Patents

Literature

117results about How to "Excellent electrochemical performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

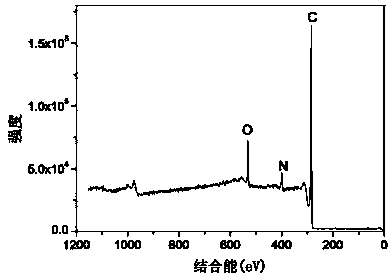

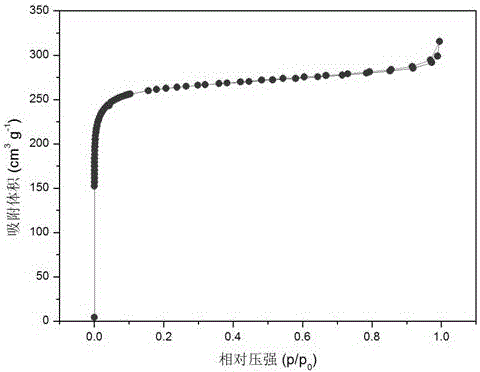

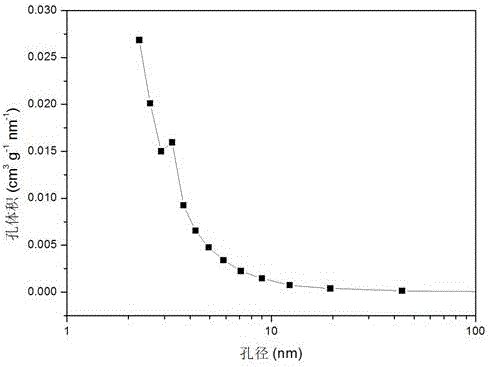

Method for preparing nitrogen-doped active carbon from nitrogen-enriched biomass raw material

InactiveCN104386685AExcellent electrochemical performanceIn situ dopingCarbon compoundsActivated carbonBiomass

The invention relates to a method for preparing nitrogen-doped active carbon from a nitrogen-enriched biomass raw material, and belongs to the technical field of preparation of carbon materials. In the method, an active carbon material with relatively high nitrogen doping amount and a large specific surface area is prepared from the biomass raw material with rich nitrogen through carbonization and activation in an inert atmosphere. The method has the advantages as follows: the raw material is environment-friendly and renewable; the preparation process is simple; in-situ nitrogen doping can be achieved; the nitrogen doping amount and a pore structure can be controlled at the same time; a new way is provided for high-added value utilization of the nitrogen-enriched biomass raw material. The prepared nitrogen-doped active carbon can be used as an efficient electrode material, an absorbent material and a catalyst carrier and applied to the field of energy and environmental protection.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of graphene-base tin dioxide composite anode material for lithium ion batteries

InactiveCN101969113AWell coveredExcellent electrochemical performanceNon-aqueous electrolyte accumulator electrodesElectrochemistryLithium electrode

The invention relates to a preparation method of a graphene-base tin dioxide composite anode material for lithium ion batteries, which belongs to the technical fields of material science and electrochemistry. The method for preparing graphene-base tin dioxide comprises the following steps: 1. dispersing graphite oxide nanosheets in an ethanol C2H5OH solution; 2. adding a certain amount of template agent cetyl trimethyl ammonium bromide (CTAB) into the suspension, adding a certain amount of tin tetrachloride hydrate (SnCl4.5H2O) and sodium hydroxide (NaOH) while vigorously stirring, and continuing stirring for 30 minutes; 3. after stirring, transferring the suspension into a high pressure reaction kettle, reacting in a baking oven at 160 DEG C for 20 hours, and washing the reaction product with ethanol and deionized water many times; and 4. carrying out vacuum drying on the product at 60 DEG C for 8 hours to obtain the graphene-base tin dioxide composite material.

Owner:SHANGHAI UNIV

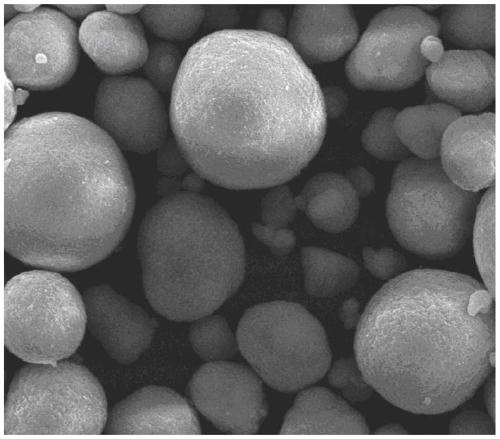

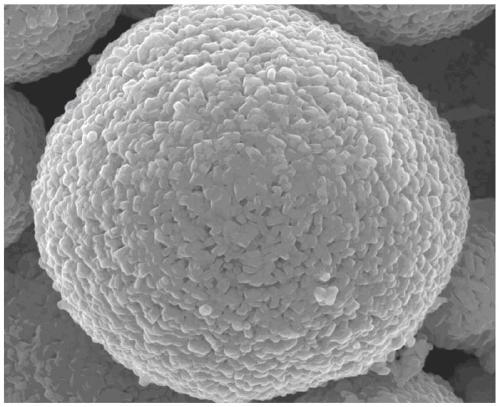

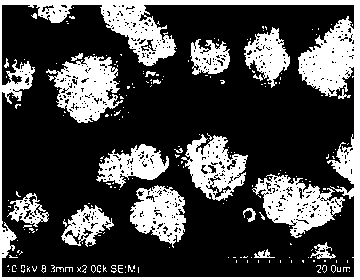

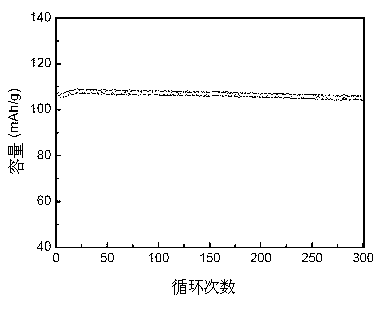

Large scale preparation method of high-nickel cobalt-free precursor and cathode material

ActiveCN109970106AExcellent electrochemical performanceConducive to large-scale market promotionCell electrodesNickel compoundsLarge capacityPrecious metal

The invention discloses a large scale preparation method of a high-nickel cobalt-free precursor and a cathode material. During the co-precipitation reaction process, the key parameters are precisely controlled, thus the crystal face, morphology, and assembly arrangement mode of primary particles are regulated and controlled to obtain the high-nickel cobalt-free cathode material precursor with uniform morphology, the precursor can be used to prepare the high-nickel cobalt-free lithium battery cathode active material, which has the advantages of low residual alkali, low pH value, water absorption resistance, and good processing performance, moreover, the cathode material does not contain any precious metal and is cheap; the prepared lithium battery has the advantages of high cell primary effect, high capacity, excellent normal temperature cycle performance, good high temperature cycle performance, and excellent high temperature storage performance; moreover, the thermal stability is greatly improved through doping and coating; the preparation process is simple and efficient; and the obtained product is highly uniform, has excellent electrochemical properties, and has a wide market prospect.

Owner:姚兵

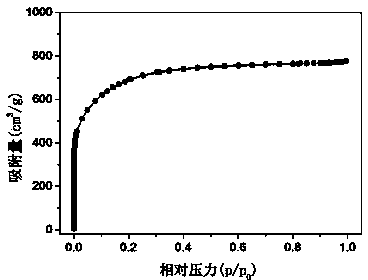

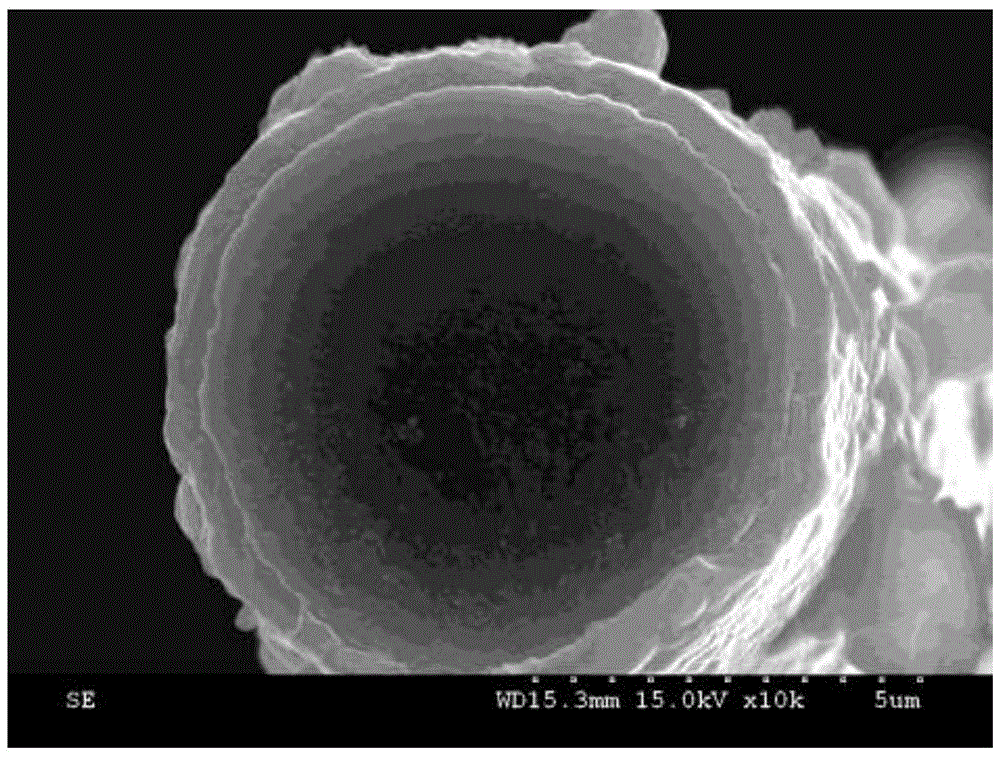

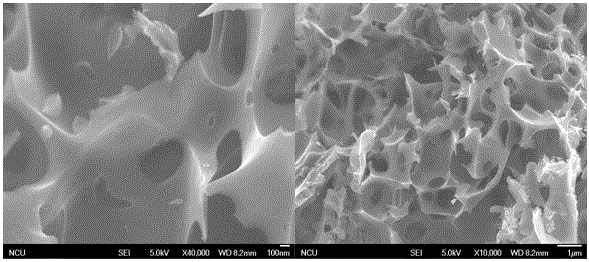

Method for preparing bamboo shoot shell-based activated carbon for super capacitor

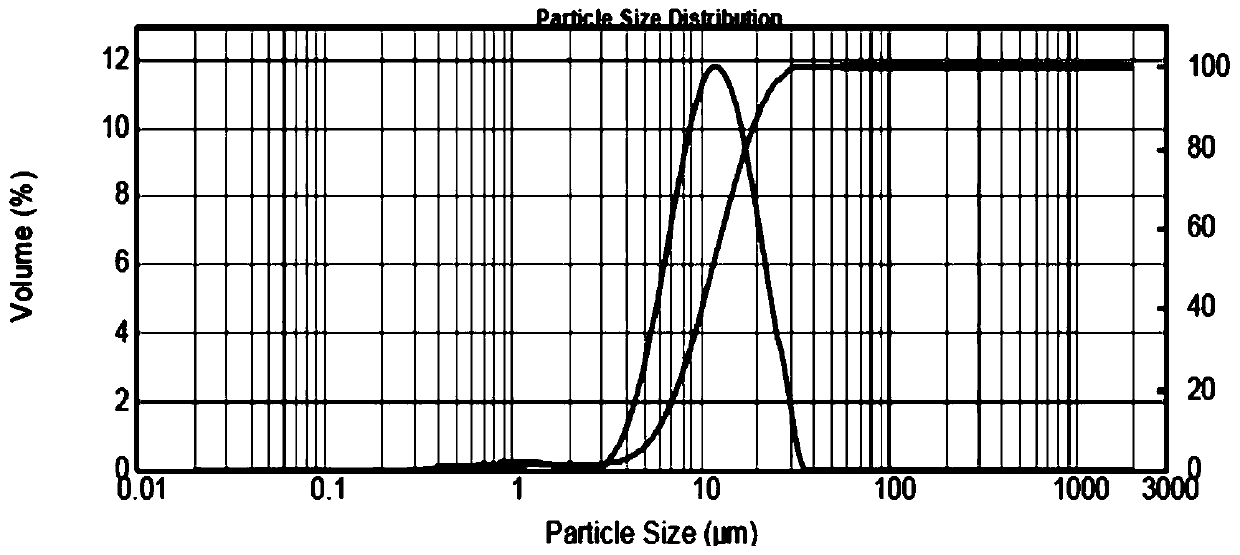

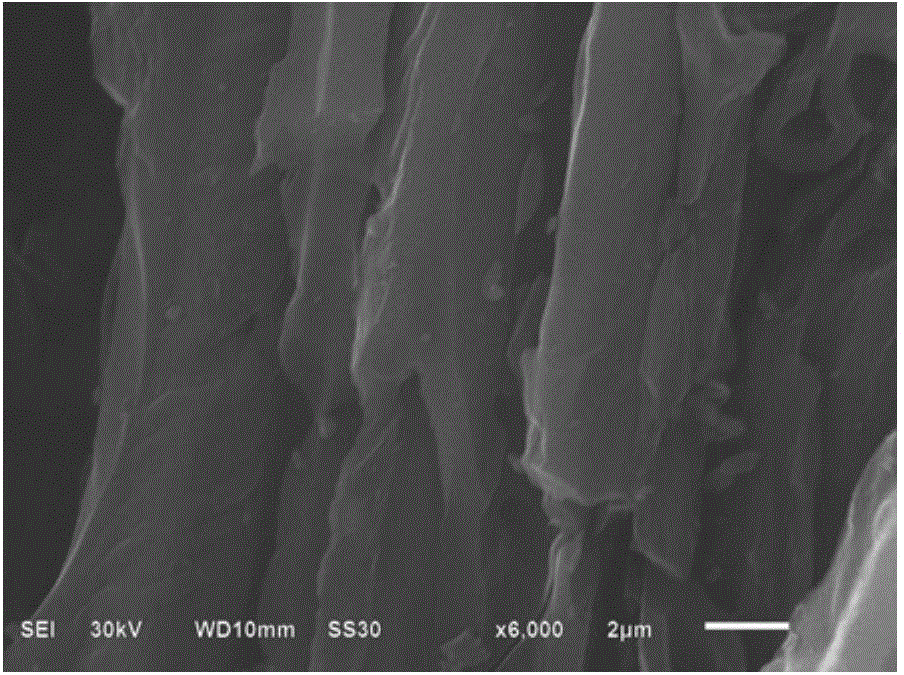

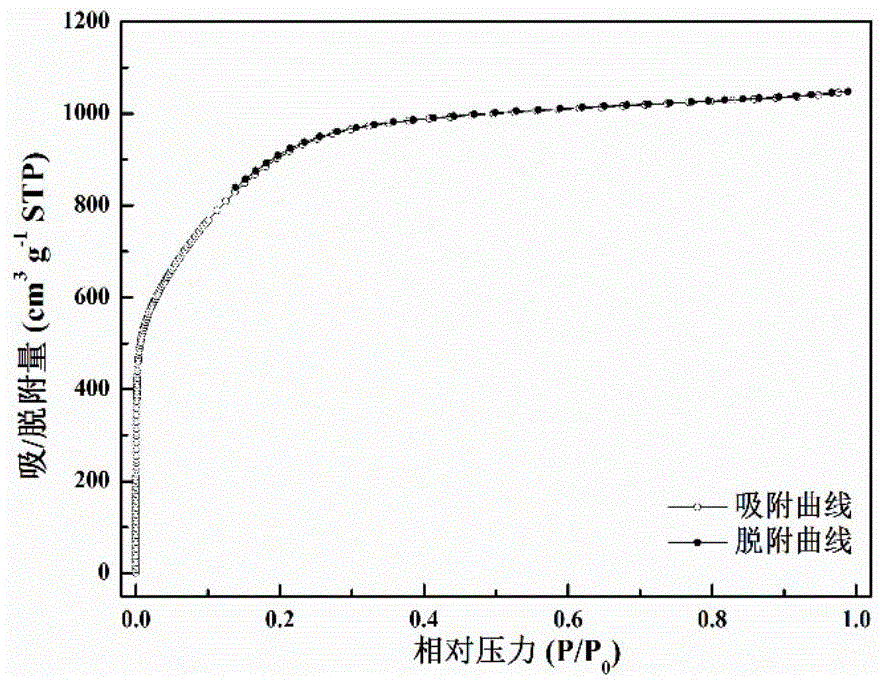

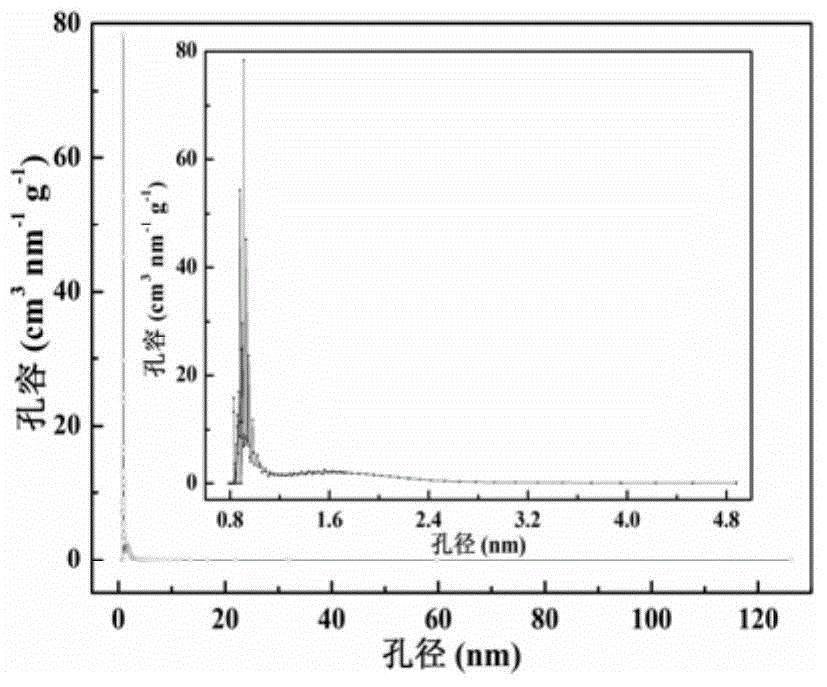

InactiveCN104891491ALarge specific surface areaExcellent electrochemical performanceActivated carbonChemistry

The invention discloses a method for preparing bamboo shoot shell-based activated carbon for a super capacitor. The method comprises the following steps of firstly carrying out pretreatment processes such as washing and drying on raw material bamboo shoot shells; then carbonizing the bamboo shoot shells at high temperature, treating by acid to remove trace metal elements, washing by using distilled water and drying; finally, activating, washing and drying to obtain bamboo shoot shell-based activated carbon. The bamboo shoot shell-based activated carbon is tubular in microstructure, the micropore structure is developed, the specific surface area is as high as 3162m<2> / g, and the specific capacitance is as high as 308Fg<-1> when the electric current density is 1Ag<-1>; when the electric current density is 2Ag<-1>, the specific capacitance has no attenuation basically and is as high as 271Fg<-1> after 10000 times of circulation, and thus the cycle performance is excellent, so that the bamboo shoot shell-based activated carbon has good application prospects in the fields of super capacitors and energy storage. In addition, according to the invention, the bamboo shoot shells are taken as raw materials, so that the comprehensive utilization of the wastes is realized.

Owner:XIANGTAN UNIV

Cobalt-nickel metal sulfide, preparation method and application thereof

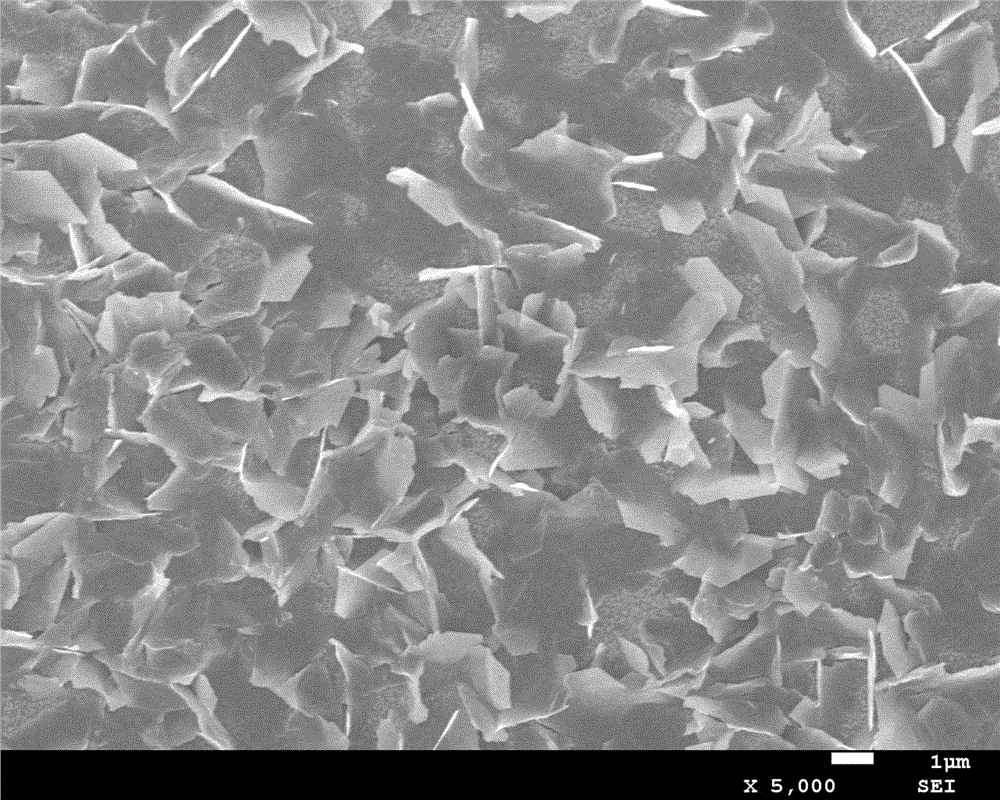

ActiveCN104616900AExcellent electrochemical performanceSimple preparation processLight-sensitive devicesNanotechnologyNickelElectrochemistry

The invention discloses a preparation method of a dye-sensitized cell of a nanometer flake-like Cobalt-nickel metal sulfide. A nanometer flake-like cobalt-nickel metal sulfide counter electrode is in-situ grown on FTO conductive glass by a two-step hydrothermal method, and dye-sensitized cell counter electrodes with different morphologies and photoelectrochemical properties can be obtained by changing preparation parameters. A prepared transparent thin-film counter electrode obtains photoelectrochemical properties equivalent to Pt and excellent transparency; and the method is low in manufacturing cost, simple in technology and good in repeatability.

