Patents

Literature

38 results about "Kilogram-force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The kilogram-force (kgf or kgF), or kilopond (kp, from Latin pondus meaning weight), is a gravitational metric unit of force. It is equal to the magnitude of the force exerted on one kilogram of mass in a 9.80665 m/s² gravitational field (standard gravity, a conventional value approximating the average magnitude of gravity on Earth). Therefore, one kilogram-force is by definition equal to 9.80665 N. Similarly, a gram-force is 9.80665 mN, and a milligram-force is 9.80665 μN. One kilogram-force is approximately 2.204622 pound-force.

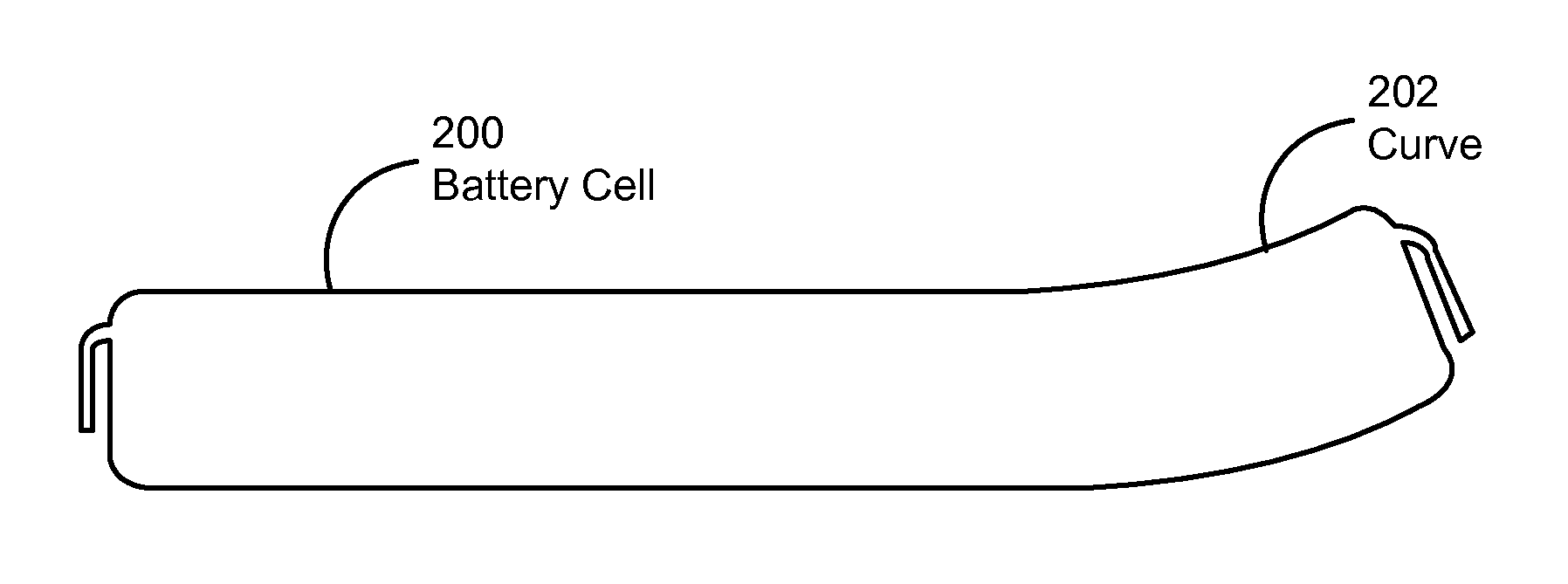

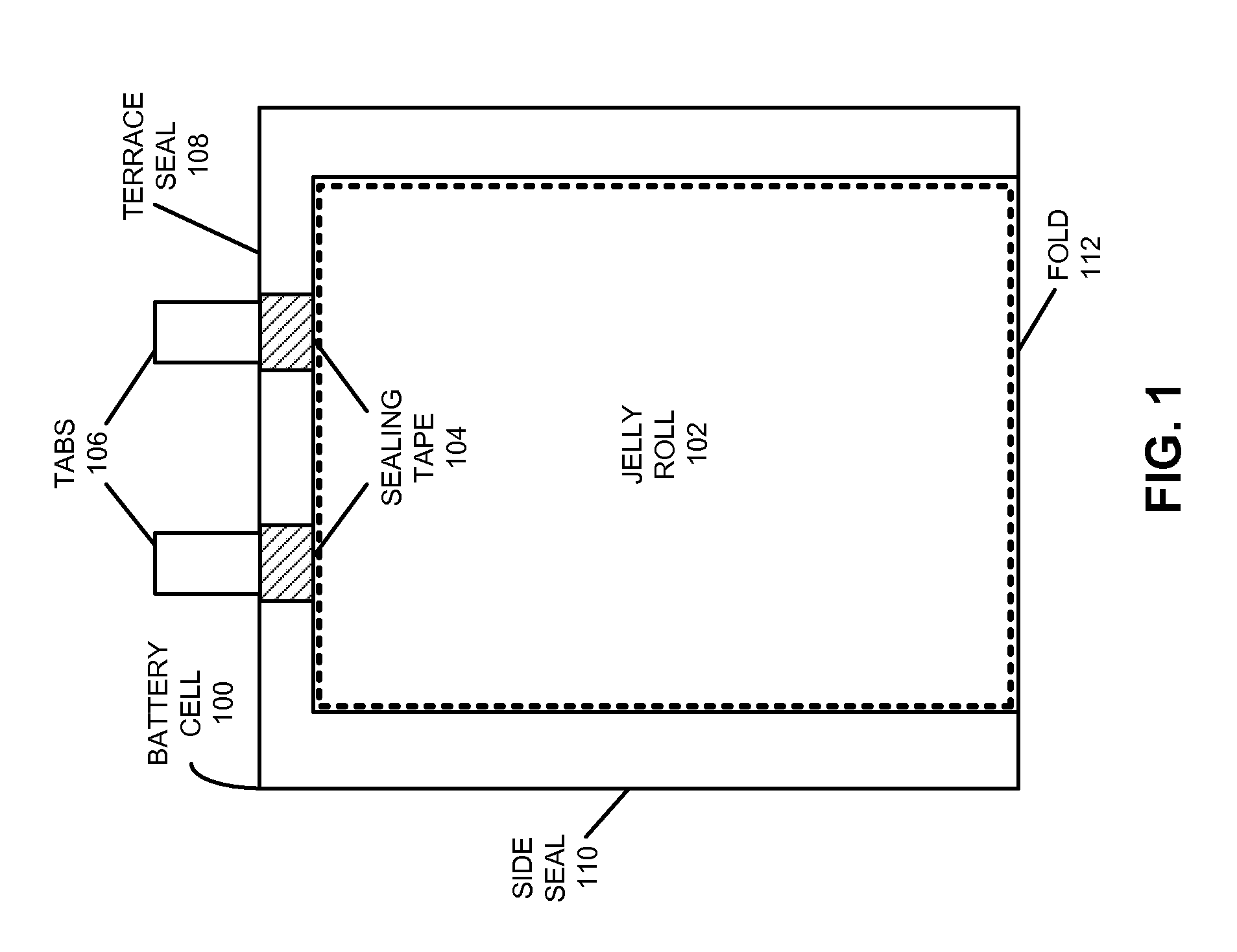

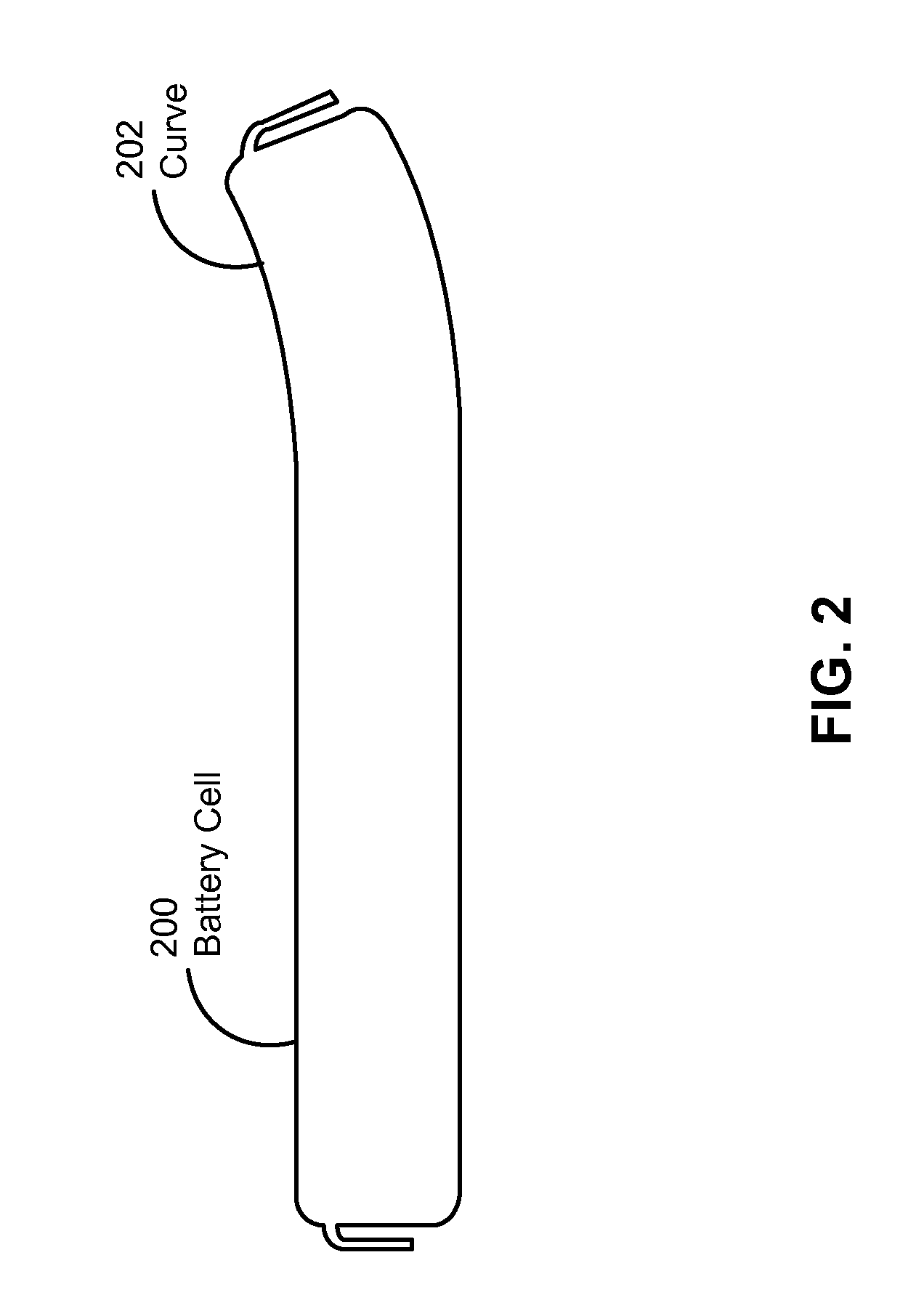

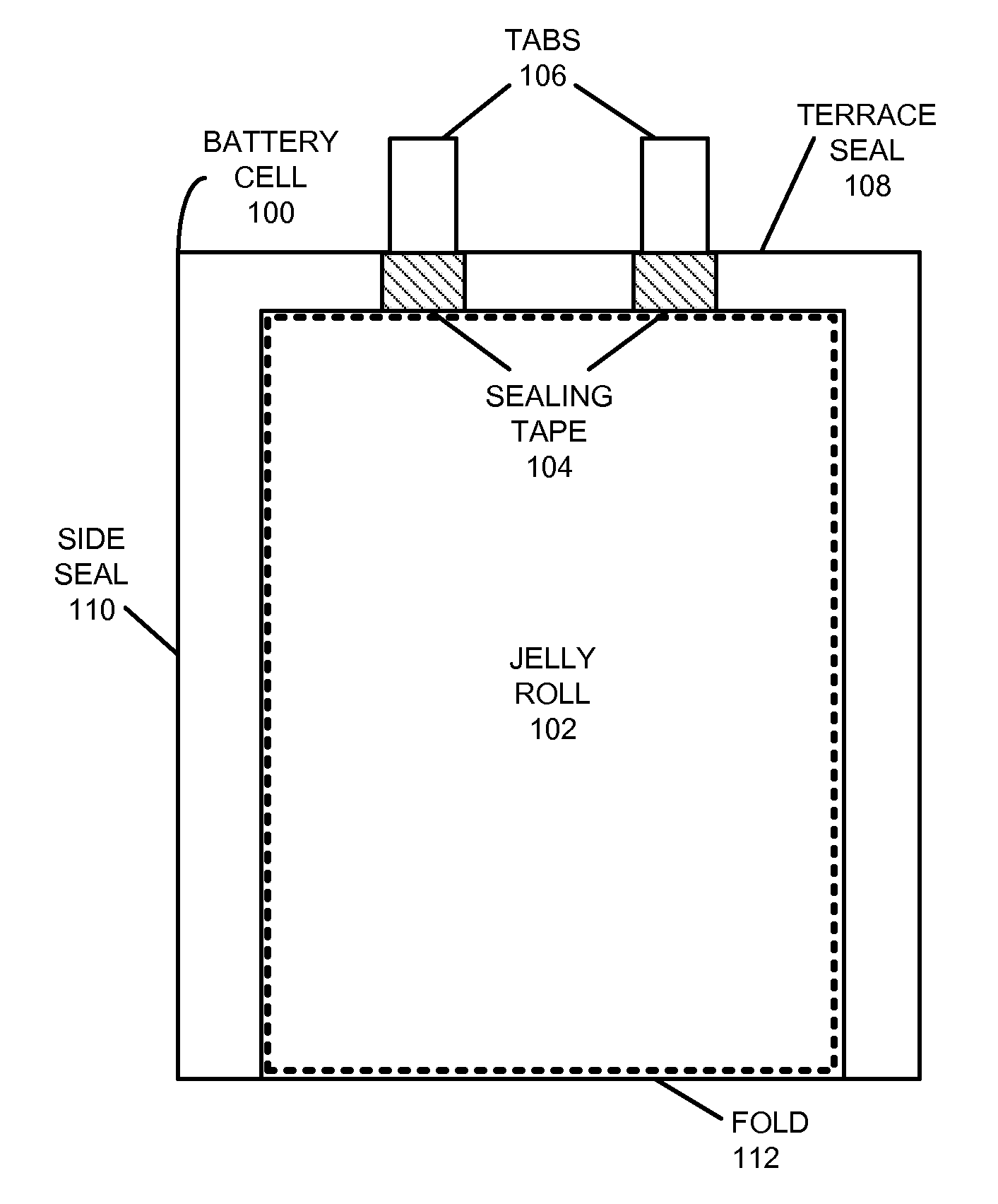

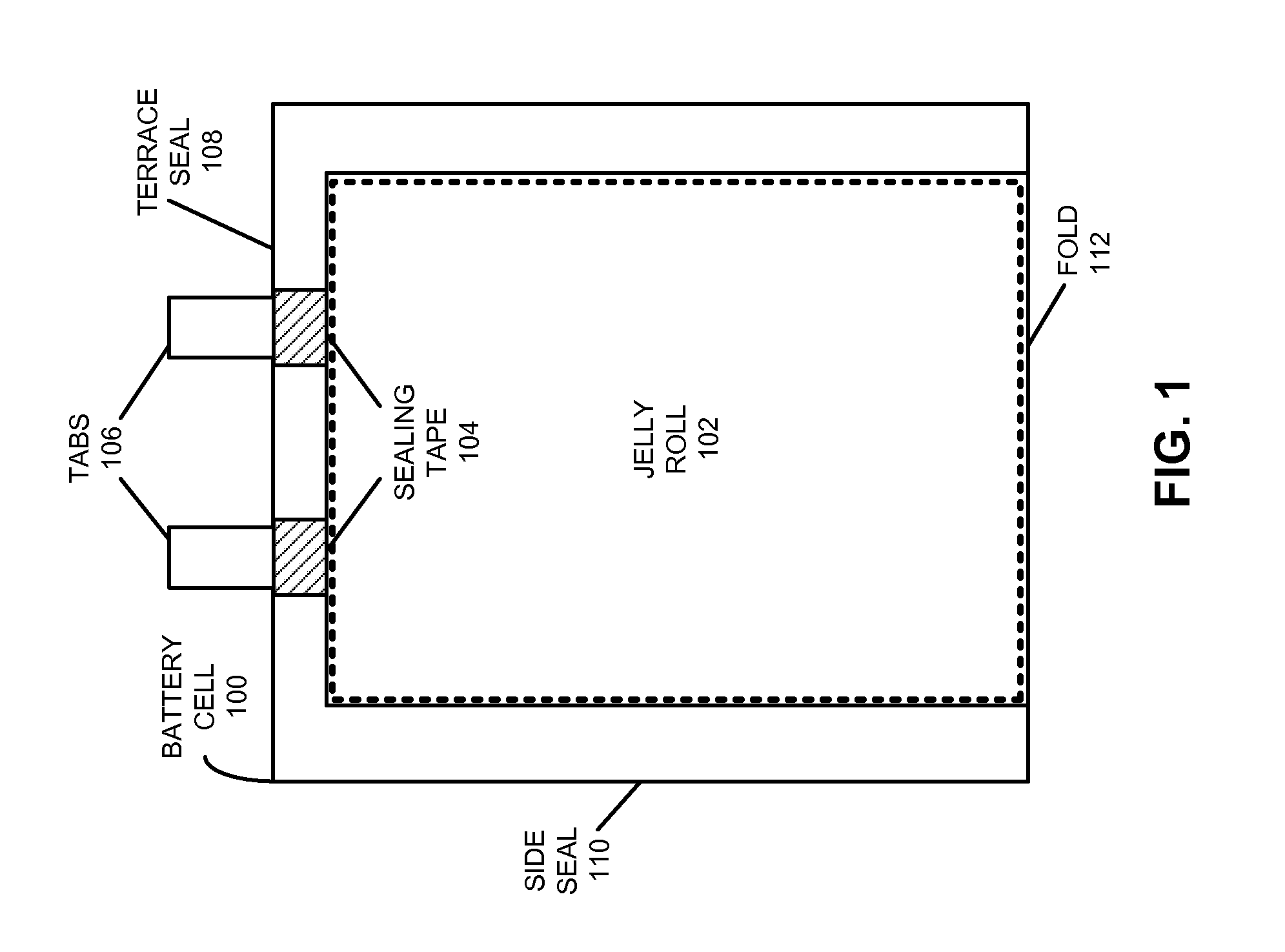

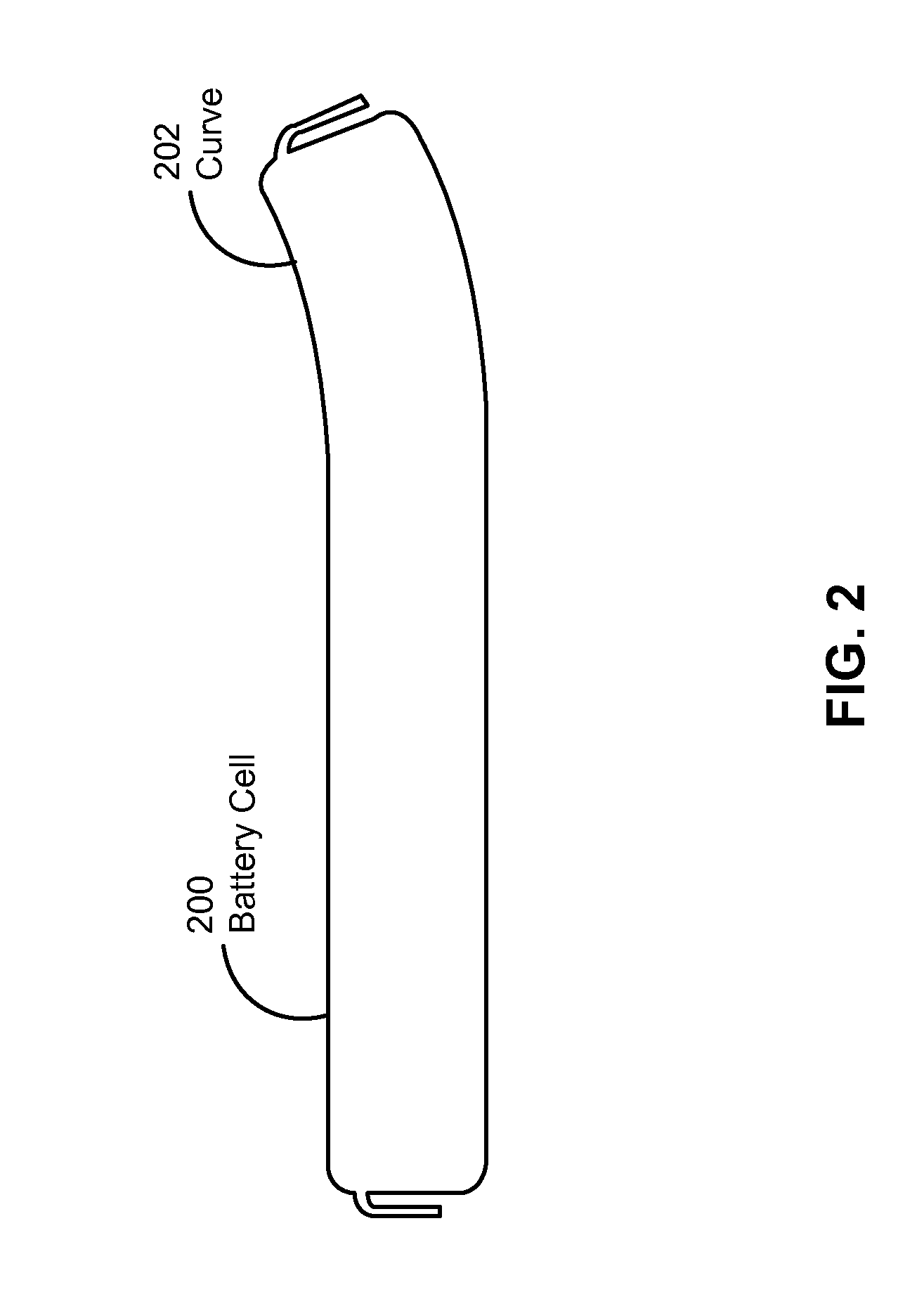

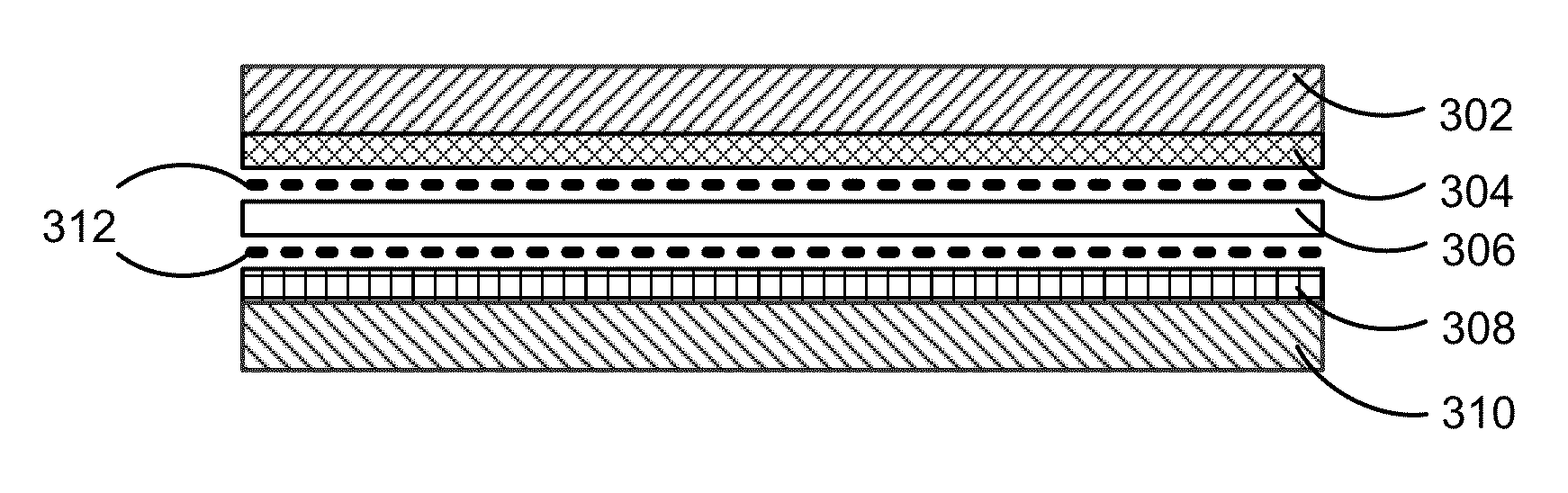

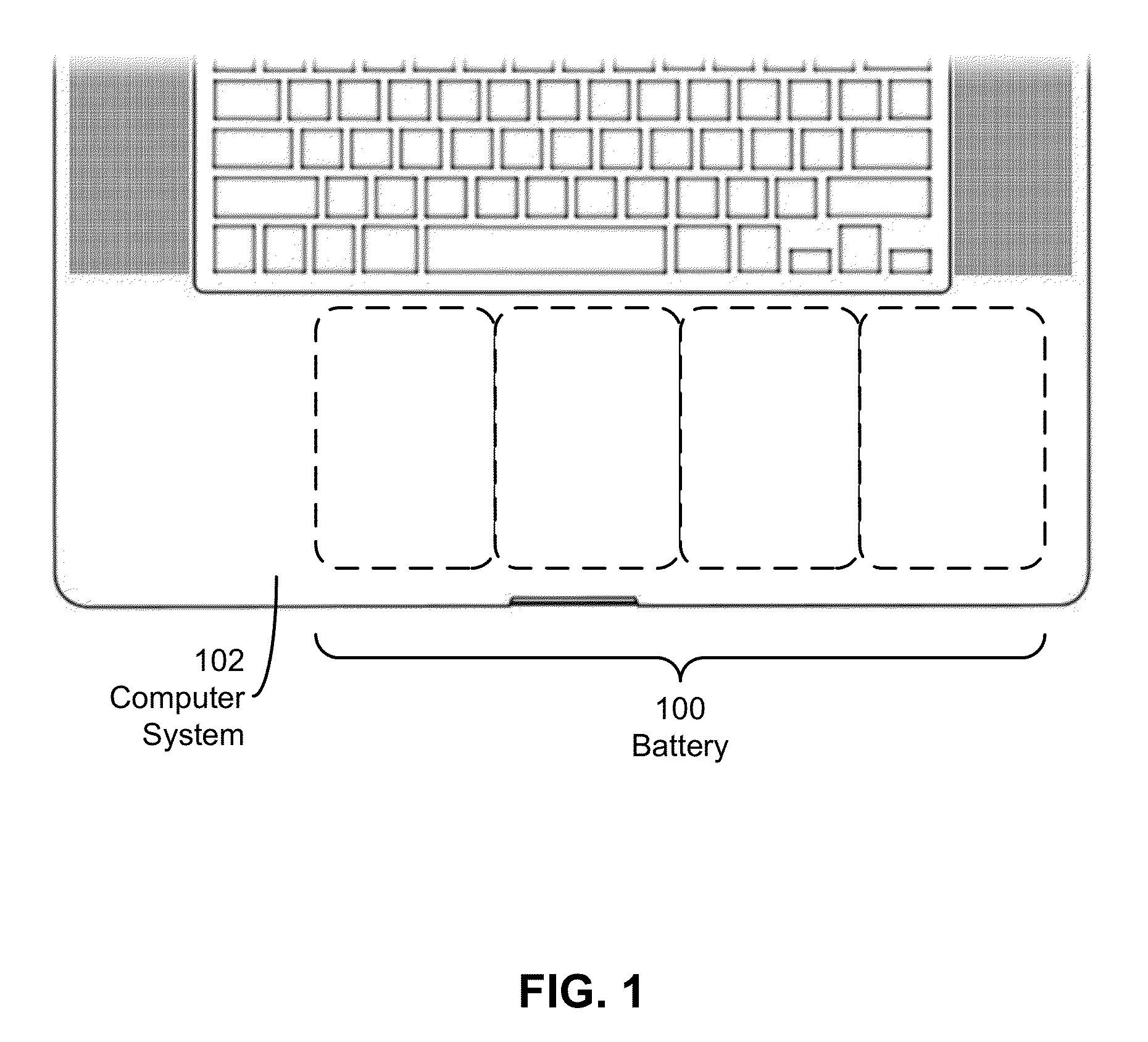

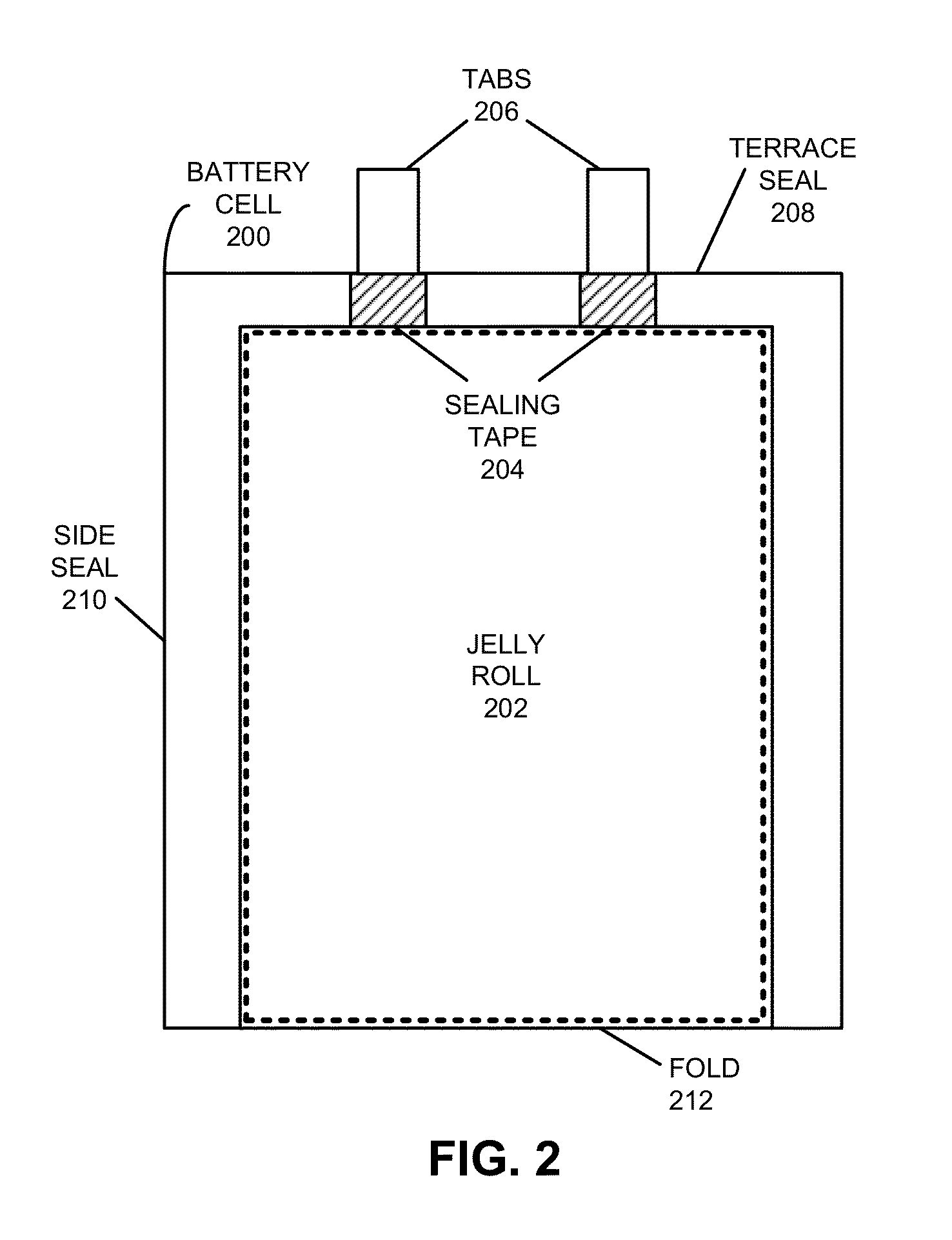

Curved battery cells for portable electronic devices

InactiveUS20130108907A1Facilitate efficient use of spaceBatteries circuit arrangementsFinal product manufactureKilogram-forceSquare Millimeter

The disclosed embodiments relate to the manufacture of a battery cell. The battery cell includes a set of layers including a cathode with an active coating, a separator, and an anode with an active coating. The battery cell also includes a pouch enclosing the layers, wherein the pouch is flexible. The layers may be wound to create a jelly roll prior to sealing the layers in the flexible pouch. A curve may also be formed in the battery cell by applying a pressure of at least 0.13 kilogram-force (kgf) per square millimeter to the layers using a set of curved plates applying a temperature of about 85° C. to the layers.

Owner:APPLE INC

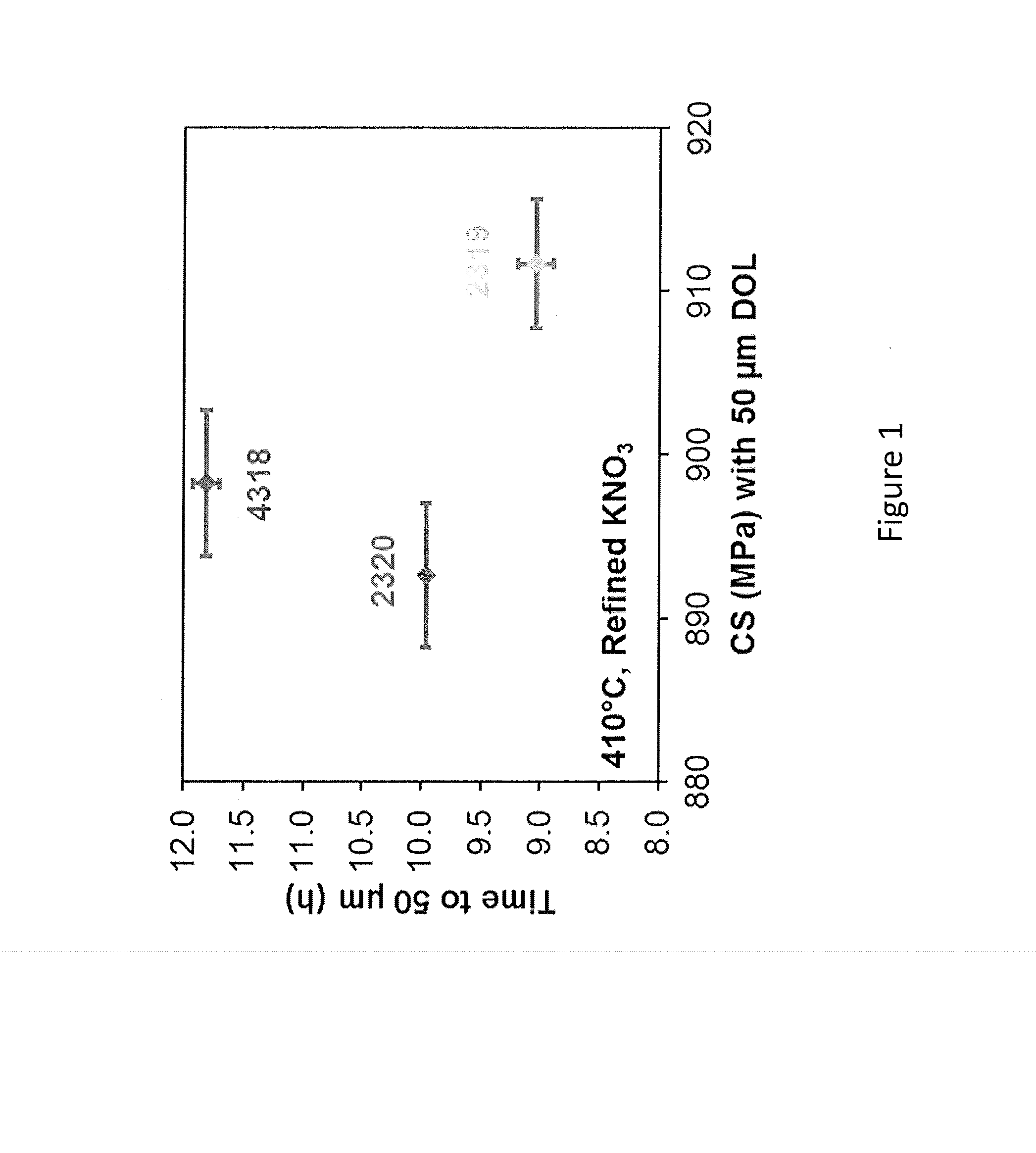

