Patents

Literature

890results about "Preparation from organic carbonates" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

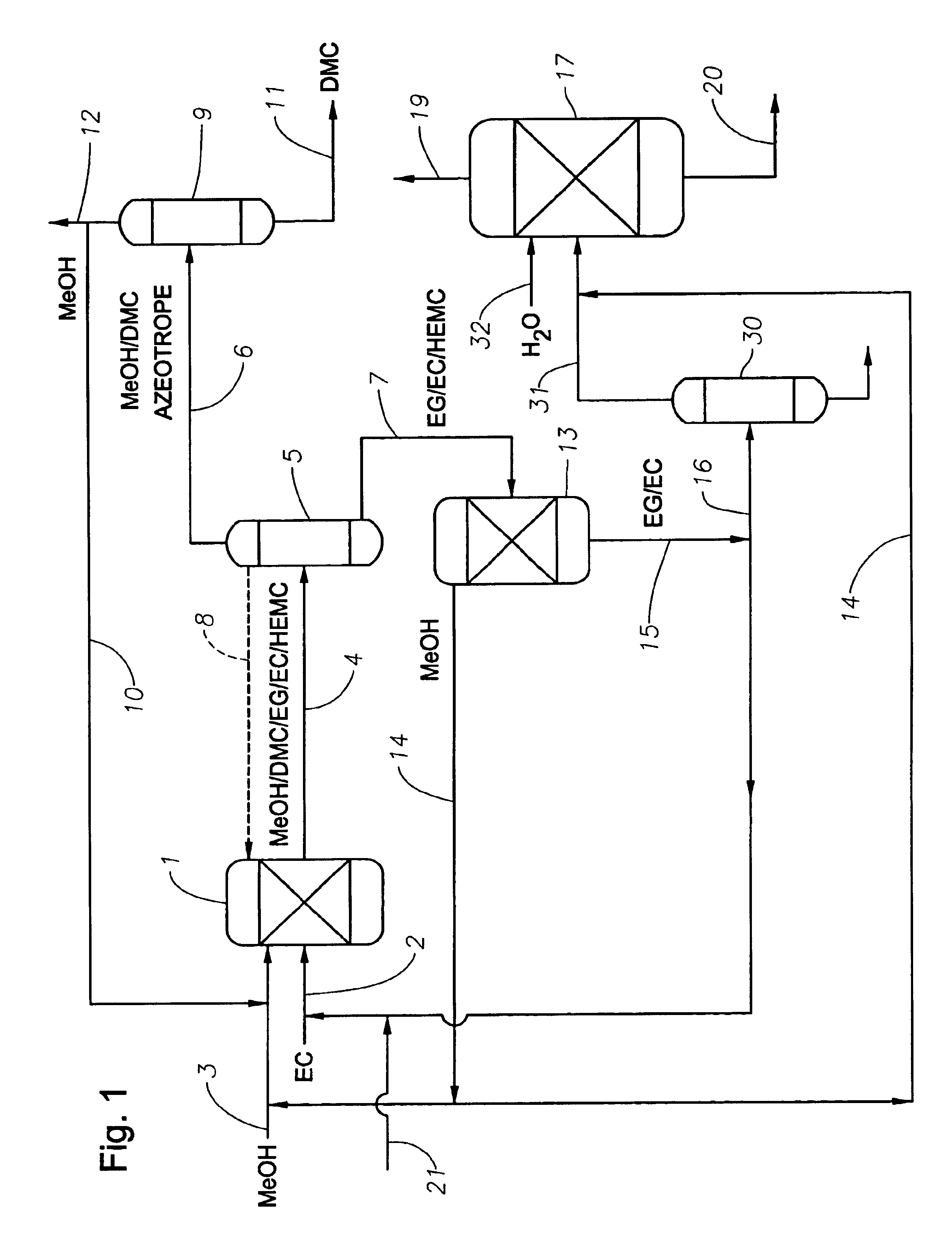

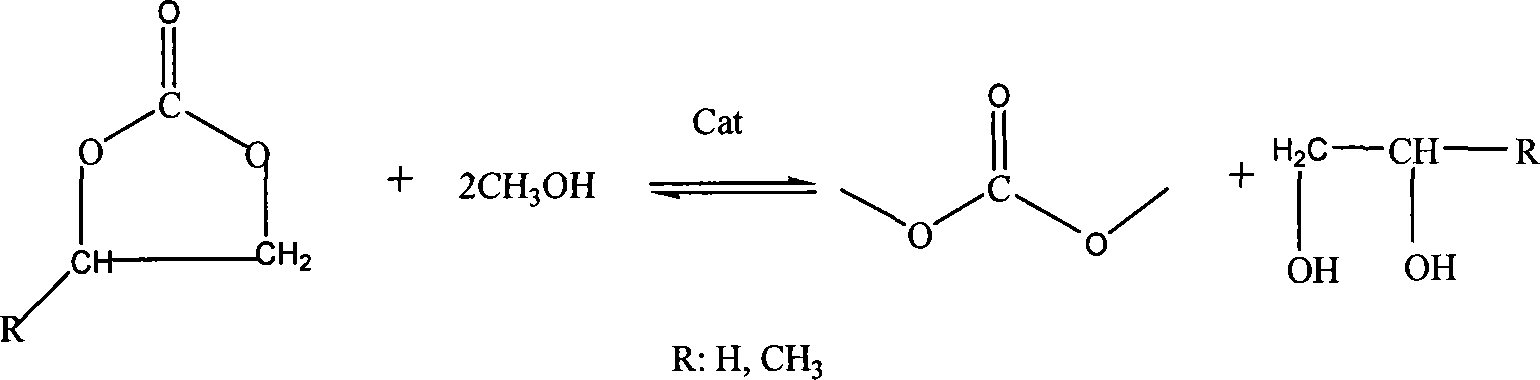

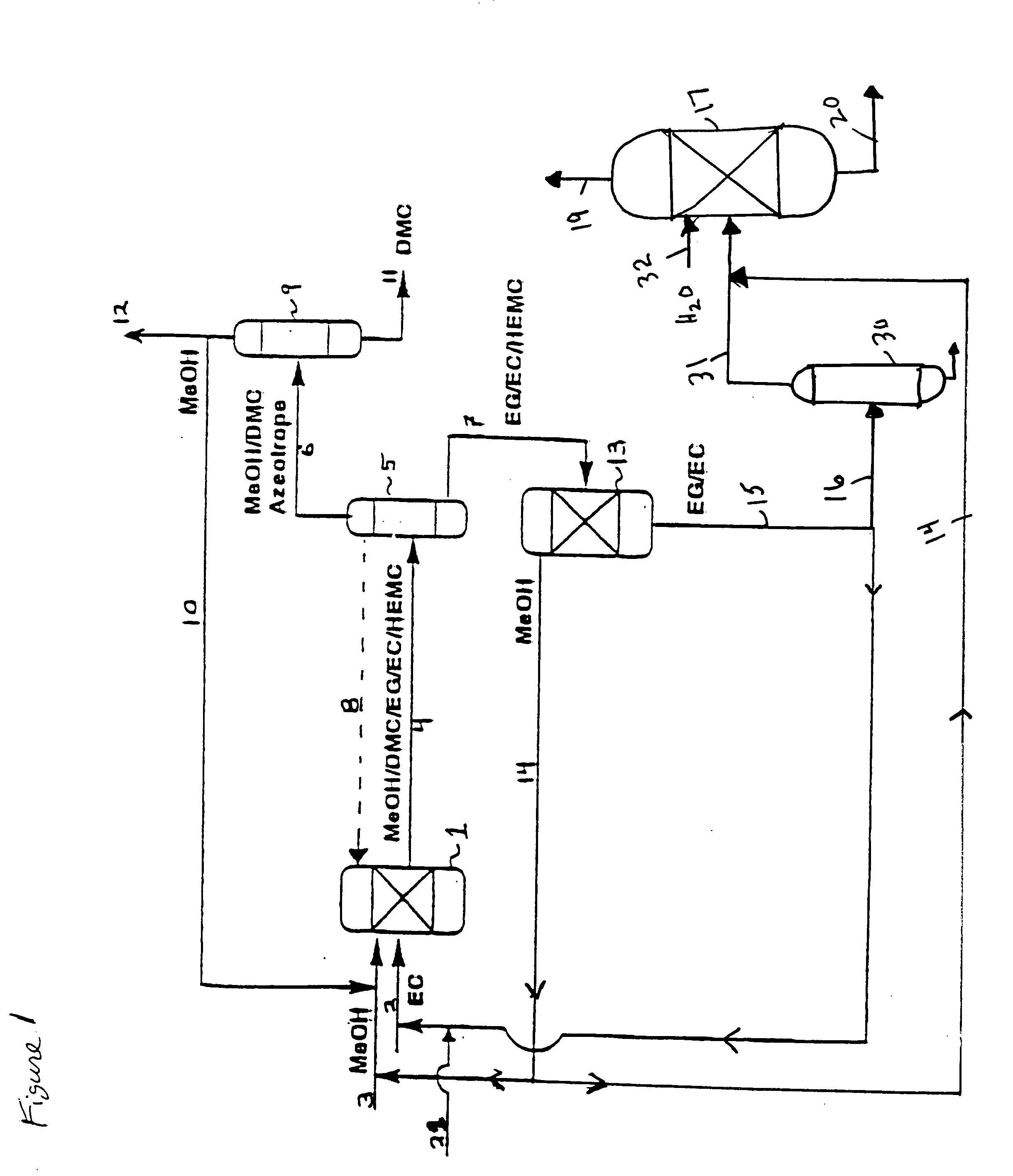

Process for co-production of dialkyl carbonate and alkanediol

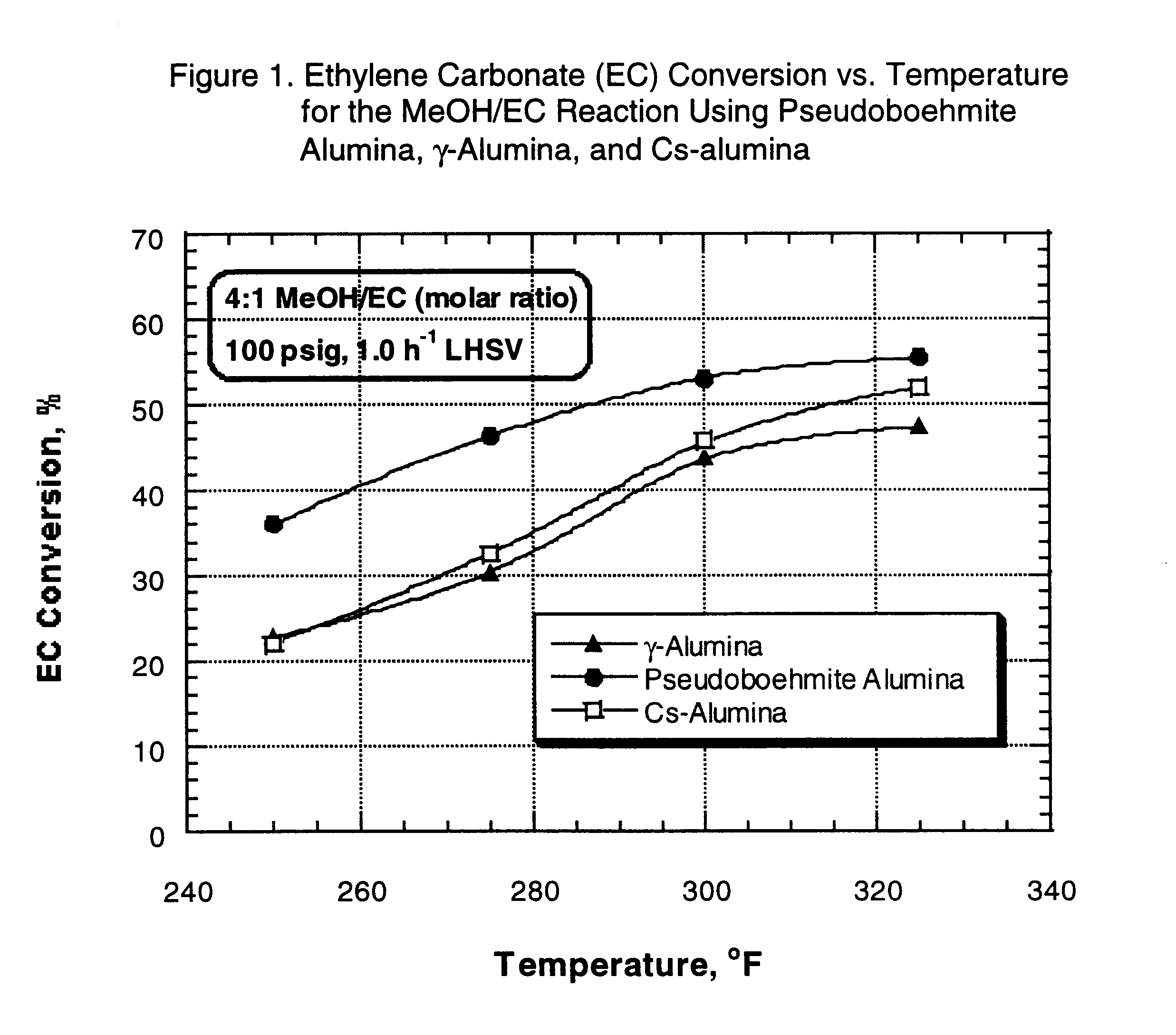

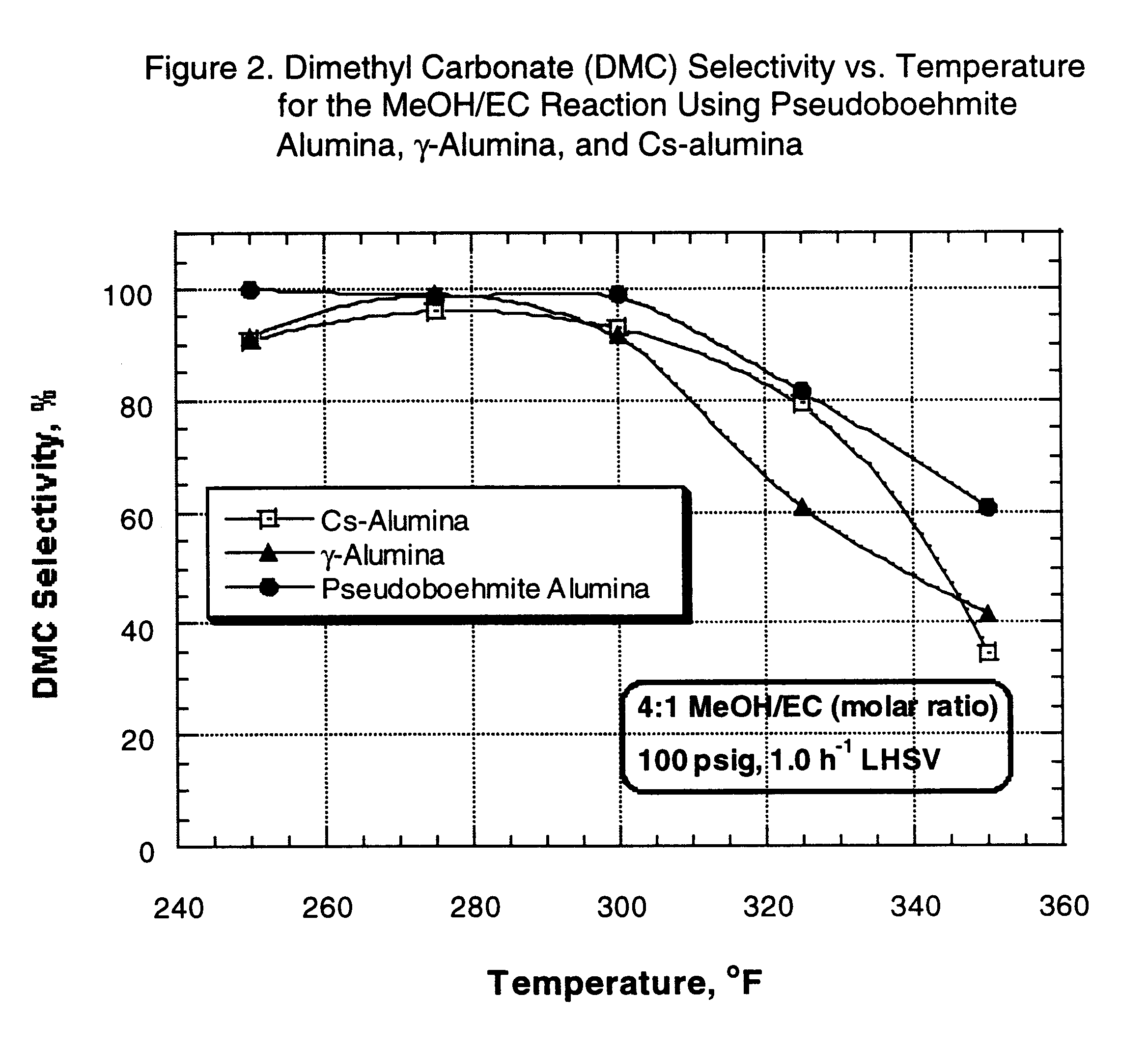

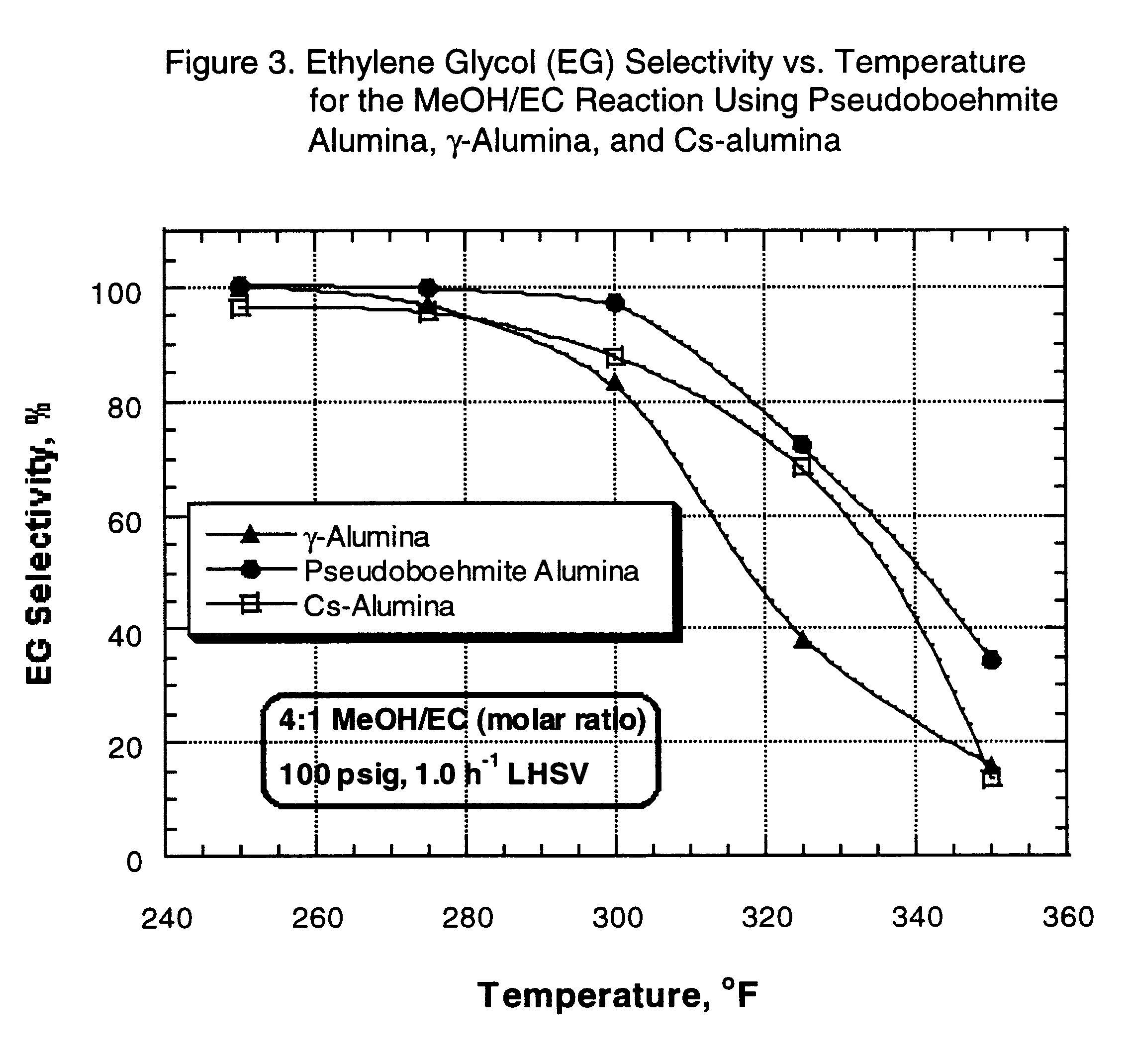

InactiveUS6207850B1Excellent regenerabilityImprove stabilityOxygen-containing compound preparationOrganic compound preparationCarbonateMetal

Owner:MOBIL OIL CORP

Process for the production of unsymmetric and/or symmetric dialkyl carbonates and diols

InactiveUS6930195B2High yieldOrganic compound preparationHydroxy compound preparationAlcoholTransesterification

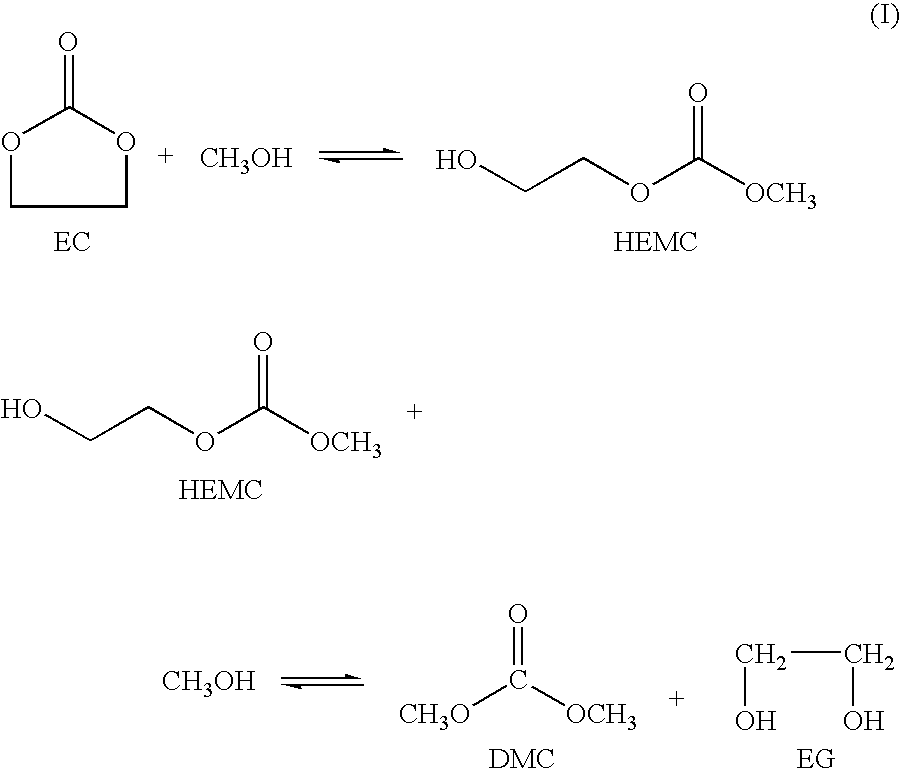

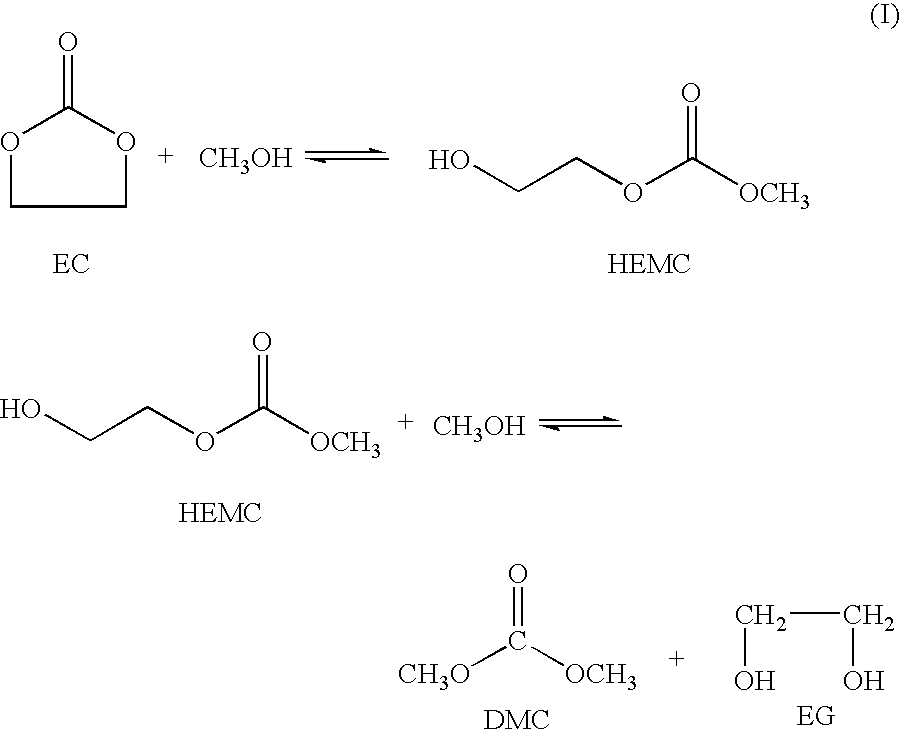

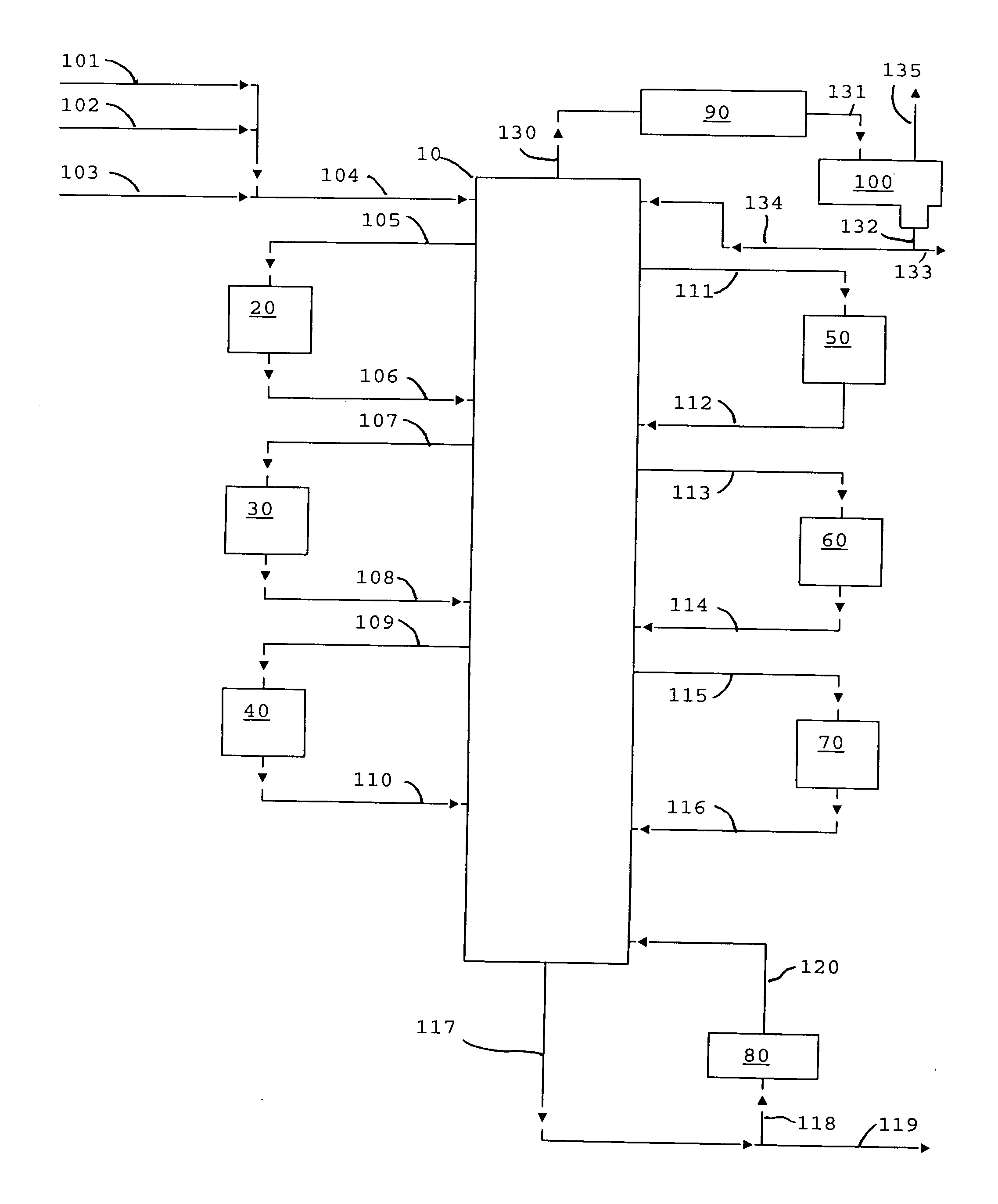

