Patents

Literature

1010results about How to "Excellent performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

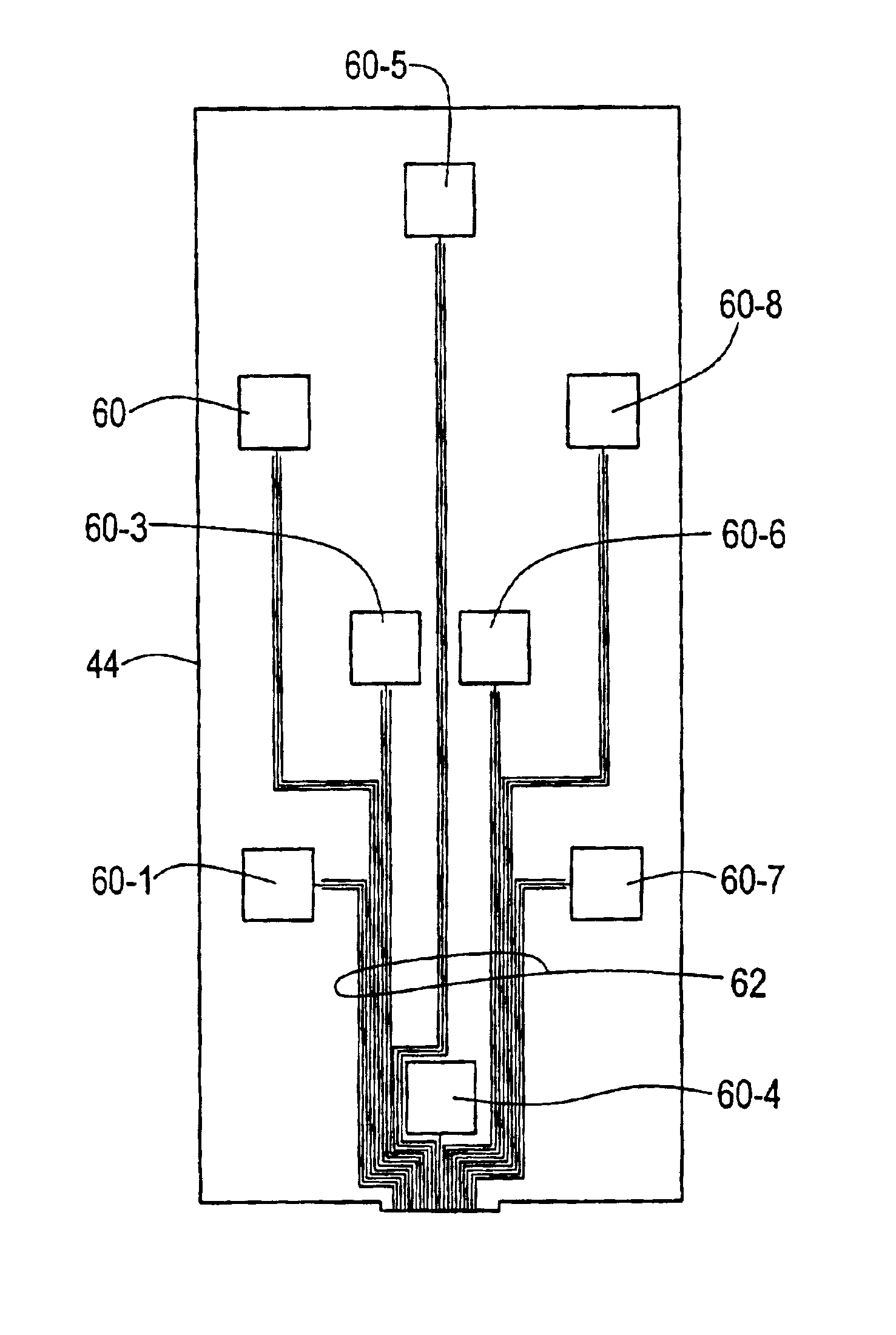

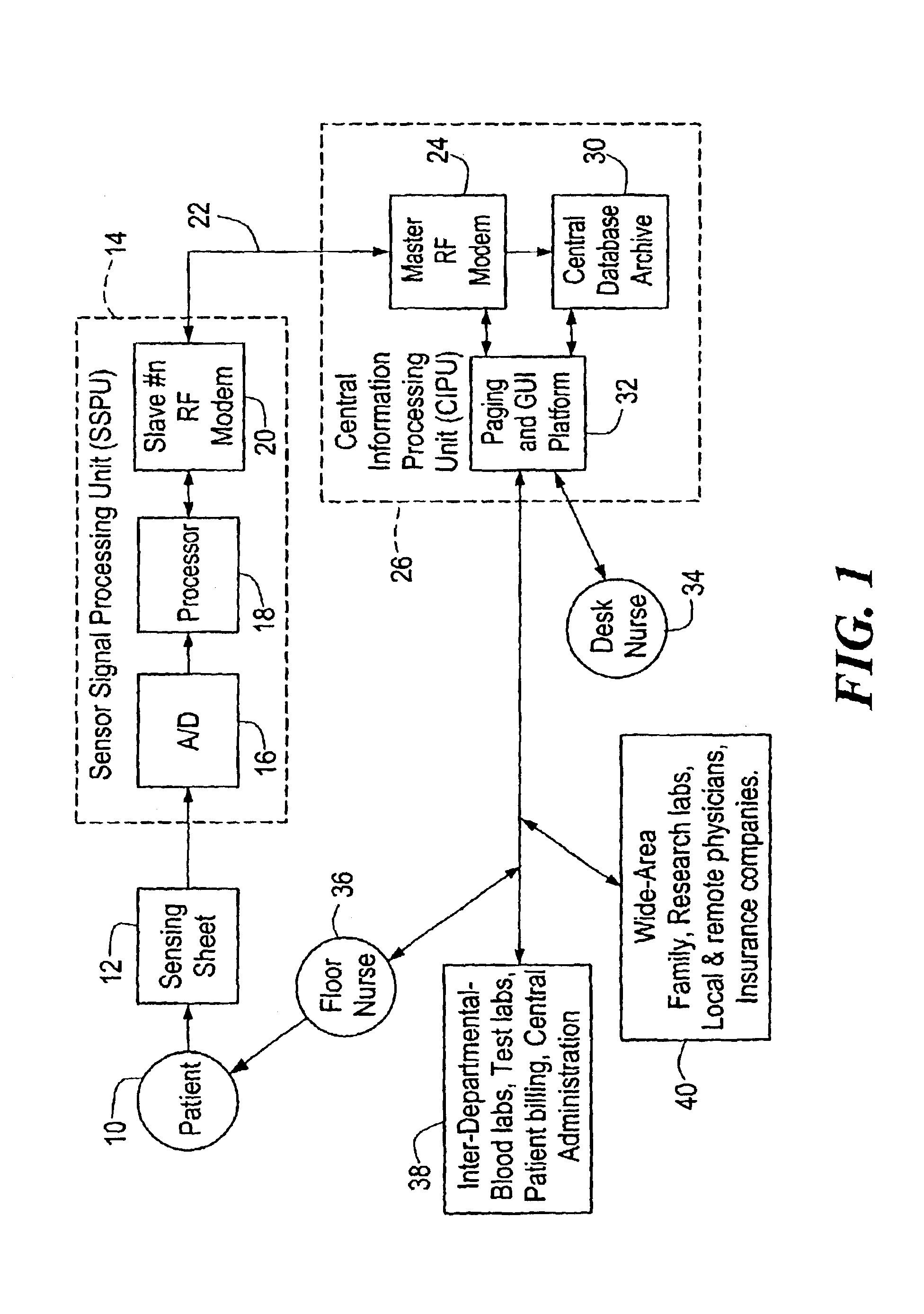

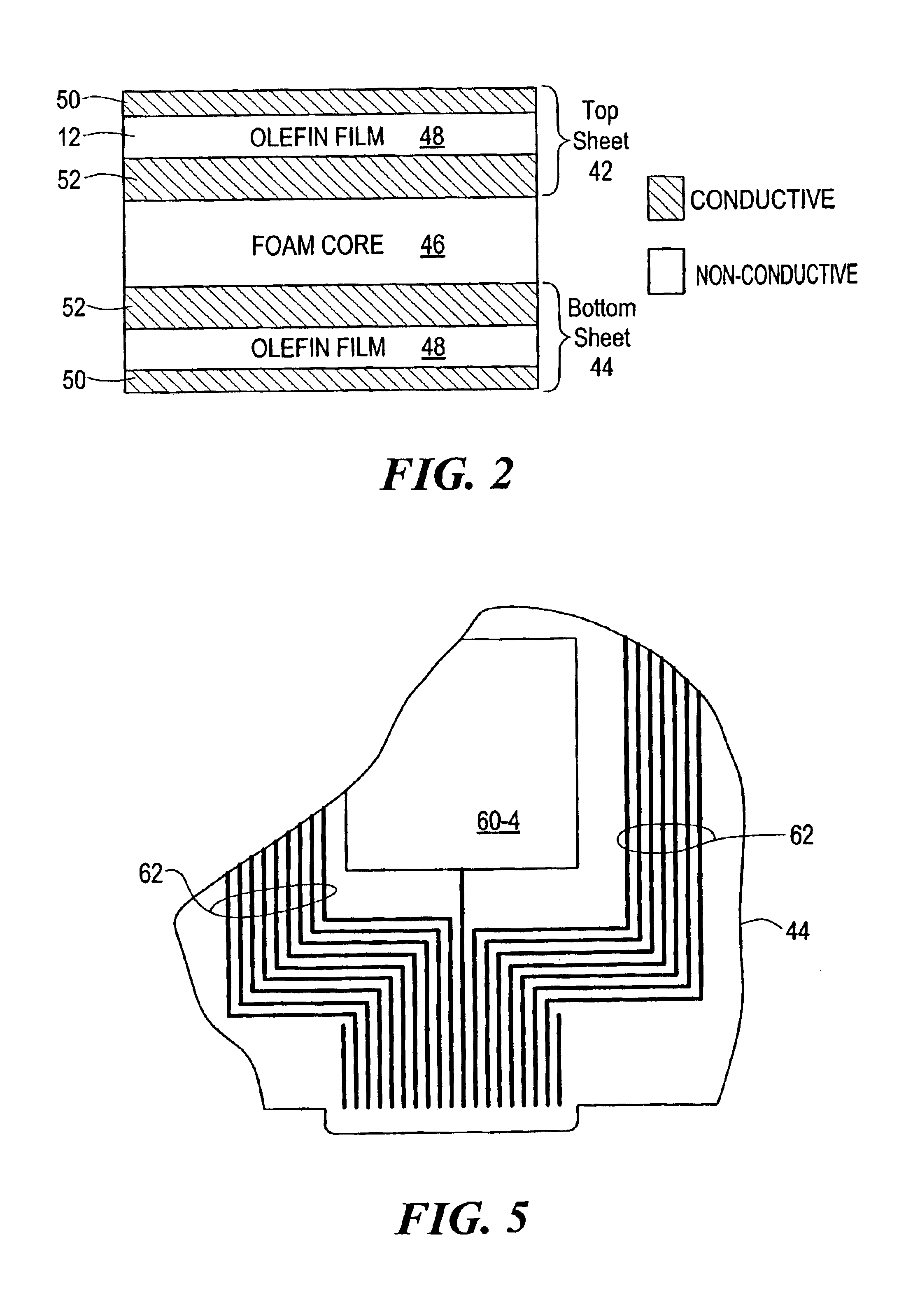

Patient monitoring system employing array of force sensors on a bedsheet or similar substrate

InactiveUS6840117B2Excellent performanceReduce incidenceVehicle seatsPedestrian/occupant safety arrangementCapacitanceEngineering

A patient monitoring system includes a replaceable laminar sensor to be placed on a bed, the sensor including distributed force sensing elements providing output signals to processing apparatus including a near-bed processor and a central processor coupled to the near-bed processor by a wireless communication link. The processing apparatus applies spatial weighting to the sensor output signals to derive the force distribution across the sensor, and processes the force distribution over time to generate patient status information such as patient presence, position, agitation, seizure activity, respiration, and security. This information can be displayed at a central monitoring station, provided to a paging system to alert attending medical personnel, and used to update medical databases. The sensor may be manufactured from layers of olefin film and conductive ink to form capacitive sensing elements.

Owner:TRUSTEES OF BOSTON UNIV

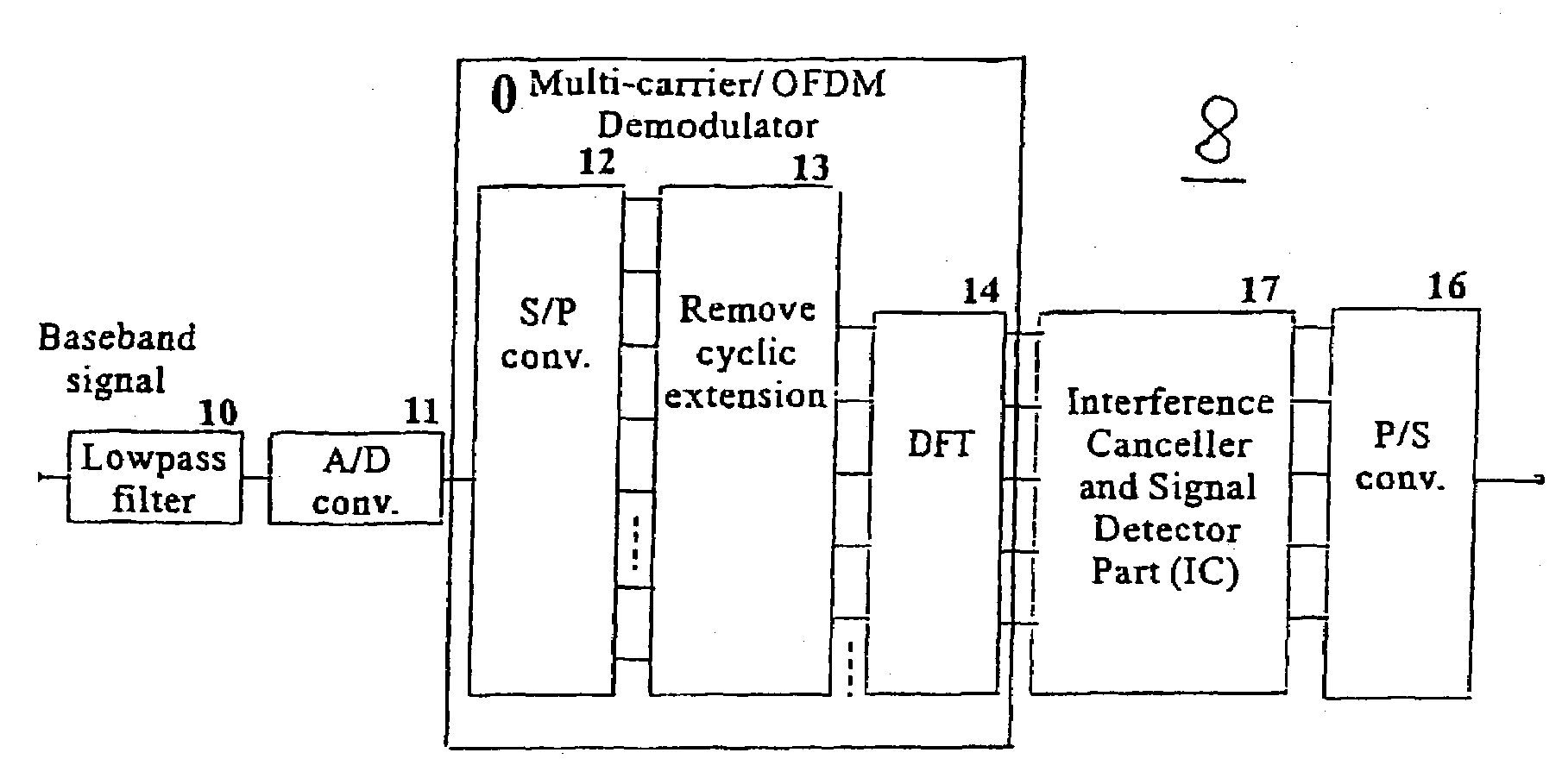

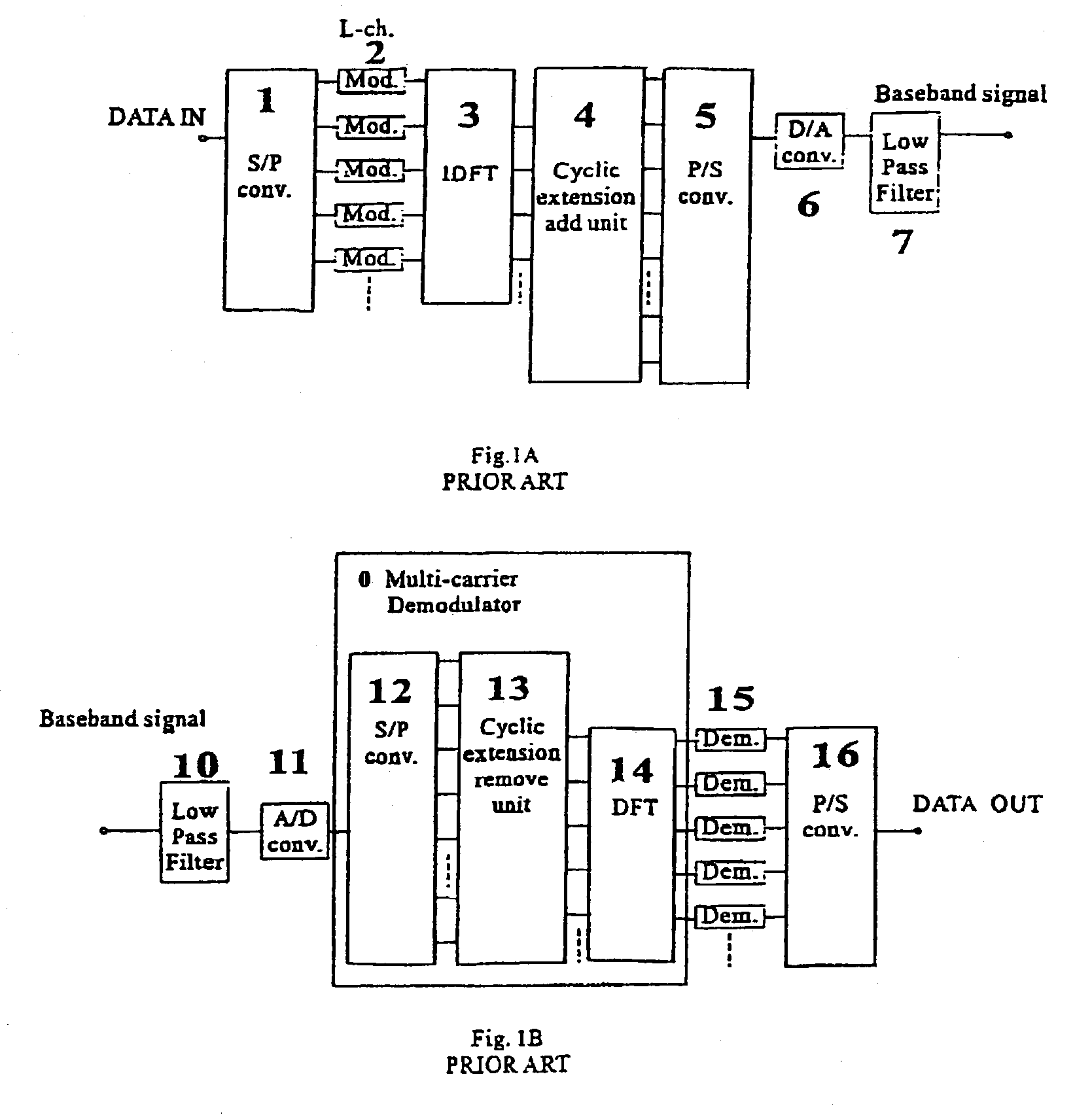

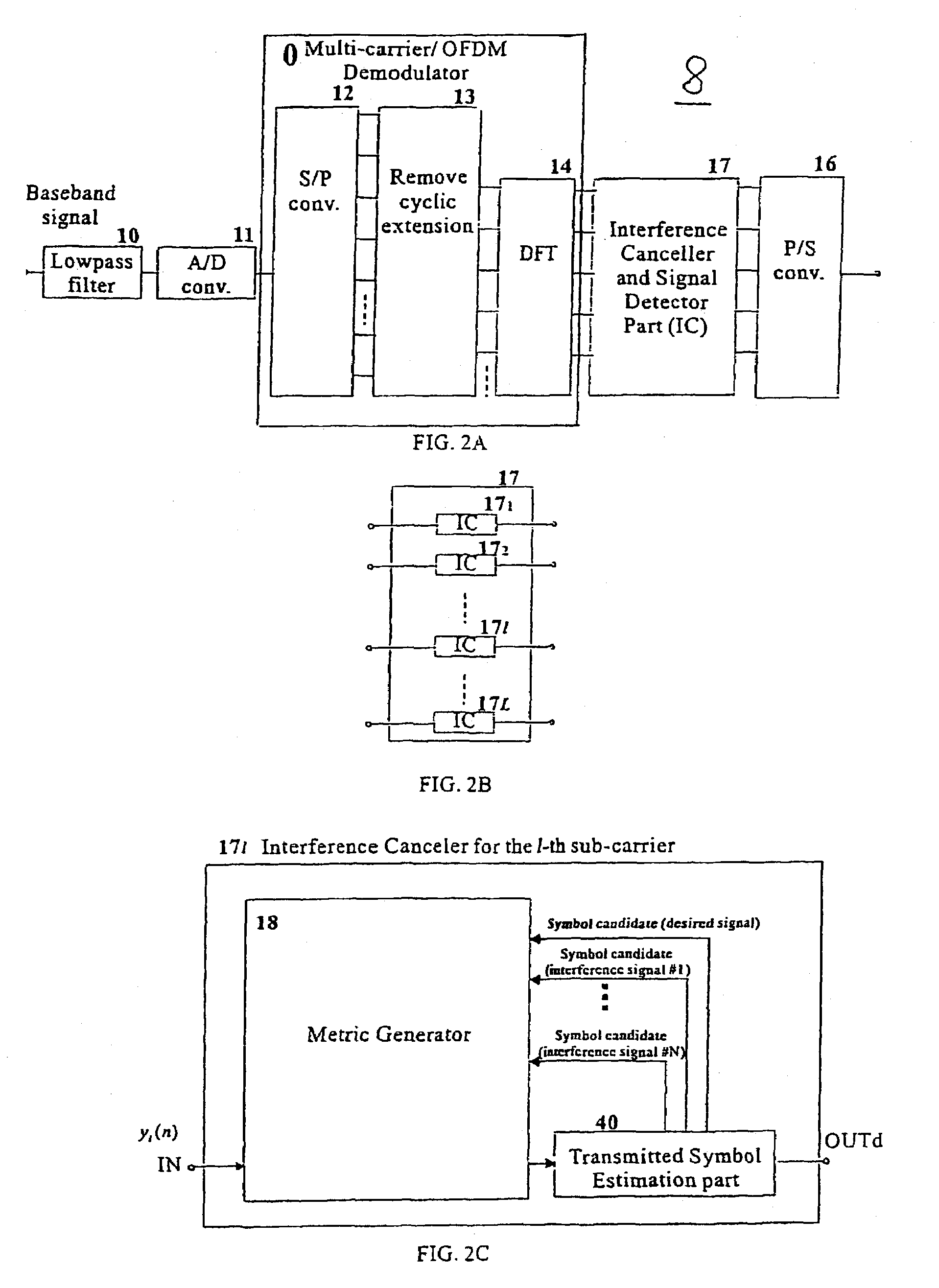

Method for co-channel interference cancellation in a multicarrier communication system

InactiveUS7324437B1Excellent performanceInhibitionSpatial transmit diversityTransmission control/equalisingCarrier signalSubcarrier

A method for cancelling co-channel interference in a multi-carrier communication system includes receiving a serial baseband multi-carrier signal including at least one desired signal and at least one interference signal over at least one receiving branch, and converting the received multi-carrier signal into a plurality of baseband sub-carrier signals. Co-channel interference in each sub-carrier signal is cancelled by subtracting an estimated desired received sub-carrier signal and an estimated interference sub-carrier signal from a received sub-carrier signal. The sub-carrier signals are converted to a multi-carrier output signal comprising the desired signal.

Owner:DEUTSCHE TELEKOM AG

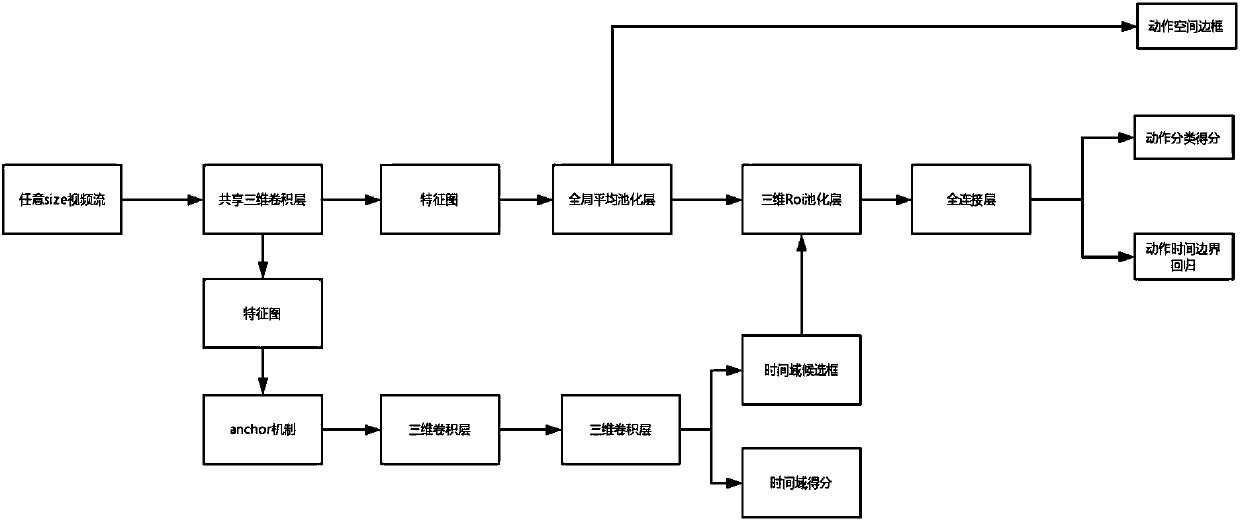

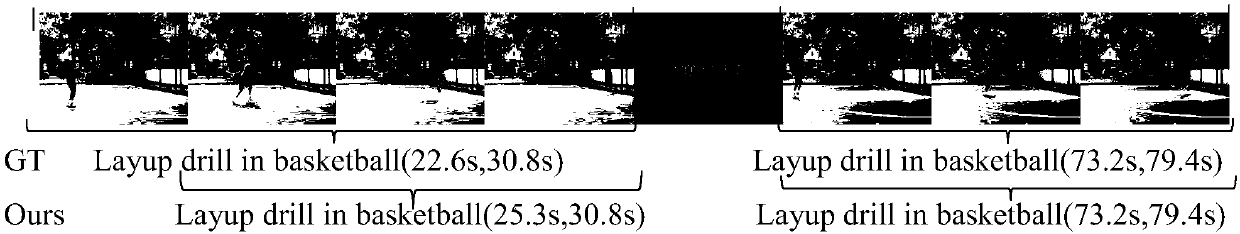

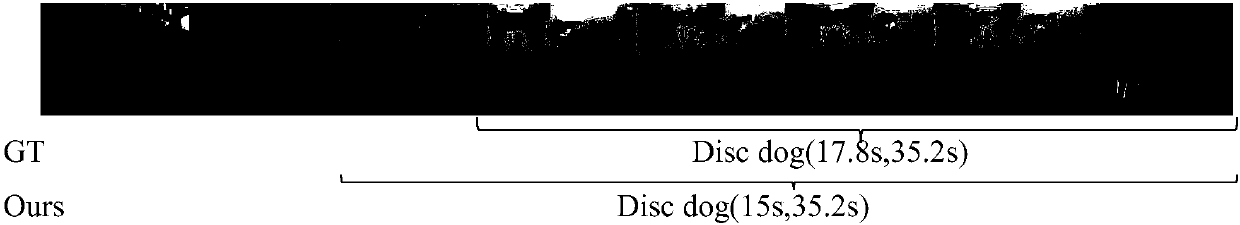

Three-dimensional convolution and Faster RCNN-based video action detection method

InactiveCN108399380AExcellent performanceRealize action positioningCharacter and pattern recognitionNeural architecturesComputer visionConvolution

The invention discloses a three-dimensional convolution and Faster RCNN-based video action detection method. The method comprises the steps of firstly introducing a new model, and encoding a video stream by using a three-dimensional full convolutional network; secondly generating candidate time regions comprising actions based on generated features, and generating a group of candidate frames; andfinally performing classified detection on the candidate frames subjected to different film editing, thereby predicting action types and video action starting and ending time in the video stream, andpredicting spatial position boundary frames of the actions. Compared with an existing method, the method provided by the invention has excellent performance in unpruned data set video time sequence action detection, and can realize action localization in the absence of spatial labeling information.