Zircon compatible, ion exchangeable glass with high damage resistance

An ion exchangeable glass having a high degree of resistance to damage caused by abrasion, scratching, indentation, and the like. The glass comprises alumina, B2O3, and alkali metal oxides, and contains boron cations having three-fold coordination. The glass, when ion exchanged, has a Vickers crack initiation threshold of at least 10 kilogram force (kgf).

Owner:CORNING INC

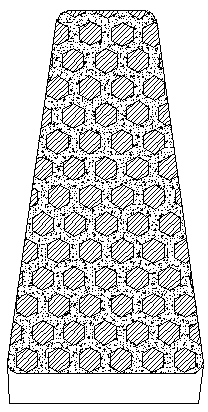

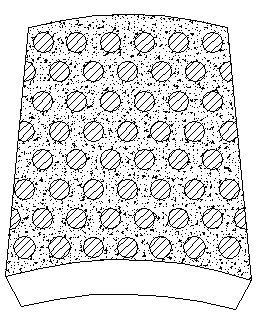

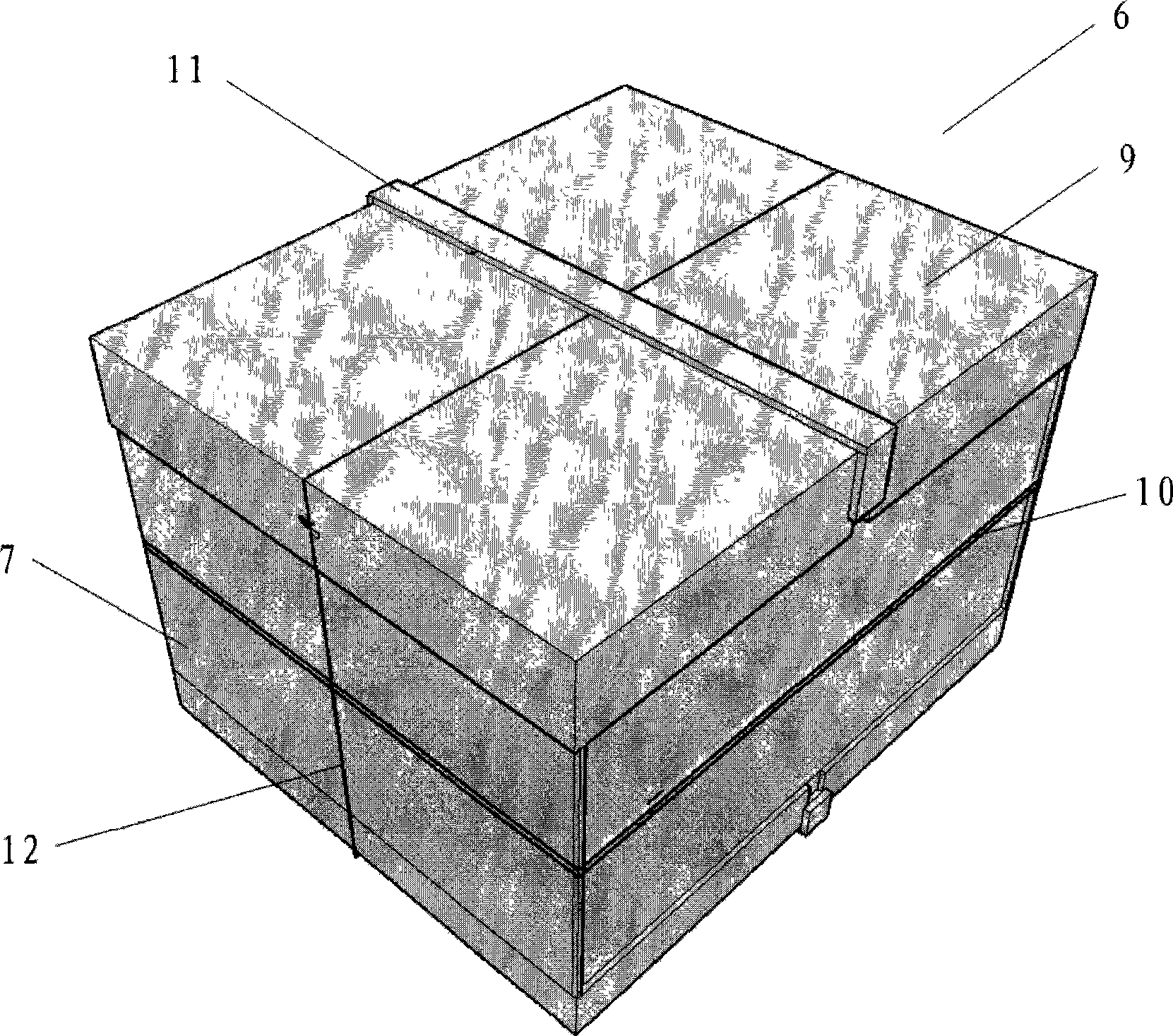

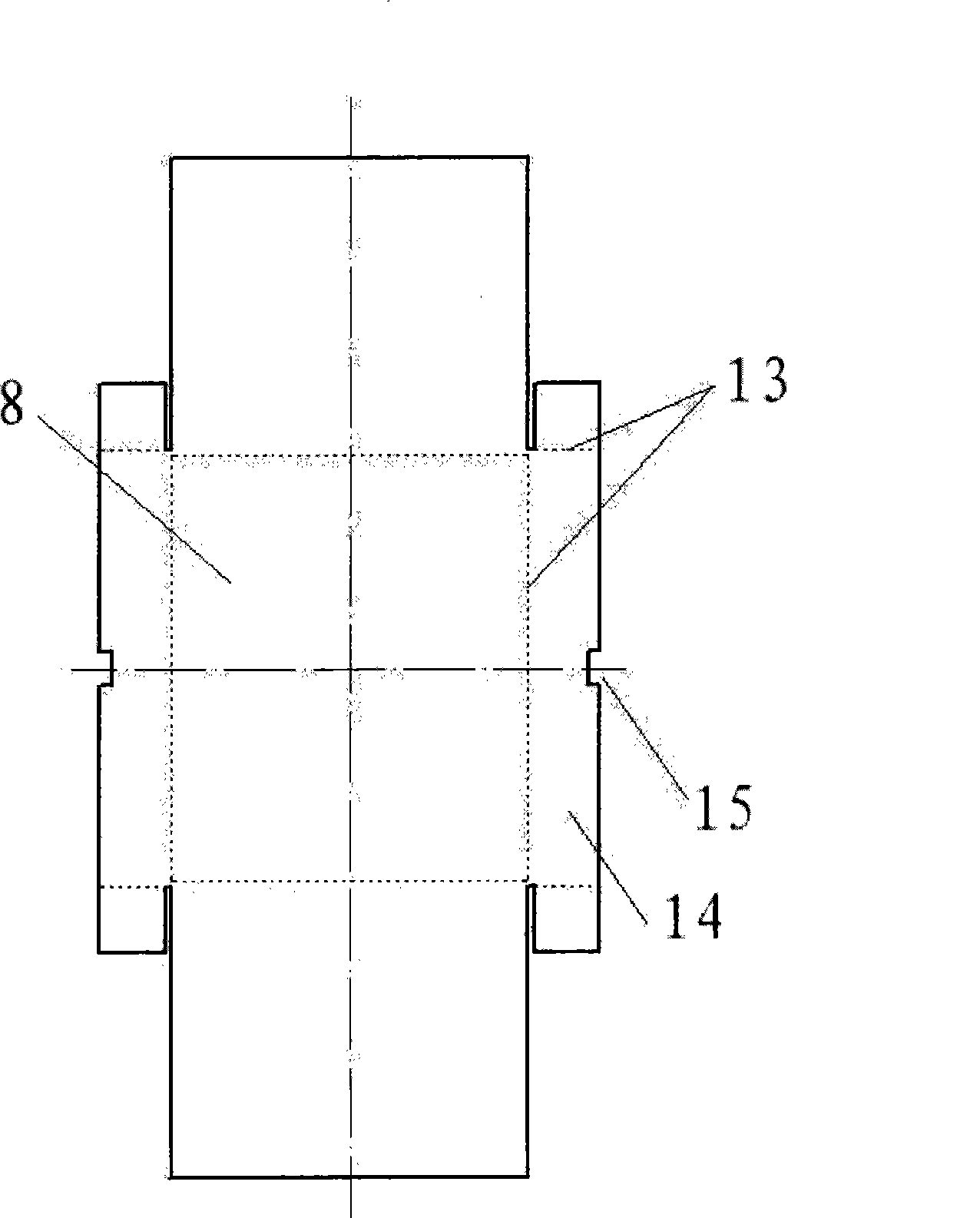

Ceramic grid enhanced metal matrix composite perform and preparation method thereof

The invention discloses a ceramic grid enhanced metal matrix composite perform and a preparation method thereof. The preparation method comprises the following steps of: uniformly mixing ceramic particles with the particle sizes of 8-30 meshes and self-fluxing alloy powder in polyvinyl alcohol to obtain a mixture; filling the mixture in a grid cavity, prepressing for preparing ceramic grids, filling the self-fluxing alloy powder into grid holes after the grids leave from a mold, wherein the monolithic material is pressed with 100-300 kilogram force, molding and demolding, placing and drying a biscuit and a mold cavity bottom plate in a 150 DEG C drying oven for 2 hours; placing the dried biscuit and the mold cavity bottom plate in a vacuum furnace, sintering for 30-90 minutes under the conditions that the temperature is 1000-1300 DEG C, and the vacuum degree is 0.1 Pa, and cooling and discharging to obtain the ceramic grid enhanced metal matrix composite perform. The ceramic grid enhanced metal matrix composite perform prepared by the method has the advantages of high density, uniform distribution of ceramic particles, good wear resistance and high grinding efficiency.

