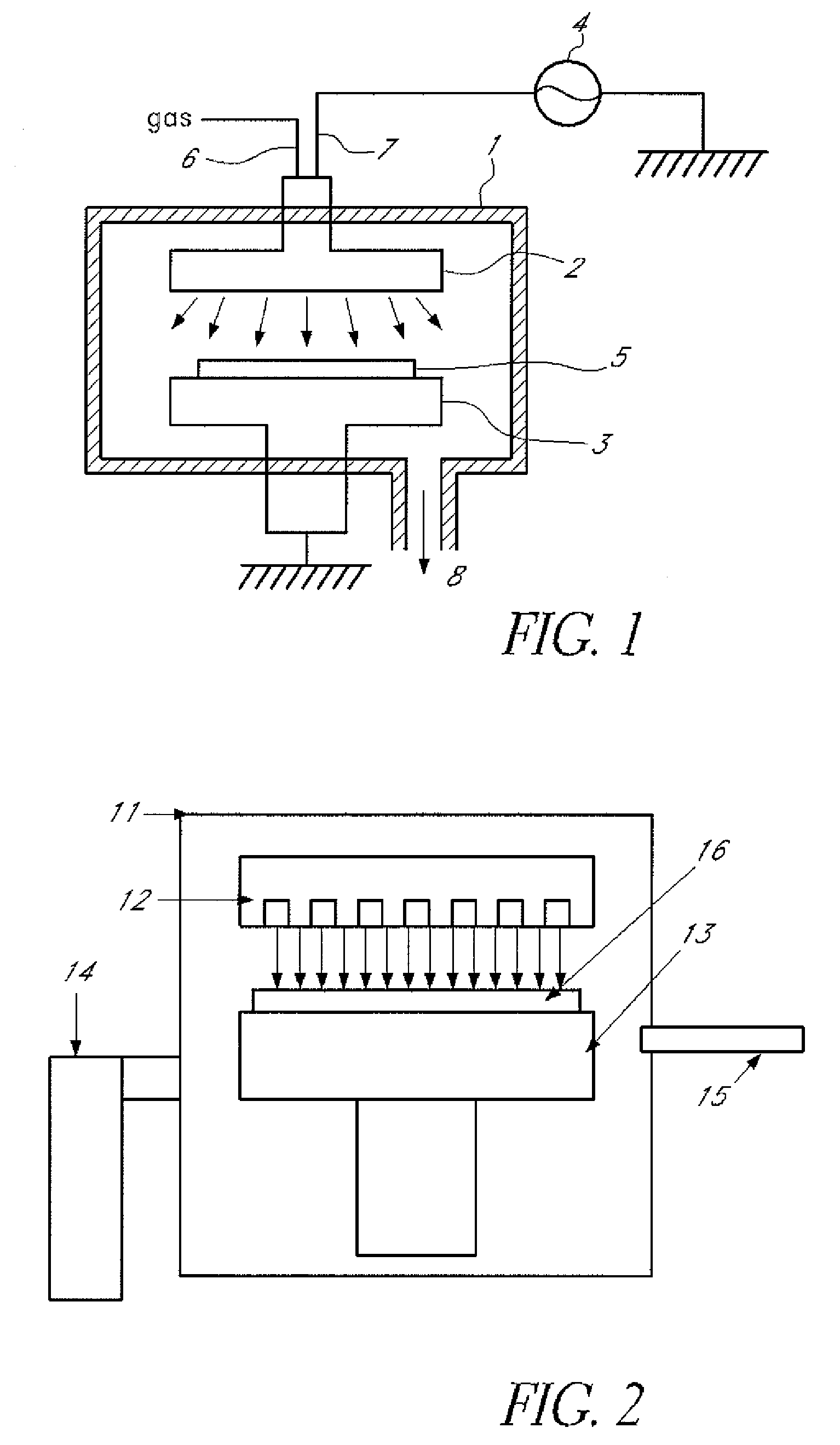

Method of forming carbon polymer film using plasma CVD

ActiveUS20070224833A1High film strengthReduction factorLiquid surface applicatorsSemiconductor/solid-state device detailsBoiling pointCapacitance

A method of forming a hydrocarbon-containing polymer film on a semiconductor substrate by a capacitively-coupled plasma CVD apparatus. The method includes the steps of: vaporizing a hydrocarbon-containing liquid monomer (CαHβXγ, wherein α and β are natural numbers of 5 or more; γ is an integer including zero; X is O, N or F) having a boiling point of about 20° C. to about 350° C. which is not substituted by a vinyl group or an acetylene group; introducing the vaporized gas and CO2 gas or H2 gas into a CVD reaction chamber inside which a substrate is placed; and forming a hydrocarbon-containing polymer film on the substrate by plasma polymerization of the gas, thereby reducing extinction coefficient (k) at 193 nm and increasing mechanical hardness.