Owner:CHINA THREE GORGES UNIV

Method for preparing tin dioxide/graphene-compounded anode material of lithium ion battery

ActiveCN103078095AExcellent electrochemical performanceRaw ingredients are simpleCell electrodesCvd grapheneLithium electrode

The invention discloses a method for preparing a tin dioxide / graphene-compounded anode material of a lithium ion battery. The method comprises the following steps: uniformly mixing choline chloride, ethylene glycol and graphene oxide to obtain a mixed solution, adding stannous chloride to the mixed solution, performing ultrasonic oscillating reaction, and performing post-processing to obtain the product. According to the method for preparing the tin dioxide / graphene-compounded anode material of the lithium ion battery, a normal-pressure and normal-temperature one-step method is adopted, the adopted raw materials are simple in components and common and easy to obtain, the reaction conditions are mild and controllable, the reaction can be performed at normal temperature and normal pressure, and the preparation process is simple and practicable, has low requirements for equipment so as to be free from geographical restrictions, and is suitable for large-scale industrial production. The prepared tin dioxide / graphene-compounded anode material of the lithium ion battery has excellent electrochemical properties, and can be used as an active electrode substance for preparing an anode of the lithium ion battery so as to have a wide market application prospect.

Owner:SHENZHEN KEXIN COMM TECH

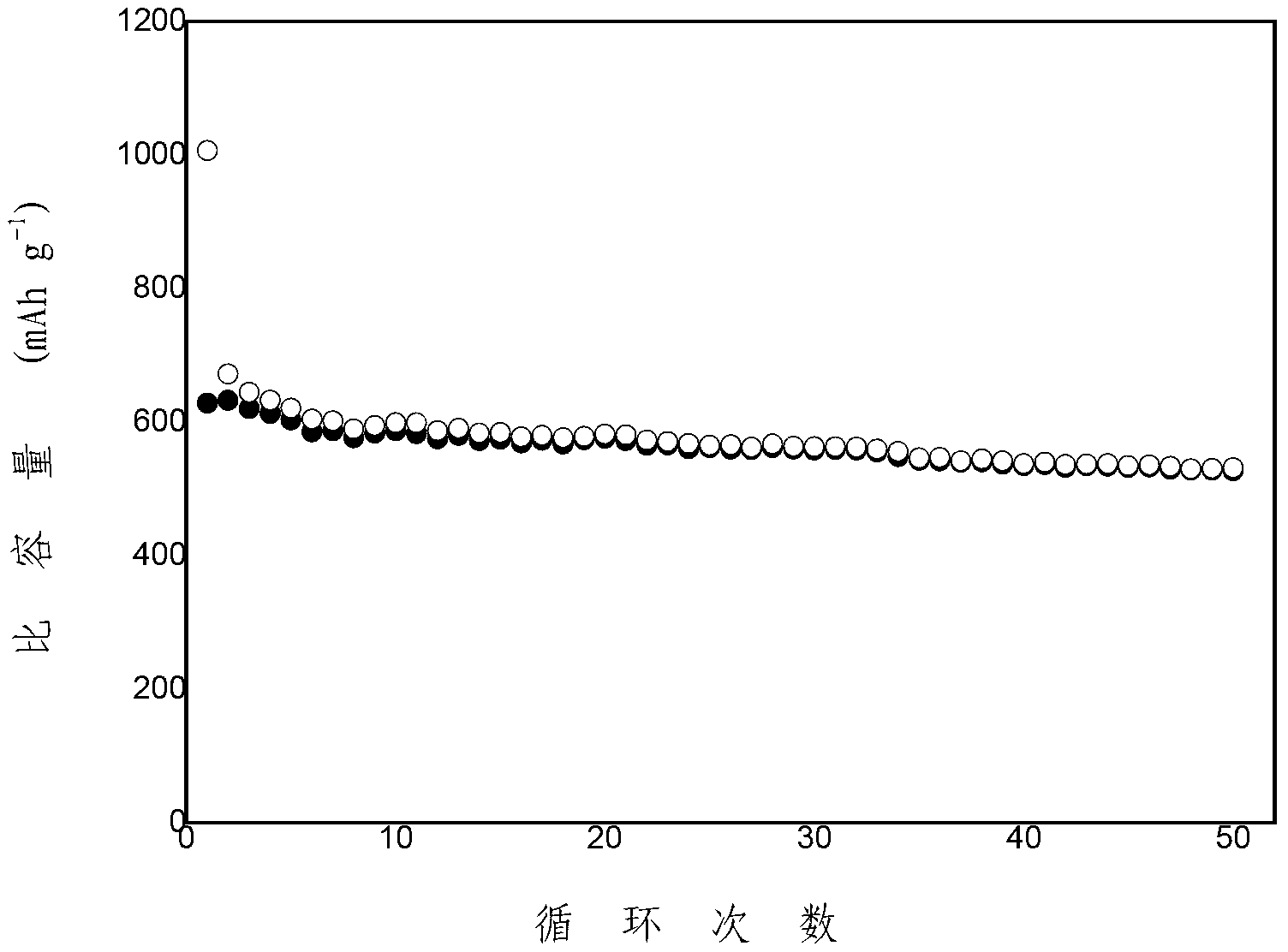

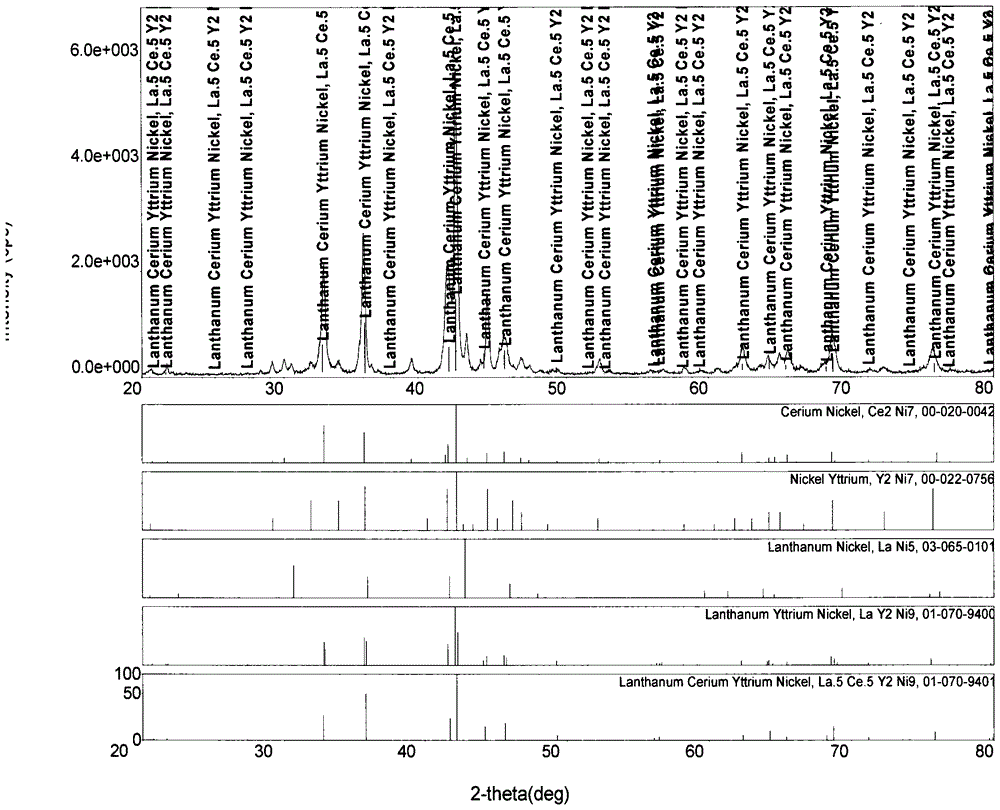

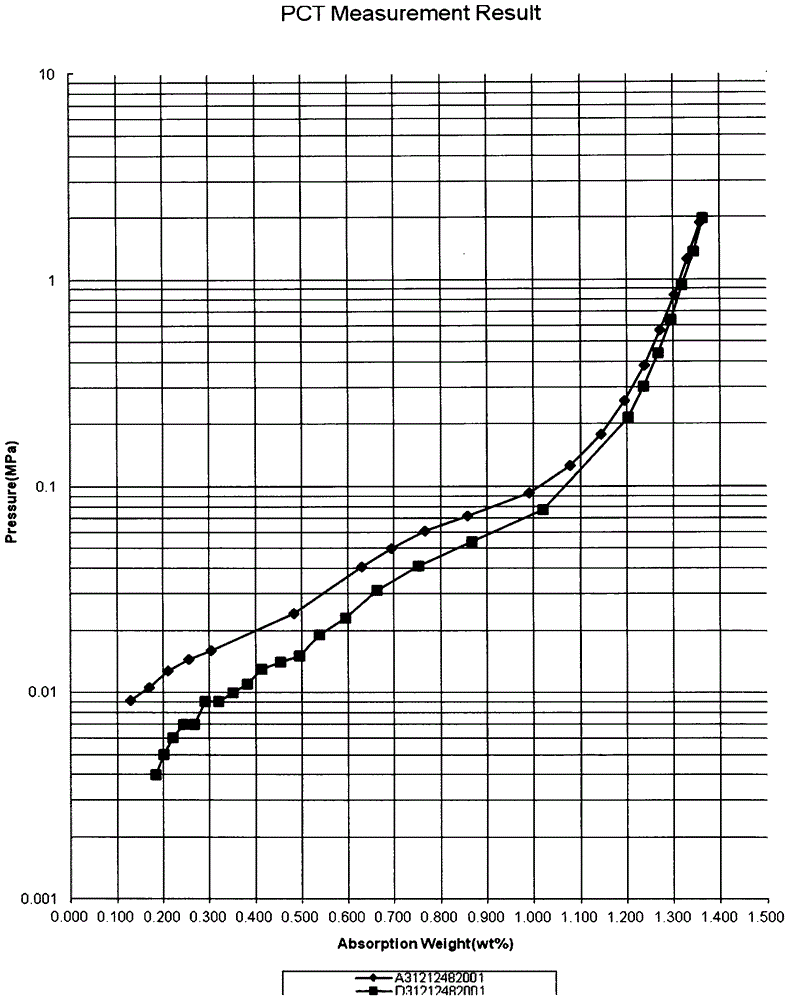

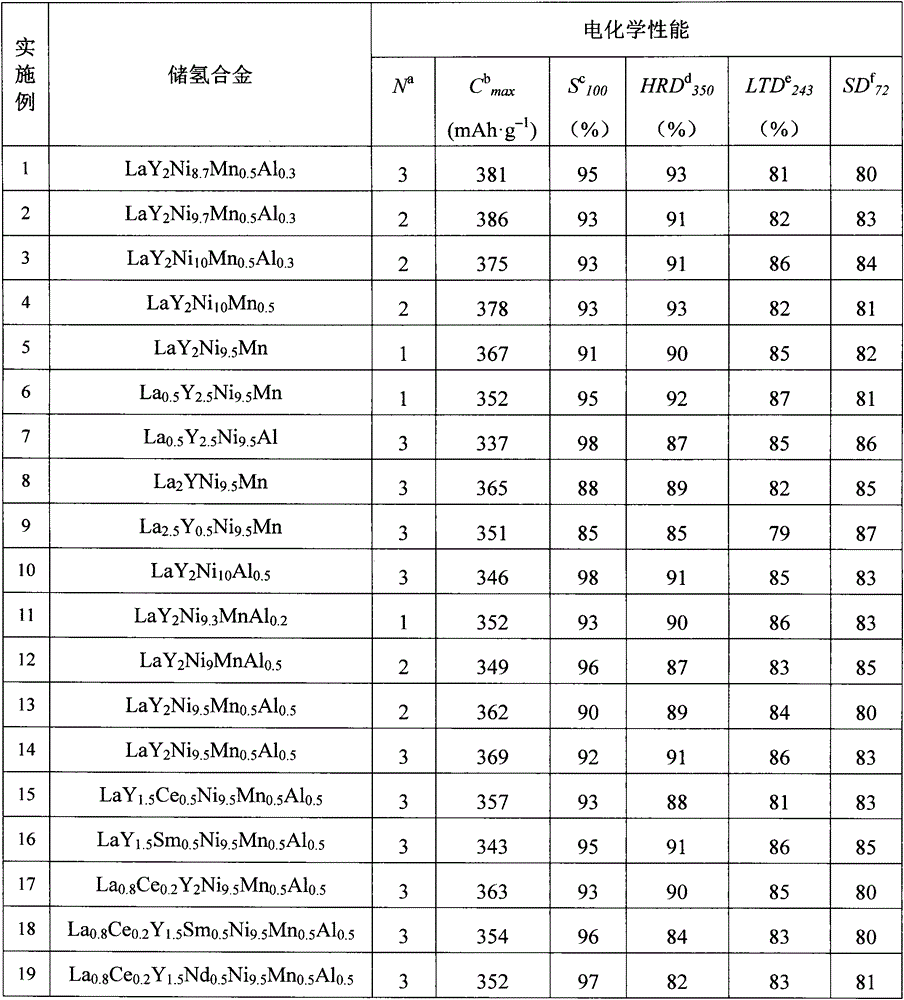

Yttrium-nickel rare earth-based hydrogen storage alloy

ActiveCN104532095AStructural stress reliefEliminate component segregationAlkaline accumulator electrodesGas phaseRare earth

The invention relates to A2B7 type RExYnNiz-a-bMnaAlb hydrogen storage alloy. The alloy is good in pressure-composition-isothermality, and has a maximum hydrogen storage amount of up to more than 1.36 wt.% under usual conditions. The alloy of the invention has better electrochemical performance as a hydrogen storage electrode and better gas-phase hydrogen absorption and desorption performance as a hydrogen storage material than traditional LaNi5 type hydrogen storage alloy; the alloy contains no magnesium element in the composition, so the preparation method of the alloy is simple and safe when compared with that of traditional rare earth-magnesium-nickel-based A2B7 type hydrogen storage alloy.

Owner:BAOTOU RES INST OF RARE EARTHS +2

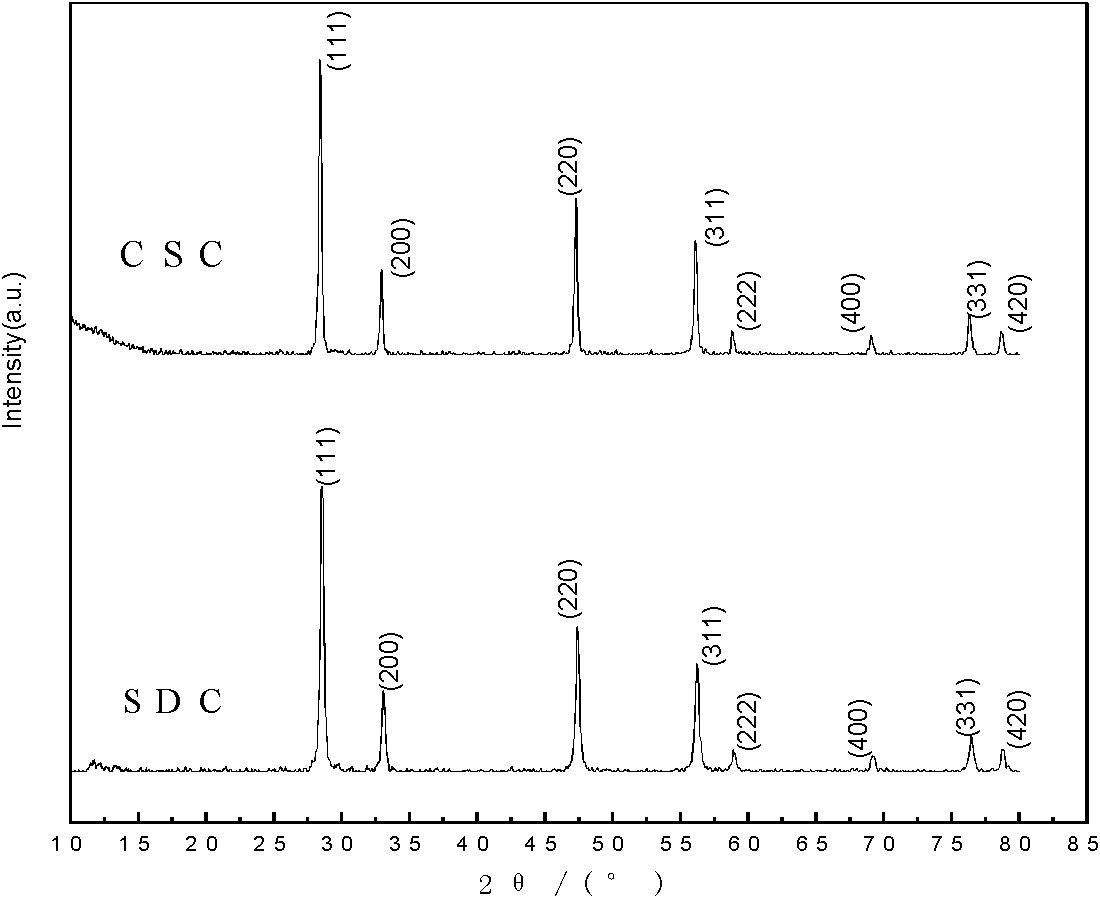

Perovskite Co-based composite negative electrode material as well as preparation and application thereof

ActiveCN102569786AHigh and medium temperature catalytic activityExcellent electrochemical performanceCell electrodesSolid electrolyte fuel cellsSolid oxide fuel cellCerium

The invention relates to an A-site double-doped Co-based perovskite composite negative electrode material as well as preparation and application thereof, and relates to the field of an intermediate-temperature solid oxide fuel cell, belonging to the field of new energy materials. The perovskite Co-based composite negative electrode material consists of the following components in percentage by mass: 50% of La0.7Sr0.15Ca0.15Co0.8Fe0.2O(3-delta), 37.5% of Ce0.8Sm0.2O(2-delta) and 12.5% of Li2CO3 and Na2CO3. The composite negative electrode material has high electronic and ionic conductivities, relatively high intermediate-temperature catalytic activity and good electrochemical performance, and is relatively well compatible with a cerium-based electrolytic material in terms of thermal performance and chemical performance; and moreover, as the negative electrode of a intermediate-temperature solid oxide fuel cell, the composite negative electrode material has relatively high output power.

Owner:锦州宇博保温建材有限公司

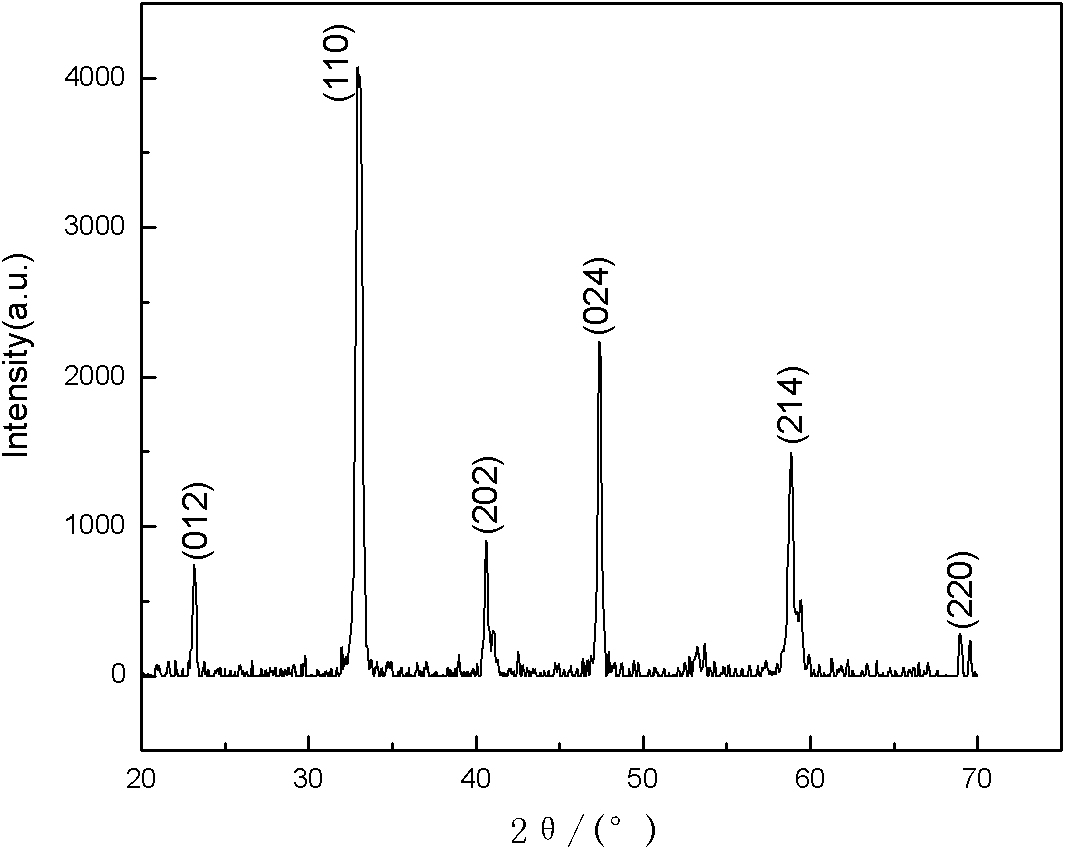

Method for preparing zinc phosphate conversion coating on surface of titanium

InactiveCN103952745AHigh crystallinityExcellent electrochemical performancePhosphatisationChemistryConversion coating

The invention discloses a method for preparing a zinc phosphate conversion coating on the surface of titanium. The method comprises the following steps: mixing a phosphorous compound, a zinc-containing compound, a calcium-containing compound and an accelerant together to form a chemical conversion basic liquid; performing activating treatment and surface adjustment on a pure titanium substrate; putting the treated pure titanium substrate in the chemical conversion basic liquid and applying an electric current field, wherein the pure titanium substrate is taken as a cathode, while platinum is taken as an anode; and obtaining the zinc phosphate conversion coating on the surface of titanium after chemical conversion. In such a manner, the reaction of the method for preparing the zinc phosphate conversion coating on the surface of titanium can be finished at a relatively low temperature, and the obtained product is high in degree of crystallinity and good in electrochemical performance; the method is low in pollution, low in cost and simple in process, and thus suitable for large-scale production and application; the zinc phosphate conversion coatings more excellent in mechanical properties can be obtained by use of the methods of solution optimization, current intensity change, time control and the like.