Owner:NANTONG GAOXIN ANTIWEAR MATERIALS TECH CO LTD

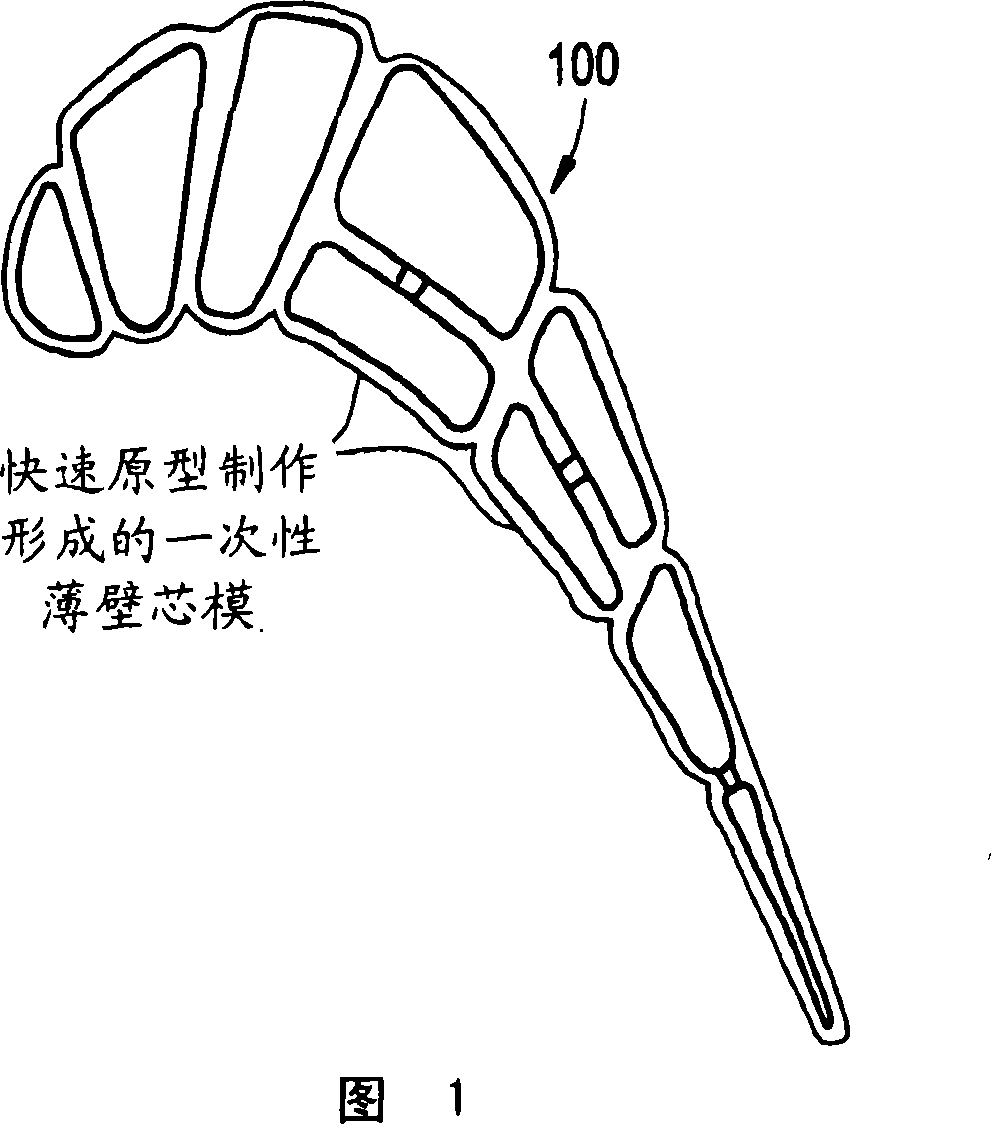

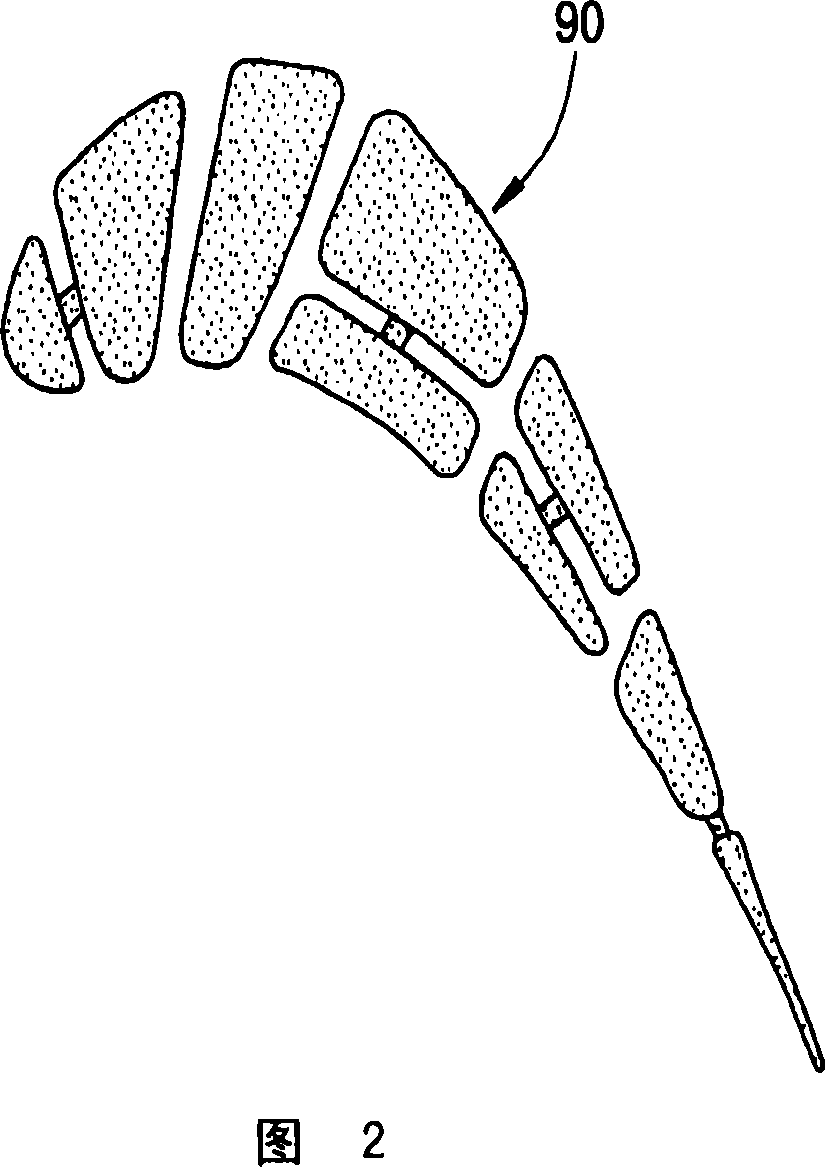

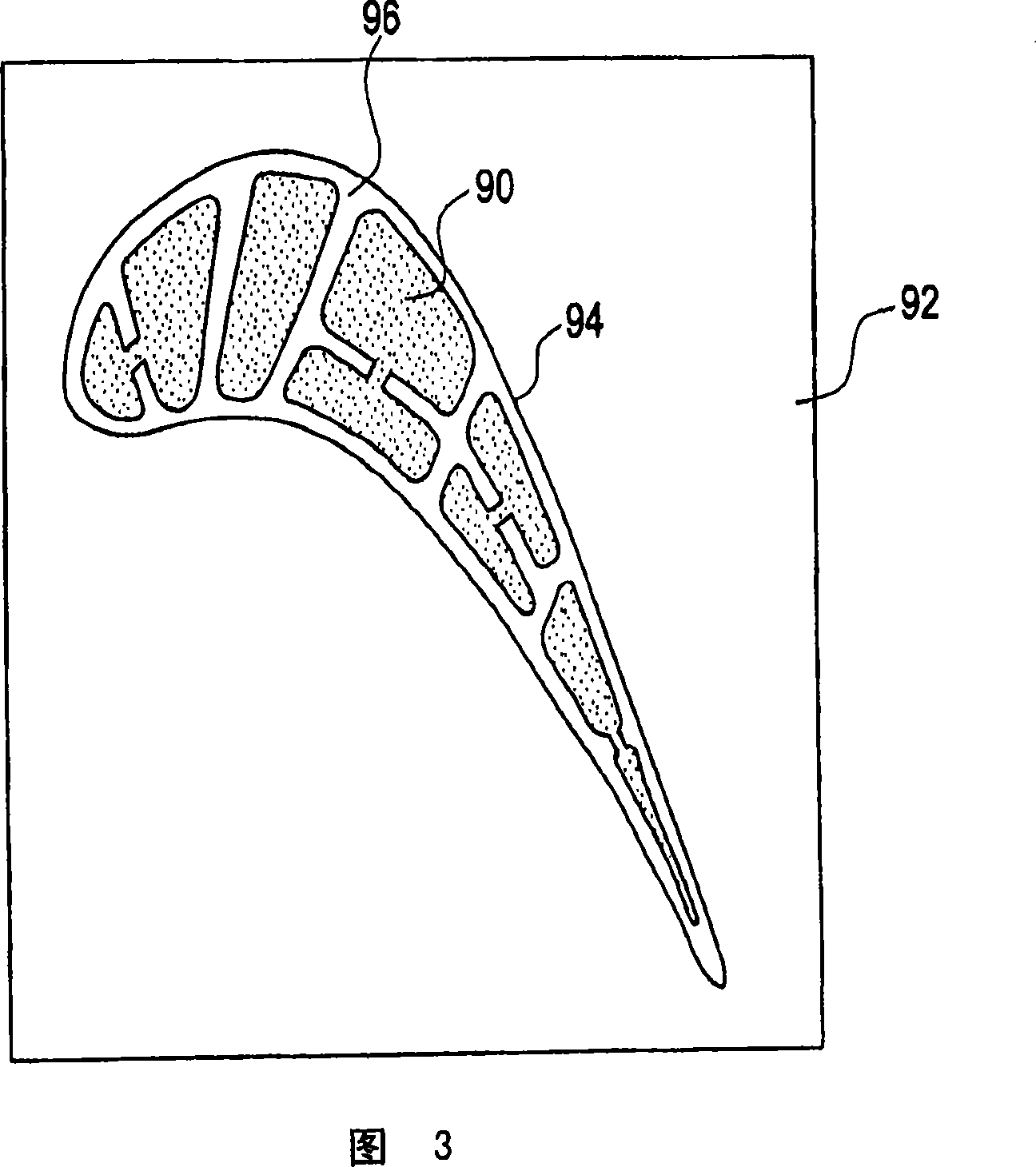

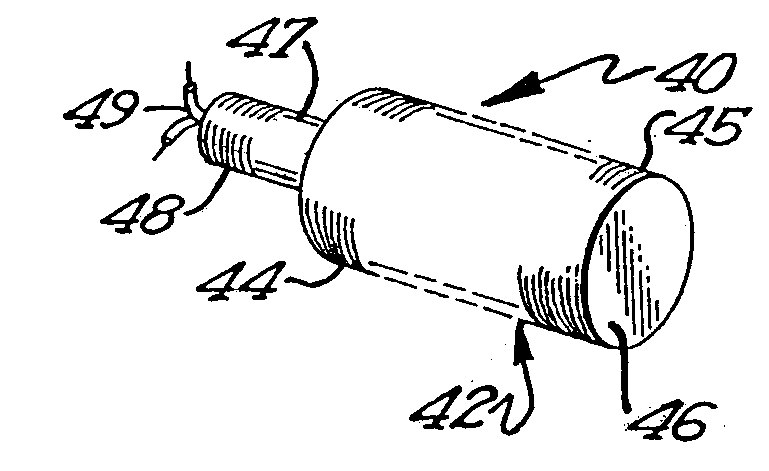

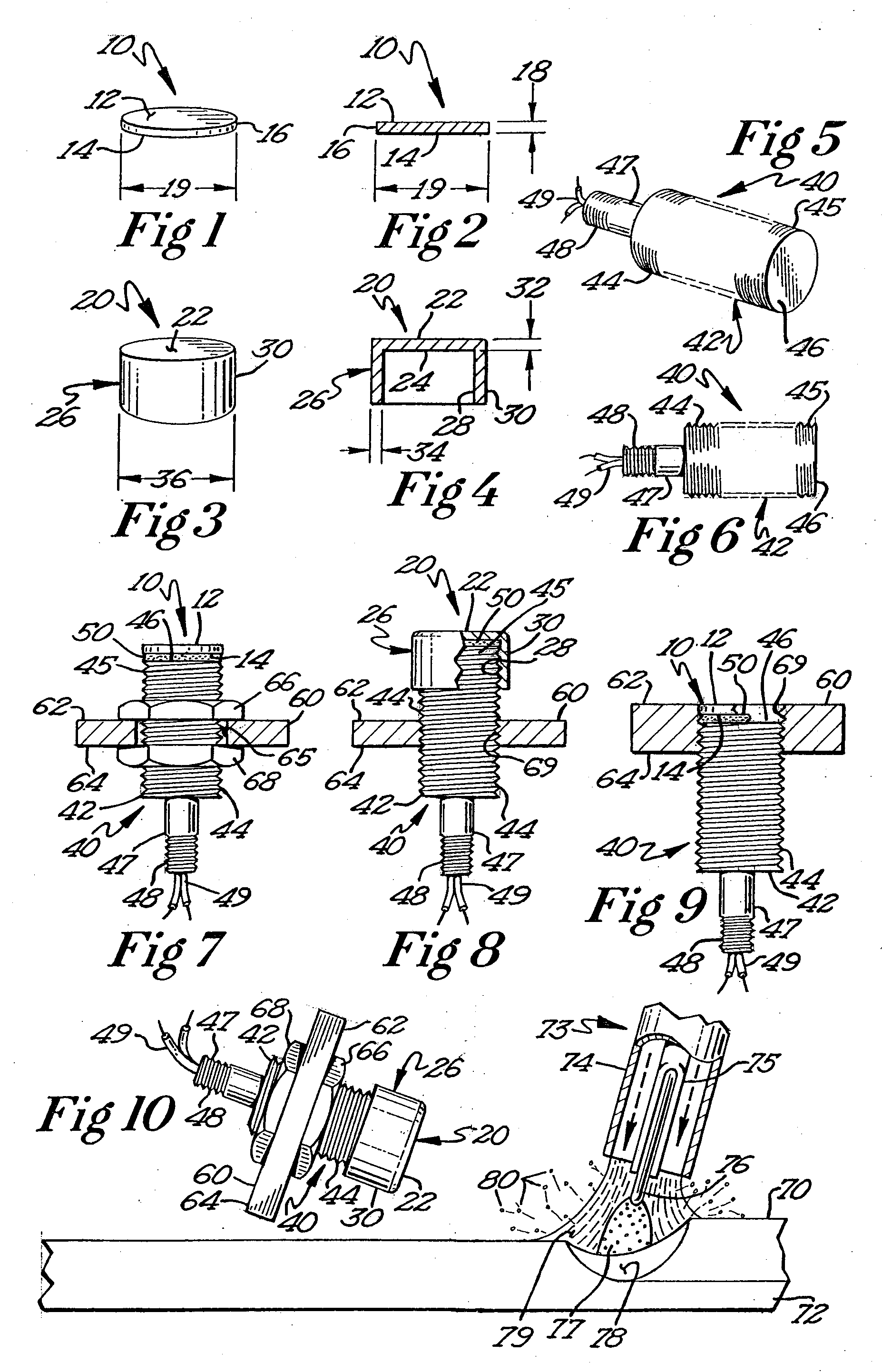

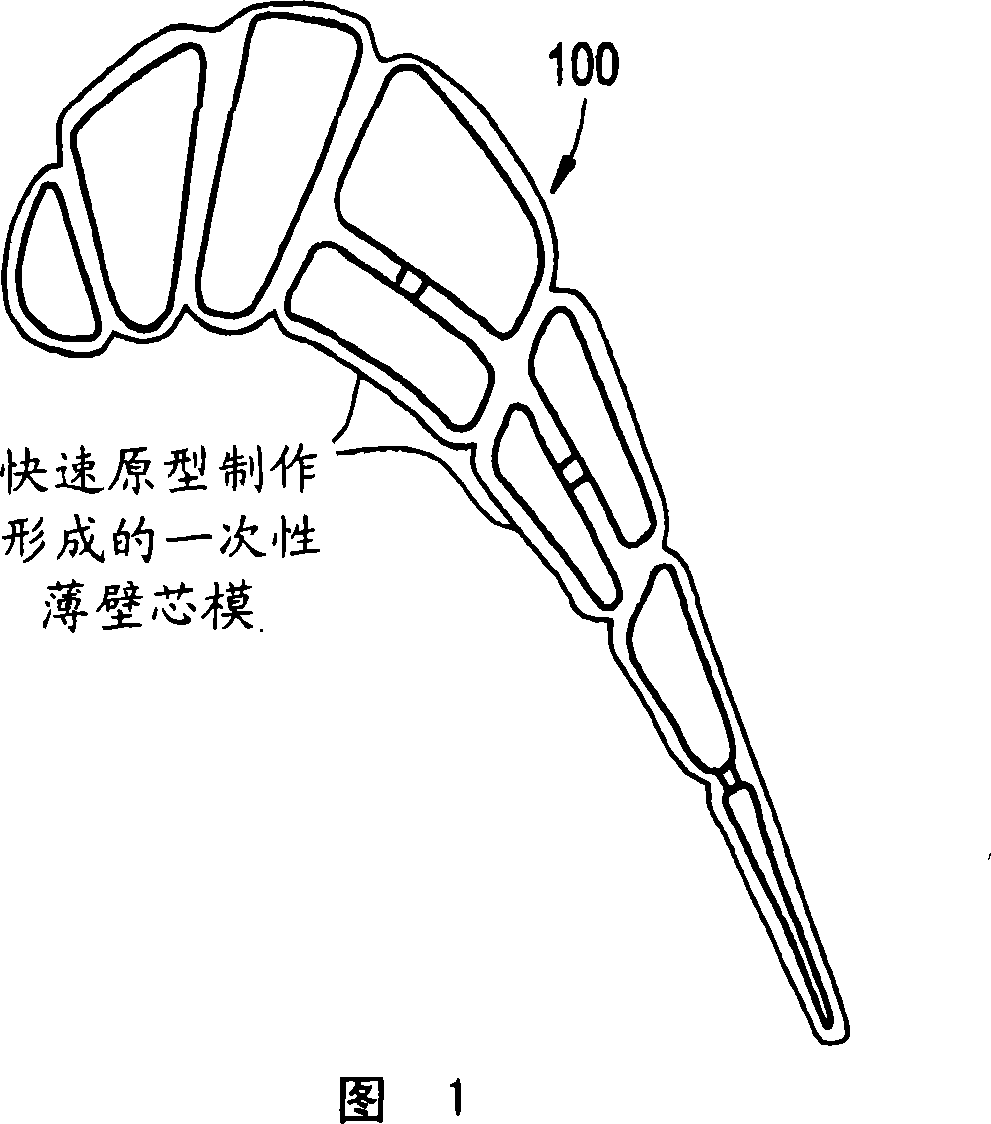

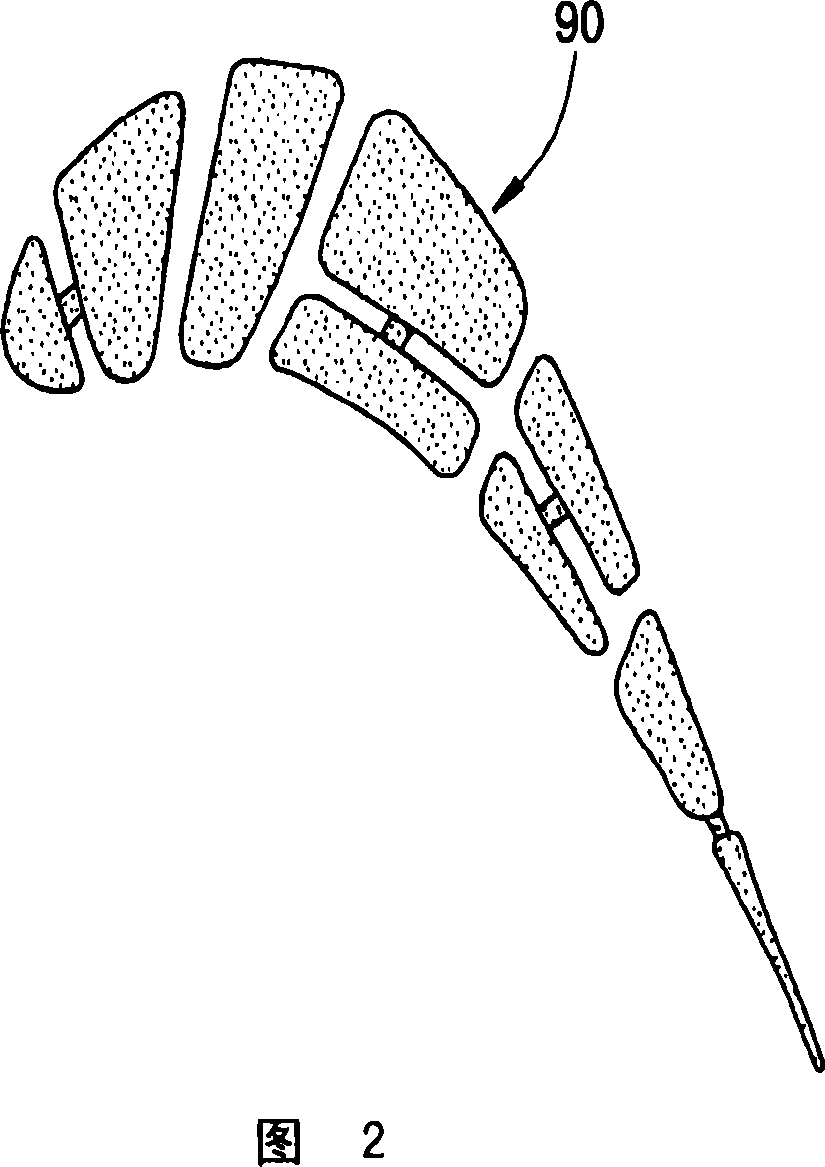

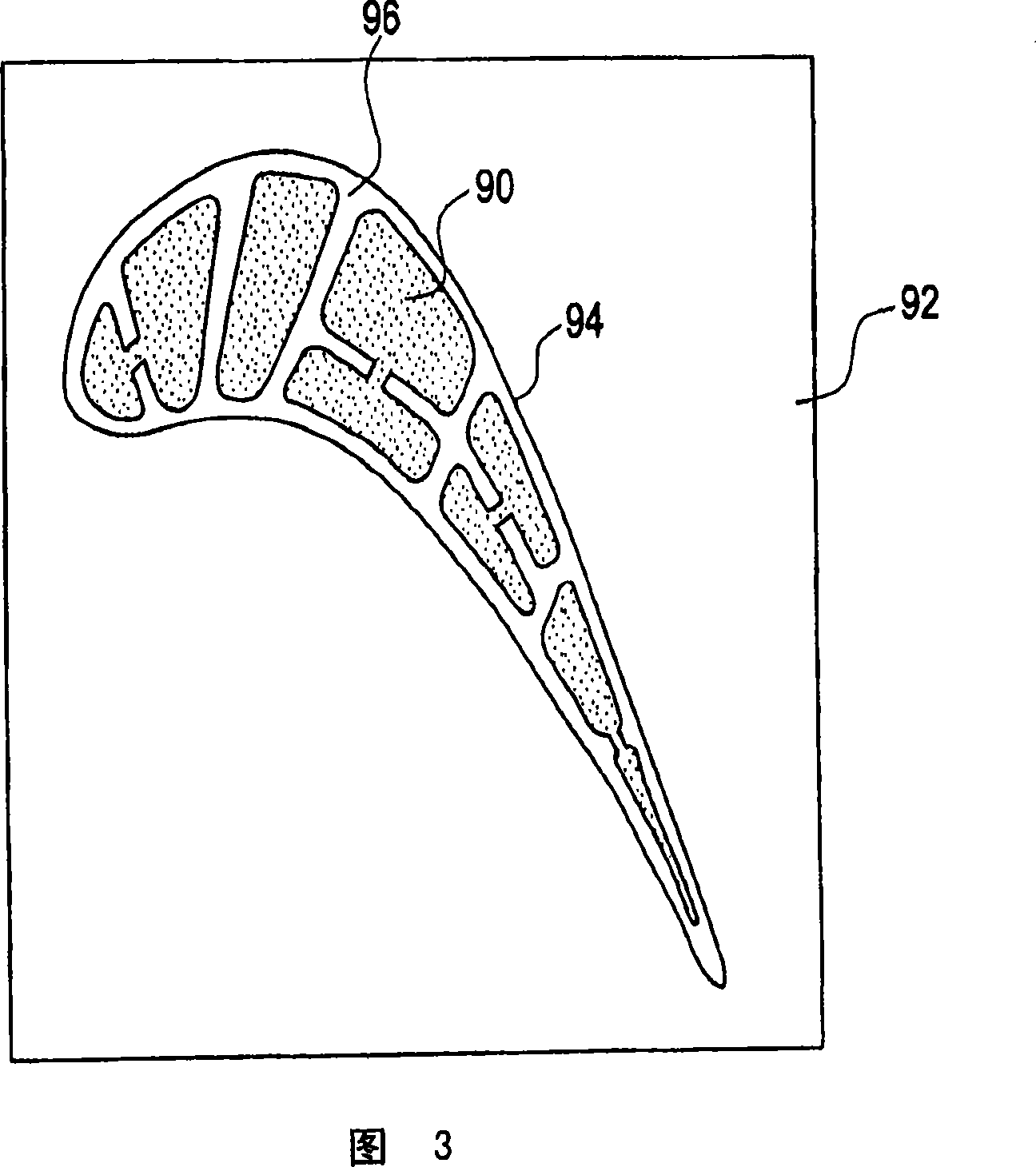

Disposable thin wall core die, methods of manufacture thereof and articles manufactured therefrom

ActiveCN101219461AResists permanent deformationFoundry mouldsFoundry coresKilogram-forceRoom temperature

Disclosed herein is a method comprising injecting into a thin wall disposable core die (100) a slurry having a viscosity of about 1 to about 1,000 Pascal-seconds at room temperature when tested at a shear rate of up to 70 seconds<-1> and a flow index of less than 0.6 at a pressure of up to about 7 kilograms-force per square centimeter; wherein the thin wall disposable core die (100) has an average wall thickness of about 1.5 to about 10 millimeters; curing the slurry to form a cured ceramic core; removing the thin wall disposable core die (100) from the cured ceramic core (90); and firing the cured ceramic core to form a solidified ceramic core (90).

Owner:GENERAL ELECTRIC CO

Curved battery cells for portable electronic devices

InactiveUS20130136967A1Facilitate efficient use of spaceFinal product manufactureActive material electrodesKilogram-forceSquare Millimeter

The disclosed embodiments relate to the manufacture of a battery cell. The battery cell includes a set of layers including a cathode with an active coating, a separator, and an anode with an active coating. The battery cell also includes a pouch enclosing the