Patents

Literature

2708 results about "Pressure range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

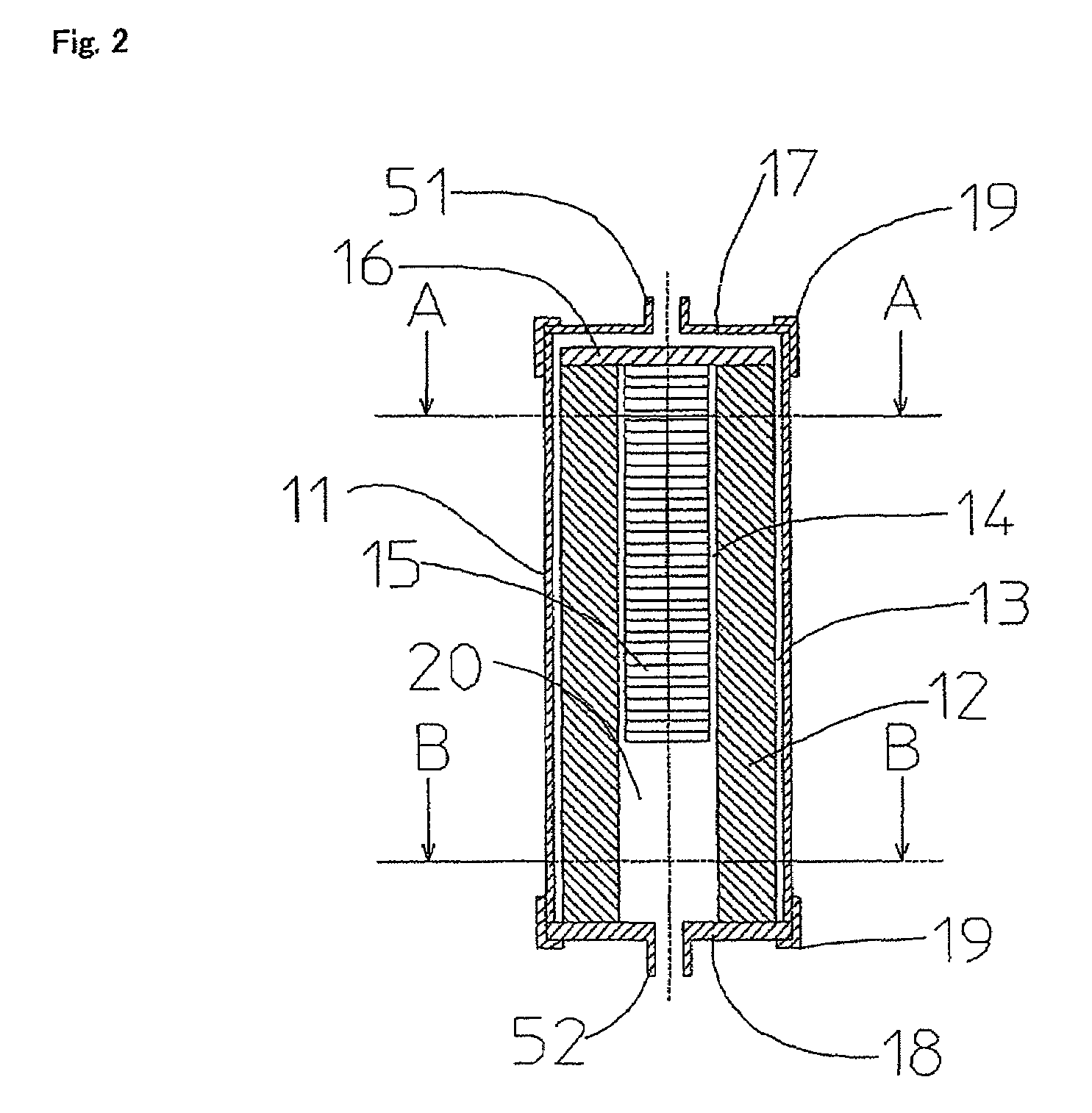

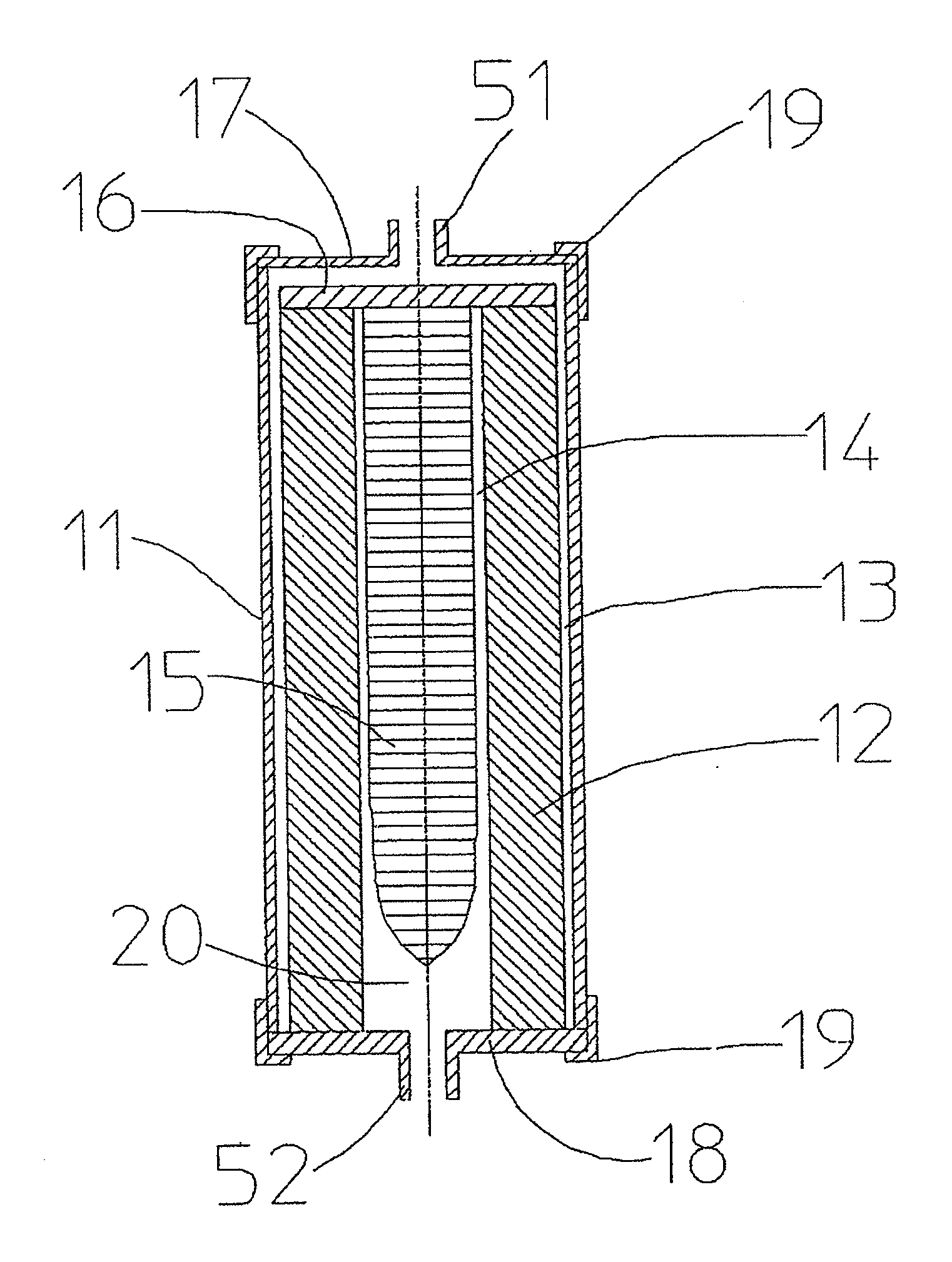

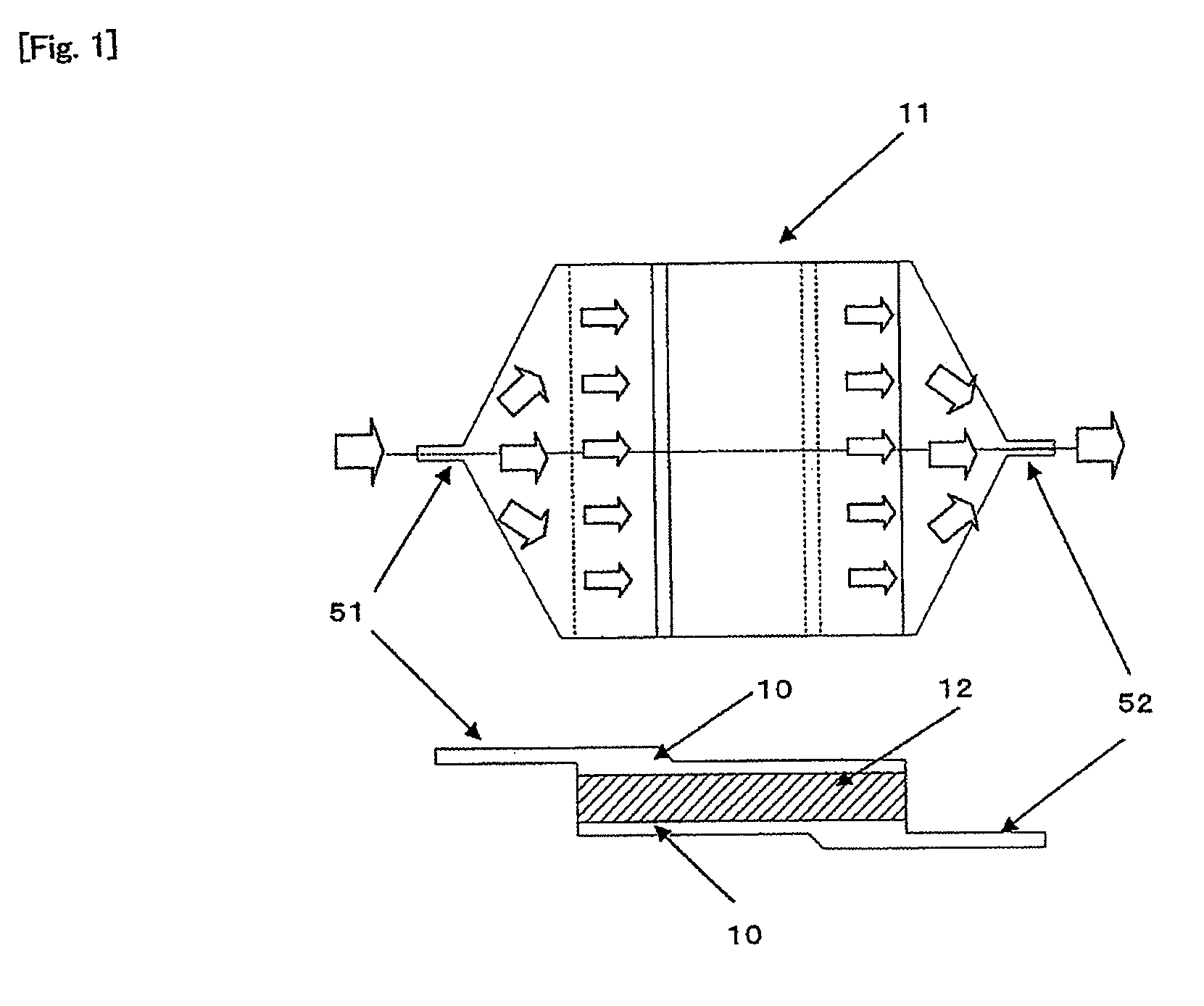

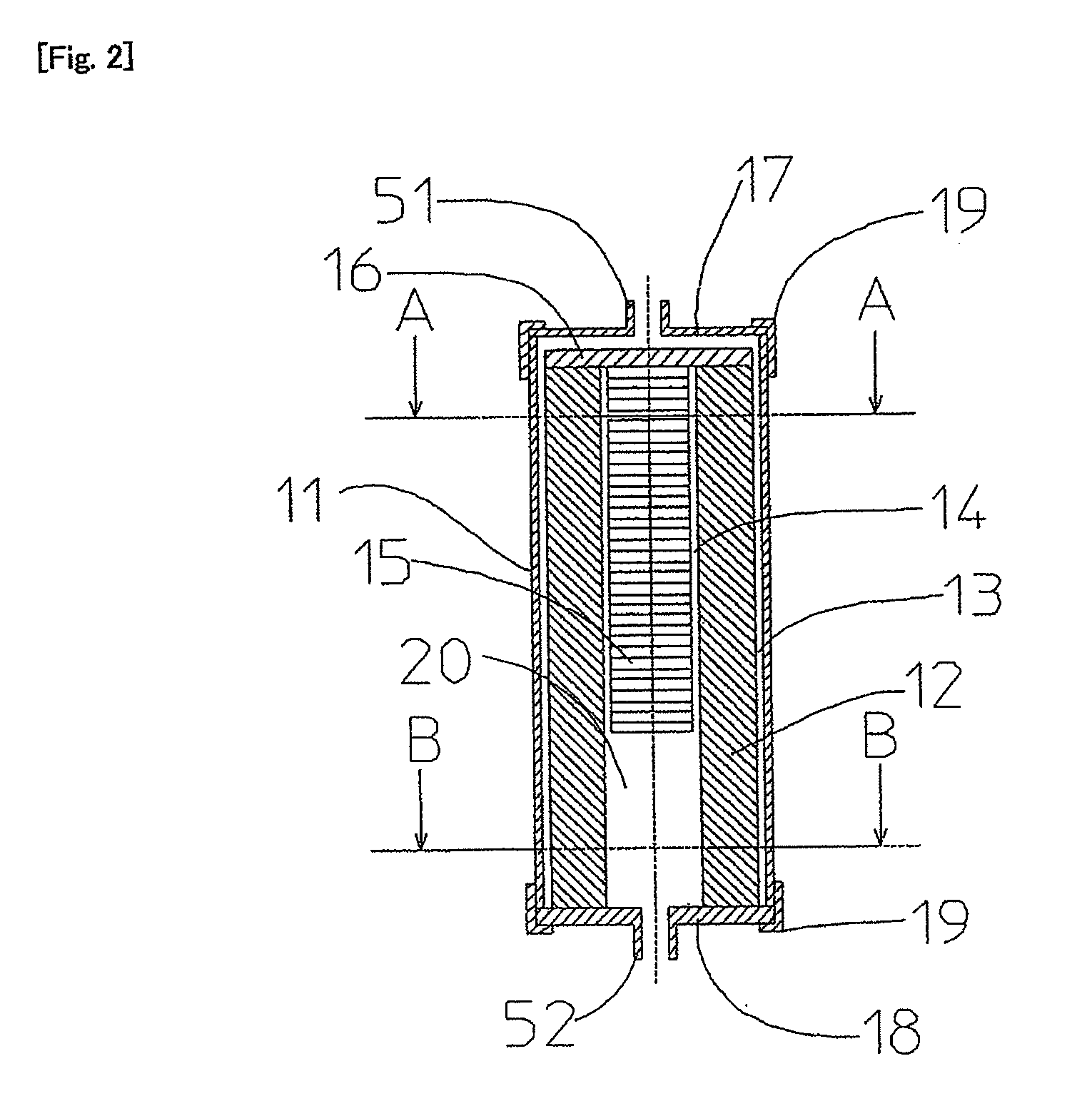

Low-temperature compatible wide-pressure-range plasma flow device

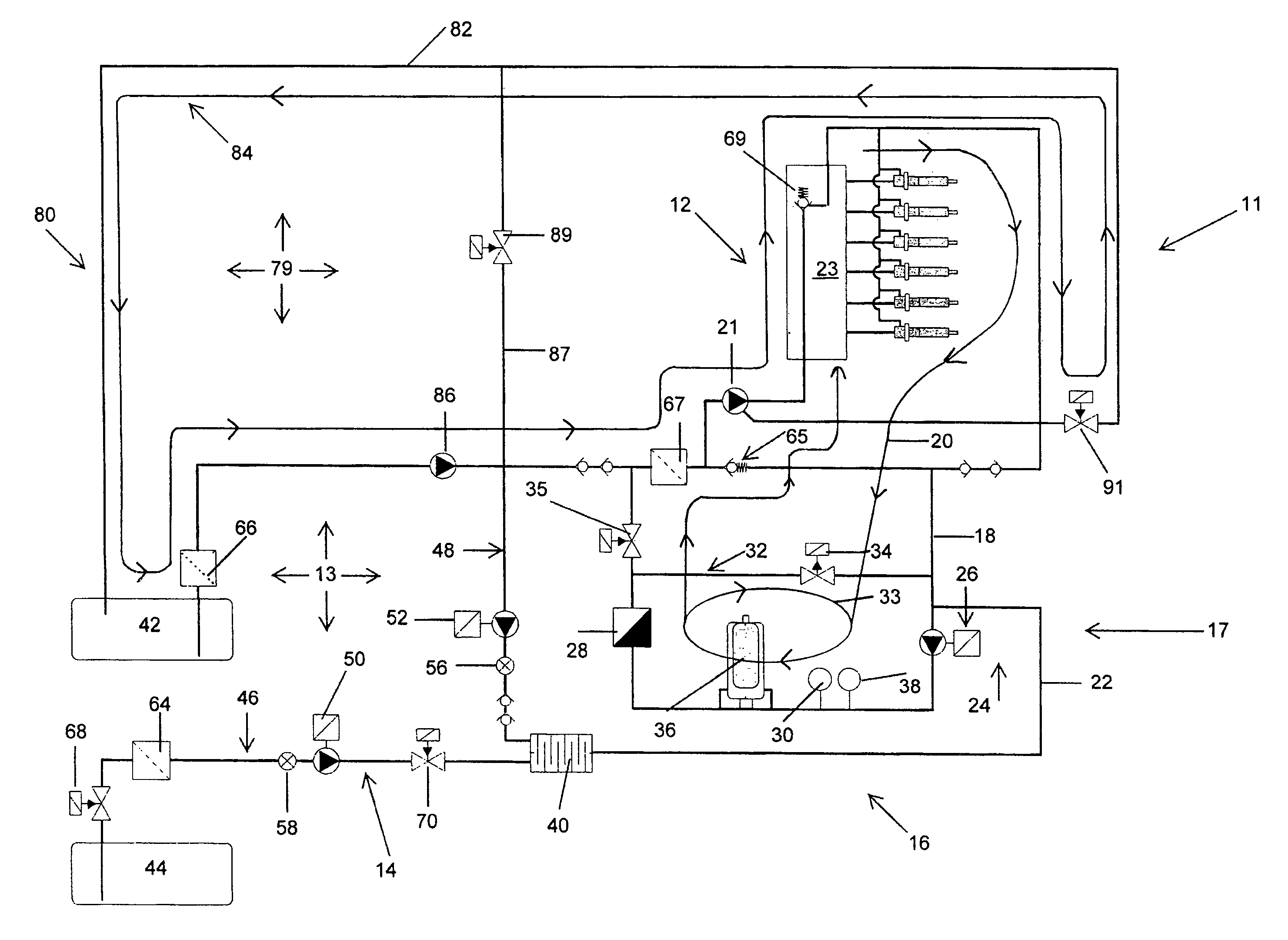

InactiveUS20020129902A1Electric discharge tubesSemiconductor/solid-state device manufacturingGas phaseReactive gas

