Patents

Literature

110results about How to "Narrow molecular weight" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

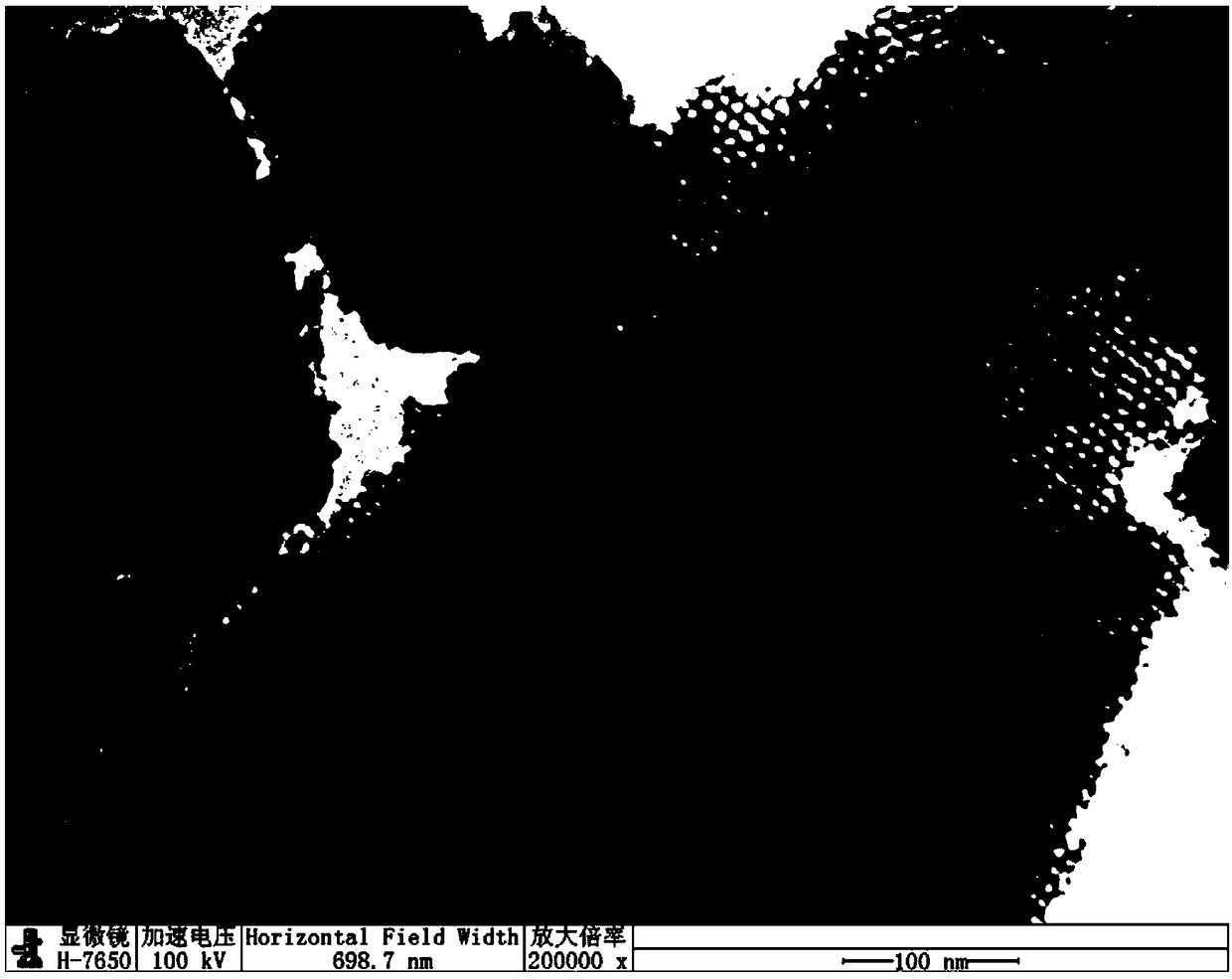

Preparation method of polymer for polyacrylonitrile base carbon fiber precursors

ActiveCN101161694ANarrow molecular weightMolecular orderFibre chemical featuresCarbon fibersPolymer science

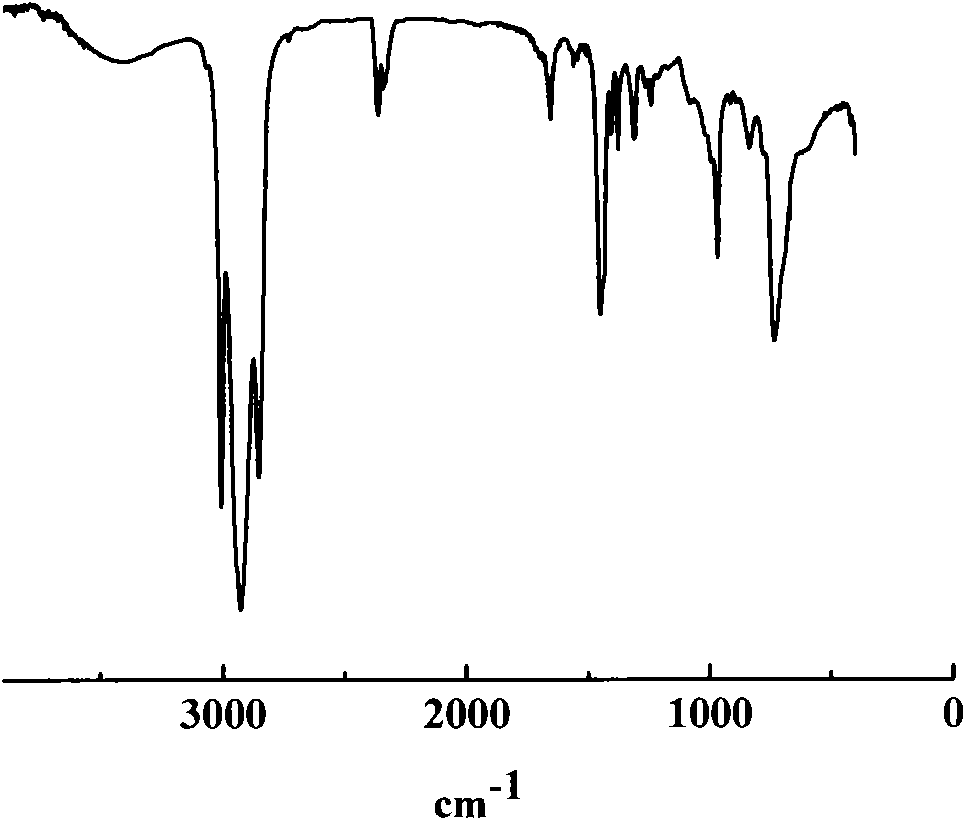

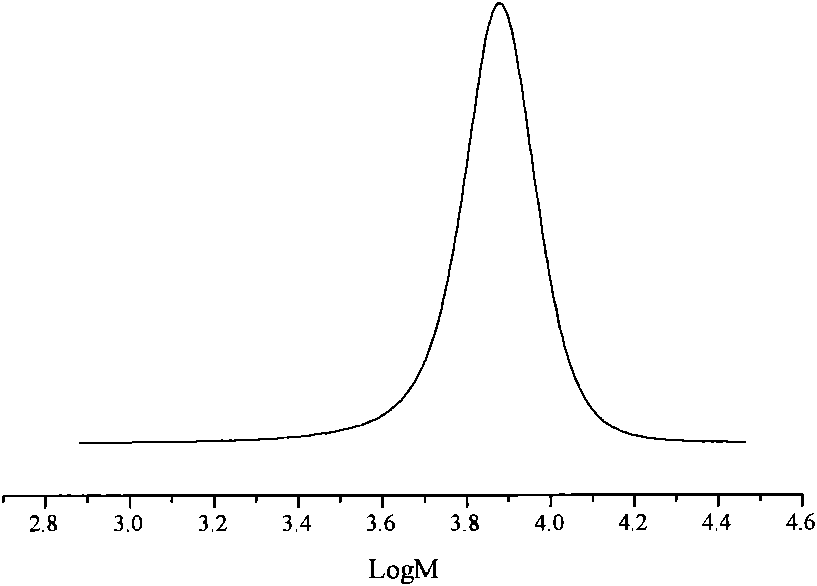

A method for preparing polymer for PAN precursor, by copolymerizing the water phase suspend using ammonium persulphate-ammonium sulfite or ammonium bisulfite as a primosome, is disclosed. The polyacrylonitrile powder material is obtained by adding the first monomer acrylonitrile, the second monomer crylic acid, methyl acrylate or acrylamide, and the third itaconic acid, or the first monomer crylic acid, the second monomer methyl acrylate or itaconic acid, and inorganic oxidation-reduction primosome without any metallic ion which comprises ammonium persulphate, ammonium sulfite or ammonium bisulfite and acidified deionized water into the polymerization kettle in defined proportions, controlling the temperature and stirring to react for a time, and discharging by removing the residual monomer, washing and drying. The average molecular weight is from 17.5 myriads to 26.1 myriads, and the distribution index of molecular weight is from 2.70 to 2.91; the intension of polyacrylonitrile precursor tested by spinning sample is from 4.58 to 6.61 CN / dtex; and the carbon fiber strength is 3.61-5.06MPa.

Owner:吉林碳谷碳纤维股份有限公司

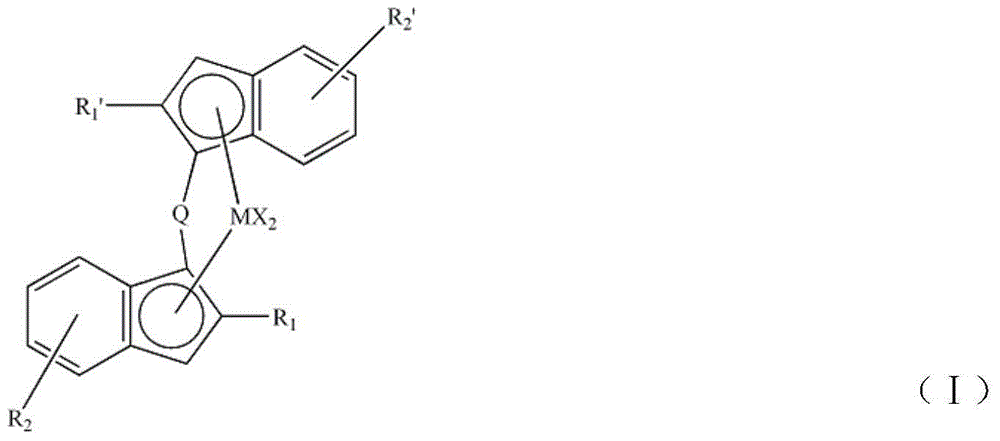

Preparation method of polypropylene wax

The invention relates to a preparation method of polypropylene wax. The method is characterized in that a liquid phase bulk polymerization technology is used, a supported metallocene catalyst is used, hydrogen is adopted as a molecular weight regulator, and a granular polypropylene wax product is directly obtained through catalyzing liquid propylene polymerization. The propylene polymerization reaction activity is not lower than 1000 times / h. The method has the characteristics of simple operation and high polymerization reaction activity, and the molecular weight of the polypropylene wax product obtained in the invention is adjustable and has narrow distribution.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight

ActiveCN101597044AEliminate the effects ofTemperature controlPhosphorus compoundsSolubilityPolymerization

The invention discloses a method for preparing crystal II-type ammonium polyphosphate with distribution of high polymerization degree and narrow molecular weight. The method comprises the following steps: putting phosphorus pentoxide and diammonium phosphate which have equal molar ratio into a malaxator which can accurately control a temperature and heated by conducting oil for mixing; under the protection of inert gas, heating the materials in the malaxator to between 100 and 250 DEG C through the circulatory conducting oil; stopping introducing the inert gas; performing ammonification on the materials and heating the materials under an atmosphere of ammonia gas till the materials are totally molten down; stopping introducing the ammonia gas; after homogenization, introducing the ammonia gas again and heating the materials; throwing a surface treating agent into the malaxator; after material throwing is completed, continuously introducing the ammonia gas, keeping warm and mixing the materials; after reaction is finished, transferring the materials to a closed vessel and reducing the temperature; simultaneously, continuously introducing the ammonia gas till the temperature of the materials is below 100 DEG C; and obtaining a finished product. The method can prepare the crystal II -type ammonium polyphosphate with the distribution of the high polymerization degree and the narrow molecular weight; and the product has the characteristics of uniform granularity shape, small water-solubility, good heat resistance, high polymerization degree, narrow distribution of molecular weight and high crystal II-type purity.

Owner:GUANGDONG JUSHI CHEM CO LTD

Cyclic azobenzene amphiphilic segmented copolymer and its preparation method

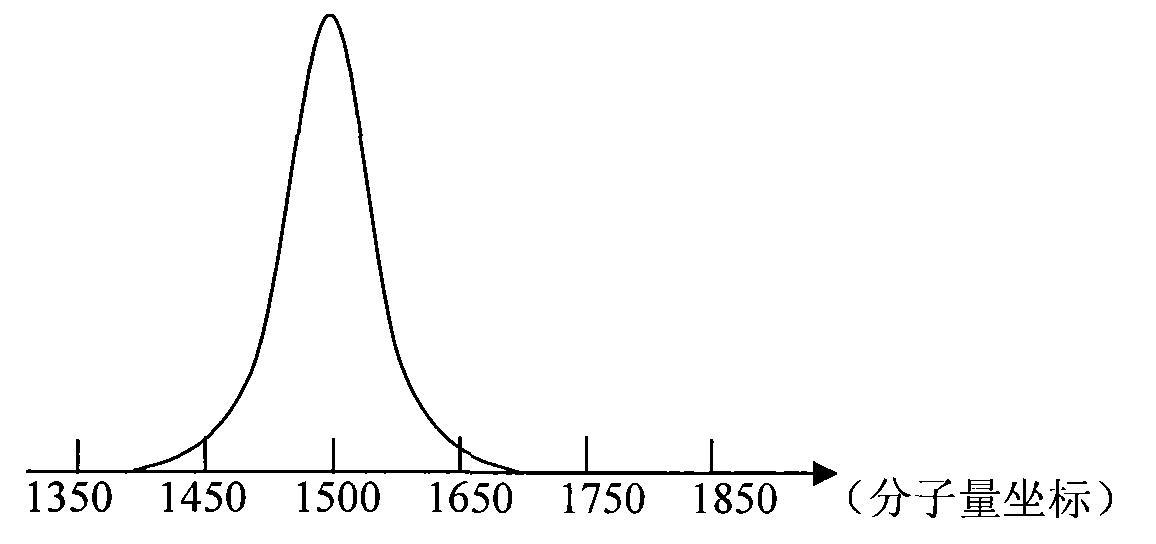

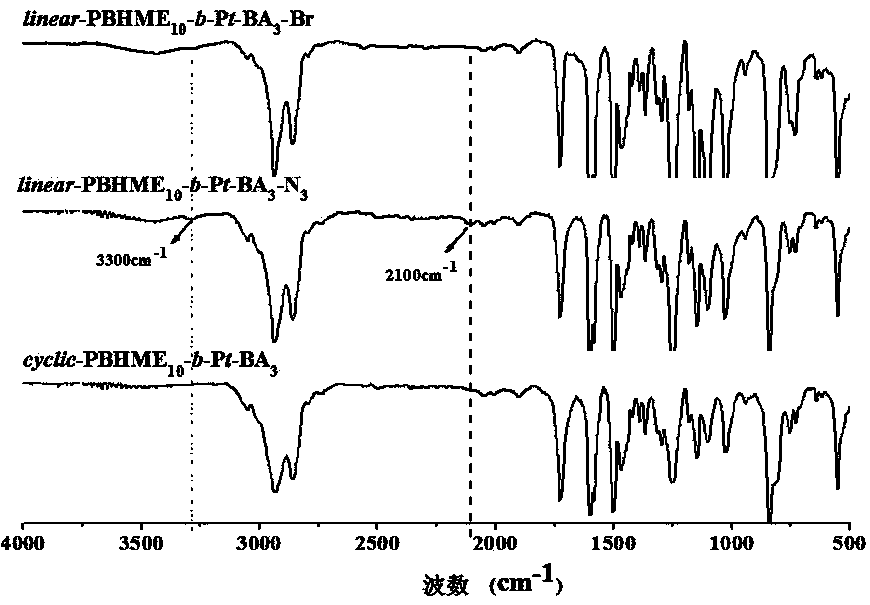

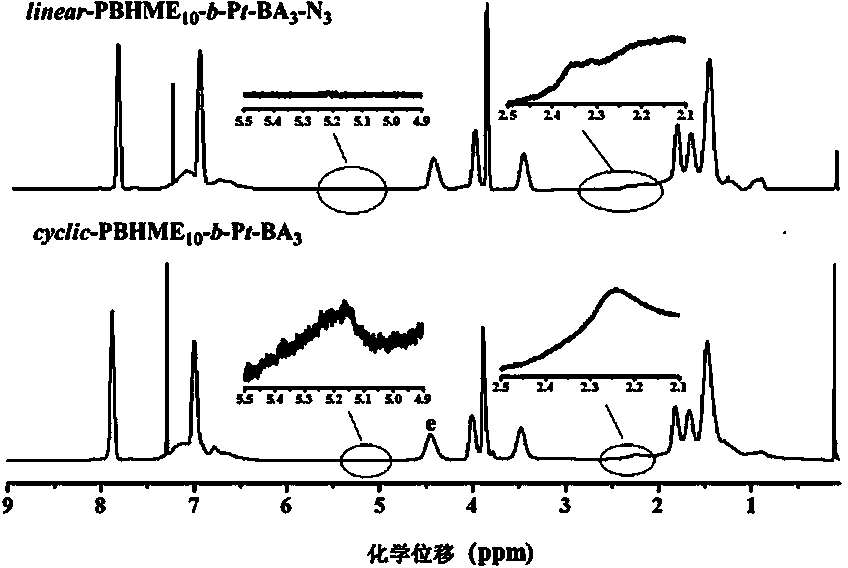

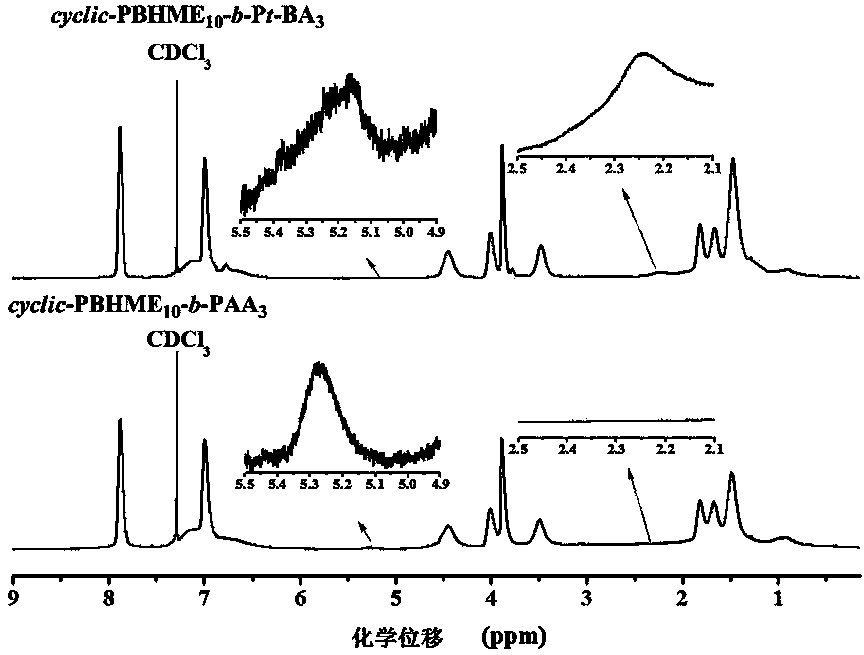

ActiveCN103819584APhotoresponsiveSmall molecular weightOrganic chemistryPolymer scienceIsomerization

The invention discloses a cyclic azobenzene amphiphilic segmented copolymer and its preparation method. The preparation method is concretely characterized in that the cyclic azobenzene amphiphilic segmented copolymer with controllable molecular weight, molecular weight distribution and ratio of a hydrophilic segment to a hydrophobic segment is obtained by combining through controllable atom transfer radical polymerization (ATRP) and an efficient CuAAC reaction. Compared with linear polymers having a same molecular weight, the cyclic polymer disclosed in the invention has the advantages of high Tg, fast photo-isomerization, sensitive light and pH response performances in an alkaline medium, and wide application potential in medicine release, surfactants, coatings, adhesives and separation films.

