Patents

Literature

101results about How to "Improve wetting properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

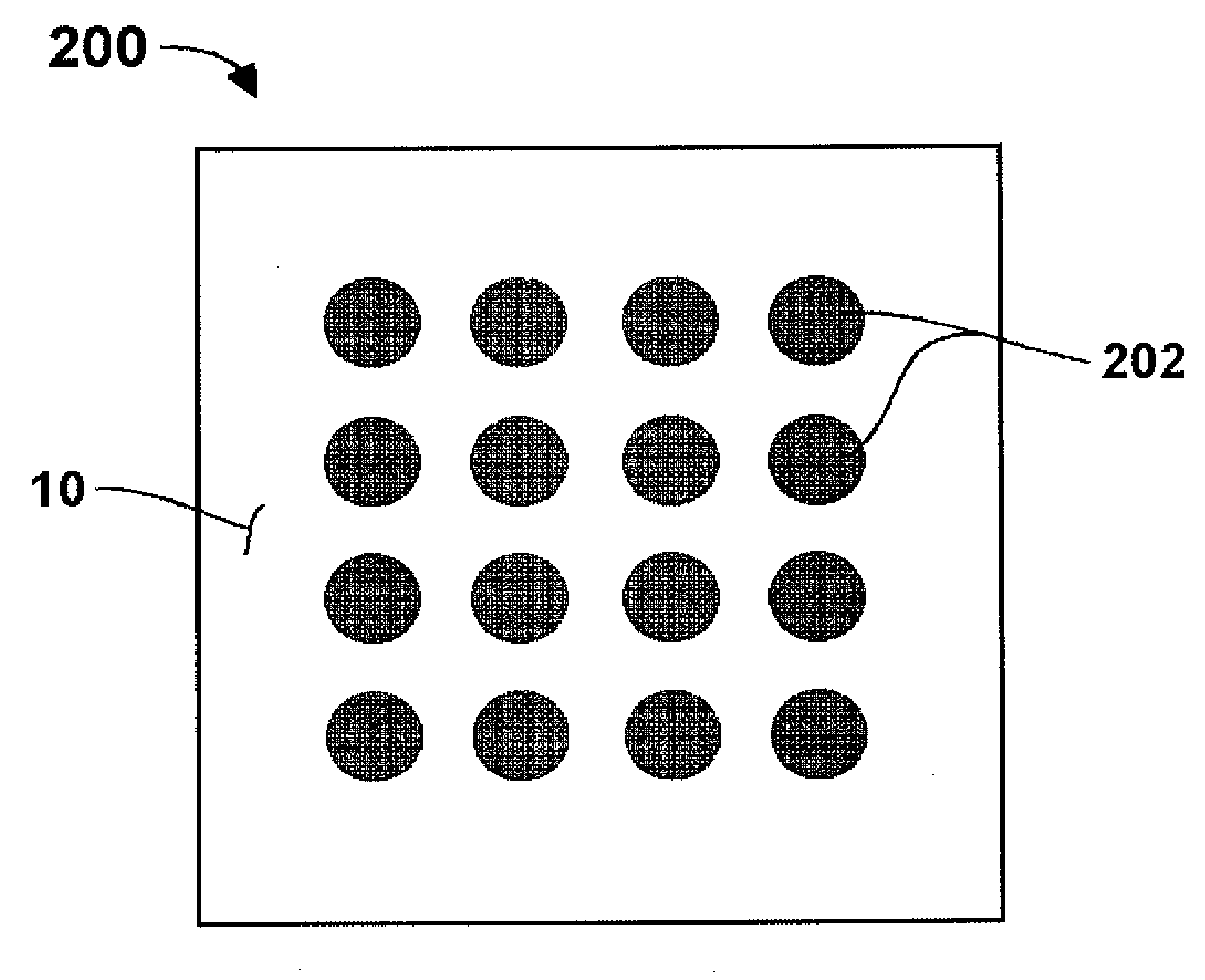

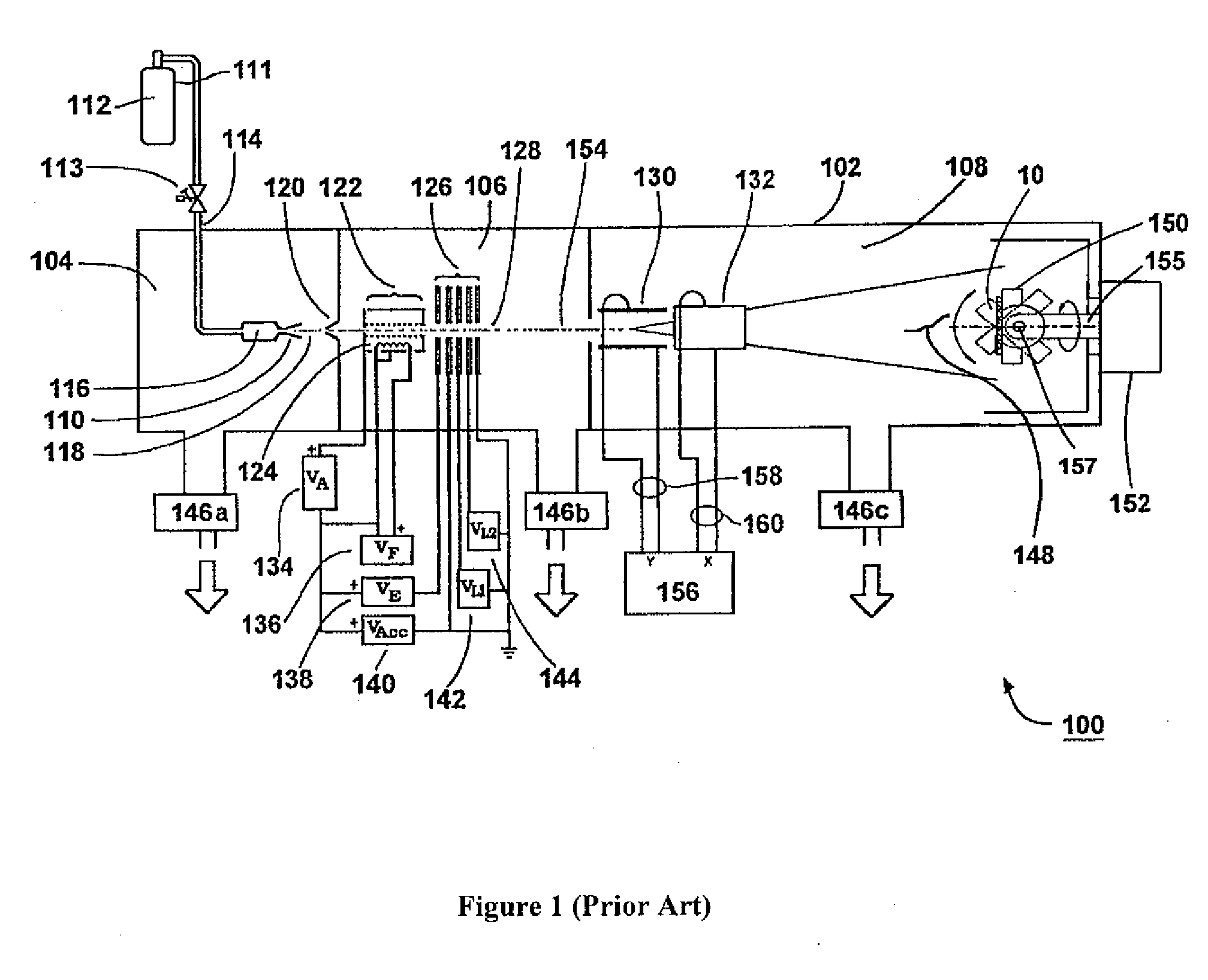

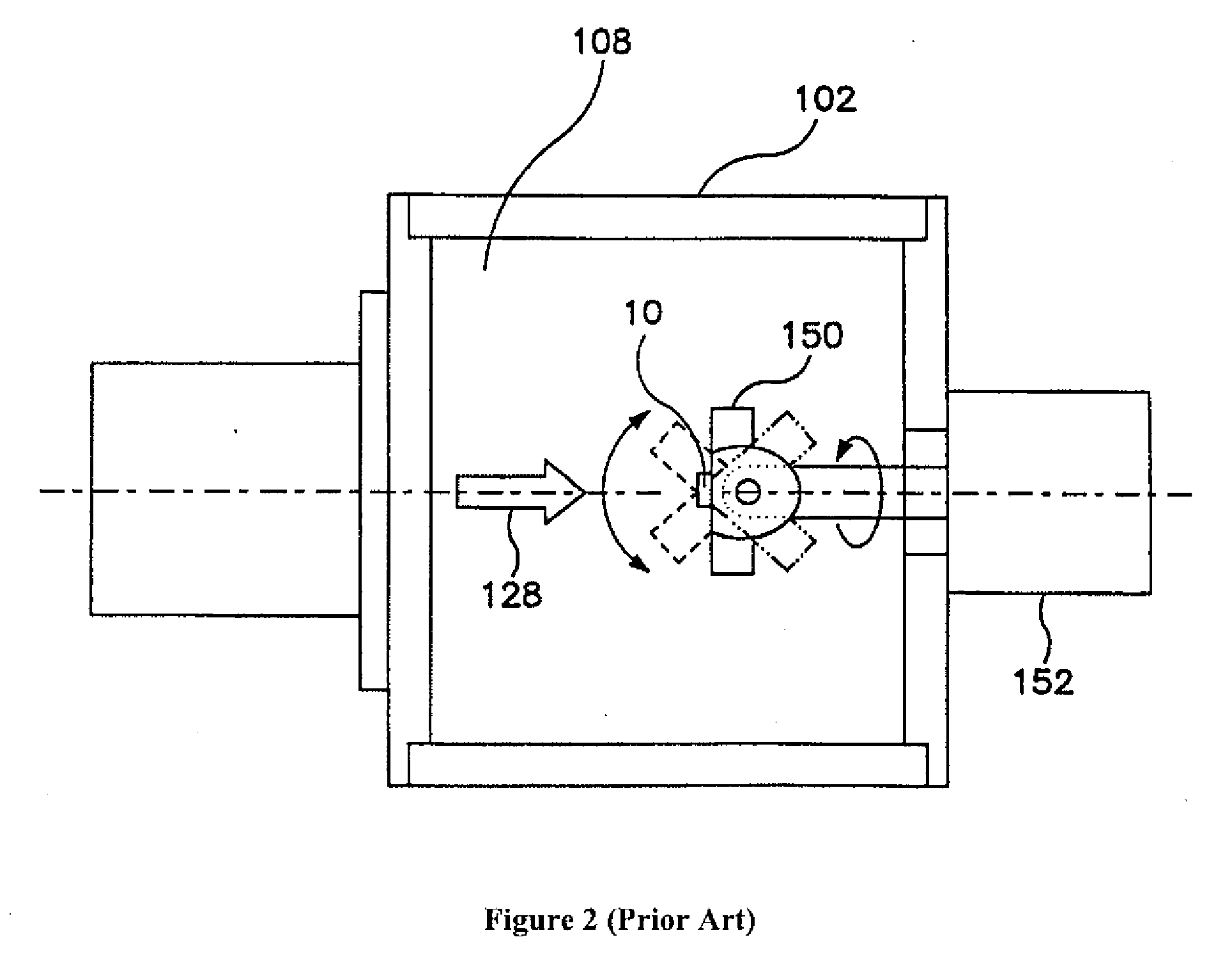

Method and system for modifying the wettability characteristics of a surface of a medical device by the application of gas cluster ion beam technology and medical devices made thereby

InactiveUS20090074834A1Improve wettabilityLow wettabilityElectric discharge tubesPharmaceutical containersEtchingGas cluster ion beam

Irradiation of a surface of a material with a gas cluster ion beam modifies the wettability of the surface. The wettability may be increased or decreased dependent on the characteristics of the gas cluster ion beam. Improvements in wettability of a surface by the invention exceed those obtained by conventional plasma cleaning or etching. The improvements may be applied to surfaces of medical devices, such as vascular stents for example, and may be used to enable better wetting of medical device surfaces with liquid drugs in preparation for adhesion of the drug to the device surfaces. A mask may be used to limit processing to a portion of the surface. Medical devices formed by using the methods of the invention are disclosed.

Owner:EXOGENESIS CORP

Asphalt modifiers for "warm mix" applications including adhesion promoter

ActiveUS20100319577A1Low viscosityImprove wetting propertiesIn situ pavingsWax coatingsRoad surfaceSurface-active agents

The present invention generally relates to an additive package for warm-mix asphalt formulations for the pavement of road surfaces, said additive package comprising a) surfactant component, and b) an asphalt rheology modifying component, wherein said asphalt rheology modifying component comprises at least one of a i) a wax component and ii) a resin component. The invention also relates to a warm mix asphalt having improved compaction at lower temperatures, and to a pavement made from said warm mix asphalt.

Owner:AKZO NOBEL CHEM INT BV

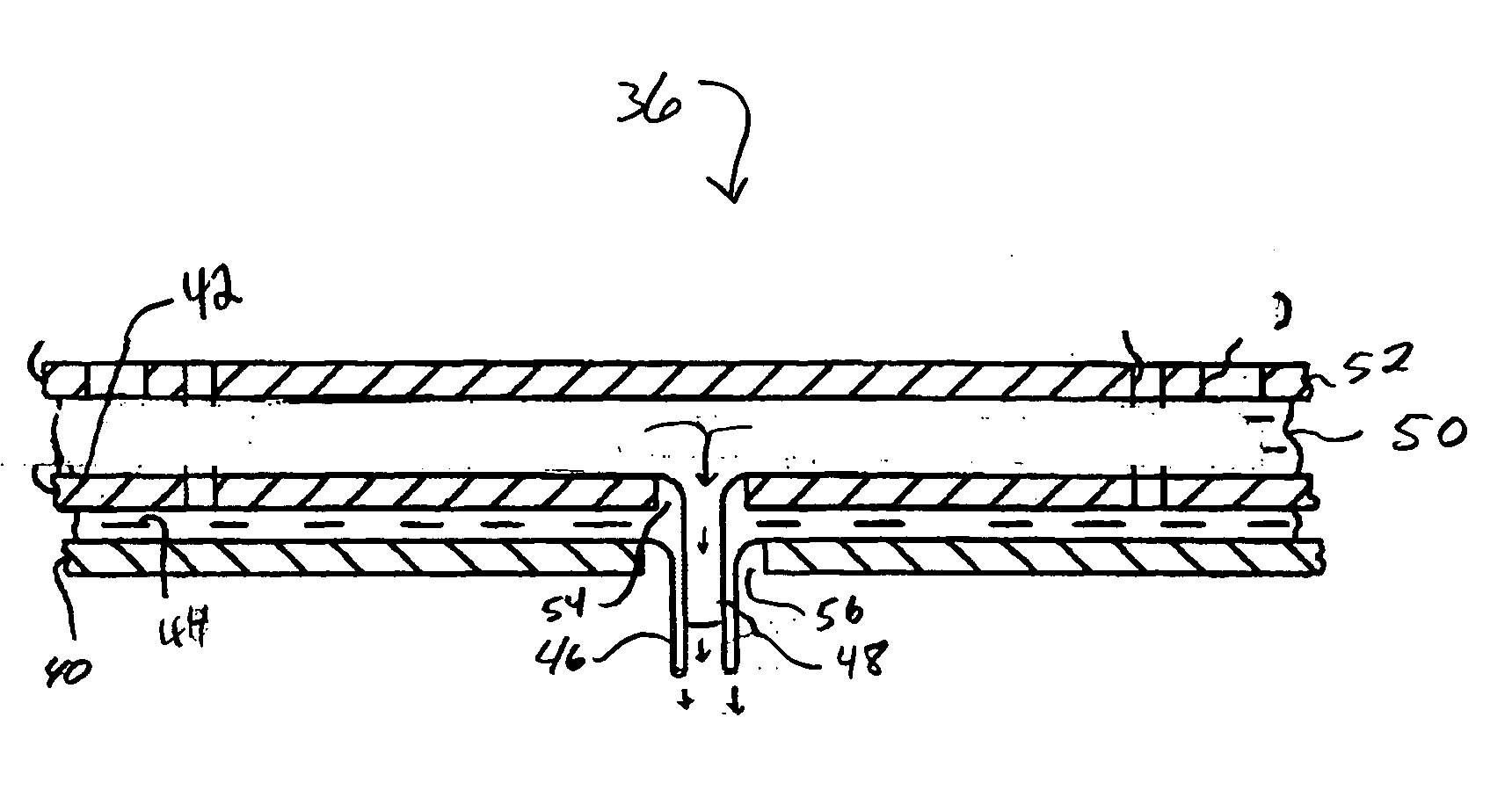

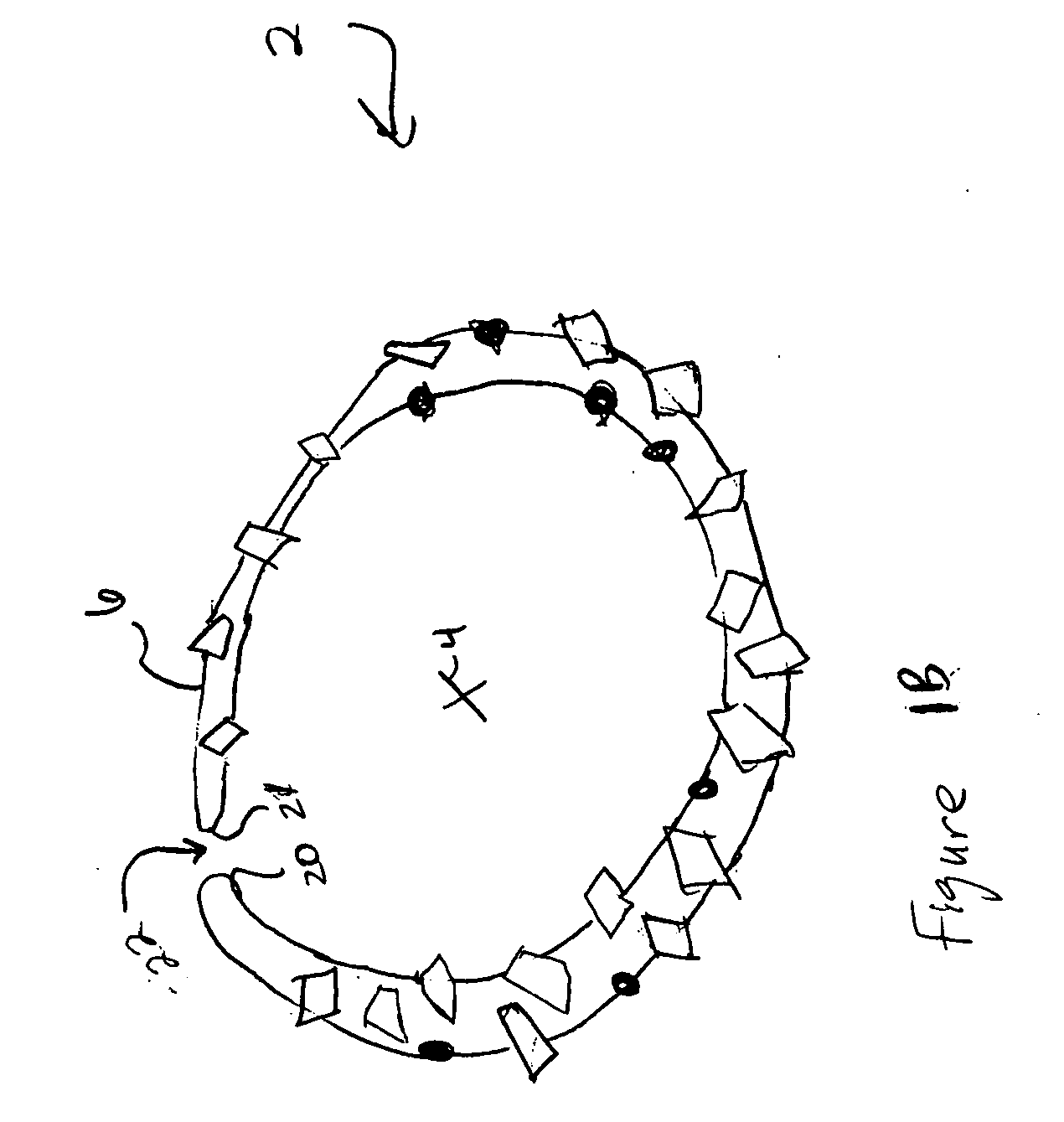

Hollow anti-microbial fibers and fibrous products

InactiveUS20050136100A1Improve wetting propertiesReduce the amount requiredDispersed particle filtrationInorganic active ingredientsFiberHollow fibre

Anti-microbial and / or anti-fungal synthetic hollow fiber (2) and various products made partially or wholly therefrom are formed in pure hollow or mock-hollow shapes and composed of various thermoplastic polymers having dispersed therein organic or inorganic, antimicrobial additives. The thickness of the fiber walls are optimally equal to or slightly less than the average maximum dimensions of the anti-microbial additive particles. Thus, a portion of the additive particles will be present at outer and / or inner surfaces of the fiber walls, effectively imparting antimicrobial characteristics to the hollow fiber and any fibrous products made therefrom. The additives can be selectively dispersed in certain regions of the fibers in order to reduce the amount of the additives required, and are resistant to separation from the fiber wall, prolonging the fiber's antimicrobial effectiveness. Additional additives can be dispersed in the fiber wall with the antimicrobial agents in order to enhance or provide different fiber properties.

