Patents

Literature

617results about How to "Improve cohesive strength" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SiCOH dielectric

InactiveUS20070173071A1Improve cohesive strengthReduce brittlenessSemiconductor/solid-state device detailsSolid-state devicesDielectricDevice material

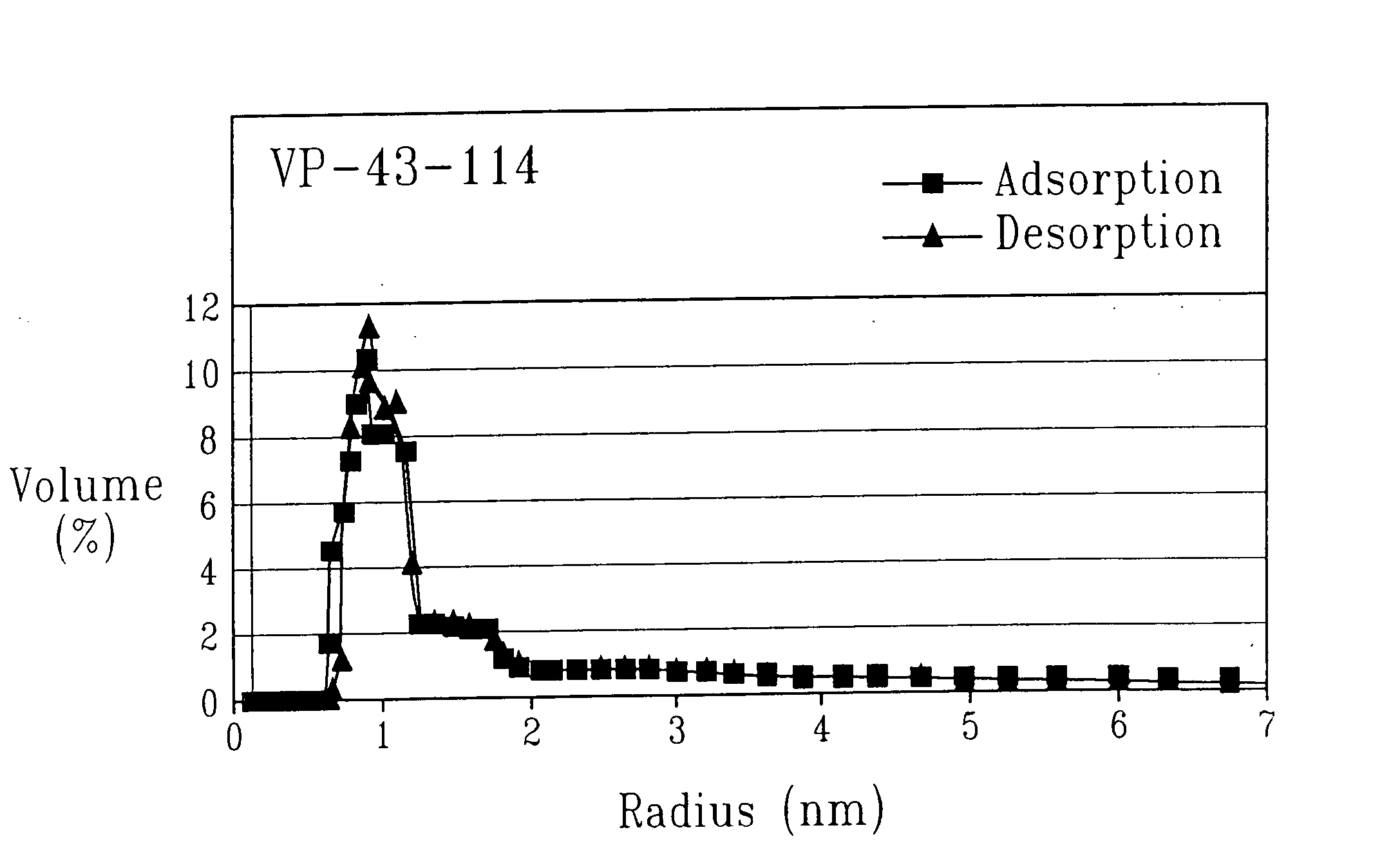

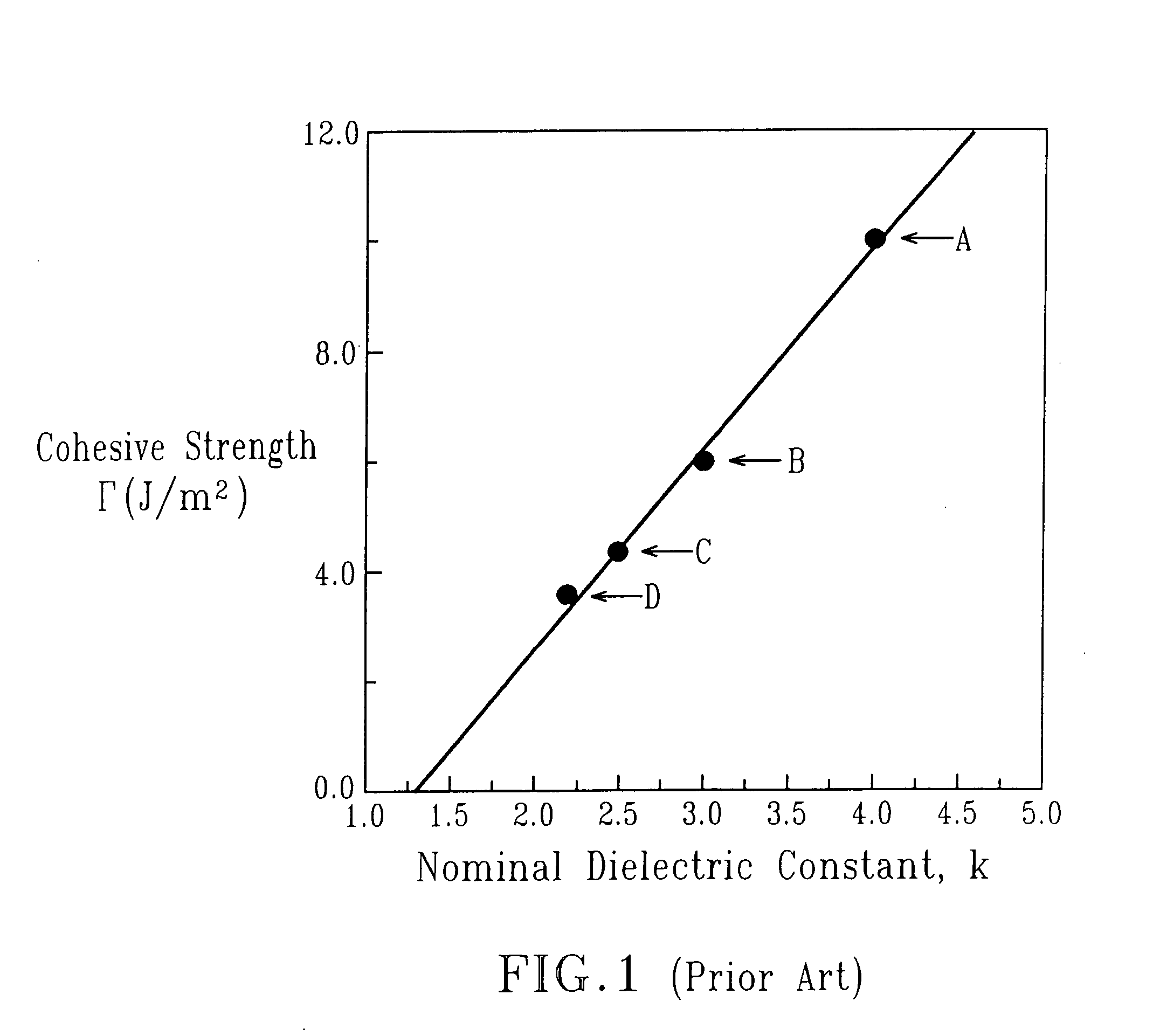

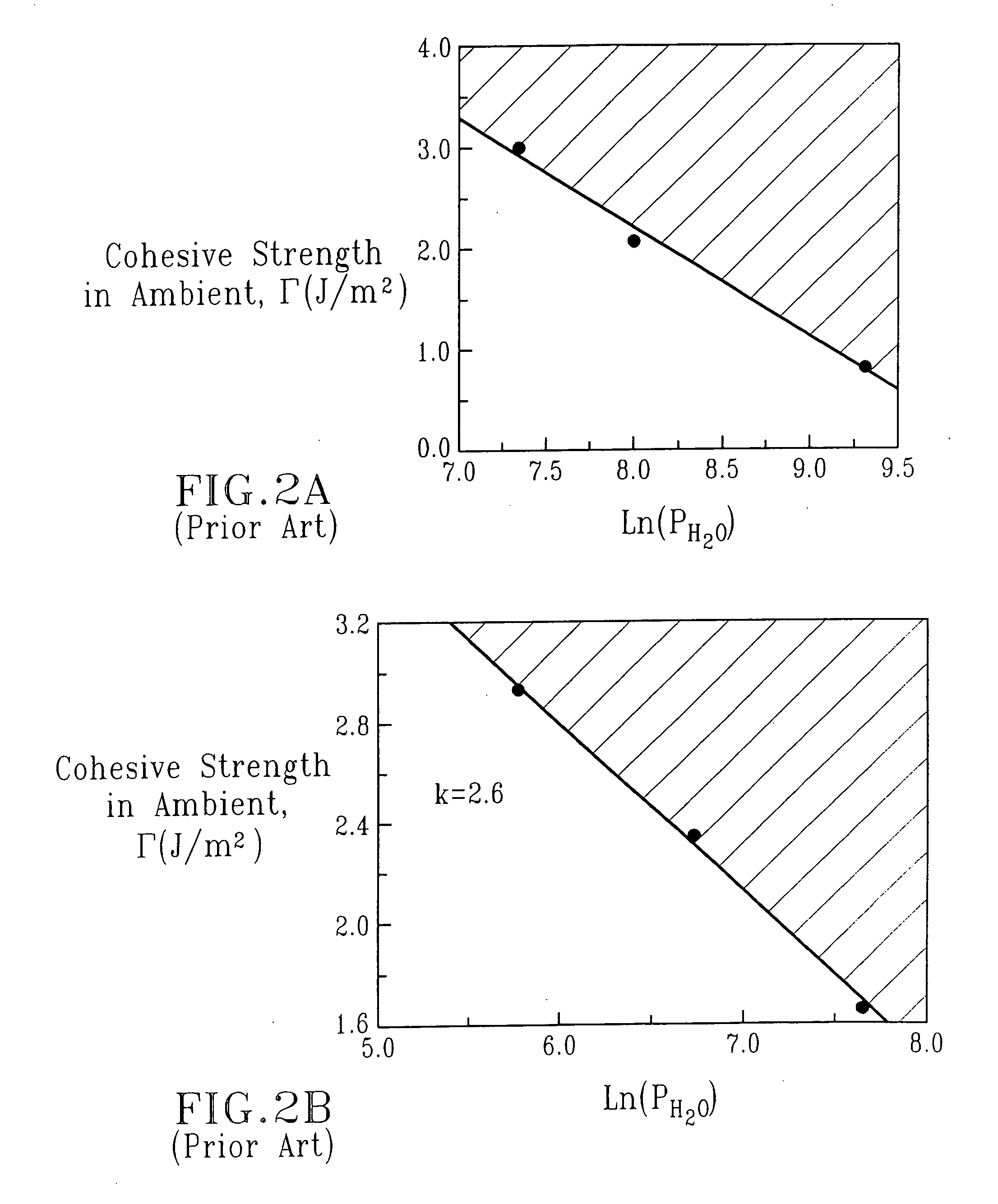

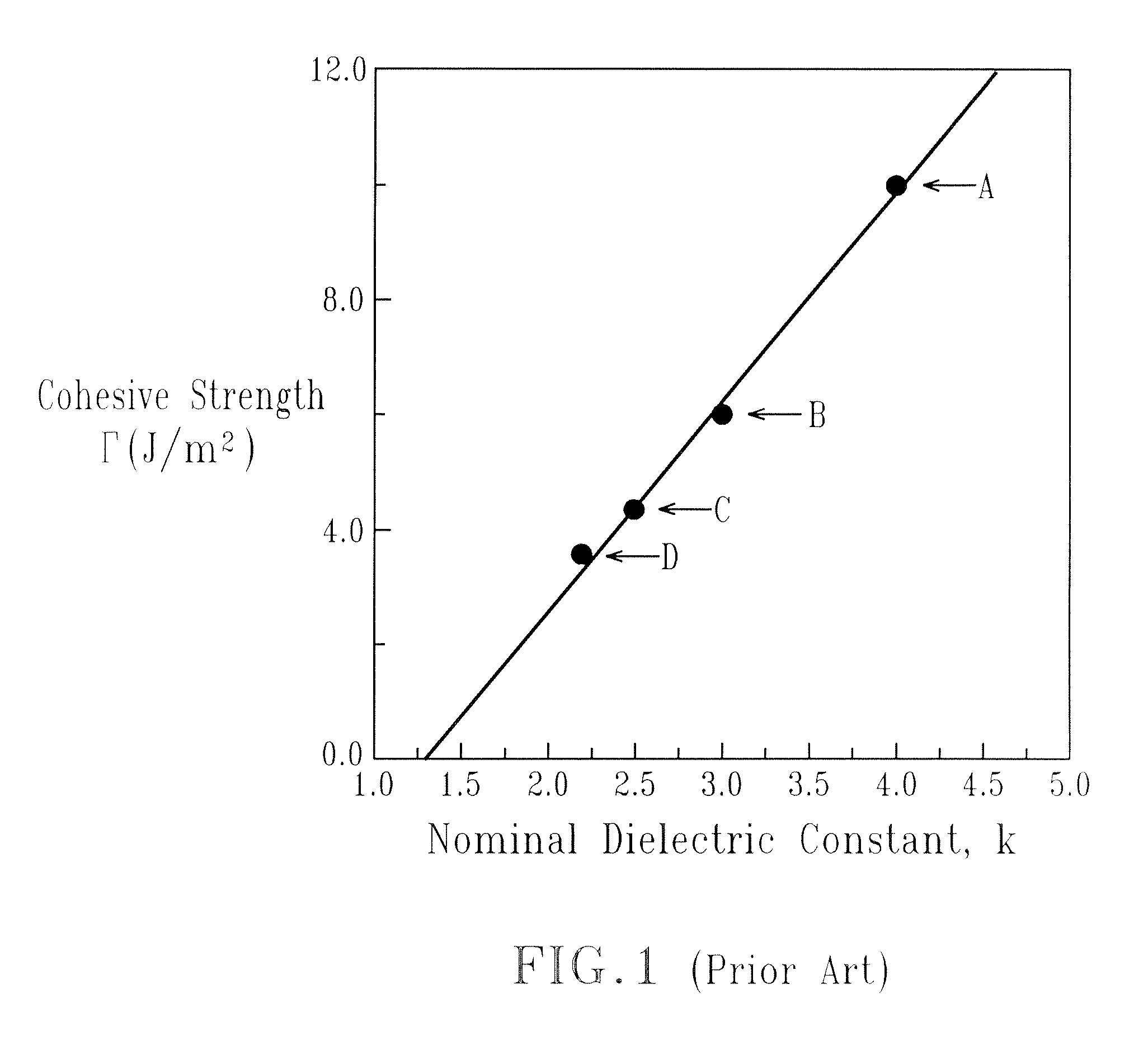

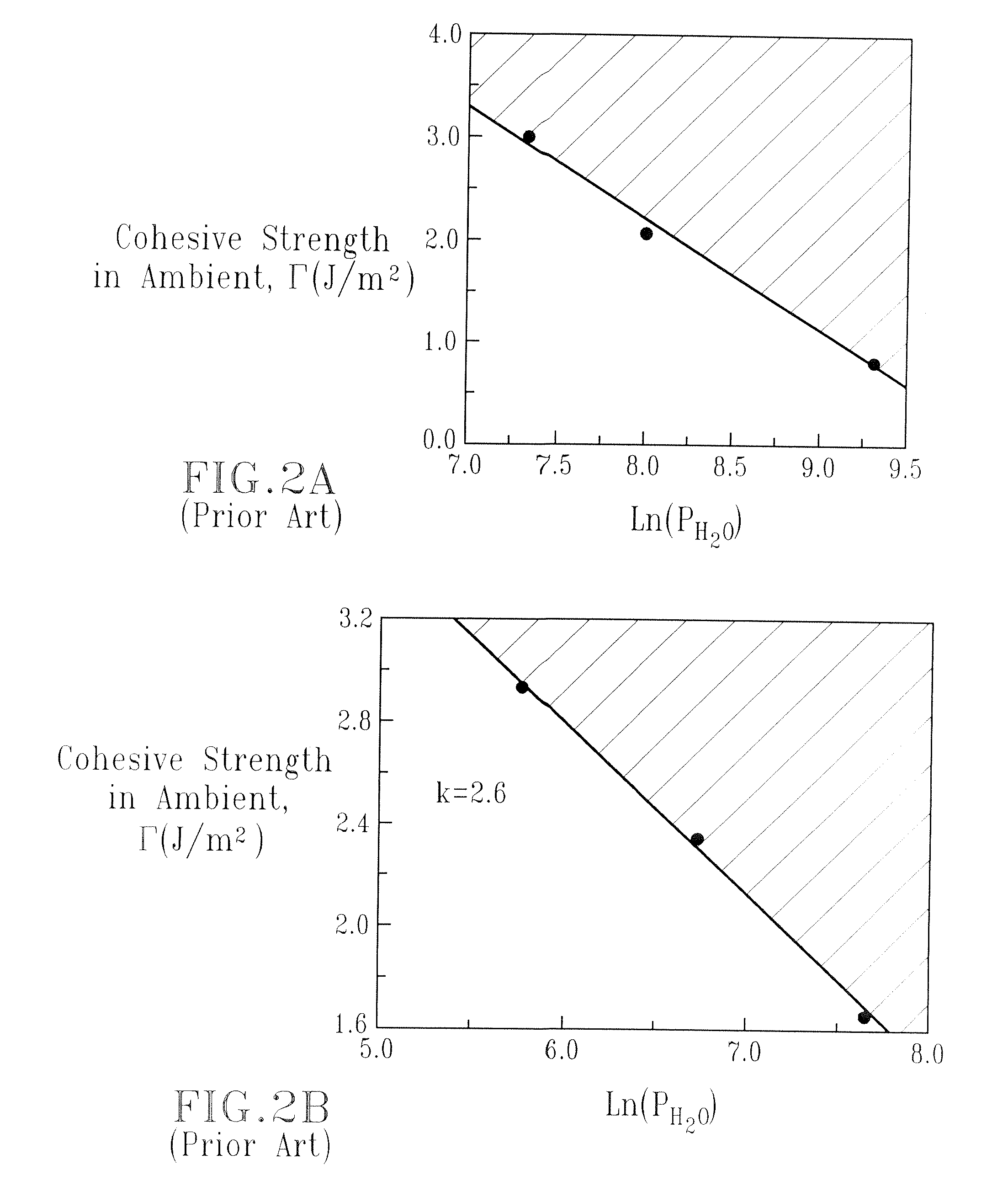

A porous composite material useful in semiconductor device manufacturing, in which the diameter (or characteristic dimension) of the pores and the pore size distribution (PSD) is controlled in a nanoscale manner and which exhibits improved cohesive strength (or equivalently, improved fracture toughness or reduced brittleness), and increased resistance to water degradation of properties such as stress-corrosion cracking, Cu ingress, and other critical properties is provided. The porous composite material is fabricating utilizing at least one bifunctional organic porogen as a precursor compound

Owner:INTEL CORP

Compositions with Improved Adhesion to Low Surface Energy Substrates

InactiveUS20080113094A1Excellent low surface energyImprove adhesionSynthetic resin layered productsOrganic dyesOligomerEnd-group

Acrylic-based pressure sensitive adhesives are modified with a telechelic hydrocarbon oligomer. The oligomer comprises a hydrocarbon polymer chain or backbone and a functional end group, e.g., an oligomer prepared from a mono hydroxyl polybutadiene polymer and toluene diisocyanate. The oligomer attaches to the acrylic backbone of the polymer as a pendant group and in a preferred embodiment, the oligomer is mixed with the PSA shortly before the PSA is coated.

