Patents

Literature

495 results about "Ammonium sulfite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ammonium sulfite is the ammonium salt of sulfurous acid with the chemical formula (NH₄)₂SO₃.

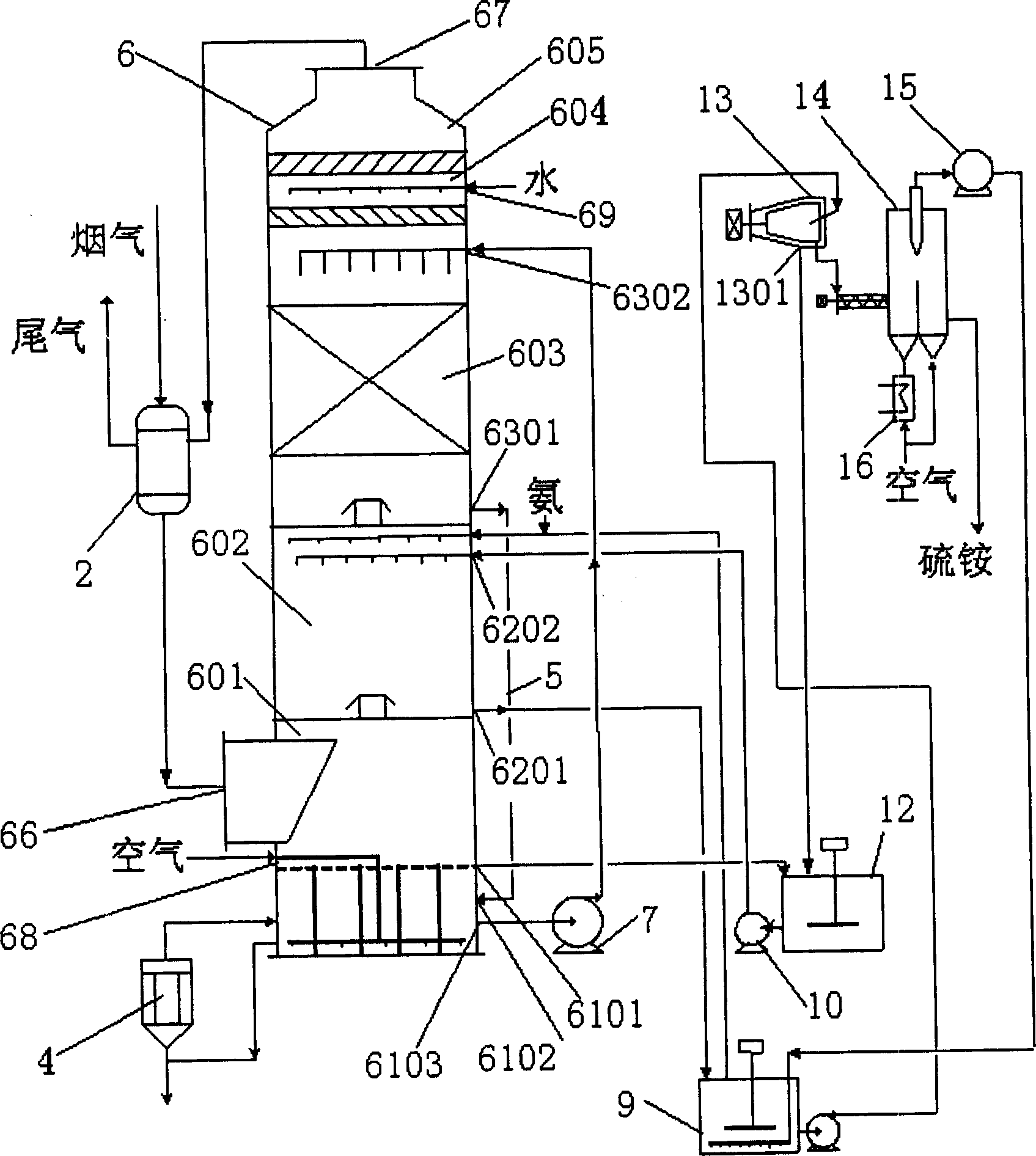

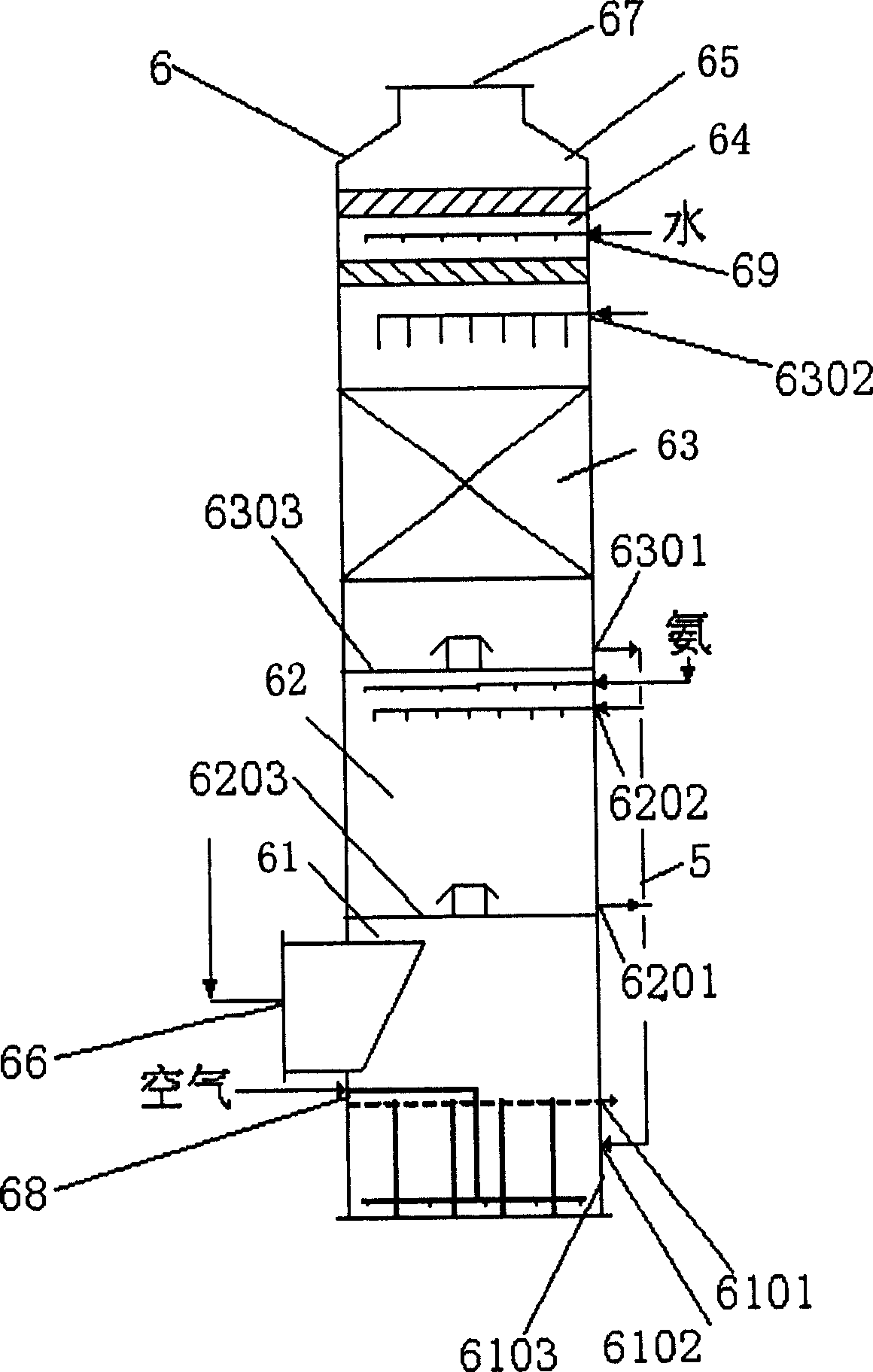

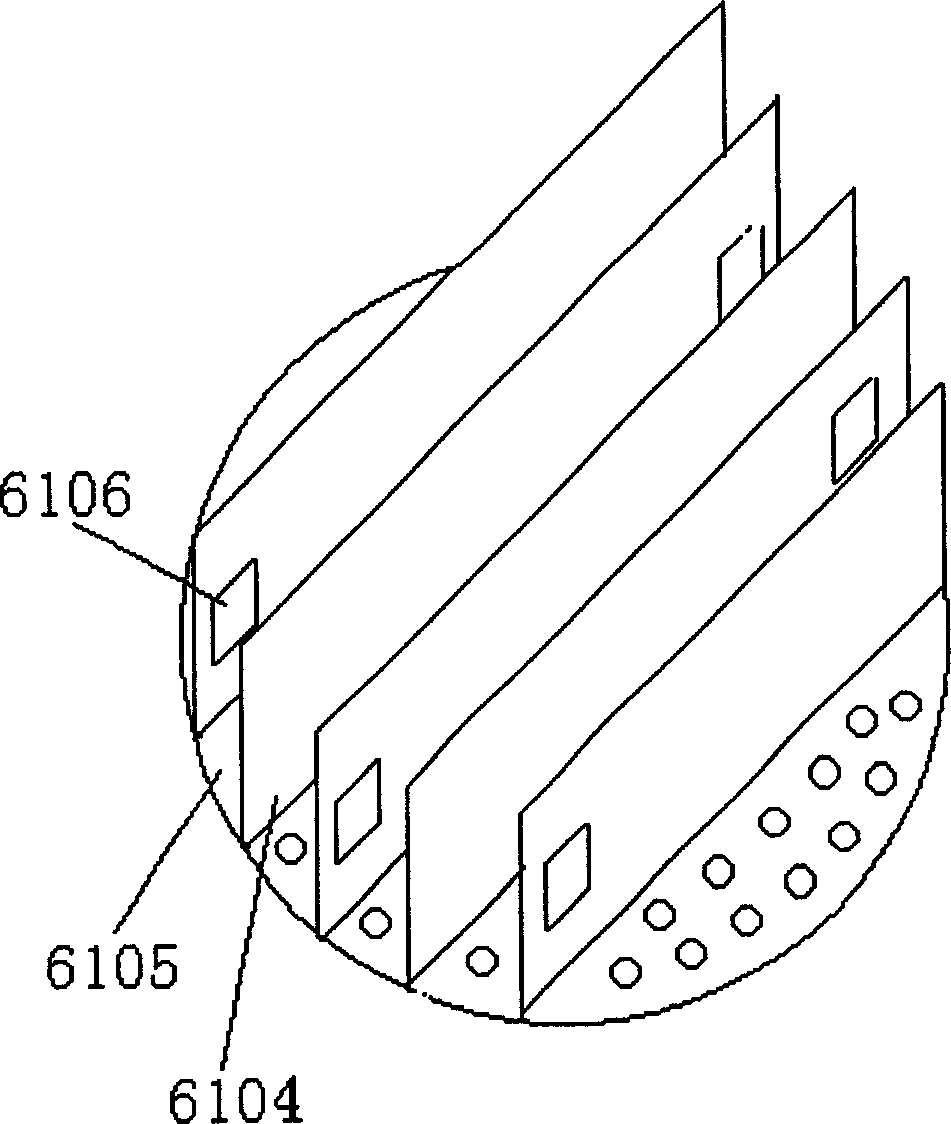

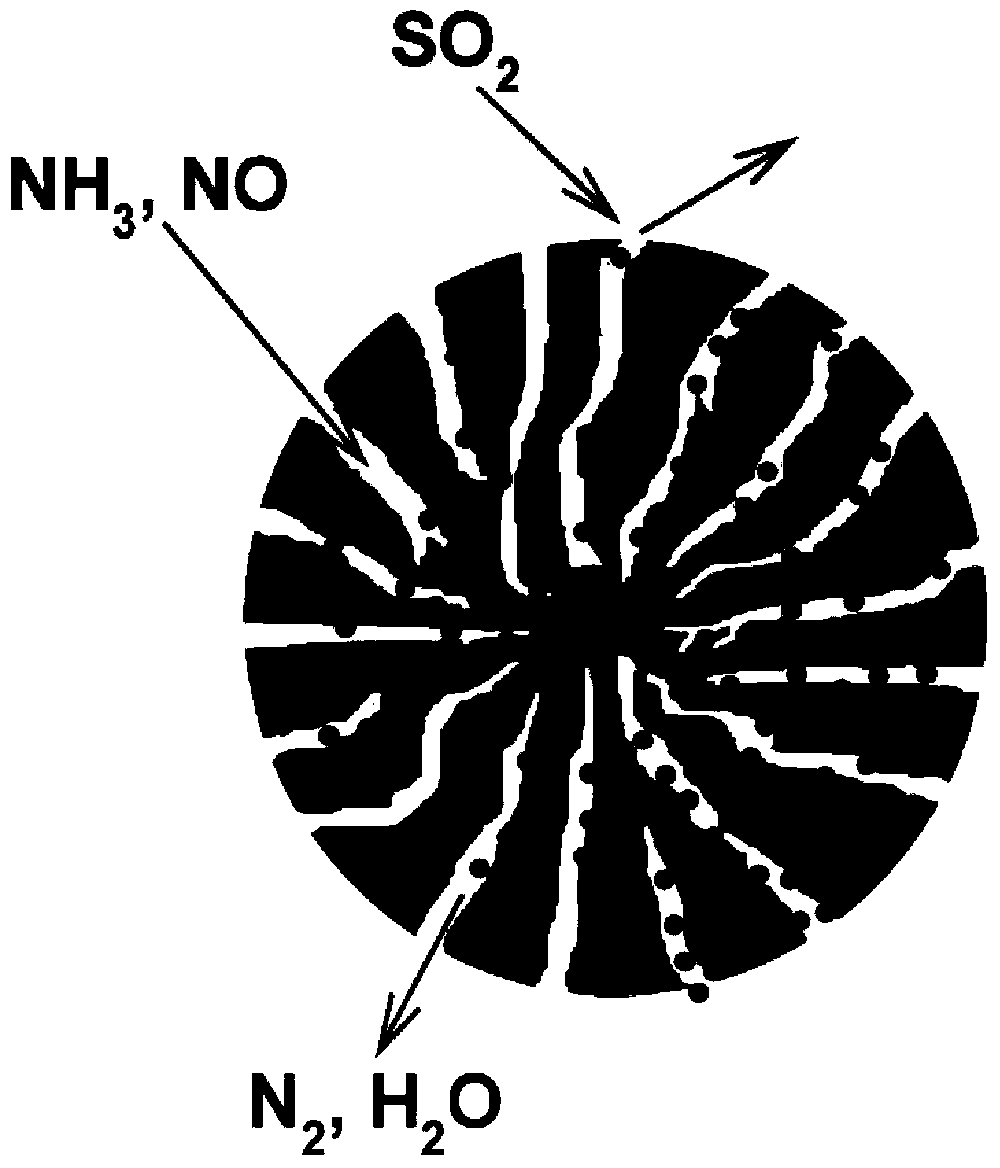

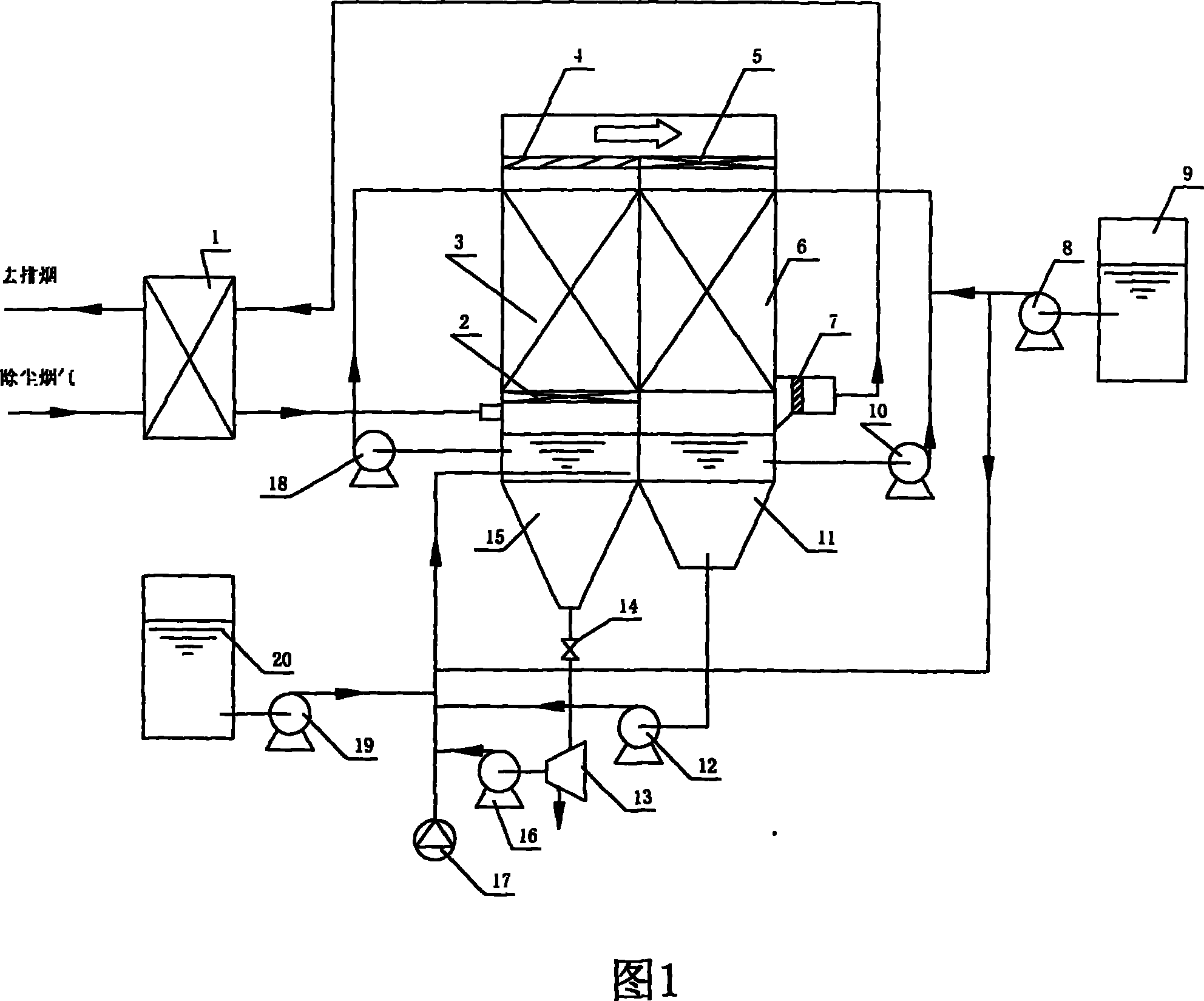

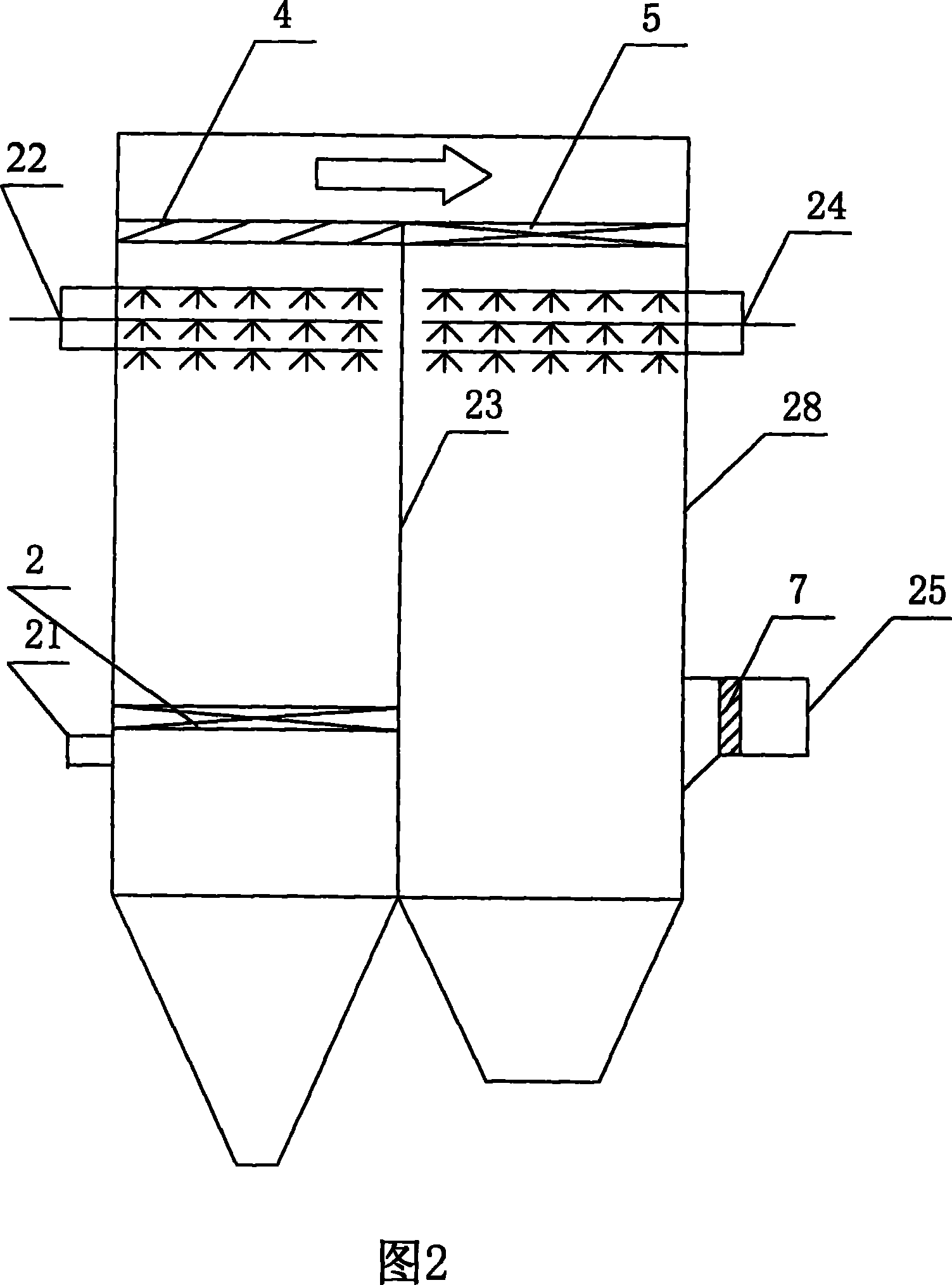

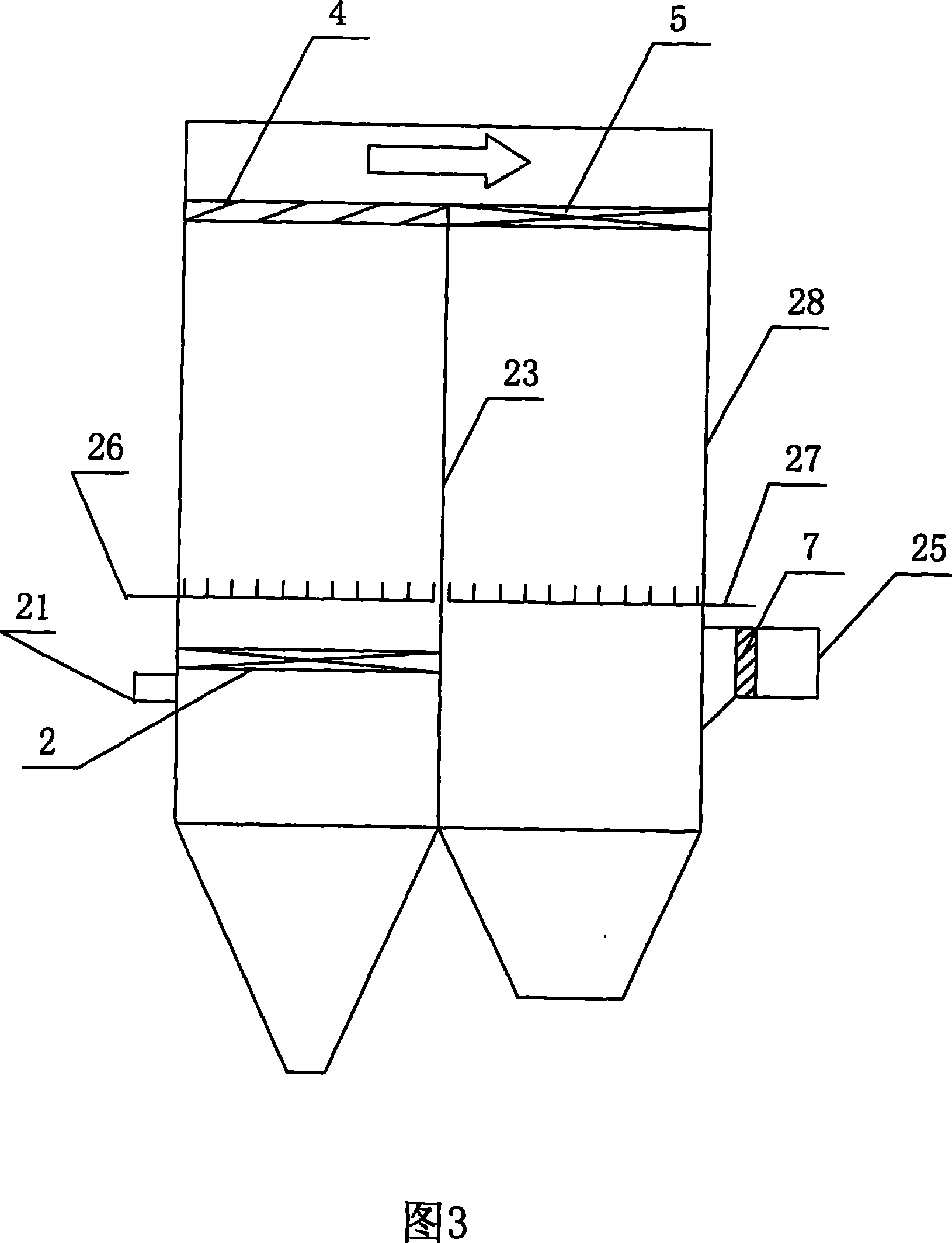

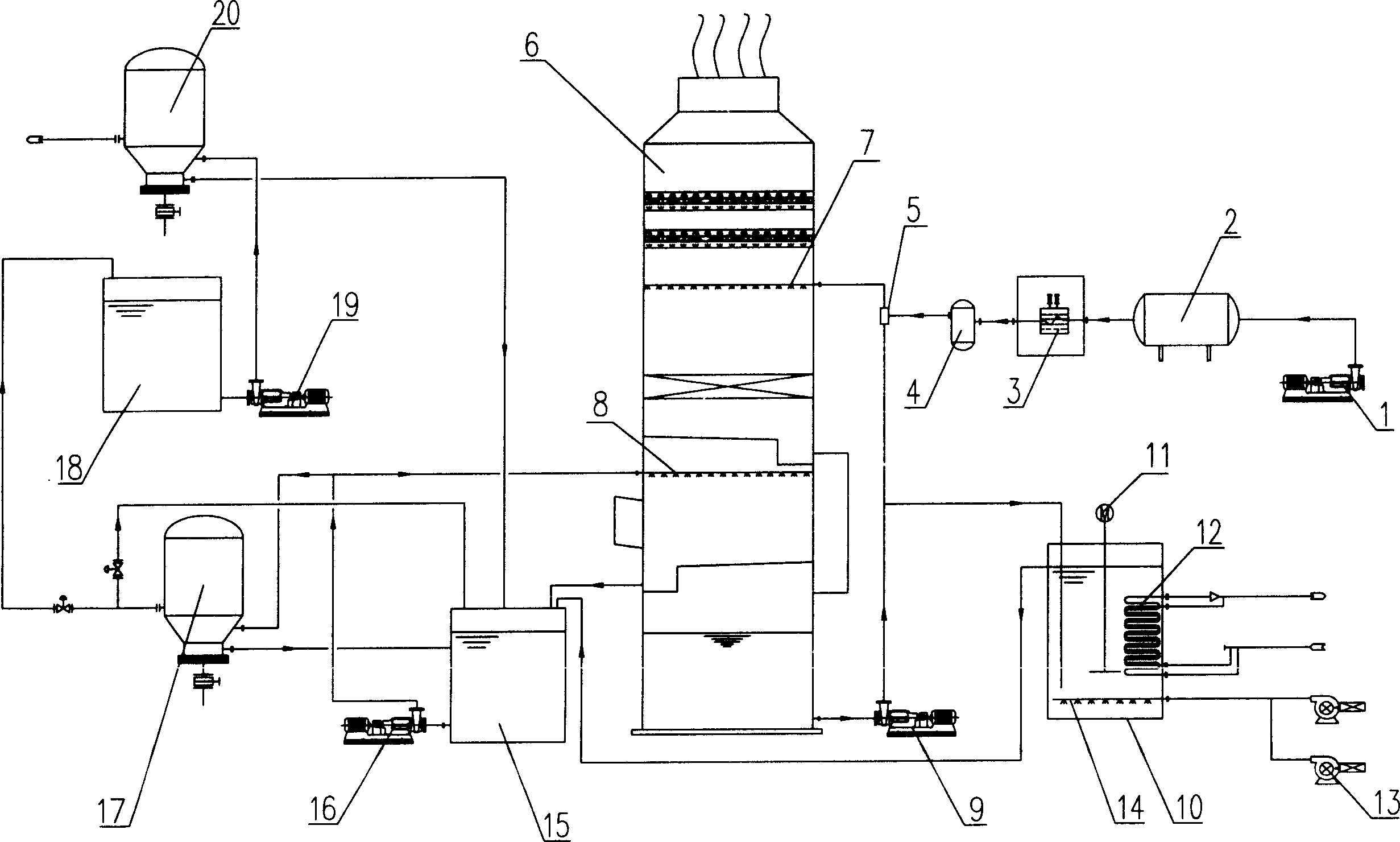

Removing and recovering process and device for SO2 in flue gas

InactiveCN1408464AReduce consumptionEasy to operateDispersed particle separationAmmonium sulfatesRecovery methodGas to liquids

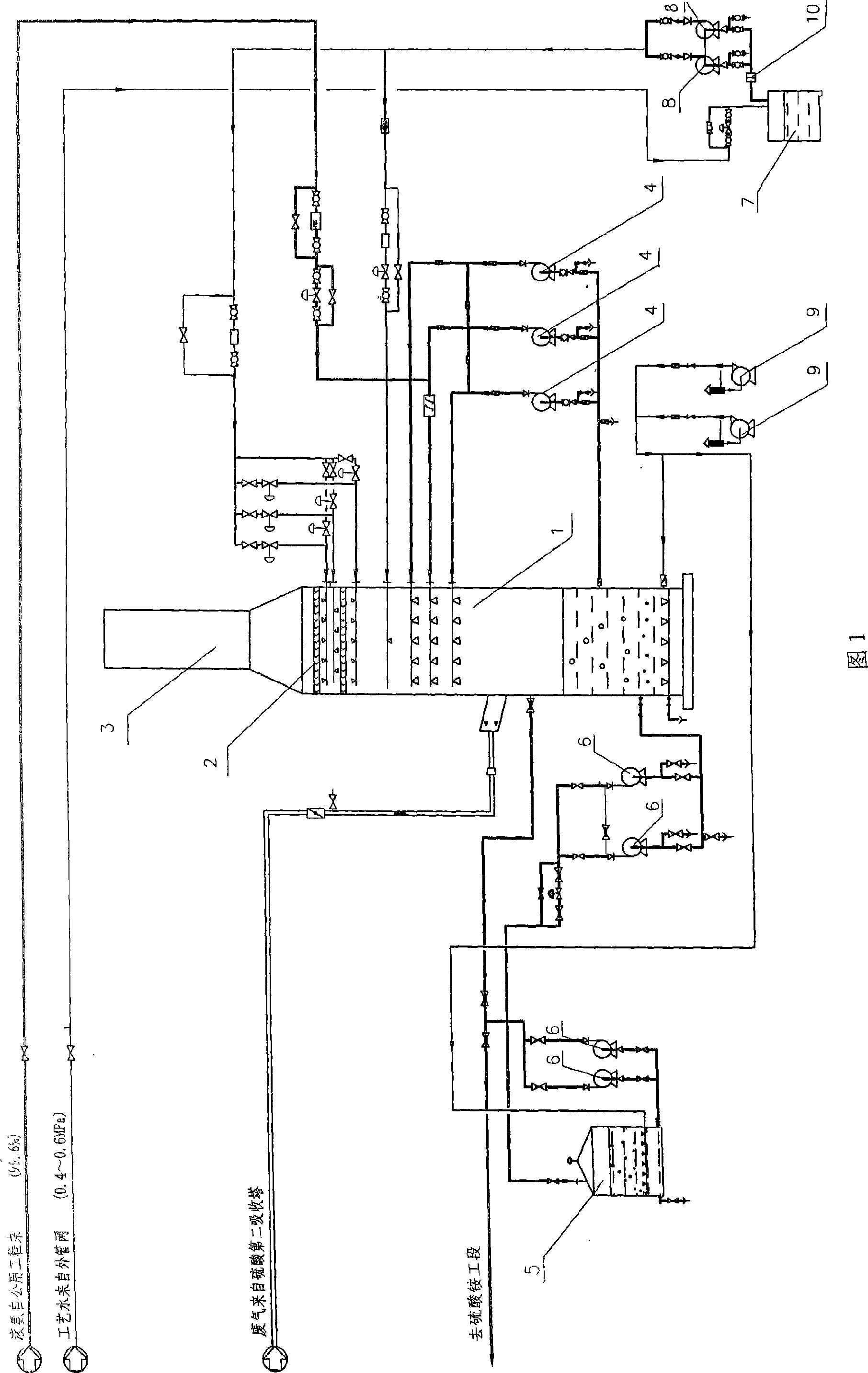

The recovering process includes the steps of: the reaction of the S containing fume with water solution of ammonia, with ammonia-to-sulphur molar ratio of 1.3-1.8 and gas-to-liquid ratio of 2000-5000, to produce ammonium sulfite solution; the oxidation of ammonium sulfite solution with air to obtain ammonium sulfate solution; the contact of the ammonium sulfate solution with hot fume to evaporatewater and the crystallization of ammonium sulfate in a crystallizer to produce commercial ammonium sulfate fertilizer. The equipment includes one desulfurizing tower with SO2 absorbing section, one ammonium sulfite oxidizing section, ammonium sulfate solution concentration section, one water washing section and mist elimianting section. The present invention can lower cost and steam consumption, reduce fume density and produce ammonium sulfate fertilizer.

Owner:EAST CHINA UNIV OF SCI & TECH

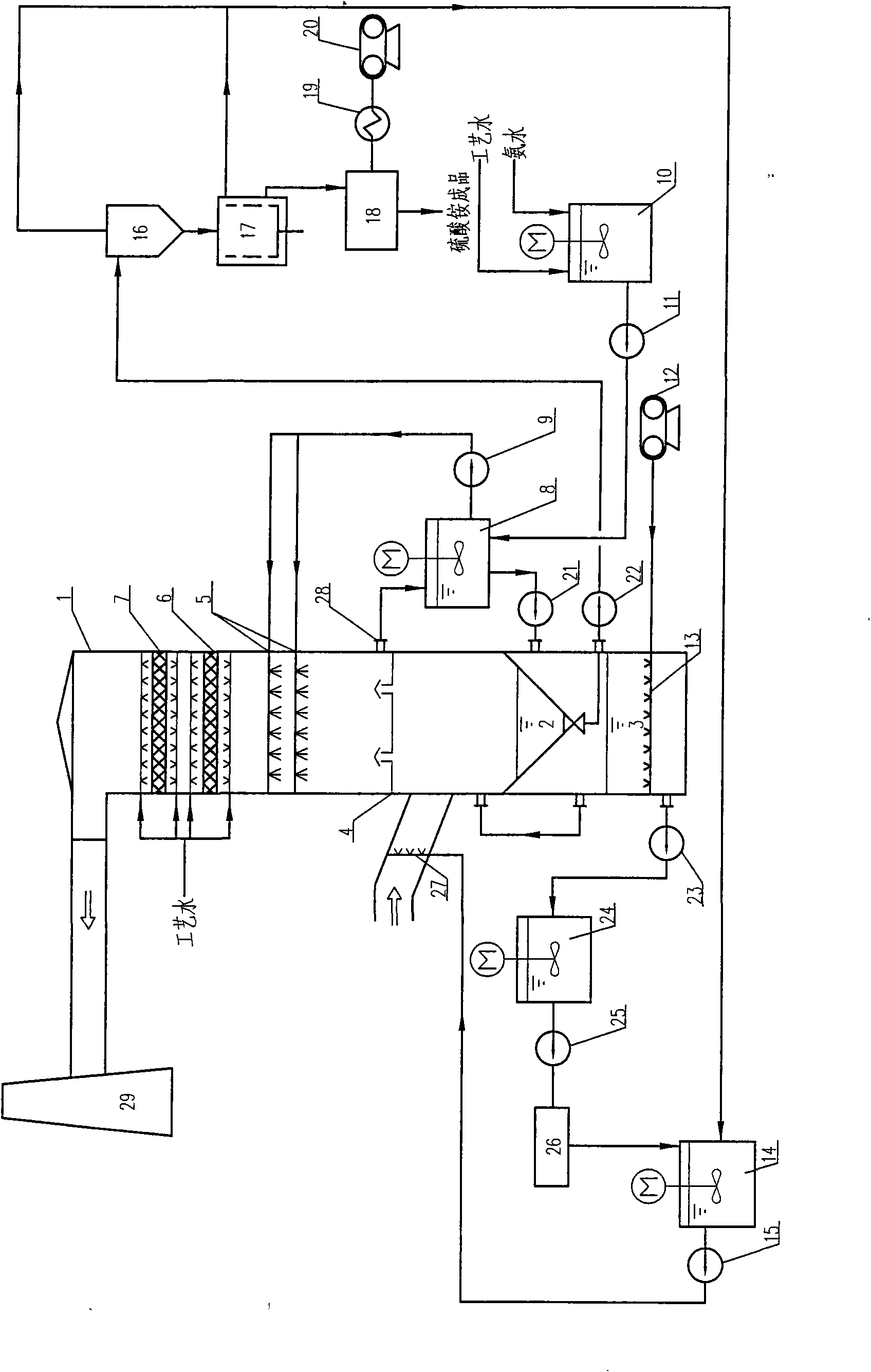

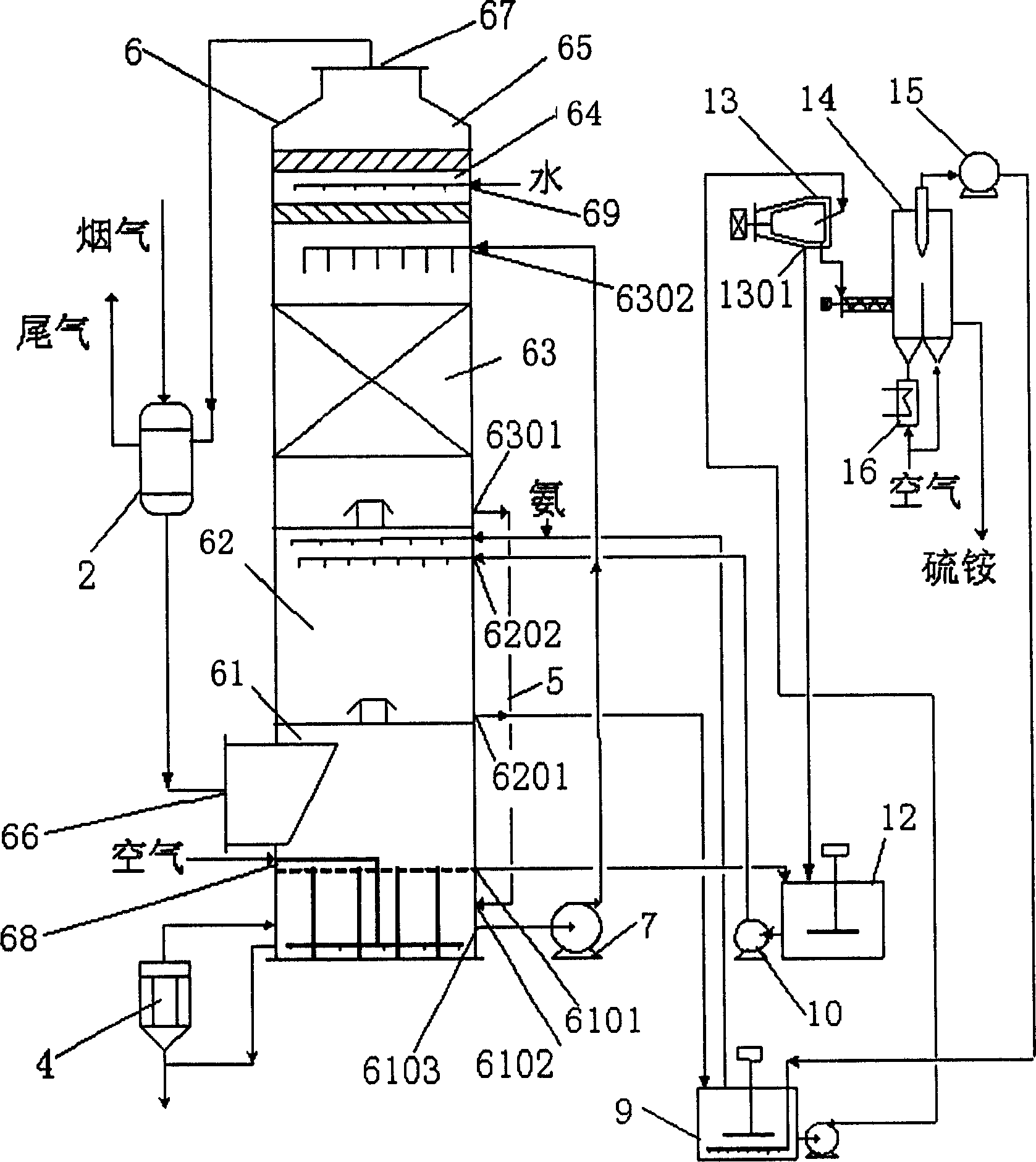

