Patents

Literature

6386results about How to "Improve shielding effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

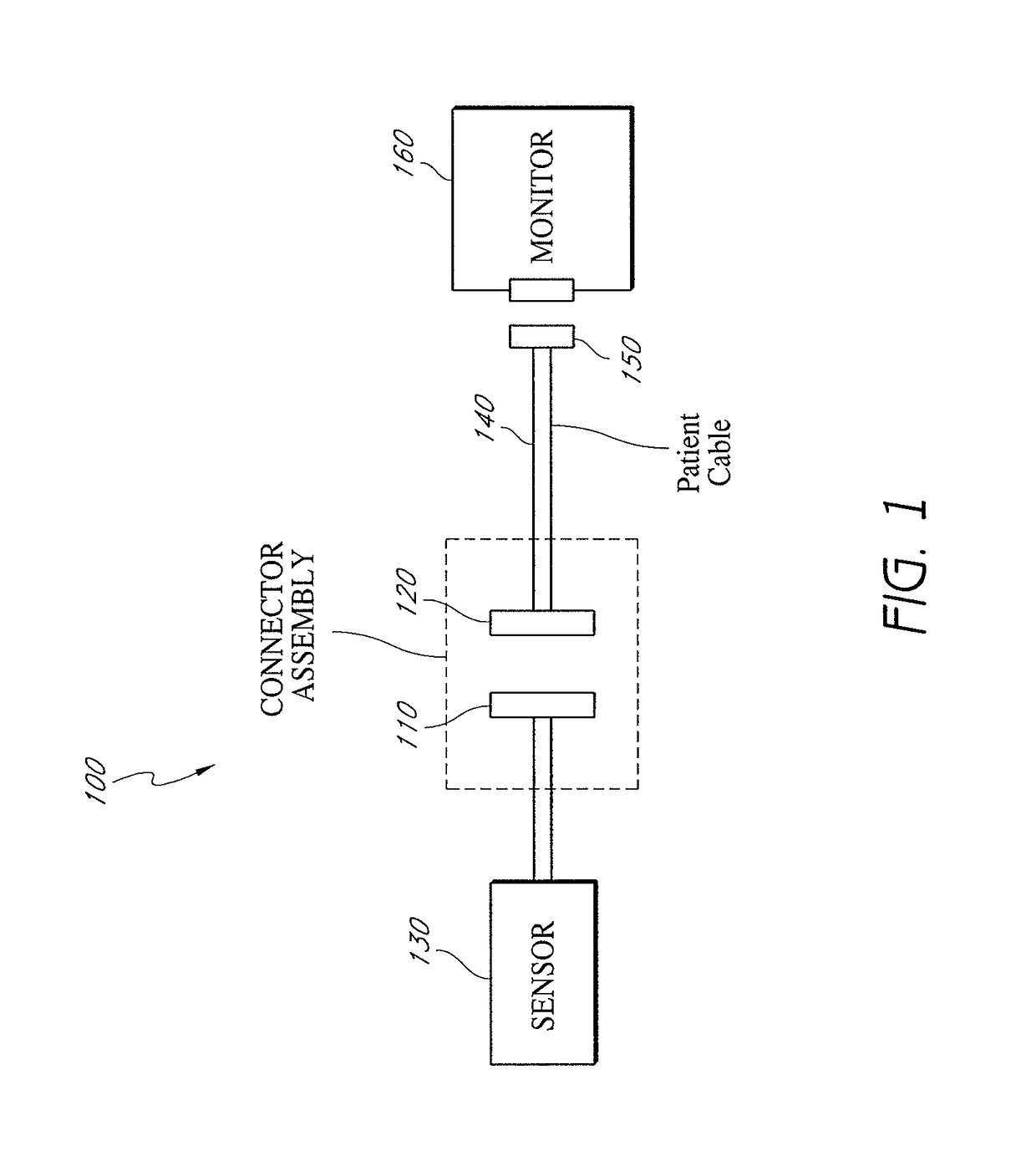

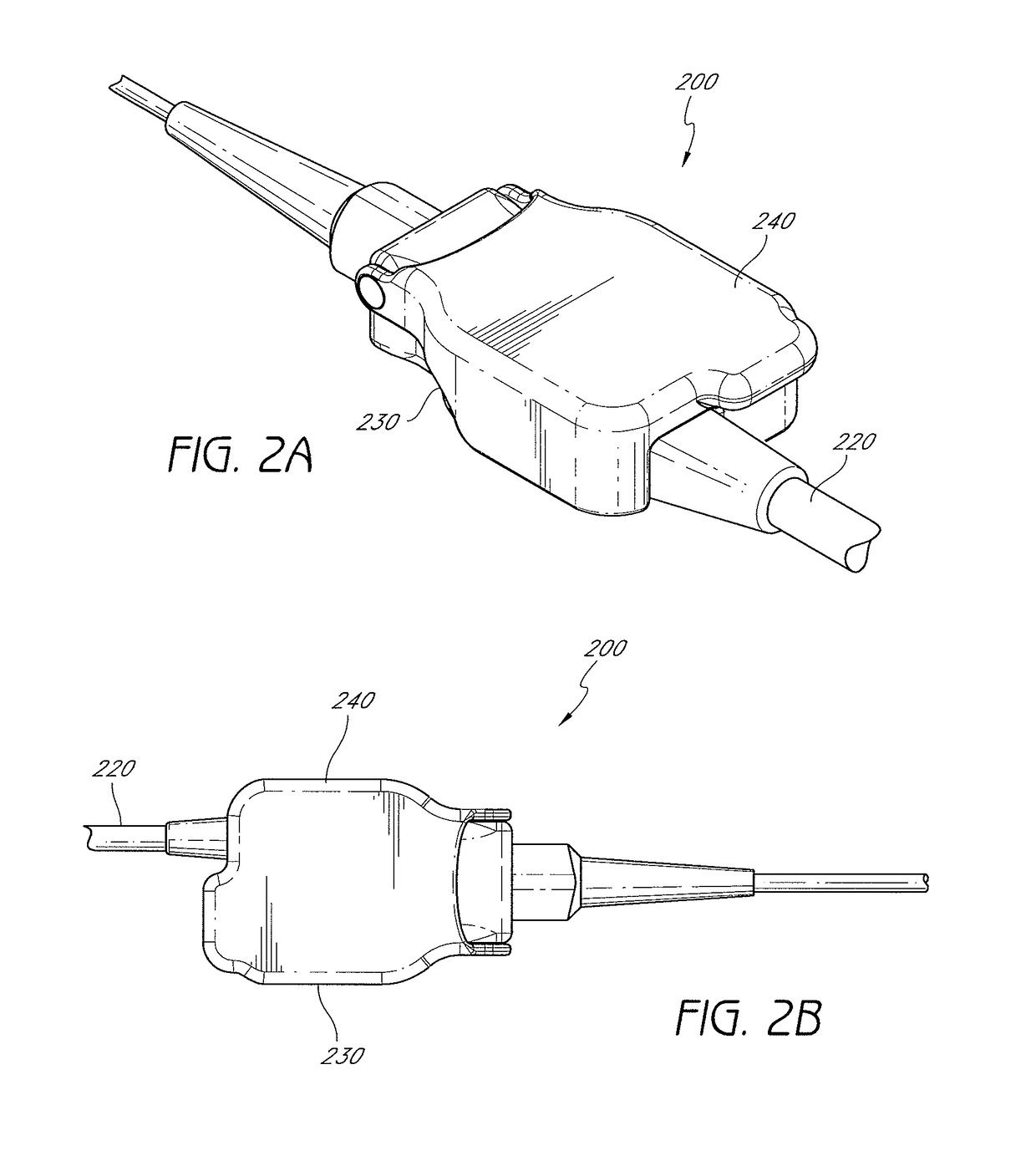

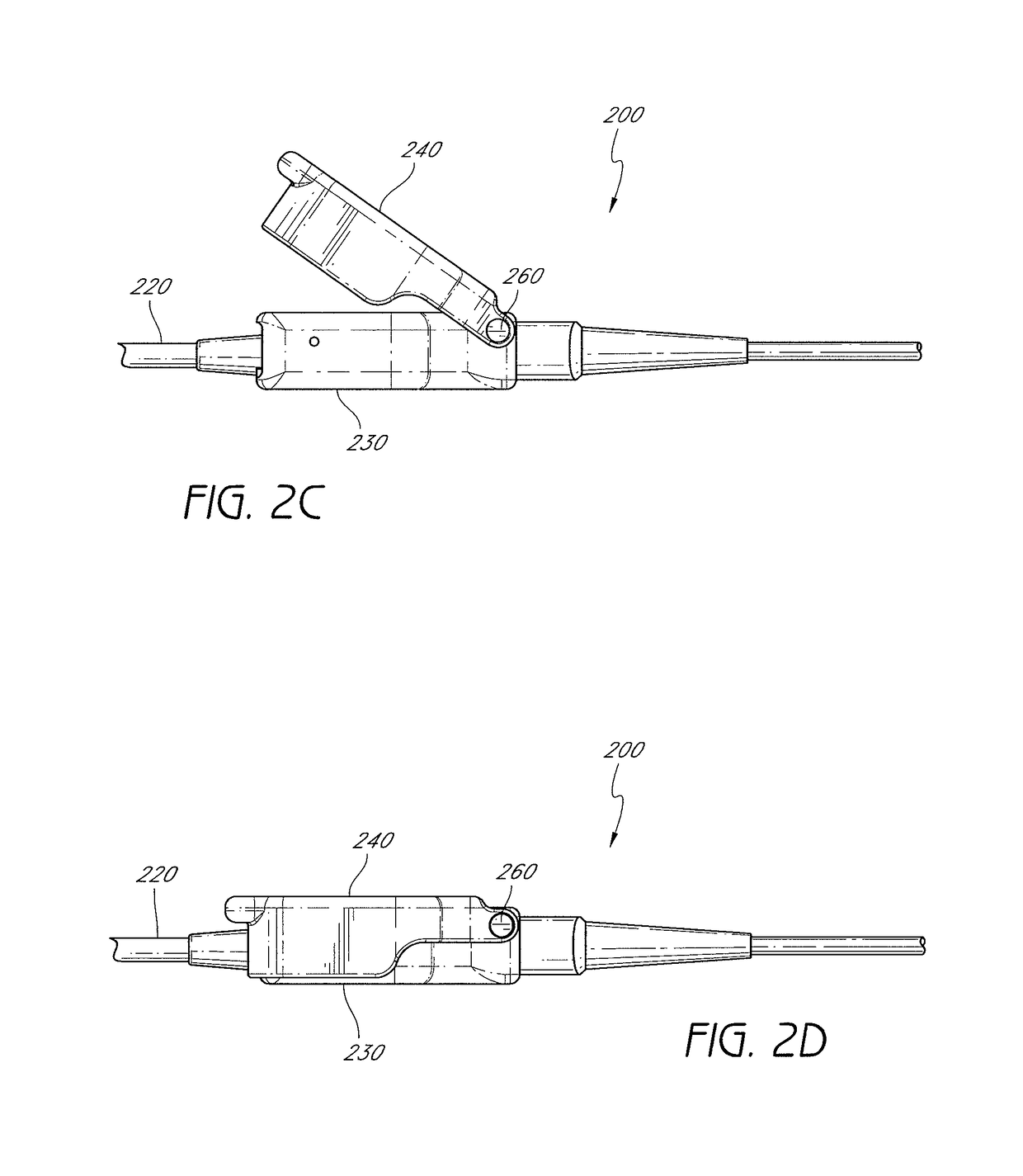

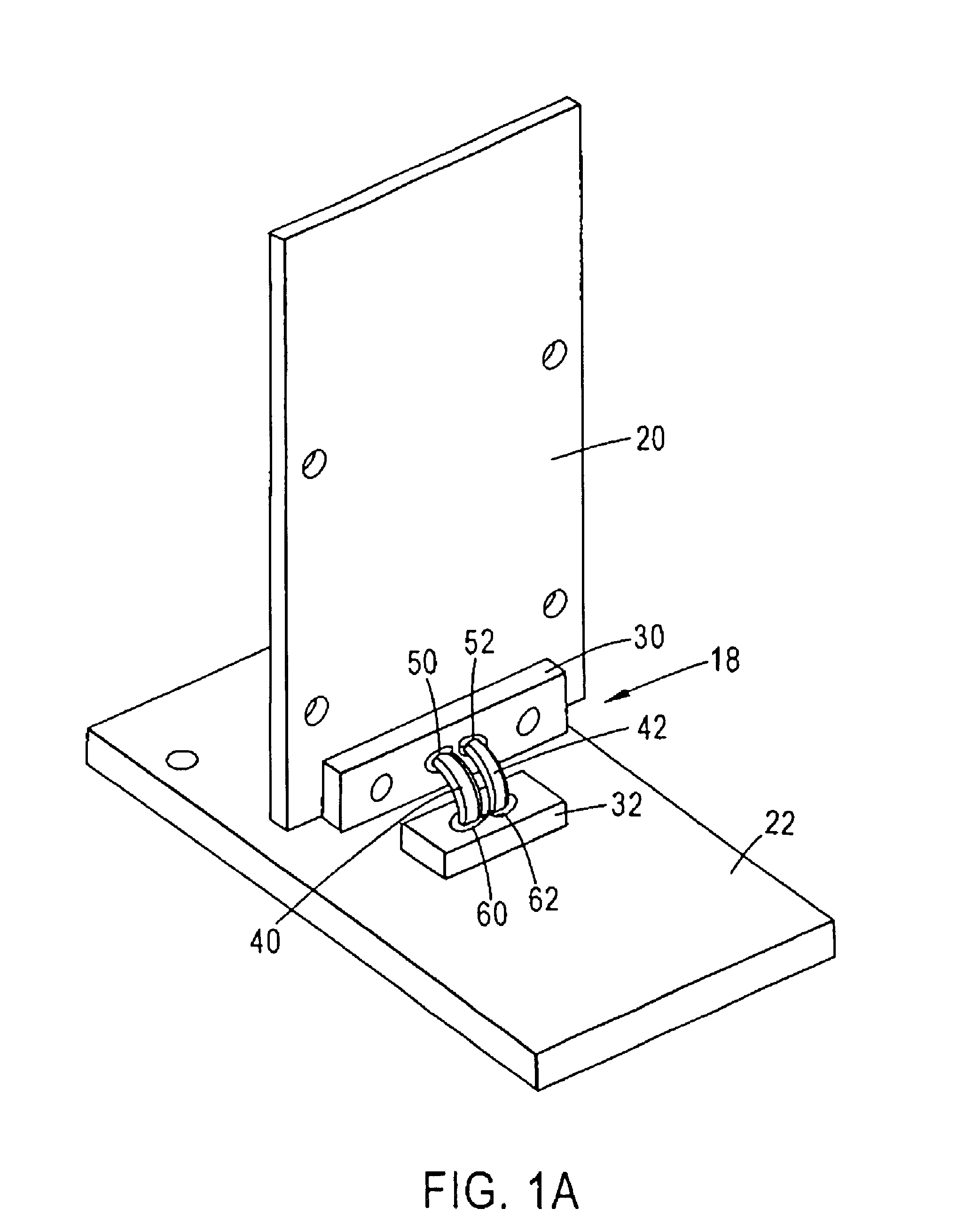

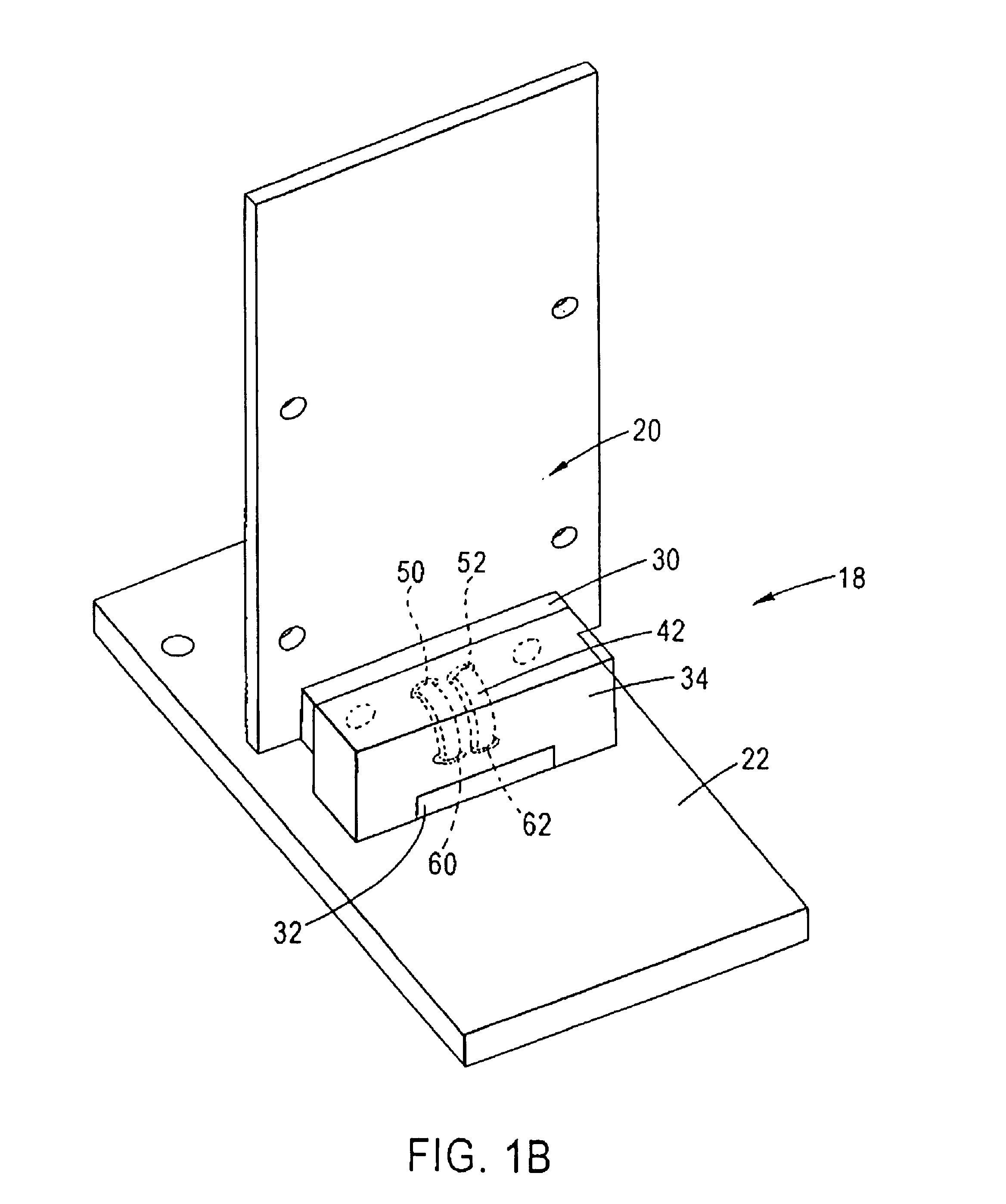

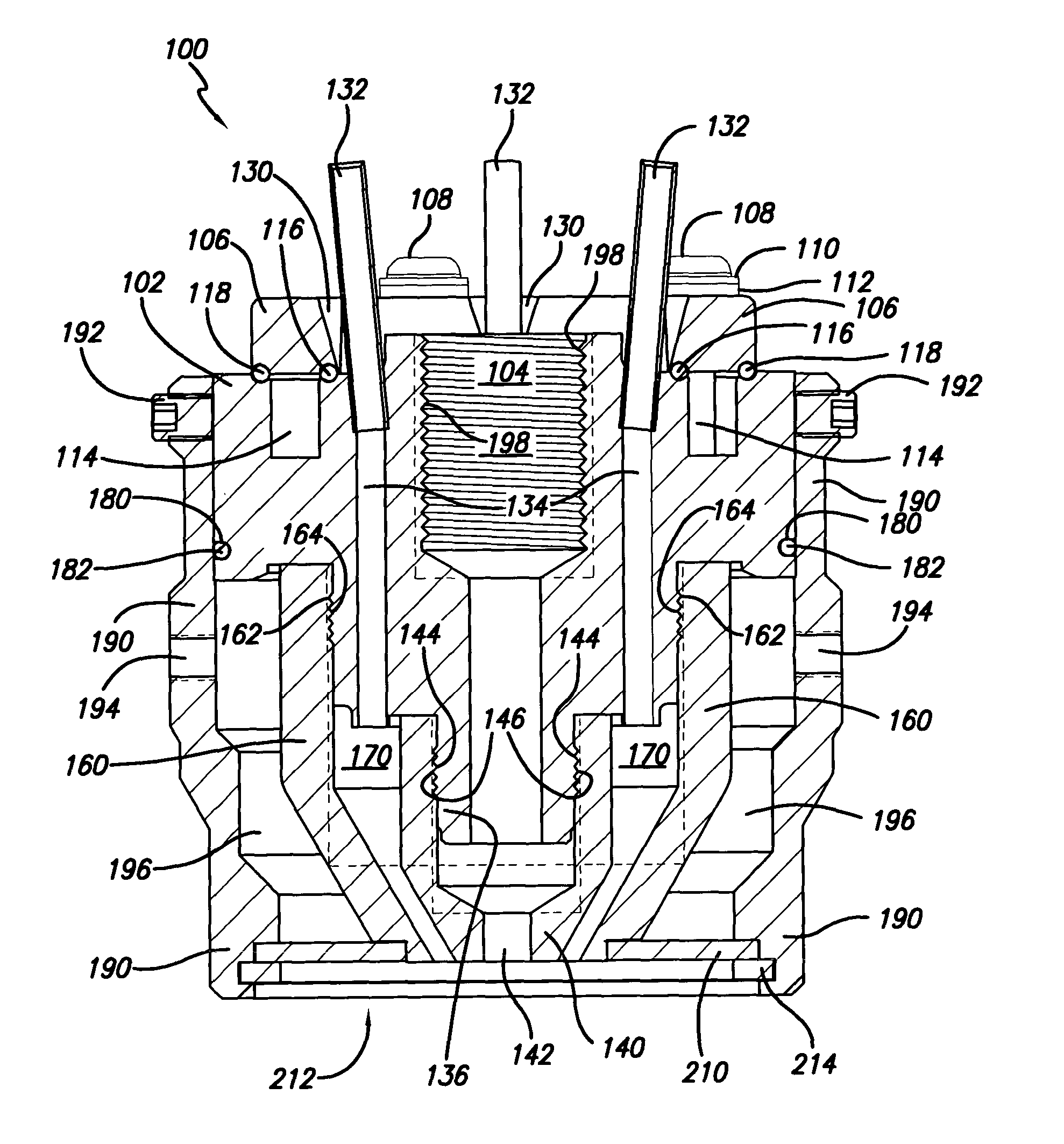

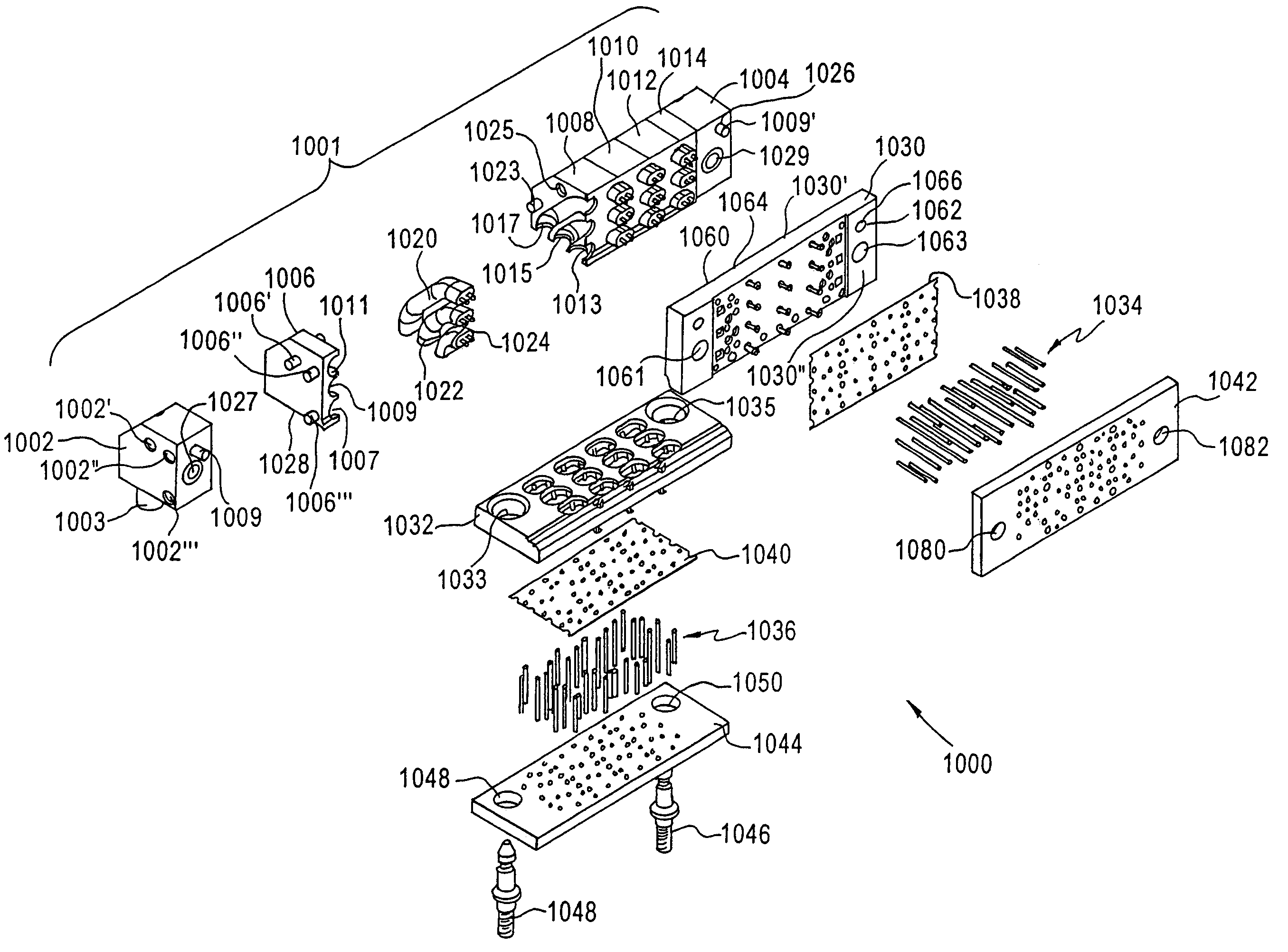

Connector assembly with reduced unshielded area

ActiveUS8118620B2Straightforwardly and efficiently joinLow costDiagnostic recording/measuringSensorsElectrical connectionEngineering

A connector assembly according to embodiments of the present disclosure is advantageously configured to allow a sensor connector to straightforwardly and efficiently join with and detach from a patient cable connector. Further, embodiments of the connector assembly advantageously reduce un-shielded area in an electrical connection between a patient cable and a sensor connector. In addition, embodiments of the connector assembly advantageously increase the shielding of detector signals coming from the patient sensor to the monitor.