Owner:BRADY WORLDWIDE INC

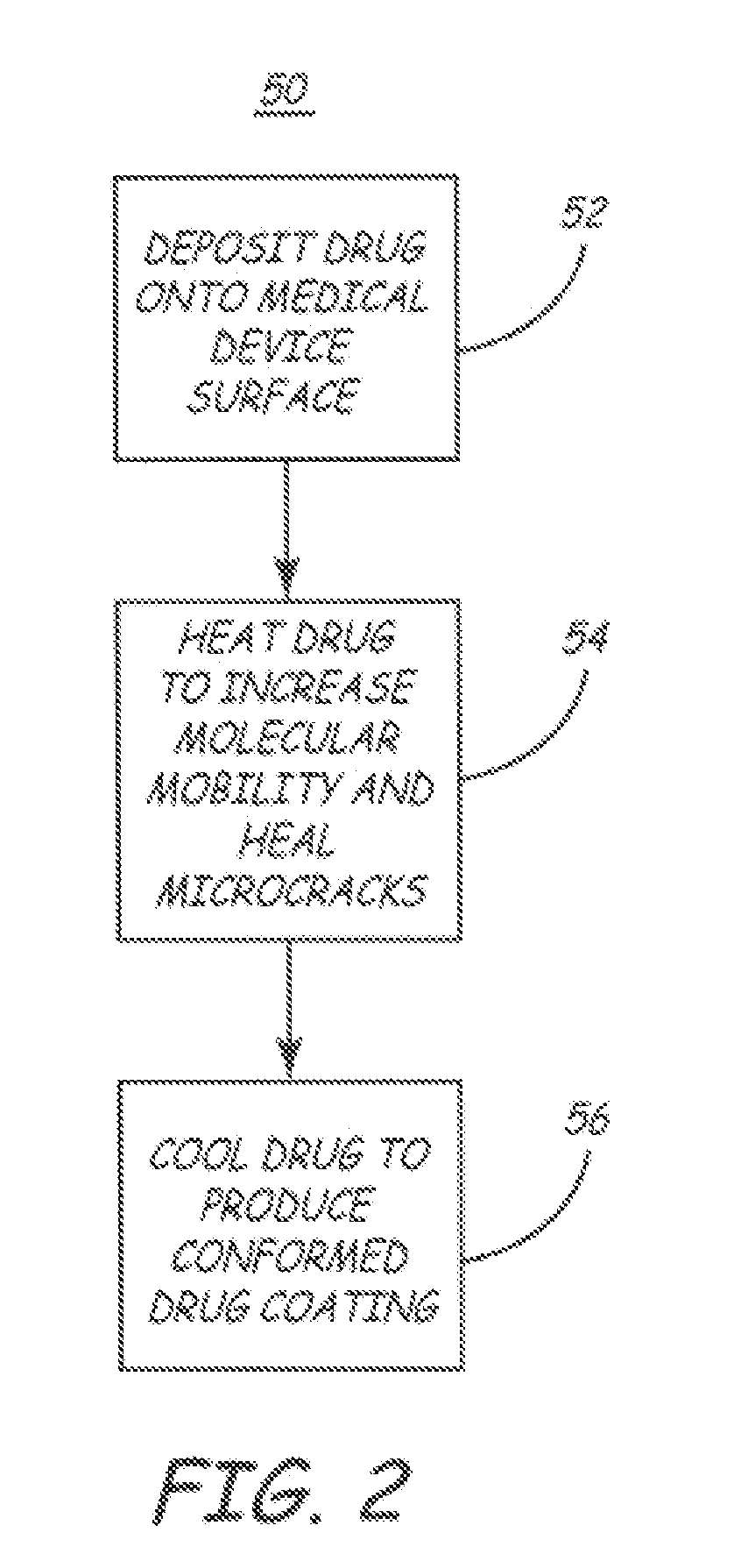

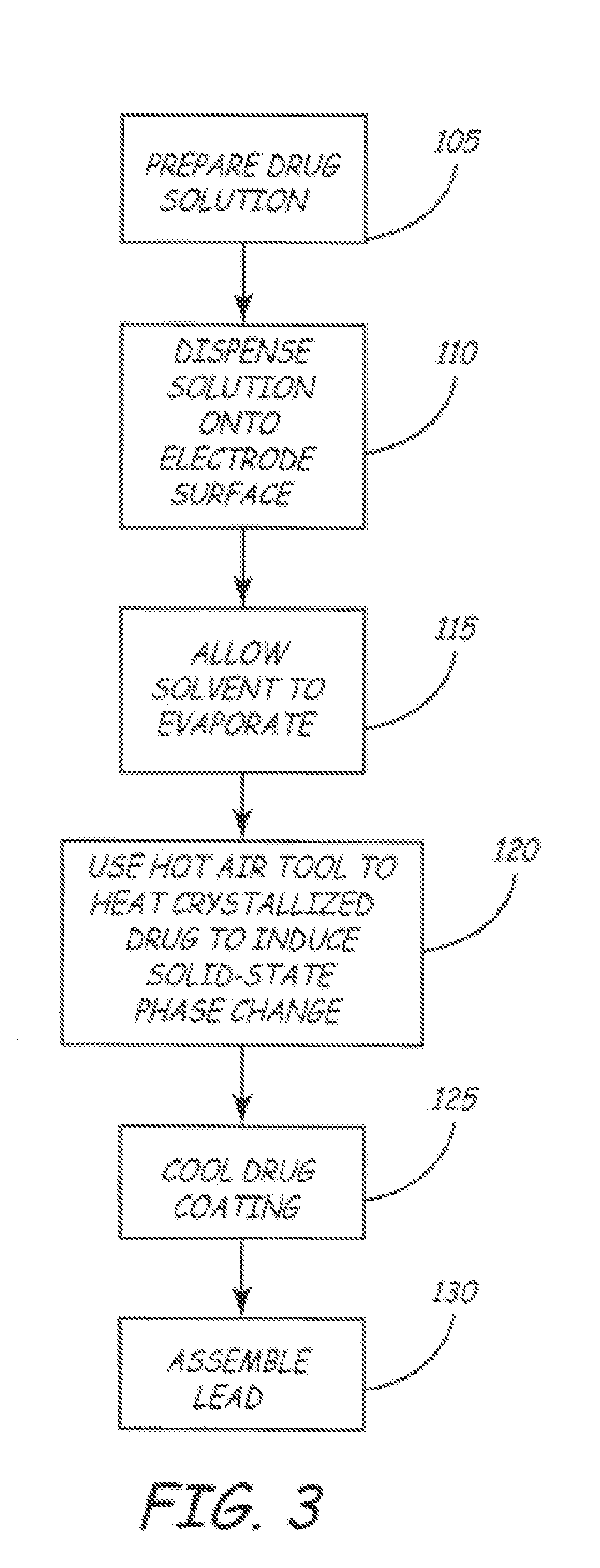

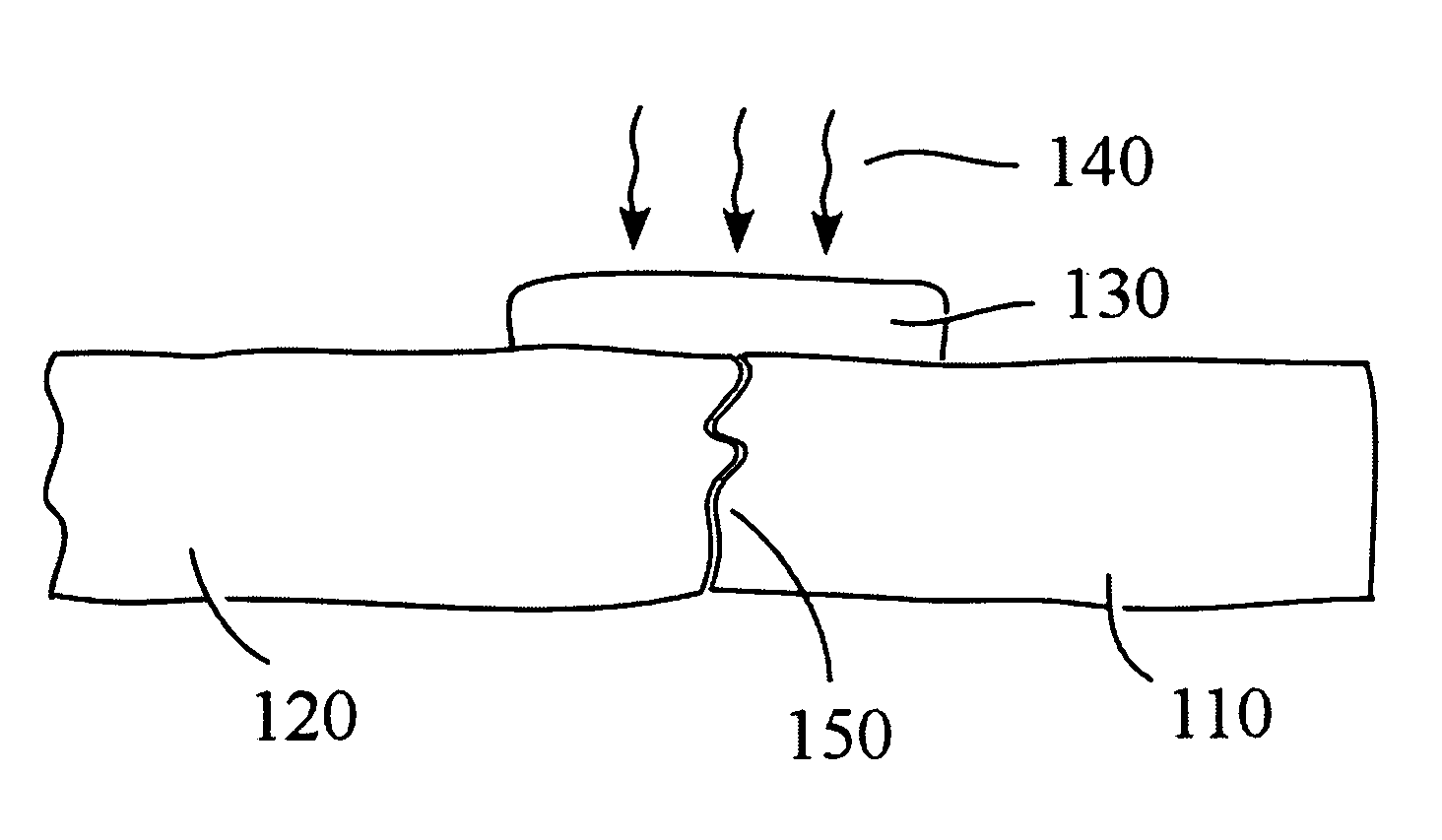

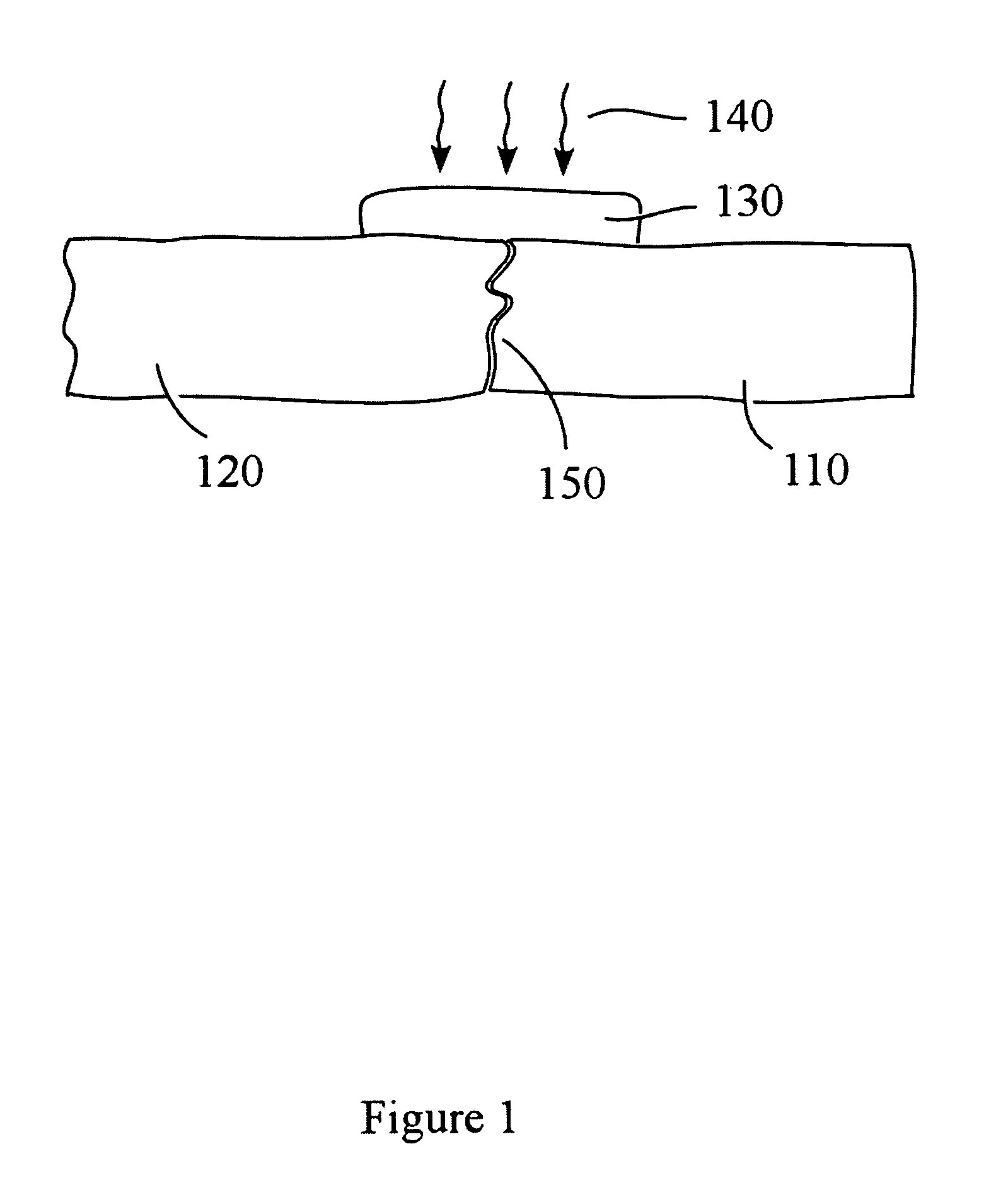

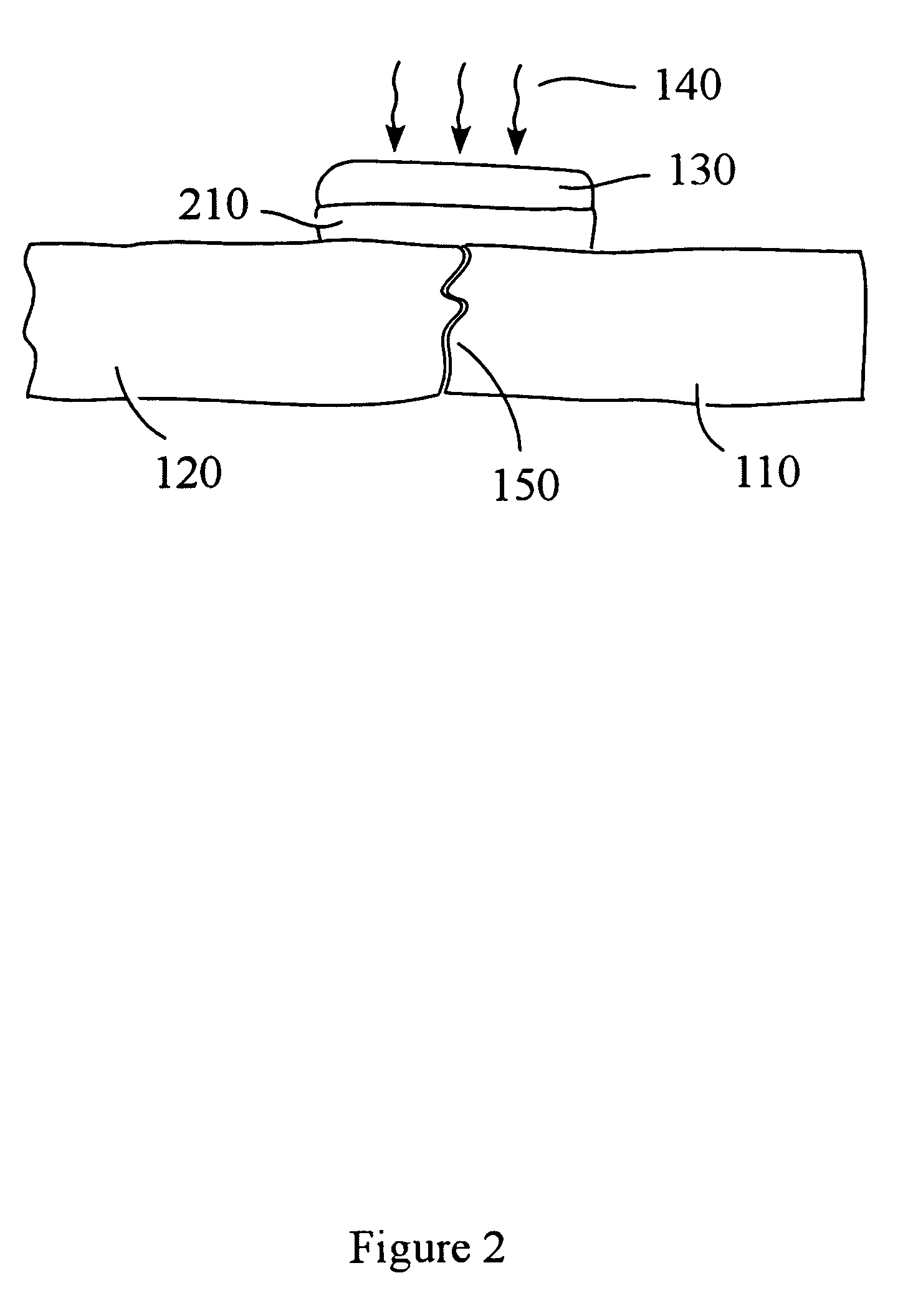

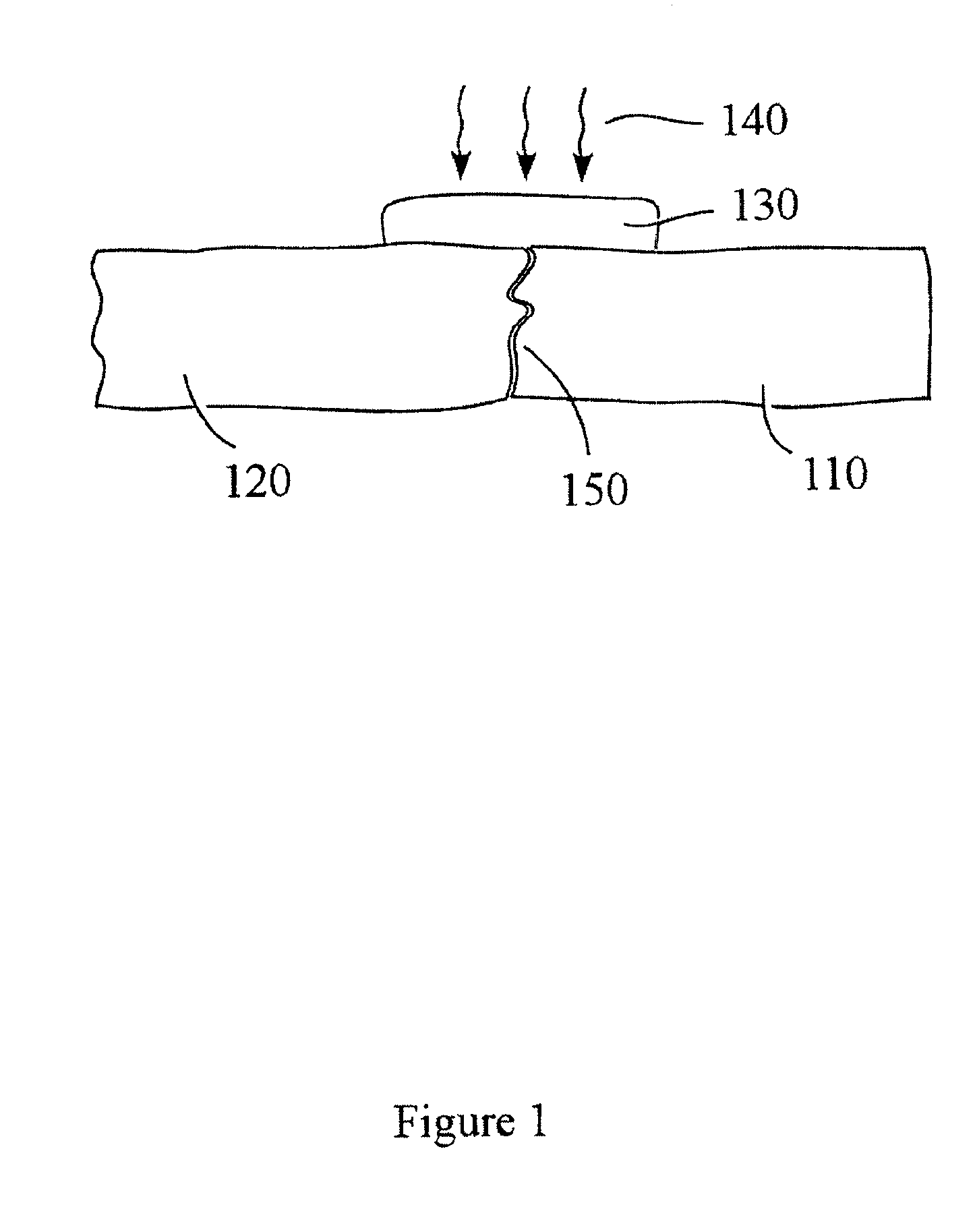

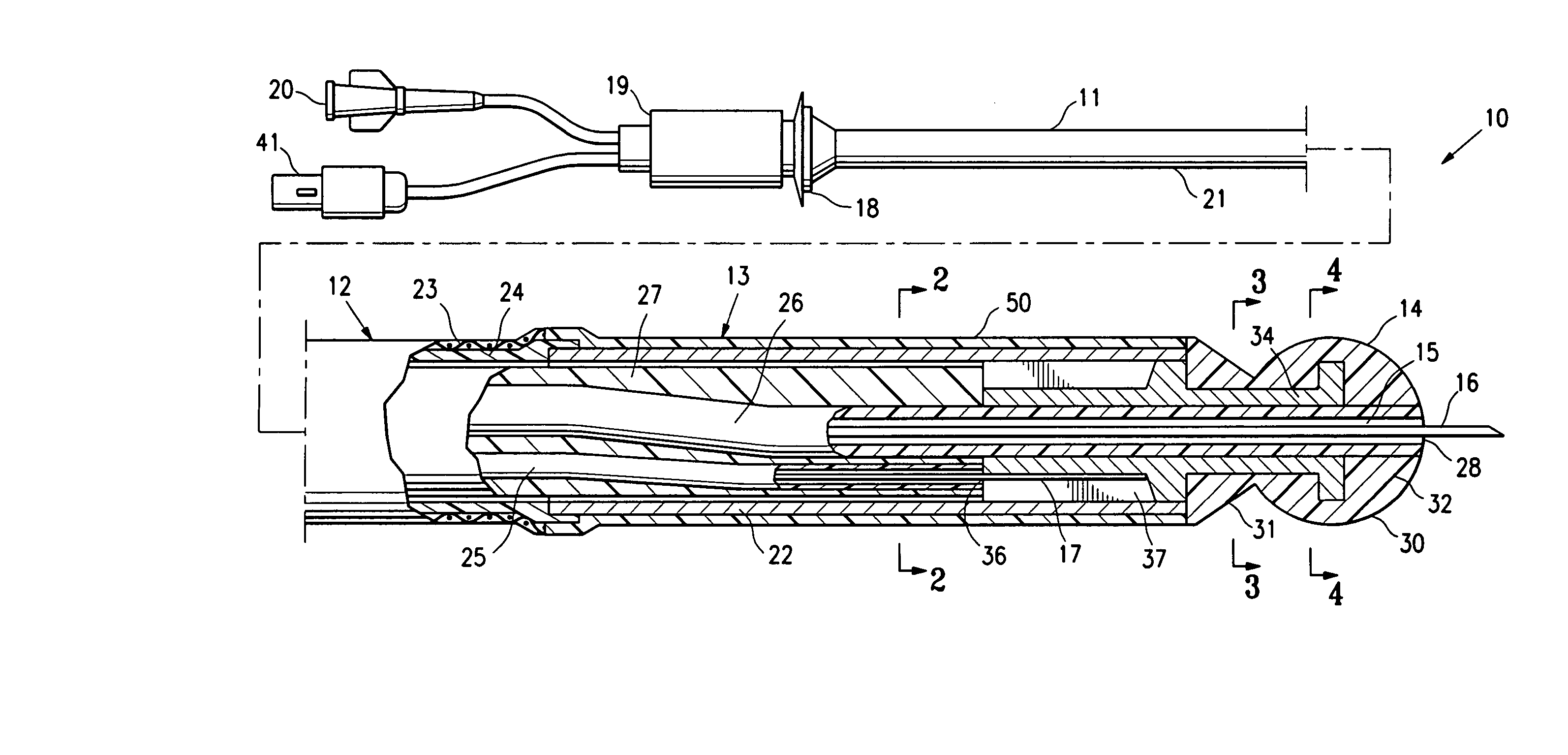

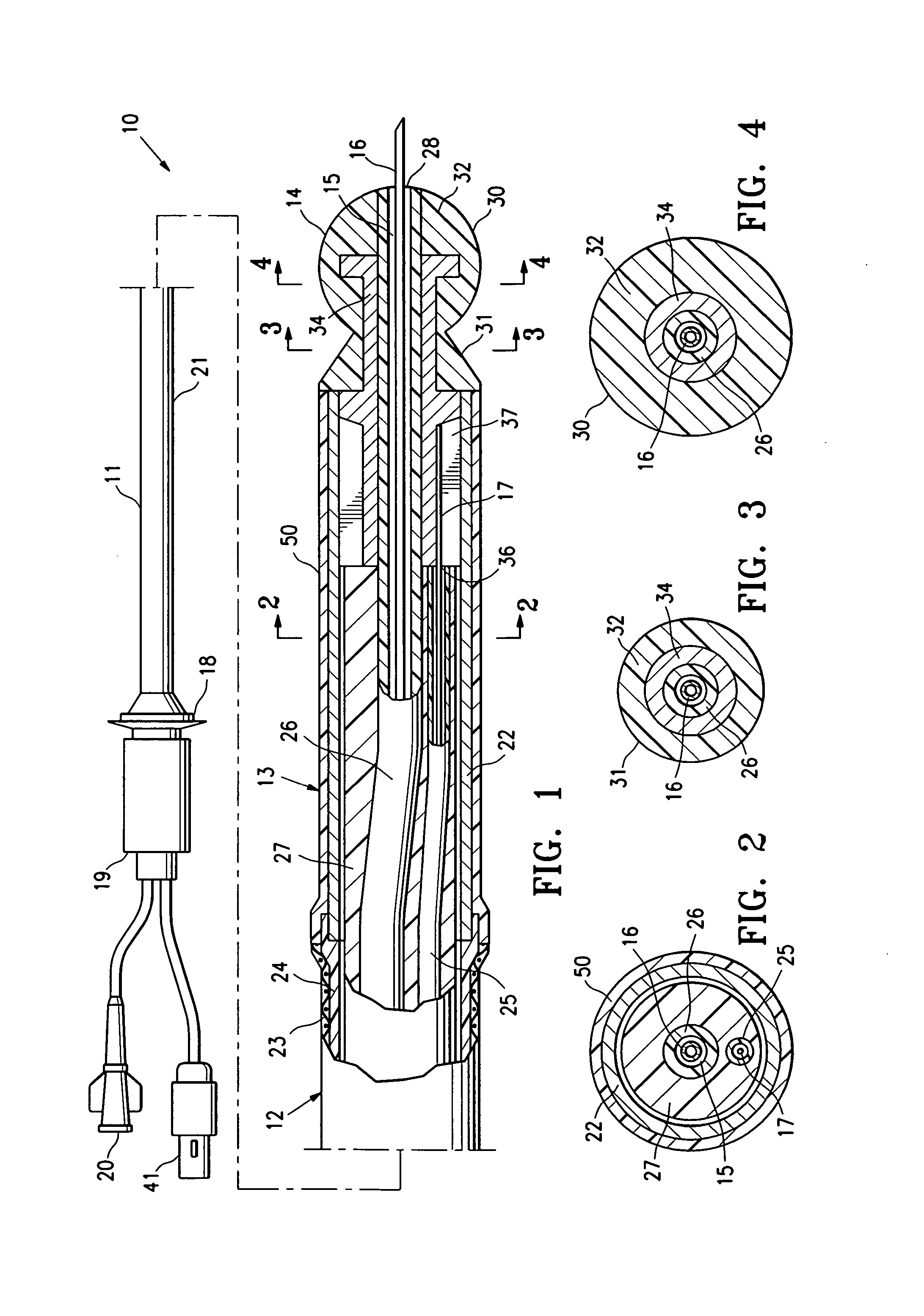

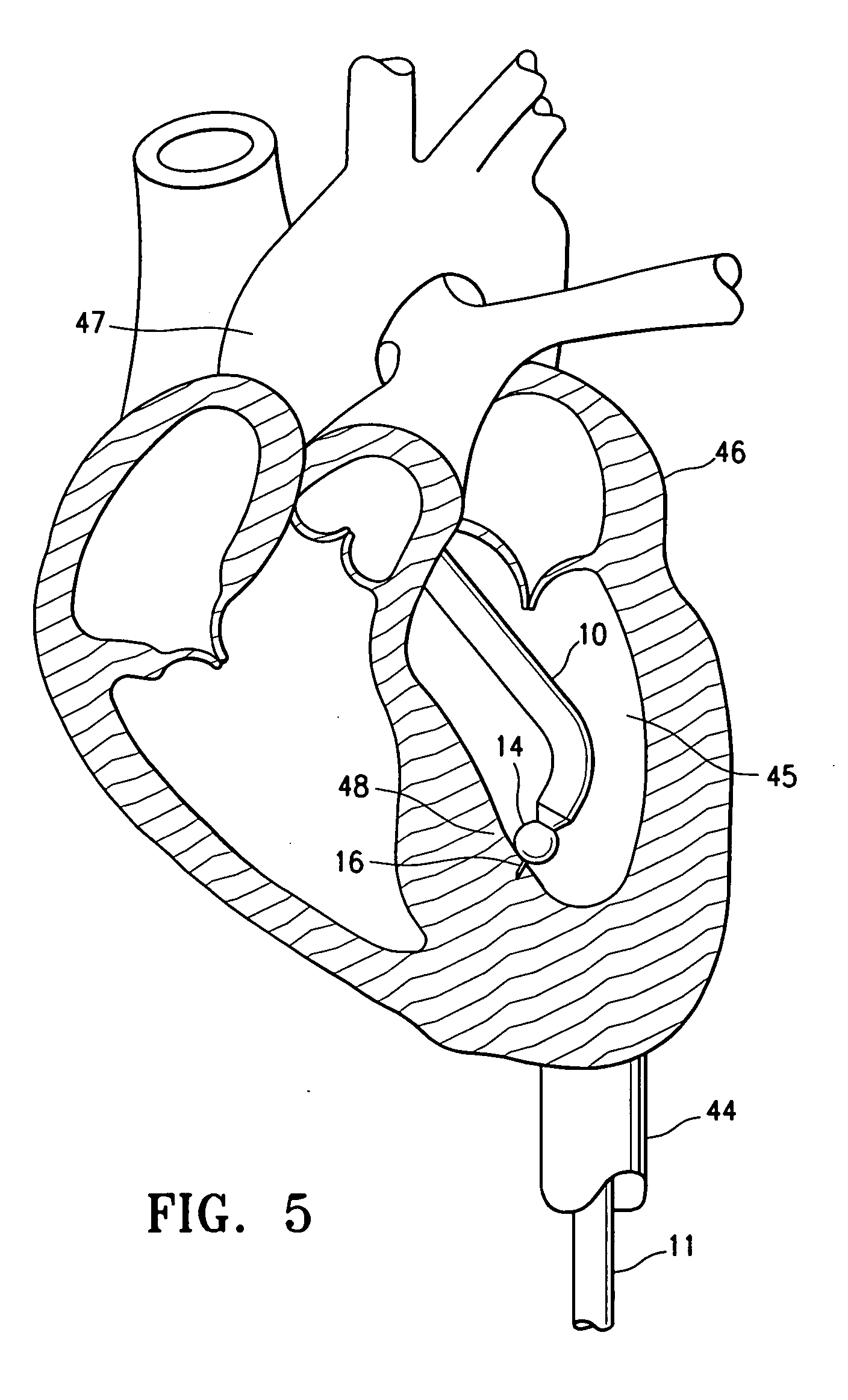

Method for applying a drug coating to a medical device

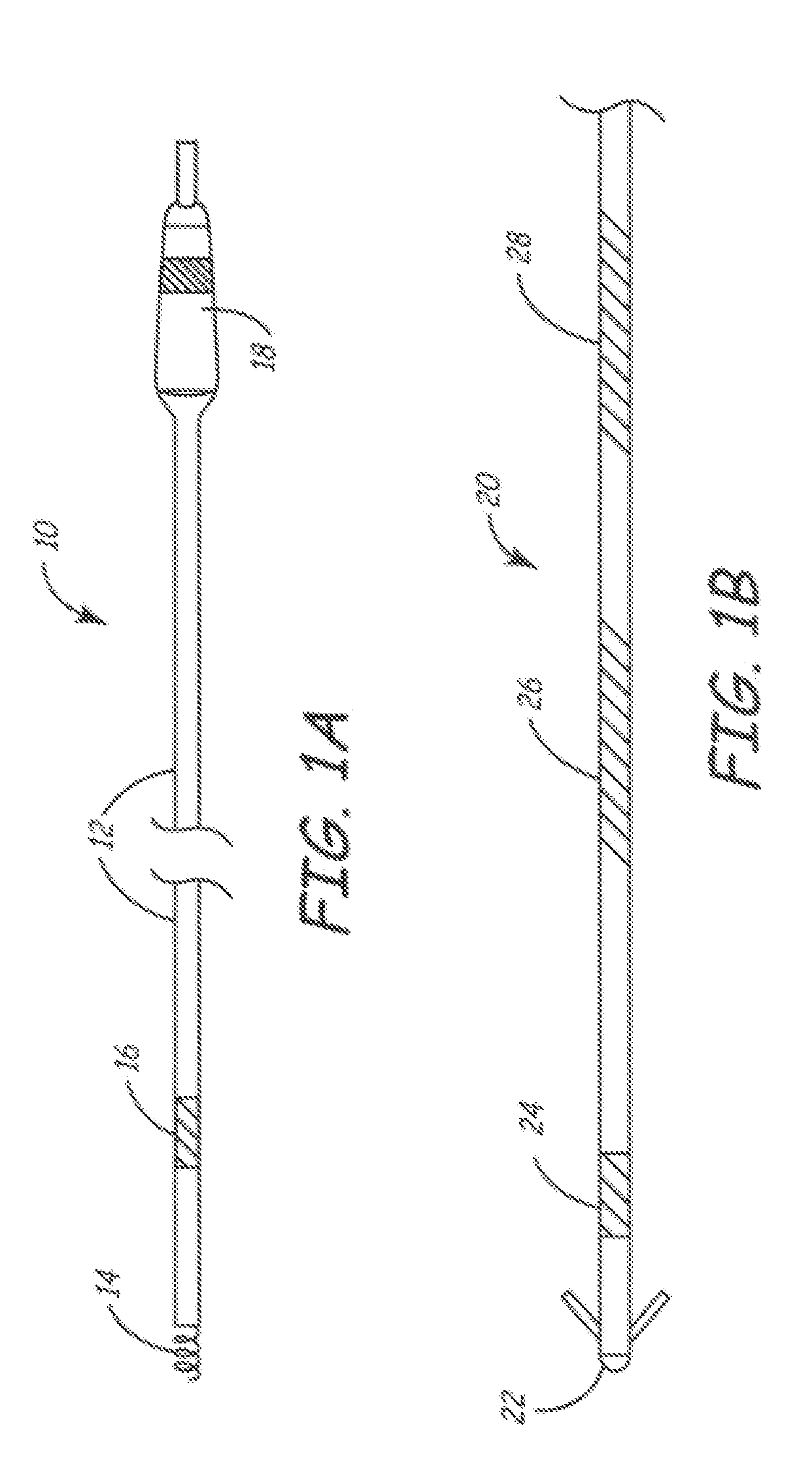

A method for coating a medical device with a drug is provided. Energy, preferably thermal energy, is applied to a crystalline deposit of a drug on the surface of a medical device to increase the molecular mobility and form a conformable drug coating with a low density of micro-cracks and other mechanical defects that can degrade the coating toughness and effective adhesion to the device surface. In a preferred embodiment, solution evaporation methods are used to deposit a crystalline coating of an anti-inflammatory steroid on a medical electrode. Heat applied at a controlled temperature, for a predetermined amount of time, induces a solid-state phase change of the drug coating providing a smooth, uniform, well-attached, conformable coating to form a layer that will elute from the electrode over time when implanted in a patient's body.

