Patents

Literature

290results about How to "Effective size control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Acrylate micro-emulsion with high solid content, its preparation method and use

The invention refers to a high-solid content acrylate micro-latex, its making method and its application to carpentry dope. It adopts the technique of half-continuous starvation feeding, and is obtained by the polymerizing method of seed latex. It leads into cross-linking groups in the course of polymerization such as amidogen, acetoacetyl and amido, depends on the reaction of the groups of form film, gets painting film with cross-linking construction, and improves the water and solvent resistance of the painting film.

Owner:SOUTH CHINA UNIV OF TECH

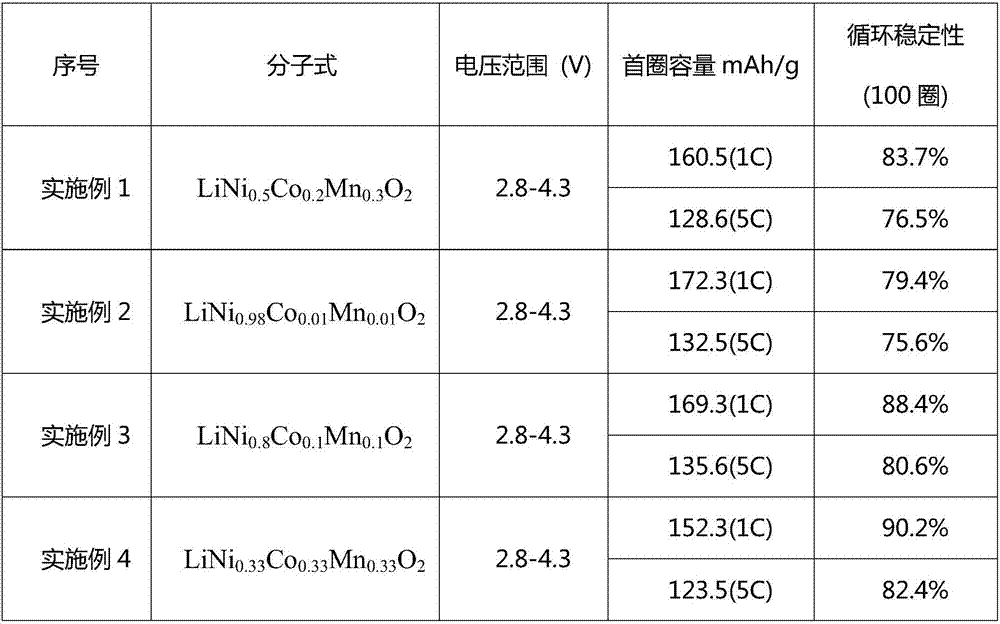

Lithium-ion battery positive electrode material and preparation method thereof

InactiveUS20150079471A1Good stretchabilityGood ductibilitySilver accumulatorsPositive electrodesLithium-ion batteryDiffusion layer

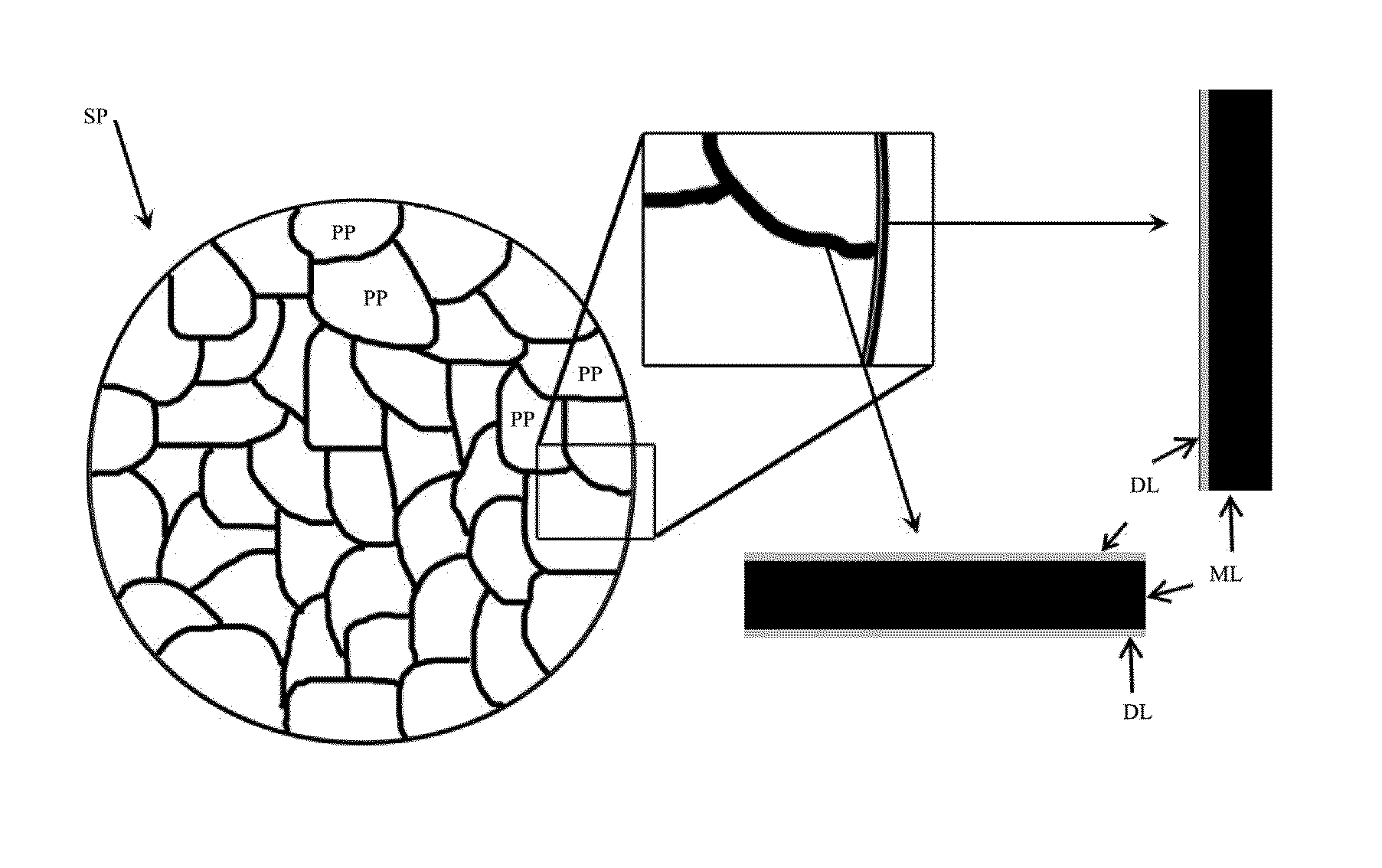

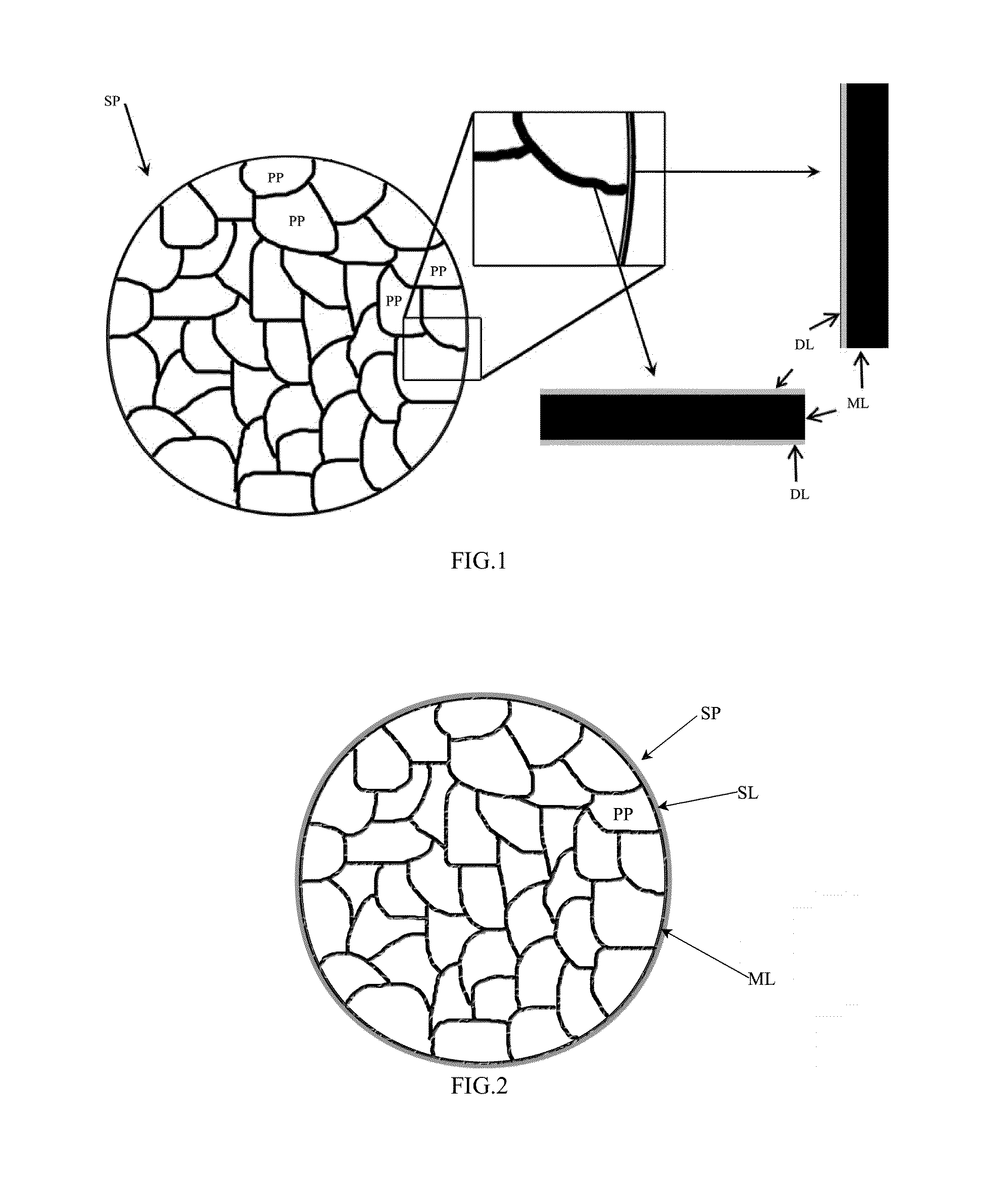

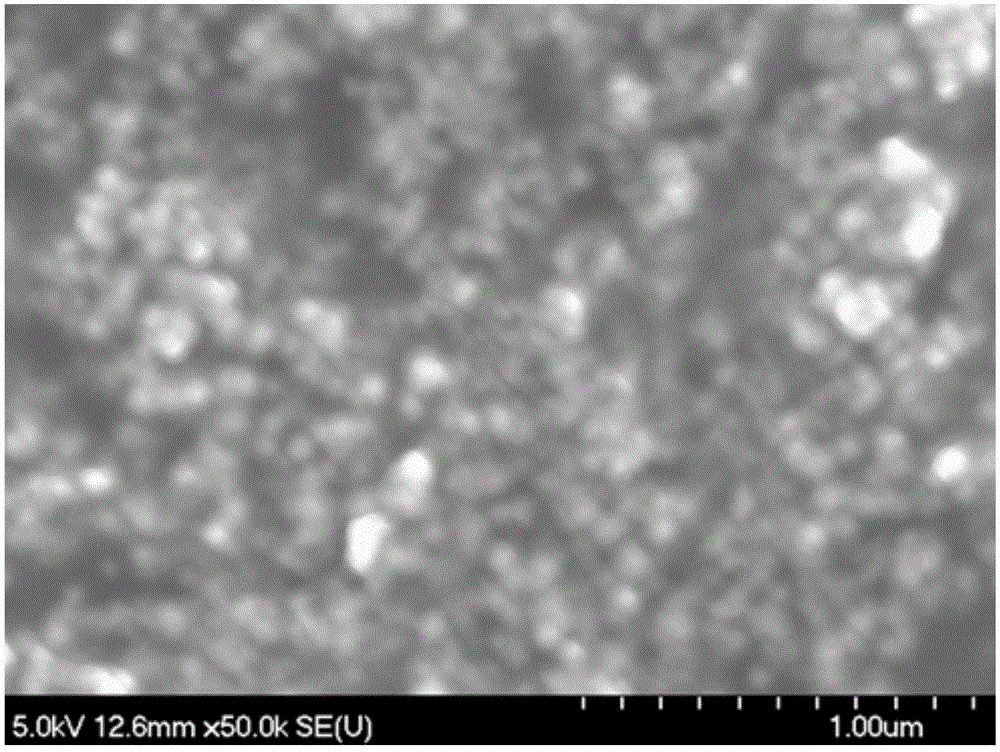

The present disclosure provides a lithium-ion battery positive electrode material and a preparation method thereof. In the lithium-ion battery positive electrode material, a secondary particle comprises lithium-containing multi-element transition metal oxide primary particles and a second phase material, a second phase material forms a second phase material layer distributed on a surface of the primary particle and forms a diffusion layer together with the lithium-containing multi-element transition metal oxide by means of atoms mutual diffusion to make the second phase material layer combined with the primary particle during formation of the secondary particle from the primary particles, thereby effectively suppressing chalking of the secondary particle along boundary among the primary particles, and effectively controlling size of the primary particles and the secondary particles, and improving specific capacity, cycling performance and safety performance of a lithium-ion battery to which the lithium-ion battery positive electrode material is applied.

Owner:NINGDE AMPEREX TECH +1

Method for preparing phosphaalkene

The invention discloses a method for preparing phosphaalkene. The method comprises the following steps: dispersing black phosphorus into a dispersion liquid, and performing ultrasonic treatment for 0.5-200 hours and then performing solid-liquid separation to obtain intercalation black phosphorus; dispersing the intercalation black phosphorus into a chemical foaming agent solution, performing ultrasonic treatment for 0.5-200 hours and then performing solid-liquid separation, and drying solids subjected to solid-liquid separation to obtain a solid mixture of black phosphorus and a chemical foaming agent; performing microwave treatment on the solid mixture of black phosphorus and the chemical foaming agent under the microwave powder of 100-1,000W, and preparing a finished product phosphaalkene after 1s-1h of microwave treatment. The phosphaalkene prepared by the method disclosed by the invention is proper and uniform in size; furthermore, the technology is simple, the cost is low, the peeling time is short, and the phosphaalkene yield is high; large-scale production is easy to realize.

Owner:延边中电阳光新能源科技有限公司

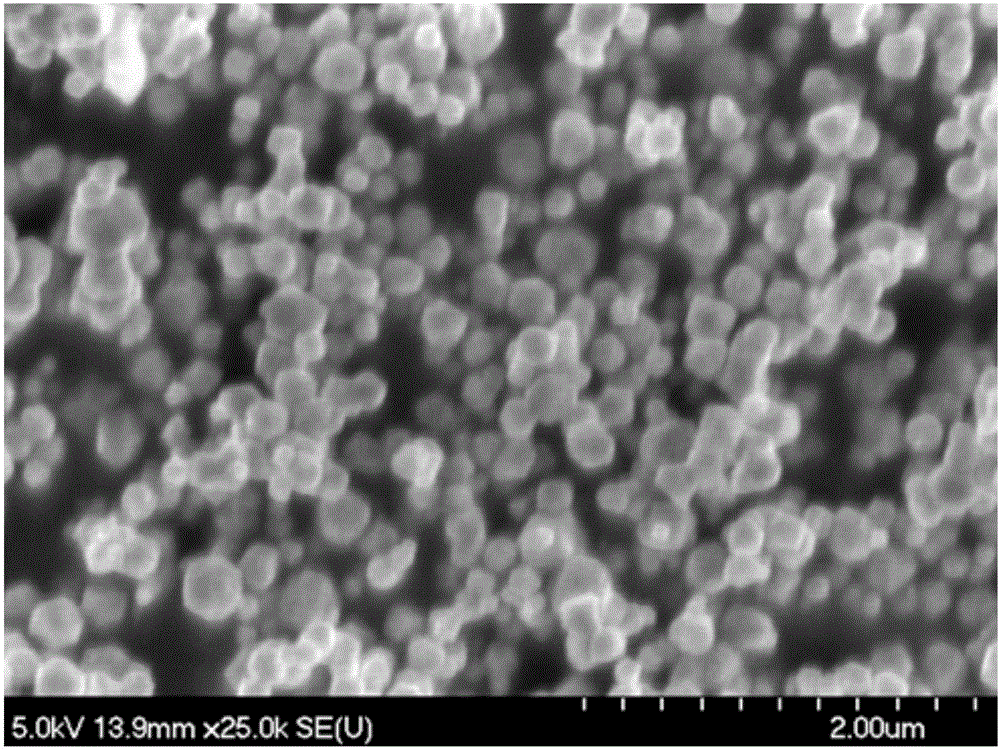

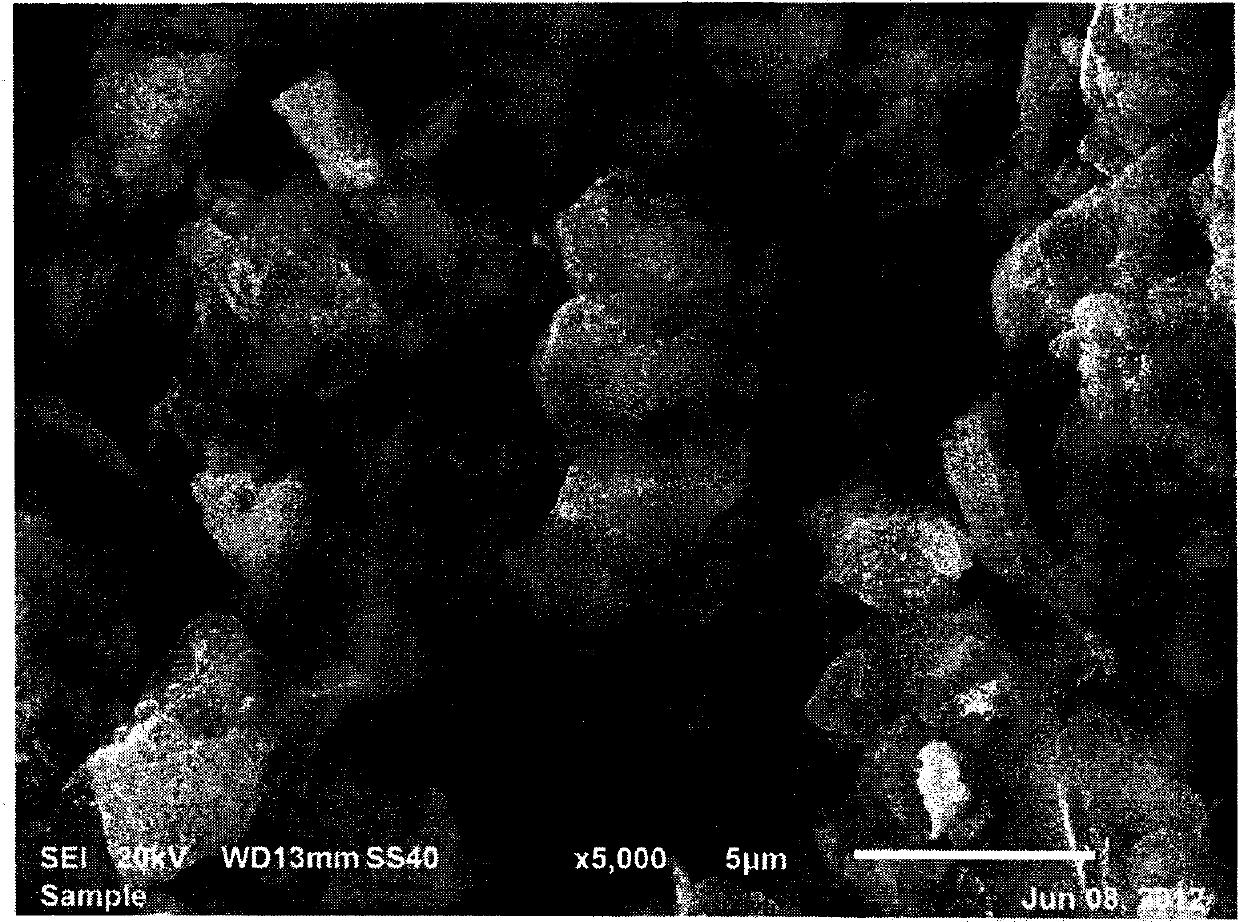

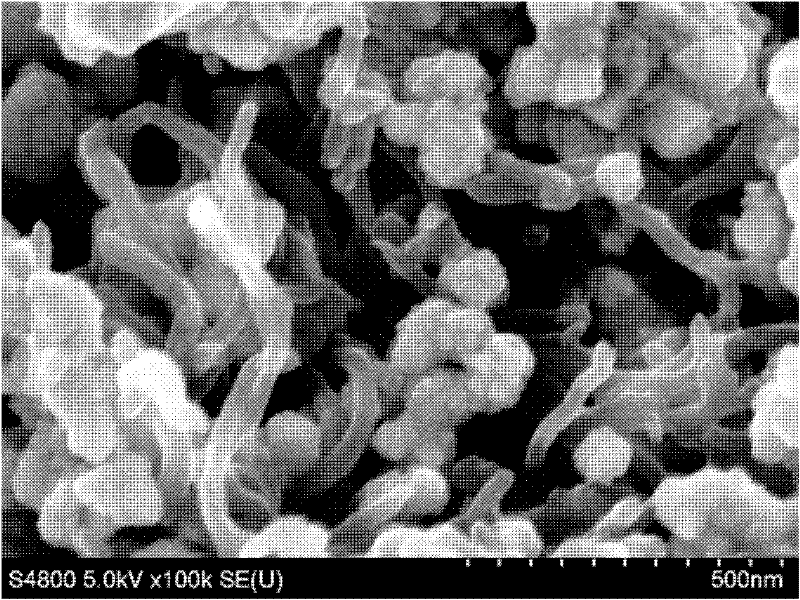

Micro-nano copper powder and preparation method thereof

ActiveCN106513696AModerate reductionEffective size controlMaterial nanotechnologyMicro nanoFiltration

The invention discloses micro-nano copper powder and a preparation method thereof. The preparation method comprises the following steps that compounds containing copper are prepared into a solution, and a system A is obtained; pH conditioning agents, additives and reducing agents are added to the system A, and a system B is obtained and reacts at 50-100 DEG C; and filtration, washing and drying are conducted after reacting, and the micro-nano copper powder is obtained. In the system B, the molarity of the compounds containing copper is 0.001-4 mol / L, the concentration of hydroxyl ion (OH-) is 10<-4>-20 mol / L, the mass concentration of the additives is 0-40%, and the molar ratio of the compounds containing copper to the reducing agents is 1:0.1-100. According to the preparation method, the effective control over the morphology and the size of the micro-nano copper powder is achieved, and the mass content of the impurity phases in the prepared copper powder can be controlled below 0.3%; and in addition, the preparation method further has the advantages that the reaction process is easy to control, and the selected reducing agents are moderate in reducibility, non-toxic, and environmentally friendly.

