Patents

Literature

1152 results about "Silver electrode" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

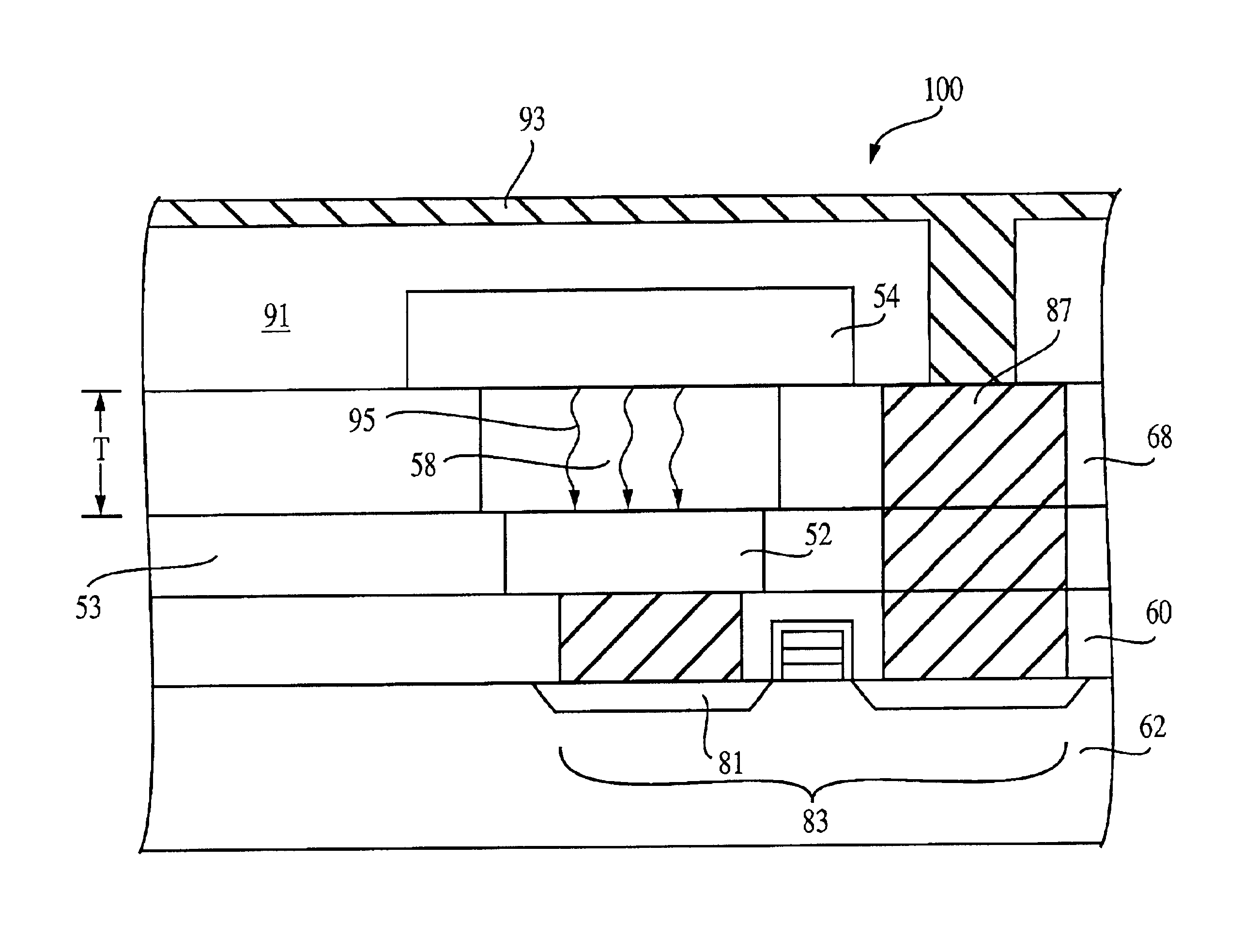

Programmable metallization memory cell with planarized silver electrode

ActiveUS20100193758A1Semiconductor/solid-state device detailsNanoinformaticsElectrical conductorSilver electrode

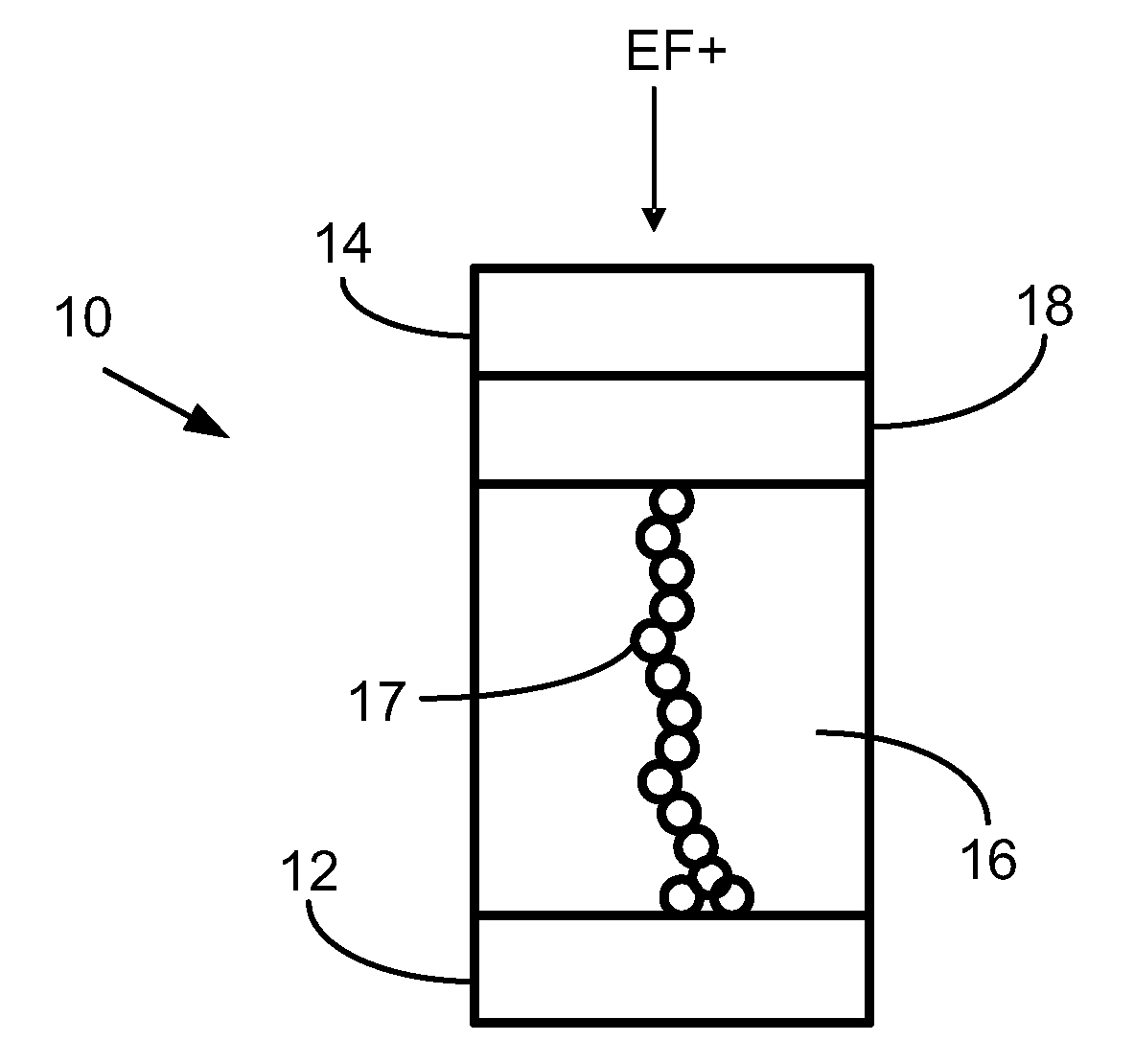

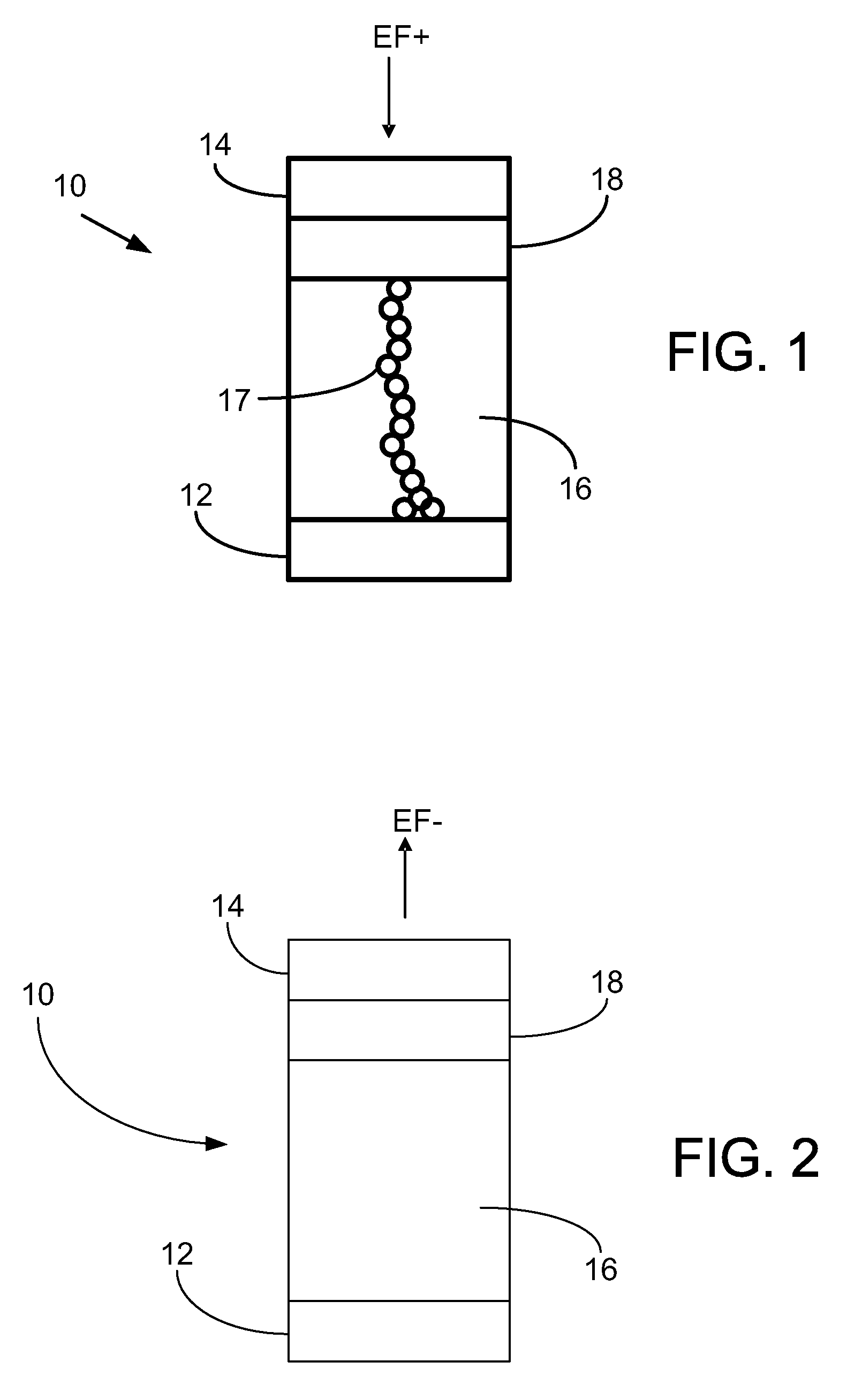

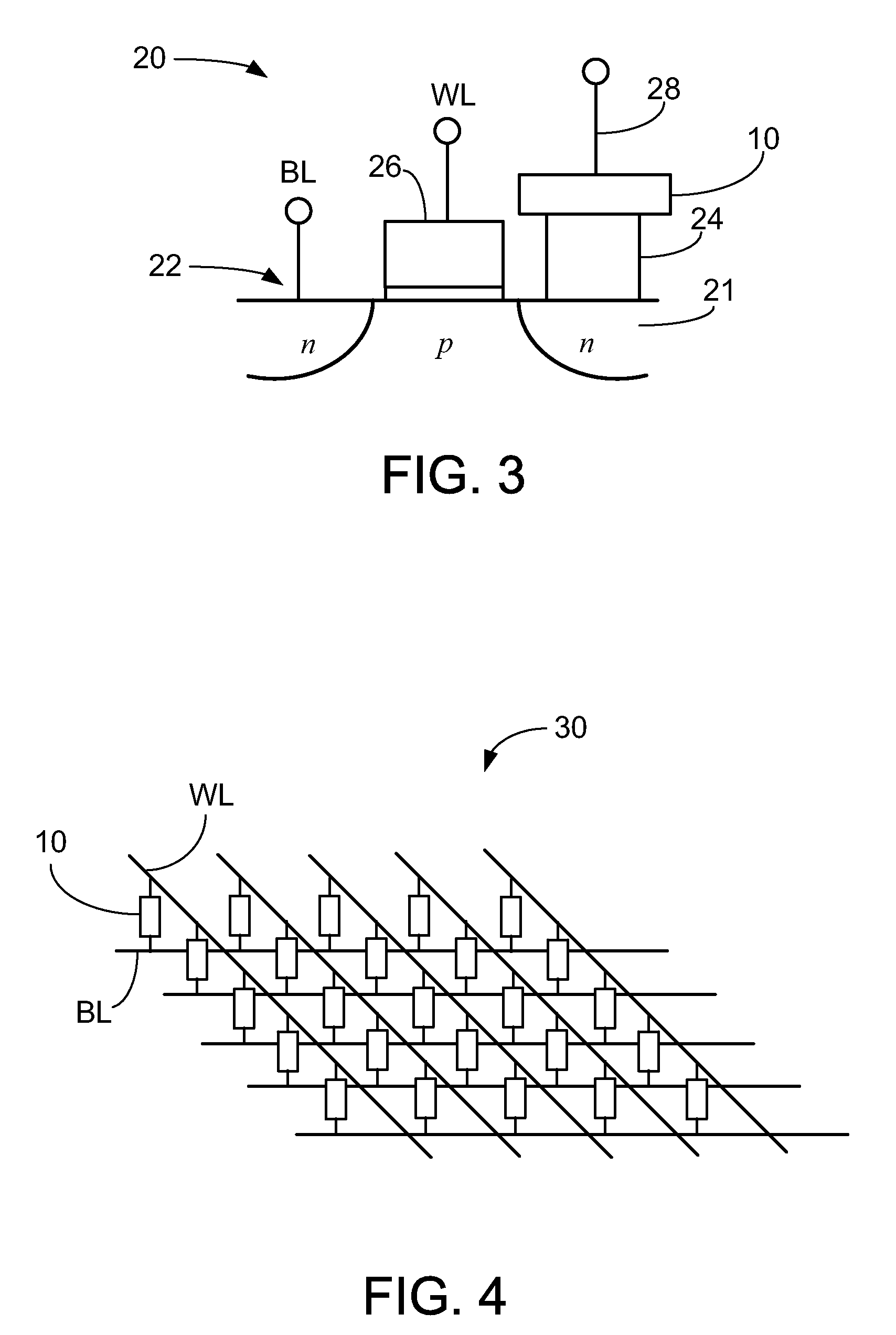

Programmable metallization memory cells having a planarized silver electrode and methods of forming the same are disclosed. The programmable metallization memory cells include a first metal contact and a second metal contact, an ion conductor solid electrolyte material is between the first metal contact and the second metal contact, and either a silver alloy doping electrode separates the ion conductor solid electrolyte material from the first metal contact or the second metal contact, or a silver doping electrode separates the ion conductor solid electrolyte material from the first metal contact. The silver electrode includes a silver layer and a metal seed layer separating the silver layer from the first metal contact.

Owner:SEAGATE TECH LLC

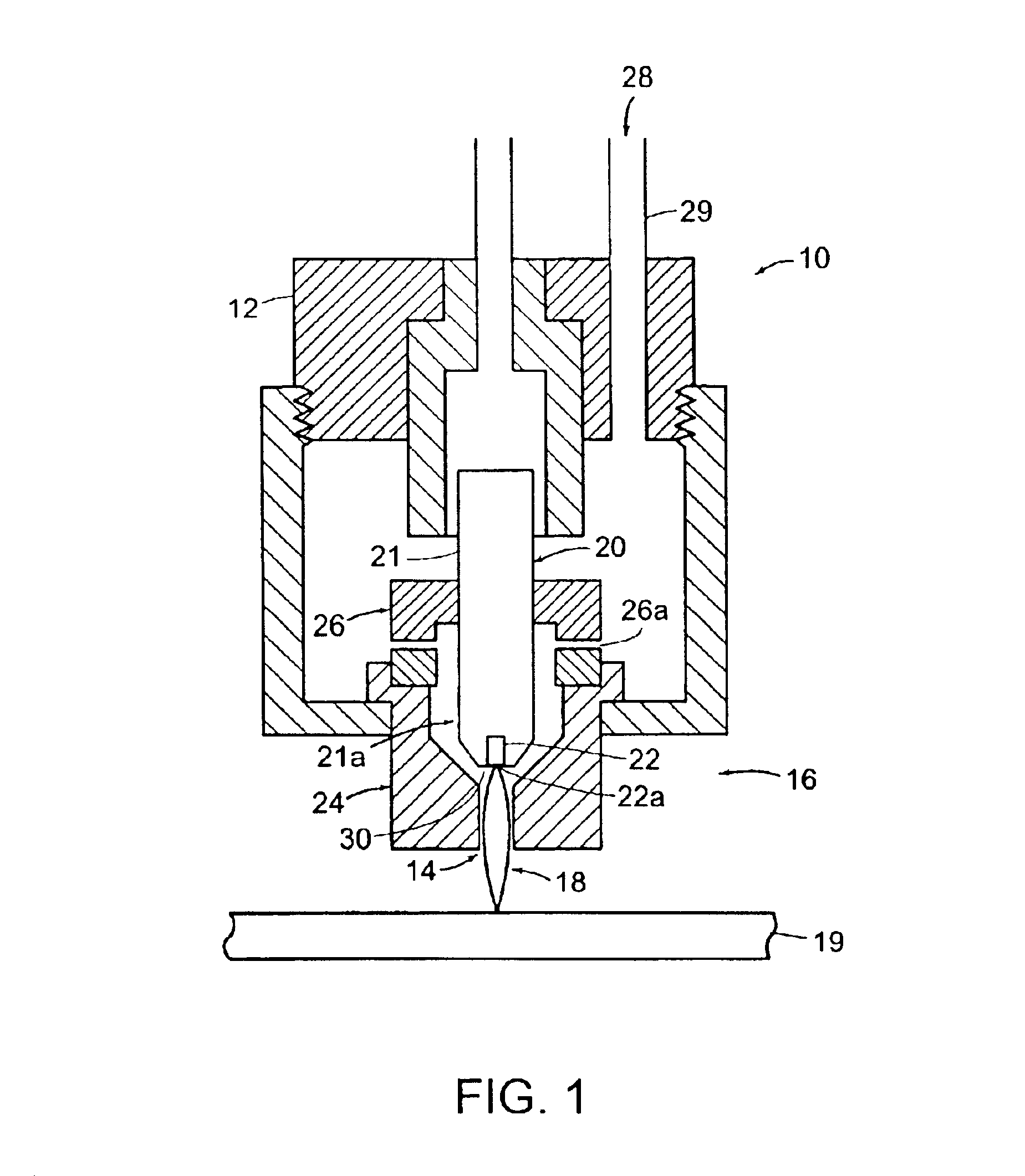

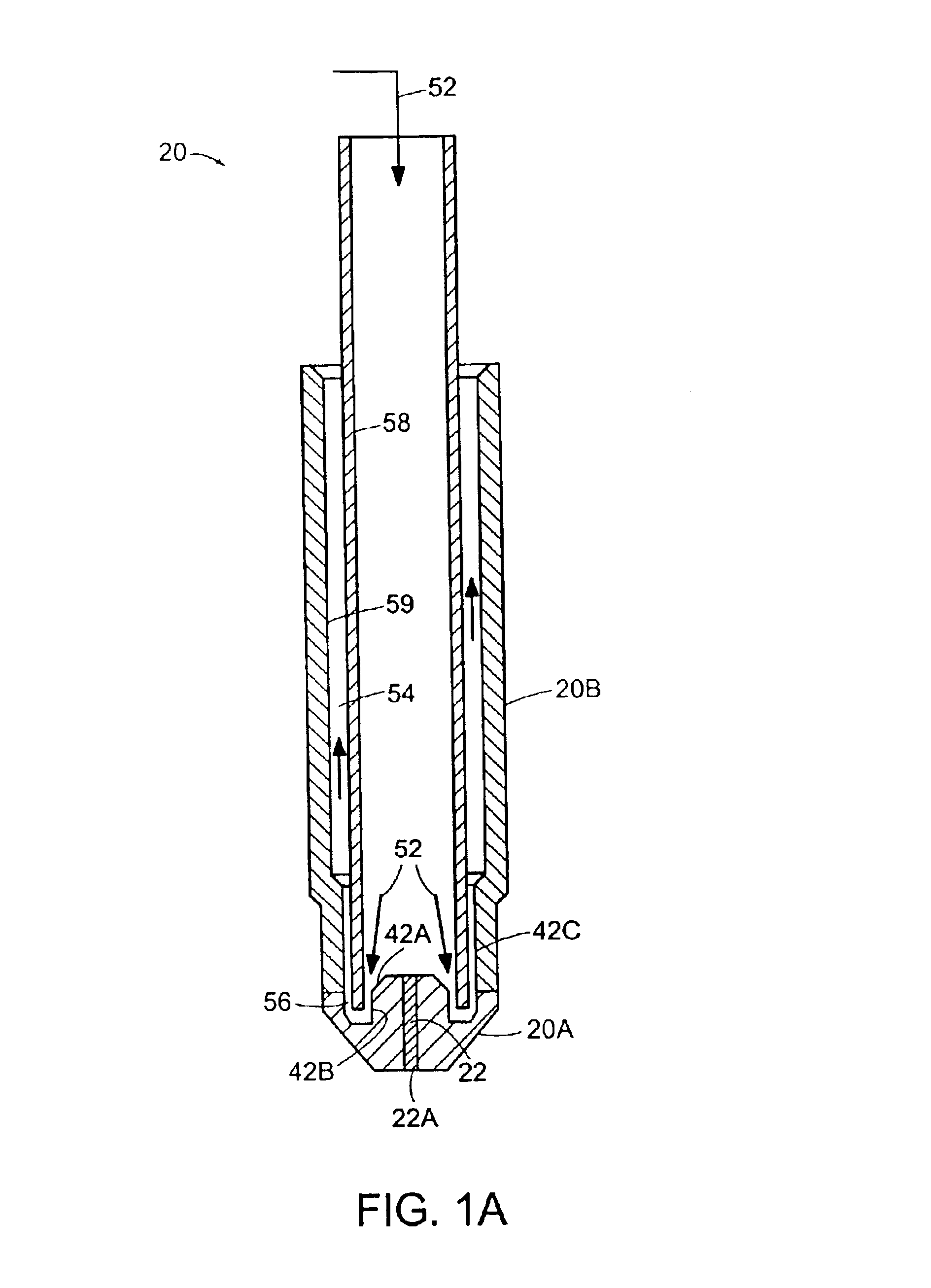

Composite electrode for a plasma arc torch

InactiveUS6841754B2Improve heat transfer performanceImprove thermal conductivityElectric discharge heatingArc welding apparatusMetallic materialsCopper electrode