Owner:JPMORGAN CHASE BANK NA

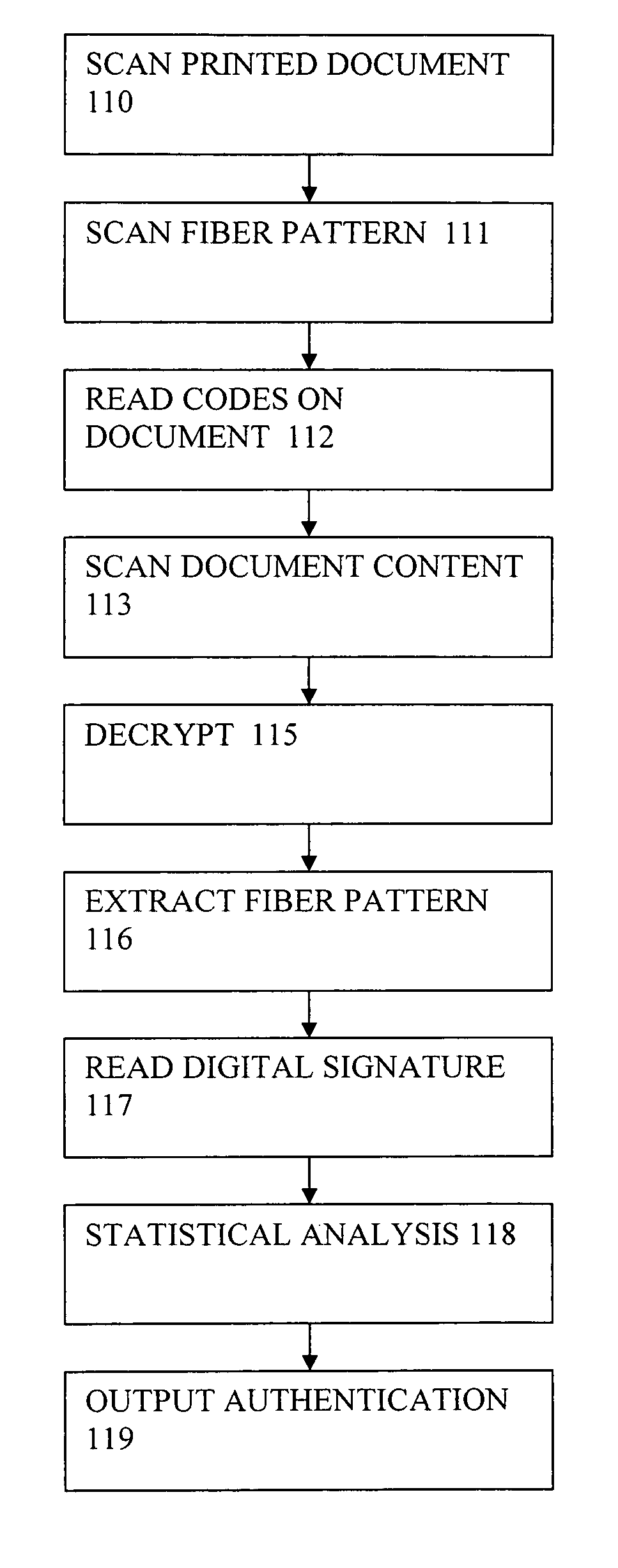

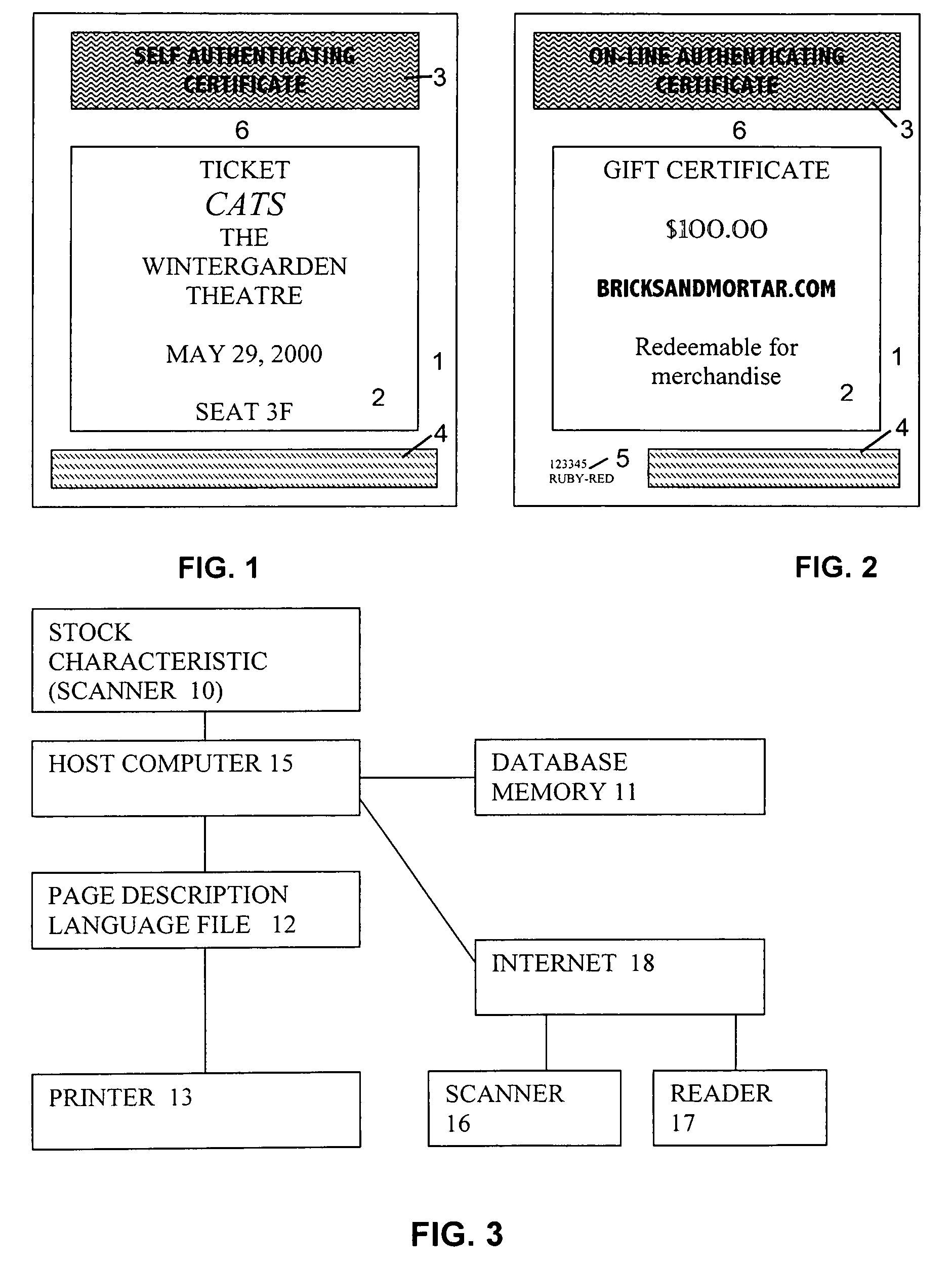

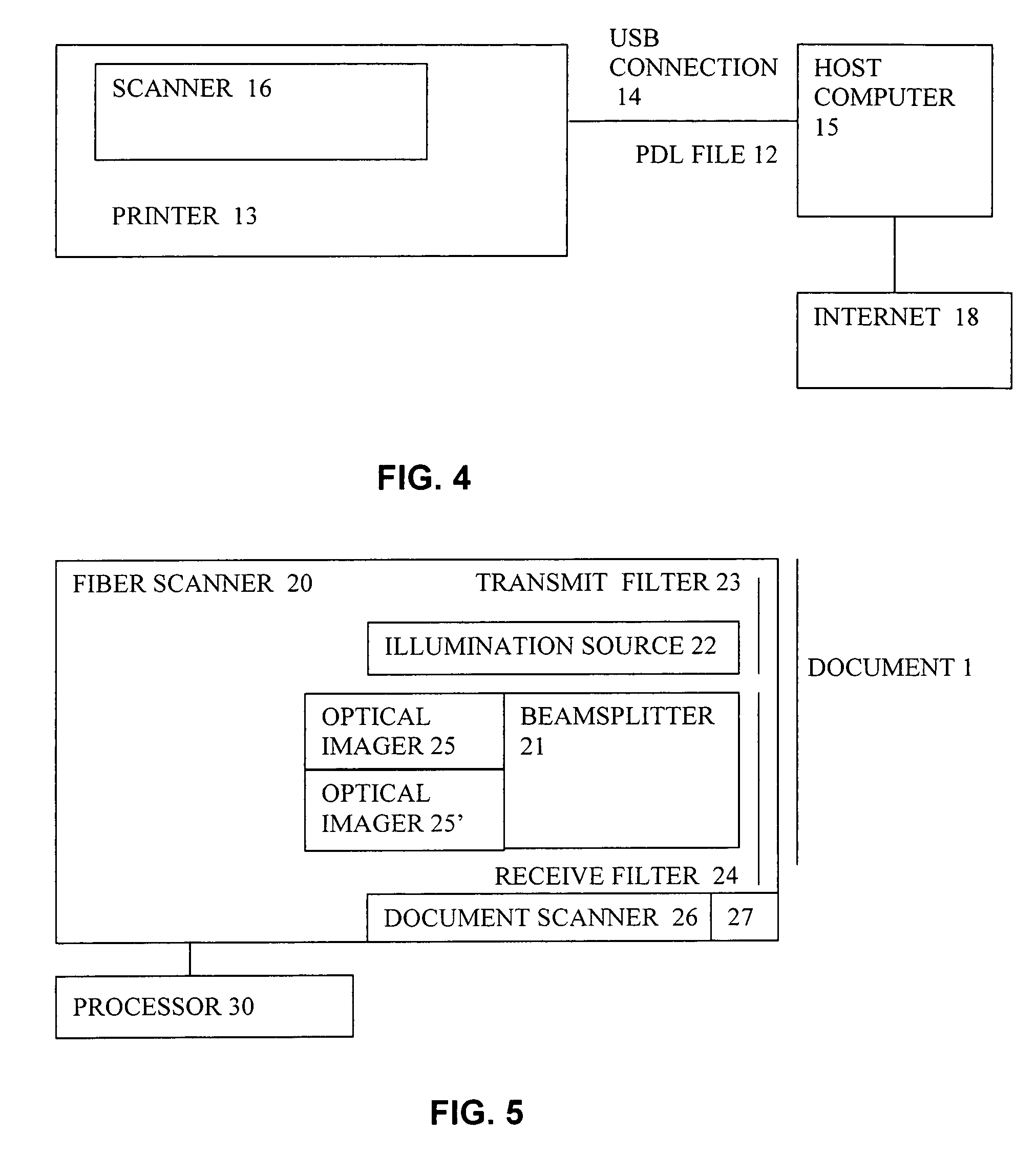

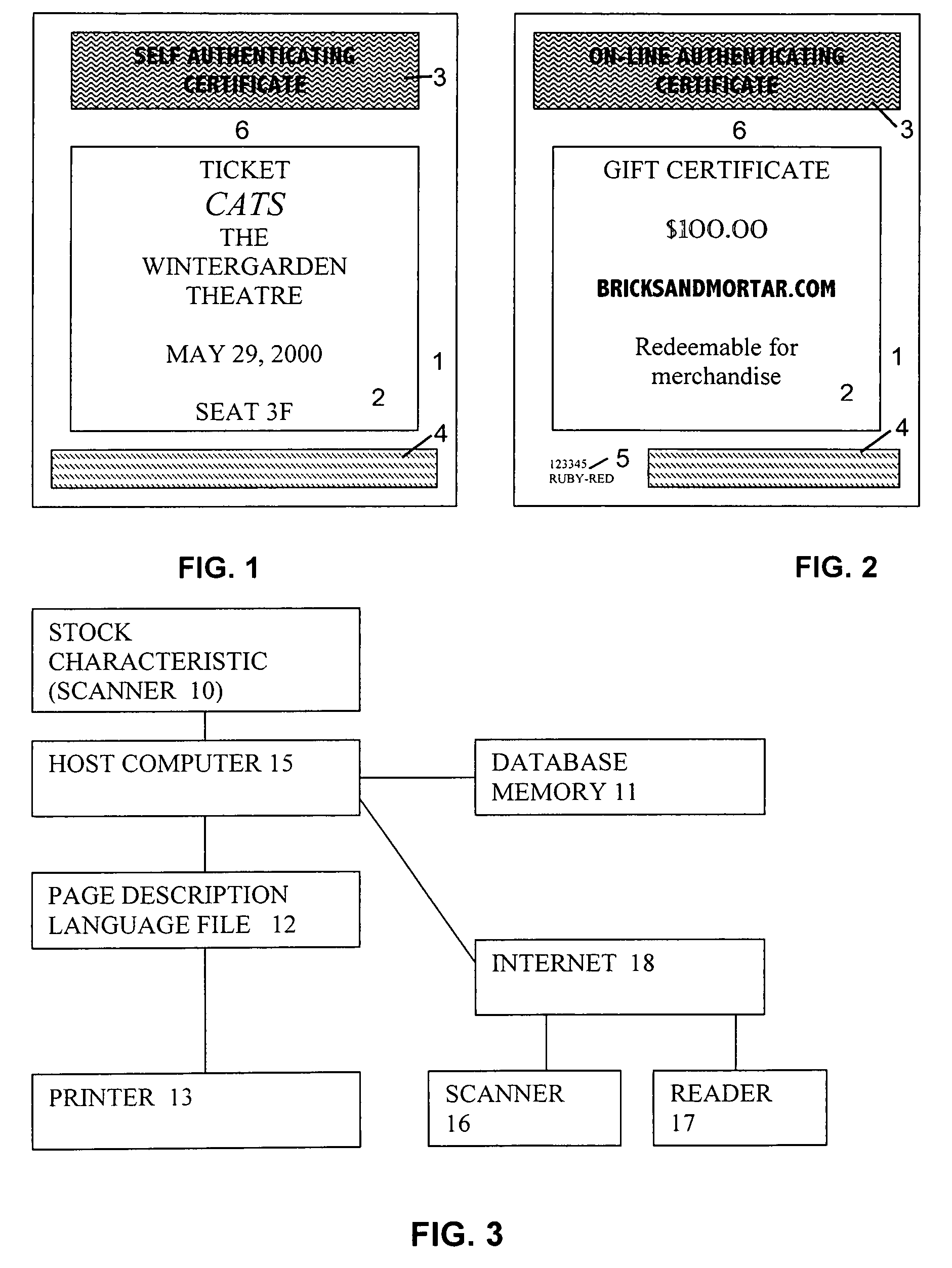

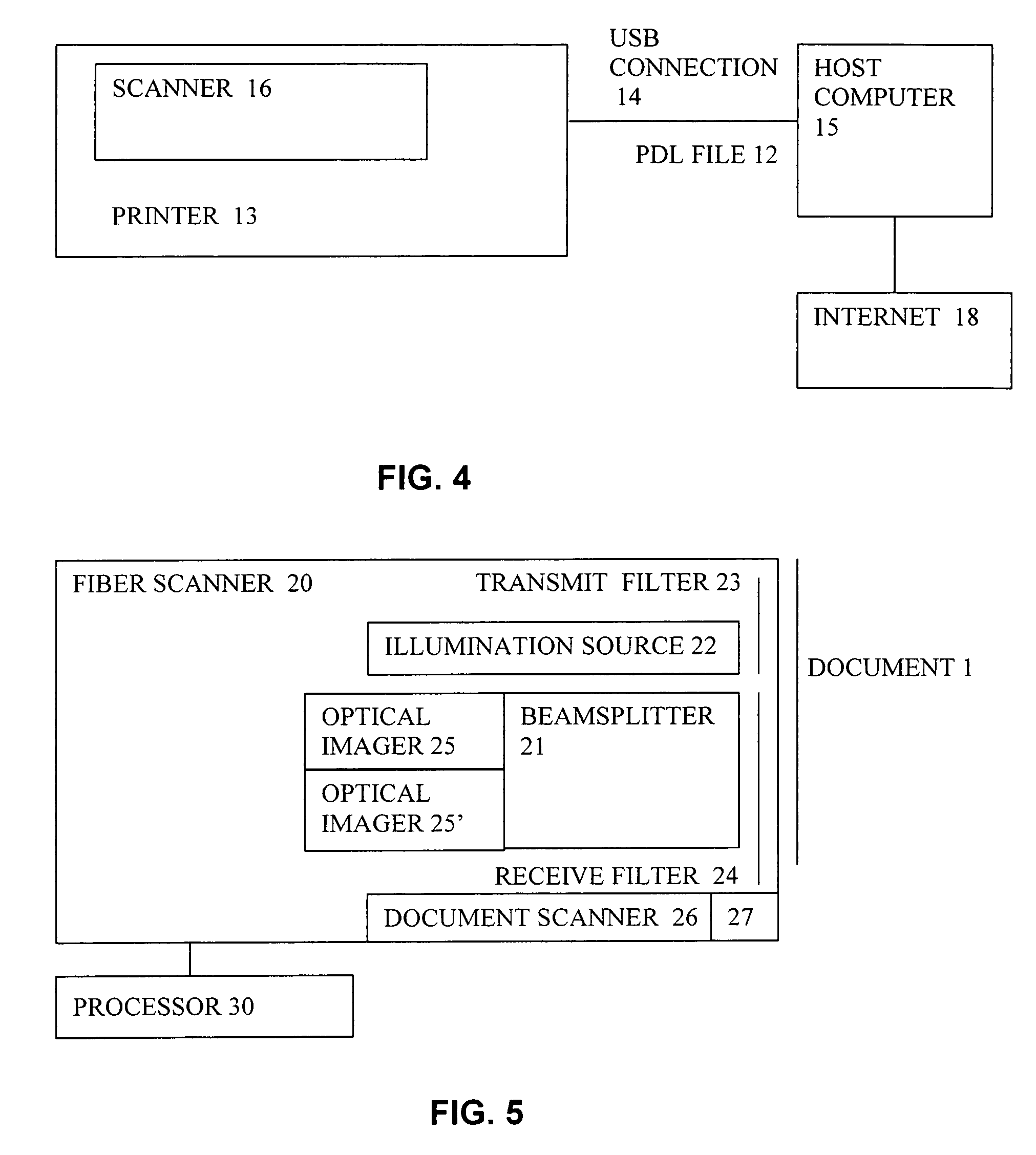

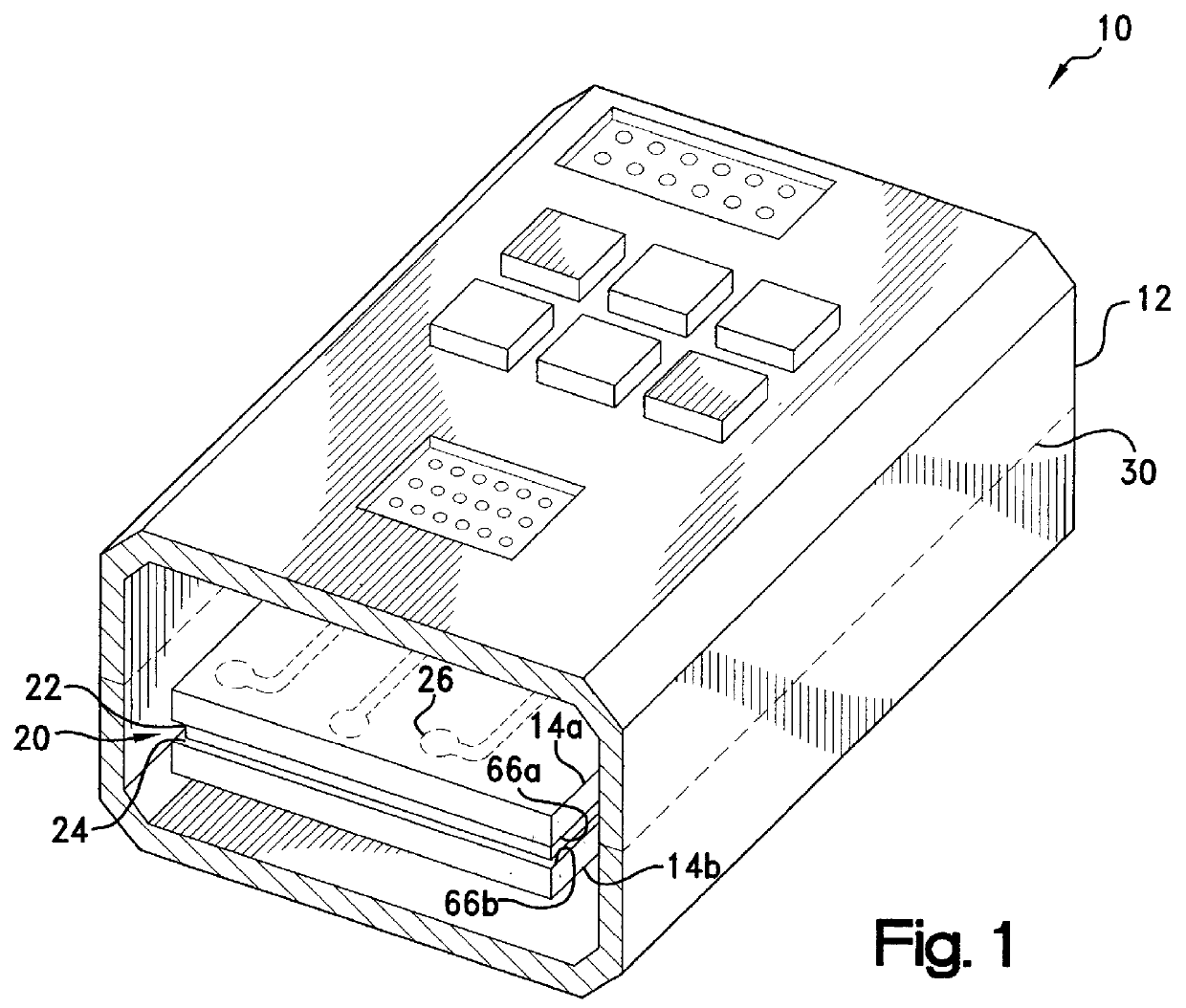

System and method for production and authentication of original documents

InactiveUS7080041B2Improve shielding effectImprove accuracyOther printing matterUser identity/authority verificationDocument IdentifierLogical security

A system and method for authenticating documents and content thereof. A counterfeit resistant document recording medium is provided, having thereon a predefined unique document identifier and at least one security feature. The recording medium is thereafter imprinted with document content, which typically varies between documents. The document content is stored in a database, indexed by an associated document identifier. The document may then be authenticated by checking the security feature and comparing the stored document content with a perceived document content. The system provides a number of opportunities for commercial exploitation, including sales of identified recording media, recording of information in a database, on-line authentication transactions, differential accounting for document validations and counterfeit identifications, imprinting devices, authentication devices, and the like. The system prevents counterfeiting of valuable documents through casual means by providing both physical and logical security.

Owner:ESECUREDOCS

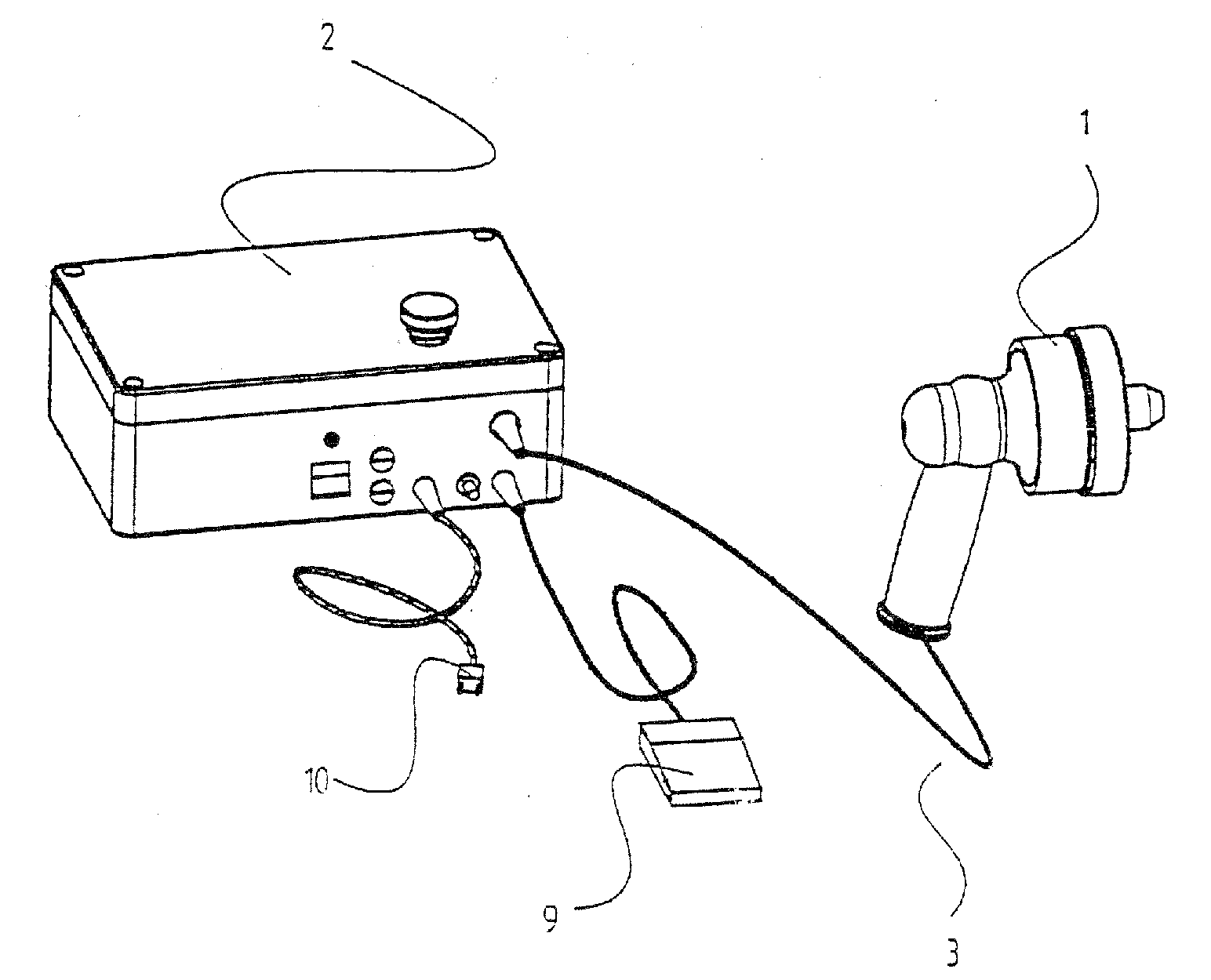

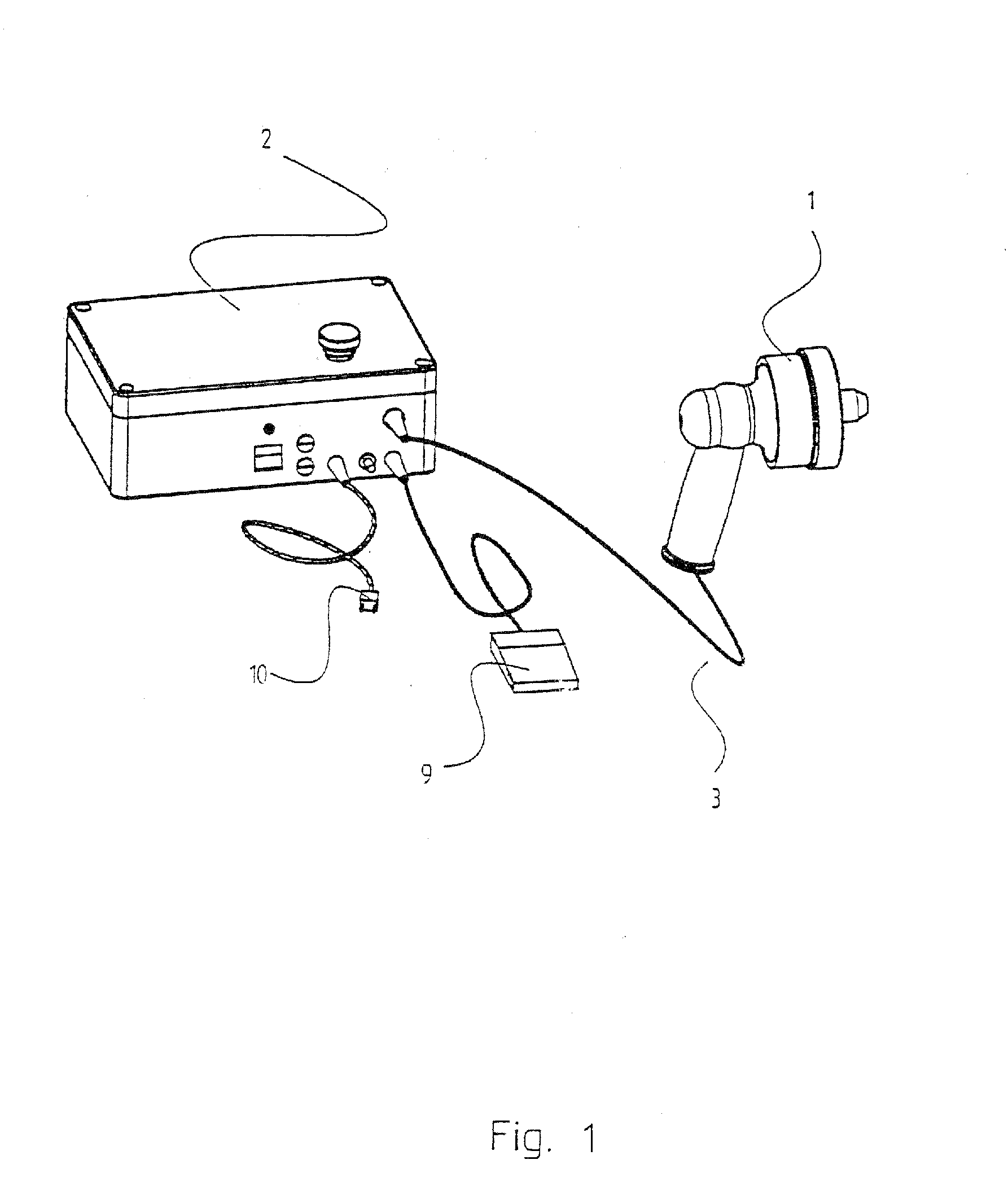

Minimally-Invasive Approach to Bone-Obstructed Soft Tissue

InactiveUS20080177268A1Improve shielding effectLow magnetic susceptibilitySurgeryMagnetic susceptibilityImaging quality

The subject invention pertains to a method and apparatus for placing a minimally-invasive access with respect to a patient's bone or other non-soft tissue. The subject invention can use a drilling machine incorporating an ultrasound motor. The subject drilling machine can be applied to sample, for example, bone biopsies under MRI control. In a specific embodiment, the subject ultrasound motor can be completely manufactured of non-magnetic materials, such as plastics, titanium, and titanium alloy, or ceramics and piezoceramics. The subject drilling apparatus can be placed into an MRI near field without influencing the image quality, and without the drilling apparatus itself being disturbed by the MRI magnet, gradient, or high-frequency field. The subject invention can incorporate good shielding with the subject drilling apparatus use of these materials, and can achieve minimal, if any, image distortions or so-called artifacts. Thus, the subject invention can involve the problem by use of non-magnetic materials of low magnetic susceptibility for the design of an actuation unit.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

System and method for production and authentication of original documents

InactiveUS20050038756A1Improve shielding effectImprove accuracyOther printing matterUser identity/authority verificationDocument IdentifierPaper document

A system and method for authenticating documents and content thereof. A counterfeit resistant document recording medium is provided, having thereon a predefined unique document identifier and at least one security feature. The recording medium is thereafter imprinted with document content, which typically varies between documents. The document content is stored in a database, indexed by an associated document identifier. The document may then be authenticated by checking the security feature and comparing the stored document content with a perceived document content. The system provides a number of opportunities for commercial exploitation, including sales of identified recording media, recording of information in a database, on-line authentication transactions, differential accounting for document validations and counterfeit identifications, imprinting devices, authentication devices, and the like. The system prevents counterfeiting of valuable documents through casual means by providing both physical and logical security.

