Patents

Literature

1359 results about "Sodium formate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sodium formate, HCOONa, is the sodium salt of formic acid, HCOOH. It usually appears as a white deliquescent powder.

Compositions and methods including formate brines for conformance control

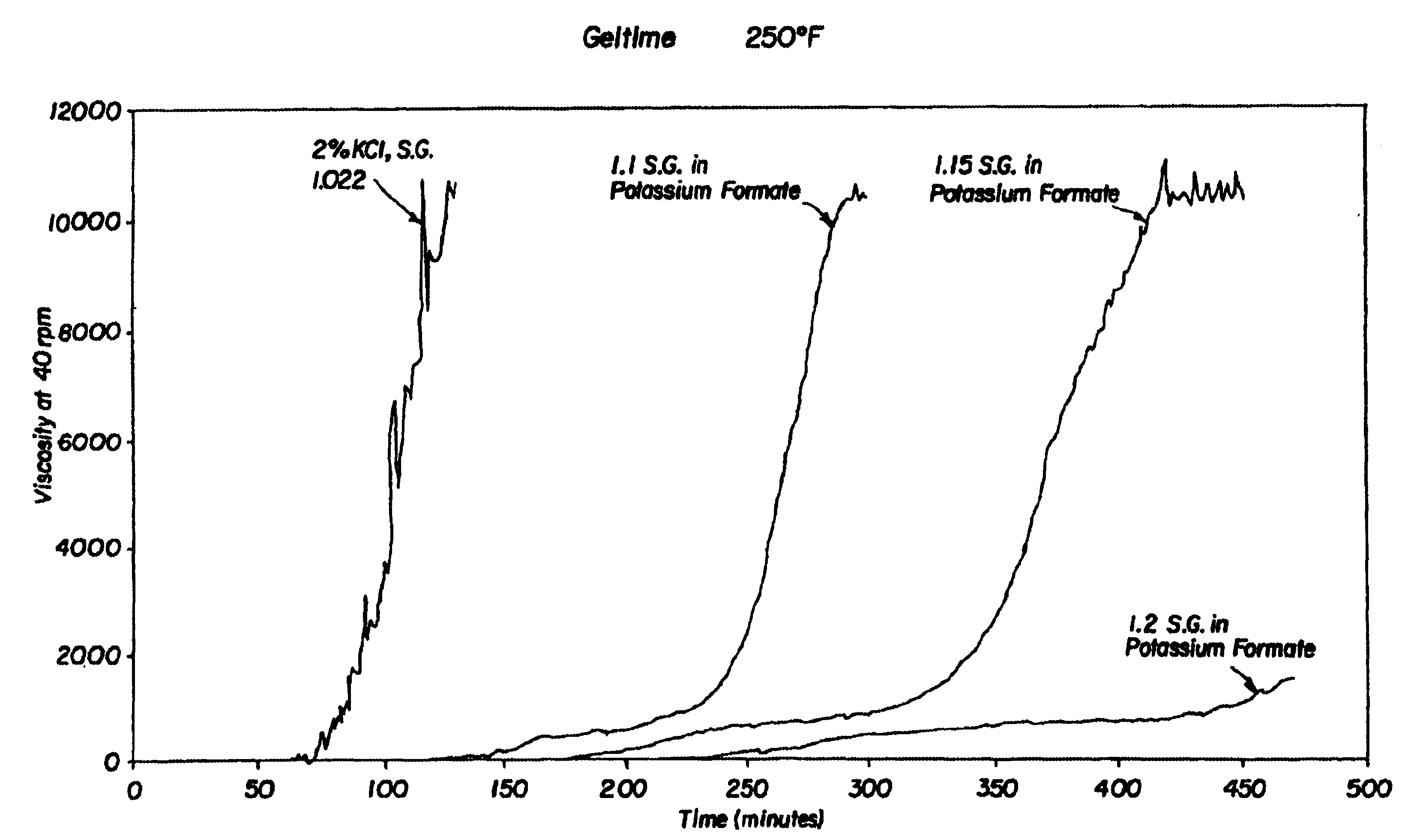

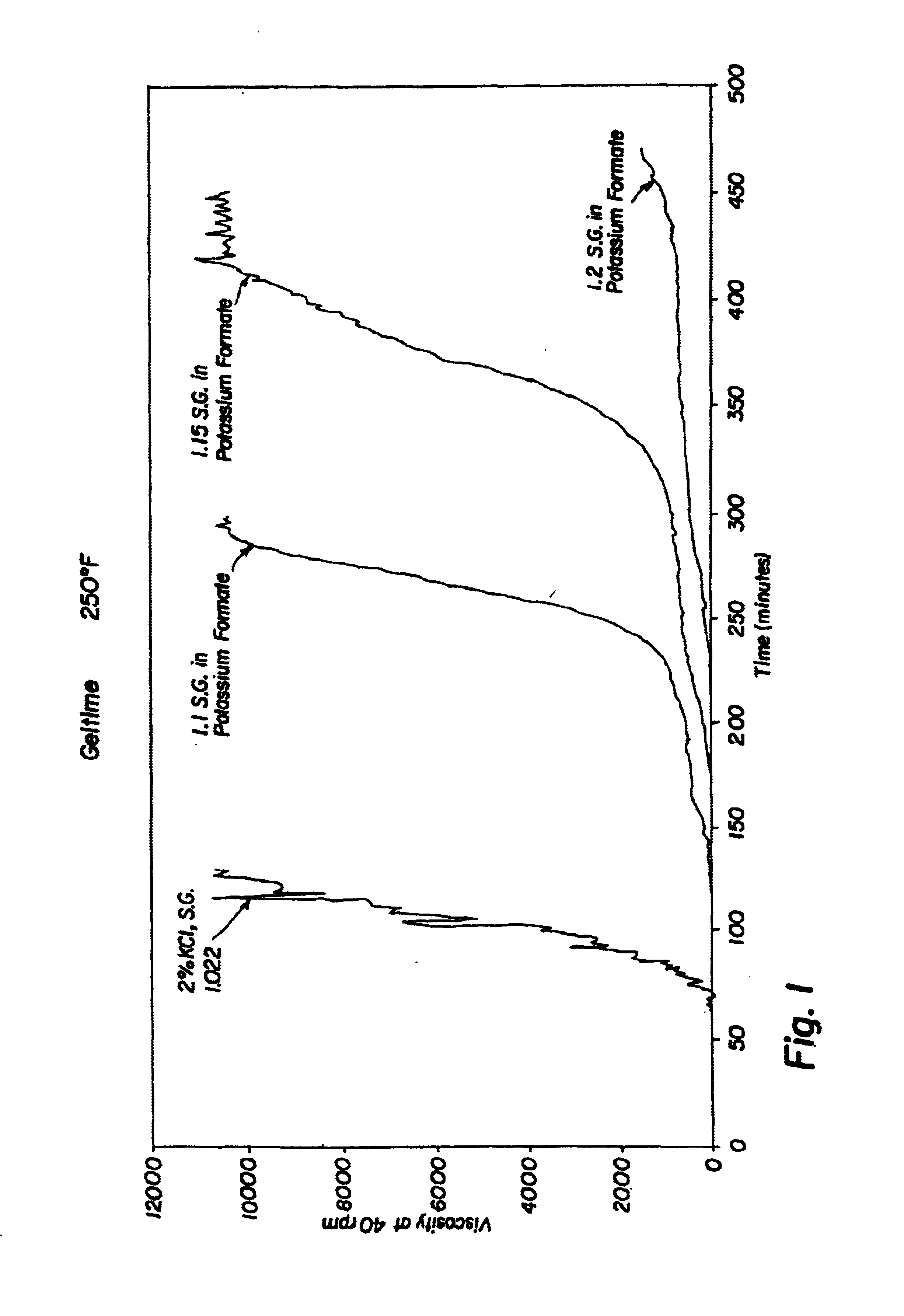

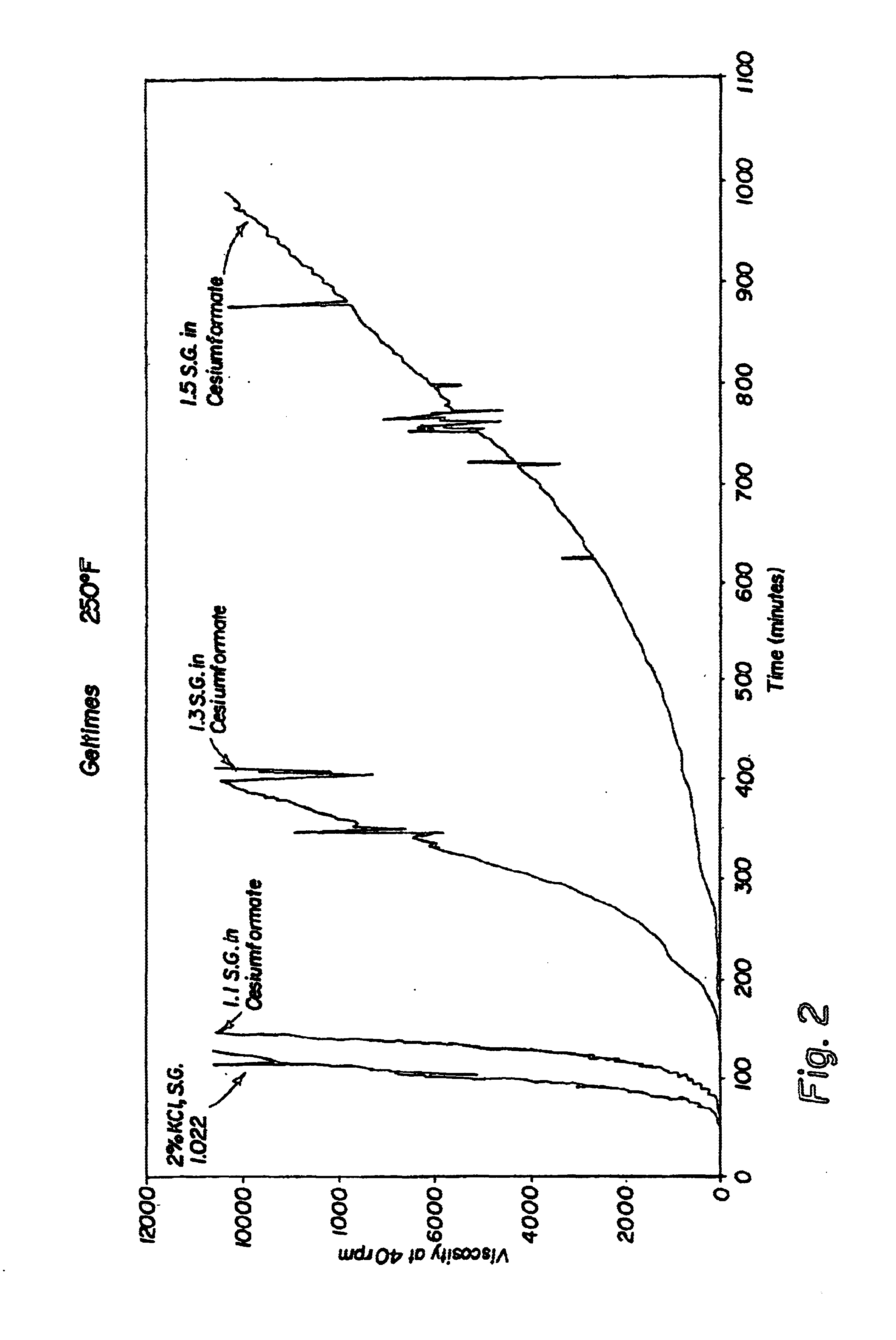

Compositions and methods are provided for reducing the permeability of subterranean zones. More particularly, water-soluble polymeric compositions which form cross-linked gels in the zones. In general, the composition comprises (a) at least one water-soluble polymer; (b) at least one organic gelling agent capable of cross-linking the water-soluble polymer; and (c) at least one water-soluble formate. More preferably, the water-soluble polymer is a copolymer of (i) at least one non-acidic ethylenically unsaturated polar monomer, and (ii) at least one copolymerisable ethylenically unsaturated ester. The gelling agent is preferably selected from the group consisting of a polyalkyleneimine, polyfunctional aliphatic amine, an aralkylamine, and a heteroaralkylamine. The preferred water-soluble formate is selected from the group consisting of ammonium formate, lithium formate, sodium formate, potassium formate, rubidium formate, cesium formate, and francium formate. Water is used to make an aqueous composition prior to use in a subterranean formation. The methods of this invention for reducing the permeability of a subterranean zone are comprised of the steps of introducing an aqueous composition according to the invention into a subterranean zone, and then allowing the aqueous composition to form a cross-linked gel in the zone. Preferably, the method includes the step of subsequently producing hydrocarbons from the subterranean formation.

Owner:HALLIBURTON ENERGY SERVICES INC

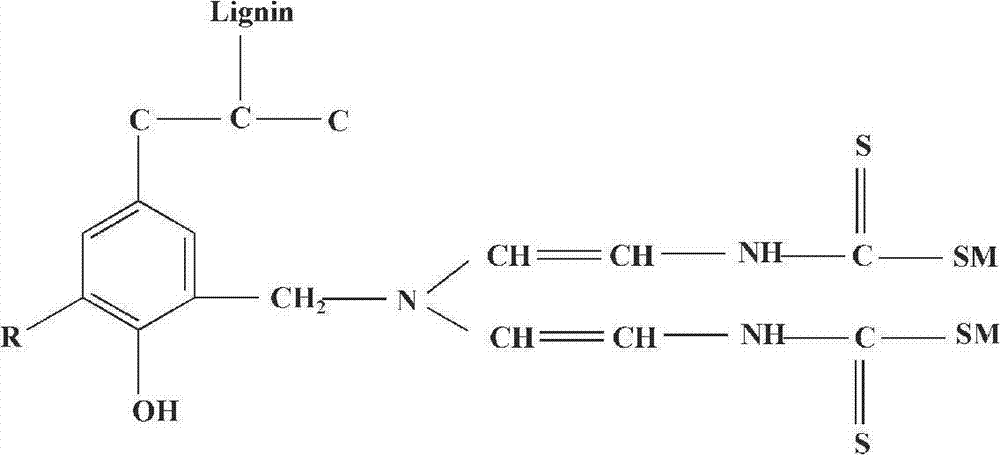

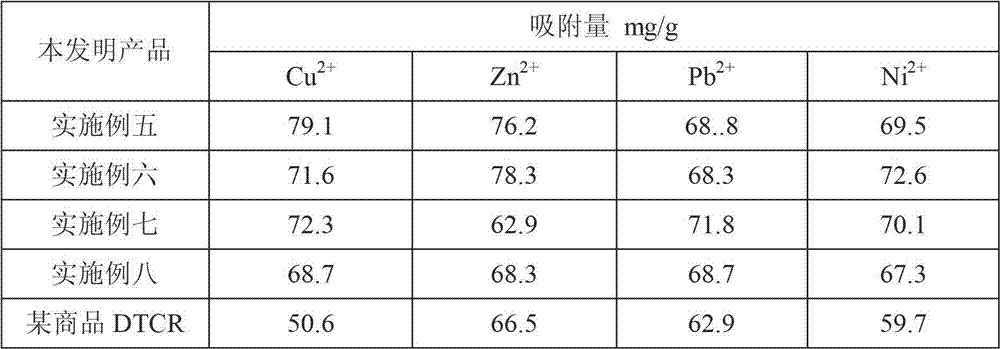

Heavy metal stabilizer for removal of heavy metal pollution and its using method

InactiveCN102784452AChemically stableFast precipitationWater contaminantsContaminated soil reclamationIonAfter treatment

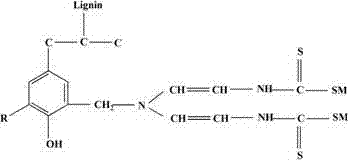

The invention relates to a heavy metal stabilizer for removal of heavy metal pollution and its using method. The heavy metal stabilizer contains the compound lignin-based dithiocarbamate, which is a combination of one or more of lignin-based sodium dithiocarbamate, lignin-based potassium dithiocarbamate, or lignin-based ammonium dithiocarbamate, and can be used for treatment of heavy metal pollution. After treatment with the heavy metal stabilizer provided in the invention, the heavy metal content can meet the requirements of environmental protection standards. A heavy metal ion chelate formed after the treatment is chemically stable and is difficult to cause secondary pollution. Meanwhile, the treatment cost of heavy metal pollution can be significantly reduced.