Owner:GUANGZHOU QIANSHUN IND MATERIAL

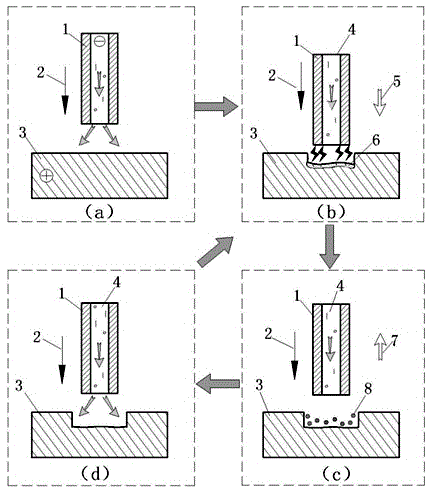

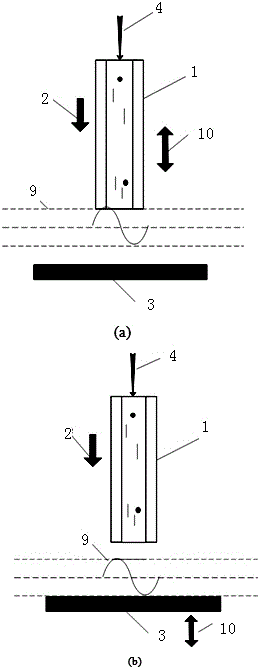

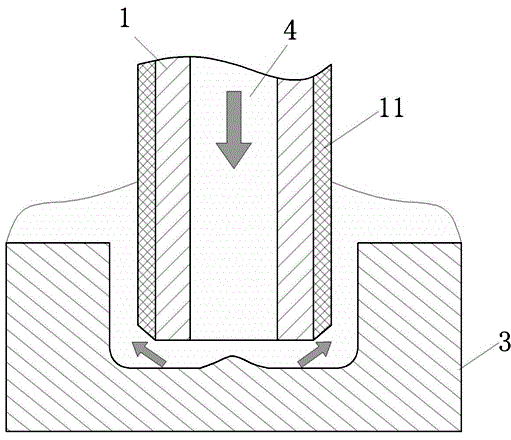

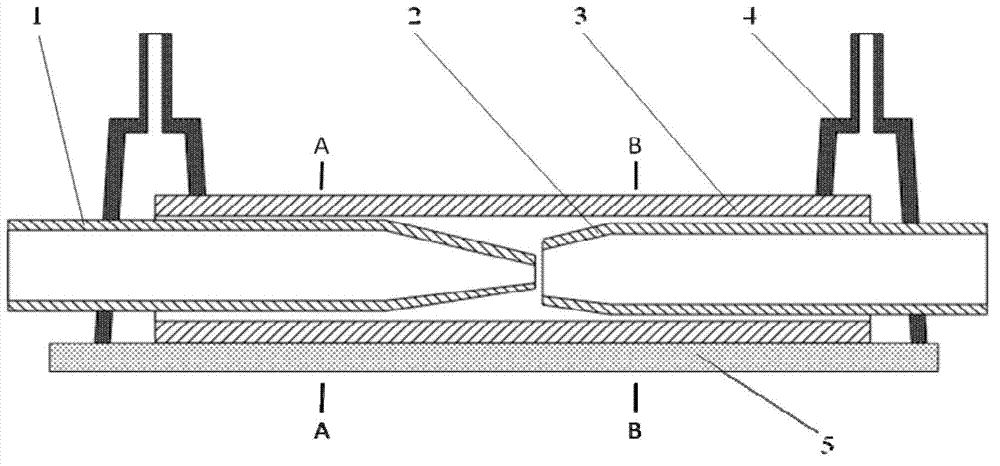

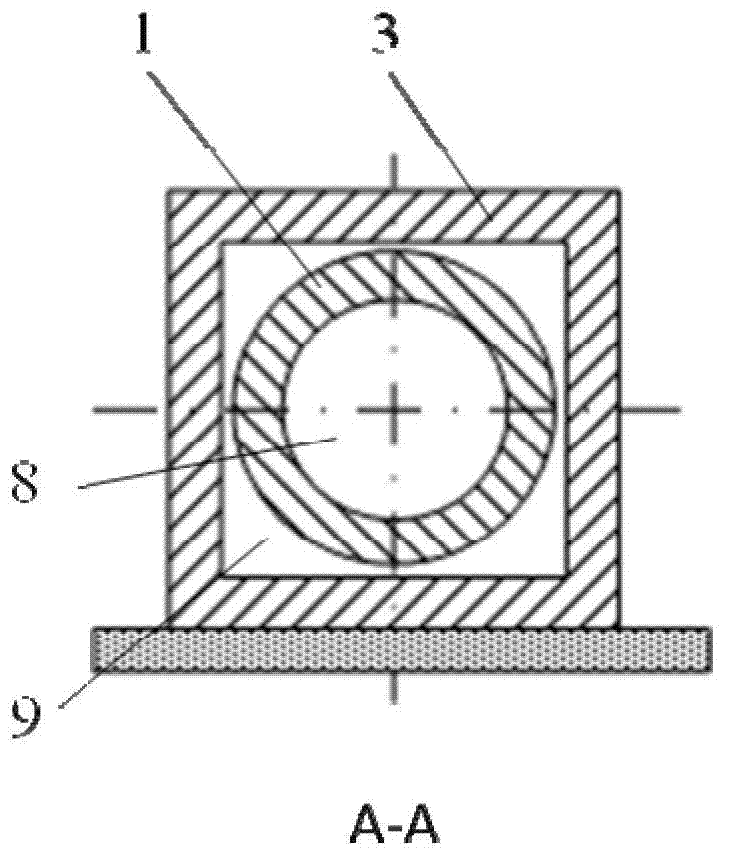

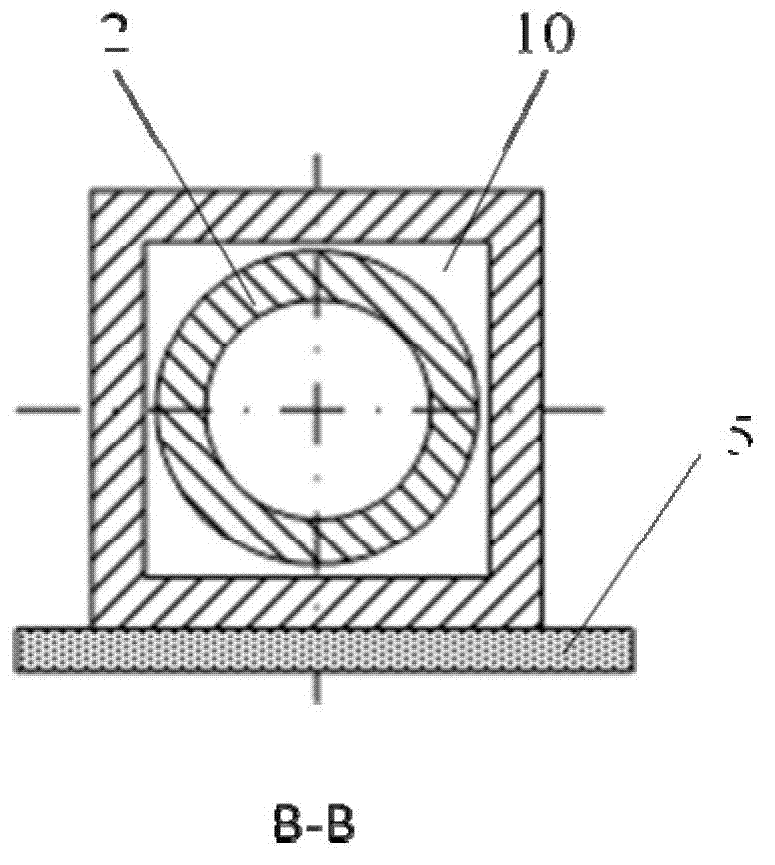

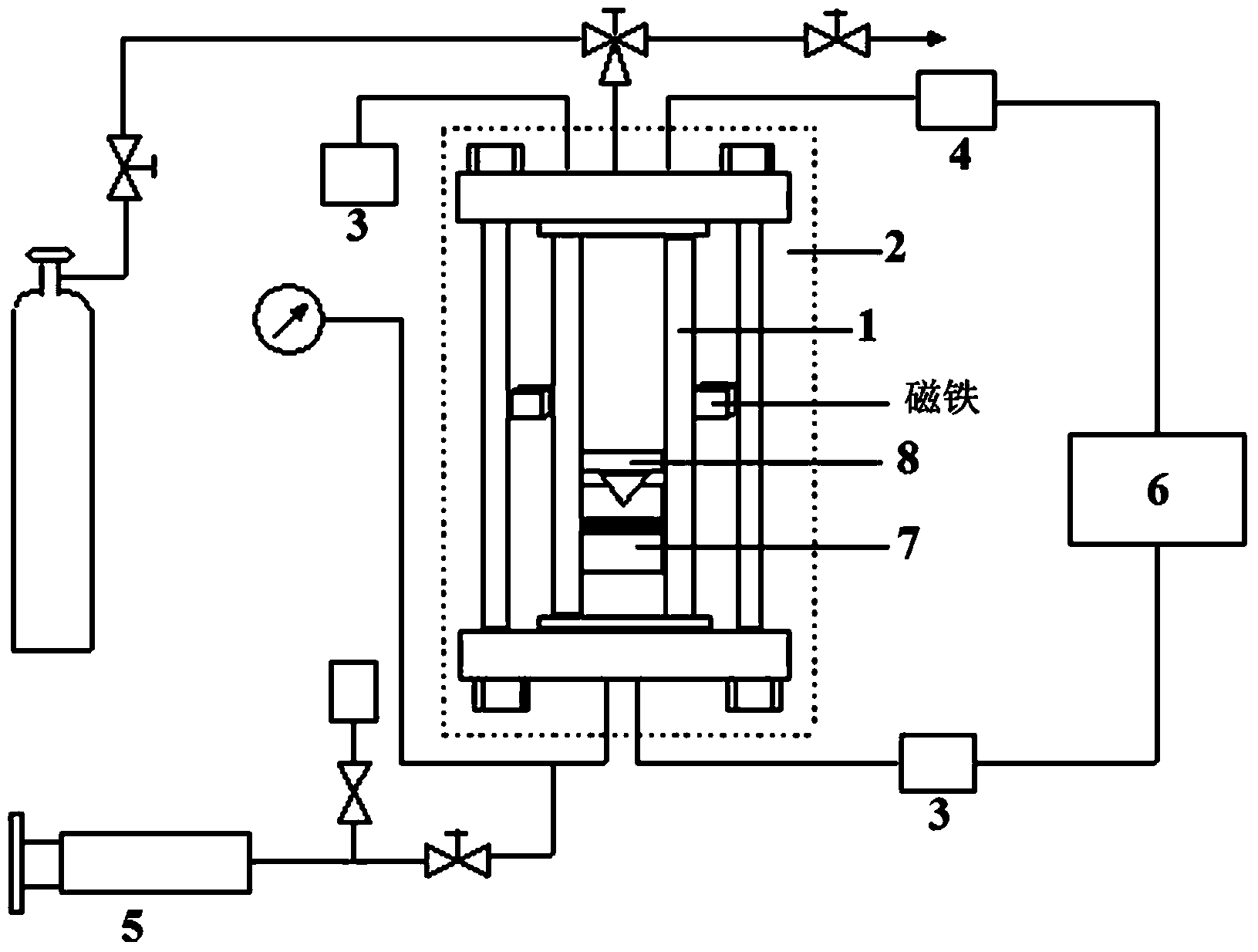

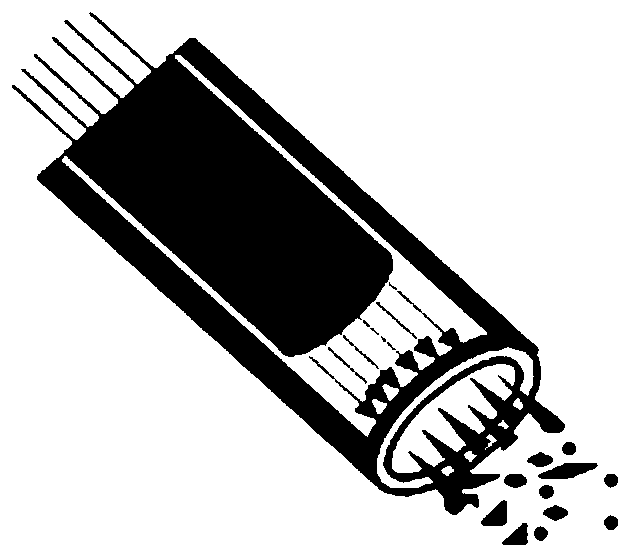

Controllable vibrating electrode electric spark and electrolytic combined machining method for micro holes and vibrating system

ActiveCN104923869AEffective size controlEasy to controlElectrical-based auxillary apparatusPhysicsPulse voltage

The invention provides a controllable vibrating electrode electric spark and electrolytic combined machining technological method and device for a single group of micro holes and belongs to the technical field of special machining. An ultralow-concentration neutral salt solution is taken as a working solution, corresponding pulse voltage is applied between the two electrodes, the electrodes vibrate in a reciprocating mode in the feeding directions of the electrodes, the gap between the two electrodes is adjusted by controlling the vibration between the electrodes, and the gap between the electrodes is made to be smaller than a spark discharge gap when the electrodes vibrate in the forward direction, so that an electric spark reaction occurs; the distance between the electrodes is larger than the discharge gap when the electrodes vibrate in the negative direction, so that spark discharge is changed into an electrolytic reaction gradually; when the distance between the electrodes is too large, the electrolytic reaction is ended, the working solution is switched to be in the deionization state, then the next machining cycle is conducted along with the feeding of the electrodes, and controllable combination of electric spark machining and electrolytic machining is achieved by optimizing the vibrating mode. By the adoption of the controllable vibrating electrode electric spark and electrolytic combined machining technological method and device, high surface quality can be obtained, and machining efficiency is improved; meanwhile, control over the machining process and machining consistency can be effectively guaranteed.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

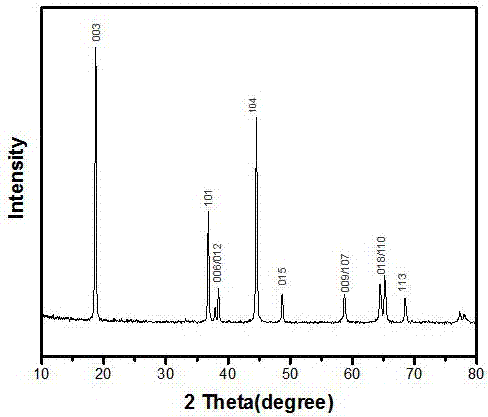

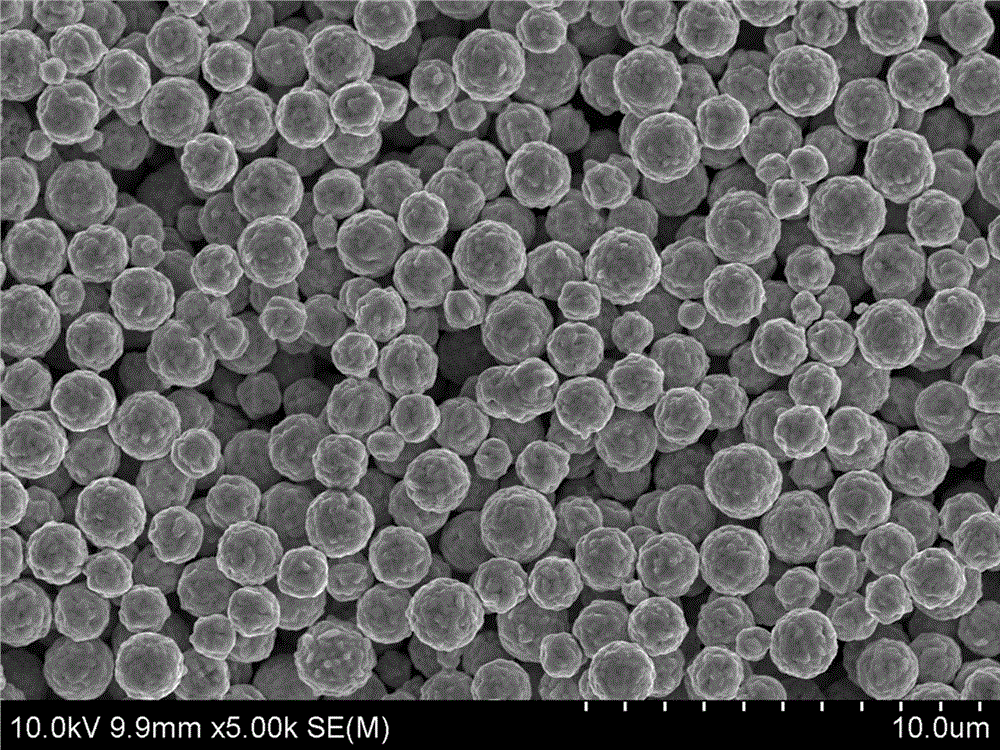

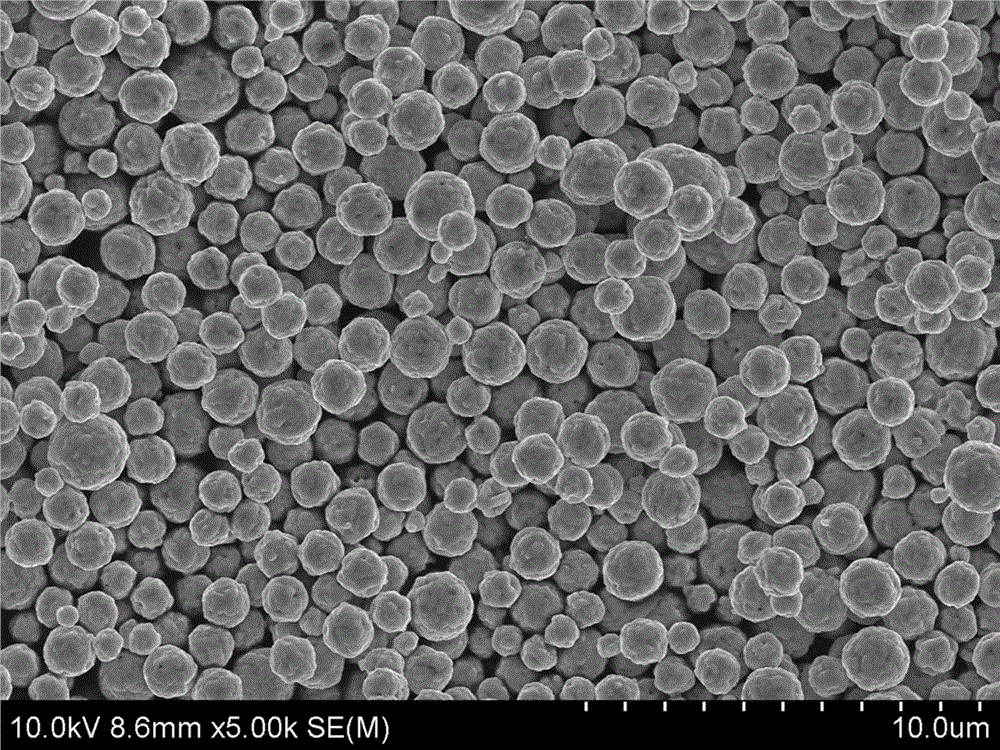

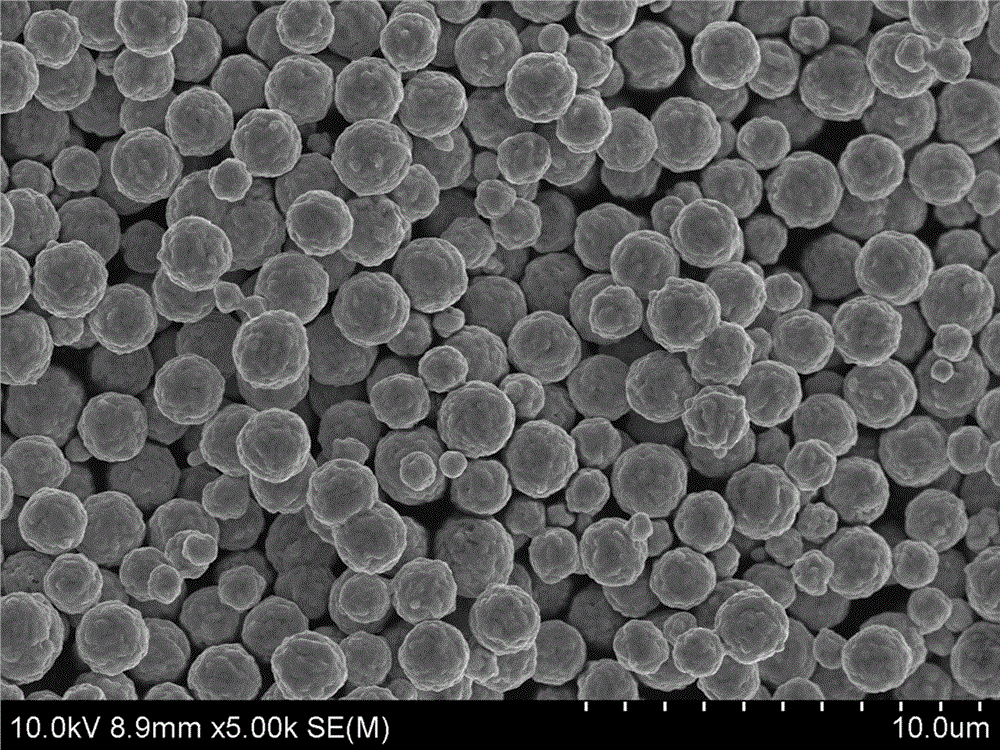

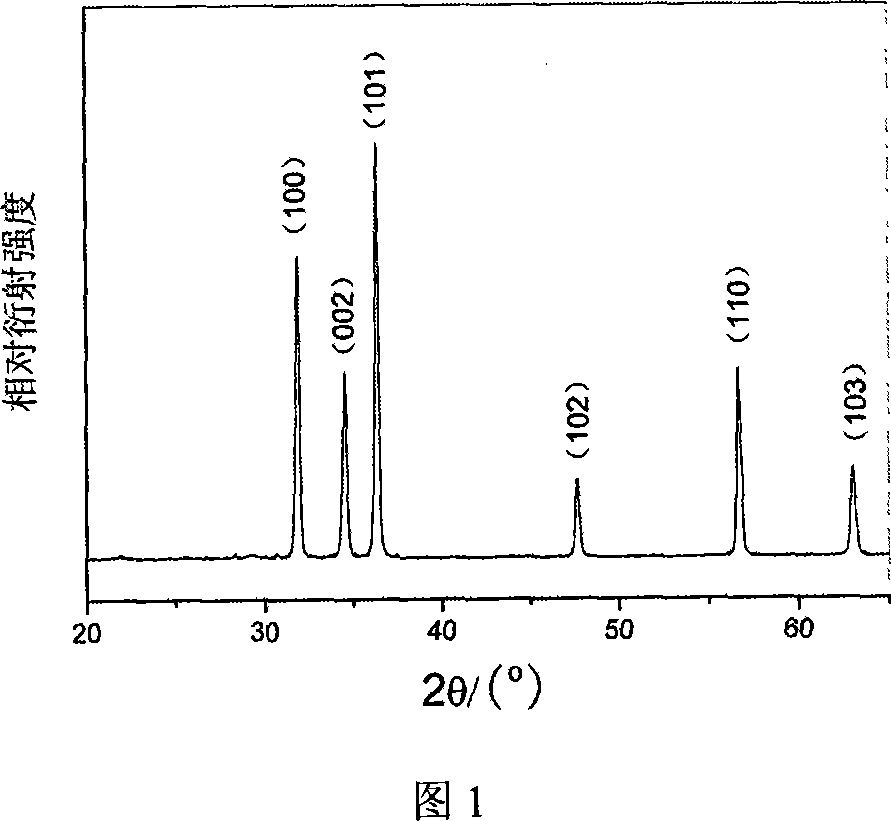

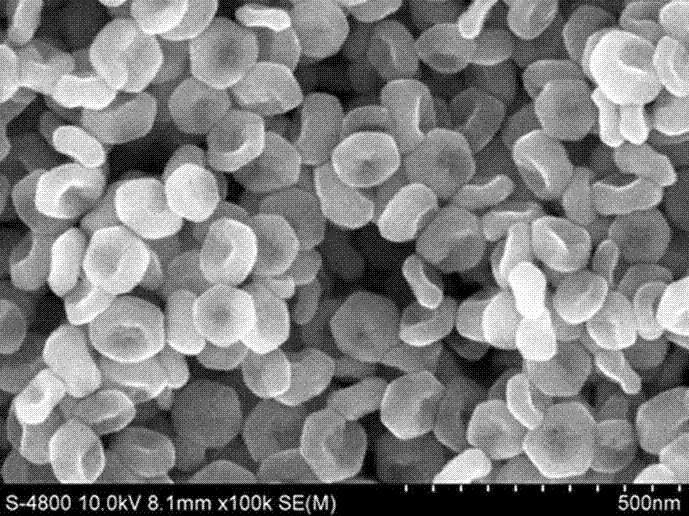

Ternary positive-electrode material prepared by solvothermal method and preparation method thereof

InactiveCN107959022ARegulatory TopographySmall sizeCell electrodesSecondary cellsFiltrationManganese

The invention discloses a ternary positive-electrode material prepared by a solvothermal method and a preparation method thereof. The preparation method includes: dissolving nickel cobalt manganese salt in a solvent, adding a surfactant and hydrolysis auxiliaries, sufficiently stirring, transferring into a reaction kettle, performing solvothermal reaction under certain temperature for 2-24 hours,cooling to room temperature, using a suction filtration method to separate out a nickel cobalt manganese ternary product, washing, drying, and pre-calcining in air to obtain a precursor; grinding andmixing the precursor and a lithium compound, and calcining to obtain the ternary positive-electrode material. The ternary positive-electrode material and the preparation method thereof have the advantages that the ternary oxide precursor prepared by the solvothermal method is small in particle size, uniform in particle distribution and controllable in morphology as compared with a ternary precursor prepared by a conventional precipitation method, so that the finally prepared ternary material is small in granularity, uniform in particle size distribution and controllable in morphology and has excellent electrochemical performance, and the capacity and stability of the prepared ternary material are better than those of a ternary positive-electrode material prepared by the precipitation method.

