Patents

Literature

125 results about "Recombination rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The recombination rate is the rate at which the association between the two loci is changed. Let , be the probability that there are crossovers betwee our two loci. The recombination rate is therefore . To make a long story short, the recombination rate is the rate at which the number of crossovers is odd.

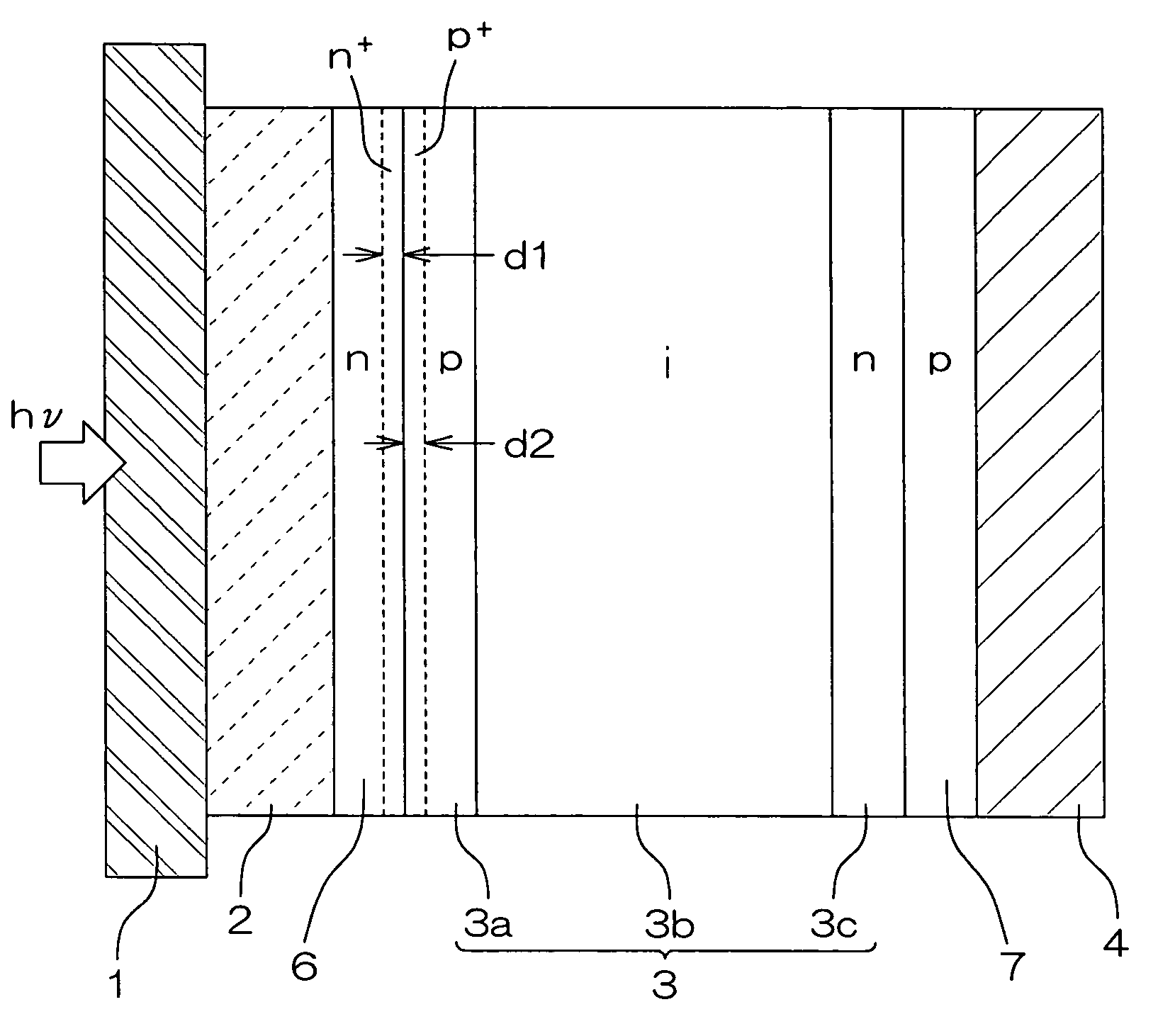

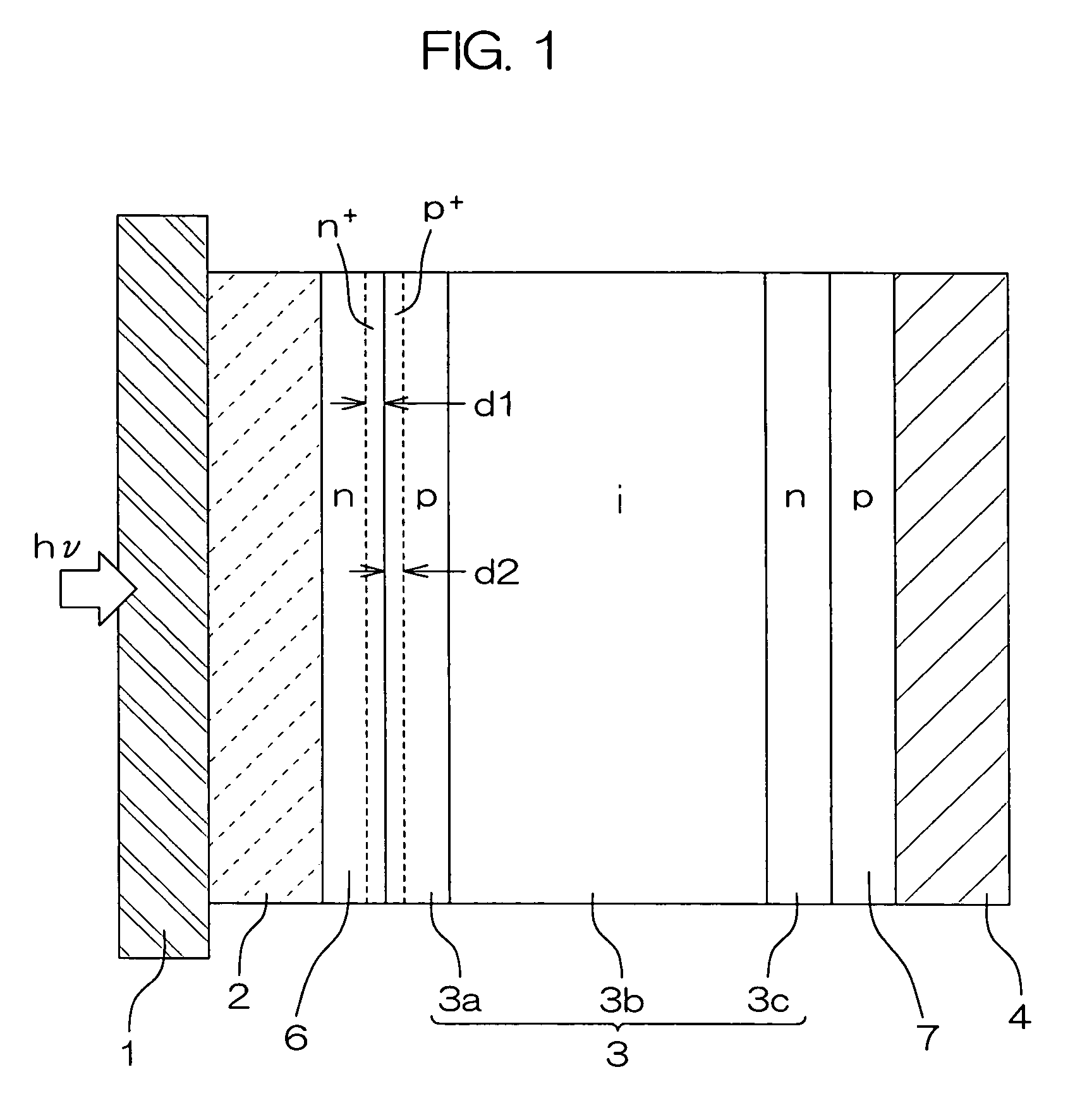

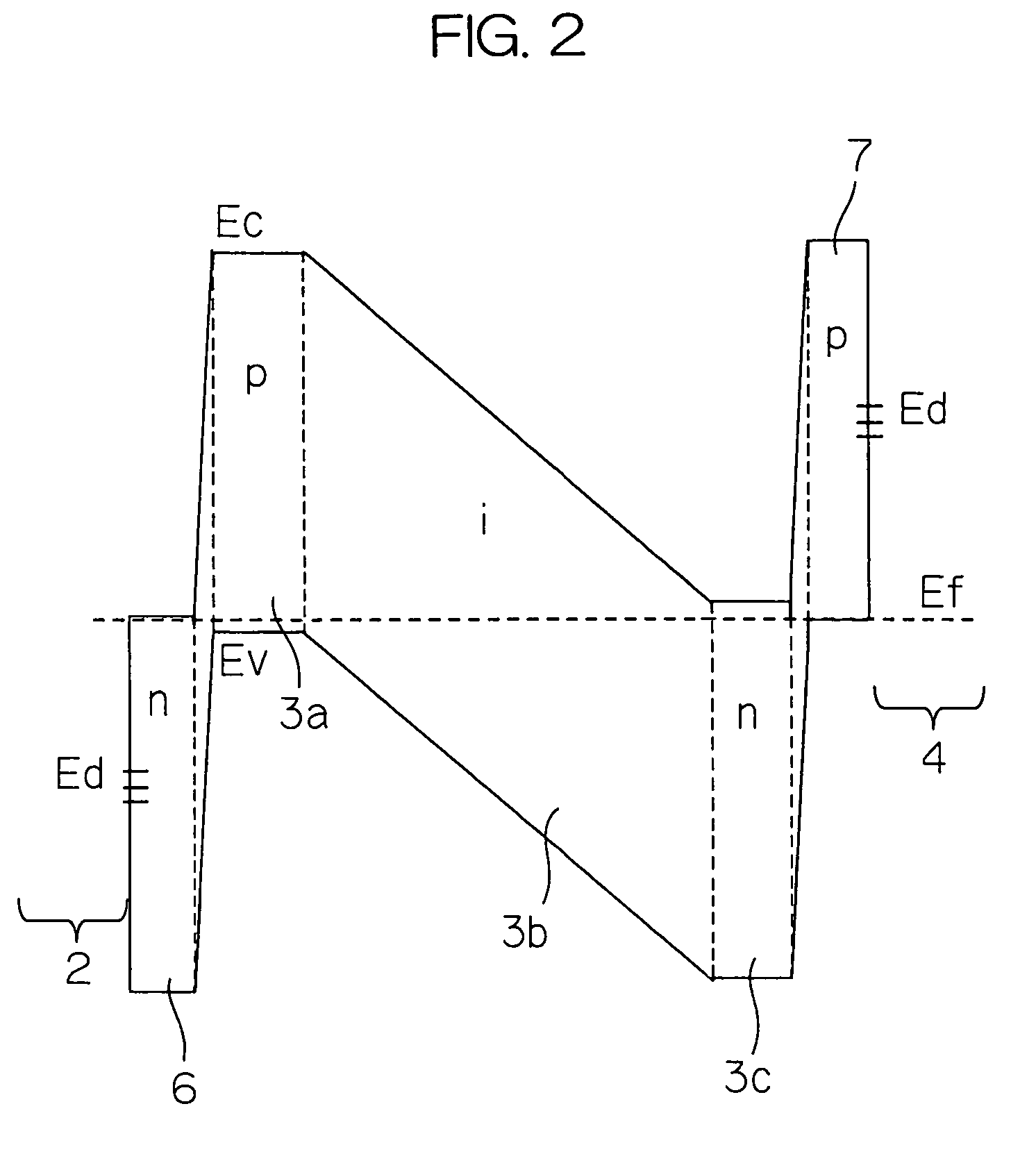

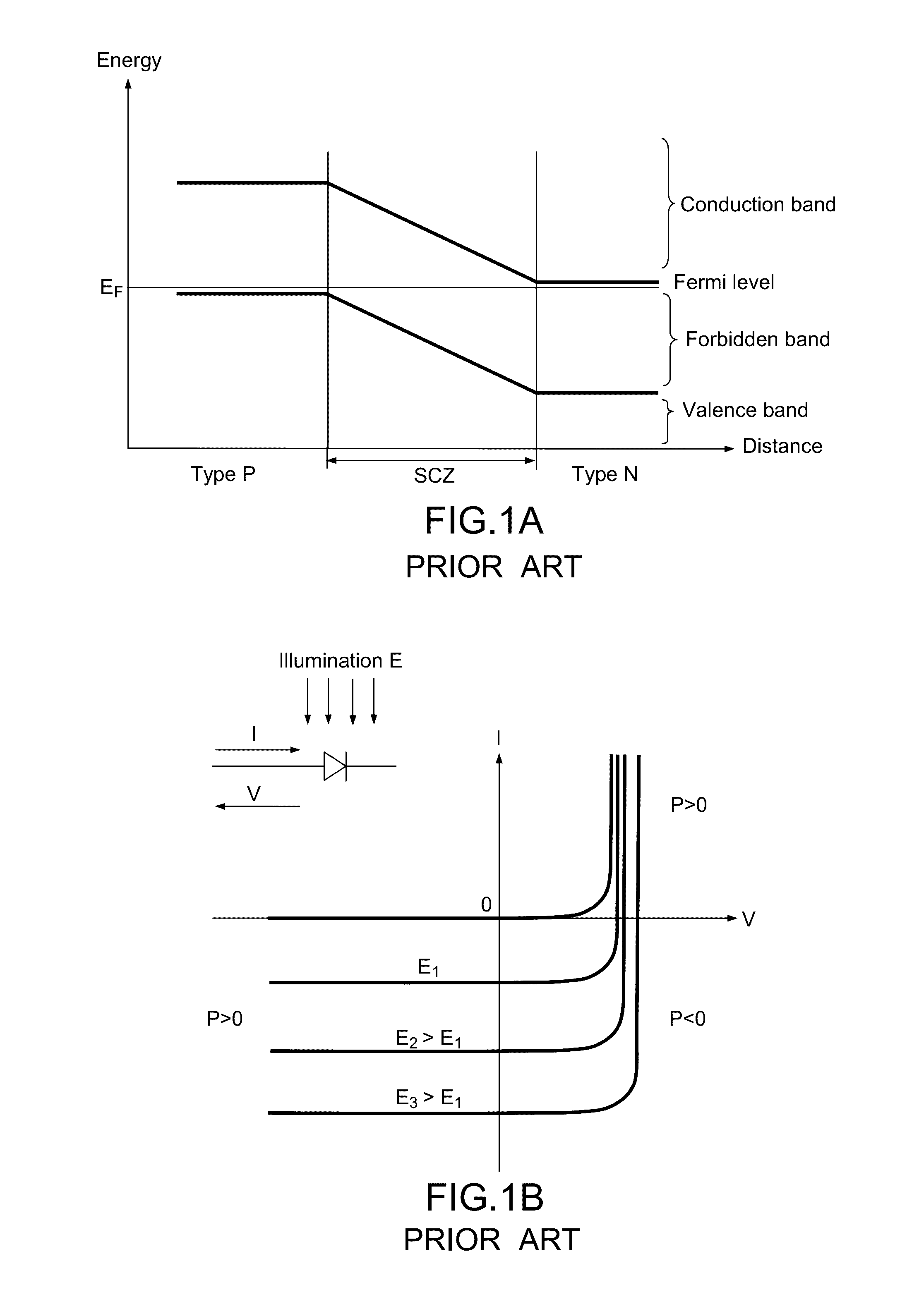

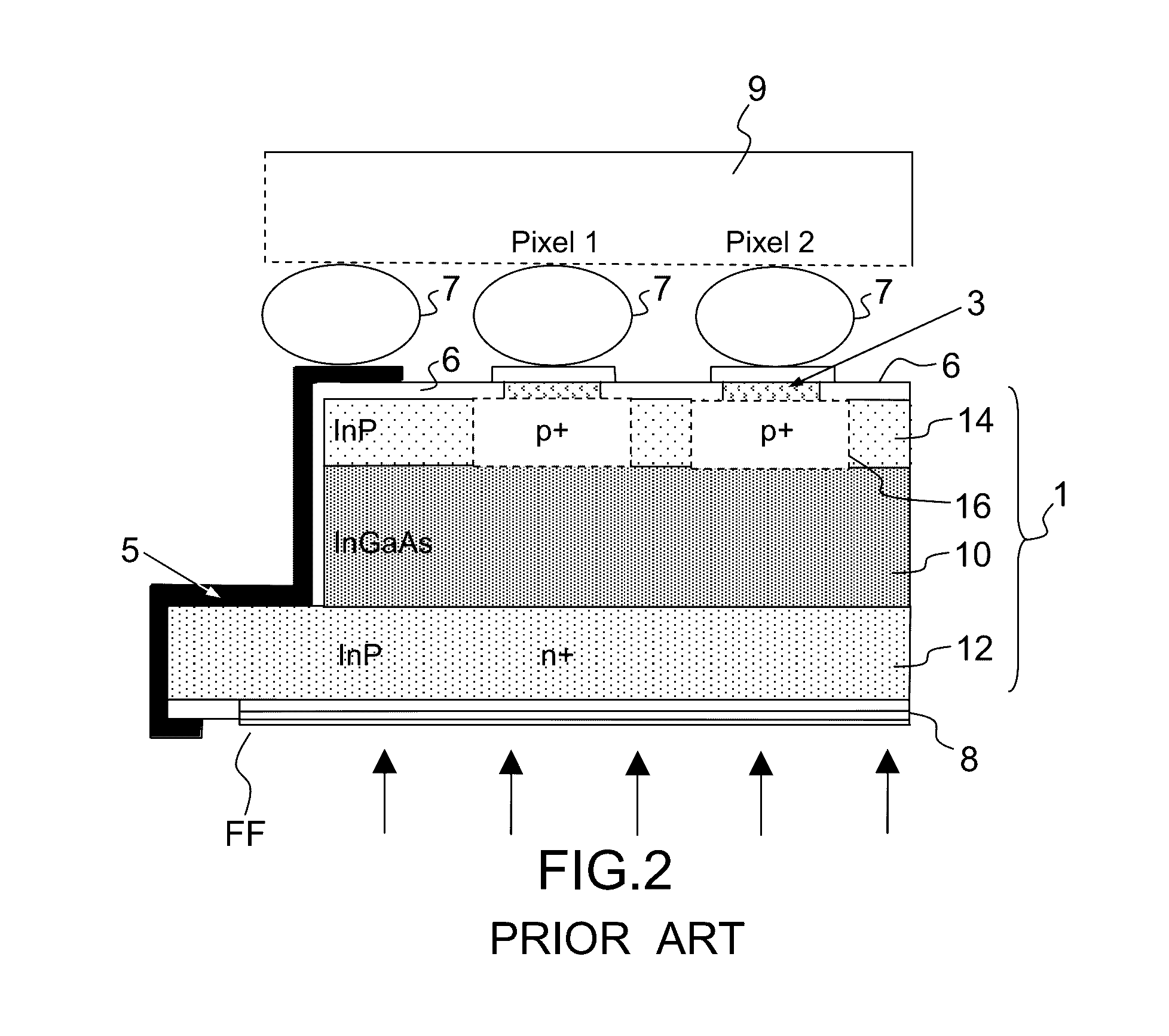

Semiconductor/electrode contact structure and semiconductor device using the same

InactiveUS20050012095A1Reduce recombination rateLow densitySuperconductor devicesPhotovoltaic energy generationSemiconductor electrodeDevice material