Owner:FOSS MFG CO LLC

Adhesive Compositions For Easy Application and Improved Durability

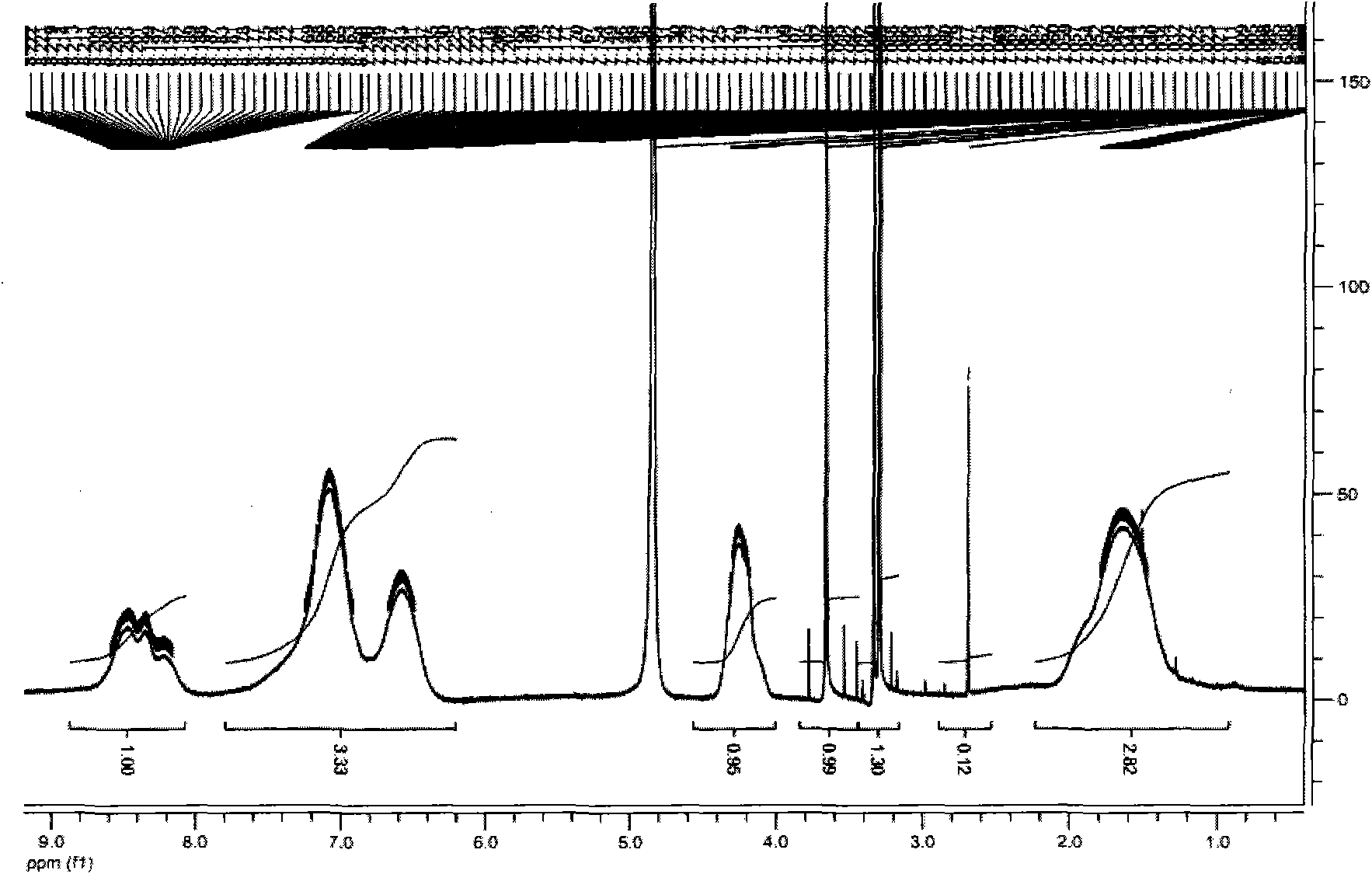

ActiveUS20120277341A1Improve wetting propertiesIncrease stiffnessEster polymer adhesivesDentistry preparationsOligomerTemperature resistance

The present invention is directed to an adhesive composition comprising a crosslinkable acrylic copolymer, a multi-functionalized crosslinkable oligomer and a photoinitiator wherein the partially cured composition exhibits excellent wet out characteristics as reflected in a tan delta value of at least 0.4, preferably greater than 0.5, more preferable greater than 0.6 as measured at 20° C. resulting from a first curing stage, and the fully cured composition exhibits an improved stiffness and temperature resistance as reflected in a storage elastic modulus of at least 175,000 Pa at 20° C. and a shear adhesion failure temperature of at least 425° F. (218.3° C.) at 1 Kg / in2 (0.155 Kg / cm2), respectively, which result from a second sequential curing stage.

Owner:MORGAN ADHESIVES COMPANY

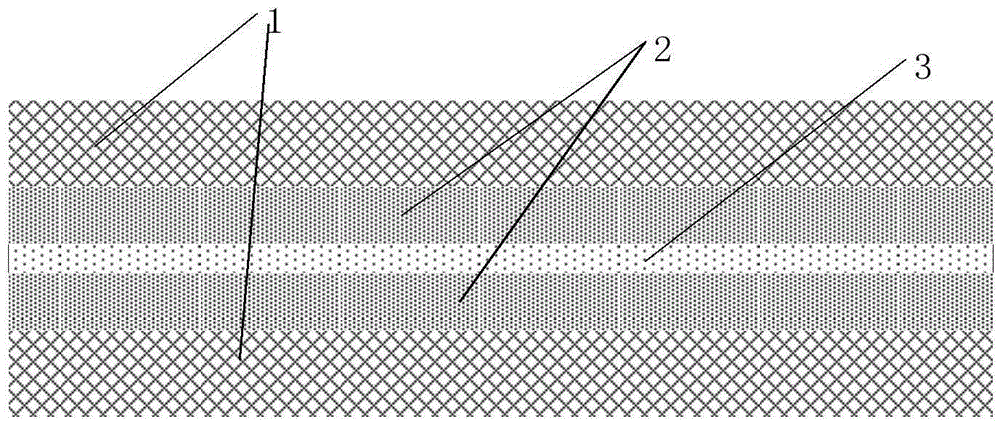

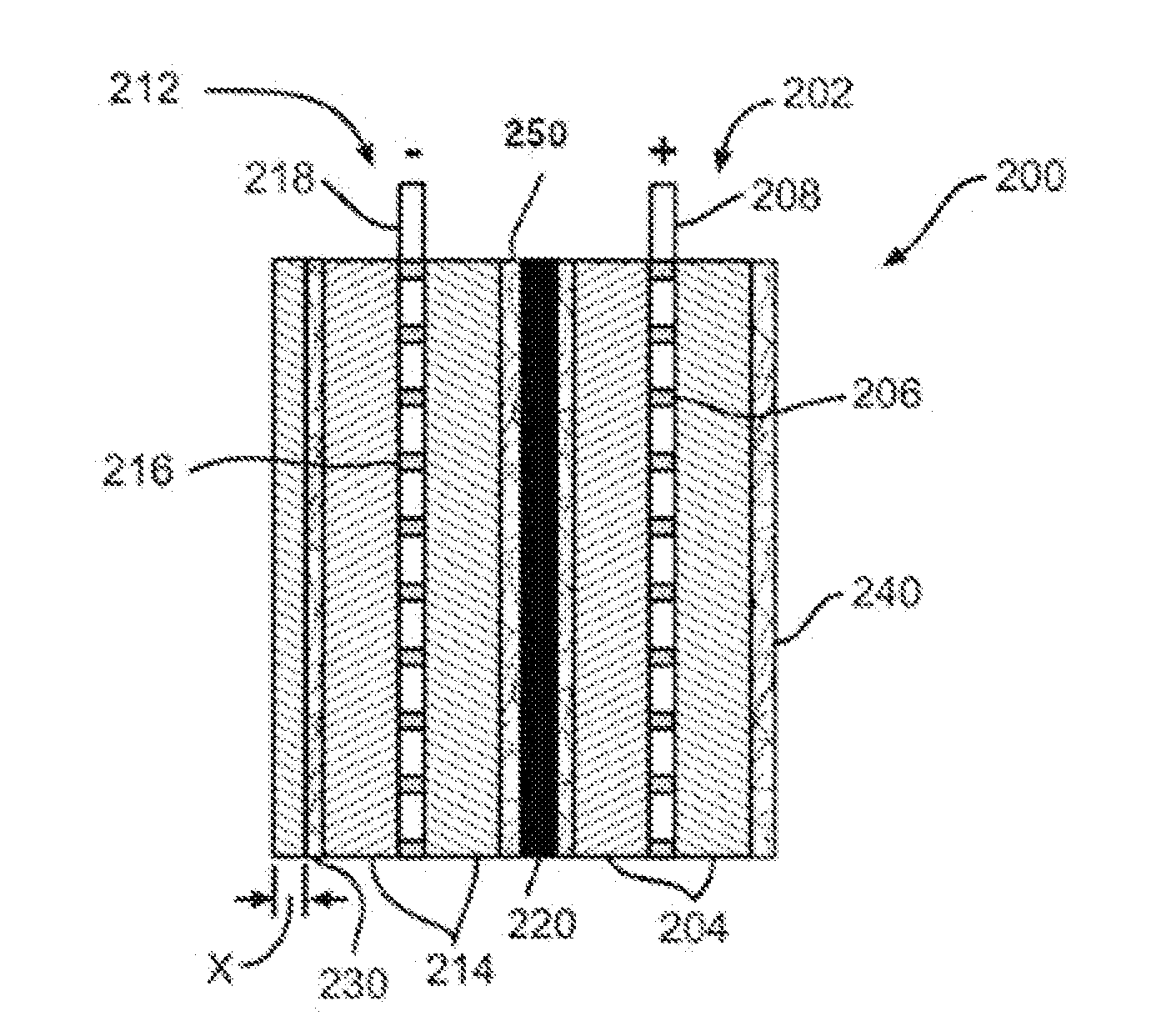

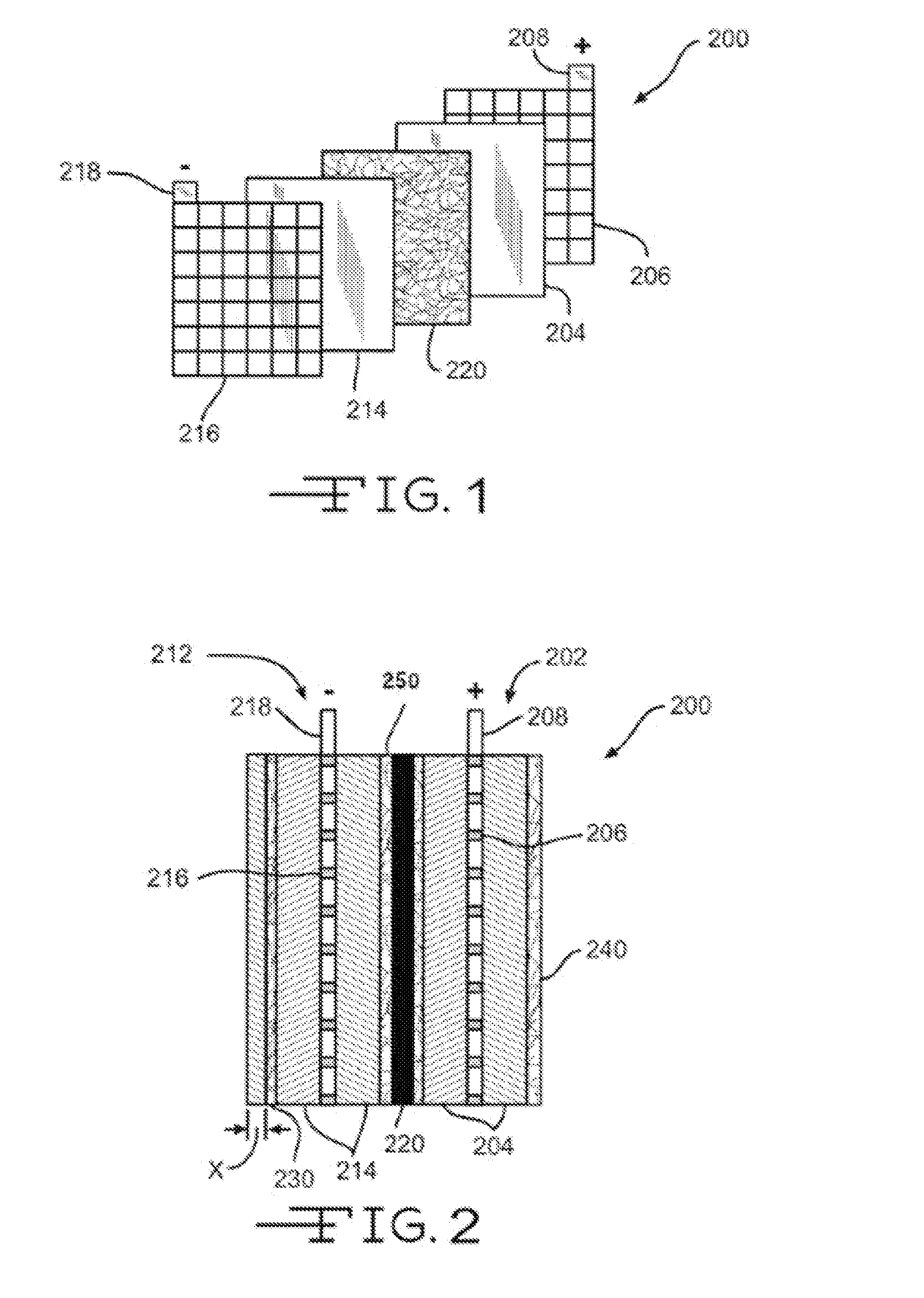

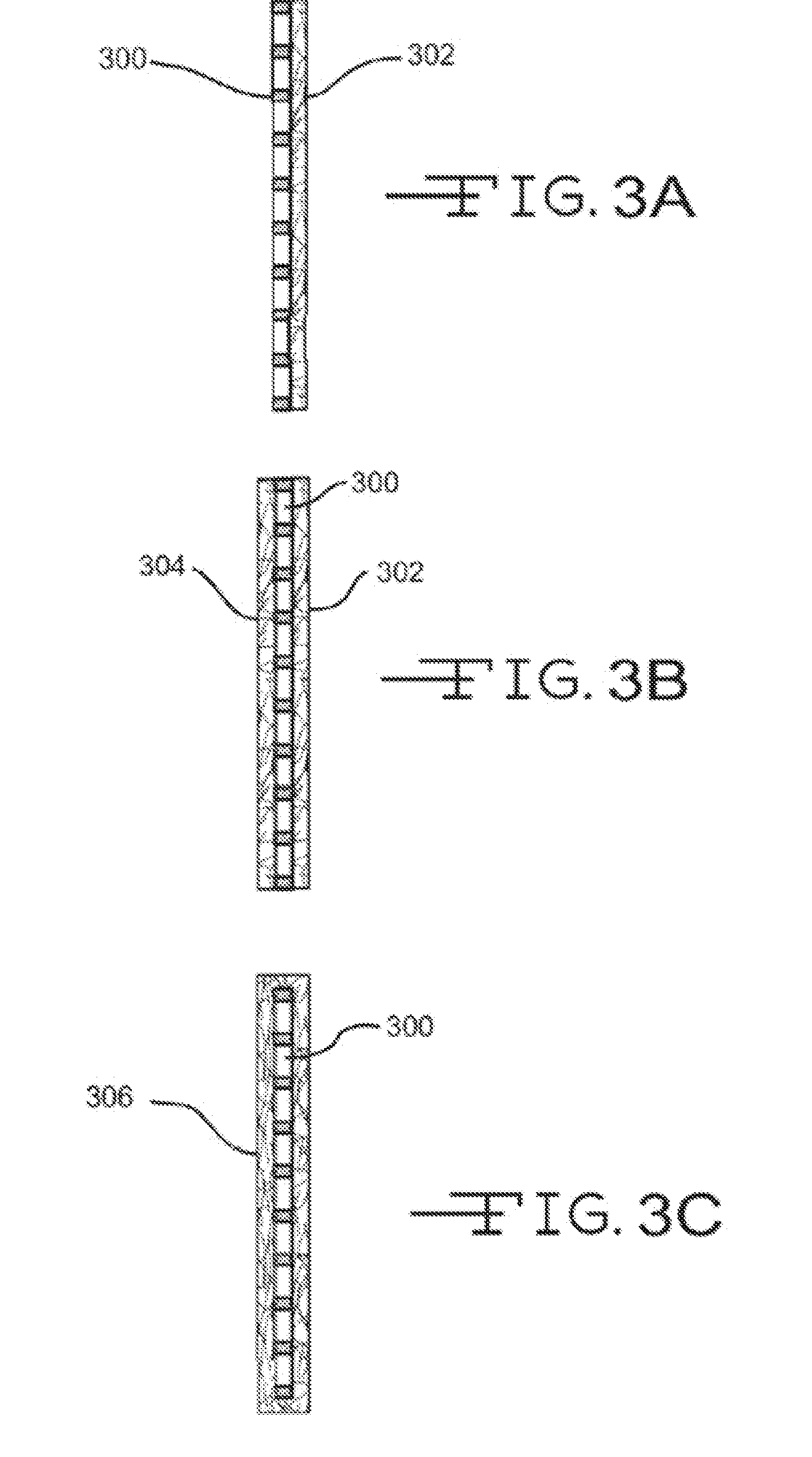

Composite non-woven fabric ceramic diaphragm for lithium ion battery and preparation method thereof

ActiveCN105304846AImprove stabilityImprove featuresSecondary cellsCell component detailsCeramic coatingSolvent

The invention discloses a composite non-woven fabric ceramic diaphragm for a lithium ion battery and a preparation method thereof. The composite non-woven fabric ceramic diaphragm for the lithium ion battery comprises two layers of non-woven fabric base materials and a ceramic coating composited between the two layers of non-woven fabric base materials. The preparation method comprises the following steps: (1) dissolving macromolecule organic matter in a solvent to form macromolecular solution; (2) dispersing inorganic particles in the macromolecular solution to form organic and inorganic mixture; (3) first coating one side of one non-woven fabric base material evenly with the organic and inorganic mixture, and then pressing the other layer of non-woven fabric base material on a coating layer, and performing drying and rolling to form the composite diaphragm. The problems that the lithium ion battery diaphragm is poor in heat resistance, absorbs water easily, drops easily and is not high in mechanical strength are solved.