Owner:GUANGXI UNIV

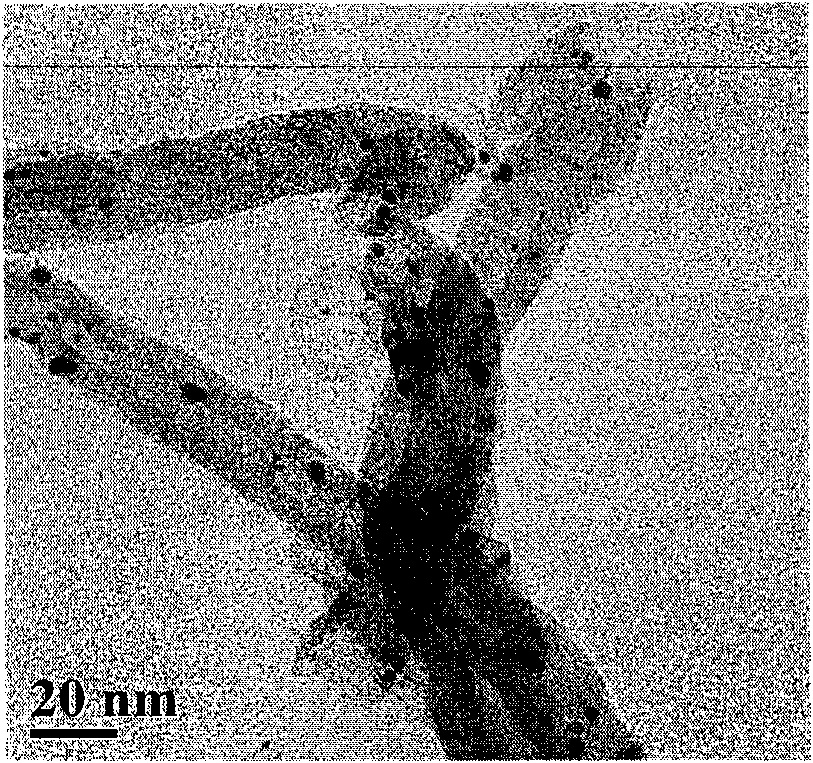

Platinum/carbon nanotube catalyst and preparation method and application thereof

InactiveCN102039121AMild conditionsEasy to manufactureOrganic reductionMaterial nanotechnologyCarbon nanotubeRoom temperature

The invention relates to a platinum / carbon nanotube catalyst suitable for multiphase asymmetric hydrogenation reaction. Platinum is loaded on a carbon nanotube carrier. A preparation method comprises the following steps of: heating a purified carbon nanotube in nitric acid, washing, filtering, washing by using water until the pH value of filtrate is neutral, drying to obtain the carbon nanotube carrier, soaking in aqueous solution of chloroplatinic acid, and performing ultrasonic treatment at room temperature; and stirring and impregnating a mixture of the carbon nanotube and the aqueous solution of chloroplatinic acid, raising the temperature to 110 DEG C from room temperature, drying at the temperature of 110 DEG C, grinding into fine powder, reducing by using aqueous solution of sodiumformate with heating, filtering, washing by using deionized water and drying. The invention also provides the preparation method of the catalyst and application of the catalyst to the multiphase asymmetric hydrogenation reaction.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

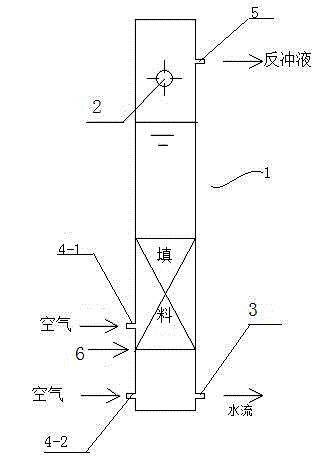

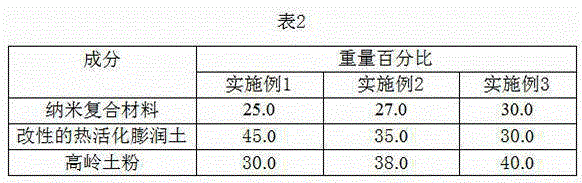

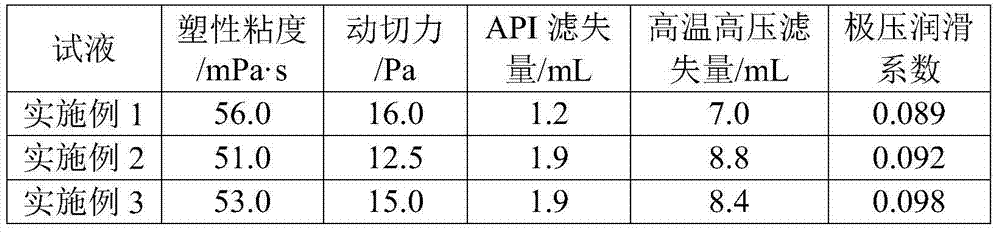

Nano biological filler for purifying aquaculture wastewater in biological filter tank and preparation method of nano biological filler

InactiveCN104085979AGood biocompatibilityLarge specific surface areaSustainable biological treatmentOn/in inorganic carrierBiological filterKaolin clay

The invention discloses nano biological filler for purifying aquaculture wastewater in a biological filter tank and a preparation method of the nano biological filler. The biological filler comprises an EM rejuvenation solution and an adsorption carrier of the EM rejuvenation solution, wherein the EM rejuvenation solution is a product obtained by performing mixed fermentation on an EM stock solution, molasses and deionized water; the adsorption carrier is obtained by performing mixed pressing on composite nano powder, kaolin powder and modified bentonite; the composite nano powder is a product obtained by performing mixing and high-temperature sintering on nano-level aluminum oxide, titanium dioxide and silicon dioxide; modified bentonite is prepared from sodium diethyldithiocarbamate modified original soil. The preparation method comprises the following steps: pressing adsorption carrier particles; fermenting to obtain the EM rejuvenation solution; dipping the EM rejuvenation solution by using the adsorption carrier to obtain the nano biological filler. The obtained nano biological filler is high in pore volume, high in cell adsorption capacity, large in specific surface area and strong in stability, has a good treatment effect on aquaculture sewage, and can be used for rapidly removing ammonia nitrogen, phosphorus and heavy metal ions in an aquaculture water body.

Owner:江苏三新山水生物科技有限公司

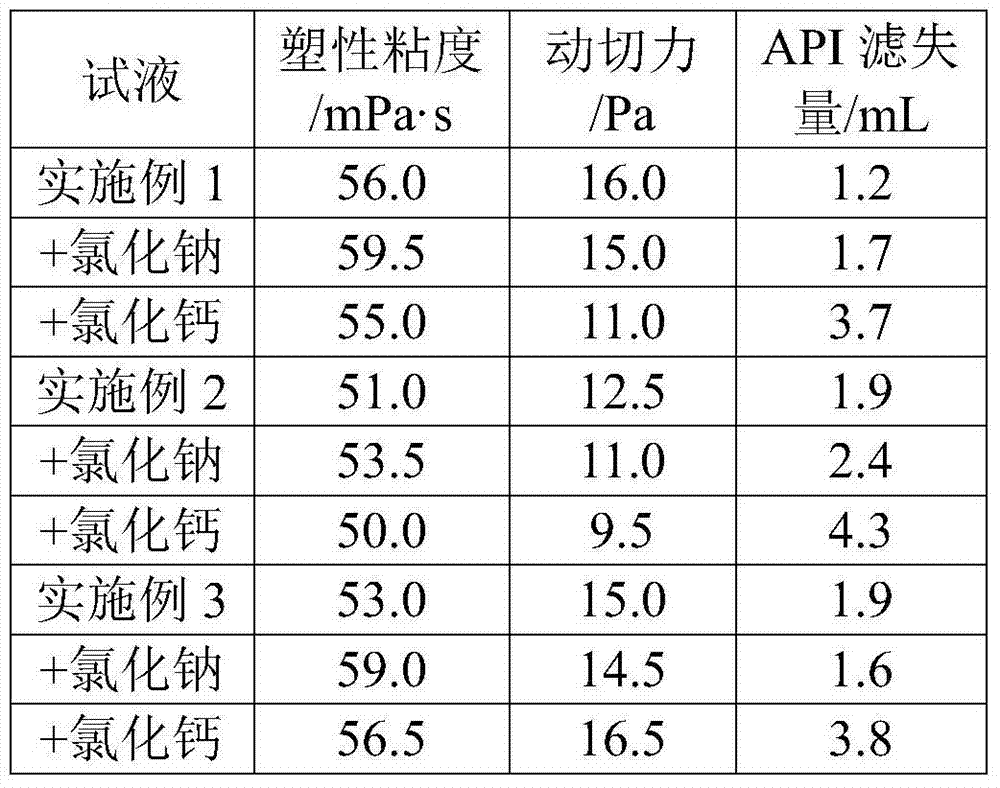

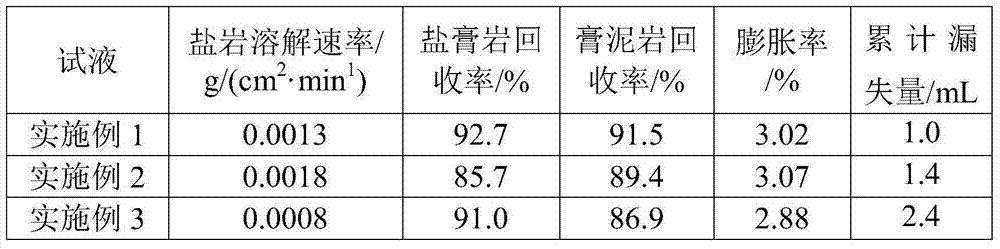

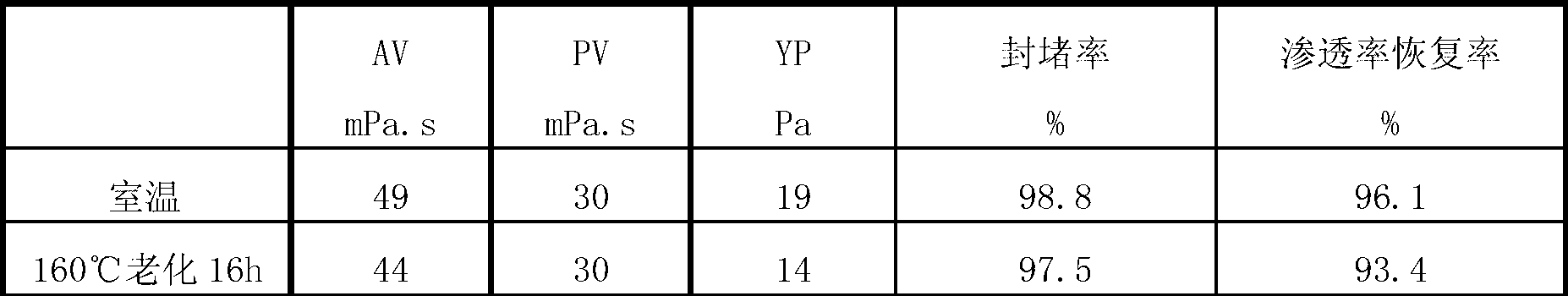

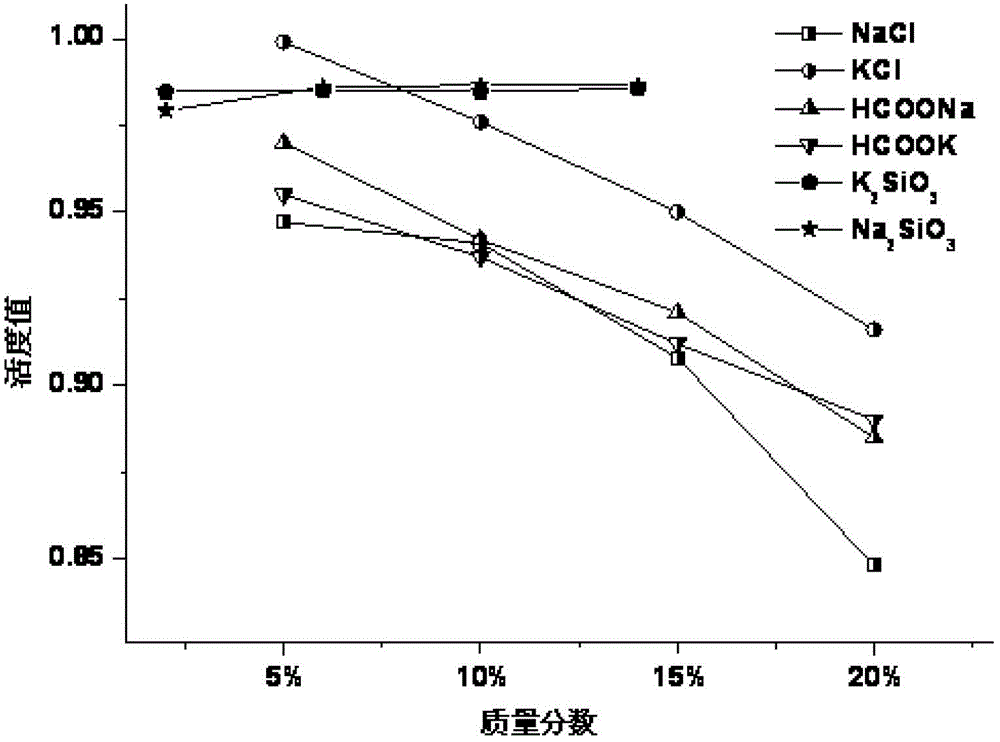

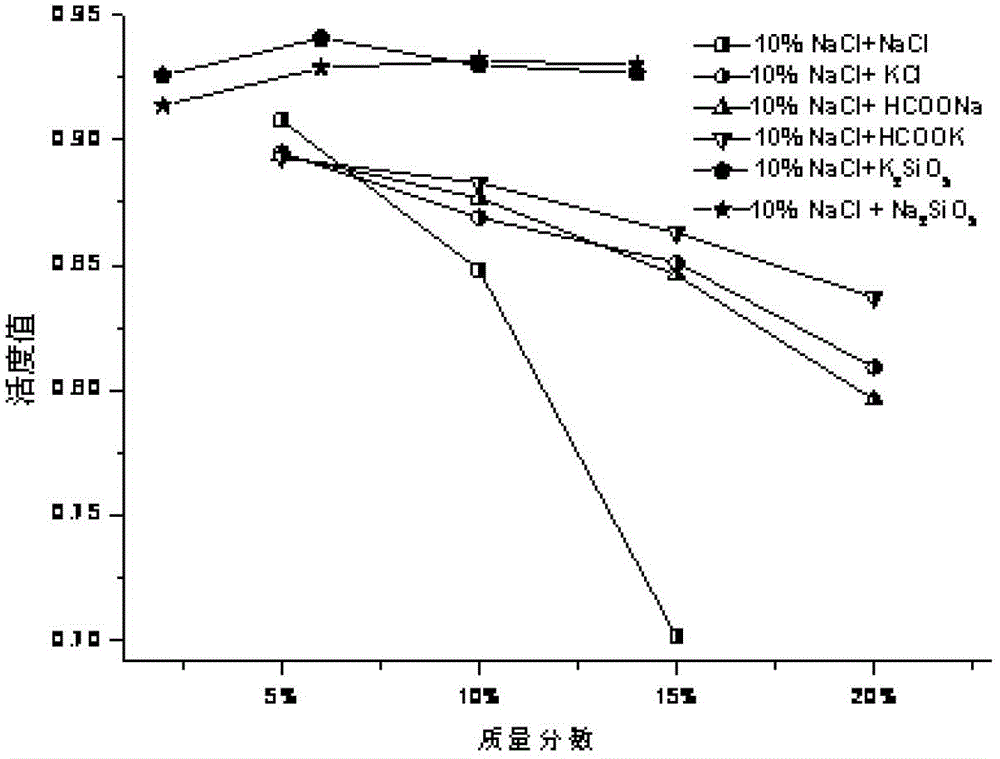

Multielement compound saltwater drilling fluid

InactiveCN103923622AImprove sealingDeterrent invasionDrilling compositionHigh densityDirectional well

The invention relates to a high-density multielement compound saltwater drilling fluid applicable to compound salt bed drilling. The high-density multielement compound saltwater drilling fluid comprises the following components in parts by weight: 100 parts of water, 15-50 parts of multielement compound salt, 1-15 parts of plugging agent, 2-8.2 parts of fluid loss additive, 0.1-0.6 part of pH regulating agent, 1-10 parts of lubricant and 1-270 parts of weighting agent. The multielement compound salt is a mixture of three or more than three of sodium chloride, potassium chloride, calcium chloride, sodium formate, potassium formate, cesium formate and sodium silicate. Due to the synergetic effect of the multielement compound salt and the plugging agent, the drilling fluid can be used for effectively sealing a well wall, meanwhile has favorable microcrack sealing capability, is capable of retarding drilling fluid filtrate transfer, has strong capability of retraining the dissolution of rock salt and gypsum and the expansion of evaporite and mud stock, and can be used for enhancing the well wall stability of an evaporite mud compound salt bed. When the density is up to 2.35g / cm<3>, the drilling fluid still has favorable rheological property and lubricating property, and can meet the requirements of straight well and directional well drilling of an evaporite bed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Preparing method for 1,2-pentadiol

InactiveCN1552684AAvoid security issuesNo pollutionOrganic compound preparationPreparation by hydrolysisOrganic solventSolvent

A process for preparing 1,2-pentanediol includes such steps as adding formic acid and H2O2 to reactor at low temp, dripping n-pentylene in it, hydrolyzing reacting at a certain temp for a certain time in alkaline condition to obtain coarse 1,2-pentanediol, extracting in organic solvent, distilling for recovering solvent, and rectifying to obtain high-purity (99%) 1,2-pentanediol and sodium formate as by-product.