Owner:ESECUREDOCS

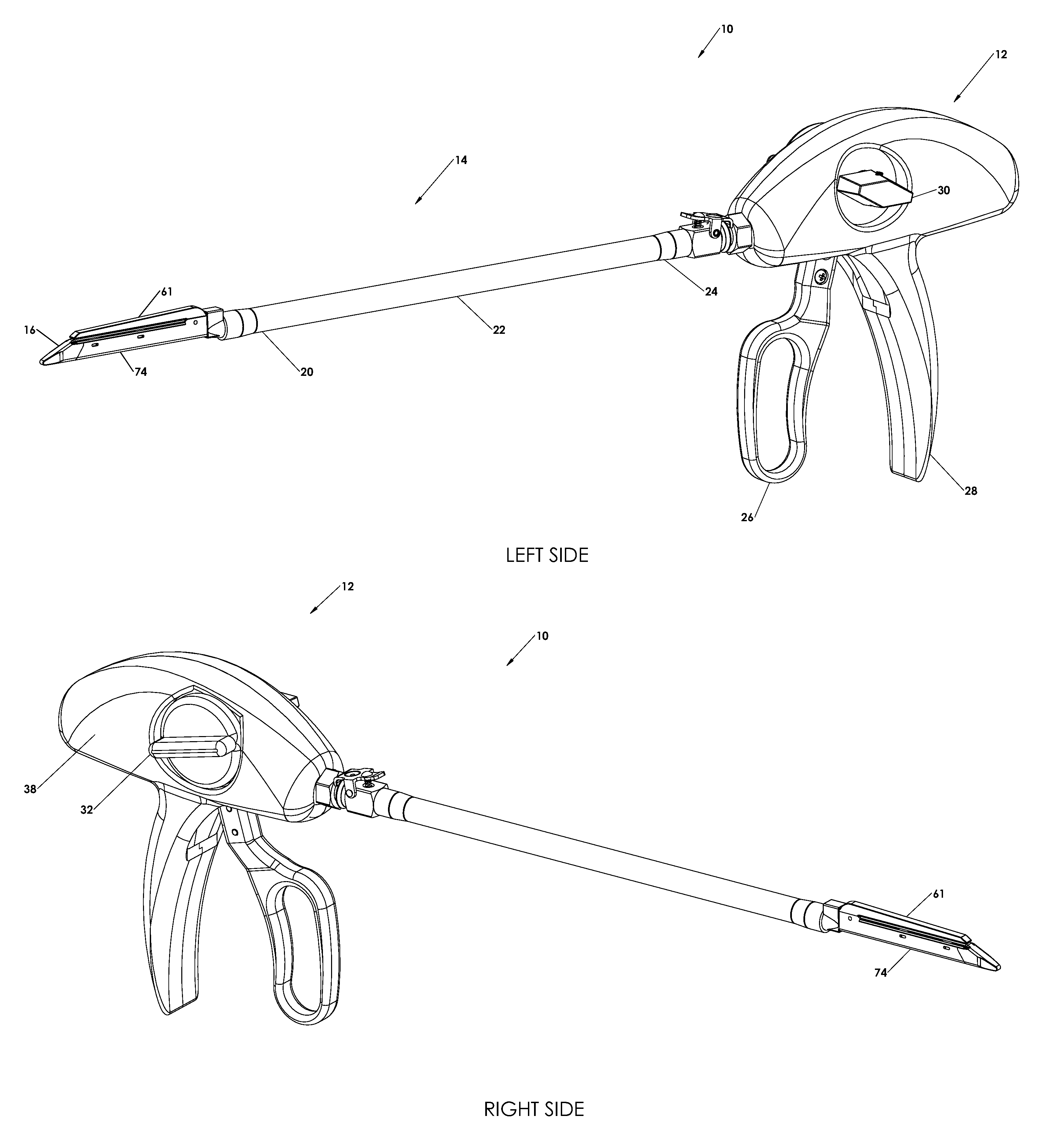

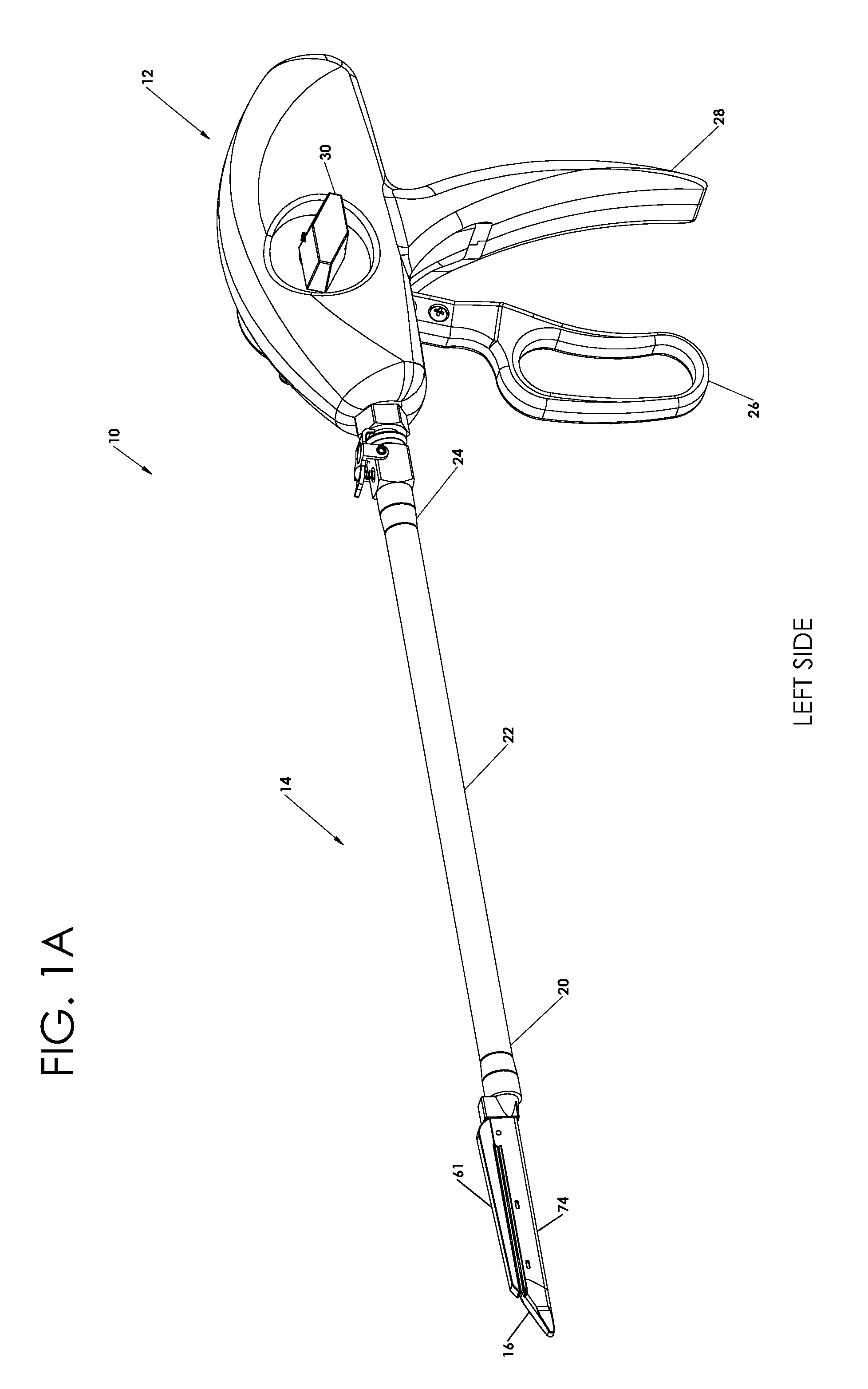

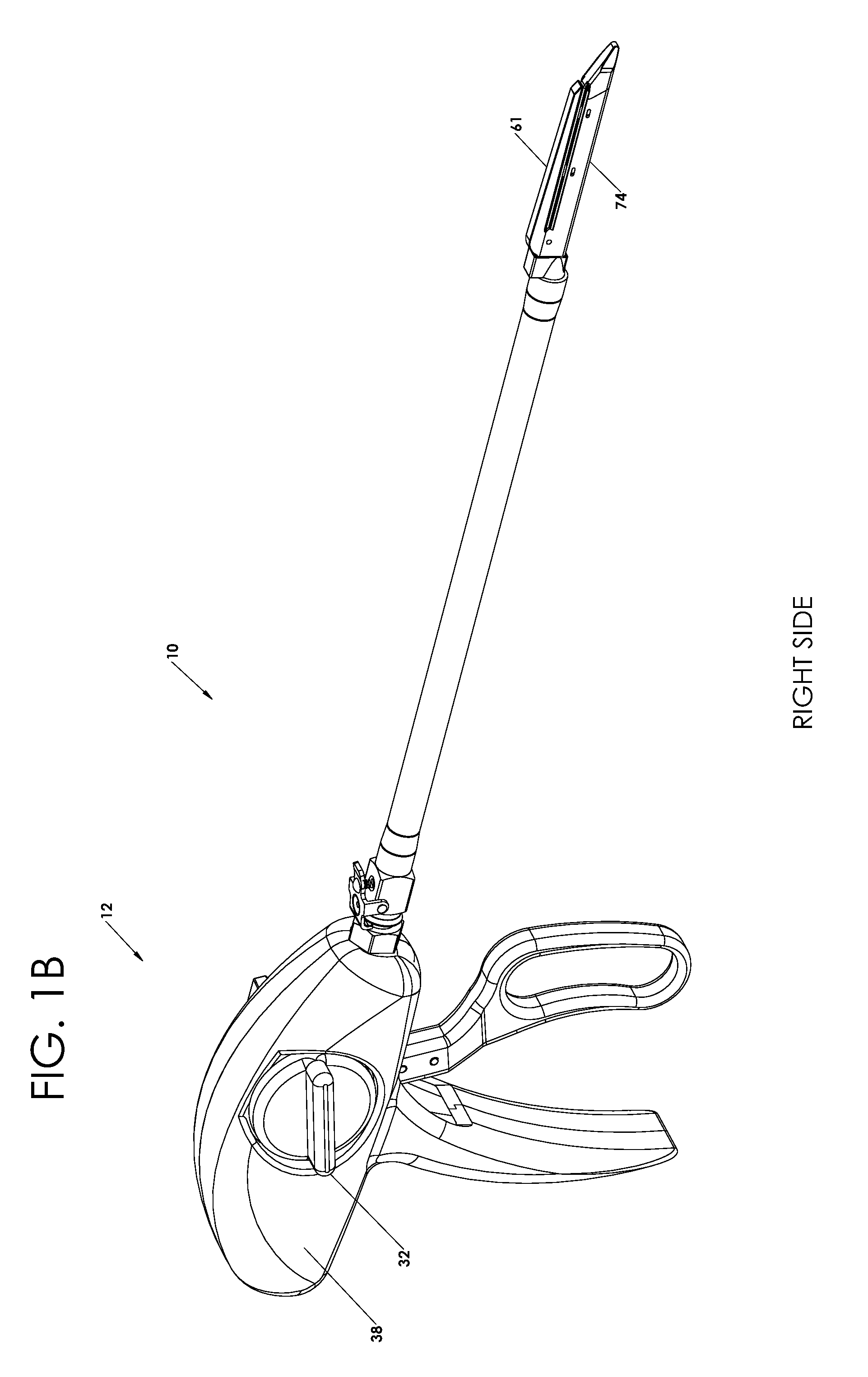

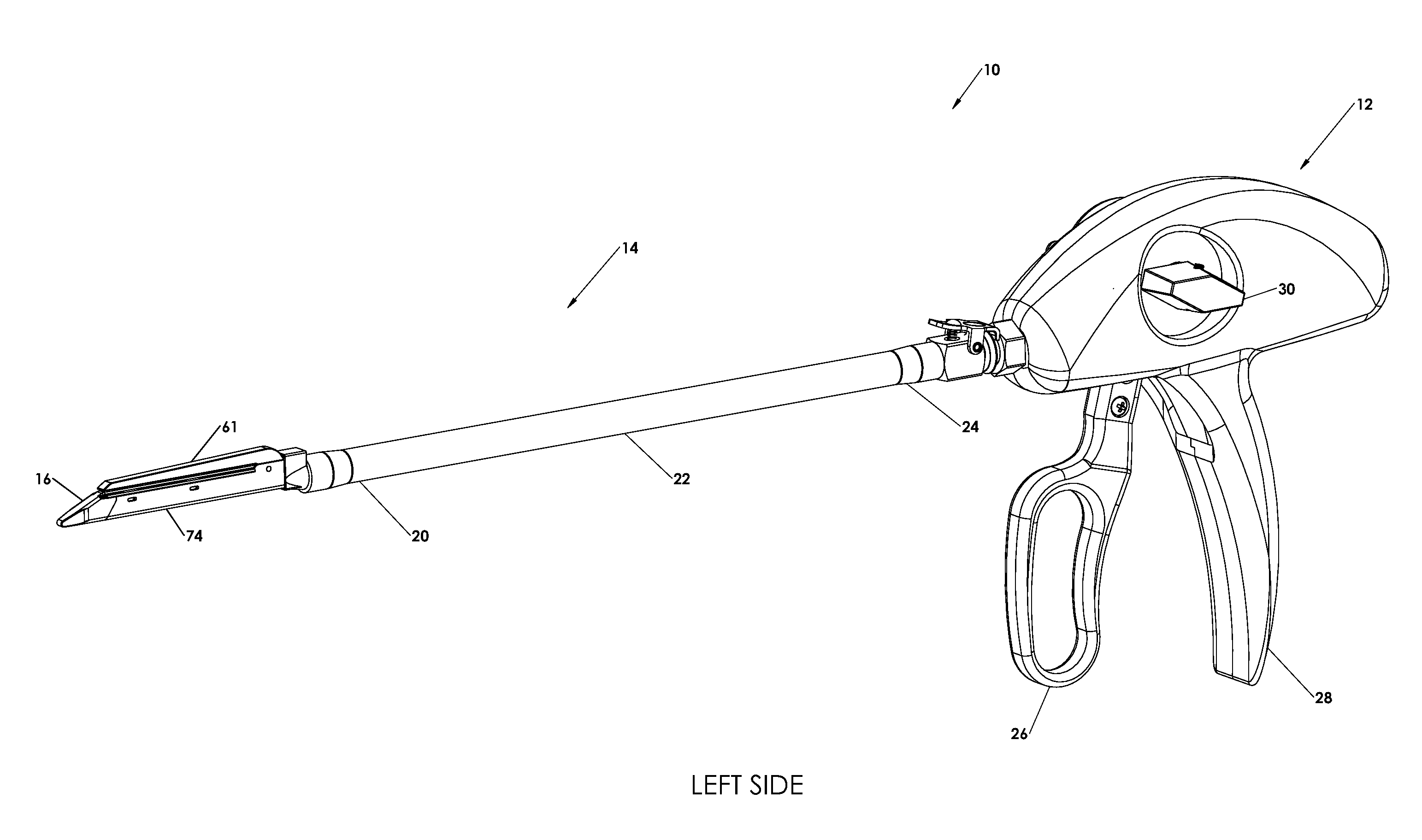

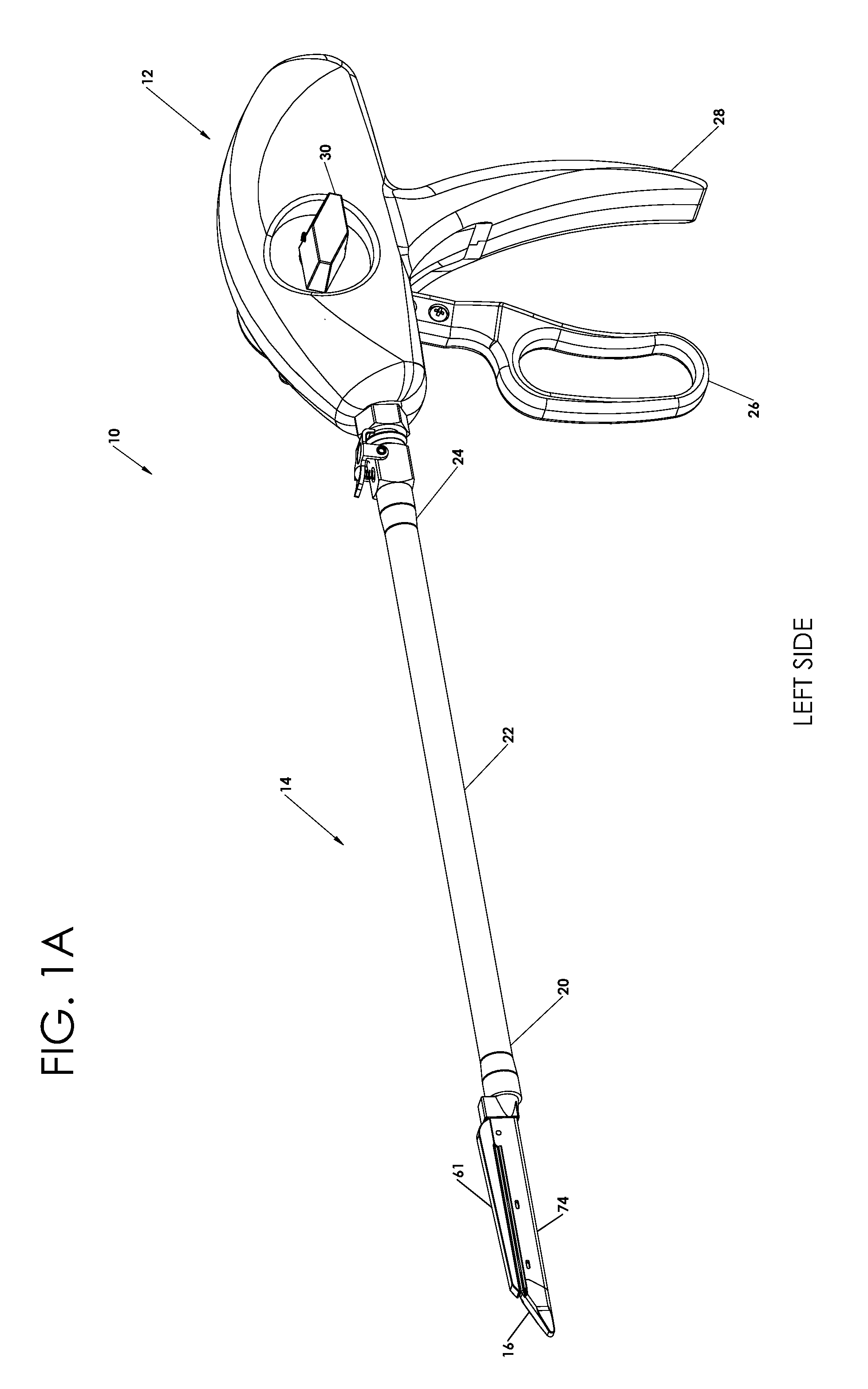

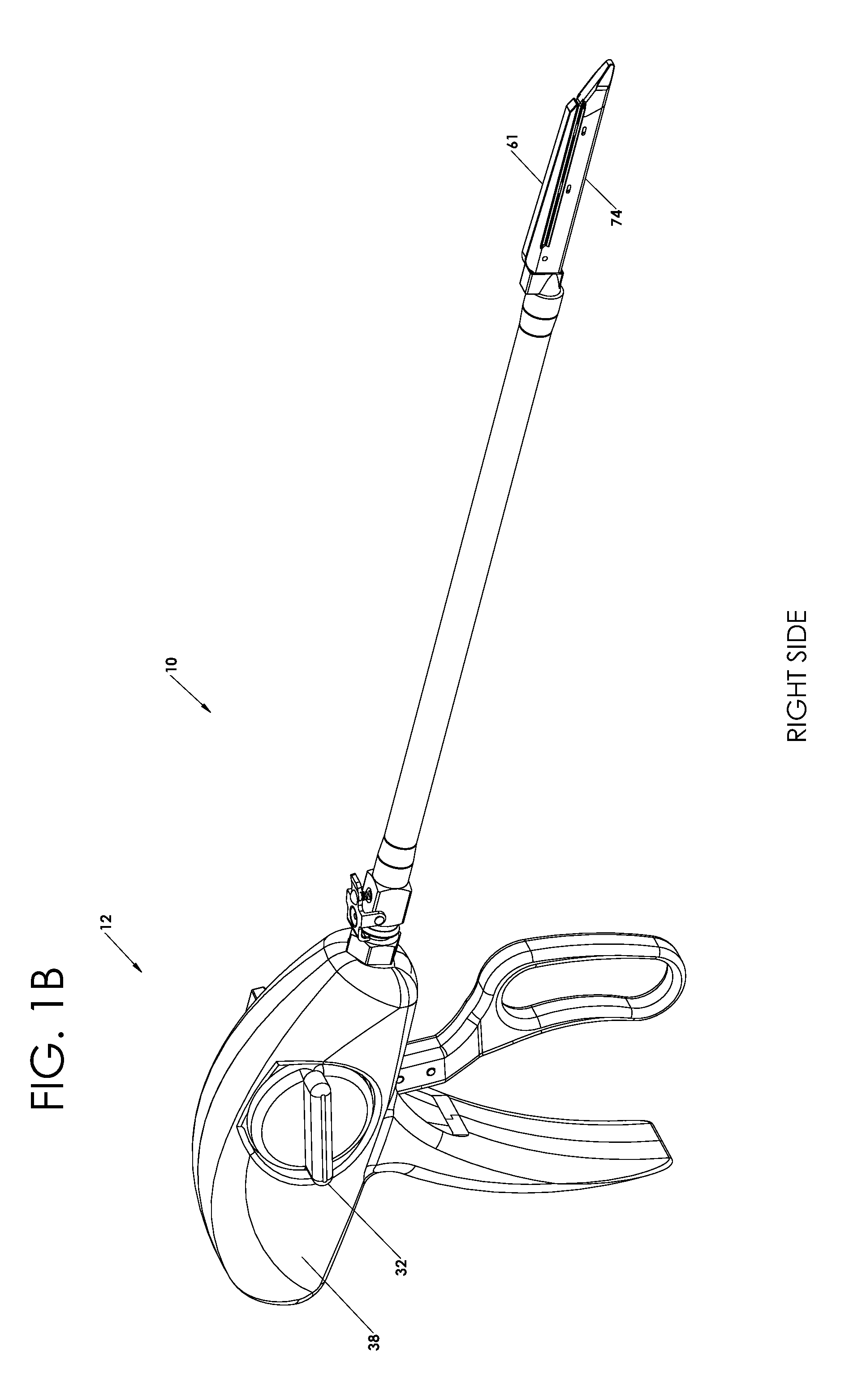

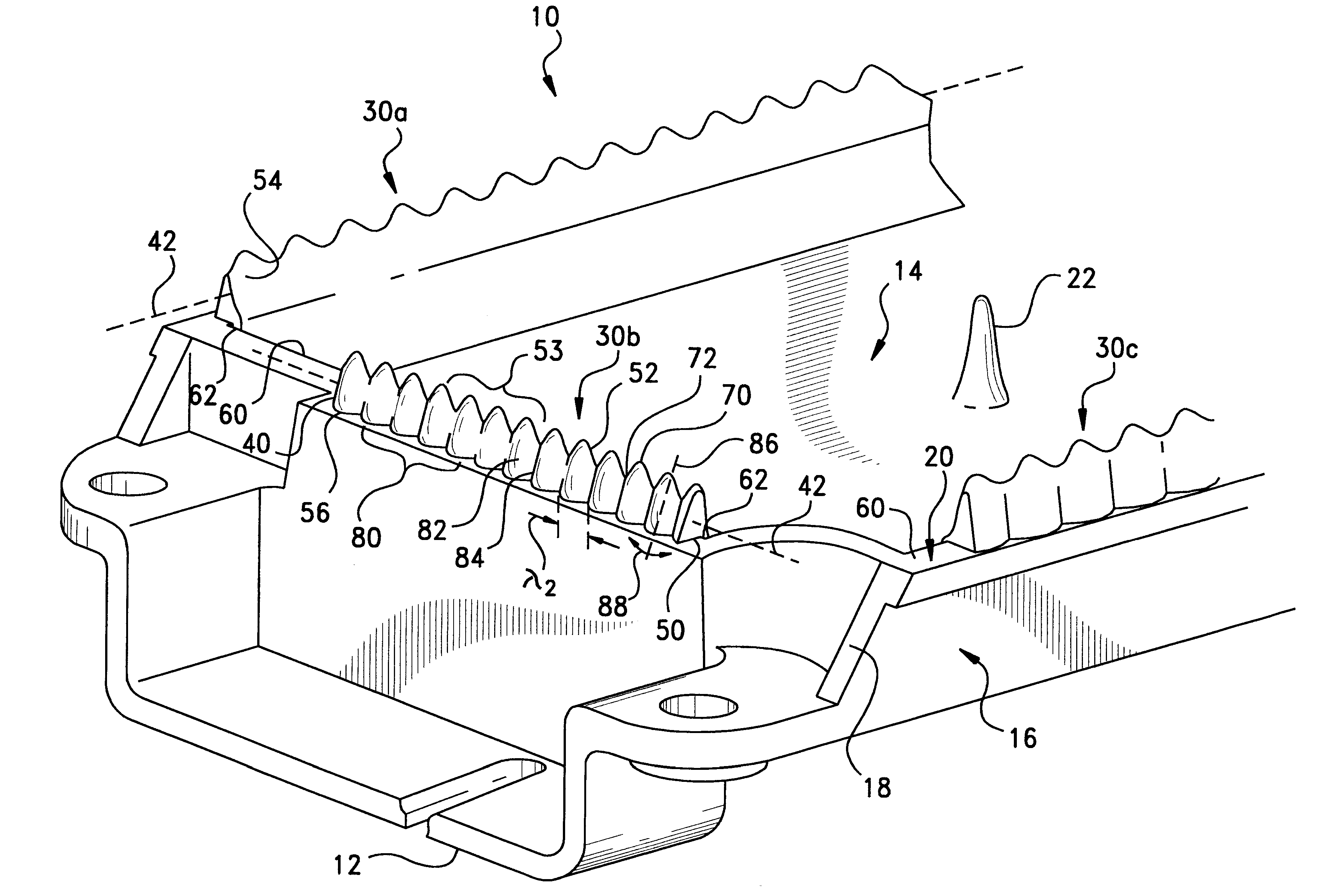

Delivery applicator for radioactive staples for brachytherapy medical treatment

InactiveUS8833631B2EffectiveMinimizing radiation doseSuture equipmentsStapling toolsSurgical stapleBrachytherapy

Owner:SOURCE PRODN & EQUIP

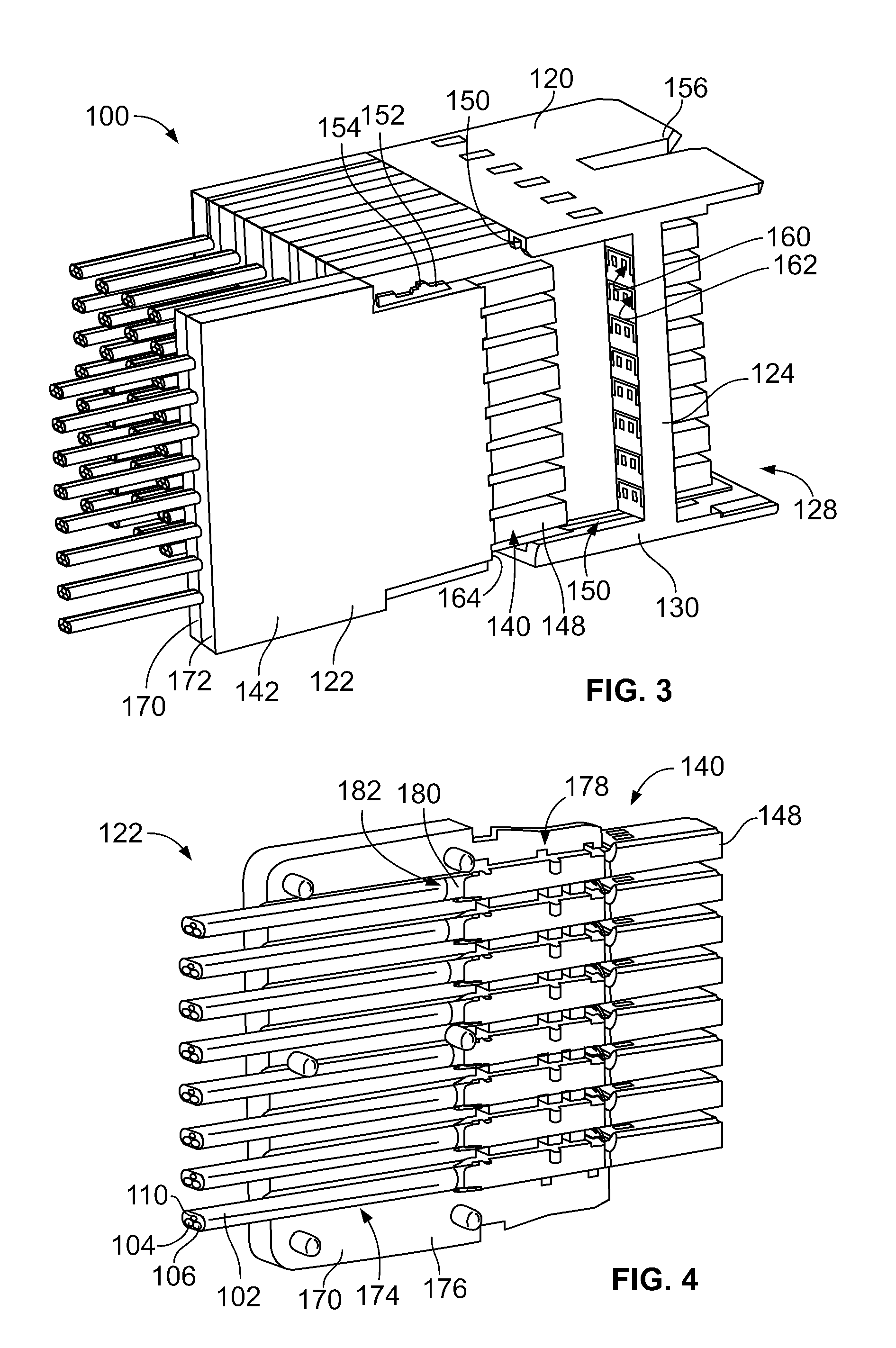

High speed, high density interconnect system for differential and single-ended transmission applications

InactiveUS6843657B2Simple and elegant latching mechanismEfficient use ofElectrically conductive connectionsCoupling contact membersHigh densityCoaxial cable

The present invention is directed to a high density electrical connector which can provide 80 or more twinax connections per linear inch in a 20 millimeter card slot. In a typical electronic system package, 20 millimeters is the spacing from center line to center line of the adjacent parallel daughtercards. Twinax cable is coaxial cable that contains two inner conducting wires rather than one. The two inner conducting wires provide two physical channels. Coaxial cable is called “coaxial” because it includes one physical channel that carries the signal surrounded (after a layer of insulation) by another concentric physical channel, both running along the same axis. The outer channel serves as ground.

Owner:WINCHESTER ELECTRONICS

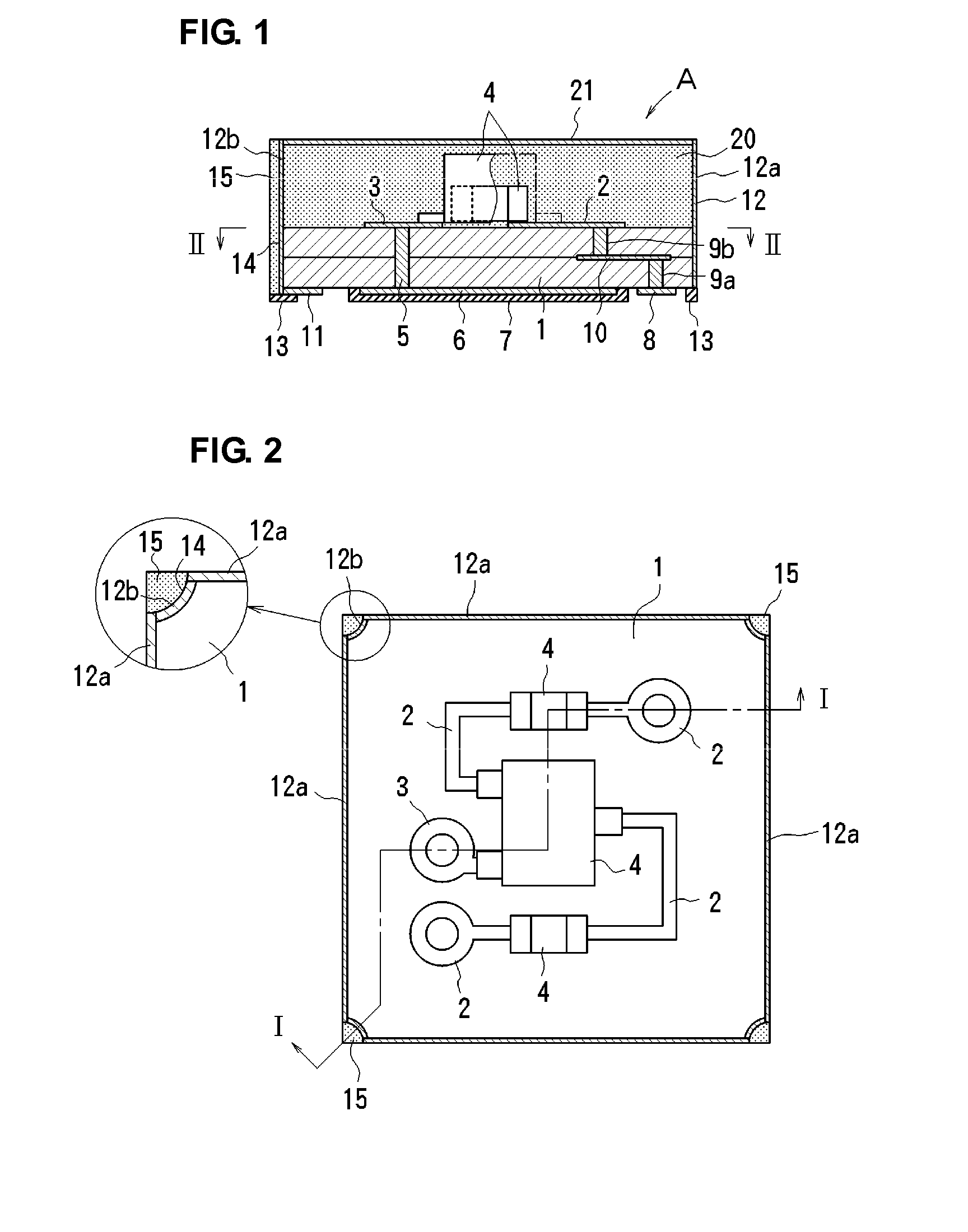

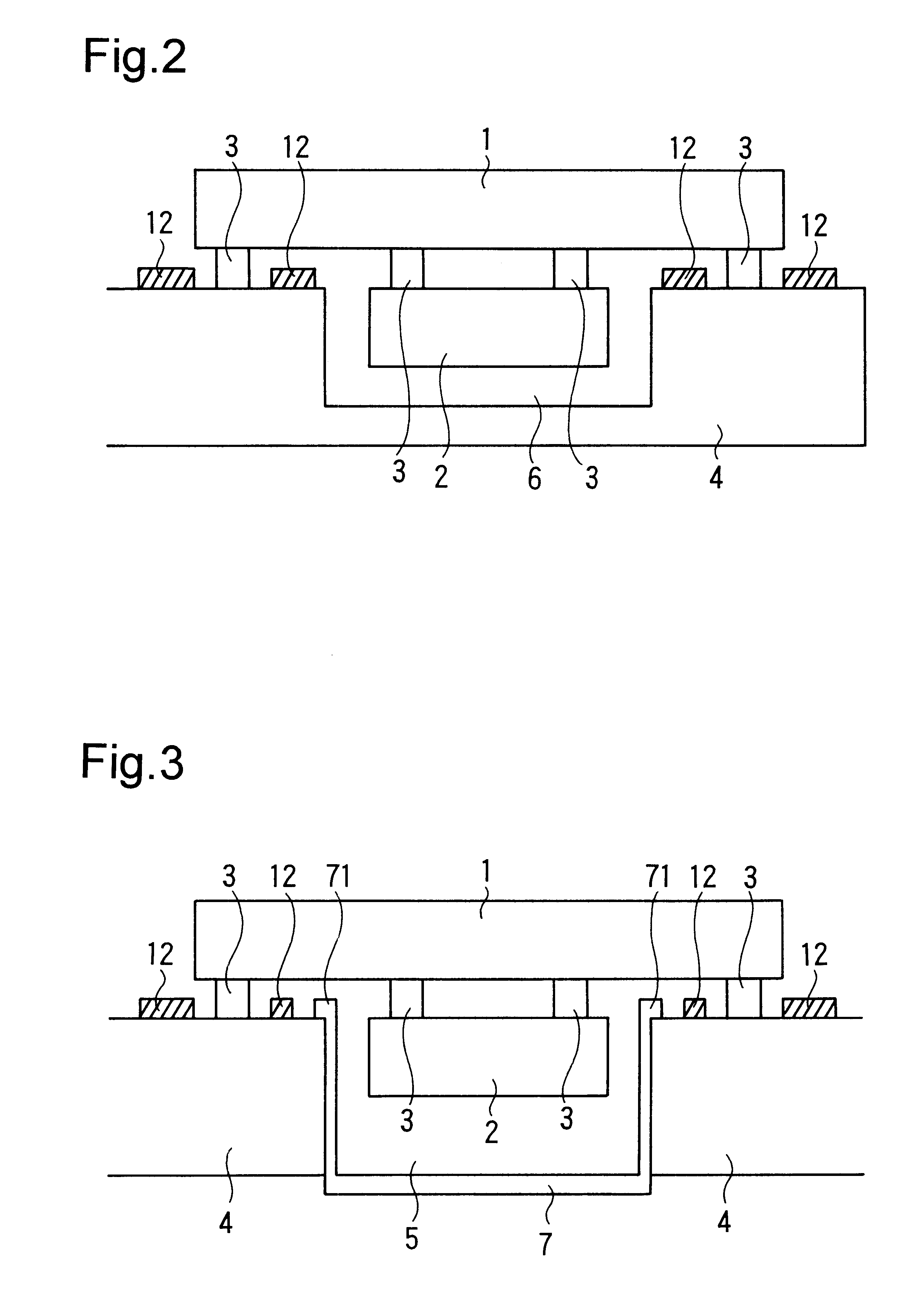

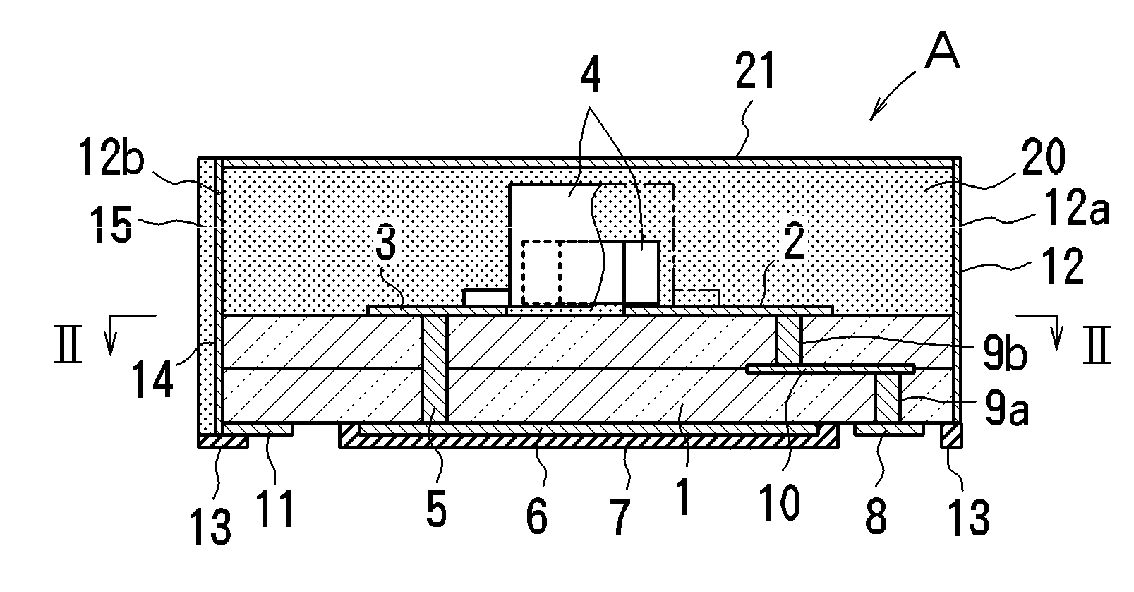

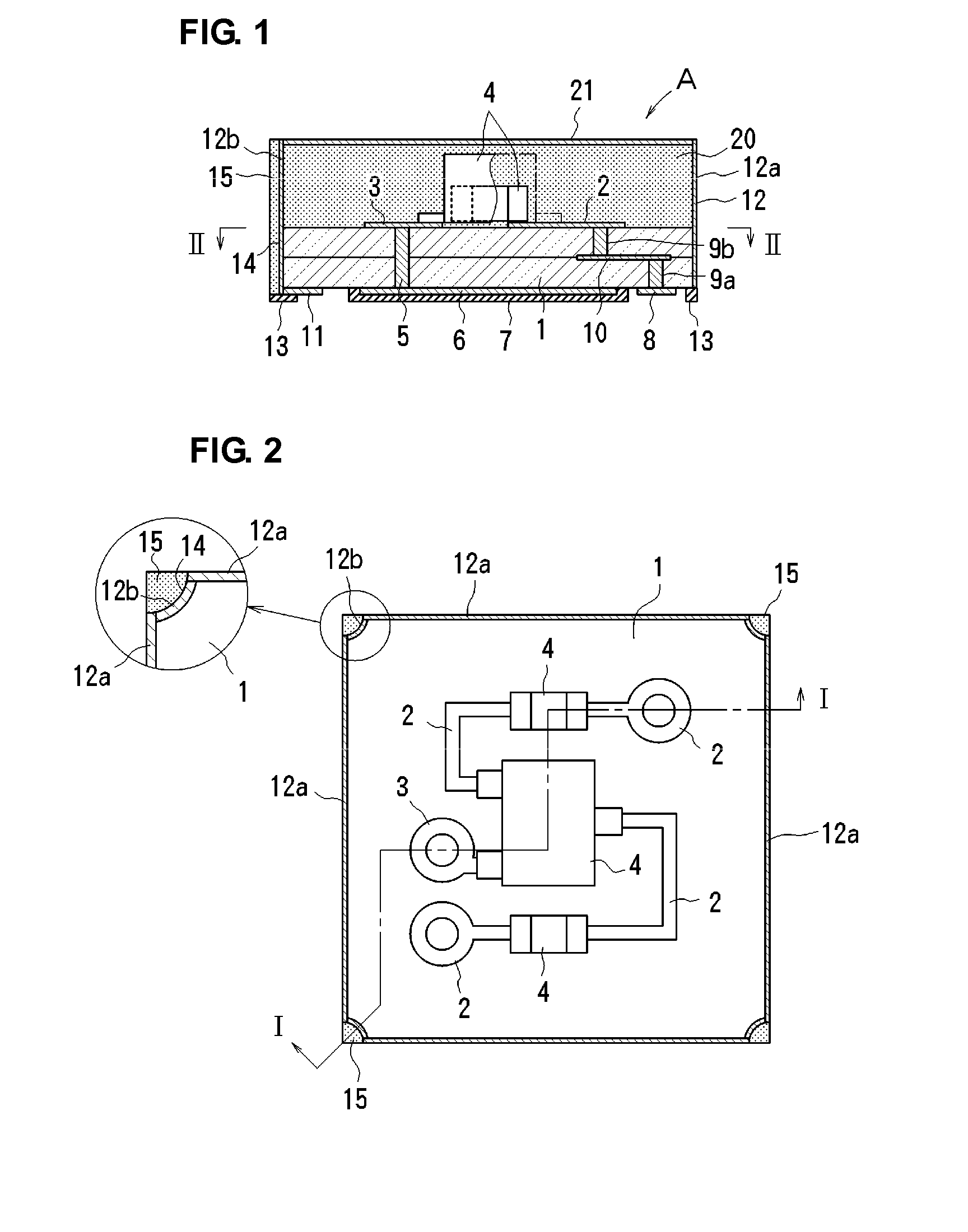

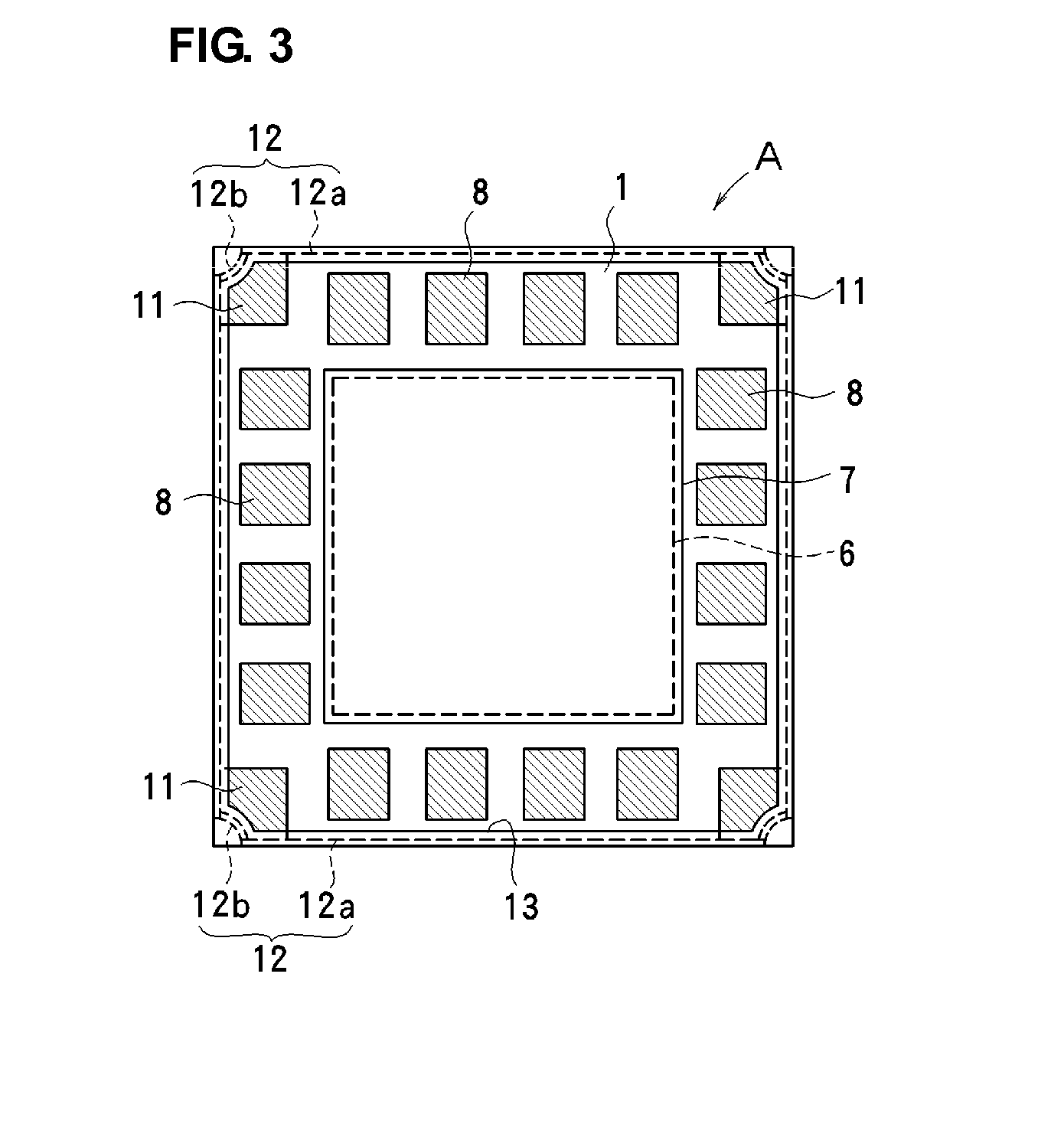

Method for manufacturing circuit modules and circuit module

ActiveUS20080210462A1Easy to manufactureImprove shielding effectPrinted circuit assemblingMagnetic/electric field screeningFilling materialsEngineering

A module substrate defined by an aggregate substrate is prepared, and circuit components are mounted on the module substrate. An insulating resin layer is formed on substantially the entire top surface of the module substrate such that the circuit components are disposed in the insulating resin layer, and a top-surface-shielding layer is formed on the top surface of the insulating resin layer. First through holes are formed in the module substrate and the insulating resin layer at locations corresponding to portions of boundary lines of small substrates so as to extend in a thickness direction of the module substrate and the insulating resin layer. First electrode films are formed on the inner surfaces of the first through holes so as to be connected to the first shielding layer, and the first through holes are filled with a filling material. Next, second through holes are formed at locations corresponding to the remaining portions of the boundary lines of small substrates so as to extend in the thickness direction, and second electrode films are formed on the inner surfaces of the second through holes so as to be connected to the top-surface-shielding layer and the first electrode films. The filling material, with which the first through holes are filled, is cut along the boundary lines of small substrates, resulting in a division of the aggregate substrate into small substrates to obtain circuit modules.