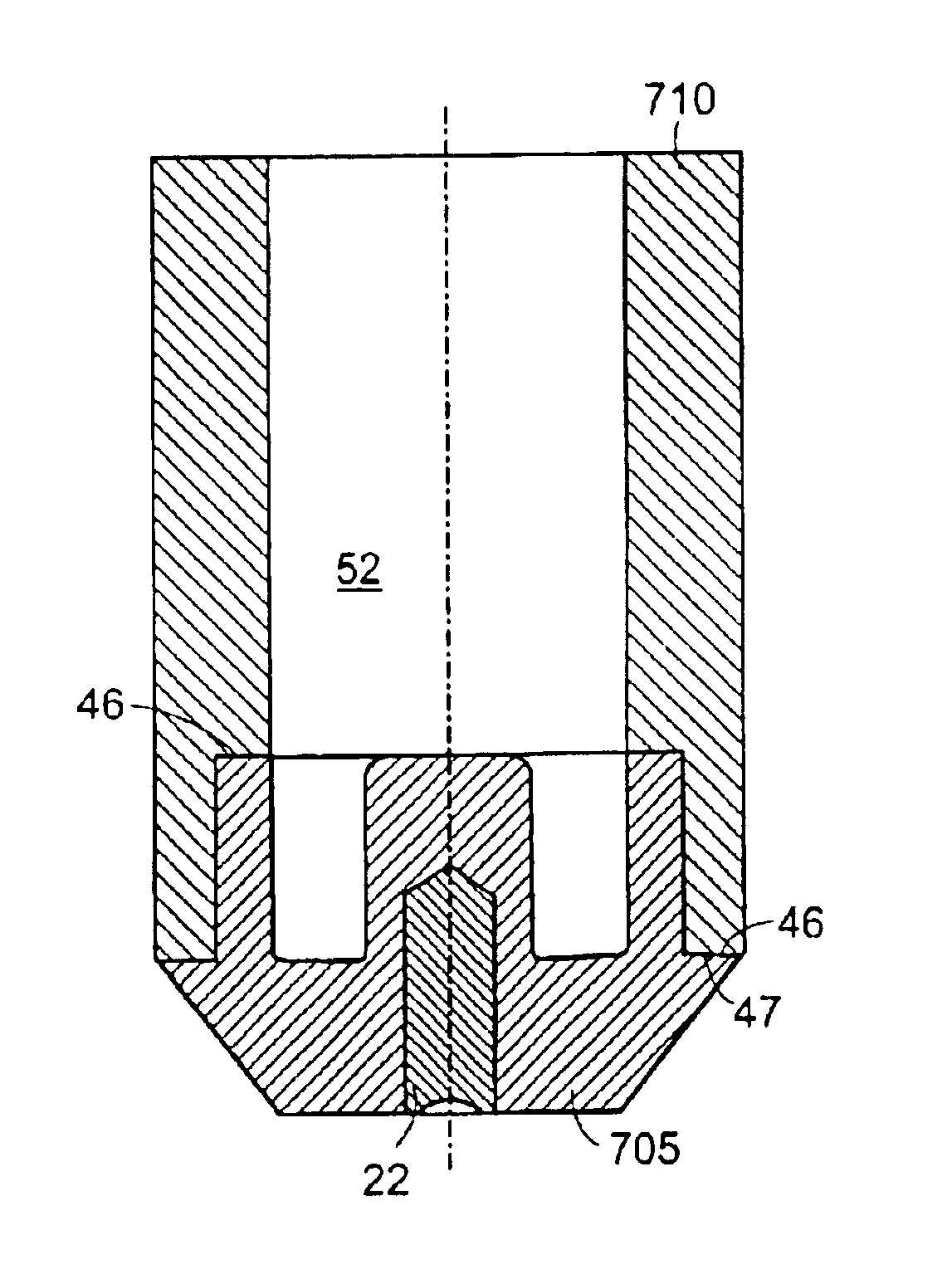

A plasma arc torch that includes a torch body having a nozzle mounted relative to a composite electrode in the body to define a plasma chamber. The torch body includes a plasma flow path for directing a plasma gas to the plasma chamber in which a plasma arc is formed. The nozzle includes a hollow, body portion and a substantially solid, head portion defining an exit orifice. The composite electrode can be made of a metallic material (e.g., silver) with high thermal conductivity in the forward portion electrode body adjacent the emitting surface, and the aft portion of the electrode body is made of a second low cost, metallic material with good thermal and electrical conductivity. This composite electrode configuration produces an electrode with reduced electrode wear or pitting comparable to a silver electrode, for a price comparable to that of a copper electrode.

Owner:HYPERTHERM INC

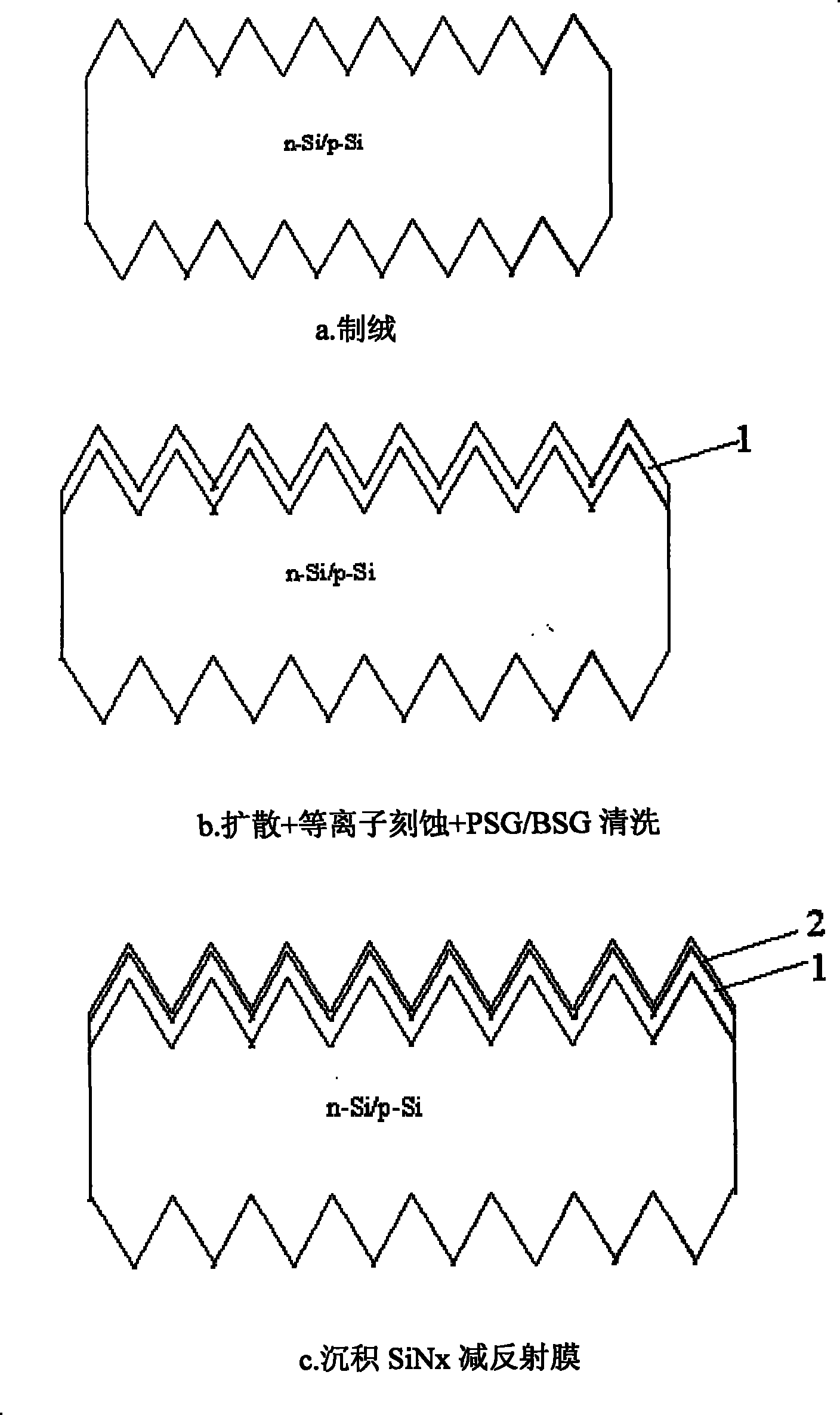

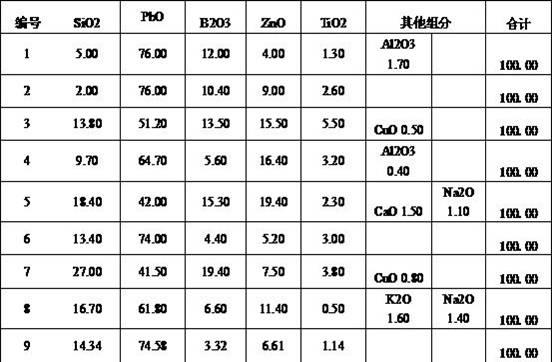

Lead-free silver conductive paste used for positive electrode of solar battery and preparation technique thereof

InactiveCN101609850AStrong adhesionLower resistanceFinal product manufactureConductive materialConductive pasteSilver electrode

The invention provides a lead-free silver conductive paste used for positive electrode of solar battery and a preparation technique thereof. The paste comprises the following materials by weight percentage: 65 to 85 percent of silver powder, 2 to 8 percent of lead-free glass powder, 10 to 25 percent of organic carrier and 0.1 to 3 percent of additive. The paste adopts the lead-free glass powder of Si-B-Bi-Al-Ti-Zn-O series to replace the traditional lead-bearing glass powder; and the series glass powder has lower softening point, can lead the silver electrode to have good adhesive force after sintering, and ensures the silver electrode to be well contacted with a silicon substrate. In addition, zinc resinate is used as the additive in the invention, not only can well improve the printing performance of the paste, but also can improve the electrical property of the electrode.

Owner:CENT SOUTH UNIV

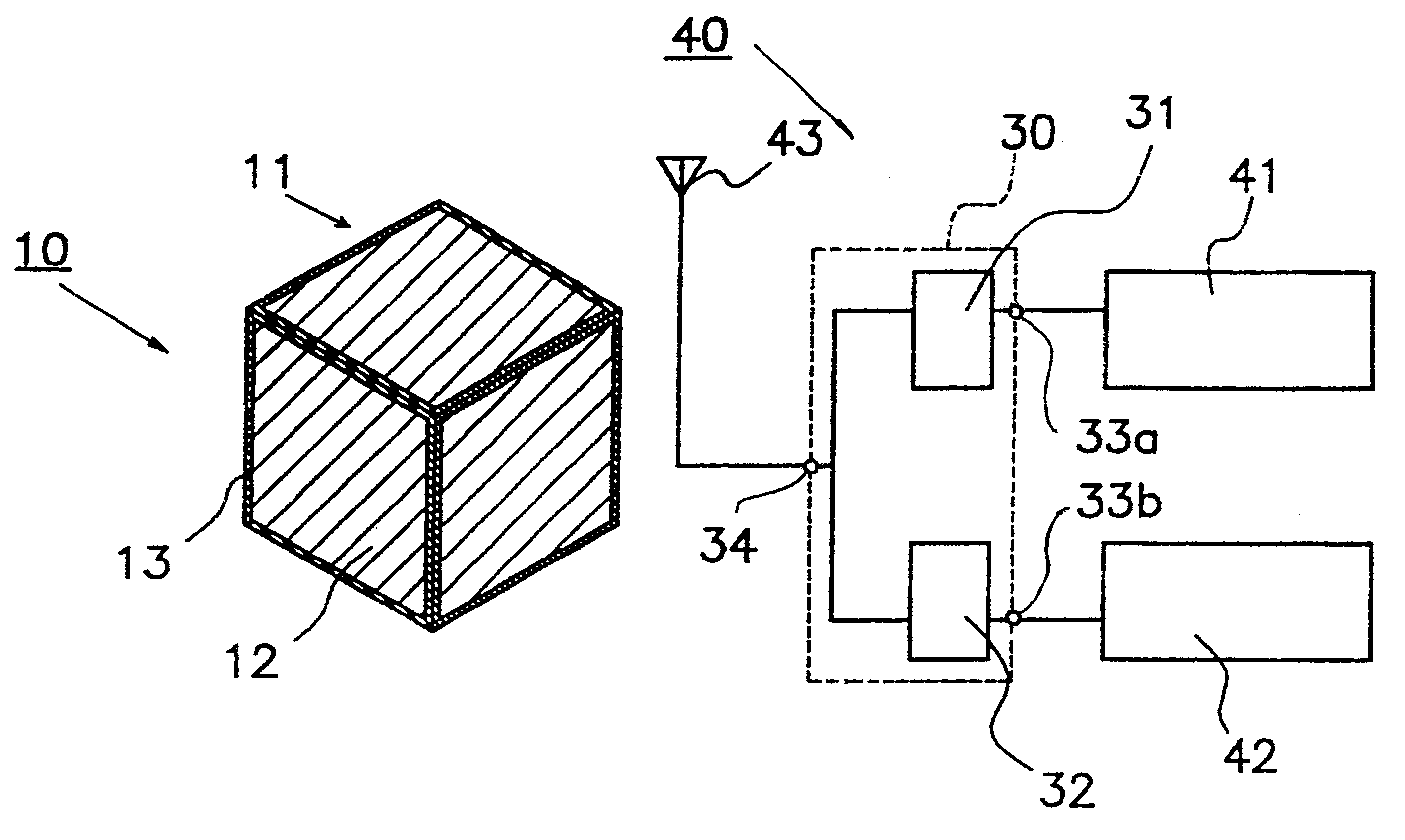

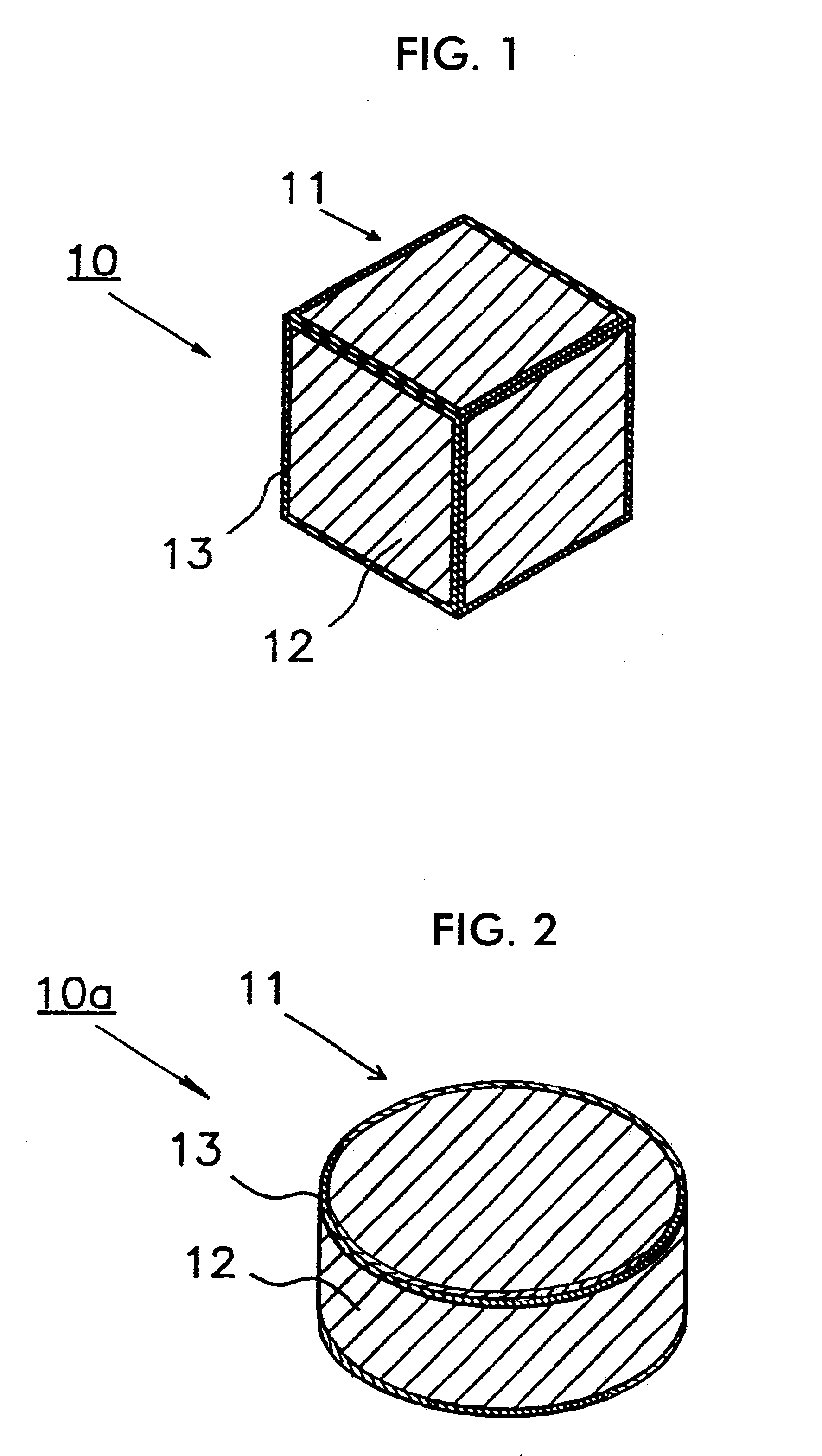

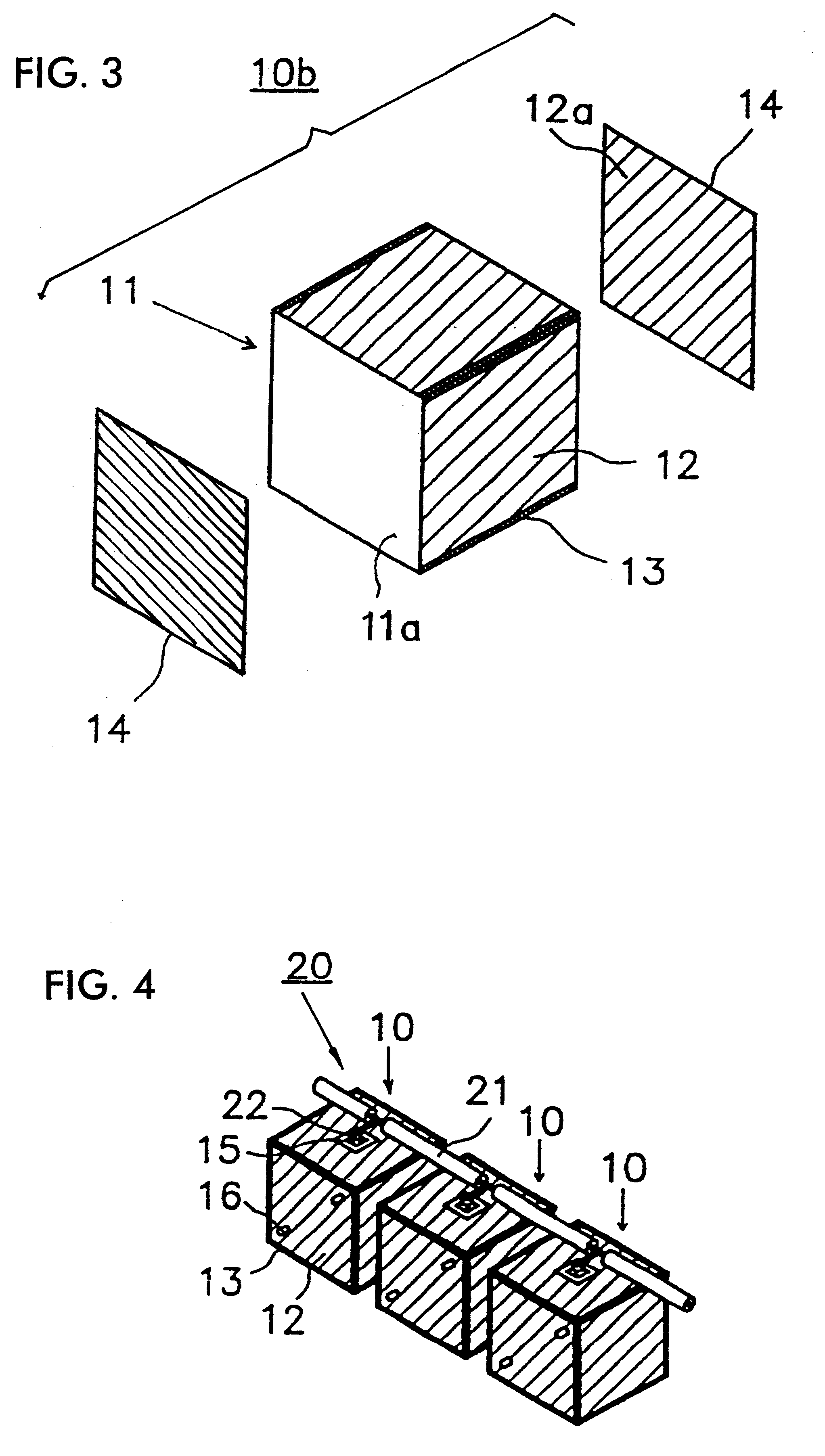

Electronic part, dielectric resonator, dielectric filter, duplexer, and communication device comprised of high TC superconductor

InactiveUS6470198B1Superconductors/hyperconductorsSuperconductor devicesElectrical conductorSilver electrode

In a dielectric resonator, a superconductor is formed on two neighboring surfaces of a cubic dielectric body, and the superconductors formed on each two neighboring surfaces are connected by a silver electrode formed in the vicinity of the edge where the neighboring two surfaces join.