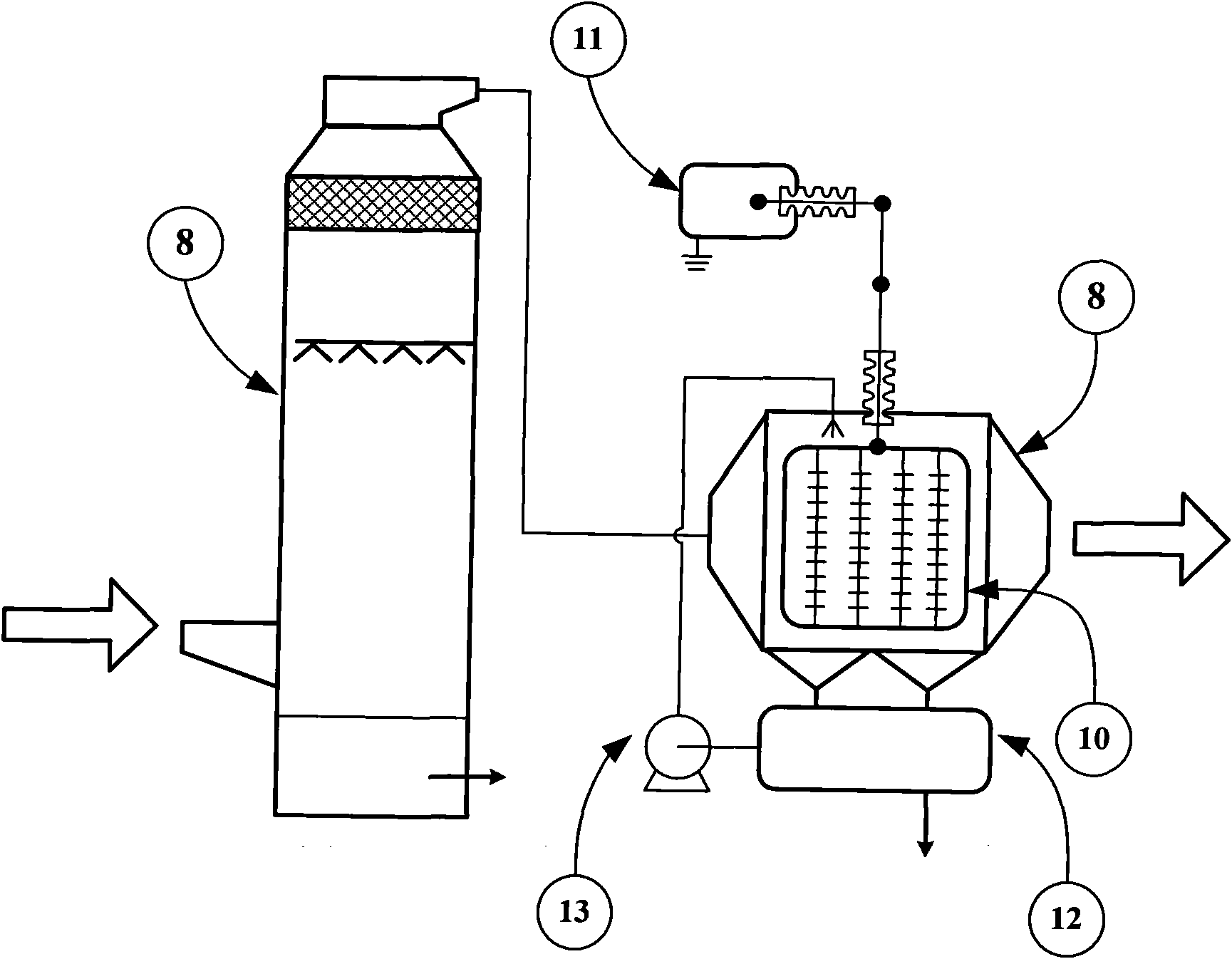

Energy-saving and high-quality ammonia desulphurization process for ammonia sulfate recovery

InactiveCN101579602ALow recycling comprehensive operating costConsiderable "positive benefit"Dispersed particle separationThermal energySulfate

The invention belongs to flue gas desulphurization technology of the environmental protection field. To solve the problems of large energy consumption, lower product quality and large investment in recovering ammonia sulfate by an ammonia desulphurization technique, the invention provides an energy-saving and high-quality ammonia desulphurization process for ammonia sulfate recovery. The process adopts ammonia water as a desulfurizer, ammonium sulfite is produced after the ammonia water and flue gas are decarbolized completely, and ammonia sulfate is produced after the ammonium sulfite is forcibly oxidized in a tower; impurities in the ammonia sulfate solution is removed by filtering, the filtrate is contacted with high-temperature flue gas in a desulfurizing tower for heat exchange, and when flue gas is cooled, the ammonia sulfate solution is heated and saturated; and then after crystallization of the saturated ammonia sulfate solution for a period of time, high-quality ammonia sulfate is produced after centrifugal drying. By adopting the technical proposal of the invention, not only thermal energy of an ammonia sulfate product which is produced by drying process can be greatly saved, high-quality ammonia sulfate fertilizer can be recovered, occupation area can be reduced and investment can be save, but also flue gas emission can meet the standard, without resulting in secondary pollution such as waste water and the like.