Owner:SOUTH CHINA UNIV OF TECH

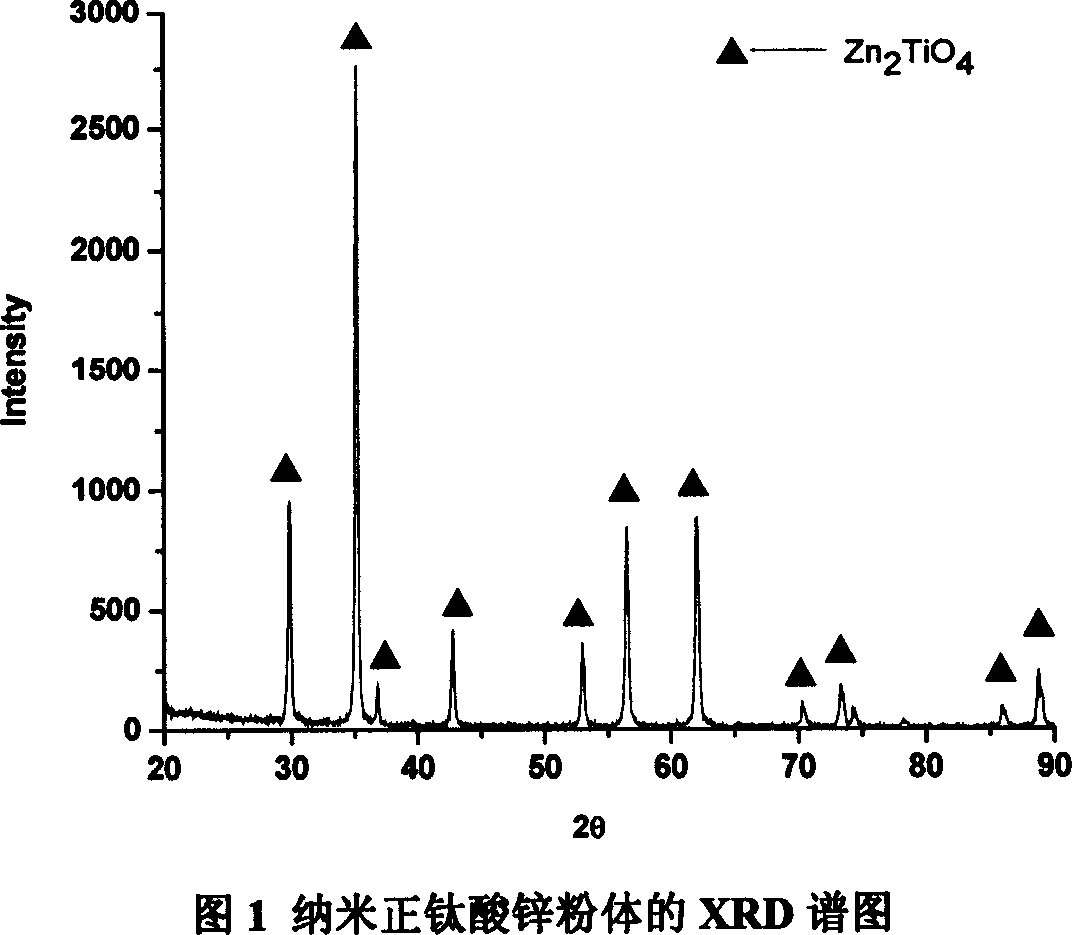

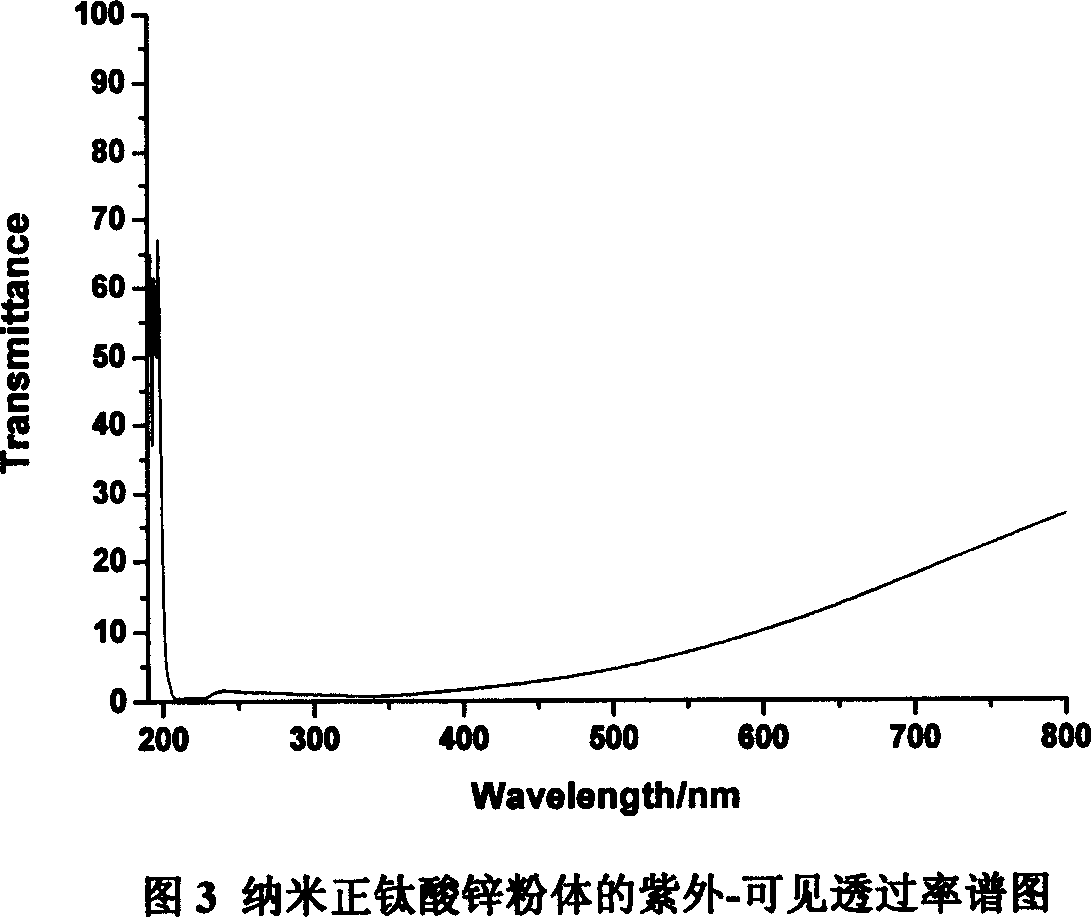

UV-shielding nano normal zinc titanate powder and process for preparing same

InactiveCN1884095AImprove shielding effectLow costCosmetic preparationsToilet preparationsSal ammoniacSulfate

The invention discloses a new ultraviolet nanometer screening titanate zinc powder and preparing method; which is characterized by the following: adopting industrial metatitanate, zinc sulfate as raw material to prepare TiOSO4 solution; blending TiOSO4 and ZnSO4; adding surface activist PEG400; utilizing ammonia as sedimenting agent to adjust system pH value to generate priority sedimentation; filtering; washing; drying; grinding; sintering to obtain Zn2TiO4 powder. The invention provides pure Zn2TiO4 analyzed by XRD phase with 70 nm for TEM observing grain size, which screens ultraviolet effectively by over 95 percent.

Owner:SICHUAN UNIV

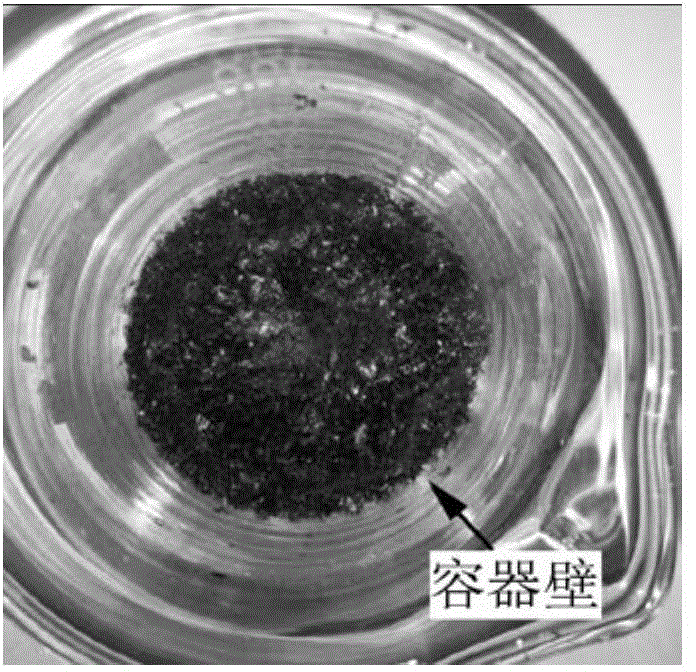

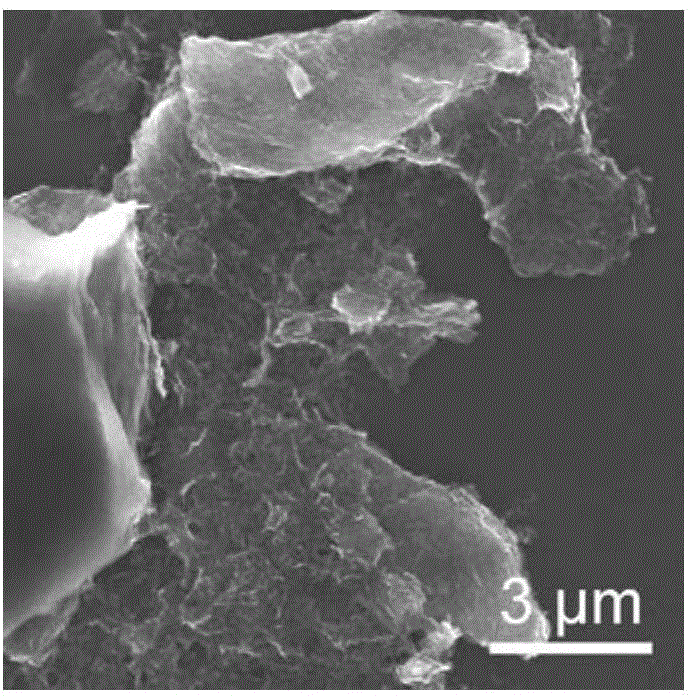

Preparation method for doped graphene foams

The invention discloses a preparation method for doped graphene foams. The preparation method comprises the following steps: adopting the hydrothermal method to enable nano particles to dope with and generate on oxidized graphene sheets to obtain oxidized graphene aerogel; reducing the oxidized graphene aerogel doped with the nano particles in a controllable manner at the low-temperature gaseous phase condition to obtain the doped graphene foams. According to the preparation method, a reductant is not used in the growing process of the nano particles, and liquid is not introduced into the reaction system, so that excessive overlap of the graphene layers is avoided, porosity of the graphene foams is maintained, polyporous shrinkage caused by surface stress is prevented, and the uniformly doped graphene foam material with the controllable appearance is obtained. The preparation method is convenient to operate, uniform in doping, controllable in product size, economical and fast, is adopted as the novel technology for the large-scale preparation of the doped graphene foam material, and is expected to provide novel materials for graphene adsorbents, graphene capacitors, graphene catalysts and the like.

Owner:四川烯城环保科技有限公司

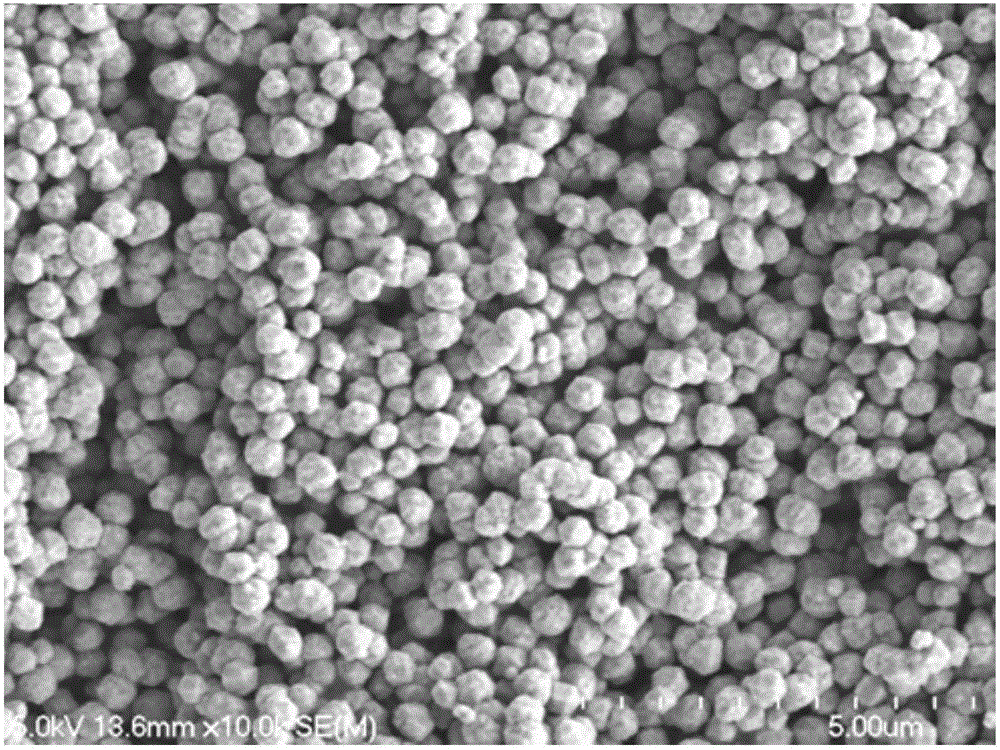

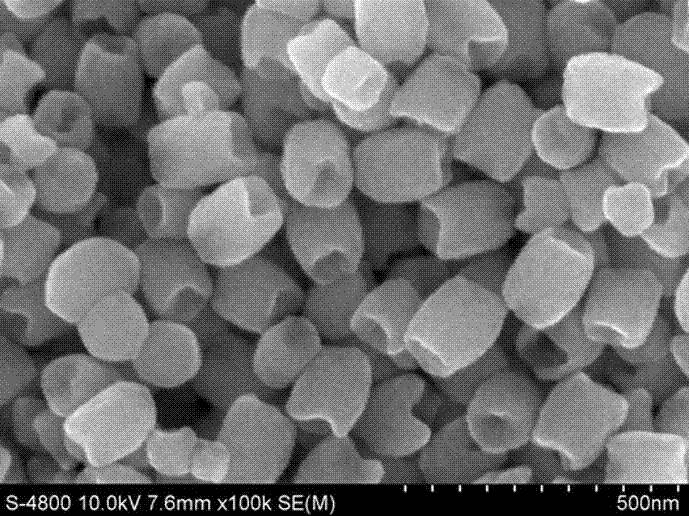

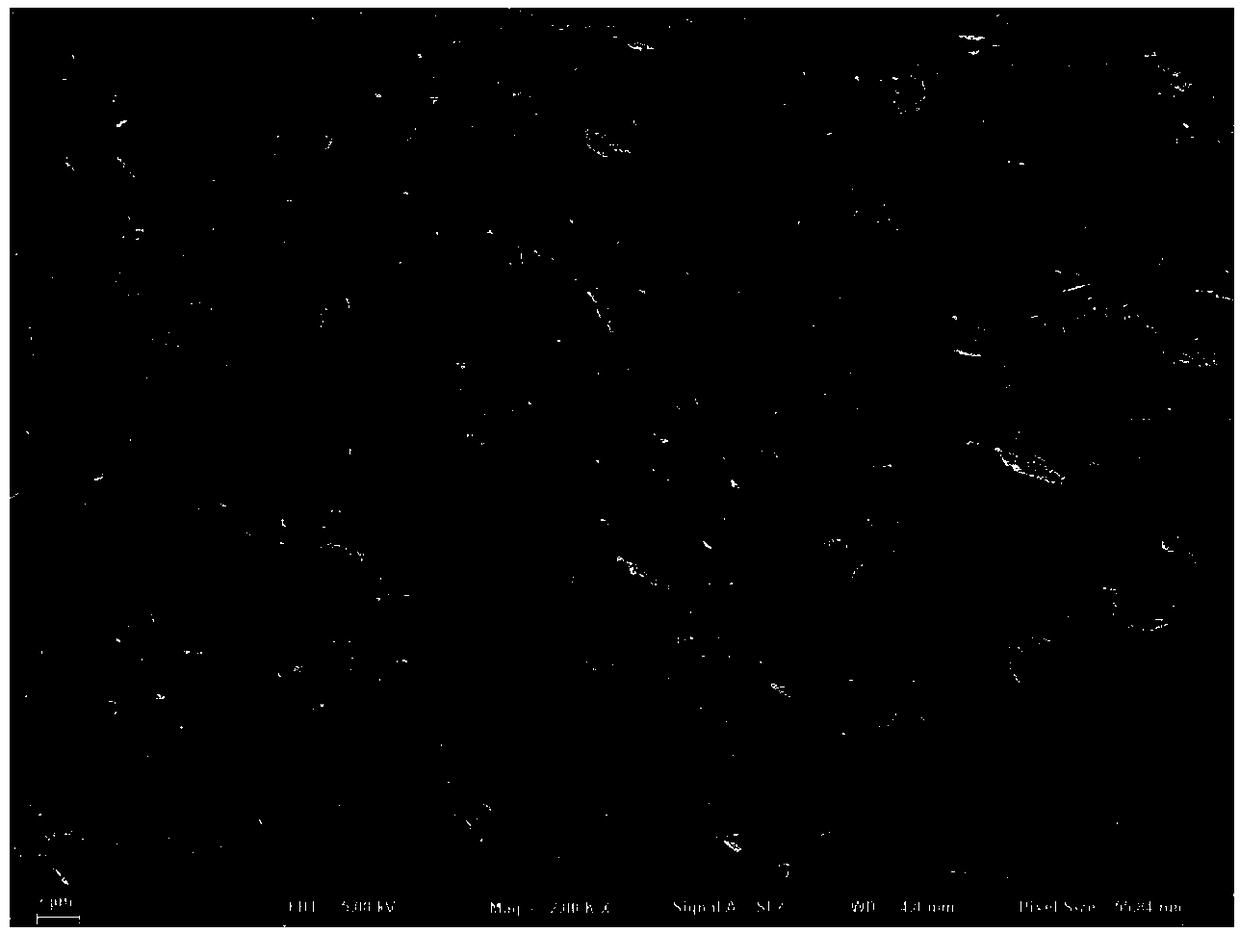

Silver powder for solar cell conductive silver pulp and preparation and application

ActiveCN106513699AEffective size controlGood lookingTransportation and packagingMetal-working apparatusOleic Acid TriglycerideMaterials science

The invention provides silver powder for solar cell conductive silver pulp and preparation and application. A silver nitrate solution is prepared and used as a silver source, and the pH of the silver nitrate solution is adjusted to 1-5 with ammonia water or nitric acid; ascorbic acid of which the mass is 0.6-1.2 times that of the silver nitrate is weighed, an ascorbic acid solution is prepared, and a dispersant is added; a redox reaction is conducted step by step; a part of silver source is quickly added to a redox under heating and stirring, oleic acid is added immediately, then the rest of the silver source is slowly added to the redox dropwise, the pH of the solution is controlled with the nitric acid or the ammonia water in the drop-by-drop adding process, and a reaction is conducted for 30 minutes after drop-by-drop adding is completed; and after the reaction is completed, supernatant is poured out and cleaned three times with deionized water and absolute ethyl alcohol, and then the supernatant is dried for 4 hours at the temperature of 60 DEG C. By the adoption of the method, the silver source is added to the redox step by step, the purpose of step-by-step implementation of silver nucleation and grain growth is achieved, and the oleic acid is added in the drop-by-drop adding process so that the grain size can be controlled effectively, and the silver powder with the narrow grain size distribution range and average grain size is prepared. The silver powder can be used for preparing the solar cell conductive silver pulp, and the high photovoltaic conversion efficiency is achieved.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Preparation method of tin mixed with zinc oxide nanowire

InactiveCN101045553AHigh purityIncrease productionNanostructure manufactureZinc oxides/hydroxidesPowder mixtureCleansing Agents

A process for preparing the Sn doped zinc oxide nanowires includes such steps as flushing the Si substrate by detergent, proportionally mixing ZnO powder, SnO powder and C powder by ball grinding, putting said substrate and powder mixture in a ceramic crucible, loading it in a quartz tube of tubular furnace, filling the mixture of argon gas and O2, heating at 850-950 deg.C while reacting, and cooling.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing zirconium dioxide ceramic microspheres with microfluid device

The invention relates to a method for preparing zirconium dioxide ceramic microspheres with a microfluid device, belonging to the technical field of material synthesis and formation. The method comprises the following steps: by using zirconium dioxide precursor sol as an inner phase fluid, an oily solution as an intermediate phase fluid and an aqueous solution as a continuous phase fluid, preparing monodisperse water-in-oil-in-water double-emulsion drops with a microfluid device by regulating the flow rates of the three phases of fluids, adding an alkaline solution into the continuous phase to initiate the gel reaction, cleaning and drying the gel microspheres obtained by the gel reaction, and sintering to obtain the ZrO2 ceramic microspheres. The zirconium dioxide ceramic microspheres prepared by the method have the advantages of high sphericity and uniform dimension; on the micrometer level, the action of surface tension of the zirconium dioxide ceramic microspheres is far larger than the deformation generated by gravity; and the reaction synthesis on the sol-gel system by using the double-emulsion drops as the template has universality, thereby having potential application prospects in the nuclear fuel preparation.

Owner:TSINGHUA UNIV

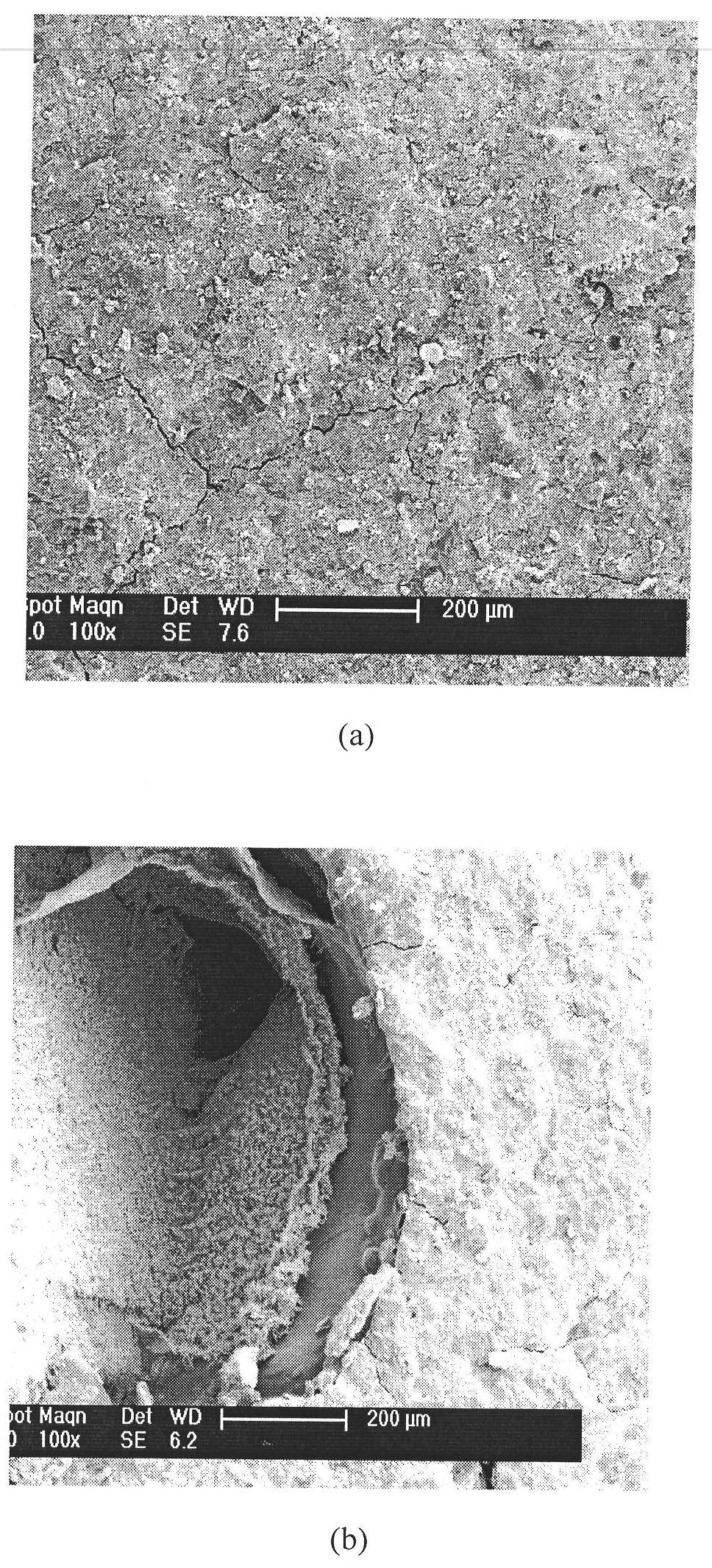

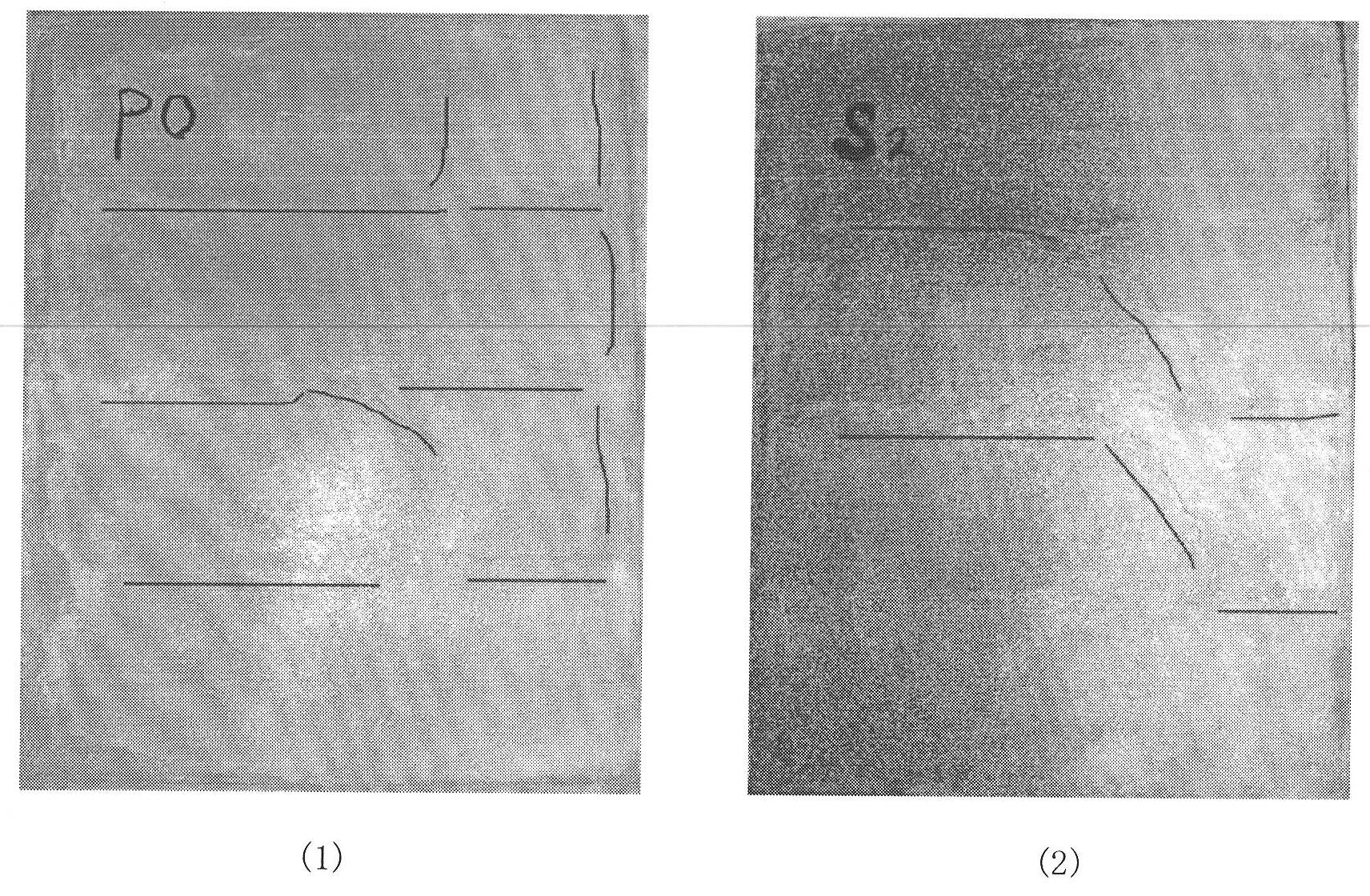

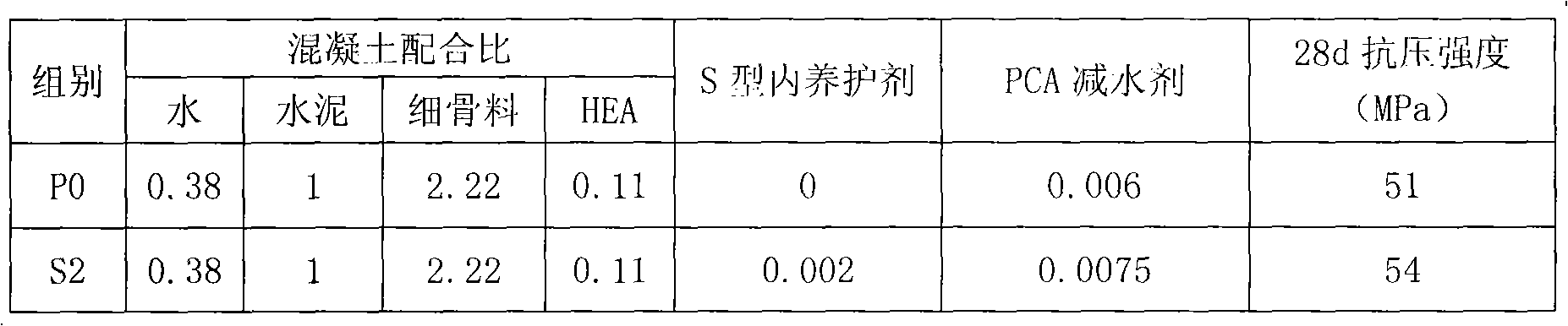

Internal curing process for improving performance of high strength and slight expansion concrete

InactiveCN101863072AIncreased hydrationLimit expansionCeramic shaping apparatusAbsorption capacitySuper absorbent

The invention provides an internal curing process for improving the performance of high strength and slight expansion concrete, which comprises: mixing and stirring sand and stones, adding a gelled material, an expanding agent and a super absorbent resin; stirring the mixture for 30 seconds, adding water and a water reducer and stirring the mixture for 120 seconds; and filling the mixture into a mold. The water absorption of the super absorbent resin is between 150 and 300 times, the salt solution absorption capacity of the super absorbent resin is between 15 and 40 times, and the added amount of the super absorbent resin is 0.15 to 0.30 percent based on the mass of the gelled material. The process solves the problems of insufficient expansion rate, contraction, cracking and damages of later-stage secondary ettringite generation to the internal structure of the concrete, which are caused by curing. The internal curing technique effectively improves the moisture field in the concrete, the internal moisture content of the concrete and the hydration degree of the concrete, contributes to the full generation of the ettringite in the slight expansion concrete and improves the internal porous structure and compactedness of the concrete.

