Patents

Literature

260results about How to "Reduce enzyme activity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

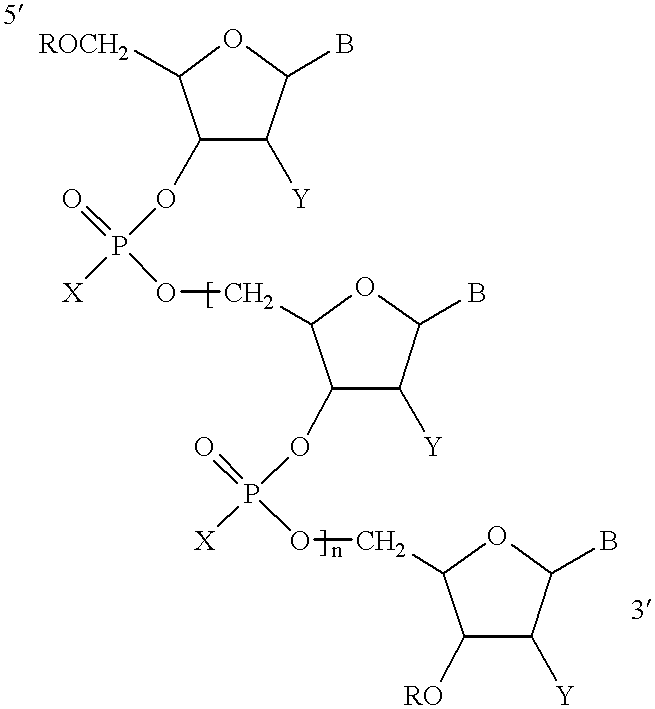

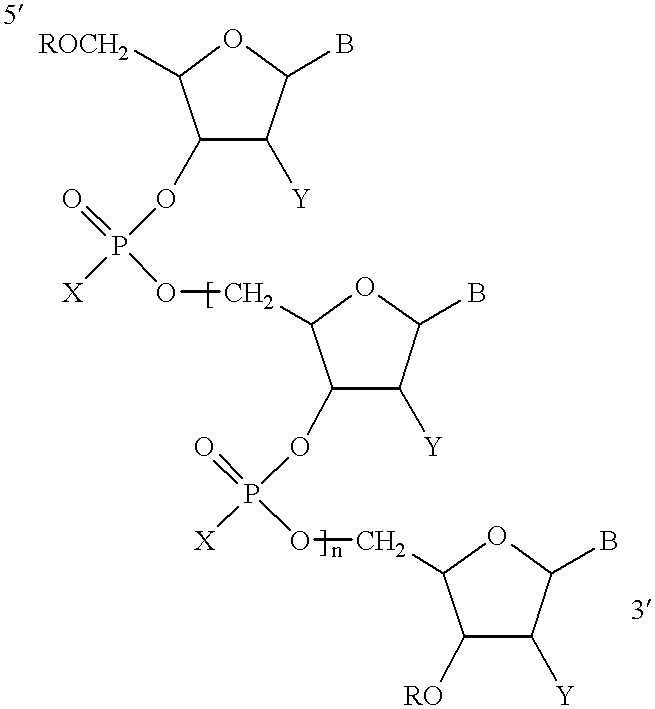

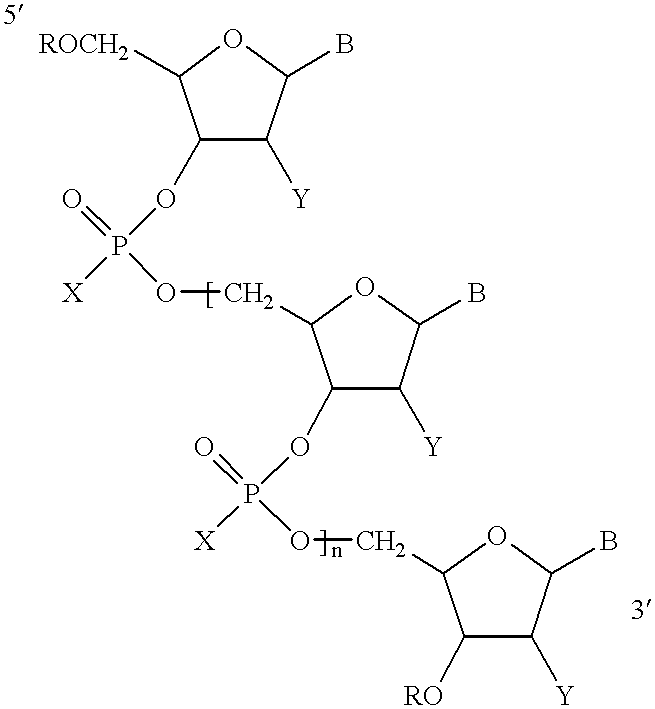

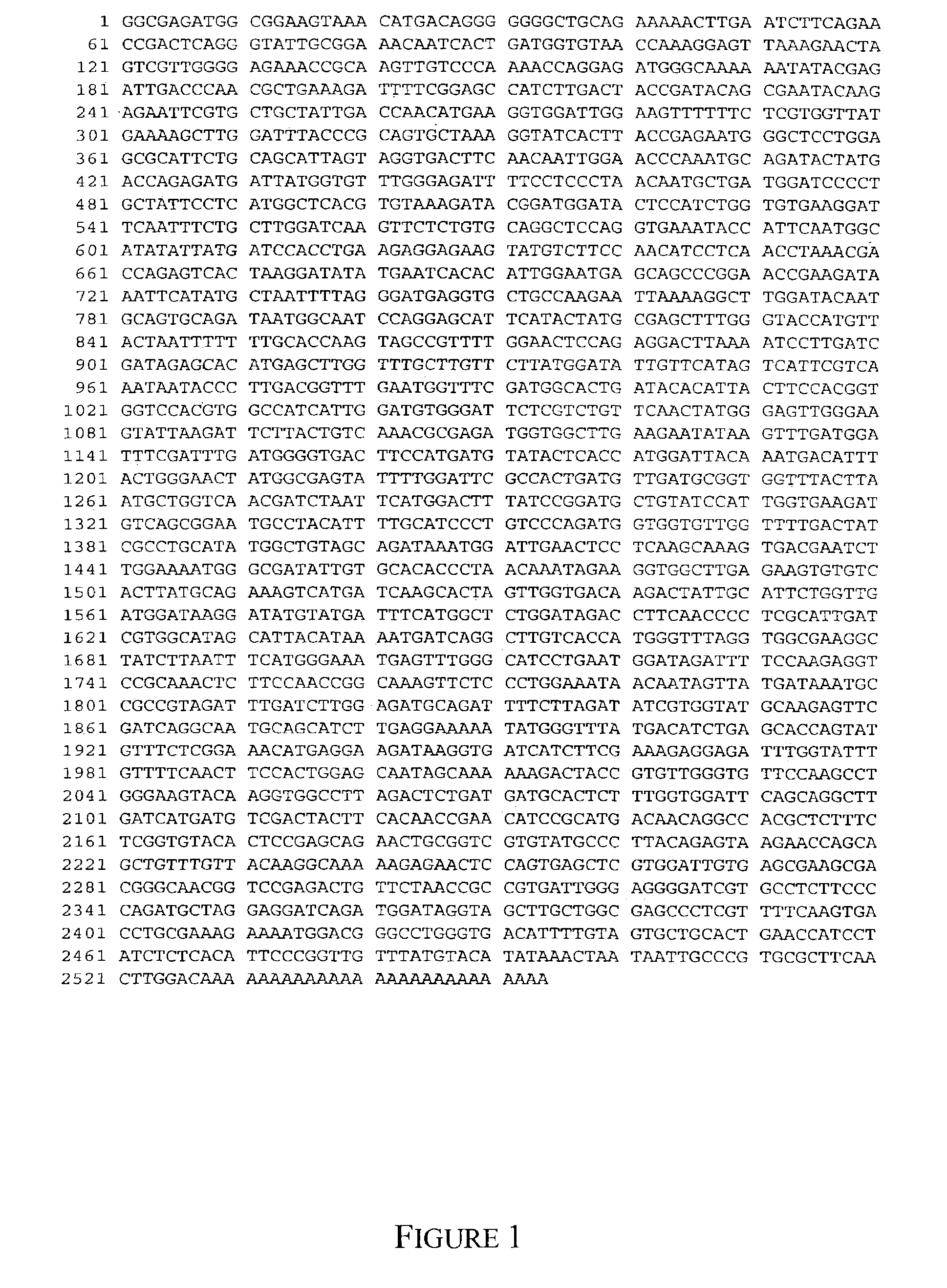

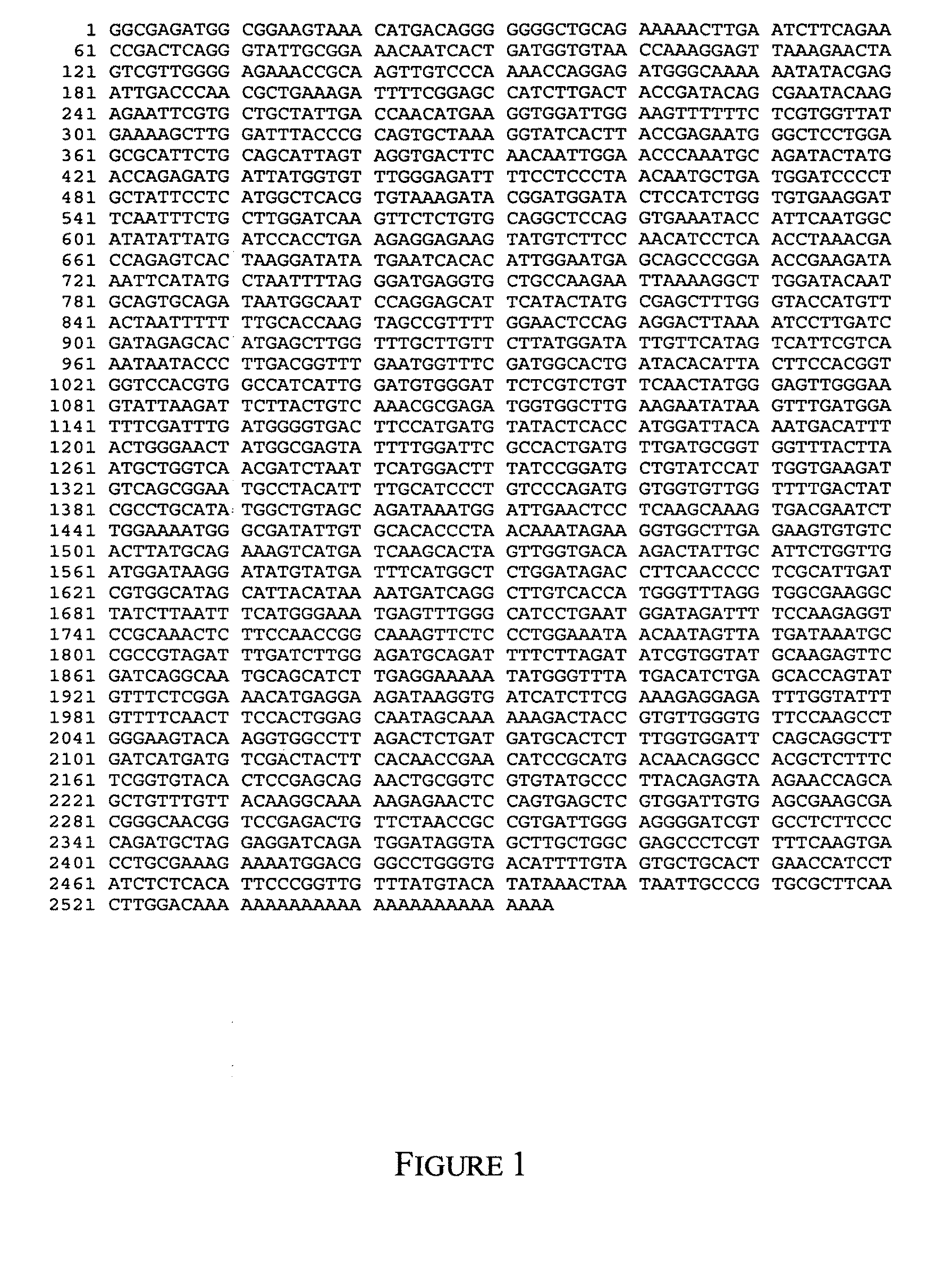

Antisense oligonucleotide compositions targeted to angiotensin converting enzyme MRNA and methods of use

InactiveUS6248724B1Zero mismatchReduce enzyme activityBiocideNanotechAngiotensin-converting enzymeDisease

Antisense oligonucleotides specific for mammalian ACE mRNA have been identified. Administration of these oligonucleotides to animals resulted in a decrease in blood pressure, but no significant change in heart rate. Methods for discovering other oligonucleotides with the same activity are taught, as are uses of the antisense molecules for treatment of human and animal diseases.

Owner:FLORIDA UNIV OF A FLORIDA +1

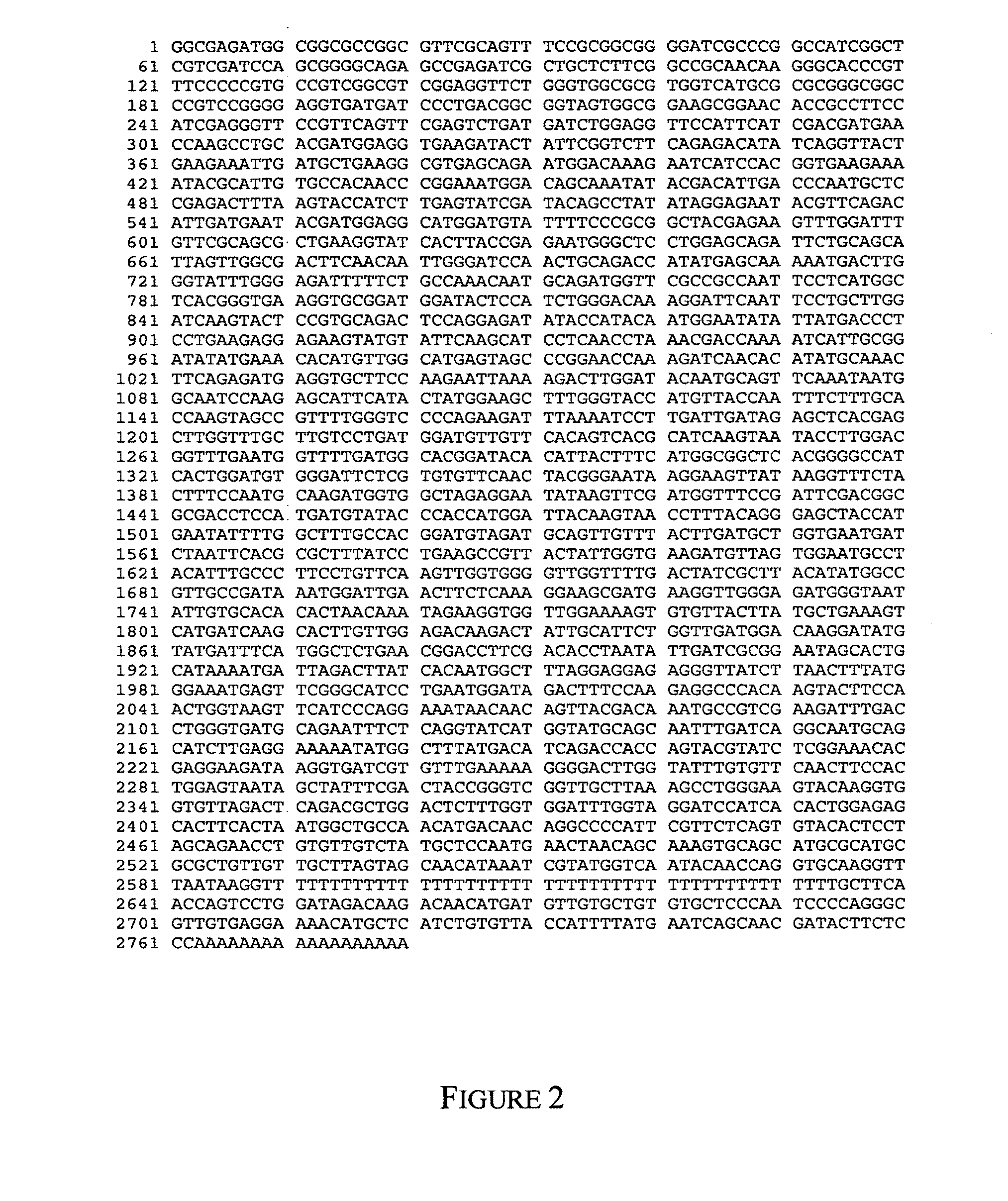

Barley with altered branching enzyme activity and starch and starch containing products with an increased amylose content

ActiveUS7521593B2Lower Level RequirementsReduced activitySugar derivativesTransferasesHordeum vulgareStarch synthesis

Barley having a reduced level of SBEIIa activity produces grain having a high relative amylose content. The barley might additionally have reduced levels of SBEIIb activity. The barley grain of this invention can be of a non-shrunken phenotype despite a lesion in the amylopectin synthesis pathway.

Owner:COMMONWEALTH SCI & IND RES ORG

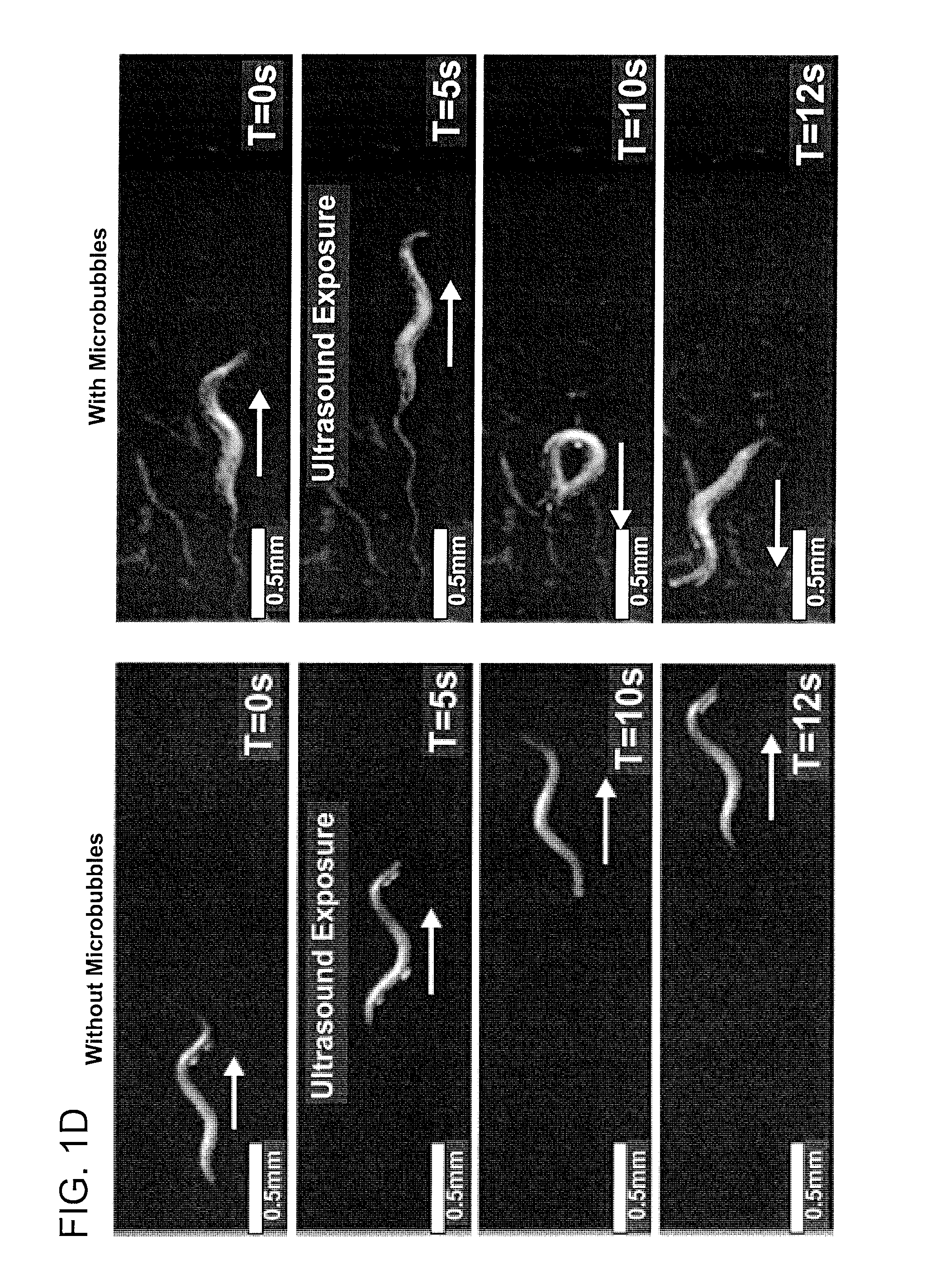

Sonogenic Stimulation of Cells

ActiveUS20160220672A1Reduce enzyme activityAvoid delayUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyCell typeBiological activation