Owner:SUZHOU RES INST SHANDONG UNIV

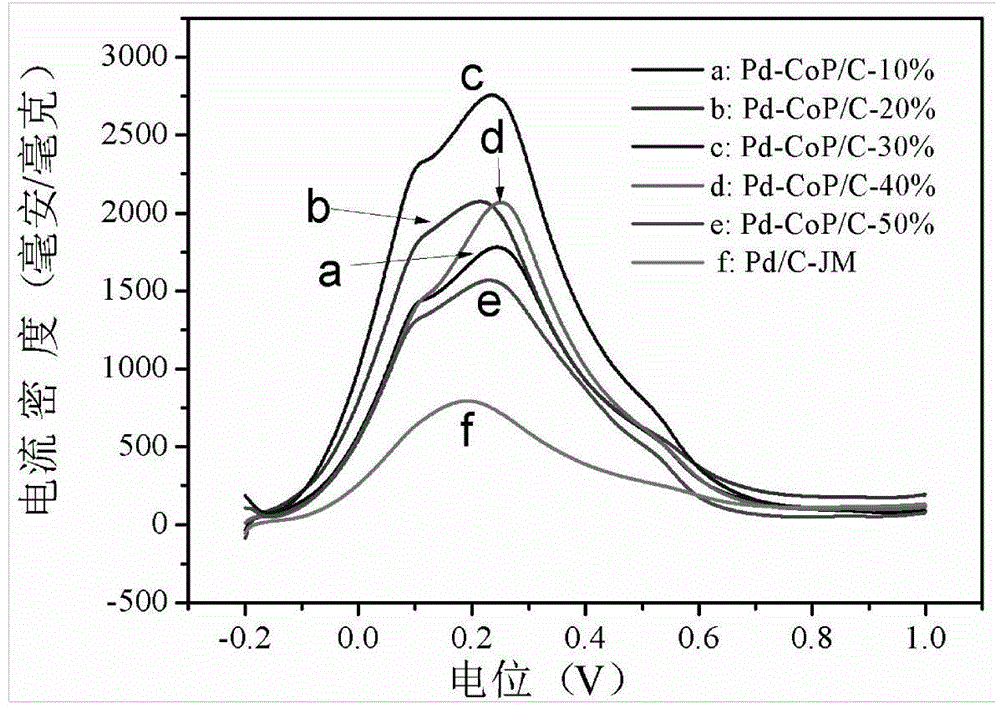

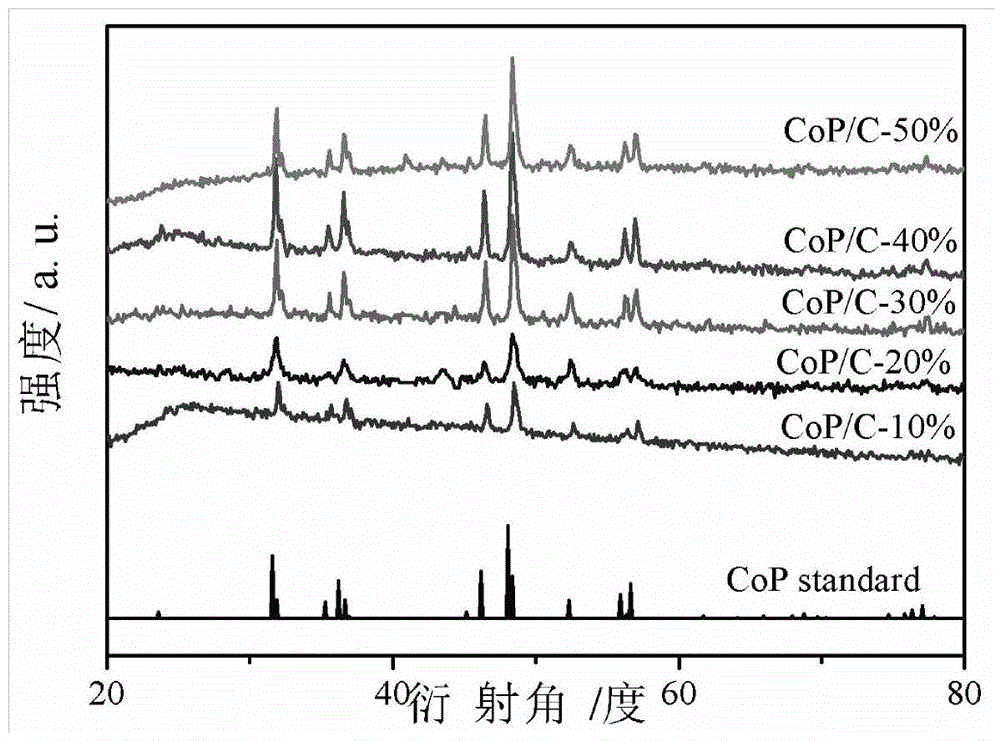

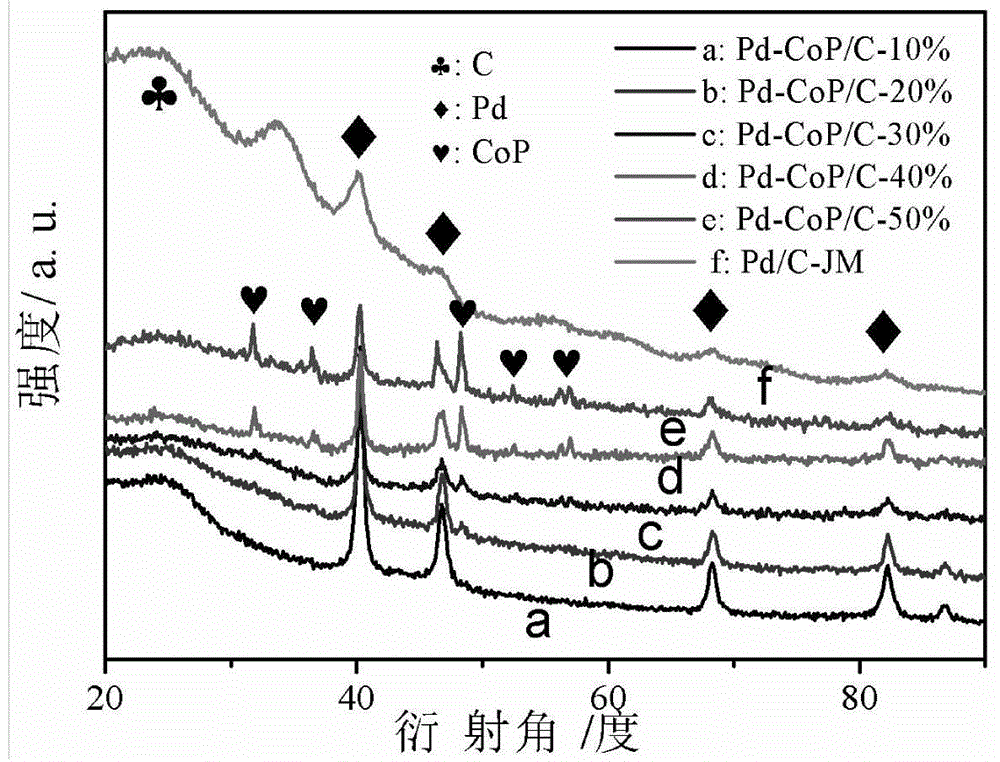

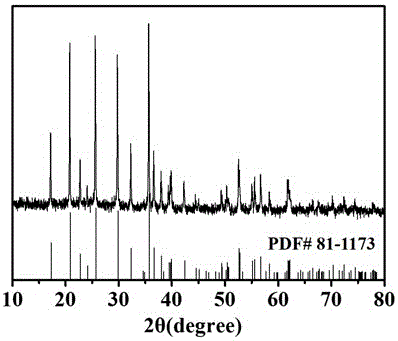

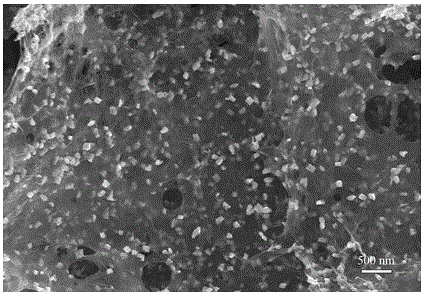

Preparation method of high-performance superlow-palladium-capacity anode electrocatalyst Pd-CoP/C of direct formic acid fuel cell

InactiveCN104409745AExcellent electrochemical performanceEasy to handleCell electrodesFormic acidDistillation

The invention relates to a preparation method of a high-performance superlow-palladium-capacity anode electrocatalyst Pd-CoP / C of a direct formic acid fuel cell and belongs to the technical field of fuel cells. The preparation method comprises the following steps: dispersing a carrier and cobalt chloride hexahydrate in water, drying to obtain a first compound carrier by distillation after ultrasonic dispersing and stirring; mixing and grinding the first compound carrier and hydrated sodium hypophosphite for one-hour reaction, and washing and drying the reactant to obtain a second compound carrier; dispersing the second compound carrier in glycol, adding hexachloropalladate, and performing ultrasonic dispersing and stirring to obtain a first turbid liquid; stirring the first turbid liquid at the room temperature, and regulating the pH value with sodium hydroxide to obtain a second turbid liquid; performing microwave radiation on the second turbid liquid, and obtaining a supported palladium catalyst. The palladium-based catalyst prepared by the method has extremely high catalytic activity and relatively high stability to formic acid electro-oxidation. Meanwhile, the capacity of the precious metal palladium can be reduced, and the method is simple to operate, short in preparation period and suitable for mass production.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Method for preparing graphene/lithium iron phosphate composite anode materials

InactiveCN105977465AGood conductivity and electrochemical performanceExcellent electrochemical performanceCell electrodesSecondary cellsCvd grapheneSpecific discharge

The invention discloses a method for preparing graphene / lithium iron phosphate composite anode materials. The method includes weighing lithium sources, iron sources and phosphate radical sources; adding the lithium sources, the iron sources and the phosphate radical sources into graphene oxide solution; carrying out hydrothermal reaction under the catalytic effects of ethanediamine to obtain graphene / lithium iron phosphate precursor materials; calcining the graphene / lithium iron phosphate precursor materials at the high temperatures of 400-800 DEG C in protective atmosphere of argon for 2-8 hours in high-temperature calcinations procedures to obtain the graphene / lithium iron phosphate composite anode materials. A molar ratio of the lithium sources to the iron sources to the phosphate radical sources is 1:1:1. The method has the advantages that the specific discharge capacity of the graphene / lithium iron phosphate composite anode materials prepared by the aid of the method is 150.9 mAh / g under 1C conditions, and the capacity retention ratio of the graphene / lithium iron phosphate composite anode materials is 97.4% after 50 charge-discharge cycles; the graphene / lithium iron phosphate composite anode materials are excellent in electrochemical performance, and accordingly the method hopefully can be industrially applied.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

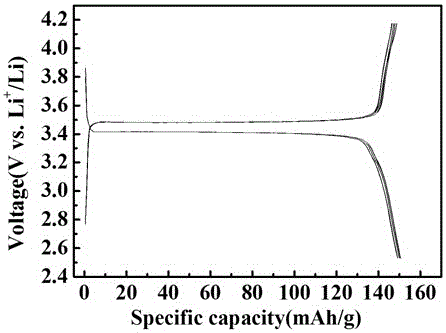

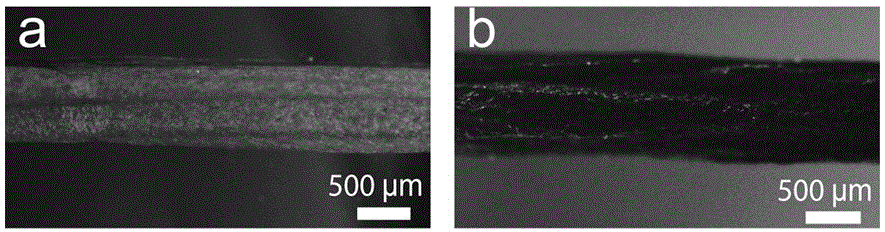

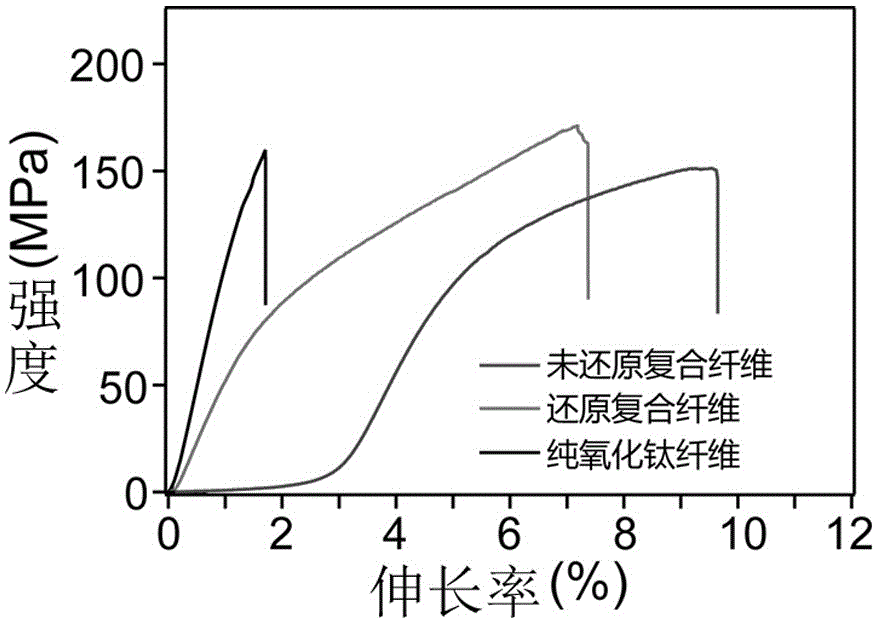

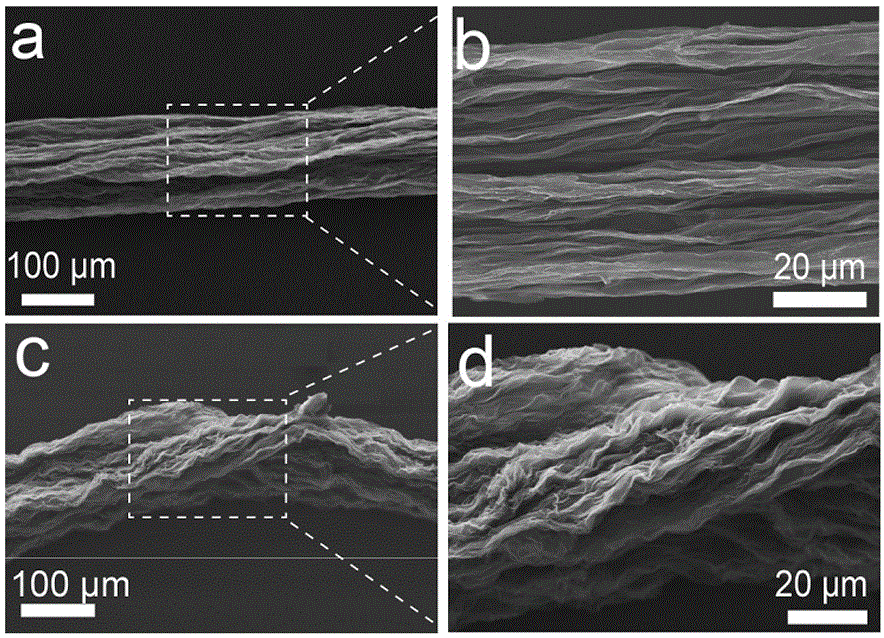

Flexible cell based on metallic oxide/graphene composite macroscopic fibers and preparation method

ActiveCN107180947AGood mechanical propertiesExcellent electrochemical performanceFinal product manufactureCell electrodesCvd grapheneHydroiodic acid

The invention relates to a flexible cell based on metallic oxide / graphene composite macroscopic fibers and a preparation method. The preparation method comprises the following steps: after mixing an anionic metal oxide aqueous solution with graphene oxide to obtain a spinning solution, adding the spinning solution in wet spinning equipment to obtain nascent fibers; repeatedly washing the obtained nascent fibers with deionized water, and drying the nascent fibers to obtain metallic oxide and graphene oxide composite fibers; reducing the metallic oxide and graphene oxide composite fibers with hydroiodic acid, and then washing and drying the metallic oxide and graphene oxide composite fibers to obtain the metallic oxide and graphene composite fibers; placing the composite fibers, lithium lines and lithium manganate loaded carbon cloth fibers in a shrinkable tube in parallel; and adding diaphragms and electrolyte so that half cells and total cells can be assembled respectively. The preparation process is simple and controllable, and large-scale production is facilitated. The metallic oxide and graphene composite fibers which are prepared by the preparation method for the first time have unlimited prospects in the field of energy storage of flexible cells.

Owner:SUZHOU UNIV

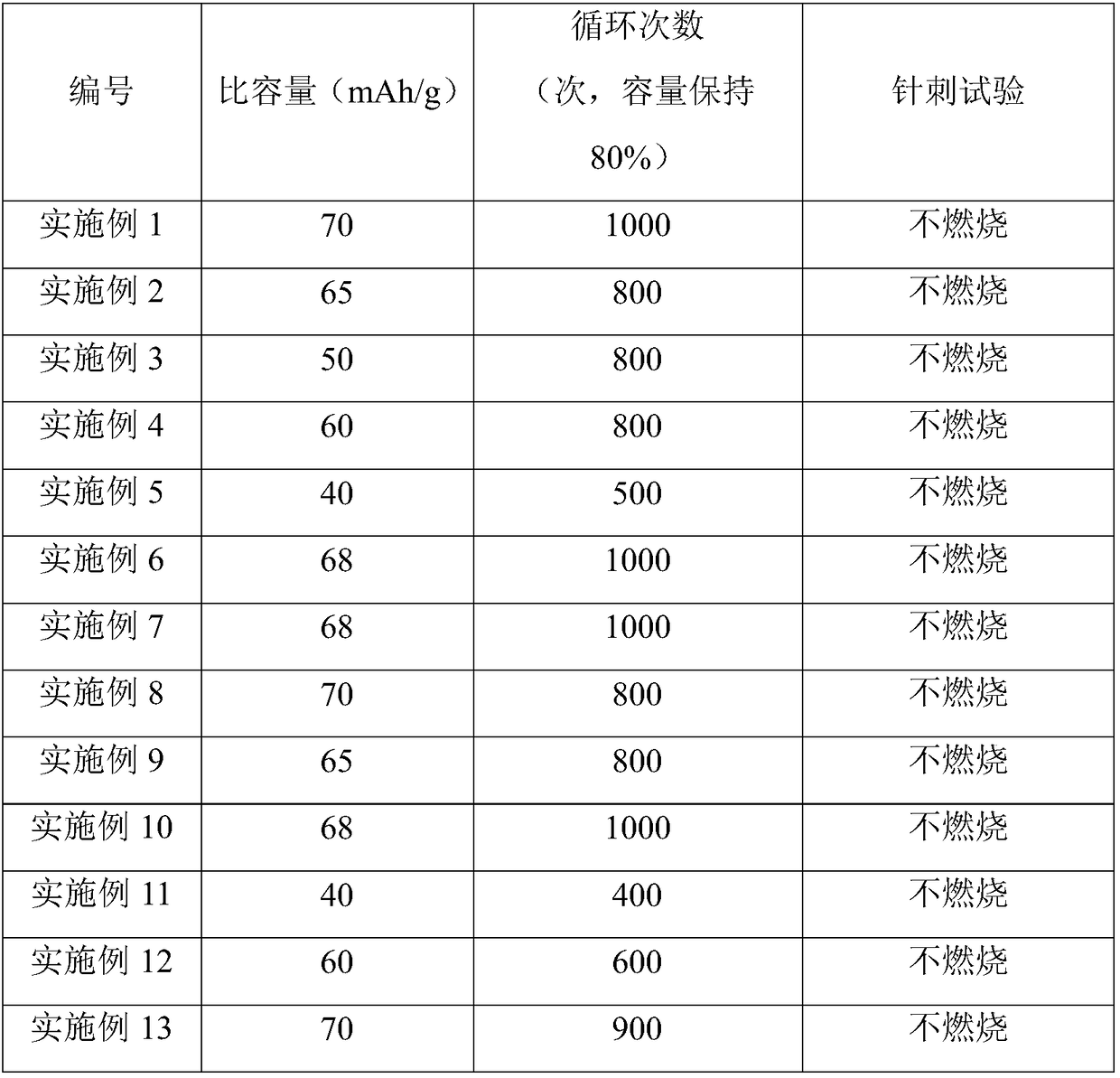

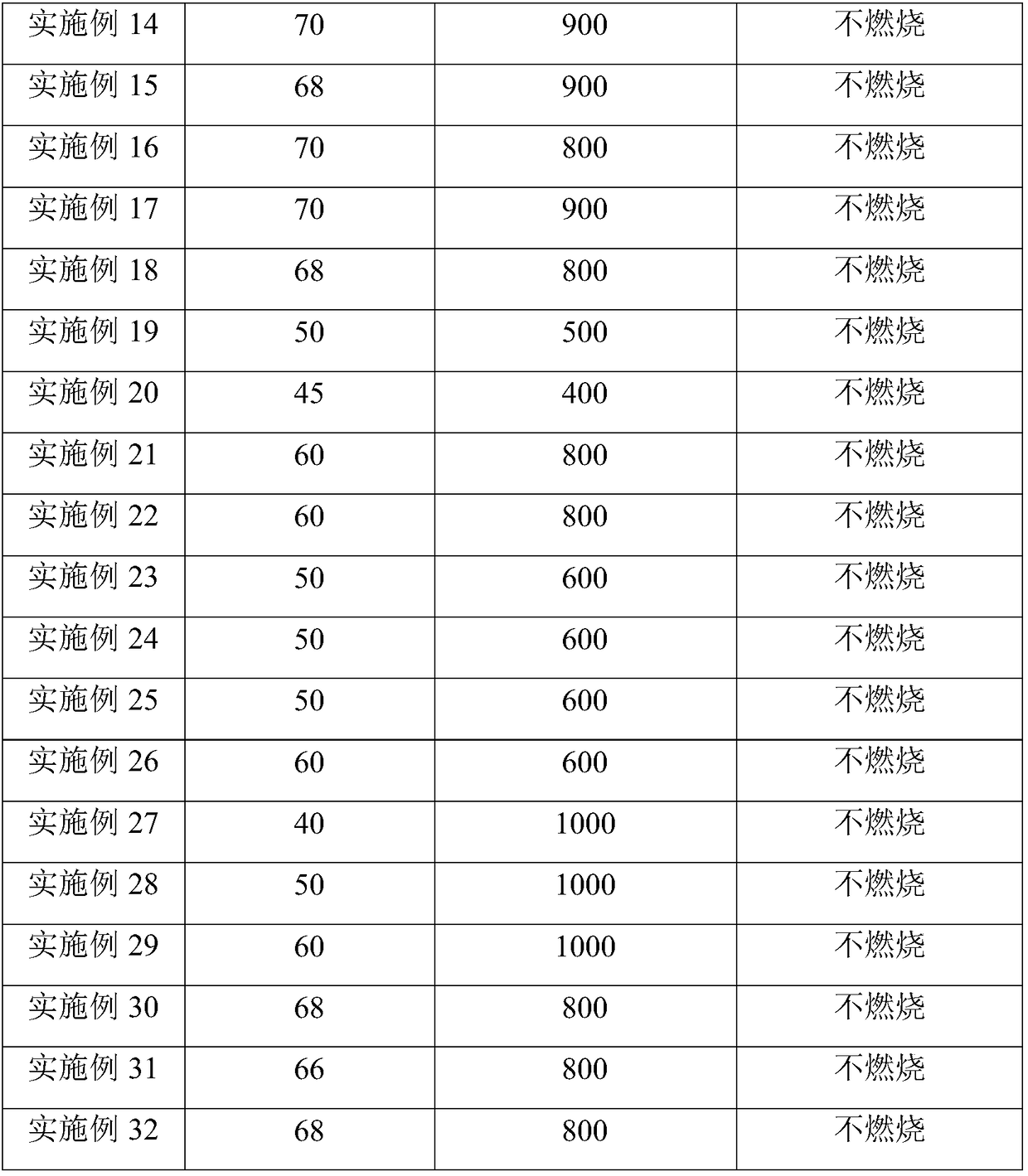

Zinc-based dual-ion battery and preparation method thereof

ActiveCN108242560AImproved capacity and cycle stability performanceExcellent electrochemical performanceCell electrodesFinal product manufactureMetal foilCurrent collector

The invention provides a zinc-based dual-ion battery which comprises a positive electrode, a negative electrode, a diaphragm arranged between the positive electrode and the negative electrode, and electrolyte, wherein the electrolyte is non-water zinc salt electrolyte; the positive electrode comprises a positive electrode current collector and a positive electrode material combined with the surface of the positive electrode current collector; the positive electrode material contains a positive electrode active material, and the positive electrode active material is a layered material enablingthe negative ions forming the zinc salt to be reversibly embedded and separated; the negative electrode is a metal foil; the metal foil serves as a negative electrode current collector as well as a negative electrode active material; and the metal foil enables reversible deposition and dissolution of zinc ions or reversible alloying reaction with zinc.

