Patents

Literature

348 results about "Diphenyl carbonate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Diphenyl carbonate is the organic compound with the formula (C₆H₅O)₂CO. It is classified as an acyclic carbonate ester. It is a colorless solid. It is both a monomer in combination with bisphenol A in the production of polycarbonate polymers and a product of the decomposition of polycarbonates.

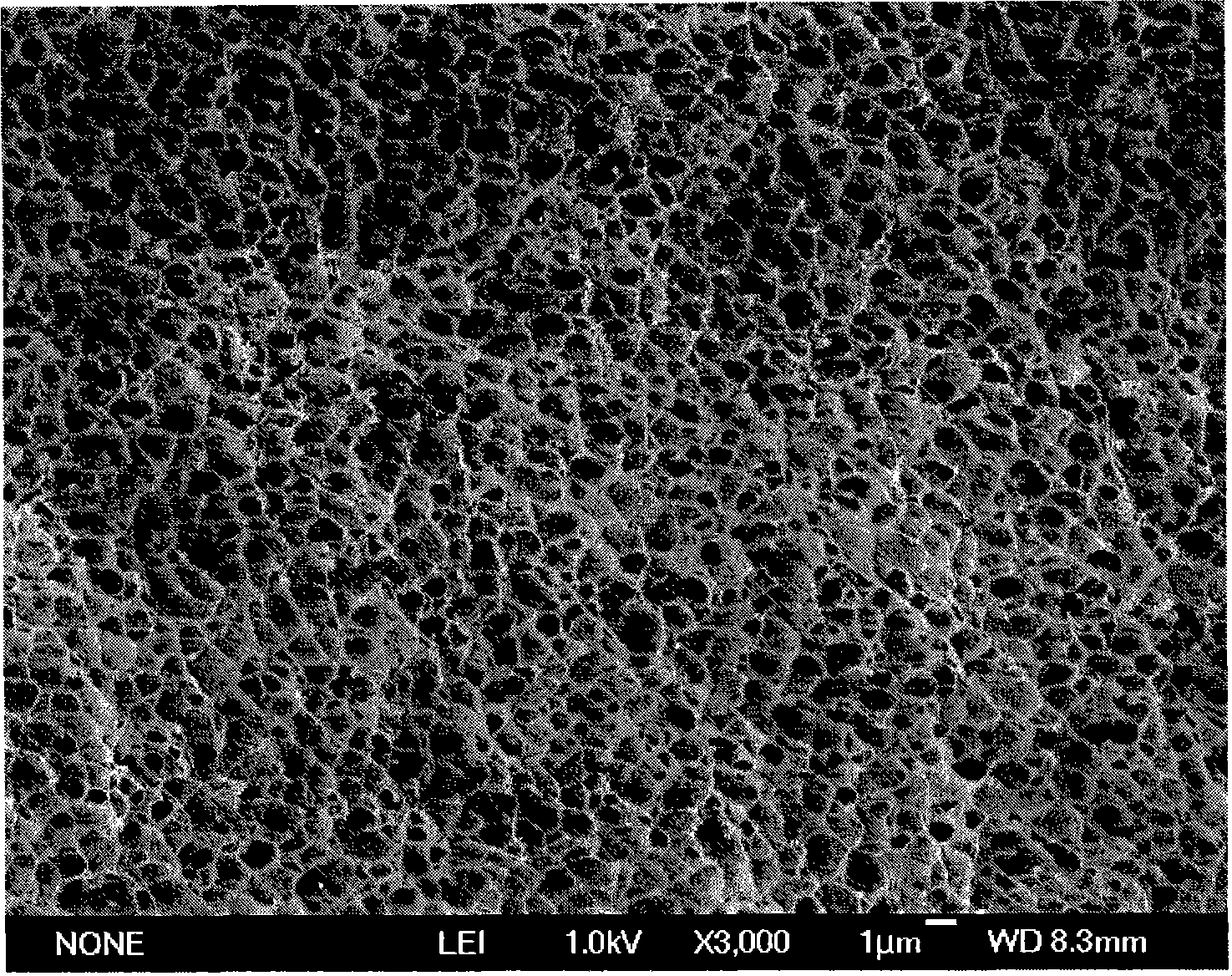

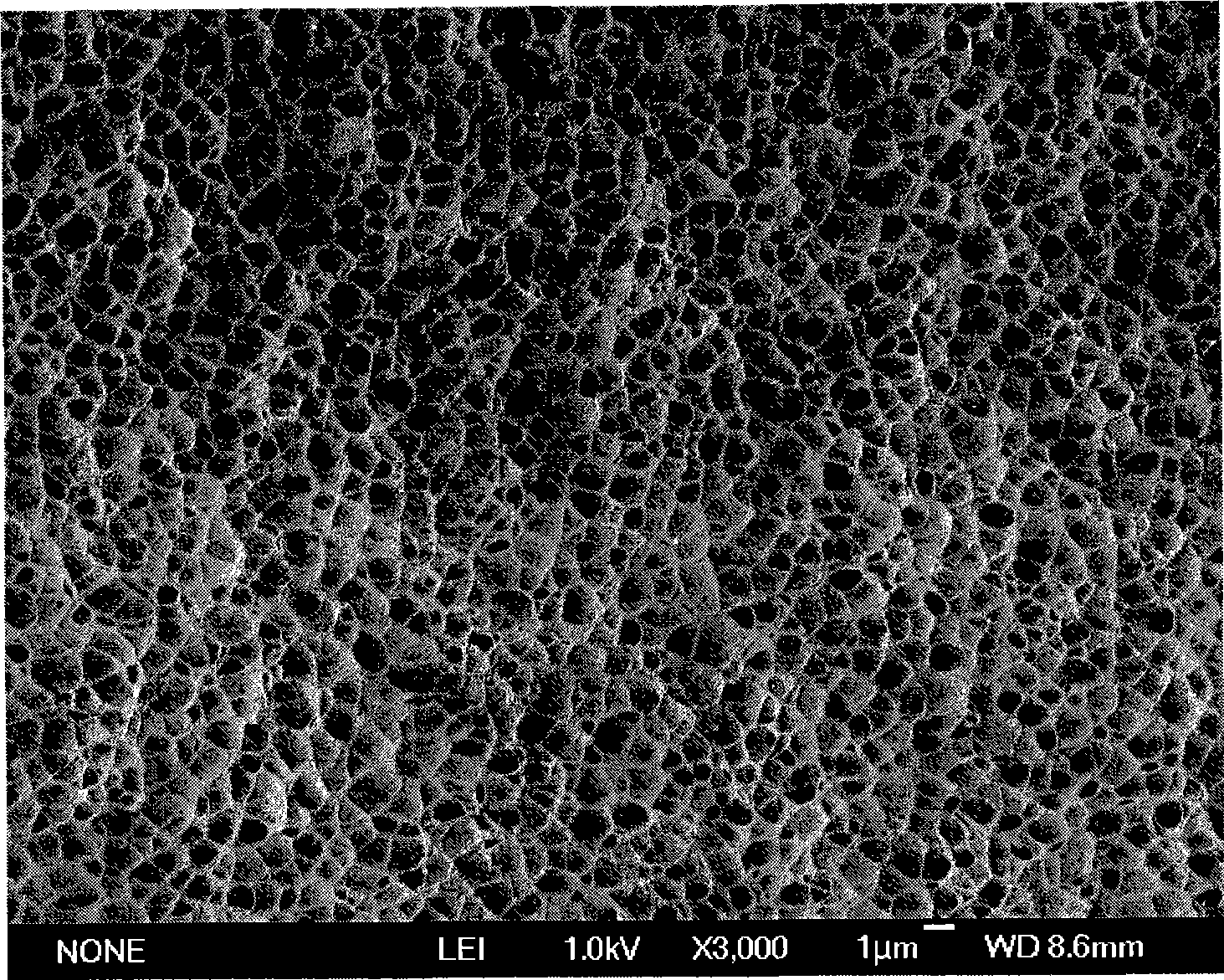

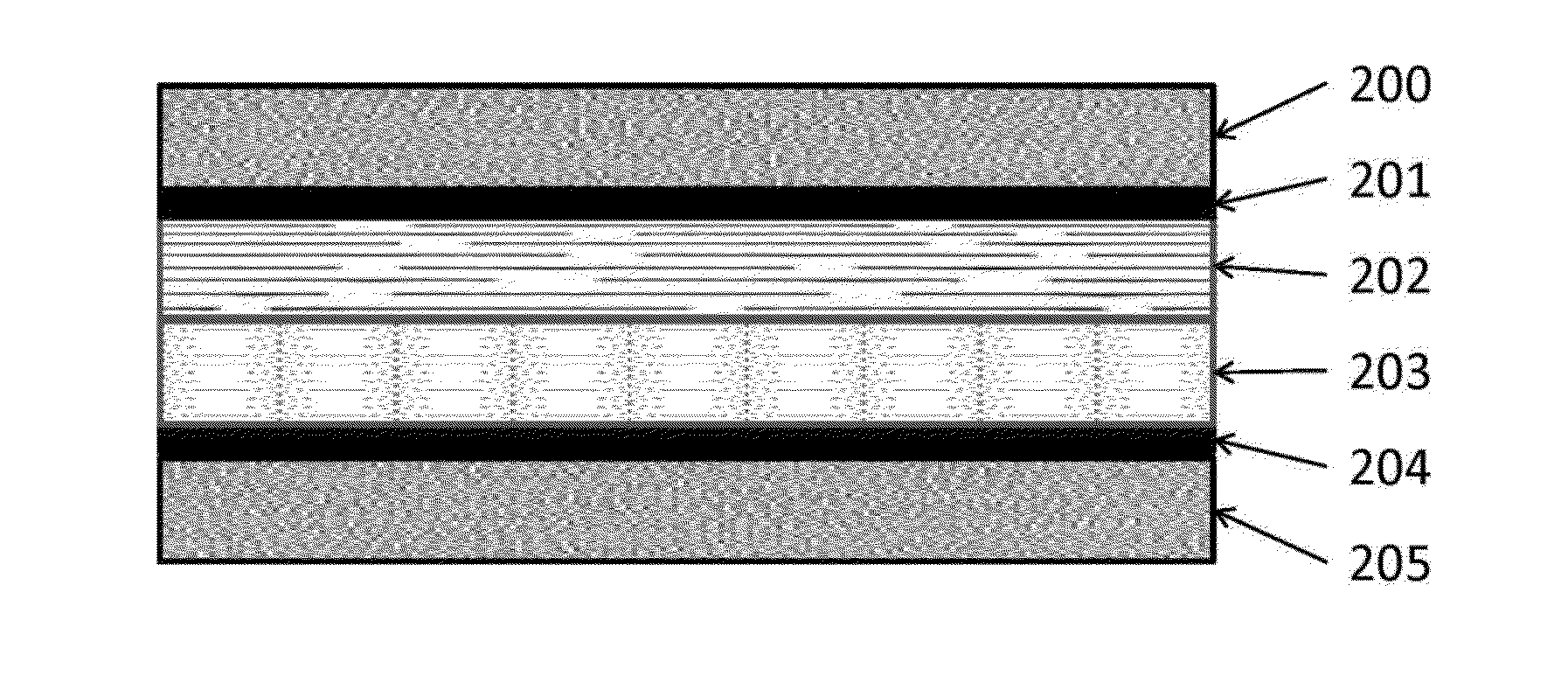

Method for preparing polyvinylidene fluoride porous membrane

ActiveCN101362057AGuaranteed StrengthGuaranteed high water fluxSemi-permeable membranesMembranesHollow fibreFiber

Owner:TSINGHUA UNIV

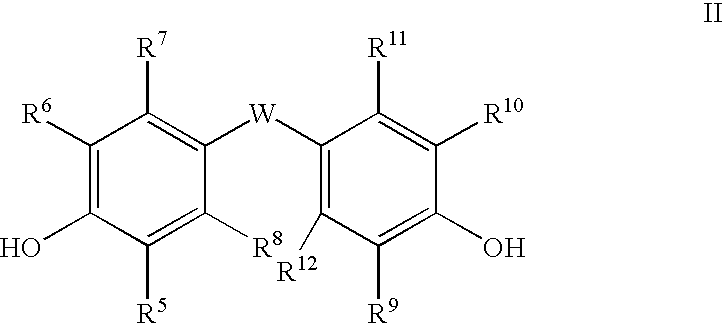

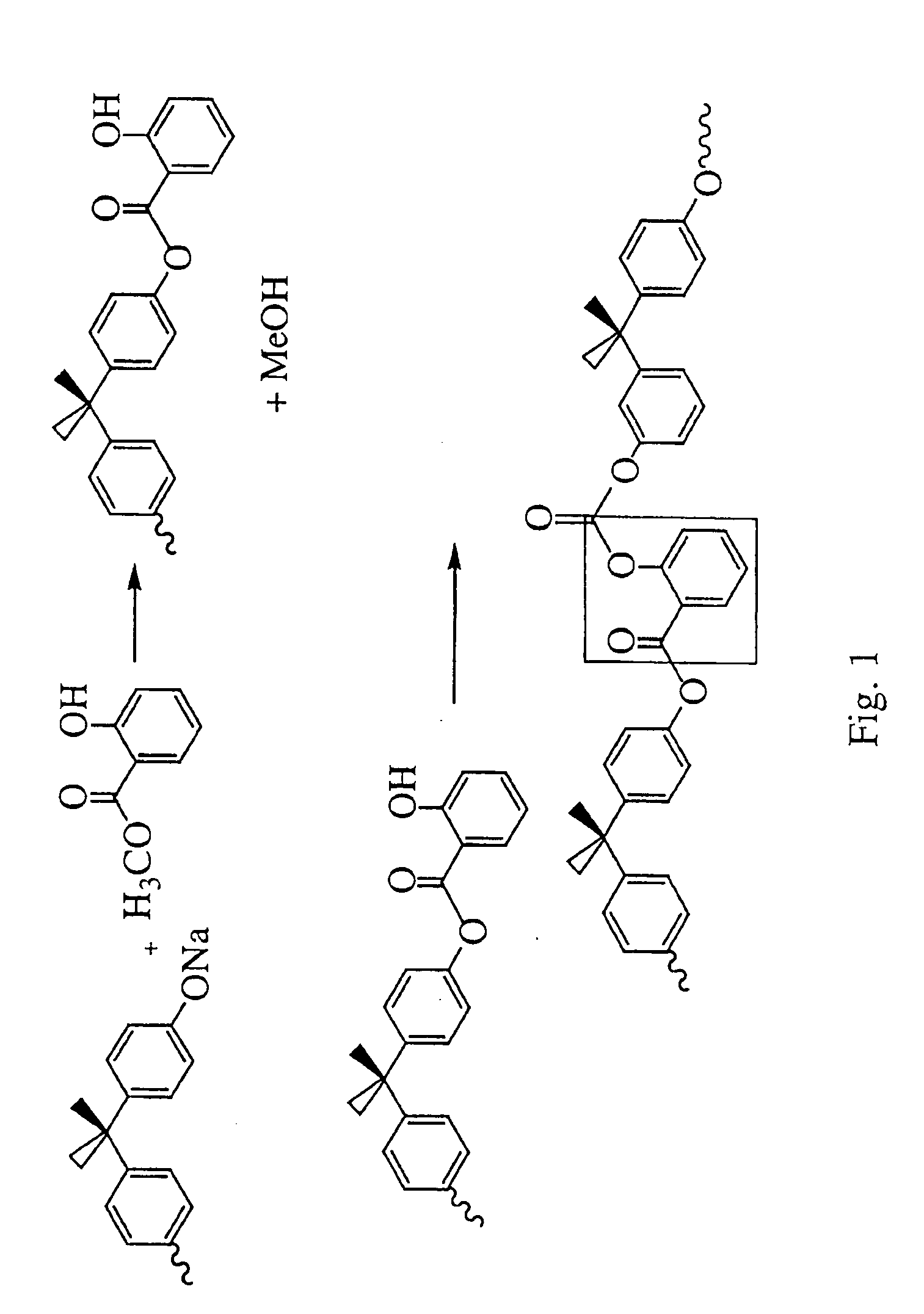

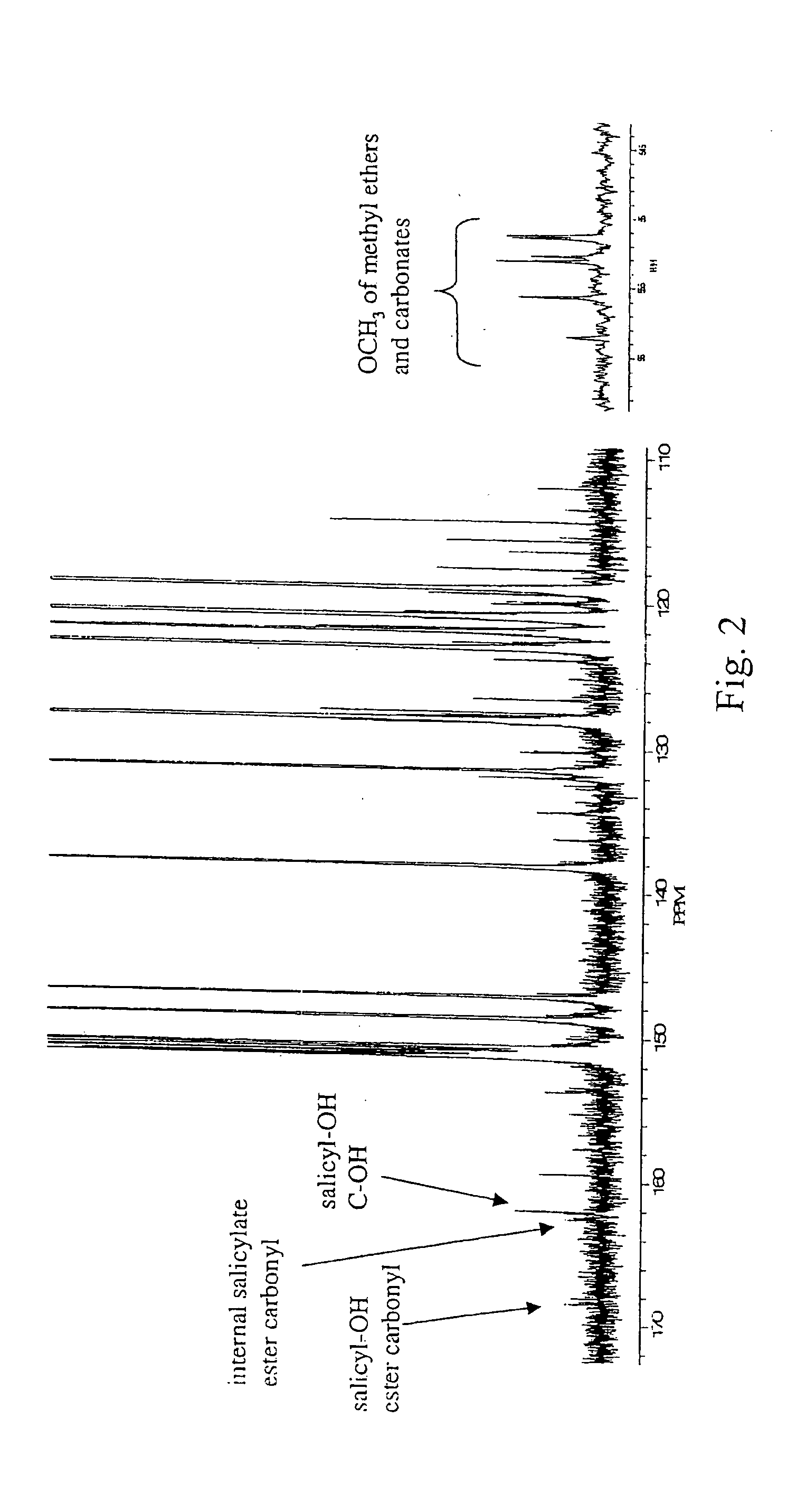

Method of polycarbonate preparation

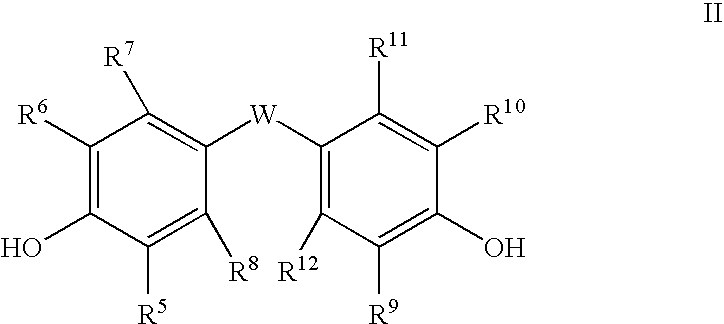

InactiveUS20050261460A1Low levelImprove the level ofCeramic shaping apparatusFries rearrangementHydroquinone Compound

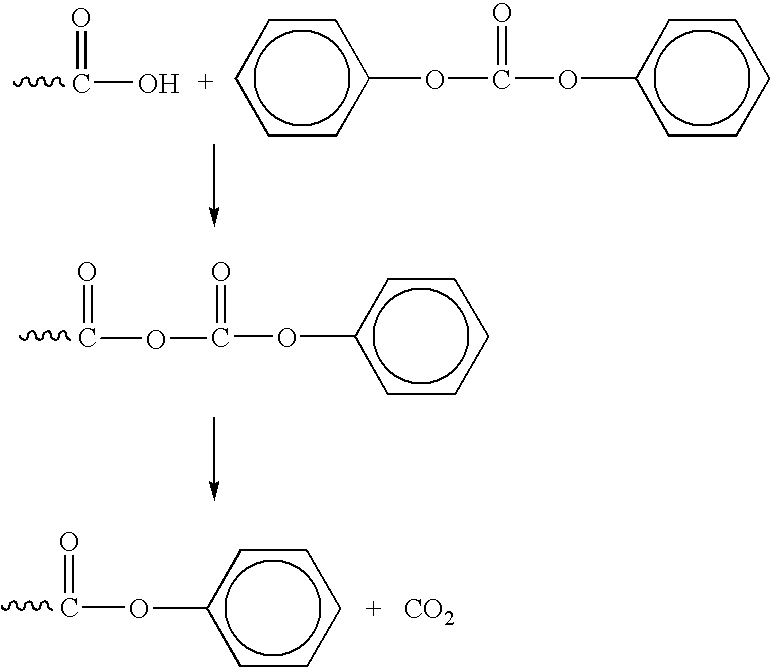

Polycarbonates containing low or undetectable levels of Fries rearrangement products and comprising repeat units derived from one or more of resorcinol, hydroquinone, methylhydroquinone, bisphenol A, and 4,4′-biphenol have been prepared by the melt reaction of one or more of the aforementioned dihydroxy aromatic compounds with an ester-substituted diaryl carbonate such as bis-methyl salicyl carbonate. Low, or in many instances undetectable, levels of Fries rearrangement products are found in the product polycarbonates obtained as the combined result of a highly effective catalyst system which suppresses the Fries reaction and the use of lower melt polymerization temperatures relative to temperatures required for the analogous polymerization reactions using diphenyl carbonate.