Owner:LINHAI LIANSHENG CHEM

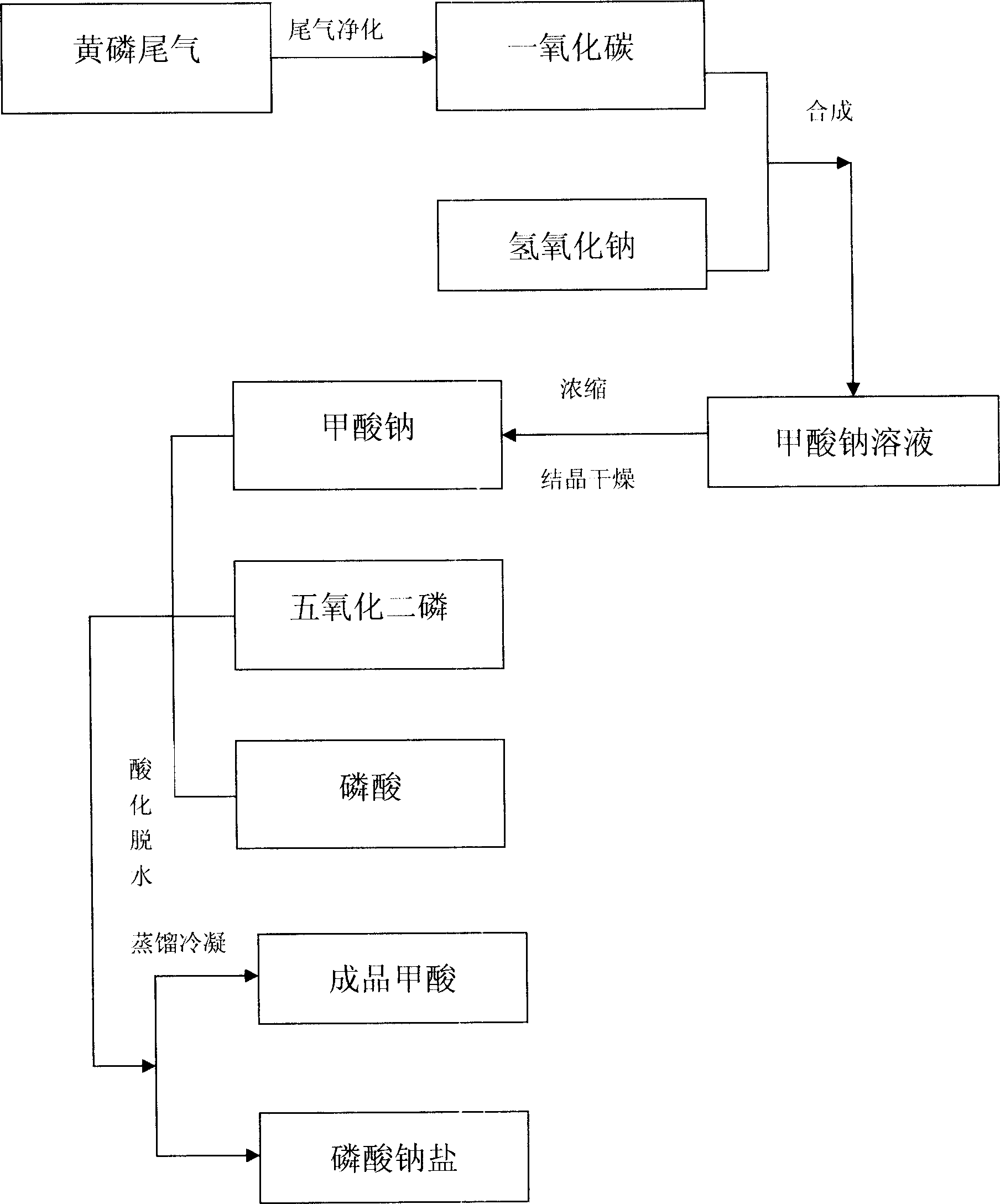

Method for producing formic acid through phosphoric acid and sodium formate

InactiveCN1915954AImprove utilizationEmission reductionPreparation from carboxylic acid saltsPhosphoric acidFormic acid

This invention discloses a method for preparing formic acid from phosphoric acid and sodium formate. The method comprises: reacting CO produced from yellow phosphorus manufacture with caustic soda to obtain sodium formate, then reacting with phosphoric acid, dehydrating with P2O5, and distilling to obtain formic acid. The method can reduce CO2 emission, thus is environmentally friendly. Besides, the method can lower the cost of yellow phosphorus and formic acid manufacture.

Owner:HUBEI XINGFA CHEM GRP CO LTD

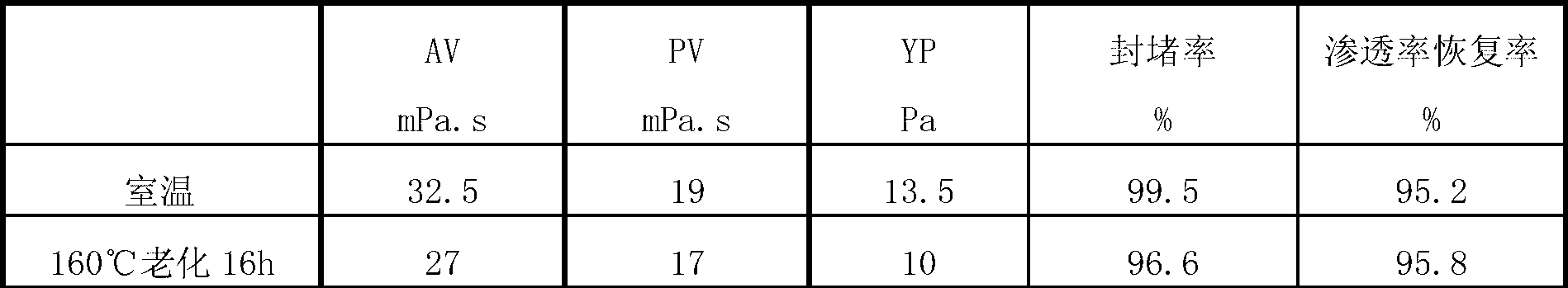

Nonclay one-way plugging drilling fluid

InactiveCN103013467ASuitable rheologyMeet drilling and completion requirementsDrilling compositionMicrospherePotassium

The invention relates to a nonclay one-way plugging drilling fluid. The raw material comprises the following components by mass part: 5-40 parts of main anchoring agent, 1-5 parts of auxiliary anchoring agent, 20-150 parts of one-way plugging agent, 5-20 parts of inhibiting agent, 0-20 parts of lubricating agent, 0-500 parts of weighting agent and 1000 parts of water, wherein the main anchoring agent is made of polyacrylamide, polyanionic cellulose or sulfonate copolymer fluid loss additive DSP-2; the auxiliary anchoring agent is made of xanthan gum or sodium carboxymethyl cellulose; the one-way plugging agent is made of polymer elastic microspheres SFH-1 or rubber particles; the inhibiting agent is made of amino polyol, potassium polyacrylate or polyhydric alcohols; the lubricating agent is made of the drilling fluid FYR lubricating agent, white oil or black lead; and the weighting agent is made of one of sodium formate and potassium formate or the mixture of sodium formate and potassium formate. The drilling fluid has the characteristic of one-way plugging, so as to be taken as drilling fluid, completion fluid or workover fluid; and the remarkable effects of improving the drilling rate, stabilizing the well wall and protecting a reservoir are achieved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

Enhanced liquid cement grinding aid

InactiveCN102115316AIncrease late strengthImprove grinding efficiencySodium acetateSodium lignosulfonate

The invention relates to an enhanced liquid cement grinding aid capable of improving the grinding efficiency of a cement grinding mill and enhancing the strength of cement. The liquid cement grinding aid comprises the components with the weight percentages as follows: 10 to 20 percent of triethanolmine, 5 to 10 percent of triisopropanolamine, 3 to 5 percent of diethylene glycol, 2 to 5 percent of sodium formate, 2 to 5 percent of sodium acetate, 1 to 3 percent of sodium lignosulfonate, 10 to 20 percent of desugarized molasses, 5 to 10 percent of glycerin, and water.

Owner:山东国元新材料有限公司

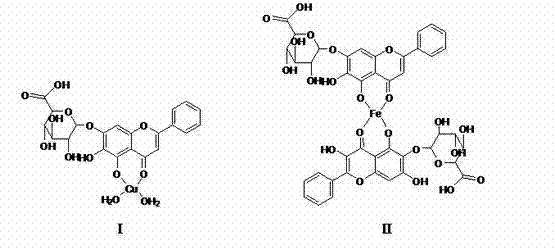

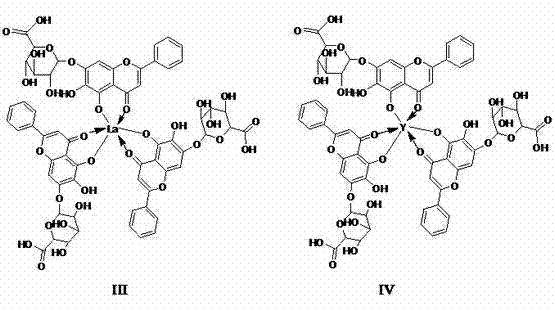

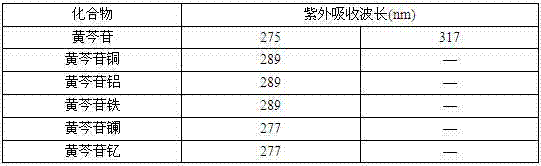

Baicalin metal complex and preparation method and application thereof

InactiveCN102516341AReduce pollutionAvoid it happening againAntibacterial agentsGroup 1/11 organic compounds without C-metal linkagesDipotassium hydrogen phosphateSodium acetate

The invention discloses a baicalin metal complex of which the molecular formula is (C21H17O11) xM (H2O) y, wherein M in the formula is Cu (II), x is 1 and y is 2; or M is Fe (III), x is 2 and y is 0; or M is La (III) or Y (III), x is 3 and y is 0. The preparation method comprises the following steps: adding aqueous alkali into baicalin until the baicalin and alkali (sodium bicarbonate, potassium bicarbonate, sodium formate, potassium formate, sodium acetate, potassium acetate, disodium hydrogen phosphate, dipotassium hydrogen phosphate, sodium phosphate or potassium phosphate) are just completely reacted, then adding metal salt (copper salt, ferric salt, lanthanum salt or yttrium salt) for reaction to obtain the baicalin metal complex. The baicalin metal complex has obviously stronger antibacterial and antitumor activities than the baicalin, can be used for preparing antibacterial drugs and antitumor drugs, and has good development and application prospects. In the preparation method, an organic solvent is not used, a strong basic condition is not adopted, and the method is simple and feasible, is green and environment-friendly and has the advantages of low cost, high product purity and high yield.

Owner:SOUTHWEST UNIVERSITY

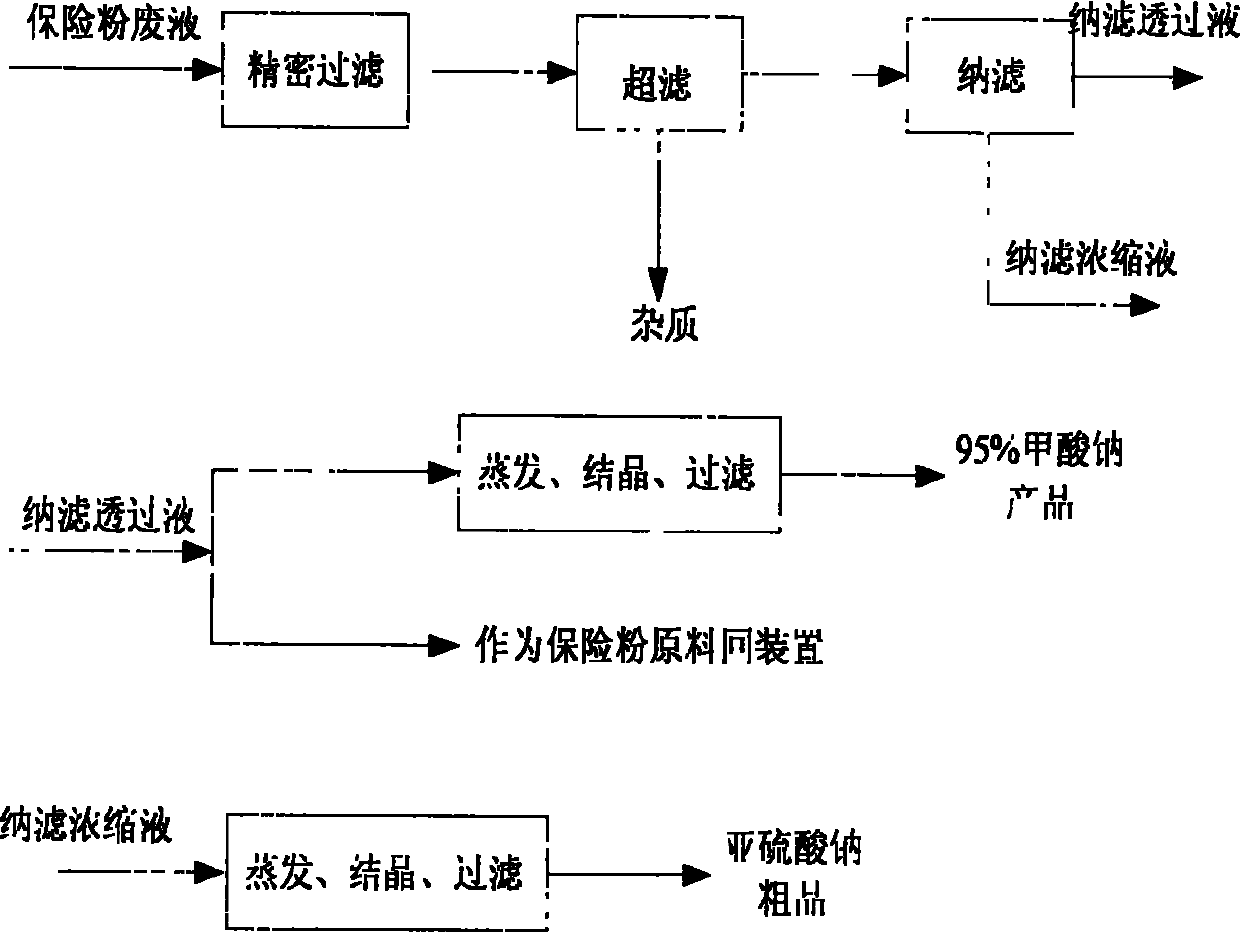

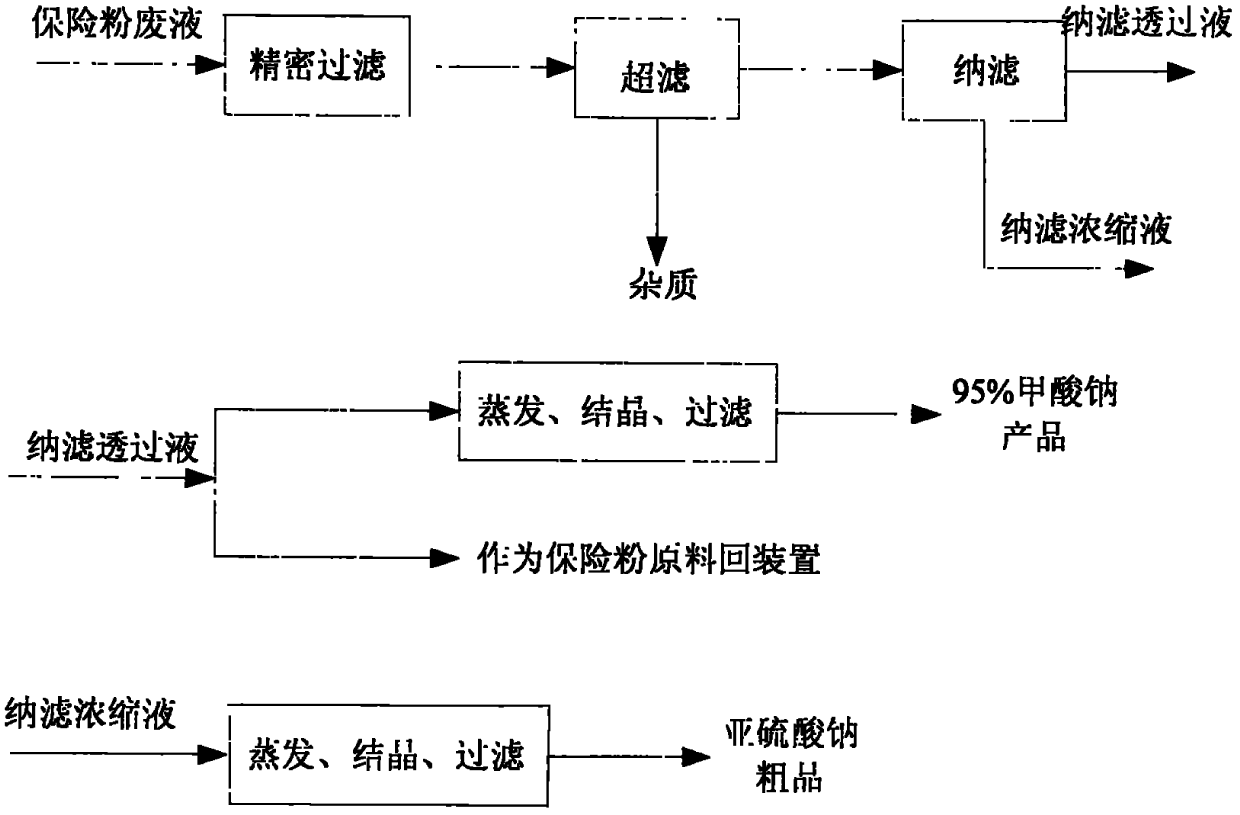

Method for recycling sodium formate and sodium sulfite from waste sodium hydrosulfite liquid with sodium formate method

InactiveCN102050471ANo secondary pollutionHigh purityAlkali metal sulfite preparationMultistage water/sewage treatmentUltrafiltrationFiltration

The invention relates to a method for recycling sodium formate and sodium sulfite from waste sodium hydrosulfite liquid with a sodium formate method. The method comprises the following steps of: carrying out precise filtration and ultrafiltration on waste sodium hydrosulfite liquid with the sodium formate method to remove insoluble substances and granular impurities in the liquid; and then introducing the liquid into a nanofiltration device for nanofiltration separation, wherein after being evaporated and concentrated, an obtained nanofiltration permeate solution can be used as a raw material of the sodium hydrosulfite and returned to a sodium hydrosulfite production station, and can also be continuously evaporated, concentrated, crystallized, centrifuged and filtered to obtain a sodium formate product of which the purity is higher than 95 percent; and an obtained nanofiltration concentrated solution can be introduced into an evaporator for concentrating and then is crystallized, centrifuged and filtered to obtain a crude sodium sulfite product. The method has the technical advantages of no secondary pollution, high purity of the sodium formate, simple process and easiness for industrial realization, wherein the purity can be up to higher than 95 percent.