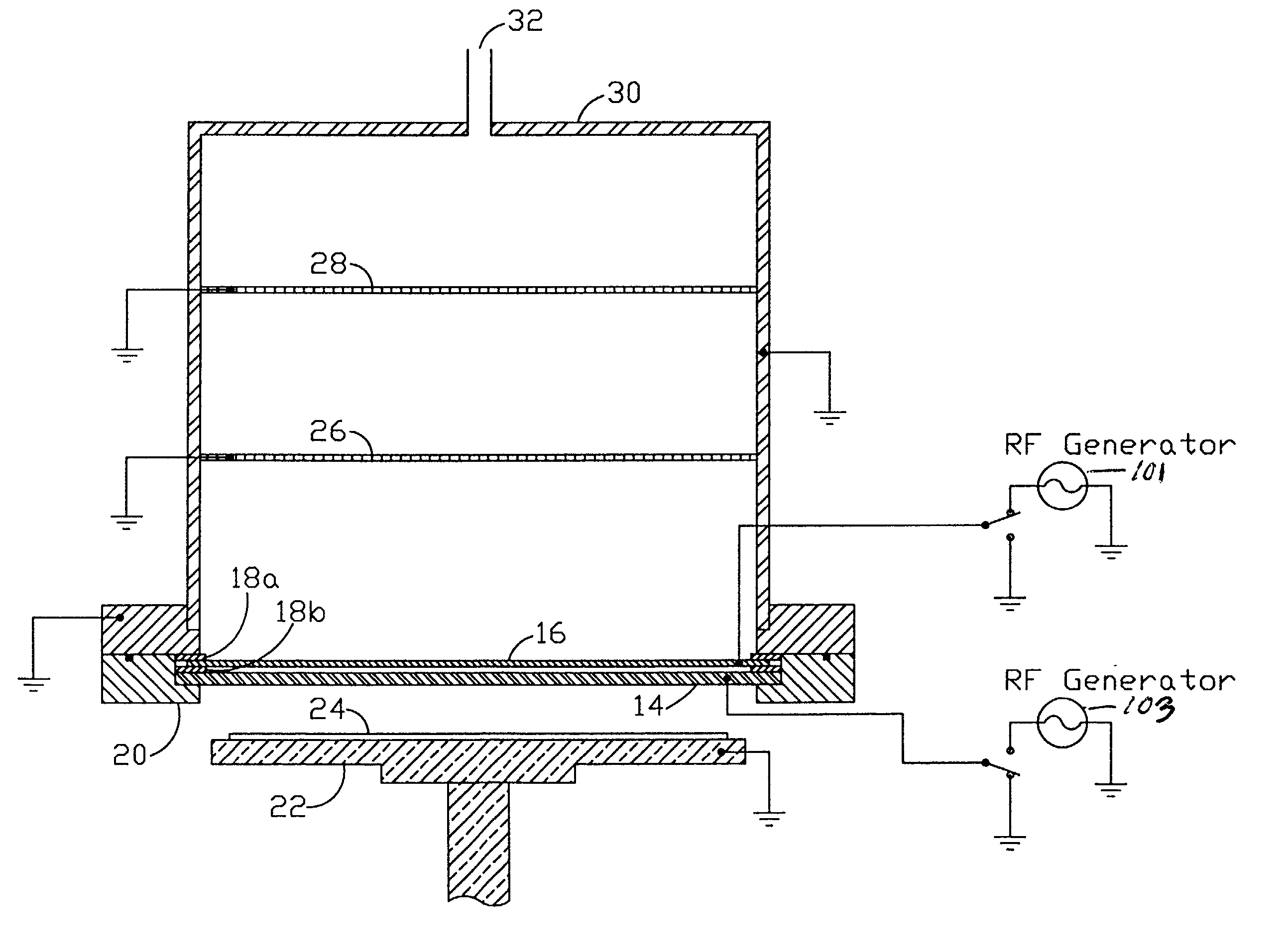

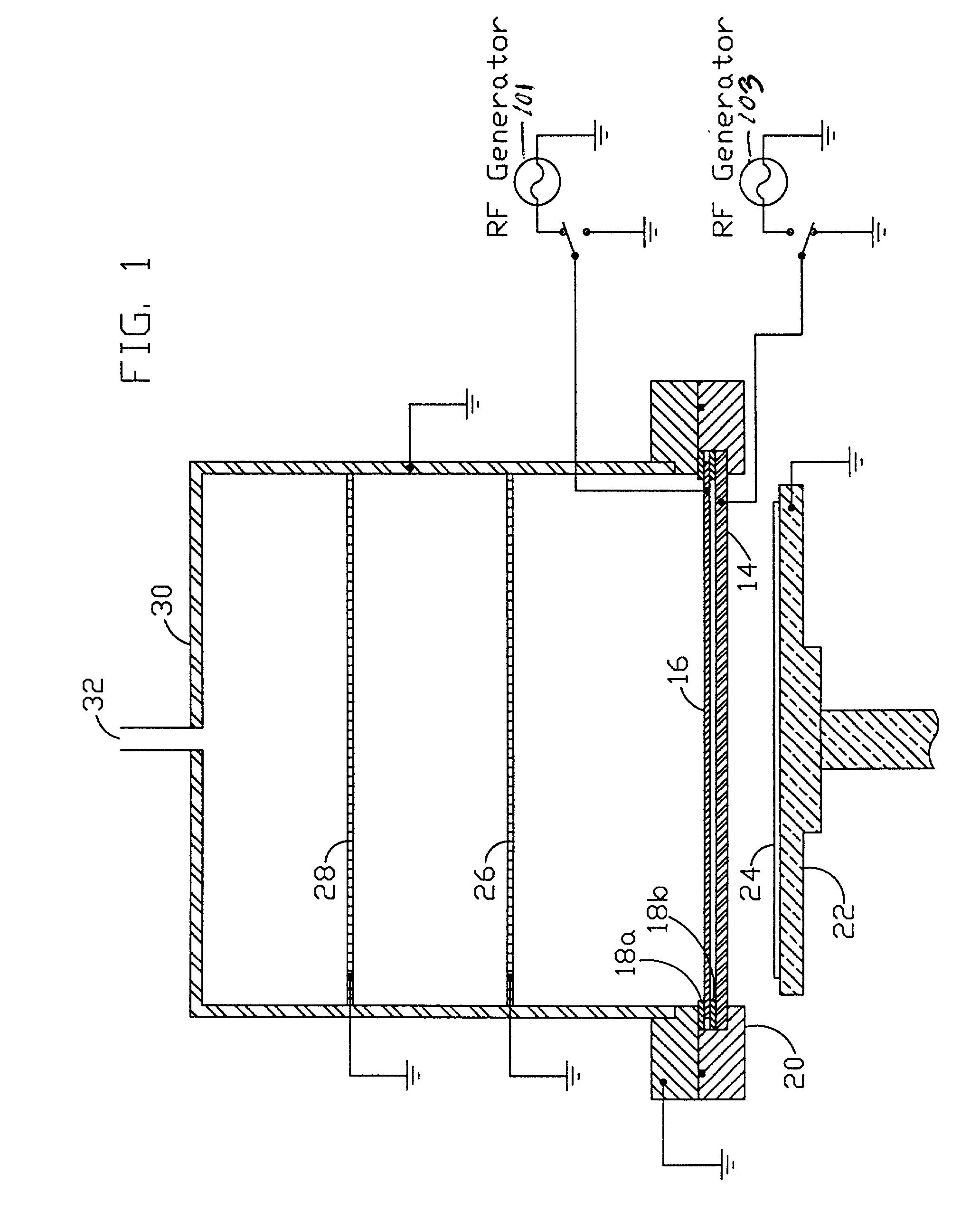

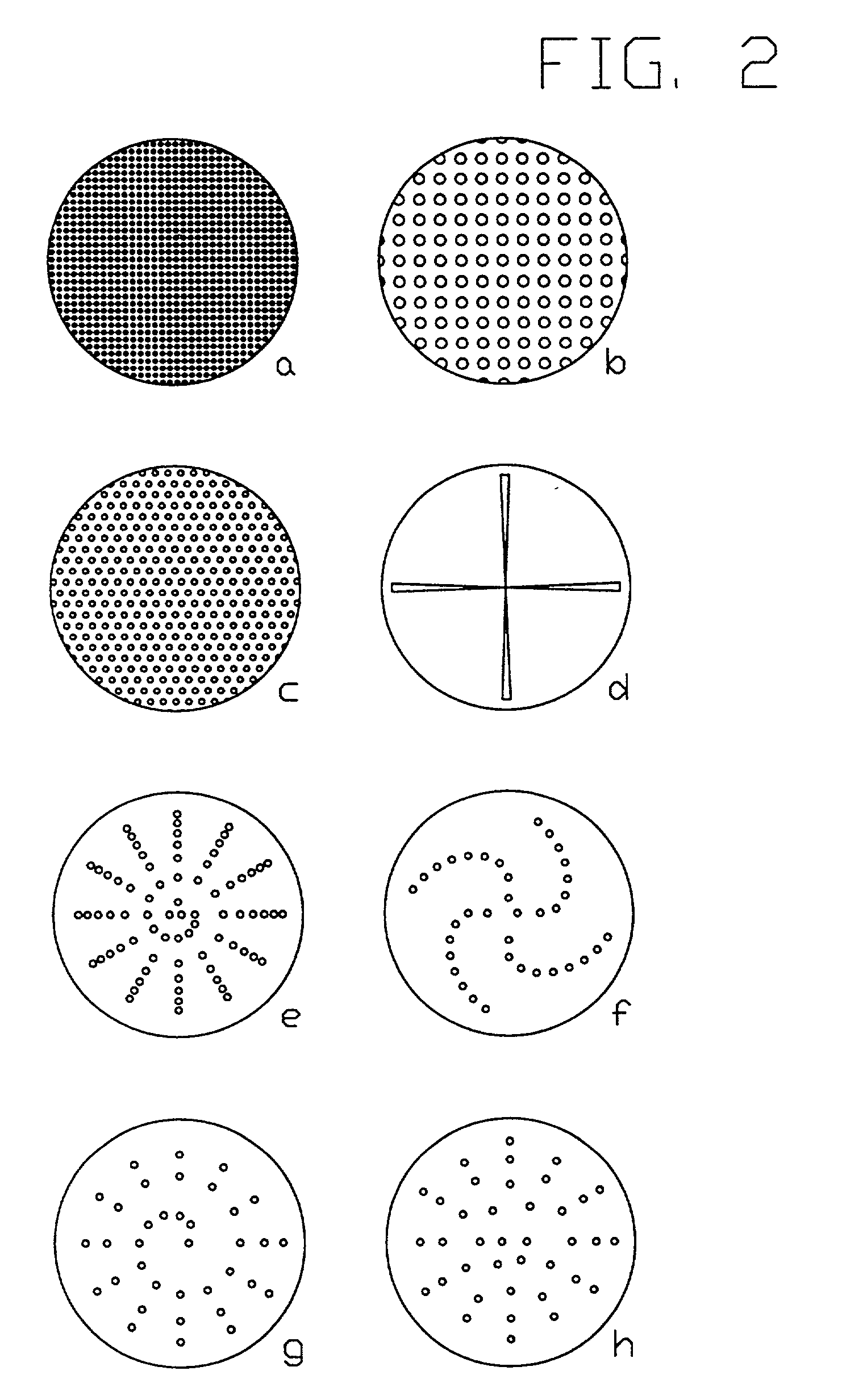

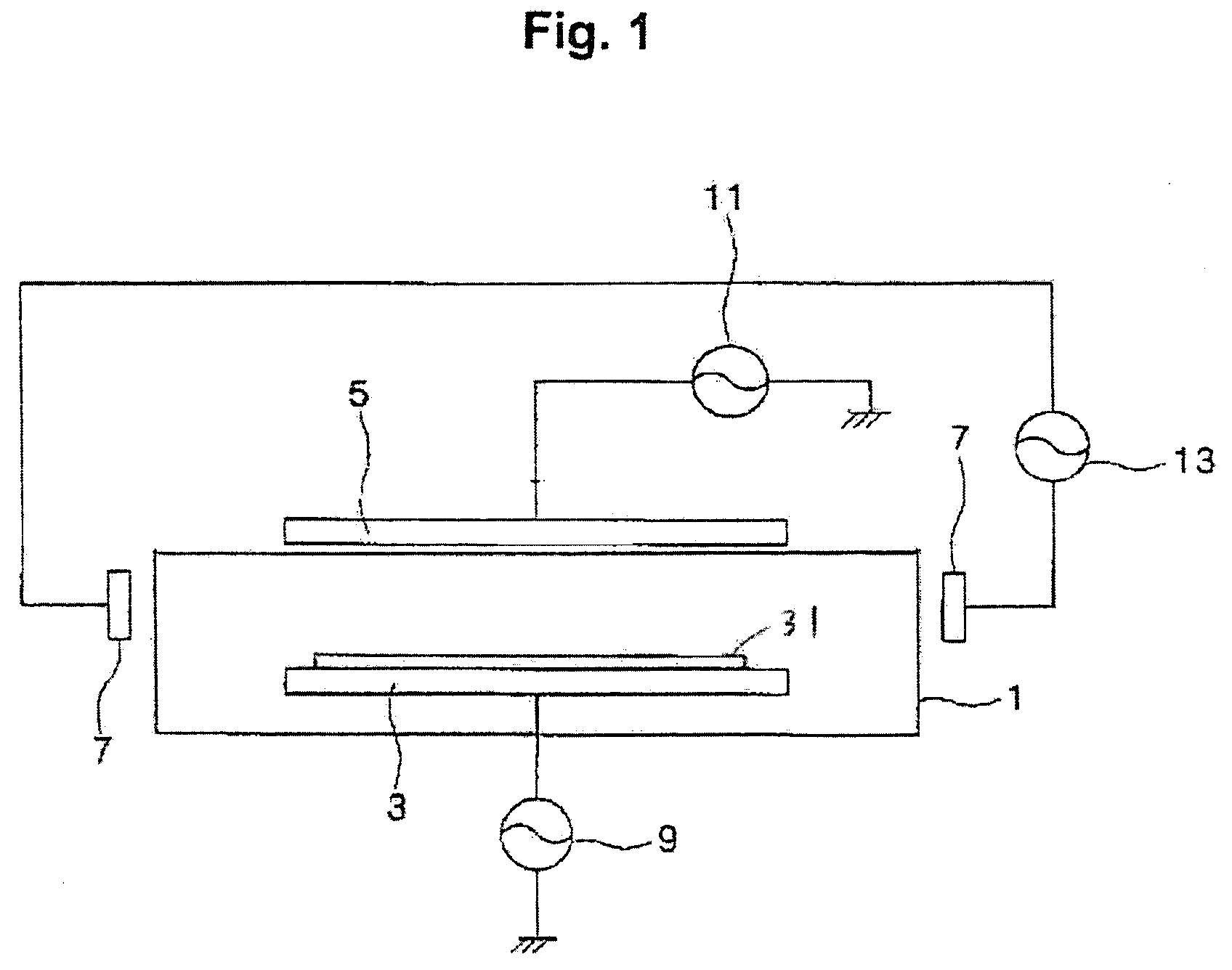

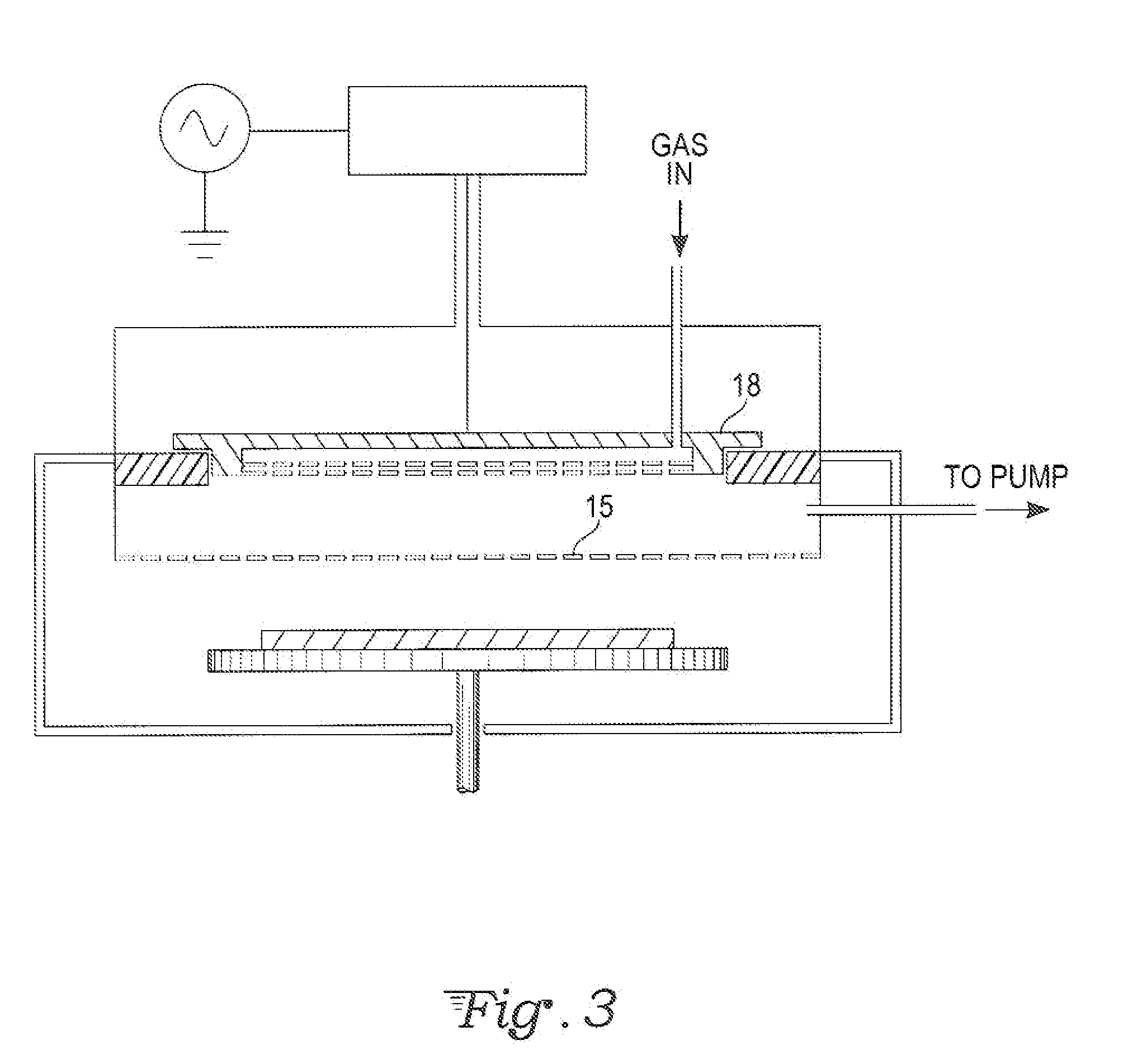

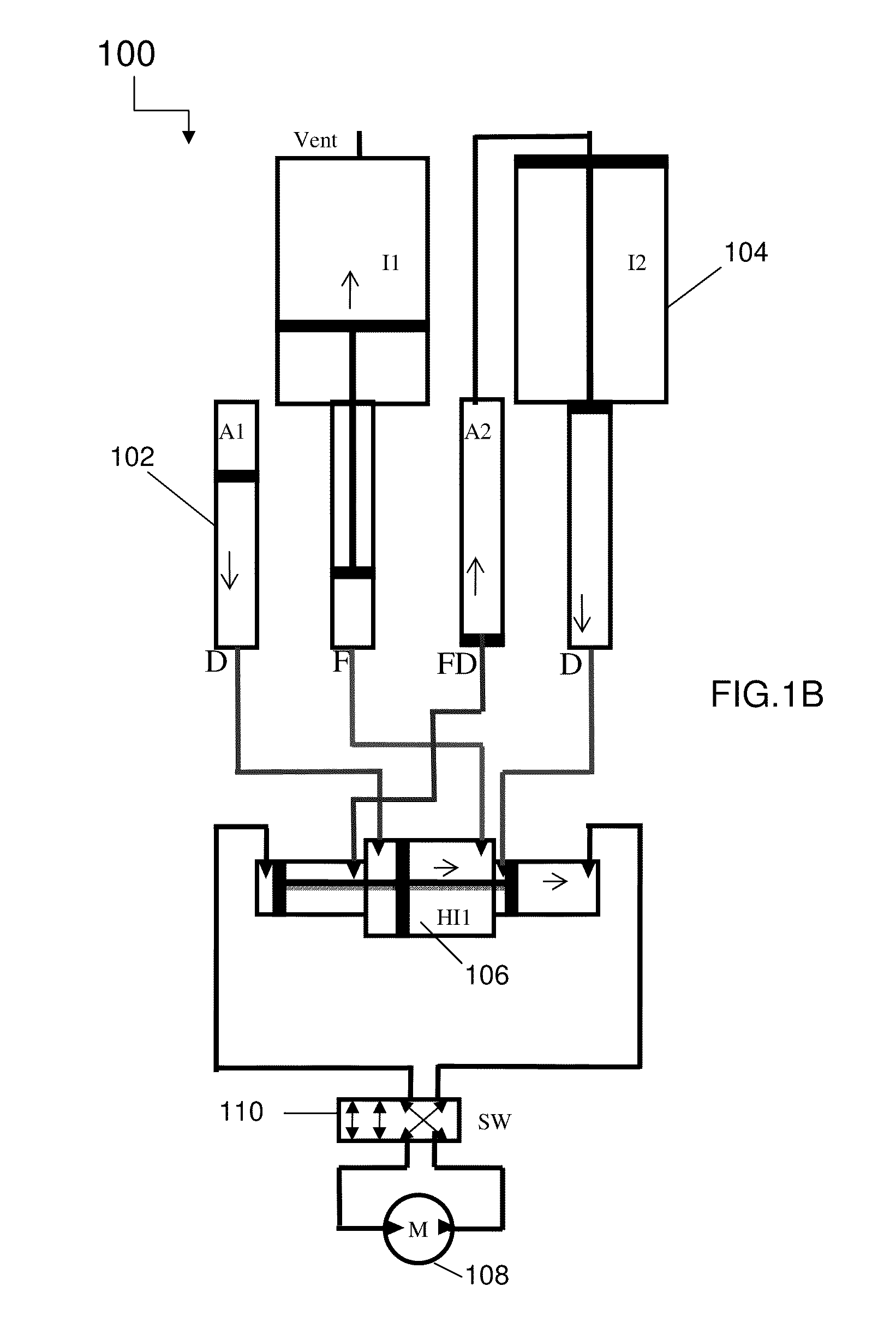

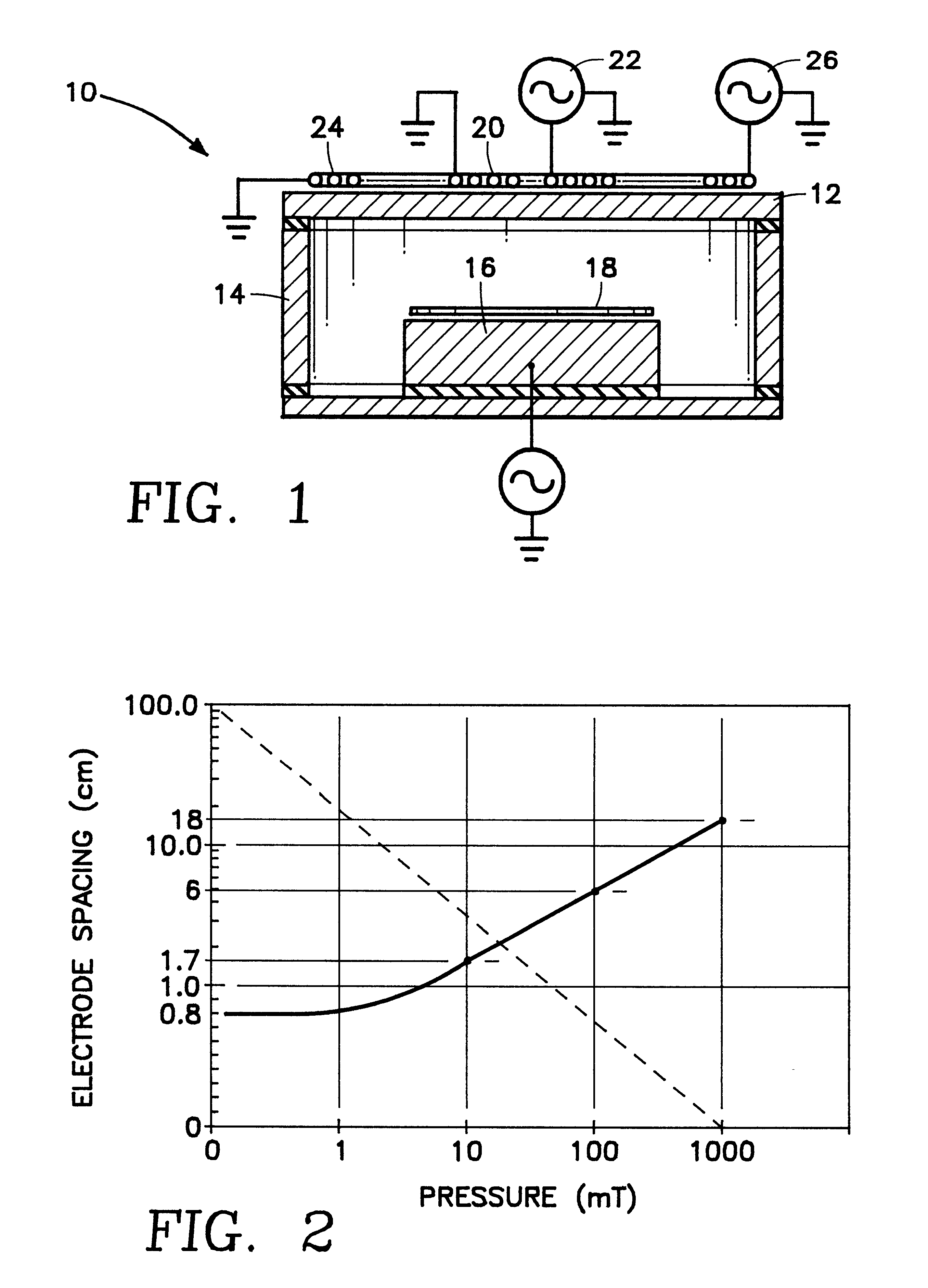

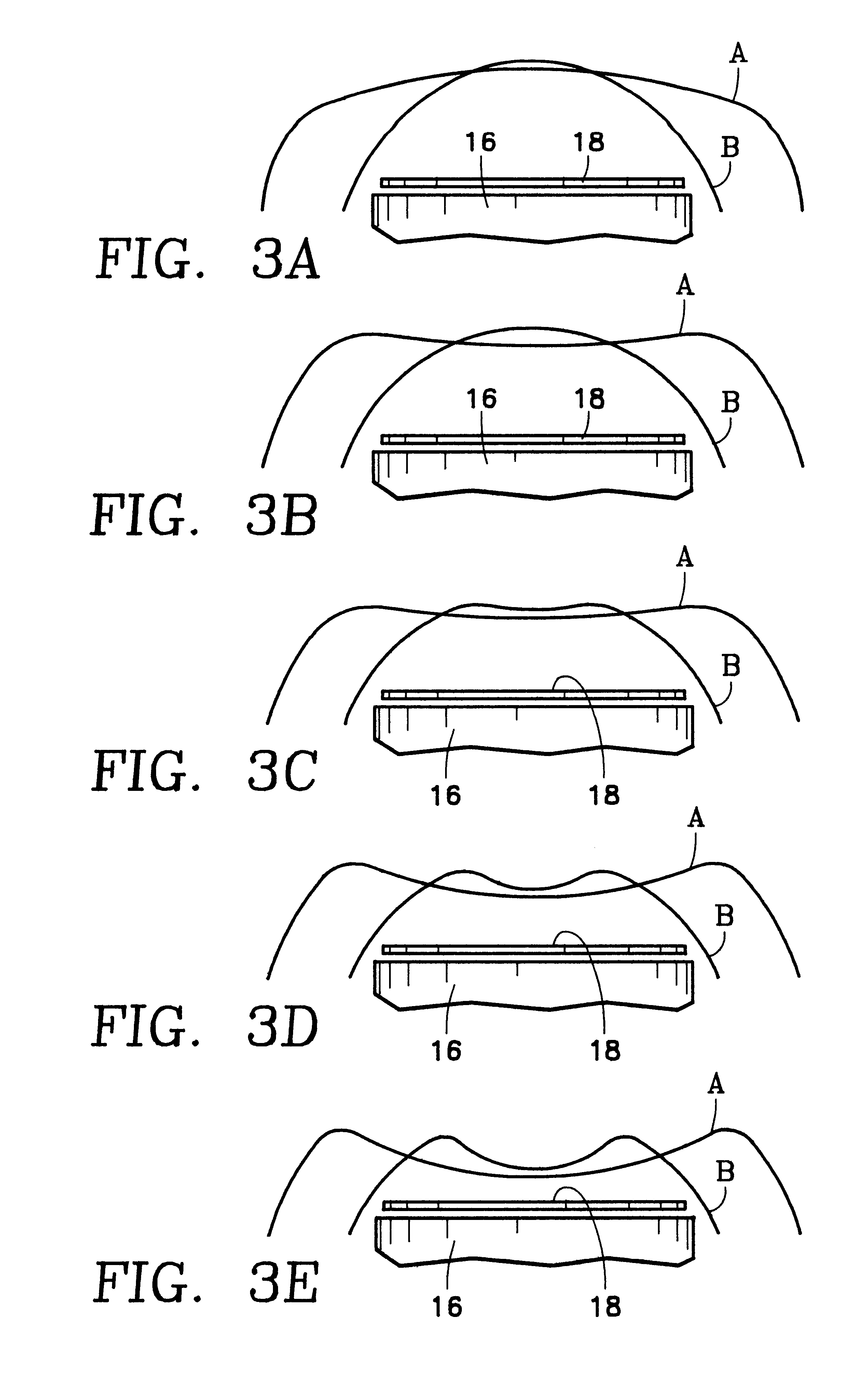

The invention is embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and a substrate or work piece is placed in the gas flow downstream of the electrodes, such that said substrate or work piece is substantially uniformly contacted across a large surface area with the reactive gases emanating therefrom. The invention is also embodied in a plasma flow device or reactor having a housing that contains conductive electrodes with openings to allow gas to flow through or around them, where one or more of the electrodes are powered by an RF source and one or more are grounded, and one of the grounded electrodes contains a means of mixing in other chemical precursors to combine with the plasma stream, and a substrate or work piece placed in the gas flow downstream of the electrodes, such that said substrate or work piece is contacted by the reactive gases emanating therefrom. In one embodiment, the plasma flow device removes organic materials from a substrate or work piece, and is a stripping or cleaning device. In another embodiment, the plasma flow device kills biological microorganisms on a substrate or work piece, and is a sterilization