Owner:TIANNENG SAFT ENERGY JOINT CO

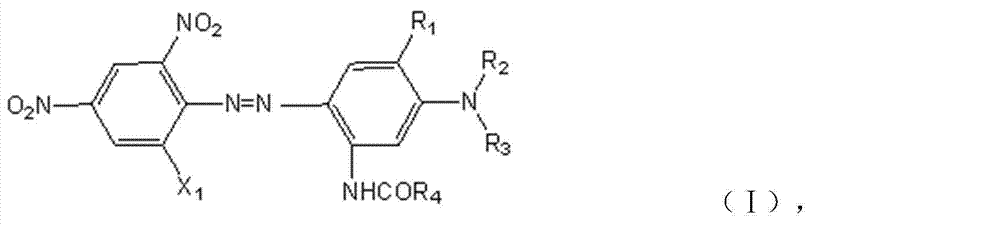

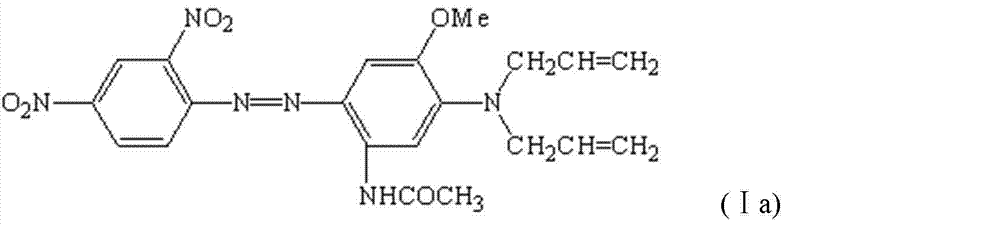

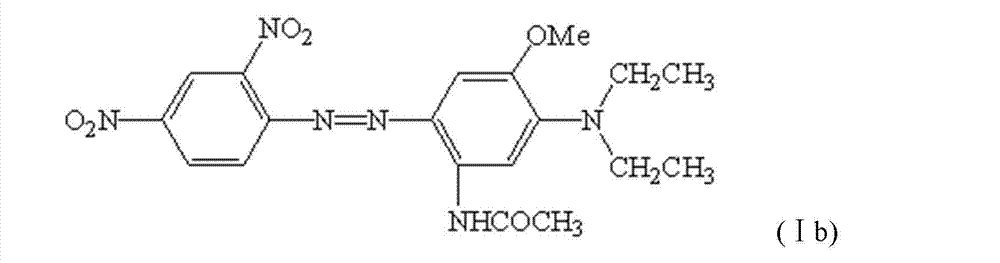

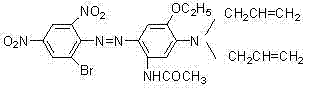

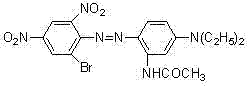

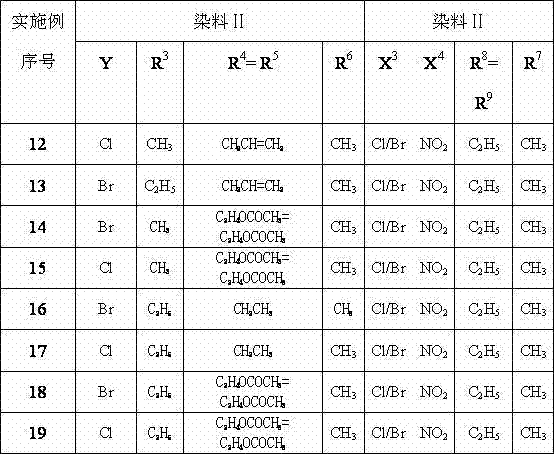

Dispersed dye mixture and application thereof

ActiveCN103113758AIncrease coverageGood compatibilityOrganic dyesDyeing processDisperse dyePhotochemistry

The invention relates to the technical field of dispersed dyes. In order to solve the problem that the dyes having a 2,4-dinitraniline structure are all poor in light fastness, the invention provides a dispersed dye mixture which is prepared by the step of mixing component A and component B, wherein the weight percentage of the component A is 10-92%. The 2,4-dinitraniline is used for synthesizing the dye so that the big problem which is always evaded in the industry is solved in a compounding and synergic way; as a result, a dye composition which is good in deep dyeing effect and excellent in light fastness can be obtained while the cost of the color matching dyes is greatly reduced.

Owner:HANGZHOU JIHUA JIANGDONG CHEMICAL CO LTD

Adhesive compositions for easy application and improved durability

ActiveUS8242185B2Improve wetting propertiesIncrease stiffnessOrganic chemistryEster polymer adhesivesOligomerTemperature resistance

Owner:MORGAN ADHESIVES COMPANY

High performance aqueous adhesive composition for artificial lawn back rubber

ActiveCN101475783AImprove wetting propertiesExcellent pull-out forceHydrocarbon polymer adhesivesPolymer sciencePortion size

The invention discloses a high-performance aqueous adhesive composition for gum application in an artificial lawn. The adhesive composition can remarkably improve drawing force, reduce the use amount of gum substantially and reduce cost. The high-performance aqueous adhesive composition for gum application in the artificial lawn comprises the following compositions in portion by weight: 100 portions of carboxylic styrene butadiene latex, 5 to 60 portions of tackifying resin, 50 to 400 portions of filler, 0 to 5 portions of thickening agent and 0 to 3 portions of paint; and the portion of water is used to adjust the viscosity of an adhesive composition system between 5,000 and 50,000 MPa.s.

Owner:COCREATION GRASS CO LTD

Novel compositions and methods

InactiveUS20090312380A1Lesser and high rateOvercome problemsPowder deliveryBiocideAdditive ingredientPhotochemistry

Owner:GENERICS UK LTD

Asphalt modifiers for “warm mix” applications including adhesion promoter

ActiveUS8440011B2Low viscosityReduce surface tensionIn situ pavingsClimate change adaptationWaxRoad surface

The present invention generally relates to an additive package for warm-mix asphalt formulations for the pavement of road surfaces, said additive package comprising a) surfactant component, and b) an asphalt rheology modifying component, wherein said asphalt rheology modifying component comprises at least one of a i) a wax component and ii) a resin component. The invention also relates to a warm mix asphalt having improved compaction at lower temperatures, and to a pavement made from said warm mix asphalt.

Owner:AKZO NOBEL CHEM INT BV

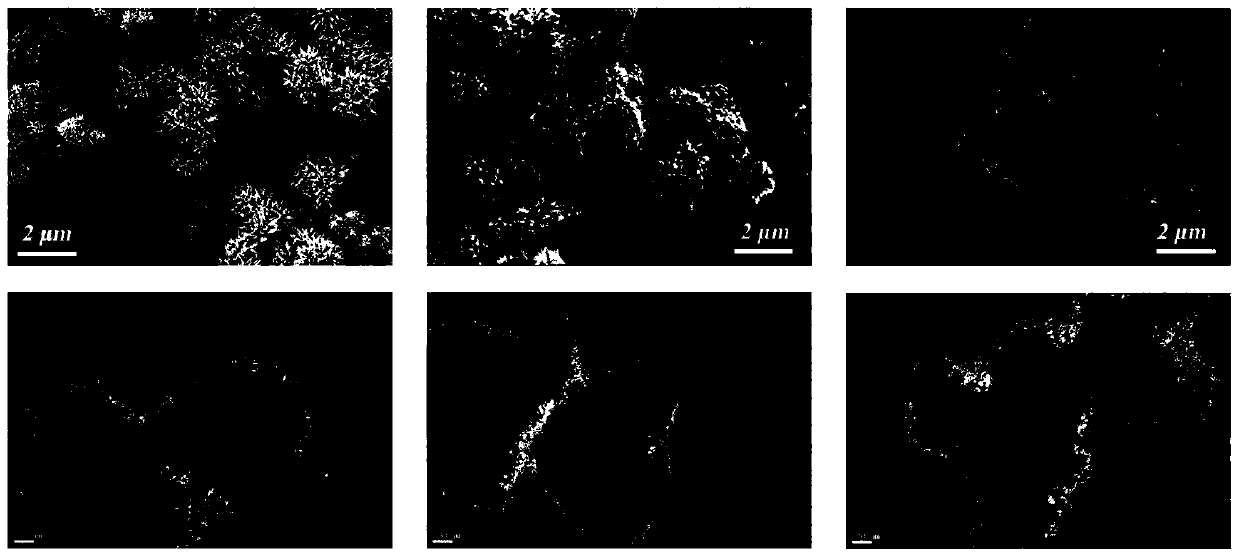

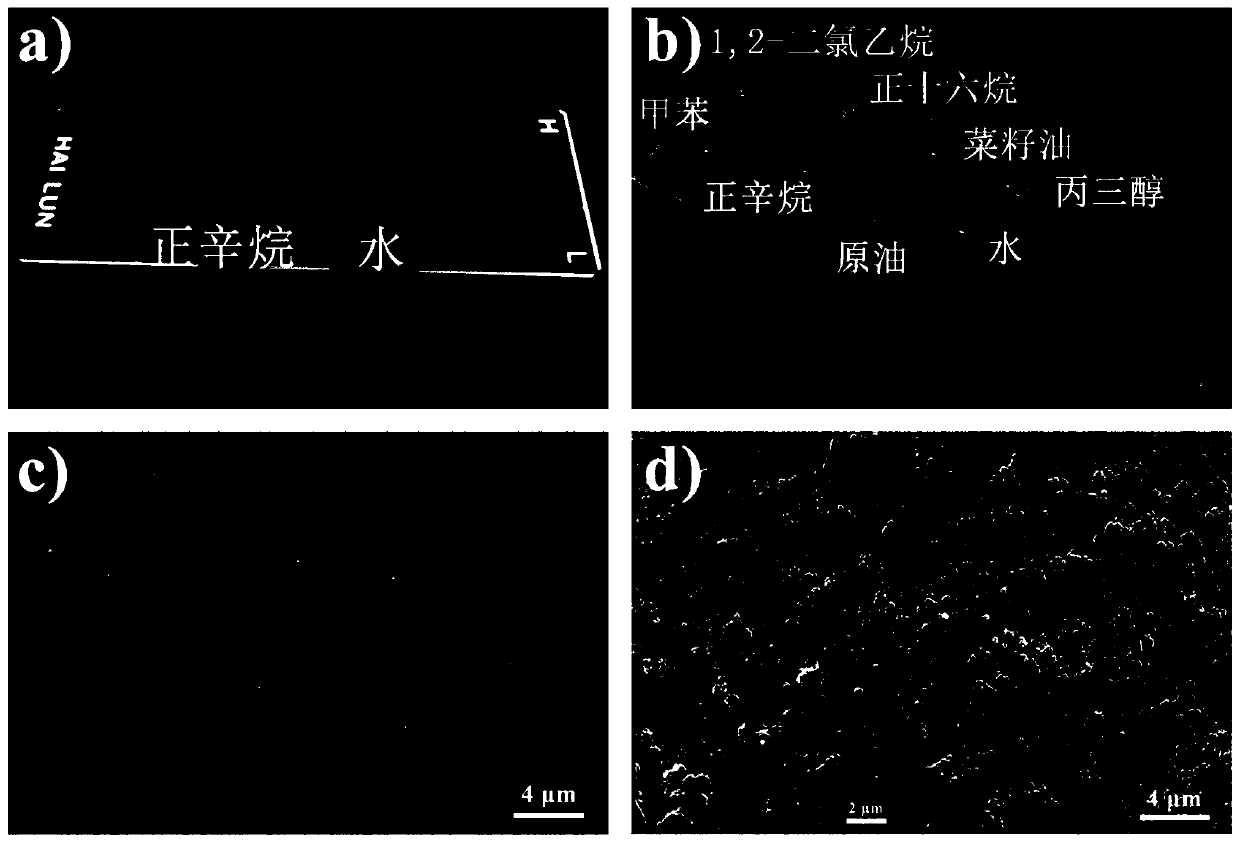

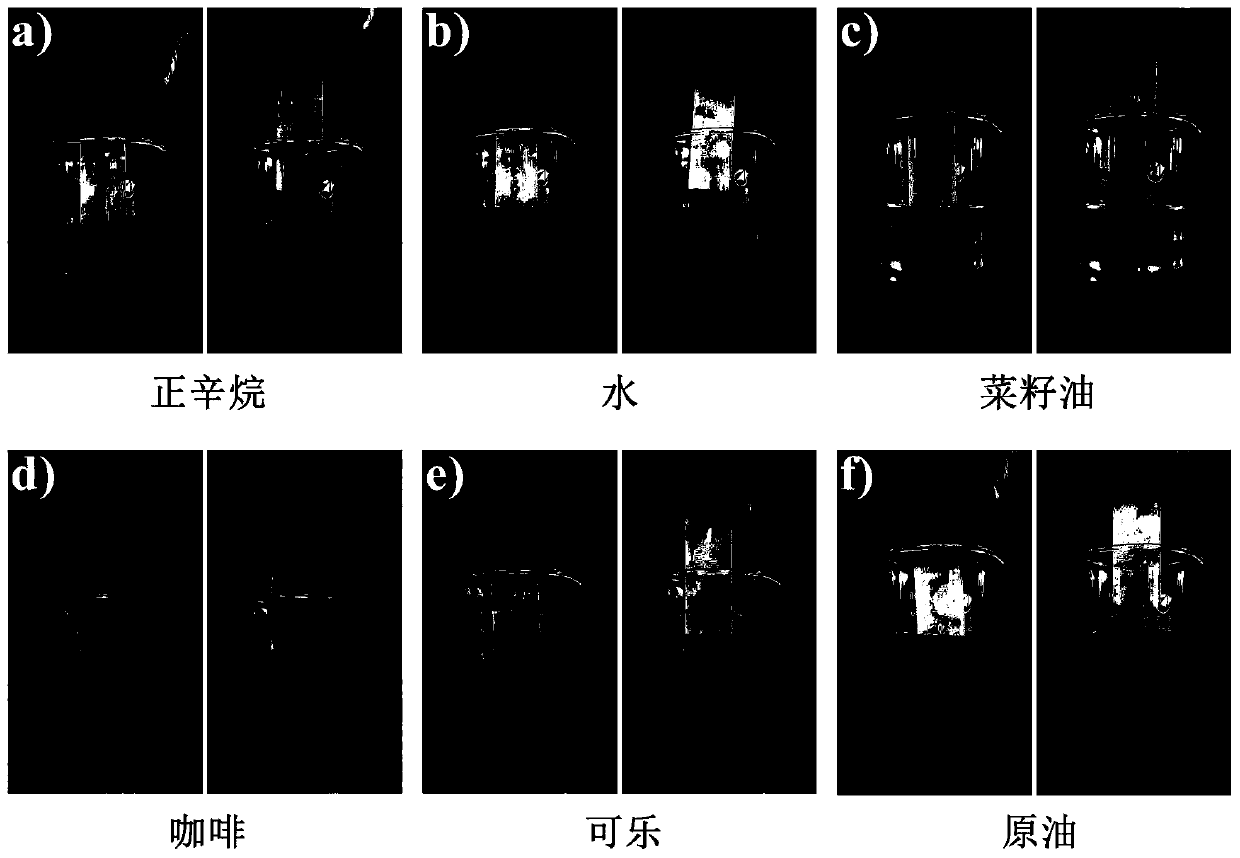

Preparation method of wear-resistant super-amphiphobic coating based on titanium dioxide/silica composite nanoparticles

The invention belongs to the field of preparation of super-amphiphobic materials, and relates to a preparation method of a wear-resistant super-amphiphobic coating based on titanium dioxide / silica composite nanoparticles. The preparation method includes the steps: preparation of flower-like titanium dioxide microparticles, preparation of multi-level titanium dioxide / silica composite particles, modification of low surface energy substances and spray preparation of the coating. The super-amphiphobic coating has good stability, a n-octane contact angle greater than 150 degrees and a rolling angleof less than 10 degrees, and has excellent wetting resistance to common water and oil-based liquids in life. The prepared coating shows good mechanical stability and good chemical stability, the preparation process is simple, the raw materials are easily available, the cost is low, and the stability is high; and the preparation process is suitable for large-area preparation and application, and the prepared coating is suitable for application in daily life and crude oil transportation and other fields at the same time.