Owner:SUZHOU UNIV

Method for preparing butadiene-isoprene copolymer

The embodiment of the invention discloses a method for preparing butadiene-isoprene copolymer, which comprises the steps of: reacting a reaction monomer under the action of a catalyst so as to obtain a solution A; and adding an ethanol solution to the solution A so as to condense butadiene and isoprene copolymer, wherein the mol ratio of the reaction monomer to the catalyst is 100 to 4000:1. In the invention, the molecular weight and the molecular weight distributions of the butadiene-isoprene copolymer are controlled by controlling the mol ratio of the reaction monomer to the catalyst, and a polymerization reaction is terminated through hydroxyl in ethanol. The experimental result proves that the butadiene-isoprene copolymer prepared by the invention has the advantages of low molecular weight and narrow molecular weight distributions, wherein the molecular weight of the butadiene-isoprene copolymer is 1,000 to 120,000, and Mw / Mn is 1.1 to 2.0.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

Method for preparing butadiene-isoprene copolymer

The embodiment of the invention discloses a method for preparing butadiene-isoprene copolymer, which comprises the steps of: reacting a reaction monomer under the action of a catalyst so as to obtain a solution A; and adding an ethanol solution to the solution A so as to condense butadiene and isoprene copolymer, wherein the mol ratio of the reaction monomer to the catalyst is 100 to 4000:1. In the invention, the molecular weight and the molecular weight distributions of the butadiene-isoprene copolymer are controlled by controlling the mol ratio of the reaction monomer to the catalyst, and apolymerization reaction is terminated through hydroxyl in ethanol. The experimental result proves that the butadiene-isoprene copolymer prepared by the invention has the advantages of low molecular weight and narrow molecular weight distributions, wherein the molecular weight of the butadiene-isoprene copolymer is 1,000 to 120,000, and Mw / Mn is 1.1 to 2.0.

