Patents

Literature

1182results about "Spinning head liquid feeder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

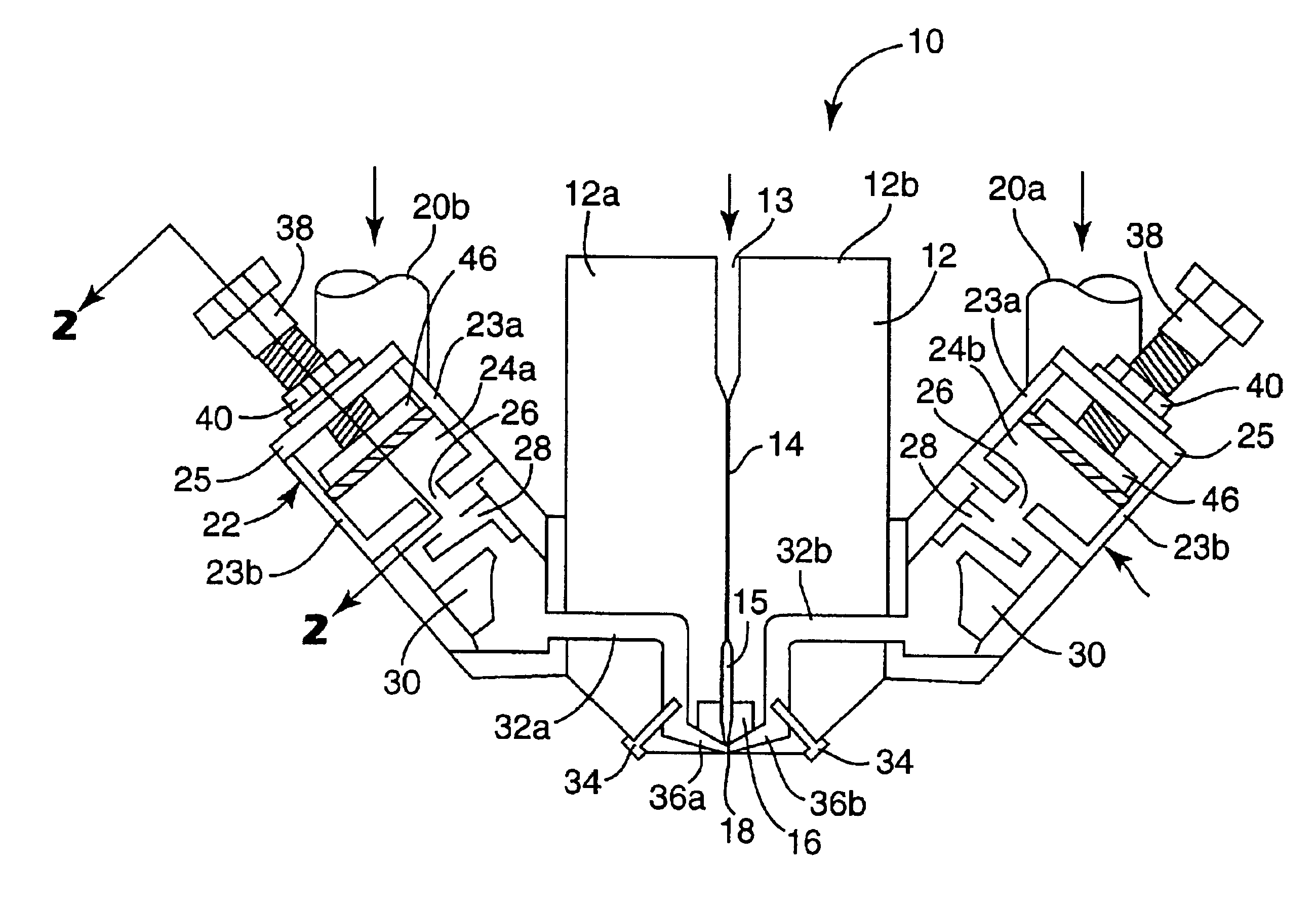

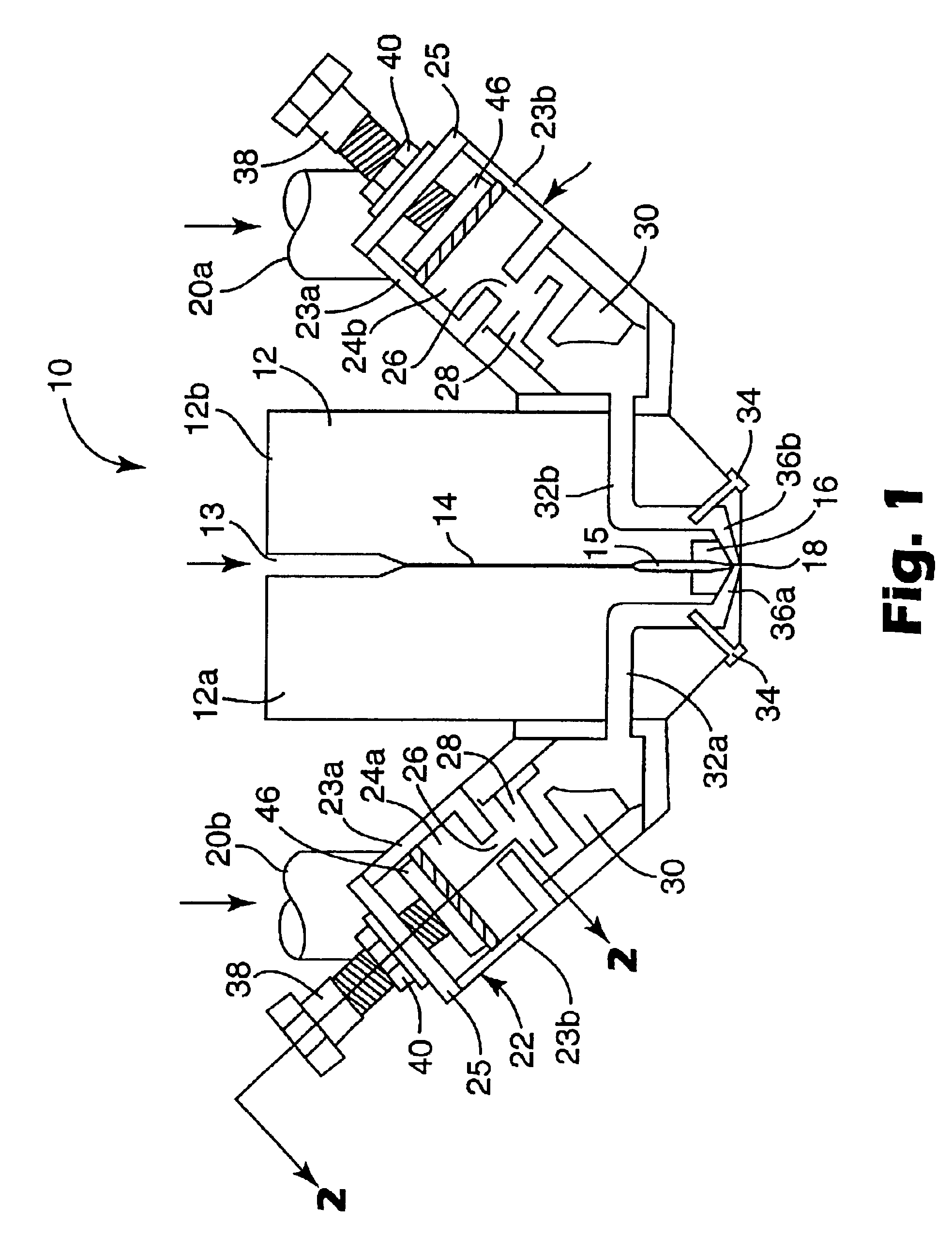

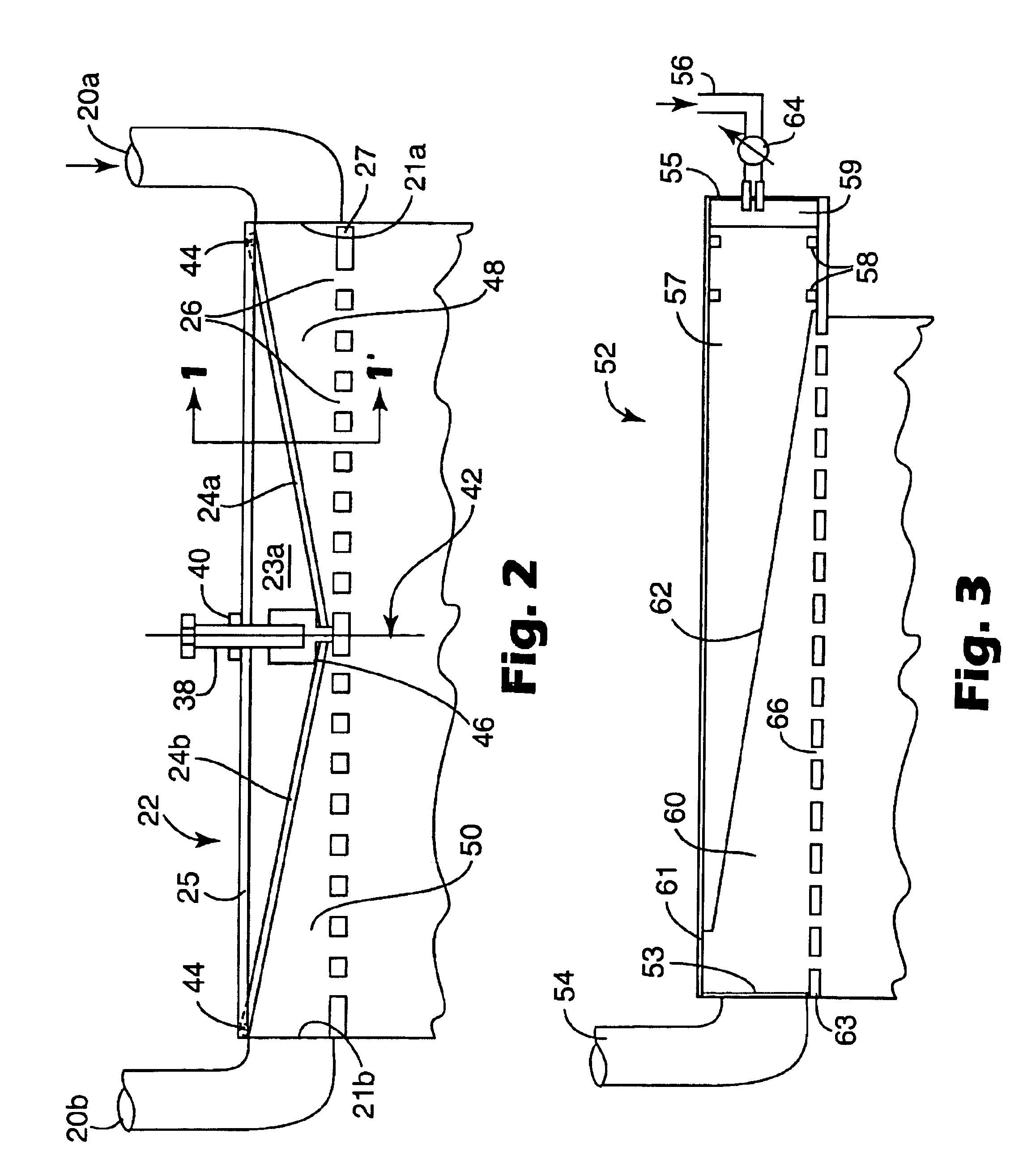

Attenuating fluid manifold for meltblowing die

InactiveUS6861025B2Quality improvementUniform physical propertiesSpinning head liquid feederConfectioneryDistribution characteristicEngineering

Melt blown nonwoven webs are formed by supplying attenuating fluid to a meltblowing die through an attenuating fluid distribution passage whose distribution characteristics can be changed while the die and manifold are assembled. By adjusting the distribution characteristics of the passage, the mass flow rate of attenuating fluid to channels in the meltblowing die and the temperature of the attenuating fluid at the die outlets can be made more uniform.

Owner:3M INNOVATIVE PROPERTIES CO

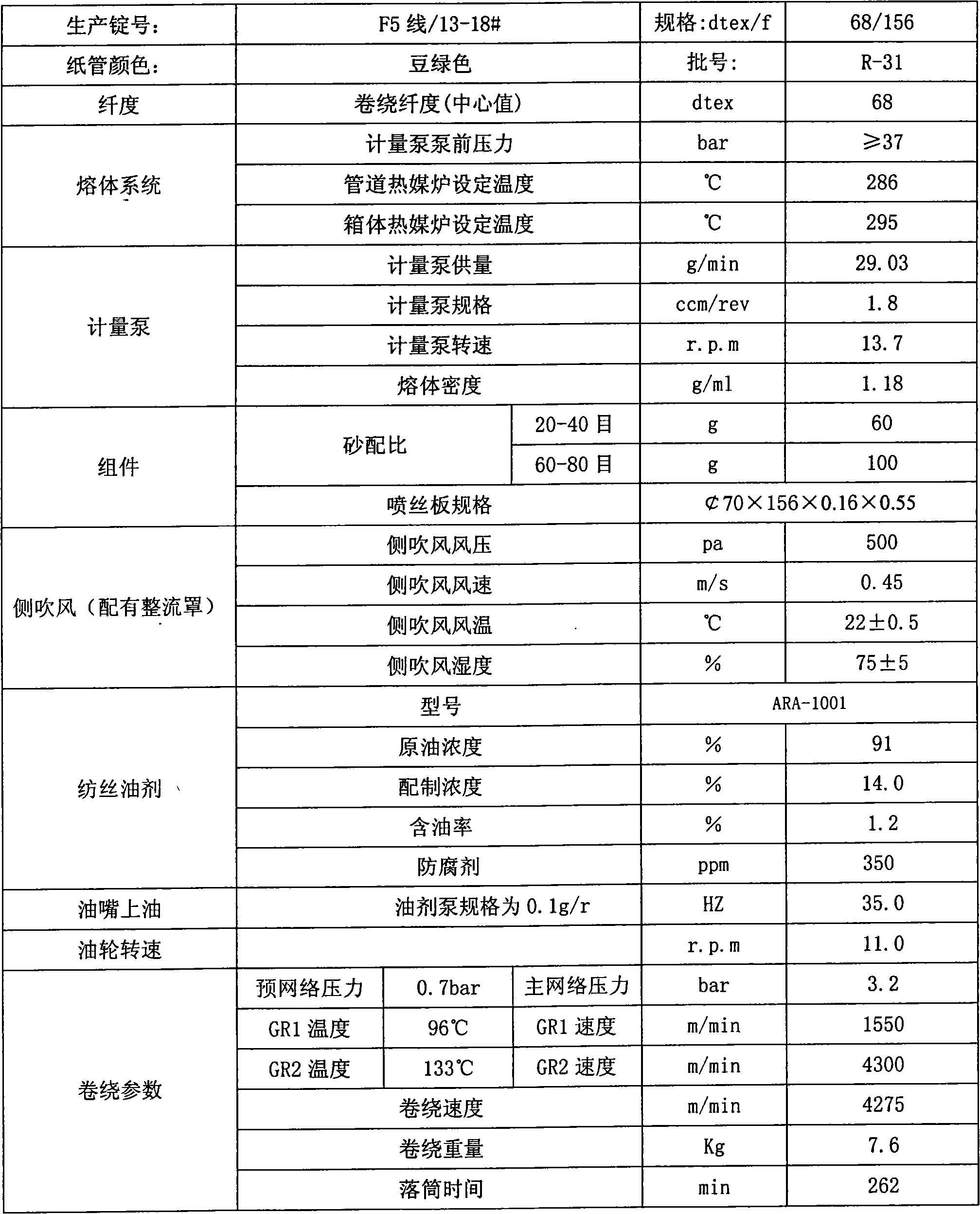

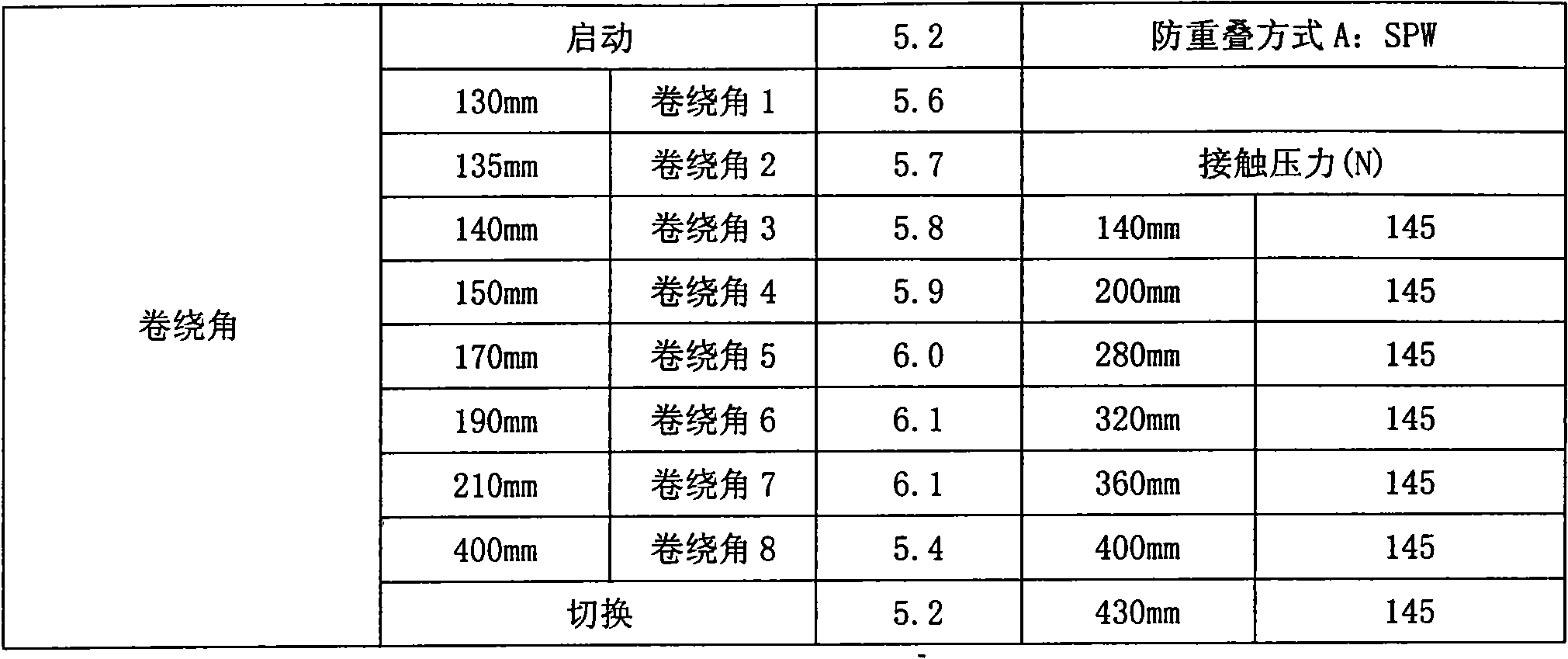

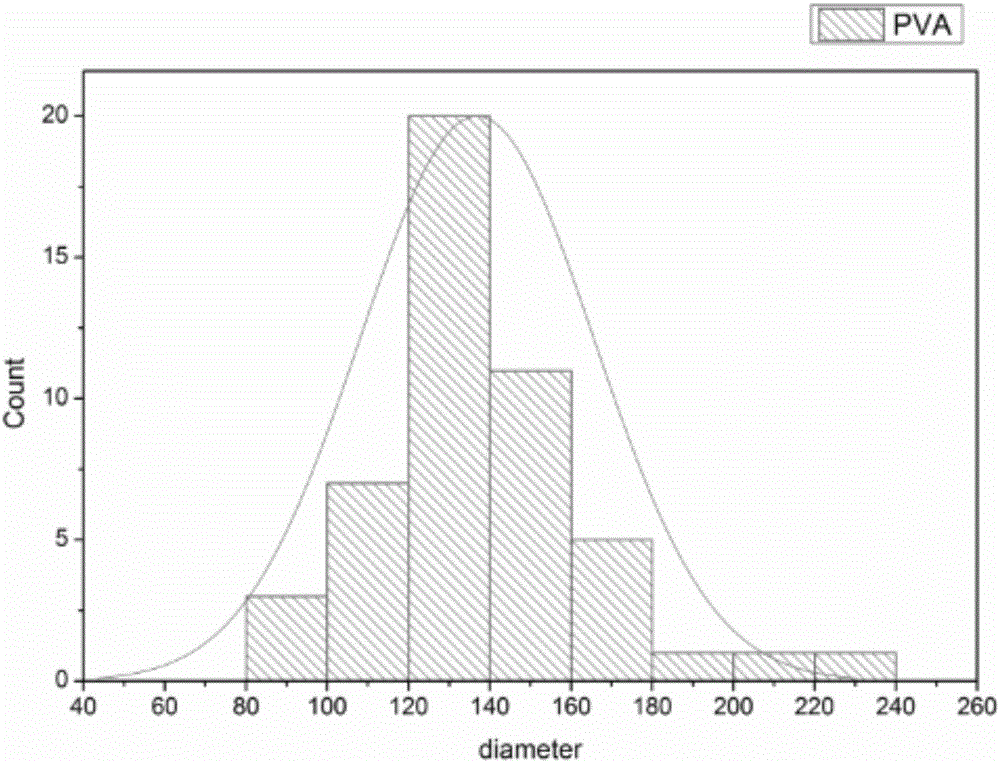

Polyester DTY fiber and preparation method thereof

ActiveCN108385186AHigh molecular weightNarrow molecular weightSpinning head liquid feederFilament/thread formingFiberThermal insulation

The invention relates to polyester DTY fiber and a preparation method thereof. The preparation method comprises: metering a modified polyester melt, extruding, cooling, oiling, and winding to preparethe polyester POY fiber. According to the present invention, during the cooling, the longitudinal height is maintained, and the cross section area of the slow cooling chamber is increased while the plate surface temperature of the spinning plate is maintained by using the thermal insulation method; the material of the fiber is the modified polyester, the molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formula of the diol chain segment having the branched chain is defined in the specification, R1 and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atomnumber of 1-5, and R4 is selected from alkyl with a carbon atom number of 2-5; the chromatic aberration [delta]E of the prepared fiber is less than 0.200; and the preparation process is simple and reasonable, and the obtained fiber has excellent performance.