Owner:SABIC INNOVATIVE PLASTICS IP BV

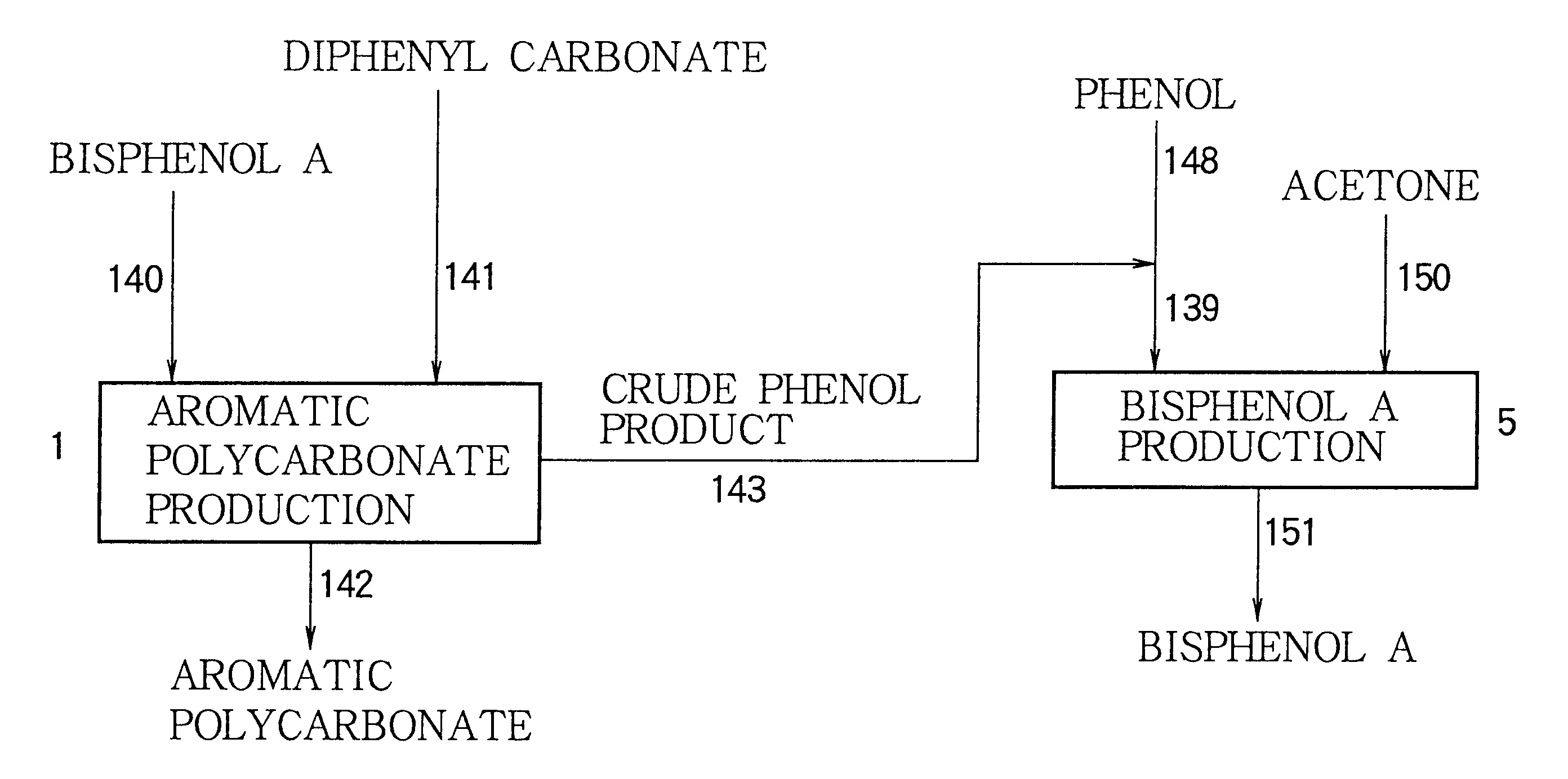

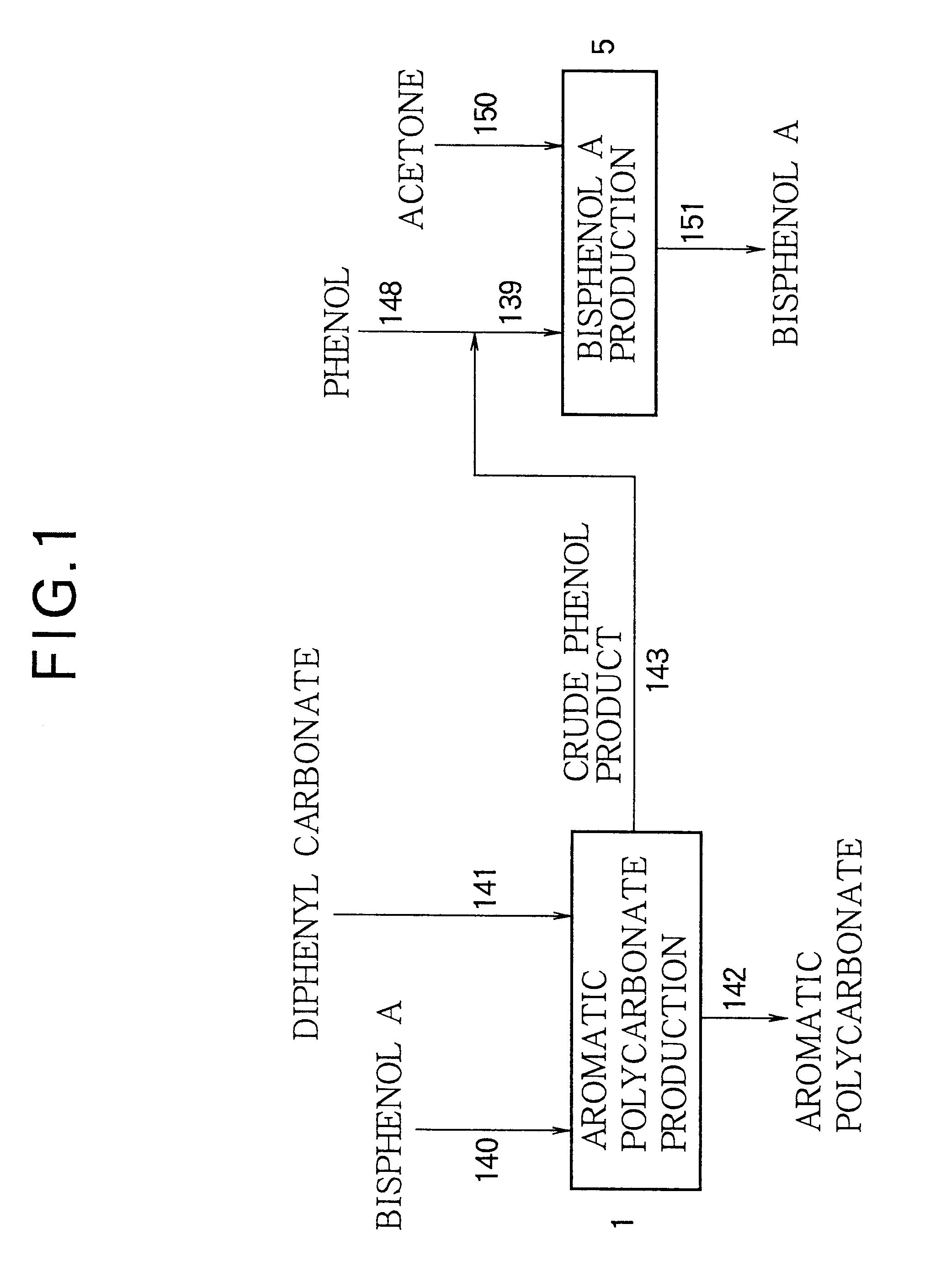

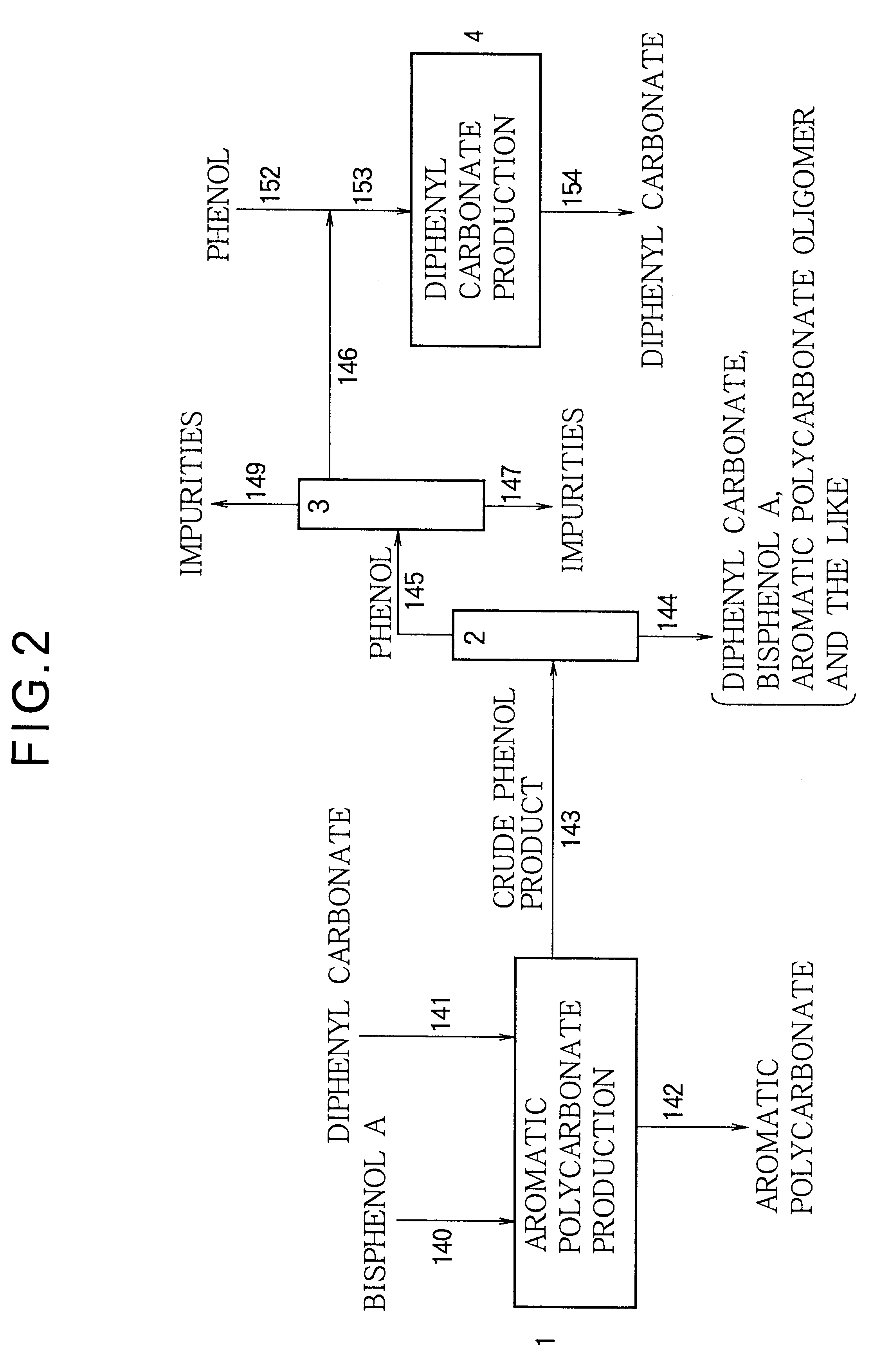

Method for producing an aromatic polycarbonate

Disclosed is a method for producing an aromatic polycarbonate, which comprises reacting acetone with a phenol material, thereby producing bisphenol A, and polymerizing the resultant bisphenol A with diphenyl carbonate to produce an aromatic polycarbonate while producing phenol as a by-product, wherein the by-product phenol is recovered as a crude phenol product containing the by-product phenol as a main component and containing impurities, and the crude phenol product is used as at least a part of the phenol material for producing bisphenol A. According to the method of the present invention, a crude phenol product as such, containing, as a main component, a by-product phenol which is by-produced during the polymerization reaction for producing an aromatic polycarbonate, and containing impurities, can be utilized for producing an aromatic polycarbonate, without any purification or the like. In the method of the present invention, not only can a necessity for complicated operations, such as a purification treatment, be reduced, but also the amount of wastes can be reduced and the yield of the aromatic polycarbonate, based on any of phenol and bisphenol A, can be improved.