Owner:SHENZHEN INST OF ADVANCED TECH

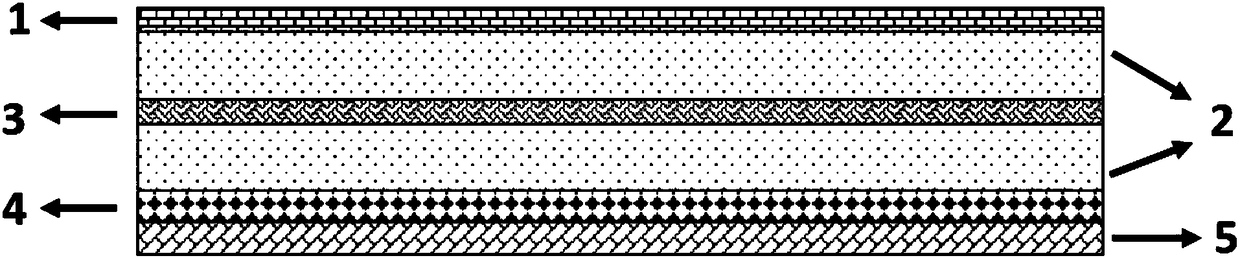

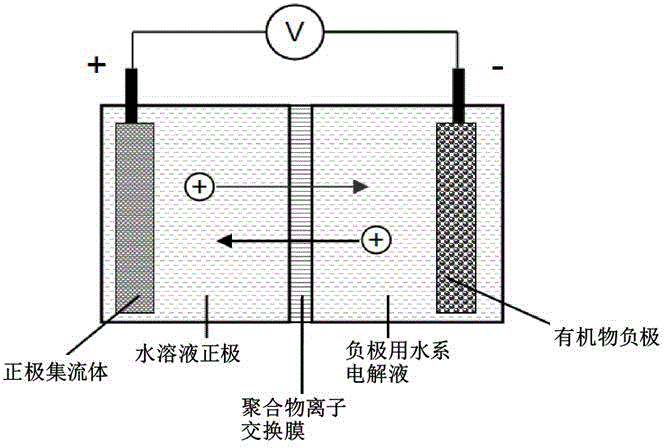

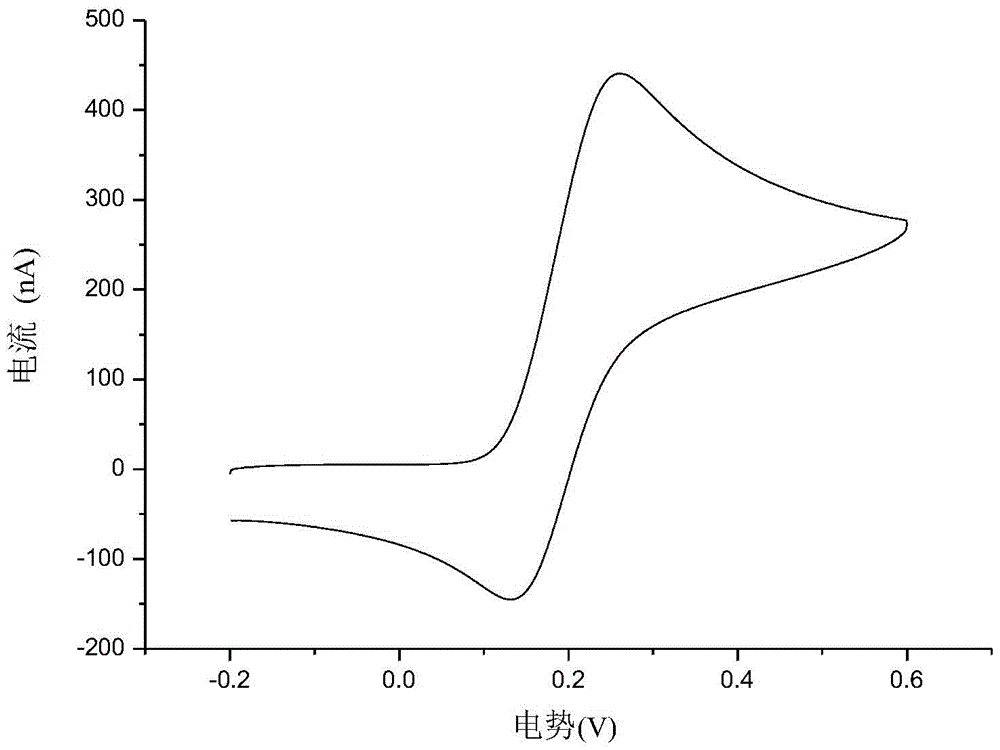

Water system lithium-ion/sodium-ion battery based on iodide ion solution cathode and organic matter anode

ActiveCN104795567ALow priceExcellent electrochemical performanceCell seperators/membranes/diaphragms/spacersCell electrodesIon-exchange membranesLiquid cathode

The invention belongs to the technical field of electrochemistry, and particularly relates to a water system lithium-ion / sodium-ion battery based on an iodide ion solution cathode and an organic matter anode. The battery specifically comprises a liquid aqueous solution cathode which contains iodide ions, lithium ions or sodium ions, an organic compound monomer or organic polymer anode which can reversibly store lithium ions or sodium ions and contains quinone, or heterocyclic quinone or conjugate pi-bond and carbon-oxygen double bond, and a polymer ion exchange membrane for separating the liquid cathode from the polymer anode. According to the invention, the anode and the cathode are separated by using the ion exchange membrane, and a solution phase active substance is adopted as the cathode material of the water system lithium-ion / sodium-ion battery, and forms the water system lithium-ion or sodium-ion battery system with the organic anode containing no metallic element. Therefore, the water system battery assembled by adopting the scheme has the advantages of being longer in cycle life, higher in specific energy, larger in power, high in safety, low in cost and environment-friendly.

Owner:FUDAN UNIV

Preparation method of hierarchical pore carbon foam used for supercapacitor electrode

InactiveCN103449396AExcellent electrochemical performanceImprove high current charge and discharge performanceCarbon preparation/purificationParaffin waxCapacitance

The invention relates to a preparation method of a hierarchical pore carbon foam used for a supercapacitor electrode. The method comprises: firstly taking formaldehyde, resorcinol, silicon dioxide nanoparticles and water according to a mass ratio of 1:1-2:0.1-1:0.5-10, mixing them uniformly and taking the mixture as a water phase; adopting liquid paraffin as an oil phase, using Span 80 and Tween 80 as emulsifiers, weighing Span 80, Tween 80, the oil phase and the water phase according to a mass ratio of 2:3:8-20:15-30, mixing the water phase, the oil phase and the emulsifiers under stirring to obtain an oil-in-water type emulsion, adding a catalyst to solidify make the emulsion, conducting drying, then performing high temperature carbonization, removing the silicon dioxide nanoparticles from the carbonized material by dissolution in an HF solution with a mass percent of 40%, thus obtaining carbon foam, mixing the carbon foam with KOH in a mass ratio of 3-7:1, then conducting activation at 800-1000DEG C, thus obtaining the hierarchical pore carbon foam. When the hierarchical pore carbon foam provided in the invention is used as a supercapacitor electrode, high specific capacitance can be effectively maintained, and simultaneously the large current charge-discharge performance of the electrode can be improved.

Owner:TONGJI UNIV

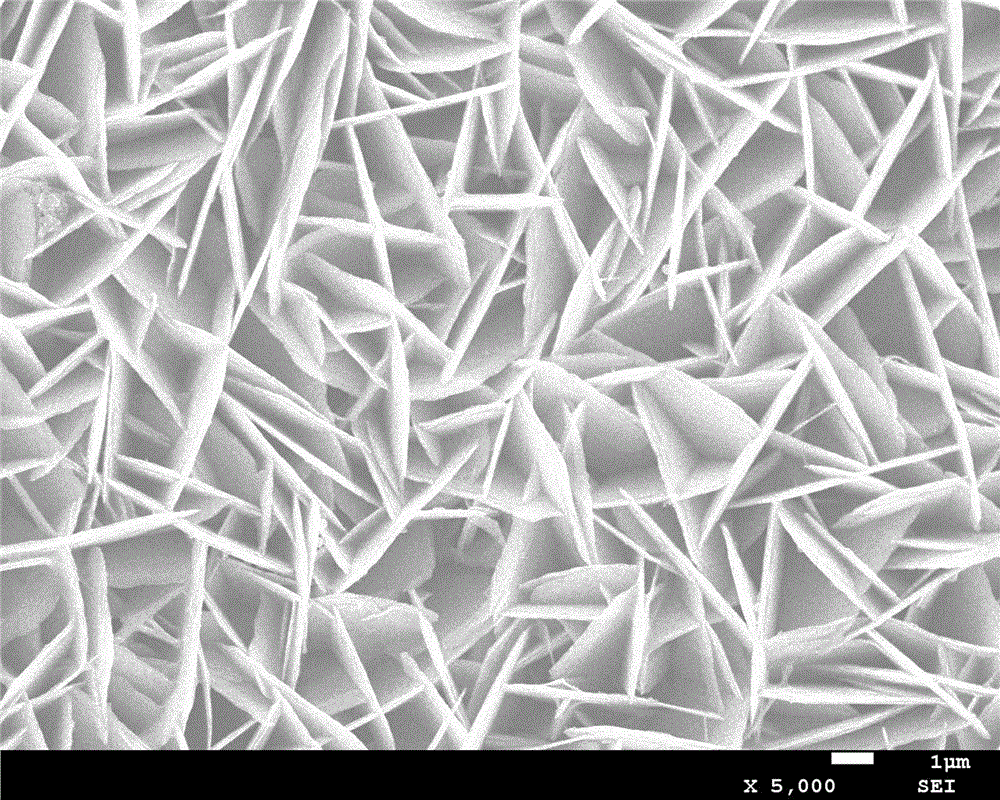

Semi-hollow bicontinuous line-structure coaxial nanowire material in H2V3O8/graphene tube, as well as preparation method and application of material

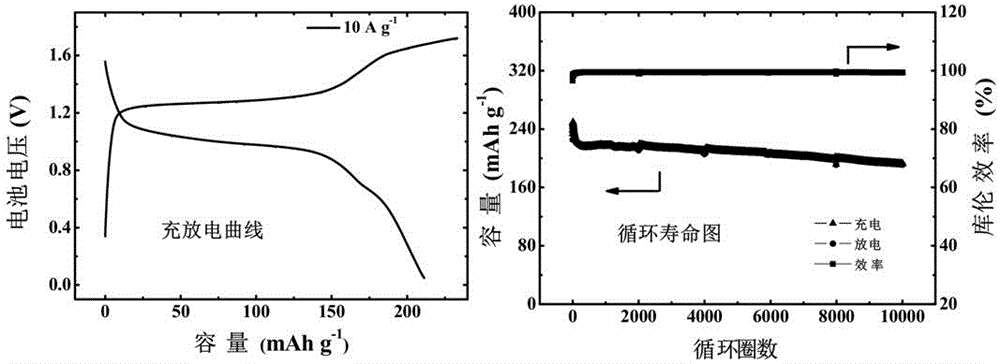

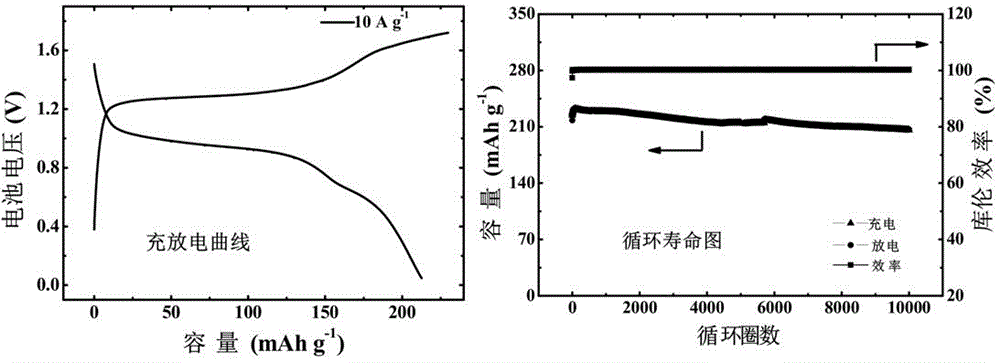

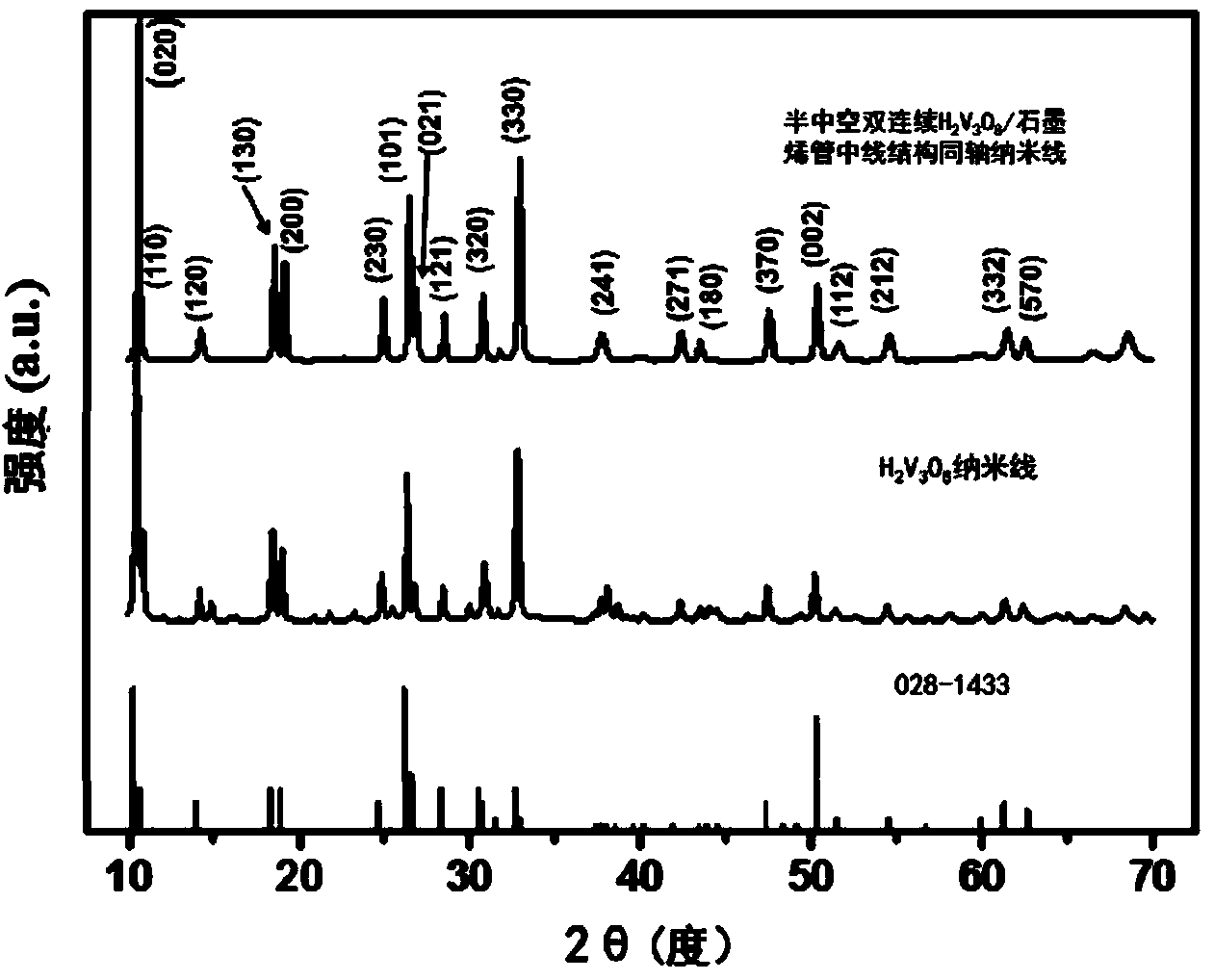

ActiveCN103474629AGood cycle stabilityExcellent electrochemical performanceMaterial nanotechnologyCell electrodesCvd grapheneCyclic stability

The invention relates to a semi-hollow bicontinuous line-structure coaxial nanowire material in a H2V3O8 / graphene tube, a preparation method and application of the material. The nanowire material is formed by coating a H2V3O8 nanowire by self curling of graphene, a gap is formed between a H2V3O8 nanowire and graphene curl formed by self curling of the graphene, wherein the diameter of the H2V3O8 nanowire is 20-80nm. The nanowire material can be used as a positive electrode active material of a lithium ion battery. The nanowire material has the advantages of simple process, low cost and the like, and the battery formed by the electrode material has the characteristics of good cycling stability, excellent electrochemical performance under high current, and the like.