Owner:JIANGSU HENGLI CHEM FIBER

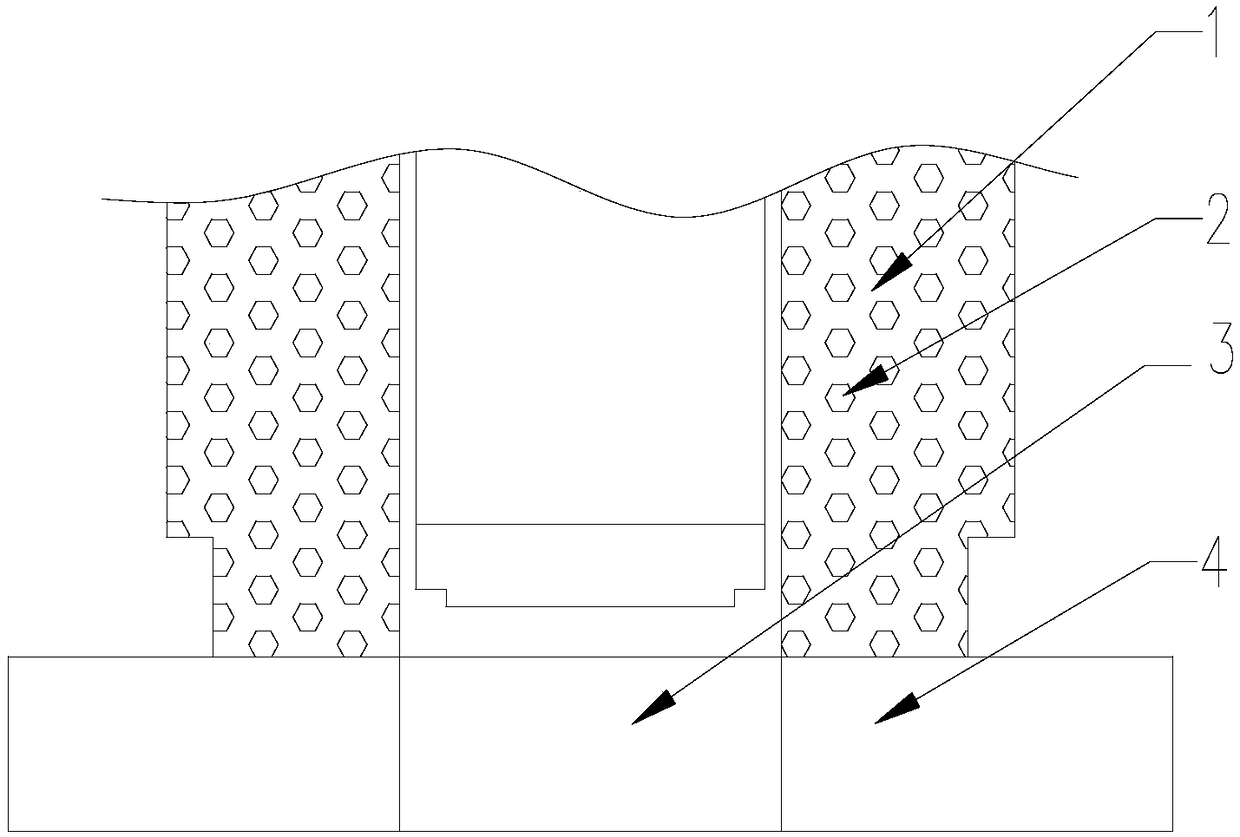

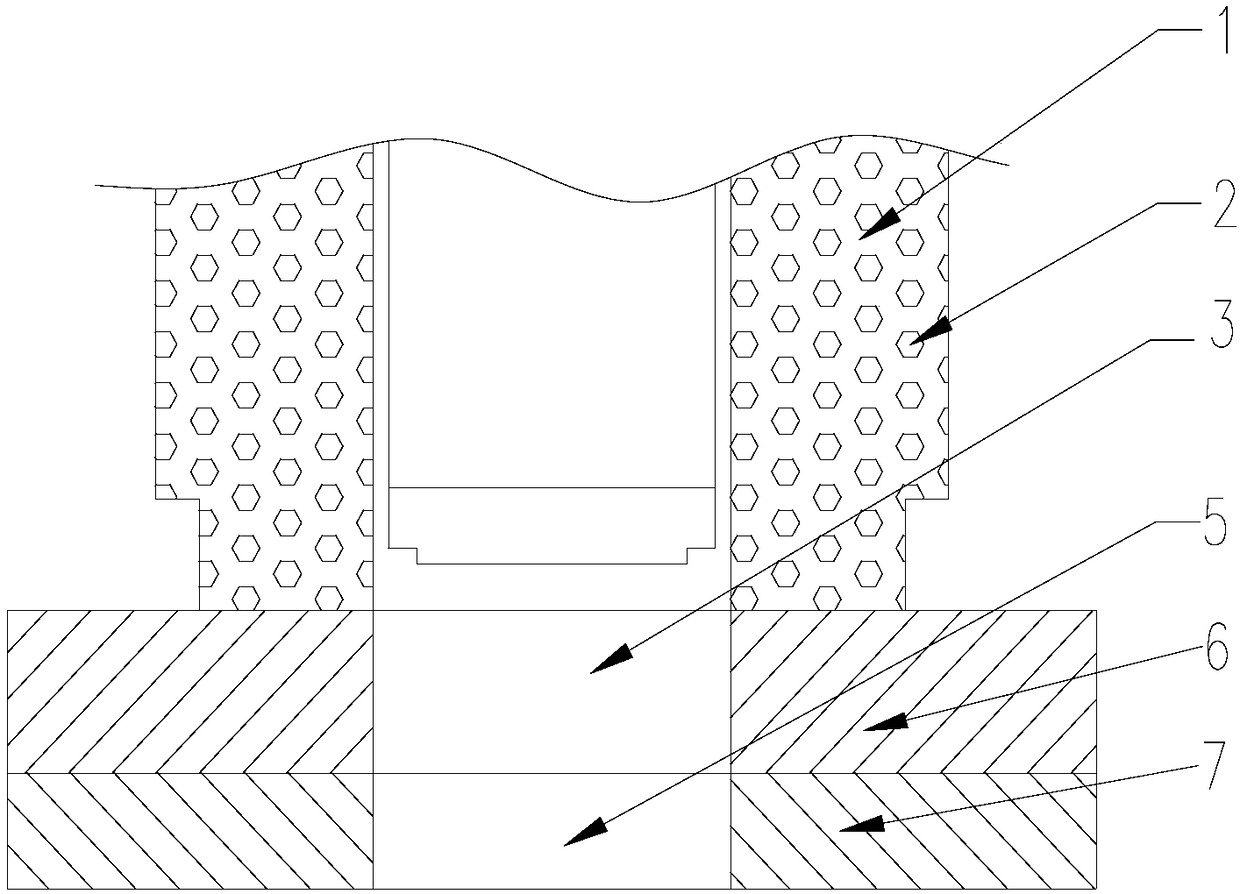

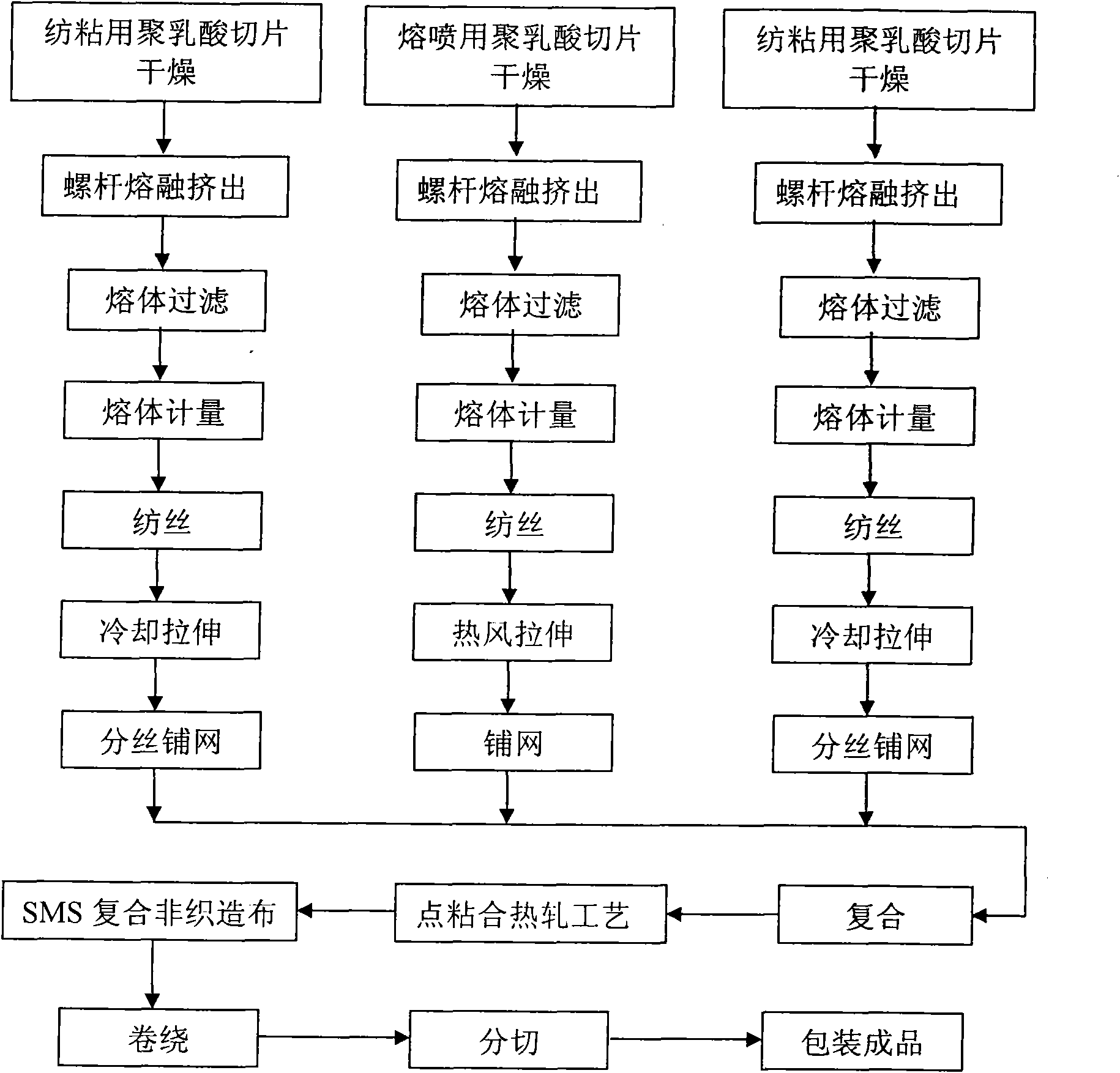

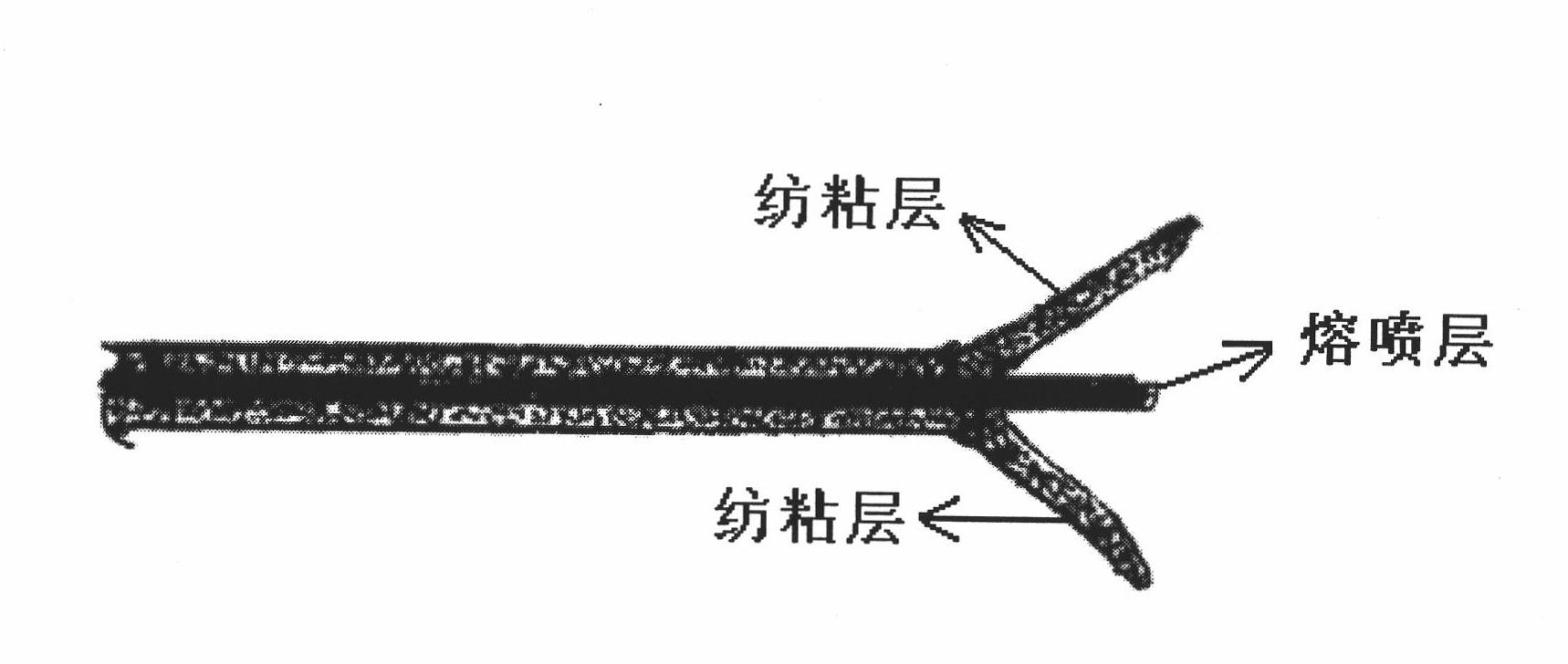

Fully-degradable polylactic acid fiber SMS compound non-woven and manufacturing method thereof

InactiveCN101851830APromote growthCapable of biocompostingSpinning head liquid feederMelt spinning methodsNonwoven fabricPhysical property

The invention discloses a fully-degradable polylactic acid fiber SMS compound non-woven and a manufacturing method thereof. The non-woven is compounded by three layers of non-woven by self-bonding or hot rolling, wherein the middle layer is polylactic acid meltblown non-woven, and the upper layer and the lower layer of the middle layer are both polylactic acid spunbonded non-woven. The SMS non-woven is even and has stable quality and excellent physical property, filtering property and shielding property. A thin SMS product has favourable waterproof permeability and is especially suitable for the fields of hygienic materials, packaging materials and the like; an SMS product with medium thickness is suitable for the disposable products of the field of medical treatments, and a thick SMS product is suitable for the field of industrial filtering. The production technology of the invention is easy to operate and control, has favorable stability and can carry out industrial production.