A process for the production of a dialkyl carbonate and a diol, such as dimethyl carbonate and ethylene glycol, by reacting a feed containing a cyclic carbonate, a hydroxy alkyl carbonate and an aliphatic monohydric alcohol in the presence of a transesterification catalyst is described. In another aspect, a process is described which is particularly useful for producing unsymmetric dialkyl carbonates, such as ethyl methyl carbonate.

Owner:BADGE LICENSING LLC

Methods for synthesis of acyloxyalkyl compounds

InactiveUS20050070715A1Carbamic acid derivatives preparationOrganic compound preparationAcyl groupMedicinal chemistry

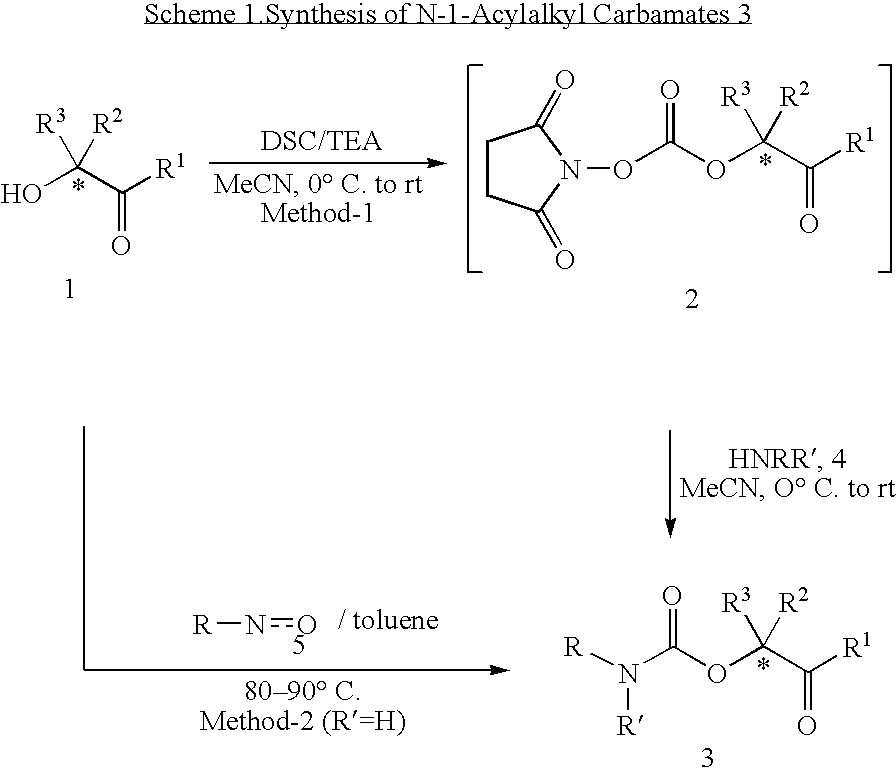

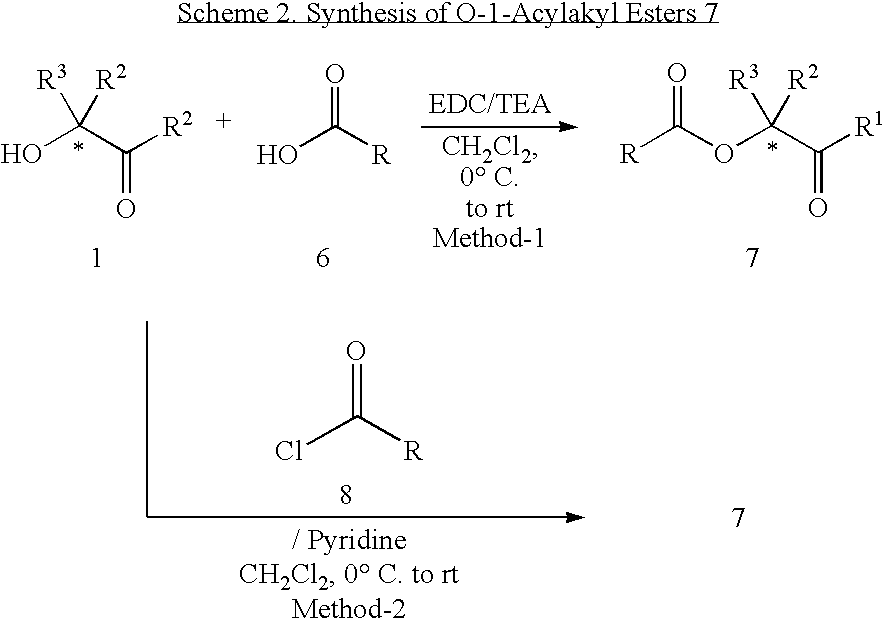

Disclosed herein are methods for synthesizing 1-(acyloxy)-alkyl prodrug derivatives of drugs through oxidation of 1-acyl-alkyl derivatives of drugs under anhydrous reaction conditions. The methods typically proceed stereospecifically, in high yield, do not require the use of activated intermediates and / or toxic compounds and are readily amenable to scale-up.