Owner:安徽国芯新材料有限公司

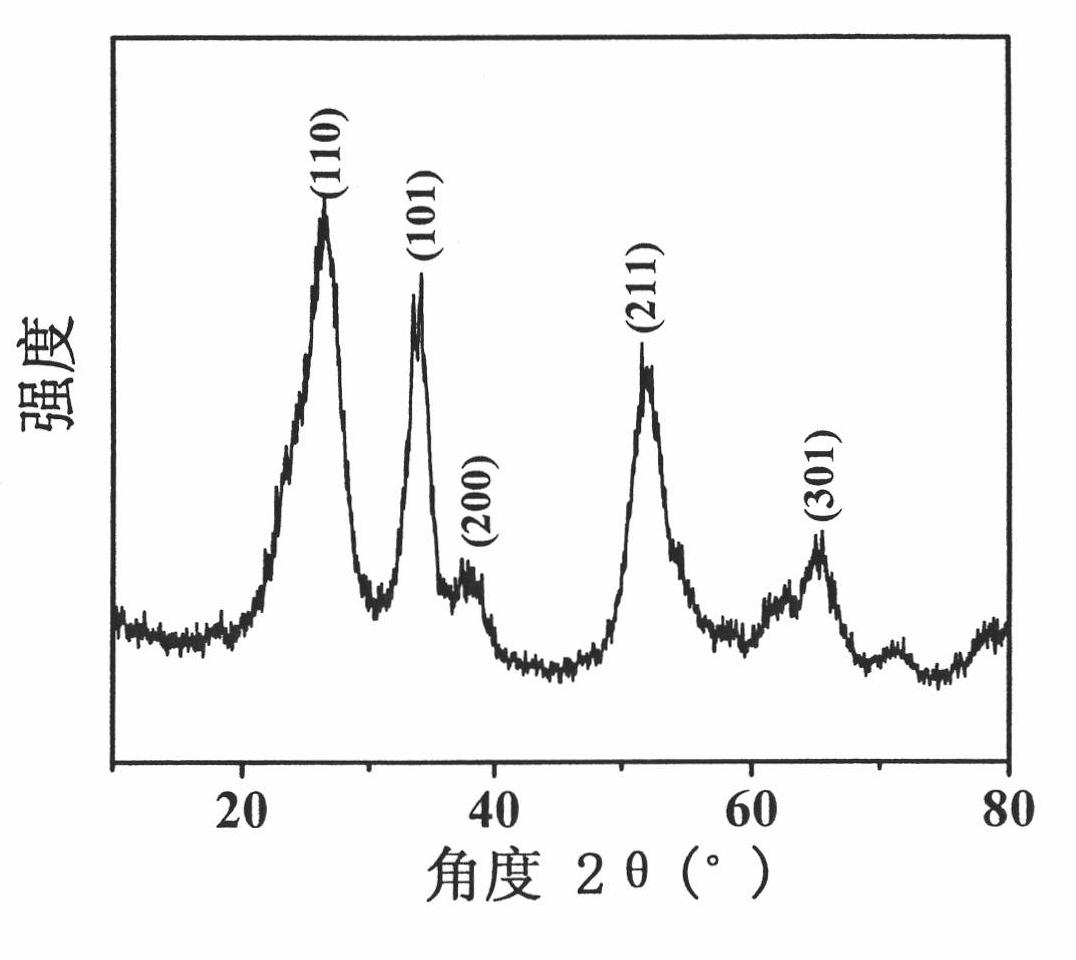

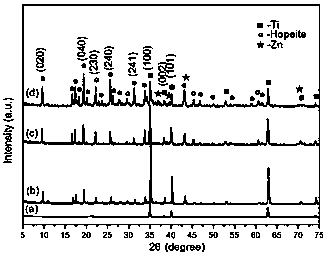

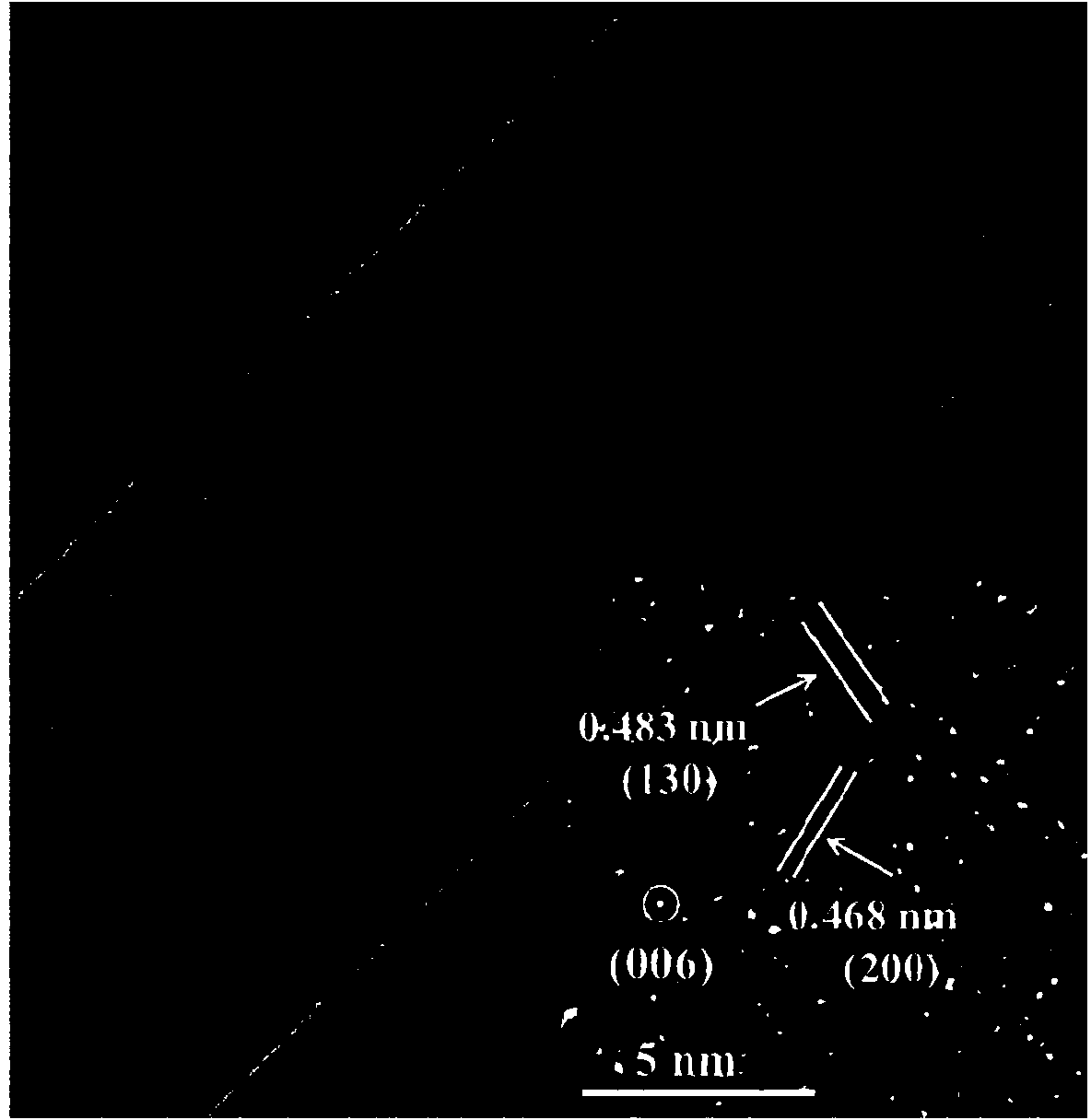

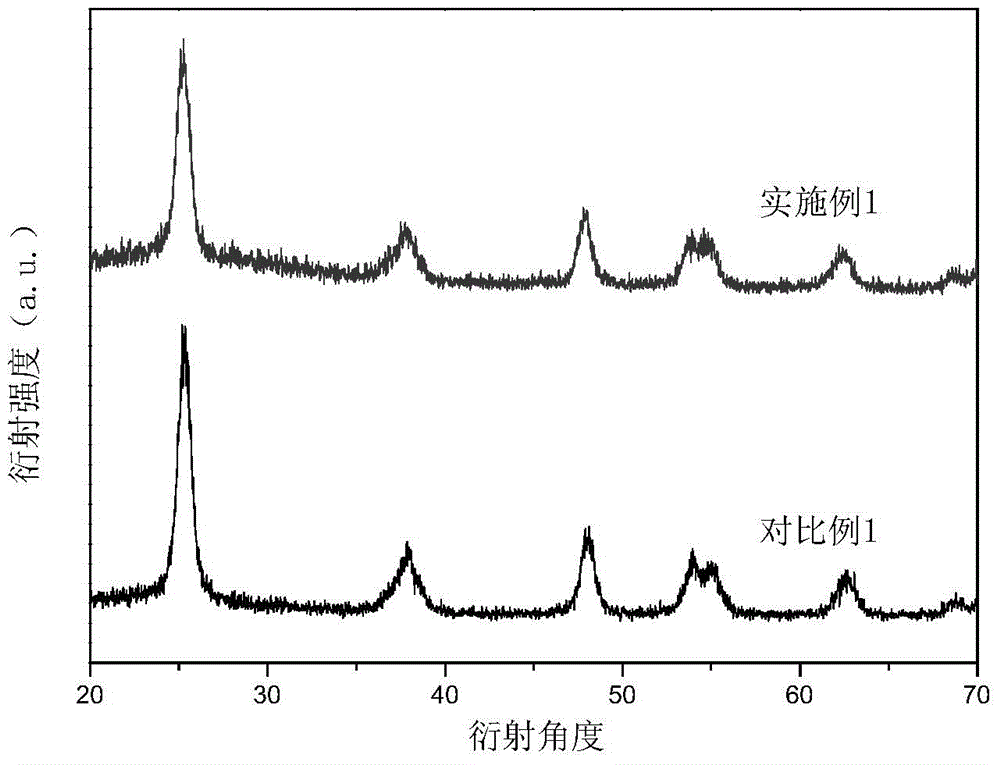

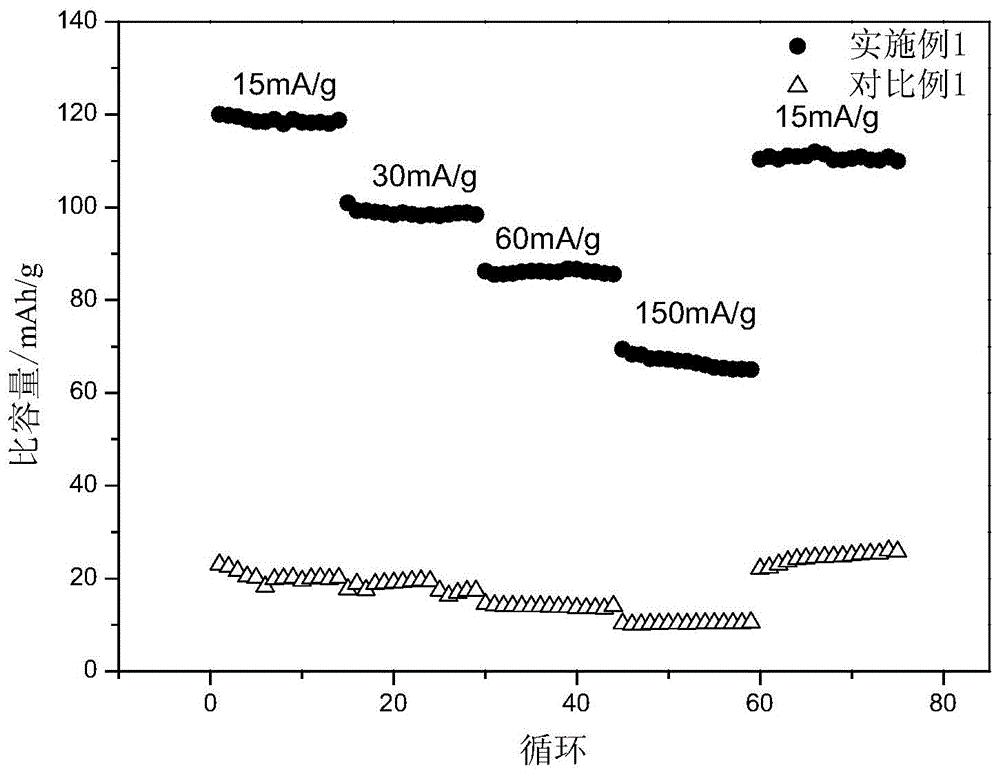

Titanic oxide negative electrode material used as sodium-ion battery and preparation method of thereof

InactiveCN104091917AWide ion transmission channelExcellent electrochemical performanceCell electrodesSecondary cellsIonTitanium

The invention relates to a titanic oxide negative electrode material used as a sodium-ion battery and a preparation method of the material. According to the titanic oxide negative electrode material, part of titanium is replaced by using doped ions, so that an ion transmission channel is expanded. The negative electrode material contains MxTi<1-x>Oy, wherein x is greater than 0 and less than 0.25, y is greater than 1.5 and less than 2.25, and M is selected from one or several out of Mn, Fe, Co, Ni, Cu, Zn, Mo, Nb, In, Sn, Bi, B or Zr. Compared with the prior art, the doped titanic oxide negative electrode material prepared by the method provided by the invention is good in electro-chemical properties such as relatively good circulation property, relatively high reversible specific capacity and good capability of removing sodium and embedding sodium; the titanic oxide negative electrode material is abundant in raw materials, low in cost and simple in preparation process; the titanic oxide negative electrode material is expected to become a sodium-ion battery negative electrode material.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

Preparation method and application of dual-purpose probe integrating solid-phase micro-extraction fibers and electrochemical detection working electrodes

ActiveCN105699452AExcellent electrochemical performanceGood environmental stabilityPreparing sample for investigationMaterial electrochemical variablesSolventCvd graphene

The invention relates to a preparation method and an application of a dual-purpose probe integrating solid-phase micro-extraction fibers and electrochemical detection working electrodes, and belongs to the field of analysis chemicals. The preparation method comprises the following steps of firstly, adhering carbon fibers and a copper conducting wire by silver conductive adhesive, inserting into a capillary tube of which one end is drawn into a tip end, sealing the two ends of the capillary tube by epoxy resin adhesive, enabling the carbon fiber to expose with 1-20mm out of the glass capillary tube, and polymerizing a polypyrrole-graphene quantum dot copolymerizing coating to the surface of carbon fiber by an electrochemical polymerizing method, so as to obtain the dual-purpose probe integrating the solid-phase micro-extraction fibers and the electrochemical detection working electrodes. The preparation method has the advantages that by integrating the solid-phase micro-extraction fibers and the electrochemical detection working electrodes, the direct online detection is realized without solvent dissolving after extraction, and a series of problems of sample thinning, sample state change and the like in the solvent dissolving after the traditional solid-phase micro-extraction are improved; the preparation method is simple, the environment-friendly effect is realized, the detection sensitivity is high, and the application prospect in the fields of biological analysis, environment analysis and the like is broad.