Owner:CHANGZHOU INST OF ENERGY STORAGE MATERIALS &DEVICES

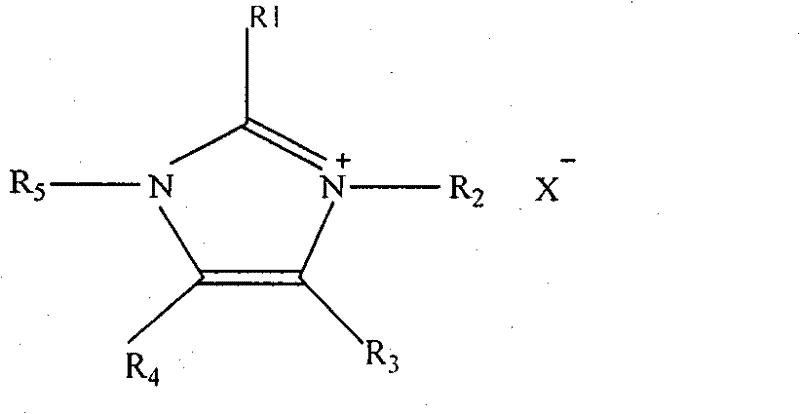

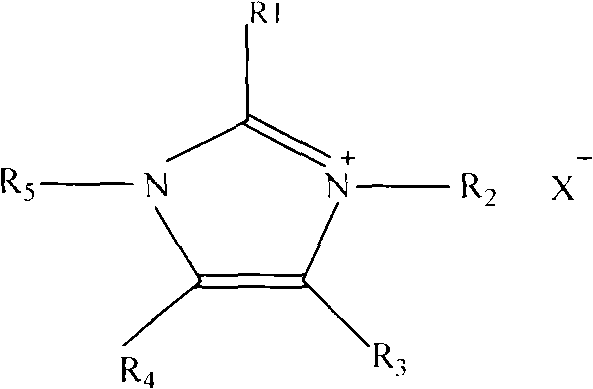

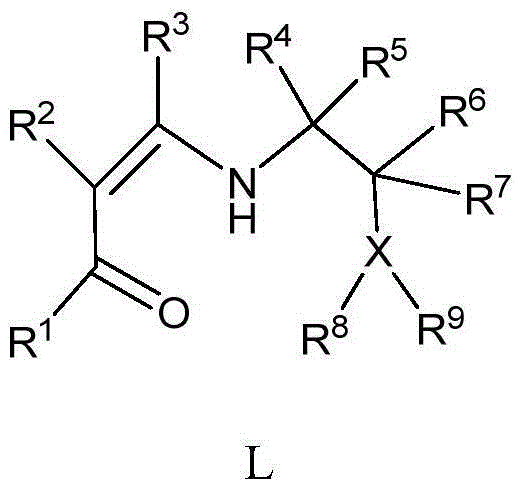

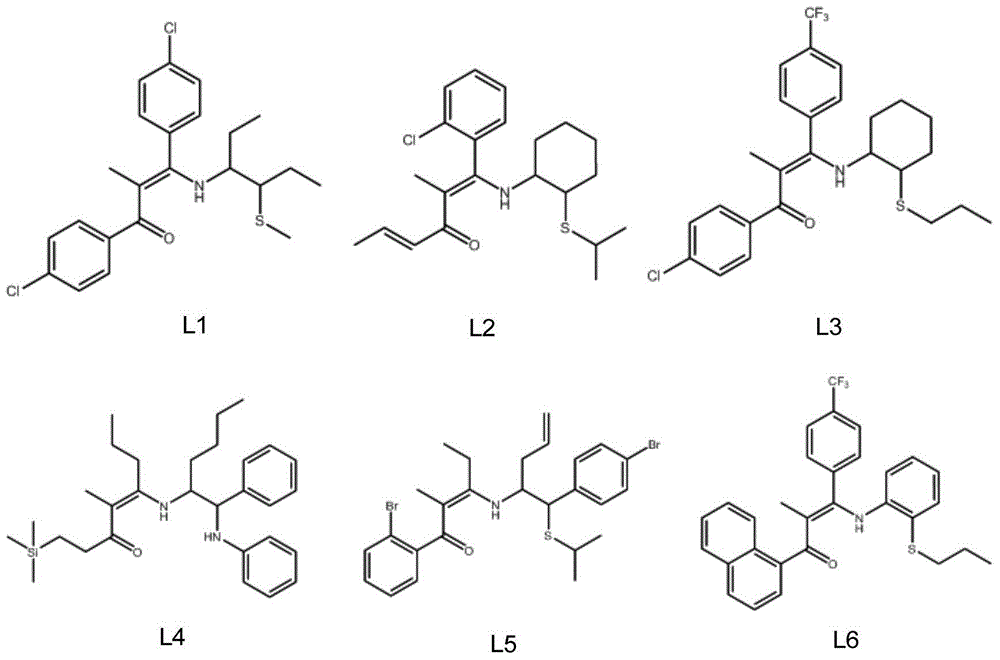

Amide initiators

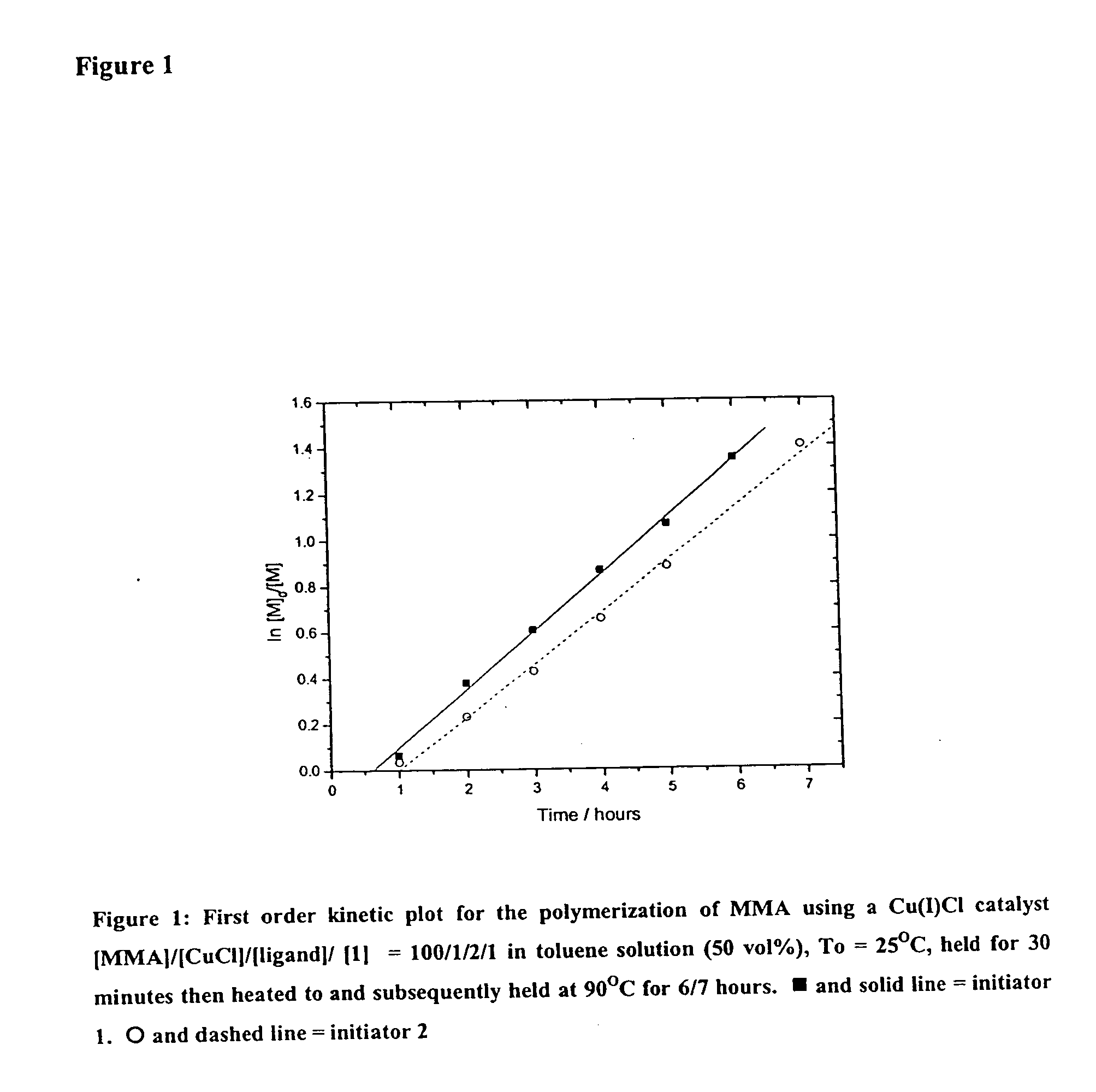

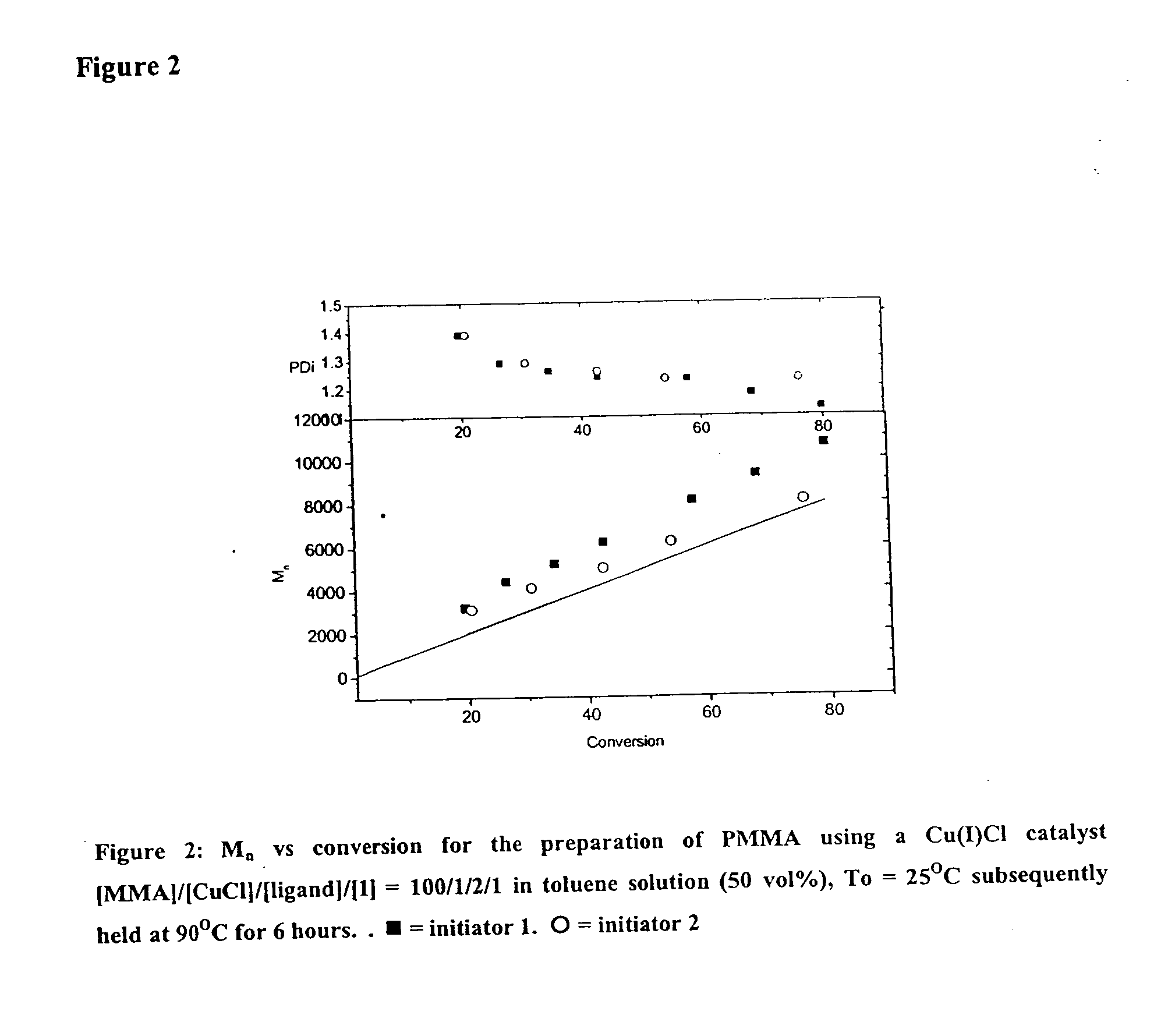

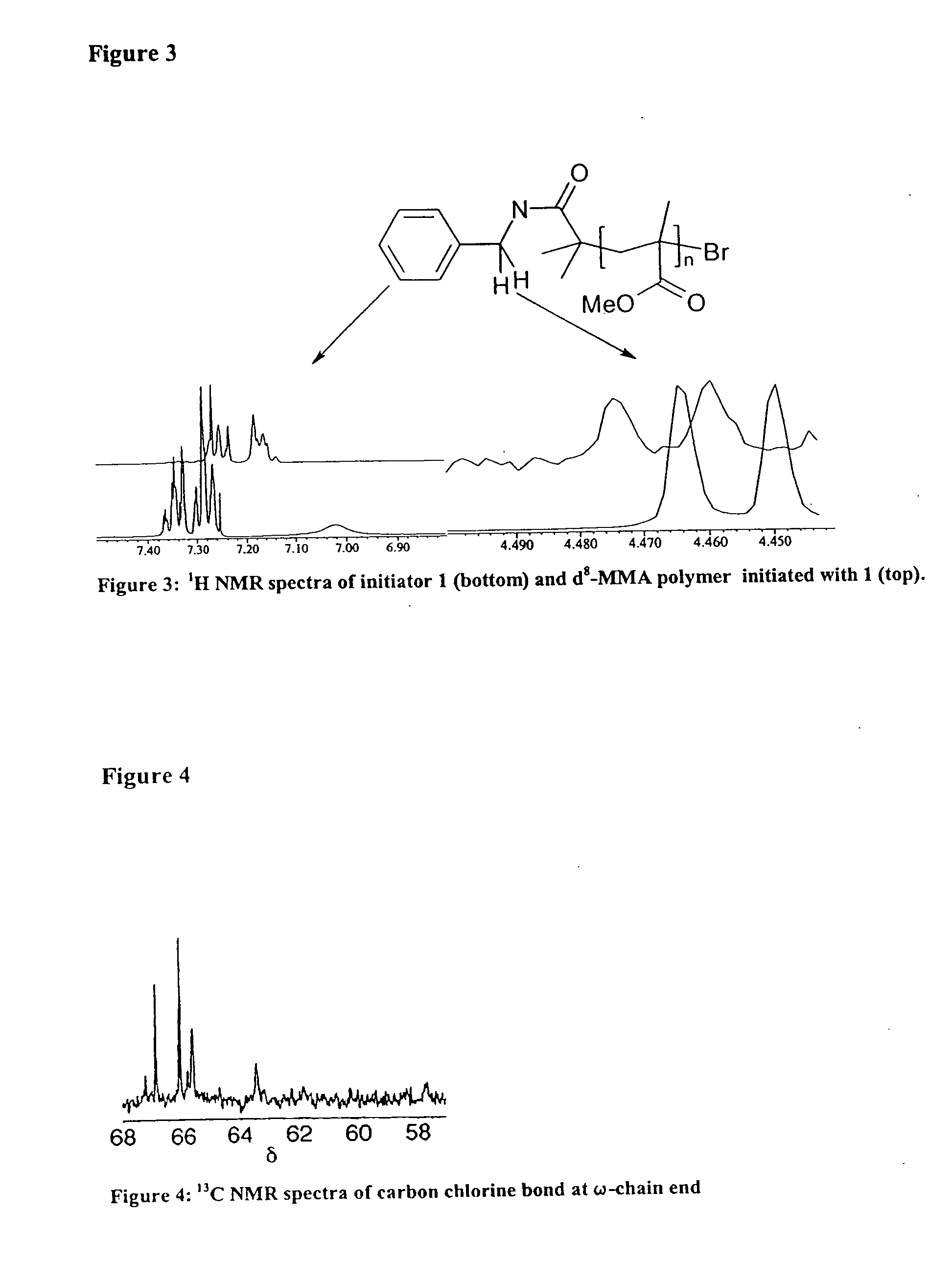

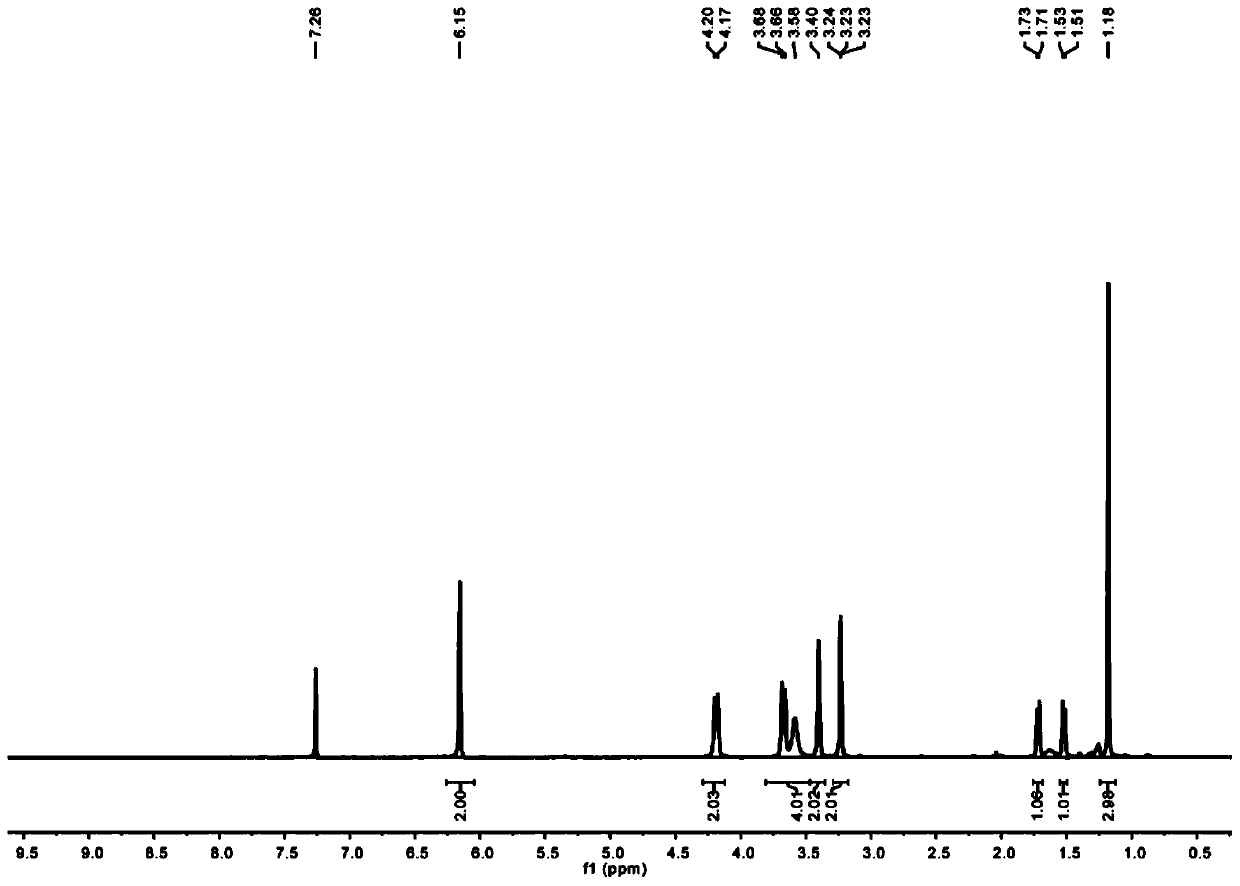

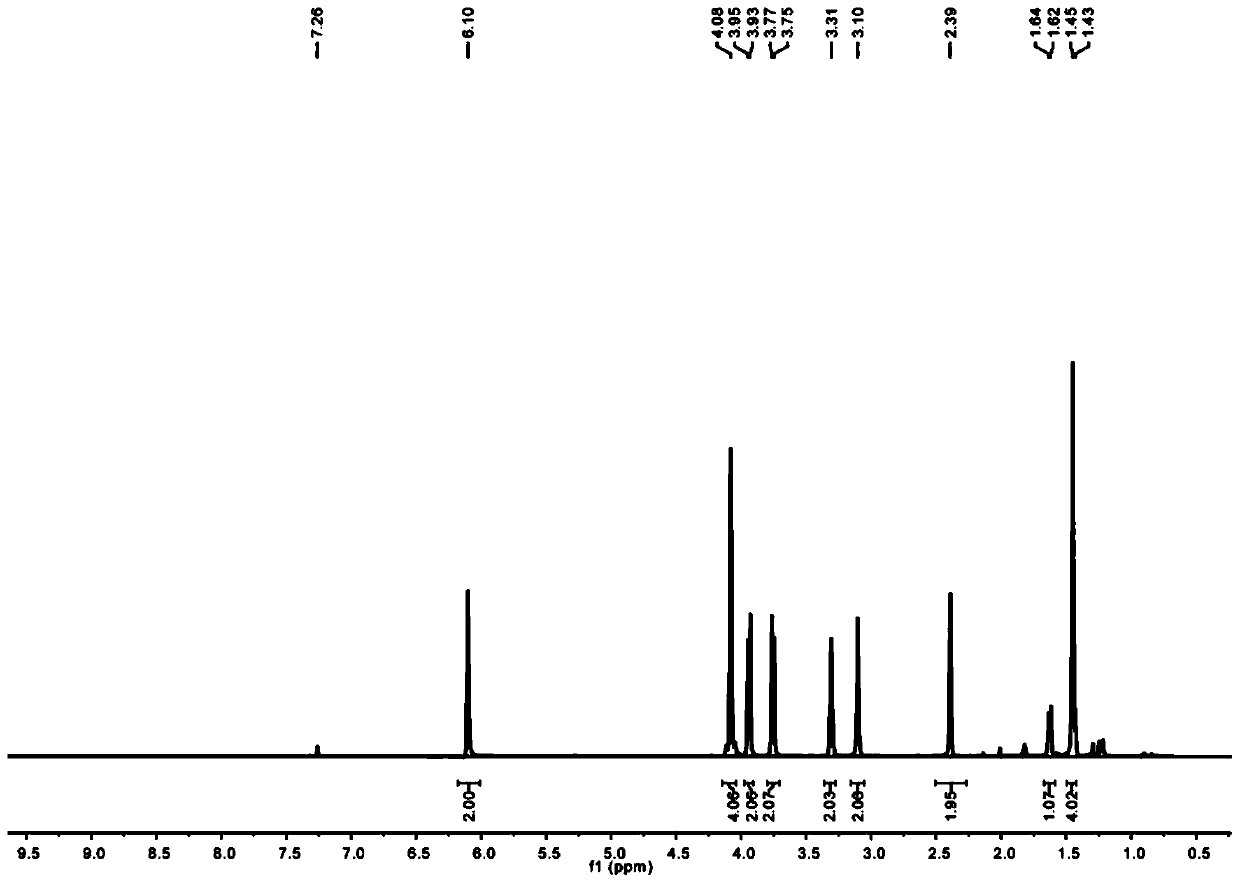

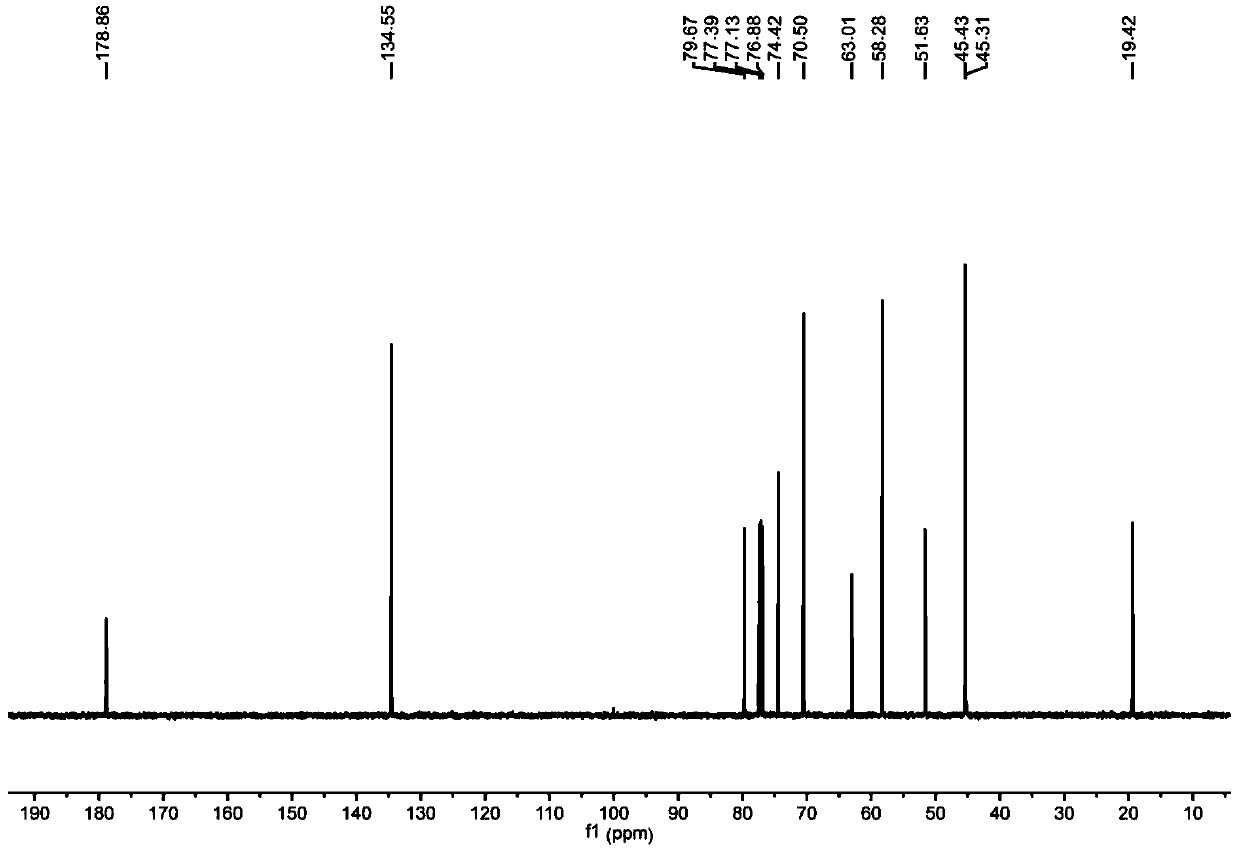

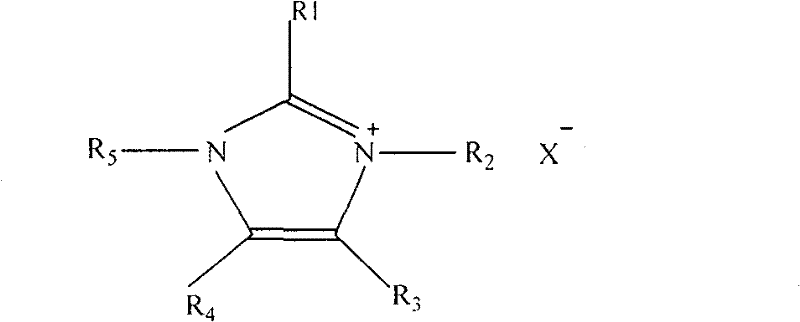

InactiveUS20070219330A1Narrow molecular weightGroup 4/14 element organic compoundsAtom-transfer radical-polymerizationPhotochemistry

The invention relates to a transition metal living free radical and / or atom transfer polymerisation process comprising the steps of: (a) mixing (i) a transition metal living free radical and / or atom transfer radical catalyst, (ii) a plurality of polymerisable monomers, and (iii) an initiator comprising a transferable atom or group a to an amide group to form a mixture; (b) incubating the mixture at a first temperature; and then (c) raising the temperature of the mixture to a second temperature to allow polymerisation of the monomers to proceed to produce polymer. Products and initiators are also provided.