Owner:SOUTHEAST UNIV

Oxide dispersion strengthening iron-base alloy powder and characterization method thereof

ActiveCN108907209AAchieve separationSolve the problem of impossibility of electrolytic separationTransportation and packagingMetal-working apparatusElectrolysisElectron microscope

The invention relates to oxide dispersion strengthening iron-base alloy powder and a characterization method of the oxide dispersion strengthening iron-base alloy powder. The alloy powder comprises abase body and a strengthening phase, the strengthening phase comprises at least two kinds of strengthening phase particles with different sizes, the volume of particles with the diameter smaller thanor equal to 50nm accounts for 85-95% of the total volume of the strengthening particles, and the base body is Fe-Cr-W-Ti alloy. The characterization method of the oxide dispersion strengthening iron-base alloy powder comprises the steps that the strengthening phase is separated from the powder base body through electrolysis, and an electron microscope is adopted for analyzing and characterizing the strengthening phase.

Owner:CENT SOUTH UNIV

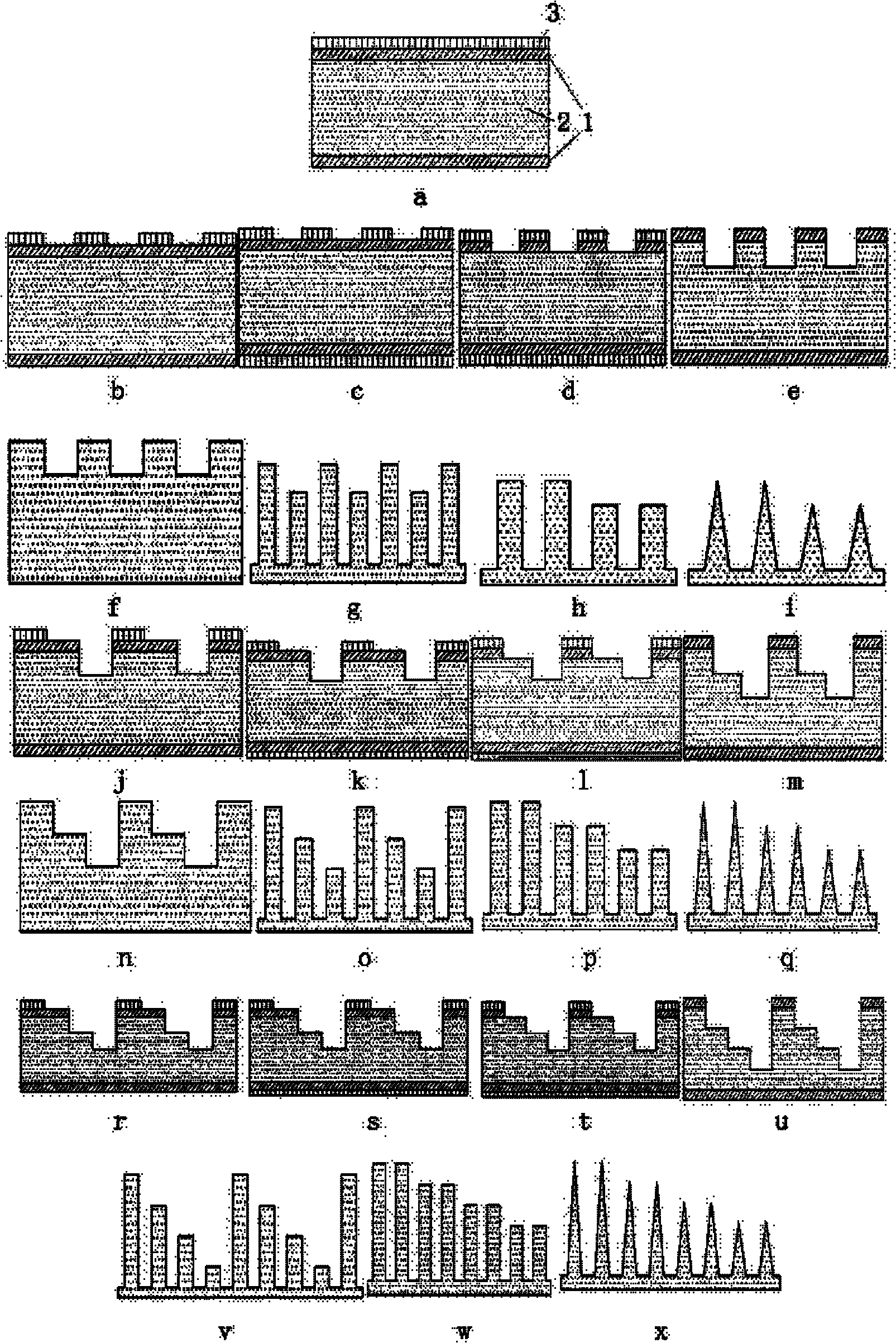

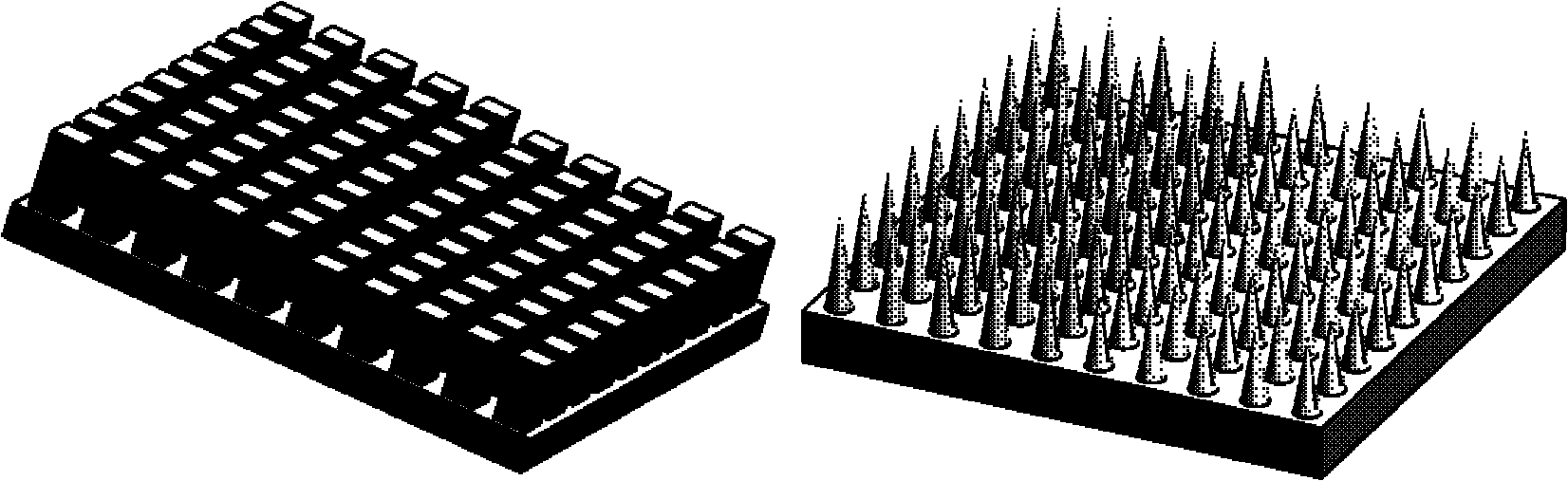

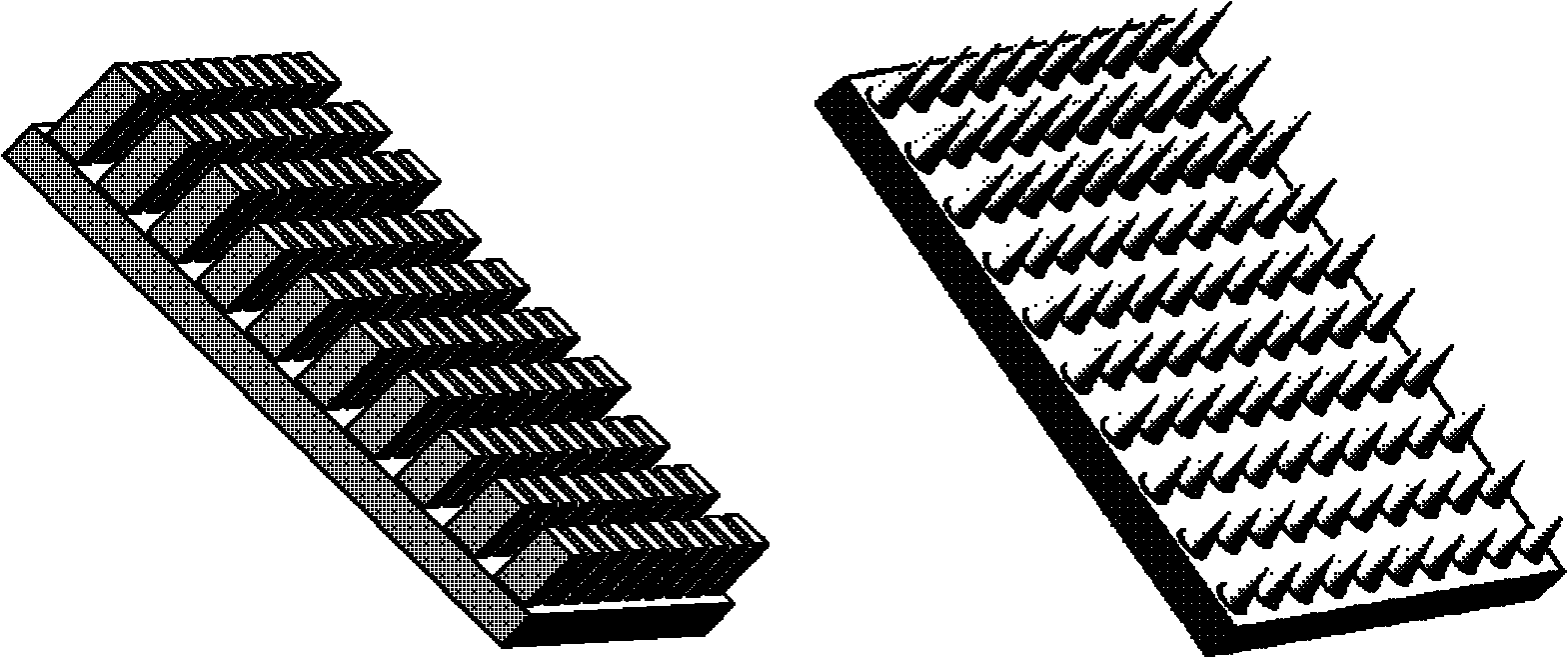

Method for preparing step micro-needle array

InactiveCN101829394AEffective size controlReduce penetration resistanceMicroneedlesPhotomechanical apparatusSilicon chipSilicon etching

The invention discloses a method for preparing a step micro-needle array in the technical field of biomedical engineering. The method comprises the following steps of: gapping a silicon etching window on a silicon chip through photoetching and performing wet etching on the silicon in the silicon etching window; cutting the silicon chip to obtain a micro square column array by using a slicing machine, and further cutting the micro square column array to obtain micro square blocks; and finally performing the wet etching on the micro square column array to obtain the step micro-needle array. Micro-needle arrays with different heights are prepared by the method, and the micro-needle arrays puncture into the skin in a progressive mode. Meanwhile, the method has the advantage of simple preparation process, and the step micro-needle array is prepared by adopting the method of combining the wet etching with machining, so the cost is low and the method is convenient to popularize.

Owner:SHANGHAI JIAO TONG UNIV

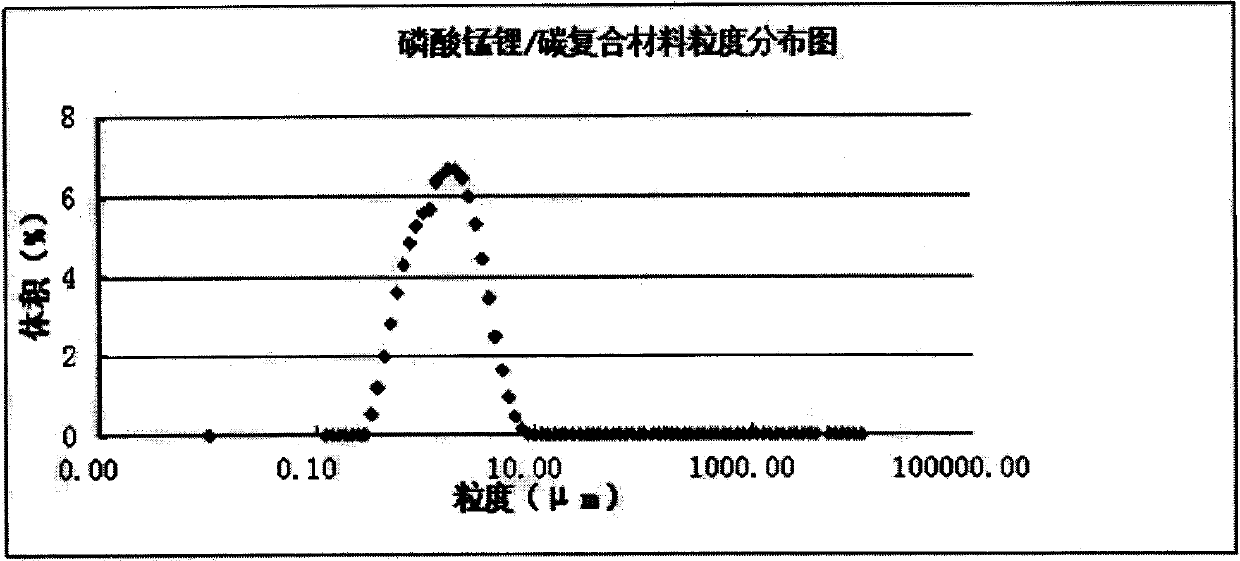

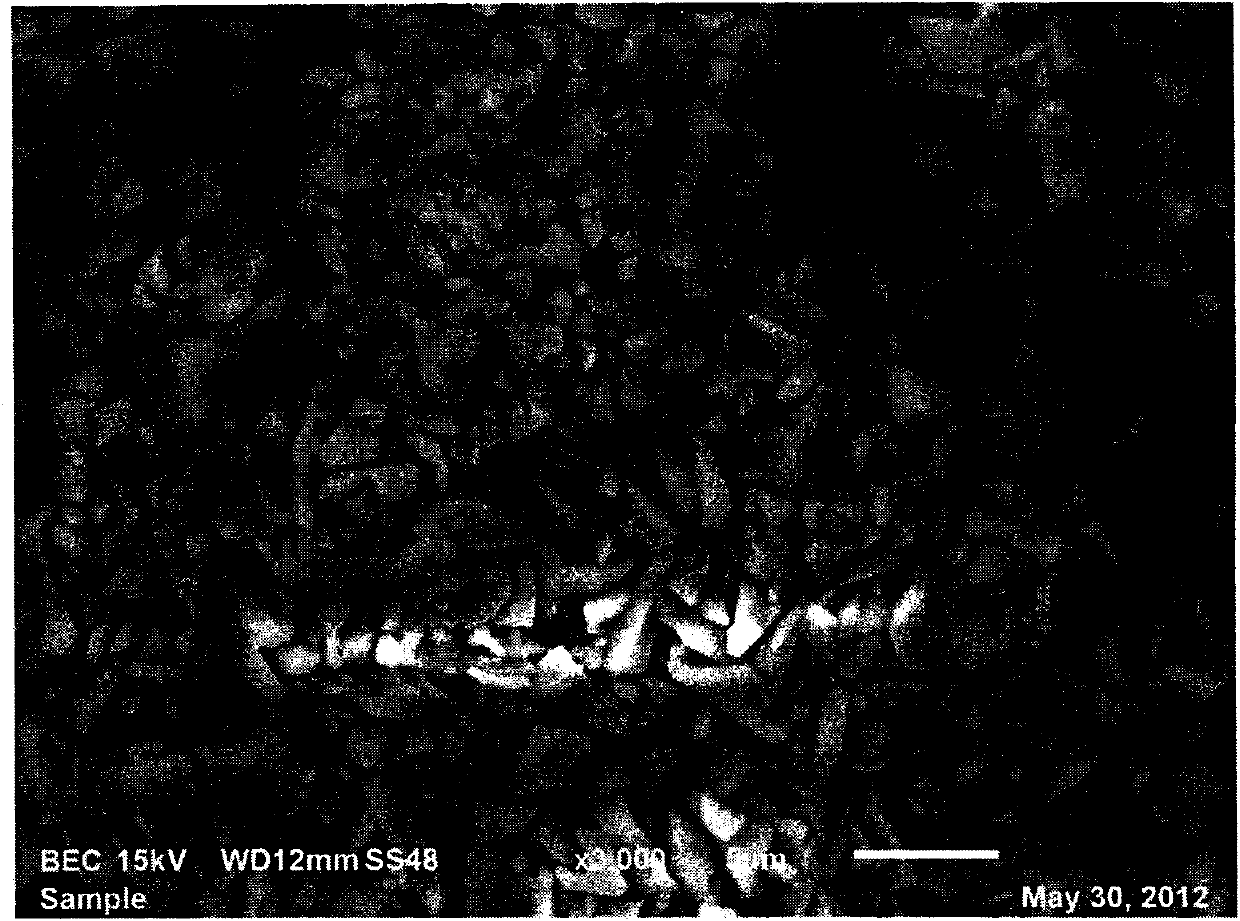

Preparation method for metal-doped lithium/carbon manganese phosphate composite from manganese phosphate

InactiveCN103474656AGood electrical conductivityImprove processability and electrochemical performanceCell electrodesDislocationChemistry

The invention discloses a preparation method for a metal-doped lithium / carbon manganese phosphate (LiMXMn1-XPO4 / C) composite from manganese phosphate. The method comprises the following steps: preparing active manganese phosphate materials (MnPO4) with different shapes by using a precipitation or sol-gel method; then subjecting prepared manganese phosphate, a lithium source and a metal-doped elemental compound to ball milling for 20 to 50 h and mixing with alcohol used as a dispersant; carrying out vacuum drying and crushing to obtain a crushed substance; placing the crushed substance in a stainless steel container, heating the crushed substance to a temperature of 450 to 800 DEG C in a furnace protected by an inert atmosphere and maintaining the temperature for 2 to 12 h; and rapidly placing the substance to a liquid coolant under the conditions of a high temperature and air isolation and carrying out rapid cooling so as to obtain the LiMXMn1-XPO4 / C composite. The method provided by the invention has shortened process flow, can maintain particle activity in a high temperature, effectively gives rise to structural dislocation, improves the ionic migration rate and electronic conductivity of the composite and is suitable for large-scale industrial production.

Owner:ZHEJIANG WELLY ENERGY CORP

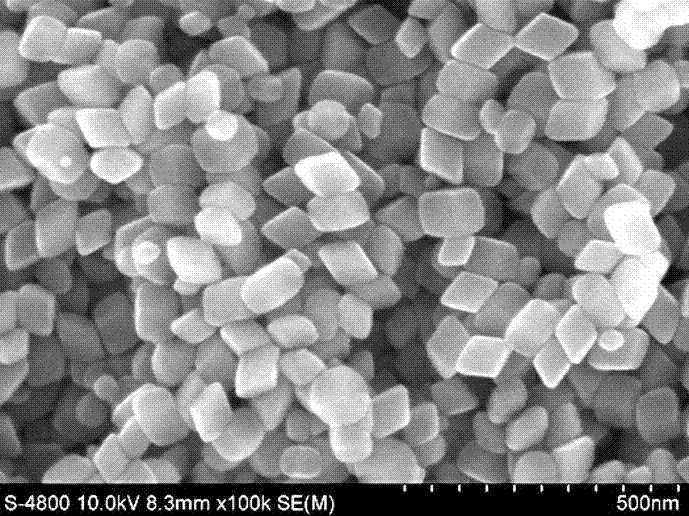

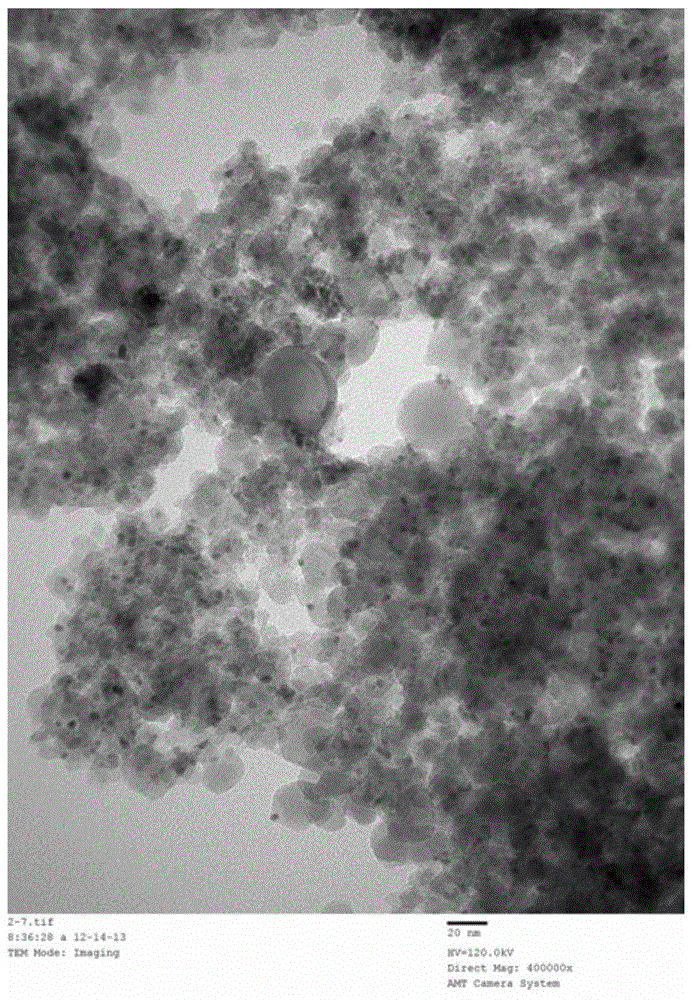

Hydro-thermal synthesis method for shape-controllable nano iron oxide

ActiveCN103754956AEffective control of morphologyEffective size controlMaterial nanotechnologyFerric oxidesIron saltsPhosphate ion

The invention relates to a preparation method for shape-controllable nano iron oxide and particularly relates to a hydro-thermal synthesis method for shape-controllable nano iron oxide. The hydro-thermal synthesis method comprises the following steps: (1) weighing dihydric phosphate, strong acid and strong alkali salts and trivalent iron salt; mixing and adding a mixture into de-ionized water; agitating until the mixture is completely dissolved to obtain a precursor solution, wherein the mol ratio of phosphate radical ions to trivalent iron ions in the precursor solution is (0-3) to 10; the mole ratio of the strong acid and strong alkali salts to the trivalent iron ions is (0-5) to 10; the mass of the de-ionized water is 50-300 times as much as the total mass of the dihydric phosphate, the strong acid and strong alkali salts and the trivalent iron salt; and (2) putting the precursor solution into a reaction kettle and heating to 150-250 DEG C and preserving the heat for 2-4 hours; cooling to the room temperature and adding the de-ionized water and alcohol into an obtained product; sufficiently shaking and centrifuging; removing liquid supernatant and transferring content matters into an electric heating vacuum drying box; drying until the weight is constant to obtain the nano iron oxide.