Owner:ASAHI KASEI KK

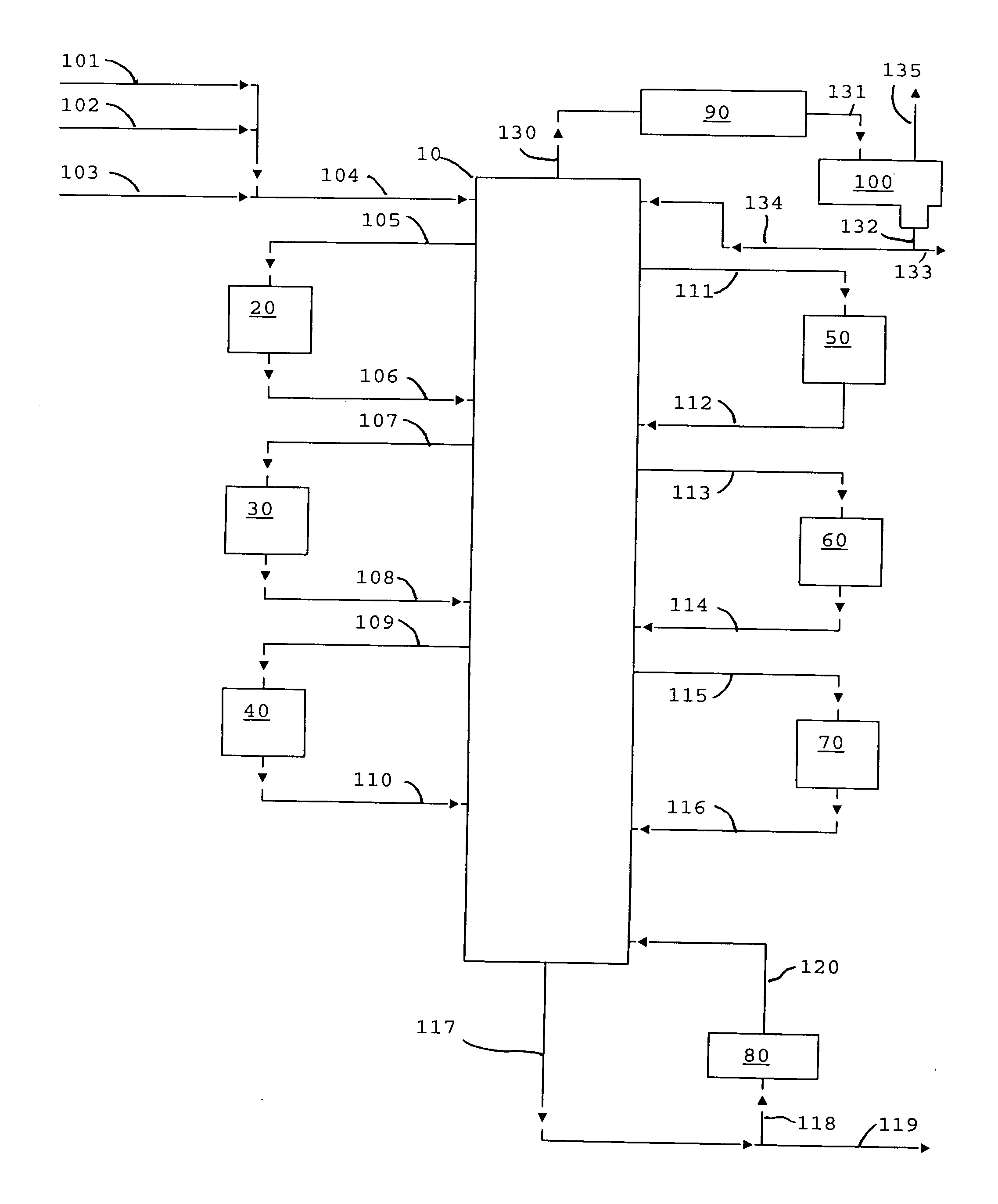

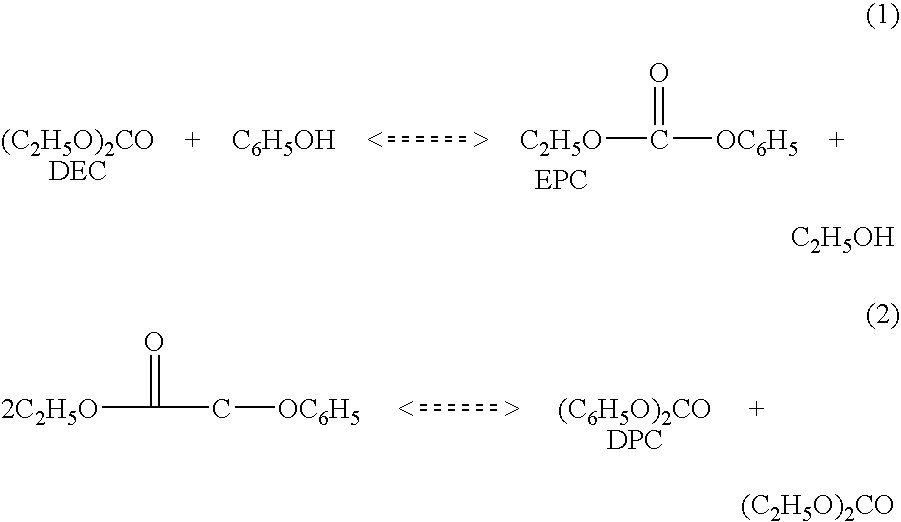

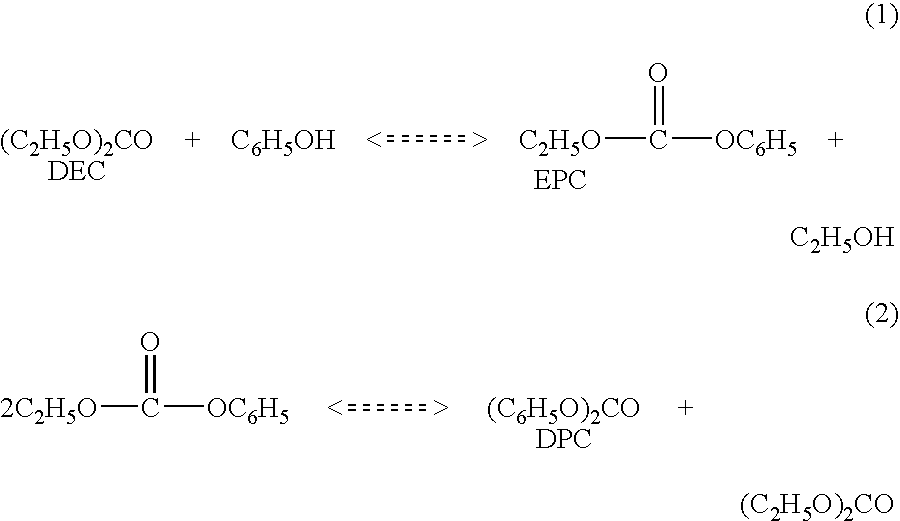

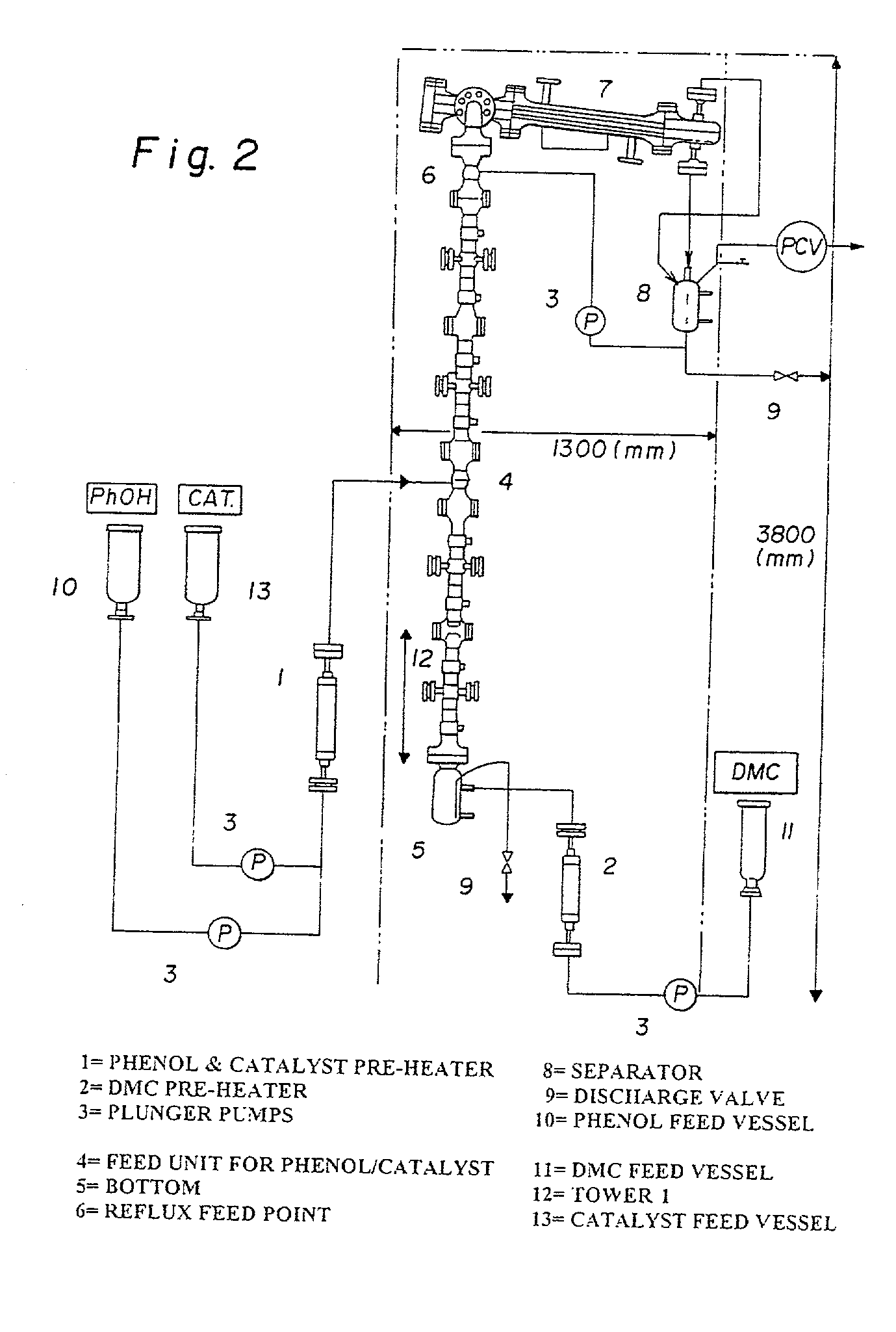

Process for making diaryl carbonate

Diphenyl carbonate is produced by reacting phenol with diethyl carbonate in a series of fixed bed reactors each of which is connected at different position on a distillation column via side draw and return streams. The composition of material in a distillation column varies along the length of the column, which is predictable under a given set of conditions of temperature and pressure, thus withdrawing streams at different stages in the column, allows the reactor receiving the feed from a particular stage to be operated under conditions to maximize the desired reaction, while allowing the unreacted or byproduct to go back into the distillation and be sent to a stage (by the equilibrium of the distillation) where they are favorably treated in a reactor.

Owner:SHELL USA INC

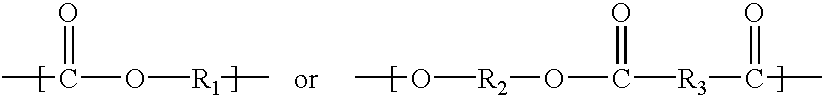

Production of poly(carbonate-co-ester) copolymers

A poly(carbonate-co-ester) block copolymer is synthesized using synthetic strategies that can be incorporated into conventional melt facilities that are commonly used in the production of polycarbonate polymers. The polycarbonate block of the poly(carbonate-co-ester) copolymer is derived from a polycarbonate reaction mixture comprising an aromatic dihydroxy compound and a carbonic acid diester, such as bisphenol A and diphenyl carbonate, respectively. The second block of the copolymer is derived from a polyester prepolymer, the polyester prepolymer comprising a diol, diacid or diester, and at least one monomer that is selected to advantageously incorporate desired properties into the poly(carbonate-co-ester) copolymer. The polyester prepolymer is introduced to the polycarbonate reaction mixture to form the poly(carbonate-co-ester) copolymer. Properties of the copolymer can be altered by varying numerous conditions of the reaction.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Process for making diaryl carbonate

Diphenyl carbonate is produced by reacting phenol with diethyl carbonate in a series of fixed bed reactors each of which is connected at different position on a distillation column via side draw and return streams. The composition of material in a distillation column varies along the length of the column, which is predictable under a given set of conditions of temperature and pressure, thus withdrawing streams at different stages in the column, allows the reactor receiving the feed from a particular stage to be operated under conditions to maximize the desired reaction, while allowing the unreacted or byproduct to go back into the distillation and be sent to a stage (by the equilibrium of the distillation) where they are favorably treated in a reactor.