Owner:山西晋丰节能环保工程设计有限公司

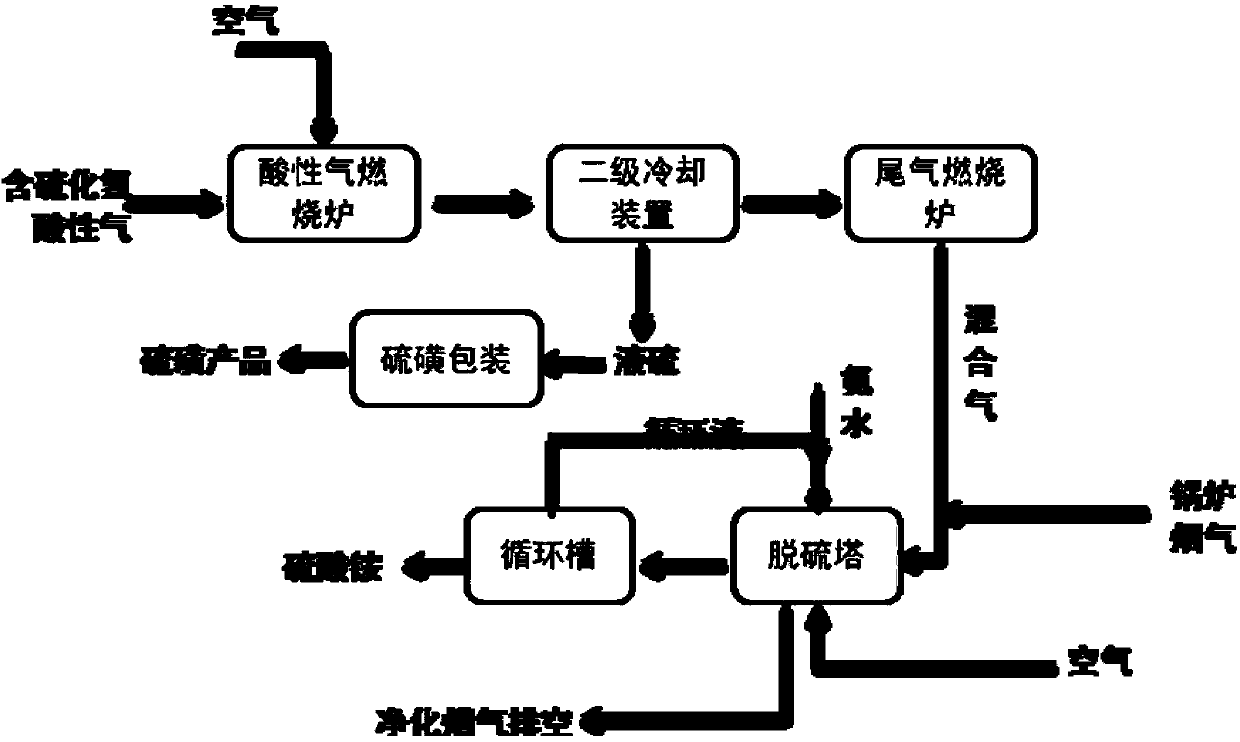

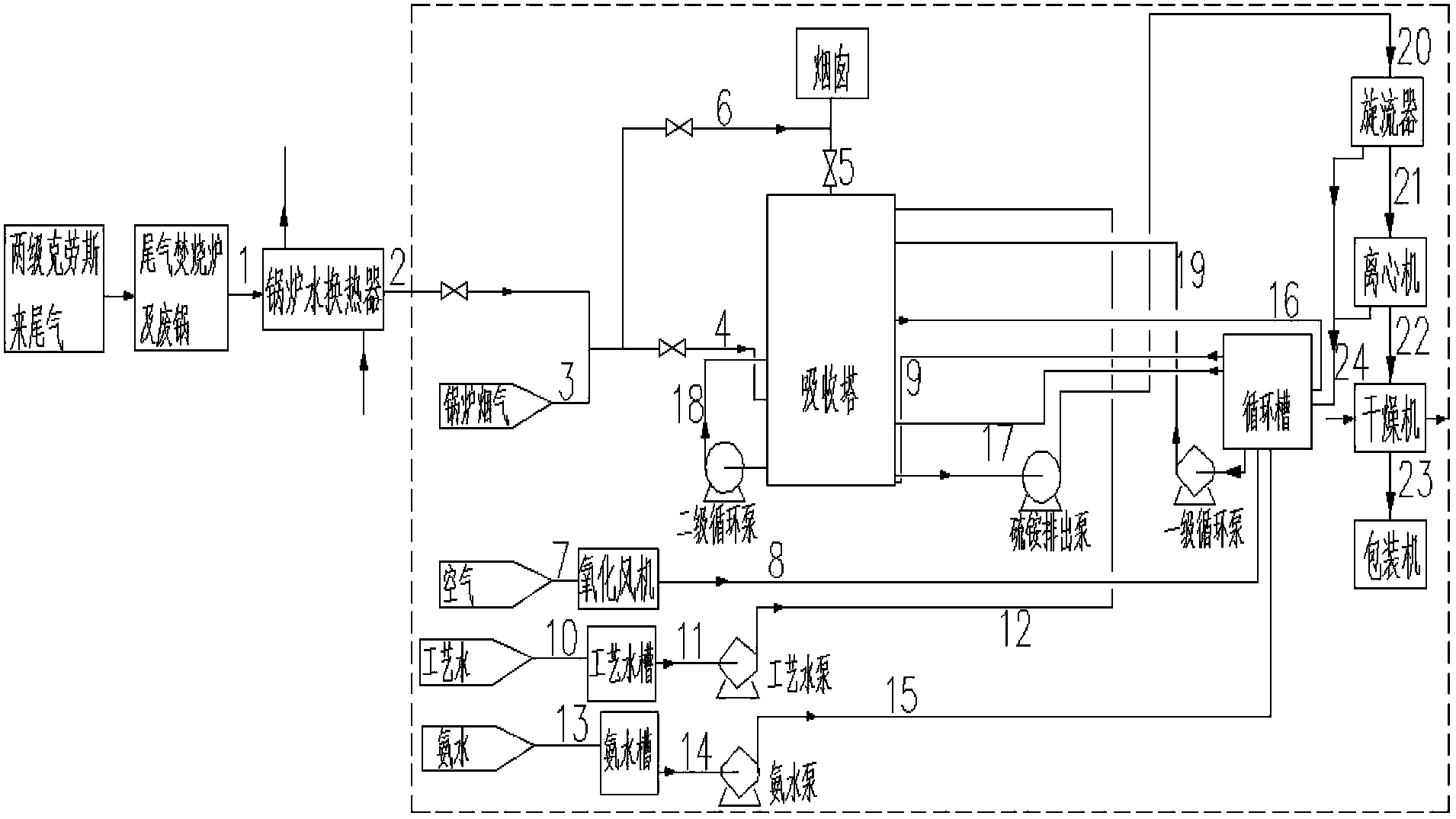

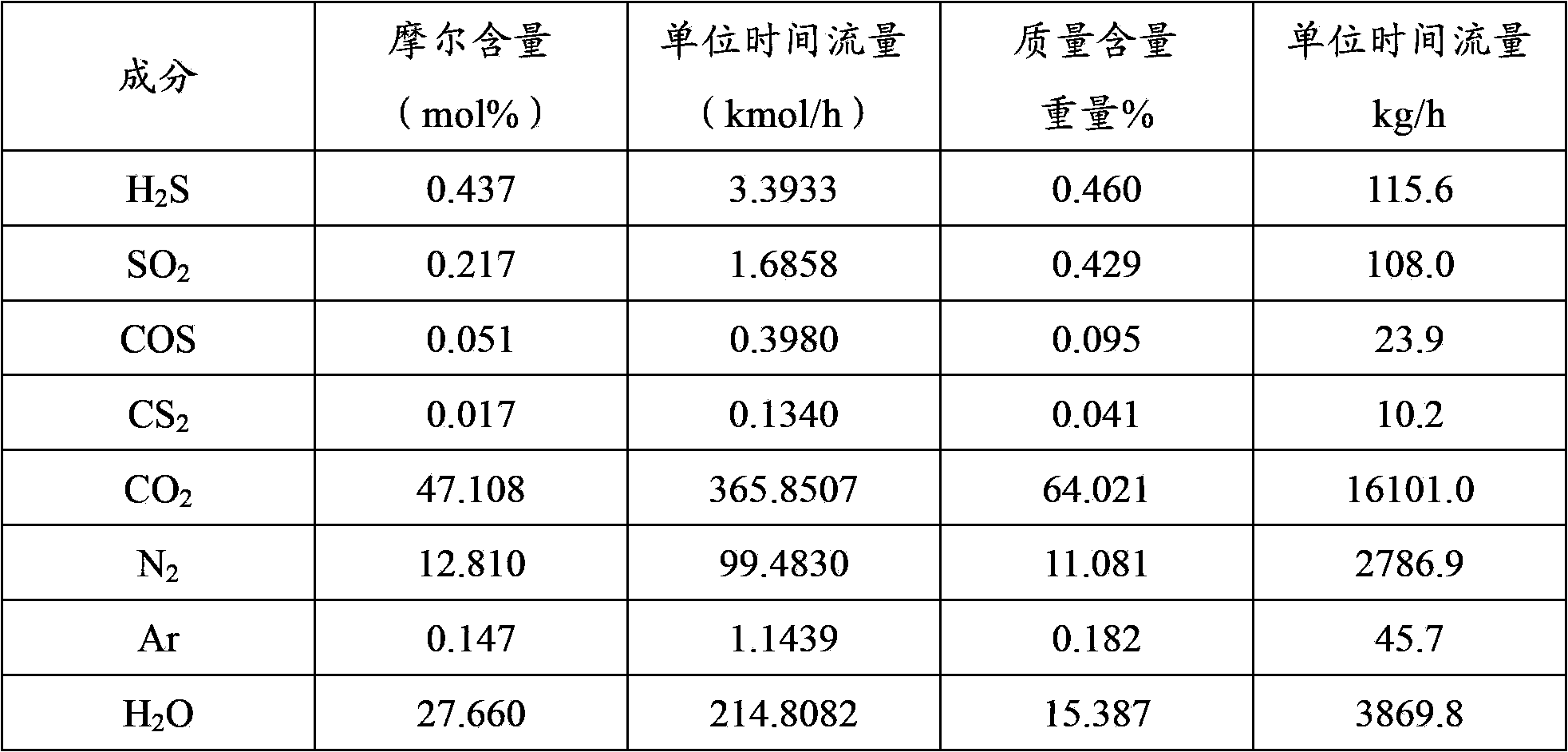

Comprehensive desulphurization technology in coal chemical industry

InactiveCN103418223AHigh recovery rateEmission reductionDispersed particle separationAmmonium sulfatesCombustionTower

The invention discloses a comprehensive desulphurization technology in the coal chemical industry. The comprehensive desulphurization technology comprises the following steps: acidic gas containing hydrogen sulfide and coming from a low-temperature methanol washing device burns to generate mixed gas, and the mixed gas is subjected to two stages of cooling to separate out liquid sulfur for producing solid sulfur; sulphuric mixed gas separated out after cooling is subjected to secondary combustion so that all sulphureous components in the mixed gas are changed into SO2, tail gas generated after combustion and boiler flue gas of a heating power station are fully mixed and enter a desulphurization tower, circulating liquid containing aqua ammonia is used as an absorbent to absorb SO2 in a countercurrent contact way and react to generate ammonium sulfite, and ammonium sulfite is further oxidized to change into ammonium sulfate; desulphurized and purified flue gas is discharged into air through a chimney; ammonium sulfate solution at the bottom of the desulphurization tower enters a circulation tank and is crystallized to form the ammonium sulfate product. The comprehensive desulphurization technology adopts a novel combined desulphurization technology to replace the traditional Klaus Scott or Super Claus technology, and can effectively lower investment, improve recovery rate of sulfur and reduce discharge of sulfur.

Owner:XINWEN MINING GROUP

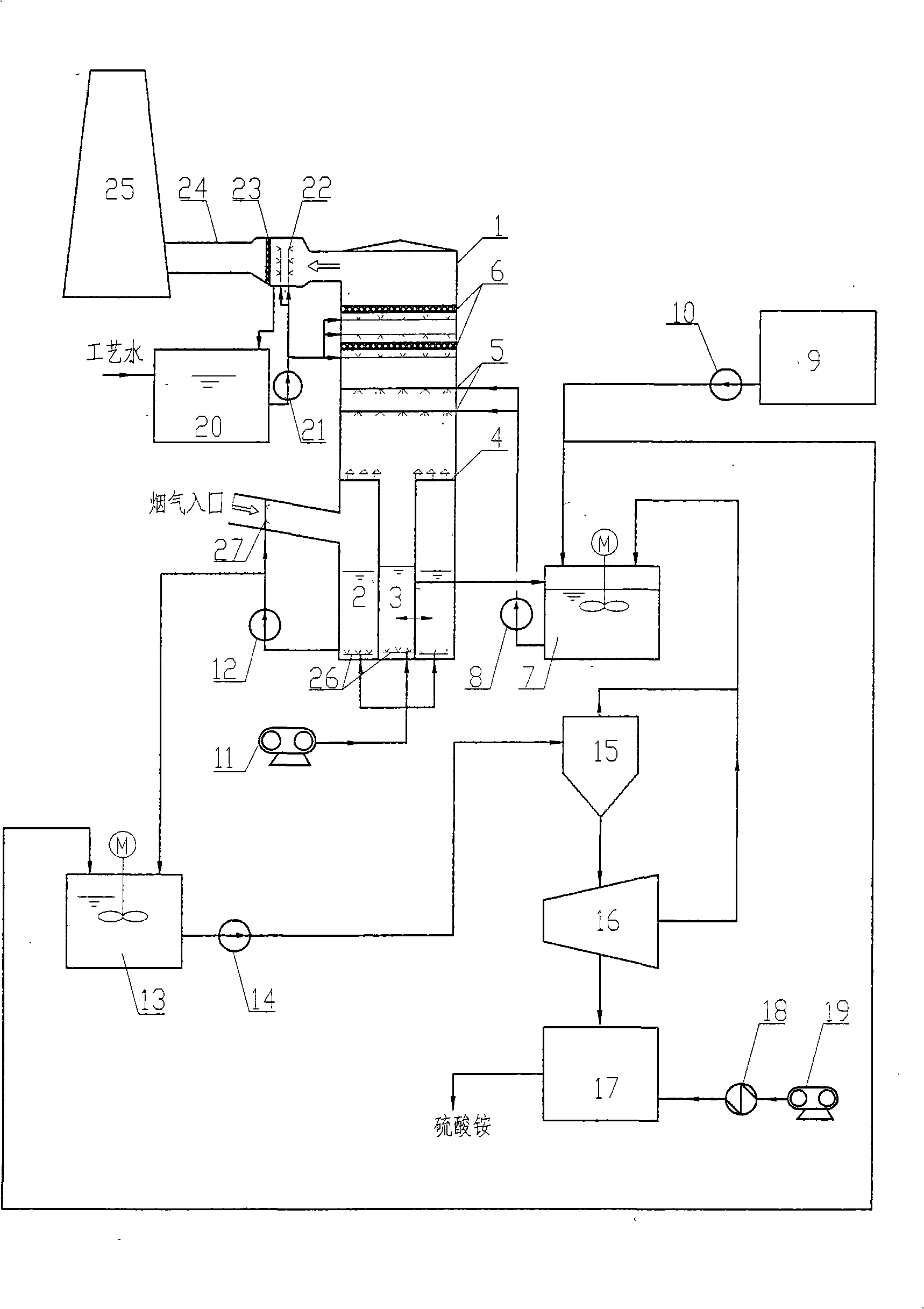

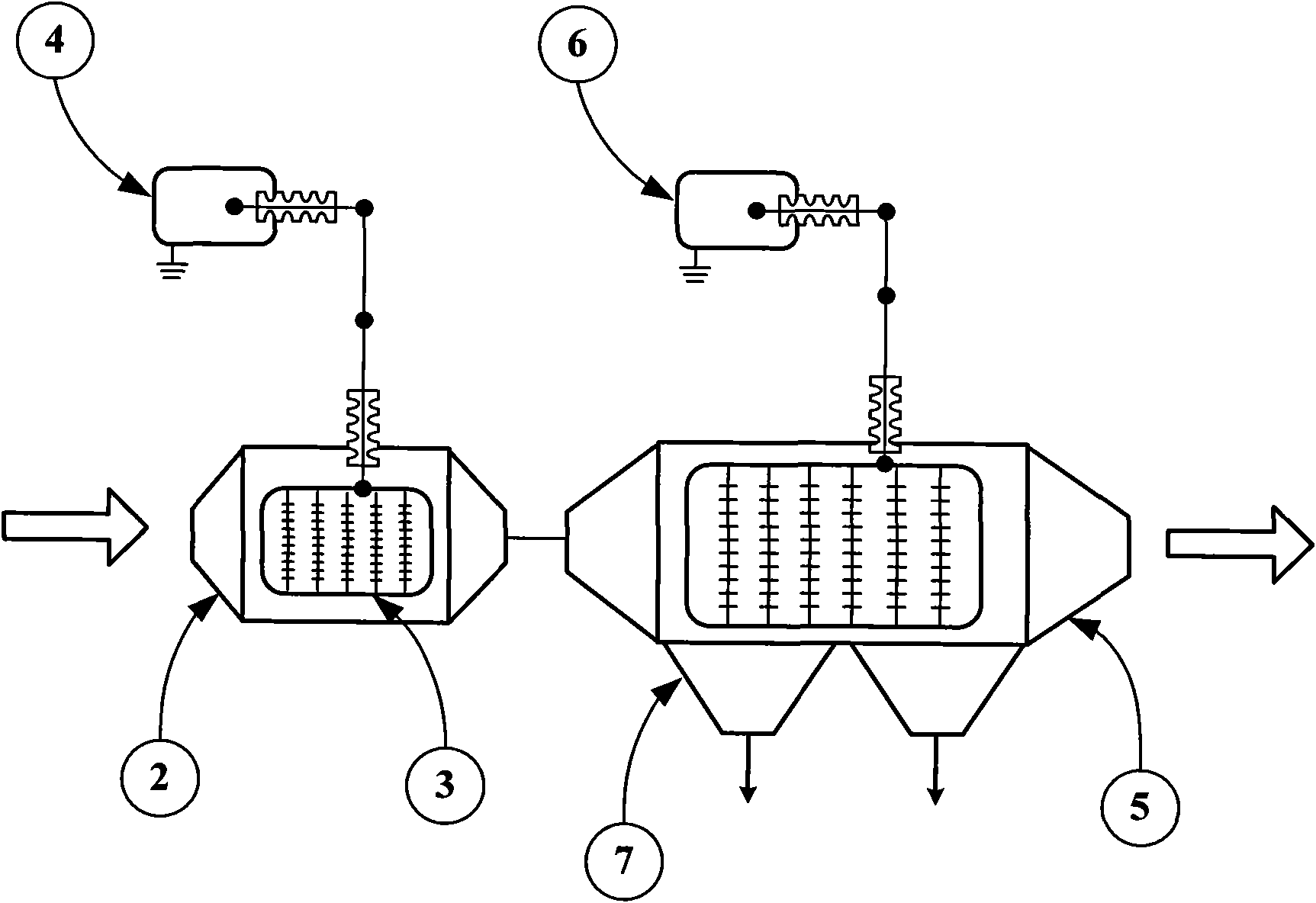

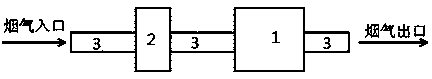

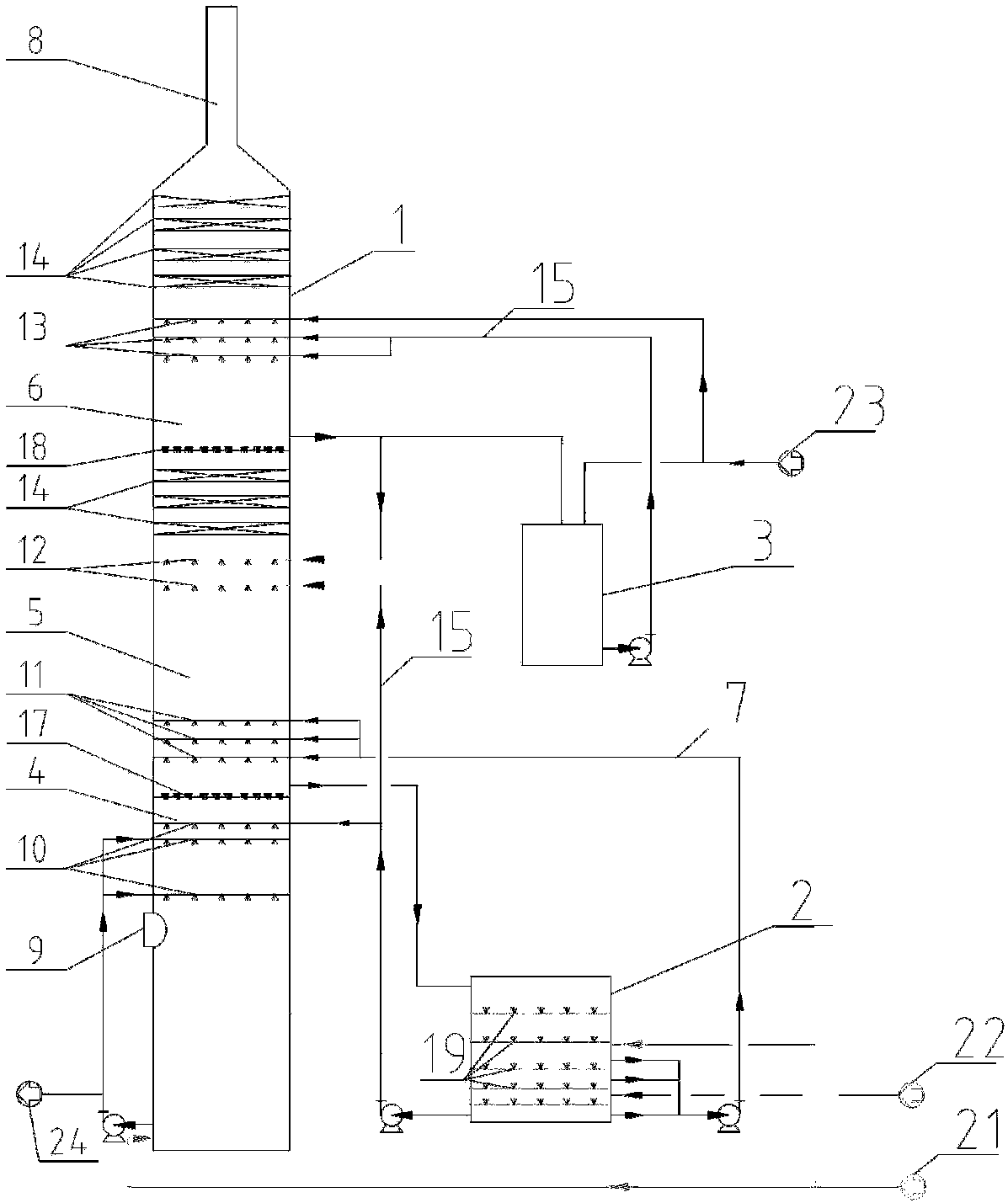

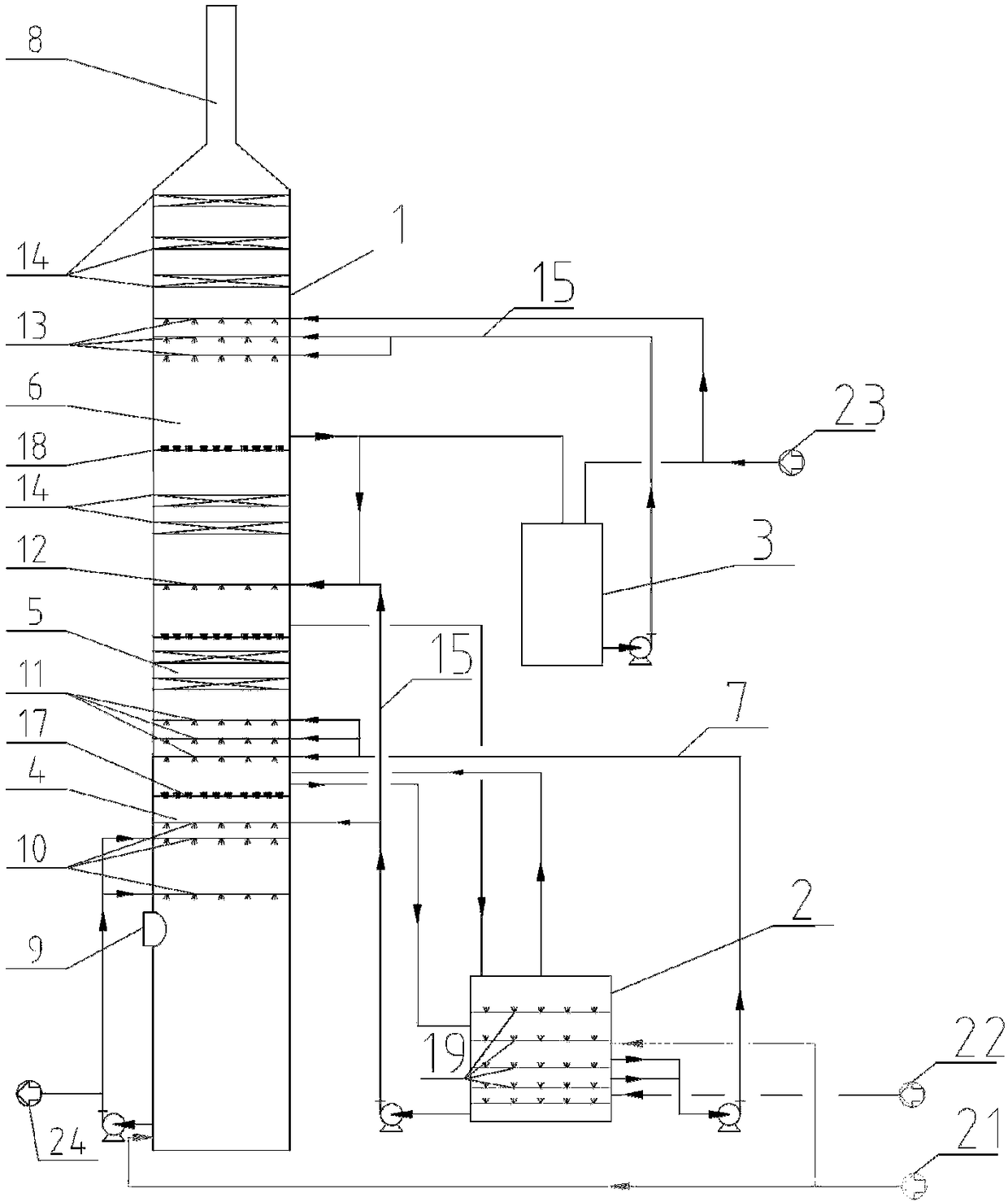

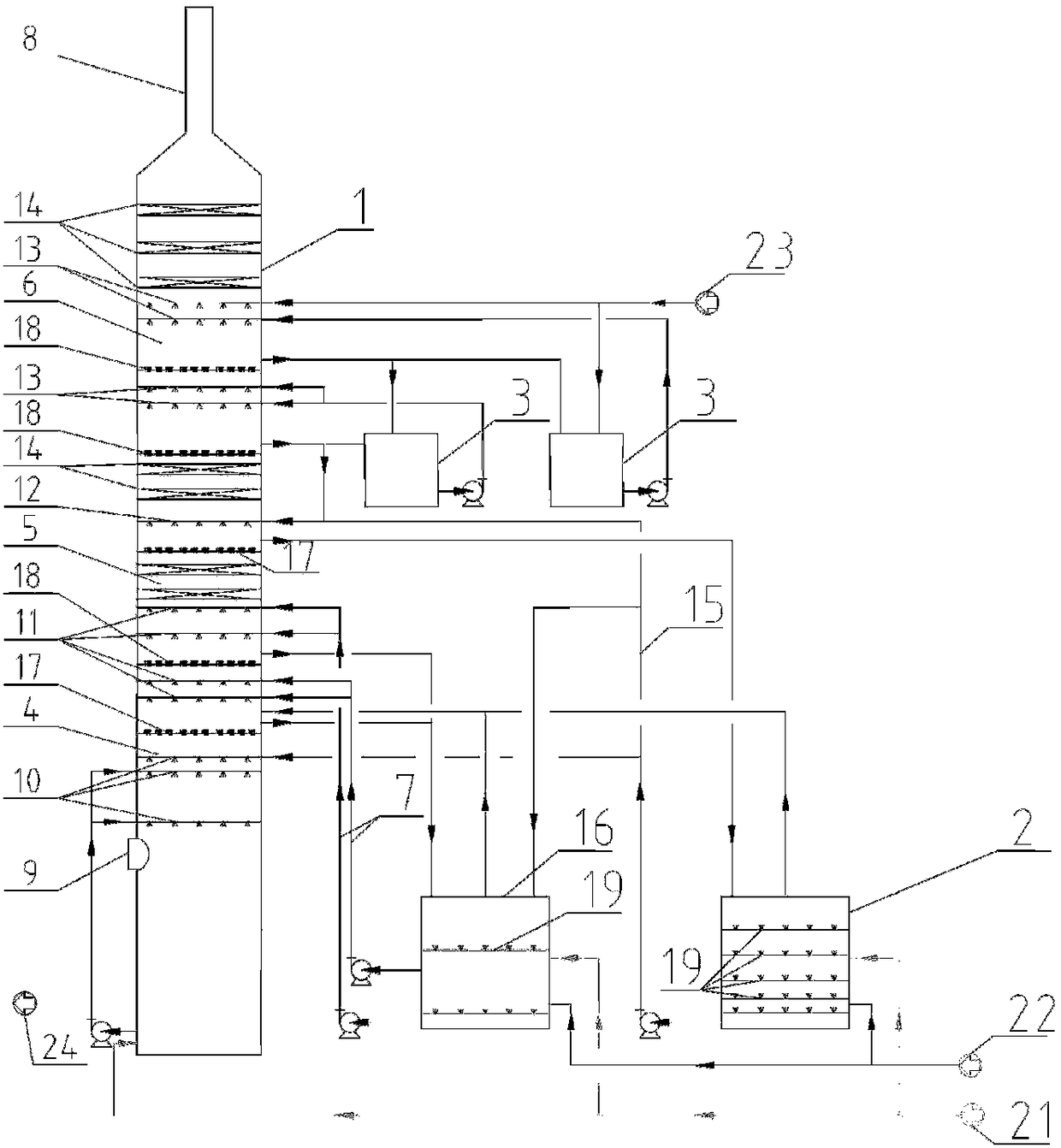

Segment-based ammonia flue gas desulfurization process and device thereof

InactiveCN101524620AHigh economic valueLow ammonia content in outlet flue gasDispersed particle separationProcess systemsPollution

