Patents

Literature

2071 results about "Dry box" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A dry box is a storage container in which the interior is kept at a low level of humidity. It may be as simple as an airtight and watertight enclosure, or it may use active means to remove water vapor from the air trapped inside.

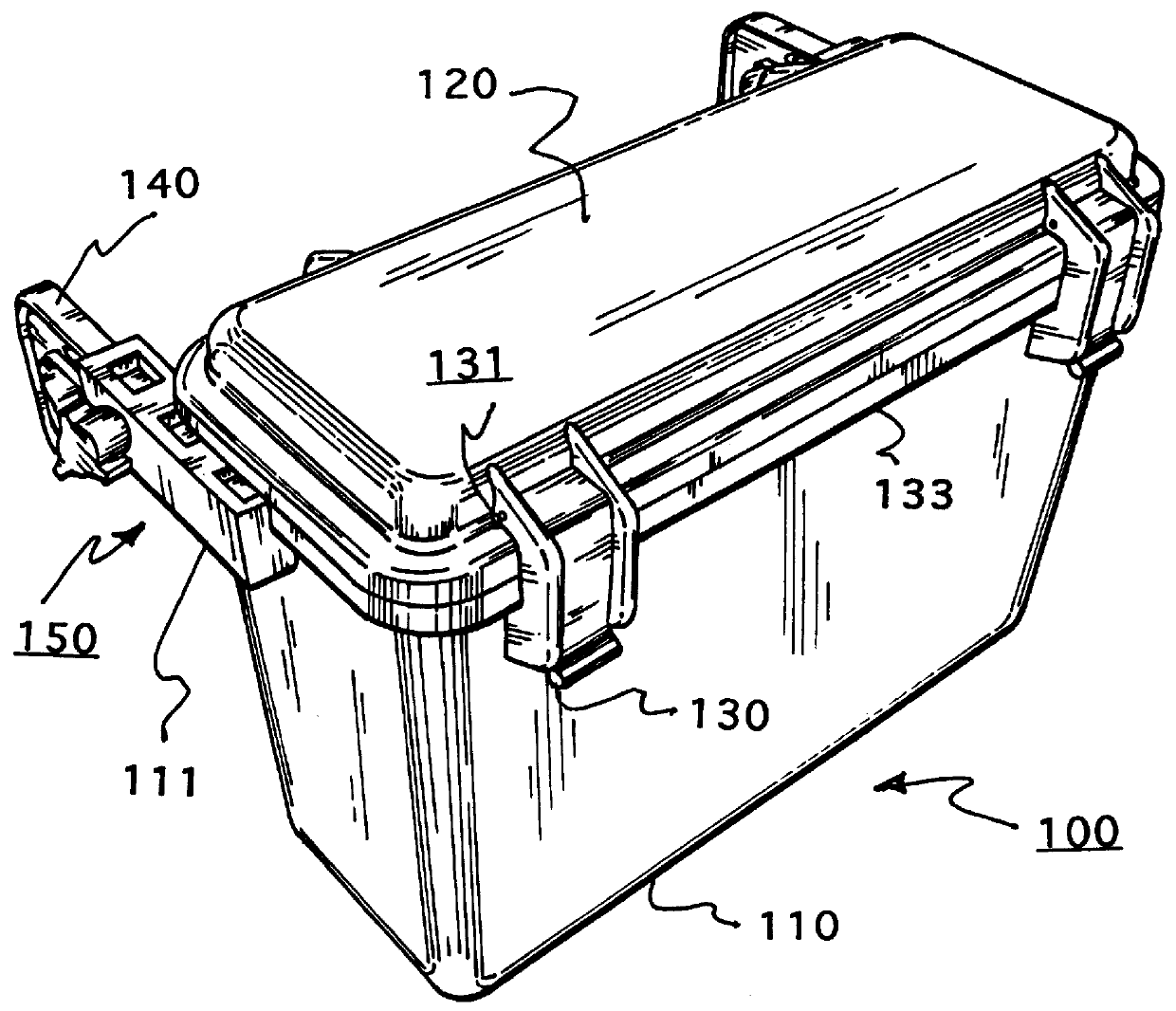

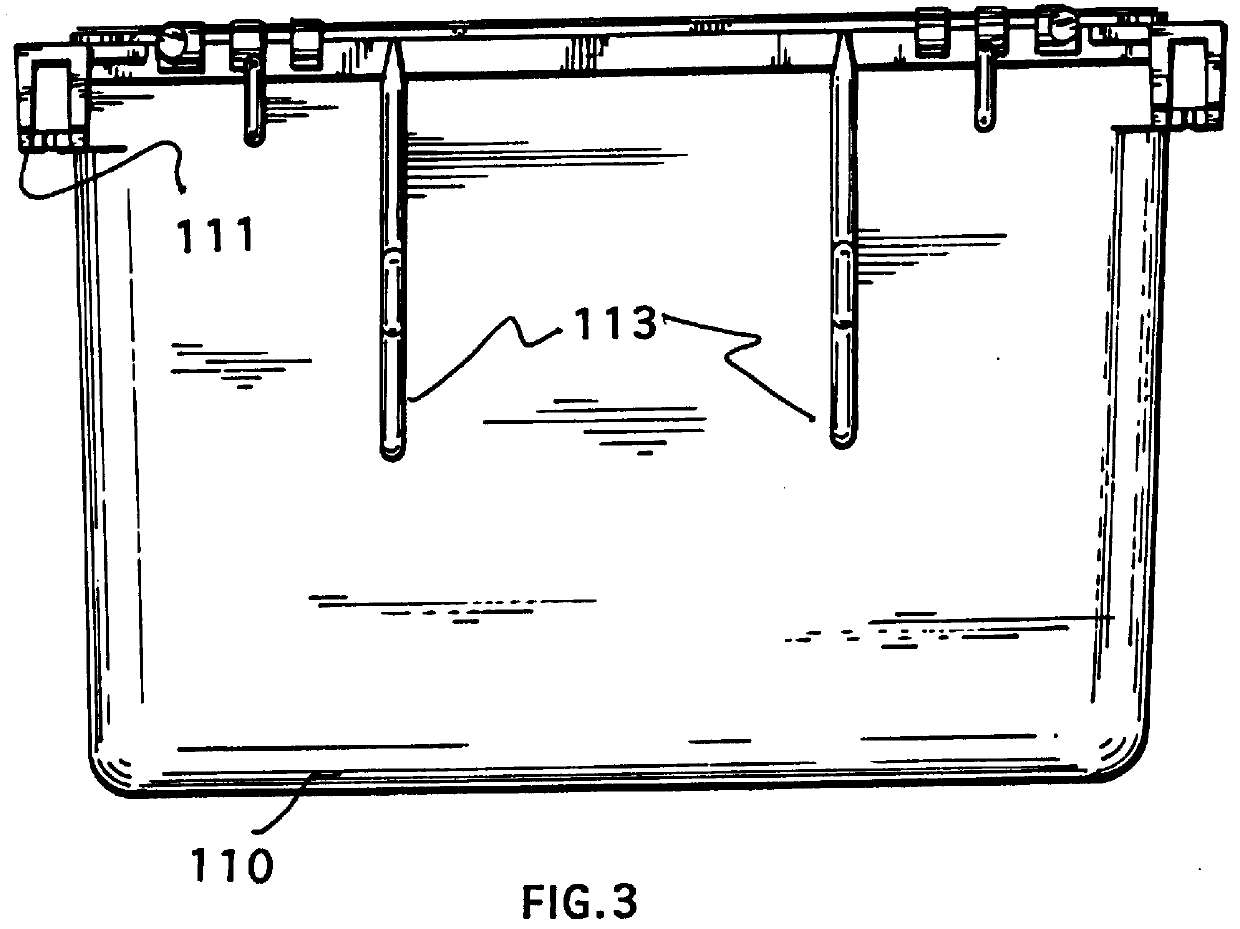

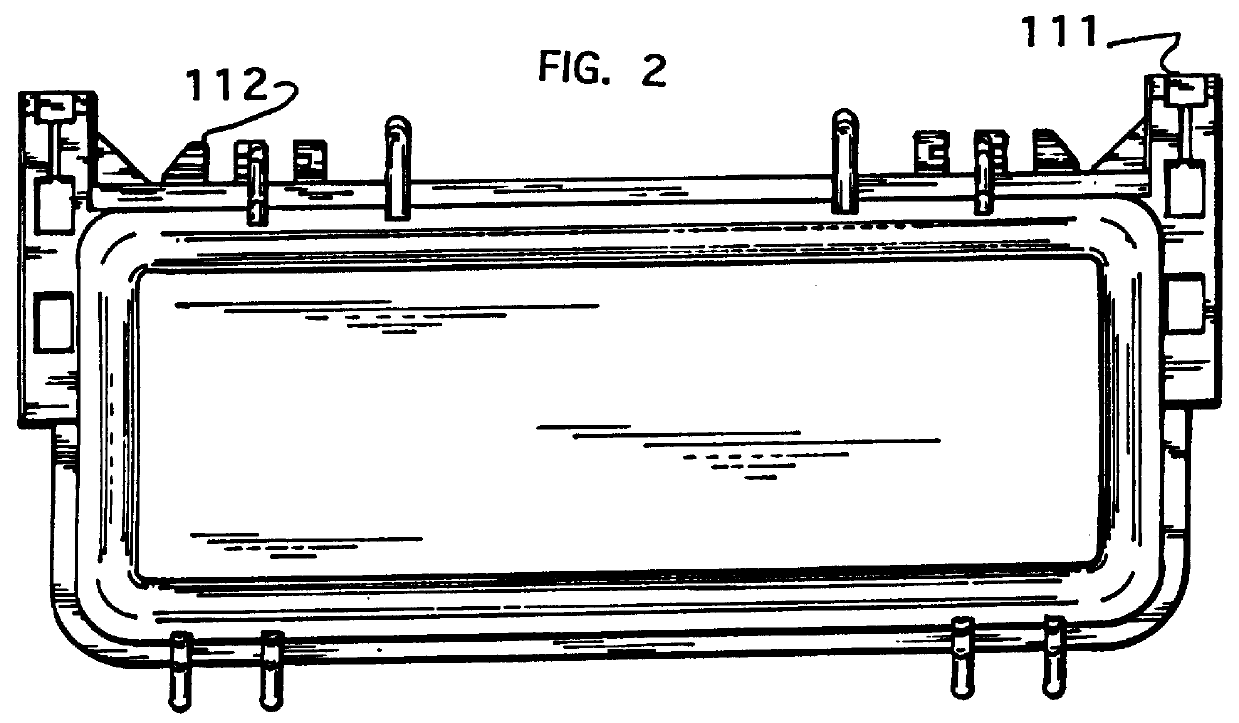

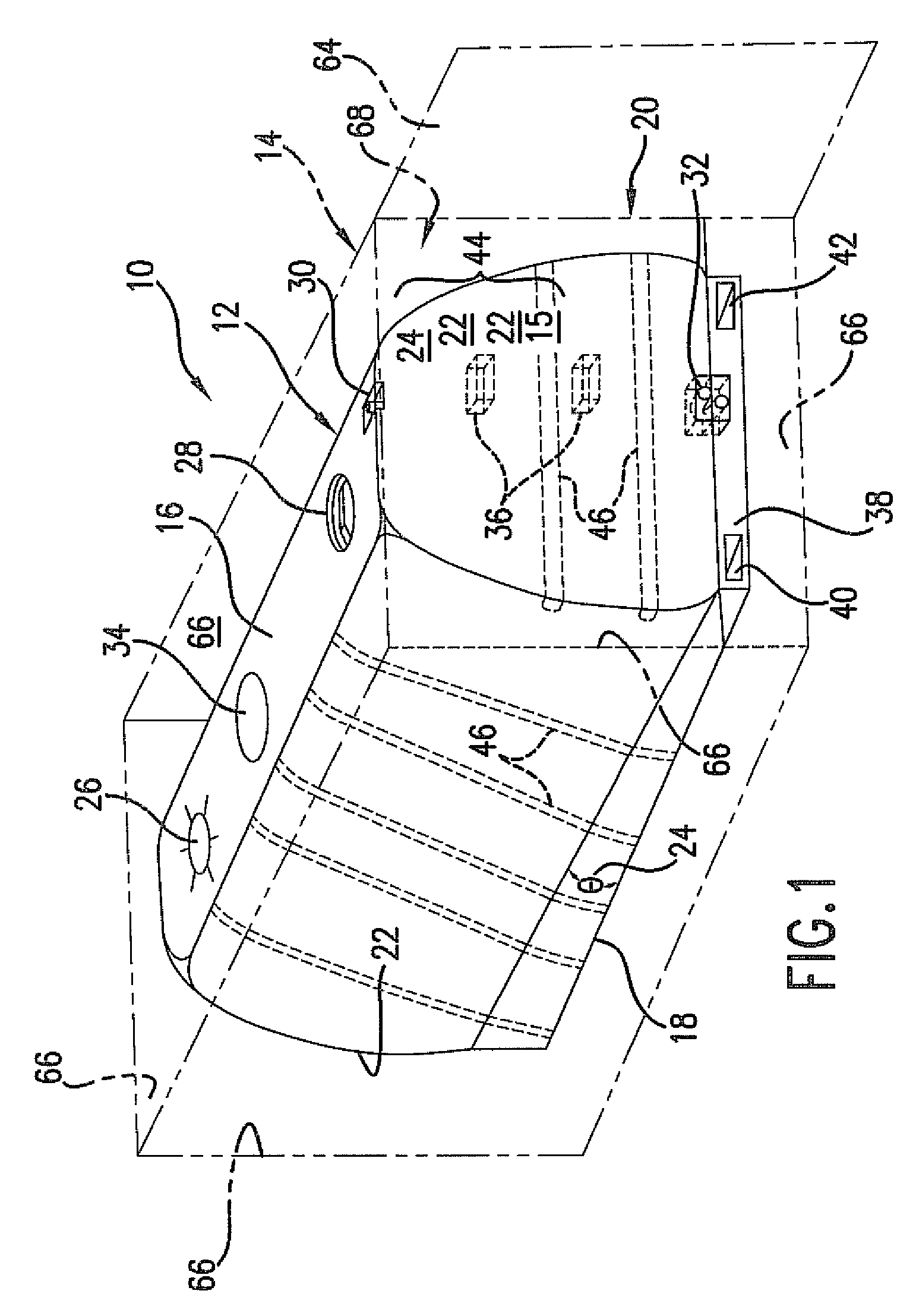

Gunwale attachable dry box for small watercraft

A dry storage box is held by a clamping device at a longitudinal location along the length of the small watercraft. Dry box provides water tight storage compartment with a hinged lid and latches for storing miscellaneous personal valuables and belongings. The clamped water tight box, in the event of capsize, remains secured to the gunwale, and thus valuables and belongings remain safe, dry and in one location. Incidentally provided are added buoyancy to the vessel in the event of a capsized condition, and when box is in normal use the longitudinal location allows free movement of the occupants about the small watercraft.