Owner:SHELL USA INC

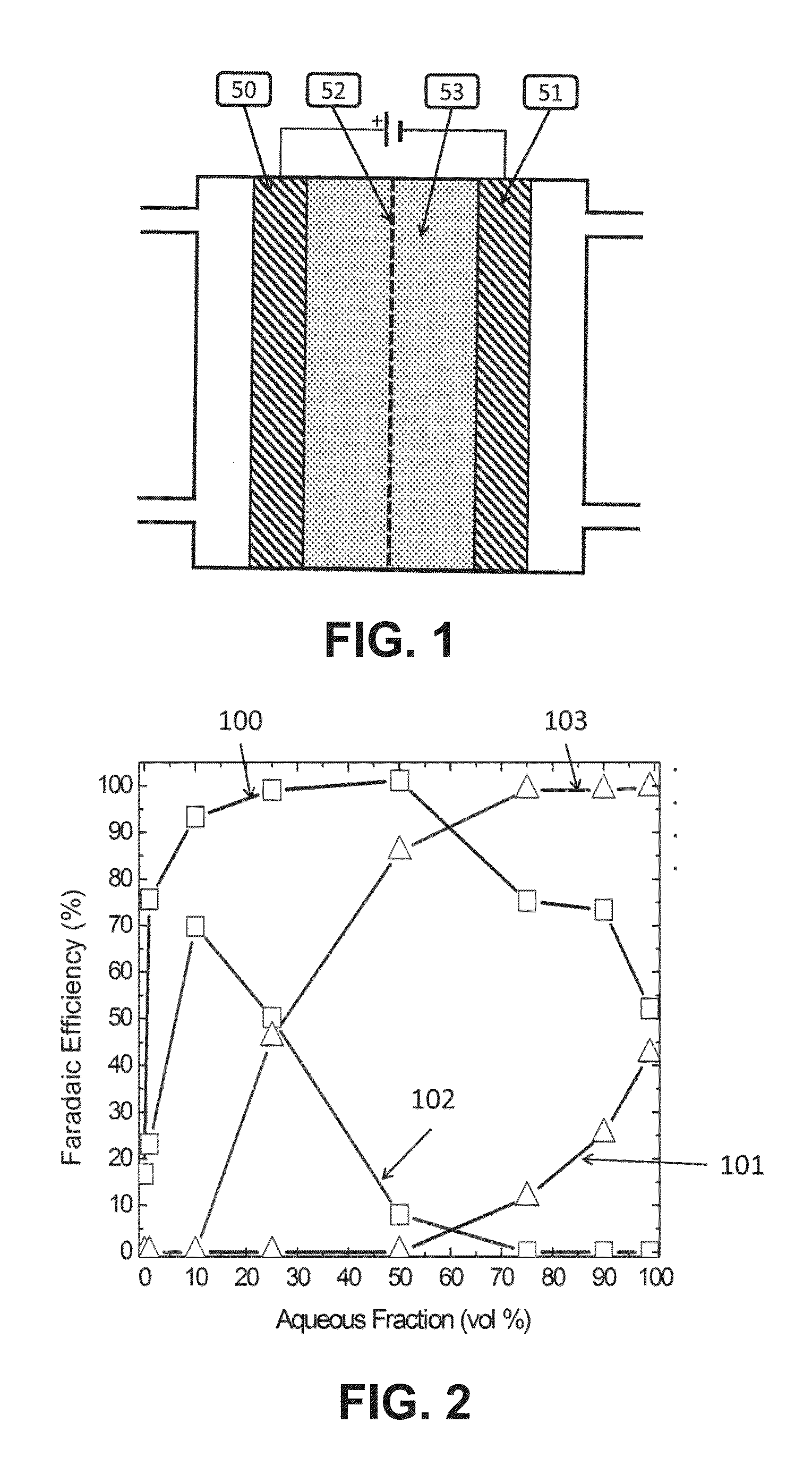

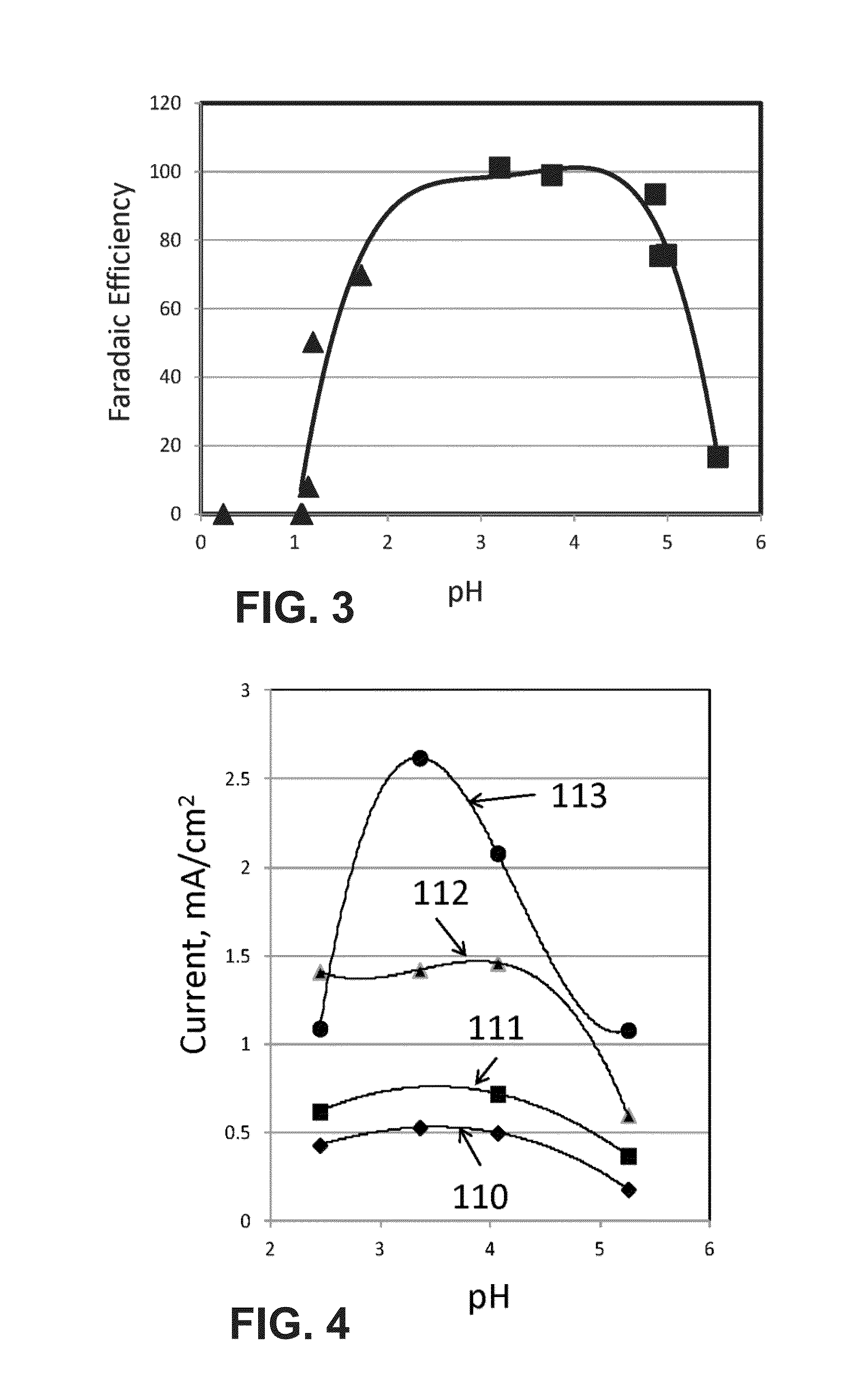

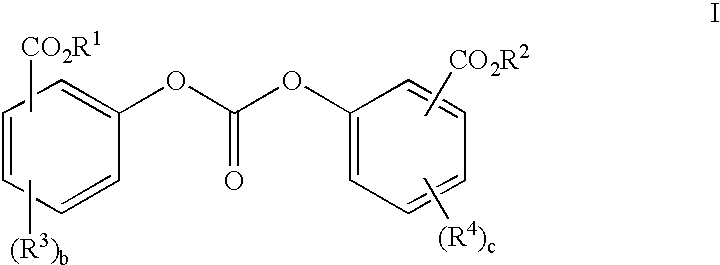

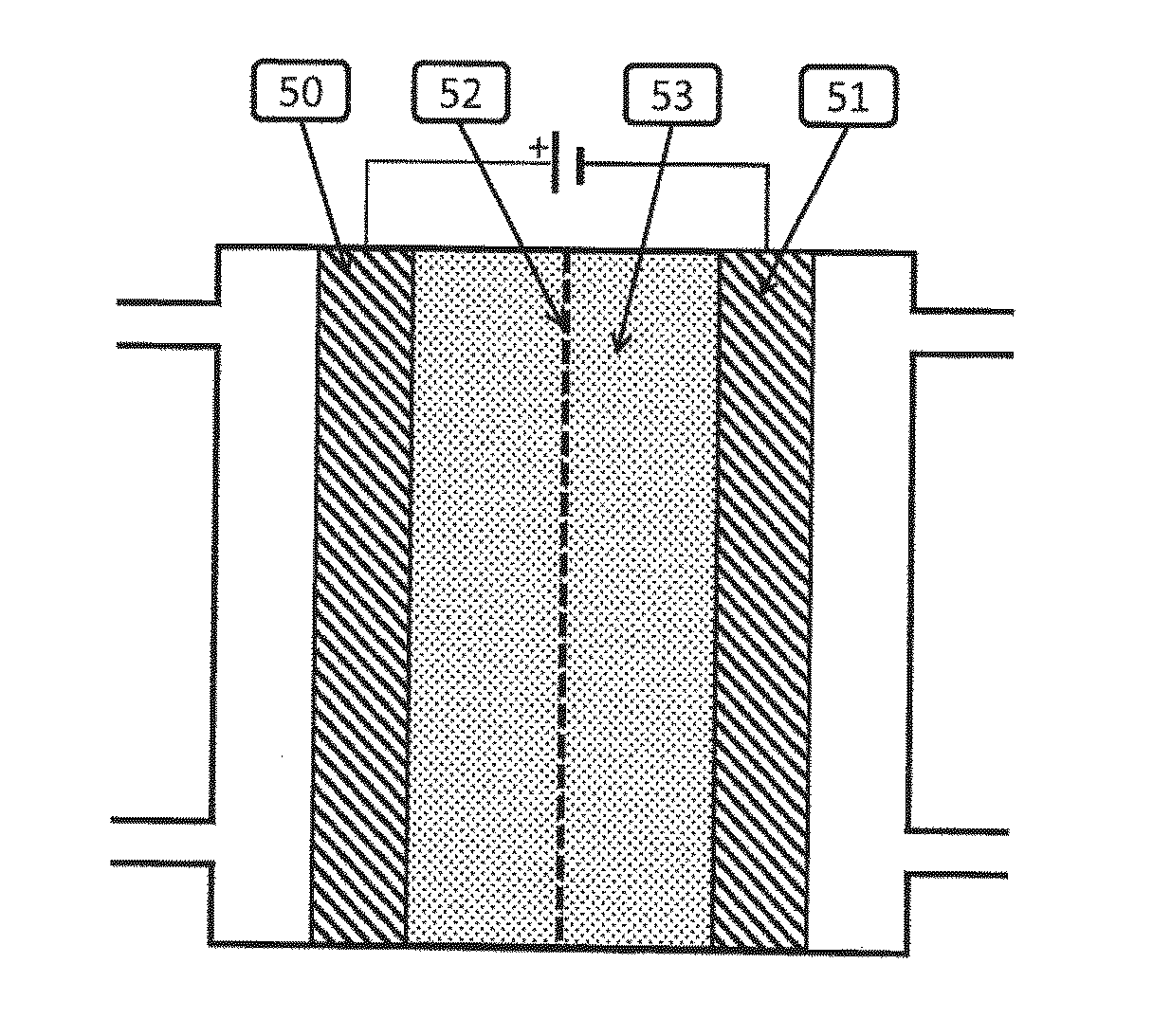

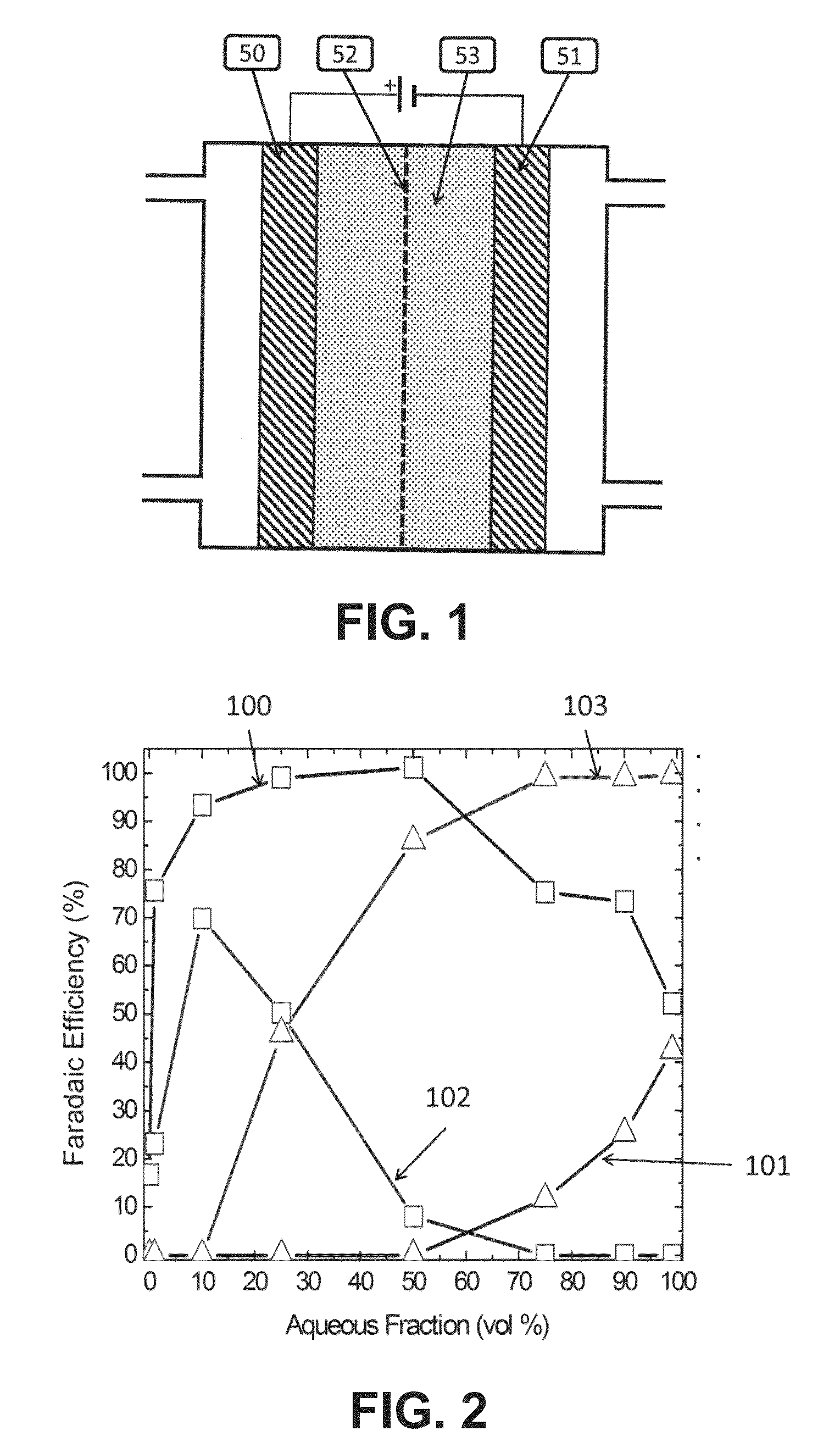

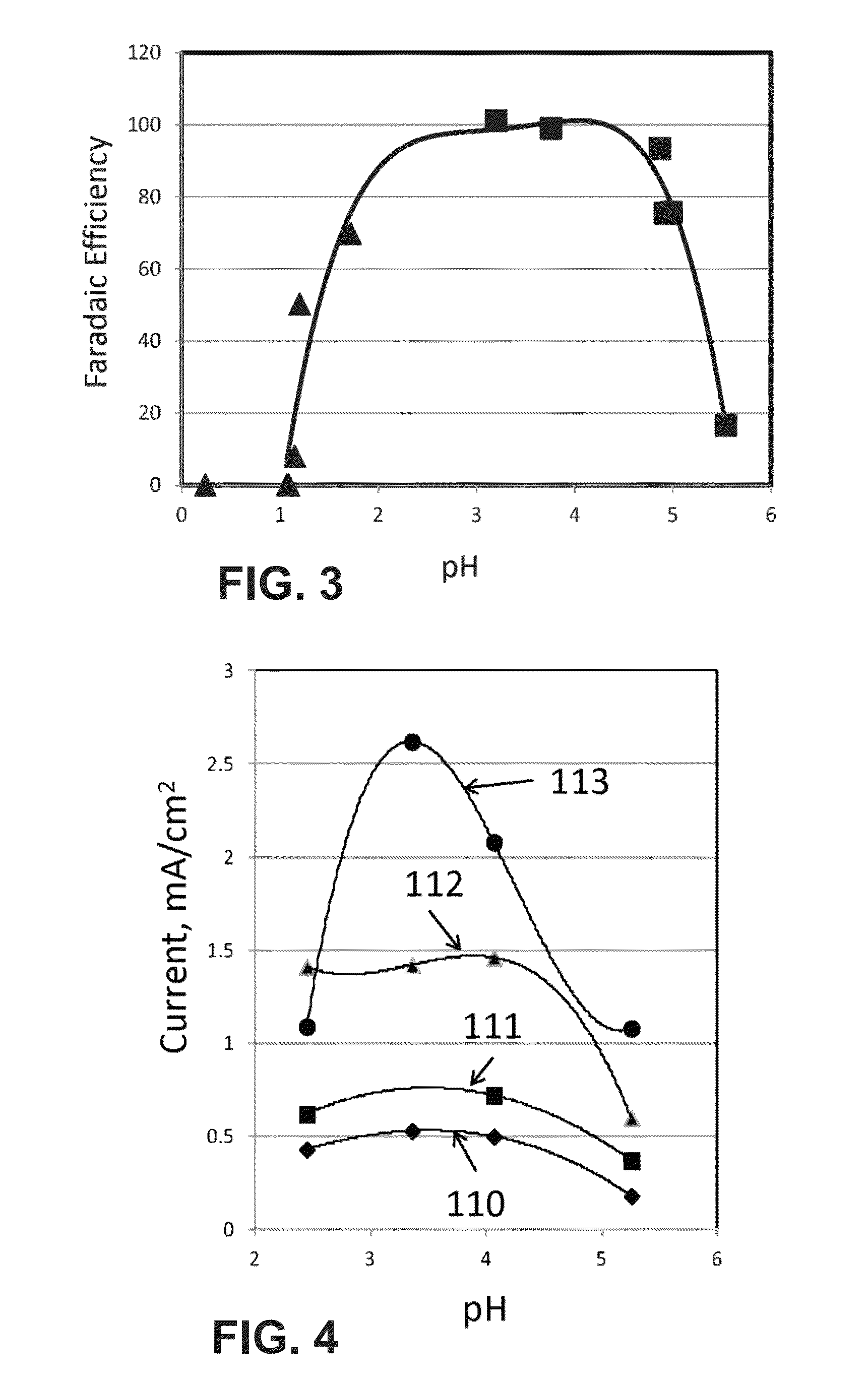

Devices And Processes For Carbon Dioxide Conversion Into Useful Fuels And Chemicals

ActiveUS20140093799A1Low rateRaise the overpotentialCellsElectrolytic organic productionOrganic acidCompound (substance)

Electrochemical devices for converting carbon dioxide to useful reaction products include a solid or a liquid with a specific pH and / or water content. Chemical processes using the devices are also disclosed, including processes to produce CO, HCO−, H2CO, (HCO2), H2CO2, CH3OH, CH4, C2H4, CH3CH2OH, CH3COO−, CH3COOH, C2H6, (COOH)2, (COO−)2, acrylic acid, diphenyl carbonate, other carbonates, other organic acids and synthetic fuels. The electrochemical device can be a CO2 sensor.

Owner:DIOXIDE MATERIALS

Bimetal composite oxide catalyst for change of methyl carbonate and phenol ester

ActiveCN1803282AHigh catalytic activityEasy to separatePreparation from organic carbonatesMetal/metal-oxides/metal-hydroxide catalystsMethyl carbonateCopper oxide

The invention discloses a two-metal composite oxide catalyst of synthetic biphenyl carbonate through ester exchange, which consists of vanadium oxide and copper oxide, wherein the mole ratio is that V:Cuú¢100í1-100; The sintering temperature is between 250 and 850 deg C; the parent body can be vanadium salt or vanadium oxide and copper salt or copper oxide; the making method adapts coprecipitation method or mechanic abrasion method. The invention improves the total productivity of biphenyl carbonate, which is easy to separate and recover the biphenyl carbonate.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

Method of polycarbonate preparation

InactiveUS6870025B2Organic-compounds/hydrides/coordination-complexes catalystsPolycarbonate4,4'-Biphenol

Polycarbonates containing low or undetectable levels of Fries rearrangement products and comprising repeat units derived from one or more of resorcinol, hydroquinone, methylhydroquinone, bisphenol A, and 4,4′-biphenol have been prepared by the melt reaction of one or more of the aforementioned dihydroxy aromatic compounds with an ester-substituted diaryl carbonate such as bis-methyl salicyl carbonate. Low, or in many instances undetectable, levels of Fries rearrangement products are found in the product polycarbonates obtained as the combined result of a highly effective catalyst system which suppresses the Fries reaction and the use of lower melt polymerization temperatures relative to temperatures required for the analogous polymerization reactions using diphenyl carbonate.