Owner:MURATA MFG CO LTD

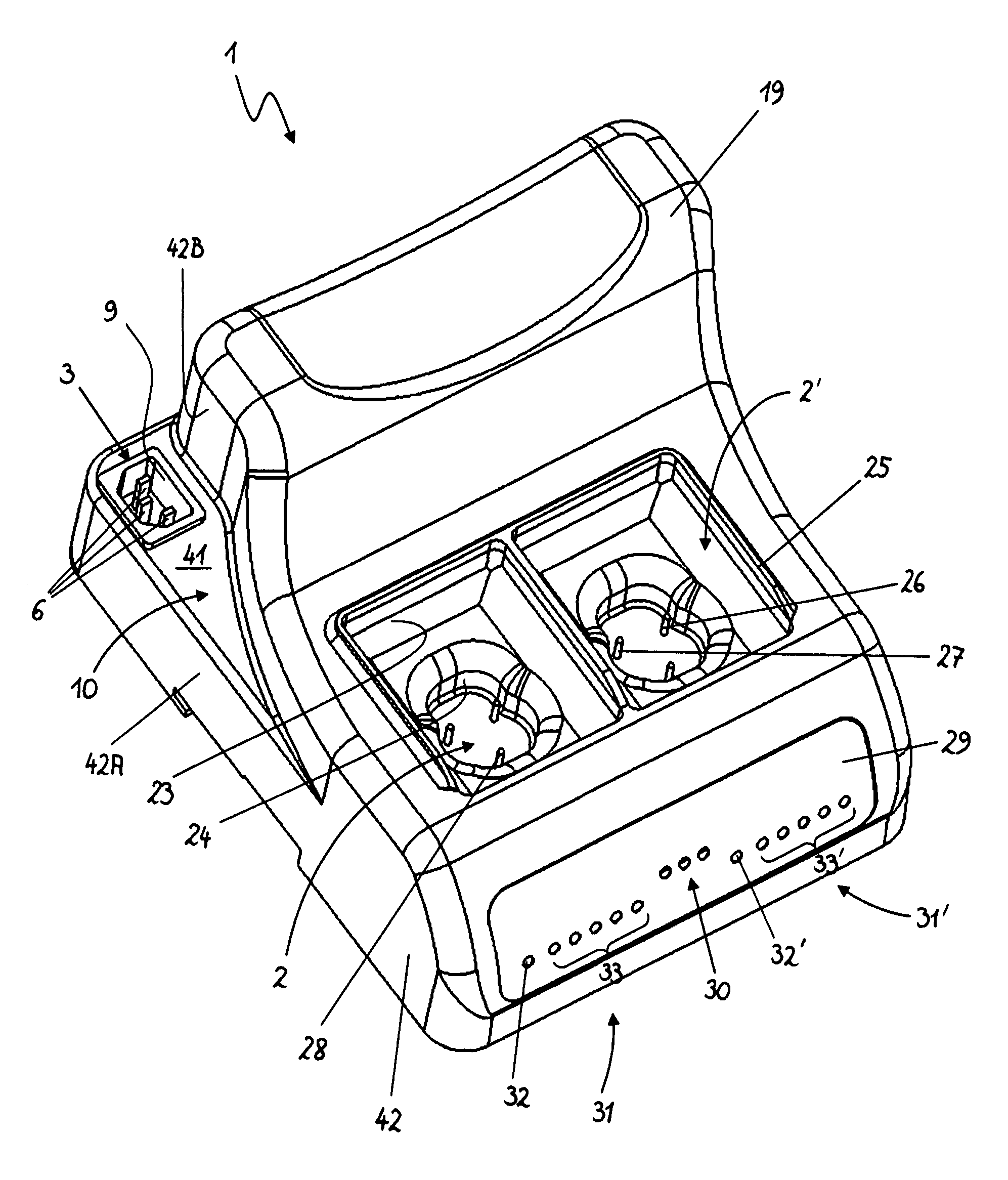

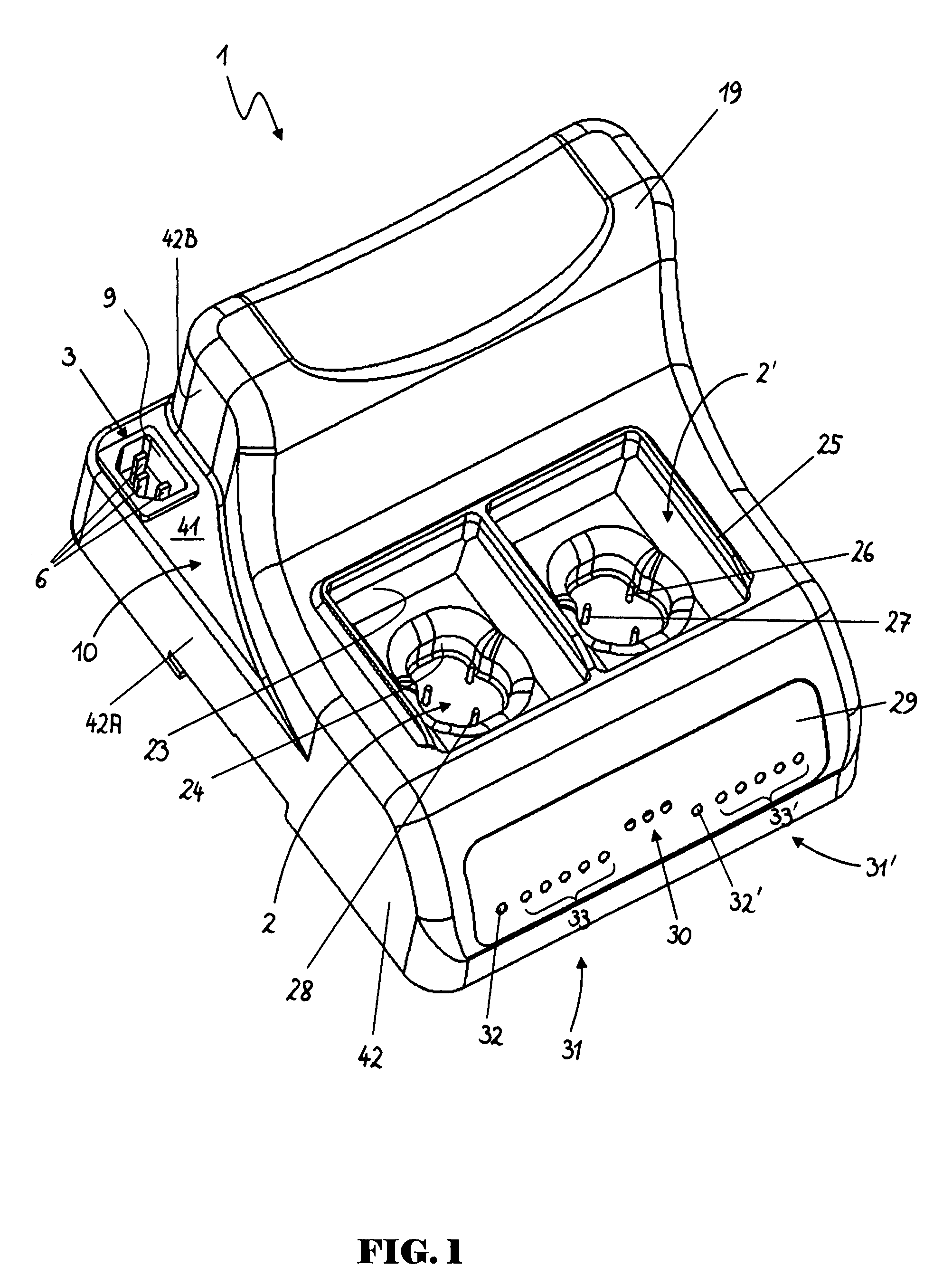

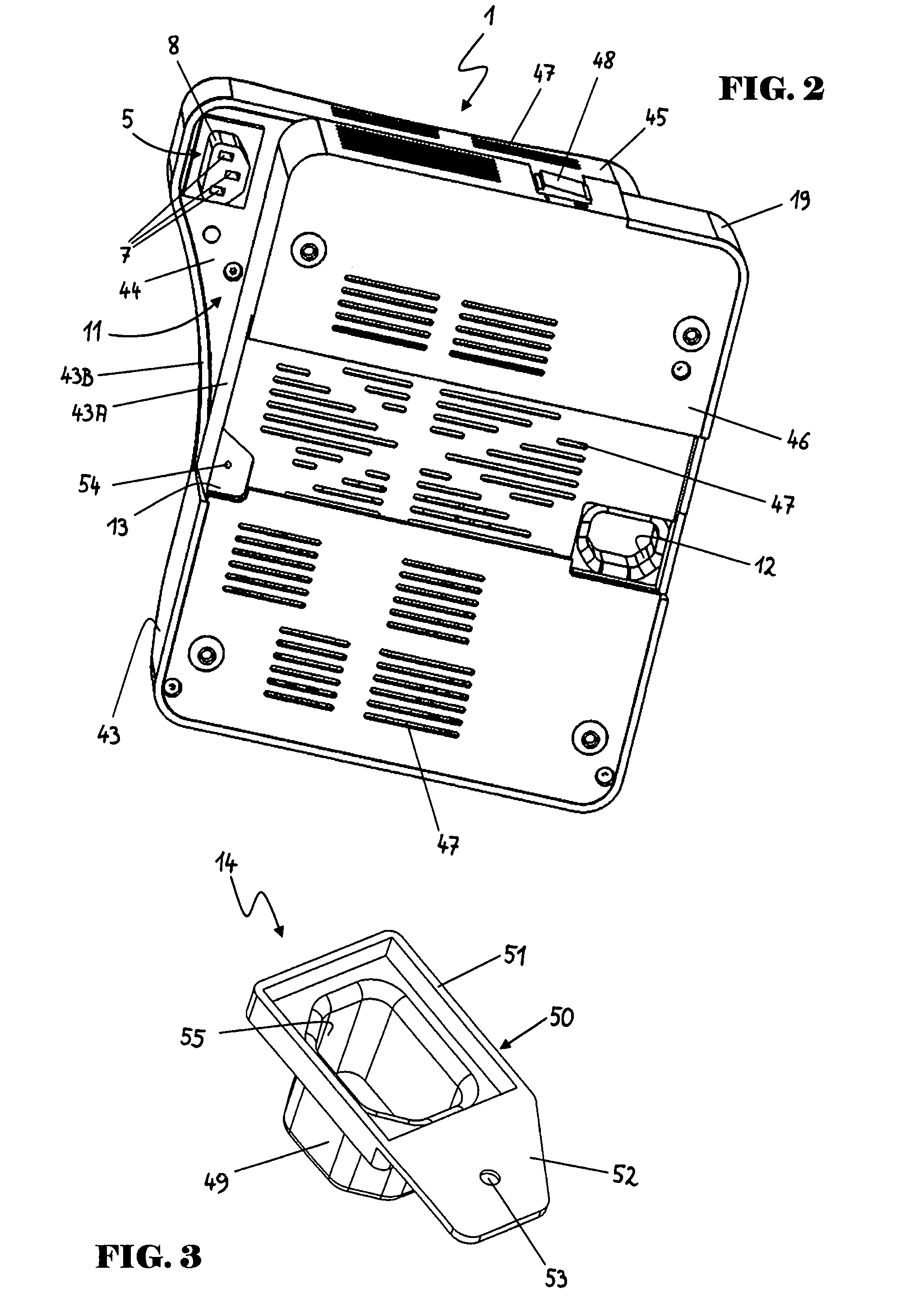

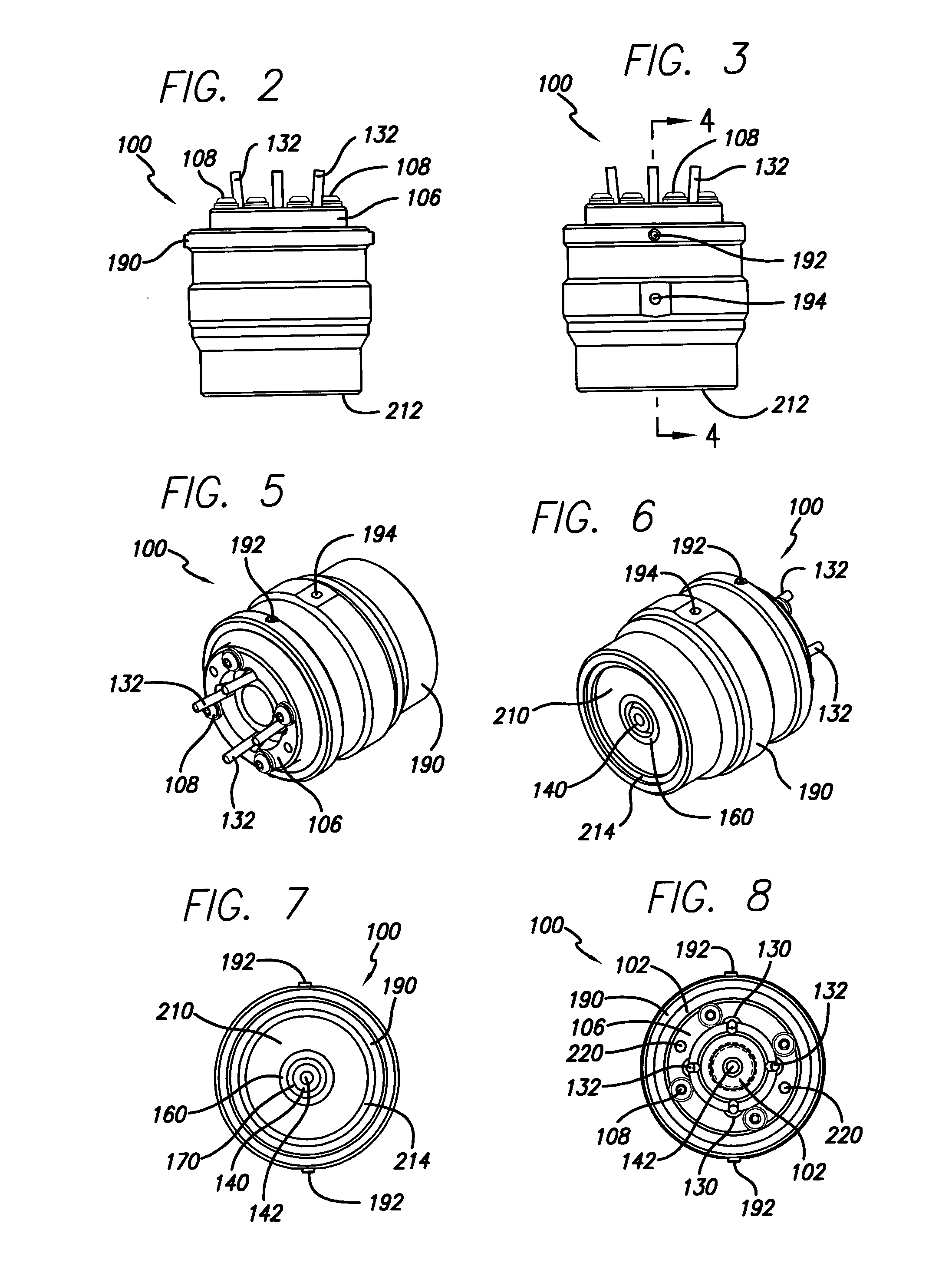

Device for charging batteries

ActiveUS20080079391A1Resistant to soilingImprove the immunityCells structural combinationSecondary cells charging/dischargingIdentification deviceEngineering

Chargers which can be connected to batteries with different charging requirements and which have an identification device for identification of the different batteries are disclosed. With these chargers, the different types of batteries are recognized by a magnetic identification device. In a first exemplary embodiment, the identification device comprises at least one magnetic sensor, which is arranged in or on the charger and detects at least one magnetic parameter of a magnetic element, which is mounted in or on the battery. In a second exemplary embodiment, the identification device has at least one magnetic element and at least one magnetic sensor for detection of at least one magnetic parameter of the at least one magnetic element. The battery comprises a shielding and / or amplifying device, which alter(s) the at least one magnetic parameter of the at least one magnetic element.

Owner:ARTHREX

Coaxial nozzle design for laser cladding/welding process

InactiveUS20050056628A1Reliably-symmetric powder flowLong-term useLaser beam welding apparatusLaser NozzleShielding gas

A laser nozzle for use in a laser powder fusion (LPF) welding process provides longer service life and ease of maintenance. Eliminating the use of laser nozzle inserts, the laser nozzle uses an inner tip that is less subject to damage from the welding process. The laser beam travels down an open central passage to exit out the inner tip in focused alignment with a conical powder flow stream ending in a point generally coincident with the laser beam. The powder supply travels through a passage that is generally coaxial to the central laser passage. A circumscribing passage for inert shielding gas or the like is coincidentally coaxial with both the laser powder flow channel and the central laser channel. Coolant is circulated through a main body portion of the nozzle in order to keep the entire assembly cool. Both the laser and the flow of powder may be adjusted according to operating preferences. A porous shielding cover prevents ejecta and other materials from entering into the shielding gas flow channel. The entire assembly is easily constructed from readily available materials and is easily disassembled for cleaning. Reassembly is also easily achieved in order to enable rapid refurbishment and reconstitution of an optimal LPF welding nozzle.

Owner:HONEYWELL INT INC

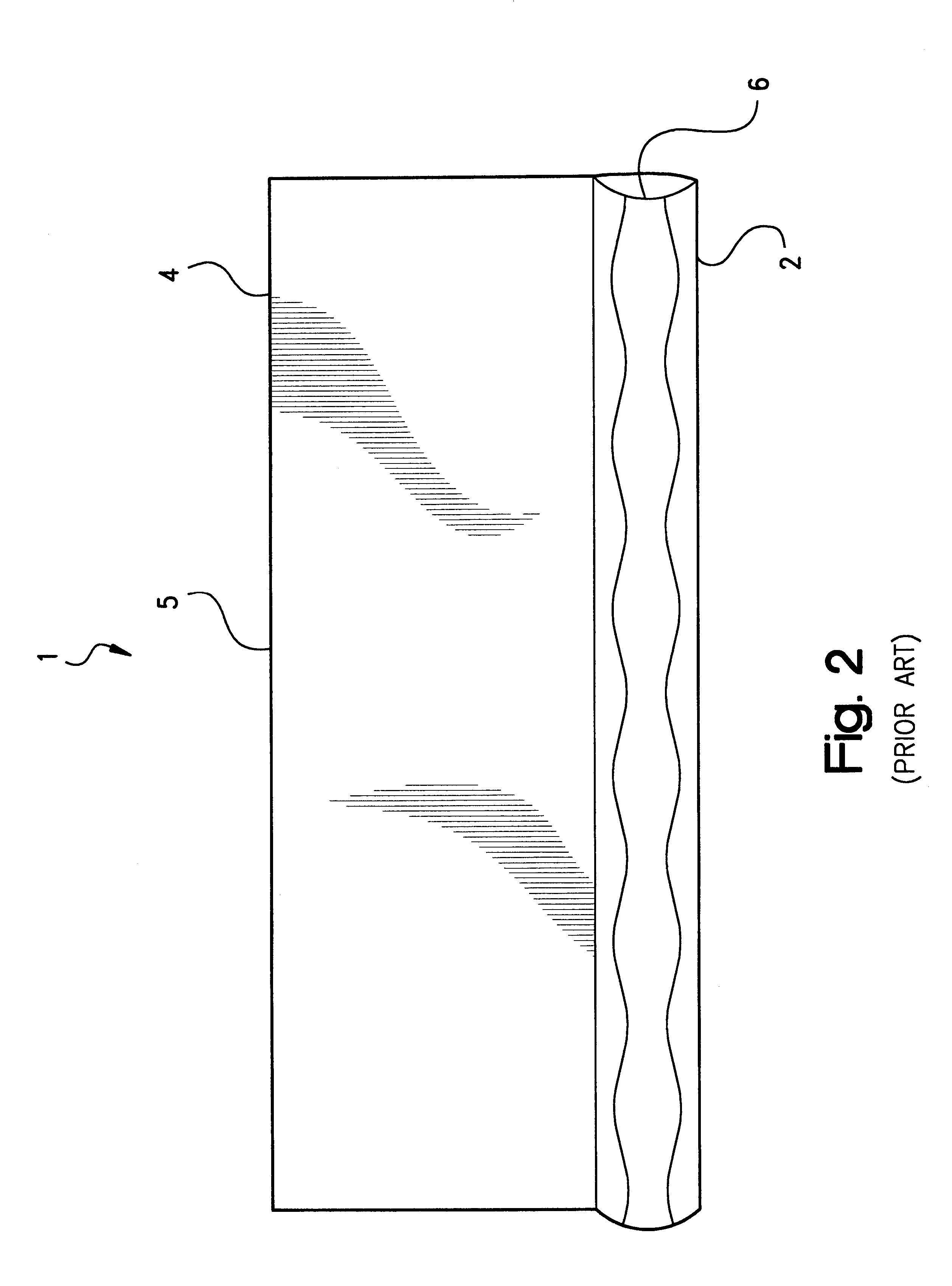

Low closure force EMI shielding spacer gasket

InactiveUS6121545AEnhance the imageEnsure electrical continuityEngine sealsScreening gaskets/sealsEdge surfaceBending moment

An EMI shielding spacer gasket assembly for interposition under a predetermined compressive load within an electronics enclosure between a first surface and an oppositely-disposed second surface of the enclosure. The assembly includes a frame member and an electrically conductive, elastomeric member extending along at least a portion of the perimeter of the frame member as retained on a corresponding peripheral edge surface thereof. The elastomeric member has an outboard side which is compressible axially under the compressive load for providing an electrically conductive pathway between the surfaces of the enclosure. In an uncompressed orientation, the outboard side of the elastomeric member exhibits elongate upper and lower bearing portions which are disposed at a spaced-apart radial distance from the frame member to define a corresponding bending moment arm. Each of the bearing portions is angularly deflectable relative to the moment arm to effect the compression of the elastomeric member under a relatively low compressive load.

Owner:PARKER INTANGIBLES LLC

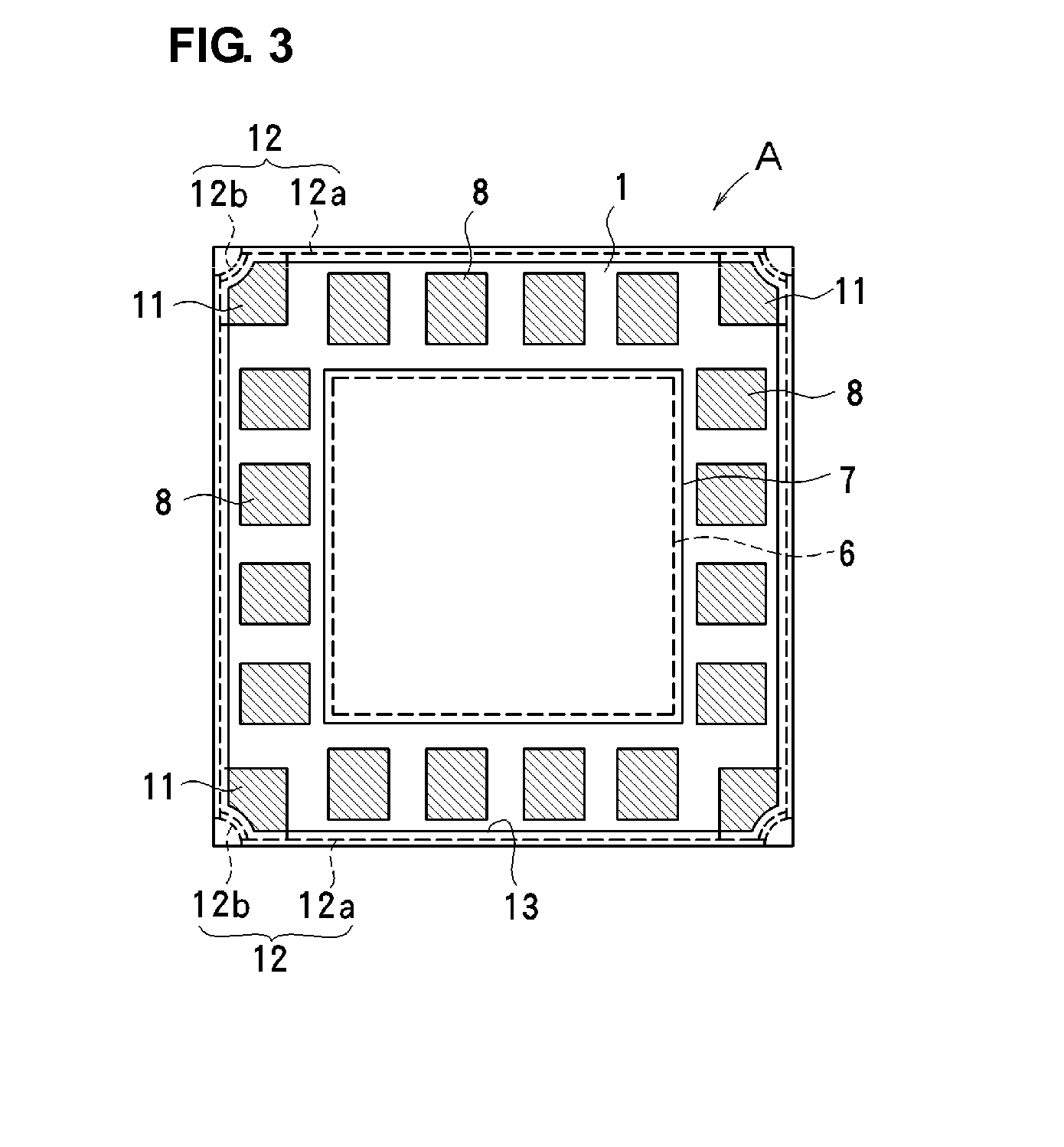

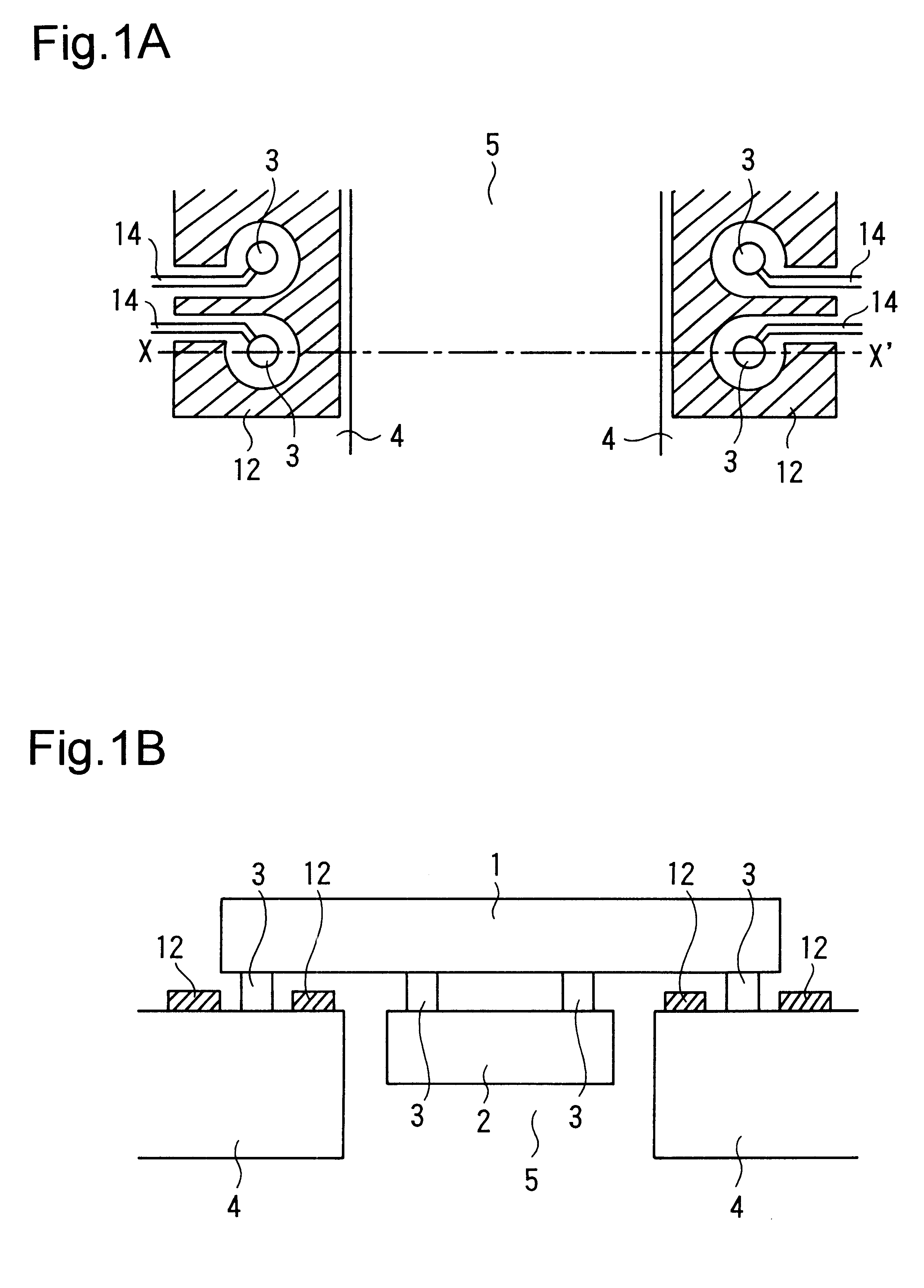

Integrated circuit device

InactiveUS6489669B2Reduce the amount requiredLow costSemiconductor/solid-state device detailsSolid-state devicesEngineeringInductance

An integrated circuit device as a first IC chip, a second IC chip, and a circuit board having a hole formed therein that is large enough to permit the second IC chip to be accommodated therein. The first and second IC chips are bonded together so as to be electrically connected together, and the first IC chip is mounted on the circuit board with the second IC chip accommodated in the hole formed in the circuit board. Here, one of the IC chips forming a chip-on-chip structure is accommodated in the hole formed in the circuit board, making further thickness reduction possible. Moreover, the obverse surfaces of the IC chips are located closer to the circuit board, making possible wireless mounting of the IC chips, despite forming a chip-on-chip structure, on the circuit board through connection using bumps. This helps reduce trouble due to inductance in a circuit that handles a high-frequency signal.

Owner:ROHM CO LTD

Carbon nanotube containing materials and articles containing such materials for altering electromagnetic radiation

InactiveUS20050272856A1Reduce performanceImprove performanceMaterial nanotechnologyMagnetic/electric field screeningCarbon nanotubeElectromagnetic radiation

Disclosed herein is a material for altering electromagnetic radiation incident on the material. The material disclosed herein comprises carbon nanotubes having a length (L) that meets the following formula (1): L≧½λ (1) where λ is the wavelength of the electromagnetic radiation incident on the material. Also disclosed herein are methods of altering electromagnetic radiation, including mitigating, intensifying, or absorbing and re-transmitting electromagnetic radiation using the disclosed material.

Owner:MULTIPURE INT

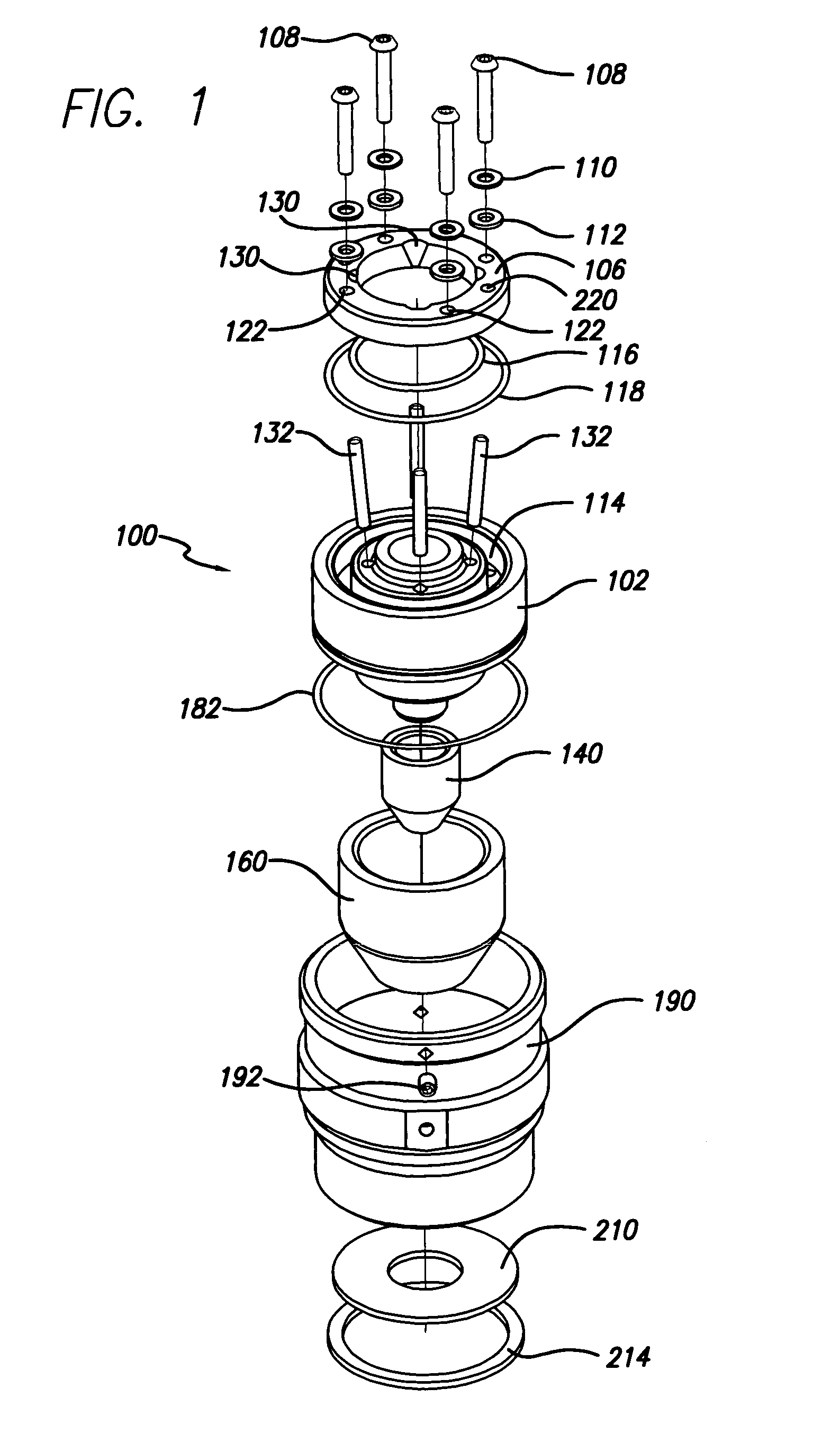

Delivery Applicator for Radioactive Staples for Brachytherapy Medical Treatment

InactiveUS20120292369A1Effective treatmentMinimizing radiation doseSuture equipmentsStapling toolsSurgical stapleBrachytherapy

A staple delivery applicator for delivering radioactive staples during brachytherapy medical treatment has an actuating device for at source staples located distally from the actuating device. The actuating device is removably attachable to an actuator arm on a proximal end. A staple applicator cartridge holder is attached to the actuator arm on a distal end. The staple applicator cartridge is mountable in the holder and having a plurality of slots for mounting of radioactive source staples therein. An anvil therein crimps the staples. The staple applicator cartridge holder is removably mountable in a connector and the connector is also removably mounted to a surgical staple holder. A trigger device being one of the actuating devices has a control for closing the anvil of the cartridge holder and for firing of the source staples in the cartridge therein to cause the staples to crimp, and a control for opening the anvil and releasing the trigger device from the actuator arm.