Owner:XENOPORT

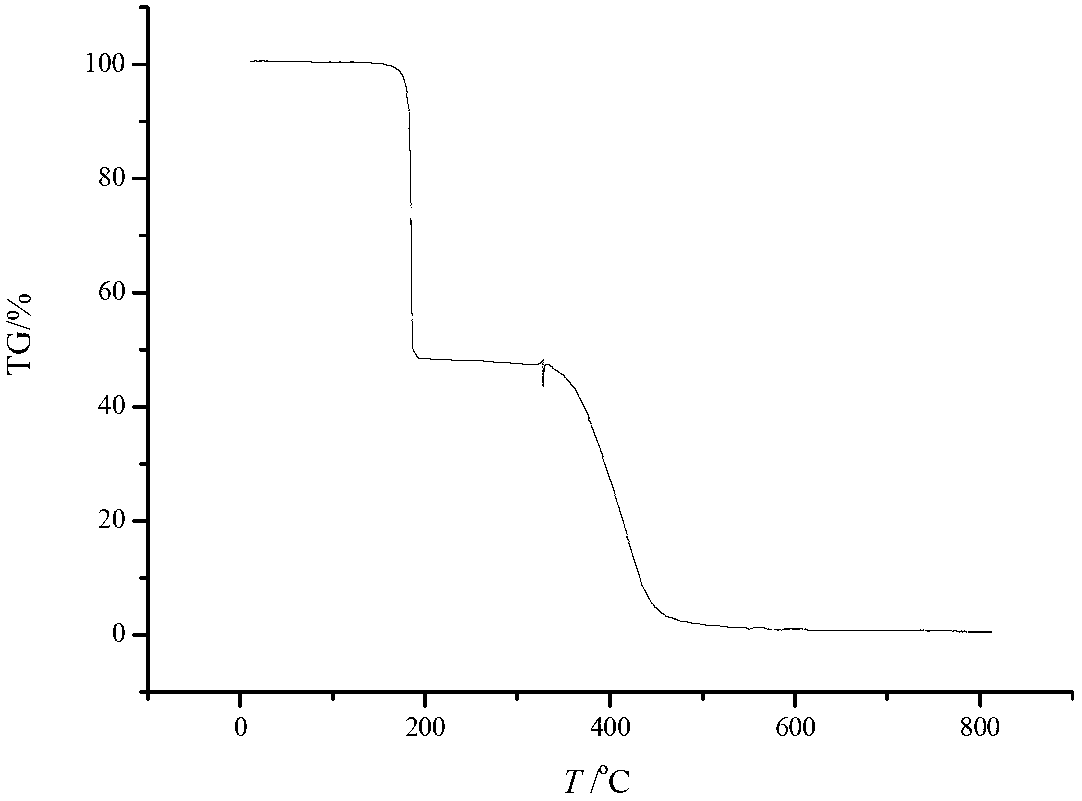

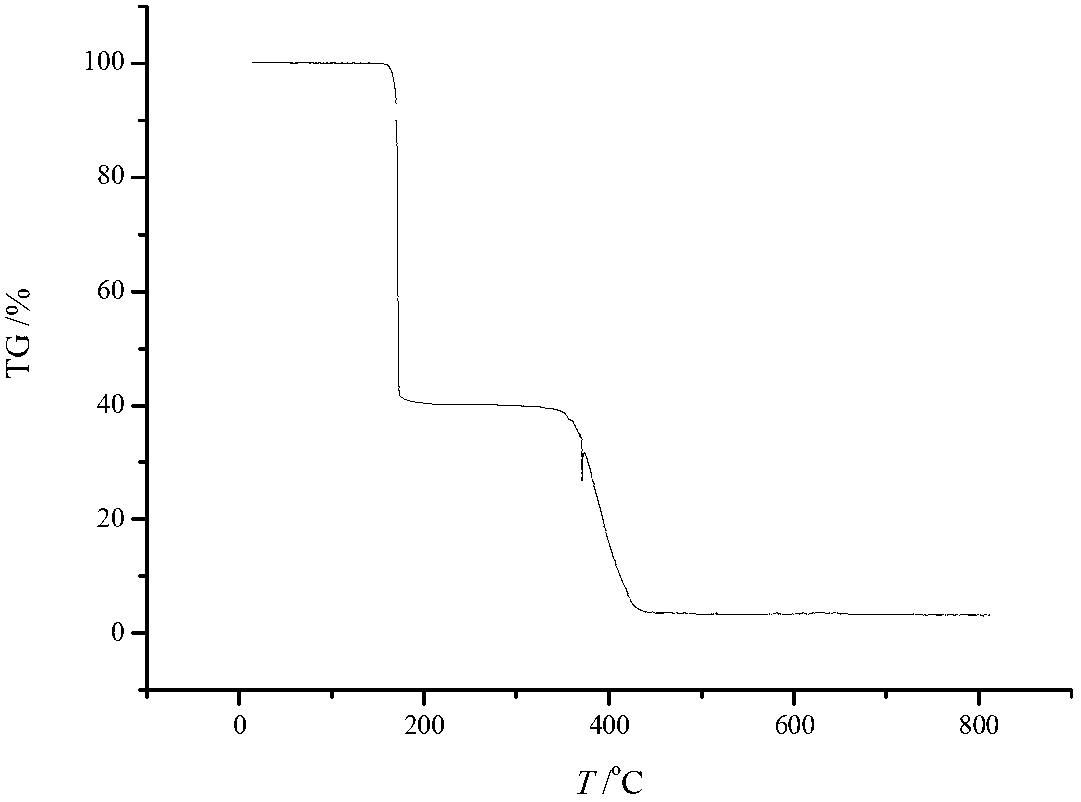

Load type solid body base catalyst of synthesizing dimethyl carbonate and method of preparing the same

InactiveCN101249452AEasy to makeEasy to preparePhysical/chemical process catalystsPreparation from organic carbonatesMethyl carbonatePotassium fluoride

The invention relates to a carrier type solid base catalyst for synthesizing dimethyl carbonate, which belongs to the technical field of catalytic material. The catalyst's formula is KF / M<2+>-N<3+>-(O), wherein M<2+>-N<3+>-(O) represents the composite metal oxide, M<2+> can be divalent metal ion (Mg<2+> or Ca<2+> ) and N<3+> can be trivalent metal ion (Fe<3+> and / or Al<3+>). The catalyst is prepared from potassium fluoride and composite metal oxide at a certain weight ratio by immersing the potassium fluoride into the composite metal oxide, wherein the composite metal oxide is prepared from hydrotalcite precursor and in nucleation / crystallization isolation method by calcining at a certain temperature. The catalyst has the advantages of nanoscaled particle size, high specific surface area and high activity, selectivity in catalytic reaction and simple preparation, and can be reused as it can be centrifugally separated after reacting.

Owner:BEIJING UNIV OF CHEM TECH

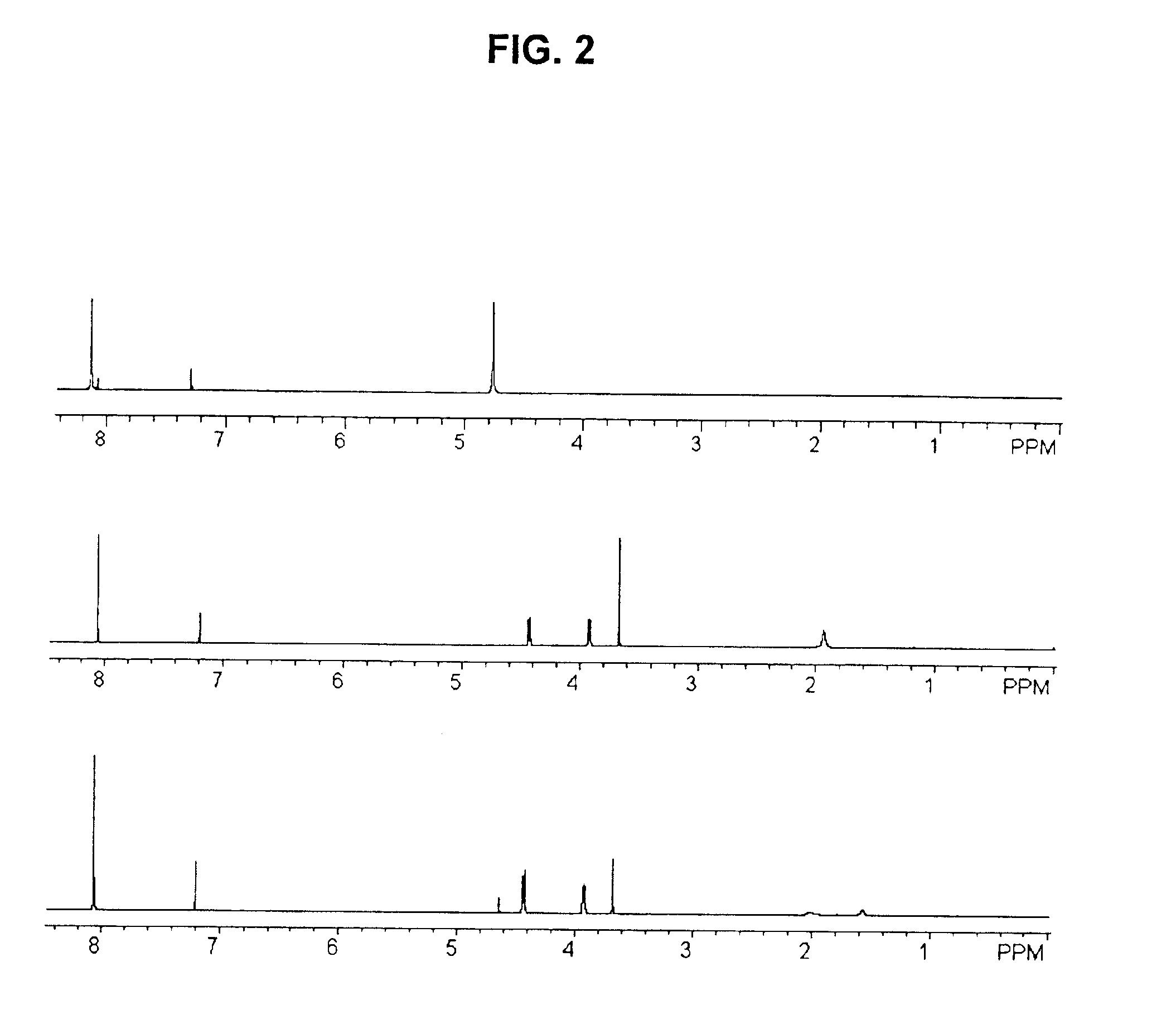

Molecular glass photoresist containing bisphenol A skeleton structure as well as preparation method and application thereof

ActiveCN103304385AOrganic compound preparationPhotomechanical coating apparatusSolventNanoimprint lithography

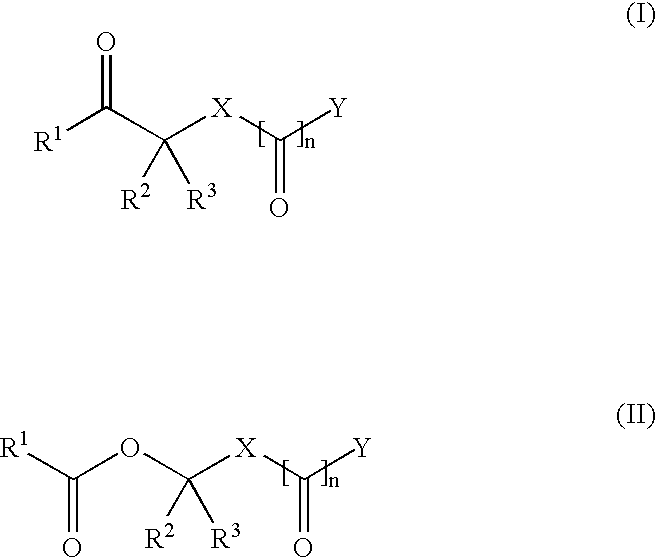

The invention relates to a series of molecular glass photoresists (I and II) based on bisphenol A as a main body structure and a preparation method thereof. The molecular glass photoresists are compounded with a photo-acid generator, a crosslinking agent, a photoresist solvent and other additives to produce positive or negative photoresists; the positive or negative photoresists are placed on a silicon wafer through a spin coating method to prepare a photoresist coating layer with uniform thickness. The photoresist formula can be used in modern lithography technologies, such as 248nm lithography, 193nm lithography, extreme ultraviolet lithography, nanoimprinting lithography and electron beam lithography, and is especially suitable for an extreme ultraviolet (EUV) photo-lithographic process.

Owner:GUOKE TIANJI (BEIJING) NEW MATERIAL TECH CO LTD

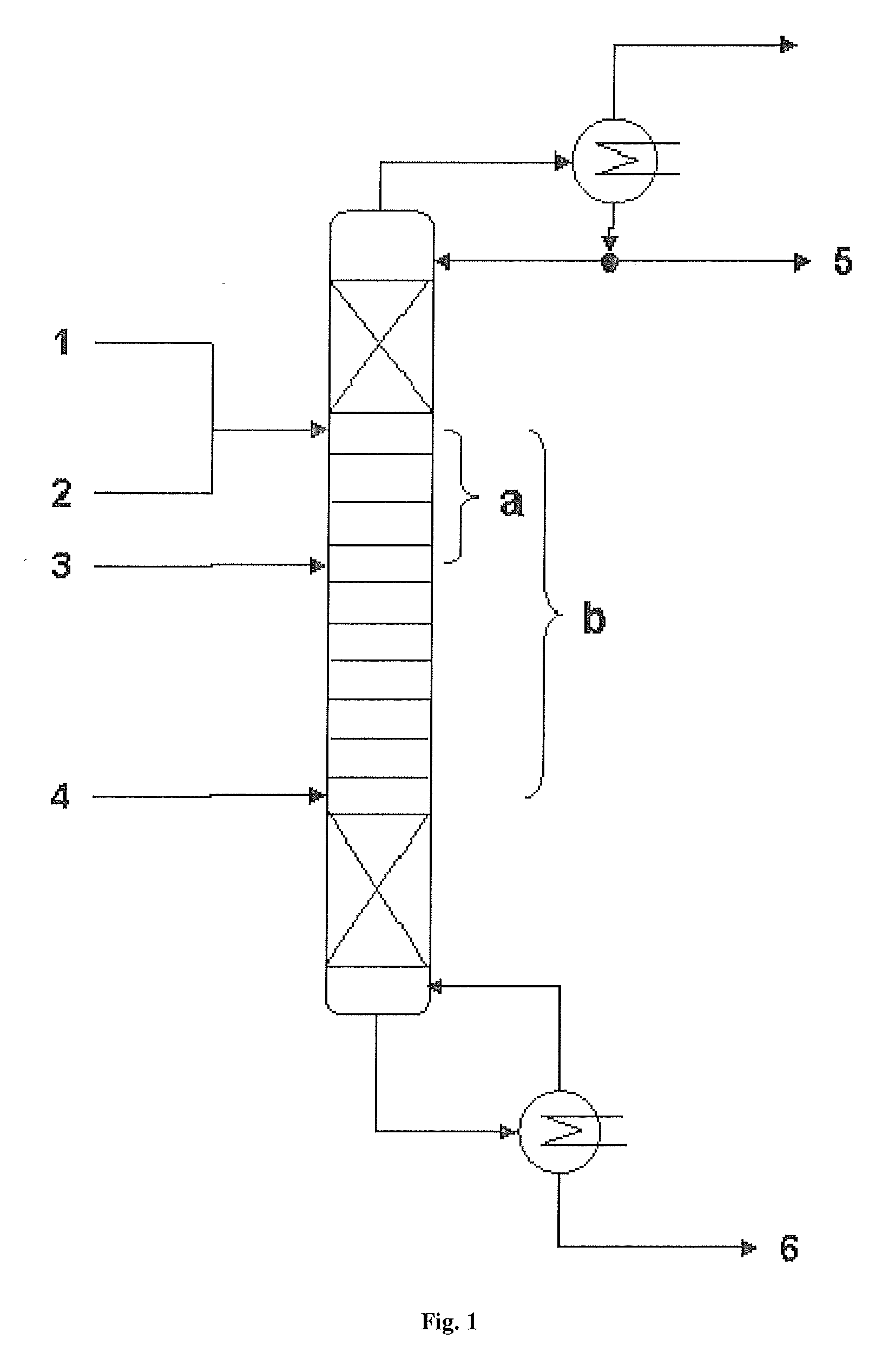

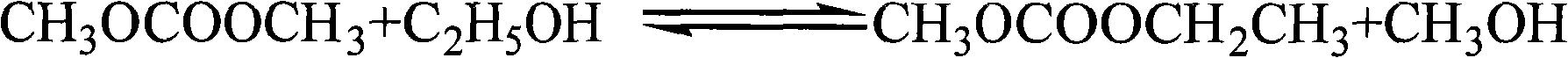

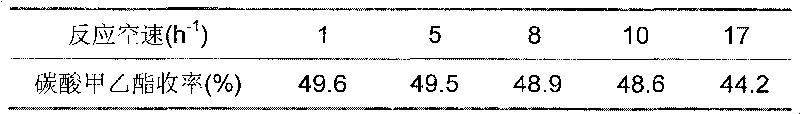

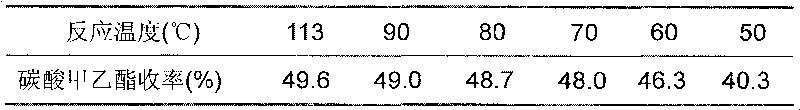

Process for preparing methyl ethyl carbonate by ester exchanging reaction

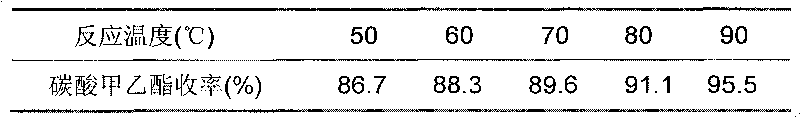

InactiveCN1900047AHigh yieldQuick responseMetal/metal-oxides/metal-hydroxide catalystsPreparation from organic carbonatesTransesterificationReaction temperature

The transesterification process for preparing methyl ethyl carbonate features that the materials dimehtyl carbonate and ethanol in the molar ratio of 1-4 to 1 produce transesterification reaction at normal pressure and 50-110 deg.c in the presence of binary heterogeneous solid alkali catalyst for 1-8 hr to prepare methyl ethyl carbonate. The solid alkali catalyst has consumption of 5-25 % of ethanol weight and is prepared through soaking process or sol-gel process, and used catalyst may be separated easy from the reaction product for reuse. The transesterification reaction is completed in a reaction-rectification apparatus and has methyl ethyl carbonate yield up to 90 %.