Owner:豆丁乐园(南京)婴儿用品有限公司

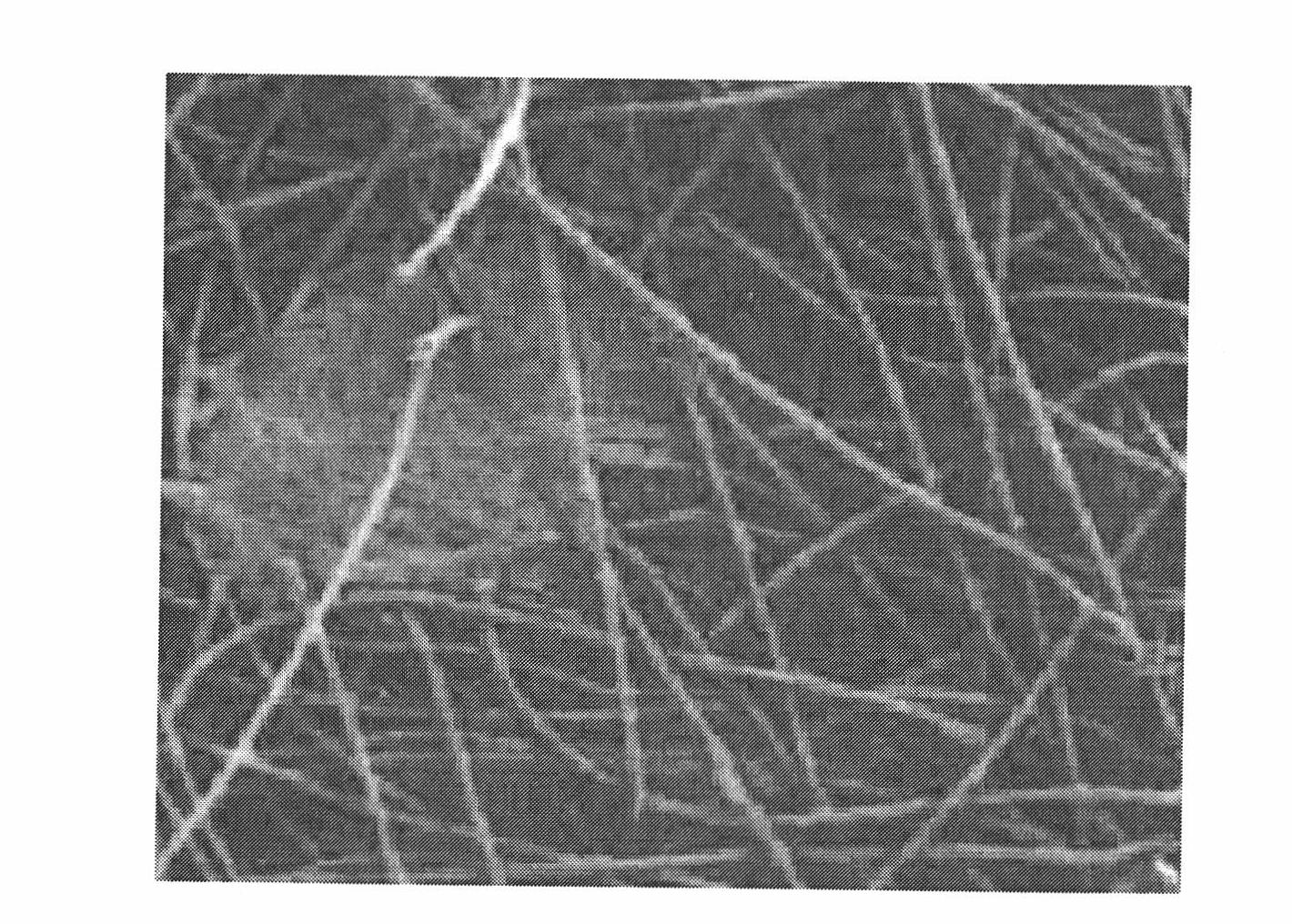

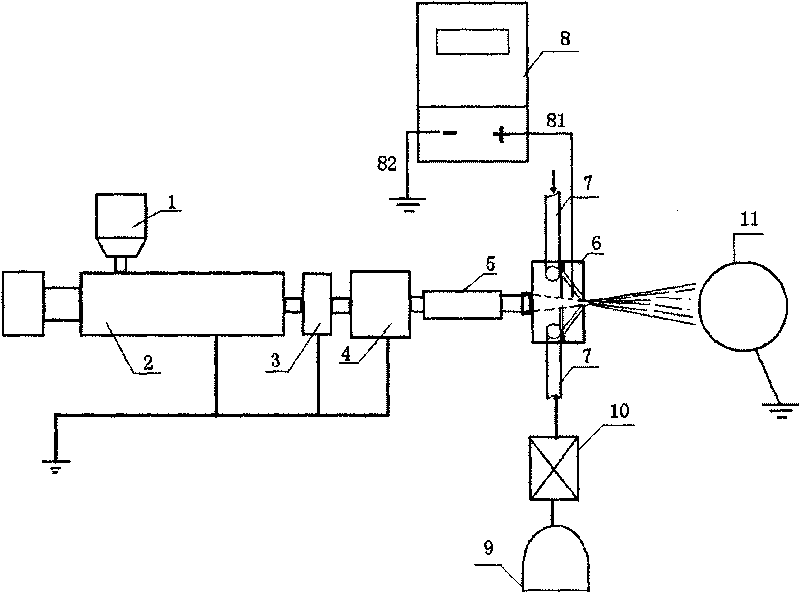

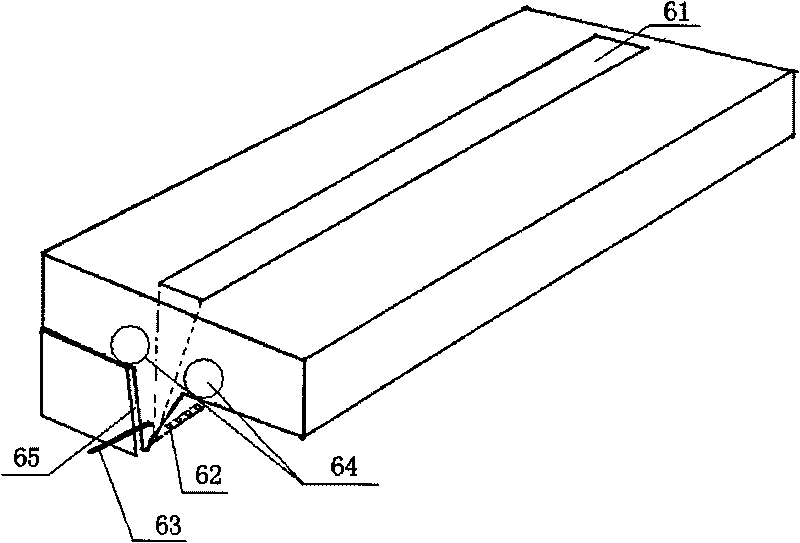

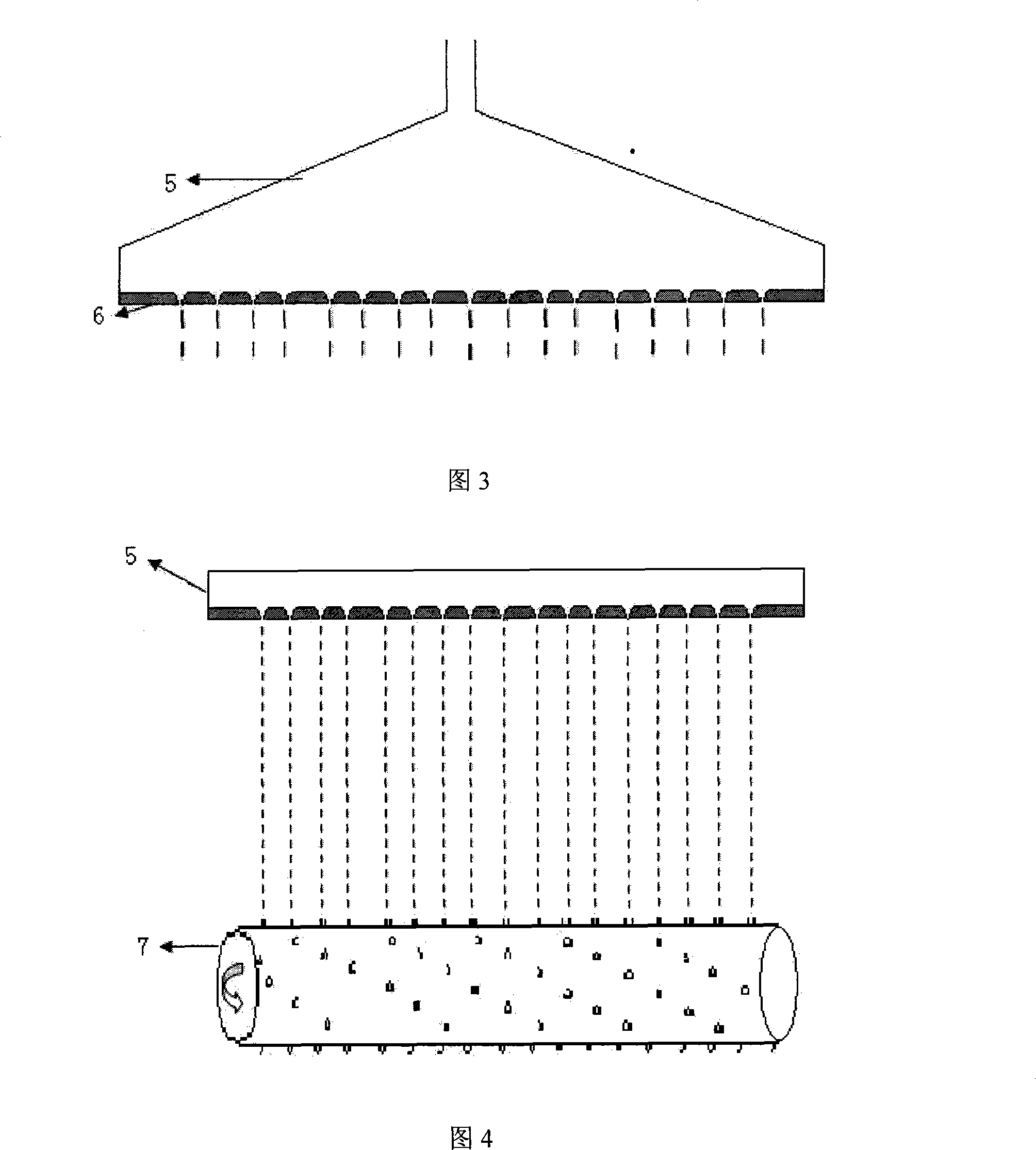

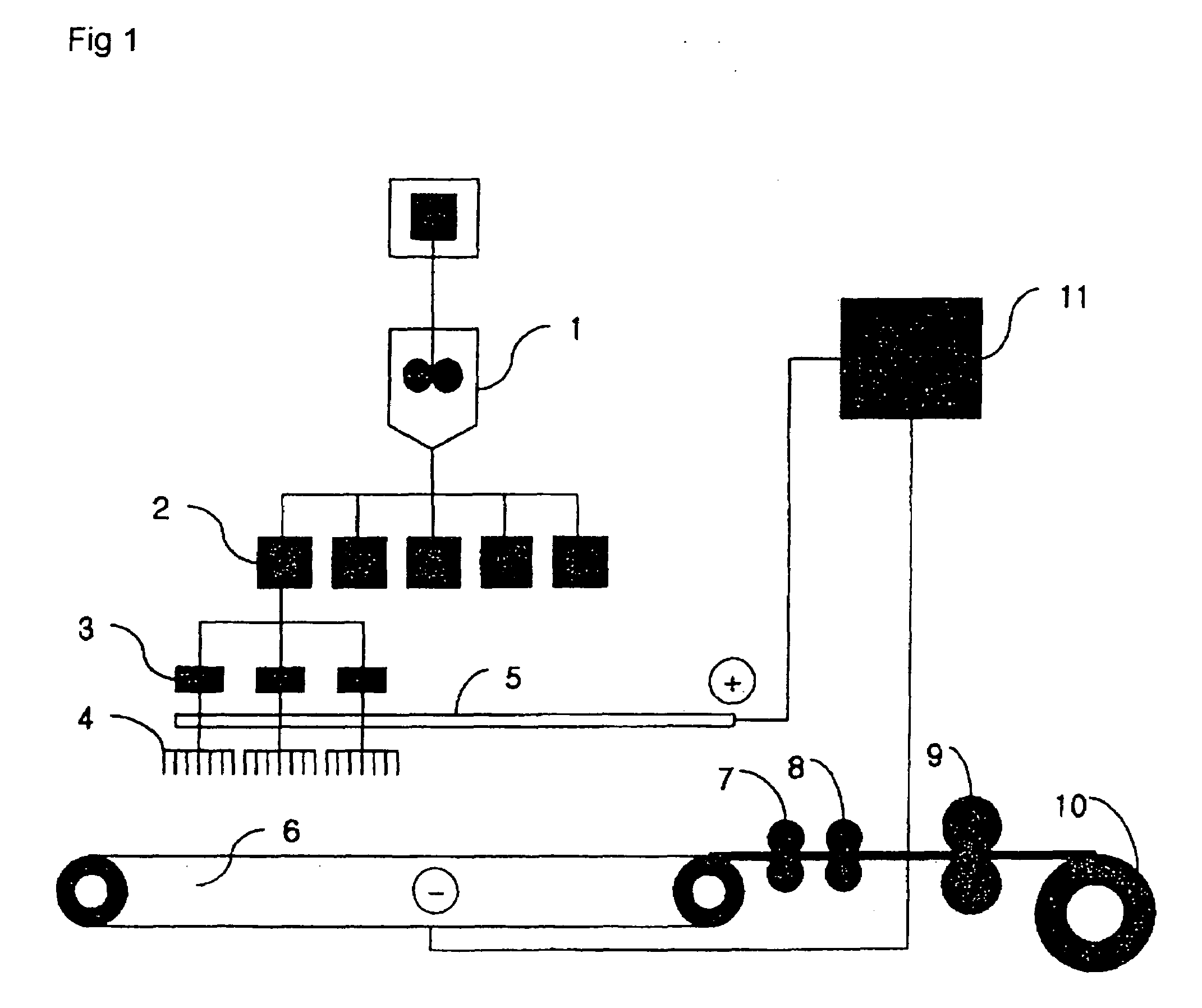

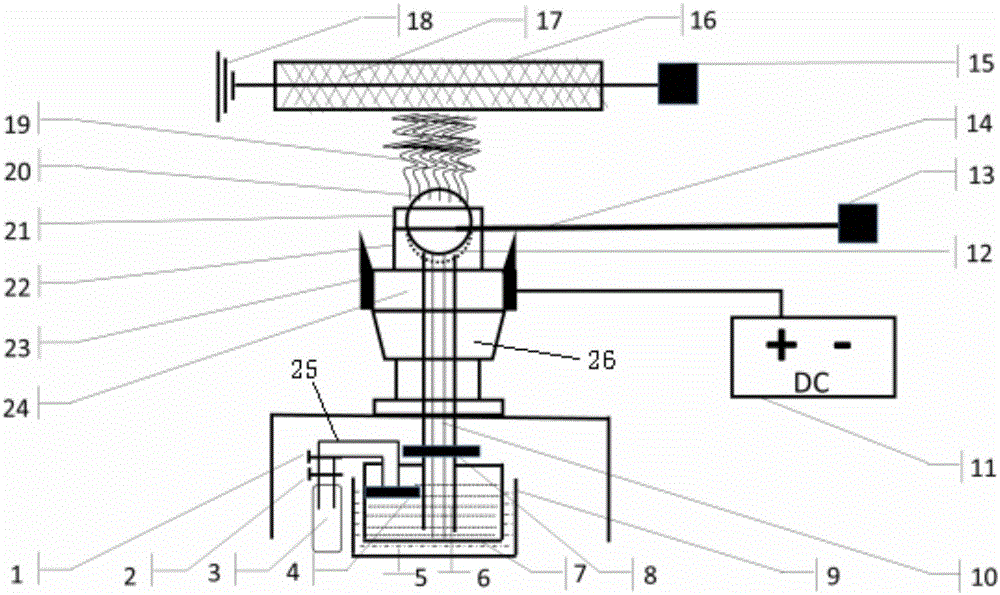

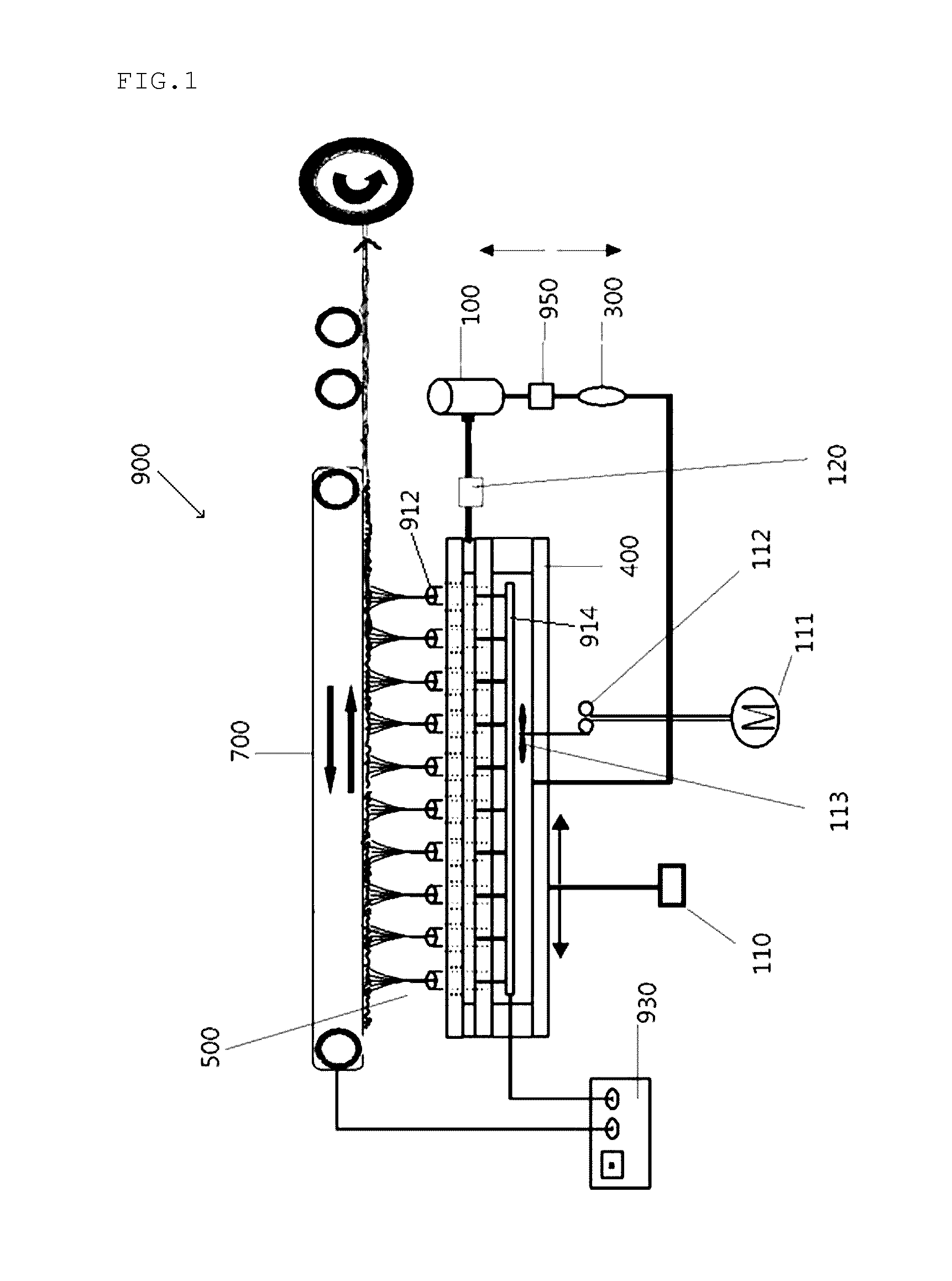

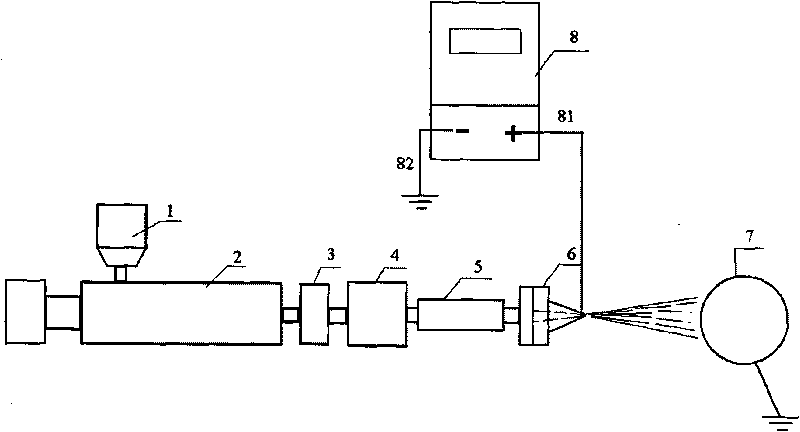

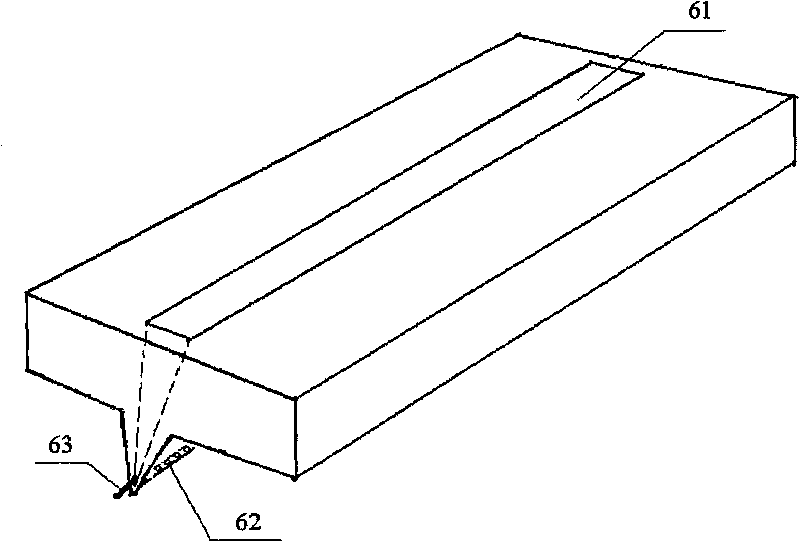

Device and method for manufacturing airflow melting electrostatic spinning nano-fiber non-woven fabric

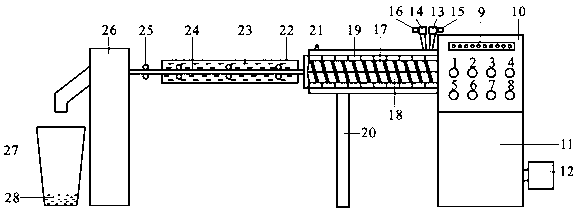

InactiveCN101709534AThin diameterNarrow distributionSpinnerette packsSpinning head liquid feederFiberManufacturing technology

The invention relates to a device and a method for manufacturing an airflow melting electrostatic spinning nano-fiber non-woven fabric. The device for manufacturing the airflow melting electrostatic spinning nano-fiber non-woven fabric comprises a stock hoper, a screw extruder, a filter, a metering pump, a material path, a melt-blown die head, a hot-air pipeline, an air compressor, a heating device, a high voltage electrostatic generator and a receiving device. The material path is made of high thermal conductivity insulating ceramics. The method for manufacturing the nano-fiber non-woven fabric adopts the device disclosed by the invention and comprises the following processing steps: (1) preparing a polymer melt; (2) jetting nano-fibers by using airflow static electricity; and (3) moulding the non-woven fabric. The method for manufacturing the nano-fiber non-woven fabric of the invention adopts airflow-melting electrostatic spinning technology, avoids a problem of pollution of electrostatic spinning solvent, and is novel environment-friendly non-woven fabric manufacturing technology. In the manufacturing method, high voltage electrostatic is directly acted on the melt-blown die head; the melt has high and uniform charge; and simultaneously by utilizing drafting of the airflow, the prepared nano-fiber has the advantages of thin diameter and narrow distribution. The device can meet production requirements by improving the conventional melt-blown manufacturing device, and has low implementation cost and easy industrialization promotion.

Owner:TIANJIN POLYTECHNIC UNIV

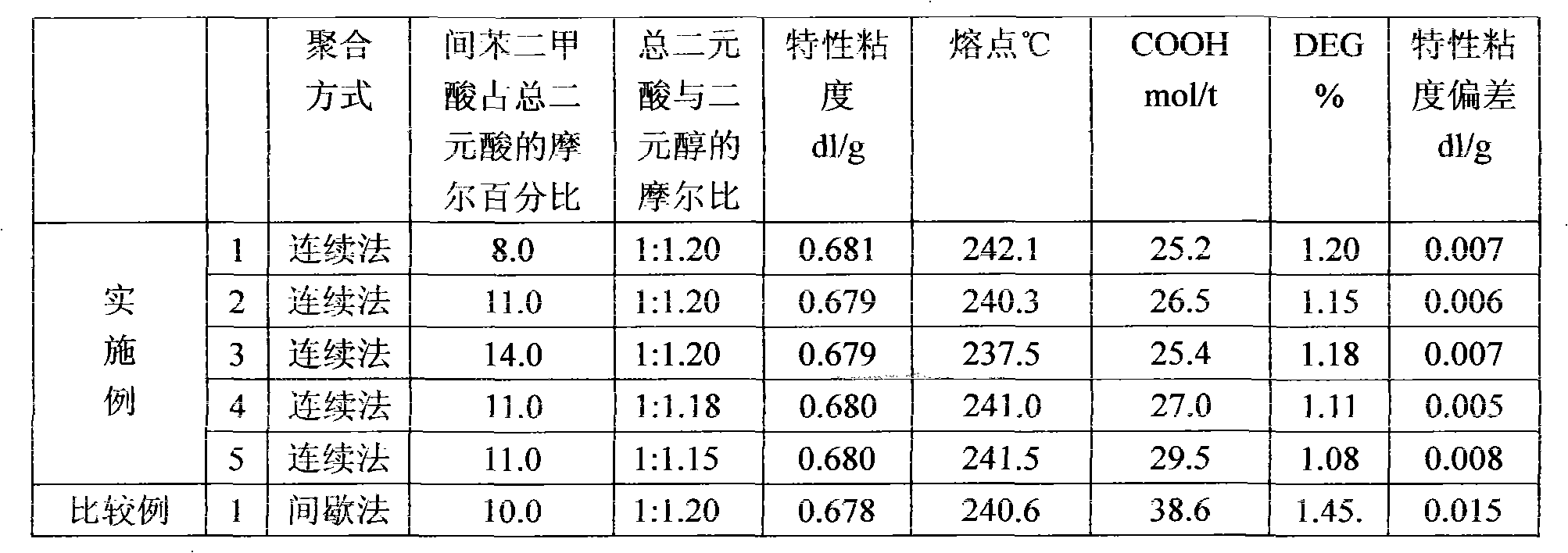

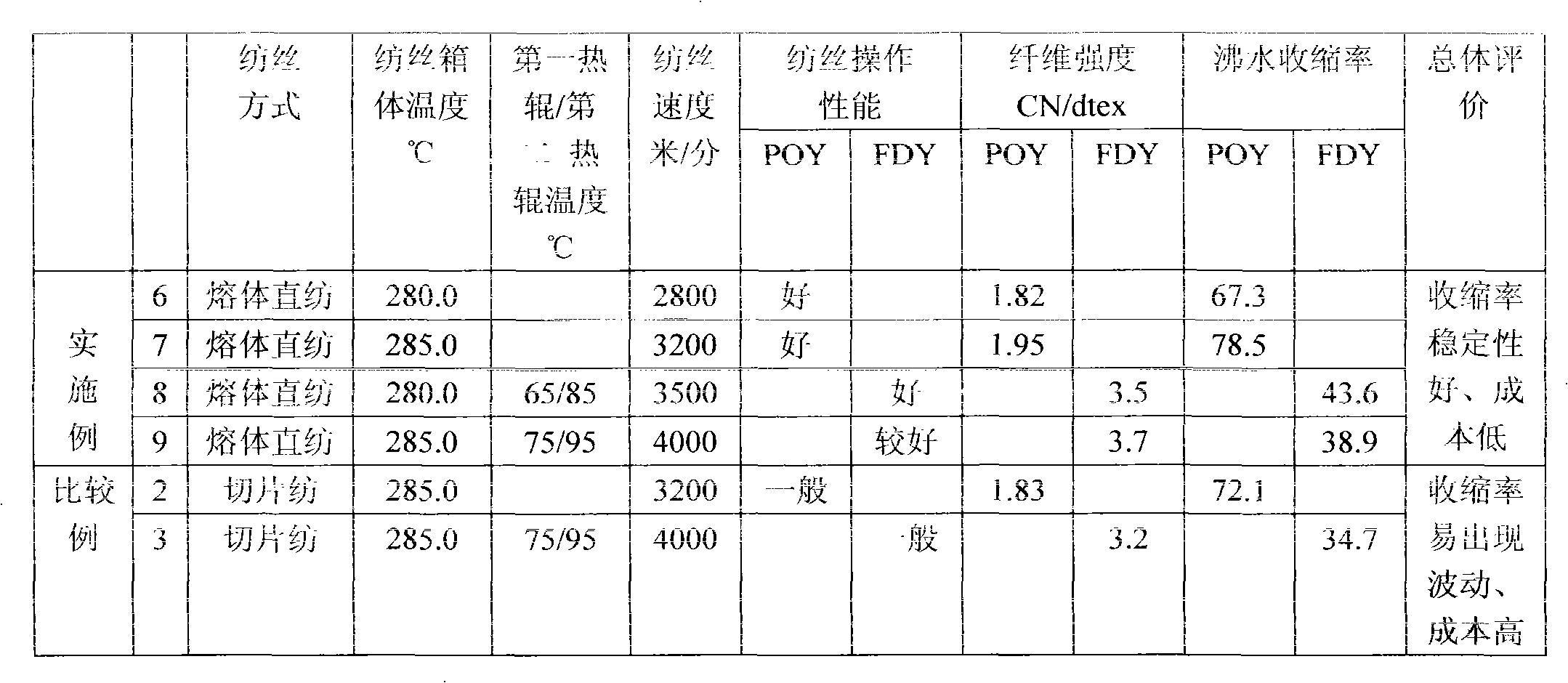

Method for preparing continuous polymerization directly-spun high-shrinkage polyester filaments

InactiveCN101787583AShrinkage stableShort processSpinning head liquid feederMonocomponent copolyesters artificial filamentYarnFiber

The invention discloses a method for preparing continuous polymerization directly-spun high-shrinkage polyester filaments, which comprises a process for preparing continuous polymerization modified copolyester melt and a process for preparing directly-spun cation-dyeable high-shrinkage polyester filaments. In the process for preparing the continuous polymerization modified copolyester melt, purified terephthalic acid, isophthalic acid and glycol monomers are taken as raw materials to prepare the modified copolyester melt; and the copolyester melt directly passes through a melt conveying piping equipment, and is metered, extruded, blown to be cooled, drawn for heat shaping, and wound to prepare one of high-shrinkage polyester preoriented yarns and high-shrinkage polyester drawn yarns. The method has the advantages of short flow, less working procedures, reasonable process, stable melt quality, and good spinning performance; and the prepared high-shrinkage fibers have good shrinkage stability and even dyeing, and the production cost is reduced obviously.