Owner:SABIC INNOVATIVE PLASTICS IP BV

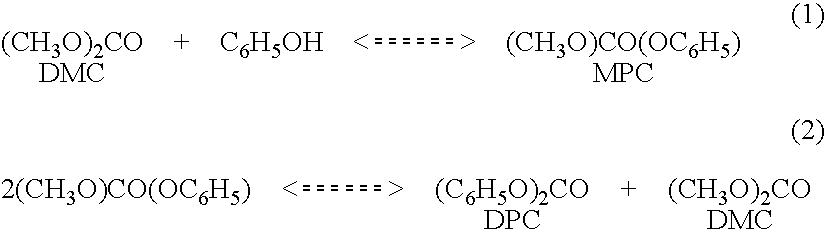

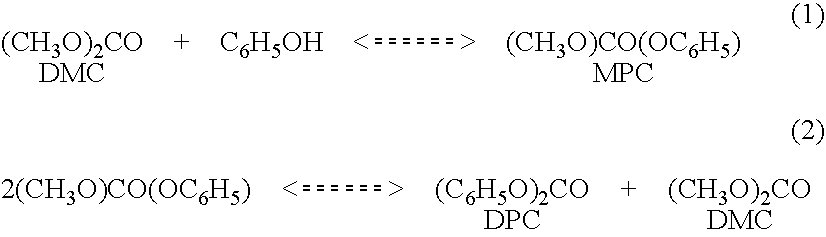

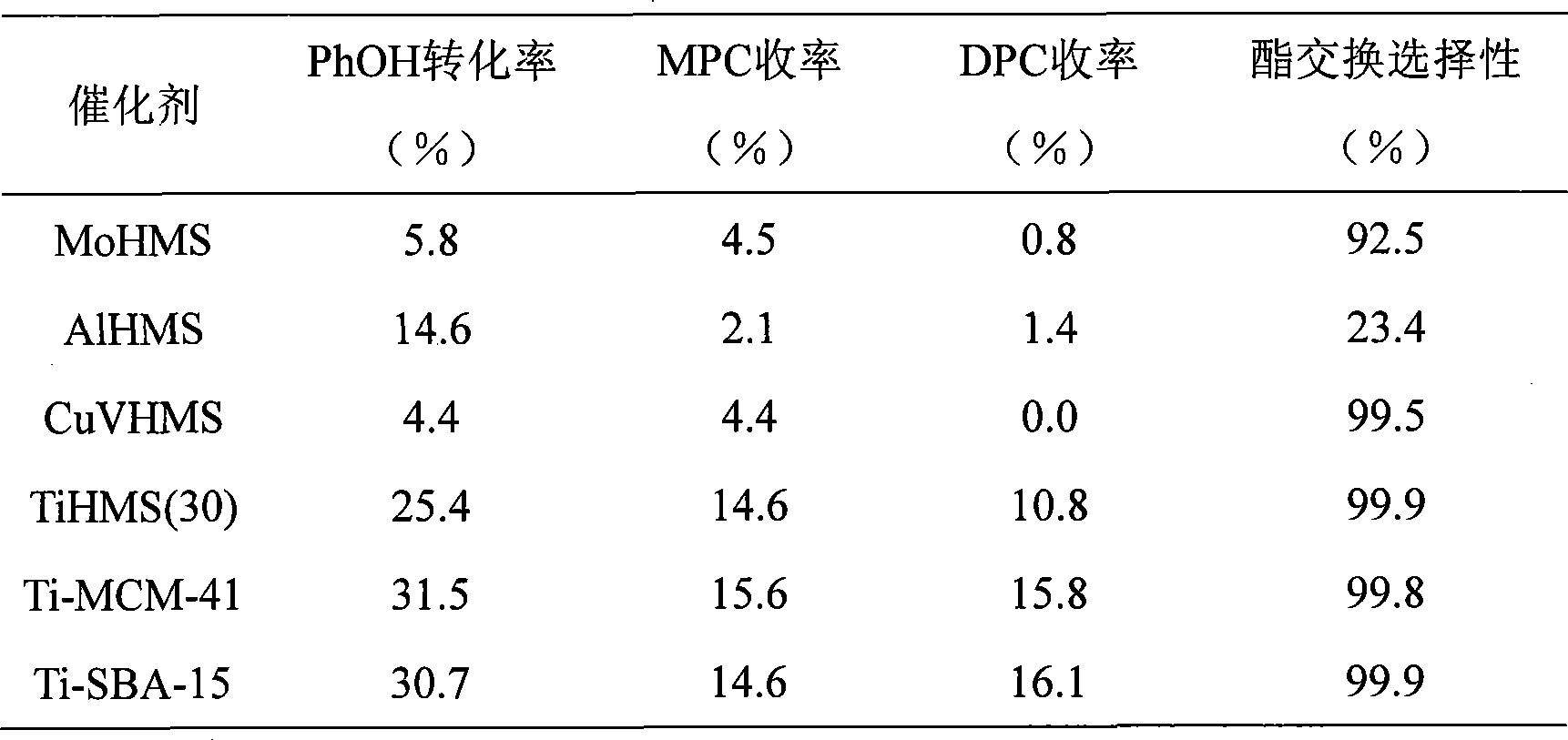

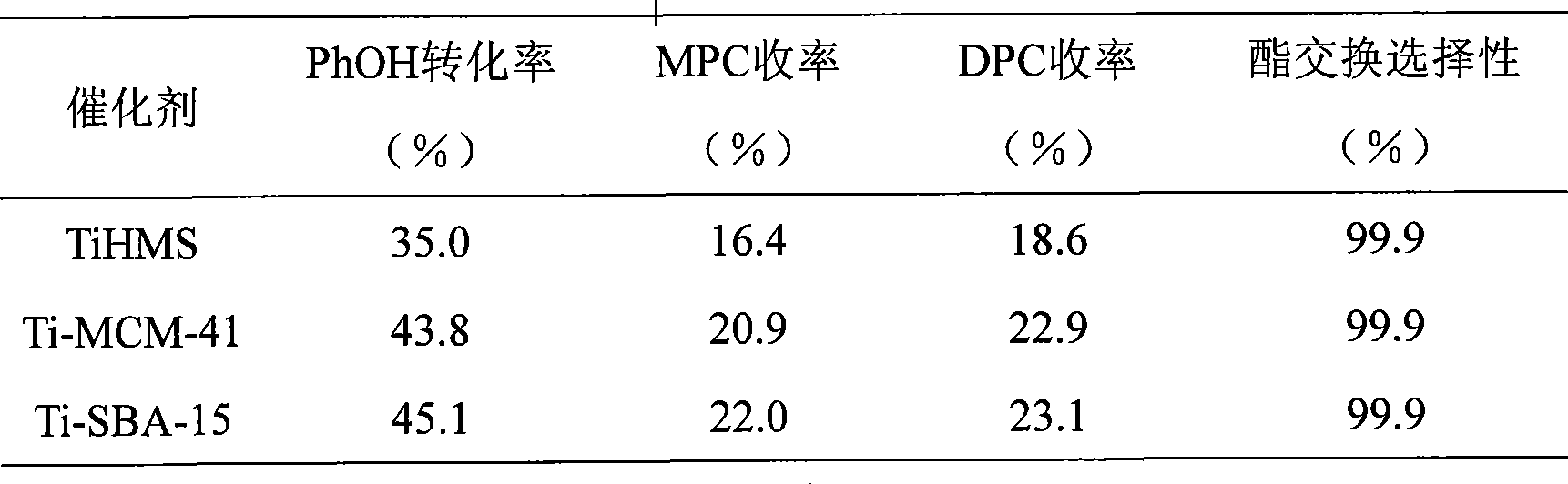

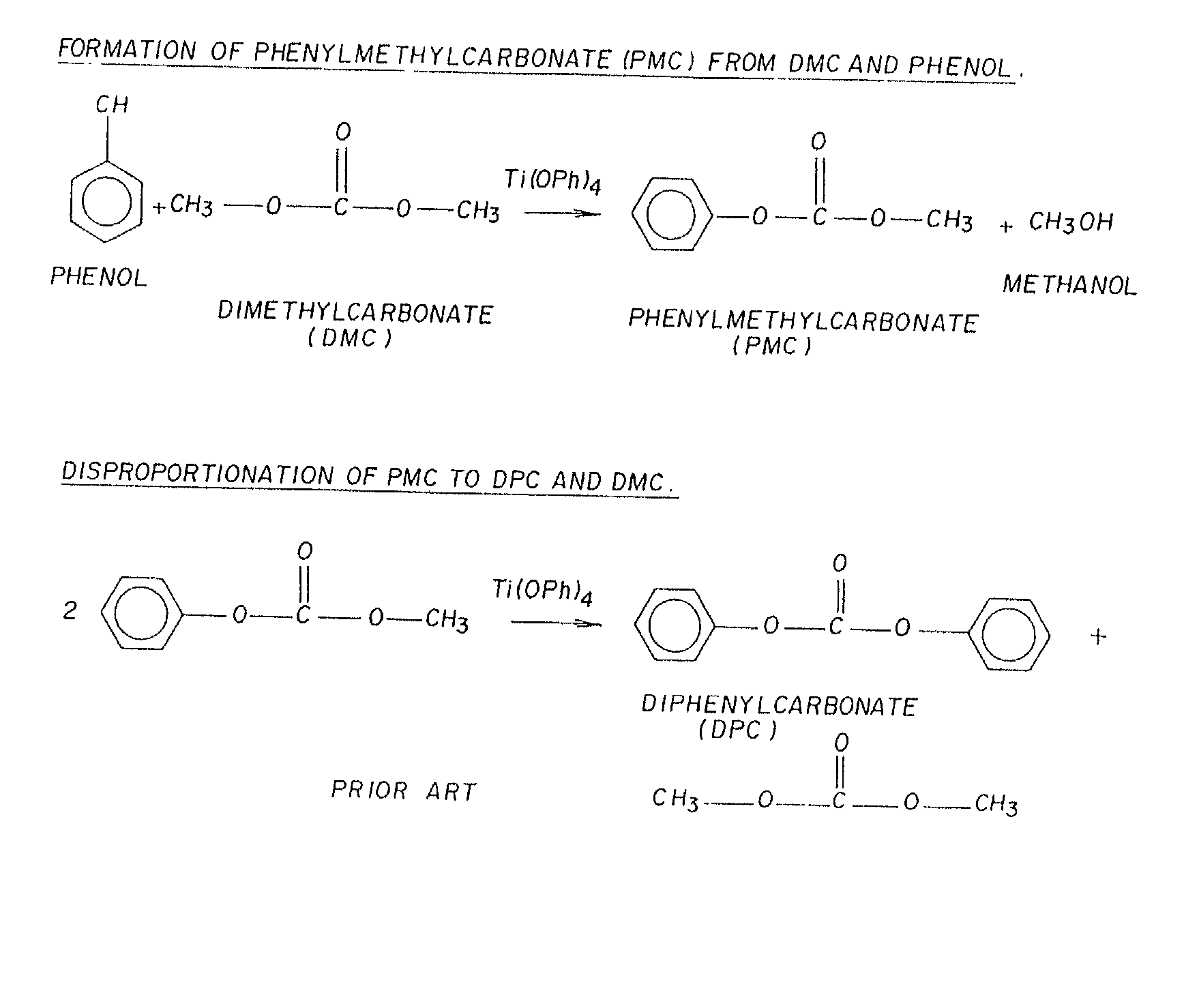

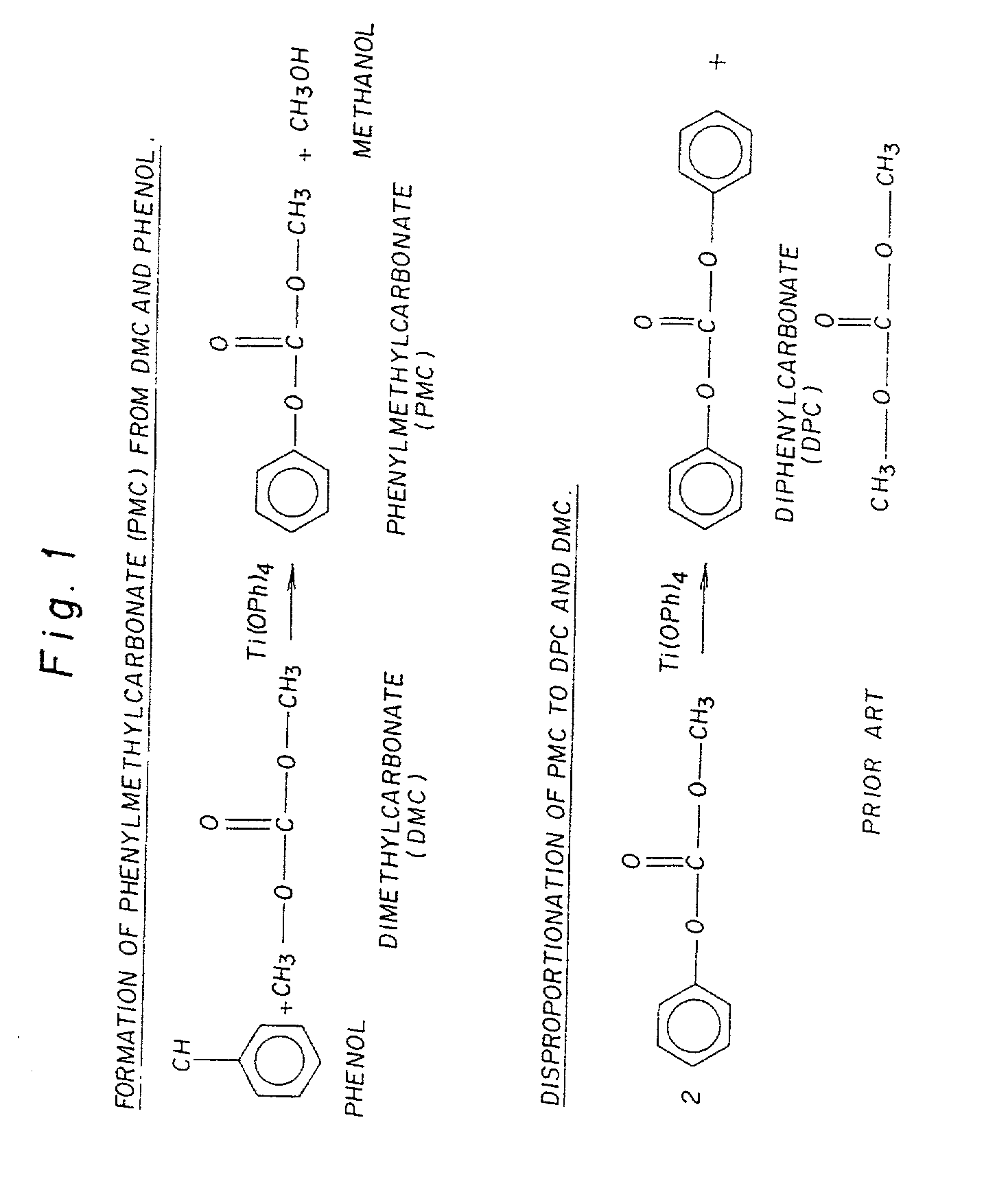

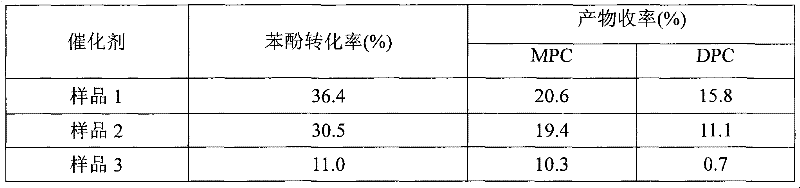

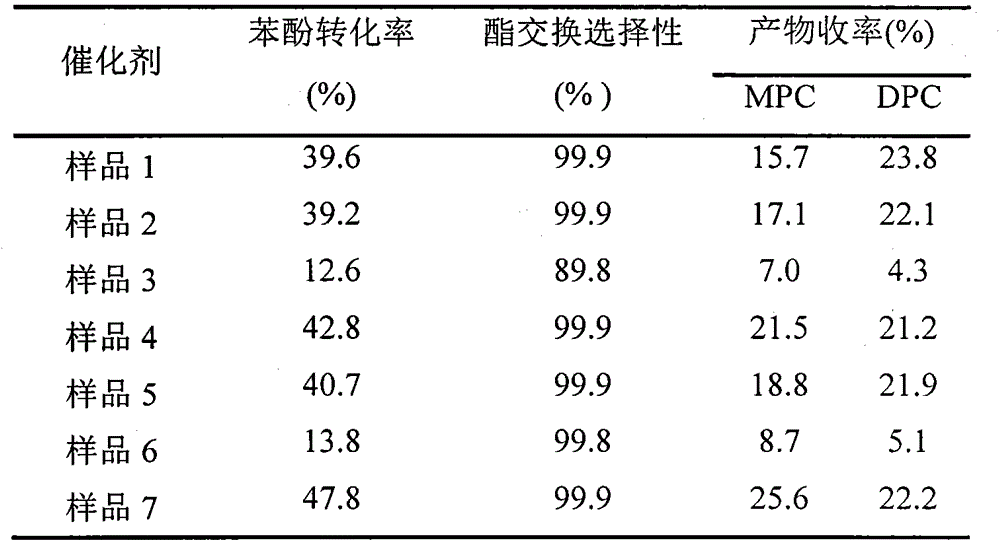

Method for synthesizing diphenyl carbonate by heterogeneous interesterification

InactiveCN101412674AHigh activityHigh selectivityMolecular sieve catalystsChemical recyclingMolecular sieveMethyl carbonate

The invention discloses a method for synthesizing diphenyl carbonate by heterogeneous ester interchange. The method uses methyl carbonate and phenol as raw materials and hetero-atom mesoporous molecular sieve as a heterogeneous catalyst to synthesize the diphenyl carbonate through ester interchange. The method mainly solves the problems of difficult separation and recycling of the catalyst, low yield of the diphenyl carbonate, and the like. The hetero-atom mesoporous molecular sieve as the catalyst can be prepared through a direct synthesis method, and can also be prepared through a post synthesis method. The ester interchange product of the method has high yield and good selectivity, wherein the yield reaches 45.1 percent and the selectivity reaches 99.9 percent; and particularly the molecular sieve catalyst used by the method has the advantages of no pollution to environment, no corrosion to equipment, easy separation and recycling, and the like, and can be widely applied to production of the diphenyl carbonate.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Method for the continuous production of aromatic carbonates

The present invention provides a method for making polycarbonates. One embodiment of the method comprises reacting diphenylcarbonate with a dihydric phenol. The diphenylcarbonate is made by reacting a reaction mixture comprising aryl alcohol together with a dialkyl carbonate in a reactor to produce aryl alkylcarbonate and diaryl carbonate.

Owner:SABIC GLOBAL TECH BV

Catalyst of composite oxides of molybdenum, cupper bimetal in use for synthesizing diphenyl carbonate through ester exchange

InactiveCN1915504AHigh catalytic activityEasy to separateMetal/metal-oxides/metal-hydroxide catalystsPreparation from organic carbonatesMethyl carbonateCopper

A catalyst with high activity and selectivity and able to be recovered easily for preparing diphenyl carbonate from dimethyl carbonate and phenol ester by ester exchange is basically and proportionally prepared from the oxide of Mo and the oxide of Cu through co-deposition or grinding, and calcining at 300-900 deg.C.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

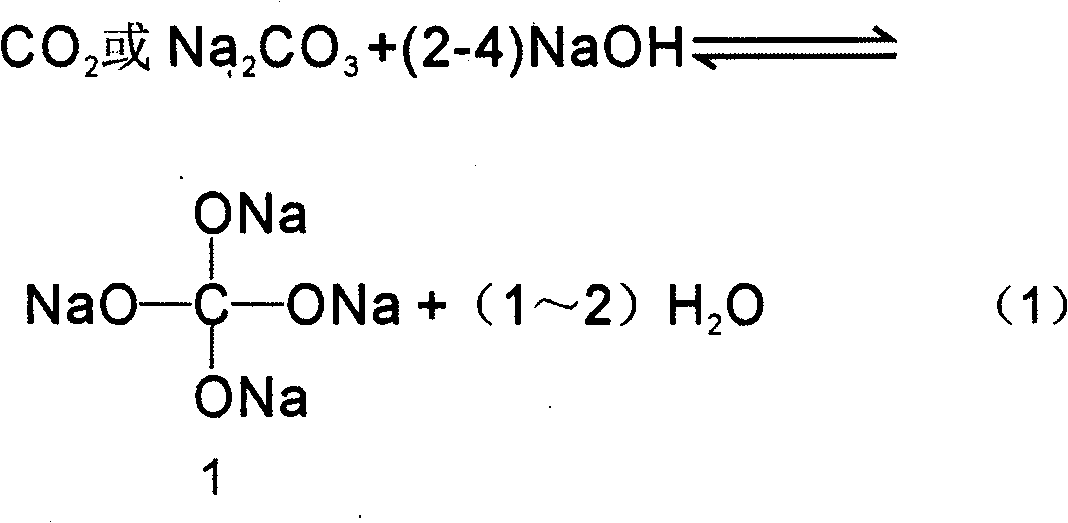

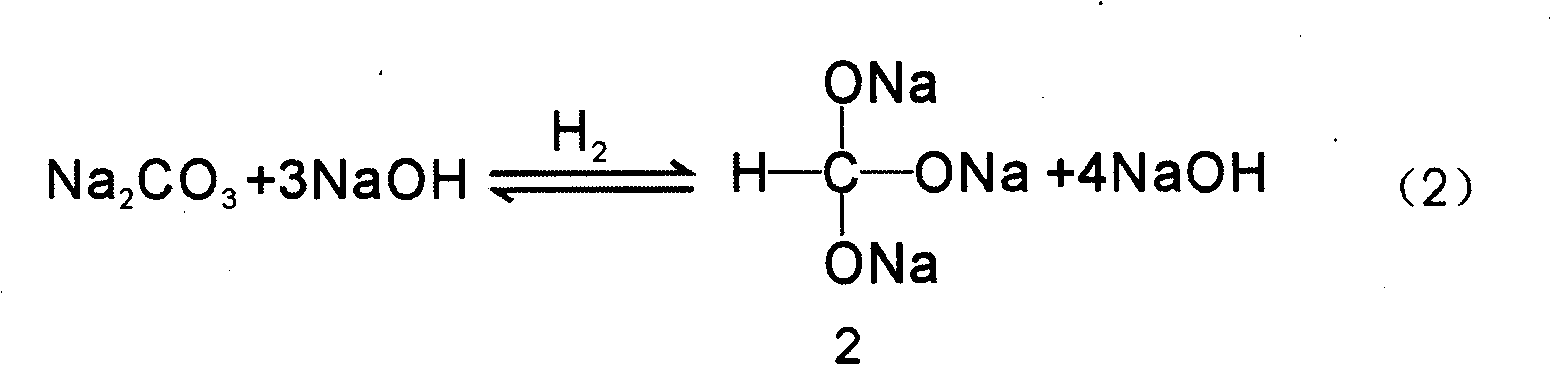

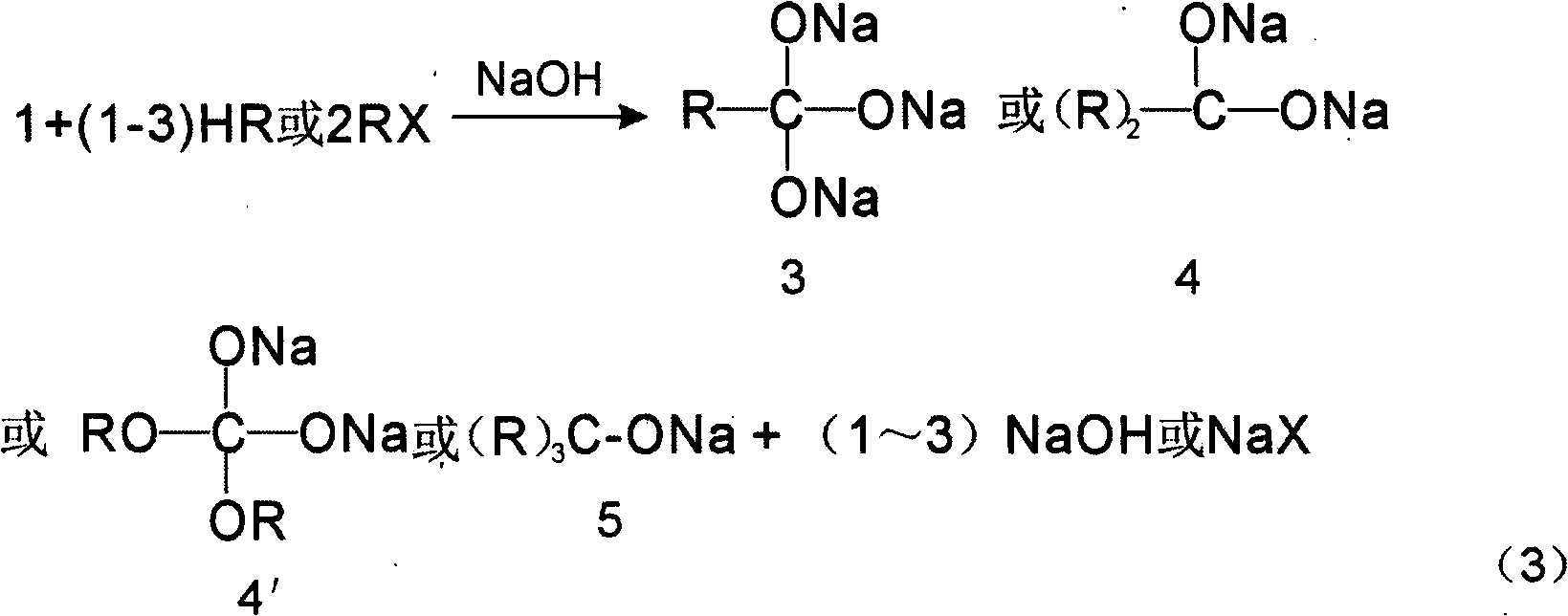

Method for preparing DMC, DPC, ortho-carbonate, ortho-formate, dimethyl ether, and the like by using Na2CO3 or sodium formate or CO2 or CO

InactiveCN103254084AOrganic compound preparationPreparation from ortho-estersSynthesis methodsProcess synthesis

The invention relates to a recently discovered universal synthesis method of tandem-substitution-rearrangement-elimination reaction (TSRE reaction) of elemental organic chemistry, production process synthesis routes of two products of dimethyl carbonate (DMC) and diphenyl carbonate (DPC) and traditional products of ortho-carbonate, ortho-formate, dimethyl ether, and the like through CO2 and CO direct synthesis method are redesigned. Compared with prior arts for producing the products, with the preparation method provided by the invention, energy can be greatly saved, emission can be greatly reduced, and cost can be greatly reduced.

Owner:李坚

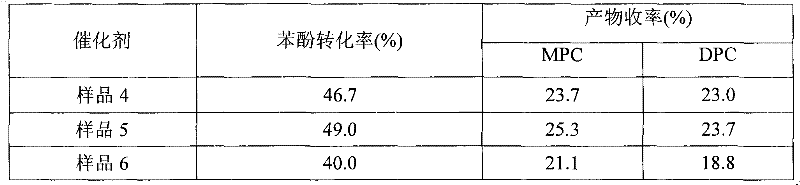

Method for interesterification synthesis of diphenyl carbonate by dimethyl carbonate

ActiveCN102050740AHigh catalytic activityHigh activityPhysical/chemical process catalystsPreparation from organic carbonatesCarbon nanotubeHigh activity

The invention relates to a method for interesterification synthesis of diphenyl carbonate by dimethyl carbonate. In the method, phenol and the dimethyl carbonate are used as raw materials, and carbon nano tube-loaded titanium dioxide is used as a catalyst; the carbon nano tube-loaded titanium dioxide used as the catalyst can be prepared by a sol gel method, a immersion method or a hydrothermal method; and the catalyst takes carbon nano tube (CNT) as a carrier and titanium dioxide as an active component. The catalyst has the high activity, good selectivity and high stability on reaction for preparing the diphenyl carbonate by using the dimethyl carbonate and the phenol, so that the total yield of the dimethyl carbonate and alkyphenyl carbonic ester reaches 49.0%, no byproducts are generated, the catalyst can be repeatedly used for four times, and the conversion rate of the phenol still keeps above 45%. The carbon nano tube-loaded titanium dioxide catalyst is a multi-phase catalyst, is easy to separate, can be recycled and has potential industry application value.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

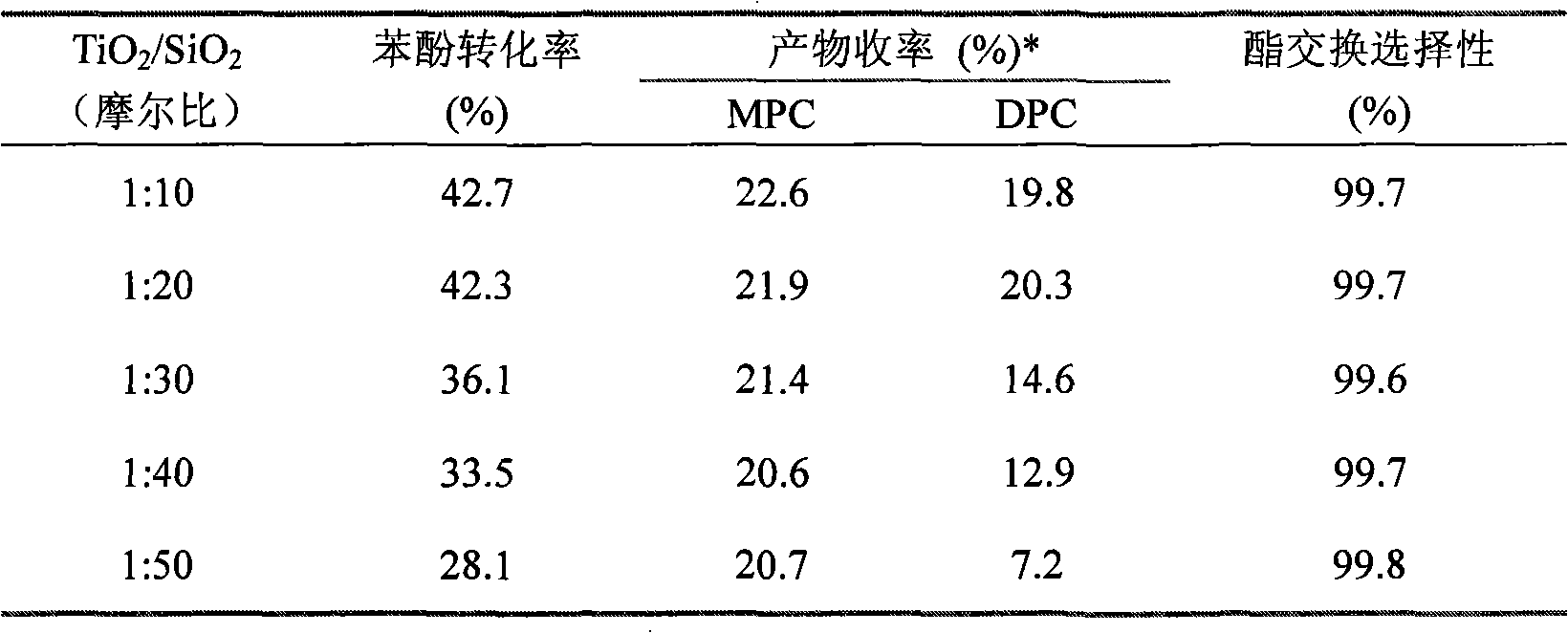

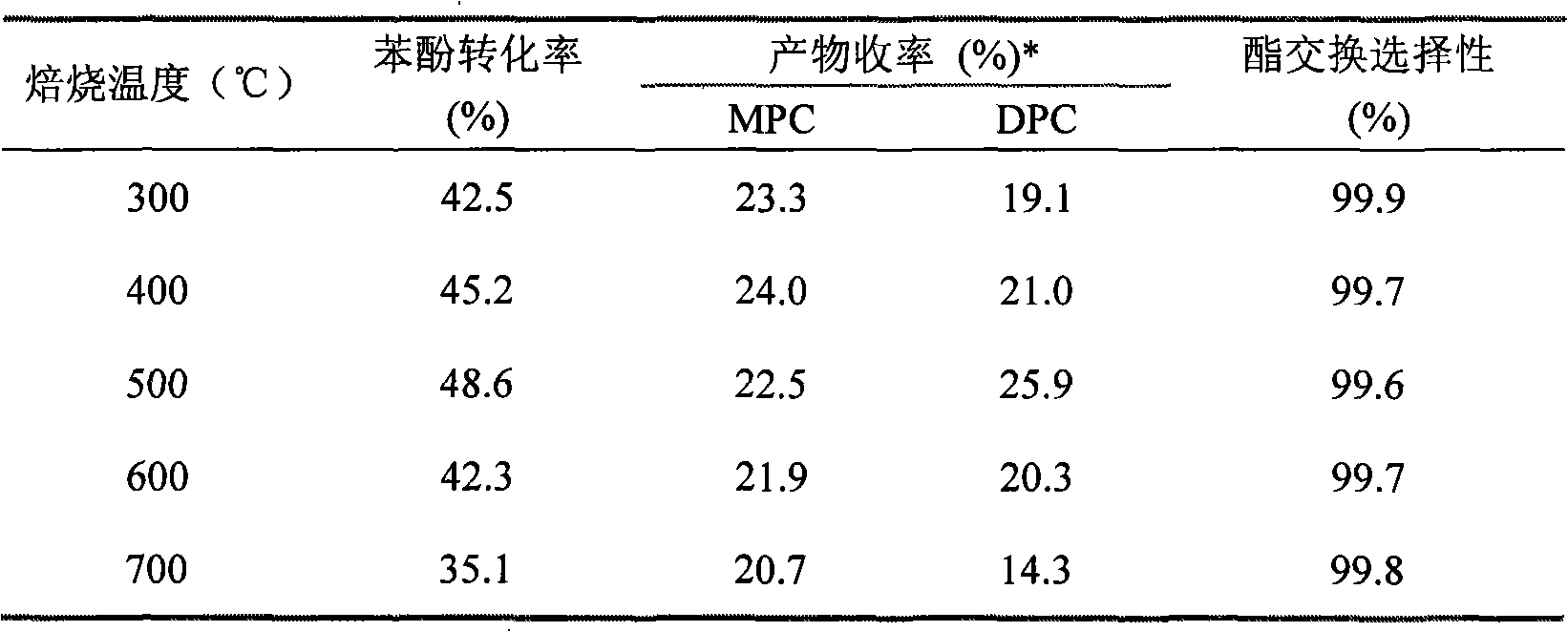

Process for preparing multiphase catalysts for ester exchange synthesizing diphenyl carbonate

ActiveCN101254460AHigh catalytic activityHigh selectivityPhysical/chemical process catalystsPreparation from organic carbonatesOrganic solventMethyl carbonate

