Iron tailing-based complex mineral admixture and preparation process thereof

A technology of mineral admixture and preparation process, which is applied in the field of iron tailings-based composite mineral admixtures for cement and concrete, which can solve the problems of difficult industrial production, limited feasibility, and complicated preparation process, and increase the strength in the later stage , Improve the pore structure, good performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to better understand the present invention, the content of the present invention is further illustrated below in conjunction with the examples, and the content is not limited to the following examples.

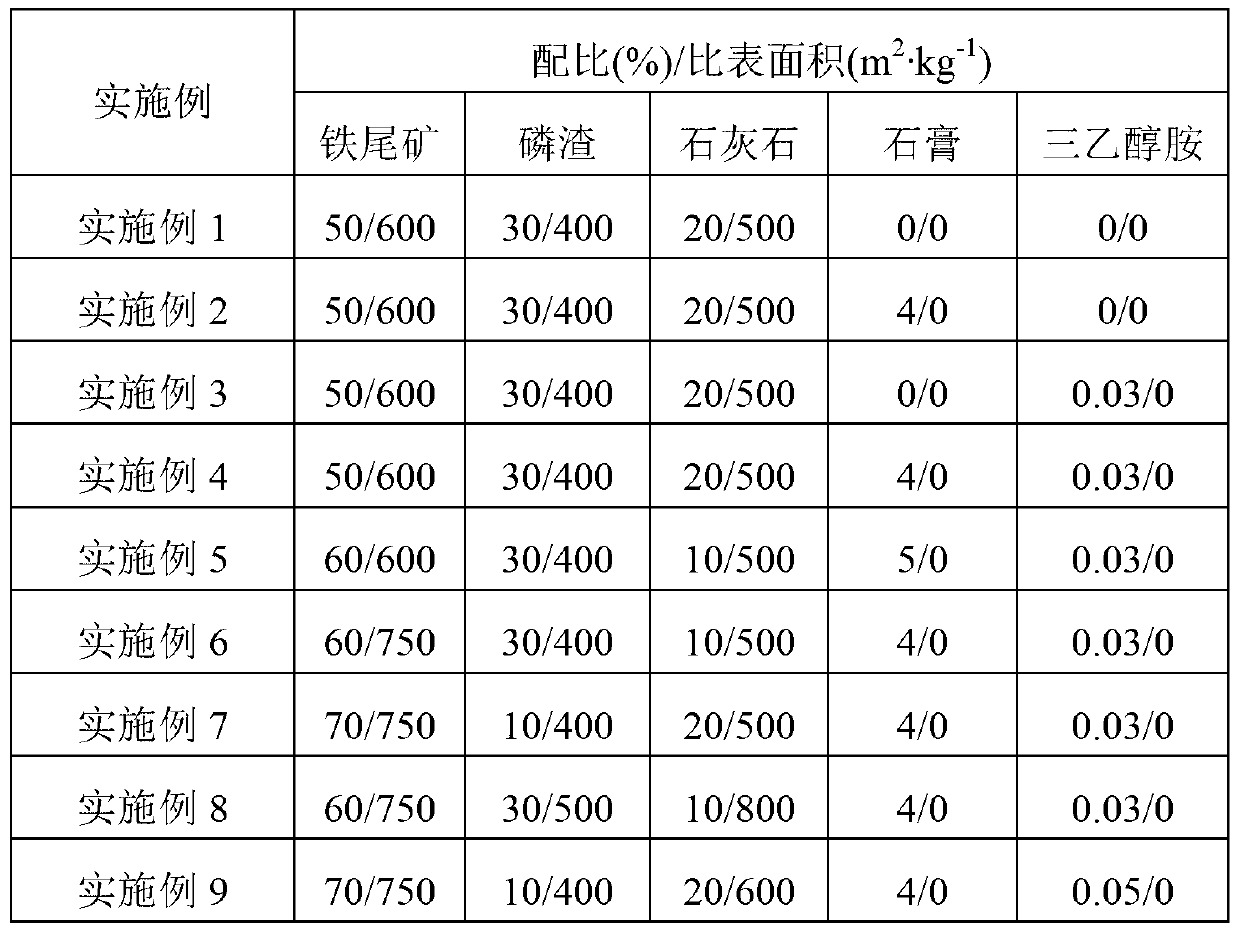

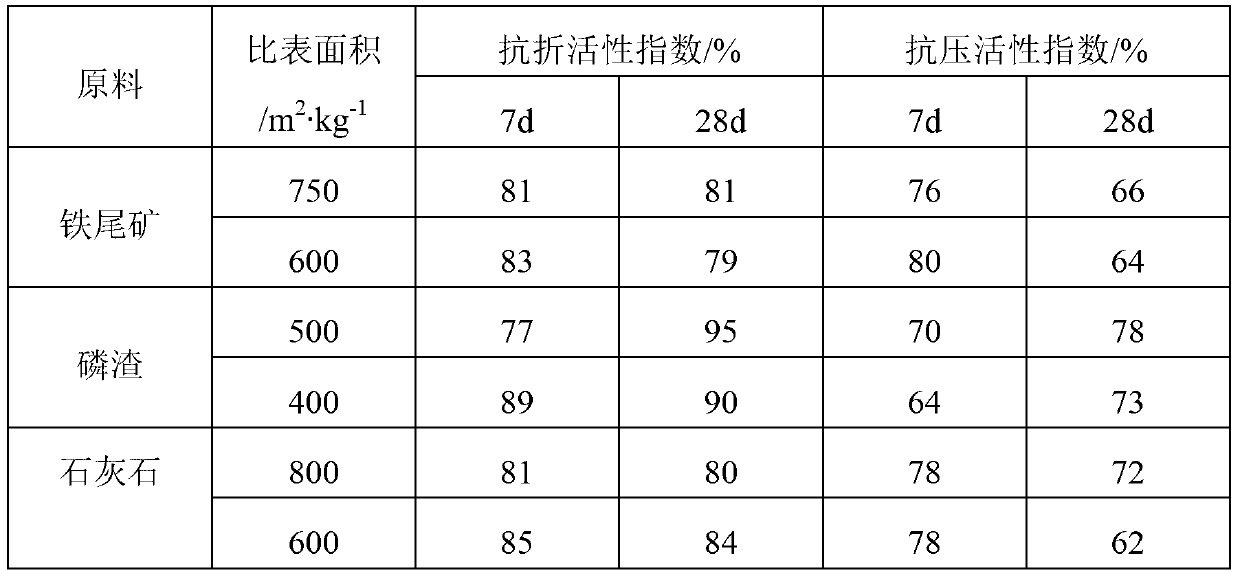