Owner:BEIJING UNIV OF TECH

Dyed polyester FDY fiber and preparation method thereof

ActiveCN108385194AExcellent performanceSimple preparation processSpinnerette packsFilament/thread formingThermal insulationSlow cooling

The invention relates to polyester FDY fiber and a preparation method thereof. The preparation method comprises: metering a modified polyester melt, extruding, cooling, oiling, drawing, carrying out heat setting, and winding to prepare the polyester FDY fiber, wherein the unchanged longitudinal height is maintained during the cooling, the cross section area of the slow cooling chamber is increasedwhile the plate surface temperature of the spinning plate is maintained by using the thermal insulation method. According to the present invention, the material of the fiber is the modified polyester, the molecular chain of the modified polyester comprises a terephthalic acid chain segment, an ethylene glycol chain segment and a diol chain segment having the branched chain, the structure formulaof the diol chain segment having the branched chain is defined in the specification, R1 and R2 are respectively and independently selected from straight chain alkylidene with a carbon atom number of 1-3, R3 is selected from alkyl with a carbon atom number of 1-5, and R4 is selected from alkyl with a carbon atom number of 2-5; the chromatic aberration [delta]E of the prepared fiber is less than 0.200; and the preparation process is simple and reasonable, and the prepared fiber has excellent performance.

Owner:JIANGSU HENGLI CHEM FIBER

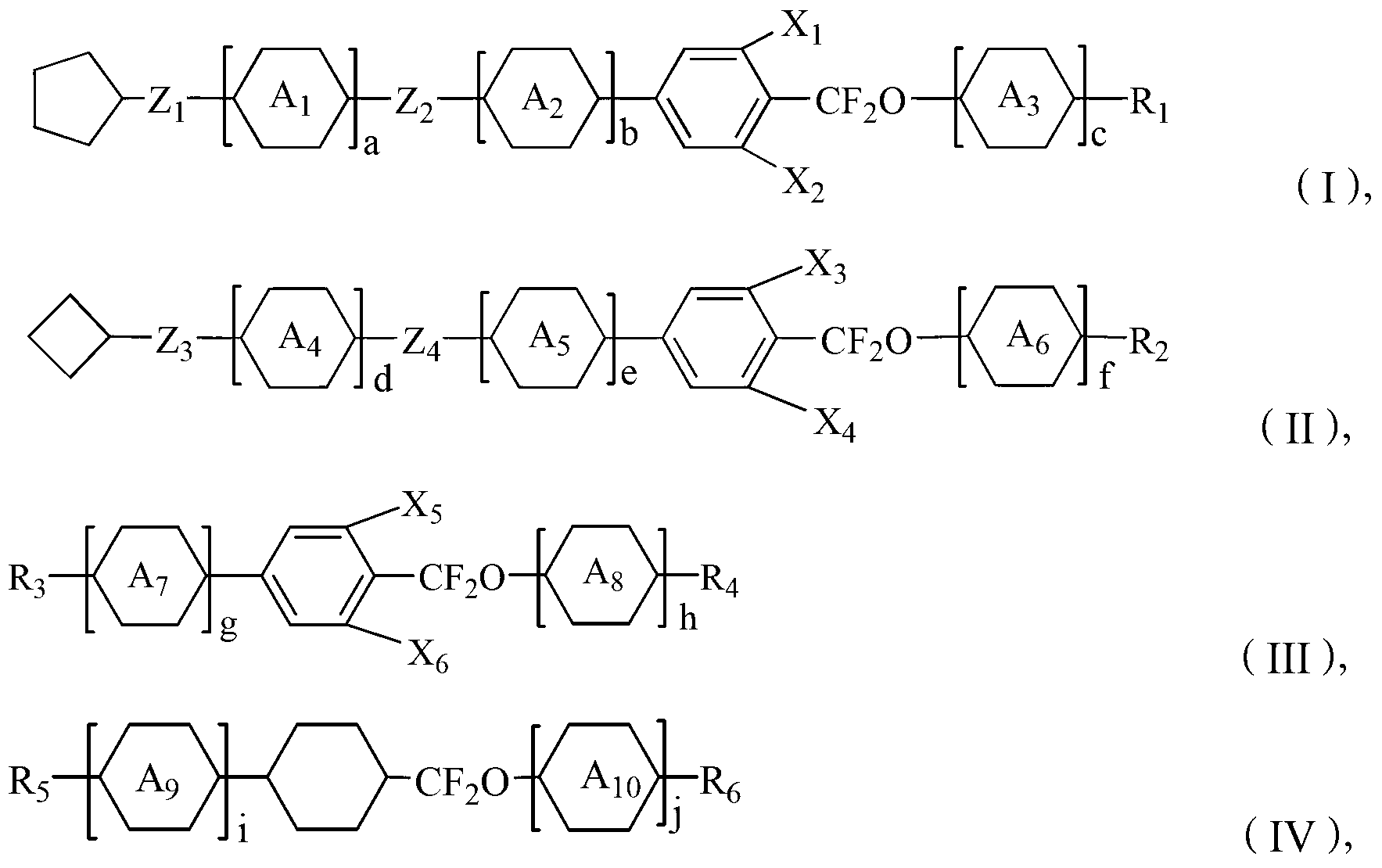

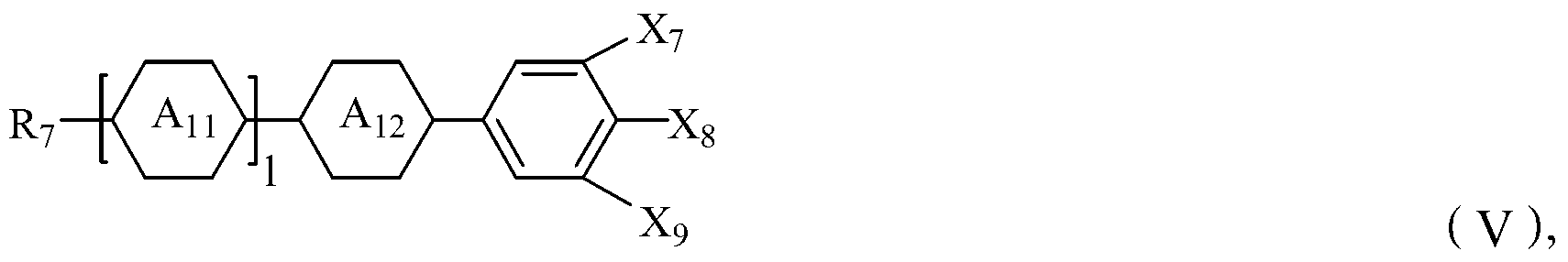

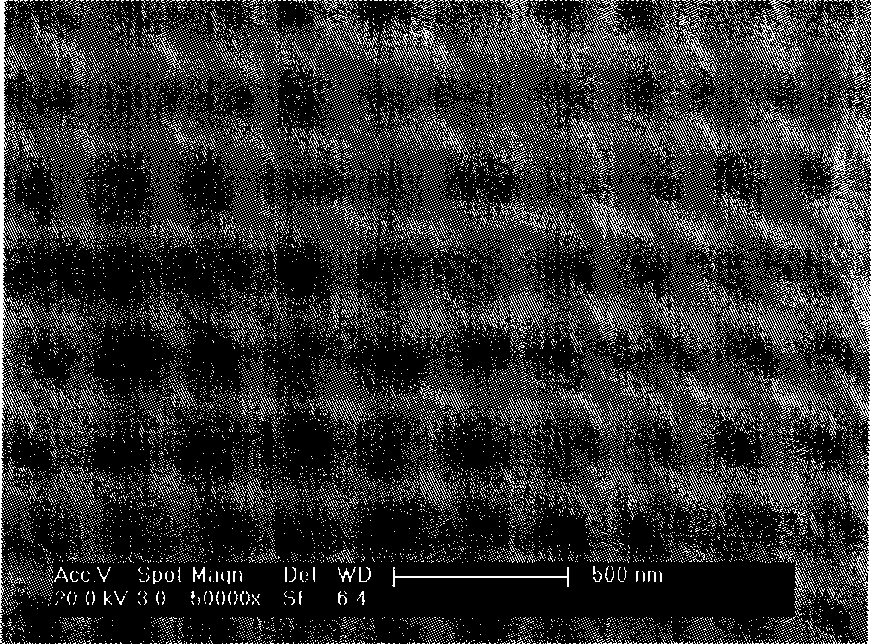

Nematic phase liquid crystal composition

ActiveCN103254912AExcellent performanceLow overall response timeLiquid crystal compositionsHigh resistivityChemistry

The invention discloses a nematic phase liquid crystal composition comprising a compound with a first component shown as the general formula I, a compound with a second component shown as the general formula II, a compound with a third component shown as the general formula III, a compound with a fourth component shown as the general formula IV and a compound with a fifth component shown as the general formula V. The nematic phase liquid crystal composition disclosed by the invention has very low overall response time, lower voltage, high resistivity and voltage retention rate, low viscosity, short response time and proper optical anisotropy and dielectric anisotropy; after being treated at high temperature, the nematic phase liquid crystal composition still has high resistivity and excellent high temperature and ultraviolet stability, can be used for a photoelectric display with an active matrix address, and is particularly suitable for manufacturing active matrix TN-TFT (Twisted Nematic Thin Film Transistor) and IPS-TFT (In-Plane Switching Thin Film Transistor) liquid crystal display elements and liquid crystal displays which are rapid in response.

Owner:BEIJING CHENGZHI YONGHUA DISPLAY TECHNOLOGY CO LTD

Method for supporting nano titanic oxide on surface of carrier material

InactiveCN101485974AExcellent performanceGuaranteed nudityNanostructure manufactureWater/sewage treatment by irradiationTitanium dioxideOxide

The invention provides a method for loading nanometer titanium dioxide on the surface of a carrier material. The method is characterized in that: the carrier material is washed; by using a silicasol solution with the weight percentage of between 5 and 25 percent, a binder coating is prepared on the surface of the carrier; and the binder coating is sprayed with a nanometer TiO2 ethanol suspension, so that the nanometer TiO2 is loaded on the surface of the carrier material. Because the binder is coated first, and then the nanometer TiO2 material is adhered to the surface of the carrier, the nudity of the nanometer particle is ensured maximally. The coating of the binder and the adhesion of the photocatalyst are completed by different working procedures, the distribution condition of the binder on the carrier surface and the loading capacity of the catalyst can be adjusted more easily as required, so that the best performance is achieved.

Owner:SOUTHEAST UNIV

Coal ash casting paint

InactiveCN101195146AExcellent performanceExcellent high temperature crack resistanceFoundry mouldsFoundry coresSurface strengthCoal

The invention belongs to the technical field of foundry, and relates to fly ash foundry coating. The invention provides foundry coating which is prepared through taking solid waste, namely the fly ash, which is produced after coal is burned as refractory aggregate, and the foundry coating is used for various nonferrous alloys and sand molds (cores) of iron castings. The foundry coating is prepared by materials according to the following weight proportion, the fly ash wt 20-100% and refractory powder wt 0-80% are taken as the refractory aggregate, and suspension concentrate, binder, thickener and carrier liquid are added to manufacture the foundry coating. The beneficial effects of the invention are that the invention provides the fly ash with an approach of waste secondary utilization, undisturbed fly ash is processed into refractory aggregate particle sizes which can be used for the foundry coating, the fly ash foundry coating which is manufactured can be applied to various different casts, performances such as coating high temperature crack resistance, coating surface strength, gas forming amount are good, and various requirements of the forging can be satisfied.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

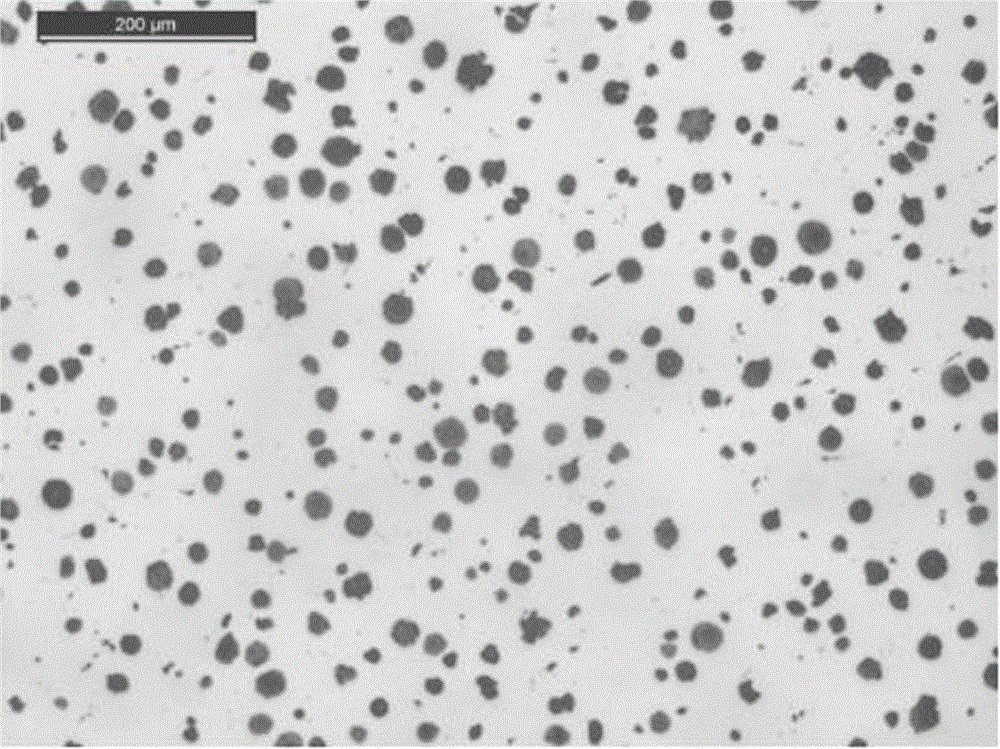

Copper flake powder, method for producing copper flake powder, and conductive paste using copper flake powder

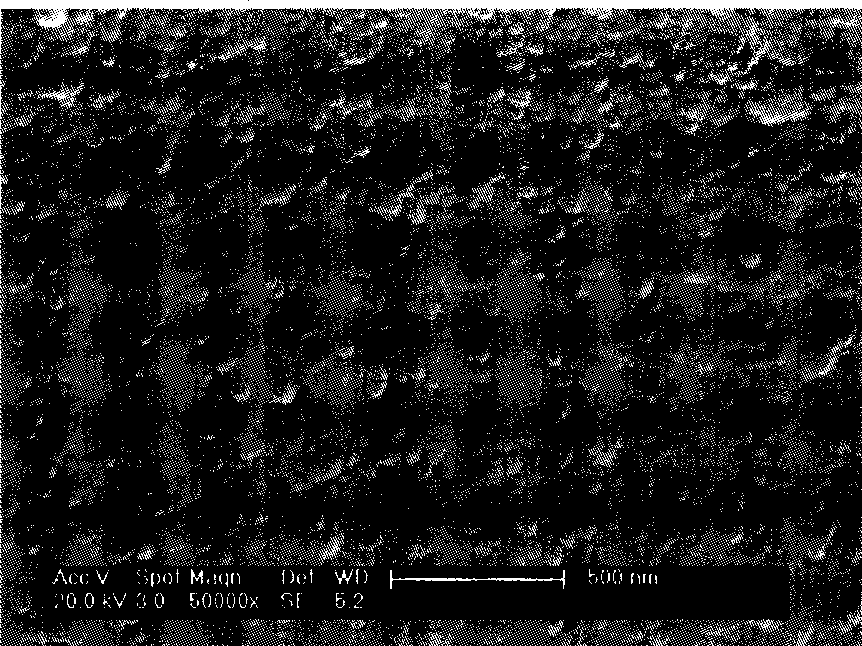

InactiveUS20060137488A1Long timeExcellent performanceTransportation and packagingSemiconductor/solid-state device detailsHigh energyBall mill

The present invention is mainly for providing a flake copper powder for a conductive paste with particle properties which are defined by that the particle thickness is thinner being possible for use to form an electrode or a circuit, and a production process thereof. To achieve the object of producing the following particles, each powder particles shape is plastically processed into a flake-shape, wherein the flake copper powder has a cumulative particle diameter D50 of 10 μm or smaller measured with laser diffraction scattering particle size distribution method. The D10, D50 and D90 measured with the laser diffraction scattering particle size distribution method are illustrative and the SD / D50 value measured by the standard deviation of particle distribution with the laser diffraction scattering particle size distribution, is 0.55 or larger and / or a D90 / D10 of 4.5 or smaller. The flake copper powder is compressed with a high energy ball mill whose media beads having fine particle diameter which plastically deforms the copper particles into flake-shaped particles, so that stable flake copper powder is produced.

Owner:MITSUI MINING & SMELTING CO LTD

Preparation method of nitrogen-doped graphene

The invention relates to a preparation method of nitrogen-doped graphene. The preparation method comprises the following steps: adding raw materials of citric acid and melamine into methanol, stirring, performing ultrasonic treatment and drying to obtain a precursor, and calcining the precursor in a tubular furnace by two stages to finally obtain the nitrogen-doped grapheme. Compared with the prior art, the preparation method has the following advantages: the raw materials are wide in source; the steps are simple; requirements on equipment are low; in the preparation process, a reducing agent is not required, so that environment pollution is low; the prepared nitrogen-doped graphene is thin in sheet, large in specific surface area, uniform in structure and good in reproducibility.

Owner:QINGDAO HAIYUAN IND

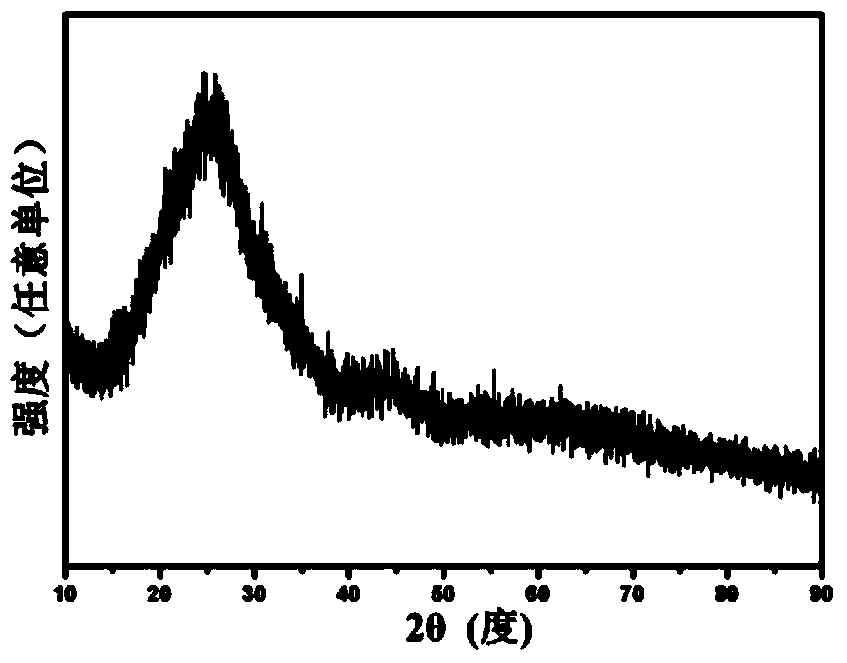

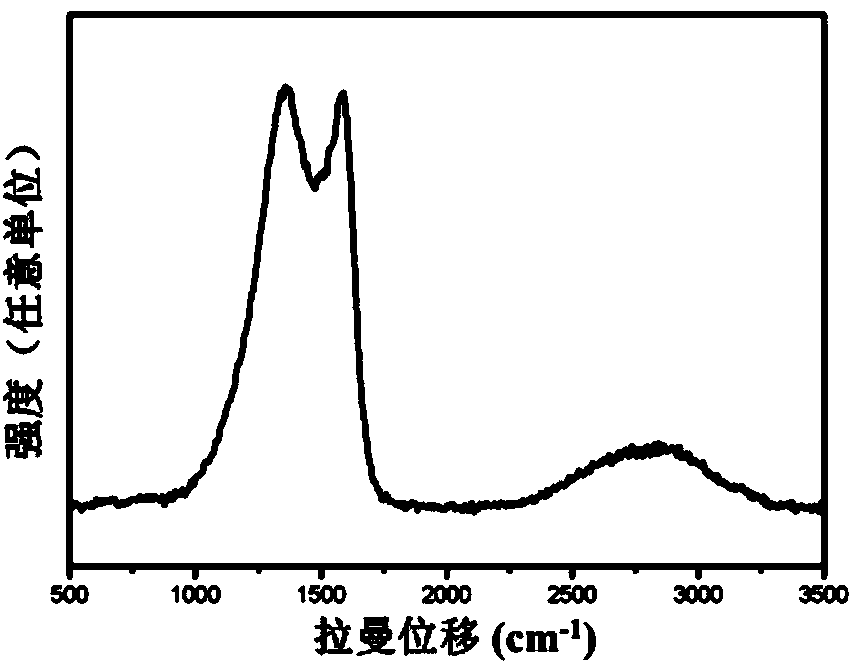

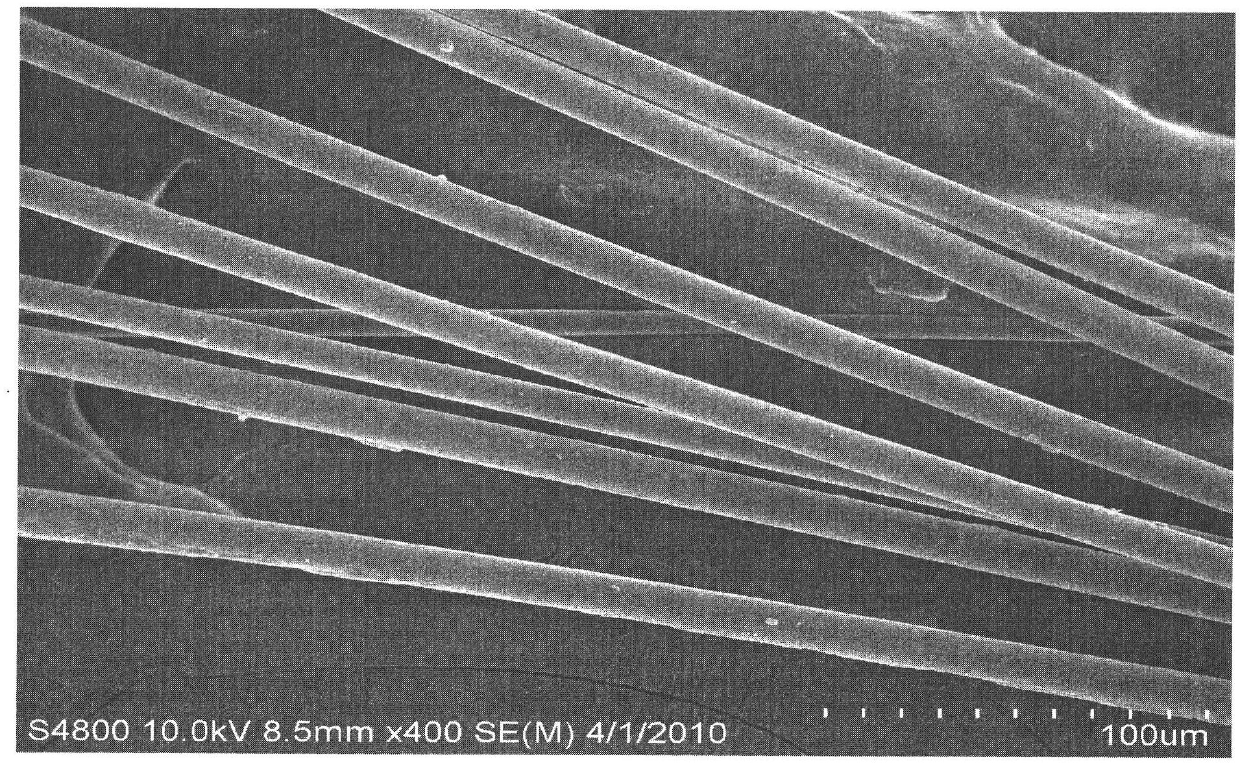

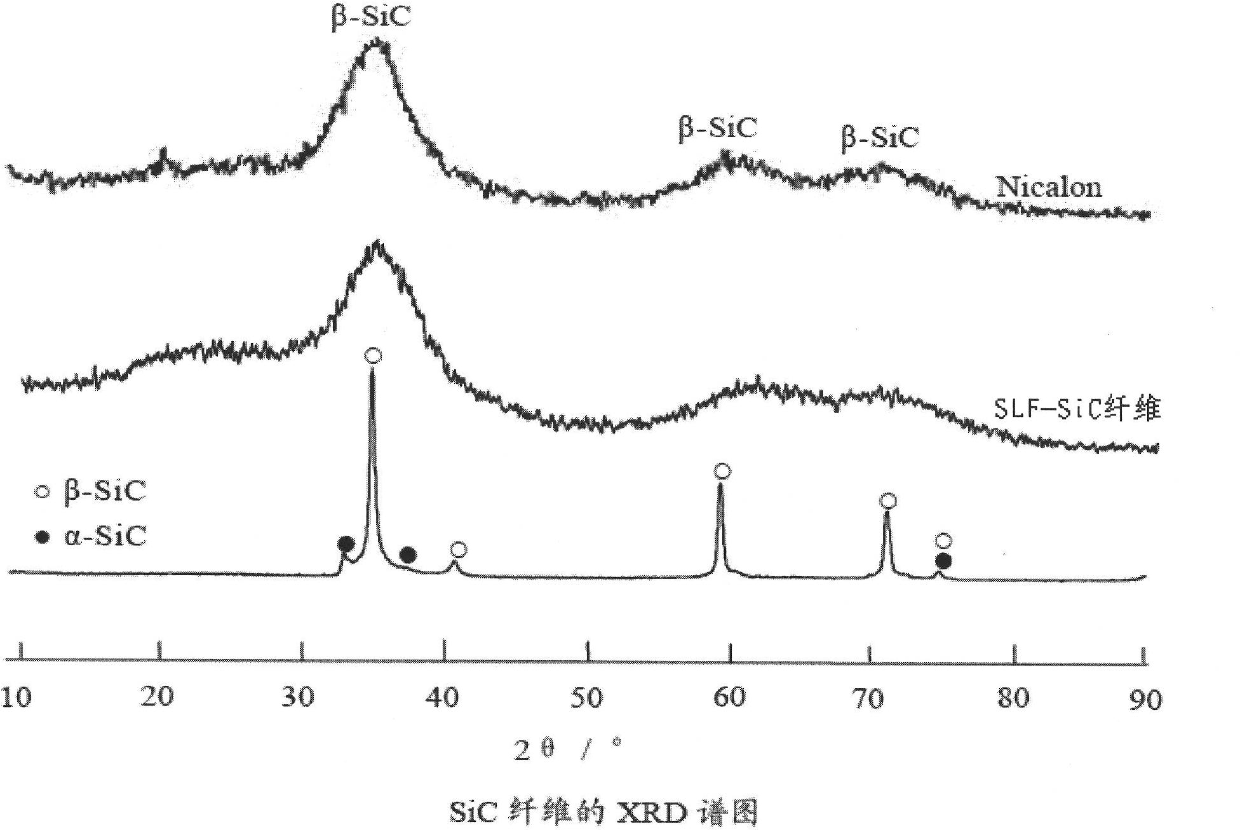

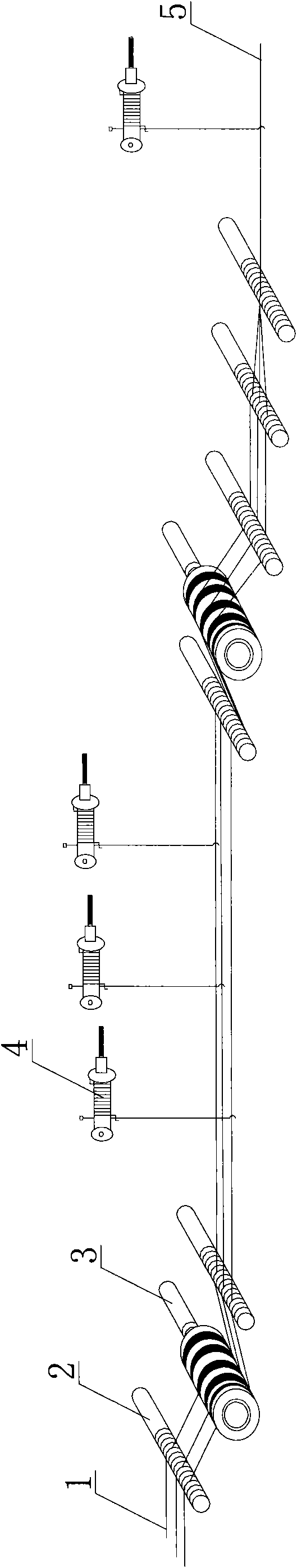

Continuous silicon carbide fiber preparation method and production device

ActiveCN101994169AExcellent performanceSimple equipmentArtificial thread manufacturing machinesFibre chemical featuresSic fiberAtmosphere

The invention discloses a continuous silicon carbide fiber preparation method, which is characterized by comprising the following steps: (1) preparing a polycarbosilane ceramic precursor by using a precursor conversion process; (2) heating and melting the polycarbosilane ceramic precursor under the protection of an inert gas, and forming polycarbosilane fibril by spinning under the action of a pressure; (3) performing the infusible treatment of the polycarbosilane fibril in an atmosphere of an oxidizing gas to increase the molecular weight of the polycarbosilane fibril by 6 to 20 weight percent with oxidization; and (4) combining strands of infusible polycarbosilane fibril to make a polycarbosilane fibril beam, and continuously passing the polycarbosilane fibril beam through a high-temperature furnace at 1,100 to 1,400 DEG C under vacuum or the protection of the inert gas for firing into the continuous silicon carbide fibers. The method can prepare continuous SiC fibers with high performance and long continuous length; the equipment required by the method is simple; the process flow adopted by the method is short; and production efficiency is high.

