Method for synthesizing methylethyl carbonate

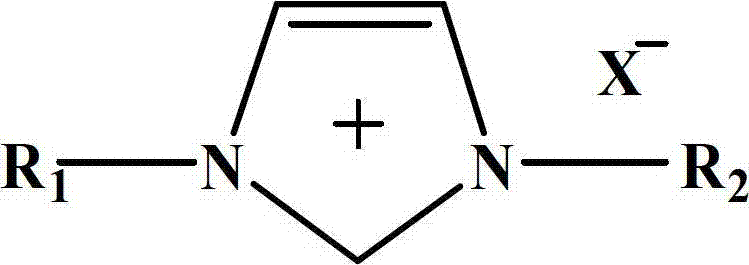

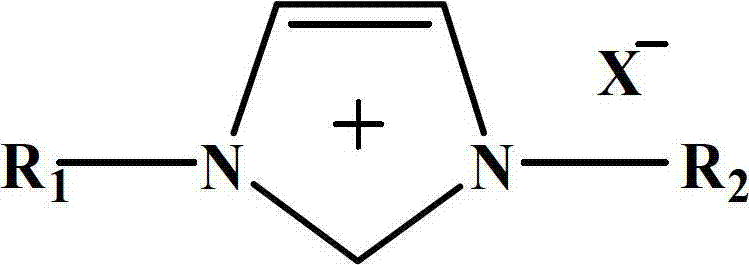

A technology of ethyl methyl carbonate and dimethyl carbonate, which is applied in the field of synthesizing ethyl methyl carbonate using ionic liquid as a catalyst, can solve the problems that the catalyst is not easy to recycle, the product yield is not high, the selectivity is not good, etc., and the service life is reached Long-term, no pollution, high catalytic activity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add reaction material dimethyl carbonate and ethanol in the reactor, its molar ratio is 1:1, 1-ethyl-3-ethylimidazolium bromide is used as catalyst, and the amount of catalyst used is the mass of reactant dimethyl carbonate 1%, the reaction temperature is 50°C, and the reaction time is 10h. Under these reaction conditions, the yield of ethyl methyl carbonate is 32.41%, and the selectivity is 74.98%.

Embodiment 2

[0023] Add reaction material dimethyl carbonate and ethanol in the reactor, its molar ratio is 3:1, 1-methyl-3-methylimidazolium chloride salt is used as catalyst, and the amount of catalyst used is the mass of reactant dimethyl carbonate 0.5%, the reaction temperature is 150°C, and the reaction time is 6h. Under these conditions, the yield of ethyl methyl carbonate is 41.27%, and the selectivity is 82.19%.

Embodiment 3

[0025] Add the reaction material dimethyl carbonate and ethanol in the reactor, the molar ratio is 1:1, 1-butyl-3-butylimidazolium hexafluorophosphate is used as the catalyst, and the amount of the catalyst used is the mass of the reactant dimethyl carbonate 1% of 1%, the reaction temperature is 80 ℃, and the reaction time is 10h. Under these reaction conditions, the yield of ethyl methyl carbonate is 12.24%, and the selectivity is 80.35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com