device. In another embodiment, the plasma flow device activates the surface of a substrate or work piece, and is a surface activation device. In another embodiment, the plasma flow device etches materials from a substrate or work piece, and is a plasma etcher. In another embodiment, the plasma flow device deposits thin films onto a substrate or work piece, and is a plasma-enhanced chemical vapor deposition device or reactor.

Owner:RGT UNIV OF CALIFORNIA

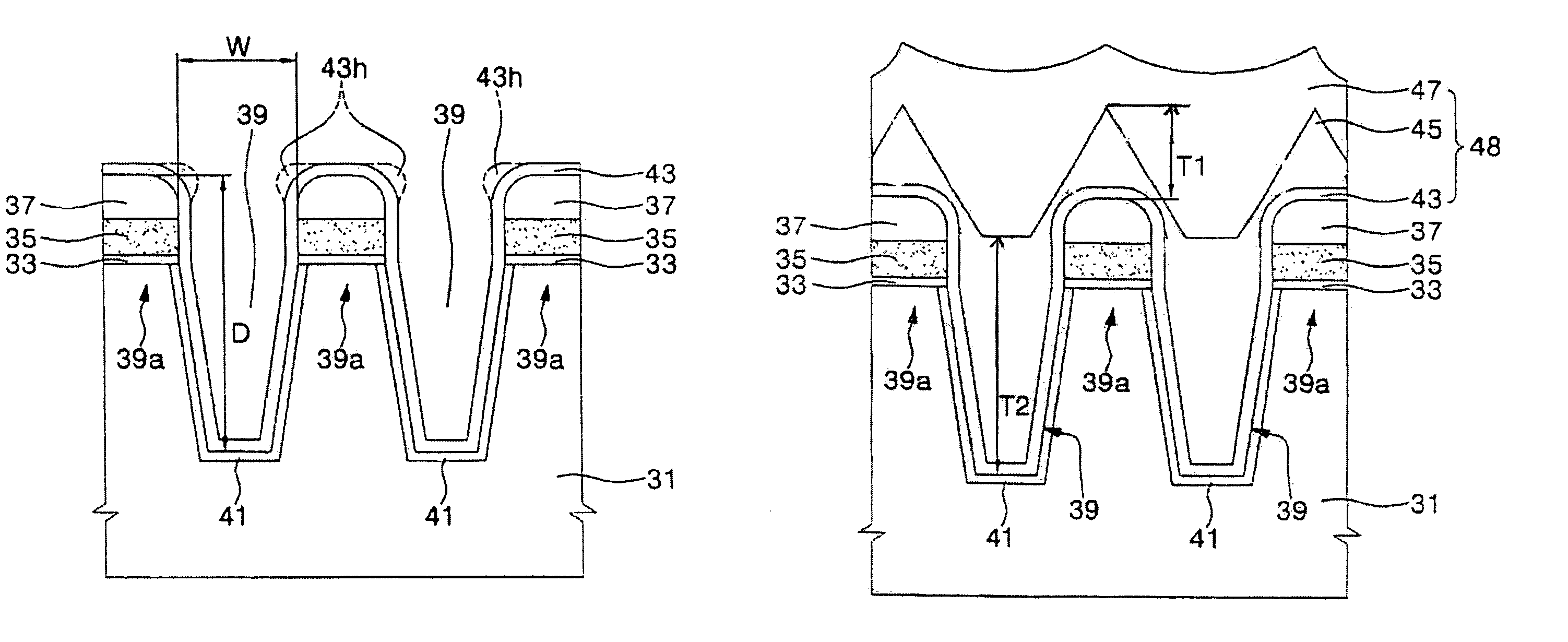

High-density plasma (HDP) chemical vapor deposition (CVD) methods and methods of fabricating semiconductor devices employing the same

InactiveUS7183214B2Reduce amountStrong Gap Filling CapabilitySemiconductor/solid-state device manufacturingPackaging toiletriesGas phaseDevice material

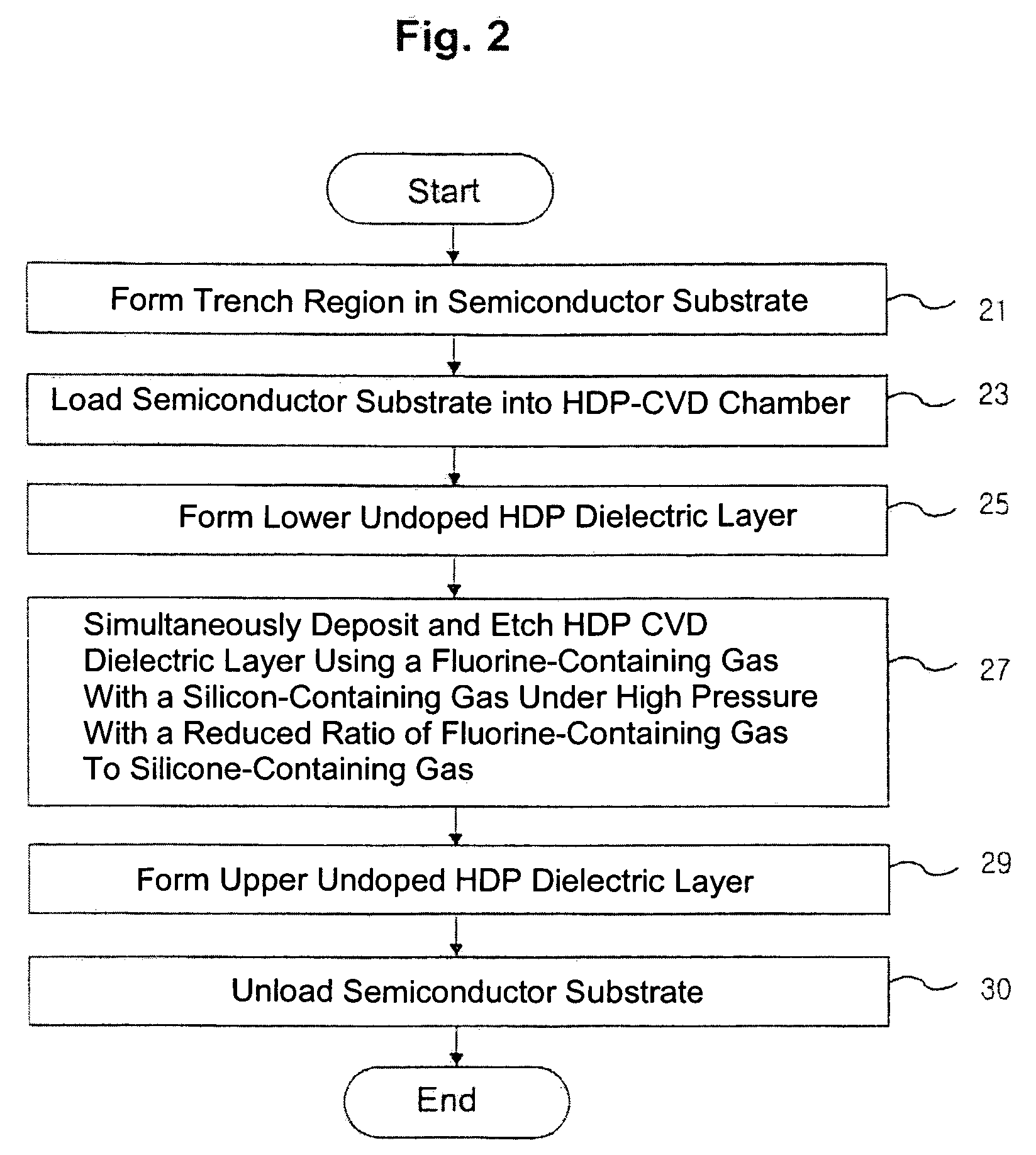

In one embodiment, a semiconductor substrate is placed into a process chamber. A gas mixture including a silicon-containing gas, a fluorine-containing gas, an inert gas, and an oxygen gas is introduced into the chamber at a pressure range of from about 30 mTorr to about 90 mTorr. During this time, deposition and etching processes are concurrently performed using a plasma to form a high-density plasma (HDP) insulating layer on the semiconductor substrate. A ratio of deposition to etching is from about 3:1 to about 10:1. A ratio of a flow rate of the fluorine-containing gas to a flow rate of the silicon-containing gas is less than about 0.9.