Owner:ZHEJIANG SCI-TECH UNIV +1

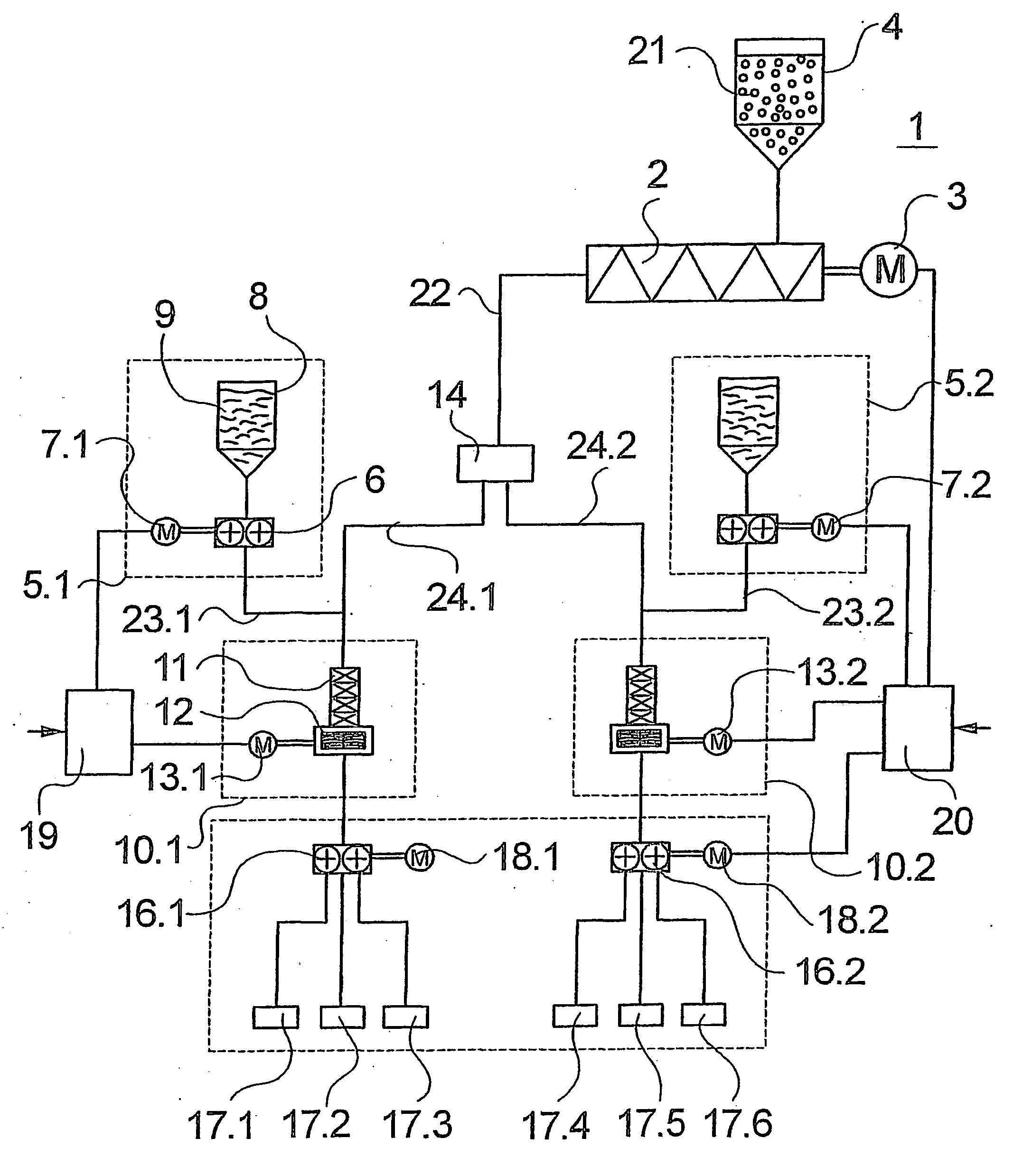

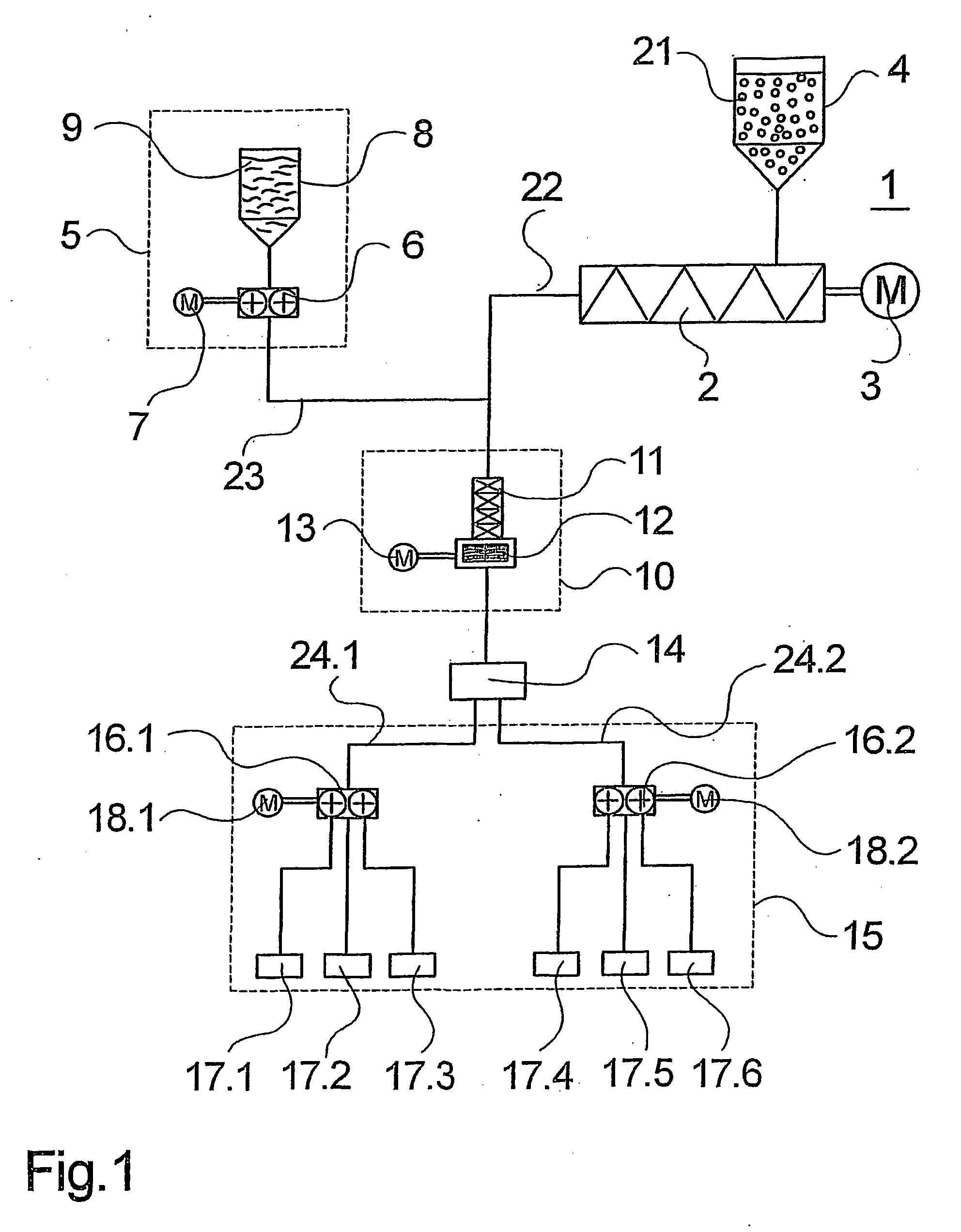

Apparatus and method for melt spinning dyed yarn filaments

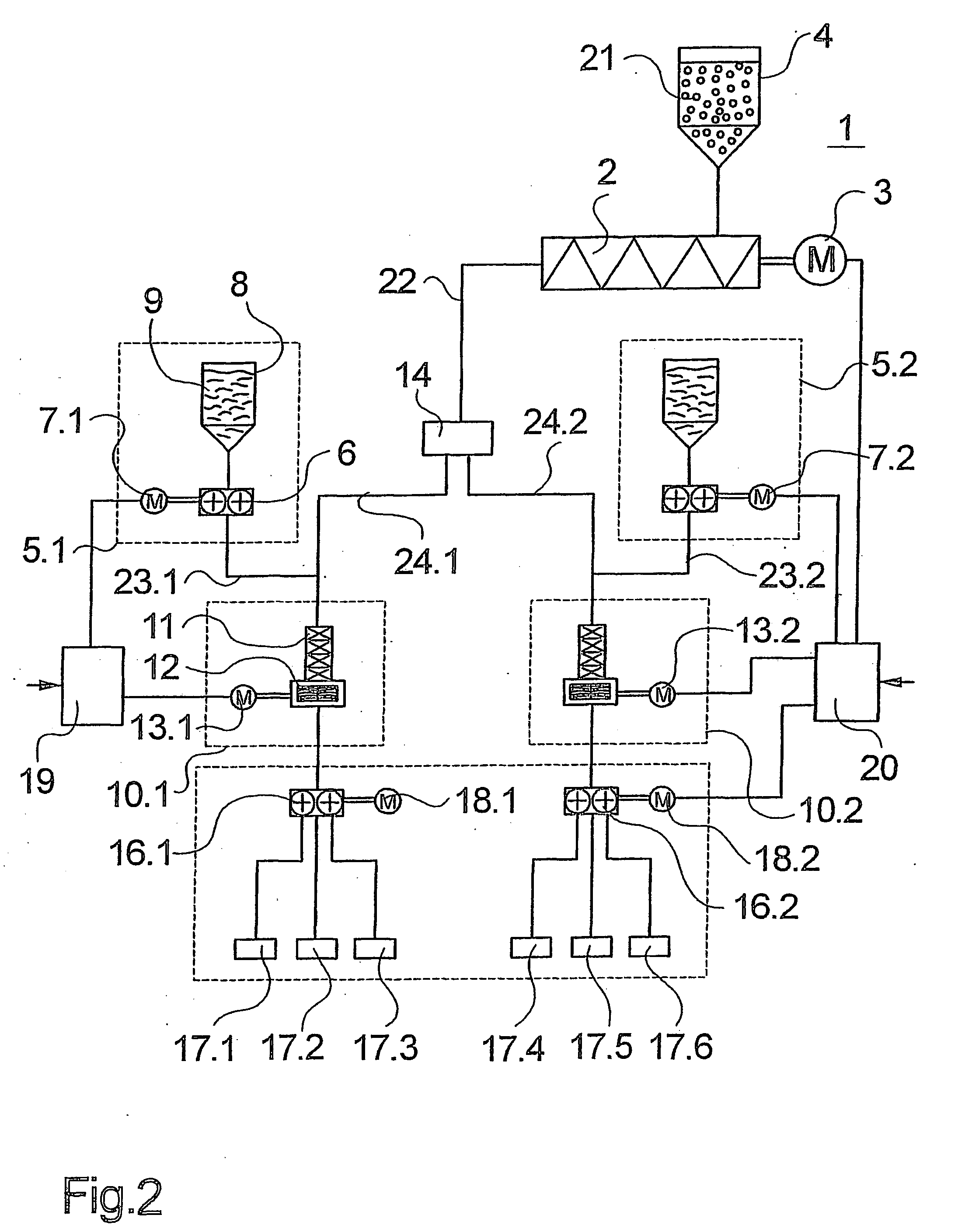

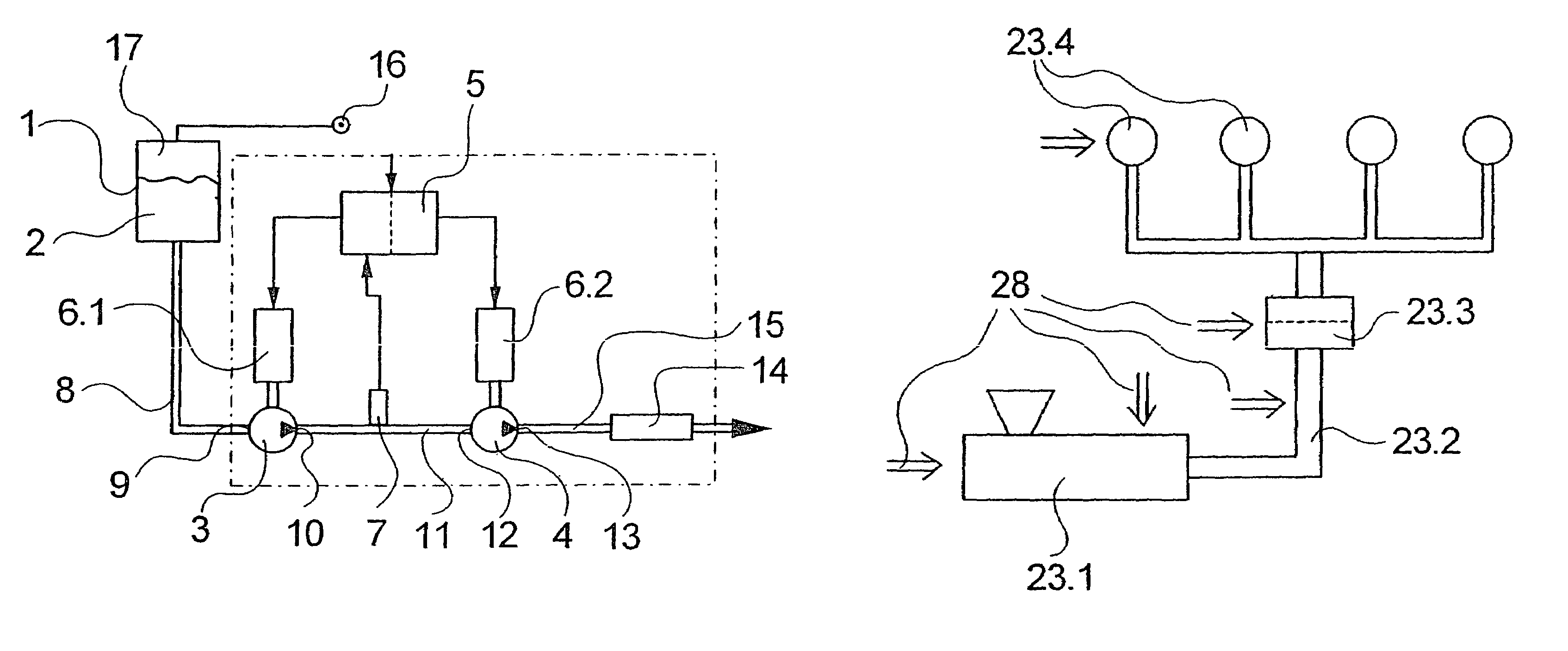

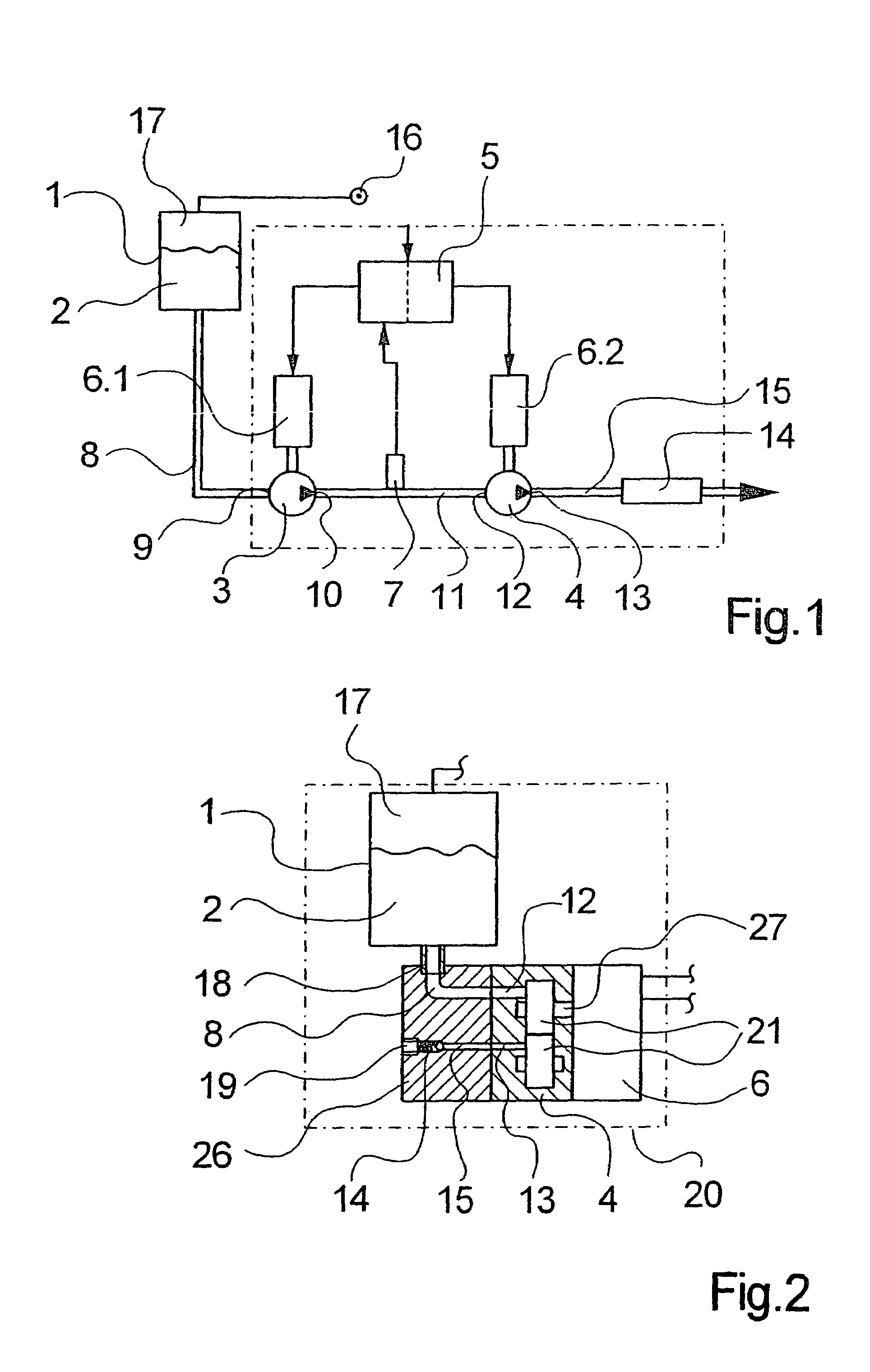

InactiveUS20050263941A1Good flexibilityPolymer meltDough homogenizationSpinning head liquid feederYarnStatic mixer

An apparatus and a method for spinning dyed filaments from a dyed polymer melt, wherein an undyed polymer melt is produced by a melt producer. A liquid dye is added to the polymer melt by means of a dye metering device. To mix the liquid dye and dye the polymer melt, a mixing unit is provided. The dyed polymer is then spun to filaments by means of a spin unit. To obtain before the spinning step a uniform coloration of the polymer melt despite the short dwelling time of the liquid dye in the polymer melt, the liquid dye and the polymer melt are mixed in a plurality of successive mixing units which are formed by a mixer combination comprising at least one static mixer and at least one dynamic mixer.

Owner:SAURER GMBH & CO KG

Preparation method of ultra-high molecular weight polyethylene fiber

ActiveCN102002769ANo force lossHigh strengthSpinning head liquid feederArtificial filament washing/dryingEnvironmental resistanceYarn

The invention relates to a novel production method for preparing a high-strength and high-elongation polyethylene fiber at low energy consumption and low cost. The method comprises the following two steps: 1, preparing a polyethylene modified master batch; and 2, uniformly mixing ultra-high molecular weight polyethylene resin with the prepared polyethylene modified master batch to prepare an ultra-high molecular weight polyethylene melt spinning yarn, wherein the fiber strength of the prepared ultra-high molecular weight polyethylene fiber is 15-25 CN / dtex, and the breaking elongation is 5-8%. The invention has the advantages of short production flow, low energy consumption, environment friendliness, low manufacturing cost and high single-machine productive capacity. Besides, the product can be widely used in various fields such as the cable twisting and weaving field, the fishnet knitting field, the industrial cloth and belt weaving field and the like and the effective use of the fiber strength can be maintained.

Owner:宁波大盛新材料有限公司

Preparation method for heat-resisting polylactic acid fiber

InactiveCN102839443AImprove heat resistanceEnsuring environmental friendlinessSpinning head liquid feederMelt spinning methodsPolymer scienceTriethoxysilane

The invention relates to a preparation method for a heat-resisting polylactic acid fiber, which comprises the following steps: drying polylactic acid grains in a vacuum drum; modifying the surface of nanometer silicon dioxide by using a silane coupling agent, namely, gamma-aminopropyl triethoxy silane; mixing the dry polylactic acid grains with the modified nanometer silicon dioxide; preparing into polylactic acid plus silicon dioxide master batches by utilizing a double-screw extruding machine; uniformly mixing the master batches and the polylactic acid grains at weight ratio; pouring the mixture into a melt spinning machine for spinning; and drafting through two areas, thereby obtaining polylactic acid plus silicon dioxide fibers. The process of the preparation method is advanced; the data is full and accurate; the preparation method is suitable for mass production; the prepared polylactic acid filament is excellent in heat resistance and mechanical property; the problem of poor heat resistance of the polylactic acid fiber is effectively solved; and the application scope of the polylactic acid fiber is widened.

Owner:TAIYUAN UNIV OF TECH

Method for producing high strength fine-denier polyamide fiber 6 fully drawn yarn

ActiveCN101476169AIncrease draft ratioReduce tensionSpinning head liquid feederMelt spinning methodsYarnHigh intensity

The invention provides a method for producing fine chinlon 6 fully drawn yarn with high strength which includes steps as follows: (1) chinlon 6 slice enters into a screw extruder with electrical heating function through a storage hopper that makes slice showing melt shape; (2) the melt material is pressed in a spinning subassembly through a metering pump quantificationally, and is spout by a spout plate for forming filament bundle in a spining box body; (3) the filament bundle is cooled by side wind through the spinning box body and is cooled further through a corridor; (4) the cooled filament bundle is oiled by an oil roll; (5) oil in the filament bundle is more uniform and has high amplexus degree through confounding; (6) the filament bundle passes through a first group filament guide roll and a second group filament guide roll for drafting forming, then passes through a third filament guide roll to reel. A grade product produced by the method has average more than or equal to 6.0cN / dtex rupture strength that is higher 22% than the product produced by normal method, and has better transparent sense and visual effect, the produced clothes has better flexible sense and handle sense for wearing cosily.

Owner:烟台华润锦纶有限公司

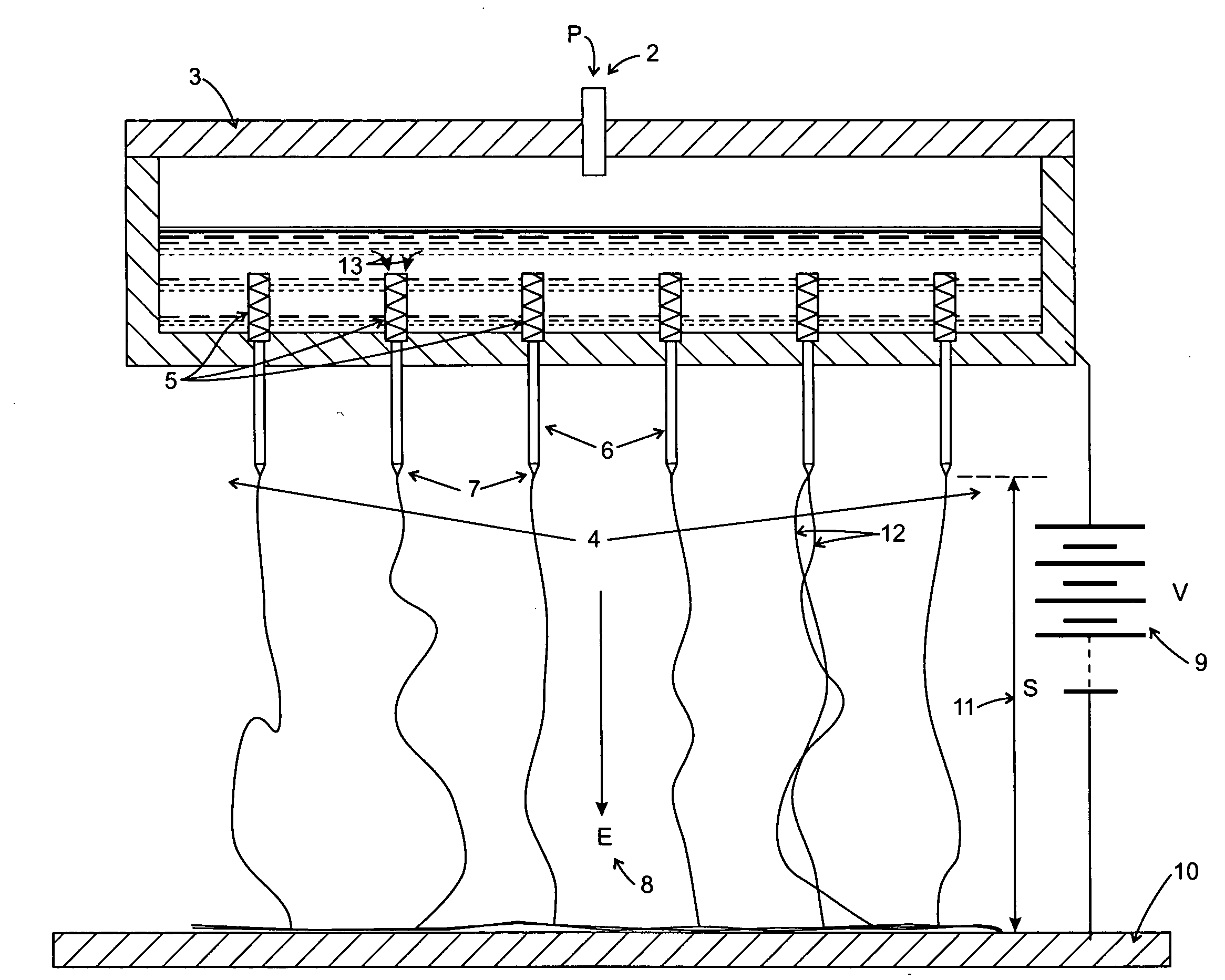

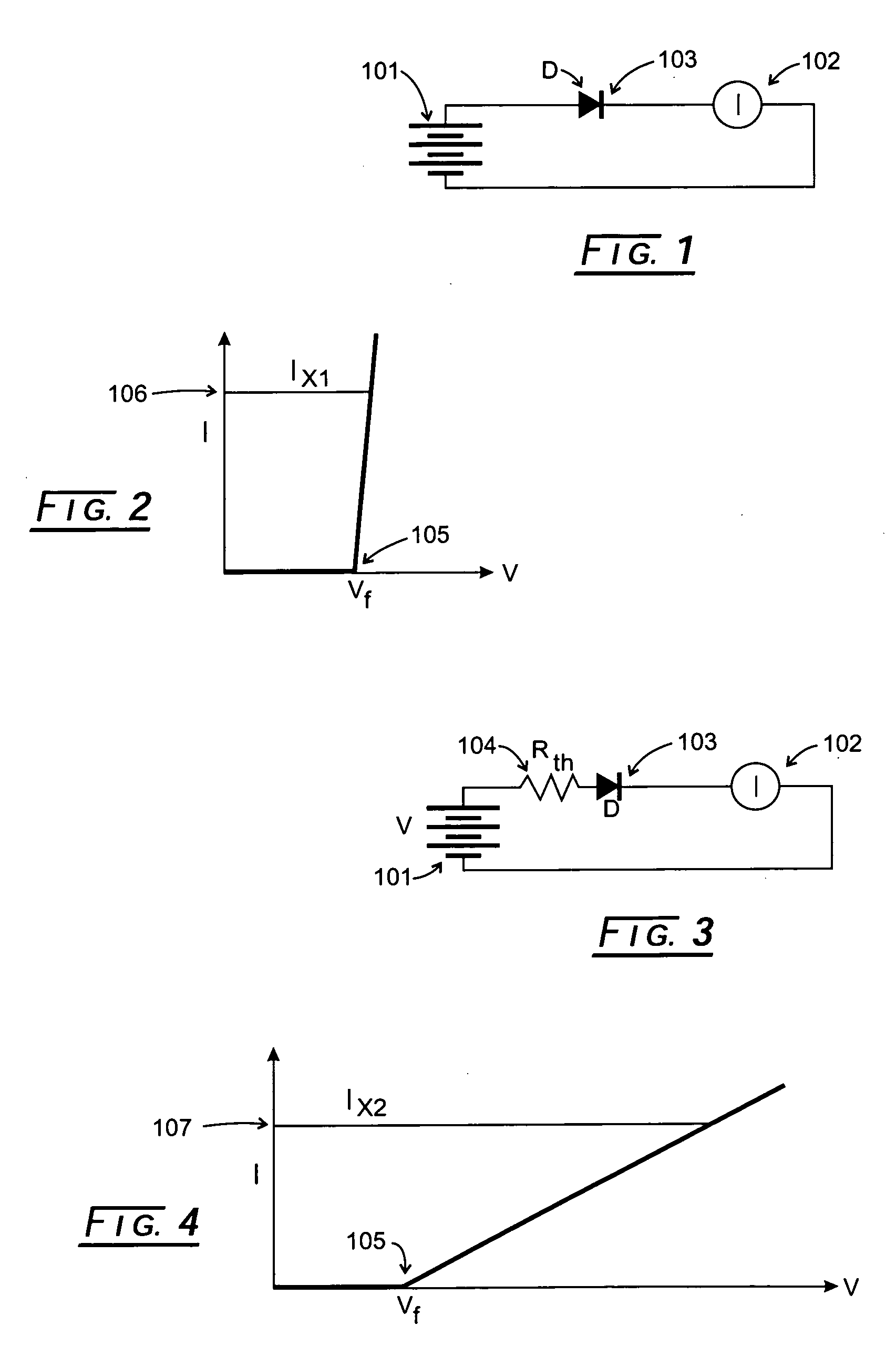

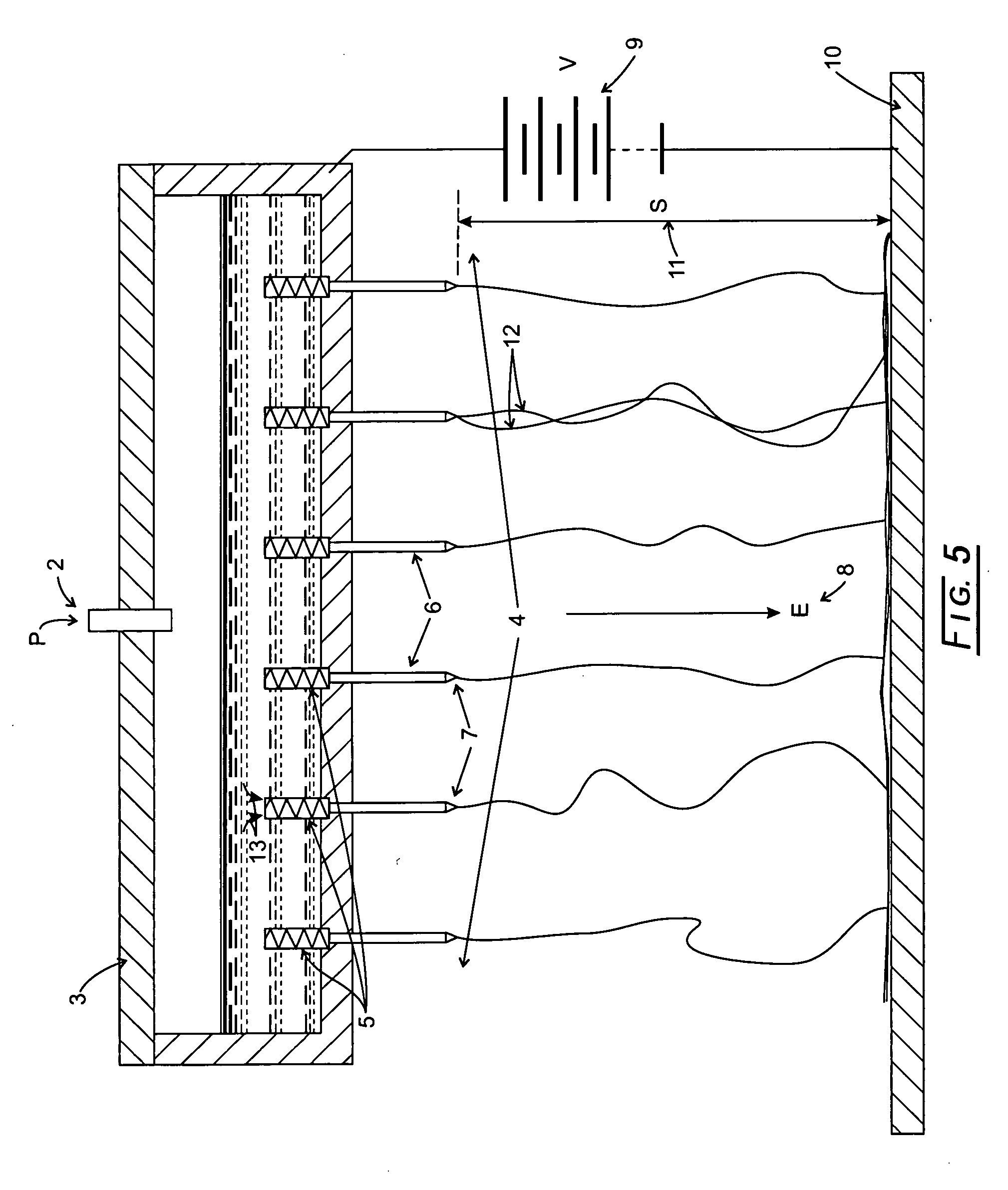

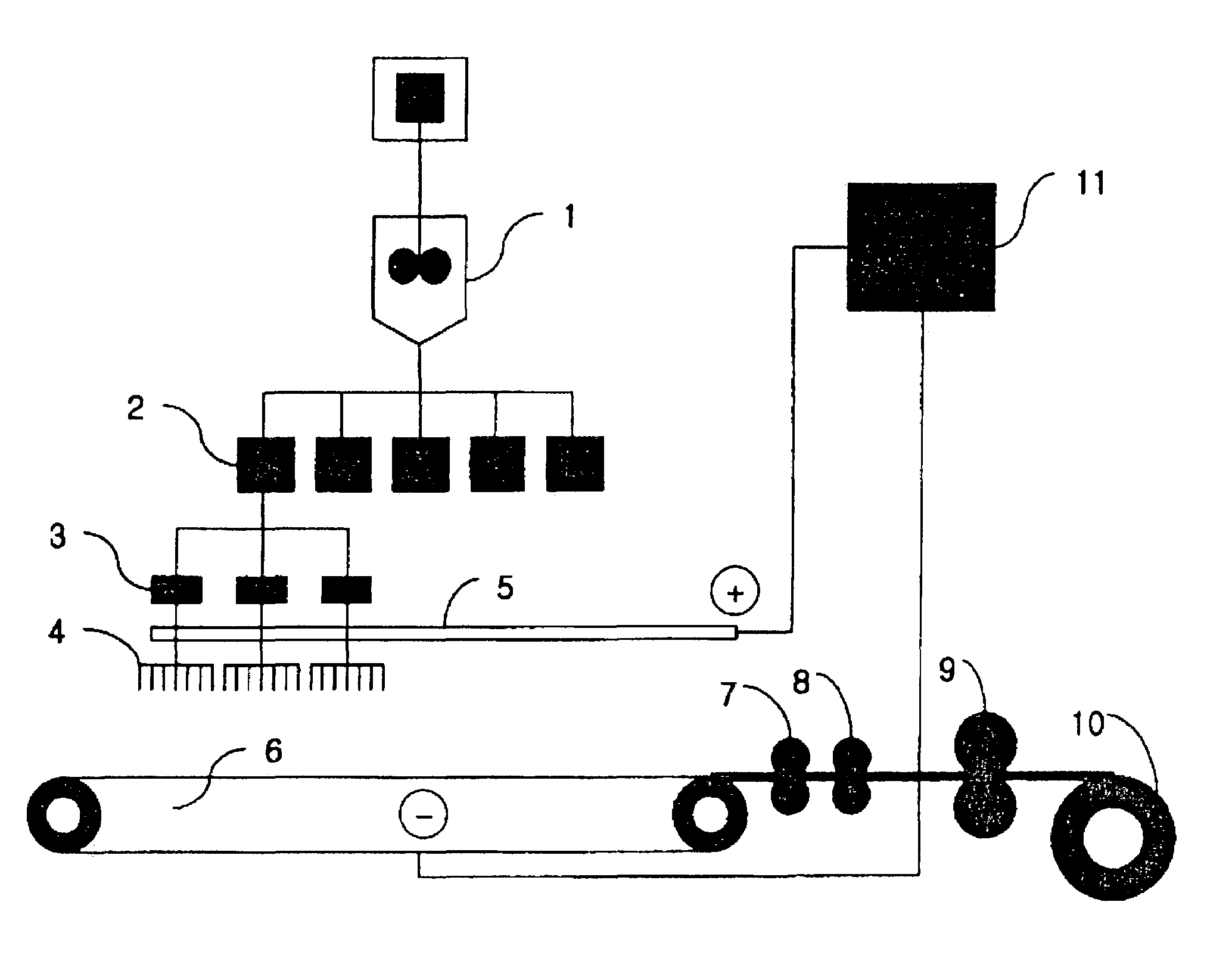

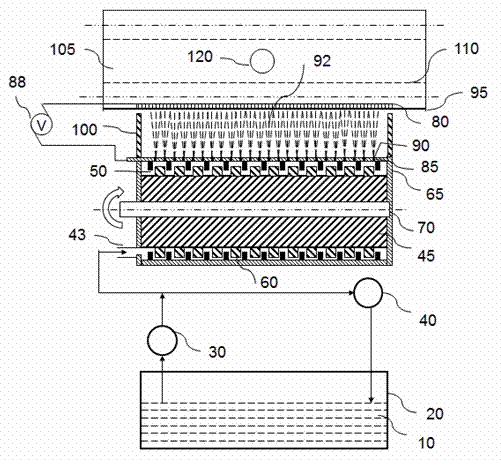

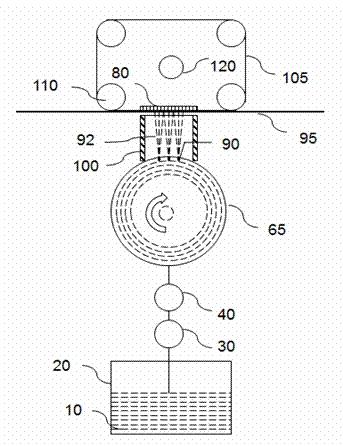

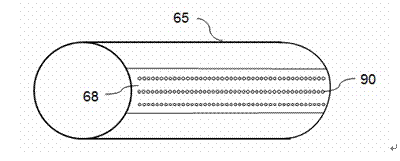

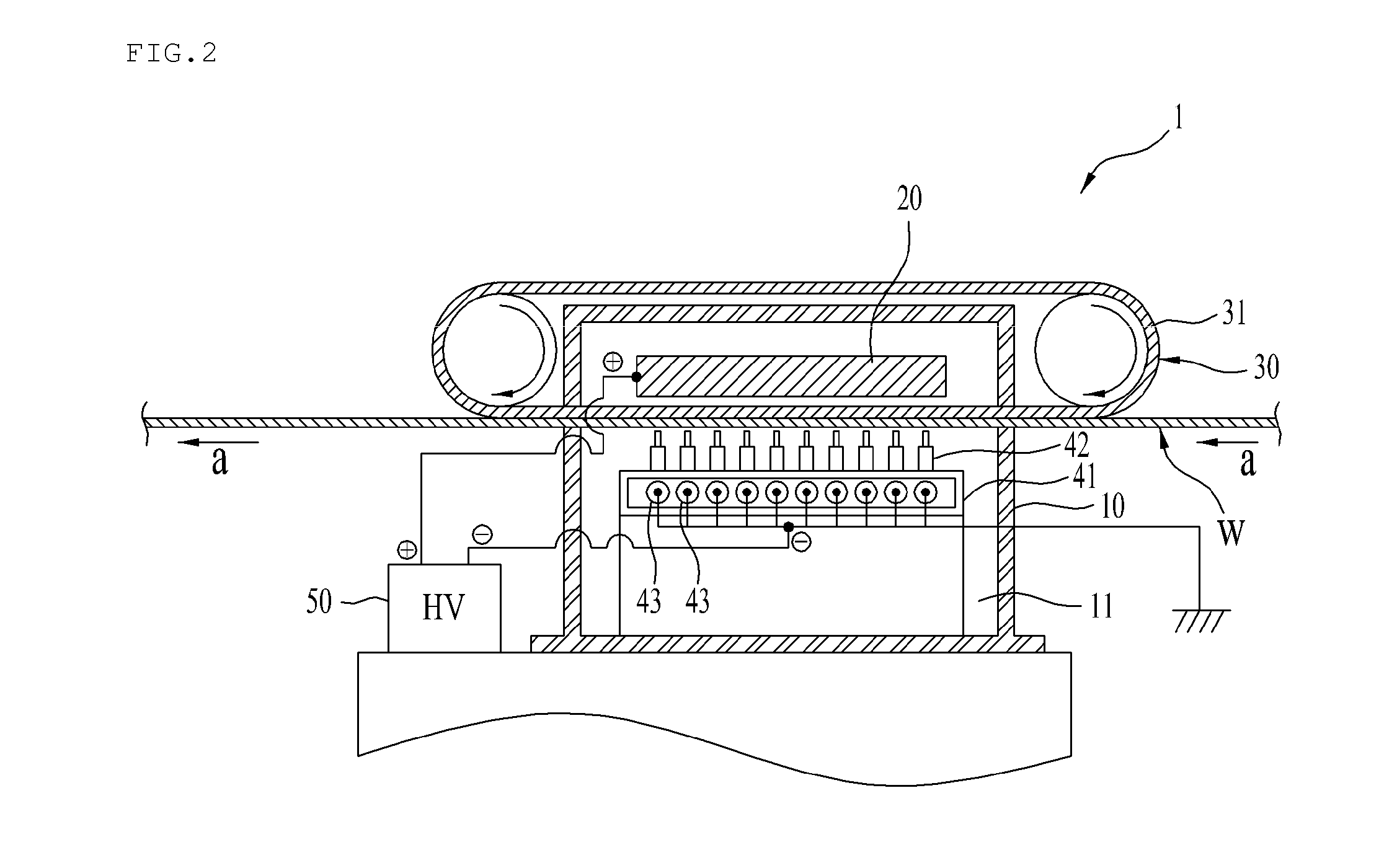

Electrospraying/electrospinning array utilizing a replacement array of individual tip flow restriction