Owner:MURATA MFG CO LTD

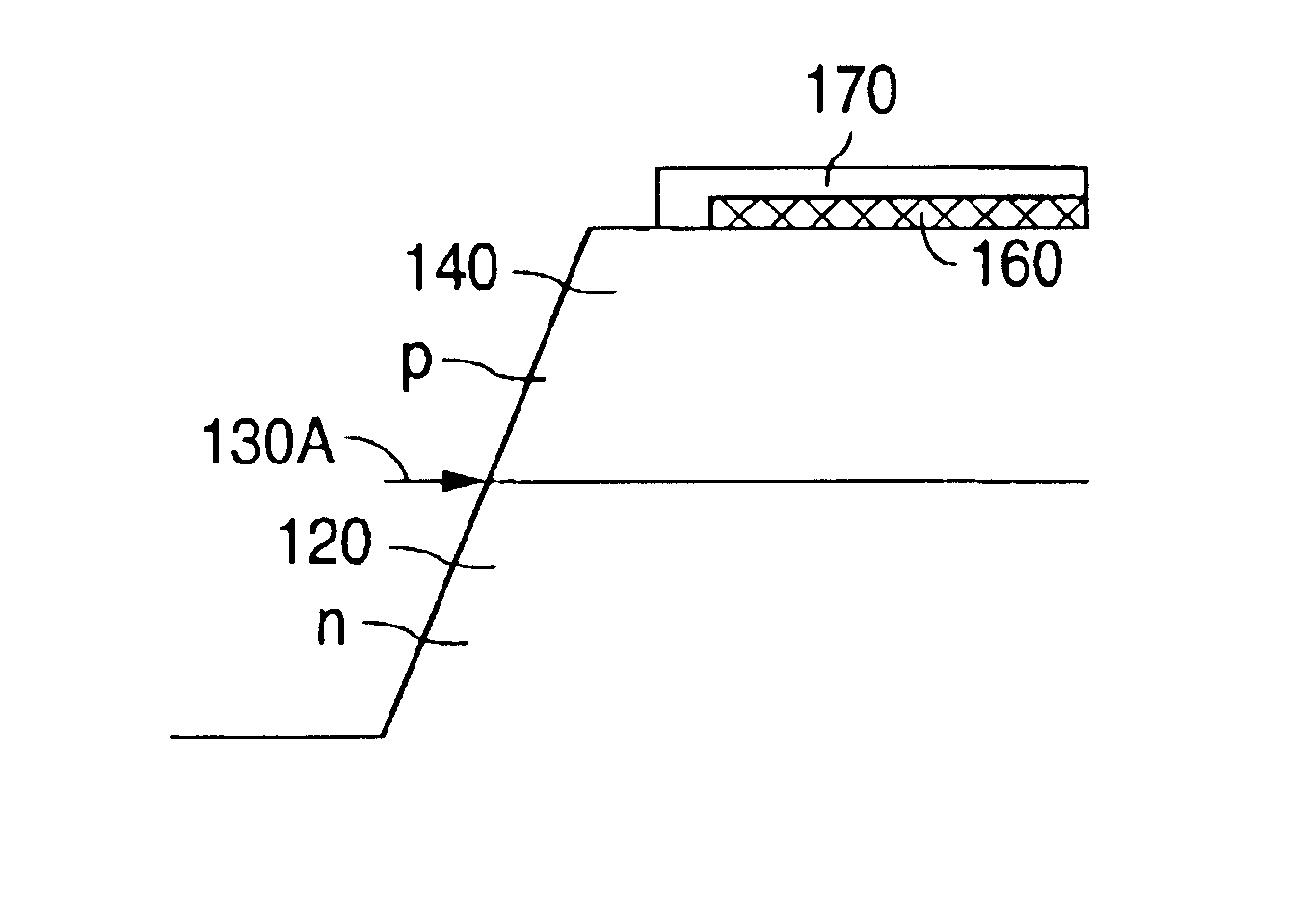

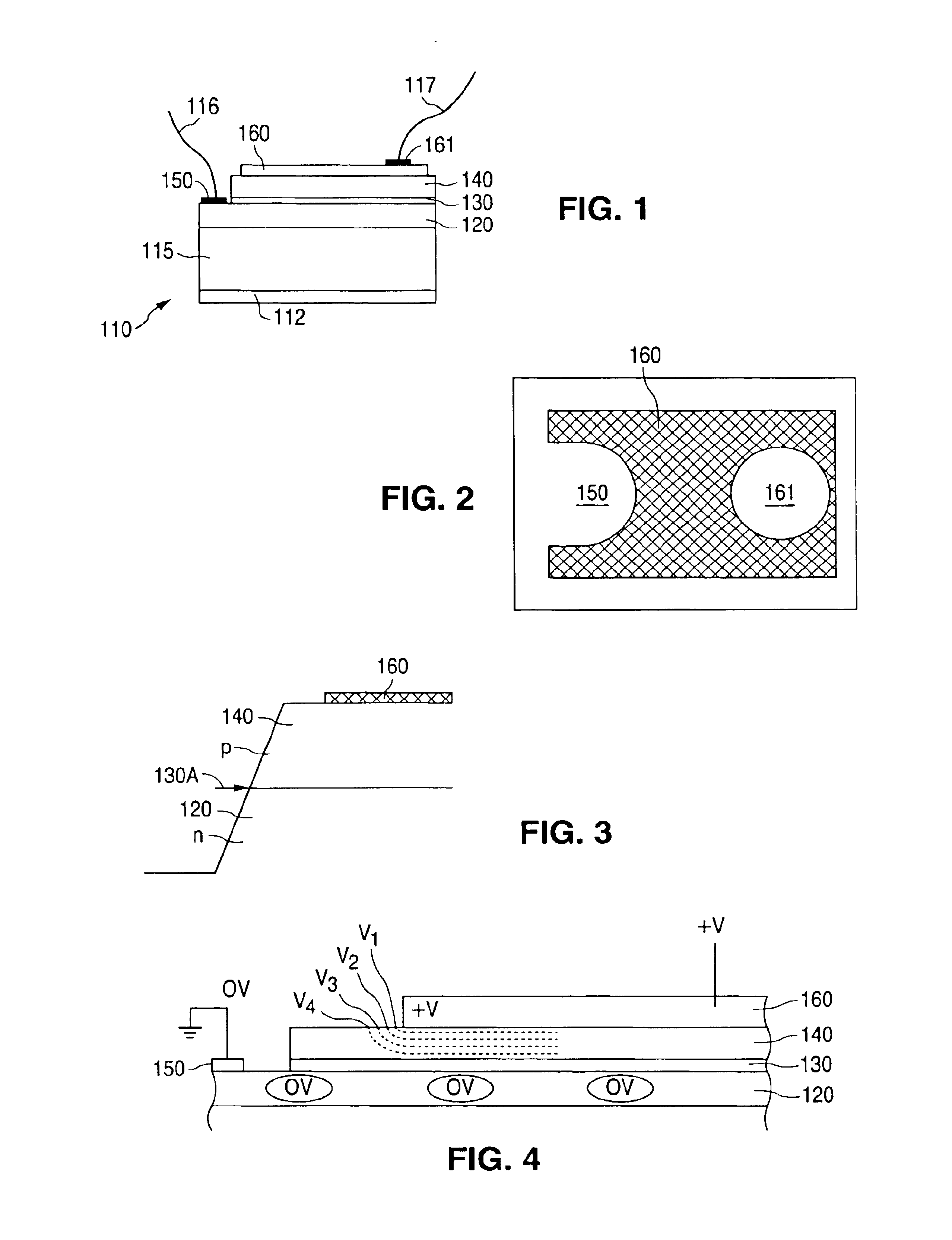

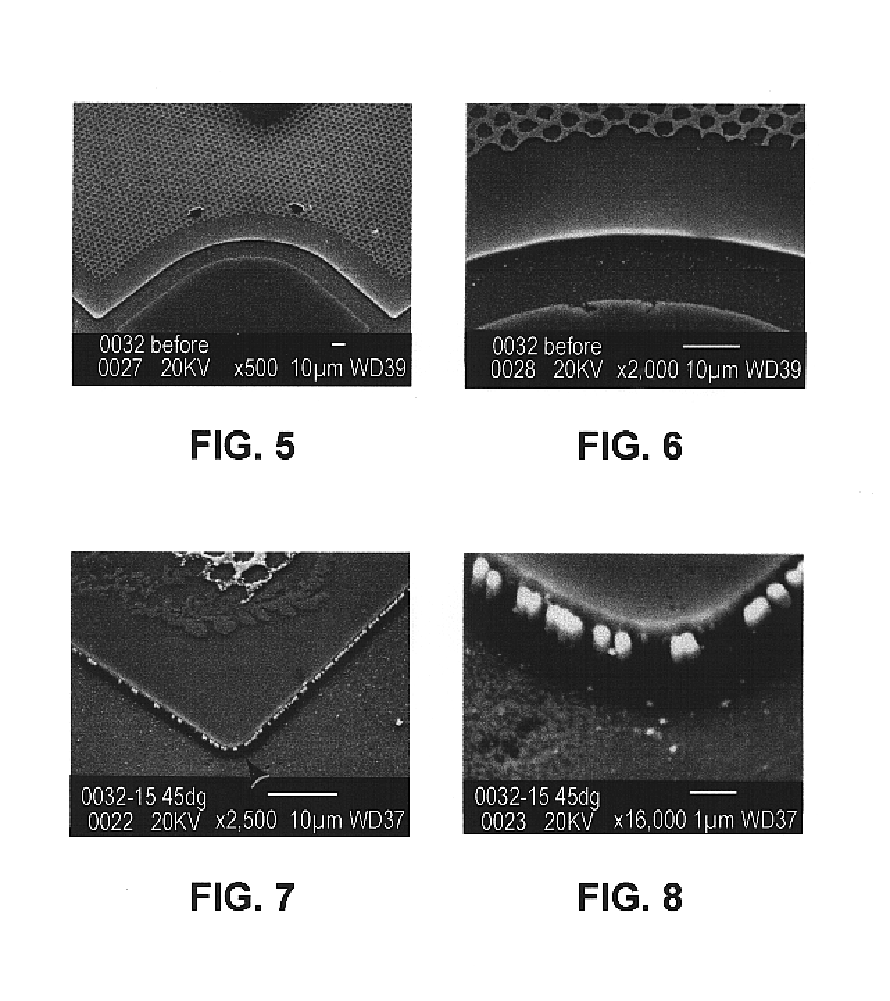

Light emitting semiconductor method and device

InactiveUS6946685B1Inhibit migrationSemiconductor/solid-state device detailsSolid-state devicesSilver electrodeElectrochemistry

Silver electrode metallization in light emitting devices is subject to electrochemical migration in the presence of moisture and an electric field. Electrochemical migration of the silver metallization to the pn junction of the device results in an alternate shunt path across the junction, which degrades efficiency of the device. In accordance with a form of this invention, a migration barrier is provided for preventing migration of metal from at least one of the electrodes onto the surface of the semiconductor layer with which the electrode is in contact.

Owner:LUMILEDS

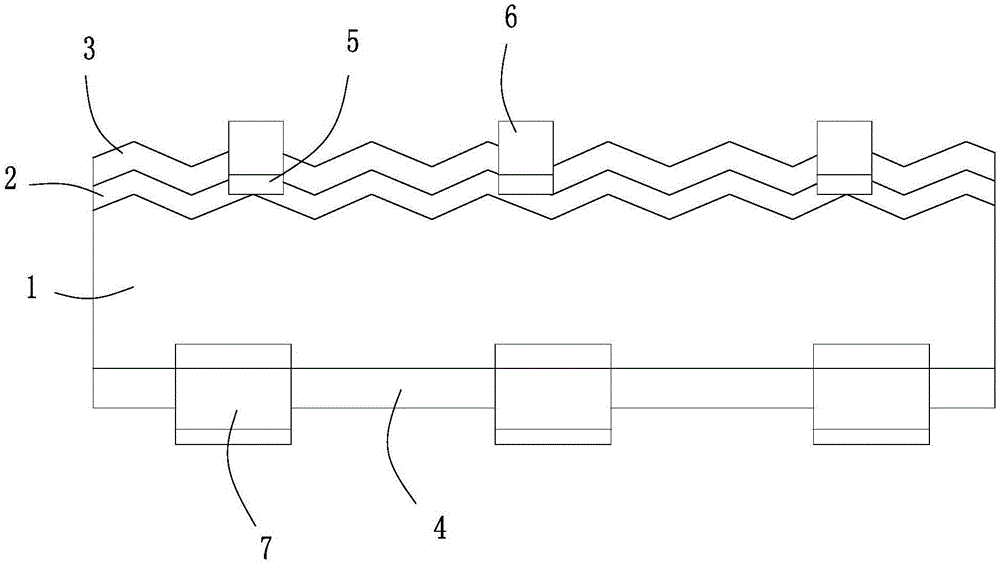

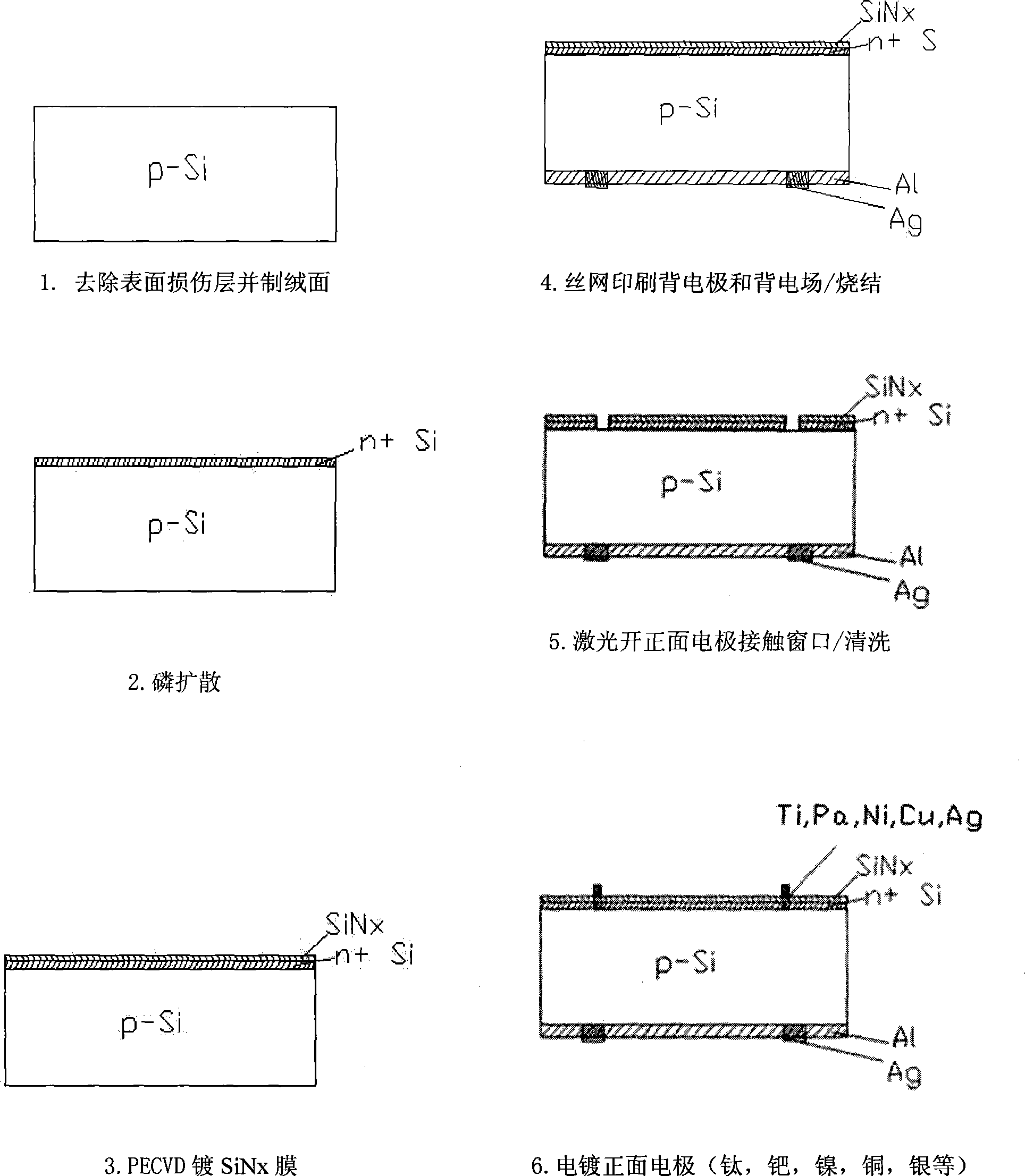

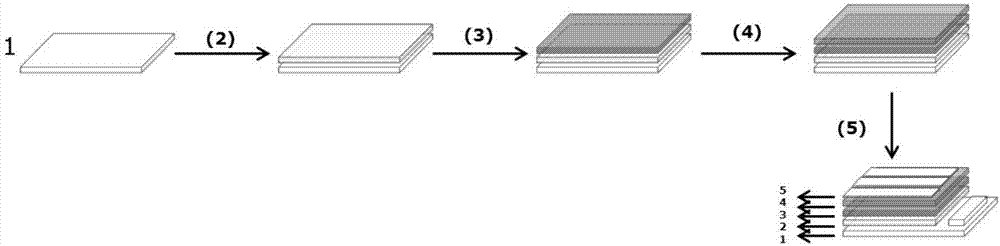

Producing method of selective emitter double-faced PERC crystalline silicon solar cell

ActiveCN106449876AEasy alignmentImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationSilicon solar cellCathode

The invention relates to a producing method of a selective emitter double-faced PERC crystalline silicon solar cell. The producing method is characterized by comprising the first step of removing affected layers of a silicon chip and conducting texturization and cleansing on the silicon chip, the second step of conducting diffusion to form a pn junction and eliminating phosphorosilicate glass in positive side of the silicon chip and the pn junction in the reverse side of the silicon chip after the diffusion; the third step of conducting deposition of aluminum oxide / silicon nitride laminated passivated film on the reverse side of the silicon chip and conducting deposition of a silicon nitride antireflection film on the positive side of the silicon chip; the fourth step of using an optical maser to conduct routing on the reverse side of the silicon chip to obtain a routing slot; the fifth step of using a phosphorous source to coat the positive side of the silicon chip; the six step of conducting laser doping on the positive side of the silicon chip to obtain a main guard line and a subsidiary guard line doped with the laser; the seventh step of conducting photoinduction on electronickelling / copper / silver electrode, conducting connections between the reverse side of the cell with a cathode of an external power supply, conducting electroplating on the positive and reverse sides of the cell simultaneously, and conducting electroplating of three metals of nickel / copper / silver in sequence; the eighth step of conducting annealing on the electroplated cell. According to the producing method of the selective emitter double-faced PERC crystalline silicon solar cell, the problem that an aluminum grid line is hard to be aligned with a laser windowing grid when a silk screen is used to conduct reverse printing of the double-faced PERC cell is solved.