Owner:ZHEJIANG UNIV

Process for the production of unsymmetric and/or symmetric dialkyl carbonates and diols

InactiveUS20050080287A1High yieldOrganic compound preparationHydroxy compound preparationAlcoholTransesterification

A process for the production of a dialkyl carbonate and a diol, such as dimethyl carbonate and ethylene glycol, by reacting a feed containing a cyclic carbonate, a hydroxy alkyl carbonate and an aliphatic monohydric alcohol in the presence of a transesterification catalyst is described. In another aspect, a process is described which is particularly useful for producing unsymmetric dialkyl carbonates, such as ethyl methyl carbonate.

Owner:BADGE LICENSING LLC

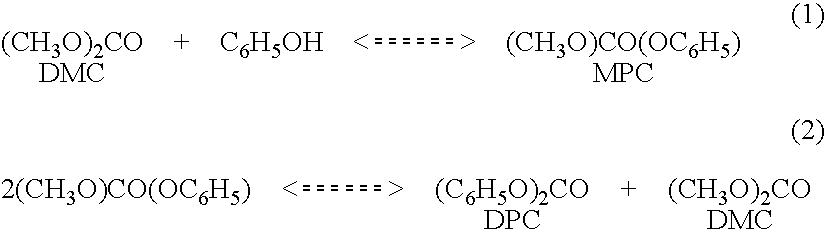

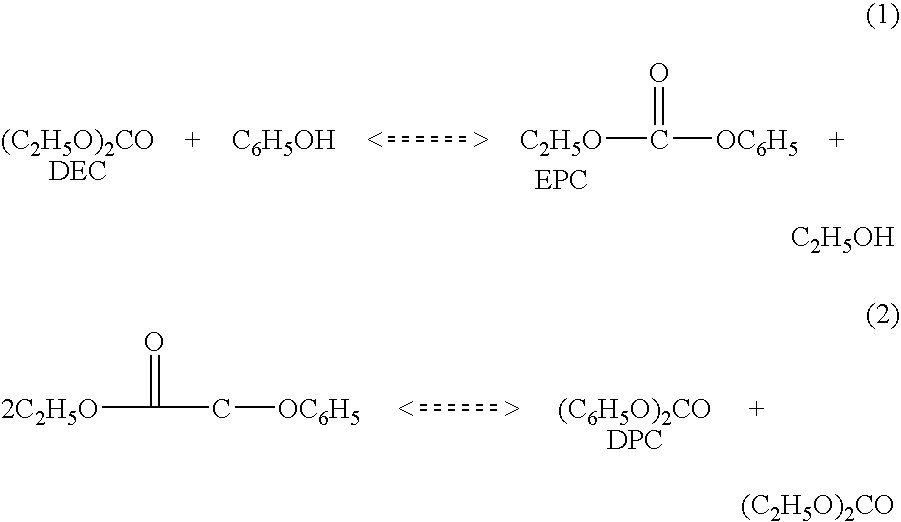

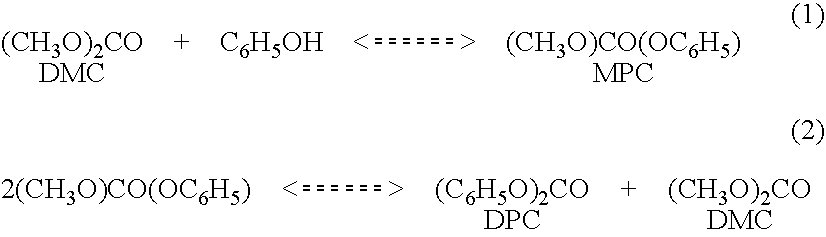

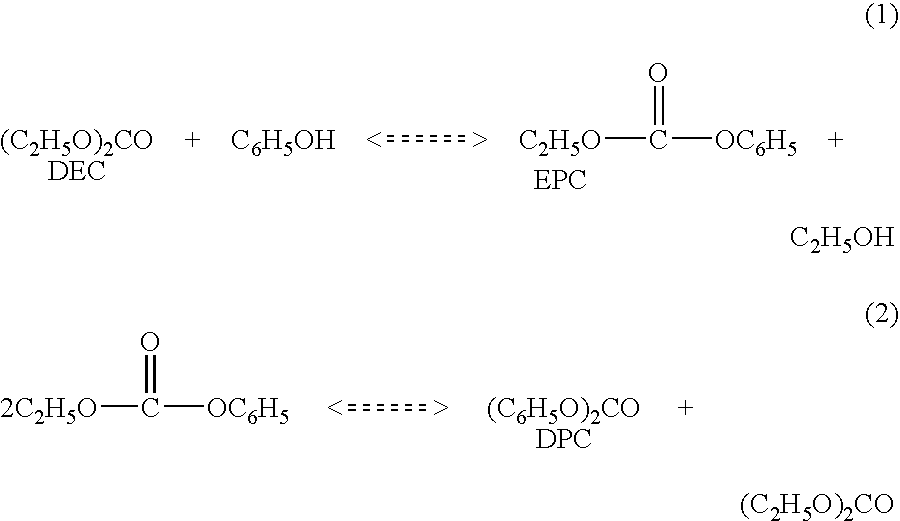

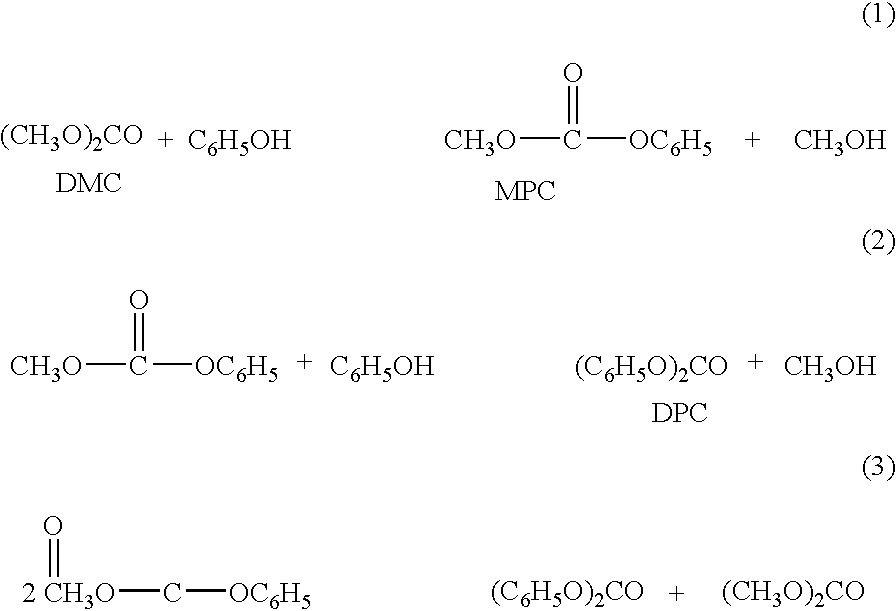

Process for making diaryl carbonate

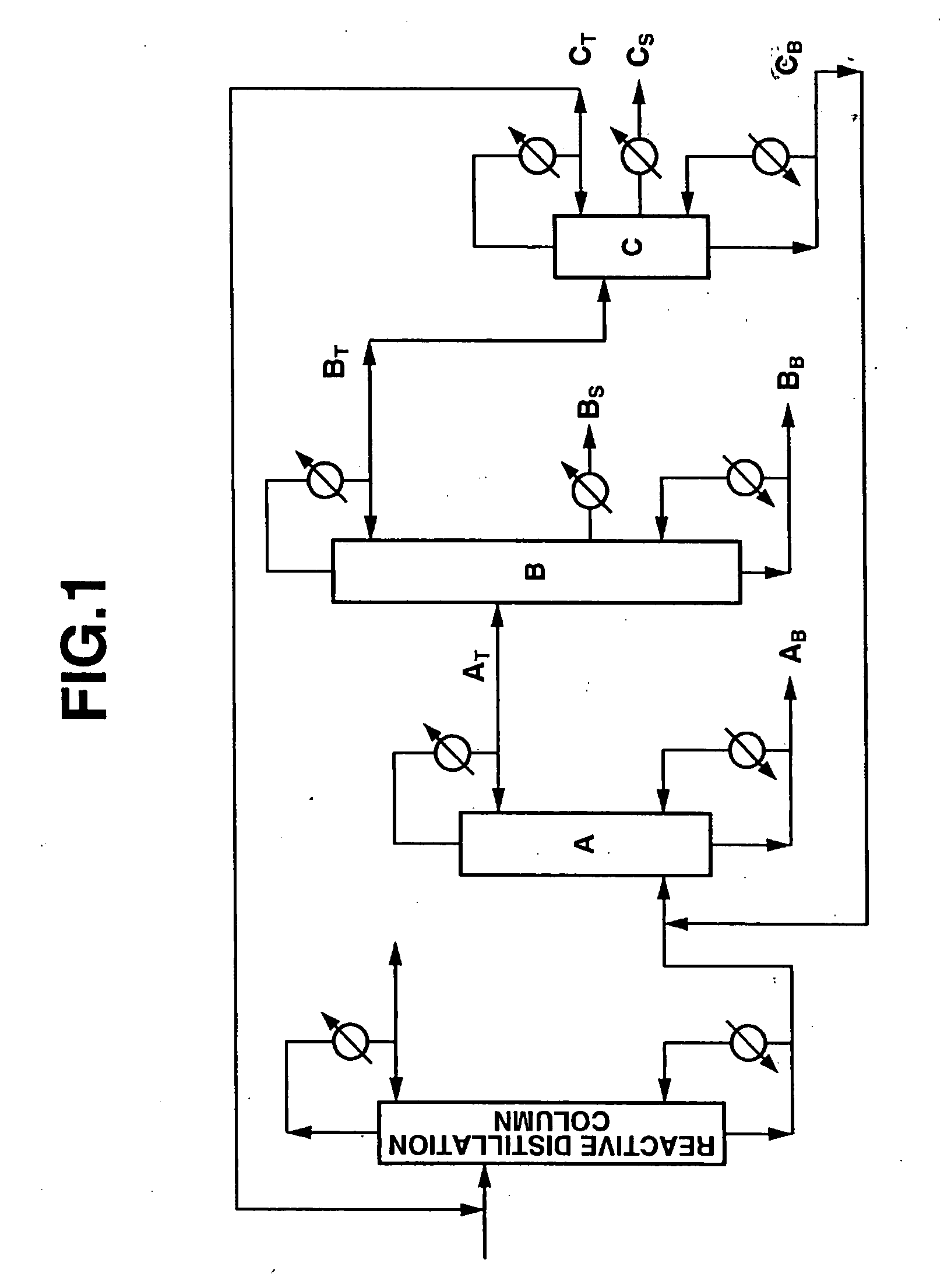

Diphenyl carbonate is produced by reacting phenol with diethyl carbonate in a series of fixed bed reactors each of which is connected at different position on a distillation column via side draw and return streams. The composition of material in a distillation column varies along the length of the column, which is predictable under a given set of conditions of temperature and pressure, thus withdrawing streams at different stages in the column, allows the reactor receiving the feed from a particular stage to be operated under conditions to maximize the desired reaction, while allowing the unreacted or byproduct to go back into the distillation and be sent to a stage (by the equilibrium of the distillation) where they are favorably treated in a reactor.

Owner:SHELL USA INC

Process for making diaryl carbonate

Diphenyl carbonate is produced by reacting phenol with diethyl carbonate in a series of fixed bed reactors each of which is connected at different position on a distillation column via side draw and return streams. The composition of material in a distillation column varies along the length of the column, which is predictable under a given set of conditions of temperature and pressure, thus withdrawing streams at different stages in the column, allows the reactor receiving the feed from a particular stage to be operated under conditions to maximize the desired reaction, while allowing the unreacted or byproduct to go back into the distillation and be sent to a stage (by the equilibrium of the distillation) where they are favorably treated in a reactor.

Owner:SHELL USA INC

Process for producing organic carbonates

ActiveUS20070093672A1Speed up the conversion processCatalyst regeneration/reactivationCatalyst activation/preparationBenzeneTransesterification

A process for producing various organic carbonates by performing transesterification and disproportionation reactions in dual vapor / liquid phase mode preferably in the presence of solid catalyst composition selected from the group consisting of oxides, hydroxides, oxyhydroxides or alkoxides of two to four elements from Group IV, V and VI of the Periodic Table supported on porous material which has surface hydroxyl groups and the method of reactivating catalyst deactivated by polymer deposition by contacting the deactivated catalyst with a solution of hydroxy containing compound in a solvent such as benzene or THF.

Owner:CHEM RES & LICENSING CO

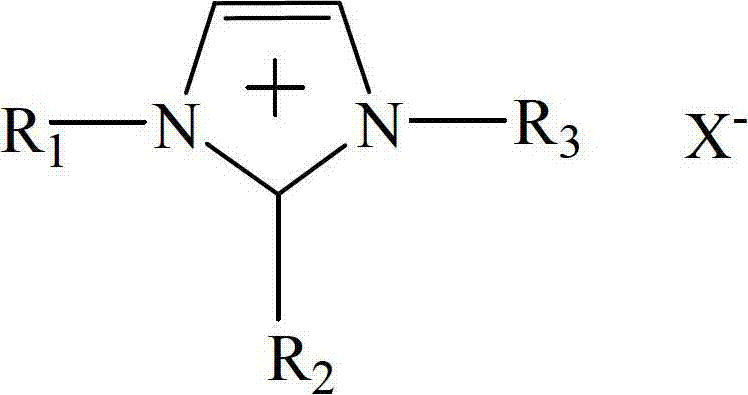

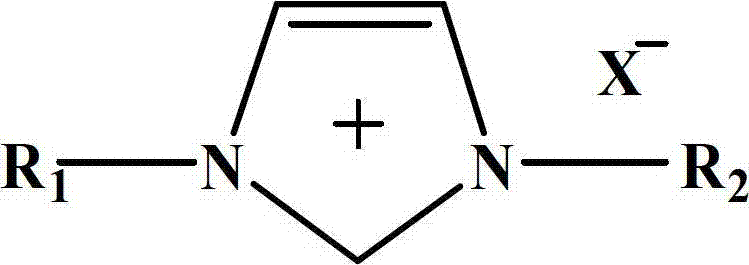

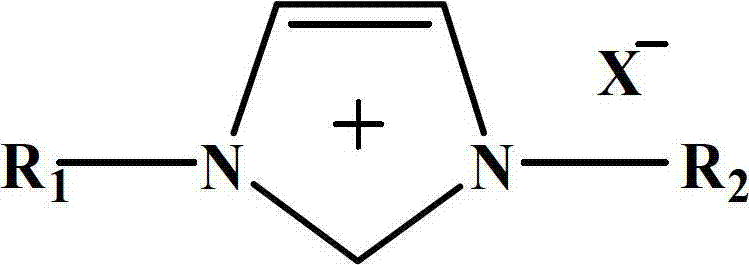

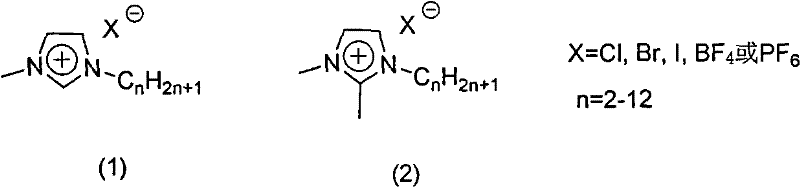

Method for synthesizing methylethyl carbonate by ester exchange of dimethyl carbonate and diethyl carbonate

ActiveCN102863339AHigh catalytic activityLow costChemical recyclingPreparation from organic carbonatesReaction temperatureIonic liquid

The invention relates to a method for synthesizing methylethyl carbonate by ester exchange of dimethyl carbonate and diethyl carbonate, which is implemented by carrying out synthetic reaction of methylethyl carbonate on raw materials dimethyl carbonate and diethyl carbonate by using an imidazole ionic liquid as a catalyst at certain reaction temperature under ordinary pressure for some reaction time. The catalyst consumption is only 0.2-2 wt% of the dimethyl carbonate; the ionic liquid catalyst has high catalytic activity in the reaction process, the maximum yield of methylethyl carbonate is up to 62.31%, and the selectivity is 100%; and the catalyst can be recycled for cyclic utilization after being subjected to simple treatment after reaction, has the advantages of long service life and no pollution, and greatly lowers the preparation cost of methylethyl carbonate.