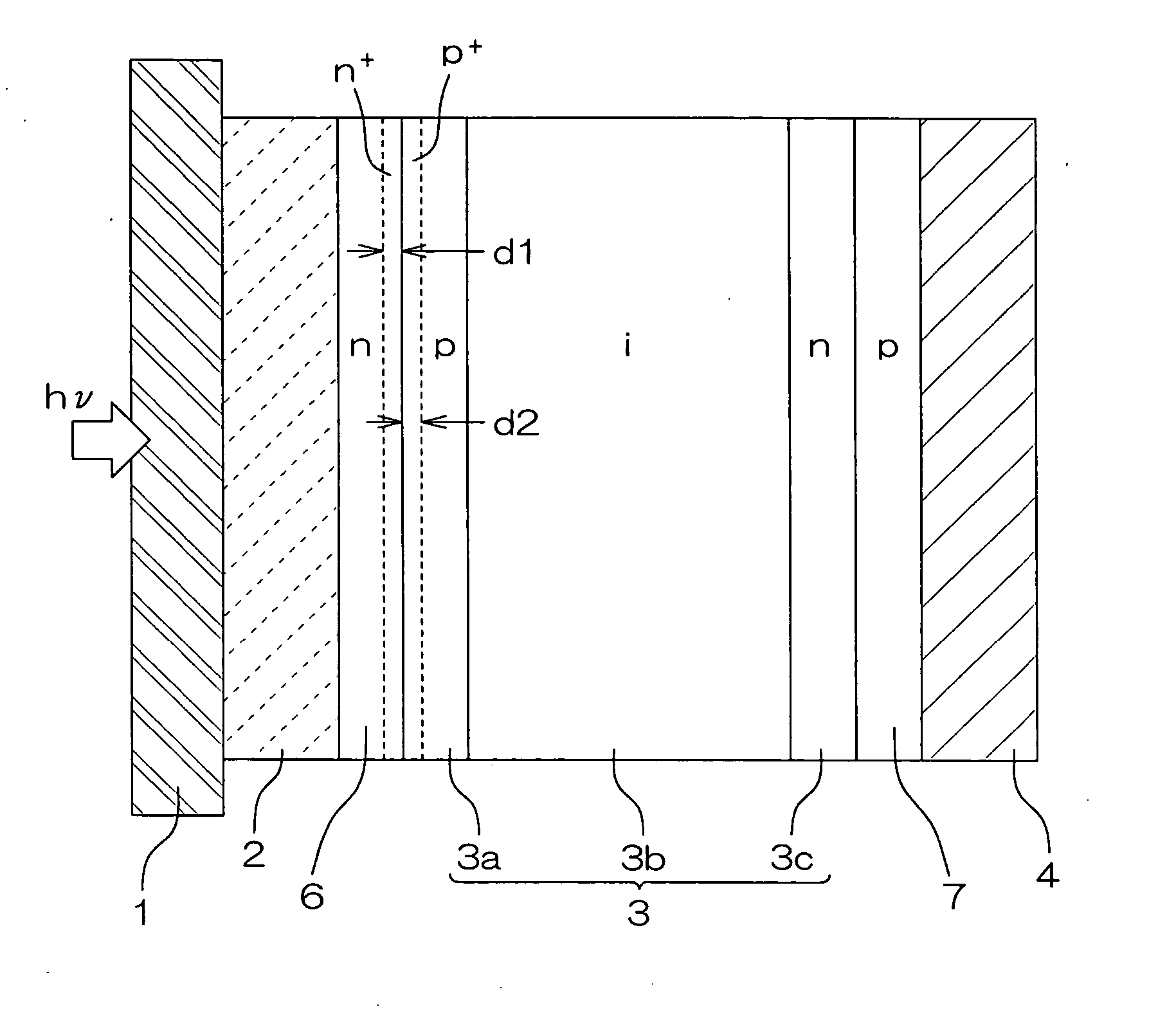

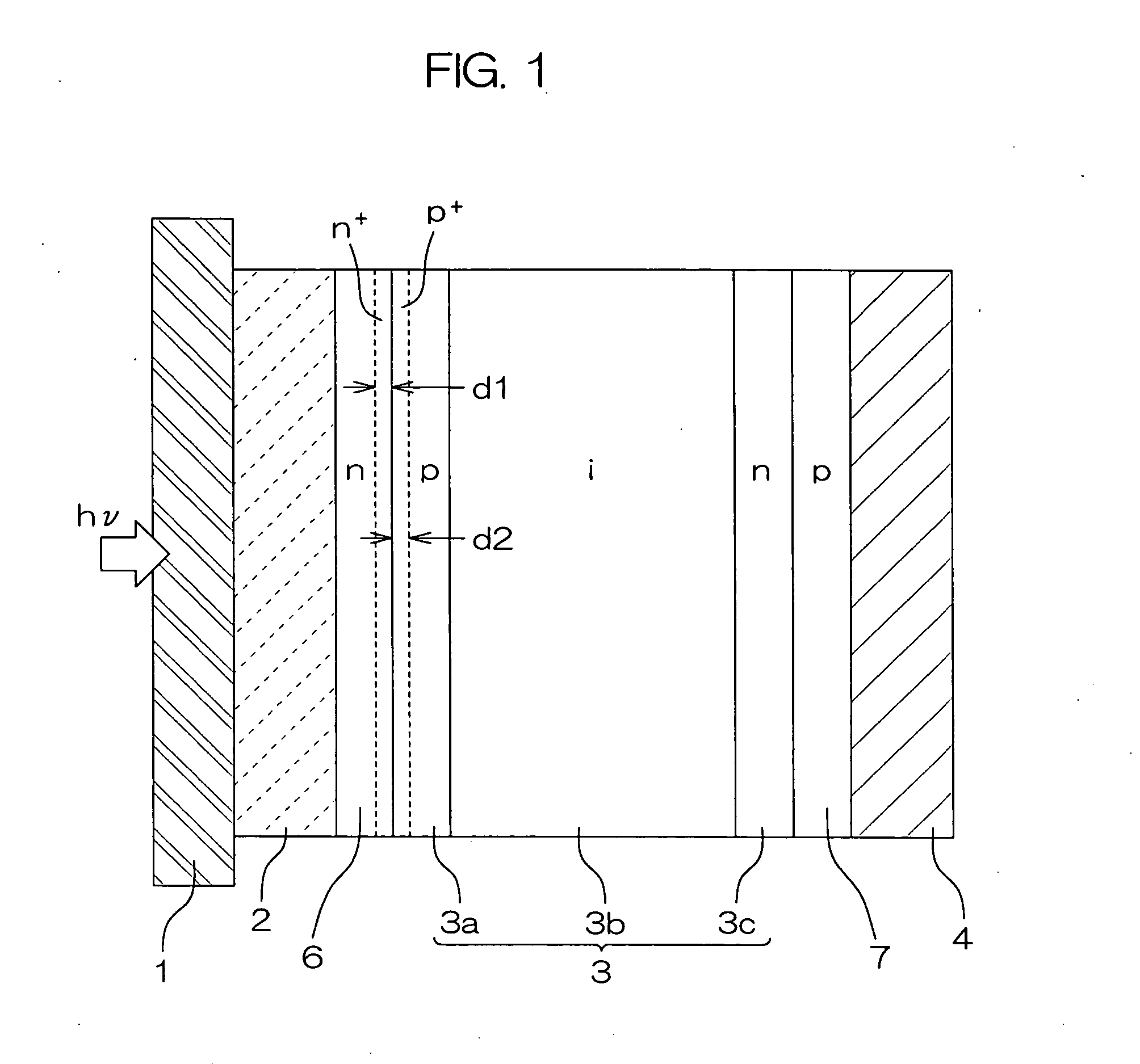

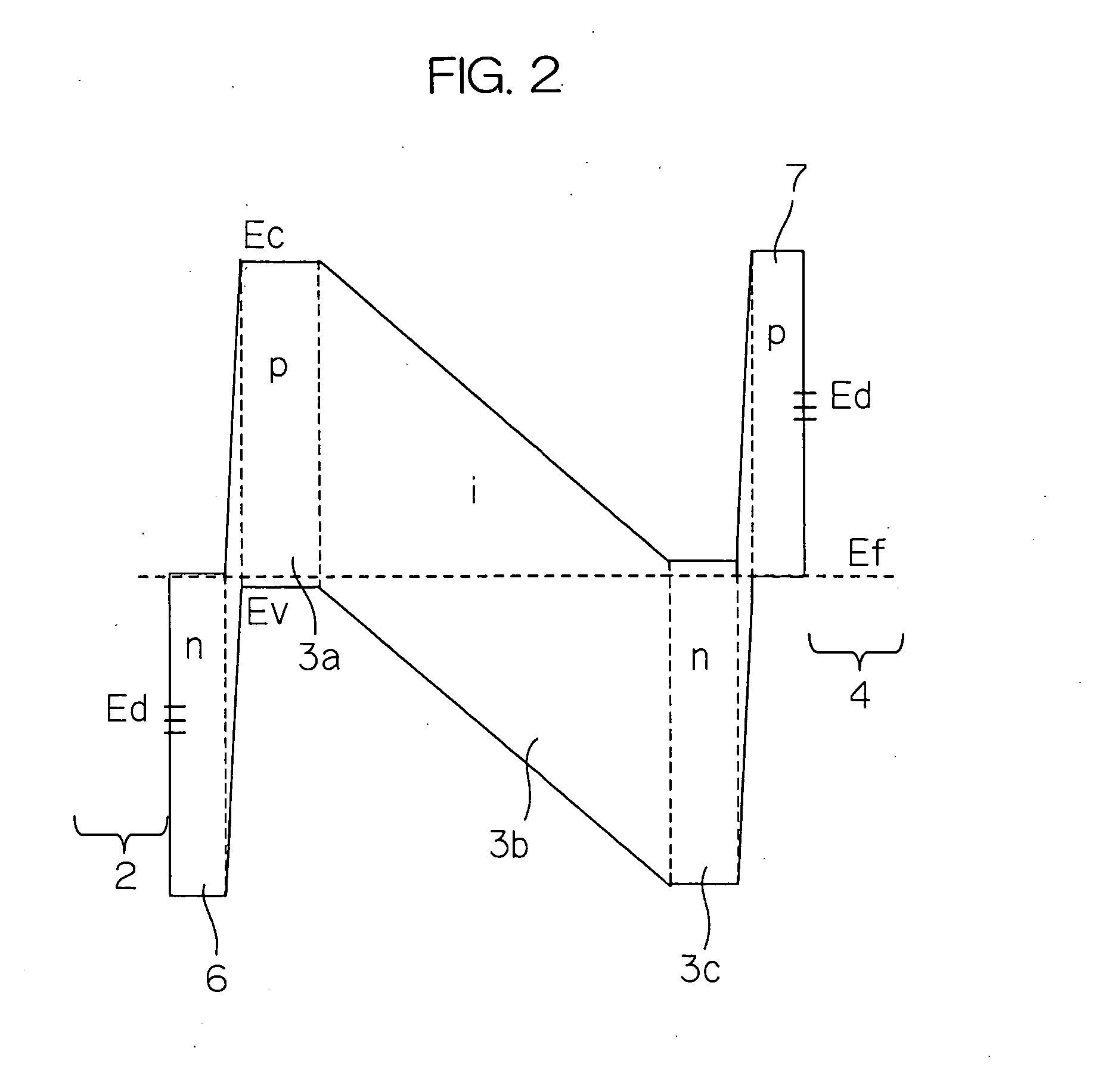

In a photoelectric conversion device, in a contact between a p-type semiconductor 3a and an electrode 2, an n-type semiconductor 6 of a conductivity type opposite to that of the p-type semiconductor is provided between the p-type semiconductor 3a and the electrode 2. The existence of the n-type semiconductor 6 allows a recombination rate of photo-generated carriers excited by incident light to be effectively reduced, and allows a dark current component to be effectively prevented from being produced. Therefore, it is possible to improve photoelectric conversion efficiency as well as to stabilize characteristics. Further, a tunnel junction is realized by increasing the concentration of a doping element in at least one or preferably both of the p-type semiconductor 3a and the n-type semiconductor 6 in a region where they are in contact with each other, thereby keeping ohmic characteristics between the semiconductor and the electrode good.

Owner:KYOCERA CORP

Metal-graphene-titanium dioxide nanotube array photocatalyst and preparation and application method thereof

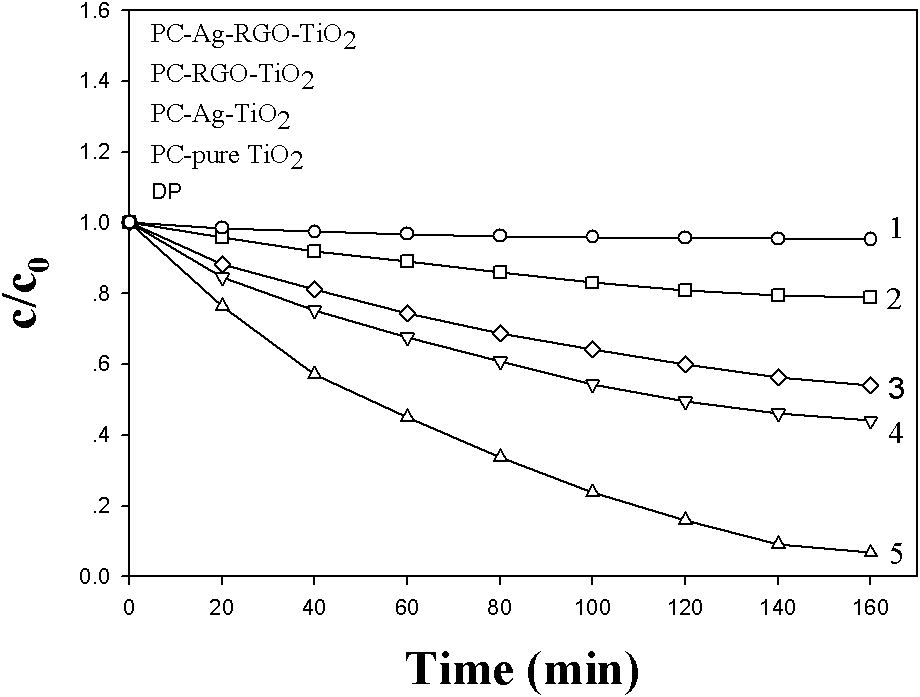

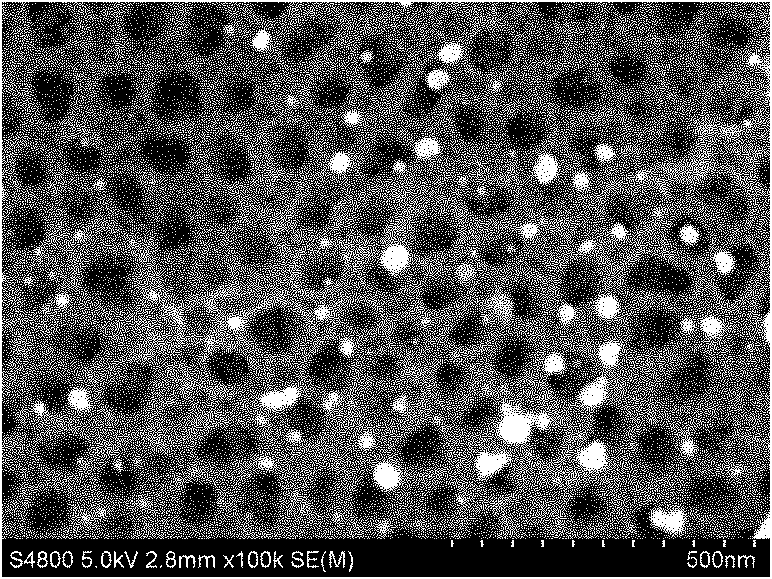

InactiveCN102125837AGood capture and transfer performanceReduce recombination rateMetal/metal-oxides/metal-hydroxide catalystsCommon carrierRecombination rate

The invention discloses a metal-graphene-titanium dioxide nanotube array photocatalyst and a preparation and application method thereof. Graphene and metal are taken as common carriers of photo-induced electrons of titanium dioxide, thus the recombination rate of the photo-induced electrons and holes is lowered, and finally, the degradation efficiency of the catalyst to organic pollutants is improved through the adsorption performance of the graphene to the organic pollutants. The catalyst has good performance in the aspect of treating water pollutants, and has the advantages of simple preparation method and low cost.

Owner:HUNAN UNIV

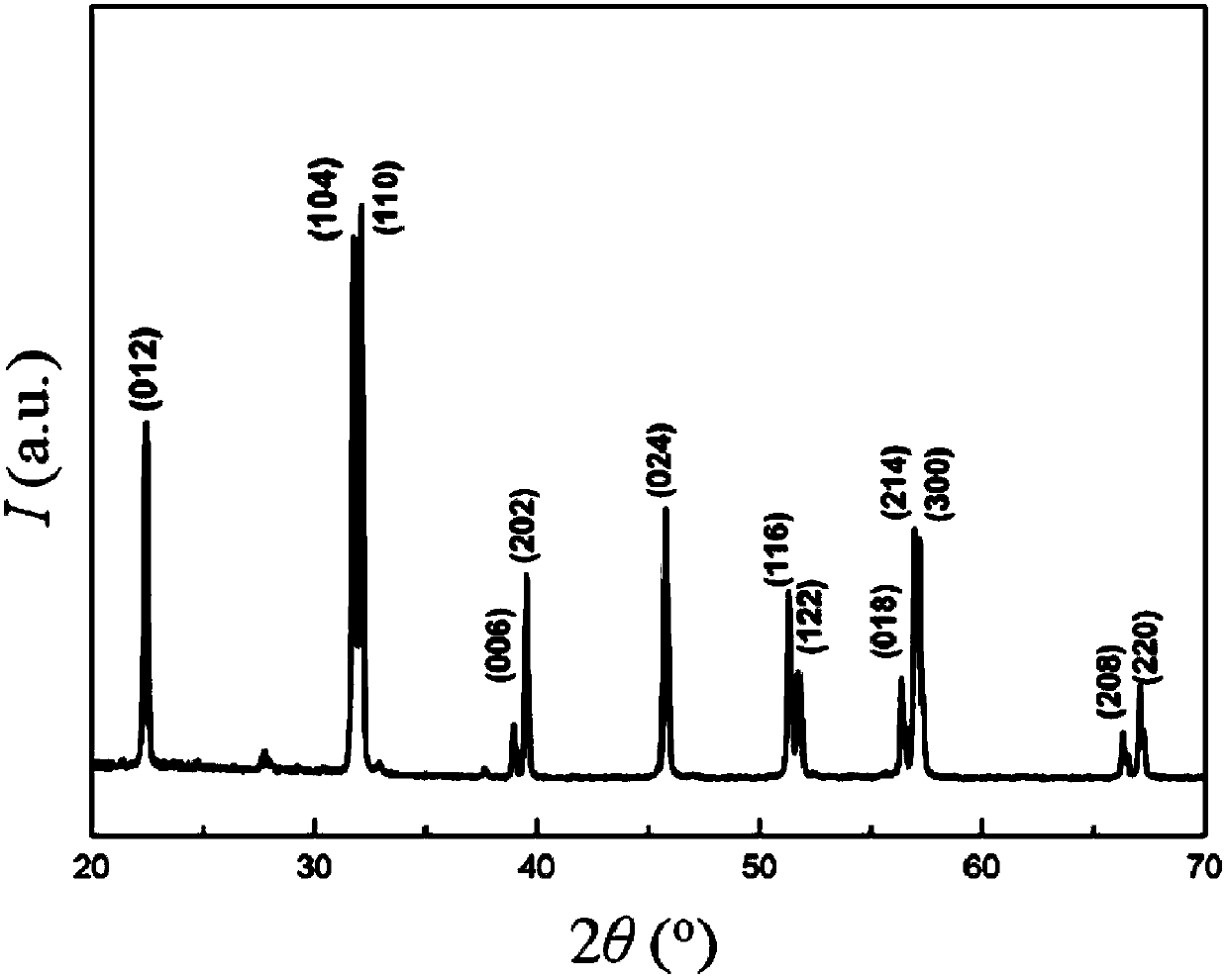

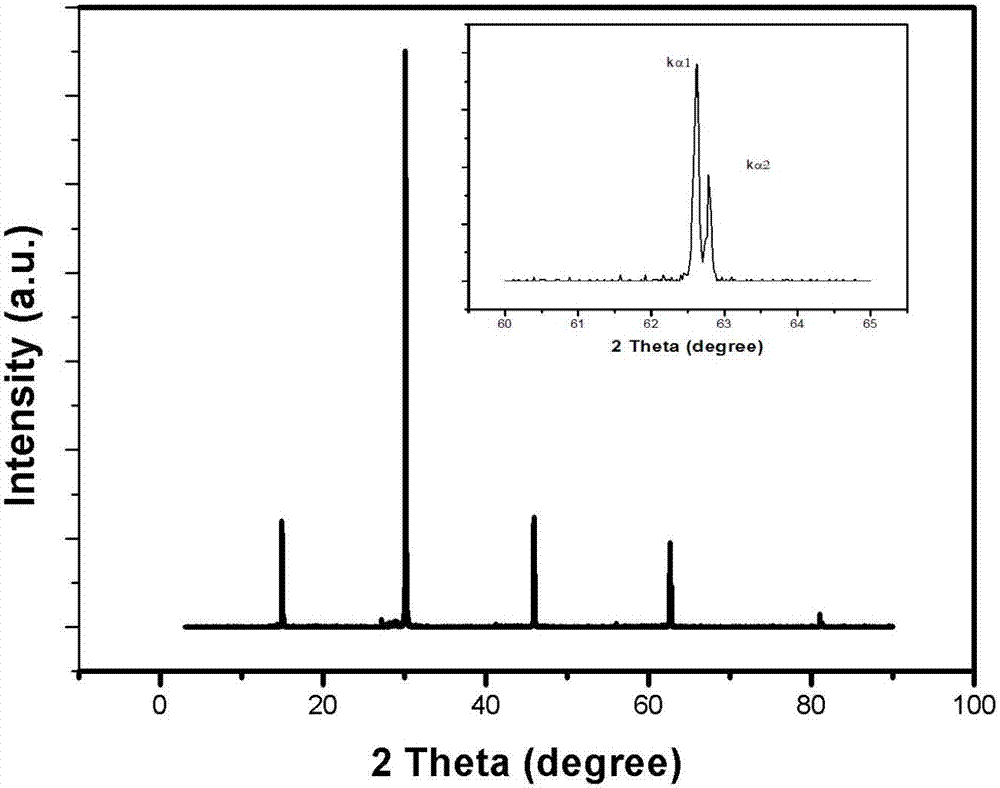

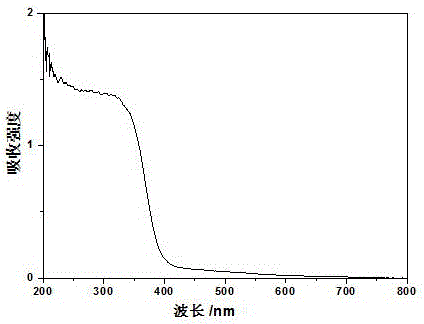

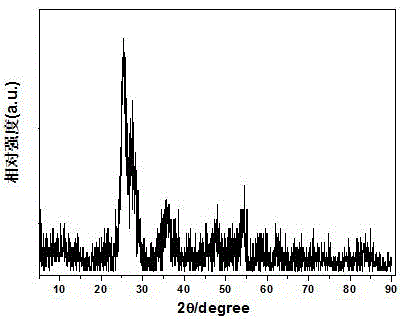

Bismuth ferrite nano fiber material and preparation method thereof

The invention discloses bismuth ferrite nano fiber and a preparation method thereof. The preparation method of the bismuth ferrite nano fiber comprises the following steps: 1) using bismuth nitrate or a hydrate thereof and iron nitrate or a hydrate thereof as raw materials, dissolving the two raw materials in a solvent, adding a complexing agent, stirring to obtain bismuth ferrite sol, then adding a polymer as a spinning aid in the bismuth ferrite sol, and stirring evenly to obtain a precursor solution; 2) performing electrostatic spinning of the precursor solution to obtain bismuth ferrite precursor fiber; and 3) performing heat treatment of the bismuth ferrite precursor fiber to remove the polymer to obtain the bismuth ferrite nano fiber. In the BiFeO3 (bismuth ferrite) nano fiber prepared by the preparation method, crystal grains of the fiber are arranged along the axial direction to form a bamboo-joint-like structure. The bismuth ferrite nano fiber has a narrow forbidden bandwidth (2.1-2.3 eV), a high utilization rate of visible light, a large specific surface area and few crystal boundaries and crystal faces, can effectively improve the separation of photogenerated carriers and reduce the recombination rate of photogenerated electrons and holes, has a high quantum efficiency, and shows more excellent photocatalytic properties than nanoparticles.

Owner:TSINGHUA UNIV

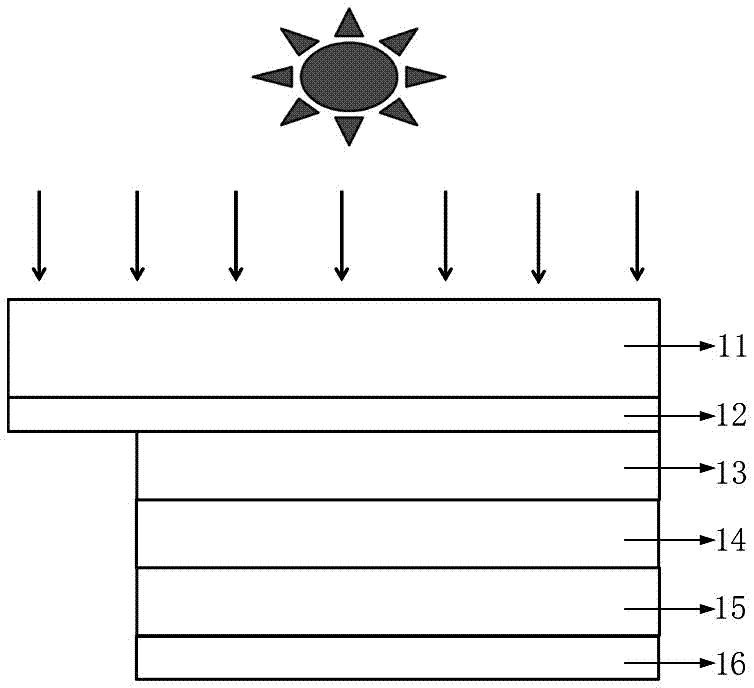

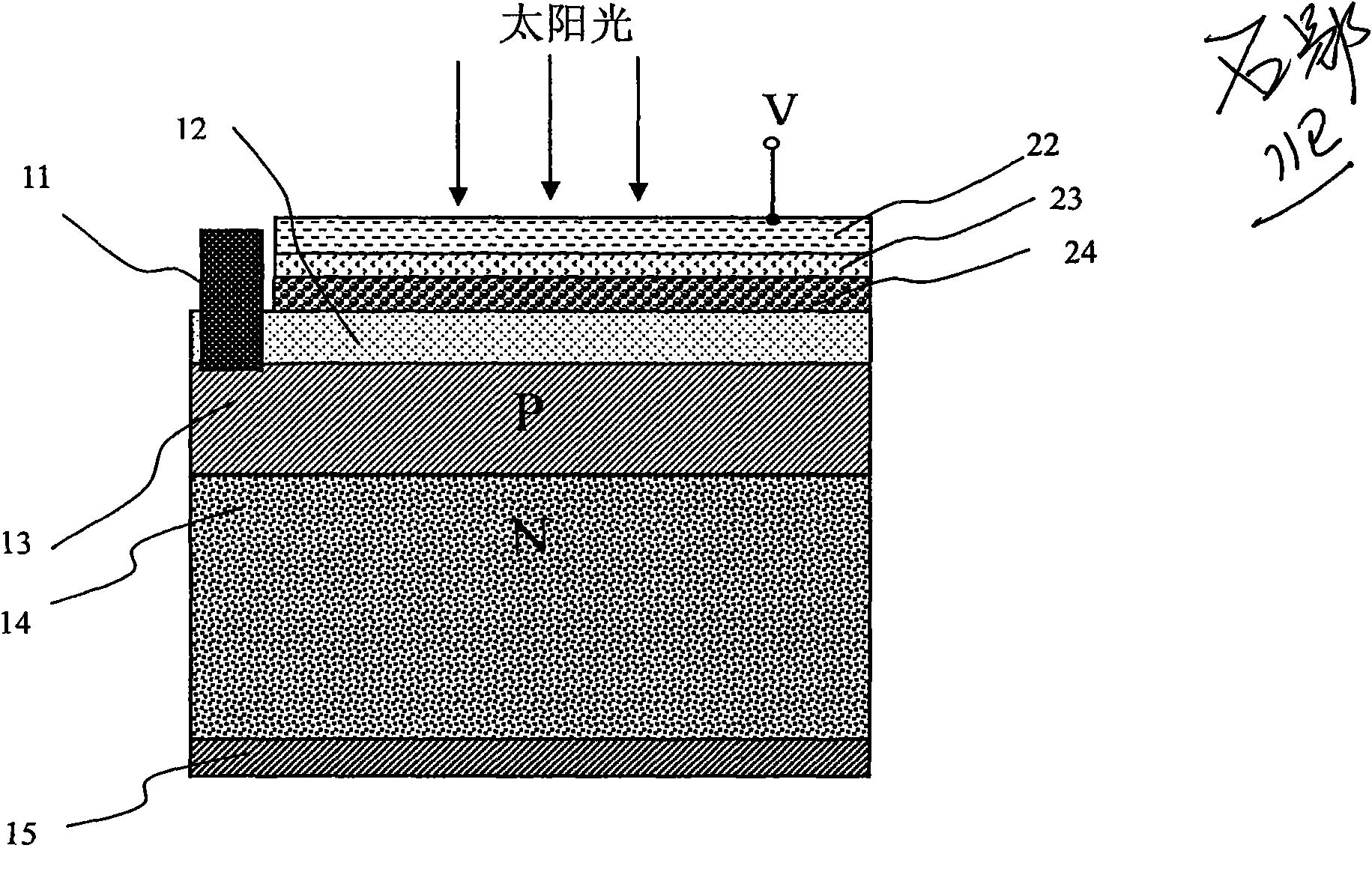

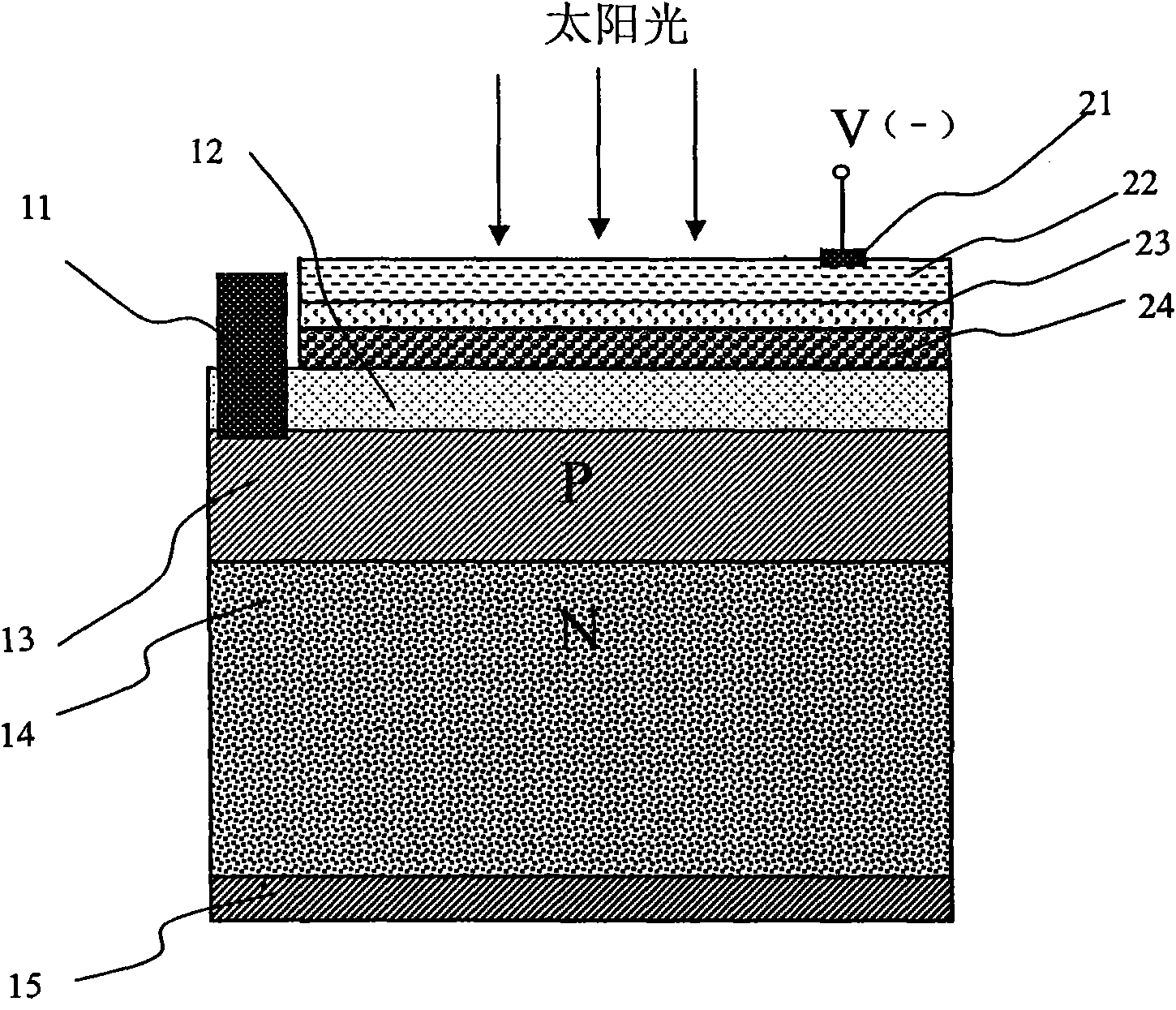

Solar cell device

InactiveUS7560750B2Carrier recombination rate RReduce carrier recombinationThyristorSuperconductor devicesPhotoelectric conversionRecombination rate

In a photoelectric conversion device, in a contact between a p-type semiconductor 3a and an electrode 2, an n-type semiconductor 6 of a conductivity type opposite to that of the p-type semiconductor is provided between the p-type semiconductor 3a and the electrode 2. The existence of the n-type semiconductor 6 allows a recombination rate of photo-generated carriers excited by incident light to be effectively reduced, and allows a dark current component to be effectively prevented from being produced. Therefore, it is possible to improve photoelectric conversion efficiency as well as to stabilize characteristics. Further, a tunnel junction is realized by increasing the concentration of a doping element in at least one or preferably both of the p-type semiconductor 3a and the n-type semiconductor 6 in a region where they are in contact with each other, thereby keeping ohmic characteristics between the semiconductor and the electrode good.