Owner:苏州赛力菲陶纤有限公司

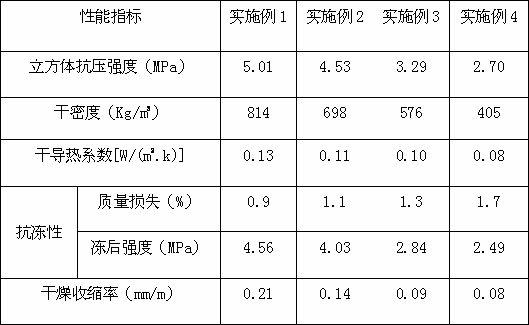

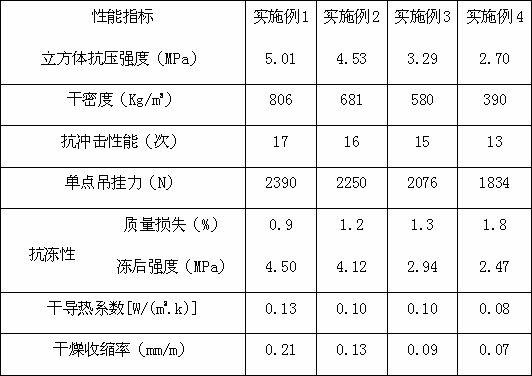

Energy-saving and waste-utilizing concrete block or board and production method thereof

InactiveCN102690094AWide range of usesExcellent performanceSolid waste managementCeramicwareIndustrial wasteEnvironmental pressure

The invention belongs to the technical field of building materials, and particularly relates to an energy-saving and waste-utilizing concrete block or board and a production method thereof. The energy-saving and waste-utilizing concrete block or board is composed of desulfurization gypsum, slag powder, ultrafine fly ash, cement, foaming agent, alkaline excitant, early strength agent, water reducer, mineral fiber and triethanolamine. The desulfurization gypsum is cold-dried. By the energy-saving and waste-utilizing concrete block or board, industrial waste such as the desulfurization and the slag powder can be consumed in a large amount and turned into treasure, and environmental pressure caused by stacking of the waste can be relieved. In addition, steam conservation is adopted, strength development of concrete block and board is accelerated, and early strength is improved greatly, so that reuse of moulds can be quickened, conservation space is economized, and the energy-saving and waste-utilizing concrete block or board is suitable for industrial production. Foamed concrete block and board produced has fine performances of light weight, heat insulation, sound absorption, flame retardancy and the like. The energy-saving and waste-utilizing concrete block or board is applicable to projects such as roof insulation, wall insulation, road sound absorption and building sound insulation.

Owner:TONGJI UNIV

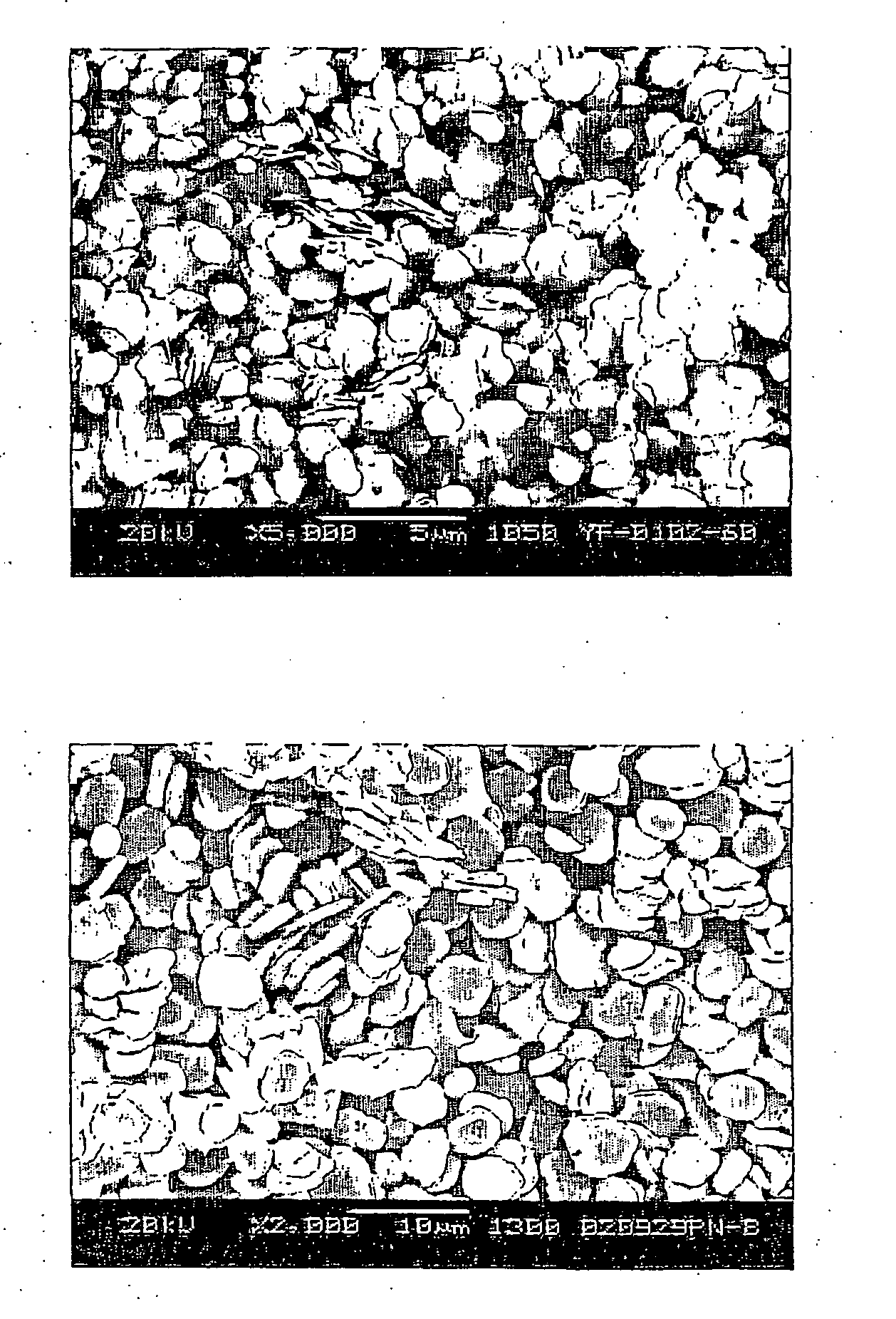

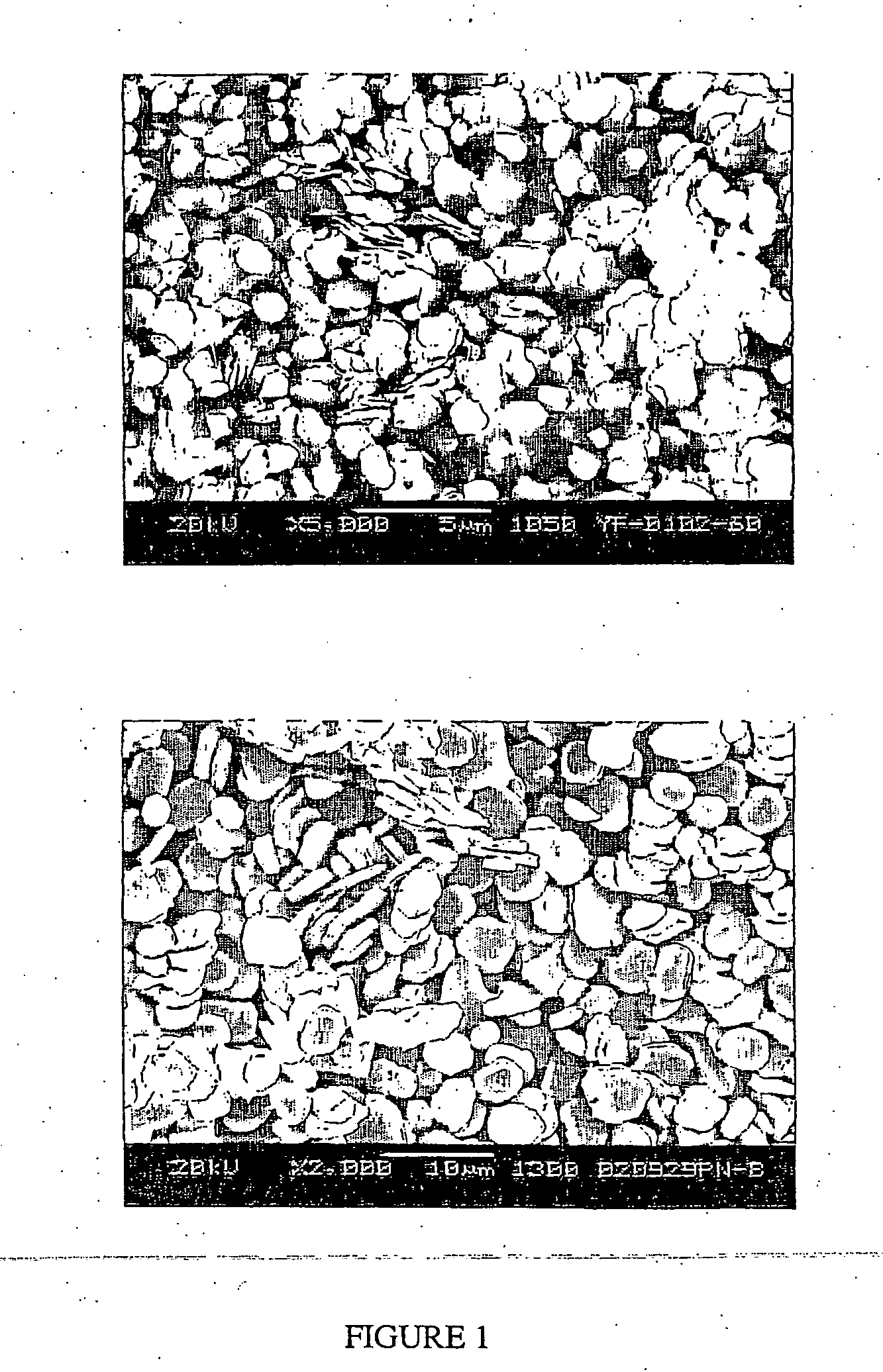

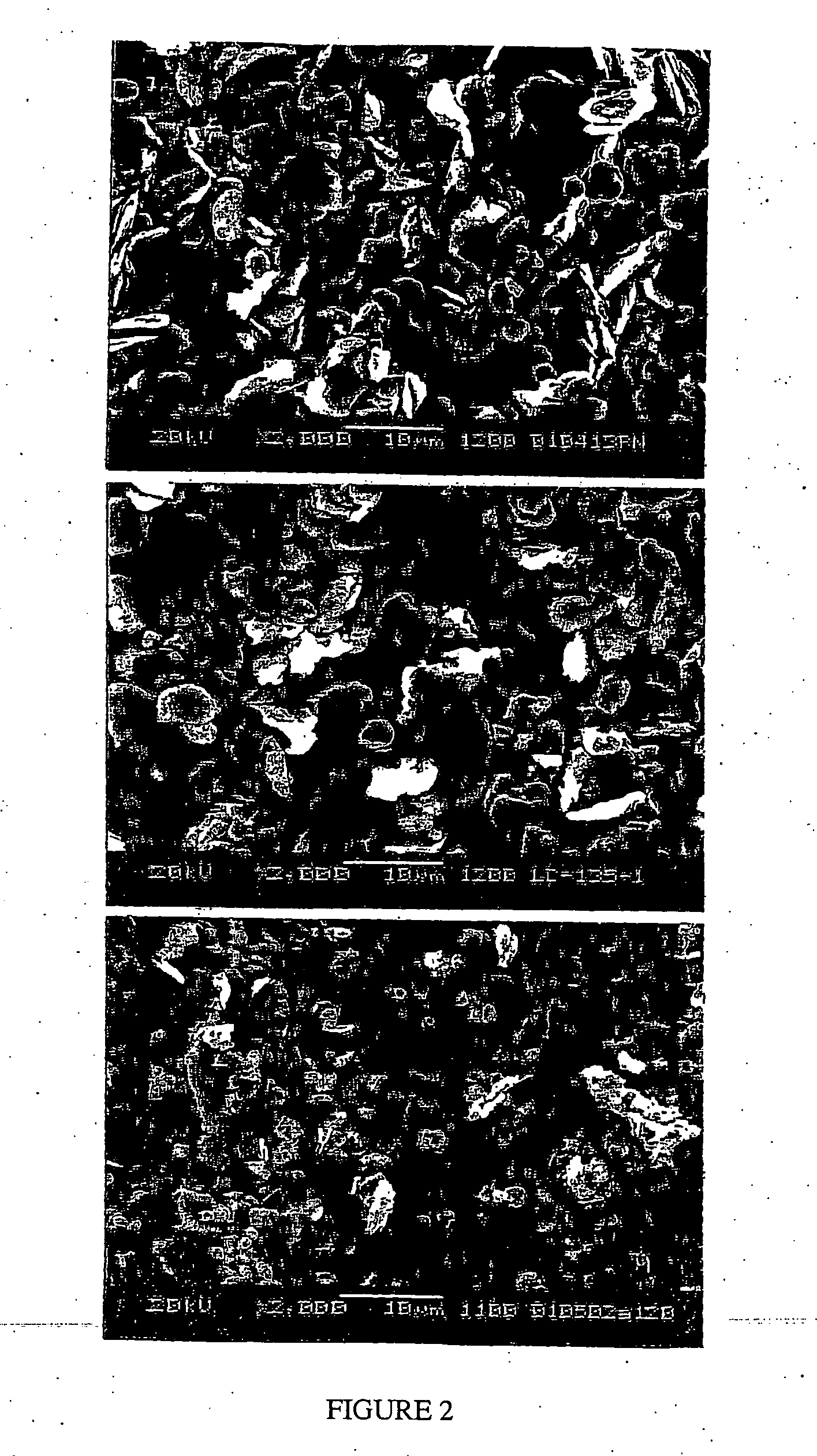

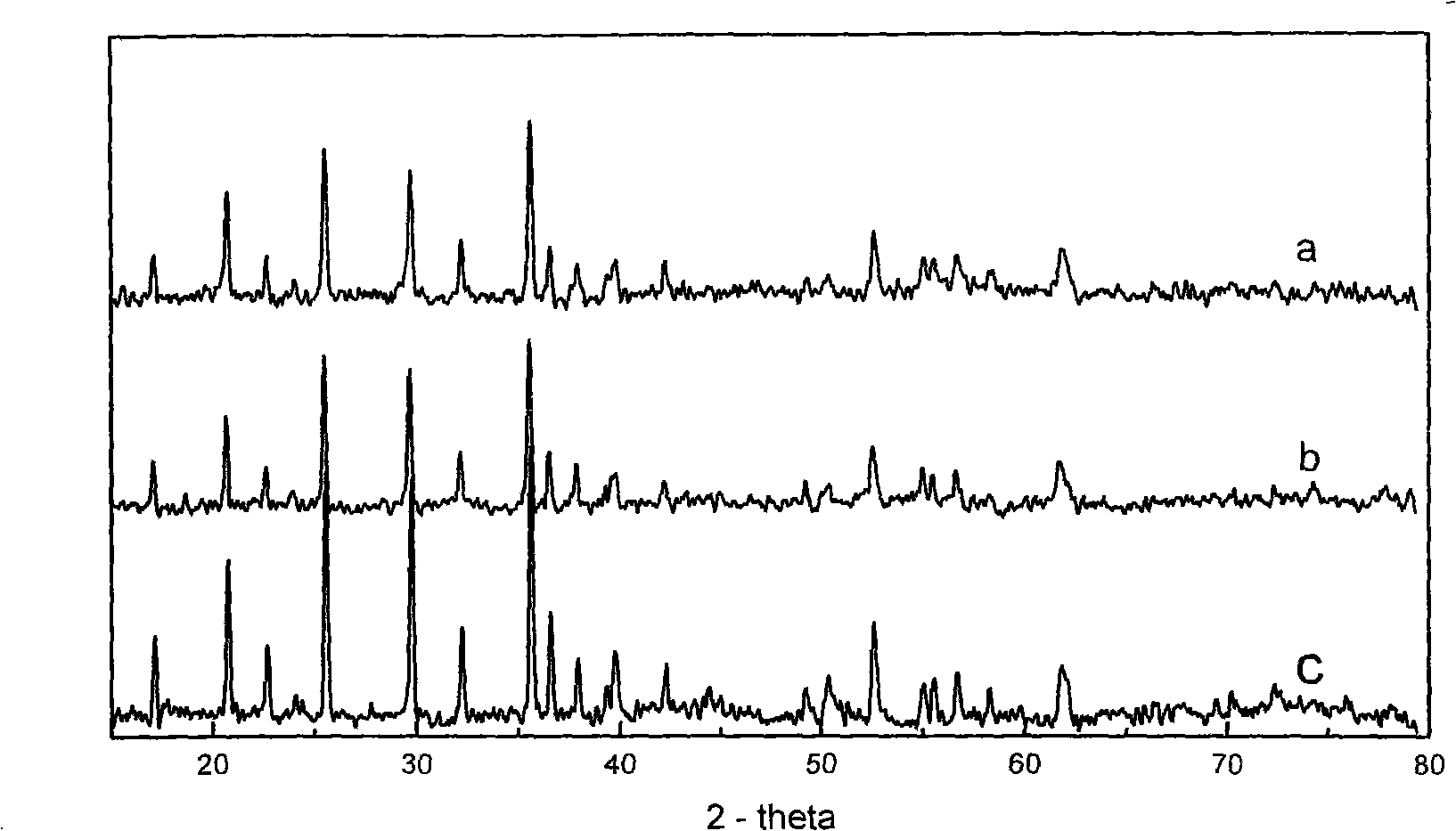

Preparation of LiFePO4

ActiveCN101327922AExcellent performanceLow priceCell electrodesPhosphorus compoundsHydrothermal synthesisSalt solution

The invention relates to a preparation method of lithium battery material, in particular to a preparation method of LiFePO4 which mainly solves the technical problems existent in the prior art such as the crystal shape of lithium iron phosphate is particle-shape, a post heat treatment is needed during the preparation process, the preparation step is complicated and the preparation cost is high. The invention comprises the following steps: charging a phosphor-containing compound solution and a surfactant into a ferric salt solution for hydrothermal synthesis, wherein the ratio of Fe atom and P atom is 1:1-1.5, the mol ratio of the compound containing Fe atom and the surfactant is 1:1-3; discharging air by introducing inert gas; charging a lithium salt solution inwhich the mol ratio of Fe atom and Li atom is 1:2.5-3.5; heating the mixture solution for hydrothermal treatment by introducing inert gas; drying the product after pumping filtration and washing to obtain flake or cylindrical LiFePO4 crystal.