Owner:SAMSUNG ELECTRONICS CO LTD

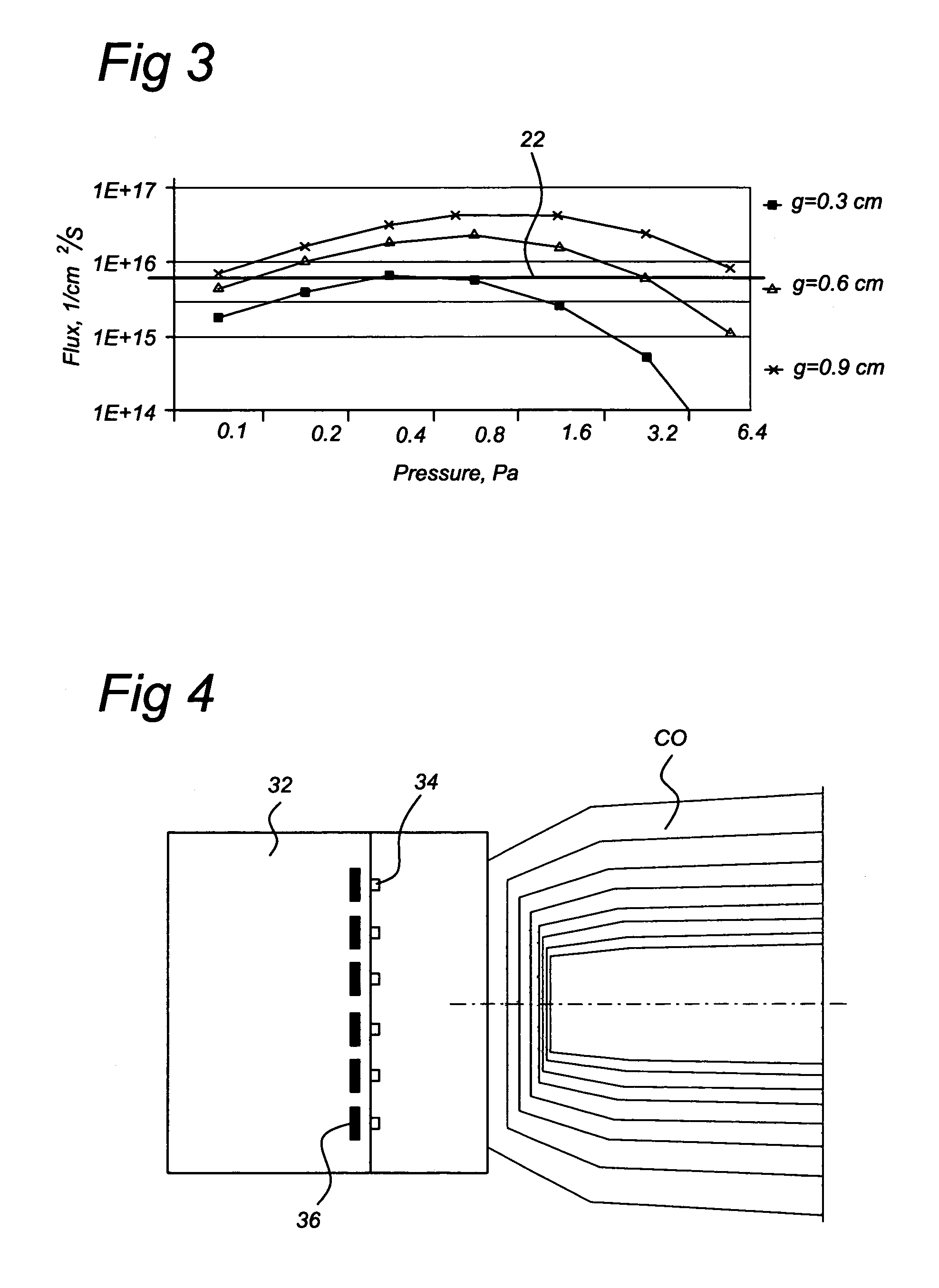

Capacitively coupled remote plasma source with large operating pressure range

InactiveUS20100101727A1System costExtension of timeElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceRadio frequency

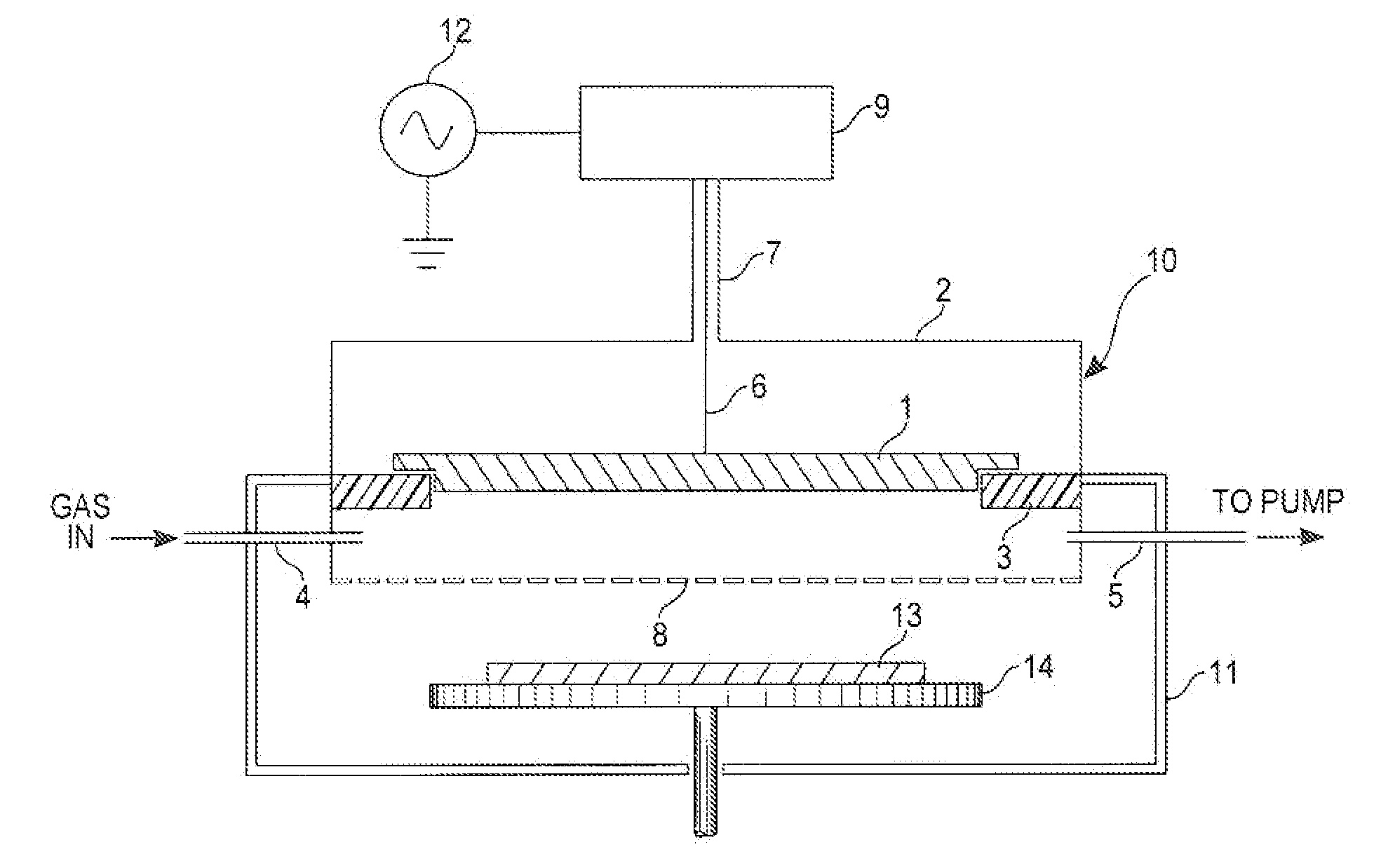

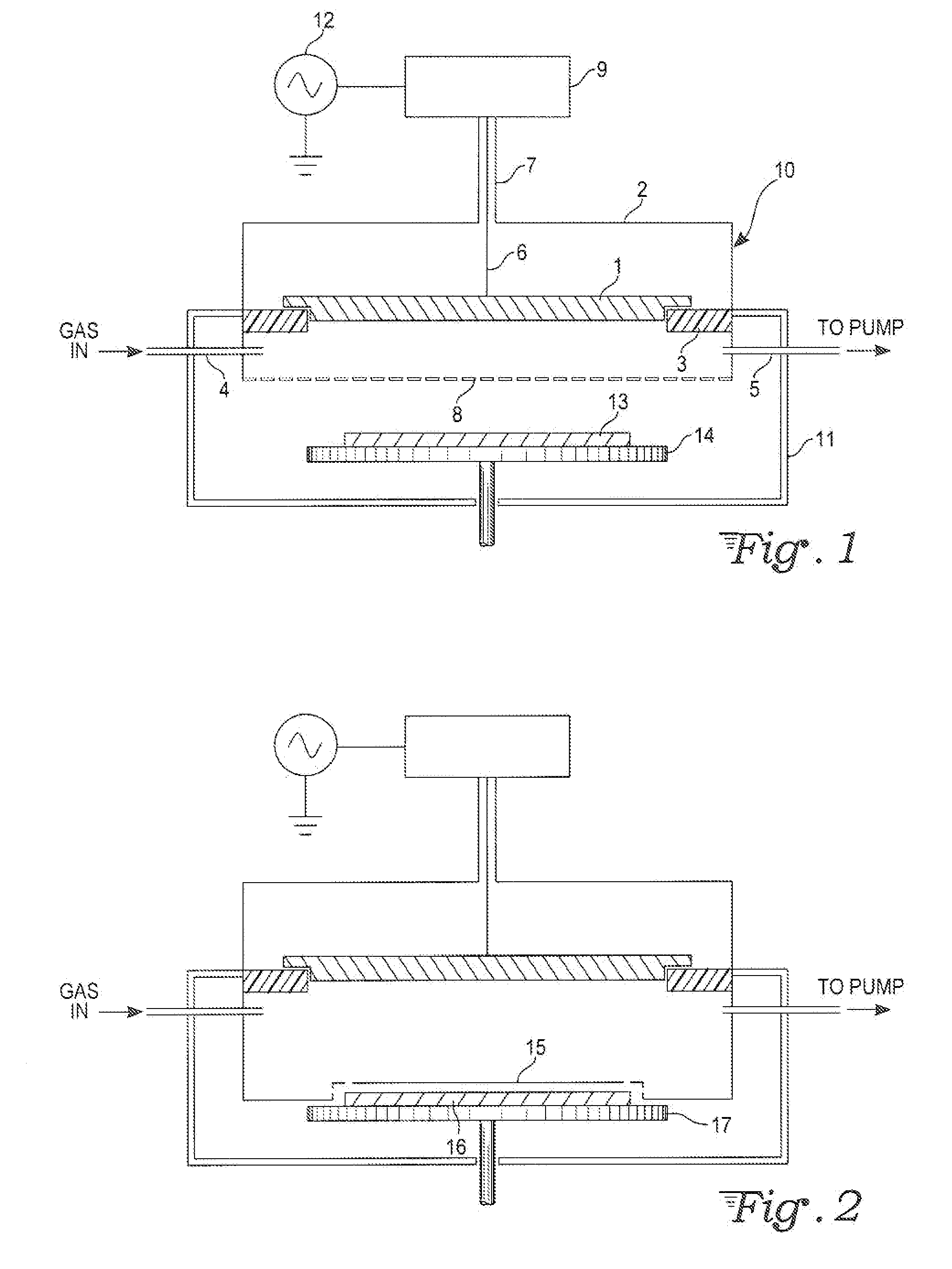

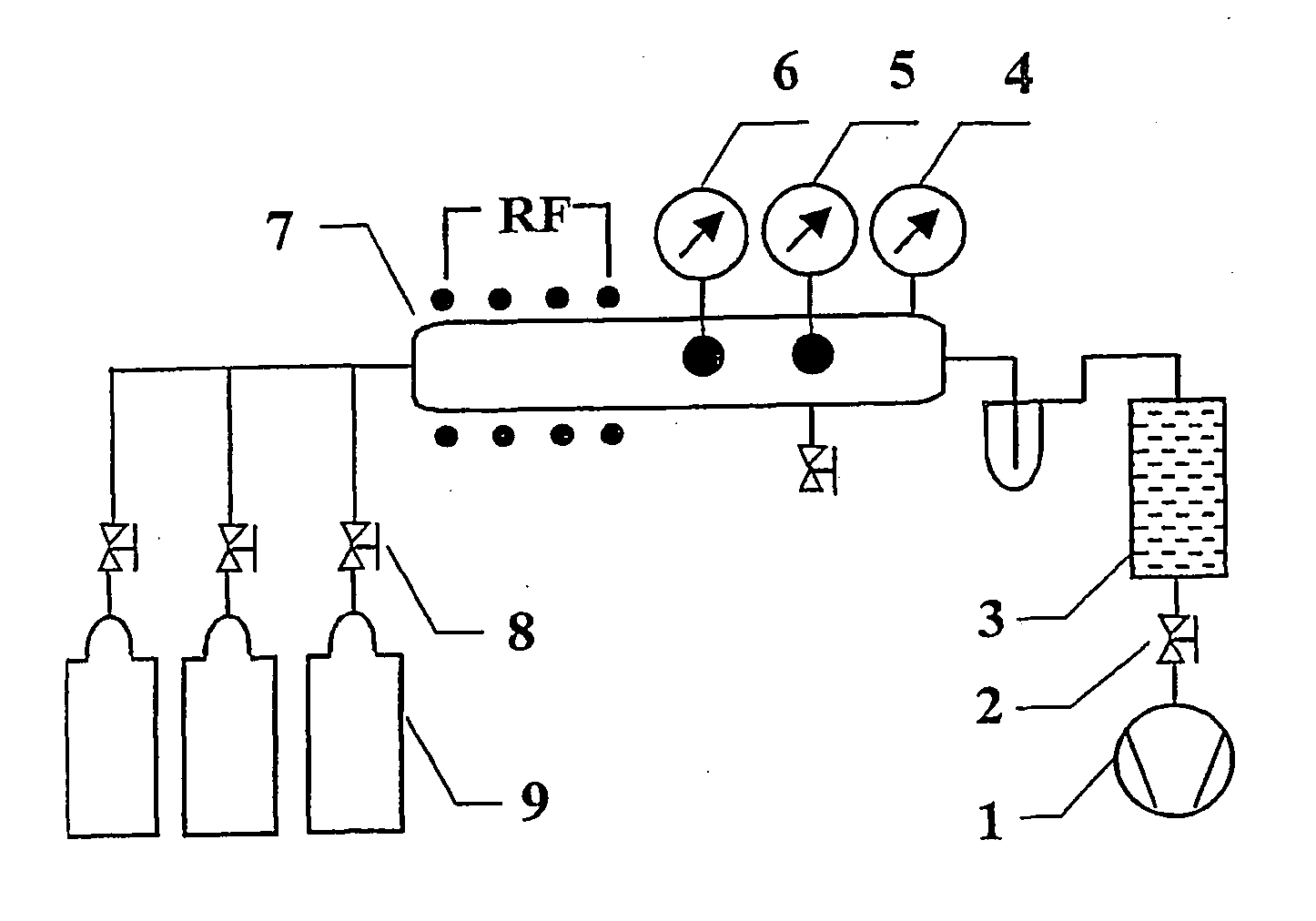

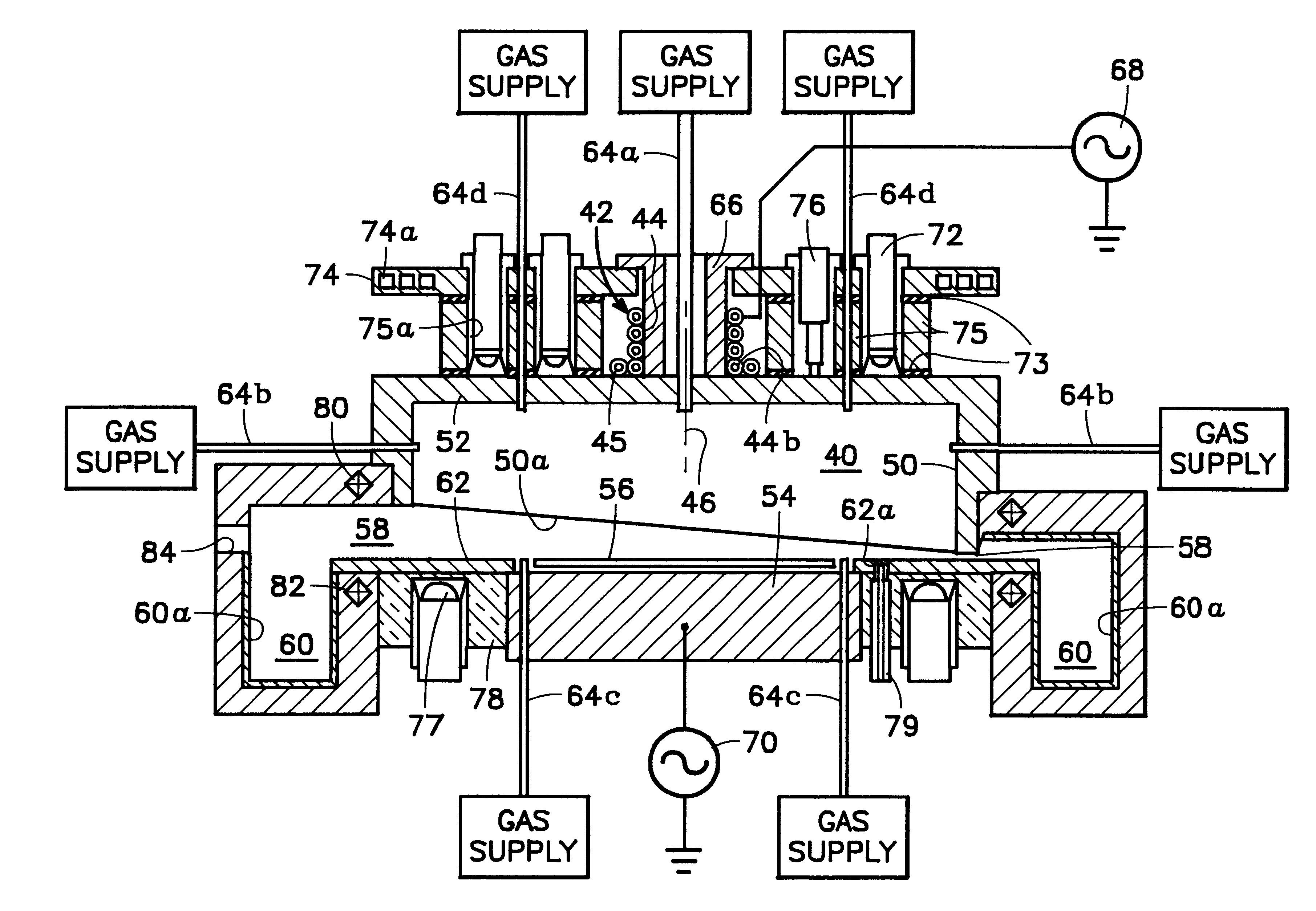

A radio frequency (RF) coaxial resonator feeding a saltshaker-like gas distributing electrode assembly forms a capacitively coupled plasma source. This apparatus can generate plasma of high density over a wide pressure range and large process window. The system may be used as a remote radical-rich plasma source for materials surface processing.

Owner:JI HELIN

Semiconductor processing system including vaporizer and method for using same

InactiveUS20090186479A1Improve performancePrevent nozzle cloggingSingle transducer incorporationMicrophonesLower limitProduct gas