Owner:KYOCERA CORP

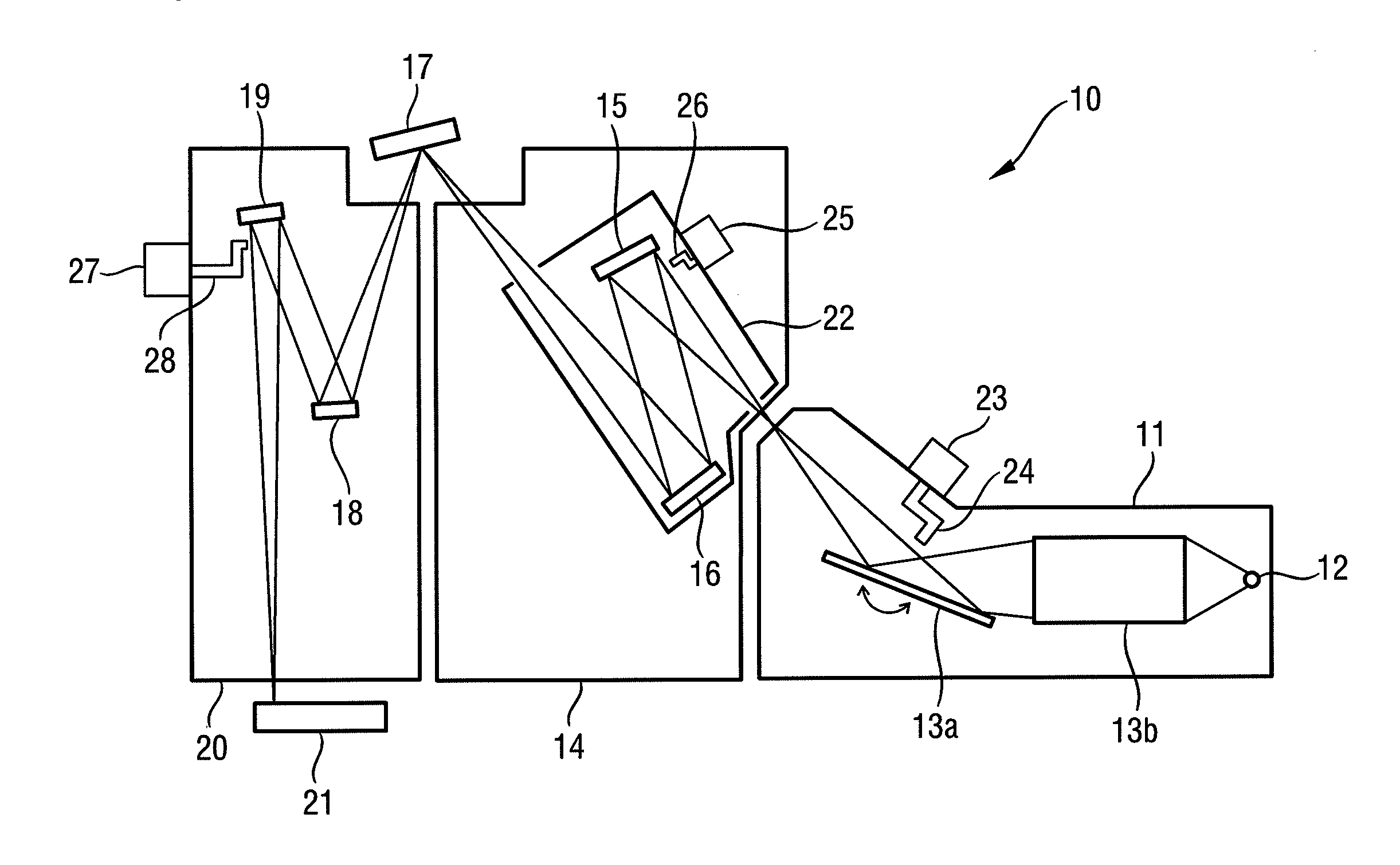

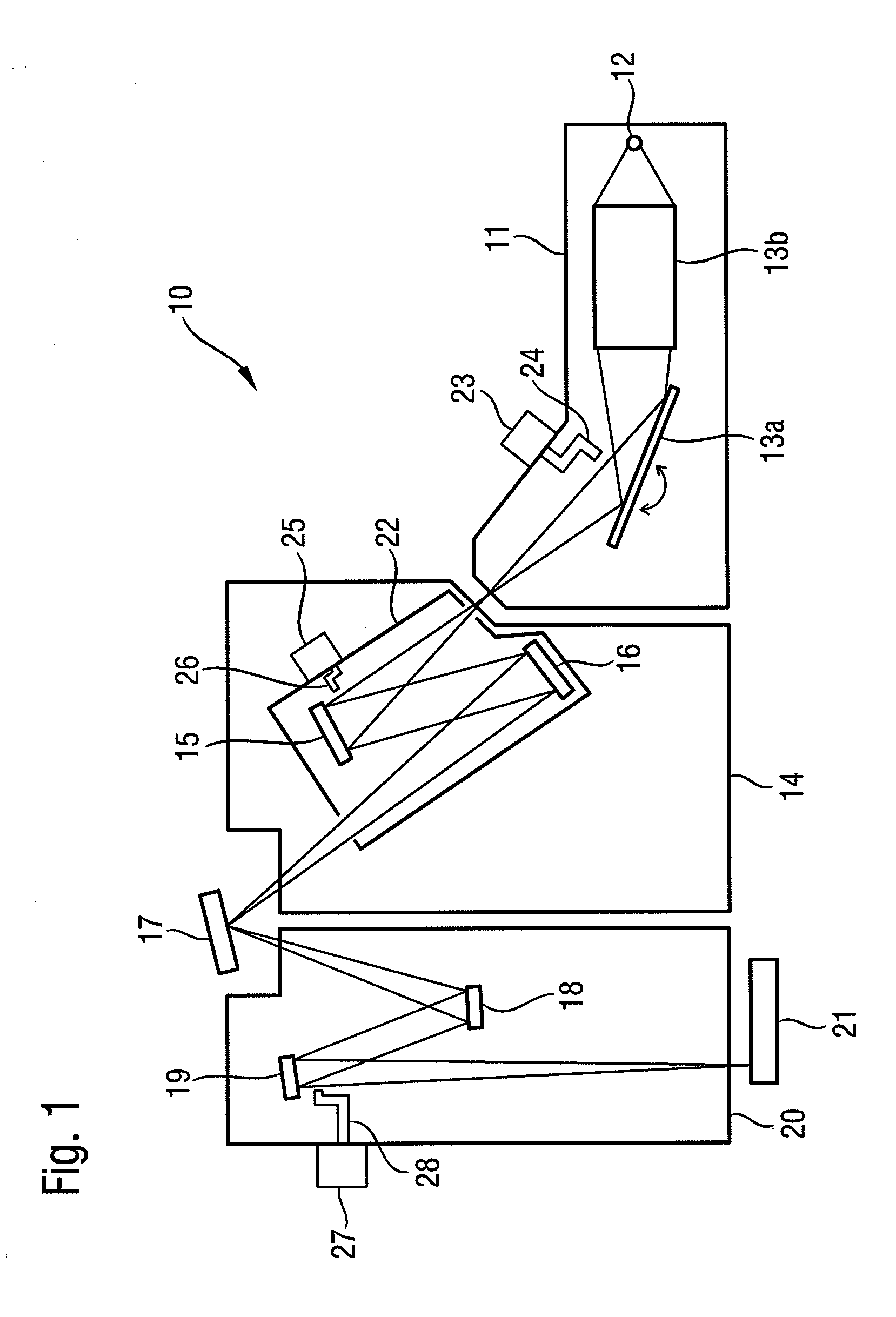

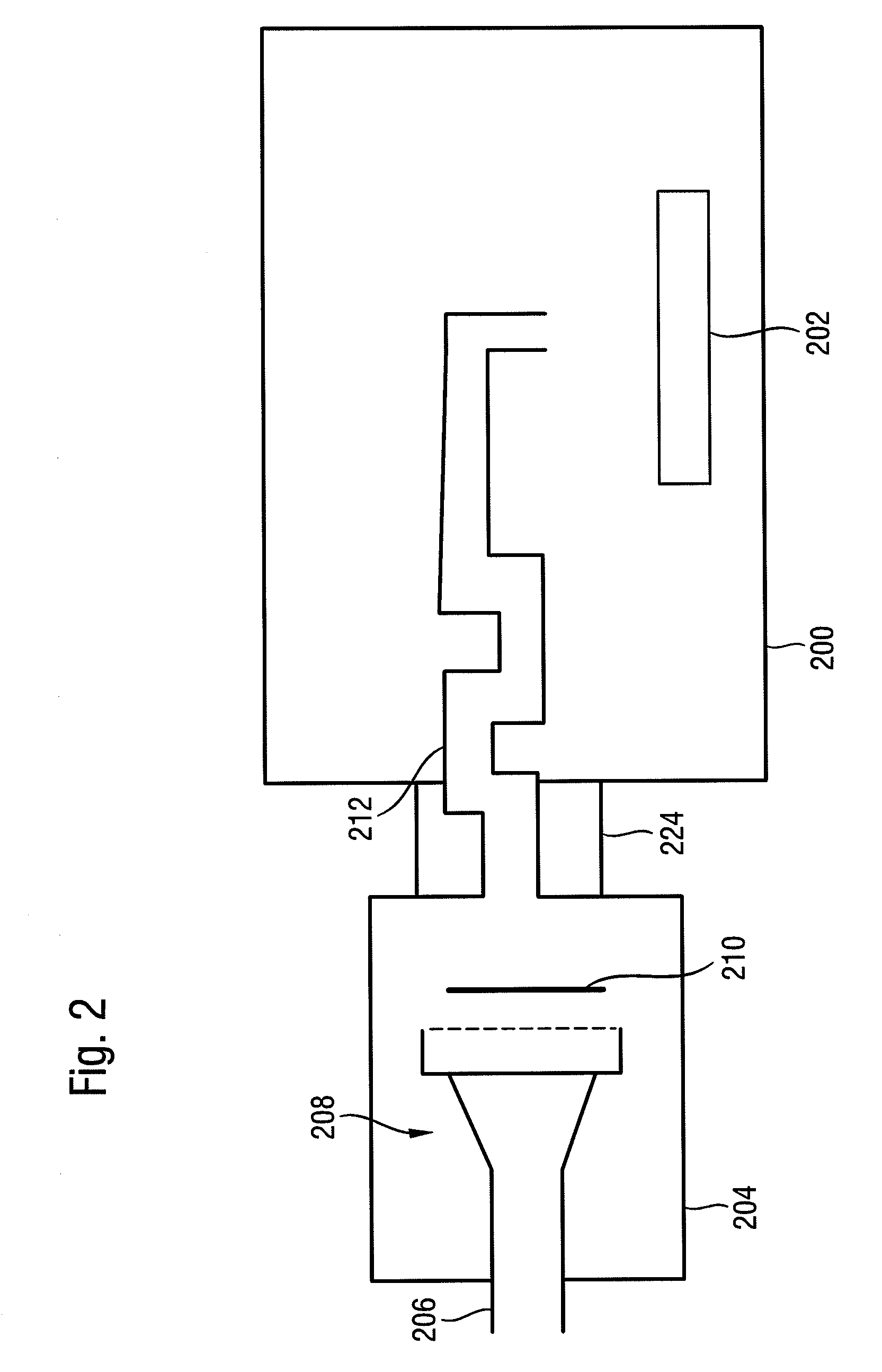

Cleaning module and EUV lithography device with cleaning module

InactiveUS20110058147A1Gentle cleaningEasy to cleanPhotomechanical apparatusSemiconductor/solid-state device manufacturingLithographic artistHydrogen

A cleaning module for an EUV lithography device with a supply (206) for molecular hydrogen, a heating filament (210) and a line (212) for atomic and / or molecular hydrogen. The line (212) has at least one bend with a bending angle of less than 120 degrees, and has a material on its inner surface which has a low recombination rate for atomic hydrogen. The supply (206) is of flared shape at its end, which faces the heating filament (210). A gentler cleaning of optical elements is achieved with such a cleaning module, or also by exciting a cleaning gas with a cold cathode or a plasma, or by filtering out charged particles via of electrical and / or magnetic fields.

Owner:CARL ZEISS SMT GMBH

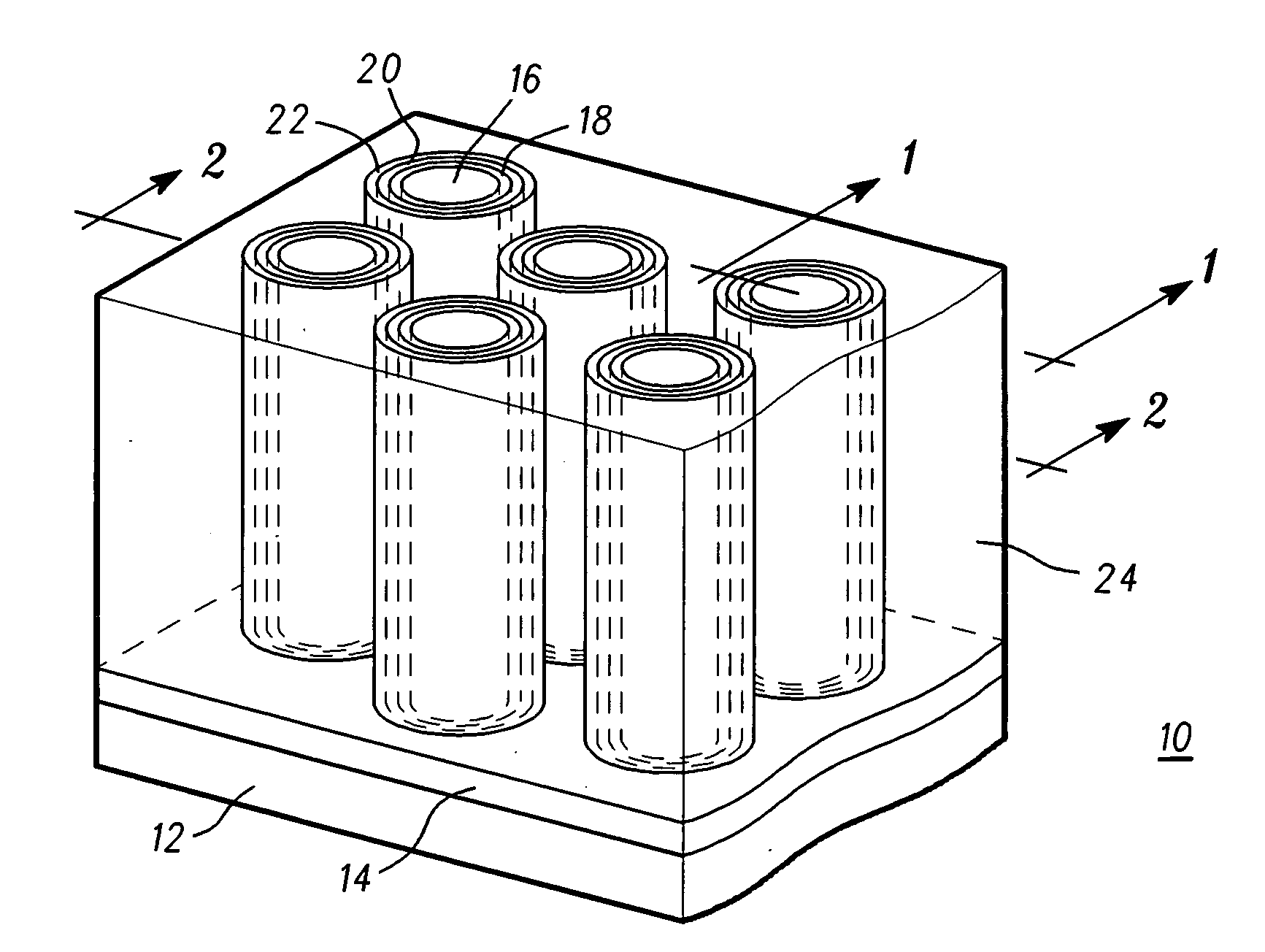

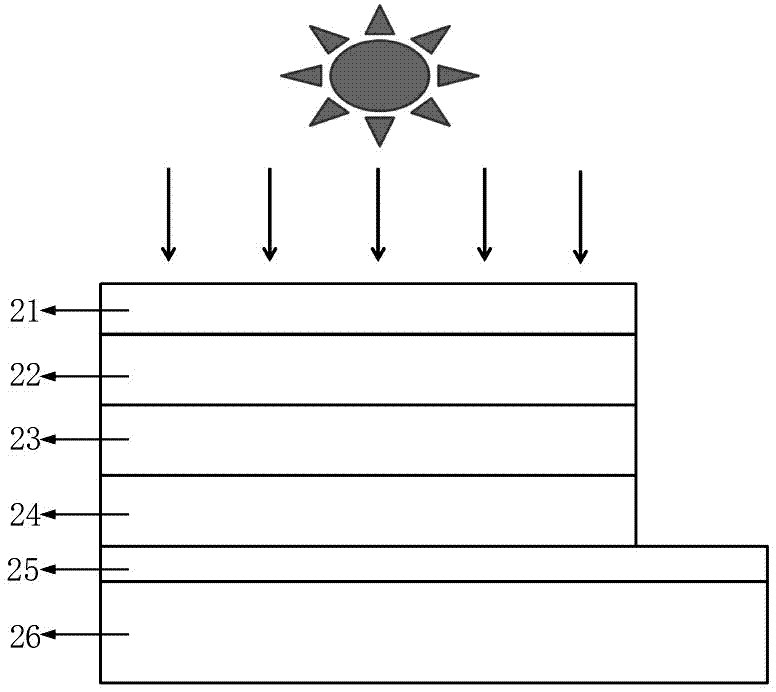

Nanosized,dye-sensitized photovoltaic cell

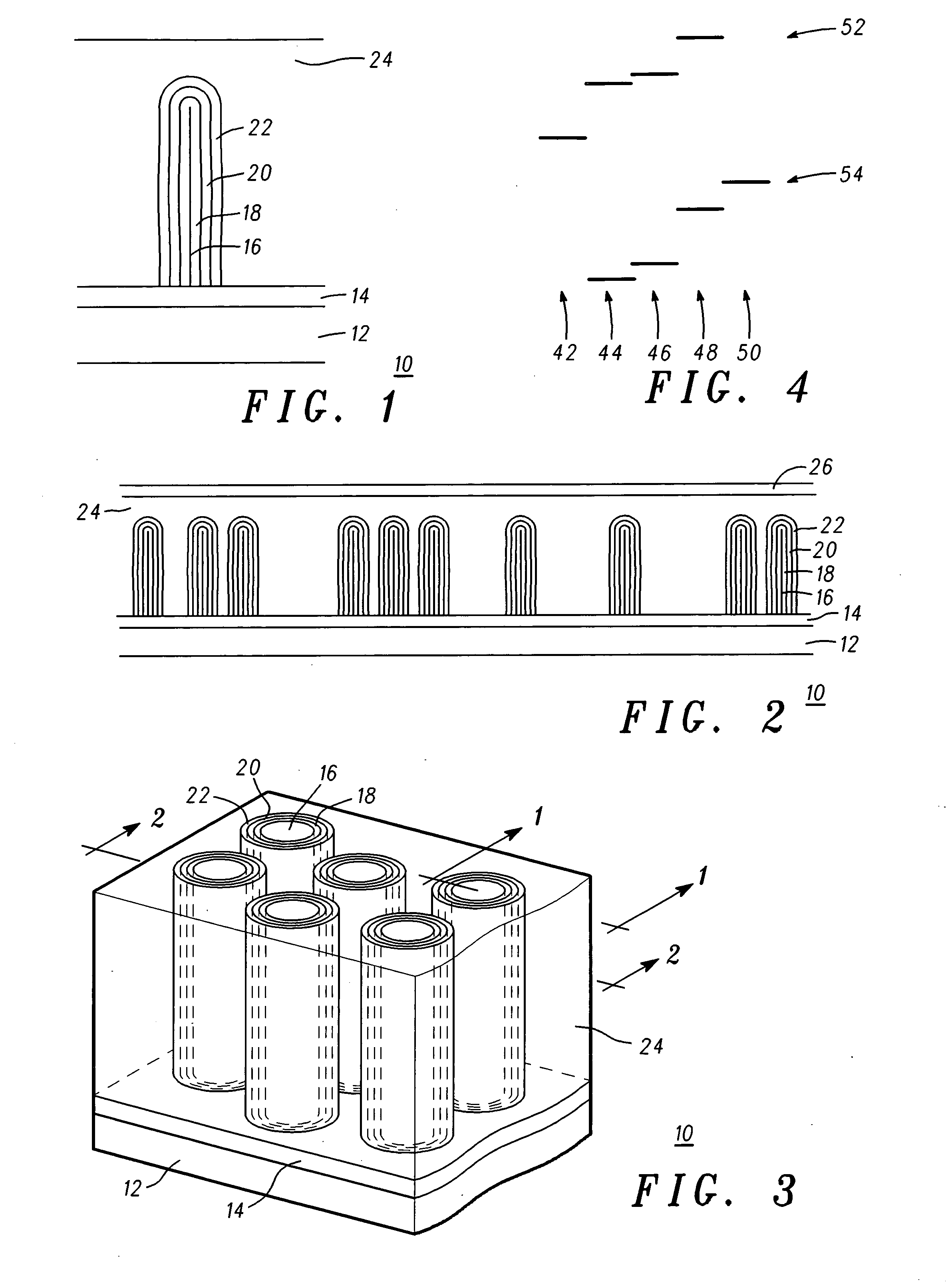

InactiveUS20080072961A1Reduce charge recombinationNanoinformaticsSolid-state devicesMolecular orbital energyEngineering

A sensitized photovoltaic device (10) provides for a reduction of the charge recombination rate and charge transport time. The device (10) includes a first electrode (12) comprising a transparent conducting oxide and a plurality of carbon nanostructures (16) formed thereon. A first layer (18) is formed on the carbon nanostructure (16) and comprises a first conduction band level (44). A second layer (20) is formed on the first oxide (18) and comprises a second conduction band level (46) higher than the first conduction band level (44). A sensitizer (22) is formed on the second layer (20) and comprises a lowest unoccupied molecular orbital level (48) higher than the second conduction band level (46). An electrolyte (24) is positioned over the sensitizer (22), and a second electrode (26) comprising a transparent conducting oxide and a layer of catalyst is formed over the electrolyte (24).