Owner:杭州金马新能源科技有限公司

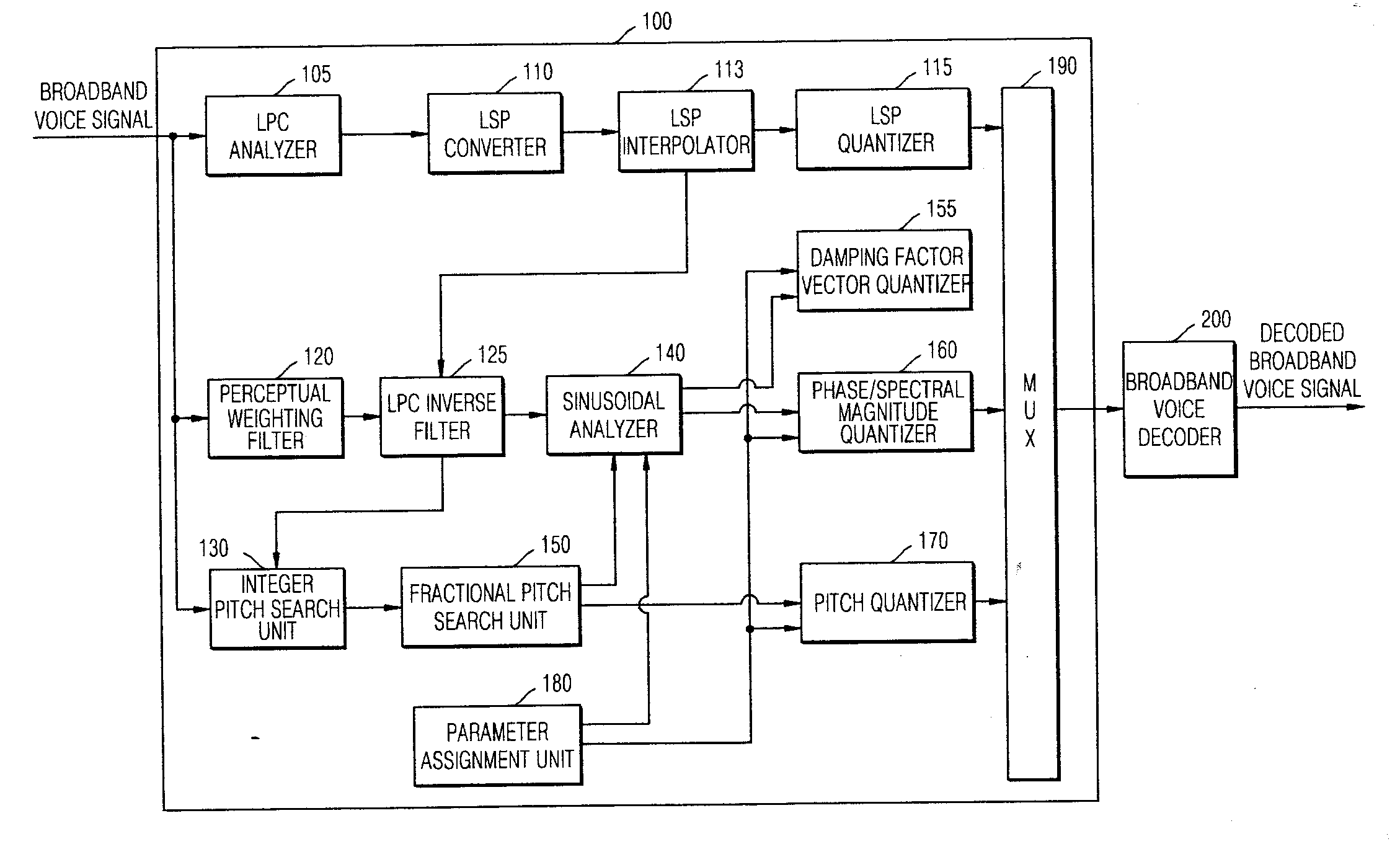

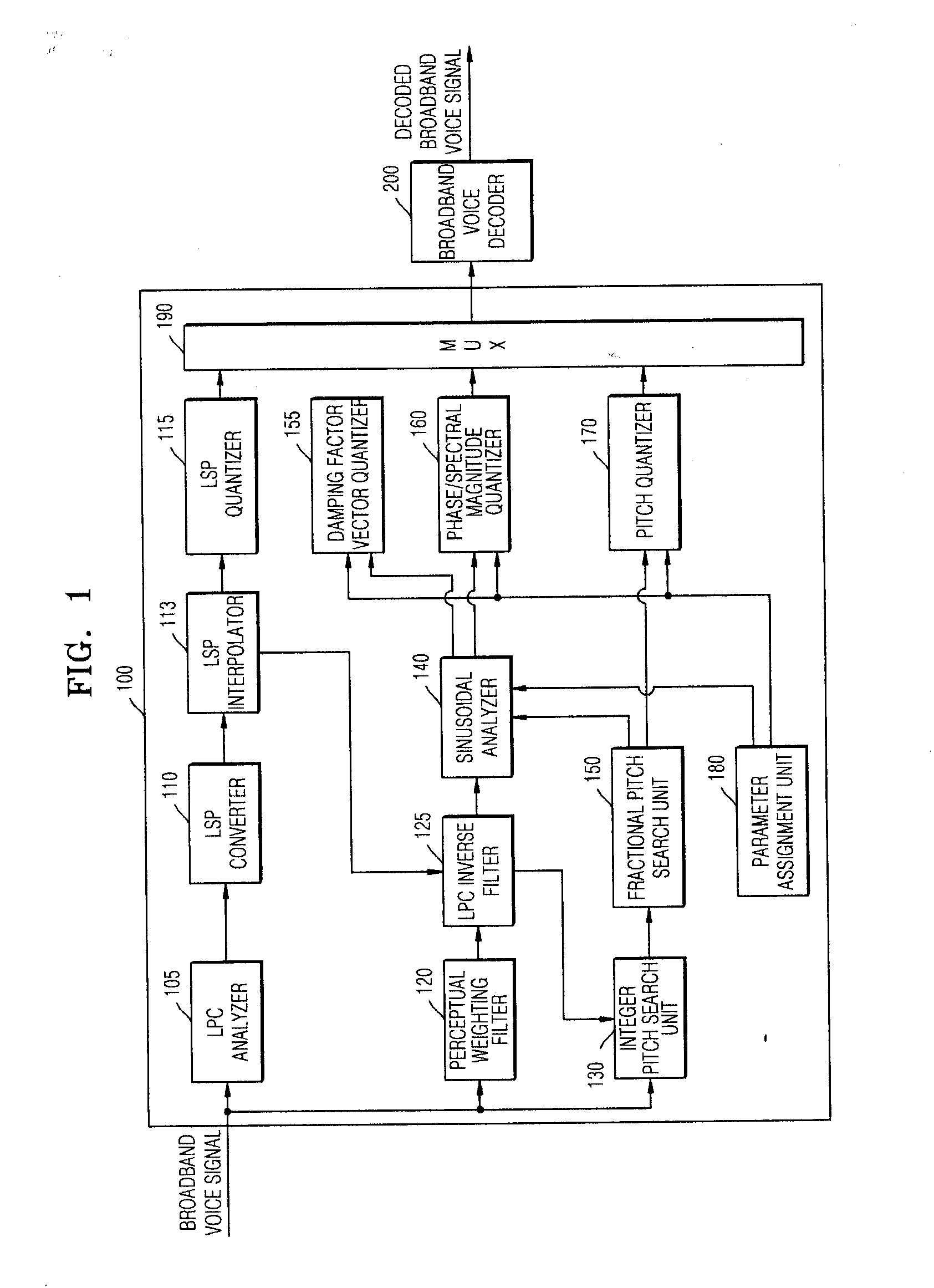

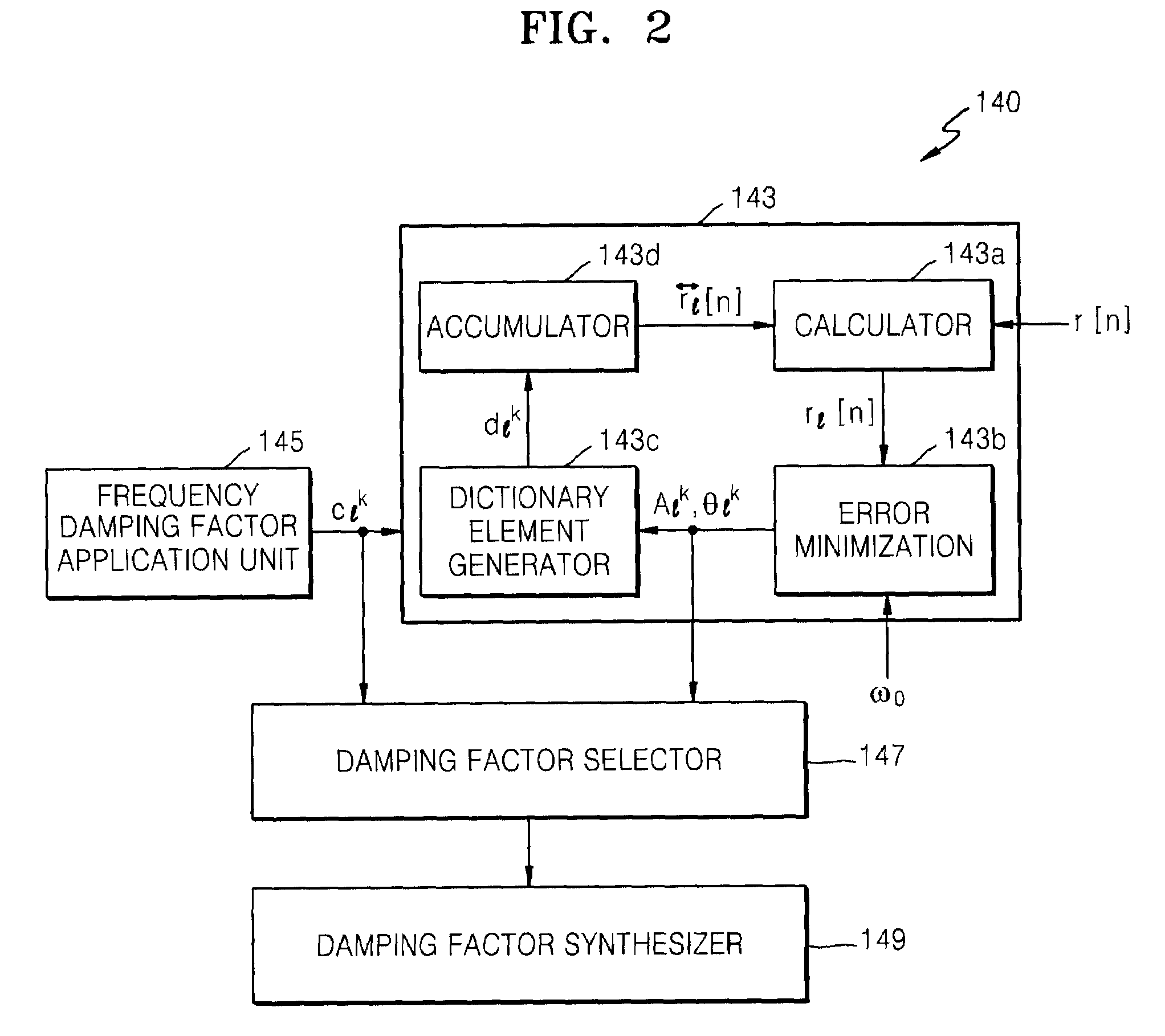

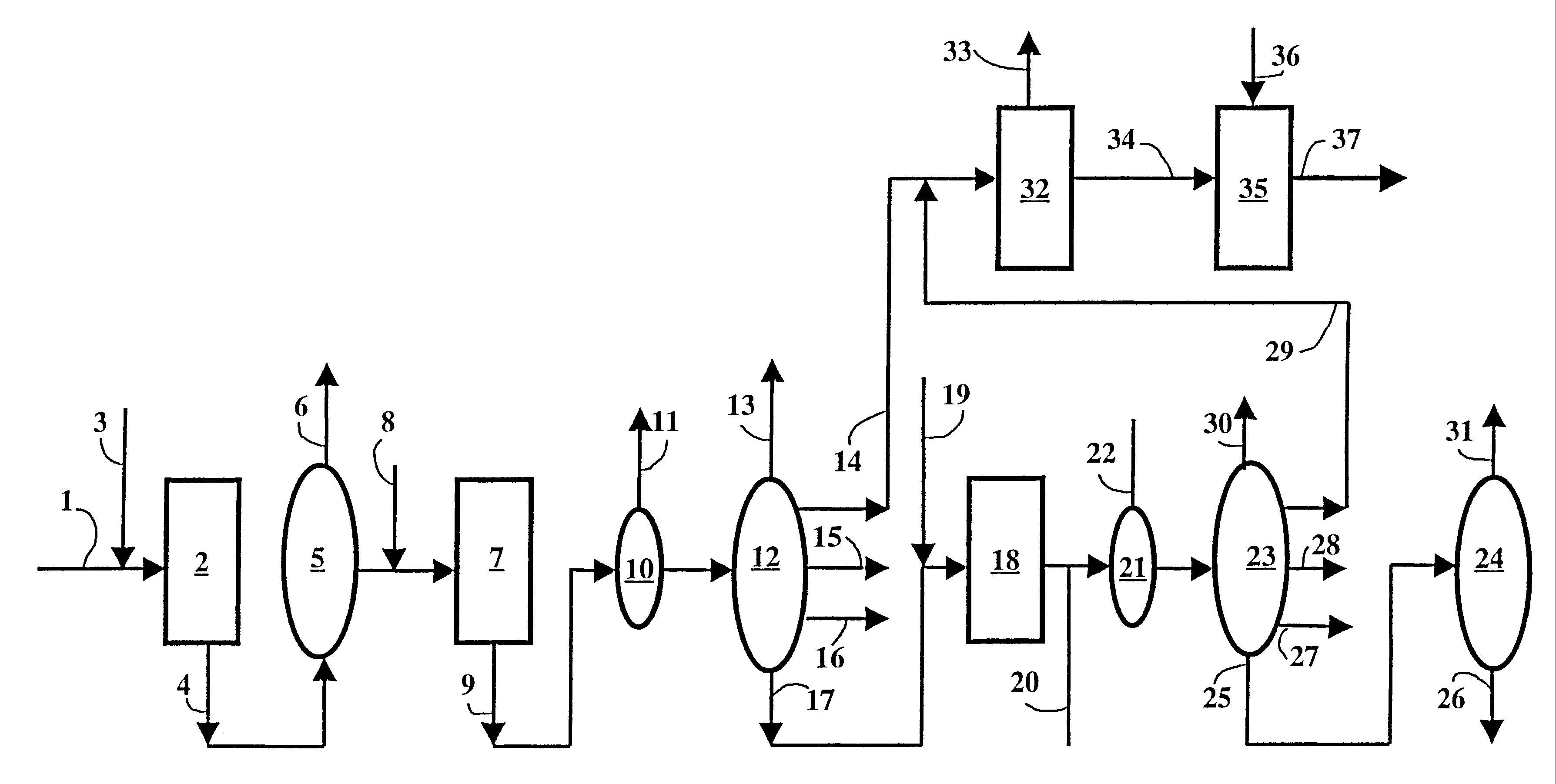

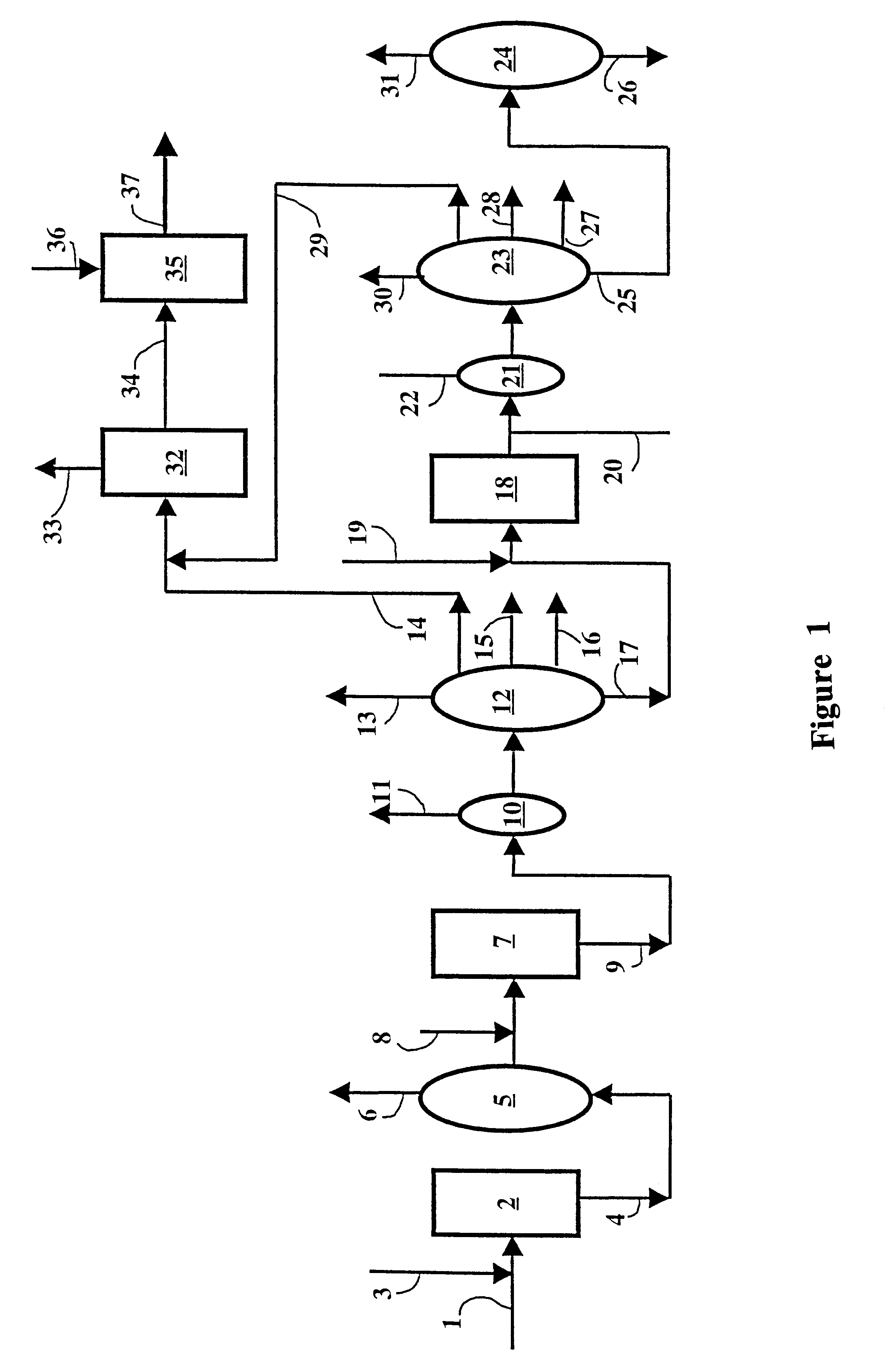

Method, apparatus and system for encoding and decoding broadband voice signal

InactiveUS20080126084A1Supporting Signal-to-Noise Ratio (SNR) expendabilityExcellent performanceSpeech analysisBroadbandAnalyser

A method, apparatus, and system for encoding or decoding a broadband voice signal are provided. The method includes extracting a linear prediction coefficient (LPC) from the broadband voice signal; outputting a linear prediction (LP) residual signal; pitch-searching a spectrum of the LP residual signal; extracting spectral magnitudes and phases of the LP residual signal, which correspond to a damping factor; obtaining, from among the extracted spectral magnitudes and phases, a first spectral magnitude and a first phase at which a power value of the LP residual signal is minimized; quantizing the first spectral magnitude and the first phase; and decoding the broadband voice signal. The apparatus includes a linear prediction coefficient (LPC) analyzer; an LPC inverse filter; a pitch searching unit; a sinusoidal analyzer; and a phase and spectral magnitude quantizer. The system includes a broadband voice encoding apparatus and a broadband voice decoding apparatus.

Owner:SAMSUNG ELECTRONICS CO LTD +1

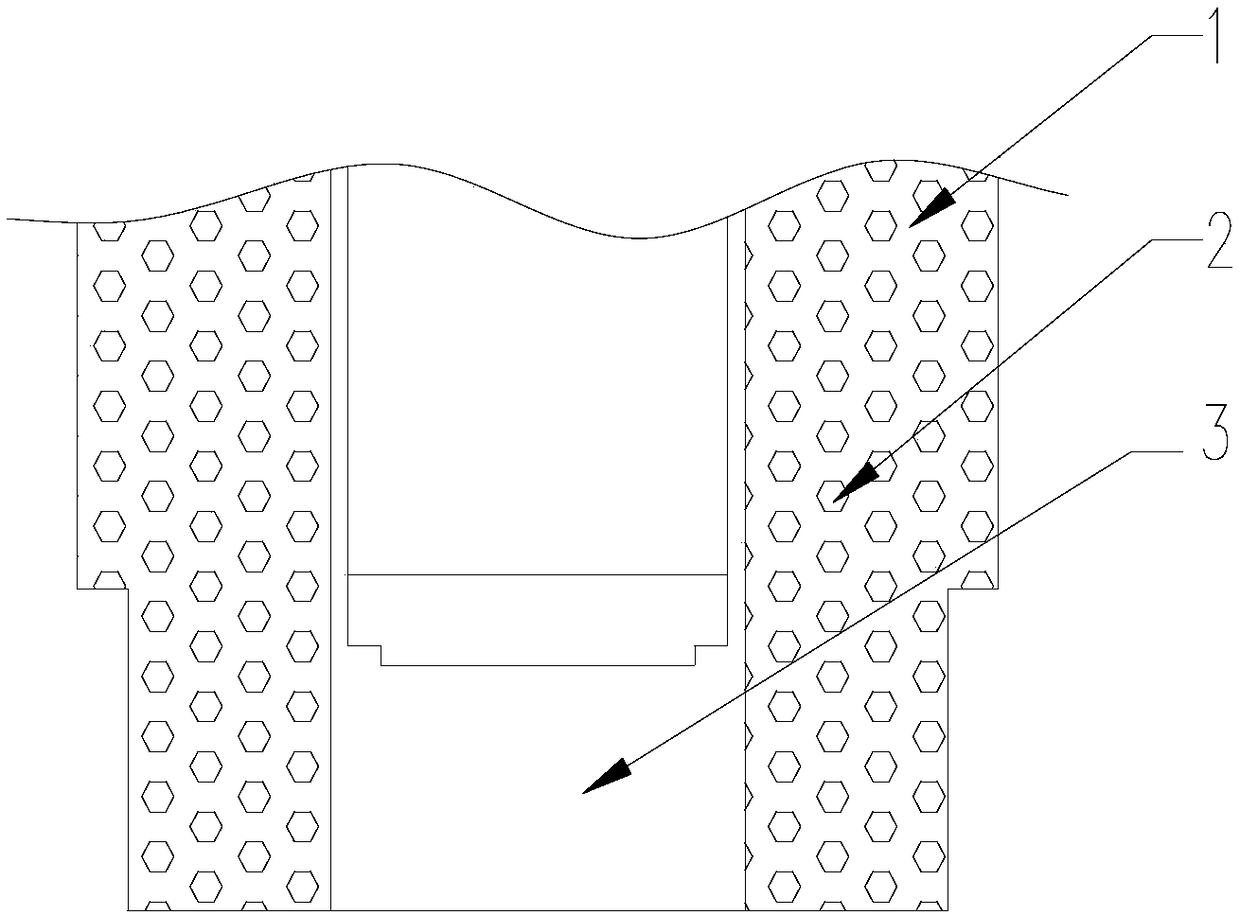

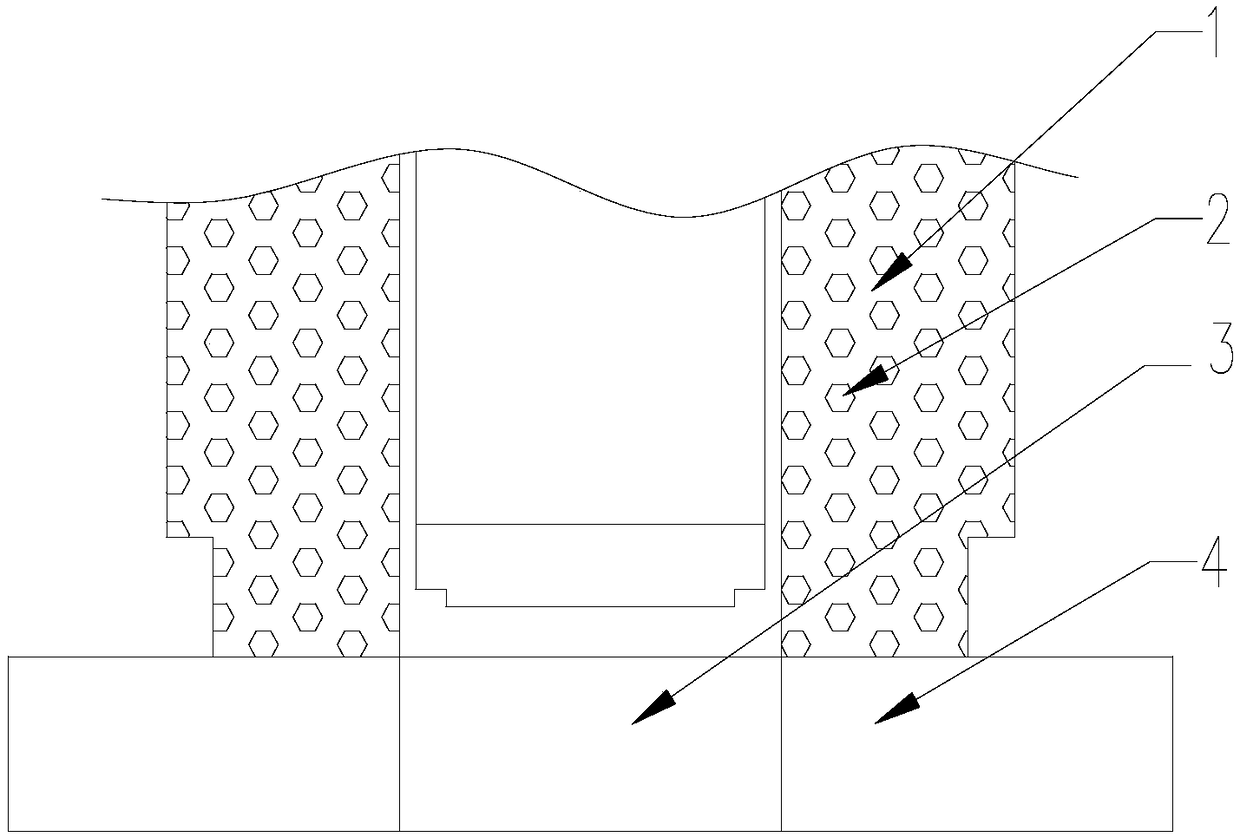

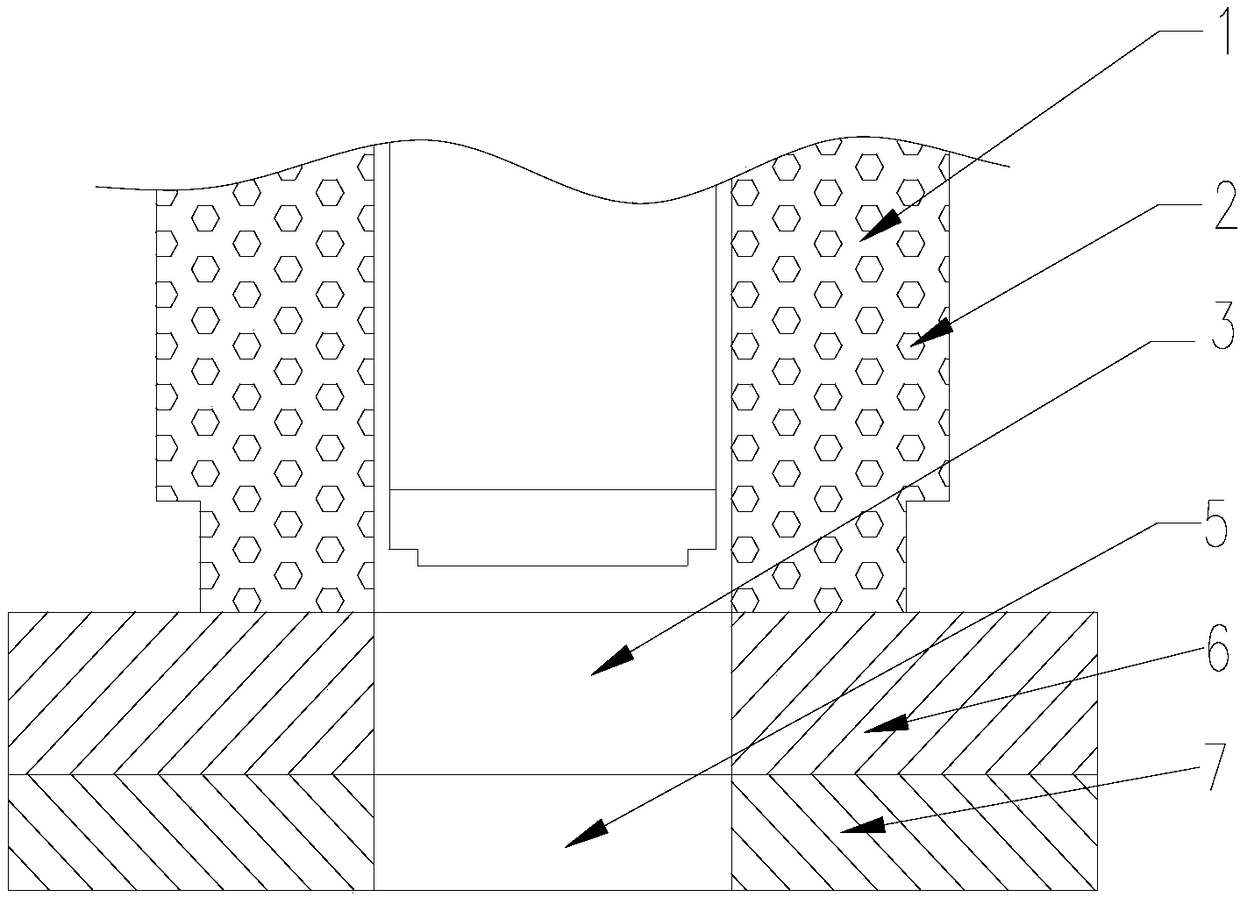

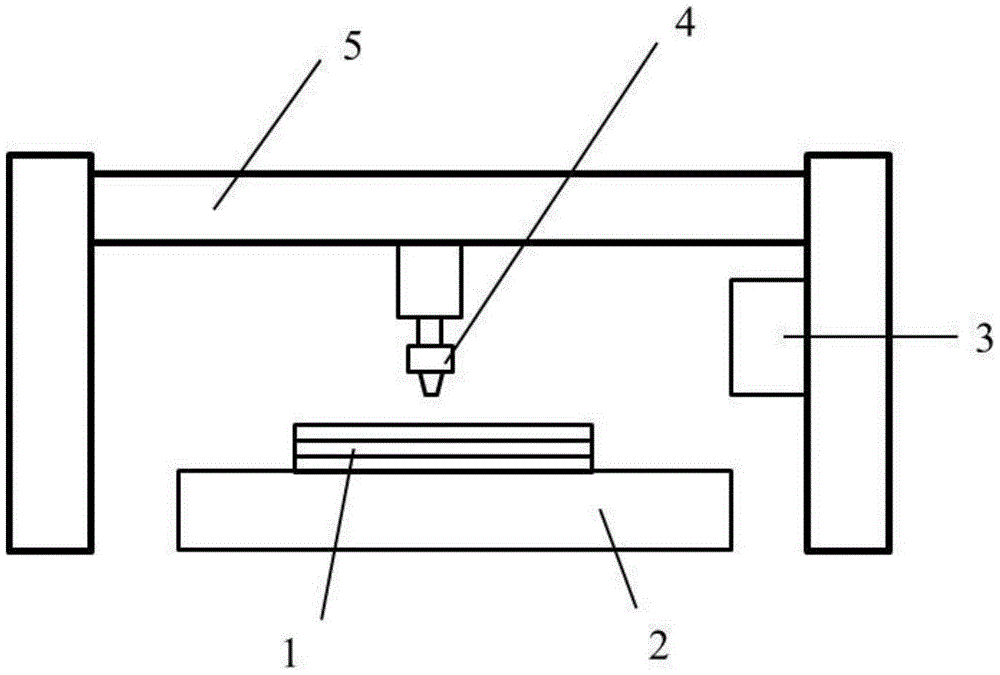

Friction stir additive manufacturing method for metal materials

InactiveCN105171229AExcellent performanceReduce stressNon-electric welding apparatusNon-ferrous metalMetallic materials

The invention discloses a friction stir additive manufacturing method for metal materials and belongs to the field of additive manufacturing (3D printing) of metal materials. The method is based on the technical principle of layer-by-layer accumulation of additive manufacturing, a friction stir head stirs two layers of metals to connect the two layers of metals, after a certain number of layers are accumulated through layer-by-layer stirring and connection, a cutter is switched for cutting to make plates of a friction stir part and a non-friction stir part separated, and the separated plates are not taken away but used as a support for subsequent friction stir. The materials are not melted in the welding process through the friction stir welding solid material connection technology, so that metal metallurgical defects such as pores and cracks are avoided, and the strength of a connection area is high. Meanwhile, welding energy input is low, and workpieces are low in stress and small in deformation after being welded. By means of the technical advantages of low stress and high performance of the friction stir welding solid connection, the low-cost and high-performance rapid manufacturing of large non-ferrous metal integral components like aluminum alloy can be achieved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Process for producing gasoline with an improved octane number

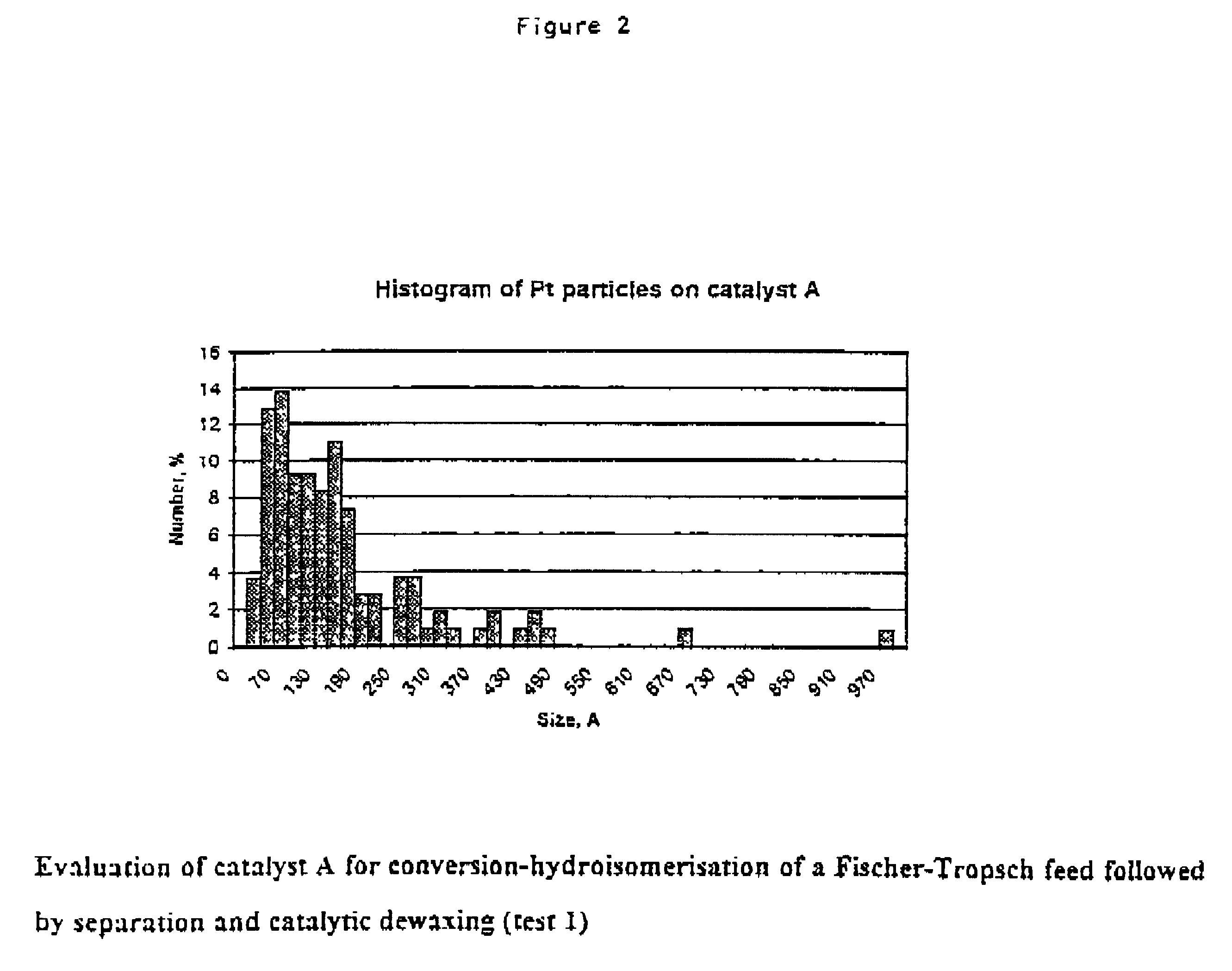

InactiveUS6436278B1Excellent performanceFacility of preparationMolecular sieve catalystsCatalytic naphtha reformingChemistryAlkane

The invention concerns a process for producing gasoline with an improved octane number, optionally accompanied by oil and / or middle distillate production, by conversion-hydroisomerization of the paraffins in the feed using a catalyst containing at least one noble metal deposited on an amorphous acidic support. Isoparaffins are separated from the gasoline cut obtained, and normal paraffins and possibly monobranched paraffins contained in the resulting effluent are isomerized using a catalyst containing at least one hydrodehydrogenating metal and at least one acidic solid. The ensemble of the streams charged with isoparaffins with an improved octane number is sent to the gasoline pool. The residue undergoes catalytic dewaxing.