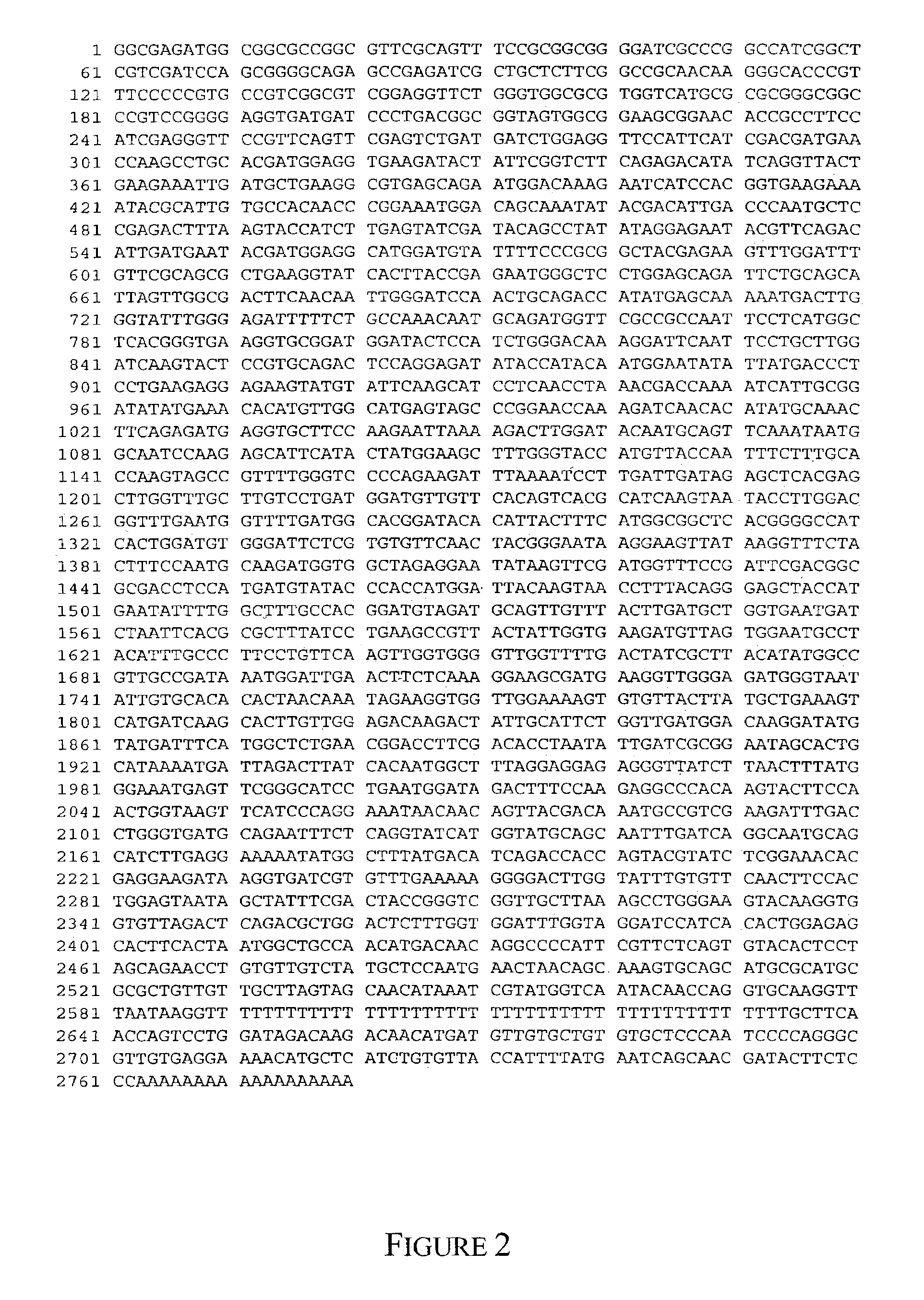

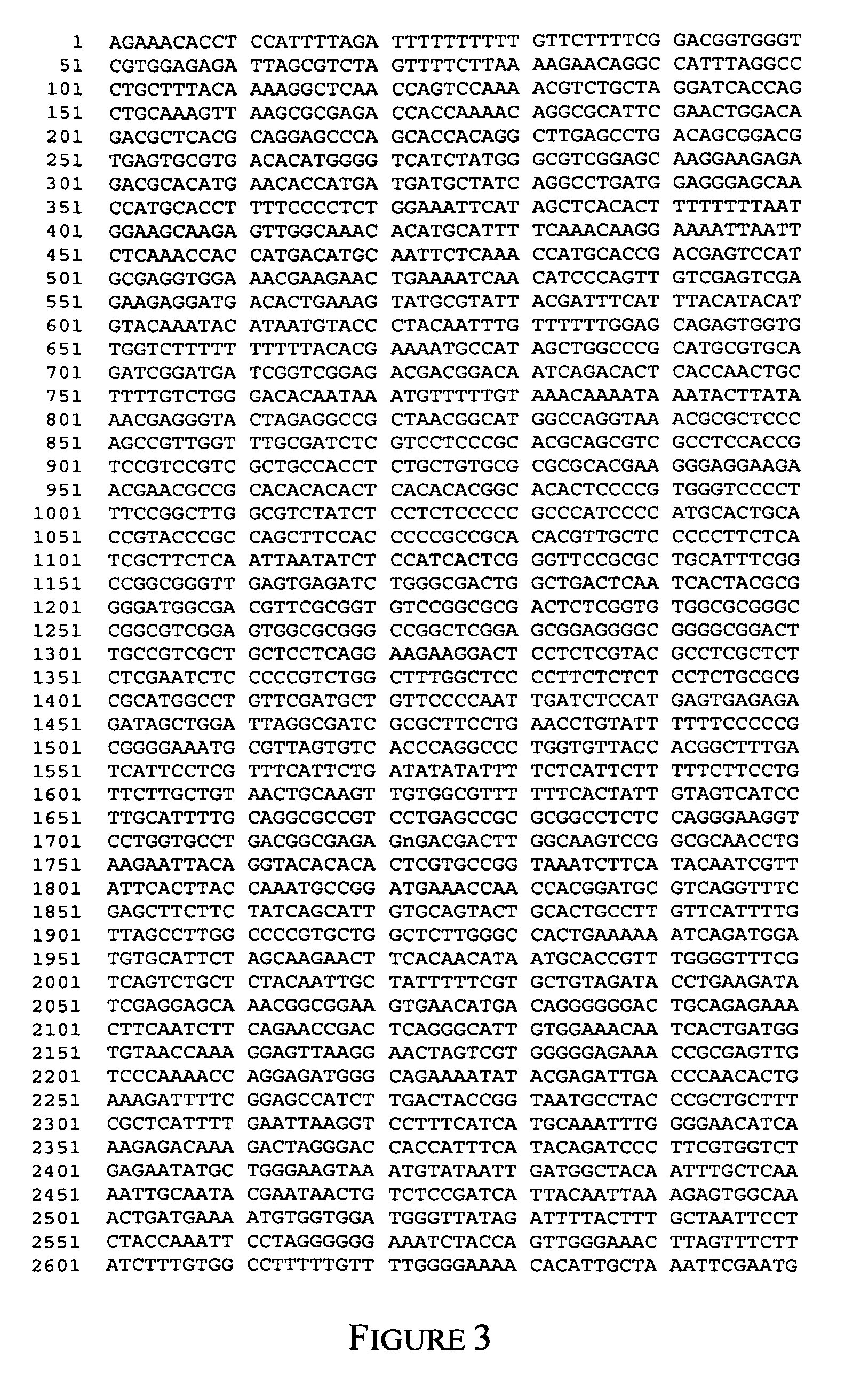

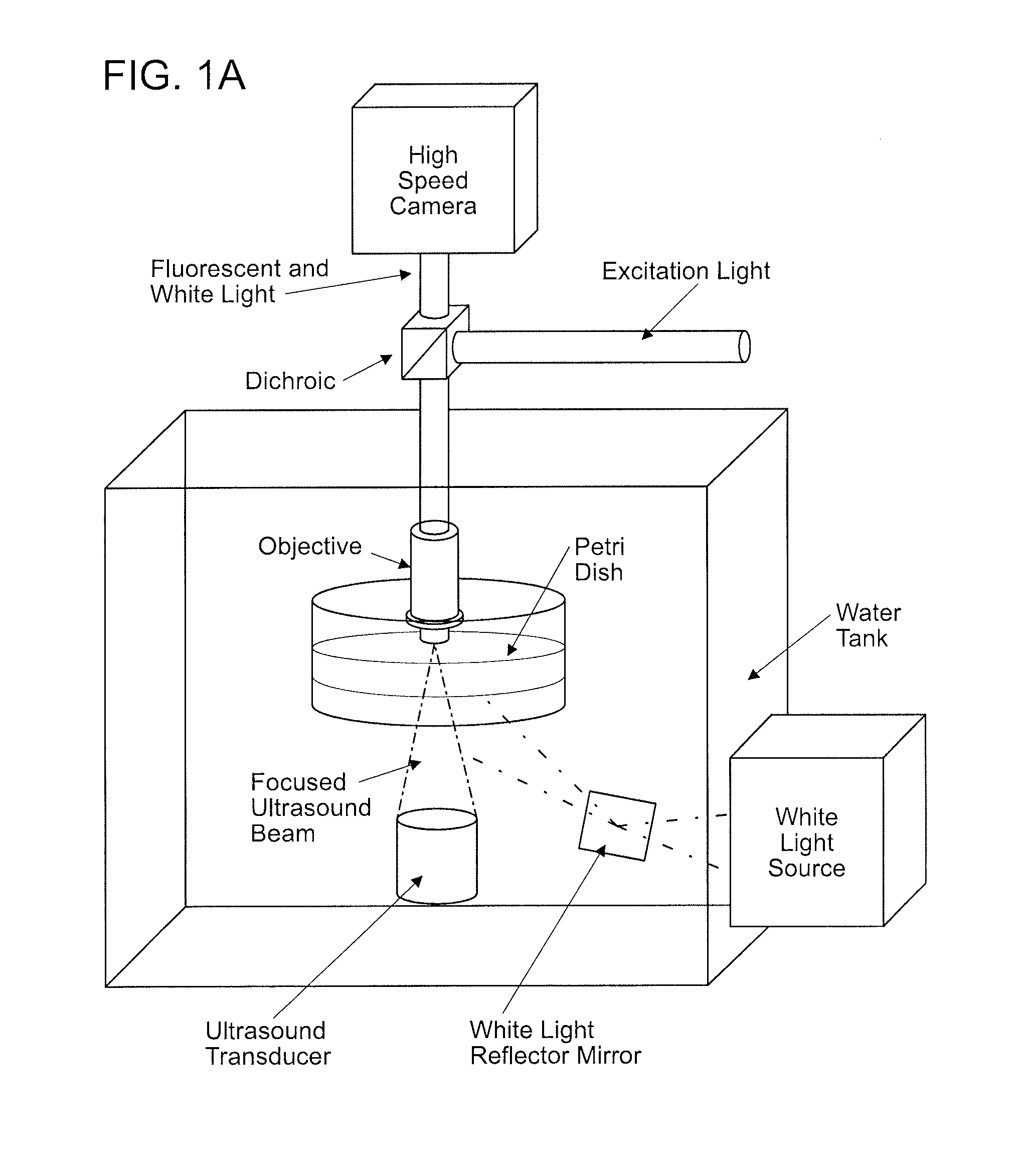

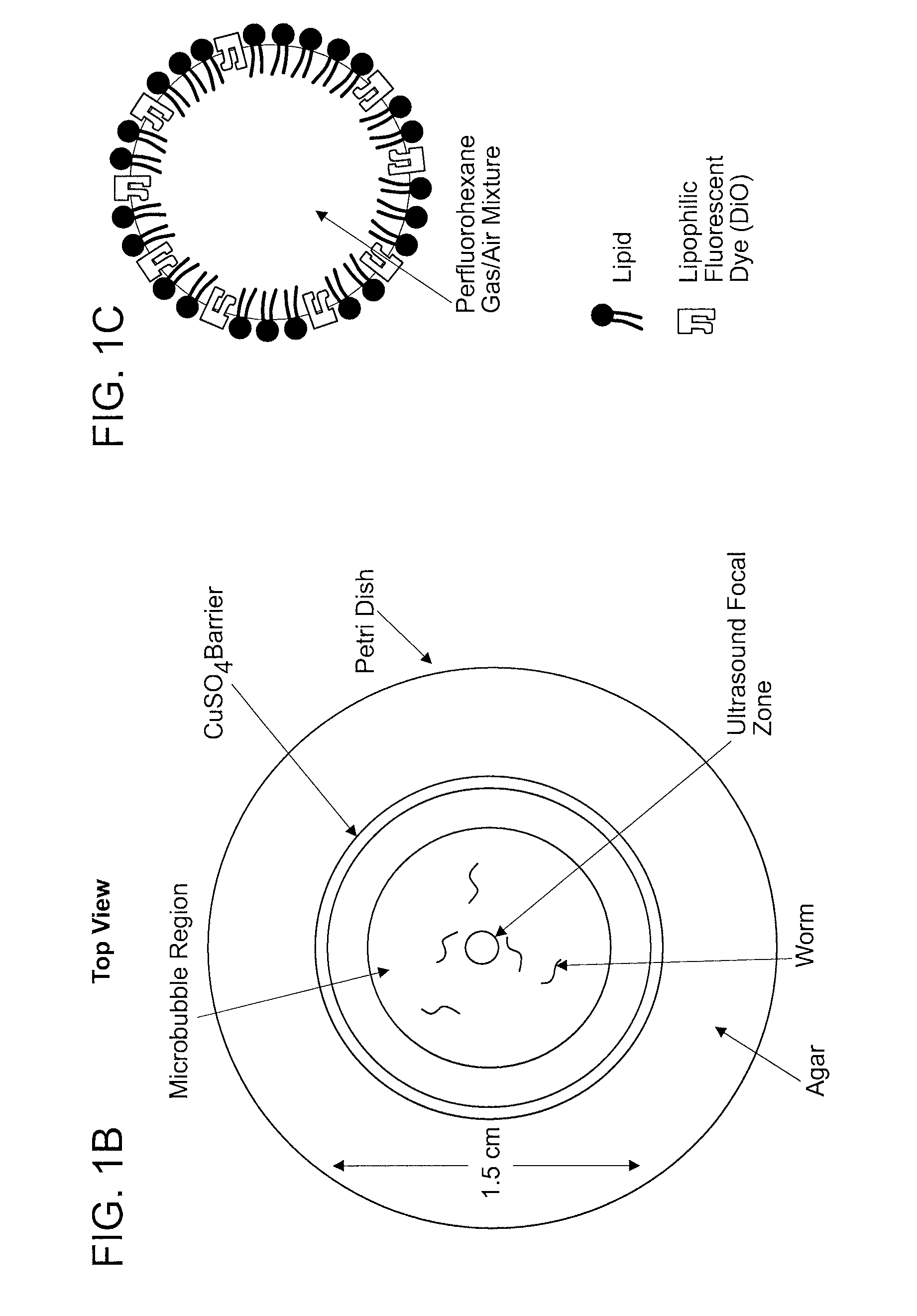

The invention provides compositions featuring TRP-4 polypeptides and polynucleotides, methods for expressing such polypeptides and polynucleotides in a cell type of interest, and methods for inducing the activation of the TRP-4 polypeptide in neurons and other cell types using ultrasound.