Owner:CLIFFORD PETER A

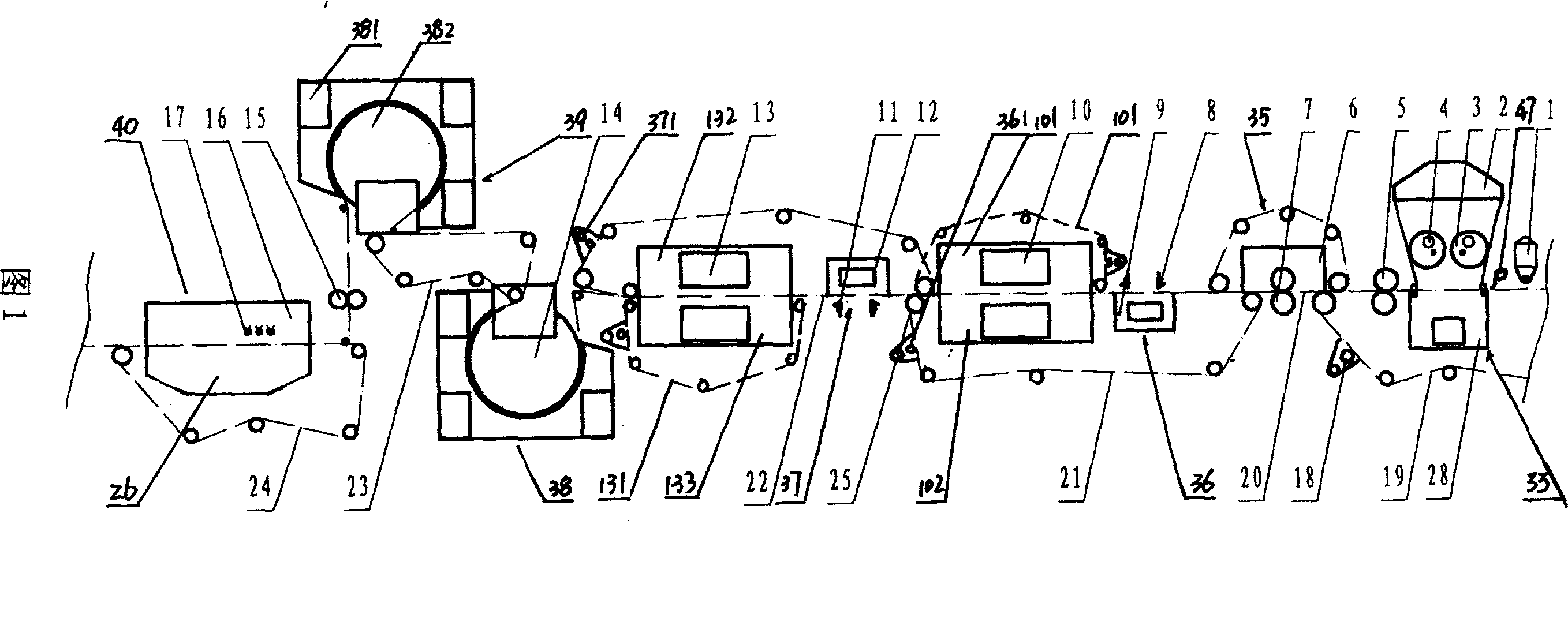

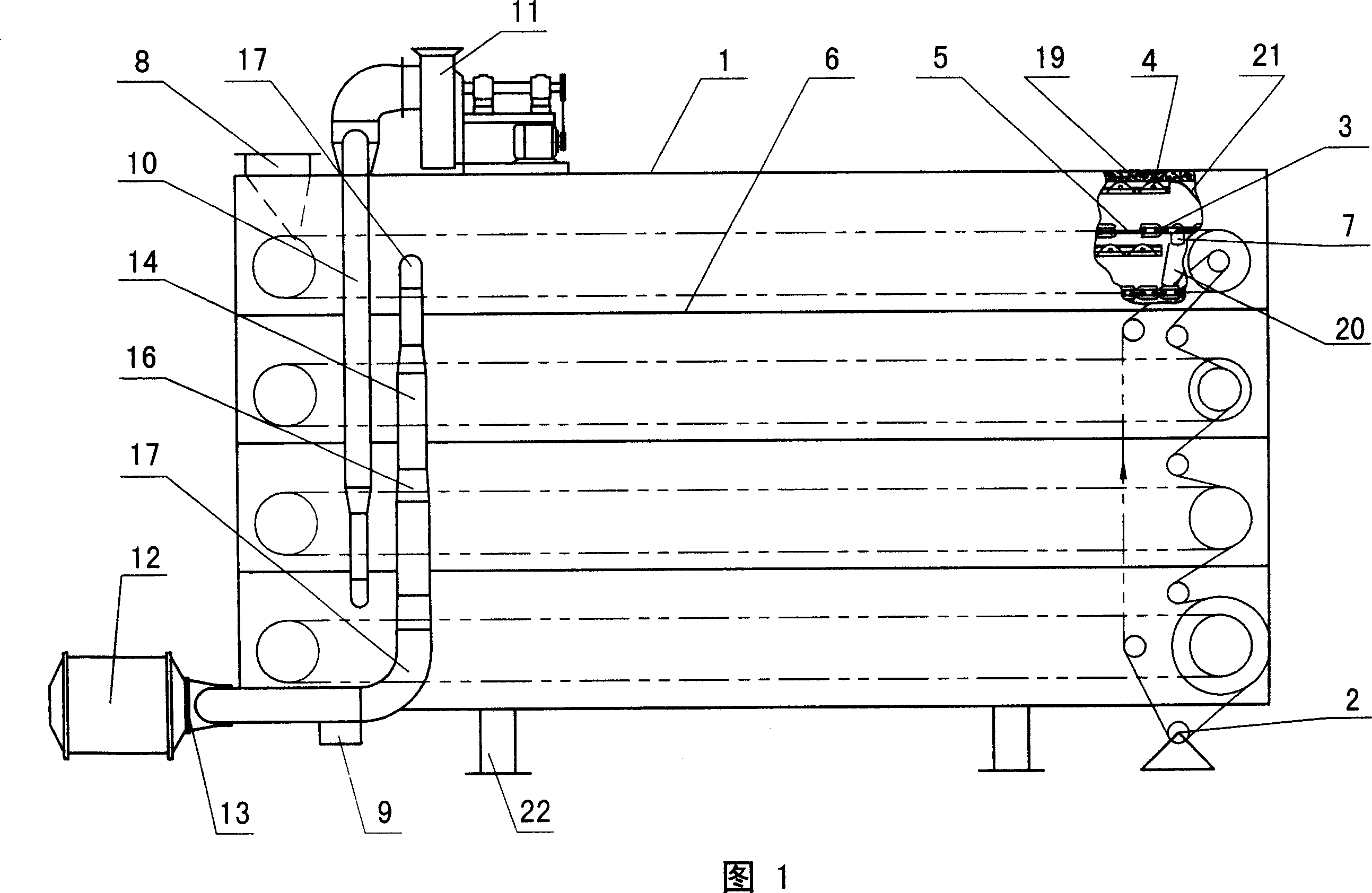

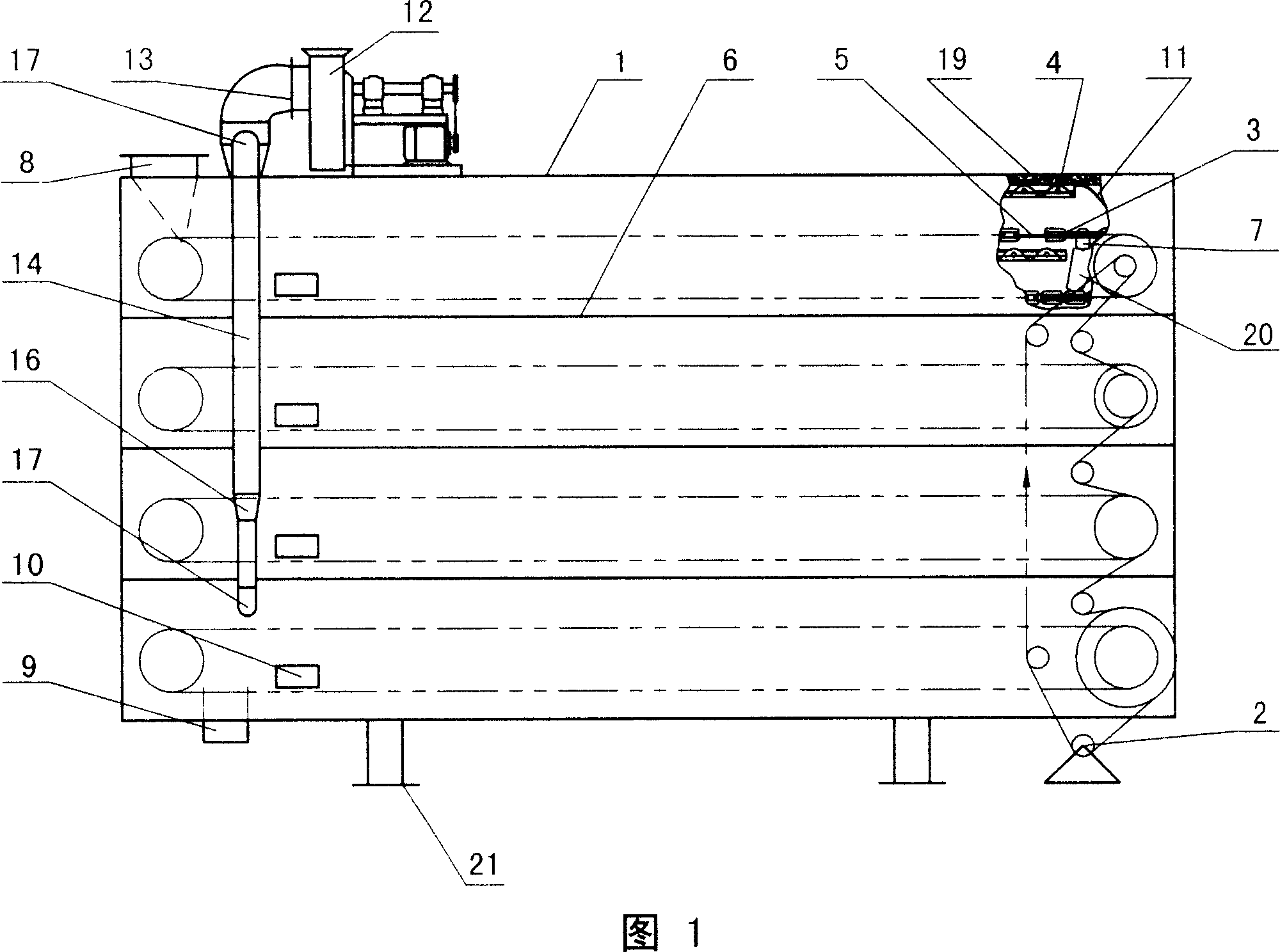

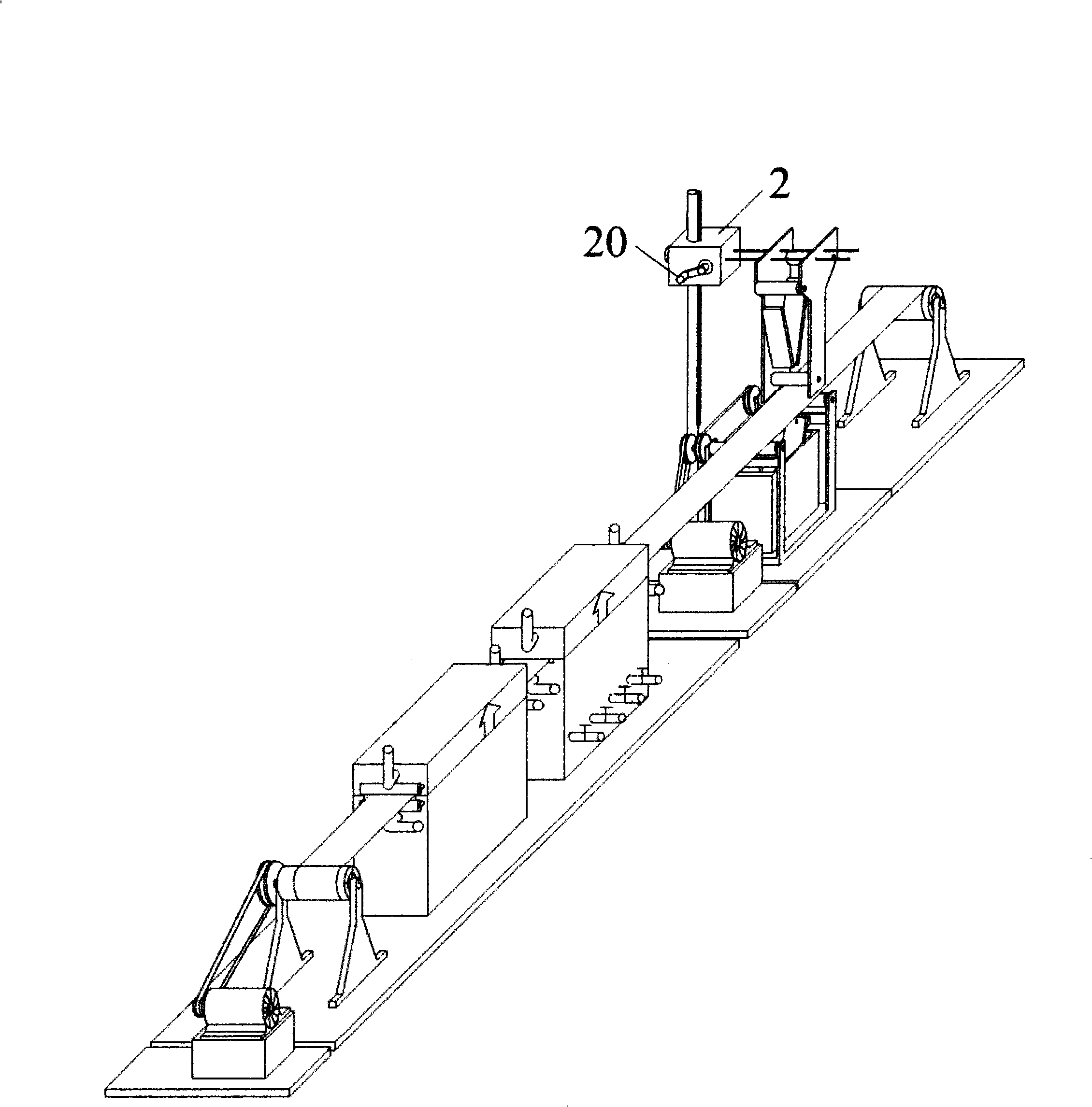

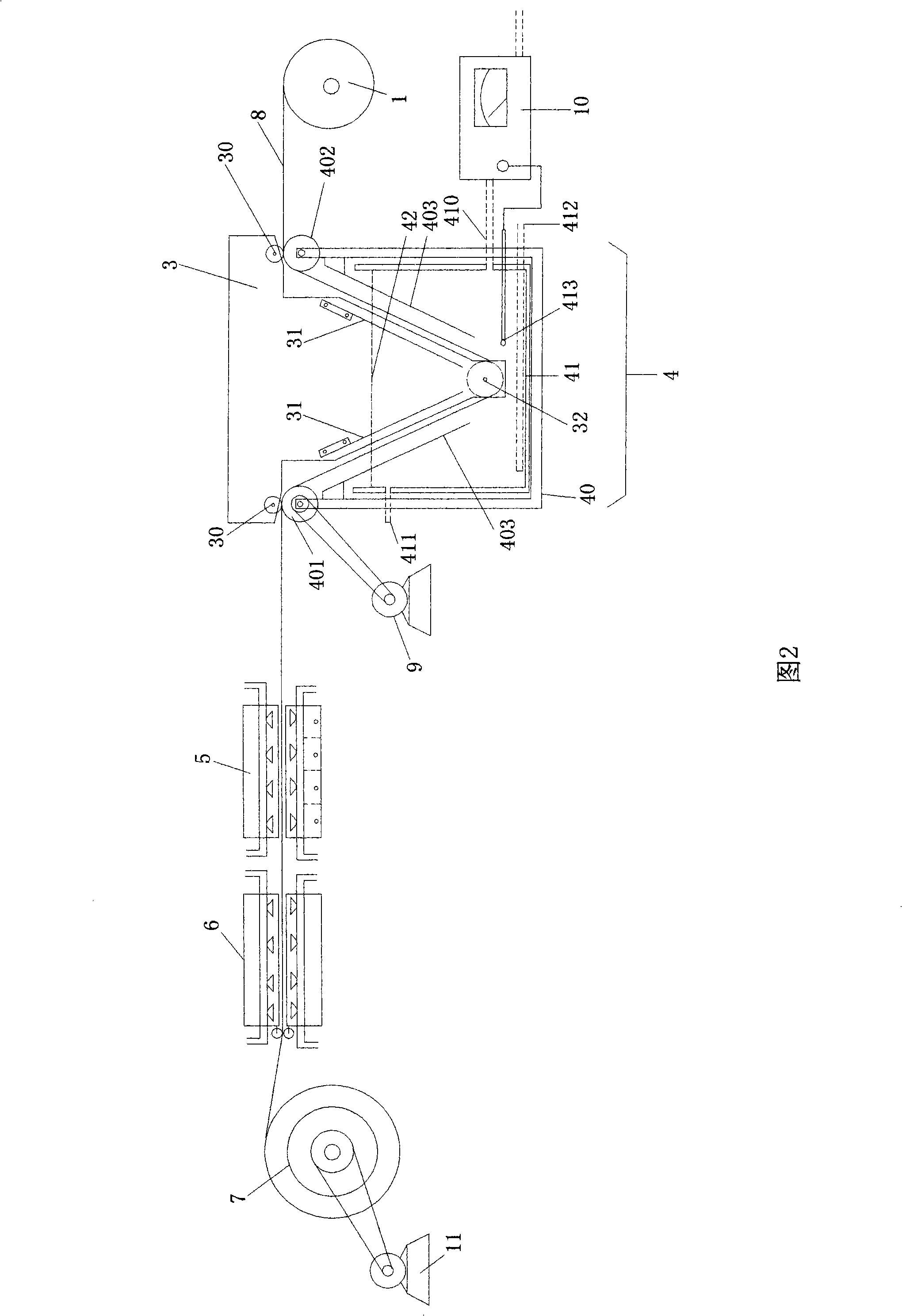

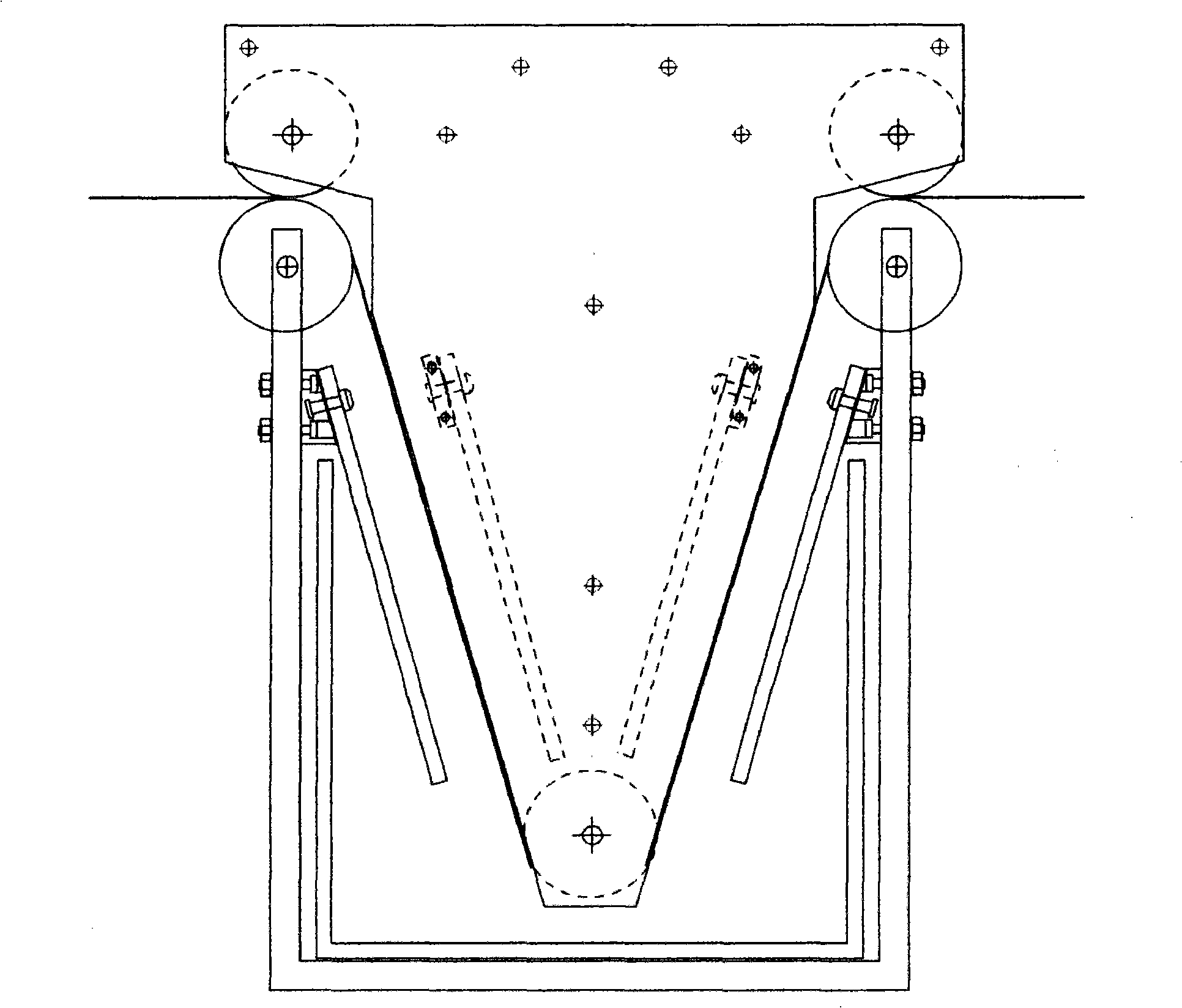

Dry-process papermaking machine through meshwork formed by airflow method

The present invention relates to an air-laying dry paper machine. It includes at least more then one forming device, sizing device, drying device and cooling device which are successively mounted on the machine frame from front to rear. Said sizing device includes at least more than two sizing devices and box type drying box. Between the forming device and sizing device an embossing device and pre-presing hot roller unit can be added, and between drying device and cooling device a calendaring device is added. Besides, it also includes fluff pulp fluffer, fibrids opening, conveying and metering device and powder additive device.

Owner:中丝(上海)新材料科技有限公司

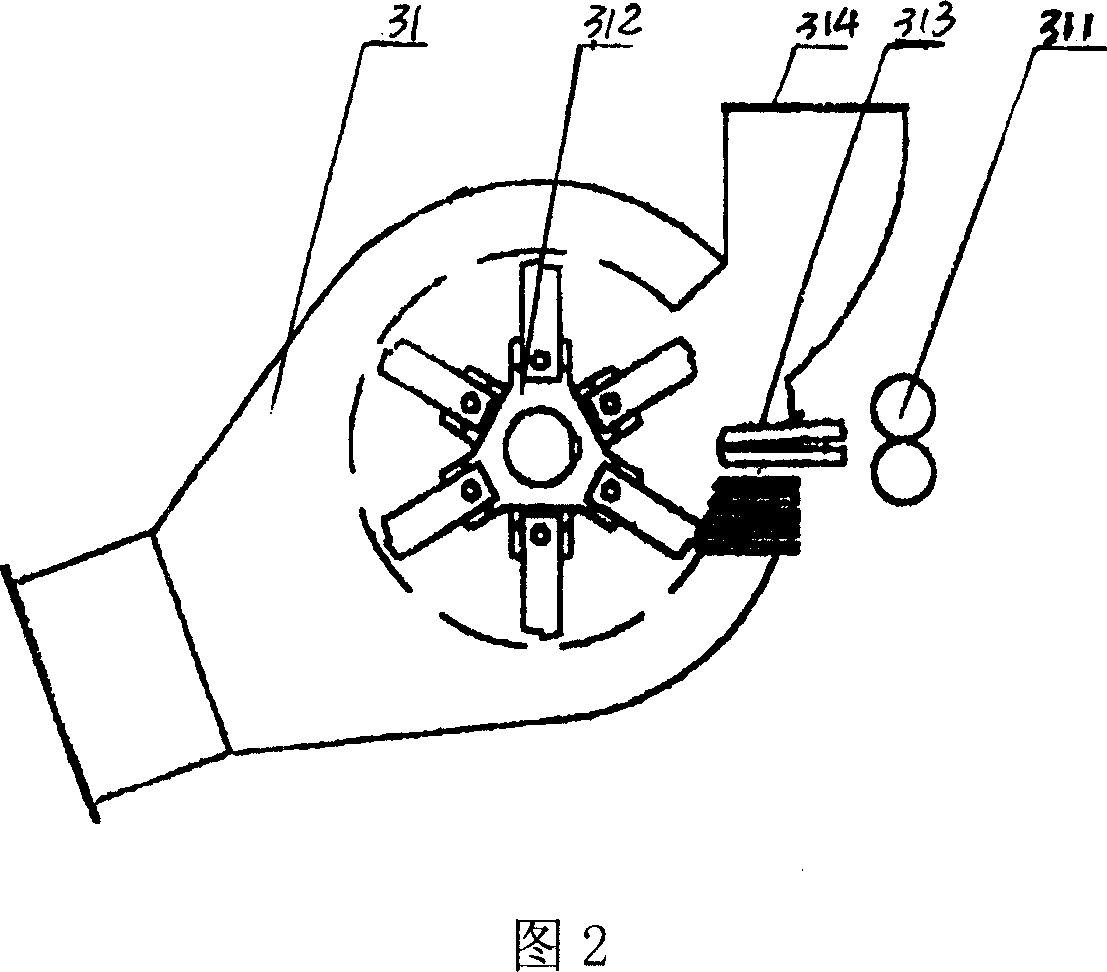

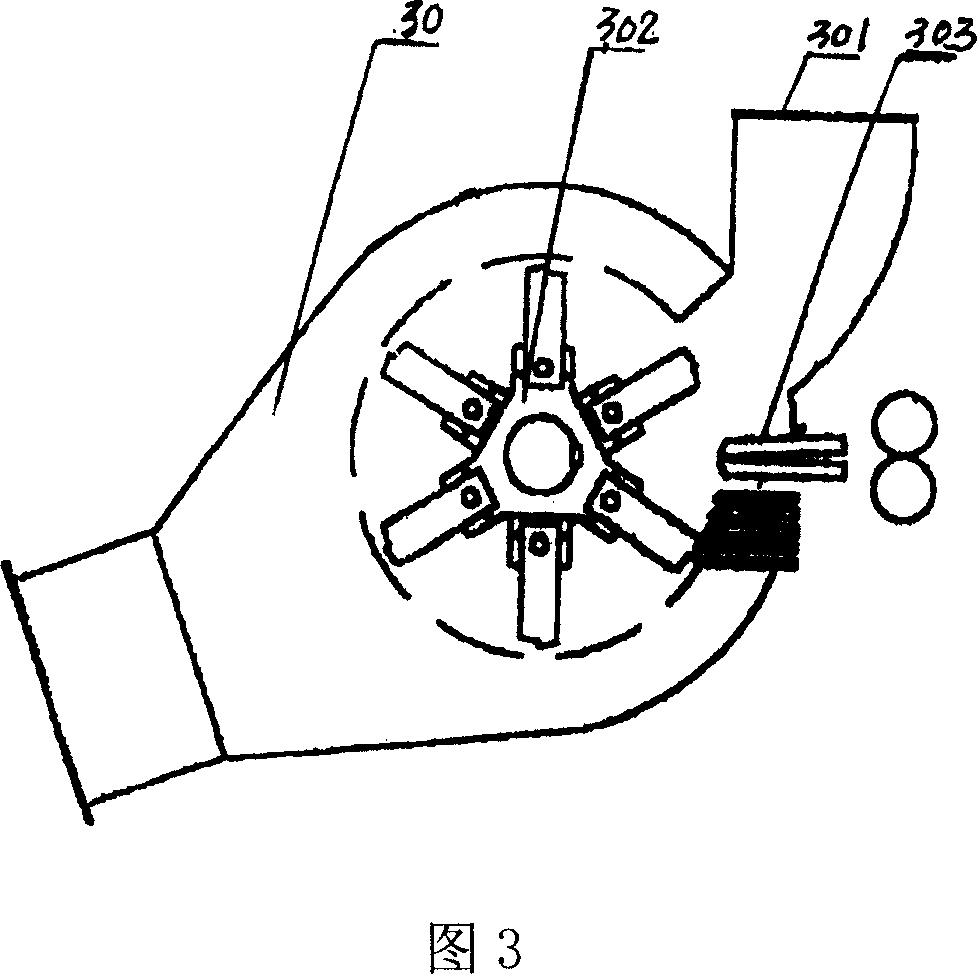

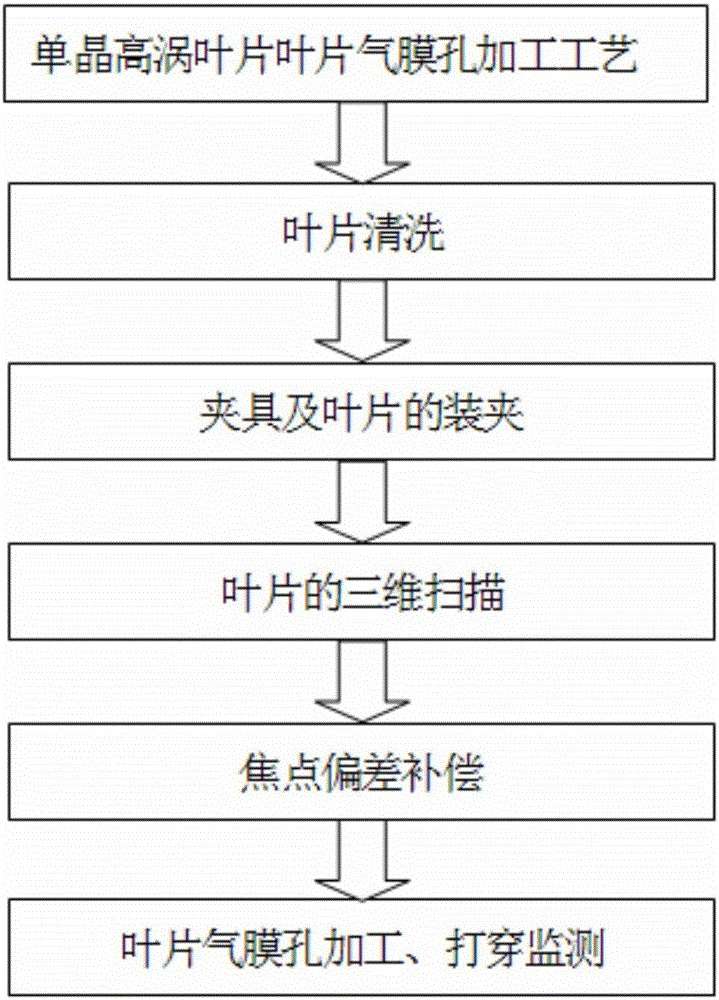

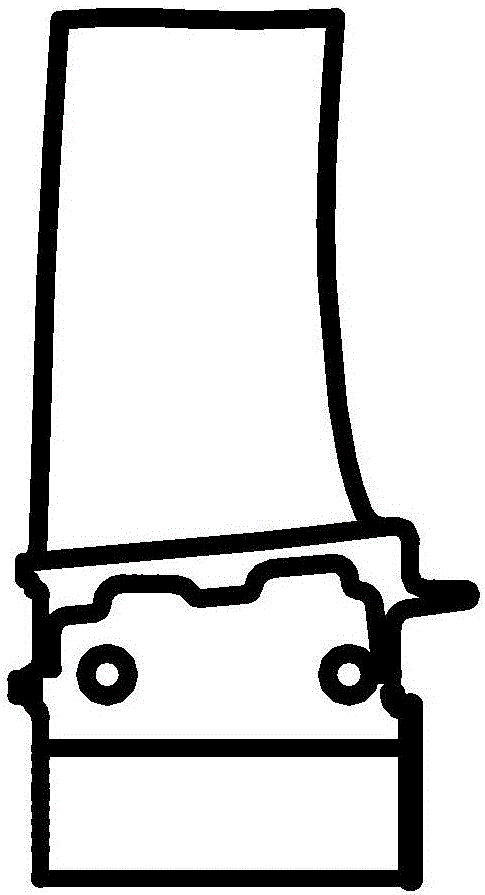

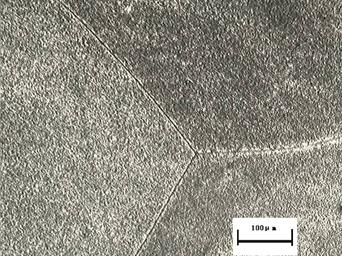

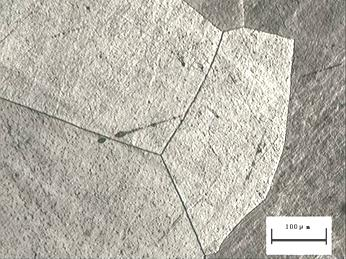

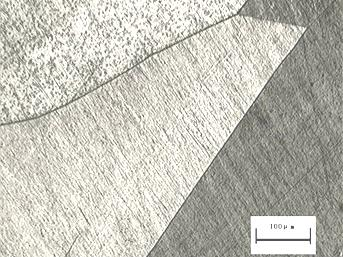

Low-damage processing method of film holes in single crystal high-pressure-turbine hollow blade of aircraft engine

ActiveCN106583949AExtend the life cycleExtended processing cycleLaser beam welding apparatusAviationEngineering

The invention provides a low-damage processing method of film holes in a single crystal high-pressure-turbine hollow blade of an aircraft engine. The low-damage processing method comprises the following steps: wiping the surface of the blade through degreasing cotton with absolute alcohol; transferring into a drying box to dry; arranging a clamp on a machine table, and aligning; assembling the dried blade on the clamp and locking; presetting scanning system parameters; scanning the blade; saving axis moving coordinate value of each hole to be processed under an automatically-generated machine coordinate system as a *.xls file; importing and generating a hole position file; performing compensative correction on the deviation value of a focus position of the hole to be processed; and setting the optimized laser processing technological parameters through a main processing interface. With the adoption of the low-damage processing method, the processed hole is outstanding in quality; a remelting layer, microcacks and recrystallization can be avoided after the single crystal material is processed, so that subsequent processing can be saved, and as a result, the fatigue life and the processing cycle of the blade can be prolonged and improved; the ablation threshold of the single crystal material can be effectively reduced; the recrystallization of the single crystal material can be avoided.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

Refining agent for copper and copper alloy smelting

A refining agent for copper and copper alloy smelting is characterized in that the components of the refining agent are 5 to 15 percent by weight of calcium fluoride, 1 to 5 percent by weight of silicon dioxide, 1 to 5 percent by weight of titanium dioxide, 2 to 10 percent by weight of sodium fluosilicate, 40 to 60 percent by weight of sodium carbonate and the balance sodium tetraborate; the refining agent materials are weighed according to a formula, uniformly mixed, placed into a drying box and dried under 120 DEG C for an hour, and a metallographic inlaying machine is used for manually pressing the refining agent into the shape of a sheet. The refining agent has the advantages that the refining agent is integrated with the functions of deoxidization, degasification, impurity removal and the like, and has strong adsorbing, dissolving and combination slagging capabilities; the surface tension between the refining agent and metal melt is high, the refining agent can promote molten slag to float up, so that the molten slag can be better separated from molten metal, and thereby the effects of refining, impurity removal and melt purification are achieved; the refining agent has high chemical stability and thermal stability, does not have the corrosion effect on metal and the furnace lining, and cannot chemically react with the molten metal, the refining agent and the molten metal cannot be melted into each other as well, and thereby the original composition and properties of alloy are guaranteed; and the refining agent does not have public hazard, is safe and environment-friendly, is convenient to use, and is cheap.

Owner:NANCHANG UNIV

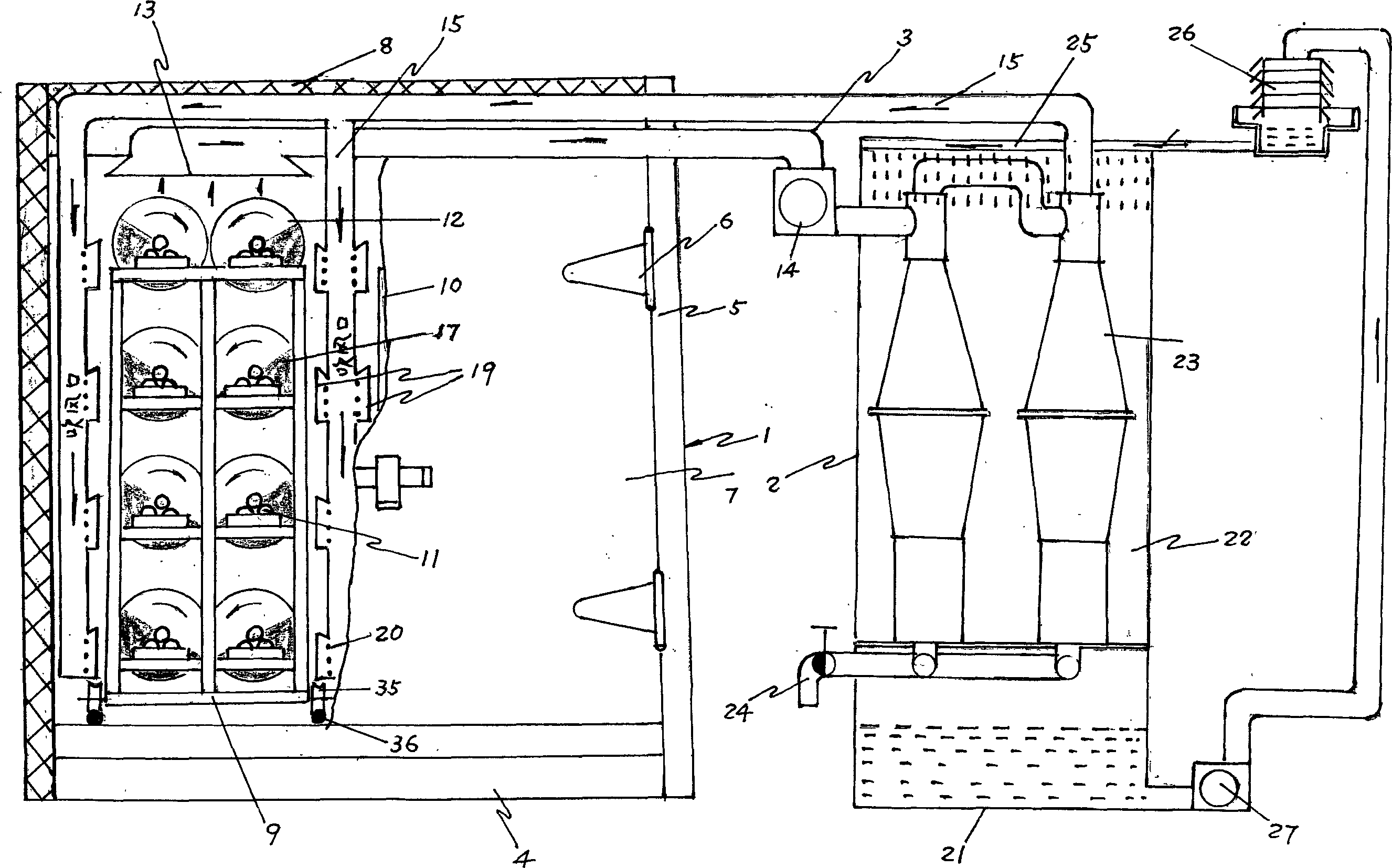

Composition heating type vegetable dewatering device

InactiveCN101053339ASolve the yellowingSolve the characteristicsFruits/vegetable preservation by dehydrationStraight tubeEngineering

The present invention provides a composition heating type vegetable dewatering device comprising a drying box, transmission device, conveying device and irradiating device, wherein the drying box constituted by the multi-layer, each layer set a set of conveying device driven by transmission device, and forming groove type material channel, above each channel set far infrared irradiating device, at the top of drying box has a feed inlet, at the bottom of drying box has a material outlet, there is air inducing vent at the upper wall of each layer, it sealing connects with fan by air inducing tube. Its characteristics are that each layer of the lower lateral wall of box is equipped with air inlet, wind supply tube sealing connects with heating device, the wind supply tube comprising flange and unequal-diameter straight tube, connecting tube connected with each layer, variable diameter tube and elbow, connecting tube diameters are reduced from top to bottom. The present invention adopts far infrared and hot wind composition heating method, solving the problem only when using far infrared heating surface materials roast will be easier yellow, and improving the quality of dried vegetables.