A segment-based ammonia flue gas desulfurization process and a device thereof combine traditional absorption towers with a crystallization tower. A regeneration tank is arranged at the outside of the tower. The processes of absorption of SO2, sulfite oxidation, regeneration of desulfurization solution, crystallization of ammonium sulphate and ammonia volatilization are carried out respectively. The process system effectively improves the removal rate of SO2, improves the oxidation of the sulfite, strengthens the crystallization of the ammonium sulphate and reduces the escape of ammonia in outlet smoke. The standard discharge of the smoke can be realized after the smoke is processed by the system. The removal rate of SO2 is above 95 percent. The whole system process is simple and has no secondary pollution. And the by-product ammonium sulphate has high economic value and can be especially configured by enterprises with fixed ammonium sources.

Owner:山西晋丰节能环保工程设计有限公司 +1

Sulphuric acid tail-gas deep desulfurization method

InactiveCN101422693AEmission reductionBig investmentDispersed particle separationEnergy conservationChemistry

The invention discloses a deep desulfurization method of sulfate acid tail gas. The method additionally arranges a desulfurization tower behind a second adsorption tower of a sulphuric acid device; after the waste gas discharged from the second adsorption tower enters the desulfurization tower, an ammoniation absorbent is used for adsorbing SO2 in the waste gas to generate ammonium sulfite; the tail gas after the desulfurization passes through a demisting layer in the tower to eliminate acid fog; the purified tail gas is discharged through a chimney at high altitude; the ammonium sulfite in the absorbent is aerated and oxidized to be ammonium sulfate solution at the bottom of the tower; and after the concentration of circulation liquid ammonium sulfate meets the requirement, the circulation liquid ammonium sulfate is sent to a follow-up process to be processed and used. The deep desulfurization method of sulfate acid tail gas can cause the concentration of the SO2 in the tail gas to be lower than 100mg / m<3> in a standard state, greatly reduces the emission of the SO2 in the tail gas, is beneficial to the improvement of the atmospheric environment quality, meets the construction principles of energy conservation, emission reduction and sustainable development and has good social benefits; in addition, the deep desulfurization method can increase the recovery amount of the ammonium sulfate, and has certain economic benefits.

Owner:GUIZHOU KAILIN GRP CO LTD

Removing and recovering process and device for SO2 in flue gas

InactiveCN1178735CReduce consumptionEasy to operateDispersed particle separationAmmonium sulfatesSulfateEnvironmental engineering

The present invention provides a method and apparatus for eliminating and recovering S02 from fume, including the following steps: l ) firstly, the fume containing low sulphur reacts with aqueous solution of ammonia, producing ammonia sulfite solution, ammonia / sulphur=1.3-1.8 (molar ratio), gas / liquid=2000-5000 (volume ratio); 2) the oxidizing reaction between the ammonium sulfite and air produces ammonia sulfate solution; 3) the ammonia sulfate solution is contacted heat fume, then the water-vaporized ammonia sulfate solution is delivered to crystallizer to be processed into ammonia sulfate fertilizer. The apparatus includes a desulphurizing tower, the desulphurizing tower includes S02 adsorption section, ammonia sulfite oxidizing section, ammonia sulfate solution condensing section, scrubbing section and demisting section. The apparatus can be operated easily. The cost can be reduced 10-30%.The vapor consumption can be reduced 90%. The concentration of S02 of fume can be reduced less than 10-100ppm. The quality of ammonia sulfate meets national standard.

Owner:EAST CHINA UNIV OF SCI & TECH

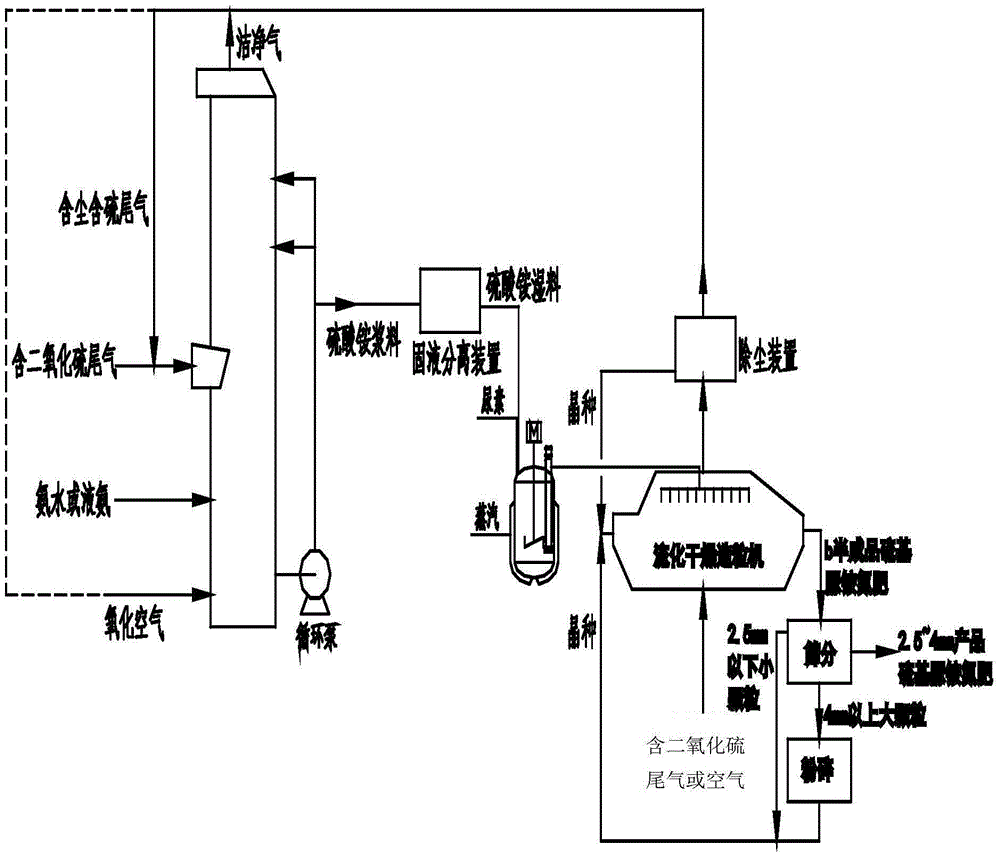

Method used for producing sulfur-based urea compound fertilizer from ammonia desulphurization by-products

The invention discloses a method used for producing sulfur-based urea compound fertilizer from ammonia desulphurization by-products. The method comprises following steps: sulfur dioxide-containing tail gas is delivered into a desulfurizing tower; ammonium hydroxide or liquid ammonia is sprayed so as to absorb sulfur dioxide, ammonium sulfite is oxidized with air, and an obtained product is subjected to concentration so as to obtain an ammonium sulfate slurry, and the ammonium sulfate slurry is subjected to solid-liquid separation so as to obtain an ammonium sulfate wet material; the ammonium sulfate wet material is delivered into a molten urea groove via a conveyor, solid urea is delivered into the molten urea groove via another hopper, and an obtained mixture is subjected to heating melting, or liquid urea is added directly; fluidization granulation is carried out, wherein dried seed crystal is delivered into a fluidized bed through one end, and is driven to flow to the other end of the fluidized bed in the fluidized bed; a mixed ammonium sulfate-urea composite solution is pumped into the fluidized bed, and multistage spraying is carried out; the sulfur dioxide-containing tail gas is delivered into the fluidized bed or / and fluidized drying with hot air is carried out, and semi-finished product sulfur-based urea compound fertilizer is obtained via seed crystal growth; and a obtained fluidization tail gas is subjected to dust separation, and is delivered into an ammonia desulphurization tower. According to the method, ammonium sulfate low in additional value is changed into sulfur-based urea high in additional value at low investment and operation cost.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

Low-temperature plasma smoke compound pollutant control method

InactiveCN102059050ALow costImprove space utilizationCombination devicesAir quality improvementNitric oxideHigh pressure

The invention discloses a low-temperature plasma smoke compound pollutant control method. By discharging at a high voltage to generate low-temperature plasmas in a dry reactor and a wet reactor, the method controls pollutants and oxidized by-products in the smoke, such as smoke dusts, sulfur dioxide, oxynitride, hydrogen sulfide, hydrogen chloride, heavy metal and the like, by combination with the conventional dedusting method, the ammonia method desulfuration, the limestone / gypsum wet method, the rotary atomization drying method and the like, wherein the dry plasma reactor is used together with a dedusting device to improve the dedusting efficiency and oxidize the nitric oxide; and an absorbing device is used together with the wet plasma reactor to remove gaseous pollutants, oxidize ammonium sulfite, namely a desulfurized product of an ammonia absorber, demist and purify the tail gas. The method can be used for controlling smoke compound pollutants of boilers or incinerators.

Owner:ZHEJIANG UNIV

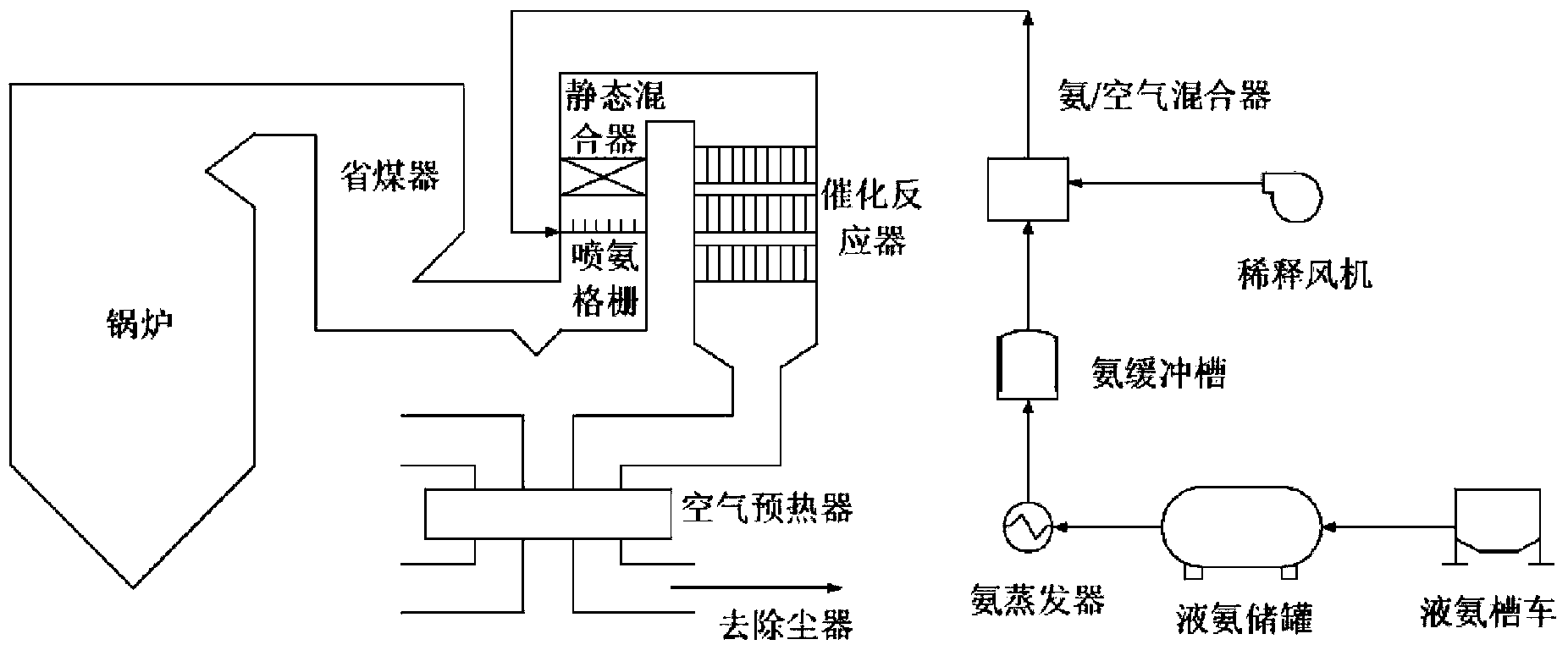

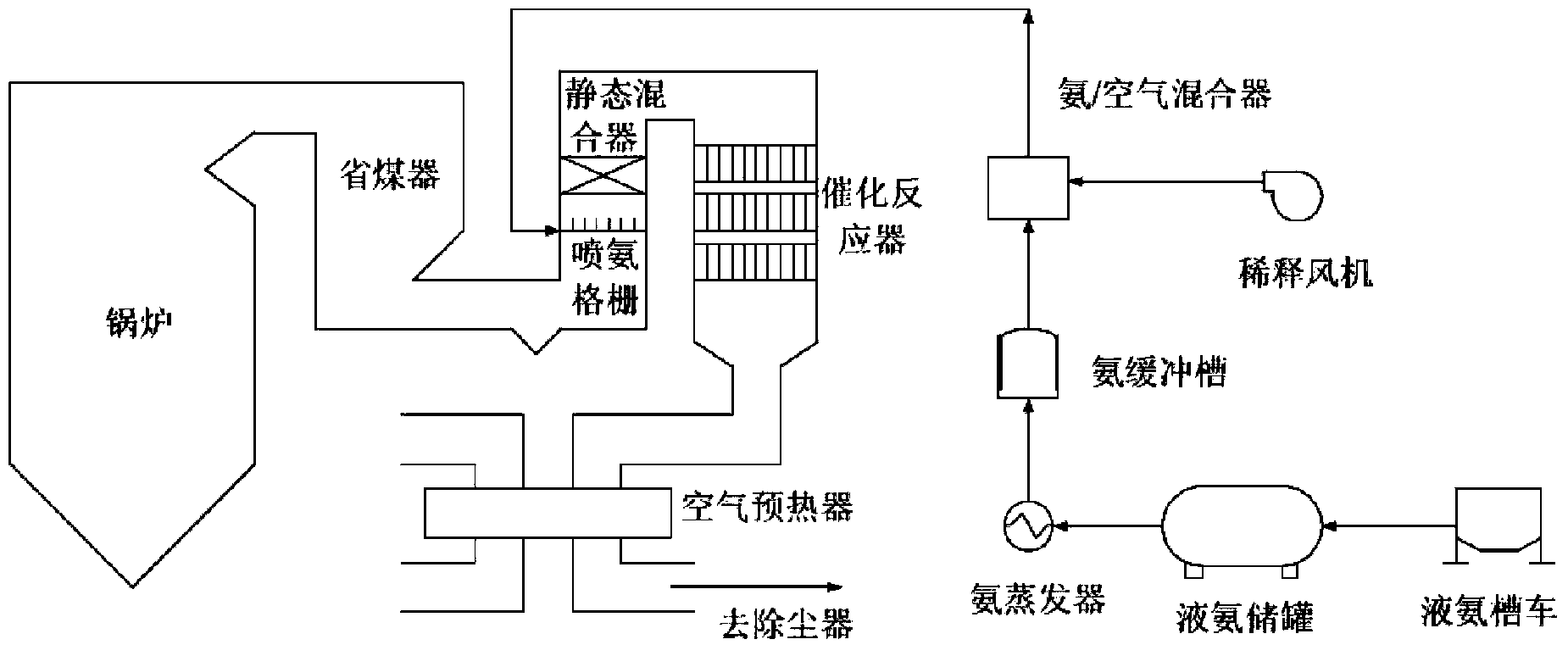

Method for desulfurization of sulfur recovery tail gas by using boiler flue gas ammonia method

ActiveCN103521060AImprove sulfur recoveryGuaranteed sulfur recoveryChemical industryDispersed particle separationTowerAqueous solution

The invention provides a method for desulfurization of a sulfur recovery tail gas by using a boiler flue gas ammonia method. The method comprises the following steps: (1) burning the sulfur recovery tail gas, wherein sulfide in the sulfur recovery tail gas is converted into sulfur dioxide; (2) converging the burnt sulfur recovery tail gas with the boiler flue gas to form merged flue gas, feeding the merged flue gas to an absorption tower, and discharging the merged flue gas after being absorbed by absorption liquid in a countercurrent manner in the absorption tower, wherein the absorption liquid is a water solution containing an ammonium salt, and the ammonium salt is a mixture of ammonium sulfate and ammonium sulfite. By adopting the method disclosed by the invention, not only can the sulfur recovery rate be better ensured, but also emission of the tail gas achieves the environmental protection requirements; meanwhile, investment and operative difficulty are reduced; the floor area is reduced; the comprehensive utilization efficiency of energy is improved; a good effect of treatment of waste by waste can also be achieved.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

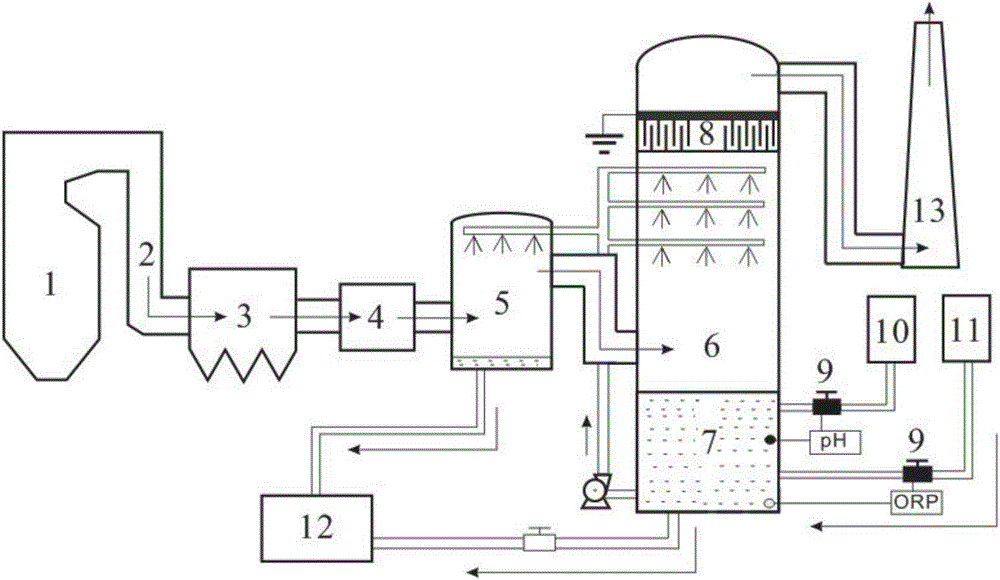

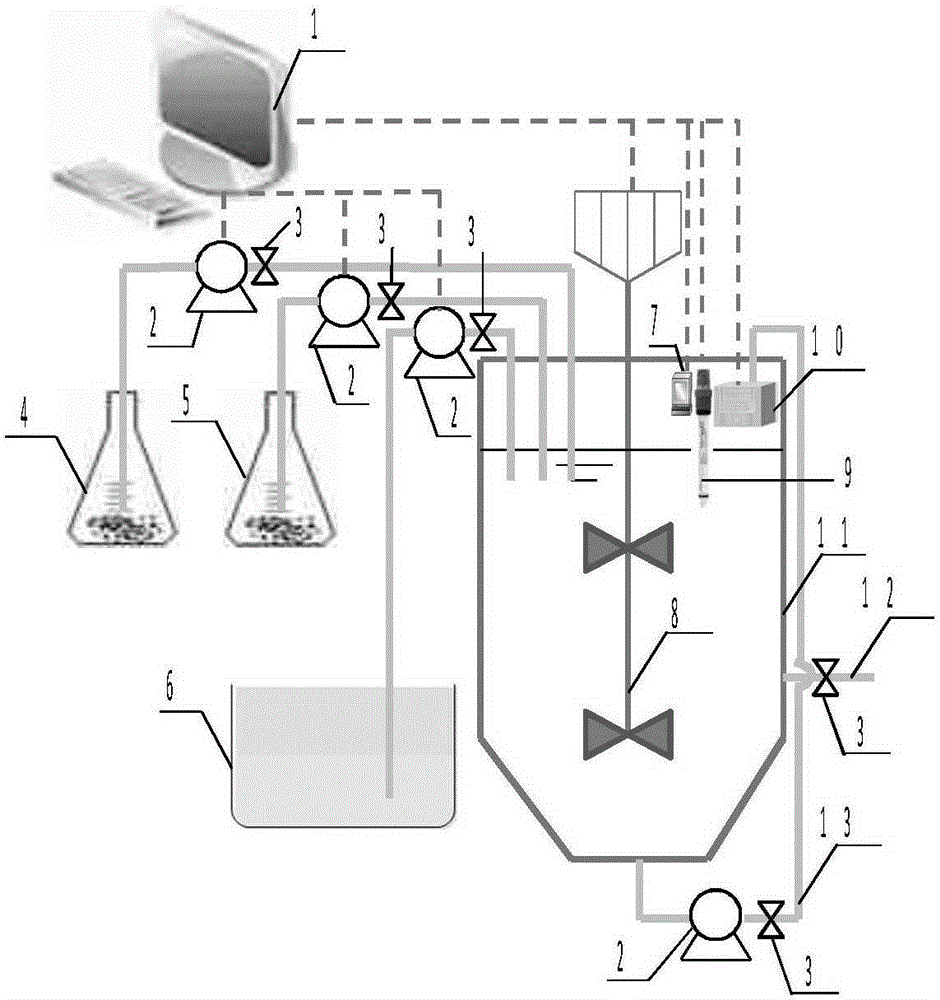

Method for automatically controlling desulphurization and denitration by flue gas based on pH value and ORP value and apparatus thereof

InactiveCN102716648AImprove desulfurization and denitrification efficiencySimple processLighting and heating apparatusDispersed particle separationElectricityAutomatic control

The invention discloses a method for automatically controlling desulphurization and denitration by flue gas based on pH value and ORP value and an apparatus thereof. The method comprises the following steps: dedusting and preoxidazing flue gas, oxidizing NO to NO2, precleaning and processing flue gas by a prewashing system, then taking ammonium sulfite as a absorption liquid, absorbing SO2 and NOx(x is 1 or 2) in flue gas, keeping the pH value and ORP value of the absorption liquid in a set scope during the absorption process for ensuring the absorption efficiency of desulphurization and denitration as well as operation stability, passing the flue gas through an electric demister, and removing the ammonia mist in the flue gas for preventing the ammonia leakage. When the concentration ratio of the absorption liquid (NH4)2SO3 / NH4HSO3 decreases to 0.9, a part of the absorption liquid in a washing tower reservoir is introduced into an ammonium sulfate byproduct treatment system, and the resource and recovery utilization can be realized. The provided desulphurization and denitration method has desulphurization efficiency with more than 95% and denitration efficiency with more than 85%, the ammonia escape amount is lower than 5mg / m<3>, and the sulfur resource can be simultaneously recovered.