Owner:SALK INST FOR BIOLOGICAL STUDIES

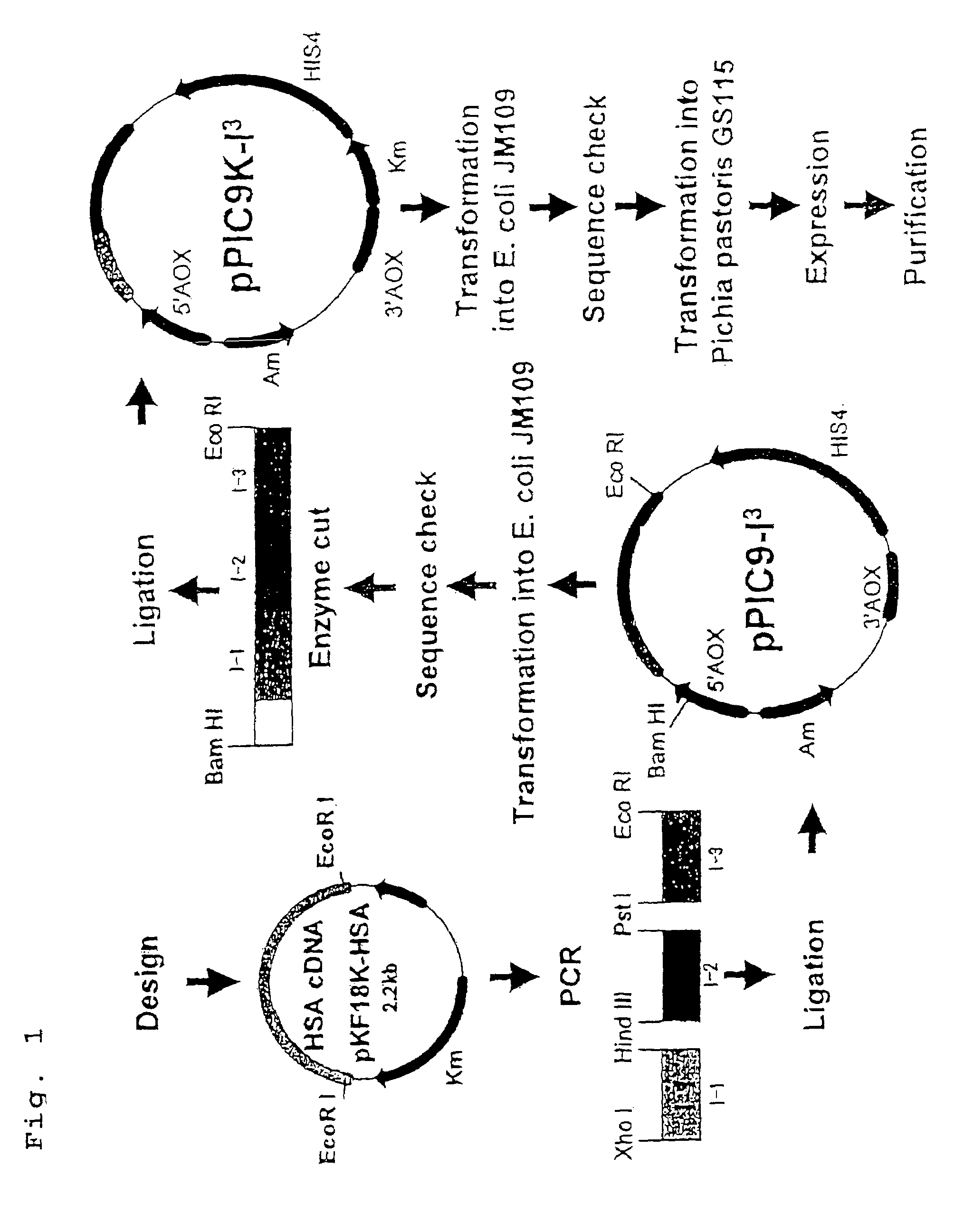

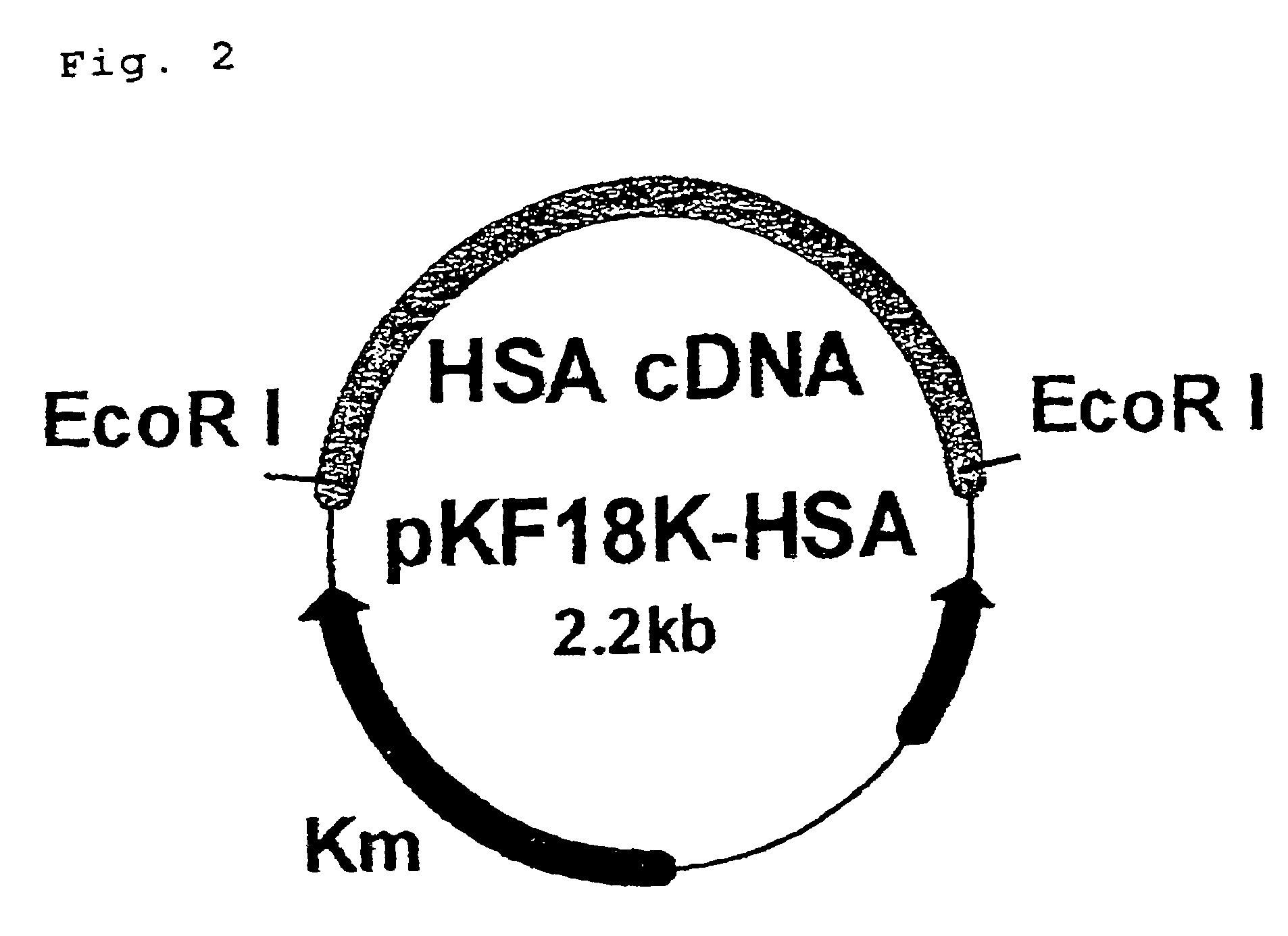

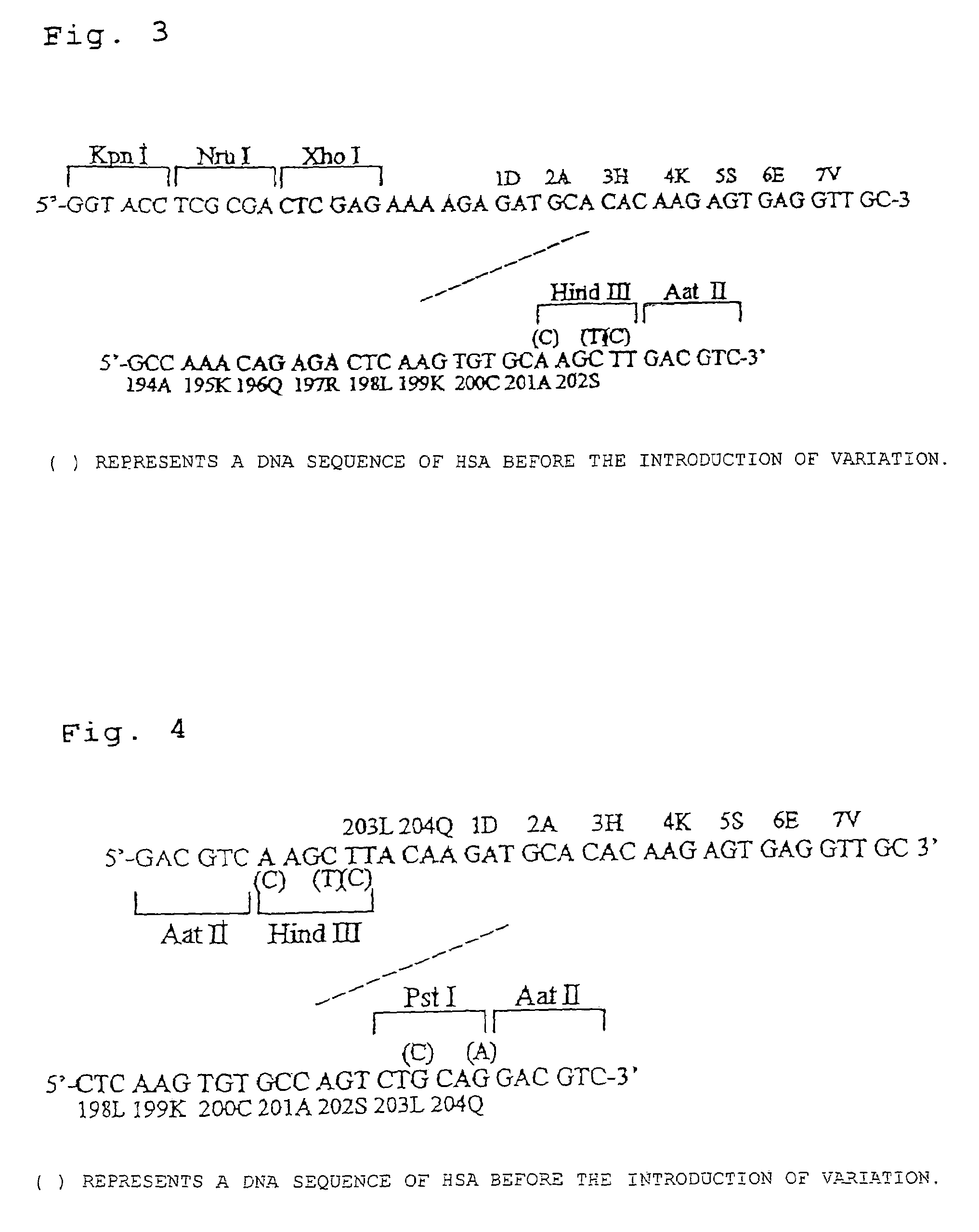

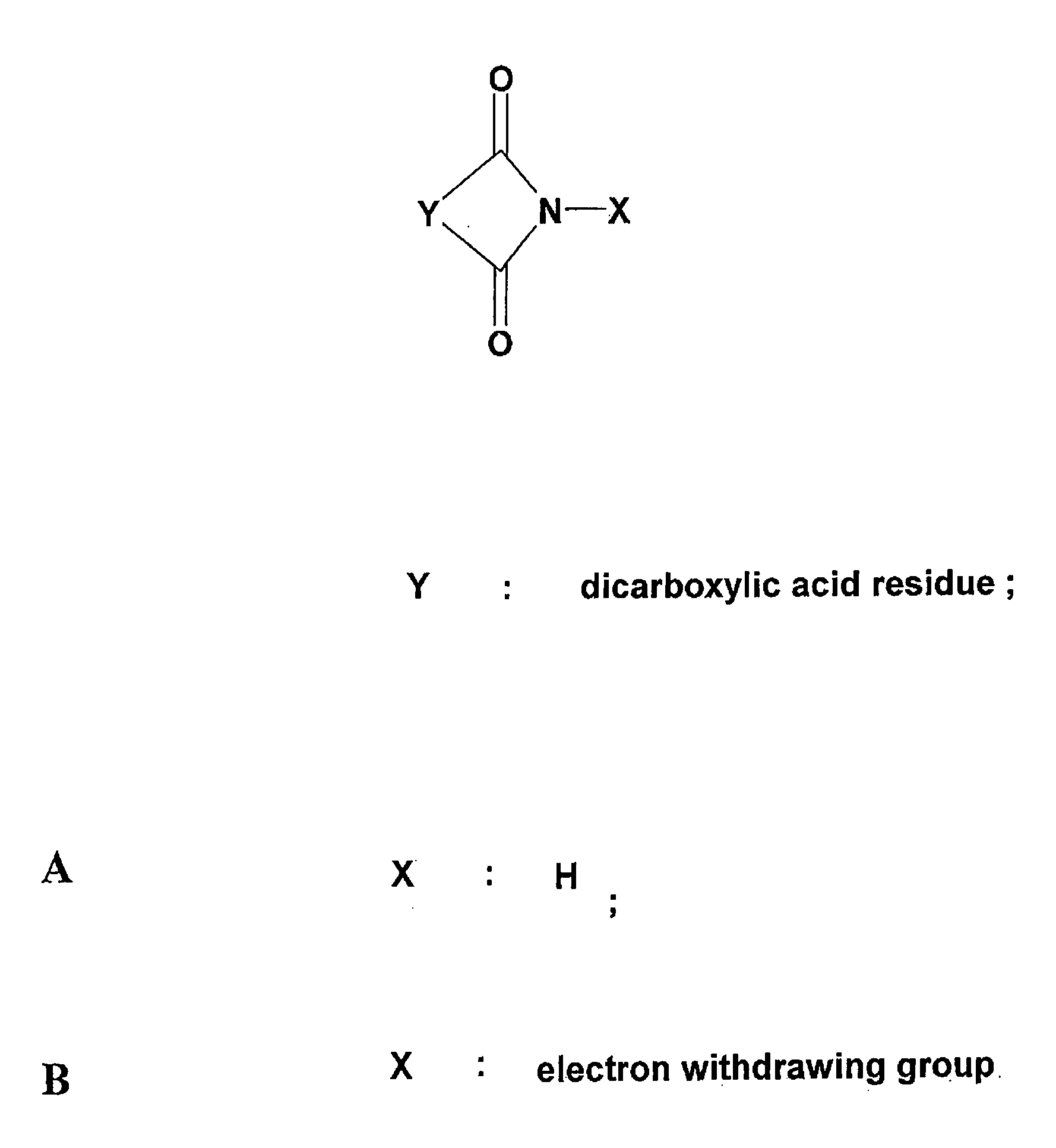

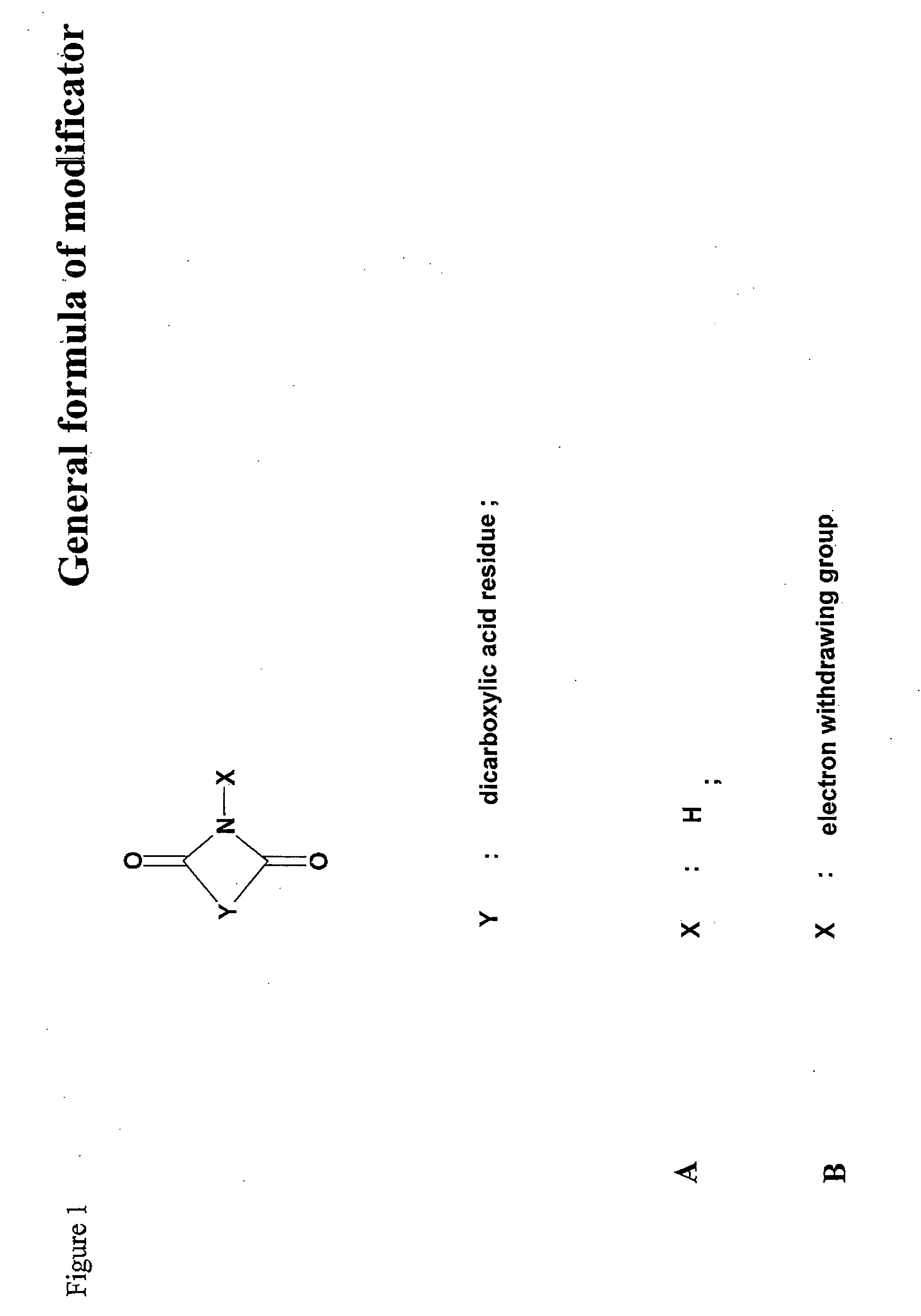

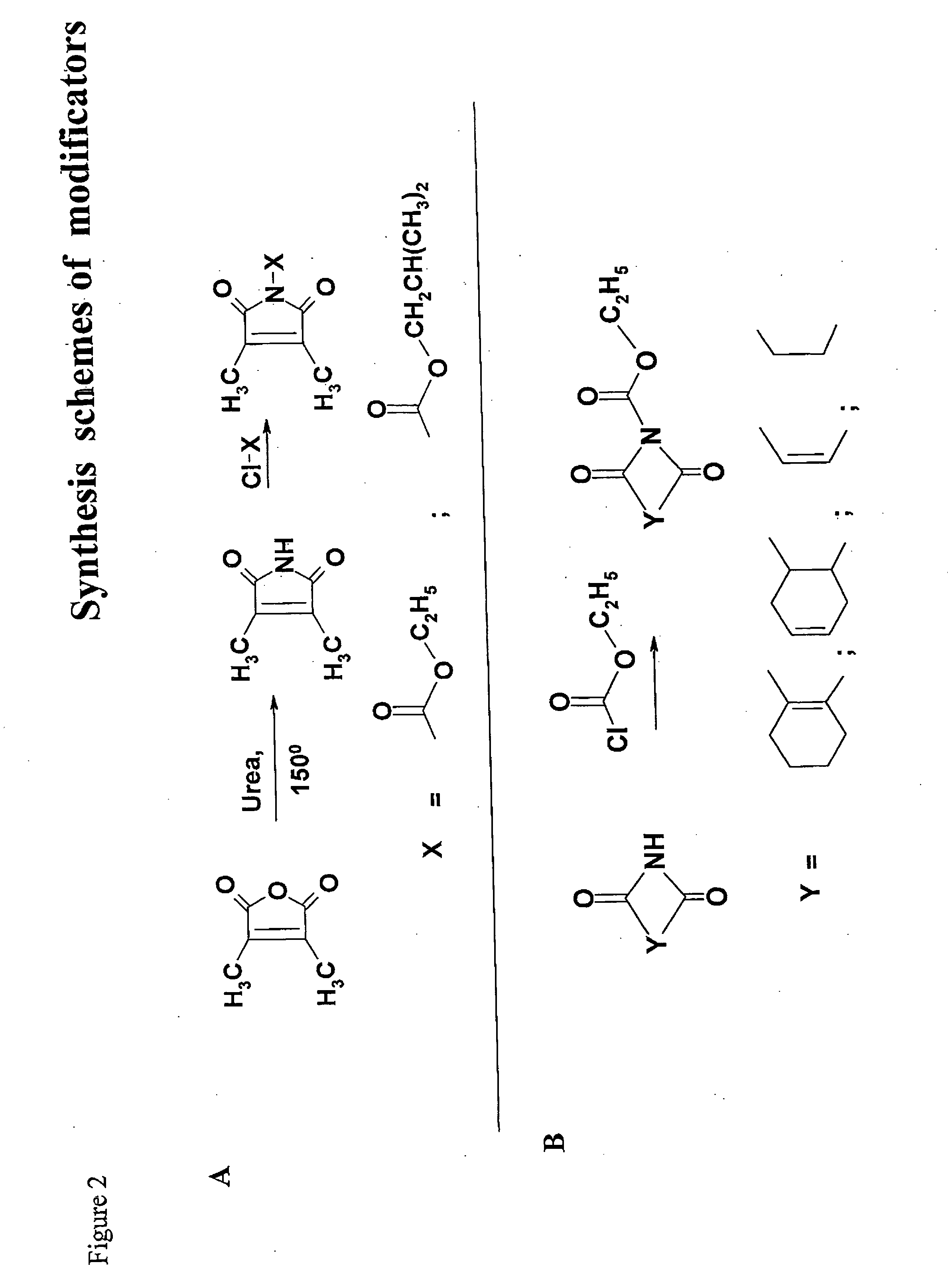

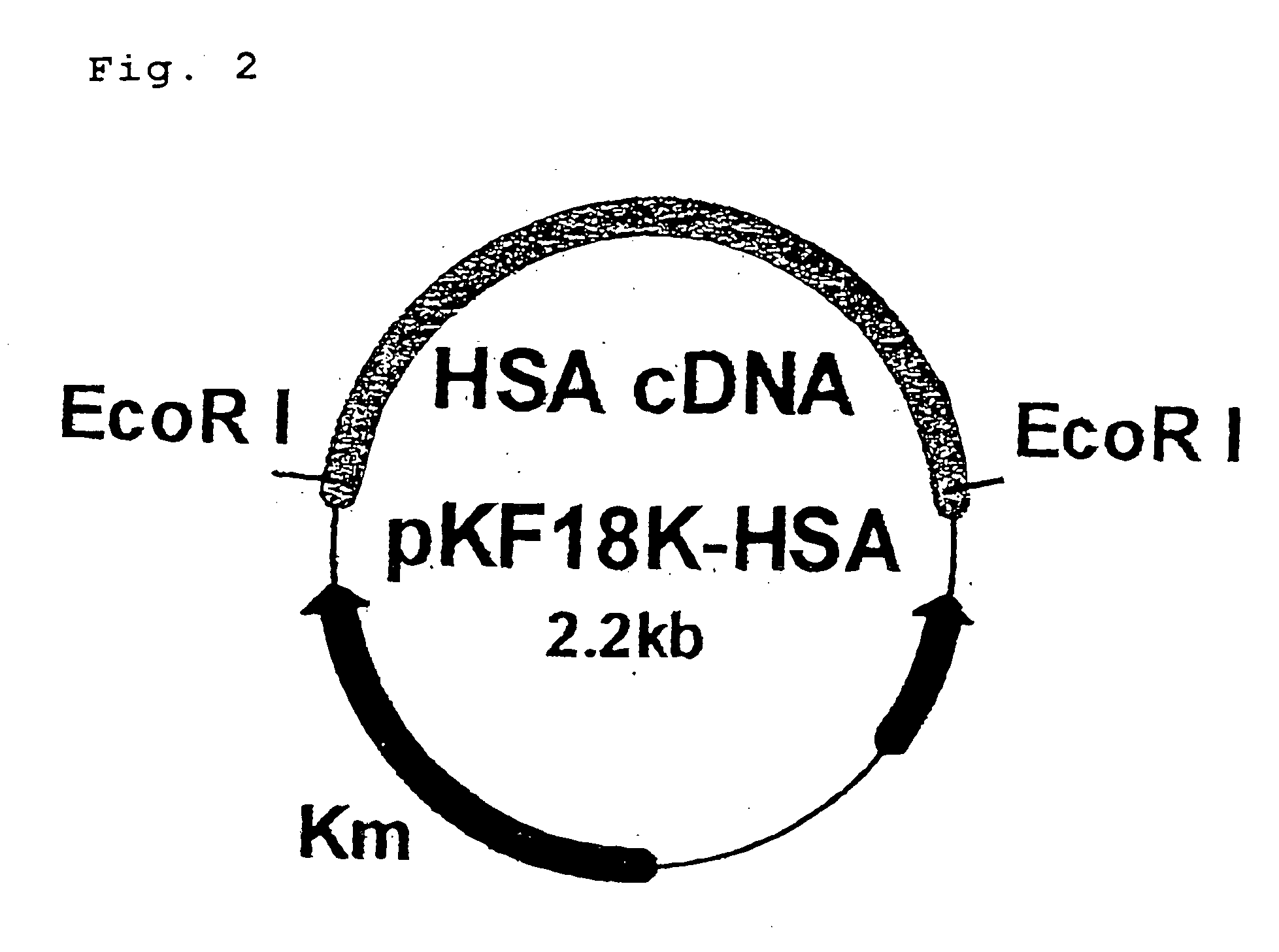

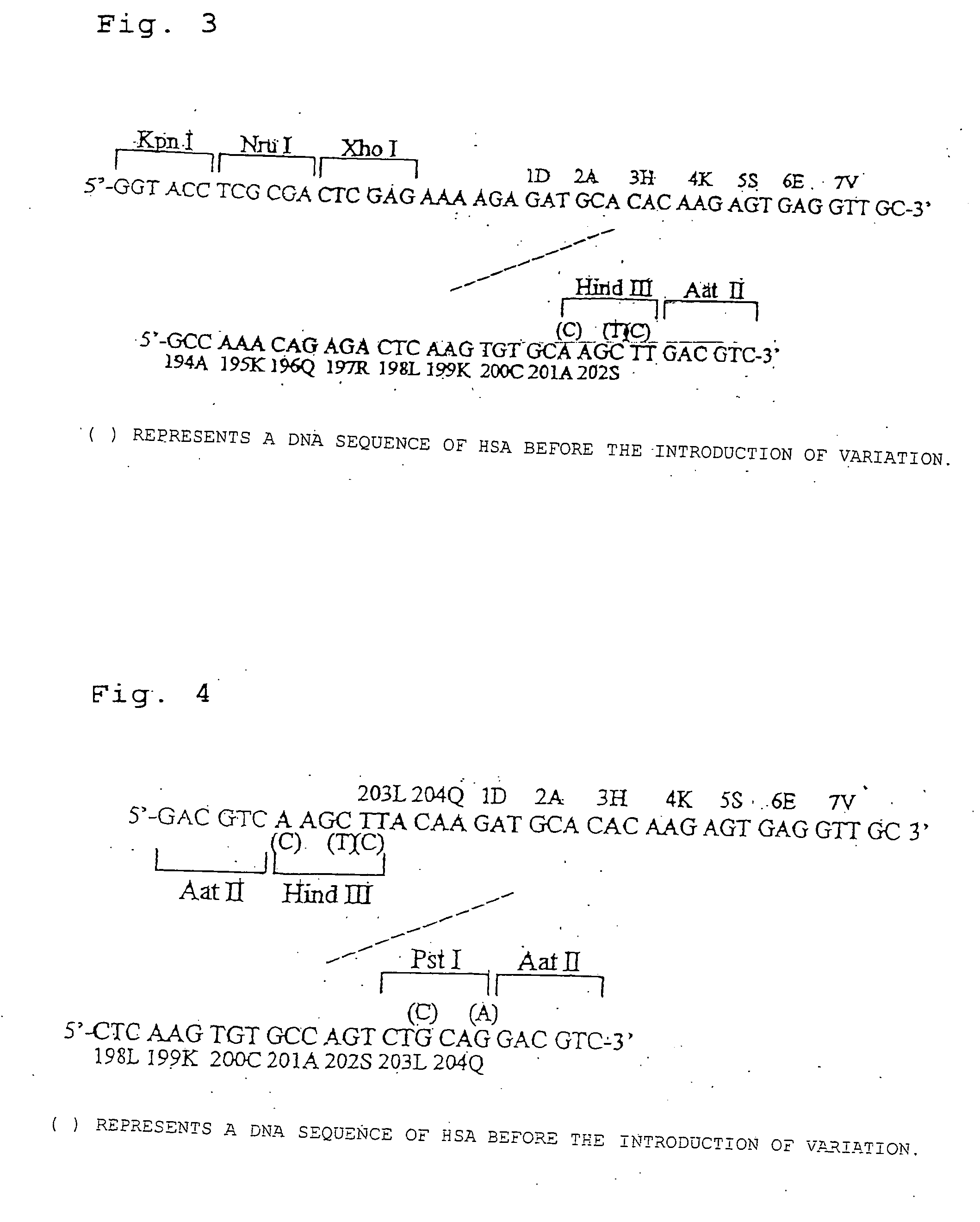

Protein containing serum albumin domain

InactiveUS7253259B2Improve functional activityImprove antioxidant capacityFungiBacteriaSerum igeADAMTS Proteins

A protein produced by gene recombinant technology, including at least one domain selected from domains I, II, and III of serum albumin but having a different structure from that of native albumin; and a method of producing the protein. The protein has an enhanced functional activity or activities selected from among various functional activities or serum albumin including antibacterial activity, antioxidative effect, inflammation inhibitory effect, in vivo substance transporting action, and enzymatic activity.