Owner:MEDTRONIC INC

Hot melt adhesive composition based on a random copolymer of isotactic polypropylene and a secondary polymer

InactiveUS7262251B2Broad processibilityImprove thermal stabilityOther chemical processesFilm/foil adhesivesWaxPlasticizer

Owner:ATO FINDLEY

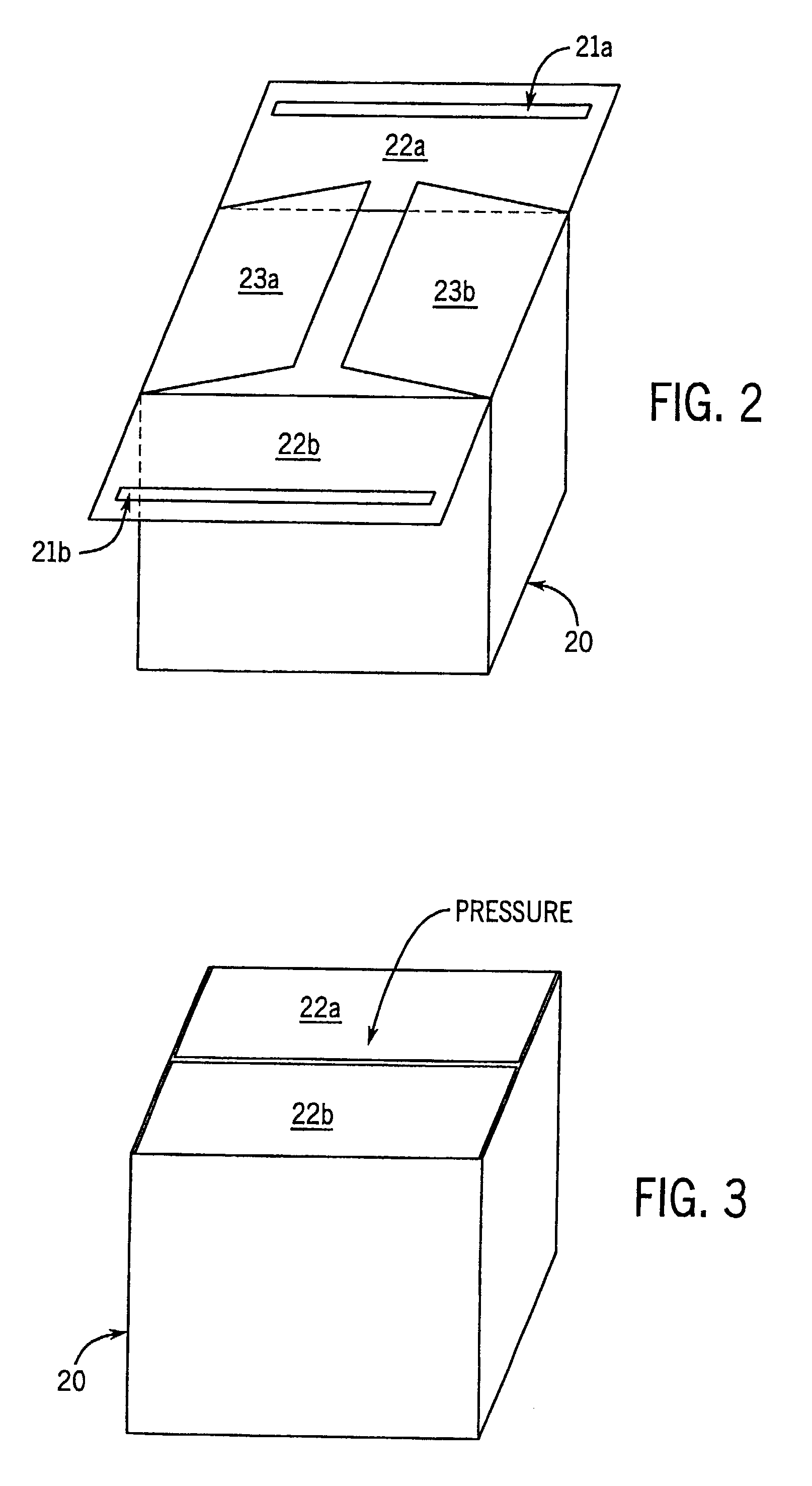

Pressure sensitive adhesive (PSA) laminates

InactiveUS20070231571A1High cohesive strength polymerImprove cohesive strengthFlat articlesThin material handlingTackifierPolymer

A PSA laminate is provided comprising at least one non-adhesive laminate and at least one tackifier layer; wherein the non-adhesive laminate comprises at least one facestock layer and at least one adhesive base layer; wherein the facestock layer comprises at least one facestock material; wherein the adhesive base layer comprises at least one adhesive base polymer; wherein the tackifier layer comprises at least one tackifier; wherein the tackifier composition is not a PSA; and wherein the tackifier layer is applied to the adhesive base layer side of the non-adhesive laminate to produce the PSA laminate. Processes for producing the PSA laminate are also provided as well as articles comprises the PSA laminates.