Owner:灯塔森佳新能源合伙企业(有限合伙)

Process for preparing dialkyl carbonates from alkylene carbonates and alcohols

The present invention relates to a continuous process for preparing lower dialkyl carbonates as main product and alkylene glycol as by-product by catalyzed transesterification of a cyclic alkylene carbonate (e.g. ethylene carbonate or propylene carbonate) with lower alcohols, where the reaction of the alkylene carbonate is carried out with an alcohol containing dialkyl carbonate in countercurrent, characterized in that introduction of a stream containing at least 99.5% by weight of alcohol takes place below the point of introduction for the alcohol containing dialkyl carbonate in a particular spacing ratio between the abovementioned points of introduction.

Owner:COVESTRO DEUTSCHLAND AG

Method for preparing methyl ethyl carbonate

InactiveCN101289395AHigh yieldPreparation from organic carbonatesTransesterificationMethyl carbonate

The invention relates to a preparation method of methyl ethyl carbonate, which takes methyl carbonate and ethanol as raw material and carries on transesterification with the existence of the catalyst with the reaction temperature of 50 DEG C to 60 DEG C. The temperature of the reaction materials rises from room temperature with a heating rate of five to ten DEG C per hour. The method also includes a water removing treatment to the ethanol so that the water content of the ethanol is less than or equal to 0.1 percent of the gross weight of the ethanol. By adopting the preparation method of the invention, the purity of the methyl ethyl carbonate is as high as 99.8 percent and the yield is higher than 70 percent. The method has the advantages of mild reaction condition, simple separation and purification of reaction products and low cost.

Owner:BYD CO LTD

Synthesis method of methyl ethyl carbonate

InactiveCN101704751AStable in natureHigh yieldPreparation from organic carbonatesSynthesis methodsFixed bed

The synthesis method of methyl ethyl carbonate belongs to the technical field of organic compounds synthesized by ester exchange. Dimethyl carbonate and diethyl carbonate, or dimethyl carbonate and ethanol are used as raw materials to perform ester exchange in the presence of catalyst. The reaction mode comprises two kinds of fixed bed continuous reaction and kettle-type reaction. The catalyst issolid alkali catalyst in which the carrier is active carbon, carbon molecular sieve or mesoporous carbon and the active component is Na2O, K2O, MgO, CaO, SrO or BaO. In the process of fixed bed continuous synthesis, the catalyst is stable without inactivation after long-term use, thereby retaining the high yield of the methyl ethyl carbonate, simplifying the production process, and achieving environmental friendliness and energy conservation. In the kettle-type reaction, the catalytic efficiency is high, the catalyst can be recovered by simple filtering and re-sintering, and the target product can be obtained in short time with high yield.

Owner:JILIN UNIV

Bimetal composite oxide catalyst for change of methyl carbonate and phenol ester

ActiveCN1803282AHigh catalytic activityEasy to separatePreparation from organic carbonatesMetal/metal-oxides/metal-hydroxide catalystsMethyl carbonateCopper oxide

The invention discloses a two-metal composite oxide catalyst of synthetic biphenyl carbonate through ester exchange, which consists of vanadium oxide and copper oxide, wherein the mole ratio is that V:Cuú¢100í1-100; The sintering temperature is between 250 and 850 deg C; the parent body can be vanadium salt or vanadium oxide and copper salt or copper oxide; the making method adapts coprecipitation method or mechanic abrasion method. The invention improves the total productivity of biphenyl carbonate, which is easy to separate and recover the biphenyl carbonate.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI +1

Method for synthesizing methylethyl carbonate

ActiveCN102850223AHigh catalytic activityLow costOrganic-compounds/hydrides/coordination-complexes catalystsChemical recyclingMethyl carbonateReaction temperature

The invention relates to a method for synthesizing methylethyl carbonate. According to the method, under ordinary pressure, dimethyl carbonate and ethanol which are used as raw materials are subjected to synthetic reaction of methylethyl carbonate at certain reaction temperature for some time by using an imidazole ionic liquid as a catalyst. The invention has the following advantages: the catalyst consumption is only 0.5-5 wt% of the dimethyl carbonate; the ionic liquid catalyst has high catalytic activity in the reaction process, the maximum yield of methylethyl carbonate is up to 71.22%, and the selectivity is up to 88.52%; and the catalyst can be recycled for cyclic utilization after being subjected to simple treatment after reaction, has the advantages of long service life and no pollution, and greatly lowers the preparation cost of methylethyl carbonate.

Owner:辽阳东昌化工股份有限公司

Method of distillation and ester exchange reaction for producing dimethyl carbonate and dihydroxyl alcohols

InactiveCN1733696AIncrease conversion rate per passReduce energy consumptionPreparation from organic carbonatesMentholAlcohol

The invention discloses a method of distillation and ester exchange reaction for producing dimethyl carbonate and dihydroxyl alcohols comprising the following steps, counterflow contacting cyclic carbonates absorbent with mixed gas containing alkylene oxide and carbon dioxide in an absorption column, reacting alkylene oxide with carbon dioxide to obtain cyclic carbonate, the cyclic carbonate synthesized liquid entering a rectifying tower, the cyclic carbonate on top of the tower entering an reaction rectifying tower through pipe lines, carrying out ester exchange reaction with menthol at the presence of ester exchange catalyst, obtaining dimethyl carbonate and dibastic alcohol.

Owner:上海衡和环保新材料科技有限公司

Transesterification catalyst and a process for the preparation thereof

ActiveUS7754643B2Easy to separateFatty acid esterificationPreparation by ester-hydroxy reactionAlcoholTransesterification

The present invention provides a novel transesterification catalyst having the general formula:Zn3M2(CN)n(ROH).xZnCl2.yH2Owherein R is tertiary-butyl and M is a transition metal ion selected from Fe, Co and Cr, x varies from 0 to 0.5, y varies from 3-5 and n is 10 or 12.The above said catalyst is useful for an efficient transesterification of glycerides, fatty acid esters and cyclic carbonates on reactions with alcohols.

Owner:COUNCIL OF SCI & IND RES

Method for synthesizing ethyl methyl carbonate through ester exchange

ActiveCN103483200AEasy to makeSimple process conditionsPreparation from organic carbonatesMolecular sieveAlcohol

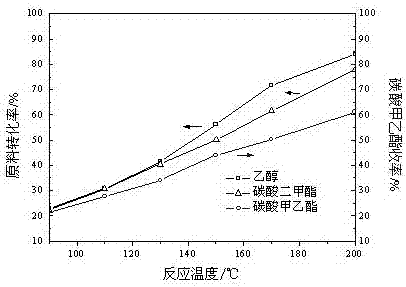

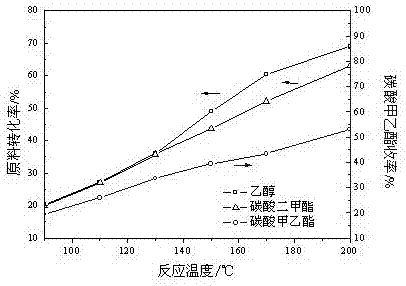

The invention relates to a method for synthesizing ethyl methyl carbonate through ester exchange. The method comprises the following steps: filling a fixed bed reactor with catalysts, pumping dimethyl carbonate and ethyl alcohol into the fixed bed reactor according to the molar ratio of 0.5-2:1 after nitrogen purging is carried out, reacting at the air speed of 0.5-15h-1, the temperature of 100-240DEG C and the reaction operation pressure of 0-1MPa, and finally the ethyl methyl carbonate is obtained. The catalysts are modified molecular sieve based catalysts. The method is simple in technology condition, easy to control, capable of achieving continuous production due to the gas-solid phase reaction and low in cost of the adopted catalysts. The selectivity of the ethyl methyl carbonate can be higher than 90%, and the yield can be higher than 55%.

Owner:HEBEI UNIV OF TECH

Method for preparing ethyl methyl carbonate through ester exchange method

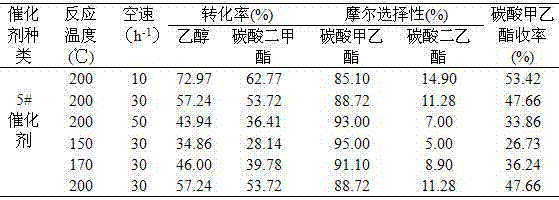

InactiveCN107473968AGood dispersionImprove mass transfer effectPhysical/chemical process catalystsPreparation from organic carbonatesDispersityMethyl carbonate

The invention provides a method for preparing ethyl methyl carbonate through an ester exchange method, and relates to a method for preparing a chemical raw material. A first catalyst prepared by the method simultaneously has macropore and micropore structures, wherein the macropores can obviously improve the mass transfer effect; and the micropores can obviously improve the specific surface area of a carrier and simultaneously improve the dispersity of active centers. Meanwhile, the prepared first catalyst simultaneously has an alkali active center and a Lewis acid catalytic active center. The prepared 15%MgO-5%MgCl2-2%La2O3 / Al2O3-SiO2 is used in a dimethyl carbonate and ethanol ester exchange fixed bed continuous reaction; when the reaction temperature is 200 DEG C and the space velocity is 30h<-1>, the catalyst is not inactivated after 5000h of continuous reaction, the dimethyl carbonate conversion rate can be kept at 70%, the ethanol conversion rate can be kept at 80%, and the yield of the product ethyl methyl carbonate is 56%; and after the reaction, the catalyst can be reused through simple filtration treatment, and the activity of the catalyst can still be kept unchanged after the catalyst is reused for multiple times.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

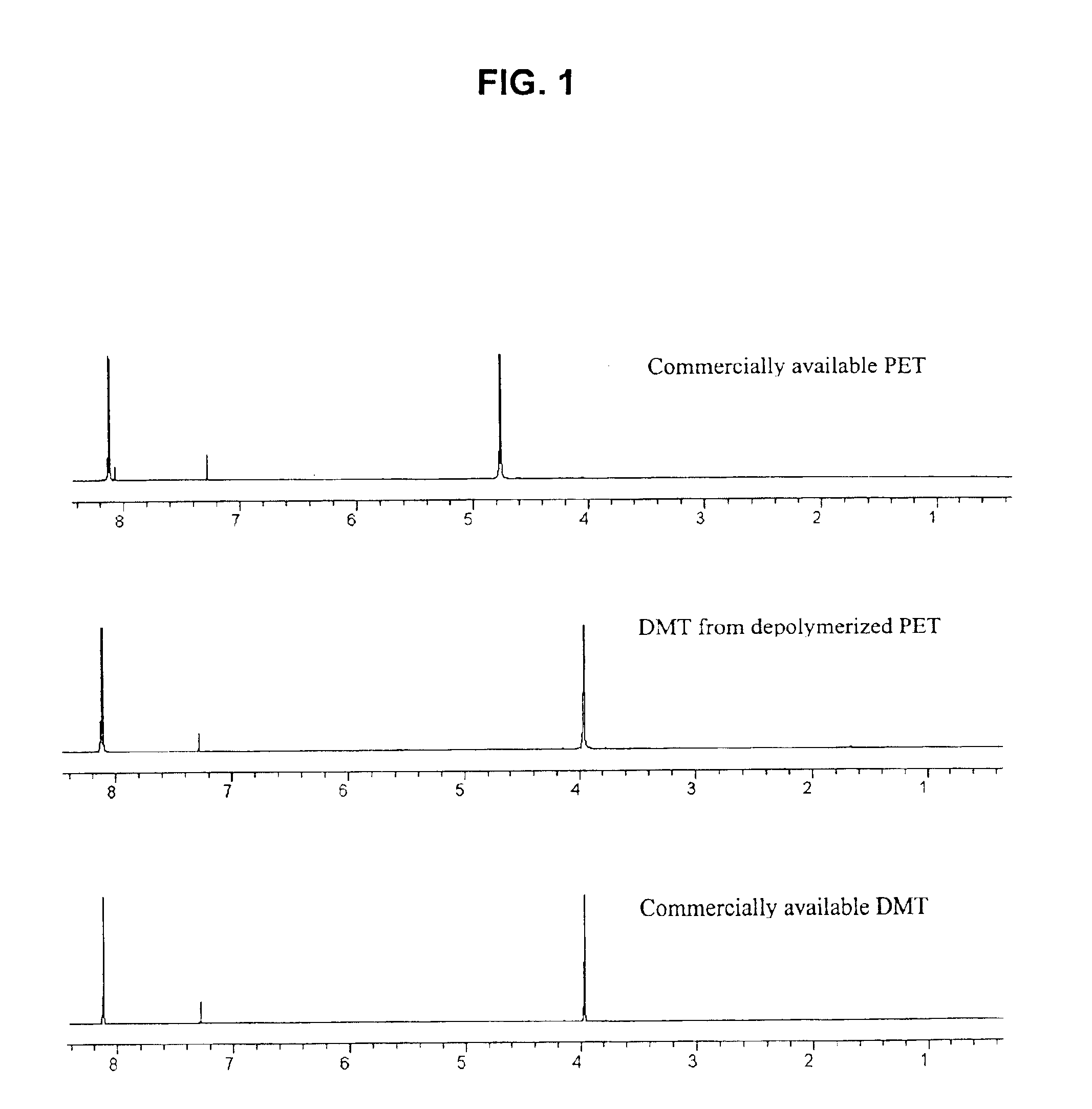

Catalytic depolymerization of polymers containing electrophilic linkages using nucleophilic reagents

InactiveUS6911546B2Minimize resultLightweight productionGroup 1/11 element organic compoundsOrganic compound preparationPolyesterDepolymerization

A method is provided for carrying out depolymerization of a polymer containing electrophilic linkages in the presence of a catalyst and a nucleophilic reagent, wherein production of undesirable byproducts resulting from polymer degradation is minimized. The reaction can be carried out at a temperature of 80° C. or less, and generally involves the use of an organic, nonmetallic catalyst, thereby ensuring that the depolymerization product(s) are substantially free of metal contaminants. In an exemplary depolymerization method, the catalyst is a carbene compound such as an N-heterocyclic carbene, or is a precursor to a carbene compound. The method provides an important alternative to current recycling techniques such as those used in the degradation of polyesters, polyamides, and the like.

Owner:IBM CORP +1

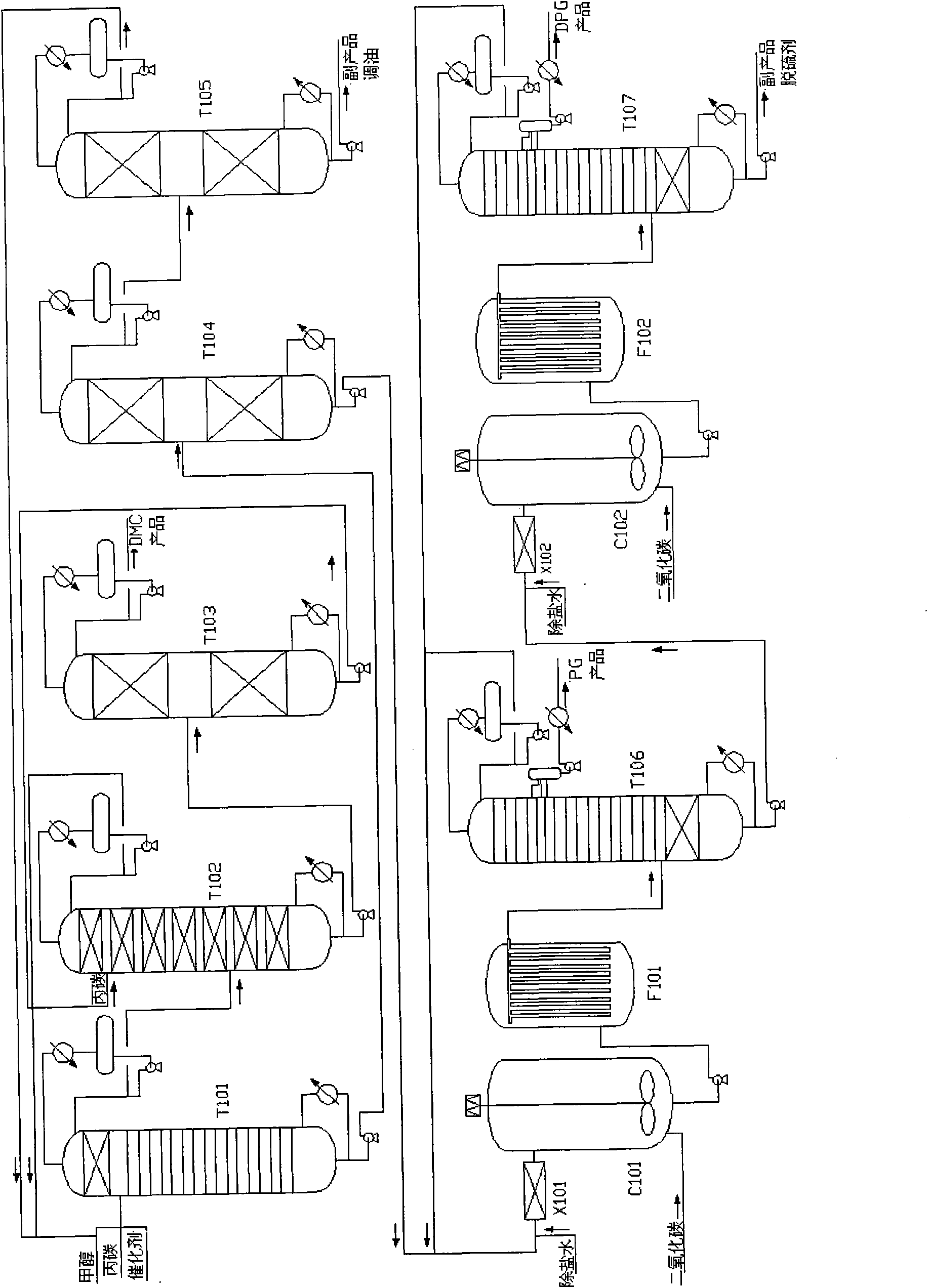

Novel technique for purifying high-quality propylene glycol in production process of dimethyl carbonate

ActiveCN101774888AHigh yieldSolve the emission problemChemical industryHydroxy compound separation/purificationFiltrationExtractive distillation

The invention relates to a technique for coproduction of dimethyl carbonate and propylene glycol, in particular to a novel technique for purifying high-quality propylene glycol in the production process of dimethyl carbonate. The technical scheme includes the steps of reactive distillation, extractive distillation, separation of the dimethyl carbonate, the recovery and refining of carbinol, primary carbonization, first filtration of sodium carbonate crystals and refining of the propylene glycol. The invention solves the problem of low recovery rate of the propylene glycol, and the recovery rate of the propylene glycol can be above 95%. Meanwhile, the propylene glycol has more stable quality, with the purity reaching 99.99% and the chroma less than 10, thereby the propylene glycol totally meets the requirements for medical auxiliary material, daily cosmetics, top grade unsaturated resin and polyether. Meanwhile, the purity of the byproduct dipropylene glycol can be above 99.50%, thus improving the benefit of the equipment.