Owner:YANTAI UNIV

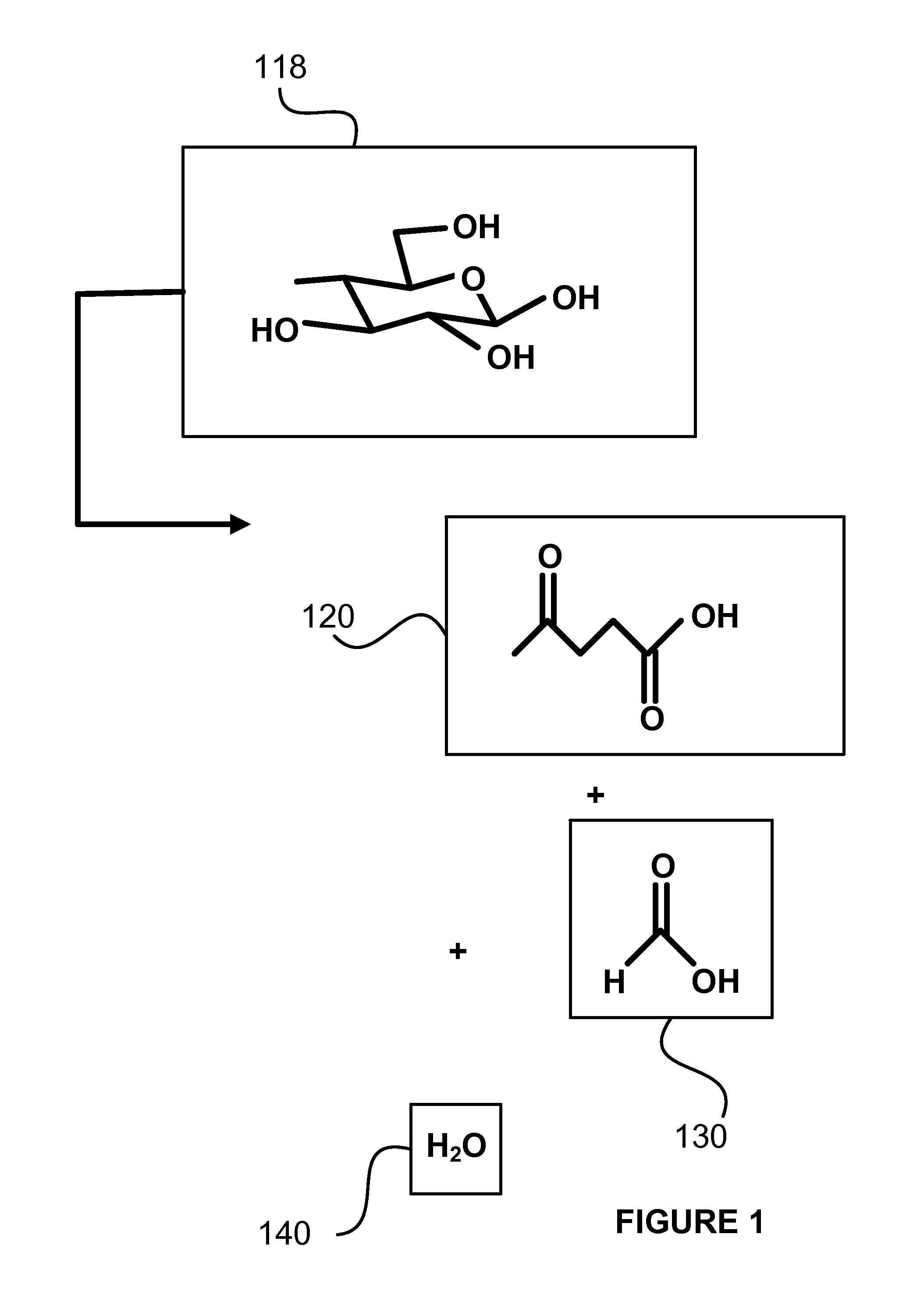

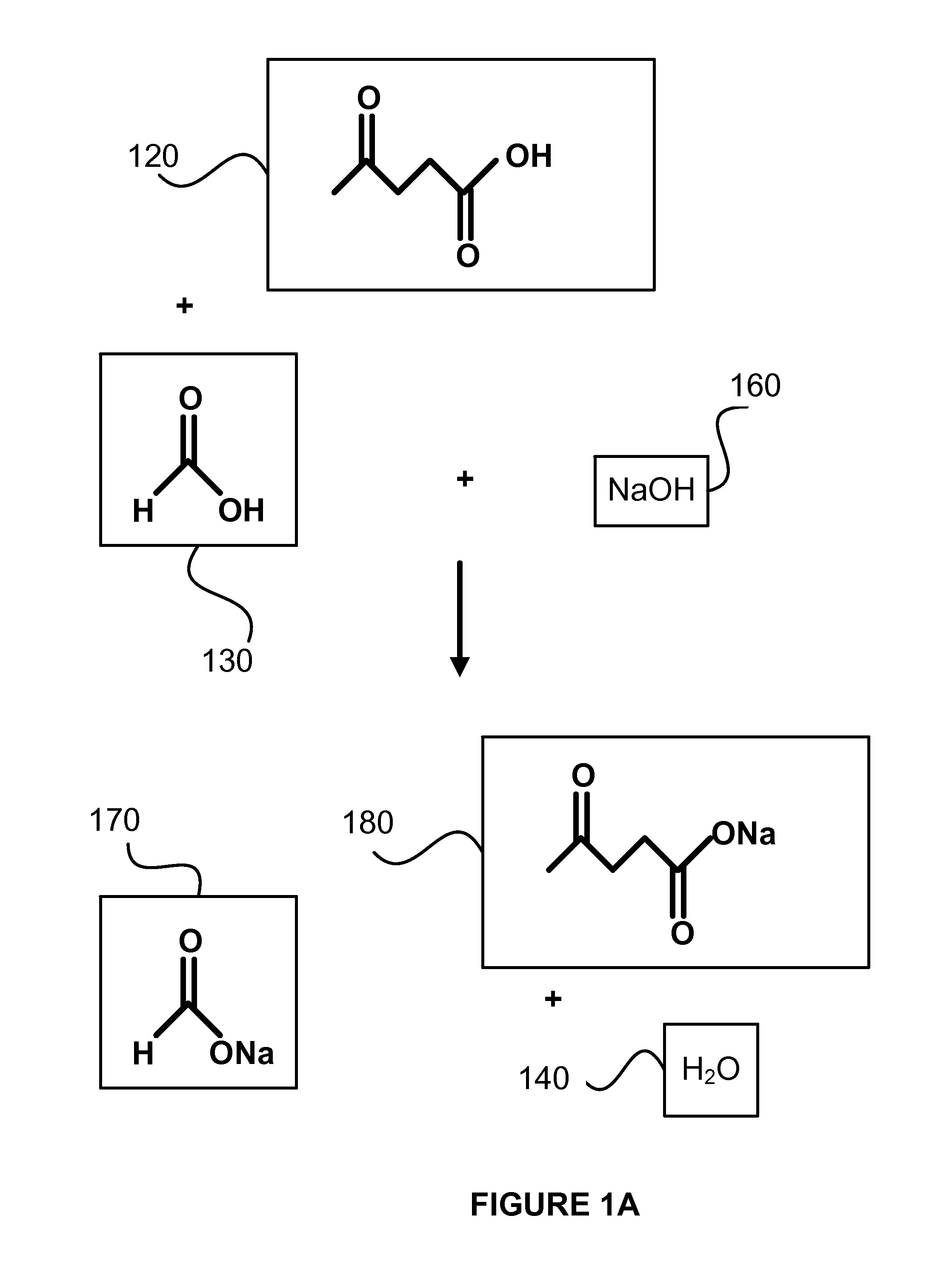

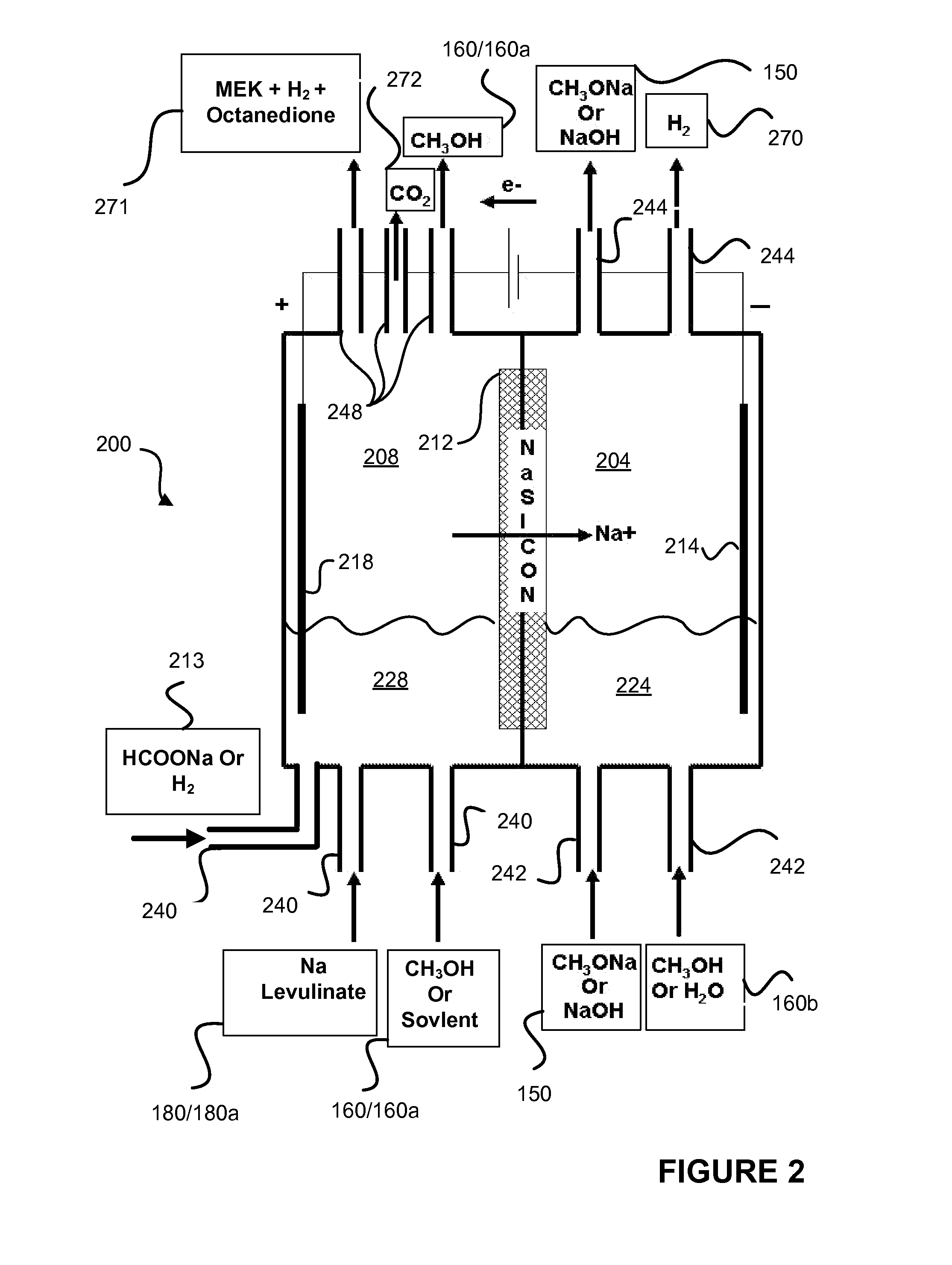

Decarboxylation of levulinic acid to ketone solvents

ActiveUS20140171688A1Low production costCellsOrganic compound preparationPropanoic acidKetone solvents

Ketones, specifically Methyl ethyl ketone (“MEK”) and octanedione, may be formed from six carbon sugars. This process involves obtaining a quantity of a six carbon sugar and then reacting the sugar to form levulinic acid and formic acid. The levulinic acid and formic acid are then converted to an alkali metal levulinate and an alkali metal formate (such as, for example, sodium levulinate and sodium formate.) The alkali metal levulinate is placed in an anolyte along with hydrogen gas that is used in an electrolytic cell. The alkali metal levulinate within the anolyte is decarboxylated to form MEK radicals, wherein the MEK radicals react with hydrogen gas to form MEK, or MEK radicals react with each other to form octanedione. The alkali metal formate may also be decarboxylated in the cell, thereby forming hydrogen radicals that react with the MEK radicals to form MEK.

Owner:ENLIGHTEN INNOVATIONS INC

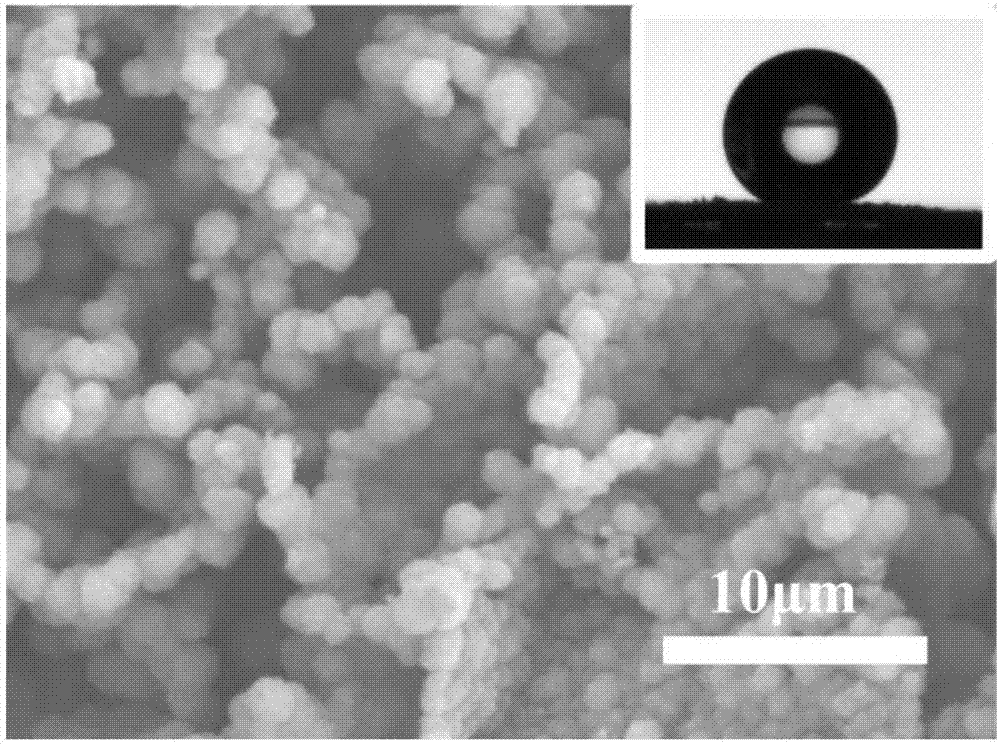

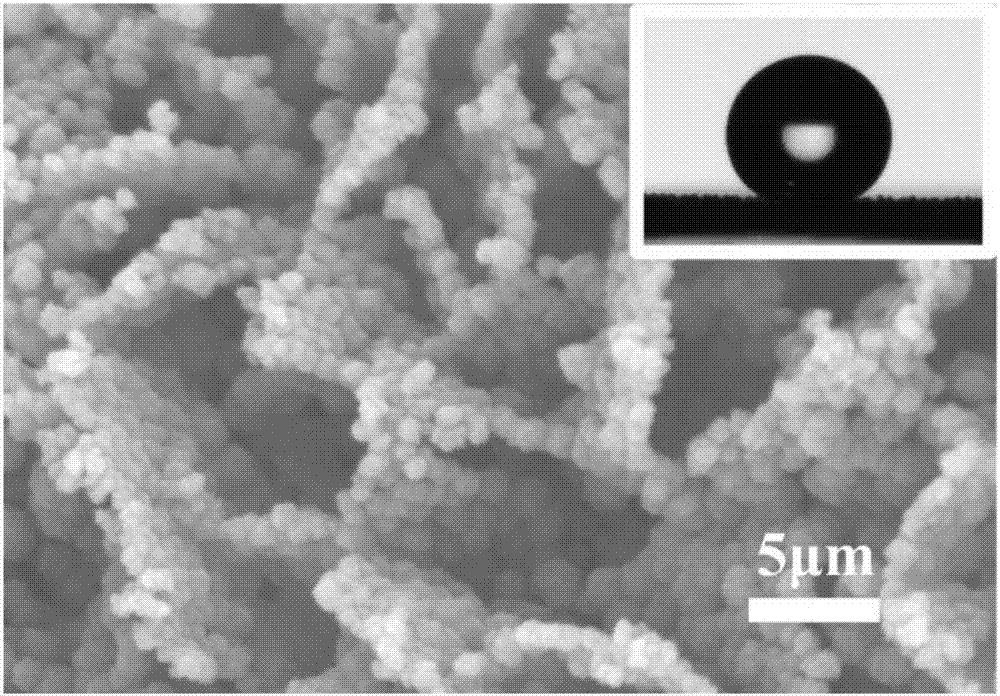

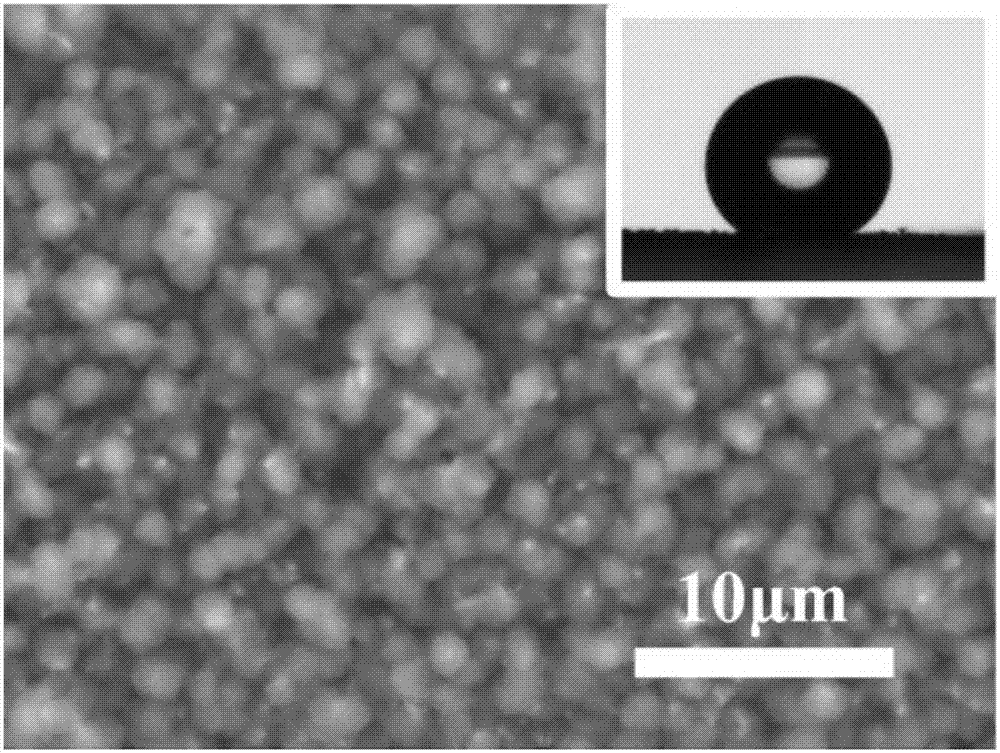

Super-hydrophobic metal-organic framework array, as well as preparation method and application thereof

ActiveCN107198891AImprove hydrophobicityStay superhydrophobicNon-miscible liquid separationN dimethylformamideMetal-organic framework

The invention discloses a preparation method for a super-hydrophobic metal-organic framework array. The method is implemented by the following steps: performing ultrasonic treatment and drying on an inorganic or organic material adopted as a substrate in an organic solvent to obtain a pretreated substrate; dissolving zinc nitrate hexahydrate, 2-methylimidazole and anhydrous sodium formate in ethanol, performing ultrasonic treatment, then adding the pretreated substrate, and performing reaction for 5 to 10h under the condition of 50 to 150 DEG C to obtain a ZnO array; dissolving benzimidazole in N,N-dimethylformamide, performing ultrasonic treatment, then adding the ZnO array, and performing reaction for 10h under the condition of 80 to 140 DEG C to obtain the super-hydrophobic metal-organic framework array. The super-hydrophobic metal-organic framework array may be applied to the field of oil-water separation; super-hydrophobicity can still be achieved under the condition of modification with no low-surface energy substance, and the array has relatively high thermal stability, and can be used for efficiently separating multiple oil-water mixtures.