Owner:MOTOROLA INC

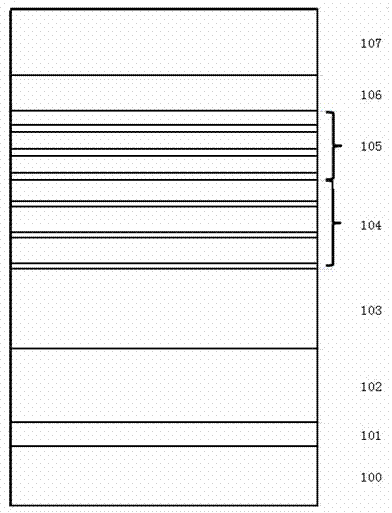

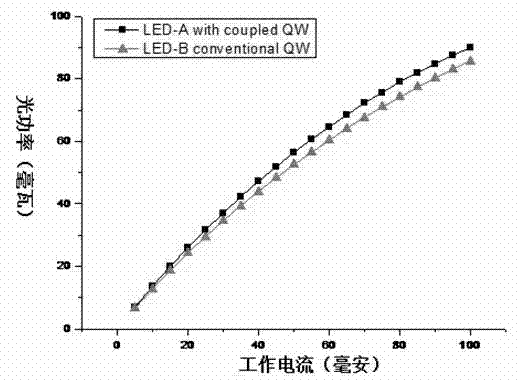

Epitaxial structure of high-brightness light emitting diode and implementation method thereof

ActiveCN102832306AQuality improvementImprove luminous efficiencySemiconductor devicesQuantum efficiencyRecombination rate

An epitaxial structure of a high-brightness light emitting diode and an implementation method thereof belong to the technical field of semiconductor production. At least three pairs of coupled quantum wells grow. When each pair of coupled quantum wells grow, firstly, quantum well layers low in In content grow; and secondly, luminous quantum well layers grow, In content of each quantum well layer low in In content gradually increases along the growth direction, and a thin GaN barrier layer grows between each adjacent quantum well layer low in In content and luminous quantum well layer. A coupled quantum well structure which is low in In content and gradually increases in composition grows before a luminous quantum well by a variable temperature and variable precursor flow method, and accordingly a quantum well low in In content cannot adsorb photons emitted by the quantum well again, built-in electric field can be lowered, localization of carriers is enhanced to increase radiative recombination rate, and internal quantum efficiency of the light emitting diode is improved greatly.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

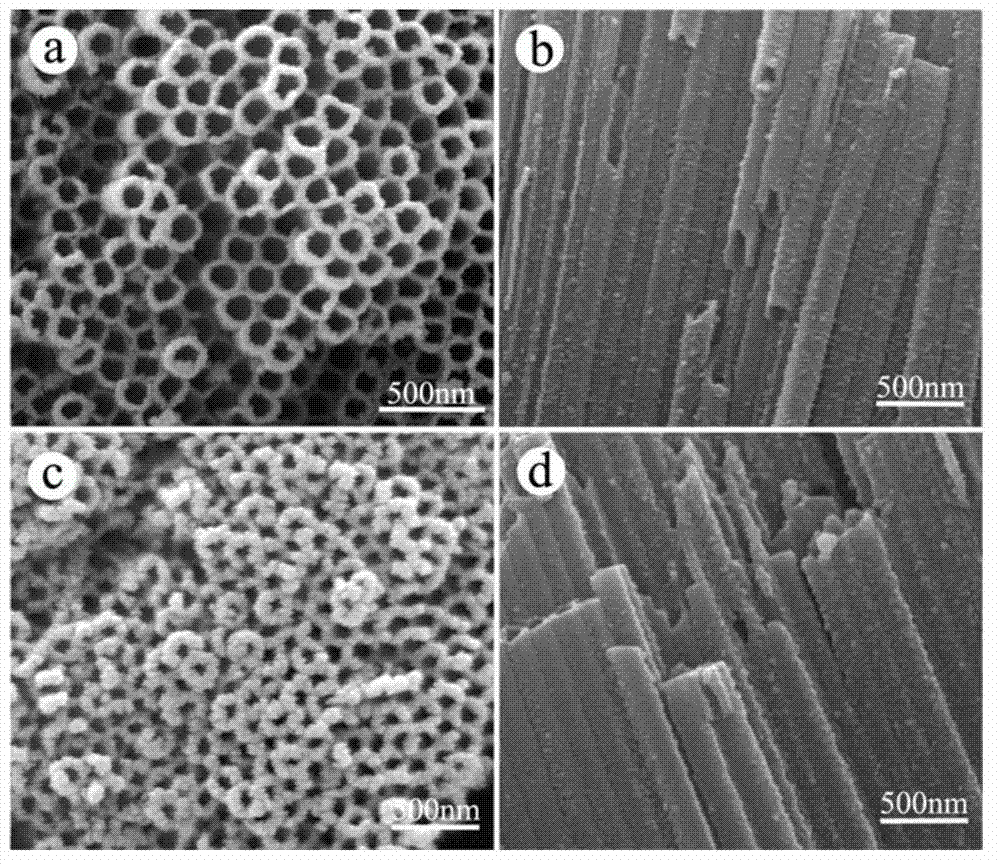

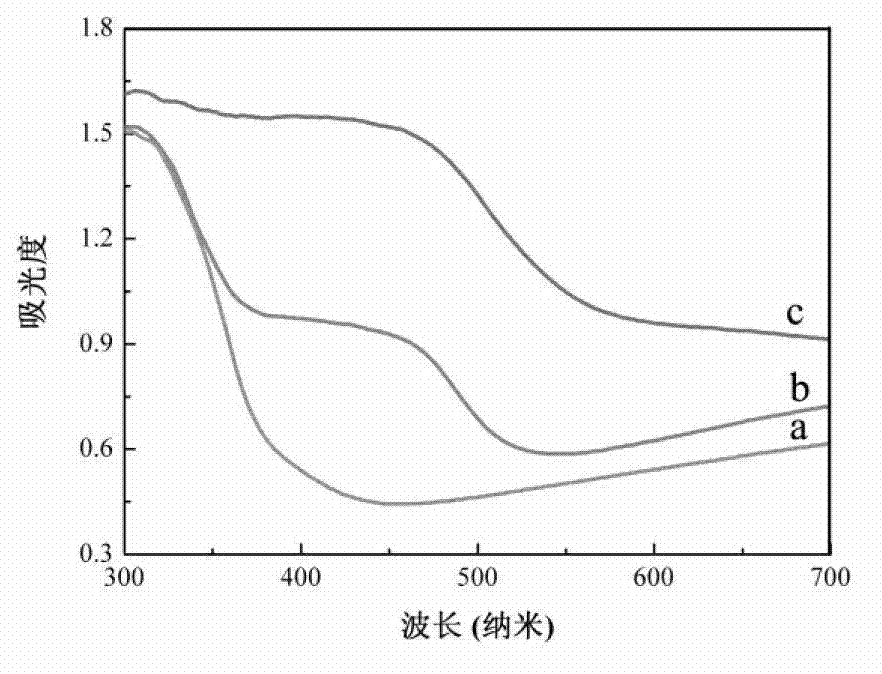

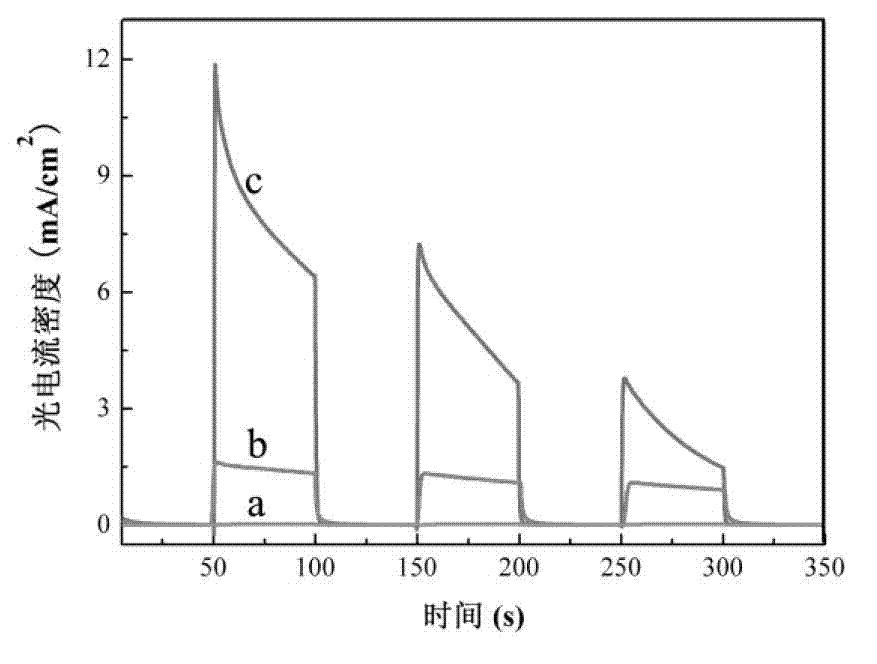

Preparation of silver/cadmium sulfide-nanoparticle-comodified titanium dioxide nanotube array

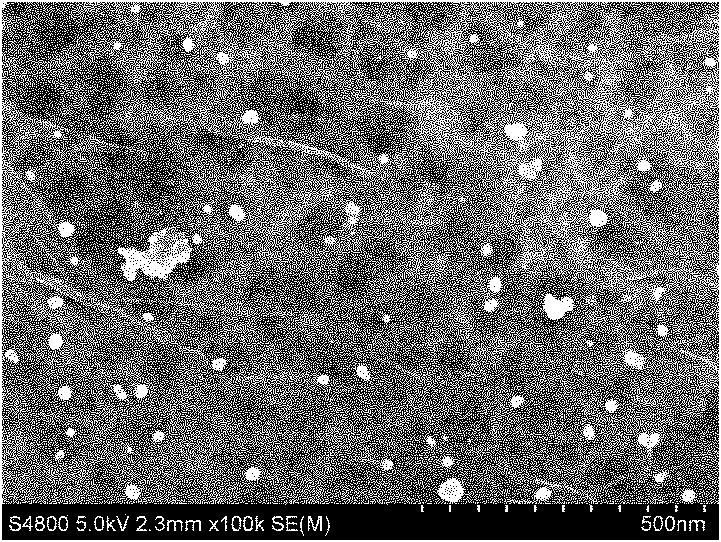

InactiveCN102965710AEffective size controlEffective control of adhesionSurface reaction electrolytic coatingArray data structureSolar cell

The invention belongs to the field of nano material preparation, and relates to a method for comodifying a titanium dioxide nanotube array with silver and cadmium sulfide nanoparticles, which comprises the following steps: carrying out ultrasonic cleaning on a high-purity titanium sheet to remove oil, removing the natural oxide film, and carrying out secondary anodization to prepare an ordered titanium dioxide nanotube array; and treating the titanium dioxide nanotube array with a coupling agent, depositing Ag nanoparticles by an SILAR (successive ionic layer adsorption and reaction) process, and modifying the Ag-modified titanium dioxide nanotube array with CdS nanoparticles, thereby obtaining the Ag / CdS-nanoparticle-comodified titanium dioxide nanotube array. The invention is simple to operate and has the advantage of low cost; the noble metal and narrow-energy-gap semiconductor nanoparticles are utilized to comodify the titanium dioxide nanotube array, thereby effectively widening the absorption range of TiO2 in the visible light region and lowering the recombination rate of the electron-hole pair; and the invention has wide prospects in the aspects of solar cells, toxic or harmful pollutant degradation and the like.

Owner:TONGJI UNIV

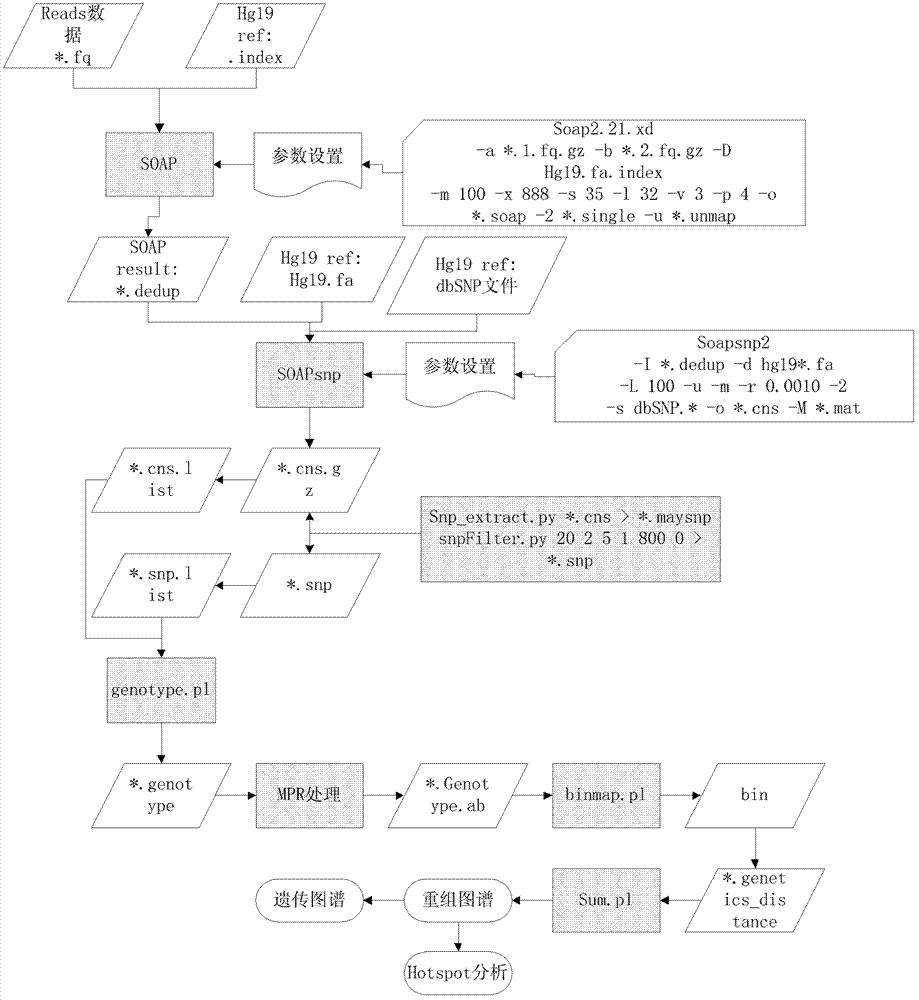

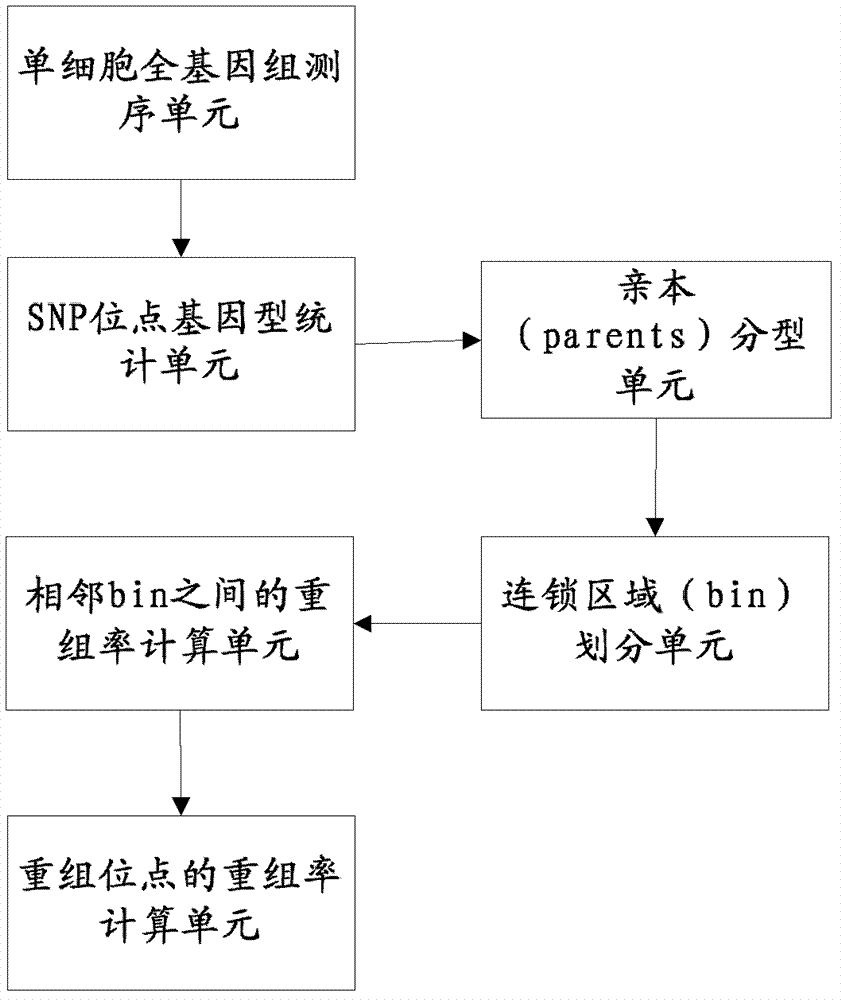

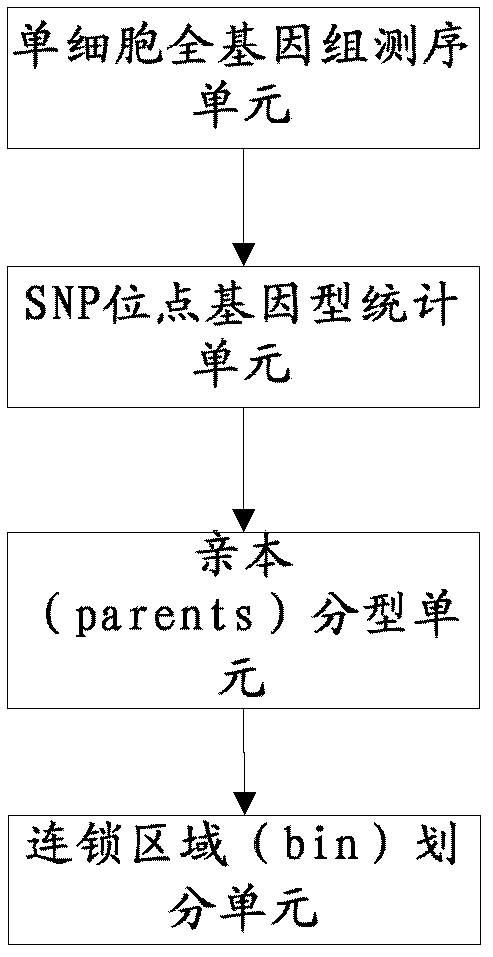

Genetic map construction method and device, haplotype analytical method and device

ActiveCN102952855AHigh resolutionUnderstand the genetic laws of reproductionBioreactor/fermenter combinationsBiological substance pretreatmentsGenomic sequencingTyping Classification

The invention relates to a genetic map construction and haplotype analytical method based on single-cell whole genome sequencing, and a device used for the method. The genetic map construction method comprises the following steps: comparing a whole genome sequence of a single cell of a species with a reference sequence to obtain a statistic result of a single nucleotide polymorphic site genotype; performing parent type classification of the genotype result to obtain a most appropriate male parent / female parent (a / b) result, so as to obtain a minimum recombination frequency of all the cells in the statistic result; according to the type classification result, dividing a linkage area (bin); calculating a change ratio of a / b to obtain recombination rates between all adjacent bins; and finally obtaining the genetic map according to the recombination rate of each recombinant site. The method of the invention can obtain a genetic map with high resolution by using a single cell, can not only applicable to human, but also applicable to some higher organisms with limited fertility, especially to endangered species.

Owner:TIANJIN MEDICAL LAB BGI

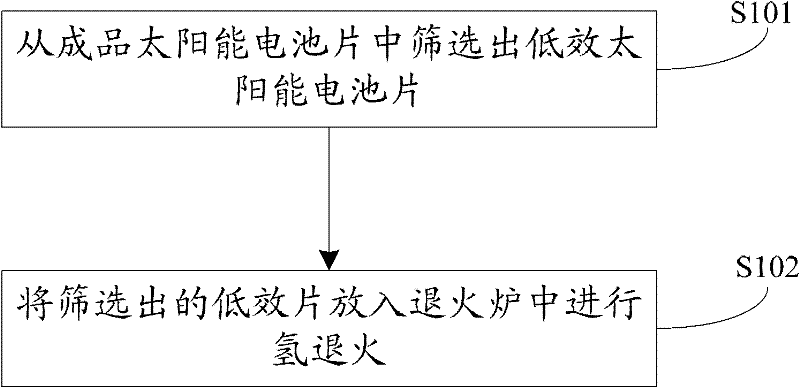

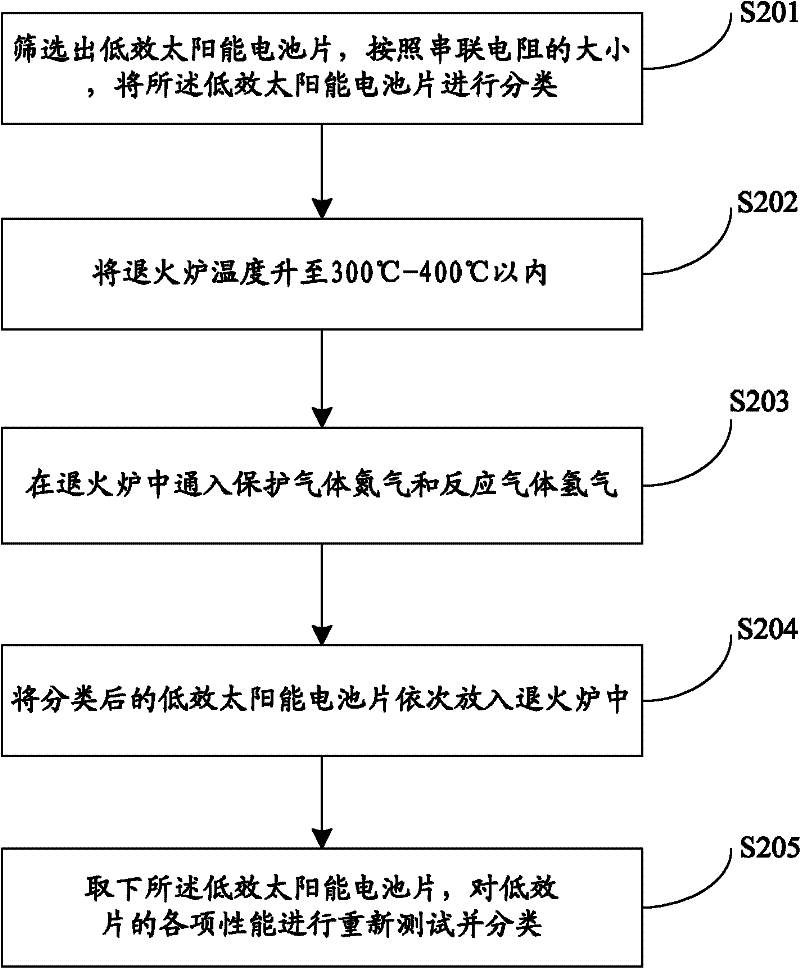

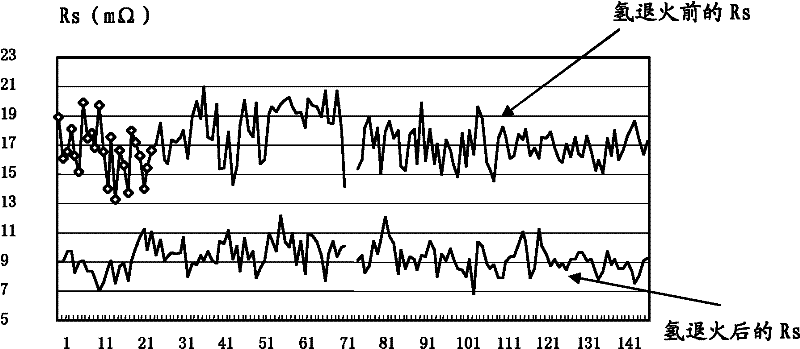

A processing method of inefficient solar cell sheets

InactiveCN102185008AReduce the series resistance RsImprove conductivityFinal product manufactureSemiconductor devicesSolar cellMetal electrodes

The invention discloses a processing method of inefficient solar cell sheets. The processing method comprises the steps of screening out inefficient solar cell sheets from solar cell sheet products, and disposing the inefficient solar cell sheets into an annealing furnace for annealing with hydrogen. In the embodiment of the invention, the inefficient cell sheets are annealed with hydrogen. Since hydrogen can reduce oxide on metal electrodes, the contact resistance between the metal electrodes and silicon is thereby reduced, and accordingly the total series resistance of the inefficient cell sheets is reduced. Moreover, since hydrogen possesses a passivation function, the electroactive impurities are passivated, the recombination rate of carriers on cell surfaces and the lifetime of minority carriers are prolonged. Therefore, the shunt resistance of the cell sheets is improved and the reverse leakage current density is reduced, accordingly the filling factors of the cell sheets are increased and the conversion efficiency is improved.

Owner:JETION SOLAR HLDG

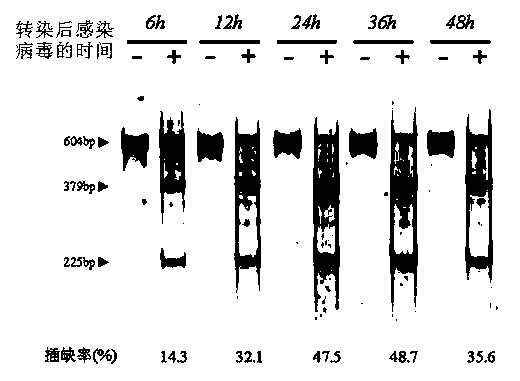

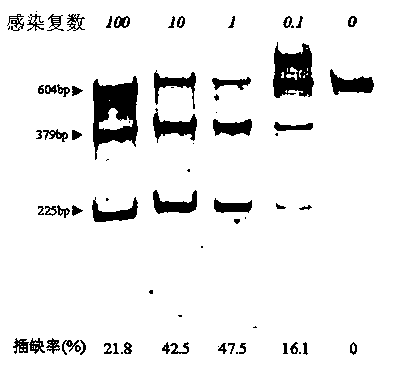

Site-directed modification method for DNA viral genome

ActiveCN103397018ARealize fixed-point transformationQuick insertRecombinant DNA-technologyFermentationFreeze thawingRecombinant virus

The invention provides a site-directed modification method for DNA viral genome, and the problems in the prior art are solved that induction of site-directed mutagenesis of DNA viral genome is difficult, the operation of inserting an exogenous fragment is complex, and recombination rate is lower. The site-directed modification method comprises: transfecting cells by a plasmid carrying a nuclease system, infecting by a virus, after the cells show pathological changes, collecting the cells with pathological changes, performing freeze-thaw or ultrasonic processing, and centrifuging, separating the liquid supernatant to obtain a progeny virus. The site-directed modification method is capable of realizing applications to screening of virus attenuated vaccine strains, construction of viral genetic carriers and an oncolytic virus, research on virus function sequences, and the like; during modification of the viral genome, the method helps to improve mutagenesis efficiency, accurately control DNA virus for genome site-directed mutagenesis and specific gene knockout, simplify operation steps of inserting the DNA virus carrier by an exogenous gene, and improve efficiency that the exogenous gene is integrated to the viral genome, so that the work of screening high-flux recombination viruses is convenient to conduct.