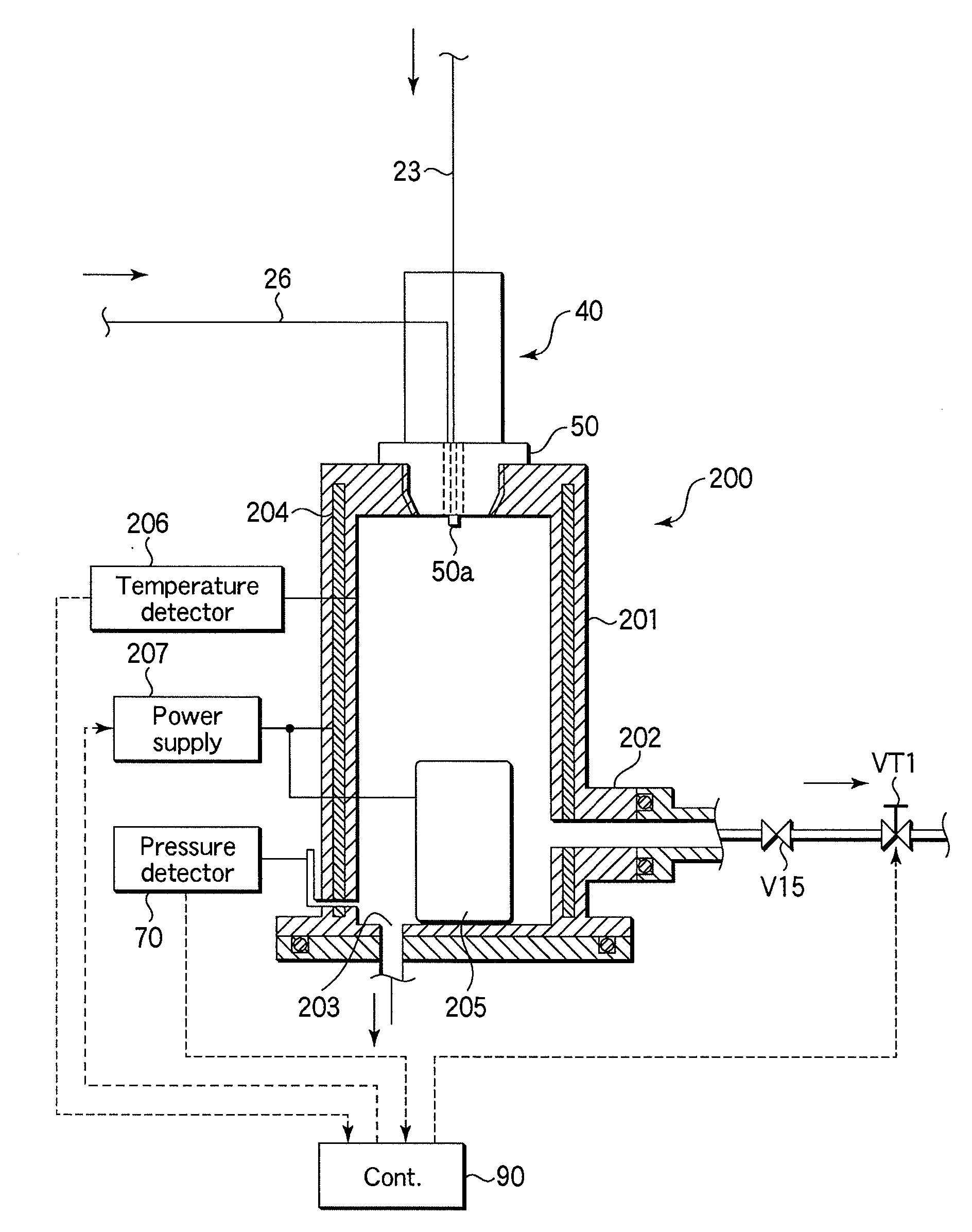

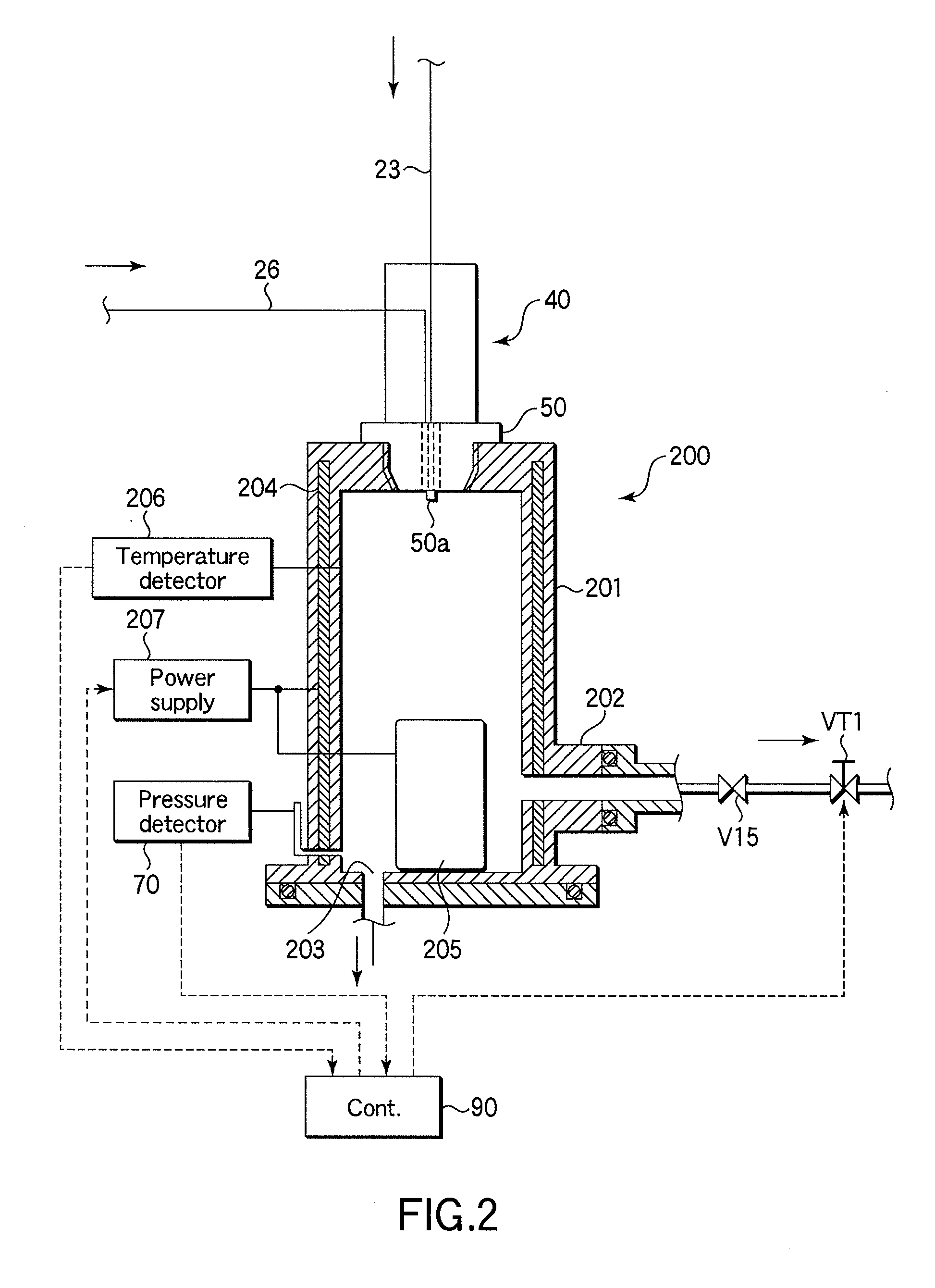

A semiconductor processing system including a semiconductor processing apparatus and a gas supply apparatus for supplying a process gas into the semiconductor processing apparatus includes a control section configured to control an operation of a pressure adjusting mechanism for adjusting the pressure inside a vaporizing chamber. The control section is preset to cause the pressure inside the vaporizing chamber to fall within a predetermined pressure range with reference to a pressure detection value obtained by a pressure detector. The predetermined pressure range is defined by an upper limit lower than a first limit value, at which vaporization of the liquid material starts being inhibited due to an increase in the pressure, and a lower limit higher than a second limit value, at which vaporization of the liquid material starts being unstable and the pressure inside the vaporizing chamber starts pulsating movement due to a decrease in the pressure.

Owner:TOKYO ELECTRON LTD

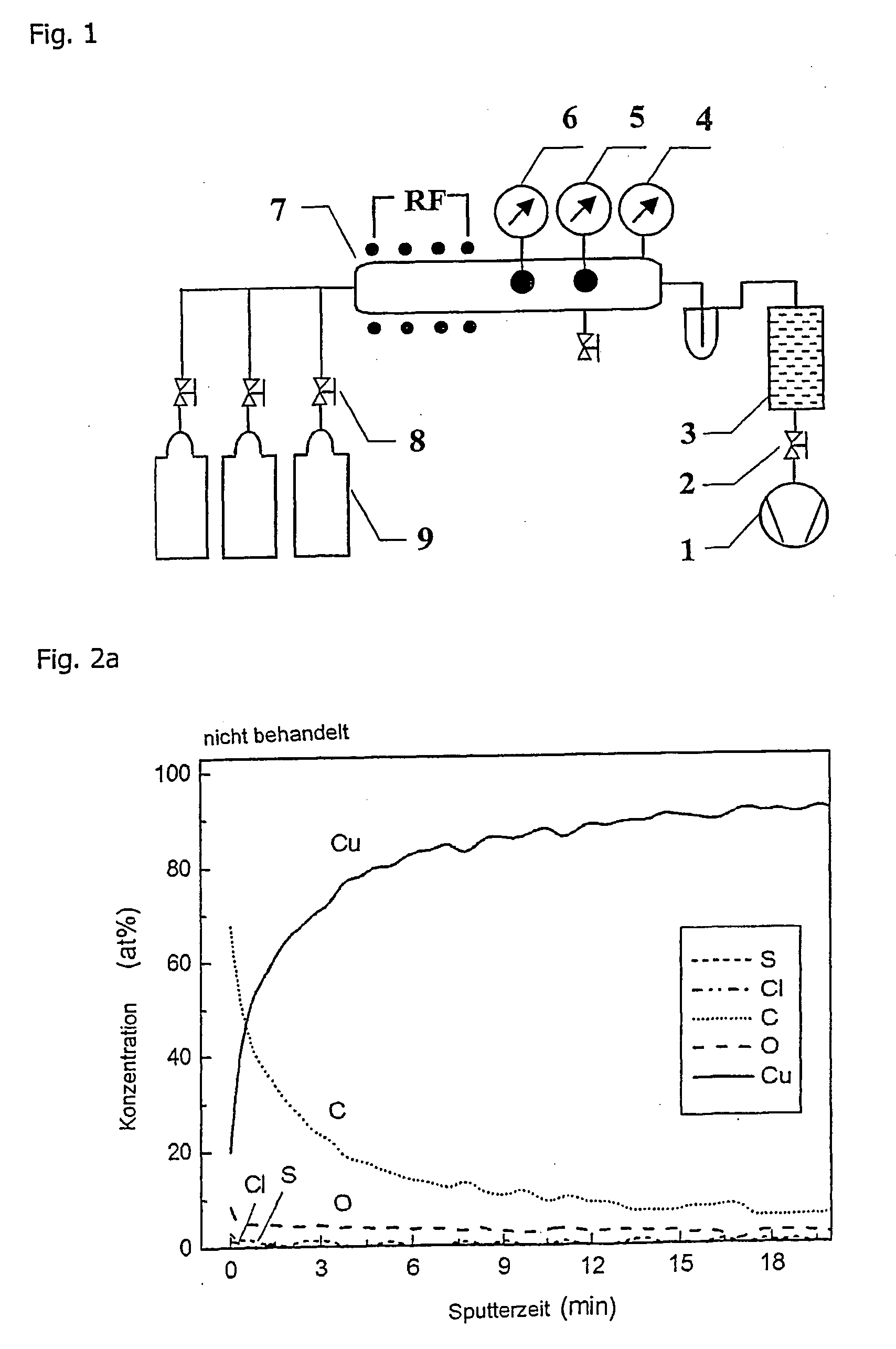

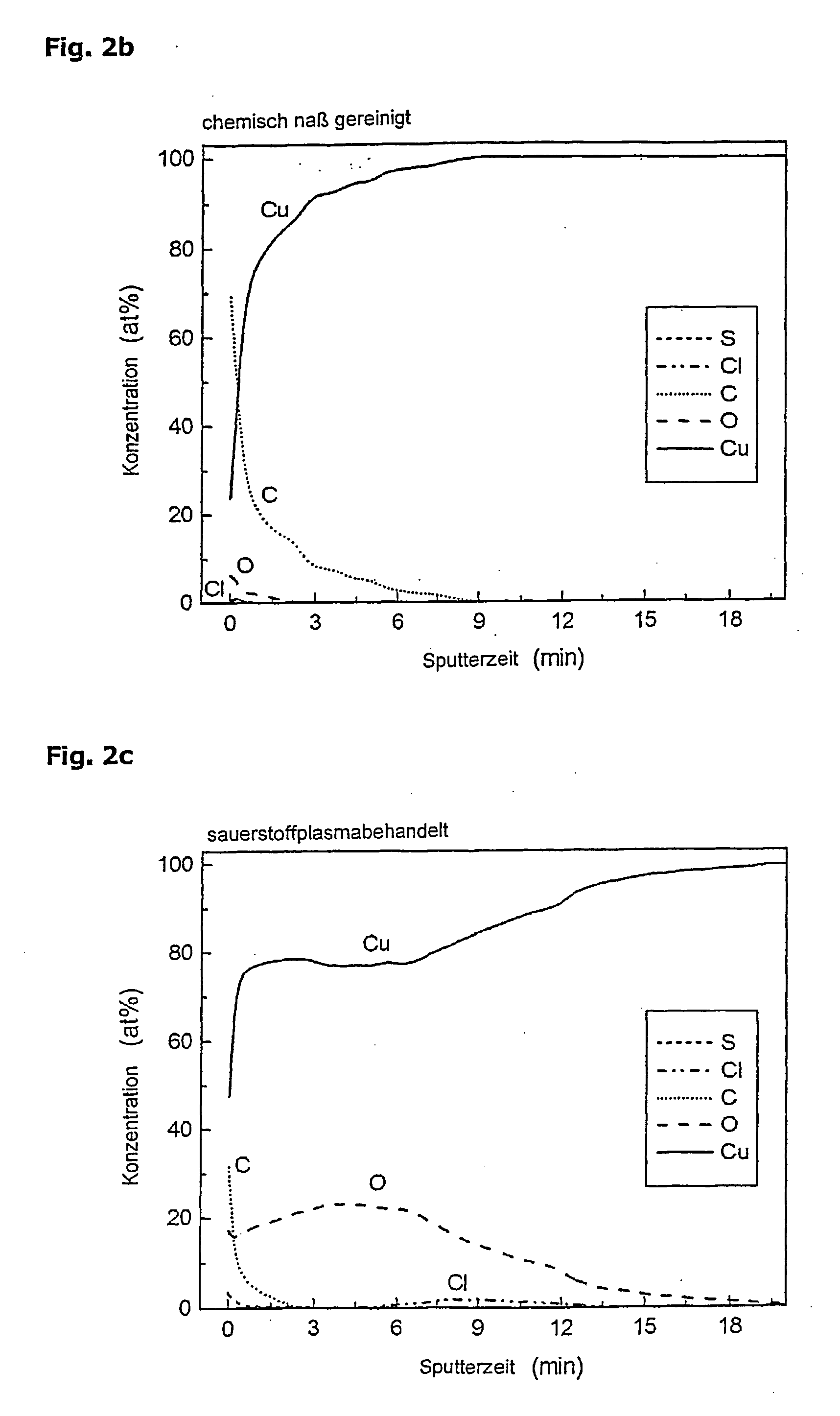

Plasma treatment for purifying copper or nickel

InactiveUS20060054184A1Reduce connection resistanceReduce impuritySoldering apparatusElectrostatic cleaningAlloyOxygen

A method for treating electronic components made of copper, nickel or alloys thereof or with materials such as brass or plated therewith and includes the steps of arranging the components in a treatment chamber, generating a vacuum in the treatment chamber, introducing oxygen into the treatment chamber, providing a pressure ranging between 10−1 and 50 mbar in the treatment chamber and exciting a plasma in the chamber, allowing the oxygen radicals to act on the components, generating a vacuum in the treatment chamber, introducing hydrogen into the treatment chamber, providing a pressure ranging between 10−1 and 50 mbar in the treatment chamber and exciting a plasma in the chamber and allowing the hydrogen radicals to act on the components.