InactiveUS20080131615A1Facilitate electrohydrodynamic (EHD) sprayingLess sensitiveLiquid surface applicatorsElectric shock equipmentsLiquid viscosityElectrospinning

An electrohydrodynamic spraying or spinning deposition system, which includes a common source of pressurized liquid within a manifold, and an array of 2 or more spraying tips, each tip being fed from the common source of pressurized liquid to create a liquid flow path. An individual flow impedance device is disposed within each tip's individual liquid flow path from the pressurized liquid source into each spraying tip. The individual flow impedance devices are disposed within a replaceable sheet, which can be easily cleaned or changed to accommodate the instance liquid viscosity and composition. A high voltage source is applied to create a high voltage potential applied between the tip array and a deposition surface.

Owner:DROPLETECH LLC

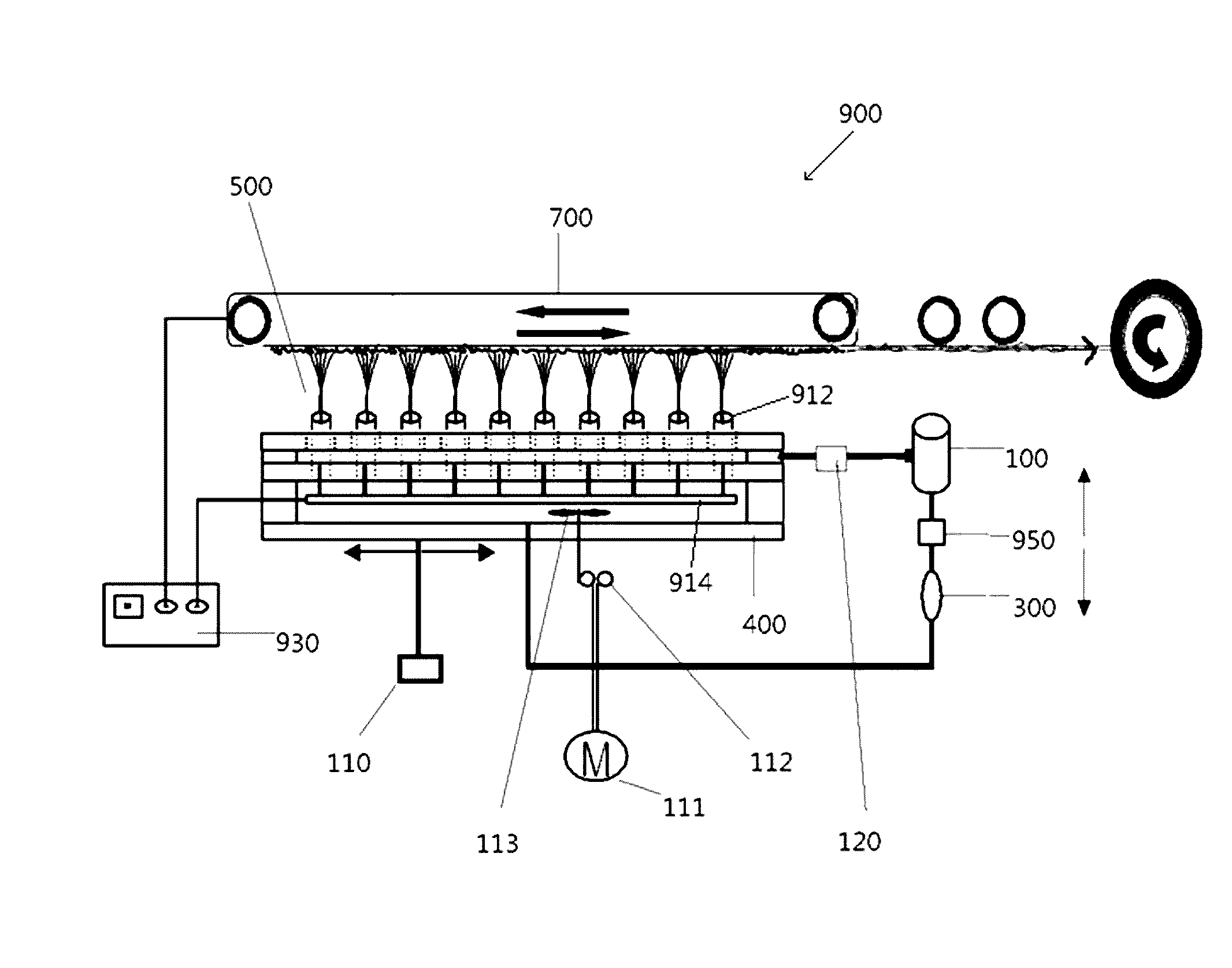

Device and method for preparing highly effective continuous electrostatic spinning nano fibre felt

InactiveCN101215762AGuaranteed continuous supplyEasily overcome surface tensionSpinning head liquid feederFilament/thread formingFiberLiquid storage tank

The invention relates to a preparing device of a high-effective continuous-type electro-spin nanometer fiber felt, the invention comprises a fluid supply system, a metal roller, a receiving device and a spinning fluid recycling groove. The process for preparing comprises firstly, preparing polymer spinning fluid with correct concentration in a dissolution kettle, temporarily storing in a liquid storage tank after passing through a filter, secondly, connecting the metal roller and the positive electrode of a high-pressure electrostatic generator, applying correct electrostatic pressure, leading an aluminium screen cloth to connect ground, thirdly, leading the metal roller to rotate in correct rotary speed, fourth, starting a measuring pump, feeding spinning liquid from the liquid storage tank to an even allotter, leading the spinning liquid to be evenly allocated to a spraying hole on the front end of the even allotter, sputtering from the spraying hole to the surface of a rotating metal roller to form Taylor awl, fifthly, leading a coiling drum to rotate to drive a fiber receiving net to move, and continuously receiving nanometer fiber felt. The process for preparation of the nanometer fiber felt of the invention has high production efficiency, which is suitable for scale production of electro-spinning.

Owner:DONGHUA UNIV

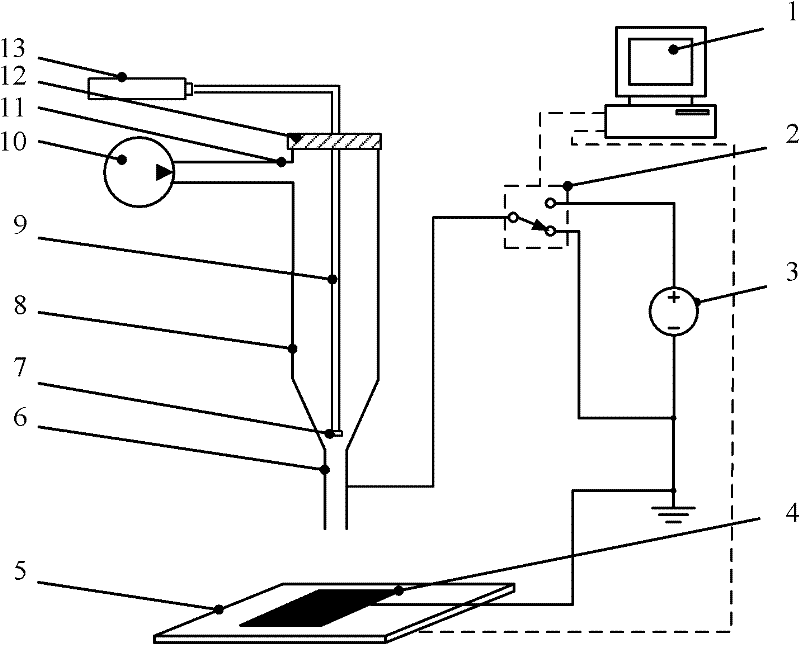

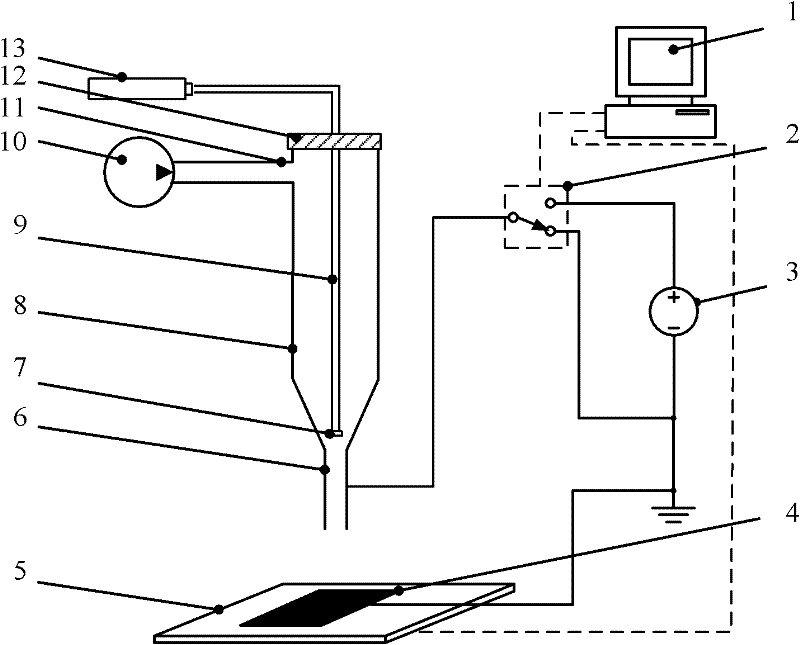

Laser-guided electrospinning direct writing device

InactiveCN102162175AImprove stabilityExtend exercise timeSpinnerette packsSpinning head liquid feederComing outElectrical conductor

The present invention provides a laser-guided electrospinning direct writing device capable of realizing long-time controllable preparation and precise positioning of single uniform micro / nanostructure. The device is provided with a controller, a high-voltage relay, an electrostatic high-voltage [power] source, a hollow nozzle, a collimating focusing lens set, optical fibers, a sealing adjusting part, a laser, a solution feed pump, a solution feed pipe, a collecting board and a motion platform, wherein the controller is connected with the high-voltage relay; ends of the high-voltage relay are respectively connected with the electrostatic high-voltage [power] source, the collecting board and a conductor nozzle arranged at the front end of the hollow nozzle; the sealing adjusting part is in a sealing connection with the rear end of the hollow nozzle; the optical fibers pass through the center of the sealing adjusting part and are fixedly connected with the sealing adjusting part; the collimating focusing lens set is arranged at the front end of the optical fibers; the rear end of the optical fibers comes out of the hollow nozzle and is connected with the laser; the solution feed pump is communicated with the hollow nozzle through the solution feed pipe; and the collecting board is fixed on the motion platform and faces the hollow nozzle. The laser constraints the disordered motion of spinning jet flow and guides the spinning jet flow to deposit at the laser spot of the collecting board.

Owner:XIAMEN UNIV

Flexible non-woven fabric and preparation method thereof

ActiveCN106192213AGood flexibilityNon-irritatingSpinning head liquid feederConjugated synthetic polymer artificial filamentsElastomerEngineering

The invention relates to the technical field of non-woven fabrics and particularly relates to a flexible non-woven fabric and a preparation method thereof. The flexible non-woven fabric is prepared from the following raw materials in parts by weight: 30-35 parts of polypropylene, 20-25 parts of regenerated polypropylene, 30-35 parts of calcium carbonate filling master batch, 10-15 parts of an elastomer, 0.2-0.25 part of flexile filling master batch and 1-3 parts of a lubricant. The high-softness environment-friendly flexible non-woven fabric has good softness, no toxin and no irritation, is safe and environment-friendly and has natural and clear lines; and the flexible non-woven fabric also has the advantages of bacterium resistance, corrosion resistance, mildew prevention and the like and has an excellent comprehensive performance.

Owner:DONGGUAN IUIU HOUSEHOLD PROD

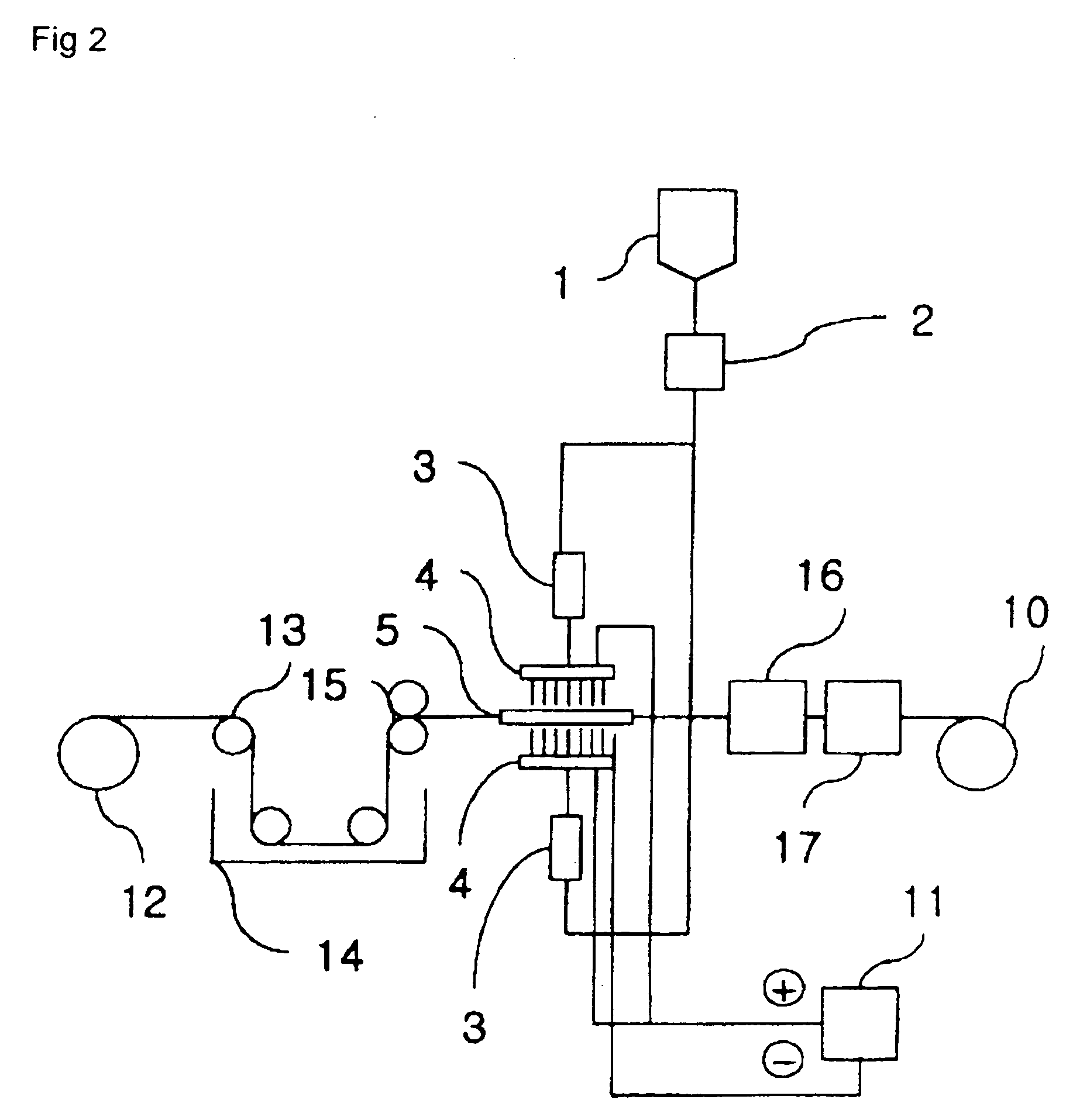

Apparatus and method for injecting a liquid dye into a polymer melt

InactiveUS7278776B2Easy to addImprove accuracyPump componentsSpinning head liquid feederInjection pressureFuel tank

An apparatus and a method for injecting a liquid dye into a polymer melt, which includes a metering pump with a metering inlet and a metering outlet. The metering inlet connects to a dye tank and the metering outlet connects to a polymer melt carrying component. To add the liquid dye to the polymer melt in the melt carrying component in a quantity that is as uniform and accurate as possible, the invention provides for connecting the metering inlet of the metering pump to a feed outlet of a feed pump, which connects with its feed inlet to the tank. With that, it is possible to generate a feed pressure at the metering inlet of the metering pump, which can be adapted to an injection pressure at the metering outlet of the metering pump.