Owner:WARWICK EFFECT POLYMERS

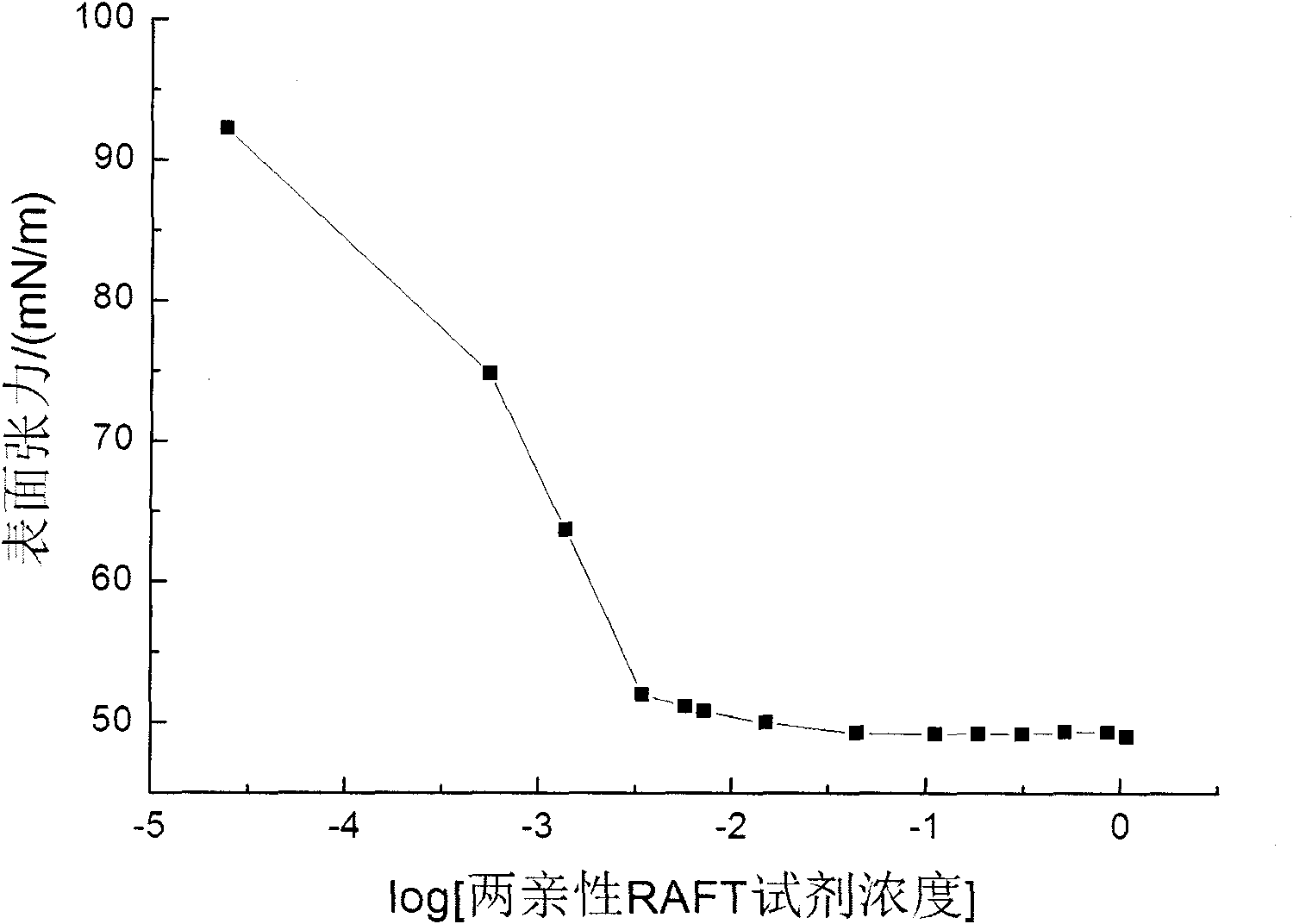

Method for preparing gradient copolymer

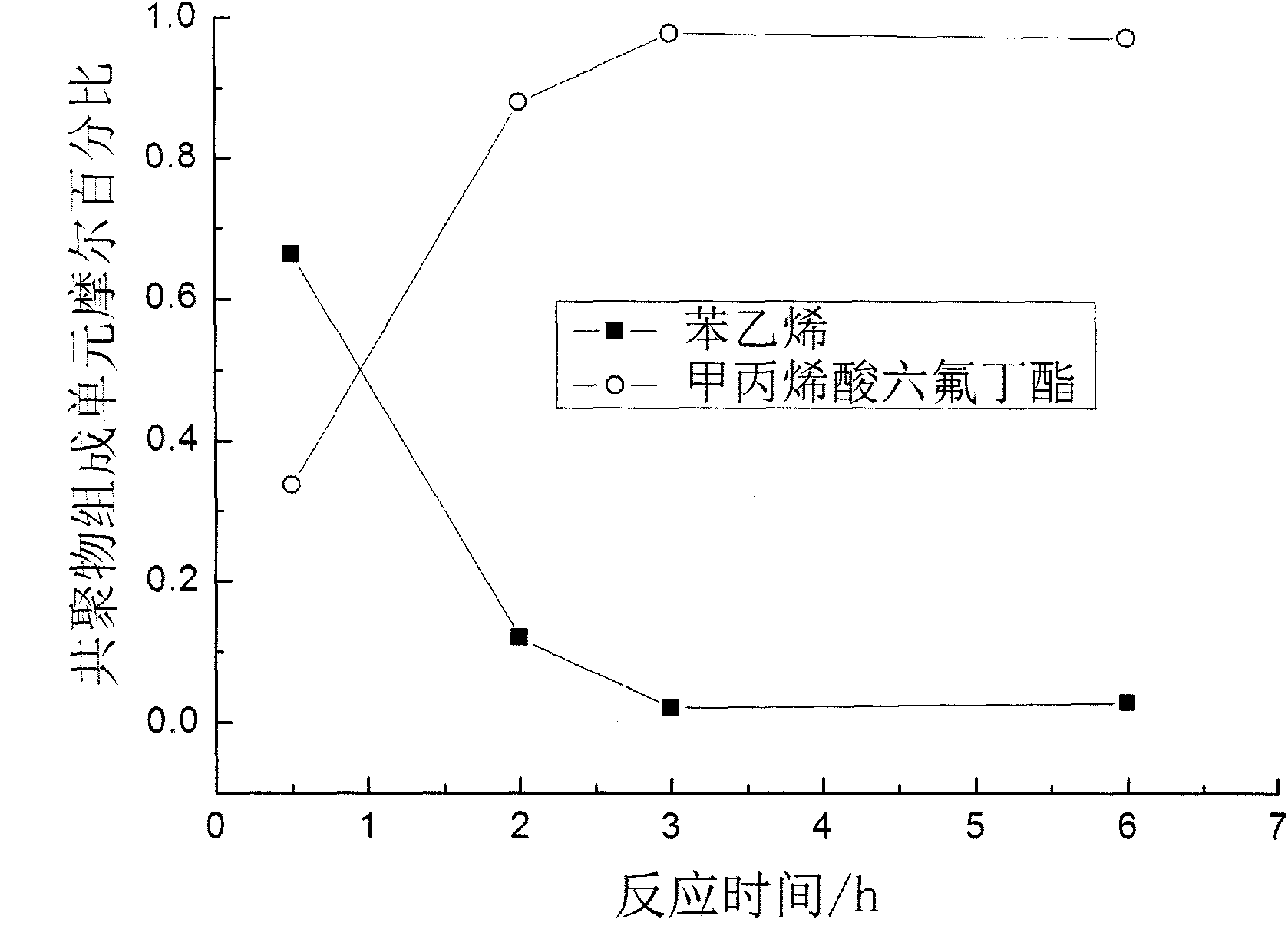

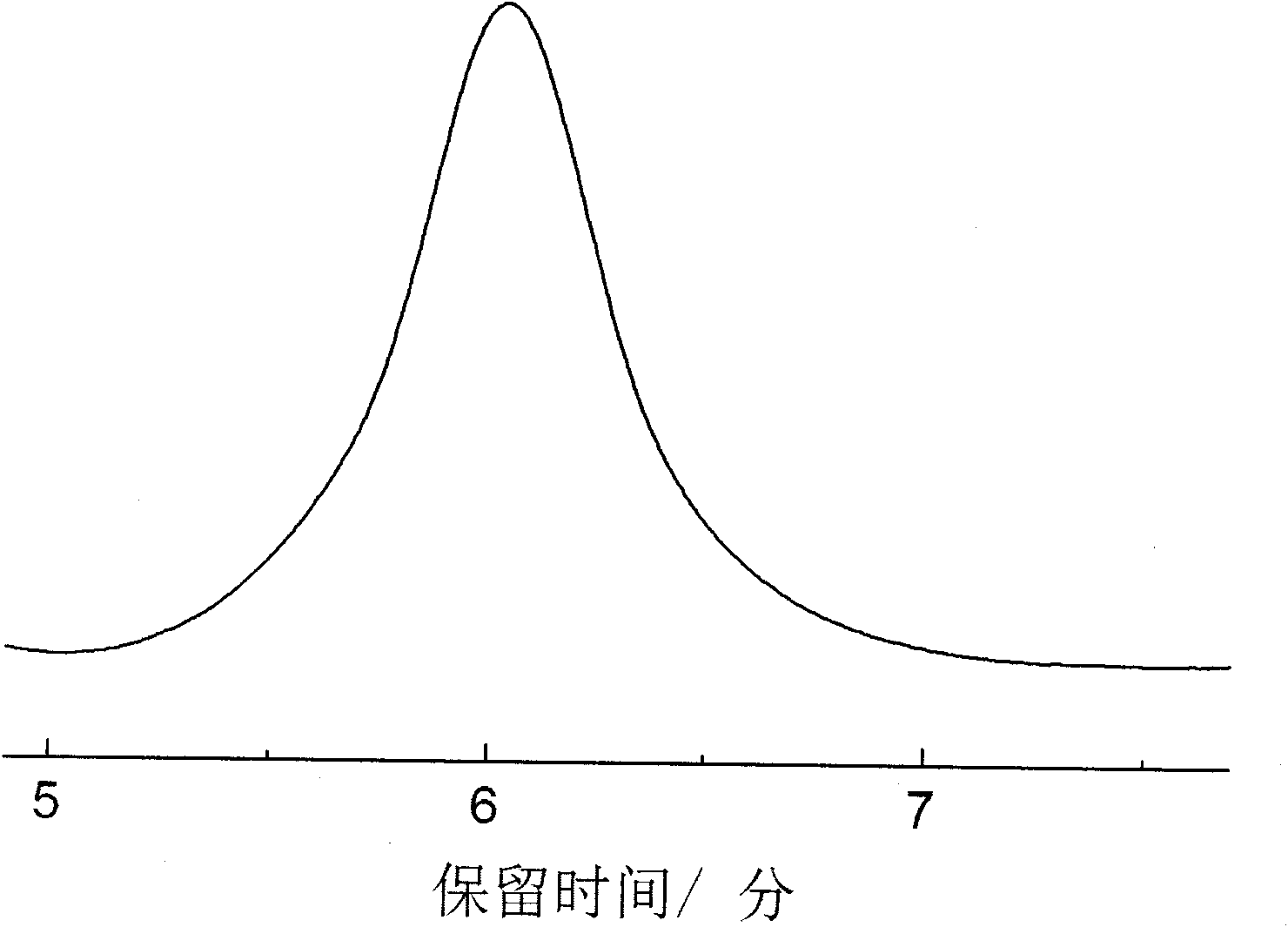

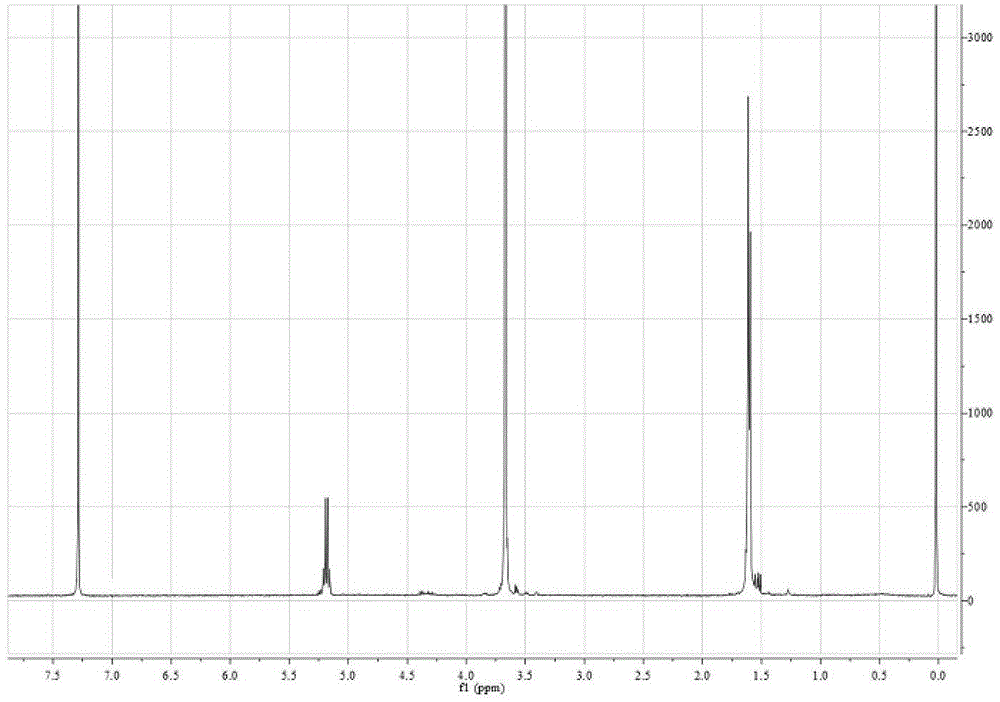

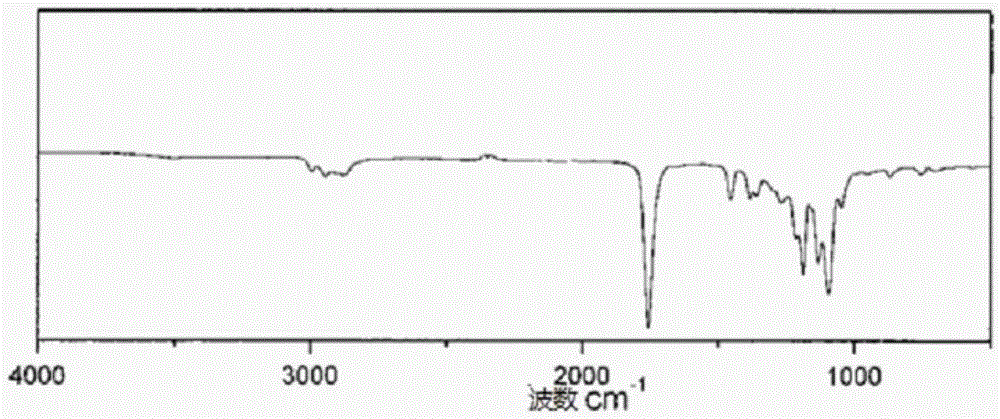

InactiveCN101792496AMolecular weight controllableNarrow molecular weightOrganic chemistryCoatingsPolymer scienceChain structure

The invention provides a method for preparing a gradient copolymer. In the method, based on the special chain transfer function and self-emulsification function of an amphiphilic reversible addition fragmentation chain transfer agent (amphiphilic RAFT reagent), under a condition of no emulsifier, the gradient copolymer is made from comonomer units by using a thermolysis initiator for initiation and water as a disperse phase and spontaneously by adopting a once feed method when the reactivity ratio of comonomers is high or forcefully by adopting a reaction material supply method when the polymerization reactivity ratio of the two comonomers is small. The molecular chain of the copolymer prepared by the method has a gradient, namely along a molecular chain, the leading position is gradually transferred from one monomer unit to the other monomer unit. The gradient copolymer is used in fields of gradient functional coatings, polymer bulking agents, damping materials and the like. The method is simple, low in cost and pollution free, and makes the control of a molecular chain structure and a polymerization process easy.

Owner:WUHAN UNIV OF TECH

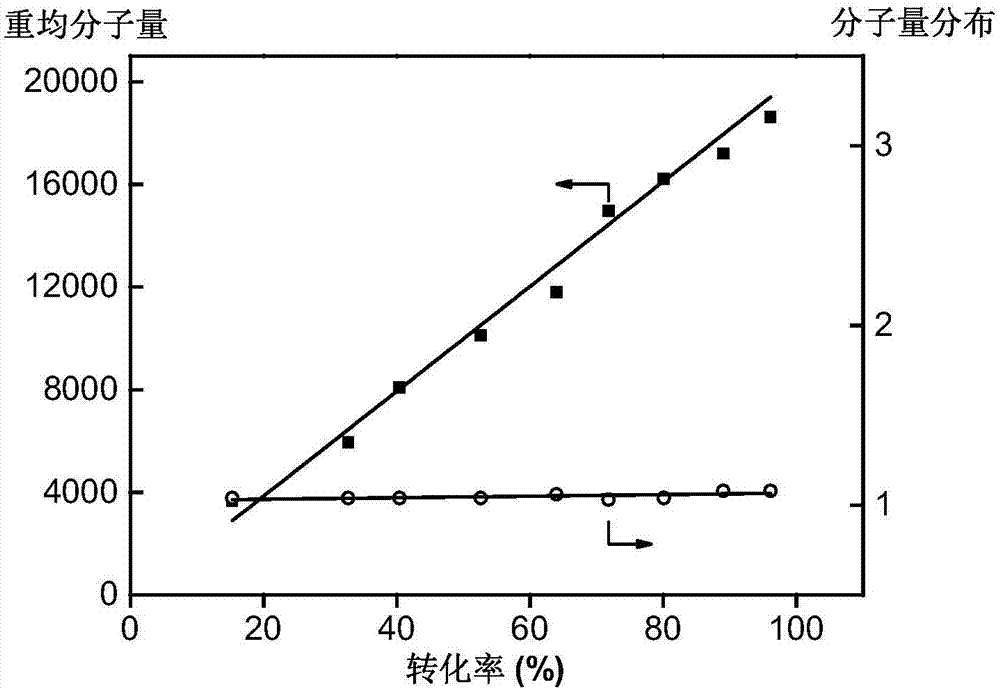

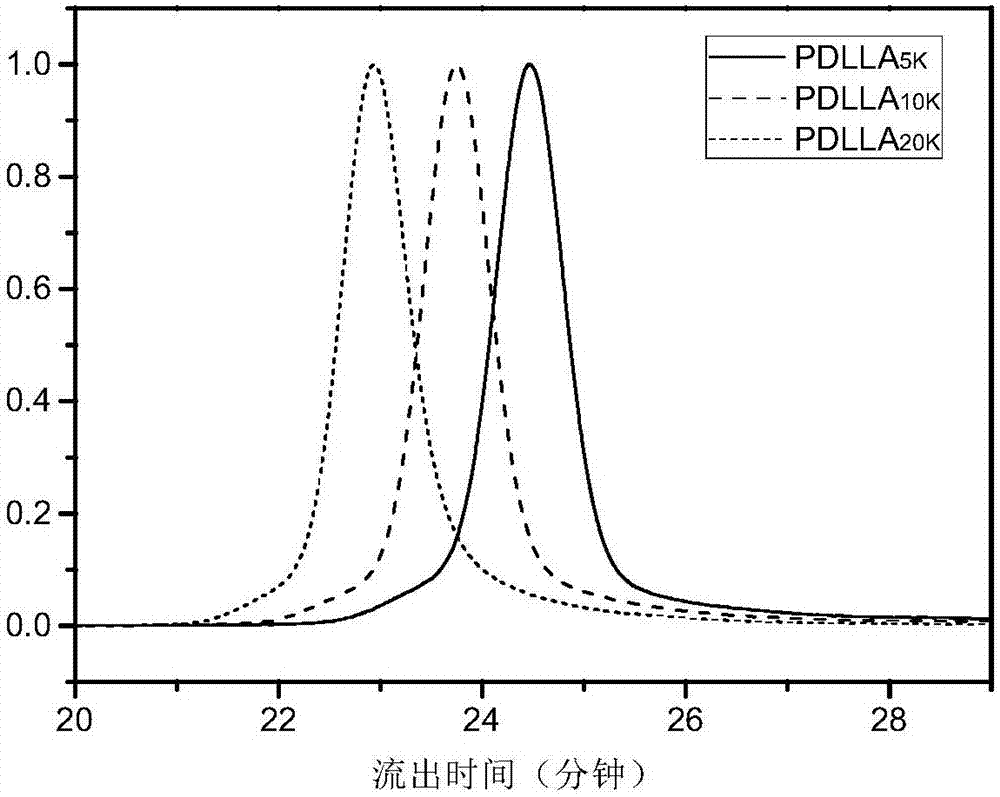

Preparation method for biodegradable polylactic acid-polyethylene glycol block copolymer

ActiveCN103980466AImprove controllabilityNarrow molecular weightSimple Organic CompoundsOrganic solvent

The invention discloses a preparation method for a biodegradable polylactic acid-polyethylene glycol block copolymer. The preparation method comprises the following steps: dissolving polyethylene glycol (PEG) or methoxy polyethylene glycol (mPEG) in anorganic solvent, in the presence of active metal and organic compound naphthalene, adding lactide, reacting for a period of time under a protective atmosphere, adding acid to end the reaction, and purifying so as to obtain the polylactic acid-polyethylene glycol block copolymer. The method uses an anionic polymerization mechanism for preparing the polylactic acid-polyethylene glycol block copolymer, the molecular weight has better controllability, the distribution of the molecular weight is narrow, the reaction temperature is low, and side effects are few.

Owner:苏州岸谷纳米技术有限公司

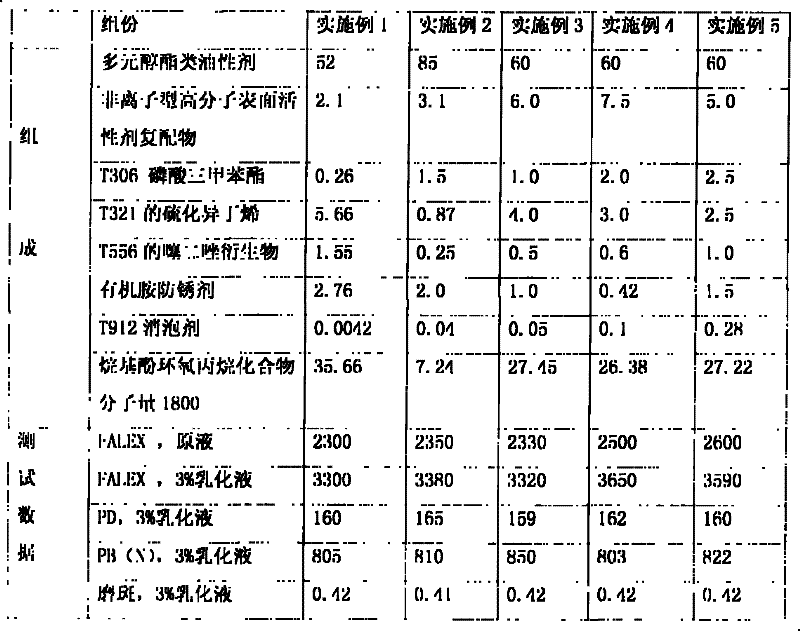

A kind of cold rolling extremely thin plate rolling oil composition

The invention discloses a novel cold rolling extreme thin plate rolling oil composition. Synthesized ester and an alkylphenol epoxypropane compound are compounded to be used as an oily agent and can form a layer of quite dense protective film on the surface of metal to form favorable annealing detergency and heat stability. A nonionic compounded emulsifying agent can increase the diameter of the elaioplast of emulsion and shows better lubricity by matching with the interaction of a metal passivator, a sulfur-containing extreme pressure antiwear agent, and the like.