[0026] For the iron tailings-based composite mineral admixture used in cement and concrete, the specific surface area and mass percentage of each component after grinding are shown in Table 1:

[0027]

[0028] Table 1 The formula of iron tailings-based composite mineral admixture

[0029] In this example, the grinding aid is triethanolamine with a mass fraction ≥ 75% (purity).

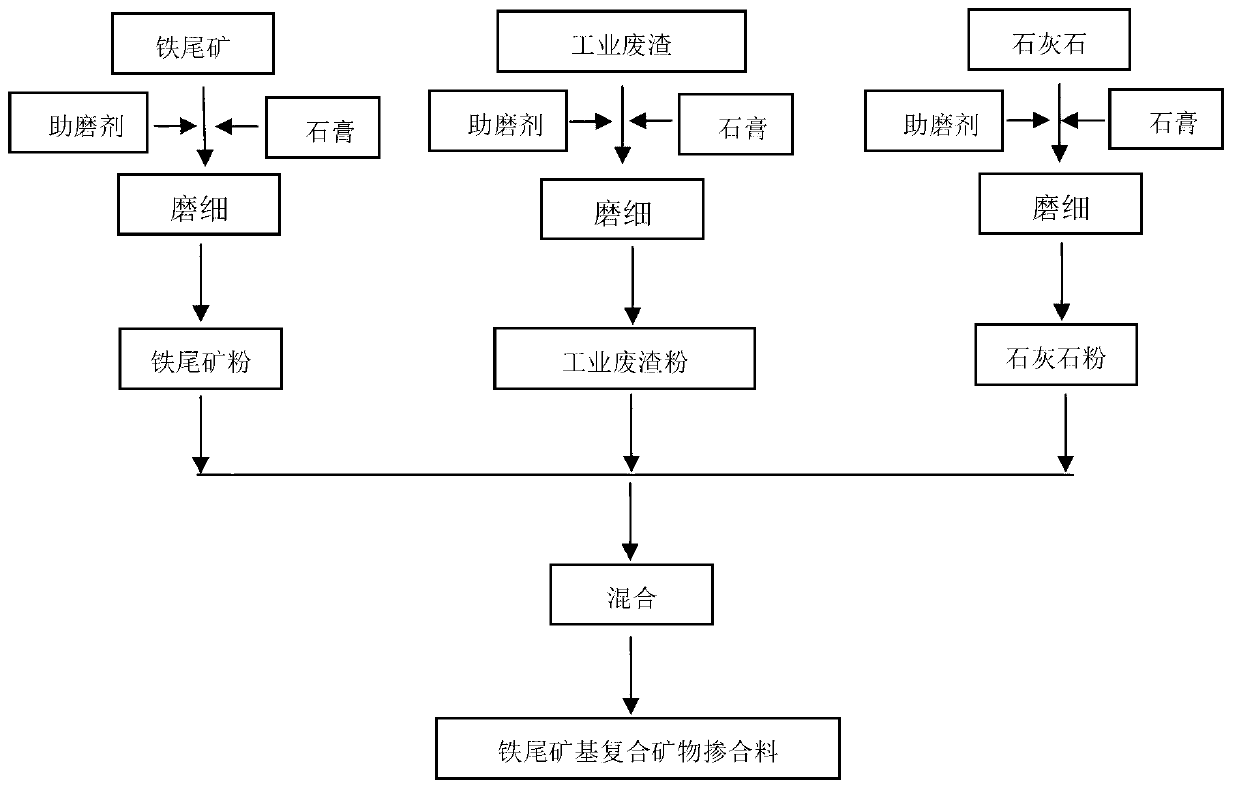

[0030] The preparation process of the iron tailings-based composite mineral admixture of the present invention is as follows:

[0031] The iron tailings sand, phosphorus slag, and limestone are firstly dried to moisture ≤ 1%. The fineness modulus of the iron tailings is 1.81, and the particles below 1.18mm have 94.6% by mass percentage. Then the dried iron tailings sand, phosphoru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com