Owner:TAIYUAN UNIV OF TECH

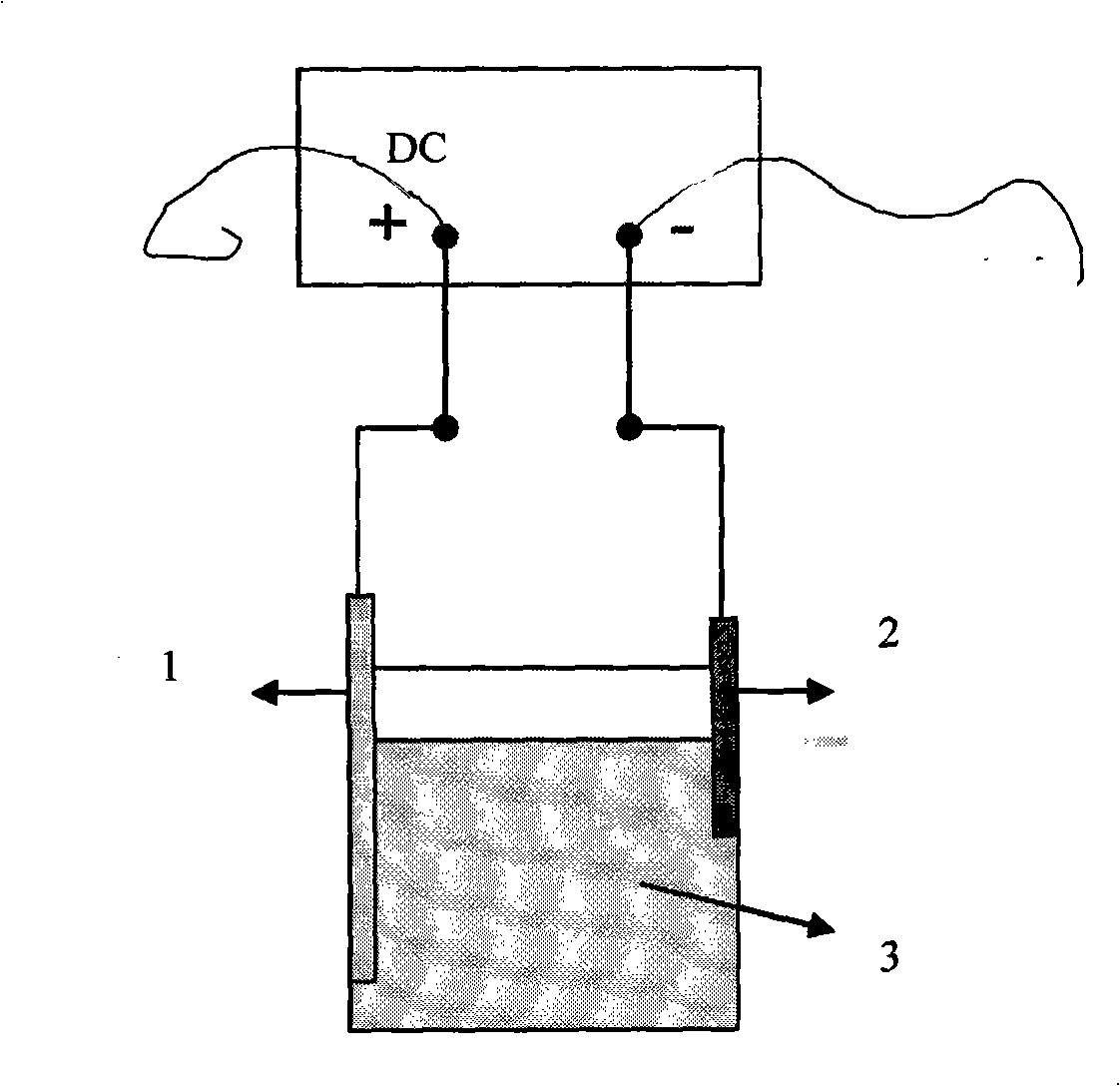

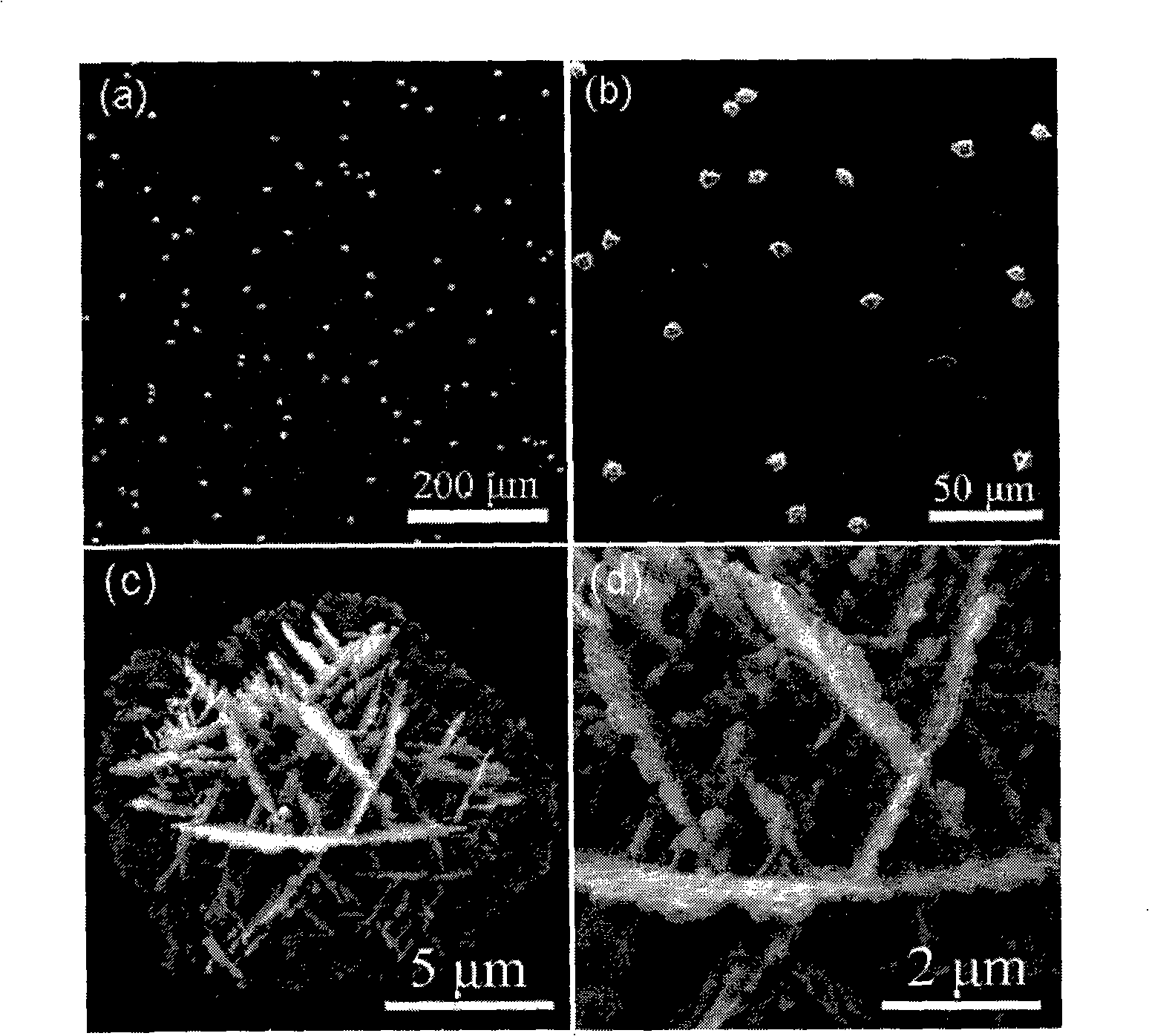

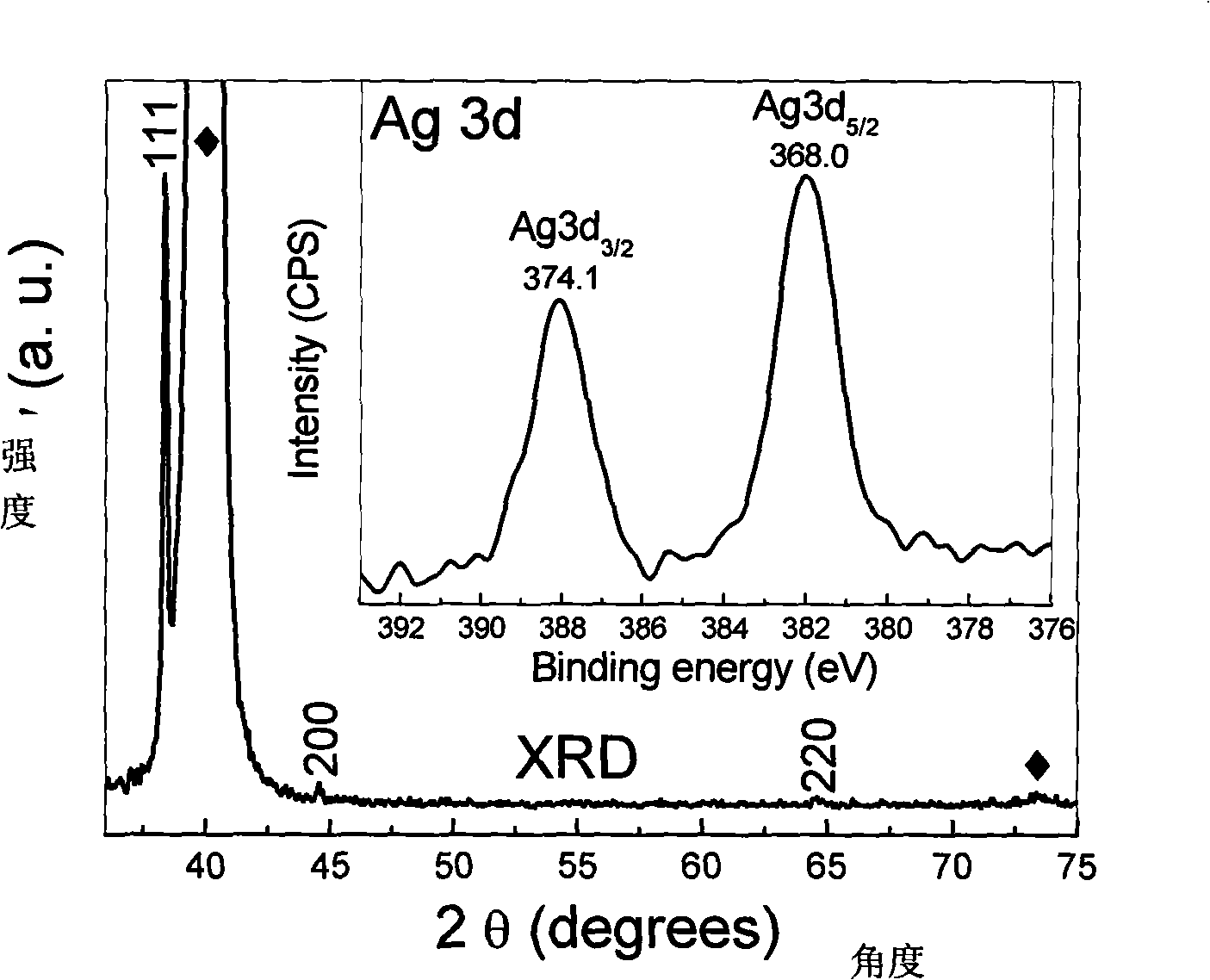

Synthetic method of load type floriform silver nanostructured material

The invention discloses a synthesizing method of a loading flower-shaped nano silver structural material, which is characterized in that a silver plate with high purity is taken as an anode, a platinum film electrode is taken as a cathode, a silver nitrate solution with the concentration of 0.003 to 0.01 mol / L is taken as an electrolytic solution, and the volume of the electrolytic solution is 20 to 100 mL; the range of constant voltage is adjusted to be 50 to 200 mV during electrolytic deposition, and the time of the electrolytic deposition lasts for 2 to 15 minutes; the cathode of the loading nano silver structural material is repeatedly rinsed by deionized water after the reaction, and then dried in nitrogen. The synthesizing method of the loading flower-shaped nano silver structural material realizes the growth anisotropy of crystal, leads the size and the microstructure of the nano metallic structure to be controllable, does not need any addition agent and electrode surface modification, and achieves simple control of appropriate voltage and concentration of the electrolytic solution; the synthesizing method is ultra-simple, and has convenient operation, easy-separated products and high purity and well industrial application prospect.

Owner:NANJING UNIV

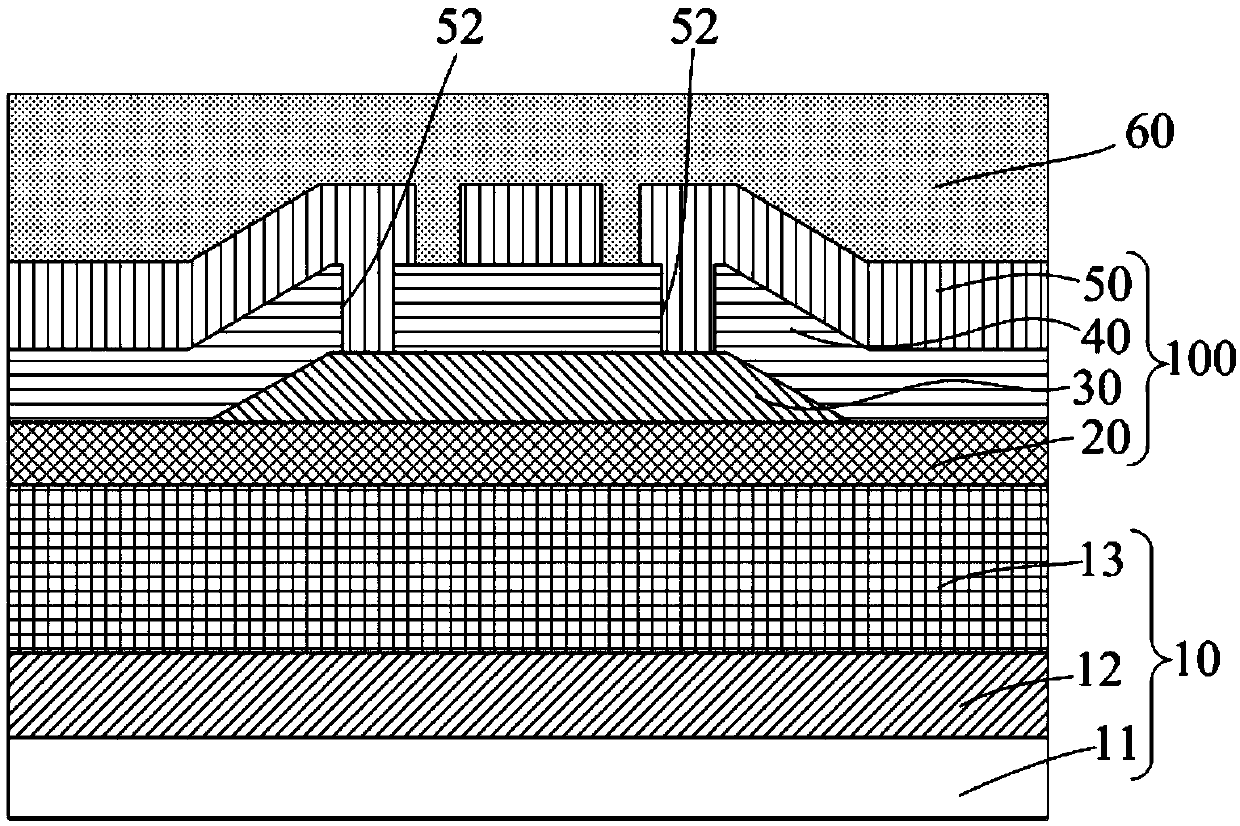

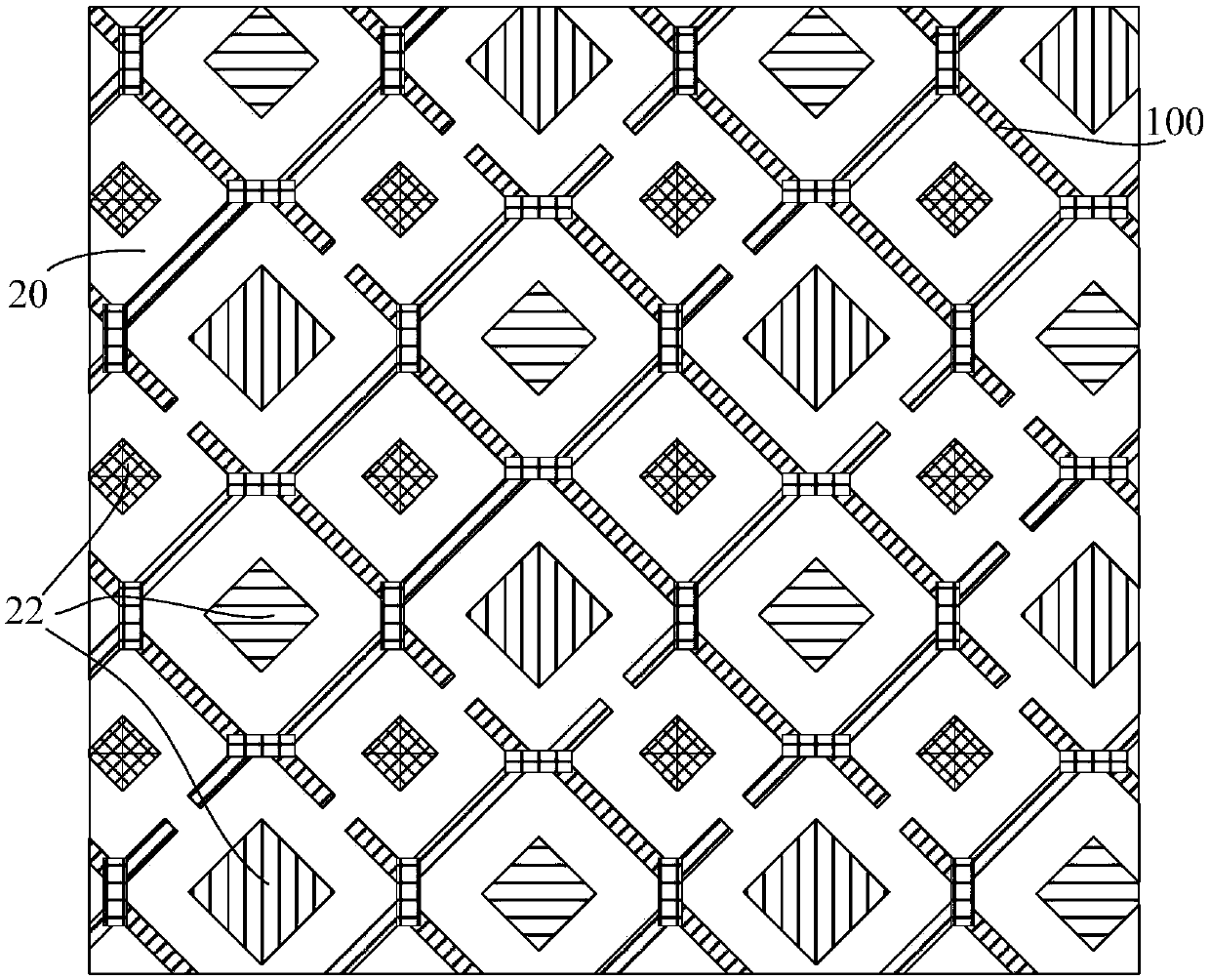

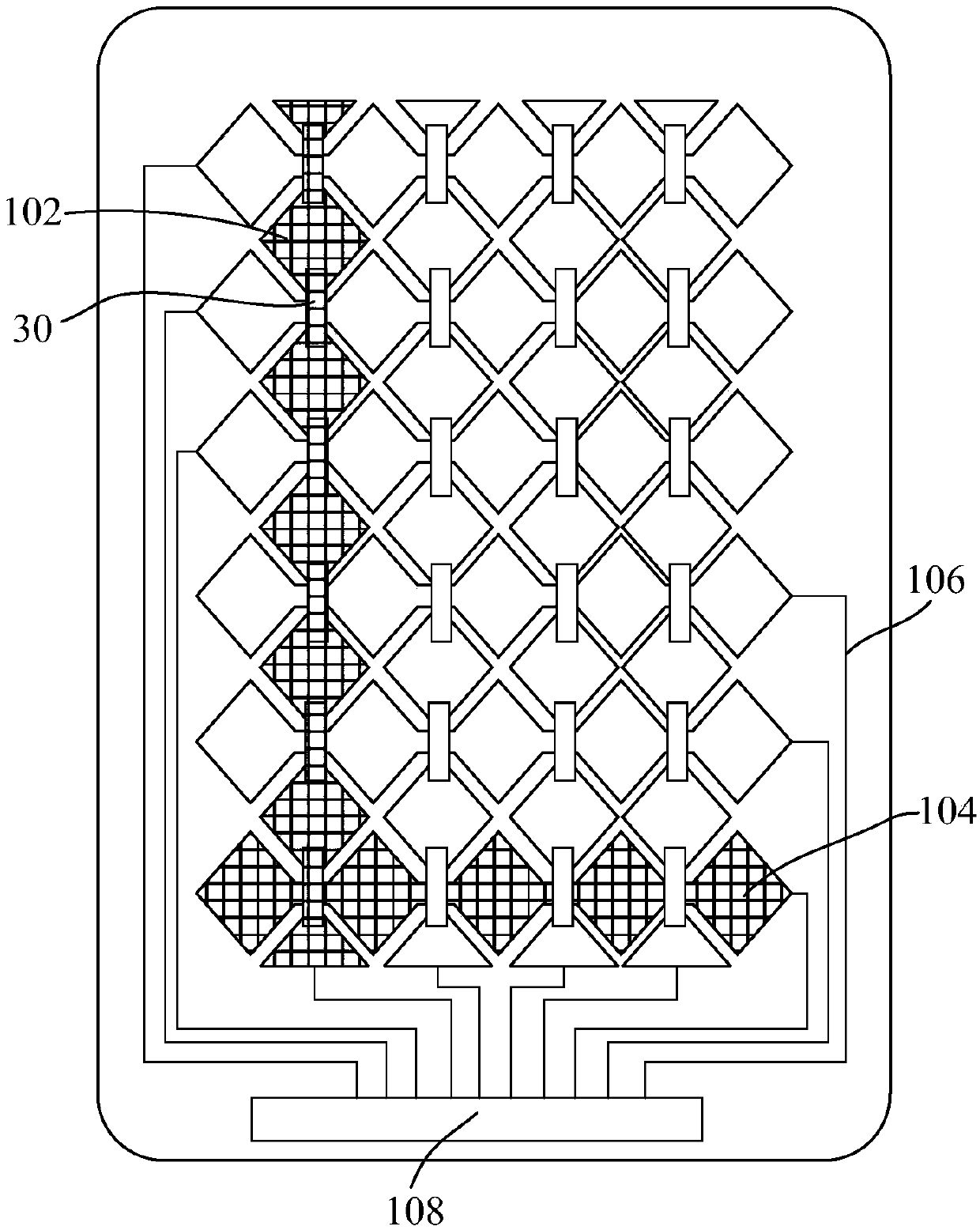

Touch display panel, manufacturing method thereof and touch display device

ActiveCN109669572AReduce distractionsReduce overlap areaInput/output processes for data processingDisplay deviceEngineering

The invention provides a touch display panel, a manufacturing method thereof and a touch display device. The touch display panel comprises a flexible substrate and a metal grid touch electrode layer.The metal grid touch electrode layer is arranged on the flexible substrate, and the metal grid touch electrode layer is provided with a plurality of driving electrodes and a plurality of sensing electrodes. A plurality of floating electrodes are arranged in each driving electrode and each sensing electrode at intervals, the floating electrodes are insulated from the driving electrodes and the sensing electrodes, and the floating electrodes, the driving electrodes and the sensing electrodes are arranged on the same layer. Therefore, the interference signal of the OLED layer is shielded and dispersed, so that the touch sensitivity is improved.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Non-ionic compound gas hydrate anti-agglomerant

InactiveCN103865505AImprove adsorption capacityAvoid disadvantagesPipeline systemsDrilling compositionAlcoholAlkyl polyglycoside

The invention provides a non-ionic compound gas hydrate anti-agglomerant which consists of an alkyl polyglycoside non-ionic surfactant and a polyhydric alcohol non-ionic surfactant in a weight ratio of (0.01-100):1. The gas hydrate anti-agglomerant is used for anti-agglomerating treatment of an oil-gas-water three phase mixed conveying system, wherein the volume of water accounts for less than or equal to 60% of the total volume of oil and water. The invention further provides an anti-agglomerating method adopting the non-ionic compound gas hydrate anti-agglomerant. The method comprises the step of adding the non-ionic compound gas hydrate anti-agglomerant into the oil-gas-water three phase mixed conveying system. The non-ionic compound gas hydrate anti-agglomerant provided by the invention is suitable for oil-gas-water three phase co-existing systems and is less in use level, good in biodegradability, economic and environmental friendly and remarkable in anti-agglomerating effect.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

