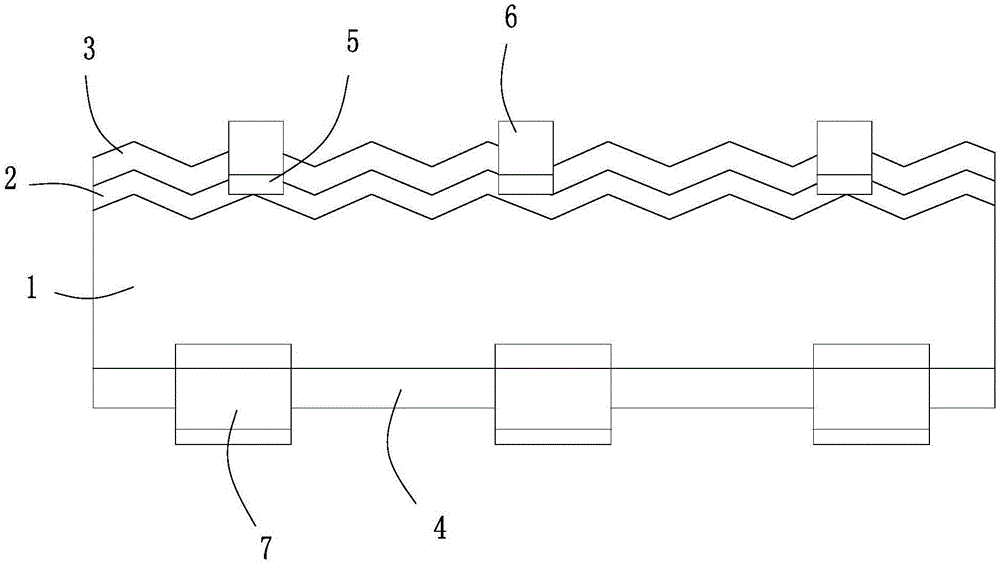

Producing method of selective emitter double-faced PERC crystalline silicon solar cell

A technology of solar cells and manufacturing methods, applied in photovoltaic power generation, circuits, electrical components, etc., can solve problems such as difficult alignment of aluminum grid lines and laser window grid lines, so as to avoid battery sheet bending, high conversion efficiency, and solve Difficult to align effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1: A method for manufacturing a selective emitter double-sided PERC crystalline silicon solar cell, comprising the following steps:

[0034] (1) Texturing: Select a 156mm×156mm P-type diamond wire-cut single crystal silicon wafer as the base material, with a resistivity of 3Ω cm, put in a mixture of potassium hydroxide concentration of 3% and additive concentration of 1.5% and heat to 80°C In the solution, the corrosion reaction is 18 minutes, the thinning amount of the texture is 0.58g, and the pyramid size of the texture is about 2.5μm; after the texture, the silicon wafer after the texture is cleaned with a mixed acid solution of HF / HCl at room temperature, and the concentration of the HF volume percentage is 4%. The HCl volume percentage concentration is 4%, and the surface reflectance of the silicon wafer after texturing is 10.8%;

[0035] (2) Diffusion: Using the method of phosphorus diffusion in a tube furnace, in the diffusion furnace at a temperature...

Embodiment 2

[0044] Embodiment 2: A method for manufacturing a selective emitter double-sided PERC crystalline silicon solar cell, comprising the following steps:

[0045] (1) Texturing: Select a 156mm×156mm P-type diamond wire-cut single crystal silicon wafer as the base material, with a resistivity of 2Ω cm, put in a mixed solution with a concentration of potassium hydroxide of 3% and an additive concentration of 1.5% and heat to 80°C During the corrosion reaction for 18 minutes, the thinning amount of the texture is 0.67g, and the pyramid size of the texture is about 2.5μm; after the texture, the silicon wafer after the texture is cleaned with a mixed acid solution of HF / HCl at room temperature, and the volume percentage concentration of HF is 4%, HCl The volume percentage concentration is 4%, and the surface reflectance of the silicon wafer after texturing is 10.5%;

[0046] (2) Diffusion: Using the method of phosphorus diffusion in a tube furnace, in the diffusion furnace at a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com