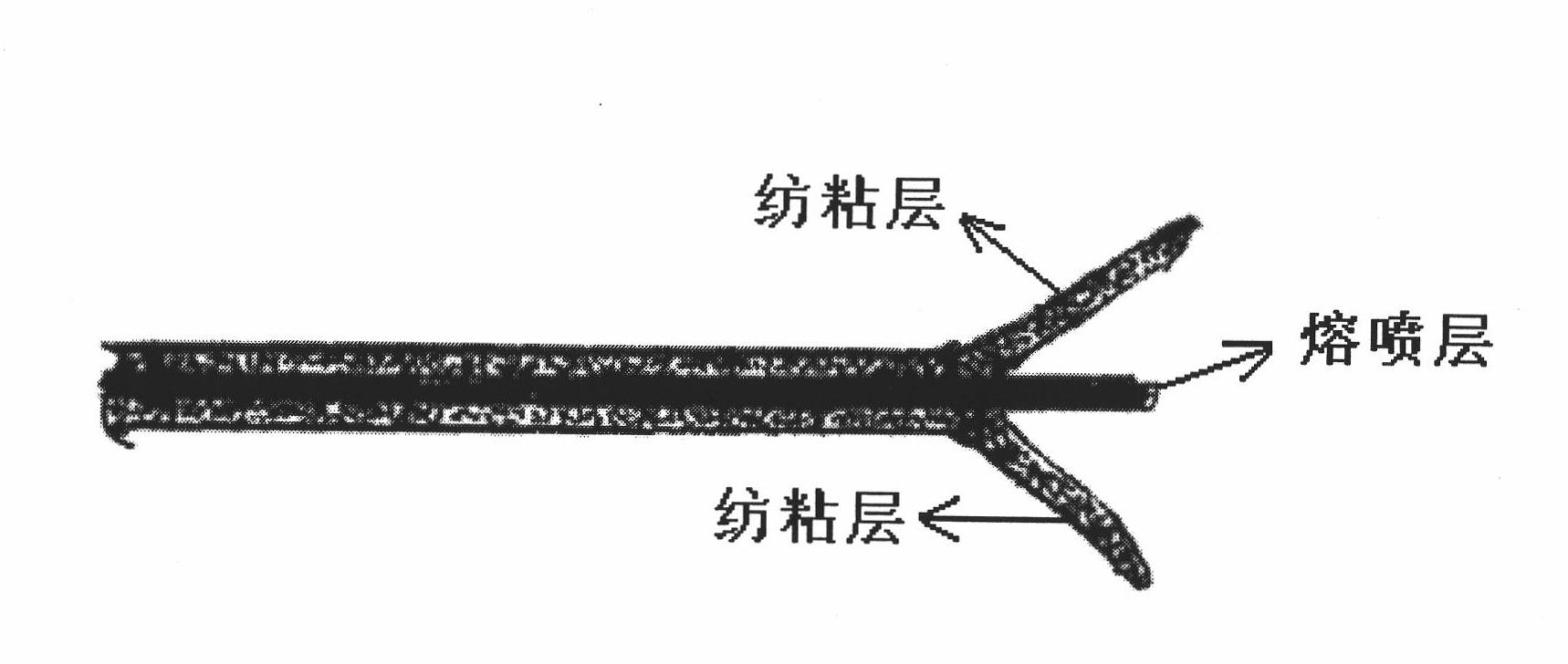

Fully-degradable polylactic acid fiber SMS compound non-woven and manufacturing method thereof

A technology of polylactic acid fibers and non-woven fabrics, which is applied in the directions of non-woven fabrics, fiber processing, textiles and paper making, etc., can solve problems such as unfavorable large-scale production, poor product stability, and improvement of polylactic acid characteristics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

