Method for coproduction of rice starch and rice protein

A technology of rice starch and rice protein, applied in the field of rice starch and rice protein, co-production of rice starch and rice protein, can solve the problems of low utilization rate of rice resources, pollution, waste of high-quality protein resources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

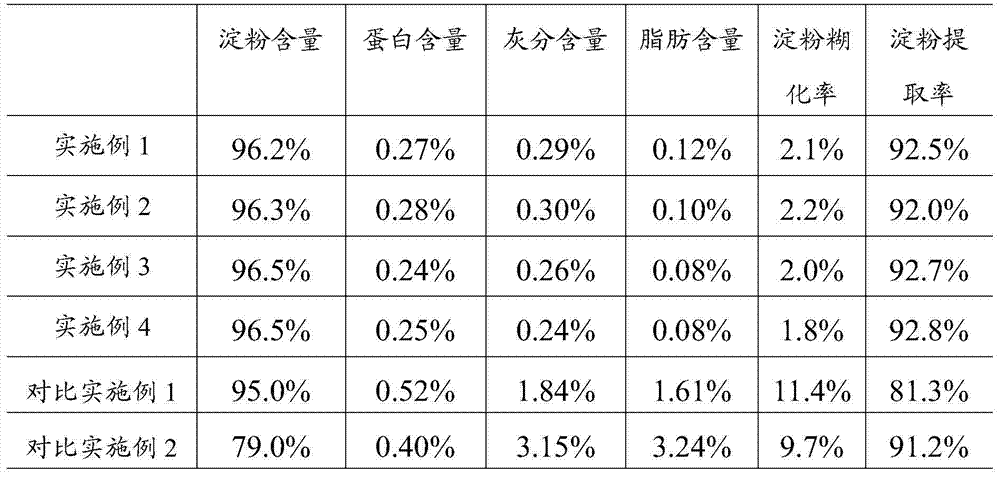

Embodiment 1

[0121] Embodiment 1: co-production of rice starch and rice protein

[0122] The implementation steps of this embodiment are as follows:

[0123] A. Raw material pretreatment

[0124] Take by weighing 1000kg the broken rice (85.1% of dry basis starch content, 6.4% of dry basis protein content) sold by Hunan Jinjian Rice Industry Co., Ltd. as raw material, remove sand and magnetize through the cleaning equipment sold by Jiangsu Muyang Group Co., Ltd. After cleaning, under the condition of the cooling fan sold by Hailin Refrigeration Fan Factory, Caota Town, Zhuji City, under the condition of cooling air, use the jet mill sold by Weifang Jingjing Powder Engineering Equipment Co., Ltd. to crush the cleaned raw materials to 120-150 mesh, get a rice noodle;

[0125] B. The first pulping and enzyme reaction

[0126] Add water to the rice flour obtained in step A to adjust the slurry to obtain a feed liquid with a concentration of 25% by weight, and then sieve the feed liquid with ...

Embodiment 2

[0140] Embodiment 2: co-production of rice starch and rice protein

[0141] The implementation steps of this embodiment are as follows:

[0142] A. Raw material pretreatment

[0143] Take by weighing 1000kg the broken rice (86.2% of dry base starch content, 6.6% of protein content) sold by Hunan Donghua Rice Industry Co., Ltd. as raw material, use the cleaning equipment sold by Changzhou Wujin Global Grain Machinery Equipment Co., Ltd. to remove sand and magnetic Select and clean up, under the condition of the refrigerating fan sold by Zhejiang Qingfeng Refrigeration Equipment Manufacturing Co., Ltd. to ventilate the cold air, use the airflow mill sold by Qingdao Shina Machinery Equipment Co., Ltd. to pulverize the cleaned raw materials to 120-150 mesh to obtain a kind of rice flour .

[0144] B. The first pulping and enzyme reaction

[0145] Add water to the rice flour obtained in step A to adjust the slurry to obtain a second slurry adjustment slurry with a concentration ...

Embodiment 3

[0159] Embodiment 3: co-production of rice starch and rice protein

[0160] The implementation steps of this embodiment are as follows:

[0161] A. Raw material pretreatment

[0162] Take by weighing 1000kg the broken rice (88.7% of dry base starch content, 7.1% of dry base protein content) sold by Jiangxi Huafeng Rice Industry Co., Ltd. as raw material, carry out desanding and Magnetic separation cleaning, under the condition of the cooling fan sold by Shanghai Hongbei Industrial Co., Ltd., the airflow mill sold by Shanghai Saishan Powder Machinery Manufacturing Co., Ltd. is used to pulverize the cleaned raw materials to 120-150 meshes to obtain a rice flour

[0163] B. The first pulping and enzyme reaction

[0164] Add water to the rice flour obtained in step A to adjust the slurry to obtain a feed liquid with a concentration of 27% by weight, and then sieve the feed liquid with a 100-mesh standard sieve to remove difficult-to-crush bran and fibers, and then sieve Add th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com