Method for preparing DMC, DPC, ortho-carbonate, ortho-formate, dimethyl ether, and the like by using Na2CO3 or sodium formate or CO2 or CO

A technology of dimethyl ether and diethyl ether, which is applied in the fields of Na2CO3 or sodium formate or CO2 or CO to prepare DMC, DPC, orthocarbonate, orthoformate, dimethyl ether, etc. , the problem of high production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

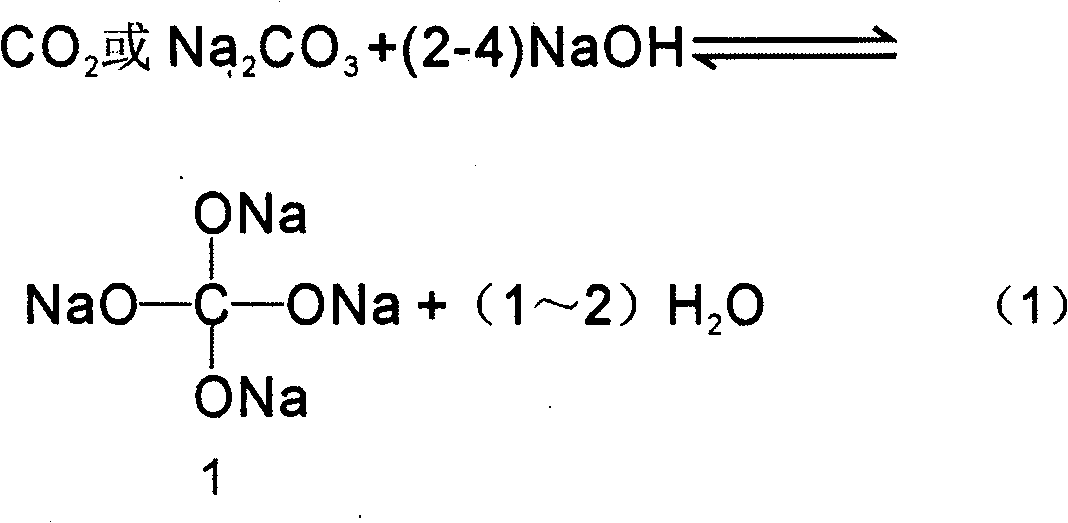

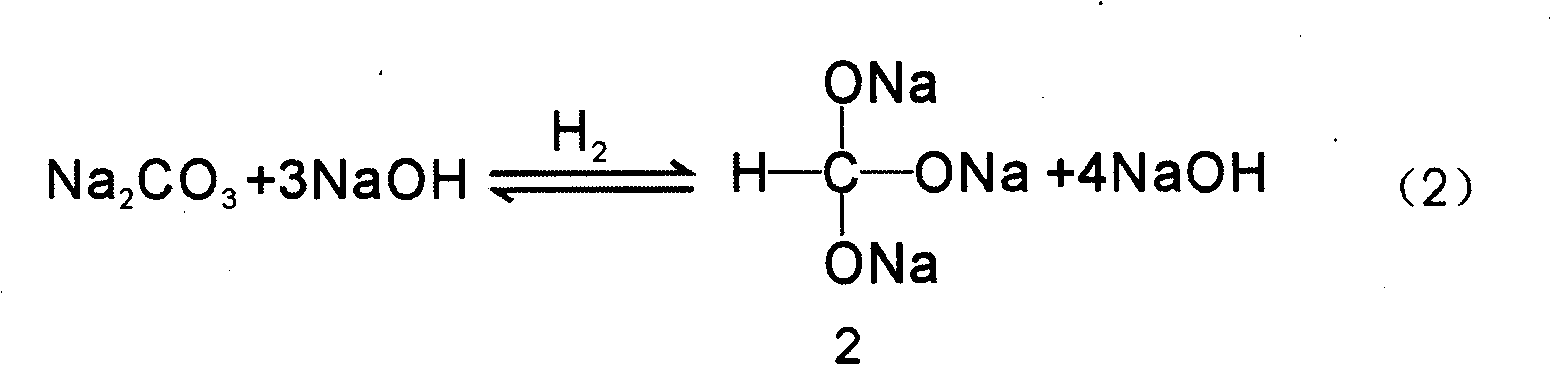

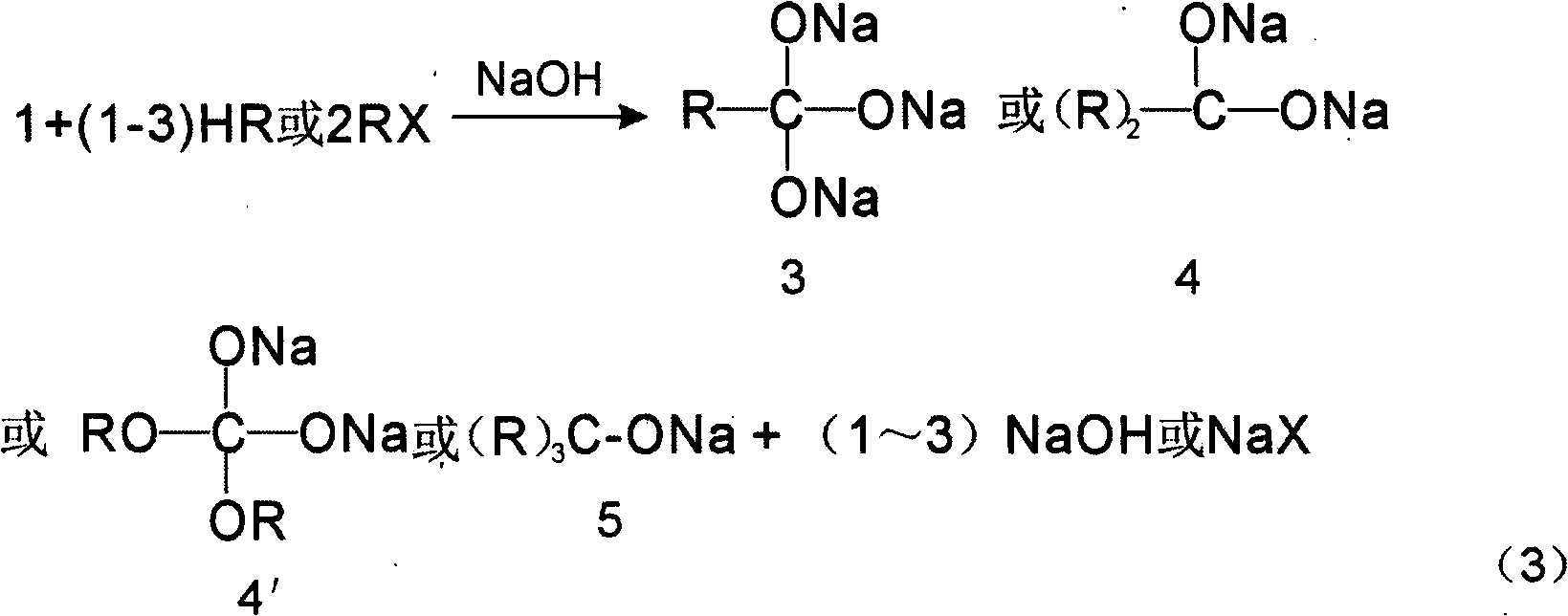

Method used

Image

Examples

Embodiment 1

[0106] Under the condition of cutting off the air, put in 30% or 98% NaOH (0.8mol) and 98% sodium carbonate solid (0.2mol), start stirring, the temperature is 40-50°C, react for 3-15 hours, add anhydrous methanol (426g), continue the insulation reaction for 14 to 20 hours, drop to normal temperature, and use carbonic acid or CO 2 Mix with water vapor to adjust the atmosphere to PH5-6, and reflux for 1 hour to obtain a methanol solution of dimethyl carbonate (DMC), Na 2 CO 3 The conversion rate is 37%, the DMC reaction yield is 85%, and dimethyl ether is produced as a by-product.

Embodiment 2

[0108] Drop into 18% sodium methoxide (0.6mol) solution in the autoclave, start stirring, pass into CO 2 Gas (0.2mol), control the temperature at 40-50°C, keep warm for 14-20 hours, then add water (0.2-0.6mol), and re-introduce CO 2 gas, to PH6, to obtain methanol solution of dimethyl carbonate, by-product Na 2 CO 3 solid. CO participating in the reaction 2 The conversion rate is 95%, and the dimethyl carbonate reaction yield is 90%.

Embodiment 3

[0110]Under the condition of cutting off air, drop into 30% NaOH (1.2mol) and 98% sodium carbonate (0.2mol), start stirring, control temperature 40~50 ℃, react 3~15 hours, add phenol (0.4mol), Control the temperature at 70-80°C, keep it warm for 14-20 hours, add 700g of benzene, stir for 0.5-1 hour, drop to room temperature, wash and separate the layers, adjust the PH of the benzene layer to 5-6 with acid, and reflux for 1 hour to obtain diphenyl carbonate Benzene suspension of ester (DPC), DPC reaction yield 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com