Method for preparing Si/C composite cathode material of lithium ion battery

A technology for lithium-ion batteries and negative electrode materials, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of limiting the large-scale practical application of silicon-based materials, material morphology changes, and poor cycle performance, and achieve good cycle stability. And the effect of rate performance, cohesion enhancement and excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

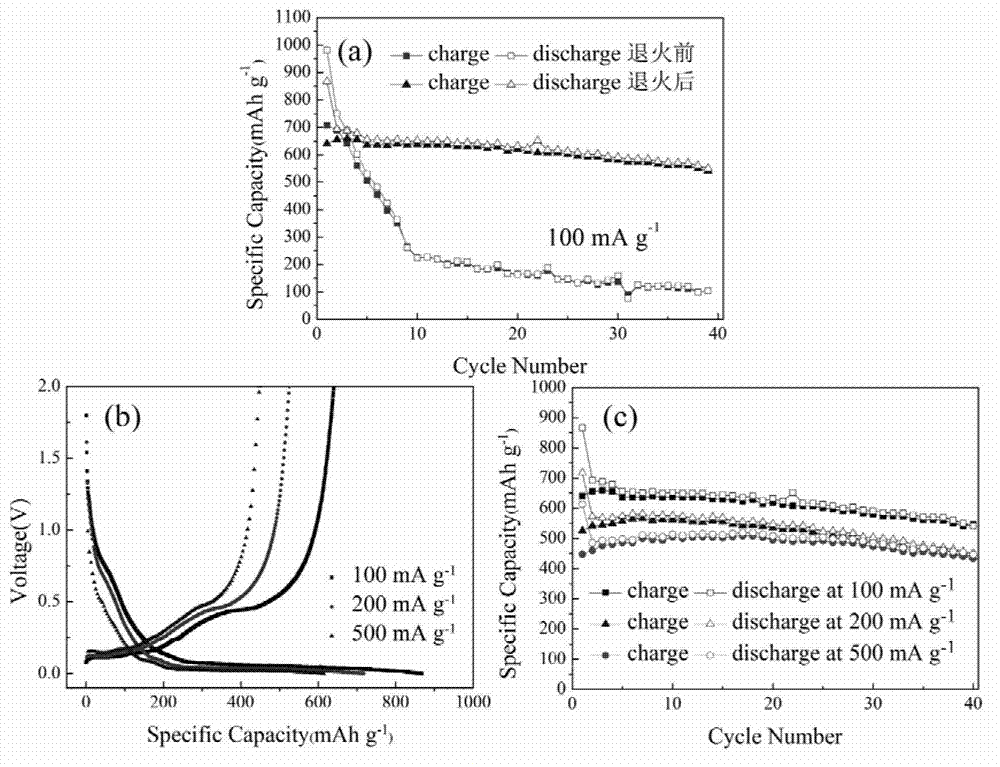

Embodiment 1

[0031] Dissolve the phenolic resin (calculated according to the content of pyrolytic carbon in the composite material after sintering) in an appropriate amount of absolute ethanol, then add an appropriate proportion of nano-silica powder and graphite to the solution, stir for 2 hours, and mix the solution evenly at 80 Evaporate and solidify at ℃. After the solvent is completely volatilized, a bulk precursor will be obtained. After drying, it will be calcined at 800℃ for 2 hours under the protection of high-purity argon, and then cooled with the furnace to obtain a Si / C composite material. Mix the synthesized Si / C composite material, conductive carbon black (SuperP) and binder (PVDF) at a mass ratio of 8:1:1, add N-methylpyrrolidone (NMP) to make a slurry, and coat it evenly On the copper foil, dry at 120°C to prepare a negative electrode sheet with Φ=14mm, heat treatment at 230°C for 3 hours under the protection of high-purity argon, and cool down with the furnace to obtain the...

Embodiment 2

[0035]Dissolve glucose (calculated according to the content of pyrolytic carbon in the composite material after sintering) in an appropriate amount of deionized water, use hexadecyl ammonium bromide as a dispersant, and then add an appropriate proportion of nano-silica powder and graphite to the solution. After stirring for 2 hours, the uniformly dispersed suspension was spray-dried at 170-200°C to obtain the composite material precursor. The obtained precursor was calcined at 800° C. for 2 h under the protection of high-purity argon, and cooled with the furnace to obtain a Si / C composite material. The synthesized Si / C composite material, conductive carbon black (Super P) and binder (PVDF) were uniformly mixed at a mass ratio of 8:1:1, and NMP was added to make a slurry, which was evenly coated on copper foil. Dry at 120°C to prepare a negative electrode sheet with Φ=14mm, heat treatment at 230°C for 3 hours under the protection of high-purity argon, and cool in the furnace to...