Owner:BEIJING UNIV OF TECH

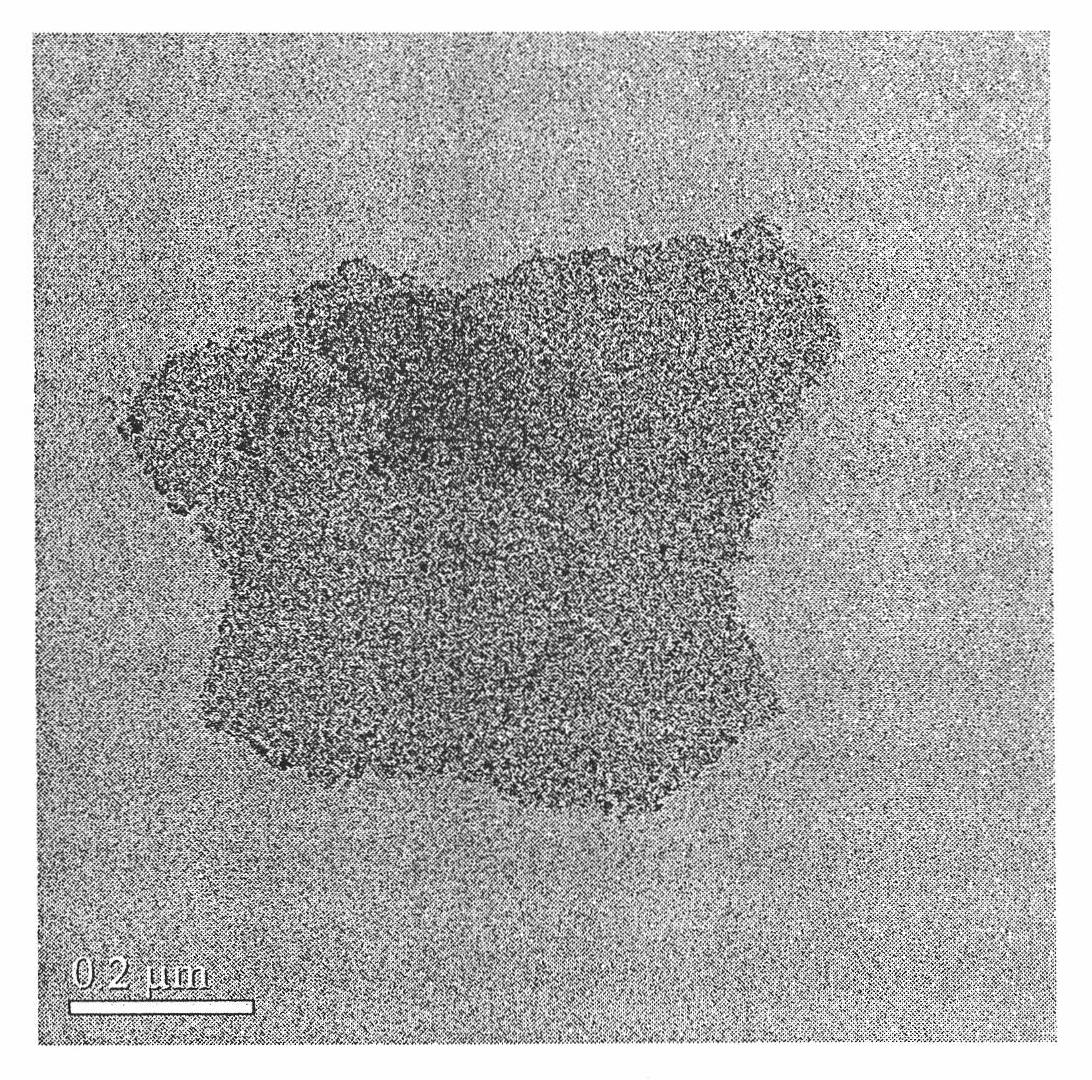

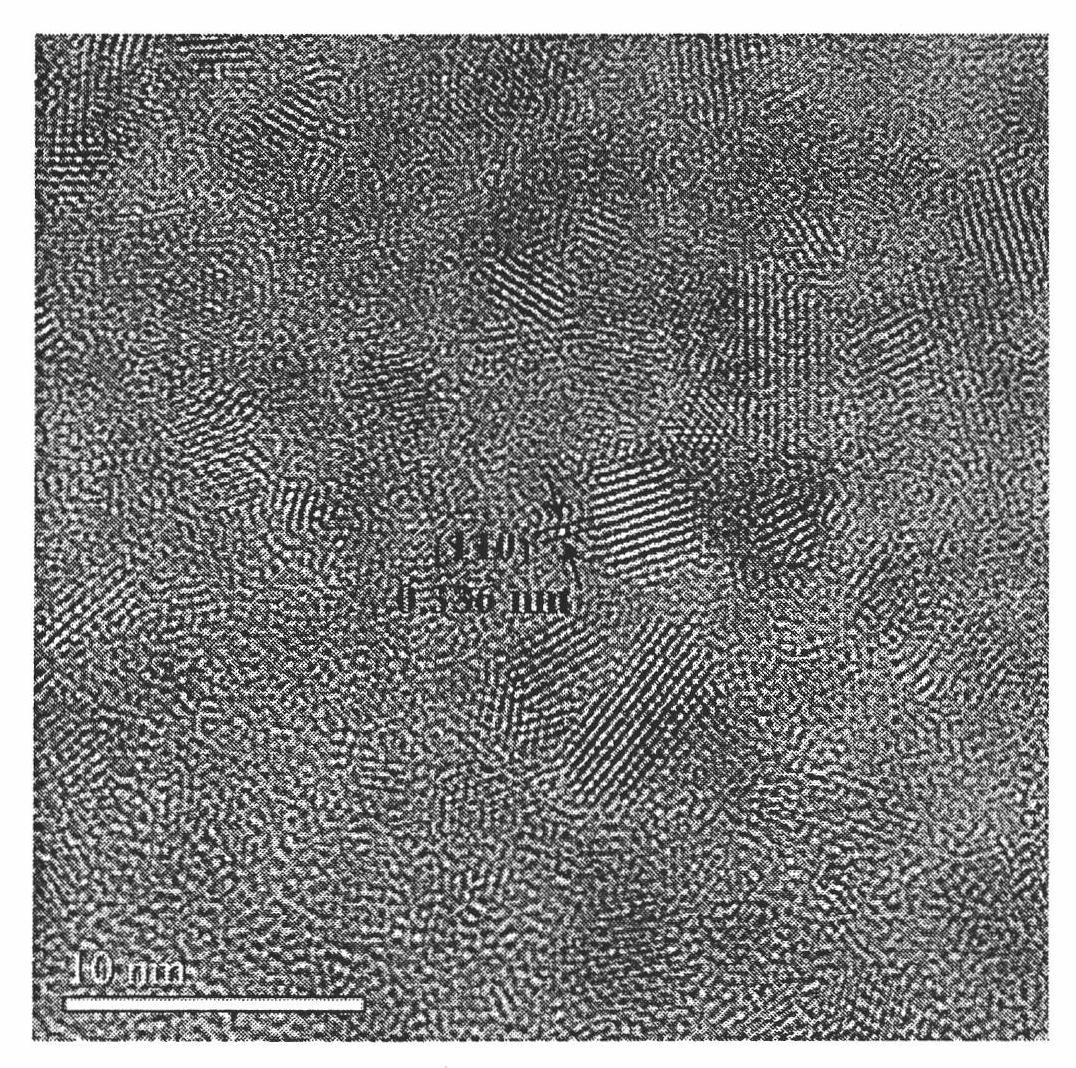

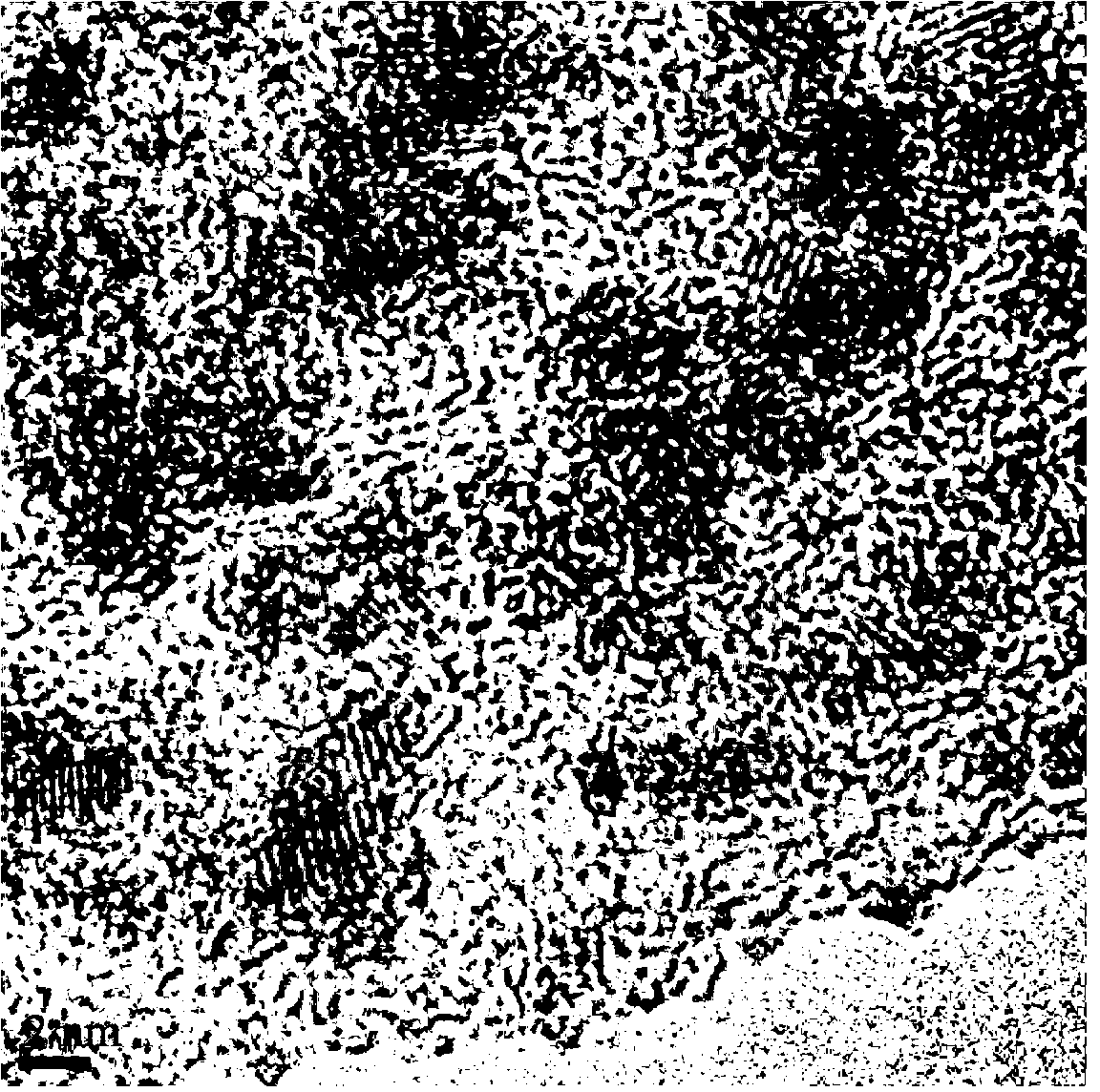

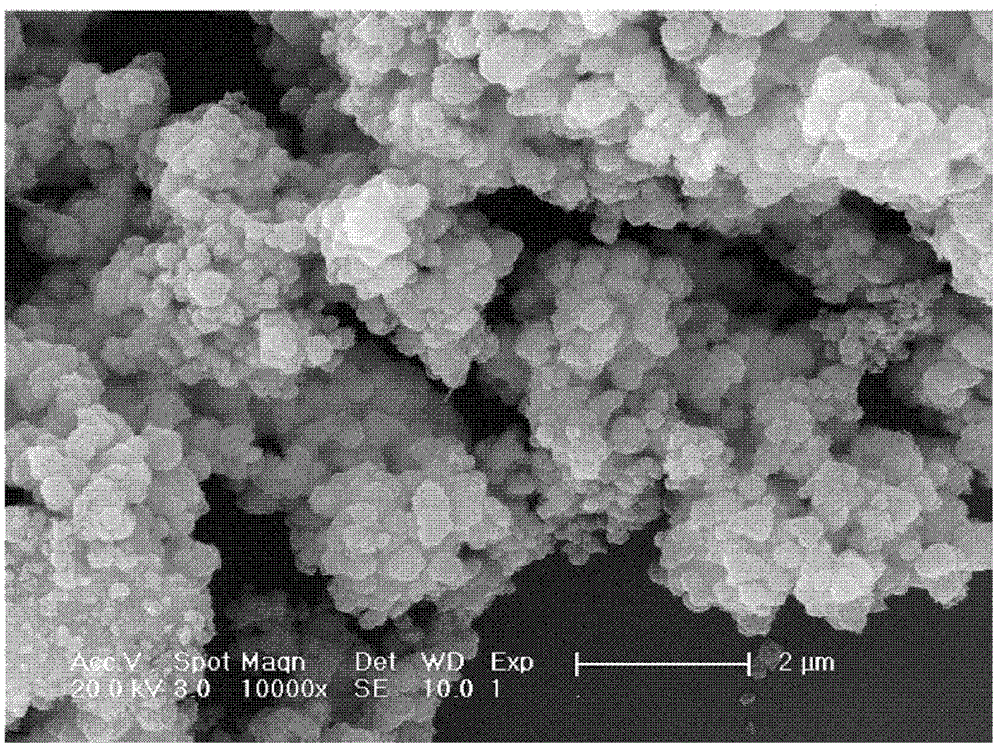

Mesoporous manganese dioxide material, preparation method thereof and supercapacitor

InactiveCN102795671AHigh BET specific surface areaExcellent electrochemical performanceElectrolytic capacitorsManganese oxides/hydroxidesPotassium permanganateAscorbic acid

The invention provides a mesoporous manganese dioxide material. Particle of the mesoporous manganese dioxide material is spherical-like, the surface of the particle is provided with mesopores and diamond-shaped bumps, the aperture of each mesopore is 5 to 30nm, and the specific surface area of the particle is 120 to 160 m<2> / g. The invention also provides a method for preparing the mesoporous manganese dioxide material. The method comprises the following steps of mixing a potassium permanganate solution and an ascorbic acid solution; and reacting to obtain the mesoporous manganese dioxide material under agitation, wherein the molar ratio of potassium permanganate to ascorbic acid is 10:(1-8). Besides, the invention provides a supercapacitor. The mesoporous manganese dioxide material has surface appearance similar to that of a walnut, the specific surface area, which is calculated by a brunauer-emmett-teller (BET) method, of the mesoporous manganese dioxide material is relatively large, and the supercapacitor has high electrochemical performance, particularly has relatively high unit specific surface area specific capacitance.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

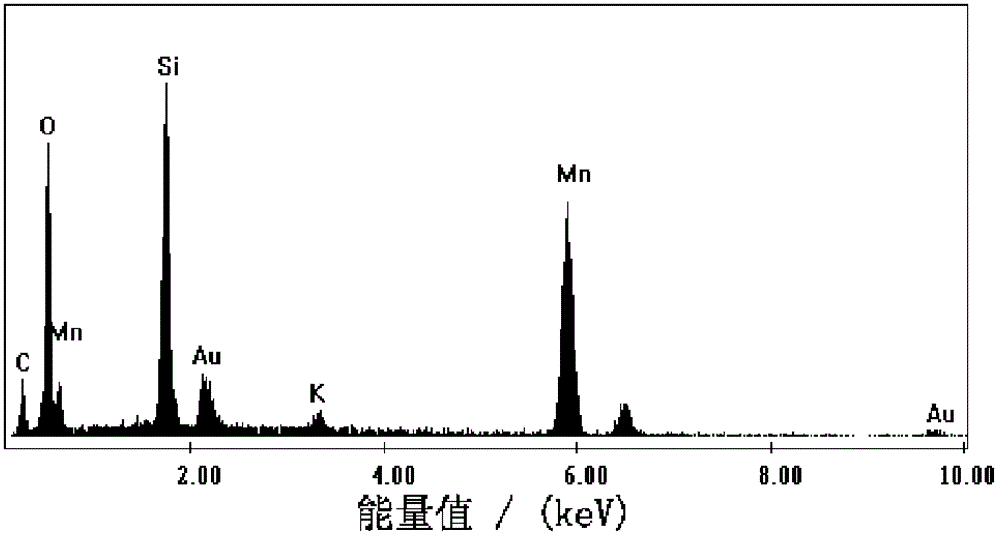

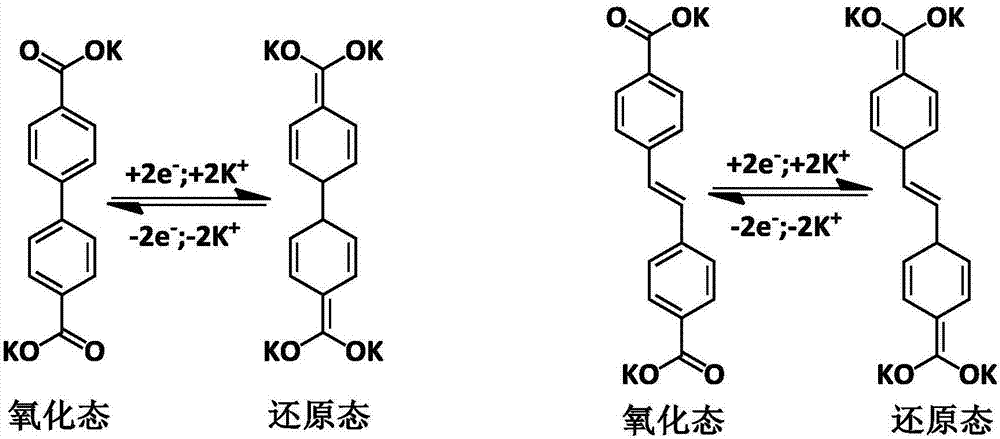

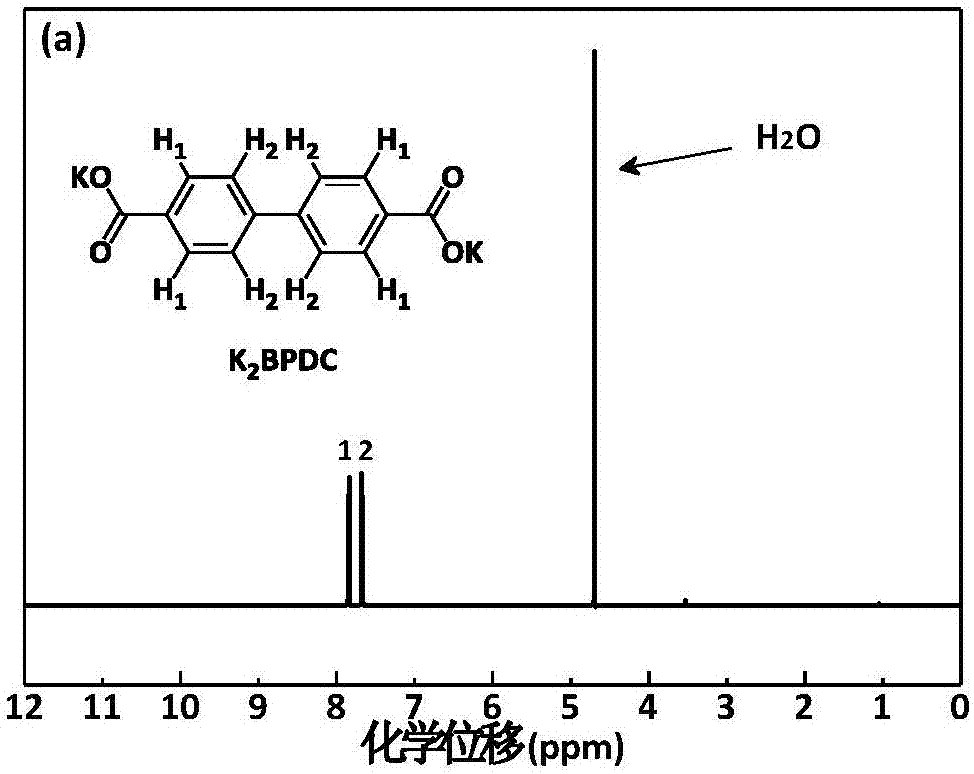

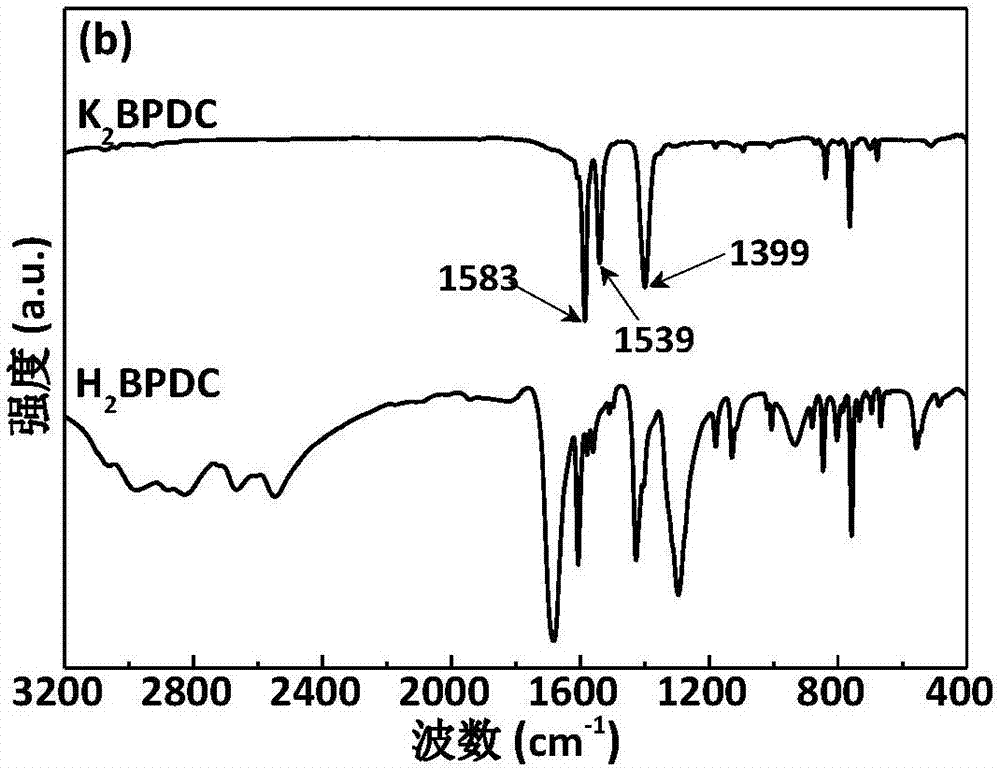

Application of aromatic hyperconjugation dicarboxylate and aromatic hyperconjugation dicarboxylate/graphene composite material

ActiveCN107275601AExcellent electrochemical performanceLarge π-conjugate three-dimensional spaceCell electrodesSecondary cellsElectron transmissionHigh rate

The invention relates to the technical field of negative materials of potassium-ion batteries and aims at solving the technical problems of poor rate performance and cycling stability of the potassium ion battery in the prior art. The invention provides an application of aromatic hyperconjugation dicarboxylate and aromatic hyperconjugation dicarboxylate / graphene composite materials. The aromatic hyperconjugation dicarboxylate and aromatic hyperconjugation dicarboxylate-graphene composite materials comprise 4, 4'-biphenyldicarboxylic acid salt, 4, 4'-diphenylethene dicarboxylate, 4, 4'-biphenyl potassium diformate / graphene composite material (K2BPDC@GR) and 4, 4'-diphenylethylene potassium dicarboxylate / graphene composite material (K2SBDC@GR). As a new family of the negative materials of the potassium-ion batteries, the aromatic hyperconjugation dicarboxylate and aromatic hyperconjugation dicarboxylate-graphene composite materialsshow a reversible disembedding potassium-ion platform, and the hyperconjugation dicarboxylate has larger pi conjugation three-dimensional space and faster potassium-ion and electron transmission channel, has high theoretical specific capacity and can realize high rate performance.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

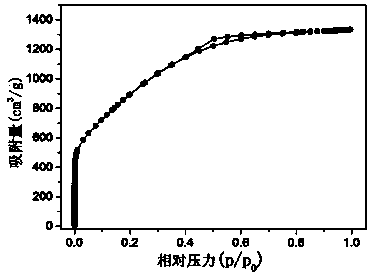

Method for preparing nitrogen-doped porous carbon material by two-step method and application thereof

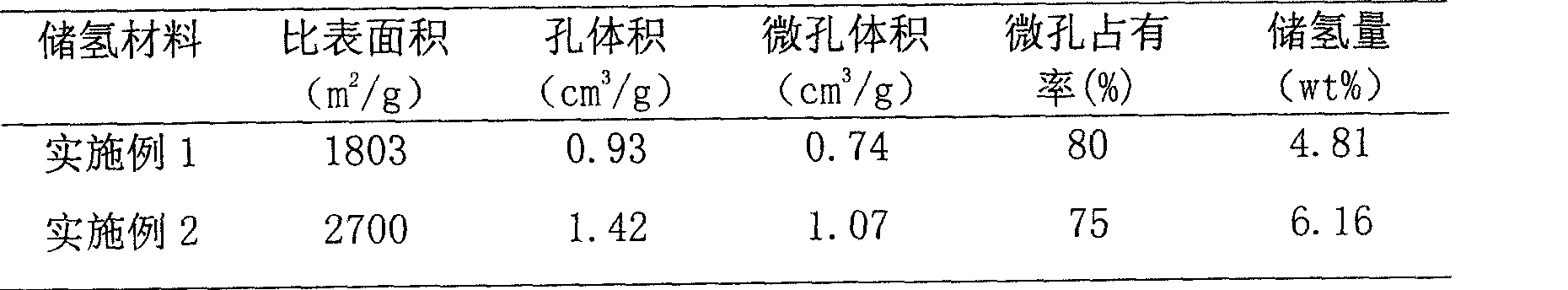

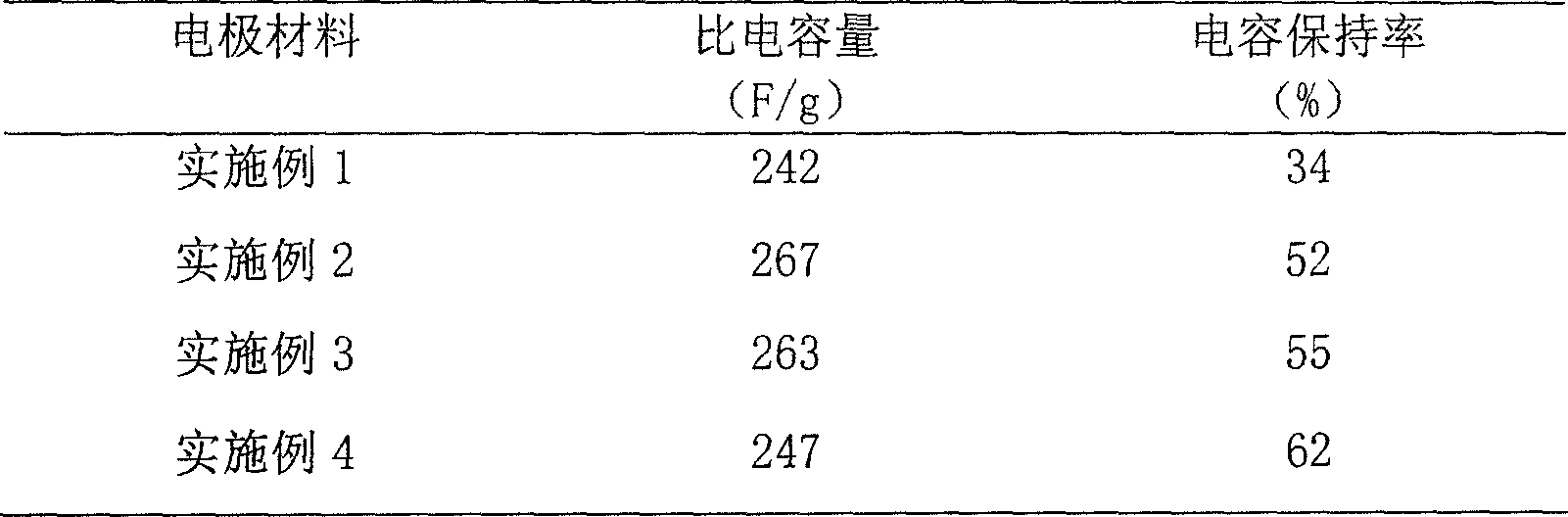

InactiveCN101531357AExcellent electrochemical performanceIncreased hydrogen storage at low temperatureFurfuryl alcoholCarbon nitrogen

The invention relates to a method for preparing a nitrogen-doped porous carbon material by a two-step method and application thereof, and belongs to the field of hydrogen storage materials and new energy materials. The nitrogen-doped porous carbon material is prepared by adopting a template carbonization method, which comprises that: firstly, a microporous molecular sieve such as ZSM-5, 3A, 5A, 13X, Y, beta and the like is used as a template, and then nitrogen-doped porous carbon material is prepared by adopting the two-step method combining liquid-phase impregnation and chemical precipitation. The liquid-phase impregnation uses sucrose, furfuryl alcohol, polyacrylonitrile and the like as a carbon or carbon-nitrogen precursor which is impregnated in the template, and the chemical precipitation comprises that propylene, acetonitrile, phenyl ethylene, methylbenzene and the like are precipitated on the template by a CVD method in turn. And then, nitrogen-doped porous carbon is further obtained through the process steps such as high temperature carbonization, template removal and the like. The nitrogen-doped porous carbon material with different structures can be obtained by controlling process conditions. The nitrogen-doped porous carbon material prepared by the method has the advantages of high specific surface area, large pore volume, narrow aperture distribution and adjustable pore structure, and can be used for the hydrogen storage materials and super-capacitor electrode materials.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

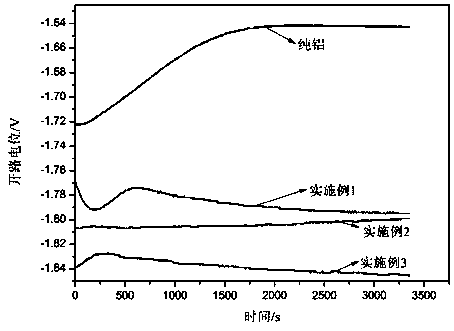

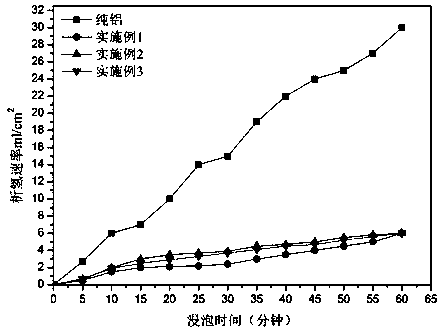

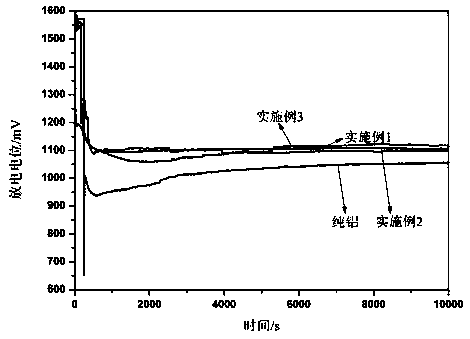

Aluminum air battery anode material and preparing method thereof

ActiveCN109321766AExcellent electrochemical performanceLow self-corrosion rateFuel and primary cellsCell electrodesAluminiumMachining process

The invention discloses an aluminum air battery anode material and a preparing method thereof. The aluminum air battery anode material comprises, by mass percent, 0.10%-0.15% of bismuth, 0.10%-0.15% of lead, 0.015%-0.035% of gallium and the balance aluminum. The anode material is prepared through the machining processes of mixing, smelting, rolling and heat treatment. The anode material componentdesign is reasonable, the cost is low, the product performance is good, the preparing process is simple, and the aluminum air battery anode material and the preparing method of the aluminum air battery anode material are suitable for large-scale industrial production.