Owner:ASM JAPAN +1

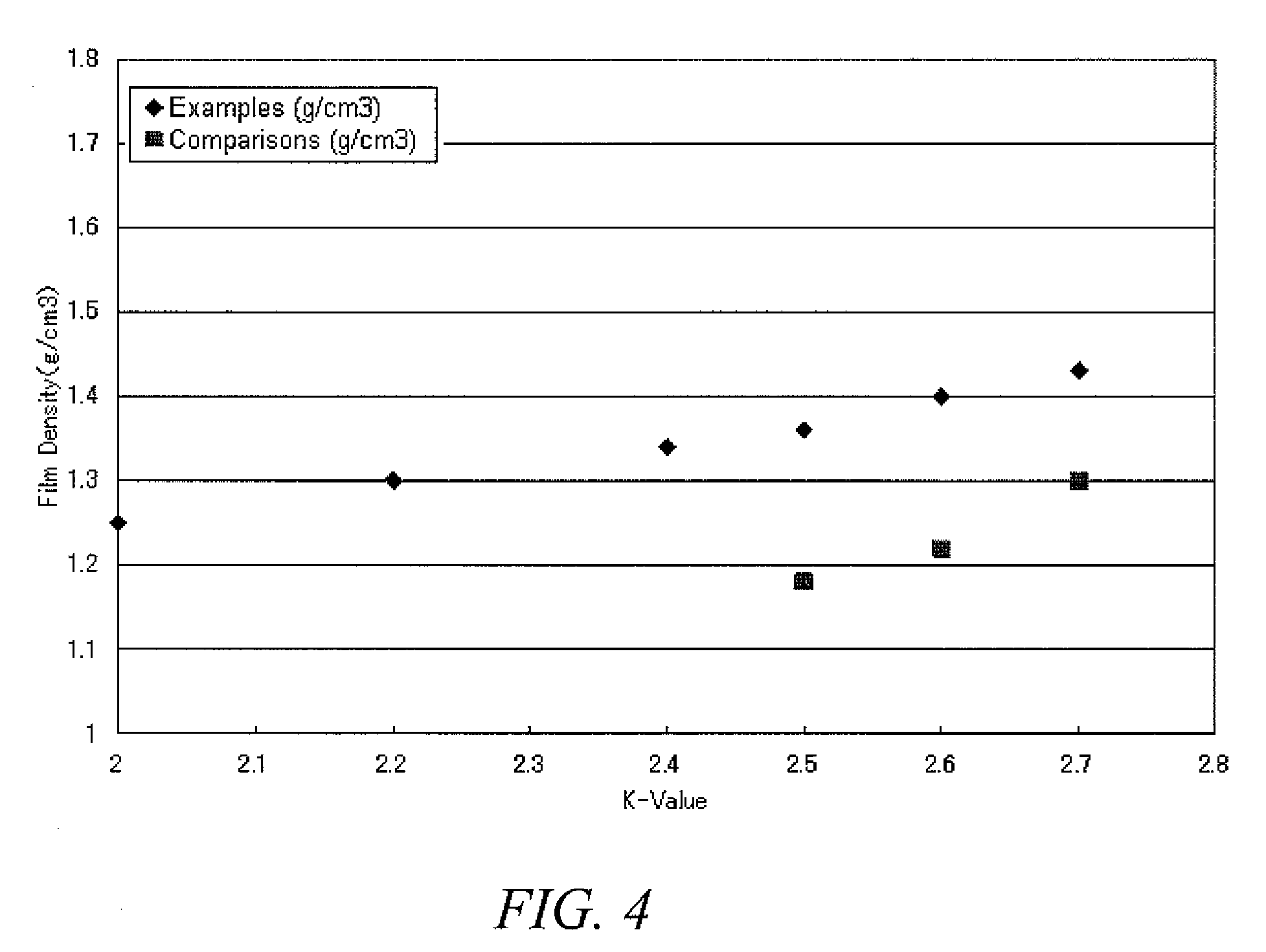

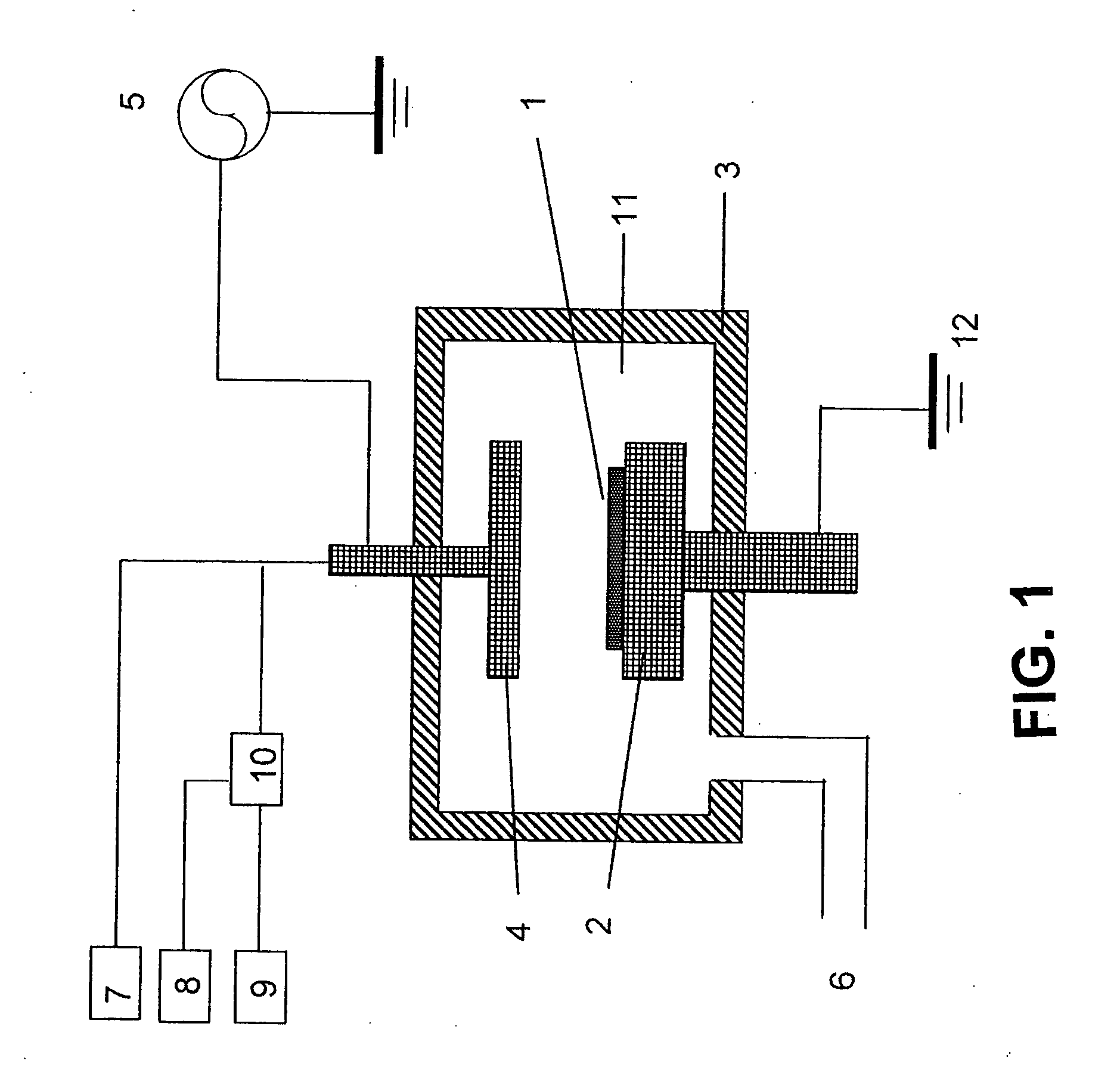

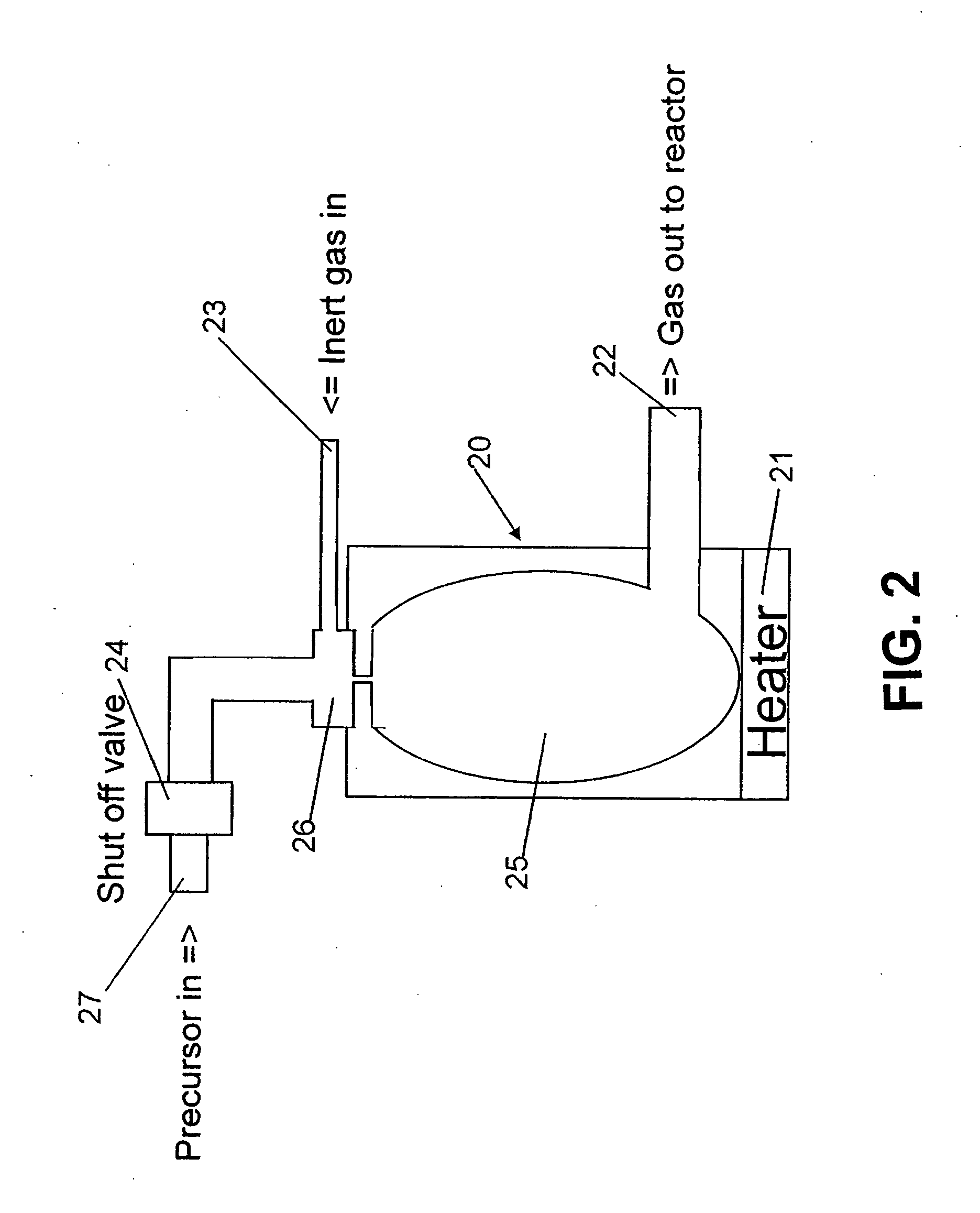

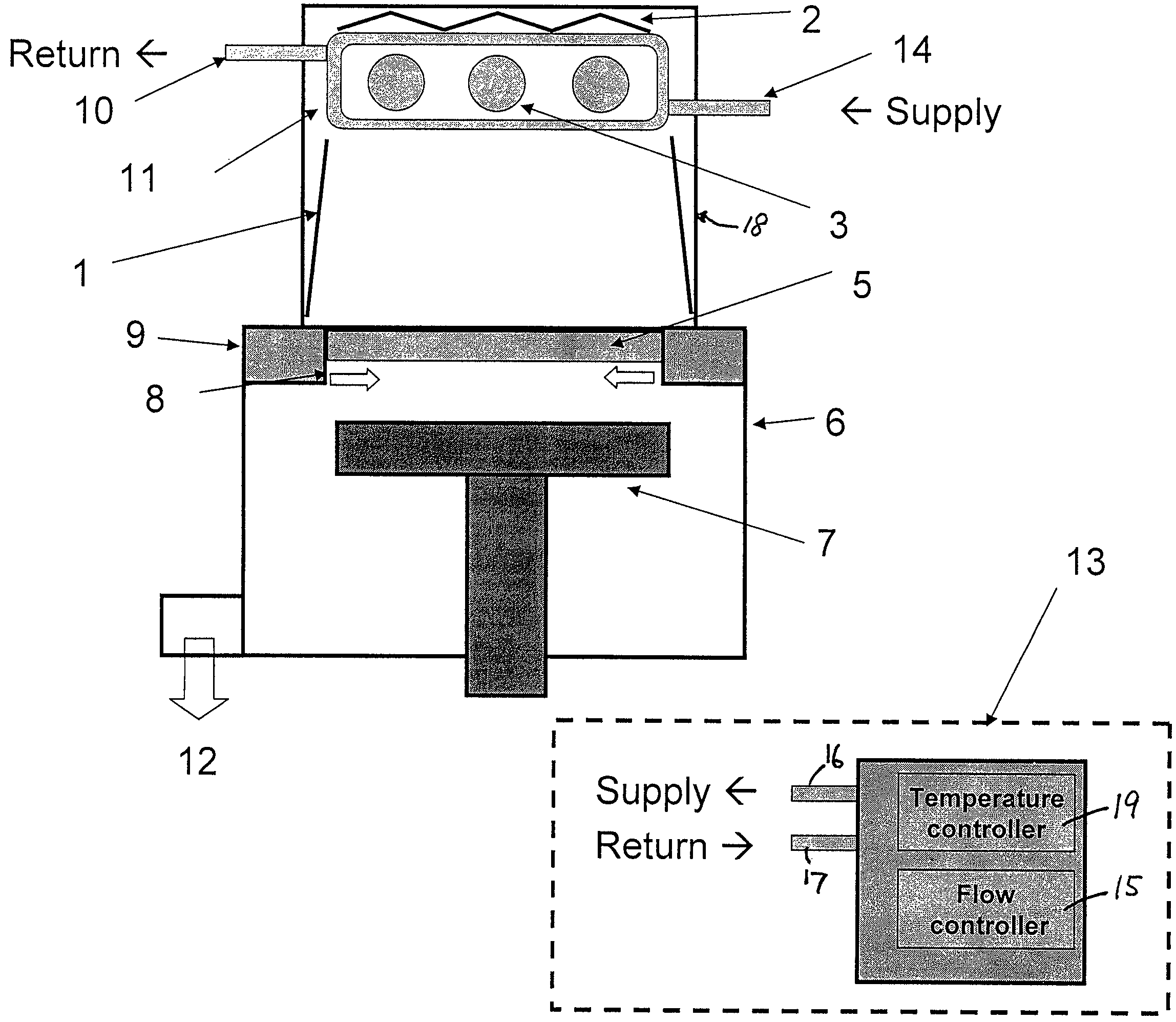

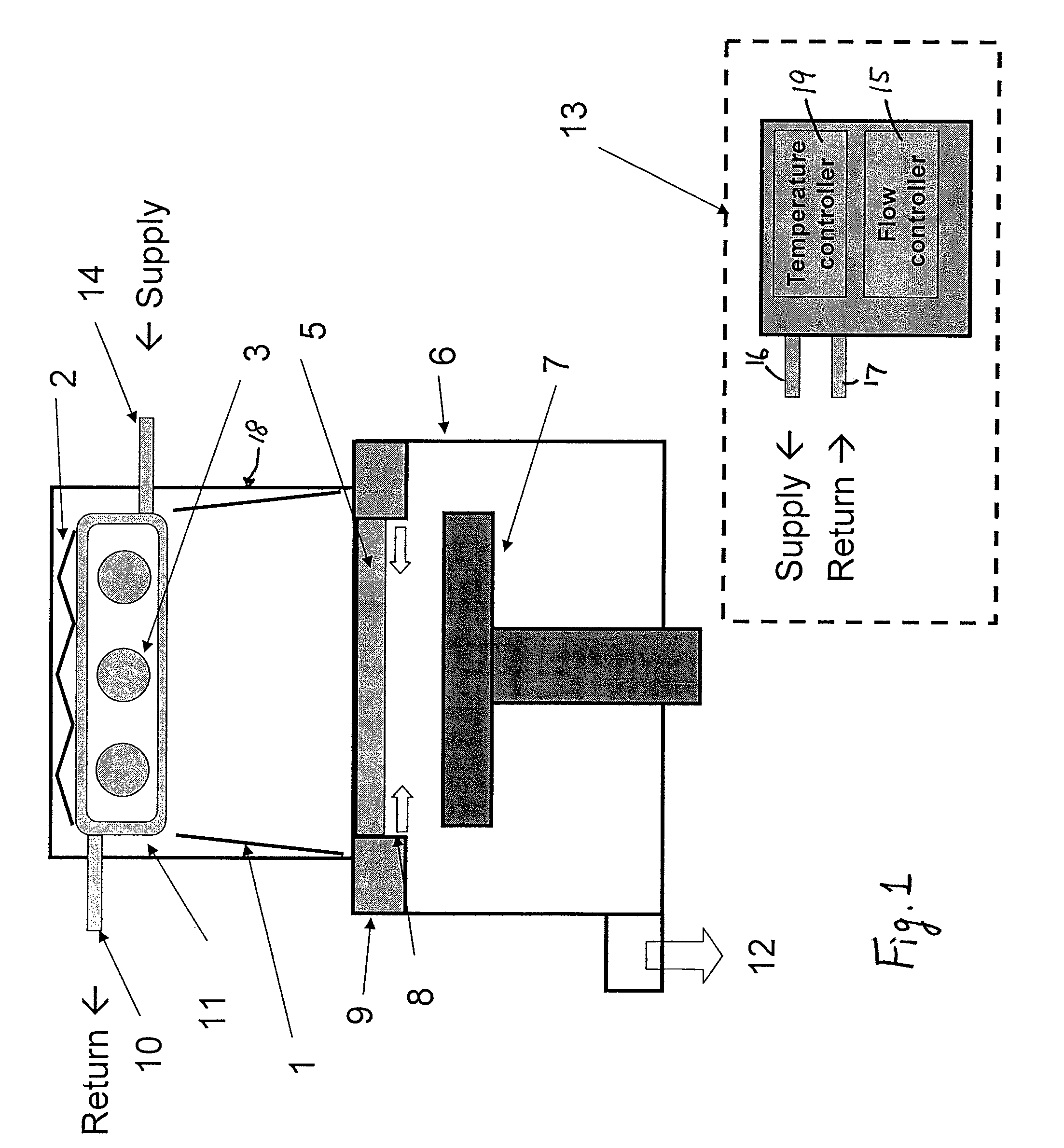

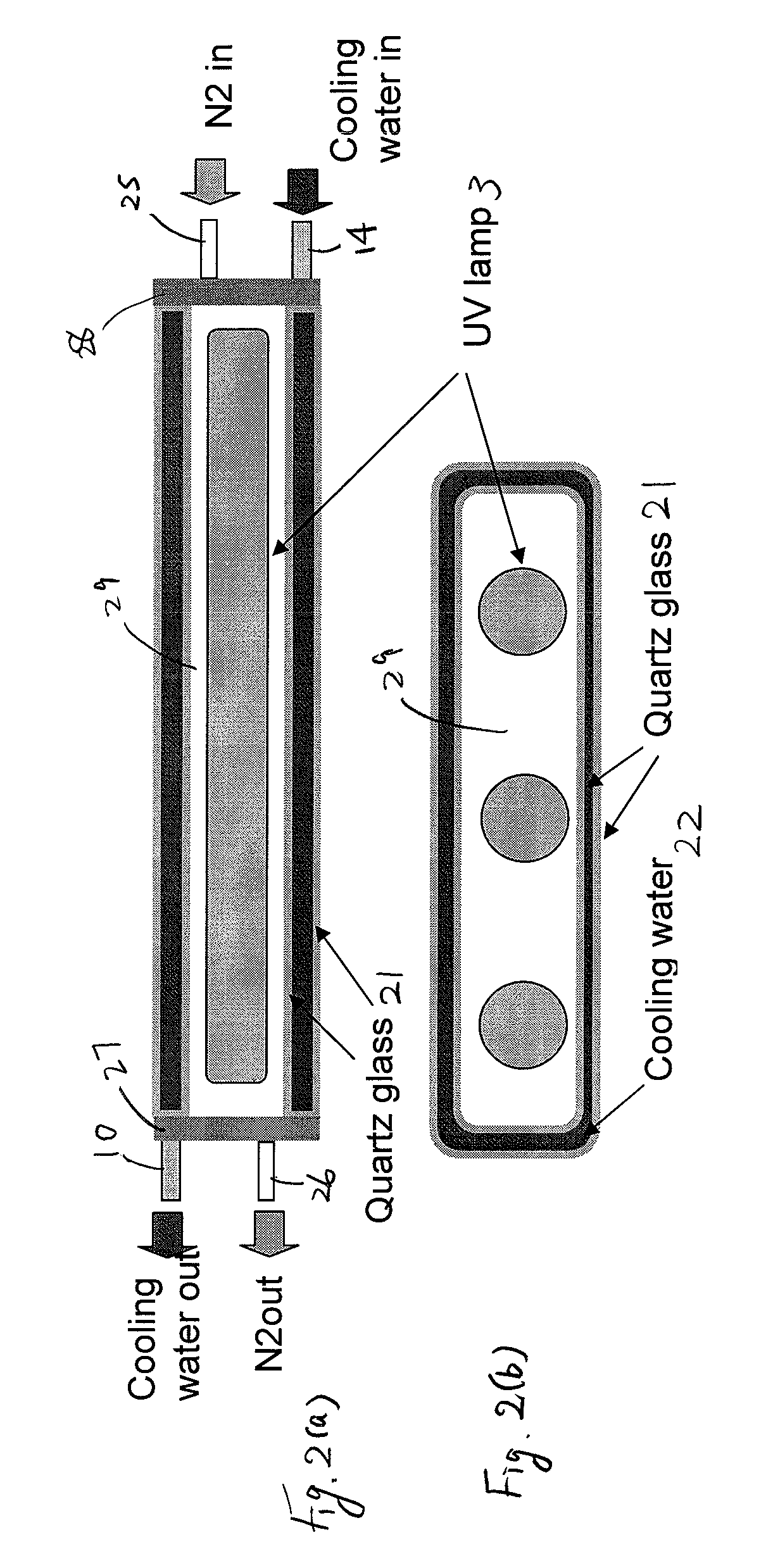

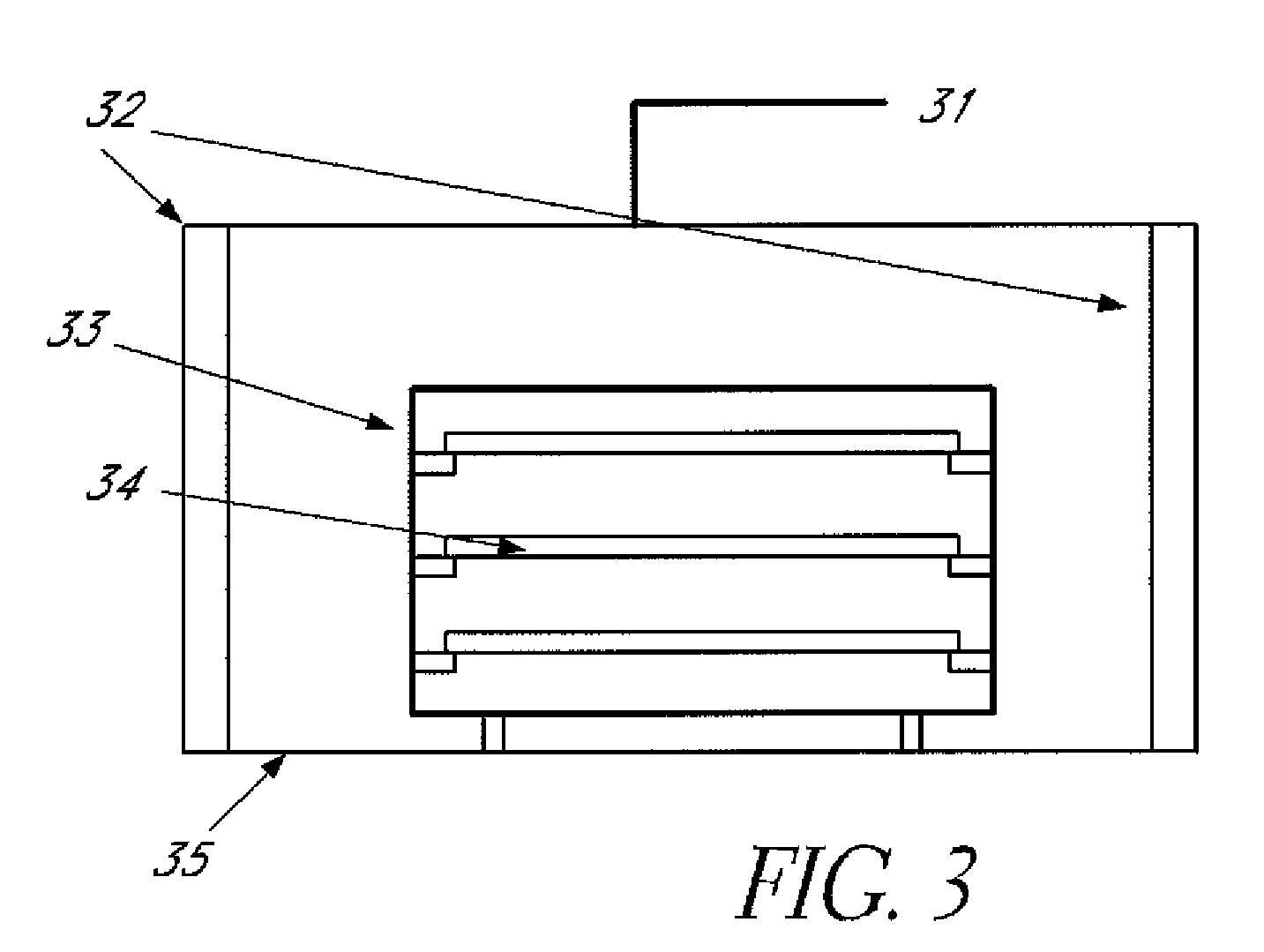

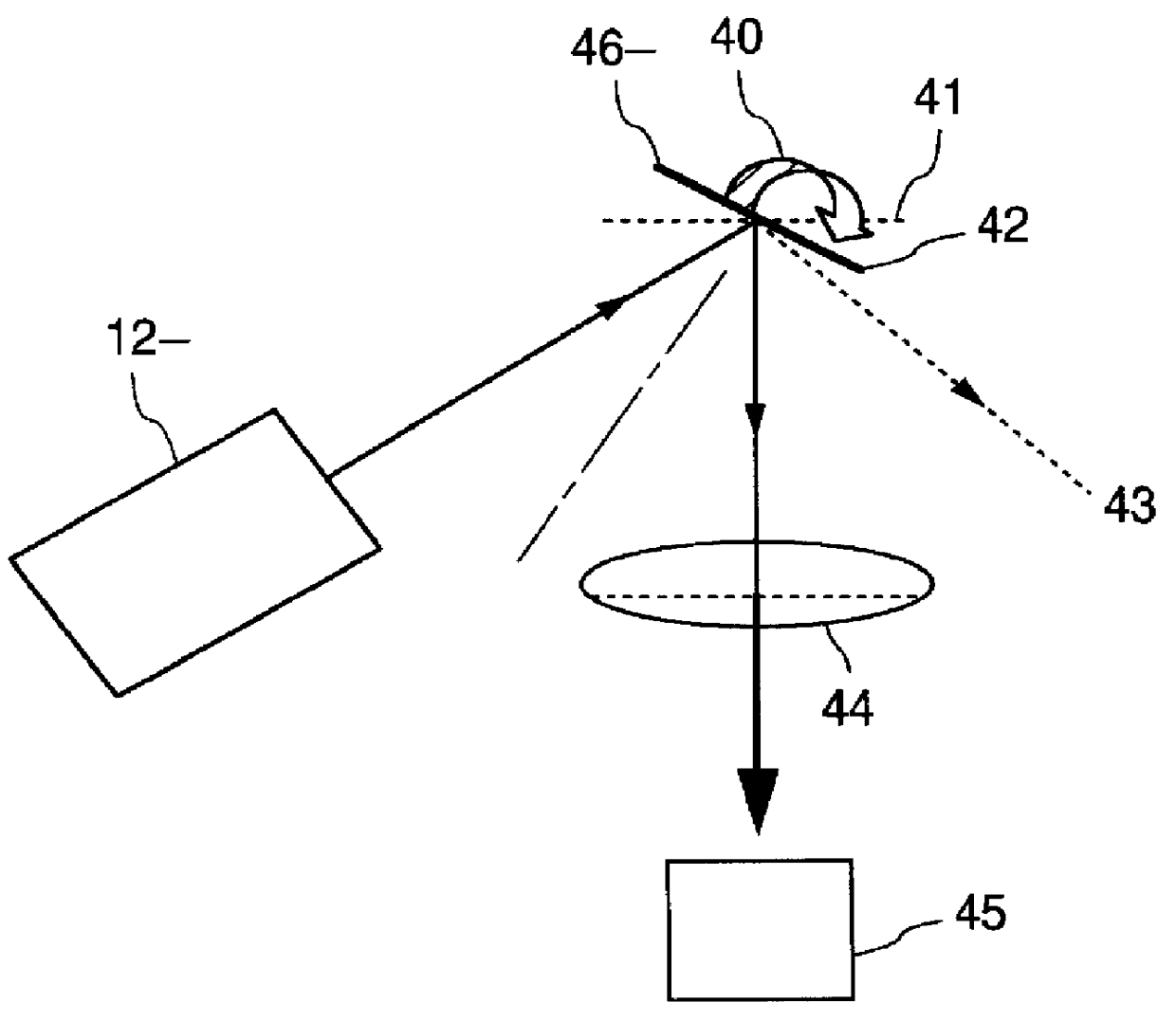

UV light irradiating apparatus with liquid filter

ActiveUS7763869B2High mechanical strengthHigh energyMirrorsOptical filtersLiquid layerLight irradiation

A UV light irradiating apparatus for irradiating a semiconductor substrate with UV light includes: a reactor in which a substrate-supporting table is provided; a UV light irradiation unit connected to the reactor for irradiating a semiconductor substrate placed on the substrate-supporting table with UV light through a light transmission window; and a liquid layer forming channel disposed between the light transmission window and at least one UV lamp for forming a liquid layer through which the UV light is transmitted. The liquid layer is formed by a liquid flowing through the liquid layer forming channel.