Owner:山东航源环境科技有限公司

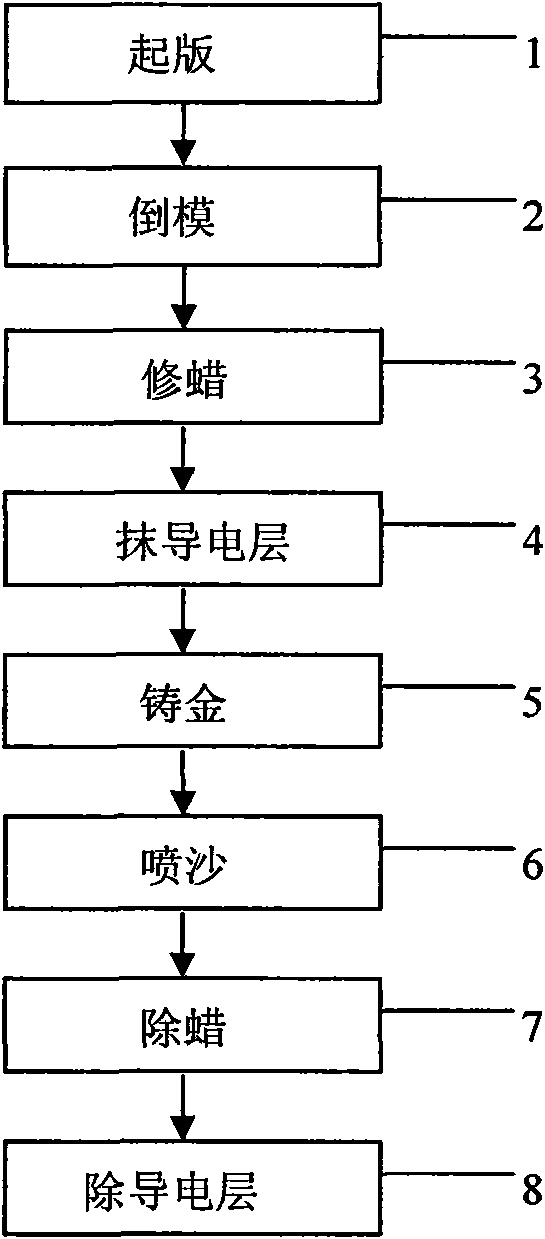

Method for electroforming hard gold product

InactiveCN101560676AIncrease in sizeHigh hardnessElectroforming processesChemical structurePotassium

The invention relates to a method for electroforming hard gold products. The method comprises the following steps: template picking, mould pouring, wax repairing and electric conducting layer coating are carried out to obtain a wax mould of a gold product to be processed, and a layer of electric conductive oil is coated on the surface of the wax mould; and a titanium net is taken as anode in the gold electroforming step, the wax mould coated with the electric conductive oil is put in an electrotyping bath as cathode, the electroforming solution is put in the electrotyping bath and includes sulfurous acid gold potassium, ammonium sulfite and potassium citrate, wherein the sulfurous acid gold potassium is combined with the ammonium sulfite, a trivalent gold ion is reduced into a univalent gold ion, the univalent gold ion generates close crystal grains, the close crystal grains are combined through the potassium citrate to form complexing gold through PH buffer solution, the gold is deposited on the wax mould to form a casting gold layer, and the half-finished product is prepared; and the wax film in the half-finished product and the electric conductive layer are removed in the wax removal step and the electric conductive layer removal step to obtain the finished product. The volume and the hardness of the gold product are changed by using the variation of the chemical structure of the gold ion, so that the hardness, the volume and the toughness of the gold product meet the standards simultaneously.

Owner:武汉金凰珠宝股份有限公司

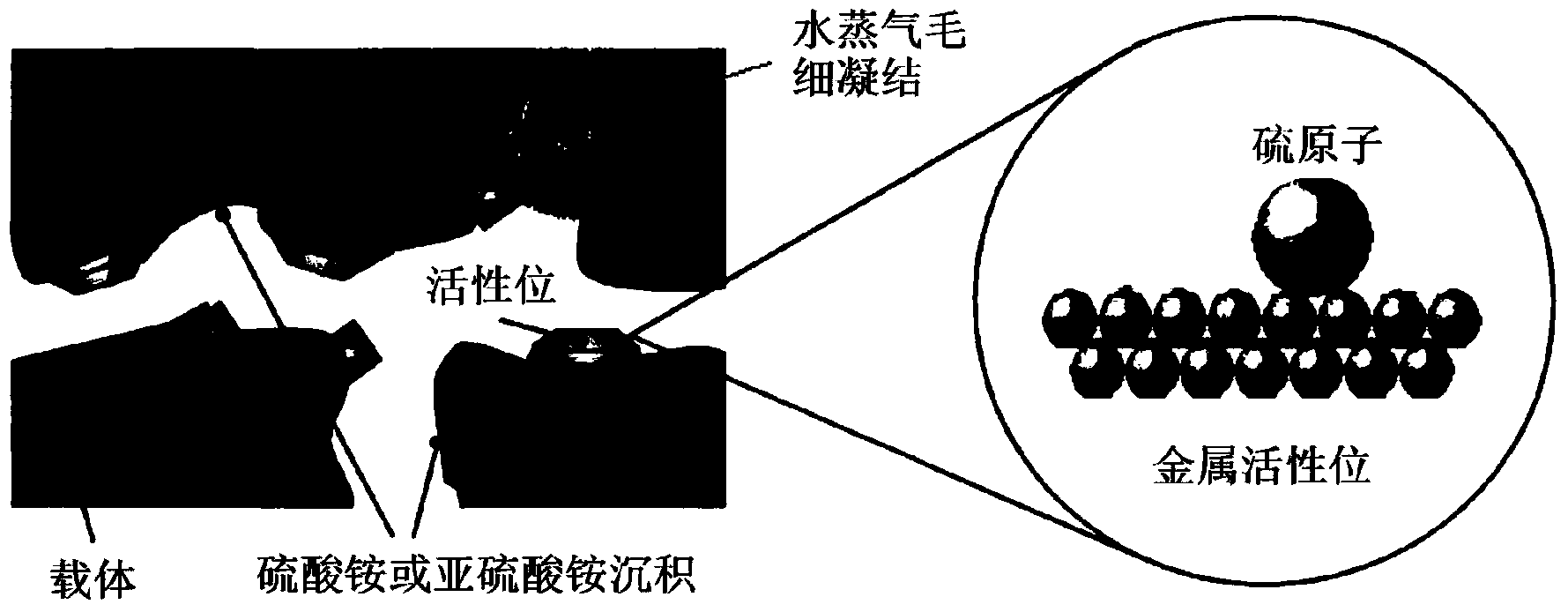

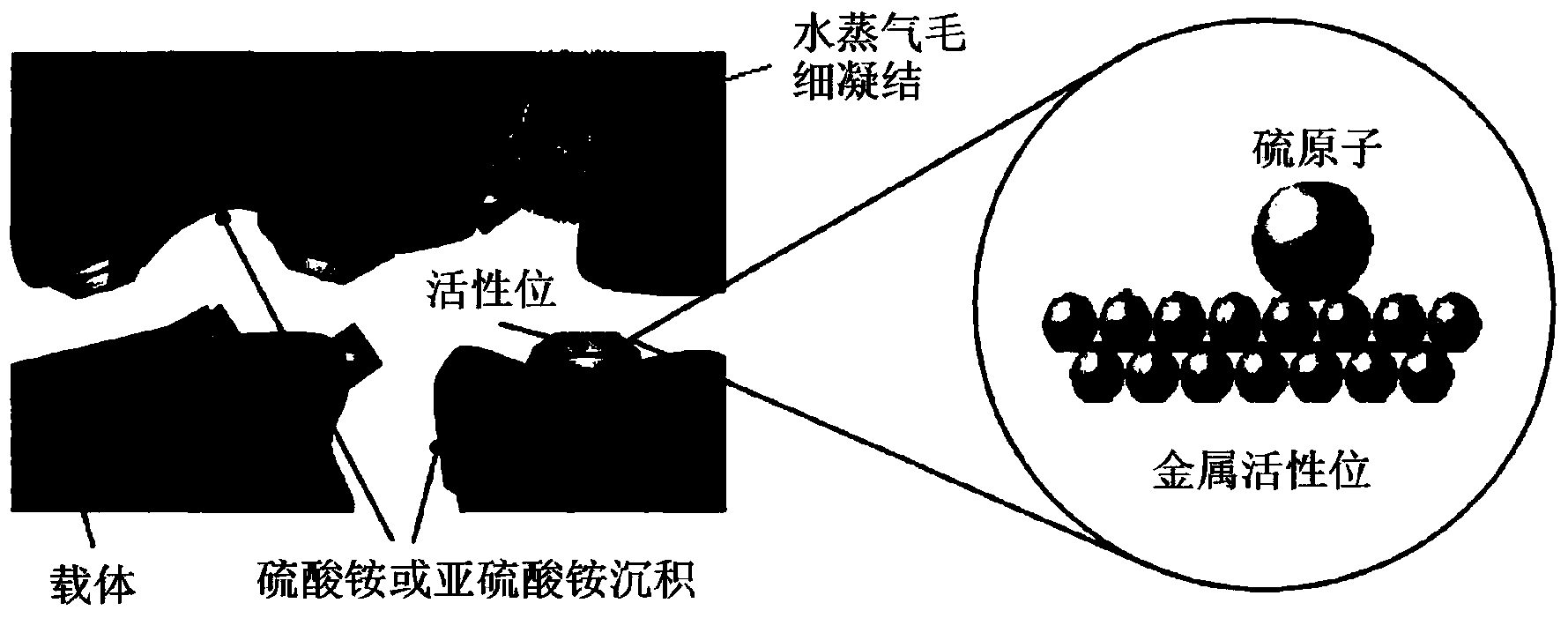

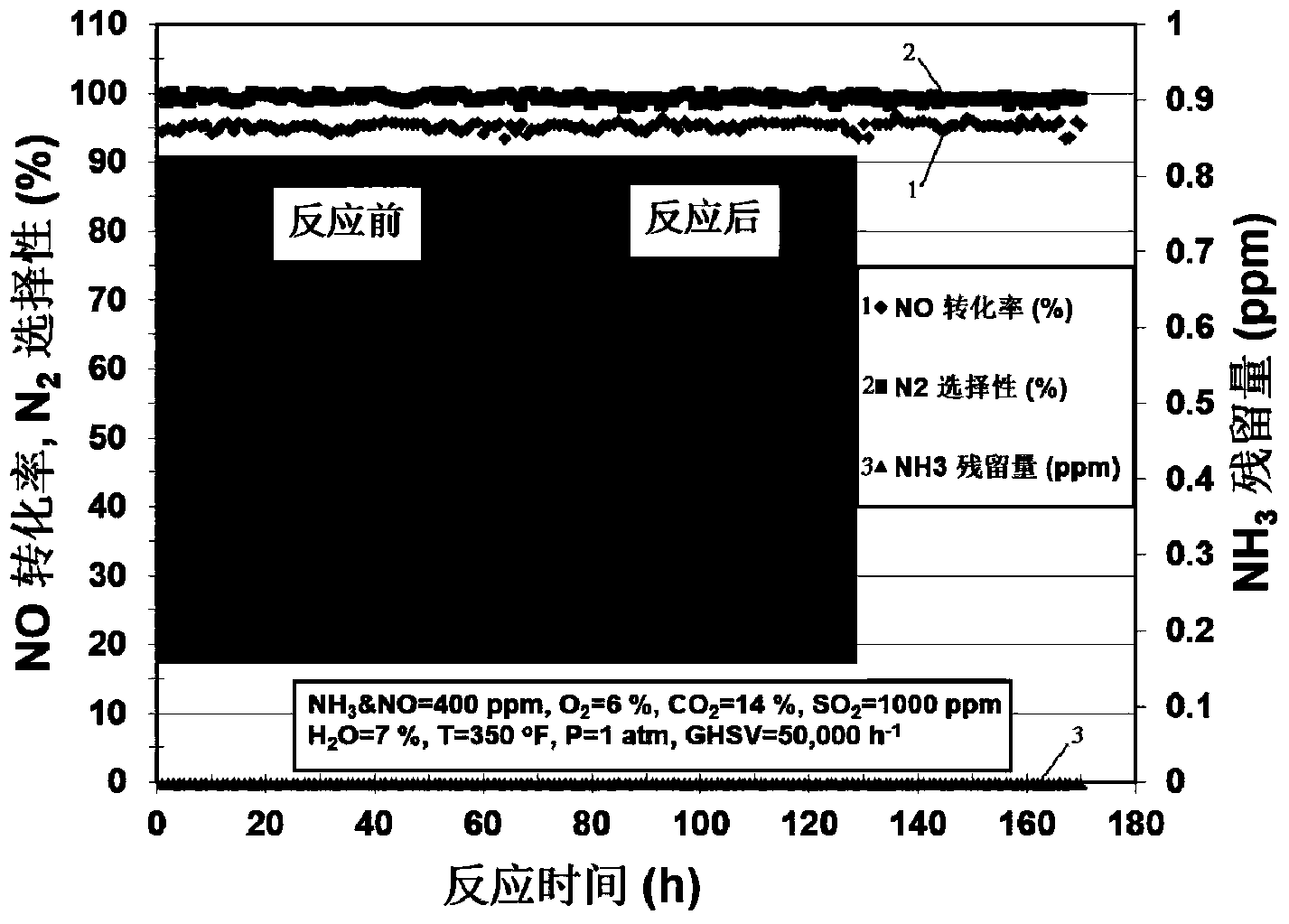

Low-temperature sulfur-resistant denitration catalyst and preparing method thereof

ActiveCN104056658AStrong water resistanceImprove low temperature denitrification performanceMolecular sieve catalystsDispersed particle separationCapillary condensationMolecular sieve

The invention discloses a low-temperature sulfur-resistant denitration catalyst and a preparing method of the low-temperature sulfur-resistant denitration catalyst. The low-temperature sulfur-resistant denitration catalyst is formed by mixing, by weight, 15%-100% of active sites and 0-85% of carbon-based carriers; the active sites are formed by mixing one or two of the first active sites and the second active sites; the first active sites are composed of Mn(0.1-0.8)Ce(0.2-0.9)Ox or Mn(0.1-0.8)Mg(0.2-0.9)Ox dispersed into a 3A molecular sieve, and the value of the x is determined according to the content and the oxidation valence state of metallic elements in the chemical formula; the second active sites are composed of Mn (0.1-0.8)Mg(0.2-0.9) or Mn (0.1-0.8)Ce (0.2-0.9)Ox with the surface coated with a TiO2 or SiO2 protecting layer. According to the method, one or more of the first active sites and the second active site are mixed with carbon-based carriers to obtain the low-temperature sulfur-resistant denitration catalyst. As surface dewatering is performed on the catalyst, water molecules contained in flue gas are attached in an open-framework structure of the catalyst to form capillary condensation very difficultly or form vitriol or sulphurous acid ammonium salt with NH3 and SO2 or SO3 to cause deactivation of the catalyst.

Owner:XIAN SINO GREEN HI TECH CO LTD

Method for synthesizing taurine

InactiveCN101100449ANo escapeImprove economySulfonic acid preparationTaurine synthesisChemical synthesis

Synthesis of taurine is carried out by: reducing esterified product of cholamine with ammonium sulfite as reducer, separating to generate crude product, and re-crystallizing to obtain final product. It's economical, has no SO2 gas discharge and has friendly production environment and can separate out taurine and sulfate at low temperature.

Owner:JIANGSU YUANYANG PHARMA

Polyvinylidene fluoride resin composition

InactiveUS6610766B1Good precisionLow hazeSynthetic resin layered productsElectrography/magnetographyPolyvinylidene difluoridePolyvinylidene fluoride

The invention relates to polyvinylidene fluoride resin compositions comprising 100 parts by weight of a polyvinylidene fluoride resin, and 0.03 to 10 parts by weight of at least one compound selected from the group consisting of alkyl quaternary ammonium sulfates and alkyl quaternary ammonium sulfites.

Owner:KUREHA KAGAKU KOGYO KK

Method for inhibiting low-temperature denitration catalyst poisoning caused by SO2

ActiveCN104162349AInhibition of poisoningThe purpose of suppressing poisoningDispersed particle separationSalt depositCatalyst poisoning

The invention discloses a method for inhibiting low-temperature denitration catalyst poisoning caused by SO2. A NO oxidation device is arranged at a flue gas inlet of a selective catalytic reduction (SCR) denitration facility, 5-70% of NO in flue gas is oxidized into NO2 by the NO oxidation device, the flue gas containing NO2 is fed into the SCR denitration facility at a space velocity of 1000-200000h<-1> and the flue gas is subjected to denitration purification at a temperature of 50-300 DEG C. Through a reaction of NO2 obtained by oxidation of NO and an ammonium salt deposited on the surface of the low-temperature denitration catalyst, the method can effectively inhibit SO2-ammonia gas reaction-caused deposition of ammonium salts such as ammonium sulfate and ammonium sulfite on the surface of the low-temperature denitration catalyst thereby inhibiting SO2-caused low-temperature SCR denitration catalyst poisoning so that a service life of the low-temperature denitration catalyst is prolonged and a SCR denitration operation cost is reduced.

Owner:ZHEJIANG UNIV

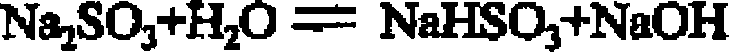

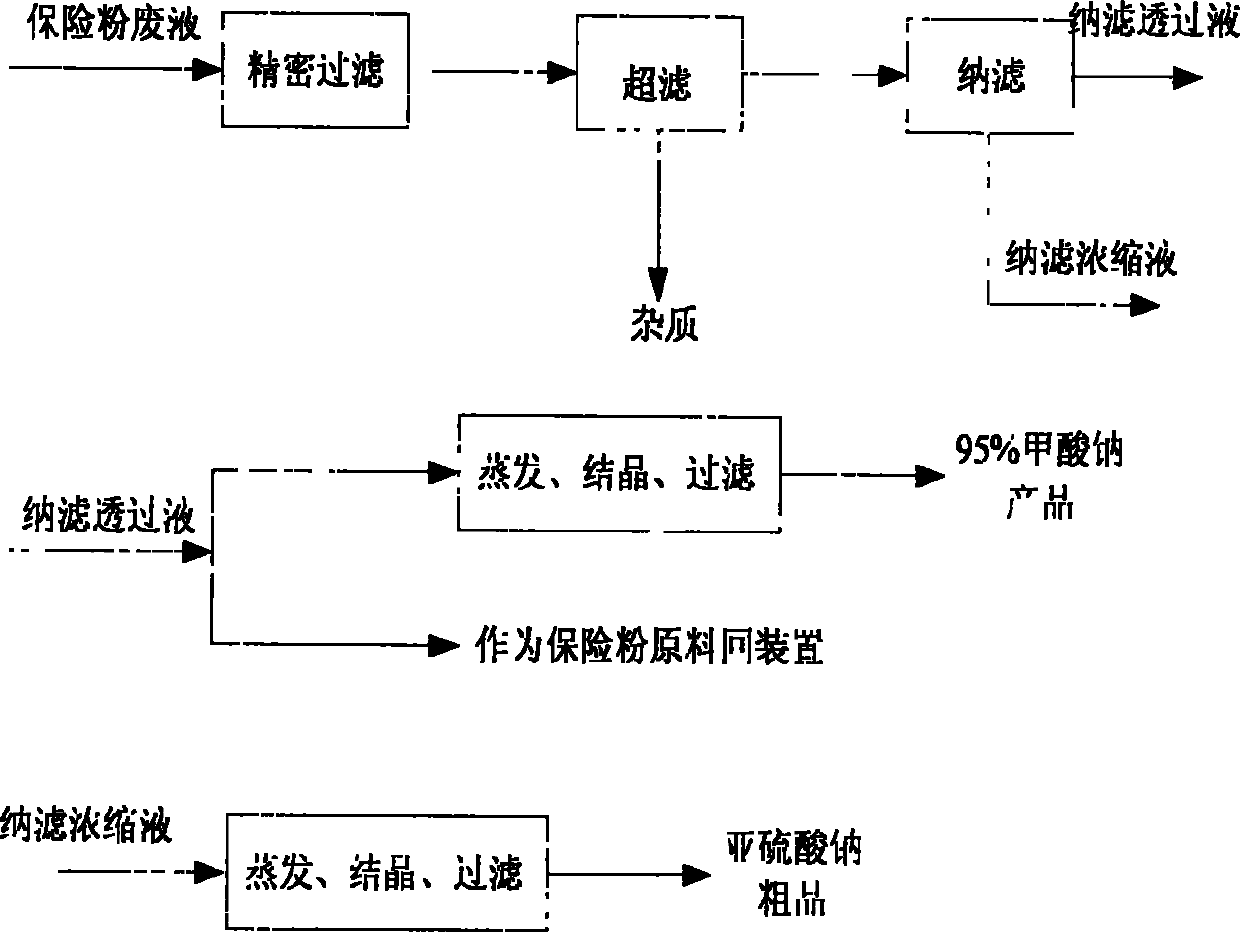

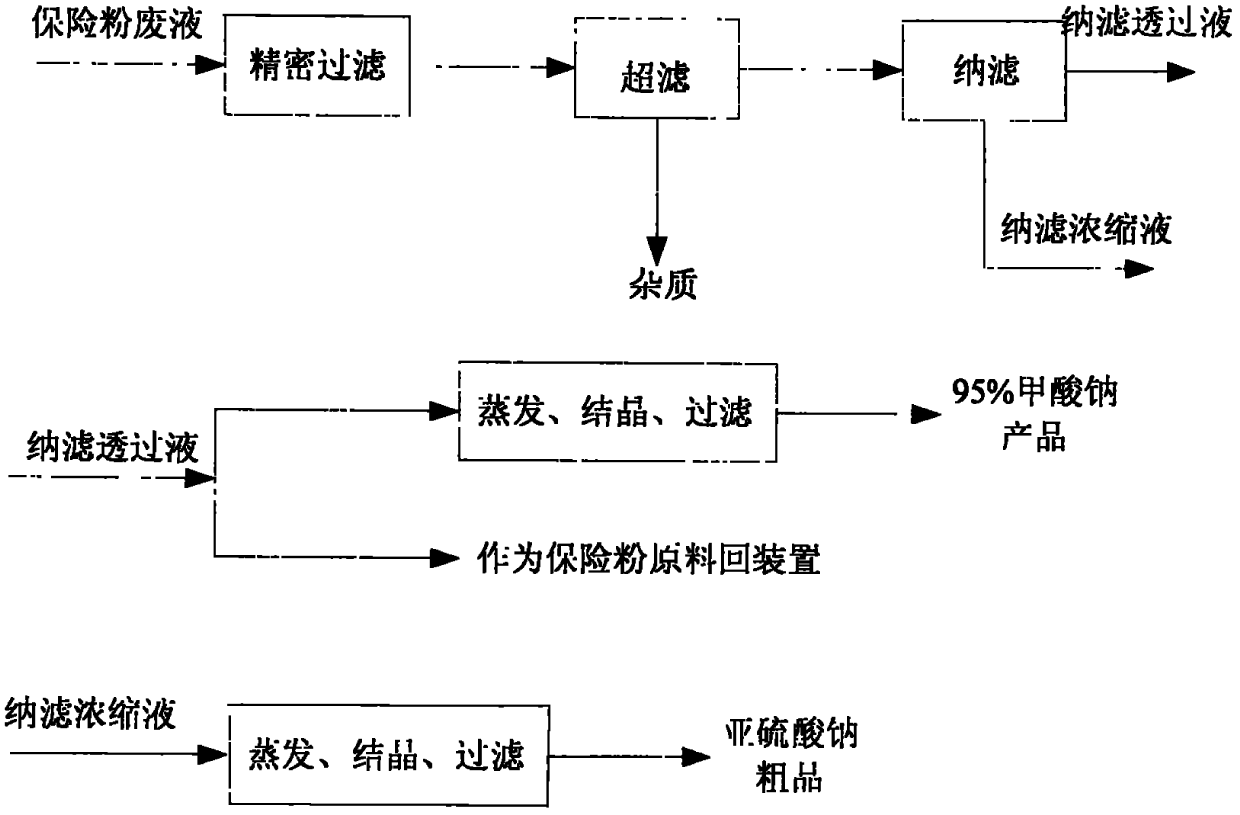

Method for recycling sodium formate and sodium sulfite from waste sodium hydrosulfite liquid with sodium formate method

InactiveCN102050471ANo secondary pollutionHigh purityAlkali metal sulfite preparationMultistage water/sewage treatmentUltrafiltrationFiltration

The invention relates to a method for recycling sodium formate and sodium sulfite from waste sodium hydrosulfite liquid with a sodium formate method. The method comprises the following steps of: carrying out precise filtration and ultrafiltration on waste sodium hydrosulfite liquid with the sodium formate method to remove insoluble substances and granular impurities in the liquid; and then introducing the liquid into a nanofiltration device for nanofiltration separation, wherein after being evaporated and concentrated, an obtained nanofiltration permeate solution can be used as a raw material of the sodium hydrosulfite and returned to a sodium hydrosulfite production station, and can also be continuously evaporated, concentrated, crystallized, centrifuged and filtered to obtain a sodium formate product of which the purity is higher than 95 percent; and an obtained nanofiltration concentrated solution can be introduced into an evaporator for concentrating and then is crystallized, centrifuged and filtered to obtain a crude sodium sulfite product. The method has the technical advantages of no secondary pollution, high purity of the sodium formate, simple process and easiness for industrial realization, wherein the purity can be up to higher than 95 percent.