Owner:SOURCE PRODN & EQUIP

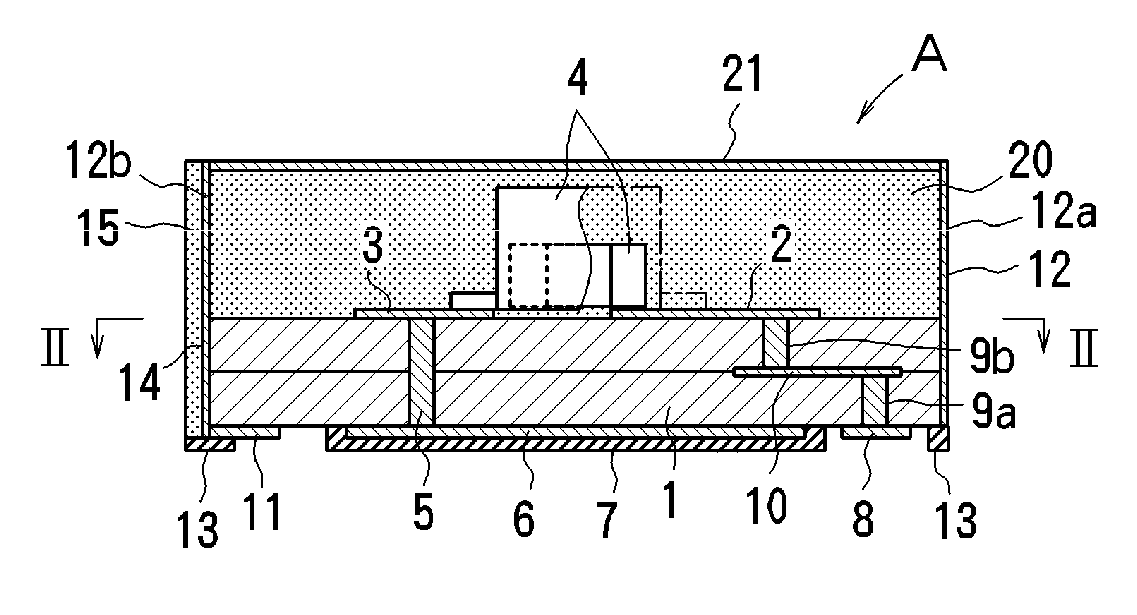

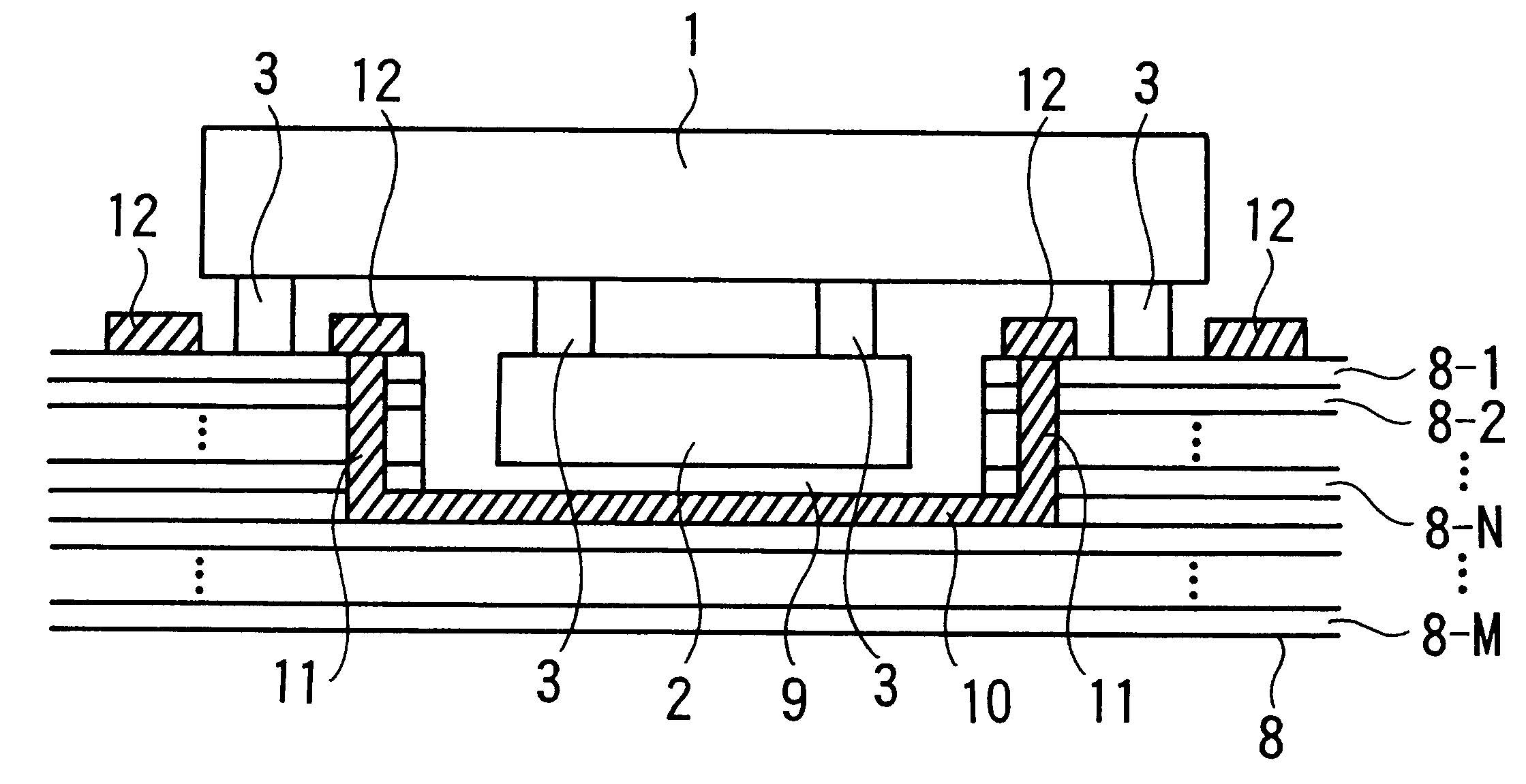

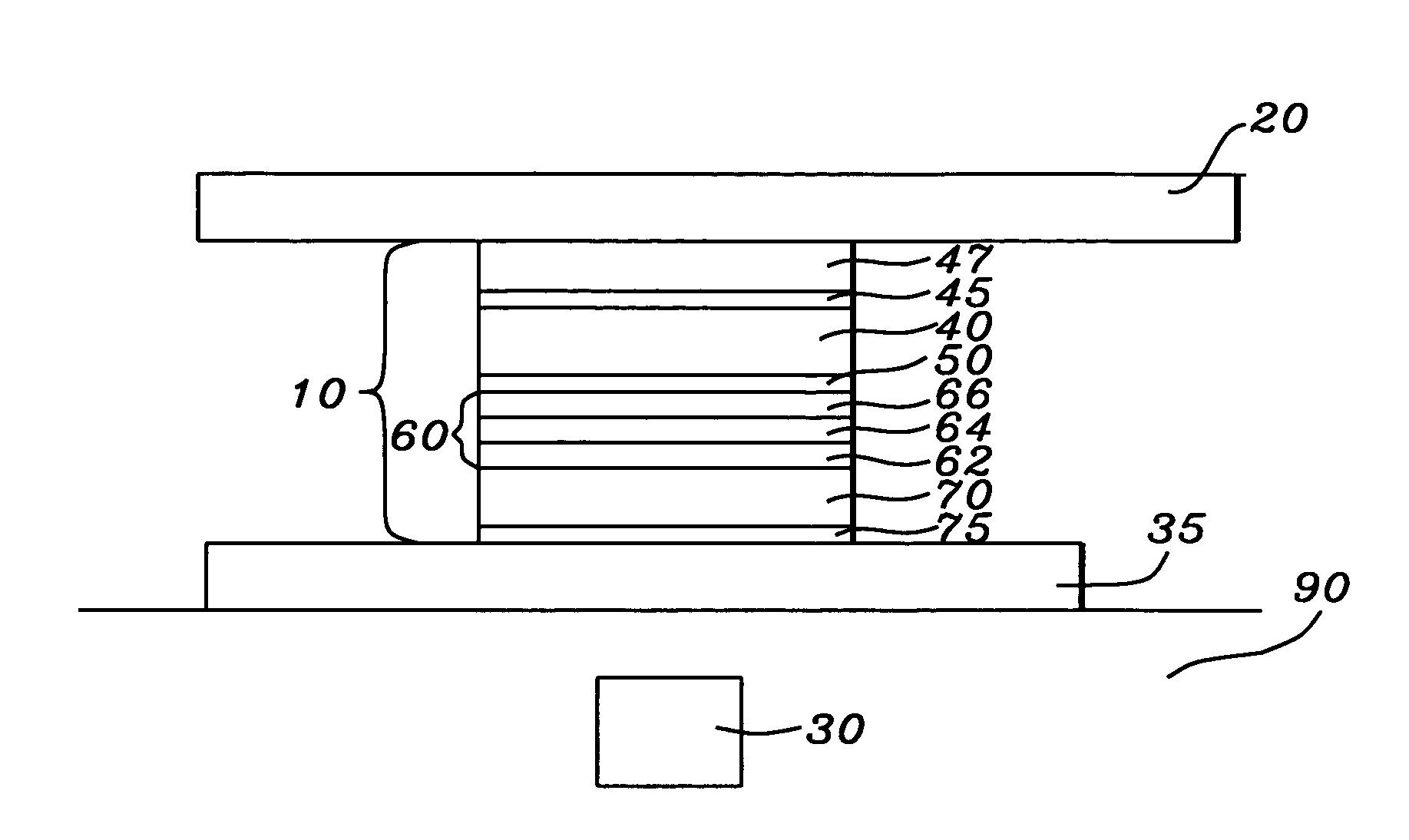

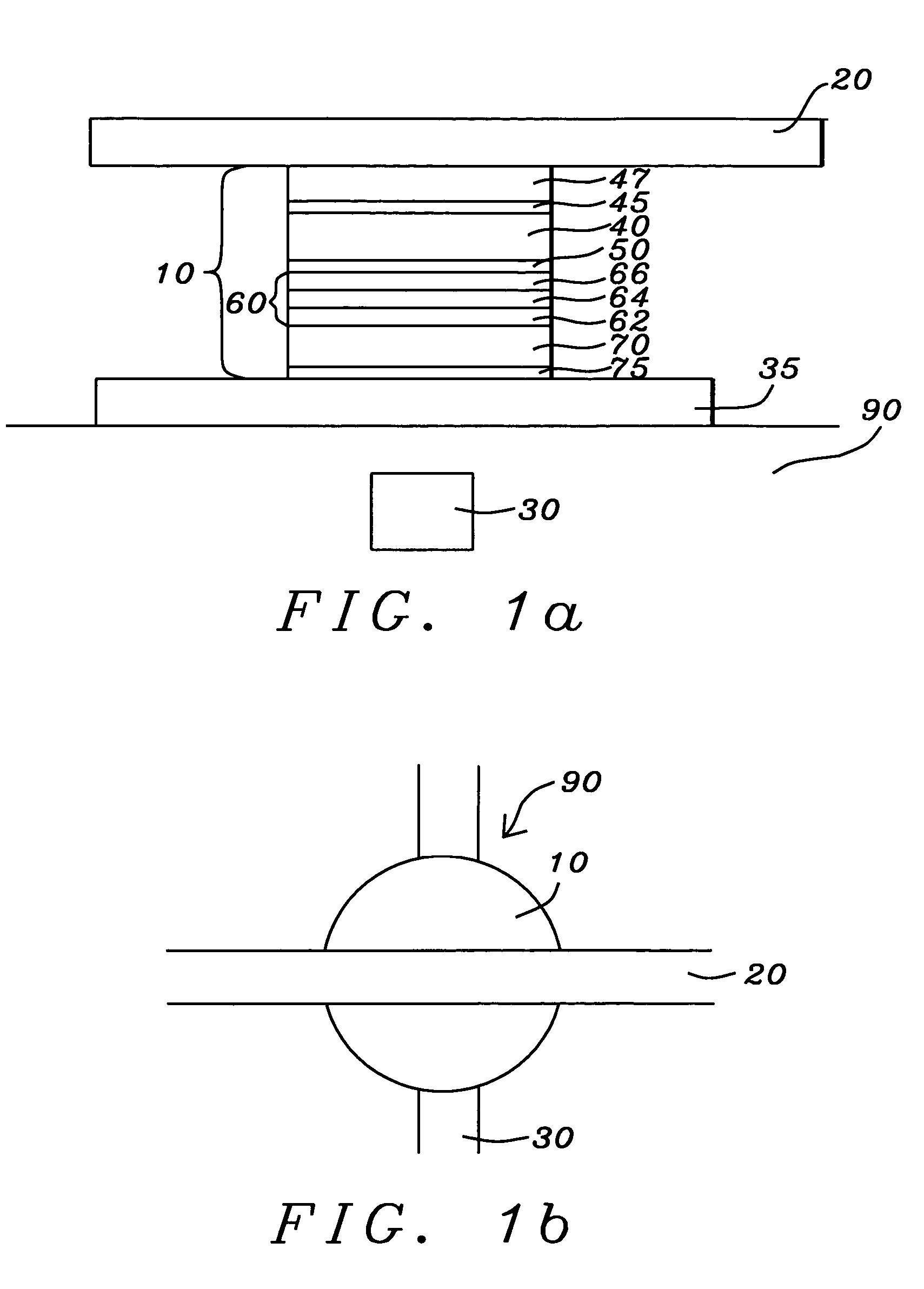

Method for manufacturing circuit modules and circuit module

ActiveUS7488903B2Easy to manufactureImprove shielding effectPrinted circuit assemblingMagnetic/electric field screeningFilling materialsEngineering

A module substrate defined by an aggregate substrate is prepared, and circuit components are mounted on the module substrate. An insulating resin layer is formed on substantially the entire top surface of the module substrate such that the circuit components are disposed in the insulating resin layer, and a top-surface-shielding layer is formed on the top surface of the insulating resin layer. First through holes are formed in the module substrate and the insulating resin layer at locations corresponding to portions of boundary lines of small substrates so as to extend in a thickness direction of the module substrate and the insulating resin layer. First electrode films are formed on the inner surfaces of the first through holes so as to be connected to the first shielding layer, and the first through holes are filled with a filling material. Next, second through holes are formed at locations corresponding to the remaining portions of the boundary lines of small substrates so as to extend in the thickness direction, and second electrode films are formed on the inner surfaces of the second through holes so as to be connected to the top-surface-shielding layer and the first electrode films. The filling material, with which the first through holes are filled, is cut along the boundary lines of small substrates, resulting in a division of the aggregate substrate into small substrates to obtain circuit modules.

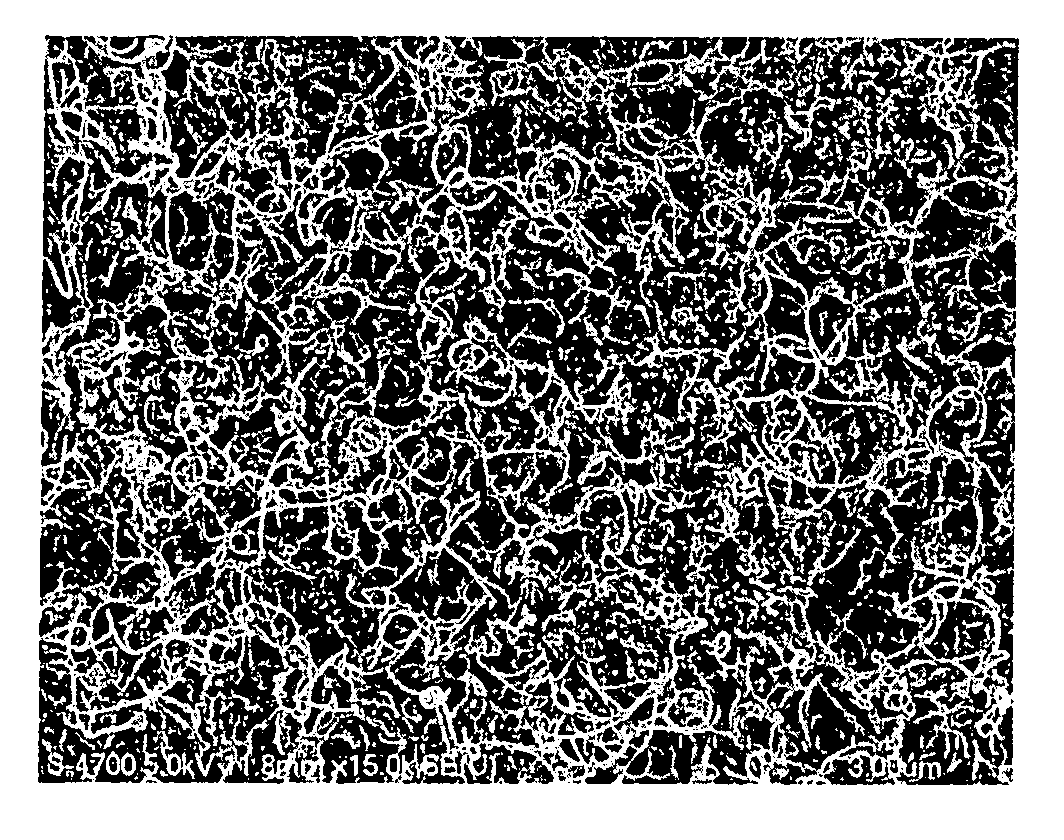

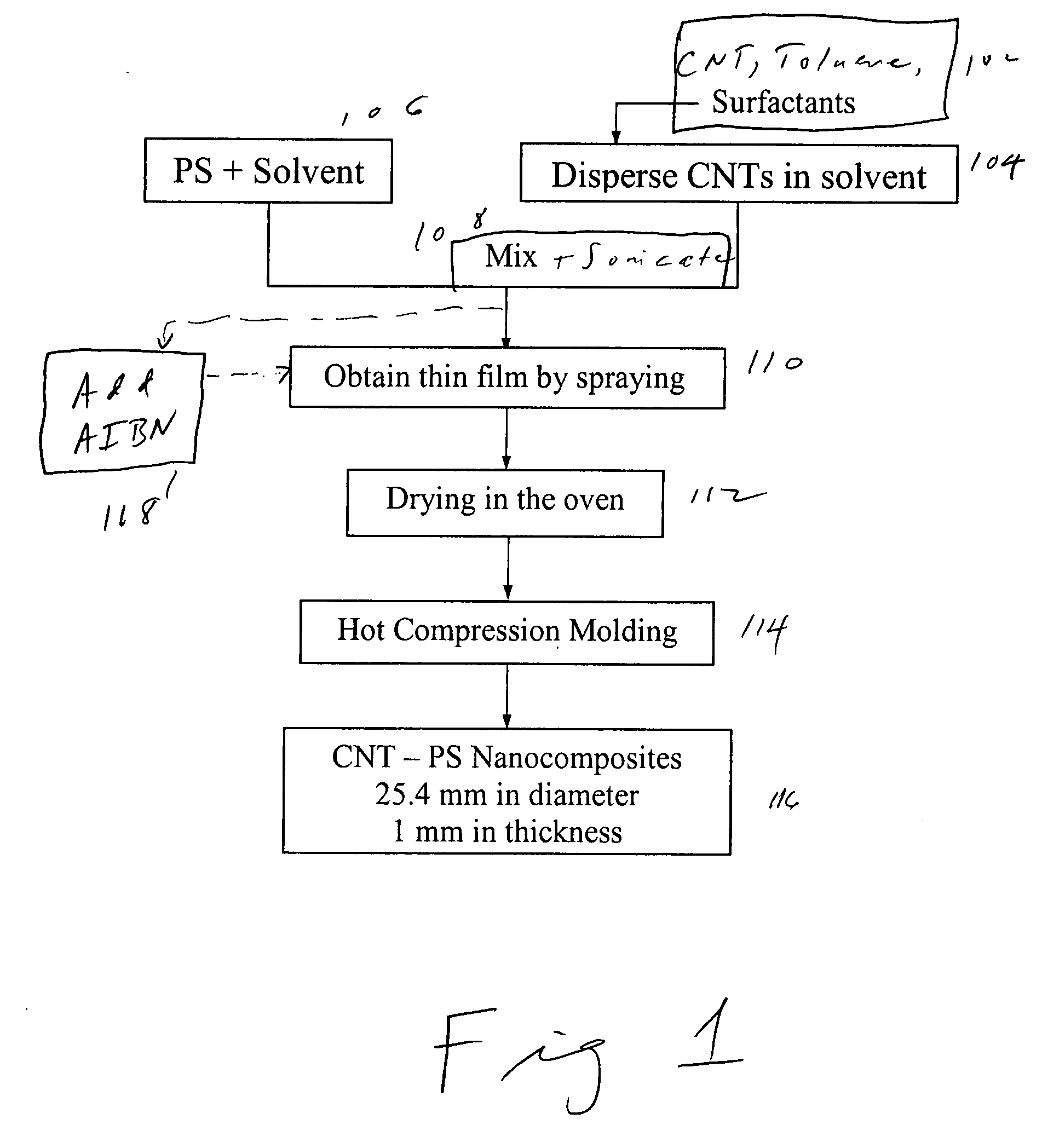

Conducting Nanotubes or Nanostructures Based Composites, Method of Making Them and Applications

ActiveUS20100000770A1High conductivity and strengthSmall diameterGroup 4/14 element organic compoundsLine/current collector detailsSolventDecomposition

An electromagnetic interference (EMI) shielding material includes a matrix of a dielectric or partially conducting polymer, such as foamed polystyrene, with carbon nanotubes or other nanostructures dispersed therein in sufficient concentration to make the material electrically conducting. The composite is formed by dispersing the nanotube material in a solvent in which the dielectric or partially conducting polymer is soluble and mixing the resulting suspension with the dielectric or partially conducting polymer. A foaming agent can be added to produce a lightweight foamed material. An organometallic compound can be added to enhance the conductivity further by decomposition into a metal phase.

Owner:NASA +1

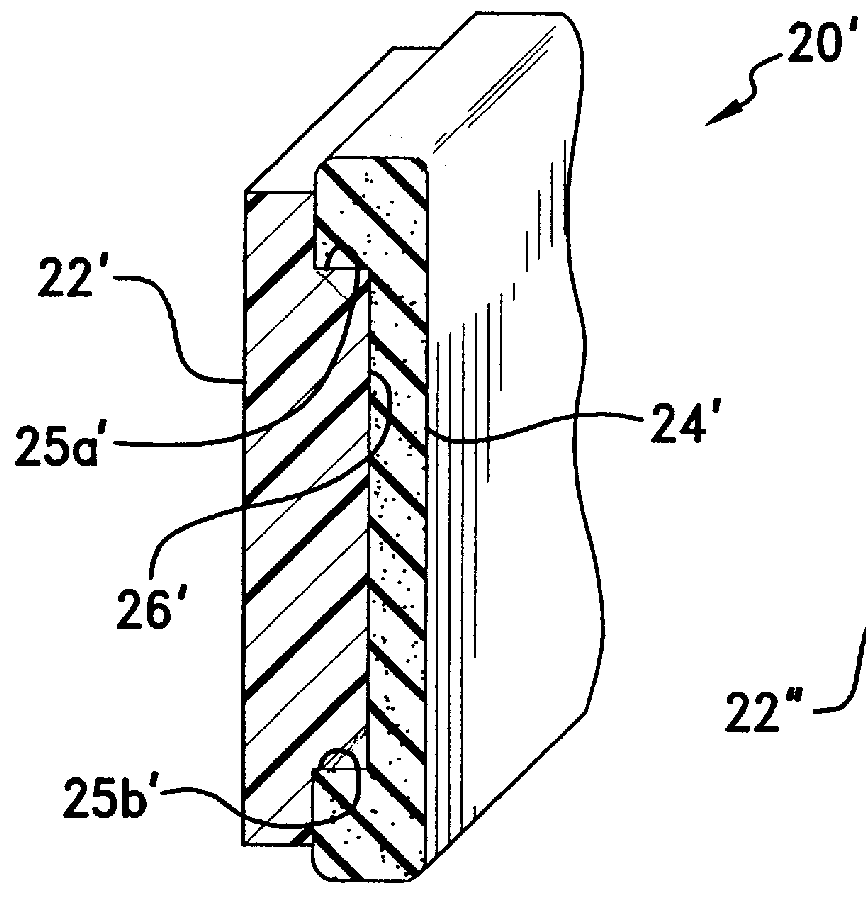

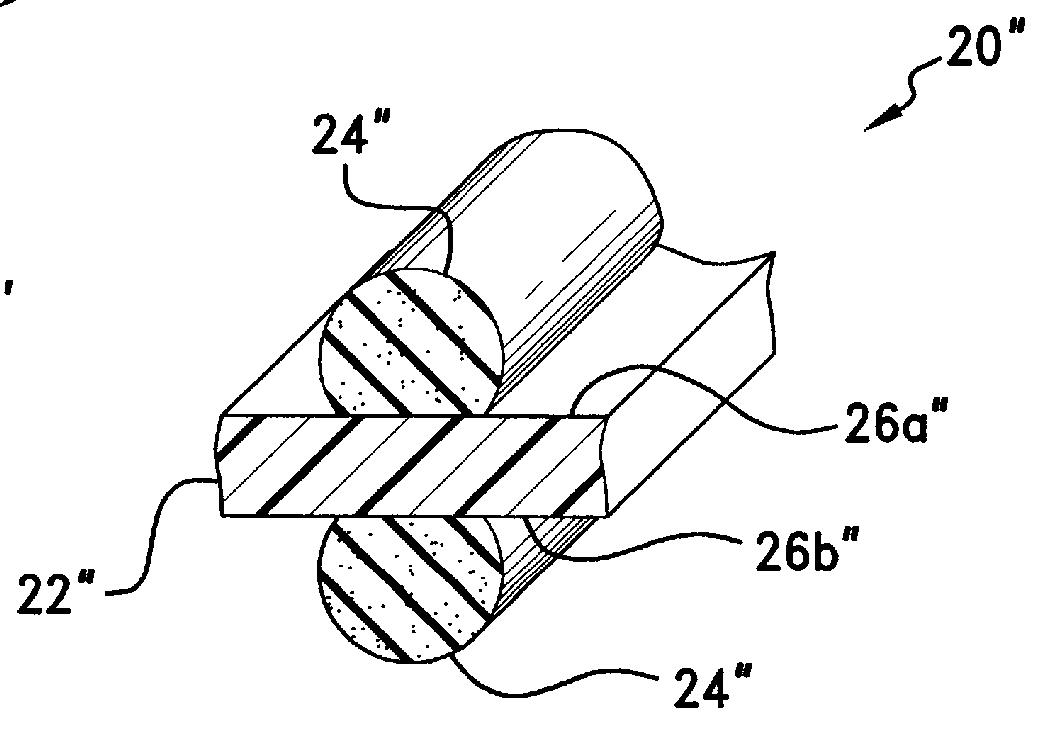

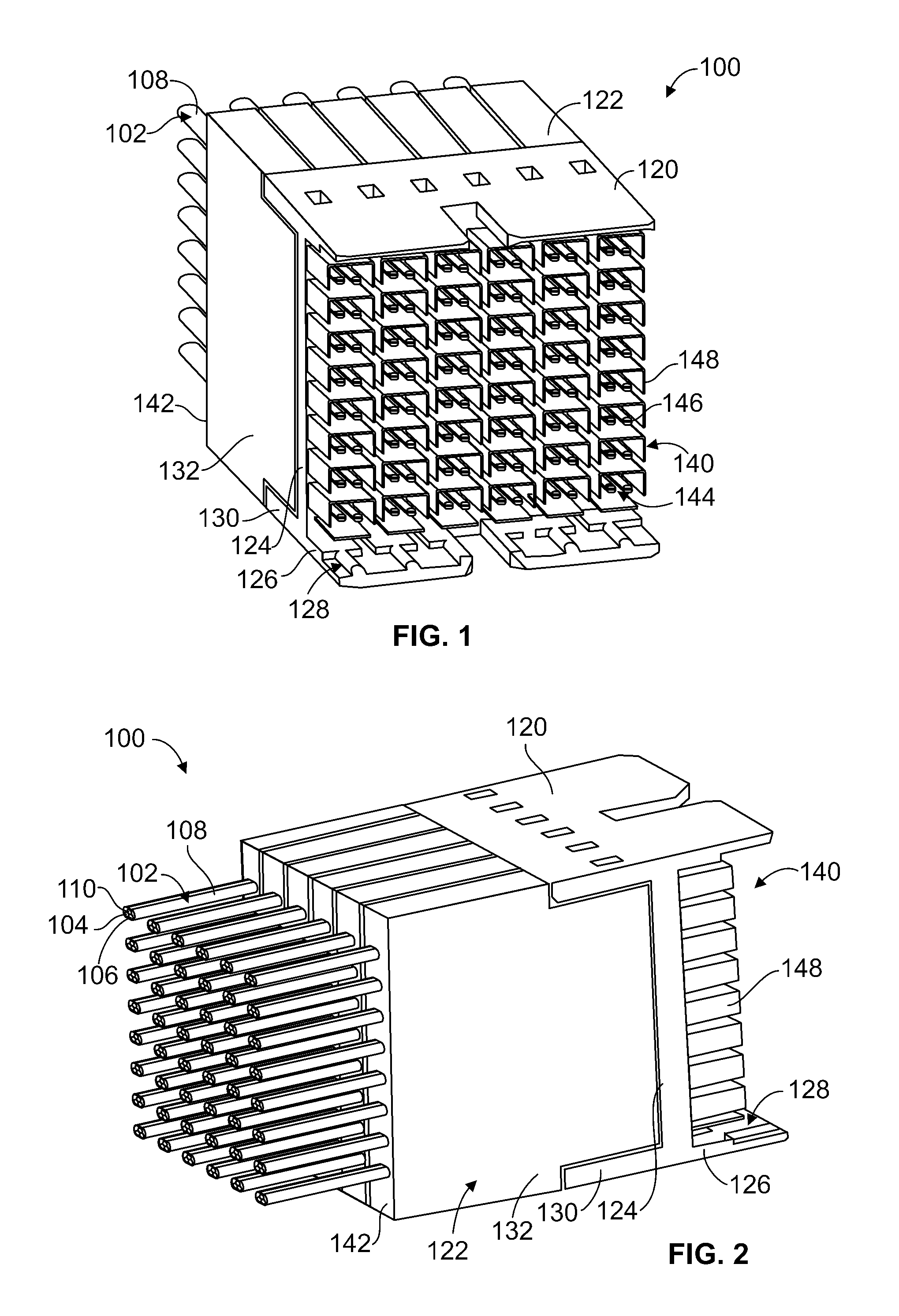

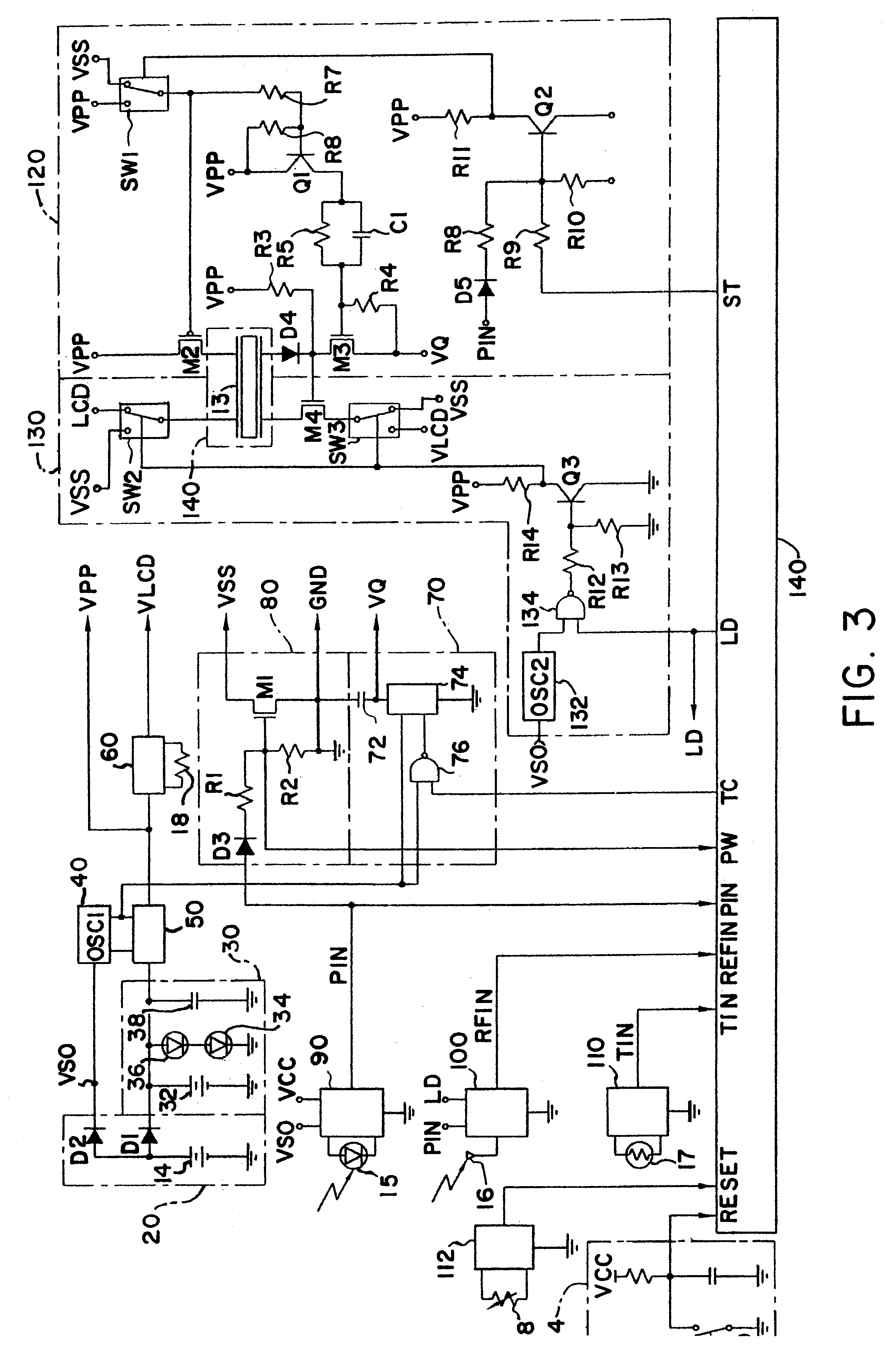

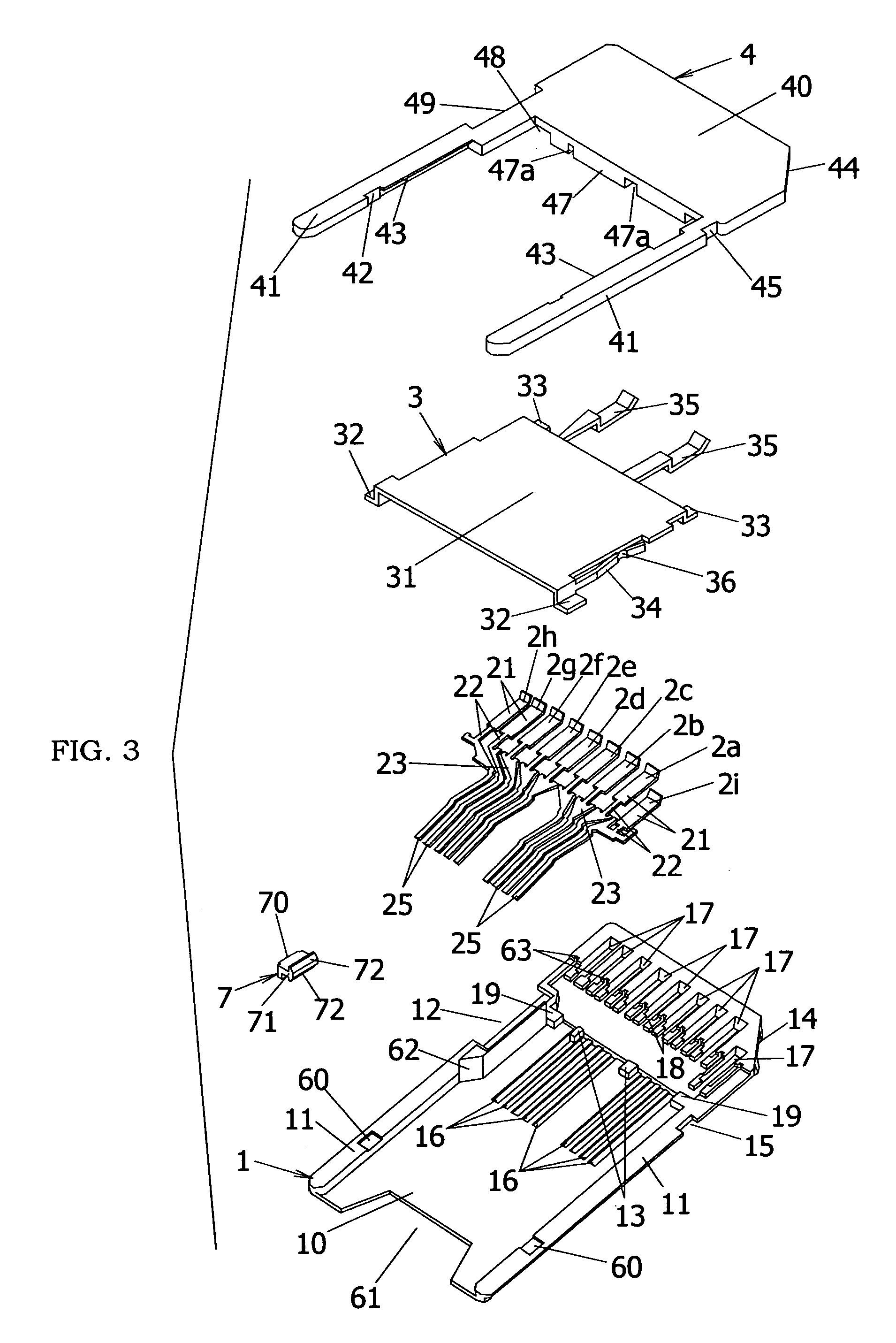

Cable header connector

ActiveUS8449330B1Improve shielding effectCoupling protective earth/shielding arrangementsElectrically conductiveEngineering

A cable header connector includes a contact module having a support body and a plurality of cable assemblies held by the support body and arranged in a column. The cable assemblies include a contact sub-assembly configured to be terminated to a cable, and a ground shield coupled to and providing electrical shielding for the contact sub-assembly. The contact sub-assembly has a pair of signal contacts extending between mating ends and terminating ends. The signal contacts are terminated to corresponding signal wires of the cable at the terminating ends. A ground bridge is coupled to the support body and is electrically conductive. The ground bridge includes intercolumn bridges arranged between corresponding cable assemblies. The intercolumn bridges engage and are electrically connected to the ground shields of corresponding cable assemblies on both sides of the intercolumn bridges. The ground bridge electrically connects corresponding cable assemblies engaged by the intercolumn bridges.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

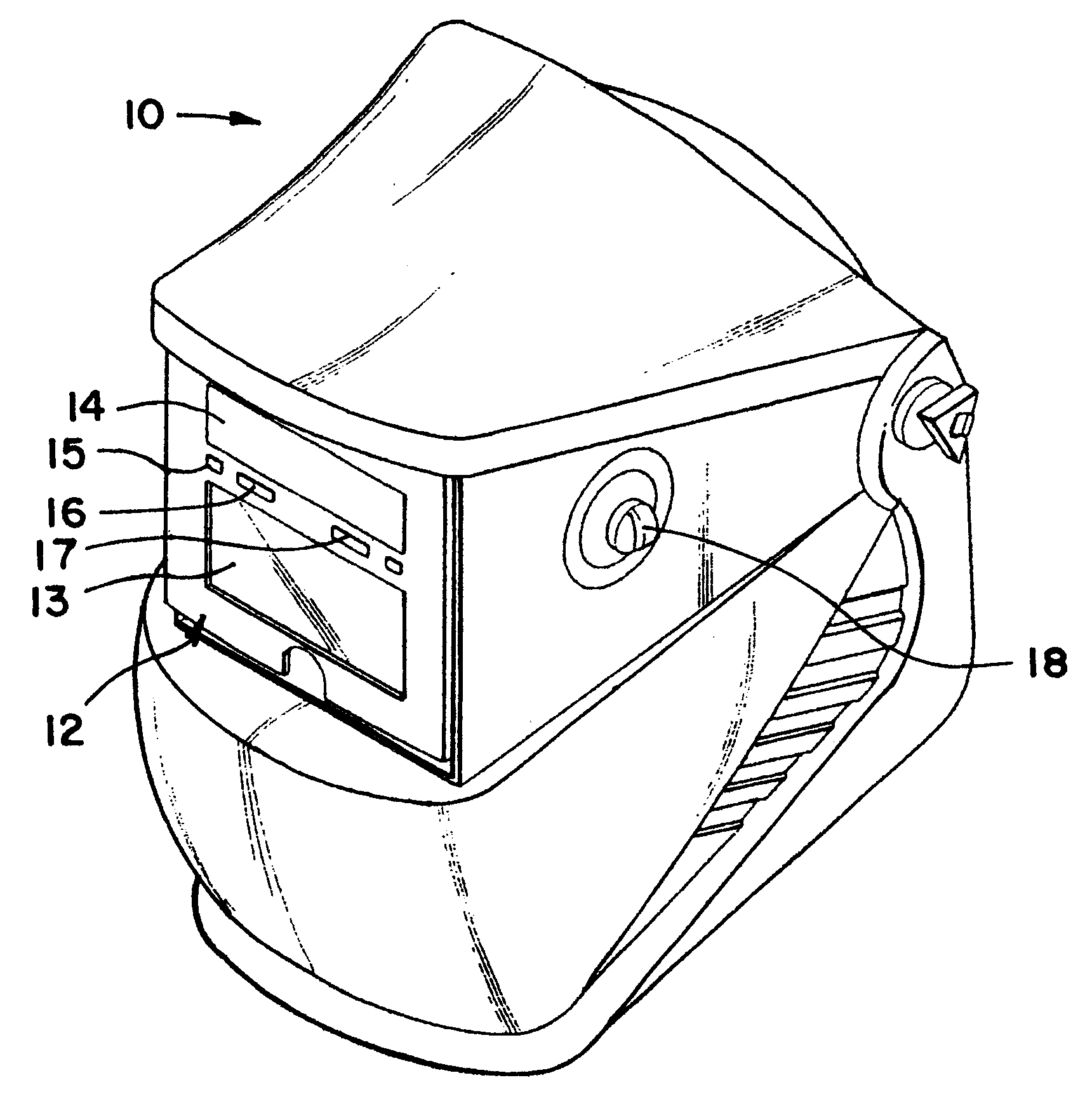

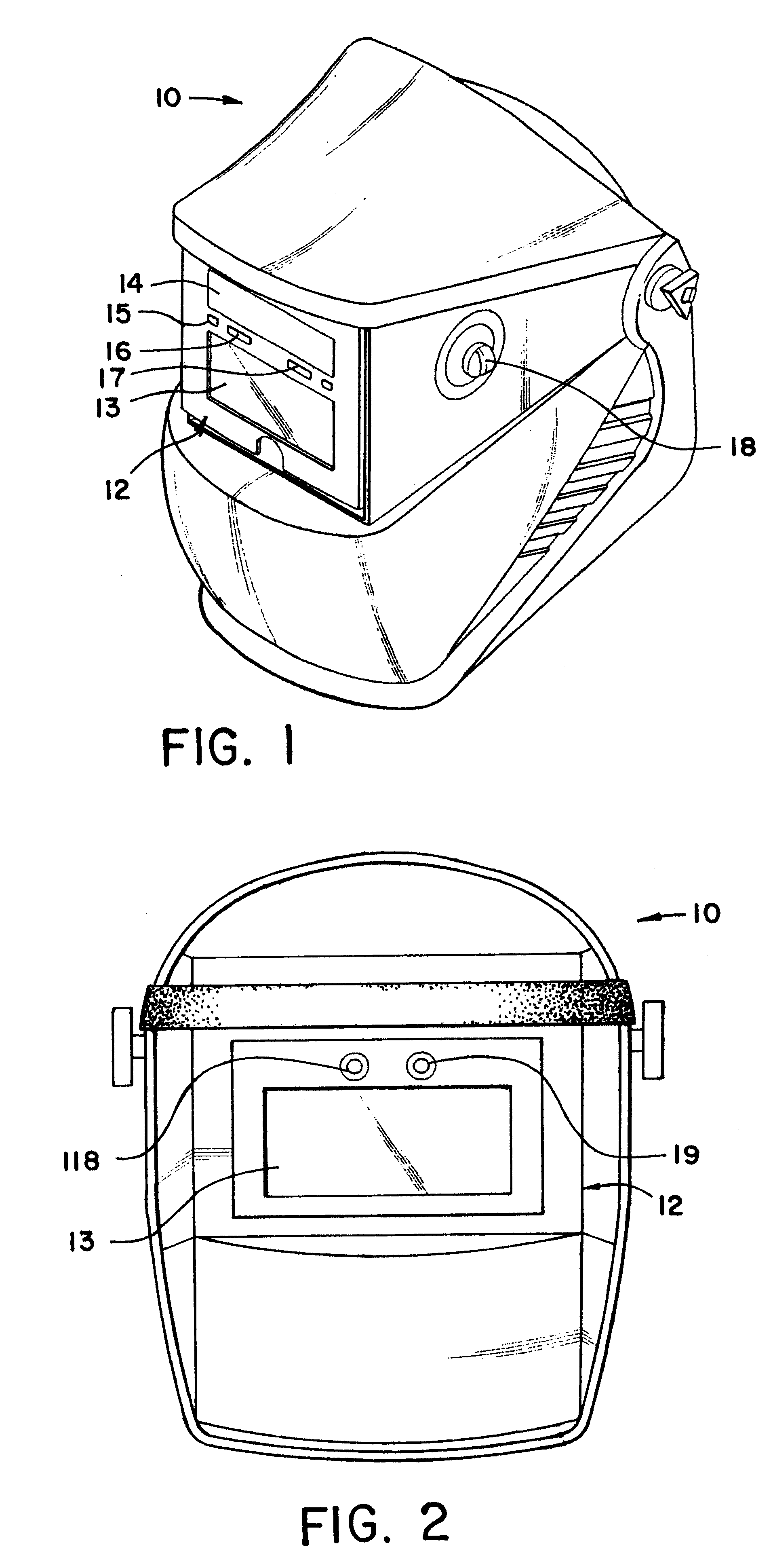

Glare shielding device of welding helmet and method of controlling the same

InactiveUS6614409B1Minimize power consumptionImprove shielding effectPhotometry using reference valueMaterial analysis by optical meansControl signalEngineering

The present invention discloses a glare shielding device. The glare shielding device includes a microprocessor for controlling an activation time and a driving time of a liquid crystal panel. The microprocessor generates an activation control signal of a liquid crystal activating portion, a driving control signal of a liquid crystal driving portion, and a power off control signal in response to a simultaneous detection of a welding light and a high frequency generated during a welding process. The liquid crystal activating portion becomes a floating state in a standby mode and activates the liquid crystal panel using a minus voltage between a high voltage and an activation voltage. The liquid crystal driving portion becomes a floating state in a standby mode and drives the liquid crystal panel in response to the driving control signal.