Owner:ASM JAPAN

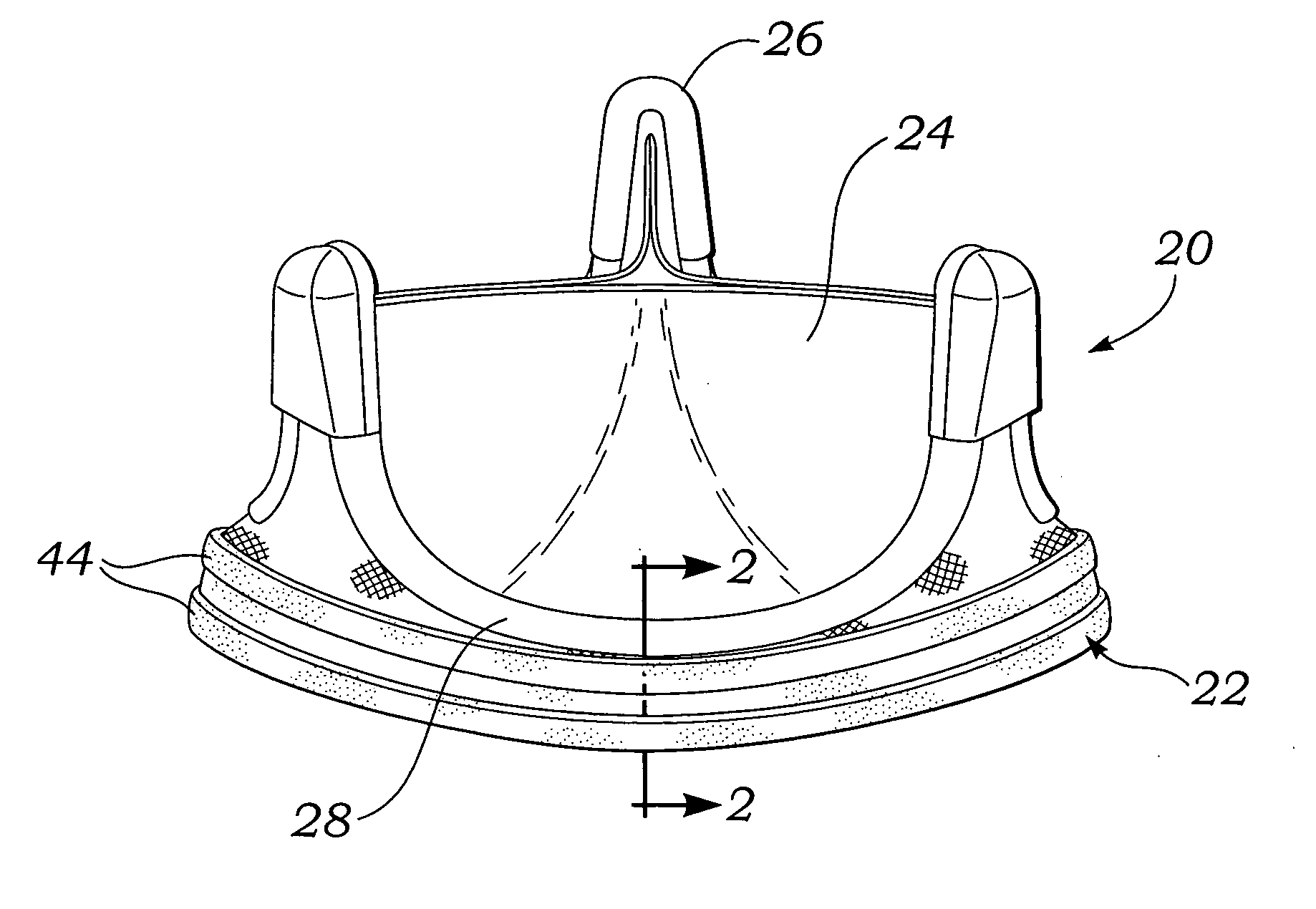

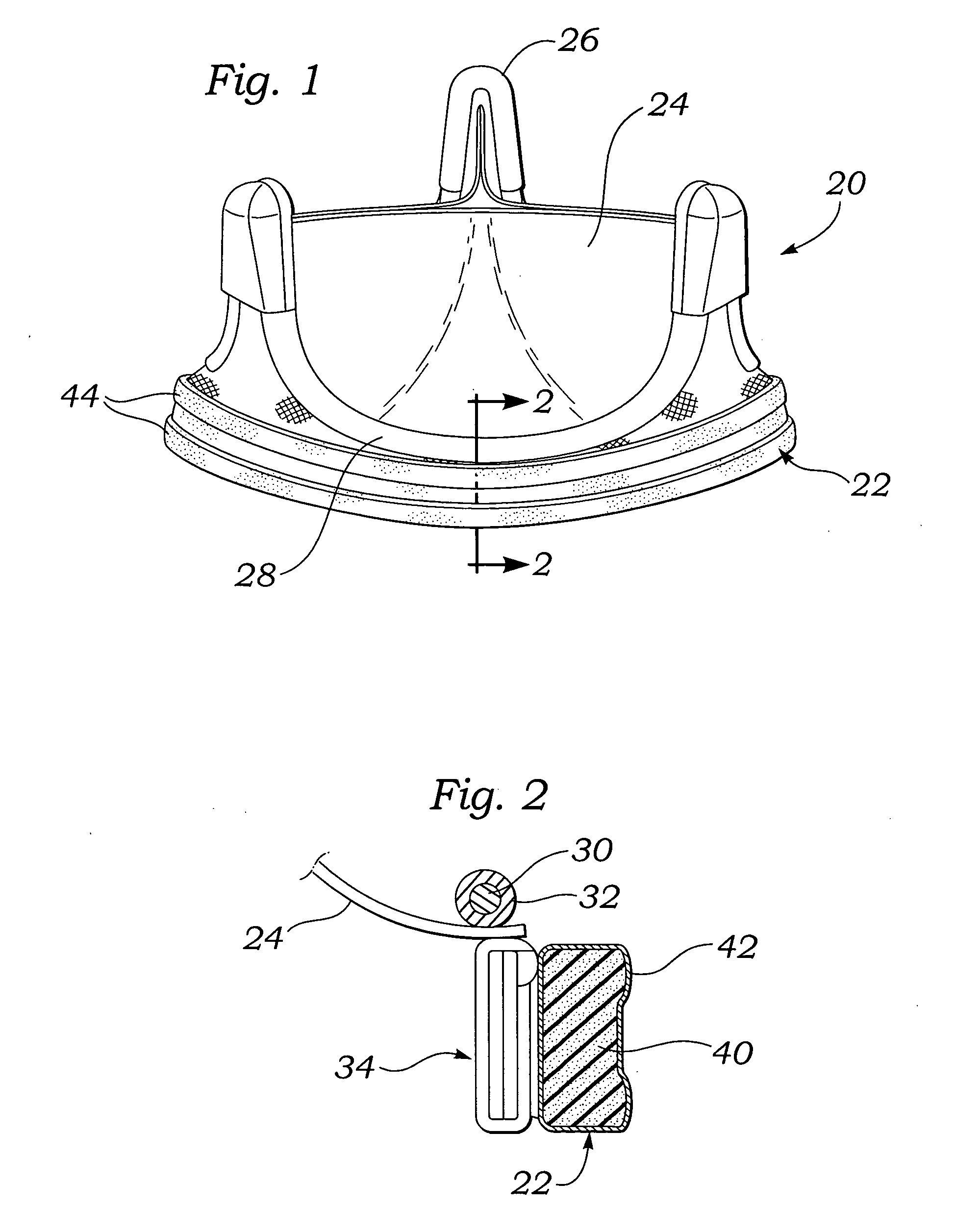

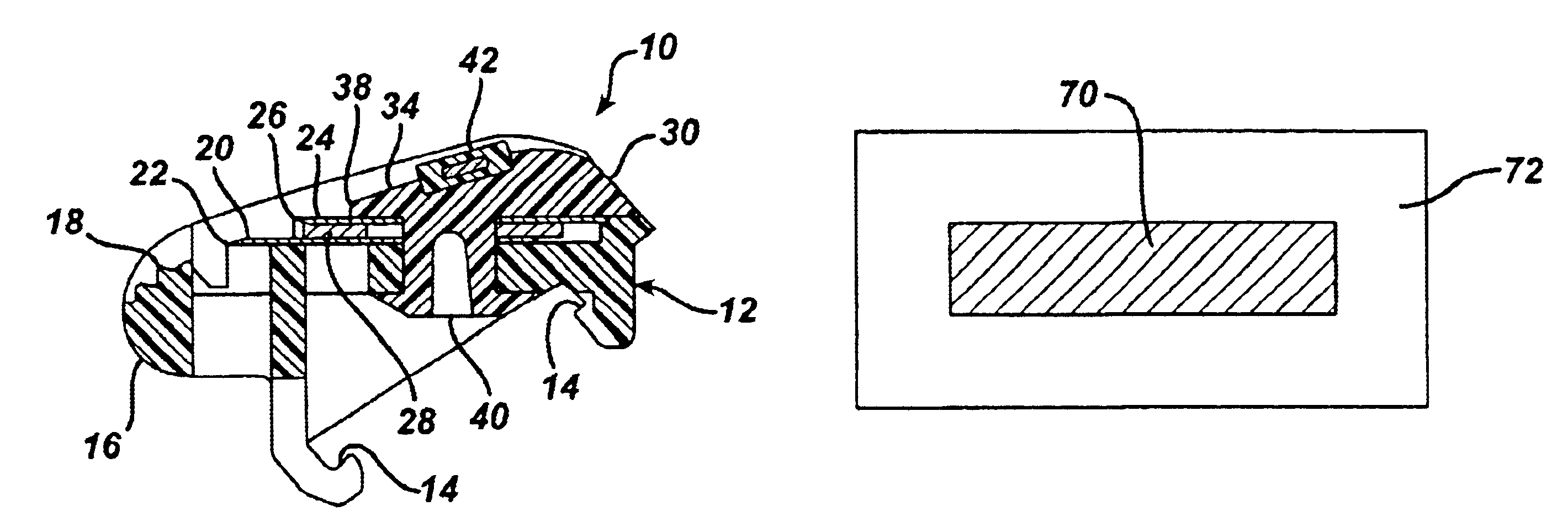

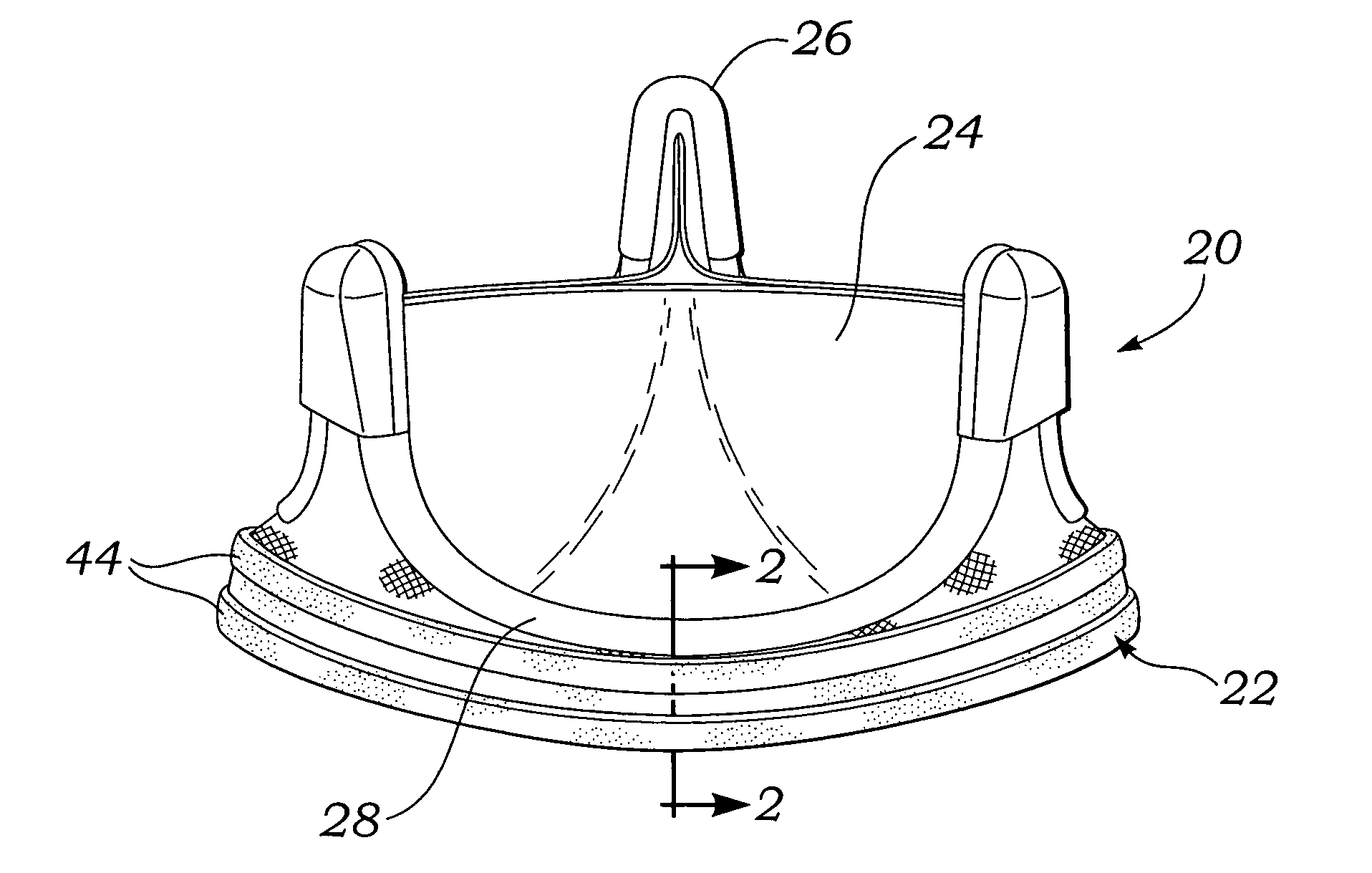

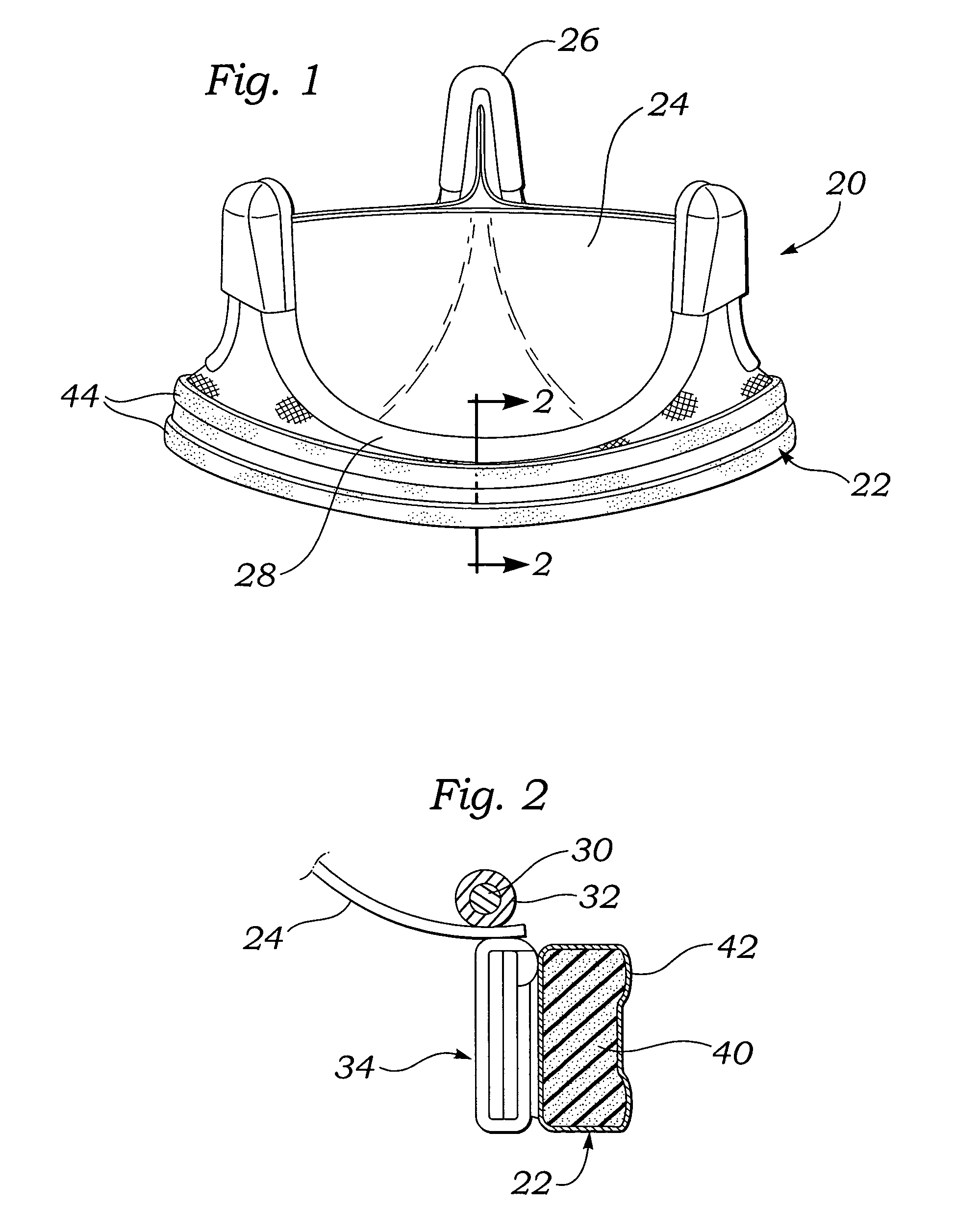

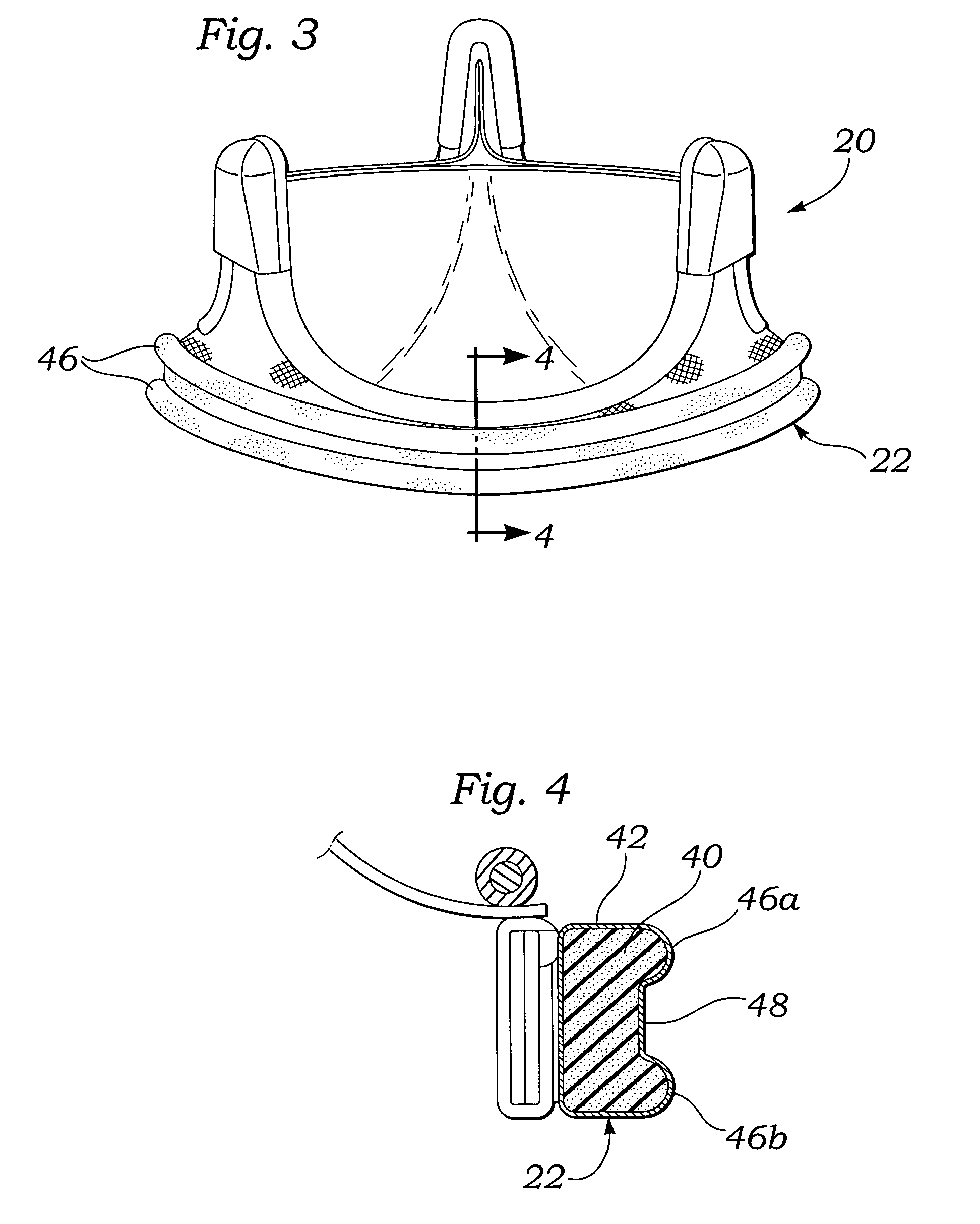

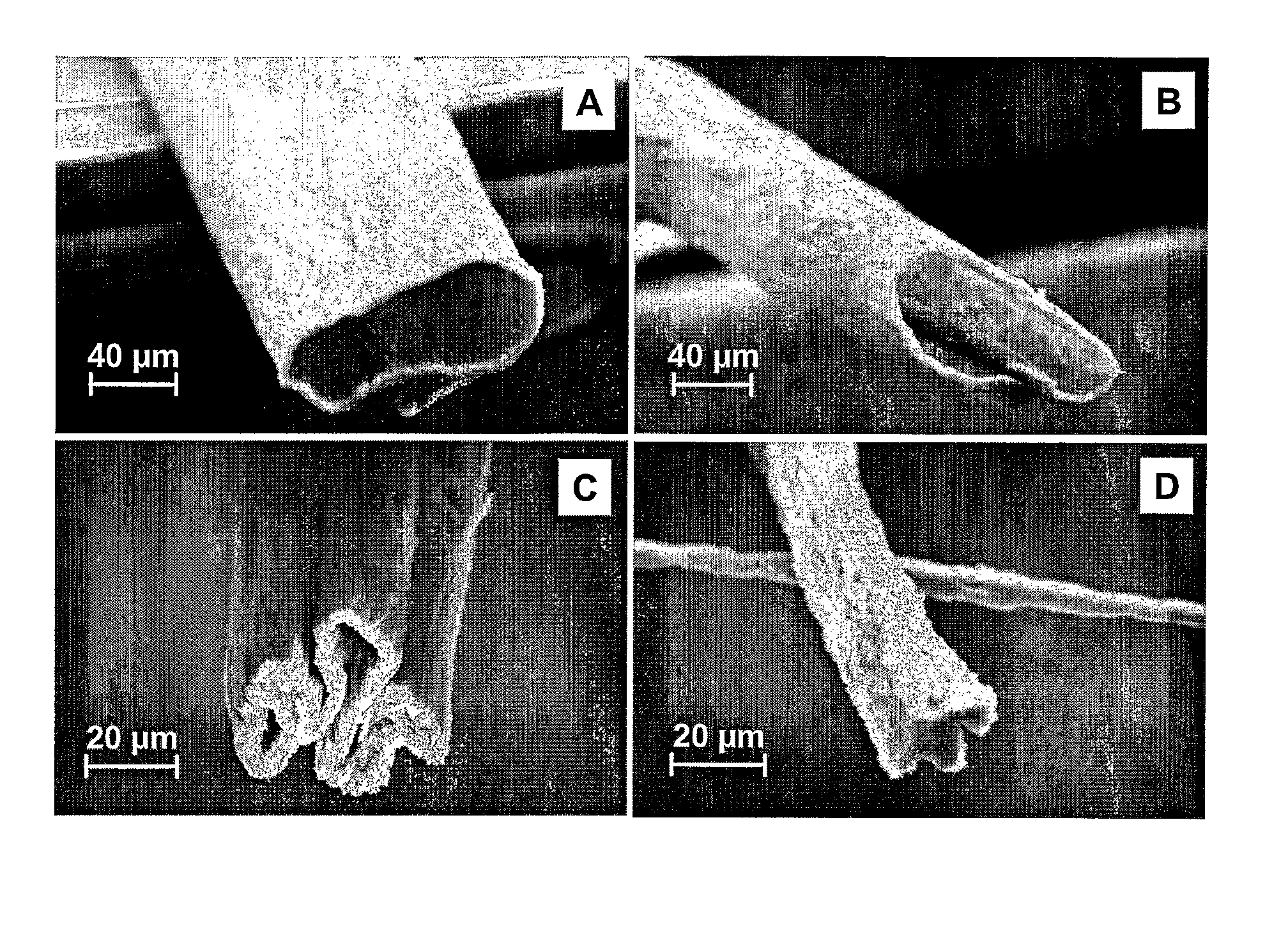

Sutureless heart valve attachment

A prosthetic heart valve having an anchoring sleeve that changes shape when the valve is implanted and contacts the surrounding annulus to prevent migration of the valve. The heart valve may be non-expandable and the anchoring sleeve may provide the primary anchoring structure of the valve. Alternatively, the valve may be expandable wherein the anchoring sleeve supplements the inherent anchoring capacity of the valve structure. The anchoring sleeve is at least partly made of a material that increases in size, i.e., swells, due to absorption of body fluids. For instance, the anchoring sleeve may be formed of an inner material that swells upon contact with body fluids enclosed by a cover. The anchoring sleeve desirably changes shape to provide spaced apart annular flanges for securing the valve around a fibrous annulus. An anchoring sleeve for a prosthetic heart valve having an expandable frame surrounds a majority of the frame and may define an external hourglass configuration.

Owner:EDWARDS LIFESCIENCES CORP

Method for reducing particle generation at bevel portion of substrate

ActiveUS9343343B2High mechanical strengthAvoid it happening againElectric discharge tubesSemiconductor/solid-state device detailsActuatorParticle generation

A method for transporting a substrate using an end effector which mechanically clamps a periphery of the substrate includes: before transporting the substrate, depositing a compressive film only on, at, or in a bevel portion of the substrate; and transporting the substrate whose bevel portion is covered by the compressive film as the outermost film, using an end effector while mechanically clamping the periphery of the substrate.

Owner:ASM IP HLDG BV

Recovery of hydrophobicity of low-k and ultra low-k organosilicate films used as inter metal dielectrics

InactiveUS20050106762A1Low costHigh mechanical strengthSolid-state devicesSemiconductor/solid-state device manufacturingChemical treatmentSilylation

Often used to reduce the RC delay in integrated circuits are dielectric films of porous organosilicates which have a silica like backbone with alkyl or aryl groups (to add hydrophobicity to the materials and create free volume) attached directly to the Si atoms in the network. Si—R bonds rarely survive an exposure to plasmas or chemical treatments commonly used in processing; this is especially the case in materials with an open cell pore structure. When Si—R bonds are broken, the materials lose hydrophobicity, due to formation of hydrophilic silanols and low dielectric constant is compromised. A method by which the hydrophobicity of the materials is recovered using a novel class of silylation agents which may have the general formula (R2N)XSiR′Y where X and Y are integers from 1 to 3 and 3 to 1 respectively, and where R and R′ are selected from the group of hydrogen, alkyl, aryl, allyl and a vinyl moiety. Mechanical strength of porous organosilicates is also improved as a result of the silylation treatment.

Owner:GLOBALFOUNDRIES INC

Tempered glass substrate and method of producing the same

ActiveUS20090197088A1High ion exchange capacityExcellent devitrification resistanceGlass/slag layered productsThin material handlingToughened glassMaterials science

A tempered glass substrate of the present invention is a tempered glass substrate, which has a compression stress layer on a surface thereof, and has a glass composition comprising, in terms of mass %, 40 to 71% of SiO2, 3 to 21% of Al2O3, 0 to 3.5% of Li2O, to 20% of Na2O, and 0 to 15% of K2O.

Owner:NIPPON ELECTRIC GLASS CO LTD

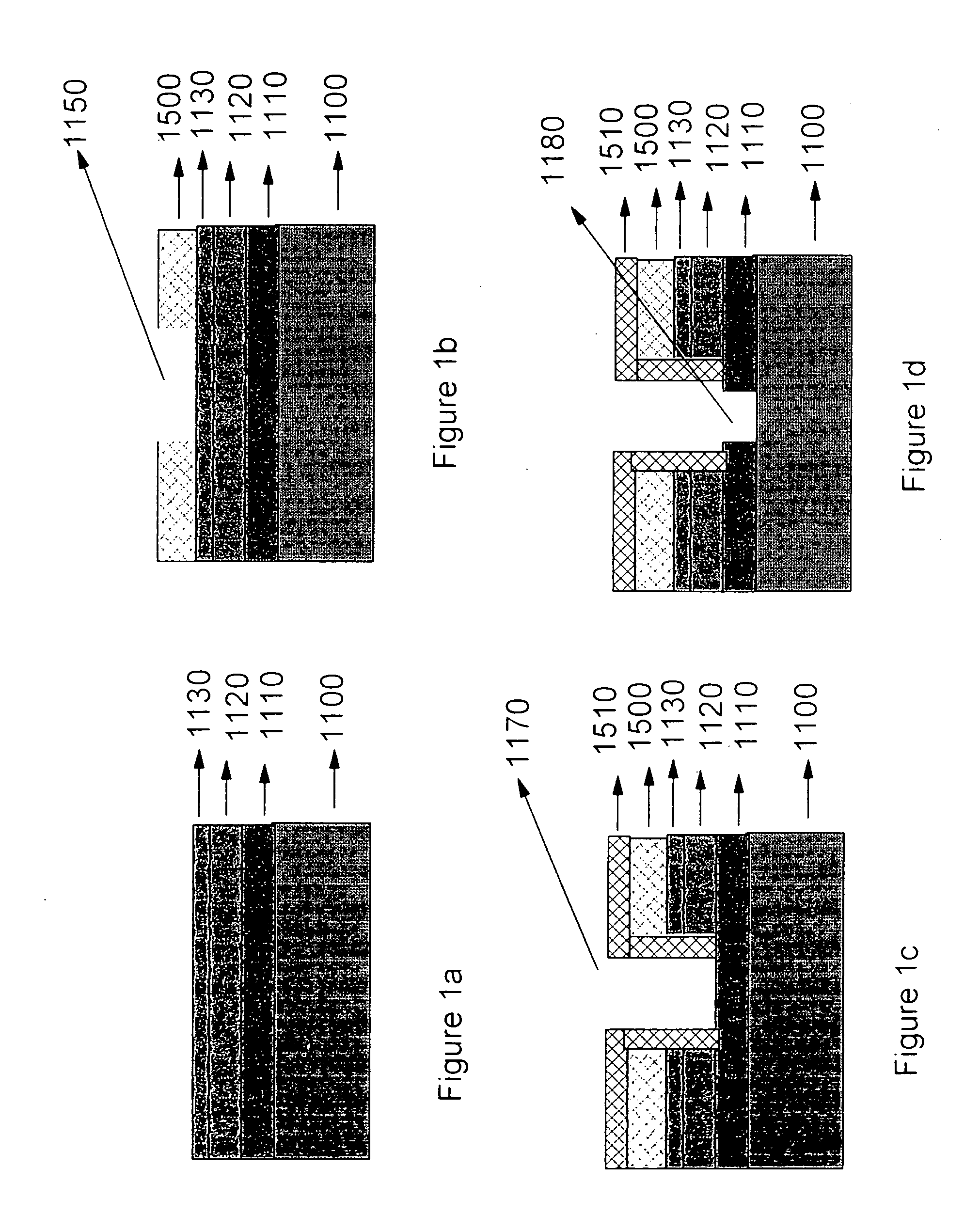

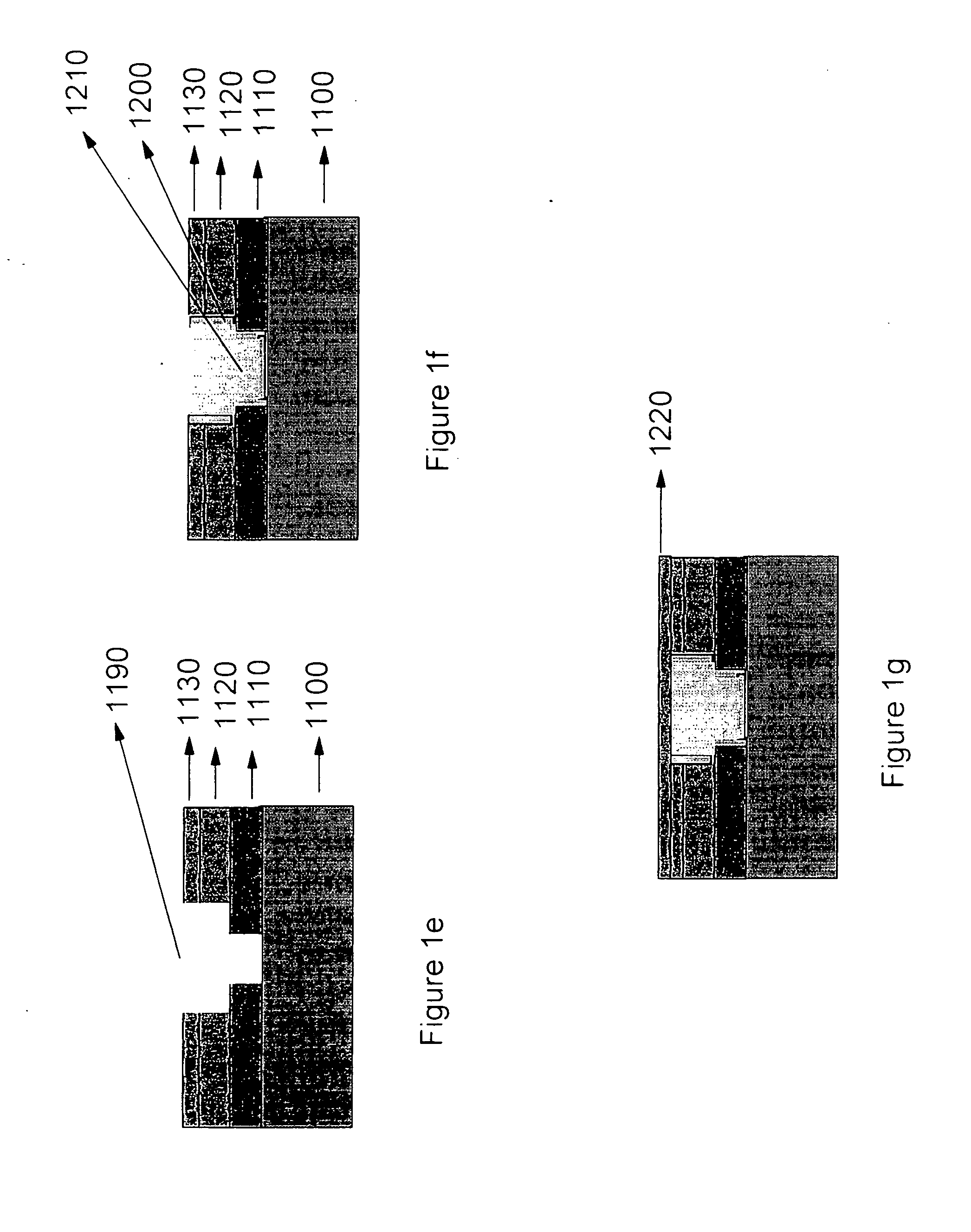

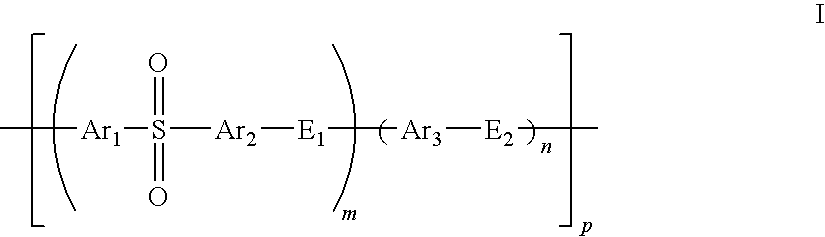

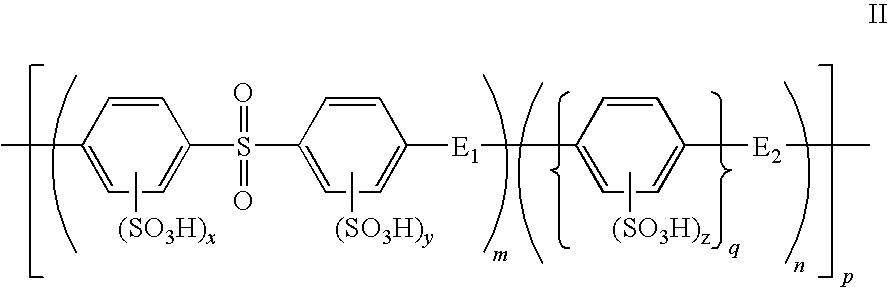

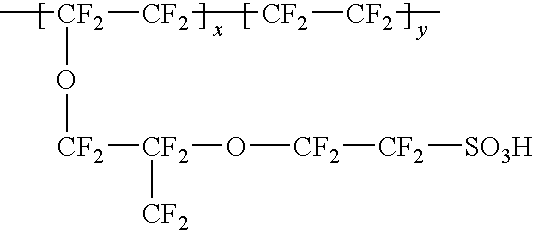

Composite solid polymer electrolyte membranes

InactiveUS7550216B2Improve performanceLow costElectrolyte holding meansMembranesPolymer electrolytesFuel cells

Owner:FOSTER-MILLER

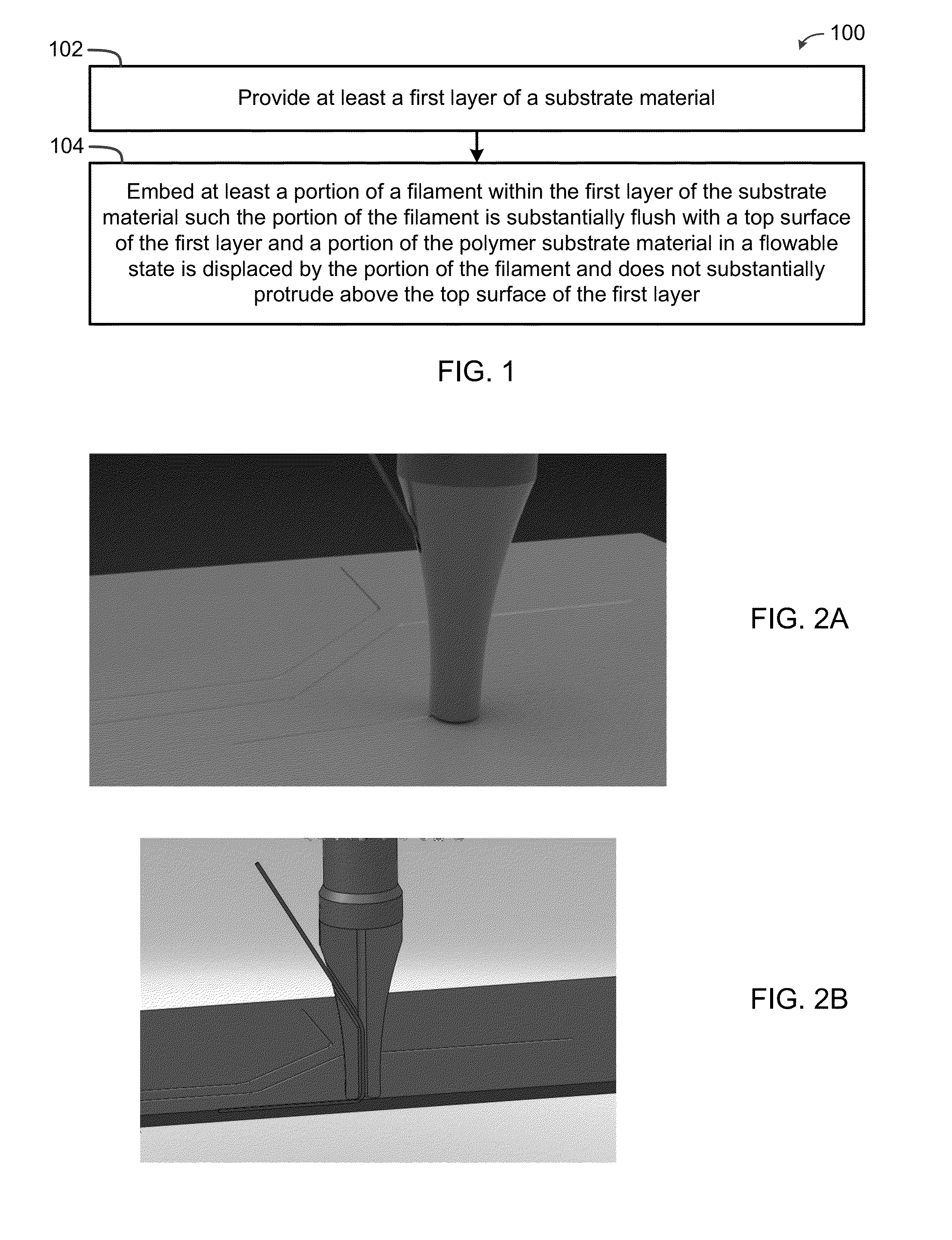

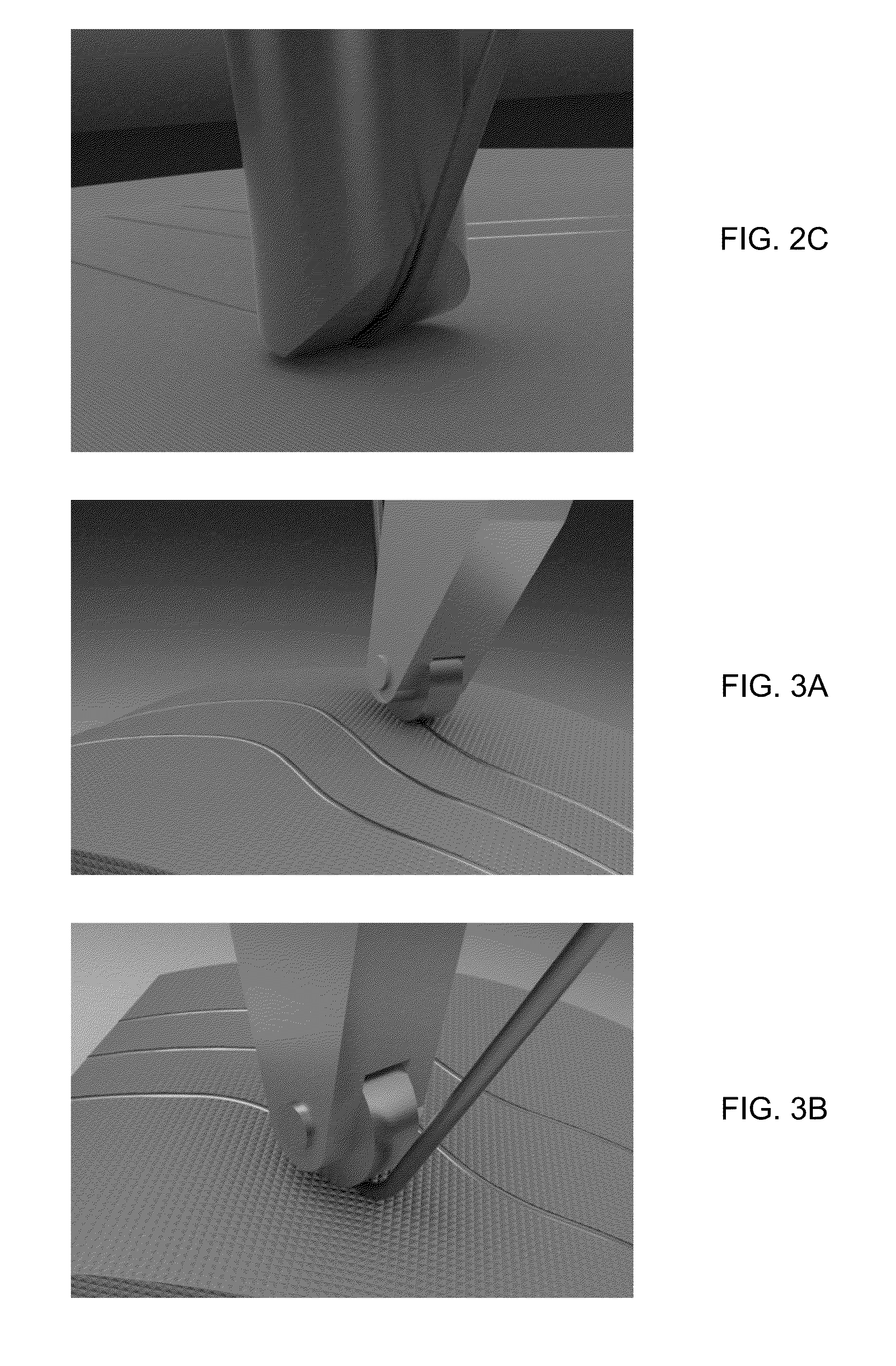

Methods and Systems For Embedding Filaments in 3D Structures, Structural Components, and Structural Electronic, Electromagnetic and Electromechanical Components/Devices