Owner:KUNMING UNIV OF SCI & TECH

Preparation method of spongy porous carbon material for supercapacitors

InactiveCN105836746AExcellent electrochemical performanceMild reaction conditionsHybrid capacitor electrodesIonNitrogen atmosphere

A method for preparing a spongy porous carbon material for a supercapacitor, comprising the following steps: cleaning the rice husk with deionized water to remove dust, and then dispersing the rice husk in an HF solution, and continuously stirring in a water bath to remove the dust from the rice husk. the ash content; filter and wash to obtain deashed rice husk; mix deashed rice husk with activator according to a certain mass ratio, then add water to make it evenly mixed, and obtain a mixture of rice husk and alkali after drying; mix the mixture in Carry out high-temperature activation treatment under the protection of nitrogen atmosphere, wash with deionized water, filter and dry to obtain a porous carbon material. The sponge-like porous carbon prepared by the invention has high specific surface area, good pore size distribution, and good electrochemical performance. The preparation has mild reaction conditions, low energy consumption, simple steps and easy operation, and is suitable for large-scale industrial production.

Owner:NANCHANG UNIV

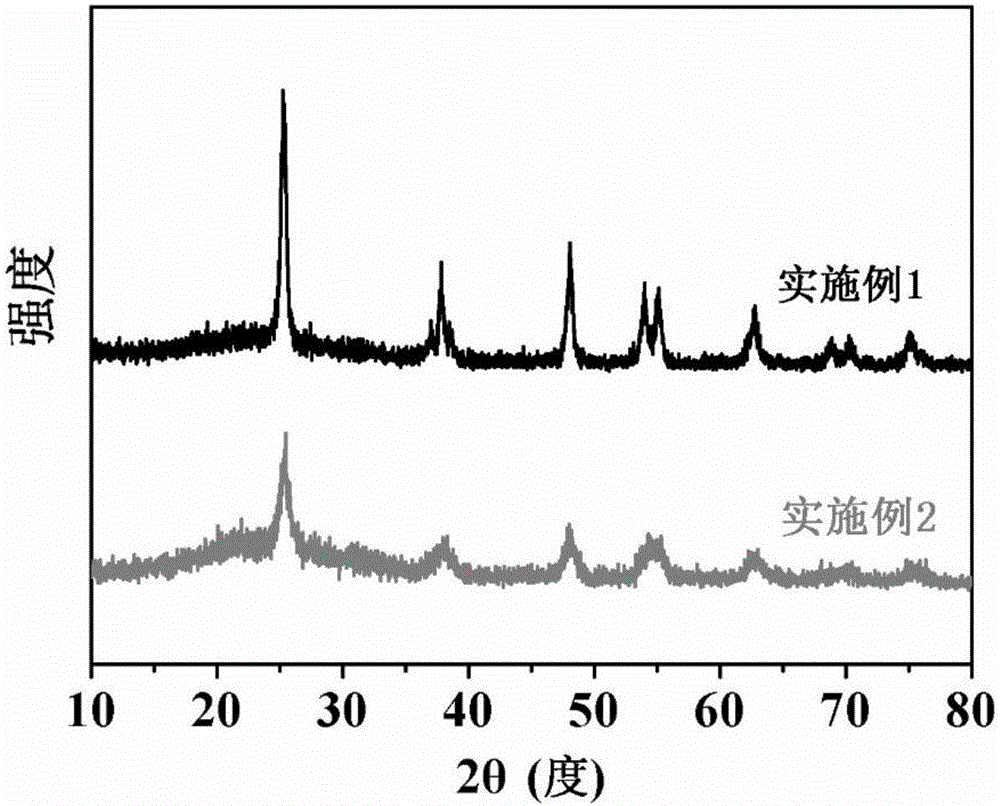

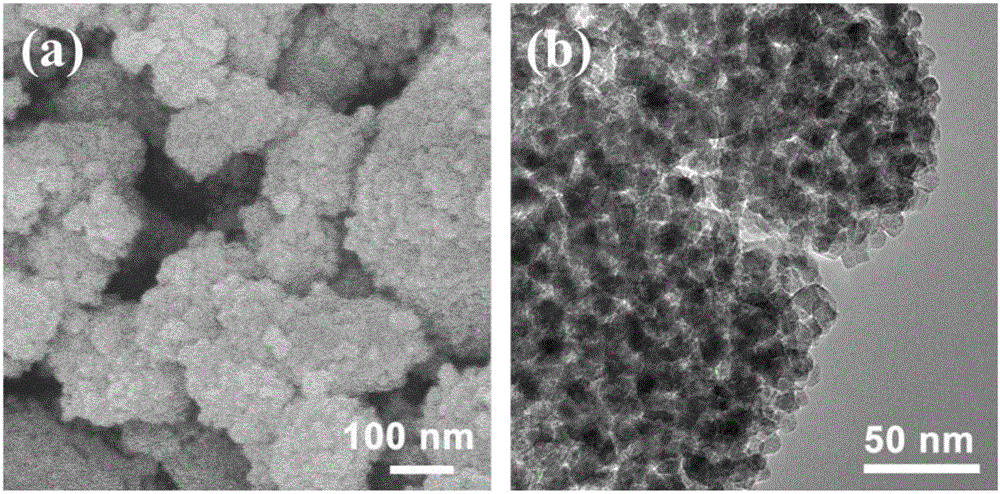

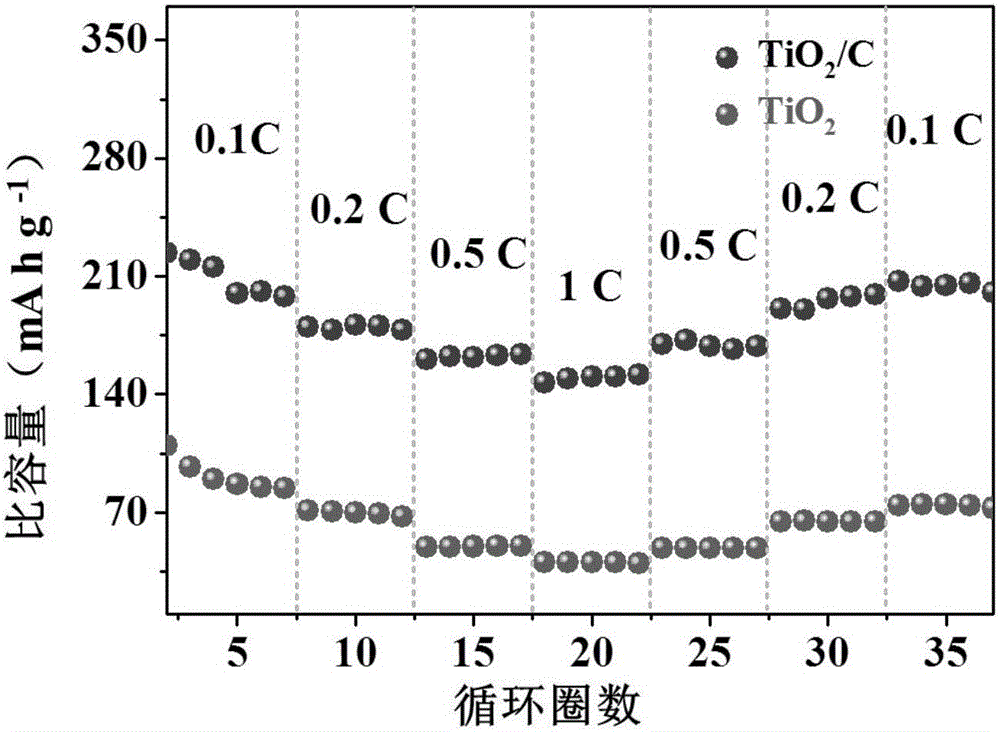

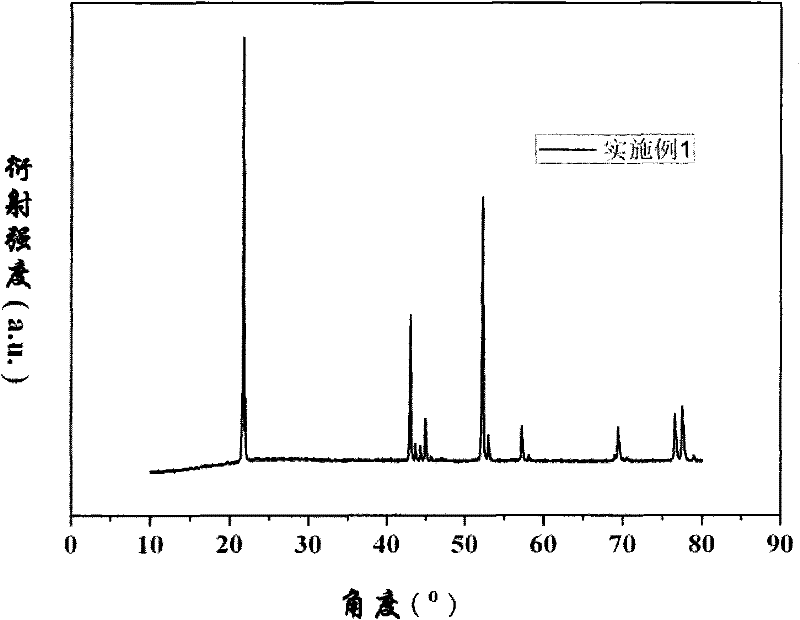

Preparation method of titanium dioxide negative electrode material coated with surfactant serving as carbon source

InactiveCN106602034AImprove electronic conductivityExcellent electrochemical performanceSecondary cellsNegative electrodesChemistryCarbon source

The invention discloses a preparation method of a titanium dioxide negative electrode material coated with a surfactant serving as a carbon source. According to the preparation method, the surfactant is taken as the carbon source, and carbon-coated titanium dioxide is prepared by a hydrothermal method and subsequent high-temperature calcination; and modulation and control of a carbon coating layer of the titanium dioxide are realized under the action of electrostatic force between the surfactant and a titanium dioxide precursor titanic acid radical carrying negative charges. The preparation method has the advantages that the problems of non-uniform carbon layer covering and loose contact in a conventional carbon-coated titanium dioxide negative electrode material are solved, and the electronic conductivity of the titanium dioxide is enhanced, thereby enhancing the important electrochemical performance such as the specific capacity, rate capability and cycling stability of the material. The preparation method has a very high practical value and a good application prospect.

Owner:NANKAI UNIV

Treatment method for ternary material and method for improving capacity and cycle performance of lithium battery

ActiveCN102237518AImprove battery capacity and cycle performanceExcellent electrochemical performanceCell electrodesAir atmosphereChemistry

The invention discloses a treatment method for a ternary material LiNixCoyMnzO2(x+y+z). The method comprises the following steps of: firstly, adjusting the pH value of a LiNixCoyMnzO2 material to be alkaline or strongly alkaline and range from 8.0 to 12.0; secondly, gradually adding a cobalt salt solution into the alkaline or strongly alkaline LiNixCoyMnzO2 turbid liquid; and finally, drying the mixed material, adding a proper amount of lithium salt, and firing the mixture for 5 to 24 hours at a proper temperature in an air atmosphere to prepare the LiNixCoyMnzO2 material with a LiCoO2 treated surface. The method is simple in process; and the prepared product has high electrochemical performance within a high voltage range and is favorable for large-scale production.

Owner:SHENZHEN BAK POWER BATTERY CO LTD

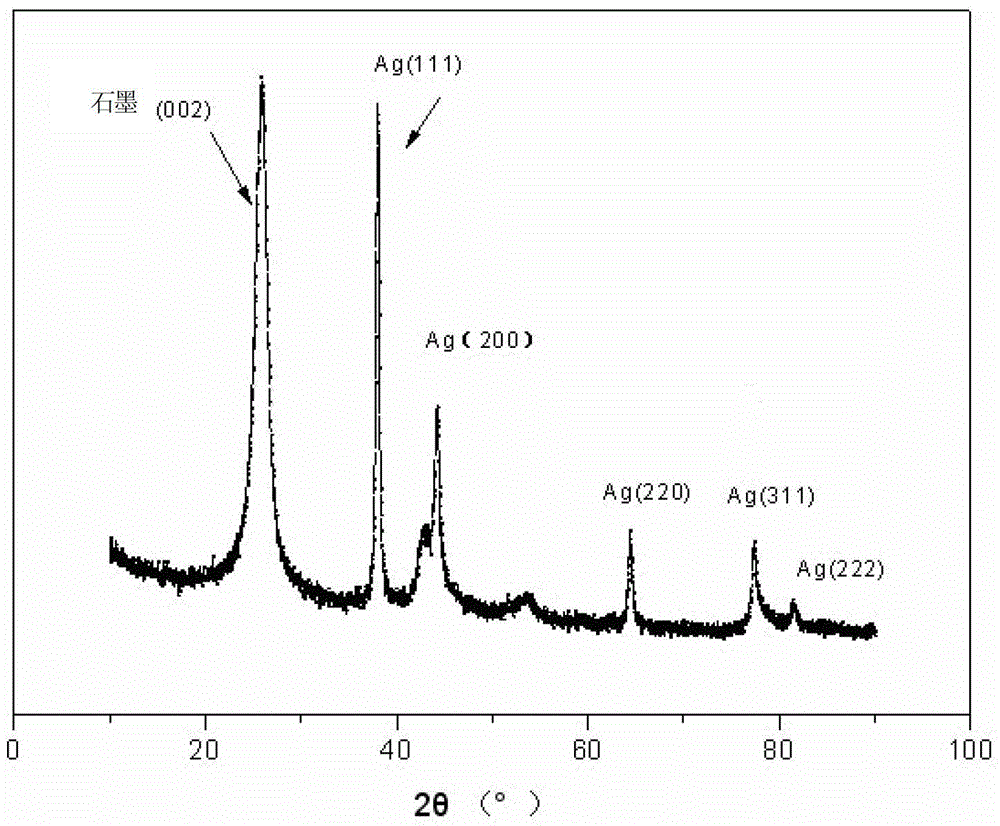

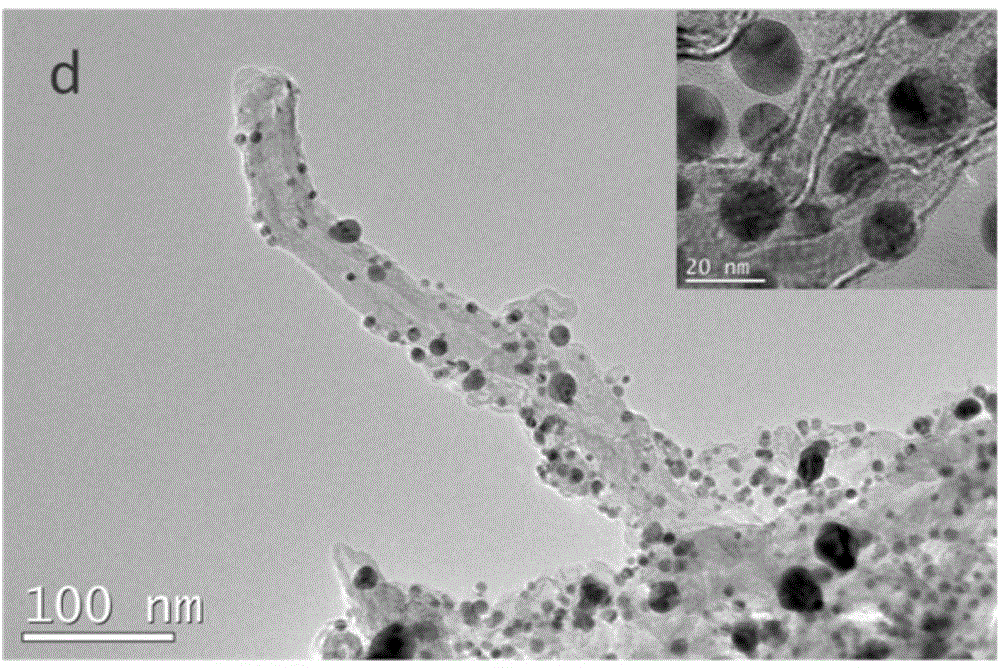

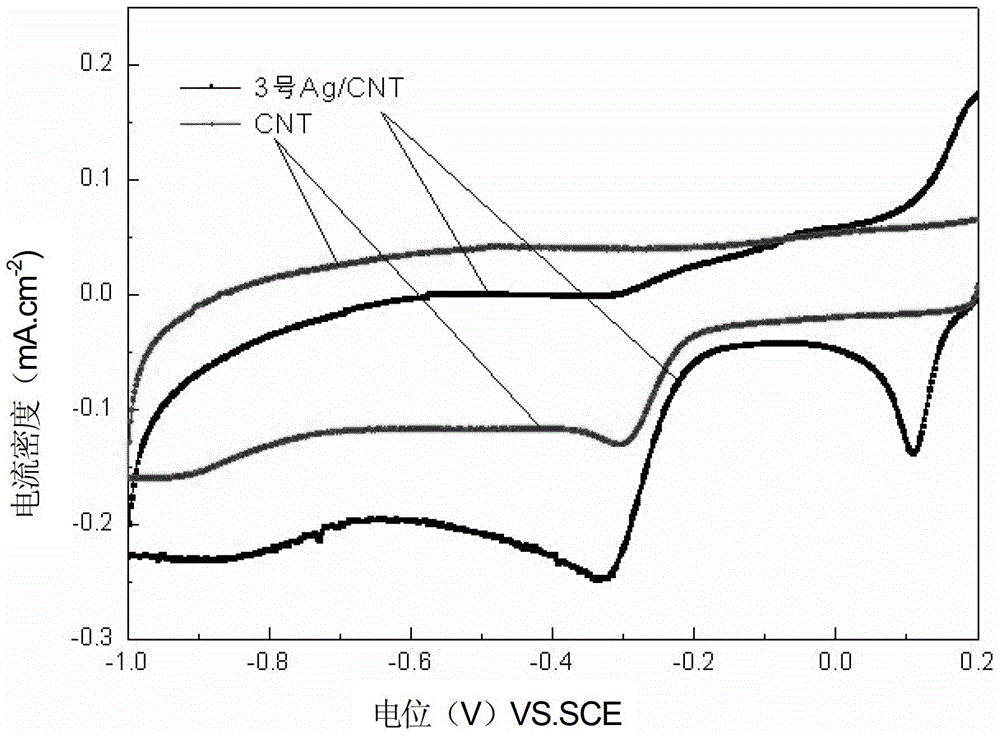

Oxygen reduction catalyst for zinc-air battery and preparation method thereof

InactiveCN103337642AUniform particle sizeExcellent electrochemical performanceCell electrodesCarbon nanotubeZinc

The invention belongs to the field of chemical power source and electrochemical catalysis, and more specifically relates to an oxygen reduction catalyst for a zinc-air battery and a preparation method thereof. The oxygen reduction catalyst is a supported catalyst, and is composed of nano Ag particles and carbon nanotubes, wherein the mass ratio of nano Ag particles and carbon nanotubes is 1:1 to 1:50, the particle size of nano Ag particles is 10 to 20nm, and the specific surface area of carbon nanotubes is 100 to 500m2 / g. The preparation method comprises following steps: Ag+ of AgNO3 solution is reduced to nano Ag particles by using solution reduction method, carbon nanotube carriers are treated by mixed acid, and then nano Ag particles are loaded on the carbon nanotube carriers. The size distribution of the nano Ag particles is uniform, and the nano Ag particles distribute on the surface of the carbon nanotubes uniformly, so that the oxygen reduction catalyst possesses excellent electrochemical performances, and can be used for oxygen reduction of the cathode of the zinc-air battery; and the oxygen reduction in an alkaline environment is mainly four-electron reaction.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

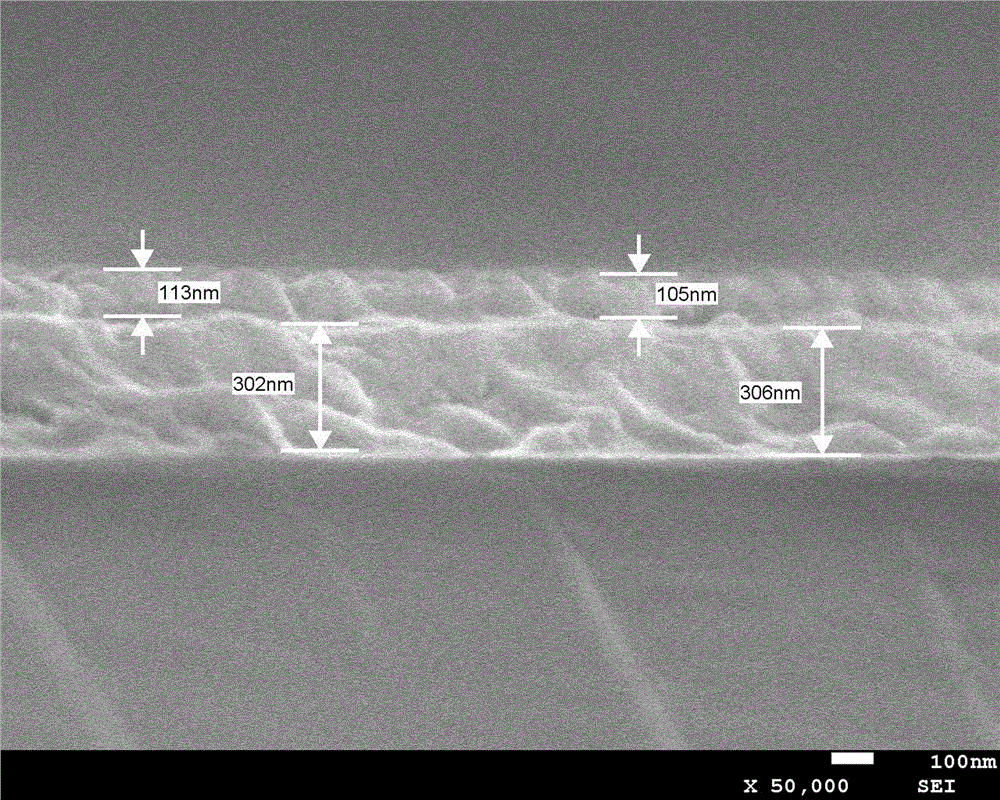

Preparation method of radiation crosslinking polymer gel electrolyte skeleton material

ActiveCN104659413AExcellent electrochemical performanceHigh mechanical strengthFinal product manufactureElectrolyte accumulators manufacturePolymer gelLithium electrode

The invention relates to a preparation method of gel polymer electrolyte skeleton material by using radiation crosslinking and electrospinning technology and belongs to the field of polymer lithium ion battery. The skeleton material can be prepared into gel polymer electrolyte with good electrochemical properties and mechanical properties. The preparation steps are as below: (1) preparation of a blending-type polymer nano fiber membrane by using electrostatic spinning technology; (2) radiation crosslinking of polymer nano fiber membrane; and (3) cutting of crosslinking nano fiber membrane and lamination compression into the polymer gel electrolyte skeleton. The electrolyte skeleton material takes into account the equalization demand of mechanics-electrochemistry performances of gel polymer electrolyte, and has strong adsorption and retention on electrolyte; the prepared gel polymer electrolyte has high ionic conductivity, stable electrochemical window and good charge discharge performance, and the excellent mechanical properties can meet the assembly needs of the commonly used button battery; and the invention can be used in preparation of secondary lithium ion battery.