Owner:ZHEJIANG UNIV OF TECH

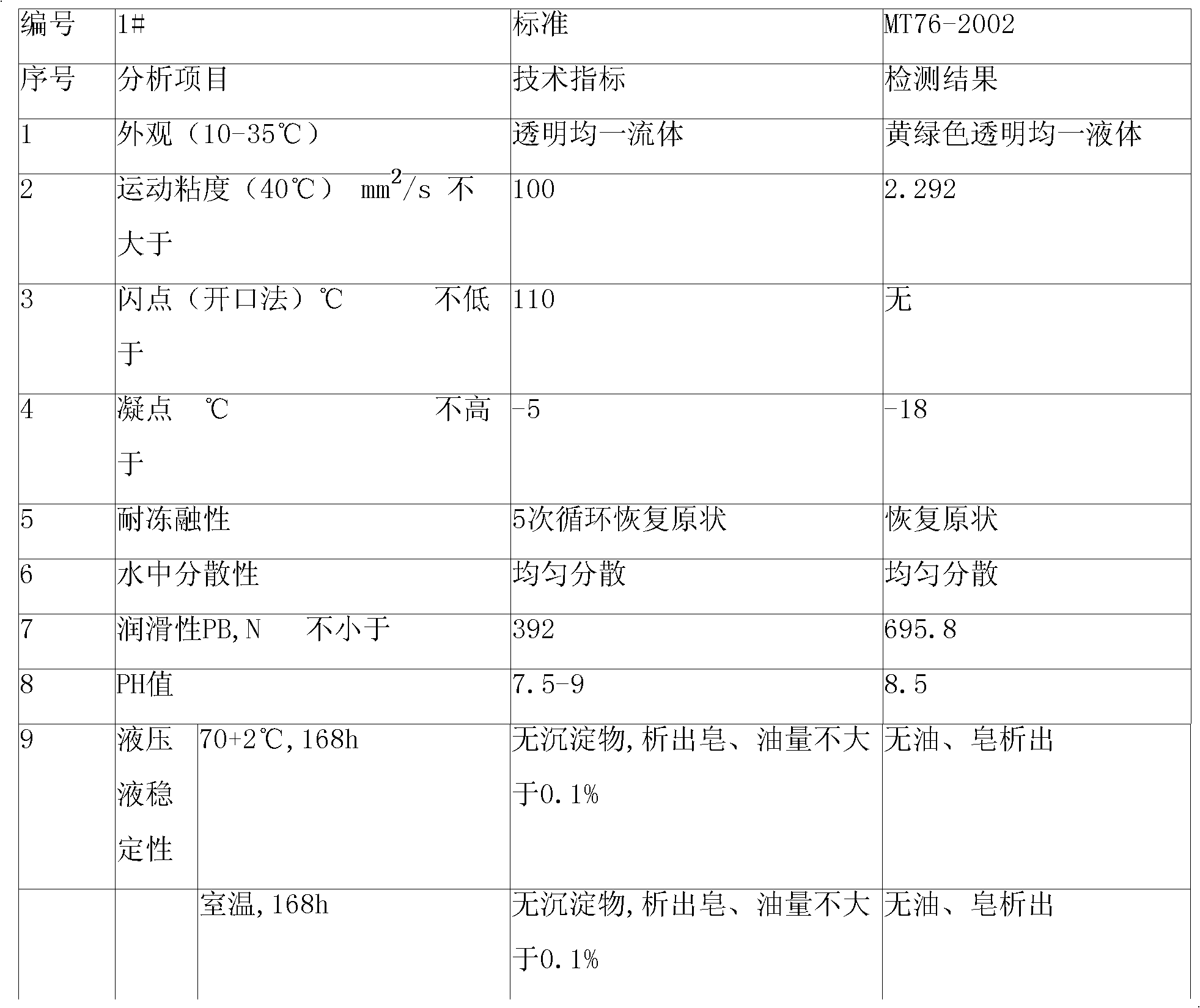

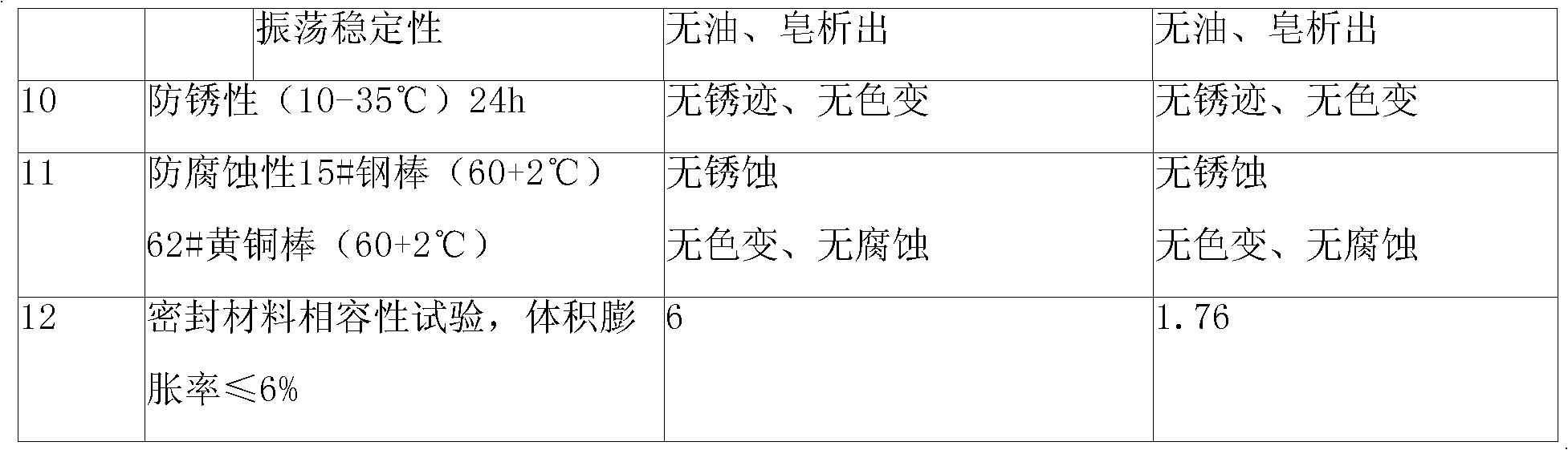

Concentrated liquid lubricant and preparation method thereof

InactiveCN101805658AImprove the lubrication effectImprove corrosion resistanceLubricant compositionChemistryLubrication

The invention relates to a concentrated liquid lubricant and a preparation method thereof, which belong to the technical field of hydraulic transmission media. The concentrated liquid lubricant of the invention is prepared from the following raw materials in percentage by weight: 50.0 to 70.0 percent of deionized water, 1.4 to 3.7 percent of KOH, 1.0 to 10.0 percent of triethanolamine, 24.0 to 15.0 percent of NaNO, 3.0 to 10.0 percent of OS-15, 0.2 to 0.8 percent of benzene benzotriazole, 2.0 to 6.0 percent of ethylenediaminetetraacetic acid, 2.0 to 10.0 percent of sodium benzoate, 0.1 to 0.5 percent of emulsified silicone oil, 5.0 to 15.0 percent of triethanolamine oleate, 1.0 to 5.0 percent of polyalkylene glycol, 1.0 to 8.0 percent of polycarboxylic antirust, and 2.0 to 8.0 percent of glycol. The concentrated liquid lubricant of the invention has the advantages of good lubrication, cooling, corrosion resistance and cleaning performance and longer service life.

Owner:成都蜀光石油化学有限公司

Preparation methods of 2,5-furandicarboxylic acid and 2,5-furanyl polyester

InactiveCN108997278ALow costLow priceOrganic chemistryBulk chemical productionSodium bicarbonatePolyester

The invention provides a preparation method of 2,5-furandicarboxylic acid. The preparation method comprises the following steps: A), with non-grain biomass as a raw material, preparing furfural; B), oxidizing the furfural to obtain furoic acid; C), performing an addition reaction on the furoic acid and carbon dioxide under the action of a catalyst to obtain the 2,5-furandicarboxylic acid, whereinthe catalyst is one or more of potassium carbonate, sodium oxalate, sodium nitrate, potassium nitrate, sodium nitrite, potassium nitrite, potassium acetate, sodium acetate, potassium formate, sodium formate, sodium hydrogen carbonate, potassium hydrogen carbonate, sodium hydroxide and potassium hydroxide. The furfural is prepared from the non-grain biomass as the raw material, so that the raw material cost is low; the furoic acid reacts with the carbon dioxide under the action of the specific catalyst to obtain the 2,5-furandicarboxylic acid; the catalyst is low in price; the used carbon dioxide is environment-friendly; by the preparation method, the yield is high.

Owner:芜湖万隆新材料有限公司

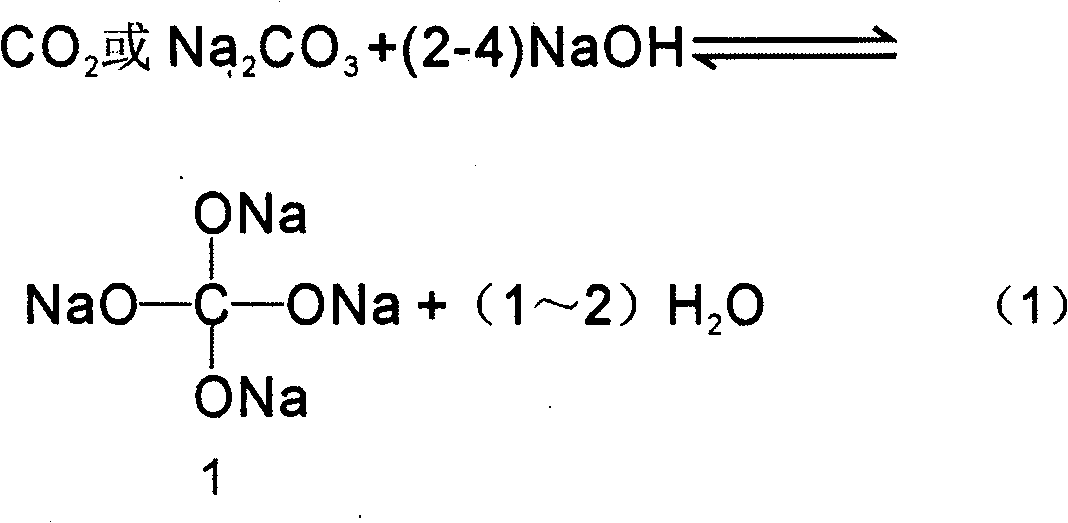

Method for preparing DMC, DPC, ortho-carbonate, ortho-formate, dimethyl ether, and the like by using Na2CO3 or sodium formate or CO2 or CO

InactiveCN103254084AOrganic compound preparationPreparation from ortho-estersSynthesis methodsProcess synthesis

The invention relates to a recently discovered universal synthesis method of tandem-substitution-rearrangement-elimination reaction (TSRE reaction) of elemental organic chemistry, production process synthesis routes of two products of dimethyl carbonate (DMC) and diphenyl carbonate (DPC) and traditional products of ortho-carbonate, ortho-formate, dimethyl ether, and the like through CO2 and CO direct synthesis method are redesigned. Compared with prior arts for producing the products, with the preparation method provided by the invention, energy can be greatly saved, emission can be greatly reduced, and cost can be greatly reduced.

Owner:李坚

Method of melting snow and/or ice and a deicer comprising sodium formate and sodium chloride

The invention provides a method of melting snow and ice on traffic areas, which comprises applying to the traffic areas covered with snow and ice a deicer in an amount of from 5 to 100 g / m2, which comprises from 30 to 70% by weight of sodium formate, from 30 to 70% by weight of sodium chloride and from 0.1 to 3% by weight of a corrosion inhibitor, and which is used in the form of solid particles having a diameter of from 0.3 to 10 mm or in aqueous solution with a content of from 5 to 25% by weight of the deicer.

Owner:CLARIANT PROD DEUT GMBH

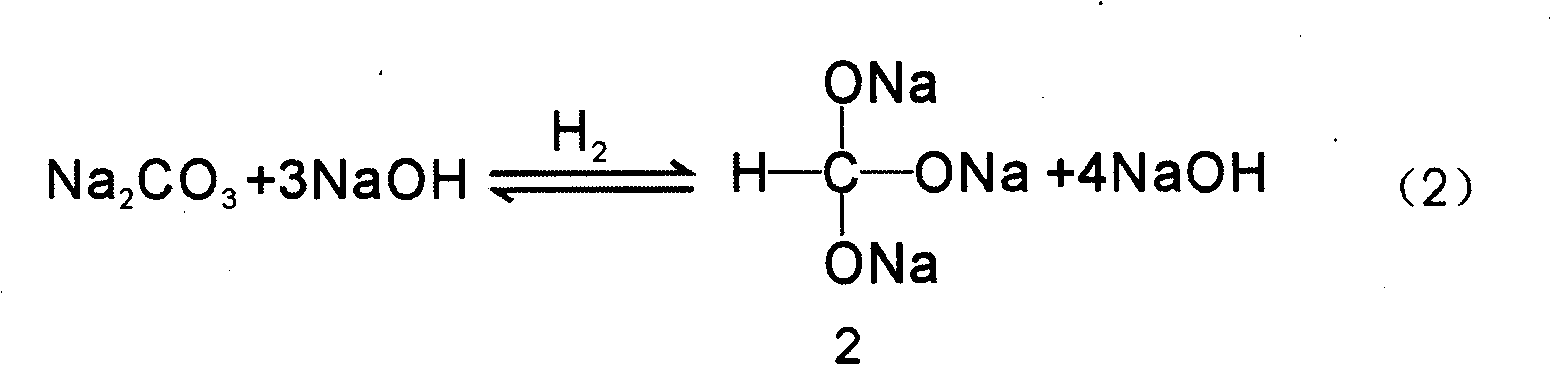

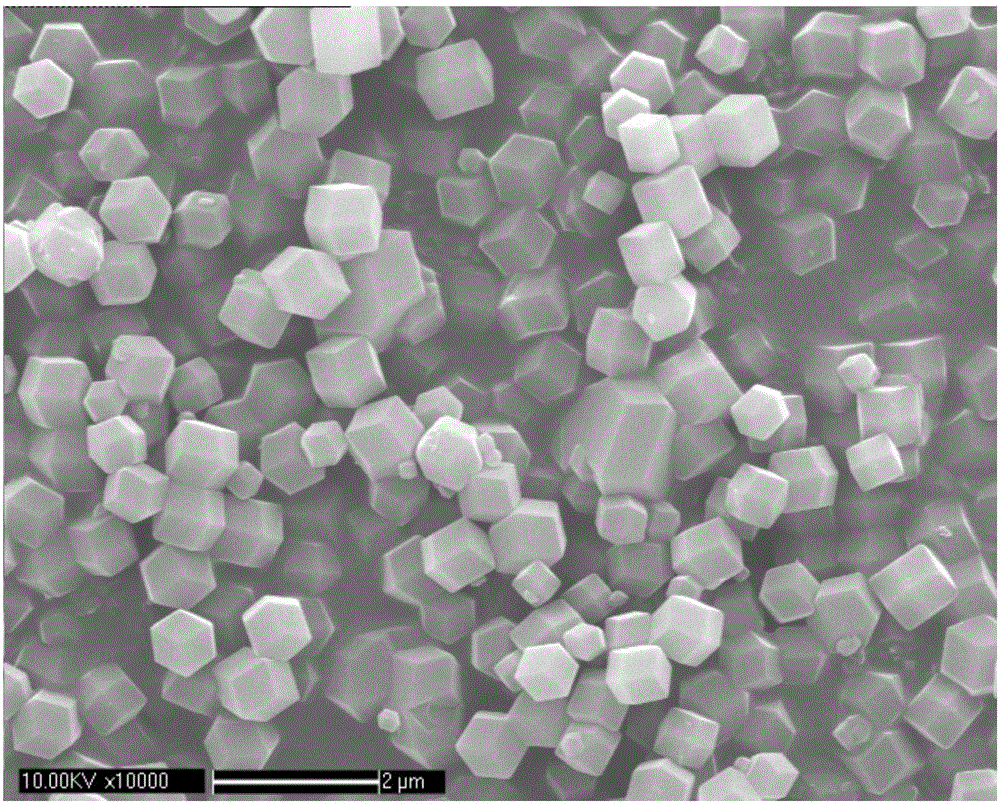

Zeolite imidazate framework/polyamide composite membrane and preparation method thereof