Owner:SHANDONG UNIV OF TECH

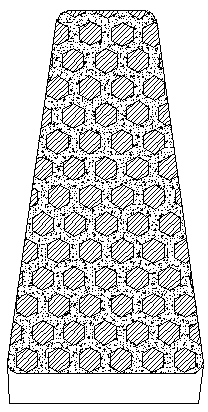

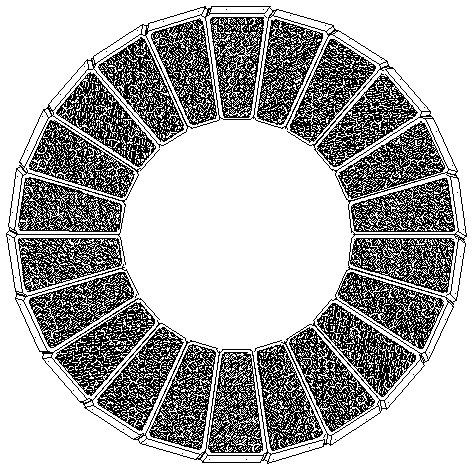

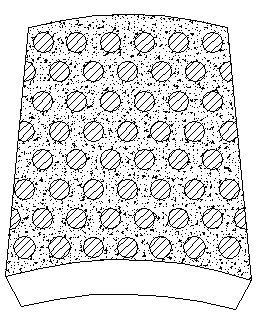

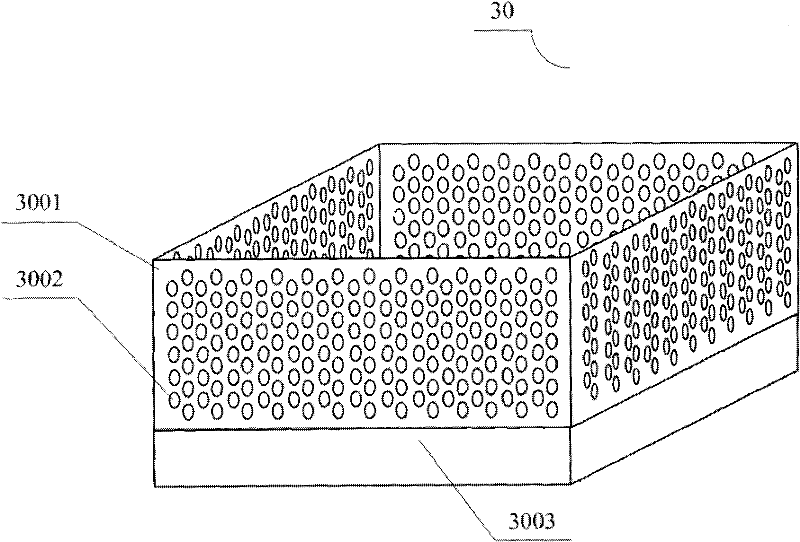

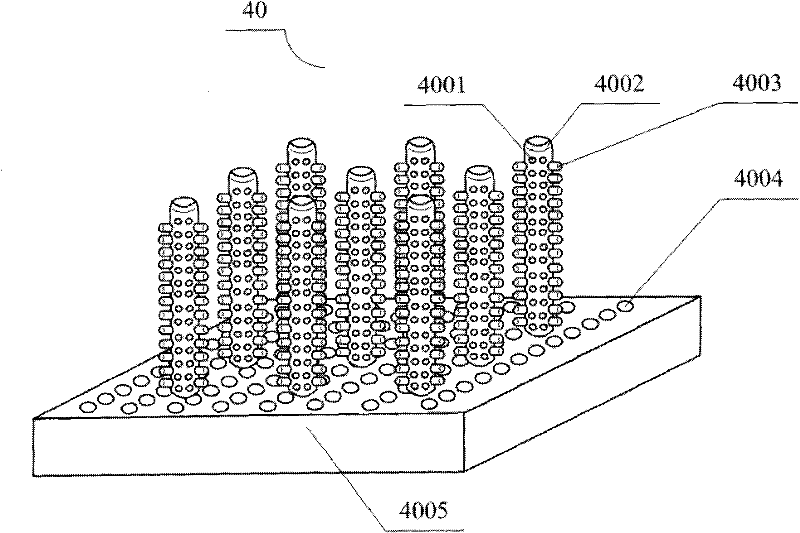

Ceramic grid enhanced metal matrix composite perform and preparation method thereof

The invention discloses a ceramic grid enhanced metal matrix composite perform and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing ceramic particles with the particle sizes of 8-30 meshes and self-fluxing alloy powder in polyvinyl alcohol to obtain a mixture; filling the mixture in a grid cavity, prepressing for preparing ceramic grids, filling the self-fluxing alloy powder into grid holes after the grids leave from a mold, wherein the monolithic material is pressed with 100-300 kilogram force, molding and demolding, placing and drying a biscuit and a mold cavity bottom plate in a 150 DEG C drying oven for 2 hours; placing the dried biscuit and the mold cavity bottom plate in a vacuum furnace, sintering for 30-90 minutes under the conditions that the temperature is 1000-1300 DEG C, and the vacuum degree is 0.1 Pa, and cooling and discharging to obtain the ceramic grid enhanced metal matrix composite perform. The ceramic grid enhanced metal matrix composite perform prepared by the method has the advantages of high density, uniform distribution of ceramic particles, good wear resistance and high grinding efficiency.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

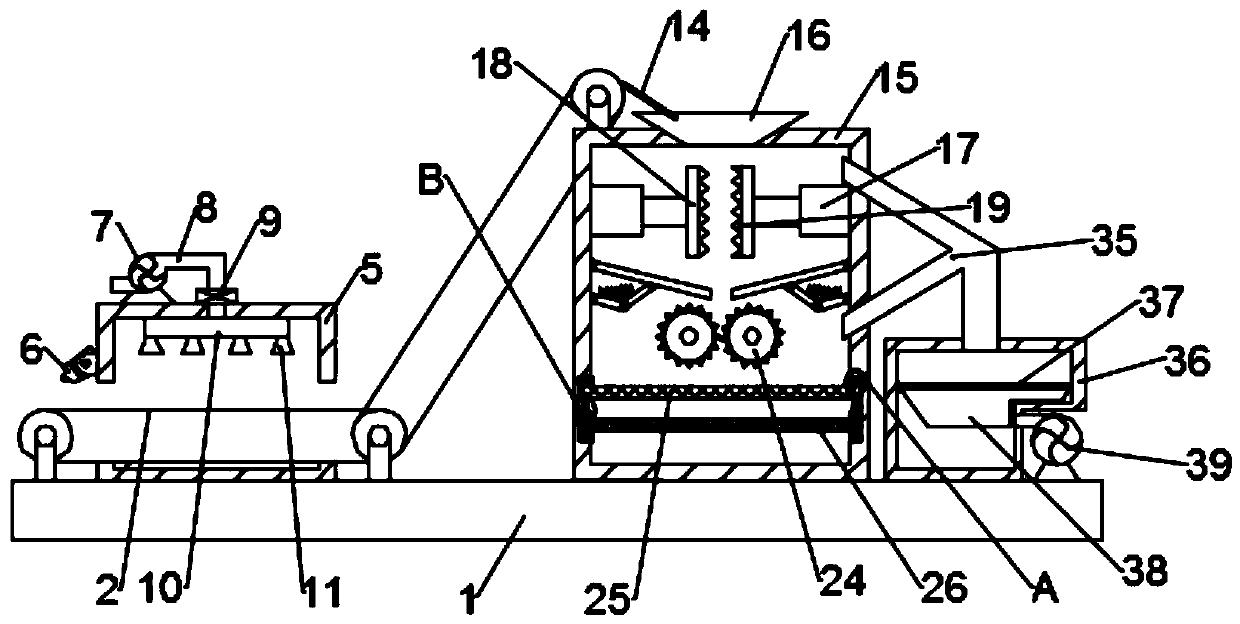

Construction waste treatment device for environmental protection

The invention relates to the technical field of environmental protection, and particularly discloses a construction waste treatment device for environmental protection. The construction waste treatment device comprises a baseplate, and the upper surface of the baseplate is provided with a conveyor mechanism, a crushing box and a dust collection box from left to right in sequence; the conveyor mechanism comprises a wet material conveyor belt and a dry material conveyor belt, and the wet material conveyor belt and the dry material conveyor belt are connected with a feeding conveyor belt separately; the feeding conveyor belt is connected with the crushing box, and the wet material conveyor belt penetrates through a drying box; a drying mechanism is arranged in the drying box; double crushingmechanisms are arranged in the crushing box, and screening mechanisms are arranged below the double crushing mechanisms; and the crushing box is connected with the dust collection box through a dust suction pipe. The construction waste treatment device is specially used for treatment of waste left in constructional engineering, especially solid waste, such as broken bricks and concrete, and the treated construction waste can be recycled; not only can the environment be protected, but also the resources can be saved; and the waste is avoided.

Owner:安徽砼筑新材料科技有限公司

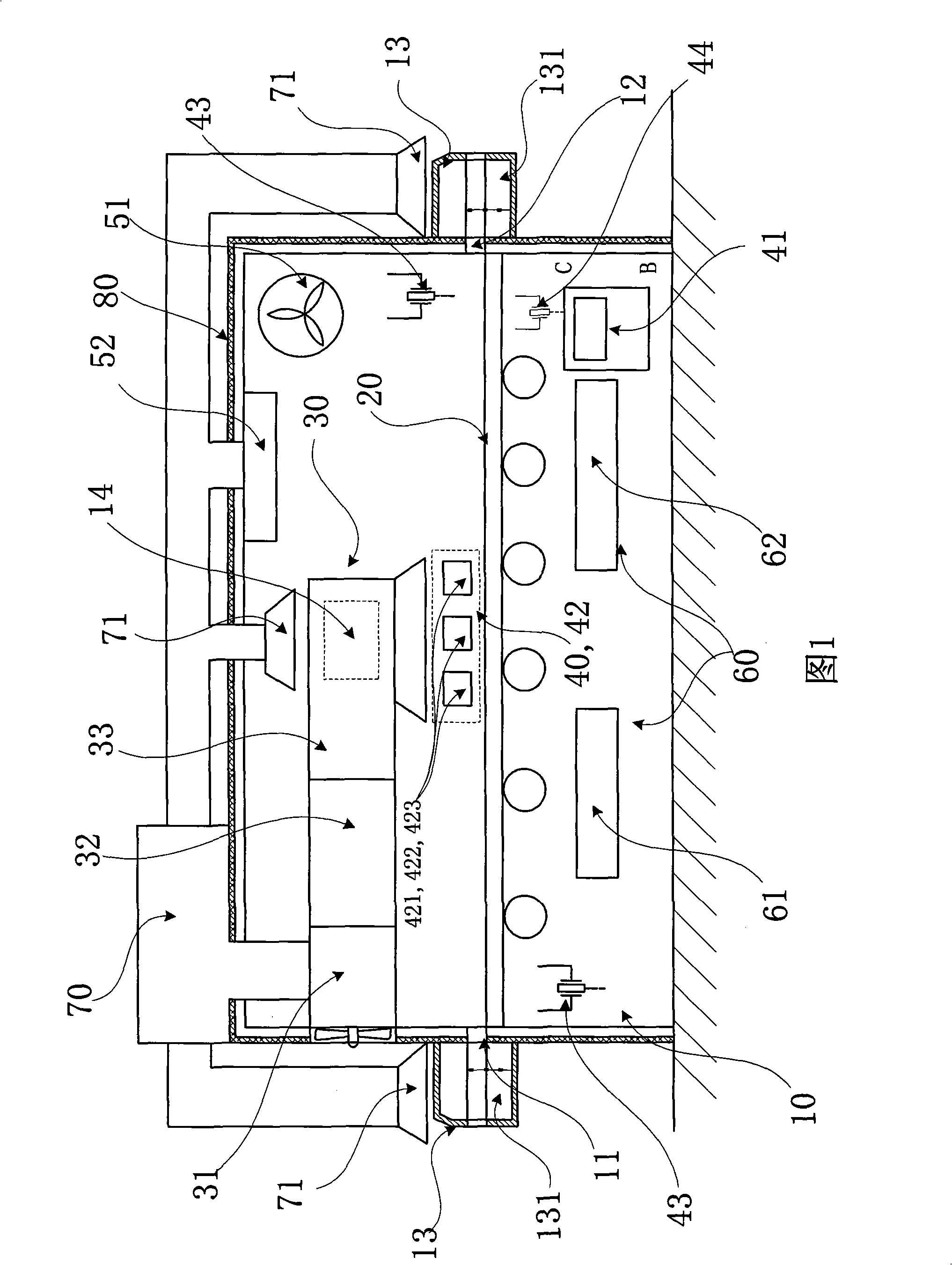

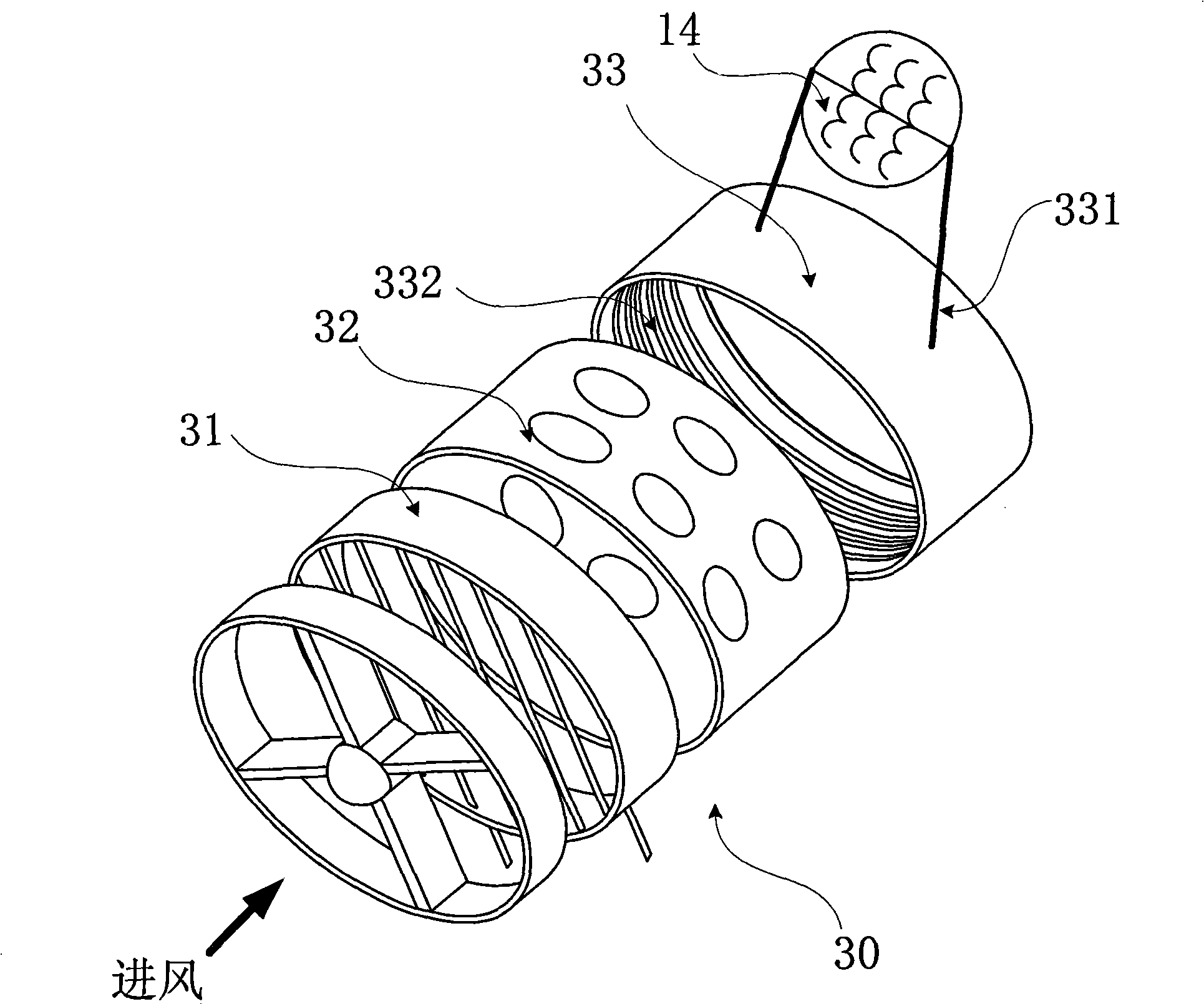

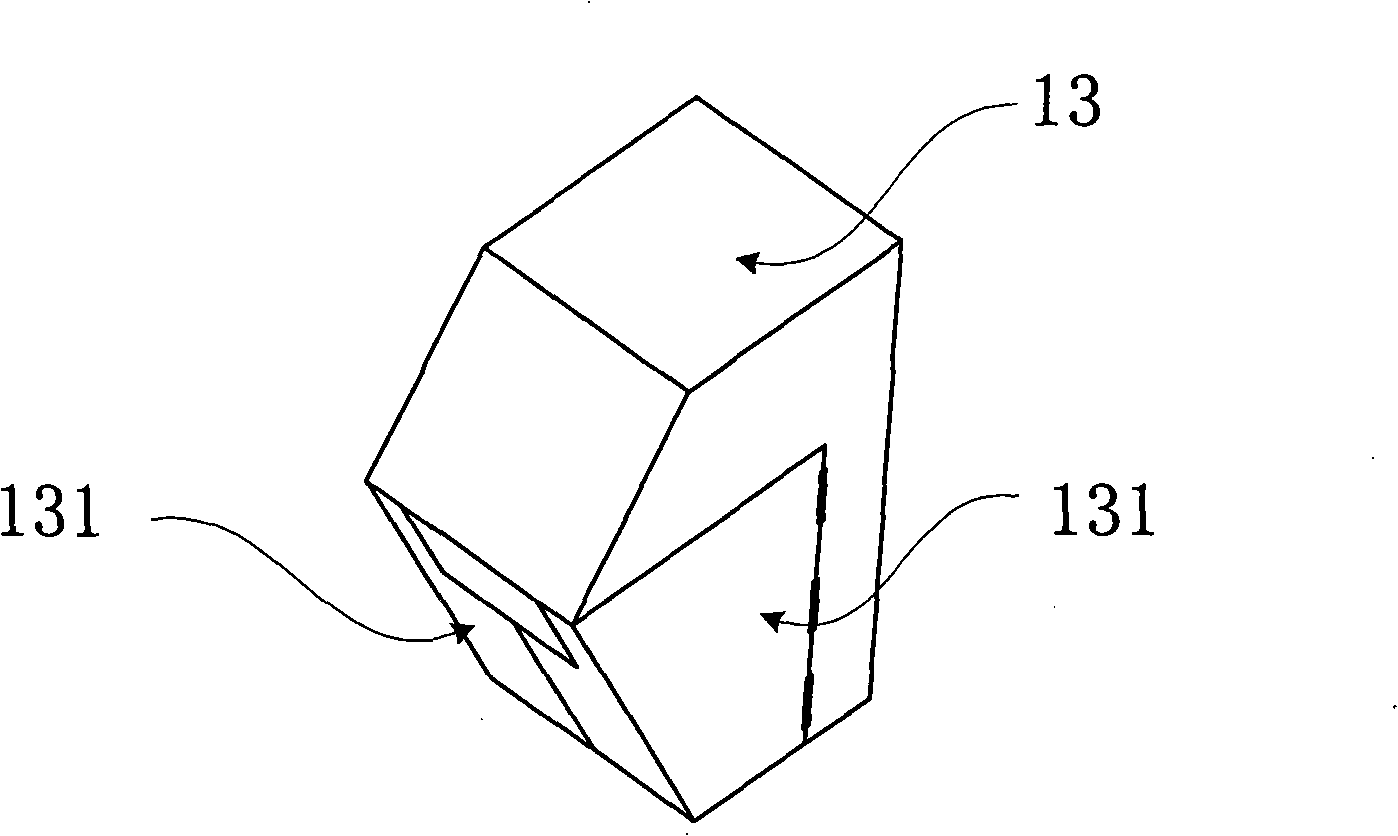

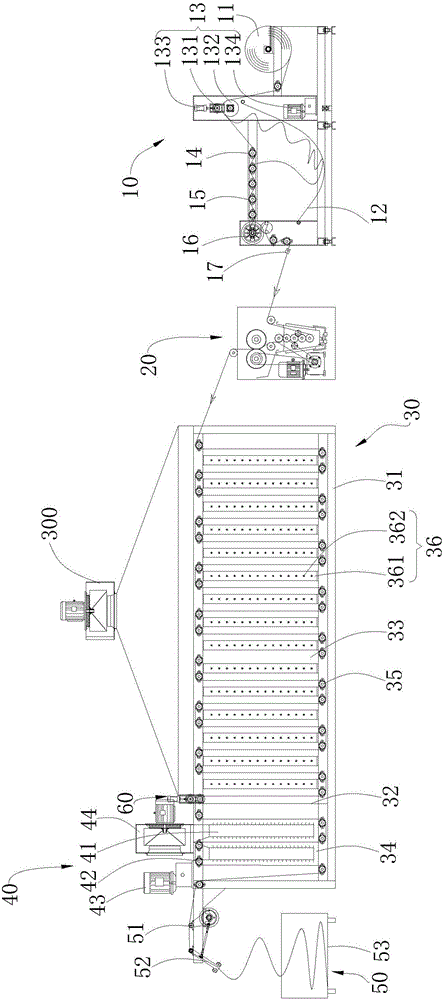

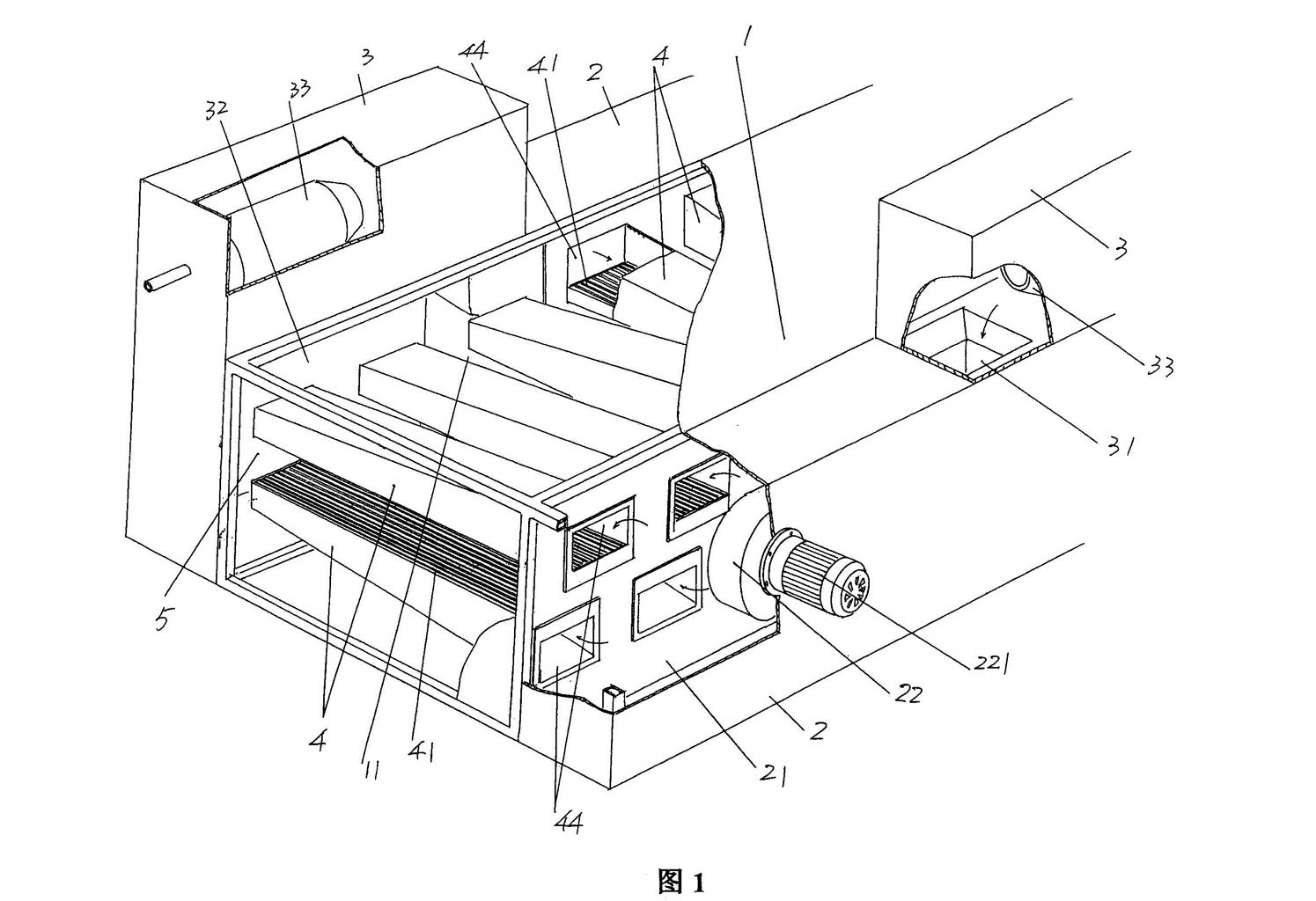

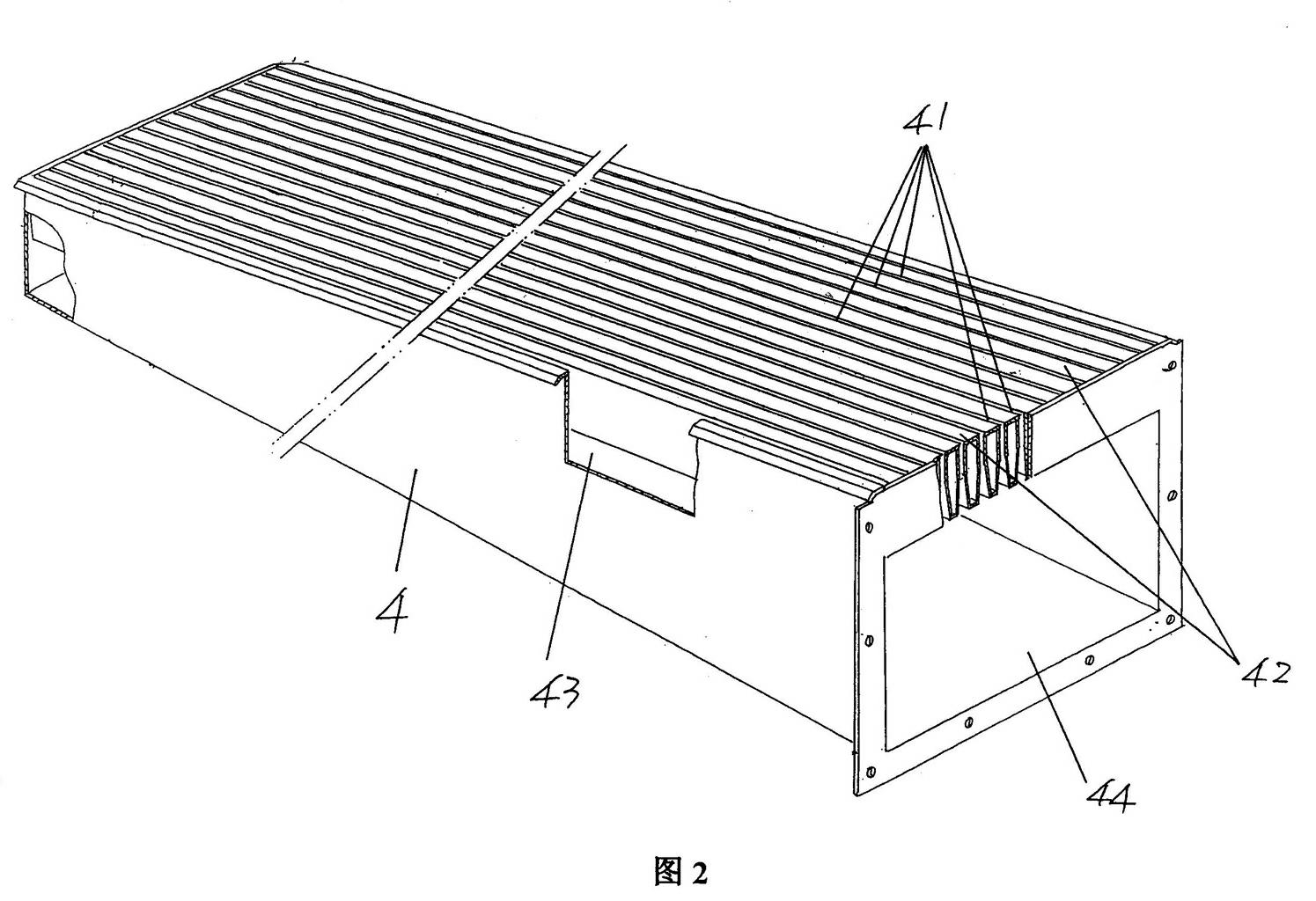

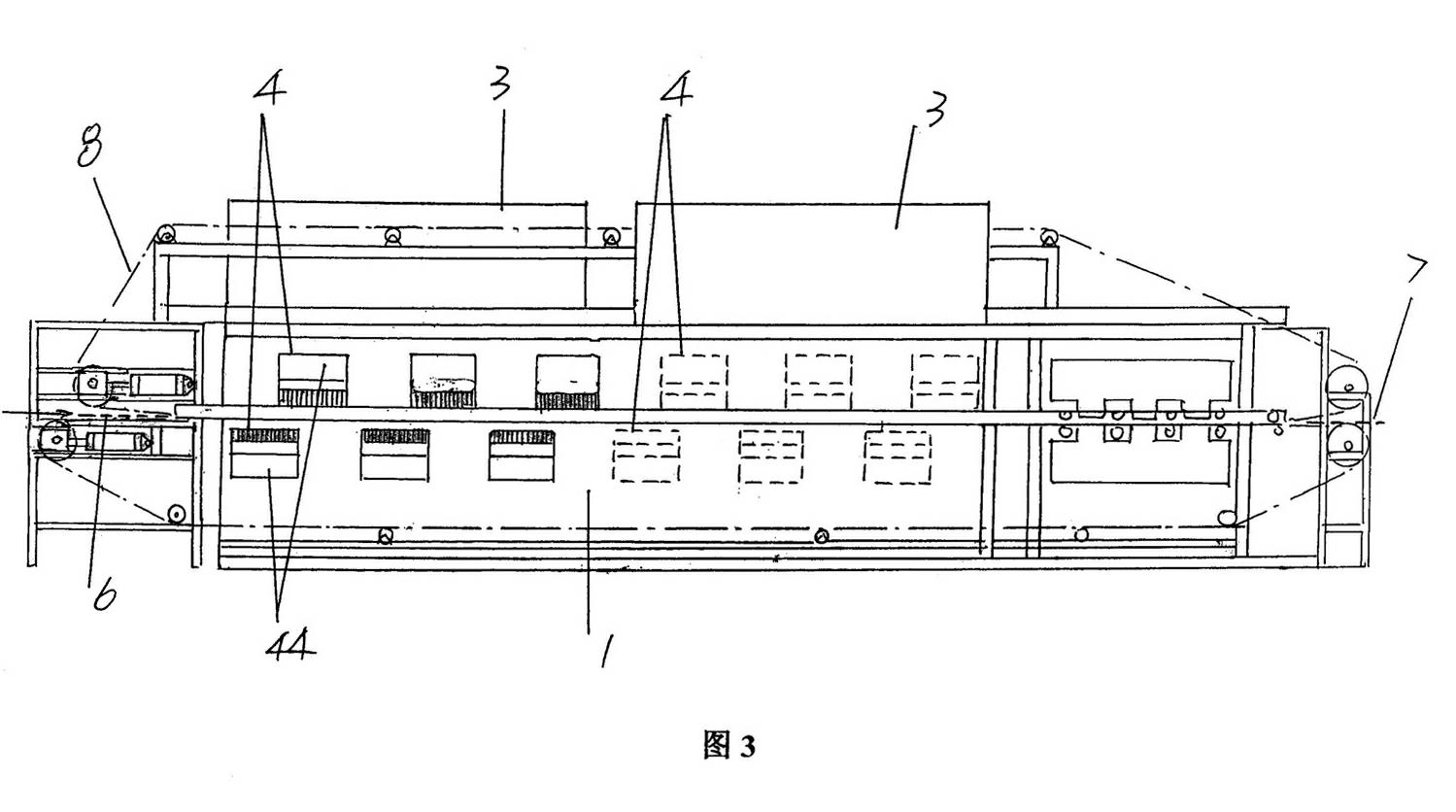

Drying apparatus of textile printing machine

InactiveCN101348032AImprove thermal efficiencySave electricityPrinting press partsTextile printerLow voltage