ActiveUS20140268604A1High mechanical strengthElectric discharge heatingCeramic shaping apparatusElectricityEngineering

The present invention provides systems and methods for embedding a filament or filament mesh in a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device by providing at least a first layer of a substrate material, and embedding at least a portion of a filament or filament mesh within the first layer of the substrate material such the portion of the filament or filament mesh is substantially flush with a top surface of the first layer and a substrate material in a flowable state is displaced by the portion of the filament and does not substantially protrude above the top surface of the first layer, allowing the continuation of an additive manufacturing process above the embedded filament or filament mesh. A method is provided for creating interlayer mechanical or electrical attachments or connections using filaments within a three-dimensional structure, structural component, or structural electronic, electromagnetic or electromechanical component / device.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Light source device using LED, and method of producing same

InactiveUS6874910B2Improve cooling effectMinimize temperature increaseLighting heating/cooling arrangementsSolid-state devicesEngineeringElectrical and Electronics engineering

A light source apparatus having a radiator plate having thermally conductive properties and an insulating member coupled to at least one side of the radiator plate having a through hole provided in a side thereof facing the radiator plate. The light source apparatus further including a LED chip installed and thermally coupled to an exposed portion of the radiator plate facing the through hole, an extension inwardly projecting at the through hole from the radiator plate end of the insulating member, and a wiring pattern provided on the insulating member electrically isolated by the insulating member from the radiator plate. The light source apparatus also including bonding wires electrically connecting portions of the wiring pattern on the extension and the electrodes of the LED chip, and a light-transmissive sealing material filling the through hole for entirely encapsulating the LED chip and the bonding wires.

Owner:SIGNIFY HLDG BV

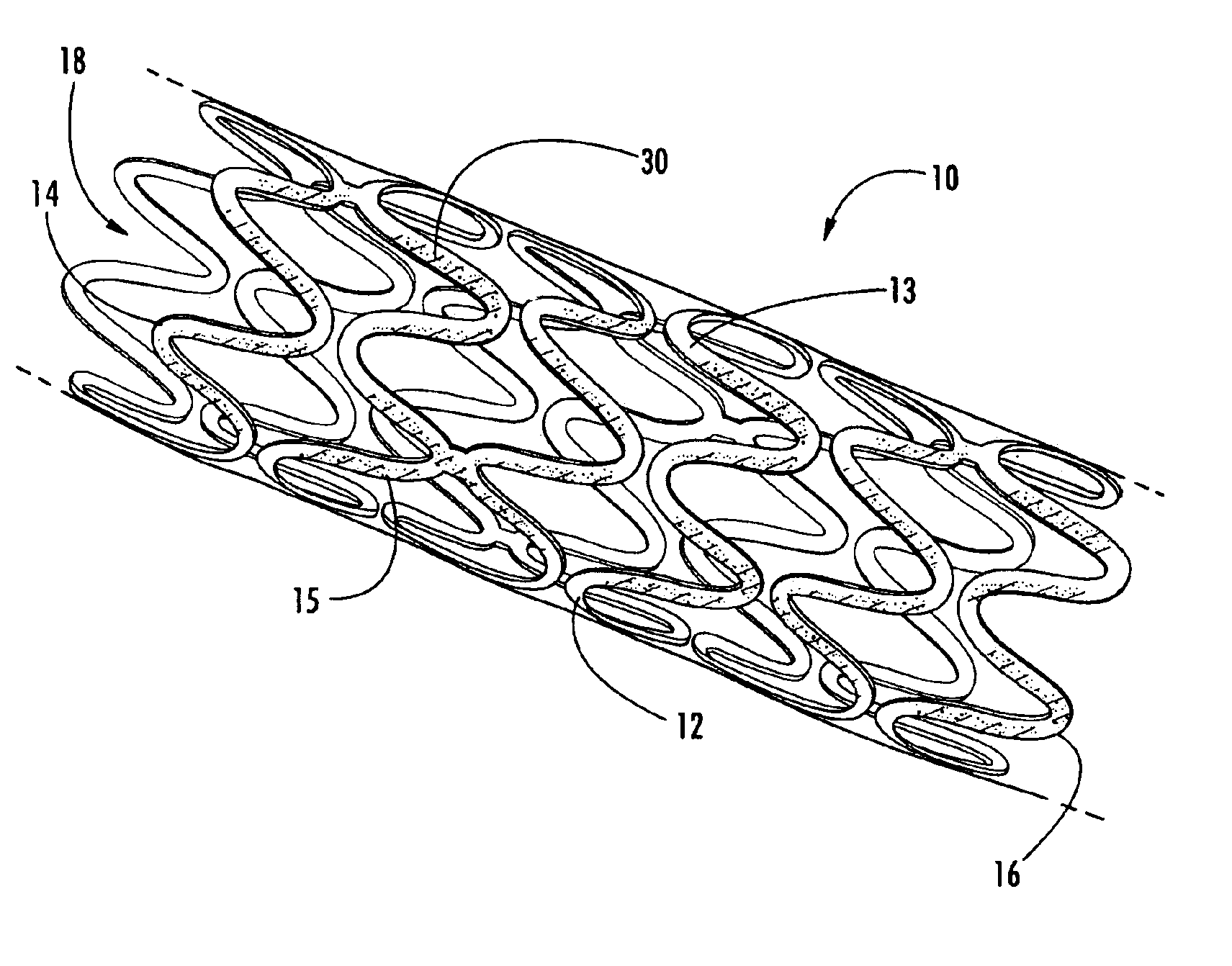

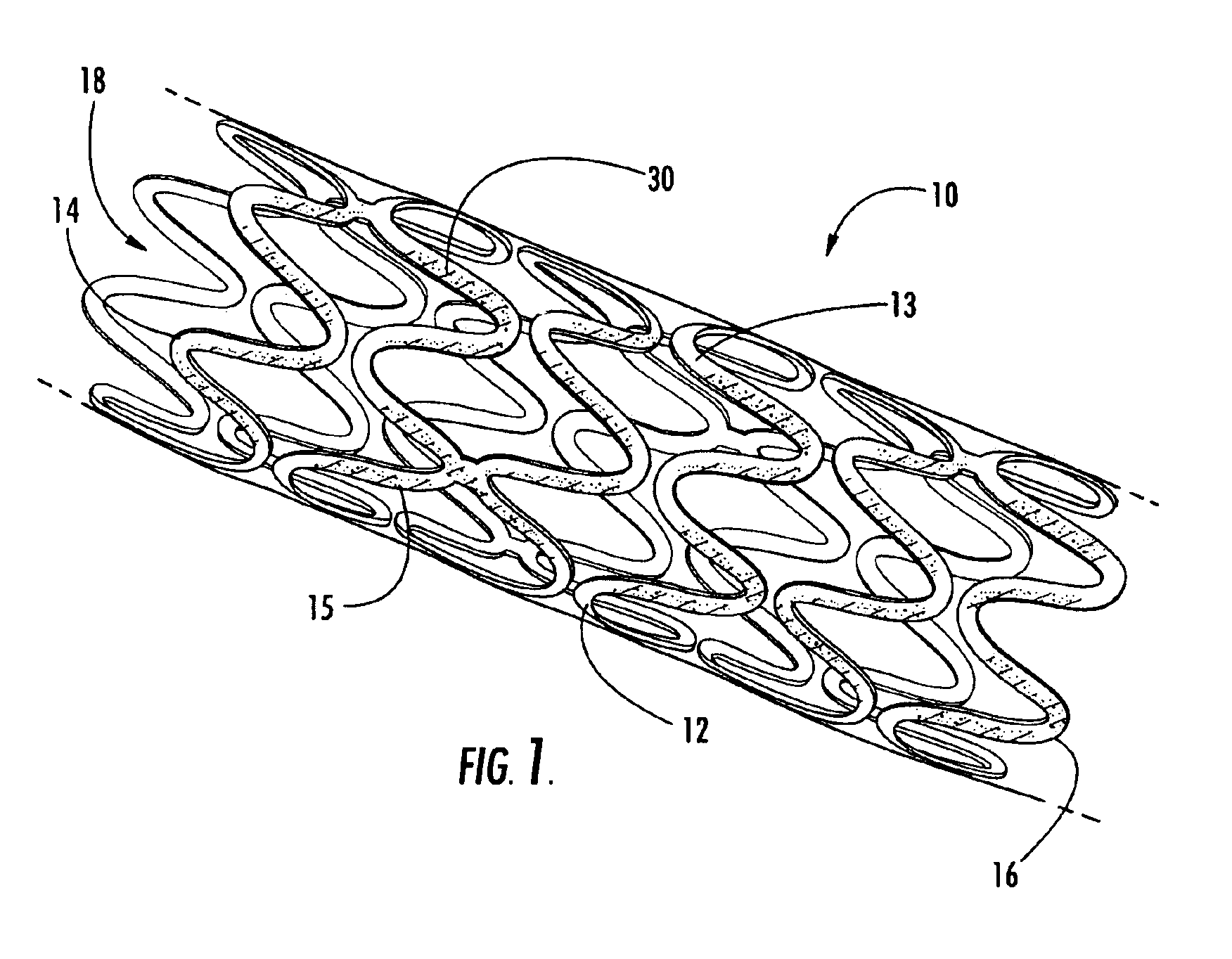

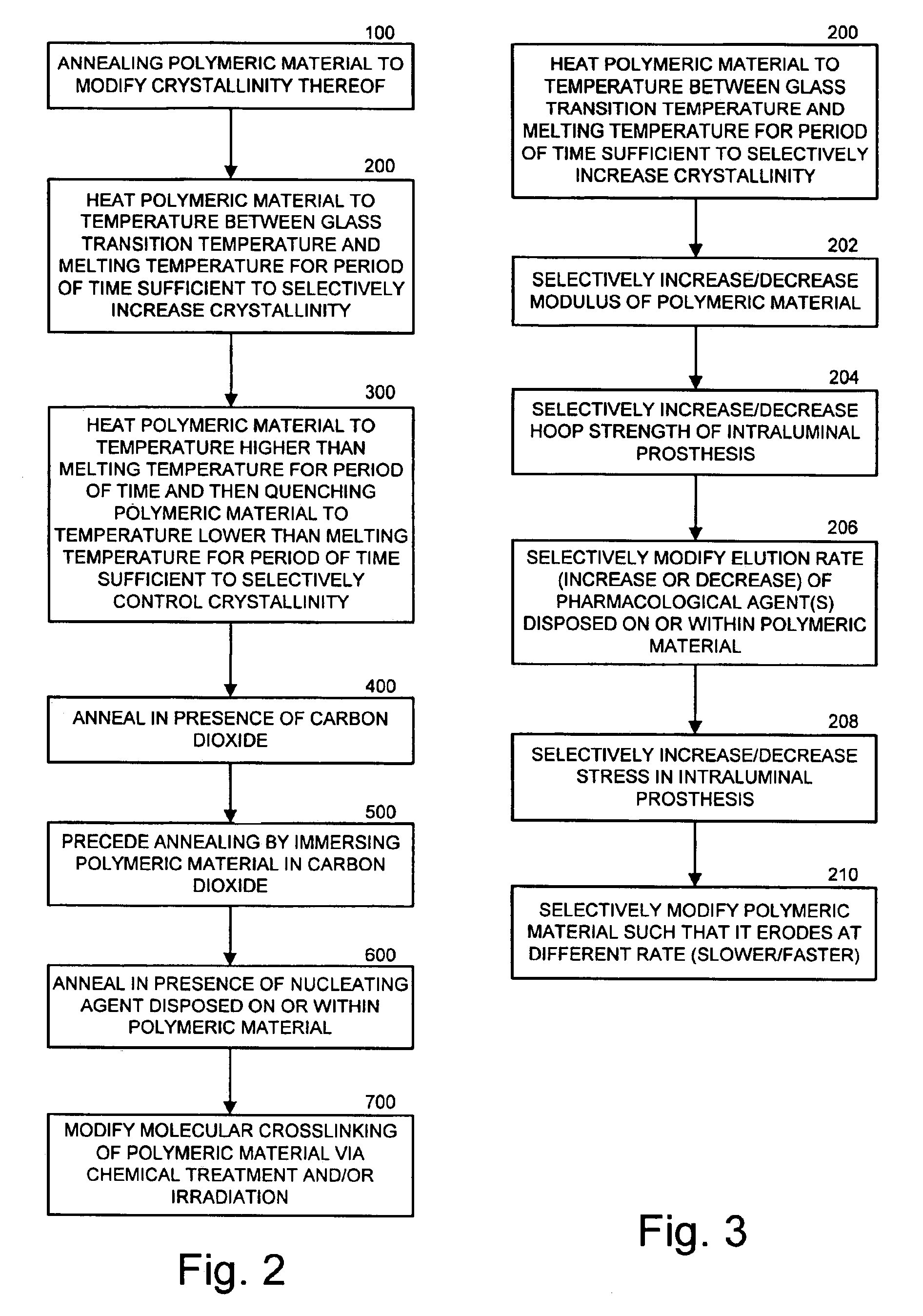

Intraluminal prostheses having polymeric material with selectively modified crystallinity and methods of making same

Methods of manufacturing polymeric intraluminal prostheses include annealing the polymeric material to selectively modify the crystallinity thereof. Annealing may be utilized to selectively modify various properties of the polymeric material of an intraluminal prosthesis, including: selectively increasing the modulus of the polymeric material; selectively increasing the hoop strength of the intraluminal prosthesis; selectively modifying the elution rate (increase or decrease) of a pharmacological agent subsequently disposed on or within the annealed polymeric material; selectively increasing / decreasing stress in the intraluminal prosthesis; and selectively modifying the polymeric material such that it erodes at a different rate.