Embodiment 3

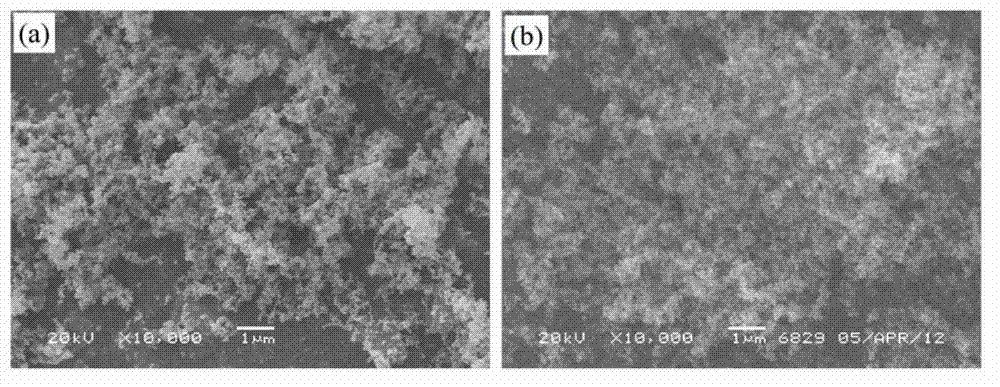

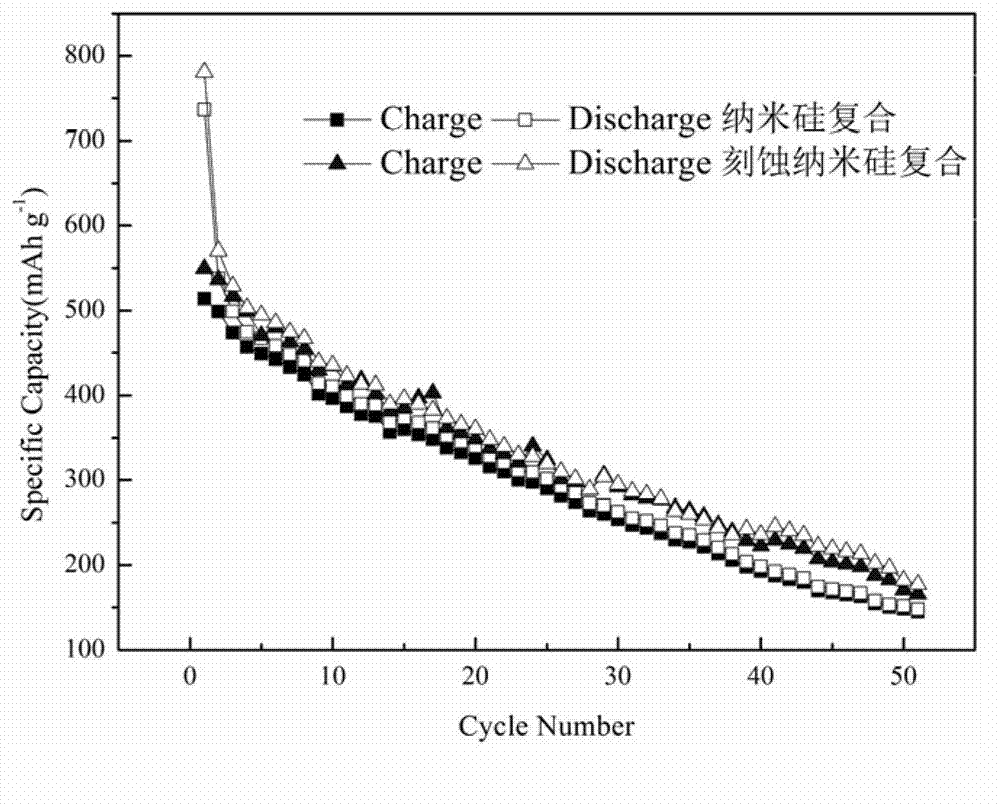

[0037] Add pure nano-silica powder to 2% hydrogen fluoride aqueous solution, add an appropriate amount of silver nitrate at the same time, stir evenly, transfer it to a centrifuge tube for ultrasonic dispersion, and then collect the silicon powder by high-speed centrifugation, and then use absolute ethanol Wash the collected silicon powder several times with deionized water, so that the nano-silicon is separated from the migration solvent, and after vacuum drying, the etching-treated nano-silicon is obtained. Comparison of morphology before and after nano-silicon etching figure 2 shown. Dissolve citric acid (calculated according to the pyrolytic carbon content in the composite material after sintering) in an appropriate amount of deionized water, use absolute ethanol as a dispersant, and then add an appropriate proportion of etched nano-silicon powder and graphite to the solution , magnetically stirred for 2 hours, mixed evenly, and the uniformly dispersed suspension was spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com