A drying device for a textile printing machine comprises a drying box body (10), a material transmission device (20), a main heating device (30), a control system (40) and an air supply system (50); wherein, the main heating device (30) comprises a heat pump heating unit (31), an electromagnetic wave heating unit (32) and a low-voltage heating unit (33), which are respectively responsible for the heat supply of the areas of 0-80 DEG C, 80-120 DEG C and above 120 DEG C; the voltage of low-voltage heating is not larger than 80V. Furthermore, the drying device further comprises a waste heat recovery device (70) and an insulating layer (80). After adopting the technical proposal, the novel drying device is characterized by high heat efficiency, electric energy saving and small heat loss and has the advantages of reducing production cost and protecting the environment.

Owner:杨栋 +1

Cocurrent induced draft far infrared vegetable dehumidifier

The cocurrent induced draft far infrared vegetable dehumidifier includes drying box, driving device, conveying device and radiating device. The drying box consists of several layers, each layer is provided with one conveying device driven with one separate driving device to constitute channel material passage, each of the passage is provided with one far infrared radiating device, and the drying box is provided with material inlet in the top and discharge port in the bottom. The present invention features that each of drying box layers is provided with air inlet and induced draft port connected to the blower hermetically through induced draft pipe. The present invention has excellent drying effect.

Owner:SHANDONG UNIV OF TECH

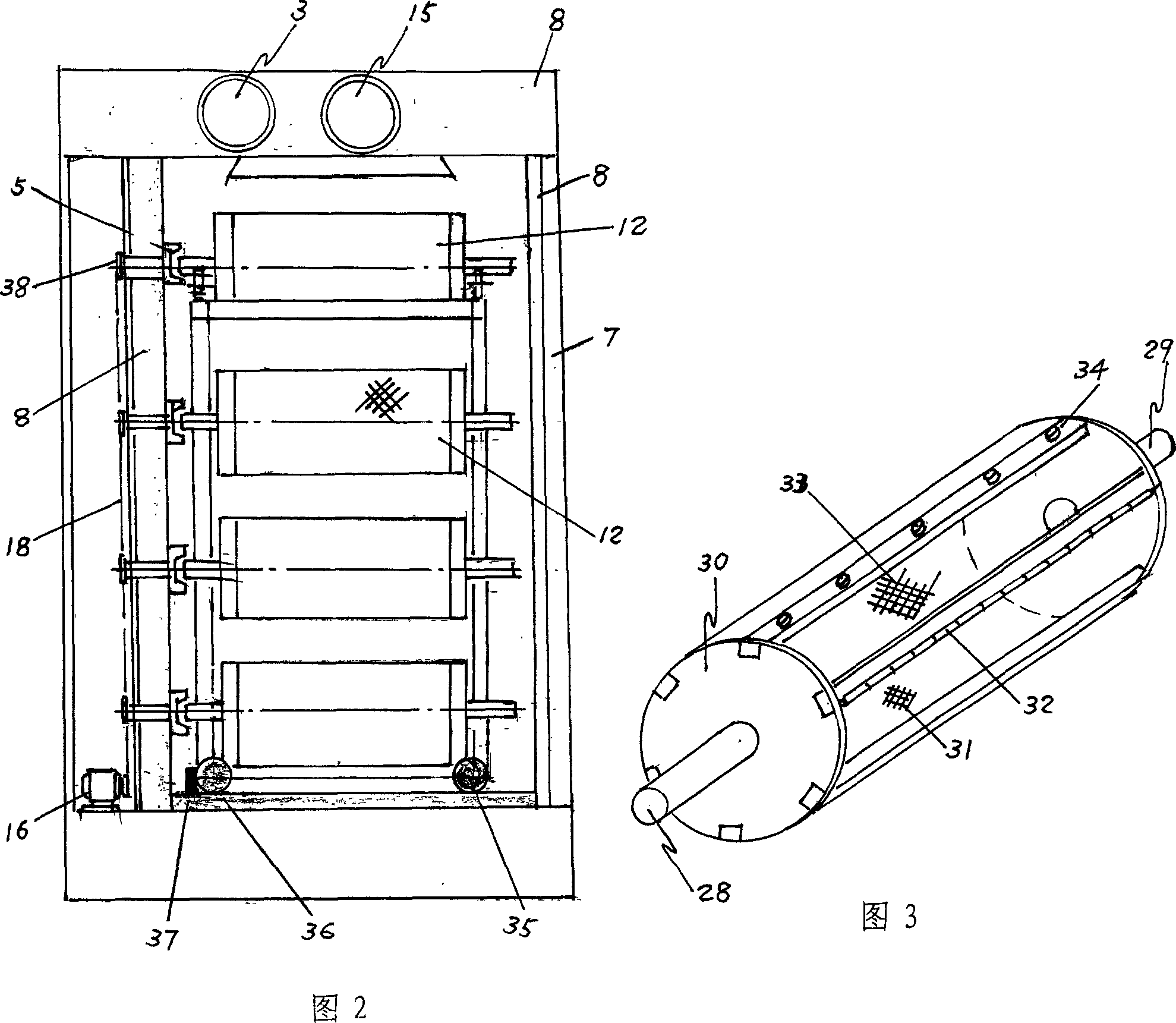

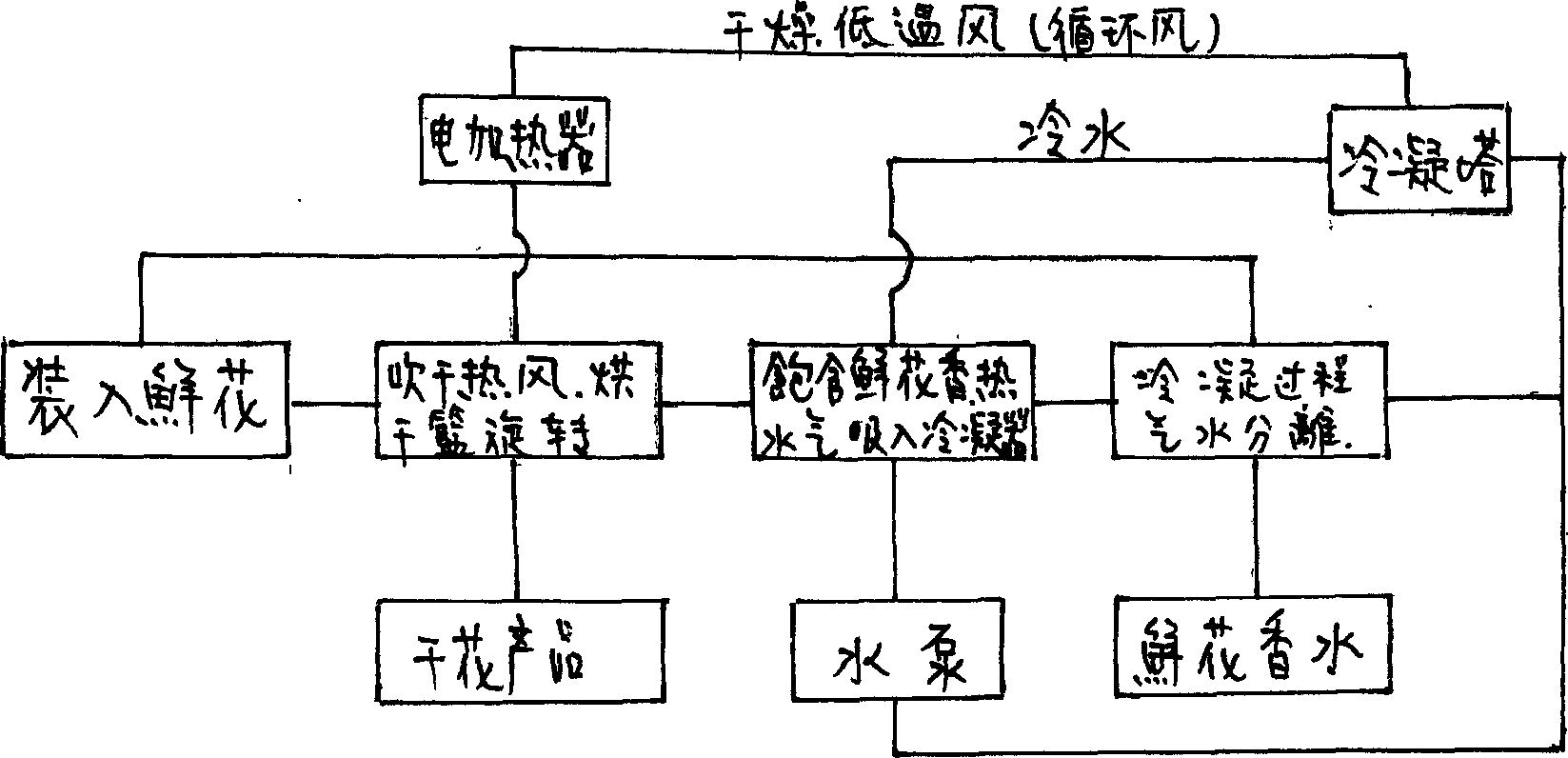

Drying, distillation device of aromatic plant and its method

The invention is a scented plants drying and distilling device and method. And the device comprises drying box, distilling condensing box and steam return air duct, where the drying box comprises base, body, door, heat insulating layer, left and right backplanes, bearing frame, rotating drying cages, steam return air inlet, fan, air inlet pipe, electric machine and drive system; the bottom left or right side of each rotating drying cage on the air inlet pipe is equipped with outlet, in which far infrared heating pipe is equipped; and the steam return air inlet is connected with the steam return air duct; the distilling condensing box comprises condenser, perfume vale, spray tank, condensing tower and water pump; the temperature of the air inlet pipe is 80-90DEG C, the speed of the rotating drying cage is 20-50r / min, and the water temperature of the spray tank is 10-50DEG C. And it saves precious scented plant resources and largely increases economic benefits, able to be widely used in processing roses and other scented plants.

Owner:戴礼森 +1

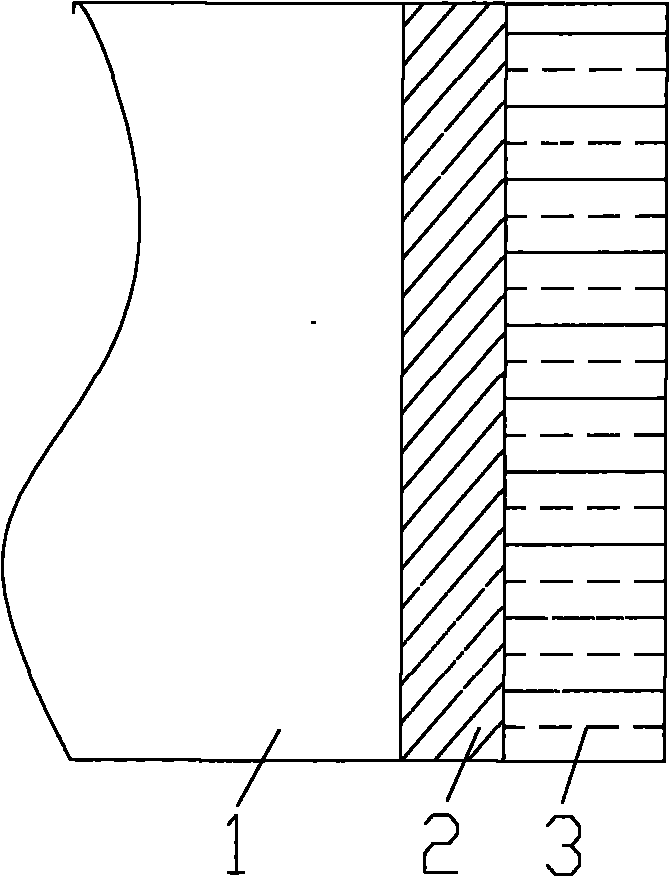

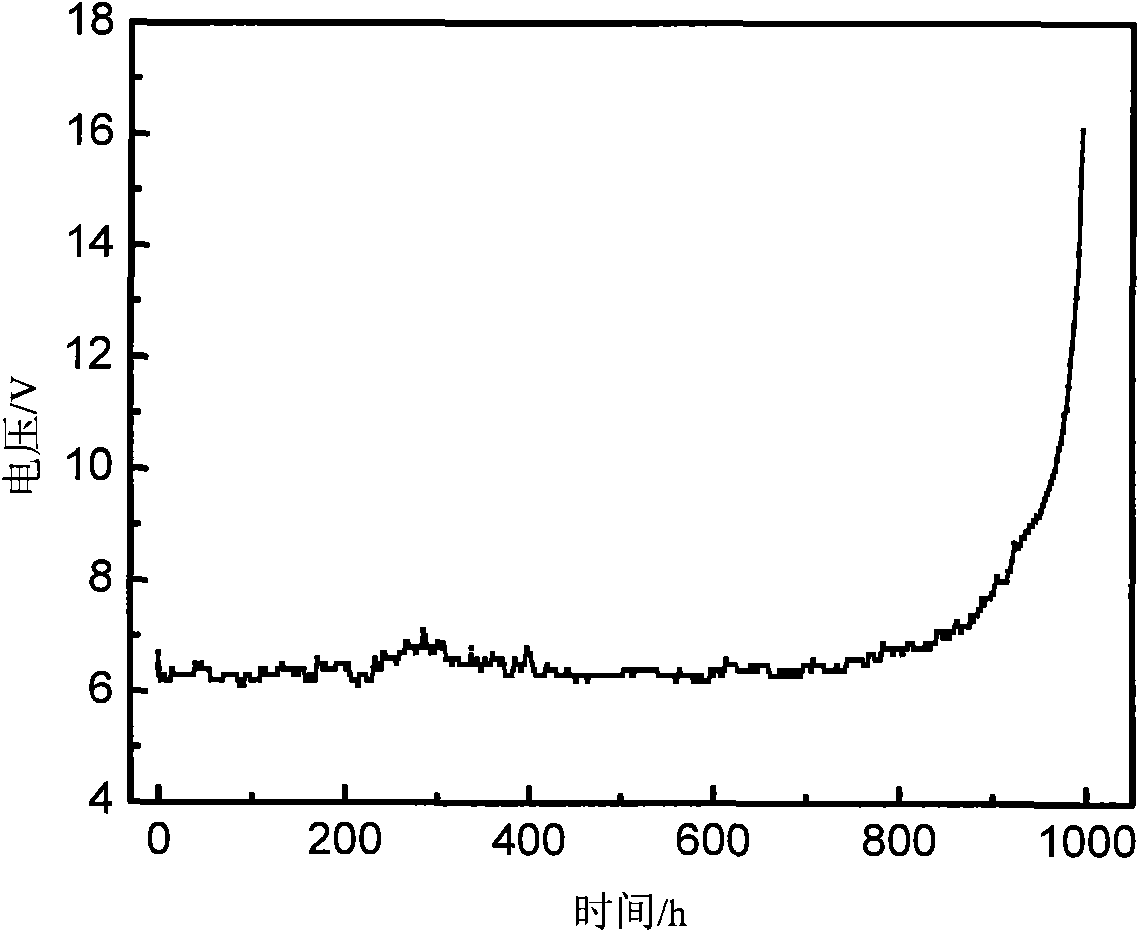

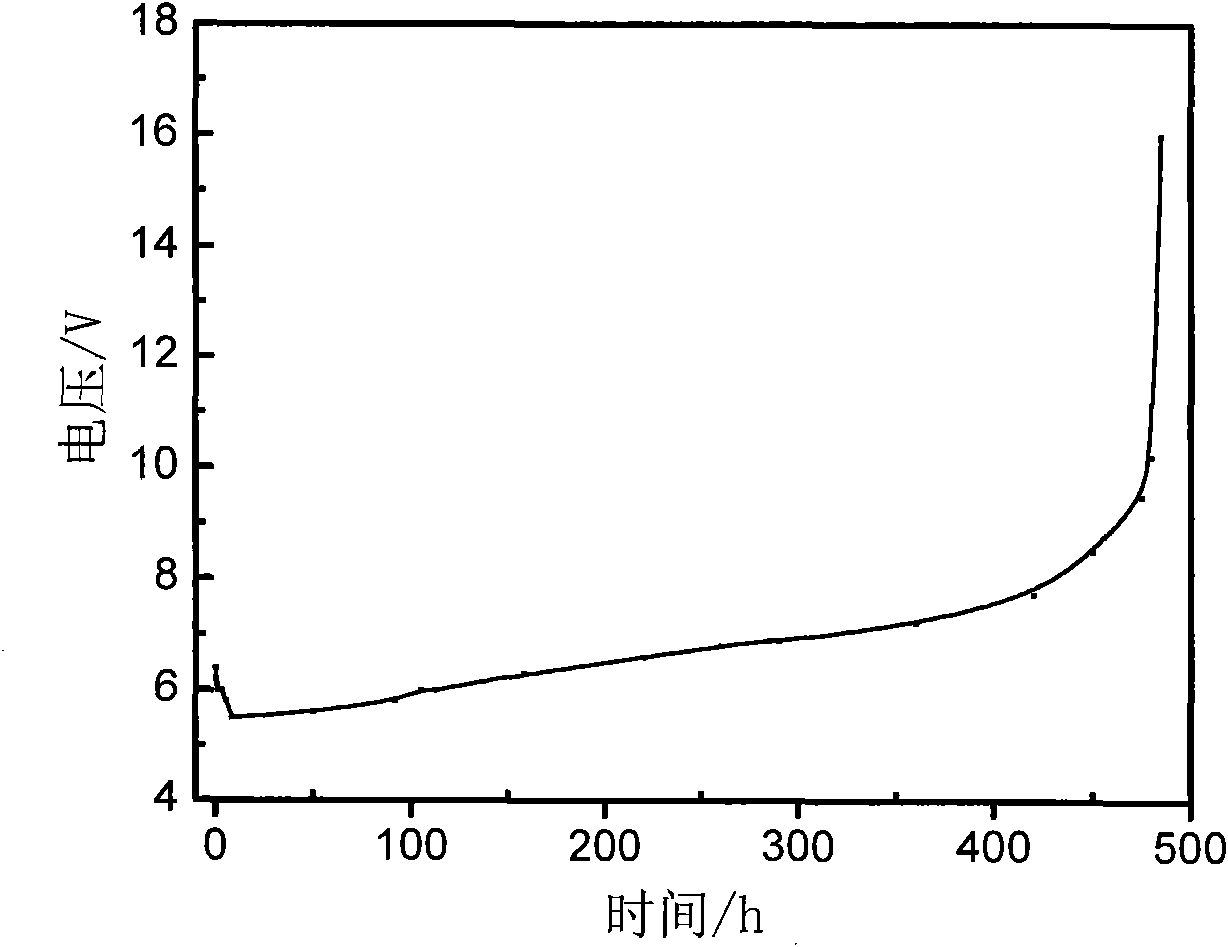

High-stability DSA anode for preparing chlorine by electrolysis and preparation method thereof

The invention relates to a high-stability DSA anode for preparing chlorine by electrolysis and a preparation method thereof. The anode comprises a titanium substrate, a middle layer and a surface active layer, wherein the IrxM (1-x) O2 middle layer is arranged between the titanium substrate and the surface layer, and M is Co, Mn or a CoTa mixture; and the components of the surface active layer are RuO2, IrO2, TiO2 and SnO2. The preparation method comprises the following steps: dissolving the components of the middle layer in proportion in isopropanol or n-butanol and other organic solvents, evenly coating on the pretreated substrate, and drying under an infrared lamp or in a drying box; then placing in a muffle furnace for thermal oxidation, and repeating the step for 1 to 10 times; and then coating the blended surface layer solution on the middle layer, repeating the preparation steps for 10 to 20 times, and holding in the muffle furnace. The service life of the anode is greatly prolonged based on the existing industry standards (20h), and the anode can be widely used in electrolyzing seawater antifouling, chlor-alkali industry and cathodic protection and other fields.

Owner:DALIAN UNIV OF TECH

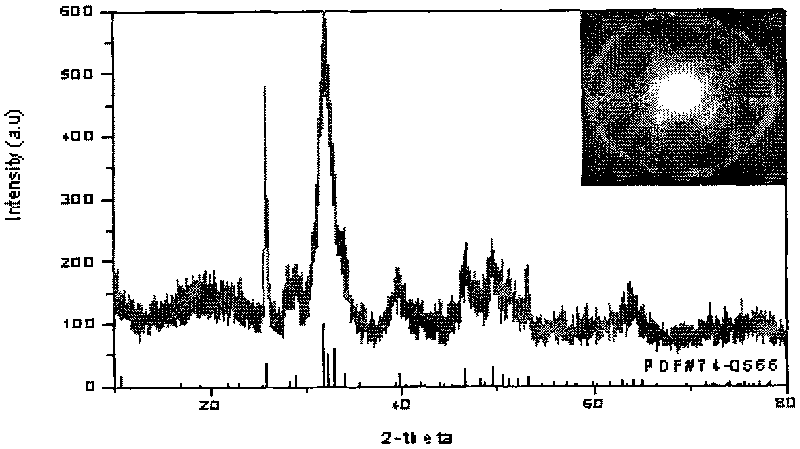

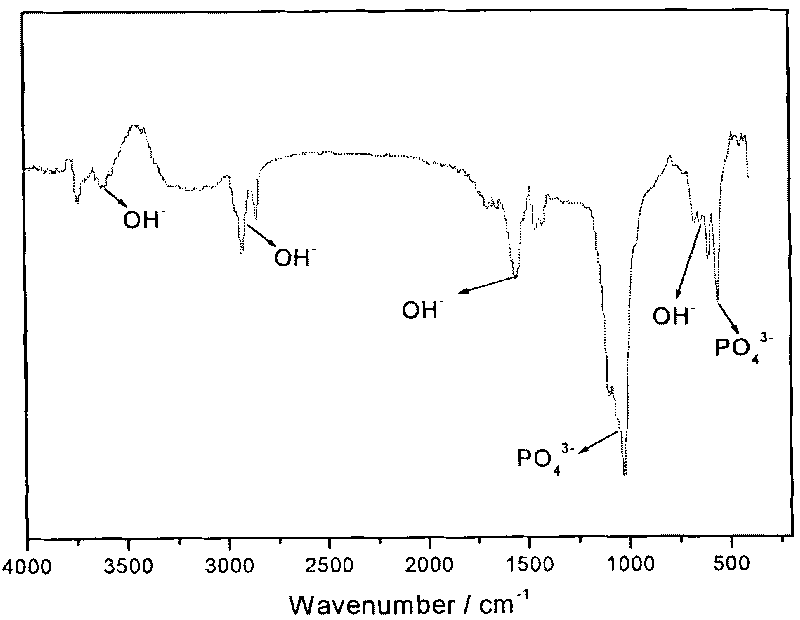

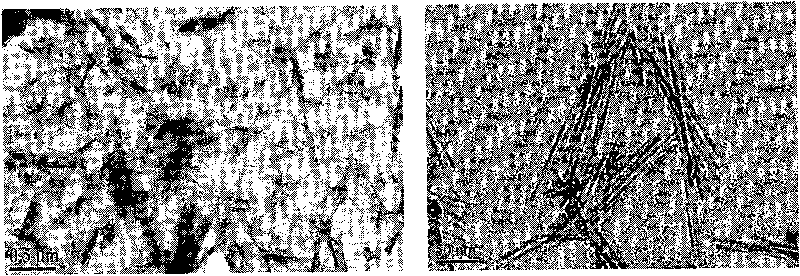

Preparation method of hydroxylapatite nano fibers or nano wires

InactiveCN101723341AHigh purityUniform particle sizeNanostructure manufacturePhosphorus compoundsFiberNanowire

The invention discloses a preparation method of hydroxylapatite nano fibers or nano wires, comprising the following steps of: (1) adding 0.1-0.5 gram of sodium phosphates into a two-mouth round bottomed flask at 20-40 DEG C; adding 3-10 mL of 2 mol.L<-1> sodium hydroxide solutions, and mechanically stirring for 20 minutes; then adding 20 mL of oleic acid and ethanol mixing solutions with the volume ratio of 1:1, and continuously stirring for three hours; then delivering into a hydrothermal kettle; placing into an infrared insulation can at 100-180 DEG C for 5-10 hours; and (2) taking out white products inside the hydrothermal kettle; washing by distilled water for three times; washing by ethanol for three times; carrying out centrifugal separation to remove reaction residues and impurities; and finally placing the white powder products into a dry box for drying at 75 DEG C for 8 hours. The hydroxylapatite nano fibers prepared by the method have high purity, uniform grain diameter and unitary appearance.