Owner:NIPRO CORP

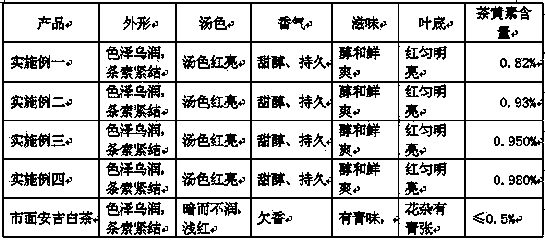

Method for preparing congou black tea from anji white tea

ActiveCN103749755AControl temperature and humidityTransformed properlyPre-extraction tea treatmentFermentationBlack teas

The invention relates to a black tea preparing method and particularly relates to a method for preparing congou black tea from anji white tea. The method sequentially comprises the following steps: picking based on a one-bud and one-leaf standard; withering; rolling; fermenting: arranging the rolled leaves to be fermented into a bamboo basket, controlling the leaf stacking thickness to be 8-10cm, uniformly spreading, and layering the leaves on a fermentation rack; fermenting by using a tea fermenting machine, controlling the air temperature at 35-40 DEG C, keeping the leaf temperature 30-32 DEG C, the relative humidity over 95% and sufficient oxygen supply, recording the fermentation time beginning from the rolling time, and controlling the fermentation time to be 5.5-6.0h. At the later period of fermentation, the temperature of a fermentation chamber is lowered and is controlled at 30-35 DEG C, so that the excessive fermentation is avoided; the moderate fermentation is carried out, and the fermented leaves are removed from the fermentation chamber, subjected to heat radiation, cooled and dried. By using the method, the anji white tea can be prepared into the congou black tea which is dark in luster, compact in strip, sweet and durable in fragrance, red bright in liquor color as well as pure, mild and fresh in taste.

Owner:浙江安吉宋茗白茶有限公司

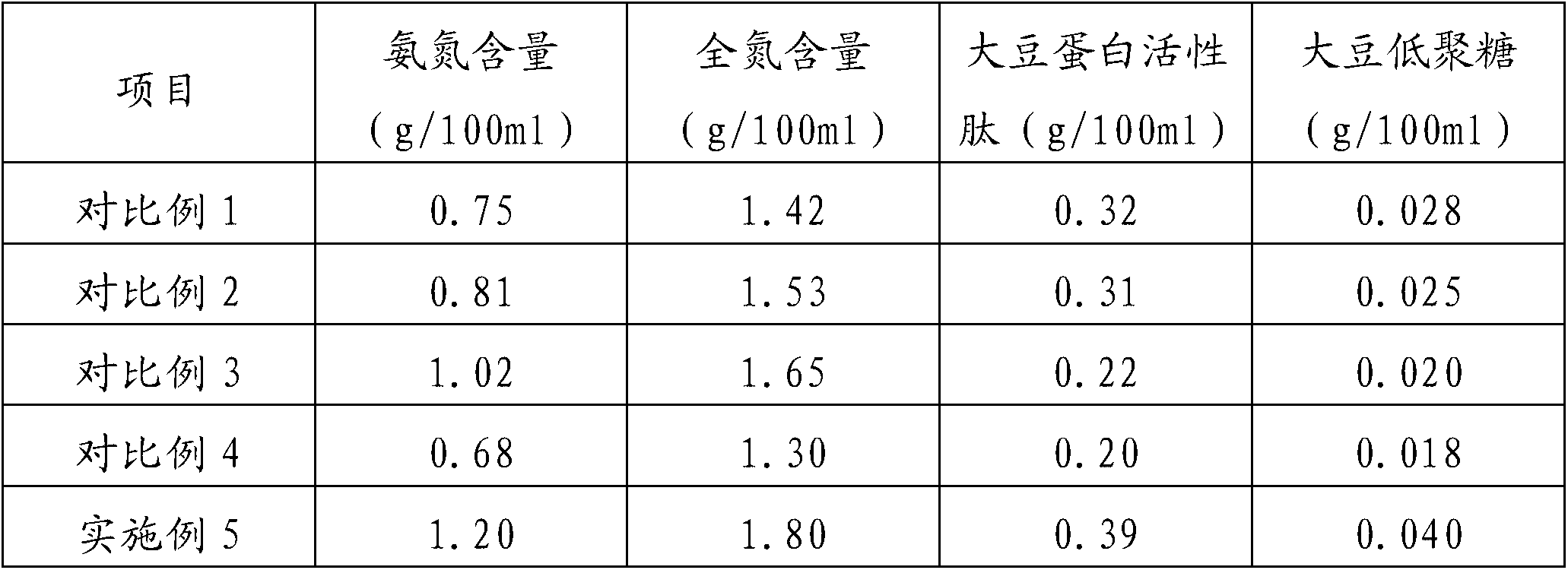

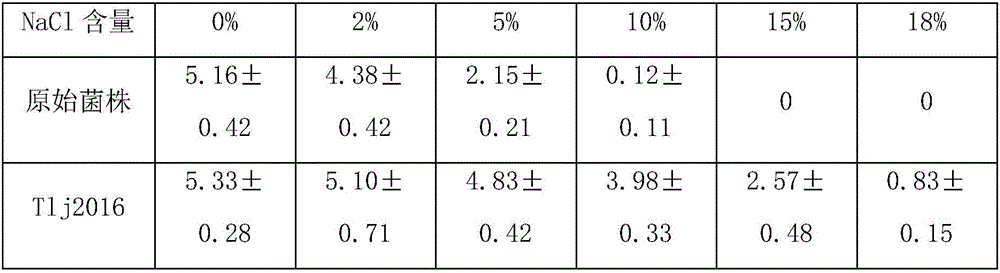

Production method of high-salt diluted and low-temperature fragrant soy sauce

The invention discloses a production method of a high-salt diluted and low-temperature fragrant soy sauce, which comprises the following steps of: (1) curing raw materials including wheat and defatted soybeans, and then uniformly mixing the wheat and the defatted soybeans; (2) inoculating aspergillus oryzae strains to the obtained raw material mixture so as to obtain a yeast; (3) cultivating the yeast for 44-48 hours at a temperature of 25-30 DEG C so as to obtain a mature yeast; (4) adding 2.0-2.5 weight times of saline water into the mature yeast so as to obtain a raw soy sauce mash; (5) moving the raw soy sauce mash to the inside of an airtight fermentation tank for fermenting: firstly fermenting for 23-27 days at a temperature of 13-17 DEG C, then continuing to ferment at a temperature of 28-32 DEG C, and on the 28-32nd days, adding mixed fermentation strains into the fermentation tank and continuing to ferment; in the process of fermentation, stirring by using a compressed air flow; and fermenting for more than six months so as to obtain a mature soy sauce mash; and (6) squeezing and filtering the mature soy sauce mash so as to obtain the low-temperature fragrant soy sauce. According to the invention, the conversion rate of proteins in raw materials is high, and the contents of ammonia nitrogen, total nitrogen, soybean peptides and soybean oligosaccharides in the prepared soy sauce are high.

Owner:好太太食品有限公司

Antibacterial, keeping foodstuff fresh, uvioresistant plastic fabricated from Nano material

An antibacterial, antistaling and ultraviolet-resistant plastics contains polyolefin plastics, montmorillonite, negative-ion microparticles, ultraviolet-resistant microparticles, photocatalyst nanoparticles, antibacterial inorganic microparticles, and titanate or silane coupling agent. Its film is prepared from said plastics, polyethylene and assistant. Its advantage is high effect.

Owner:陈建强 +1

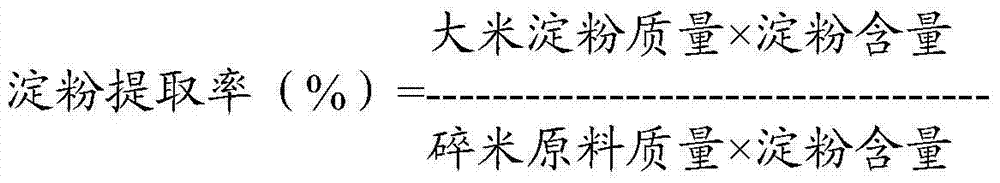

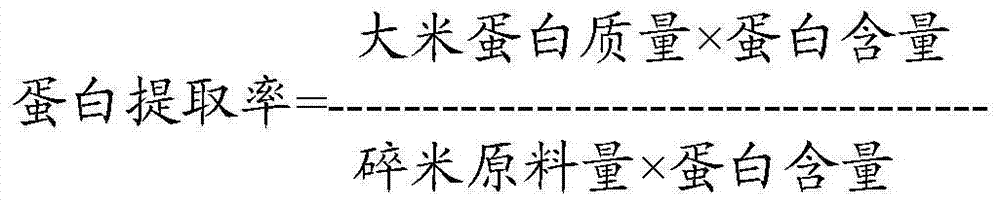

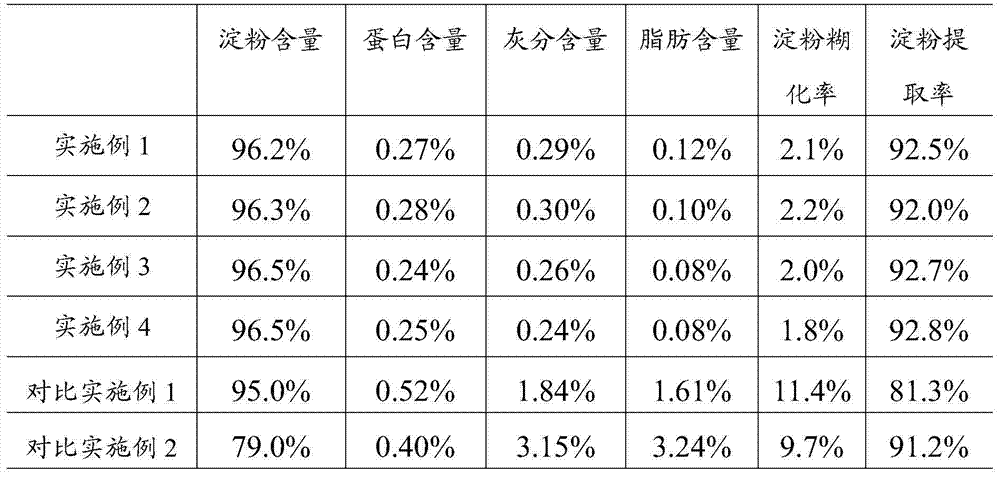

Method for coproduction of rice starch and rice protein

InactiveCN103931867APacked tightlyCompact structureFood preparationStarch gelatinizationAdditional values

The invention relates to a method for coproduction of rice starch and rice protein. The method comprises the step of pretreatment of raw materials, first mixing and enzyme reaction, first separation and washing, homogenization, second separation and washing, second mixing and enzyme reaction, third separation and washing, drying and the like. The method disclosed by the invention is used for realizing the coproduction of the rice starch and the rice protein. In the rice starch produced by the method disclosed by the invention, the content of protein is below 0.3%, the content of starch is above 96%, the dextrinization rate of the starch is below 2.5%, the extraction rate is above 90%, the degree of hydrolysis of the rice protein is below 10%, the content of the protein is above 90% and the extraction rate of the rice protein is above 85%. The rice starch produced by the method disclosed by the invention can be widely applied to the industries such as foods, medicines and cosmetics, while the rice protein can be widely applied to the fields of health foods, nutritious foods and the like, and the additional value of deep processing of rice is increased greatly.

Owner:无锡新禾创工食品科技有限公司

Gradient wheat wetting process

The invention discloses a gradient wheat wetting process, and belongs to the technical field of processing of wheat powder. Ultrasound, microwaves, refrigeration and functional wheat wetting solution are combined to perform gradient wheat wetting for wheat grains by three times, so that the separation of bran from wheat germs is improved, the evacuating degree and the permeation capacity between such structures as wheat grain epidermises, seed coats, germs and endosperm, and macromolecular nutrient substances are improved, the water permeation speed is accelerated, the total wheat wetting process time is shortened to 6-12 h, the flour yield is 78.5-79.5%, the oxidation resistance and the nutrient value of flour are improved, the appearance quality, the physicochemical quality and the food safety of wheat flour are improved, the consumption of such processes as subsequent flour milling is reduced, the production cost is reduced, and a new road is sought for the wheat wetting process.

Owner:宁夏鑫德粮油工贸有限公司

Barley with altered branching enzyme activity and starch and starch containing products with an increased amylose content

InactiveUS20090226592A1Reduced activityReduce enzyme activityDough treatmentTransferasesHordeum vulgareStarch synthesis

Barley having a reduced level of SBEIIa activity produces grain having a high relative amylose content. The barley might additionally have reduced levels of SBEIIb activity. The barley grain of this invention can be of a non-shrunken phenotype despite a lesion in the amylopectin synthesis pathway.

Owner:COMMONWEALTH SCI & IND RES ORG

Method for refining papain

InactiveCN101570748AGuarantee product qualityIncrease material specific gravityHydrolasesPre treatmentHigh activity

The invention discloses a method for refining papain, which comprises the following steps: preparation of pawpaw puree; pretreatment; milling; heat exchange; two stages of centrifugation; micro-filtration; hyperfiltration; freeze drying in vacuum; pulverization and modulation; and preparation of a finished product. The extraction method is characterized in that: (1) by carrying out the pretreatment and the heat exchange and keeping an extraction process being carried out under a low-temperature condition, the influence on activity reduction of the papain under the conditions of high temperature for a long time, and the like can be effectively reduced; (2) by milling, the papain can be sufficiently dissolved in material liquid so as to be beneficial to improving the extraction and recovery ratio of the papain; (3) the papain extracted by the method has high purity and activity (the highest activity can reach 3,000,000u / g) and good thermal stability; indexes such as appearance, rationalization, microbial limit, and the like can reach or exceed relevant food and medicine standards at home and abroad; by modulation, products in different specifications can be produced and widely applied to the industries and the fields of medicinal health products, foods, cosmetics, chemical leather manufacture, and the like; and (4) the method has simple process, low production cost, high yield and industrial production.