Owner:SAURER GMBH & CO KG

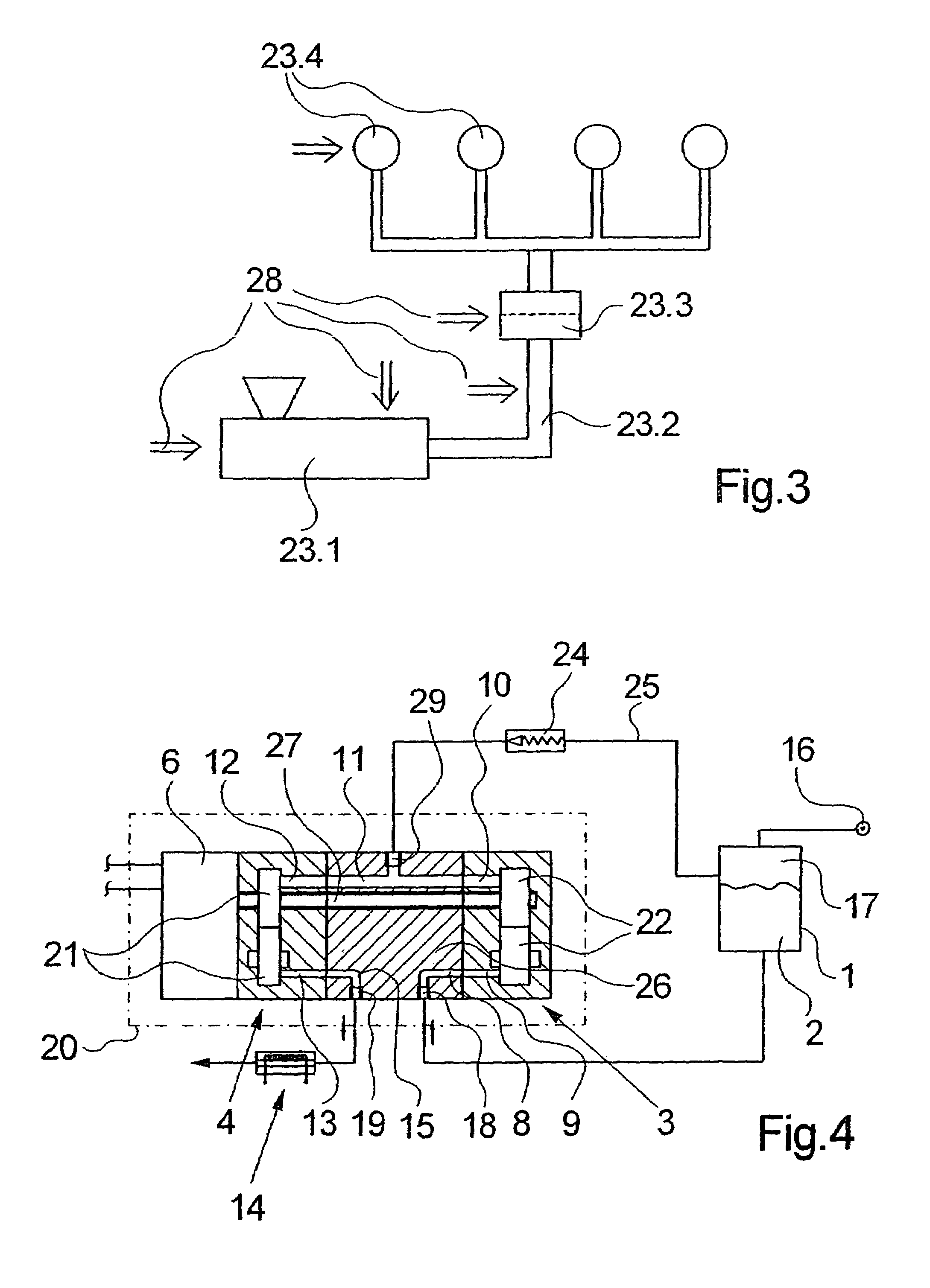

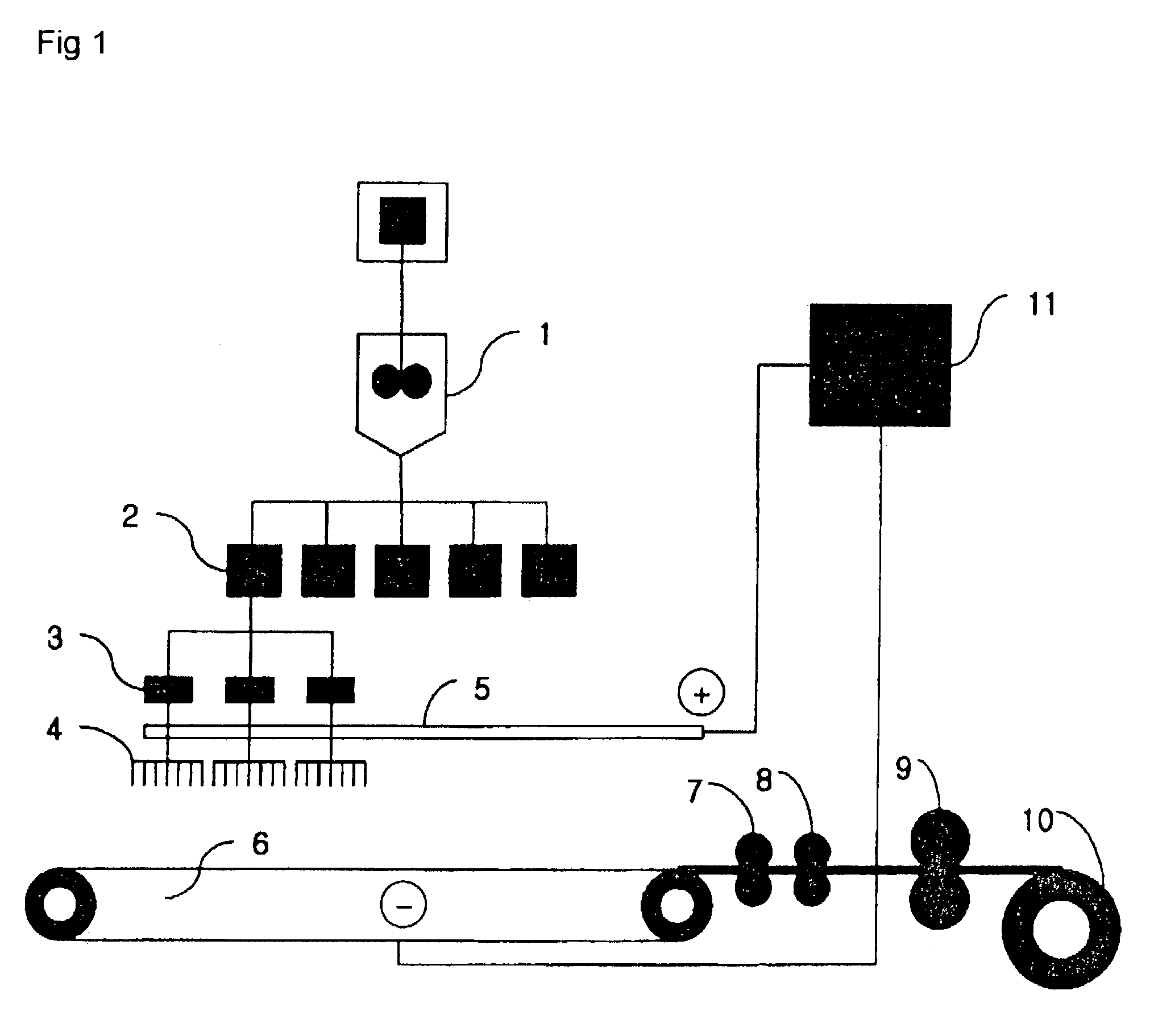

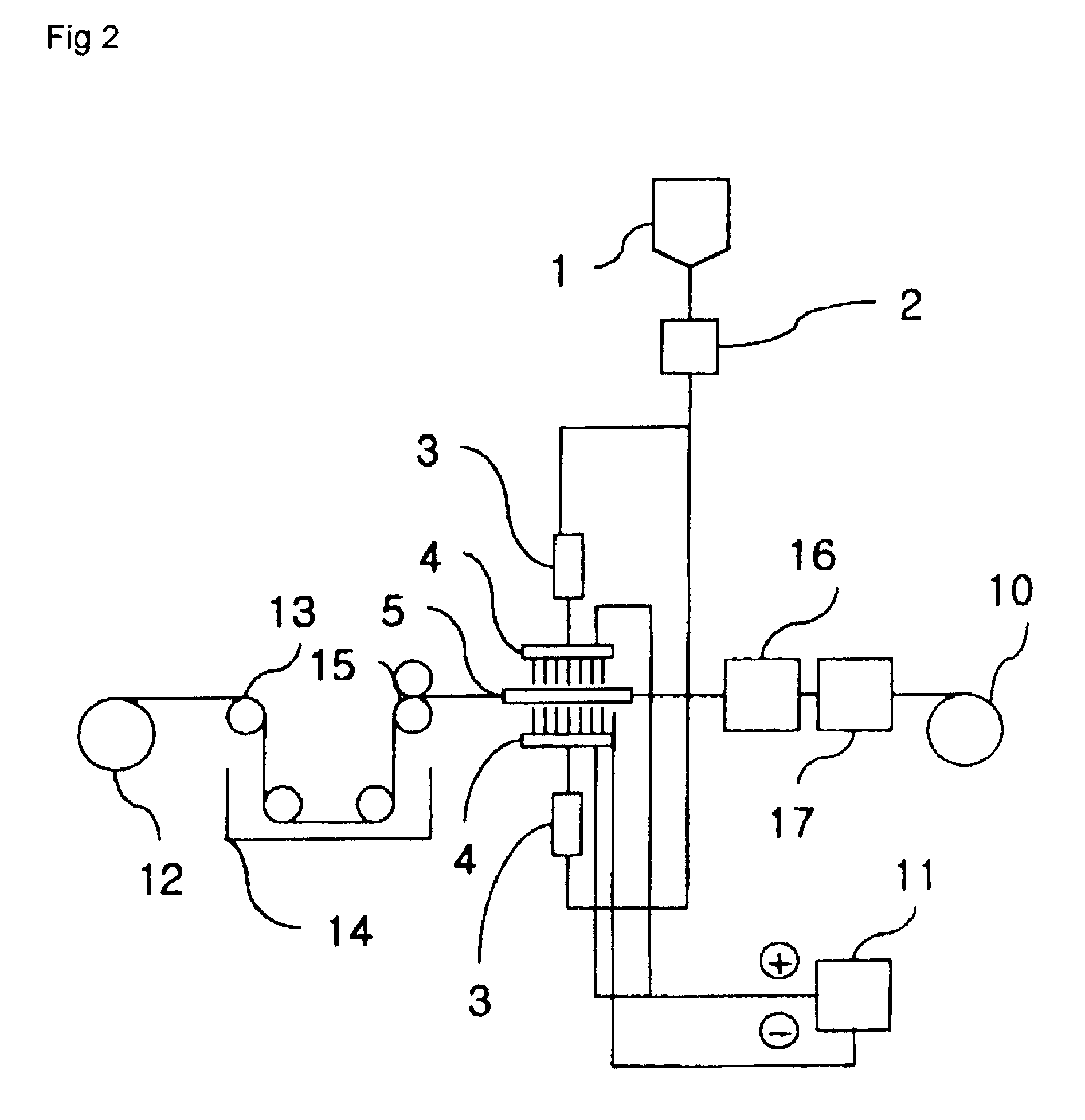

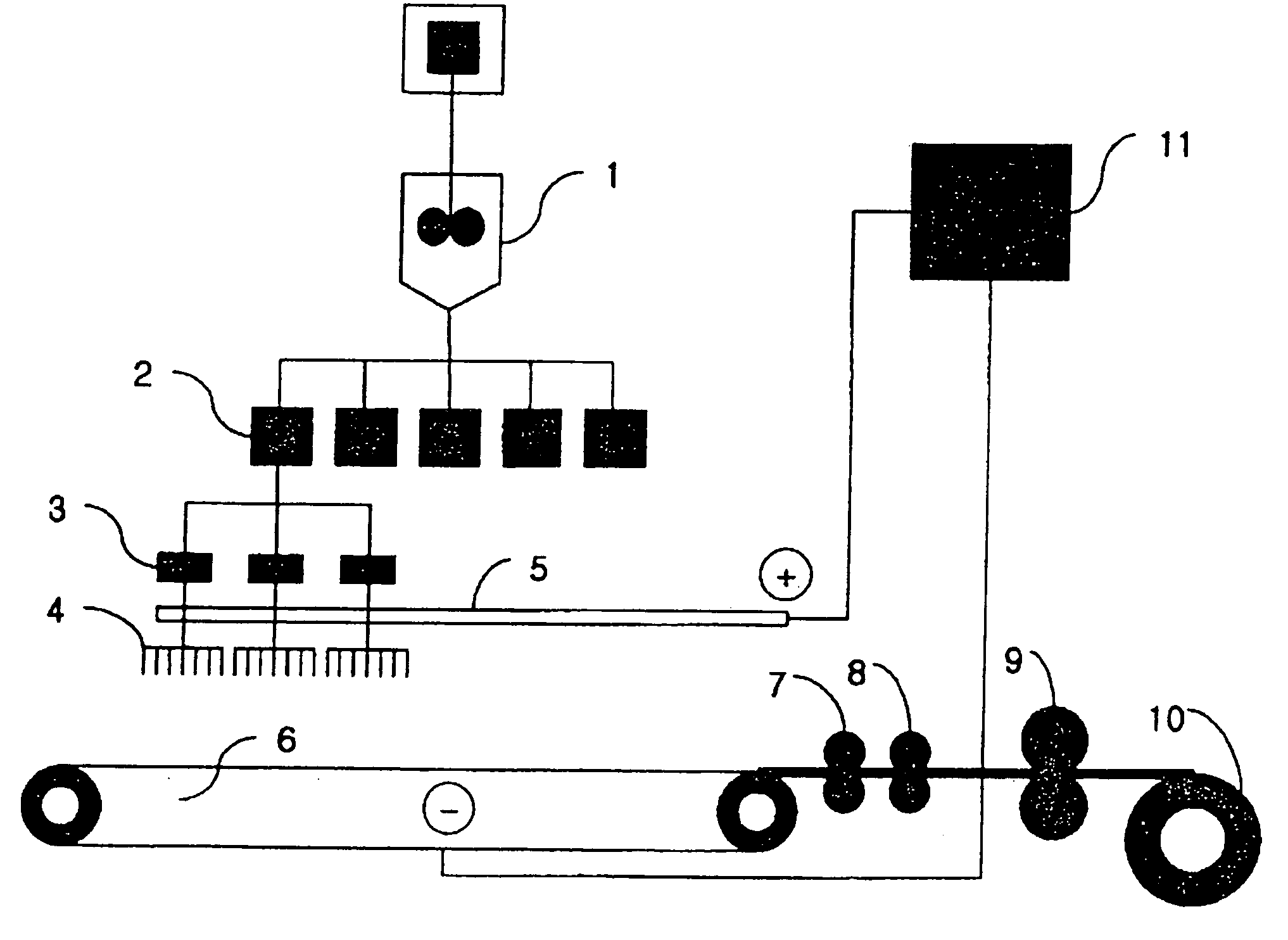

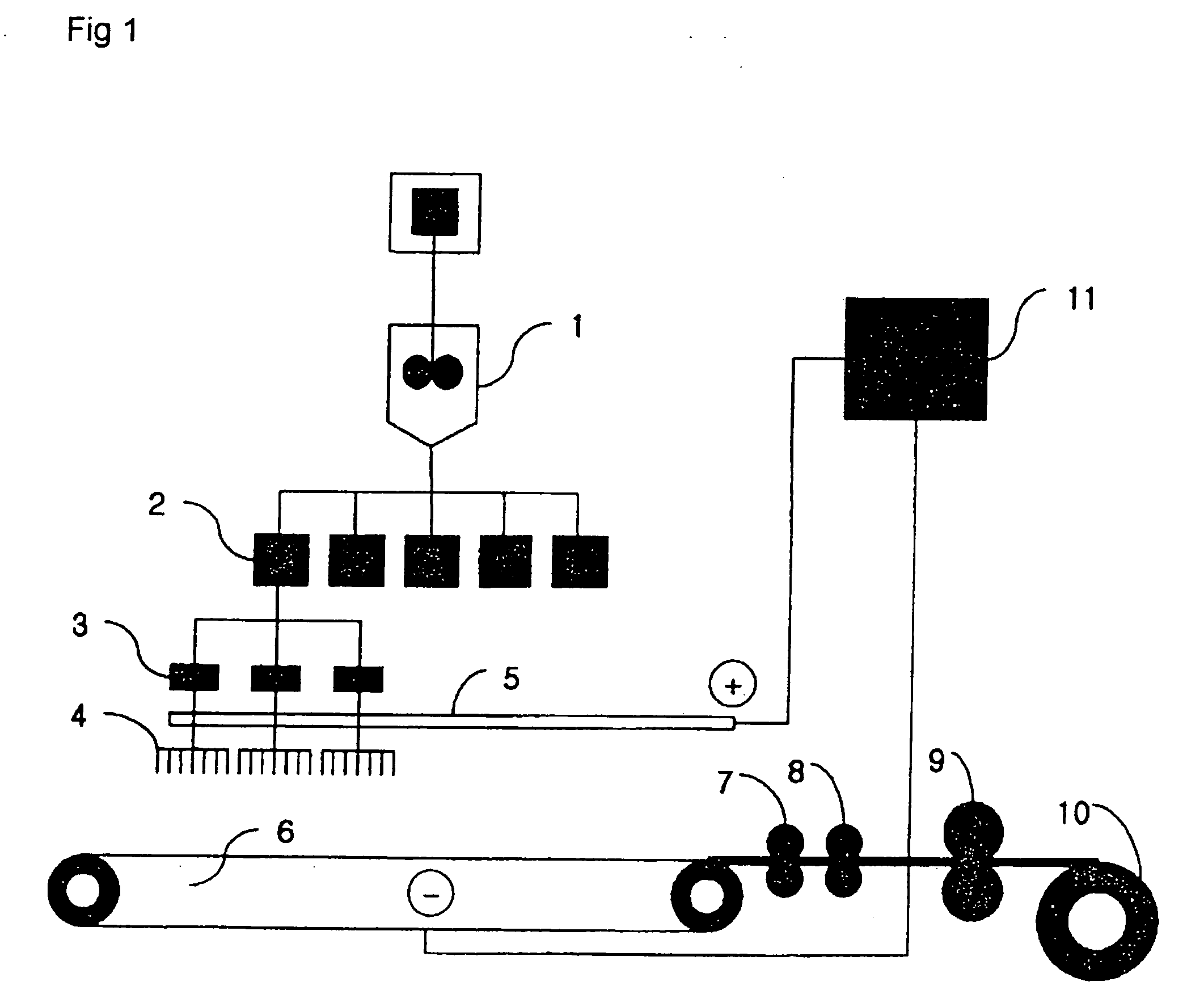

Electronic spinning apparatus

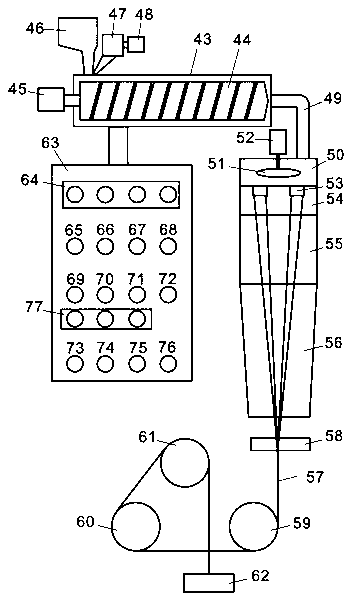

InactiveUS6991702B2Improve fiber performanceMaximizing electric forceMechanical working/deformationTurning machine accessoriesFiberVoltage generator

An electrospinning apparatus including a spinning dope main tank, a metering pump, a nozzle block, a collector positioned at the lower end of the nozzle block for collecting spun fibers, a voltage generator, a plurality of units for transmitting a voltage generated by the voltage generator to the nozzle block and the collector, said electrospinning apparatus containinga spinning dope drop device positioned between the metering pump and the nozzle block, the spinning dope drove device having(i) a sealed cylindrical shape,(ii) a spinning dope inducing tube and a gas inletting tube for receiving gas through its lower end and having its gas inletting part connected to a filter aligned side-by-side at the upper portion of the spinning dope drop device,(iii) a spinning dope discharge tube extending from the lower portion of the spinning dope drop device and(iv) a hollow unit for dropping the spinning dope from the spinning dope inducing tube formed at the middle portion of the spinning dope drop device.

Owner:FINETEX TECH GLOBAL +2

Electronic spinning apparatus, and a process of preparing nonwoven fabric using the same

InactiveUS20060048355A1Maximizing electric forceImprove the ability to formLamination ancillary operationsElectric discharge heatingVoltage generatorElectrospinning

An electrospinning apparatus including a spinning dope main tank, a metering pump, a nozzle block, a collector positioned at the lower end of the nozzle block for collecting spun fibers, a voltage generator, a plurality of units for transmitting a voltage generated by the voltage generator to the nozzle block and the collector, said electrospinning apparatus containing: a spinning dope drop device positioned between the metering pump and the nozzle block, the spinning dope drop device having (i) a sealed cylindrical shape, (ii) a spinning dope inducing tube and a gas inletting tube for receiving gas through its lower end and having its gas inletting part connected to a filter aligned side-by-side at the upper portion of the spinning dope drop device, (iii) a spinning dope discharge tube extending from the lower portion of the spinning dope drop device, and (iv) a hollow unit for dropping the spinning dope from the spinning dope inducing tube formed at the middle portion of the spinning dope-drop device.

Owner:FINETEX TECH GLOBAL

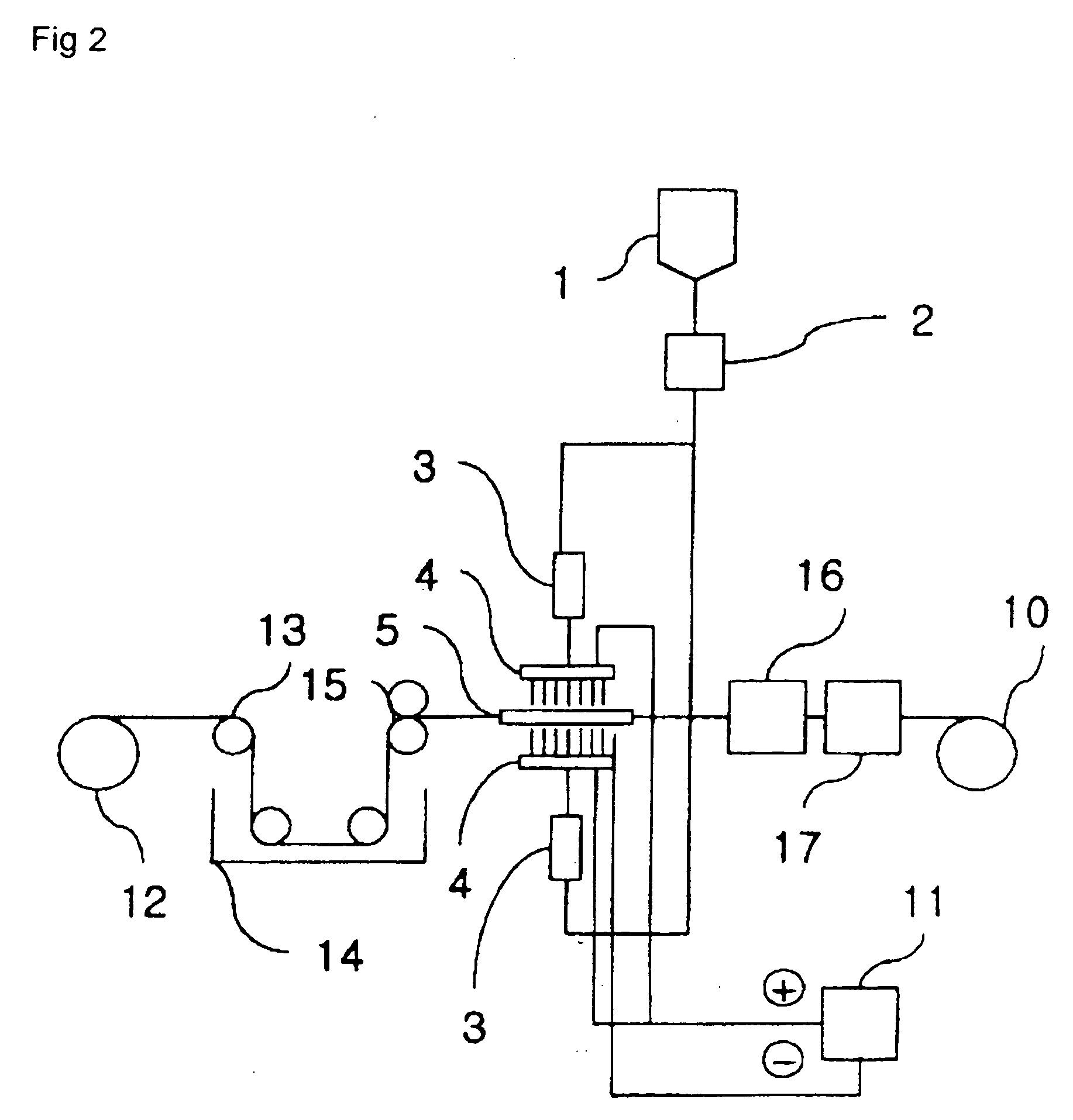

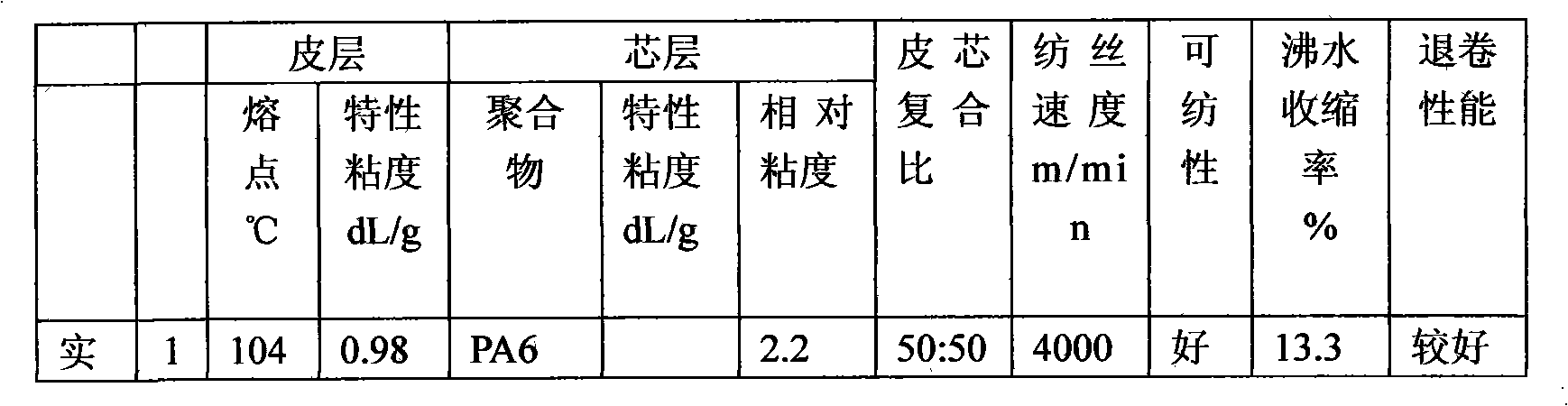

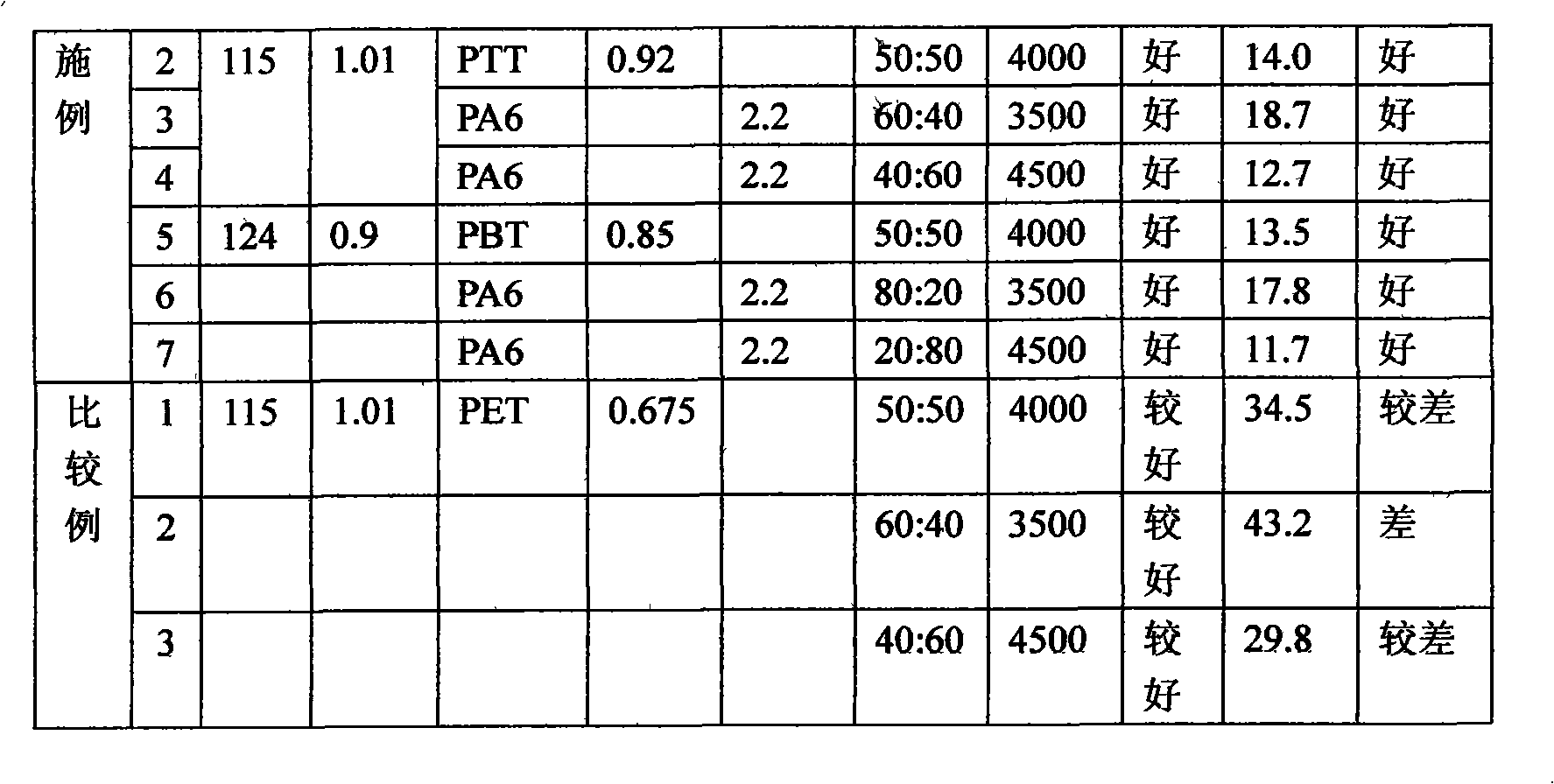

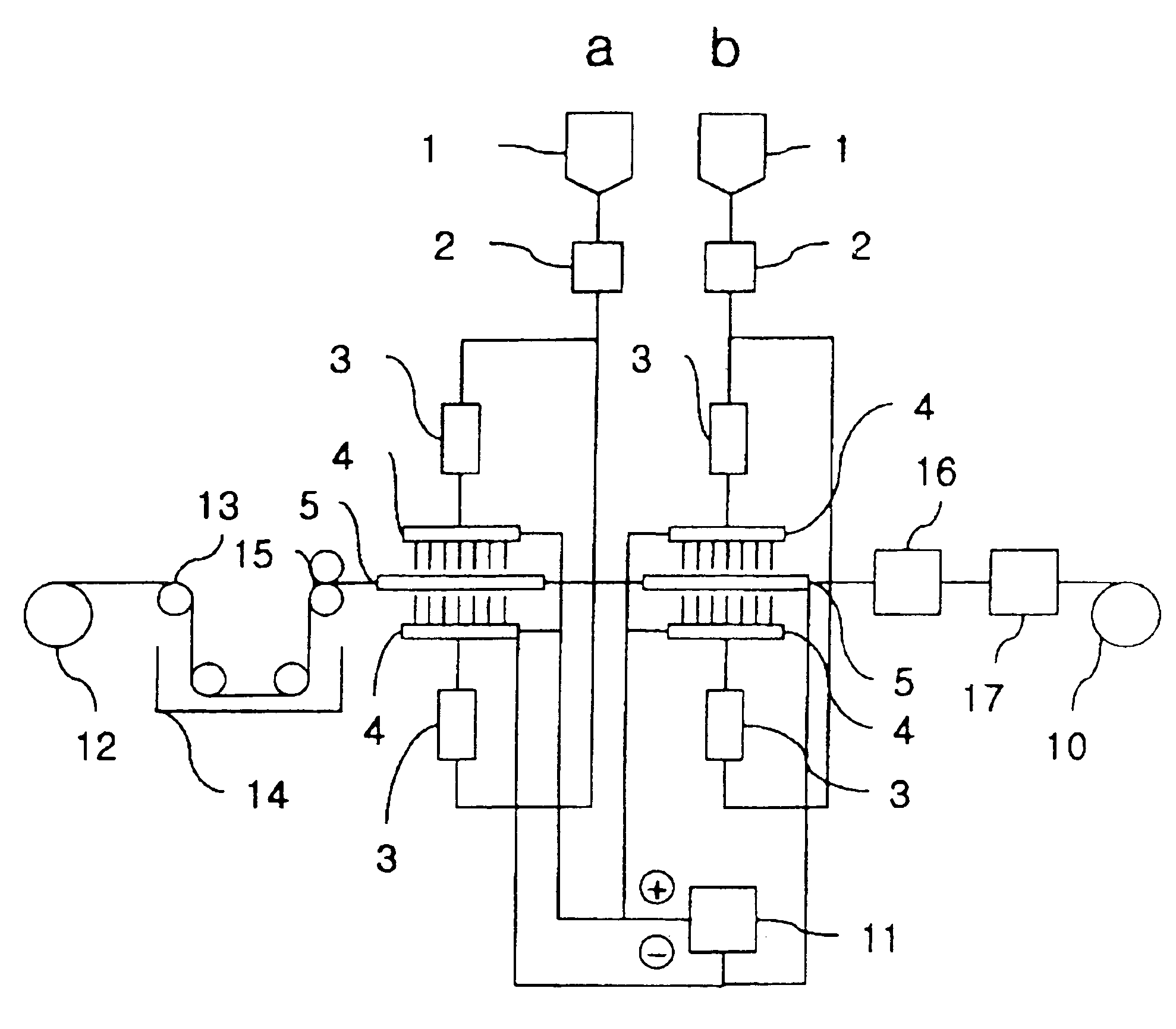

Method for preparing sheath core composite long fiber with low melting point

InactiveCN101619506AHigh boiling water shrinkageProcessing conditions are not easy to controlSpinning head liquid feederFilament/thread formingFiberState of art

The invention discloses a method for preparing a sheath core composite long fiber with a low melting point, which comprises the following steps: (1) drying components of a sheath layer and a core layer; (2) preparing a sheath core composite long fiber with a low melting point; respectively melting and extruding the two components by a screw rod extruder, after fusant is metered by a metering pump, leading the fusant to flow into an assembly of a composite spinning machine to carry out the composite spinning of the two components and ejecting a fiber from a fiber ejecting plate; cooling the fiber by blowing, oiling the fiber by an oil tanker, controlling the tension of the fiber by a fiber guide disk and coiling the fiber to obtain the sheath core composite long fiber with the low melting point. Aiming at the defects in the prior art, the invention provides a method for preparing the sheath core composite long fiber with a low melting point, which has low sheath layer melting point, low and stable fiber boiling water shrinking rate and favorable dyeing performance.

