Continuous silicon carbide fiber preparation method and production device

A technology of silicon carbide fiber and production device, which is applied in the directions of chemical characteristics of fibers, complete sets of equipment for producing artificial threads, melt spinning method, etc., can solve the problems that continuous silicon carbide fiber products are difficult to obtain polycarbosilane fibrils without melting treatment, etc. Achieve the effect of high production efficiency, good performance and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Example 1 Preparation of ceramic precursor polycarbosilane

[0041] Polycondensate dimethyldichlorosilane and metal sodium in xylene to obtain polydimethylsilane, neutralize with methanol and wash with water to dry to obtain white solid powder;

[0042] The white solid powder is decomposed into CPS, a liquid substance mainly composed of cyclosilane, at an appropriate temperature of 200-500°C.

[0043] Add 120-160 kg of CPS into a 300-liter rearrangement polymerization reactor with an external heating and ring-opening cracking system, fill it with pure nitrogen, heat it to 300-350°C, and turn on the external heating device at 200-550°C. Strictly control the liquid reflux rate, rearrange polymerization, gradually (heating rate 0.1 ℃ / min) to 360 ~ 490 ℃, heat preservation 10 ~ 20 hours.

[0044] Stop heating, and after cooling to a certain temperature (200-250°C), a viscous yellow-brown liquid is obtained. Dissolve the yellow-brown liquid and xylene (weight ratio) = 1:4-6...