Owner:KOLEKTOR GRP D O O

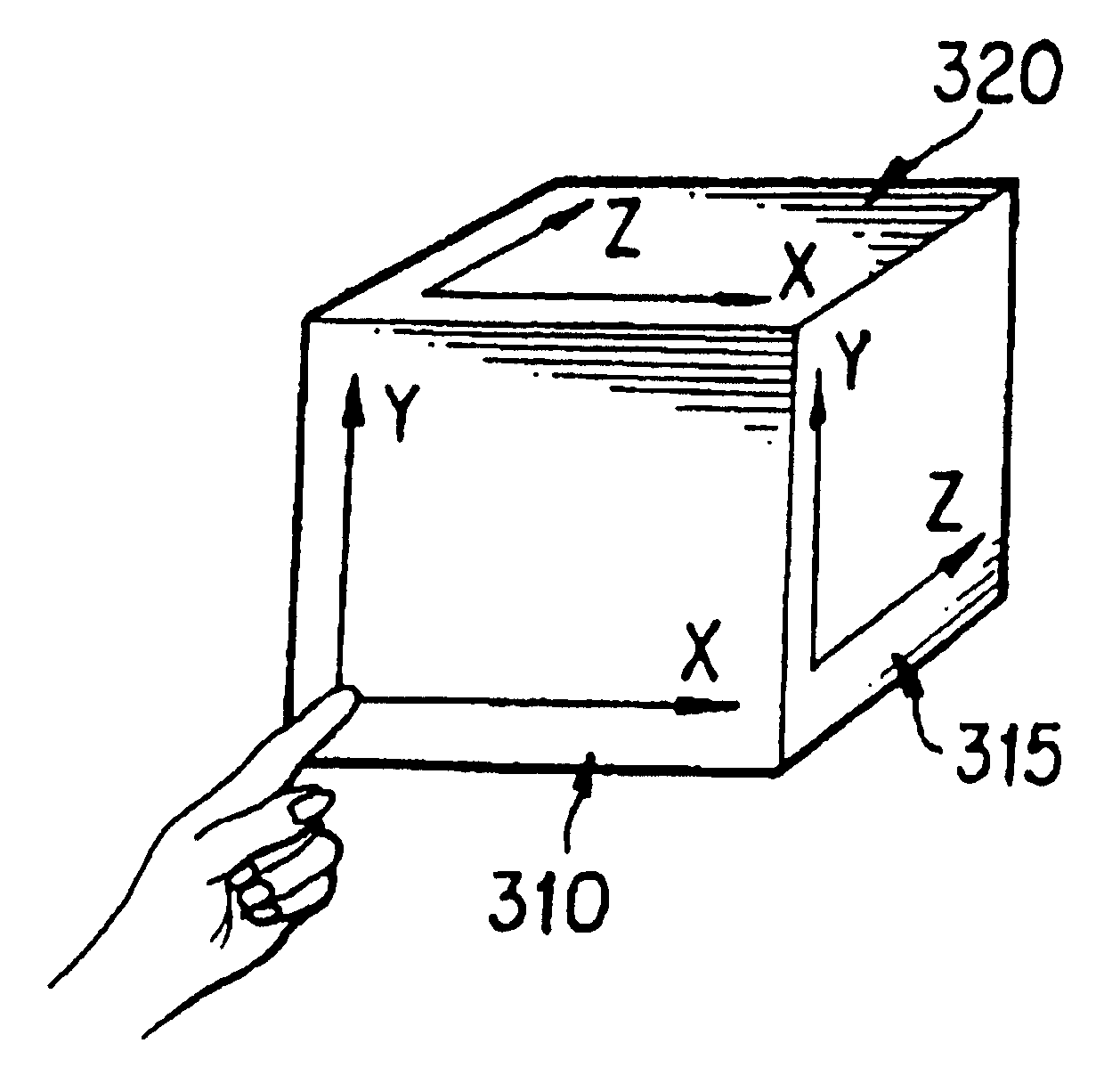

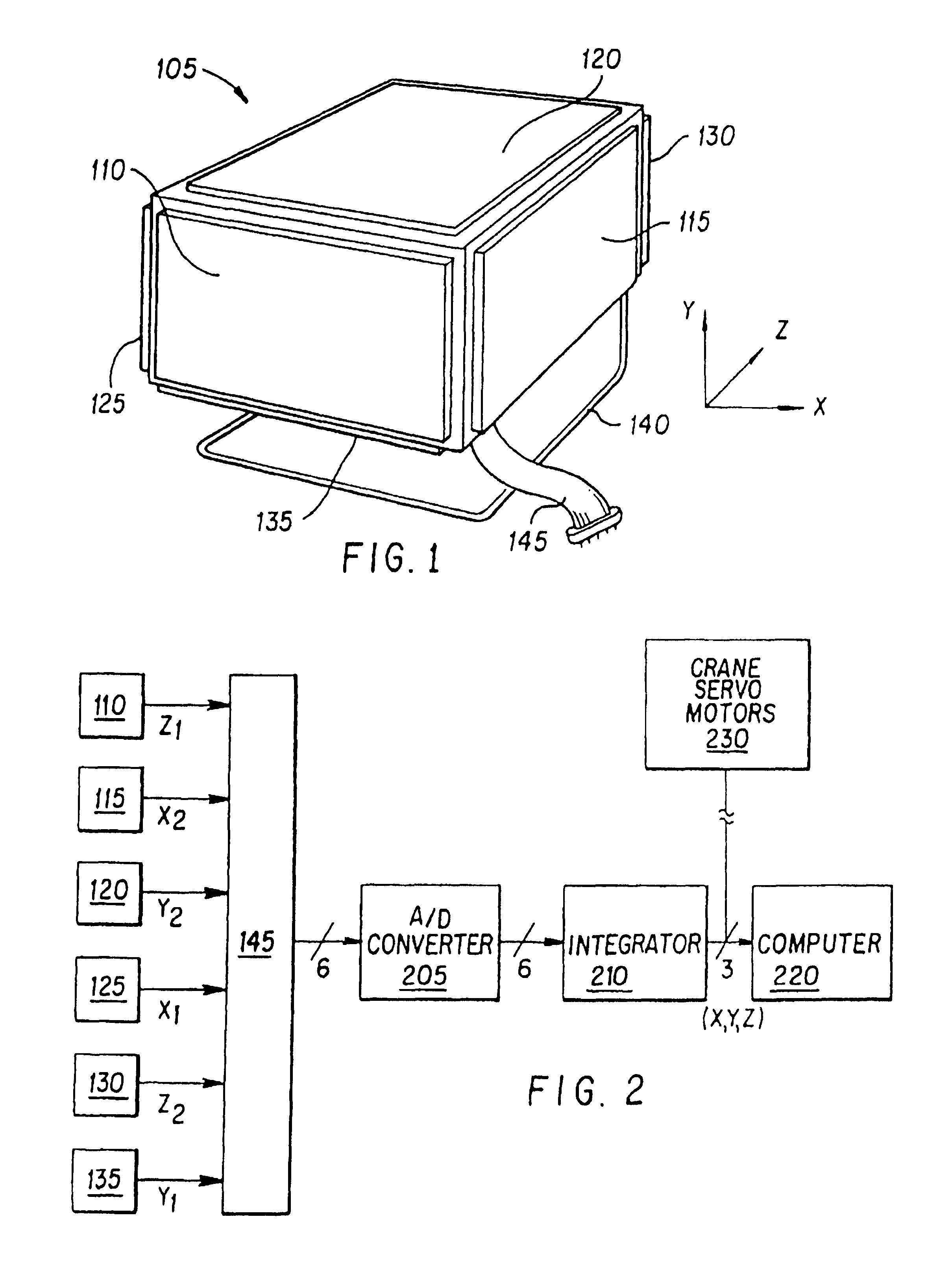

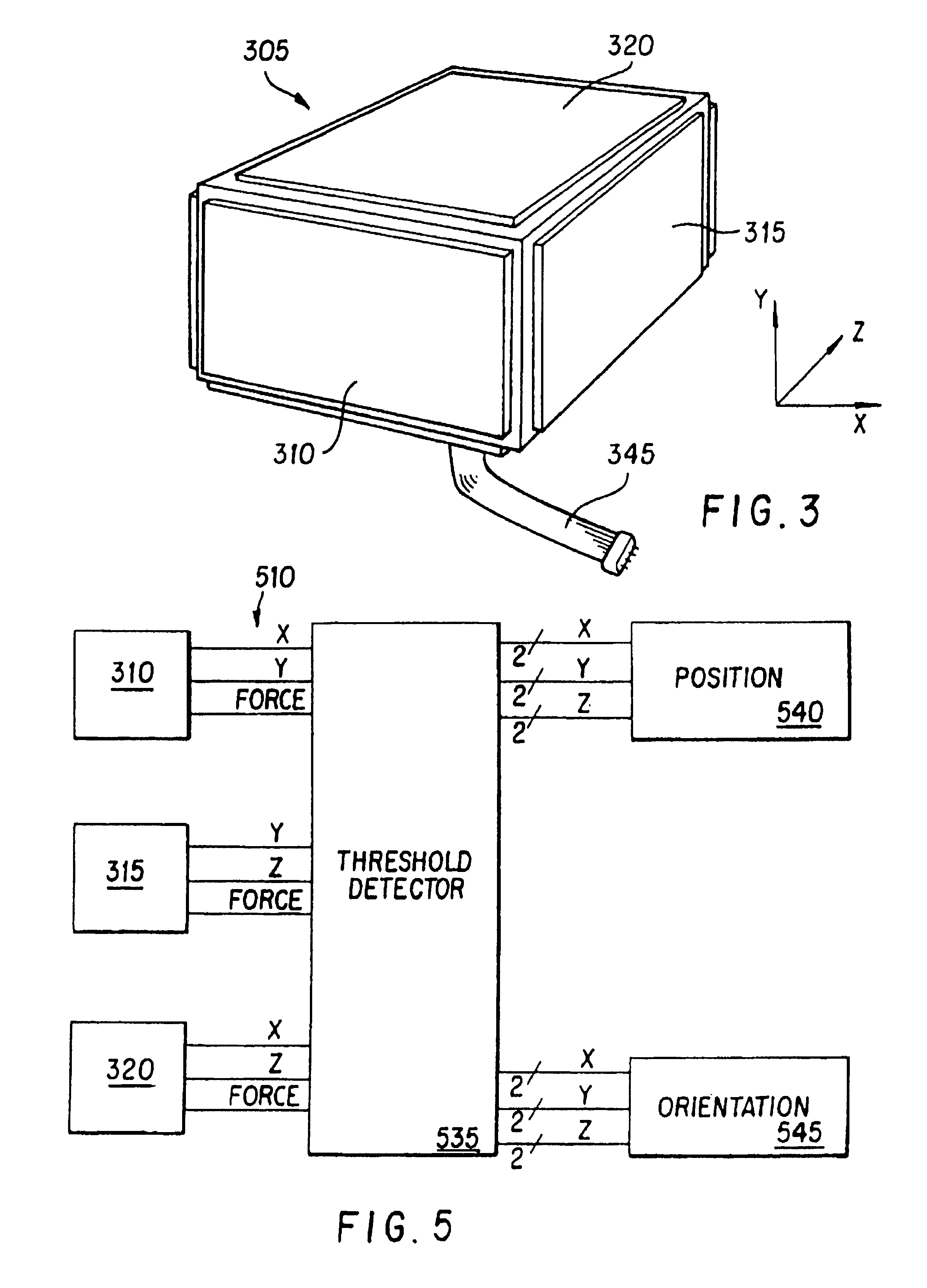

Methods and apparatus for providing touch-sensitive input in multiple degrees of freedom

InactiveUSRE40891E1Simple inputInexpensiveIndoor gamesTransmission systemsElectrical polarityTransducer

Disclosed is a multiple coordinate controller device having a three-dimensional body with a first surface portion and a second surface portion where the second surface portion is not coplanar with the first surface. A first transducer with a first sensing surface is coupled to the first surface portion of the body and capable of detecting both positions and a range of pressure forces at positions on the first sensing surface. The first transducer is further capable of providing a first range of z coordinates at a detected x,y coordinate in response to the range of pressure forces on said first sensing surface. A second transducer having a second sensing surface is coupled to the second surface portion of the body and capable of detecting both positions and a range of pressure forces at the positions on the second sensing surface. The second transducer is further capable of providing a second range of z coordinates of opposite polarity to the first range of z coordinates in response to the range of forces on second sensing surface.

Owner:SANDIO TECH

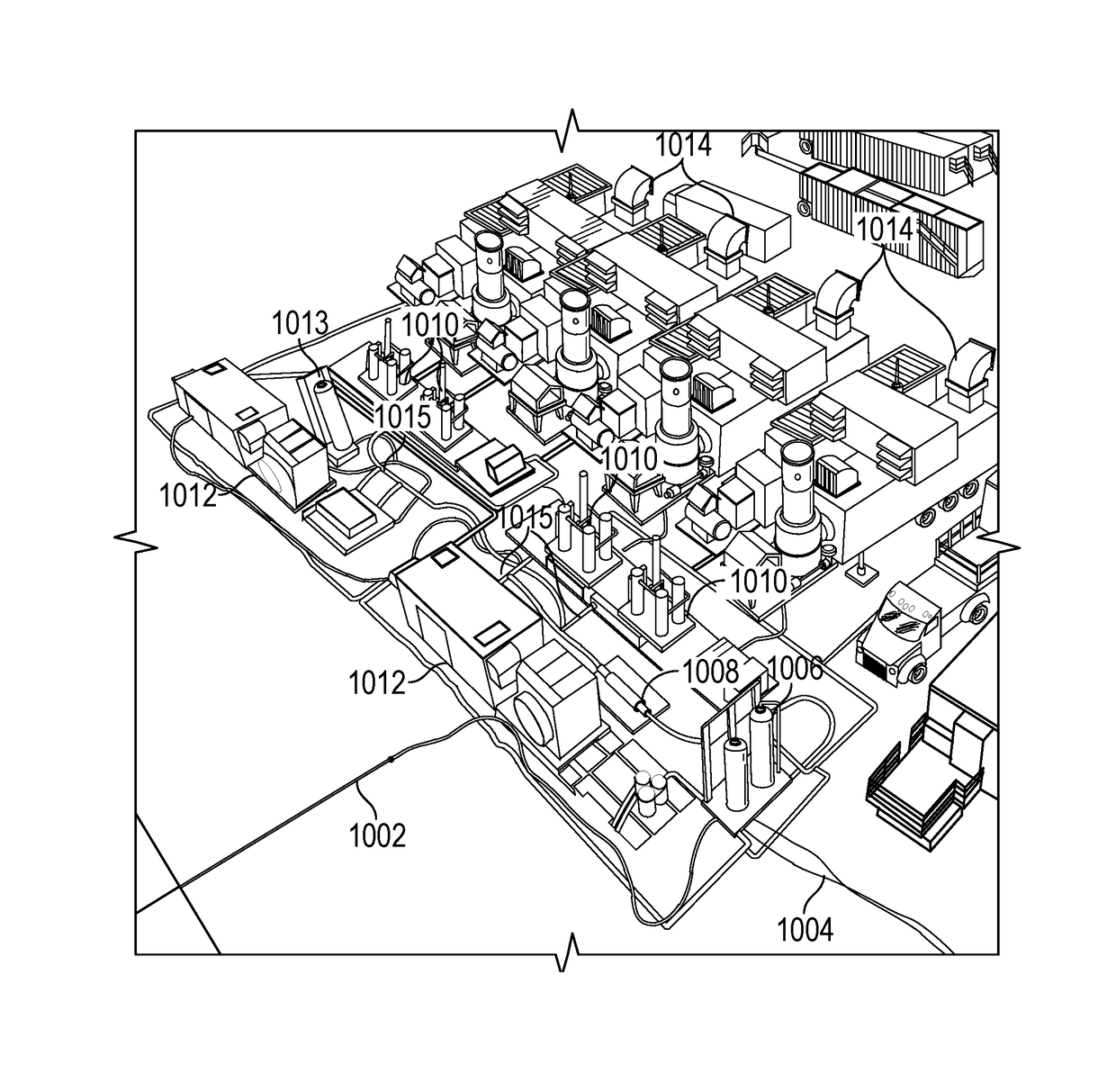

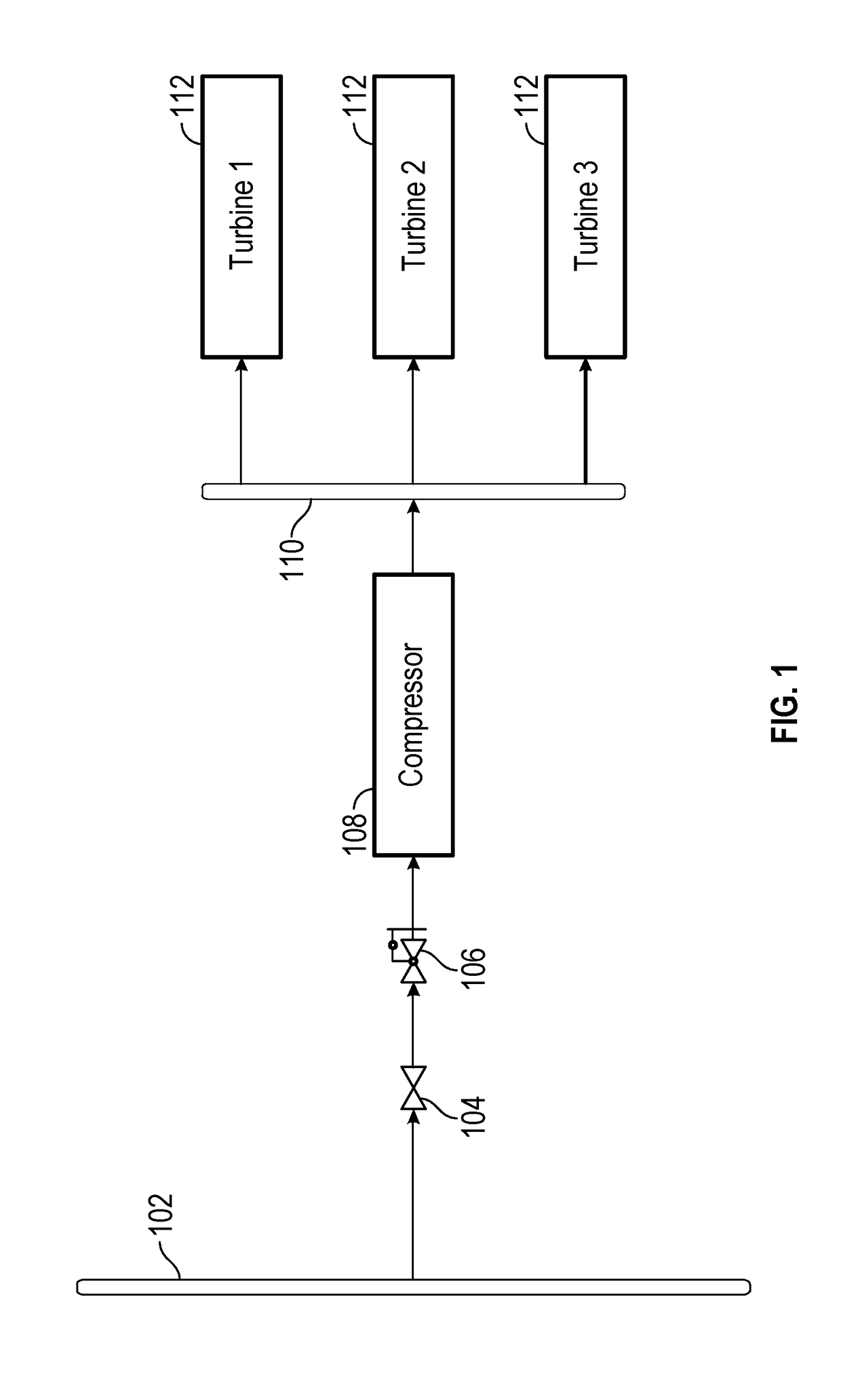

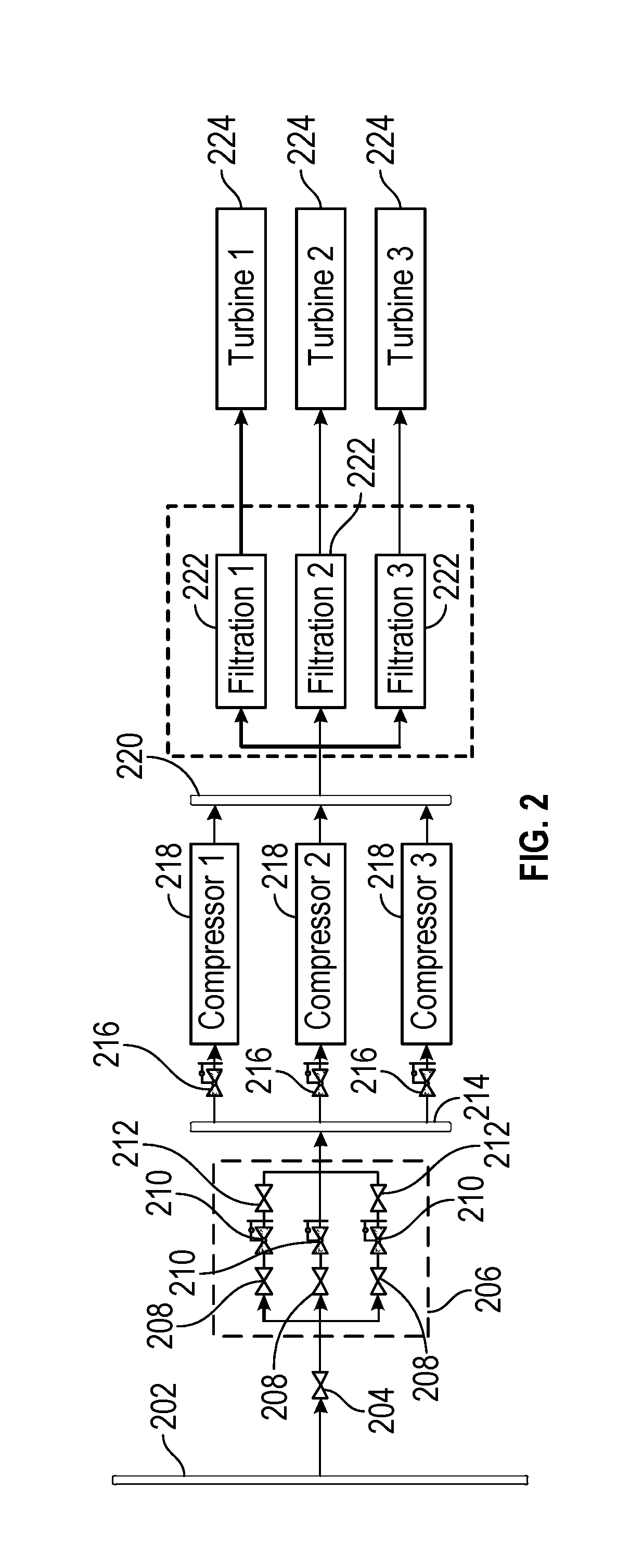

System for gas compression on electric hydraulic fracturing fleets

PendingUS20170145918A1Reduce pressureTurbine/propulsion fuel supply systemsGas turbine plantsElectricityGas compressor

Embodiments relate to hydraulic fracturing equipment powered by one or more natural gas turbine generators. Natural gas from a supply line is released via a valve into a turbine gas line. The turbine gas line includes one or more regulators to reduce the pressure of the natural gas stream in the turbine gas line to a pressure or pressure range optimum for one or more gas compressors. The gas compressors increase the pressure of the natural gas stream, which is then directed to one or more natural gas turbine generators. The natural gas turbine generators combust the natural gas to produce electricity, which powers electric hydraulic fracturing equipment.