Owner:石家庄新泰特种油有限公司

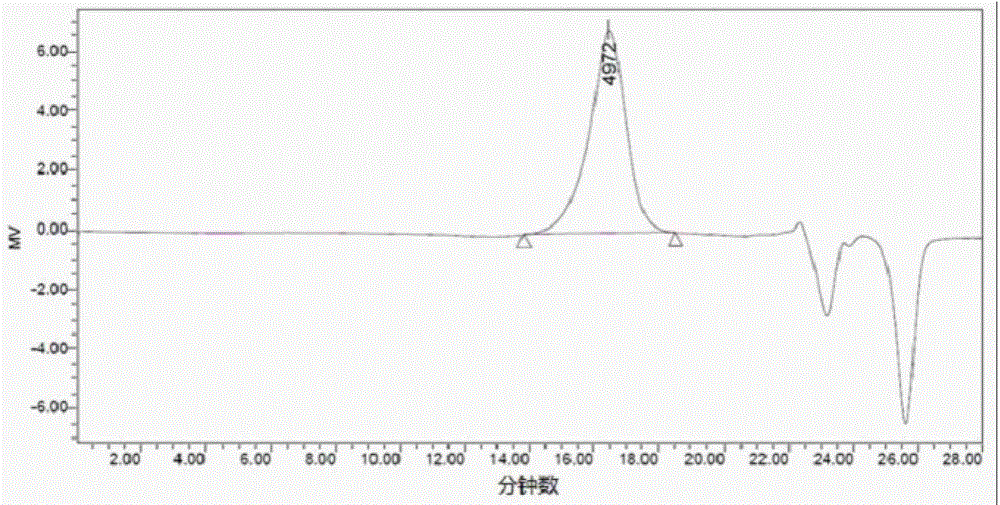

Method for preparing high-performance polyacrylonitrile solution for carbon fibers

ActiveCN102746453AImprove technical effectHigh molecular weightMonocomponent synthetic polymer artificial filamentSpinning solutions preparationCarbon fibersAcrylonitrile

The invention relates to a method for preparing a high-performance polyacrylonitrile solution for carbon fibers, and especially relates to a method for preparing the polyacrylonitrile solution through adopting a new initiator to mainly solve a problem of difficult process control caused by wide molecular weight distribution or abundant gel generation of solutions prepared through a single initiator used for preparing an acrylonitrile solution in the prior art. According to the invention, the initiator comprises 70-100 parts by weight of azodiisobutyronitrile and 1-30 parts by weight of azobisisoheptonitrile. The method well solves the problem through above technical scheme, and can be used for the industrial production of the acrylonitrile solution polymerization

Owner:CHINA PETROLEUM & CHEM CORP +1

Modified polyolefin resin

InactiveUS20070191547A1Improve adhesion strengthExcellent water resistance and gasohol resistanceInksGraft polymer adhesivesCooking & bakingPolymer science

A modified polyolefin resin which is obtained by graft modifying a propylene-based random copolymer having a melting point of 50 to 130° C. obtainable by polymerization in the presence of a metallocene catalyst, with an unsaturated carboxylic acid and / or its derivative, and has a weight average molecular weight of 15,000 to 200,000, the graft weight of the unsaturated carboxylic acid and / or its derivative therein being in the range of 0.2 to 50% by weight, is suited as a binder, a primer, an adhesive and the like against a base to which a coating or the like is difficult to adhere in a stable manner. The polyolefin resin of the present invention is superior in adhesive strength, gasohol resistance, blocking resistance and the like. The polyolefin resin of the present invention is also superior in adhesive strength even when low temperature baking is conducted.

Owner:NIPPON PAPER CHEM

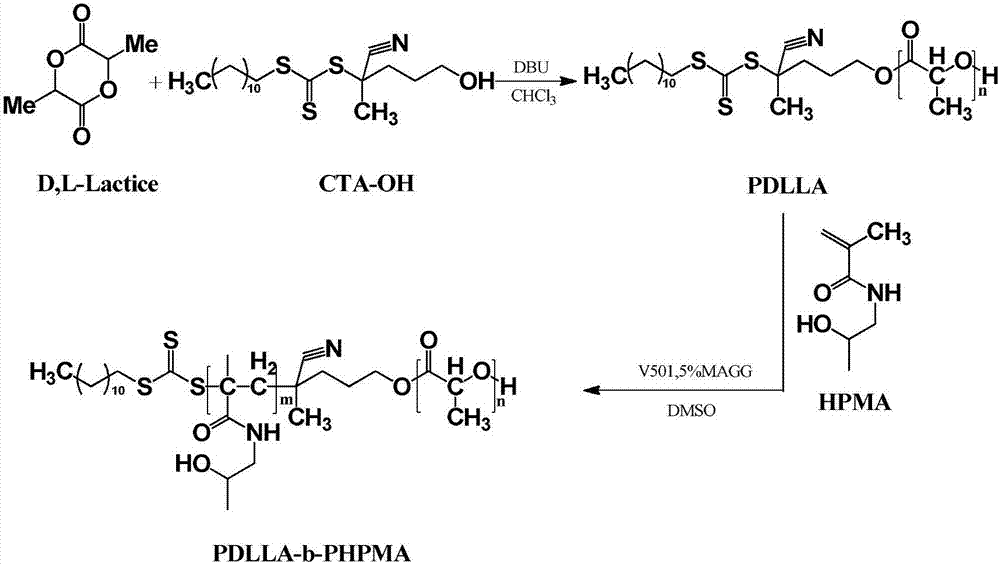

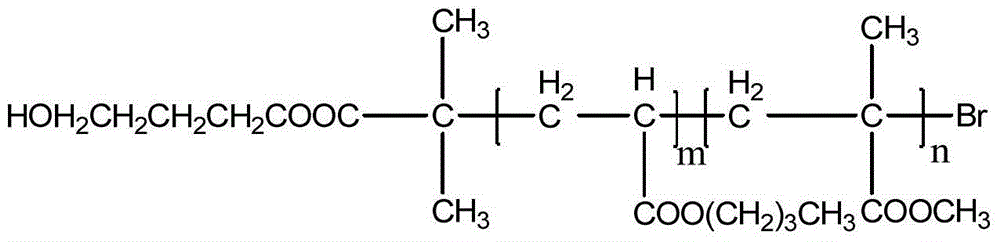

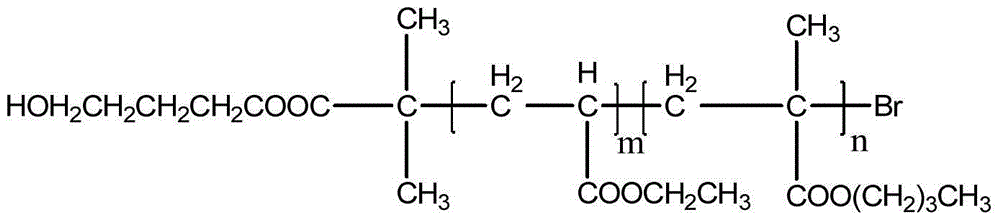

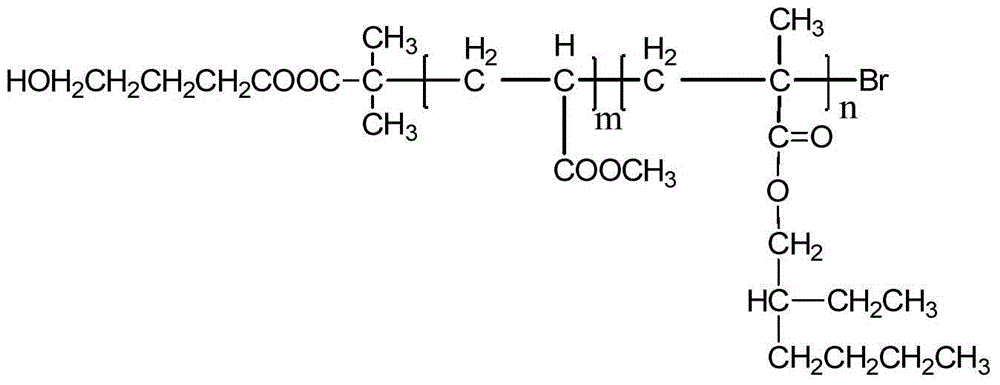

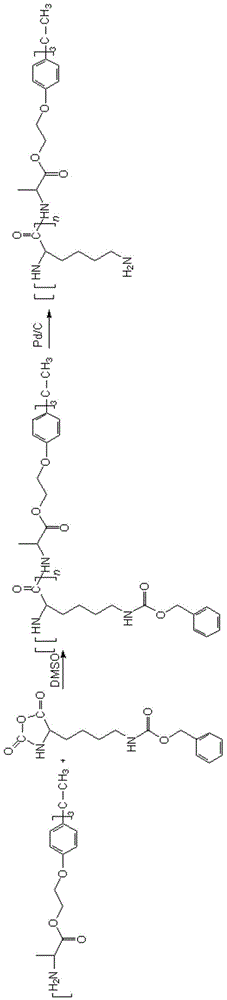

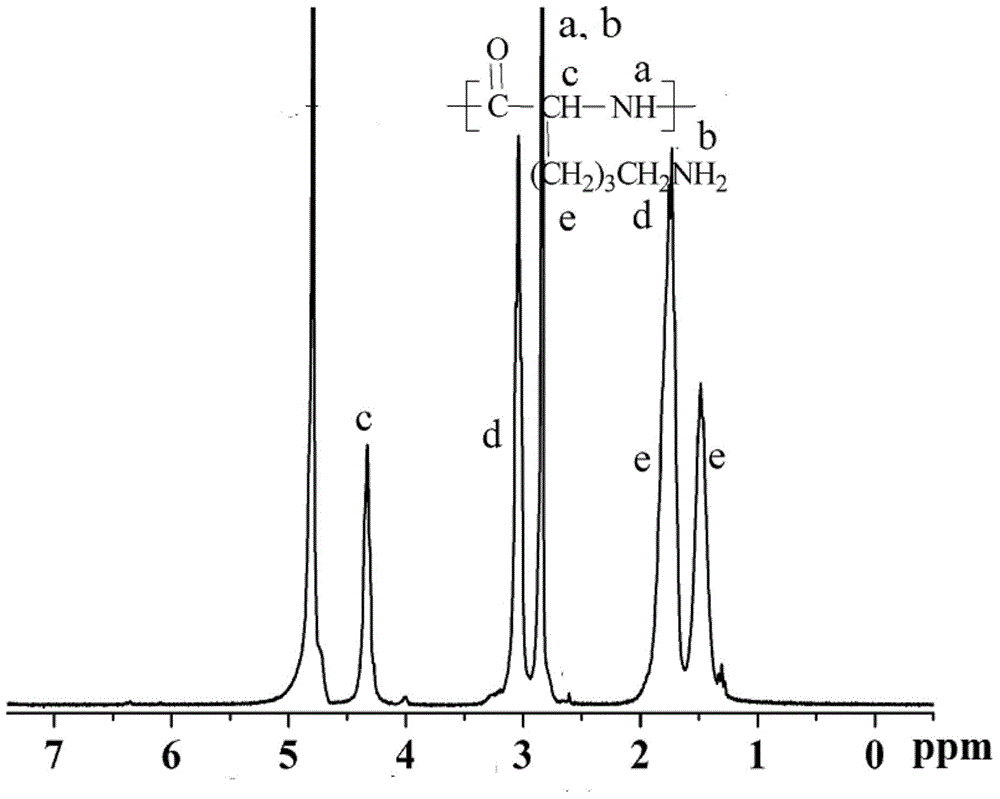

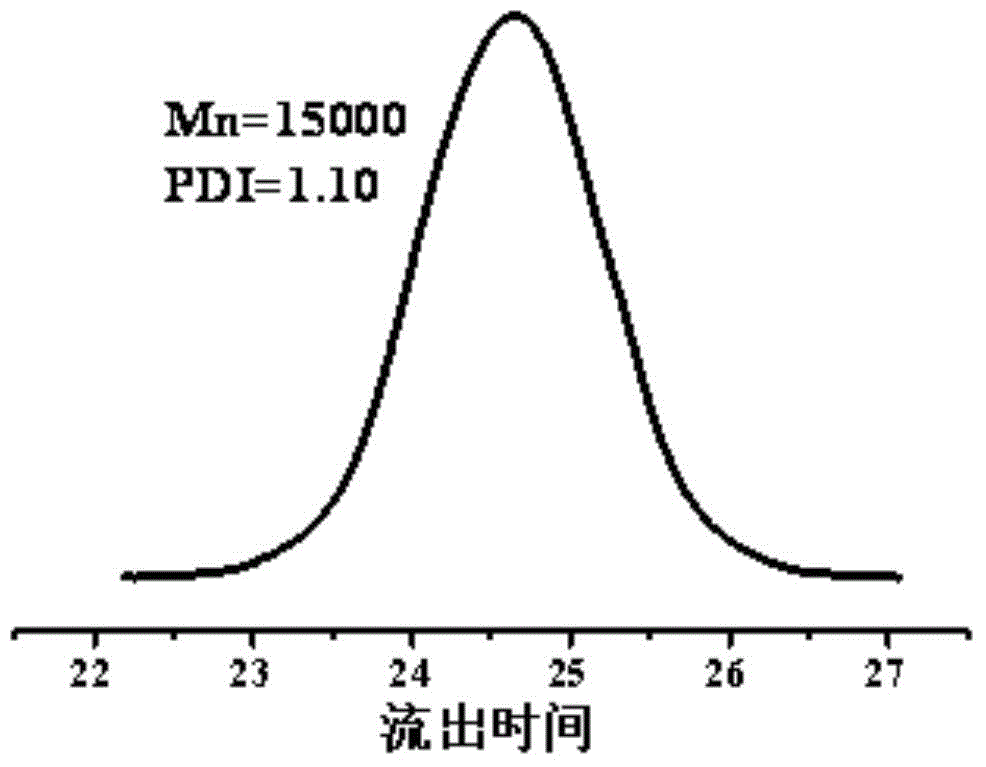

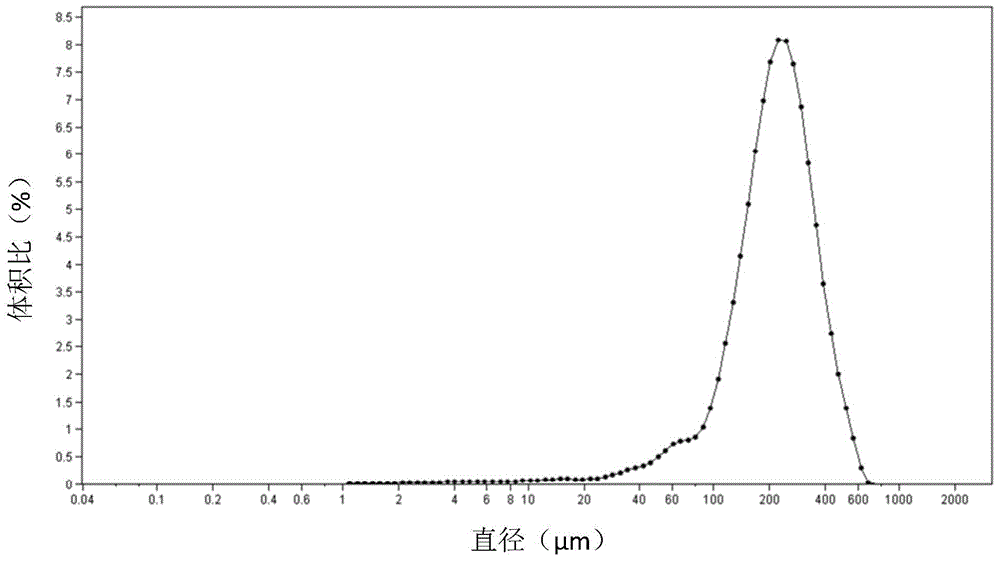

Block polymer, drug carrier containing same, and preparation method and application of block polymer

ActiveCN107298741AMolecular weight controllableNarrow molecular weightPharmaceutical non-active ingredientsIn-vivo testing preparationsTumor targetTumor targeting

The invention discloses a block polymer, a drug carrier containing the same, and a preparation method and application of the block polymer. According to the block polymer, a copolymer with controllable copolymerization components, controllable molecular weight and narrow molecular weight distribution (the molecular weight distribution d<1.2) are obtained by adopting ring-opening polymerization (ROP) and reversible addition fragmentation chain transfer (RAFT) or atom transfer radical polymerization (ATRP) method. The drug carrier prepared from the polymer has relatively good slow release and tumor passive targeting effects, so that the polymer can be applied to targeting transportation of anti-tumor drugs; and the polymer has a high targeting property and good biocompatibility and is an anti-tumor targeting drug carrier with good performance.