Owner:HUBEI UNIV

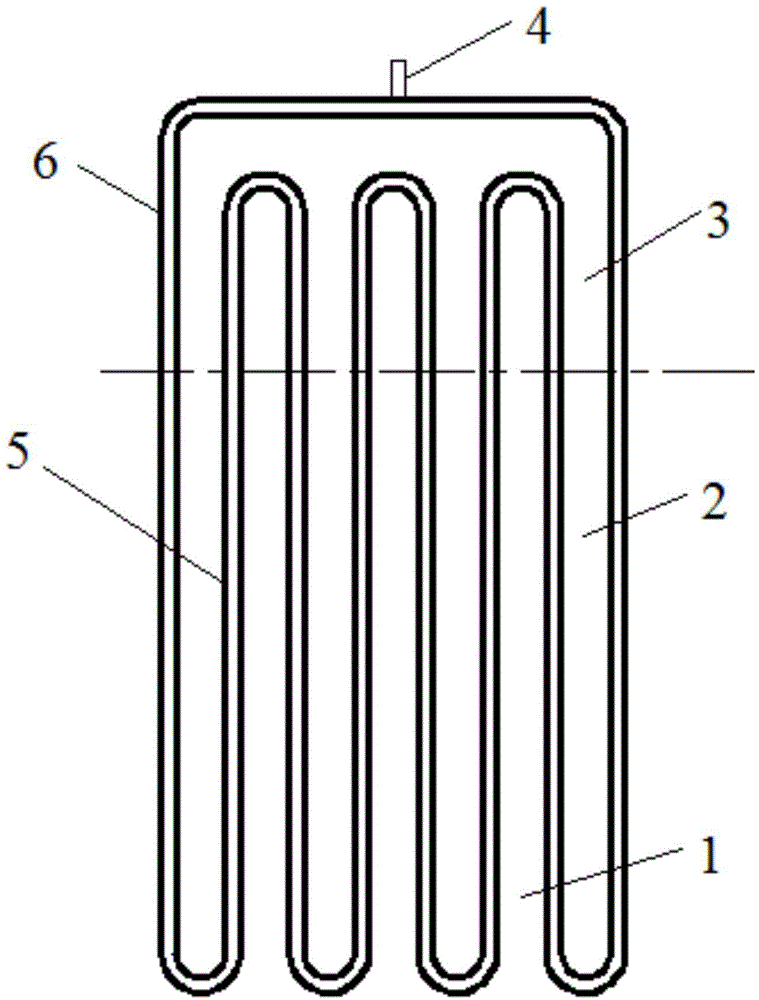

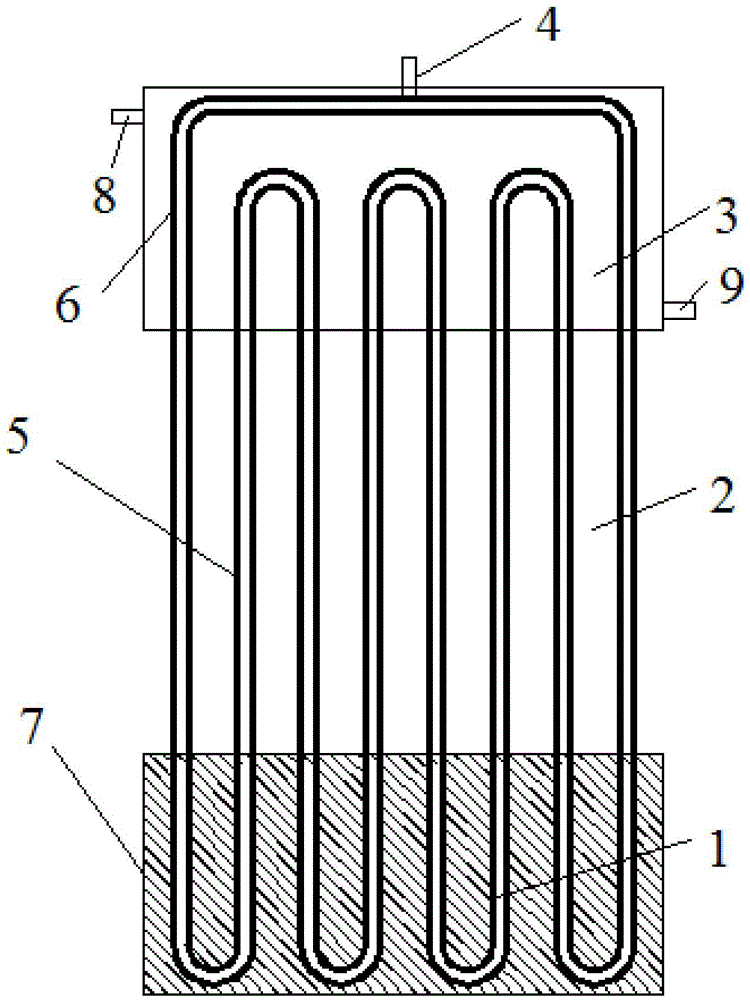

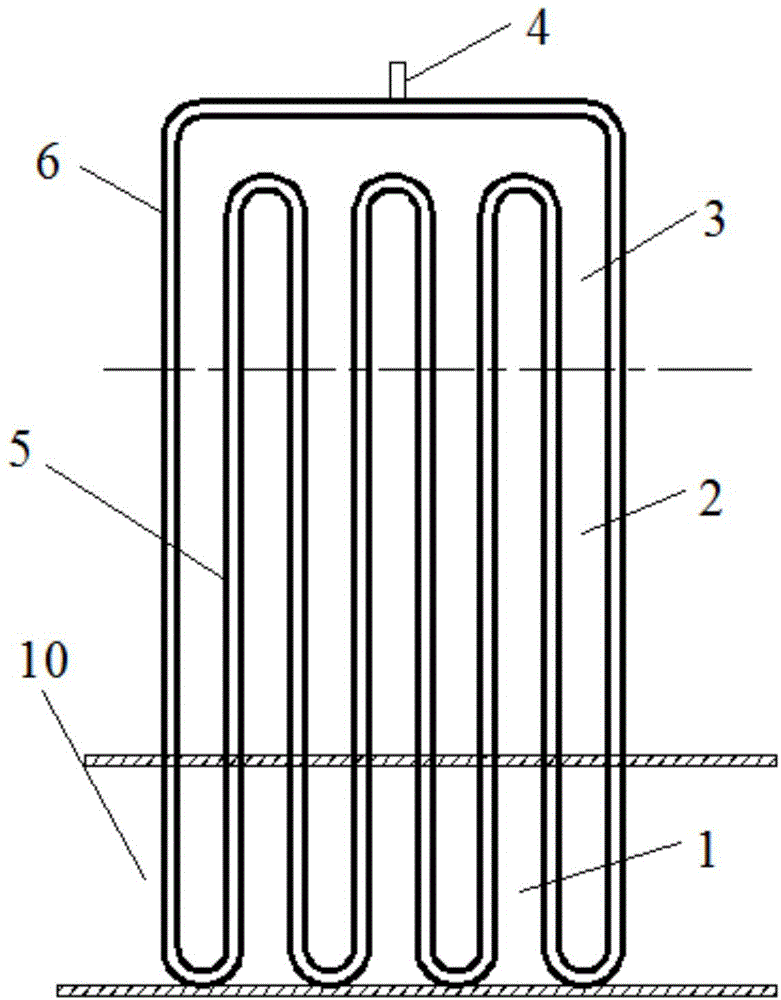

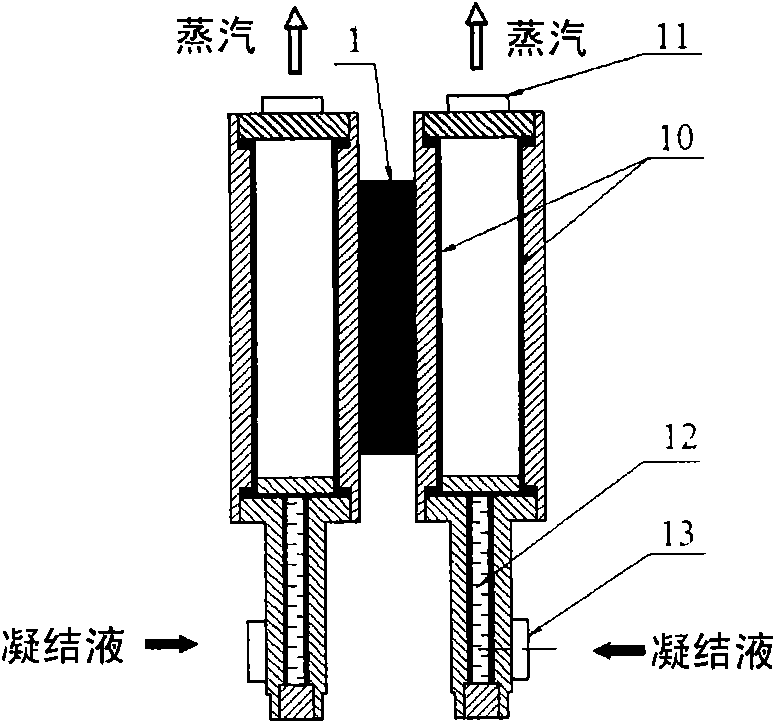

Pulsating heat pipe heat exchanger with lyophilic coatings

InactiveCN104792200AImprove heat transfer coefficientReduce processing costsIndirect heat exchangersPlate heat exchangerEngineering

The invention discloses a pulsating heat pipe heat exchanger with lyophilic coatings. The pulsating heat pipe heat exchanger comprises an evaporating segment, a heat insulation segment and a condensation segment which are connected in sequence, and the evaporating segment, the heat insulation segment and the condensation segment are filled with heat exchange working media. The pulsating heat pipe heat exchanger is characterized in that the inner wall of the evaporating segment, the inner wall of the heat insulation segment and the inner wall of the condensation segment are coated with the lyophilic coatings corresponding to the heat exchange working media. The lyophilic coating is arranged on the inner wall of a pulsating heat pipe, the thickness and materials of the coatings correspond to the type of the working media injected into the pulsating heat pipe, and therefore the working media can be spread out on the surfaces of the materials well. Due to the lyophilic coatings, the heat exchange process of the liquid phase working media and the wall of the pipe is greatly enhanced, the heat transfer performance of the pulsating heat pipe can be effectively improved, the temperature difference of the evaporating segment and the condensation segment of the pulsating heat pipe is reduced, the work occasion of the pulsating heat pipe heat exchanger is further widened, and the pulsating heat pipe heat exchanger has very good application prospects.