layers, wherein the pouch is flexible. The layers may be wound to create a jelly roll prior to sealing the layers in the flexible pouch. A curve may also be formed in the battery cell by applying a pressure of at least 0.13 kilogram-force (kgf) per square millimeter to the layers using a set of curved plates applying a temperature of about 85° C. to the layers.

Owner:APPLE INC

Increasing the stiffness of battery cells for portable electronic devices

InactiveUS20130095357A1Increase stiffnessIncreasing resistance of batteryFinal product manufactureElectrode carriers/collectorsKilogram-forceSquare Millimeter

The disclosed embodiments relate to the manufacture of a battery cell. The battery cell includes a set of layers including a cathode with an active coating, a separator, and an anode with an active coating. The battery cell also includes a pouch enclosing the layers, wherein the pouch is flexible. The layers may be wound to create a jelly roll prior to sealing the layers in the flexible pouch. The stiffness of the battery cell may be increased by applying a pressure of at least 0.13 kilogram-force (kgf) per square millimeter and a temperature of about 85° C. to the layers.

Owner:APPLE INC

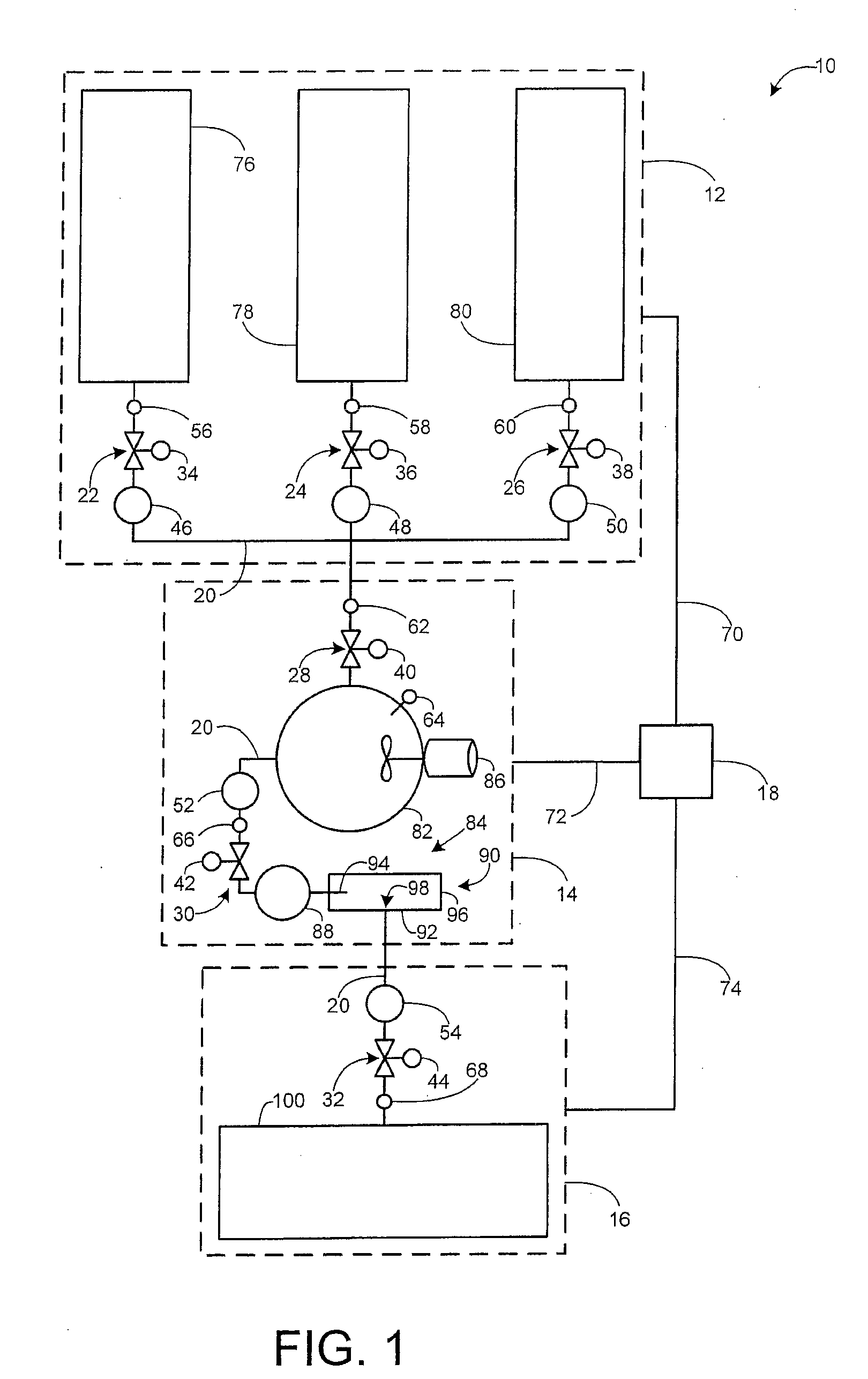

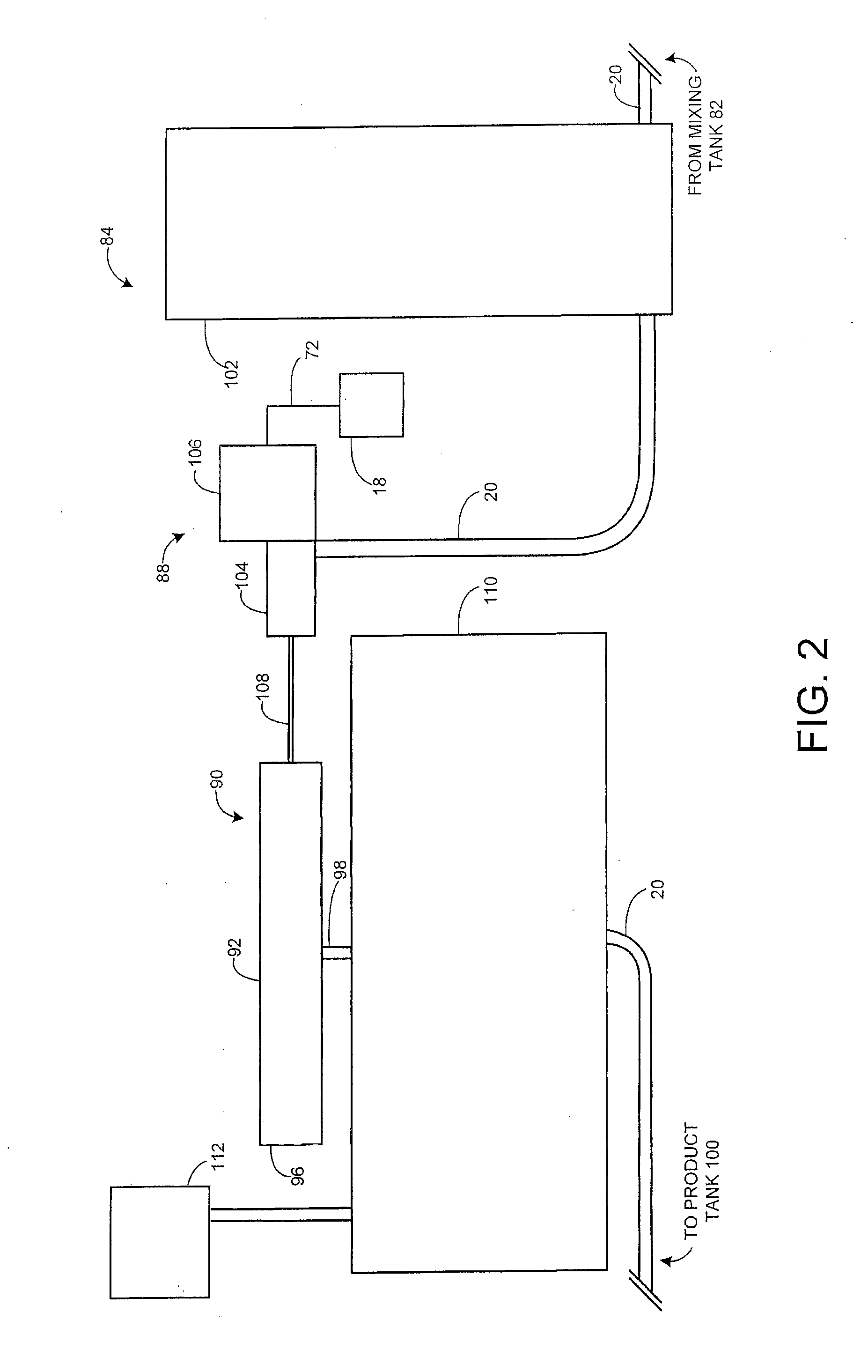

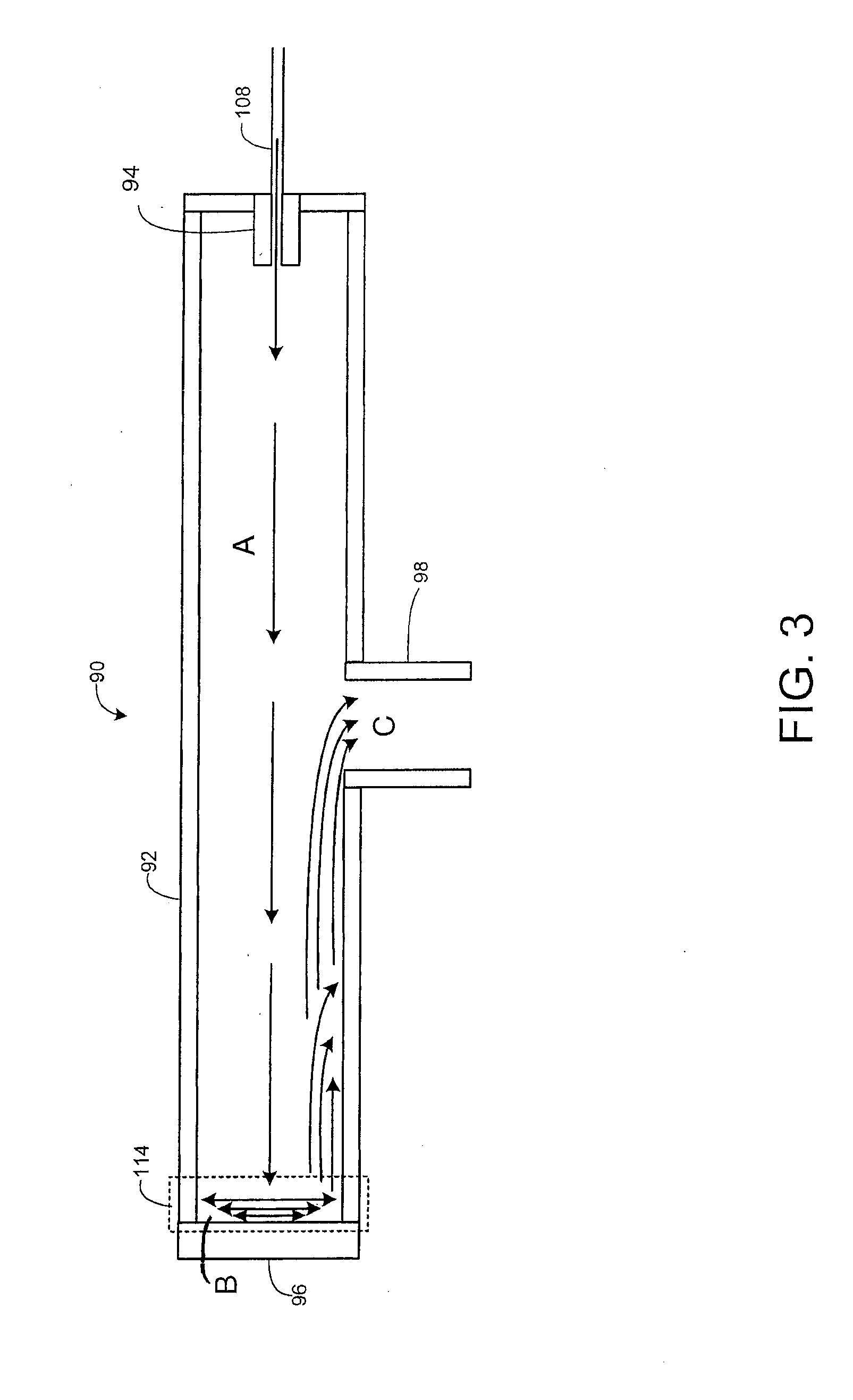

Biofuel production method and system

In an embodiment of the present invention, a renewable energy fuel is prepared by a process including the steps of: a) providing a renewable energy feedstock; b) providing an alcohol; c) providing a catalyst; d) mixing (a), (b), and (c) to form a blend; and e) homogenizing the blend at a pressure greater than 400 kilogram-force per square centimeter (Kg / cm2).