ActiveCN106390768AImprove interface compatibilityImprove permeabilitySemi-permeable membranesDispersed particle separation2-aminobenzimidazoleCentrifugation

The invention discloses a zeolite imidazate framework / polyamide composite membrane and a preparation method thereof. The preparation method comprises the following steps: dissolving sodium formate, 2-aminobenzimidazole and 2-methylimidazole into deionized water so as to obtain a mixed solution; dissolving zinc salt into N,N-dimethyl formamide so as to obtain a zinc salt solution; performing mixing reaction on the mixed solution and the zinc salt solution, and performing centrifugation, washing and drying so as to obtain an NH2-ZIF-8 nano material; and soaking a substrate membrane into an organic phase solution, pouring off an organic phase solution on the substrate membrane, naturally drying in air, soaking the substrate membrane into a water-phase solution, pouring off the water-phase solution on the substrate membrane, cleaning the surface of the substrate membrane with deionized water, and drying in air at room temperature, thereby obtaining an NH2-ZIF-8 / polyamide composite membrane. The prepared NH2-ZIF-8 / polyamide composite membrane is used for separating gases such as CO2, N2, H2, CH4 and NOx, and the permeability and the selectivity of the membrane can be improved.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

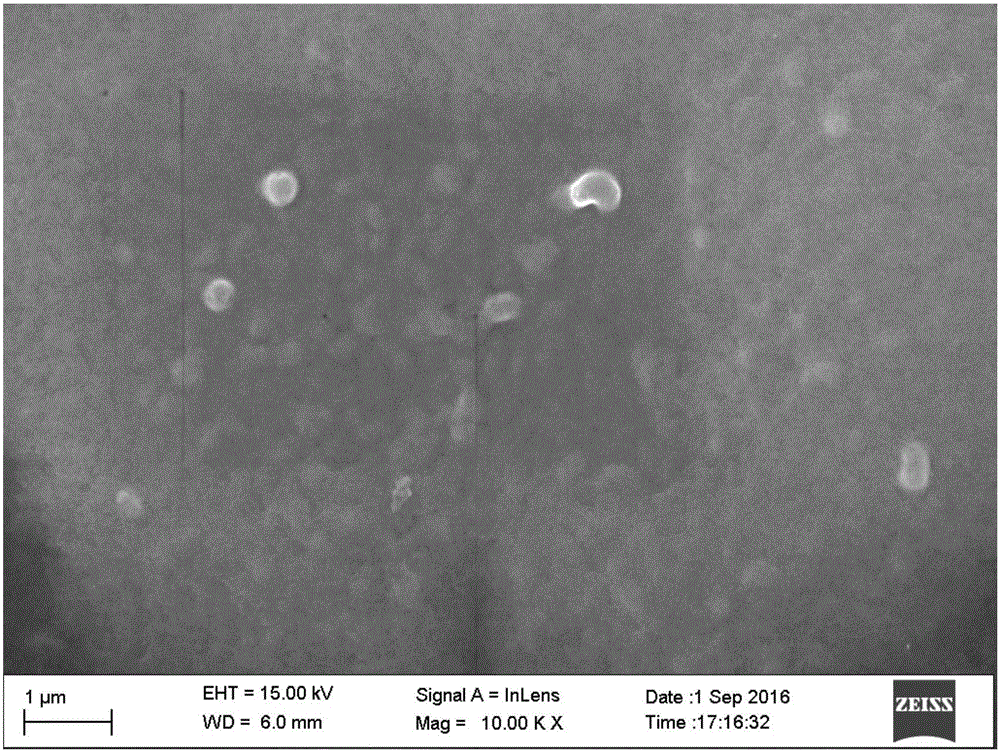

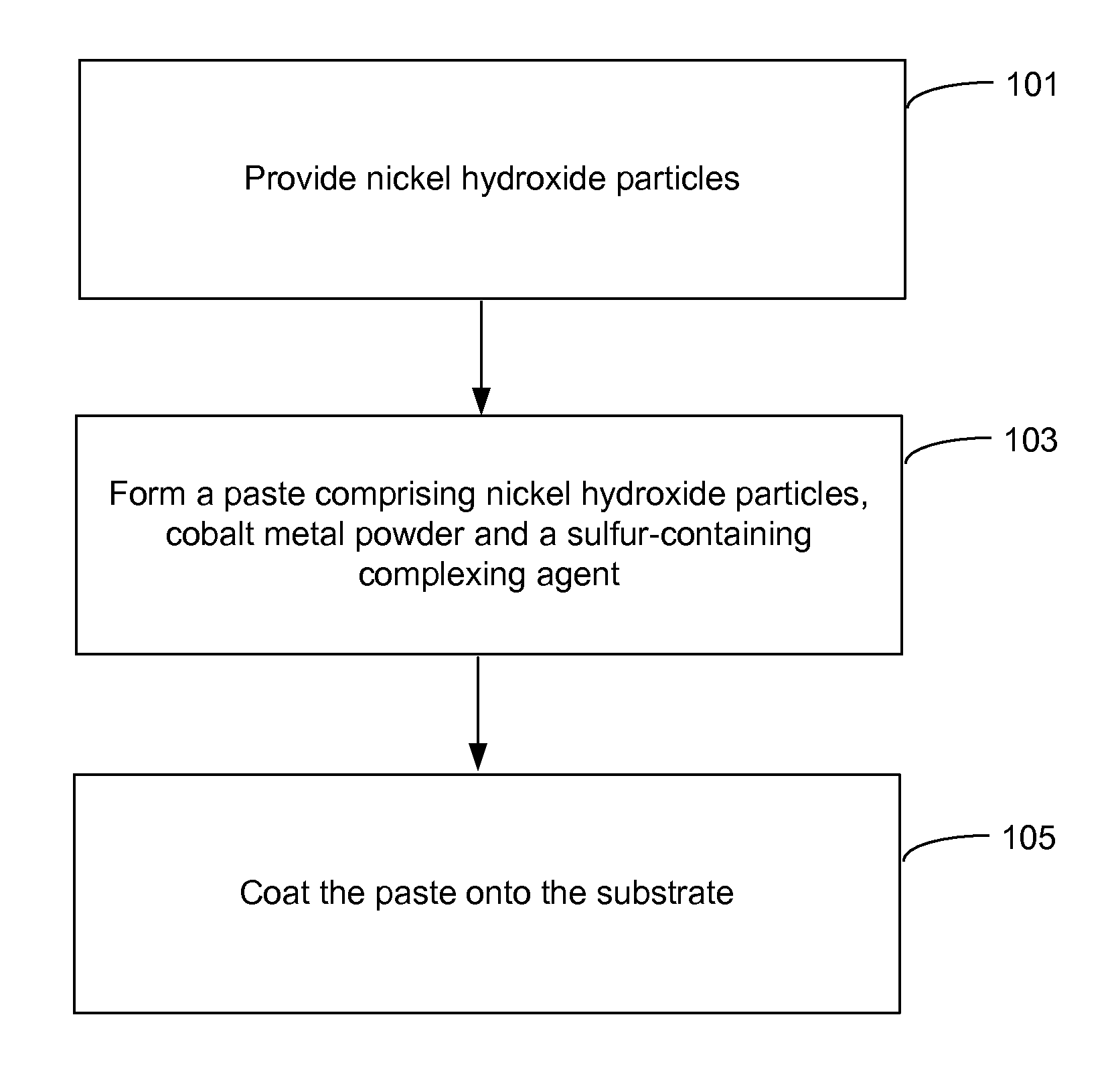

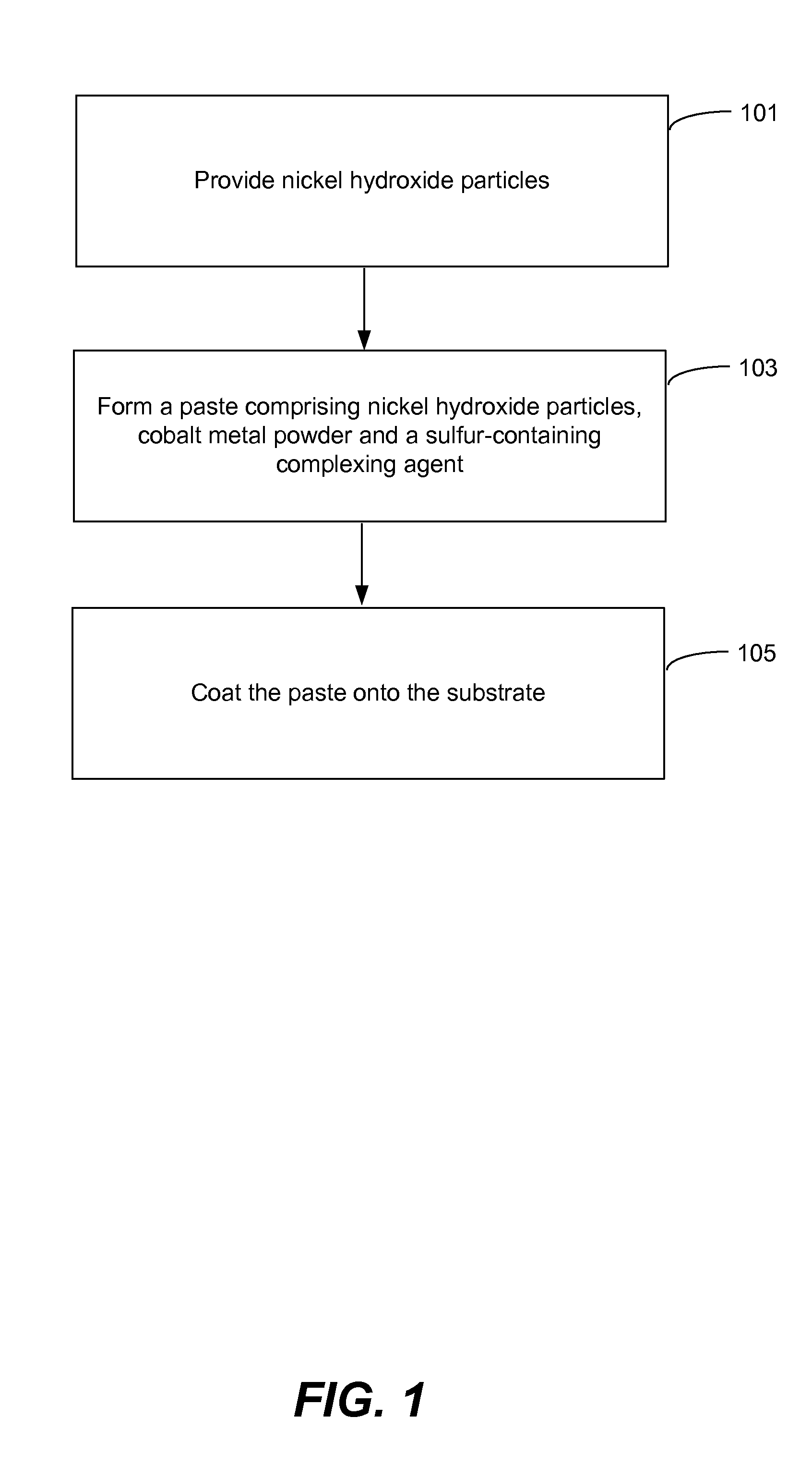

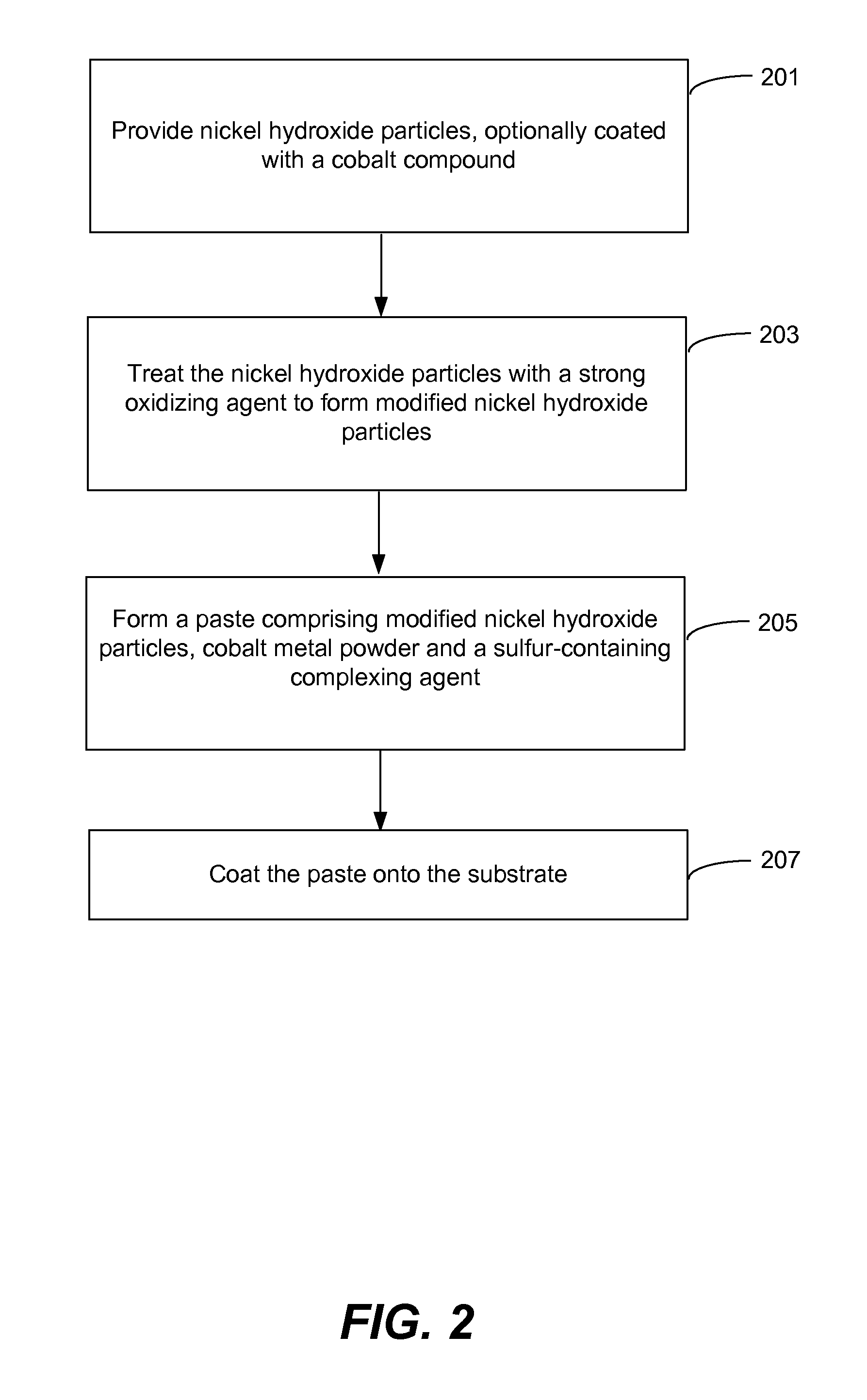

Pasted nickel hydroxide electrode and additives for rechargeable alkaline batteries

ActiveUS20140199591A1Prevent peelingMinimize migrationFinal product manufactureConductive materialNickel electrodeNickel zinc

A pasted positive nickel hydroxide electrode for use in battery cells (e.g., in nickel zinc cells, and nickel metal hydride cells) includes nickel hydroxide particles, a cobalt metal and / or cobalt compound and a sulfur-containing complexing agent capable of forming a complex with cobalt. The presence of the sulfur-containing complexing agent, such as dialkyldithiocarbamate (e.g., sodium diethyldithiocarbamate) improves lifetime and capacity utilization of the nickel electrode. The resulting pasted nickel hydroxide electrode includes a CoOOH conductive matrix after formation. The surface of the nickel hydroxide particles in the electrode is modified in some embodiments by providing a cobalt-containing coating onto the surface of the nickel hydroxide particles, followed by oxidation with a strong oxidizing agent. The complexing agent can be added before, after, or during the oxidation.