Owner:SYNECOR LLC

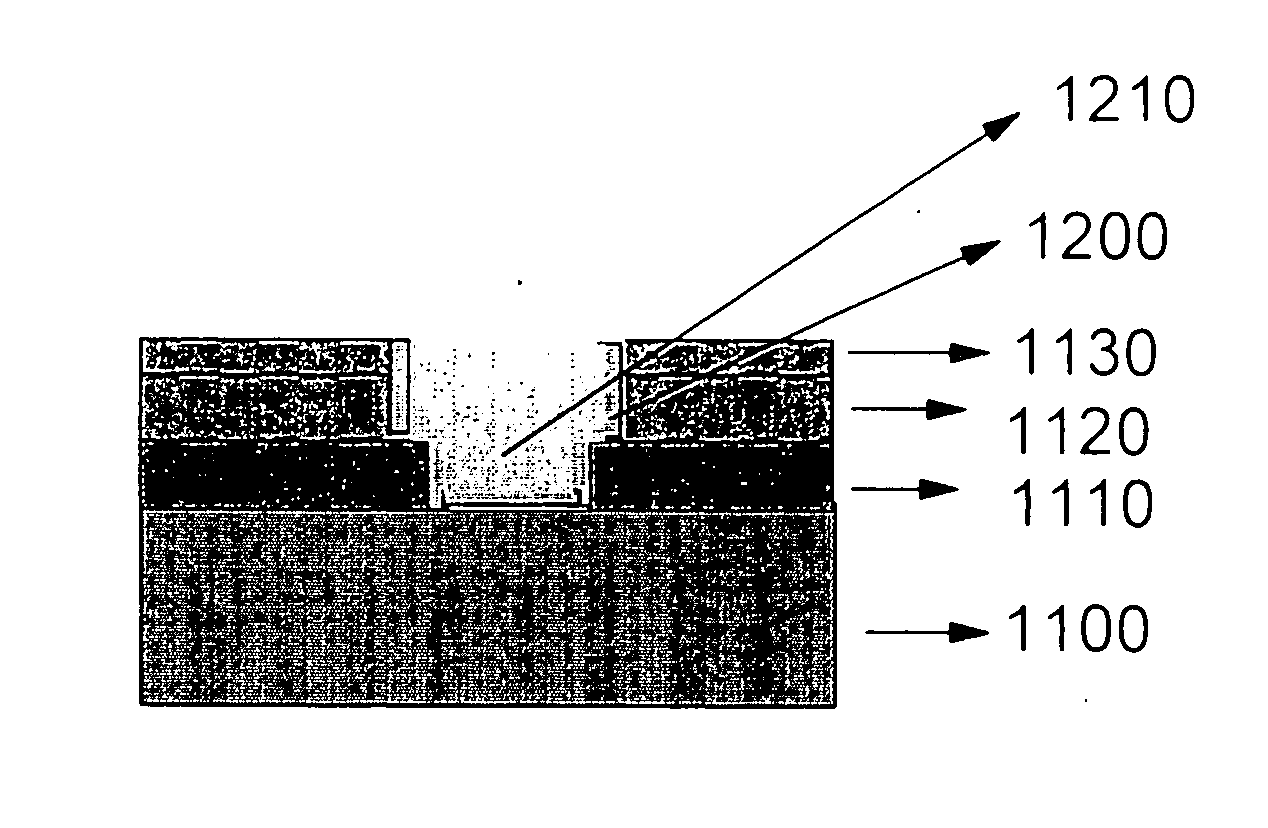

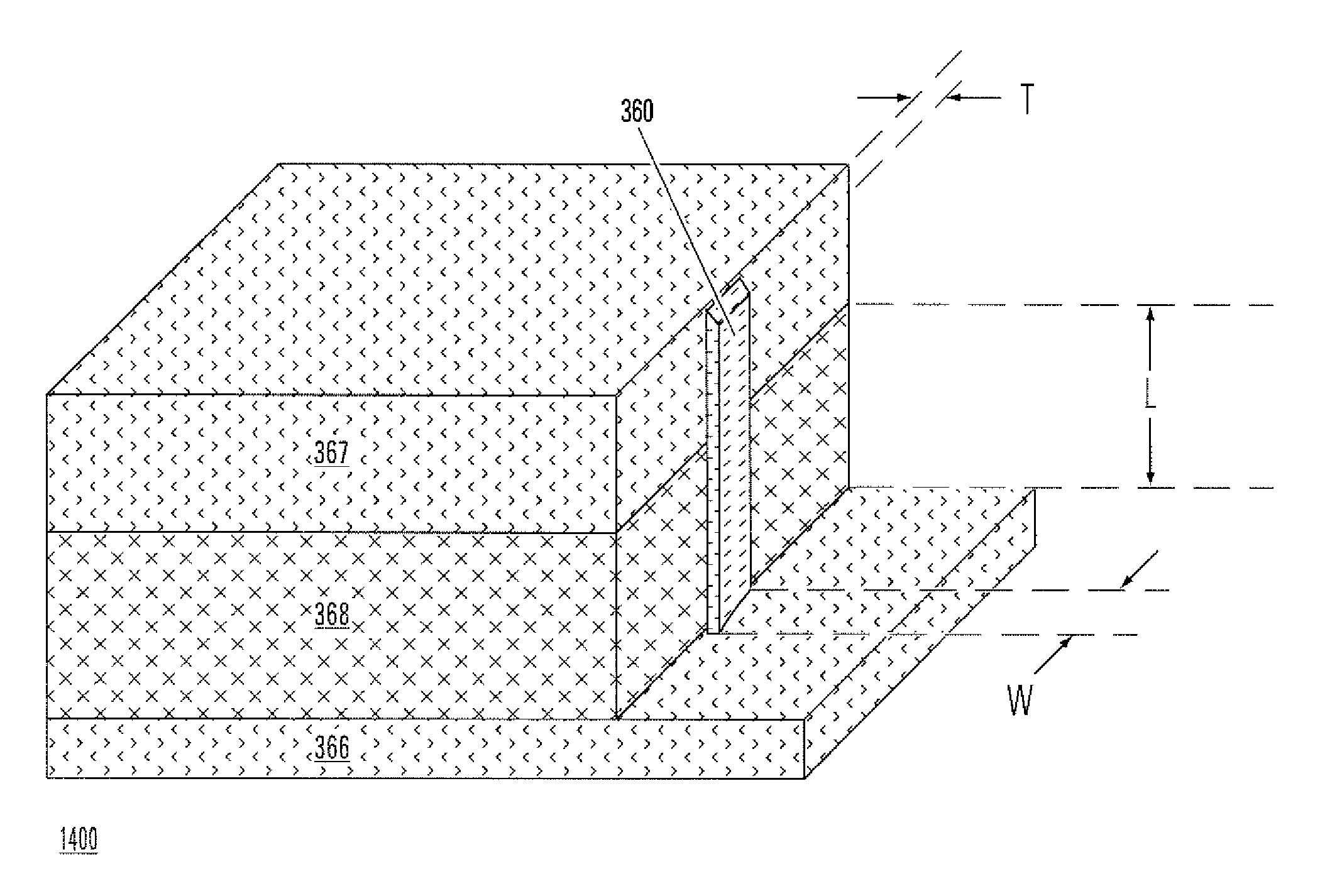

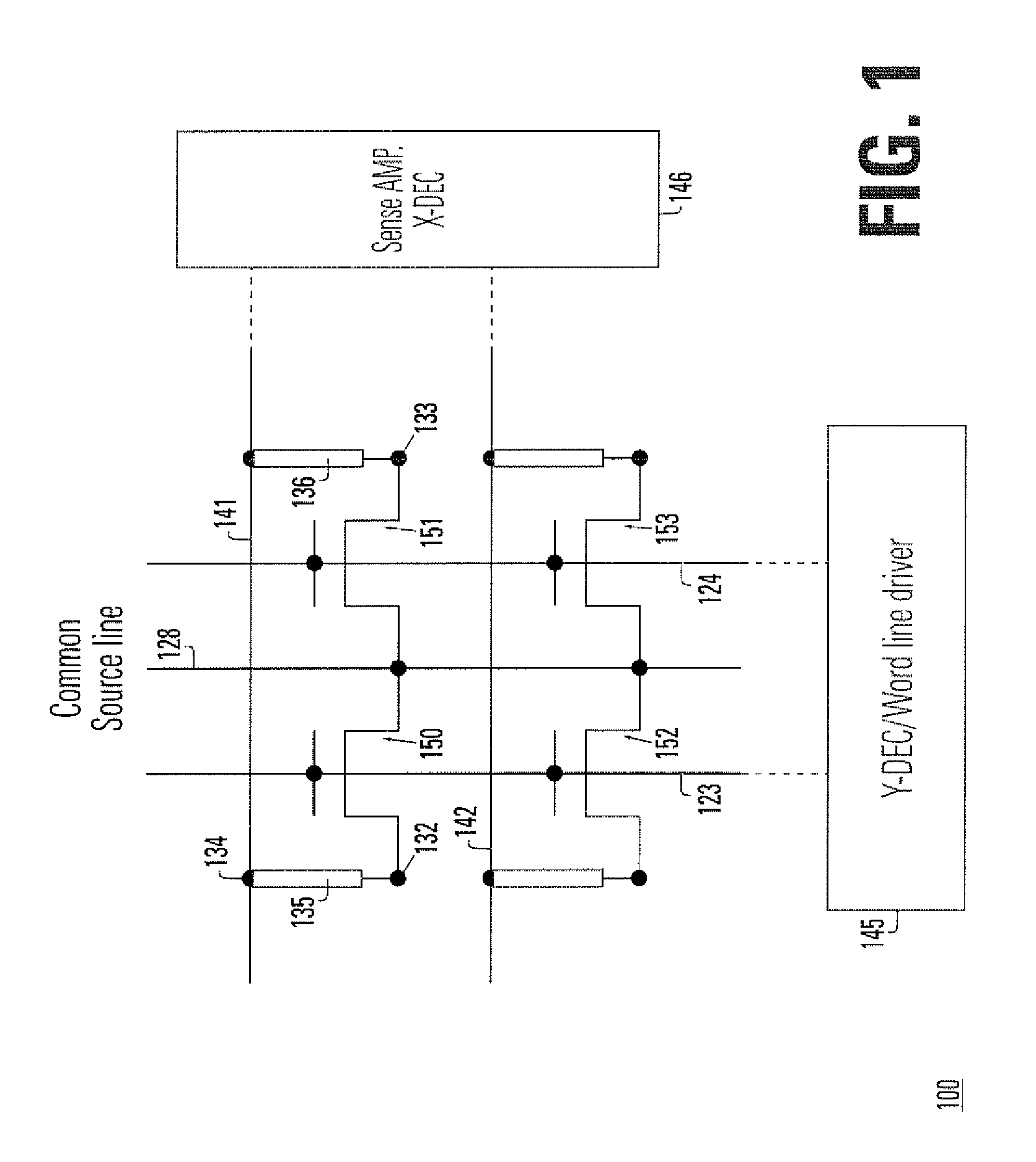

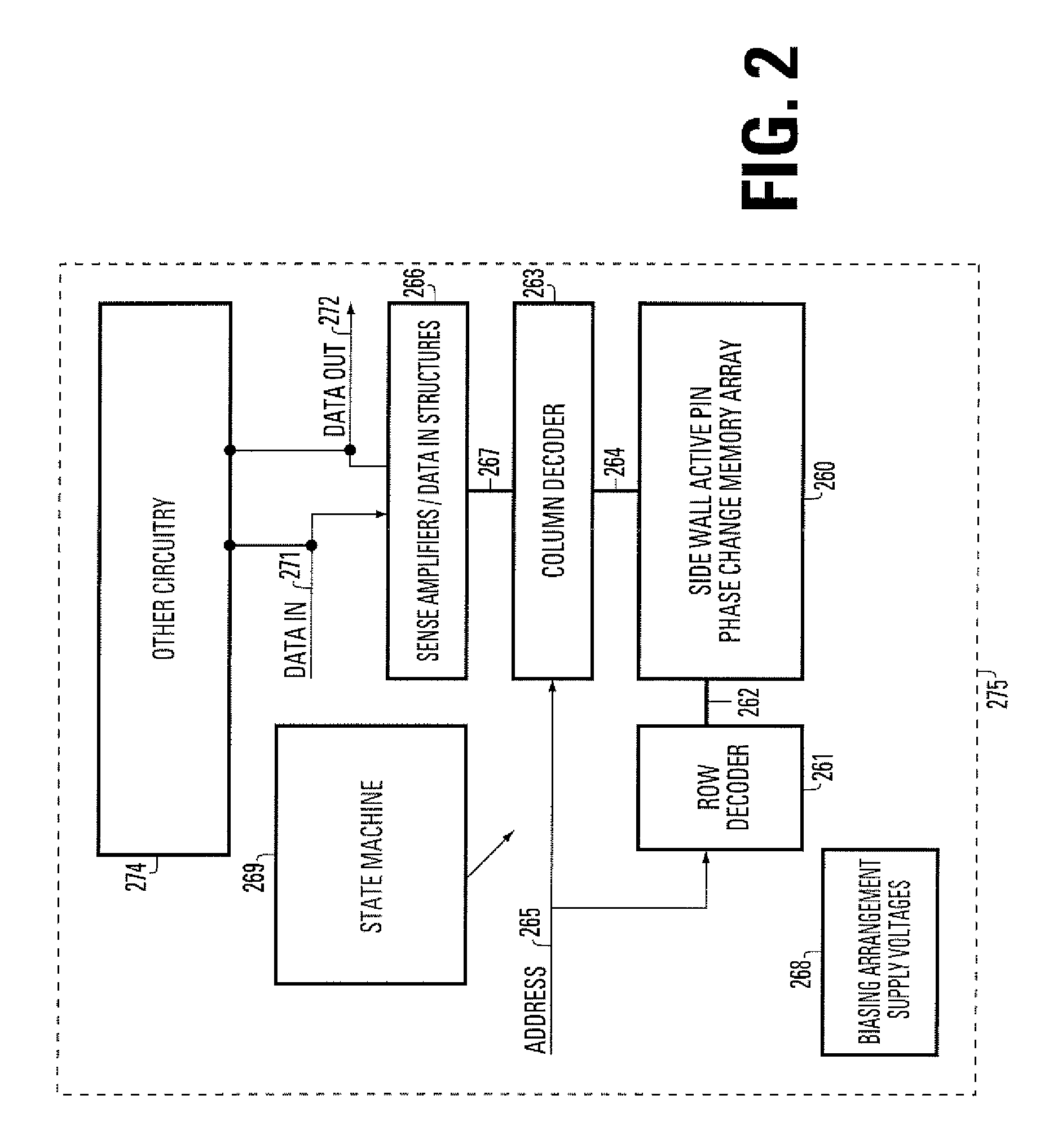

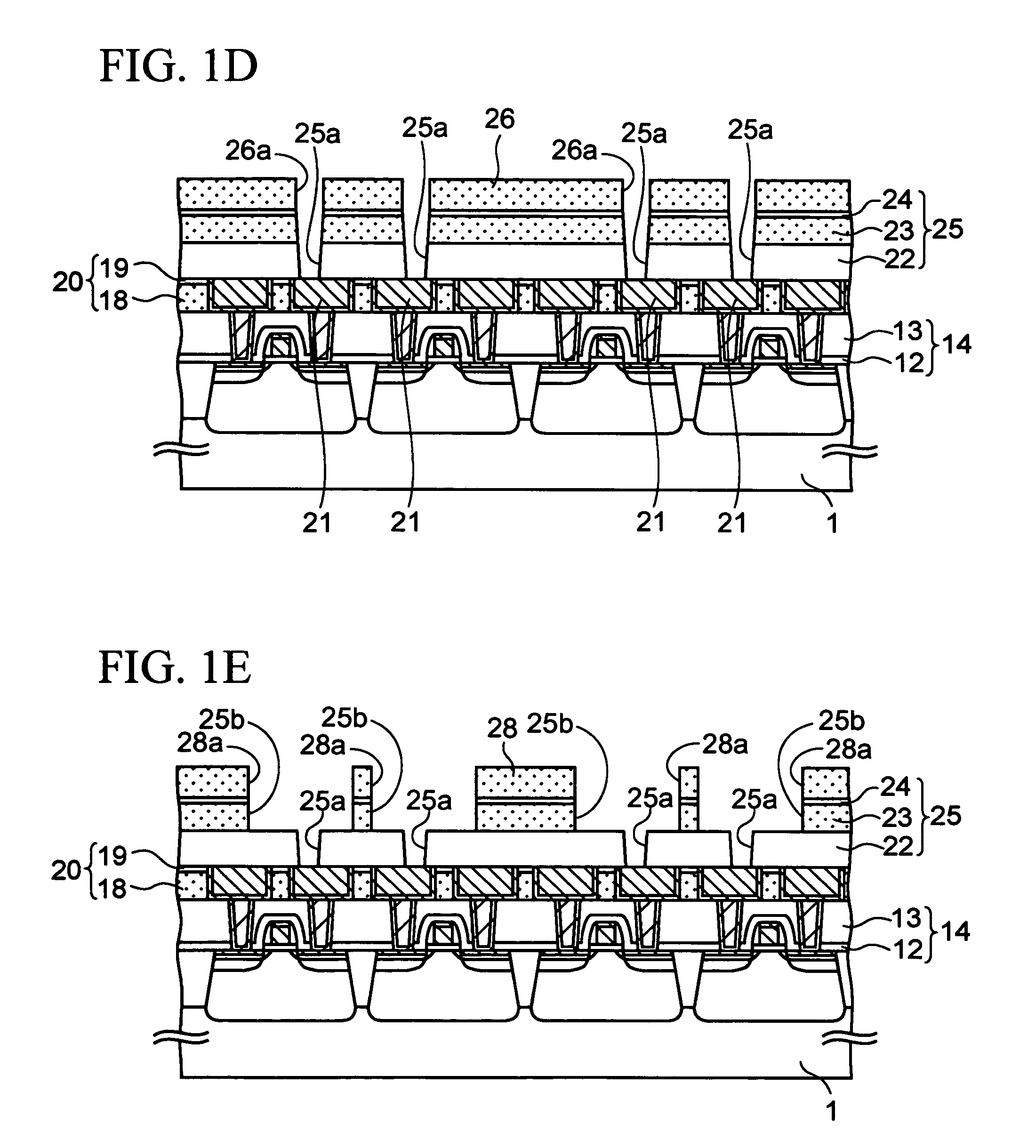

Vertical Side Wall Active Pin Structures in a Phase Change Memory and Manufacturing Methods

ActiveUS20070176261A1Reduce electrical currentLow resistivitySolid-state devicesSemiconductor devicesEngineeringPhase-change material

A programmable resistor memory, such as a phase change memory, with a memory element comprising narrow vertical side wall active pins is described. The side wall active pins comprise a programmable resistive material, such as a phase change material. In a first aspect of the invention, a method of forming a memory cell is described which comprises forming a stack comprising a first electrode having a principal surface with a perimeter, an insulating layer overlying a portion of the principal surface of the first electrode, and a second electrode vertically separated from the first electrode and overlying the insulating layer. Side walls on the insulating layer and on the second electrode are positioned over the principle surface of the first electrode with a lateral offset from the perimeter of the first electrode.

Owner:MACRONIX INT CO LTD

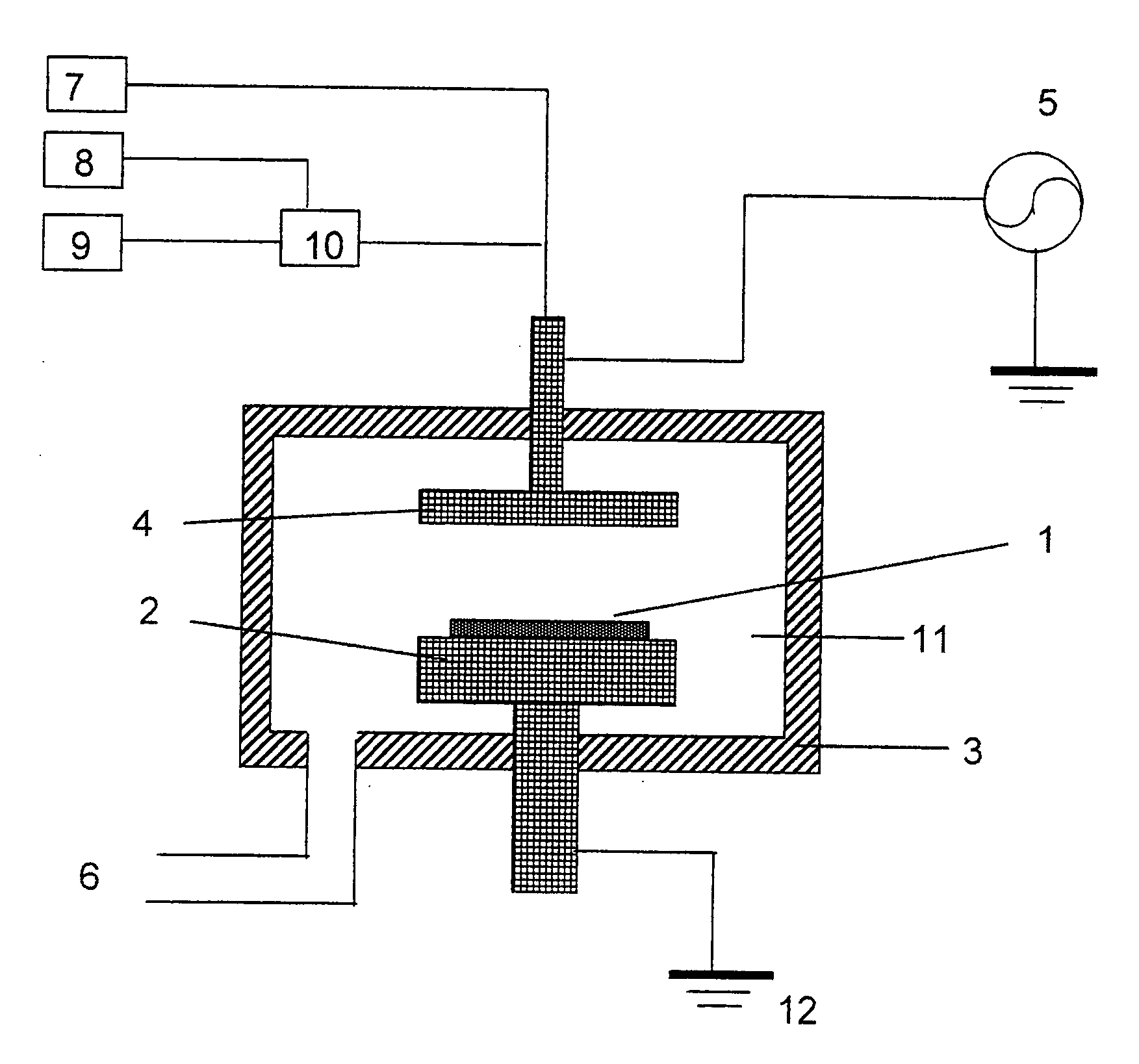

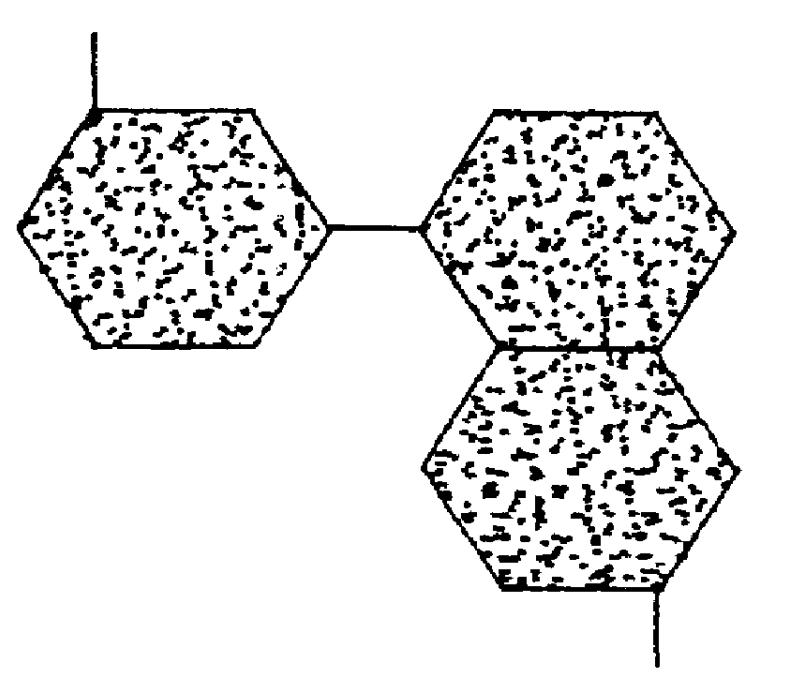

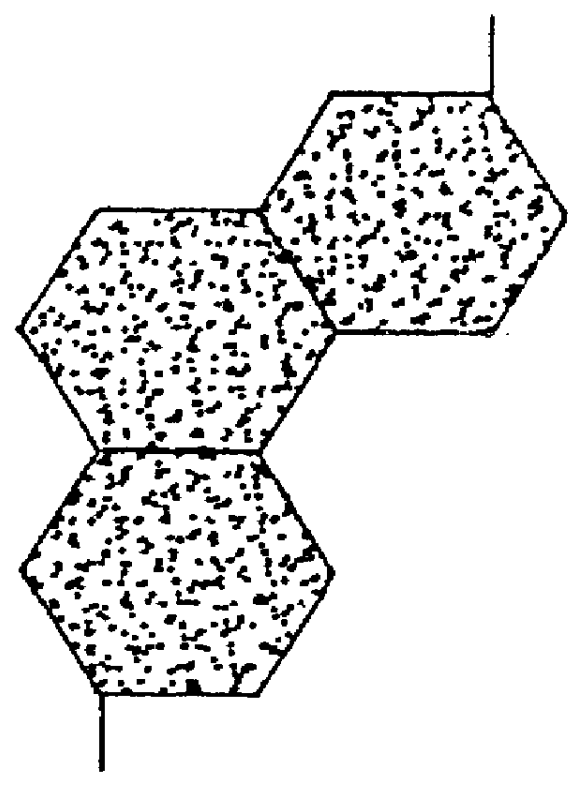

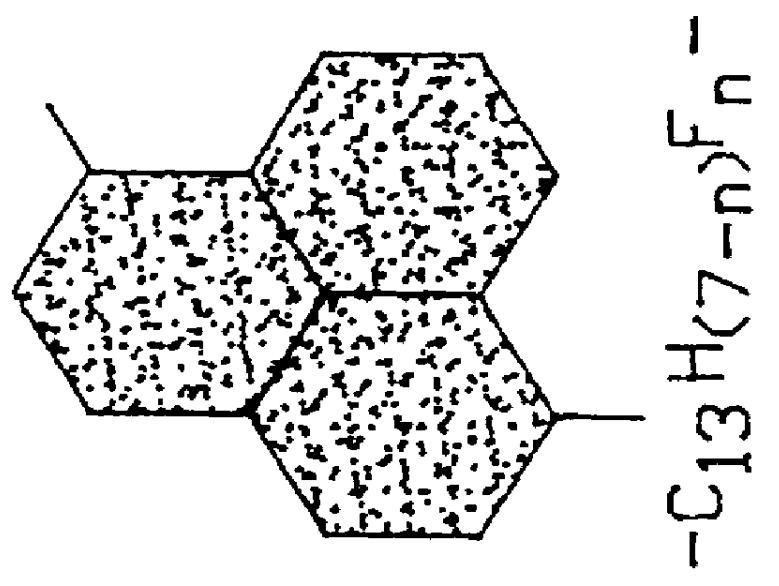

Low dielectric constant materials and method

InactiveUS6051321AImprove rotational flexibilityTightly boundSemiconductor/solid-state device detailsSynthetic resin layered productsElectrical conductorCopper

Intermetal dielectric (IMD) and interlevel dielectric (ILD) that have dielectric constants (K) ranging from 2.0 to 2.6 are prepared from plasma or photon assisted CVD (PACVD) or transport polymerization (TP). The low K dielectric (LKD) materials are prepared from PACVD or TP of some selected siloxanes and F-containing aromatic compounds. The thin films combine barrier and adhesion layer functions with low dielectric constant functions, thus eliminating the necessity for separate adhesion and barrier layers, and layers of low dielectric constant. The LKD materials disclosed in this invention are particularly useful for <0.18 .mu.m ICs, or when copper is used as conductor in future ICs.