The invention relates to a method for preparing a multiphase catalyst used for ester exchange synthesis of diphenyl carbonate from methyl carbonate and phenol. The catalyst is obtained by immersion-graft reaction of SiO2 as carrier, TiO2 as active component and triethylamine in the presence of organic solvents, followed by calcination. The invention solves the problem of low ester exchange efficiency in the prior art. The TiO2 / SiO2 catalyst prepared by the inventive method has higher catalytic activity and ester exchange selectivity in the ester exchange synthesis of diphenyl carbonate from methyl carbonate and phenol, wherein the phenol conversion rate reaches 48.1% and the overall selectivity of ester exchange products (methoxyphenyl carbonate and diphenyl carbonate) is more than 99.5%. Additionally, the inventive method has the advantages of easily-available raw materials, low cost and simple process.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

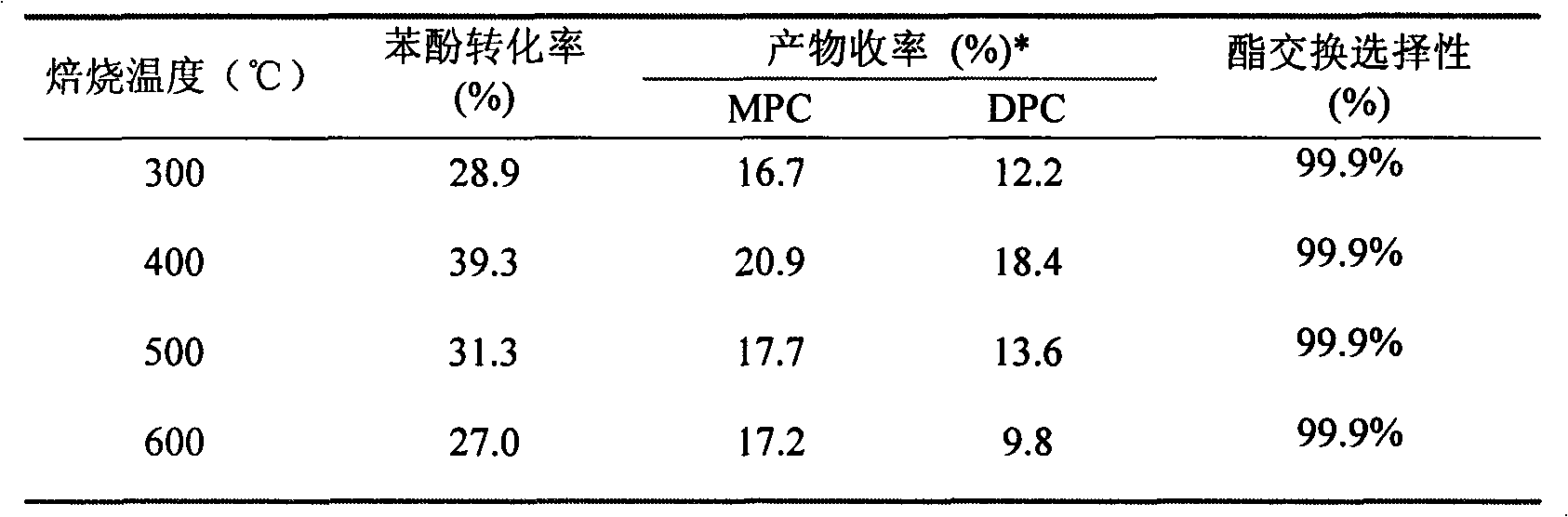

Complex metal oxide catalyst for synthesis of diphenyl carbonate by ester exchange reaction and preparation method thereof

InactiveCN101905155AHigh catalytic activityImprove catalytic performanceCatalyst activation/preparationPreparation from organic carbonatesCoprecipitationTitanium

The invention discloses a complex metal oxide catalyst for synthesis of diphenyl carbonate by ester exchange reaction and a preparation method thereof. The catalyst basically consists of a molybdenum-titanium complex oxide, wherein the weight ratio of the molybdenum to the titanium is 100:10-100; the roasting temperature is between 300 and 600 DEG C; base raw materials for preparing the catalyst are a molybdenum compound and a titanium compound; and the preparation method adopts a coprecipitation method or mechanical grinding method. The catalyst has high catalytic activity and good selectivity for the reaction of synthesizing the diphenyl carbonate by ester exchange, and particularly has the advantages of simple preparation method, easy separation and recycling, no environmental pollution, no corrosion to equipment and the like, so the catalyst can be widely applied to production of the diphenyl carbonate.

Owner:CHANGZHOU INST OF CHEM

Devices and processes for carbon dioxide conversion into useful fuels and chemicals

ActiveUS9181625B2Raise the overpotentialLow rateCellsNoble metal coatingsOrganic acidCompound (substance)

Owner:DIOXIDE MATERIALS

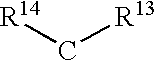

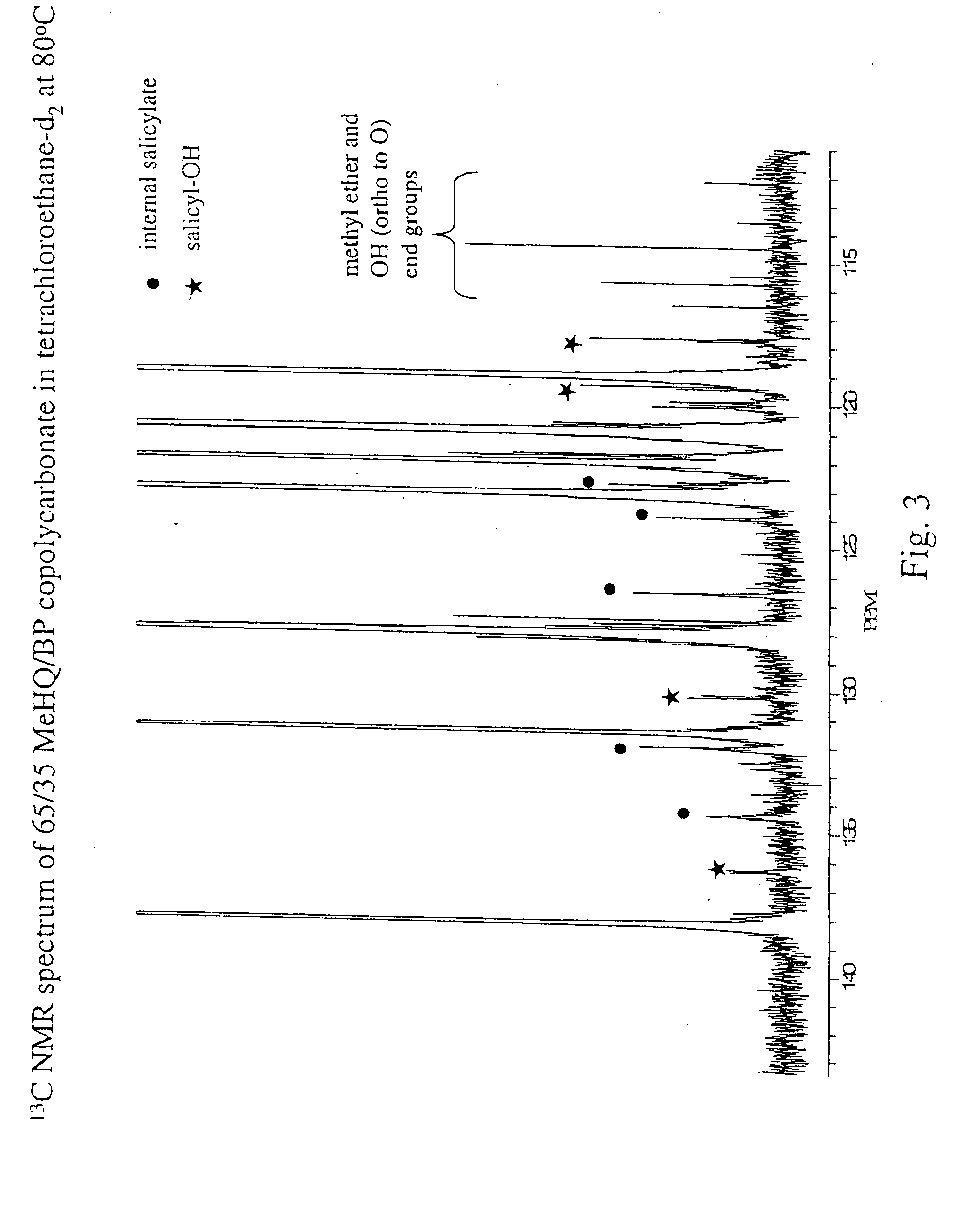

Liquid crystal polycarbonates and methods of preparing same

ActiveUS20050192424A1Liquid crystal compositionsOrganic-compounds/hydrides/coordination-complexes catalystsHydroquinone CompoundDiol

Liquid crystal polycarbonates are made by forming a reaction mixture containing (a) an activated diaryl carbonate; (b) at least two species of aromatic diols selected from among resorcinol, 4,4′-biphenol, hydroquinone, methylhydroquinone, 4,4′-dihydroxyphenylether, dihydroxynaphthalene, including in particular the 2,6, 1,5, and 2,7 isomers, 4,4′-dihydroxybenzophenone and 2,6-dihydroxyanthraquinone (anthraflavic acid); and (c) optionally bisphenol A in a maximum amount of 10 mole %; and processing the reaction mixture in a melt transesterification reaction to form a liquid crystal polycarbonate. While the product composition has the same overall characteristics as compositions made using diphenyl carbonate as the donor moiety for the carbonate linkage, they are analytically distinguishable because of limited incorporation of intermediate or end-cap residues derived from the activated diaryl carbonate.

