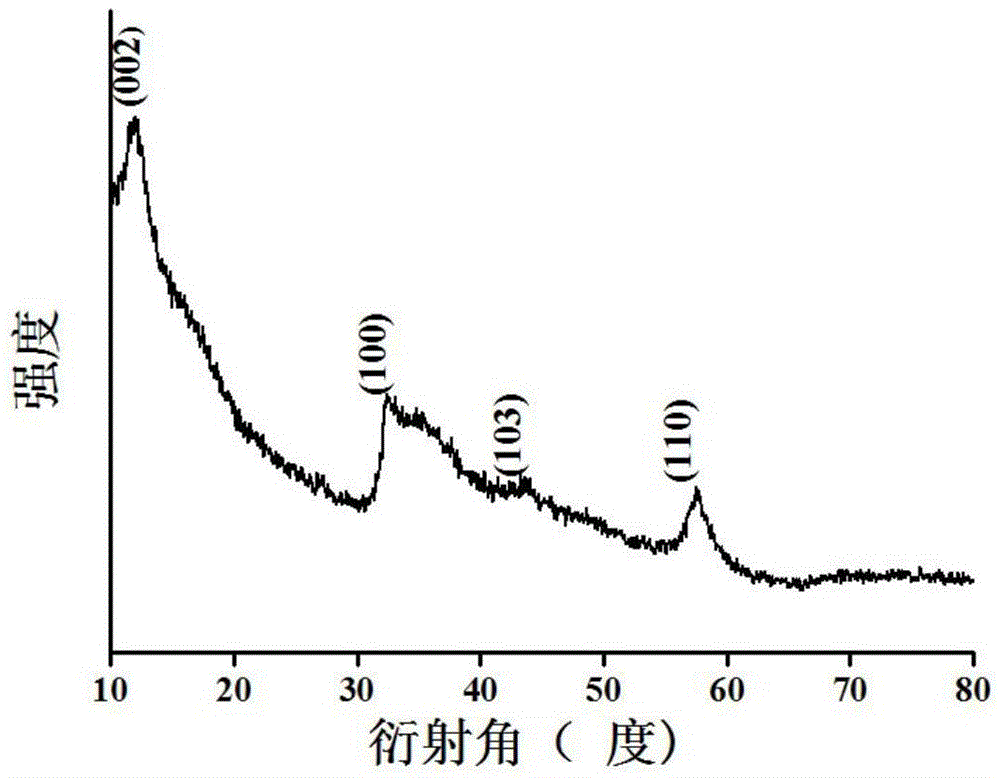

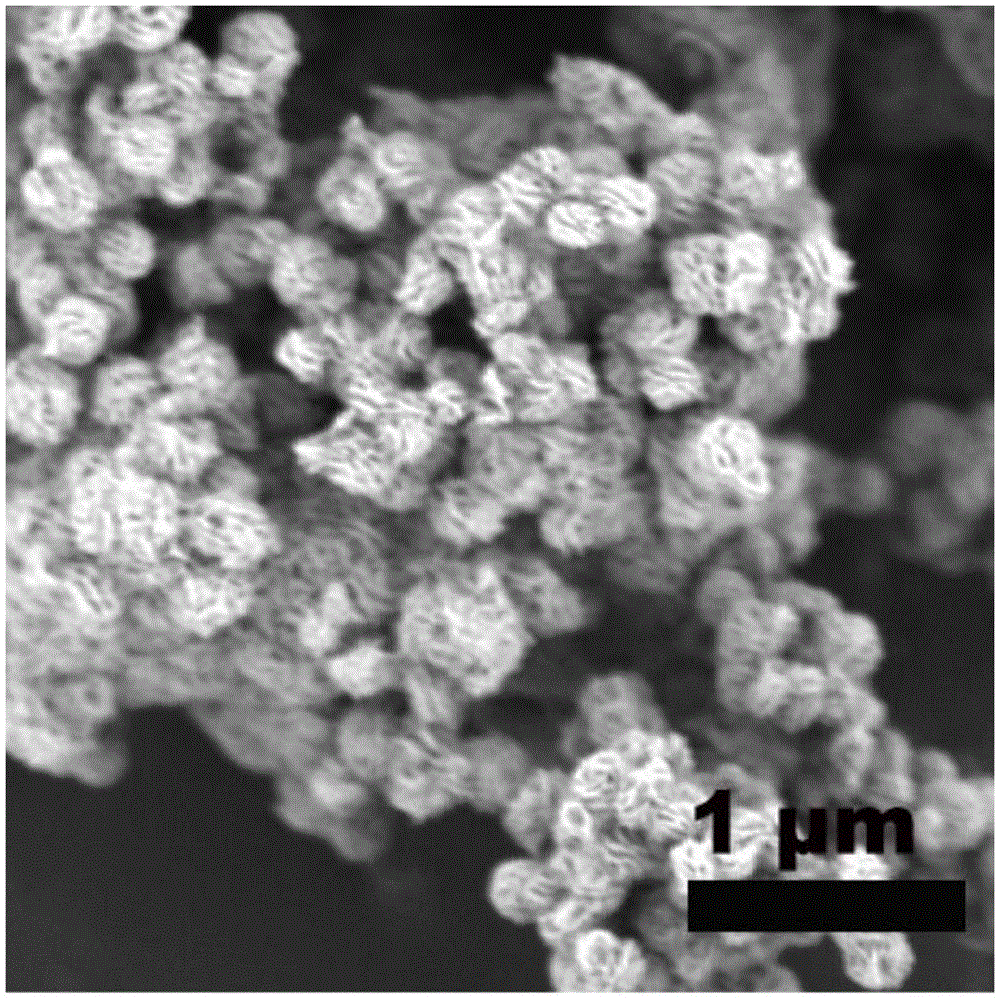

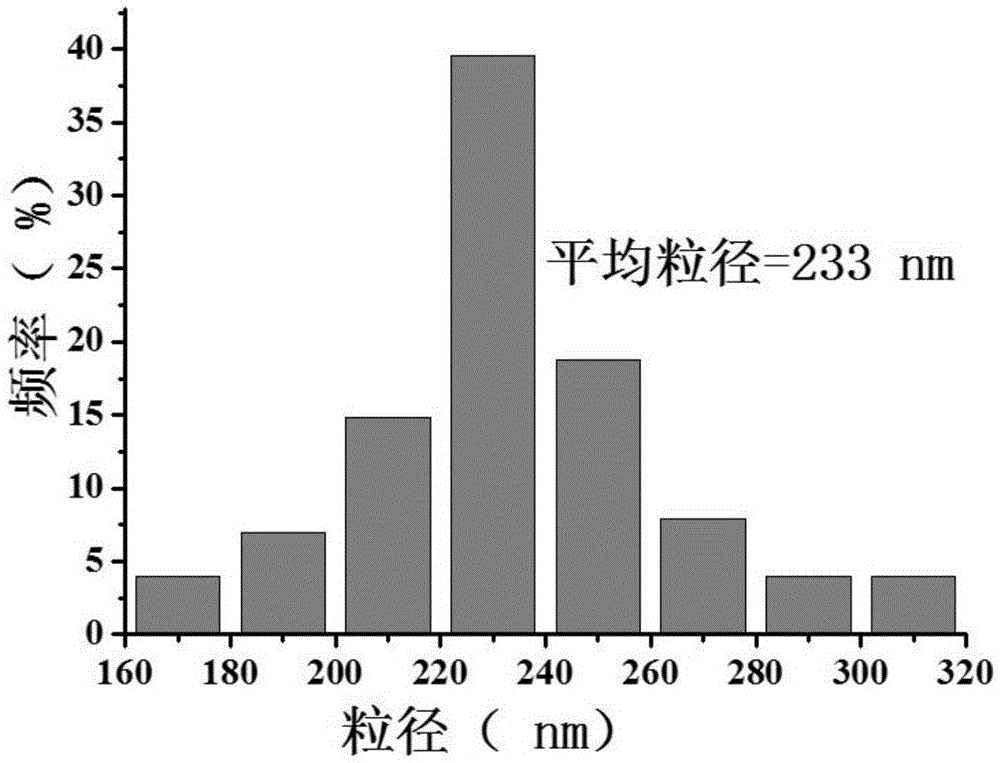

Preparation method for multi-level structured molybdenum disulfide microsphere negative electrode material of lithium battery

A technology of molybdenum disulfide and negative electrode materials, applied in battery electrodes, secondary batteries, structural parts, etc., can solve the problems of uneven distribution, poor cycle performance and rate performance, cumbersome preparation process, etc., and achieve excellent electrochemical performance , excellent electrochemical performance, and the effect of shortening the transmission path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Weigh the required amount of sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) and urea (H 2 NCSNH 2 ) and dissolved in deionized water to prepare a mixed solution of sodium molybdate and urea, so that sodium ammonium molybdate (Na 2 MoO 4 ) and urea (H 2 NCSNH 2 ) was controlled at a mol ratio of 1:1, using a magnetic stirrer to stir the mixed solution for 15min at a speed of 150r / min to obtain a clear mixed solution that was evenly mixed. The pH of the solution was 1, and then the mixed solution was transferred to a reaction kettle with