Owner:YANTAI UNIV

Method for recovering thiocyanate from coke oven gas desulfuration and decyanation wastewater

ActiveCN102424401AMeet the requirements of green circular economyEasy to handleThiocyanic acidPersulfateThiocyanate

The invention discloses a method for recovering thiocyanate from coke oven gas desulfuration and decyanation wastewater. The method comprises the steps of: adding persulfate or sulfuric acid to polyamine salt wastewater for reacting with ammonium thiosulfate so as to generate ammonium sulfate and ammonium sulfite, and further oxidizing into ammonium sulfate and sulfur, thus the wastewater is changed into a two-component mixed liquid which contains ammonium thiocyanate and ammonium sulfate and is easy to separate by crystallization from a three-component mixed liquid, and high-efficiency separation is realized. The purity of the obtained ammonium thiocyanate crystal can reach 99%.

Owner:江苏燎原环保科技股份有限公司

Method for controlling aerosol generation in absorbing process by ammonia process of desulfurization

ActiveCN108722163ALow investment costLow running costGas treatmentUsing liquid separation agentParticulatesReaction temperature

The invention discloses a method for controlling aerosol generation in absorbing process by an ammonia process of desulfurization. Sulfurdioxide is removed from flue gas with an absorption circulatingliquid containing ammonium sulfite in order to control generation of aerosol during absorption in the ammonia process of desulfurization. Efficient desulphurization and dust removal are realized by graded solution component control and reaction condition control, ammonia escape and generation of aerosol in the absorbing process are controlled during efficient desulfurization, initially cooled andpurified flue gas comes into contact with the absorption circulating liquid and a fine particle washing circulating liquid in sequence, the components of each stage of solution and reaction temperature are controlled, synergistical control of absorption, oxidization and concentration is realized, the absorbing efficiency in the absorbing process is ensured, ammonia escape and aerosol are controlled, meanwhile energy consumption is lowered, and long-term stable running of the device is realized.

Owner:JIANGSU NEW CENTURY JIANGNAN ENVIRONMENTAL PROTECTION

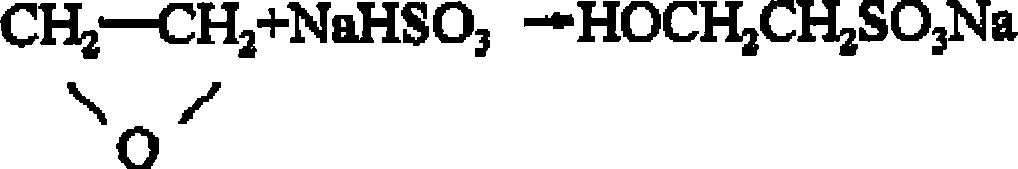

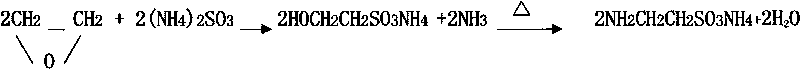

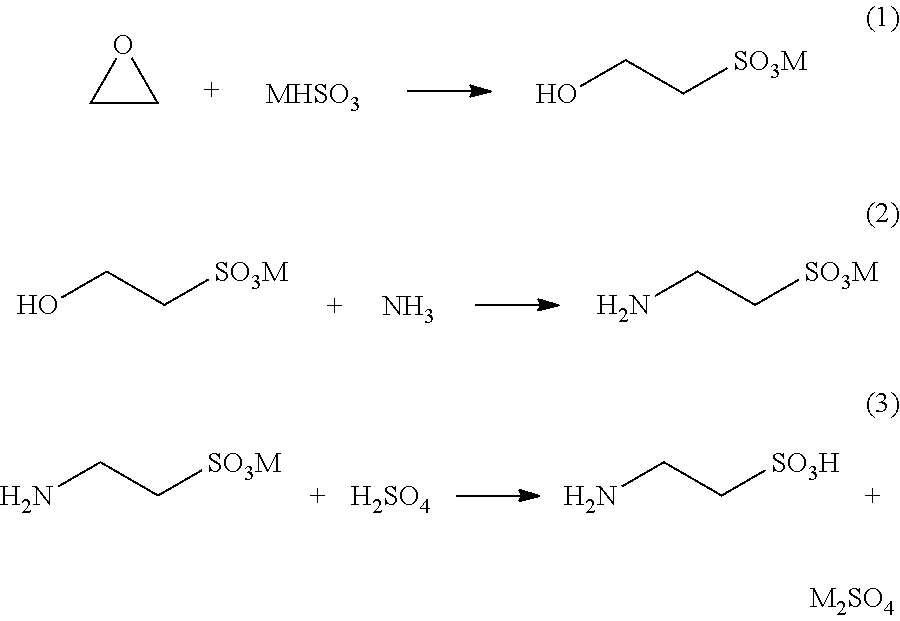

Synthesis method of taurine

InactiveCN101717353AFew reaction stepsSimple craftSulfonic acid preparationChemical synthesisSynthesis methods

The invention relates to a synthesis method of taurine, belonging to the technical field of organic chemical synthesis. The synthesis method comprises the following steps of: reacting the oxirane with ammonium sulfite to obtain taurine ammonium salt, and acidating and refining to obtain the taurine. The reaction steps of the technical scheme are less, the taurine ammonium salt can be obtained just by one-step reaction between the oxirane and the ammonium sulfite, the crude taurine can be obtained by acidating, and the taurine is obtained by refining, therefore, the synthesis method has simple process and can embody the economical efficiency and the cleaning production.

Owner:JIANGSU YUANYANG PHARMA

Method and apparatus for combined removing sulfur-dioxide and nitrogenoxide by mixed solution

InactiveCN101073741AOvercome the shortcoming of single purification process functionImprove efficiencyDispersed particle separationAir quality improvementSulfateDust control

The invention is concerned with a method to remove sulfur dioxide and compounds of nitrogen and oxygen by using a kind of mixed solution. Drop the temperature of gas after moving dust to 100 to 110 degree, and contact with carbamide / ammonia mixed solution with additive to absorb sulfur dioxide and compounds of nitrogen and oxygen, then blow compressed air into the solution to get ammonia sulfate. Remove the solution and make gas contact with carbamide solution with additive, then let out after reaction. It can adopt double level spray or column reactor to coupling the first and second reactors into a same container and separate double lever reactor with clapboard, this predigests the connecting structure of double lever reactor and reduce the height of cleaning equipment and heat lost.

Owner:SOUTHEAST UNIV

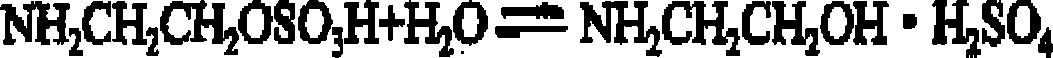

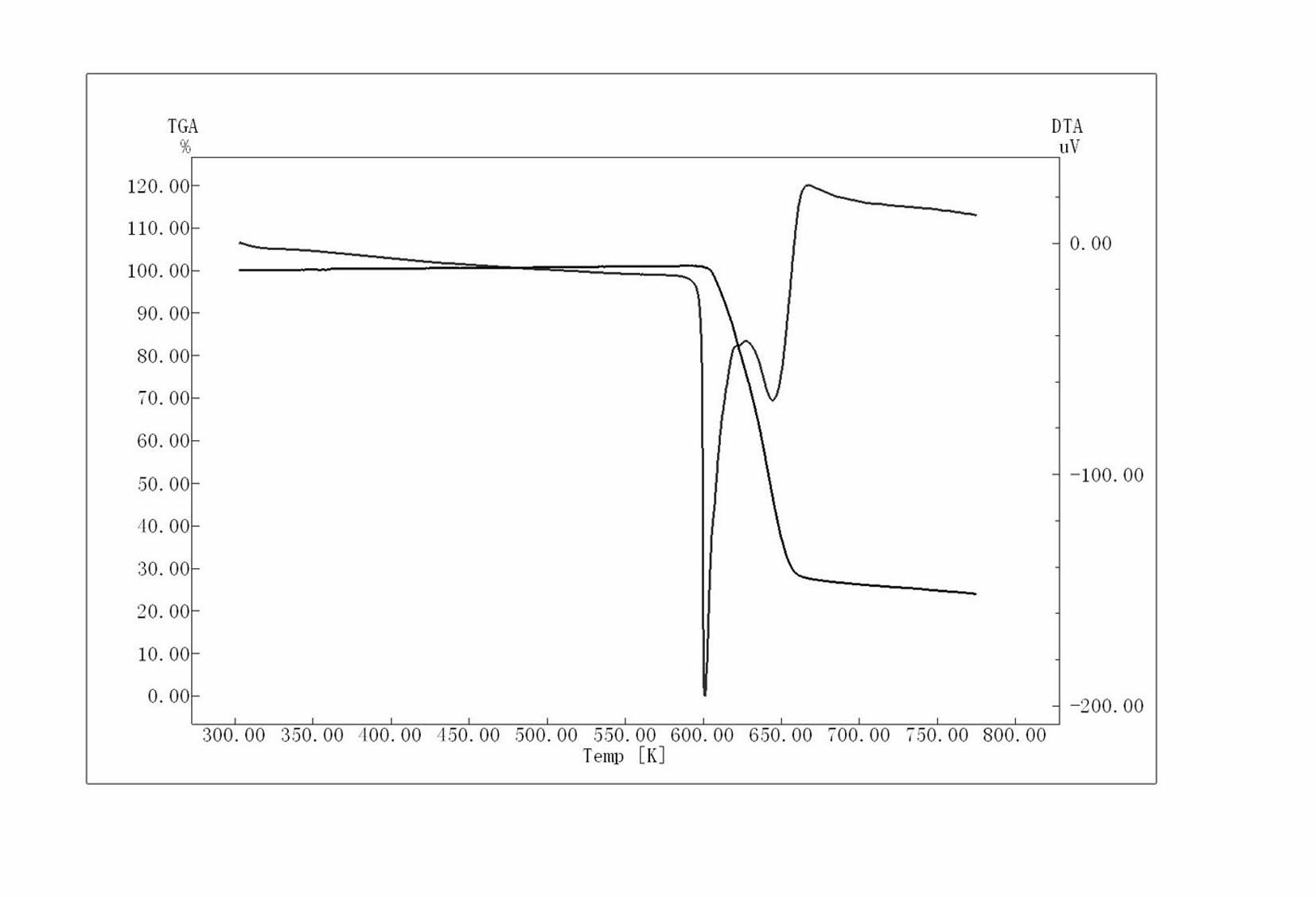

Method for preparing taurine by adopting sulfonation of ammonium sulfite

InactiveCN102633689ASimple operation processMild reaction conditionsOrganic compound preparationSulfonic acid preparationTaurineSulfuric Acid Esters

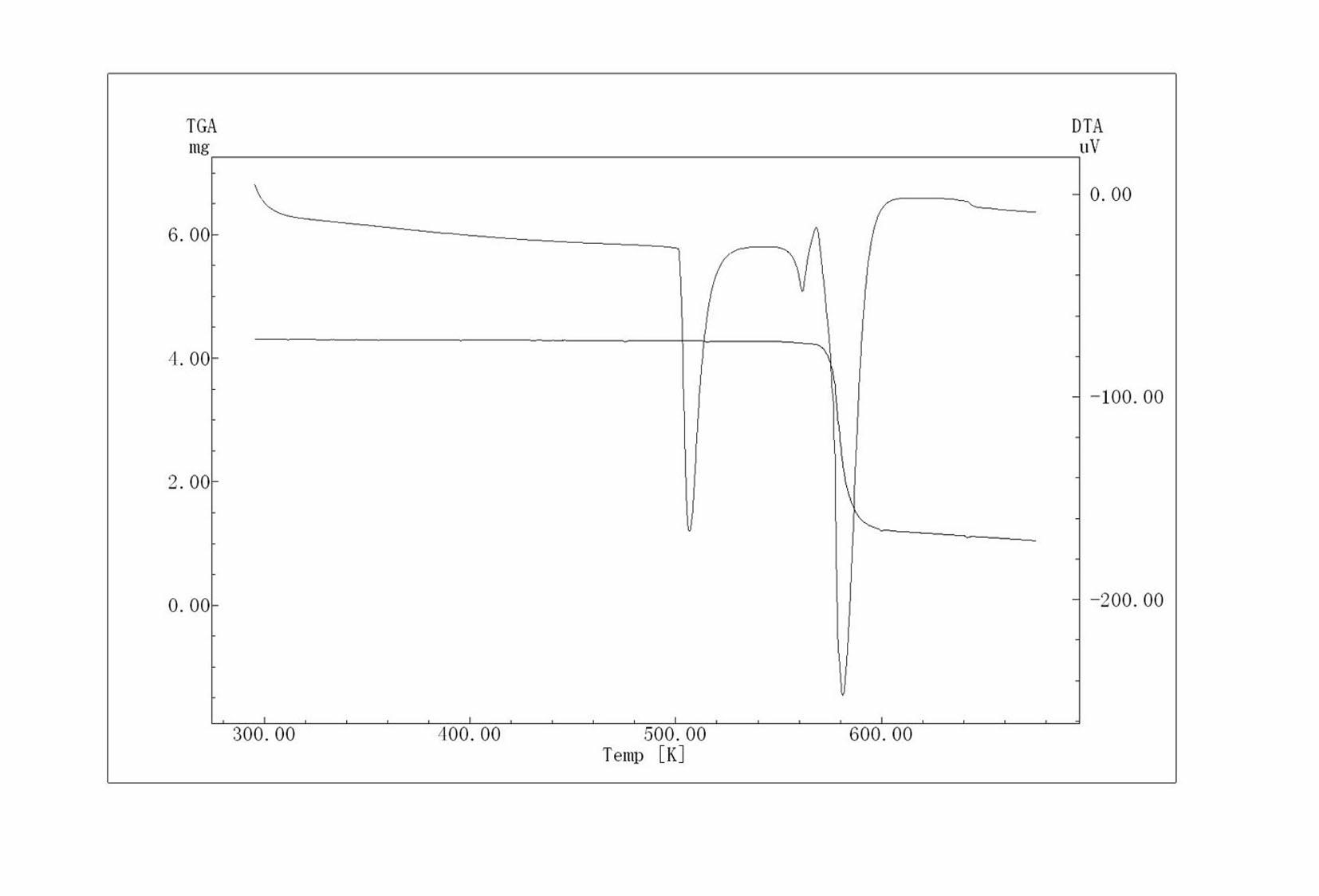

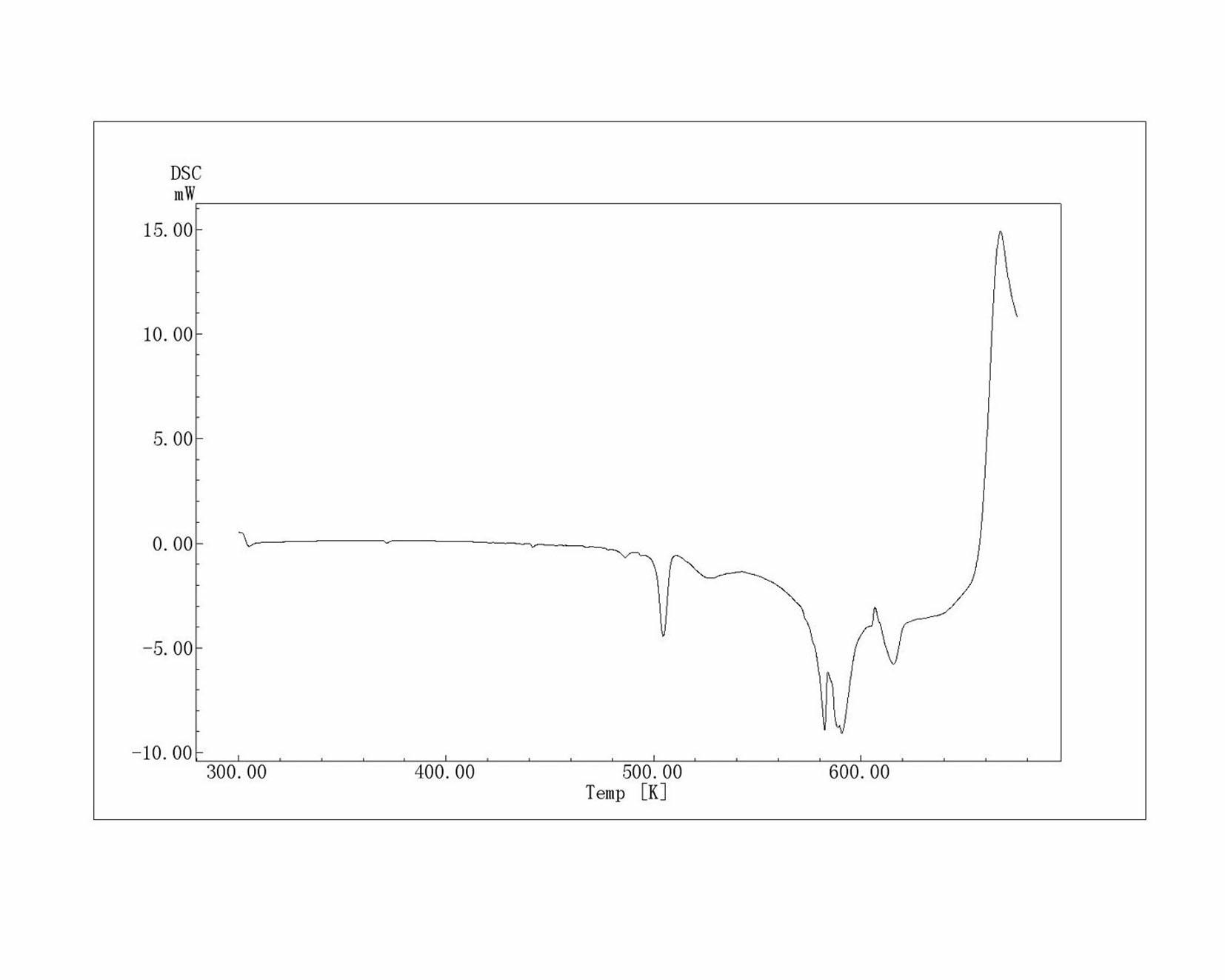

The invention discloses a method for preparing taurine by adopting sulfonation of ammonium sulfite. The method comprises the steps of: firstly carrying out esterification reaction to synthetize an intermediate 2-aminoethanol sulfate by taking concentrated sulfuric acid and ethanolamine as raw materials; carrying out sulfonation reaction to prepare taurine by taking ammonium sulfite and 2-aminoethyl sulfate as the raw materials, wherein ammonia is introduced to protect before the reaction, the temperature of the reaction solution is reduced after the sulfonation reaction is finished, and the conversion ratio of 2-aminoethyl sulfate is analyzed by adopting a sodium thiosulfate inverse titration method; cooling the reaction solution to room temperature, adding calcium hydroxide, heating, agitating and filtering to remove calcium sulfate, removing ammonia in mother liquor and repeatedly utilizing the mother liquor; then purifying the taurine by a cooling and crystallizing method to obtain crystal, carrying out suction filtration and baking the obtained crystal, and analyzing the taurine crystal by a thermal analysis method. The method disclosed by the invention is an integrated preparation method of combining the synthesis and separation of the taurine. The method is the preparation method of the taurine with simple operating process and mild reaction condition, wherein the primary conversion rate of 2-aminoethyl sulfate can be up to 79% and the desalination efficiency is 99.12%.