Owner:INST FR DU PETROLE

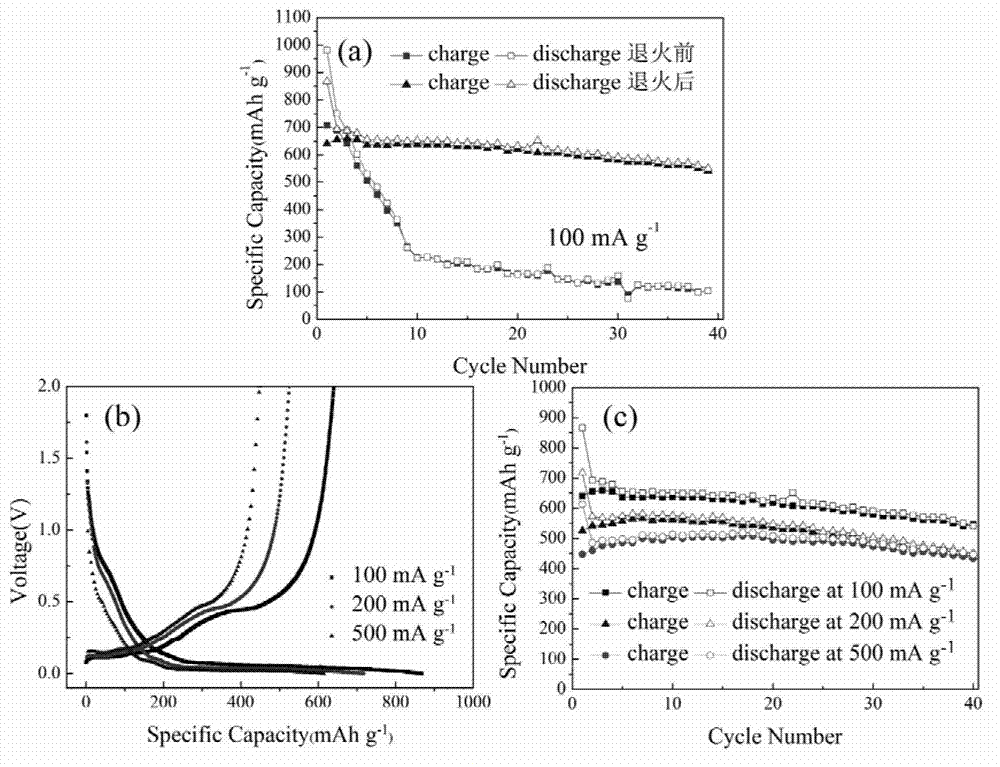

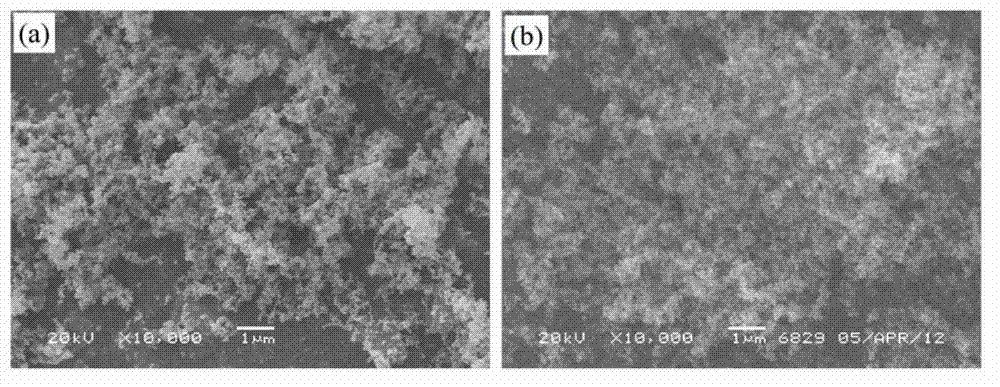

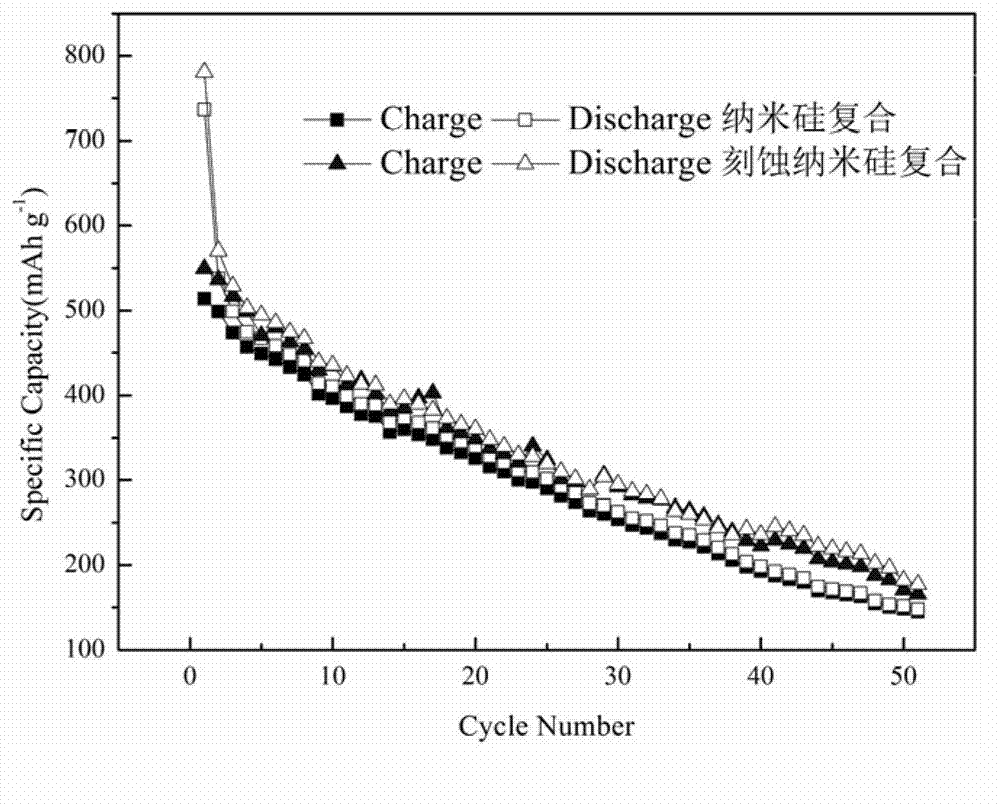

Method for preparing Si/C composite cathode material of lithium ion battery

ActiveCN103078092AUniform particle distributionExcellent performanceCell electrodesSolventCarbon source

The invention discloses a method for preparing a Si / C composite cathode material of a lithium ion battery. The method is characterized in that through a liquid phase solidification-high temperature pyrolysis-low temperature treatment combined method, the Si / C composite cathode material having good cycling stability and good rate capability is prepared. Concretely, the method comprises the following steps of uniformly dispersing a silicon source (before or after etching) and graphite in an appropriate solvent in the presence of a second-type additive with control of a temperature to obtain a solid precursor after the solvent is volatilized completely, transferring the solid precursor into a protective atmosphere, carrying out pyrolysis at a high temperature so that the carbon source is pyrolyzed into amorphous carbon and forms a coating layer, carrying out furnace cooling to obtain the Si / C composite cathode material, uniformly mixing the Si / C composite cathode material, a conductive agent and a binder, coating the mixture on a pole piece, carrying out drying, carrying out low-temperature treatment, and carrying out an electrochemical performance test. The method is simple and feasible and has a high practical degree. The Si / C composite cathode material prepared by the method has a high capacity and good cycling stability and a good rate capability after the low-temperature treatment.

Owner:CENT SOUTH UNIV

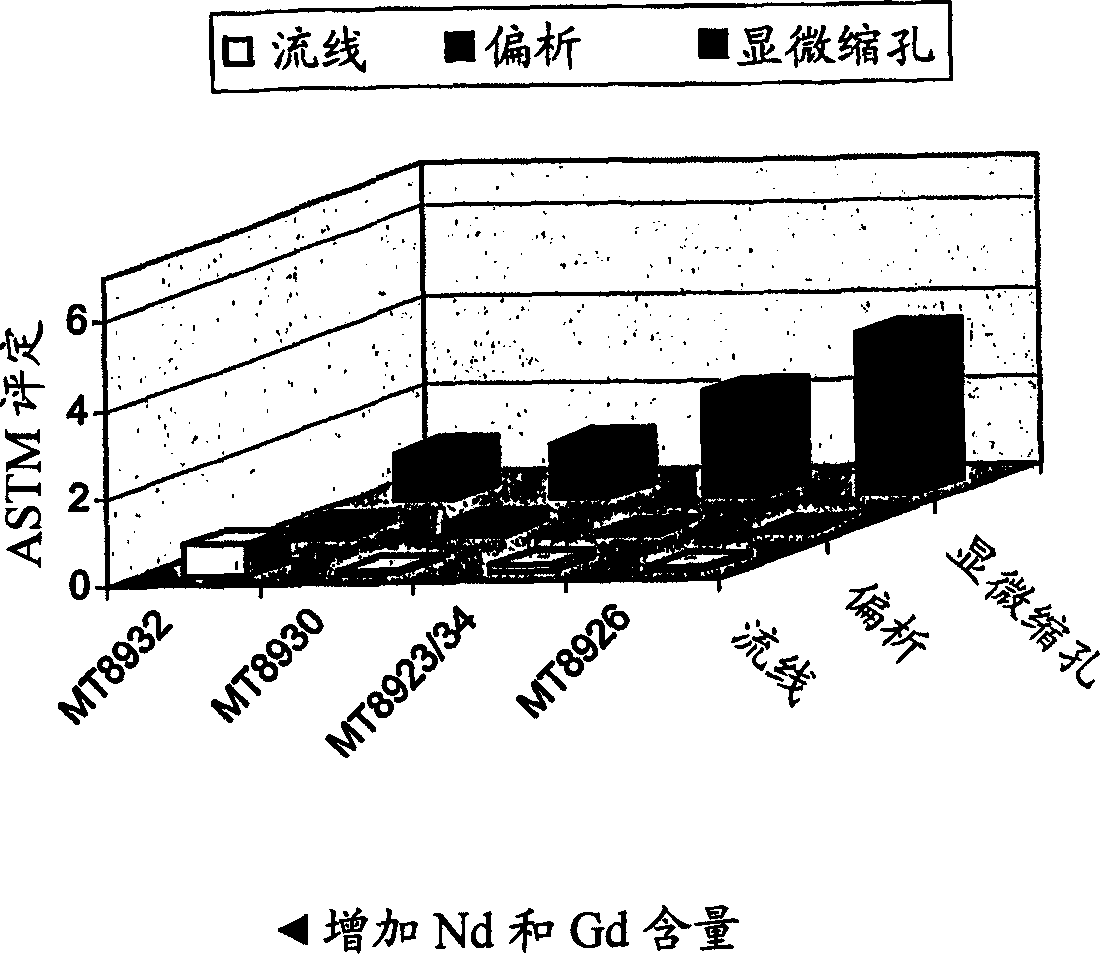

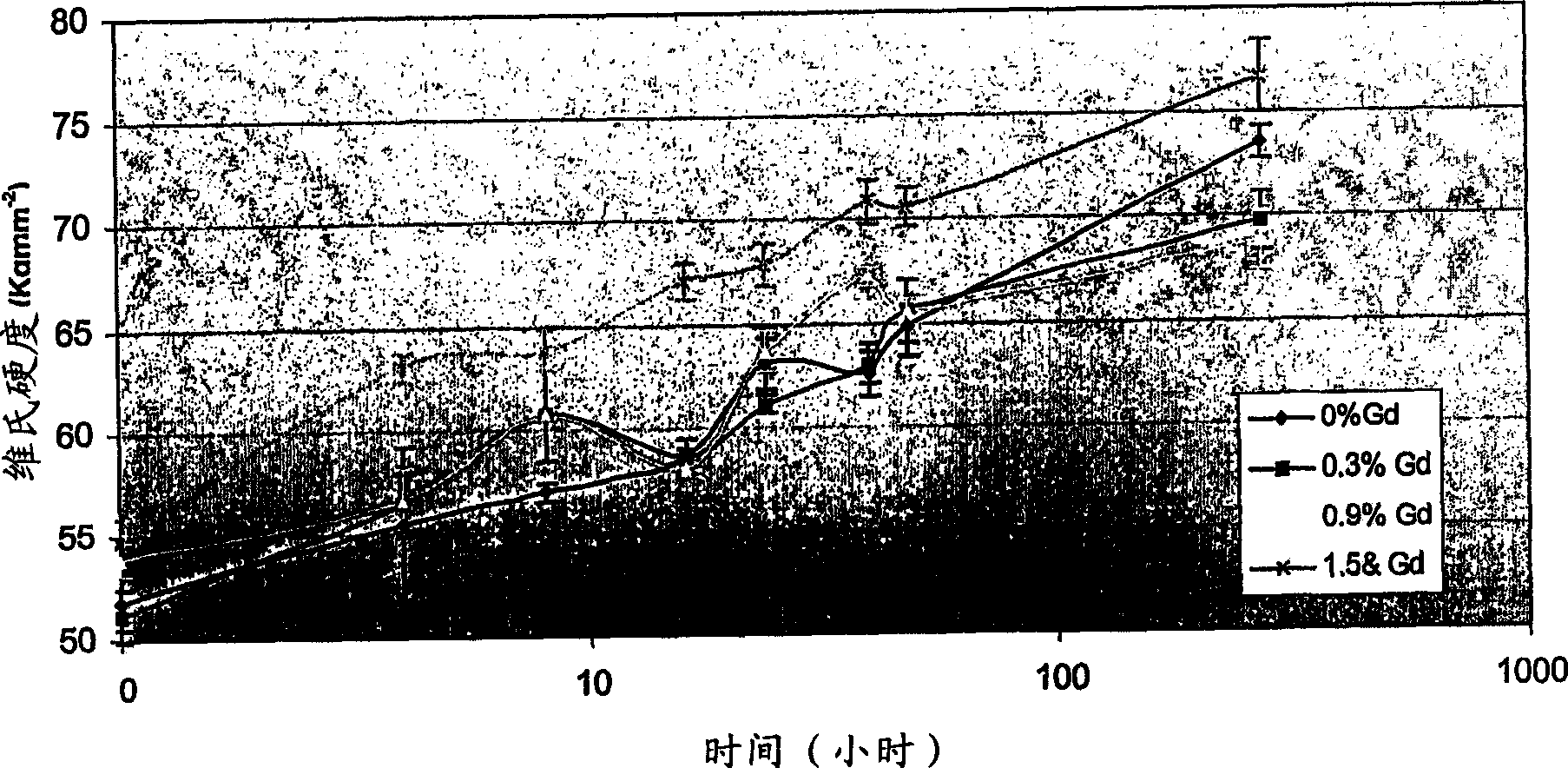

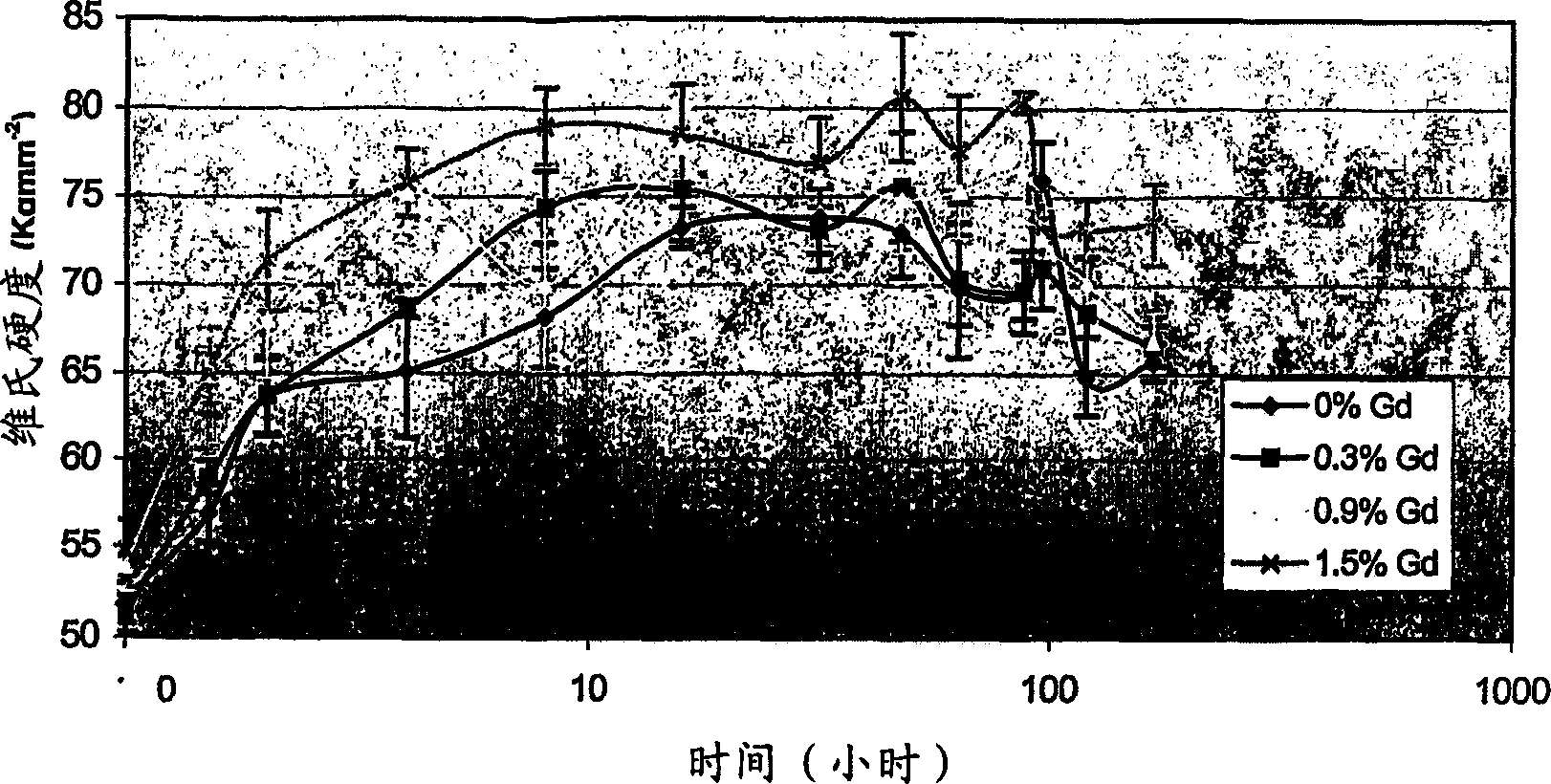

Castable magnesium alloys

This invention relates to magnesium-based alloys particularly suitable for casting applications where good mechanical properties at room and at elevated temperatures are required. The alloys contain: 2 to 4.5% by weight of neodymium; 0.2 to 7.0 of at least one rare earth metal of atomic No. 62 to 71; up to 1.3% by weight of zinc; and 0.2 to 0.7% by weight of zirconium; optionally with one or more other minor component They are resistant to corrosion, show good age-hardening behaviour, and are also suitable for extrusion and wrought alloy applications.

Owner:MAGNESIUM ELETRON LTD

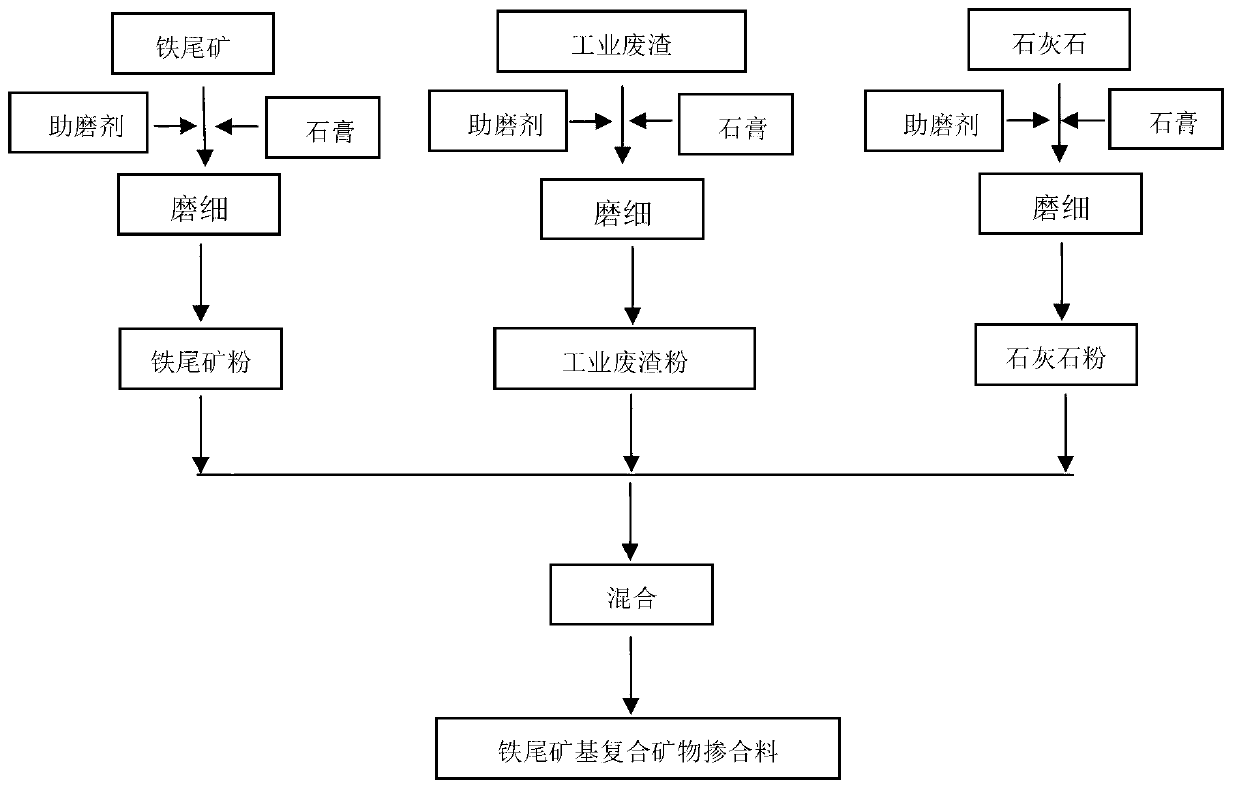

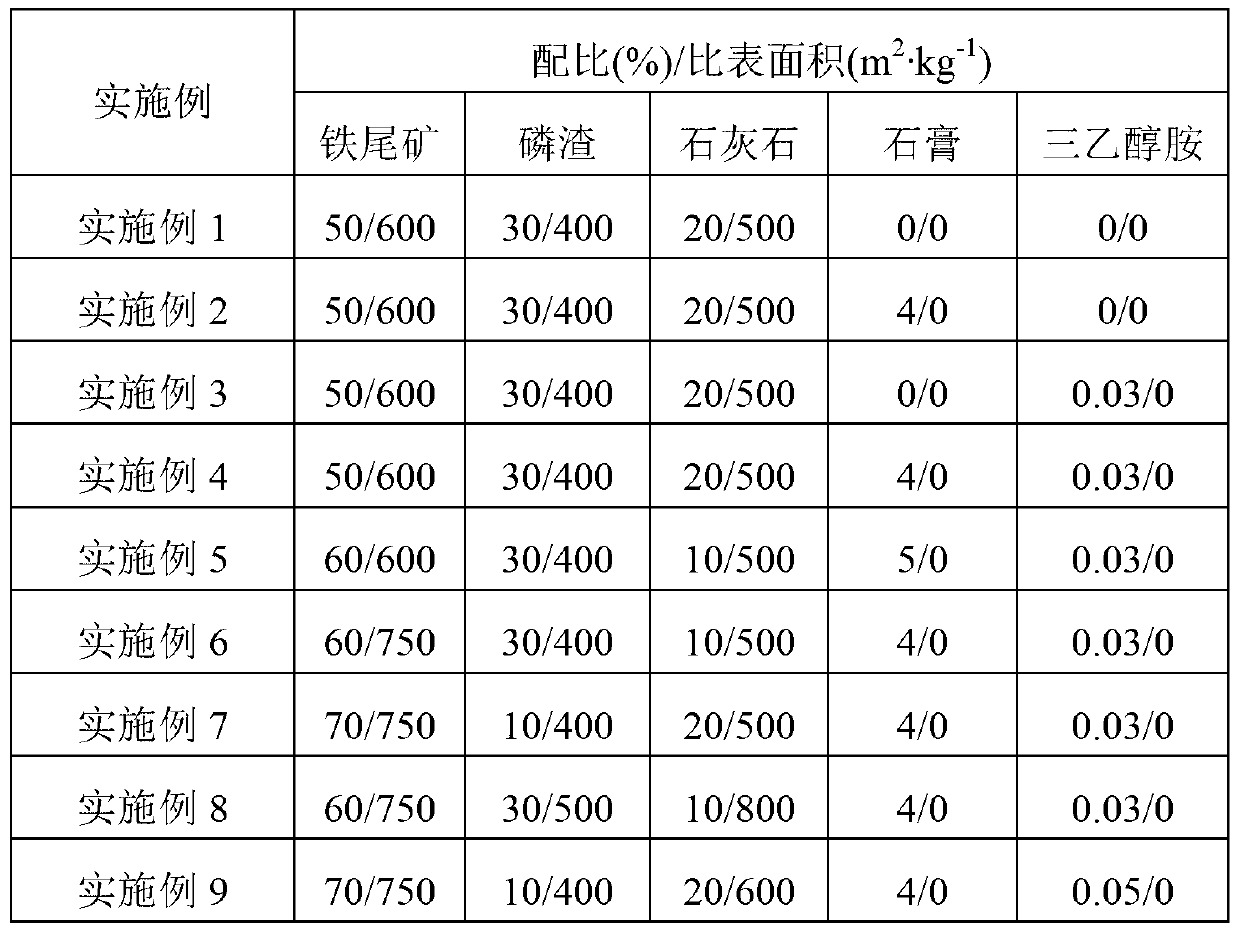

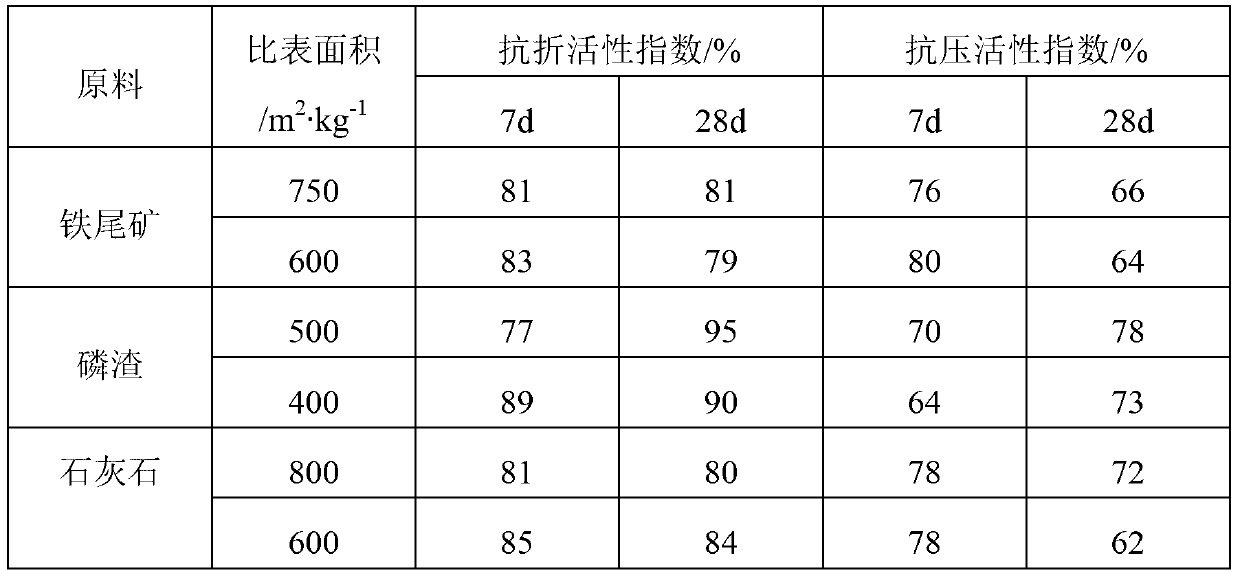

Iron tailing-based complex mineral admixture and preparation process thereof

InactiveCN103342491AExcellent performanceImprove pore structureSolid waste managementWater contentSlag