Owner:ZHEJIANG UNIV

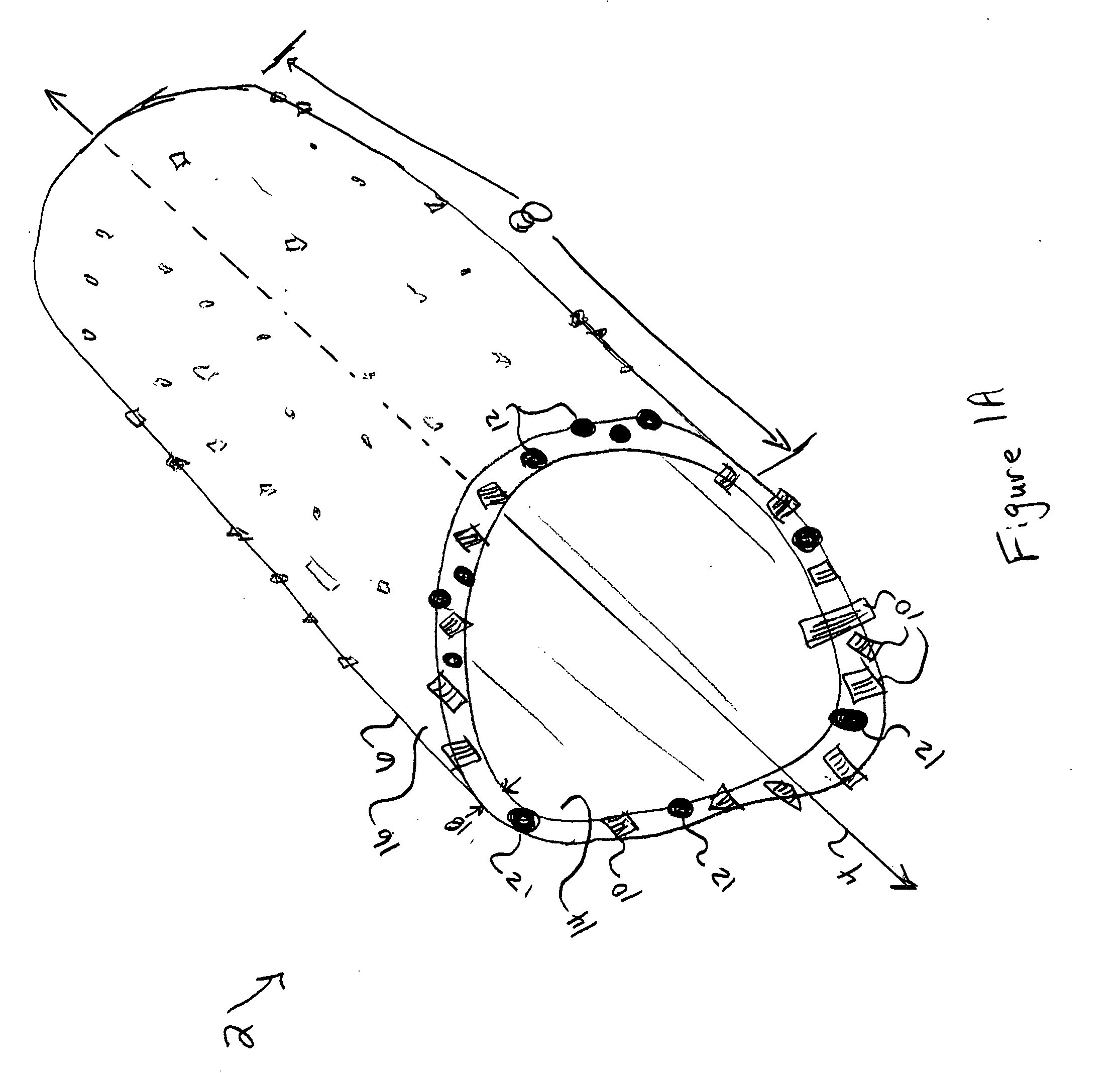

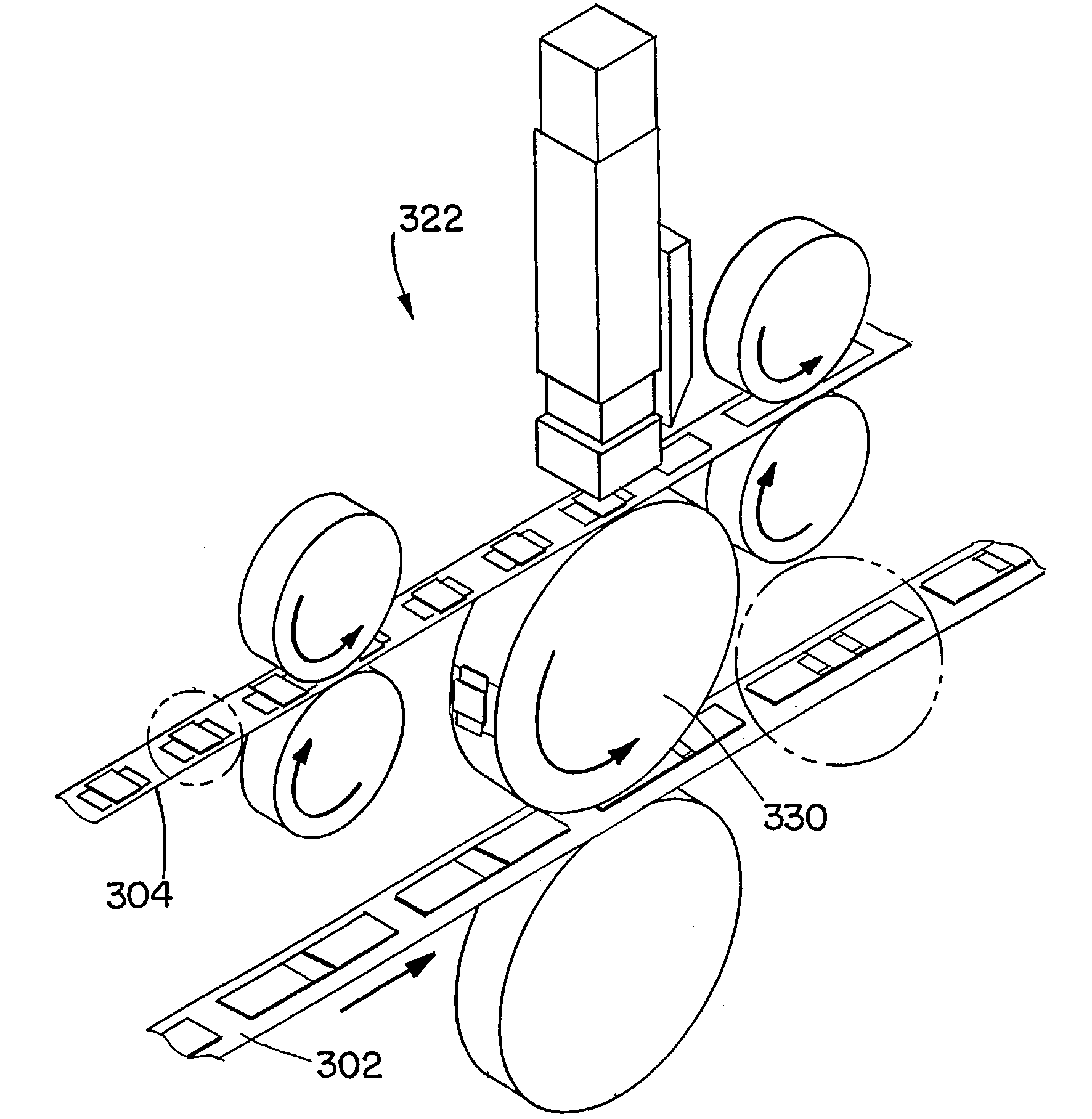

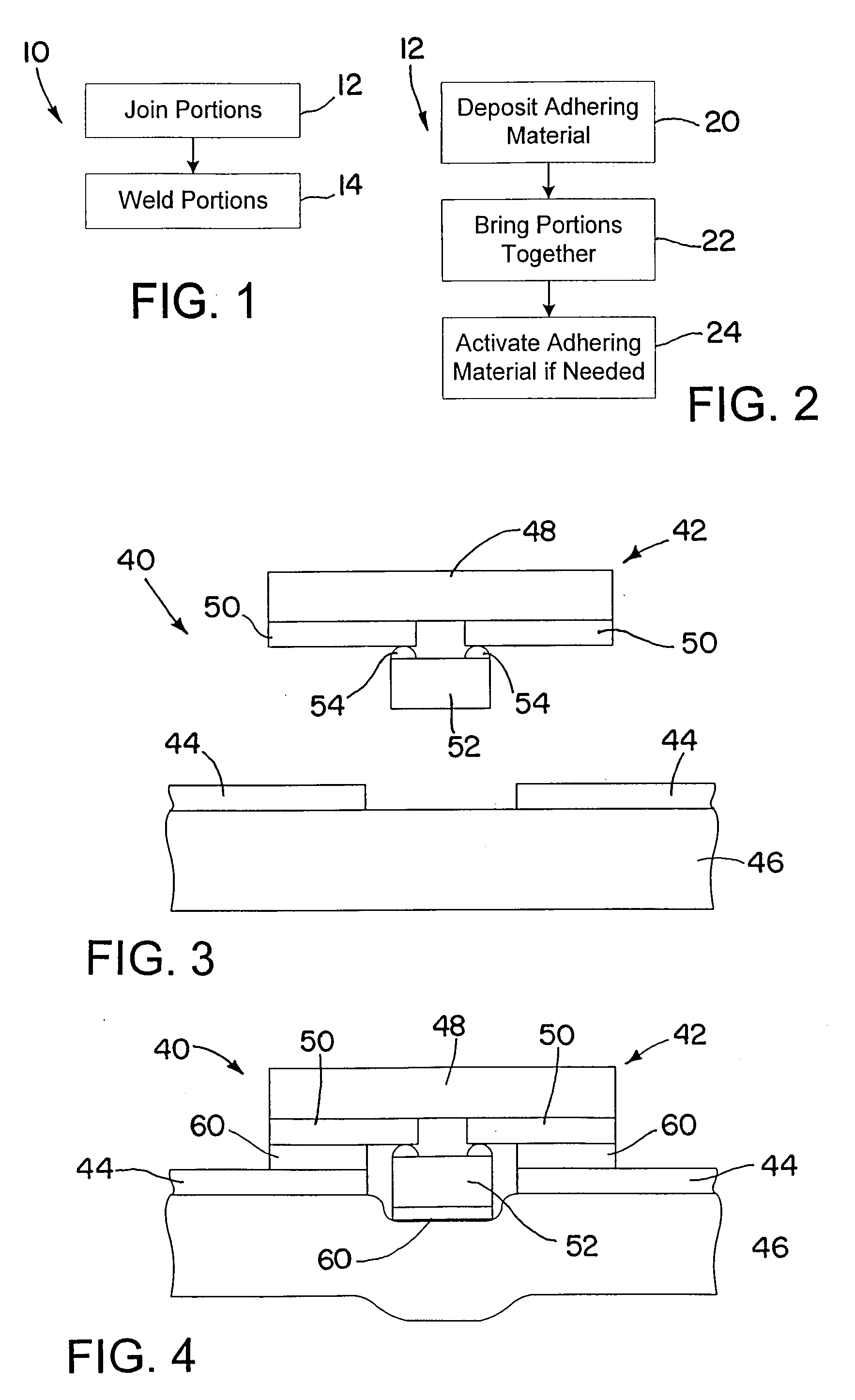

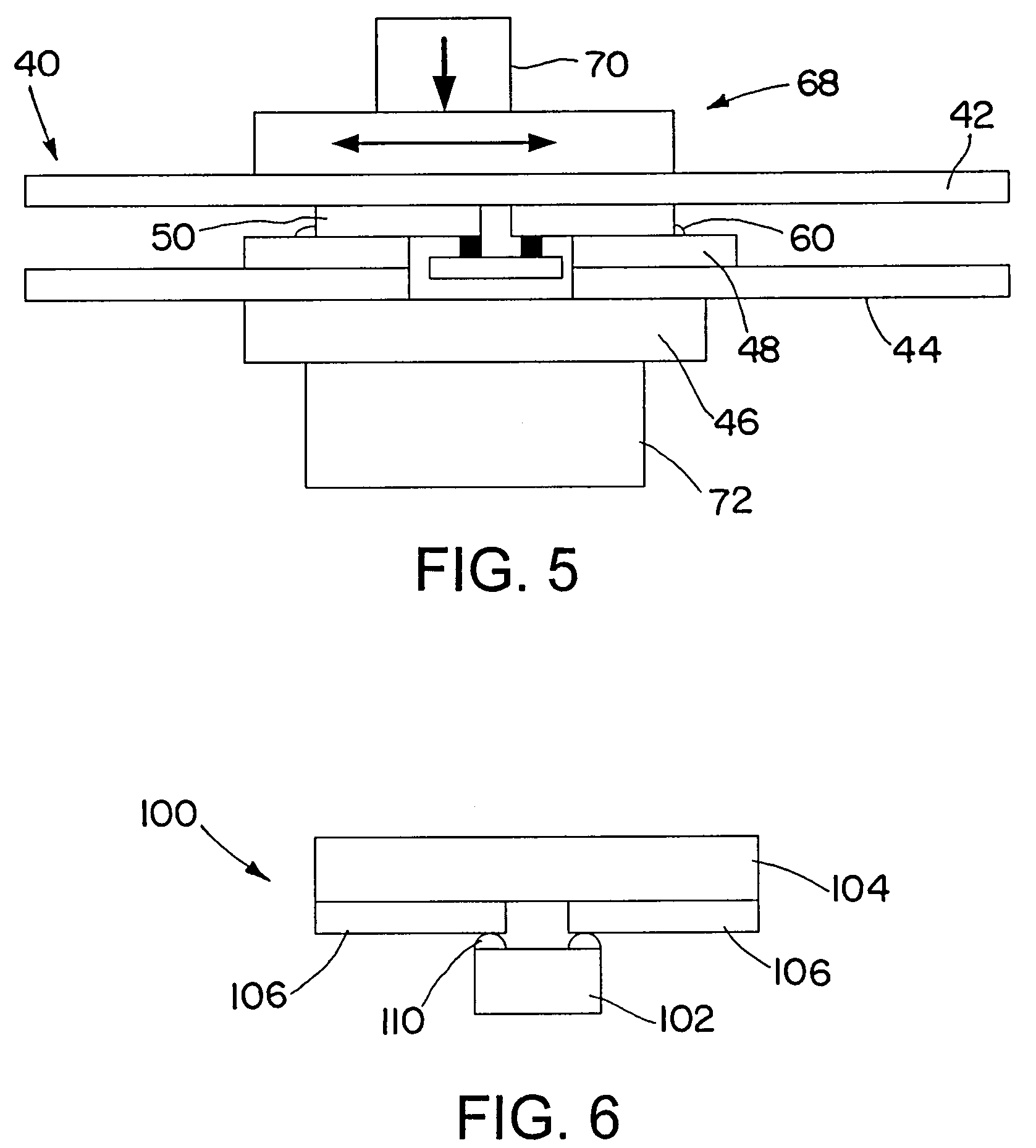

Method of making RFID devices

A method of making a radio frequency identification (RFID) device includes temporarily adhering an RFID interposer to an antenna, and subsequently ultrasonically welding the interposer leads to the antenna. The temporary adhering may involve use of any of variety of suitable adhering materials, such as an adhesive, wax, or even water. The adhering and the ultrasonic welding may be parts of a process that involves mostly continuous movement of an antenna web that has multiple antennas on it. The adhering material temporarily holds the interposer in place prior to the ultrasonic welding, which is important in a process that involves a moving web. The adhering may be such that there is no material between the conductive material interposer leads, and conductive material of the antenna. This allows the ultrasonic welding to proceed without any need to push intervening material aside.

Owner:AVERY DENNISON CORP

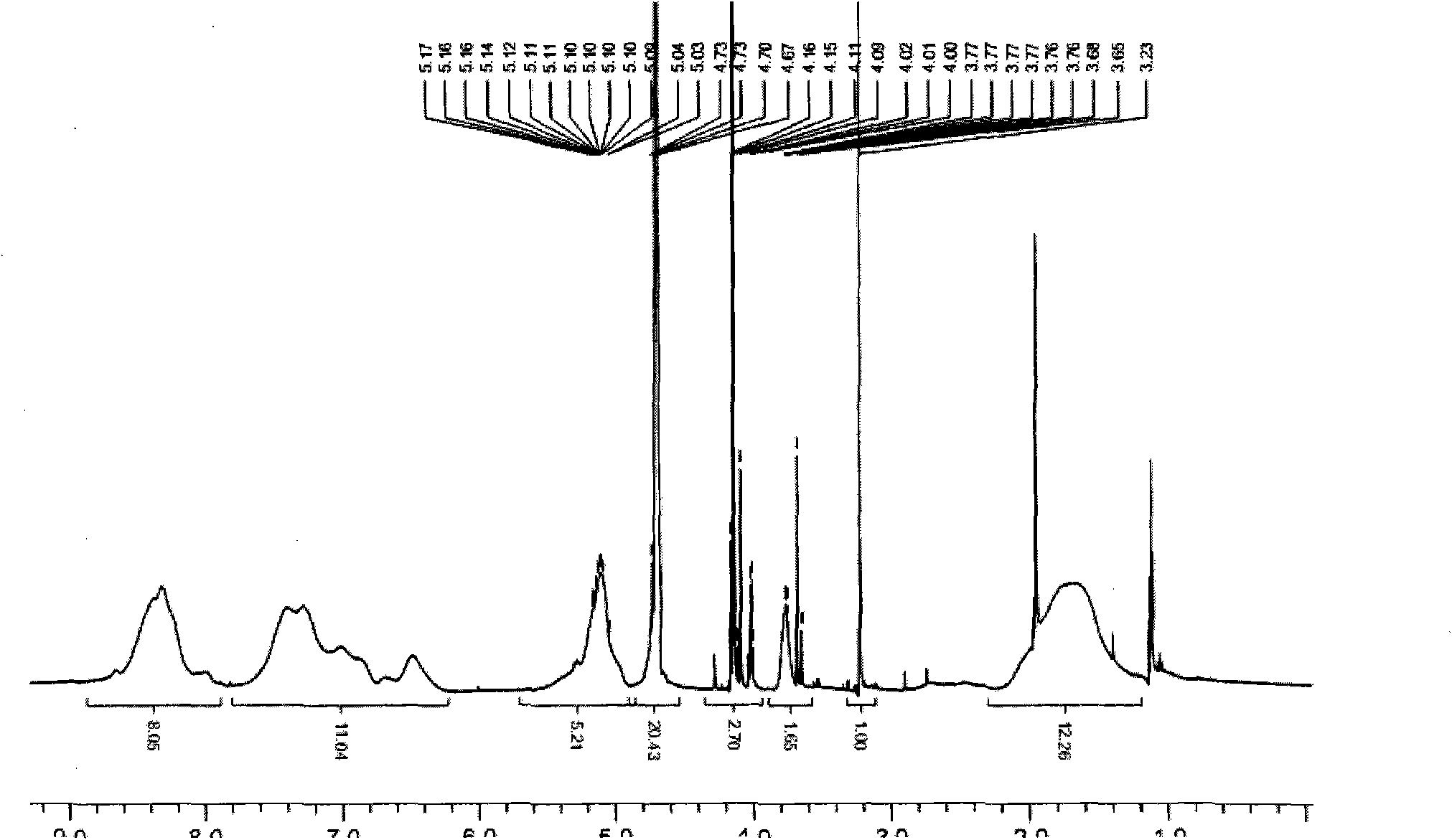

Hydrophilic mixed matrix material having reversible water absorbing properties

InactiveUS7485233B2Improve wetting propertiesMaterial nanotechnologySemi-permeable membranesNanometreOrganic polymer

Polymer-ceramic mixed matrix compositions contain one or more organic polymers and a nano-sized dispersion of inorganic metal oxide particles which are dispersed throughout the composition. Materials have use in making membranes that act as transfer agents.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

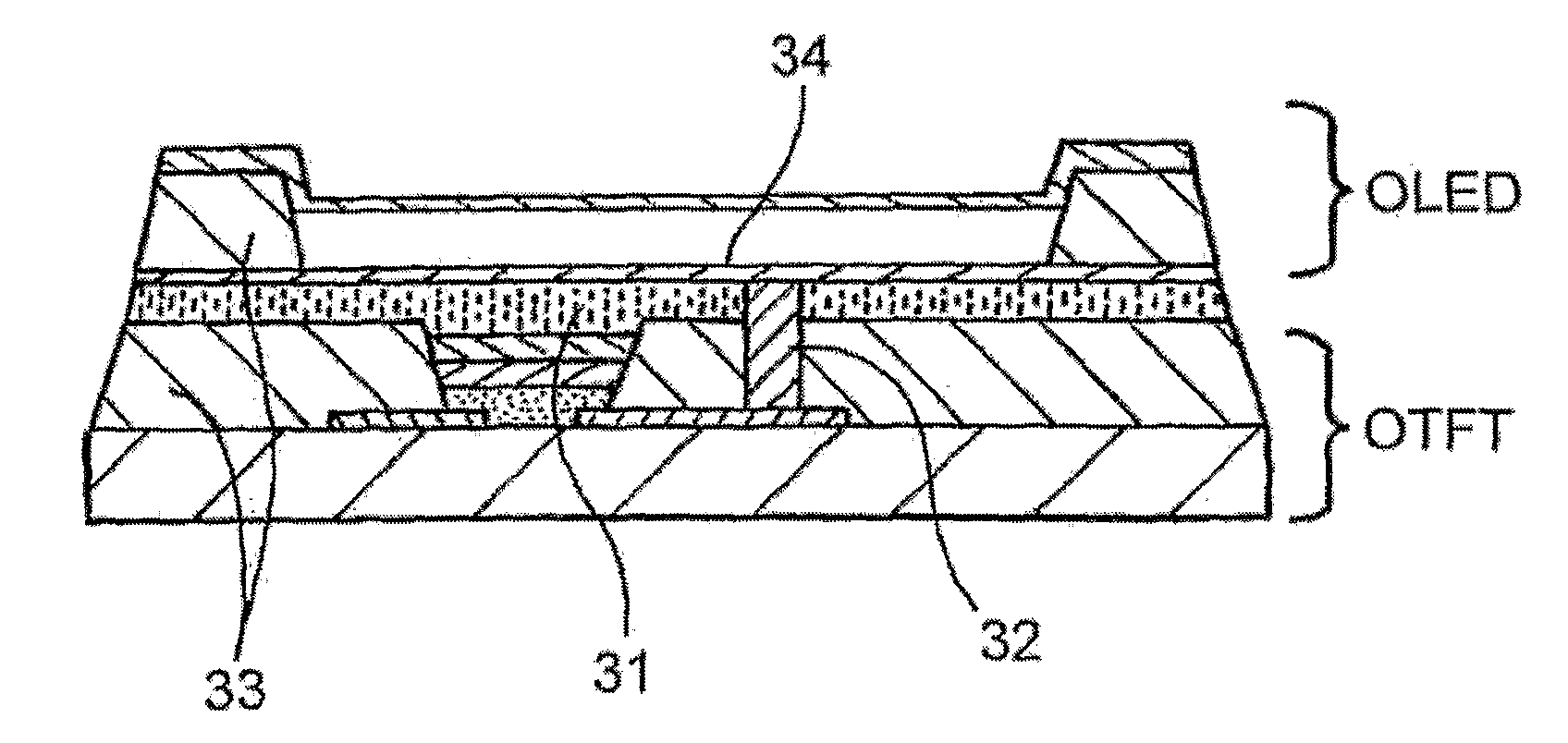

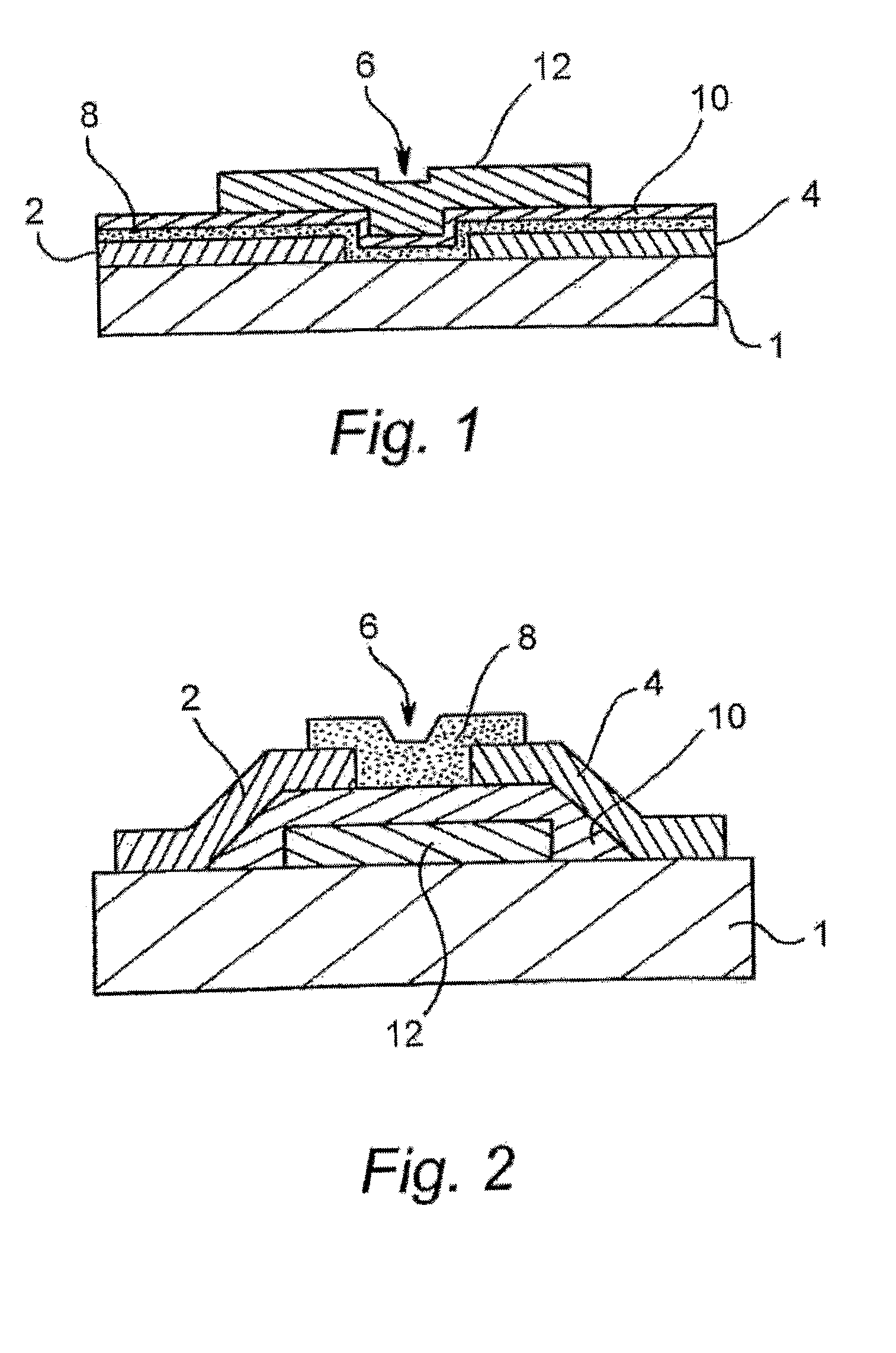

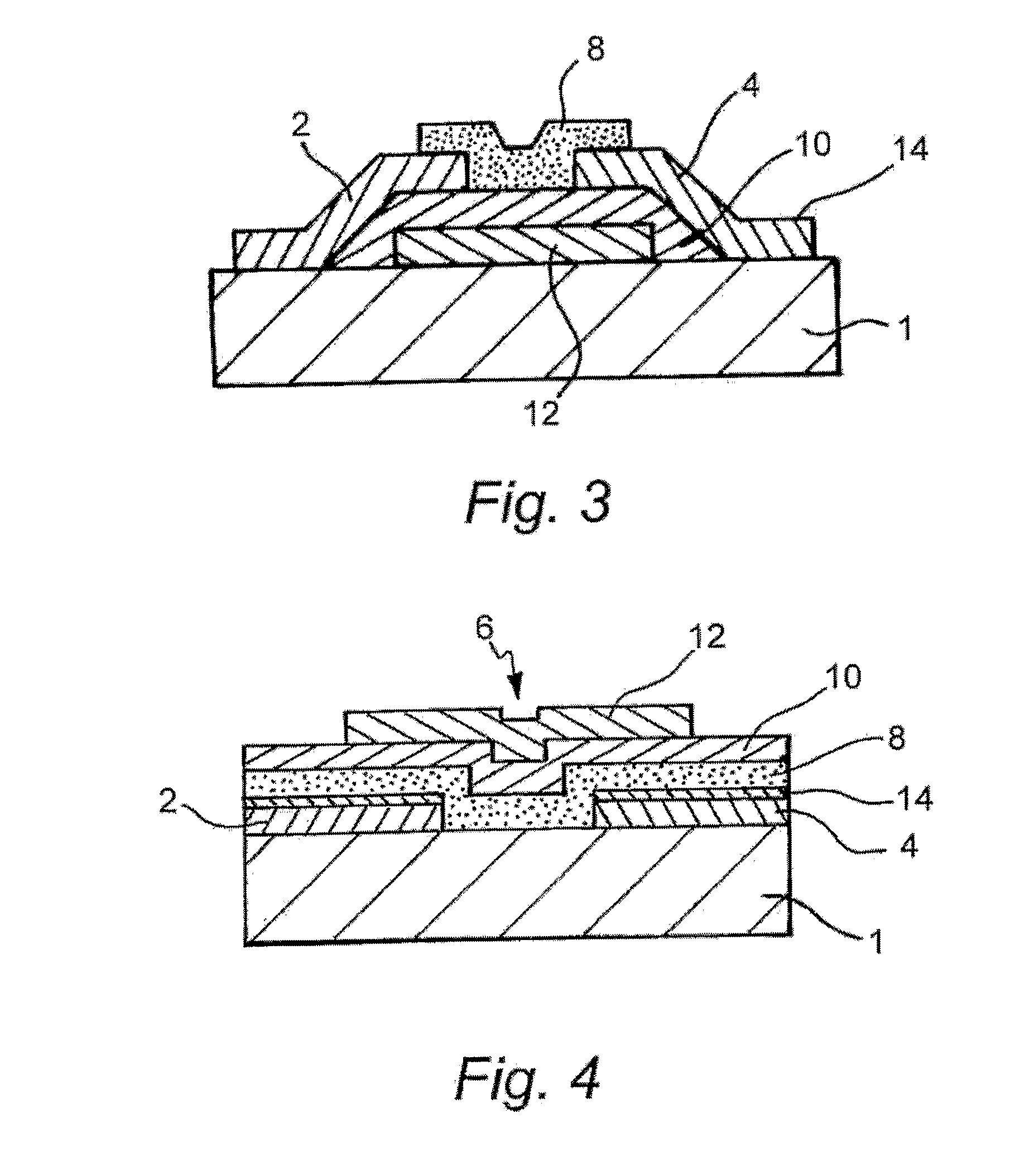

Organic Thin Film Transistors and Methods of Making the Same

ActiveUS20110024728A1Easy to acceptGood attractionSolid-state devicesSemiconductor/solid-state device manufacturingOrganic semiconductorOrganic film

An organic thin film transistor, and a method of making the same, comprising a source and drain electrode and organic semi-conductive material disposed therebetween in a channel region, in which the source and drain electrodes have disposed on them a thin self-assembled layer of a material comprising a dopant moiety for chemically doping the organic semi-conductive material by accepting electrons, the dopant moiety having a redox potential of at least 0.3 eV relative to a saturated calomel electrode in acetonitrile.