Owner:ZHENGZHOU UNIV

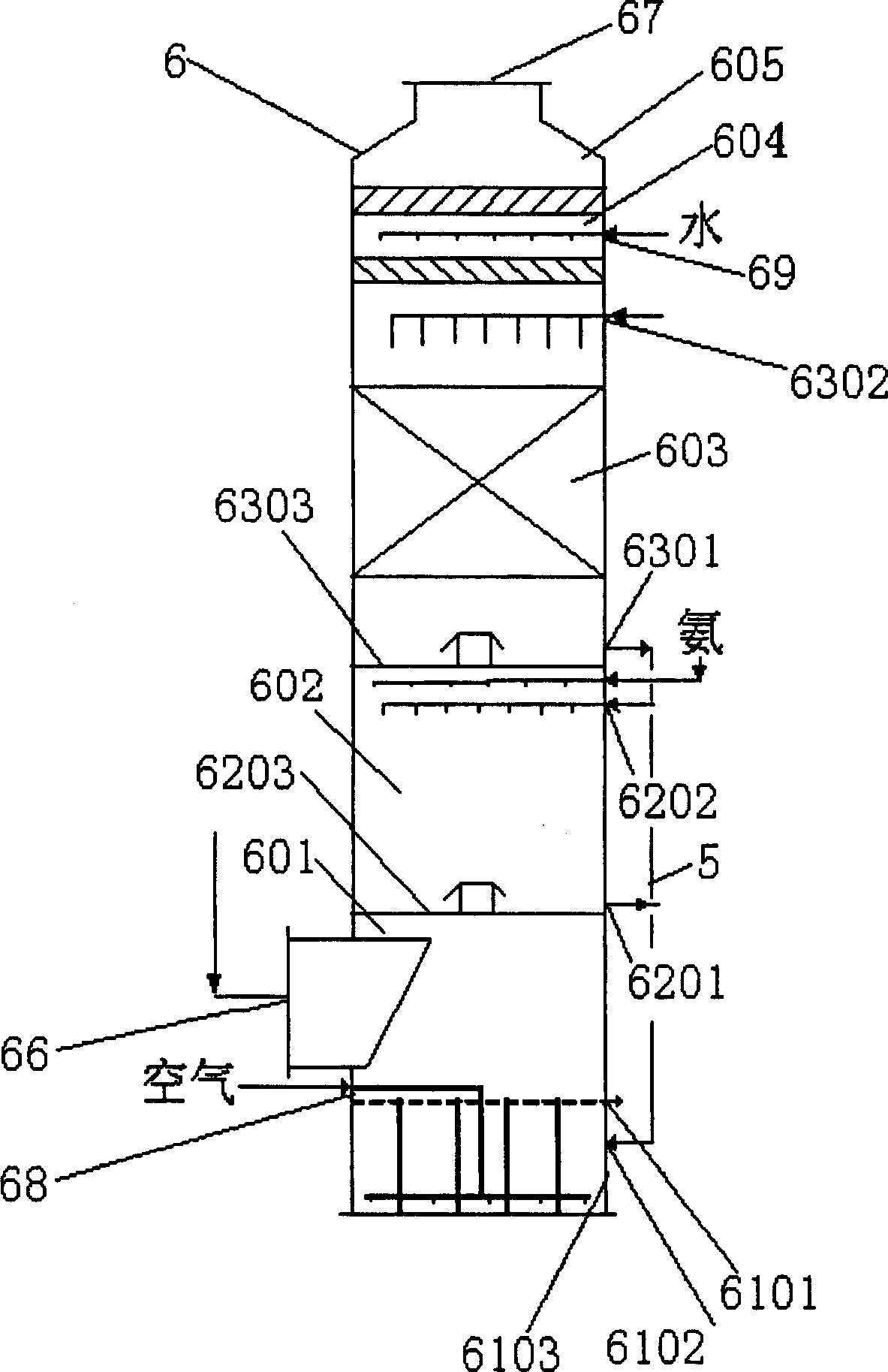

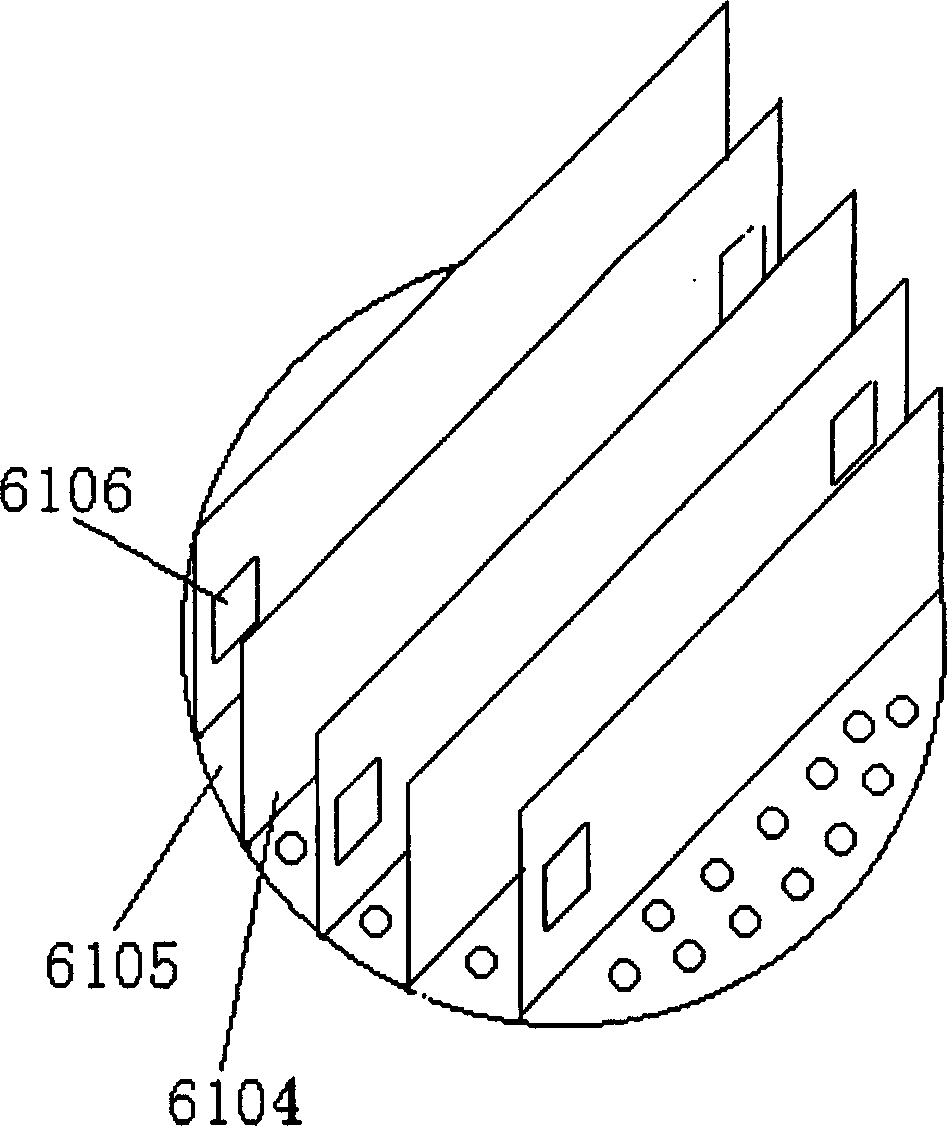

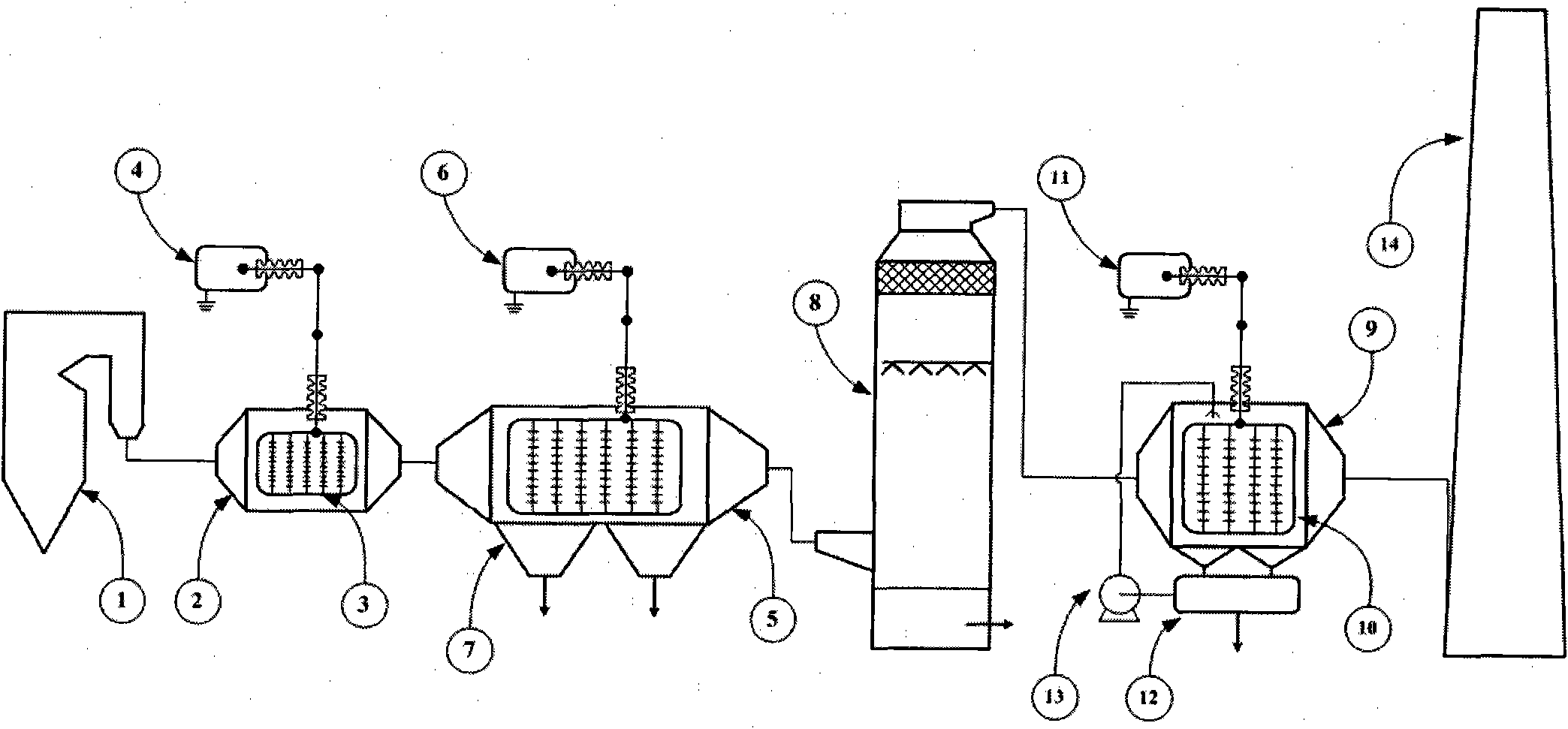

Sintering flue gas ammonia method desulfurizing system

ActiveCN101053760AReasonable processEmission complianceDispersed particle separationFurnace typesHigh concentrationCarbonization

The invention relates to an ammonia desulfurization system for sintering flue gas, and the system comprises a gasifying equipment, a absorbing equipment, an oxidation equipment, a concentration equipment and filter equipment etc. The ammonia desulfurization system for sintering flue gas of the invention can removes the SO2 in the flue gas effectively, but also can desulfurizate by reacting with SO2 in the flue gas using carbonization waste water (liquid ammonia gasified). The product of ammonium sulfite is oxidated in a low concentration at the common pressure, and then is concentrated by evaporation by the quantity of heat of the flue gas to greatly save the heat dissipation of concentration by evaporation to arrive at the aim of economize on energy. The ammonia sulfate solution in high concentration is filtrated, and then is send to the ammiaonia sulfate plant to produce chemical fertilizer. The flue gas desulfurization system of the invention has a reasonable process, makes the discharge of the flue gas reach the standard, forms without secondary pollution, treatment the waste gas by waste carbonization waste water, and produces the byproduct-chemical fertilizer.

Owner:CHINA CITY ENVIRONMENT PROTECTION ENGINEERING LIMITED COMPANY

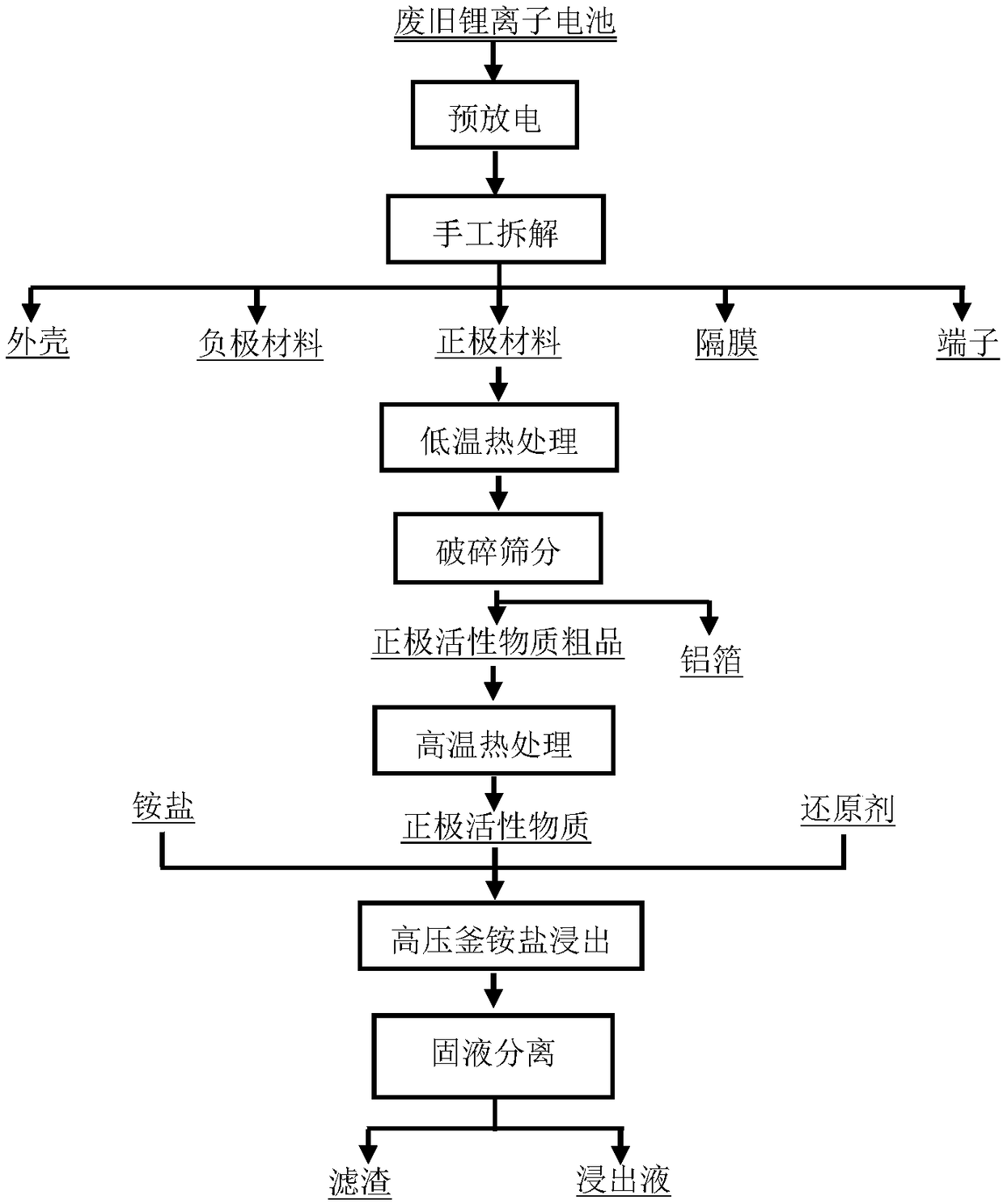

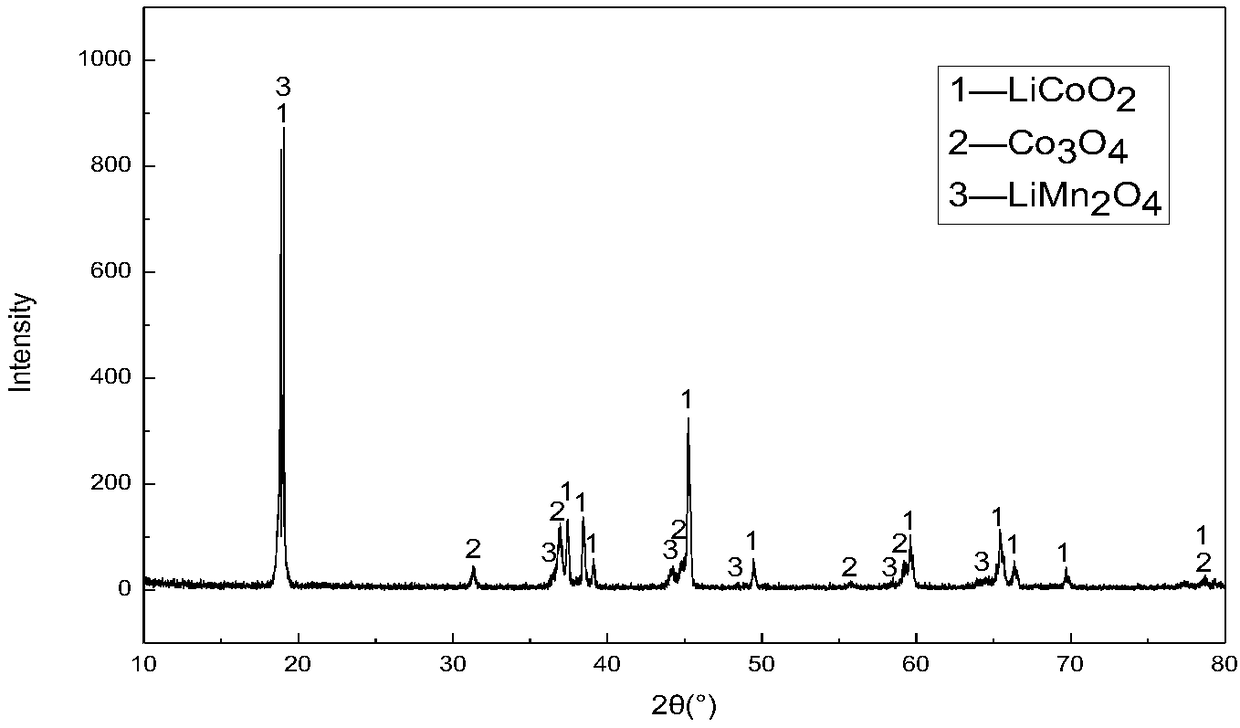

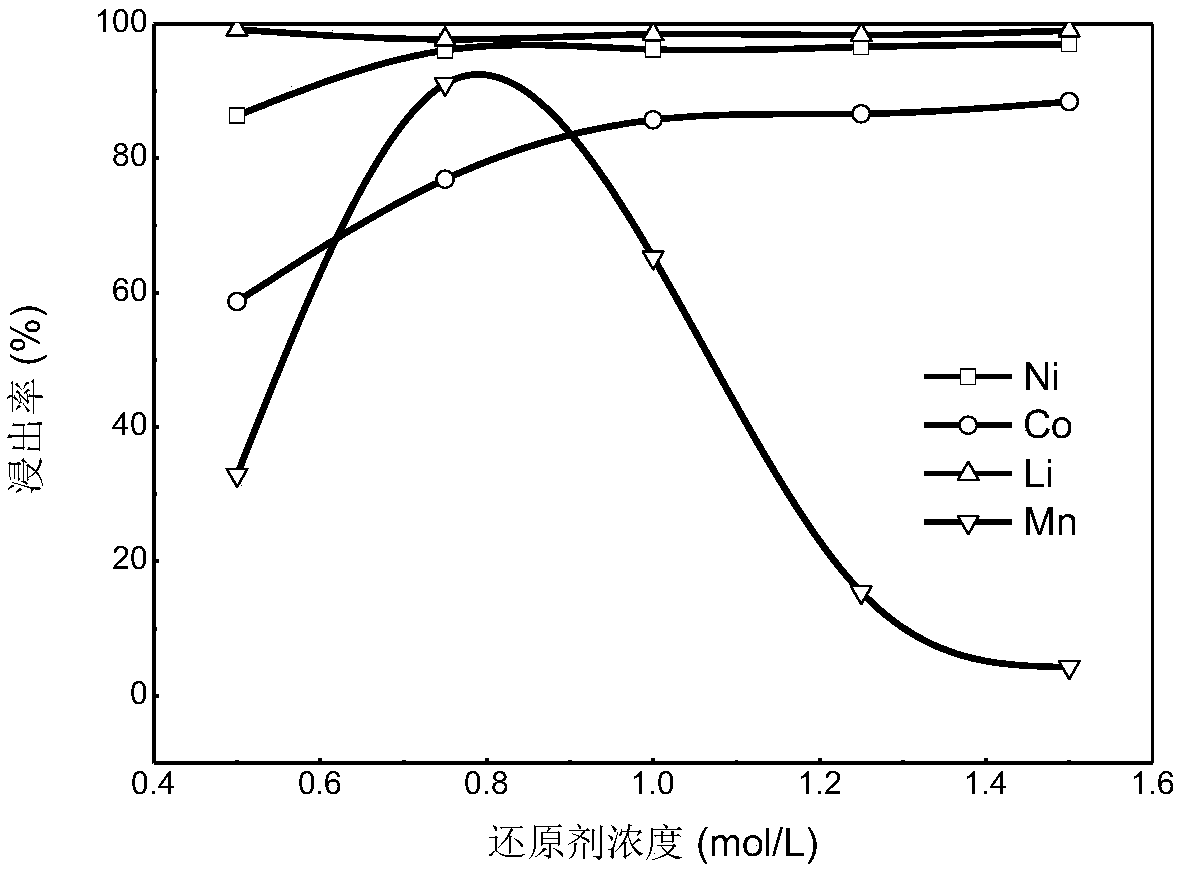

Method for leaching metals in anode material of waste lithium ion battery

InactiveCN108486376AImprove leaching rateHigh selectivityWaste accumulators reclaimingProcess efficiency improvementManganeseHigh pressure

The invention relates to a method for leaching metals in an anode material of a waste lithium ion battery. The method for leaching the metals in the anode material of the waste lithium ion battery comprises the steps that anode active substances are obtained after the waste lithium ion battery is pretreated, then the anode active substances are made to react with an ammonium salt solution containing a reducing agent, solid-liquid separation is conducted after the reaction, and thus, leachate and filter residues are obtained. According to the method, the process is simple, the metal leaching rate is high, and the metal selectivity is high; by controlling the type and quantity of the reducing agent used in the leaching process, selective leaching of the metals can be achieved, for instance,when the anode material contains metals such as Li, Co and Mn, the reducing agent is ammonium sulfite, the leaching rate of Mn is 90% when the concentration of the reducing agent is 0.75 mol / L, and the leaching rate of Mn is 4% when the concentration of the reducing agent is 1.5 mol / L; the impurity content of the leachate is low, so that the cost for the subsequent impurity removal procedure is low; and the leaching process is conducted in a high-pressure kettle, emission of poisonous gas is avoided in the operation process, and the operation environment is good.

Owner:CENT SOUTH UNIV

Zero residual base normal-pressure or low-pressure boiling high-concentration pulp preparing method by using base process

InactiveCN101215794ARapid responseNo residual alkaliDigestersNon-macromolecular organic additionHigh concentrationSodium metasilicate

The invention relates to a method for boiling high concentration pulping in normal pressure or low pressure by an alkaline method with zero residual alkaline, and the method comprises adding accelerating agent in the boiling process and utilizing a double screw to rub and squeeze a pulper, leading pulp making and boiling process with an alkaline method to go on in normal pressure or low pressure, and leaving no residual alkaline in black liquor, leading pulp to always keep a higher density in the pulping process of boiling, washing and bleaching, and the pulp which is prepared can meets the requirement of paper making. Accelerating agent chooses one or a plurality of magnesium hydrate, potassium hydrate, sodium metasilicate, sodium sulfide, sodium sulfite, ammonium sulfite and carbamide. Special-purpose pulping boiling equipment and high-pressure boilers are not needed by pulping paper mills through utilizing the invention, in the process of pulping, pulp always keeps higher density, and black liquid has high density, little numbers and low energy consumption, alkaline recovery project with great investment is not needed to be built, and the invention enables black liquid to prepare fertilizer or other chemical products with high quality, and the invention is suitable for popularizing and applying.

Owner:晏永祥

New material with air cleaning function and preparation method thereof

InactiveCN105478003ARealize "Deep Oxygenation"Promote absorptionOrnamental structuresDispersed particle separationFiberDisease

The invention relates to a new material with air cleaning function and a preparation method thereof. The artware material comprises the following compositions in percent by weight: 10-50% of a plant active raw material, 0.4-4% of an antiseptic, 0.1-5% of water-soluble essence, 0.1-5% of a fixative, 0.3%-2% of sodium sulfite, 0.5%-3% of sodium sulfite, 1%-10% of aluminium sulfate, 0.15%-1% of sodium hypochlorite, 0.2%-1% of a pigment, 20%-60% of a solid porous adsorbent, 10%-30% of an active catalyst, 5%-15% of flocculent fiber, and 10%-35% of a binder. A prepared artware possesses unique artistry, natural plant delicate fragrance and strong effects of removing formaldehyde and other harmful gases, performing sterilization and disinfection and purifying air, long-acting infrared ray can guarantee health of family members, and prevention and treatment of diseases are integrated. Also, the manufacture cost is low, operation is simple, and the material and the preparation method are suitable for industrialized production, and are beneficial for the nation and the people. The additive and the chemical reagents added during preparation do not contain harmful substances, and environment pollution is not caused during usage of the new material.

Owner:韦力

Low-temperature sulphur-resisting denitration catalyst and preparation method thereof

ActiveCN104069852AStrong water resistanceImprove low temperature denitrification performanceDispersed particle separationMetal/metal-oxides/metal-hydroxide catalystsCapillary condensationOpen framework

The invention discloses a low-temperature sulphur-resisting denitration catalyst and preparation method thereof. The catalyst is formed by mixing the following components in weight percent: 1-15% of active site and 85-99% of a carbon-base carrier, wherein the active site is formed by mixing one or several of Ag2O, K2O, BaO, SnO2, Bi2O3 or PbO improved vanadium-base alloy oxides. The preparation method comprises the steps of mixing the active site and the carbon-base carrier to prepare the low-temperature sulphur-resisting denitration catalyst. Since the surface hydrophobic treatment is performed on the catalyst prepared by the invention, the situation that water molecules in the flue gas adhere to an open-framework structure of the catalyst to form capillary condensation or form sulfuric acid or ammonium sulfite with adsorbed NH3 and SO2 or SO3 to inactivate the catalyst is avoided.