The invention relates to an iron tailing-based complex mineral admixture and a preparation process thereof. The preparation process comprises the following steps of: respectively drying iron tailing sand, industrial waste slag and limestone till water content is not more than 1% for later use; adding gypsum to match with iron tailings, the industrial waste slag and the limestone after drying, then sending into a ball grinding machine to perform powder grinding, and adding grinding aids during the powder grinding process; and uniformly mixing the obtained iron tailing powder, industrial waste slag powder and limestone powder to obtain the iron tailing-based complex mineral admixture. The iron tailing-based complex mineral admixture disclosed by the invention has the beneficial effects that 1) the iron tailings are matched with other industrial waste slag, the admixture for concrete is prepared by simple mechanical fine grinding, and the performance is better; 2) the performance is good, and the iron tailing-based complex mineral admixture can be used for preparing the concrete with the strength grade of C50-C80; 3) a variety of industrial wastes are scientifically and effectively compounded, the activity and particle size synergy of each component against cement and the concrete can be fully exerted to enable the advantages of all the components to complement each other, and the over-superimposed effect is further realized; and 4) the production process is simple and conductive to industrial production, popularization and application.

Owner:WUHAN UNIV OF TECH

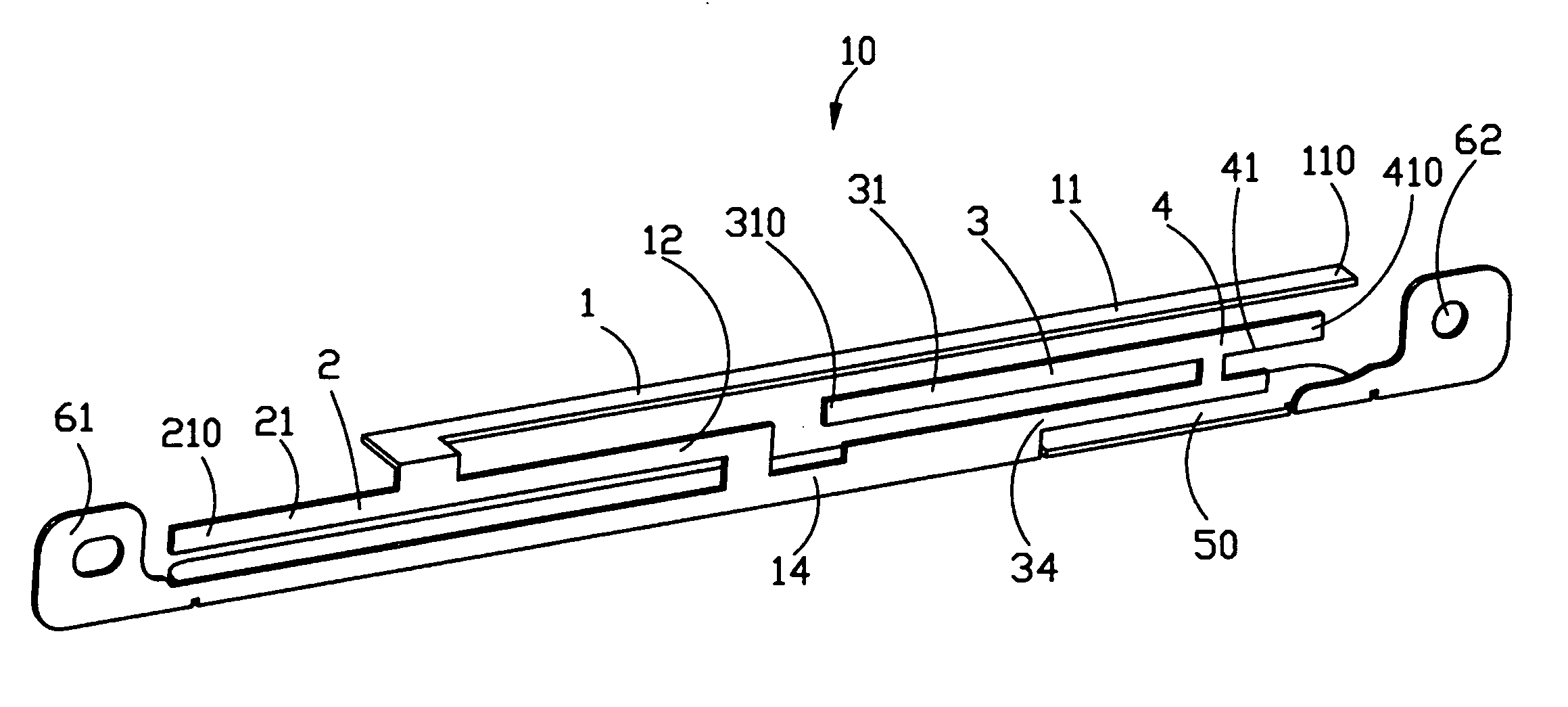

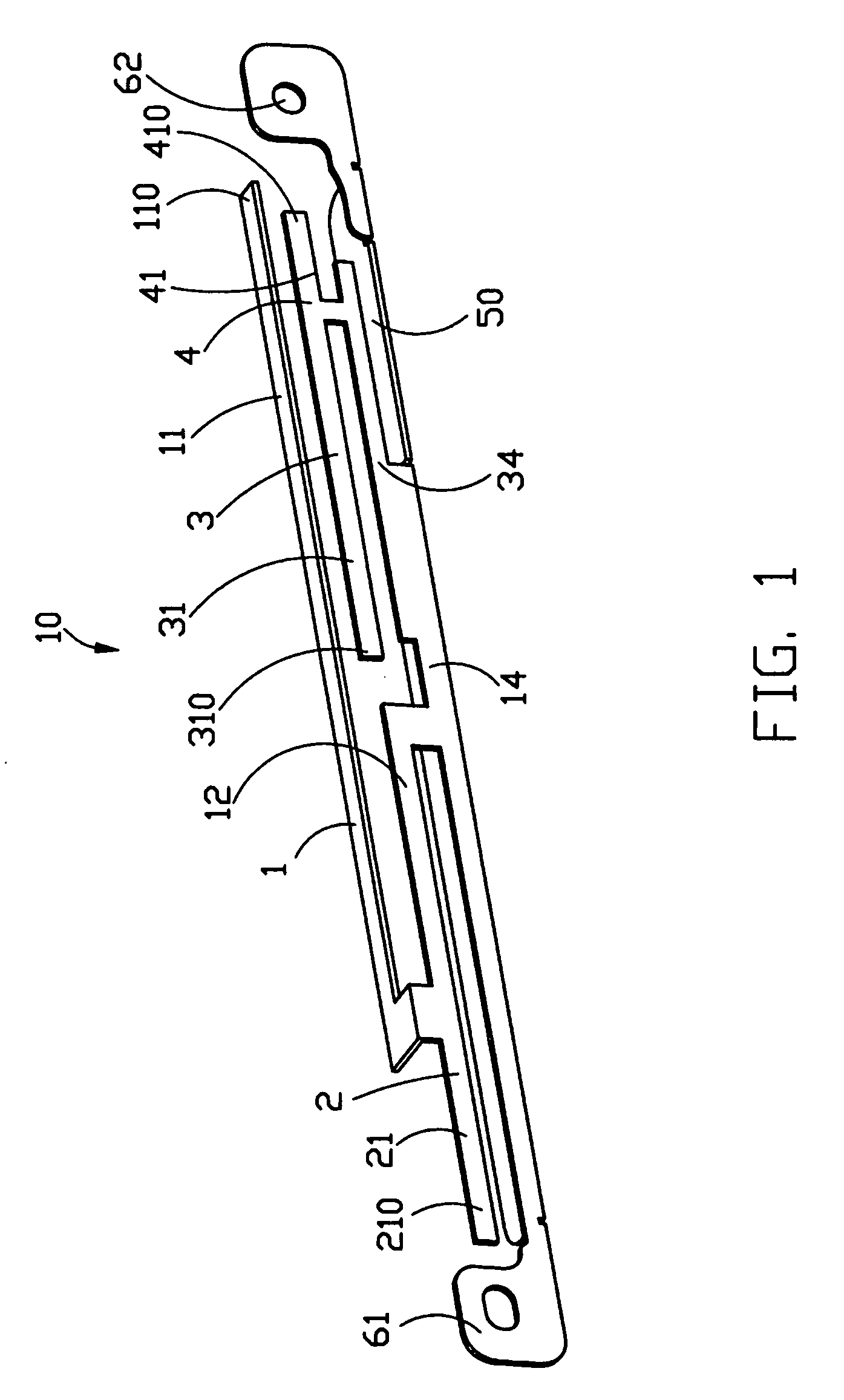

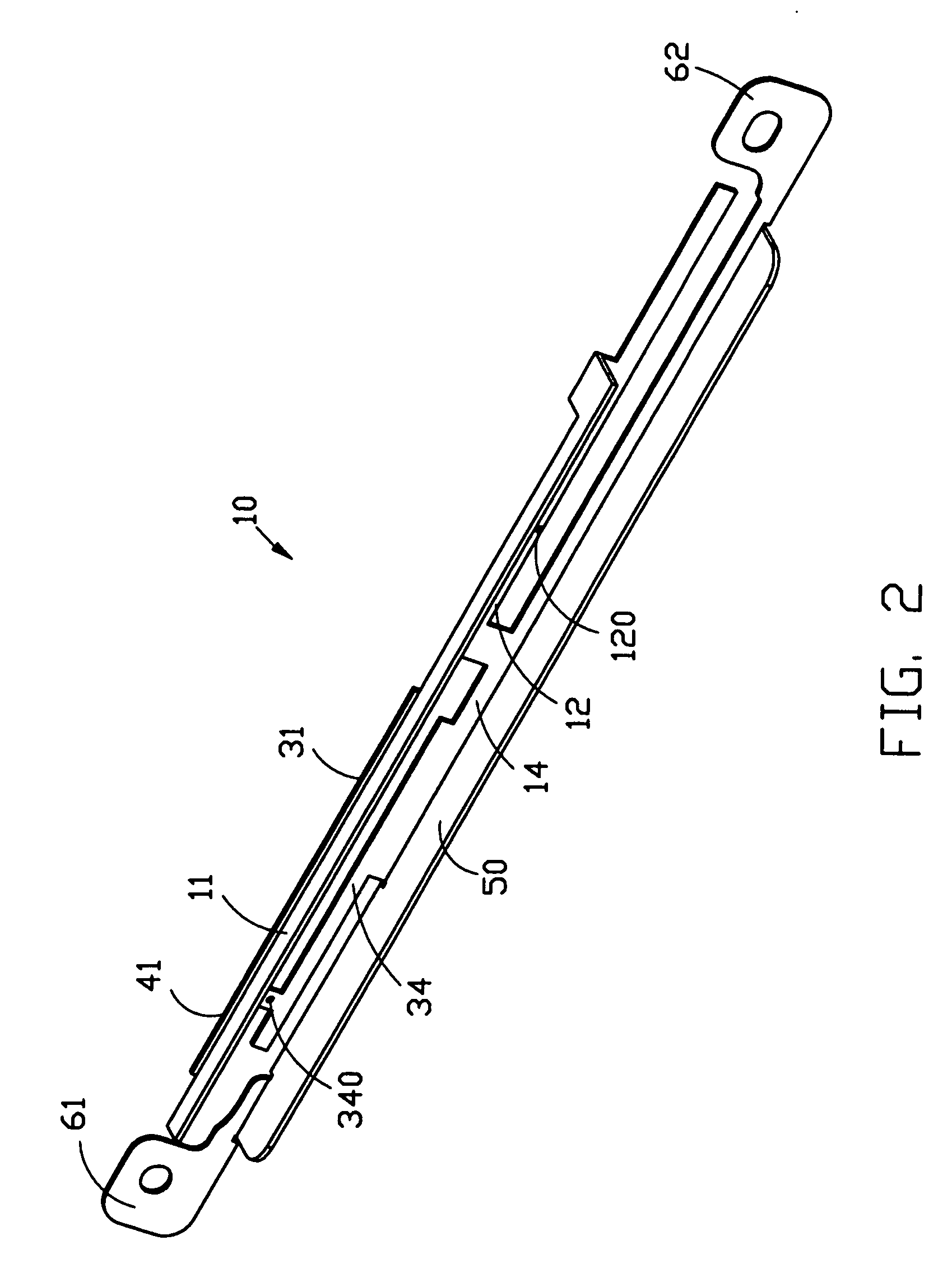

Multi-frequency antenna

InactiveUS20060262016A1Reduce installation spaceExcellent performanceSimultaneous aerial operationsAntenna supports/mountingsLocal area networkElectrical and Electronics engineering

A multi-frequency antenna includes a first antenna (1) and a second antenna (2) both operating at wireless wide area network, a third antenna (3) and a fourth antenna (4) both operating at wireless local area network. The first antenna, the second antenna, the third antenna and the fourth antenna are integrally made from a metal sheet and have a common grounding portion (50). The first and the second antennas have a first connecting portion (12) on which a feeding point (120) is located, and the third and the fourth antenna have a second connecting portion (34) on which another feeding point (340) is located.

Owner:HON HAI PRECISION IND CO LTD

Energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and preparation method thereof

ActiveCN102746784AExcellent performanceGood compatibilityAnti-corrosive paintsPolyurea/polyurethane coatingsChemistryWetting

The invention discloses an energy-saving insulated flame-retardant water-proof corrosion-proof functional coating and a preparation method thereof. The functional coating is prepared from the following raw materials: an aqueous polyurethane dispersion, a flame retardant, a flame-retardant antismoke agent, a hollow glass bead, a wetting dispersant, an anti-settling agent, a thickening agent, water, a leveling agent and a de-foaming agent, has the functions of heat preservation, flame retarding, water prevention and corrosion resistance and the like, is unlikely to become yellow when in use, is safe and reliable, is excellent in performance, is good in compatibility with pigment dyestuff, is unlikely to damage the coated surface, is easy to modify, is nontoxic, is safe to use, does not pollute environment and is suitable for the fields of inner and outer wall coating, pipeline coating, wood furniture coating, decoration coating, chemical corrosion-proof coating and the like.

Owner:江苏瑞丰科技实业有限公司

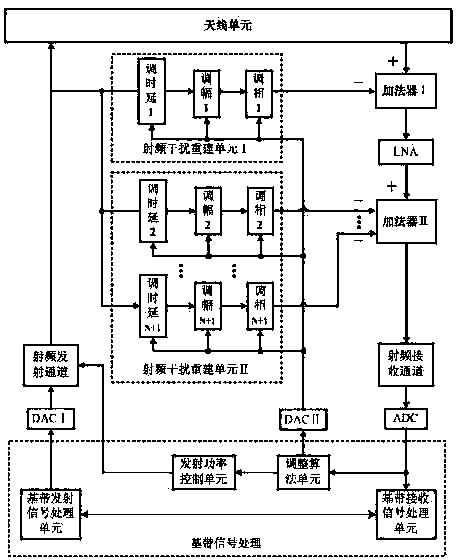

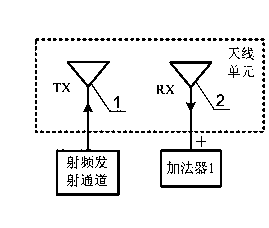

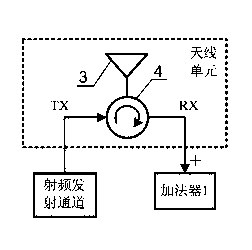

System and method for canceling high-transmission-power same-time same-frequency self-interference under multi-path environment

ActiveCN103427874AExcellent performanceAvoid signal distortionTransmissionPower controlRadio frequency signal

The invention discloses a system and method for canceling high-transmission-power same-time same-frequency self-interference under the multi-path environment. The method includes the steps that at the transmitting end, a transmission power control unit is used for controlling radio-frequency signal power of the transmitting end to be a low noise amplifier unsaturated low power value of the receiving end and sending radio-frequency signals of the transmitting end into a radio-frequency interference reestablishing unit I and a radio-frequency interference reestablishing unit II; at the receiving end, and radio-frequency signals output by an antenna unit and the signals processed by the radio-frequency interference reestablishing unit I are subtracted to complete cancellation of radio-frequency self-interference for the first time; then the radio-frequency signal power of the transmitting end is controlled to be a high-power value, and at the receiving end, after the signals enabling the radio-frequency self-interference to be canceled for the first time are amplified by a low noise amplifier, the signals and the signals processed by the radio-frequency interference reestablishing unit II are subtracted to complete cancellation of radio-frequency self-interference for the second time. The system and method for canceling the high-transmission-power same-time same-frequency self-interference under the multi-path environment are suitable for a same-time same-frequency system, improve canceling capacity of high-transmission-power radio-frequency self-interference signals, improve communication stability, and double the spectrum utilization rate.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

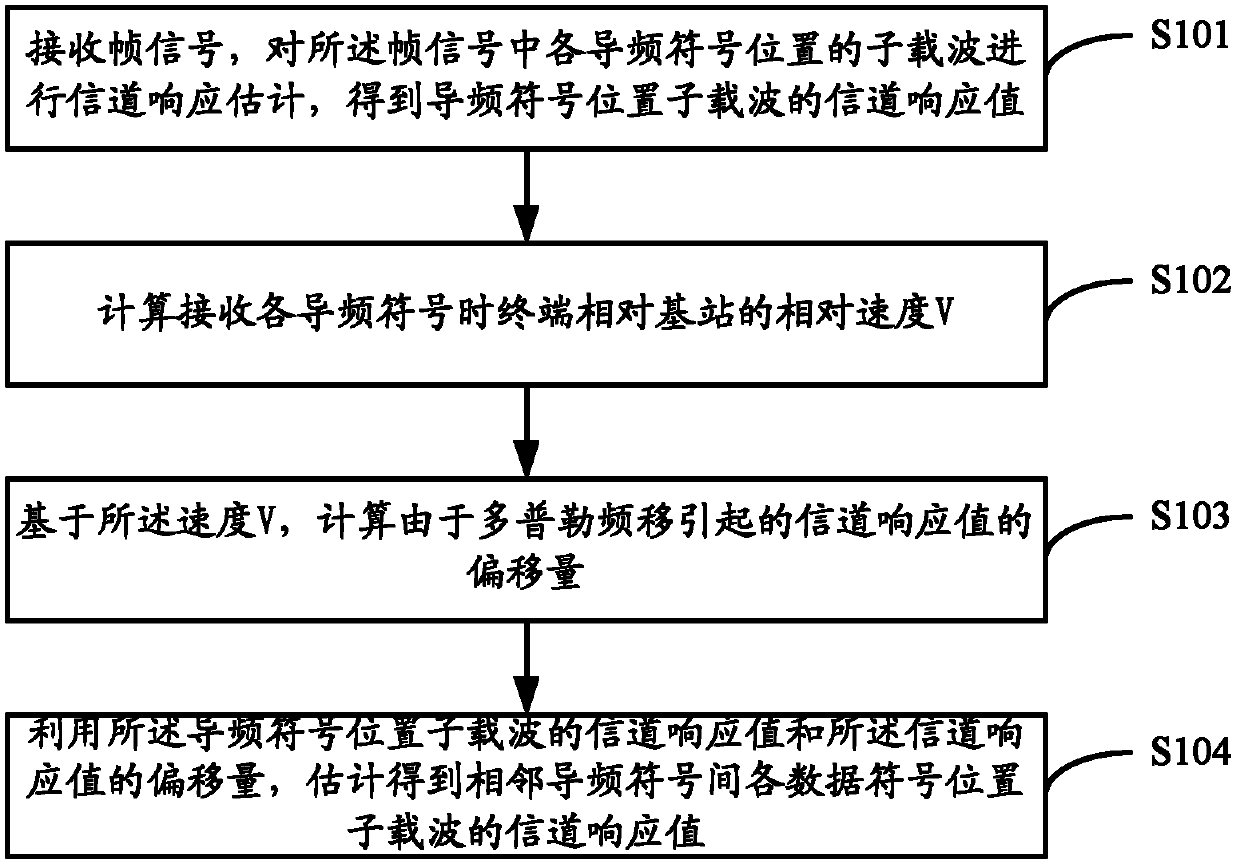

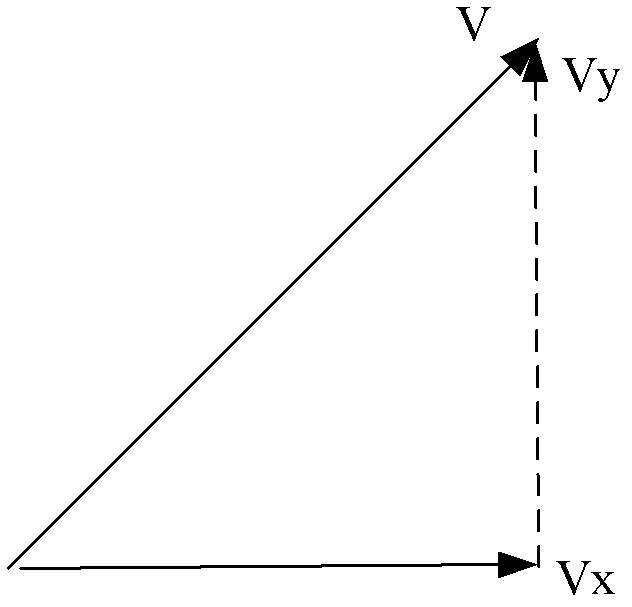

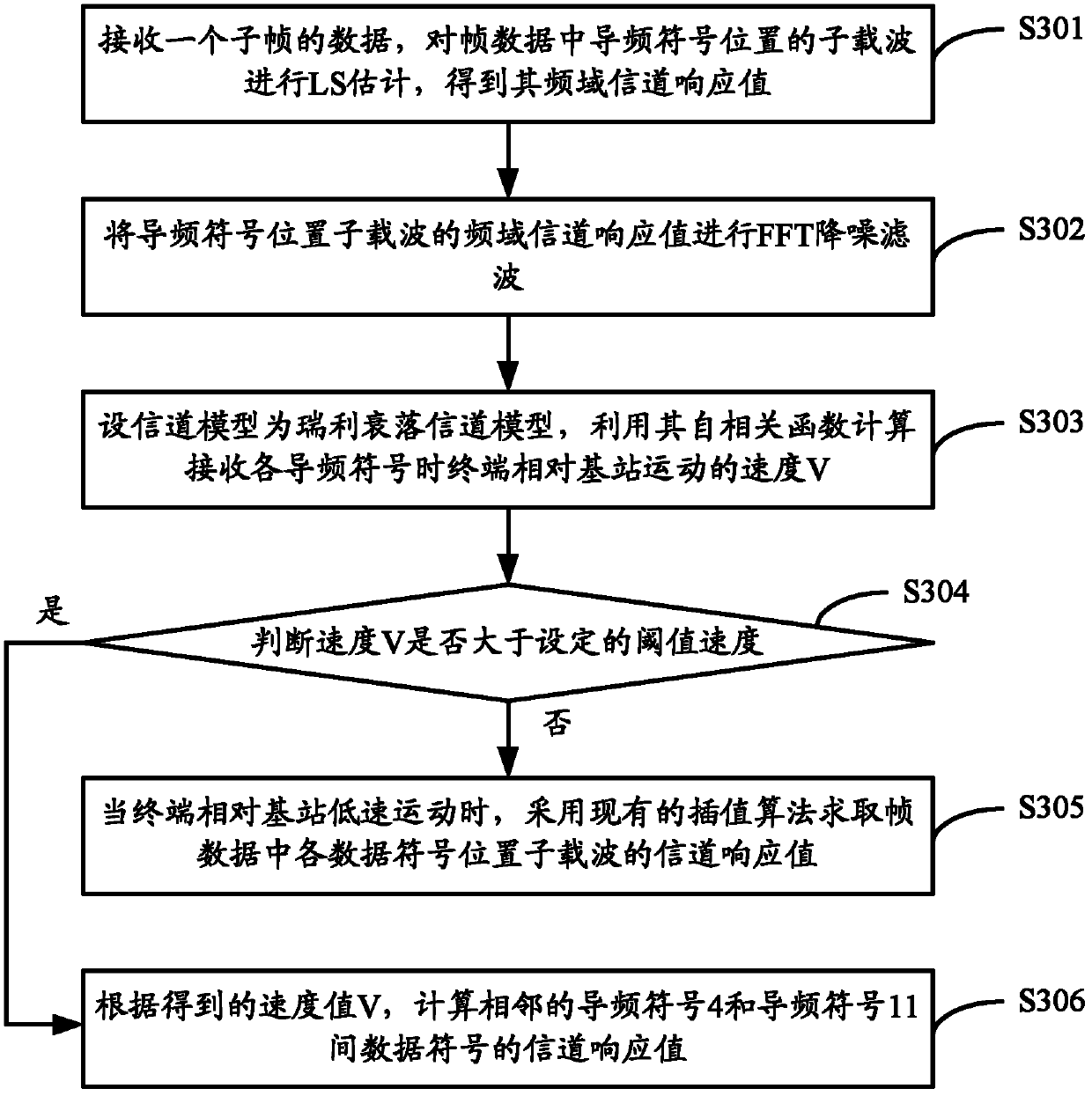

Channel estimation method and device based on Doppler frequency shift

ActiveCN102223326AReduce system bit error rateExcellent performanceTransmitter/receiver shaping networksSystem errorCarrier signal

The invention discloses a channel estimation method and a device based on Doppler frequency shift. The method comprises the following steps: receiving a frame signal, and carrying out channel response estimation to subcarriers at pilot frequency symbol positions in the frame signal to obtain channel response values of the subcarriers of the pilot frequency symbol positions; computing relative velocity V of a terminal relative to a base station during receiving pilot frequency symbols; based on the velocity V, computing the shift quantity of channel response values, caused by the Doppler frequency shift; and utilizing the channel response values of the subcarriers of the pilot frequency symbol positions and the shift quantity of the channel response valves to estimate so as to obtain the channel response values of the subcarriers of data symbol positions between adjacent pilot frequency symbols. By the method disclosed by the invention, the requirement of a user on the accuracy of the system channel estimation under the condition of high-velocity moving can be met, the system error rate is reduced, and the good property of a system can be ensured.