polytetrafluoroethylene as the substrate, the reaction kettle was placed in an oven, and kept at 150°C for 4 hours, and then the reaction kettle was naturally cooled to At room temperature, take out the mixed solution after the reaction, centrifuge the reaction solution at a speed of 3000r / min and wash the centrifuged reactant with deionized water, then centrifuge the washed reactant at a speed of 3000r / min, and centrifuge the prec...

Embodiment 2

[0041] Weigh the required amount of sodium molybdate dihydrate (Na2MoO 4 2H 2 O) and urea (H 2 NCSNH 2 ) and dissolved in deionized water to prepare a mixed solution of sodium molybdate and urea, so that sodium ammonium molybdate (Na 2 MoO 4 ) and urea (H 2 NCSNH 2 ) was controlled at a mol ratio of 1:5, using a magnetic stirrer to stir the mixed solution for 20min at a speed of 150r / min to obtain a clear mixed solution that was evenly mixed. The pH of the solution is 1, and then the mixed solution is transferred to a reaction kettle with polytetrafluoroethylene as the substrate, the reaction kettle is placed in an oven, and kept at 200 ° C for 5 hours, and then the reaction kettle is naturally cooled to At room temperature, take out the mixed solution after the reaction, centrifuge the reaction solution at a speed of 5000r / min and wash the centrifuged reactant with deionized water, then centrifuge the washed reactant at a speed of 5000r / min, and centrifuge the precipita...

Embodiment 3

[0045] Weigh the required amount of sodium molybdate dihydrate (Na 2 MoO 4 2H 2 O) and urea (H 2 NCSNH 2 ) and dissolved in deionized water to prepare a mixed solution of sodium molybdate and urea, so that sodium ammonium molybdate (Na 2 MoO 4 ) and urea (H 2 NCSNH 2) in a mol ratio of 1:10, using a magnetic stirrer to stir the mixed solution for 15 min with a rotating speed of 150r / min, to obtain a clear mixed solution that was evenly mixed, at this time dropwise dripping a mass fraction of 37% hydrochloric acid solution to make the mixed solution The pH of the solution was 0.7, and then the mixed solution was transferred to a reaction kettle with polytetrafluoroethylene as the substrate, the reaction kettle was placed in an oven, and kept at 250°C for 6 hours, and then the reaction kettle was naturally cooled to At room temperature, take out the mixed solution after the reaction, centrifuge the reaction solution at a speed of 6000r / min and wash the centrifuged reactan...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Interplanar spacing | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com