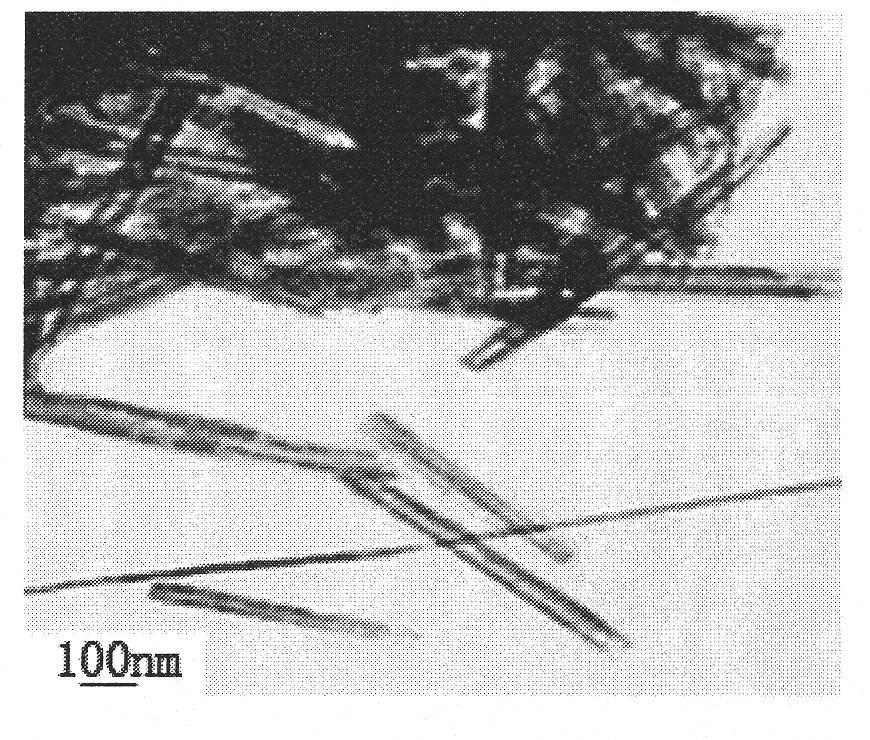

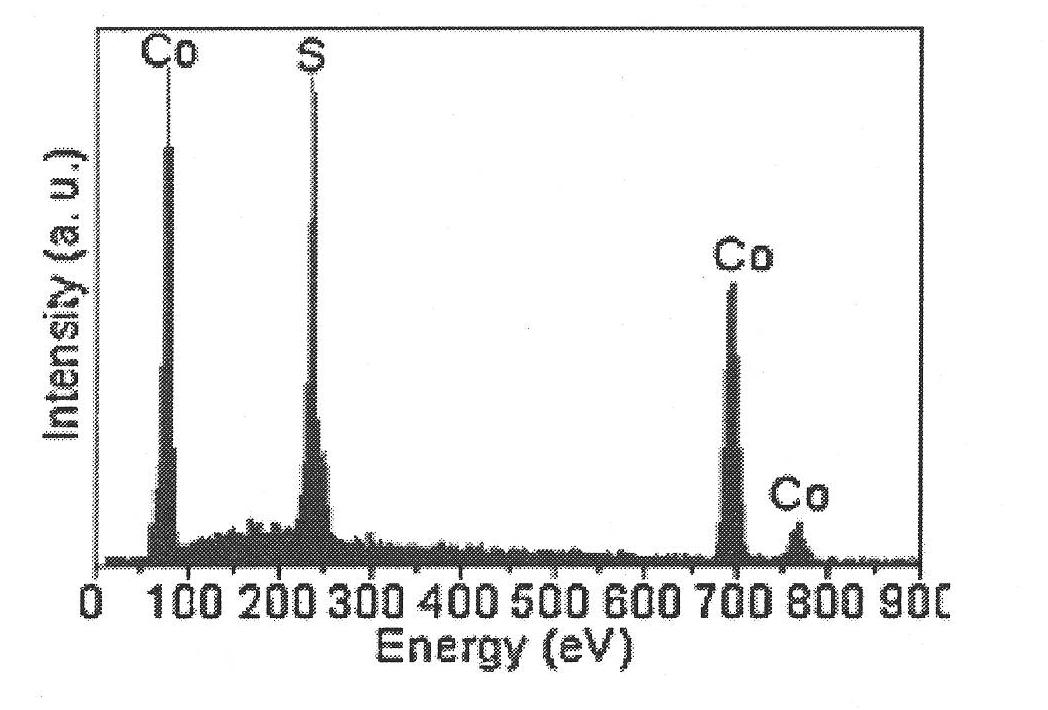

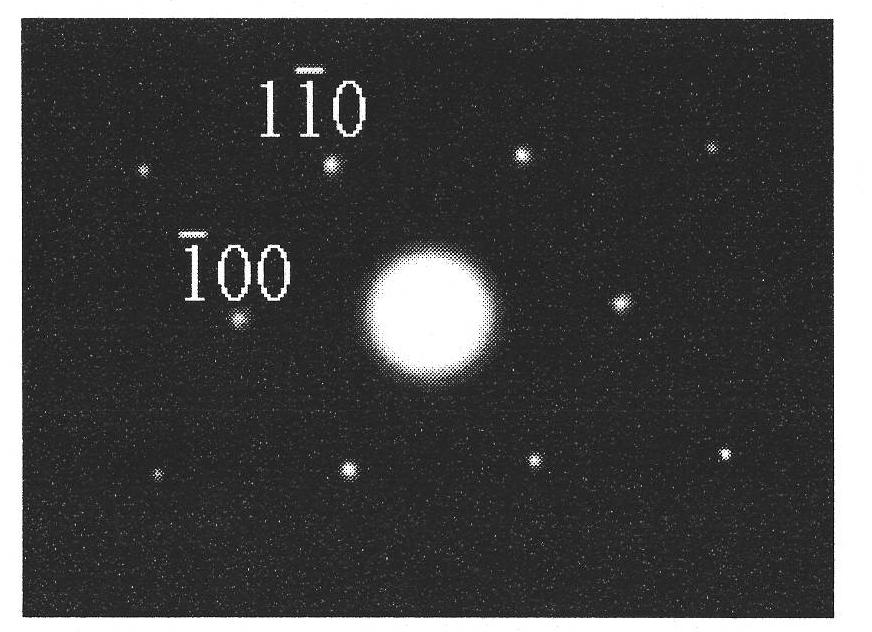

Preparation method of cobalt sulfide nanotubes or nanowires based on porous anodic aluminum oxide template

The invention discloses a preparation method of cobalt sulfide nanotubes or nanowires based on a porous anodic aluminum oxide template, which comprises the following steps: producing the porous aluminum oxide template; filling cobalt chloride and thiourea solution into holes of the aluminum oxide template; adopting the step-by-step heating method to prepare the cobalt sulfide nanotubes or the nanowires; and placing the aluminum oxide template in strong base solution for etching off the aluminum oxide template, and preparing the cobalt sulfide nanotubes or the nanowires with the controllable size, wherein the nanowires or the nanotubes are placed in the holes of the aluminum oxide template. The cobalt sulfide nanotubes or the nanowires have cheap raw materials, simple operation, short synthesis time and low temperature. The size of the cobalt sulfide nanotubes or the nanowires and the size of the holes of the template can be controlled and adjusted. The outer diameter of the holes of the cobalt sulfide nanotubes is 60-150nm, and the inner diameter is 20-80nm. The diameter of the nanowires is about 60-150nm. The invention relates to the method for preparing the cobalt sulfide nanotubes or the nanowires and an array thereof, which is relatively economical.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY AND SCIENCE

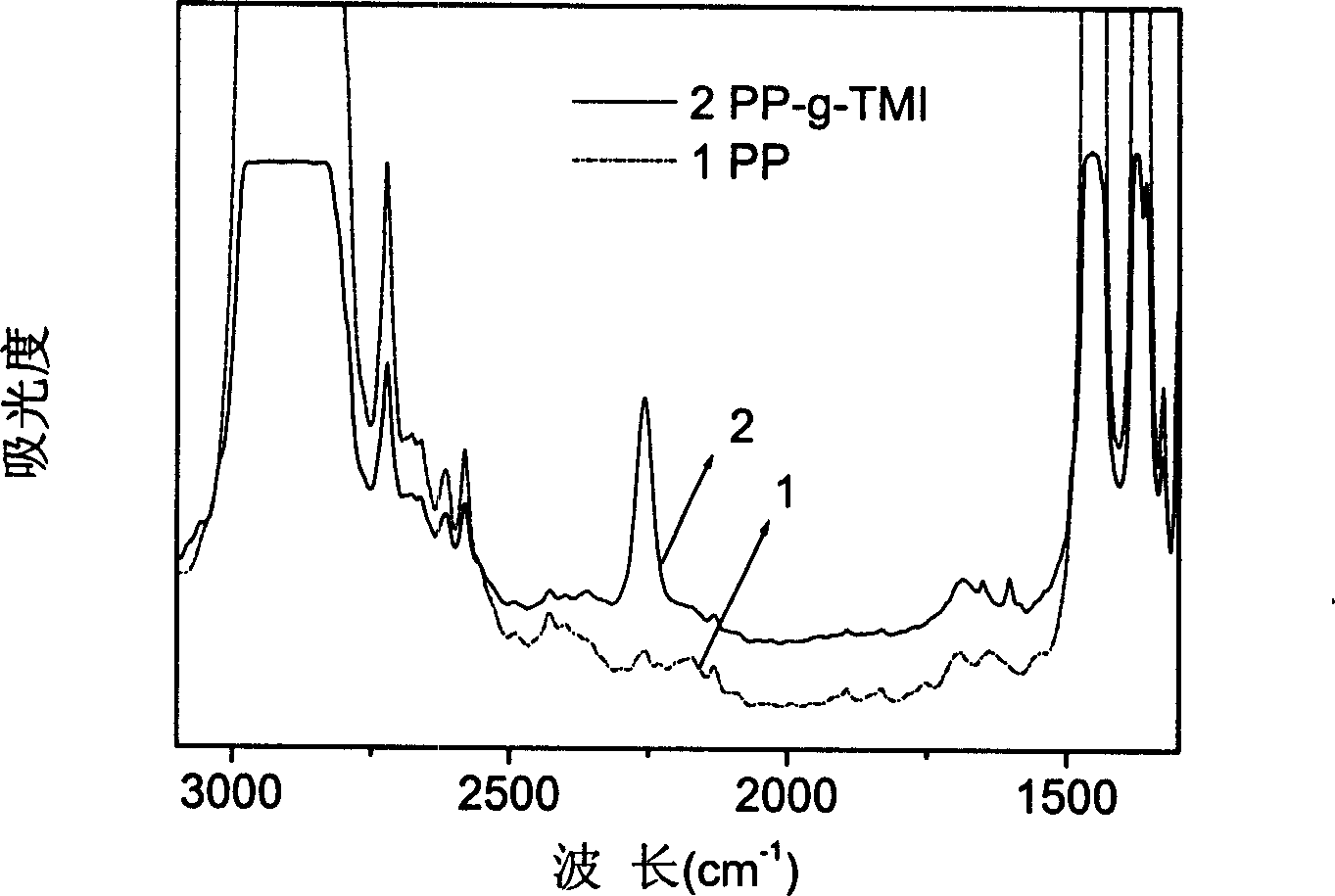

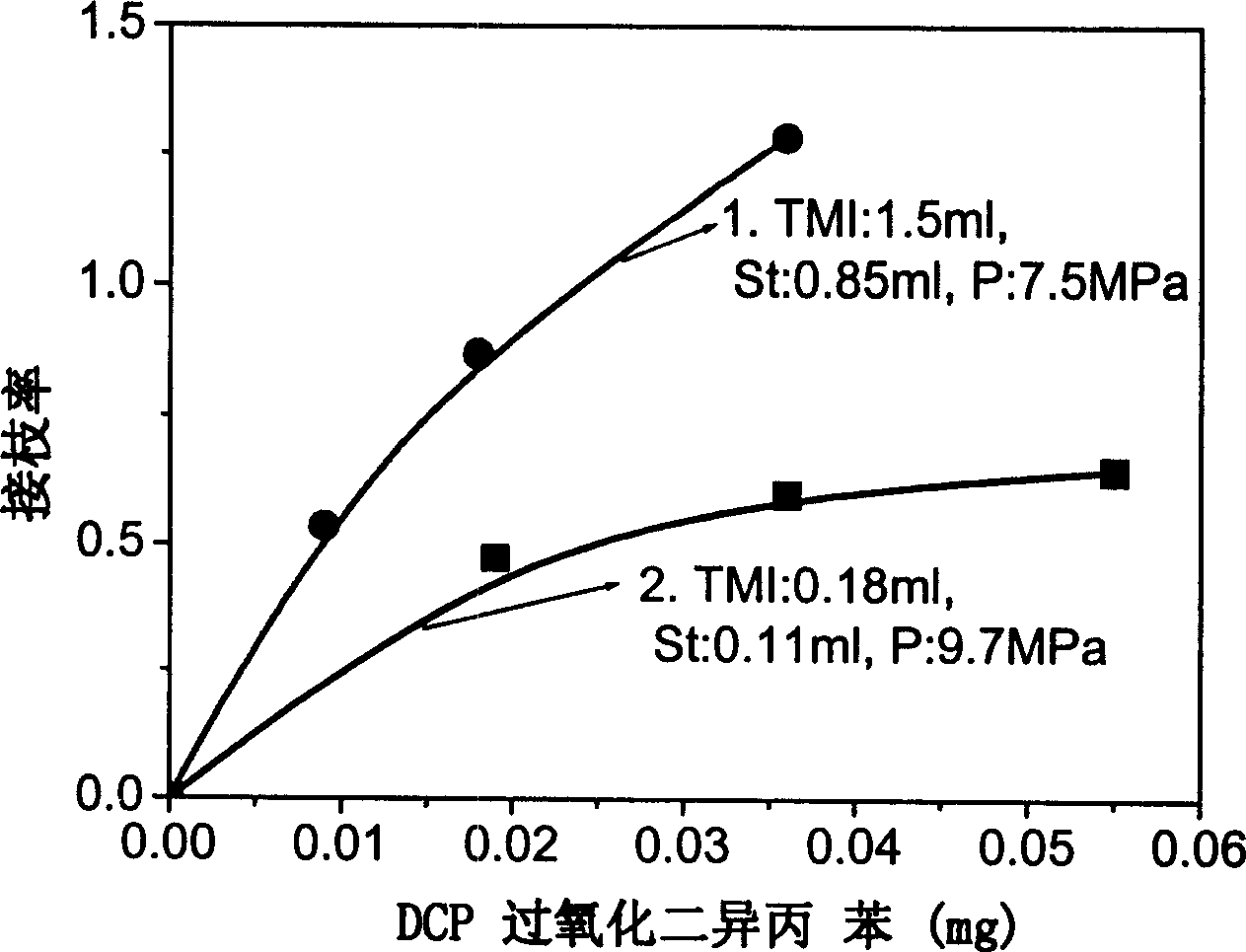

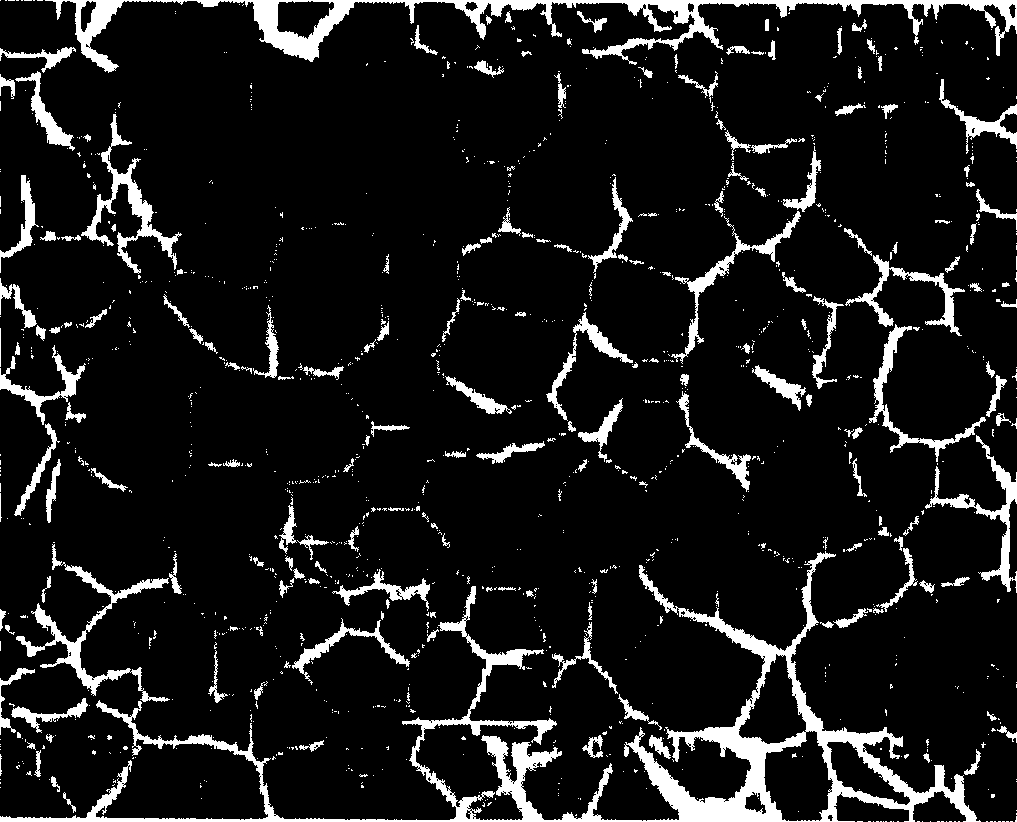

In situs polymerization and compatibilization blending method with microporous foaming polymer as matrix

An in situ polymerization and compatibilization blending method with micro-porous foamed polymer as matrix is carried out by modifying for the chosen polymer matrix, grafting active polymerized group on polymer by supercritical technology, taking it as compatilizer or active group for initiating reaction, supercritical foaming for modified polymer, cooperating to permeate the monomer of another polymer, and in situ polymerizing to obtain the final product. The size of granule is controlled by size of foaming aperture. It has excellent bond with other materials and effective control for dispersion-phase particle size.

Owner:CHINA PETROLEUM & CHEM CORP +1

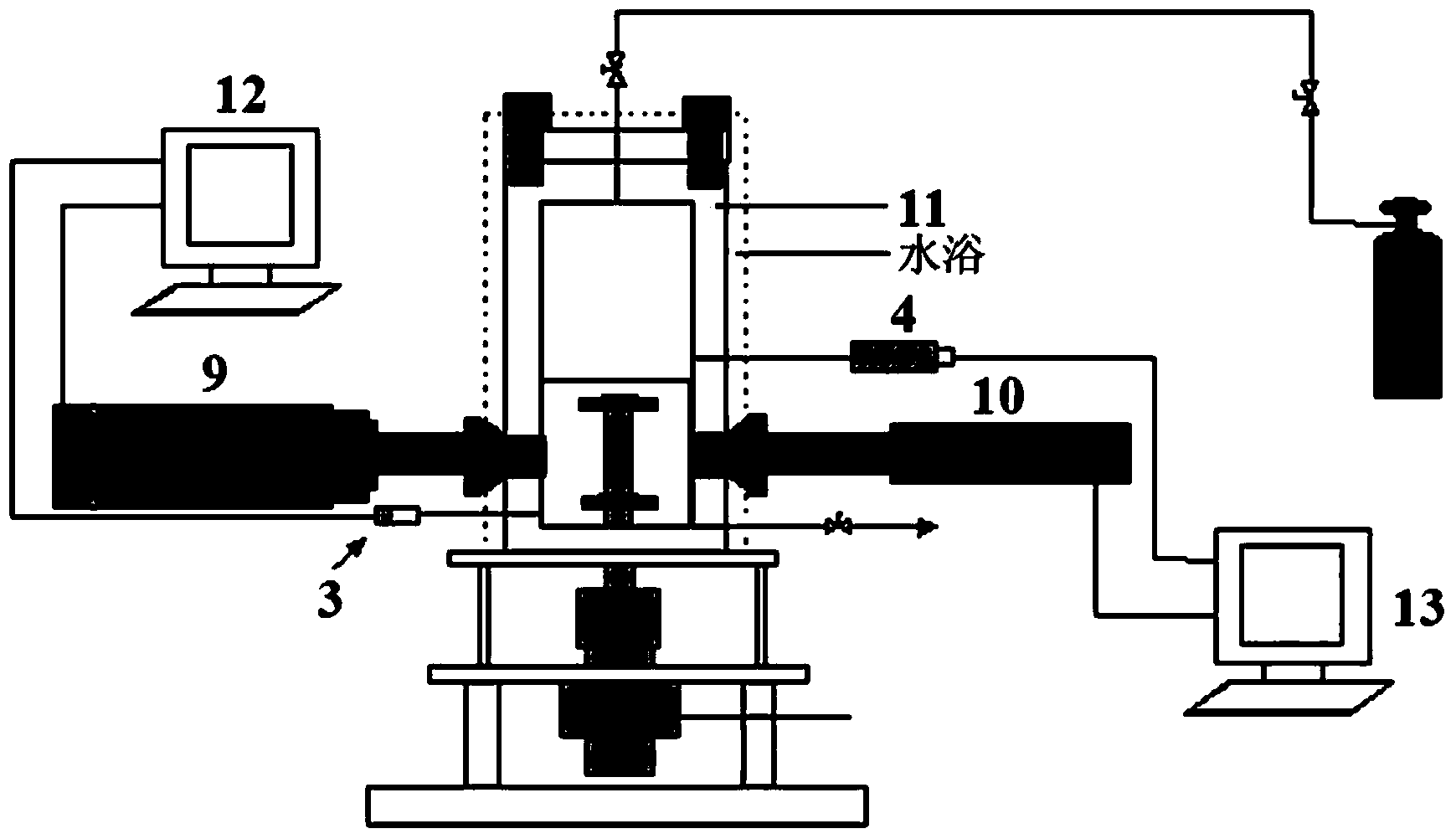

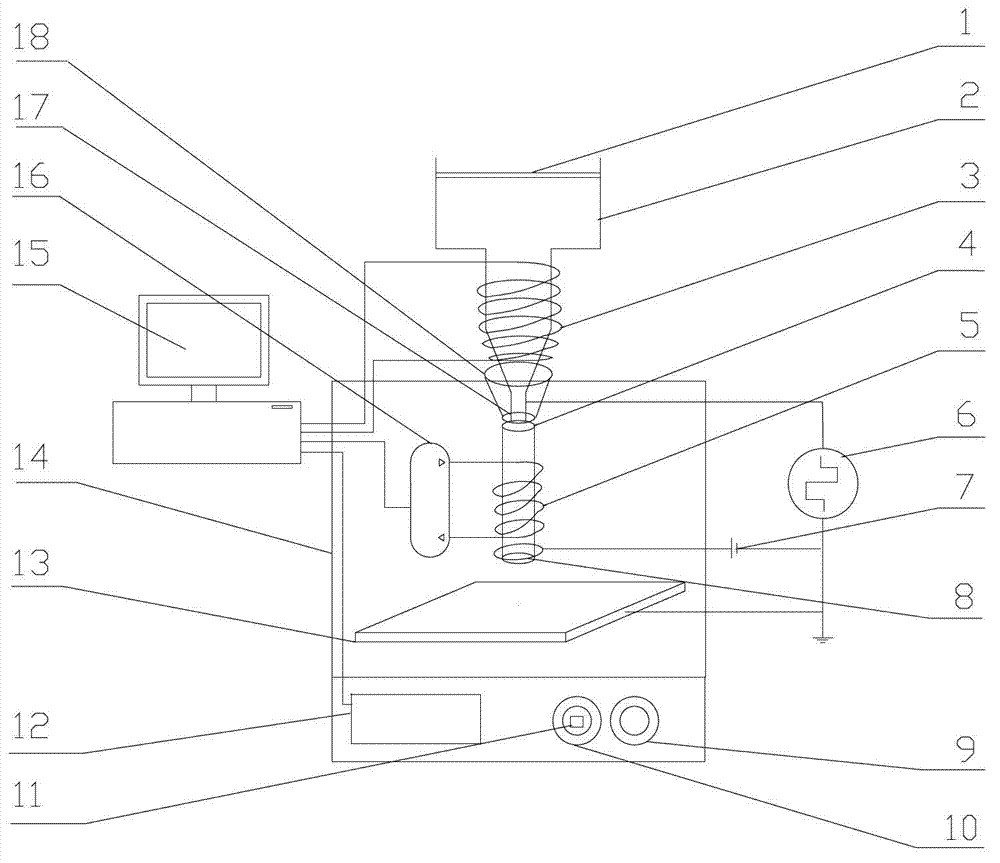

Electro-hydraulic jet printing device of metal micro-nanometer structure

ActiveCN102922891AAchieving Vacuum Environment EjectionIncrease temperatureDuplicating/marking methodsPattern printingTemperature controlElectro hydraulic

The invention discloses an electro-hydraulic jet printing device of a metal micro-nanometer structure and relates to an electrostatic spraying device. The electro-hydraulic jet printing device of the metal micro-nanometer structure, provided by the invention, is good in continuity and stability and is capable of realizing precise jet printing manufacturing of the metal micro-nanometer structure. The electro-hydraulic jet printing device is provided with a pressure controller, a feeding groove, a heater, an insulating sleeve, a temperature-controlled condenser pipe, a high-voltage pulse power supply, an auxiliary power supply, a restraining electrode ring, an air exhausting port, an air inflow port, a pressure valve, a pressure gage, a collection plate, a protection cover, a computer, a temperature controller, a spraying nozzle and an annular air vent. According to the electro-hydraulic jet printing device of the metal micro-nanometer structure, the advantages of alternating current electro-hydraulic jet printing and surrounding atmosphere gas focusing are combined, and the purposes of good continuity, good continuity and precise jet printing manufacturing of metal micro-nanometer structure can be achieved.