Owner:徐闻县美仑生物制品有限公司

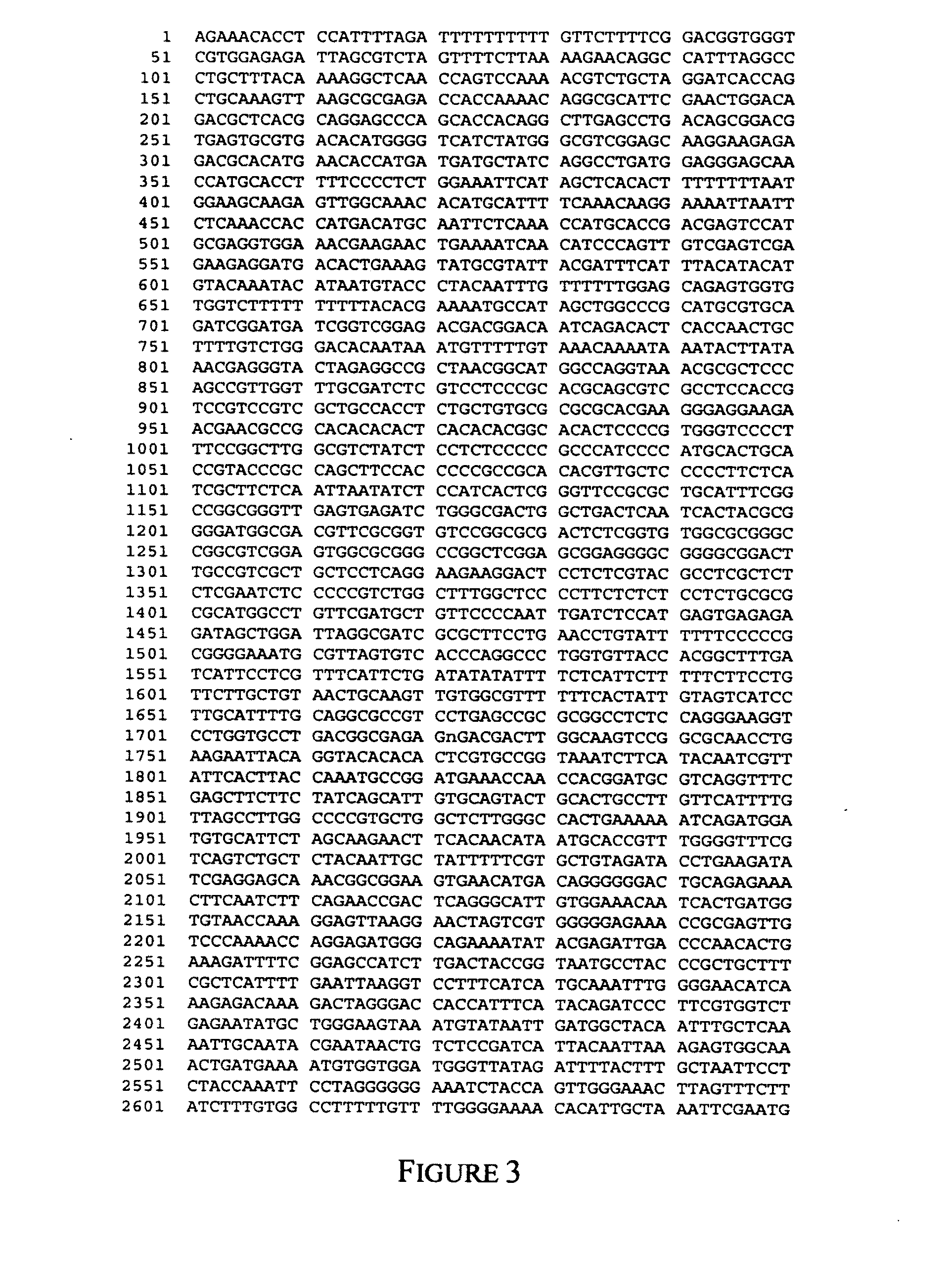

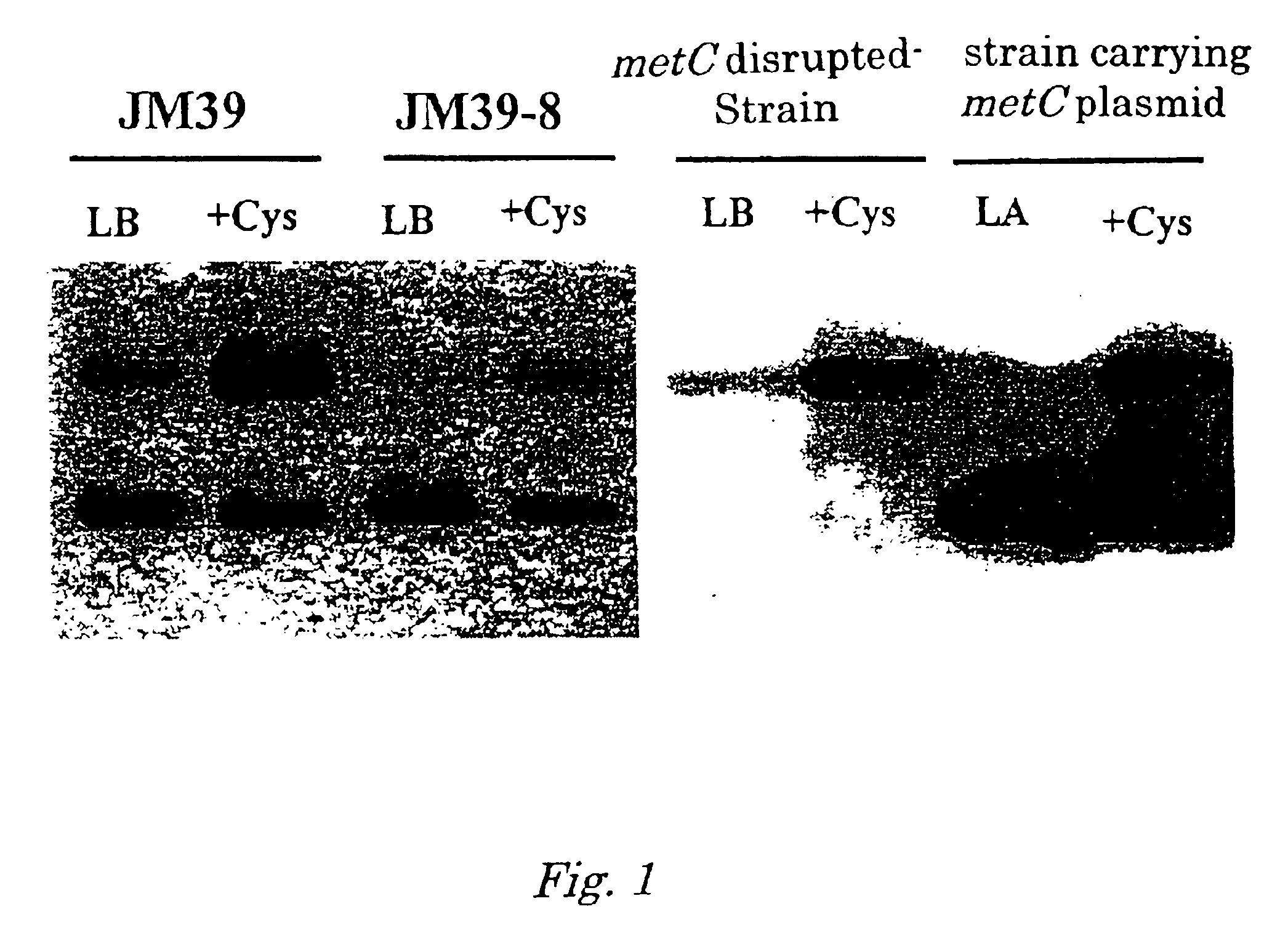

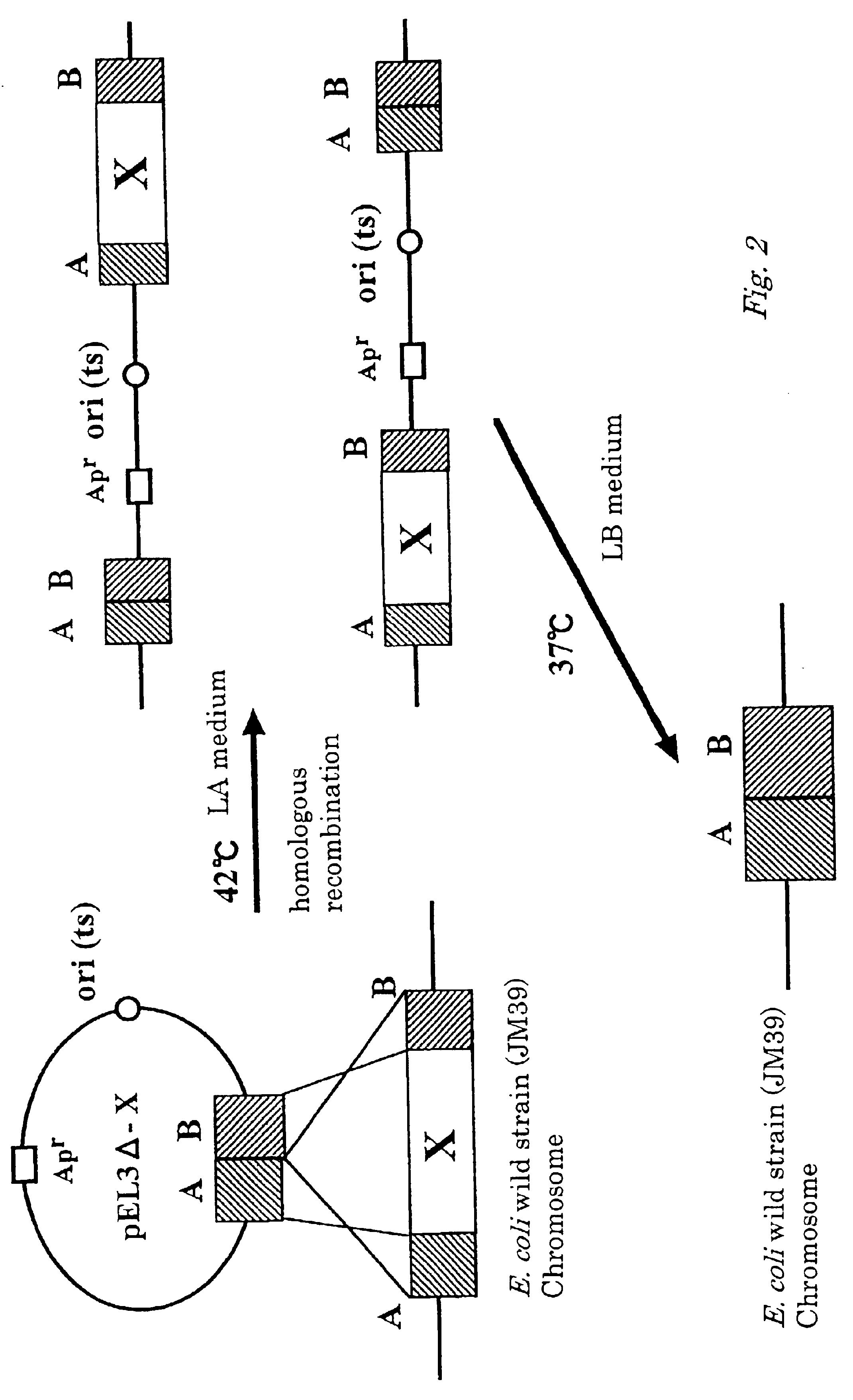

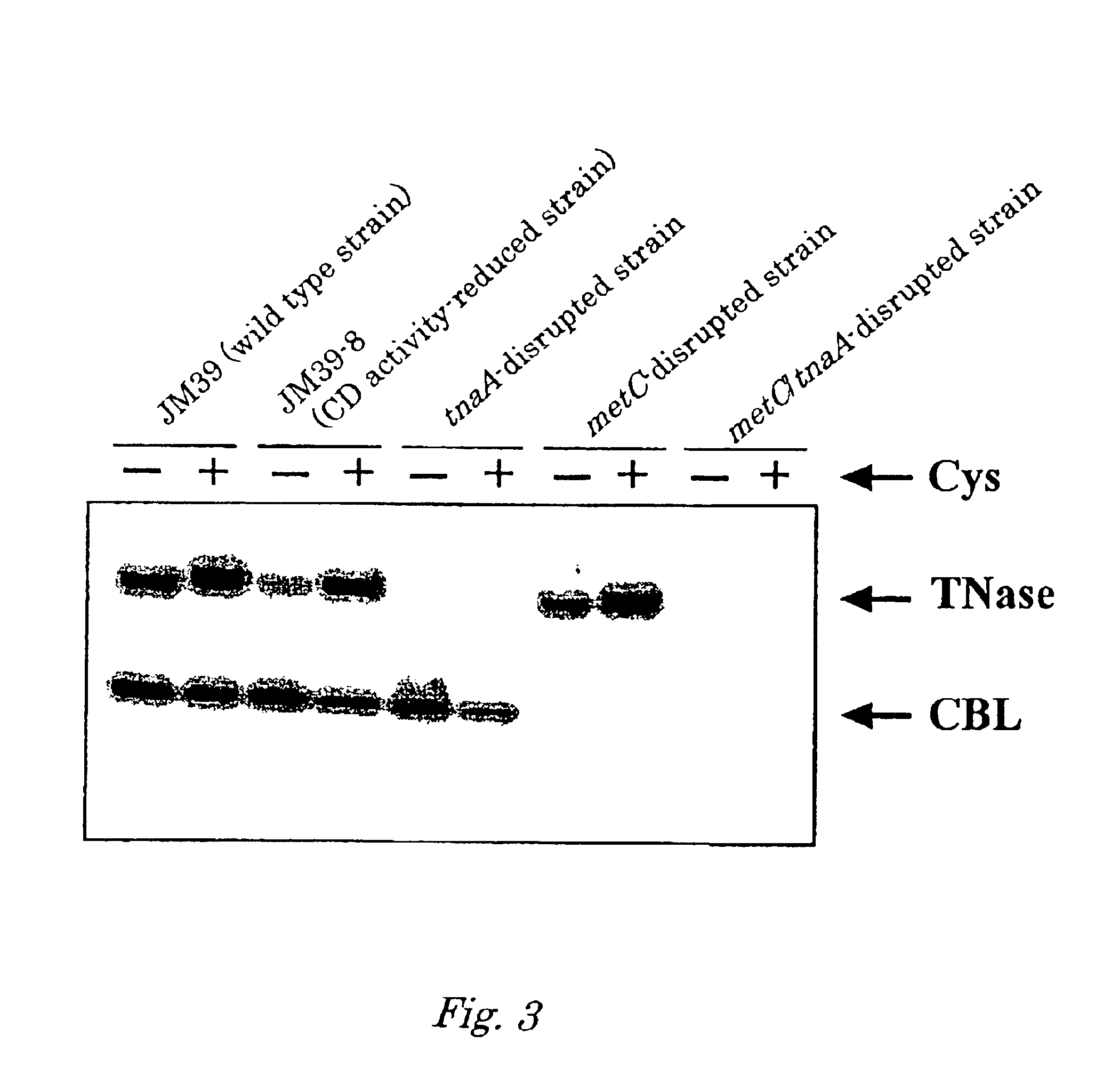

L-cysteine producing bacterium and method for producing L-cysteine

InactiveUS6946268B2Improve abilitiesReduce enzyme activityBacteriaSugar derivativesBacteroidesLyase activity

L-Cysteine is produced by culturing a bacterium belonging to the genus Escherichia having an L-cysteine producing ability and modified so that cystathionine-β-lyase activity or cystathionine-β-lyase activity and tryptophanase activity should be reduced or eliminated in a medium to produce and accumulate L-cysteine in the medium and collecting the L-cysteine from the medium.

Owner:AJINOMOTO CO INC

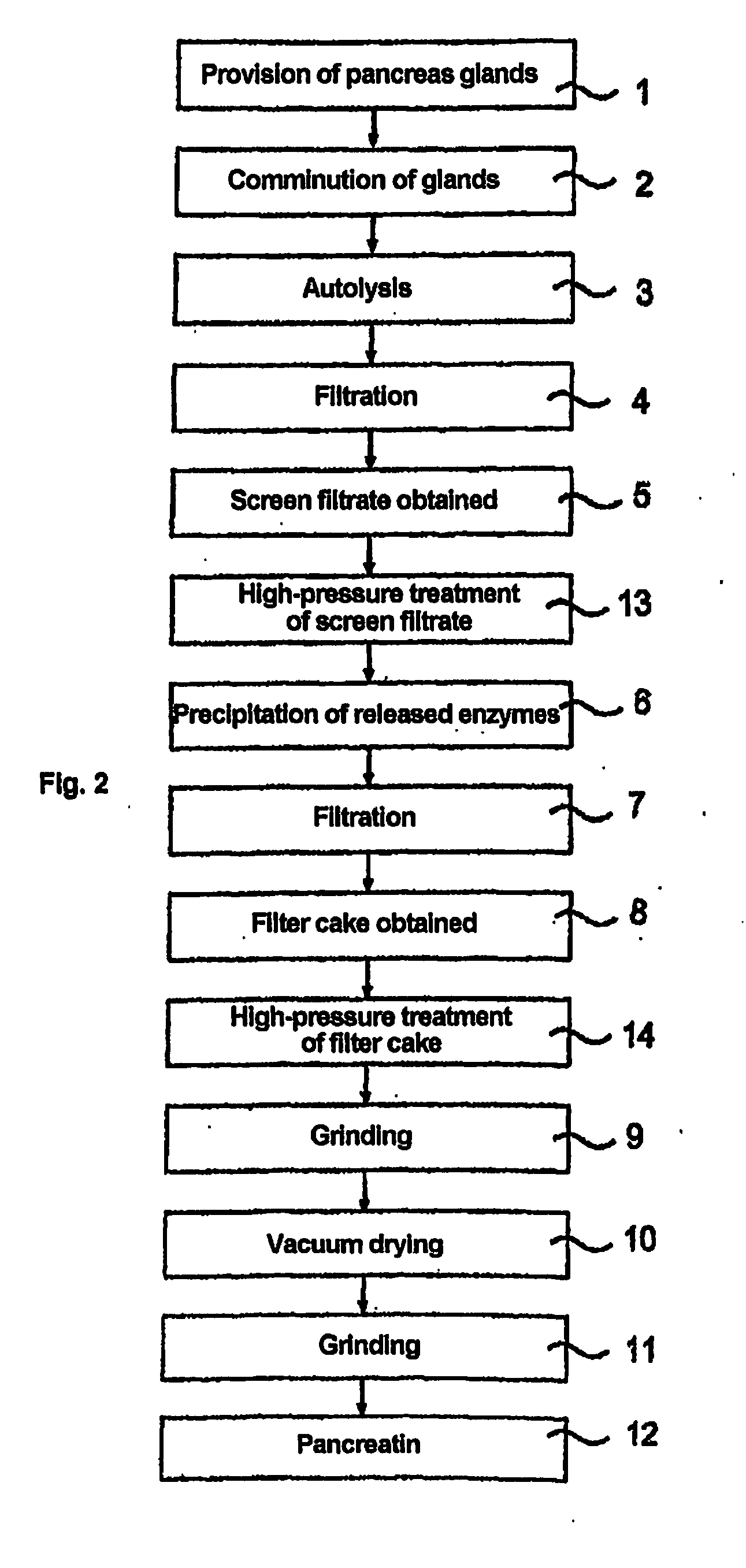

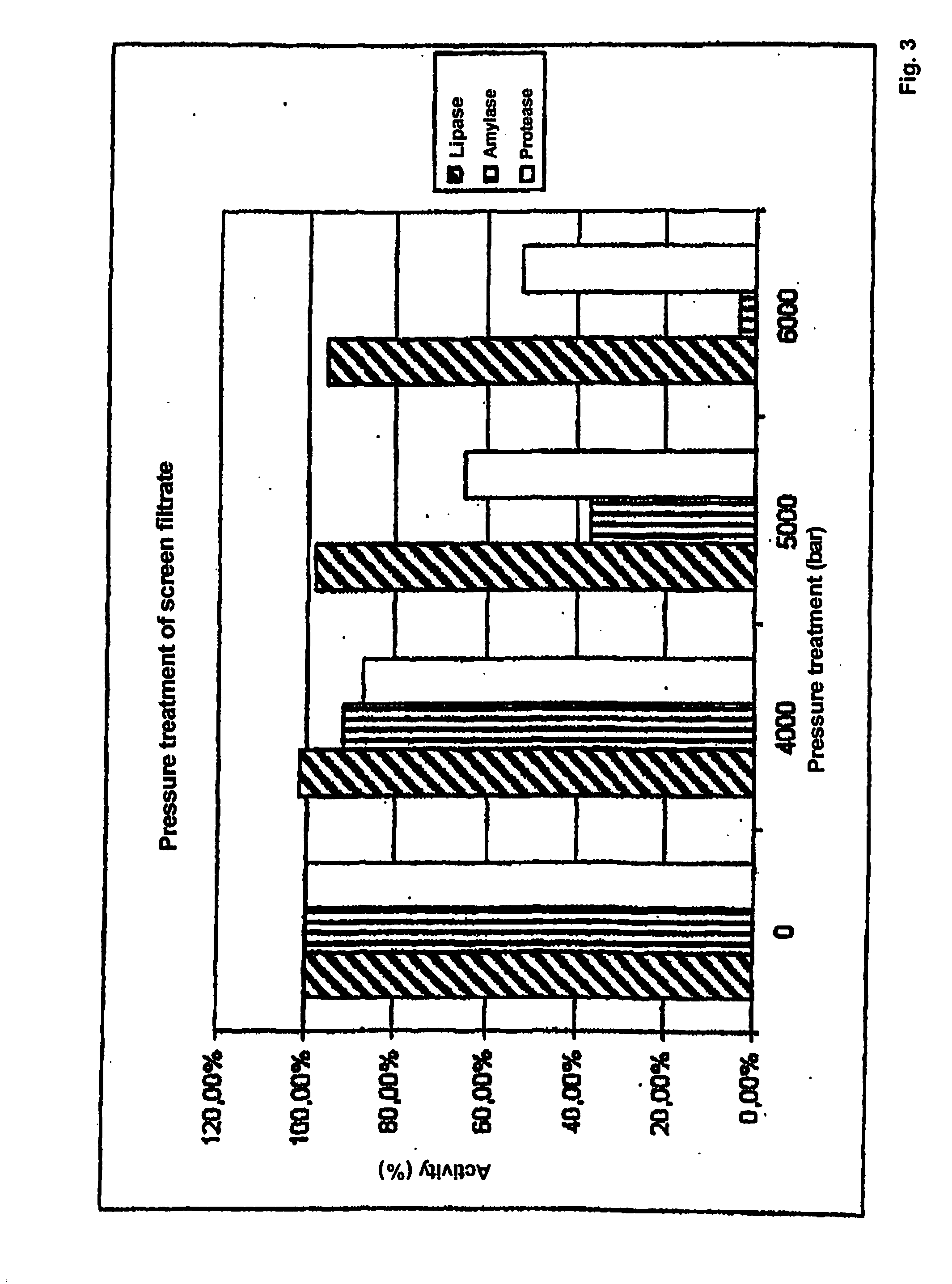

Method for reducing the viral and microbial load of biological extracts containing solids

ActiveUS20110268844A1Reduce contentEnzymic activity being substantially reducedMilk preparationPeptide/protein ingredientsBiotechnologyMicroorganism

The invention relates to a method for reducing the viral and microbial content of biological extracts which contain solids. It is provided that the method comprises the steps(a) provision of the biological extract which contains solids, comprising a biologically active substance, selected from enzymes, proteins and peptides, or a mixture of such substances; and(b) subjecting the biological extract provided in step (a) to a high-pressure treatment;wherein the biological activity of the biological extract which contains solids after the high-pressure treatment is at least 50% of the biological activity of the biological extract which contains solids before the high-pressure treatment.

Owner:NORDMARK PHARMA GMBH

Method for preparation of bromelin

InactiveCN101319208AReduce enzyme activitySubsequent separation is simpleHydrolasesFiltrationFreeze-drying

The method relates to a manufacturing method for bromelin, in particular to a new method for the industrialized extraction of the bromelin with pineapple stems (plant) as a main raw material. The method comprises the following steps of: (1) cleaning pineapple stems; 2) crushing the pineapple stems; (3) pressing and extracting juice; (4) carrying out coarse filtration; (5) carrying out heat exchange; (6) centrifuging; (7) carrying out micro-filtration; (8) carrying out ultrafiltration; (9) refining and synthesizing; (10) vacuum freeze-drying; and (11) crushing, concocting, packaging, and manufacturing a finished product. The manufacturing method for the bromelin can save energy and reduce production cost with an enzyme extraction reclaiming rate up to 0.2 percent, high enzyme purity, high enzyme activity above 3,000G DU / g and good stability.

Owner:广西美仑生物科技有限公司

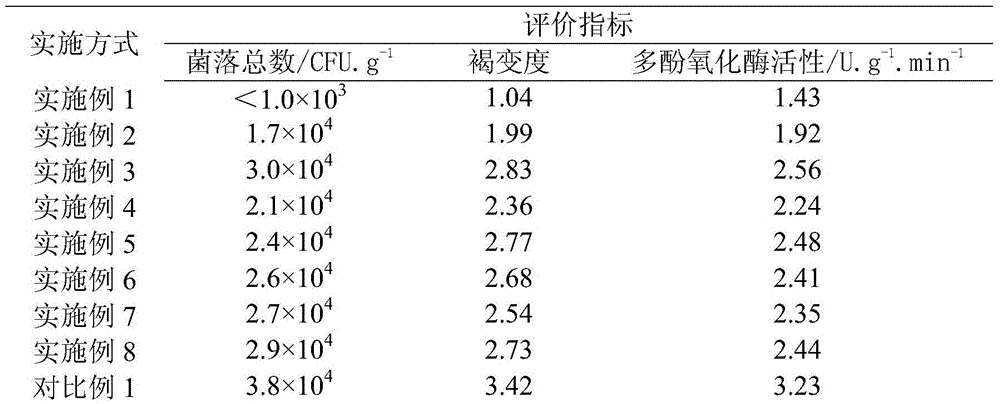

Preservation method for fresh-cut common yam rhizomes

ActiveCN105557994AFull of nutritionAdd flavorFruits/vegetable preservation by irradiation/electric treatmentFruits/vegetable preservation by coatingRhizomeNutrients substances

The invention relates to a preservation method for fresh-cut common yam rhizomes. The preservation method includes the following specific steps that 1, the common yam rhizomes without traumas or rot are selected, flushed with water for silt and impurity removal, and then peeled; 2, the peeled common yam rhizomes are immersed in an emulsified coating compound solution for 25-45 min, wherein the emulsified coating compound solution is prepared from, by mass, 2%-6% of majoram essential oil, 2%-6% of mint essential oil and 2%-6% of litsea cubeba essential oil; 3, the common yam rhizomes obtained after immersion in the step 2 are diced or sliced through a stainless steel knife; 4, the blocky or flaky common yam rhizomes are immersed in a color-protecting coating solution for 20-60 min; 6, the vacuum-packed common yam rhizomes are subjected to electron beam irradiation treatment; 7, the common yam rhizomes are refrigerated at the temperature of 0-4 DEG C. The preservation method is used for preserving the fresh-cut common yam rhizomes, loss of nutrient substances of the common yam rhizomes can be reduced, growth of microorganisms can be effectively restrained, enzymatic activity can be reduced, and brown stains can be controlled; the color and flavor of the common yam rhizomes are well kept, eating is convenient, rich nutrients are obtained, preservation is easy, and the storage life can be prolonged to 35 days or above when the common yam rhizomes are stored at the temperature of 0-4 DEG C.