Owner:BEIJING UNIV OF CHEM TECH

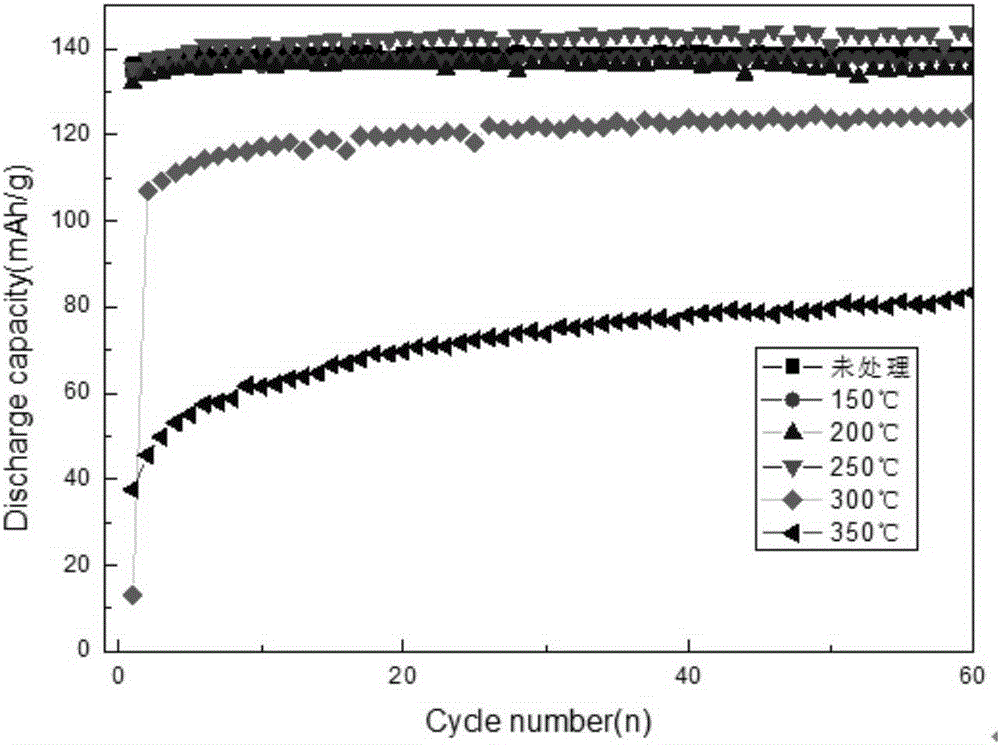

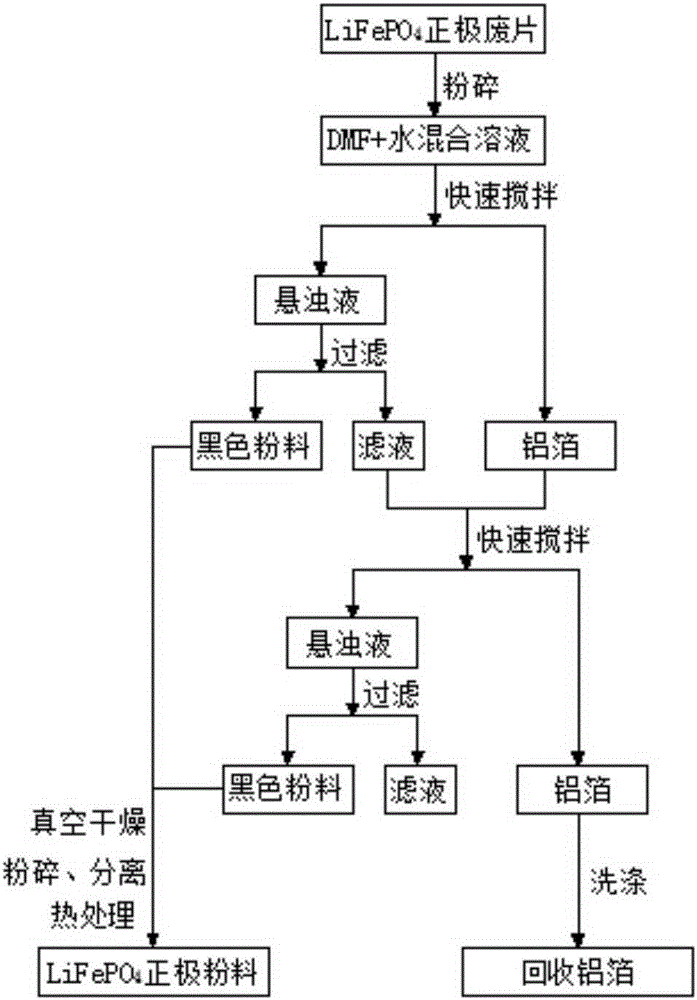

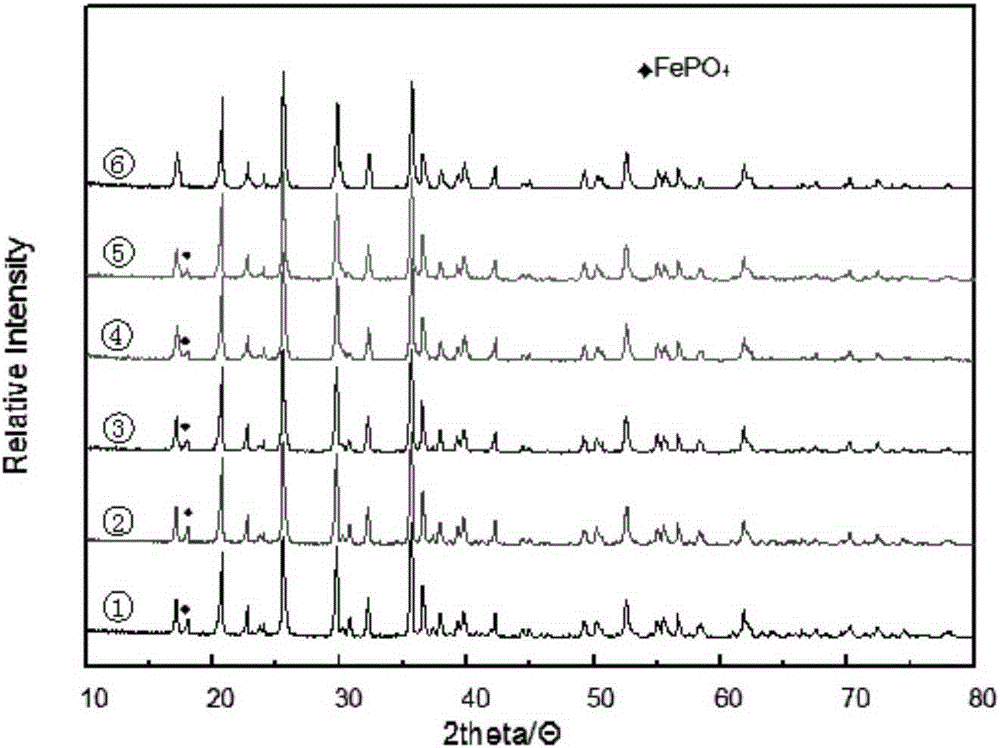

Recovery method of LiFePO4 positive electrode material

InactiveCN105355998AExcellent electrochemical performanceHigh recovery rateWaste accumulators reclaimingBattery recyclingLithium electrodeThermal treatment

Belonging to the technical field of lithium ion batteries, the invention provides a recovery method of an LiFePO4 positive electrode material. The method is characterized by comprising the steps of: (1) crushing an LiFePO4 positive electrode waste sheet, then mixing the crushed LiFePO4 positive electrode waste sheet with a mixed solution of DMF and water, performing rapid stirring, conducting vacuum pumping and filtration to obtain black powder and filtrate, and collecting black powder; (2) mixing the obtained filtrate with an aluminum foil, conducting rapid stirring, separating the black powder from the aluminum foil again, and carrying out vacuum pumping and filtration so as to obtain black powder and filtrate, collecting the black powder, and repeating the step (2) until the residue on the aluminum foil is little; (3) mixing the collected black powder, and then performing vacuum drying; (4) crushing the dried black powder and conducting separation to obtain a mixture of LiFePO4 positive electrode powder and carbon; and (5) subjecting the separated mixture of LiFePO4 positive electrode powder and carbon to heat treatment. The method provided by the invention has the characteristics of green and environmental protection, and no pollution, the recovered LiFePO4 positive electrode material has considerable electrochemical performance, the recovery rate is high, and the cost is saved.

Owner:百顺松涛(天津)动力电池科技发展有限公司

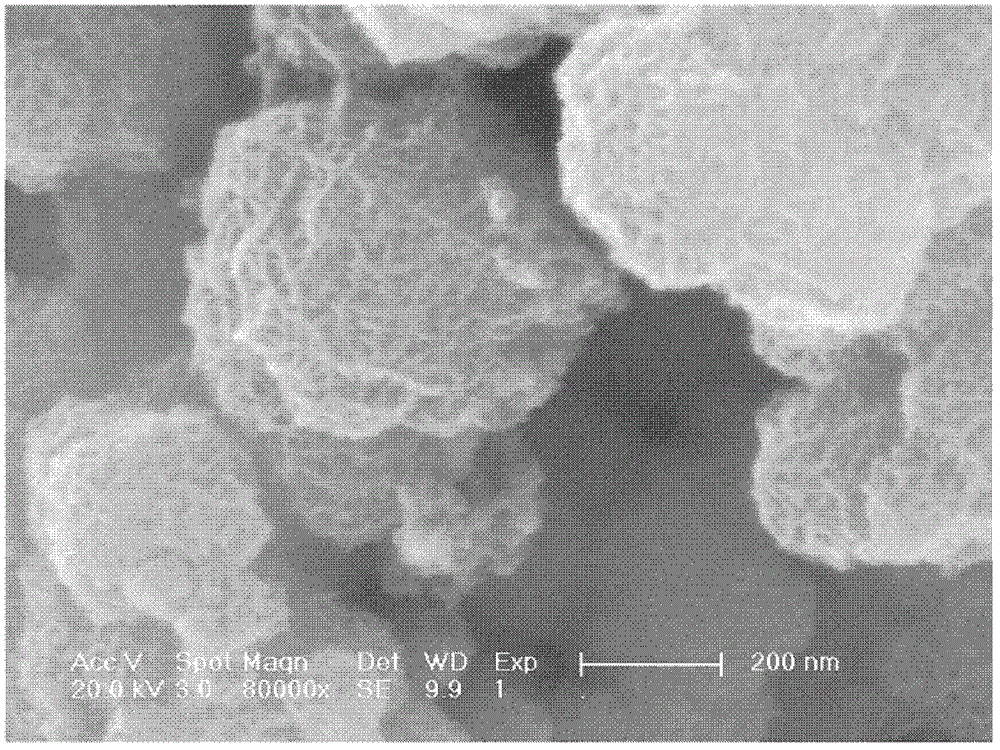

Preparation method for multi-level structured molybdenum disulfide microsphere negative electrode material of lithium battery

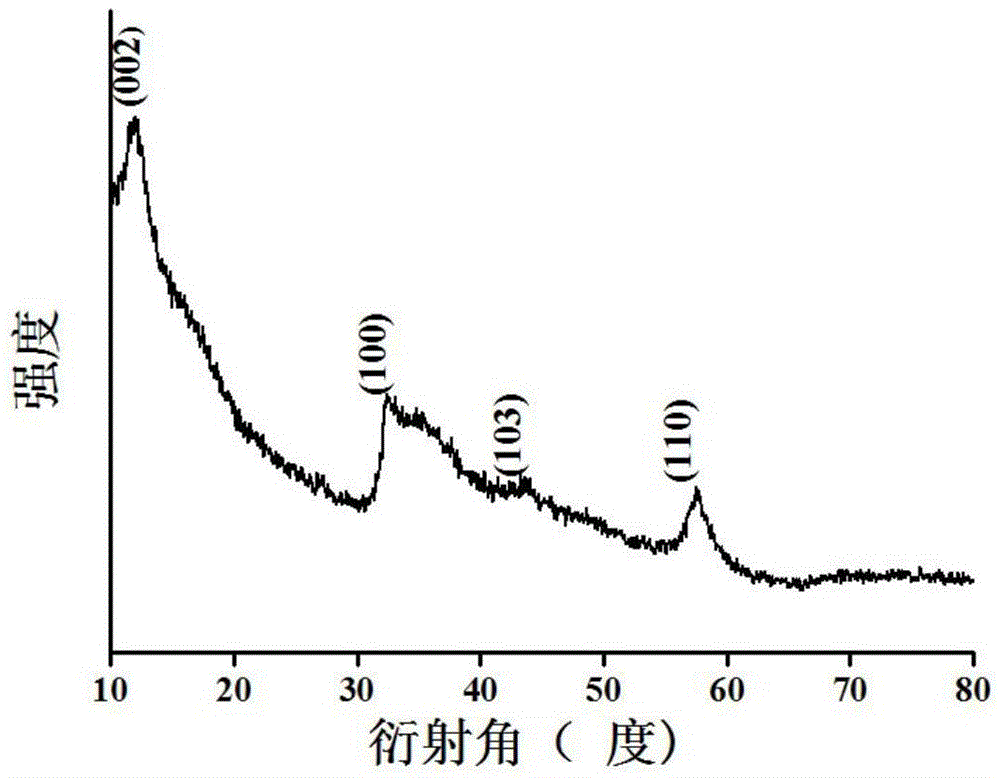

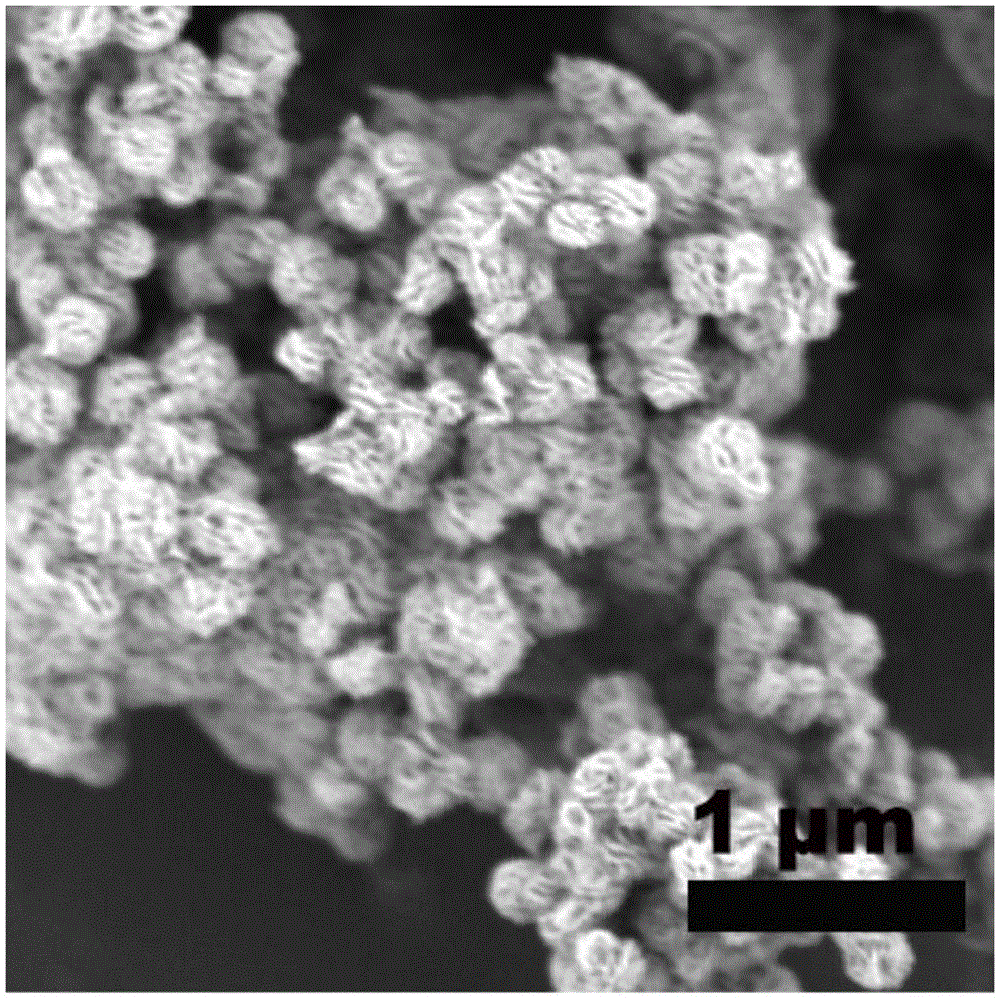

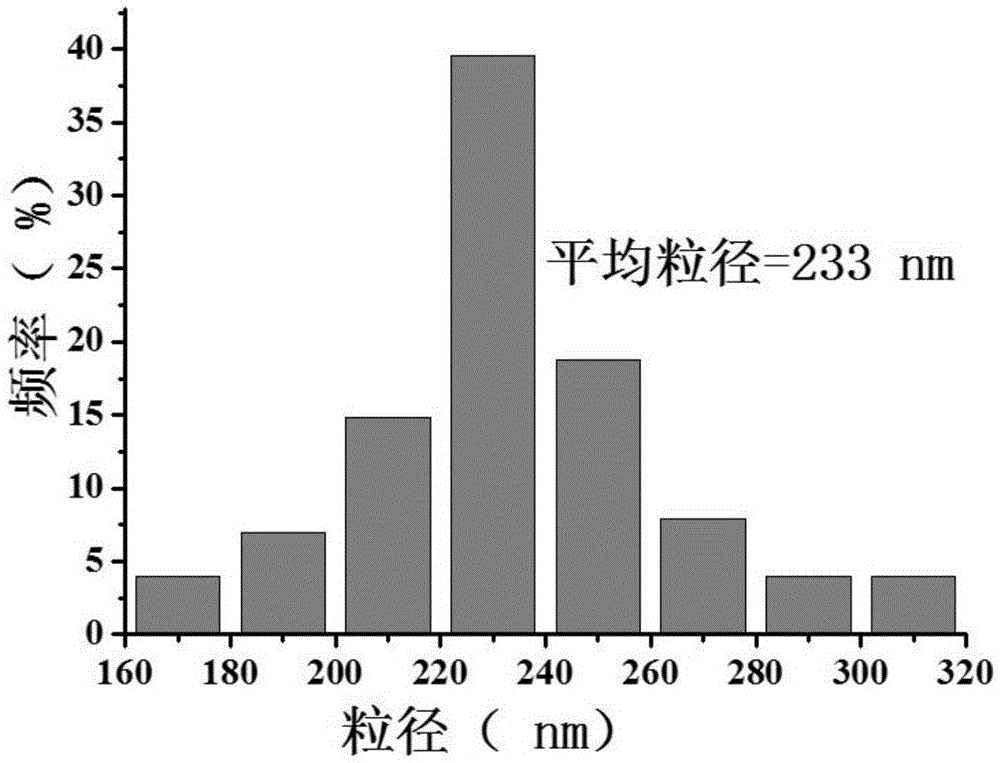

InactiveCN105609769AExcellent electrochemical performanceImproved size distributionCell electrodesSecondary cellsIonSodium Molybdate Dihydrate

The invention relates to a preparation method for a multi-level structured molybdenum disulfide microsphere negative electrode material of a lithium battery. The method comprises the following steps of firstly, dissolving sodium molybdate dehydrate and urea in deionized water, and stirring the mixed solution for 15-60 minutes; secondly, dropwise adding hydrochloric acid to adjust a pH value to be 0-1, transferring the mixed solution in a reaction kettle taking polytetrafluoroethene as a substrate, preserving the mixed solution at 150-250 DEG C for 1 to 40 hours, naturally cooling the mixed solution to a room temperature, taking out the mixed solution after reaction, washing sediments after centrifugal separation, placing the mixed solution in an electrothermal blowing dry box for drying, taking out the mixed solution and placing the mixed solution in a mortar to grind into fine powder; and finally preparing the multi-level structured molybdenum disulfide microsphere negative electrode material of the lithium battery. With the adoption of a simple test method and process steps, the multi-level structured molybdenum disulfide microspheres with relatively small grain sizes (200-250 nanometers) and which are uniformly distributed are prepared, and the negative electrode material has excellent electrochemical performance.

Owner:SYNERGY INNOVATION INST OF GDUT HEYUAN

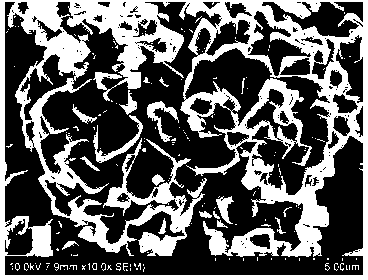

Aluminum-doped spinel manganese-based material and preparation method thereof

ActiveCN102938460AImprove uniformityExcellent electrochemical performanceCell electrodesAluminiumOxide

The invention discloses an aluminum-doped spinel manganese-based material and a preparation method thereof. The method comprises the steps of respectively putting configured manganese source compound solution, or a nickel source compound, aluminum salt compound solution and a precipitator solution into a reactor according to the flow rate being 0.5-2L / h, stirring to control the pH value of a system to be 7-8.5 and the heating temperature of the system to be 30 DEG C-60 DEG C, heating and then curing for 10h-20h to obtain a spherical precipitate precursor, washing and drying the spherical precipitate precursor; forging the dried precipitate for 5-20h under the temperature being 600-900 DEG C; and sufficiently mixing oxidizing materials and a lithium source compound according to a proportion that the stoichiometric ratio exceeds the lithium source compound by 1-10%, and forging for 5-20h under the temperature being 600-900 DEG C to obtain the modified spinel manganese-based material. According to the method disclosed by the invention, the feature of the precursor and the distribution uniformity of an Al element can be improved effectively; due to the reasonable high forging temperature and doping proportion, the structure stability of the aluminum-doped spinel manganese-based material can be improved greatly, and the circulation performance and high-temperature and low-temperature performances of the material can be improved; and the process is simple, and the repeatability is good.

Owner:SHANGHAI INST OF SPACE POWER SOURCES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com