Owner:ZHEJIANG SCI-TECH UNIV

Electronic spinning apparatus, and a process of preparing nonwoven fabric using the same

InactiveUS7332050B2Maximizing electric forceImprove the ability to formLamination ancillary operationsElectric discharge heatingVoltage generatorElectrospinning

An electrospinning apparatus including a spinning dope main tank, a metering pump, a nozzle block, a collector positioned at the lower end of the nozzle block for collecting spun fibers, a voltage generator, a plurality of units for transmitting a voltage generated by the voltage generator to the nozzle block and the collector, said electrospinning apparatus containing:a spinning dope drop device positioned between the metering pump and the nozzle block, the spinning dope drop device having(i) a sealed cylindrical shape,(ii) a spinning dope inducing tube and a gas inlet tube for receiving gas through its lower end and having its gas inlet part connected to a filter aligned, side-by-side, at the upper portion of the spinning dope drop device,(iii) a spinning dope discharge tube extending from the lower portion of the spinning dope drop device, and(iv) a hollow unit for receiving the spinning dope from the spinning dope inducing tube provided at the middle portion of the spinning dope-drop device.

Owner:FINETEX TECH GLOBAL

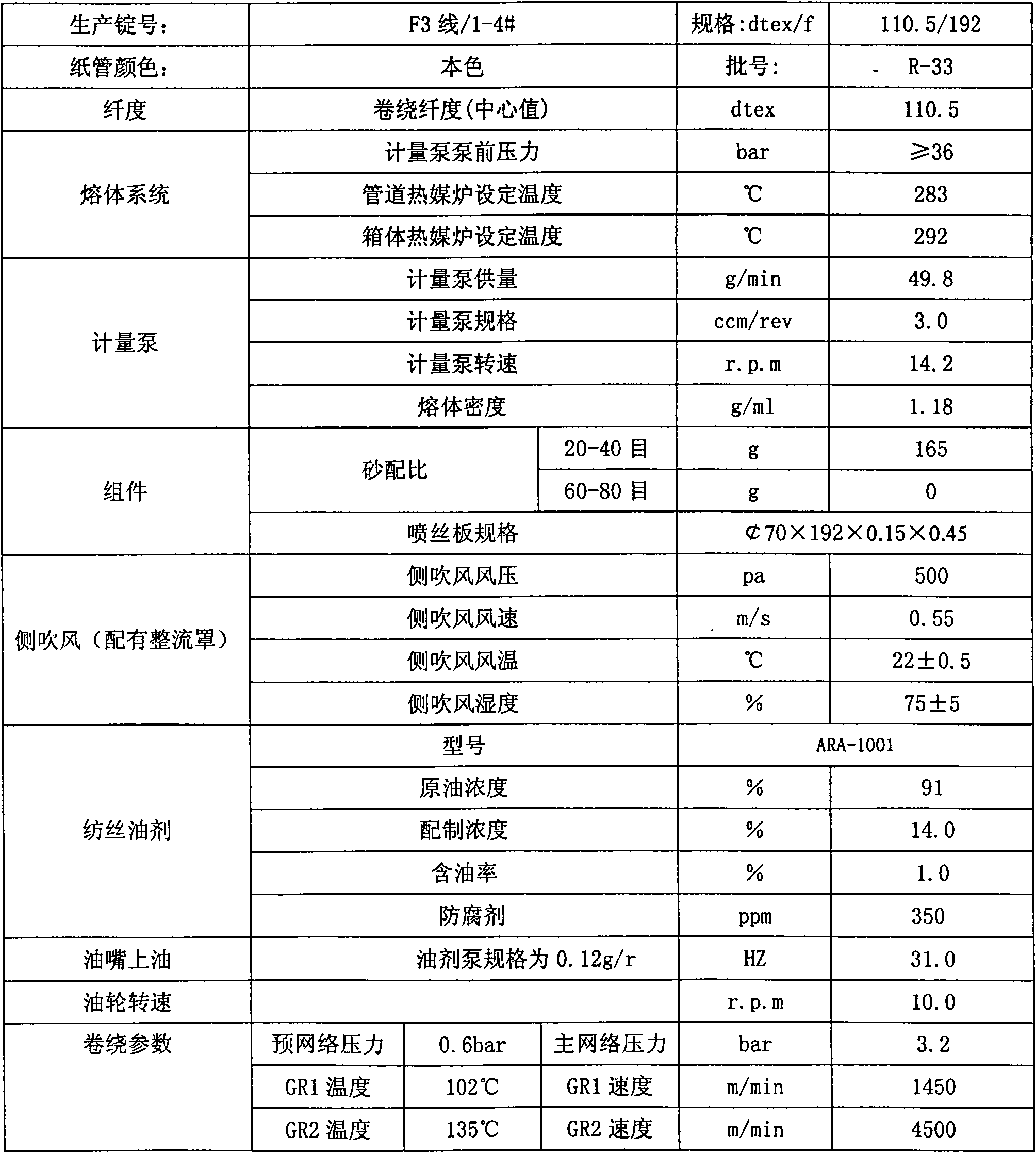

Melt direct spinning superfine denier terylene FDY filament and preparation process thereof

ActiveCN101634051ALow costIncrease productivitySpinning head liquid feederMelt spinning methodsFiberPolymer science

The invention discloses a melt direct spinning superfine denier terylene FDY filament and a preparation process thereof. The superfine denier terylene FDY filament is prepared by the following steps: adopting a production line of a melt direct spinning one-step method, using a spinning plate with the diameter of capillary of 0.15 to 0.2mm, L / D of 2.6 to 3.6 and diameter of plate surface of 70 to 90mm, installing fairing in a fiber cooling area and adopting a two-way oil feeding system to directly produce the superfine denier terylene FDY filament; and the obtained dpf (denier per filament) is 0.3 to 0.6, the number of orifices of one strand of filameter is 144F to 192F. The process routine can improve internal quality, simultaneously greatly reduces the processing cost, and has the capability of replacing imported similar products.

Owner:JIANGSU HUAYA FIBER

Spherical revolving brush type batched electrostatic spinning device and usage method thereof

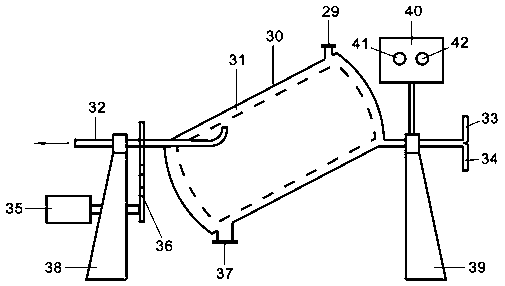

ActiveCN106811811ARealize automatic supplyEasy to controlSpinning head liquid feederFilament/thread formingGas cylinderControl system

The invention relates to a spherical revolving brush type batched electrostatic spinning device and a usage method thereof. The spherical revolving brush type batched electrostatic spinning device comprises a liquid supply system, a separating electric field control system, a spherical rotary spinning system and a nanofiber collecting system, wherein the liquid supply system comprises an air cylinder, a spinning solution storage bottle, an oil batch tank and a solution guiding tube, the spinning solution storage bottle is arranged in the oil batch tank, the spinning solution storage bottle and the solution guiding tube form a communicator structure through a solution brushing tank, the spinning solution storage bottle is connected with the air cylinder through an air tube, and a main valve and a pressure reducing valve are sequentially arranged at the position, close to the air cylinder, on the air tube. The separating electric field control system comprises a high-pressure generator, a metal round ring, a cylindrical seat and a support, wherein the support is arranged at the upper end of the spinning solution storage bottle, the cylindrical seat is arranged on the support, and the metal round ring is installed on the cylindrical seat in a sleeving mode to be connected with the high-pressure generator. Automatic supply of a high polymer solution and stable batched nanofiber preparation can be completed.

Owner:安徽弋尚纺织科技有限公司

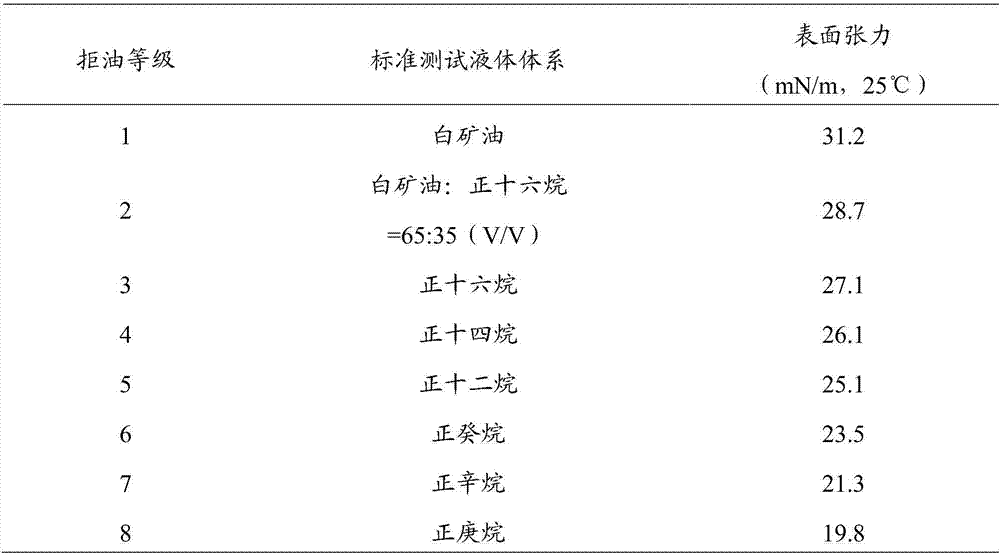

SMS-type non-woven fabric manufacture method, SMS-type non-woven fabric and application thereof

InactiveCN107447372AWith hydrostatic pressureBreathableSpinning solution de-aeratingSpinning head liquid feederFiberInter layer

The invention provides an SMS-type non-woven fabric manufacture method. The SMS-type non-woven fabric manufacture method comprises mixing, extruding and fusing, spinning, and splitting and lapping spunbond raw material polypropylene and spunbond master batch to obtain a spunbond layer fiber web; mixing, extruding and fusing, spinning and lapping meltblown raw material modified polypropylene and meltblown master batch to obtain a meltblown layer fiber web; taking the meltblown layer fiber web as the intermediate layer, and the spunbond layer fiber webs as the upper layer and the lower layer, and bonding the three layers of fiber webs in a hot pressing manner to obtain the SMS-type non-woven fabric. The invention also provides an SMS-type non-woven fabric prepared through the above method, and an application of the SMS-type non-woven fabric for preparing a disposable hygienic material. The SMS-type non-woven fabric is characterized by being excellent in blood repellent property, oil repellent property and alcohol repellent property.

Owner:山东荣泰新材料科技有限公司

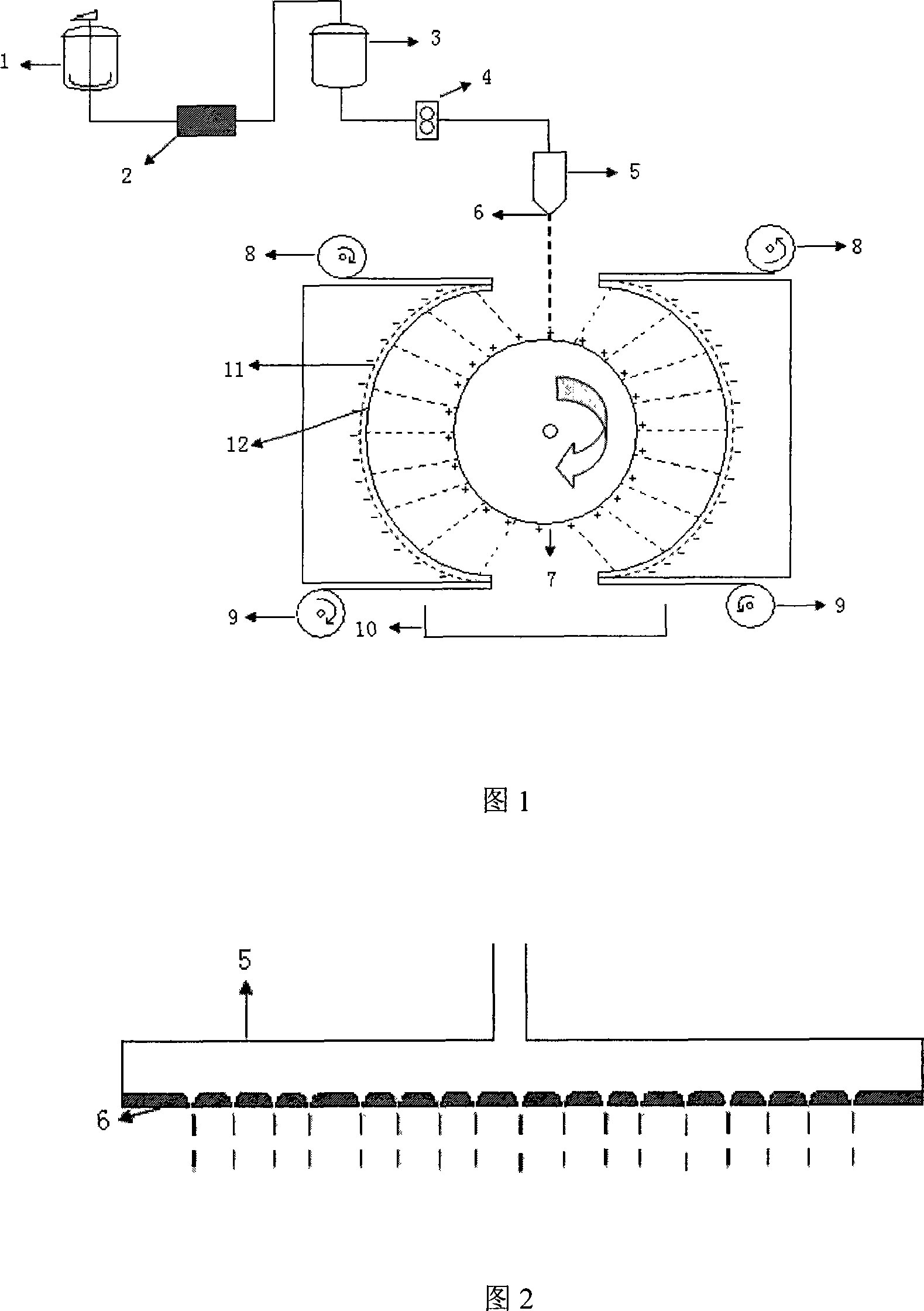

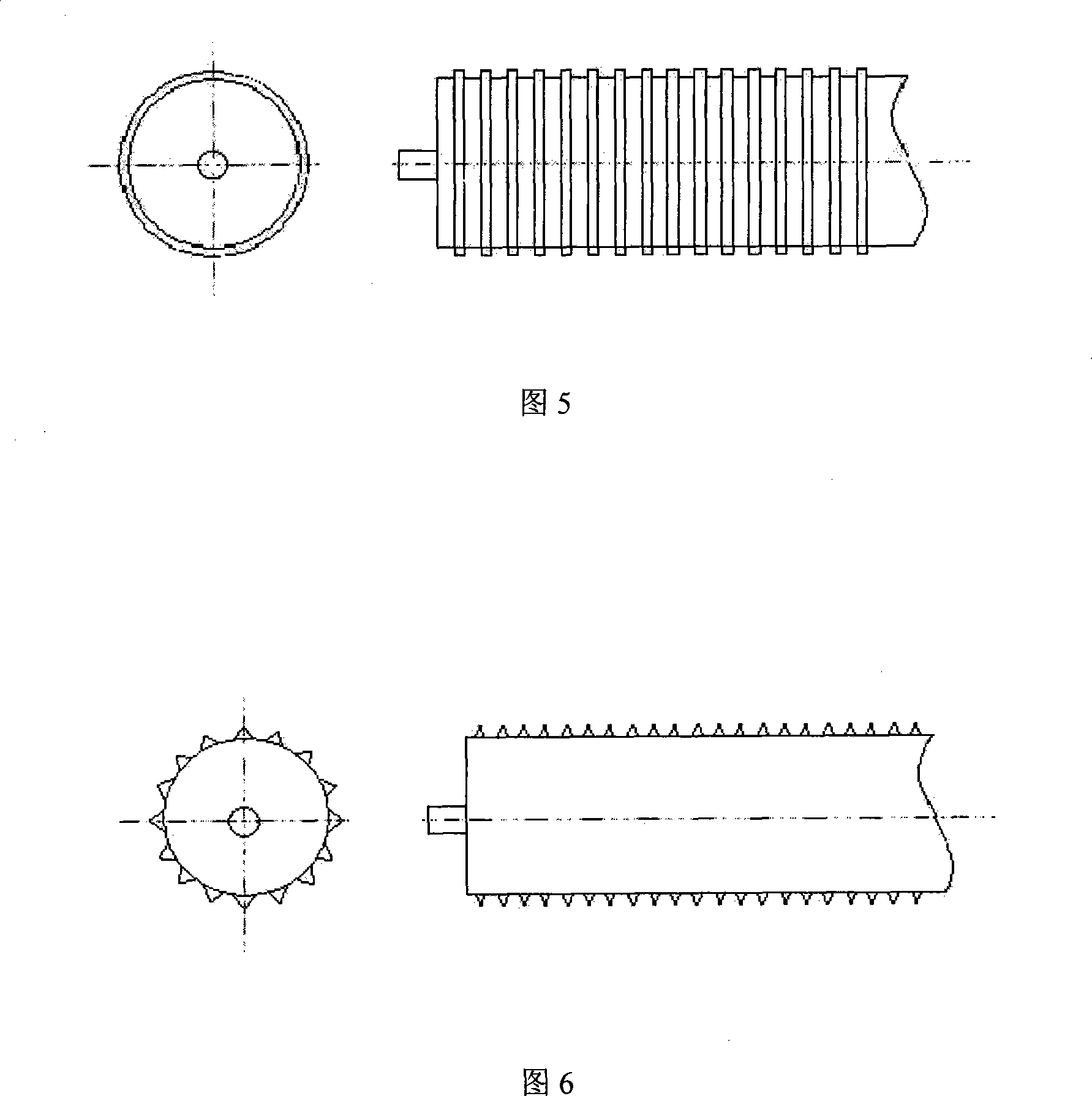

Centrifugal needle-free electrostatic spinning device

ActiveCN102828260AReduce lossAvoid wastingSpinning head liquid feederFilament/thread formingNeedle freeControl system

The invention discloses a centrifugal needle-free electrostatic spinning device, which comprises a liquid supply system, a spinning system, a high-voltage electrostatic generation system, a power supply system, a receiving system, a transmission system and a control system. The device is characterized in that the spinning system mainly comprises an inner round roller, an outer cylinder and a center shaft; outer lugs are uniformly distributed on the outer surface of the inner round roller, and can be driven by the center shaft to rotate; the outer cylinder is a static or fixed thin-walled hollow cylinder; inner lugs are uniformly distributed on the inner surface of the outer cylinder; the outer cylinder with a proper shape and a proper dimension can be sleeved outside the inner round roller, the outer cylinder and the inner round roller can be coaxially assembled, the outer lugs of the inner round roller and the inner lugs of the outer cylinder can be staggered and embedded, and proper gaps are reserved; and in addition, 1 to 3 rows of spinning holes are axially and uniformly reserved in the highest upper surface of the outer cylinder.

Owner:重庆中纳科技有限公司

Nylon 56 short fiber and melt direct spinning preparation method thereof

InactiveCN105887230AShort processImprove efficiencyNew-spun product collectionSpinning head liquid feederWinding machineInternal pressure

The invention discloses a melt direct spinning preparation method of nylon 56 short fibers. The method includes steps: (1) allowing reaction of bio-based pentamethylene diamine and adipic acid in water under nitrogen protection to obtain a nylon 56 salt solution; (2) adding the nylon 56 salt solution and a molecular weight regulator into a reactor, and keeping the pressure under the condition that the temperature is 210-240 DEG C and the pressure is 1.7-1.85MPa; releasing the internal pressure of the reactor, and heating to 280-290 DEG C; vacuumizing and stirring to obtain nylon 56 polymer melt; (3) feeding the nylon 56 polymer melt into a spinning manifold; subjecting the nylon 56 polymer melt to spinning through a spinneret, cooling, leading to a winding machine to realize finishing and conditioning, and sequentially performing drafting, crimping, finishing, relaxed heat setting and cutting to obtain the nylon 56 short fibers. The melt direct spinning preparation method has advantages of short process, high efficiency and product stability and provides guidance for industrial direct spinning of bio-based nylon and nylon polymers.

Owner:优纤科技(丹东)有限公司 +2

Electrospinning apparatus

InactiveUS20160083868A1Uniform qualitySimple manufacturing processSpinning solution filteringArtificial filament recoveryHigh volume manufacturingElectrospinning

The present invention relates to an electrospinning apparatus, and the purpose of the present invention is to provide an electrospinning apparatus capable of producing nanofiber having various ingredients and thicknesses by controlling the temperature of at least one solution discharged from nozzles mounted on the tubular bodies of a nozzle block and thus controlling the viscosity of the solution which is electrospun; producing nanofiber having uniform quality without applying a density difference and a voltage difference by disposing the front end portions of the nozzles in a flare shape; and mass-producing nanofiber at a low cost as well as reducing the amount of the solution used by removing an overflow prevention system and using a metering pump alone or by using the metering pump and the overflow prevention system alternatively or in a hybrid manner.

Owner:FINETEX ENE

Producing method for spinning heterogeneous colored terylene preoriented continuous yarn by recycled polyester bottle sheet materials

InactiveCN101638813AGuaranteed uptimeExpand the scope of applicationSpinning head liquid feederFilament/thread formingEngineeringBottle

The invention discloses a producing method for spinning heterogeneous colored terylene preoriented continuous yarn by recycled polyester bottle sheet materials. Recycled polyester bottle sheets and special masterbatches are used as main materials and made into products similar to heterogeneous colored terylene preoriented continuous yarn products produced by slice spinning of virgin polyester through the fused extruding of a screw extruder, the filtering of an on-line switchable fusant filter, the spinning of a spinneret, drawing, cooling and oiling, yarn building and the like. Spinneret orifices of a used spinneret plate are formed by the combination of holes shaped like a Chinese character ren and are in a concentric circle arrangement mode, the number of the holes shaped like a Chinesecharacter ren is same as that of fiber monofils, and the cross sectional shape of the fibers formed by the spinning-out of the spinneret orifices, the drawing, the cooling and subsequent handlings islike a Chinese character ren. Products produced by the method conform to the requirements of FZ / T54003-93 standard and can replace the heterogeneous terylene preoriented continuous yarn produced by aconventional method. The continuous yarn can be widely used for the production of lying-in woman fabrics and industrial fabrics.

Owner:JIANGSU FEILIN FIBER TECH

Method for producing full drafting silk of fine denier chinlon 66

ActiveCN101634053ASave spaceBest spinning processSpinnerette packsSpinning head liquid feederEngineeringMetering pump

The invention discloses a method for producing full drafting wires of fine denier chinlon 66, comprising the following steps: (1) adding chinlon 66 slices by a drying tower for drying for 20 to 40 hours; (2) transmitting the dried chinlon 66 slices into a screw extruder with the function of electrical heating for forming a silk spinning melting body; (3) quantitatively pressing the obtained silk spinning melting body into a silk spinning component by a metering pump; spraying by a silk spraying plate in a silk spinning box body for forming silk, wherein the hole diameter of the silk spraying plate is from 0.20 to 0.28 mm and the ratio of the length to the diameter is (2 to 4):1; (4) cooling the obtained silk bundle by side blowing wind with more than 70% of humidity; passing through a pre-communicating nozzle after oiling by an oil mouth; spraying out compressed air by the pre-communicating nozzle; treating the silk bundle, wherein the pressure of the compressed air is from 0.5 to 1.2 bar; (5) drafting and shaping the obtained silk bundle by a first group of silk guiding rollers and a second group of silk guiding rollers ,wherein the speed ratio of the second group of silk guiding rollers to the first group of silk guiding rollers is (1.2 to 2.5):1; and (6) bringing the obtained silk bundle to a high-speed rolling machine by a third silk guiding roller for rolling.