Owner:EASTMAN CHEM CO

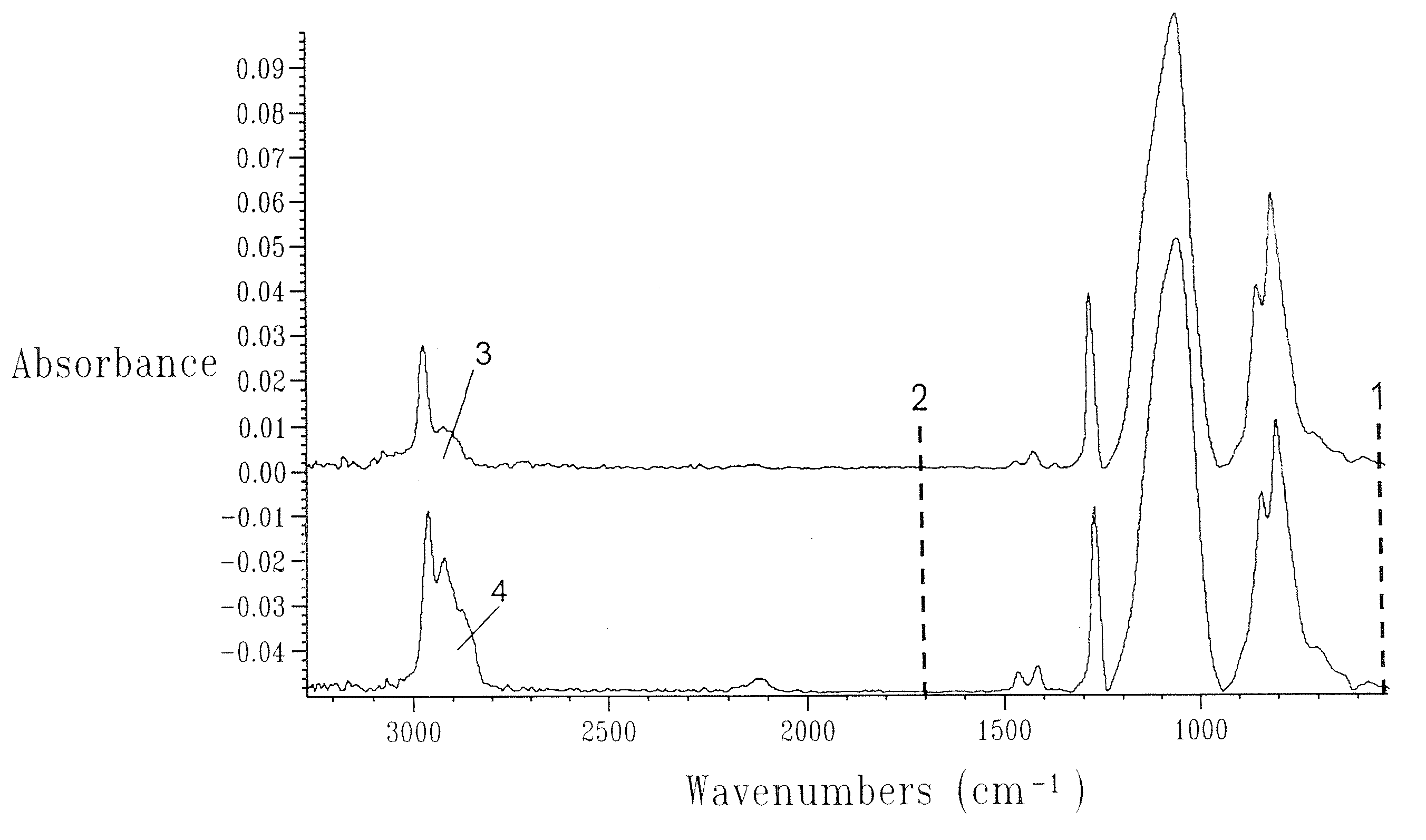

Composite tissue adhesive

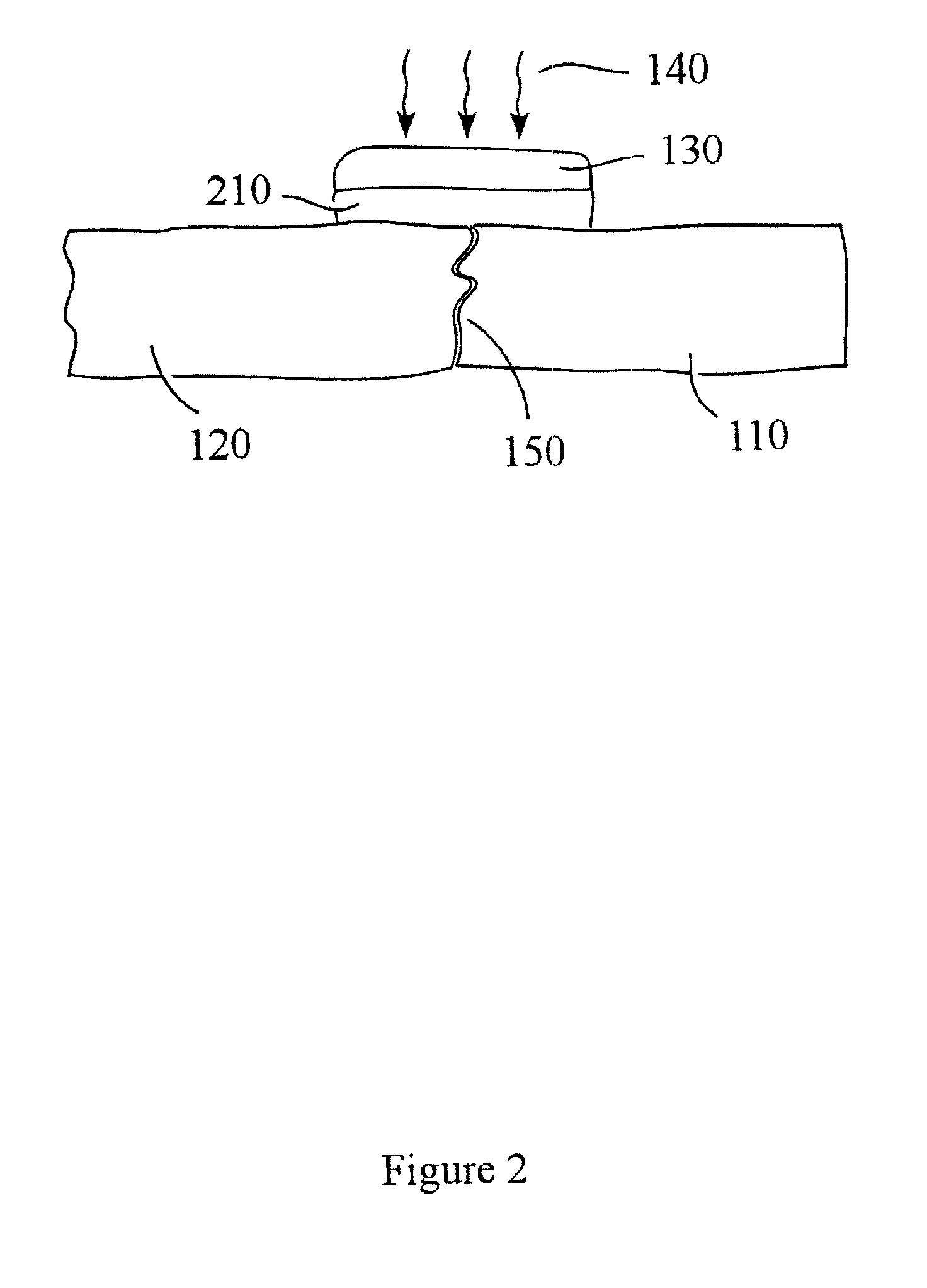

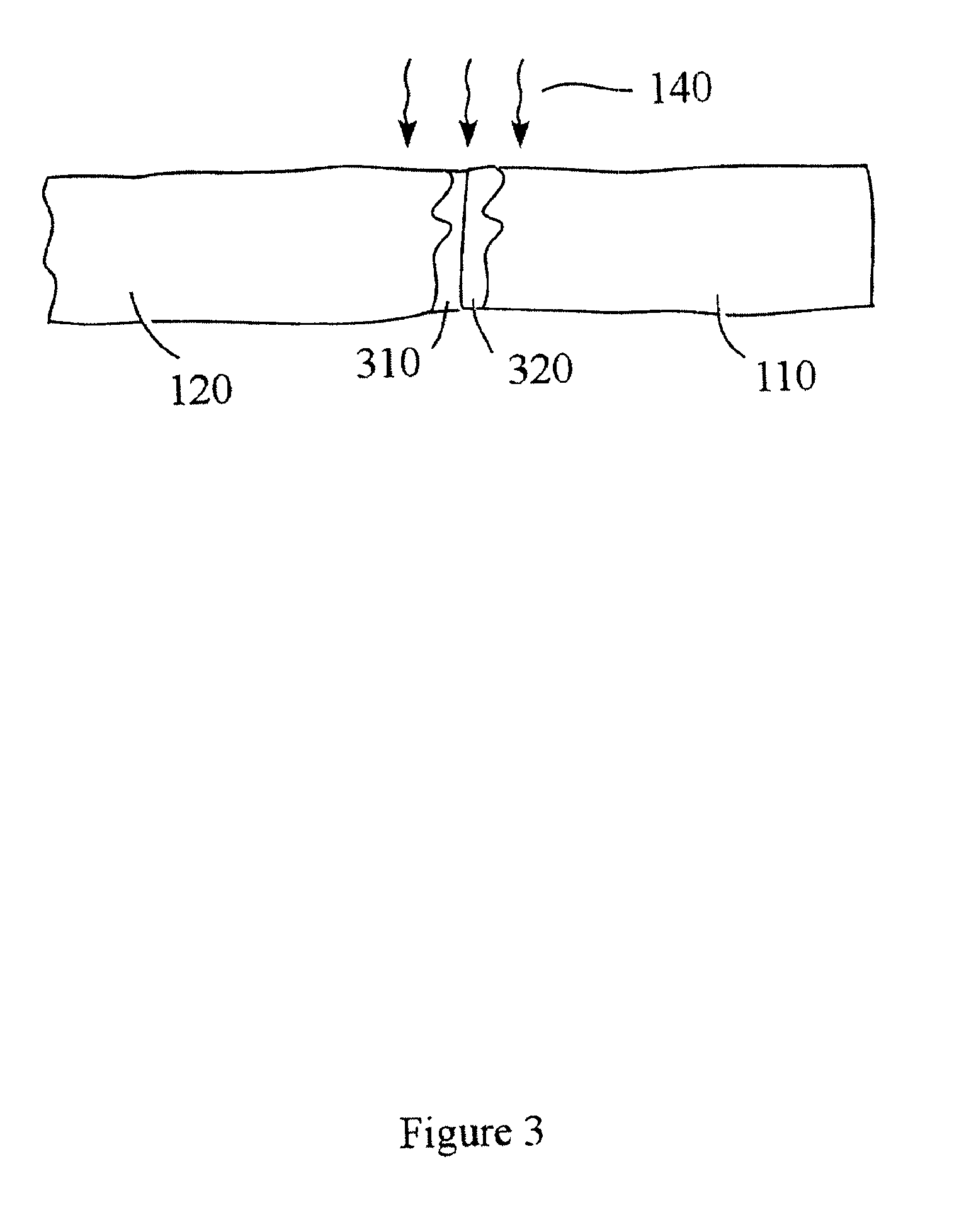

InactiveUS6939364B1Precise temperature controlShorten treatment timeSurgical instrument detailsSurgical veterinaryThermal energyHigh concentration

Consistent with the present invention, tissue adhesive compositions and an associated laser exposure system are provided for bonding or sealing biological tissues. The compositions are comprised of chemically derivatized soluble collagen which is formulated to concentrations ranging from 300 mg / ml (30%) to 800 mg / ml (80%) collagen protein. In particular, Type I collagen, for example, is first prepared by extraction from bovine or porcine hide and purified. The collagen preparations are then chemically derivatized with sulfhydryl reagents to improve cohesive strength and with secondary derivatizing agents, such as carboxyl groups, to improve the adhesive strength of the solder to the tissue. The compositions are then formed into viscous solutions, gels or solid films, which when exposed to energy generated from an infrared laser, for example, undergo thermally induced phase transitions. Solid or semi-solid protein compositions become less viscous enabling the high concentration protein to penetrate the interstices of treated biological tissue or to fill voids in tissue. As thermal energy is released into the surrounding environment, the protein compositions again become solid or semi-solid, adhering to the treated tissue or tissue space.

Owner:CONVERSION ENERGY ENTERPRISES

Methods to form SiCOH or SiCNH dielectrics and structures including the same

InactiveUS20080009141A1Low costSimple methodSemiconductor/solid-state device manufacturingChemical vapor deposition coatingDielectricElectronic structure

Methods of forming dielectric films comprising Si, C, O and H atoms (SiCOH) or Si, C, N and H atoms (SiCHN) that have improved cohesive strength (or equivalently, improved fracture toughness or reduced brittleness), and increased resistance to water degradation of properties such as stress-corrosion cracking, Cu ingress, and other critical properties are provided. Electronic structures including the above materials are also included herein.

Owner:GLOBALFOUNDRIES INC

Wet surface adhesives

InactiveUS6855386B1Overcome environmentalOvercome safety undesirabilityEnvelopes/bags making machineryFilm/foil adhesivesMeth-Solvent

A wet stick pressure sensitive adhesive comprising the solventless polymerization product of: a) about 30 to about 70 parts by weight of an (meth)acrylate ester monomer wherein the (meth)acrylate ester monomer, when homopolymerized, has a Tg of less than about 10° C.; b) about 70 to about 30 parts by weight of a hydrophilic acidic comonomer; and c) about 10 to 100 parts based on 100 parts of the sum of components (a+b) of a non-reactive plasticizing agent, wherein the pressure sensitive adhesive adheres to wet substrate surfaces and a method of making.