Owner:CANON USA

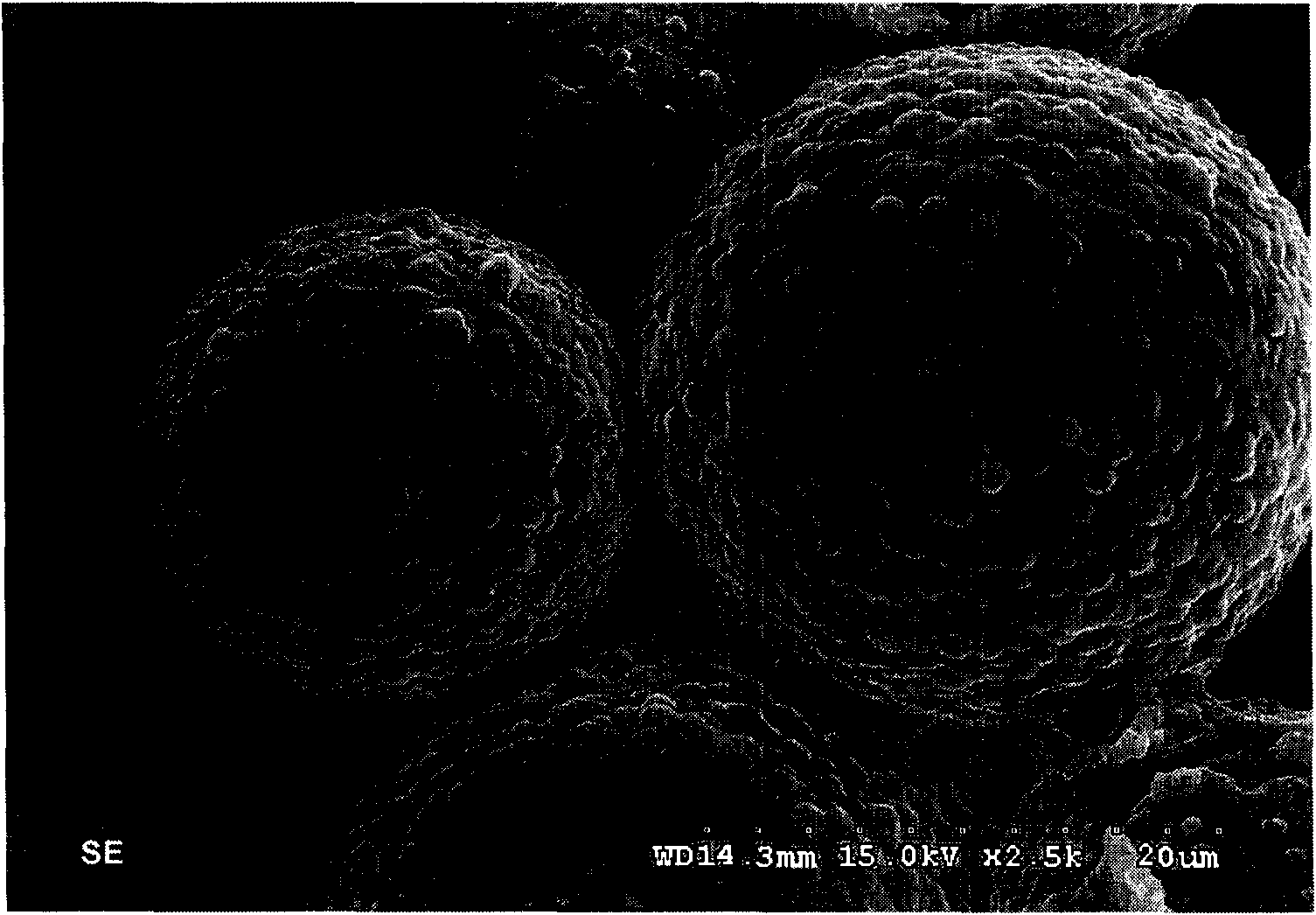

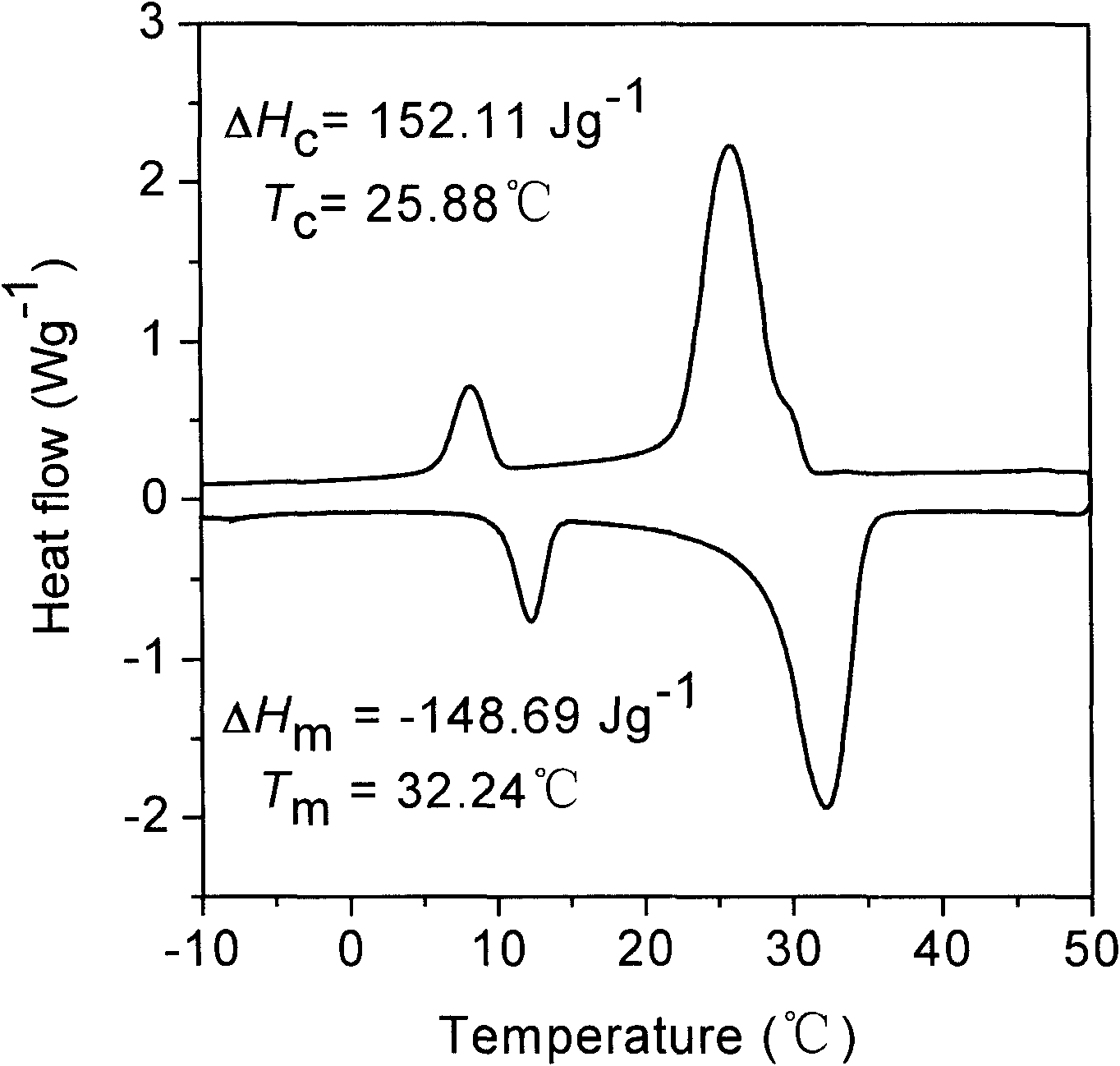

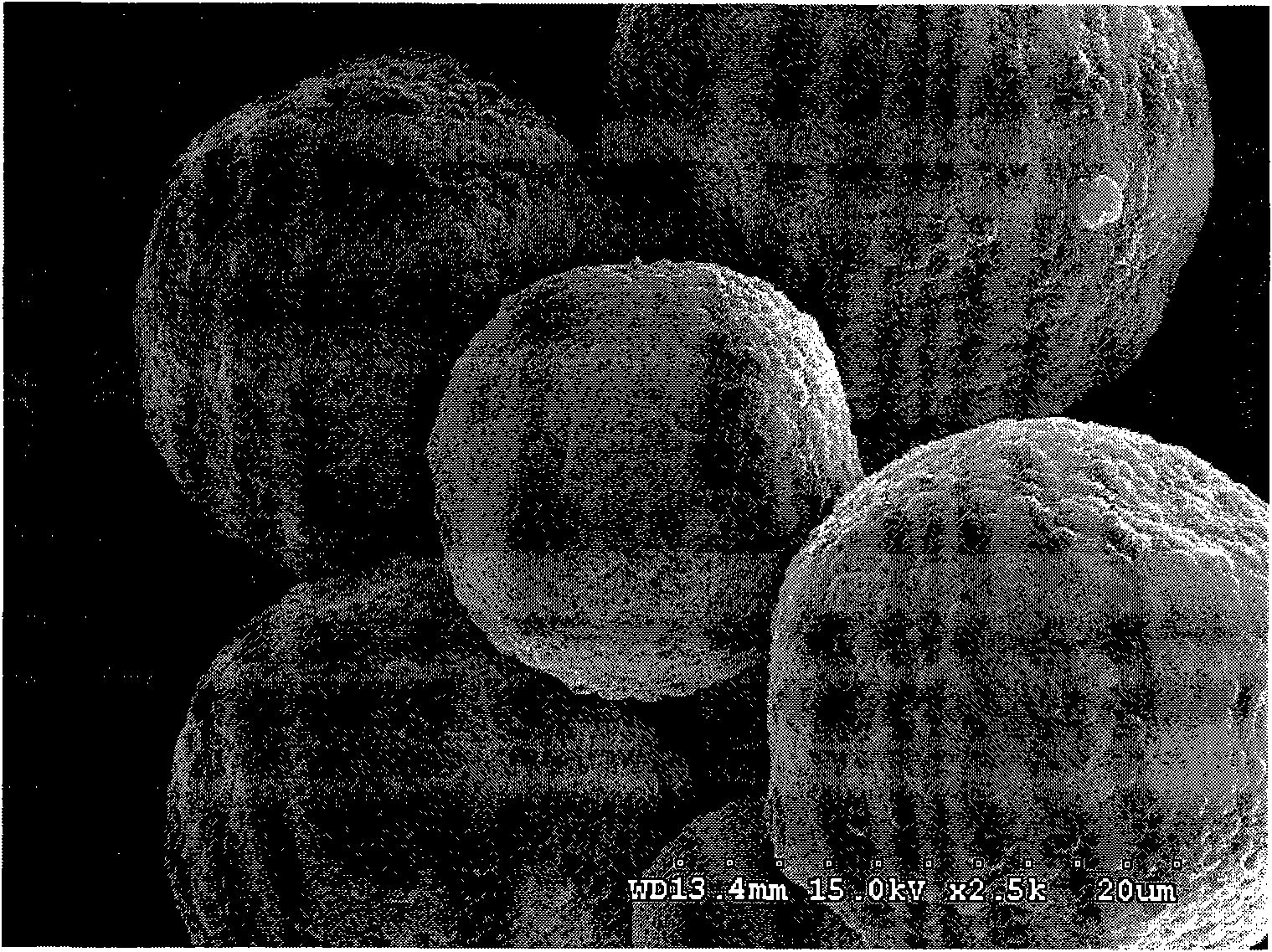

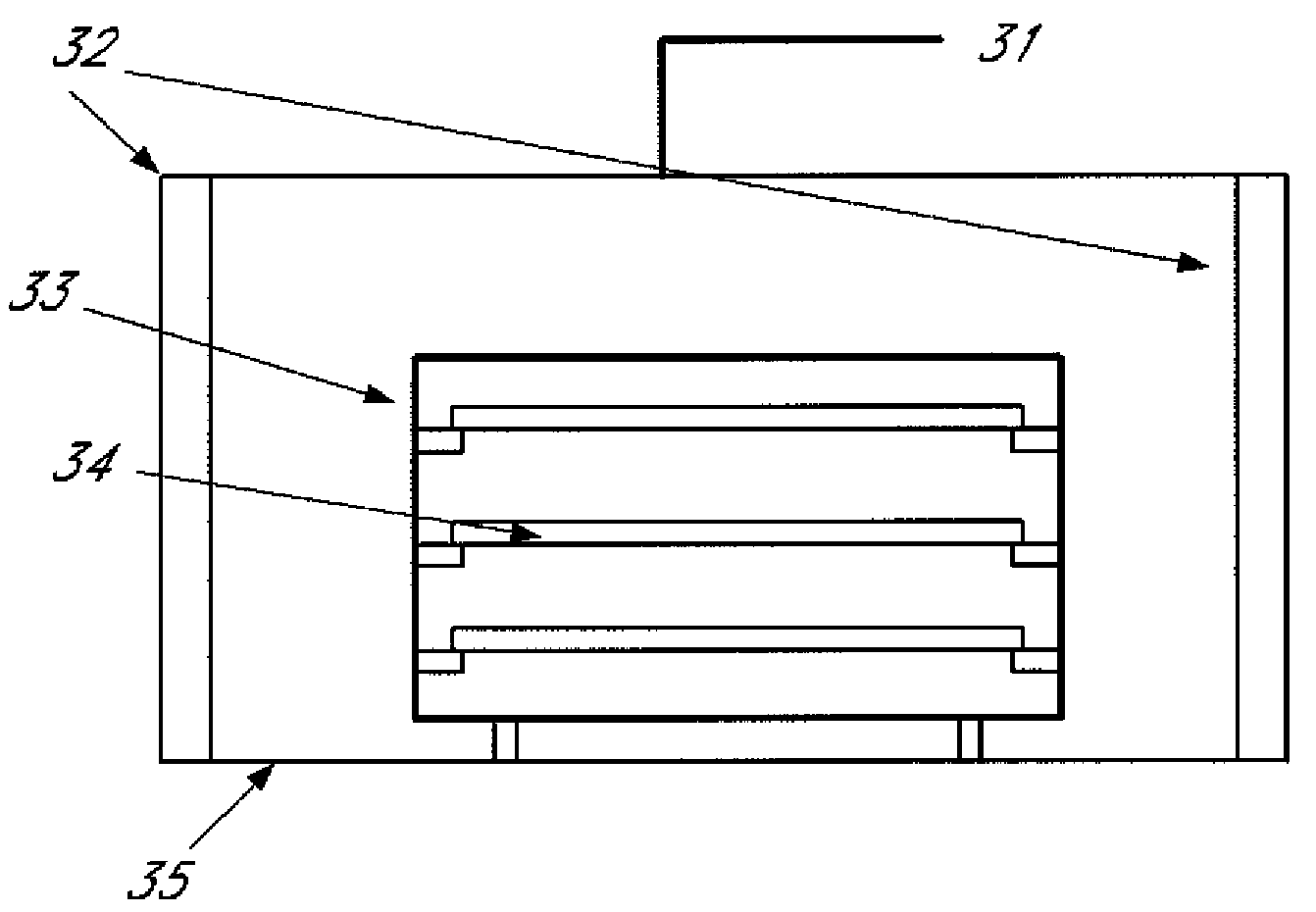

Microcapsule of organic phase change energy storage material and preparation method thereof

ActiveCN101555401AHas infrared reflective propertiesHas infrared absorption propertiesEnergy storageHeat-exchange elementsChemistryIn situ polymerization

The invention discloses a microcapsule of an organic phase change energy storage material and a preparation method thereof. The microcapsule of an organic phase change energy storage material comprises a core and a nucleocapsid, wherein the material of the core comprises the organic phase change energy storage material; the nucleocapsid at least comprises an inner layer and an outer layer, the inner layer is packaged by any one of an in situ polymerization method, an interface polymerization method, a reaction phase separating method, a double agglomeration method and a sol-gal process, and the outer layer is packaged by any one of an in situ polymerization method, a reaction phase separating method, a sol-gal process and a double agglomeration method. The microcapsule has adjustable size, nucleocapsid composition and shell thickness, favorable flexibility, mechanical strength, penetrability resistance and dispersibility and can be widely applied to the fields of energy sources, materials, aero-space, textile, electric power, medical apparatus, architecture, and the like, such as solar utilization, industrial afterheat and waste heat recovery, architecture energy storage, dress with constant temperature, air conditioners for cool and heat accumulation, constant temperature of electric appliances, and the like.

Owner:BEIJING NEW BUILDING MATERIAL

Method for forming dielectric film using siloxane-silazane mixture

ActiveUS20090156017A1High densityHigh strengthPretreated surfacesSemiconductor/solid-state device manufacturingSilazaneMetallurgy

A method of forming a dielectric film, includes: introducing a siloxane gas essentially constituted by Si, O, C, and H and a silazane gas essentially constituted by Si, N, H, and optionally C into a reaction chamber where a substrate is placed; depositing a siloxane-based film including Si—N bonds on the substrate by plasma reaction; and annealing the siloxane-based film on the substrate in an annealing chamber to remove Si—N bonds from the film.

Owner:ASM JAPAN

Light emitting device with silicone resin layer formed by screen printing

ActiveUS7745818B2Improve heat resistanceConvenient lightingDischarge tube luminescnet screensLamp detailsScreen printingPolystyrene

Owner:NICHIA CORP

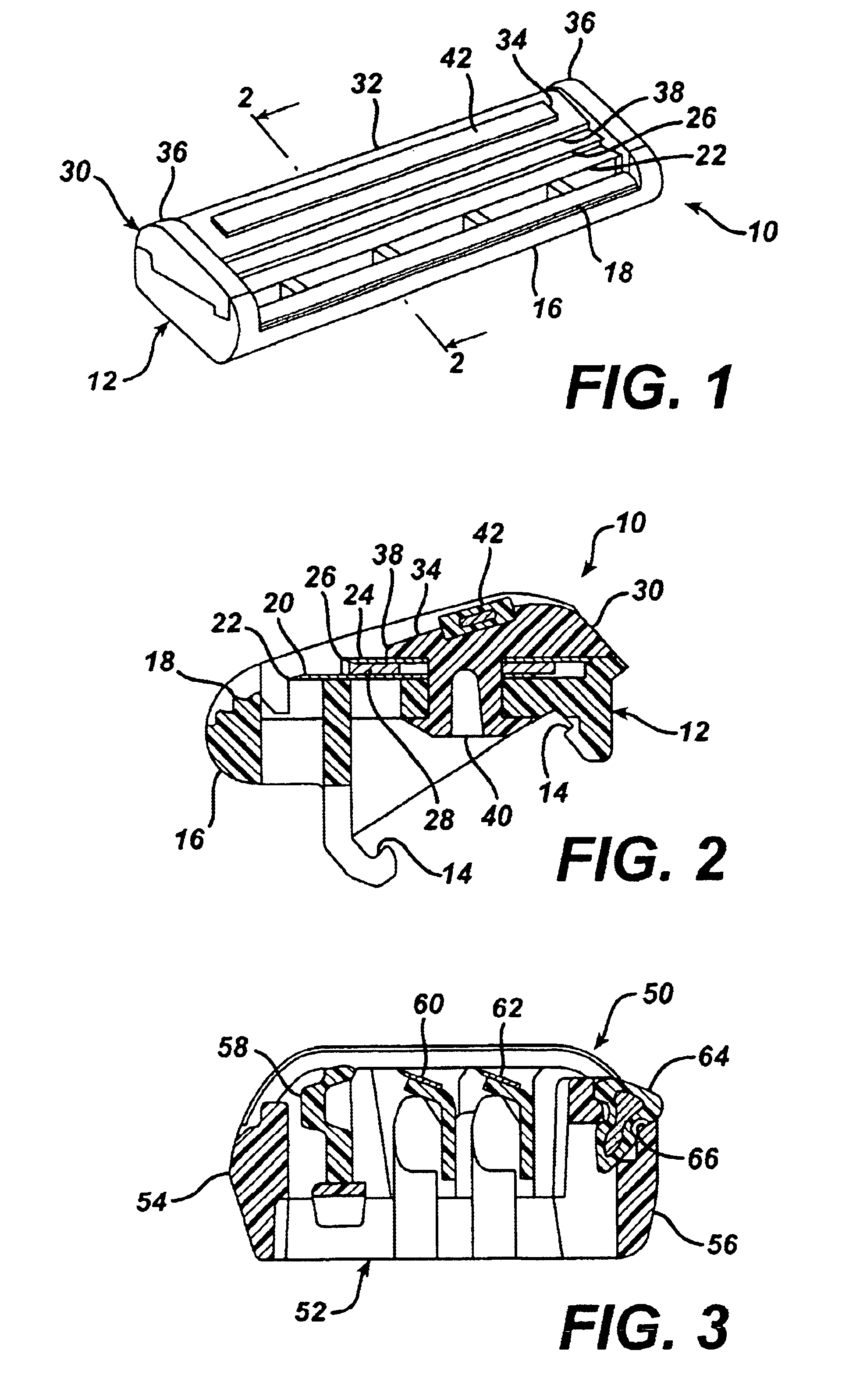

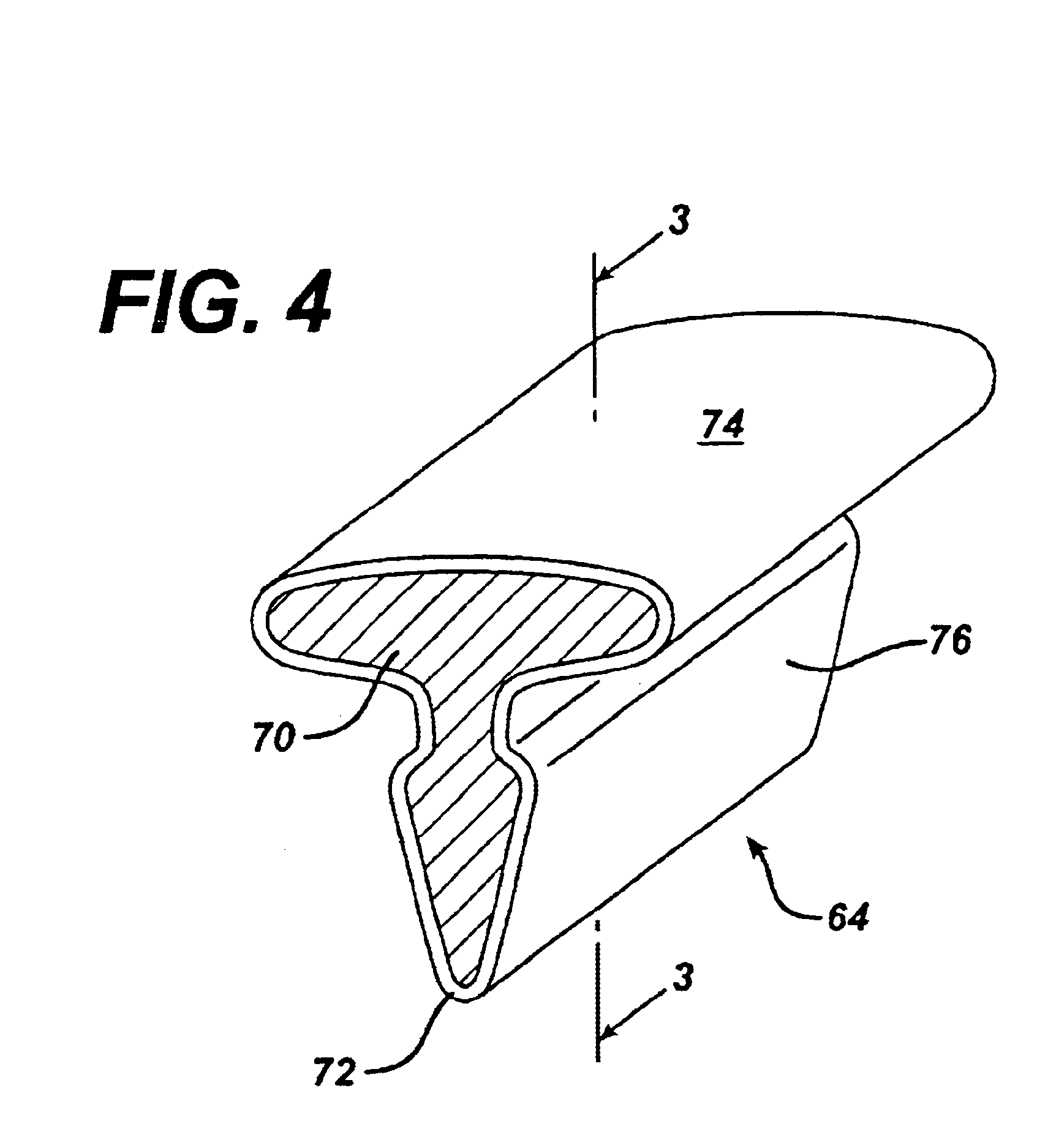

Shaving system

InactiveUS6944952B1High mechanical strengthImproved shaving aid release characteristicMeasurement devicesPhysics instrumentsWater insolubleRigid core

A shaving unit that comprises at least one blade and a skin engaging member that has a surface for engaging the user's skin adjacent the blade edge. The shaving unit may be of a disposable cartridge type adapted for coupling to and uncoupling from a razor handle or may be integral with a handle so that the complete razor is discarded as a unit when the blade or blades become dulled. The blade edge (or edges) cooperate with skin engaging surfaces to define a shaving geometry. The skin engaging member is comprised on an elongated sheath (or skin engaging layer) made of a mixture of water insoluble matrix and an effective amount of shaving aid and a rigid core (or non-skin engaging layer) extending axially through out said sheath. The axial position of the core need not be through the central axis.

Owner:THE GILLETTE CO

Sutureless heart valve attachment

Owner:EDWARDS LIFESCIENCES CORP

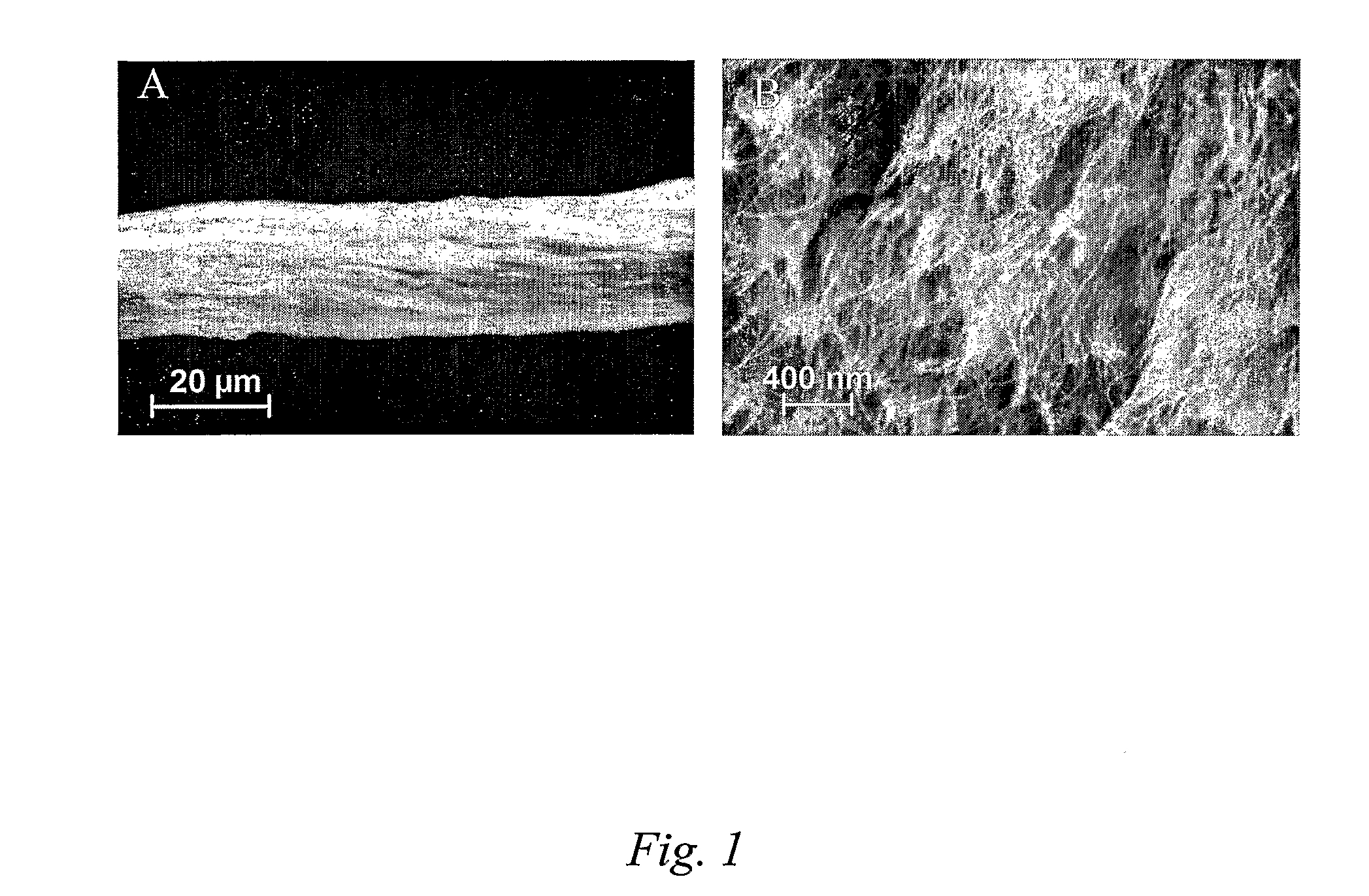

Polymer-Free Carbon Nanotube Assemblies (Fibers, Ropes, Ribbons, Films)

InactiveUS20070243124A1Improve mechanical propertiesHigh mechanical strengthMaterial nanotechnologyPigmenting treatmentCarbon nanotubeElectromechanical actuator

Process, apparatus, compositions and application modes are provided that relate to nanofiber spinning without the use of superacids in the spinning solution. The methods employ either acids or bases for a flocculation solution. The advances disclosed therein enable the use of nanofibers, including carbon nanotubes, for a variety of applications including, but not limited to, electromechanical actuators, supercapacitors, electronic textiles, and in devices for electrical energy harvesting.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