Owner:湖北军梦生态农业发展股份有限公司

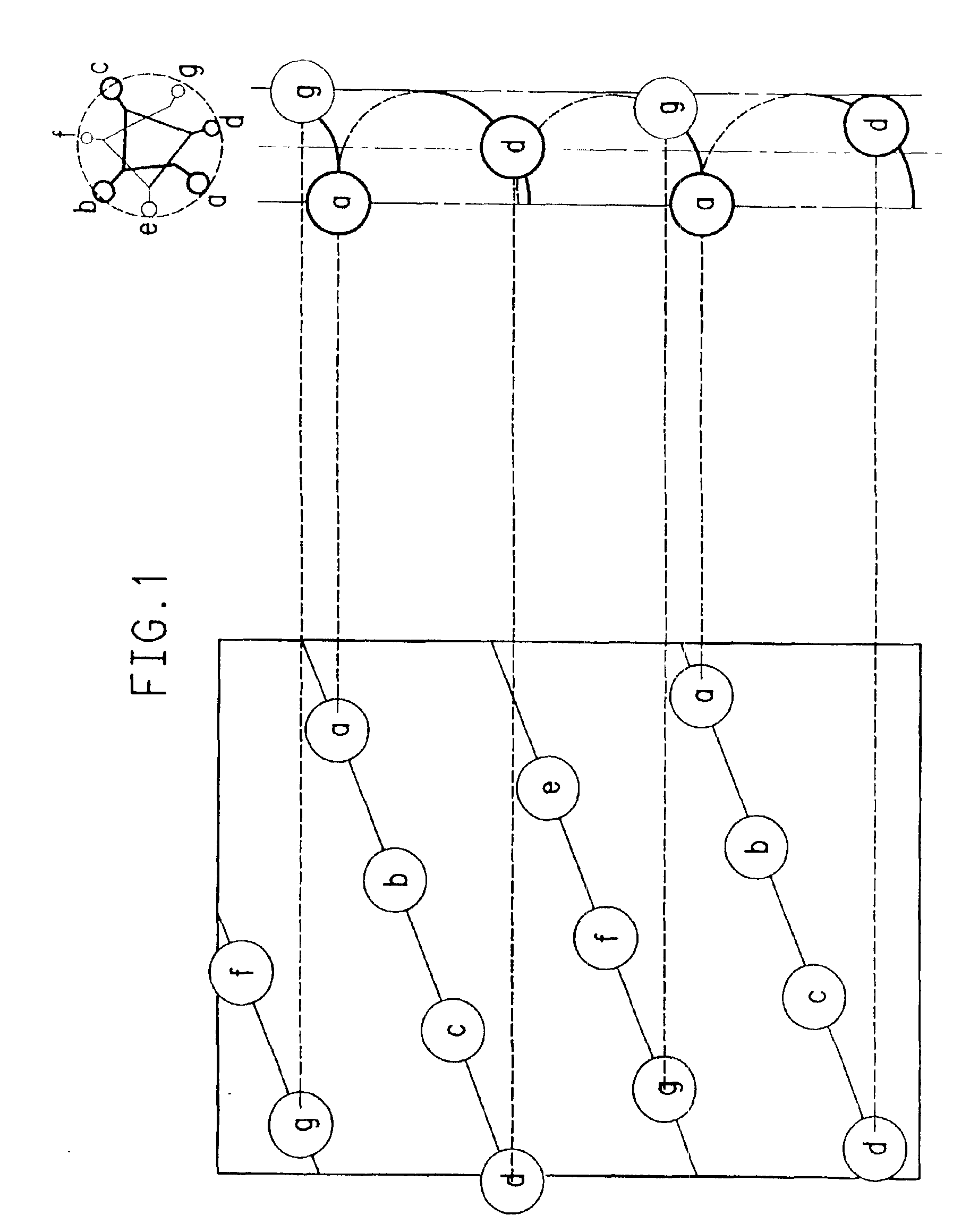

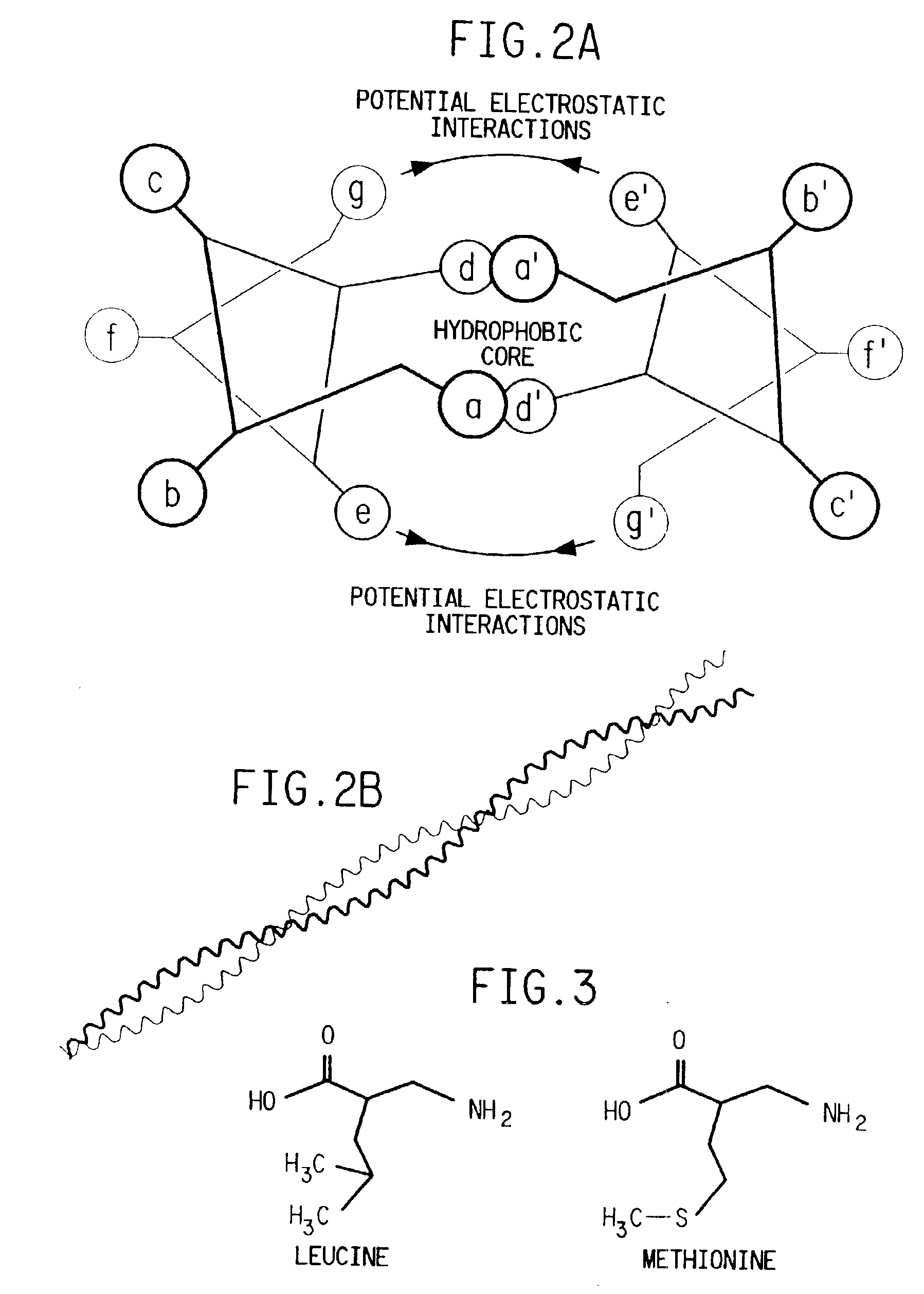

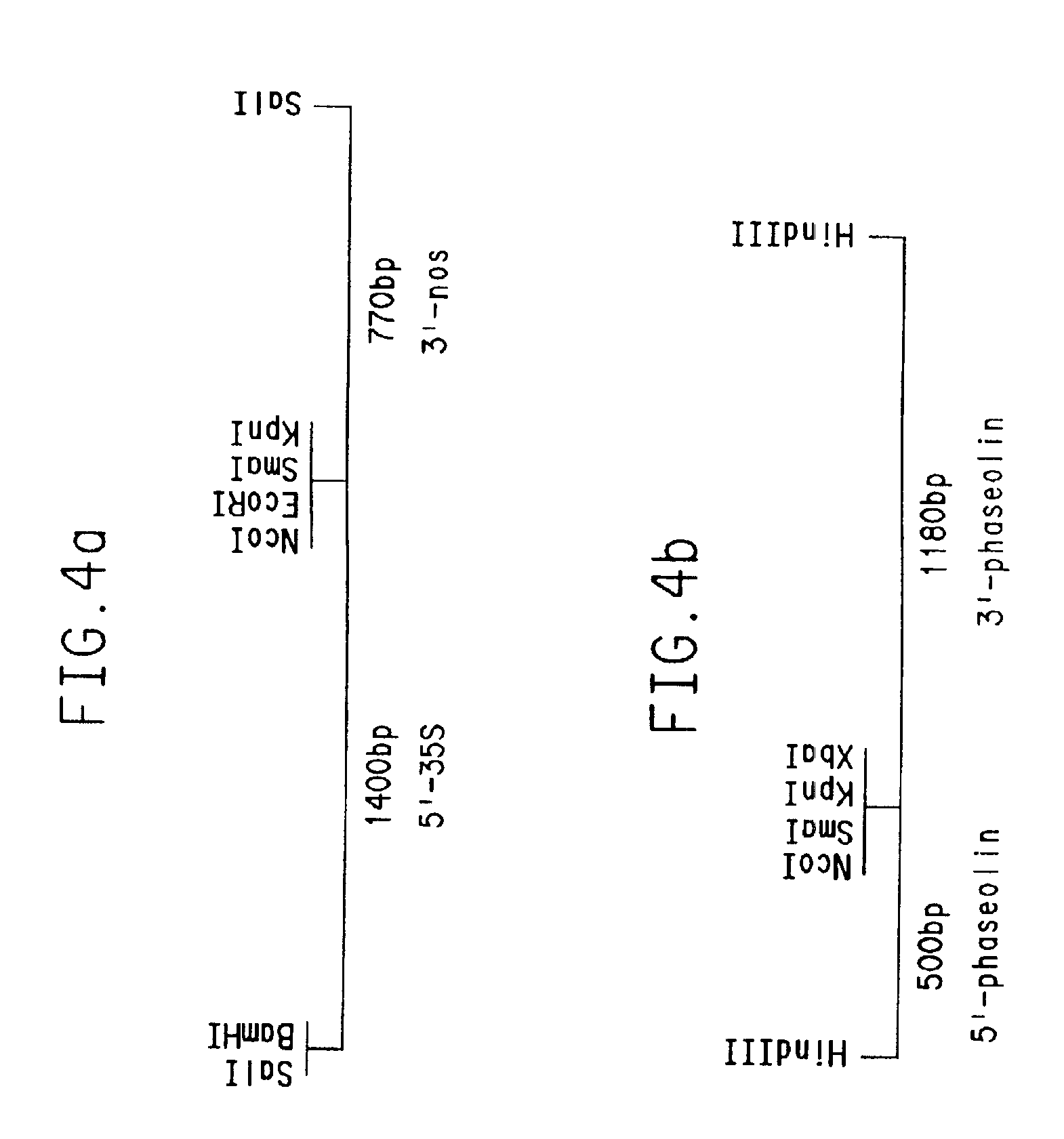

Chimeric genes and methods for increasing the lysine and threonine content of the seeds of plants

InactiveUS7071383B2Reduce enzyme activityReduce accumulationSugar derivativesTransferasesBiotechnologyPlanting seed

This invention relates to four chimeric genes, a first encoding lysine-insensitive aspartokinase (AK), which is operably linked to a plant chloroplast transit sequence, a second encoding lysine-insensitive dihydrodipicolinic acid synthase (DHDPS), which is operably linked to a plant chloroplast transit sequence, a third encoding a lysine-rich protein, and a fourth encoding a plant lysine ketoglutarate reductase, all operably linked to plant seed-specific regulatory sequences. Methods for their use to produce increased levels of lysine or threonine in the seeds of transformed plants are provided. Also provided are transformed plants wherein the seeds accumulate lysine or threonine to higher levels than untransformed plants.

Owner:EI DU PONT DE NEMOURS & CO

Preparation method of immobilized beta-glucosidase

The invention discloses a preparation method of immobilized beta-glucosidase in the field of enzyme preparations. According to the method, fructose is adopted as a pore-foaming agent, and the immobilized beta-glucosidase is prepared through the tetraethoxysilane hydrolysis reaction sol-gel method. Different immobilized beta-glucosidase samples are prepared by adding fructose water solutions with different concentrations and beta-glucosidase of different dosages. For the obtained immobilized beta-glucosidase, the invalid adsorption in the enzymolysis process of cellulose can be avoided, so that the enzymolysis conversion efficiency of cellulose is obviously improved, the immobilized enzyme has the advantages of good mechanical strength and multiple times of recycling, and the hydrolysis and saccharifying costs of cellulose are reduced.

Owner:PETROCHINA CO LTD

Comprehensive fresh keeping method of chilled chickens

ActiveCN105901108AAvoid cross infectionReduce aggregationPoultry cleaning/disinfectionFood ingredientsMicroorganismPre cooling

The invention discloses a comprehensive fresh keeping method of chilled chickens, and relates to the technical field of the food processing industry and food irradiation. The method sequentially comprises the following steps: quarantined living chicken bloodletting, disinfection flushing, hair scalding, hair picking, cleaning, eviscerating, chilled chicken pre-cooling disinfection, fresh keeping treatment, air cooling, anti-oxidation treatment, packaging, irradiation and constant temperature storage. The disinfection flushing step is carried out to prevent cross infection of microorganisms in a high-temperature immersion tank; foams in an immersion scalding tank are timely removed in the hair scalding step in order to effectively aggregation of bacteria; and air cooling timely carried out after the fresh keeping treatment is a key process for reducing the initial bacterium quantity of the chilled chickens.

Owner:JIANGSU LIXIAHE REGION AGRI RES INST +1

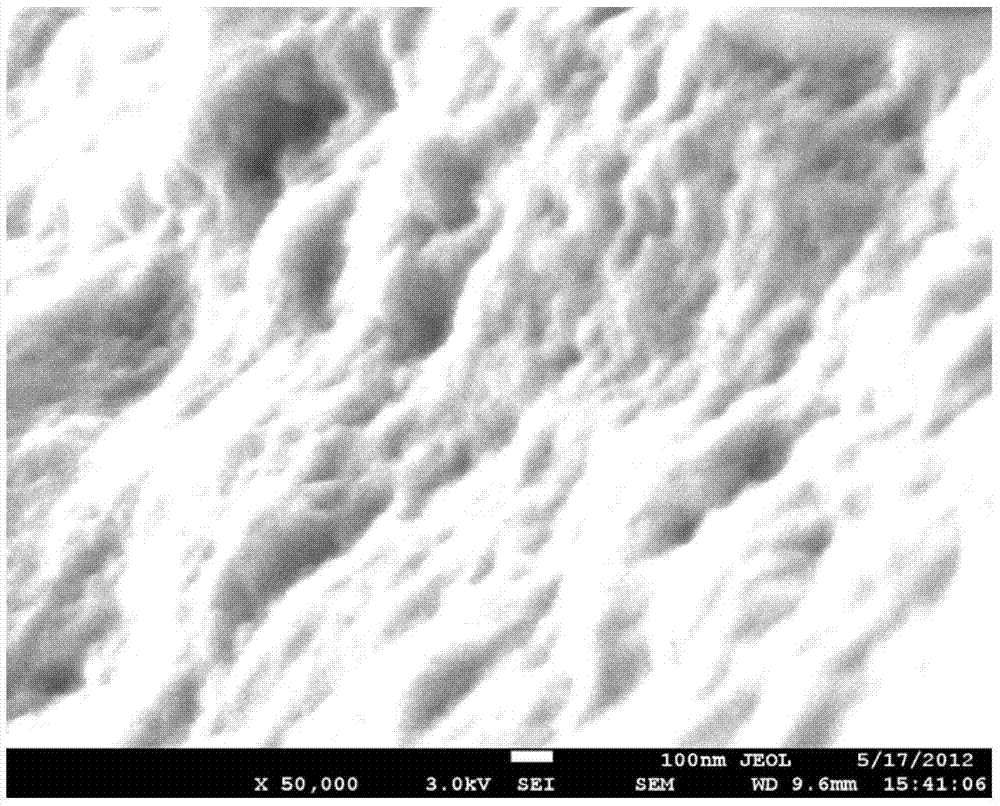

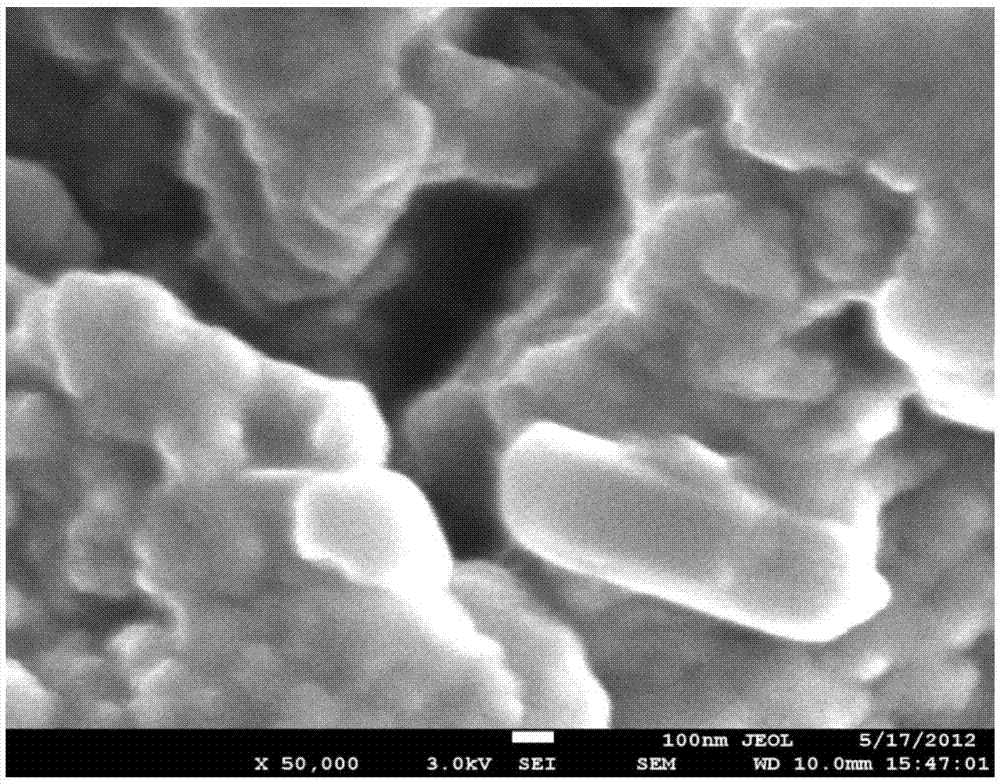

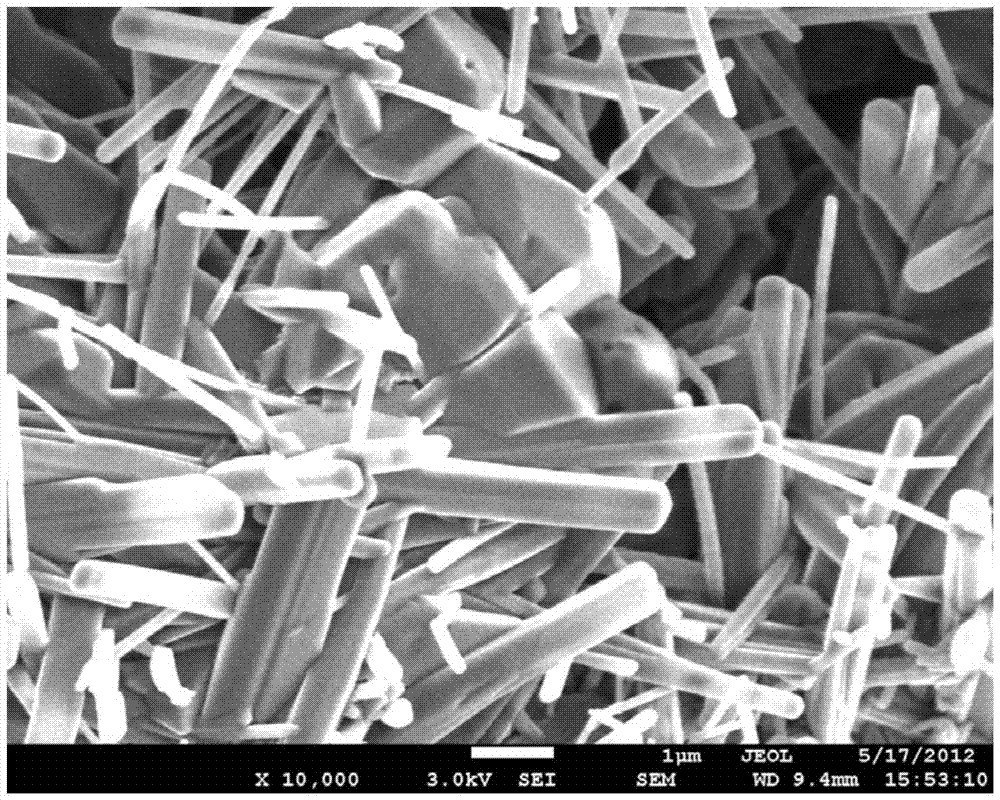

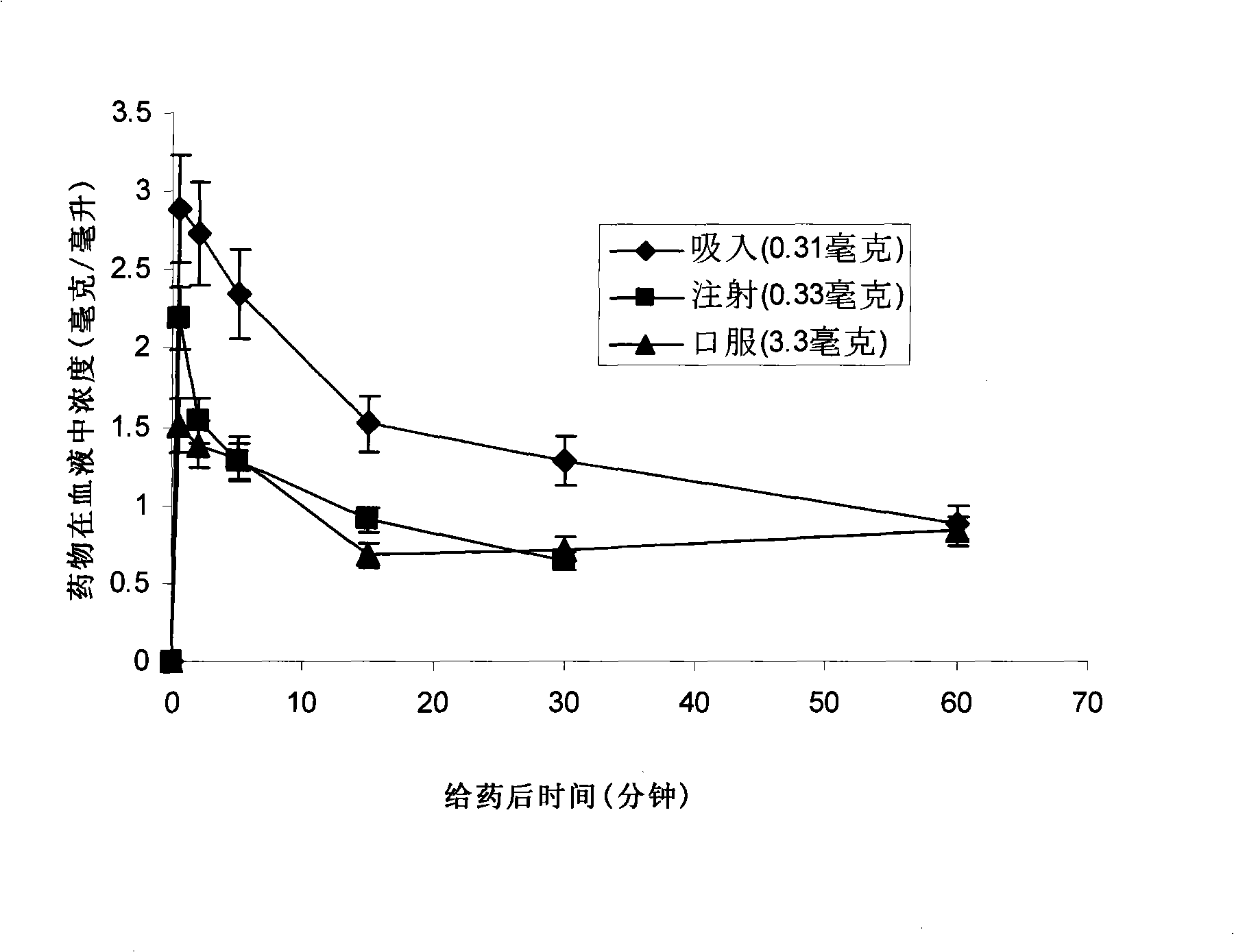

Ultra-fine dry powder particle suitable for drug administration for lung, and preparation method thereof

ActiveCN101317821AGood aerosolization propertiesLow biological toxicityPowder deliveryInorganic non-active ingredientsAdditive ingredientVolumetric Mass Density

The invention discloses a superfine drymeal granule suitable for pulmonary administration and a preparation method thereof. The drymeal granule has good air-atomizing property. With smaller geometric dimension, the drymeal granule can deposit in the alveolus area to maximum extent, so the active molecule of the medicine has higher bioavailability. In addition, the drymeal granule can be used for DNA and RNA lung administration. The invention is also designed to introduce how to use volatility salt to prepare the superfine drymeal granule with good air-atomizing property. The invention solves the technique defects of the over size of the drymeal granule, the low density of the granule, inconvenient application and easy inactivation of active drug ingredients caused by the sharp decline of the air-atomizing property resulting from the water absorbability in the lung superfine drymeal granule prepared by the existing drymeal preparation technique. Meanwhile, the invention also solves the problem that the drymeal produced by the spray drying technology which is developed by Nektar Company, U.S.A, has relatively small deposition rate in the alveolus area and can not be used for transmitting protein, peptide or nucleic acid drugs containing DNA and RNA, and the like, caused by relatively small granule size and relatively high granule density.