Owner:GER ENTERPRISES

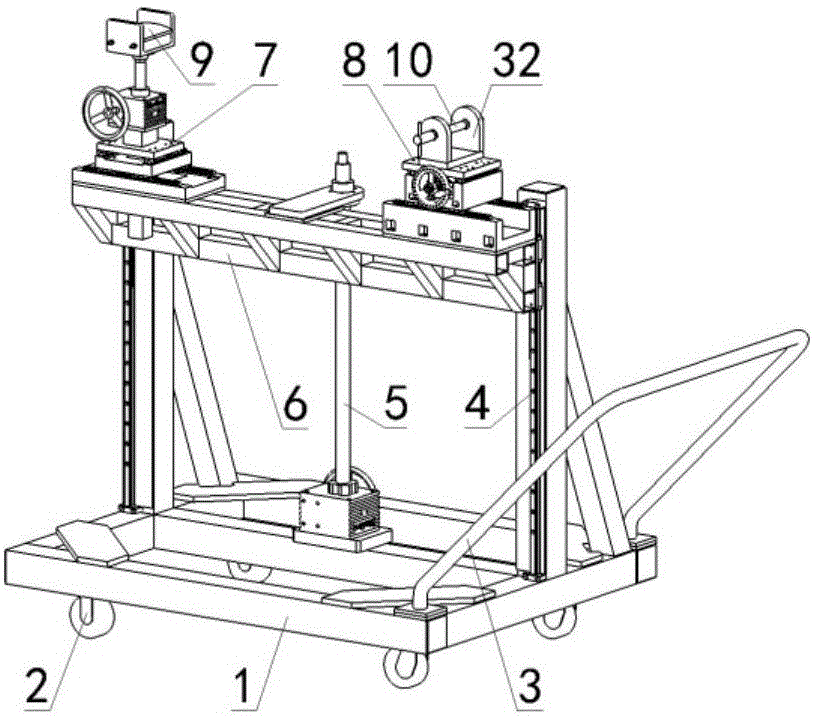

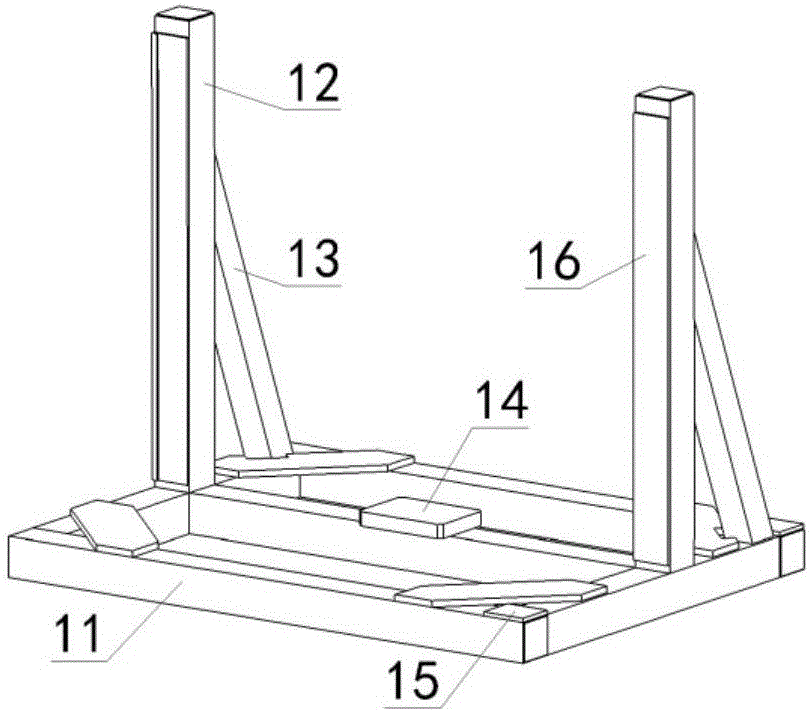

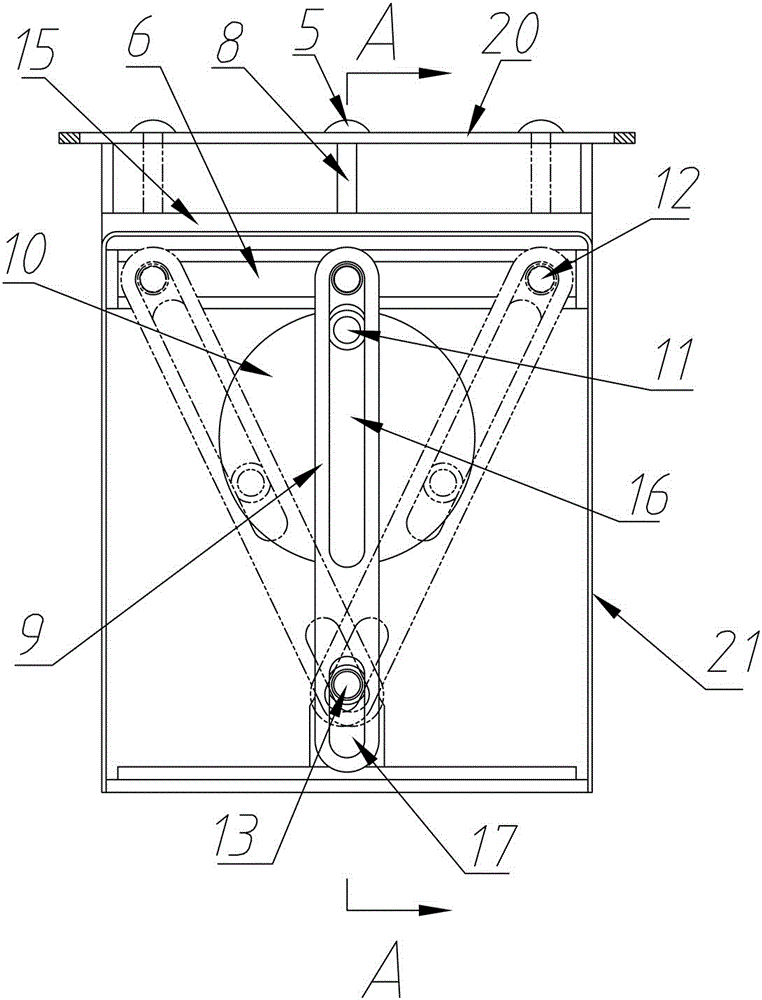

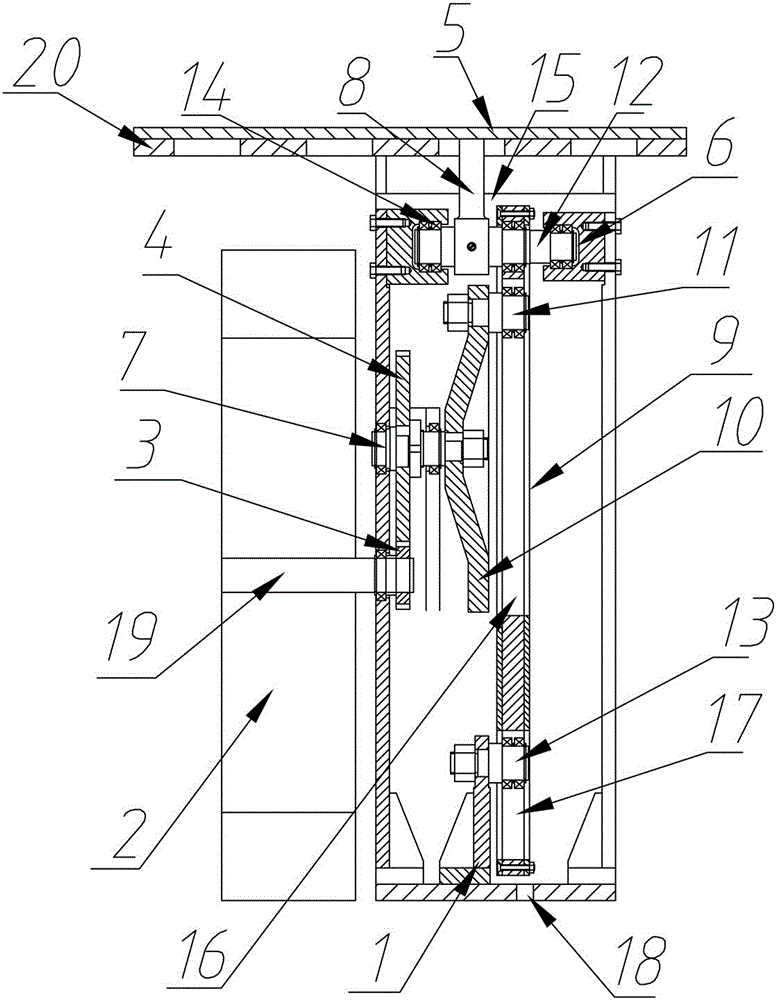

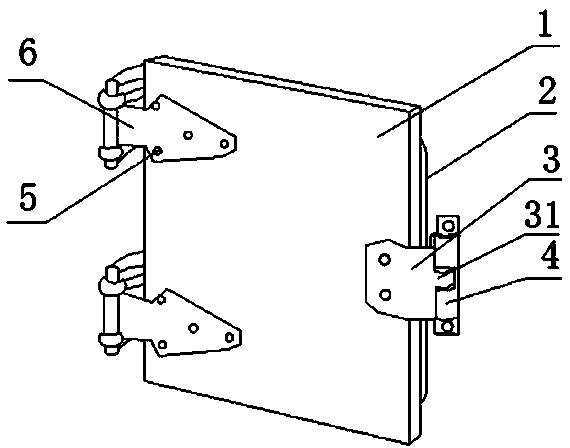

Flexible mounting vehicle for aircraft sliding rail and sliding rail positioning and mounting method

The invention provides a flexible mounting vehicle for an aircraft sliding rail and a sliding rail positioning and mounting method. The flexible sliding rail mounting vehicle comprises a frame, wheels, a handle, a guide rail slide block, a lifting mechanism, a lifting platform, a sliding rail surface attitude-adjusting positioning mechanism, a sliding rail intersection attitude-adjusting positioning mechanism, a sliding rail surface bracket, a sliding rail intersection positioning seat and an intersection positioning pin. The mounting vehicle is a sliding rail mounting vehicle with three adjustable degrees of freedom and great enough adjusting travel, the whole mounting vehicle is about 200kg heavy and can be pushed by manual labor of 15 kilogram force, the mounting vehicle wheel set is braked at the sliding rail assembling position, the adjusting mechanism in different directions can be adjusted according to the mounting height and inclination degree of different sliding rails, and the mounting function of a sliding rail mounting vehicle applicable to multiple sliding rails is realized.

Owner:XI'AN AIRCRAFT INTERNATIONAL

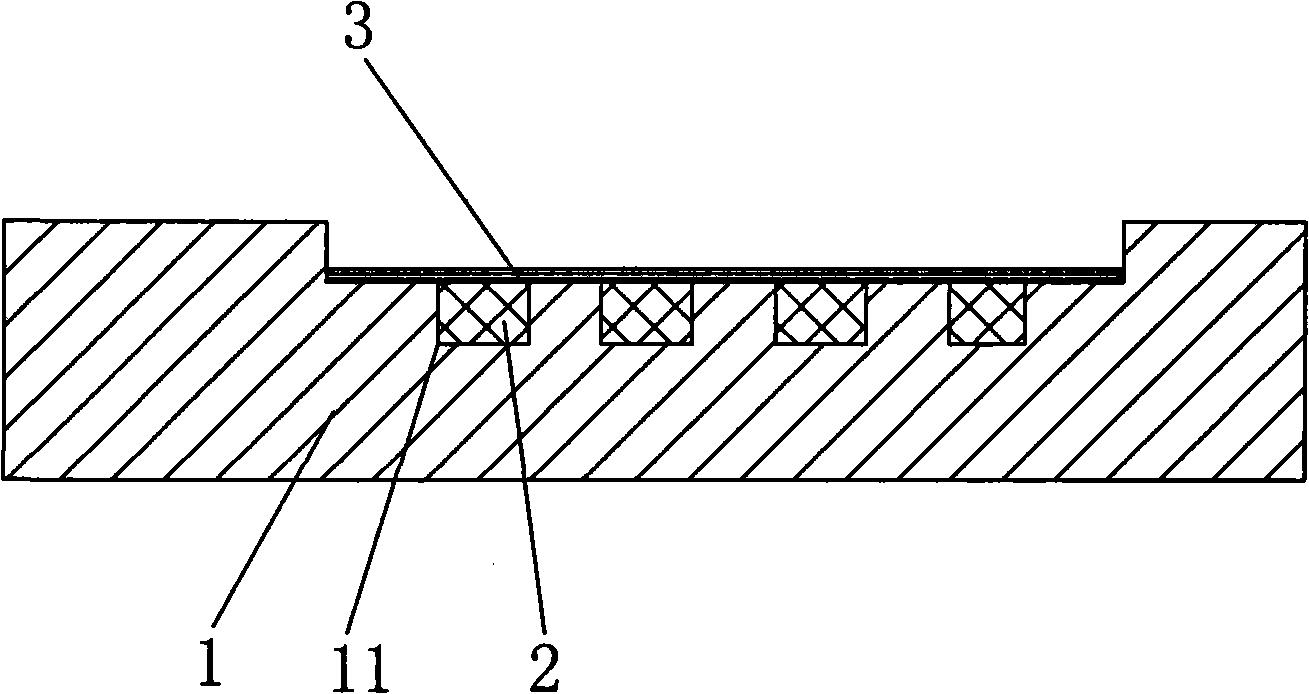

Graphene capacitor microarray-based flexible pulse condition detection probe

The invention belongs to the field of biomedical detection instruments, and mainly relates to a pulse condition detection device. The pulse condition detection device comprises a probe rigid body, a flexible silica gel pad, a pressure sensing flexible thin film, and a fastener and an elastic connecting piece for fixing the pressure sensing flexible thin film, wherein a planar end of the flexible silica gel pad is closely adhered to the probe rigid body; the pressure sensing flexible thin film consists of a graphene capacitor microarray flexible thin film, and the bottom layer of the pressure sensing flexible thin film is closely attached to a cambered surface of the flexible silica gel pad; the two ends of the pressure sensing thin film are fixedly arranged on the two sides of the probe rigid body by the fastener and the elastic connecting piece respectively, one end is closely fixed, and the other end can shrink with pressure change of the contact surface. According to the pulse condition detection probe, the spatial resolution of the pulse condition information is obviously improved, the pressure range of the pulse condition detection probe is expanded to enable that the upper limit value of the pulse condition detection probe reaches 2.5 kilogram force, the stability and the durability of the pulse condition detection probe are improved, and the structural feature of the device realizes a function of simulating the finger pulp of a doctor better.

Owner:郭福生

Pressure type liquid quick heater

InactiveCN103876635ASolve the problem of overheating and temperature riseIncrease in sizeBeverage vesselsKilogram-forceEngineering

A pressure type liquid quick heater comprises a water feeding tube, a water draining tube and a heating tube, wherein the heating tube is a coating type electric heating glass tube, and is arranged in a shell of a heating element; electrode clamps at two ends of the heating tube extend out from electrode grooves of inner end caps; the water feeding tube is communicated with a preheating tube through a silica gel sealing ring; the outer wall of the preheating tube is in contact with the shell of the heating element; the preheating tube is communicated with the heating tube via the silica gel sealing ring and the lower end cap; and the top of the heating tube is communicated with the water draining tube via an upper end cap. By using the pressure type liquid quick heater, a heating element subassembly can work under the pressure condition that the water pressure is 7-15 kilogram force, can bear the test of pressure of 40 kilogram force, can be quickly assembled or disassembled, and is convenient to mount and replace. Double temperature controllers are arranged on the shell of the heating element, abnormal temperature rising of the heating tube can be rapidly detected, the power supply can be automatically cut off, and abnormal dry burning of the heating tube is prevented.

Owner:NINGBO GOLDEN MOUNTAIN FOODS TECH CO LTD

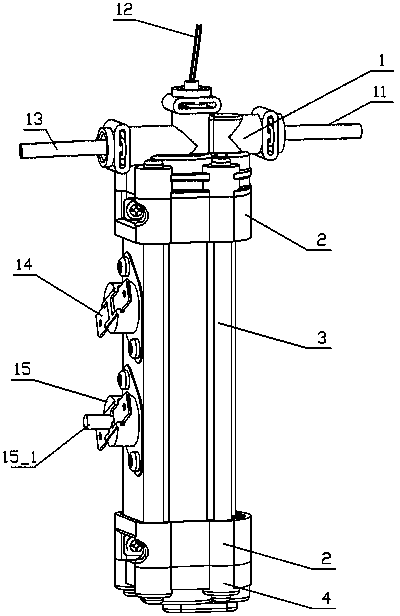

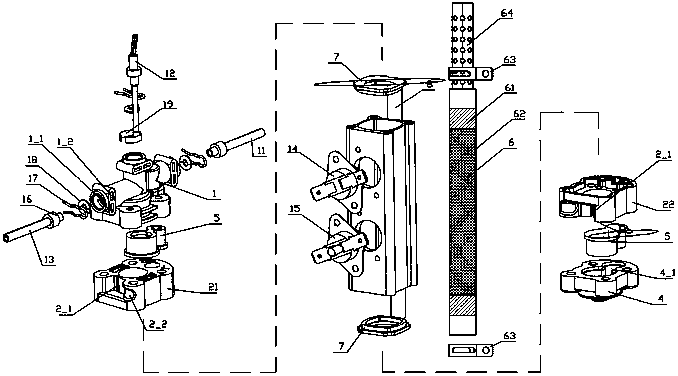

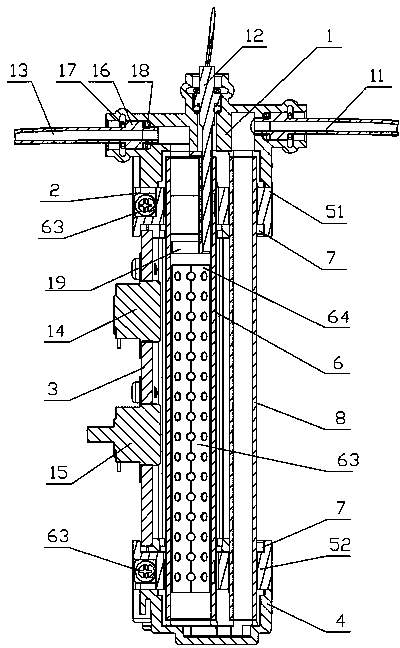

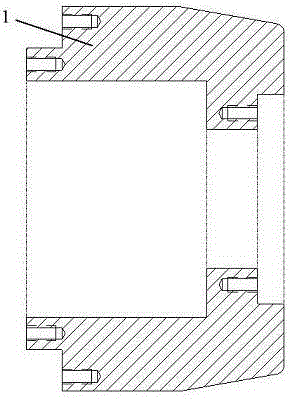

Guide rail type piston rack for electro-hydraulic switch machine

InactiveCN106870505ALow starting pressureGuaranteed service lifePortable liftingFluid-pressure actuatorsKilogram-forceRolling resistance

The present invention relates to the technical field of switch machine manufacturing, in particular to a guide-rail piston rack for an electro-hydraulic switch machine, which includes a rack body. Both sides of the rack body are respectively provided with V groove, the lower part of the rack body is provided with an inclined surface, the rack body is slidingly fitted with the inner wall of the oil cylinder seat, and the inner wall of the oil cylinder seat corresponds to the V-shaped groove and the inclined surface. A groove, steel balls are arranged in the groove. The guide rail type piston rack used in the oil cylinder of the present invention changes the previous sliding friction into rolling friction. The friction force is also relatively reduced, the driving power is reduced, and the wear is reduced. The calculated maximum load capacity can reach 300 kg force, which reduces the starting pressure of the oil cylinder, improves the mechanical efficiency and ensures the service life of the oil cylinder.

Owner:TIANJIN HUIHUANG LUYANG TECH

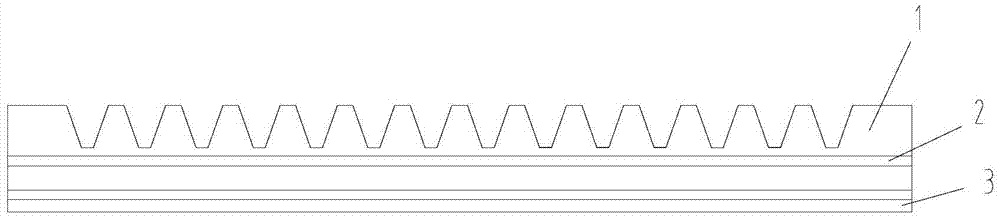

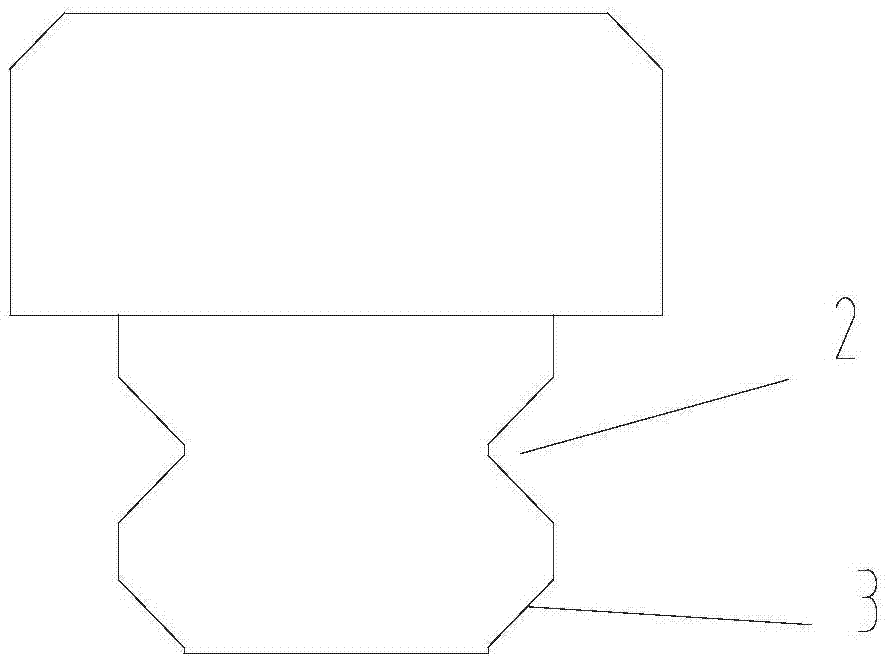

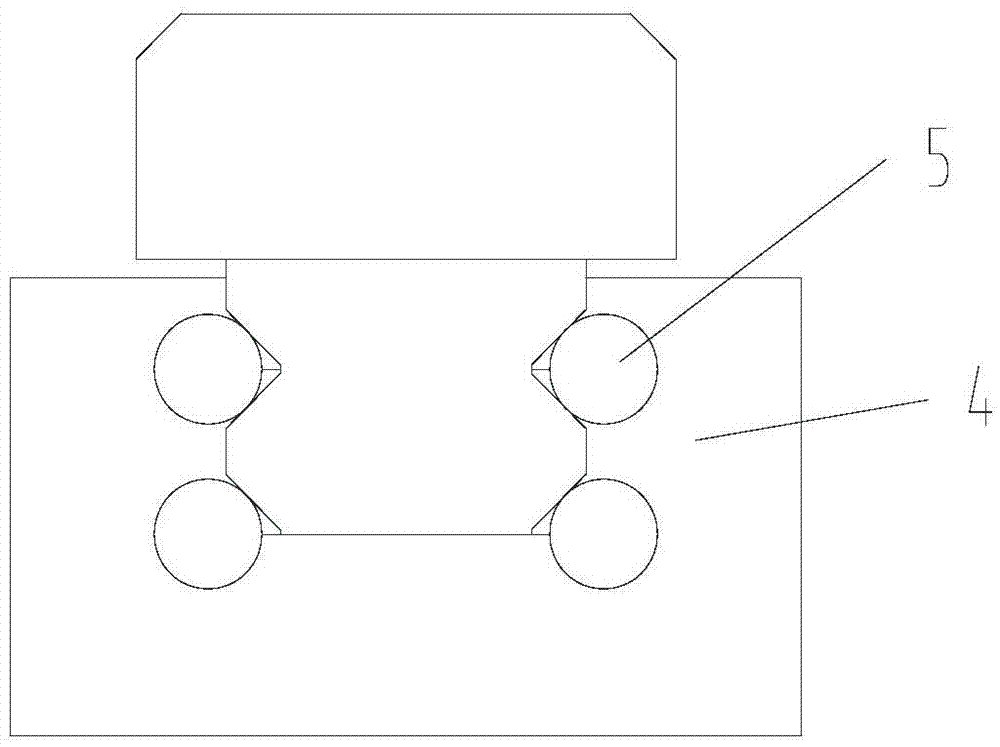

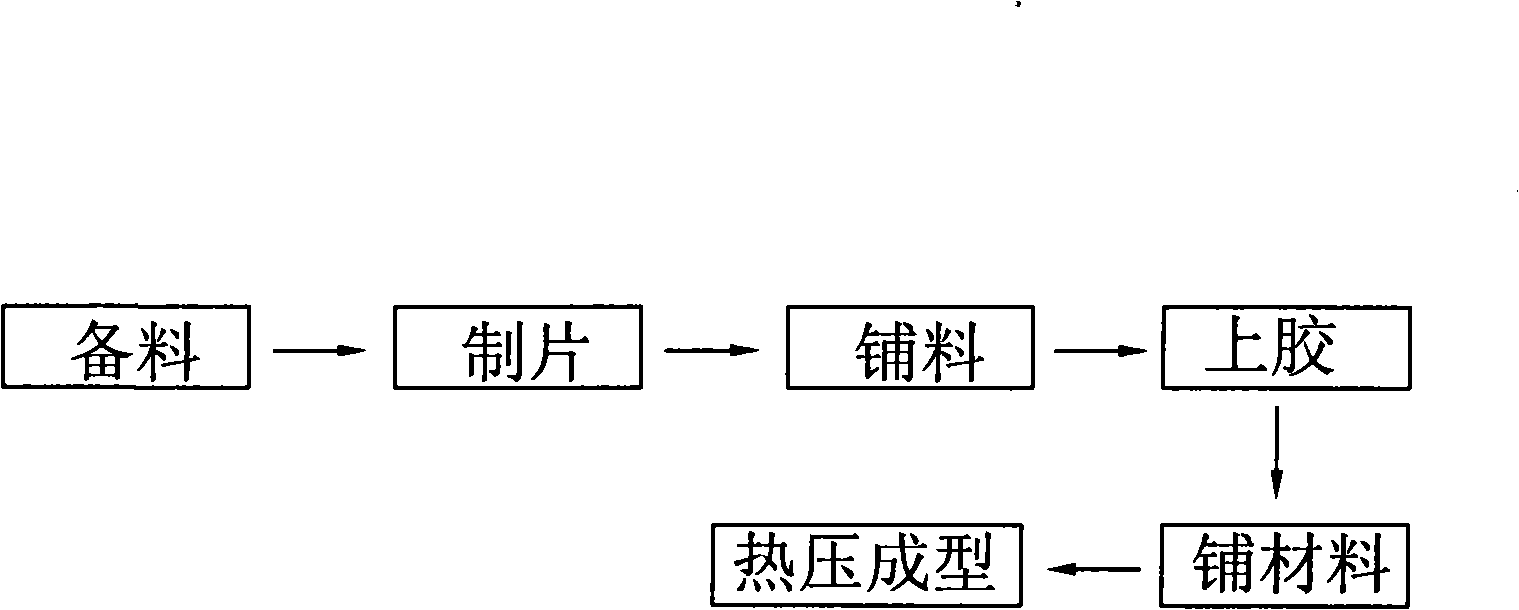

Producing and processing process integrally combining rubber quad with leather or cloth

InactiveCN101306596ATightly boundImprove bindingLaminationLamination apparatusMaterials preparationKilogram-force

The invention relates to the technology field of rubber product processing, particularly a production process for bonding a rubber embedded piece with leather or fabric material. The production process comprises the following steps: a. material preparation, b. sheet preparation, c. material laying, d. binder application, e. material laying, and f. hot-press molding. During the production process, the rubber sheet piece is laid in the die cavity of a die after the sheet preparation, a binder is coated in the upper part of the die cavity with the sheet piece, the leather or fabric material is laid in the upper part of the die cavity of the die, and finally, the die with the leather or fabric material is placed on a template at 100-170 DEG C for pressurized molding under such condition that the pressure is adjusted within the range of 50-150 kilogram force and the molding time is controlled within 4-7 minutes, the final product is taken out after the vulcanization molding is completed. In the production process, the embedded piece is tightly and firmly bonded with the leather or the fabric material without separation under the action of the binder at high temperature and high pressure. The final product has long service life.