Owner:INST OF MEDICAL BIOLOGY CHINESE ACAD OF MEDICAL SCI

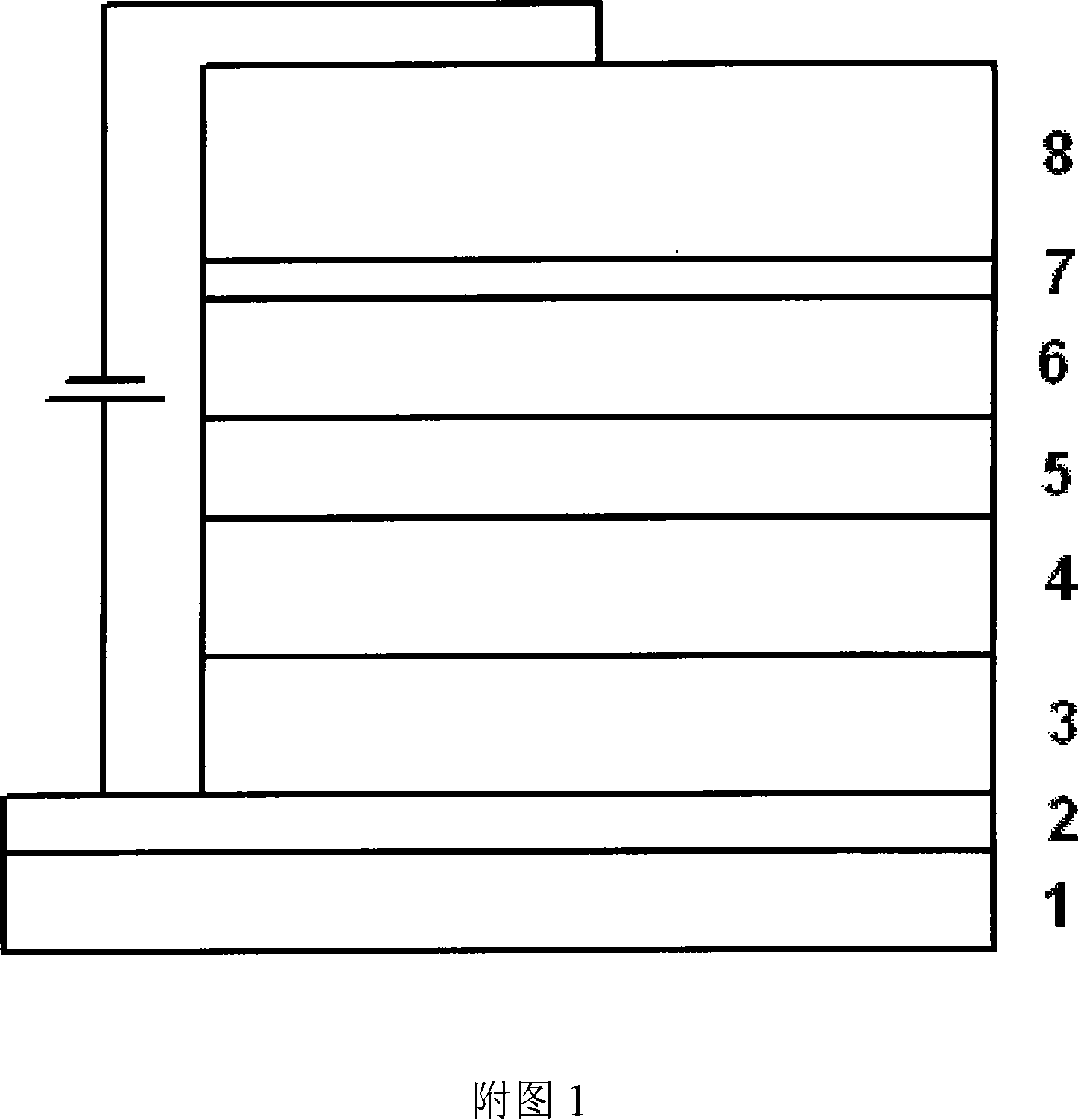

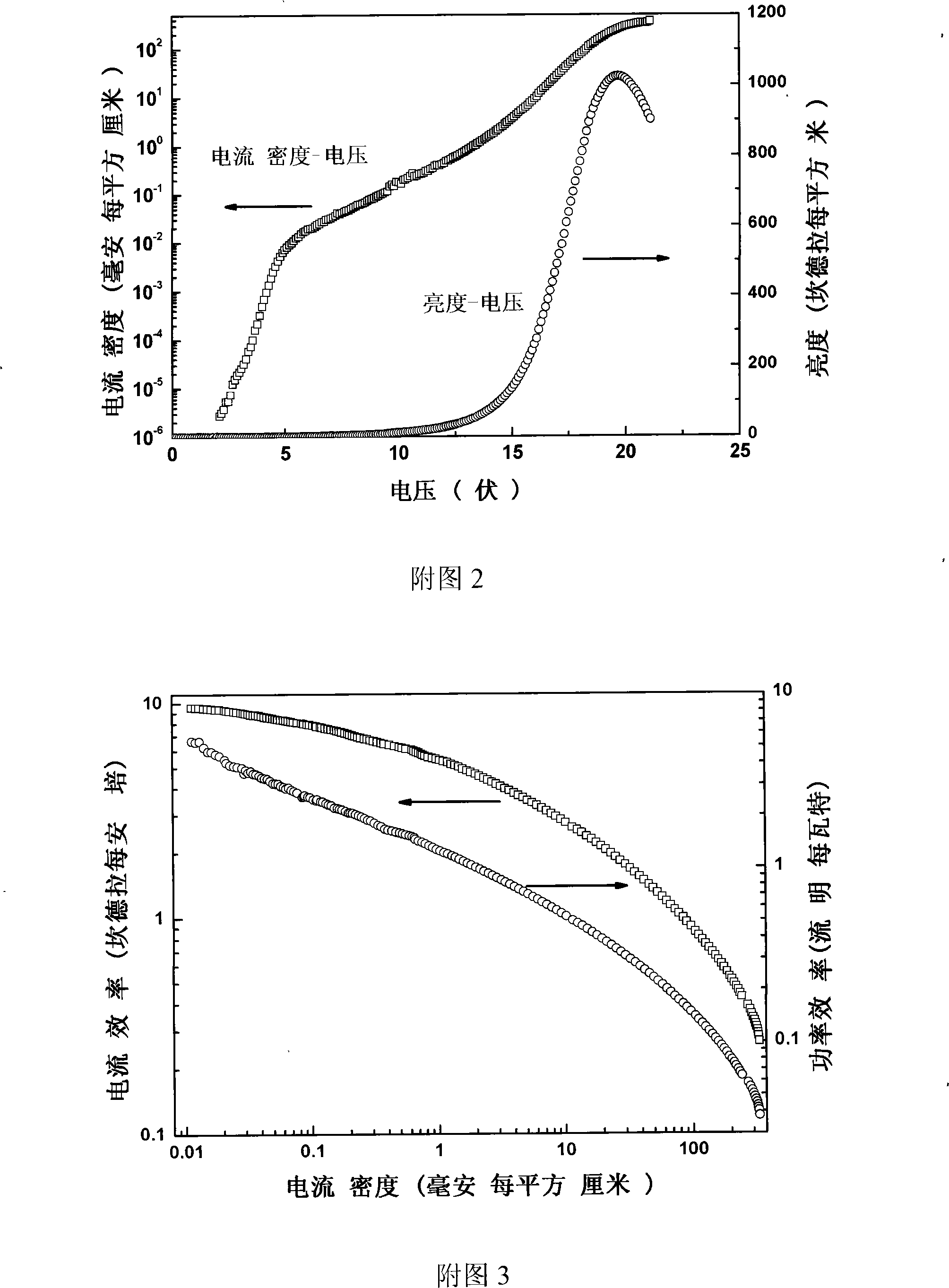

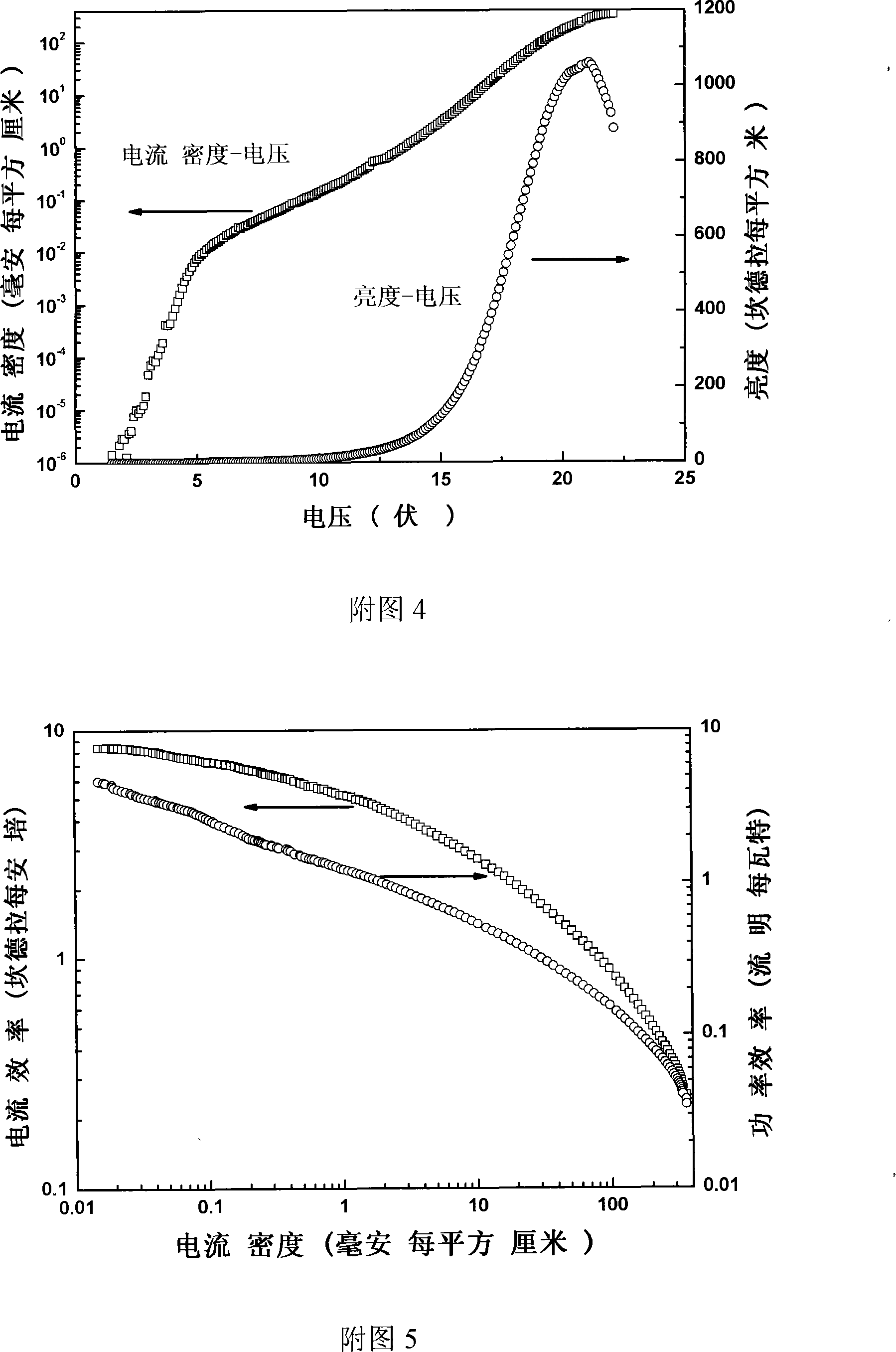

Red organic electroluminescent device and method for fabricating the same

InactiveCN101159315AImproved hole injection performanceIncrease the probability of carrier recombinationSolid-state devicesSemiconductor/solid-state device manufacturingElectron injectionQuinoline

The invention relates to a red organic electroluminescence device and a fabrication method thereof. By using vacuum evaporation technique, a red organic electroluminescence device is fabricated, and the host materials are 4, 4'-N, N'-dicarbazole-diphenyl / 2, 9-dimethyl-4, 7-diphenyl-1, 10- phenanthroline / 8-hydroxyl quinoline / lithium fluoride (LiF) / aluminum (Al) with a configuration of indium tin oxide (ITO) / 4, 4'-di[N-(p-methylphenyl)-N-phenyl-amino]dimethyl / Eu(TTA)3phen, wherein Eu(TTA)3phen is the classical europium complex with trifluoroacetyl thiophene acetone (TTA) and o-phenanthroline (phen) as the first and the second ligands. The low-pressure oxygen plasma treatment on ITO anode is used to enhance hole injection, and the thickness of LiF and Al is precisely adjusted to suitably limit electron injection. The maximum electroluminescence current efficiency of the device is 9.53cd / A, the maximum power efficiency is 5.35lm / W, the maximum external quantum efficiency is 5.15 percent, and the corresponding maximum recombination rate of the device is 85.8 percent.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

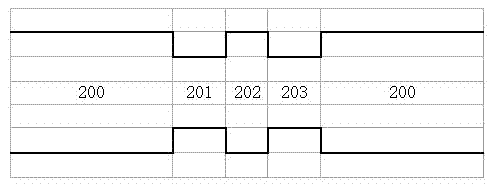

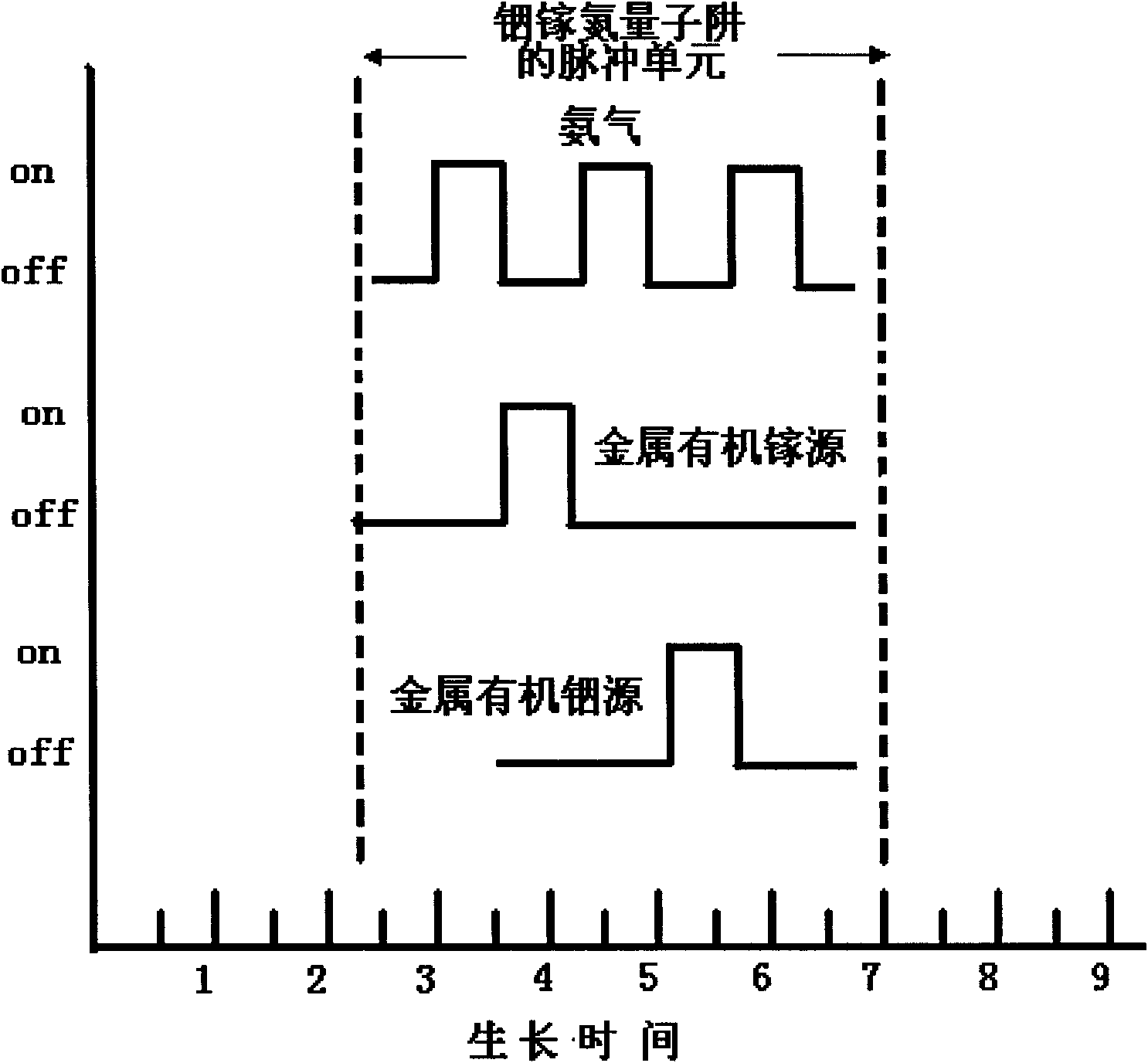

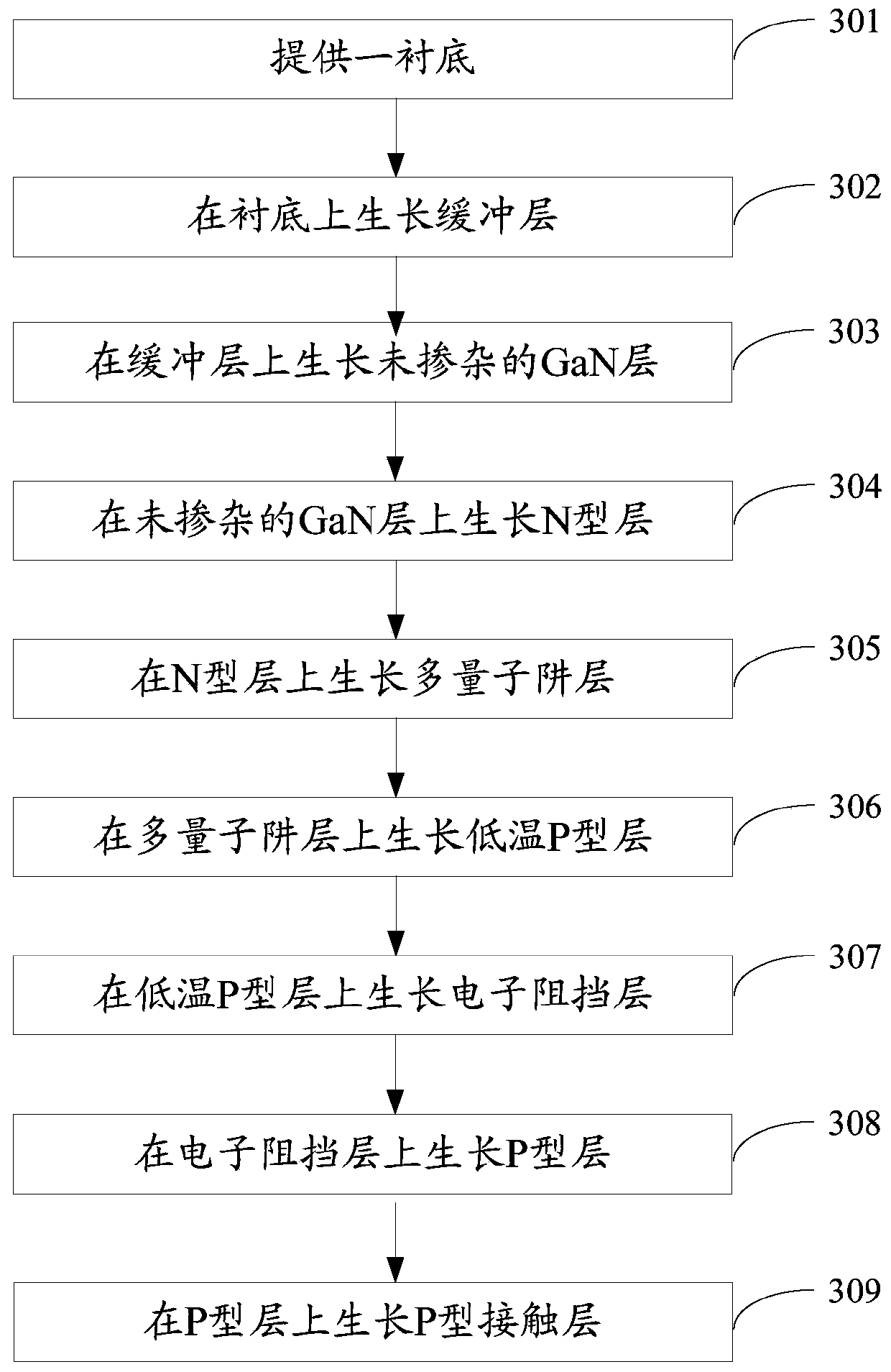

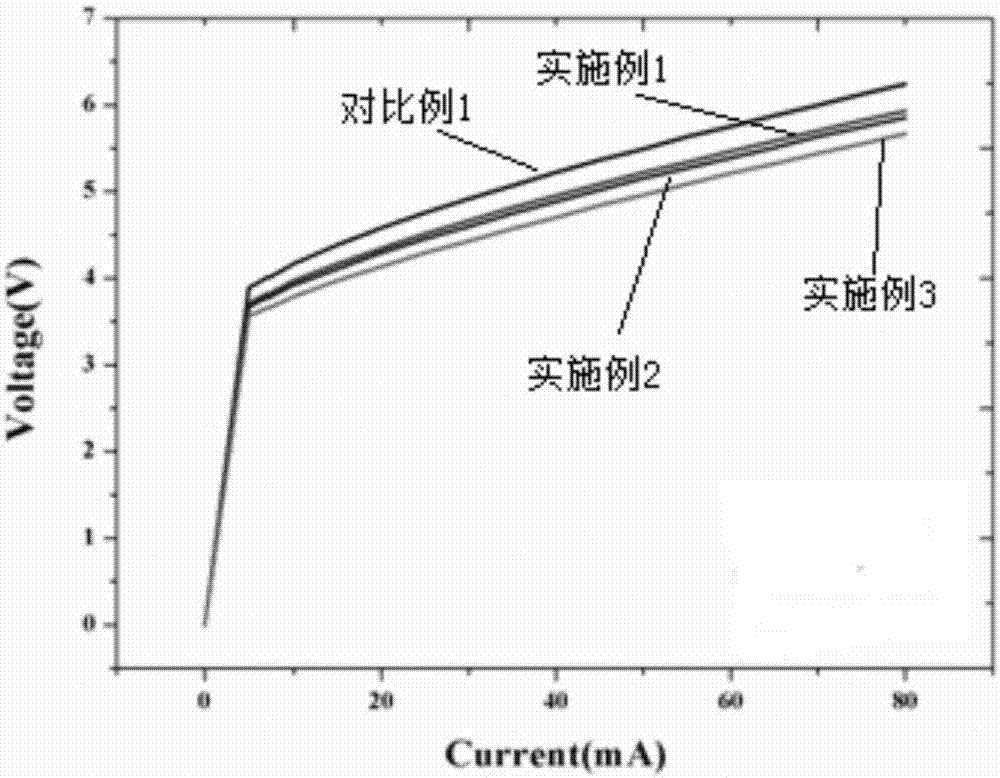

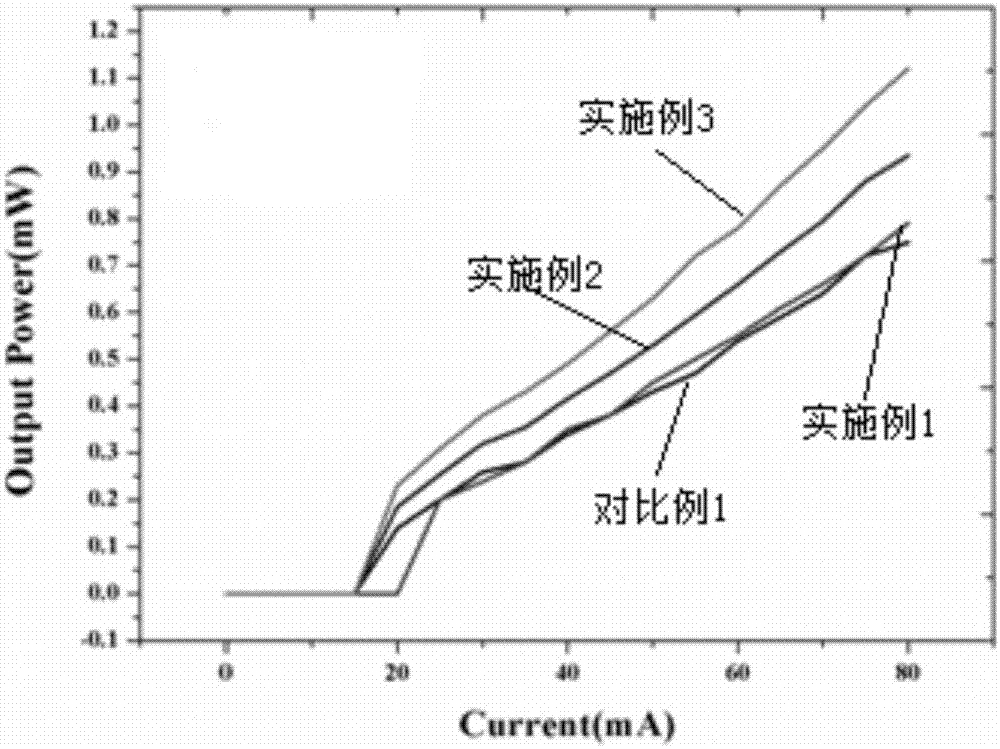

Epitaxial growth method for improving inner quantum efficiency of GaN-based LED

ActiveCN101937954AWeaken the built-in electric fieldImprove luminous efficiencyChemical vapor deposition coatingSemiconductor devicesIndiumSource material

The invention relates to an epitaxial growth method for improving the inner quantum efficiency of a GaN-based LED, belonging to the technical field of semiconductors. The method comprises the following steps of: alternately inputting ammonia gas as well as Group III metal organic source materials of gallium and indium in a growth reaction chamber in a pulsing way during the growth of an In-Ga-N quantum well layer of a GaN-based blue / green light LED active area; and forming a In-Ga-N quantum well luminous layer with high luminous efficiency in a modulation growth process under a set duration, a set interval and a set pulse period. The method can weaken an internally-built electric field of the In-Ga-N / GaN quantum well, improve the quantum localization effect, enhance the radiative recombination rate and increase the inner quantum efficiency of luminescence so as to improve the luminous efficiency and the brightness of the LED. The method is suitable for the MOCVD (Metallo Organic Chemical Vapor Deposition) epitaxial growth of a nitride-based blue / green light LED epitaxial material with high brightness and high luminous efficiency.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