Owner:3M INNOVATIVE PROPERTIES CO

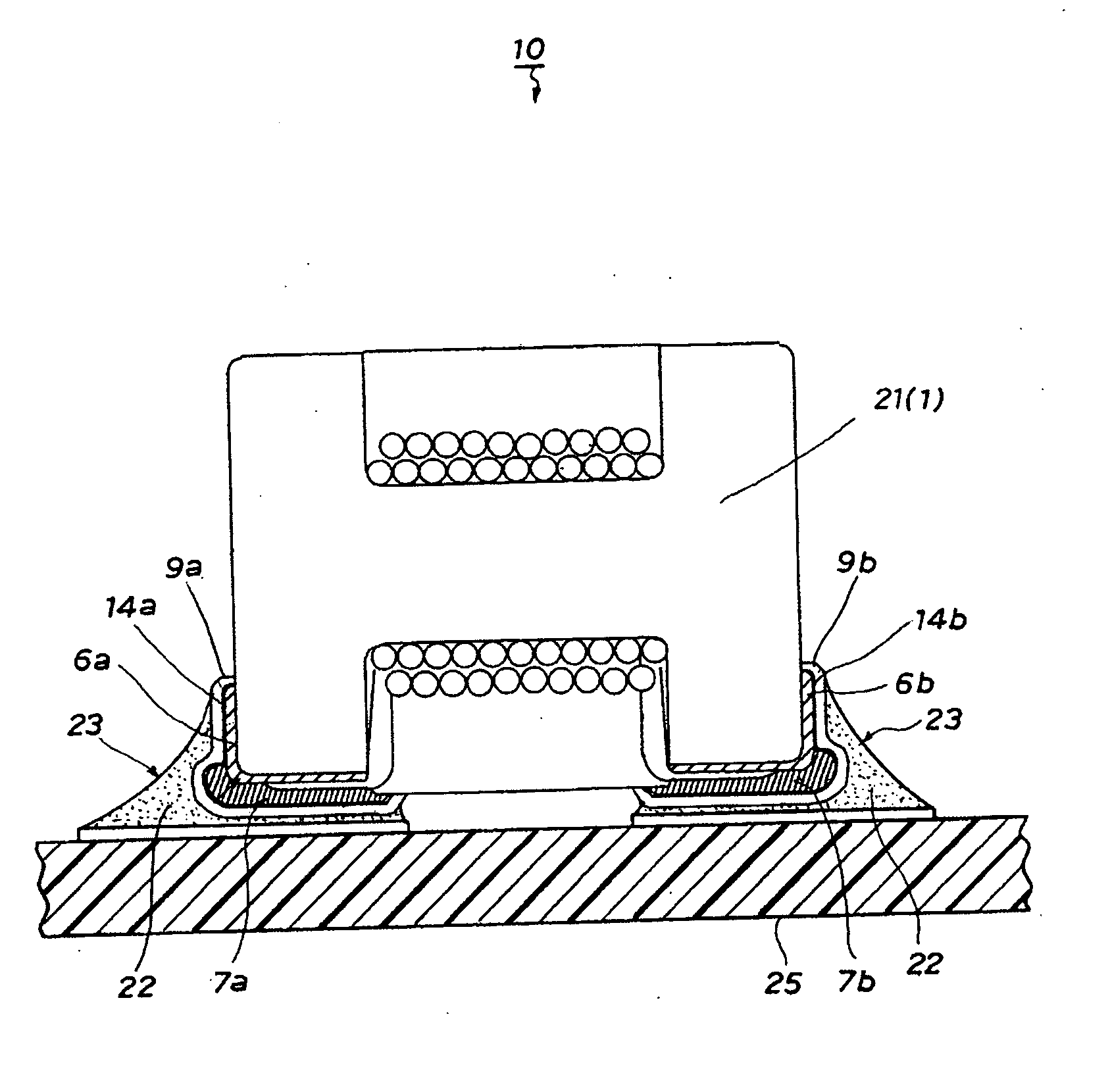

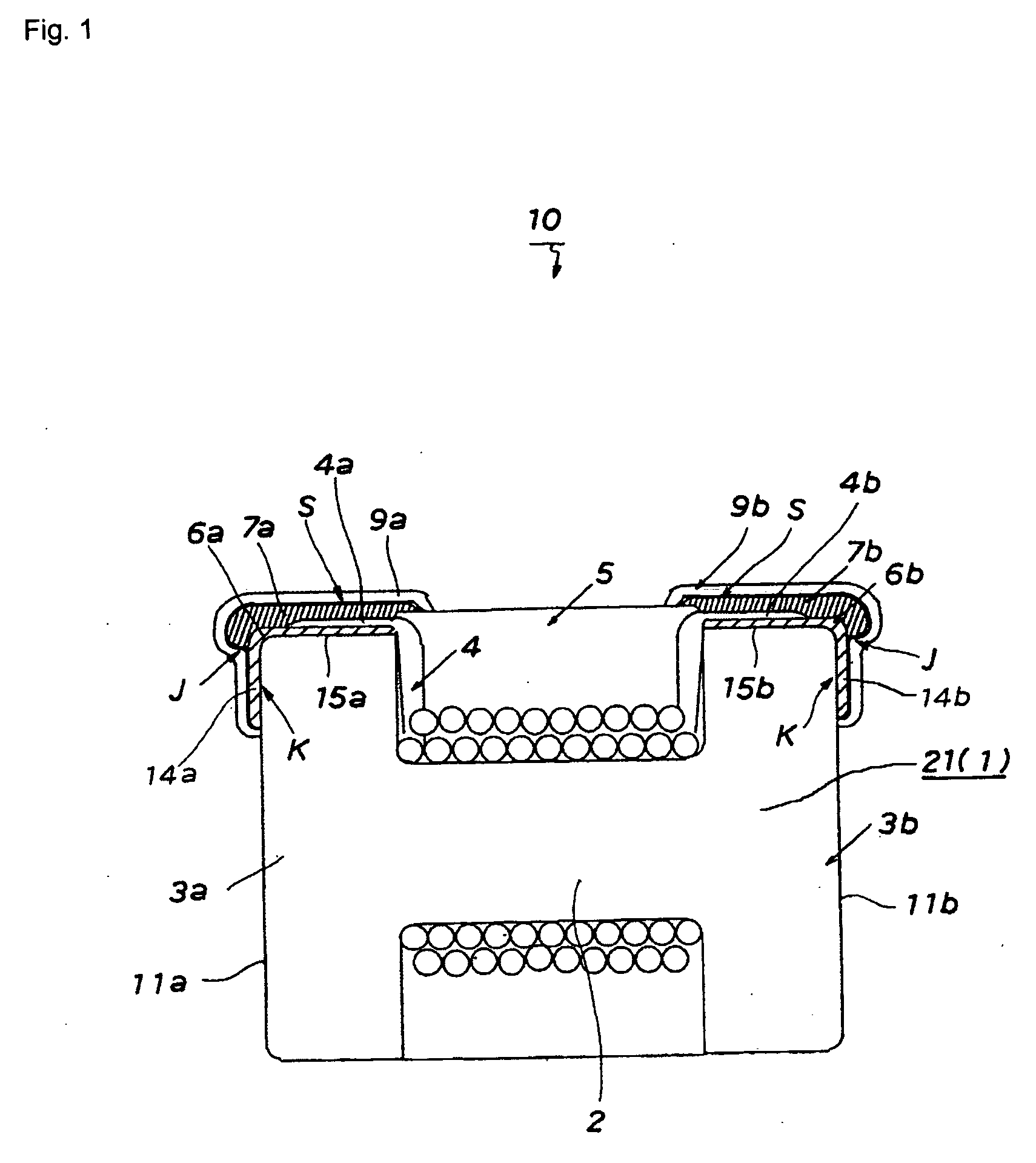

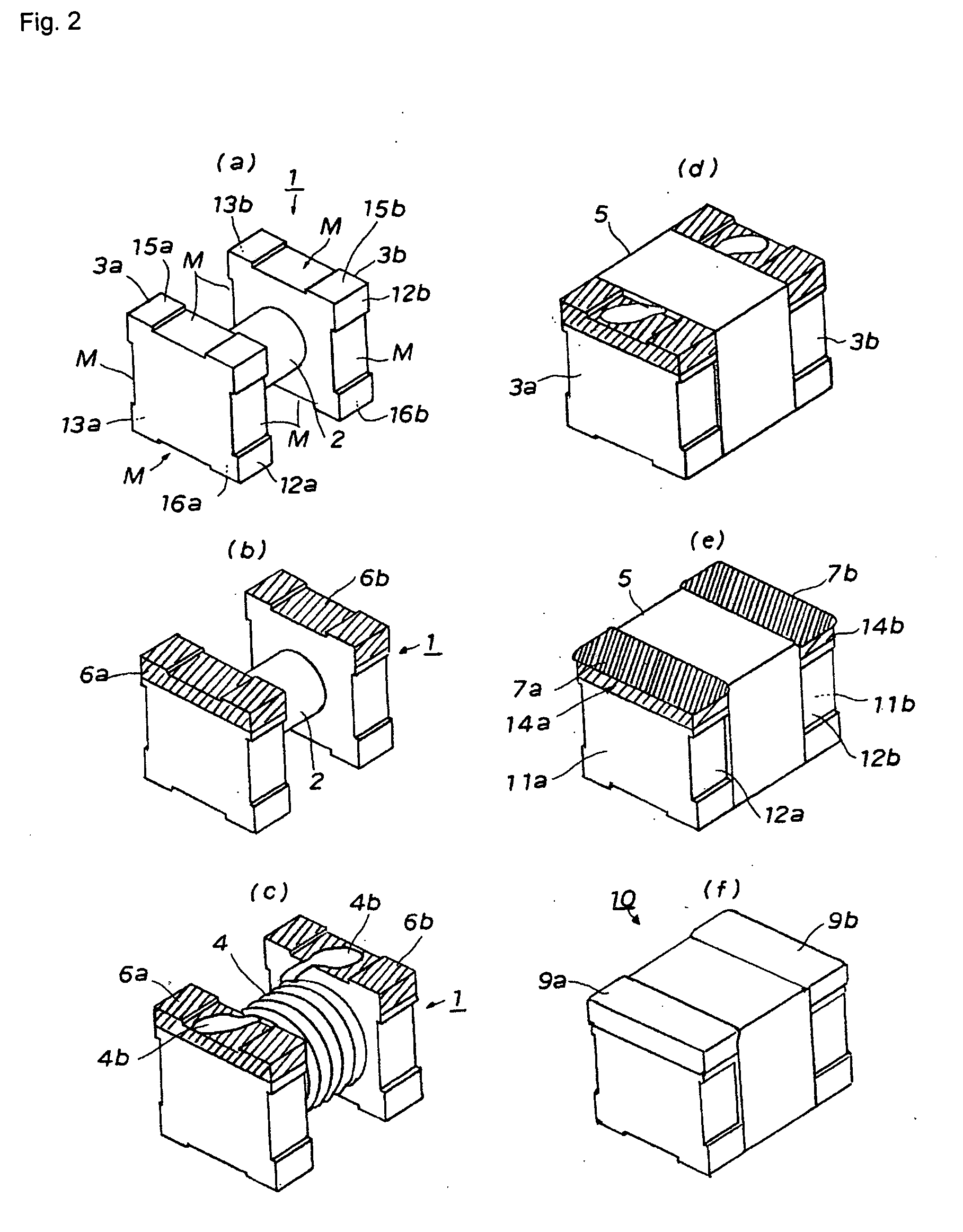

Surface mount coil component and surface mount coil component mounted substrate

ActiveUS20060071749A1High in cohesion strengthImprove cohesionTransformers/inductances casingsPrinted circuit manufactureElectrical conductorSurface mounting

A surface mount coil component has an electrode part including: internal electrodes mounted on both flanges of a drum type core over bottom surfaces and wraparound portions extending from the bottom surfaces to the end surfaces and parts of both sides. The coil conductor is conductively joined to the internal electrodes at both ends thereof. Intermediate electrodes cover from the top sides of wraparound portions of the internal electrodes on the sides of the flanges through top sides of the wraparound portion thereof on the end surfaces of the flanges to top sides of the wraparound portion thereof on the other sides of the flanges so as to leave C-shaped cross section of exposed areas of the internal electrodes. Also, plating conductive films extend from surfaces of the exposed areas of the internal electrodes to surfaces of the intermediate electrodes.

Owner:TAIYO YUDEN KK

Method for preparing modified aqueous adhesion agent of polyurethane

InactiveCN101003715AIncrease the degree of cross-linkingImprove cohesive strengthPolyureas/polyurethane adhesivesEpoxyPolyester

This invention discloses a method for preparing modified aqueous polyurethane adhesive. The method comprises: (1) modifying epoxy resin with modifier to obtain modified epoxy resin; (2) reacting polyisocyanate with polyester or polyol polyether, and adding chain extender to obtain polyurethane with prepolymer; (3) modifying polyurethane prepolymer with modified epoxy resin to obtain modified polyurethane prepolymer; (4) adding water, dispersing by a high-speed disperser, and adding neutralizer and crosslinking agent to obtain modified aqueous polyurethane adhesive. This invention introduces epoxy resin into the modification of aqueous polyurethane adhesive, thus combines high modulus, high strength and good chemical resistance of epoxy resin with the advantages of polyurethane resin. The modified aqueous polyurethane adhesive can meet the needs of automobile inner decoration materials. The method has such advantages as simple process, and low cost.

Owner:SOUTH CHINA UNIV OF TECH

Hot melt adhesive composition based on a random copolymer of isotactic polypropylene

InactiveUS7067585B2High bond strength retentionGood adhesionOther chemical processesFilm/foil adhesivesWaxPlasticizer

A hot melt adhesive composition is based on an isotactic polypropylene random copolymer (RCP). The composition contains about 4%–50% by weight of the RCP copolymer, about 20%–65% by weight of a compatible tackifier, about 0%–40% by weight of a plasticizer, about 0%–3% by weight of a stabilizer, about 0%–40% by weight of a wax, and optionally about 0%–60% by weight of an atactic poly-α-olefin (APAO). The adhesive composition may be used in a number of applications such as, for example, in disposable nonwoven hygienic articles, paper converting, flexible packaging, wood working, carton and case sealing, labeling and other assembly applications.

Owner:BOSTIK INC

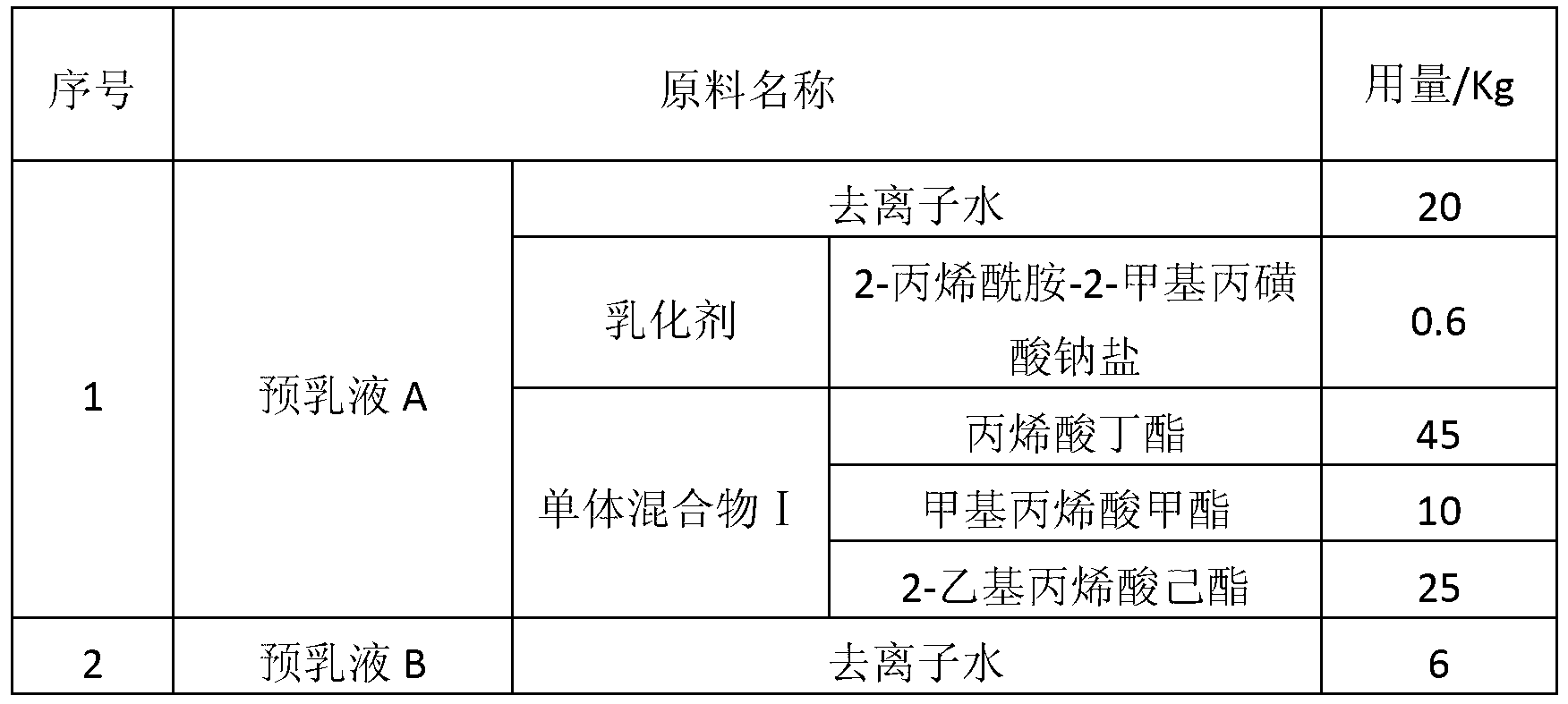

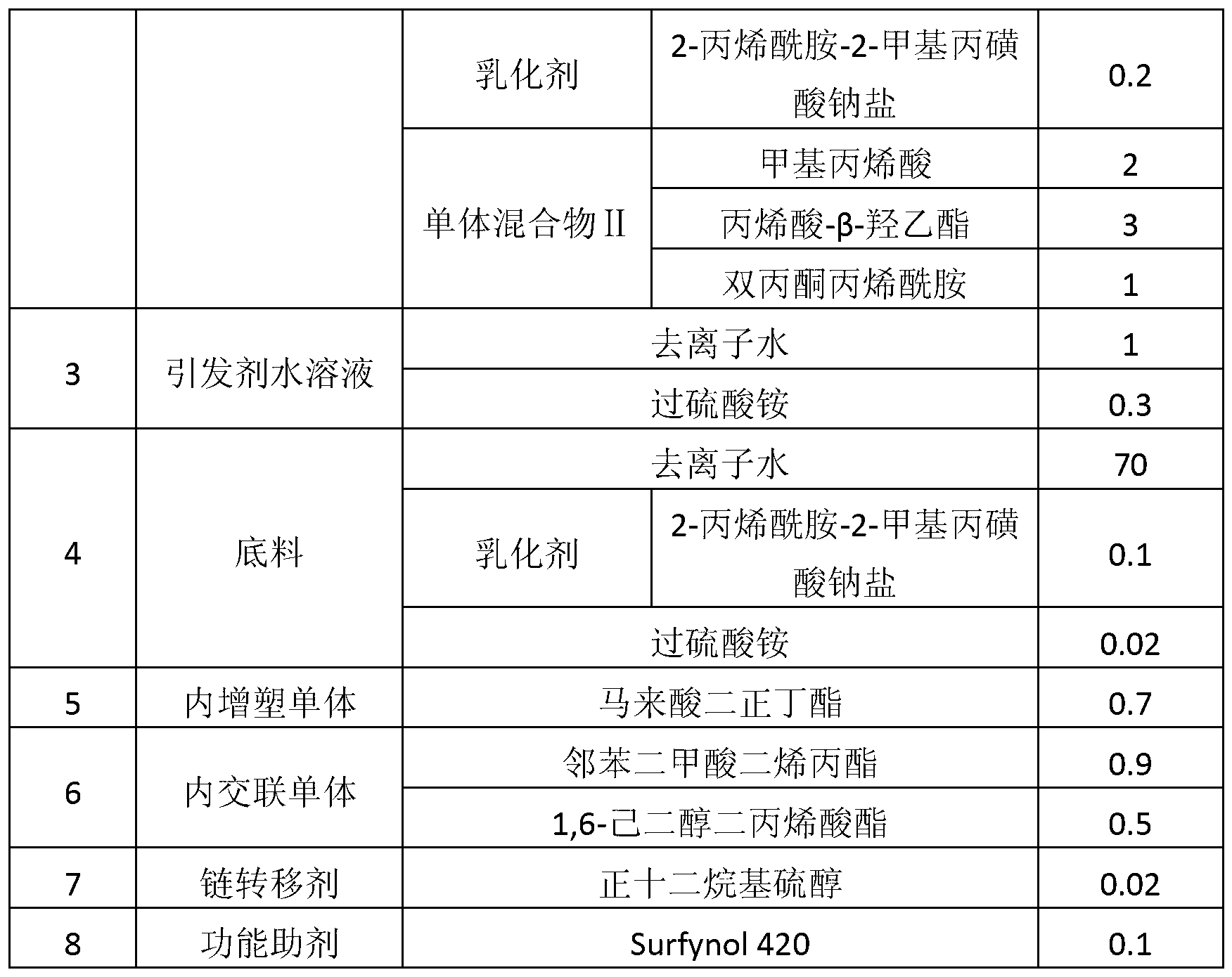

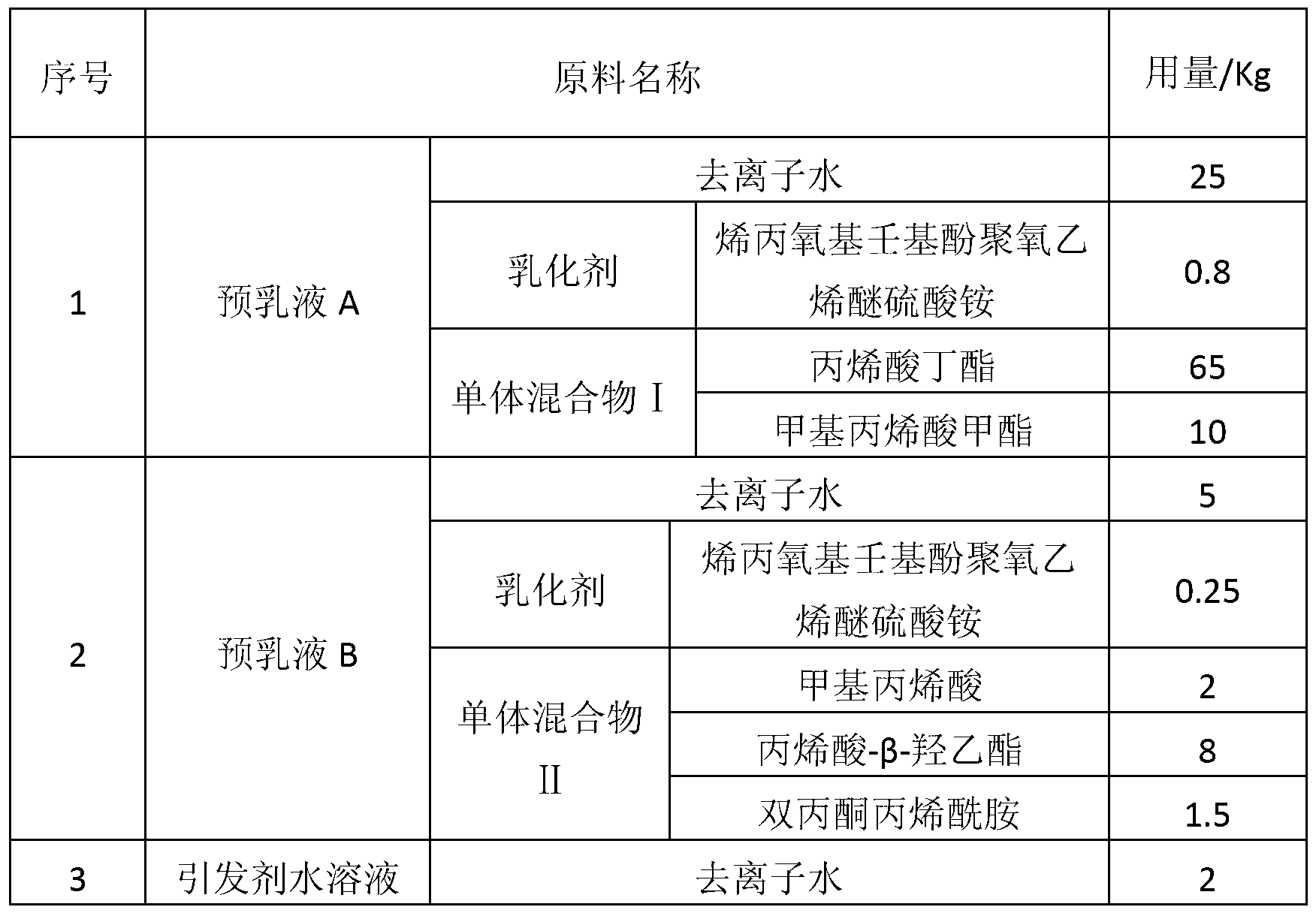

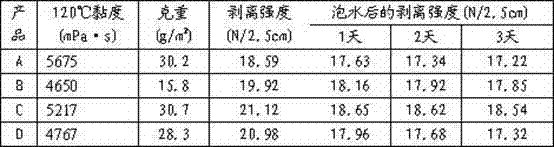

Water-based plastic-plastic compound adhesive for food and drug flexible package and preparation method thereof

ActiveCN103059784AHigh bonding strengthImprove stabilityEster polymer adhesivesWater basedPolyurethane adhesive

The invention discloses a water-based plastic-plastic compound adhesive for food and drug flexible packages and a preparation method thereof. The preparation method comprises the following steps of: carrying out pre-emulsification by using 20-30 parts by weight of deionized water, 0.4-1.0 part by weight of emulsifying agents and 75-90 parts by weight of monomer mixtures to obtain a pre-emulsion A; then carrying out the pre-emulsification by using 5-8 parts by weight of the deionized water, 0.2-0.3 part of the emulsifying agents and 3-20 parts by weight of the monomer mixtures to obtain a pre-emulsion B; preparing an initiator water solution C by using 1-3 parts by weight of the deionized water and 0.2-0.8 part by weight of initiators; and dropping the monomer mixture I with lower polarity and the monomer mixture II with higher polarity step by step by adopting a pre-emulsification seed emulsion polymerization process to obtain the water-based plastic-plastic compound adhesive for the food and drug flexible packages. The water-based plastic-plastic compound adhesive disclosed by the invention has the advantages of no organic solvent, no formaldehyde release, good adhesivity and high stripping strength and permanent adhesion and can be applied to a flexible package industry and substitute for a solvent type two-component polyurethane adhesive maturely applied to the present market.