Owner:XIAN SINO GREEN HI TECH CO LTD

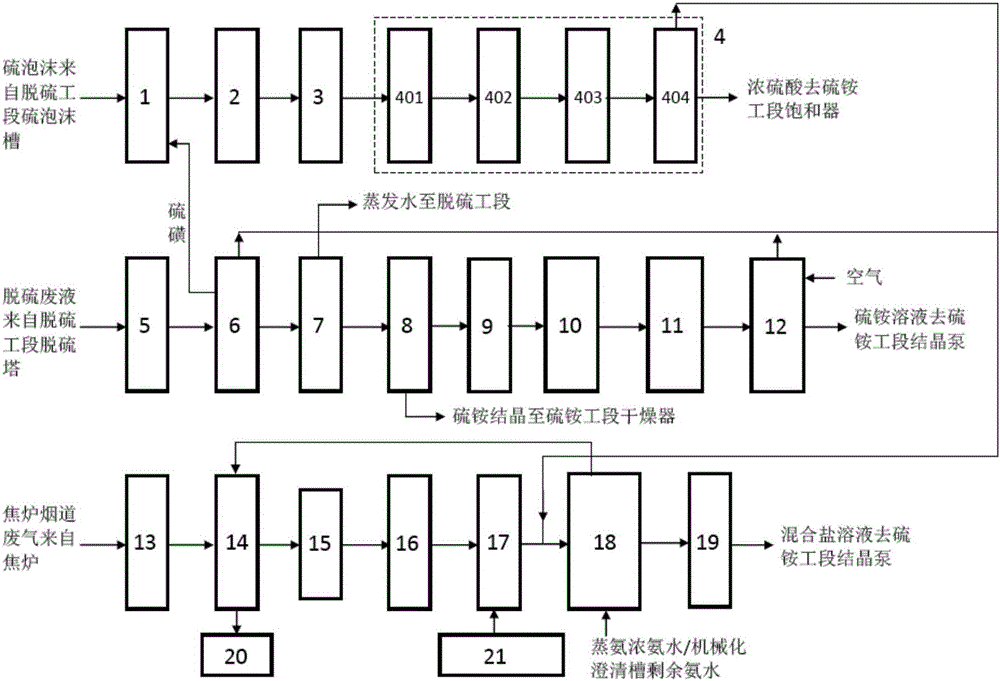

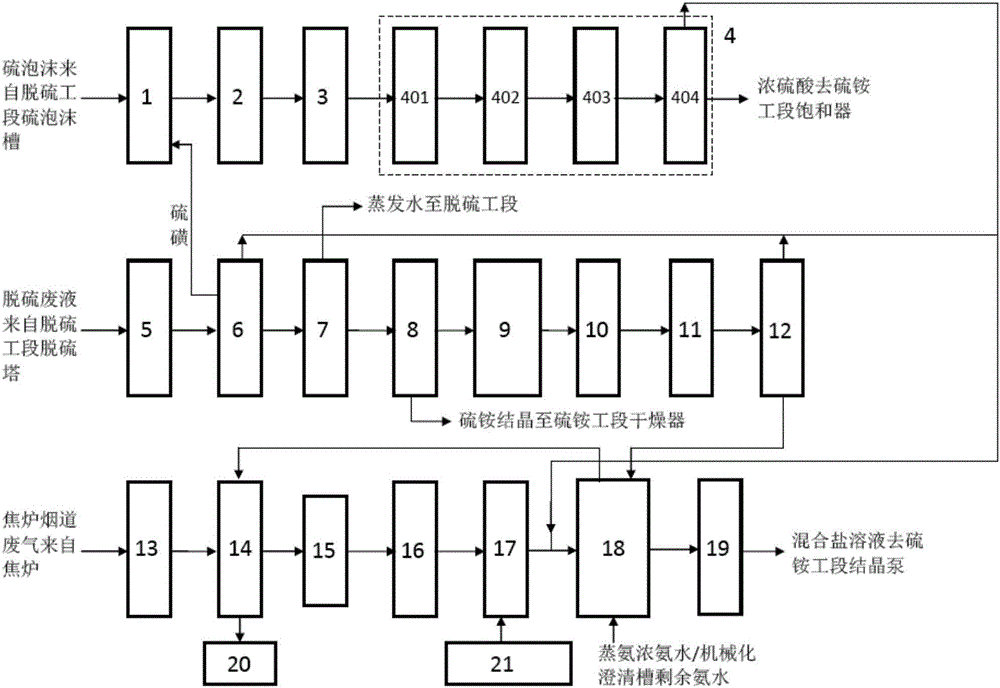

Distributed recycling system and method for sulfur in coking industry

ActiveCN106276973AImprove qualityImprove productivityAmmonium nitratesEnergy inputSelf purificationAmmonium nitrate

The invention relates to a distributed recycling system and method for sulfur in coking industry. Based on coking flow system resource balance, the self-purification function of coking flows are brought into full play, the system considers coupling treatment of sulfur foams, sulfur-containing waste gas and sulfur-containing waste liquid, waste materials are recycled, and the resource process value is increased. According to the technical scheme, sulfur foams are purified, then, pure sulfur is obtained, incineration is performed to produce acid, and obtained concentrated sulfuric acid absorbs ammonia in coke oven gas to produce ammonium sulfate; the desulfurization waste liquid is subjected to decoloration and then subjected to sulfo-oxidation, sulfur is separated out for incineration to produce acid, after solution crystallization and separation, ammonium sulfate and ammonium thiocyanate mother liquor are obtained, the ammonium thiocyanate mother liquor is incinerated to produce SO2, ammonium hydroxide is used for absorbing the produced ammonium sulfite, the ammonium sulfite is oxidized to produce ammonium sulfate or ammonium sulfite to be adopted as a denitrification agent for flue gas denitrification; waste heat of coke oven flue gas is recycled, the coke oven flue gas is mixed with ozone, some or all NO in the flue gas is oxidized, then, the flue gas and the recycling process tail gas are subjected to desulfurization and denitrification, and finally ammonium sulfate and ammonium nitrate are produced.

Owner:TSINGHUA UNIV

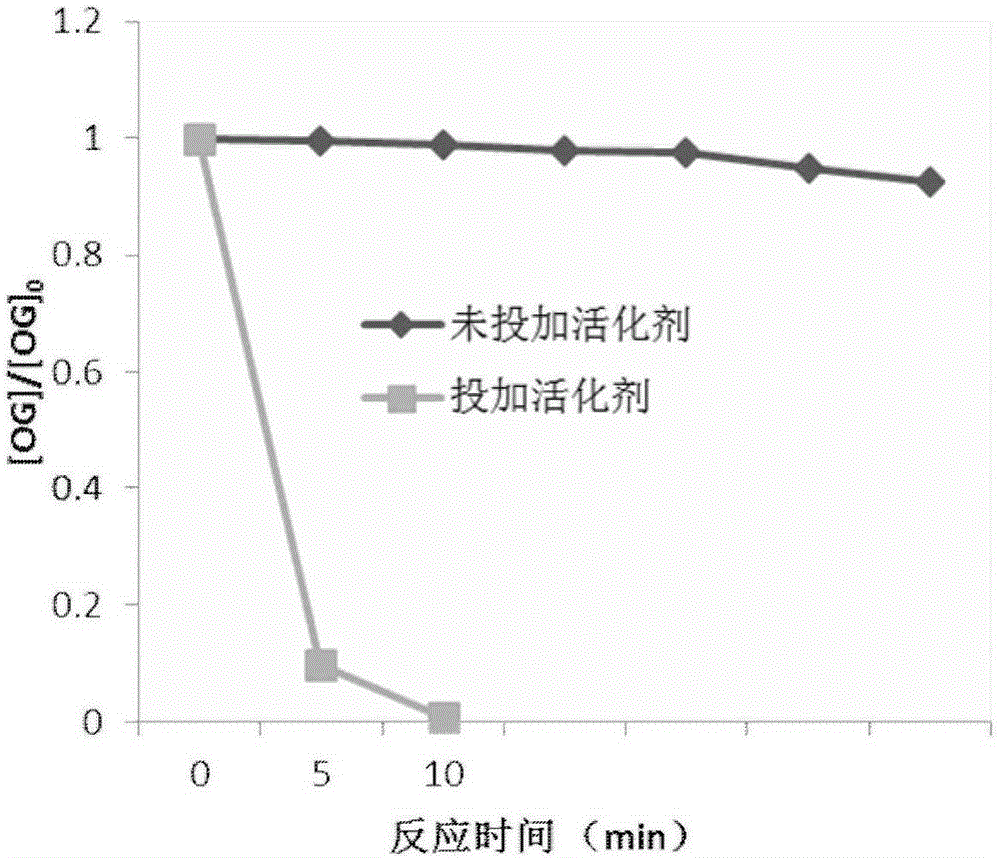

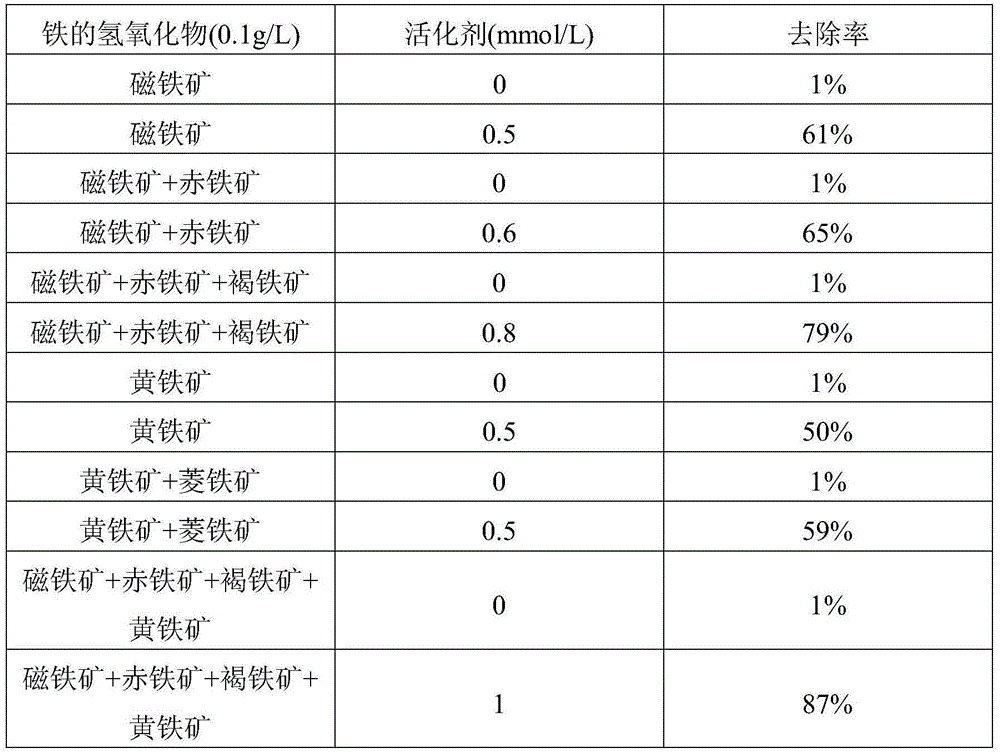

Method for recycling iron waste for fenton technology and water treating device of method

InactiveCN105174413AIncrease reaction rateRealize resource utilizationWater/sewage treatment by oxidationPotassium borohydrideSulfite salt

The invention discloses a method for recycling iron waste for the fenton technology. The method comprises the following steps that hydrogen peroxide, the iron waste and an activating agent are added to waste water to be treated, stirring is conducted so that the iron waste can be dispersed in a reaction system, a reaction is conducted, and then solid and liquid separation is conducted, wherein the activating agent is any one or a mixture of sodium sulfite, potassium sulfite, magnesium sulfite, calcium sulfite, sodium thiosulfate, potassium thiosulfate, calcium thiosulfate, magnesium thiosulfate, sodium borohydride, potassium borohydride, hydroxylamine hydrochloride and ascorbic acid. By means of the method, various kinds of iron waste are recycled, meanwhile, zero iron mud emission is achieved, and thus pollution to the environment is effectively reduced. The invention further provides a water treating device capable of achieving the method. By means of the method and the water treating device, the reaction speed of the iron waste in the fenton system is greatly increased, the effective pH range of the fenton system is expanded, meanwhile zero iron mud emission is achieved, and thus pollution to the environment can be easily reduced.

Owner:HOHAI UNIV

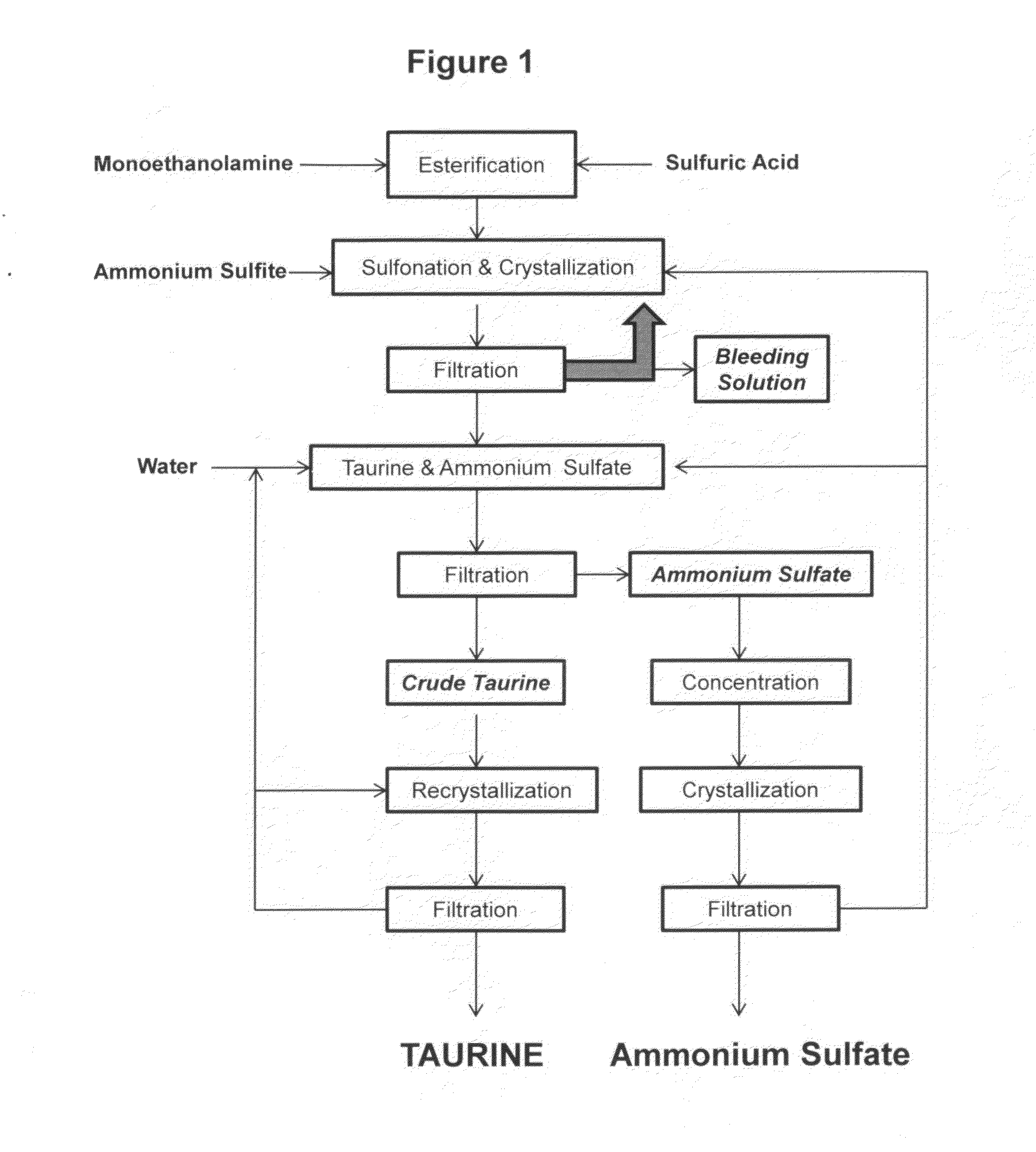

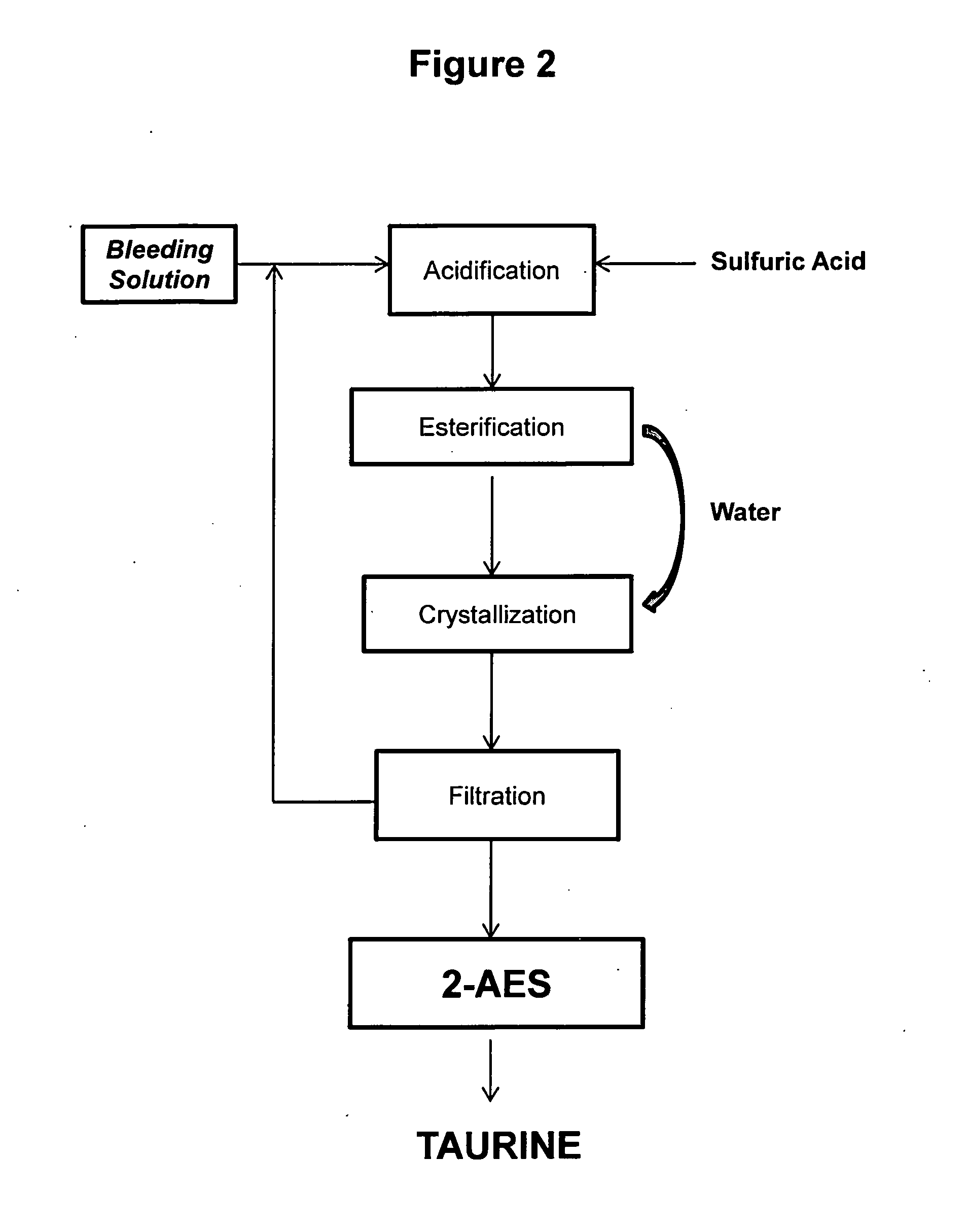

Cyclic process for the production of taurine from monoethanolamine

ActiveUS20150183731A1Avoid huge wasteOrganic compound preparationSulfonic acid esters preparationCyclic process2-aminoethyl hydrogen sulfate

A method is disclosed for the production of taurine in high yield by a cyclic process of reacting monoethanolamine, sulfuric acid, and ammonium sulfite in the presence of additives to inhibit the hydrolysis of 2-aminoethyl hydrogen sulfate intermediate. The cyclic process is economical and little waste is generated.

Owner:VITAWORKS IP LLC

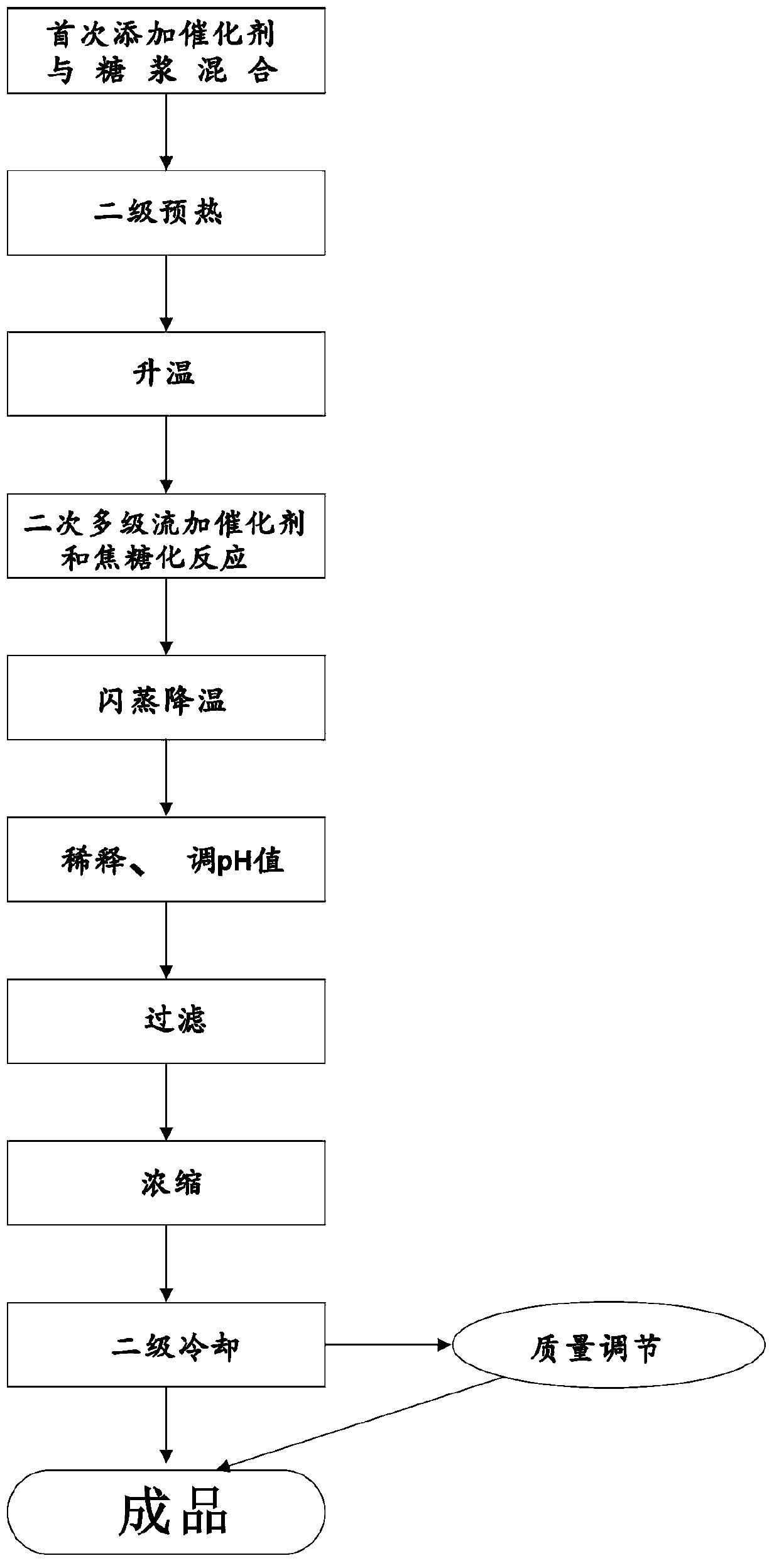

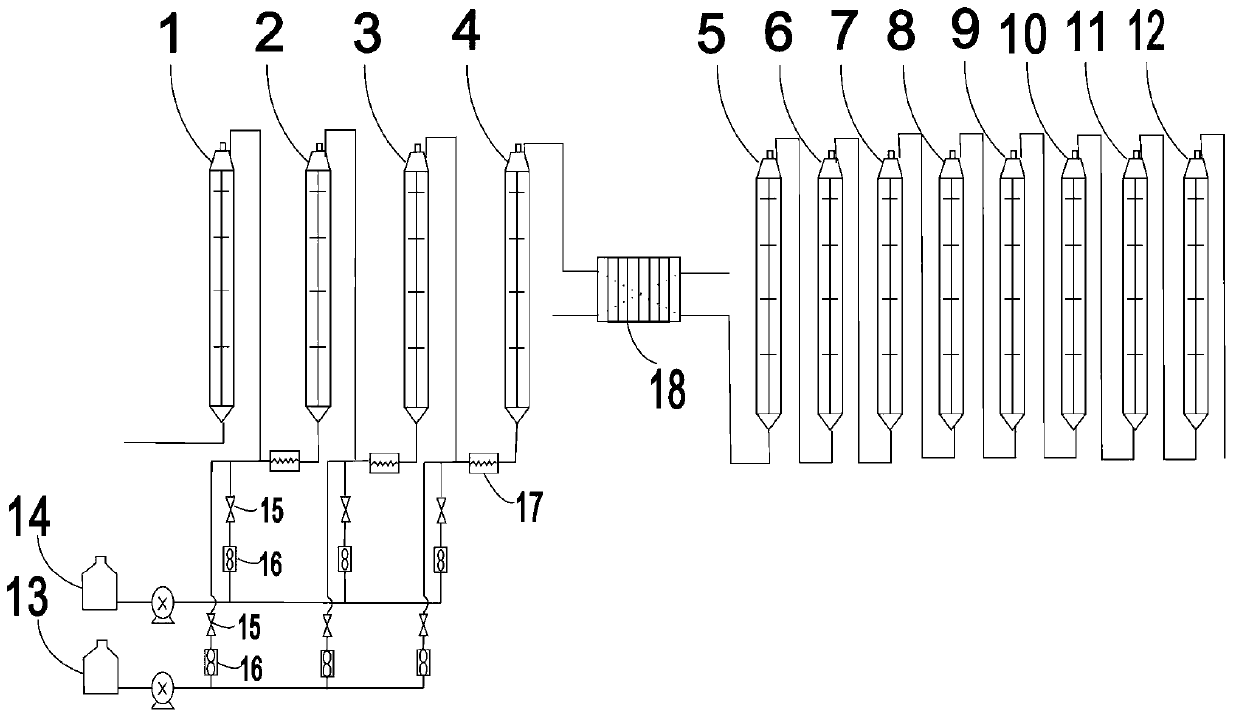

Process for continuous preparation of caramel pigment by ammonium sulfite method

The invention discloses a process for continuous preparation of caramel pigment by an ammonium sulfite method, which comprises the following steps of: (1) adding a catalyst for the first time, and mixing with syrup; (2) performing two-stage pre-heating; (3) increasing temperature; (4) performing secondary multi-stage catalyst feeding and caramelization; (5) flashing and reducing temperature; (6) diluting and regulating pH value; (7) filtering; (8) condensing; (9) performing two-stage cooling, and (10) quality regulating which can be further comprised. The process for continuous preparation of the caramel pigment by the ammonium sulfite method disclosed by the invention can realize continuous and sealed preparation of the caramel pigment by the ammonium sulfite method, improve production efficiency and output, improve safety of the product and reduce the energy consumption; the produced caramel pigment is stable in quality, and is capable of simultaneously meeting high color index and high red index, being ideal caramel pigment in many fields, particularly in soy sauce.

Owner:GUANGZHOU SHUANGQIAO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com