Owner:烟台华润锦纶有限公司

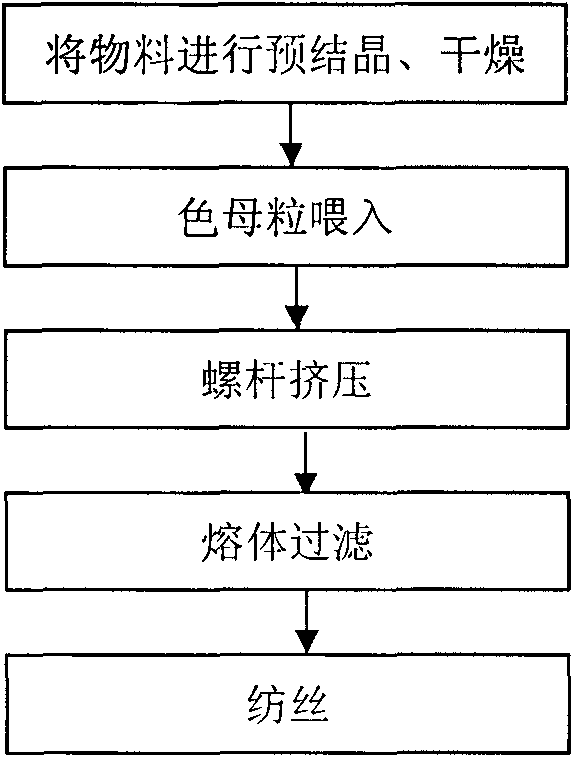

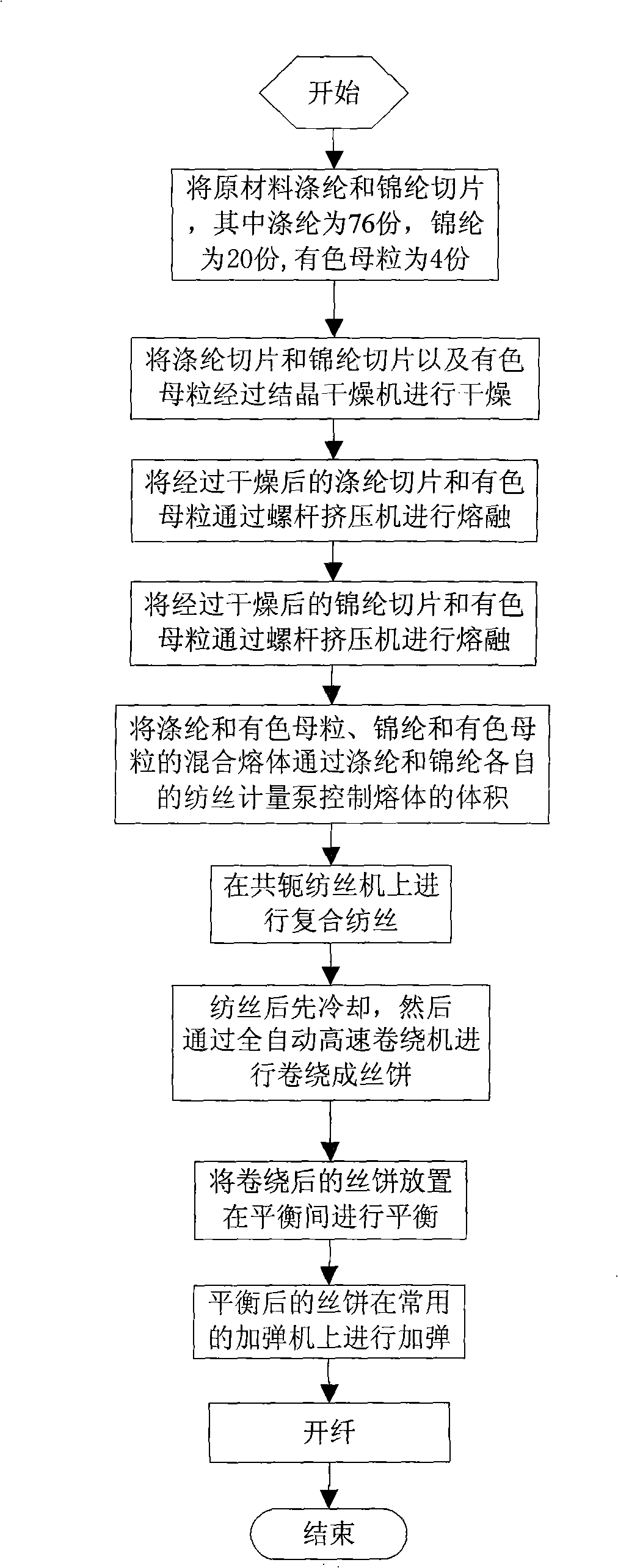

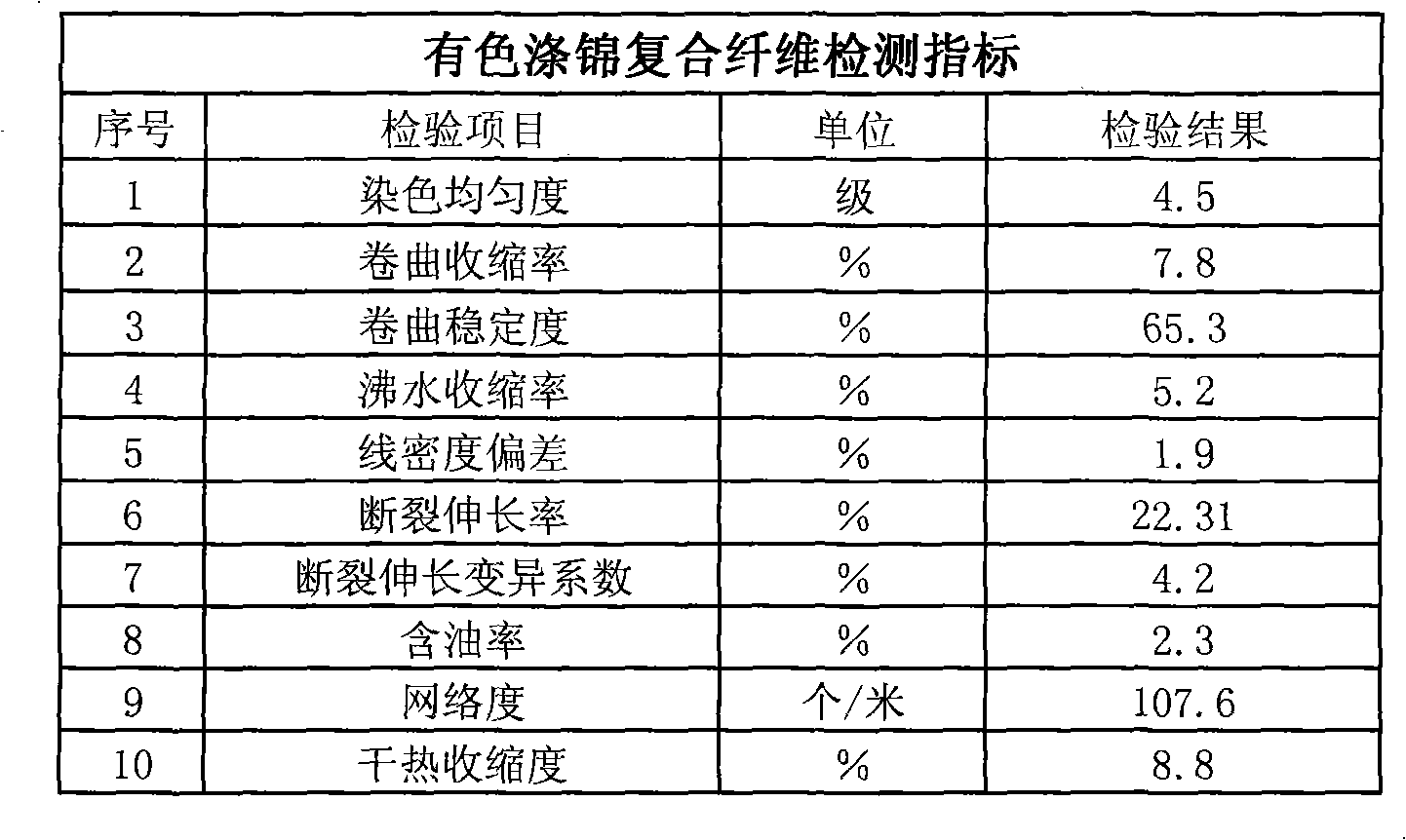

Manufacturing process for colored polyester-nylon composite superfine fibre

InactiveCN101343797AIncrease coverageGood coverage, good fluffinessSpinning head liquid feederMelt spinning methodsPolyesterWinding machine

The invention relates to a color polyester cotton compound superfine fiber manufacturing process. The color polyester cotton compound superfine fiber manufacturing process is characterized in that the manufacturing process comprises the following steps: firstly, the raw material polyester fiber and the nylon are sliced; secondly, the sliced polyester fiber and the nylon are dried with a crystallization dryer; thirdly, coloring material particles are added to the crystallization dryer through a color printing machine to perform drying; fourthly, the dried polyester fiber slices, the nylon slices and the coloring material particles are melted with a screw rod extruding machine; fifthly, the melted body volume is controlled through a spinning finish measuring pump and a spinning measuring pump; sixthly, compound spinning is performed on a conjugated spinning machine; seventhly, after spinning, the fiber is rolled into a spinning cake through an automatic high speed winding machine; eighthly, the winded spinning cake is placed in a balancing chamber to be balanced; and ninthly, texturing is performed to the balanced spinning cake on a common texturing machine. Compared with the prior art, the process has the advantages that the coloring can be directly realized during the spinning process, the color fastness, the sunlight fastness and the thermal fastness are good, the gloss is even, and the color rendering property is good.

Owner:NINGBO SANBANG MICROFIBER

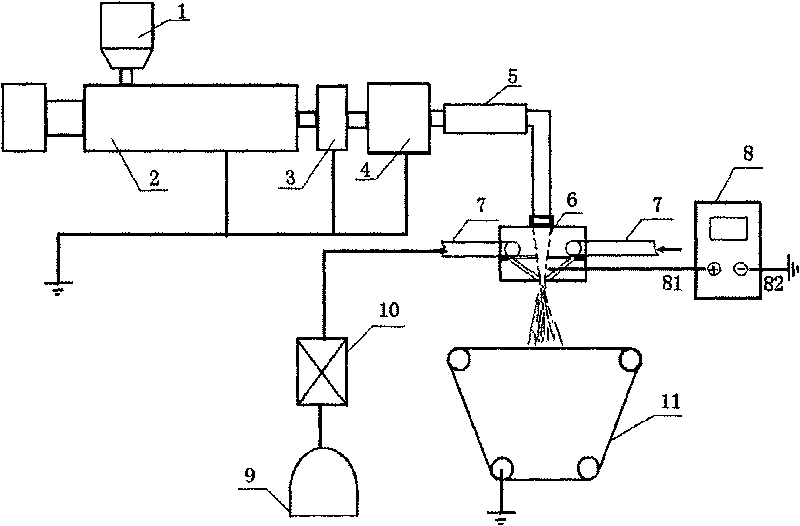

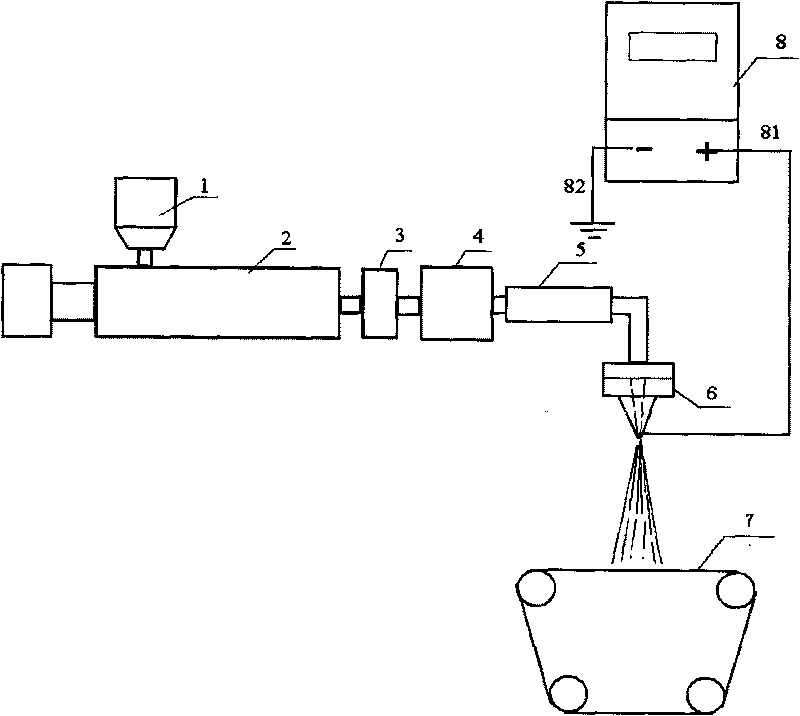

Device and method for manufacturing melting electrostatic spinning nano-fiber non-woven fabrics

InactiveCN101709535AAvoid electrificationRealize continuous productionSpinnerette packsSpinning head liquid feederSolventHigh voltage

The invention relates to a device and a method technique for manufacturing melting electrostatic spinning nano-fiber non-woven fabrics. The device for manufacturing the melting electrostatic spinning nano-fiber non-woven fabrics comprises a material storage tank, a screw extruder, a filter, a measuring pump, a material path, a spinning component, a receiving device and a high-voltage electrostatic generator; and the material path is made of high thermal conductivity insulating ceramics. The method for manufacturing the nano-fiber non-woven fabrics adopts the device for manufacturing the same and comprises the following process steps: (1) preparing a polymer melt; (2) jetting nano-fibers; and (3) molding the non-woven fabrics. By adopting a melting electrostatic spinning technique, the method for manufacturing the nano-fiber non-woven fabrics avoids the pollution problem caused by a solution electrostatic spinning solvent, which is a novel environment-friendly technique for manufacturing the non-woven fabric; and the device is reconstructed on the basis of the conventional screw extrusion melting spinning production equipment to meet the requirement on production, has a low implementation cost, and is easy for industrialized popularization.

Owner:TIANJIN POLYTECHNIC UNIV

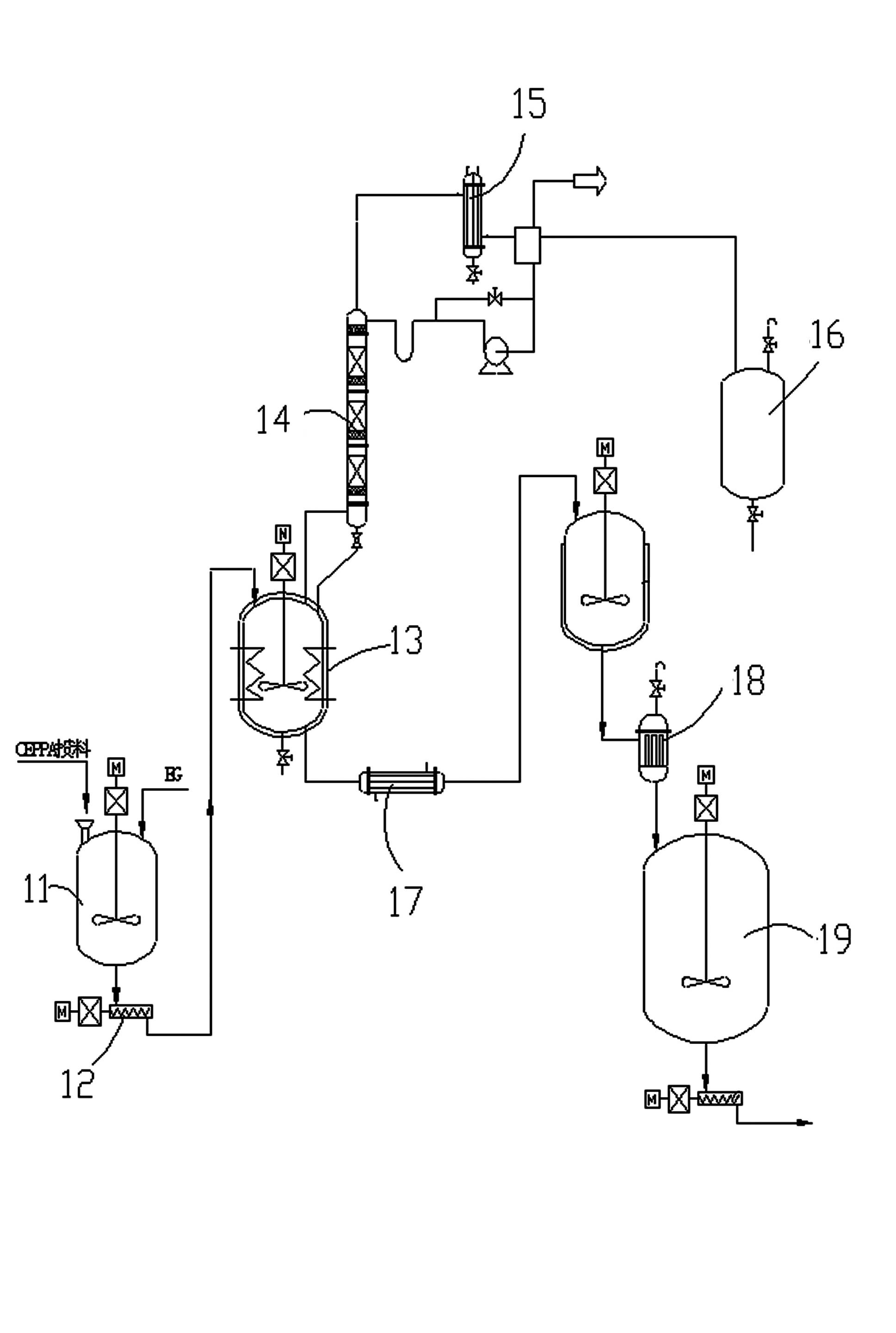

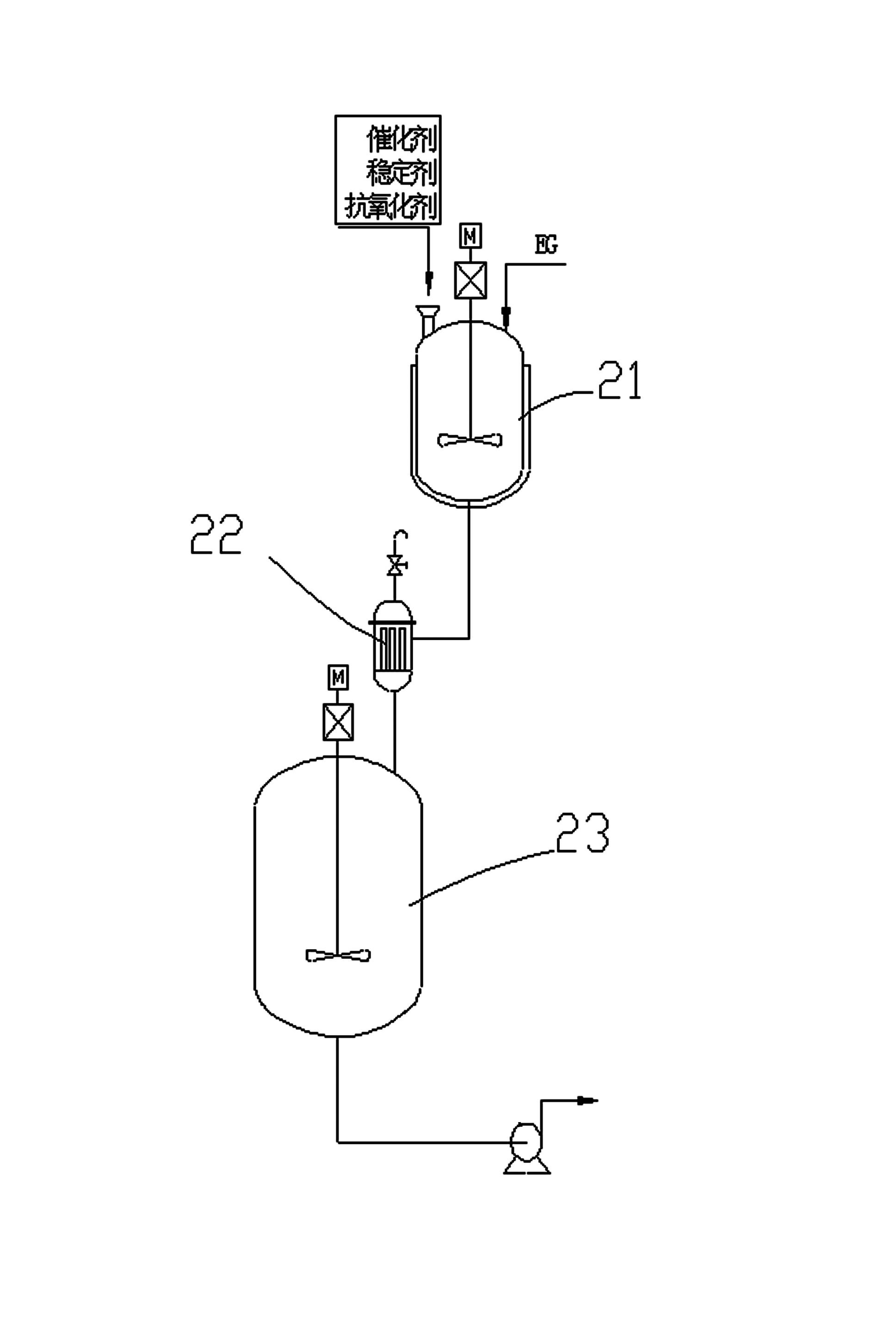

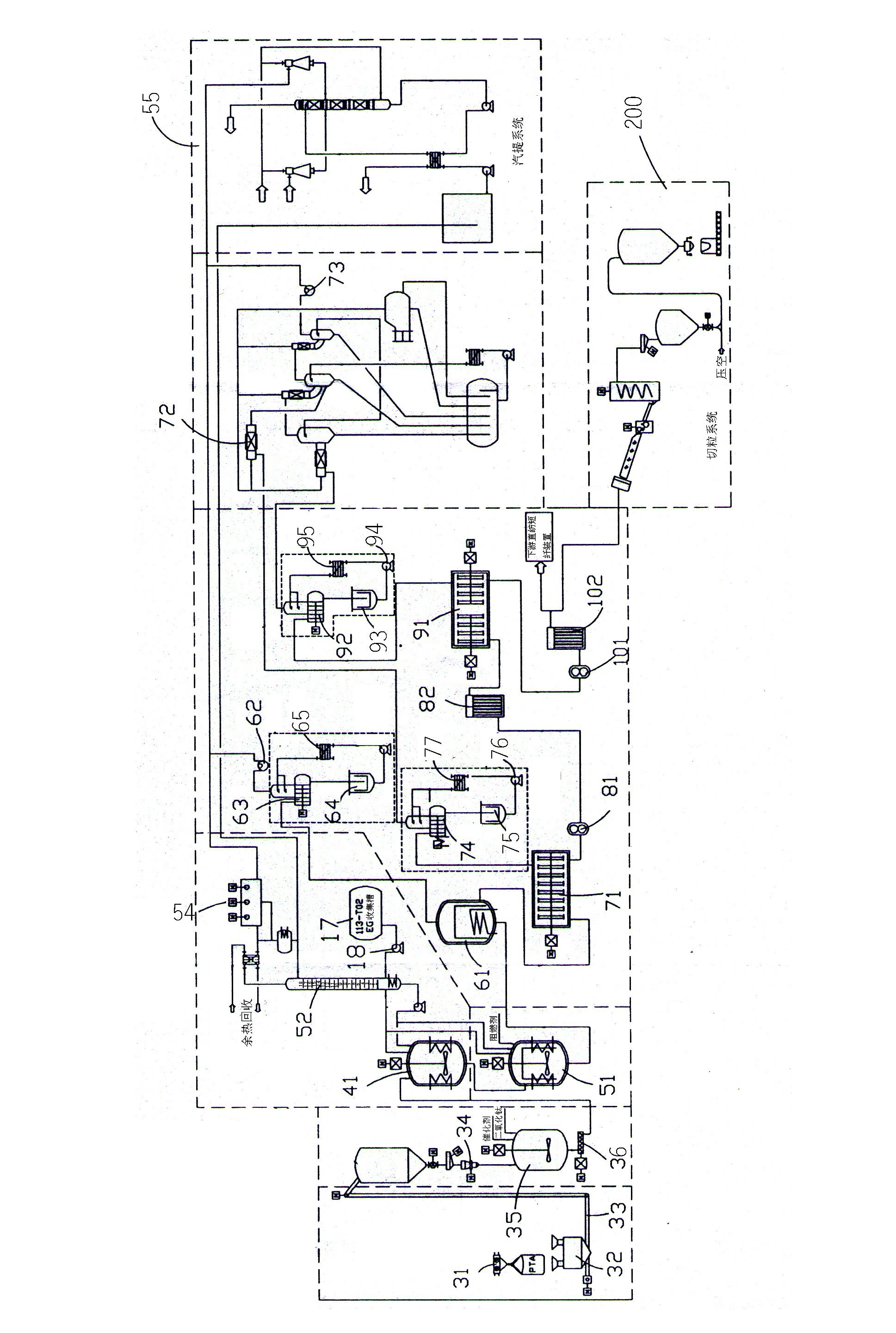

Process for manufacturing fire-retardant polyester fiber

ActiveCN102691130AIncrease productivityReduce consumptionFlame-proof filament manufactureSpinning head liquid feederFiberPolyester

The invention provides a process for manufacturing fire-retardant polyester fiber. The process comprises the steps of: fire retardant preparation, catalyst and promoter preparation, size preparation, two grading esterification reactions, two pre-polycondensation reactions, pre-polymer conveying and filtering, final polycondensation reactions, final polymer conveying and filtering, spinning melt conveying and distributing, spinning and drafting. According to the invention, phosphorus-based non-toxic fire retardant 2-carboxyethyl (phenyl) phosphinic acid-ethylene glycol (CEPPA-EG) esterifying liquid is adopted to ensure that the heat resistance is better; compared with a conventional generally-adopted two-step fiber producing process of firstly producing chips through batch or semicontinuous polymerization and then carrying out chip spinning, the process adopts an one-step fiber producing process of a continuous polymerization melt direct spinning method and therefore has the advantages of high production efficiency, low consumption and loss and low production cost; the manufactured fire-retardant polyester fiber has the advantages of excellent spinnability and fiber physical property and excellent fire retardation of polymer per se; and the fabric manufactured by adopting the fire-retardant polyester fiber has the advantages of more excellent and lasting fire retardation, high limit oxygen index (LOI) which is more than 34, excellent washing durability and safety and no harm to human body.

Owner:福建经纬新纤科技实业有限公司

Manufacturing method of polyaniline composite nano fiber membrane optical sensor and detection method thereof

InactiveCN101973713AUniform colorHigh color saturationMaterial analysis by observing effect on chemical indicatorSpinning head liquid feederFiberComposite nanofibers

The invention relates to a manufacturing method of polyaniline composite nano fiber membrane optical sensor and a detection method thereof. The manufacturing method includes: eigenstate polyaniline raw material is dissolved; blending polymer is added into polyaniline solution; the solution is subject to electrostatic spinning, so as to prepare nano composite fiber; the nano composite fiber is deposited onto ITO conductive glass, so as to obtain conductive glass deposited with polyaniline composite fiber membrane, namely the polyaniline composite nano fiber membrane optical sensor. The detection method includes that the polyaniline composite nano fiber membrane optical sensor is placed into solution or gas sample containing substance to be detected, and standing and vacuum drying are carried out; a spectral measuring system is utilized to detect reflection and absorption spectrums thereof, Lab colour mode and RGB colour mode are adopted to calculate colour variation value, and the concentration of the detected substance is obtained. The invention has the advantages that equipment is simple, cost is low, no pre-treatment is required to be carried out on sample, detection range is wide, detection sensitivity is high, and real-time detection can be carried out.

Owner:DONGHUA UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com