Owner:东莞市鑫艺来塑胶制品有限公司

Protective cover for a sensor

InactiveUS20080224881A1Extended service lifeWave based measurement systemsAlarmsKilogram-forceCelsius Degree

A protective cover for a sensing surface of a control sensor / proximity detector. The protective cover comprises a material having a preferred shore-A durometer hardness in the range of 60-90, a preferred tensile strength of 1320 psi (92.82 kilogram-force per square centimeter (kgf / cm2)) or greater, a preferred dielectric strength of around 300 volts / mil, and a preferred thermal conductivity of 0.3 to 0.5×1031 3 cal / sec2, and a temperature stability of about −55 to +200 degrees Celsius. The protective cover may be adhesively secured to the proximity detector so that the sensing surface is effectively covered. The protective cover may be in the form of a sheet or may be in the form of a cap. Preferably, the protective cover comprises silicone material.

Owner:TURCK INC

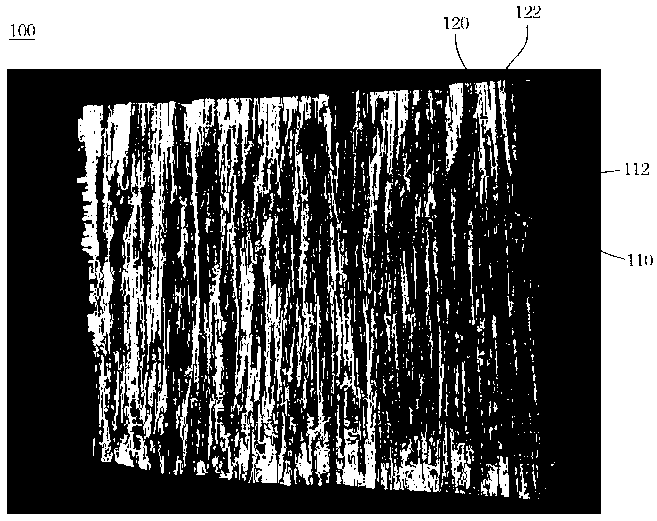

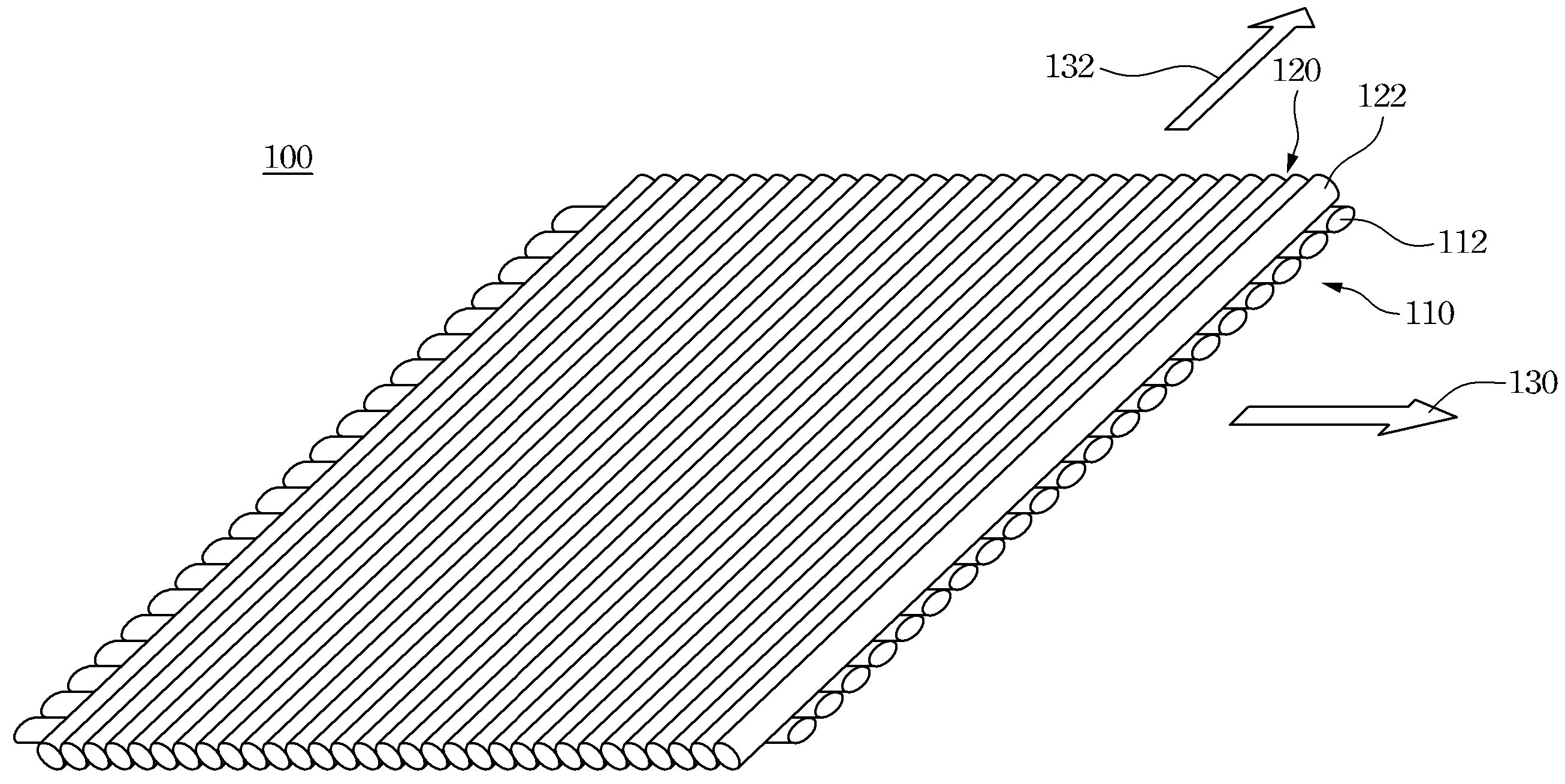

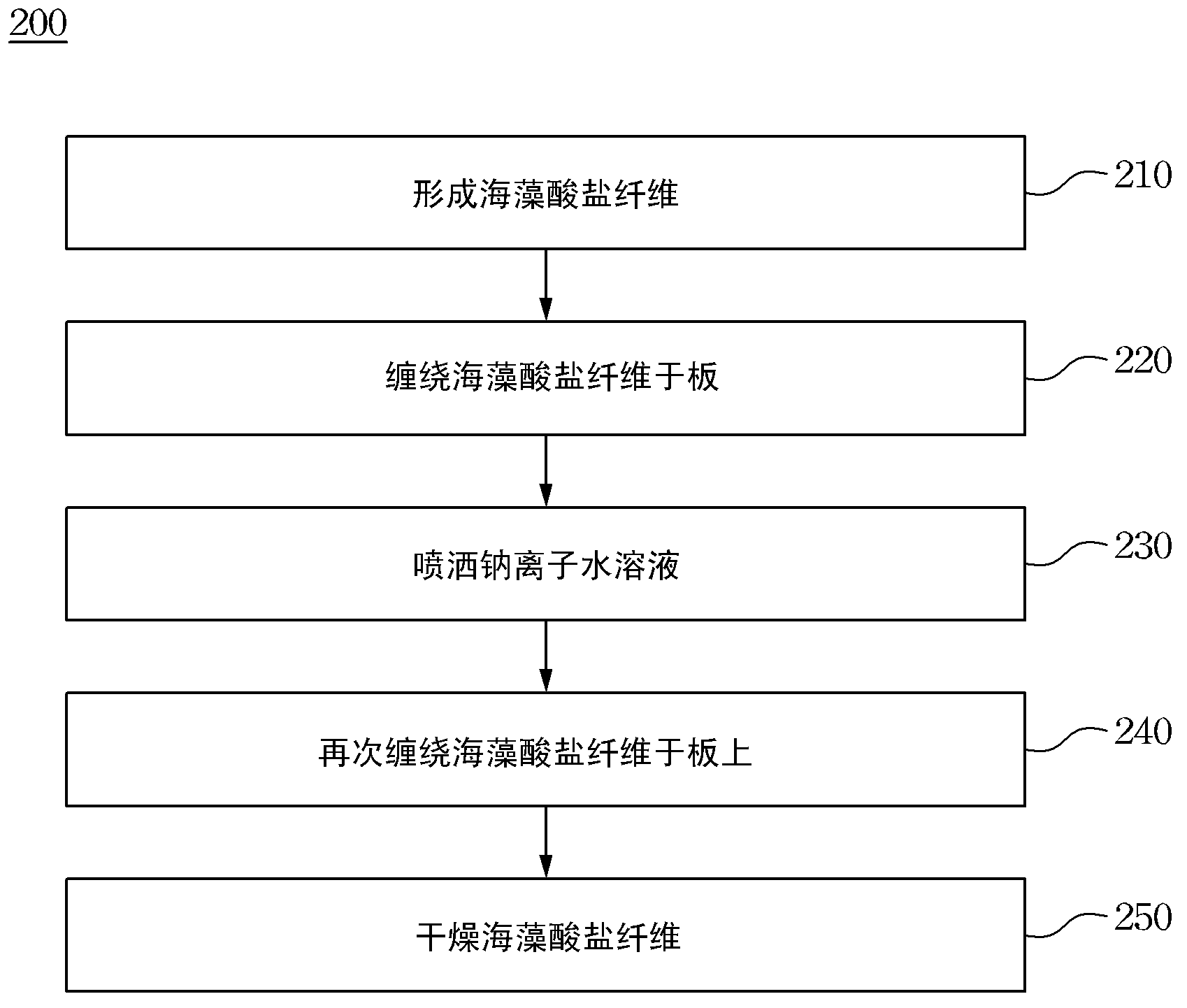

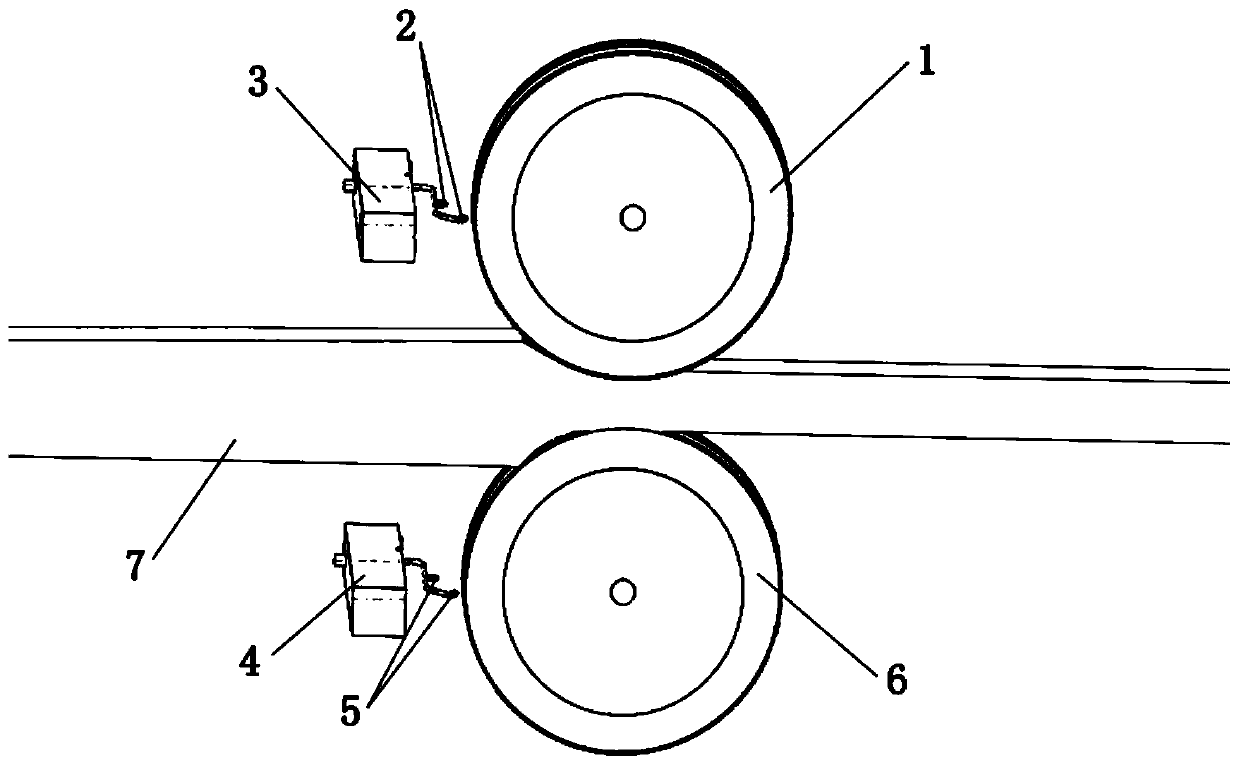

Alginate wound dressing as well as manufacture method and manufacture device of alginate wound dressing

ActiveCN103211681AHigh breaking strengthAdhesive dressingsAbsorbent padsBreaking strengthKilogram-force

The invention relates to an alginate wound dressing as well as a manufacture method and a manufacture device of the alginate wound dressing. The wound dressing comprises a first fiber layer and a second fiber layer, wherein the first fiber layer consists of a plurality of mutually bonded first fibers, the second fiber layer consists of a plurality of mutually bonded second fibers, and the first fibers and the second fibers are made of alginate. The first fibers are parallel and extends in a direction approximately parallel to the first direction, the second fibers are parallel and extends in a direction approximately parallel to the second direction, the first direction is not parallel to the second direction, the second fiber layer is stacked on the first fiber layer, and in addition, the second fibers are bonded with the first fibers. The length of the first fibers and the second fibers is proper, so the fracture strength of the wound dressing is greater than about 1.5 kilogram force.

Owner:TAIWAN TEXTILE RESEARCH INSTITUTE

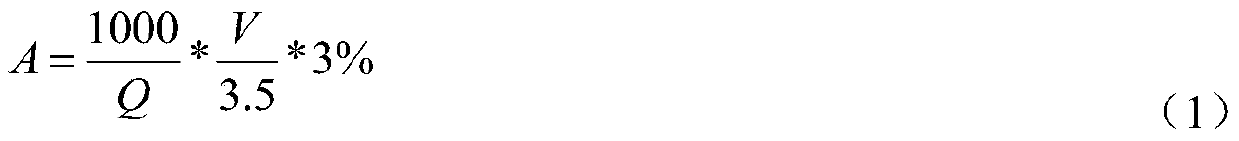

Lubricating method for sectional material rolling

ActiveCN110170531AReduce stuckImprove surface qualityRollsMetal rolling arrangementsKilogram-forceProduction rate

The invention relates to a lubricating method for sectional material rolling. Lubricating fluid is used for lubricating a roller by adopting a full-hole type lubricating method through a nozzle. The volume percentage concentration of the lubricating fluid is in the range of 3% to 11%; the flow range of the lubricating liquid is 0.8 to 1.2m<3> / h; the pressure range of the lubricating fluid is 3-6 kilogram force; and athe relationship among the rolling speed of a sectional material, the volume percentage concentration of the lubricating liquid and the injection flow is as shown in specifications. The lubricating method has the advantages that the surface quality of the product is improved, and the roll consumption and power consumption are reduced; the adhesion of iron sheets on a roller isreduced; the rolling rhythm is improved; and the productivity is improved.