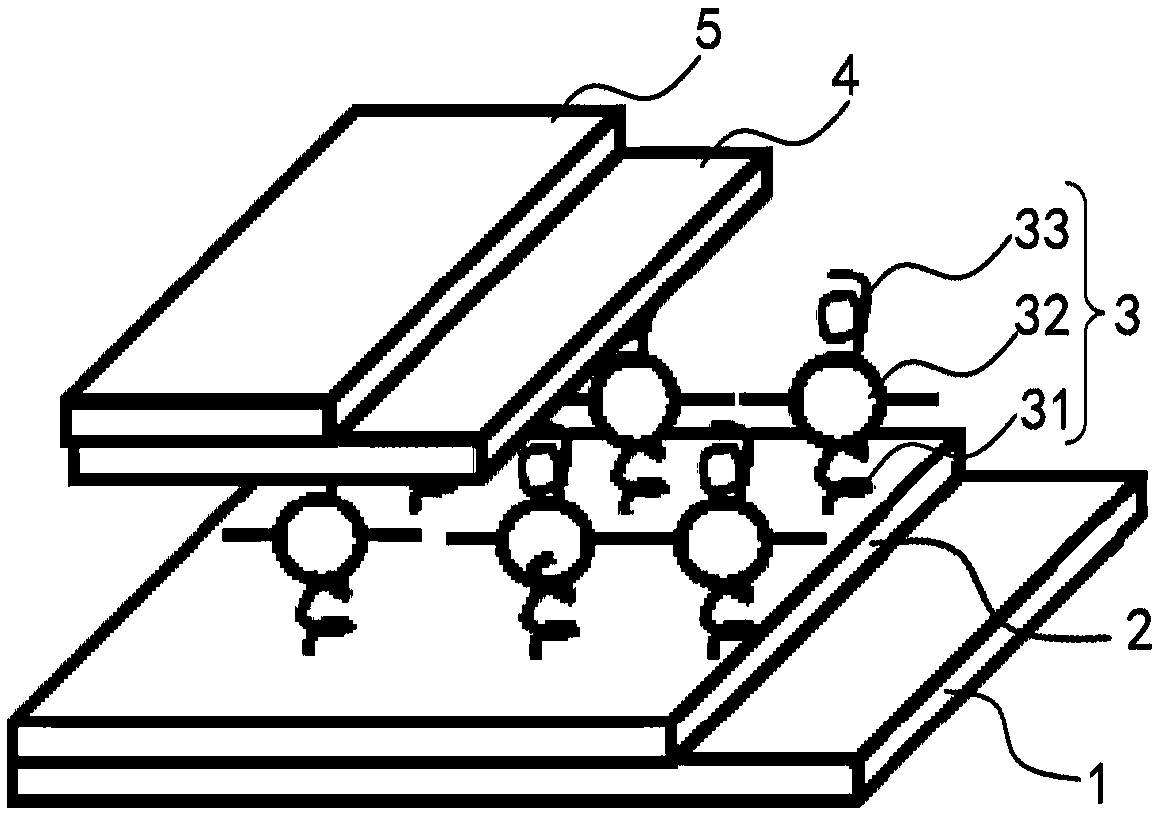

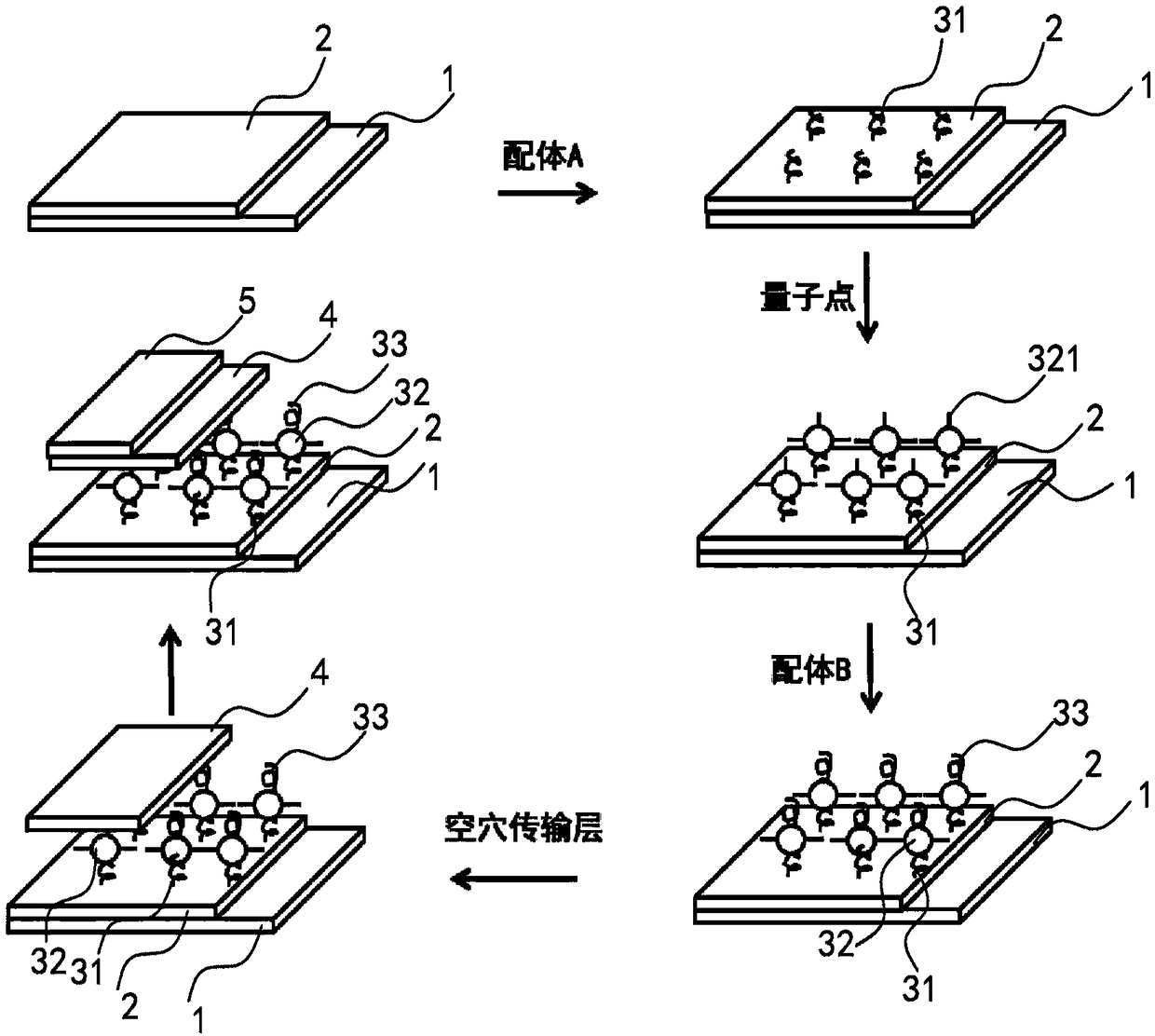

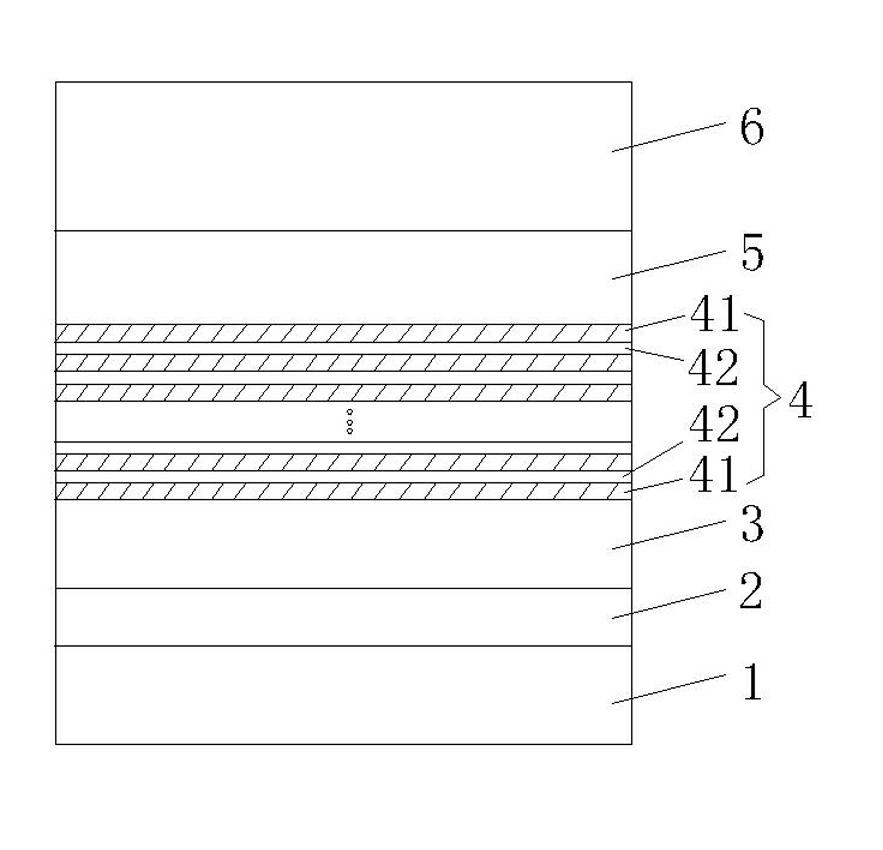

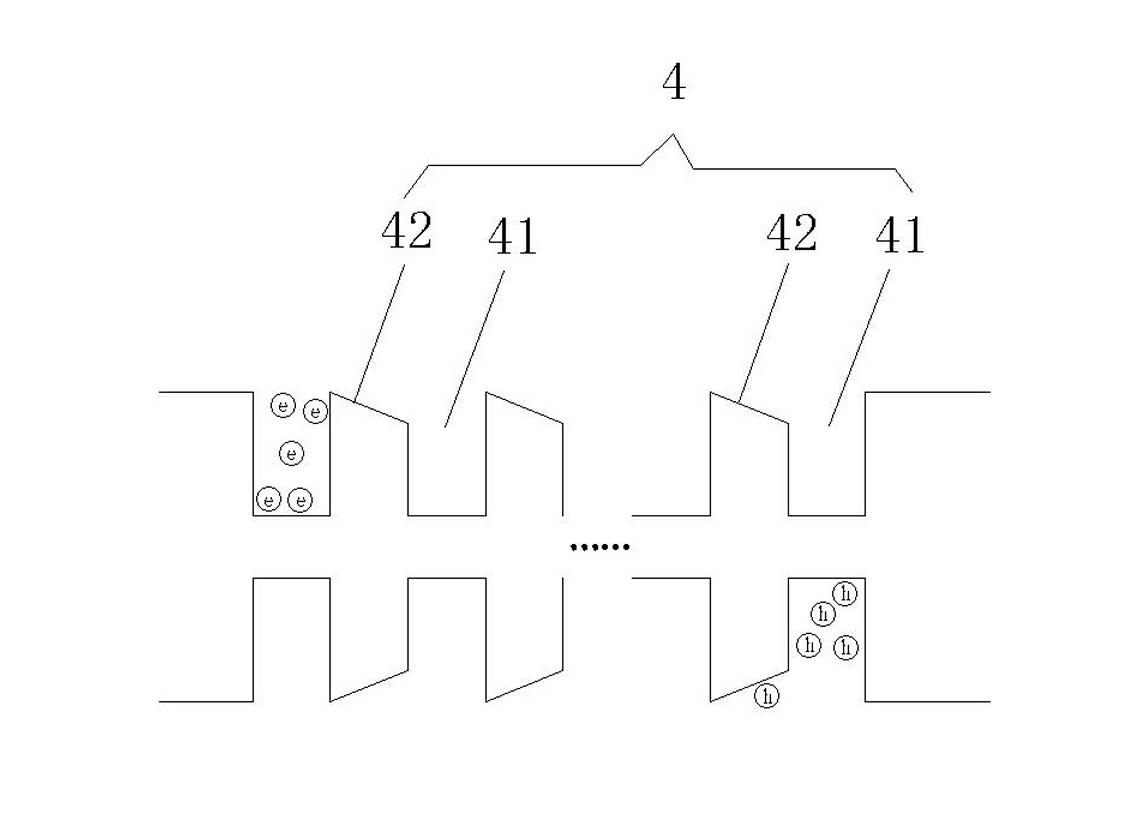

Quantum dot light-emitting diode and preparation method thereof, and display panel

InactiveCN109509842AEasy transferWeaken the interface potential gradientSolid-state devicesSemiconductor/solid-state device manufacturingElectronic transmissionCoated surface

The invention provides a method of preparing a quantum dot light-emitting diode. The method comprises steps of forming a cathode, forming an electron transport layer, forming a light emitting layer, forming a hole transport layer, and forming an anode. The step of forming a light emitting layer is implemented as follows: forming a coating including an electron barrier compound next to the electrontransport layer; forming a coating containing a quantum dot material on the surface of the coating containing the electron barrier compound; and / or forming a coating containing a hole transport compound on the surface of the coating containing the quantum dot material. The electron barrier compound and the hole transport compound make ligand exchange with the surface ligand of the quantum dot material. In addition, the invention also provides a quantum dot light-emitting diode. According to the quantum dot light-emitting diode provided by the invention, the electron transport rate is reducedand / or the hole transport rate is increased to regulate the injection balance of electrons and holes and improve the carrier recombination rate of the QLED device; and thus the luminous efficiency ofthe QLED device is improved.

Owner:BOE TECH GRP CO LTD +1

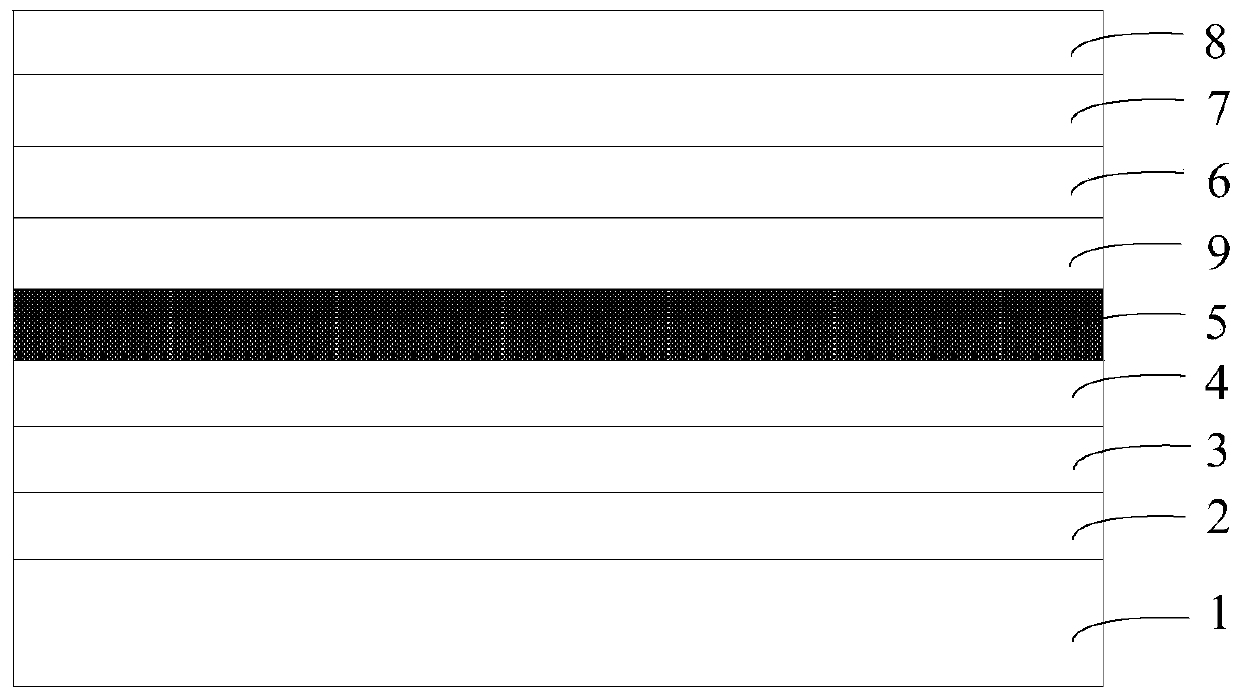

Epitaxial structure of a light emitting diode and its manufacturing method

InactiveCN102299223AIncrease the restrictive effectLow mobilitySemiconductor devicesQuantum wellCompound structure

The invention discloses an epitaxial structure of a light-emitting diode and a manufacturing method thereof. On a GaAs substrate layer, there are a Bragg reflection layer, a first-type confinement layer, an active layer, a second-type confinement layer, and a current spreading layer in sequence from bottom to top. , the active layer is composed of n sets of quantum wells and quantum barriers alternately, where 100≥n≥2, and the barrier height in the same quantum barrier is a gradual distribution or the barrier height between different quantum barriers It is a gradual distribution; its manufacturing method includes the following steps: select GaAs as the substrate layer, and grow a Bragg reflection layer, a first-type confinement layer, an active layer, a second-type confinement layer, and a current spreading layer sequentially on the GaAs substrate layer, wherein The active layer is formed by alternately growing n groups of quantum wells and quantum barriers, and the quantum barriers are made of (AlxGa1-x)yIn1-yP group III and V compounds, where 1≥x≥0.5, and the invention enhances the quantum barrier’s effect on electrons The confinement effect increases the recombination rate of electrons and holes in the quantum well, thereby increasing the brightness of the light-emitting diode.

Owner:XIAMEN CHANGELIGHT CO LTD

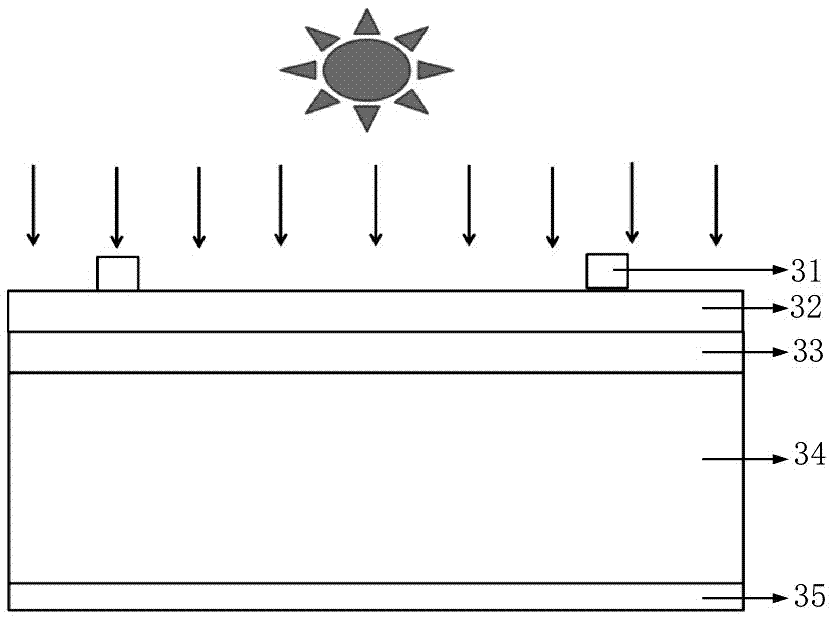

P-i-n-type antimony selenide thin-film solar cell

ActiveCN106898662ASimple structureImprove performancePhotovoltaic energy generationSemiconductor devicesLattice mismatchRecombination rate

The invention discloses a p-i-n-type antimony selenide thin-film solar cell which comprises, from top to bottom, a top electrode layer, a p-type antimony selenide semiconductor layer, an intrinsic semiconductor i-type layer, an n-type antimony selenide semiconductor layer, and a bottom electrode layer. The structure of the solar cell can reduce the lattice mismatch of a pn-junction interface and reduce the high recombination rate due to the high interfacial defect density. Further, the intrinsic semiconductor i-type layer is inserted into the homogeneous antimony selenide pn junction so that a built-in field can be expanded in the intrinsic semiconductor i-type layer, thereby being beneficial to the separation of photon-generated carrier charges, increasing the collection efficiency of the photon-generated carriers, and further improving the performance of the solar cell. The solar cell is simple in preparation process and suitable for industrial production and application.

Owner:HEBEI UNIVERSITY

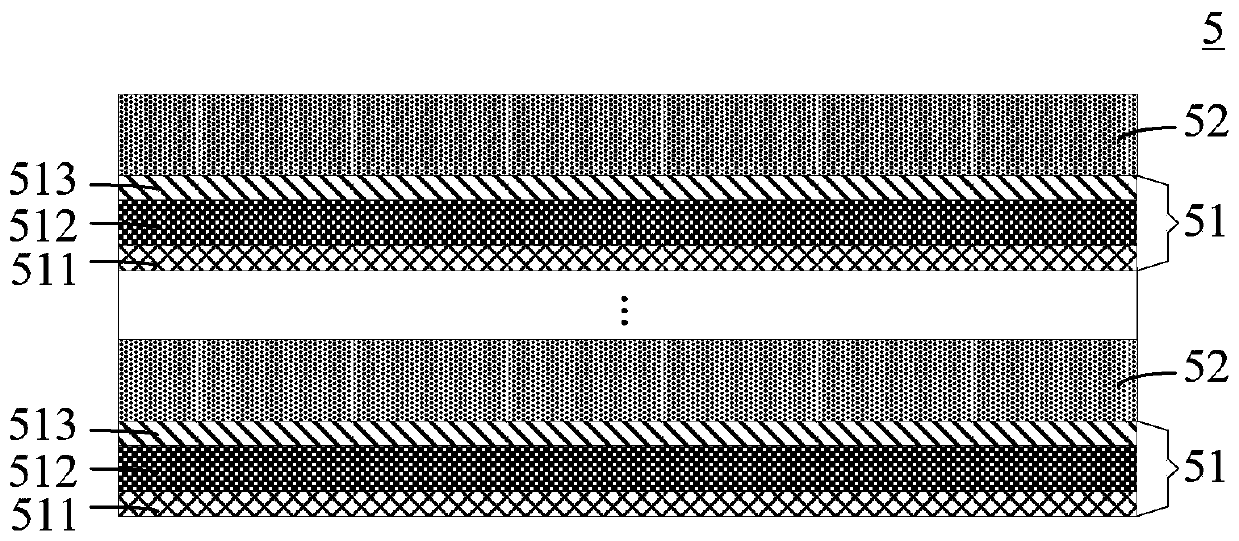

LED epitaxial wafer and manufacturing method thereof

ActiveCN109950372AImprove luminous concentrationReduced polarization effectsNanotechnologySemiconductor devicesRecombination rateLight-emitting diode

The invention discloses an LED epitaxial wafer and a manufacturing method thereof, and belongs to the technical field of semiconductors. The multi-quantum well layer of the LED epitaxial wafer includes alternately grown multiple quantum well layers and multiple quantum barrier layers. Each quantum well layer includes a first sub-layer, a second sub-layer and a third sub-layer which are successively stacked. The first sub-layer, the second sub-layer, and the third sub-layer are all InxGa1-xN layers, 0<x<1. The In components in the first sub-layer and the third sub-layer accounts for 25% to 35%of the In component in the second sub-layer. The part of each quantum well layer in contact with the quantum barrier layer is low in In component content, which can weaken a polarization effect due tolattice mismatch at an interface between the quantum well layer and the quantum barrier layer and improve the radiation recombination rate of electrons and holes, thereby improving the luminous efficiency of the LED. The middle part of each quantum well layer has higher In component content, which can further improve the luminous concentration of the LED.

Owner:HC SEMITEK SUZHOU

Nanometer titania photocatalyst for degrading VOC and preparation method of nanometer titania photocatalyst for degrading VOC

InactiveCN104174391AMicrostructural changesEasy to separatePhysical/chemical process catalystsDispersed particle separationHigh concentrationCalcination

The invention discloses a preparation method of a nanometer titania photocatalyst for degrading VOC. The method comprises the following steps: S1, putting nanometer titania powder into a tube furnace, and then introducing ammonia gas of which the purity is not lower than 99.9%; S2, heating up the furnace body to 550-750 DEG C at the heating rate of 4 DEG C / min to 10 DEG C / min, and carrying out heat preservation, wherein the ammonia gas is lastingly introduced in the process S2; S3, carrying out vacuum calcination under the condition that the air pressure is lower than the barometric pressure in the tube furnace, wherein the heat preservation temperature in the S3 is the same as that in the S2; and S4, cooling and taking out a sample. The nanometer titania photocatalyst prepared by adopting the method disclosed by the invention has the relatively strong visible light absorption ability and relatively low electron-cavity recombination rate, high-concentration benzene pollutants can be quickly and completely degraded, and 5.256*10<-3>mg of benzene contained in a space of 0.002m<3> can be completely degraded only by consuming 0.1g of mass energy within four hours under visible light irradiation.

Owner:HUAZHONG UNIV OF SCI & TECH

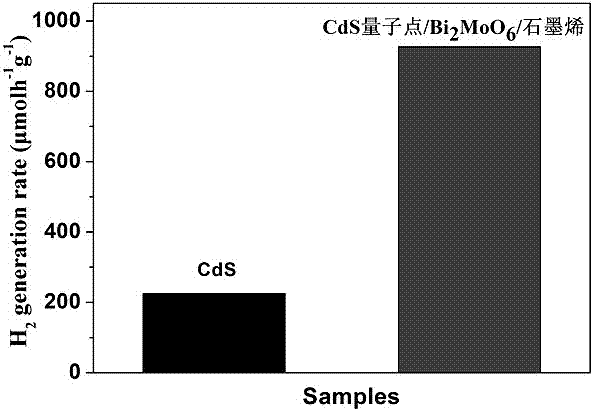

Method for preparing CdS quantum dot/Bi2MoO6/graphene composite photocatalyst

InactiveCN107233899AImprove hydrogen production performanceImprove separation efficiencyMaterial nanotechnologyMolybdeum compoundsPhotocatalytic water splittingQuantum dot

The invention discloses a method for preparing a CdS quantum dot / Bi2MoO6 / graphene composite photocatalyst and belongs to the technical field of synthesis of inorganic environmental-friendly photocatalytic materials. According to key points of the technical scheme of the present invention, the method for preparing the CdS quantum dot / Bi2MoO6 / graphene composite photocatalyst disclosed by the invention comprises the following step: compounding CdS quantum dots, Bi2MoO6 and graphene, to obtain the CdS quantum dot / Bi2MoO6 / graphene composite photocatalyst, wherein a molar ratio of the CdS quantum dot to Bi2MoO6 is 1:(0.1-0.5); and the mass ratio of the graphene to Bi2MoO6 is (0.03-0.15):1. According to the CdS quantum dot / Bi2MoO6 / graphene composite photocatalyst prepared by the method disclosed by the invention, the recombination rate of photo-induced electrons and holes is effectively reduced, photocatalytic water splitting hydrogen production catalytic activity of the CdS quantum dots is improved, and a light etching phenomenon of the CdS quantum dots in the photocatalytic water splitting process is retarded. Moreover, the method has the advantages of mild operating conditions, low agglomeration degree of the prepared product and high photocatalytic activity.