Owner:WUXI SUNTECH POWER CO LTD

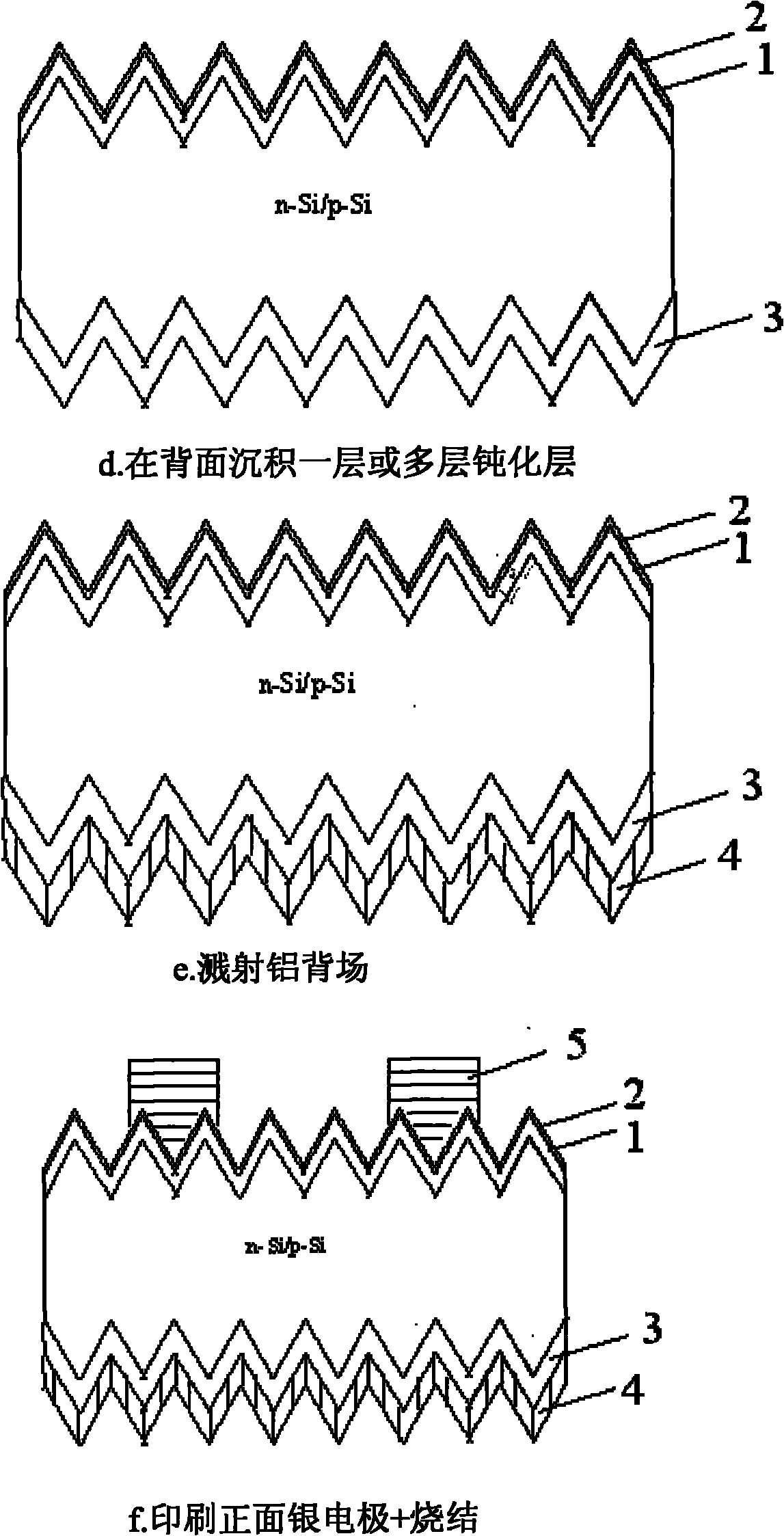

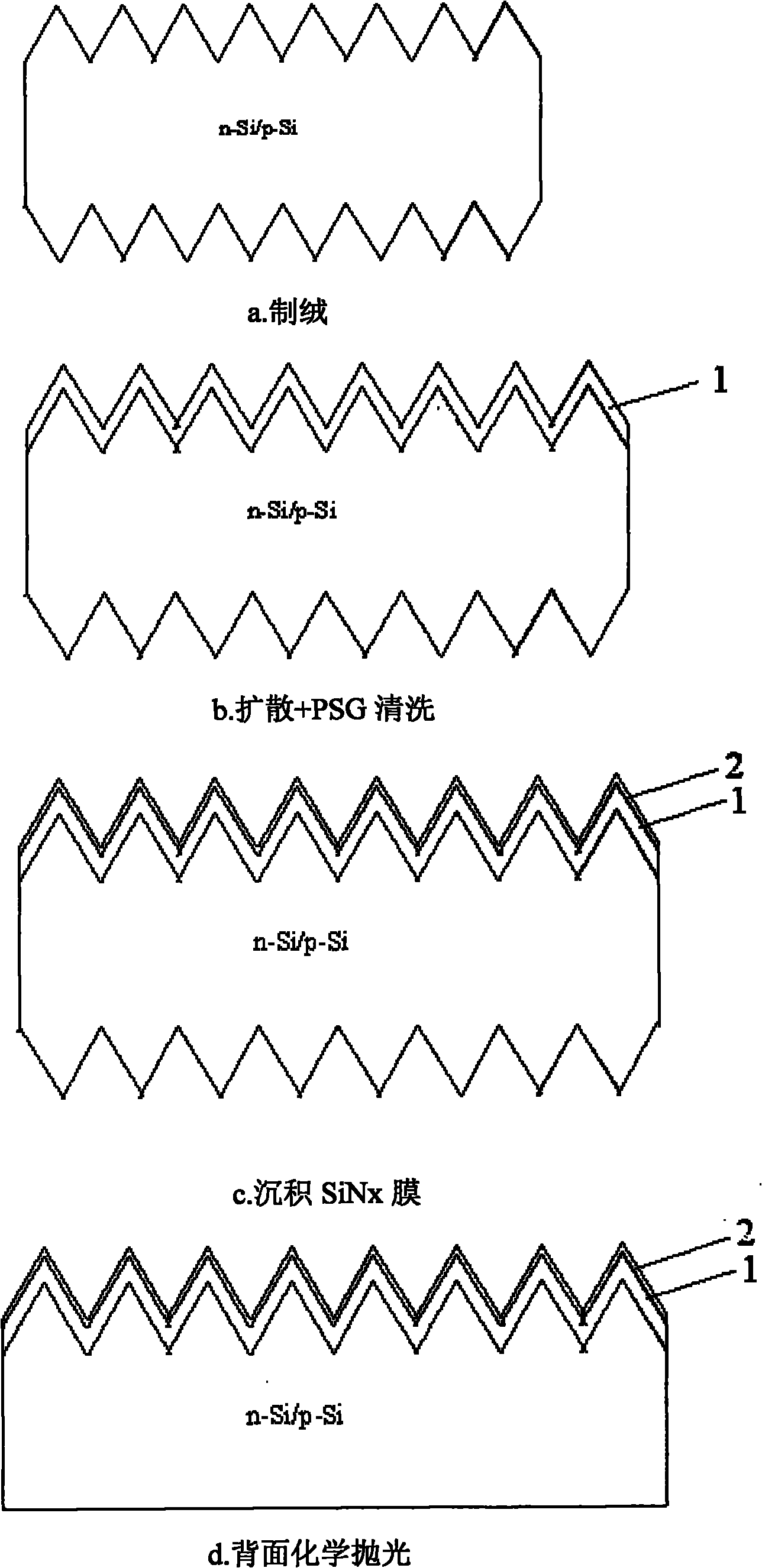

Method for preparing solar cell by using local area back field

ActiveCN101853899AEliminate the etching processSolve the leakFinal product manufactureSemiconductor devicesScreen printingSilver electrode

The invention discloses a method for preparing a solar cell by using a local area back field, which comprises the following steps of: selecting a silicon chip and making the silicon chip into a soft silicon chip, then performing boron or phosphorus dispersion, cleaning a boron-silicon glass layer or a phosphorus-silicon glass layer left on the surface of the silicon chip after the dispersion, depositing a silicon nitride film on the front of the silicon chip by using PECVD, polishing the back of the silicon chip by using hot alkali liquid, and depositing a passive film, performing laser perforation and sputtering an aluminum layer on the polished back; and finally, screen-printing a silver electrode on the front of the silicon chip, and sintering, testing and separating the silicon chip. The method avoids the problem of current leakage caused by lamination during etching; the PECVD process adopted by the passive film on the back is more suitable for large-scale production; the adoption of the back laser perforation improves the manufacturing speed, reduces the process step and avoids pollution brought by corrosive slurry; and the Al layer can be well sintered and contacted with the silicon through pores so that the contact area of the metal and the back surface silicon is smaller and the current carrier compounding rate of the back surface is reduced.

Owner:JA SOLAR TECH YANGZHOU

RTV silicone rubber composition for electric and electronic part protection, circuit boards, silver electrodes, and silver chip resistors

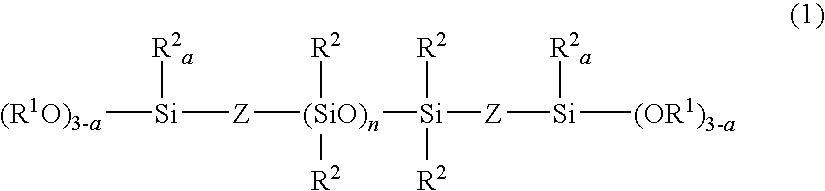

InactiveUS7553901B2Prevent and retard partPrevent short-circuitingLayered productsSemiconductor/solid-state device detailsSulfur containingElectron

RTV silicone rubber compositions are provided comprising (A) an organopolysiloxane, (B) an organosilicon compound or partial hydrolytic condensate thereof, and (C) a non-aromatic amino-bearing compound. The compositions, when electric and electronic parts having a copper, silver or other metal portion on their surface are encapsulated or sealed therewith, can prevent or retard the parts from corrosion with sulfur-containing gas.

Owner:SHIN ETSU CHEM IND CO LTD

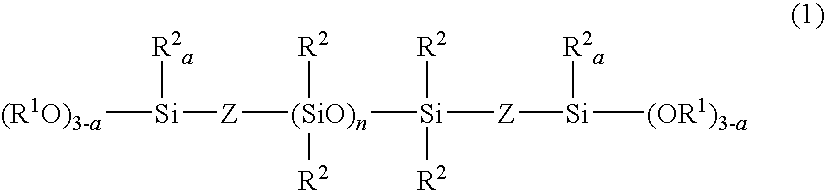

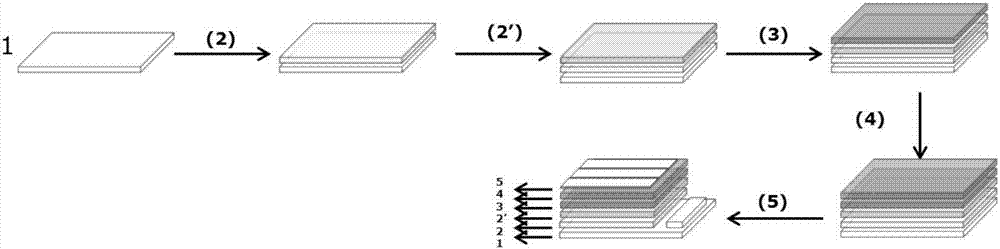

Perovskite solar cell and manufacturing method of perovskite solar cell

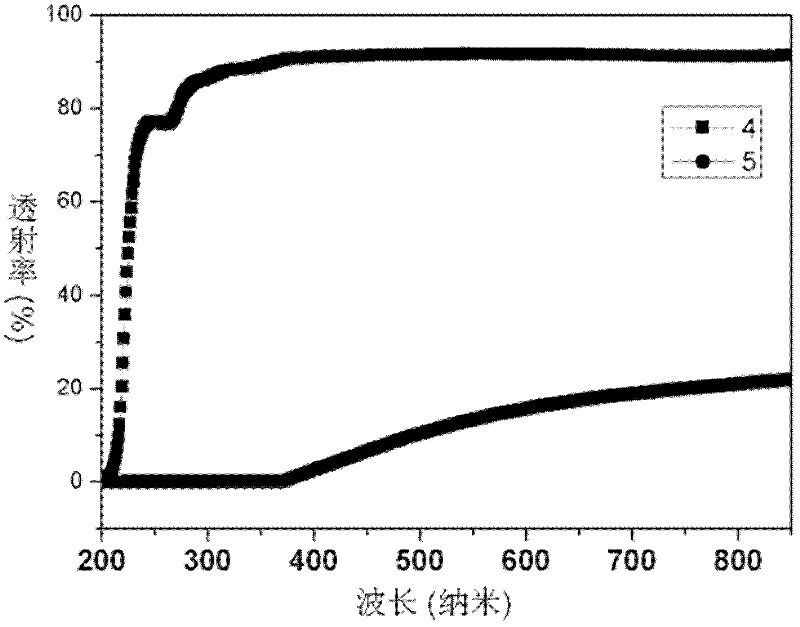

ActiveCN104576930AInsulationImprove efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSilanesEvaporation

The invention discloses a perovskite solar cell. The perovskite solar cell is characterized by sequentially comprising a conductive glass layer, a compact titanium dioxide film, a porous titanium dioxide film, a methylamine lead iodine polycrystalline film, a hole-transport material layer and an evaporation silver electrode layer. Interface modification is carried out on the methylamine lead iodine polycrystalline film through long-chain alkyl silane coupling agents, and the number of carbon atoms of the long-chain alkyl silane coupling agents is larger than six and smaller than sixteen. The invention further discloses a manufacturing method of the perovskite solar cell. Compared with the prior art, the perovskite solar cell and the manufacturing method have the advantages that as interface modification is carried out through the long-chain alkyl silane coupling agents, the recombination of electrons in the cell can be suppressed, and the stability of the cell in the wet environment can be improved.

Owner:NINGBO UNIV

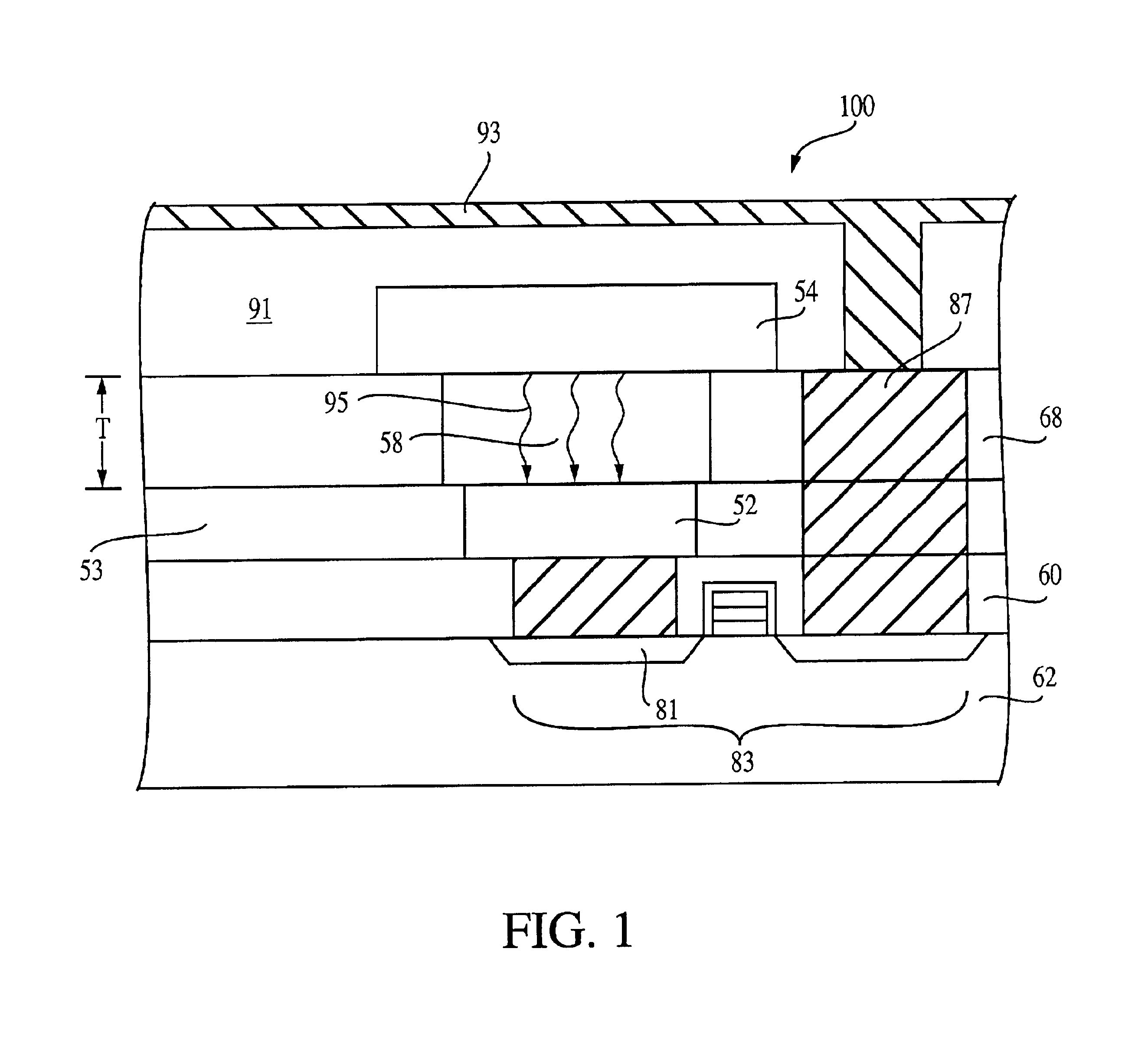

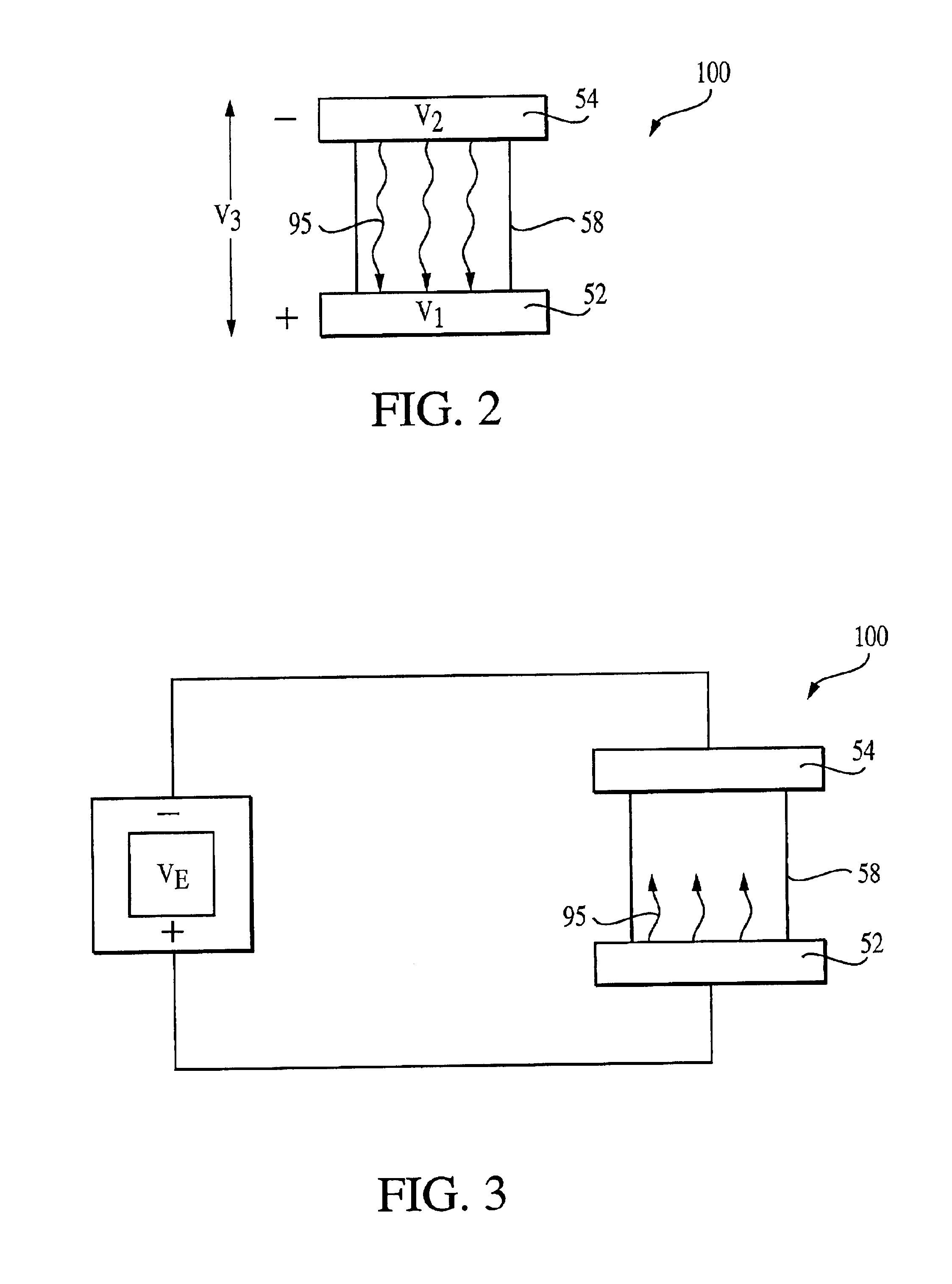

Resistance variable 'on ' memory

A resistance variable memory element and method for stabilizing the resistance variable memory element by providing a first and second electrode connected to a resistance variable material whereby the first and second electrodes comprise materials capable of providing a differential electrochemical potential across the resistance variable memory element which causes the resistance variable memory element to write to a predetermined “on” state. The resistance variable memory element is stabilized in a low resistance “on” state by the differential electrochemical potential. The first electrode preferably is a platinum electrode and the second electrode is preferably a silver electrode. The method and circuitry further includes a reverse refresh for stabilizing the resistance variable memory element in a high resistance state by applying a reverse voltage to the memory element.