Owner:ANSTEEL BEIJING RES INST

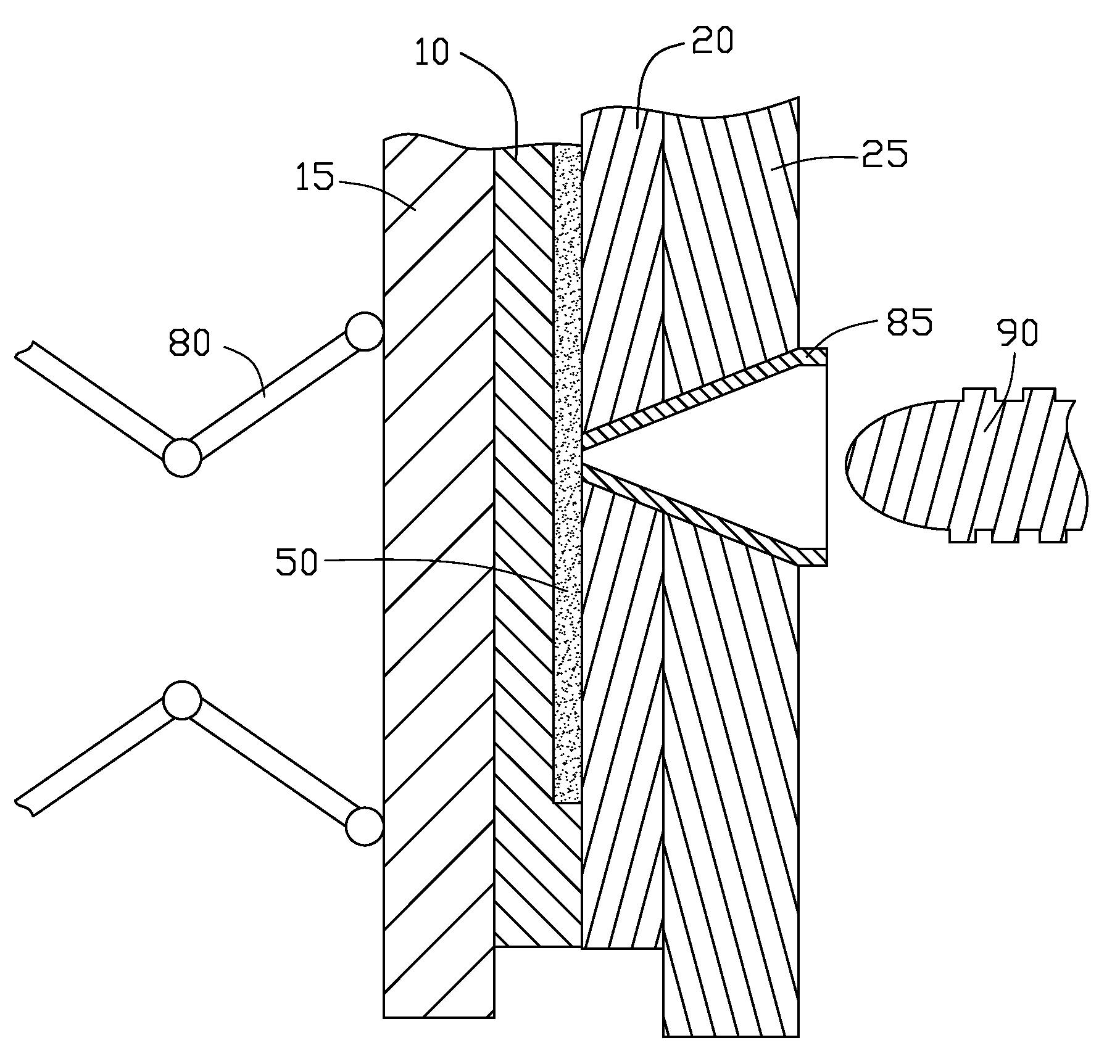

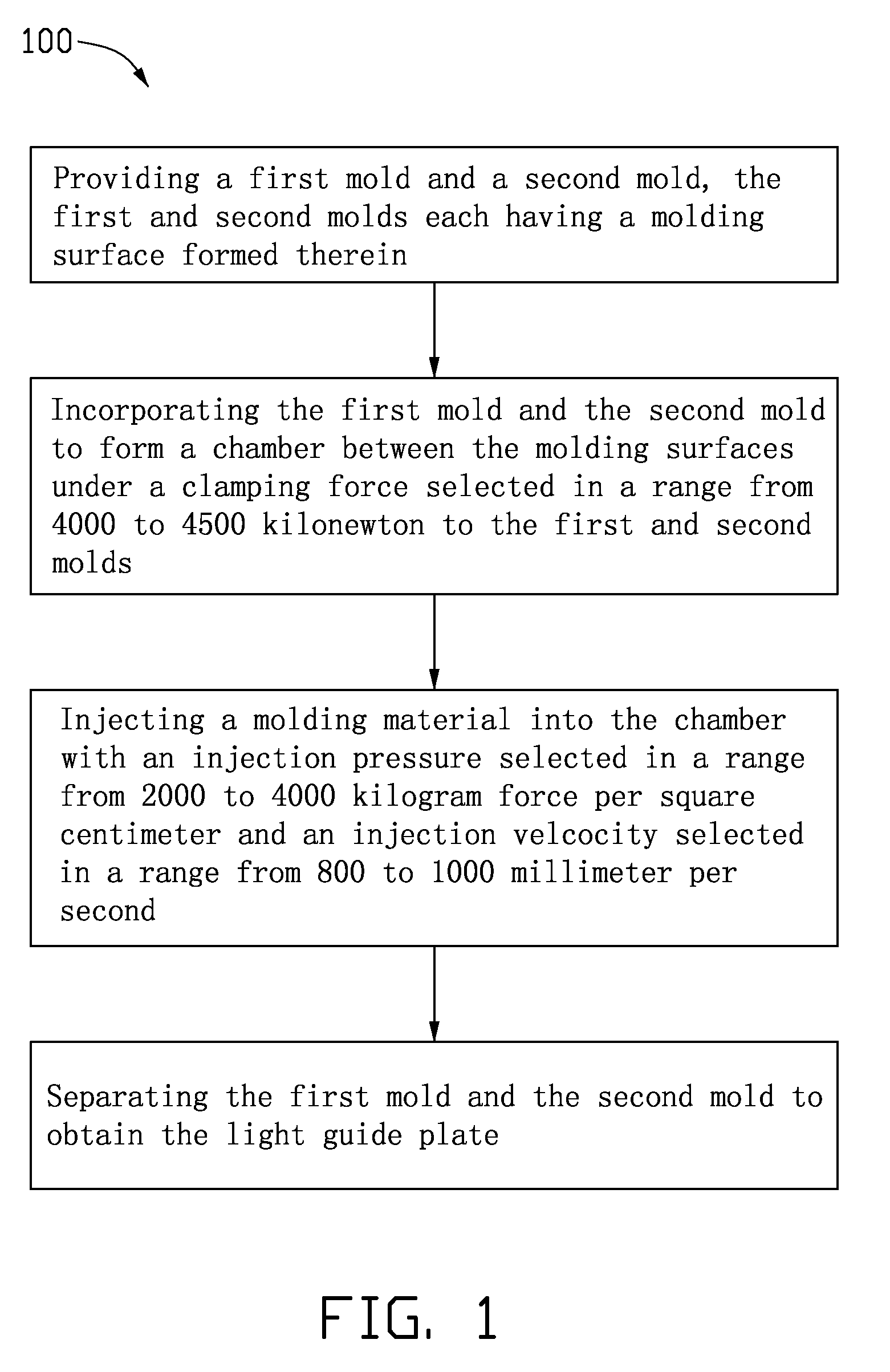

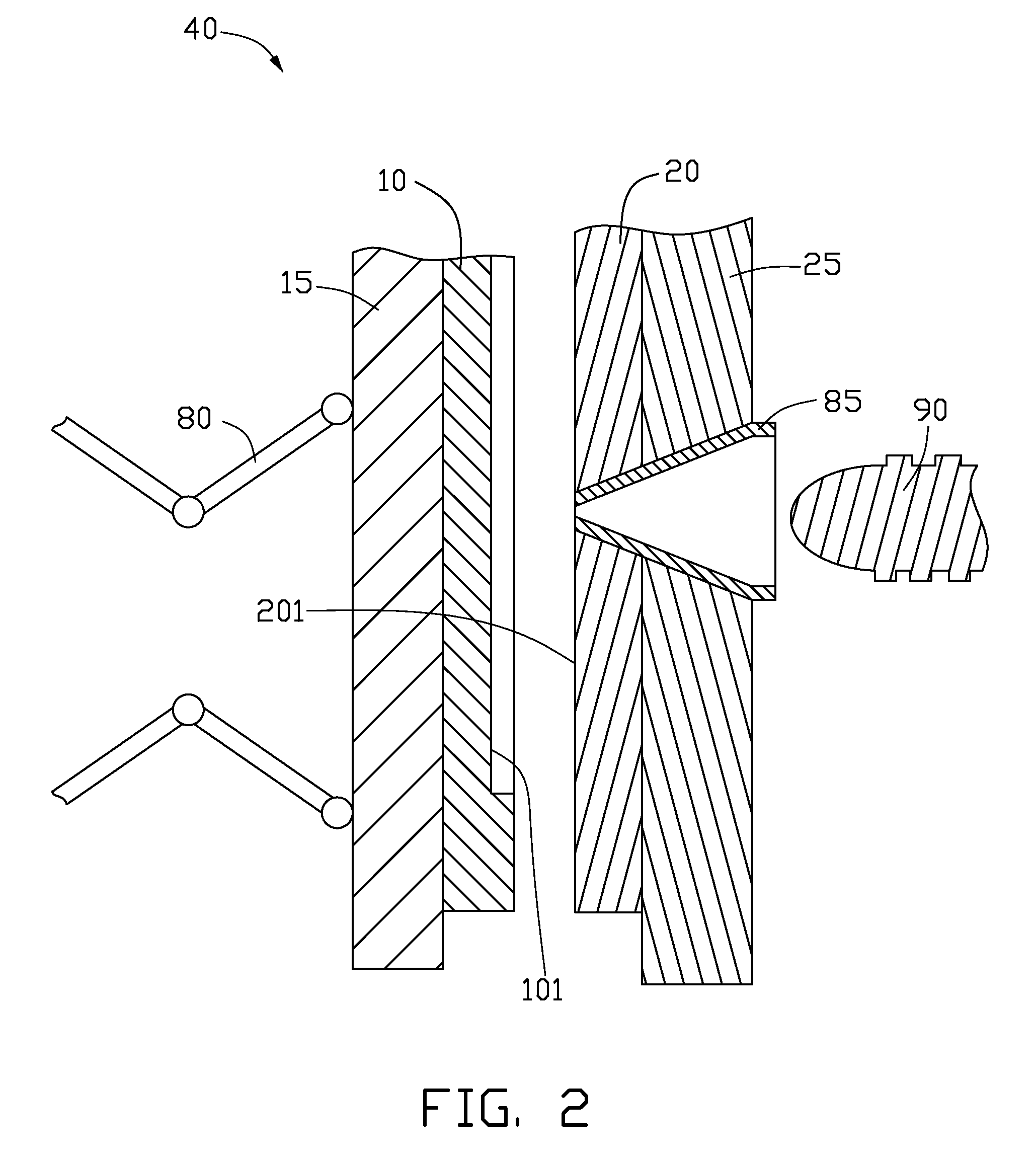

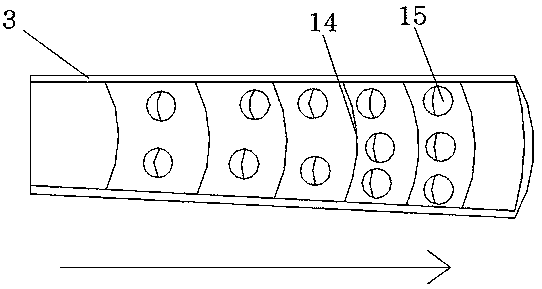

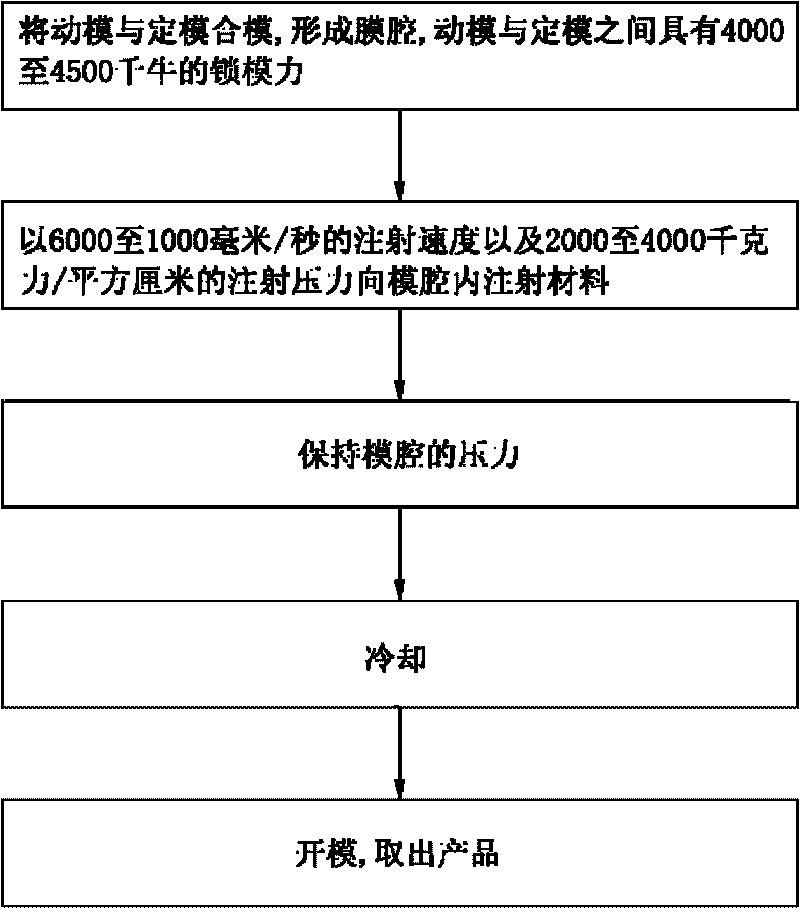

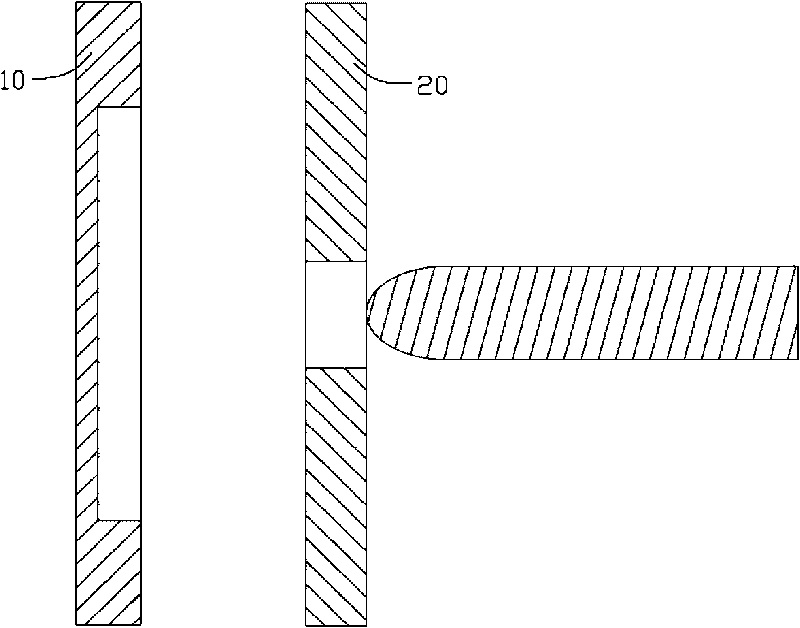

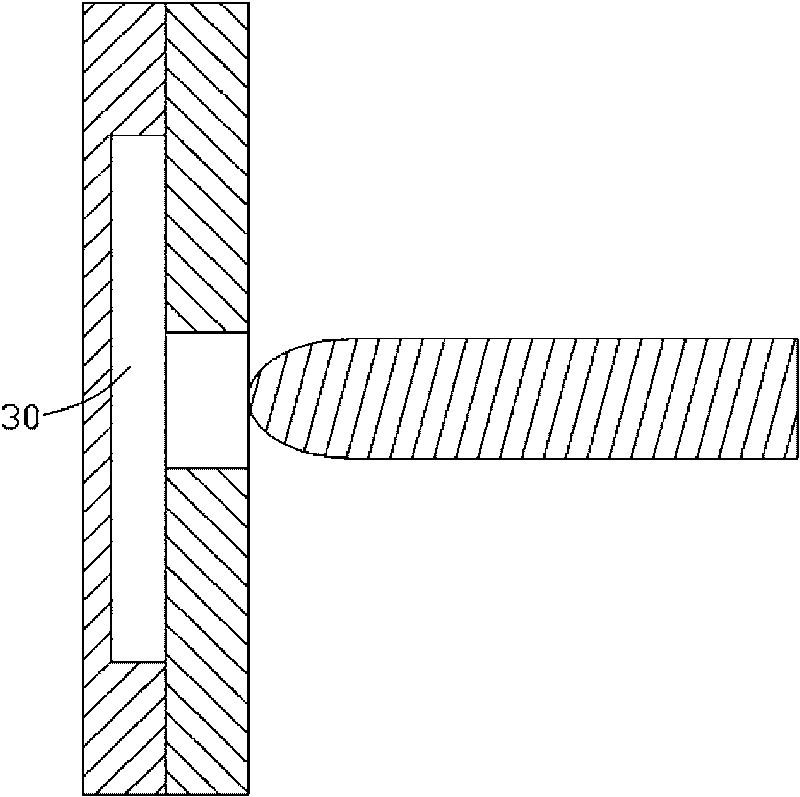

Injection molding method for making large and thin light guide plate

An injection molding method for making a large and thin light guide plate, is provided. First, a first mold and a second mold are provided. The first and second molds each have a molding surface formed thereon. Second, the first mold and the second mold are incorporated together to define a chamber between the molding surfaces under a clamping force selected in a range from 4000 to 4500 kilonewton to the first and second molds. Third, inject a molding material into the chamber with an injection pressure selected in a range from 2000 to 4000 kilogram force per square centimeter and an injection velocity selected in a range from 800 to 1000 millimeter per second. Finally, the first mold and the second mold are separated to obtain the light guide plate.

Owner:HON HAI PRECISION IND CO LTD

Hydrophilic biaxially-oriented polytetrafluoroethylene microporous membrane

ActiveCN104785130AReduce the temperatureShort cooldownSemi-permeable membranesInorganic saltsTetrafluoroethylene

The invention relates to the technical field of membranes and particularly provides a hydrophilic biaxially-oriented polytetrafluoroethylene microporous membrane. The water flux of the film is 1200-3000 kg / h.sq.m (1 kilogram force of pressure / sq.cm). A processing method of the hydrophilic biaxially-oriented polytetrafluoroethylene microporous membrane comprises the following steps: mixing materials: uniformly mixing polytetrafluoroethylene resin powder, liquid lubricating oil and inorganic salt powder according to the weight ratio of 1:(0.2-0.28):(0.01-0.2) and leaving to stand at the temperature of 40-80 DEG C for 10-16 hours to form a polytetrafluoroethylene material, wherein the degree of crystallinity of the polytetrafluoroethylene resin powder tested by virtue of differential scanning calorimetry is 98-99.9% and the number-average molecular weight is 2000-10000 thousands; compacting and calendering; longitudinally drawing; transversely drawing and carrying out heat setting. The polytetrafluoroethylene microporous membrane provided by the invention can be formed in one time, and the membrane is endowed with integral hydrophilic performance through the processing method.

Owner:ZHEJIANG LUCKING ENVIRONMENTAL PROTECTION CO LTD

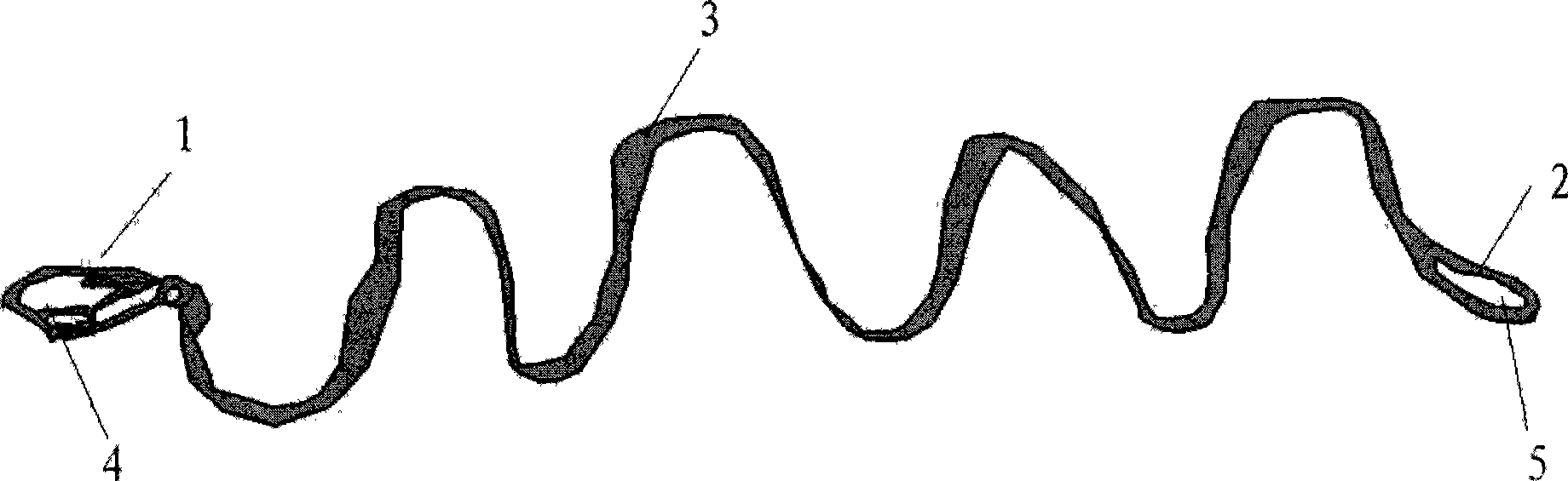

Scattering pull rope for hygroscopic warm cloud catalyst

The invention discloses a hygroscopic warm cloud catalyst seeding pull rope, including a first end and a second end. The first end and the second end are connected by a rope body material, wherein, the first end is provided with a hanging part, the second end is provided with a hole, the breaking tenacity of the seeding pull rope is more than 900 kilograms force and the length of the seeding pull rope is more than 5 meters. The invention provides the hygroscopic warm cloud catalyst seeding pull rope with the hanging part, can hang the first end of the seeding pull rope on a fixed part of a plane, after an enclosed and packed paper box filled with catalyst powder is thrown out of the plane, the seeding pull rope is straightened and unfolded, and then the paper box is opened and the sowing is carried out; as the breaking tenacity of the seeding pull rope is more than 900 kilograms force, the seeding pull rope can be ensured not to be broken when in the processes of straightening and unfolding; and as the length of the seeding pull rope is more than 5 meters, one end of the seeding pull rope can be led to separate from the turbulent region of the plane after being straightened.

Owner:BEIJING WEATHER MODIFICATION OFFICE

A kind of hydrophilic biaxially stretched polytetrafluoroethylene microporous film

ActiveCN104785130BReduce the temperatureShort cooldownSemi-permeable membranesTetrafluoroethyleneKilogram-force

The invention relates to the technical field of membranes and particularly provides a hydrophilic biaxially-oriented polytetrafluoroethylene microporous membrane. The water flux of the film is 1200-3000 kg / h.sq.m (1 kilogram force of pressure / sq.cm). A processing method of the hydrophilic biaxially-oriented polytetrafluoroethylene microporous membrane comprises the following steps: mixing materials: uniformly mixing polytetrafluoroethylene resin powder, liquid lubricating oil and inorganic salt powder according to the weight ratio of 1:(0.2-0.28):(0.01-0.2) and leaving to stand at the temperature of 40-80 DEG C for 10-16 hours to form a polytetrafluoroethylene material, wherein the degree of crystallinity of the polytetrafluoroethylene resin powder tested by virtue of differential scanning calorimetry is 98-99.9% and the number-average molecular weight is 2000-10000 thousands; compacting and calendering; longitudinally drawing; transversely drawing and carrying out heat setting. The polytetrafluoroethylene microporous membrane provided by the invention can be formed in one time, and the membrane is endowed with integral hydrophilic performance through the processing method.