Owner:DONGYING HI TECH SPRING CHEM IND

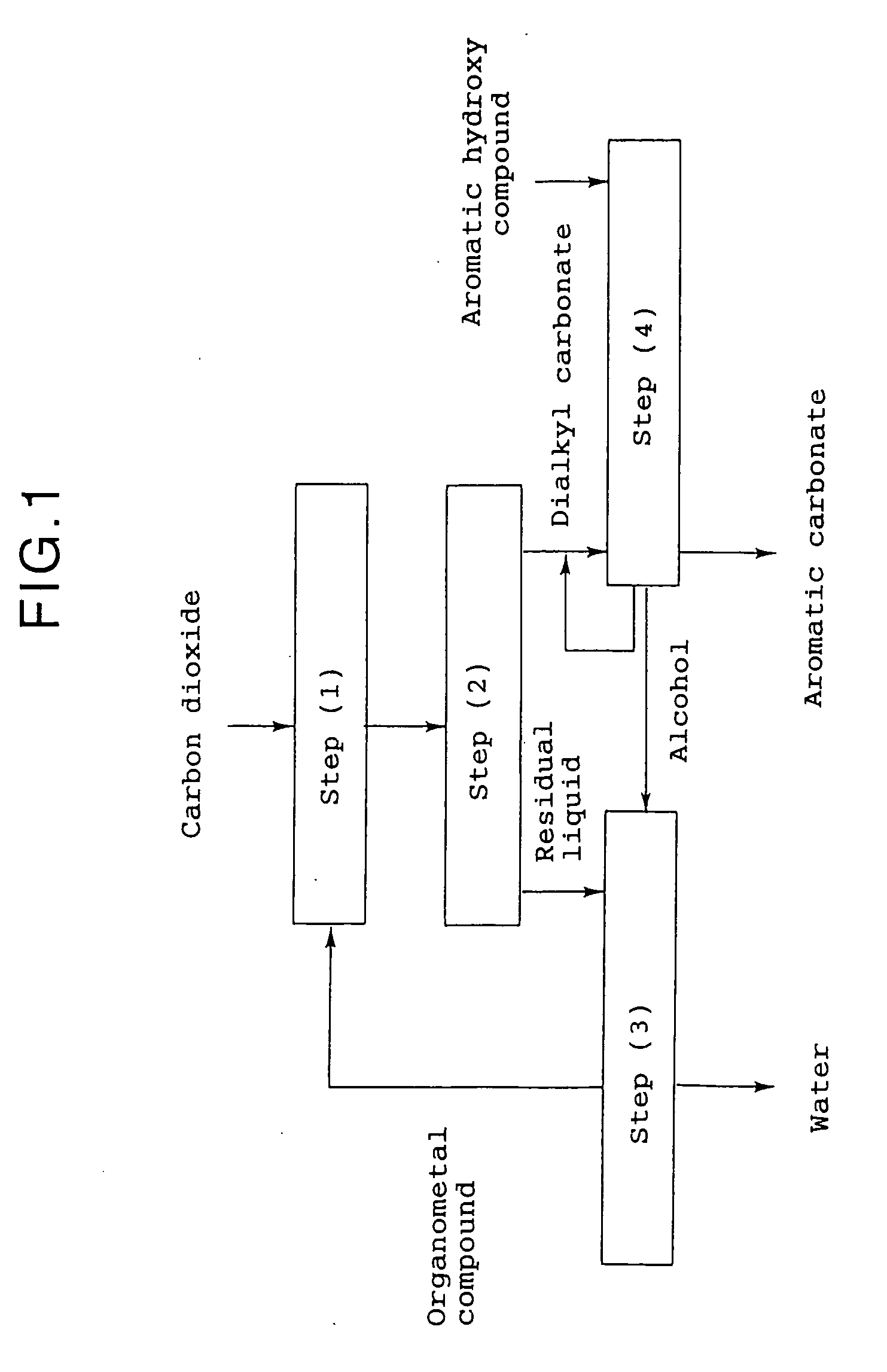

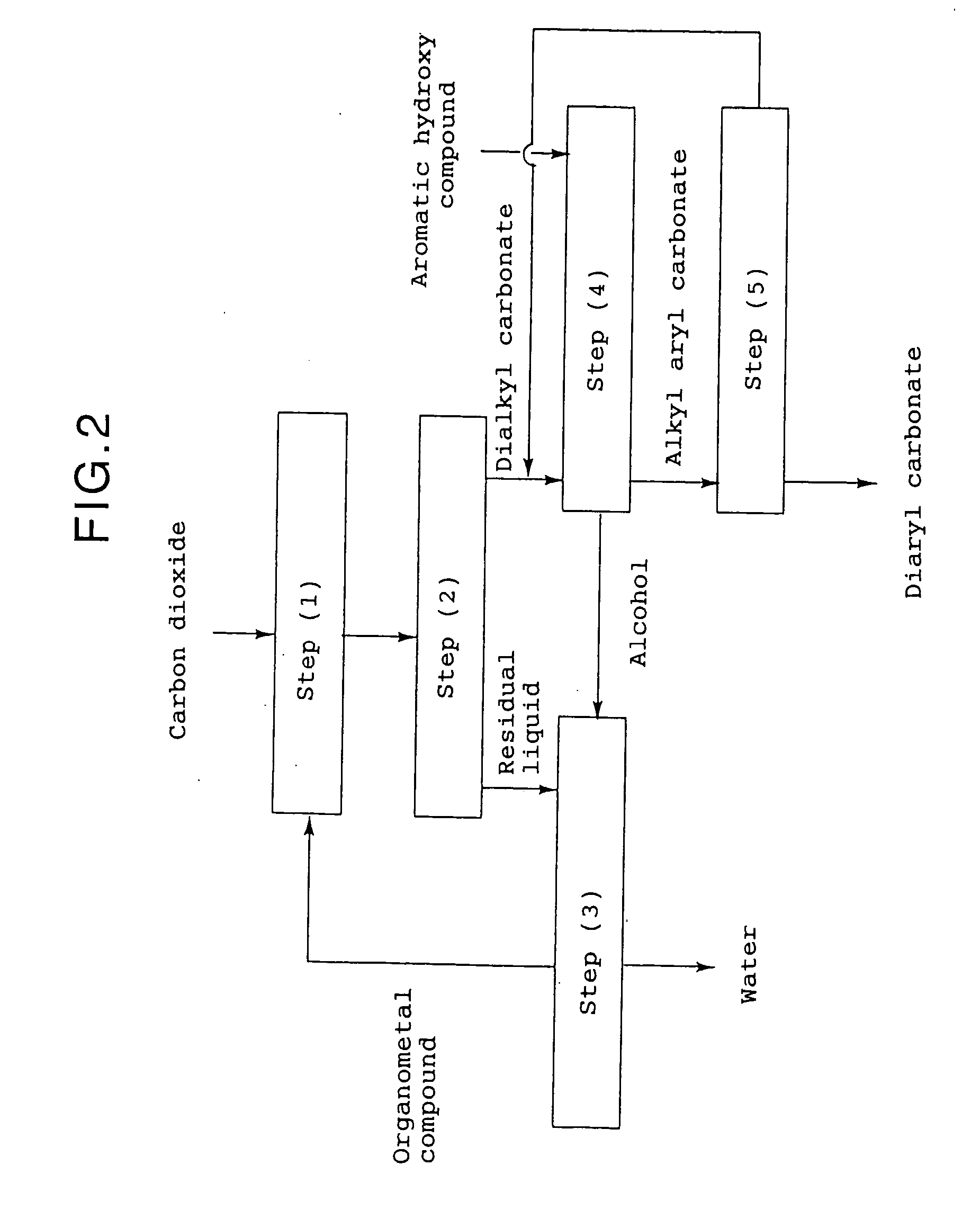

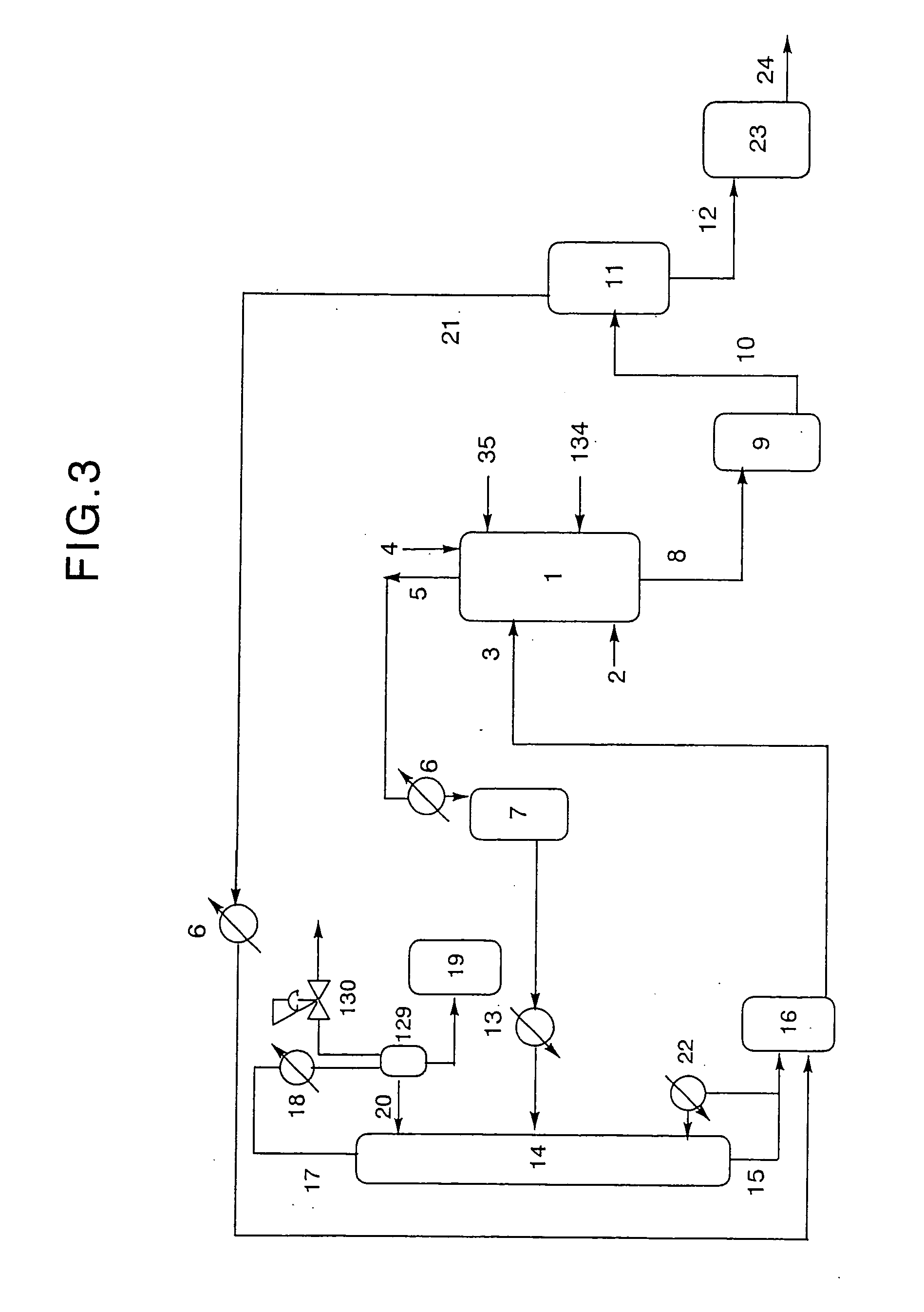

Method for producing an aromatic carbonate

ActiveUS20070055042A1Simple and efficient productionHigh purityPreparation from organic carbonatesPreparation from carbon dioxide or inorganic carbonatesAlcoholAromatic agent

A method for producing an aromatic carbonate, comprising: (1) performing a reaction between an organometal compound and carbon dioxide to obtain a reaction mixture containing a dialkyl carbonate formed by the reaction, (2) separating the dialkyl carbonate from the reaction mixture to obtain a residual liquid, (3) reacting the residual liquid with an alcohol to form at least one organometal compound and form water and removing the water from the organometal compound, and (4) reacting the dialkyl carbonate separated in step (2) with an aromatic hydroxy compound to obtain an aromatic carbonate.

Owner:ASAHI KASEI KK

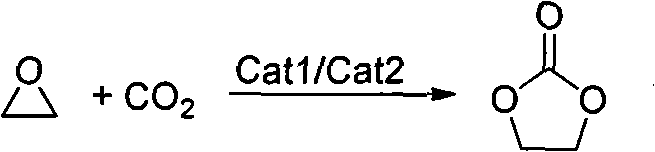

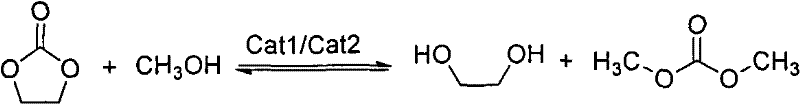

Catalytic method for preparing dimethyl cabonate along with ethylene glycol

ActiveCN102126956AOxygen-containing compound preparationOrganic compound preparationCatalytic methodEthylene oxide

The invention relates to a catalytic method for preparing dimethyl cabonate along with ethylene glycol. The invention is characterized in that ethylene oxide and carbon dioxide are used as raw materials to prepare ethylene carbonate under the catalysis of a composite catalyst; the composite catalyst and cyclic carbonate are not separated and are used to further catalyze the reaction of ethylene carbonate and methanol and prepare dimethyl cabonate and ethylene glycol. The synthesis method is characterized by high catalyst activity, low cost, long service life and the like.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