Owner:ZINCFIVE POWER INC

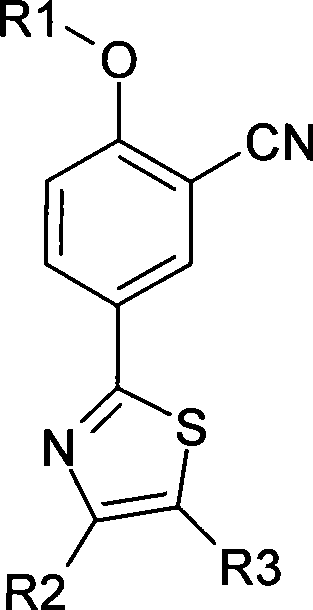

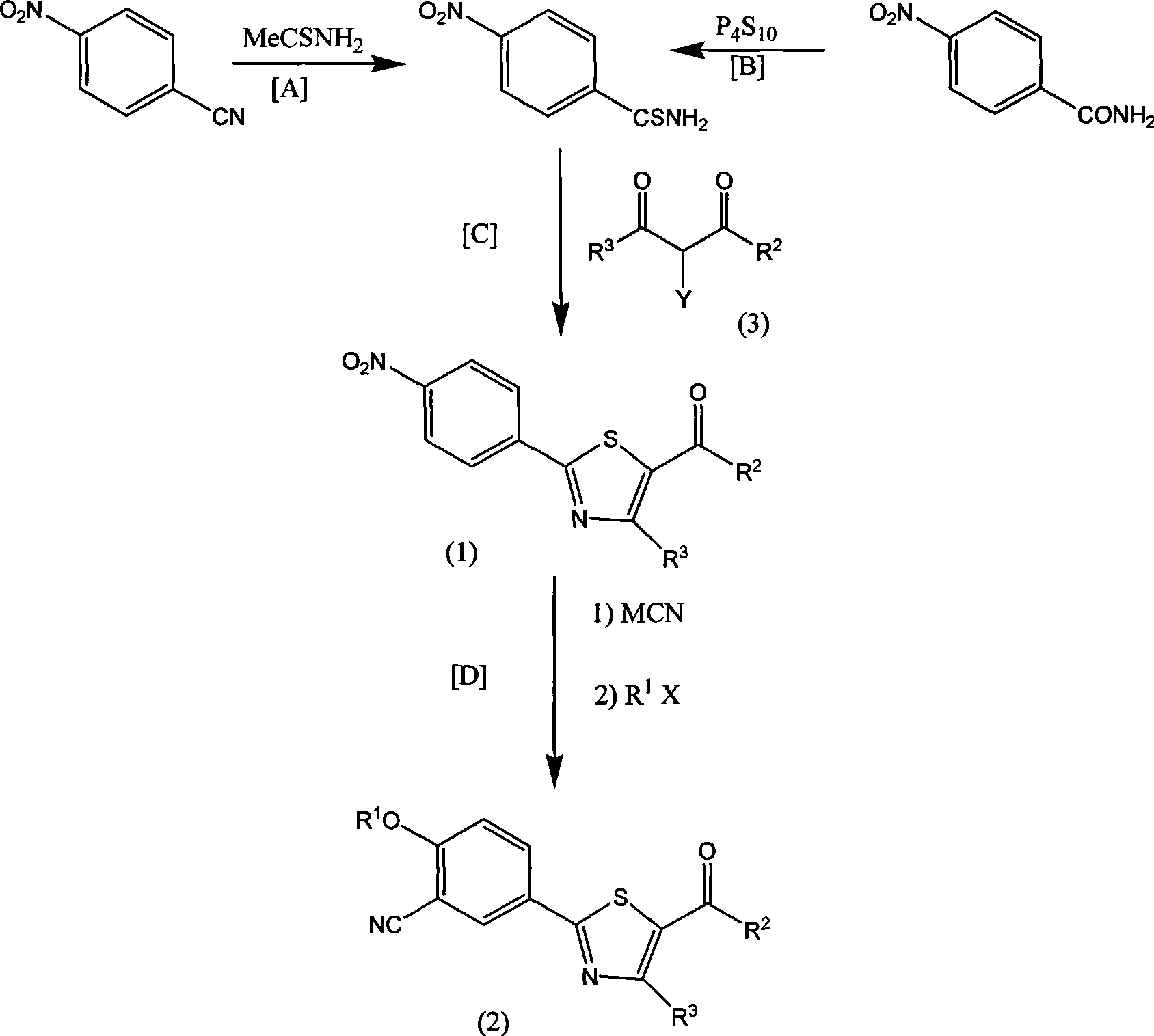

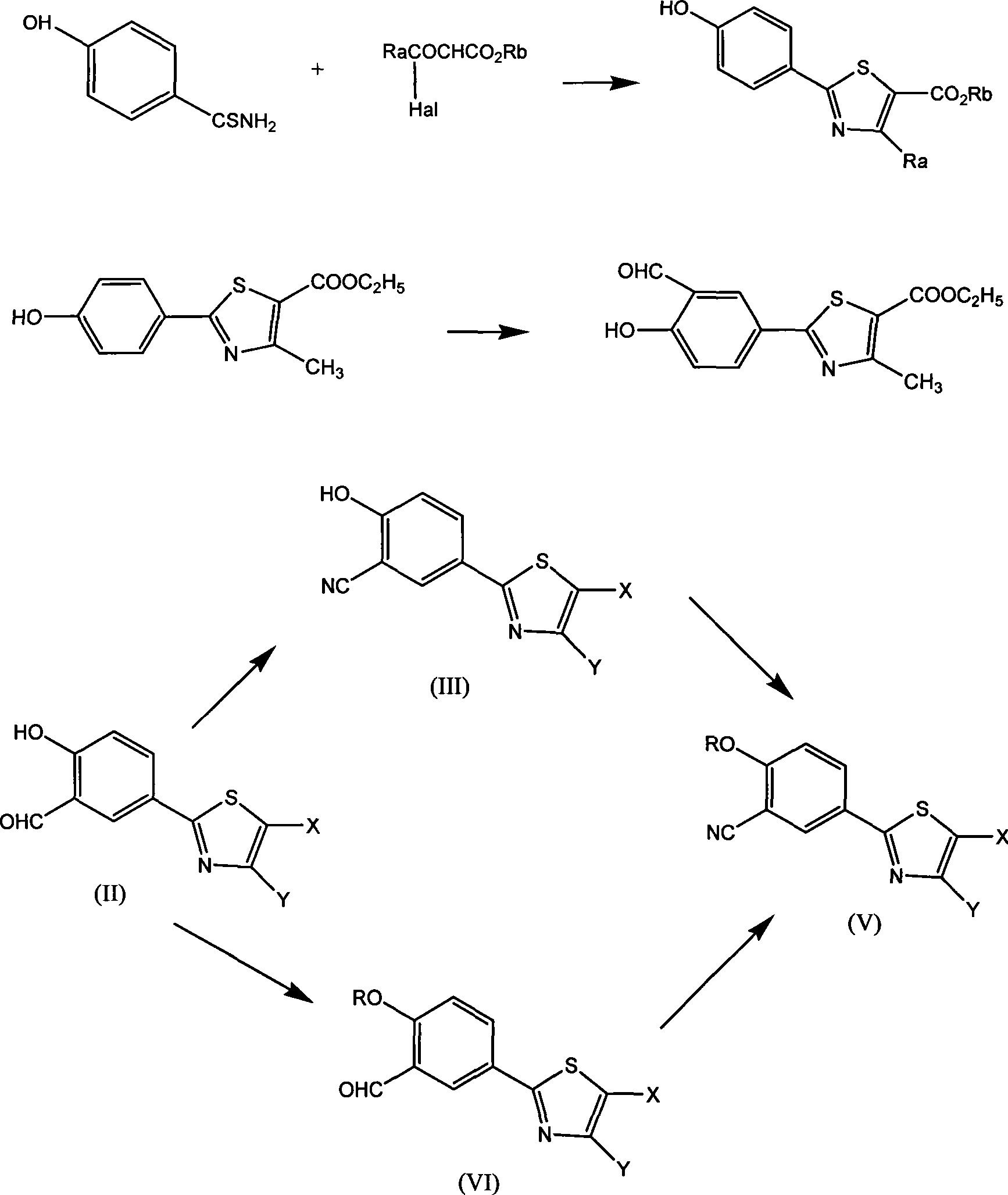

Aromatic nitrile-base thiazole derivatives for inhibiting xanthine oxidase activity, preparation method and application

ActiveCN101386604AEasy to operateHigh yieldOrganic active ingredientsOrganic chemistryCyclobutaneLithium formate

The invention disclosed an aryl nitrile group thiazole derivative for inhibiting the activity of xanthine oxidase, a method for preparing the same and application thereof. In the aryl nitrile group thiazole, R1 is methyl, ethyl, propyl, isopropyl, isobutyl, methyl cyclopropane, methyl cyclobutane, isoamyl, methyl cyclopentane, methyl cyclohexane or aromatic ring methyl, R2 is methyl or trifluoromethyl, and R3 is formic acid, sodium formate, potassium formate, lithium formate, methyl formate, or ethyl formate. Simultaneously, the invention discloses a method for synthesizing the aryl nitrile group thiazole derivative by using inexpensive raw materials, which has the advantages of simple operation, high yield, easy purification of products, application to industrial production and the like, and can obtain an efficient compound with low toxicity through screening; besides, the effective compound is expected to be widely applied to inhibit the activity of the xanthine oxidase required on animals and humans, and to become a new generation of antigout drugs and hyperuricemia drugs with special effect.

Owner:HANGZHOU ADAMERCK PHARMLABS INC

Method of subterranean formation treatment

A method of treating a subterranean formation with a xanthan-viscosified cesium formate brine wherein the pH and / or another characteristic selected from density, xanthan loading, sodium formate loading, potassium formate loading and combinations thereof are modified to delay solid hydrogel formation and maintain pumpability. Also disclosed is a method of delaying onset of solid hydrogel formation, in a gel comprising cesium formate brine viscosified with xanthan polymer, comprises introducing acid into the brine in an amount effective for a pH from 7 to 11, wherein the acid introduction is before, during or after xanthan viscosification and prior to hydrogel formation, wherein the hydrogel formation in the acidified gel occurs at a later time relative to the same gel at a natural pH.

Owner:SCHLUMBERGER TECH CORP

Method for treating metronidazole waste water

ActiveCN102344220AAvoid pollutionAchieve recyclingPreparation from carboxylic acid saltsOrganic compound preparationNitroimidazoleSODIUM SULFATE ANHYDROUS

The invention relates to a method for treating metronidazole waste water, which comprises the following steps of: concentrating the metronidazole waste water into 1 / 3-1 / 5 of total amount, and crystallizing and filtering the concentrated metronidazole waste water at 45-100 DEG C to obtain anhydrous sodium sulfate and sodium formate; adjusting the PH to 3-6 by using sulfuric acid or formic acid, and precipitating 2-methy-5-nitro imidazole; concentrating the filter liquid to anhydrous sticky state, dissolving organic matter by using methanol or ethanol, and filtering the solution to obtain anhydrous sodium sulfate and sodium formate; merging the sodium formate and the anhydrous sodium sulfate obtained in two times, successively adding formic acid and sulfuric acid, and recovering the formic acid to obtain anhydrous sodium sulfate; and rectifying and separating the organic mixture extract of methanol or ethanol to obtain methanol or ethanol and glycol. The method for treating metronidazole waste water provided by the invention is simple and convenient to operate, the content of polluting organic matter and inorganic slats in the metronidazole waste water can be obviously reduced, environmental pollution can be preveneted, various kinds of useful organic matter and inorganic matter can be recovered, raw materials are saved, and the production cost is lowered.

Owner:HUBEI HONGYUAN PHARMA

Enzyme preparation for one-bath process of deoxidizing, polishing and dyeing

ActiveCN101624775AEmission reductionAffect the biopolishing effectBiochemical fibre treatmentDry-cleaning apparatus for textilesCelluloseSurface-active agents

The invention provides an enzyme preparation for one-bath process of deoxidizing, polishing and dyeing, relates to an enzyme preparation, in particular to an enzyme preparation for one-bath process of deoxidizing, polishing and dyeing for dyeing and processing cotton fabrics. The invention provides the enzyme preparation for one-bath process of deoxidizing, polishing and dyeing for dyeing and processing cotton fabrics as well as an application thereof. The enzyme preparation for one-bath process of deoxidizing, polishing and dyeing comprises the following components by weight percent: 5-40 percent of deoxyenzyme, 20-80 percent of neutral cellulose, 1-20 percent of non-ionic surface active agent, 0.2-5 percent of sodium benzoate, 0.2-3 percent of citric acid, 0.2-5 percent of sodium citrate and the balance of deionized water. The enzyme preparation for one-bath process of deoxidizing, polishing and dyeing can be used for dyeing and processing cotton fabrics and achieve the aim of combining three steps of deoxidizing, polishing and dyeing into a whole.

Owner:福建省晋江新德美化工有限公司

Building anti-freezing accelerator

The invention discloses a antifreeze early strength admixture used in construction using concrete that includes anhydrous calcium chloride, fly ash, inositol hexaphosphate, triethanolmine, sodium benzoate, azimidobenzene, and adding monoethanolamine to adjust the pH value to 9-9.5. The advantages of the invention are that: low cost, easy to gain raw material, no toxin, and no pollution to environment; improving the compressive strength and anti-leaking, anti-charring, antifreeze ability; shortening time limit for a project; ensuring intension and saving cement content.

Owner:北京中通润泽科技有限公司 +1

Method for integrated treatment of electroplating wasterwater

ActiveUS20200048125A1Efficient removalSolve problemsTreatment using aerobic processesGeneral water supply conservationCarboxyl radicalThio-

A method for integrated treatment of electroplating wastewater includes steps of: adjusting and maintaining pH of wastewater at 10.5-12; oxidizing pollutants such as sodium cyanide and hydroxyl-containing organic amine complexants with sodium hypochlorite; precipitating carboxyl-containing organic acid complexants with synergistic effect of ferrous and calcium ions; reducing hexavalent chromium to trivalent chromium and forming chromium hydroxide precipitate; removing precipitate by filtering; adjusting wastewater to pH of 4.5-5.5; precipitating heavy metal ions with sodium dimethyldithiocarbamate or sodium diethyldithiocarbamate; adsorbing precipitate and heavy metal capturing agents with activated carbon; filtering to remove precipitate; adjusting wastewater to pH of 6-8; and destroying aliphatic polyamine complexants and reducing COD using an available biological degradation technique. This method can effectively and economically remove the pollutants such as heavy metals in the electroplating wastewater for a good market prospective.

Owner:GUANGZHOU ULTRA UNION CHEM LTD

Method for formate dehydrogenation under catalysis of supported Ag-Pd/C3N4 nano-catalyst

ActiveCN105217568AHigh activityHigh selectivityHydrogenPhysical/chemical process catalystsNano catalystHydrogen

The invention discloses a method for formate dehydrogenation under catalysis of a supported Ag-Pd / C3N4 nano-catalyst and belongs to the technical fields of chemistry and chemical engineering. The well-prepared supported Ag-Pd / C3N4 nano-catalyst is put in a reactor, the reactor is put in an oil bath and heated to a certain temperature, a mixed solution of formic acid and sodium formate is added to the reactor for a reaction, and generated hydrogen is collected with a drainage method. The supported Ag-Pd / C3N4 nano-catalyst is prepared as follows: a solution is prepared from Ag and Pd in a certain mole ratio, a carrier C3N4 is added to the solution, a reducer is added to the mixed solution, and filtration and drying are performed. Compared with conventional supported catalysts, the high-activity and high-selectivity supported Ag-Pd / C3N4 nano-catalyst used for formate dehydrogenation to prepare hydrogen can be prepared by adjusting the content of Ag, Pd and C3N4.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