Owner:OTOS TECH

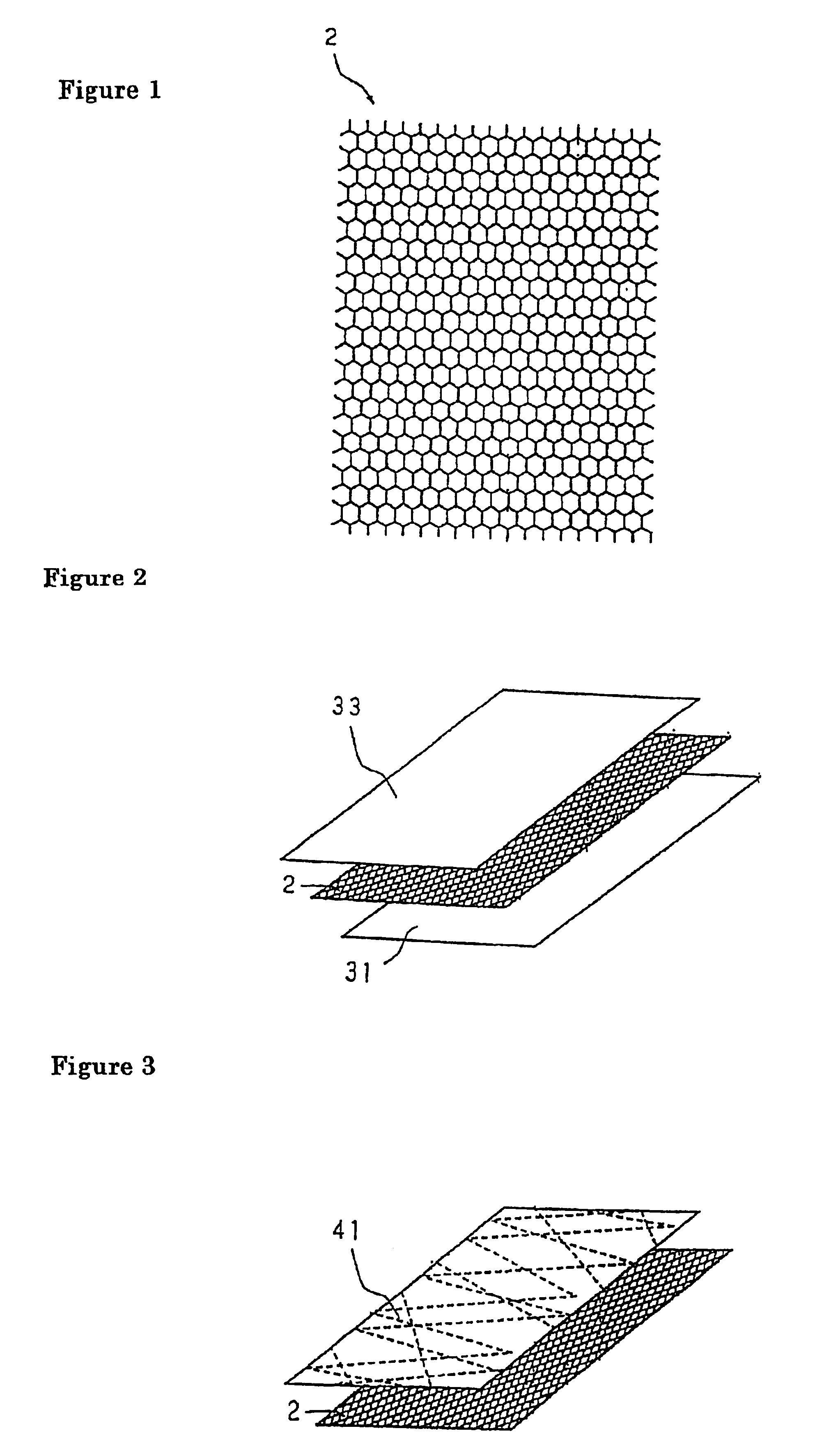

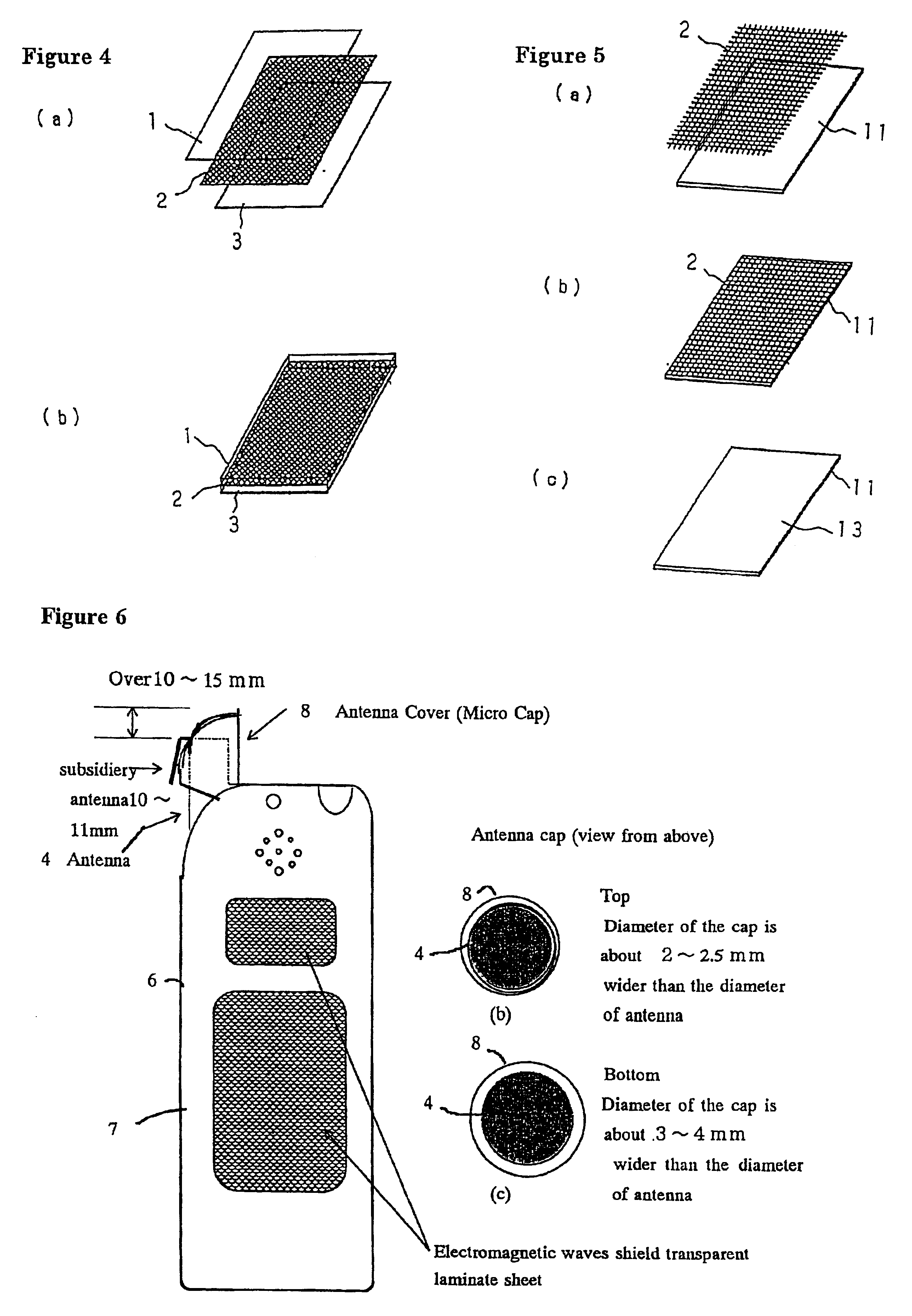

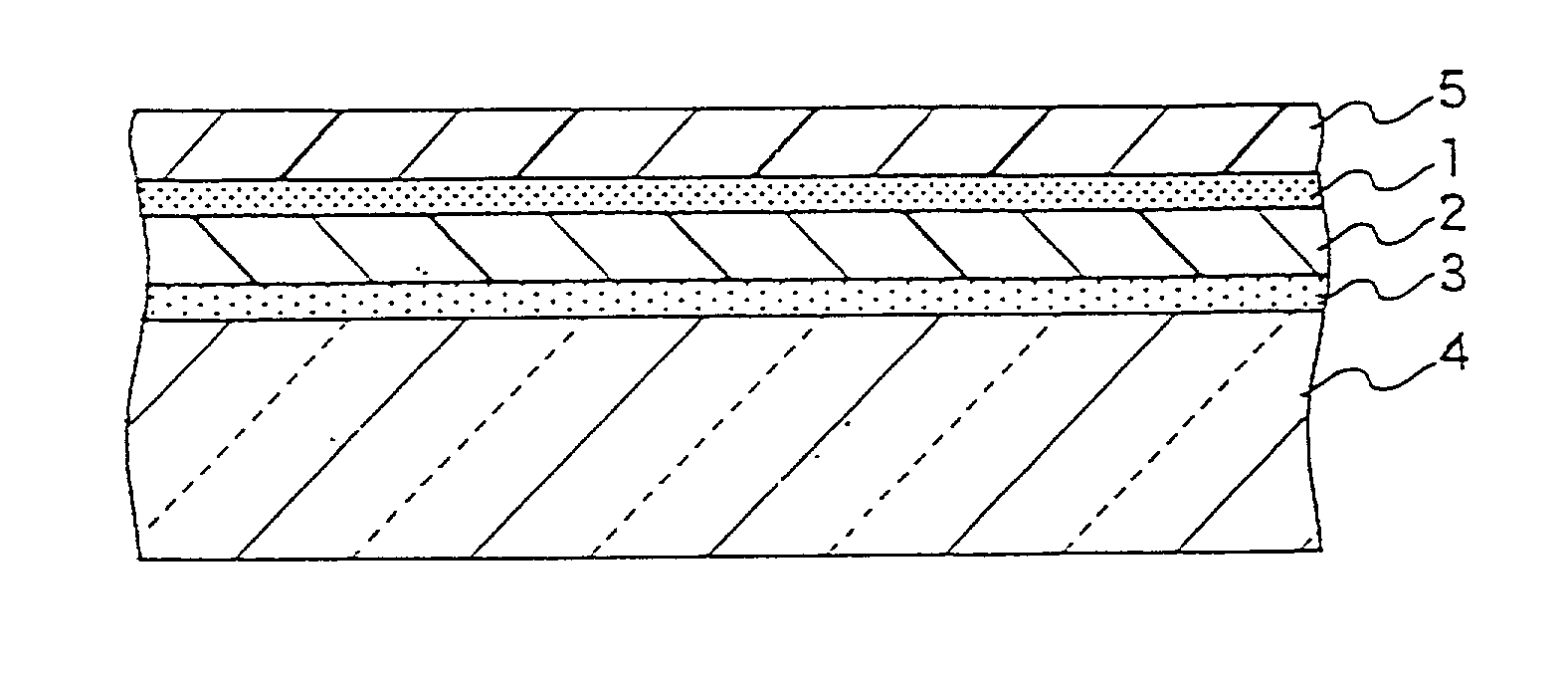

Electromagnetic wave blocking material and electromagnetic wave blocking case

InactiveUS6855883B1Improve shielding effectReduce total usageShielding materialsAntenna supports/mountingsFiberElectricity

This invention provides the electromagnetic waves shield material that has a sufficient effect of shielding the electromagnetic waves by making the electric conductive fibers into mesh. And this invention also provides the electromagnetic waves shield mobile phone case that avoids a harmful effect on the human body without reducing the function of communication of the mobile phone used the said electromagnetic waves shield material.The fibers with electric conductivity are woven into mesh by a general knitting machine like a machine for tricot. The cost is low even used for the wide area to shield the electromagnetic waves because the consumption of the fibers needed is less. The coarseness of the net is maintained the same by controlling the movement of the length and breadth each other.To avoid the radiation to the head direction, the electromagnetic waves shield material is used for the front and upper sides of the mobile phone case which are the direction to the head when the mobile phone is in use. The regular material without electromagnetic waves shield effect is used for the both sides of the mobile phone case.The antenna cap with electromagnetic shield structure is attached to the said upper side of the electromagnetic wave shield case. The electricity with high frequency is conducted between the above antenna cap and the upper side of the electromagnetic wave shield case. The said antenna cap is a conic tube cut it's head obliquely. The opening part is made to face in the opposite side of the head when it is attached to the antenna. A metallic pin is attached to the outside of the antenna cap. This metallic pin conducts high frequent electricity with the wire antenna at the mobile phone body when it is attached. It functions as an additional antenna to the wire antenna at the mobile phone body.

Owner:KAZU INVESTMENT

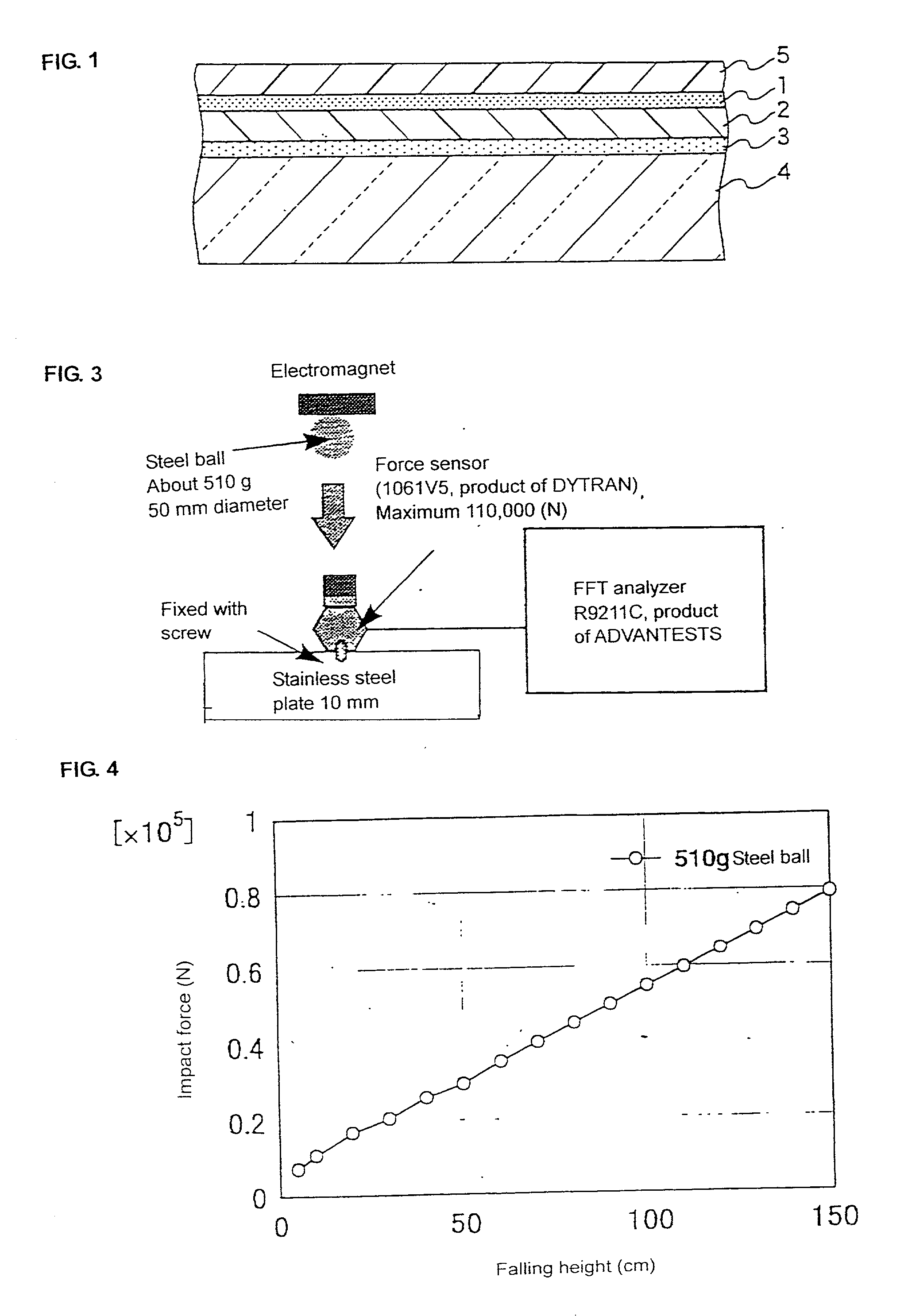

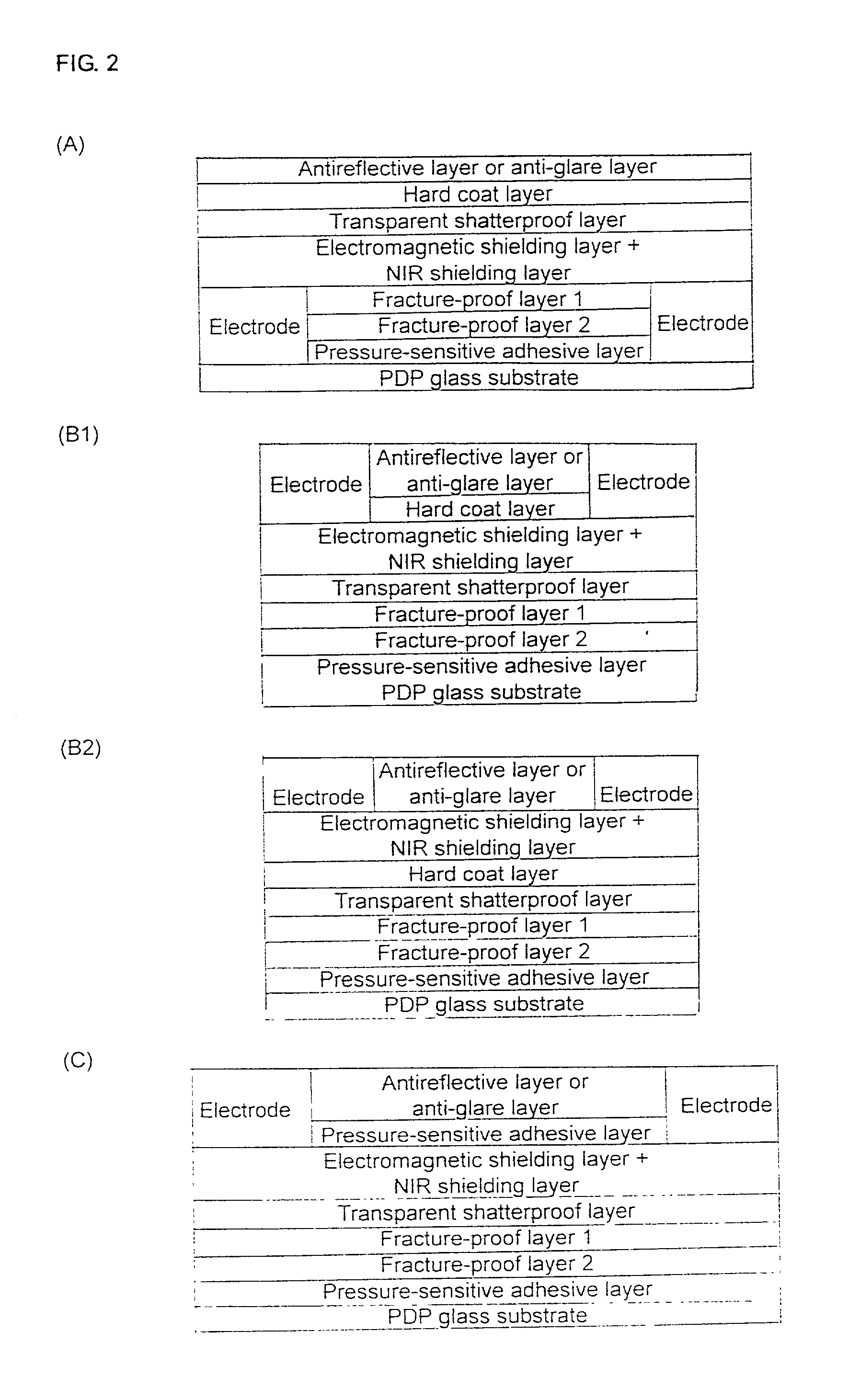

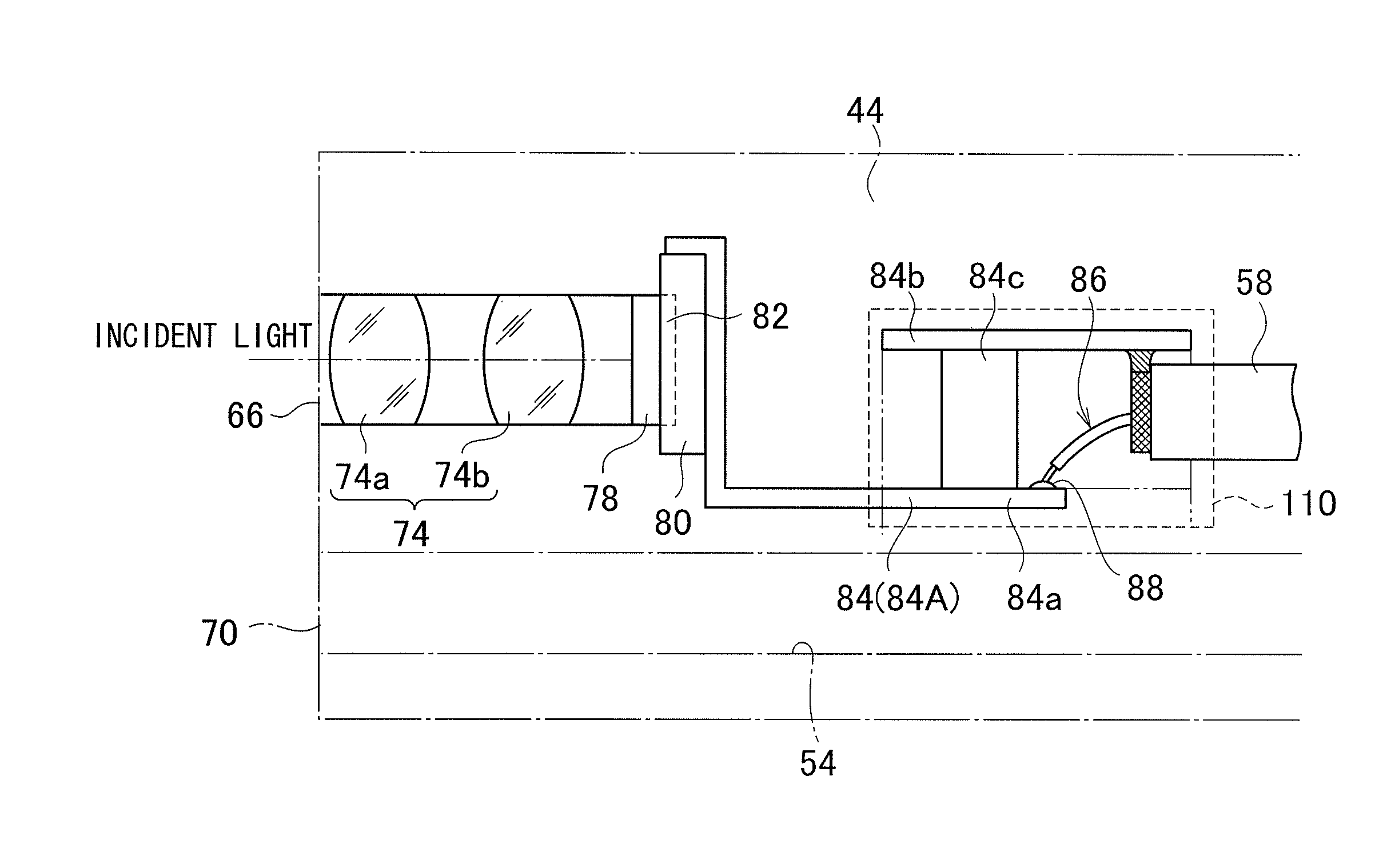

Transparent shock-absorbing laminate and flat panel display using the same

A transparent shock-absorbing laminate to be formed on a glass substrate for a display panel having a fracture strength such that it is fractured by a falling ball impact (drop height: 1.5 m; ball weight: 510 g) corresponding to 79,000 N, the transparent shock-absorbing laminate comprising a shatterproof layer having a shearing modulus of 2x108 Pa or more, at least two fracture-proof layers having a shearing modulus ranging from 1x104 to 2x108 Pa, each having different modulus, and a transparent pressure-sensitive adhesive layer.

Owner:NITTO DENKO CORP

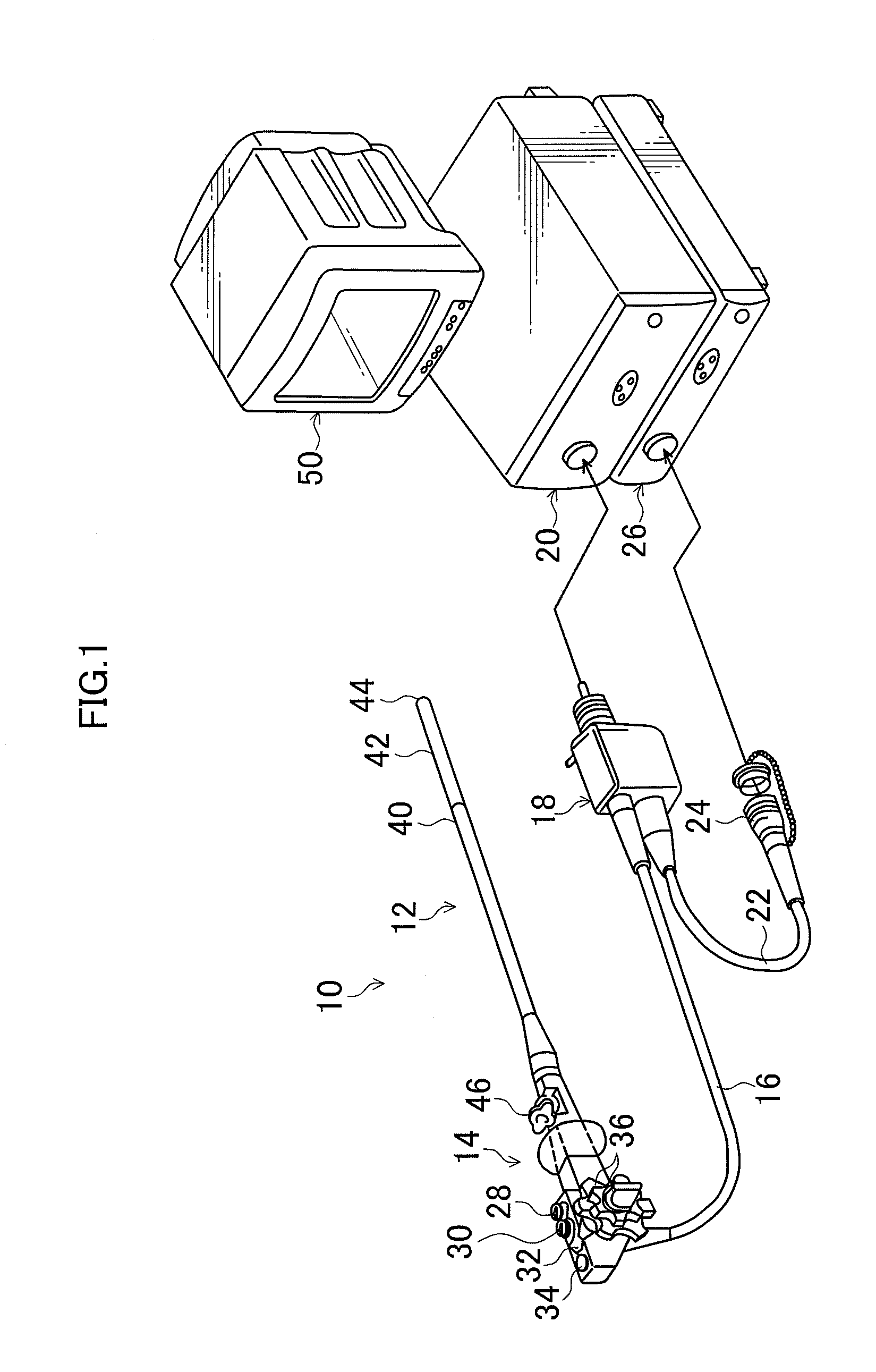

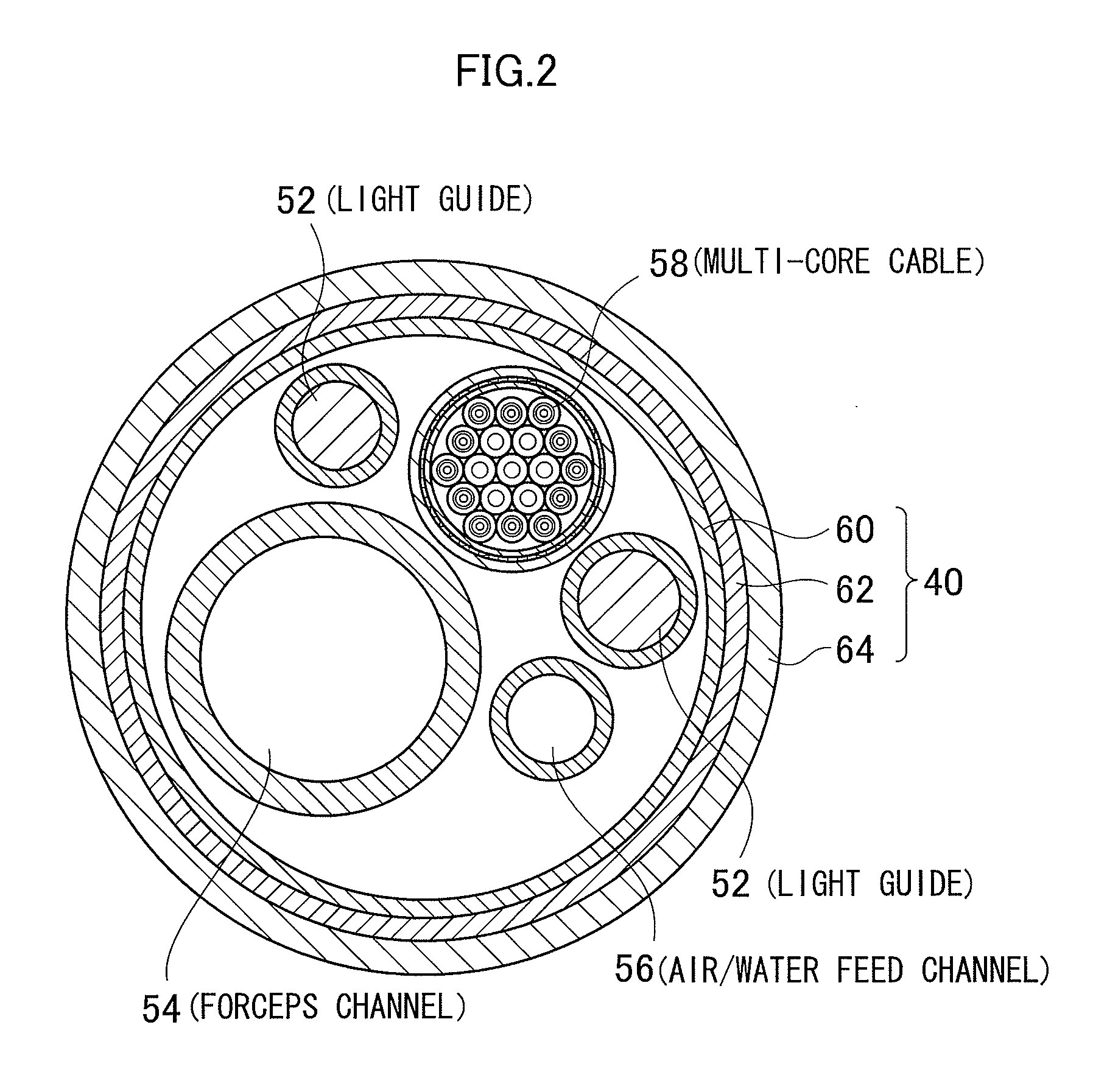

Solid-state image pickup device and endoscopic device

InactiveUS20110245600A1Improve shielding effectSimple configurationTelevision system detailsSurgeryEngineeringEndoscope

A solid-state image pickup device, comprising:a solid-state image pickup element;a circuit-board main body to which the solid-state image pickup element is connected;a shield piece consecutively connected to the circuit-board main body, capable of being folded, and having a shield pattern disposed; anda signal cable which is connected to a connection terminal disposed on the circuit-board main body and transmits an input / output signal to the solid-state image pickup element, whereinthe shield piece is folded at least to one face side of a region where the connection terminal is formed.