Owner:US WELL SERVICS LLC

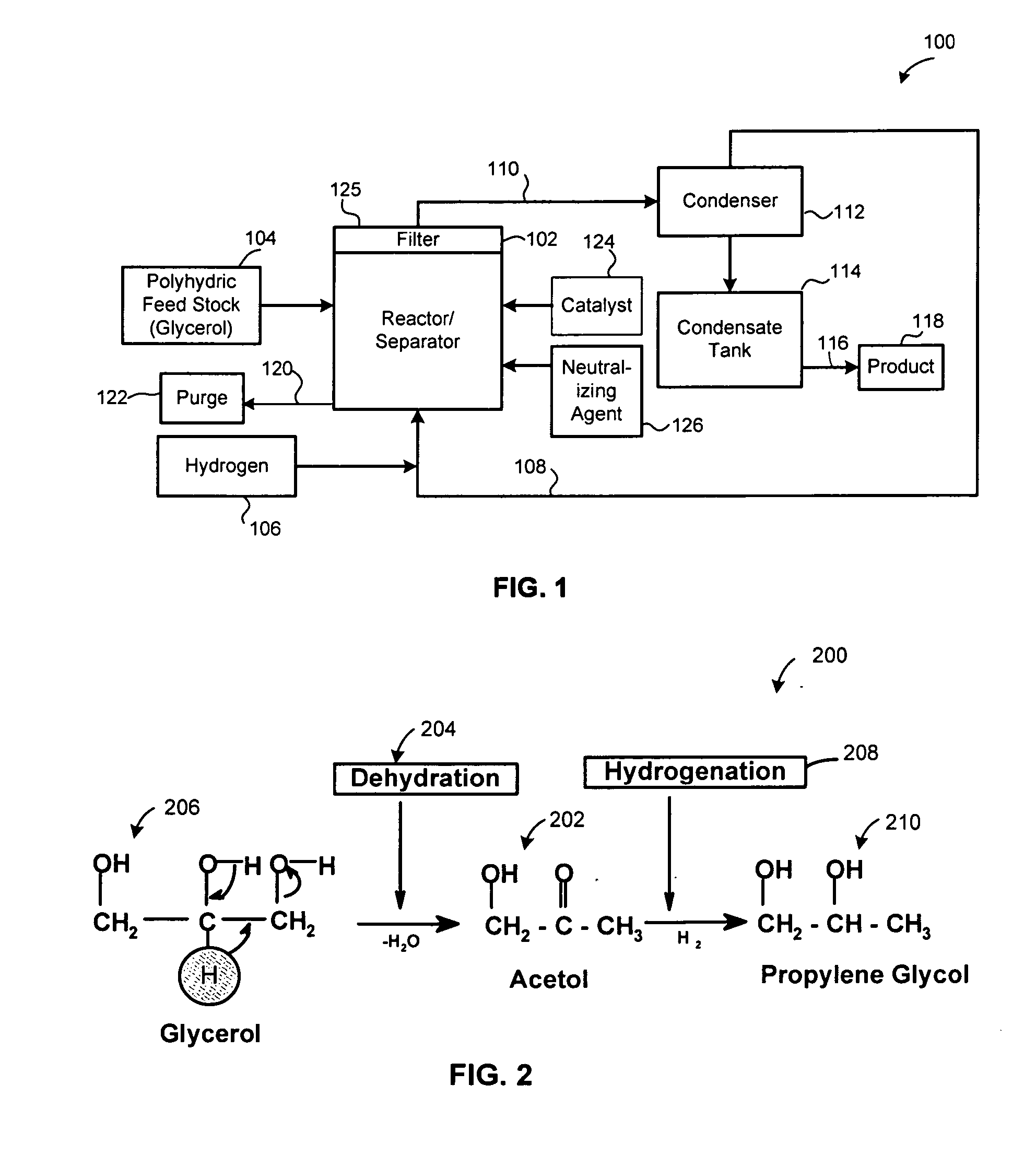

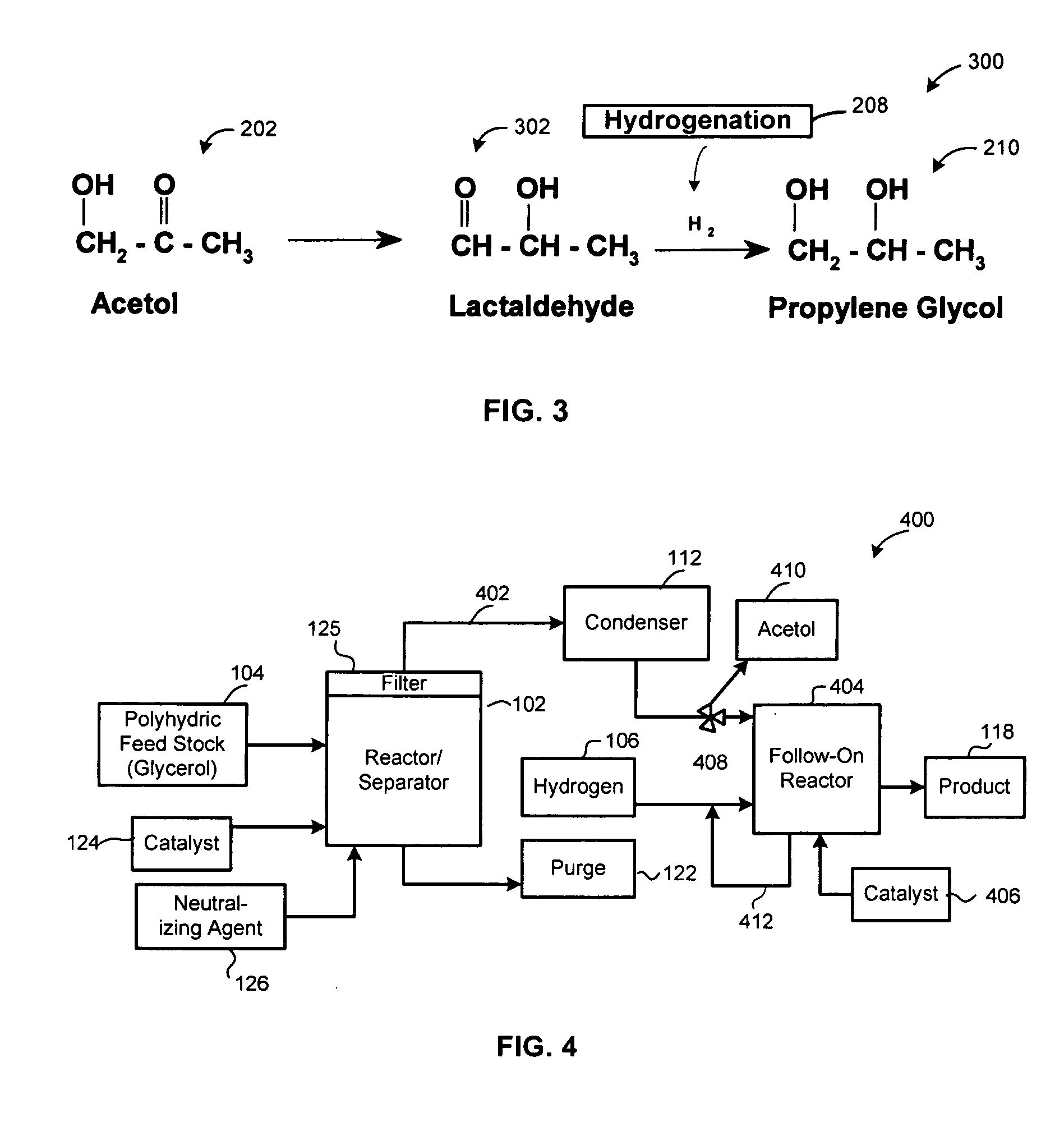

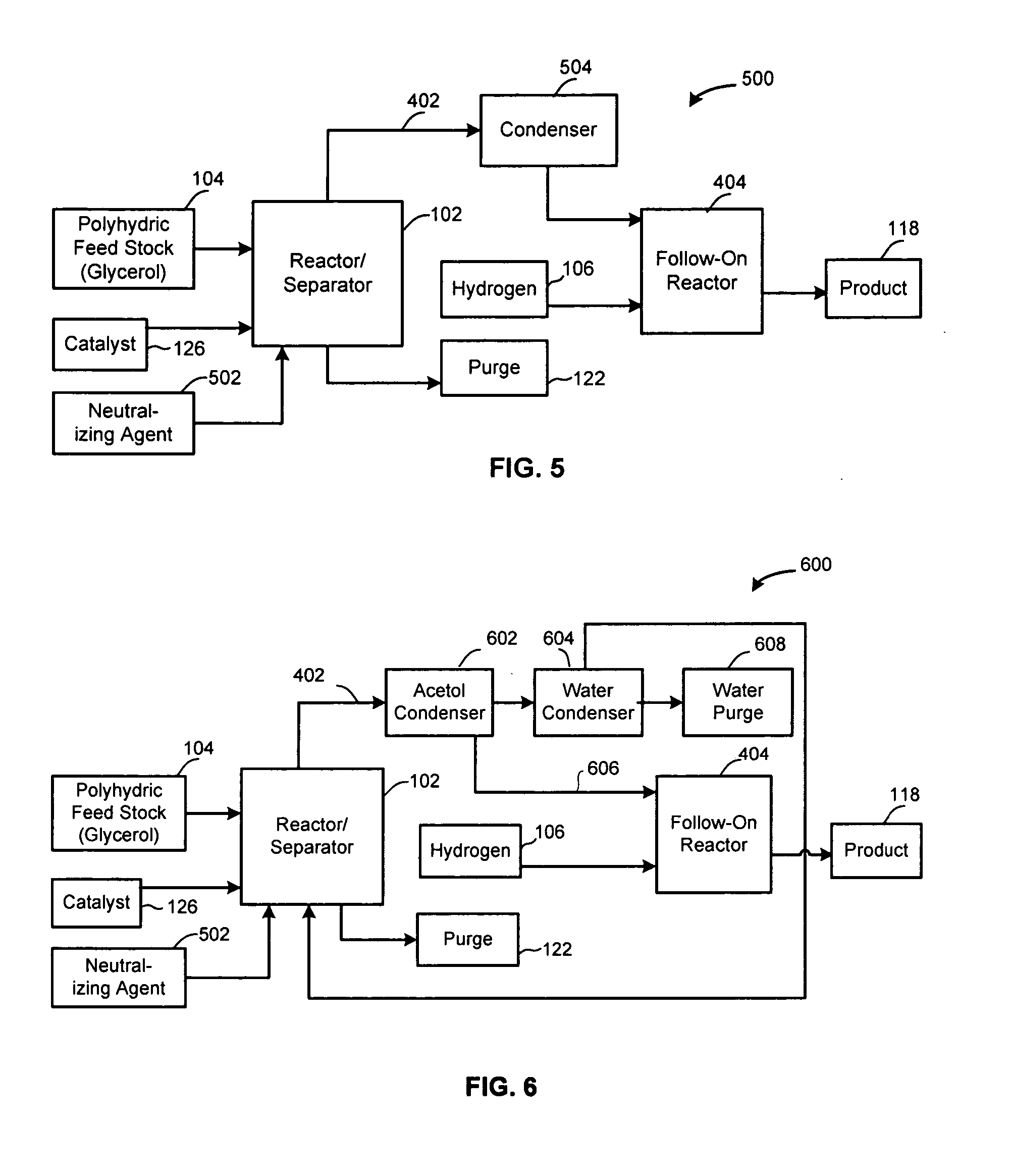

Method of producing lower alcohols from glycerol

ActiveUS20050244312A1High selectivityOrganic compound preparationOxygen compounds preparation by reductionAlcoholBoiling point

A reactive-separation process converts glycerin into lower alcohols, having boiling points less than 200° C., at high yields. Conversion of natural glycerin to propylene glycol through an acetol intermediate is achieved at temperatures from 150° to 250° C. at a pressure ranging from 1 and 25 bar. The preferred applications of the propylene glycol are as an antifreeze, deicing compound, or anti-icing compound. The preferred catalyst for this process in a copper-chromium powder.

Owner:RENEWABLE ALTERNATIVES LLC +1

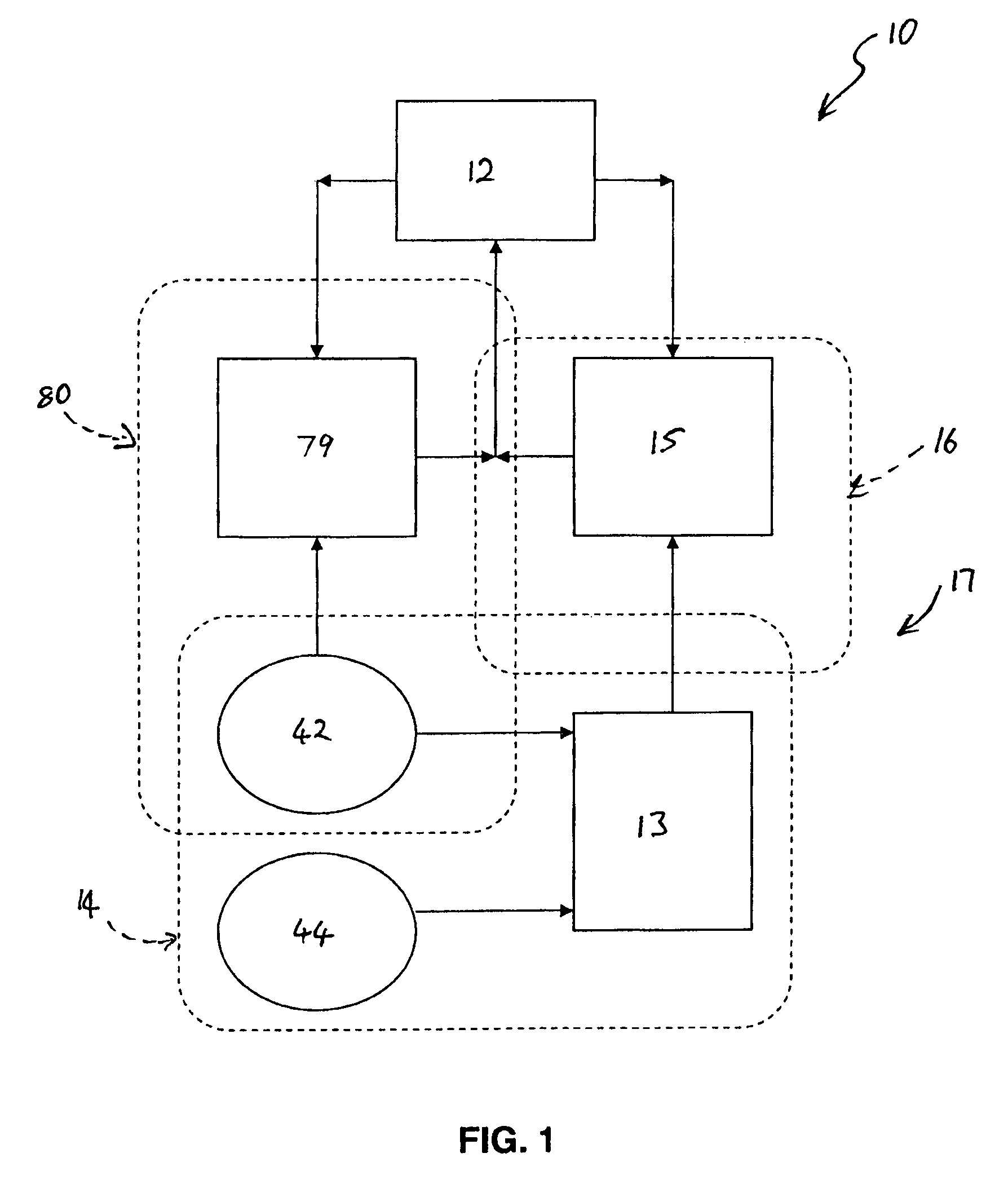

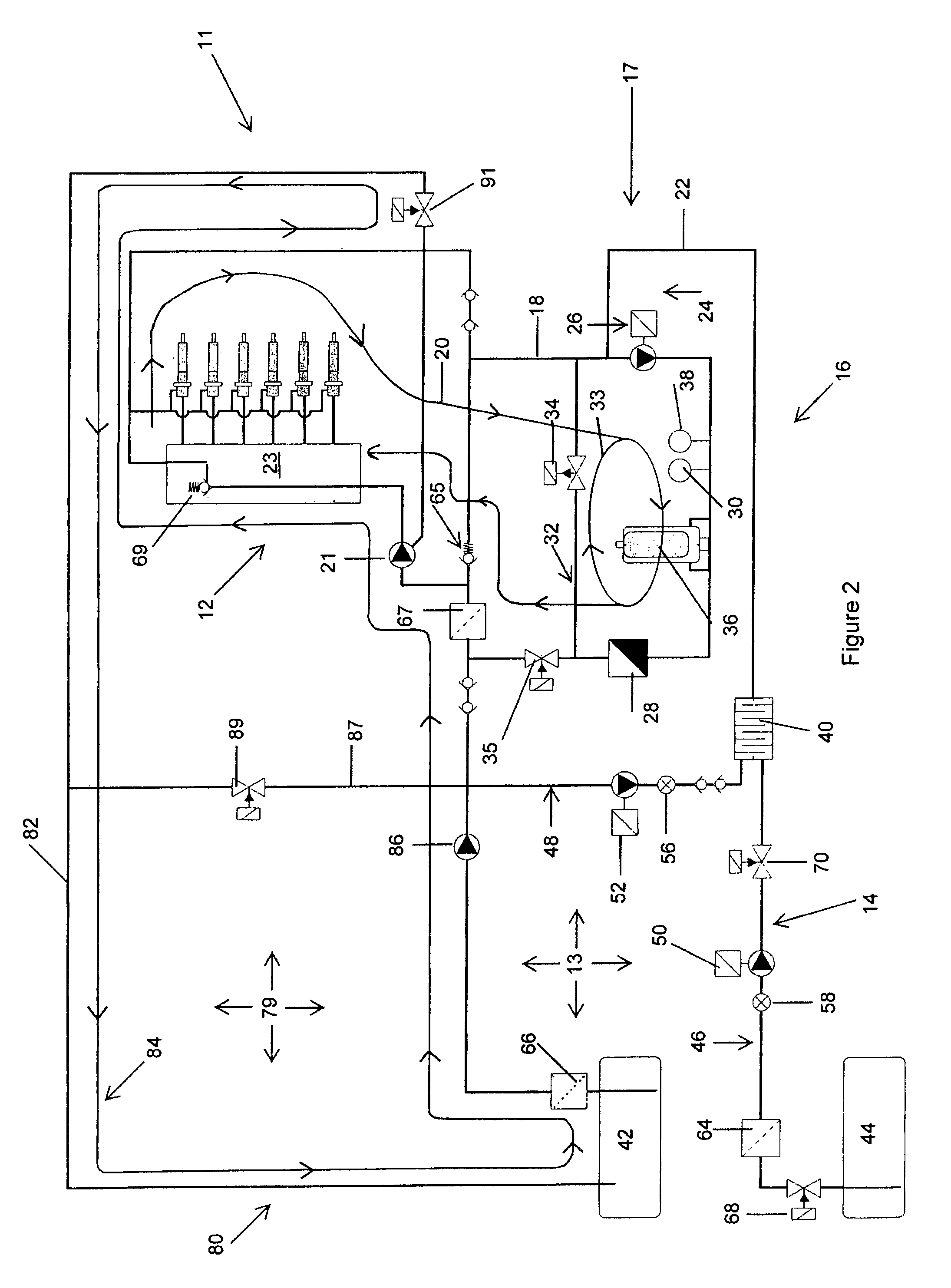

Dual fuel supply system for a direct-injection system of a diesel engine with on-board mixing

InactiveUS8973560B2Non-fuel substance addition to fuelInternal combustion piston enginesOn boardEngineering

The present invention is directed to a dual fuel supply system for supplying fuel to a direct-injection system of a diesel engine. The dual fuel supply system includes a diesel supply system to supply diesel to the direct-injection system; and a mixed fuel supply system that is operatively able to supply a liquid fuel premixture of diesel and liquefied gaseous fuel to the direct-injection system at a supply pressure within a fuel demand pressure range of the direct-injection system and at a corresponding temperature range that retains the fuel premixture below its vapor temperature as it flows through the fuel path of the direct-injection system and the diesel engine. The dual fuel supply system is configured to permit selective change over between the diesel supply system and the mixed fuel system to supply the direct-injection system selectively with either diesel or liquid fuel premixture respectively.