Owner:SHANGHAI NORMAL UNIVERSITY

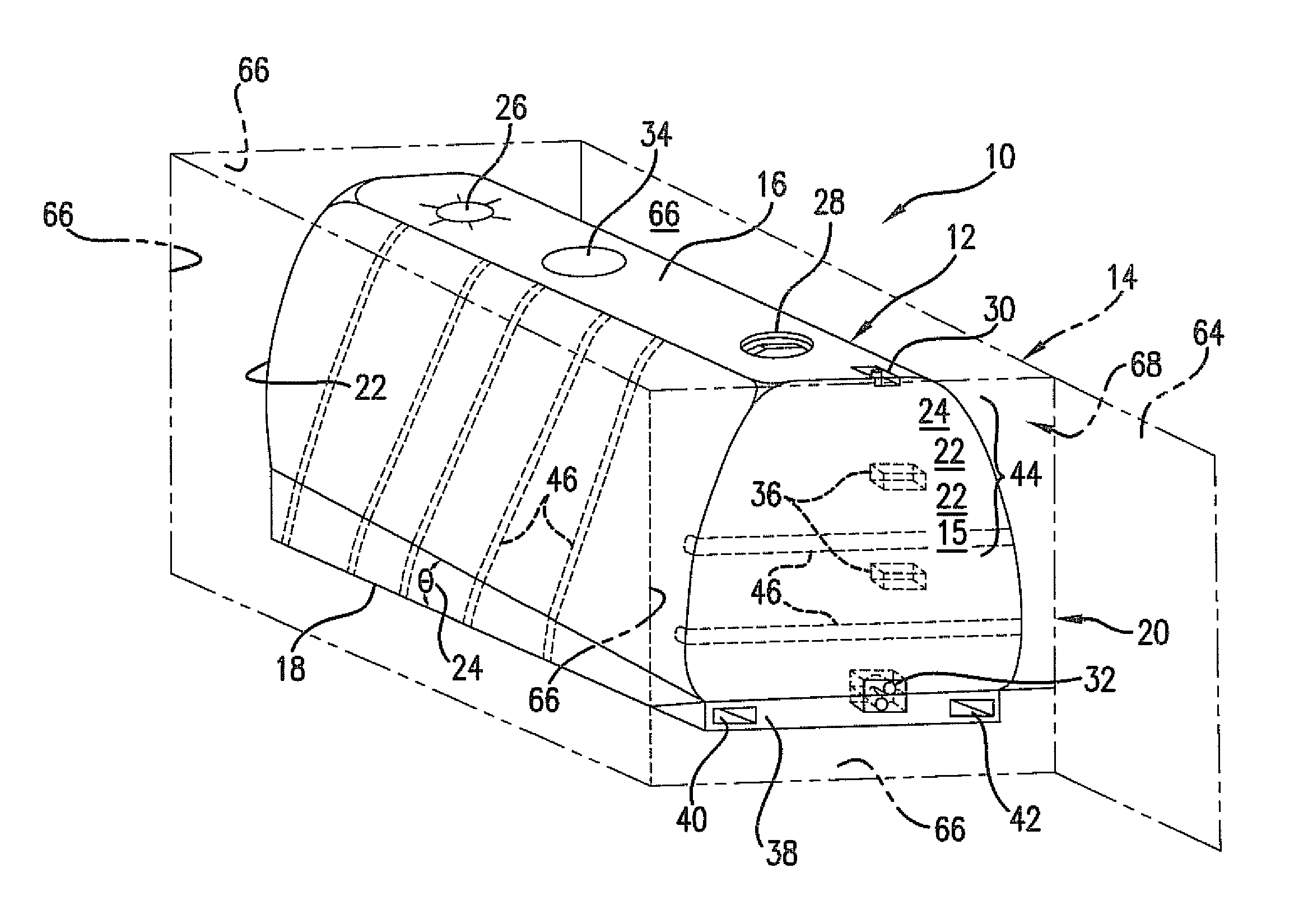

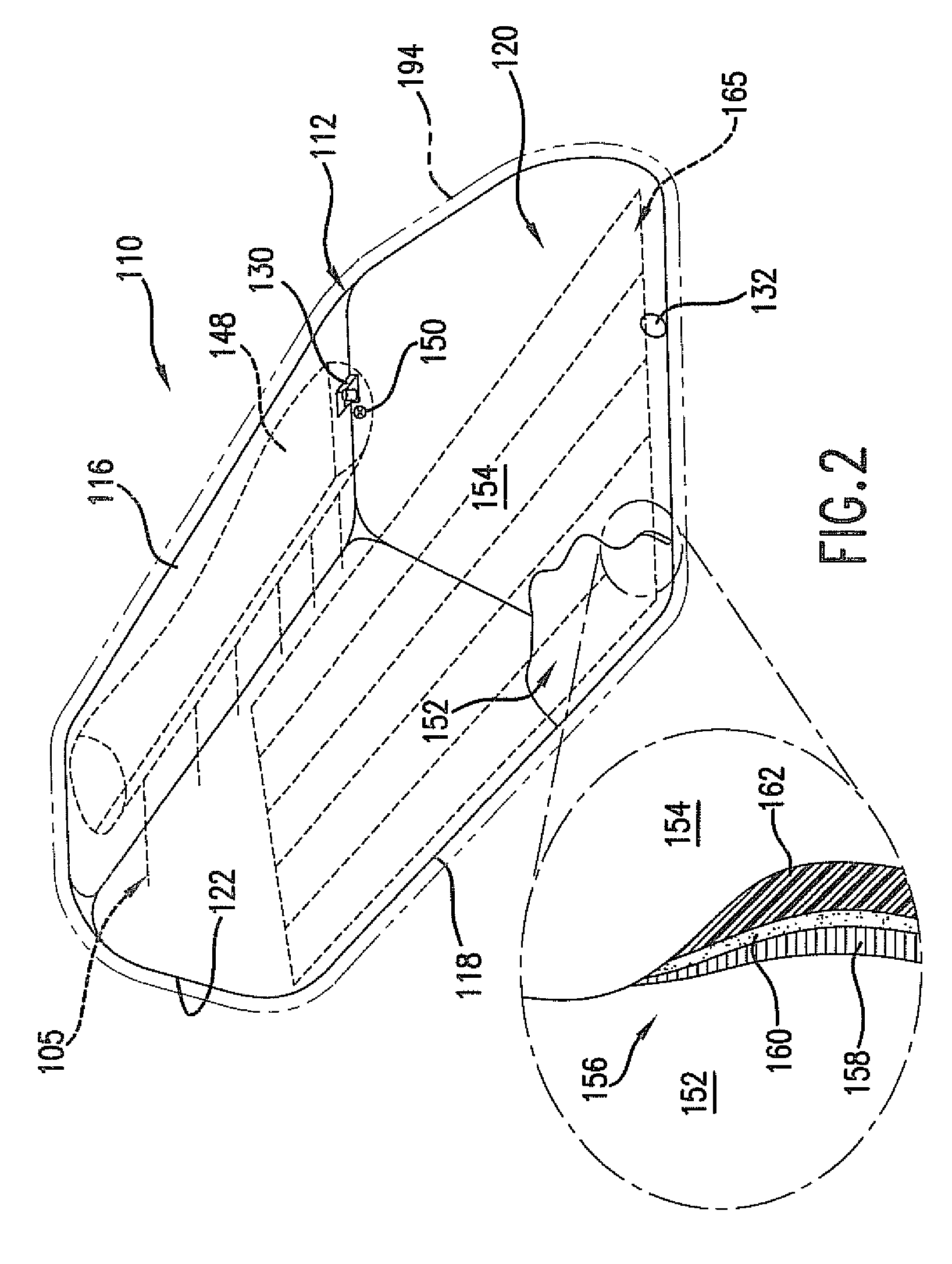

Bulk liquid transport system

InactiveUS20080257894A1Easy to processEasy to installLarge containersCoatingsTransport systemEngineering

A transport tank system includes a molded thermoplastic tank defining an aperture therethrough and having a discharge end and an opposing end, the thermoplastic tank being rigidly configured for holding a consumable cargo received through the aperture and including a material resistant to passage of oxygen to preserve the consumable cargo. The tank is capable of standing alone for storing the consumable cargo, or the tank can be loaded into a standard dry box container to convert the dry box container into a bulk liquid transport container.

Owner:PODD STEPHEN D +1

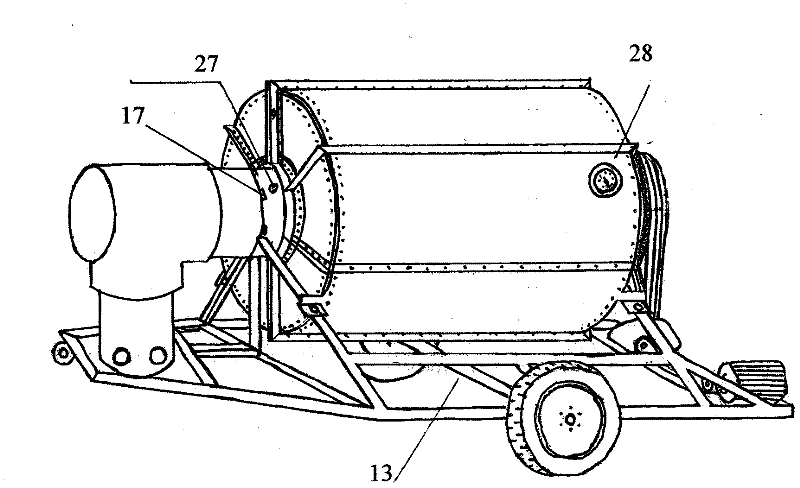

Movable multi-use drying machine

InactiveCN102538414ADry fastConsistent dryDrying gas arrangementsSeed preservation by dryingWalnut NutReducer

The invention relates to a drying device, in particular to a movable multi-use drying machine for dried fruits such as a walnut, a pepper, a Chinese chestnut and the like and a variety of traditional Chinese medicines as well as grains. The movable drying machine comprises a heating part, a main body part and a transmission part, wherein the heating part comprises a coal ball stove, a hot air cover and an axial-flow fan; the main body part comprises an inner drying box, an outer drying box and an insulation cover; and the transmission part comprises a main shaft, a bearing, a chassis frame, a big belt wheel, a motor and a speed reducer. According to the movable multi-use drying machine provided by the invention, dried matters can be rotated by 360 degrees in the drying boxes. In addition, the movable multi-use drying machine has the effects of realizing multiple functions and saving labor intensity.

Owner:尹雄虎

Method for preparing pervaporation membrane for separating alcohol-water system

The invention discloses a preparation method of an infiltration vaporizable membrane used for an alcohol-water separation system, comprising the following steps: (1) polydimethyl siloxane and solvent are put into a vessel and are stirred; (2) cross-linking agent and catalyst are added into the vessel and are stirred for 2 to 3 hours under room temperature to obtain a mixed liquor after reaction; (3) the mixed liquor is performed with filtering, deaeration and stewing consecutively and then membrane-scraping treatment is conducted to obtain a membrane cog; (4) the membrane cog is vulcanized under room temperature and after the solvent volatizes, the membrane cog is put into a dry box for further high temperature vulcanization to obtain the infiltration vaporizable membrane. The preparation method of the infiltration vaporizable membrane used for the alcohol-water separation system has the advantages of high separation performance and excellent stability.

Owner:CHINA PETROLEUM & CHEM CORP

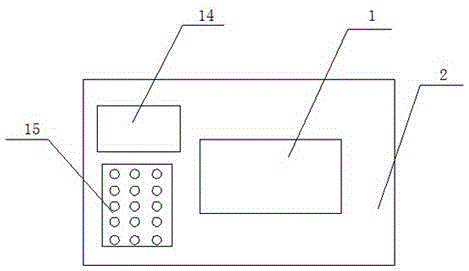

Electrothermal blowing dry box

InactiveCN105180604AAvoid getting lostIncrease profitDrying gas arrangementsDrying machines with local agitationLiquid-crystal displayEngineering

The invention discloses an electrothermal blowing dry box. The electrothermal blowing dry box comprises a box door, an air blower and a box body, wherein the air blower is arranged at the top of the box body; a radiating window is arranged at the right side of the box body; a rotating platform is arranged in the box body; a tray is arranged above the rotating platform; a humidity inductor is arranged on the tray; a temperature inductor is arranged on the inner wall of the box body; a protection plate is arranged at the upper part of the box body; air dispersing holes are uniformly distributed on the protection plate; the box door is arranged at the left side of the box body; an observation window is arranged at the middle part of the box door; a liquid crystal display screen is arranged at the left side of the box door; and an operation panel is arranged below the liquid crystal display screen. The electrothermal blowing dry box is reasonable in structure and practical in function; as the rotating platform is arranged, products are uniformly heated, and the temperature in the box is low in disturbance; electric heating wires are used for heating, so that the temperature adjustment is convenient and precise; and as the heat preservation layer is arranged, the heat loss can be effectively prevented, and the energy utilization rate is largely improved.

Owner:湖州周吴鼎盛化工有限公司

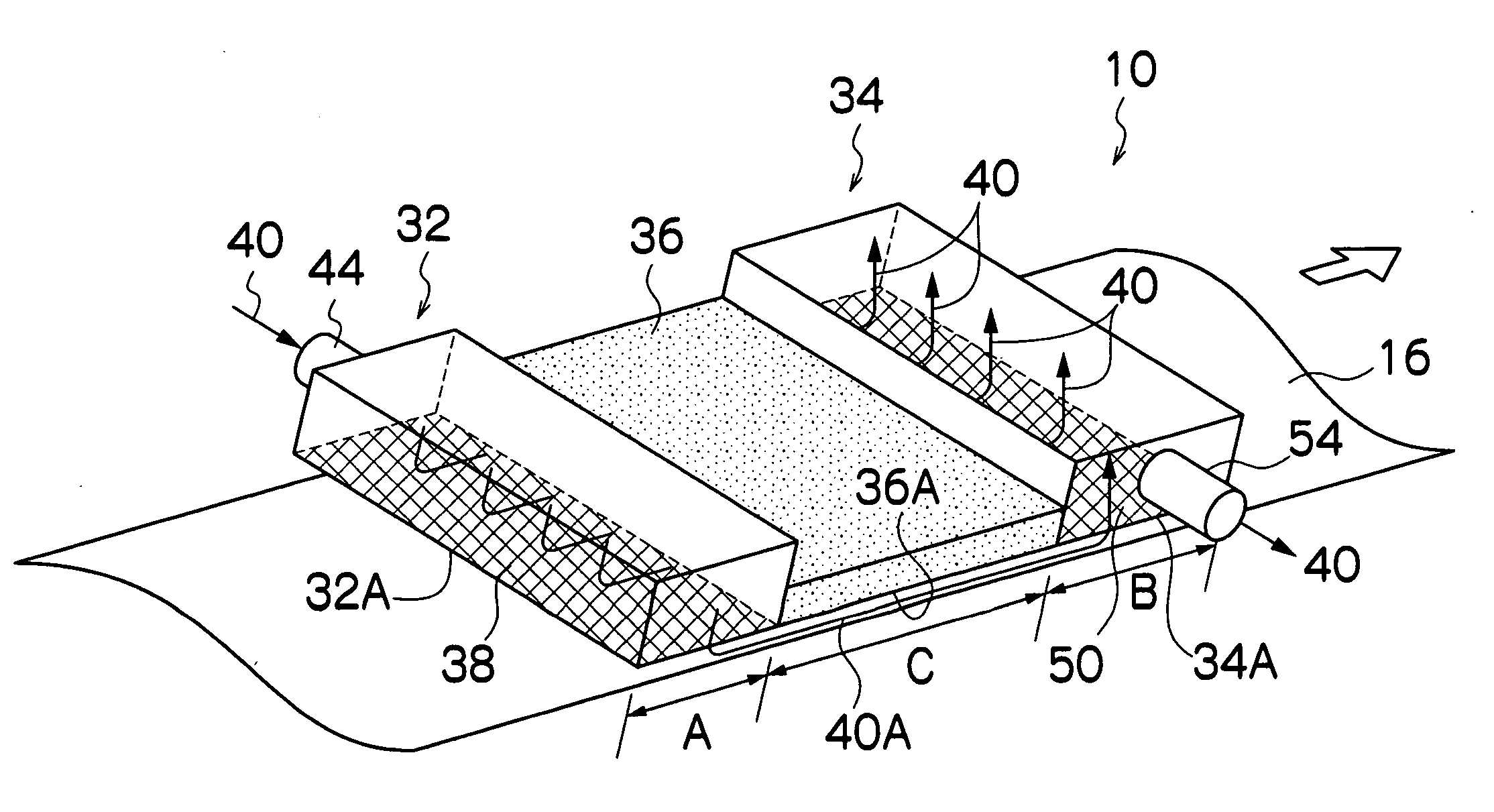

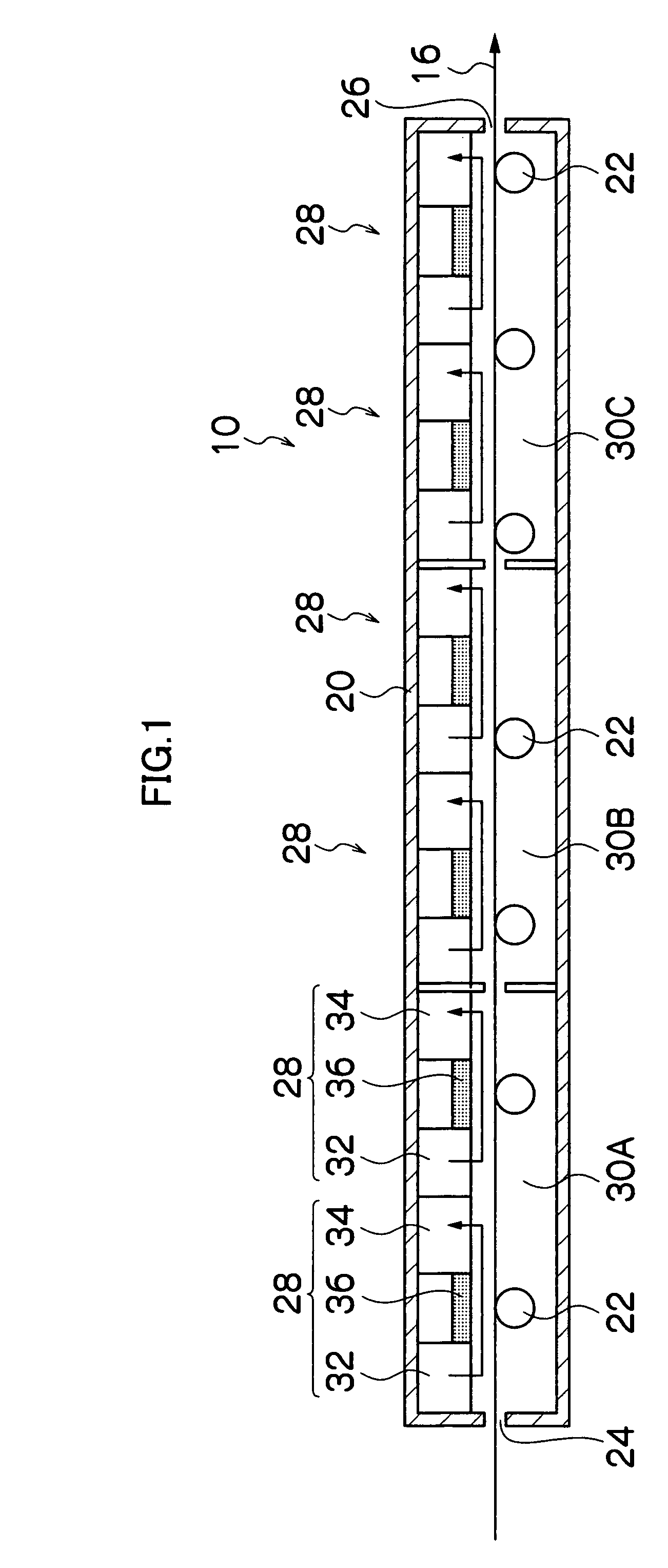

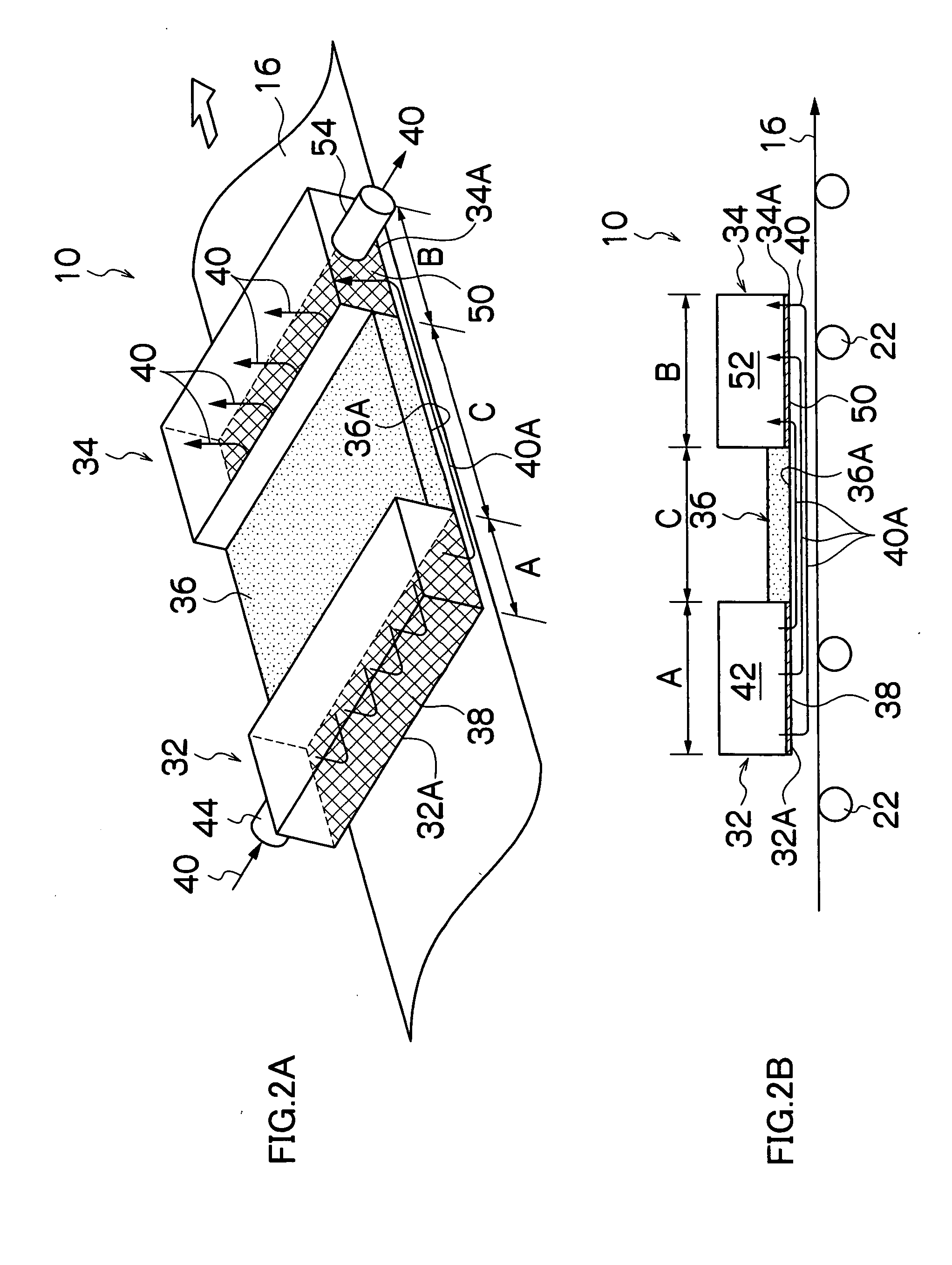

Method and apparatus for drying coated film, and method for manufacturing optical film

InactiveUS20070227034A1Dry evenlyHighly accurate drying of an optical filmDrying solid materials with heatDrying gas arrangementsEngineeringDistributor

A coated film drying method for drying a film which is coated on a surface of a web while the web is running through a tunnel-shaped dry case having a web entrance and a web exit, comprising the steps of:blowing dry air toward a surface of the coated film through an outlet port which is provided with a porous distributor; andsucking the dry air through an inlet port which is disposed at a position downstream or upstream of the position where the dry air is blown out and on the same side as that on which the outlet port is disposed relative to the coated film, so that a stream of the dry air which flows in a direction parallel to the running direction of the web is formed across the entire width of the surface of the coated film.