Owner:HENAN NORMAL UNIV

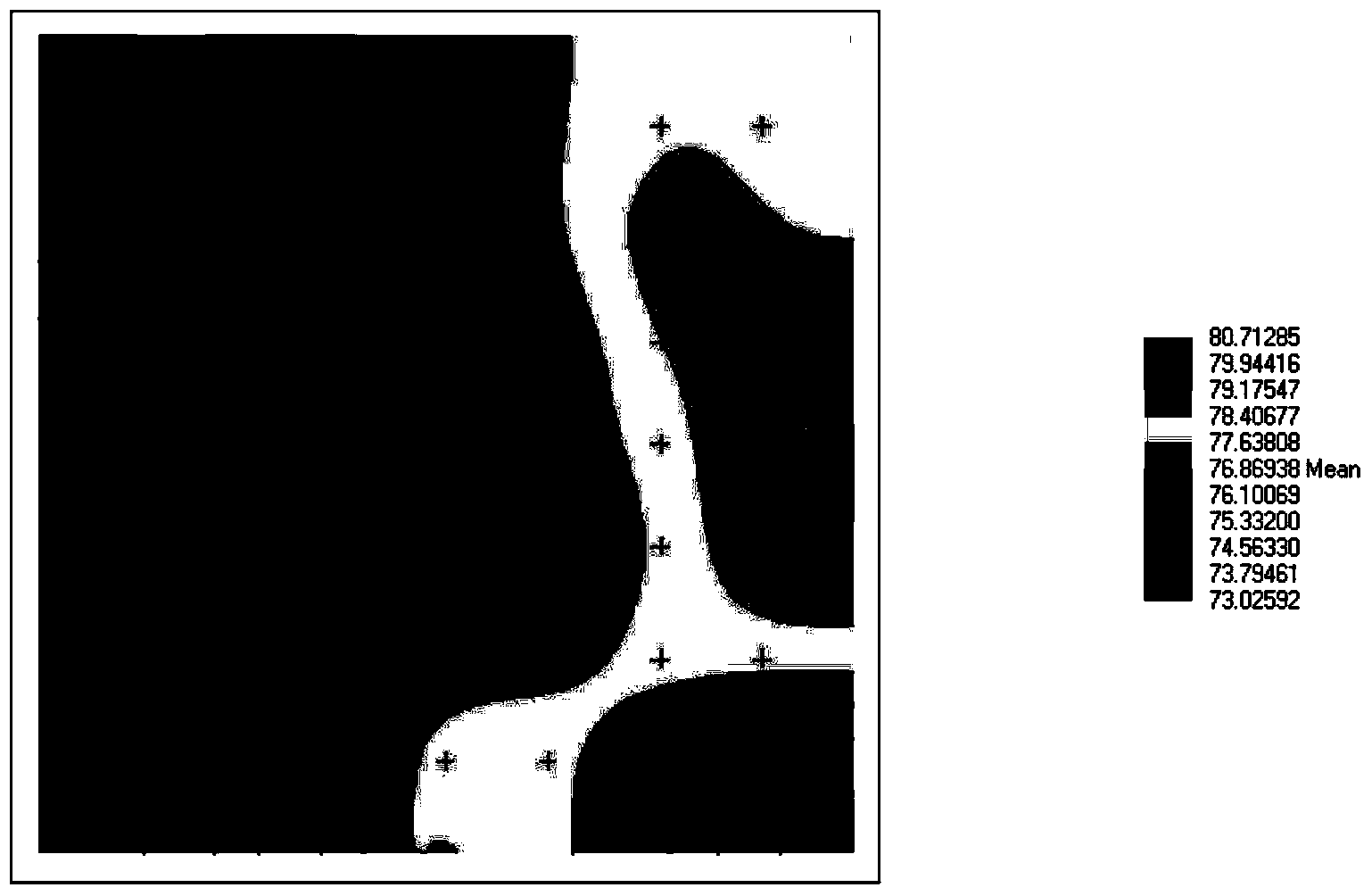

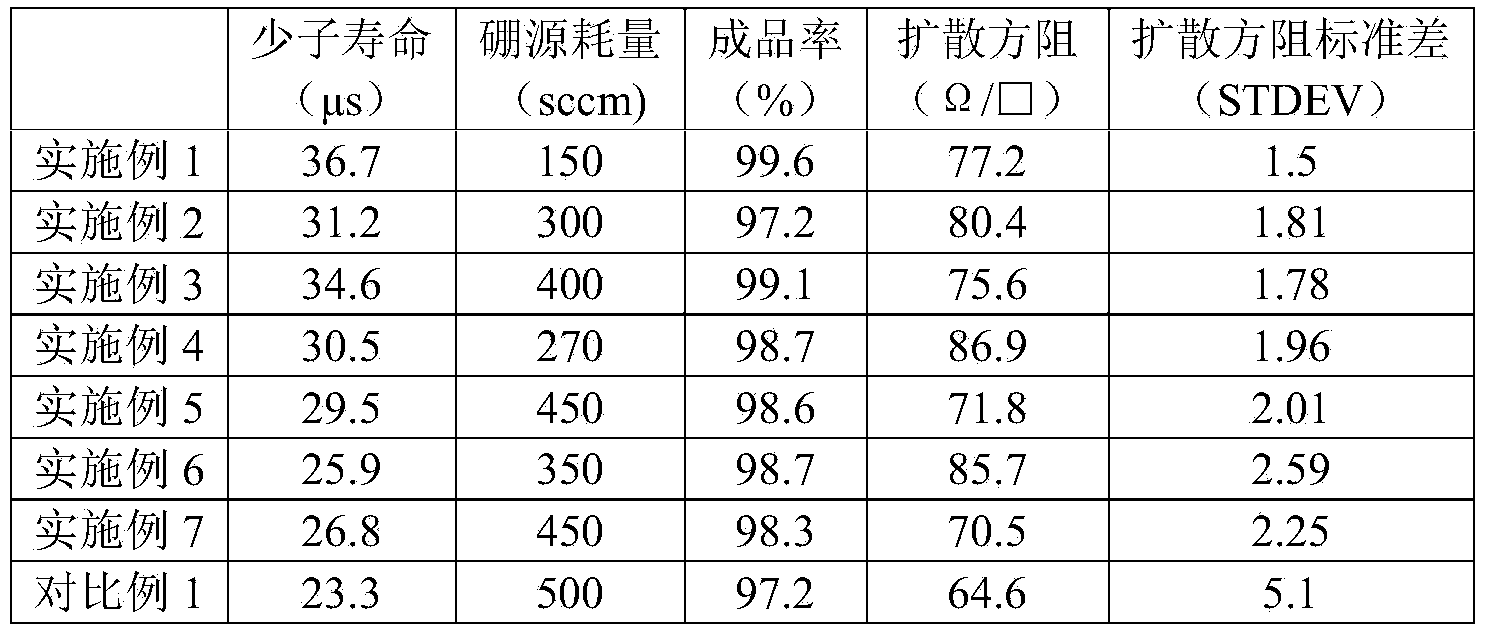

Boron diffusion method of N type silicon chip, crystalline silicon solar cell and manufacturing method of crystalline silicon solar cell

ActiveCN103632933AReduce consumptionLower Boron Atomic ConcentrationFinal product manufactureSemiconductor/solid-state device manufacturingEtchingOxygen

The invention discloses a boron diffusion method of an N type silicon chip, a crystalline silicon solar cell and a manufacturing method of the crystalline silicon solar cell. The boron diffusion method comprises the following steps of a deposition stage: placing the silicon chip subjected to wet etching into a diffusion furnace, and then introducing nitrogen, oxygen and a boron source for depositing the surface of the silicon chip; a diffusion stage: raising the temperature of the silicon chip with the surface being deposited to a preset temperature for promoting the diffusion of boron; a temperature dropping stage: dropping the temperature of the silicon chip with the boron being diffused, and introducing nitrogen in the temperature dropping process to obtain the silicon chip with the boron being diffused. After the deposition diffusion process disclosed by the invention is adopted, the concentration of boron atoms on the surface of the silicon chip is reduced, the recombination rate and the lattice damage of the surface are reduced, the STDEV (standard deviation) is controlled to be about 2.0, the sheet resistance uniformity of boron diffusion is improved, the battery conversion efficiency is improved, the consumption of boron sources is also reduced, BGS (borosilicate glass) is prevented from being excessively generated, and the cost is reduced.

Owner:一道新能源科技(衢州)有限公司

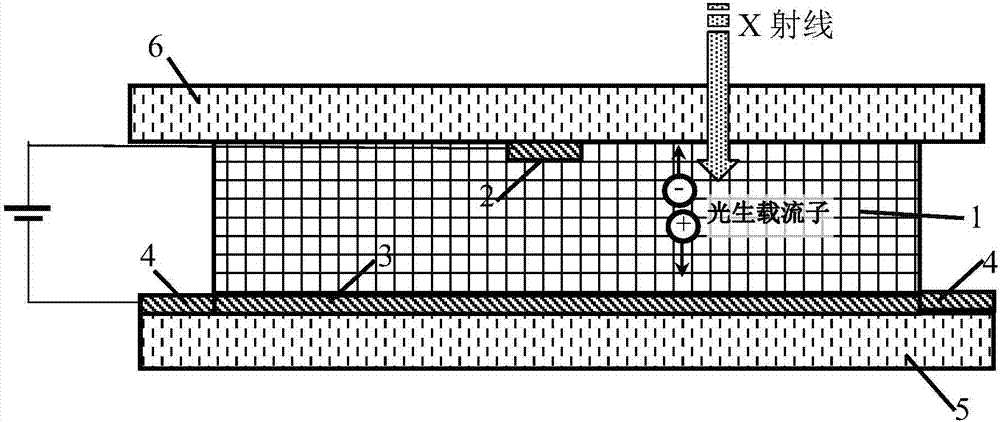

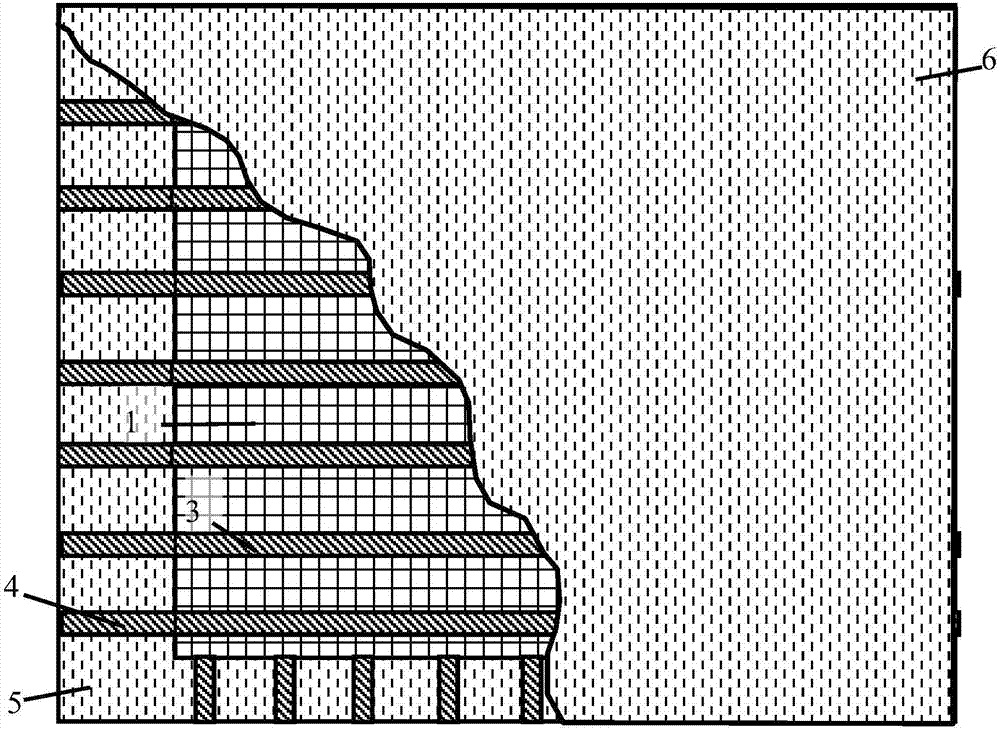

High performance X-ray sensor based on CH3NH2PbBr3 perovskite single crystals and preparation method thereof

InactiveCN106856222AImprove photoelectric conversion efficiencyCapture moreSolid-state devicesSemiconductor/solid-state device manufacturingMetallic materialsX-ray

The invention discloses a high performance X-ray sensor based on CH3NH2PbBr3 perovskite single crystals and a preparation method thereof. The high performance X-ray sensor is low in cost and high in performance and can be used for digital X-ray detection. The sensor comprises 1. a CH3NH2PbBr3 perovskite single crystal substrate which is prepared by using a temperature changing crystallization method, wherein the single crystals have high crystallization quality and the preparation method is suitable for preparation of the large area substrate; 2. row electrodes which are arranged on the perovskite crystals and formed by conductive material of less X-ray absorption; and 3. column electrodes which are arranged below the perovskite crystals and mutually perpendicular to the row electrodes and formed by metal material of great conductive performance. The CH3NH2PbBr3 perovskite single crystal substrate has high thickness and high atomic number metal and has high photoelectric conversion efficiency for X-rays; besides, the recombination rate of the photo-generated carries in the CH3NH2PbBr3 perovskite single crystal substrate is low so that the X-ray sensor has high sensitivity.

Owner:SOUTHEAST UNIV

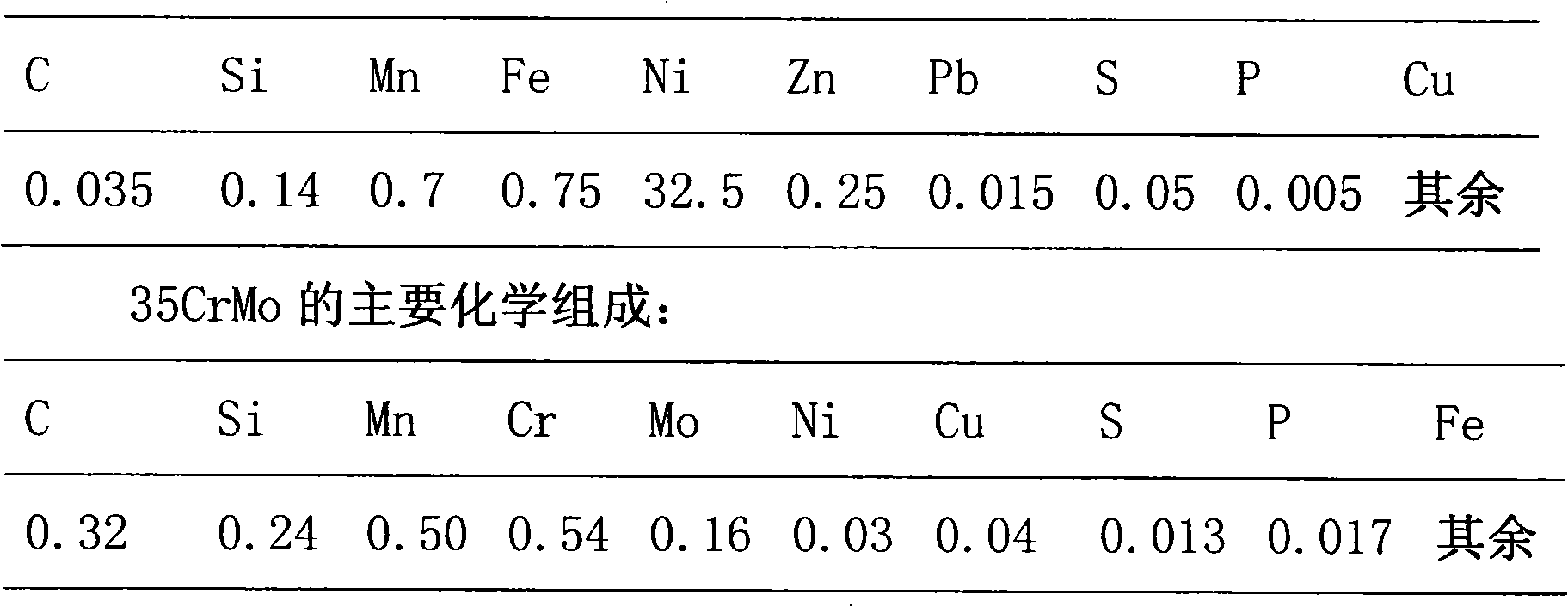

Big thickness BFe30-1-1/35CrMo explosive welding high intensity high corrosion resistance composite board

The invention provides a heavy section BFe30-1-1 / 35CrMo explosion welding high-strength high-anticorrosion composite plate. Firstly, the explosion speed of dynamite is controlled within about 800-1000m / s by the optimal design of dynamite formula. Secondly, by a principle of selecting the lower limit of the charging main parameter, the charging auxiliary parameters such as clearance and charging size of basic composite plate are reasonably designed, sand soil foundation added by water is selected and configured and the water content and density thereof are controlled, thus ensuring the once recombination rate of the heavy section BFe30-1-1 / 35CrMo explosion welding high-strength high-anticorrosion composite plate to achieve 100 percent and the adhesion strength thereof to achieve or even exceed the national standard, and avoiding the crack generation of the heavy section composite plate and high-strength basic plate during the explosion welding process. Finally, the subsequent crack of the composite pate is ensured not to be generated in the subsequent processing by the formulation of heat disposal parameters. The composite plate has ultra-high anticorrosion performance and extremely high high-temperature strength and anti-impact toughness.

Owner:JIANGSU RUNBANG NEW MATERIAL GRP CO LTD

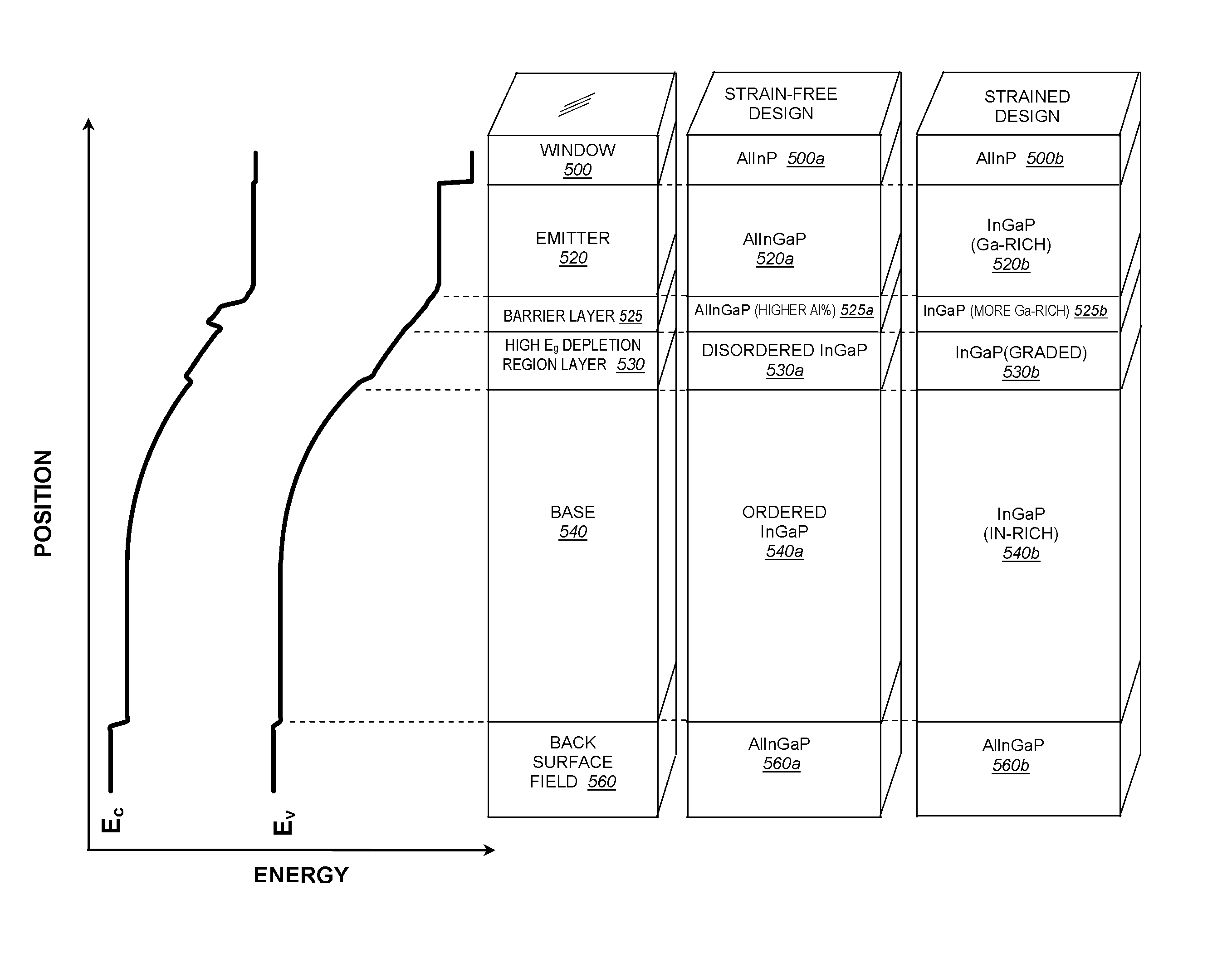

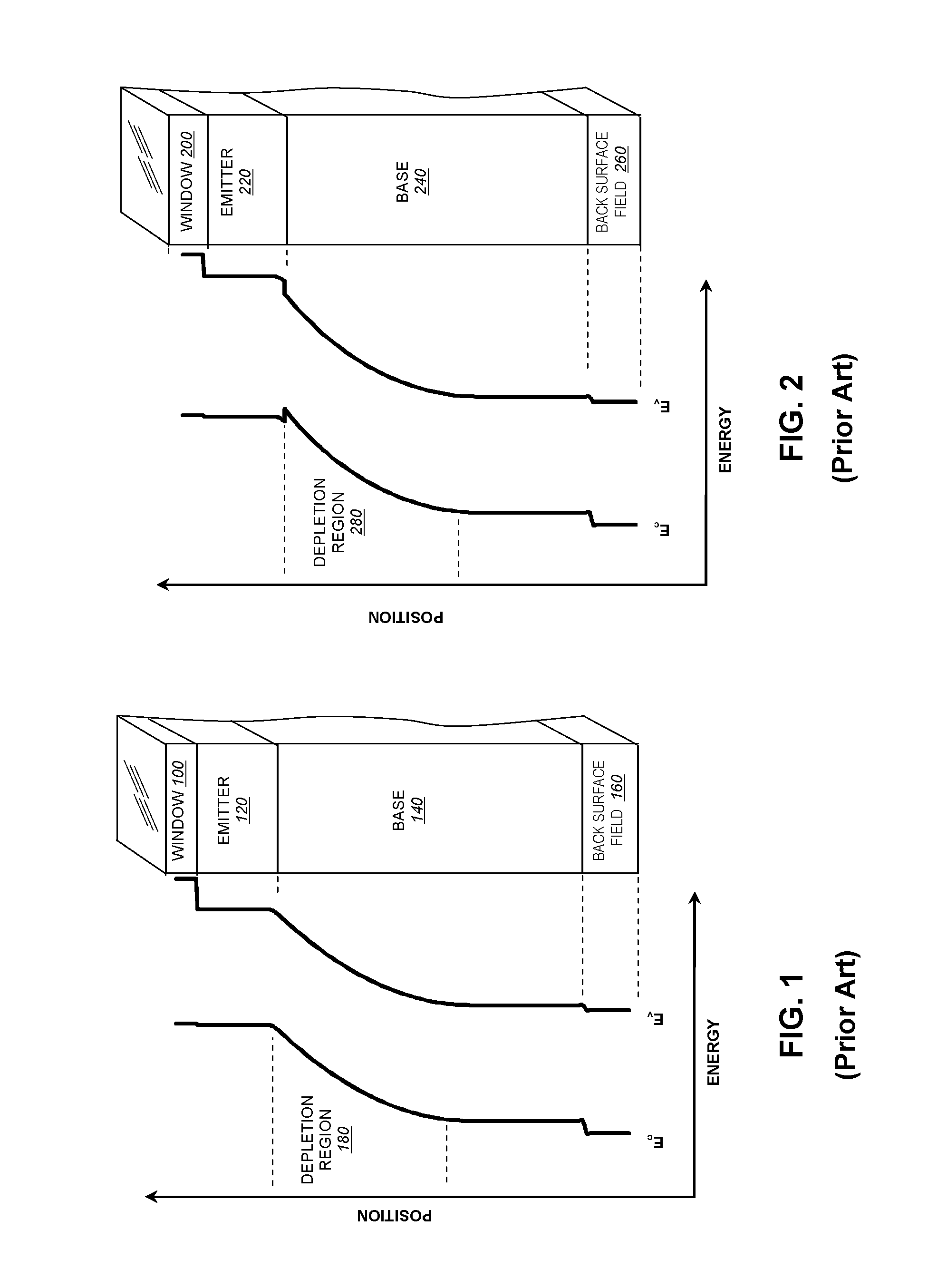

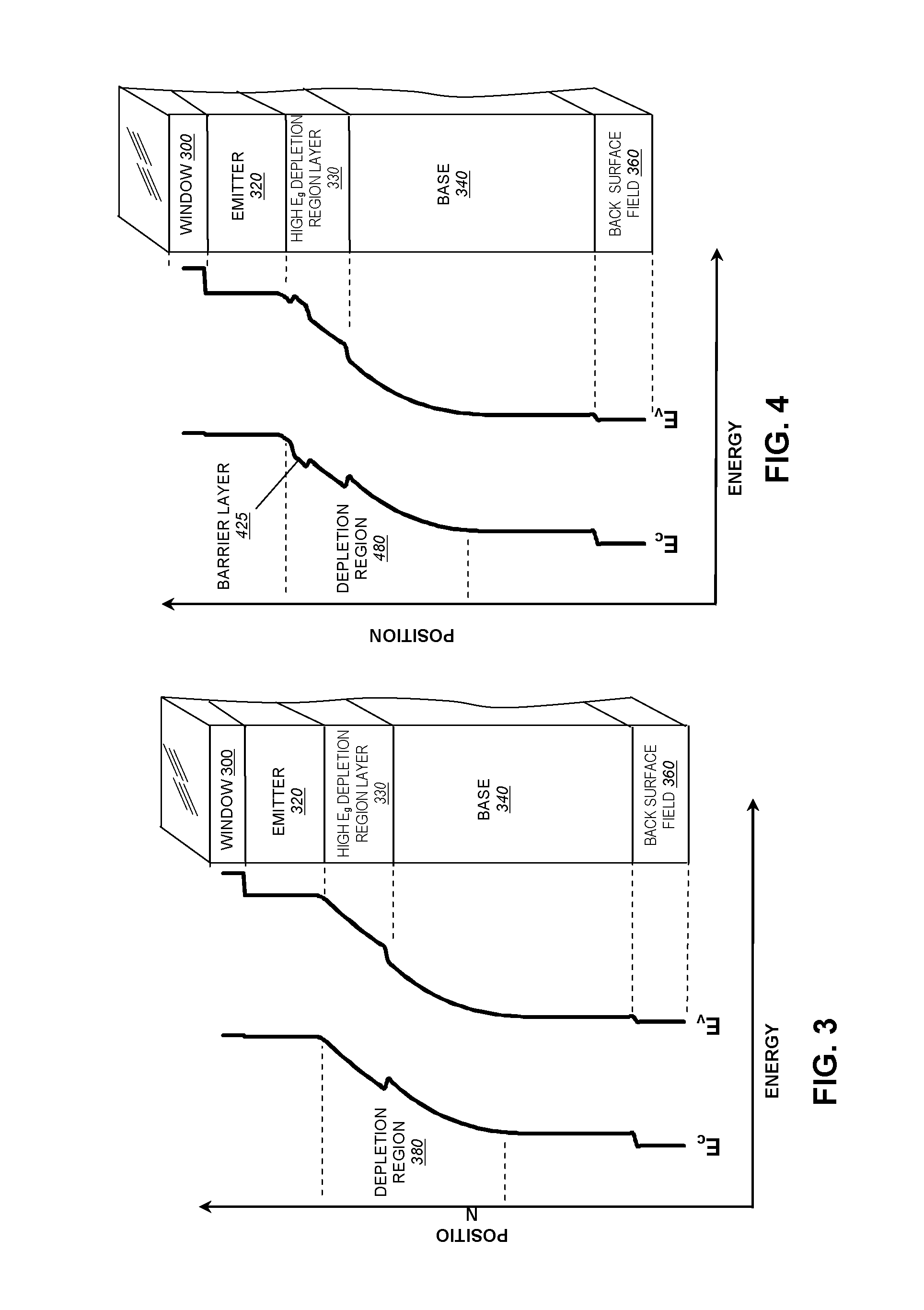

Multijunction solar cell employing extended heterojunction and step graded antireflection structures and methods for constructing the same

ActiveUS8895838B1High power outputImprove rendering capabilitiesPhotovoltaic energy generationSemiconductor devicesHeterojunctionHigh energy

Material and antireflection structure designs and methods of manufacturing are provided that produce efficient photovoltaic power conversion from single- and multijunction devices. Materials of different energy gap are combined in the depletion region of at least one of the semiconductor junctions. Higher energy gap layers are positioned to reduce the diode dark current and enhance the operating voltage by suppressing both carrier injections across the junction and recombination rates within the junction. Step-graded antireflection structures are placed above the active region of the device in order to increase the photocurrent.