Owner:BEIJING UNIV OF CHEM TECH

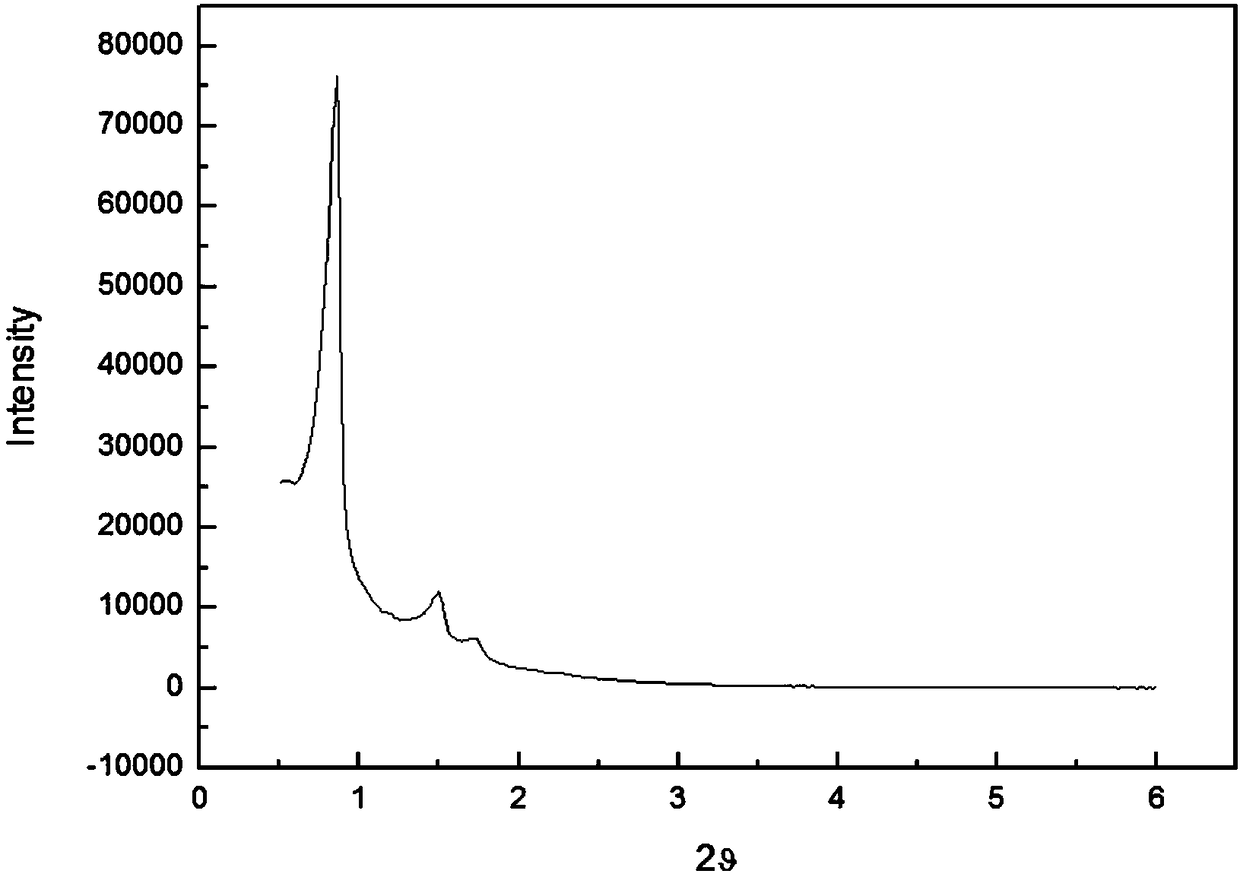

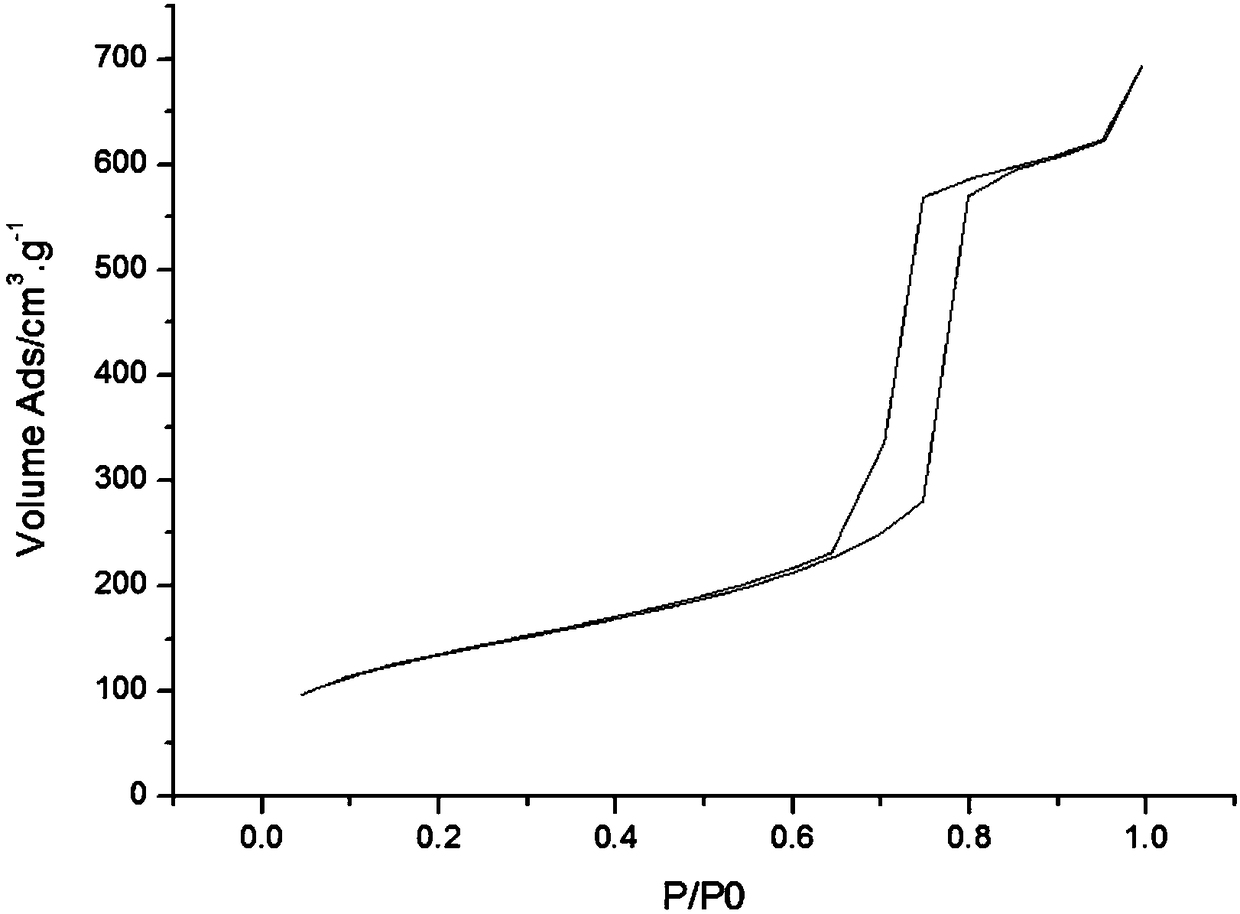

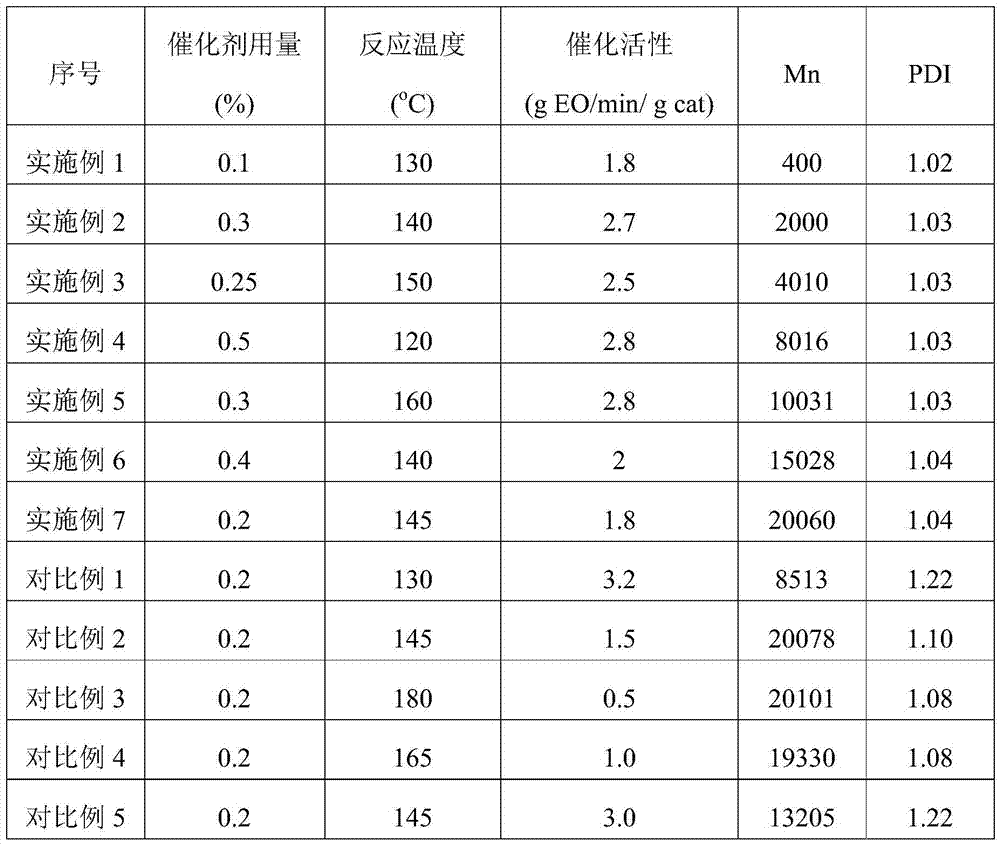

Preparation and application of Al-SBA-15 mesoporous molecular sieve and fatty alcohol ethoxylation reaction method

ActiveCN108187726ALarge specific surface areaOrdered microstructureMolecular sieve catalystsEther preparation from oxiranesMolecular sieveReaction temperature

The invention discloses a preparation method of an Al-SBA-15 mesoporous molecular sieve, application of the Al-SBA-15 mesoporous molecular sieve as a catalyst, and a method for catalyzing ethoxylationreactions of fatty alcohol. The fatty alcohol ethoxylation reaction method comprises the following steps: dispersing the Al-SBA-15 mesoporous molecular sieve into a certain amount of fatty alcohol, putting a dispersion liquid into a high-pressures kettle, performing nitrogen replacement, after the reaction temperature is 110-130 DEG C, adding ethylene oxide in batches, adding the ethylene oxide till the initial reaction pressure is 0.6-1.0 MPa each time, and cooling and discharging materials after reactions are completed. The Al-SBA-15 mesoporous molecular sieve catalyst prepared by using themethod has a relatively large specific surface area and an ordered microstructure, is good in catalysis activity, is narrow in catalyst product molecular weight distribution and can be repeatedly used.

Owner:JIANGSU SAILBOAT PETROCHEMICAL CO LTD +1

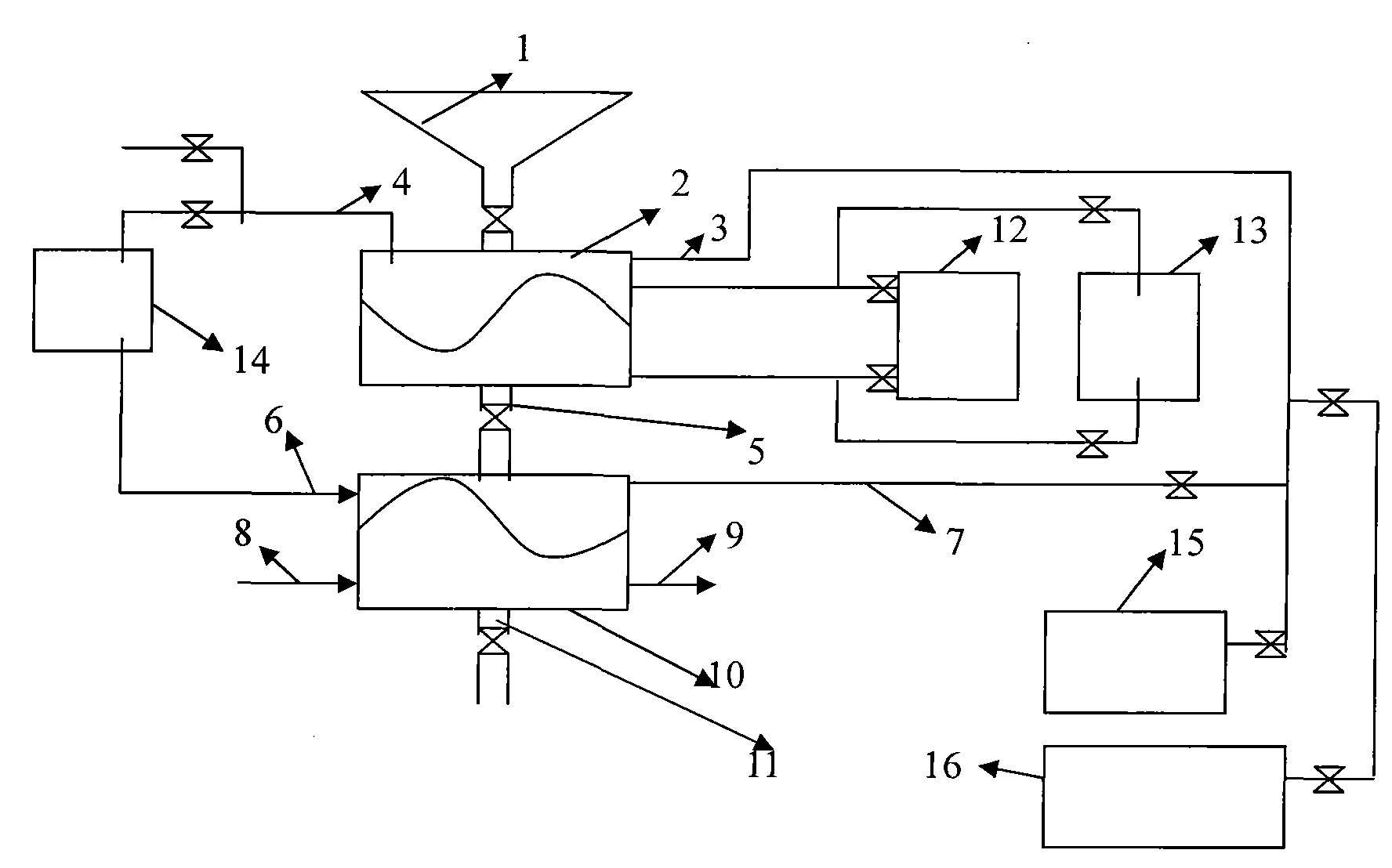

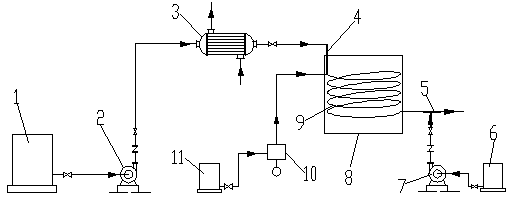

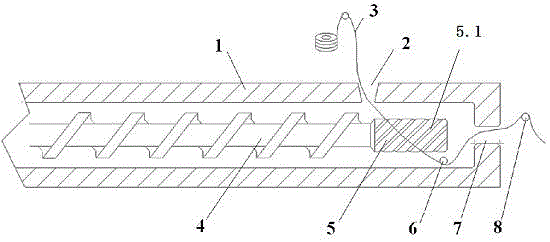

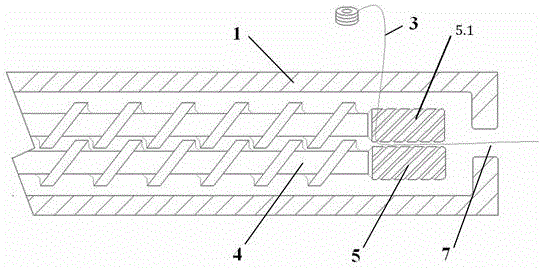

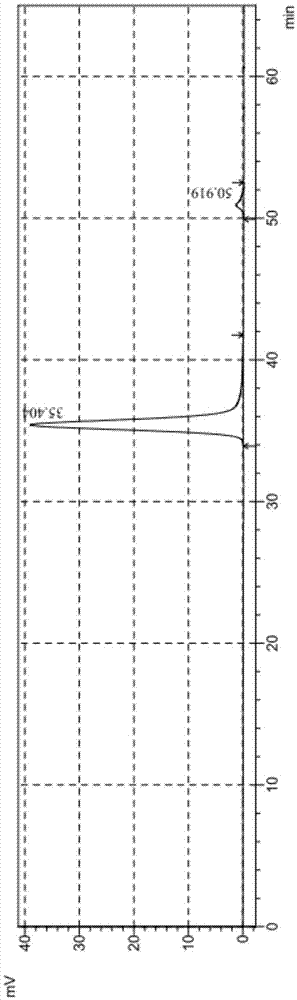

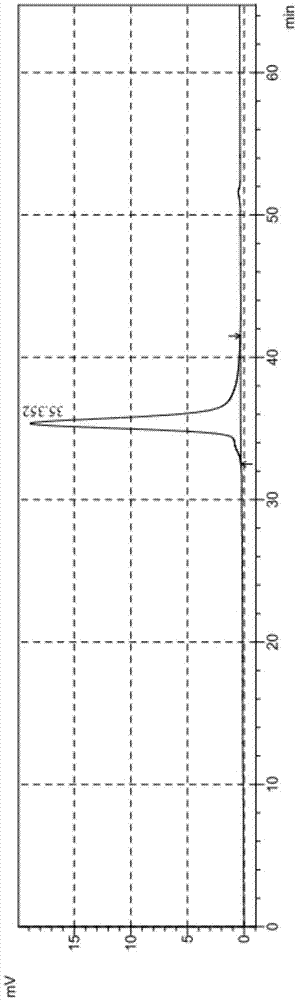

Preparation system and preparation method for polyisobutylene

The invention discloses a preparation system and a preparation method for polyisobutylene. The system comprises an isobutylene storage tank, a catalyst storage tank, a termination agent storage tank, a rapid mixer, a static mixing tube type polymerization reactor and a rapid reaction termination mixer. The isobutylene storage tank is connected to an isobutylene cooler through a pipeline and a raw material delivery pump. The isobutylene cooler is in pipeline connection with a raw material inlet of the rapid mixer. The catalyst storage tank is connected to the catalyst inlet of the rapid mixer through a pipeline and a catalyst metering pump. The outlet of the rapid mixer is communicated with the inlet of the static mixing tube type polymerization reactor, the outlet of which is communicated with the reaction feed inlet of the rapid reaction termination mixer. The termination agent storage tank is connected to the termination agent inlet of the rapid reaction termination mixer through a pipeline and a termination agent delivery pump. The static mixing tube type polymerization reactor is located in a constant temperature brine bath groove. The system provided by the invention has the advantages of uniform reaction temperature, narrow molecular weight distribution of polyisobutylene, and controllable molecular weight, etc.

Owner:HEBEI UNIVERSITY OF SCIENCE AND TECHNOLOGY

Prepolymer containing mixture of C10, C15, C20 olefin, preparation and application thereof

ActiveCN100513528CHigh yieldHigh softening pointLiquid hydrocarbon mixtures productionAdhesive cementPolymer science

The invention relates to a method for preparing a prepolymer containing C10, C15, and C20 olefins by using ethylene cracking C5 fractions as raw materials. , carry out Diels-Alder reaction at a pressure of 1.0-12.0 MPa for 3-12 hours, then cool down and discharge the material, and rectify to remove unreacted C5 components to obtain a prepolymer containing a mixture of C10, C15, and C20 olefins. The C5 petroleum resin produced by the prepolymer prepared by the method of the present invention has a narrow molecular weight distribution, can improve the compatibility of the resin with other hot-melt adhesive substrates SIS, SBS, EVA, greatly expands the scope of use of the petroleum resin, and can It is widely used in adhesives, coatings, inks, asphalt, rubber tires and other fields; at the same time, it can effectively improve the utilization rate of polymerizable olefins in C5 fractions.

Owner:SINOPEC LANZHOU GASOLINEEUM CHEM IND CORP

Continuous long glass fiber reinforced PBT composite material and preparation method thereof

The invention relates to a continuous long glass fiber reinforced PBT composite material. The composite material is prepared from, by mass, 40-80 parts of PBT resin, 20-50 parts of long glass fiber, 1-4 parts of a flow modifier, 2-6 parts of a flexibilizer, 1-3 parts of a nucleating agent, 0.3-0.6 parts of an antioxidant, 0.3-1 part of a lubricant, 0.1-1 part of diisocyanate or polyisocyanate and 0-5 parts of POE. The long glass fiber reinforced PBT composite material prepared in the invention has the advantages of excellent mechanical performances and good temperature tolerance, and the corresponding preparation method has the advantages of simplicity, no obvious increase of the production cost, and substantial economic benefit, and is worth to be popularized and applied.

Owner:JIANGYIN POLYTECHNIC COLLEGE

Composite calcium-based catalyst and application thereof

ActiveCN106905522ARaw materials are cheap and easy to getHigh activityPolyethylene glycolOperability

The invention discloses a composite calcium-based catalyst and an application thereof. The composite calcium-based catalyst comprises the following components in percent by weight: 10%-40% of alkali metal hydroxide, 40%-80% of calcium salt and 10%-30% of cocatalyst. The composite calcium-based catalyst can be used for preparing polyethylene glycol with the molecular weight of more than 8000, is simple in process, strong in operability, easy in implementation, fast in reaction speed, and is beneficial to large-scale industrial production; simultaneously, the molecular weight of the prepared polyethylene glycol is accurate in control and narrow in molecular-weight distribution, no residual toxic metal ions are generated, so that the safety is good; in addition, the composite calcium-based catalyst has the advantages that the material is low in price, the activity is high and the induction period is short.