Owner:江苏溢泽给排水设备有限公司

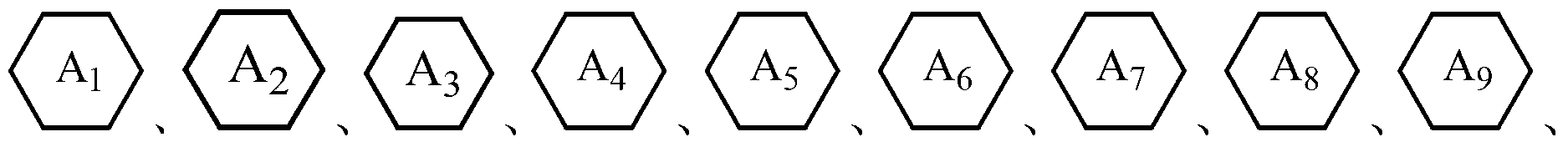

Method for producing expediting setting type aquosity ultraviolet light solidifying composition

The invention provides a preparation method of a high-gloss and high-speed curing water-based ultraviolet light curing composition applied on a printing surface. The composition includes (1) polyhydric alcohols or polybasic acids containing double bonds in different proportions are polycondensed to form hydroxyl-terminated unsaturated polyesters as soft segments of polyurethane, and self-made hydroxyl-terminated water-based monomers containing double bonds and iso The reaction of phorone diisocyanate to prepare water-based photocurable polyurethane prepolymer; (2) react epoxy resin and acrylic acid to open the epoxy group, and then use acid anhydride to react with the hydroxyl group in the epoxy prepolymer to prepare water-based polyurethane prepolymer. Photocurable epoxy resin prepolymer; (3) Cold blend the two prepolymers, neutralize them with a weak base, add water to disperse them under high-speed stirring, and remove the solvent, thereby preparing a self-emulsifying water-based photopolymer. Cured composite resin. The invention can adjust various properties of the resin (paint) by adjusting the molar ratio of raw materials in the resin, and the prepared dispersion has small particle size (20nm-120nm), excellent performance and easy industrialization.

Owner:广东天银实业有限公司 +1

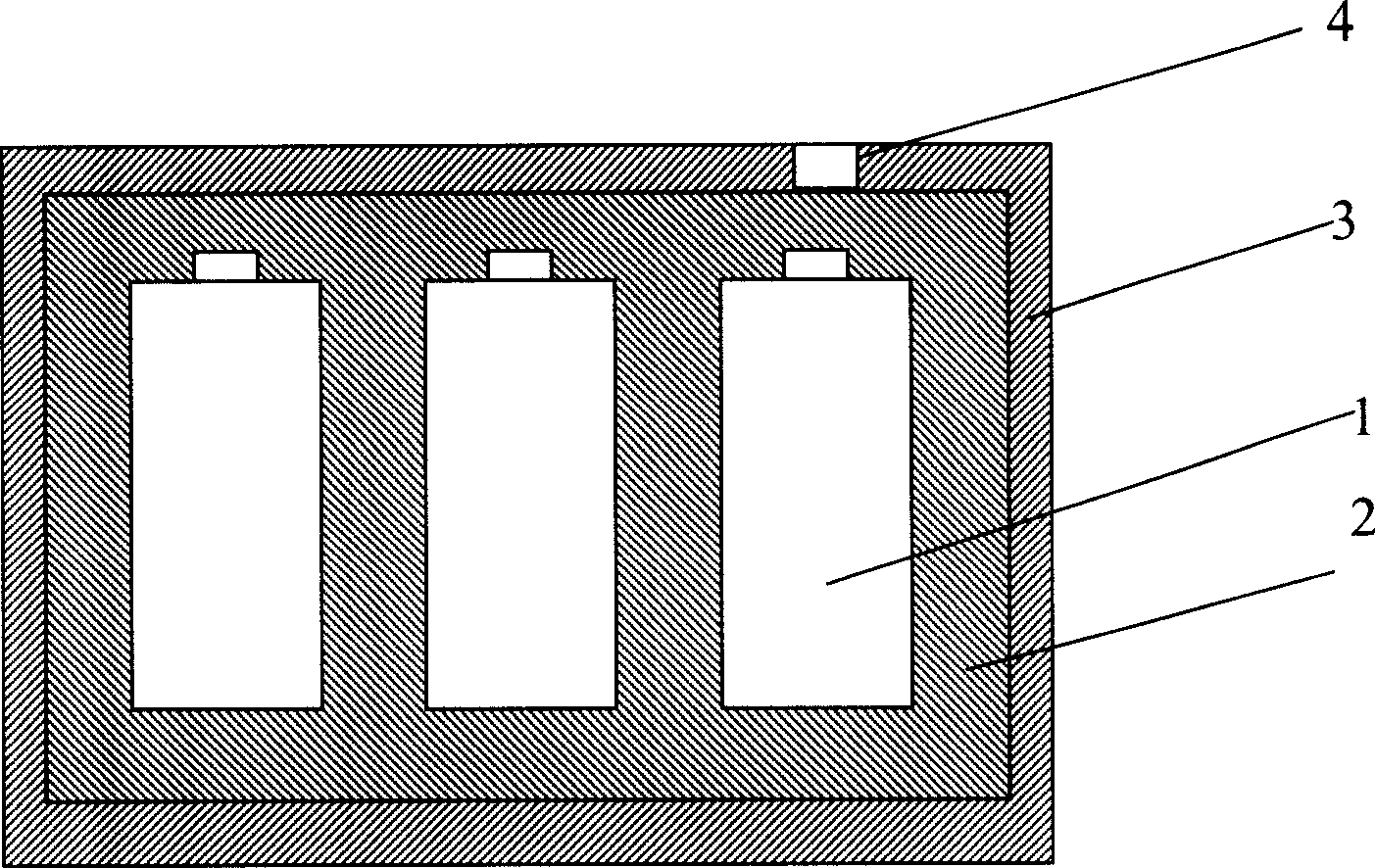

Flat, bonded-electrode rechargeable electrochemical cell and method of making same

InactiveUS6413667B1Excellent performanceLong operate lifeFinal product manufactureCell temperature controlSolventIon

A Li-ion battery cell comprising a polymeric matrix positive electrode layer member, a polymeric matrix negative electrode layer member, and an interposed microporous polyolefin separator layer member is laminated into a unitary, flexible cell structure by means of heat and pressure without necessity of applied interlayer adhesive. A volatile vehicle solution of a primary plasticizer for the electrode member polymer matrix is applied to the microporous separator member where it is absorbed into the porous structure. Evaporation of the volatile vehicle solvent deposits the plasticizer upon and within the pores of the separator member. During the lamination operation the plasticizer is forced into contact with the electrode member polymer where it softens the polymer into a thermoplastic adhesive in the region of the electrode / separator interface, thereby enabling the electrode polymer alone to form a strong bond to the separator upon cooling.

Owner:LITHIUM WERKS TECH BV

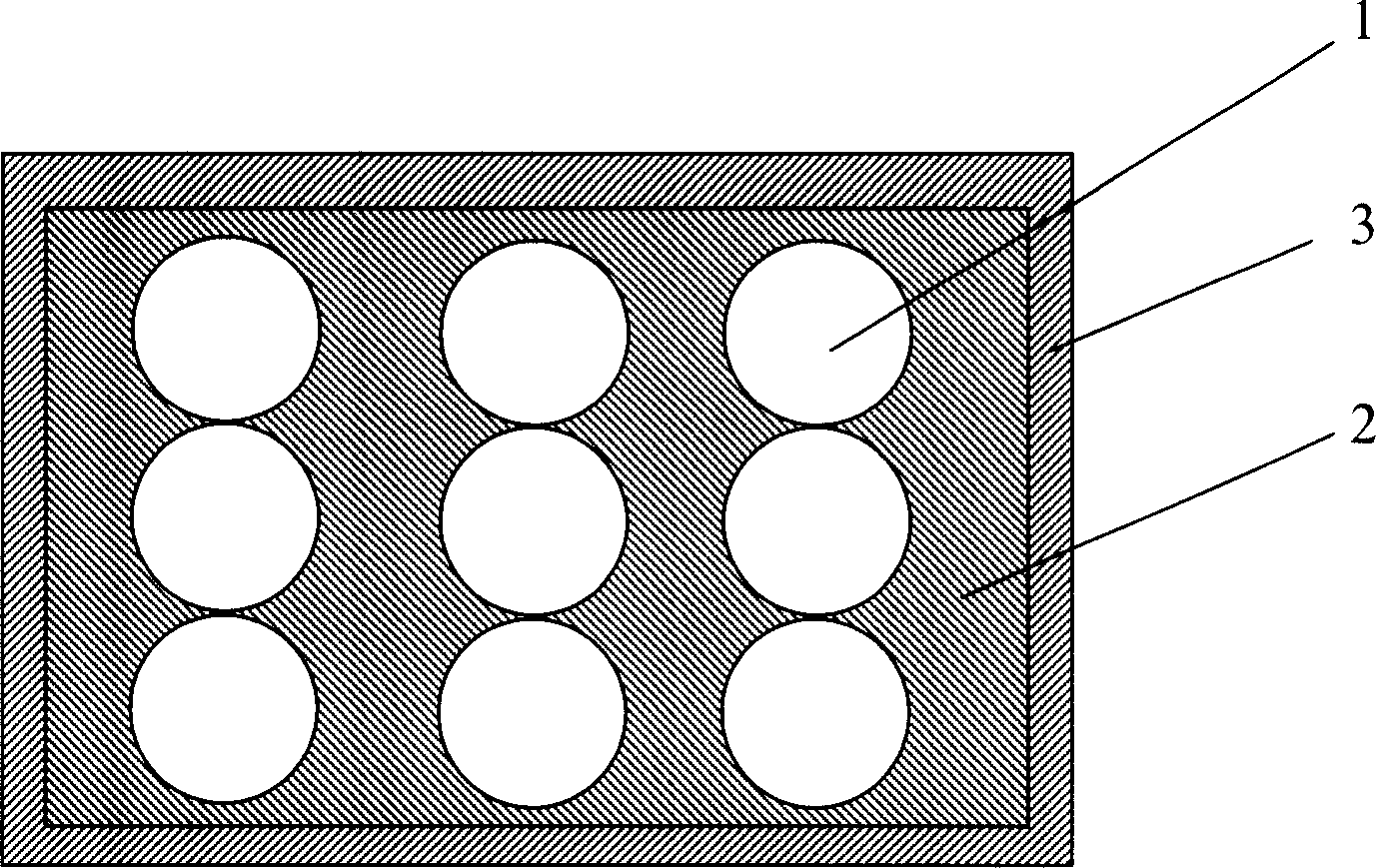

Battery bag with temp regulating function

InactiveCN1870347AExcellent performanceExtended service lifeTemperatue controlBattery isolationPhase change temperatureElectrical and Electronics engineering

This invention provides a cell package with a temperature regulation function including a package shell, in which, a phase change material of 0-60deg. C is filled between the cell set and the package and contacted with the cell set directly, which can prolong the life time of cells and reduce the cost.

Owner:BYD CO LTD

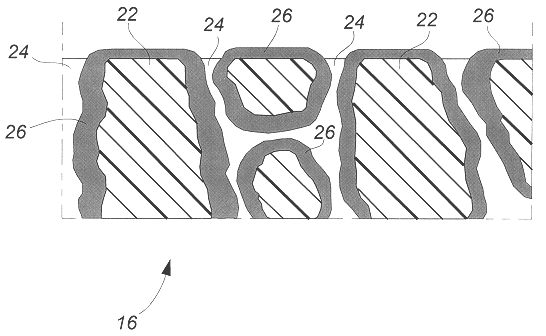

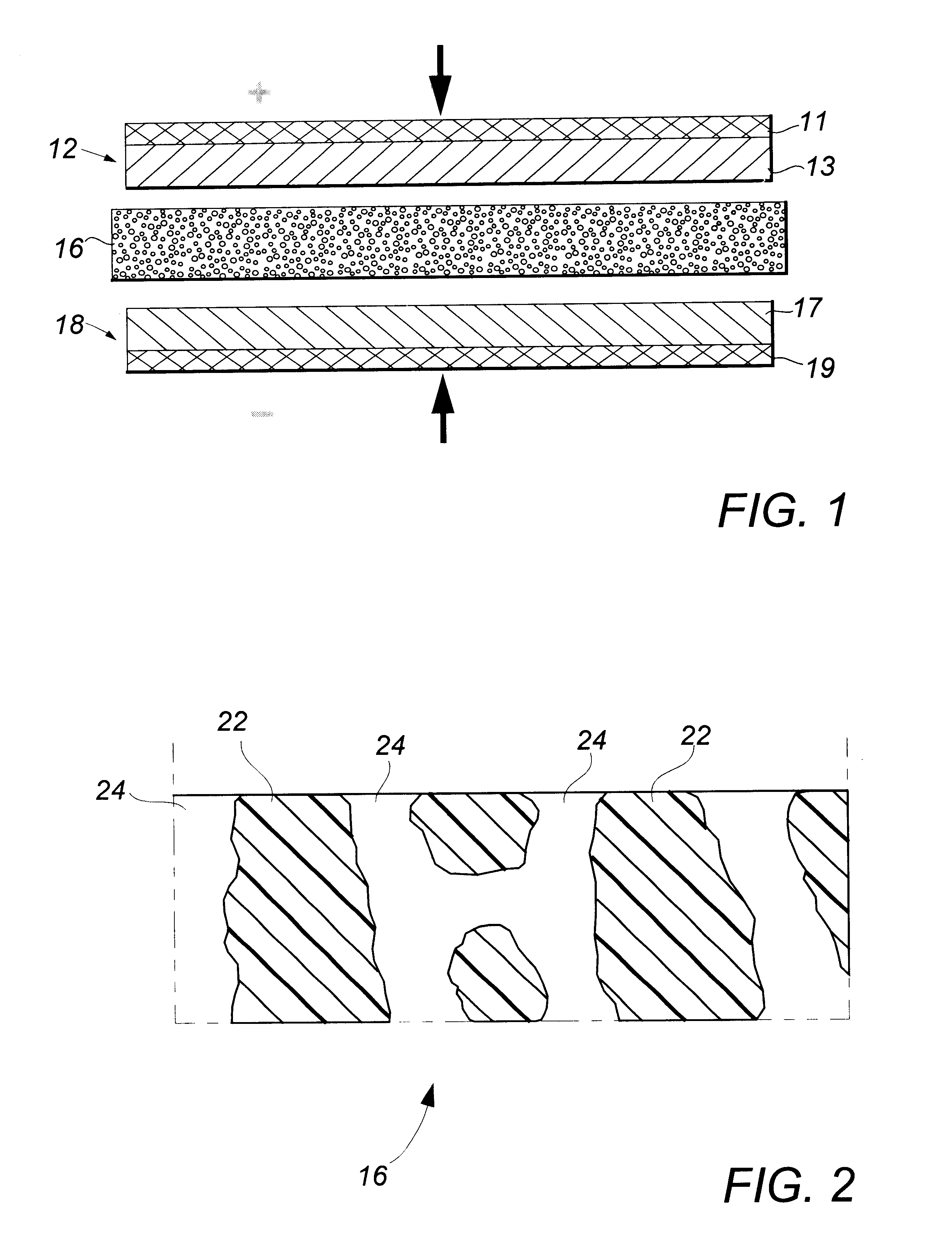

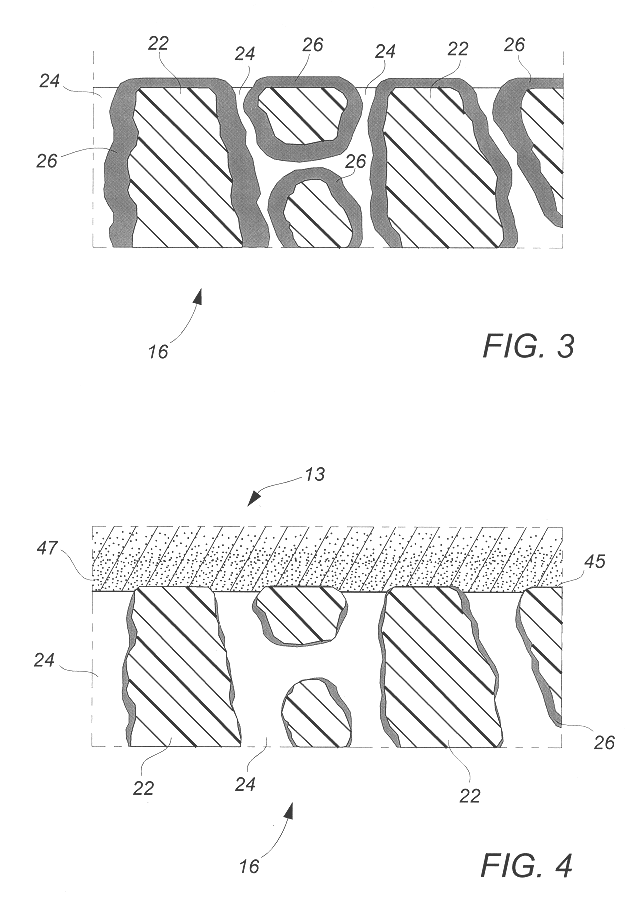

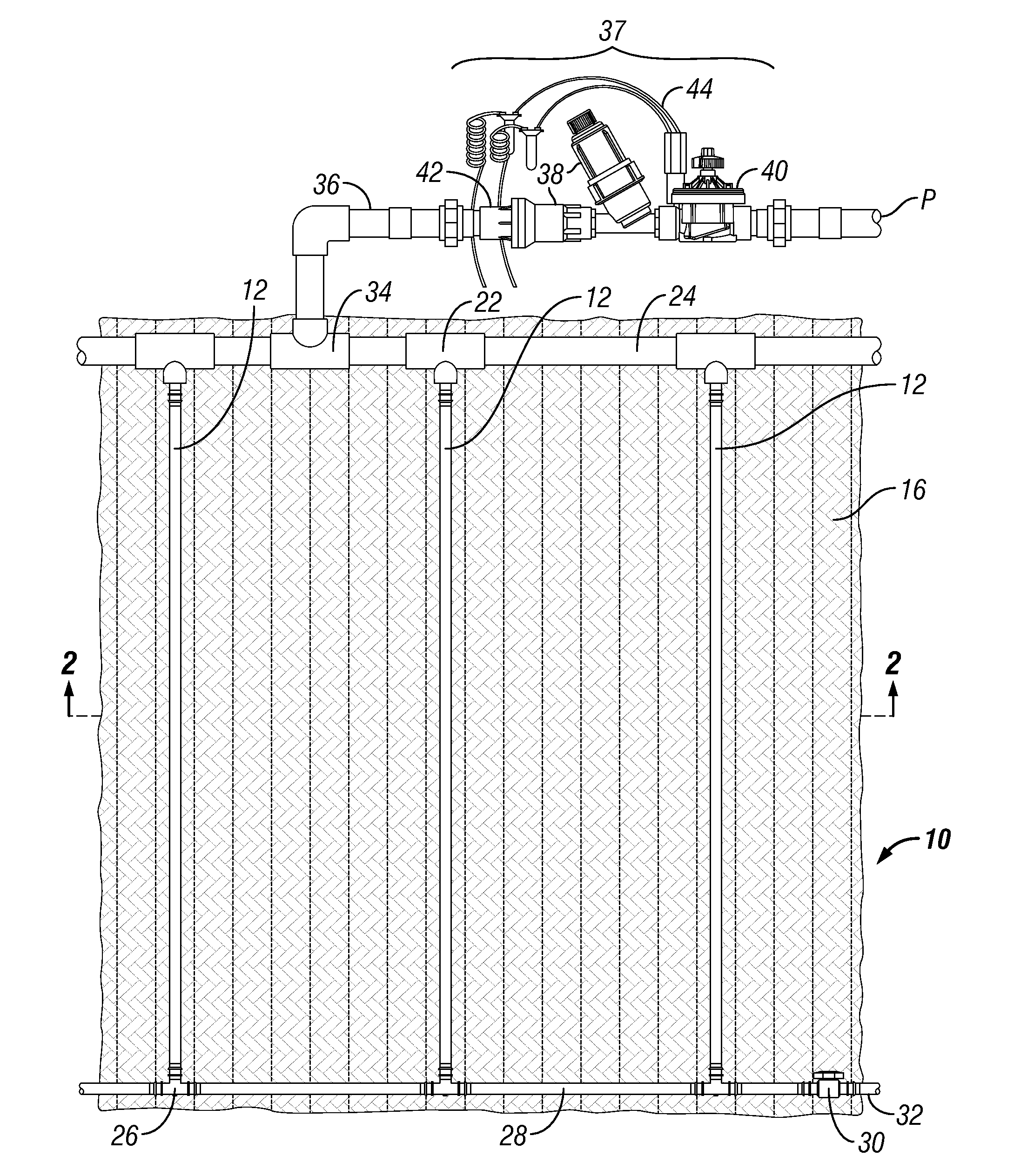

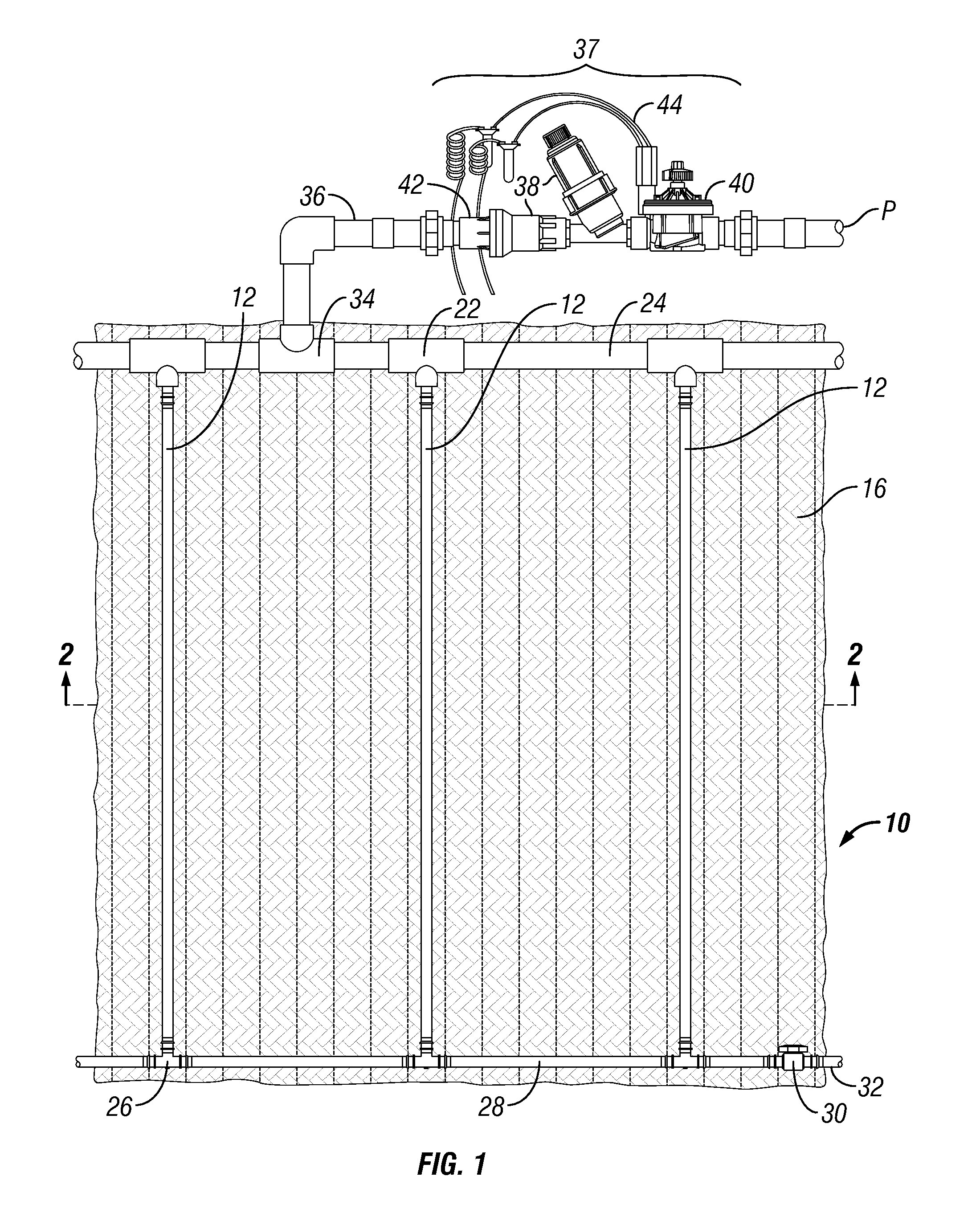

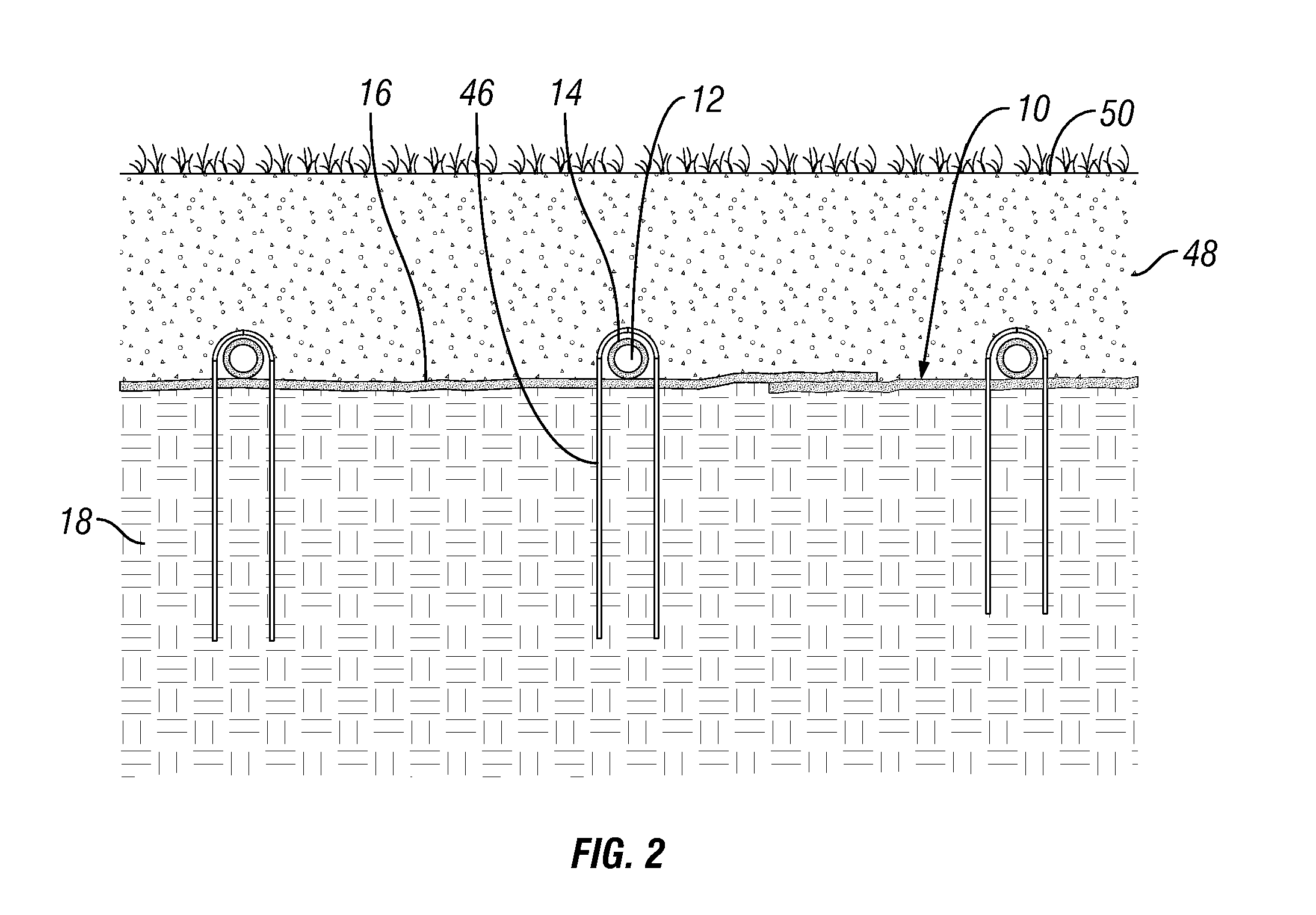

Subsurface Irrigation Mat

ActiveUS20130074400A1Excellent performanceIncrease irrigationWatering devicesCultivating equipmentsEngineeringCapillary action

A subsurface irrigation mat includes at least one perforated tube, a web made of a first capillary textile, and a casing made of a second capillary textile. The casing surrounds substantially an entire circumference of the perforated tube along at least a portion of a length of the tube. At least one attachment secures the casing to the web so that the casing extends across the web. Water leaving through the holes in the perforated tube can saturate the casing, seep into the web from the casing, and then be carried across the web by capillary action. The result is a substantially uniform discharge of water from the web into a root zone of plants growing in a layer of a growing medium located above the web.