Owner:SHPP GLOBAL TECH BV +1

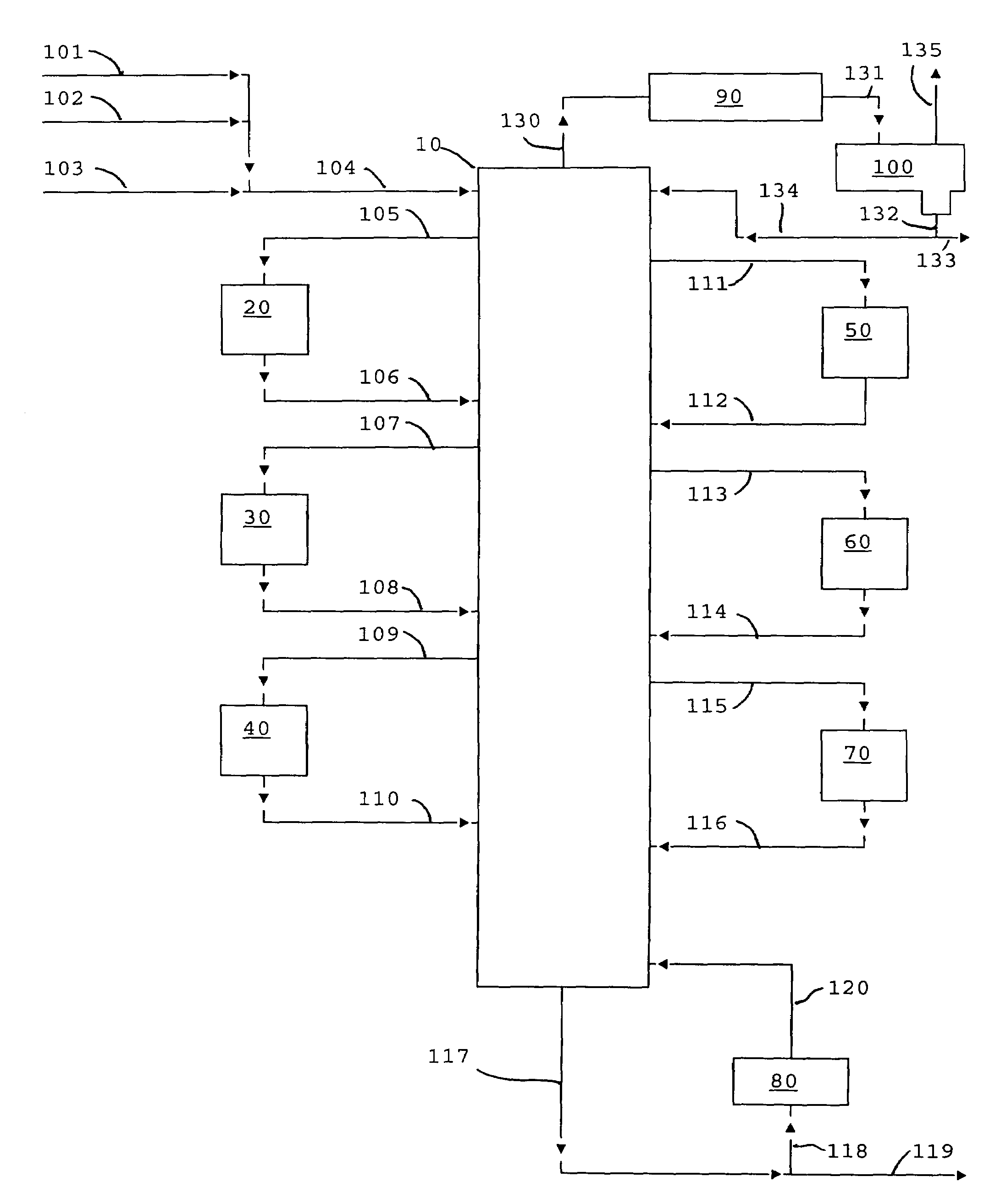

Industrial process for production of high-purity diphenyl carbonate

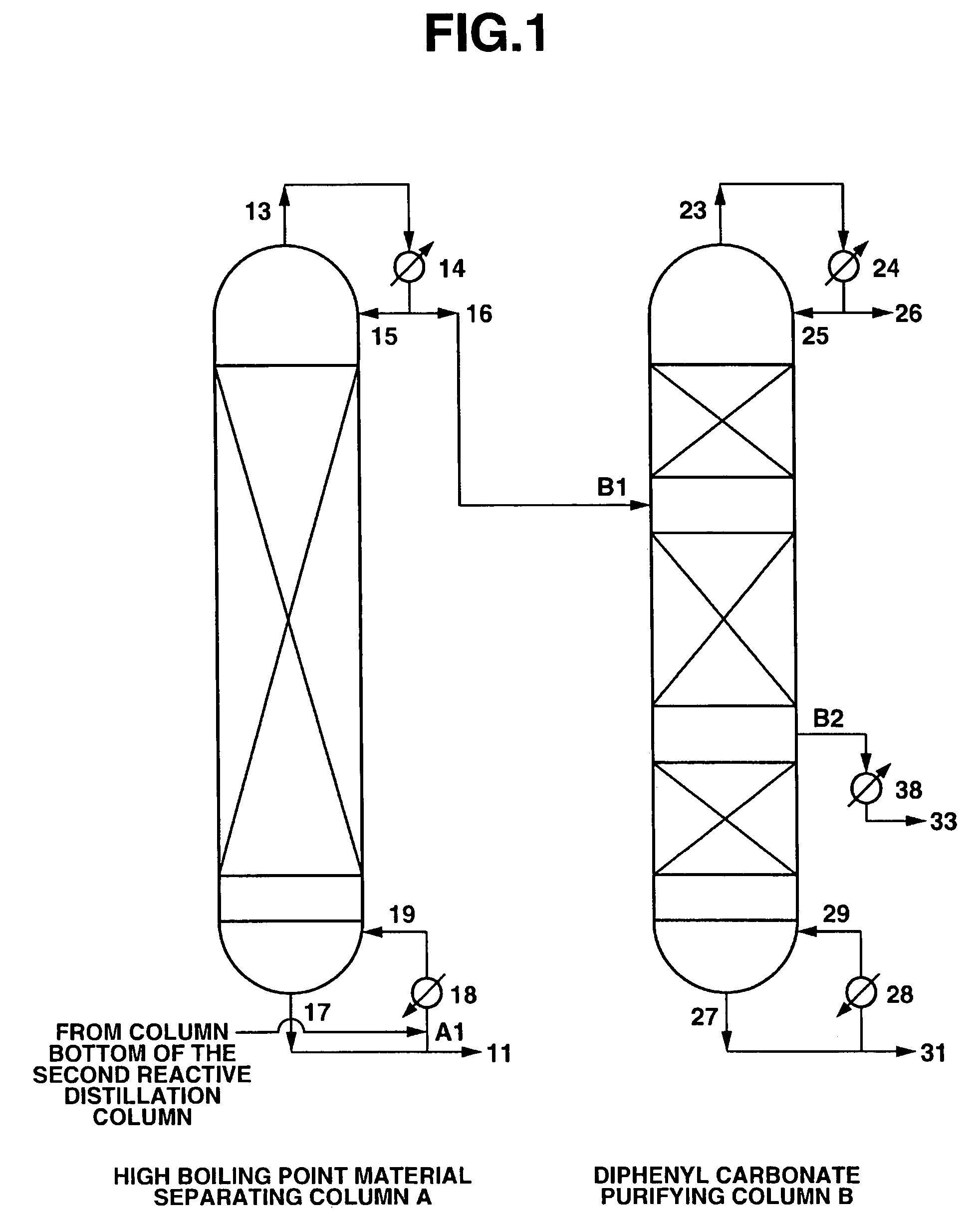

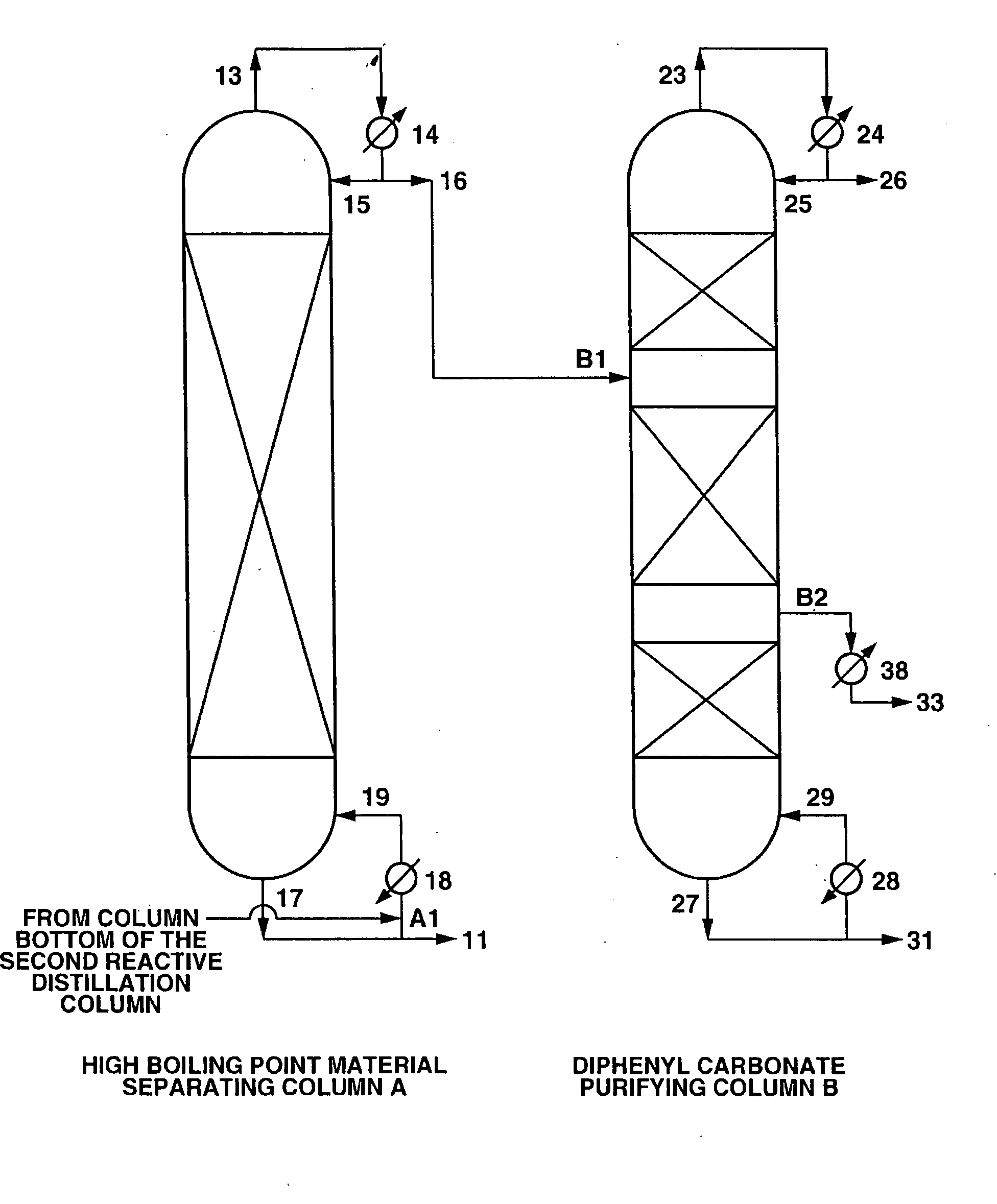

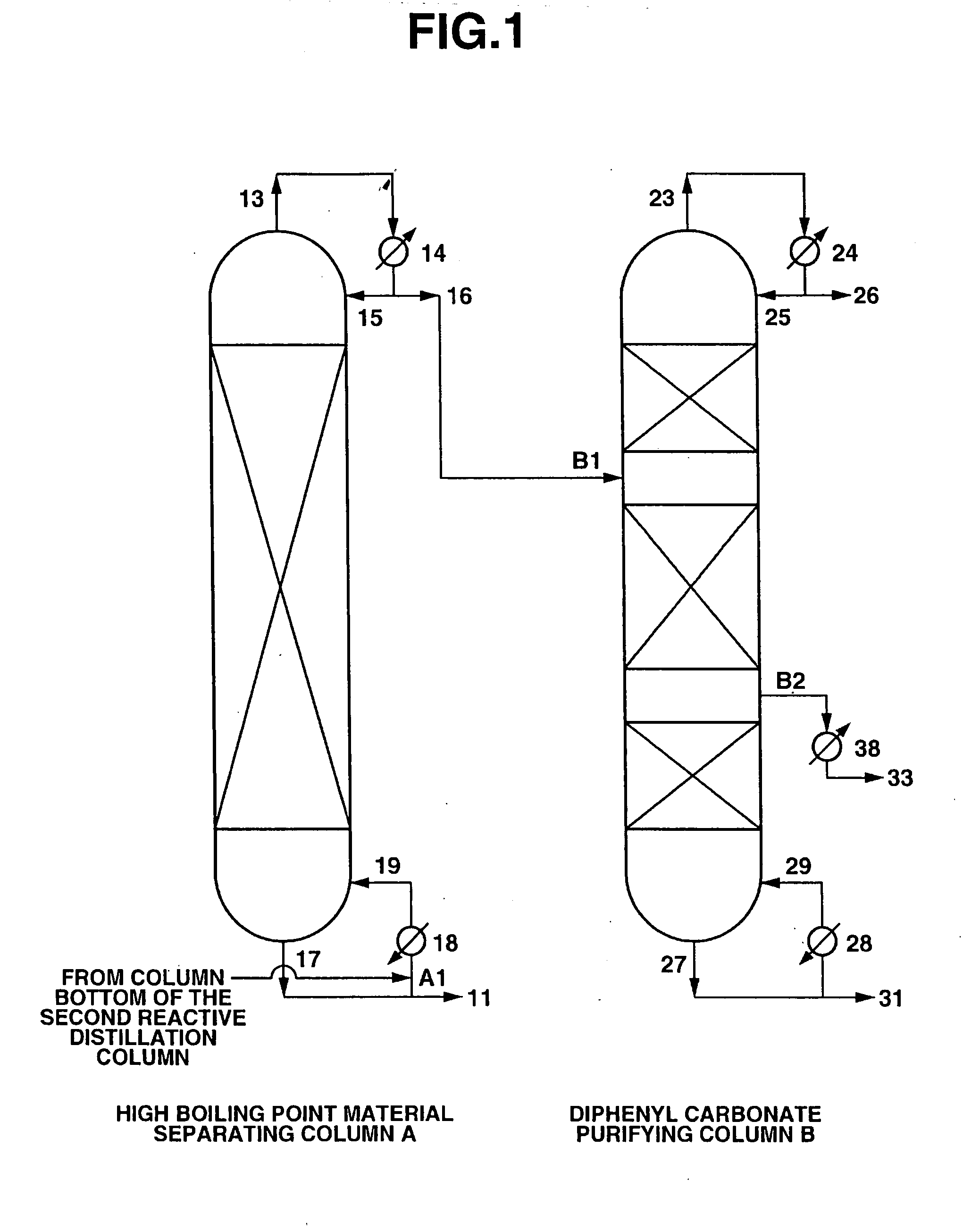

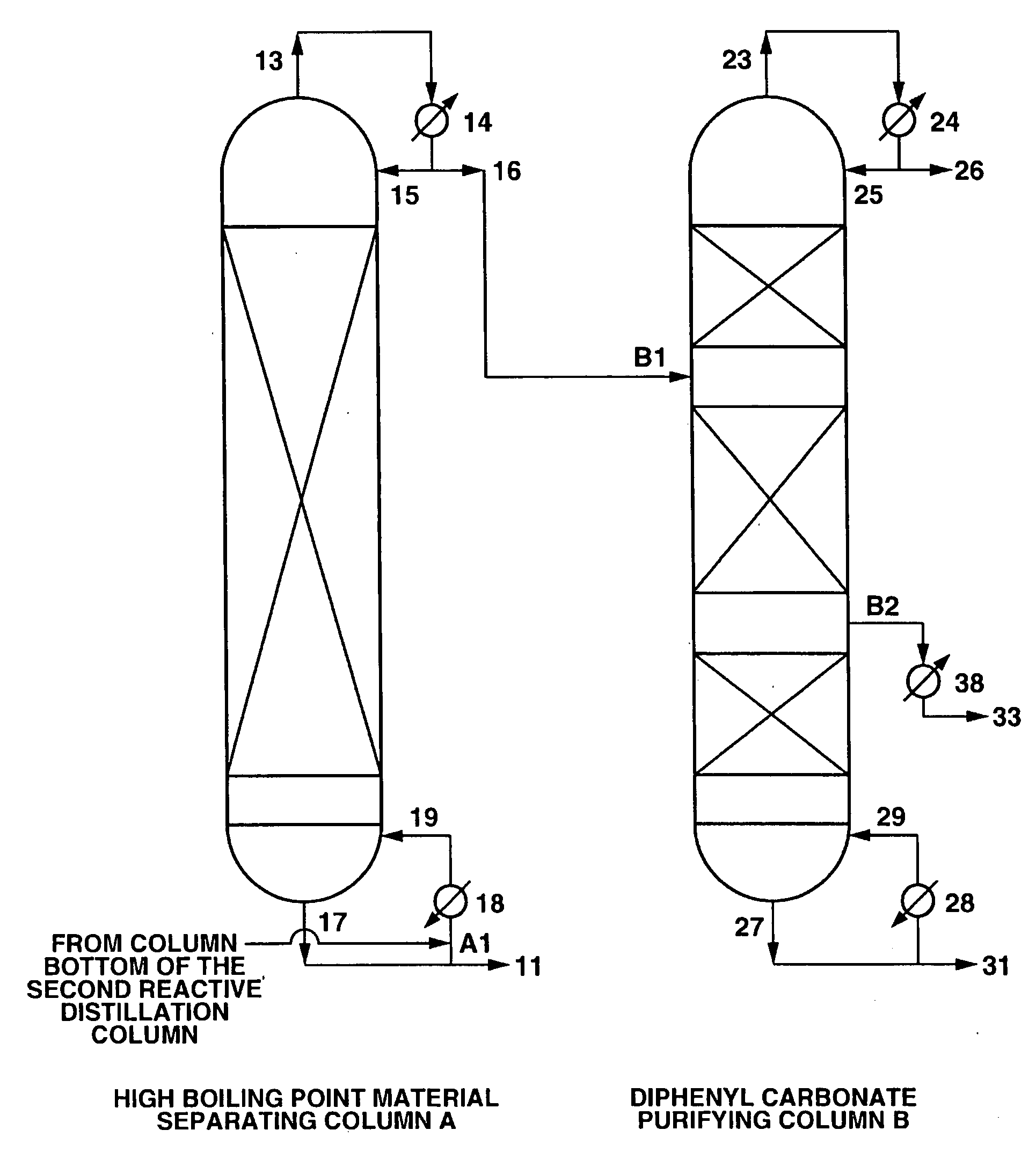

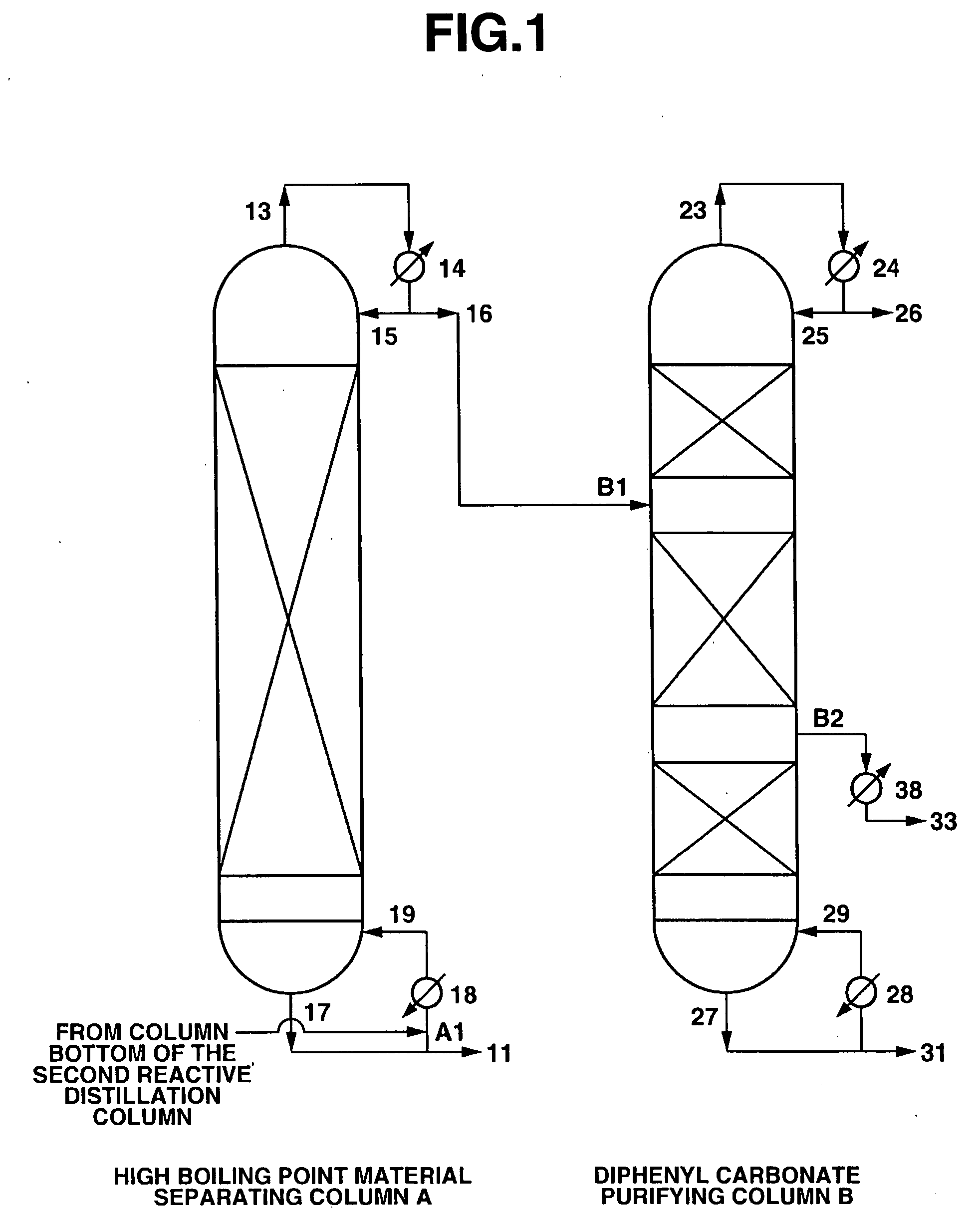

According to the present invention, there are provided a high boiling point material separating column A and a diphenyl carbonate purifying column B each comprising a continuous multi-stage distillation column having specified structures, and there is provided a specific process that enables a high-purity diphenyl carbonate which is important as a raw material of a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time on an industrial scale of not less than 1 ton / hr from a reaction mixture containing the diphenyl carbonate using an apparatus in which these two continuous multi-stage distillation columns are connected together.

Owner:ASAHI KASEI KK

Load type heteropoly compound catalyzer for interesterification synthesis reacting

InactiveCN101138731AHigh activityGood choiceCatalyst carriersPreparation from organic carbonatesArylMethyl carbonate

The present invention relates to a supported heteropoly compound catalyst used for an ester exchange synthesis reaction and is in particular applicable for a reaction to synthesize alkyl aryl carbonate (for example, methyl phenyl carbonate) and diaryl carbonate (for example, diphenyl carbonate) through the ester exchange of dialkyl carbonates (for example, dimethyl carbonate) and aromatic phenolic compound (for example, phenol). The catalyst uses a supported heteropoly compound as an active component, and a mulit-pore material as a carrier to make the total yield ratio reach 46 percent, and the selectivity reach 99 percent. Moreover, the catalyst is provided with the advantage that the catalyst is environment-friendly, causes no corrosion to the equipment, and can be separated easily, the preparation is simple, and so on.

Owner:PETROCHINA CO LTD

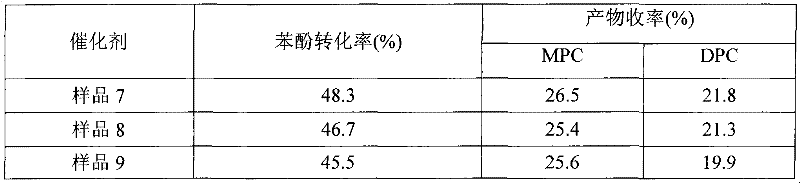

Preparation method of catalyst used for synthesizing diphenyl carbonate by ester exchange method

ActiveCN105327709AEvenly dispersedHigh activityMolecular sieve catalystsPreparation from organic carbonatesMethyl carbonateAmmonium metavanadate

The invention relates to a preparation method of a catalyst used for synthesizing diphenyl carbonate by an ester exchange method. The method is characterized in that a mesoporous molecular sieve MCM-41 is taken as a carrier, butyl titanate and ammonium metavanadate are taken as active components, an immersion method is employed for loading the active components, technical steps of ultrasonic processing and calcination are combined, so that the catalyst containing two active components titanium and vanadium is prepared. The catalyst has the advantages that active components are fine, distribution is uniform, the catalyst has high phenol conversion rate and ester exchange selectivity during a process for preparing diphenyl carbonate by reacting dimethyl carbonate and phenol, a phenol conversion rate can reach more than 46.0%, and no by product is generated. According to the invention, the preparation method is simple, raw materials of the catalyst have the advantages of low cost and easy acquisition, preparation cost is low, and the prepared catalyst does not generate pollution for environment and equipment.

Owner:SHAANXI YANCHANG PETROLEUM GRP

Industrial Process for Production of High-Purity Diphenyl Carbonate

InactiveUS20070260083A1Organic chemistry methodsChemical industryPolycarbonateTransesterification reaction

It is an object of the present invention to provide a specific process that enables a high-purity diphenyl carbonate that can be used as a raw material of a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time on an industrial scale of not less than 1 ton / hr from a reaction mixture containing a catalyst and reaction by-products that has been obtained through transesterification reaction and the like using a dialkyl carbonate and a phenol as a starting material. Although there have been various proposals regarding processes for the production of reaction mixtures containing aromatic carbonates by means of a reactive distillation method, these have all been on a small scale and short operating time laboratory level, and there have been no disclosures on a specific process or apparatus enabling mass production on an industrial scale from such a reaction mixture to a high-purity diphenyl carbonate that can be used as a raw material of a high-quality and high-performance polycarbonate. According to the present invention, there are provided a high boiling point material separating column A and a diphenyl carbonate purifying column B each comprising a continuous multi-stage distillation column having specified structures, and there is provided a specific process that enables a high-purity diphenyl carbonate which is important as a raw material of a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time on an industrial scale of not less than 1 ton / hr from a reaction mixture containing the diphenyl carbonate using an apparatus in which these two continuous multi-stage distillation columns are connected together.

Owner:ASAHI KASEI CHEM CORP

Double component carried catalyst for synthesizing diphenyl carbonate and its preparing method

InactiveCN1391986AHigh catalytic activityGood repeatabilityMolecular sieve catalystsOrganic compound preparationPhenolOxidative carbonylation

The present invention relates to double-component carried catalyst PdCl2-Cu(OAc)2 / zeolite for synthesizing diphenyl carbonate and its preparation. The catalyst consists of zeolite in 50-100 weight portions, PdCl2 in 0.1-10 weight portions and Cu(OAc)2 in 0.1-30 weight protions. It is prepared through equi-volume soaking and roasting at 250-750 deg.c. The catalyst system has also metal acetate as inorganic oxidation-reduction assistant, hydroquinone as organic oxidation-reduction assistant, and tetrabutyl ammonium bride as surfactant. The catalyst has very high catalytic activity and excellent selectivity to liquid phenol in synthesizing diphenyl carbonate. The catalyst is easy to separate from product, easy to recover and regenerate and has simple preparation process.

Owner:HEBEI UNIV OF TECH

Industrial Process For Production Of High-Purity Diphenyl Carbonate

ActiveUS20080041712A1Improve performanceOrganic chemistry methodsChemical industryPolycarbonateTransesterification reaction

It is an object of the present invention to provide a specific process that enables a high-purity diphenyl carbonate that can be used as a raw material of a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time on an industrial scale of not less than 1 ton / hr from a reaction mixture containing a catalyst and reaction by-products that has been obtained through transesterification reaction and the like using a dialkyl carbonate and a phenol as a starting material. Although there have been various proposals regarding processes for the production of reaction mixtures containing aromatic carbonates by means of a reactive distillation method, these have all been on a small scale and short operating time laboratory level, and there have been no disclosures on a specific process or apparatus enabling mass production on an industrial scale from such a reaction mixture to a high-purity diphenyl carbonate that can be used as a raw material of a high-quality and high-performance polycarbonate. According to the present invention, there are provided a high boiling point material separating column A and a diphenyl carbonate purifying column B each comprising a continuous multi-stage distillation column having specified structures, and there is provided a specific process that enables a high-purity diphenyl carbonate which is important as a raw material of a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time on an industrial scale of not less than 1 ton / hr from a reaction mixture containing the diphenyl carbonate using an apparatus in which these two continuous multi-stage distillation columns are connected together.