Owner:SHANGHAI DONGDA CHEM

Preparation method of multi-arm acrylate block copolymer

The invention relates to a preparation method of multi-arm acrylate block copolymer. The preparation method includes the steps of preparing hydroxyl terminated acrylate macromolecular initiator, preparing hydroxyl terminated acrylate block copolymer and preparing the multi-arm acrylate block copolymer. The preparation method has the advantages that an ARGET ATRP method is adopted to synthesize the multi-arm acrylate block copolymer, so that composition and structure of arms can be controlled accurately; dispersity of the copolymer is controlled through ATRP, so that regularity of the block copolymer is improved greatly, and product yield is increased; polymerization reaction can be performed in relatively open space, amount of catalyst is smaller than 500ppm, and the product can be used directly without removing the catalyst, and the preparation method is high in efficiency and low in cost as compared with conventional methods; reaction of hydroxy and isocyanate base is utilized to connect the arms on polyisocyanate in a keyed manner to form a multi-arm structure using polyisocyanate as the center and acrylate block copolymer as the arms; an arm-first core-second method is utilized to simplify the process and implementation.

Owner:CHANGZHOU UNIV

Process for producing polyester ether poly- or mono-ol

To provide a process for producing a polyester ether poly- or mono-ol having a narrow molecular weight distribution, which is obtained by copolymerizing an initiator having hydroxyl groups with a cyclic ester compound and an alkylene oxide.It is possible to produce a polyester ether poly- or mono-ol having a molecular distribution (Mw / Mn) of from 1.02 to 1.4 by copolymerizing a cyclic ester compound which carbon number is from 3 to 9 and an alkylene oxide which carbon number is from 2 to 20 with an initiator having from 1 to 12 hydroxyl groups and having a number average molecular weight (Mn) of from 18 to 20,000 in the presence of a double-metal cyanide complex catalyst is having tert-butyl alcohol as at least a part of an organic ligand.

Owner:ASAHI GLASS CO LTD

Synthetic method of saccharide-containing copolymer with biological specific recognition performance

InactiveCN110283286ASolve protection problemsSolve yieldColor/spectral properties measurementsSynthesis methodsSolvent

The invention relates to a synthetic method of a saccharide-containing copolymer with biological specific recognition performance. The synthetic method comprises following steps: in an inert atmosphere, alpha-D-mannose monomer M1 and Grubbs third-generation catalyst are reacted in a solvent; beta-D-galactose monomer M2 is added for reaction; ethyl vinyl ether is added to stop polymerization, and post-treatment is carried out so as to obtain a segmented copolymer containing alpha-D-mannose and beta-D-galactose. Compared with the prior art, the polymer monomer synthetic method is simple and reliable; the obtained polymer structure is linear; the molecular weight is controllable; and the synthetic method can be applied in the fields such as high molecular material and biological medicine engineering.

Owner:SHANGHAI INST OF TECH

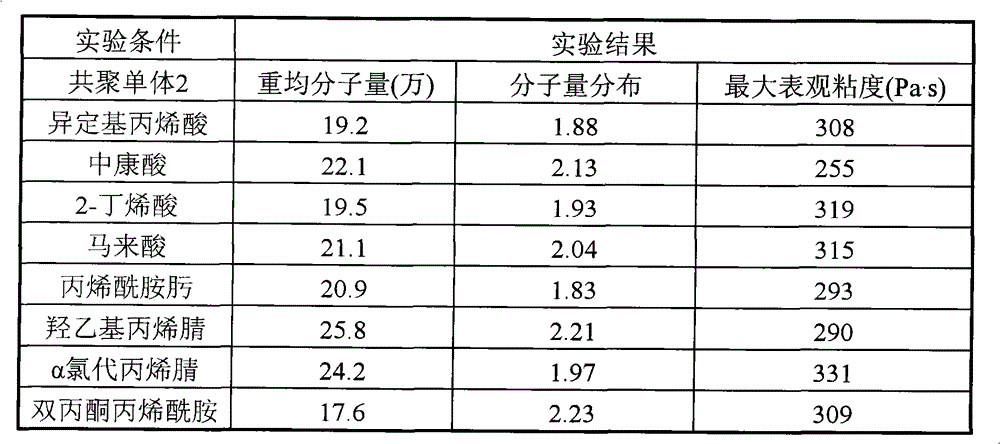

Method for preparing polyacrylonitrile spinning solution for high-performance carbon fiber in ionic liquid

ActiveCN101759837BHigh solid contentImprove performanceFibre chemical featuresBulk chemical productionPolymer scienceCarbon fibers

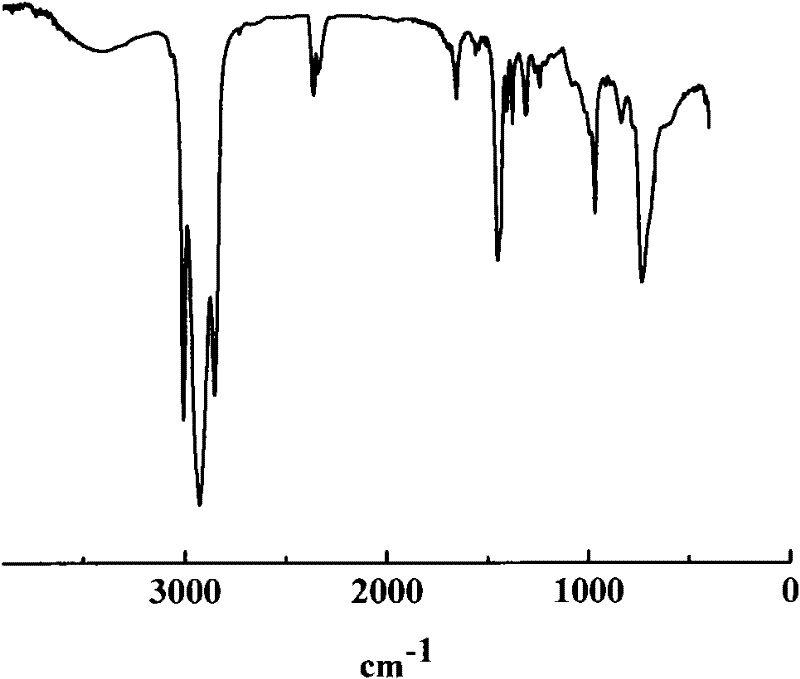

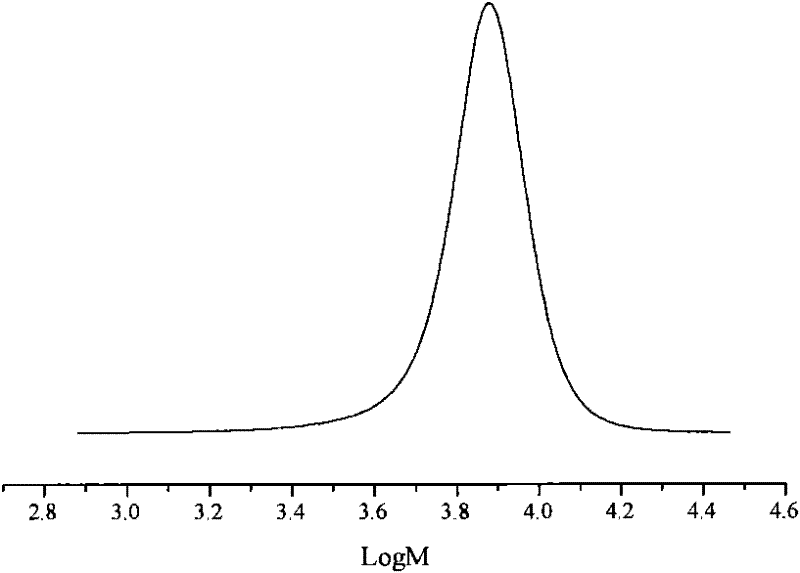

The invention relates to a method for a preparing polyacrylonitrile spinning solution for a high-performance carbon fiber in an ionic liquid. The method comprises the following steps: sequentially adding a monomer in an acrylonitrile binary copolymerization system or a monomer in an acrylonitrile ternary polymerization system into the ionic liquid, dissolving at the room temperature, adding an evocating agent, and charging inactive gas for free radical polyreaction, stopping the polyreaction with ice-bath after reaction, solidifying the polymerisate with water and obtaining the polyacrylonitrile material after repeated water rinsing, oven drying and purification, and mixing to dissolve the obtained polyacrylonitrile powder material with dimethyl sulfoxide as the solution, thereby obtaining the polyacrylonitrile spinning solution with high-performance carbon fiber. In the method, the ionic liquid is used as the reaction solvent, with a wide melting point range, thereby facilitating thecontrol of the polymerization temperature, and greatly speeding up the polymerization; and the obtained polyacrylonitrile has high molecular weight and narrow molecular weight distribution, thereby facilitating the preparation of the polyacrylonitrile precursor with stable performance for carbon fiber, improving the productivity and reducing the cost.

Owner:ZHONGFU SHENYING CARBON FIBER

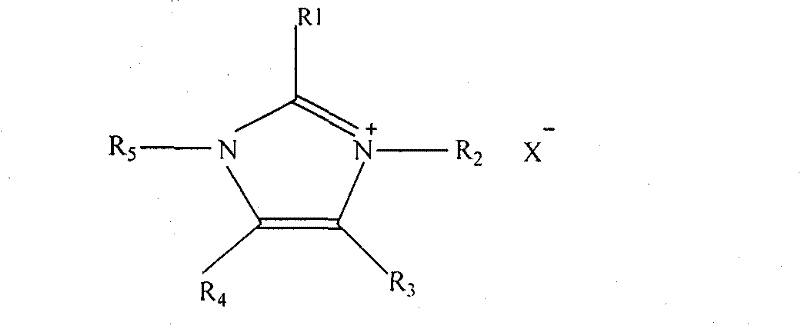

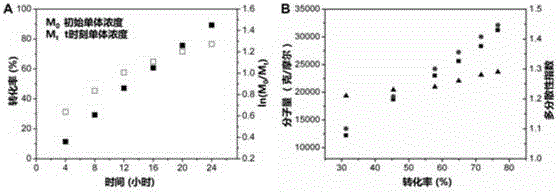

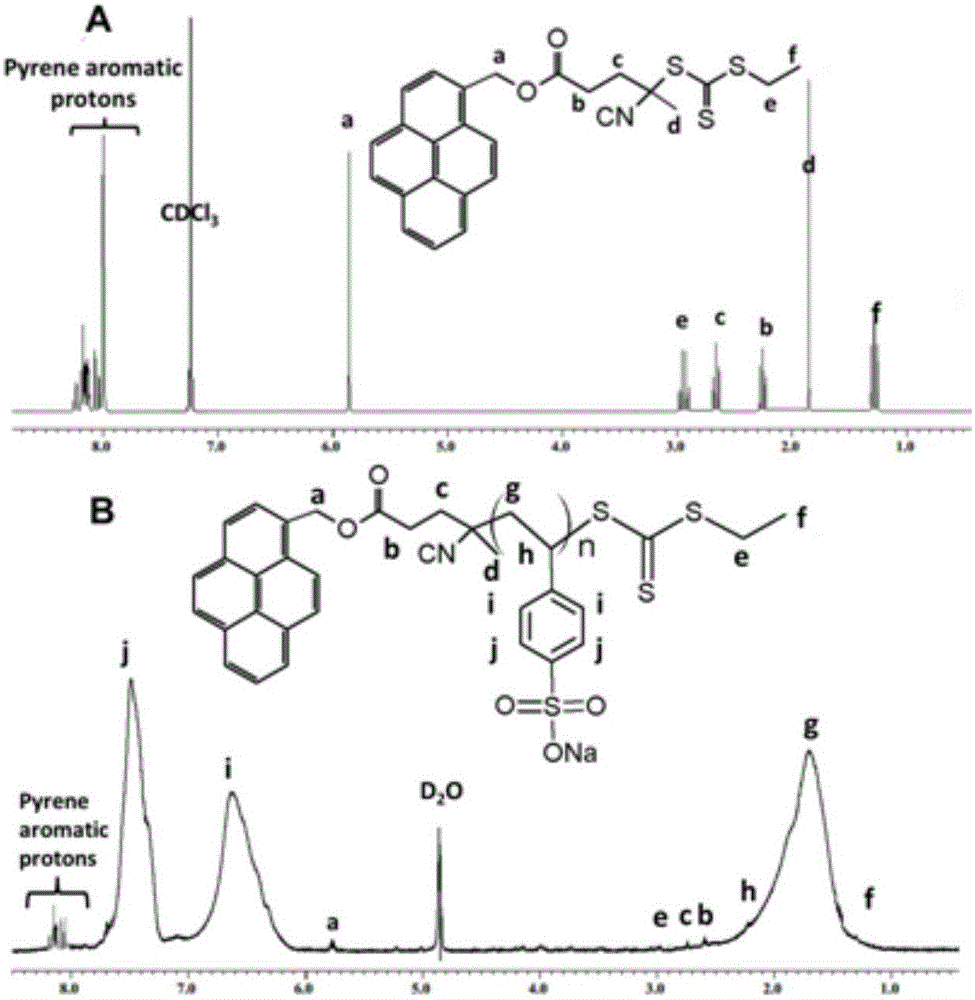

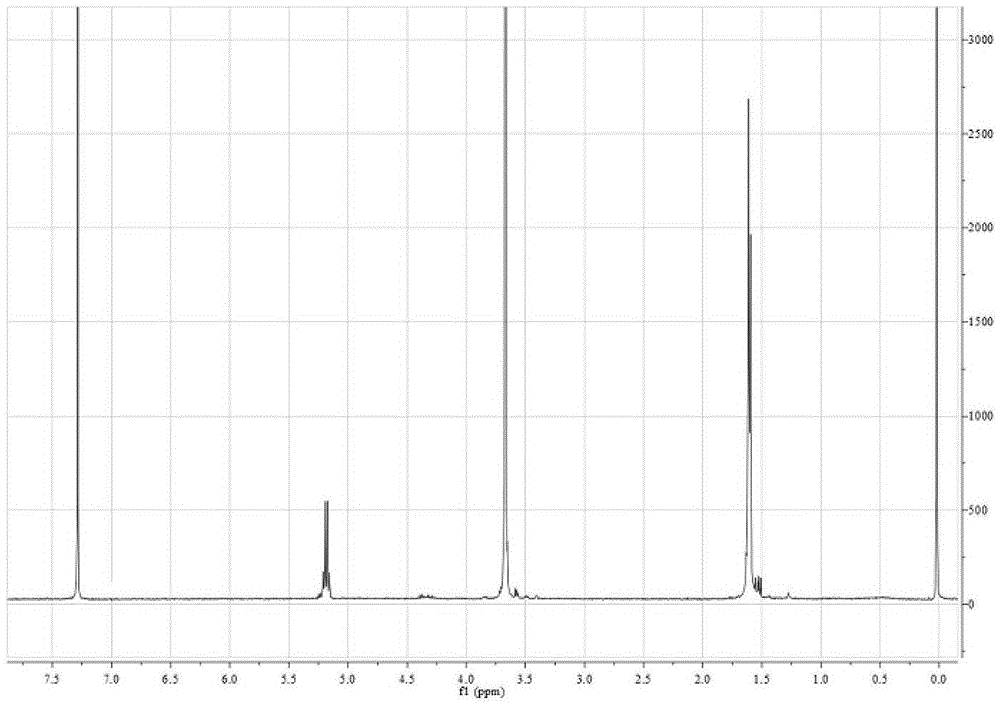

Method for synthesizing poly(sodium-styrenesulfonate) with terpyridyl ruthenium initiator

InactiveCN105884943ASuccessfully synthesizedNarrow molecular weightChemical synthesisControllability

The invention belongs to the technical field of chemical synthesis and relates to a method for synthesizing PSS (poly(sodium-styrenesulfonate)) with uniform molecular weight and controllability by polymerization of reversible addition fragmentation chain transfer (RAFT) based on terpyridyl ruthenium serving as a photoinitiator. The method comprises: preparing PSS mainly from 4-cyano-4-ethyltrithiopentanoic acid, sodium p-styrenesulfonate and terpyridyl ruthenium, using pyrenemethanol, 4-cyano-4-ethyltrithiopentanoic acid (CETP), dicyclohexylcarbodiimide (DCC), 4-dimethylaminopyridine (DMAP) and tetrahydrofuran (THF) to prepare a functionalized RAFT reagent (4-cyano-4-ethyltrithiopentanoic acid CETP), and the using the functionalized RAFT reagent (4-cyano-4-ethyltrithiopentanoic acid CETP) to prepare PSS. The preparation process is simple, preparation efficiency is high, product quality is good, product stability is high, and a product is friendly to application environments.

Owner:QINGDAO UNIV

Nitrogen-bridged bis(phenolate) yttrium dibenzyl oxygen compound and preparation and application thereof

InactiveCN101591349ANarrow molecular weight distributionHigh molecular weightGroup 3/13 element organic compoundsOxygen compoundYttrium

The invention discloses a nitrogen-bridged bis(phenolate) yttrium dibenzyl oxygen compound and preparation and application thereof. A bridged bis(phenolate) lanthanide complex is the nitrogen-bridged bis(phenolate) yttrium dibenzyl oxygen compound, of which the chemical formula is p-C6H4[CH2OYL(THF)]2, wherein Y refers to lanthanide yttrium; and L refers to a nitrogen-bridged bis(phenolate) complex; L=Me2NCH2CH2N{CH2-(2-O-C6H2-R-3,5)}2, wherein 3 position and 5 position of an aromatic ring are provided with alkyl group substituents R, and R is selected from C1-C4 saturated alkyl. The double active center type nitrogen-bridged bis(phenolate) yttrium dibenzyl oxygen compound is synthesized simply and conveniently, not only can be used as a single-component catalyst under a mild condition to catalyze ring opening polymerization of epsilon-Hexalactone and L-lactide controllably with high activity, but also can initiates copolymerization of the two monomers to generate ABA type block copolymer.