Owner:OVONYX MEMORY TECH LLC

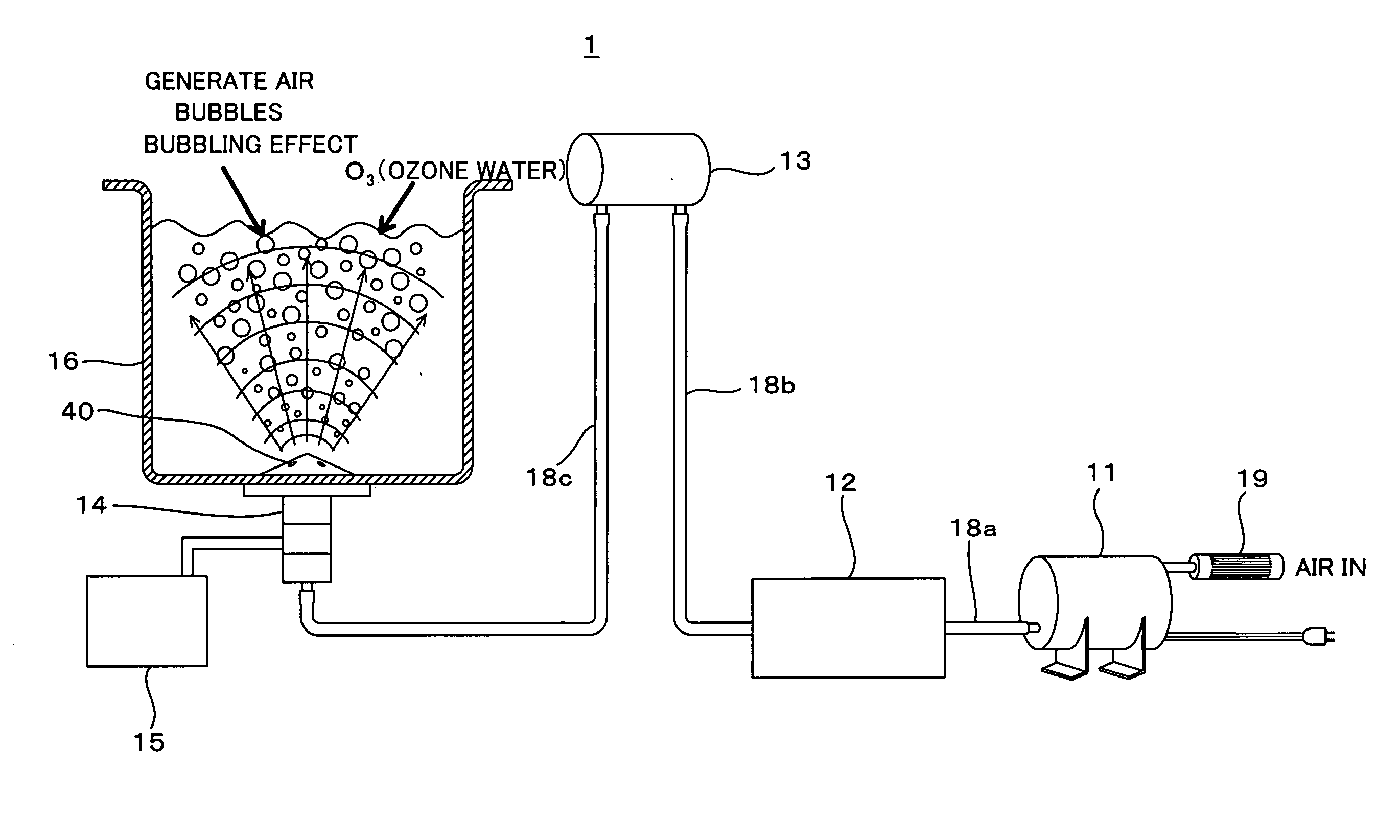

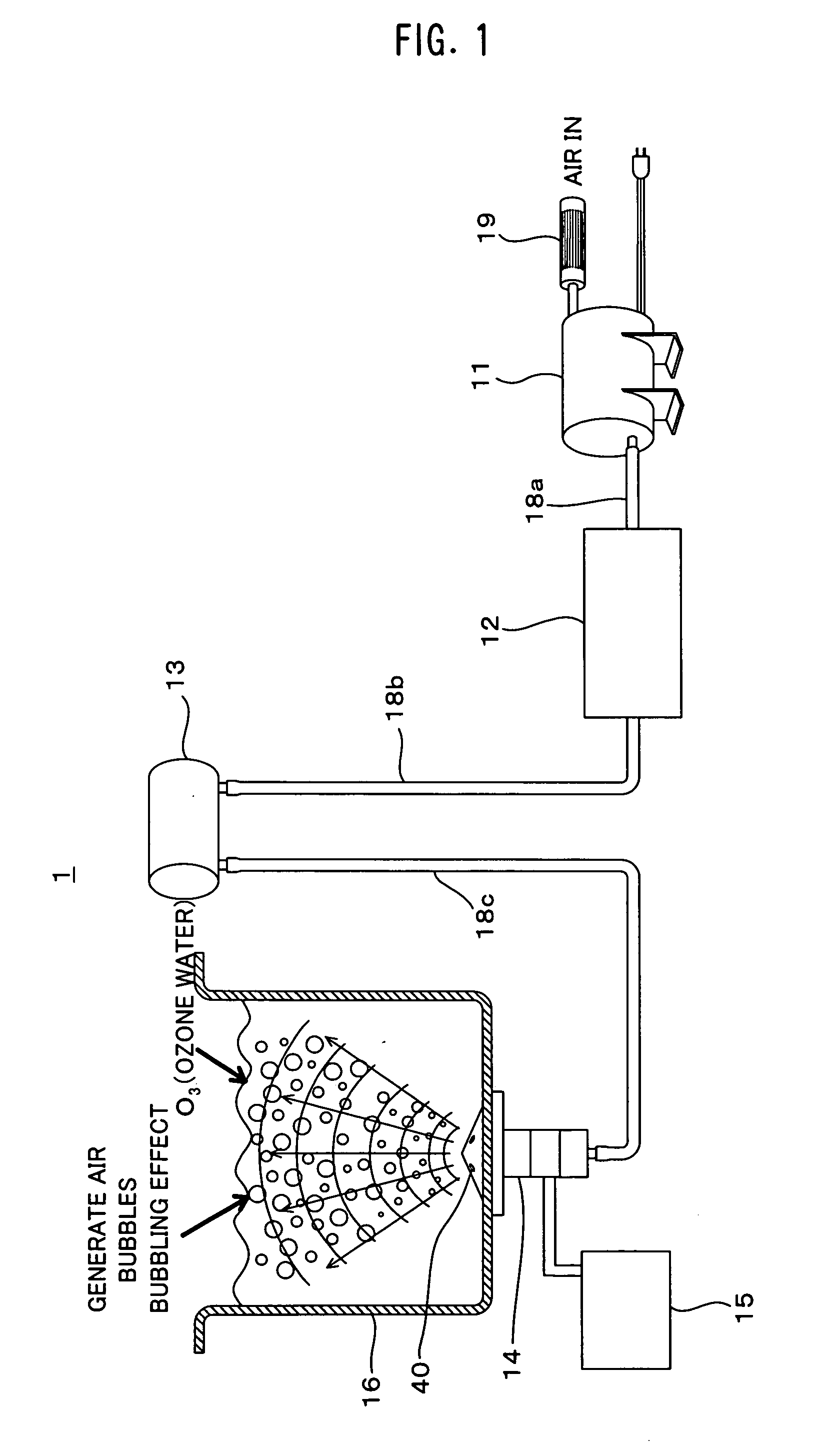

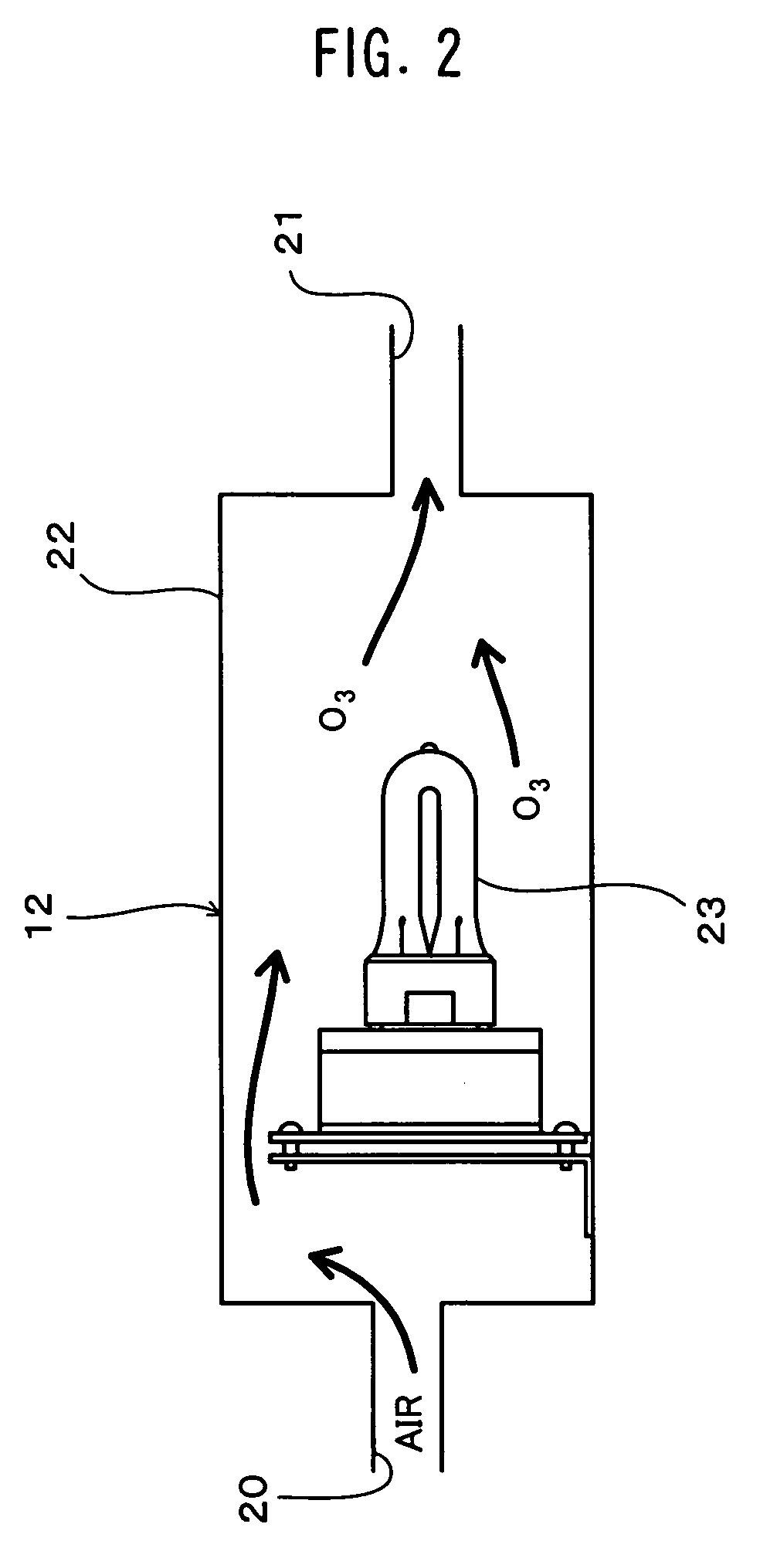

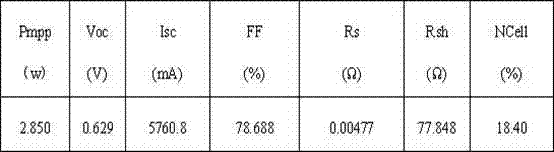

Ultrasonic Cleaning Method and Device

InactiveUS20080289971A1Clean and sterilize medical appliancesFrom normal temperature solutionsLiquid separation by electricitySilver electrodeMegasonic cleaning

An ultrasonic cleaning method and an ultrasonic cleaning device are provided, which are capable of performing simultaneously cleaning and sterilization of medical appliances or the like, and which can also be used for washing hands for disinfection without any special waste water treatment. The ultrasonic cleaning method for cleaning an object to be cleaned by using an ultrasonic wave includes the steps of putting cleaning fluid and the object to be cleaned in a cleaning tank (16), and applying ultrasonic vibrations to the cleaning fluid from an ultrasonic vibration member disposed in the cleaning tank (16) while ejecting air containing ozone into the cleaning fluid. The vibration portion has a communicating conduit 40 that opens at the surface thereof, and air containing ozone is discharged into the cleaning fluid from the communicating conduit. A silver electrode is disposed in the cleaning fluid, and electrolytic sterilization by silver ions is performed for the object to be cleaned adding to sterilization by ozone.

Owner:KAGOSHIMA SUPERSONIC TECHN LAB

Silver paste for back face of lead-free crystal silicon solar cell and preparation method thereof

InactiveCN102364583AToxicStrong pollutionNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSilver electrode

The invention discloses silver paste for the back face of a lead-free crystal silicon solar cell. The paste is characterized by being prepared from the following components in percentage by weight: 55-84 percent of silver powder, 15-38 percent of modified organic bonding agent and 1-10 percent of inorganic bonding agent. The invention further discloses a preparation method of the silver paste forthe back face of the lead-free crystal silicon solar cell. The silver paste has the advantages of excluding of toxic substances such as lead and the like, small damage to human bodies and realizationof high adhesion between a silver electrode and a silicon substrate.

Owner:NINGBO GUANGBO NEW NANOMATERIALS STOCK

Flexible semi-clarity strain sensor and preparation method thereof

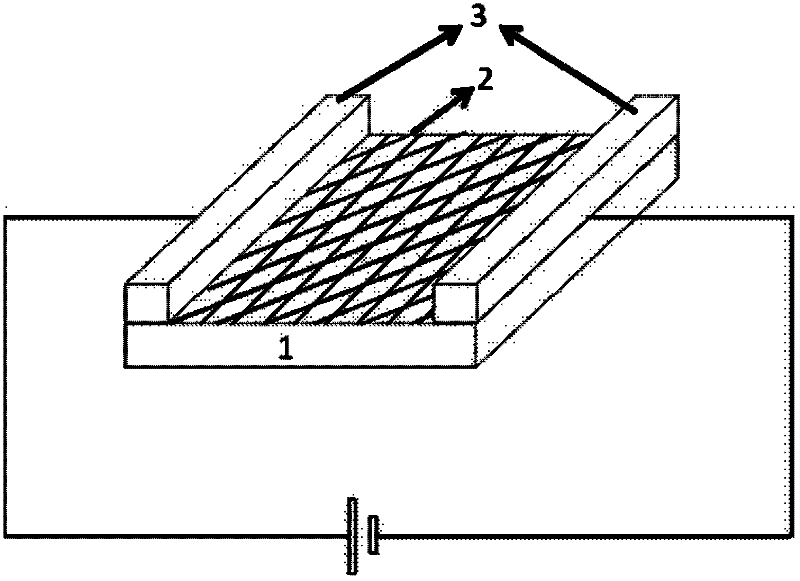

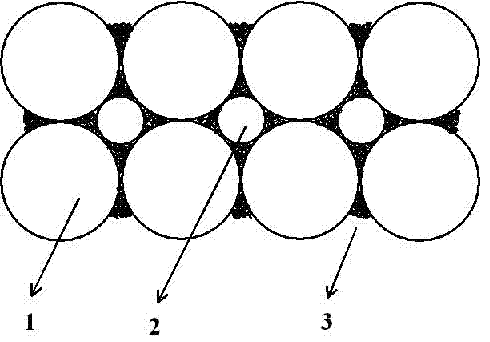

InactiveCN102353324AIncreased durabilityIncreased sensitivityDecorative surface effectsElectrical/magnetic solid deformation measurementPolystyreneEngineering

The invention discloses a flexible semi-clarity strain sensor and a preparation method thereof. The sensor is characterized in that: a functional layer is provided on a flexible polymer substrate, the functional layer is a latticed structure which is formed by ZnO and nanofiber, and two sides of the functional layer are titanium and silver electrodes. The invention provides a method for preparinga super-high strain resistance semi-clarity stretching type mechanics sensor based on a zinc oxide nano wire / polystyrene nanofiber hybrid structure on a polydimethylsiloxane substrate. Transmissivities of the sensor before and after zinc oxide growth are represented. The sensor can detect force as high as 50% and has high endurance, rapid response and high sensitivity. A device can be applied to a human body rapid motion test simultaneously. In addition, through driving of a solar energy cell, the device becomes potential application of an outdoor self driven sensor system. The method in the invention has the characteristics of simplicity and a low price, and the sensor has the characteristics of semi-clarity, high strain resistance, high sensitivity, rapid response and the like.

Owner:HUAZHONG UNIV OF SCI & TECH

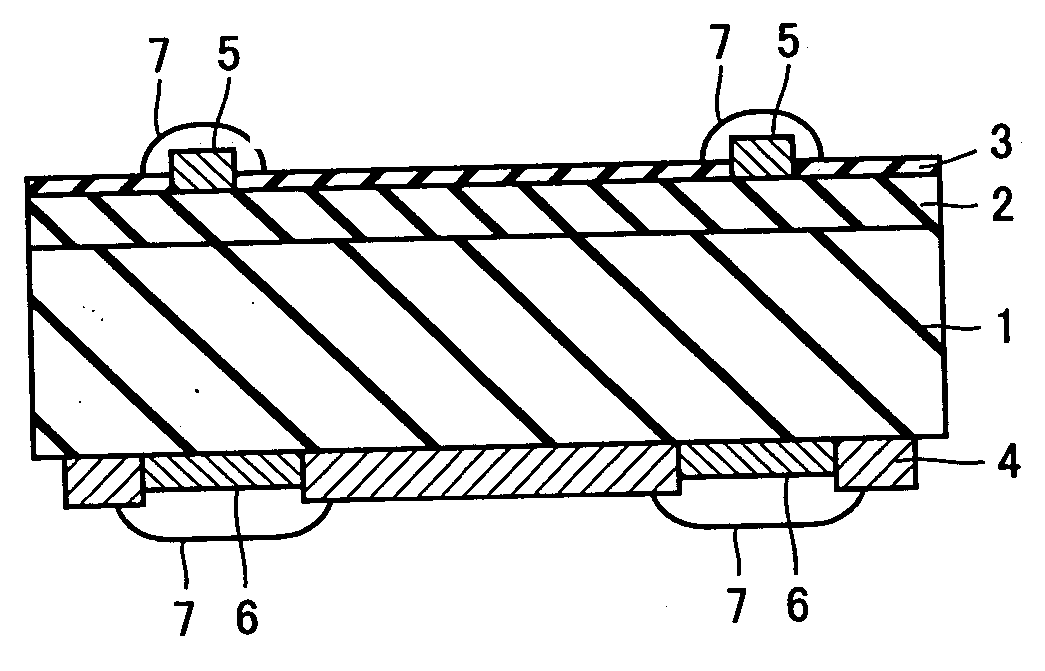

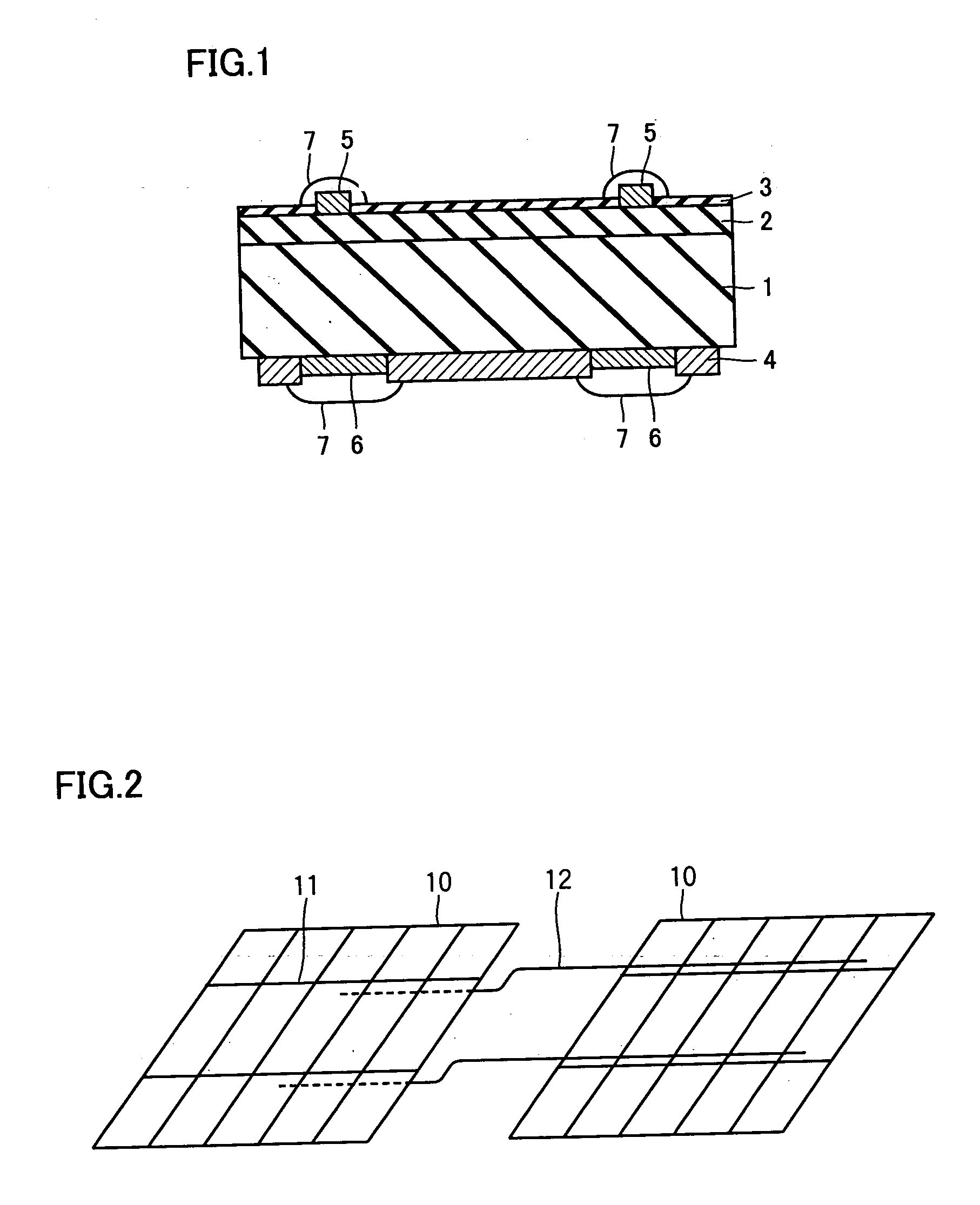

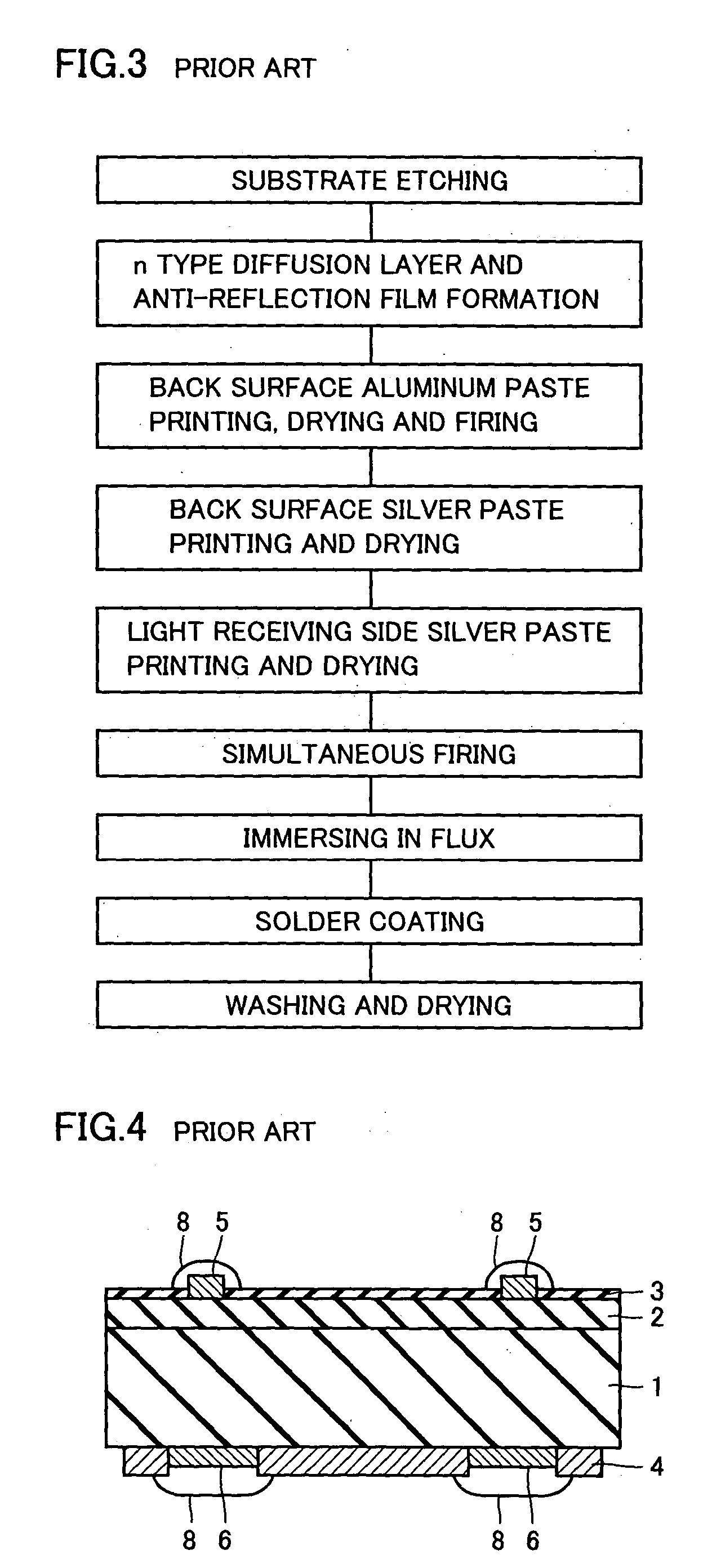

Solar cell and fabrication method thereof, interconnector for solar cell, solar cell string, and solar cell module

InactiveUS20040154658A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationSilver pasteSilver electrode

A solar cell has phosphorus included in a lead-free solder layer that covers silver electrodes. The amount of phosphorus in the lead-free solder is preferably 0.00001 to 0.5 mass %. The silver electrodes are silver paste electrodes formed by firing silver paste. A solar cell string interconnects such solar cells with an interconnector coated with the lead-free solder. A solar cell module incorporates such a string. Thus, a solar cell of high reliability, improved in wettability of lead-free solder, exhibiting thin coating of an electrode by lead-free solder, suppressed in detachment of interconnector a solar cell string, or a solar cell module can be provided.