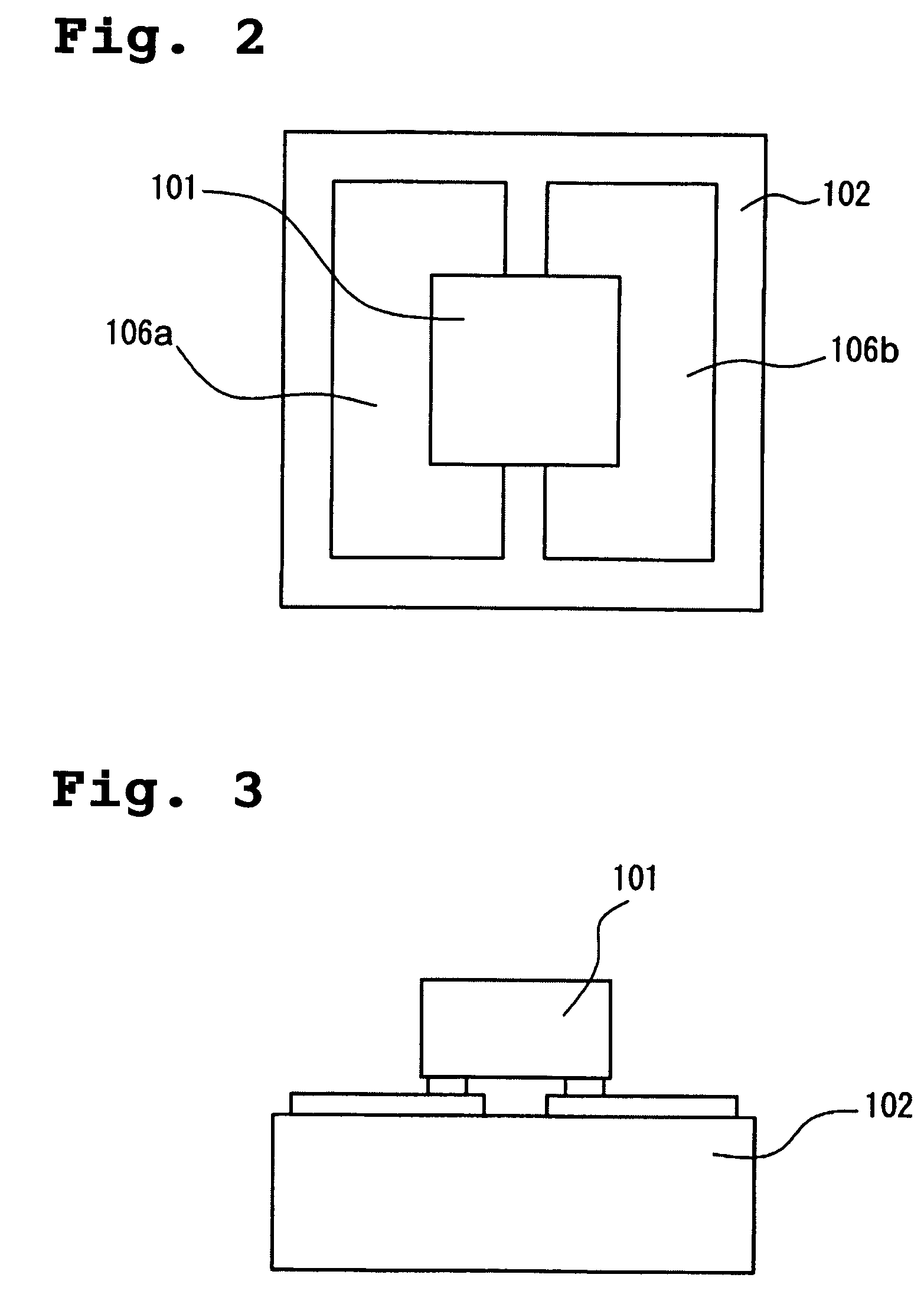

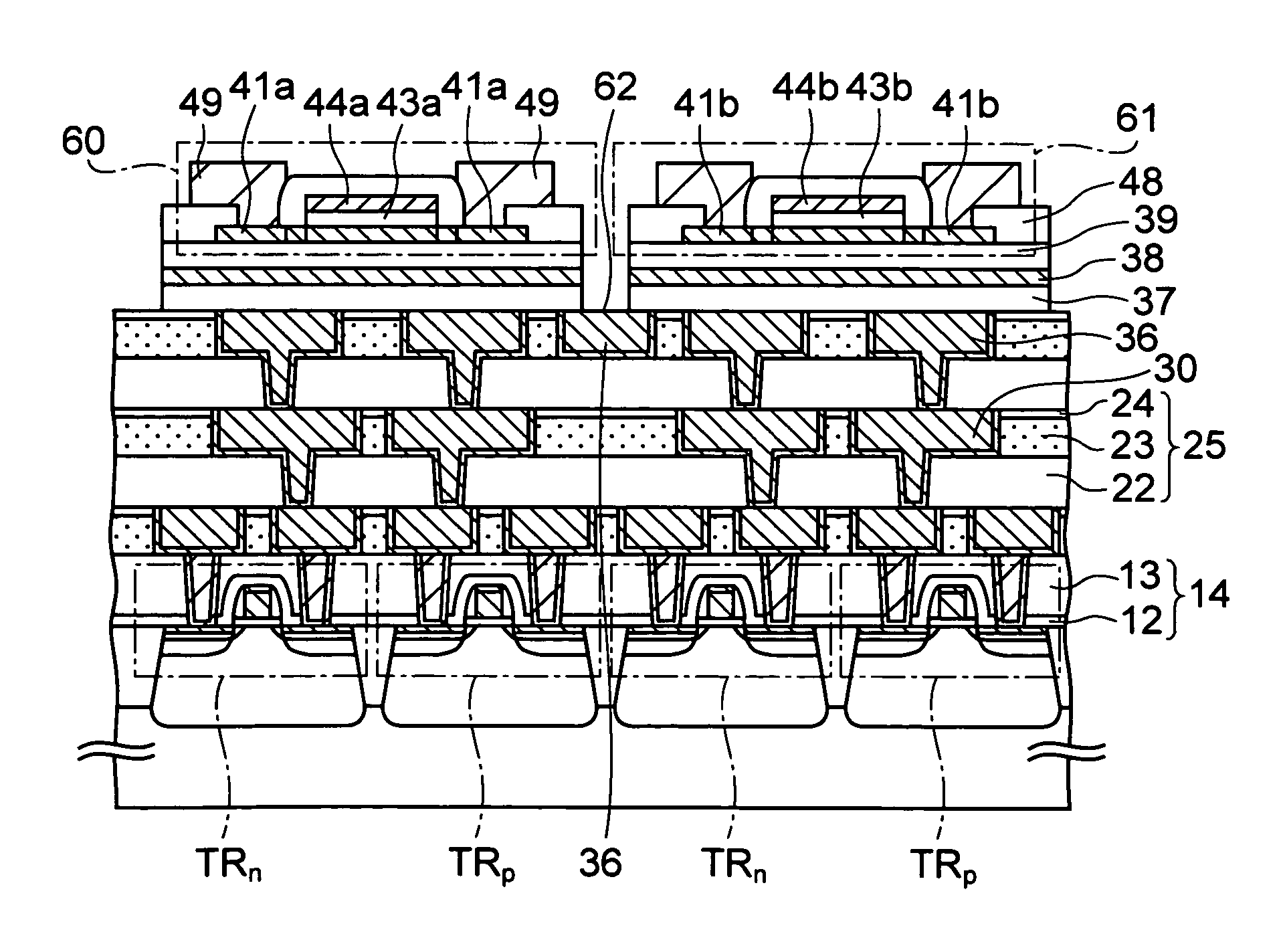

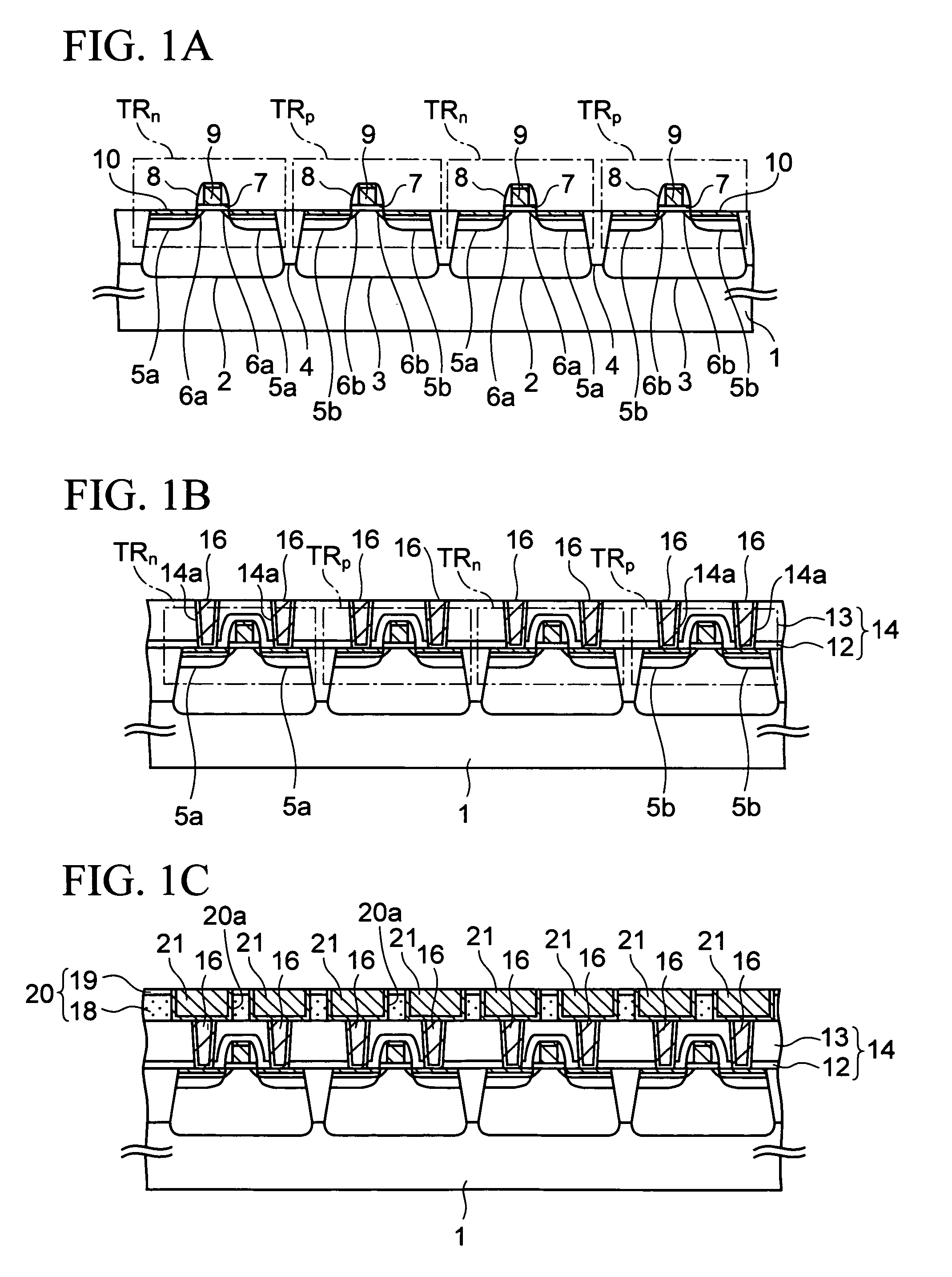

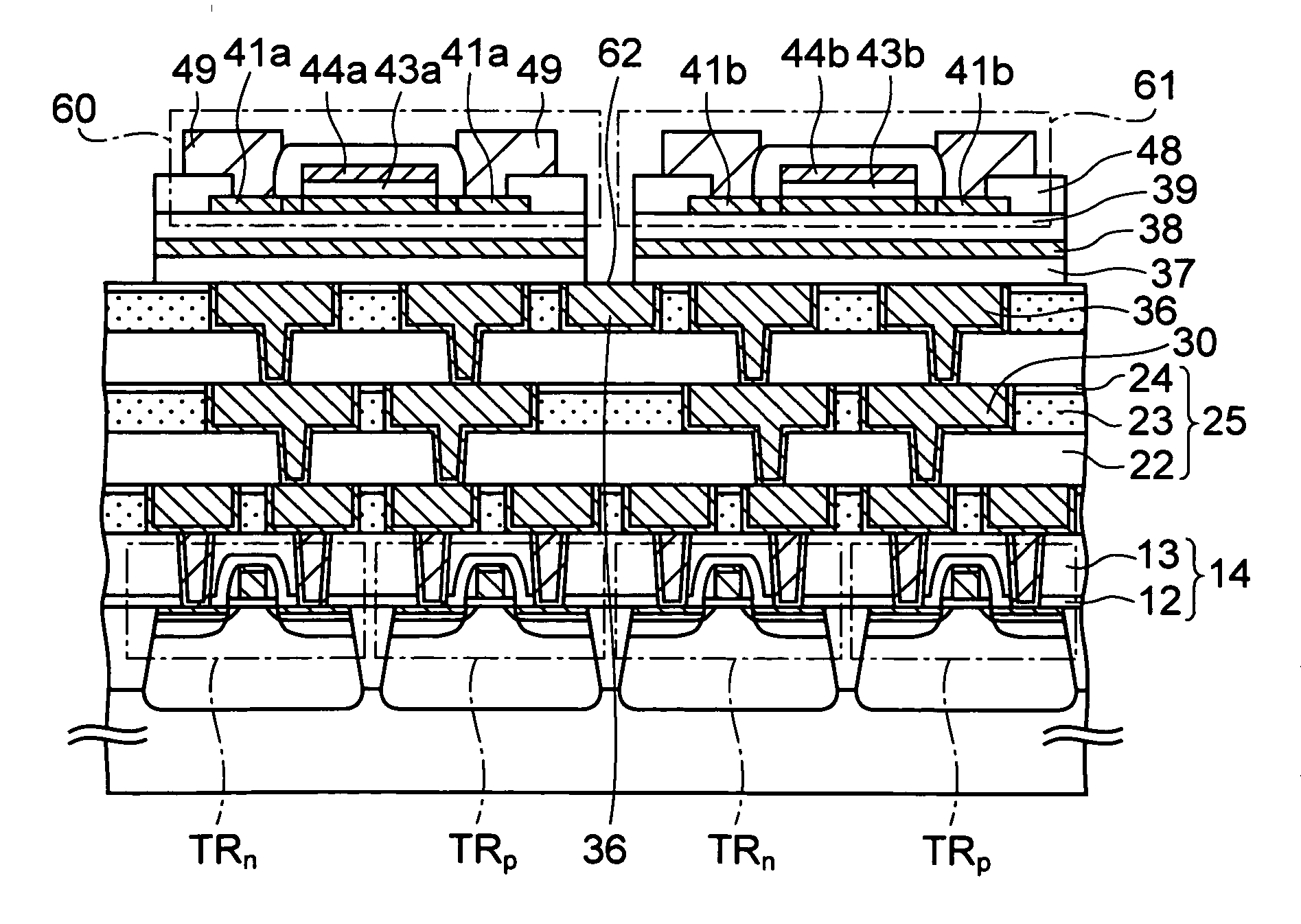

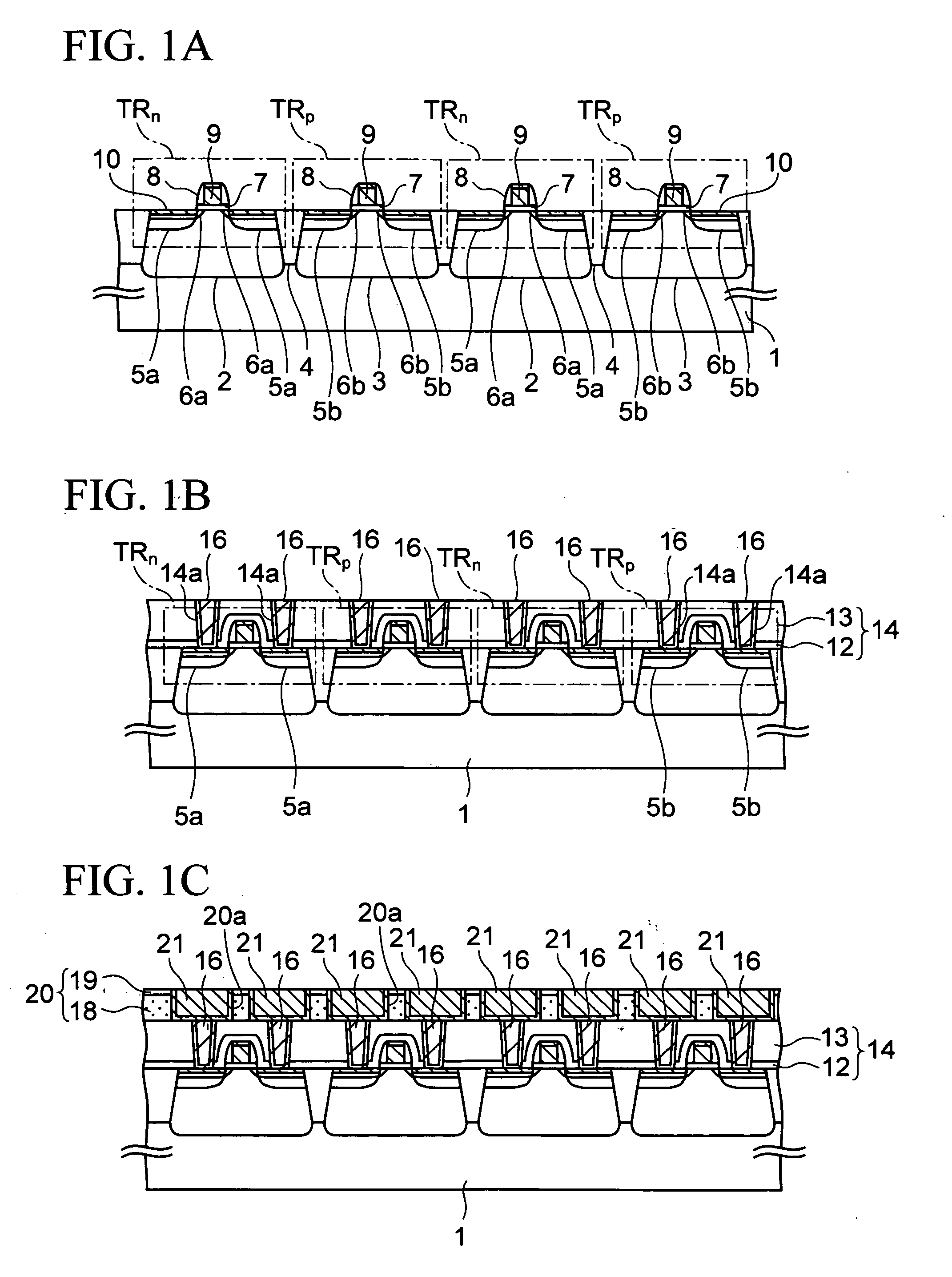

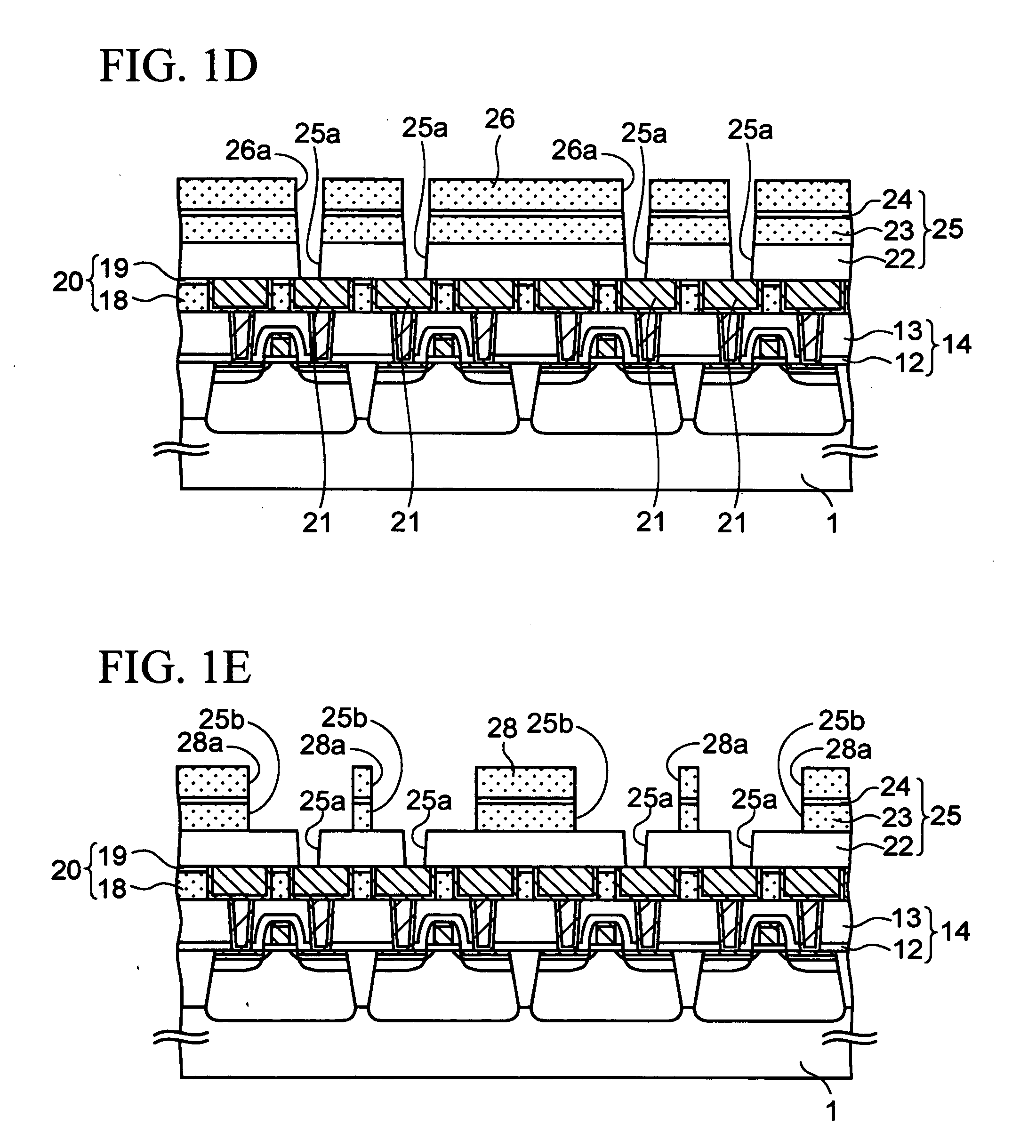

Semiconductor device

InactiveUS7795619B2Inhibit deteriorationPrevent short-circuitingSemiconductor/solid-state device detailsSolid-state devicesTransistorPhysics

A method for manufacturing a semiconductor device, including the steps of: forming a shielding film 38 on a first insulating film 37; sequentially forming a second insulating film 39 and an amorphous semiconductor film 40 on the shielding film 38; melting the amorphous semiconductor film 40 at least in portions to be channels of thin-film transistors by irradiating an energy beam onto the amorphous semiconductor film 40, and converting the amorphous semiconductor film 40 into a polycrystalline semiconductor film 41; sequentially forming a gate insulating film 43a and a gate electrode 44a on the polycrystalline semiconductor film 41 on the channels; and forming source and drain regions 41a in the polycrystalline semiconductor film 41 on sides of the gate electrode 44a, and forming a TFT 60 by use of the source and drain regions 41a, the gate insulating film 43a, and the gate electrode 44a.