Owner:CAMBRIDGE DISPLAY TECH LTD

Hydrophilic mixed matrix material having reversible water absorbing properties

InactiveUS20060175249A1Improve wet characteristicImprove wetting propertiesMaterial nanotechnologySemi-permeable membranesMembrane configurationOxide

Polymer-ceramic mixed matrix compositions contain one or more organic polymers and a nano-sized dispersion of inorganic metal oxide particles which are dispersed throughout the composition. Materials have use in making membranes that act as transfer agents.

Owner:ENVIRONMENTAL PROTECTION AGENCY US

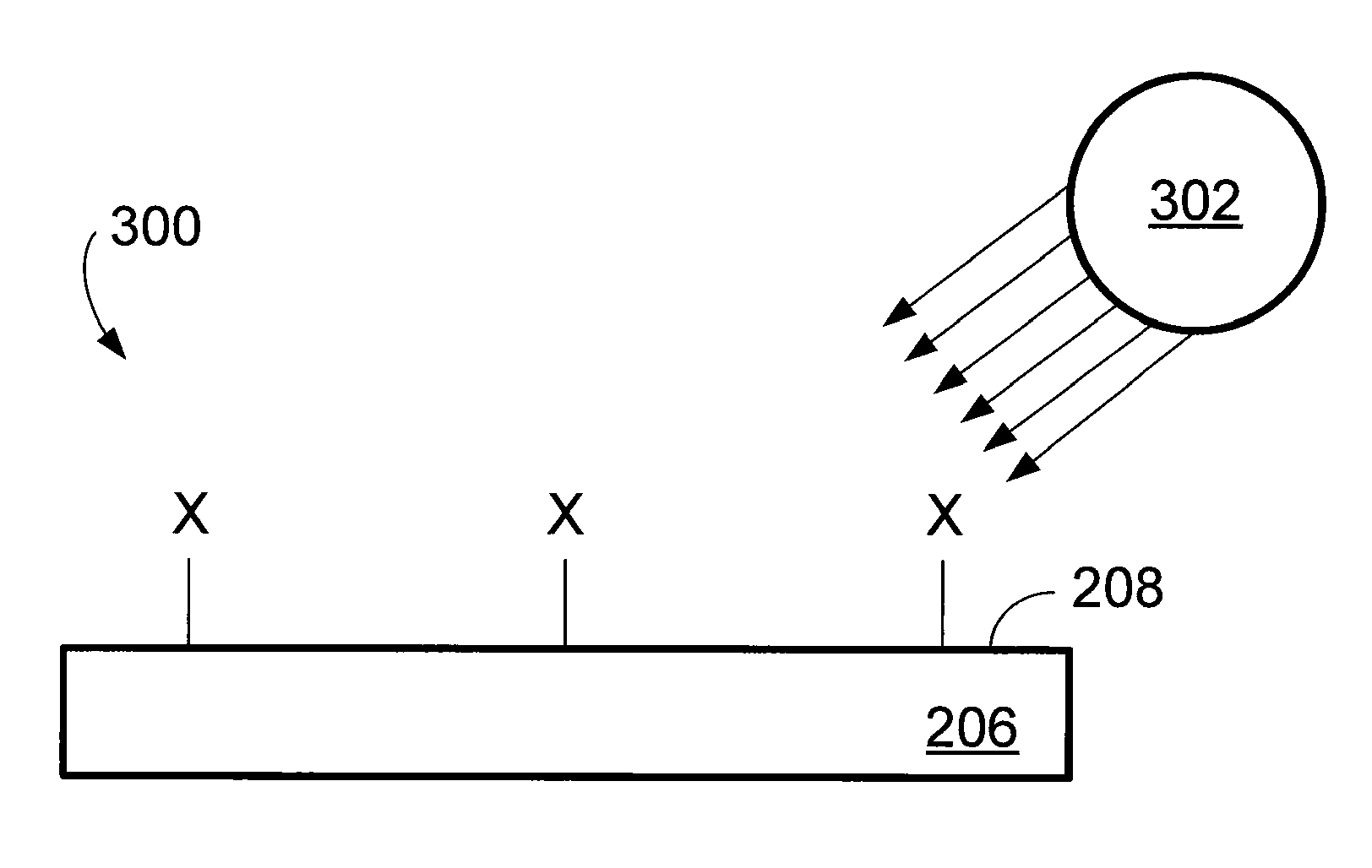

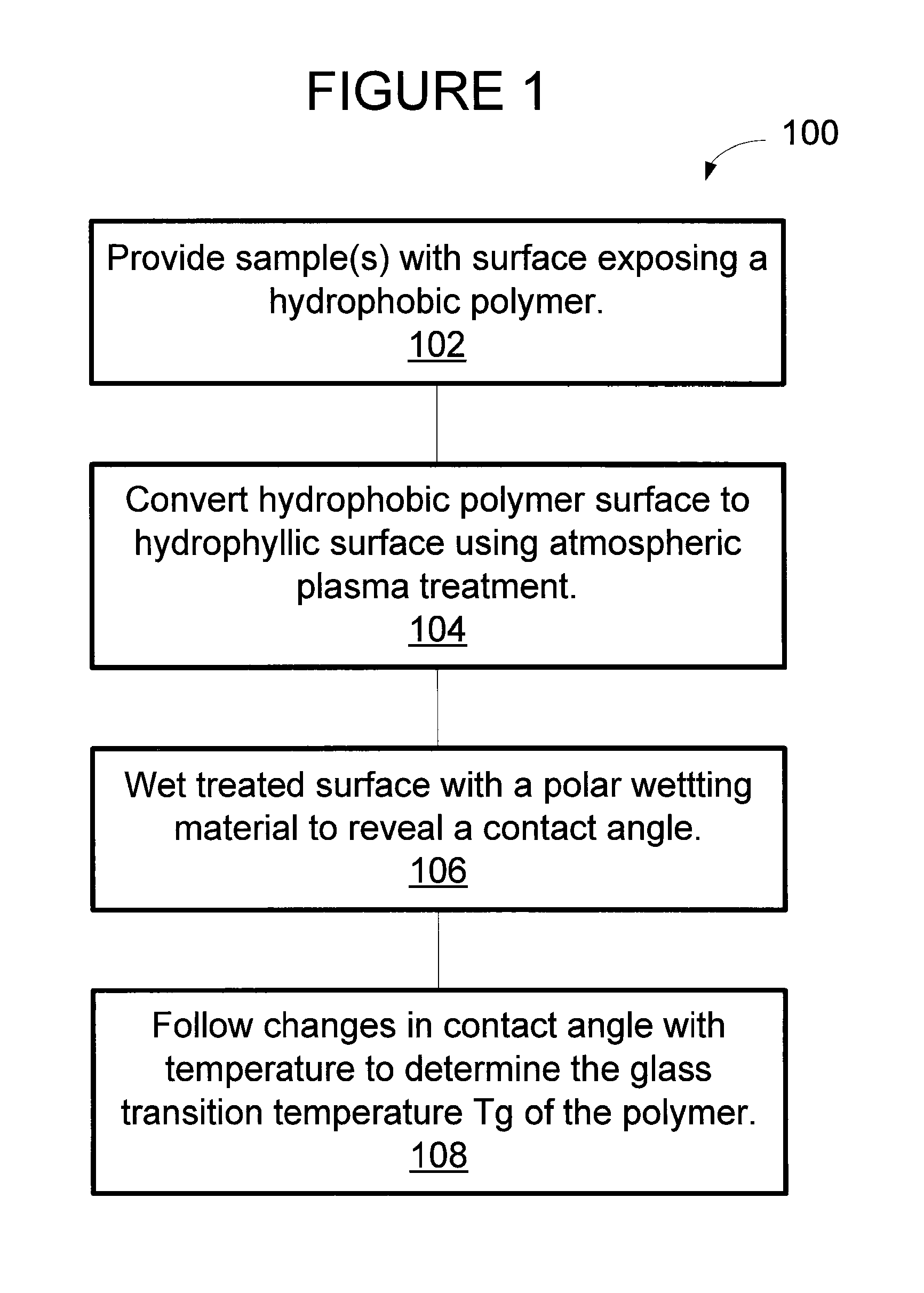

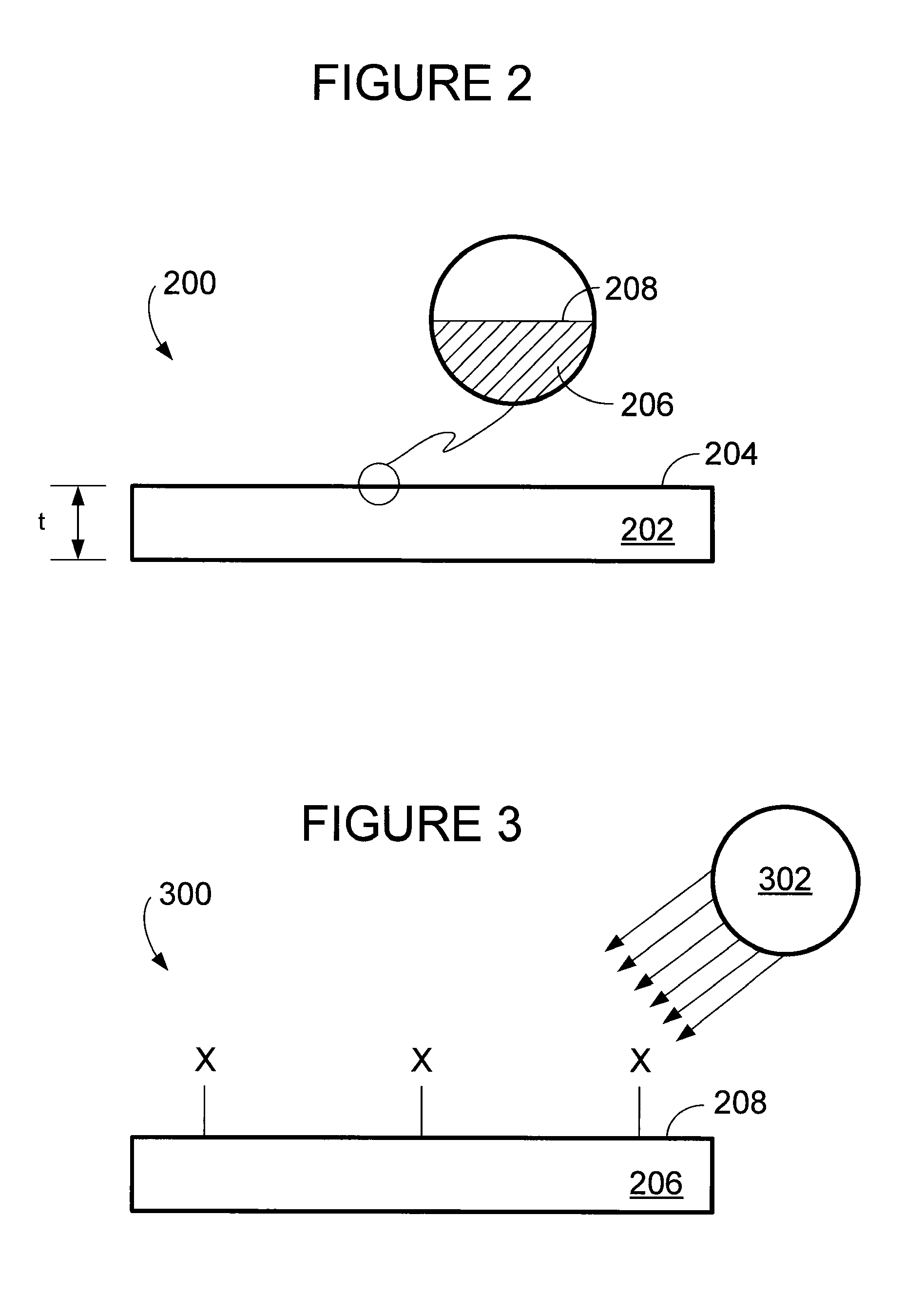

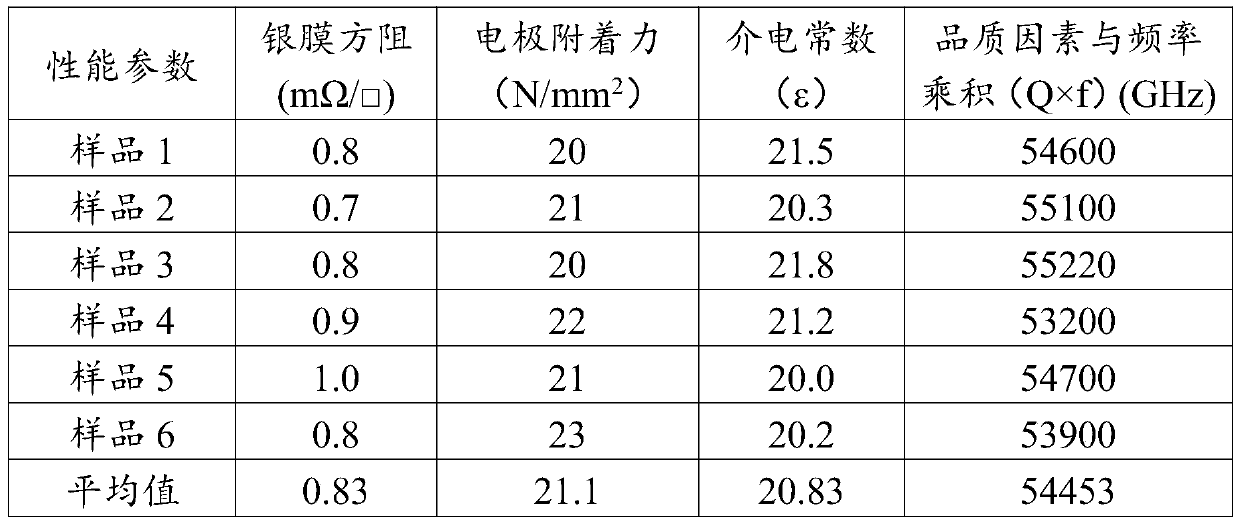

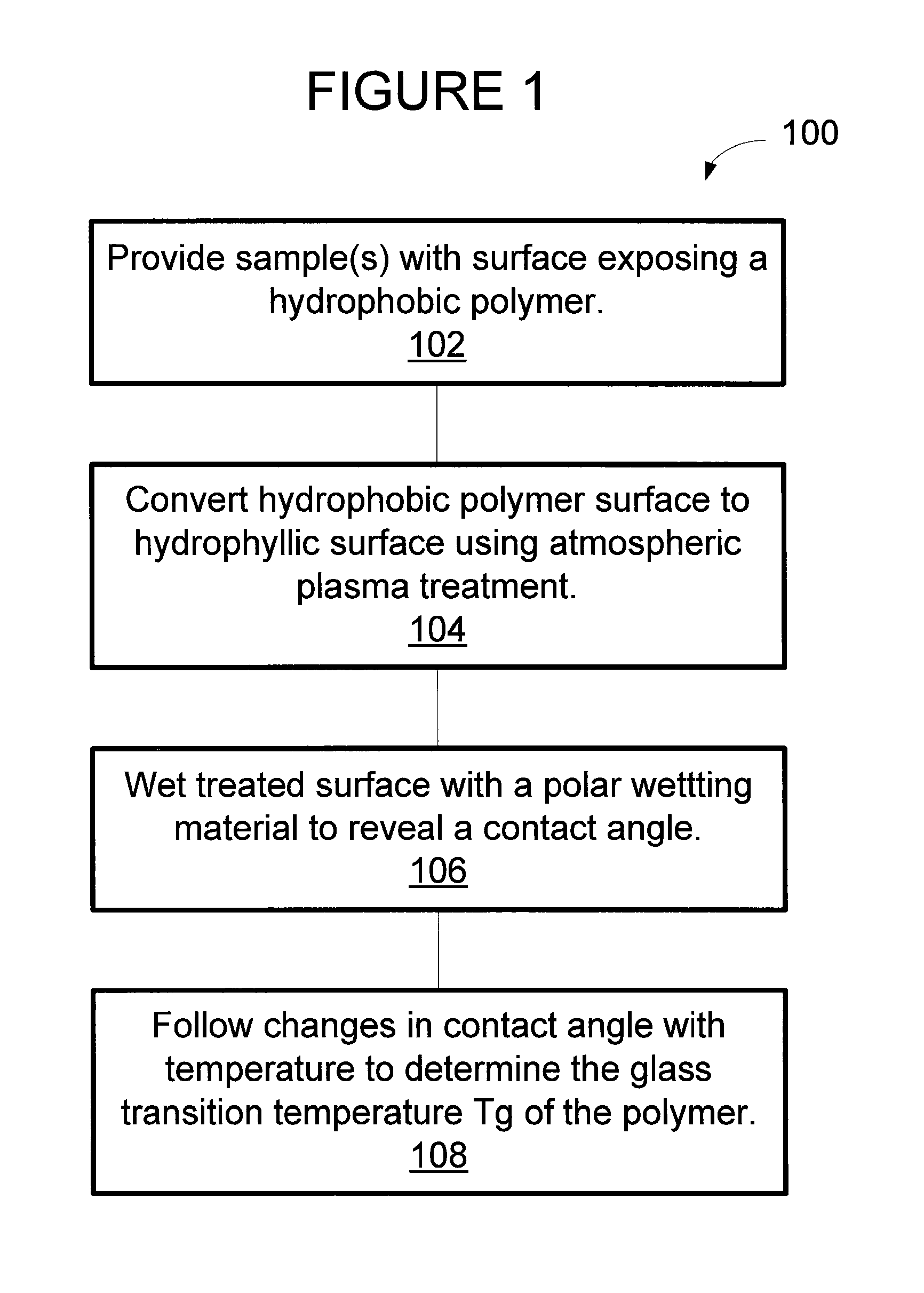

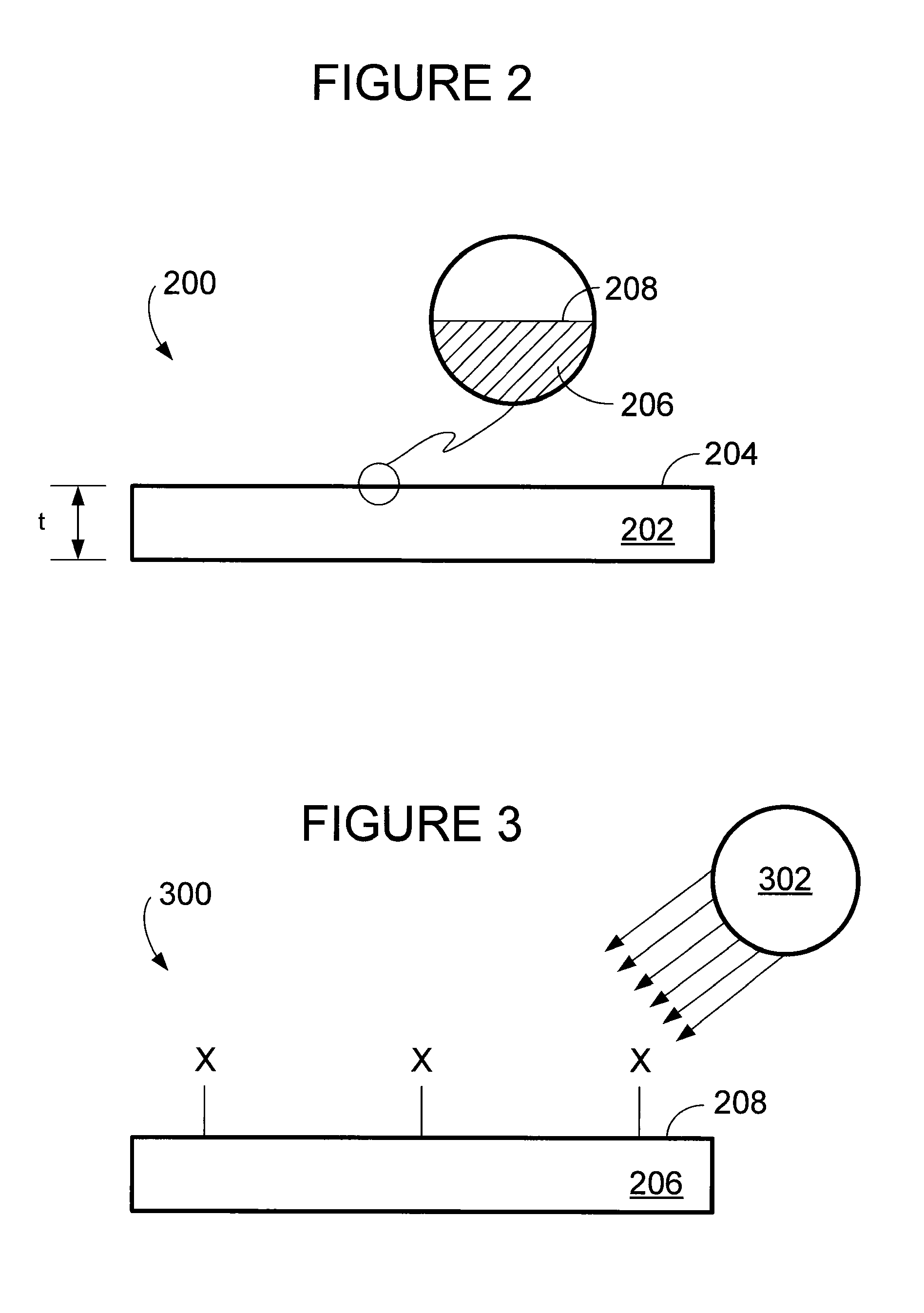

System and mehtod for measuring glass transition temperature

ActiveUS20120307860A1Improve wetting propertiesAccurate assessmentSurface/boundary effectInvestigating phase/state changeVitrificationHydrophobic polymer

A system and method for measuring a glass transition temperature of a hydrophobic polymer having a surface tagged with an atmospheric plasma.

Owner:THE AEROSPACE CORPORATION

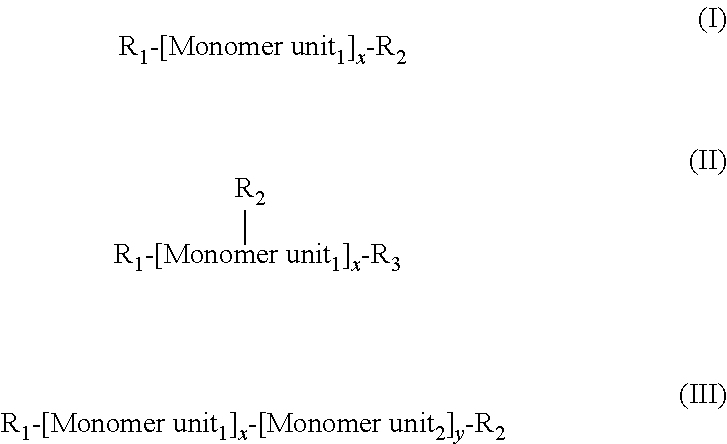

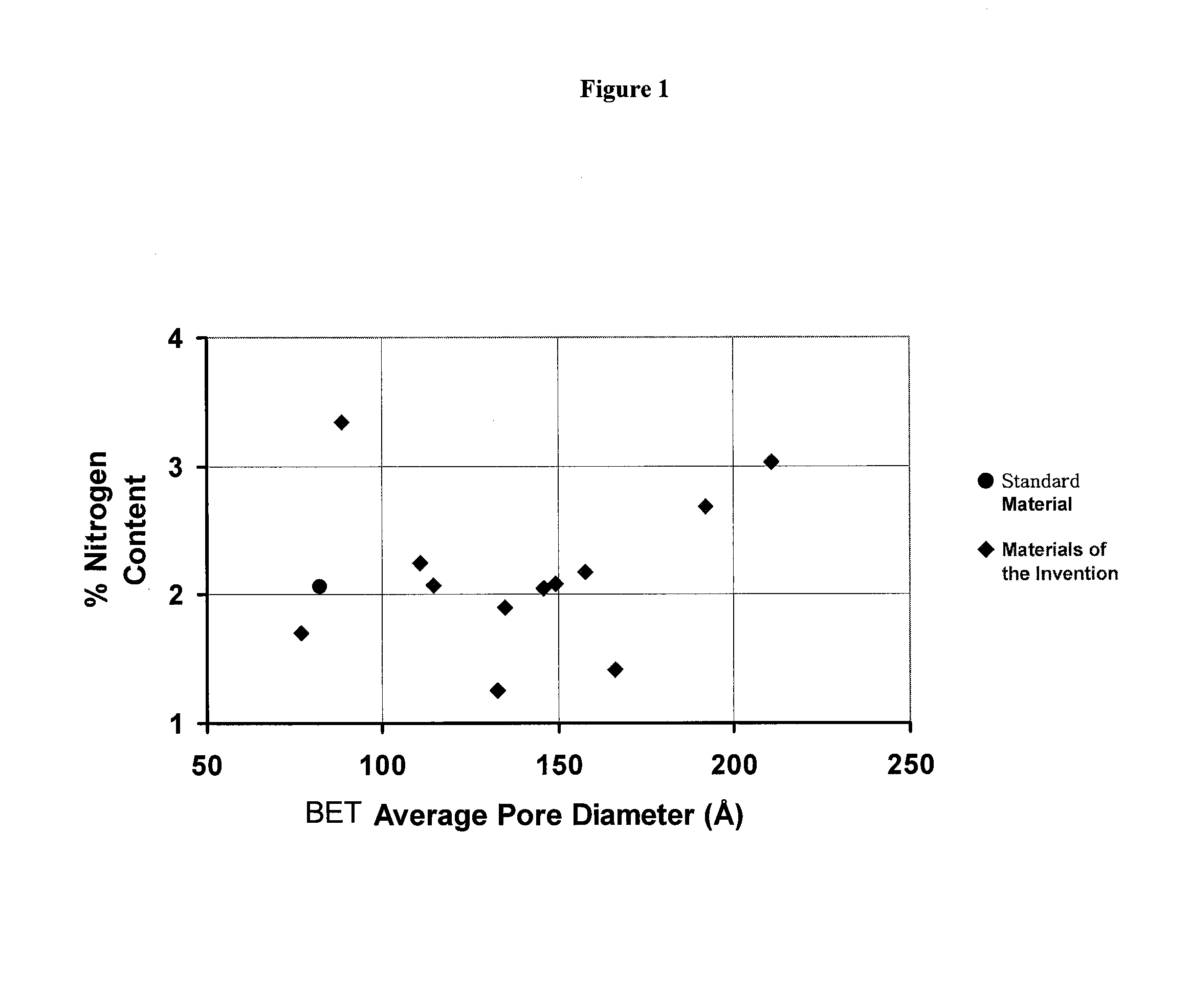

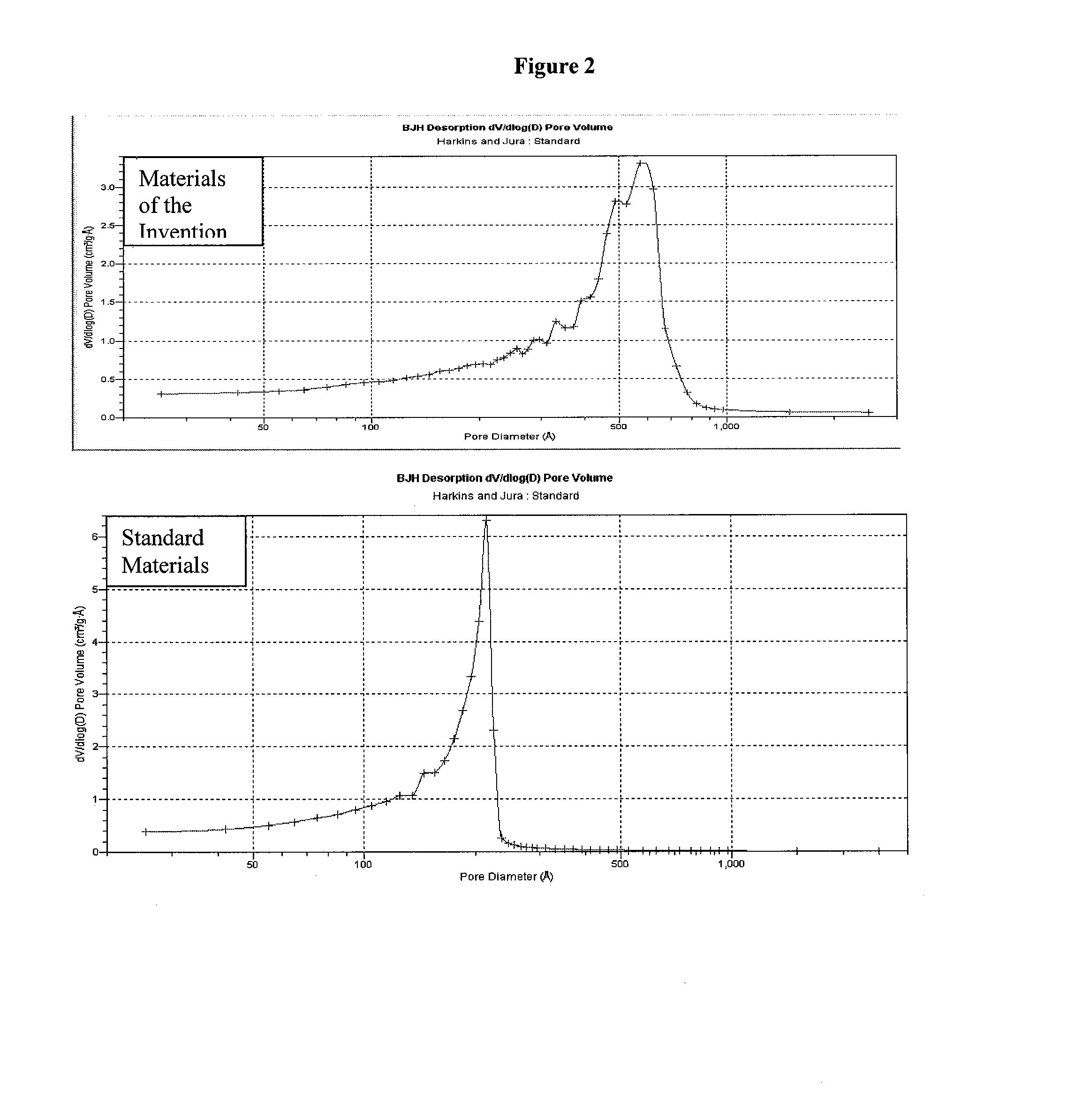

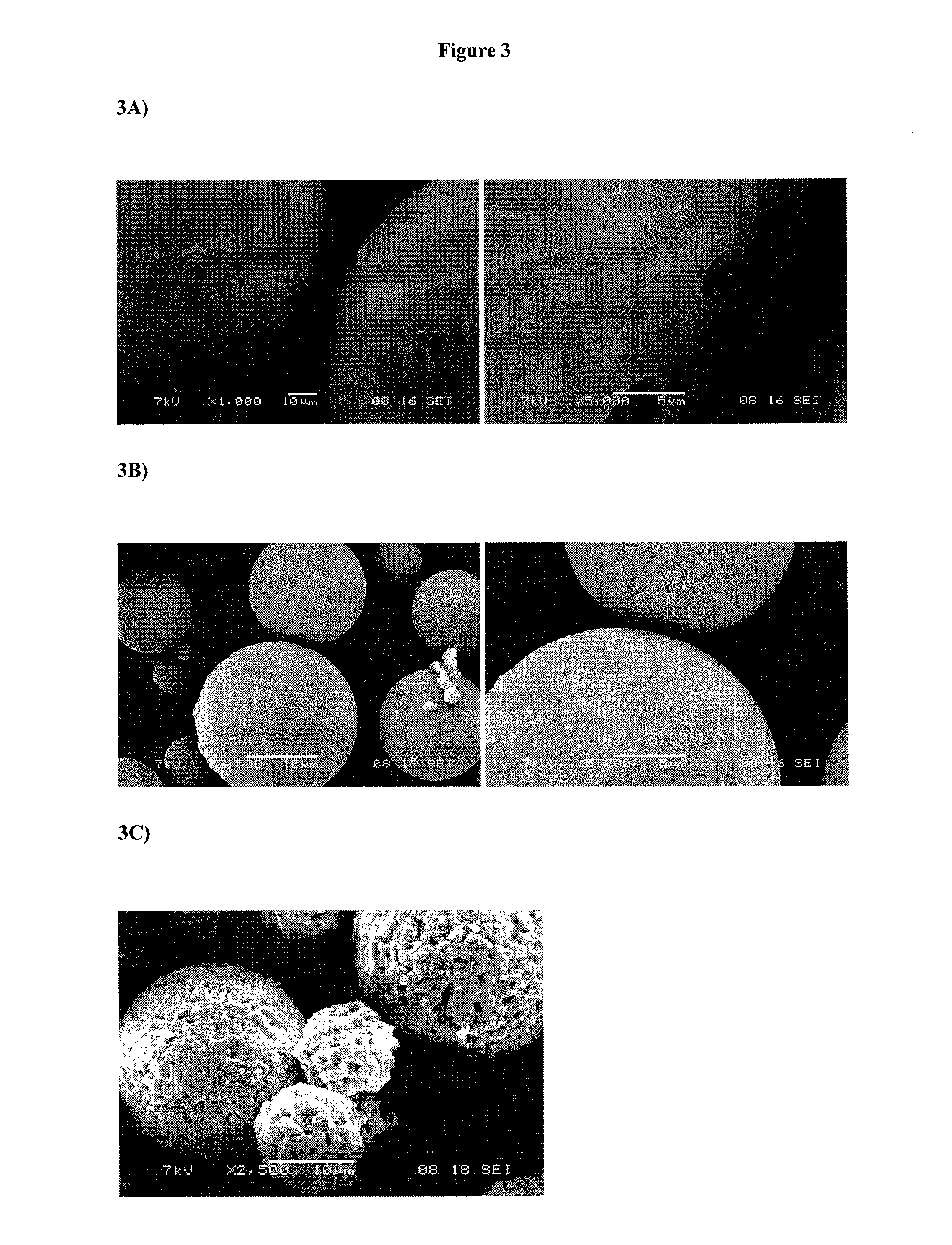

Porous materials for solid phase extraction and chromatography and processes for preparation and use thereof