Owner:FUJIFILM CORP

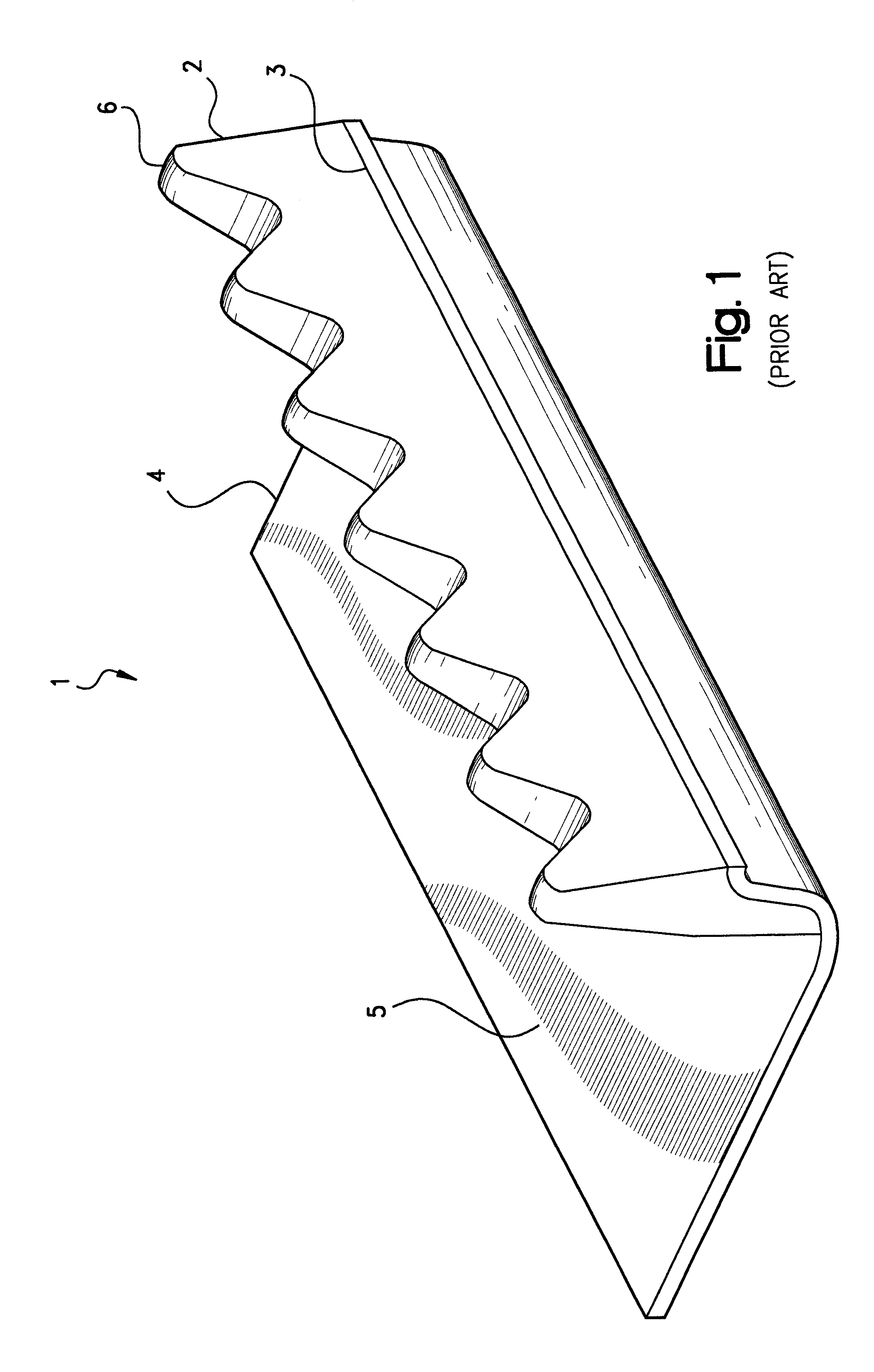

Compound waveform gasket for low closure force EMI shielding applications

InactiveUS6348654B1Reduce loadAssured electrical and physical continuityEngine sealsScreening gaskets/sealsWave shapeEngineering

A resilient EMI shielding and / or environmental sealing gasket for interposition between a first interface surface and an oppositely-disposed second interface surface. The gasket is formed of an elongate body of indefinite length which extends along a longitudinal axis. The body includes base and apex surfaces, and opposing first and second lateral surfaces which extend intermediate the base and apex surfaces. The base surface itself extends along the length the body as configured for proximally supporting the gasket on the first interface surface. The apex surface, in turn, extends radially from the longitudinal axis for distal contact with the second interface surface, and further extends along the longitudinal axis as defining a first waveform profile characterized as having a first periodic series of alternating first high and low amplitude intervals. The second lateral surface also extends along the longitudinal axis as defining a second waveform profile which is disposed generally transverse to the first waveform profile and which is similarly characterized as having a second periodic series of alternating second high and low amplitude intervals. The gasket so formed is deformable under a predetermined compressive force between the first and second interface surfaces into a stressed orientation characterized in that the body is deflected intermediate the base and apex surfaces.

Owner:PARKER INTANGIBLES LLC

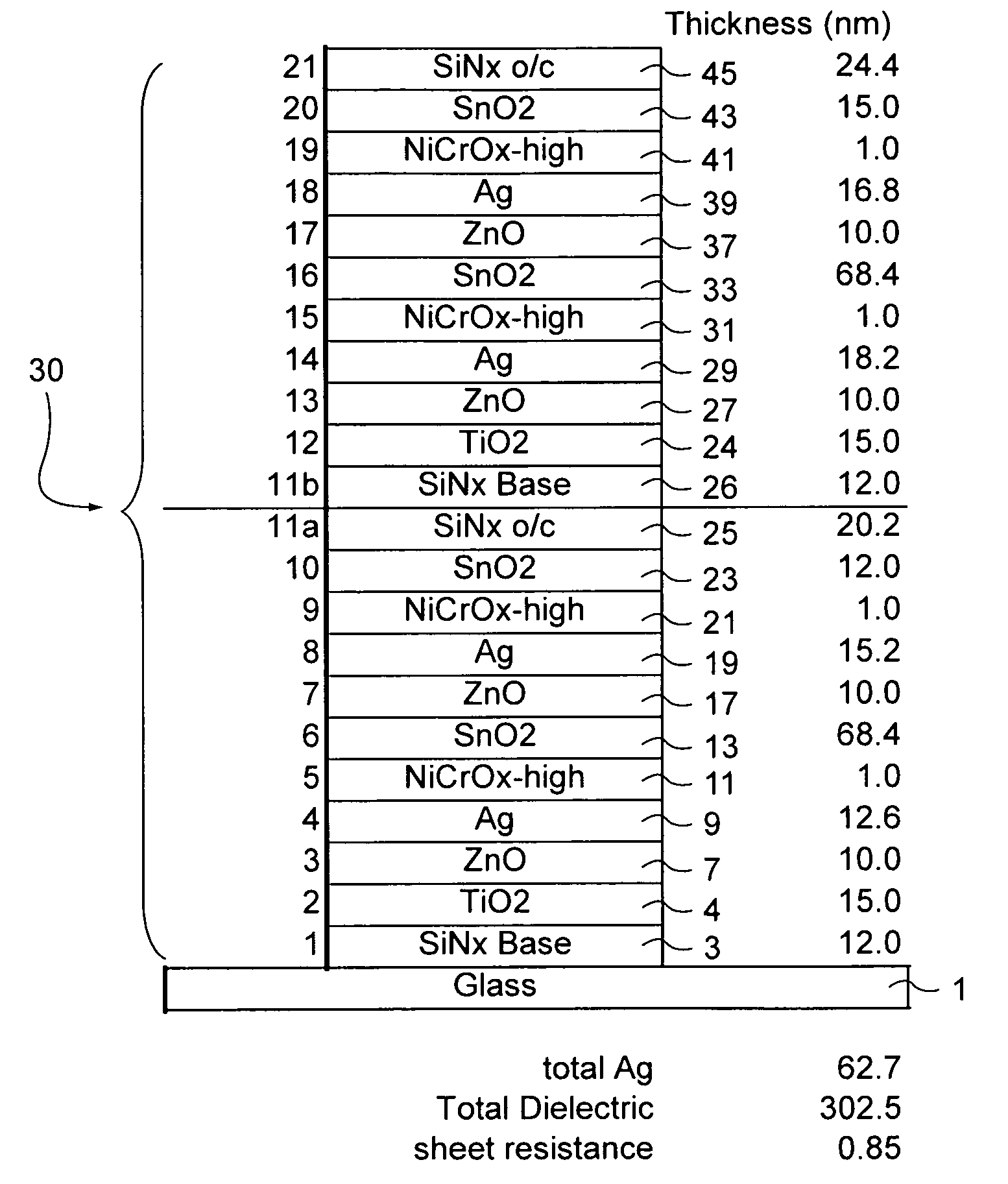

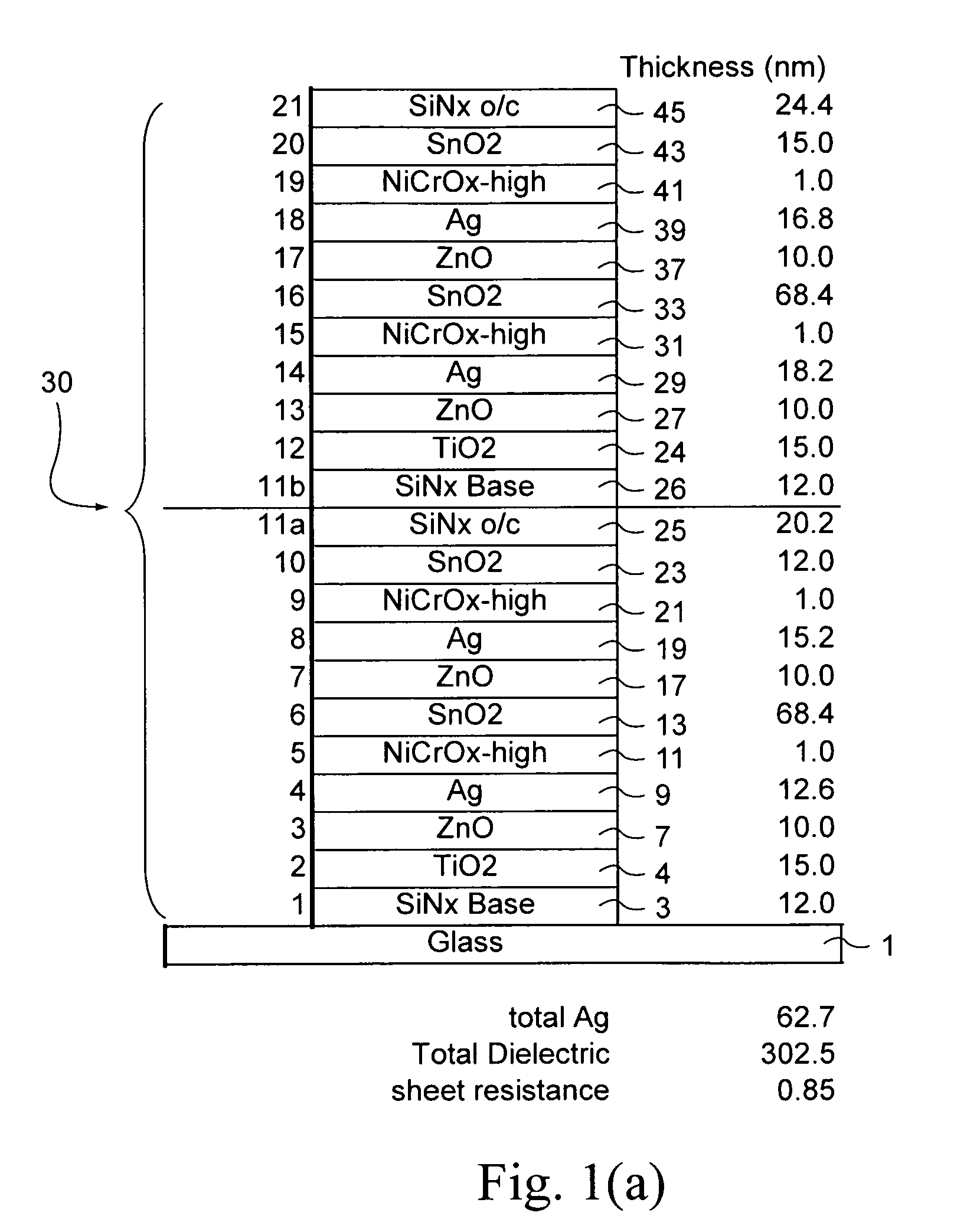

Plasma display panel including frameless EMI filter, and/or method of making the same

ActiveUS20100046191A1Easy to makeImprove display effectMagnetic/electric field screeningAlternating current plasma display panelsInfraredConductive coating

A plasma display panel (PDP) includes a frameless EMI filter supported by a glass substrate for blocking / shielding substantial amounts of electromagnetic waves, with the filter being supported by a side of the substrate opposite a viewer. In certain example embodiments, the PDP filter includes a transparent conductive coating (TCC) for electromagnetic interference (EMI) and near infrared (NIR) blocking without the need for a conductive, peripheral buss bar. Additionally, in certain example embodiments, the need for a conductive frame is reduced or eliminated. The filter has high visible transmission, and is capable of blocking / shielding electromagnetic waves.

Owner:GUARDIAN GLASS LLC

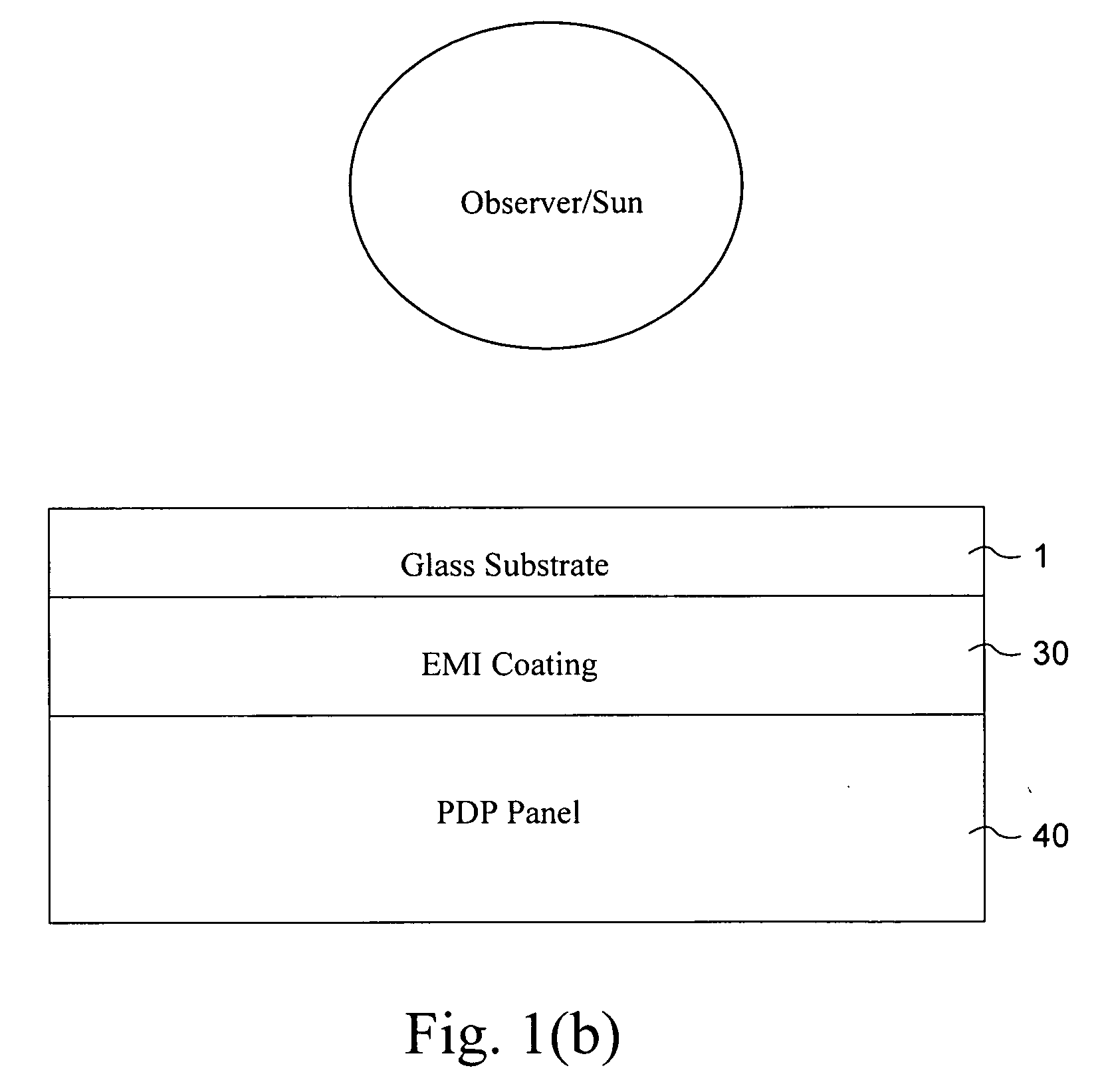

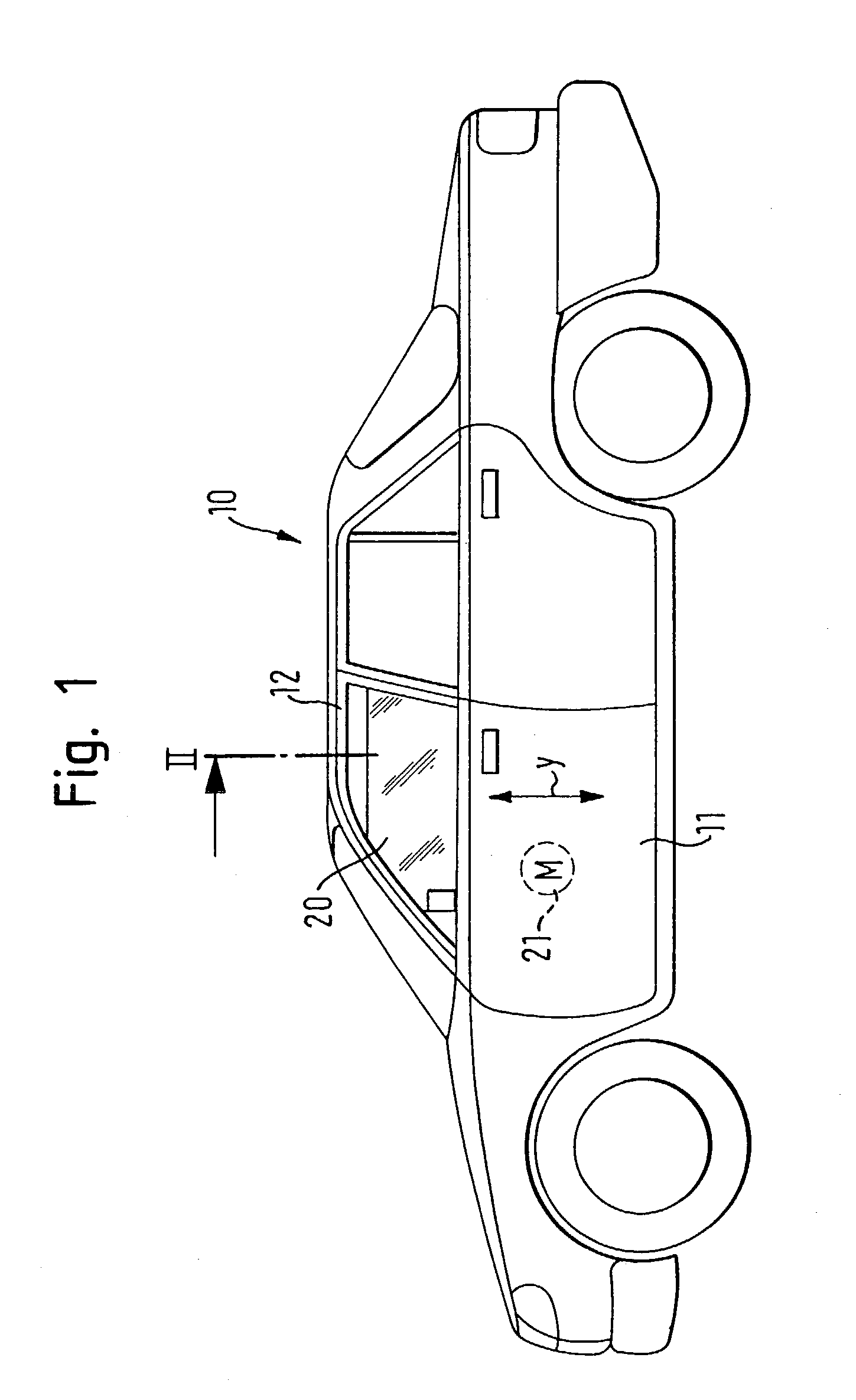

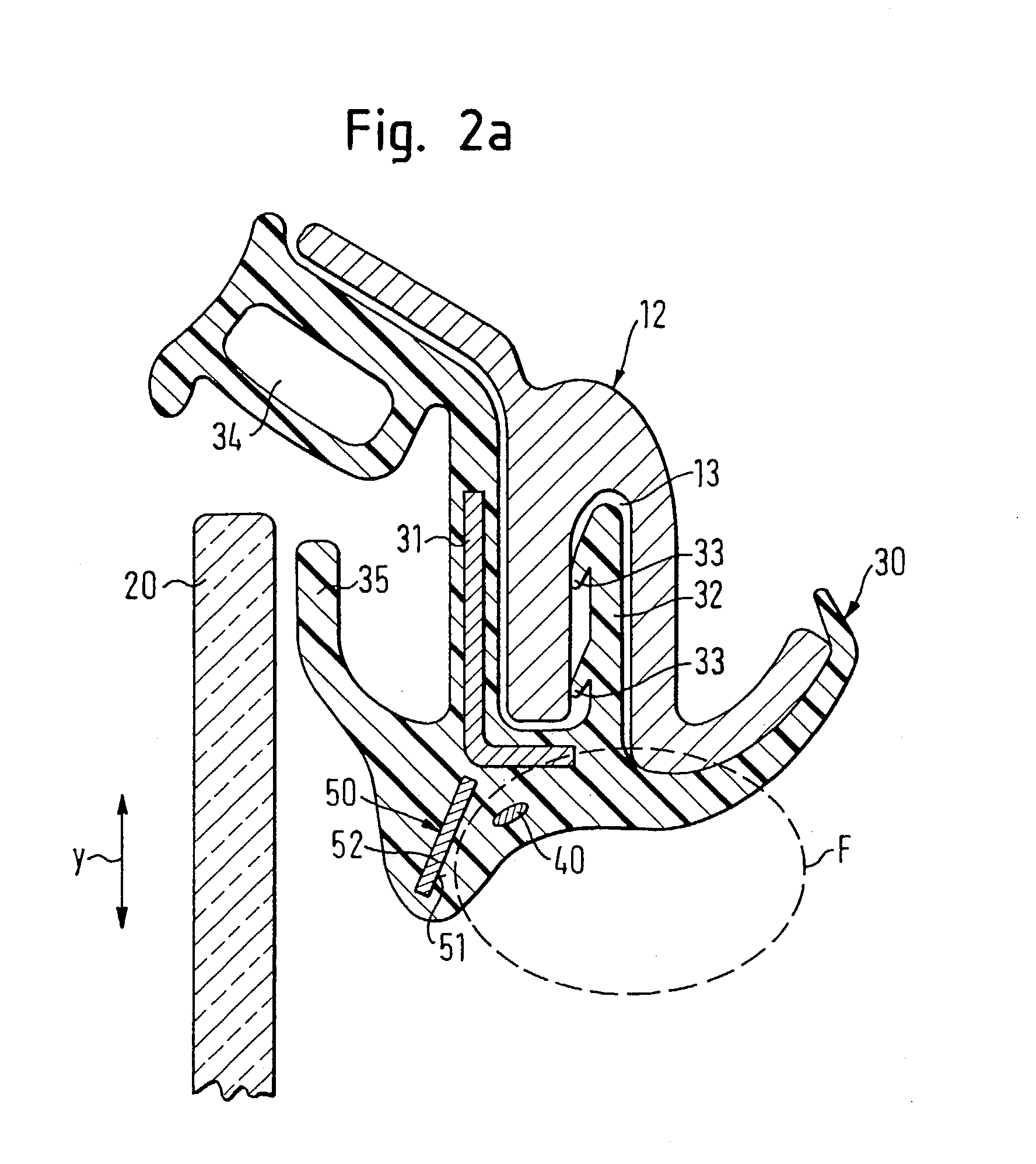

Device for sensing an obstacle in the opening range of a closure element of a motor vehicle

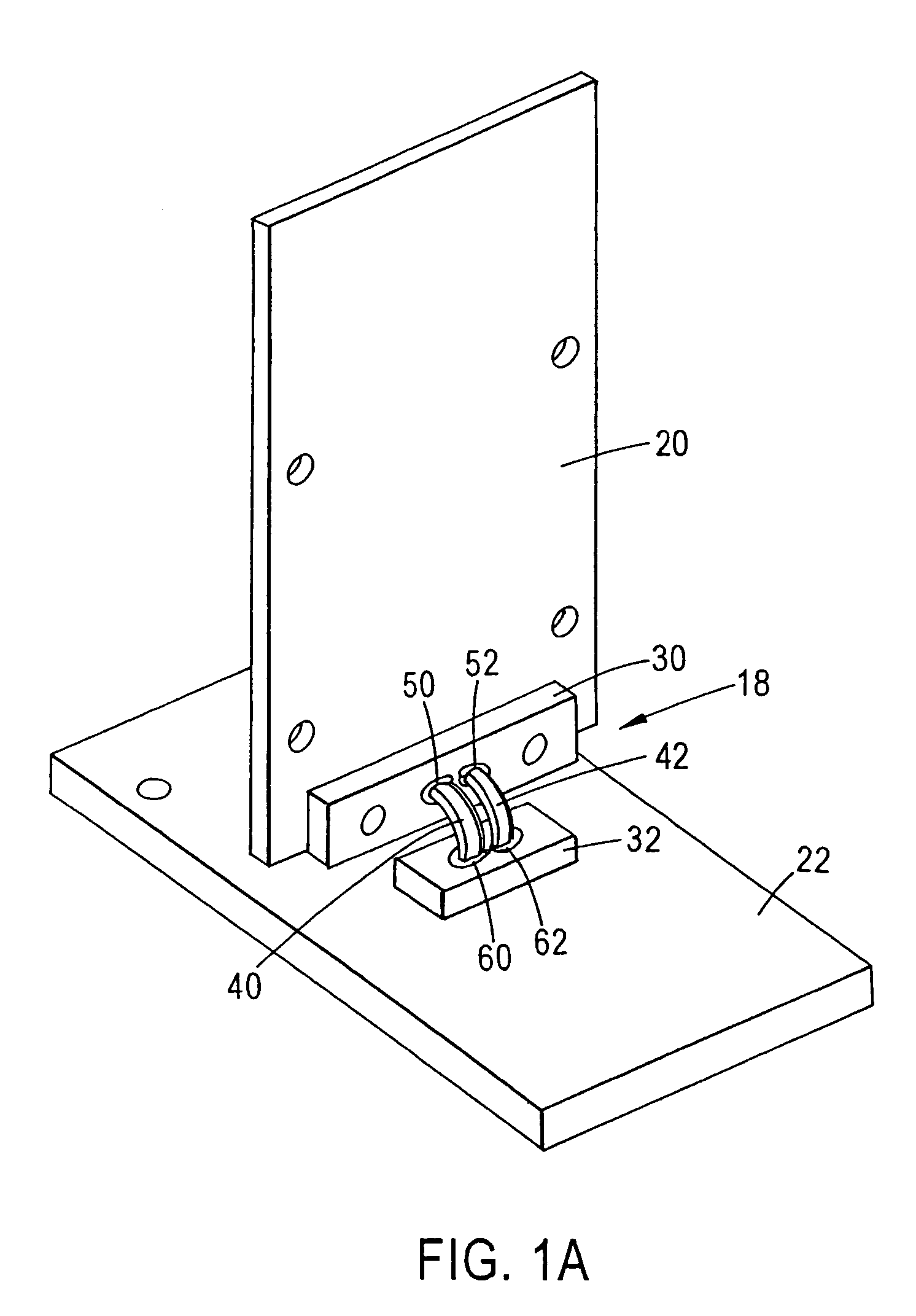

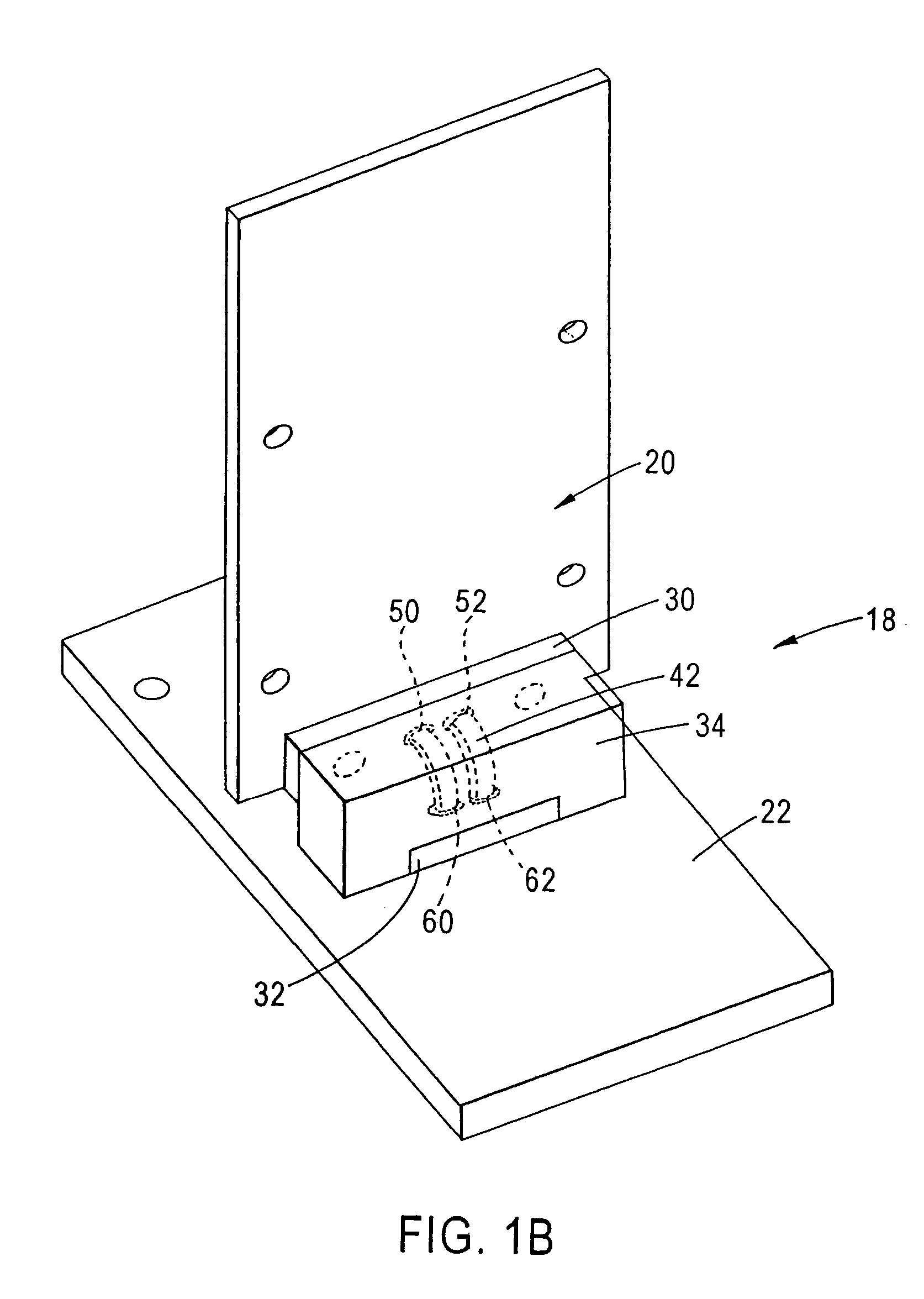

ActiveUS7015666B2Easy to solveEliminate needDC motor speed/torque controlEmergency protective circuit arrangementsCapacitanceMobile vehicle

A device for sensing an obstacle in said opening range of an automotive closure element movable between an open position and and closed position, more particularly an electrically powered door window (20) or sunroof is provided with a weatherseal (30) sealing the window pane (20). The weatherseal (30) is made of an elastomeric material and secured to a frame (12) of the motor vehicle (10). The device comprises in addition a sensor for sensing an obstacle in the opening range of the closure element (20), the sensor comprising at least one electrical conductor (40) generating an electrical field (F) in the opening range of the closure element (20).The device achieves by simple ways and means an engineered orientation of the electrical field such that any interference by the closure element (20) to the capacitive change in the electrical field (F) is precluded by reason of conductive means (50) comprising a conductive surface (51) made of an electrically conductive material. The conductive means (50) are electrically insulated and shield the window pane (20) from the electrical field (F) generated by the electrical conductor (40).

Owner:METZELER AUTOMOTIVE PROFILES GMBH

Magnetic tunneling junction film structure with process determined in-plane magnetic anisotropy

ActiveUS7105372B2Data efficientSmall sizeNanomagnetismMagnetic-field-controlled resistorsIn planeMagnetic anisotropy

A method of forming an MTJ memory cell and / or an array of such cells is provided wherein each such cell has a small circular horizontal cross-section of 1.0 microns or less in diameter and wherein the ferromagnetic free layer of each such cell has a magnetic anisotropy produced by a magnetic coupling with a thin antiferromagnetic layer that is formed on the free layer. The MTJ memory cell so provided is far less sensitive to shape irregularities and edge defects than cells of the prior art.