Owner:XIAMEN UNIV

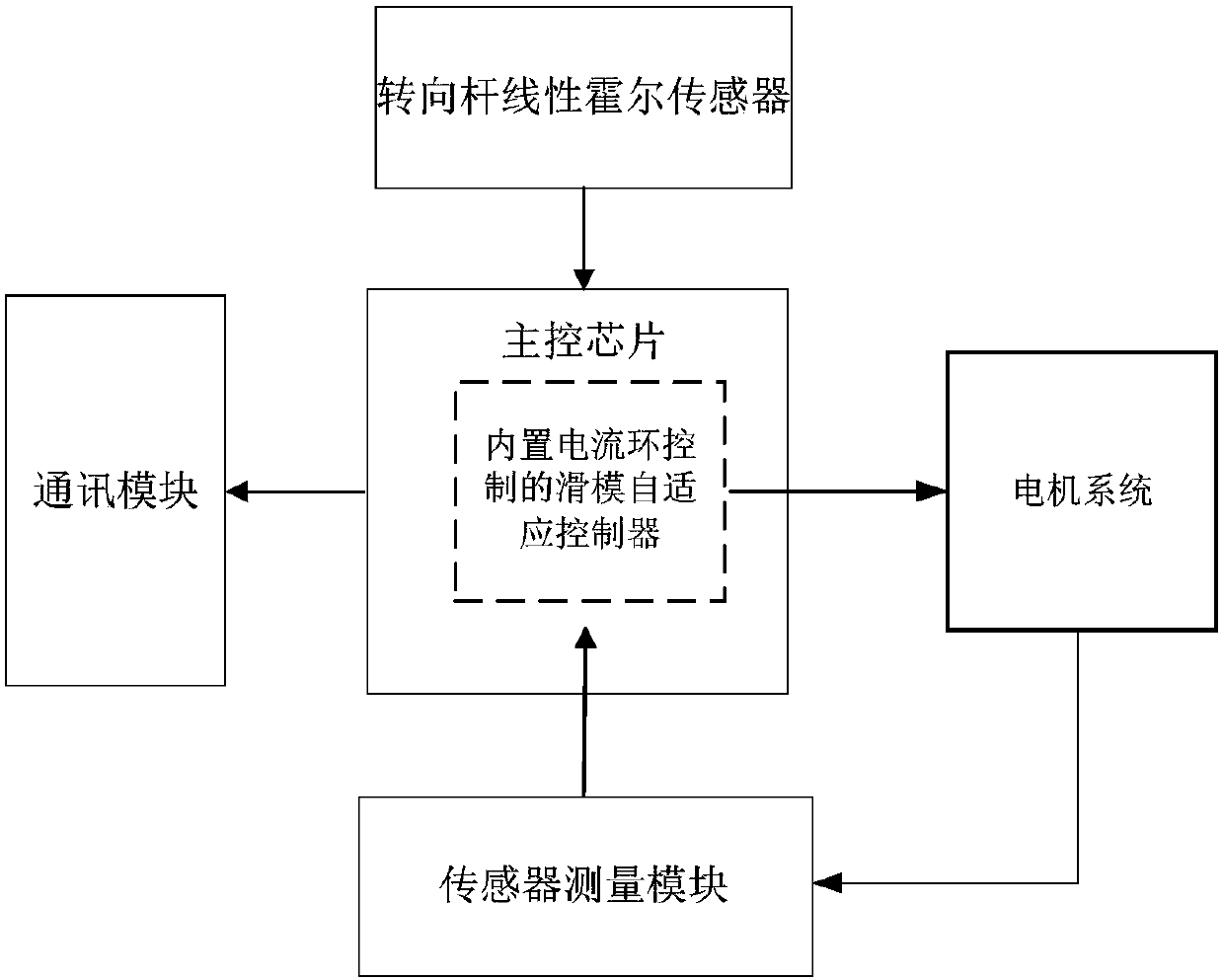

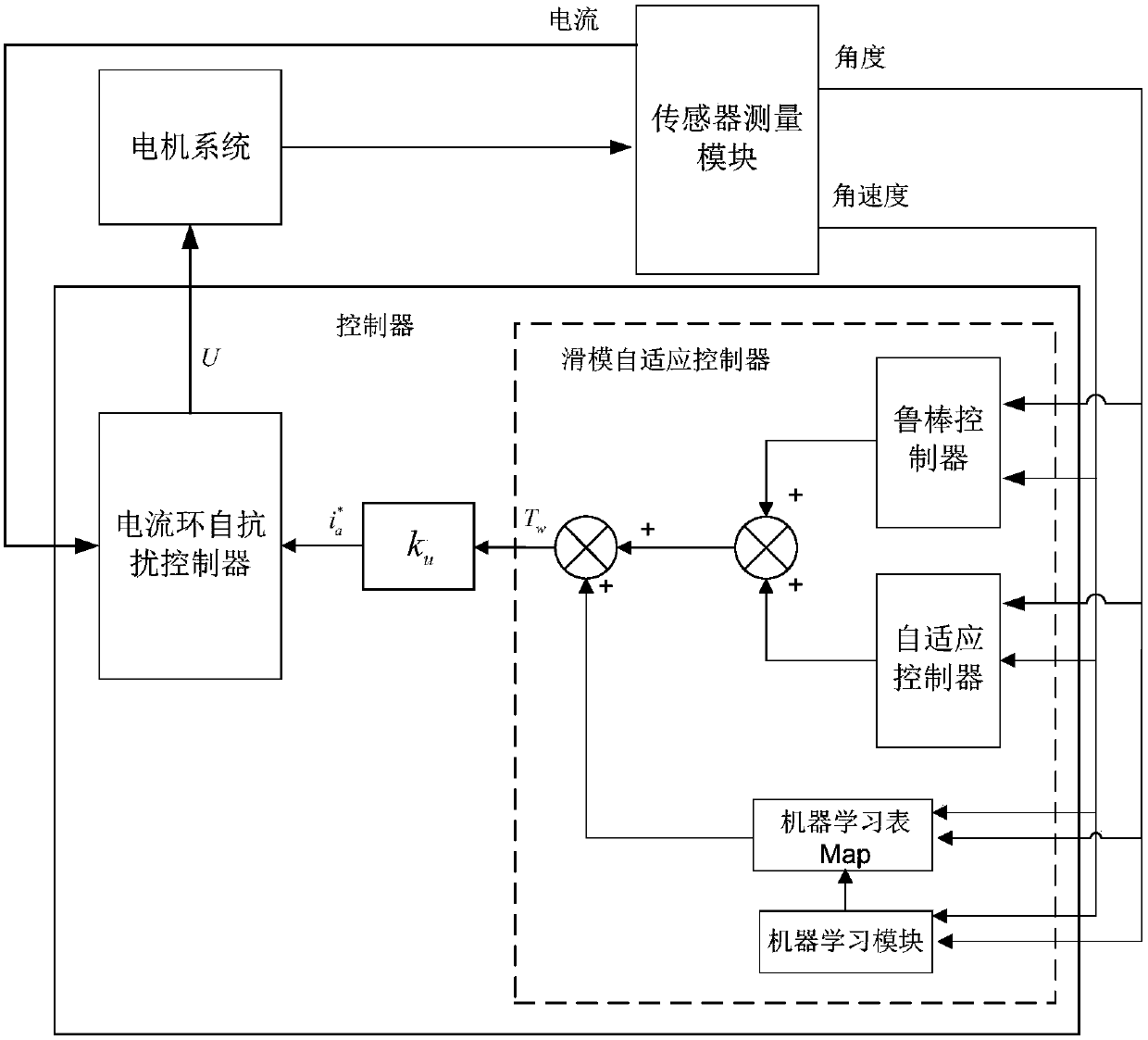

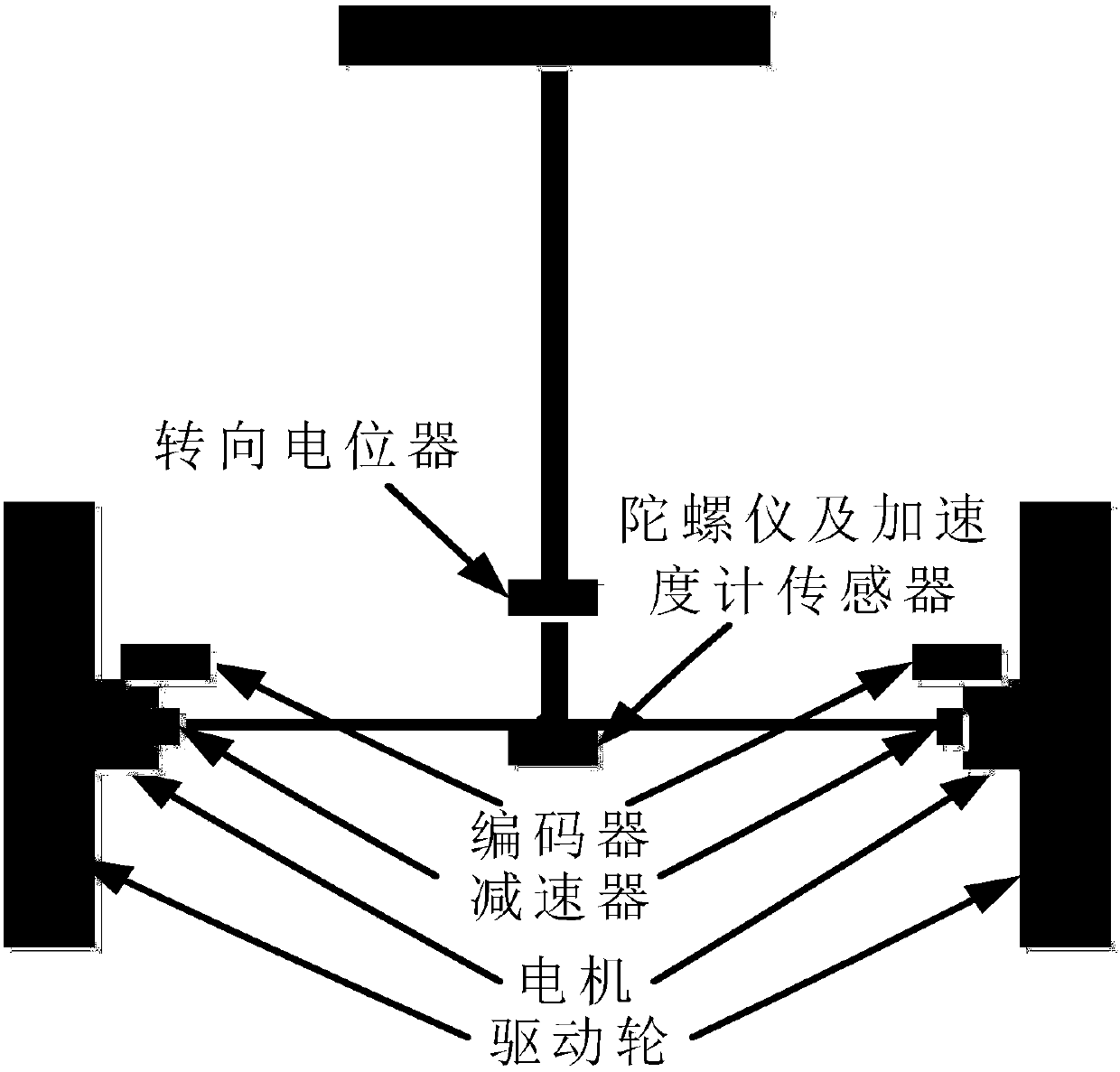

Sliding mode adaptive controller with built-in brushless DC motor current loop control for two-wheeled self-balancing robot

ActiveCN106452206AReduce the impactImprove performanceProgramme-controlled manipulatorCurrent controllersBrushless motorsDriving current

The invention discloses a sliding mode adaptive controller with built-in brushless DC motor current loop control for a two-wheeled self-balancing robot. The controller at least comprises a sliding mode adaptive controller and a current loop active-disturbance-rejection controller, wherein the sliding mode adaptive controller is used for controlling an output motor torque T<w> according to an angle parameter Theta and an angular speed Theta-bar and converting the motor torque T<w> to a current i<*>, and the current loop active-disturbance-rejection controller is used for controlling an output voltage U<*><a0>(t) to drive a motor system to move according to the current i<*> and a motor current i detected by a sensor measurement module. With the adoption of the technical scheme disclosed by the invention, current loop control is added into the controller, thus, the size of the driving current is effectively controlled, a large current cannot be generated, the driving of a brushless motor is protected, the lifetime of a balance car is greatly prolonged, and the application safety of the balance car is greatly improved.

Owner:HANGZHOU DIANZI UNIV

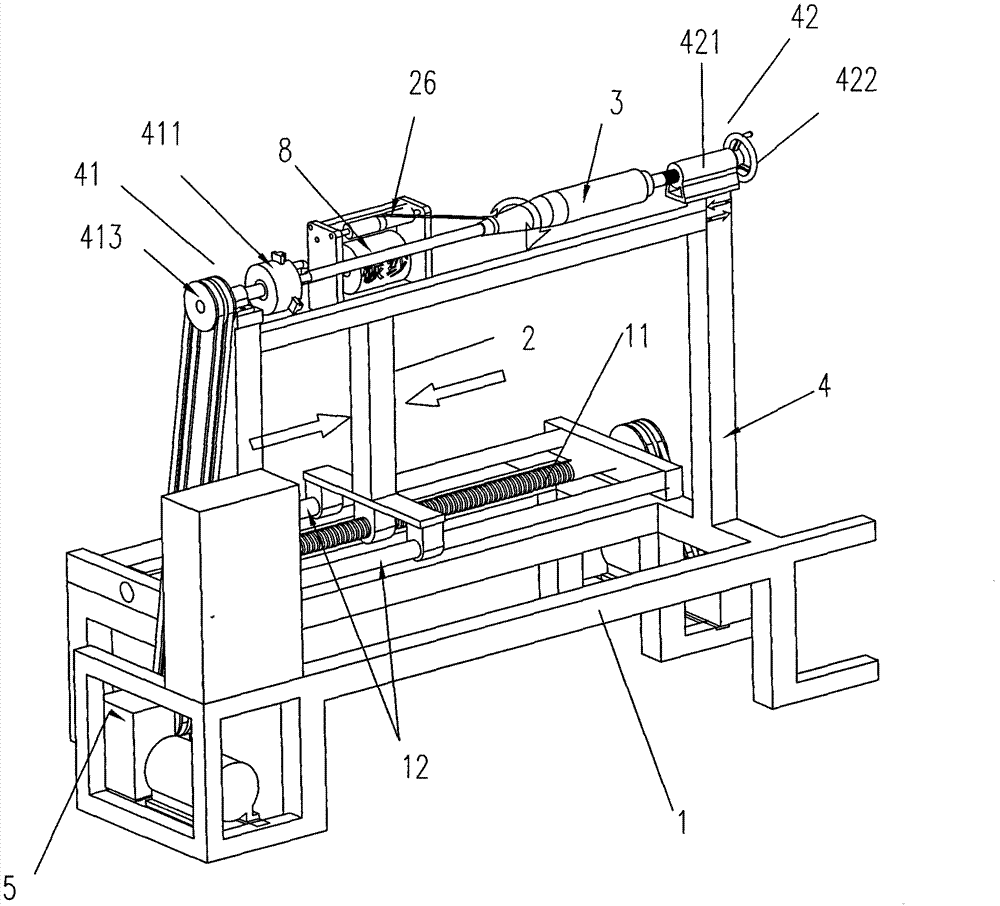

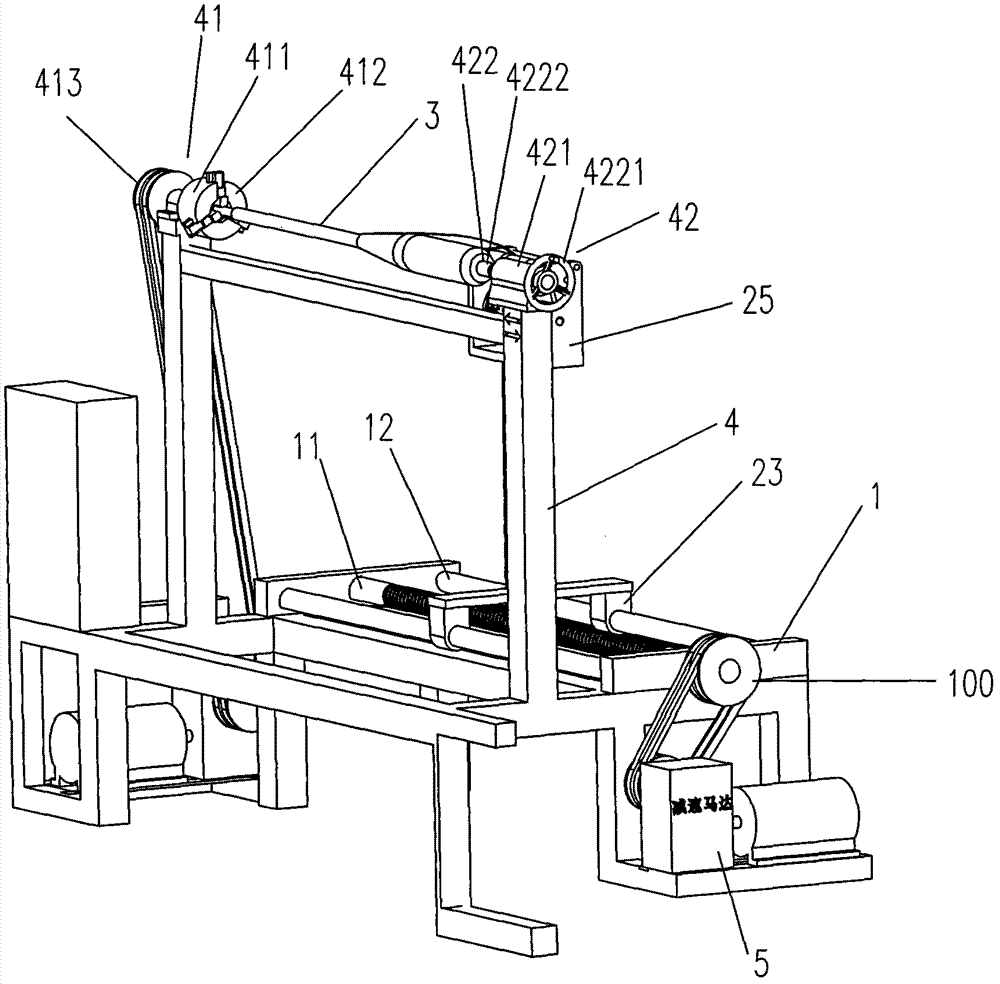

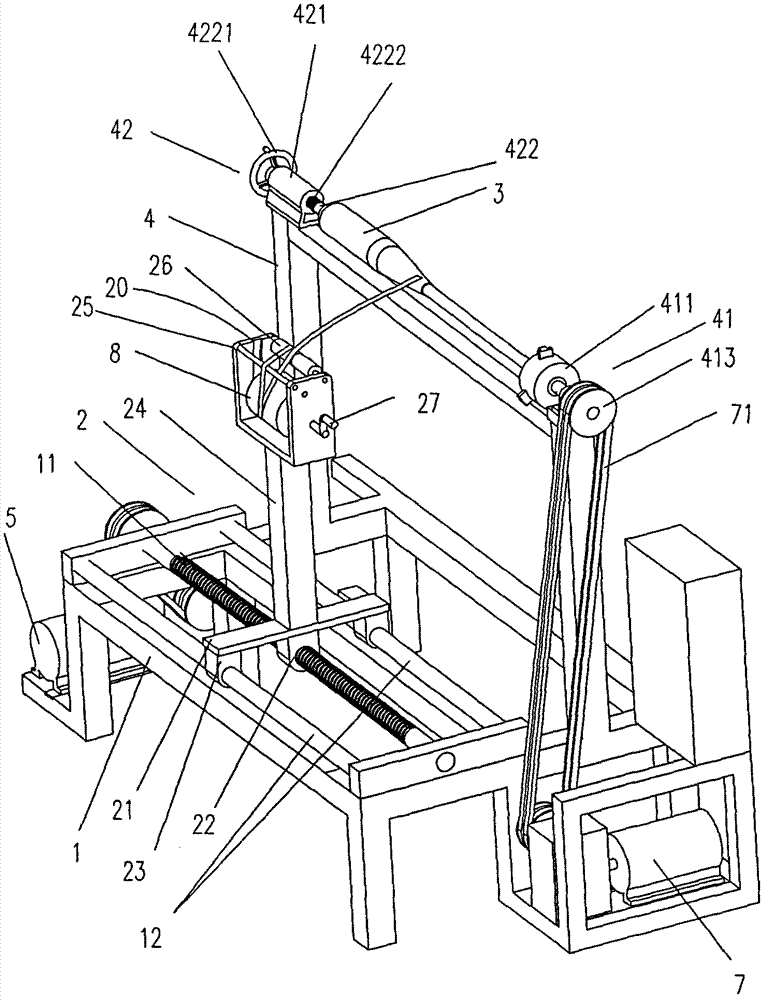

Yarn twining method and yarn twining device for carbon fiber baseball

The invention discloses a yarn twining method and a yarn twining device for a carbon fiber baseball. The yarn twining device comprises a workbench provided with a screw rod, a coiled yarn stand and a support frame for clamping and fixing a baseball core shaft; the coiled yarn stand and the support frame are both arranged on the workbench; as the baseball core shaft is fixed on the yarn twining device, coiled yarn moves left and right along the core shaft for continuous twining yarn so as to reduce labor power and time and improve production efficiency; a chuck is driven to rotate by a motor, rotate speed is uniform and stable, and force and gaps for twining the yarn are uniform, so that a defect that the yarn is not twined flat in the prior art is overcome, accordingly rigidity and strength of finished product can be better ensured, not only is rejection rate reduced, a carbon fiber layer of the product is flat, wall thickness is uniform and the product does not deform, but also product size can be effectively controlled.

Owner:王景山

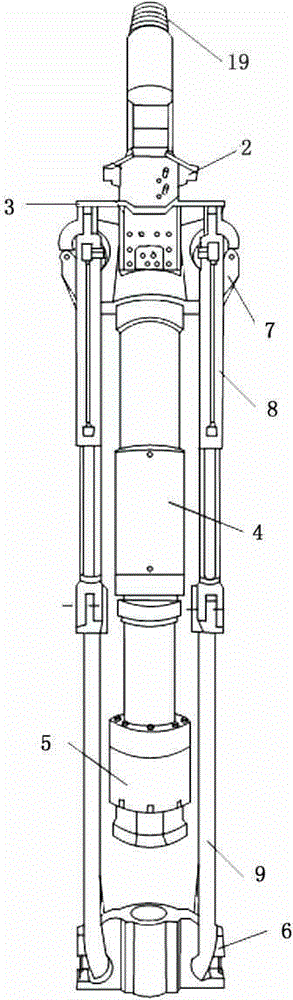

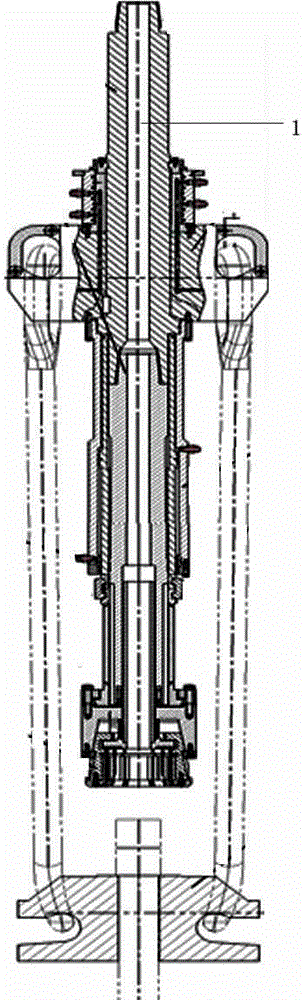

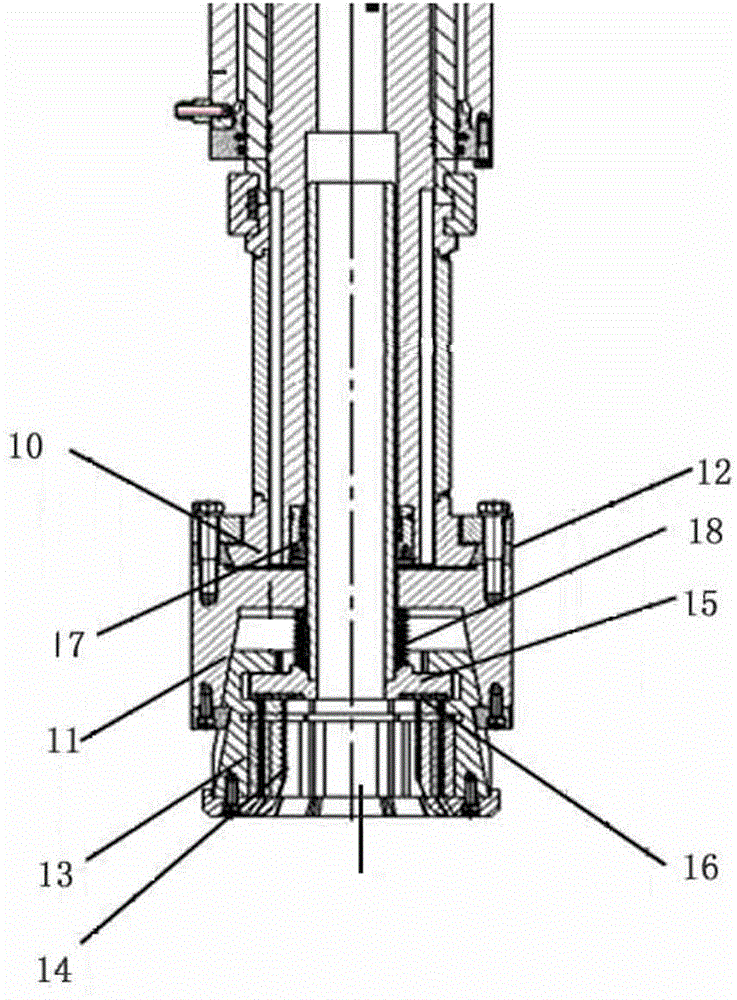

Top drive drilling device coupling clamping type sleeve lowering device and application method thereof

ActiveCN104131781AEffective size controlImplement the rotation functionDrilling rodsDrilling casingsHydraulic cylinderTop drive

The invention relates to a top drive drilling device coupling clamping type sleeve lowering device and an application method of the top drive drilling device coupling clamping type sleeve lowering device. The top drive drilling device coupling clamping type sleeve lowering device comprises a top drive hydraulic system. A central pipe is arranged below the top drive hydraulic system. A rotating sealing connecting plate, a suspended supporting base, a main hydraulic cylinder and a pincers head body are sequentially arranged on the central pipe from top to bottom. A sleeve hanging clamp is arranged below the pincers head body. A suspended body is arranged at the lower end of the suspended supporting base. The lower end face of the suspended body is fixedly connected with a hanging ring. The lower end of the hanging ring is connected with the sleeve hanging clamp. A hanging ring inclined hydraulic cylinder is arranged on the surface of the hanging ring. The central pipe is connected with the top drive device, the hydraulic cylinder provides main power so as to drive the central pipe to drive the pincers head body, the pincers head body firmly grasps a sleeve through coordination of two wedge-shaped flange inclined faces, the sleeve can be appropriately buckled in a rotating mode and pressed downwards in the sleeve lowering process while the sleeve is prevented from falling, and therefore the drilling tool jamming phenomenon is prevented, the top drive drilling device coupling clamping type sleeve lowering device is safe and reliable, work efficiency is improved, and the labor amount of workers is decreased.