ActiveUS20140096596A1Improve wetting propertiesSelective captureIon-exchange process apparatusCation exchanger materialsTarget analysisAnalyte

The invention provides novel porous materials that are useful in chromatographic processes, e.g., solid phase extraction, and that provide a number of advantages. Such advantages include superior wetting characteristics, selective capture of analytes of interest, and non-retention of interfering analytes. The invention advantageously provides novel porous materials having a large percentage of larger pores (i.e. wide pores). The invention advantageously provides novel porous materials that overcome the problems of SPE of biological samples.

Owner:WATERS TECH CORP

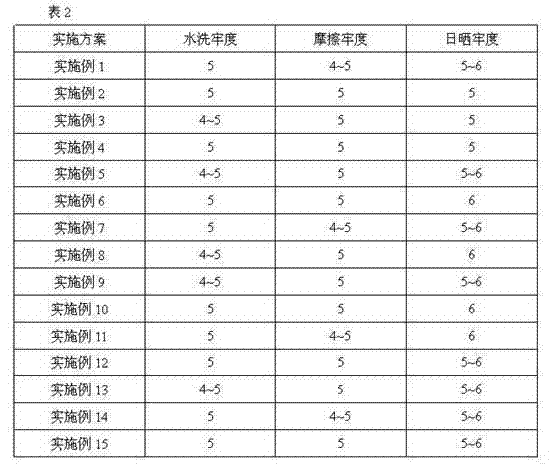

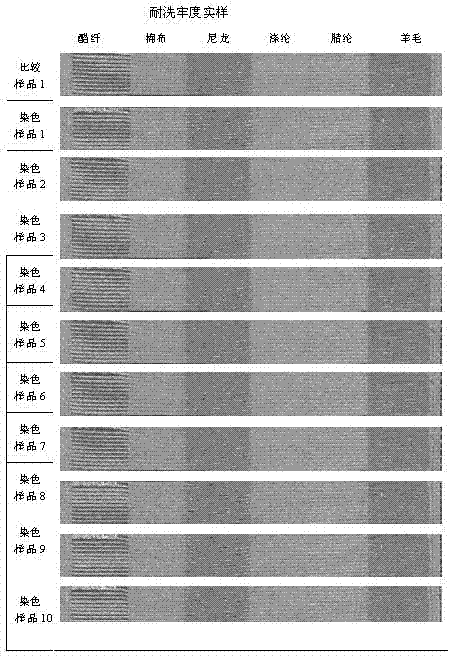

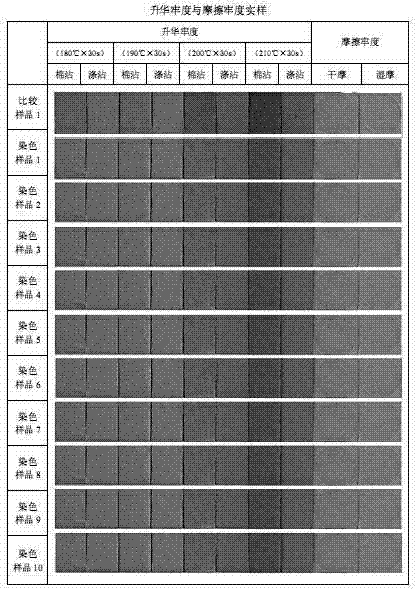

Disperse dye mixture and application thereof

ActiveCN102775812AImprove wetting propertiesGood dispersionOrganic dyesDyeing processDisperse dyePhotochemistry

The invention relates to the technical field of dye, and provides a disperse dye mixture and application thereof, aiming to solve the problems that the wash resistance and crockfastness resistance of an ordinary sunshine disperse dye cannot be ensured at the same time. The disperse dye mixture is prepared by mixing a dye A, a dye B, a dye C, a dye D and a dye E. By adopting the dye mixture for dyeing, wash resistance and crockfastness resistance are satisfactory.