Owner:杭州畅溪制药有限公司

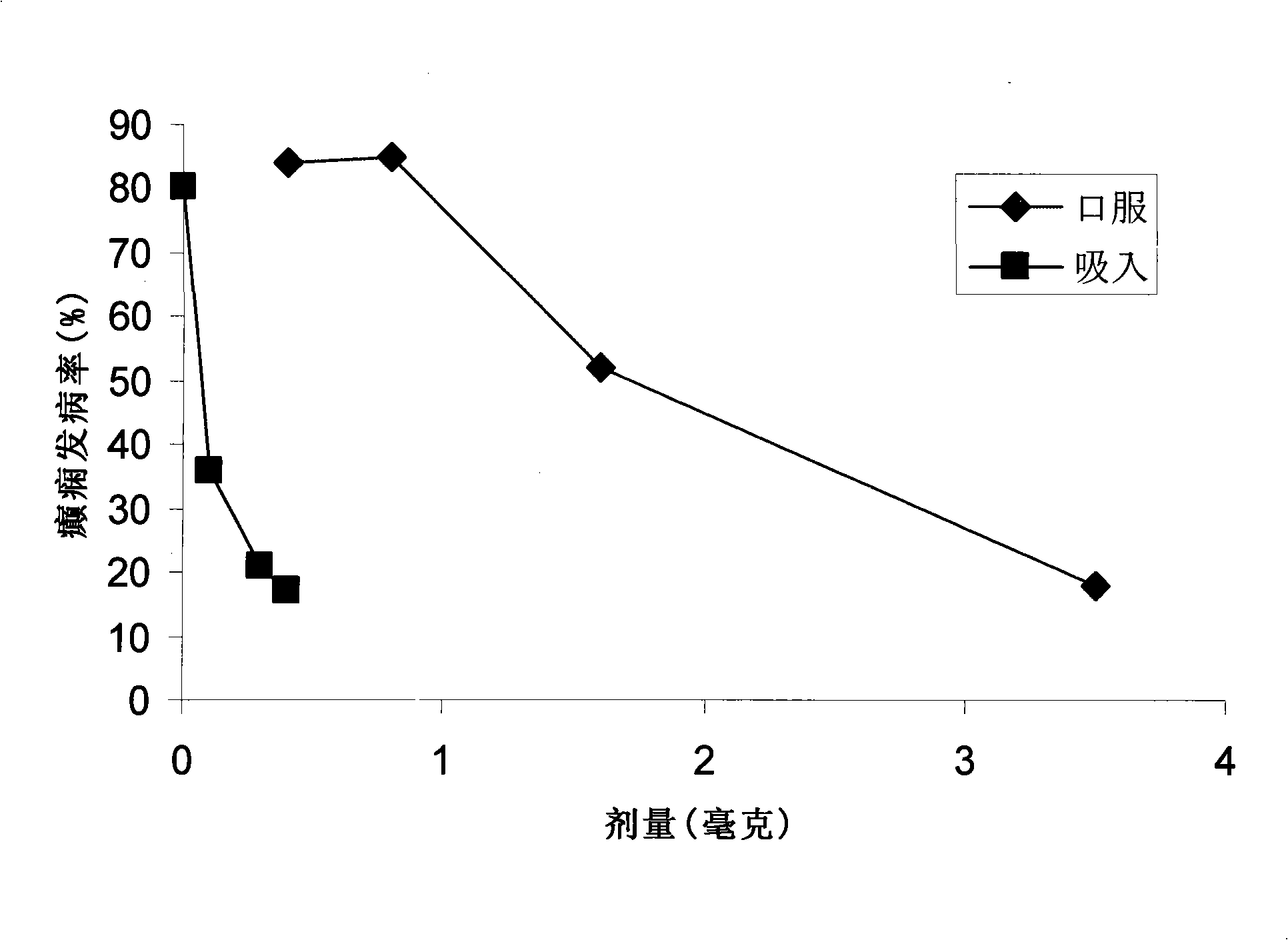

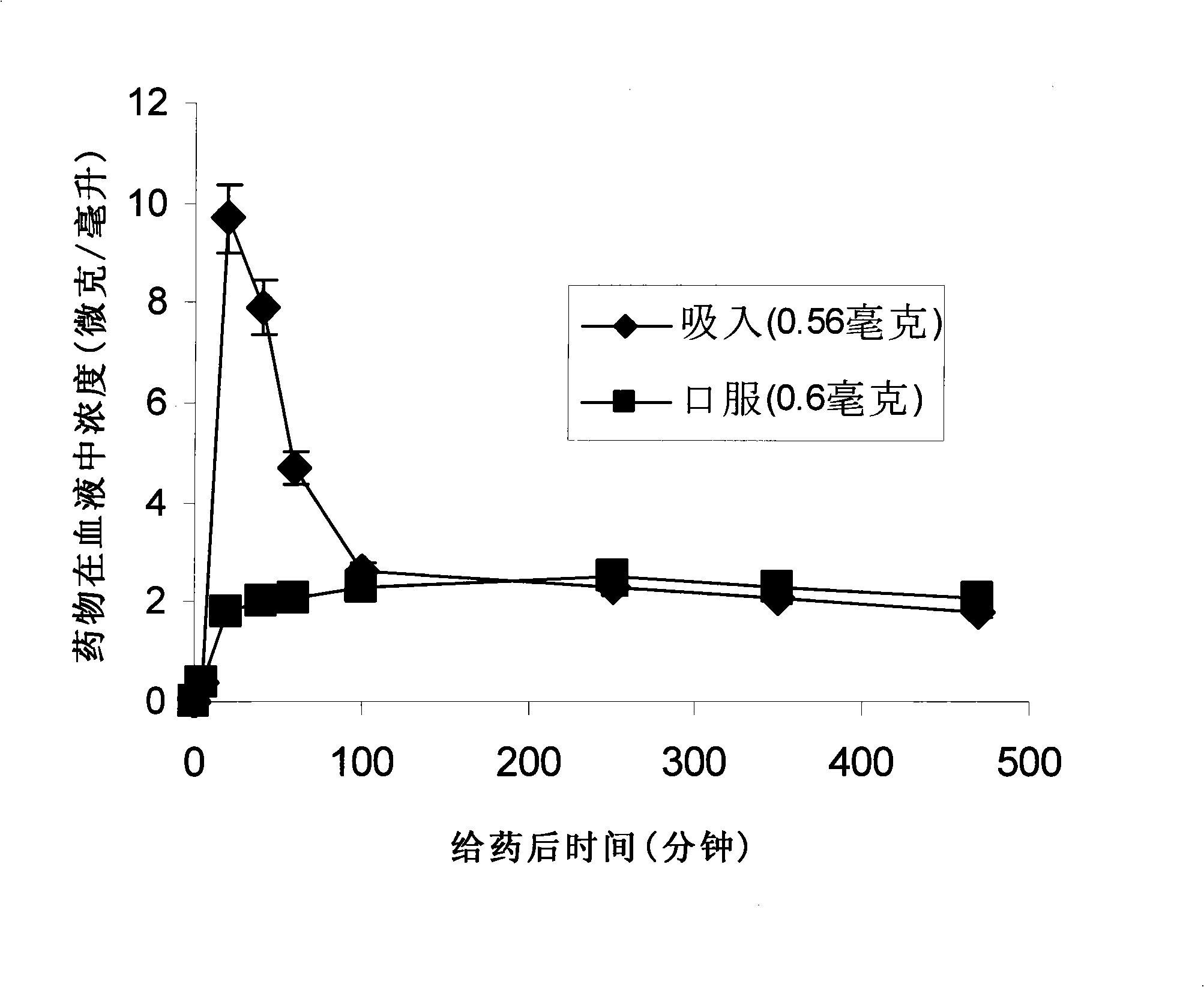

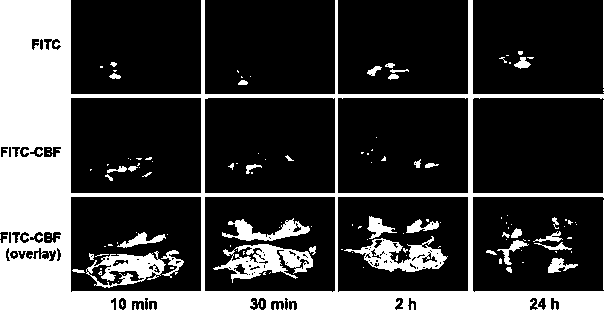

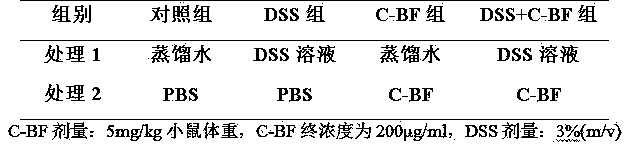

Model for protecting mouse ulcerative colitis by antibacterial peptide C-BF

InactiveCN104031883AReduce enzyme activityIncrease secretionTumor/cancer cellsVeterinary instrumentsUlcerative colitisBowels diseases

The invention discloses a model for protecting mouse ulcerative colitis by antibacterial peptide C-BF. Cathelicin-BF has broad-spectrum antibacterial activity, especially for Gram negative bacteria. Inflammatory bowel diseases (IBDs) comprise ulcerative colitis (UC) and Crohn disease (CD), and pathomechanisms of the diseases are not clear yet. A model for inducing the mouse ulcerative colitis by 3% dextran sulphate sodium (DSS) is built; a PBS solution of the C-BF is subjected to rectal injection once per day, the dose of the C-BF is 5mg / kg, the continuous injection time is one week, a mouse is weighed and the body weight data of the mouse is recorded each day during experimental period, and the rectal bleeding and dung forming situations of the mouse are observed. The model is used for making a research on a protection effect on the mouse UC caused by the C-BF.

Owner:ZHEJIANG UNIV

Immobilization myrosin and method for producing the same

InactiveCN101173266AHigh mechanical strengthImprove stabilityHydrolasesOn/in organic carrierChlorideCalcium alginate

The invention relates to immobilized myrosinase and the preparation method thereof. Cruciferae vegetable seeds, especially broccoli seeds are adopted, and glycerin, EDTA and DTT are added in the process of extracting the myrosinase to protect the enzyme activity; operation is performed at a lower temperature of 4 DEG C, to complete impurity removal and to obtain primary enzyme extracting solution; sodium alginate is added in the immobilization step, is dissolved and mixed at a temperature at which enzyme activity is not influenced, calcium chloride solution is instilled to be produced into calcium alginate granules, glutaraldehyde solution is used for treating the granules, in order to immobilize the free myrosinase. The immobilization method of the invention enables the activity of the myrosinase after being immobilized to achieve 70.84 percent; the pH value stability range of catalytic reaction is widened from 5-7 to 4-9, and the heat-resistant capacity is improved from original 55 to 65 DEG C; the frequency of use of the myrosinase is increased from the original once to three times.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

Restoration of t cell activity via the cd39/cd73 axis

InactiveUS20190218308A1Reduce immunosuppressionGood curative effectHydrolasesPharmaceutical delivery mechanismT cellCancer research

The present invention relates to methods of using compounds that inhibit the enzymatic activity of soluble human CD39 to treat cancer, including but not limited to the treatment of cancers characterized by CD73 expressing cells.

Owner:INNATE PHARMA SA

External skin preparations for suppressing sebum secretion

InactiveUS20060057229A1Growth inhibitionMatrix metalloproteinase is enhancedBiocideCosmetic preparationsExternal applicationMedicine

A drug for external application to the skin, for inhibiting sebum secretion, comprising a matrix metalloproteinase inhibitor.