Owner:FUJIFILM CORP

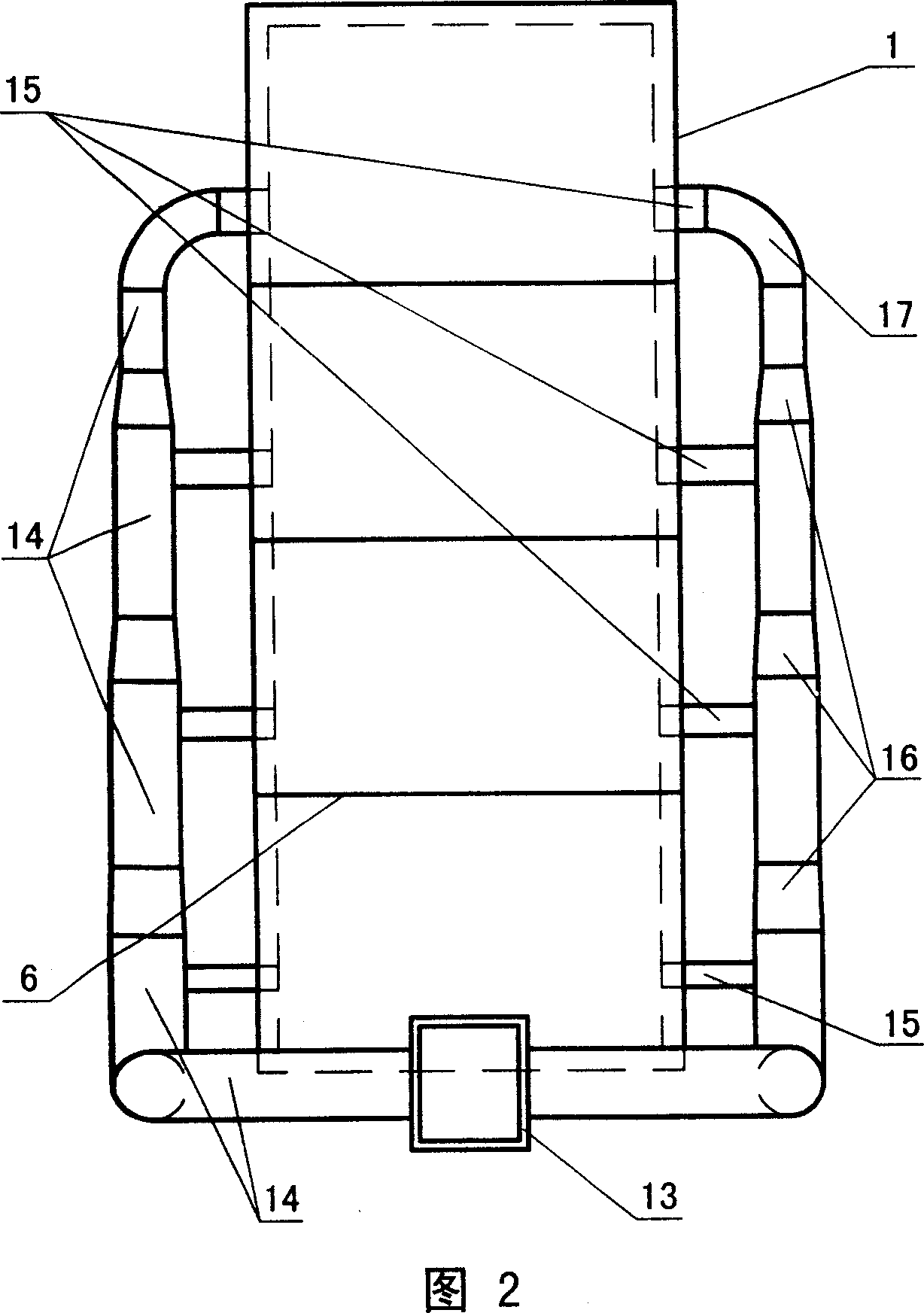

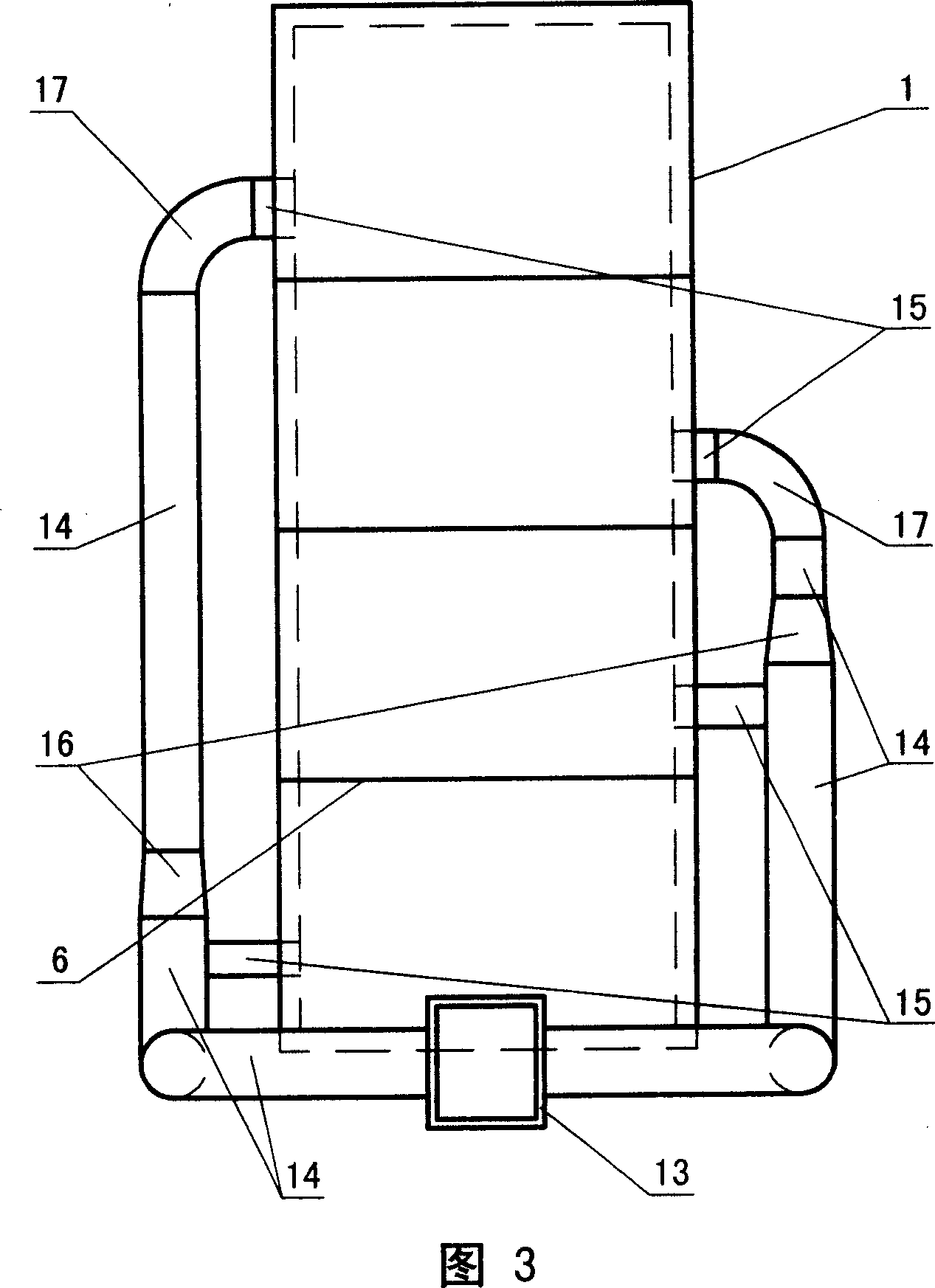

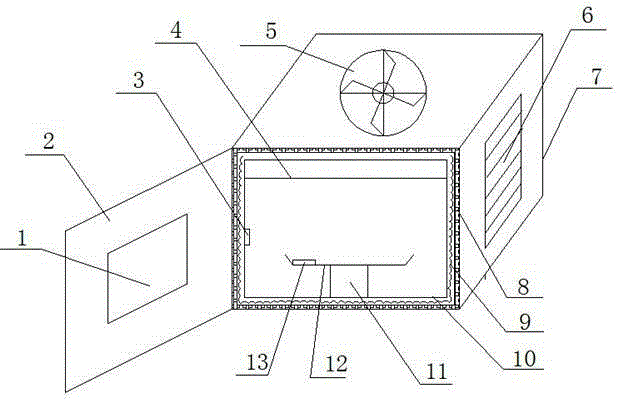

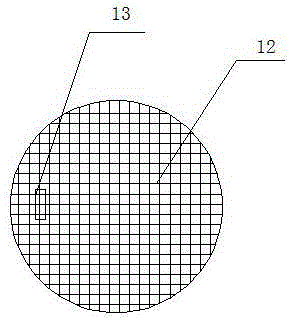

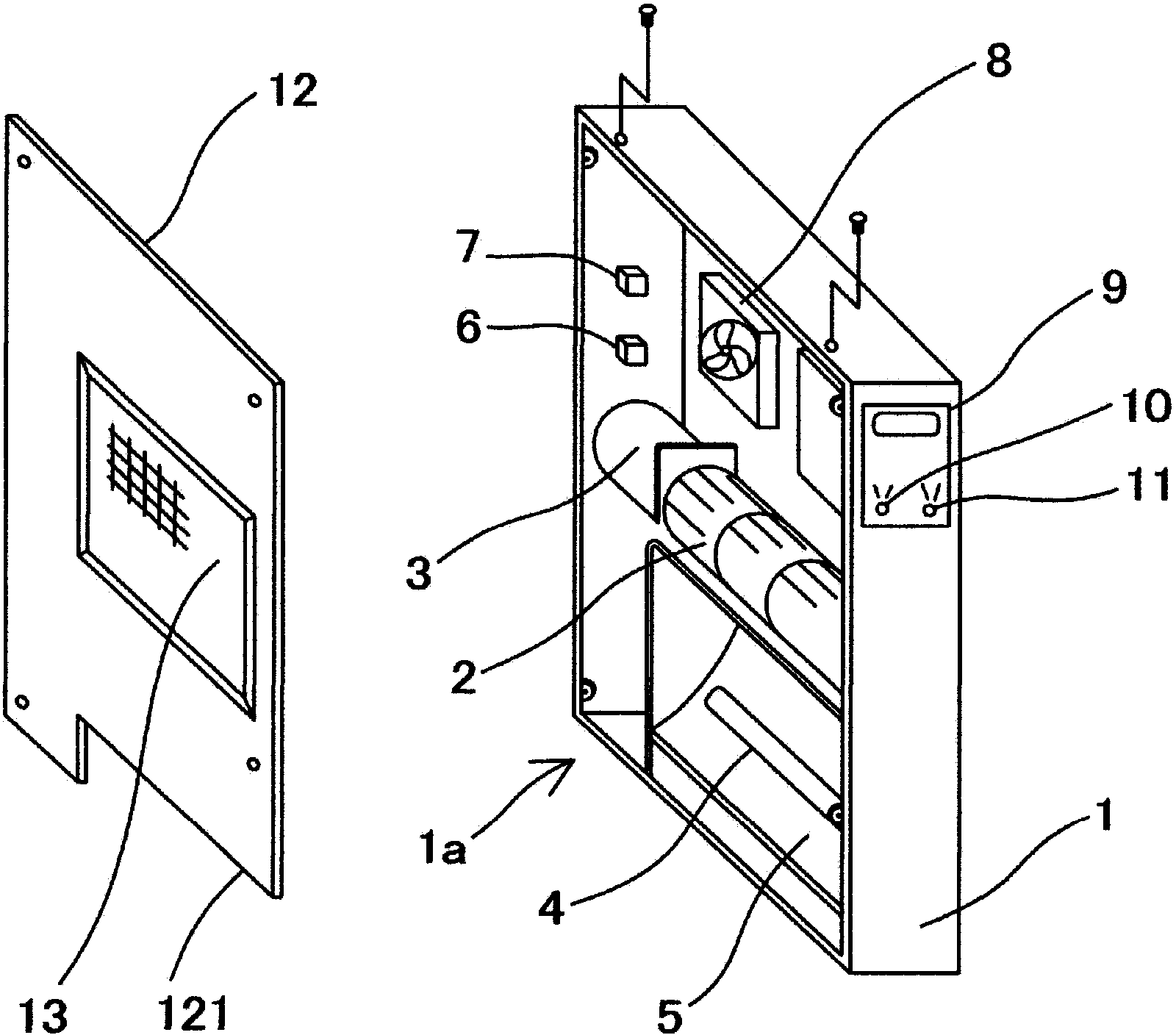

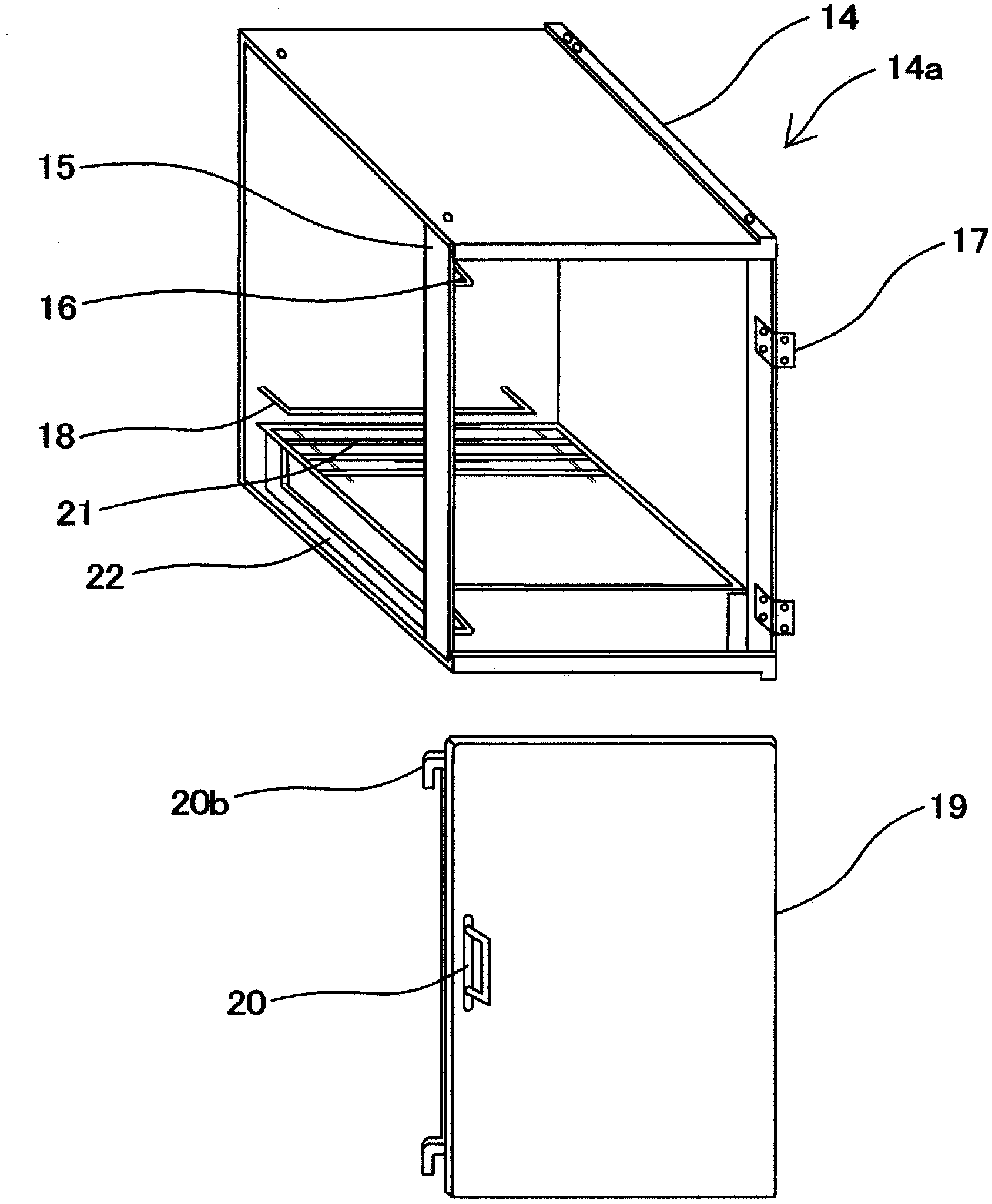

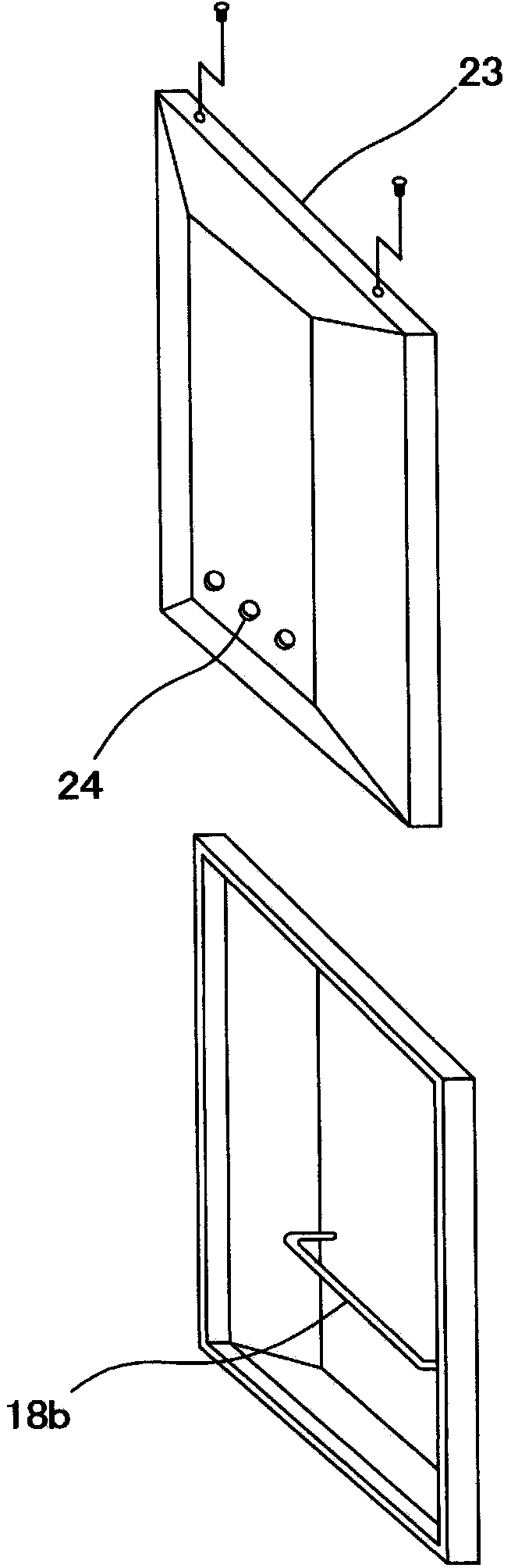

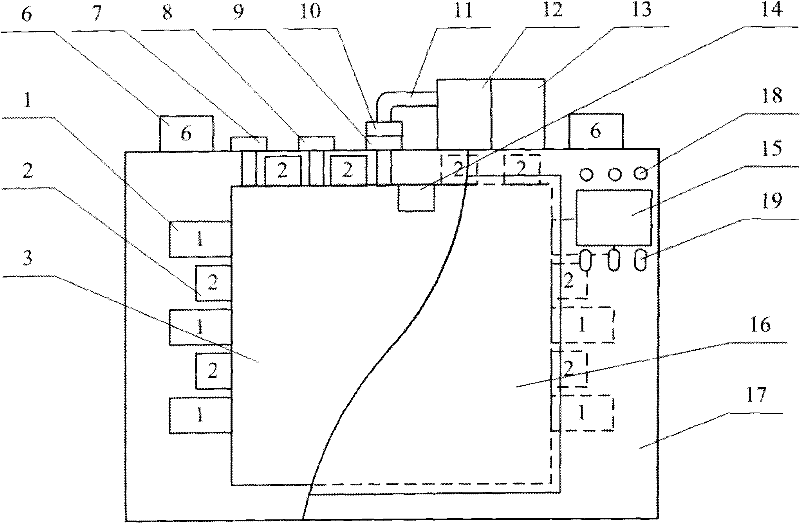

Drying box for pet

ActiveCN104320970AImplement energy-saving measuresEasy to assembleGrooming devicesAir volumeElectrical control

The invention provides a drying box for a pet, and uses electrical control device and frame body unitization / modularization technology to realize rationalization of production processes, rationalization of service / maintenance, low cost of equipment expansion, environment improvement, energy-saving strategies and the like. The electrical control device (1) has functions of adjusting air volume / temperature through a temperature sensor and controlling the rotation speed of a fan motor through a humidity sensor, is provided with a separator plate which separates the electrical control device (1) and a side opening part of the frame body (14), an approximately central part of the separator plate is equipped with a window with a filtering part, a warm air outlet is arranged between the separator plate, the frame body (14) is equipped with a door leaf (19) used for entering and exiting of a pet in the front, a side face opposite to the side opening part is equipped with a side plate (23), and assembling and disassembling can be easily performed by joining of the electrical control device (1) and the frame body (13) at the side opening part.

Owner:DREAM IND

High-flowability elastic powder for 3D printing and preparation method of high-flowability elastic powder

The invention provides high-flowability elastic powder for 3D printing. The high-flowability elastic powder is characterized in that nano molybdenum disulfide modified elastic powder is adopted, and the high-flowability elastic powder is prepared from materials in parts by weight as follows: 100 parts of polyurethane resin, 10-20 parts of a solid flowable agent, 5-10 parts of inorganic filler, 1-5 parts of a lubricating agent and 0.5-2 parts of a coupling agent. Materials are dried by a vacuum drying box and uniformly mixed by a coulter type mixing machine, molybdenum disulfide is attached to the surface of the elastic powder after the mixture is dried by a spray drier, products have good uniformity and flowability, the particle diameters are uniform, the mechanical performance is excellent, and 3D printing of the elastic powder is realized; the production process is simplified, and operation and control are convenient.

Owner:福建慧思通三维技术有限公司

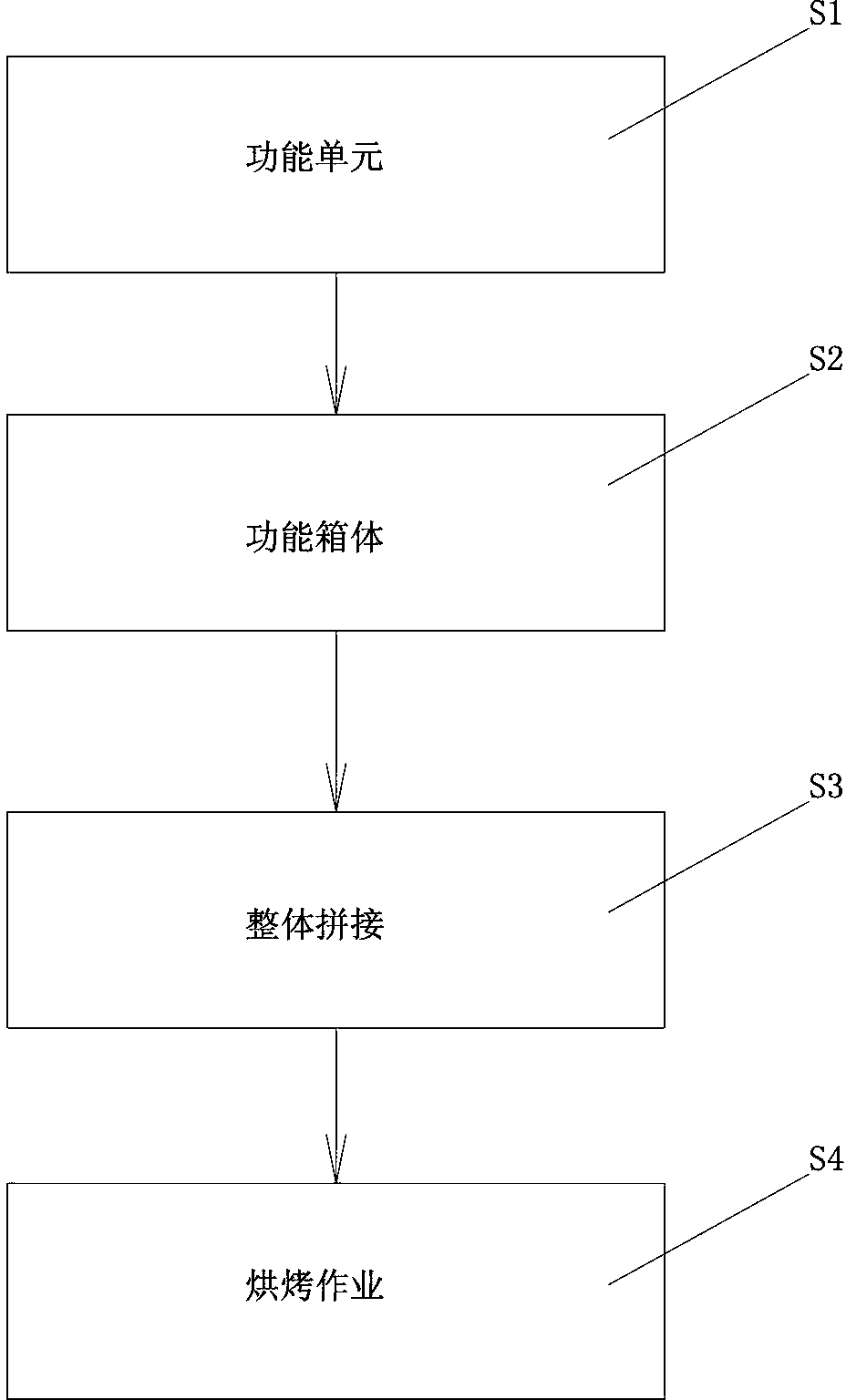

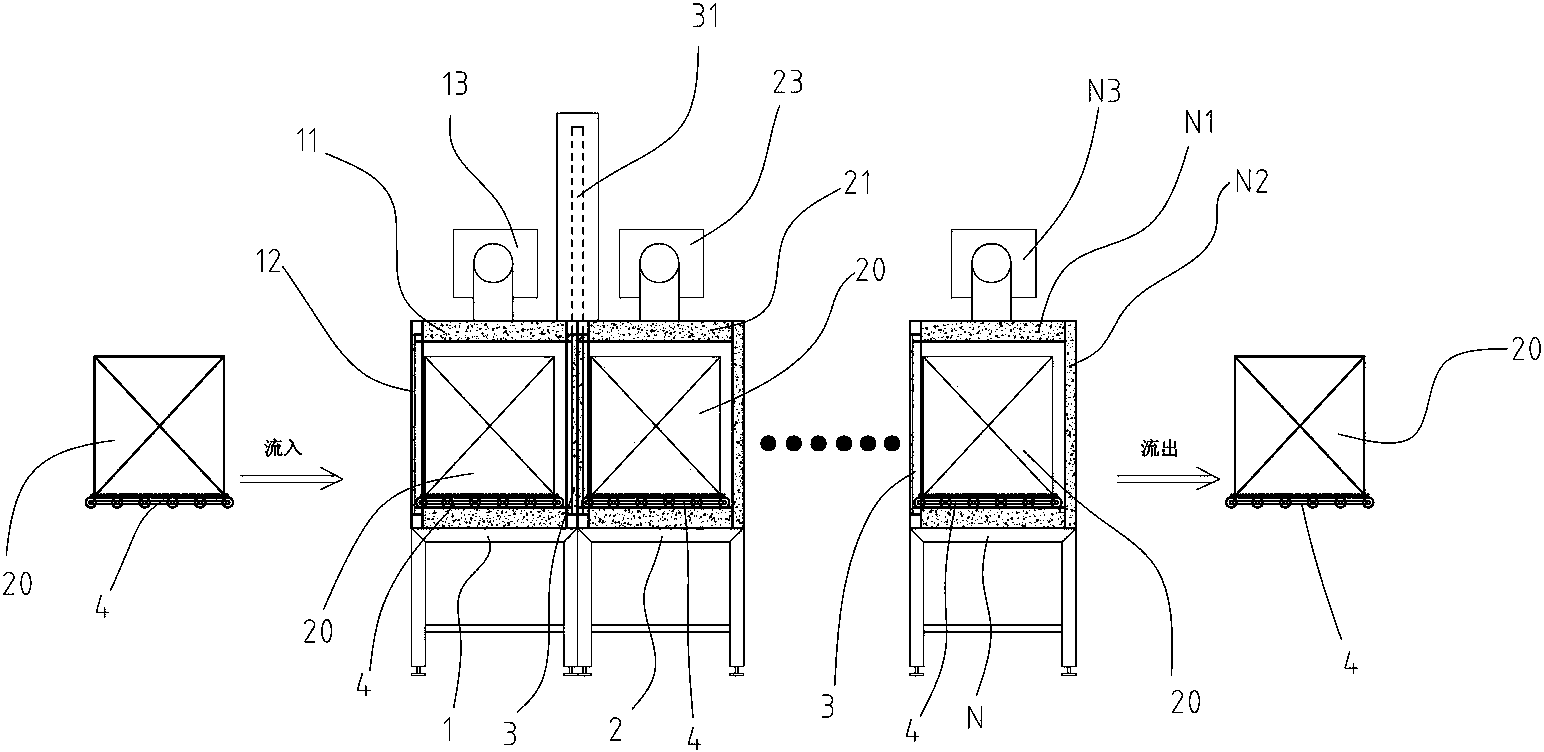

Full-automatic combining module new energy material vacuum baking method and vacuum baking line

ActiveCN103398558AReduce labor intensityShorten the timeCell electrodesDrying chambers/containersProduction lineThermodynamics