Owner:DONGGUAN STAR COSM POLYMER

Latent, over-tackified, adhesives and methods of use

InactiveUS20050061435A1Aggressive and permanent tackSufficient abilityNon-macromolecular adhesive additivesLayered productsPressure sensitiveChemistry

Methods of applying a pressure sensitive adhesive to a substrate and adhering substrates together that includes applying a latent, over-tackified, adhesive to a substrate and applying a plasticizing agent to activate the latent, over-tackified, adhesive to form a pressure sensitive adhesive.

Owner:3M INNOVATIVE PROPERTIES CO

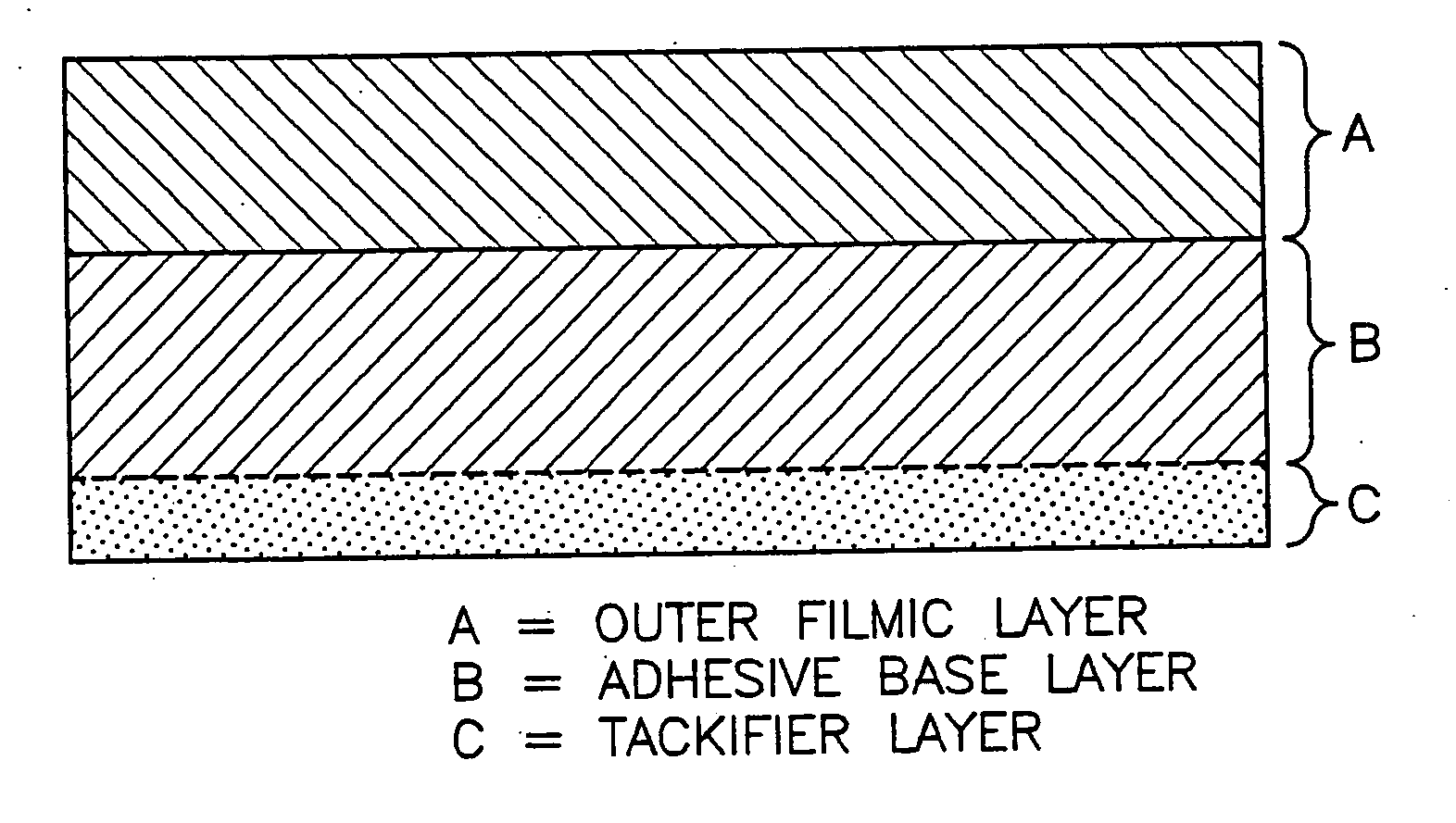

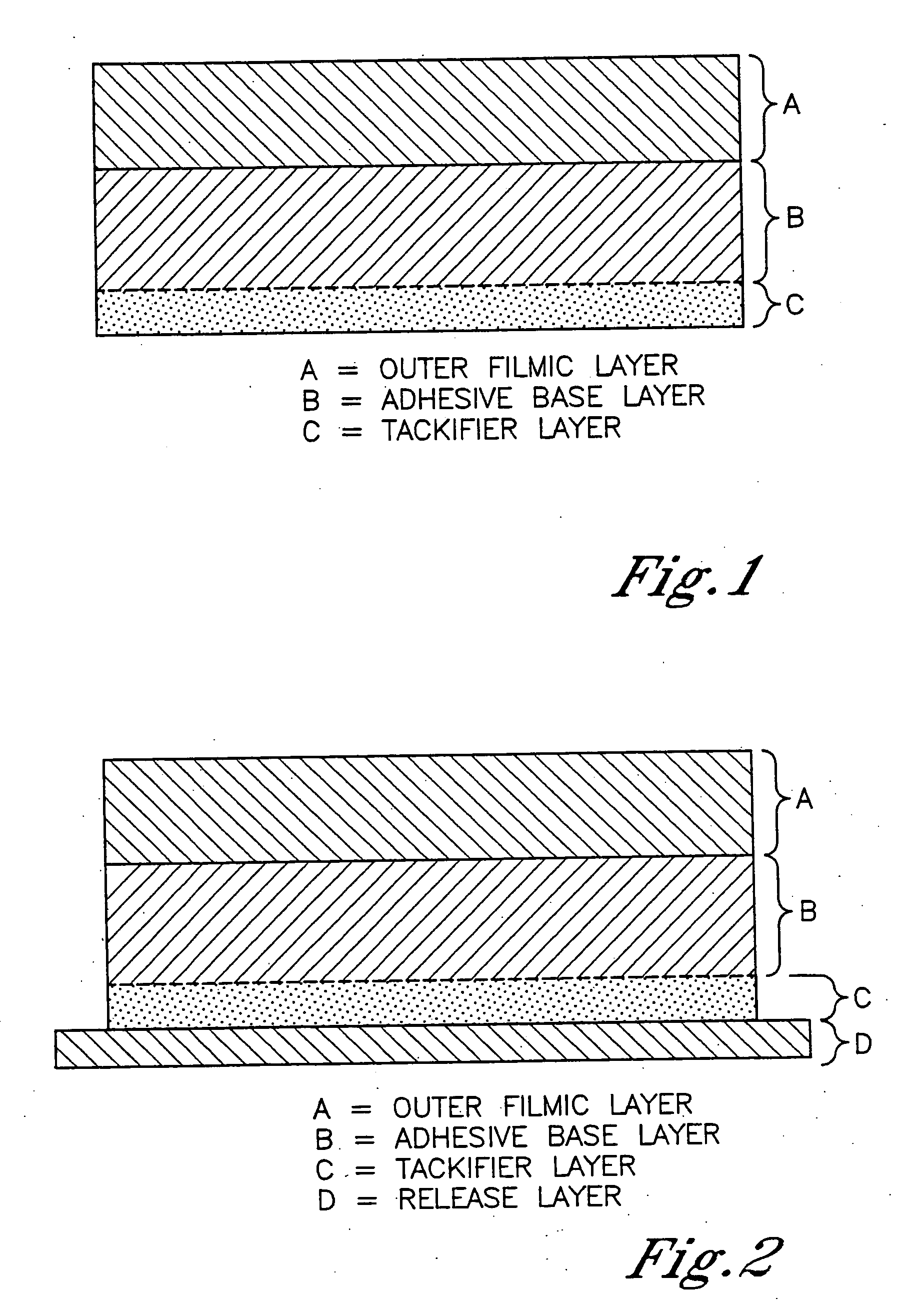

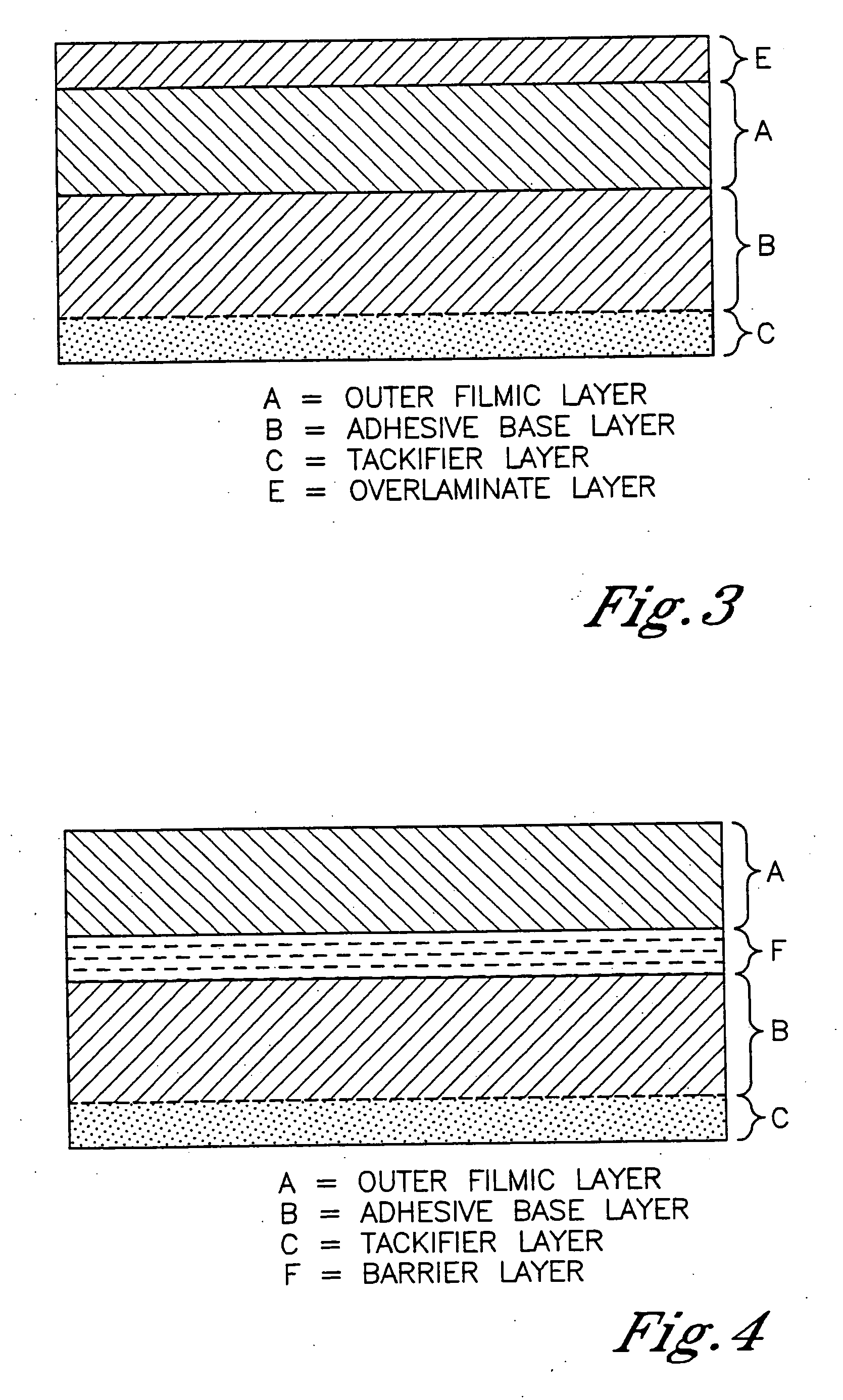

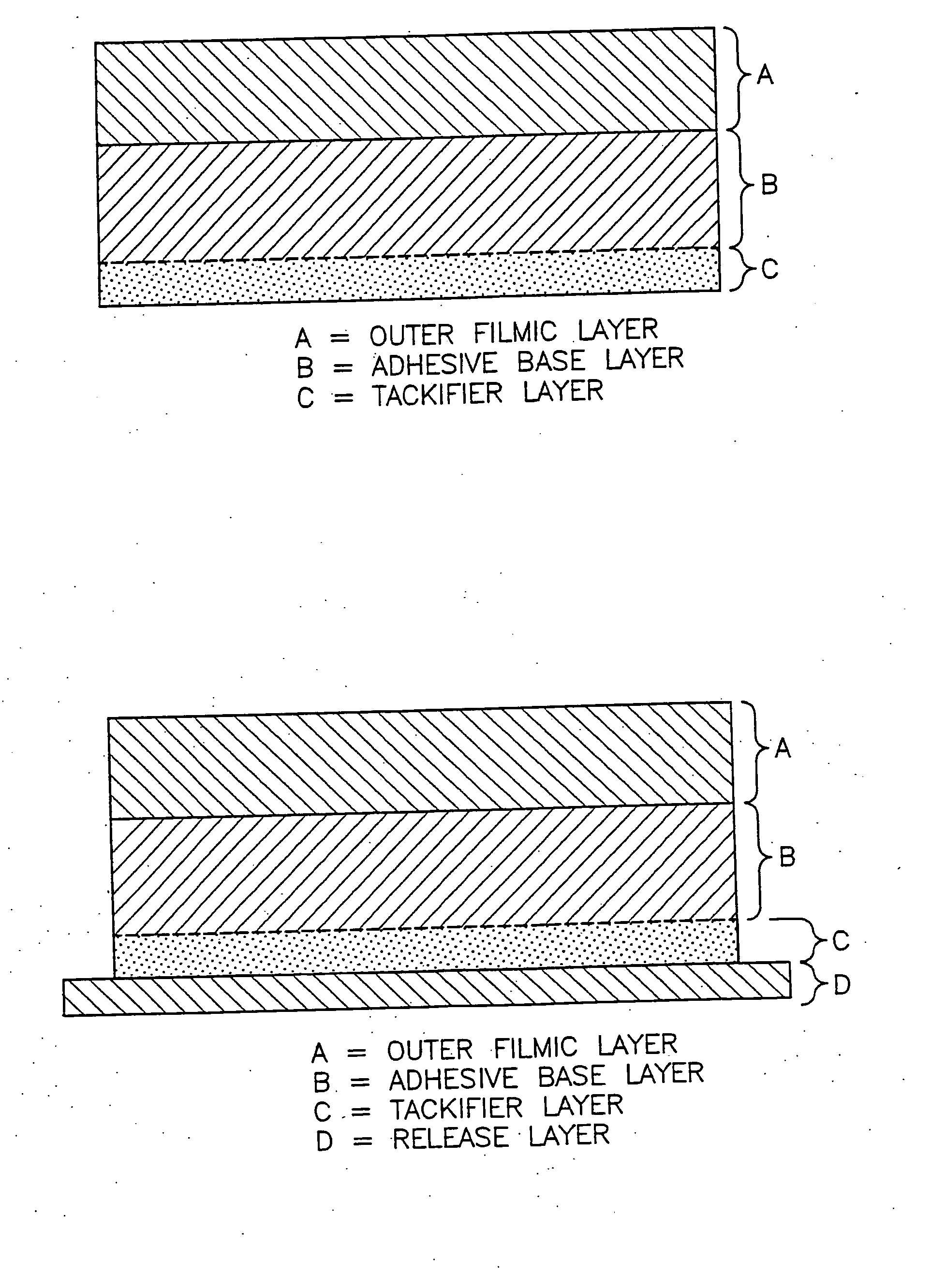

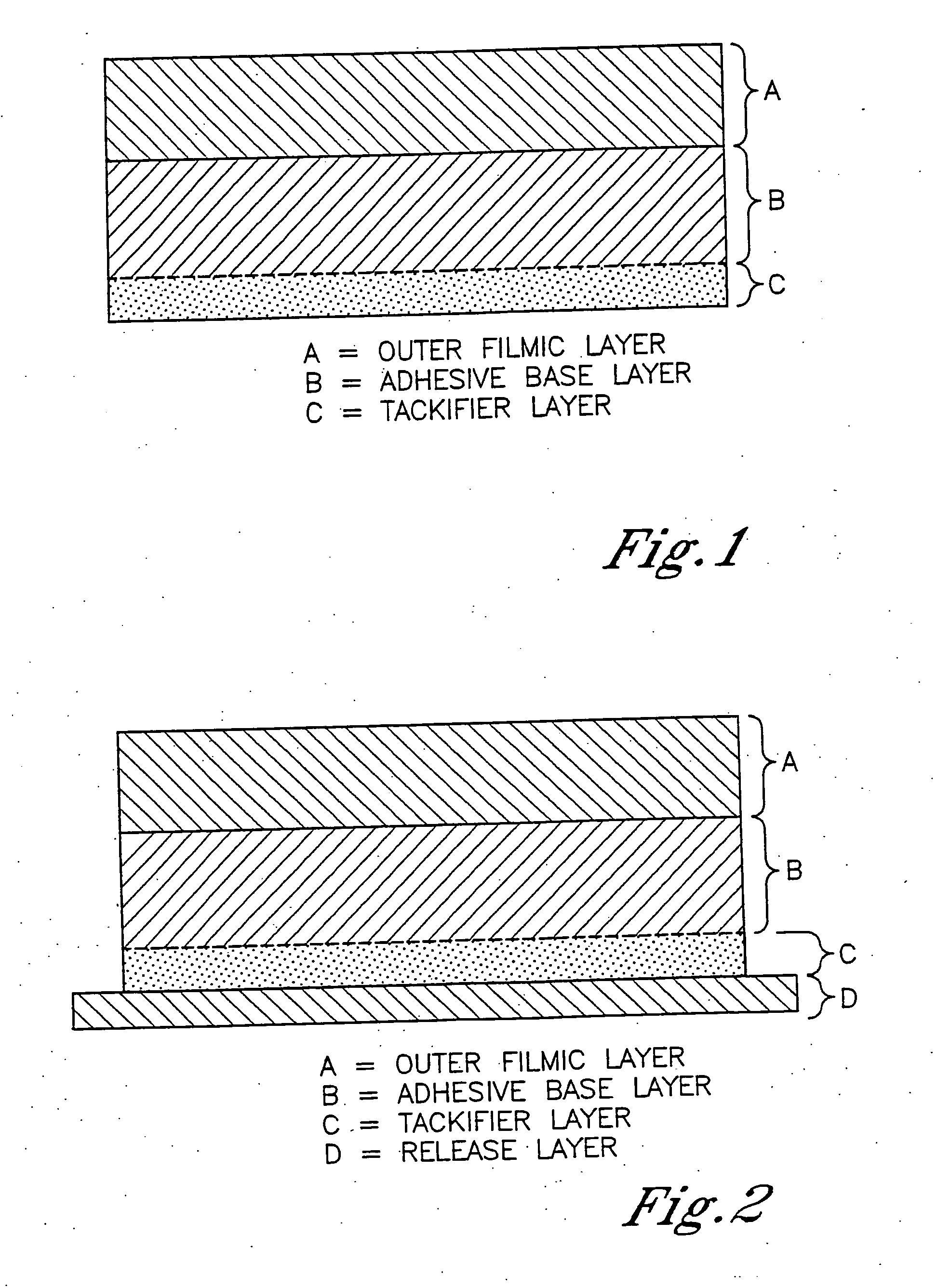

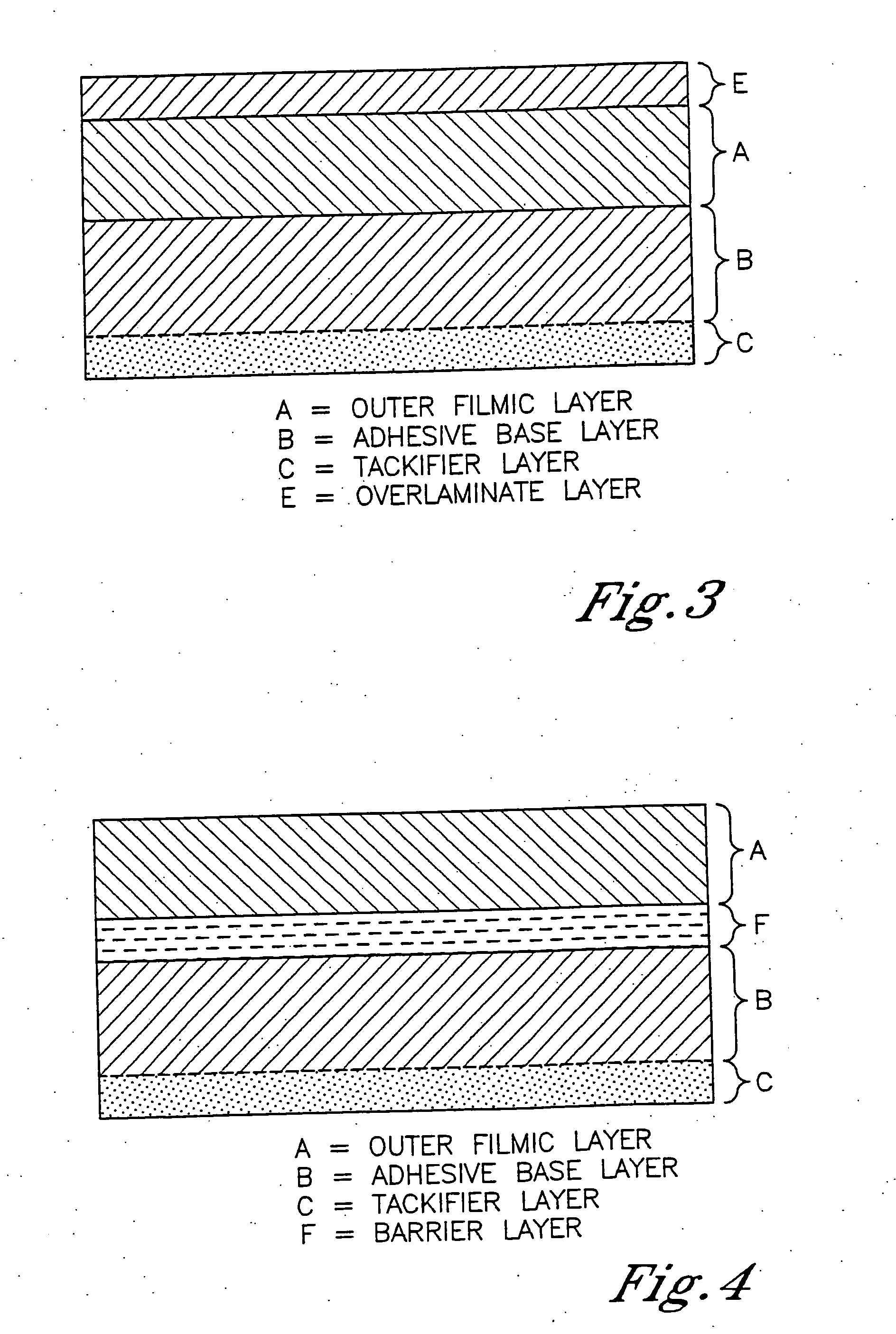

Pressure sensitive adhesives (PSA) laminates

InactiveUS20060263596A1High cohesive strength polymerHigh cohesive strengthAdhesive articlesSynthetic resin layered productsPressure sensitivePolymer

A PSA laminate is provided comprising: a) at least one outer filmic layer (A) comprising at least one filmic polymer; b) at least one adhesive base layer (B) comprising at least one adhesive base polymer; and c) at least one tackifier layer (C) comprising at least one tackifier and at least one polymer; wherein the pressure sensitive adhesive laminate is obtainable by co-extruding the outer filmic layer (A) with the adhesive base layer (B) to produce a non-adhesive laminate and applying the tackifier layer (C) to the adhesive base layer side of the non-adhesive laminate to produce the PSA laminate. Processes for producing the PSA laminate, and articles comprising the PSA laminate are also provided.

Owner:EASTMAN CHEM CO

Abrasion and impact resistant coating compositions, and articles coated therewith

InactiveUS20030157344A1Superior abrasionAvoid serious impactSynthetic resin layered productsGlass/slag layered productsHigh humidityShock resistance

Disclosed are abrasion and impact resistant coating compositions, and substrates coated therewith. These coating compositions provide high abrasion and impact resistance, chemical protection to the substrate, and exhibit enhanced stability to high temperature and high humidity conditions. Coating compositions may also be tailored to provide a balanced combination of abrasion resistance, impact resistance, and weatherability. These coatings may be transparent or not, depending on the intended applications. These coatings may also comprise additives such as UV absorbers, corrosion inhibitors, and electrically conductive materials. Substrates for use herein may be plastic or metal.

Owner:TRITON SYST INC

Low odor, light color hot pick-up adhesive

A hot melt label or other paper stock pick-up adhesive can be formulated using a hydrogenated tackifying resin combined with waxes, oils, stabilizers and other additive materials. Such a material has hot tack and other properties that produce excellent pick-up properties. The hot melt materials are hypoallergenic and are safe to use.

Owner:ADHERENT LAB

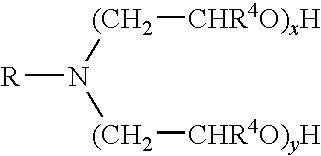

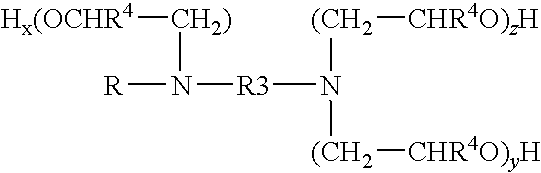

Asphalt modifiers for "warm mix" applications including adhesion promoter