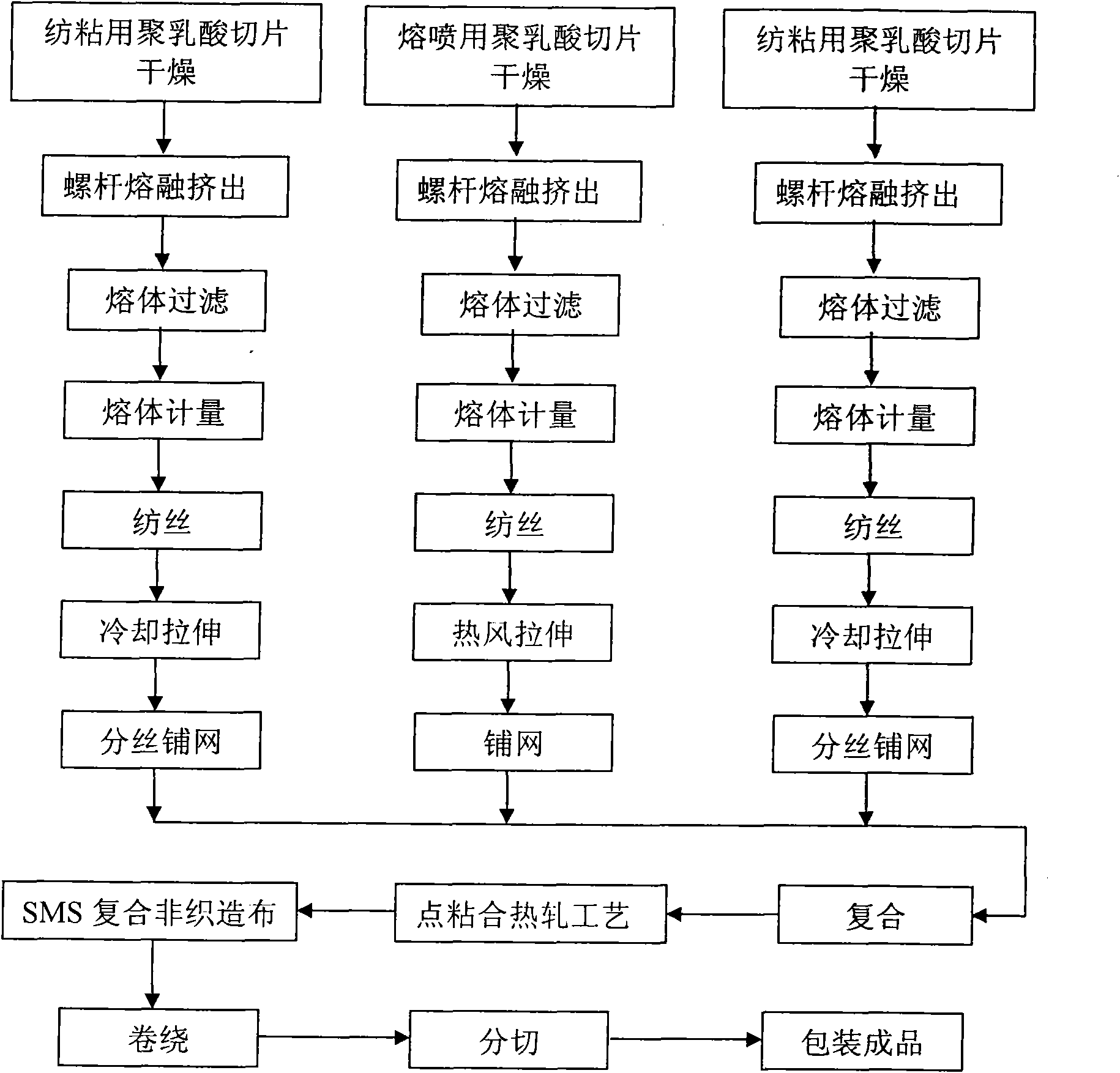

Method used

Image

Examples

Embodiment 1

[0047] (1) Polylactic acid chip SB8206 for spunbonding, with a molecular weight of about 120,000, a melt index of 30g / 10min at 210°C, a melting point of 185°C, and a thermal cracking temperature of 295°C; polylactic acid chip MB3602 for meltblown Type, the molecular weight is about 90,000, the melting index at 210°C is 70g / 10min, the melting point is 170°C, and the thermal cracking temperature is 325°C.

[0048] (2) Melt spinning by spunbond method. The polylactic acid slices are fed into the feeding hopper, and sent to the hot air drying equipment part of the spunbond production line through the pipeline, and the slices are dried by circulating high-temperature airflow, which can remove moisture in a short time, and the drying temperature is set at 80 ℃, the drying time is 6 hours, and the water content of the PLA slices after drying is below 100ppm; the dried polylactic acid slices are sent into the screw extruder through the filter device and metering pump, and the length-t...

Embodiment 2

[0059] (1) Polylactic acid chip SB8204 for spunbonding, with a molecular weight of about 150,000, a melt index of 25g / 10min at 210°C, a melting point of 185°C, and a thermal cracking temperature of 290°C; polylactic acid chip MB3604 for meltblown Type, the molecular weight is about 120,000, the melting index at 210°C is 85g / 10min, the melting point is 175°C, and the thermal cracking temperature is 295°C.

[0060] (2) Melt spinning by spunbond method. The polylactic acid slices are fed into the feeding hopper, and sent to the hot air drying equipment part of the spunbond production line through the pipeline, and the slices are dried by circulating high-temperature airflow, which can remove moisture in a short time, and the drying temperature is set at 80 ℃, the drying time is 5 hours, and the water content of the PLA slices after drying is below 100ppm; the dried polylactic acid slices are sent into the screw extruder, and the aspect ratio of the screw extruder is 33, and the f...

Embodiment 3

[0071] (1) Polylactic acid chip SB8200 for spunbonding, with a molecular weight of about 150,000, a melt index of 35g / 10min at 210°C, a melting point of 178°C, and a thermal cracking temperature of 275°C; polylactic acid chip MB3602 for meltblown Type, the molecular weight is about 140,000, the melting index at 210°C is 80g / 10min, the melting point is 165°C, and the thermal cracking temperature is 285°C.

[0072] (2) Melt spinning by spunbond method. The polylactic acid slices are fed into the feeding hopper, and sent to the hot air drying equipment part of the spunbond production line through the pipeline, and the slices are dried by circulating high-temperature airflow, which can remove moisture in a short time, and the drying temperature is set at 100 ℃, the drying time is 4 hours, and the water content of the PLA slices after drying is below 100ppm; the dried polylactic acid slices are sent into the screw extruder, and the aspect ratio of the screw extruder is 36, and the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Cloth density | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Areal density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com