Owner:SHENZHEN XINYUREN TECH

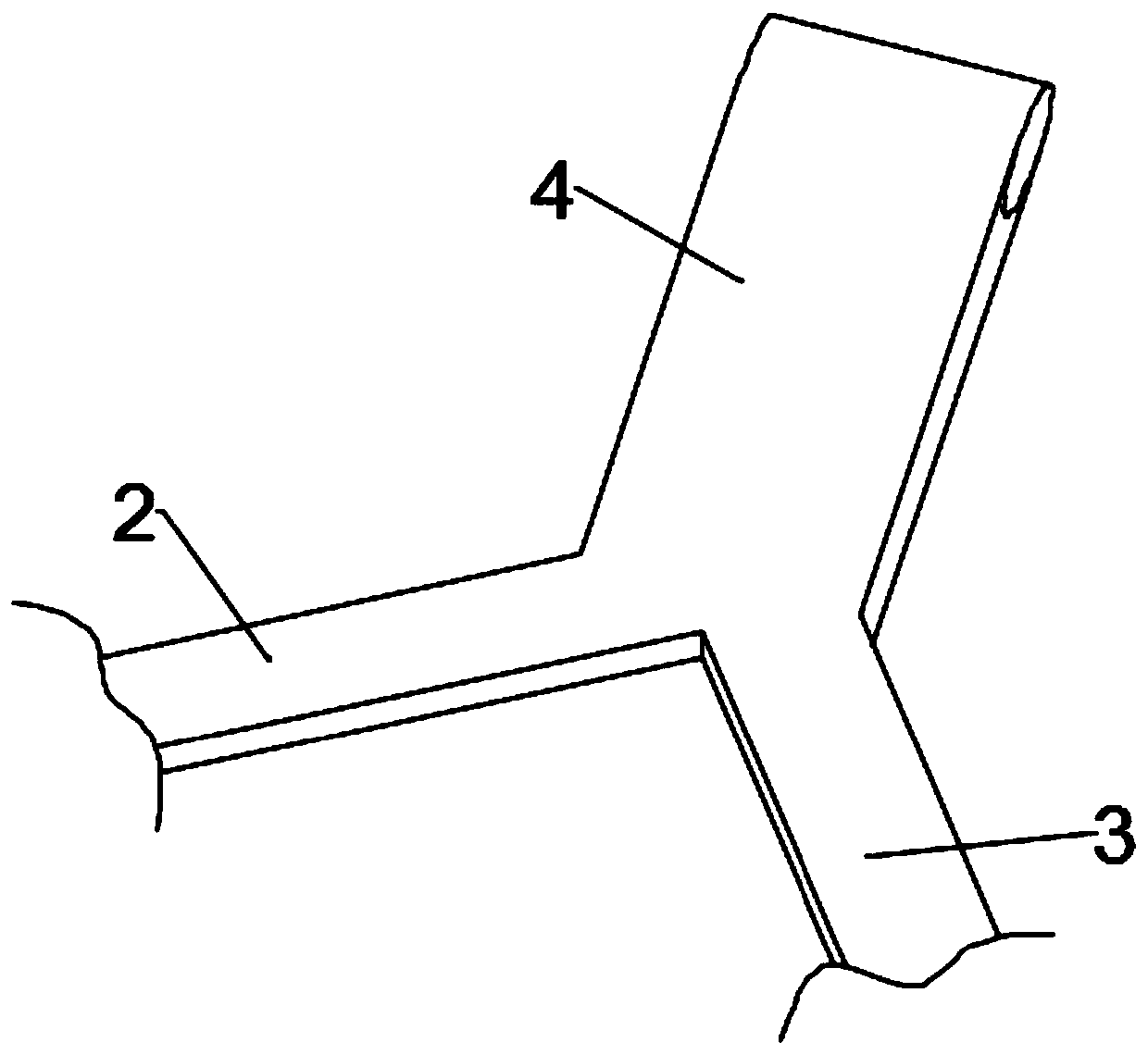

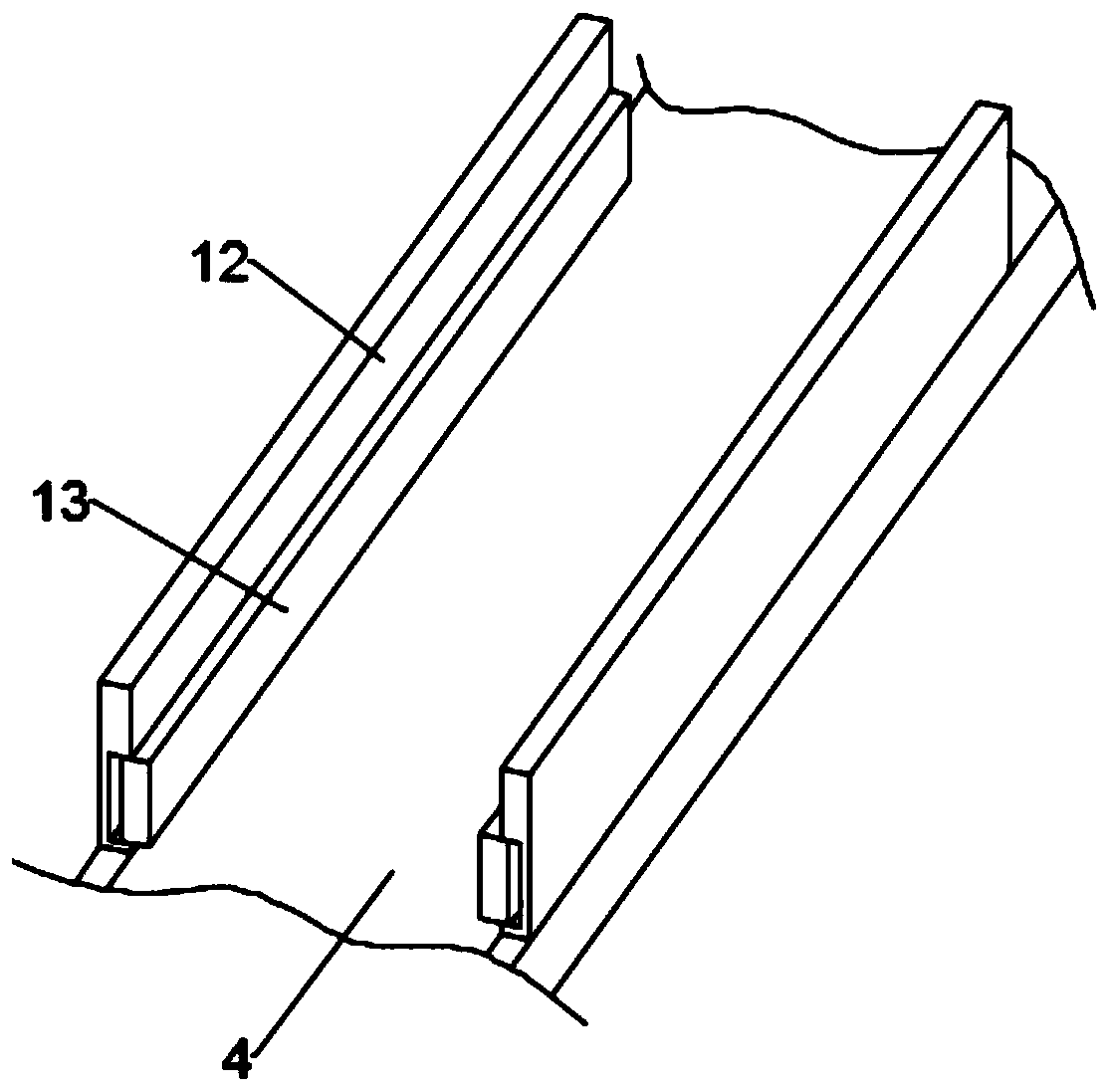

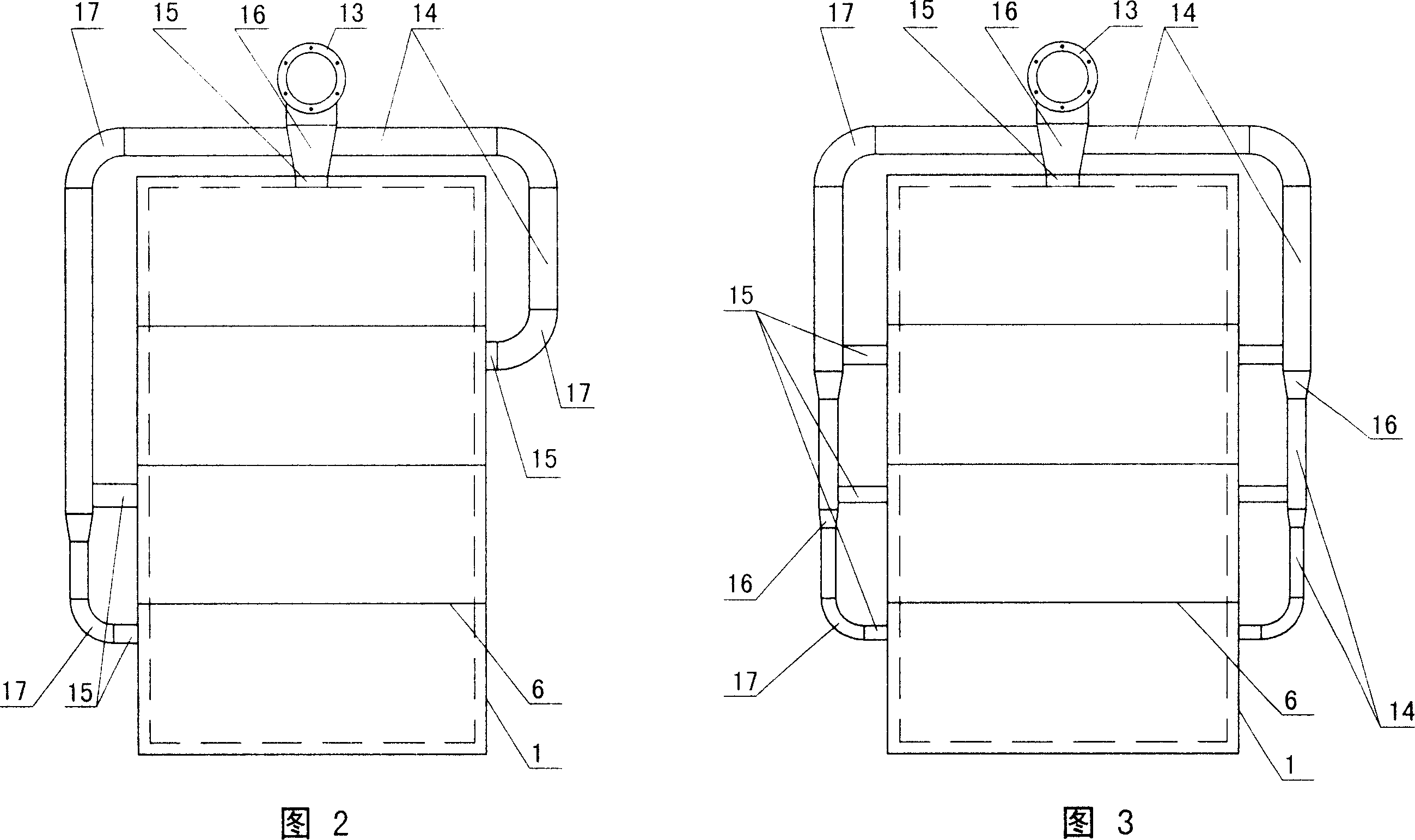

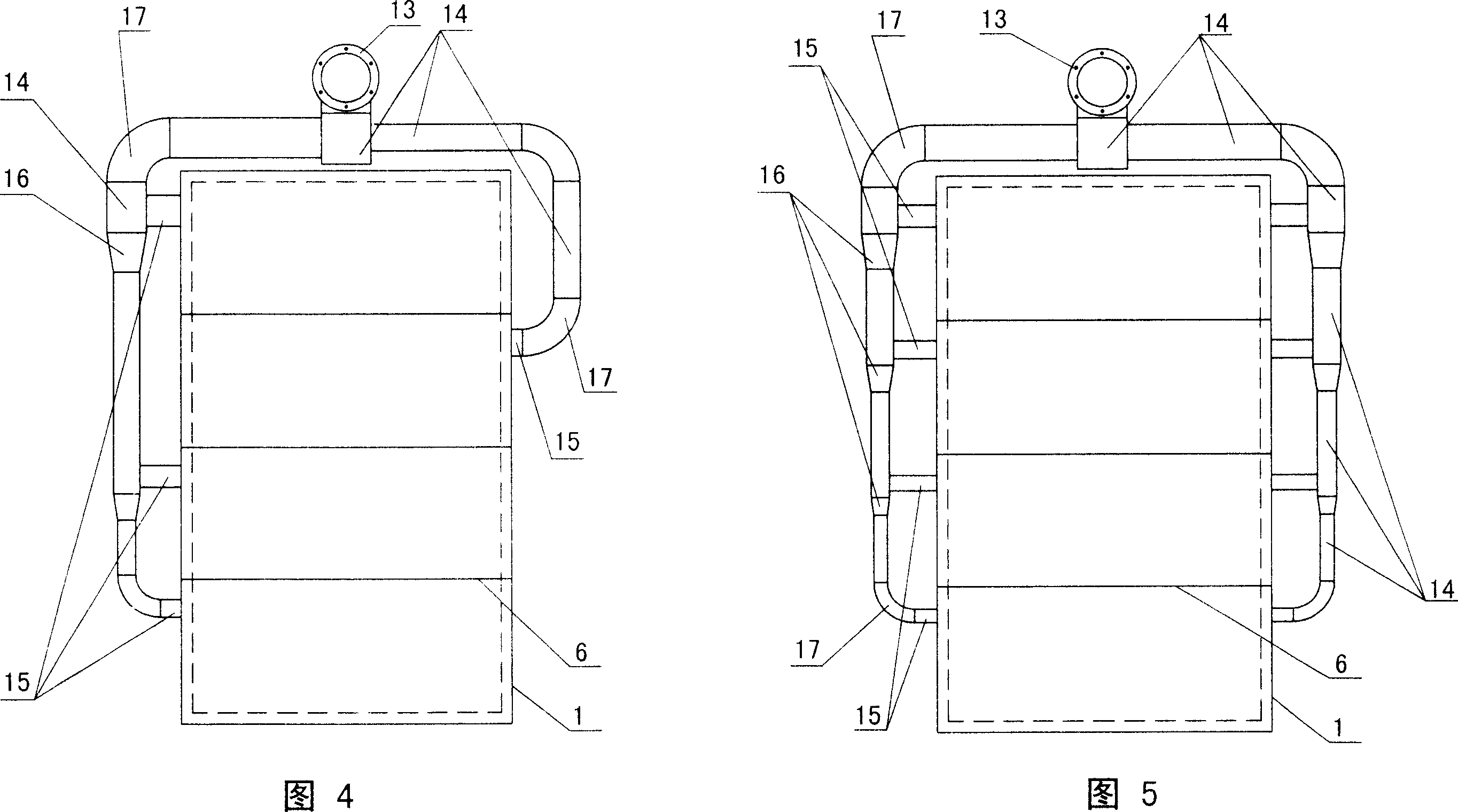

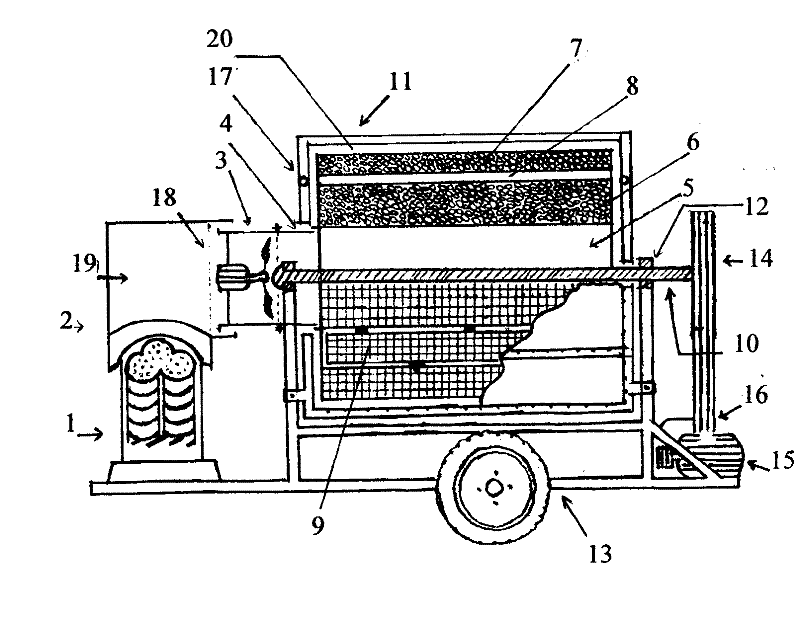

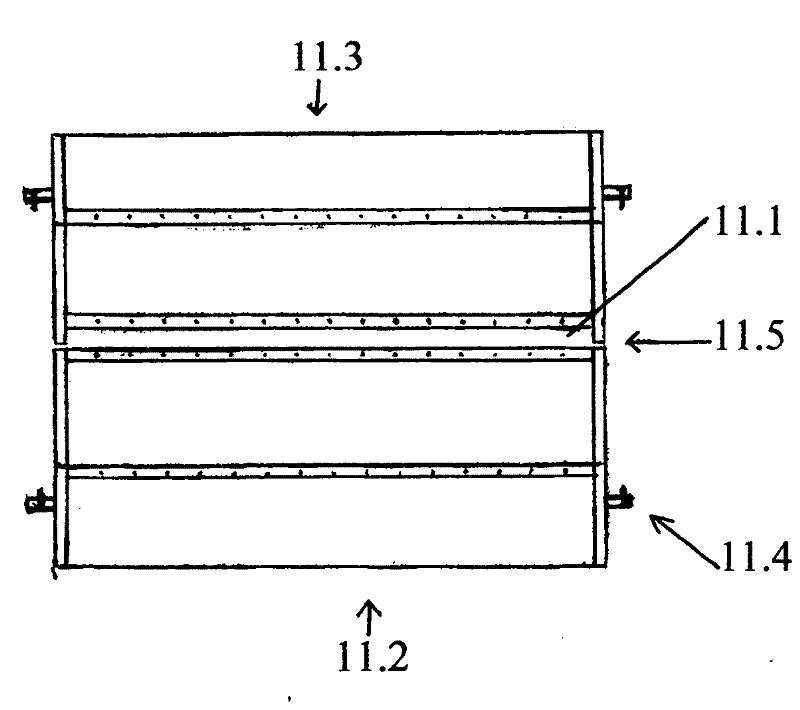

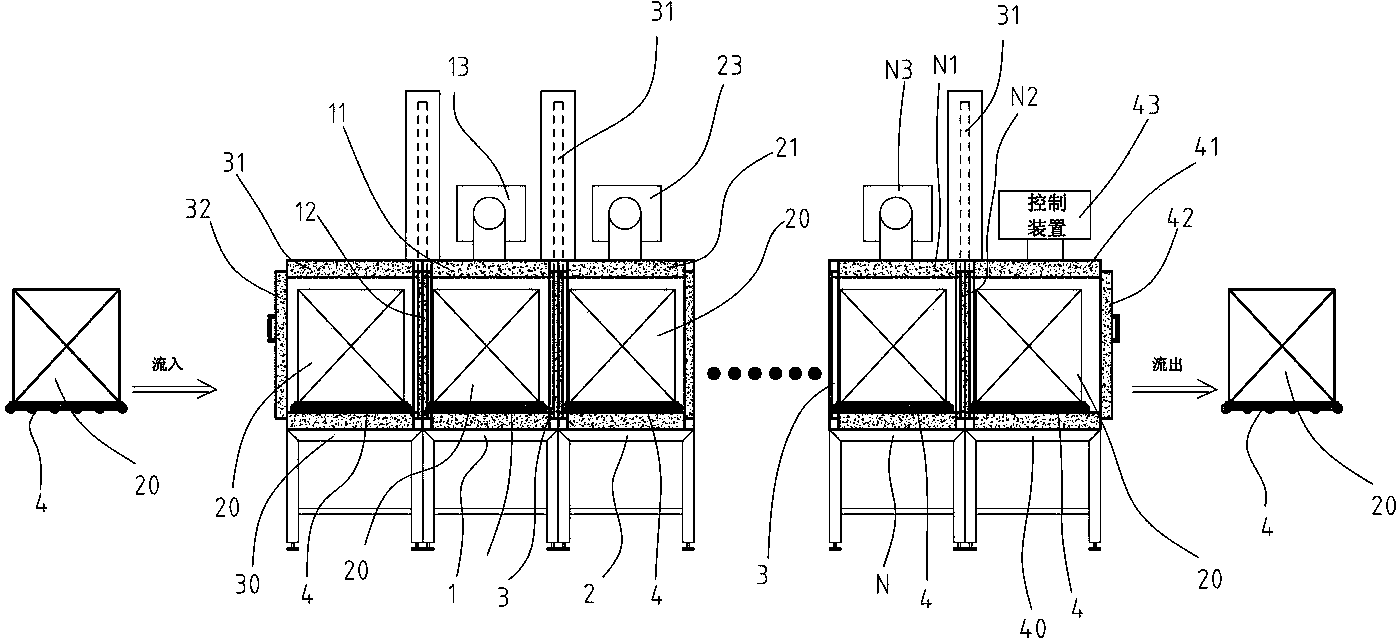

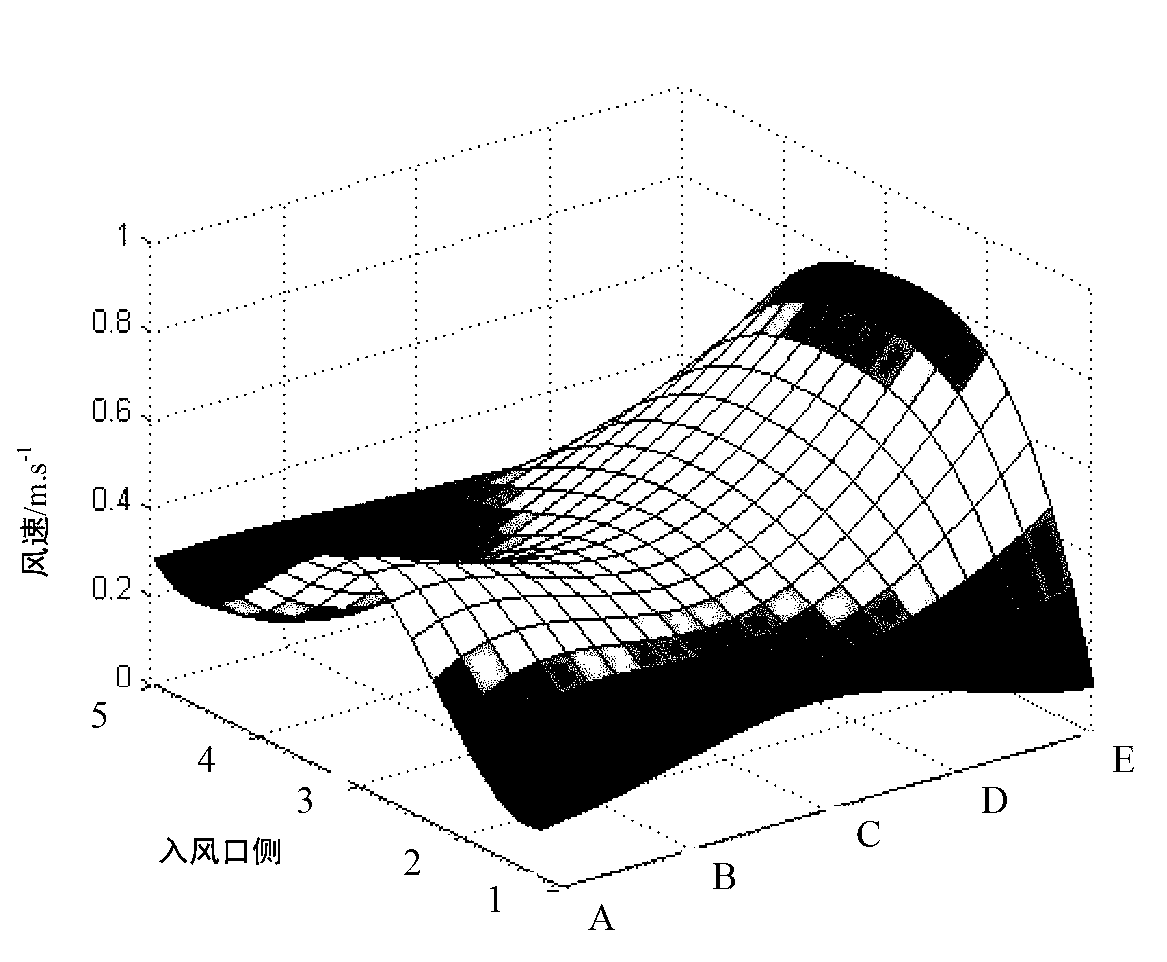

Reversible ventilating box type drying machine and method for drying grain and oil crops

ActiveCN103004977AImprove drying uniformityImprove energy utilizationDrying gas arrangementsSeed preservation by dryingEngineeringDry box

The invention relates to a box type drying machine, and belongs to the field of crop drying. A reversible ventilating box type drying machine comprises a closed drying box body, wherein ventilating openings are formed in one side of the drying box body and are connected with a fan through air inlet pipes; a temperature measurement sensor is arranged in the drying box body and is electrically connected with a controller; and the controller is electrically connected with heating equipment and the fan. The reversible ventilating box type drying machine is characterized in that two air inlet pipes and two ventilating openings are provided; the ventilating openings are formed in the lower part of the drying box body; a baffle is vertically arranged in the drying box body, so that the inner part of the drying box body is divided into two half box chambers of which the tops are communicated; the baffle is vertically fixed at the bottom surface of the drying box body; meshed plates for placing materials to be dried are horizontally arranged in the two half box chambers; a left air chamber and a right air chamber are arranged below the meshed plates in the two half box chambers; and each air pipe and each ventilating opening are respectively connected with each air chamber. According to the eversible ventilating box type drying machine, the high-water-content grain and oil crops can be dried by using a method for alternately ventilating or simultaneously ventilating by the left air chamber and the right air chamber.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

Outflow-preventing type eye flushing device

InactiveCN104887490AReduce the burden onVersatileBathing devicesSuction devicesEye closureEngineering

The invention relates to an outflow-preventing type eye flushing device, and belongs to the technical field of medical apparatuses and instruments. The outflow-preventing type eye flushing device comprises a hydrops recovering tank, an eye flushing tank and a drainage flushing blinder; a recovering tank door is arranged on the left side of the hydrops recovering tank and is connected with the hydrops recovering tank through a recovering tank door hinge, and a flushing tank door is arranged on the eye flushing tank and is connected with the eye flushing tank through a flushing tank hinge; and an air blowing drying box is arranged on the upper side of the drainage flushing blinder and is connected with drainage flushing blinder through a drying box connection socket, an eye soft backing ring is arranged on the left side of the drainage flushing blinder, an atomizing nozzle is arranged on a flushing fluid conveying head, and an external flushing liquid catheter interface is arranged on the right side of the flushing fluid conveying head. The outflow-preventing type eye flushing device is complete in function and convenient to use; when ophthalmology clinical examination and treatment are carried out, operation is easy and convenient, time and labor are saved, and the outflow-preventing type eye flushing device is clean and sanitary; and the working difficulty of a medical worker is reduced.

Owner:陈健

Preparation method of graphite oxide

The invention discloses a preparation method of graphite oxide. The preparation method comprises the steps: adding concentrated sulfuric acid in a dry beaker, cooling with ice water, adding a solid mixture of flake graphite and NaNO3 under constant stirring, and then slowly adding a potassium permanganate powder; after finishing addition of KMnO4, removing the water bath, and continuing stirring; slowly adding deionized water, stirring, then adding deionized water for dilution, carrying out a reaction under a condition of normal temperature, then adding hydrogen peroxide, reducing a residual oxidant until the solution becomes bright yellow, and then centrifuging to obtain a yellow-brown residue; respectively washing by an HCl solution and deionized water for 3 times, and centrifuging for one time after each washing until the filtrate is neutral; and finally placing the filter cake in a 60 DEG C drying box, and fully drying. The preparation method is safe and simple in operation and low in equipment requirements, can prepare graphite oxide with relatively high carbon-oxygen ratio; and moreover, the graphite oxide prepared by the method can be used for preparing graphene, and graphene is further applied in battery materials, composite materials, electronic devices, energy storage materials and other fields.