Owner:SUZHOU UNIV

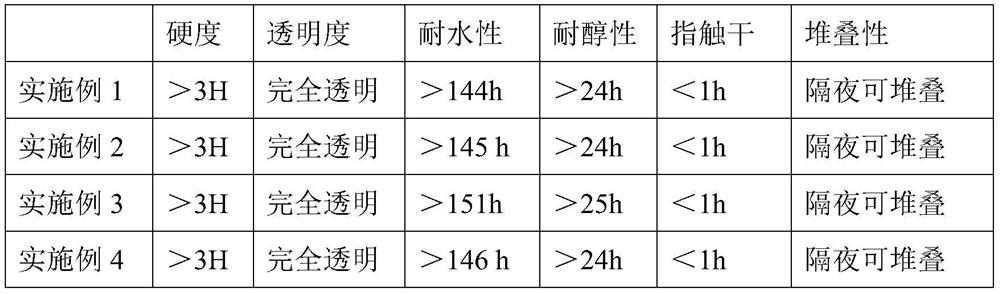

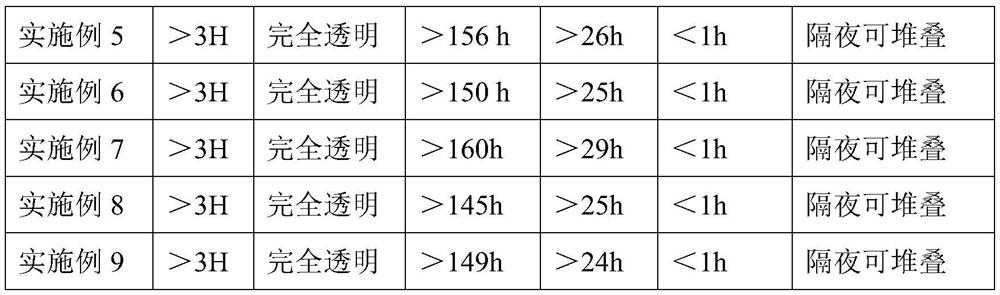

Water-based organic silicon modified cationic acrylic resin and synthesis method thereof

The invention discloses water-based organic silicon modified cationic acrylic resin and a synthesis method. The water-based organic silicon modified cationic acrylic resin is prepared from the following raw materials: a monomer, a functional monomer, a solvent, acid, a chain transfer agent and an initiator, wherein the monomer comprises, by weight, 100-400 parts of methyl methacrylate, 5-50 partsof butyl acrylate and 20-200 parts of styrene, the functional monomer comprises, by weight, 10-100 parts of vinyltriethoxysilane, 20-200 parts of dimethylaminoethyl methacrylate and 30-250 parts of hydroxyethyl acrylate, the solvent comprises, by weight, 100-400 parts of propylene glycol monomethyl ether, 50-400 parts of absolute ethyl alcohol and 20-200 parts of N, N-dimethylformamide, the acid is 5-60 parts by weight of lactic acid, the chain transfer agent is 1-50 parts by weight of a methyl styrene linear dimer, and the initiator is 1-50 parts by weight of azodiisobutyronitrile. The invention solves the fundamental problems of unsatisfactory hardness, transparency, solvent resistance and other properties, high cost and the like of the traditional water-based wood paint, can completelyreplace the oil-based PU wood paint, and can generate great advantages for environmental beautification without losing the properties under the large situation of environmental protection.

Owner:HUBEI JIADE PUAN PAINT

A kind of preparation method of biodegradable polylactic acid-polyethylene glycol block copolymer

ActiveCN103980466BImprove controllabilityNarrow molecular weightSimple Organic CompoundsPolymer science

The invention discloses a preparation method for a biodegradable polylactic acid-polyethylene glycol block copolymer. The preparation method comprises the following steps: dissolving polyethylene glycol (PEG) or methoxy polyethylene glycol (mPEG) in anorganic solvent, in the presence of active metal and organic compound naphthalene, adding lactide, reacting for a period of time under a protective atmosphere, adding acid to end the reaction, and purifying so as to obtain the polylactic acid-polyethylene glycol block copolymer. The method uses an anionic polymerization mechanism for preparing the polylactic acid-polyethylene glycol block copolymer, the molecular weight has better controllability, the distribution of the molecular weight is narrow, the reaction temperature is low, and side effects are few.

Owner:苏州岸谷纳米技术有限公司

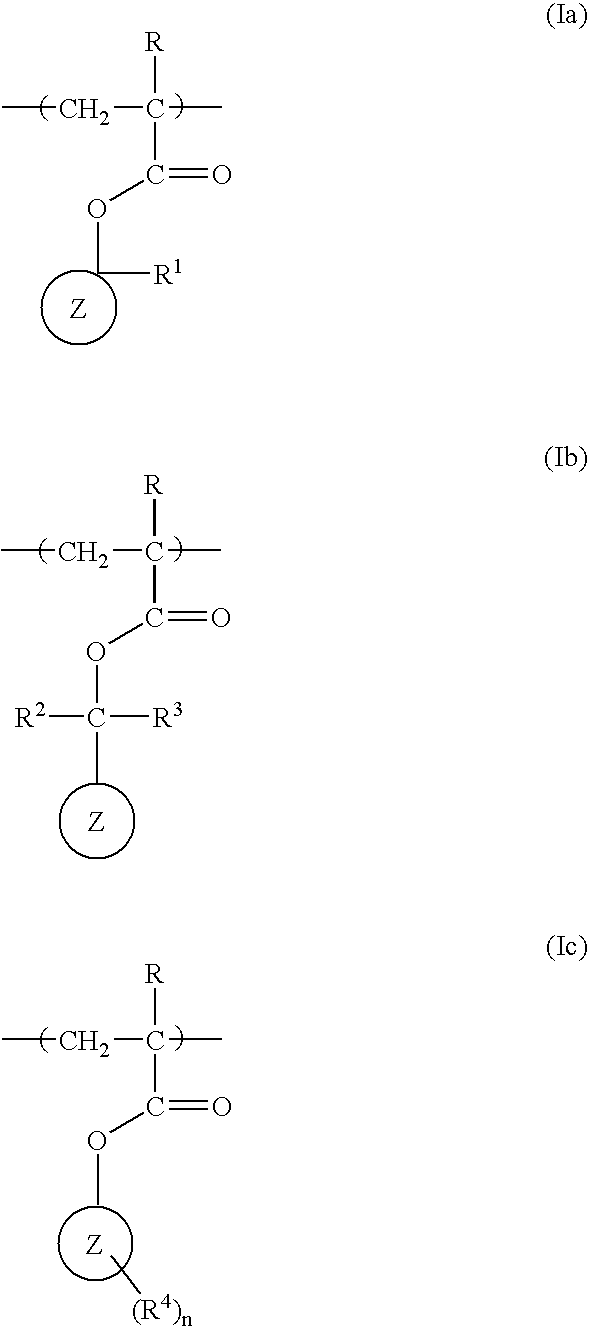

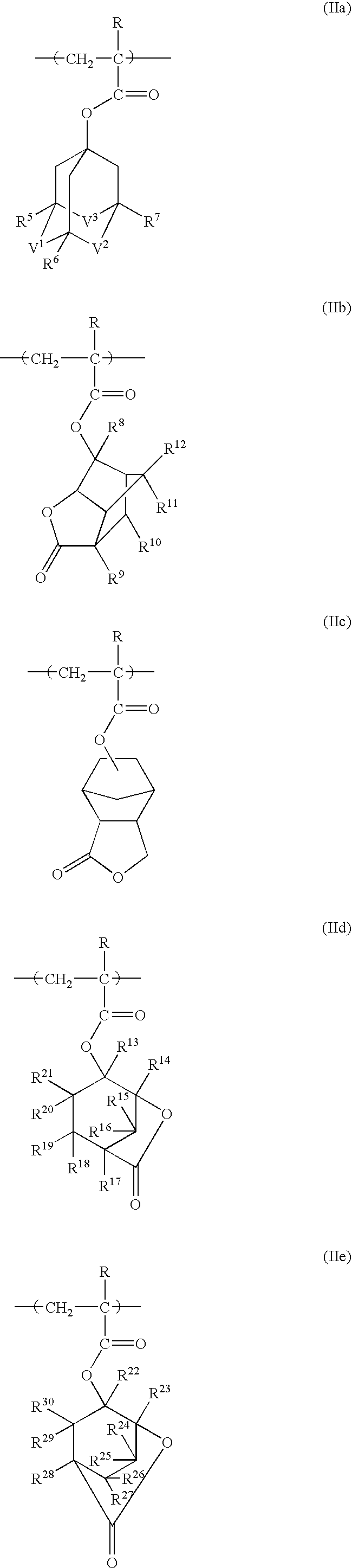

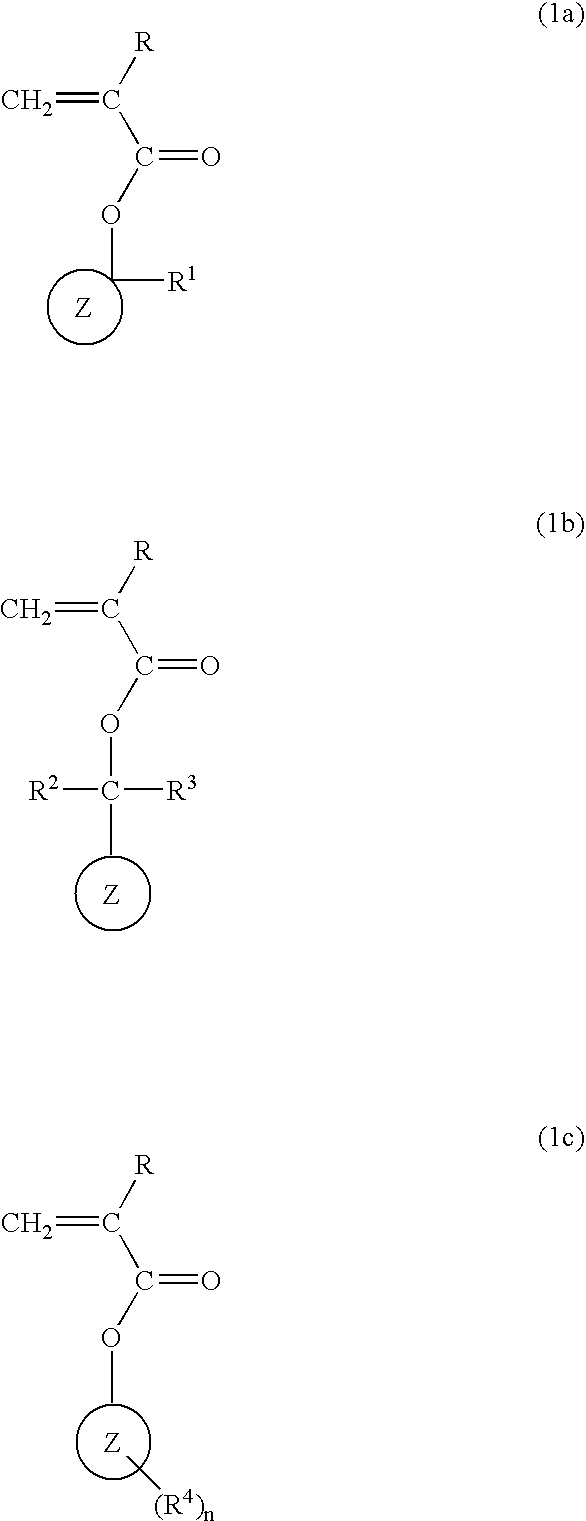

Photoresist resin and photoresist resin composition

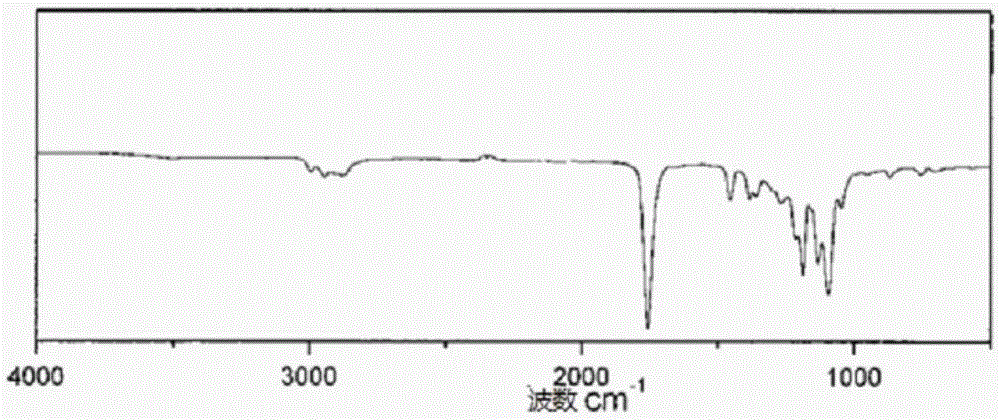

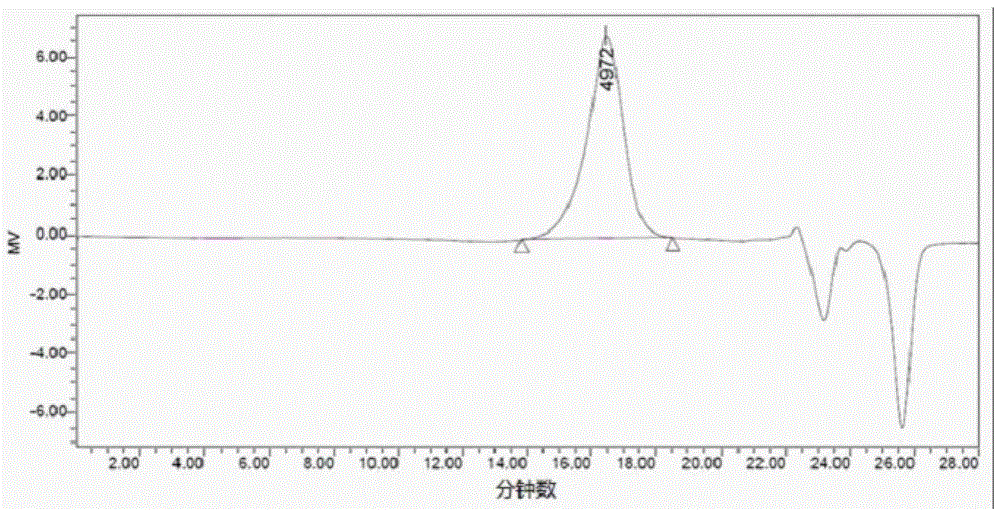

InactiveUS20050238990A1Narrow molecular weightReduce contentPhotomechanical apparatusSilver halide emulsionsElectrical polarityPhotoresist

A photoresist resin of the invention contains at least a constitutional repeating unit A containing a group capable of partially leaving by the action of an acid to thereby become soluble in an alkali, and a constitutional repeating unit B containing an alicyclic skeleton having a polar group, and has a weight-average molecular weight of 3000 to 15000 and has a content of polymer fractions each having a molecular weight exceeding 40000 of 4 percent by weight or less of the total resin. The molecular weight distribution (Mw / Mn) of the resin is, for example, from about 1.1 to about 3.0, and preferably from about 1.5 to about 2.5.

Owner:DAICEL CHEM IND LTD

Method for preparing polyacrylonitrile spinning solution for high-performance carbon fiber in ionic liquid

ActiveCN101759837AHigh solid contentImprove performanceFibre chemical featuresBulk chemical productionCarbon fibersPolymer science

The invention relates to a method for a preparing polyacrylonitrile spinning solution for a high-performance carbon fiber in an ionic liquid. The method comprises the following steps: sequentially adding a monomer in an acrylonitrile binary copolymerization system or a monomer in an acrylonitrile ternary polymerization system into the ionic liquid, dissolving at the room temperature, adding an evocating agent, and charging inactive gas for free radical polyreaction, stopping the polyreaction with ice-bath after reaction, solidifying the polymerisate with water and obtaining the polyacrylonitrile material after repeated water rinsing, oven drying and purification, and mixing to dissolve the obtained polyacrylonitrile powder material with dimethyl sulfoxide as the solution, thereby obtaining the polyacrylonitrile spinning solution with high-performance carbon fiber. In the method, the ionic liquid is used as the reaction solvent, with a wide melting point range, thereby facilitating the control of the polymerization temperature, and greatly speeding up the polymerization; and the obtained polyacrylonitrile has high molecular weight and narrow molecular weight distribution, thereby facilitating the preparation of the polyacrylonitrile precursor with stable performance for carbon fiber, improving the productivity and reducing the cost.

Owner:ZHONGFU SHENYING CARBON FIBER

Preparation method of anti-microbial star type poly-polypeptide

ActiveCN105085905AEasy to implementEasy to purifyAntibacterial agentsOrganic active ingredientsGramAntibacterial activity

The invention relates to the technical field of anti-microbial materials, in particular to a preparation method of anti-microbial star type poly-polypeptide. According to the method, an arm-first method is adopted, an N-carboxyl-alpha-amino anhydride polymerization method (NCA polymerization method) serves as a measure, and the three-arm star type poly-polypeptide with the controllable molecular structure is synthesized. The artificial macromolecule anti-microbial agent has the efficient targeted anti-microbial property, is not prone to degradation and has good anti-microbial activity for gram negative and gram-positive bacteria. In addition, no drug-resistant bacterium is caused by the macromolecule anti-microbial agent, and the macromolecule anti-microbial agent cannot permeate into the skin and the pores of the human body and is an ideal substitute object for antibiotic drugs.

Owner:UNIV OF SCI & TECH OF CHINA

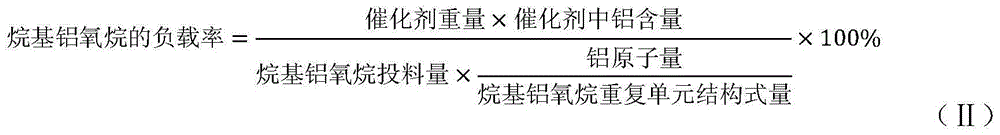

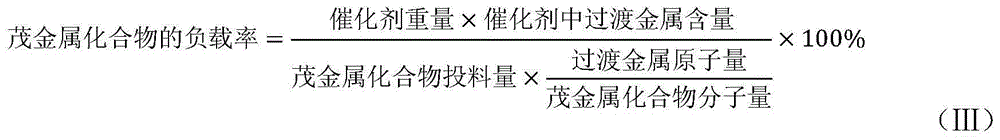

Polyethylene powder, composition, cross-linked polyethylene pipe and preparation methods of polyethylene powder and cross-linked polyethylene pipe

InactiveCN105482016ANarrow molecular weightNarrow molecular weight distributionPolymer scienceAluminoxane

The present invention discloses polyethylene powder, a composition, a cross-linked polyethylene pipe and preparation methods of the polyethylene powder and the cross-linked polyethylene pipe. The polyethylene powder preparation method comprises that under the co-effect of a supported non-metallocene olefin polymerization catalyst and a co-catalyst, in the presence or absence of hydrogen, ethylene and alpha-olefin are subjected to slurry polymerization in an organic solvent, wherein the co-catalyst is one or a plurality of materials slected from an alkyl aluminum compound, a halogenated alkyl aluminum compound and alkyl aluminoxane. According to the present invention, the cross-linking degree of the obtained cross-linked polyethylene pipe can achieve more than or equal to 90%, the compression resistance can achieve and exceed the national standard related requirements, and the test results through the experiment examples show that the polyethylene powder prepared of the present invention has good environmental stress cracking resistance compared to the ethylene copolymer raw material prepared by using the existing technology.

Owner:SHANGHAI INST OF ORGANIC CHEM CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com