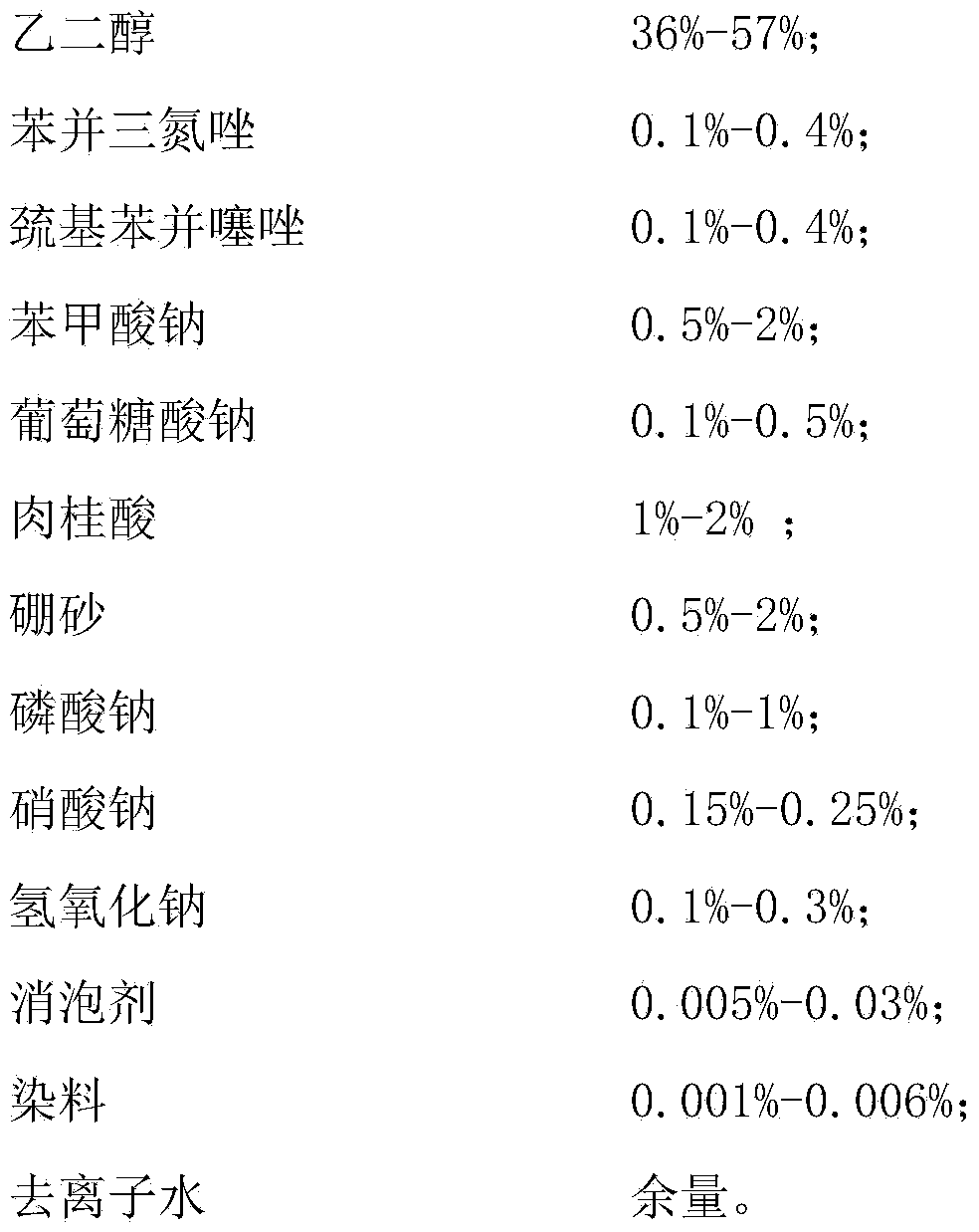

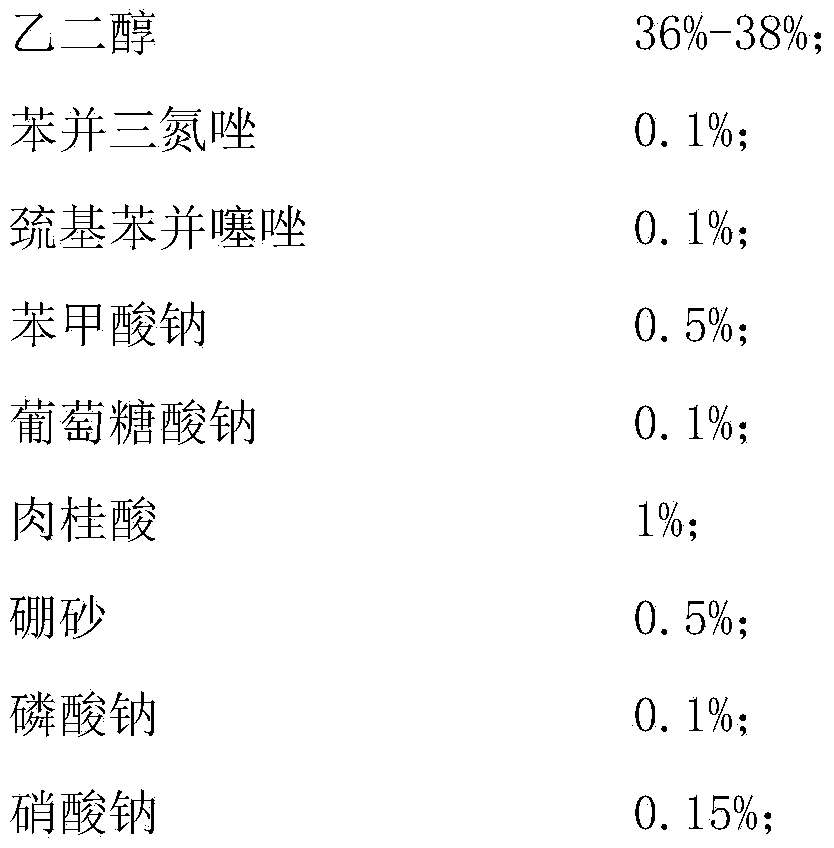

Anti-freezing fluid for solar water heater and preparation method thereof

The invention discloses an anti-freezing fluid for a solar water heater. The anti-freezing fluid is composed of the following components by weight percent: 36-57 percent of glycol, 0.1-0.4 percent of 1H-Benzotriazole, 01.-0.4 percent of mercaptobenzothiazole, 0.5-2 percent of sodium benzoate, 0.1-0.5 percent of sodium gluconate, 1-2 percent of cinnamic acid, 0.5-2 percent of borax, 0.1-1 percent of sodium phosphate, 0.15-0.25 percent of sodium nitrate, 0.1-0.3 percent of sodium hydroxide, 0.005-0.03 percent of an antifoamer, 0.001-0.006 percent of dye and deionized water in balancing amount. The anti-freezing fluid is good in stability, has the PH rangeability smaller than that of a common anti-freezing fluid at high temperature for a long time, does not separate out particles and flocculent precipitates to block a pipeline, and has good rust inhibition effect on metal material for manufacturing the solar heater. Moreover, the invention further provides a preparation method for the anti-freezing fluid, which is simple and easy to operate.

Owner:RICHU DONGFANG SOLAR ENERGY

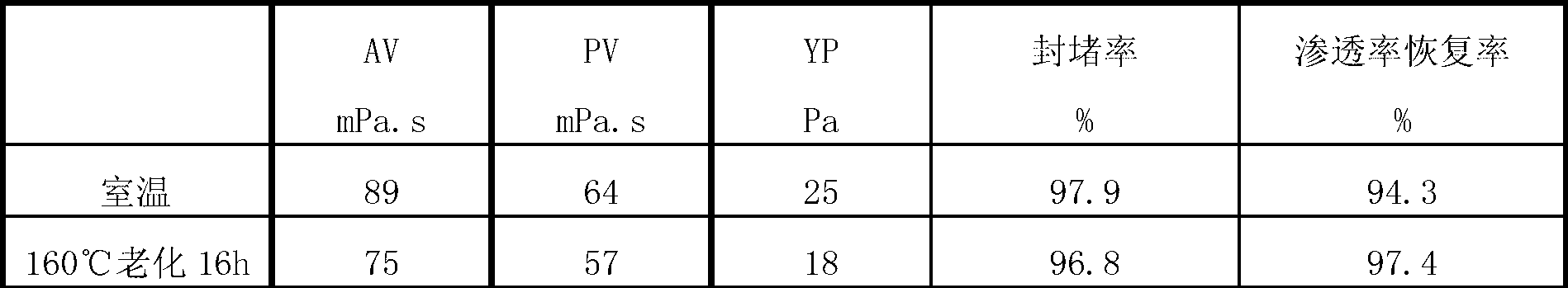

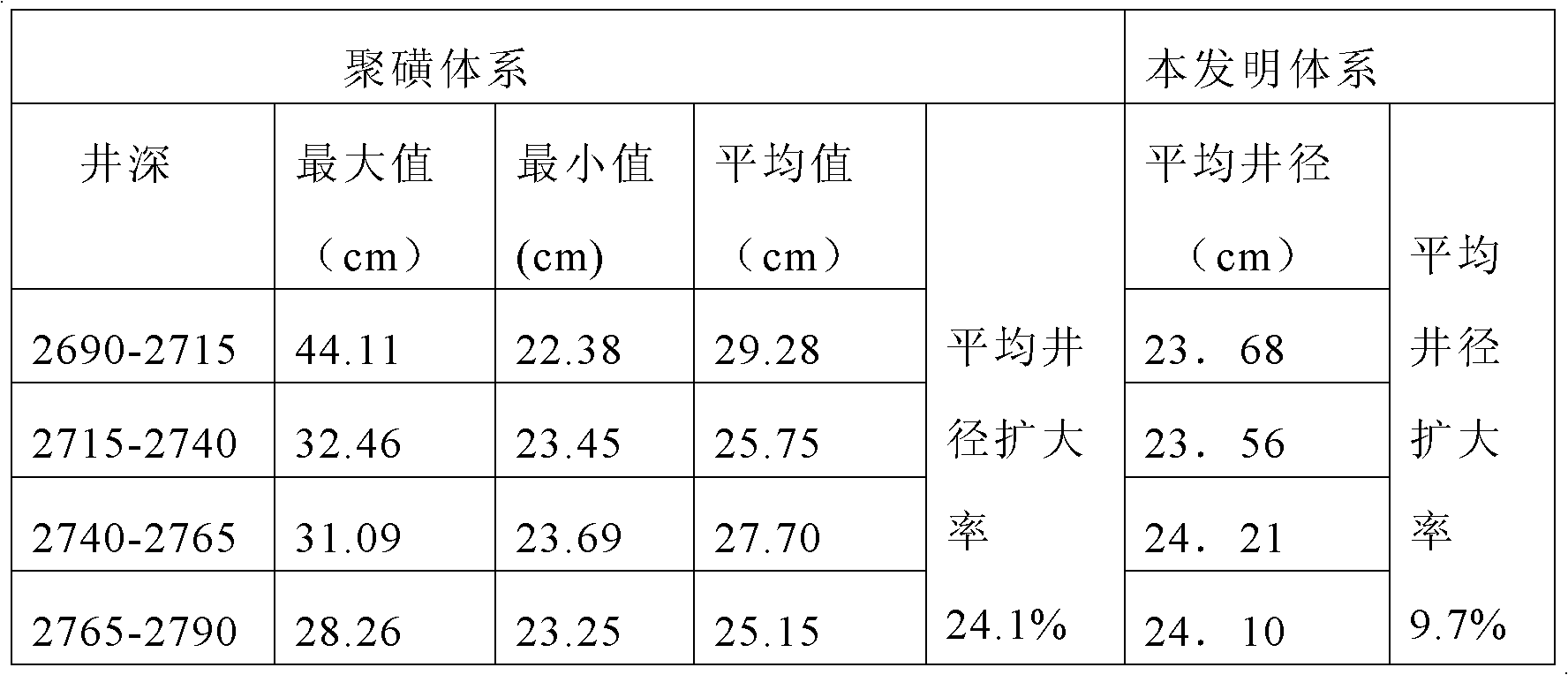

Composite salt low-activity anti-sloughing drilling fluid and construction method thereof

InactiveCN103146363AAvoid differential pressure lossThe system has strong chemical inhibition and anti-collapse effectDrilling compositionSealing/packingFriction reductionMass ratio

The invention discloses a composite salt low-activity anti-sloughing drilling fluid and a construction method thereof. The composite salt low-activity anti-sloughing drilling fluid consists of the following raw materials in percentage by mass: 0.2-0.3% of drilling fluid viscosifier, 2-3% of carboxymethyl starch, 1.5-2% of aqueous dispersion cation emulsified asphalt, 0.2-0.3% of anti-salt anti-calcium filtrate reducer, 1% of sulfonated phenolic resin, 2% of acid-soluble temporary seal reservoir protective agent, 1% of superfine calcium, 0.1% of caustic soda and the balance of clean water. In construction, the composite salt accounting for 5-15% of the dosage of the composite slat low-activity anti-sloughing drilling fluid is added, and the composite salt is formed by mixing sodium formate and sodium chloride at a mass ratio of 2:1. By utilizing the composite salt, the function of chemically suppressing mudstone and preventing sloughing in the drilling fluid as well as the density of the drilling fluid are improved. With strong chemical suppression and low solid phase, the composite salt low-activity anti-sloughing drilling fluid completely meets the strict high-quality requirements of a long open-hole section for friction reduction and resistance reduction of the drilling fluid.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

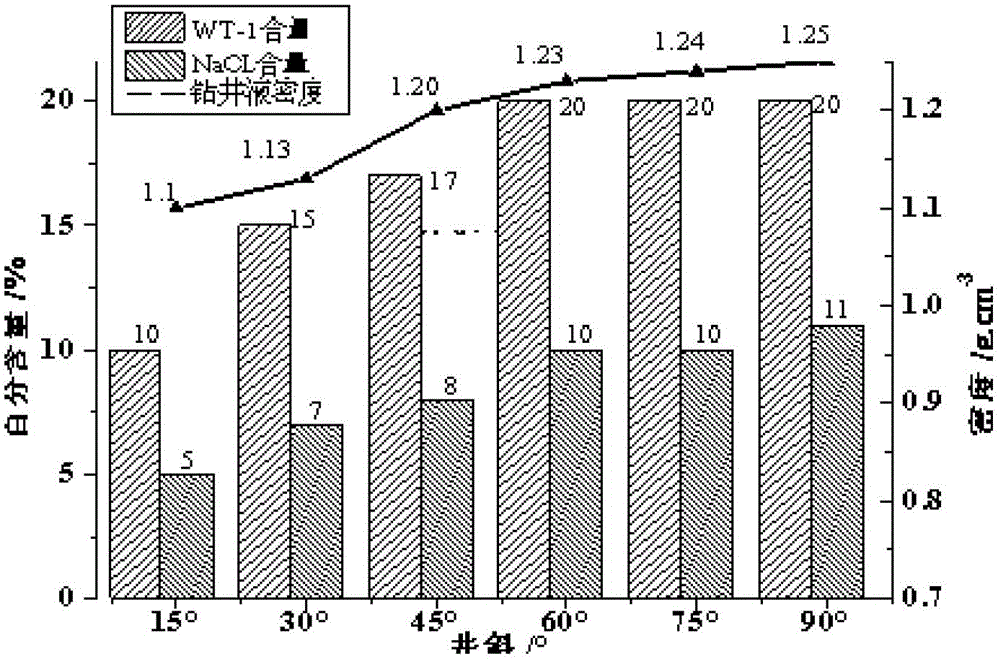

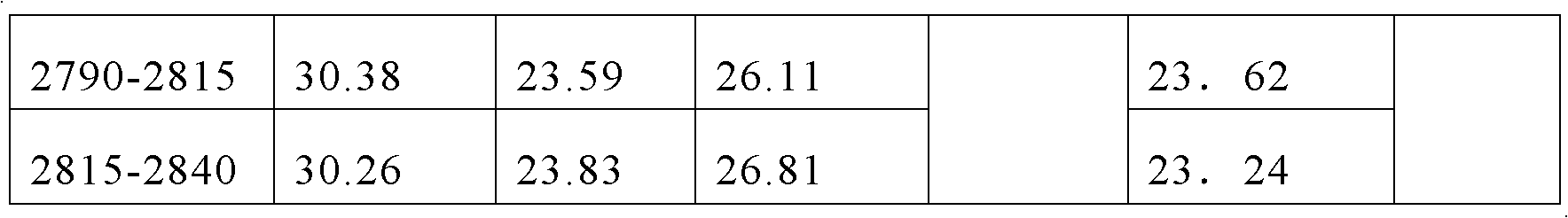

Process for preparing drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling

InactiveCN101892036AImprove anti-slump performanceImprove integrityDrilling compositionCelluloseWater dispersible

The invention relates to a process for preparing drilling fluid, in particular to a process for preparing the drilling fluid for preventing polycrystalline diamond compact (PDC) bit balling. The process comprises a construction process and a dosage formula of treating agents and is characterized in that: according to the dosage formula, the treating agents are prepared by mixing clear water polymer original slurry, poly anionic cellulose (PAC), calcium carbonate (QS-4), carboxymethyl starch (CMS), sulfonated phenolic resin(SMP-2), water dispersible cation emulsified asphalt powder (SFT-1), sodium chloride(NaCL) and sodium formate (WT-1) in a mass ratio of 1,000:2-3:30-40:20-30:2-3:1.5-2:50-100:20; and the construction process comprises the following steps of: according to a circulation circle, uniformly mixing a coating agent PAC, a filtrate reducer CMS, a salt and high-temperature resistant filtrate reducer SMP-2 and an anti-sloughing lubricant SFT-1 for 12h at first; adding QA-4, NaCL, WT-1 into the mixture and uniformly mixing the mixture; and regulating the mixture to have a density Rho of 1.06 to 1.10g / cm<3>, a funnel viscosity T of 38 to 45s and an API water loss FL of 4 to 6ml. The process has the advantages of effectively preventing the balling of a sticking bit and a PDC bit at a lower curved section, reducing a frictional resistance and a torque, eliminating a sticking phenomenon, improving a mechanical drilling rate and ensuring downhole safety.

Owner:中国石油集团川庆钻探工程有限公司长庆钻井总公司

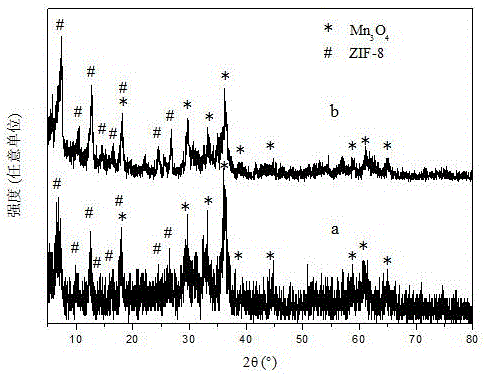

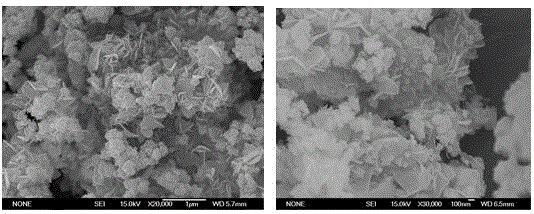

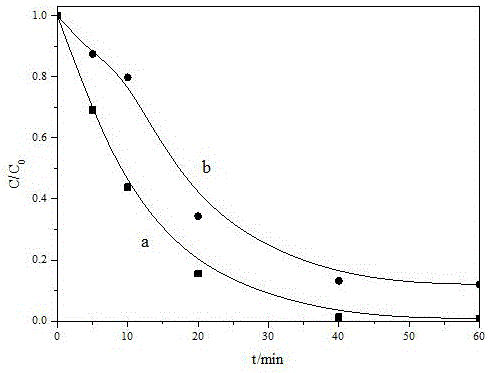

Preparation method of catalytic composite material Mn3O4/ZIF-8 (Zeolite Imidazate Framework-8) for activating PMS (Potassium Monopersulfate)

ActiveCN106423293AOrganic-compounds/hydrides/coordination-complexes catalystsWater contaminantsPotassiumCatalytic effect

The invention relates to a preparation method of a catalytic composite material Mn3O4 / ZIF-8 (Zeolite Imidazolate Framework-8) for activating PMS (Potassium Monopersulfate). The method comprises the following steps of first, preparing a ZIF-8 according to the mole ratio, which is 1 to 4 to 3 to 33 of zinc nitrate hexahydrate to 2-methylimidazole to sodium formate dihydrate to N,N-dimethyl formamide; afterwards, weighing to take potassium hypermanganate and the ZIF-8 with corresponding masses respectively according to the mass ratio, which is (0.52 to 1.04) to 1, of the potassium hypermanganate to the ZIF-8, dispersing the ZIF-8 into a 60-percent ethanol solution, sufficiently agitating an obtained first mixture, then adding the potassium hypermanganate into an ethanol solution containing the ZIF-8, sufficiently agitating an obtained second mixture, transferring the agitated second mixture into a reaction kettle, and making the transferred second mixture react for 8 hours at 120 DEG C, so as to obtain the Mn3O4 / ZIF-8 composite material through centrifugation, multiple washing and the drying at 60 DEG C for one night. In the obtained catalytic composite material Mn3O4 / ZIF-8, the ZIF-8 is cauliflower-shaped; Mn3O4 is sheet-shaped, and is evenly distributed on the surface of the ZIF-8. The catalytic composite material has an excellent catalytic effect on the PMS; the degradation rate, on rhodamine B, of the PM aSctivated through the composite material reaches 81 percent to 99 percent.

Owner:SHANGHAI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com