Owner:ZHEJIANG LUCKING ENVIRONMENTAL PROTECTION CO LTD

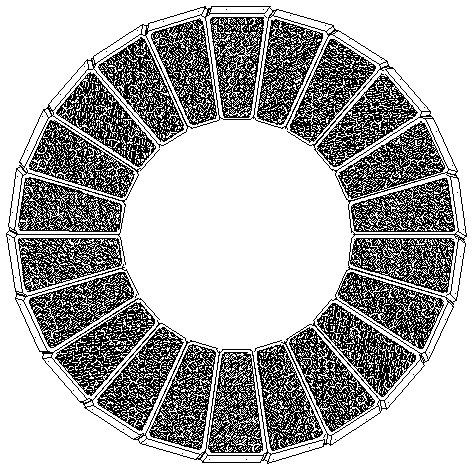

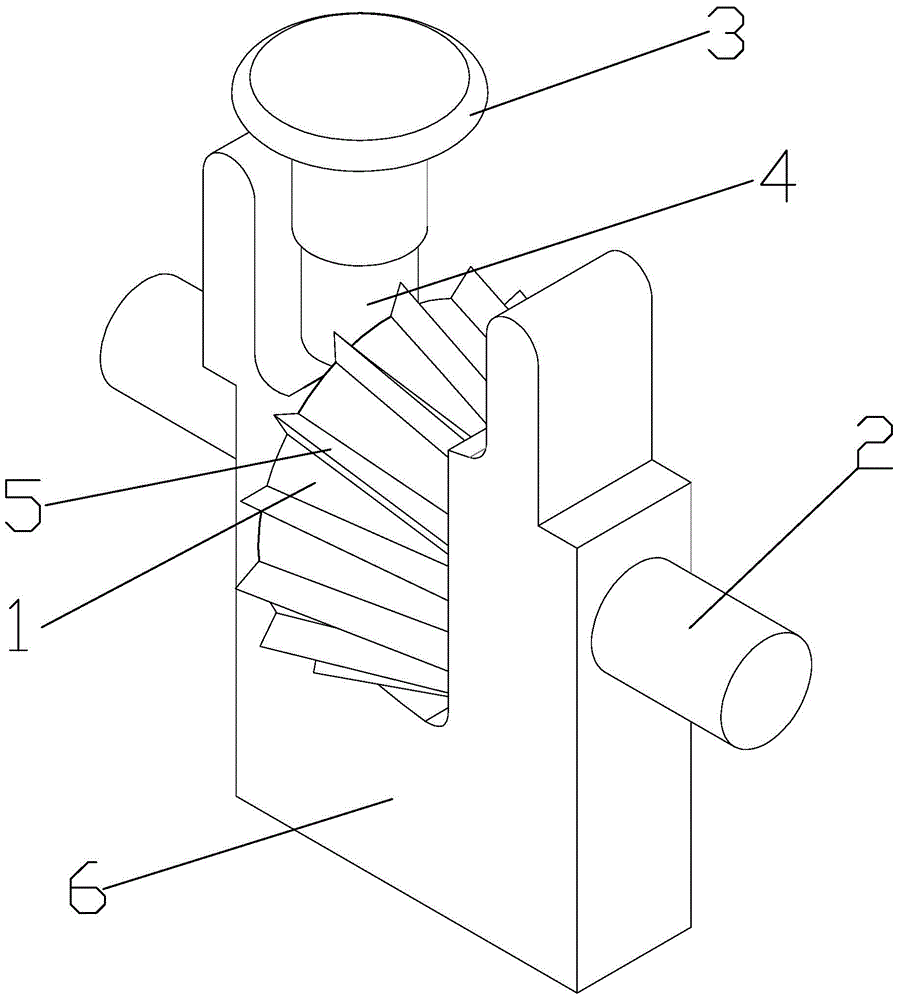

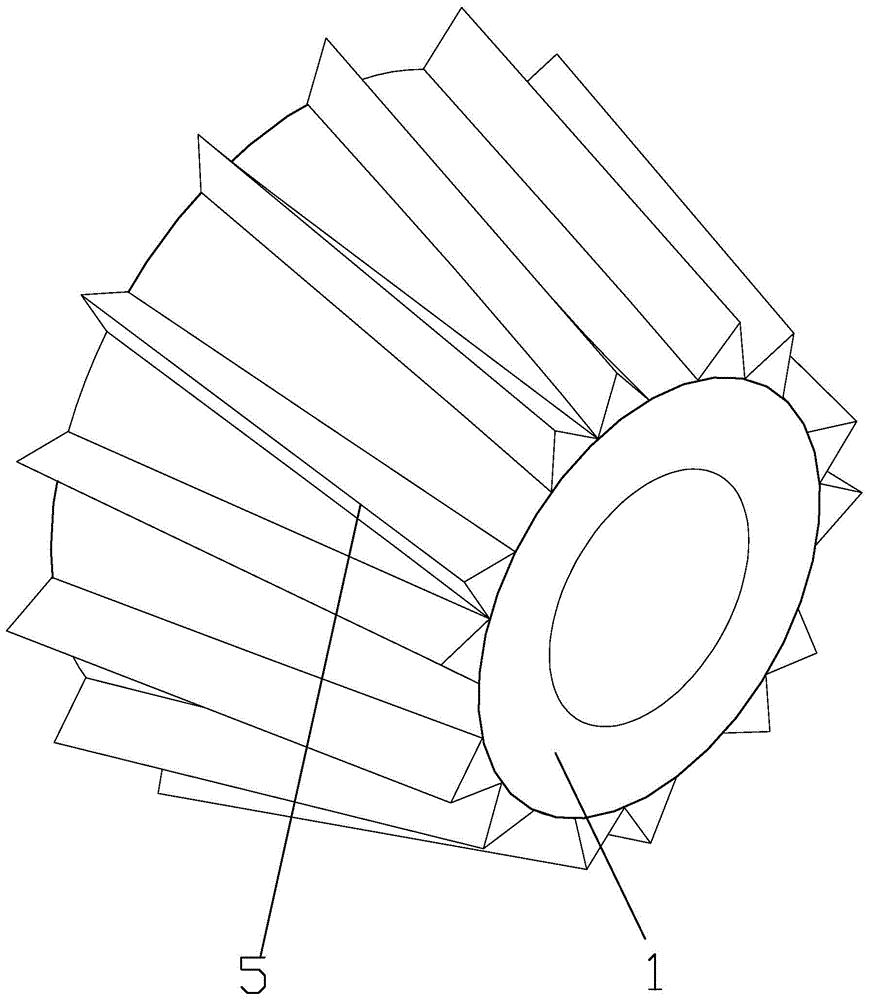

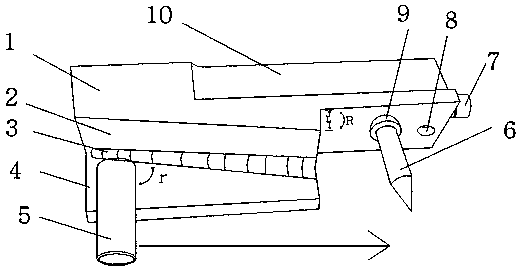

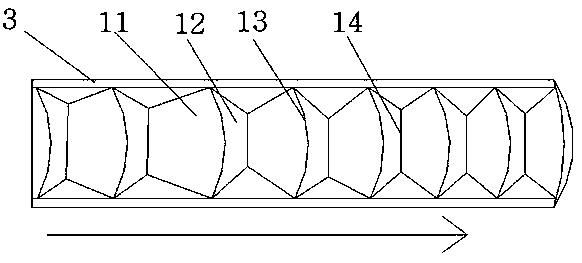

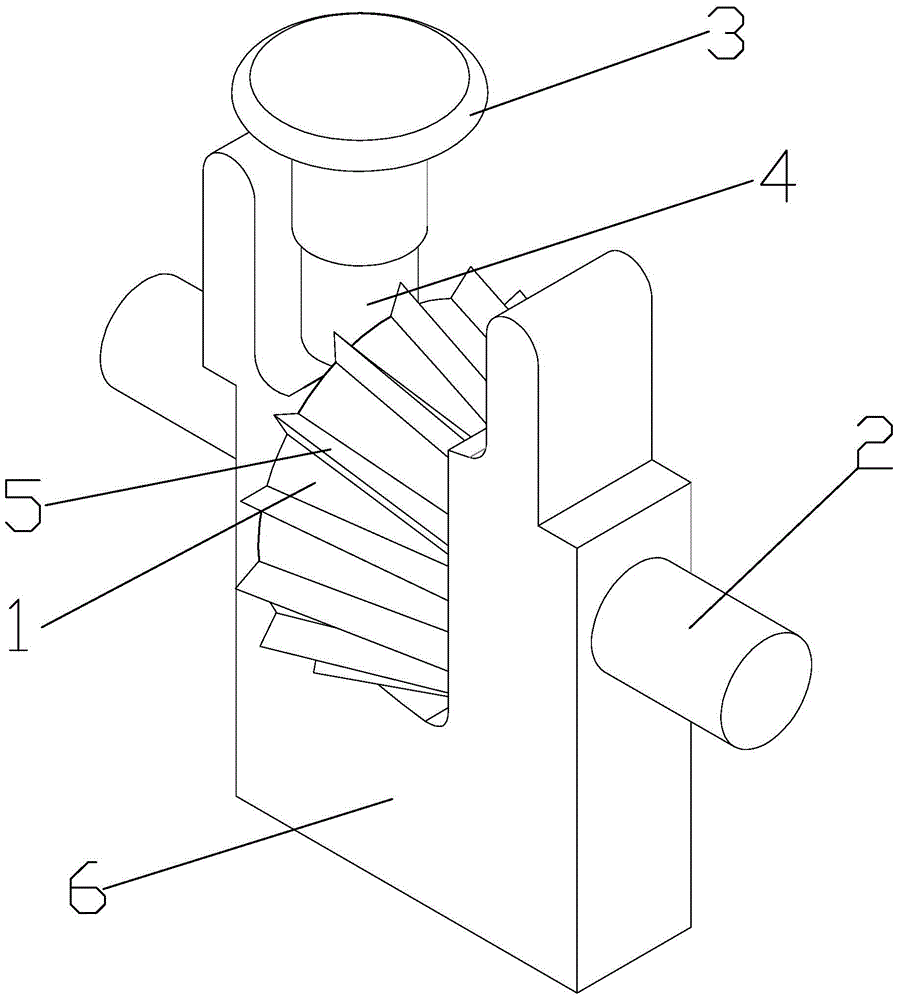

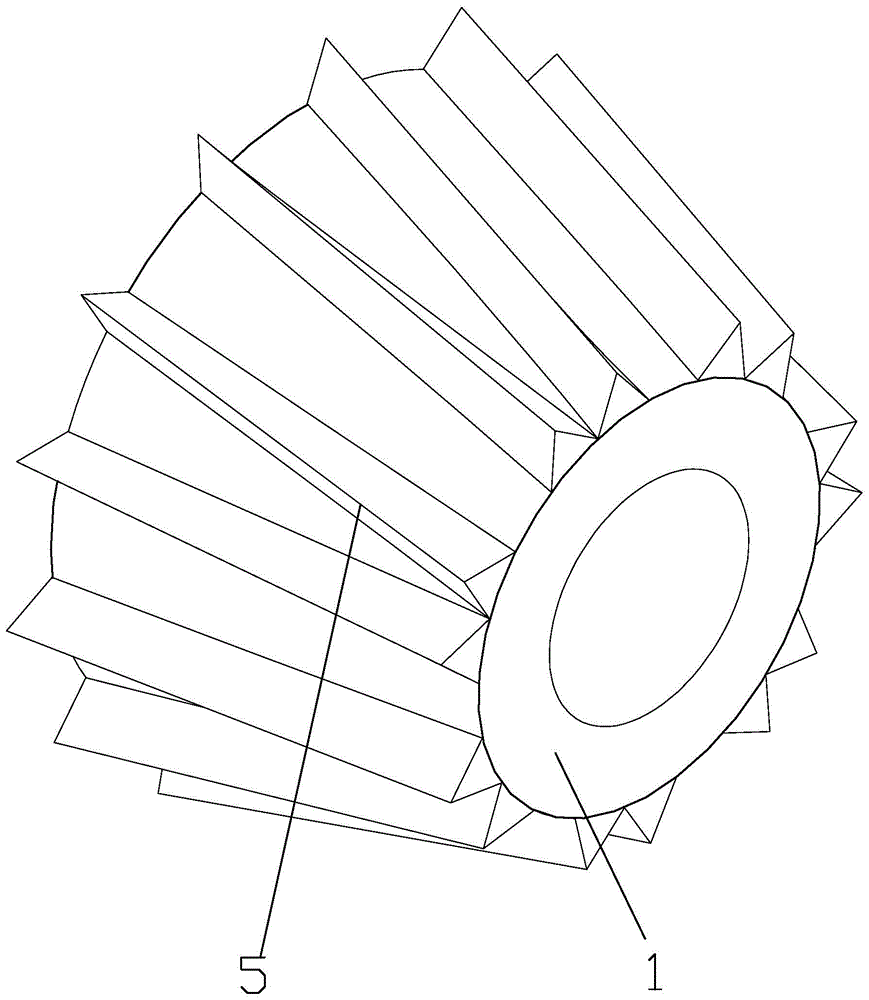

Technology for cold rolling extrusion teeth of cylindrical end face

ActiveCN104588783AOvercome processing defectsReduce processing inputGear teeth manufacturing toolsGear teethKilogram-forceMechanical equipment

The invention relates to a technology for cold rolling extrusion teeth of a cylindrical end face. The technology comprises the following steps that 1 a rolling tool is prepared, wherein the rolling tool is a hollow circular truncated cone adopting alloy steel as materials, and the outer surface of the rolling tool is provided with rack-shaped blades; 2 a to-be-machined workpiece is fixed in a fixture of a lathe, the rolling tool is inserted in a tool bar in a penetrating mode, and the tool bar is fixed on a carriage; 3 a machine tool is started, the revolving speed of the fixture is regulated to be at 1000 r to 1800 r, the carriage provided with the rolling tool is pushed to the direction of the end face of the workpiece to enable the outer surface of the rolling tool to make contact with the end face of the workpiece, and the rolling tool makes contact with the end face of the workpiece for three to five seconds under the environment of 30-kilogram force; 4 the carriage is loosened, the workpiece is taken down, the machine tool is switched off, the whole process is over, and machining of a small tooth face of the end face of the workpiece is completed. According to the technology for cold rolling extrusion teeth of the cylindrical end face, automation is achieved in the whole process, the defect that a traditional technology has to perform machining through mechanical equipment machining such as planing equipment and milling equipment is overcome, machining investment is small, and efficiency is high.

Owner:绍兴柯桥珂阳五金汽配厂

Automatically dredging device of preventing perforated strainer of underground well from blocking

PendingCN106522346APrevent waterloggingNo safety hazardSewerage structuresKilogram-forceQuiescent state

The invention relates to the field of urban municipal drainage, in particular to an automatically dredging device of preventing a perforated strainer of an underground well from blocking. The device comprises a scraping rod, the scraping rod is movably arranged on the perforated strainer of the underground well, the scraping rod is connected to a driving device through a driving rod, the driving device drives the scraping rod to make straight reciprocating motions on the perforated strainer of the underground well, the output force of the scraping rod is no more than 10 kilogram force, when water current enters the underground well, the driving device drives the scraping rod to move, and when no water current enters the underground well, the driving device is in a quiescent state. According to the automatically dredging device of preventing the perforated strainer of the underground well from blocking, the structure is simple, the scraping rod is in the quiescent state when there is no rainwater, the driving device is used for driving the scraping rod to move when there is rain, so that leaves and municipal waste on the perforated strainer of the underground well are scraped and pushed away without intermittence and then the rainwater successfully flows into the underground well, therefore, the condition of water logging of a road is prevented; in addition, due to the fact that the output force of the scraping rod is no more than 10 kilogram force, the scraping rod has no potential safety hazards towards vehicles and pedestrians.

Owner:西安天成金属材料有限公司

Blackberry lily coated decoction piece and preparation method thereof

InactiveCN108379405ALow boiling pointPromote leachingRespiratory disorderPlant ingredientsKilogram-forceIsoflavones

The invention discloses a blackberry lily coated decoction piece and a preparation method thereof. The method comprises the following steps that 1) a crude high-class blackberry lily is selected and cleaned for purification; 2) the cleaned blackberry lily is cut into slices after being fished up and drained; 3) the slice-shaped blackberry lily is placed into a pressure pan, the pressure is increased to 2-4 kilogram forces per square centimeter for 15-25 minutes, and is reduced to 0 kilogram force per square centimeter within 0-3 seconds; 4) the slice-shaped blackberry lily obtained in step 3)is placed into a coating machine to be coated, and the blackberry lily coated decoction piece is obtained. The blackberry lily coated decoction piece and the preparation method thereof have the advantages that through the pressurization and sudden depressurization, the blackberry lily coated decoction piece is performed with decoction easily, the pharmaceutical effect is improved, additional drying or insolation drying is not needed, the palatability of the product is good, the security is high, the decoction piece can be prevented from being oxidized and absorbing moisture due to the coatingon the outer wall of the decoction piece, and the isoflavone effective constituent is prevented from being oxidized to prolong the storage period, the preparation technology is simple, the cost is lower, and the method is suitable for industrial production.

Owner:ZHEJIANG KAIRUN PHARMA

Expansion pipe necking method

ActiveCN110116170AHigh densityImprove thickening uniformityShaping toolsOther manufacturing equipments/toolsKilogram-forceVolumetric Mass Density

The invention provides an expansion pipe necking method. A workpiece is hit by a die to form an inwards overturned and necked expansion pipe, the workpiece is heated, thereby being softened, and forceof each time of hitting is smaller than 100 kilogram force. The end of the expansion pipe is heated and softened and then is hit by the die, when hitting force is larger than 100 kilogram force, theexpansion pipe is liable to be twisted, when force is too small, machining efficiency of an inner necked opening of the expansion pipe is too low, meanwhile the second time of plastic deformation canbe conducted on the expansion pipe, the density of the end of the expansion pipe can be improved, connection strength between the expansion pipe and the inner necked opening and structural strength ofthe inner necked opening are improved effectively, connection strength of the expansion pipe and an outer connector can be improved conveniently, the expansion pipe is rotated while the inner neckedopening is machined, the thickening uniformity of the inner necked opening can be improved conveniently, attractiveness of the end of the inner necked opening of the expansion pipe is achieved conveniently, and machining quality can be improved conveniently.

Owner:远军热能动力科技有限公司

Strong bonding type ceramic tile laying method with high safety

InactiveCN110578392AImprove bonding strengthImprove efficiencyCovering/liningsKilogram-forceRough surface

The invention relates to a strong bonding type ceramic tile laying method with high safety, and belongs to the technical field of refined decoration of the building industry. According to the technical scheme, the strong bonding type ceramic tile laying method with high safety comprises the following steps that S1, a spraying gun is used for spraying the wall face to wash out a demolding agent, the pressure of the spraying gun is 15 to 20 kilogram force, and the wall is washed into a rough surface; S2, after two to three hours of finishing the operation that the wall is washed into the rough surface, an interface agent is brushed to the wall in a coating manner, and the brush coating thickness is 1 to 2 mm; S3, after the wall is smeared with the bonding layer, the bonding layer is formed through mixing of cement, mortar and building glue according to the proportion of 1:3:0.5, and the thickness of the bonding layer is 2 to 4 mm; S4, tile pasting is carried out, according to the large master drawing and the wall size, transverse and vertical tile arranging is carried out, uniformity of gaps between the adjacent tiles can be ensured, and the design drawing needs are met; S5, pointingtreatment is carried out, horizontal pointing is carried out, then vertical pointing is carried out, the slot width is controlled to 6 to 8 mm, and the effect of improving the bonding firmness between the tiles and the wall is achieved.

Owner:深圳市弘景装饰工程有限公司

Injection molding method for manufacturing light panel

InactiveCN101722637AThe overall thickness is thinReduce volumeOptical articlesKilogram-forceInjection pressure

The invention relates to an injection molding method for manufacturing a light panel, which is realized in a way that: the light panel is molded by injection under the injection pressure of 2000-4000 kilogram force / square centimeter at the injection speed of 600-1000 millimeter / second. The method molds the light panel under high injection pressure at high injection speed, the high injection speed by injection and high injection speed and pressure can enhance the dimensional accuracy of the product, and thus, the method can manufacture a product with small thickness.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Environmental anti-compression material and preparation method thereof

The invention relates to an environmental anti-compression material and a preparation method thereof. Raw materials comprise the following ingredients (by weight): 40-50 parts of polyethylene, 5-10 parts of titanium alloy powder, 2-5 parts of 2,4-dimethyl-6-tert-butyl phenol, 10-15 parts of ceramic fiber, 6-10 parts of polyvinyl alcohol, 5-8 parts of styrene butadiene rubber, 3-5 parts of carbon black, 2-5 parts of polyoxyethylene polyoxypropylene polyether, 3-6 parts of fatty alcohol polyoxyethylene ether, 30-40 parts of deionized water, and 10-20 parts of argon. The material is easily available, has no odor or toxicity, has excellent low temperature resistance, good chemical stability, corrosion resistance, good mechanical property and high self-lubricating degree, has good electrical insulating property and water resistance, has strong antioxidant capacity, and has longer service life, high tensile strength and strong impact resistance. The tensile strength can reach 250-280 kilogram force / square centimeter.

Owner:MAANSHAN SONGHAK INFORMATION TECH CO LTD

Disposable thin wall core die, methods of manufacture thereof and articles manufactured therefrom

Disclosed herein is a method comprising injecting into a thin wall disposable core die (100) a slurry having a viscosity of about 1 to about 1,000 Pascal-seconds at room temperature when tested at a shear rate of up to 70 seconds -1 and a flow index of less than 0.6 at a pressure of up to about 7 kilograms-force per square centimeter; wherein the thin wall disposable core die (100) has an average wall thickness of about 1.5 to about 10 millimeters; curing the slurry to form a cured ceramic core; removing the thin wall disposable core die (100) from the cured ceramic core (90); and firing the cured ceramic core to form a solidified ceramic core (90).

Owner:GENERAL ELECTRIC CO

A process for cold-rolling and extruding teeth on the end face of a cylinder

ActiveCN104588783BOvercome processing defectsReduce processing inputGear teeth manufacturing toolsGear teethKilogram-forceMechanical equipment

The invention relates to a technology for cold rolling extrusion teeth of a cylindrical end face. The technology comprises the following steps that 1 a rolling tool is prepared, wherein the rolling tool is a hollow circular truncated cone adopting alloy steel as materials, and the outer surface of the rolling tool is provided with rack-shaped blades; 2 a to-be-machined workpiece is fixed in a fixture of a lathe, the rolling tool is inserted in a tool bar in a penetrating mode, and the tool bar is fixed on a carriage; 3 a machine tool is started, the revolving speed of the fixture is regulated to be at 1000 r to 1800 r, the carriage provided with the rolling tool is pushed to the direction of the end face of the workpiece to enable the outer surface of the rolling tool to make contact with the end face of the workpiece, and the rolling tool makes contact with the end face of the workpiece for three to five seconds under the environment of 30-kilogram force; 4 the carriage is loosened, the workpiece is taken down, the machine tool is switched off, the whole process is over, and machining of a small tooth face of the end face of the workpiece is completed. According to the technology for cold rolling extrusion teeth of the cylindrical end face, automation is achieved in the whole process, the defect that a traditional technology has to perform machining through mechanical equipment machining such as planing equipment and milling equipment is overcome, machining investment is small, and efficiency is high.

Owner:绍兴柯桥珂阳五金汽配厂

Anti-explosion pressure relief device of cement brick making kiln

An anti-explosion pressure relief device of a cement brick making kiln comprises a pressure relief opening and a pressure relief door, the pressure relief opening is formed in the back of a kiln body and connected with the pressure relief door, a protecting layer wrapping the inner edge of the pressure relief door fits the pressure relief opening in size, and borne kiln chamber thrust is not more than three kilogram force. The anti-explosion pressure relief device of the cement brick making kiln is simple in structure, low in cost and capable of guaranteeing timely pressure relief of the cement brick making kiln under unexpected conditions, so that the service life of equipment is prolonged and personnel safety is guaranteed.

Owner:LEIYANG JINYAN NEW BUILDING MATERIAL

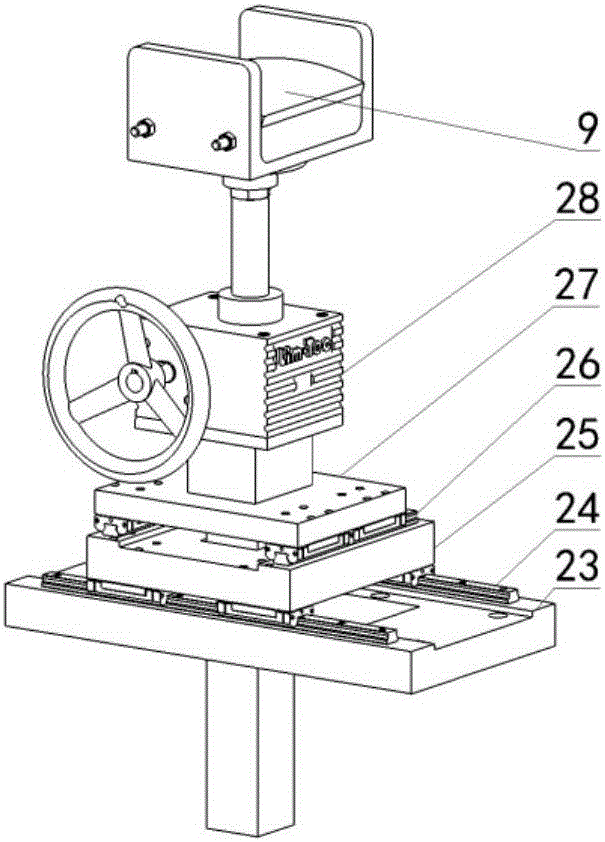

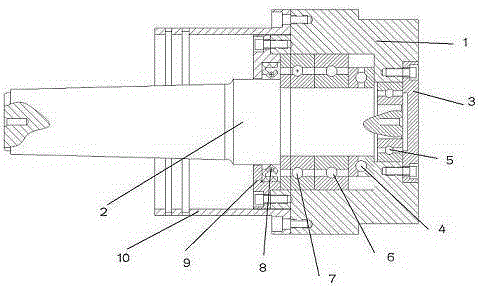

An active top tooling

ActiveCN104149215BImprove machining accuracyImprove carrying capacityWorking accessoriesFine working devicesKilogram-forcePhotovoltaic industry

The invention relates to a novel movable centring tool for guide wheel slotting. The movable centring tool is specially designed for the guide wheel slotting in the photovoltaic industry and can bear guide wheels with the length larger than 1000mm and smaller than 1500mm and the weight smaller than or equal to 500kg, the axial centring force can reach 900 Kgf (kilogram-force), and the spherical jitter value, measured through a micrometer gauge after assembling, is smaller than 0.007mm. The movable centring tool is accurate in centralized positioning, convenient to operate, low in labor intensity and capable of completing clamping of a workpiece at one step; a framework oil seal arranged inside the movable centring tool can prevent water and dust; a water shield integrated with the outer circle of a tailstock taper hole is designed externally, so that water and garbage can be more effectively prevented from entering transmission parts.

Owner:江苏美科太阳能科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com