Owner:MAGNOLIA SOLAR

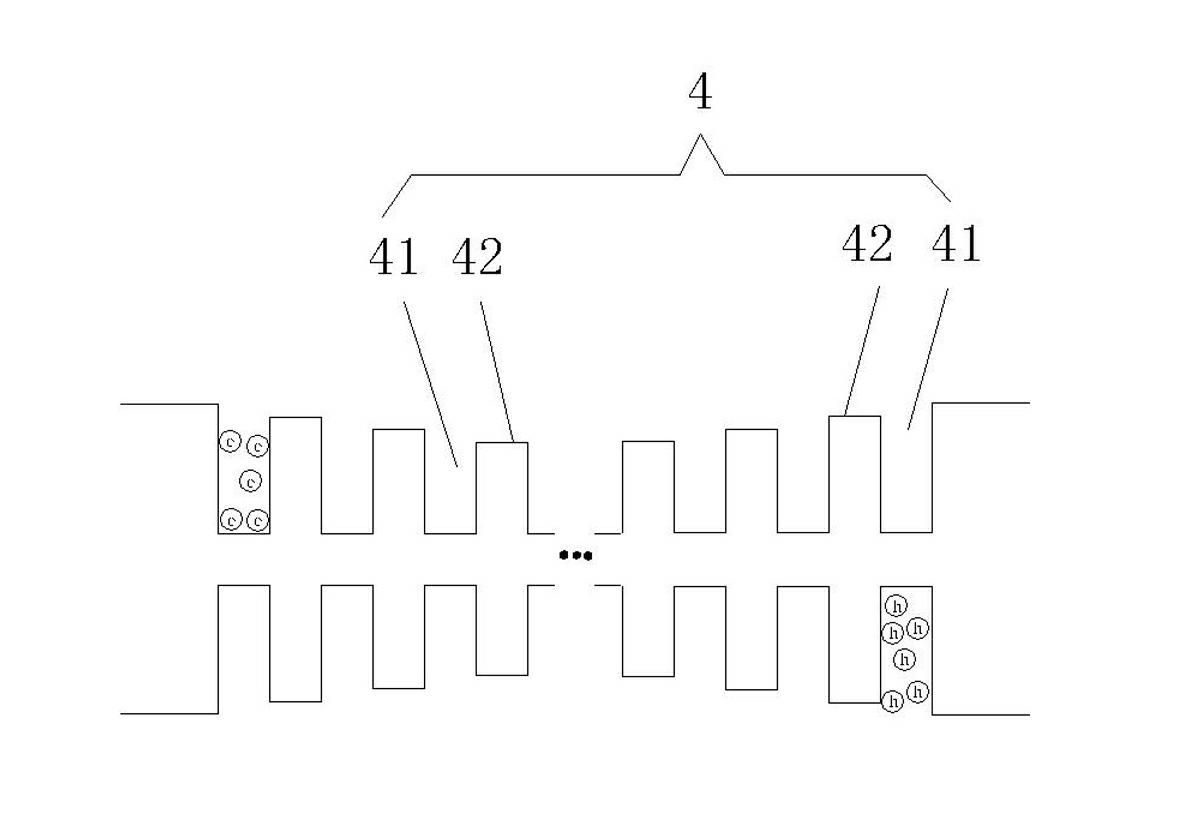

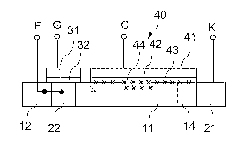

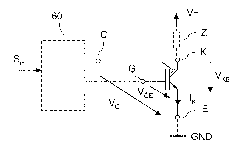

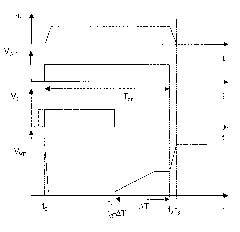

Controlling the recombination rate in a bipolar semiconductor component

ActiveCN102195623AElectronic switchingSemiconductor devicesRecombination rateSemiconductor components

The invention relates to controlling the recombination rate in a bipolar semiconductor component. Disclosed is a method for controlling the recombination rate in the base region of a bipolar semiconductor component, and a bipolar semiconductor component.

Owner:INFINEON TECH AUSTRIA AG

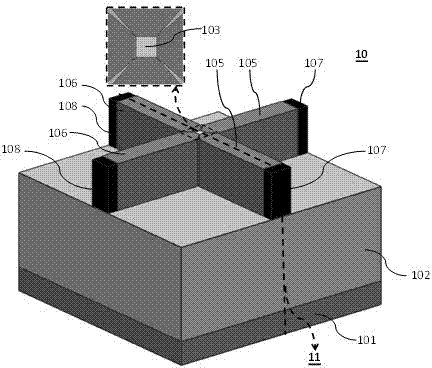

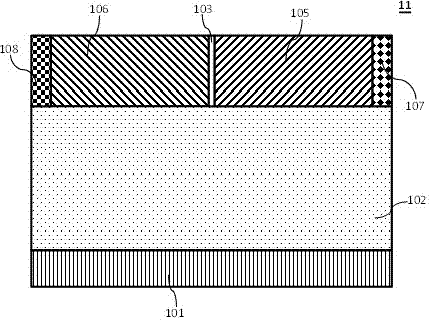

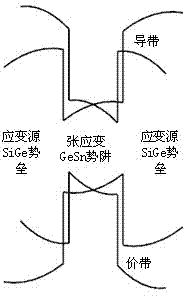

GeSn quantum well infrared illuminator with strain source

InactiveCN104300049AThe lattice constant decreasesFast and Efficient Radiative RecombinationSemiconductor devicesHeterojunctionElectron hole

The invention provides a GeSn quantum well infrared illuminator with a strain source. The structure is characterized in that a relaxation layer GeSn is arranged on a silicon substrate; strain source potential barriers n+ SiGe and p+ SiGe are arranged on the relaxation layer and grows at the peripheral region of an active region GeSn in pairs; and one end of the strain source potential barrier SiGe is a metal contact electrode. The lattice constant of the material of the strain source SiGe is smaller than that of the material of the active region GeSn, thereby forming single-axis compression strain along the z axis direction on the active region GeSn material, and forming a double-axis tensile strain along the xy plane; the strain state facilitates the GeSn material to change from an indirect band gap to a direct band gap; and through forming a heterojunction quantum well structure through the GeSn and the SiGe, fast and efficient radiative recombination of electron-hole is realized. The structure can limit electrons and holes in the well efficiently, thereby enlarging recombination rate of the electron and hole pairs, and improving luminous efficiency of an illuminator.

Owner:CHONGQING UNIV

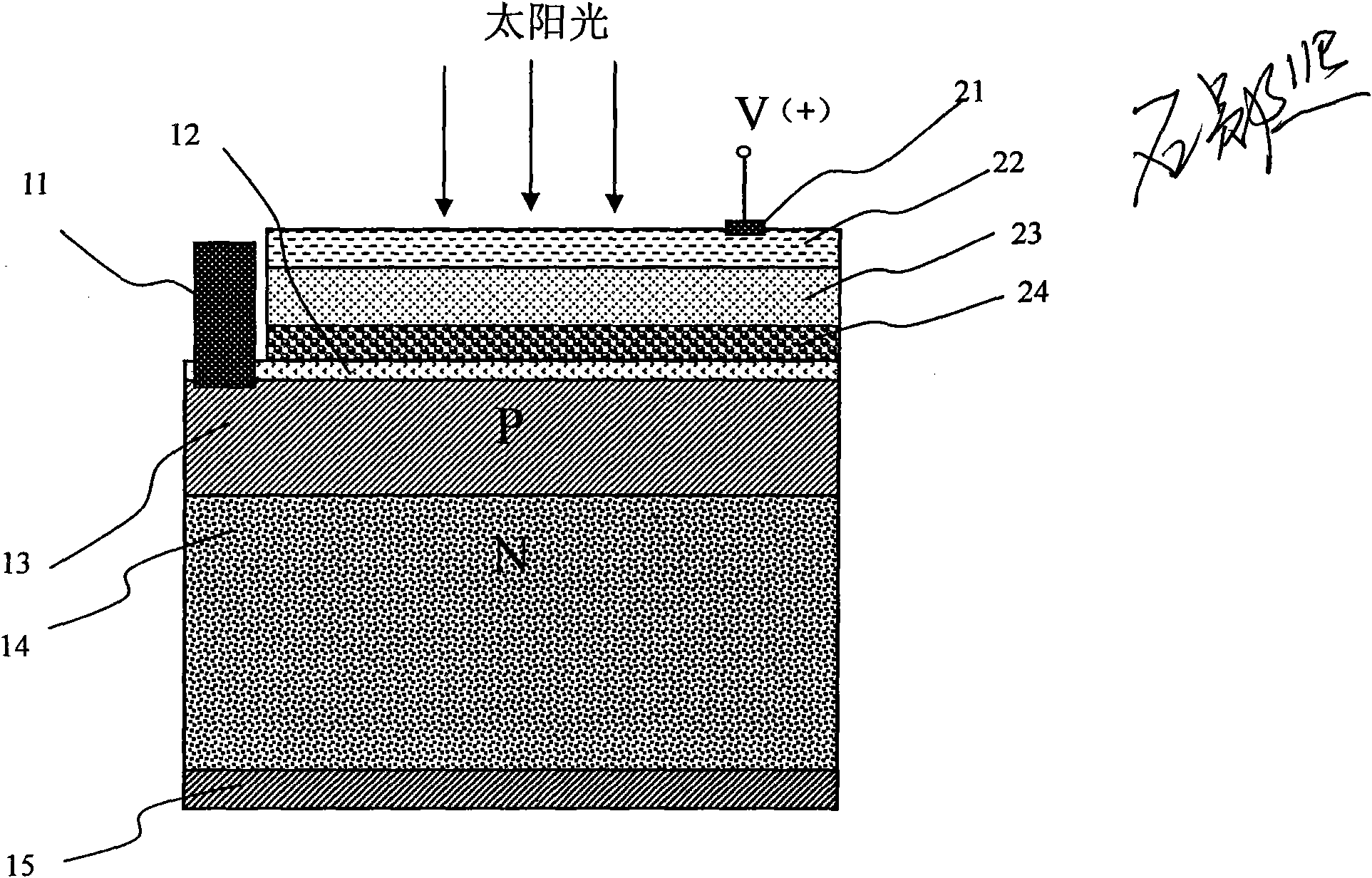

Technology for improving conversion efficiency of solar photovoltaic battery

InactiveCN102315314AFinal product manufactureSemiconductor devicesSemiconductor materialsEffective surface

The invention belongs to the technical field of semiconductor solar photovoltaic batteries and in particular relates to a technology for improving the conversion efficiency of a solar photovoltaic battery. An additional layer comprising a transparent conductive film layer is additionally arranged on an insulation medium mask layer on the front surface of the solar photovoltaic battery, a voltage is applied to the transparent conductive film, and ions are injected to a transparent negative charge capturing layer and captured by the transparent negative charge capturing layer to achieve the purposes of changing the surface potential, the surface space charge region and the surface energy band of a semiconductor material under the insulation medium mask layer on the front surface of the solar photovoltaic battery. An exhaust (or reverse type) state of the surface space charge region of the semiconductor is changed into a stacked state, and a conduction band in the surface energy band is moved to an interface defect energy level near a position far away from the center of a forbidden band, both of which are beneficial to reducing the effective surface recombination rate of a photon-generated carrier and collecting photon-generated minority carriers as much as possible, increasing photocurrent output of the solar voltaic battery and improving the conversion efficiency of the solar voltaic battery.

Owner:石郧熙

Hot-rolled stainless steel-aluminium-stainless steel composite board production method and application

InactiveCN102873092AReduce work intensityIncrease productionAuxillary arrangementsMetal rolling arrangementsSS - Stainless steelRecombination rate

The invention discloses a hot-rolled stainless-steel-aluminium-stainless-steel composite board production method and application. The composite board consists of three parts A, B and C, the A and the C are stainless steel plates and the B is a pure aluminium plate, wherein the stainless steel plates A and C are 201, 202, 303, 304 and 316L stainless steel plates and have the specifications of length*width*thickness of 2,440mm*1,220mm*(0.3 to 2.5mm); and the pure aluminium plate B is a civil 1050-series pure aluminium plate and has the specification of length*width*thickness of 2,440mm*1,220mm*(1.0 to 50mm). Compared with the prior art, the hot-rolled stainless-steel-aluminium-stainless-steel composite board production method has the advantages that the composite board with the thickness of 1.5mm to 50mm can be produced; the interface recombination rate reaches 100 percent; the working intensity is low; the yield is high; energy is saved; and no pollution or noise is generated.

Owner:黎汉东

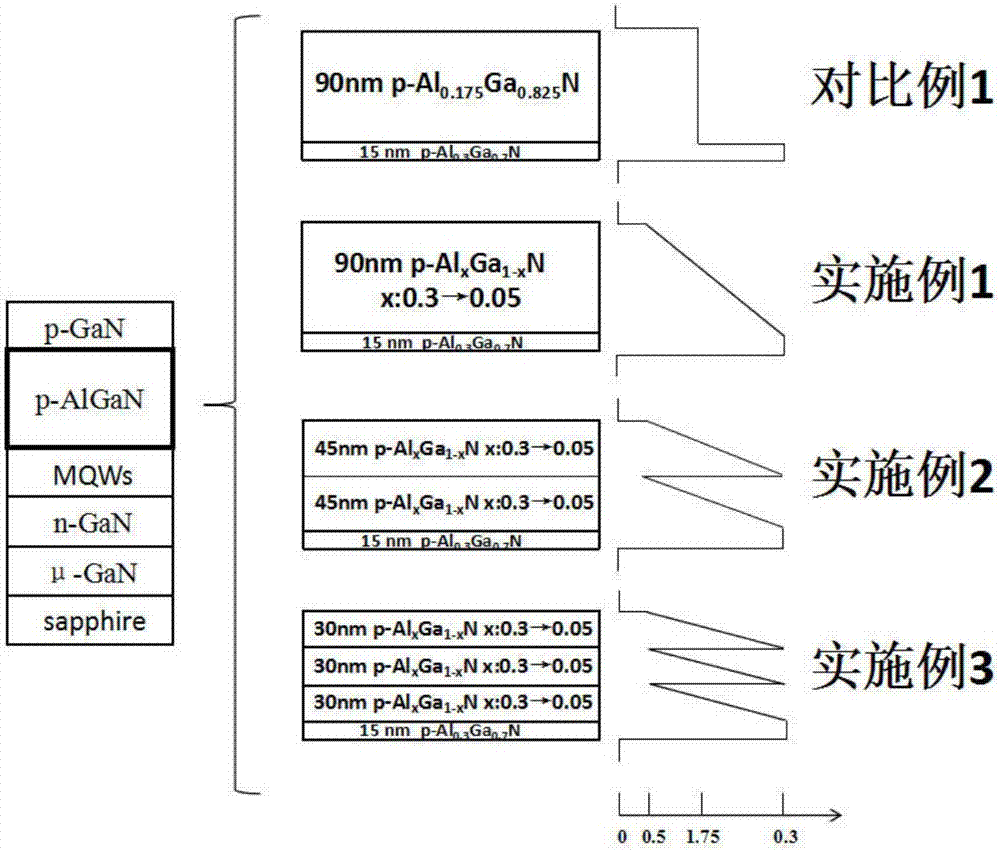

LED epitaxial wafer and preparation method therefor

InactiveCN107170864AImprove luminous efficiencyImprove internal quantum efficiencySemiconductor devicesQuantum efficiencyQuantum well

The invention relates to the preparation field of a photoelectric material, particularly to an LED epitaxial wafer. The LED epitaxial wafer comprises a substrate, a gallium nitride layer, an N type gallium nitride layer, an aluminum gallium nitride / gallium nitride multi-quantum-well layer, an electron barrier layer, a P type aluminum gallium nitride layer, a P type contact layer and a P type electrode which are arranged in an overlaying manner in sequence; and the P type aluminum gallium nitride layer is a Mg-doped multilayered polarization-induced Al<x>Ga<1-x>N layer, wherein x is 0.3 to 0.05. The invention aims to solve the technical problems of low luminous efficiency, low internal quantum efficiency and the like caused by electronic leakage and relatively low radiative recombination rate due to spontaneous and piezoelectric polarization in the LED; and the LED epitaxial wafer has the advantages of simple structure, simple and convenient process, convenience in production and suitability for industrial production.

Owner:SOUTH CHINA NORMAL UNIVERSITY

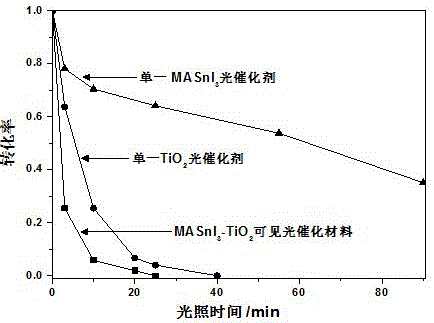

Preparation method for stannous methyl amino iodide-titanium dioxide visible light catalytic material

InactiveCN105772103ASimple preparation processMild reaction conditionsOrganic-compounds/hydrides/coordination-complexes catalystsIodideMethyl group

The invention discloses a preparation method for a stannous methyl amino iodide-titanium dioxide visible light catalytic material. The preparation method comprises the following steps: 1) preparing ammonium methyl iodide; 2) preparing stannous iodide; 3) preparing stannous methyl amino iodide; 4) preparing the stannous methyl amino iodide-titanium dioxide visible light catalytic material: adding stannous methyl amino iodide and tetrabutyl titanate into normal hexane, mixing, heating and stirring at 70 DEG C for reaction under reflux, centrifugally separating turbid liquid by using a high speed centrifuge, adding into deionized water after centrifugal separation, magnetically stirring, filtering, washing and drying to obtain dry solid powder, and putting into a muffle furnace for roasting, thereby acquiring the methyl amino stannous iodide-titanium dioxide visible light catalytic material. The preparation method is simple and convenient in operation and low in cost; the photoproduction electron generated by the visible light catalytic material can quickly transfer to a TiO2 guide tape; the recombination rate of photoproduction electron and hole can be reduced; the separation of the photoproduction electron-hole on the material interface can be promoted; the visible light catalytic activity of the material is promoted.

Owner:SHANGHAI UNIV

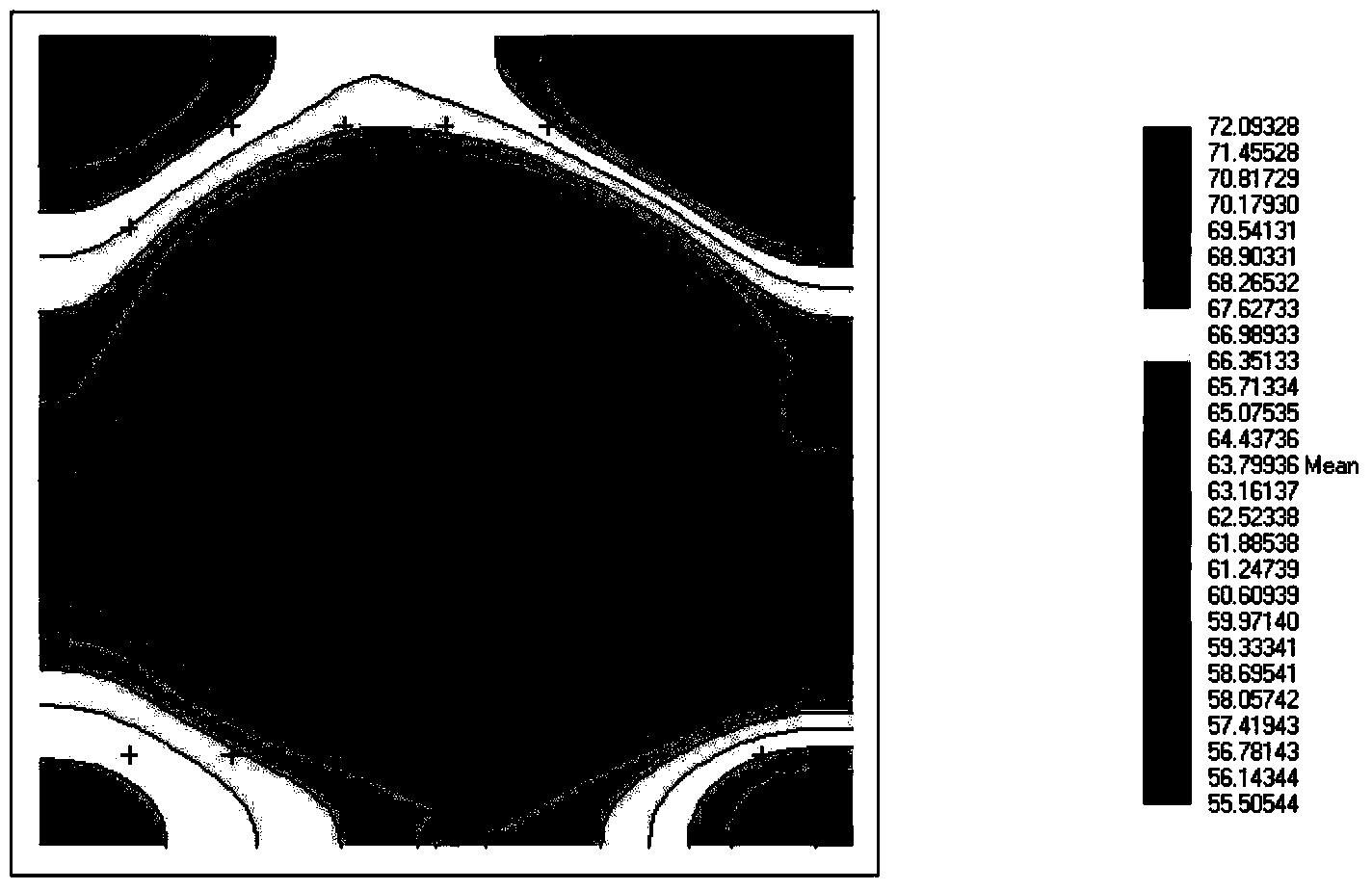

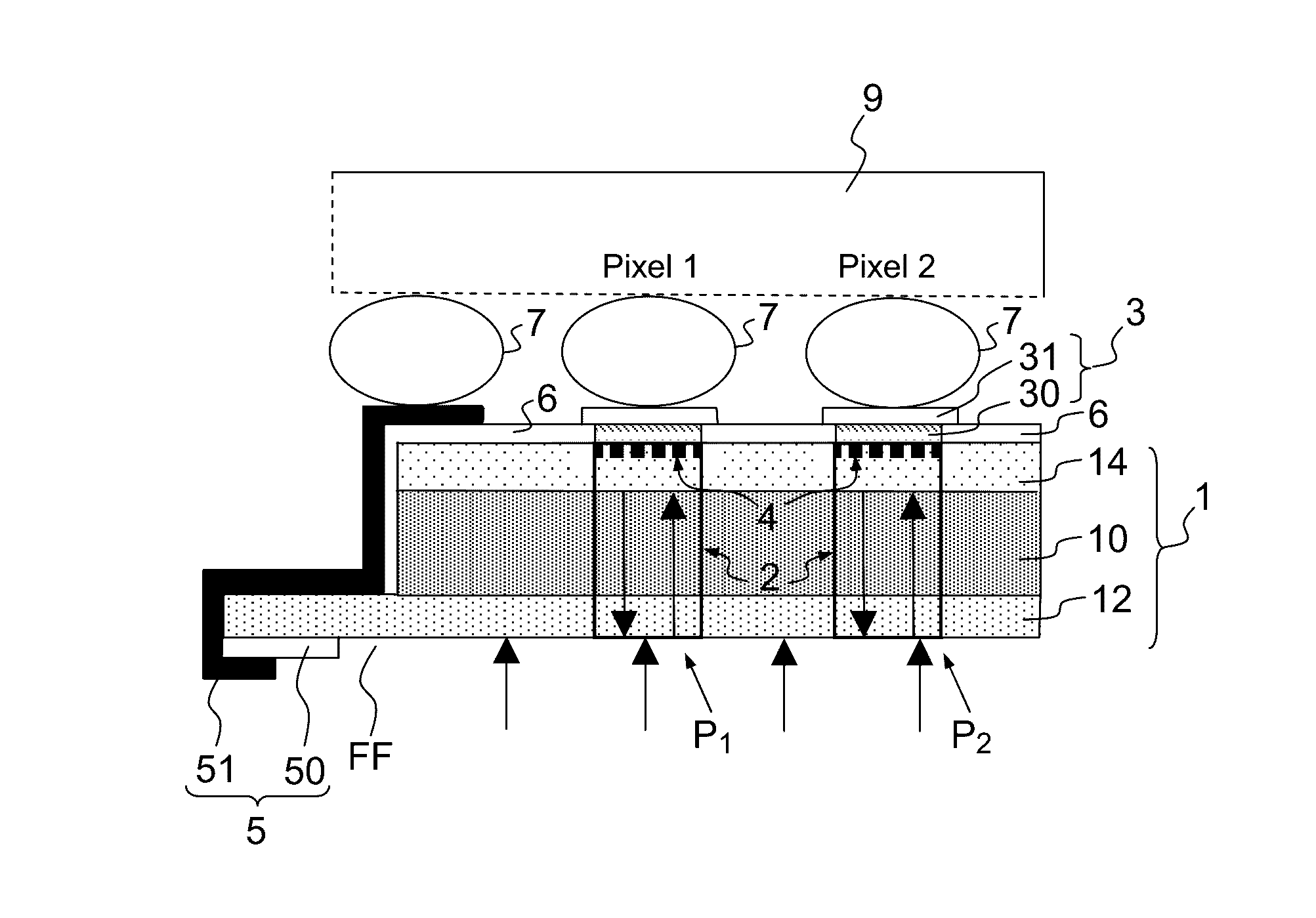

Quantum detection element with low noise and method for manufacturing such a photodetection element

ActiveUS20160322516A1Controlled absorptionPromote productionFinal product manufacturePhotovoltaic energy generationLow noiseSemiconductor materials

According to one aspect, the invention relates to an element for quantum photodetection of an incident radiation in a spectral band centred around a central wavelength λ0, having a front surface intended for receiving said radiation, and including: a stack of layers of semiconductor material forming a PN or PIN junction and including at least one layer made of an absorbent semiconductor material having a cut-off wavelength λ0>λ0, the stack of layers of semiconductor material forming a resonant optical cavity; and a structure for coupling the incident radiation with the optical cavity such as to form a resonance at the central wavelength λ0 allowing the absorption of more than 80% in the layer of absorbent semiconductor material at said central wavelength, and an absence of resonance at the radiative wavelength λrad, wherein the radiative wavelength λrad is the wavelength for which, at operating temperature, the radiative recombination rate is the highest.

Owner:CENT NAT DE LA RECHERCHE SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com