ActiveUS20100319577A1Low viscosityImprove wetting propertiesIn situ pavingsWax coatingsRoad surfaceSurface-active agents

The present invention generally relates to an additive package for warm-mix asphalt formulations for the pavement of road surfaces, said additive package comprising a) surfactant component, and b) an asphalt rheology modifying component, wherein said asphalt rheology modifying component comprises at least one of a i) a wax component and ii) a resin component. The invention also relates to a warm mix asphalt having improved compaction at lower temperatures, and to a pavement made from said warm mix asphalt.

Owner:AKZO NOBEL CHEM INT BV

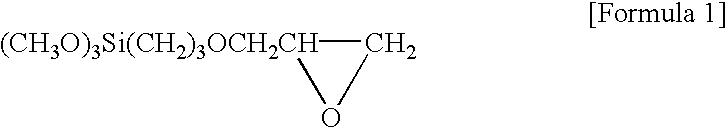

Reactive polymer waterproofing coiled material

ActiveCN101871248AHigh hardnessImprove cohesive strengthRoof covering using flexible materialsFilm/foil adhesivesCross-linkPolymer science

The invention discloses a reactive polymer waterproofing coiled material which comprises a fetal membrane layer, a reactive composite rubber layer and an anti-sticking isolation film layer; the reactive composite rubber layer is covered on the surface of the fetal membrane layer, and the anti-sticking isolation film layer is covered on the other surface of the reactive composite rubber layer; thereactive composite rubber comprises the following components in percentage by weight: 85.0 to 92.0 percent of SIS hot melt adhesive, 3.0 to 5.0 percent of talcum powder, 2.0 to 3.5 percent of composite ore powder, 1.0 to 2.5 percent of gaseous silica, 0.5 to 2.0 percent of silane coupling agent, and 0.5 to 2.0 percent of nano calcium carbonate. The waterproofing coiled material can have chemical cross-linking reaction and be cured with a cast-concrete matrix, fundamentally avoids 'watermoving between layer', and has the advantages of high strength, high toughness, aging resistance, long service life and the like.

Owner:KESHUN WATERPROOF TECH CO LTD

Hydrogel paste and preparation method thereof

ActiveCN102626401AImprove sustained release performanceProlong the action timeAntibacterial agentsCosmetic preparationsOxidation resistantSide effect

The invention discloses a hydrogel paste and a preparation method thereof, wherein the hydrogel paste is composed of three layers: a backing layer, a hydrogel layer and a protecting film layer. The hydrogel layer is arranged between the backing layer and the protecting film layer; the hydrogel layer comprises the following components: 5-10% of macromolecule framework material, 0.5-2% of tackifier, 0.5-1% of filler, 0.03-1% of cross-linking agent, 0.03-1% of cross-linking regulator, 0.5-1% of acid-base regulator, 3-10% of humectant, 0.01-2% of preservative and the balance of distilled water; and the hydrogel layer also comprises 0.01-10% of active ingredient, such as whitening agent, antiphlogistic agent, essential oil, and the like. The hydrogel paste has an excellent slow-release property; the action time of the hydrogel paste is prolonged; a cross-linking effect of the cross-linking agent is fully utilized, so that the hydrogel paste is excellent in viscosity and cohesive strength; and the hydrogel paste is high in oxidation resistance, is safe and free from toxic side effect and is suitable for the treatment of dry, fragile and sensitive skins.