Owner:SUZHOU SHIYOUJIA ELECTRONICS TECH

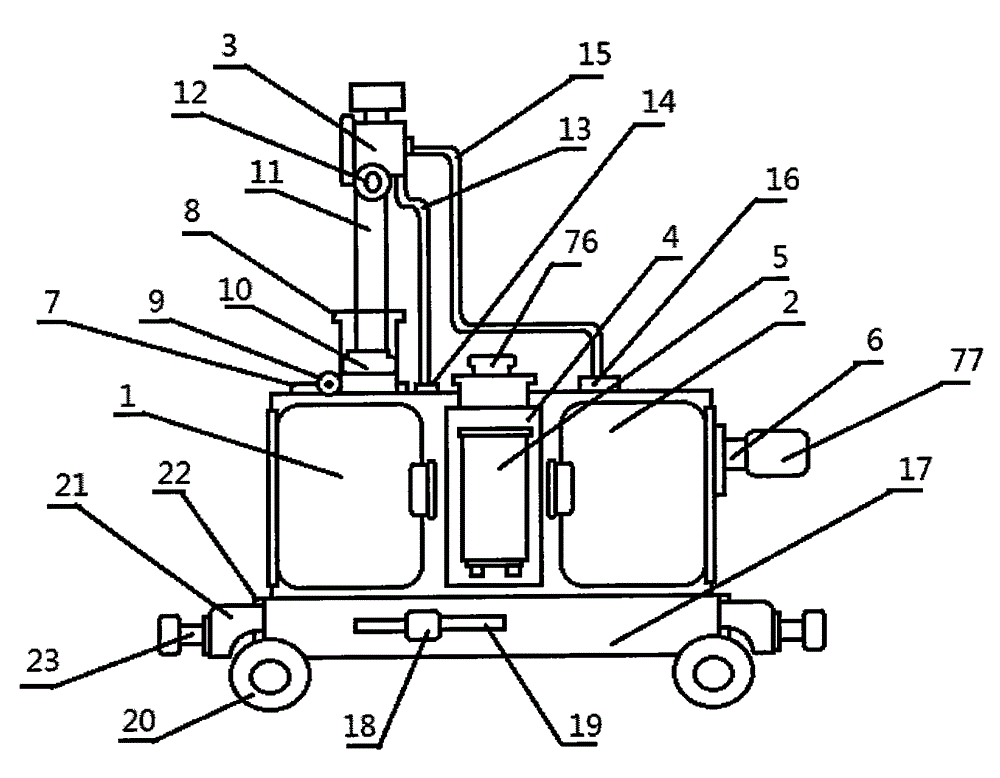

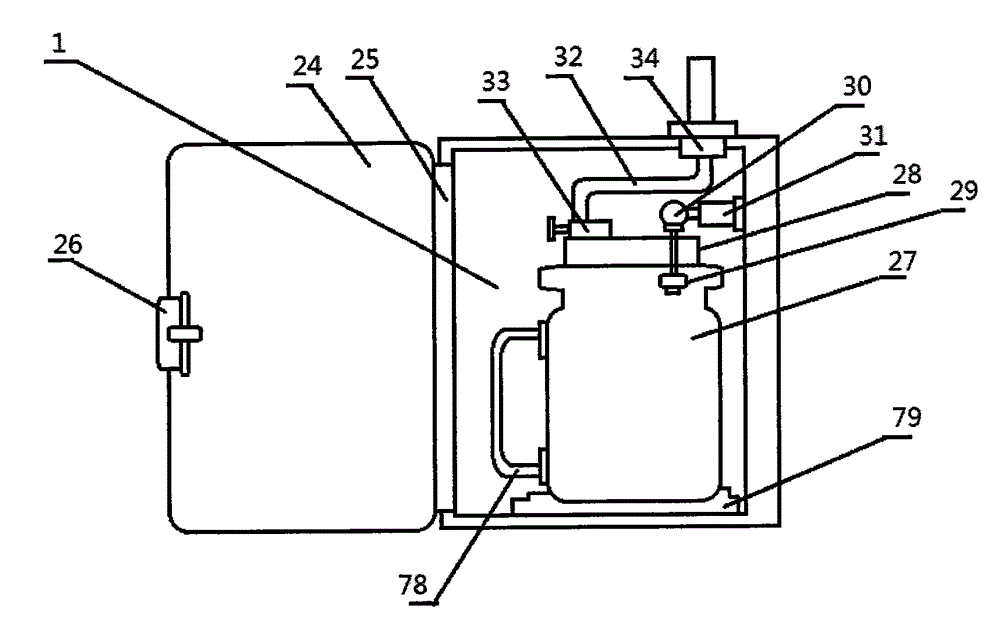

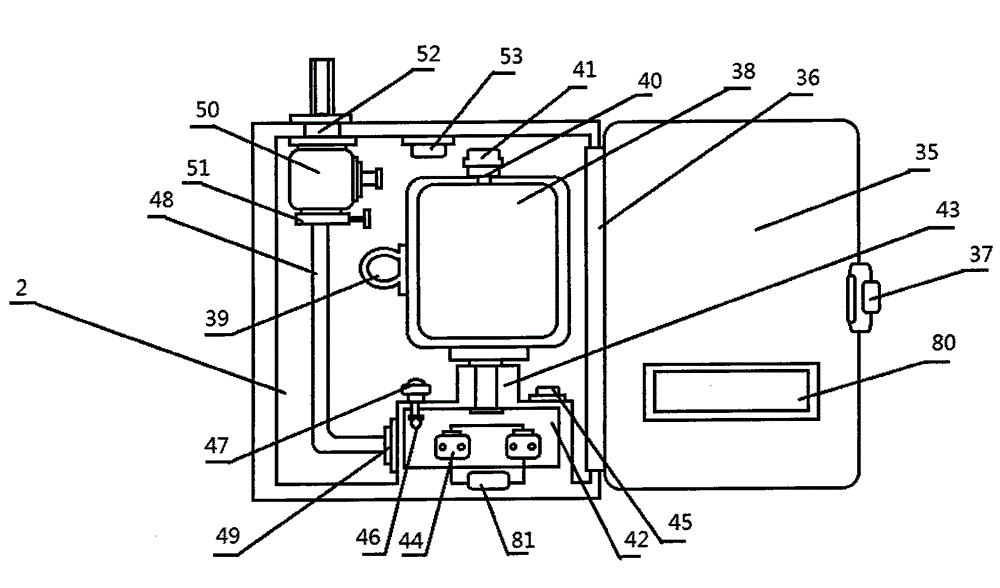

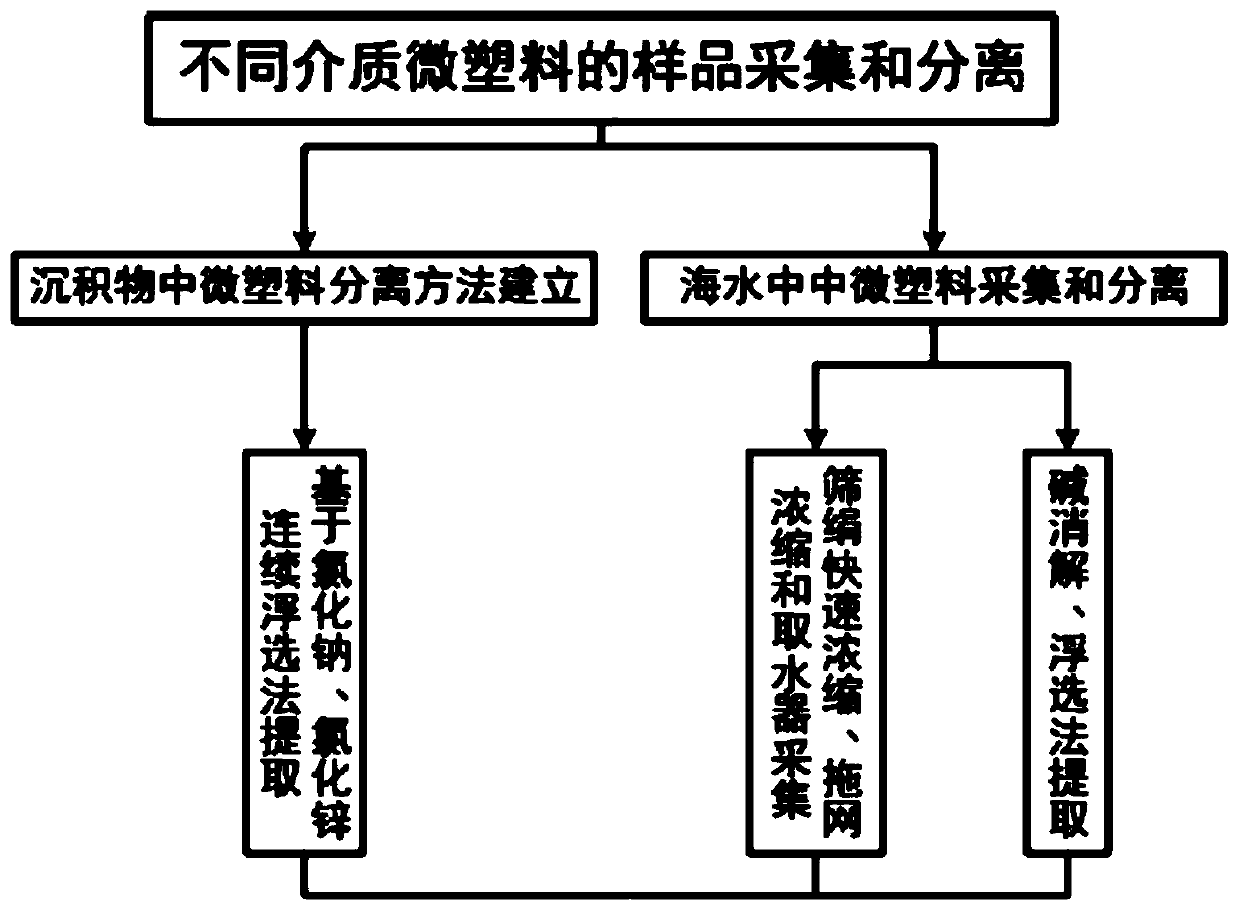

Efficient separation device and method for ocean microplastics

InactiveCN111346729AImprove extraction efficiencySuitable for separation and extractionPreparing sample for investigationColor/spectral properties measurementsSpectrographEngineering

The invention provides an efficient separation device for ocean microplastics. The efficient separation device comprises an electrothermal constant-temperature air blast dry box, a heat-collection type magnetic stirrer, an electronic balance, a numerical control ultrasonic wave cleaner, a stereomicroscope, a Fourier transform infrared spectrograph, a microscope system and an ultrapure water processing system, wherein the ultrapure water processing system is used for flushing filtered salt on a filter and a filtering membrane; the microplastics are put in the numerical control ultrasonic wave cleaner; the electrothermal constant-temperature air blast dry box is connected with the heat-collection type magnetic stirrer for concentrating a microplastics flotation liquid; and a solution and themicroplastics, which are separated, are analyzed through the Fourier transform infrared spectrograph, the solid electronic balance, the stereomicroscope and the microscope system to form microplastics recovery rate data. A corresponding separation method comprises the following steps of: on the basis of sodium chloride and zinc chloride, carrying out continuous floatation method extraction on themicroplastics in sediments; carrying out quick concentration, trawling concentration and collection by a water taking device on the microplastics in seawater; carrying out alkali digestion; and carrying out extraction by a floatation method.

Owner:TIANJIN ENVIRONMENT MONITORING CENT

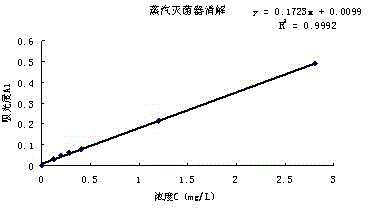

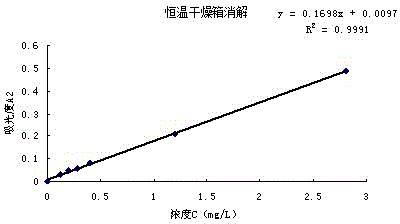

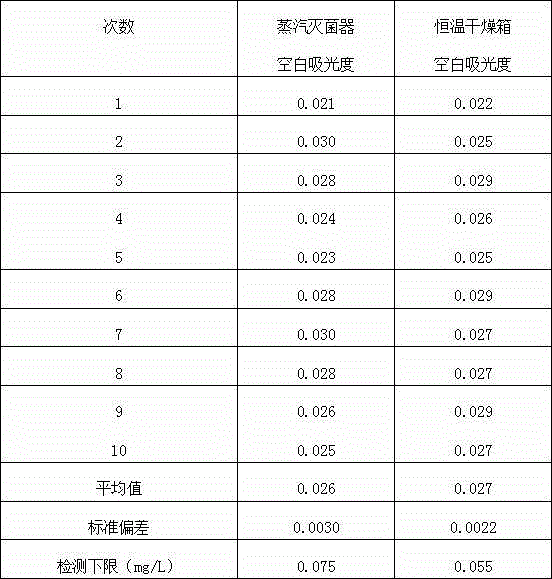

Improved determination method for total nitrogen in water

InactiveCN104155258ABig spaceSimple and fast operationColor/spectral properties measurementsPotassium nitrateNitrate

The invention provides an improved determination method for total nitrogen in water. The method comprises the following steps: respectively taking colorimetric pipes, adding a potassium nitrate standard working solution, adding water to dilute the potassium nitrate standard working solution to 10.00 ml, then adding a potassium persulphate solution, tightly plugging and fastening pipe plugs and then drying and cooling the colorimetric pipes; determining absorbance of the colorimetric pipes respectively at 220 nm and 275 nm so as to obtain correction absorbance Ar; after calculation of the correction absorbance, calculating a difference between the correction absorbance of a standard series and the correction absorbance of a blank solution and drafting a standard curve according to A and corresponding mass concentrations of nitrogen in nitrate; and detecting the content of total nitrogen in a sewage sample. According to the invention, since an electrothermal constant-temperature drying box is used for digestion, operation is simple, temperature is easily controllable, experimental requirements are met, so digestion with the constant-temperature drying box enables problems in digestion with an autoclave to be overcome; moreover, the constant-temperature drying box has great space and can treat a plurality of samples at the same time.

Owner:广州衡创测试技术服务有限公司

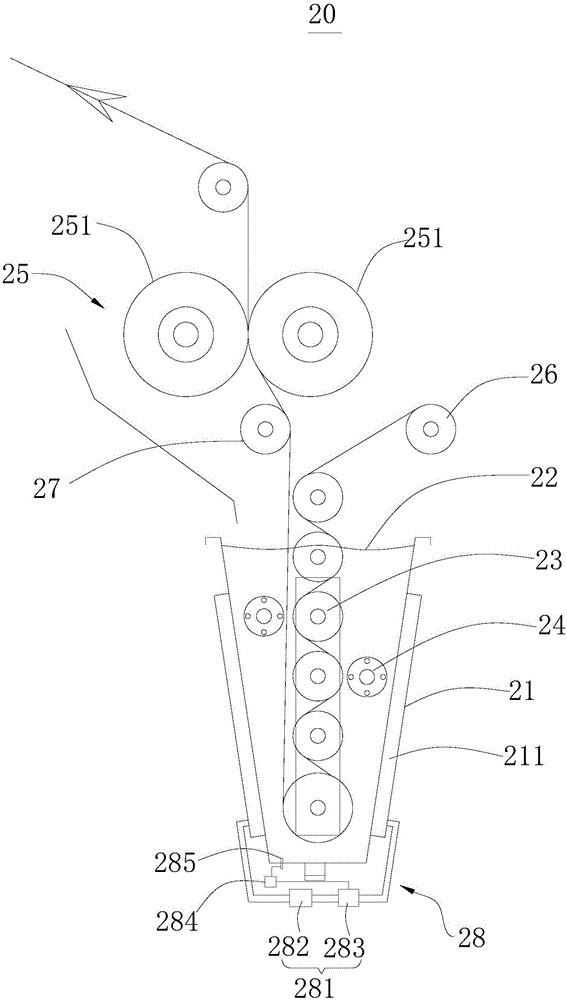

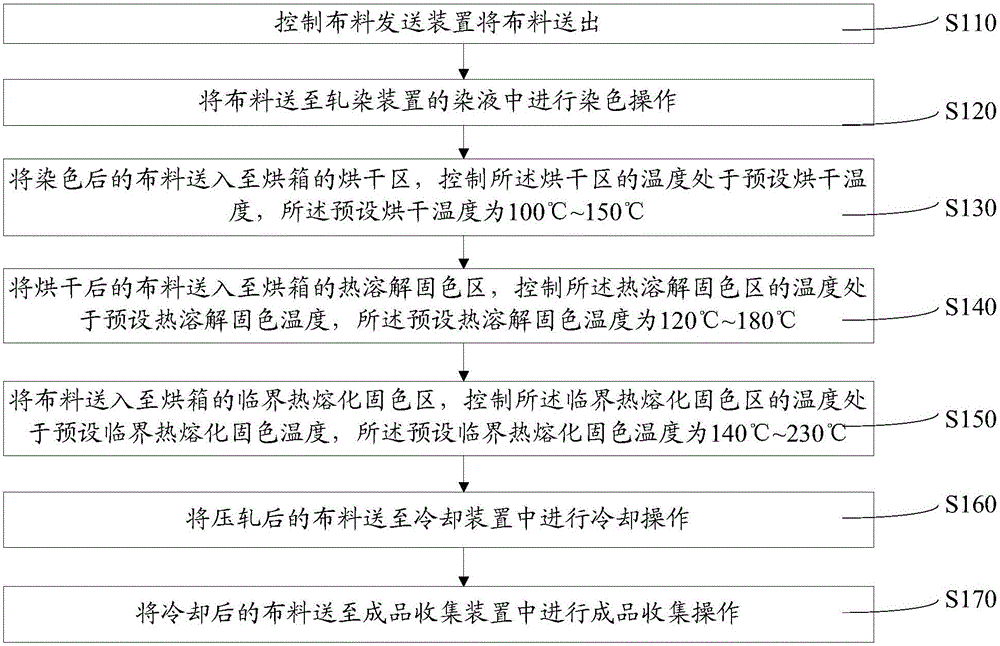

Dyeing equipment and method

ActiveCN105821606AReduce energy consumptionEmission reductionLiquid/gas/vapor removalTextile treatment machine arrangementsFiberSurface layer

The invention relates to dyeing equipment and method. The dyeing equipment comprises a cloth sending device, a pad dyeing device, a drying box, a cooling device and a finished-product collection device, wherein the drying box comprises a drying region, a heat dissolving and color fixing region and a critical heat melting and color fixing region in sequence along a cloth conveying direction; the drying region is used for drying cloth at a pre-set drying temperature; the heat dissolving and color fixing region is used for heating the cloth to a heat dissolving temperature at a pre-set heat dissolving and color fixing temperature; the critical heat melting and color fixing region is used for heating the cloth to a critical heat melting temperature at a pre-set critical heat melting and color fixing temperature. After a critical heat melting curing process is finished, dye molecules and fiber molecules are tightly combined together through rapid cooling, and dye micro-particles are fixedly arranged on a fiber surface layer of the cloth; the cloth is repeatedly bent and wound through a plurality of guide wheels so that the cloth has a soft hand feeling and a finished product is obtained to finish a dyeing process; compared with traditional dyeing equipment, the dyeing equipment has the advantages of relatively low energy consumption and less sewage discharging amount.

Owner:东莞市金银丰机械实业有限公司

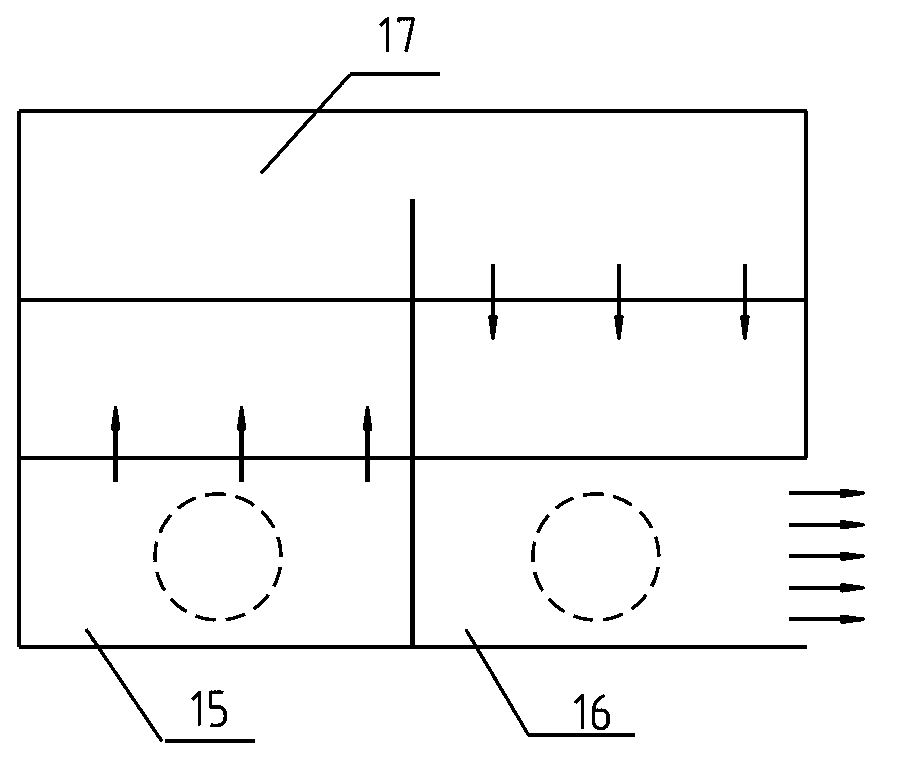

Hot air drying box

ActiveCN102384639AStrong penetrating powerReduce consumptionDrying gas arrangementsDrying machines with progressive movementsThermodynamicsNonwoven fabric

The invention relates to a hot air drying box, and belongs to the technical field of nonwoven machines. The hot air drying box comprises a box body, a hot air chamber and a combustion chamber which are arranged on two sides of the box body and are provided with fans, and two groups of hot air lead-out pipes which are arranged in a box body cavity. The hot air drying box is characterized in that each group comprises the same number of hot air lead-out pipes which are arranged at intervals to form upper and lower rows; a fabric guiding cavity is formed between the hot air lead-out pipes on the upper and lower rows; air outlet channels positioned on the hot air lead-out pipes on the upper row are downward, air outlet channels positioned on the hot air lead-out pipes on the lower row are upward, and the adjacent air outlet channels are partitioned by air flue partition pipes; each air flue partition pipe is contracted gradually towards the direction of pipe cavities of the hot air lead-out pipes and forms a structure of which the cross section is in a trapezoidal shape; and the widths of the air outlet channels are reduced towards the direction away from the pipe cavities from the pipe cavities. The hot air drying box has the advantages that an ideal hot drying effect can be achieved, the non-uniform heating phenomenon is avoided, large-thickness nonwoven fabrics or cotton fleeces are easy to penetrate, and the consumption of energy is reduced.

Owner:常熟市伟成非织造成套设备有限公司

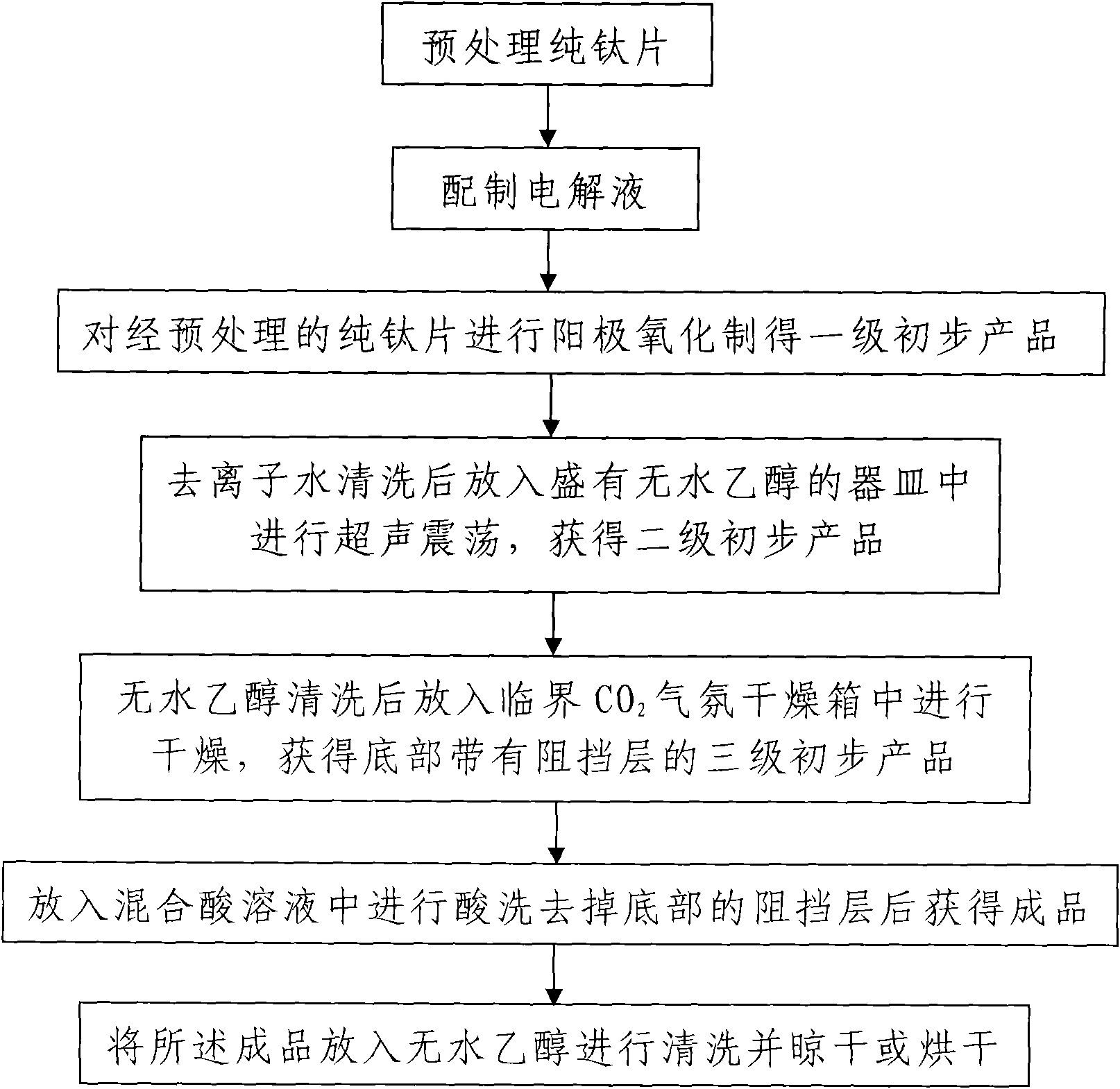

Preparation method of bi-pass large-area TiO* nanotube array film

ActiveCN101550581AImprove performanceClean thoroughlySurface reaction electrolytic coatingTio2 nanotubeMaterials science

The invention discloses a preparation method of a bi-pass large-area TiO2 nanotube array film, which includes the following steps of: preparing a first-grade preliminary product through the anodic oxidation of a pretreated titanium sheet; obtaining a second-grade preliminary product by cleaning the first-grade product with de-ionized water, putting the first-grade product into a vessel with absolute ethyl alcohol, putting the vessel into an ultrasonic cleaner for ultrasonic vibration and causing the TiO2 nanotube array film to be separated from a pure titanium matrix; obtaining a third-grade preliminary product with a barrier layer at the bottom after cleaning the second-grade product with absolute ethyl alcohol and putting and drying the second-grade product in a threshold CO2 drying box; obtaining the finished product by putting the second-grade product into the mixed acid solution and removing the barrier layer at the bottom through acid cleaning; and cleaning, airing or drying the finished product after being put into the absolute ethyl alcohol. The preparation method is simple and convenient in technical operation and reasonable in design. The prepared bi-pass large-area smooth TiO2 nanotube array film has higher photoelectric efficiency and can be effectively applied in the fields of gas separation, drug delivery, bone fixation, and the like.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

Low-temperature negative pressure drying method and device for textile materials and textiles

InactiveCN102175071AOvercoming the bottleneck of the relatively long isokinetic drying phaseFast drying processDrying using combination processesDrying machines with local agitationResonant cavityMicrowave

The invention discloses a low-temperature negative pressure drying method and a low-temperature negative pressure drying device for textile materials and textiles. The device comprises a microwave source, a temperature sensor, a resonant cavity, an air-cooled or water-cooled device, a vacuum sensor, an air release valve, a humidity sensor, an air extraction valve, an air extraction pipeline, a vacuum pump, a vacuum pump motor, a stirrer, a panel, a controller, a shielding sealing door, a shell, an indicating lamp, a switch, a scattered article drying box and a cheese drying bracket; and the scattered textile materials or textiles are put into the scattered article drying box, or cheeses are stacked on the cheese drying bracket and then put into the resonant cavity, and the dried articles are heated and dried under the low-temperature negative pressure working condition. Relatively long bottleneck at the uniform velocity drying stage when single microwave is used for drying can be effectively overcome, over drying is avoided, and the whole drying process is quick and energy-saving; and the method and the device can particularly meet the drying requirements of special animal fibers, artificial fibers, synthetic fibers and like and the products thereof with special temperature requirements.

Owner:SHANGHAI ZHONGFANG BAODA TEXTILE INTELLIGENT INSTR +2

Metal foil band electroplating system and application thereof

InactiveCN101260554ASuitable for double-sided platingImprove efficiencyElectrolysis componentsAlloyEngineering

The invention discloses a metal foil belt material electroplating system, which comprises an unreeling machine, a plated head lifter, a plated head, an electroplating bath, a washing box, a blasting drying box and a wrapup machine, wherein, one end of a metal foil belt material is connected with the unreeling machine and the other end of the metal foil belt material is connected with the wrapup machine; the electroplating bath, the washing box and the blasting drying box are arranged on the forward direction of the metal foil belt material in turn; and the plated head lifter is connected with the plated head which is arranged above the electroplating bath. The metal foil belt material electroplating system is applied to continuous preparation of novel alloy cathode materials of a lithium ion battery and can perform double-sided electroplating on various metal foil belt materials. The metal foil belt material electroplating system performs continuous integrated processing of electroplating, washing and drying on the metal foil belt materials, thereby the efficiency is high and the operation is convenient. Moreover, the metal foil belt material electroplating system has the advantages of low cost, small pollution, capability of performing double-sided coating, tight cladding which is difficult to fall off, controllable thickness and particle diameter and so on.

Owner:SOUTH CHINA NORMAL UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com