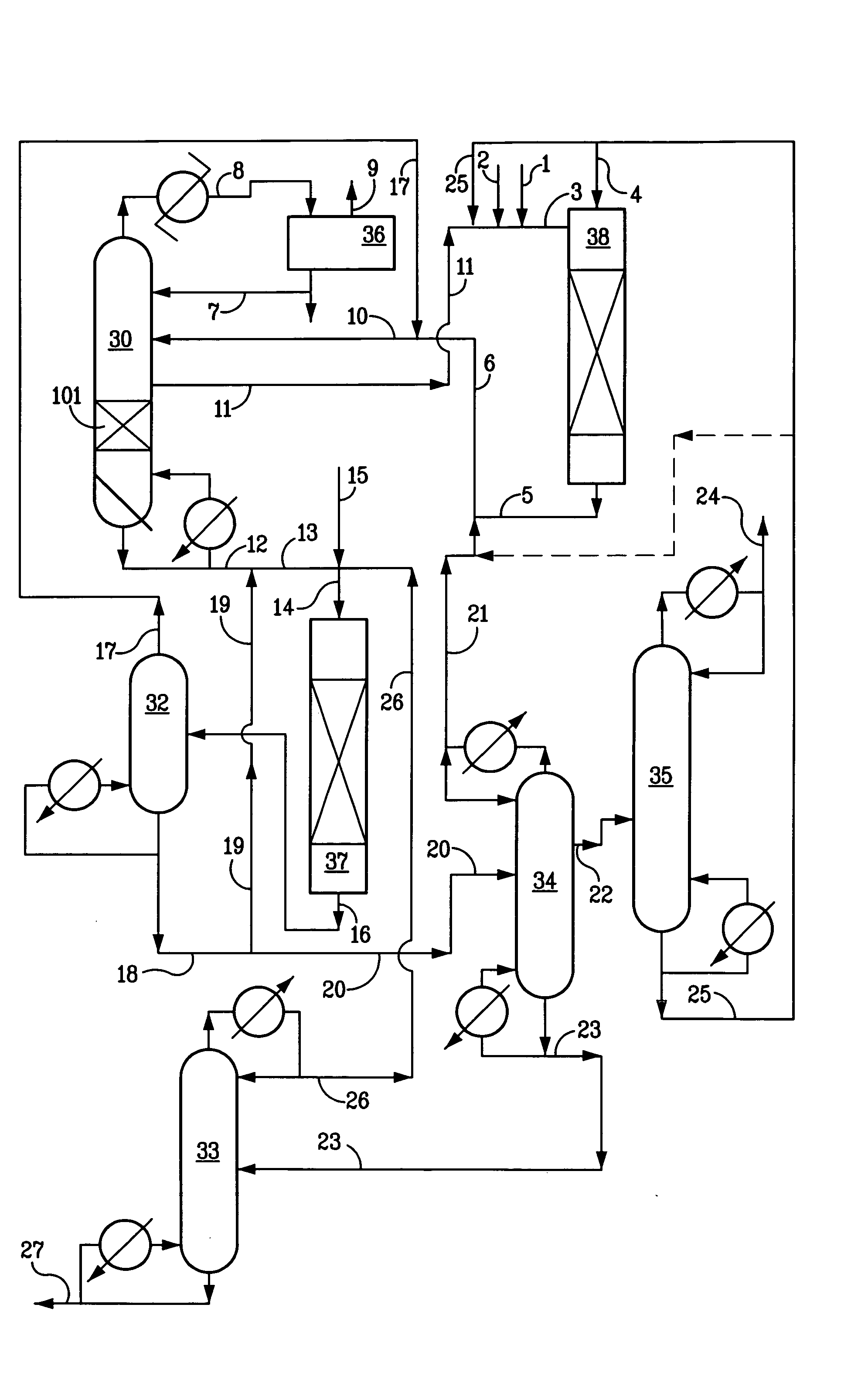

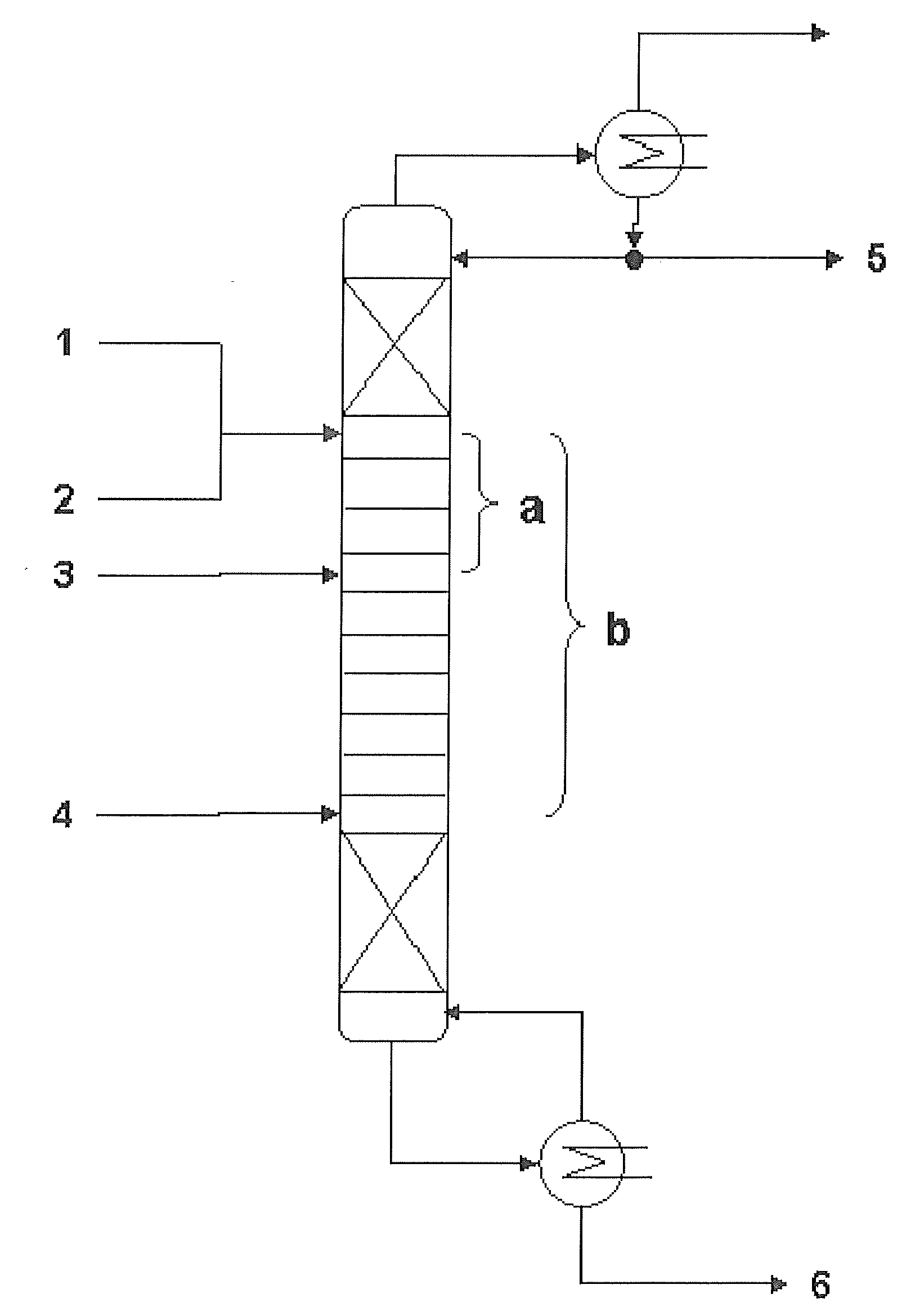

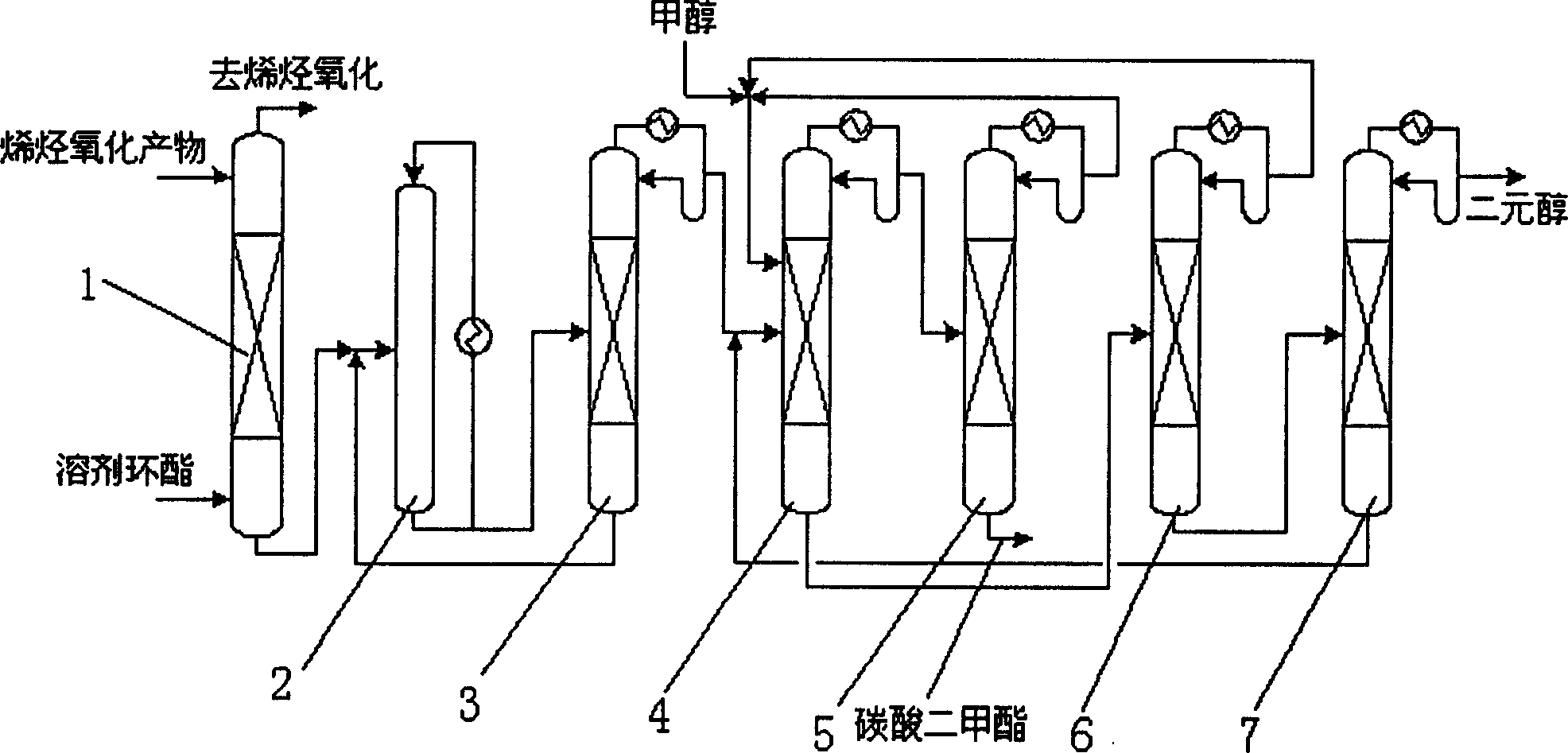

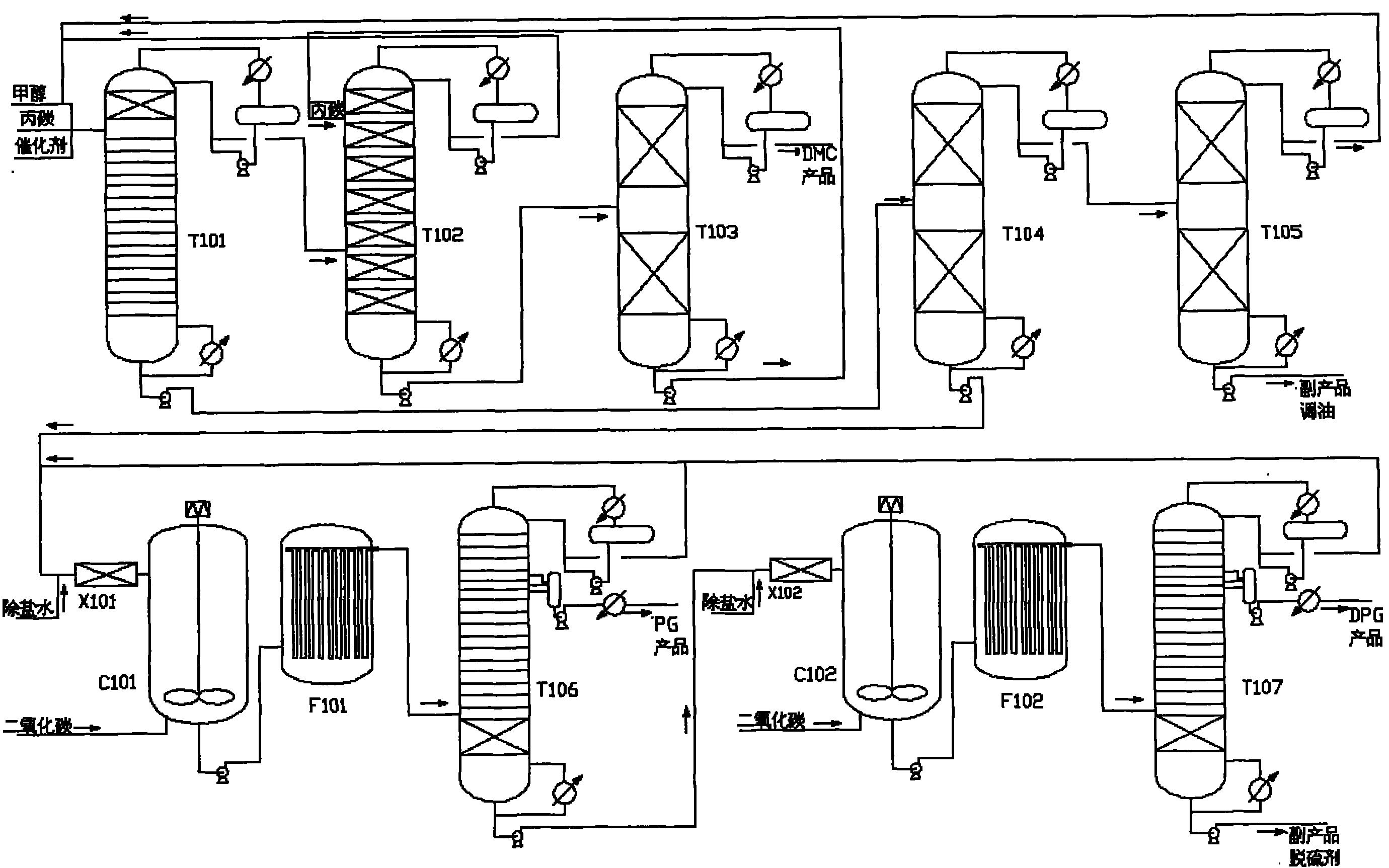

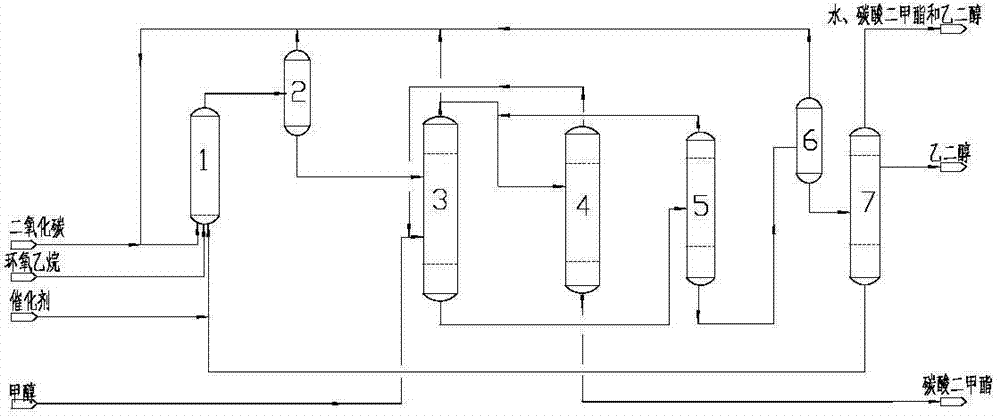

Dimethyl carbonate and ethylene glycol production process

ActiveCN104761429ALow conversion rate per passReduce energy consumptionOxygen-containing compound preparationOrganic compound preparationMethyl carbonateEthylene oxide

The invention relates to a dimethyl carbonate and ethylene glycol production process which is characterized in that the process comprises the following five steps: (a) the carbonylation step for production of ethylene carbonate by catalysis of reaction of ethylene oxide and carbon dioxide by use of an ionic liquid composite catalyst; (b) the step of alcoholysis for ester exchange reaction of the ionic liquid composite catalyst-containing ethylene carbonate solution of the step (a) and methanol in a reaction distillation tower and product separation; (c) the step of purification and refining of dimethyl carbonate from tower top condensate in the reaction distillation tower of the step (b); (d) the step of separation, transformation and refining of ethylene glycol from tower bottom liquid in the reaction distillation tower of the step (b); and (e) the step of circulation cycle of from the ionic liquid composite catalyst in the step (d) to the catalyst in the step (a). The process has the characteristics of high ethylene carbonate one-way conversion rate, simple process flow, small equipment investment, less waste emissions, low energy consumption and the like, and can make companies stronger in competitiveness.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Process for co-production of dialkyl carbonate and alkanediol

InactiveUS6166240AHigh catalytic activityHigh selectivityOrganic compound preparationPreparation from organic carbonatesCarbonateMetal

Owner:BADGE LICENSING LLC

Method for preparing carbonic acid glyceride by catalytic reaction-azeotropic reification coupling

InactiveCN101717338AEasy to recycleAchieve recyclingPreparation from organic carbonatesMethyl carbonateGlycerol

The invention discloses a method for preparing carbonic acid glyceride by catalytic reaction-azeotropic reification coupling, and belongs to the technical field of fine chemistry. In the method, the catalytic reaction and the azeotropic rectification are finished in the same rectification tower; glycerol, dimethyl carbonate, a solid base catalyst and an azeotropic agent are added into a tower; the tower is heated while the raw materials are stirred; the tower operation temperature is between 60 and 120 DEG C; the tower top operation temperature is between 50 and 80 DEG C; a mixture of methanol and the azeotropic agent is taken out of the top of the tower in a reflux ratio of 2 to 6; the reaction time is 0.1 to 3 hours; the operational pressure of the top of the rectification tower is the normal pressure; the mol ratio of the dimethyl carbonate to the glycerol is 1-1.5:1; the reaction products in the tower are subjected to vacuum evaporation to remove the azeotropic agent and filtered to remove the catalyst; and finally the carbonic acid glyceride is obtained. The solid base catalyst in the method has the advantages of low in price, convenient recovery, and cyclically used. Due to the lower mol ratio of the methyl carbonate to the glycerol, the consumption of the methyl carbonate is lowered. The process for purifying the carbonic acid glycerol products is simple.