Owner:佛山拜澳生物科技有限公司

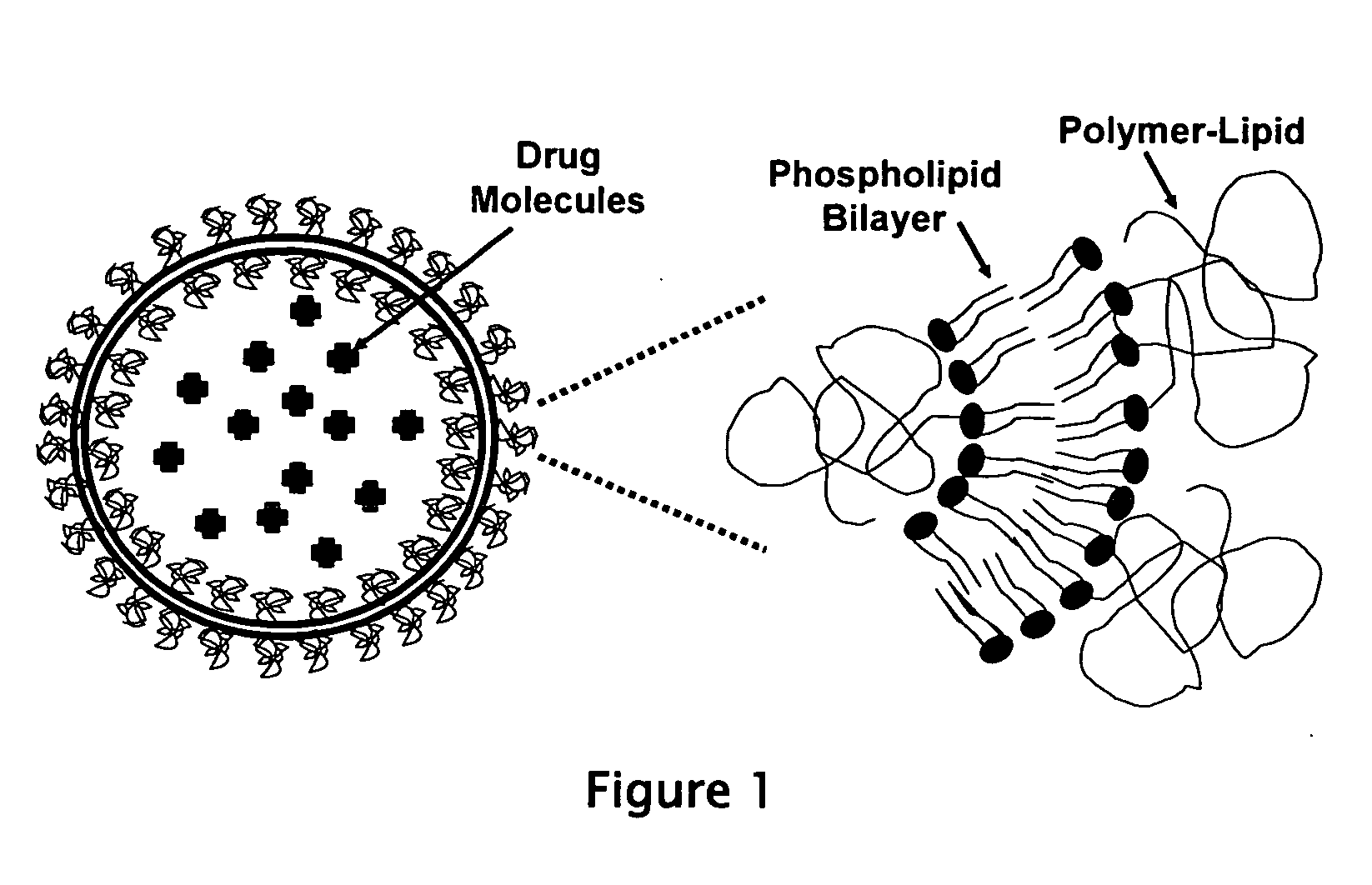

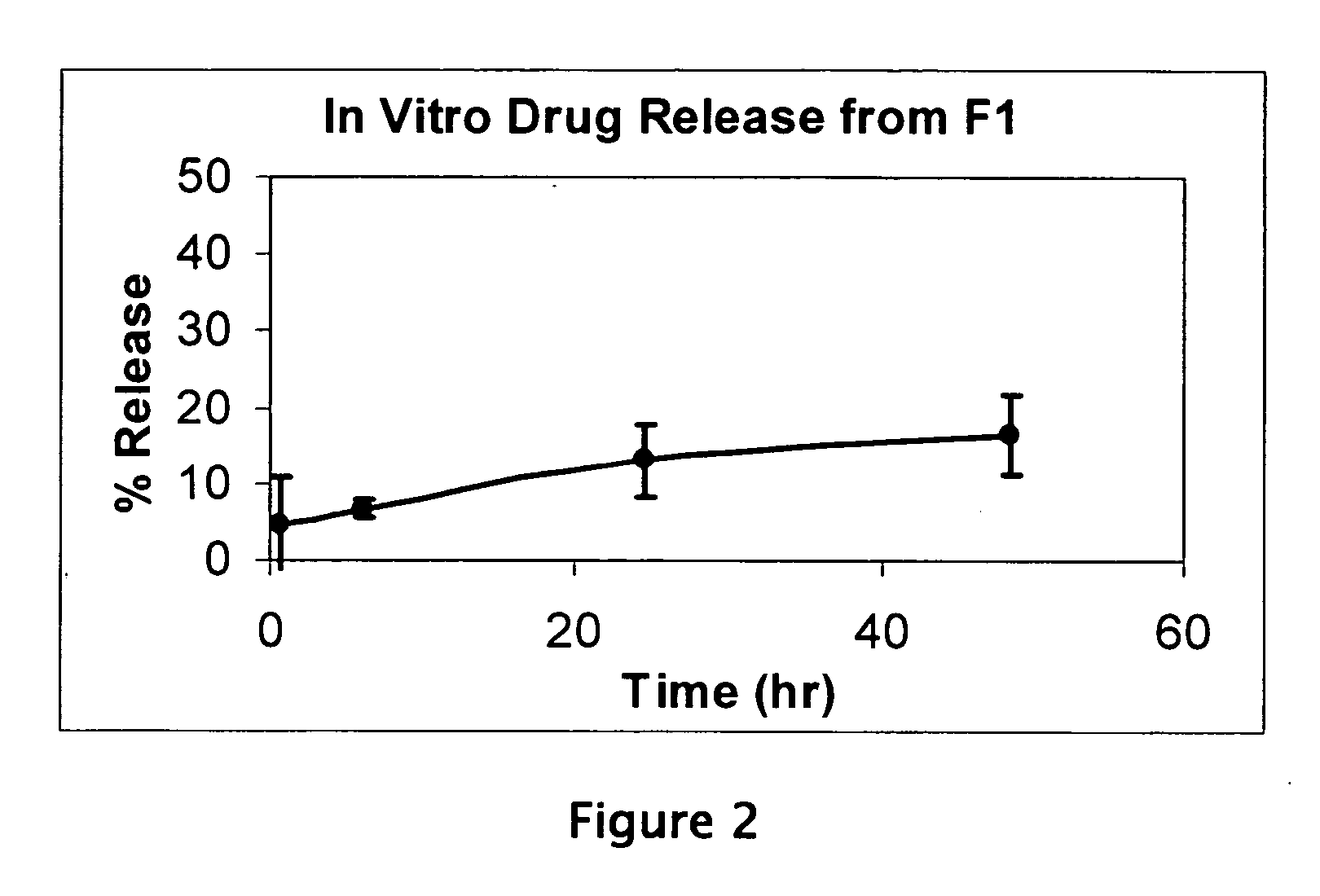

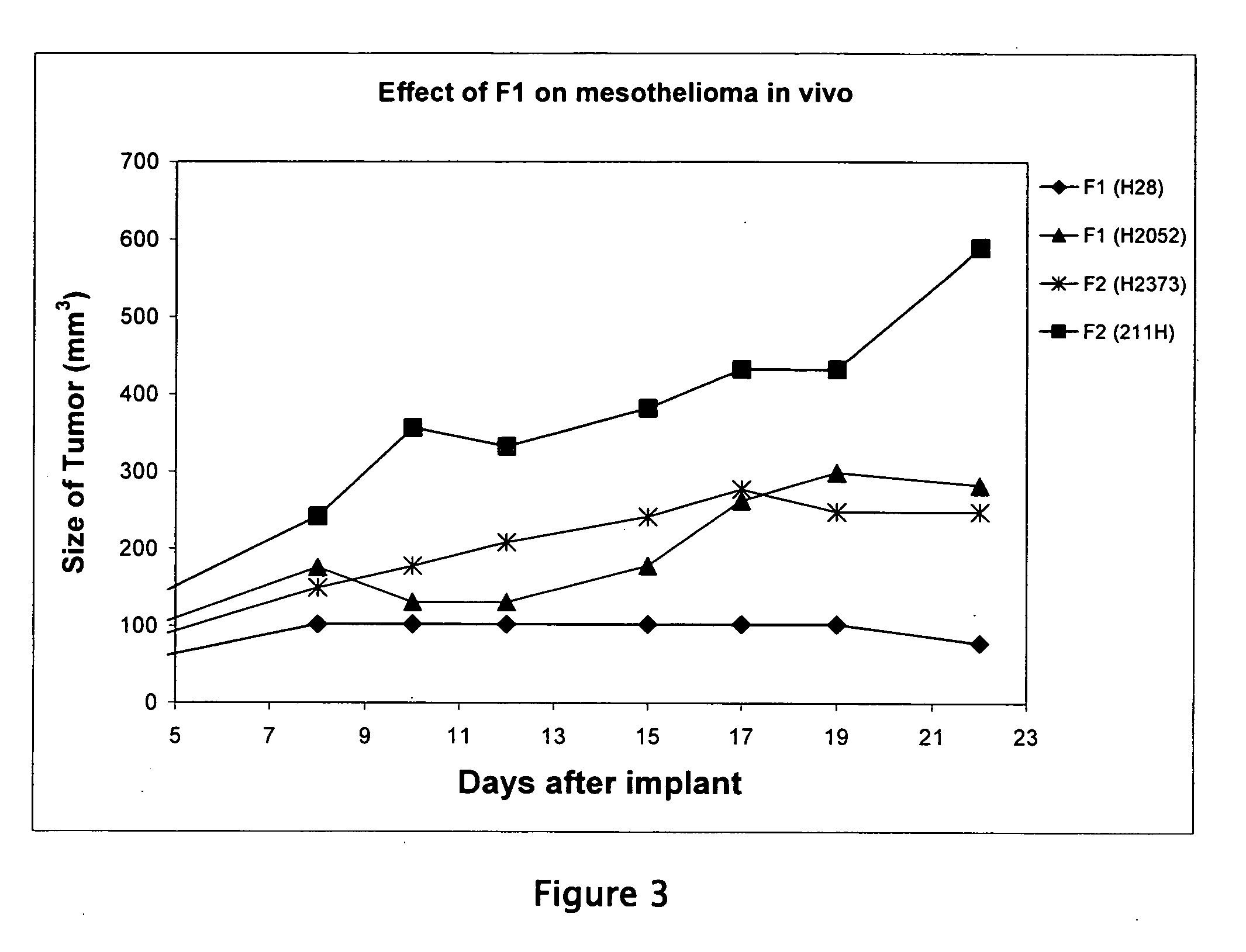

Liposome compositions for the delivery of macromolecules

InactiveUS20050260260A1Good curative effectReduce penetrationLiposomal deliveryLipid formationSterol

This invention provides for a liposome composition which demonstrates greatly increased therapeutic efficacy when used to deliver encapsulated macromolecular drugs. The liposome composition excludes the use of sterols, sterol derivatives, and cationic lipids, contrary to conventional formulations. The invention liposome is also unique in that it utilizes low gel to fluid phase transition temperature lipids in its membrane.

Owner:KISAK EDWARD +1

Light energized tissue adhesive

InactiveUS6875427B1Lower requirementPrecise temperature controlBiocideSurgical adhesivesHigh concentrationThermal energy

Consistent with the present invention, tissue adhesive compositions and an associated laser exposure system are provided for bonding or sealing biological tissues. The compositions are comprised of chemically derivatized soluble collagen which is formulated to concentrations ranging from 300 mg / ml (30%) to 800 mg / ml (80%) collagen protein. In particular, Type I collagen, for example, is first prepared by extraction from bovine or porcine hide and purified. The collagen preparations are then chemically derivatized with sulfhydryl reagents to improve cohesive strength and with secondary derivatizing agents, such as carboxyl groups, to improve the adhesive strength of the solder to the tissue. The compositions are then formed into viscous solutions, gels or solid films, which when exposed to energy generated from an infrared laser, for example, undergo thermally induced phase transitions. Solid or semi-solid protein compositions become less viscous enabling the high concentration protein to penetrate the interstices of treated biological tissue or to fill voids in tissue. As thermal energy is released into the surrounding environment, the protein compositions again become solid or semi-solid, adhering to the treated tissue or tissue space.

Owner:CONVERSION ENERGY ENTERPRISES

Low odor, light color, disposable article construction adhesive

InactiveUS20050014891A1Improve cohesive strengthEasy to processMonocarboxylic acid ester polymer adhesivesPersonal carePolymer scienceHot melt

We have found a novel spray-on adhesive composition made from components including a high melt index polymer and a high melt tackifier that interact to produce a composition that can form a low odor, light color, non-tacky, hot melt adhesive material that can be used in disposable article manufacture. The adhesive is thermally stable at hot melt application conditions, is low in cost, is easily applied and produces high quality disposable articles.

Owner:ADHERENT LAB

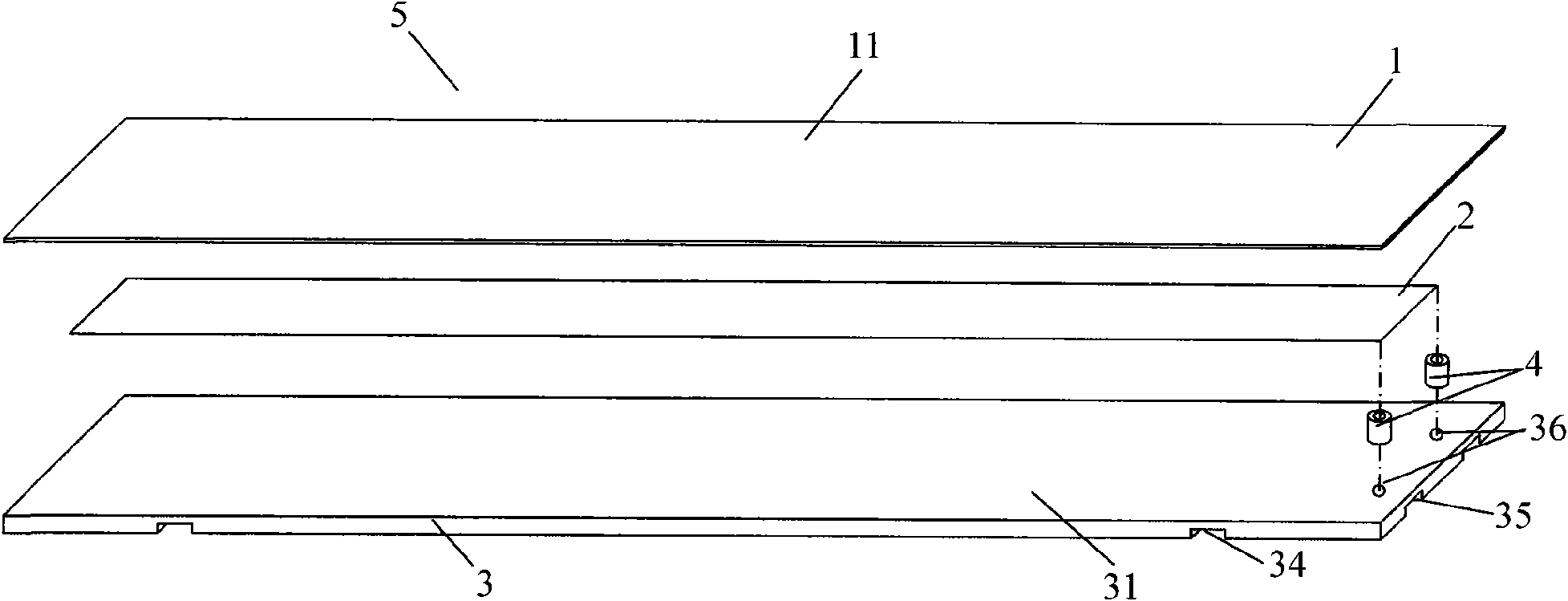

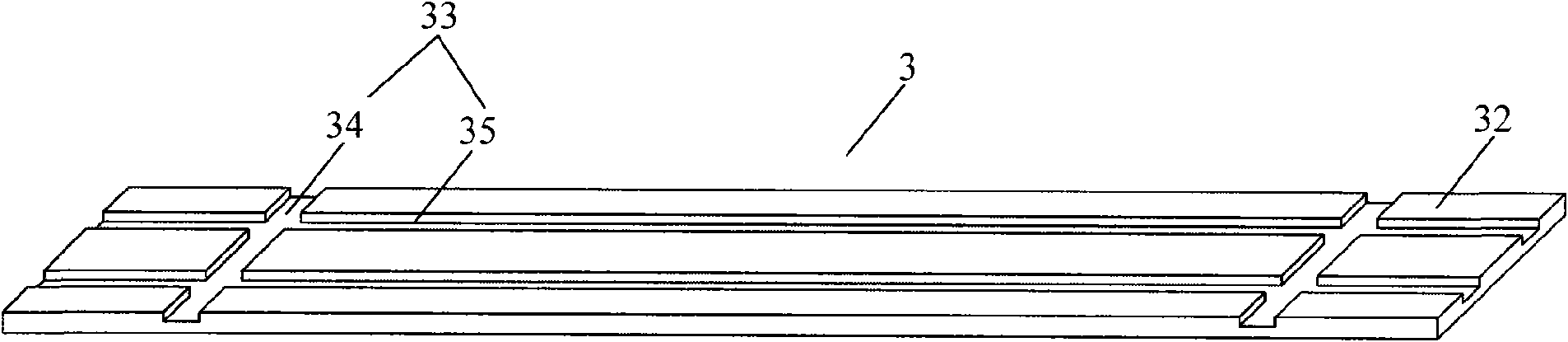

Far-infrared heat energy wood floor and manufacturing method and paving method thereof

InactiveCN101660803AIngenious designBreak through the natural functionLighting and heating apparatusElectric heating systemElectric heatingHardwood

The invention relates to a far-infrared heat energy wood floor, the carbon crystal electric heating material sheets of which are respectively pasted on the second surface of a surface board of the wood floor and the third surface of a base board of the wood floor. Preferably, the surface board of the wood floor is a hardwood board, the air-dry density of which is 0.5-0.7g / cm<3>, the thickness of which is 2-4mm and the moisture content of which is 6-8%; the thickness of each of the carbon crystal electric heating material sheets is 0.2-0.5mm; and the base board of the wood floor is a softwood board, the air-dry density of which is 0.3-0.6g / cm<3>, the thickness of which is 13-16mm and the moisture content of which is 6-8%. The far-infrared heat energy wood floor comprises an even number of layers of wood boards which are sequentially pasted, and the textures of the wood boards are crisscrossed; and air guiding grooves are arranged on the fourth surface of the base board of the wood floor. The invention also provides a manufacturing method and a paving method. The invention has the advantages of skillful design, safety, environment protection, energy saving and automatic adjustment oftemperature, breaks through the natural functions of the wood floor, organically combines a far-infrared heat energy heating element and the wood floor, has important breakthrough in the aspects of service life, energy saving, safety, environment protection, health, physical therapy and the like of the geothermal heating materials, and is a revolution in the international wood floor industry.

Owner:陆上驰 +1

Polymer powders, pressure sensitive adhesives and methods of making the same

InactiveUS7019067B2Stable in solutionEnhance sheet feedingCosmetic preparationsLiquid surface applicatorsPressure sensitiveEthyl ester

A method for making hydrophilic homopolymers and copolymers of poly 2-hydroxyethyl methacrylate. Also disclosed are coatings, films, hydrogels, cosmetic compositions, dermatological compositions, pressure sensitive adhesives containing the hydrophilic homopolymers or copolymers of poly 2-hydroxyethylmethacrylate. Further disclosed are methods of coating substrates with the hydrophilic homopolymers and copolymers of poly 2-hydroxyethyl methacrylate and hydrophilic pressure sensitive adhesives.

Owner:AVERY DENNISON CORP

Method for preparing multiple modified self-crosslinking aqueous polyurethane adhesive agent

InactiveCN101182406AIncrease the degree of cross-linkingImprove cohesive strengthPolyureas/polyurethane adhesivesEpoxyCross-link

The invention discloses a preparation method of self cross-linking water-based polyurethane adhesive of multiple modifications. Polyisocyanate and oligomer polyol are added into a reaction device for reaction; then chain extender is added for reaction to prepare polyurethane prepolymer; then polyurethane prepolymer modified by rosin and epoxy resin is added to prepare modified polyurethane prepolymer; finally water is added into the modified polyurethane prepolymer and a high-speed disperser is used for dispersion; neutralizer and cross-linker are added to prepare the self cross-linking water-based polyurethane dispersoid of multiple modifications; thickening agent and defoamer are added into the dispersoid to prepare the modified polyurethane adhesive. The adhesive prepared in the invention has the rapid drying, good water resistance and high bond strength; the adhesive can meet the bonding requirements of vehicles and a plurality of other materials; the invention has the advantages of simple operation, simple process, short production cycle, low cost of operation and easiness of promotion and application.

Owner:SOUTH CHINA UNIV OF TECH

Abrasion and impact resistant coating compositions, and articles coated therewith

InactiveUS6905772B2High abrasion and impact resistanceImprove adhesionSynthetic resin layered productsGlass/slag layered productsHigh humidityShock resistance

Disclosed are abrasion and impact resistant coating compositions, and substrates coated therewith. These coating compositions provide high abrasion and impact resistance, chemical protection to the substrate, and exhibit enhanced stability to high temperature and high humidity conditions. Coating compositions may also be tailored to provide a balanced combination of abrasion resistance, impact resistance, and weatherability. These coatings may be transparent or not, depending on the intended applications. These coatings may also comprise additives such as UV absorbers, corrosion inhibitors, and electrically conductive materials. Substrates for use herein may be plastic or metal.

Owner:TRITON SYST INC

Preparation method of wet curing reaction-type polyurethane hot melt adhesive for textile

ActiveCN103497725AHigh initial bond strengthGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyesterPolymer science

The invention discloses a preparation method of a wet curing reaction-type polyurethane hot melt adhesive for a textile. The preparation method mainly comprises the following steps: (1) stirring and mixing polyether polyol 4000E, polyether polyol 3000H and an antioxidant, heating and warming to about 120 DEG C, dewatering for 0.5 hour when the vacuum degree is smaller than 100Pa; (2) adding a tackifying resin, continuing to warm to 135-140 DEG C, dewatering for 1.5 hours when the vacuum degree is smaller than 100Pa; (3) cooling to 87 DEG C, adding 4,4'-diphenyl methane diisocyanate and a catalyst, stirring and reacting for 2 hours when the vacuum degree is smaller than 100Pa; (4) relieving a vacuum state, adding white carbon black, quickly stirring and evenly mixing, and continuing to stir for 10 minutes when the vacuum degree is smaller than 100Pa; and (5) keeping the discharge temperature at 85-100 DEG C, quickly discharging and encapsulating, and then curing for 4 hours under the condition of 80-85 DEG C, so as to obtain a target product. The product is applied to compounding of the textile, and has excellent peel strength, short opening time, good hydrolysis resistance and good storage stability.

Owner:KUNSHAN TIANYANG HOT MELT ADHESIVE CO LTD +2

Echogenic needle catheter configured to produce an improved ultrasound image

InactiveUS20070265516A1Minimize amount of metalReduces and eliminates artifactElectrocardiographyBlood flow measurement devicesUltrasound imagingNeedle catheter

An echogenic catheter, such as a needle catheter, formed at least in part of an intrinsically conductive organic polymer for providing a highly conductive surface in combination with an improved ability to ultrasonically image the catheter, and a method of performing a medical procedure using a catheter of the invention.

Owner:ABBOTT CARDIOVASCULAR

Single-component moisture-curing polyurethane adhesive and preparation method thereof

ActiveCN104263310AMeet the actual requirementsHigh activityPolyureas/polyurethane adhesivesPolyesterAdhesive cement

The invention discloses a single-component moisture-curing polyurethane adhesive and a preparation method thereof. The preparation method of the adhesive is characterized by comprising the following step: by adopting an organic solvent as a solvent, performing reaction on polyether glycol and / or polyester glycol, diphenyl methane diisocyanate, polymethylene polyphenyl isocyanate and triatomic primary alcohol of which the molecular weight is less than 200 to prepare the adhesive. The average degree of functionality of an obtained high-functionality NCO-terminated prepolymer is more than or equal to 3, and the single-component moisture-curing polyurethane adhesive disclosed by the invention is suitable for splicing and tenoning (or assembling) of woods and bonding and compounding of stone materials, fireproof plates, plastic aluminum plates, bakelite plates, oak boards, some metals such as aluminum and iron, zinc-plating plates, PVC membranes and the like, is especially suitable for adhesion of rosewoods and red woods, and can meet the special requirements of some products.

Owner:周建明

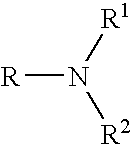

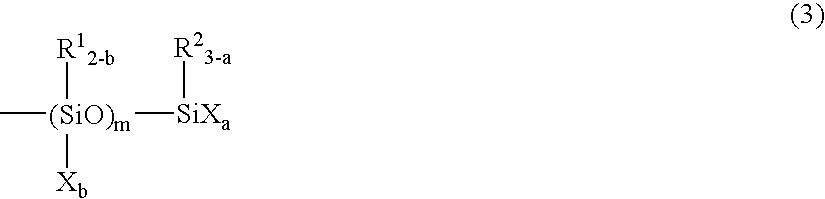

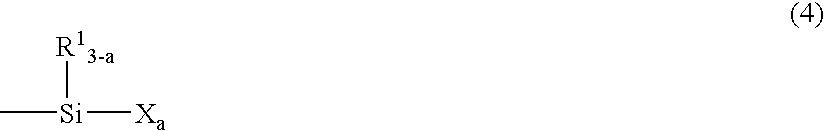

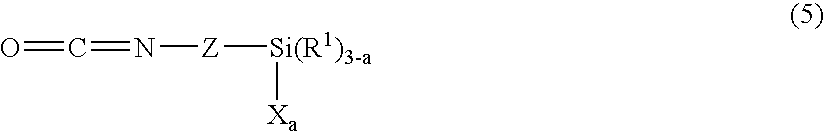

Silane functional prepolymer and isocyanate functional prepolymer blend based adhesive composition

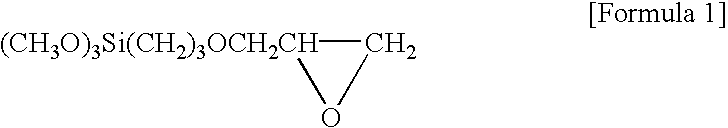

ActiveUS7345130B2Improve cohesive strengthFast curingLayered productsFilm/foil adhesivesPolyolefinPhosphate

The invention is an adhesive composition comprising a) one or more silane functional prepolymers comprising a polyether or a polyolefin backbone and silane moieties capable of silanol condensation; b) one or more isocyanate functional prepolymers comprising a polyether backbone and isocyanate moieties; c) one or more organotin compounds or titanate or zirconate compounds having one or more ligands comprising a hydrocarbyl phosphate ester or a hydrocarbyl sulfonate ester, or a mixture thereof; d) a tertiary amine or an anhydrous strong organic acid which is miscible with the polymer and enhances the bonding of the adhesive to a coated unprimed substrate. In one embodiment, the invention is a method of bonding two or more substrates together using the adhesive compositions of this invention. The process comprises applying an adhesive as described herein to one or more of the substrates; contacting the one or more substrates with the adhesive disposed between the substrates; and allowing the adhesive to cure.

Owner:DOW GLOBAL TECH LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com