Owner:SHISEIDO CO LTD

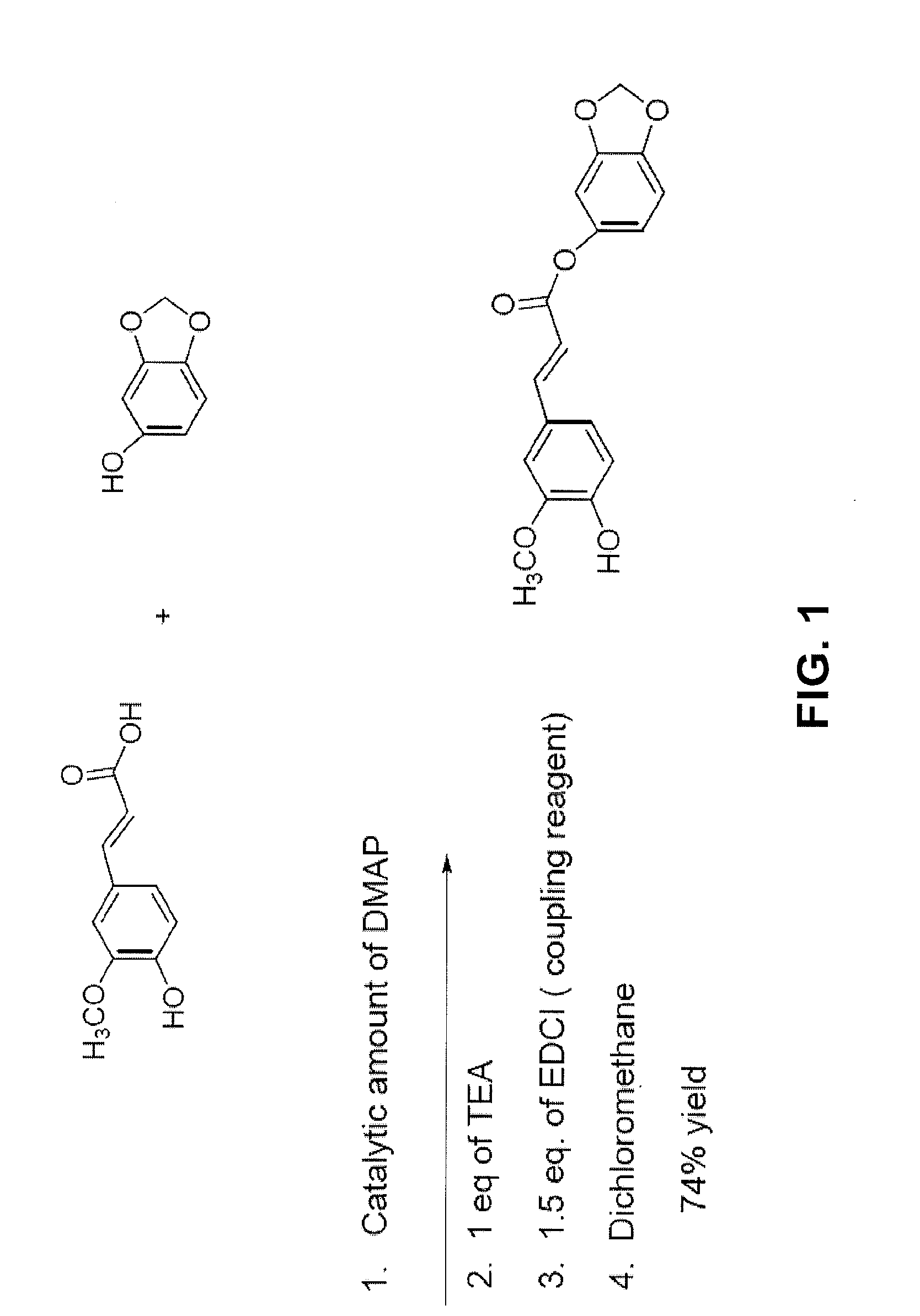

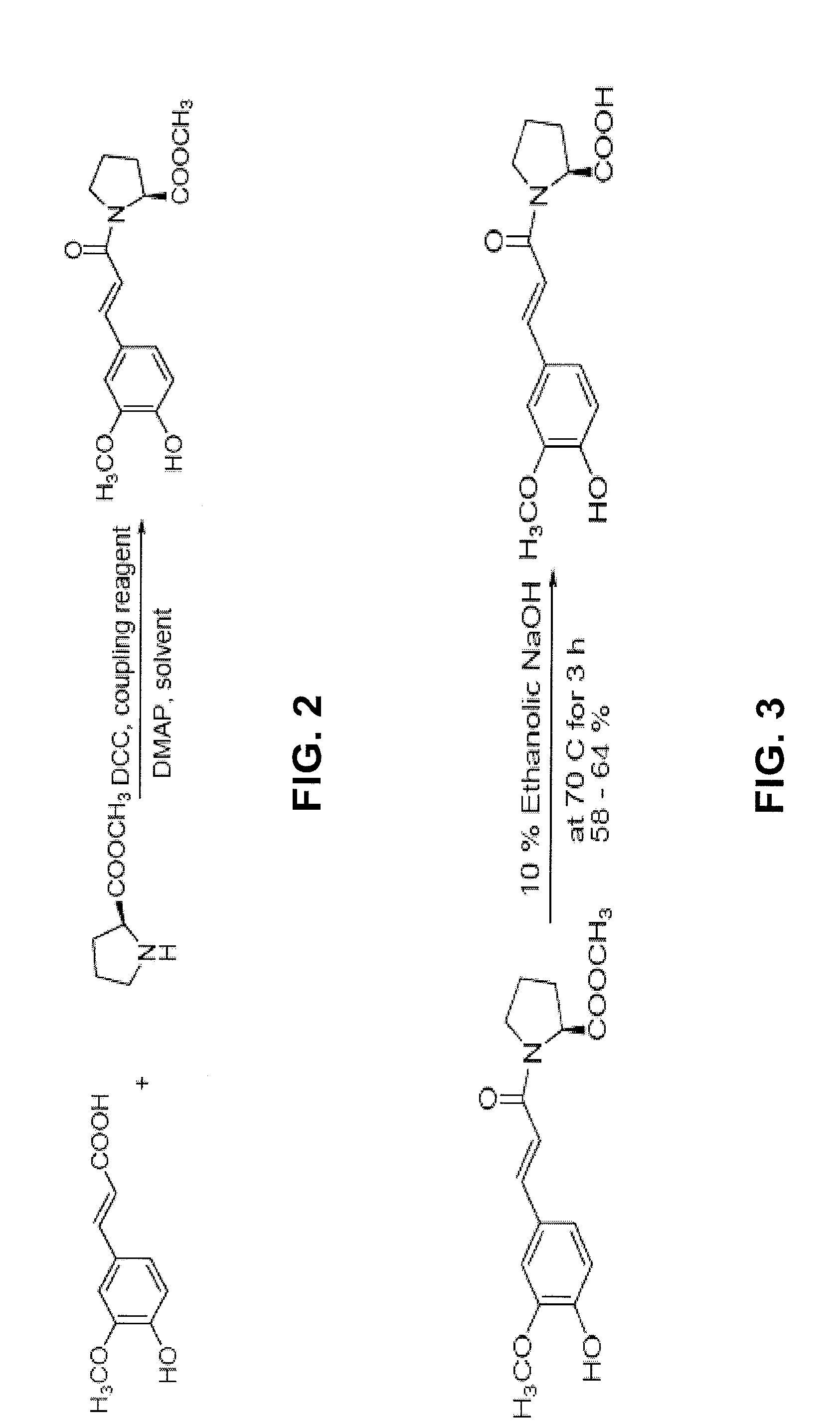

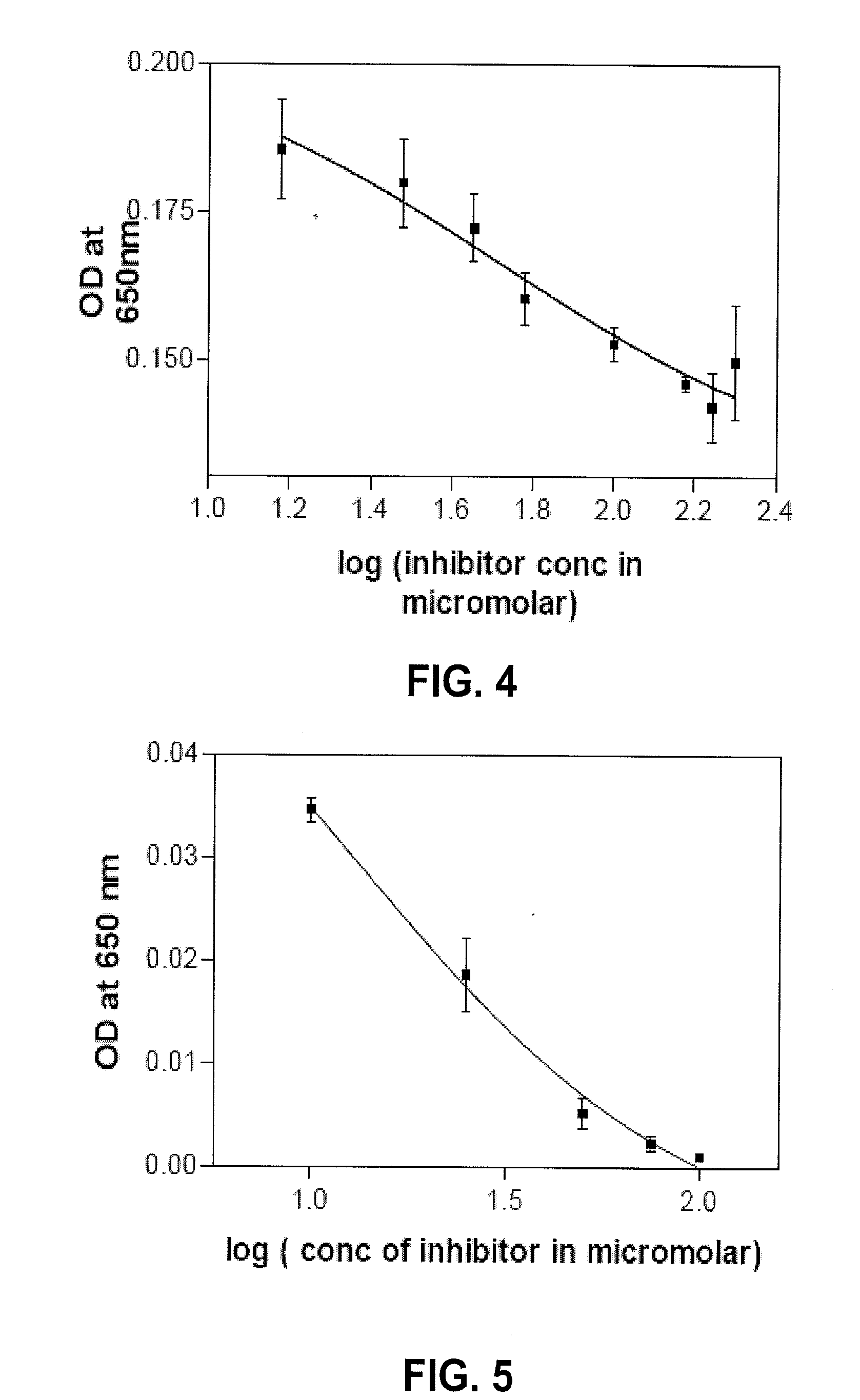

Compositions and Methods for Treatment of Cardiovascular Disease

InactiveUS20120129818A1Minimal toxicityInhibit enzyme activityBiocideOrganic chemistryAnginaCoronary heart disease

Ortho methoxy phenolic compounds are provided that include methylenedioxyphenyl ferulate and ferulylproline and derivatives thereof. Pharmaceutical compositions comprising the compounds and methods of using the compounds for treating cardiovascular diseases, including hypertension, atherosclerosis, coronary heart disease, angina, stroke, and myocardial infarction, are further provided. The compounds are also useful in reducing low-density lipoprotein oxidation, improving or increasing vasodilation, and reducing plaque destabilization in a subject.

Owner:CARMEL BIOSCI

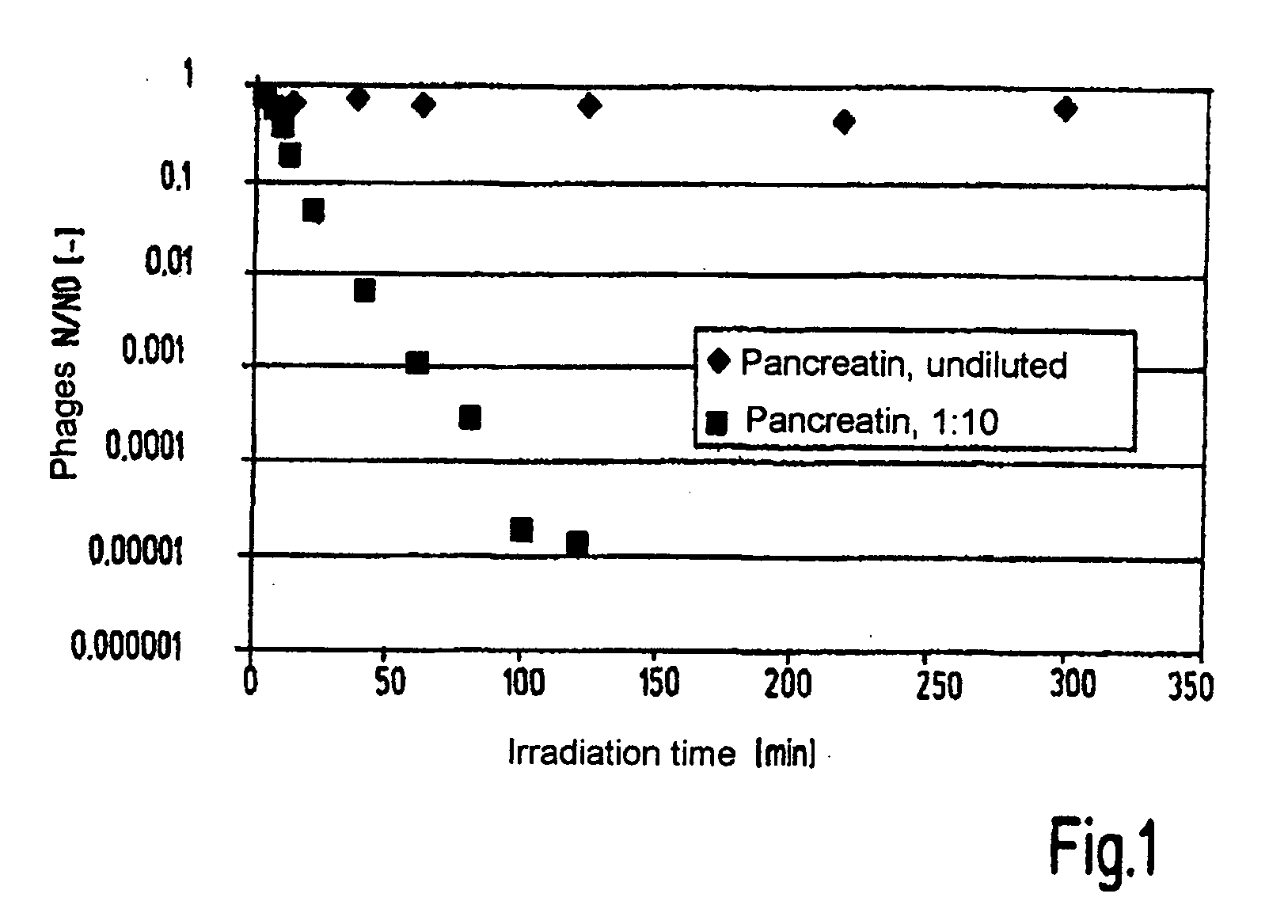

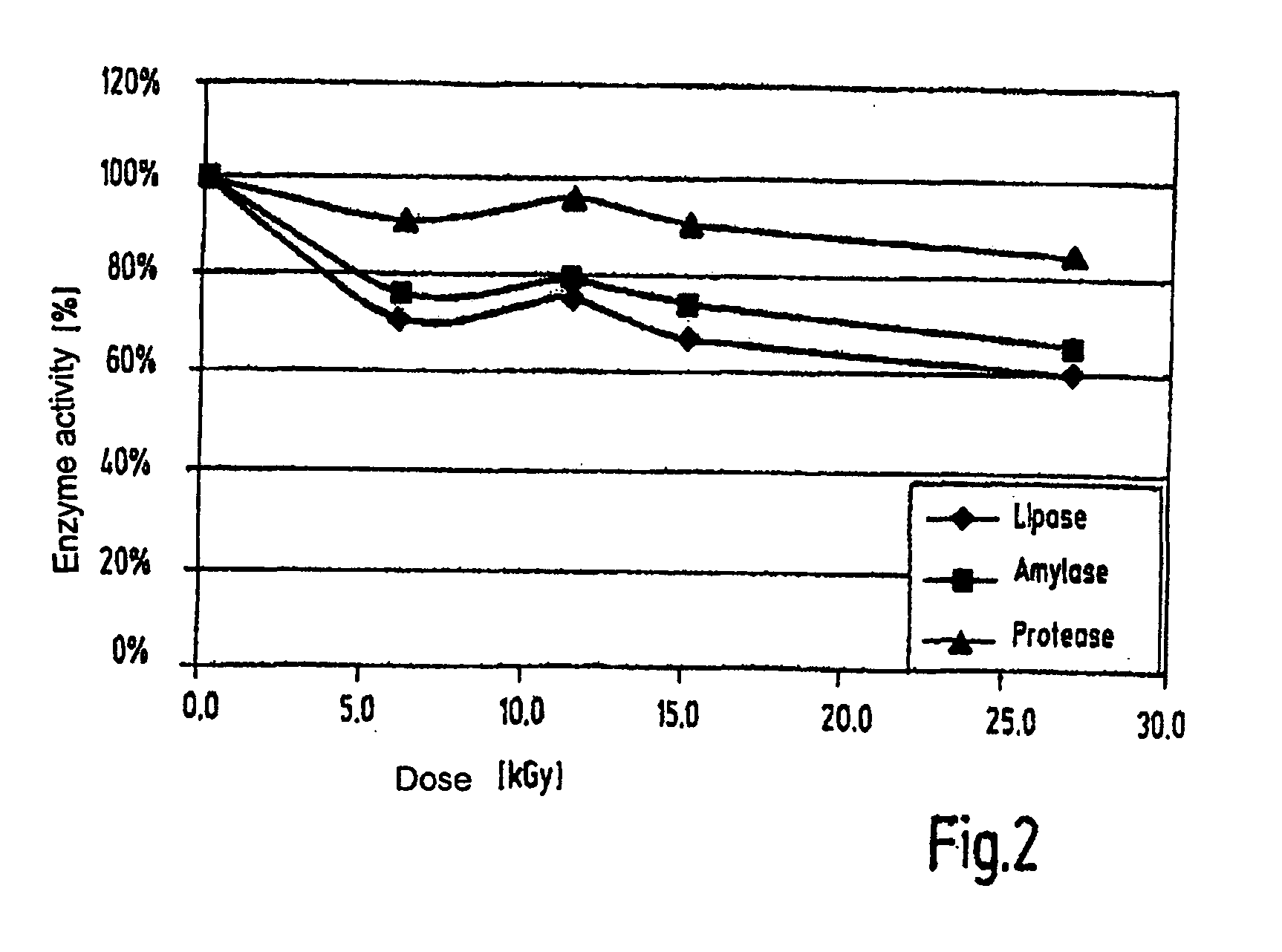

Method for reducing the virus and micro-organism content of biological extracts which contain solids and extract produced according to the method

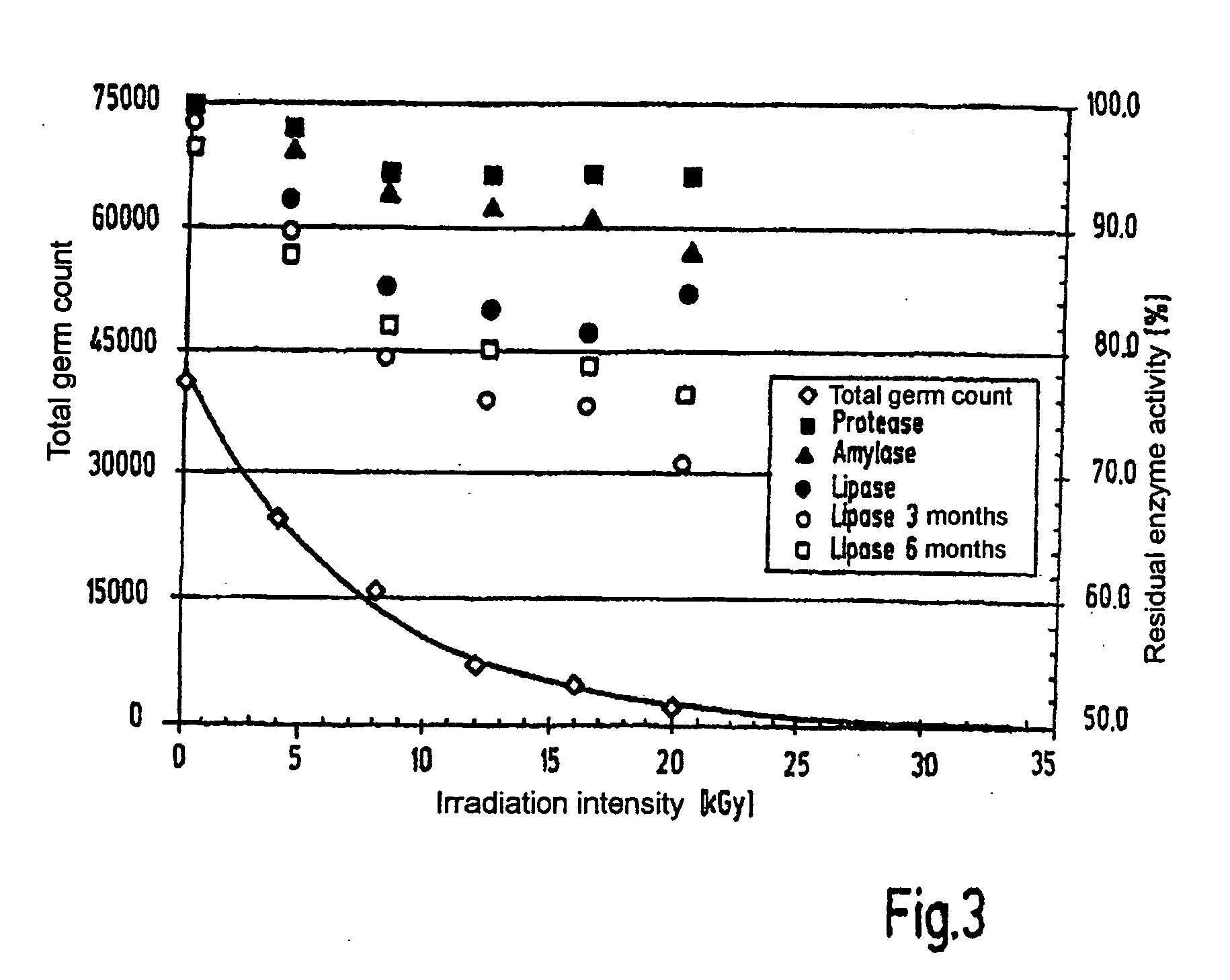

InactiveUS20100119654A1Reduce enzyme activityNot impair pharmacologically intended propertyMilk preparationEnergy modified materialsMicroorganismMedicine

The invention relates to a method for reducing the virus and micro-organism content of biological extracts which contain solids. It is provided that the method comprises the steps(a) provision of a biological extract which contains solids in the form of a suspension, which consists of a liquid phase and solid particles dispersed therein, wherein the extract in step (a) comprises a mixture of enzymes, proteins and peptides, some of which is dissolved in the liquid phase and some of which can be bound to the solid particles or is present in pulverulent, solid form; and(b) irradiation of the biological extract provided in step (a);whereinthe radiation used for the irradiation is selected from the group comprising ultra-violet radiation, x-ray radiation, β radiation and γ radiation; andthe enzymic activity of the biological extract which contains solids after irradiation is at least 50% of the enzymic activity of the biological extract which contains solids before irradiation.

Owner:NORDMARK-WERKE GMBH 2000 HAMBURG

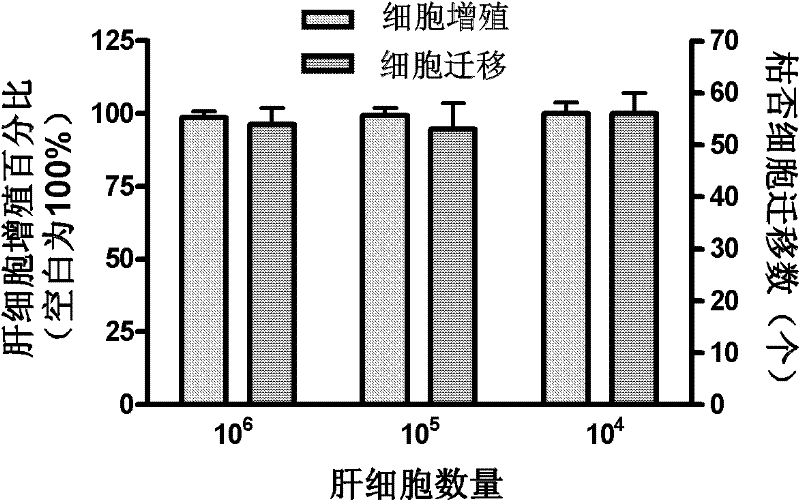

Co-culture system for liver cells and Kupffer cells and application thereof

InactiveCN102220281ADoes not affect proliferationRapid cultivationMicrobiological testing/measurementArtificial cell constructsSerum glutamate pyruvate transaminaseFactor ii

The invention discloses a co-culture system for liver cells and Kupffer cells and application thereof. The co-culture system is characterized in that in a Millicell double-layer culture room, 1-100 ng / mL LPS (lipopolysaccharides) is added into a culture medium, the Kuffer cells are cultured in the upper layer of the Millicell double-layer culture room, and the liver cells are cultured in the lower layer of the Millicell double-layer culture room; and half of the fresh culture medium is replaced every other day so as to keep the concentration of the LPS. The co-culture system for liver cells and Kupffer cells provided by the invention has the advantages that the Kupffer cells continuously secrete inflammatory cell factors (such as TNF-alpha) in vitro after being stimulated by the LPS; the liver cells can generate a great number of enzymes, such as AST (aspartate aminotransferase), ALT (alanine transaminase) and GGT (gamma-glutamyl transpeptidase) in the environment so as to stimulate the liver injury based on immunoreaction caused by the immune / inflammation response after the liver tissue undergoes virus infection in vivo; and moreover, the co-culture system is used for screening medicaments resisting immune liver injury according to the influence of the medicaments on the secretion amount of immune factors and the enzymatic activity.

Owner:SHAANXI INST FOR FOOD & DRUG CONTROL

Inactivation method

ActiveUS20070224611A1Reduce enzyme activityInhibition formationBiocideOrganic chemistryThermostable enzymesChemical modification

The present invention relates to the field of thermostable enzymes, methods for their inactivation, and related uses, kits and reagents. In particular, the invention relates to a method for reversible inactivation of thermophilic enzymes by chemical modification under aqueous or non-aqueous conditions.

Owner:THERMO FISHER SCI BALTICS UAB

Dehydrated dried bamboo shoots

InactiveCN107439672ABright colorInhibit the degree of browningFruits/vegetable preservation by dehydrationMicrowaveBamboo shoot

The invention discloses a dried dehydrated bamboo shoot, which relates to the technical field of bamboo shoot processing and comprises the following steps: (1) pretreatment; (2) air-drying treatment; (3) vacuum freezing treatment; (4) microwave drying; The dehydrated dried bamboo shoots, the color is close to fresh bamboo shoots, the properties are basically unchanged, the tissue is loose, the surface pores are large, and the taste is crisp and crisp.

Owner:NINGGUO MAOSHENG FOOD

Protein containing serum albumin domain

InactiveUS20050256303A1Improve functional activityImprove antioxidant capacityFungiBacteriaFunctional activityAntibacterial activity

A protein produced by gene recombinant technology, including at least one domain selected from domains I, II, and III of serum albumin but having a different structure from that of native albumin; and a method of producing the protein. The protein has an enhanced functional activity or activities selected from among various functional activities or serum albumin including antibacterial activity, antioxidative effect, inflammation inhibitory effect, in vivo substance transporting action, and enzymatic activity.

Owner:NIPRO CORP

Method for preparing idesia polycarpa edible vegetable oil by immobilized enzyme and hot brine treatment process

InactiveCN102041167AHigh yieldLess alkali consumptionFatty-oils/fats refiningEdible oils/fatsEdible oilImmobilized enzyme

The invention discloses a method for preparing idesia polycarpa edible vegetable oil by an immobilized enzyme and hot brine treatment process, belonging to the field of food. The method comprises the following steps: raw oil degumming, acidity reduction by immobilized enzyme, alkali refining, water washing, debitterizing by hot brine, and vacuum deodorization. The invention is characterized in that the immobilized enzyme is utilized to treat degummed oil, thereby lowering the acidity and reducing the alkali consumption and the amount of the formed saponin; the hot brine is utilized to treat the alkali-refined oil and thoroughly remove the bitter principles from the oil to finally obtain the high-quality edible vegetable oil, thereby saving the removal time and the water consumption; and meanwhile, the invention has the advantages of simple technological process, mild operating conditions, low requirements for equipment, high safety and environmental protection, and has wide application prospects in the production of idesia polycarpa edible oil.

Owner:四川省毛叶山桐子科技股份有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com