Owner:SHARP KK

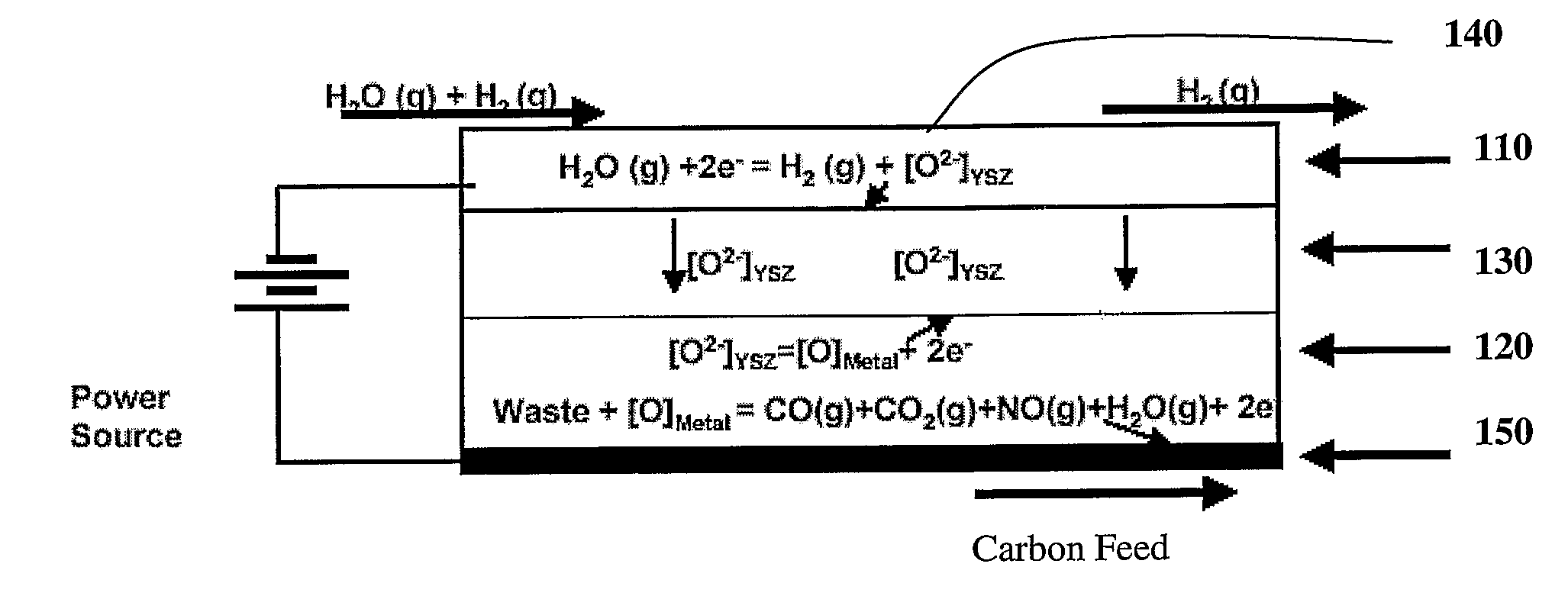

Waste to hydrogen conversion process and related apparatus

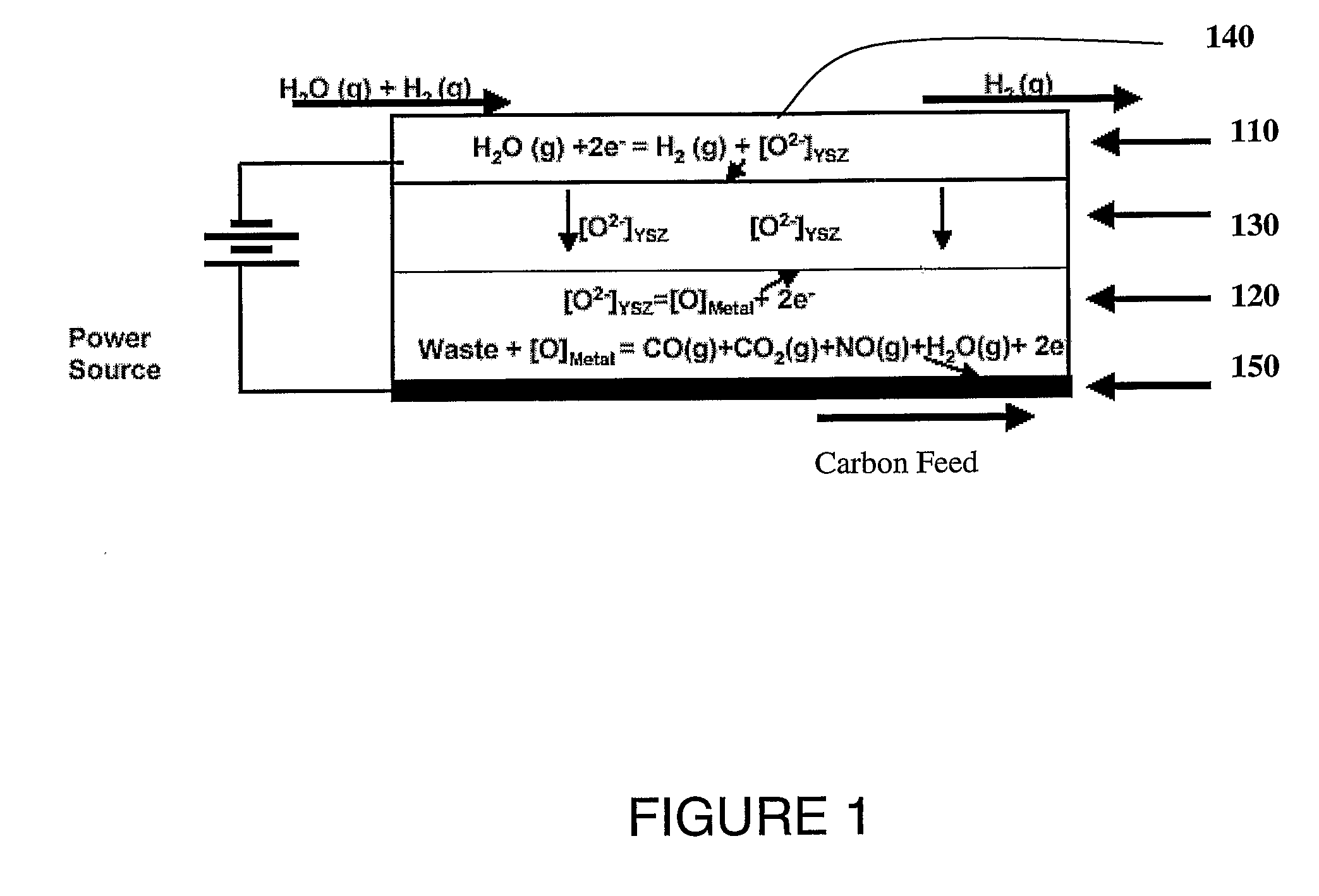

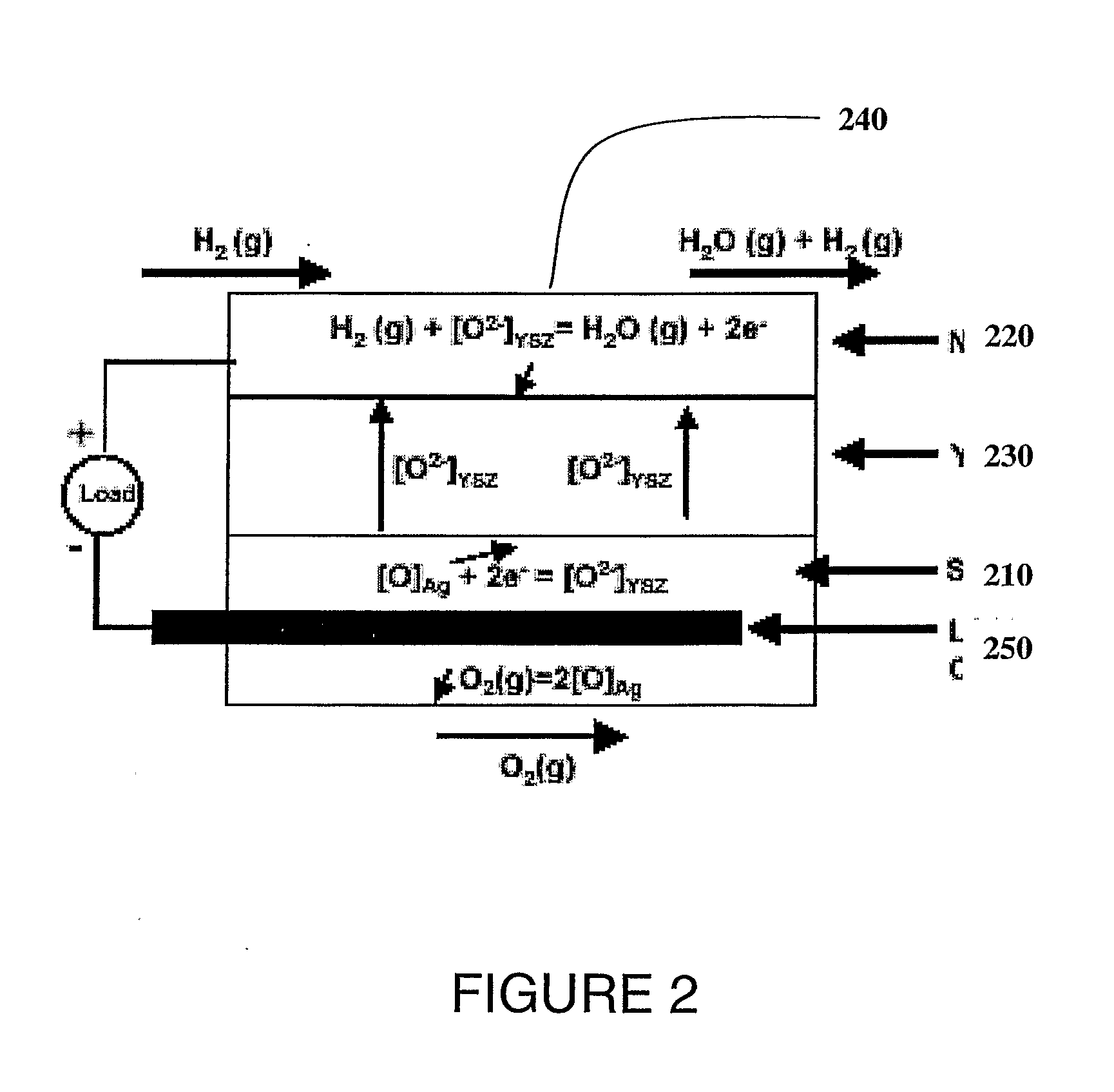

InactiveUS20090071841A1Efficiently reduce steamEfficient decompositionCellsHydrogen separationElectrolysisSilver electrode

A reversible electrochemical system includes a first electrode comprising liquid silver metal and a second electrode, said first and second electrodes separated by a oxygen ion-conducting solid electrolyte; a conduit for directing a first reactive material across the second electrode; and a conduit for contacting second reactive material with the first liquid silver electrode, wherein the cell is capable of steam electrolysis when the polarity of the electrodes is selected such that the liquid silver is an anode and the cell is capable of electrical energy generation when the polarity of the electrodes is selected such that the liquid silver is a cathode.

Owner:TRUSTEES OF BOSTON UNIV

Silver conductive paste for front electrode of crystalline silicon solar cell and preparation method thereof

ActiveCN102354544AImprove efficiencyAvoid reunionNon-conductive material with dispersed conductive materialCable/conductor manufactureConductive pasteSilver electrode

The invention relates to silver conductive paste for a front electrode of a crystalline silicon solar cell. The silver conductive paste comprises the following components in parts by mass: 75-98 parts of silver powder, 1-15 parts of glass powder, 5-60 parts of an organic carrier, 0-10 parts of an additive and 0.1-10 parts of a lead mixture, wherein, the silver powder contains silver particles andsilver particles which are provided with a core-shell structure and the surfaces of which are coated with silicon alloy powder; the glass powder is a glass metal aggregate formed by microwave-meltingand drying and co-grinding an oxide and one or more of Pt, Co, Pd, Sn, Bi, Se and Mo metal powder; and the lead mixture contains the components such as PbO particles and PbS compound particles with acore (PbS)-shell structure. The silver conductive paste has the advantages of good thixotropic property and good printing performance; and the silver electrode layer formed by the silver conductive paste has the advantages of good compactness, small series resistance and good ohmic contact property.

Owner:JIANGSU HOYI TECH

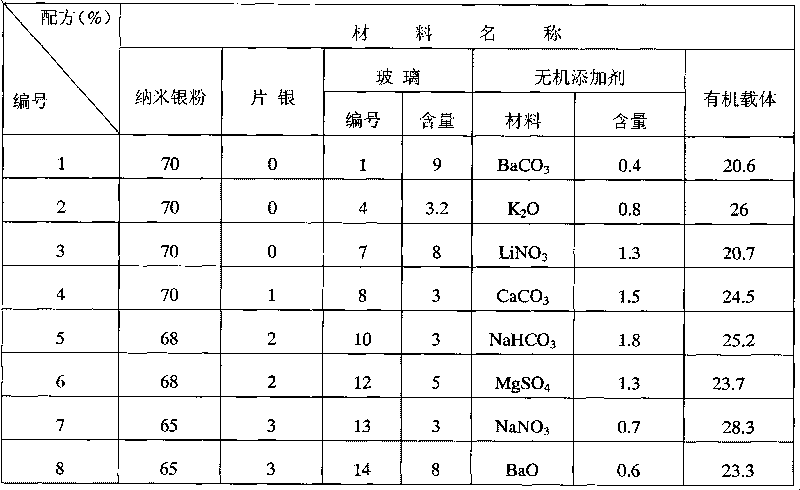

High-conductivity lead-free silver paste used for crystalline silicon solar cell and preparation method thereof

InactiveCN102368391AReduce conductivityImprove conductivityNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteSilver electrode

The invention discloses a high-conductivity lead-free silver paste used for a crystalline silicon solar cell and a preparation method thereof. The high-conductivity lead-free silver paste is prepared by compounding nano silver powder and micro silver powder, wherein a silver electrode formed by performing optimized grading and sintering on the micro silver powder has extremely high conductivity. The nano-modified high-conductivity lead-free silver paste comprises the following components in percentage by weight: 8 to 9 percent of micro silver powder with the grain diameter of 2 to 4.5 mu m, 56 to 62 percent of micro silver powder with the grain diameter of 5 to 10 mu m, 5 to 10 percent of nano silver powder, 3 to 5 percent of glass cement, 3 to 5 percent of inorganic additive, and 15 to 20 percent of organic carrier, wherein the grain diameter of the nano silver powder is 20 to 70 nm; the glass cement is a bismuth-silicon-boracium mixed glass system; and the organic carrier consists of an organic solvent and an organic additive. The high-conductivity lead-free silver paste has a simple preparation process, is simple and easy to produce in large scale, and has practical significance of improving the photoelectric conversion efficiency of the crystalline silicon solar cell.

Owner:NANCHANG UNIV

Copper electrode slurry material and manufacturing method thereof

ActiveCN101136261AAvoid performance degradationLow priceFixed capacitor electrodesElectrolytic capacitorsSilver electrodeHazardous substance

This invention discloses a kind of slurry of copper electrodes and a manufacturing method, in which, the weight percentage of the slurry includes: Ball copper: 25-64%, sheet copper: 10-40%, glass powder: 2-8%, macromolecular resin: 0.5-6% and solvent: 16-26%, in which, the slurry does not contain harmful materials of Pb, Cd and hexavalent Cr and meets the needs of environment protection, first of all, organic carrier is prepared and then the glass powder is put into the carrier to be mixed and form precursor dispersed mixture, then the balls and sheets are put into the mixture to form copper electrode slurry used in piezoelectric resistors, the sintered copper electrode is good in weld, the anti-welding performance is better than silver electrode and has better adherence than porcelain.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG +1

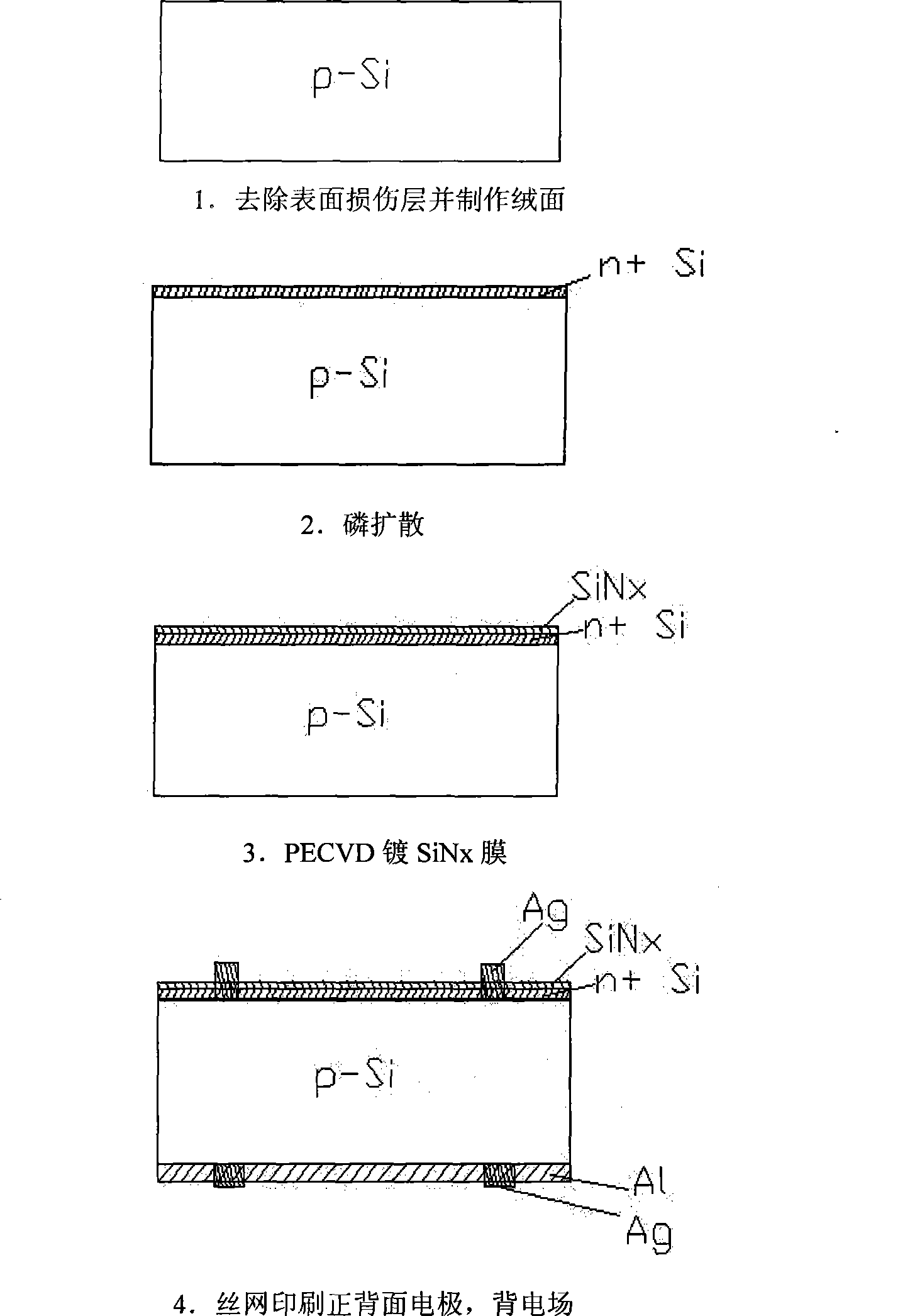

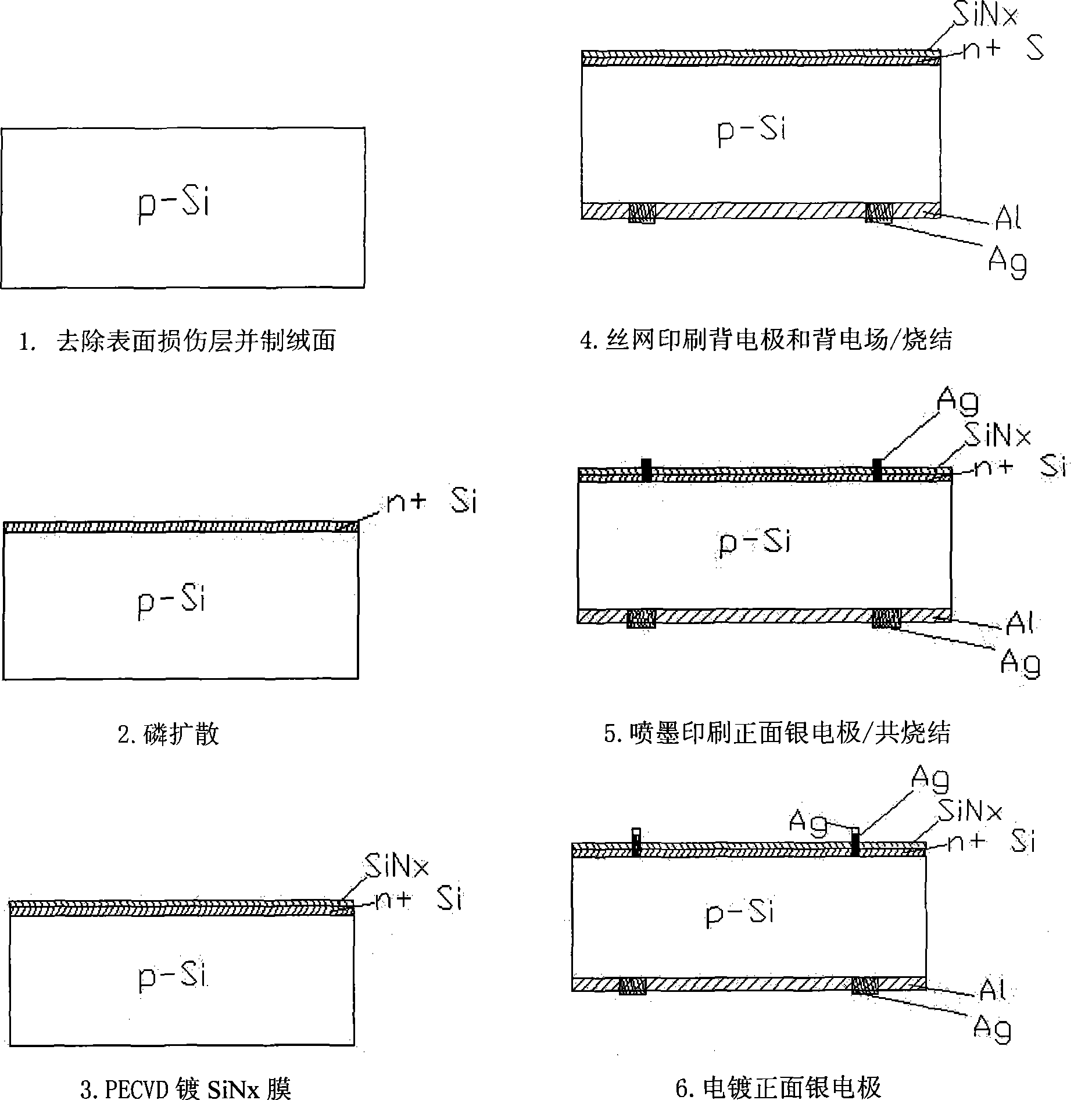

Preparation method for front electrode of solar cell

InactiveCN101447531AIncrease widthNarrow widthFinal product manufactureSemiconductor devicesSilver electrodeAgricultural engineering

The invention discloses a preparation method for a front electrode of a solar cell, and namely an electroplating method is adopted to manufacture the front electrode. The preparation method comprises two modes: the first mode is that an ink-jet printing method is first adopted to print a layer of silver electrode in a gate line area, and then the electroplating method is adopted to continue to sediment a layer of silver on the layer of silver electrode, thereby causing the front electrode to rise; and the other mode is that lasers are adopted to open a front electrode contact window, and then the electroplating method is adopted to electroplate the front electrode on the contact window. The preparation method causes the width of the front gate line electrode to be reduced and the height thereof to be increased, thereby causing series resistance of the cell to be decreased and a sunlight area to be enlarged, and helping improve the performance of the solar cell.