Owner:ASAHI KASEI KK

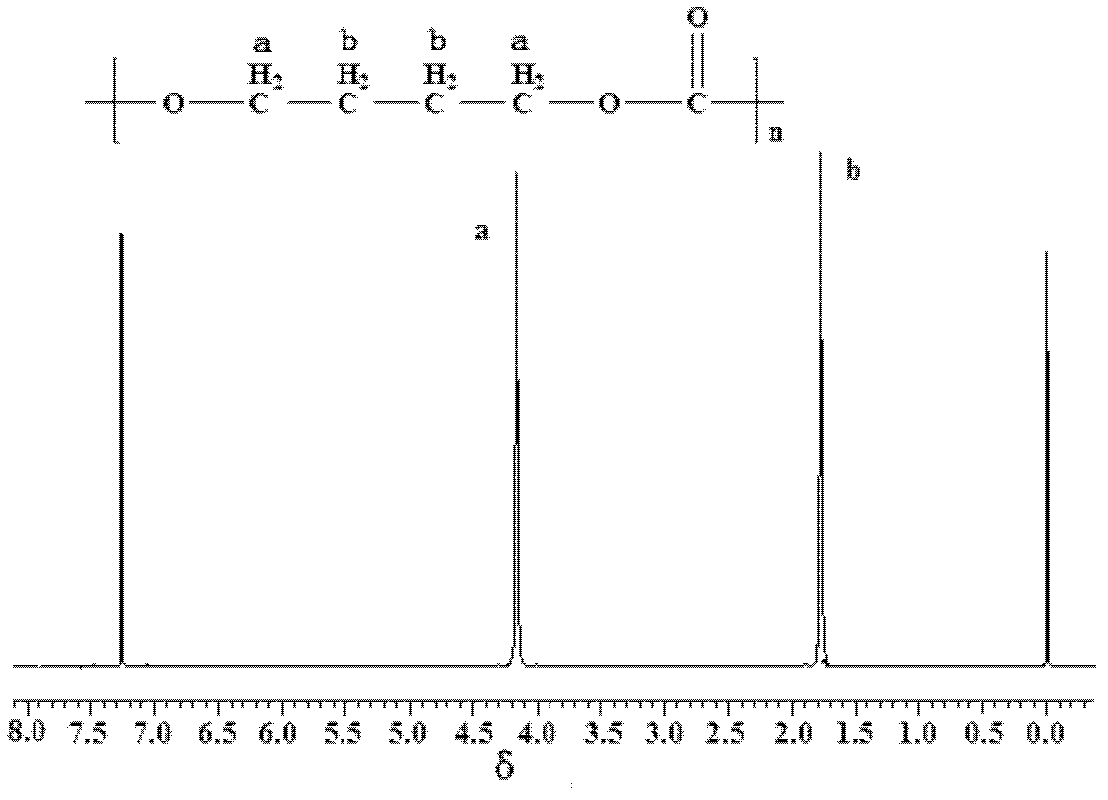

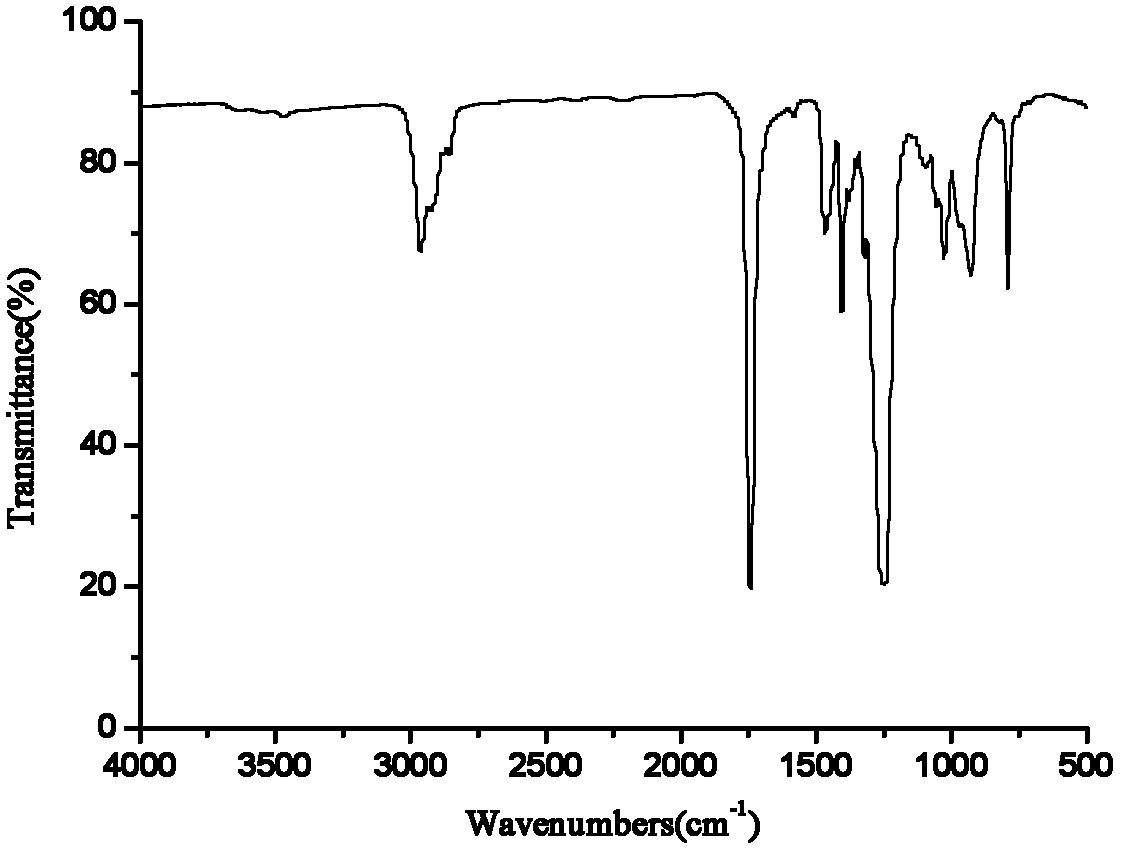

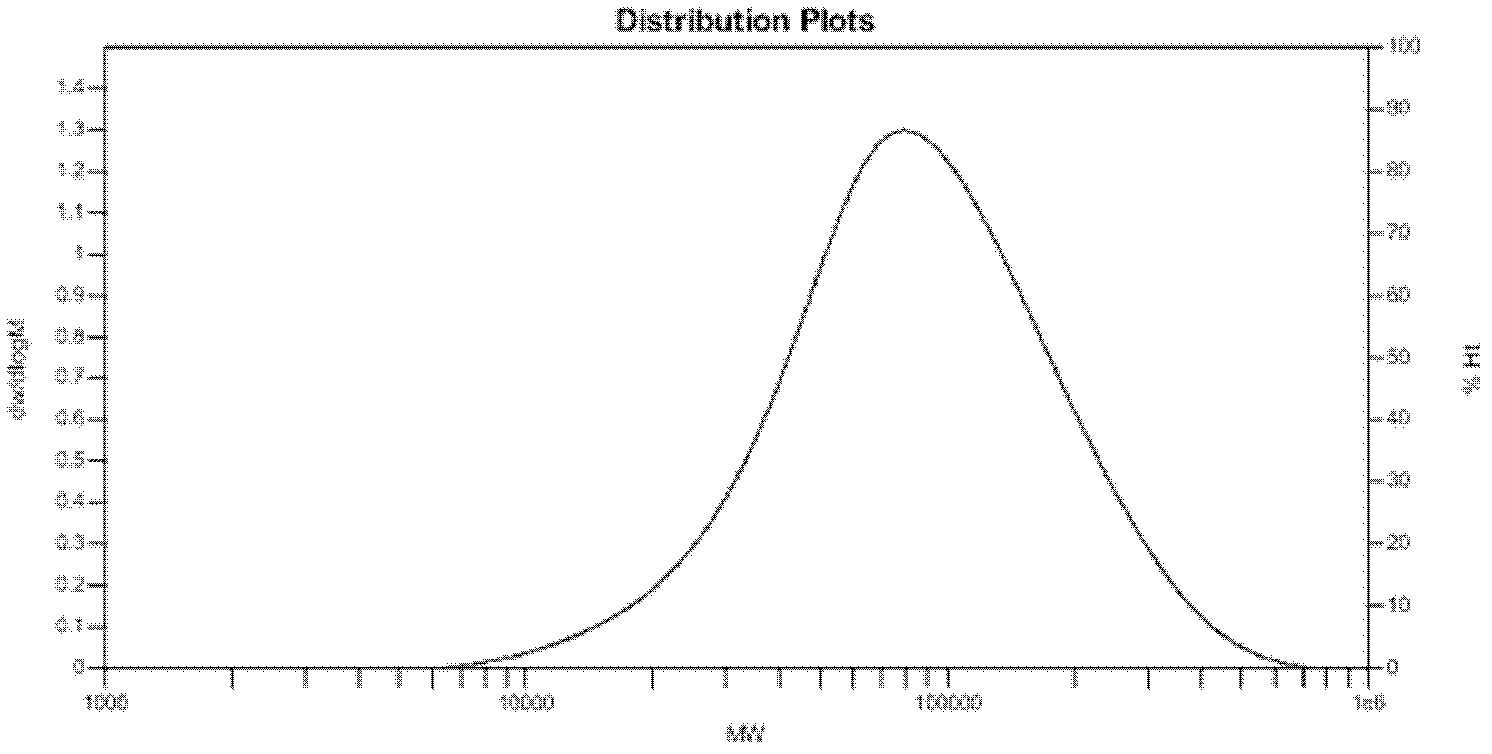

Method for synthesizing high-molecular-weight aliphatic polycarbonate

The invention discloses a method for synthesizing high-molecular-weight aliphatic polycarbonate through a trans-esterification method. The invention relates to a multi-stage trans-esterification reaction of aliphatic or alicyclic diol and diphenyl carbonate, and the high-molecular-weight aliphatic polycarbonate is formed by condensation during a process for removing a reaction byproduct phenol. Through the regulation upon the diol type or the ratio of mixed diol, polycarbonates with different structures can be obtained. The method provided by the invention has the advantages of simple preparation method, short reaction time, low catalyst dose, good product color, high device utilization rate, reduced production cost, and low pollution. The byproduct phenyl can be recycled and reused. Therefore, possibilities are provided for large-scale production and application of polycarbonate synthesized through the trans-esterification method. With the method, the obtained high-molecular-weight aliphatic polycarbonate is white solid with good heat resistance. The high-molecular-weight aliphatic polycarbonate can be completely biodegraded, and can be used as raw materials in polyurethane or polyester elastomer preparations, packaging material in food industries, additive in rubber industries, and medicine sustained-release agent, sutures lines, and bone fixation materials in the medical field.

Owner:CHANGZHOU INST OF CHEM +1

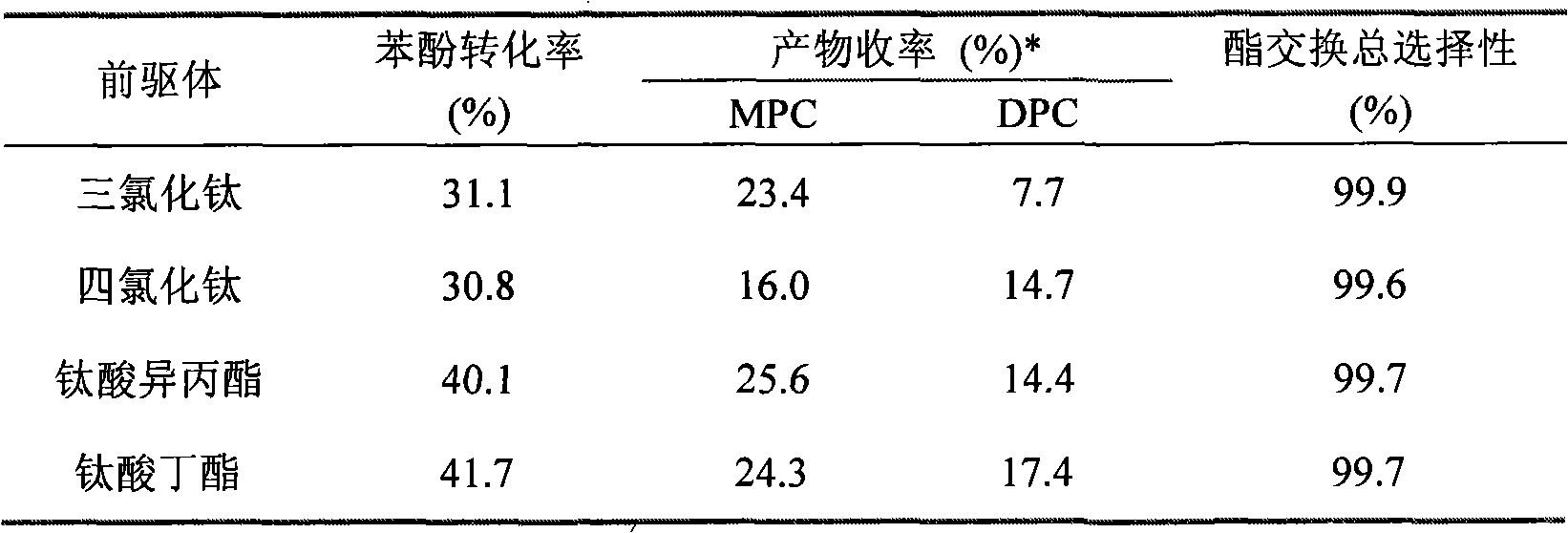

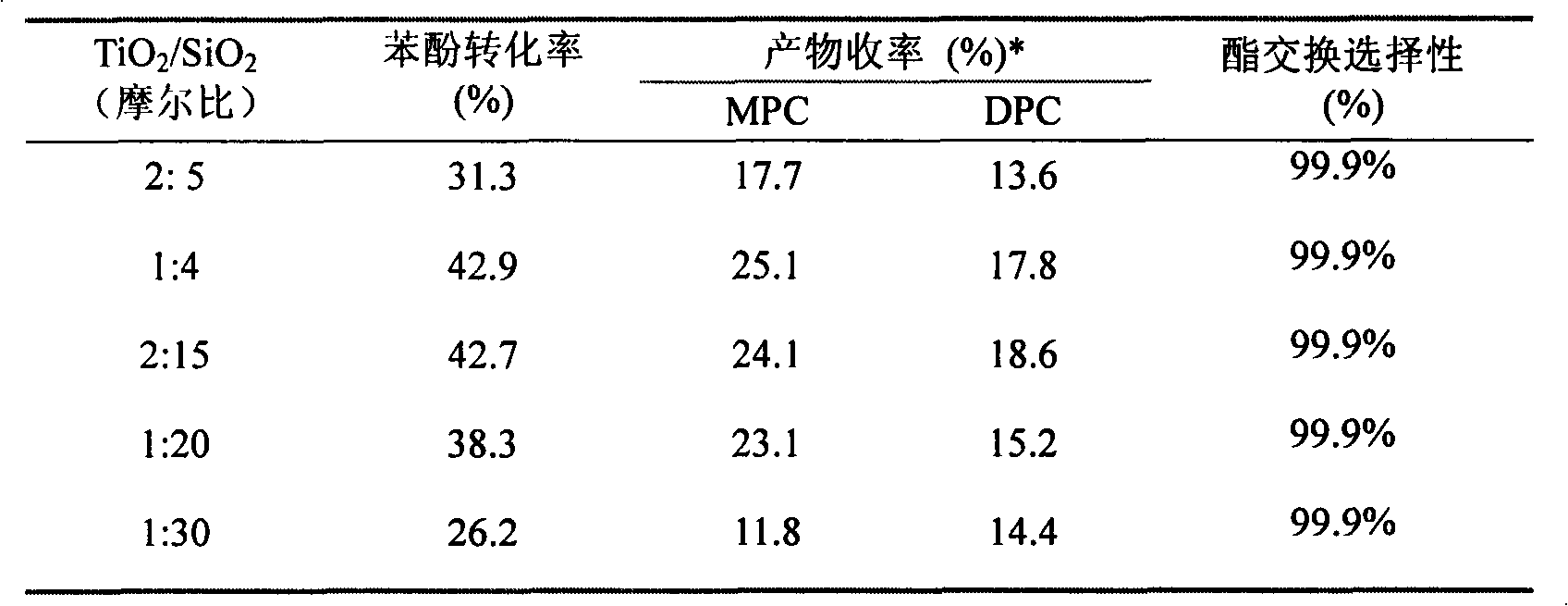

Organic titanium catalyst for exchange reaction of dimethyl carbonate and phenol ester

ActiveCN104860810AWill not polluteEasy to prepareOrganic-compounds/hydrides/coordination-complexes catalystsTitanium organic compoundsAcetic acidMethyl carbonate

The invention relates to an organic titanium catalyst for an exchange reaction of dimethyl carbonate and phenol ester. The catalyst is composed of titanium oxyacelate formed through coordination of titanium and an acetate radical, and a solvothermal method is adopted to solve the catalyst and mainly solves the problems of difficult catalyst separation and recovery and low ester exchange activity. The organic titanium catalyst prepared through the method has a high catalysis effect on a reaction for synthesizing diphenyl carbonate through an ester exchange process, and allows the phenol conversion rate to reach 47.8% and the ester exchange selectivity to reach above 99.9%. The catalyst has the advantages of cheap and easily available raw materials, simple preparation method, insolubility in a reaction system, easy separation and recovery from the reaction system after the reaction, and repeated use.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Preparation method of catalyst for synthesizing diphenyl carbonate

ActiveCN106179515AIncrease production capacityReduced catalytic efficiencyOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsChloramine BChloramine

The invention discloses a preparation method of a catalyst for synthesizing diphenyl carbonate, and belongs to the technical field of catalyst synthesis. The catalyst is obtained by modifying a transition metal oxide by poly-electrolyte until the transition metal oxide is positively or negatively charged, and wrapping a layer of metal organic framework (MOFs) on the outer surface of the transition metal oxide by an electrostatic layer-by-layer self-assembling method, namely the oxide is used as a core, and the MOFs is used as a shell; the catalyst is MalphaObeta@MOFs fort short (M is one of transition metal elements, and alpha and beta are valences). The catalyst is enabled to react with ammonia chloride with a certain concentration to convert the core MalphaObeta into corresponding chloramine salt M(NH3)nClbeta (n is the number of ammonia molecules and is equal to 1 to 8); after ammonia is removed by low-temperature roasting, the catalyst MClbeta@MOFs is obtained. The catalyst can be used in a system for generating diphenyl carbonate by transesterification between urea or carbamic acid ester and phenol; new coordination adsorption is performed on the catalyst and ammonia generated by the reaction system to push the reaction to move rightwards; the yield of a diphenyl carbonate product is up to 90 percent or above; after the catalyst is used for 5 times, the catalysis effect is still good.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method and application of diphenyl carbonate synthesis catalyst

ActiveCN103464208AYield did not decrease significantlyYield completeOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsMethyl carbamatePtru catalyst

The invention discloses a preparation method of a diphenyl carbonate synthesis catalyst. The catalyst belongs to metal organic framework compounds. In the catalyst, an organic framework catalyst is formed by coordinating organic ligand trimesic acid and zinc-copper bimetal ions, and corrosion and pollution are avoided; the catalyst is used for catalyzing the synthesis of diphenyl carbonate from methyl carbamate and phenol, and the selectivity on a target product is relatively high; the catalyst has good stability, is easy to regenerate and can be repeatedly used for more than three times without obviously reducing the yield of diphenyl carbonate; the framework structure is basically kept complete and is easy to separate and recover; the application prospect is good.

Owner:昆明理工大学设计研究院有限公司

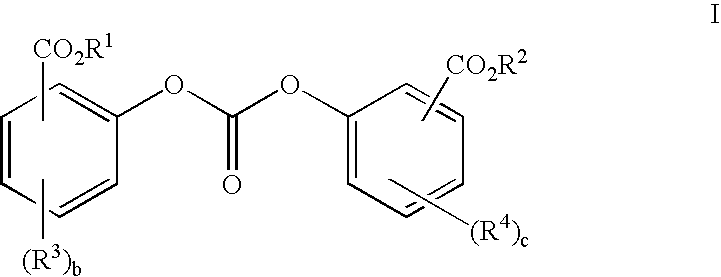

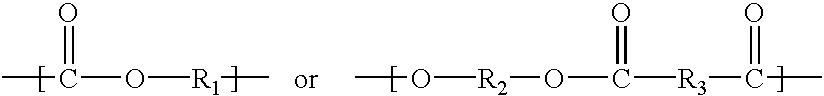

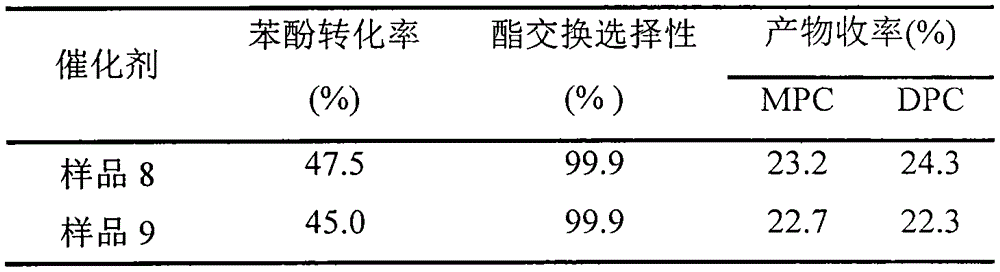

Method for synthesizing diphenyl carbonate through ester exchange reaction of dimethyl carbonate and phenylethyl acetate

InactiveCN101628874AImprove performanceEasy to useOrganic-compounds/hydrides/coordination-complexes catalystsPreparation from organic carbonatesDiketoneHalogen

The invention discloses a method used for synthesizing diphenyl carbonate through ester exchange reaction by using dimethyl carbonate (DMC) and phenylethyl acetate (PA) as raw materials. The method is characterized in that a catalyst system used by the method basically consists of beta-diketone compounds (seen in structural general formulas 1 and 2) belonged to IVB-class metals, and also can be homologous compound thereof. The catalyst system can exist stably in the air, the catalyst has good selectivity and catalytic activity on products comprising methyl phenyl carbonate (MPC) and the diphenyl carbonate (DPC), and the using amount of the catalyst is little. Therefore, the catalyst system can be widely applied to the production of the diphenyl carbonate. In the structural general formulas 1 and 2, M is Ti, Zr and Hf; and R and R' are substituted groups on the beta-diketone compounds, and can be alkyl, alkoxyl and halogen.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

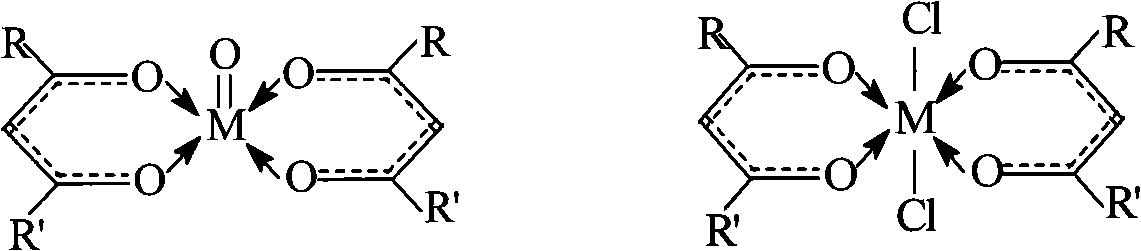

Method for preparing TiO2/SiO2 catalyst for exchanging and synthesizing diphenyl carbonate by dimethyl carbonate and phenol ester

InactiveCN103120934AEasy to prepareShort preparation timePhysical/chemical process catalystsPreparation from organic carbonatesMethyl carbonatePhenol

A method for preparing TiO2 / SiO2 catalyst for exchanging and synthesizing diphenyl carbonate by dimethyl carbonate and phenol ester includes: utilizing SiO2 as a carrier and TiO2 as an active component, utilizing urea as additives and diacetone as inhibitor, and roasting after dissolving and gelling, wherein the titanium and silicon mole ratio is 1:1-60. The method mainly solves the problem about low ester exchange yield of multi-phase catalyst. The TiO2 / SiO2 catalyst prepared by the method has higher catalytic activity and ester exchange selectivity for exchanging and synthesizing diphenyl carbonate by dimethyl carbonate and phenol ester, phenol transformation rate can reach 42.9%, overall selectivity of ester exchange products (methyl phenyl carbonate and diphenyl carbonate) is larger than 99.9%, and byproducts are not detected. The method for preparing TiO2 / SiO2 catalyst for exchanging and synthesizing diphenyl carbonate by dimethyl carbonate and phenol ester is simple and short in preparation time, and raw materials therefore are low in cost and easy to obtain.

Owner:JIANGSU OXIRANCHEM CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com