Owner:ZHEJIANG JIHUA GROUP +1

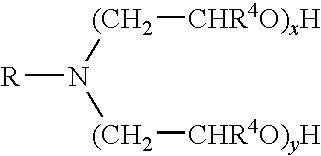

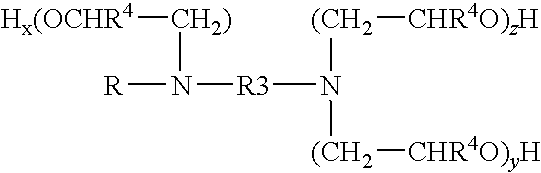

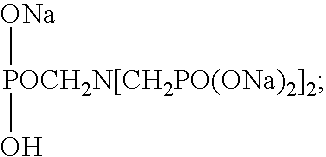

Raw wool scouring agent

InactiveCN102041187AImprove cleaning rateLow residual fat rateOrganic detergent compounding agentsNon-ionic surface-active compoundsDiethylene glycolScouring agent

The invention relates to a raw wool scouring agent which is characterized by comprising the following components by weight percent: 40%-80% of iso-tridecanol polyoxyethylene ether, 2%-14% of alkyl aryl sodium sulfonate, 3%-8% of diethylene glycol, 2% of glycol and the balance of water. The invention further discloses a wool scouring agent with an antistatic function and a bactericidal function. The wool scouring agent has the advantages of high cleaning rate, low fan and oil content, excellent whiteness, good hand feeling and good biodegradability.

Owner:傅科杰

Acid resistant glass mats that include binders with hydrophilic agents

ActiveUS20160268566A1Improve wetting propertiesImprove wettabilityCell component detailsDomestic articlesGlass fiberAqueous solution

Glass-fiber mats for lead-acid batteries are described. The glass-fiber mats may include a plurality of glass fibers held together with a binder. The binder may be made from a binder composition that includes (i) an acid resistant polymer, and (ii) a hydrophilic agent. The hydrophilic agent increases the wettability of the glass-fiber mat such that the glass-fiber mat forms a contact angle with water or aqueous sulfuric acid solution of 70° or less. Also described are methods of making the glass-fiber mats that include applying a binder composition to the glass fibers, and including a hydrophilic agent in the glass fiber mat that increases the wettability of the mat. The hydrophilic agent may be added to the binder composition, applied to the glass-fiber mat, or both.

Owner:JOHNS MANVILLE CORP

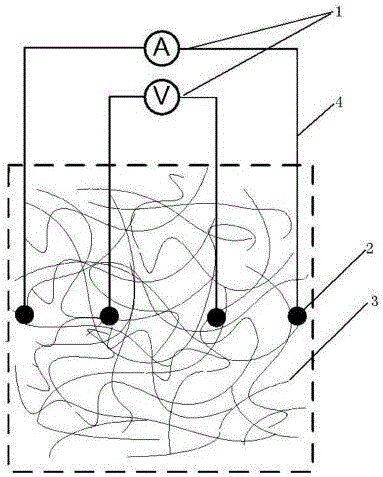

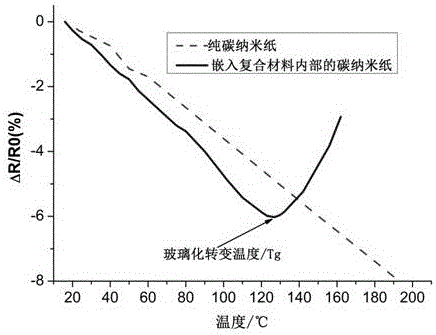

Method for monitoring Tg of polymer-based composite material by using carbon nano-paper sensor

InactiveCN106680311ALow costRealize real-time online monitoringMaterial analysis by electric/magnetic meansMaterial testing goodsCopper conductorVitrification

The invention belongs to the technical field of characterization of polymer properties, and particularly relates to a method for monitoring a Tg (glass-transition temperature) of a polymer-based composite material by using a carbon nano-paper sensor. The method comprises the following steps: fixing four copper conductors on the surface of rectangular carbon nano-paper to form a carbon nano-paper sensor; embedding the sensor into a prepreg of a polymer-based composite material to be monitored; performing curing molding according to a standard curing process of the prepreg of the polymer-based composite material so as to obtain the polymer-based composite material; heating the composite material again; and measuring the resistance of the carbon nano-paper sensor in the composite material by using a four-probe resistance measuring meter so as to obtain a resistance variation-temperature relation curve of the carbon nano-paper sensor during heating of the composite material after curing molding, wherein a resistance variation catastrophe point of the curve is the glass-transition temperature of the composite material. The method provided by the invention is simple and convenient in measuring process, is feasible, and is low in sensor and demodulating system cost; and most importantly, the method can achieve real-time online monitoring of a molding process of a composite material in the field of engineering application.

Owner:SHENYANG AEROSPACE UNIVERSITY

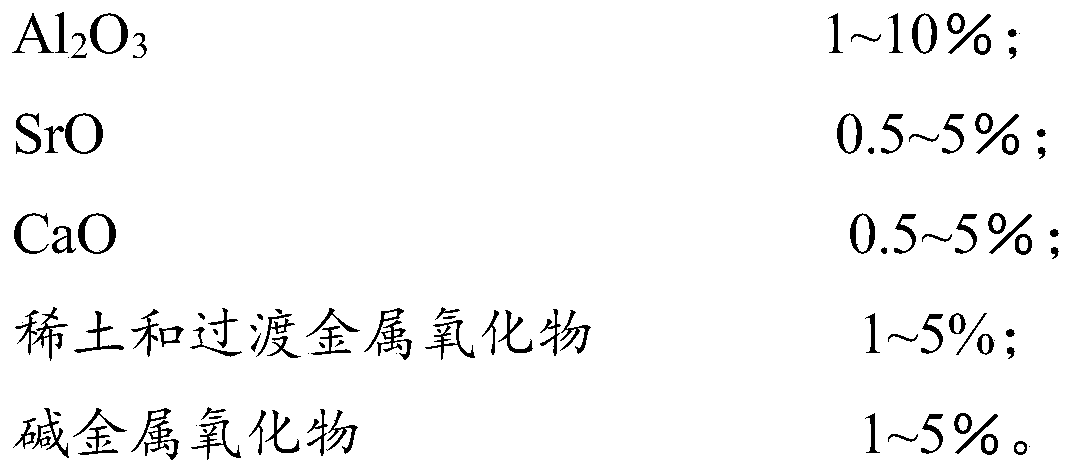

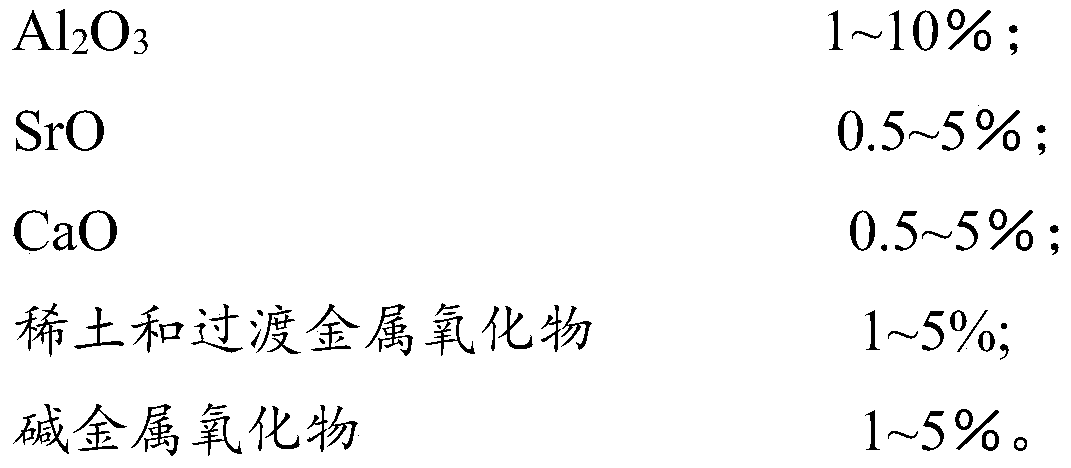

Titanate-based lead-free silver electrode paste, preparation method and use method thereof

ActiveCN111564234AGood effectImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSilver electrode

The invention discloses titanate-based lead-free silver electrode slurry, a preparation method and a use method thereof, and belongs to the technical field of preparation of microelectronic components. The silver paste comprises the following components in percentage by weight: 70-85% of high-activity silver powder, 1-5% of glass powder, 10-25% of an organic carrier, 1-5% of an inorganic additiveand 1-5% of a paste modifier. According to the silver paste developed by the invention, the V-B-Si-Zn-Bi-Ti glass frit is used for realizing the lead-free effect of the paste, the lead content of thepaste is less than 100ppm, and the contents of other harmful substances such as Hg, Cd, Cr and the like meet the requirements of RoHS environmental protection indexes; and with the application of thesilver paste in the electrode of the titanate-based 5G microwave ceramic filter, the silver paste with different viscosities can meet the requirements of printing, dip-coating or spraying processes, the adhesive force after sintering is greater than 10N / mm<2>, the solderability is good, the conductivity is excellent, the insertion loss of the filter can be reduced, and the filter has a relativelyhigh quality factor.

Owner:武汉硕美特电子材料有限公司

System and method for measuring glass transition temperature

ActiveUS8858070B2Improve wetting propertiesAccurate assessmentInvestigating phase/state changeSurface tension analysisVitrificationHydrophobic polymer

Owner:THE AEROSPACE CORPORATION

Preparation process of functional soybean protein concentrate

InactiveCN101617736AImprove water holding capacityIncrease elasticityVegetable proteins working-upSolubilityDry weight

The invention relates to a preparation process of functional soybean protein concentrate. The preparation process comprises the following steps: (1) putting soybean protein concentrate curd which is prepared by an alcohol extraction process or soybean protein concentrate which is sold on markets and screened by a 80-mesh screen in a dissolving tank; adding 6-15 times of water to mix and stir for 10-20 minutes while controlling water temperature at 50-60 DEG C; (2) using sodium hydroxide to adjust the pH value of the protein liquid to 7.0-8.0 and stirring the protein liquid for 10-20 minutes; (3) using a feeding pump to pump the protein liquid in an ultra-high temperature sterilizer so that the temperature reaches 120-155 DEG C, processing the protein liquid for 1-240 seconds and setting the temperature of a liquid outlet at 40-80 DEG C; (4) pumping the protein liquid in a spray drying tower for spraying and drying; (5) heating phospholipid at different processing stages, wherein the addition of the phospholipid is 0.1-1 percent of the dry weight of protein, and the HLB value of the phospholipid is 4-10; and (6) together adding sucrose ester and / or amber acid direactive glyceride and the phospholipid to the protein liquid, wherein the additions are respectively 0.1-0.5 percent of the dry weight of the protein. The invention remarkably improves the dissolvability of products, achieves the NSI of 50-80 percent and the haloduric index of 30-80 and has light color, mild flavor and good oil and moisture retention.

Owner:天津实发中科百奥工业生物技术有限公司

Red environment-friendly disperse dye mixture and application thereof

ActiveCN102952414AImprove dyeing effectGood sublimation fastnessOrganic dyesDyeing processDisperse dyeNuclear chemistry

The invention relates to the technical field of dye. Aiming at solving the problem that the textile products are required to meet the standard of ecological textile (Oeko-Tex Standard 100) in China, the invention provides a red environment-friendly disperse dye mixture which is prepared by mixing three components, i.e. mixing a dye A, a dye B and a dye C with auxiliaries, wherein the mixture comprises the following components based on parts by weight of: 15-80% of dye A, 10-69% of dye B, 0-10% of dye C and the balance of auxiliaries. After the dye mixture provided by the invention is used for dying, chlorophenasic acid and chlorophenosic acid can not be detected on the polyester fiber.

Owner:ZHEJIANG JIHUA GROUP +1

Rinse aid composition for use in automatic dishwashing machines, and methods for manufacturing and using

InactiveUS20090131297A1Reducing untoward appearanceLittle riskInorganic/elemental detergent compounding agentsAnionic surface-active compoundsWater solubleInorganic chemistry

A combination warewashing detergent rinse aid composition is provided according to the invention. The warewashing detergent composition includes an alkaline source and a water-soluble anion. The rinse aid composition comprises an acid. The alkaline source is provided in an amount effective to provide a use composition having a pH of at least about 8. The anion is present in sufficient amount to leave a residue of anions on the surface of the wares. The acid of the rinse aid has a sufficiently low pKa to react with the anions to form an insoluble oxide on the surface of the wares. The insoluble oxide reduces the surface tension of water on the surface of the wares thus reducing water spotting. Methods for using and manufacturing a combination warewashing detergent-rinse aid composition are provided.

Owner:ECOLAB USA INC

Hydrophilic mixed matrix materials having reversible water absorbing properties

InactiveUS6881364B2Improve wetting propertiesNon-fibrous pulp additionFlat articlesPolymer scienceOragene

Owner:U S ENVIRONMENTAL PROTECTION AGCY

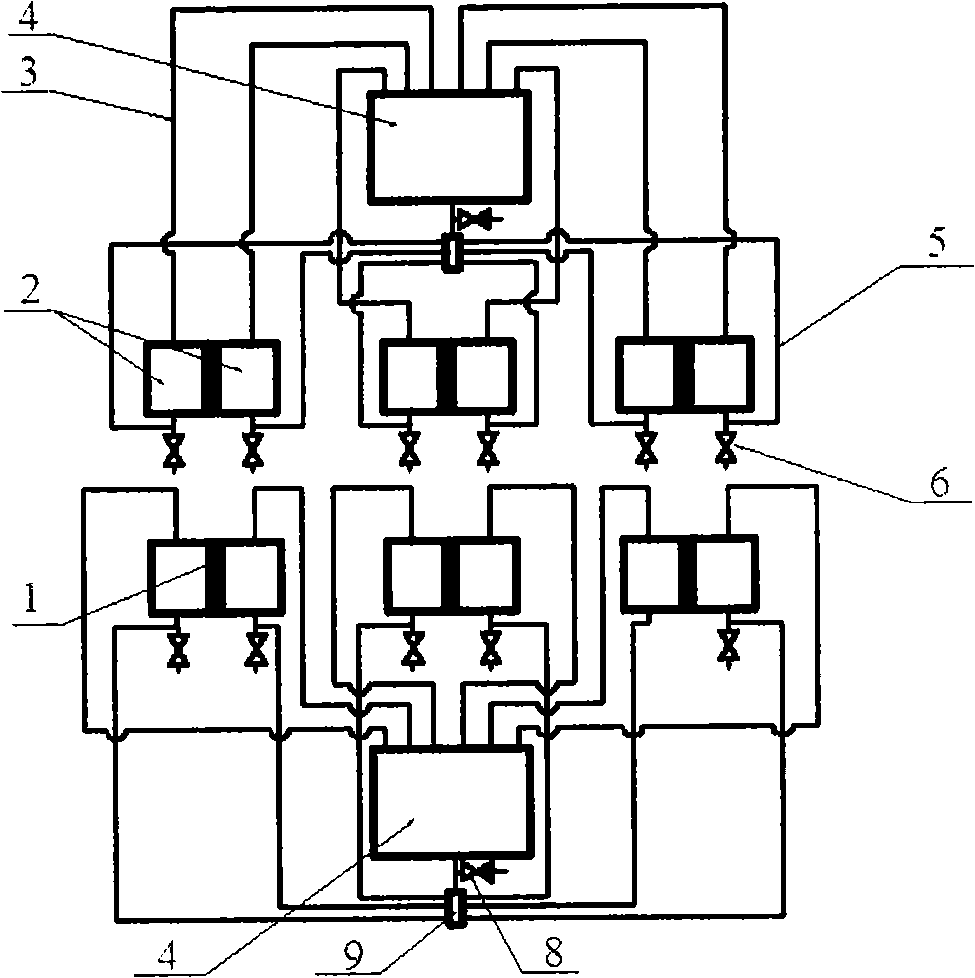

Silicon controlled thyristor device micro slot group composite phase change integrated cooling heat dissipation method and device

InactiveCN101814464AHigh strengthImprove stabilityThyristorSemiconductor/solid-state device detailsTemperature controlHeat flow

The invention provides a silicon controlled thyristor micro slot group composite phase change integrated cooling heat dissipation method and device, relating to the heat dissipation technology. The method includes that micro dimension composite phase change heat transfer characteristic of thin liquid film evaporation and thick liquid film boiling of liquid in open composite phase change micro slot group in a micro slot group composite phase change heat remover is utilized to remove heat. The device is provided with a micro slot group composite phase change heat remover at the two sides of single silicon controlled thyristor respectively, the silicon controlled thyristor removes heat in multiple groups, each group is provided with a wall type condenser heat dissipation structure, heat emitted by each silicon controlled thyristor can be taken out respectively and is carried into the wall type condenser by steam, condensation heat dissipation is carried out in condensation micro slot thereof, heat is taken away by external cooling water or air, condensed liquid reflows to the micro slot group composite phase change heat remover, and heat dissipation of silicon controlled thyristor with high power, large quantity and strong electric field is realized. The invention is safe and reliable, has small area, high heat-flow density, strong temperature control capability, high efficiency and low energy consumption and can be applicable to integrated cooling heat dissipation of a plurality of high power heat-emitting silicon controlled thyristors.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Dispersed azo dye mixture and application thereof

The invention relates to the technical field of dyes. As people pay more attention to the safety and health of textiles currently, the invention discloses a dispersed azo dye mixture and application of the azo dye mixture to solve the problem that organochlorine dyeing carriers are present in the textiles. The dispersed azo dye comprises the following components by weight parts: 1-40 weight partsof dye A, 1-49 weight parts of dye B, 0-60 weight parts of dye C, and 20-89 weight parts of dispersant. After dyeing with the dye mixture of the invention, no organochlorine dyeing carrier is detected in polyester fiber and the dyeing effect is not affected.

Owner:ZHEJIANG JIHUA GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com