Owner:上海晶澳太阳能光伏科技有限公司

Sliver electrode slurry for back electric field of silicon solar cell and preparation method thereof

ActiveCN102354545AImprove wettabilityImprove solder resistanceNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver electrodePhysical chemistry

The invention discloses sliver electrode slurry for a back electric field of a silicon solar cell and a preparation method thereof, and the silver electrode slurry for the back electric field of the silicon solar cell comprises the following components by weight percent: 60-70% of spherical silver powder, 0-5% of flaky silver powder, 2-6% of glass powder with a high-temperature softening point, 1-3% of glass powder with a low-temperature softening point and 20-30% of organic bonding agent. The particle size of the spherical silver powder is 0.5-2.5 mu m, and the tap density is above 4.5g / ml; the particle size of the flaky silver powder is below 5 mu m, and the tap density is above 4.0g / ml; and the glass powder with the high-temperature softening point is a PbO3-B2O3-SiO2-ZnO glass system, and the glass powder with the low-temperature softening point is a Bi2O3-B2O3-SiO2 glass system. The slurry is applied to a sliver electrode of the back electric field of the silicon solar cell; furthermore, after fast high-temperature sintering by a chained belt furnace, the adhesive capability is strong, the soldering resistance is good and the photoelectric conversion efficiency of a product is high.

Owner:ZHEJIANG GUANGDA ELECTRONICS TECH

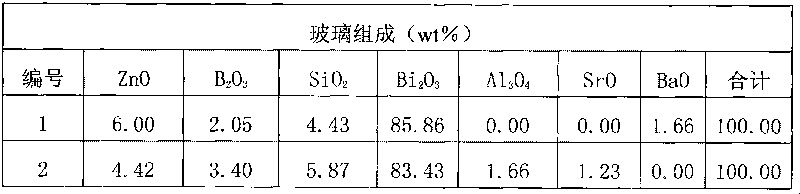

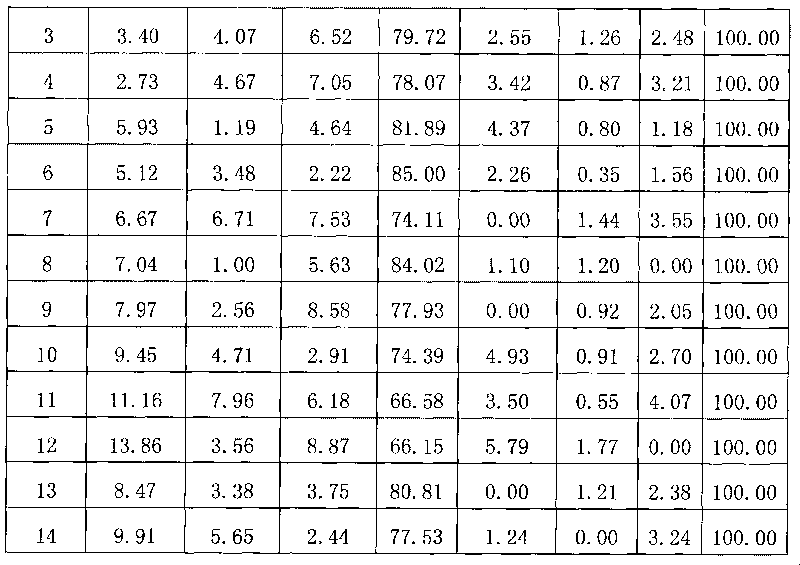

Low-temperature sintering silver electrode slurry

ActiveCN101699565ASmall particle size distributionImprove antioxidant capacityConductive materialMetal/alloy conductorsDispersitySilver electrode

The invention discloses low-temperature sintering silver electrode slurry, comprising the following ingredients by weight percentage: 65-75wt percent of nanometer silver powder, 0-5wt percent of strip silver powder, 2-10wt percent of glass powder, 0.2-1.8wt percent of inorganic additives and 20-30wt percent of organic carriers. The glass powder is a ZnO-B2O3-SiO2-Bi2O3 glass system, comprising the following ingredients by weight percentage: 2-15wt percent of ZnO, 1-15wt percent of B2O3, 2-10wt percent of SIO2, 60-90wt percent of Bi1O3, 0-6wt percent of Al2O3, 0-2wt percent of SrO and 0-5wt percent of BaO. The silver electrode slurry is suitable for sensitive resistance electrode and has good dispersity, small size distribution and high inoxidizability.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

Silicon solar cell front face electrode silver paste and preparing method thereof

InactiveCN104157328AImprove compactnessImprove smoothnessNon-conductive material with dispersed conductive materialCable/conductor manufactureAdhesivePotassium

The invention discloses silicon solar cell front face electrode silver paste. The silicon solar cell front face electrode silver paste comprises, by mass, 75-80 percent of silver powder, 3-10 percent of lead-free glass powder, 10-15 percent of organic vehicle and 0.5-3 percent of additive. The silver powder is the spherical micro silver powder with nano bismuth serving as the core, the silver content is 99.1-99.7 percent, the bismuth content is 0.3-0.9 percent, the particle size is 1-2 microns, the tap density is 4.5-5.0 g / ml, the specific surface area is 0.4-1.0 m<2> / g, and the silver powder is prepared by conducting liquid-phase chemical reduction on bismuth nitrate and silver nitrate through glyoxal or acetaldehyde. Bismuth-silicon-antimony-molybdenum lead-free glass powder serves as an adhesive, and potassium fluotitanate, potassium fluoroaluminate, magnesium fluoride and the like are added to serve as the silicon nitride antireflective film eroding additive. According to the silicon solar cell front face electrode silver paste, the contact resistance between a silver electrode and a silicon wafer can be reduced, the stripping strength of the electrode is improved, the electrical property of a solar cell is improved, the production cost of the conductive silver paste is reduced, and the requirement for nonexistence of lead and environmental friendliness are met.

Owner:天津顺御科技有限公司

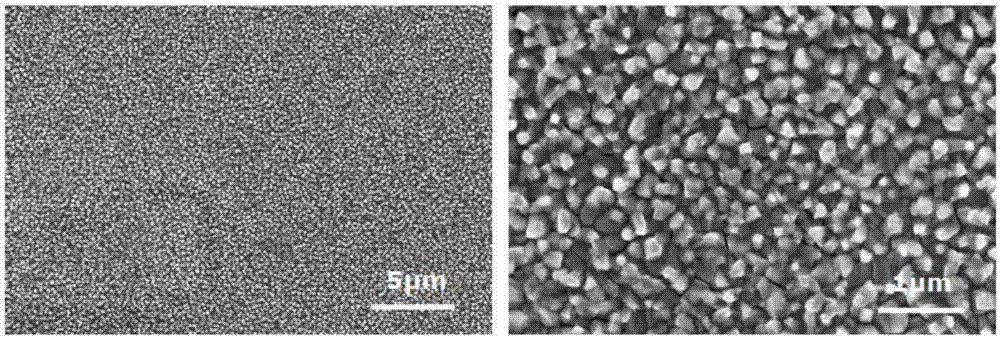

Solar energy cell with double-layer perovskite film structure and manufacturing method thereof

ActiveCN106910828AIncrease UV-Vis absorptionHigh crystallinitySolid-state devicesSemiconductor/solid-state device manufacturingSilver electrodeEngineering

The invention discloses a manufacturing method for the solar energy cell with double-layer perovskite film structure, and the method comprises the following steps: 1) selecting a conductive substrate; etching patterns on the conductive substrate and obtaining the etched conductive substrate; 2) preparing an electron transport layer or a hole transport layer; (3) preparing a film with a double-layer perovskite structure; 4) preparing a hole transport layer or an electron transport layer; and 5) hotly plating a gold or silver electrode on the hole transport layer or the electron transport layer to obtain an n-I-P-type or p-I-N-type solar cell with the double-layer perovskite thin film structure. The invention further discloses a solar energy cell manufactured and obtained from the above method. The manufacturing method is environmentally friendly, can change the morphology, the crystallinity and the interface of the perovskite film and increases the photoelectric performance of a device.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Method for forming crystalline silicon solar cell front electrode

InactiveCN102738301AImprove photoelectric conversion efficiencyAvoid direct contactFinal product manufacturePattern printingSilver electrodeOhmic contact

The invention relates to a method for forming a crystalline silicon solar cell front electrode, which comprises the steps that after the double-sided texturing monocrystalline silicon backside printing aluminum subjected to texturing, diffusing, surface passivating and front antireflection coating forming is dried by field and back silver electrodes, a thin grid silver electrode is firstly printed at the front side of a silicon wafer and dried; then, only the main grid electrode is printed, or the main grid electrode is printed and a thin grid electrode is printed for the second time, and are dried; and the dried main grid electrode and the thin grid electrode are fed into a tunnel furnace for sintering, so the crystalline silicon solar cell front electrode is obtained. Because the secondary printing technology is adopted, the method has the advantages of the secondary printing technology, and is suitable for industrial production; and under the condition of ensuring the enough good ohmic contact of the thin grid electrode, the main grid electrode is prevented from being directly contacted with the silicon wafer, the surface passivation area is increased, the interfacial compound of the photon-generated carrier is reduced, and the photoelectric conversion efficiency of a solar cell is improved.

Owner:上海中智光纤通讯有限公司

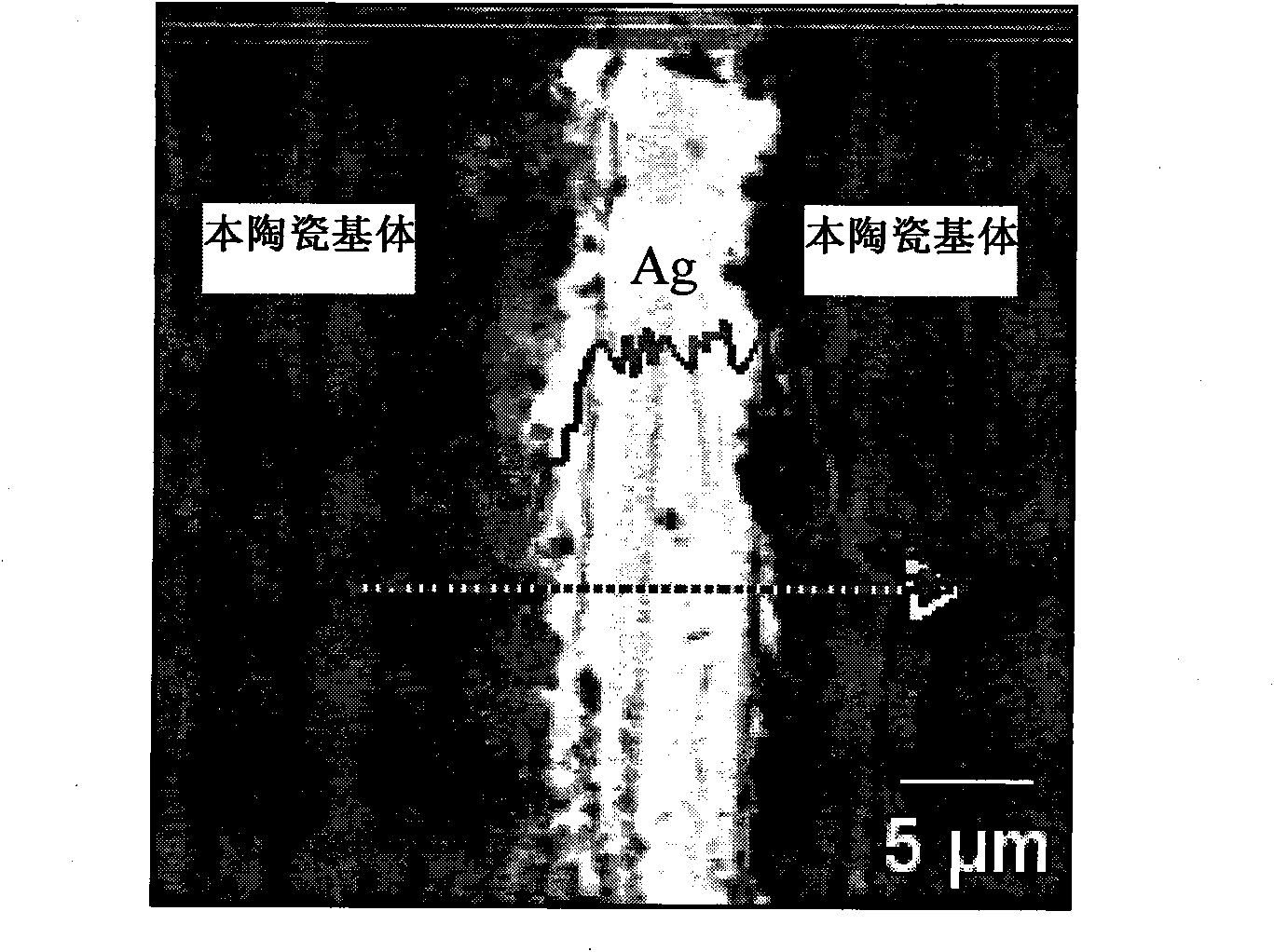

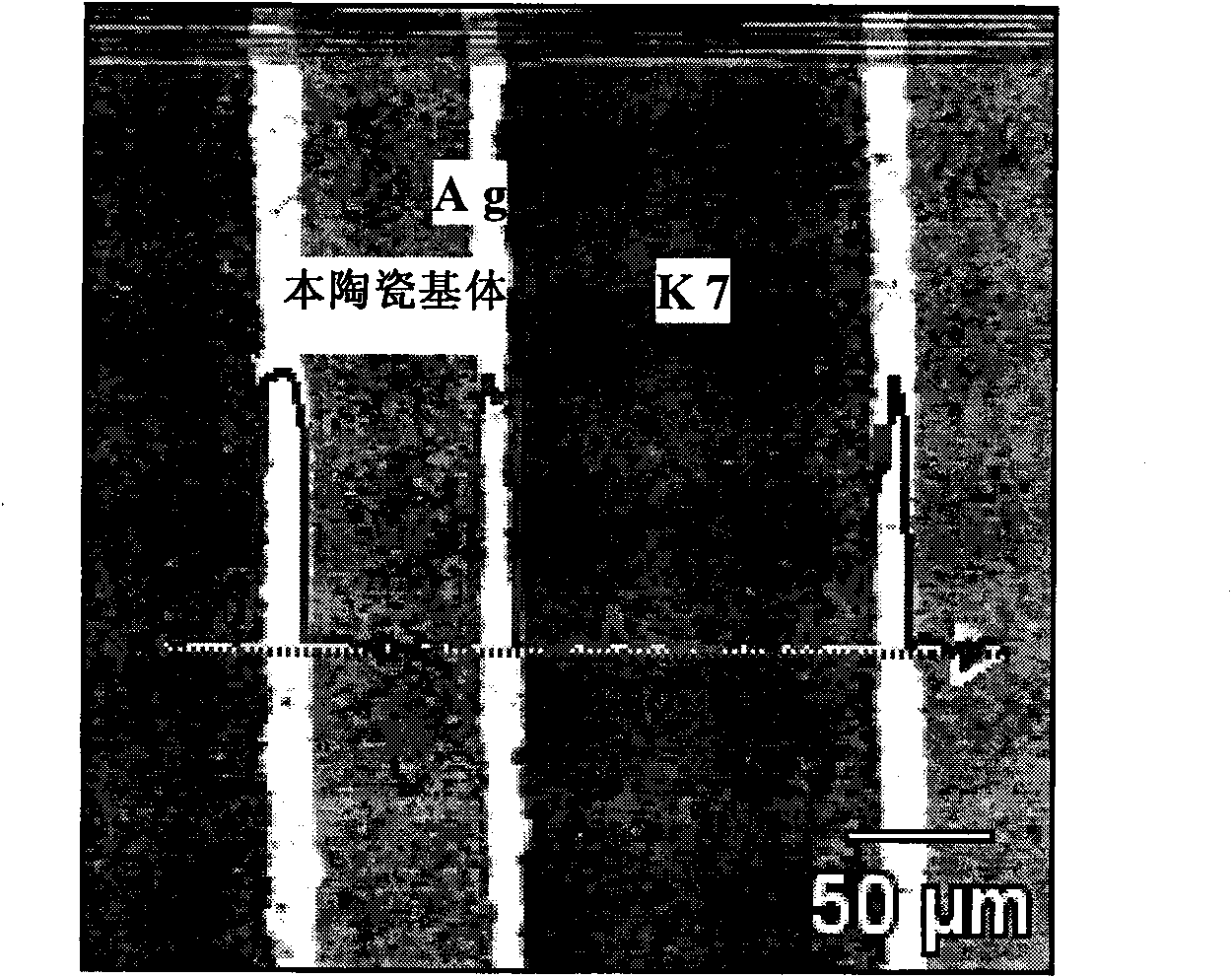

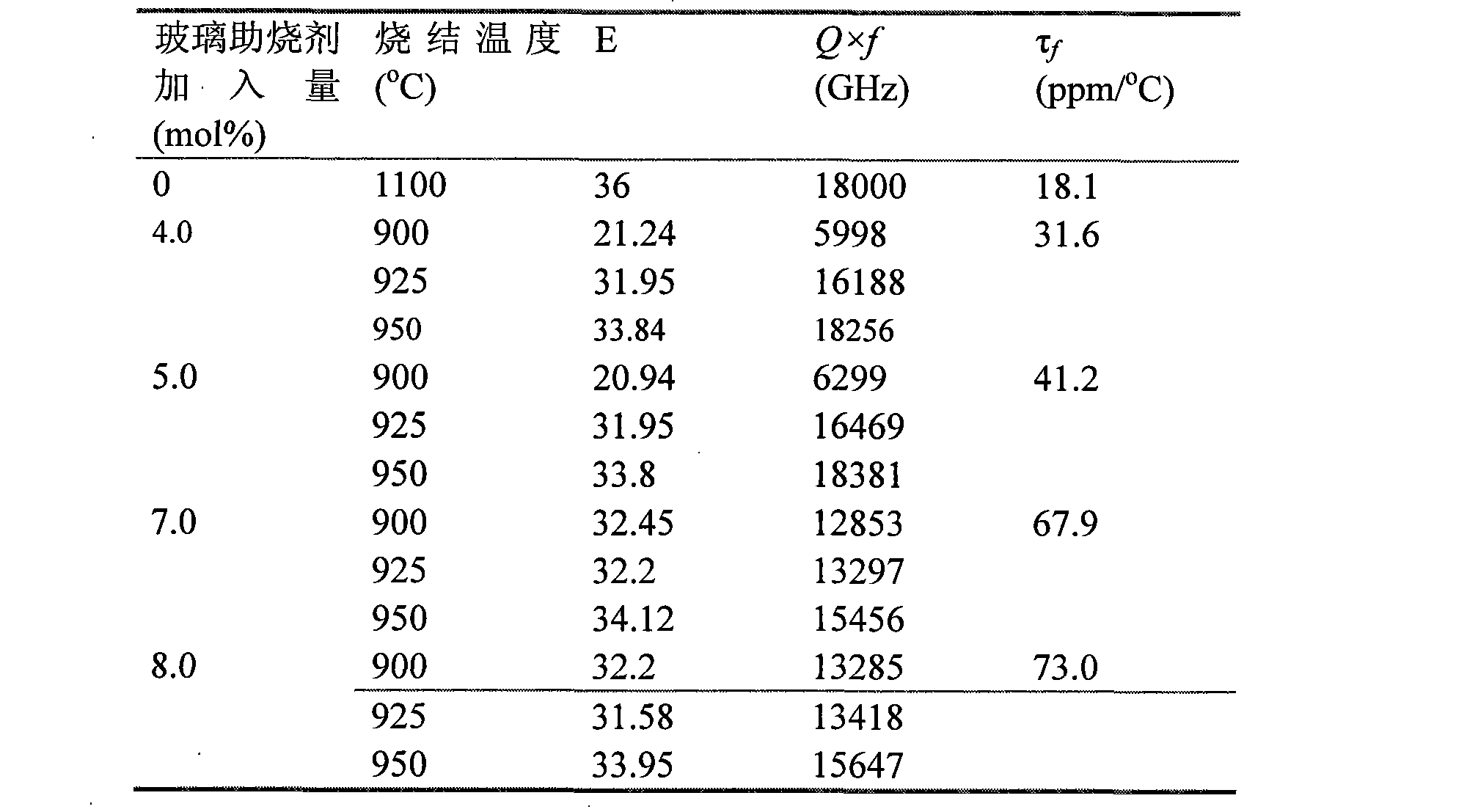

Low-temperature sintered microwave medium ceramic material and preparation method thereof

ActiveCN101613200AImprove performanceExcellent microwave dielectric propertiesCeramicsCombustionSilver electrode

The invention discloses a low-temperature sintered microwave medium ceramic material and a preparation method thereof. The material comprises the raw materials with the mol ratio: BaCO3:ZnO:TiO2:Q=1:x:(4+y):z, wherein x=0.01-0.5, y=0.01-0.5, z=0.01-0.1, and Q is glass combustion-supporting agent or BaCu (B2O5); the glass combustion-supporting agent comprises the raw materials with the mol ratio being Li2O:ZnO:B2O3=1:2:7 or Li2O: B2O3-1:2:7=3:2:5. The material can be obtained through traditional solid phase reaction synthesis. The material has lower sintering temperature (is capable of being fired at the temperature below 900 DEG C to form ceramics), is capable of being fired at the temperature of 900 DEG C to form ceramics and has better microwave dielectric property, wherein Epsilon r is equal to 25-35, Q*F is larger than 12,000, and Pi f is equal to -10ppm / DEG C to +30ppm / DEG C; in addition, the material has stable process and good repeatability and can be better co-fired and matched with a silver electrode. The low-temperature sintered microwave medium ceramic material can be used for manufacturing microwave devices, such as lower temperature co-fired ceramic (LLCC) systems, multilayer medium resonators, microwave antennae, wave filters, and the like.