Embodiment 2

[0045] Example 2 Preparation of continuous SiC fiber

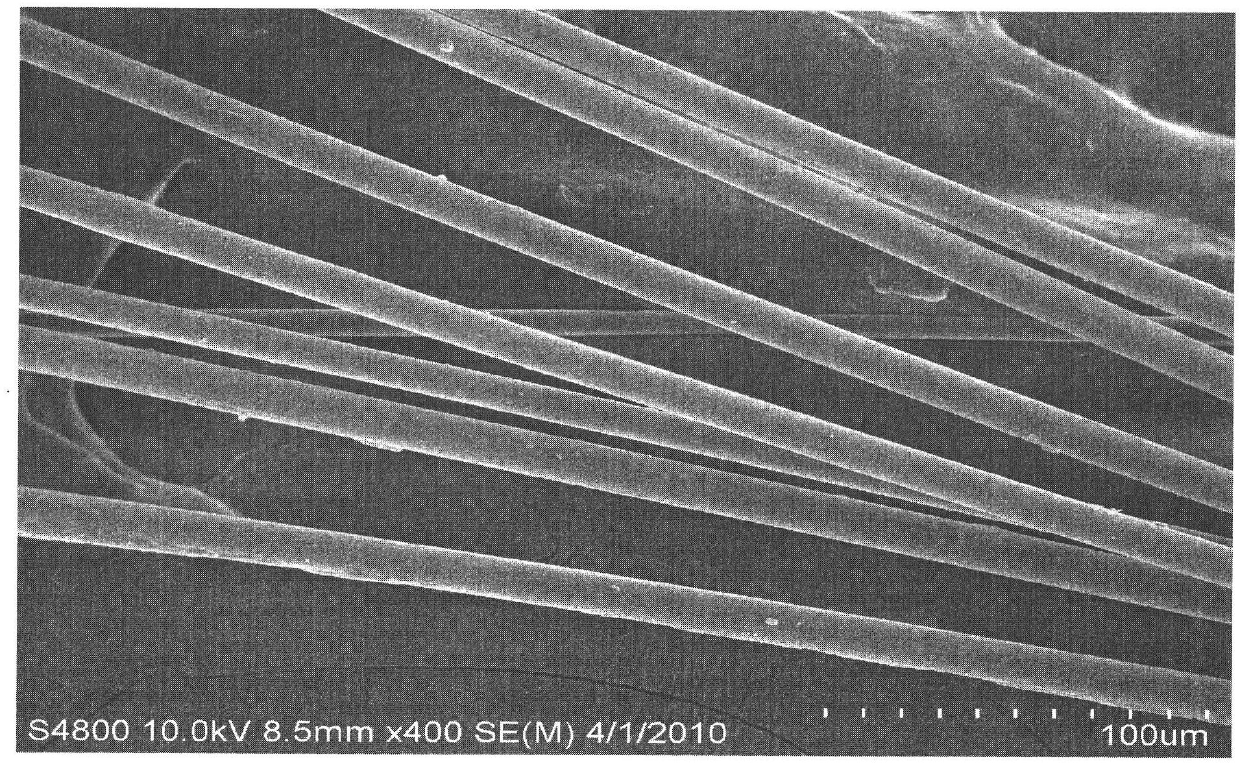

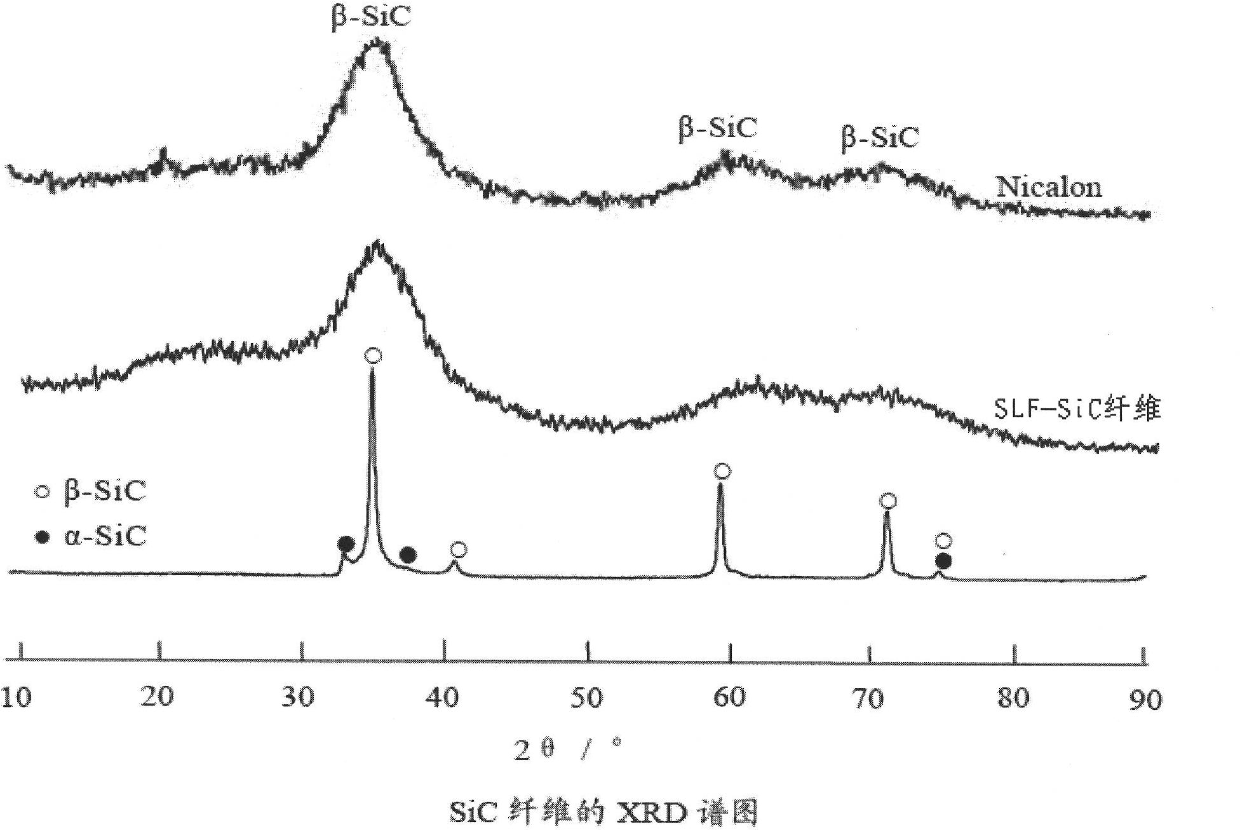

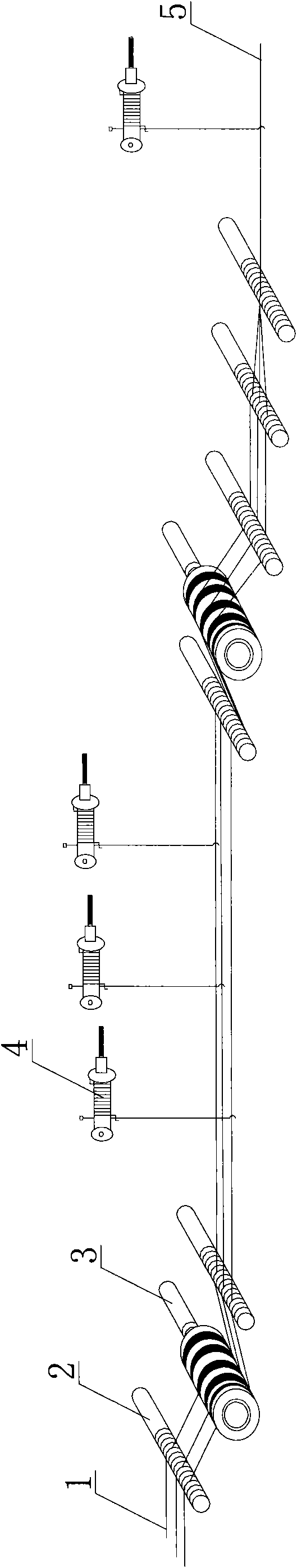

[0046] Put 20 kg of polycarbosilane whose softening point and melting range conform to melt spinning (generally, the softening point is 180-240°C, and the melting range is 8-20°C), put it in the melt-spinning device, and gradually heat it to a certain temperature under the protection of nitrogen flow. Temperature (generally controlled at 250-380°C), adjust the molecular weight distribution, heat preservation and aging for 2-10 hours, carry out spinning with 200-hole spinnerets, obtain a continuous temperature of more than 1000 meters, a diameter of 10-18 microns, and a broken wire rate controlled at 2-5% polycarbosilane fibers, using a unique air oxidation crosslinking, control the degree of crosslinking at 70-90% (the degree of Si-H bond reaction in polycarbosilane fibers is controlled at 60-85%) and then wait Tension plied into fiber bundles (generally 400-1200 / bundle) (the schematic diagram of fiber tension machinery is...

Embodiment 3

[0047] Example 3 Fiber physical property test without applying tension.

[0048] As in the operating conditions in Example 2, if no tension is applied when the fibers are plied, the tensile strength of the obtained continuous SiC fiber (batch SC100810-1) is significantly lower than the mechanical properties in Example 2. The tensile strength of the continuous SiC fiber obtained by the same test method is 1.5GPa, the strength CV value is 23-77%, the tensile modulus is 143.2GPa, the modulus CV value is 20%, and the fiber diameter is 12.9μm. while using as image 3 The continuous SiC fiber (batch SC100811) prepared by the tension device has a tensile strength of 1.8GPa, a strength CV value of 12%, a tensile modulus of 142GPa and a fiber diameter of 13.1μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Softening point | aaaaa | aaaaa |

| Melting range | aaaaa | aaaaa |

| Fiber diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com