Owner:ANSHAN ZHENGFA SURFACE TECHN & ENG CO LTD

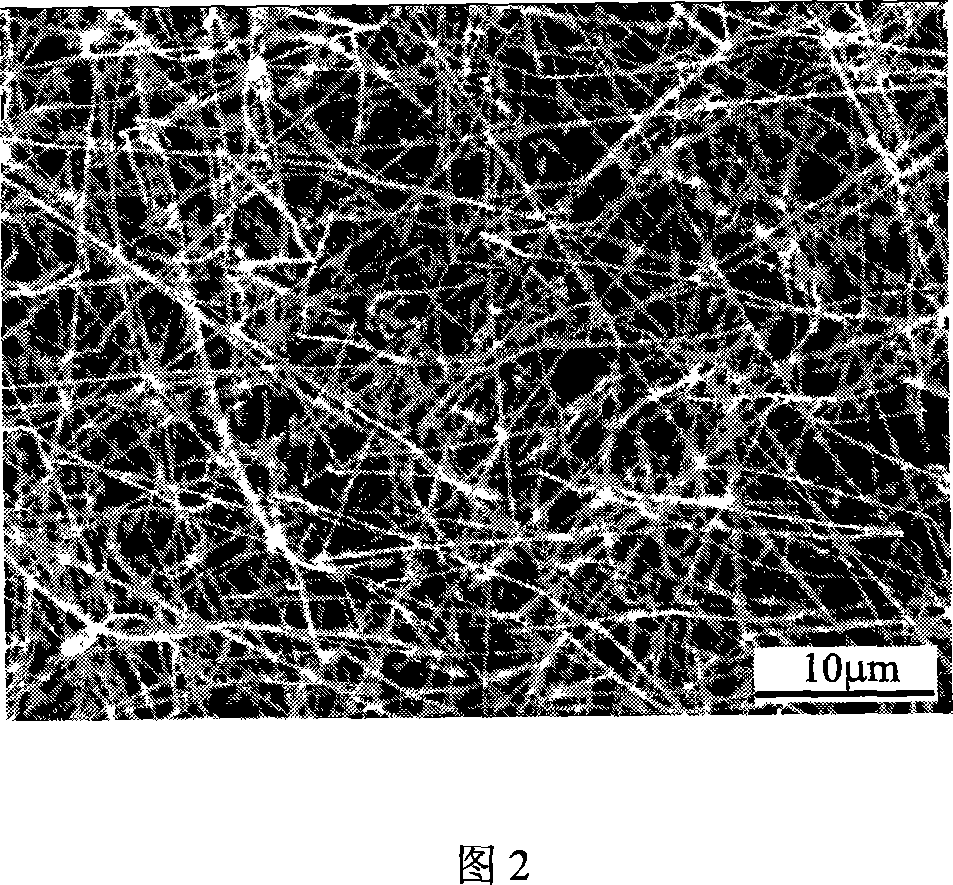

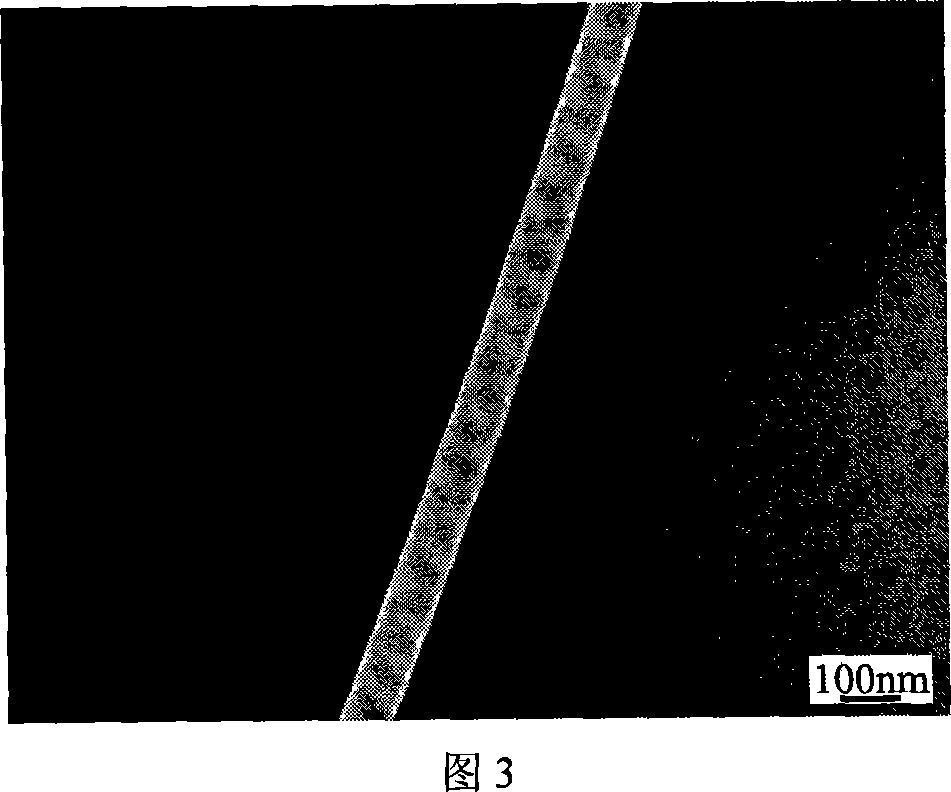

Method for preparing nano copper/carbon nano tube composite powder by liquid phase method

InactiveCN102198510APrevent oxidationReaction does not affectMaterial nanotechnologyFiltrationHydrazine compound

The invention discloses a method for preparing a nano copper / carbon nano tube composite powder by a liquid phase method, and relates to a preparation method of nano copper / carbon nano tube composite powder. The method solves the problems that the conventional preparation method of the nano copper / carbon nano tube composite powder is complex and high in cost and the nano copper particles are difficultly controlled. The method comprises the following steps of: adding acidified carbon nano tube and polyvinyl pyrrolidone (PVP) into copper sulfate solution, regulating pH, then adding hydrazine hydrate to obtain mixed solution, reacting the mixed solution at the temperature of between 60 and 80 DEG C, cooling to room temperature, performing suction-filtration to obtain powder, and drying the powder in vacuum at the temperature of 50 DEG C to obtain the composite powder. The nano copper in the prepared composite powder is uniformly distributed on the surface of the carbon nano tube, and the nano copper and the carbon nano tube form a chemical bond. Under the alkali condition, the hydrazine hydrate is used as a reducing agent, and a large amount of nitrogen is generated at the same time of reducing copper ions, so that oxidation of the nano copper can be effectively prevented; and the size of the nano copper particles can be controlled in a range of 40 to 50 nanometers by adding the PVP. The preparation method is simple in process and low in cost, and the nano copper particles are easily controlled.

Owner:HEILONGJIANG UNIV

Method for controlling detonator zone during explosion cladding of multilayer thick zirconium/titanium/steel composite plate

ActiveCN103639585AEffective size controlSolve the big problemWelding/soldering/cutting articlesMetal working apparatusDetonatorTitanium

The invention discloses a method for controlling a detonator zone during the explosion cladding of a multilayer thick zirconium / titanium / steel composite plate. The method comprises the following steps: (1), welding a steel block to one side of a titanium / steel composite plate, and welding a titanium block to one side of a multilayer zirconium plate; (2), assembling the titanium / steel composite plate with the multilayer zirconium plate, ensuring that the titanium block is aligned with the steel block, then arranging an explosive on the surface of the multilayer zirconium plate, and mounting a satchel charge on the titanium block for explosion cladding so as to obtain the multilayer thick zirconium / titanium / steel composite plate. The method is easy in operation and convenient to implement, can effectively control the size of the detonator zone during cladding of the multilayer thick zirconium / titanium / steel composite plate, and thus solve the problem that a detonator zone is overlarge when a detonator is directly mounted on the surface of the multilayer zirconium plate. Besides, the detonator zone can be removed completely during the subsequent cutting of the multilayer thick zirconium / titanium / steel composite plate, and the size and the corrosion resisting property of the finished zirconium steel composite plate cannot be affected. The multilayer thick zirconium / titanium / steel composite plate prepared through the method can completely meet the requirements of subsequent large equipment.

Owner:XIAN TIANLI CLAD METAL MATERIALS

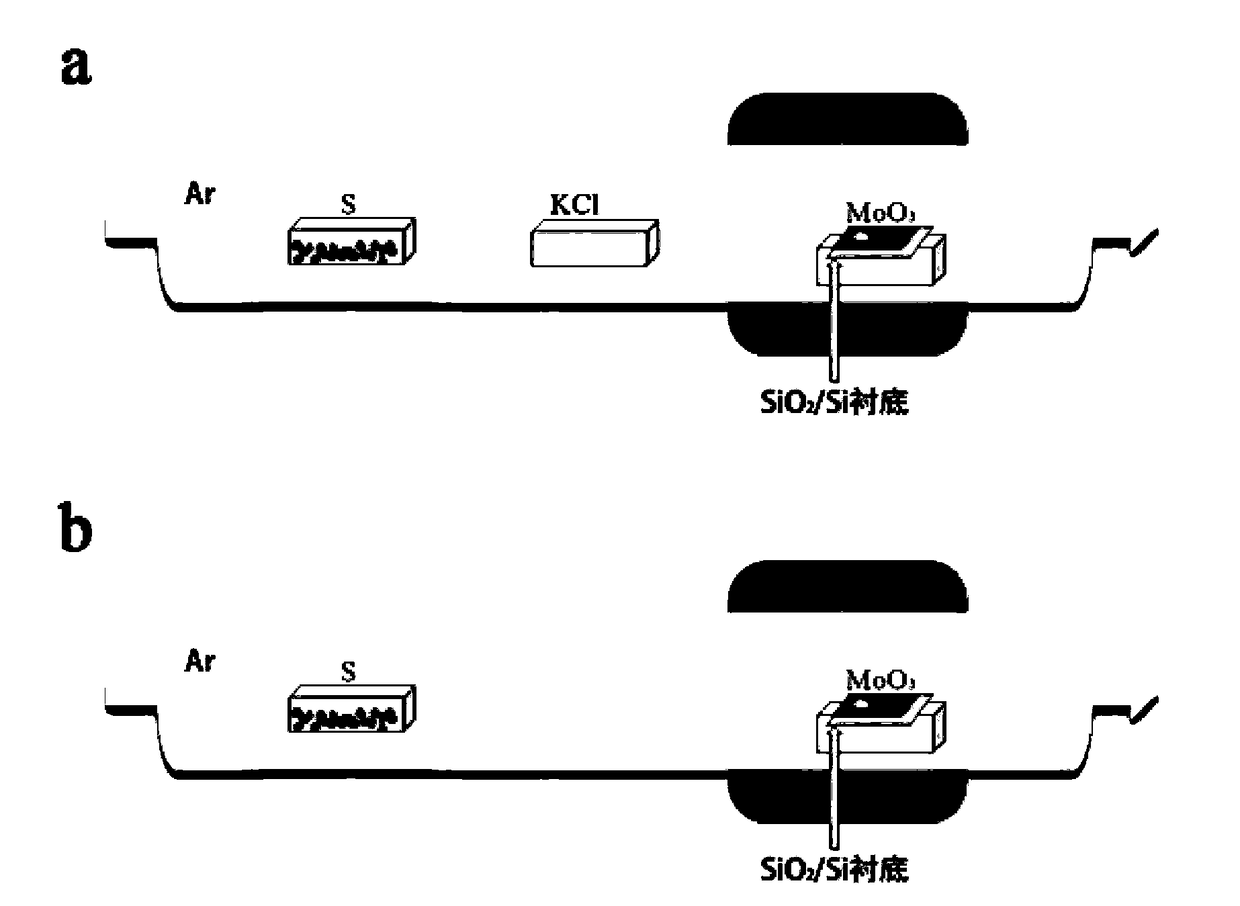

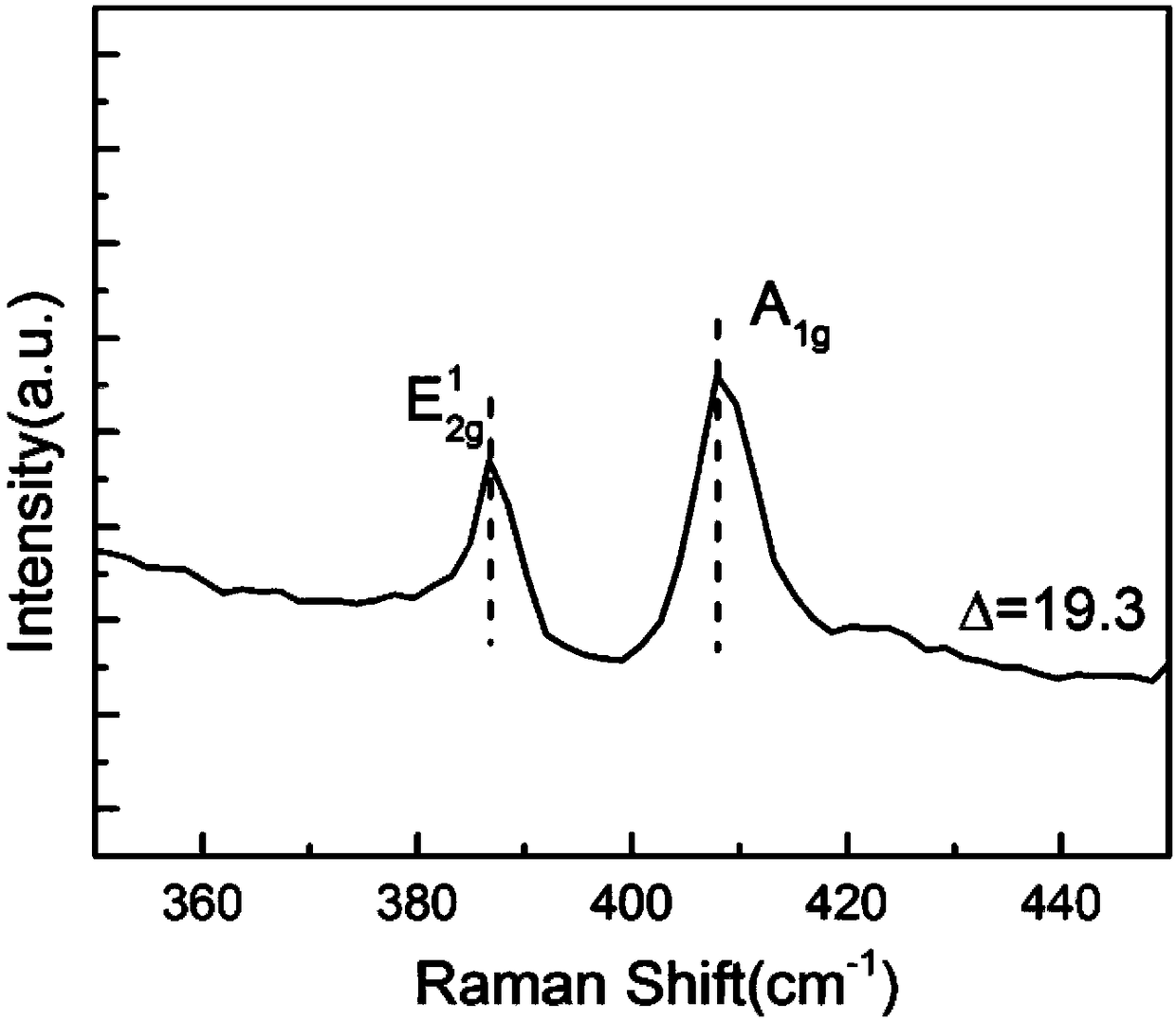

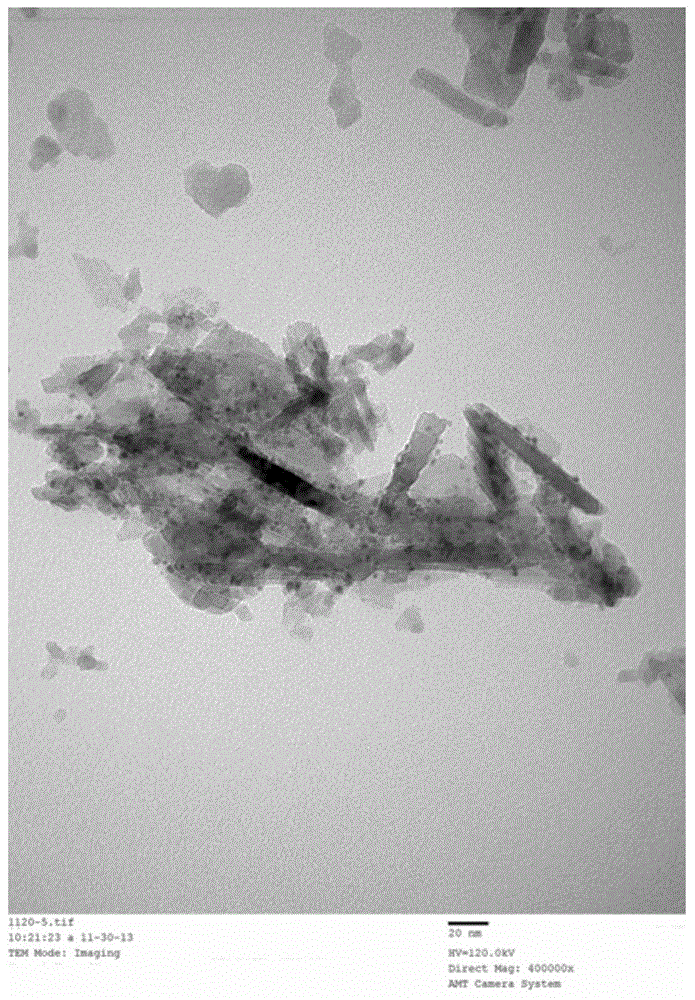

Method for preparing high-quality molybdenum disulfide thin films with layer numbers being uniform

InactiveCN108286042AEasy to addGood repeat testChemical vapor deposition coatingPotassiumSilicon dioxide

The invention discloses a method for preparing high-quality molybdenum disulfide thin films with the layer numbers being uniform. Potassium chloride is used for assisting a chemical vapor deposition method in preparing of large-area single-layer molybdenum disulfide thin films on a silicon substrate covered by a silicon dioxide layer with the thickness being 300nm, and the single-layer molybdenumdisulfide thin films of different dimensions can be obtained by controlling the amount of different sorts of the potassium chloride. The method has the advantages that the high-quality molybdenum disulfide thin films with good homogeneity can be effectively prepared through the potassium chloride, and the experimental method is simple in technology, low in cost and suitable for mass production; the prepared molybdenum disulfide thin films can be used as two-dimensional transparent semiconductor films to be applied to the fields of photoelectric devices, flexible and transparent devices, optical detectors and the like; and the method is of high application value and significance to electronic material preparation and production.

Owner:NORTHWEST UNIV(CN)

Highly-dispersed catalyst for hydrogen peroxide synthesis and preparation method thereof

InactiveCN105268433AHigh activityOvercoming large grain sizePeroxides/peroxyhydrates/peroxyacids/superoxides/ozonidesMetal/metal-oxides/metal-hydroxide catalystsDispersityPetrochemical

A highly-dispersed catalyst for hydrogen peroxide synthesis and a preparation method thereof belong to the field of petrochemical engineering. The catalyst mainly comprises catalyst active ingredients and a catalyst carrier. All the catalyst active ingredients are supported on the carrier to form a granular catalyst. The main catalyst active ingredient is a platinum-family precious metal active ingredient which accounts for 0.01-2wt% of the total weight of the catalyst weighed on the basis of the simple substance of precious metal. The catalyst carrier accounts for 98-99.00 wt% of the total weight of the catalyst. The preparation method comprises the following steps: carrying out heat treatment on the platinum-family precious metal active ingredient under the action of a reducing agent and a protective agent to prepare nano-particle sol, supporting the nano-particle sol onto the granular catalyst carrier, and drying to prepare the catalyst. In comparison with a traditional catalyst prepared by an immersion method, the highly-dispersed granular catalyst has advantages as follows: problems of large crystalline grain of the active ingredients and low dispersity are overcome, and catalyst activity is raised. In addition, use of toxic reagents such as organic tin and the like is avoided during the preparation process. The preparation method is green and environmentally friendly and is suitable for production.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

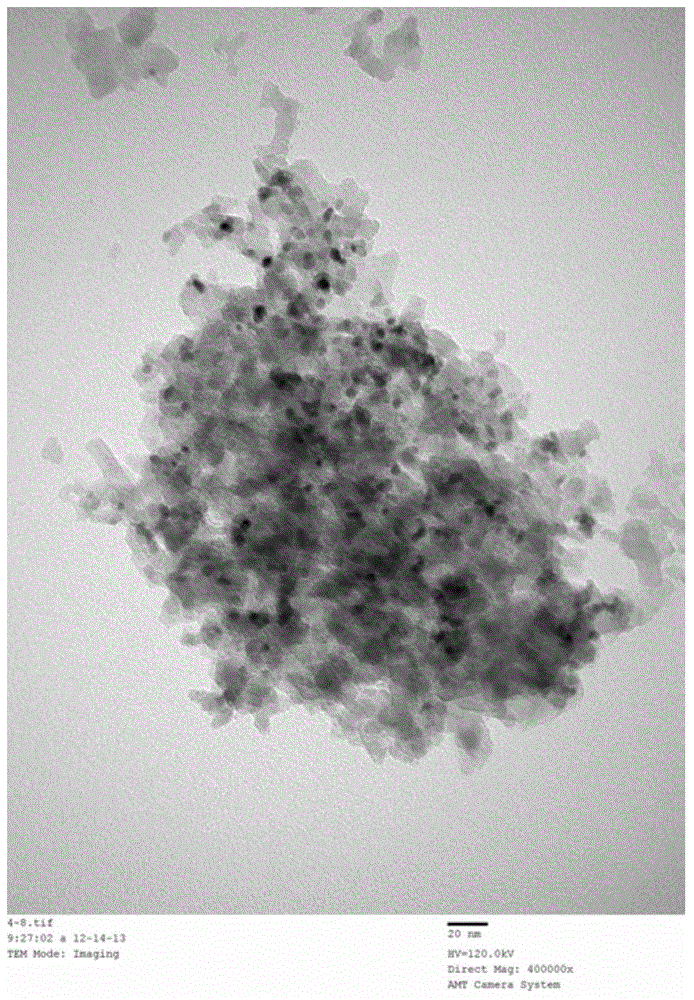

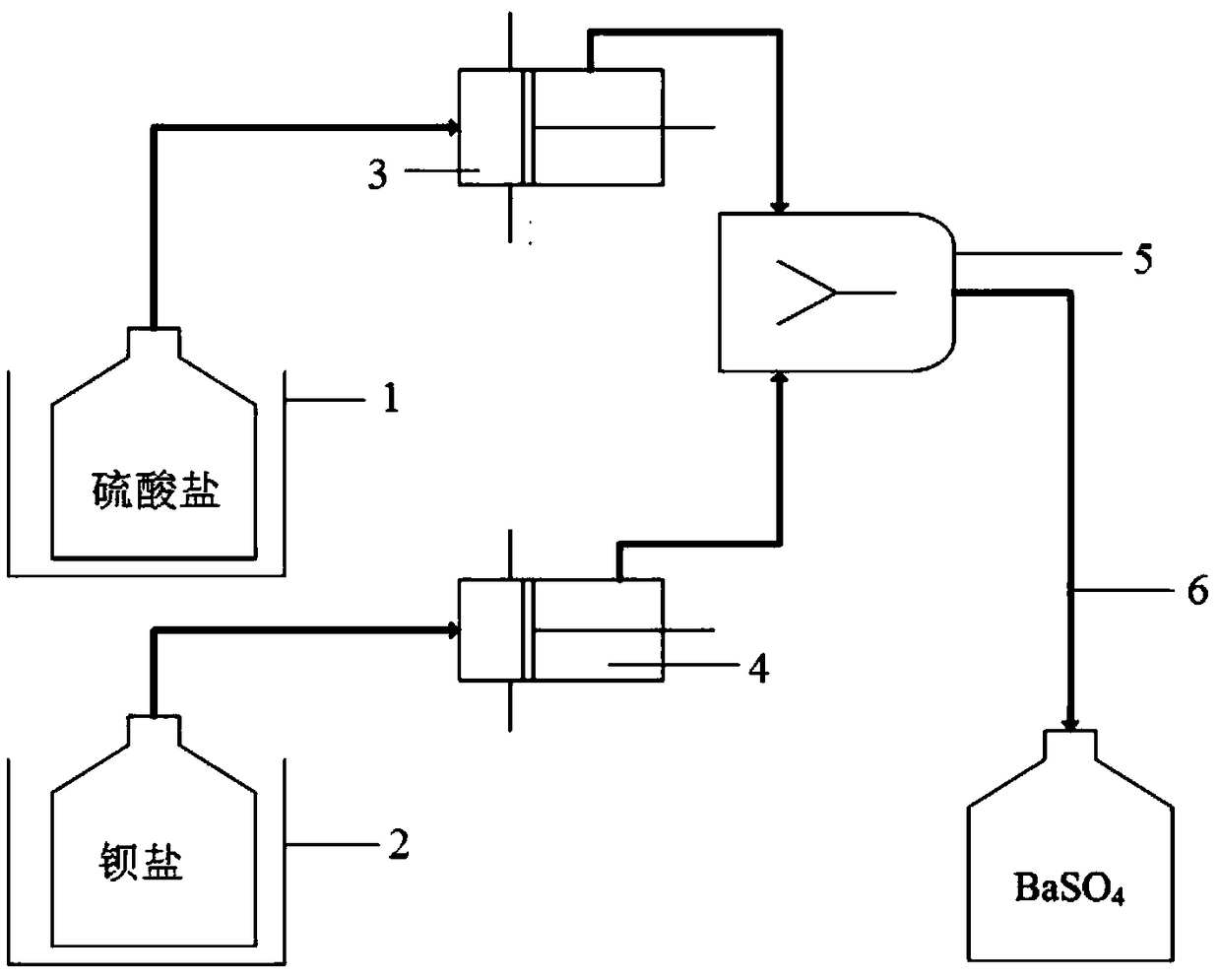

Method for preparing barium sulfate particles through microchannel method

ActiveCN108862355ALarge specific surface areaShort stayMaterial nanotechnologyCalcium/strontium/barium sulfatesBarium dichlorideBarium salt

The invention belongs to a method for preparing barium sulfate particles through a microchannel method in the technical field of nanomaterial preparation. The method comprises the following steps: introducing a sulfate water solution and a barium salt water solution into a microchannel reactor for reacting and ageing, and centrifuging, washing and drying an obtained reaction solution, thus obtaining the barium sulfate particles, wherein selected sulfate is sodium sulfate, ammonium sulfate or sodium persulfate, and barium salt is barium chloride, barium acetate or barium nitrate. The morphologyand the particle size distribution of the obtained barium sulfate particles are controllable, and industrial application of medical dry films can be met to a larger extent.

Owner:BEIJING INSTITUTE OF PETROCHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com