Owner:XI AN JIAOTONG UNIV

Silicon solar cell front face electrode lead-free silver paste and preparing method thereof

InactiveCN104157332AImprove compactnessImprove smoothnessNon-conductive material with dispersed conductive materialCable/conductor manufactureTetramethylammonium hydroxidePotassium

The invention discloses silicon solar cell front face electrode lead-free silver paste and a preparing method thereof. The silicon solar cell front face electrode lead-free silver paste is characterized in that inorganic glass powder is not contained in the silver paste, and the silver paste comprises, by mass, 75-85 percent of conductive silver powder, 1-5 percent of antireflective film corrosive, 10-20 percent of organic vehicle and 1-5 percent of additive; the conductive silver powder is formed by mixing micro silver powder and nano silver powder with the mass ratio of 10:1-2; the antireflective film corrosive comprises one or more of potassium fluotitanate, potassium fluoroaluminate, potassium fluosilicate and potassium fluoborate; the additive comprises one or more of ethanol amine, diethanol amine, triethanol amine, tetramethylammonium hydroxide, tetraethylammonium hydroxide and tetramethylammonium hydroxide. According to the silicon solar cell front face electrode lead-free silver paste and the preparing method thereof, lead-free silver paste printing and antireflective film removing are conducted in one step, sintering can be conducted at a low temperature, the compactness and the smoothness of a silver electrode film are improved, and the photoelectric conversion efficiency of a silicon cell piece is improved.

Owner:TIANJIN VOCATIONAL INST

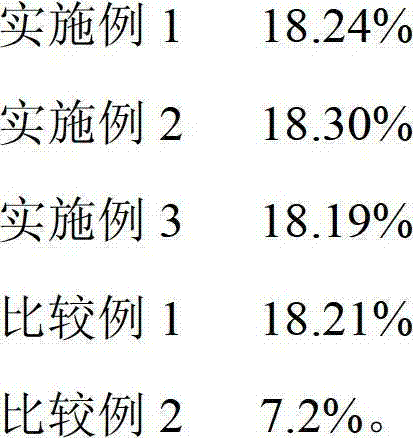

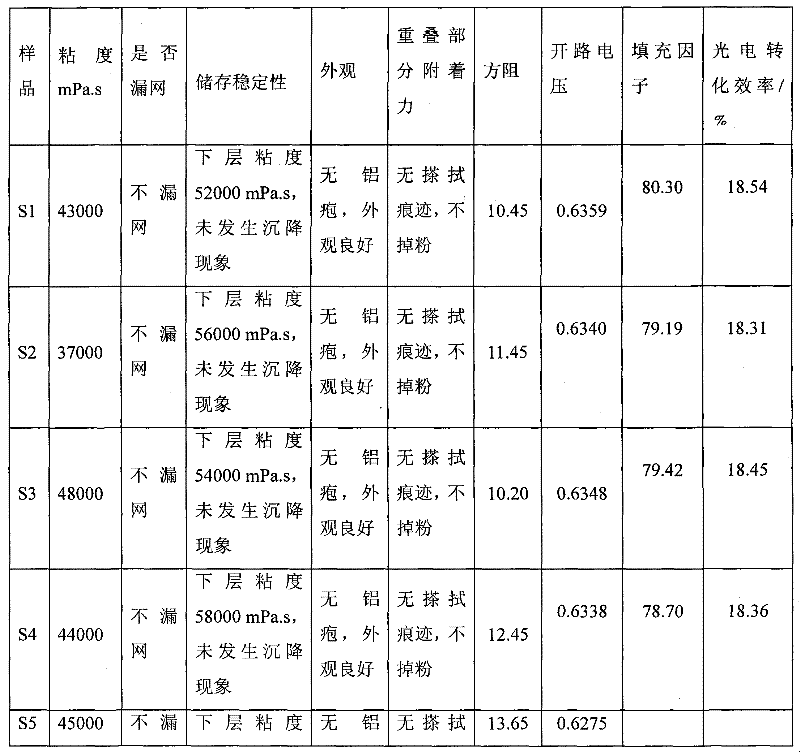

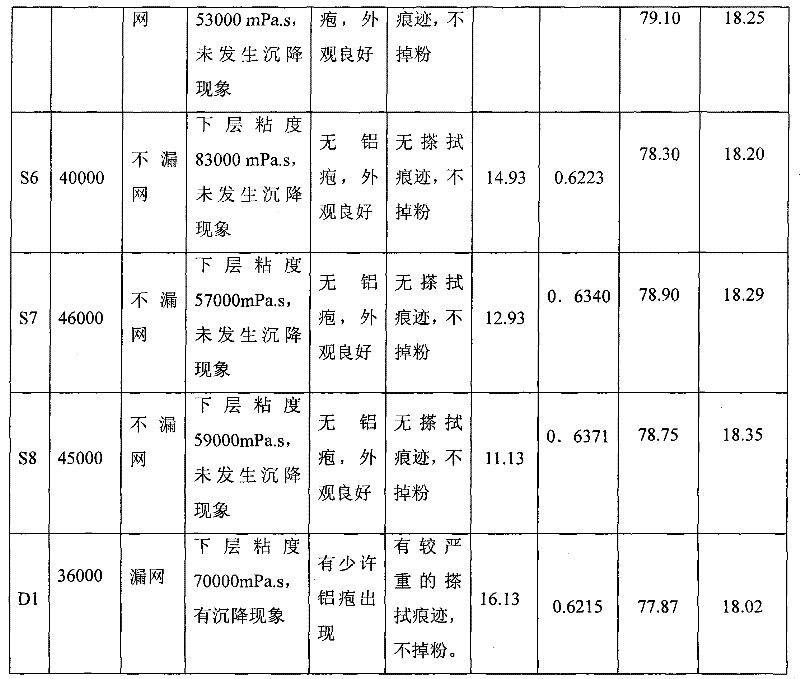

Conductive paste for solar cell and preparation method thereof

ActiveCN102479568AImprove rheologyEasy constructionNon-conductive material with dispersed conductive materialCable/conductor manufactureOpen-circuit voltageSedimentation

The invention provides a conductive paste and a preparation method thereof. The conductive paste comprises aluminum powder, an inorganic binding agent, an organic carrier and metal-glass composite powder, wherein the metal-glass composite powder is of nano-particles and a core-shell structure, glass is used as a core material, and metal is used as a shell material. The conductive paste disclosed by the invention is good in storage stability and less prone to sedimentation and agglomeration, and the conductive paste is less prone to leakage from a screen during screen printing; after sintering, an aluminum film is smooth in surface and grey white, and has no aluminum vesicles or aluminum beads; and furthermore, the part in contact and superimposition with a back silver electrode, of the aluminum film is wiped by a non-dust cloth, and wiping traces and powder dropping can be avoided. The series resistance of the produced solar cell is reduced obviously, a filling factor is increased obviously, and the average photoelectric conversion efficiency of a monocrystalline silicon cell piece can be above 18.20%. Simultaneously, the conductive paste disclosed by the invention is good in construction performance, a film layer formed after sintering is compact, the sintering thickness is uniform, the bending of a silicon chip is small, the sheet resistance is small and the open circuit voltage (Voc) of the formed cell is high.

Owner:BYD CO LTD

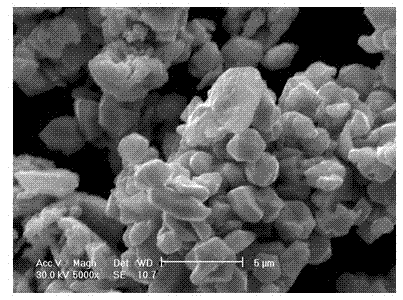

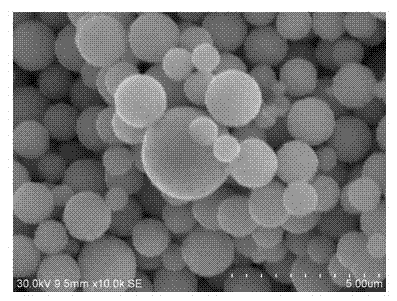

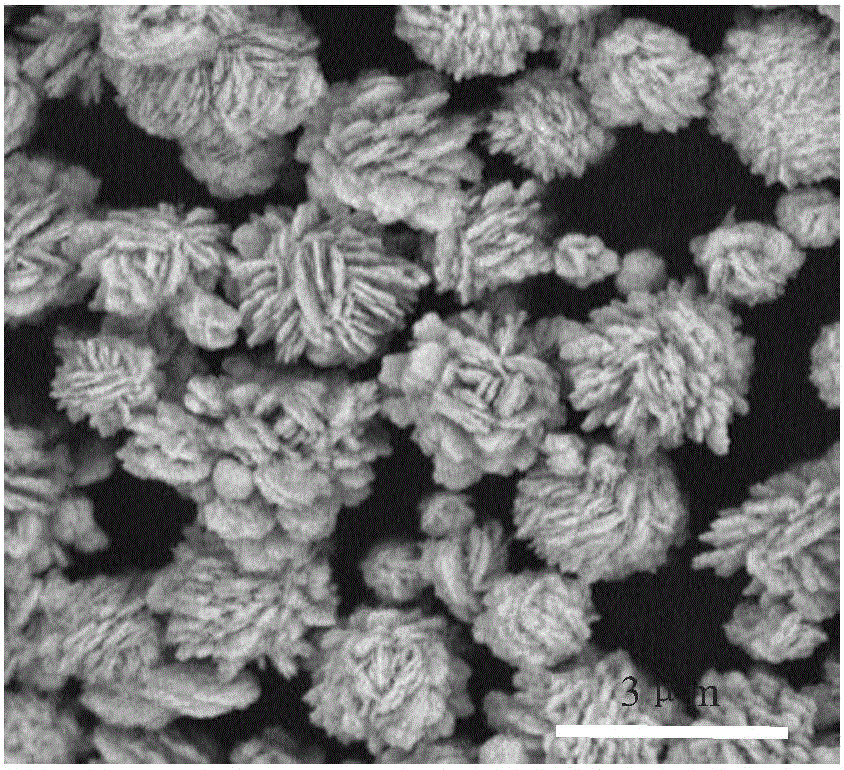

Silver powder for printing size for solar cell electrodes and preparation process thereof

The invention provides silver powder for printing size for solar cell electrodes and a preparation process thereof. The silver powder is composed of spherical, dendritic and random shaped silver powder bodies, the tap density is 3.96-5.21g / mL, the mean particle size is 0.6-3.5 microns, and the apparent density is 2.35-2.72g / mL. The preparation process includes preparing a silver nitrate solution and a reducing agent solution; respectively adding in a dispersing agent for dispersion; adding a silver precursor solution dropwise into a reducing mixed solution for reaction and standing; separating out liquid and solids; washing the solids with deionized water and ethanol respectively; and soaking in a protective agent and drying to obtain the silver powder for the printing size for the solar cell electrodes. The silver powder prepared through the process has a good crystallization surface and high dispersibility, a single particle size is large, the silver powder in various particle forms is mixed and can achieve high photoelectric converting efficiency when used on conductive fillers of conductive paste required by forming of front silver electrodes of crystalline silicon solar cells, and better filling and electric properties are provided compared with commonly used silver powder.

Owner:昆明高聚科技有限公司

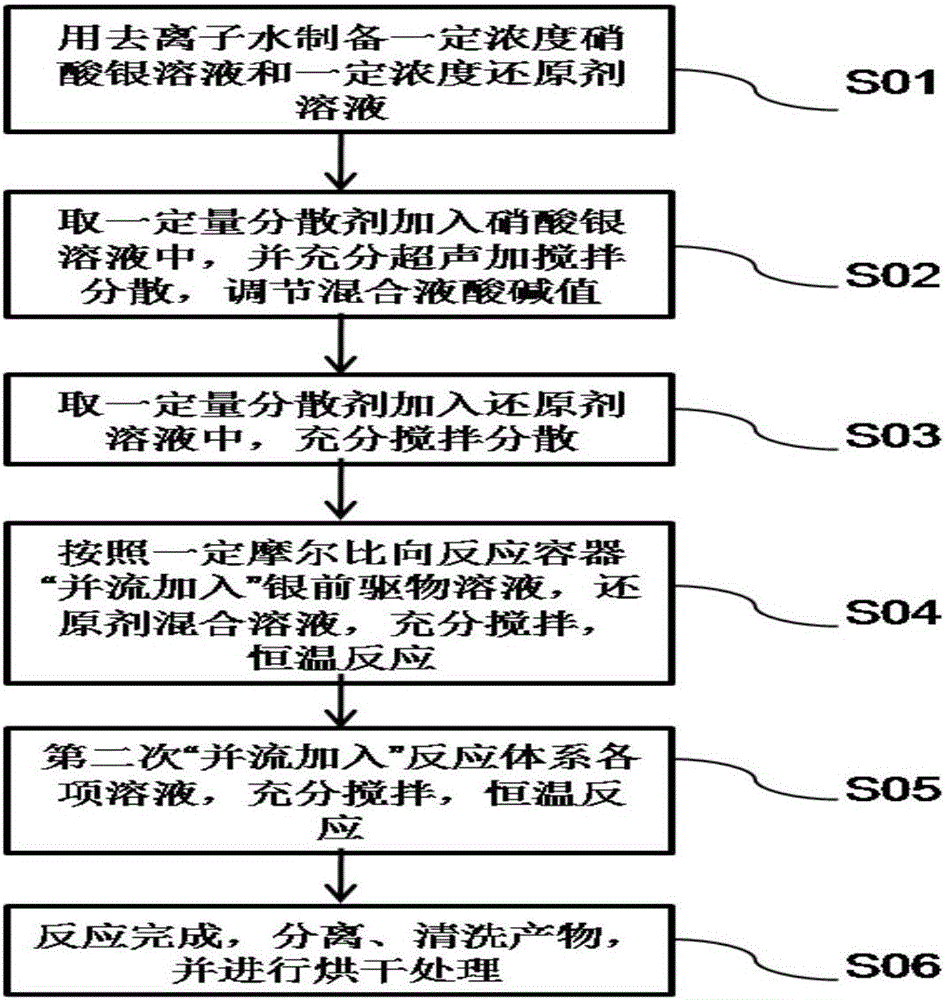

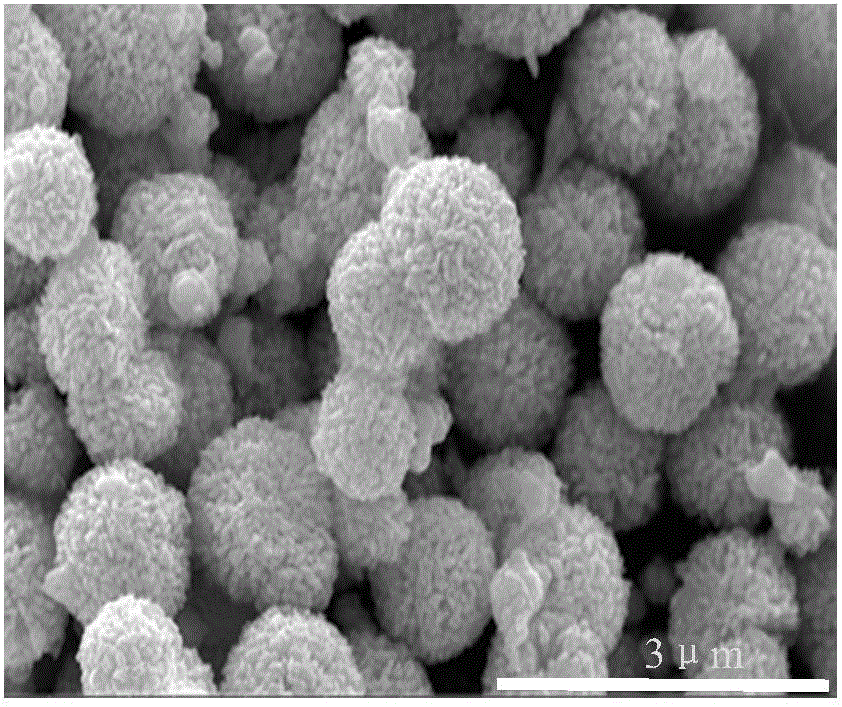

High specific surface area silver powder improving conductivity of solar battery electrode and preparation method

InactiveCN106825544AImprove photoelectric conversion efficiencyGood dispersionTransportation and packagingMetal-working apparatusDispersitySlurry

The invention discloses high specific surface area silver powder improving conductivity of a solar battery electrode and a preparation method. The silver powder has an average particle size of 0.6-0.75 micrometers, an apparent density of 2.5-5.0g / mL, a tap density of 4.15-6.95g / mL and specific surface area of 0.45-0.75m<2> / g. The method comprises the steps of preparing a silver nitrate solution and a reducer solution, adding a dispersing agent, performing parallel flow addition of various reaction system solutions into a reaction vessel by twice in a twice addition manner, uniformly mixing the reaction system solutions for the first time, keeping a PH value and temperature of reaction liquid as 2-5 and 25-60 DEG C, continuing stirring for 10-30min after feeding, and adding a mixed reaction solution in a parallel flow addition manner with the addition volume of 0.25-0.75 time of the total addition volume of the first time. The silver powder is a spheroid covered with bulges on the surface, is uniform in particle size and has a good crystal surface and high dispersity; the photoelectric conversion efficiency can be improved when the silver powder is used as front silver electrode slurry of crystalline silicon solar battery; the silver powder particularly has excellent characteristics in aspects of short-circuit current, contact resistance, fill factor and the like.

Owner:ENVIRONMENTAL NATURAL CHEM JIANGSU

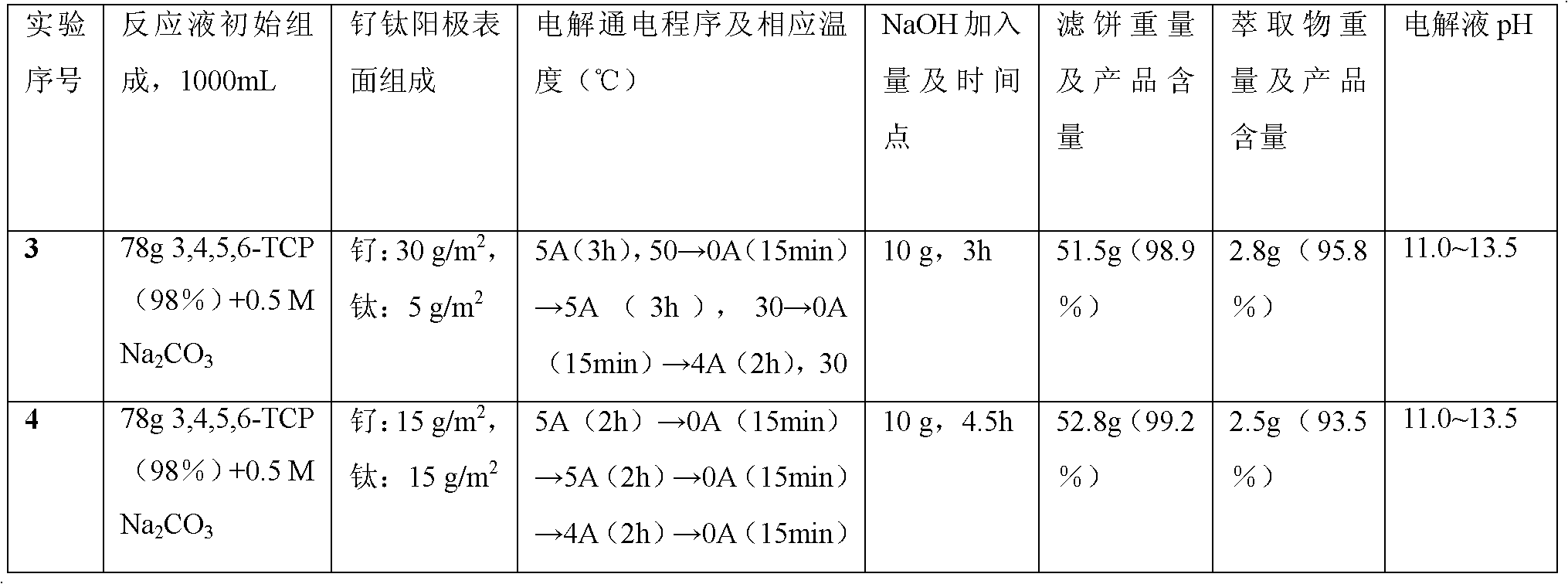

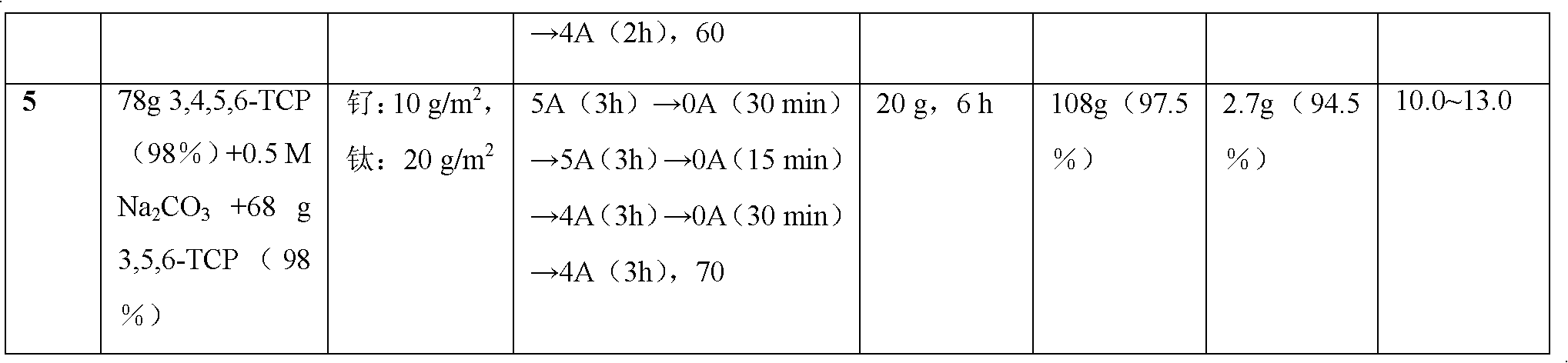

Selective electrolysis hydrogenation and dechlorination method for chlorinated organic matter

ActiveCN102181880ALong-term activityReduce reaction energy consumptionOrganic chemistryElectrolytic organic productionElectrolysisSilver electrode

The invention discloses a selective electrolysis hydrogenation and dechlorination method for a chlorinated organic matter. The method comprises the following steps of: dissolving the chlorinated organic matter in alkaline solution serving as a reaction medium, and performing an electrolytic reaction; and acidizing after the electrolytic reaction is finished to obtain a target product, wherein a ruthenium titanium positive electrode is used as the positive electrode of the electrolytic reaction, a silver electrode is used as the negative electrode of the electrolytic reaction, and energizationis stopped for 5 to 60 minutes when electrolysis is performed for 1 to 5 hours every time in the electrolysis reaction process. The method is easy to operate; and by the method, the step of repeatedly performing electrochemical oxidation on the activated silver electrode in the reaction process can be prevented, and the energy consumption of the reaction can be effectively reduced.

Owner:ZHEJIANG UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com