Owner:TSINGHUA UNIV

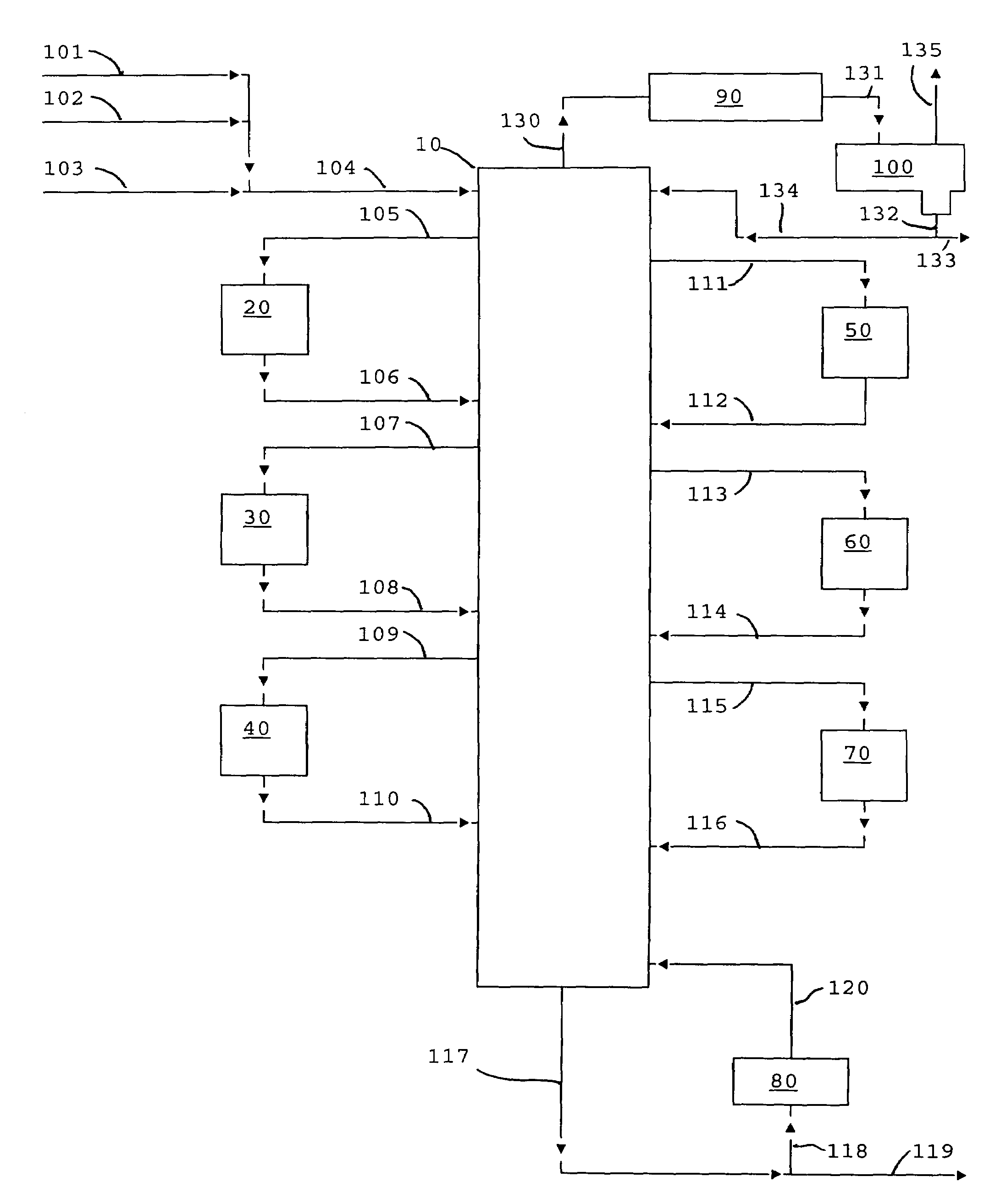

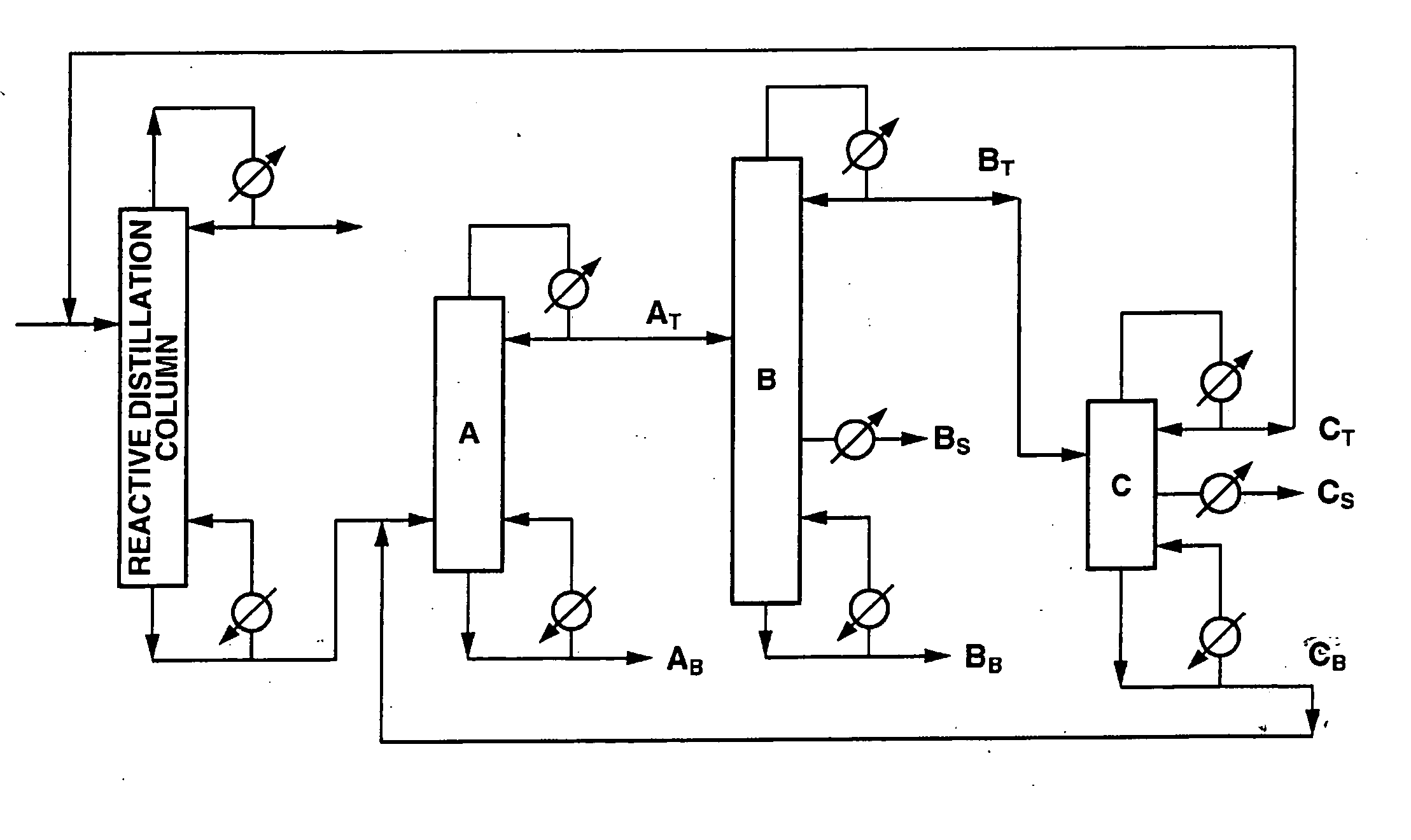

Process for Production of High-Purity Diaryl Carbonate

ActiveUS20070270604A1Stable productionChemical recyclingPreparation from organic carbonatesArylBoiling point

It is an object of the present invention to provide a specific industrially useful process that enables a high-purity diaryl carbonate having low contents of intermediate boiling point and high boiling point impurities as required for producing a high-quality and high-performance polycarbonate to be produced stably for a prolonged period of time using as a starting material a reaction mixture containing an alkyl aryl carbonate obtained through a transesterification reaction between a dialkyl carbonate and an aromatic monohydroxy compound. There have been various proposals regarding processes for the production of reaction mixtures containing aromatic carbonates by means of a reactive distillation method. The present inventors have now carried out studies aimed at discovering a specific process enabling a high-purity diaryl carbonate that can be used as a raw material of a high-quality and high-performance polycarbonate to be continuously produced stably for a prolonged period of time from such a reaction mixture. As a result, the present inventors have reached to the present invention after discovering that the above object can be attained through a process in which separation by distillation is carried out using three distillation columns in a specified order. Moreover, the present inventors have discovered that it is particularly preferable if a reactive distillation column and the three distillation columns, each of which has a specified structure, and the three distillation columns are each operated under specified distillation conditions.

Owner:ASAHI KASEI KK

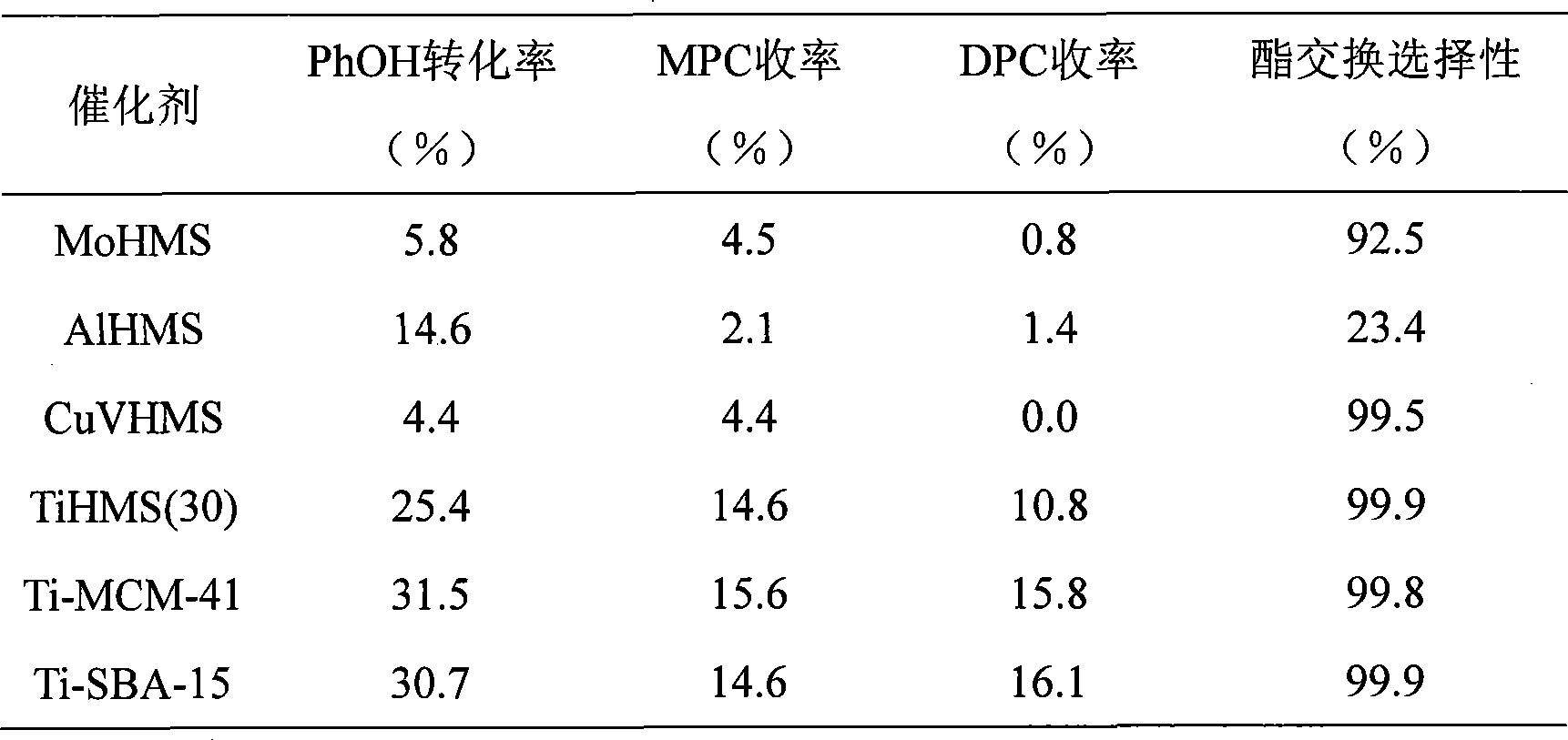

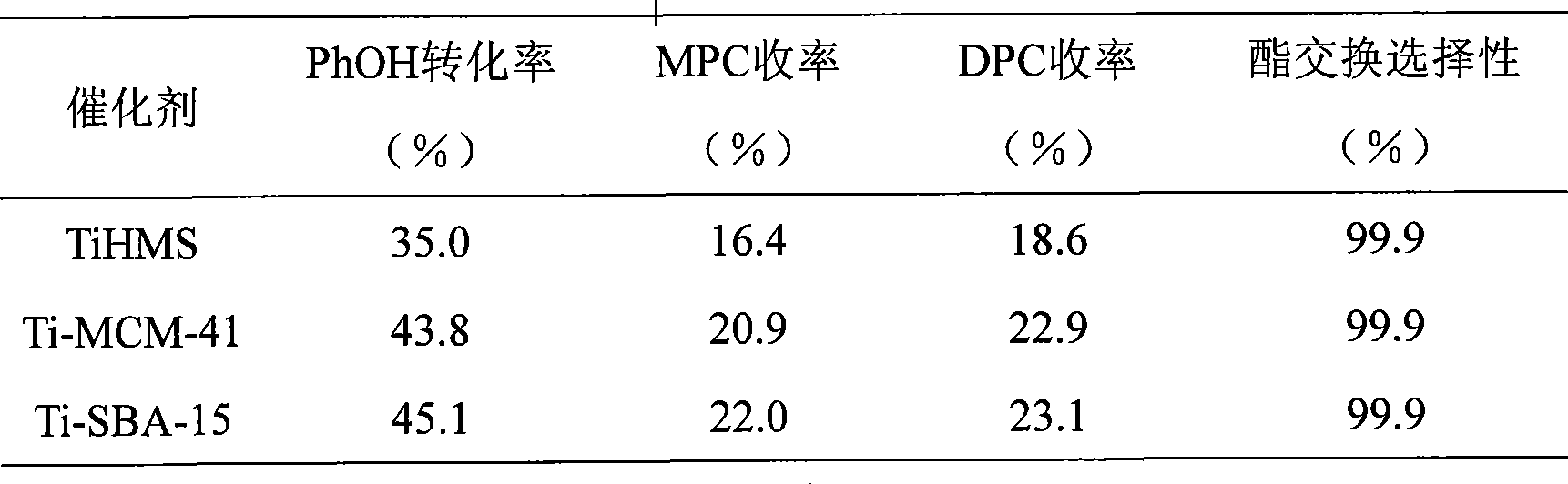

Method for synthesizing diphenyl carbonate by heterogeneous interesterification

InactiveCN101412674AHigh activityHigh selectivityMolecular sieve catalystsChemical recyclingMolecular sieveMethyl carbonate

The invention discloses a method for synthesizing diphenyl carbonate by heterogeneous ester interchange. The method uses methyl carbonate and phenol as raw materials and hetero-atom mesoporous molecular sieve as a heterogeneous catalyst to synthesize the diphenyl carbonate through ester interchange. The method mainly solves the problems of difficult separation and recycling of the catalyst, low yield of the diphenyl carbonate, and the like. The hetero-atom mesoporous molecular sieve as the catalyst can be prepared through a direct synthesis method, and can also be prepared through a post synthesis method. The ester interchange product of the method has high yield and good selectivity, wherein the yield reaches 45.1 percent and the selectivity reaches 99.9 percent; and particularly the molecular sieve catalyst used by the method has the advantages of no pollution to environment, no corrosion to equipment, easy separation and recycling, and the like, and can be widely applied to production of the diphenyl carbonate.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

Solid basic catalyst, preparation method of solid basic catalyst and application of solid basic catalyst in ester exchange reaction

InactiveCN102698811AImprove stabilityImprove catalytic performanceOrganic-compounds/hydrides/coordination-complexes catalystsPreparation from organic carbonatesOrganic baseSilicon oxide

The invention discloses a solid basic catalyst, a preparation method of the solid basic catalyst and an application of the solid basic catalyst in ester exchange reaction. The solid basic catalyst catalyzes the ester exchange reaction by the reaction of metal organic compound and hydroxyl on a carrier under the moderate conditions to synthesize dimethyl carbonate. The solid basic catalyst provided by the invention consists of metal organic alkali and the carrier. The metal organic alkali is linked to the carrier in bond-forming manner; the metal organic alkali is one or more of lithium methoxide, lithium ethoxide, lithium isopropoxide, lithium n-butoxide, lithium tert-butoxide, sodium methoxide, sodium ethoxide, sodium isopropoxide, sodium n-butoxide, sodium tert-butoxide, potassium methoxide, potassium ethoxide, potassium isopropoxide, potassium n-butoxide and potassium tert-butoxide; the carrier is one or more of silicon oxide, aluminium oxide, titanium oxide, zirconia, mesoporous silicon oxide synthesized by the template method, mesoporous aluminium oxide synthesized by the template method, mesoporous titanium oxide synthesized by the template method, and mesoporous zirconia synthesized by the template method.

Owner:NANJING UNIV OF TECH

Popular searches

Preparation by alcoholysis Carboxylic acid esters preparation Sulfonic acid esters preparation Phosphorus organic compounds Photomechanical exposure apparatus Microlithography exposure apparatus Ether preparation Distillation separation Carbonic/haloformic acid esters purification/separation Liquid hydrocarbon mixture production

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com