Owner:HUNTER INDUSTRIES

Methanol gasoline and its preparation method

InactiveCN102260548AEasy to prepareExcellent performanceLiquid carbonaceous fuelsFuel additivesTruckSolvent

The invention discloses a methanol gasoline and a preparation method thereof, relating to the field of new energy. The methanol gasoline comprises 15-30wt% of methanol, 67-83wt% of gasoline and 2-3wt% of additive. The preparation method comprises the following steps: pouring solubilizer, energy increasing and consumption reducing agent, anti-oxidant, metal corrosion inhibitor, rubber swelling inhibitor into a reaction vessel according to a required proportion with stirring, mixing uniformly to obtain an additive; mixing the additive with methanol according to a required proportion to obtain modified methanol; and mixing the modified methanol with gasoline according to a required proportion to obtain the methanol gasoline. The methanol gasoline disclosed in the invention has the advantagesof simple preparation and good performance, can be used mixed with a national standard gasoline in any proportion with similar energy consumption with the national standard gasoline and emission indexes that conforms to requirements of environmental protection, and can be widely used for various petrol-engined motor vehicles, such as car, carriage, fork truck, power-assisted vehicle, farm vehicle, motorcycle, load wagon and forklift.

Owner:永州锦溁新能源开发有限公司

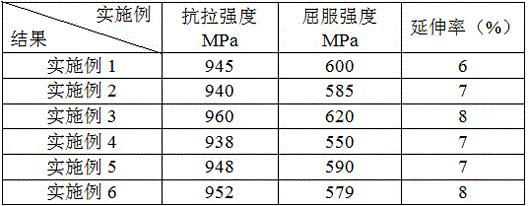

High-strength nodular cast iron QT900-6 and preparation method thereof

ActiveCN106011610AExcellent performanceImprove high temperature mechanical propertiesTrace elementMechanical property

The invention discloses high-strength nodular cast iron QT900-6 which consists of the following elements in percentage by weight: 3.2-3.7% of C, 2.4-2.8% of Si, less than or equal to 0.2% of Mn, less than or equal to 0.03% of P, 0.005-0.02% of S, 0.8-1.4% of Cu and the balance of Fe and unavoidable trace elements. The high-strength nodular cast iron QT900-6 has high compressive strength, high yield strength and excellent mechanical property.

Owner:西峡县内燃机进排气管有限责任公司

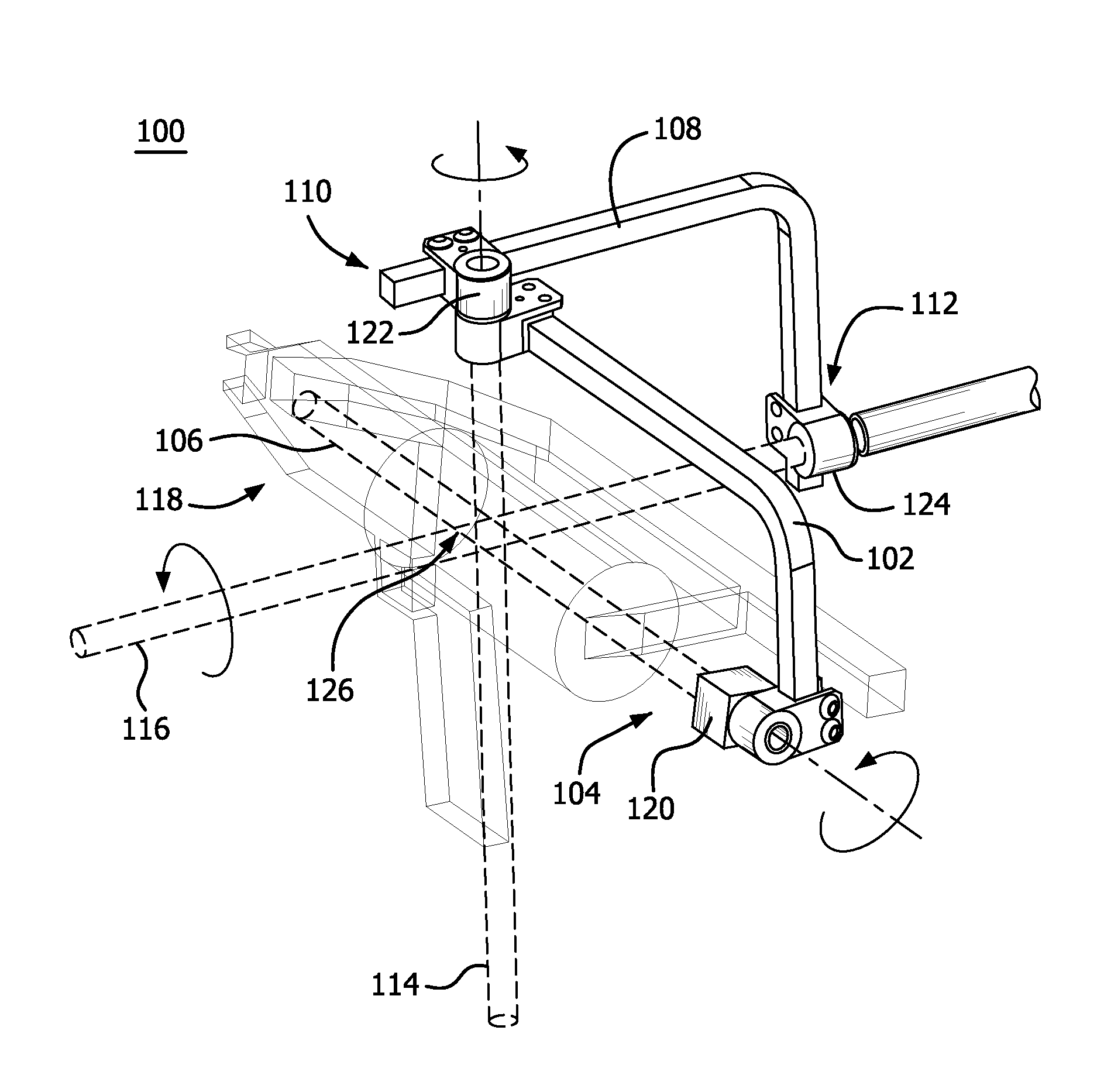

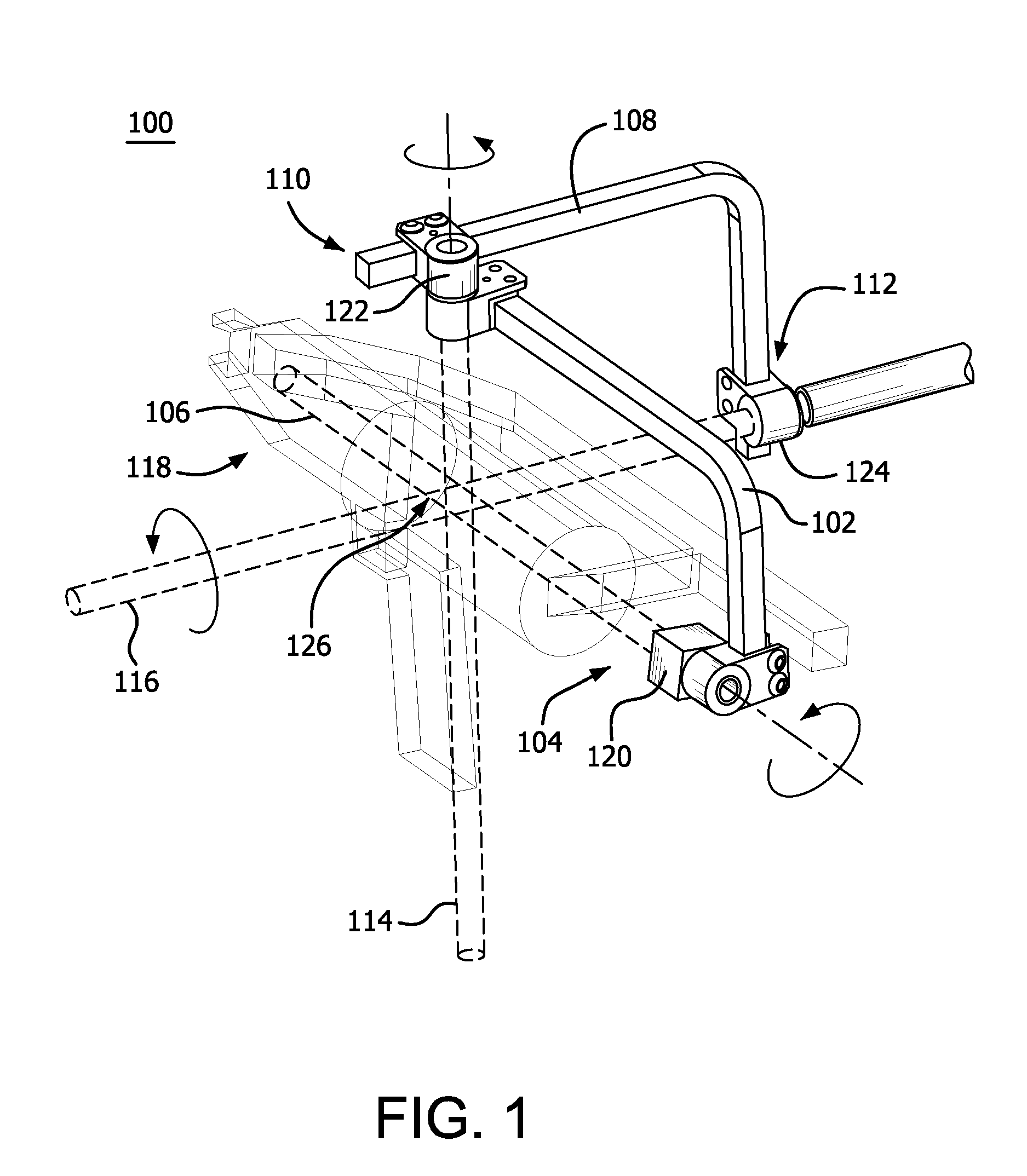

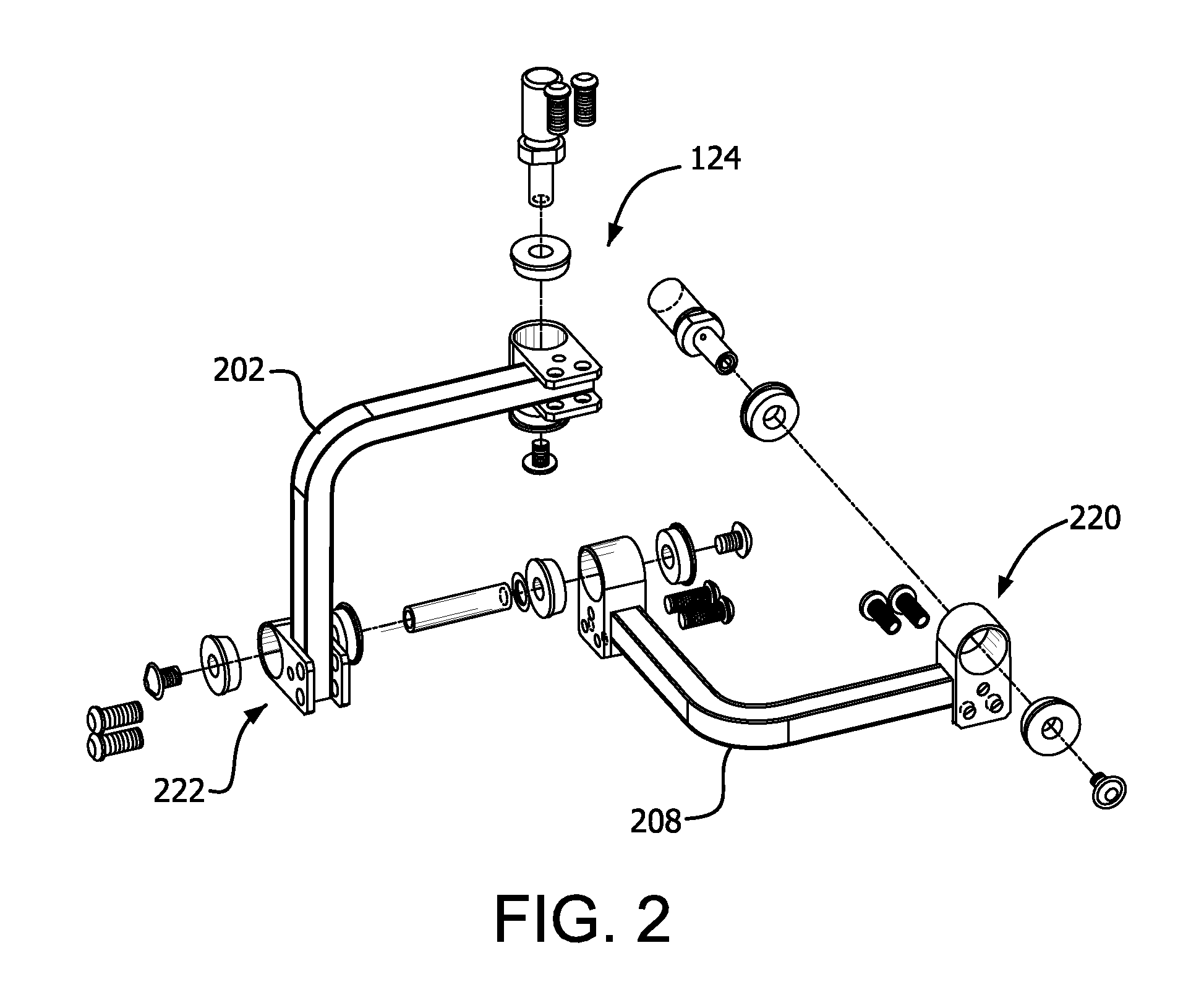

Multi-arm gimbal system

The invention provides a gimbal support apparatus to support tools or other payloads for use during performance of tasks using those payloads. The payload can be selectively biased to achieve an optimum position for performance of the task. The gimbal support apparatus comprises rotationally connected gimbal arms that can be adjusted with respect to one another and to an equipoising support arm to attain the selected payload bias.

Owner:BROWN GARRETT W

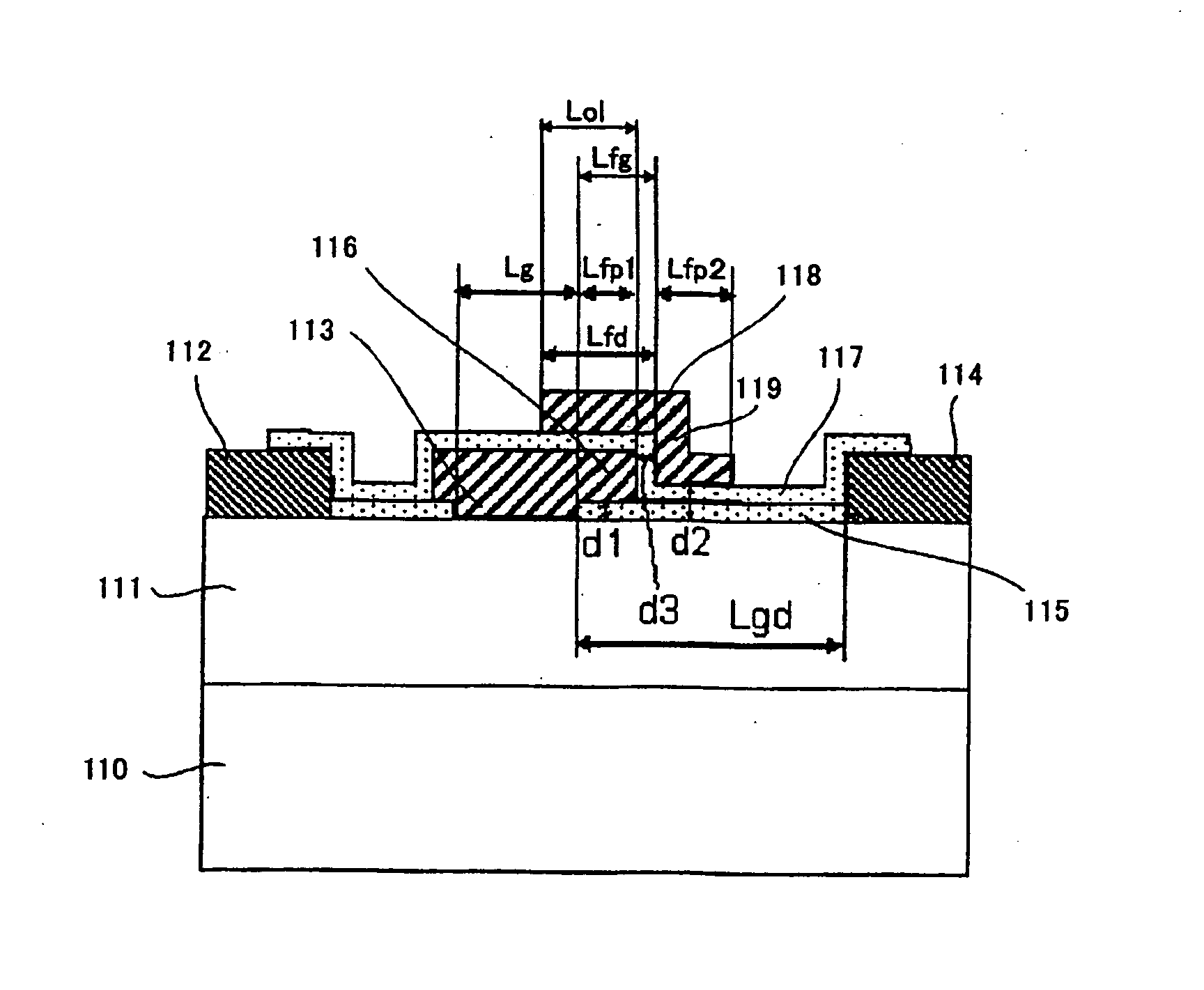

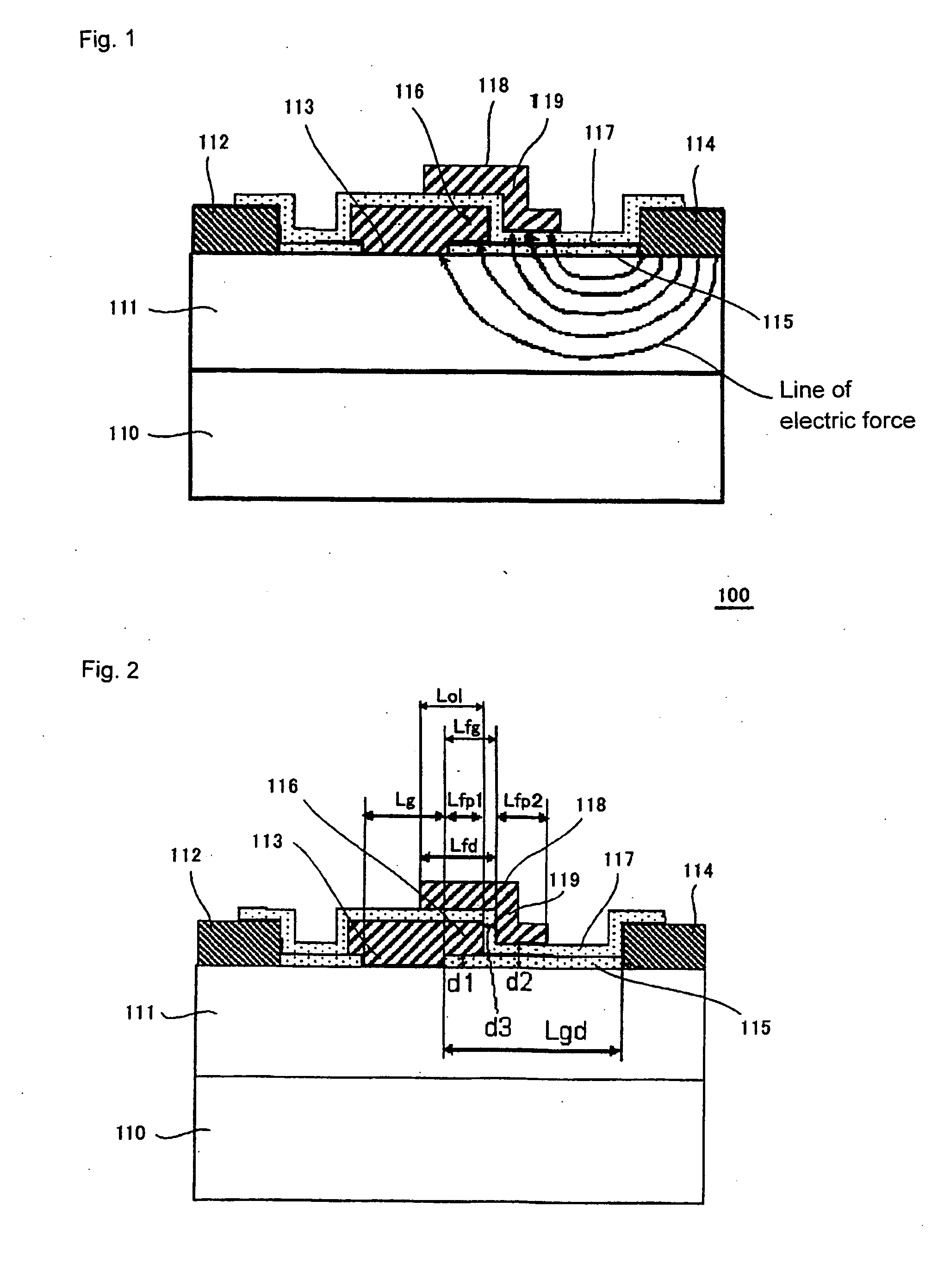

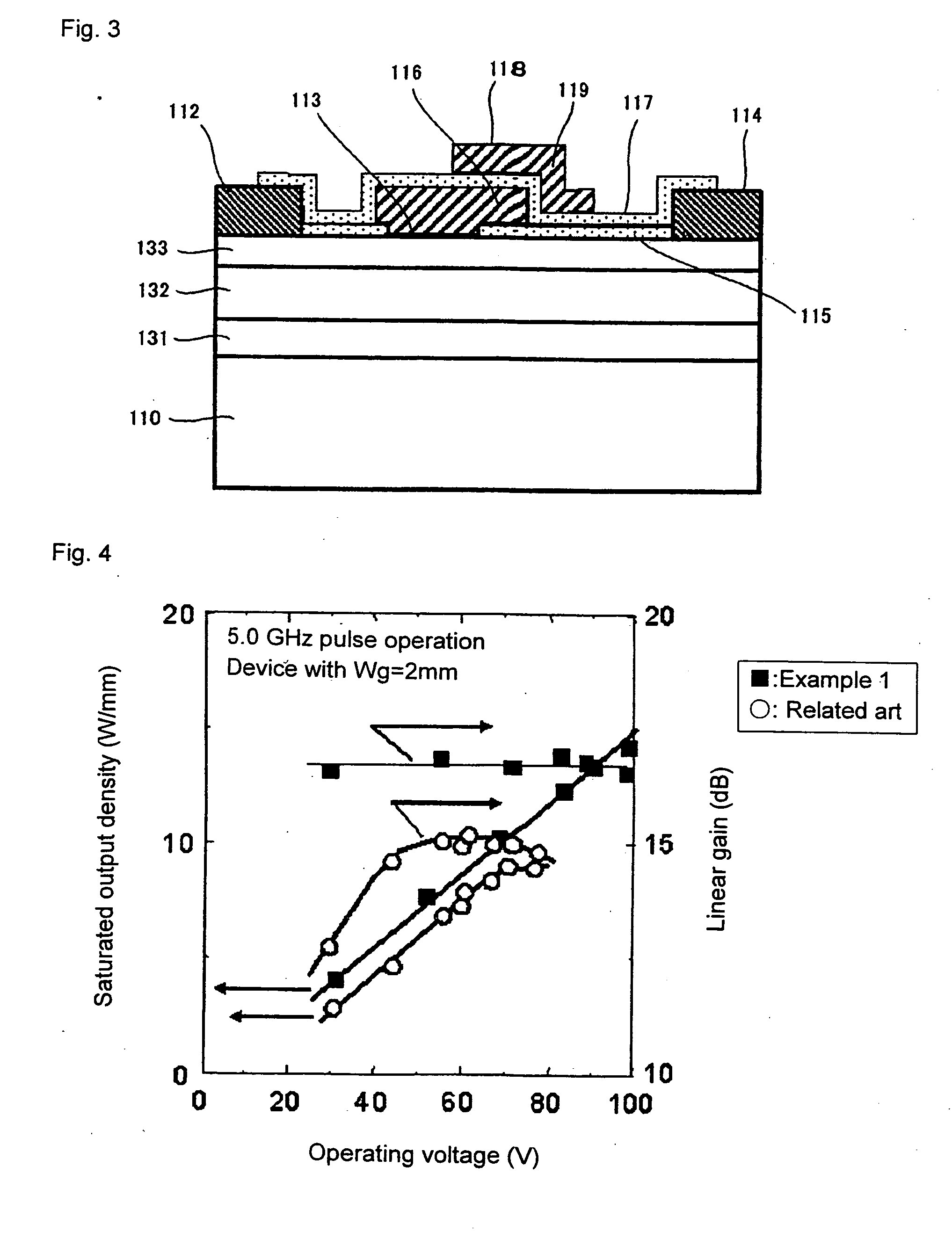

Field effect transistor

ActiveUS20090230429A1Excellent performanceImprove performanceTransistorField-effect transistorPlate electrode

A field effect transistor (100) exhibiting good performance at high voltage operation and high frequency includes a first field plate electrode (116) and a second field plate electrode (118). The second field plate electrode includes a shielding part (119) located in the region between the first field plate electrode and a drain electrode (114), and serves to shield the first field plate electrode from the drain electrode. When in the cross sectional view in the gate length direction, the length in the gate length direction of an overlap region where the second field plate electrode (118) overlap the upper part of a structure including the first field plate electrode and a gate electrode (113) is designated as Lol, and the gate length is Lg, the relation expressed as 0≦Lol / Lg≦1 holds.

Owner:MITSUBISHI ELECTRIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com