Owner:HEADWAY TECH INC

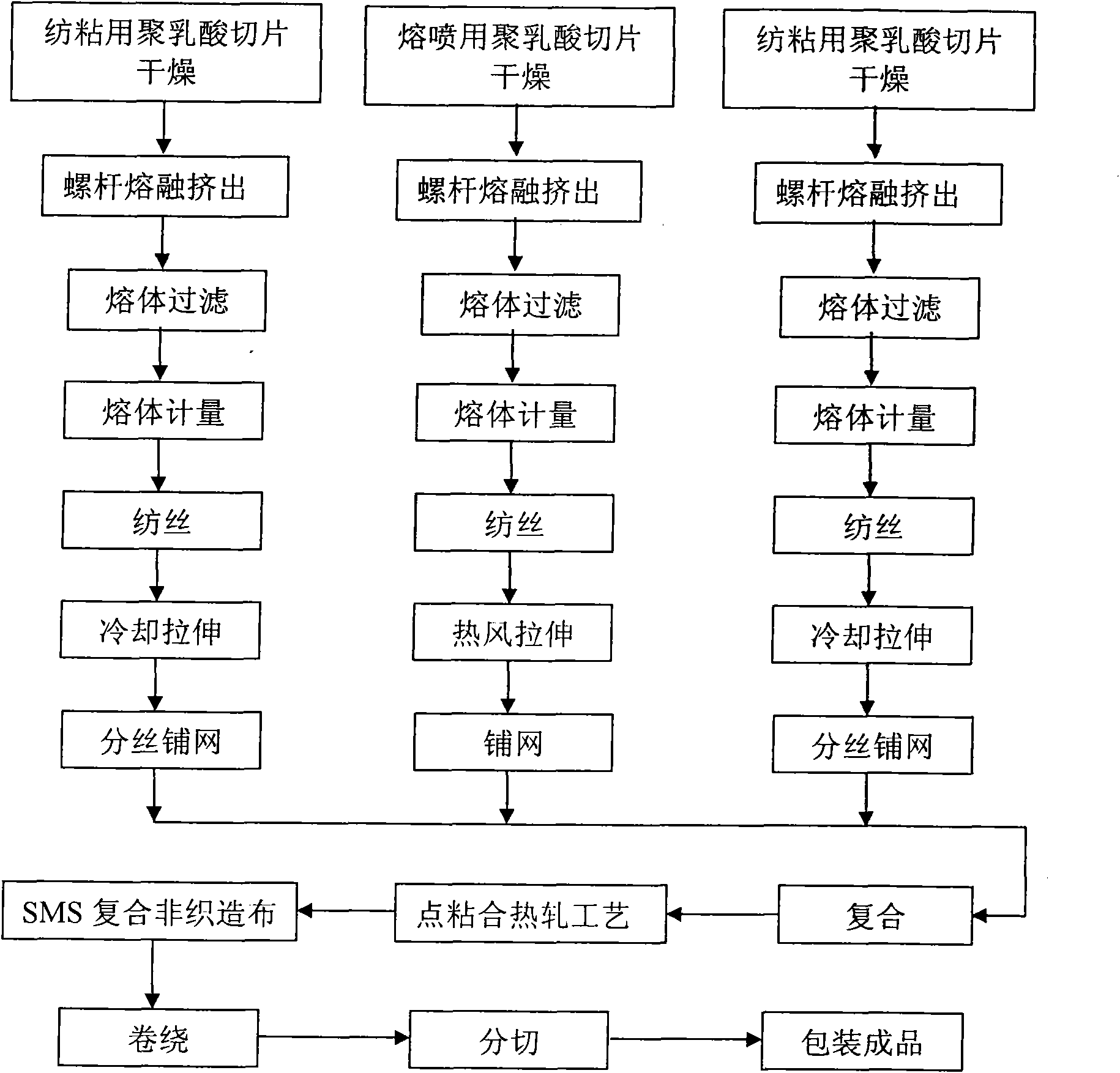

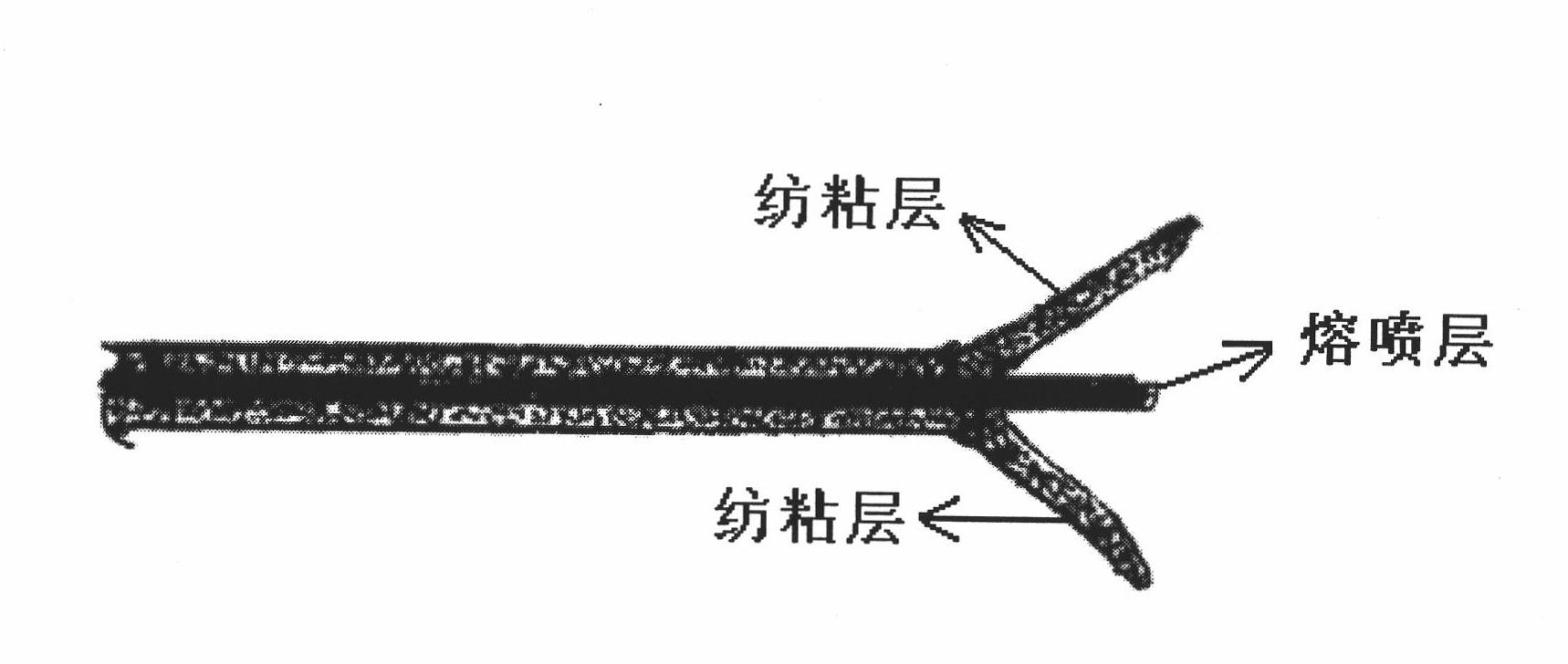

Fully-degradable polylactic acid fiber SMS compound non-woven and manufacturing method thereof

InactiveCN101851830APromote growthCapable of biocompostingSpinning head liquid feederMelt spinning methodsNonwoven fabricPhysical property

The invention discloses a fully-degradable polylactic acid fiber SMS compound non-woven and a manufacturing method thereof. The non-woven is compounded by three layers of non-woven by self-bonding or hot rolling, wherein the middle layer is polylactic acid meltblown non-woven, and the upper layer and the lower layer of the middle layer are both polylactic acid spunbonded non-woven. The SMS non-woven is even and has stable quality and excellent physical property, filtering property and shielding property. A thin SMS product has favourable waterproof permeability and is especially suitable for the fields of hygienic materials, packaging materials and the like; an SMS product with medium thickness is suitable for the disposable products of the field of medical treatments, and a thick SMS product is suitable for the field of industrial filtering. The production technology of the invention is easy to operate and control, has favorable stability and can carry out industrial production.

Owner:豆丁乐园(南京)婴儿用品有限公司

High speed, high density interconnect system for differential and single-ended transmission systems

InactiveUS7056128B2Simple and elegant latching mechanismEfficient use ofElectrically conductive connectionsCoupling device detailsCoaxial cableHigh density

The present invention is directed to a high density electrical connector which can provide 80 or more twinax connections per linear inch in a 20 millimeter card slot. In a typical electronic system package, 20 millimeters is the spacing from center line to center line of the adjacent parallel daughtercards. Twinax cable is coaxial cable that contains two .inner conducting wires rather than one. The two inner conducting wires provide two physical channels. Coaxial cable is called “coaxial” because it includes one physical channel that carries the signal surrounded (after a layer of insulation) by another concentric physical channel, both running along the same axis. The outer channel serves as ground.

Owner:WINCHESTER ELECTRONICS CORP

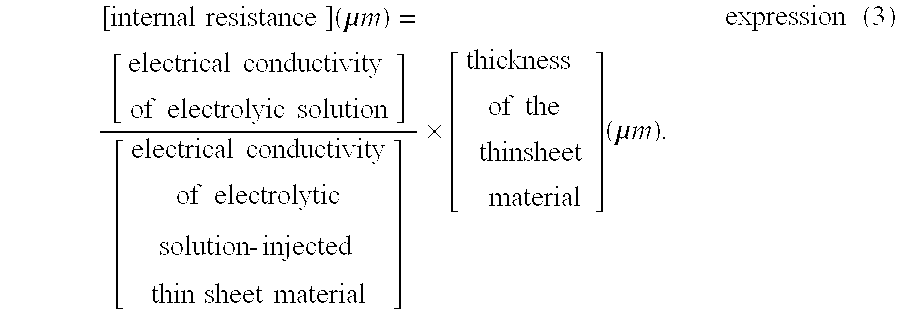

Aramid thin sheet material and electrical/electronic parts using the same

InactiveUS20070167101A1High strengthMaintain good propertiesHybrid capacitor separatorsPlastic/resin/waxes insulatorsInternal resistanceAramid

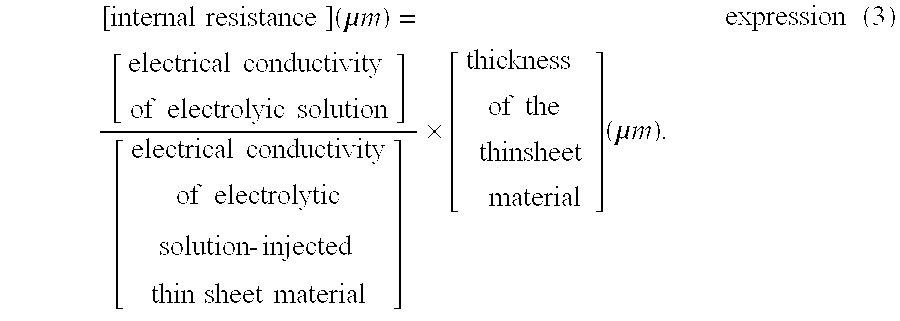

The invention provides an aramid thin sheet material comprising two components of aramid staple fibers and fibrillated aramid, or said two components and aramid fibrid, in particular, characterized by satisfying both of the following expressions (1) and (2): [internal resistance] (μm)≦250 (μm) expression (1) [Oken-type gas permeability] (sec / 100 cm3)≧0.5 (sec / 100 cm3) expression (2) wherein the [internal resistance] is a resistance value calculated by the following expression (3): [internal resistance ](μ m)=[electrical conductivity of electrolyic solution][electrical conductivityof electrolyticsolution-injected thin sheet material]×[thickness of the thinsheet material](μ m).expression (3)

Owner:DUPONT TEIJIN ADVANCED PAPERS JAPAN

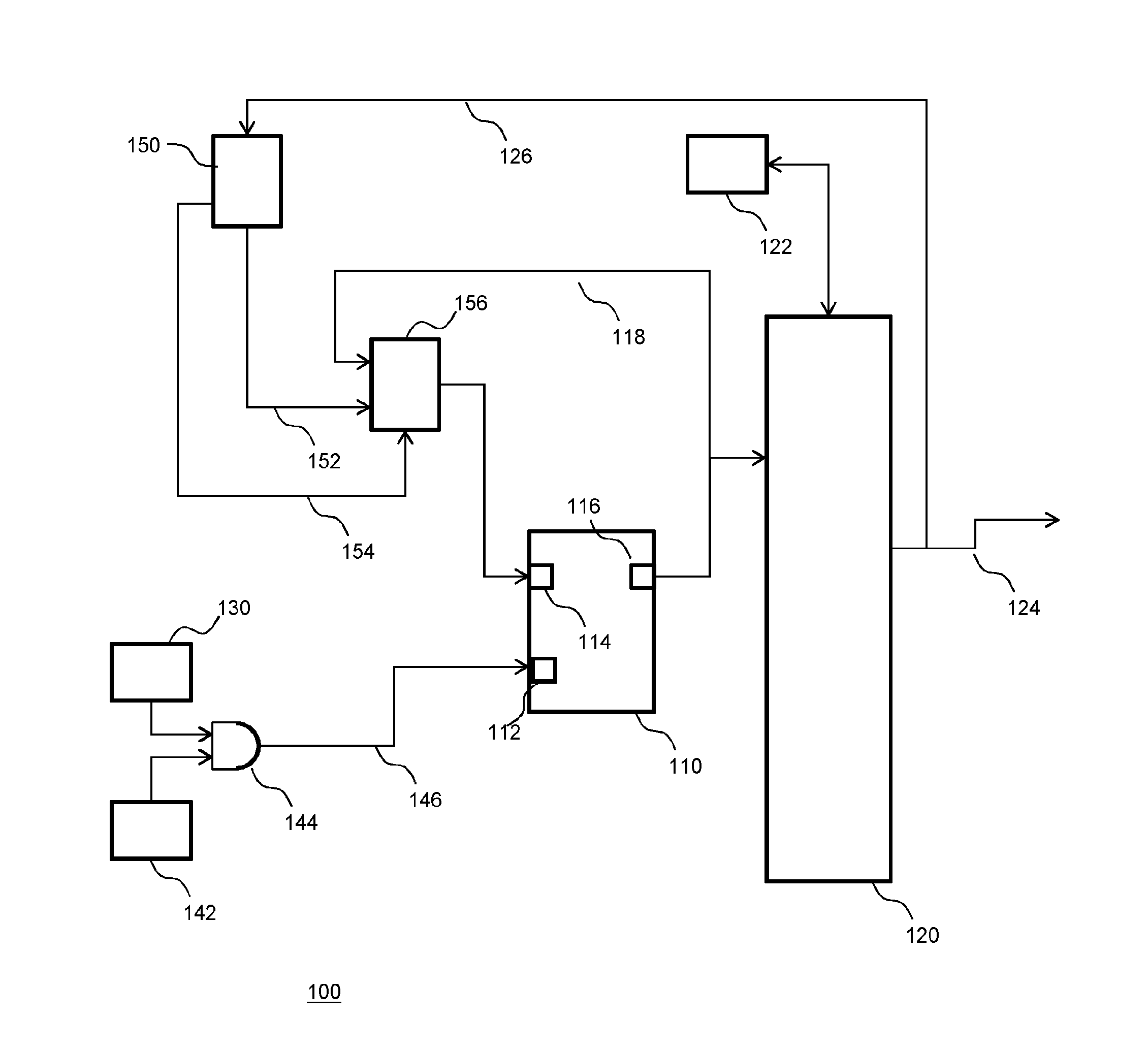

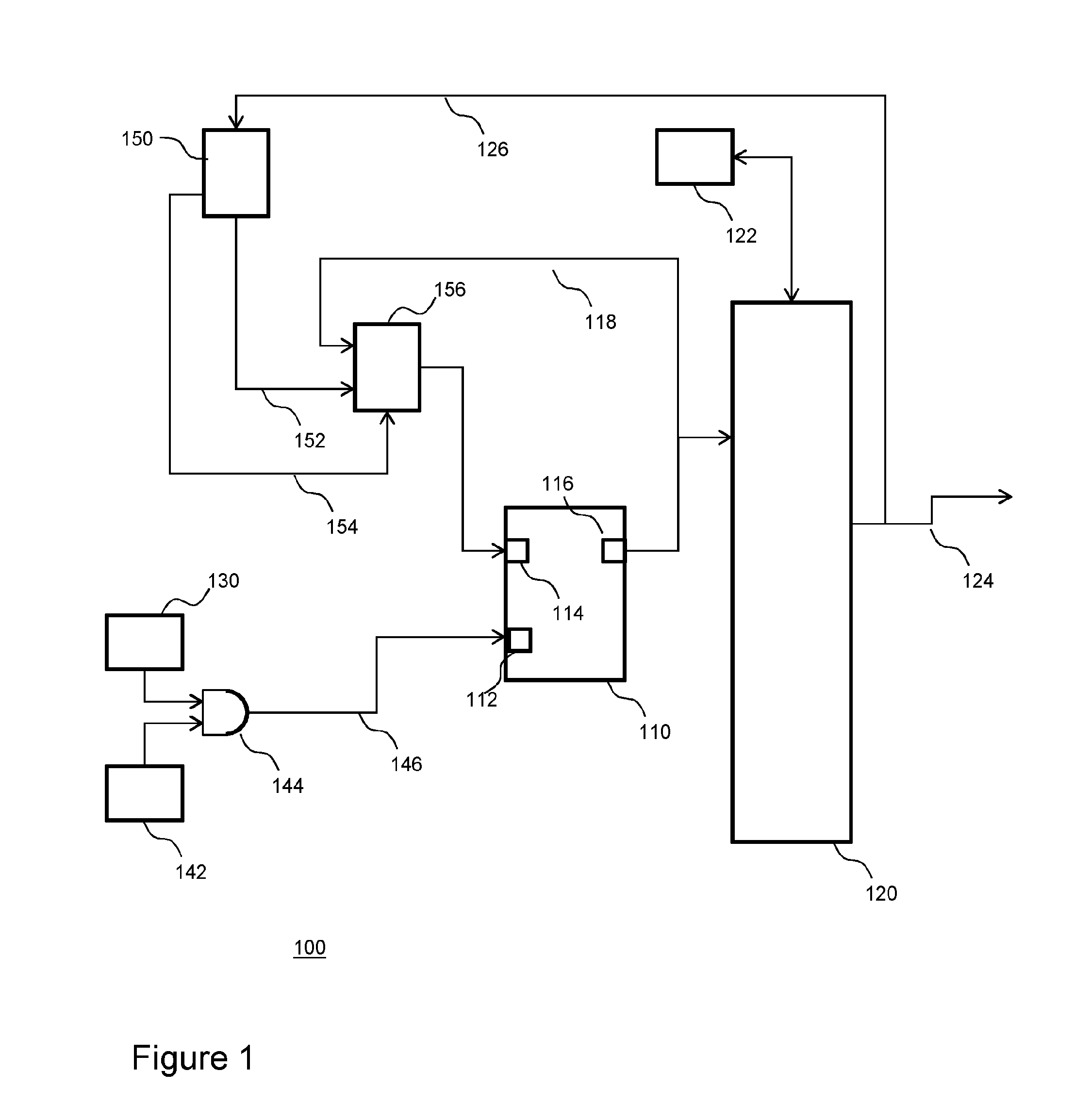

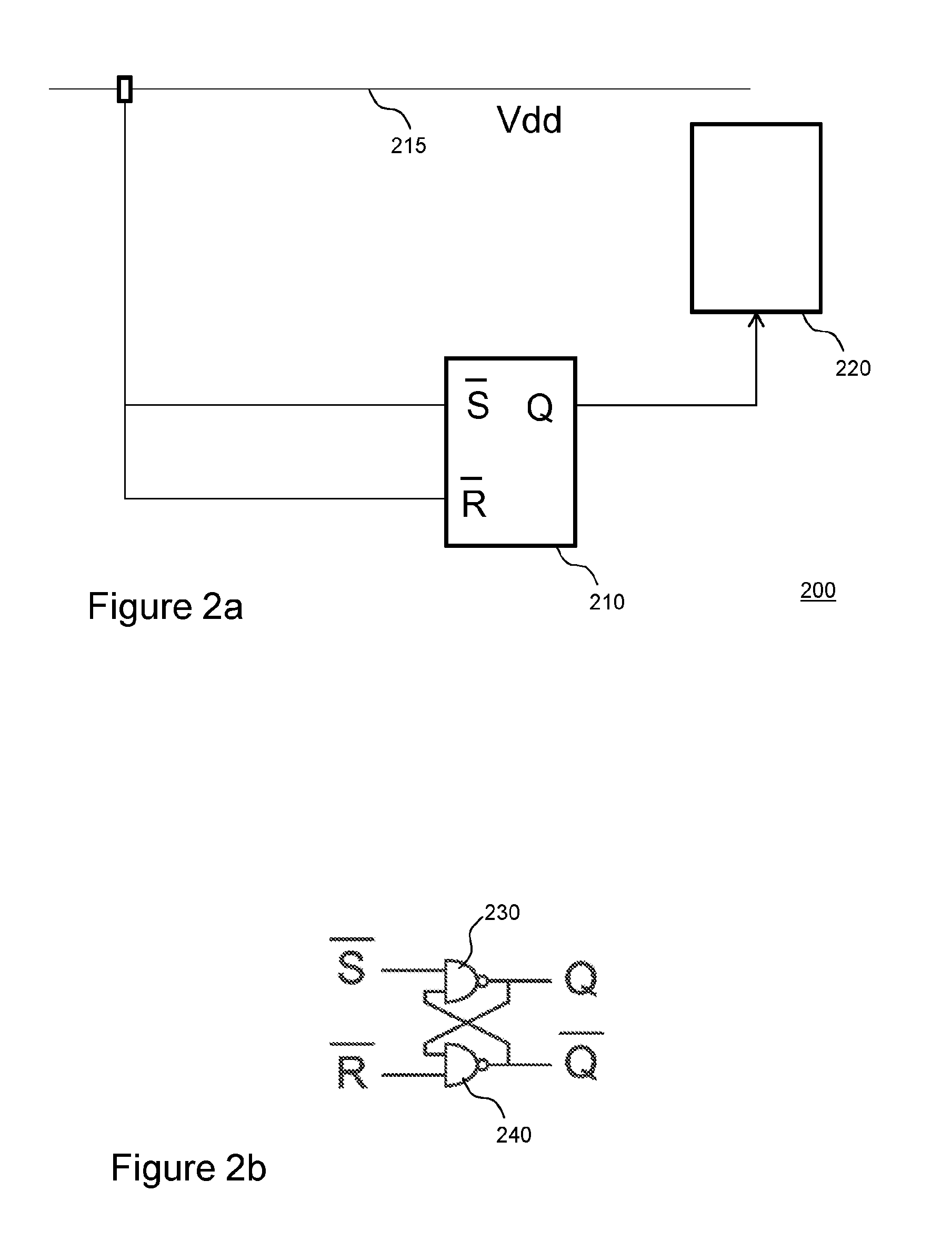

Physical unclonable function with improved start-up behavior

ActiveUS20130194886A1Improve featuresReduce control signalingDigital data processing detailsDigital storageElectricitySettling

An electric physical unclonable function (PUF) (100) is provided comprising a semiconductor memory element (110) connectable to a PUF control means for reading content from the memory element and for deriving at least in part from said content a digital identifier, such as a secret key. Upon powering the memory element it settles into one of at least two different stable states. The particular stable state into which the memory element settles is dependent at least in part upon random physical characteristics of the memory element introduced during manufacture of the memory element. Settling of the memory element is further dependent upon a control input (112) of the memory element. The electric physical unclonable function comprises shielding means (142, 144) for shielding, during a time period including the power-up of the memory element and lasting at least until the settling of the memory element, the control input from receiving control signals upon which the particular stable state into which the memory element settles is dependent. In this way, the dependency of the memory element on its physical characteristics is improved, and dependency on possibly irreproducible control signals is reduced.

Owner:INTRINSIC ID

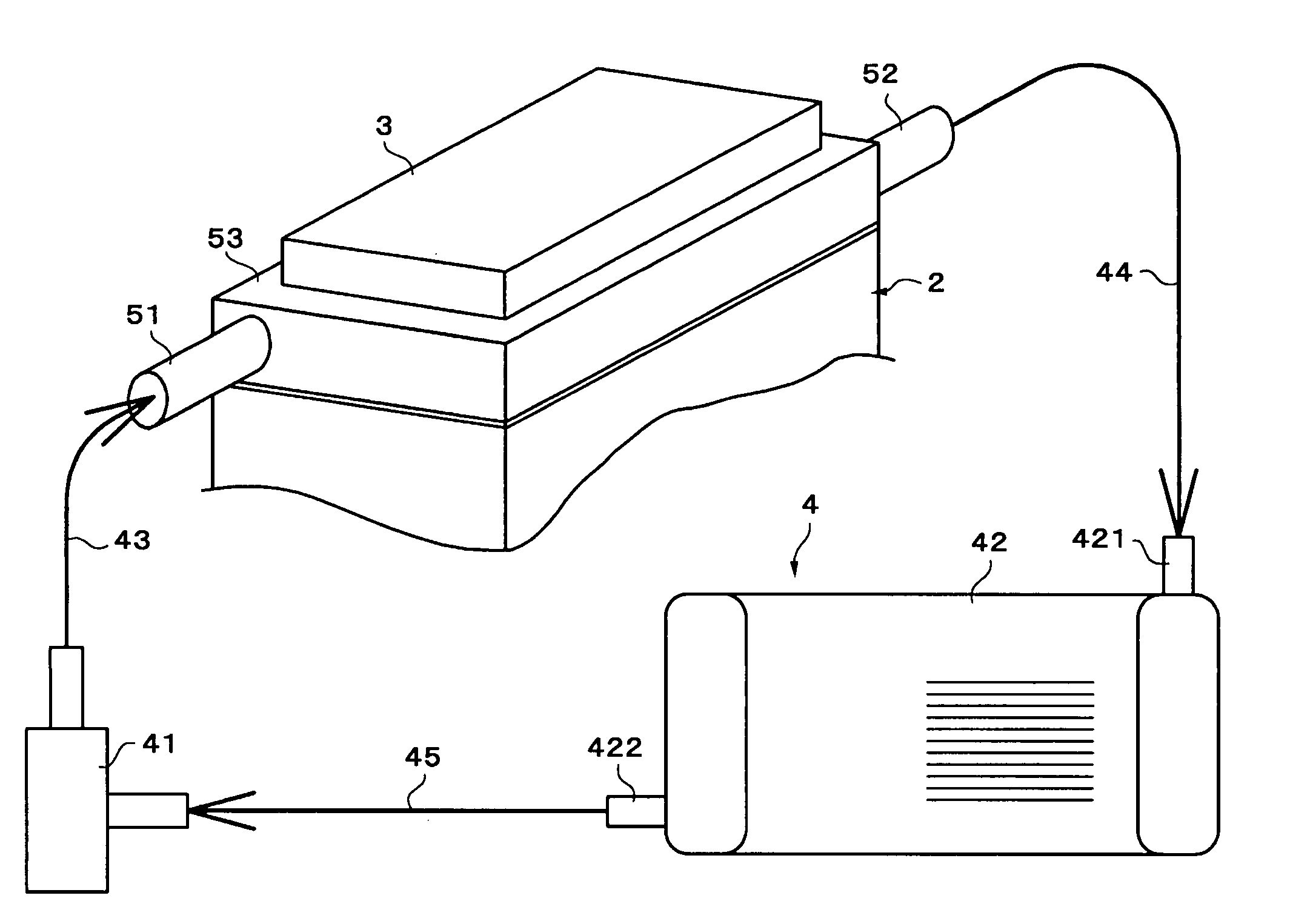

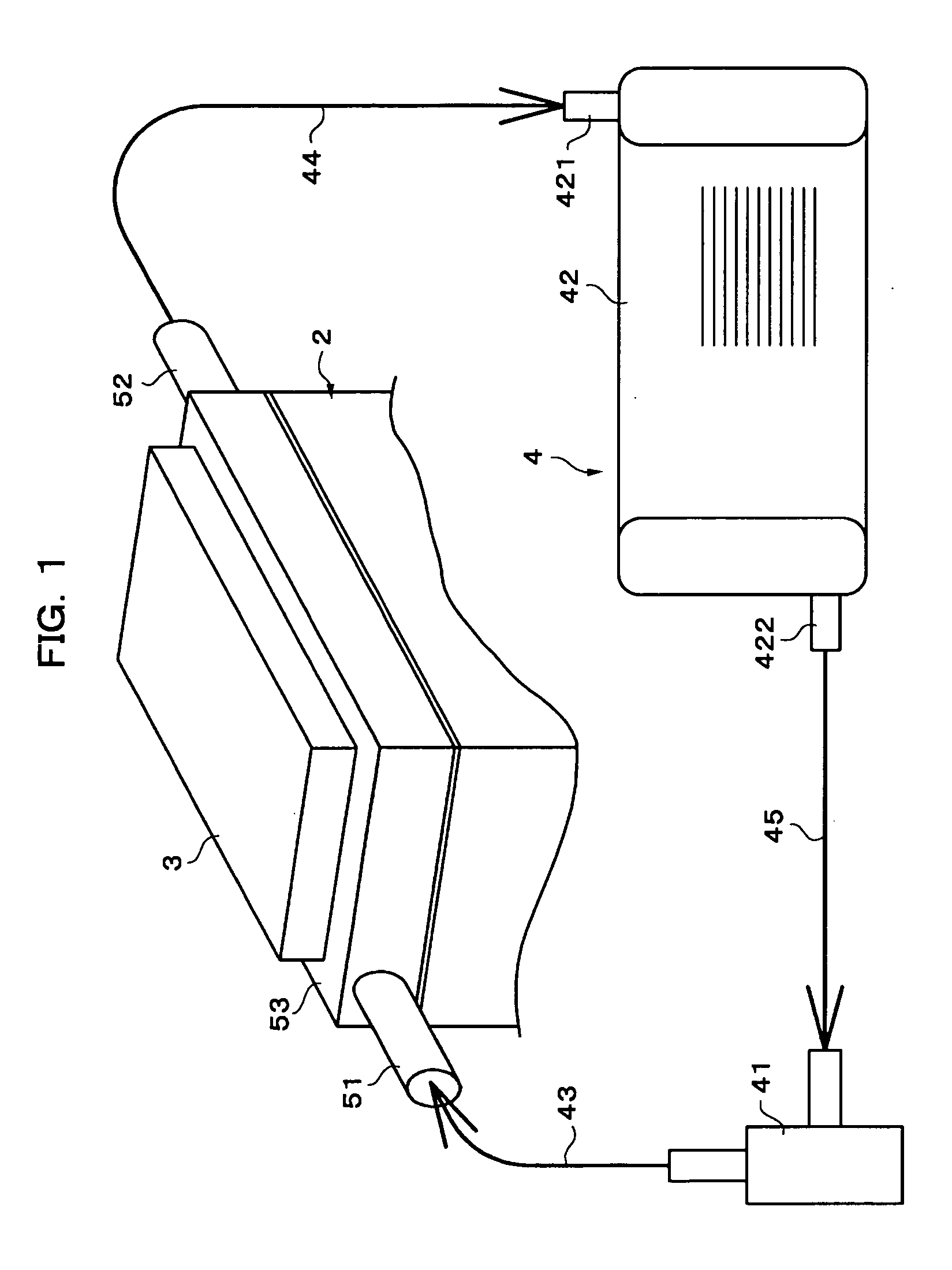

Drive device

InactiveUS20050253465A1Prevent excess flowIncrease the areaAssociation with control/drive circuitsElectric propulsion mountingEngineeringRefrigerant

A drive unit comprises an electric motor, a drive unit casing 2 accommodating therein the electric motor, an inverter 3 that controls the electric motor, and a flow passage of a refrigerant that cools the inverter. The inverter defines a space R between it and a heat sink 5 integral with a substrate of the inverter, and is mounted to the drive unit casing, the space being communicated to the flow passage of the refrigerant. The heat sink comprises fins 56 that cross the space R, and abuts against the drive unit casing in a state of low thermal conduction. Thereby, the heat sink is effectively cooled by heat exchange with a cooling refrigerant in wide areas. Also, the fins contact with the drive unit casing in a state of low thermal conduction via a heat insulation material, etc., whereby direct heat conduction is avoided and efficient cooling is enabled while temperature gradient conformed to heat-resistant temperatures of the inverter and the electric motor is maintained.

Owner:AISIN AW CO LTD

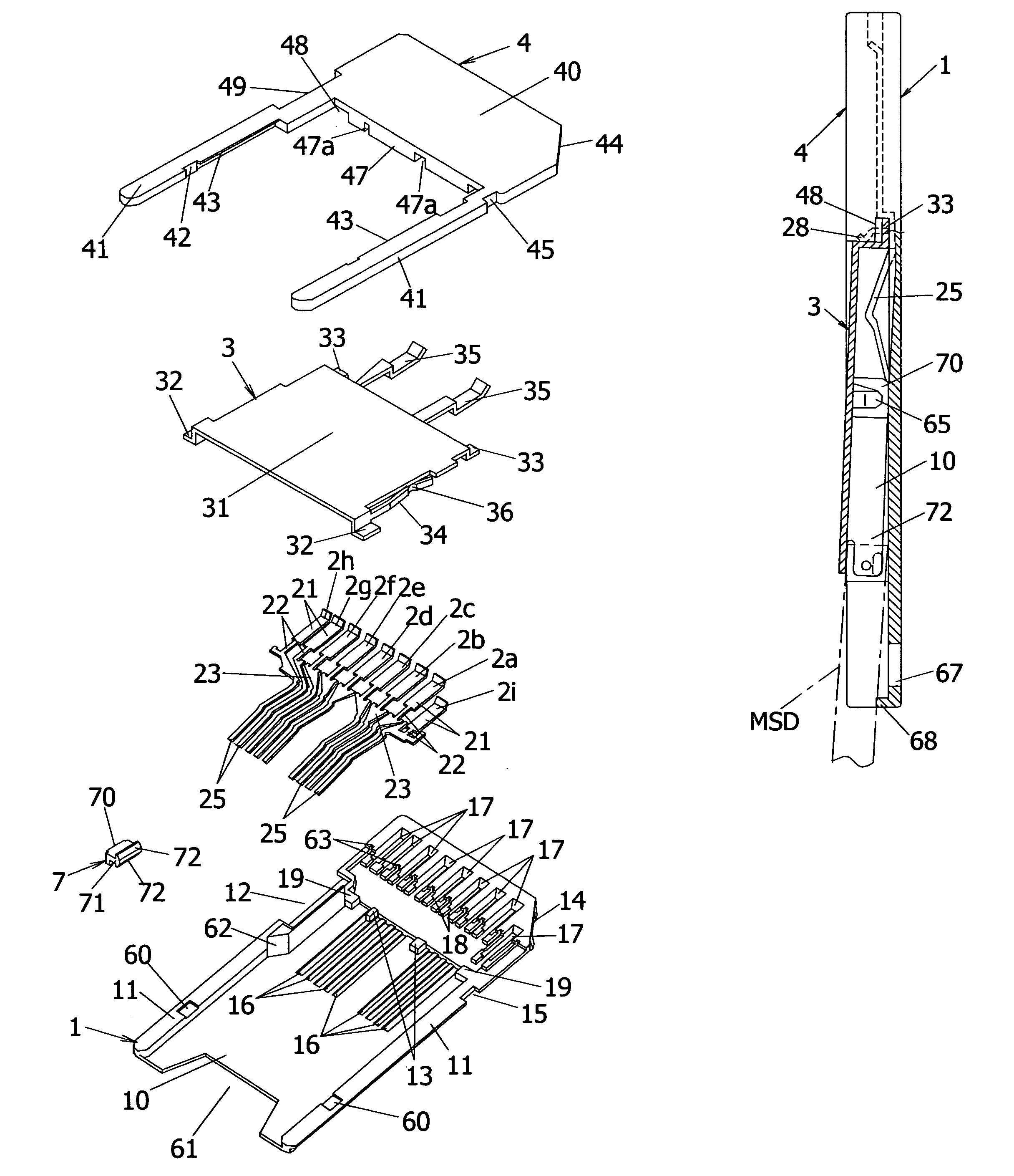

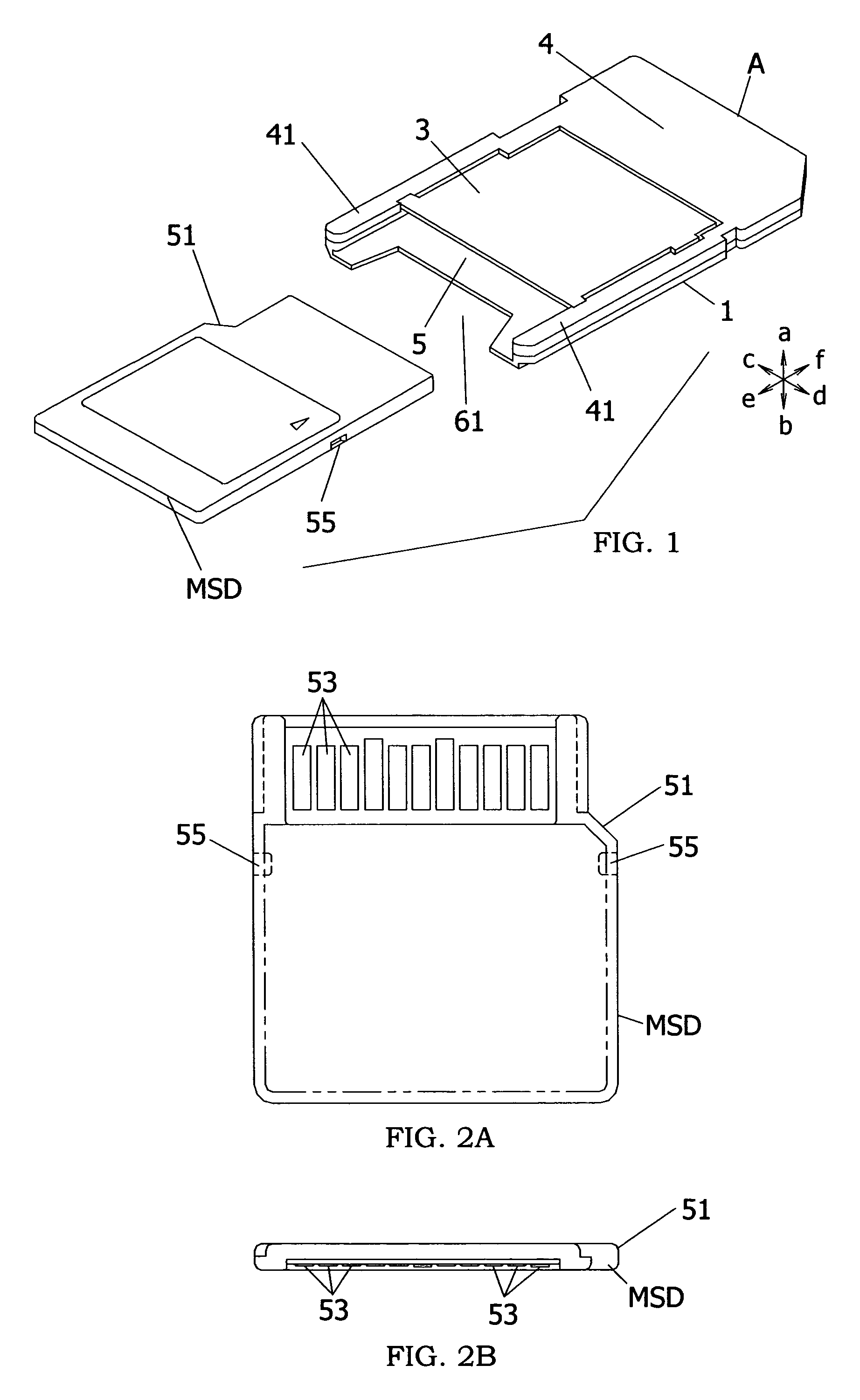

Adaptor for memory card

InactiveUS7094106B2Prevent occurrence of damageImprove reliabilityEngagement/disengagement of coupling partsCo-operative working arrangementsComputer scienceMemory cards

An adaptor for using a mini-sized memory card in an appliance having a slot for a regular-sized memory card is provided. This adaptor is formed with a base and a cover made of a resin material, a plurality of electrically conductive members fixed to the base so as to electrically contact a plurality of I / O terminals of the memory card in the adapter, and a metal shell held between the base and the cover. A memory-card storage room is provided by a space surrounded by the metal shell and the base. By use of the metal shell, it is possible to improve rigidity of the adaptor, obtain a reliable compatibility, and prevent that the thin, mini-sized memory card is damaged.

Owner:MATSUSHITA ELECTRIC WORKS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com