Owner:FUJITSU SEMICON LTD

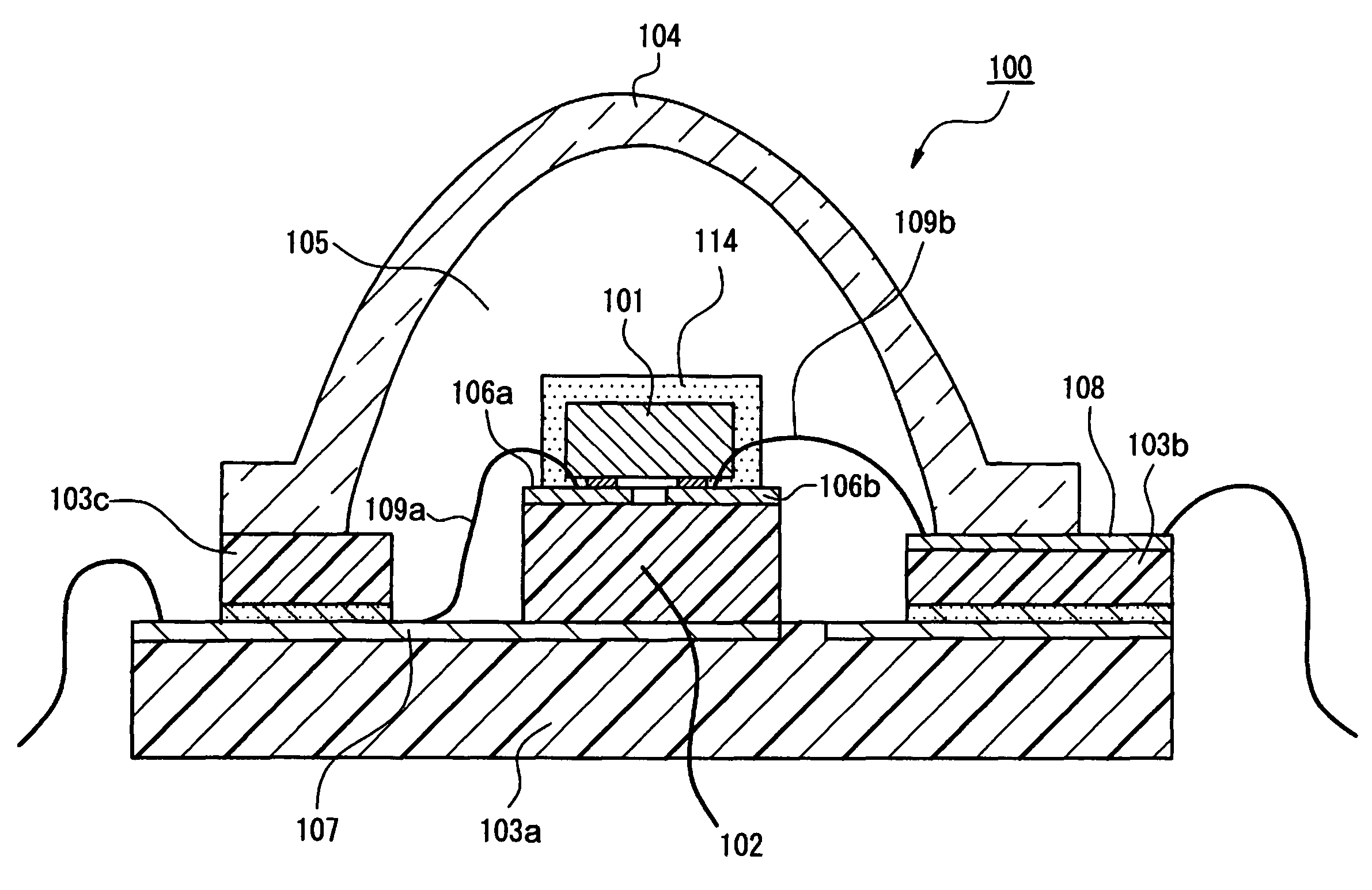

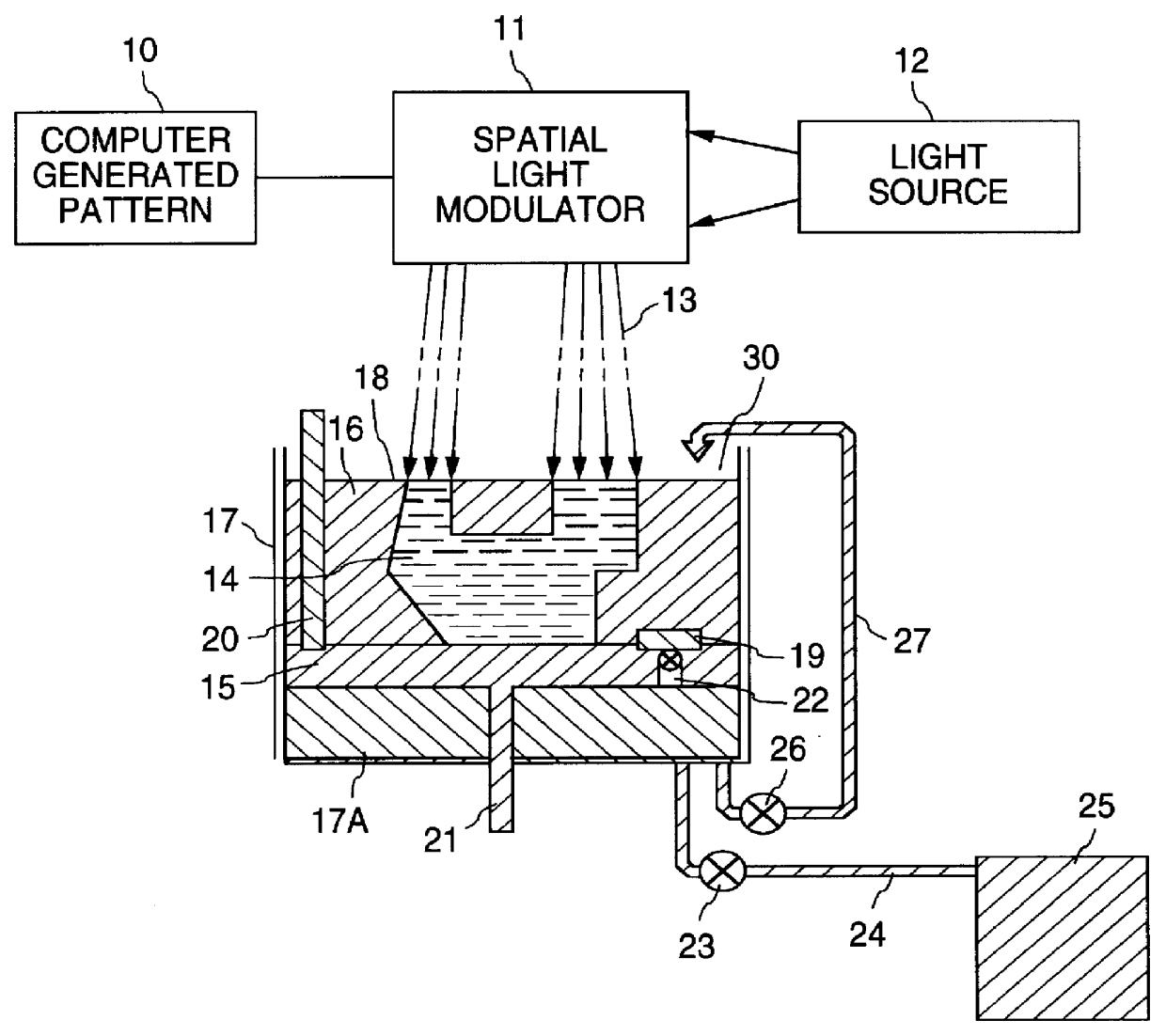

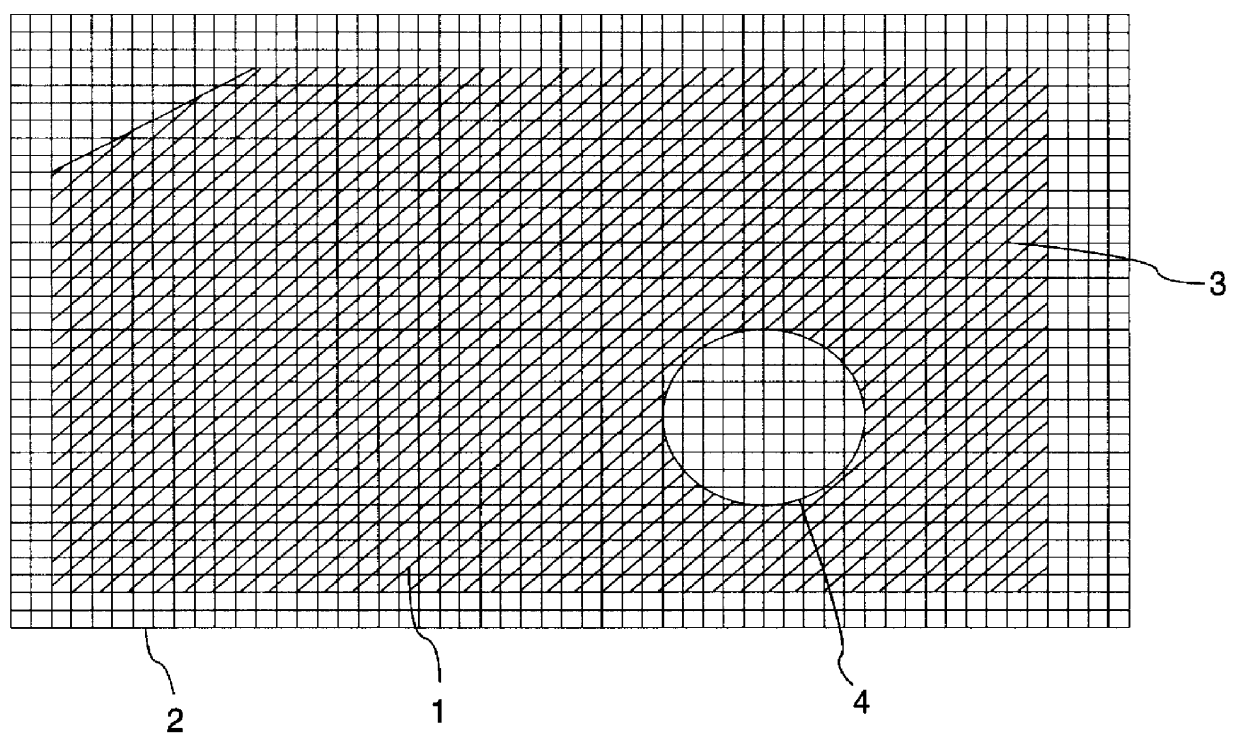

Apparatus and method for production of three-dimensional models by spatial light modulator

InactiveUS6051179AFacilitate cross-linkingHigh mechanical strengthAdditive manufacturing apparatusAnalogue computers for control systemsSpatial light modulatorWide beam

An apparatus and the method of its operation for rapid prototyping of a three-dimensional object which includes a radiant energy source of a wide beam of radiant energy of suitable intensity and wavelength for curing a layer of photo-curable resin contained in an open vat, a spatial light modulator (SLM) having an array of pixel elements which are individually digitally controllable by a computer, for modulating the radiant energy beam projected from the radiant energy source on a pixel by pixel basis, to form a series of time sequential images of the cross-sectional laminae of the object, an optical system for focusing each image formed by the SLM, one at a time, onto successive layers of photo-curable resin for predetermined exposure times to thereby form stacked laminae of cured resin, each lamina of cured resin being in the shape of a different one of the cross-sectional laminae, and a piston support for lowering each lamina of cured resin after it is formed by the SLM and for depositing a layer of resin corresponding to the thickness of one cross sectional lamina of the three-dimensional object before the step of projecting a new image by the SLM. The SLM, the piston support for lowering, and the optical system operate repeatedly and sequentially until a complete copy of the object is thereby produced.

Owner:GLOBAL FILTRATION SYST

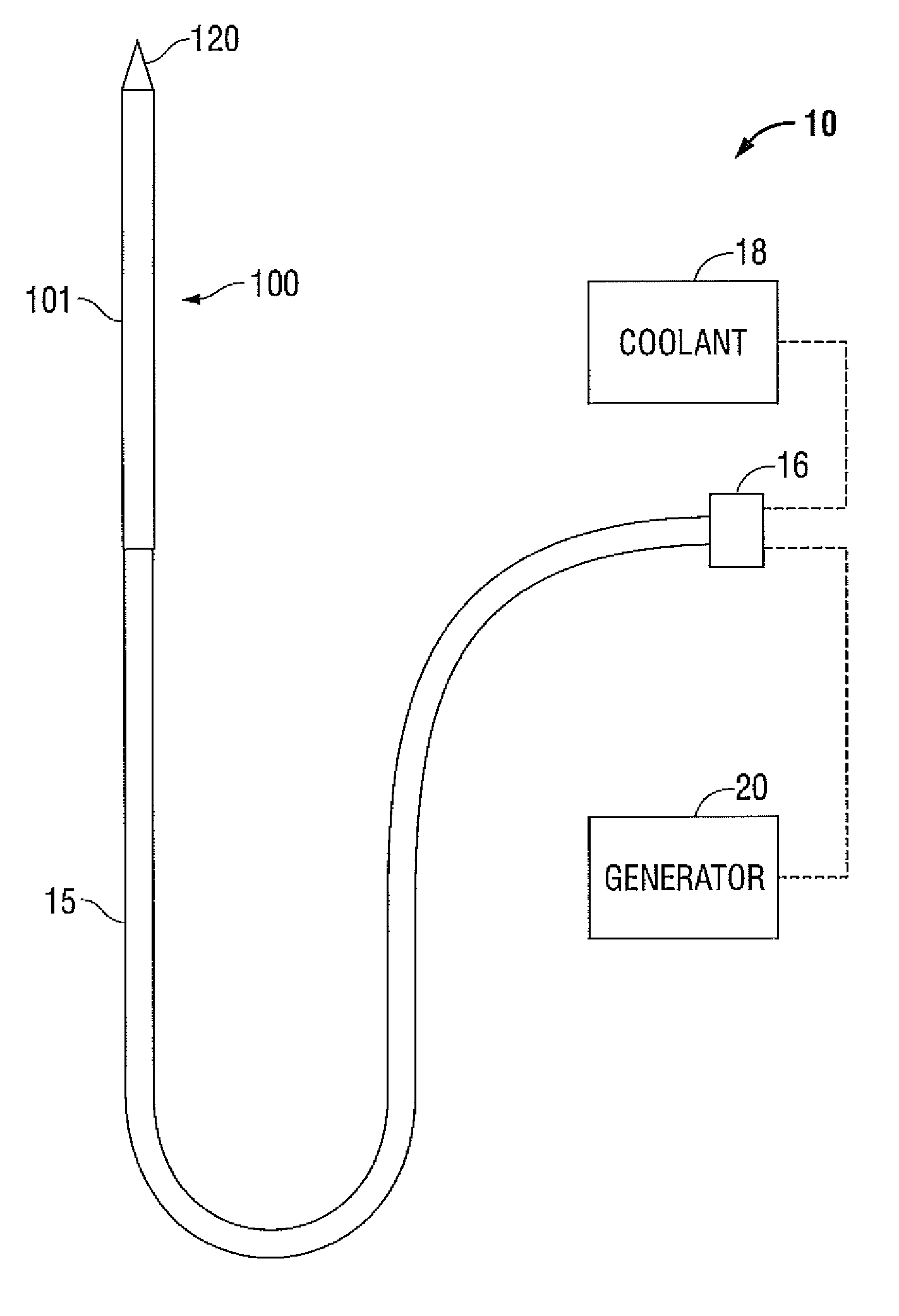

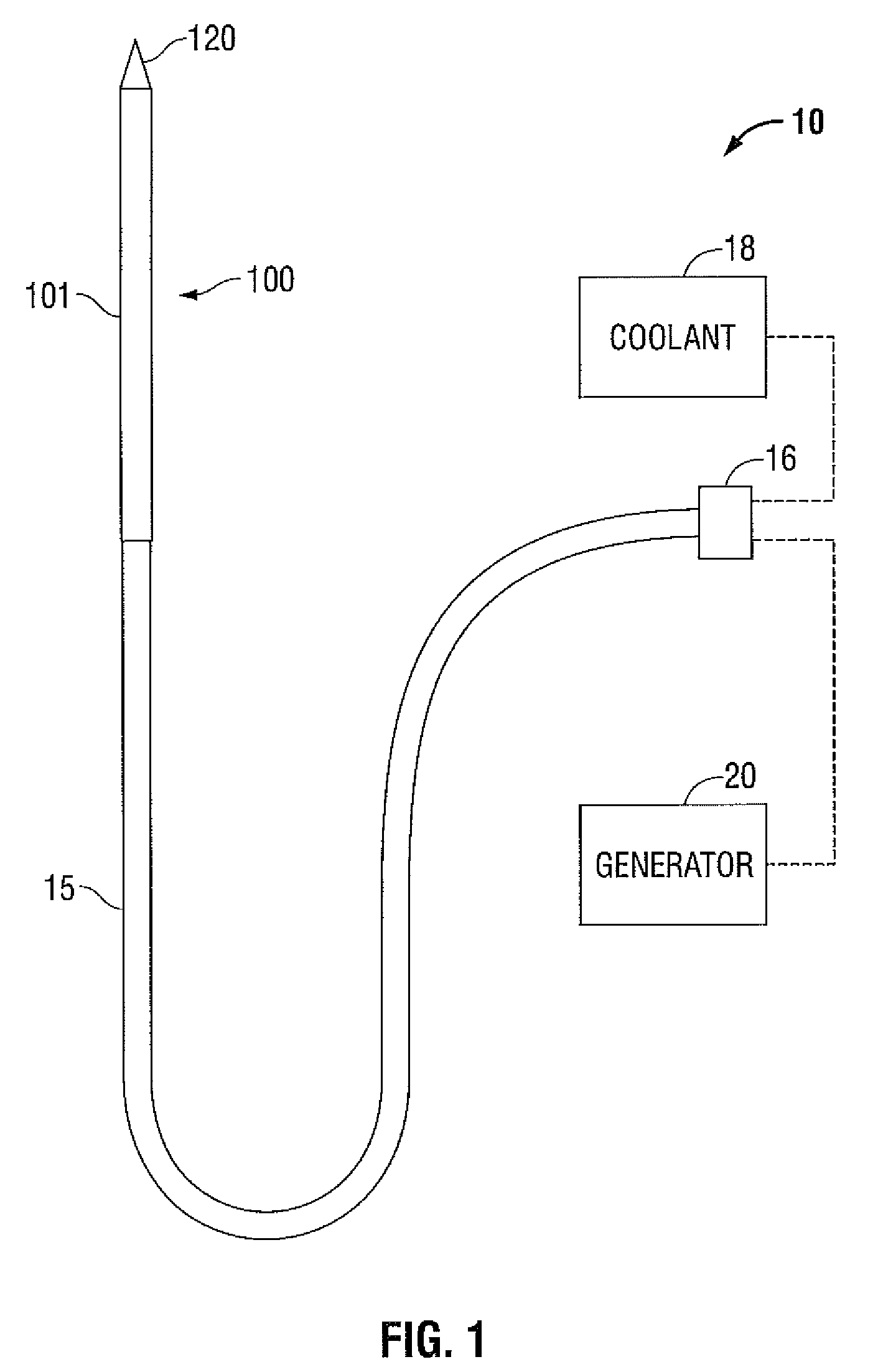

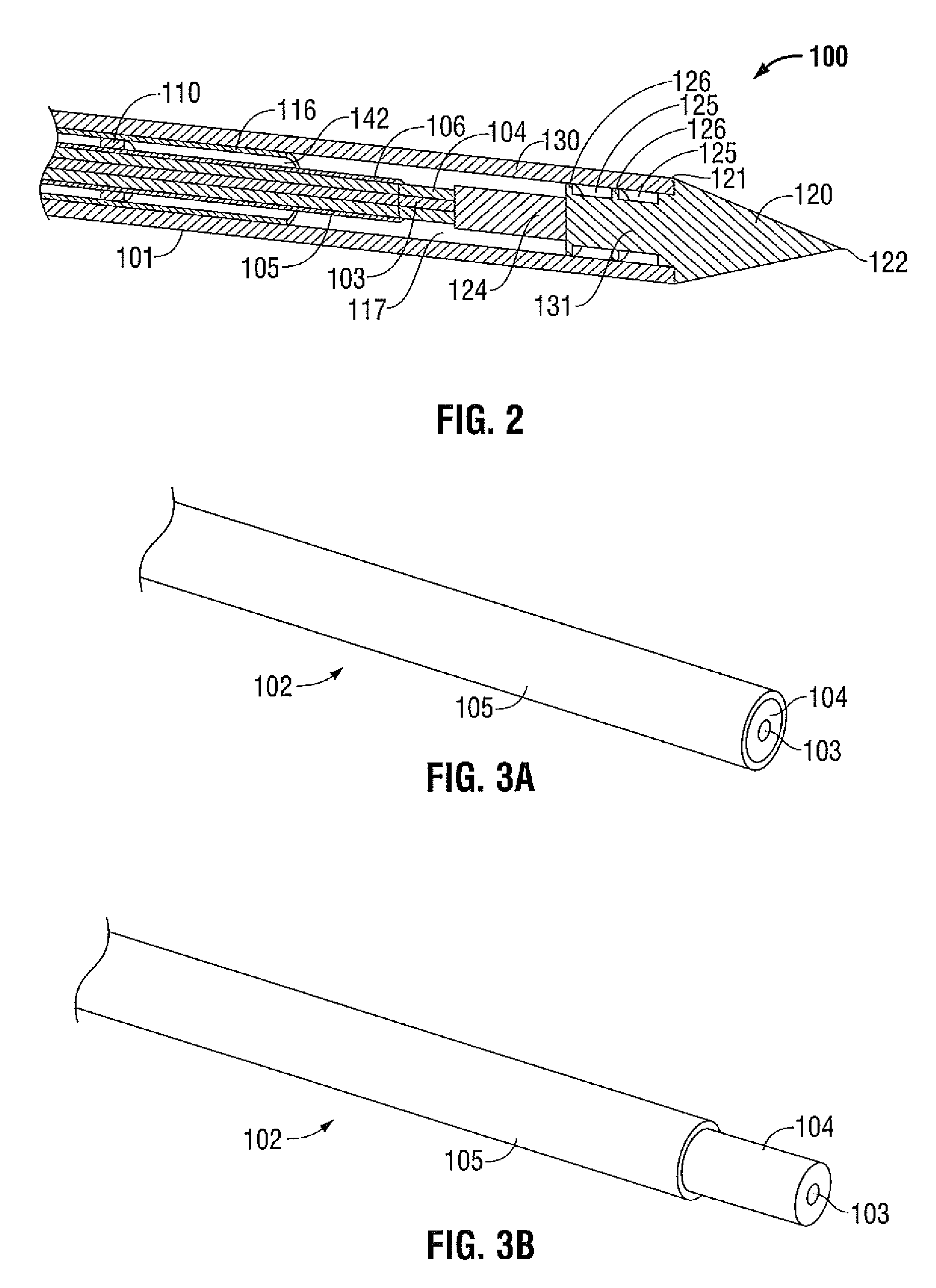

Narrow gauge high strength choked wet tip microwave ablation antenna

ActiveUS8292881B2Improve performanceIncrease powerSurgical needlesSurgical instruments for heatingCooling chamberDipole antenna

An electromagnetic surgical ablation probe having a coaxial feedline and cooling chamber is disclosed. The disclosed probe includes a dipole antenna arrangement having a radiating section, a distal tip coupled to a distal end of the radiating section, and a ring-like balun short) or choke, which may control a radiation pattern of the probe. A conductive tube disposed coaxially around the balun short includes at least one fluid conduit which provides coolant, such as dionized water, to a cooling chamber defined within the probe. A radiofrequency transparent catheter forms an outer surface of the probe and may include a lubricious coating.

Owner:TYCO HEALTHCARE GRP LP

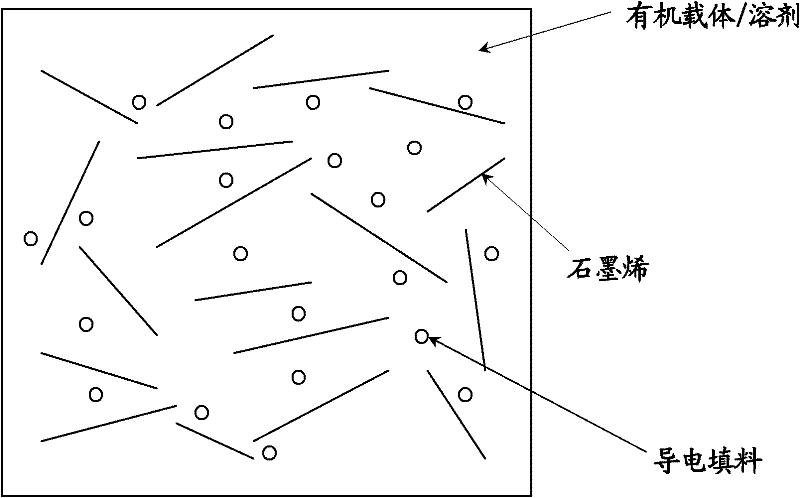

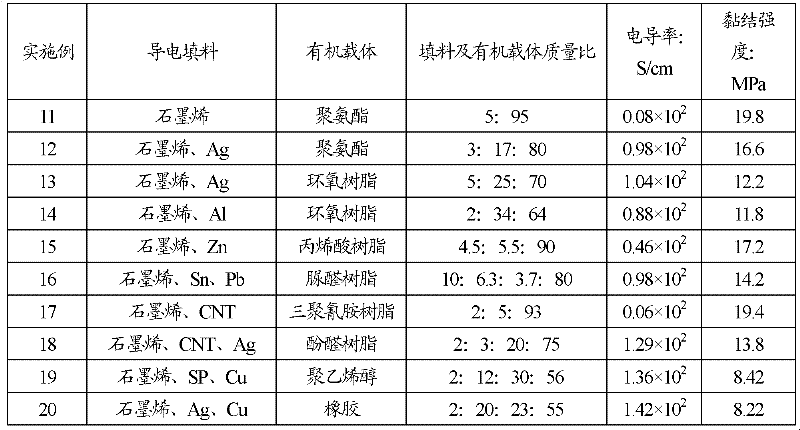

General electronic paste based on graphene filler

ActiveCN102254584AImprove conductivityConductivity regulationNon-conductive material with dispersed conductive materialNano structuringConductive coating

The invention discloses general electronic paste based on graphene filler. The electronic paste contains graphene-containing conductive filler, an organic carrier, a solvent and an auxiliary agent. Because the graphene has good electronic conductivity and a unique two-dimensional laminar nano structure, the graphene forms a conductive network in the organic carrier more easily, and the electric conductivity of the electronic paste is improved by adding the graphene. Further, the conductive filler also contains a conductive material with relatively high electric conductivity, so that the electric conductivity of the electronic paste is further improved. Because the graphene and the conductive material are compounded to form the conductive filler, the electronic paste has good electric conductivity. The electronic paste can obtain a relatively wide electric conductivity range by changing the category of the conductive material mixed with the graphene and adjusting the relative proportion of the graphene to the conductive material of different category. The electric conductivity of the electronic paste is 1*10<-3>S / cm to 1*10<3>S / cm. The paste can be widely applied, and can be particularly used as a conductive coating or adhesive.

Owner:NINGBO GRAPHENE INNOVATION CENT CO LTD

Semiconductor device and manufacturing method thereof

InactiveUS20060170046A1Inhibit deteriorationPoor heat resistanceSemiconductor/solid-state device detailsSolid-state devicesAmorphous semiconductorsEngineering

A method for manufacturing a semiconductor device, including the steps of: forming a shielding film 38 on a first insulating film 37; sequentially forming a second insulating film 39 and an amorphous semiconductor film 40 on the shielding film 38; melting the amorphous semiconductor film 40 at least in portions to be channels of thin-film transistors by irradiating an energy beam onto the amorphous semiconductor film 40, and converting the amorphous semiconductor film 40 into a polycrystalline semiconductor film 41; sequentially forming a gate insulating film 43a and a gate electrode 44a on the polycrystalline semiconductor film 41 on the channels; and forming source and drain regions 41a in the polycrystalline semiconductor film 41 on sides of the gate electrode 44a, and forming a TFT 60 by use of the source and drain regions 41a, the gate insulating film 43a, and the gate electrode 44a.

Owner:FUJITSU SEMICON LTD

Methods of forming a chemical casing

InactiveUS6848519B2High mechanical strengthInhibit migrationLiquid/gas jet drillingFluid removalParticulatesCross-link

Methods of forming chemical casings include drilling a well bore with a drilling fluid having a pH in the range of from about 6 to 10 and comprising water, a water soluble or water dispersible polymer which is capable of being cross-linked by a thermoset resin and causing the resin to be hard and tough when cured, a particulate curable solid thermoset resin, a water soluble or dispersible thermoset resin, and a delayed dispersible acid-catalyst for curing the solid thermoset resin and the water soluble thermoset resin, whereby the drilling fluid forms a filter cake on the walls of the wellbore that cures into a hard and tough cross-linked chemical casing thereon.

Owner:HALLIBURTON ENERGY SERVICES INC

Semiconductor device

InactiveUS20050236623A1Well mixedGood heat dissipationTransistorSolid-state devicesDevice materialEngineering

An integrated circuit is formed on a flexible substrate by using an amorphous semiconductor thin film, or a polycrystalline or a monocrystalline semiconductor thin film crystallized by laser annealing. A plurality of such flexible integrated circuit boards and mounted on a separate support substrate. This can enhance the mechanical strength of devices, such as an IC card and a liquid crystal display, and allow those devices to be manufactured at a low cost. It is also possible to provide a semiconductor device with a higher performance, on which a flexible integrated circuit board and an IC chip made from a silicon and / or glass wafer. Adhering a film substrate having a high thermal conductivity, such as a metal, to the bottom side of the flexible integrated circuit board improves the heat discharging characteristic of the integrated circuit and suppress the problem of self-heating.

Owner:NEC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com