Owner:DGC IND

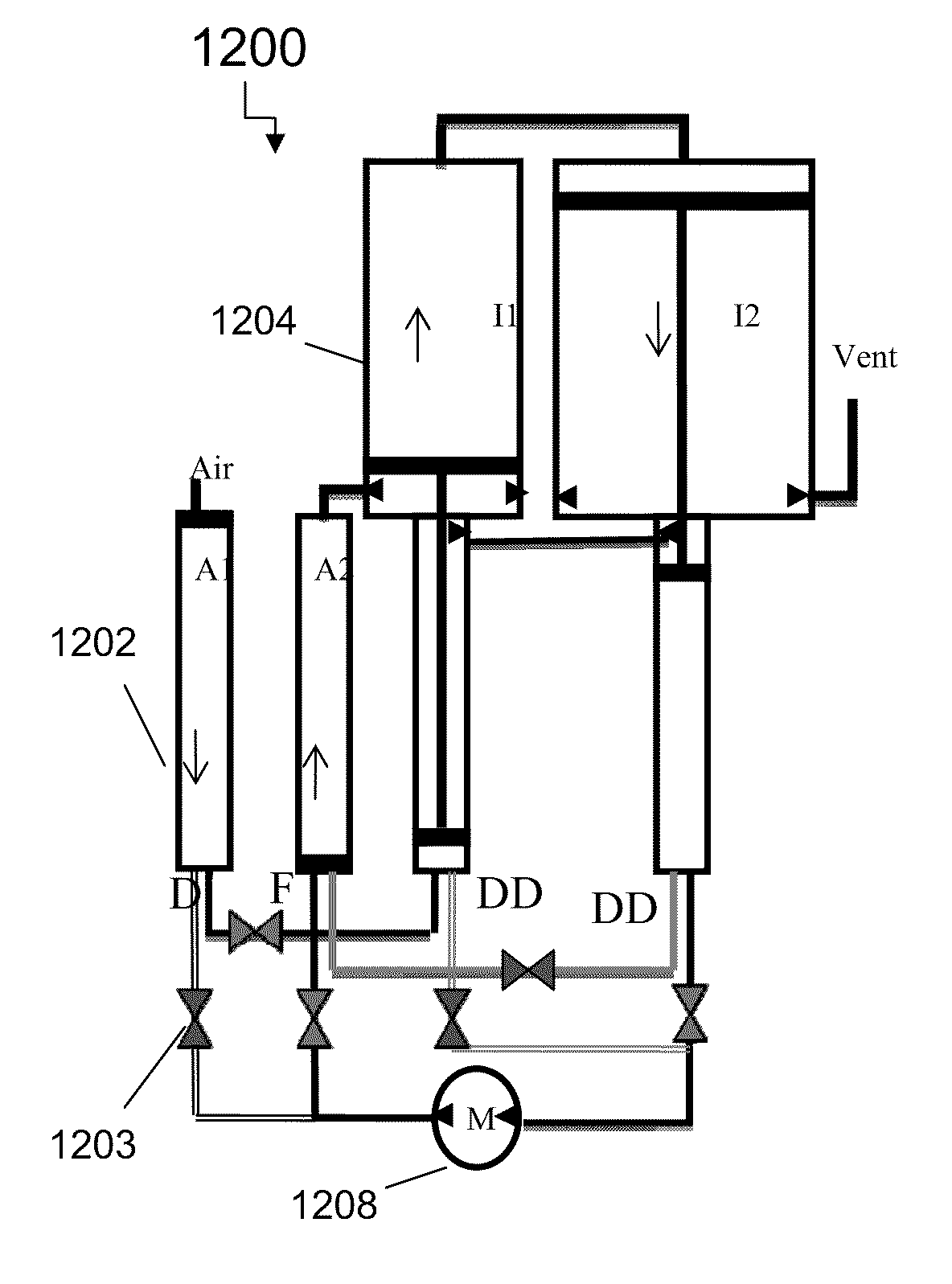

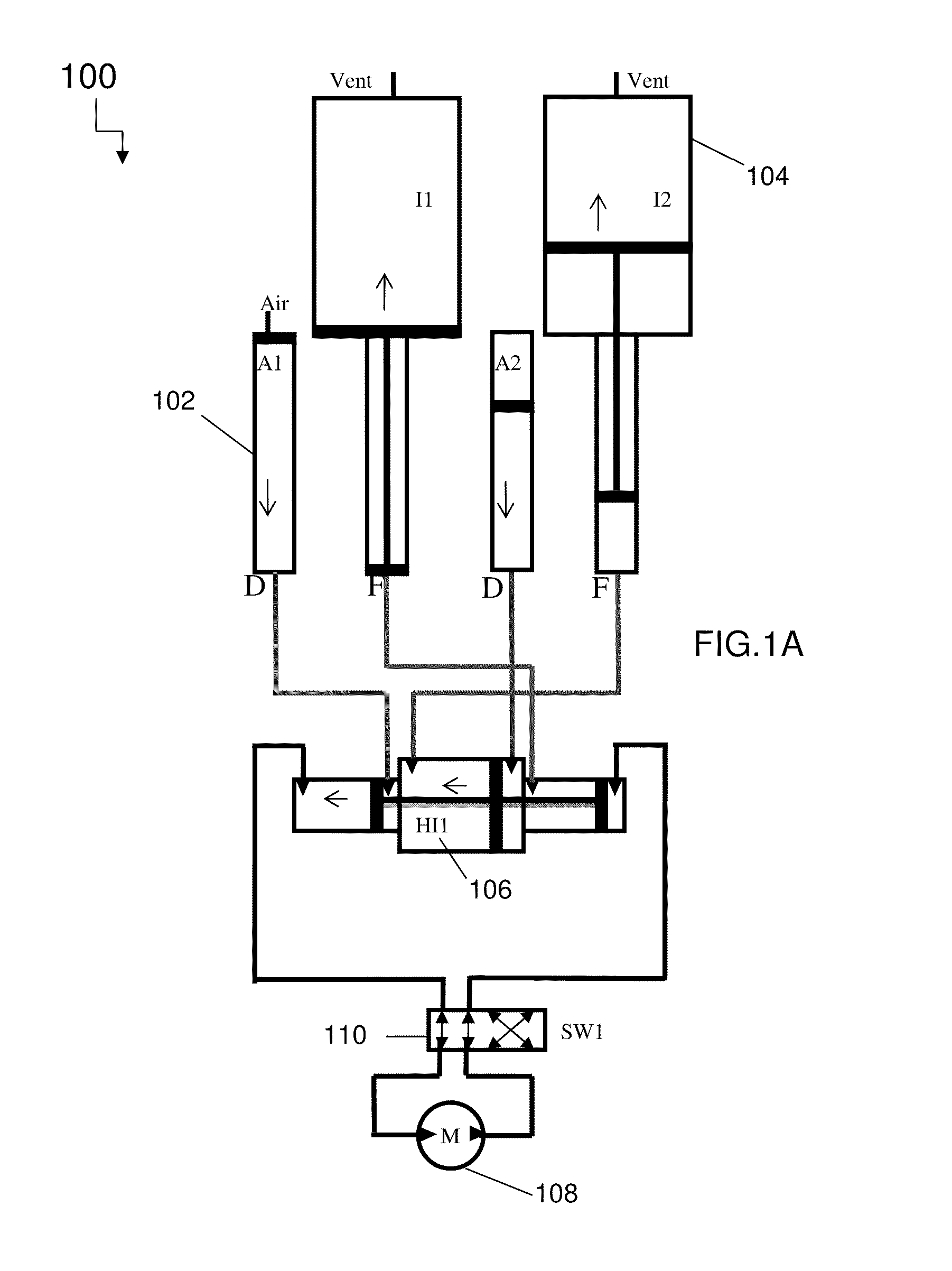

Systems and Methods for Improving Drivetrain Efficiency for Compressed Gas Energy Storage and Recovery Systems

InactiveUS20100307156A1Easy to testLow costElectrical storage systemGas turbine plantsHydraulic motorDrivetrain

The invention relates to power generation and energy storage and recovery. In particular, the invention relates to compressed gas energy storage and recovery systems using staged pneumatic conversion systems for providing narrow pressure ranges to a hydraulic motor.

Owner:SUSTAINX

Compositions and method for removing photoresist and/or resist residue at pressures ranging from ambient to supercritical

InactiveUS20040050406A1Accelerate photoresist strippingImprove reaction kineticsNon-surface-active detergent compositionsSemiconductor/solid-state device manufacturingResistAlcohol

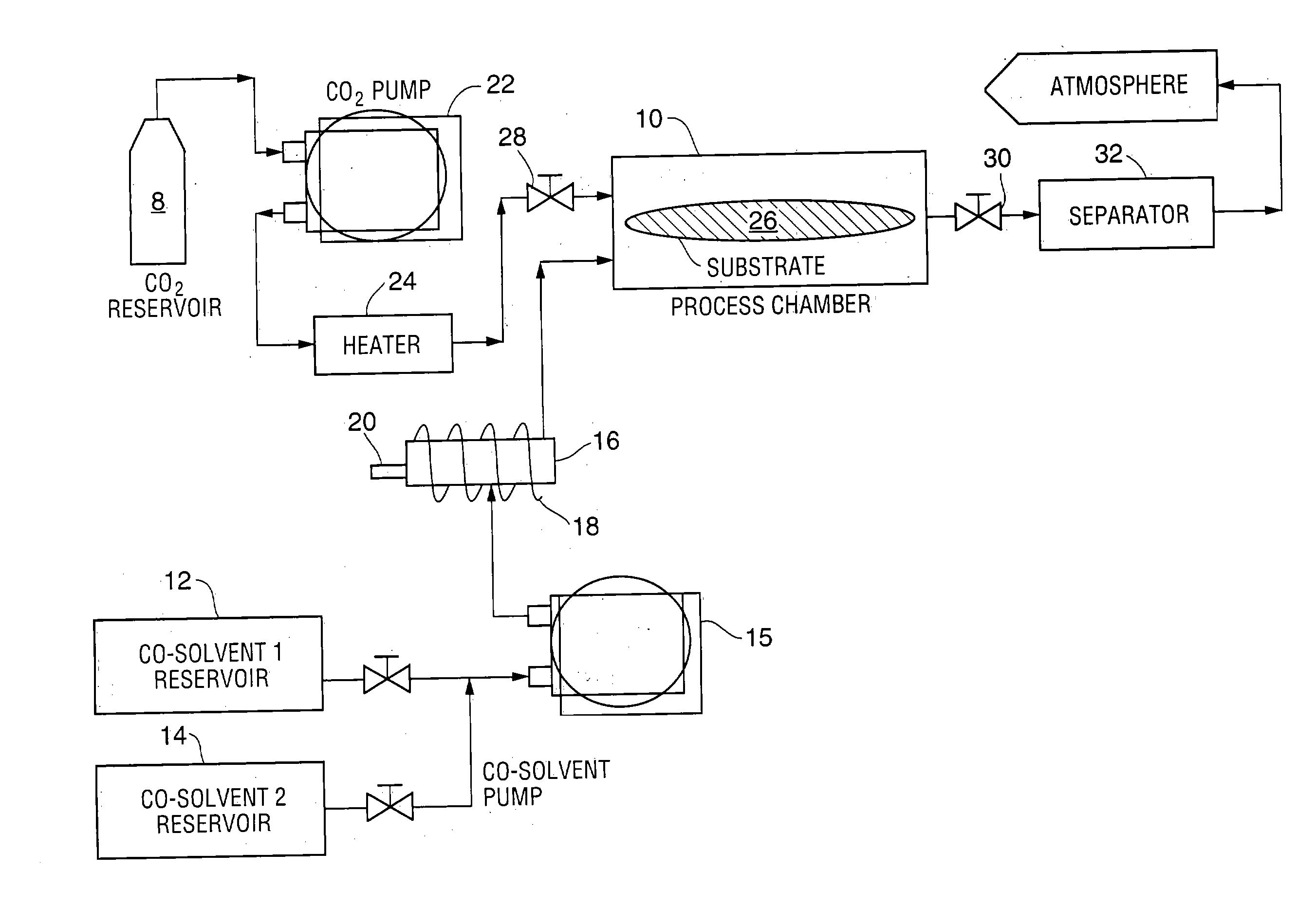

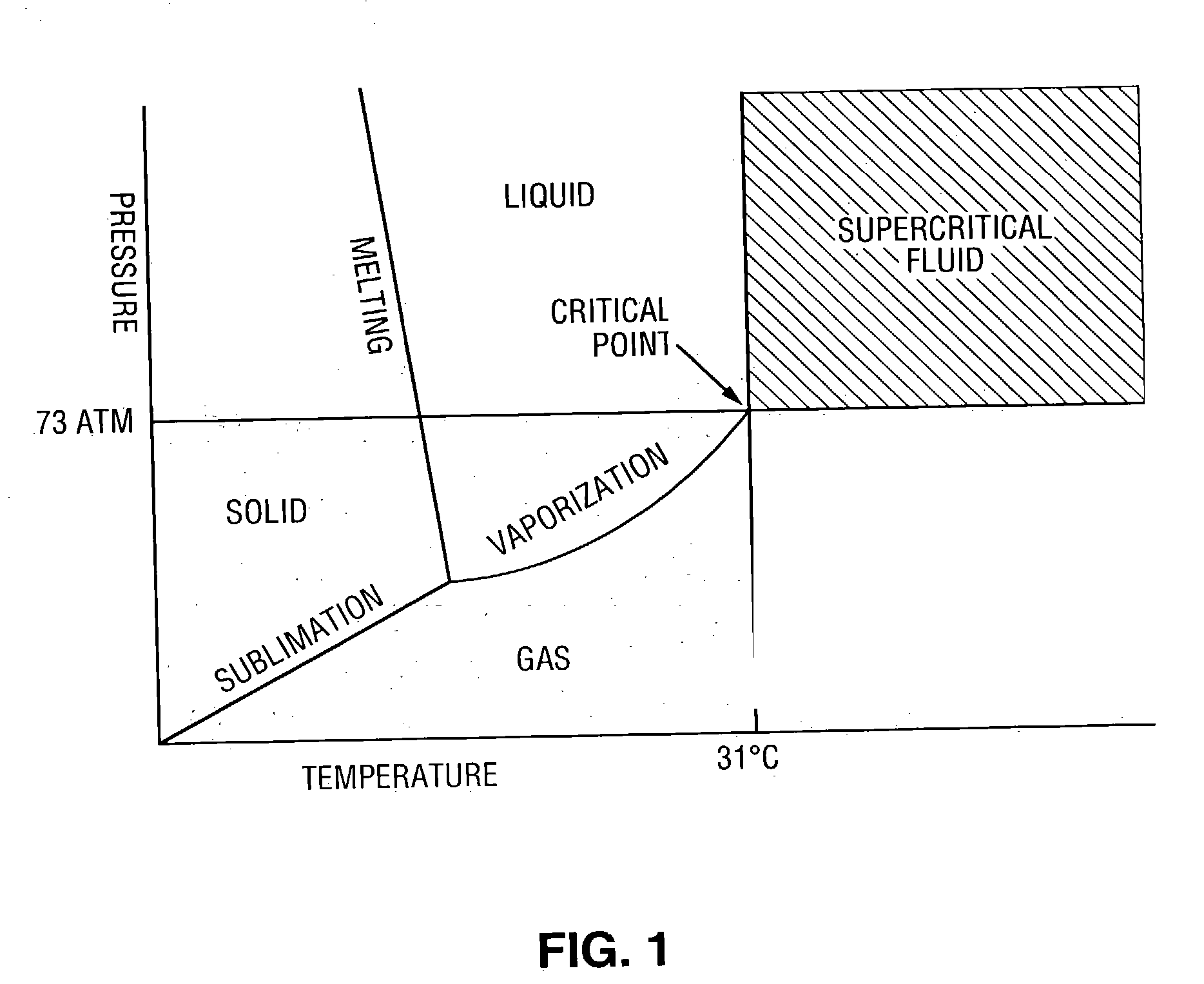

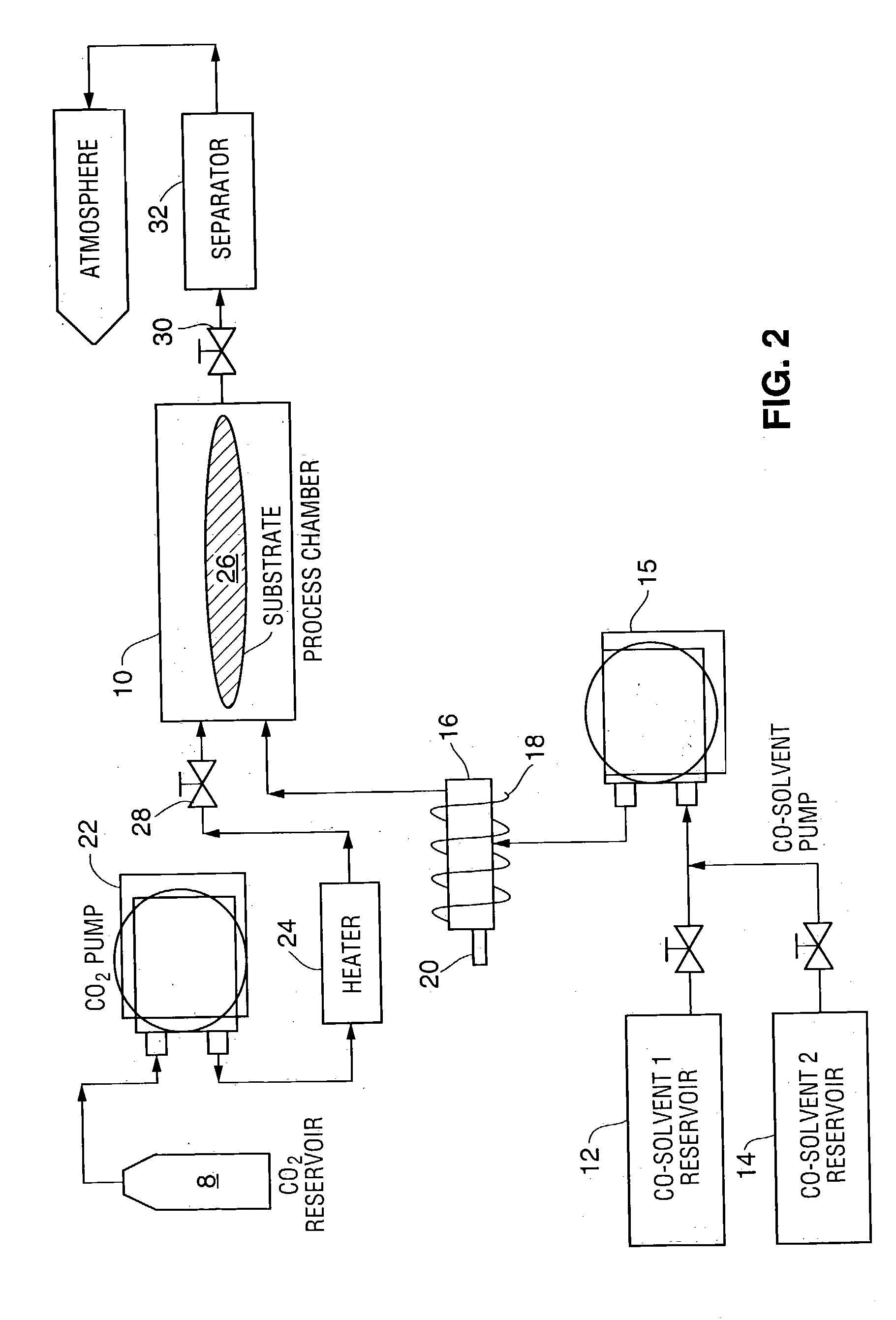

A method of enhancing removal of photoresist and / or resist residue from a substrate includes exposing the substrate to an environmentally friendly, non-hazardous co-solvent mixture comprising a carbonate, an oxidizer and an accelerator. The stripping process may be performed under ambient conditions, or in the presence of a supercritical fluid such as supercritical carbon dioxide with the supercritical cleaning step itself being a desirable "green" process. In one embodiment, the co-solvent mixture includes propylene carbonate, benzyl alcohol, hydrogen peroxide and an accelerator such as formic acid. If desired, supercritical carbon dioxide in combination with a second co-solvent mixture may be subsequently applied to the substrate to rinse and dry the substrate. In one embodiment, the second co-solvent mixture includes a lower alkyl alcohol such as isopropyl alcohol.

Owner:SCP GLOBAL TECH INC

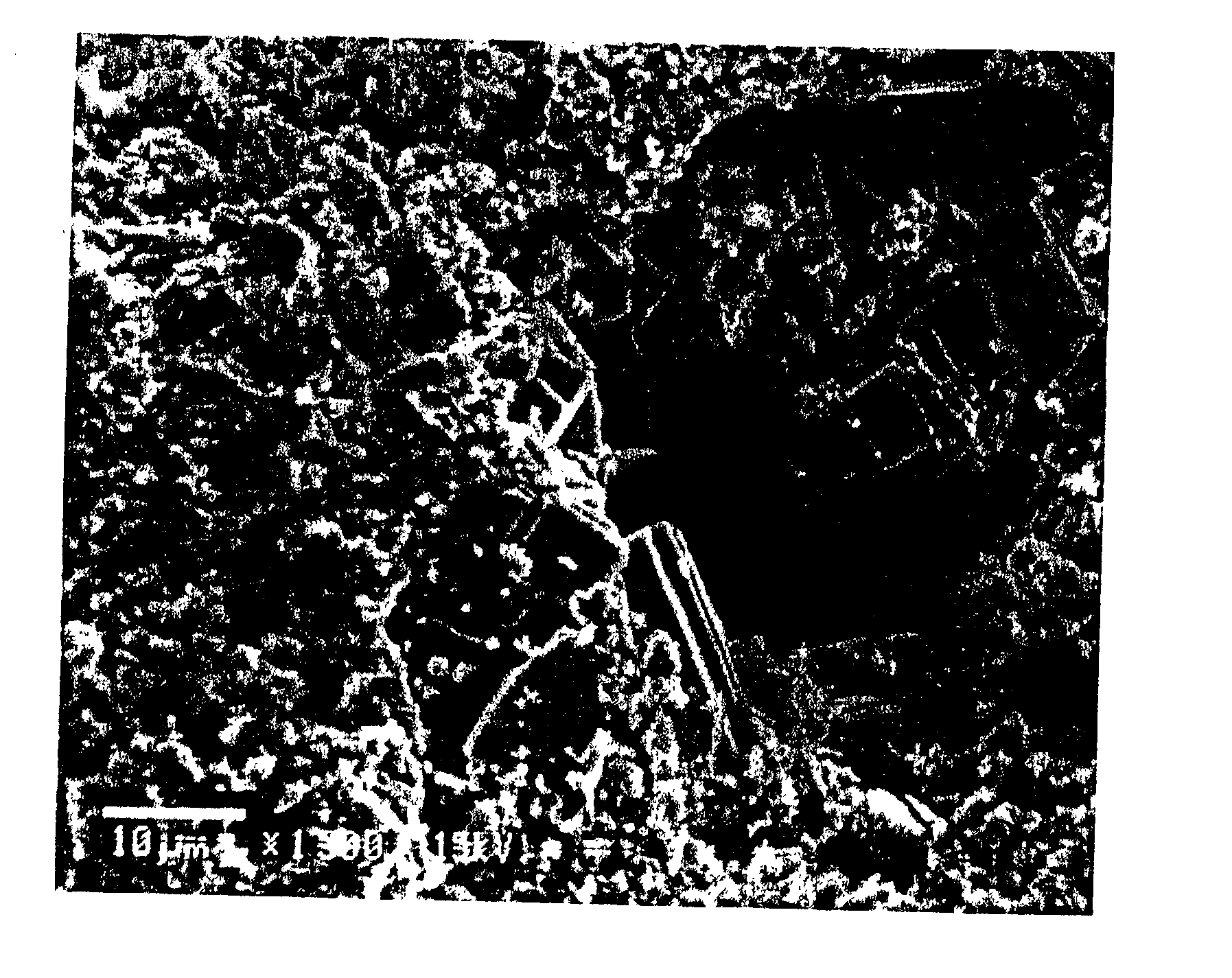

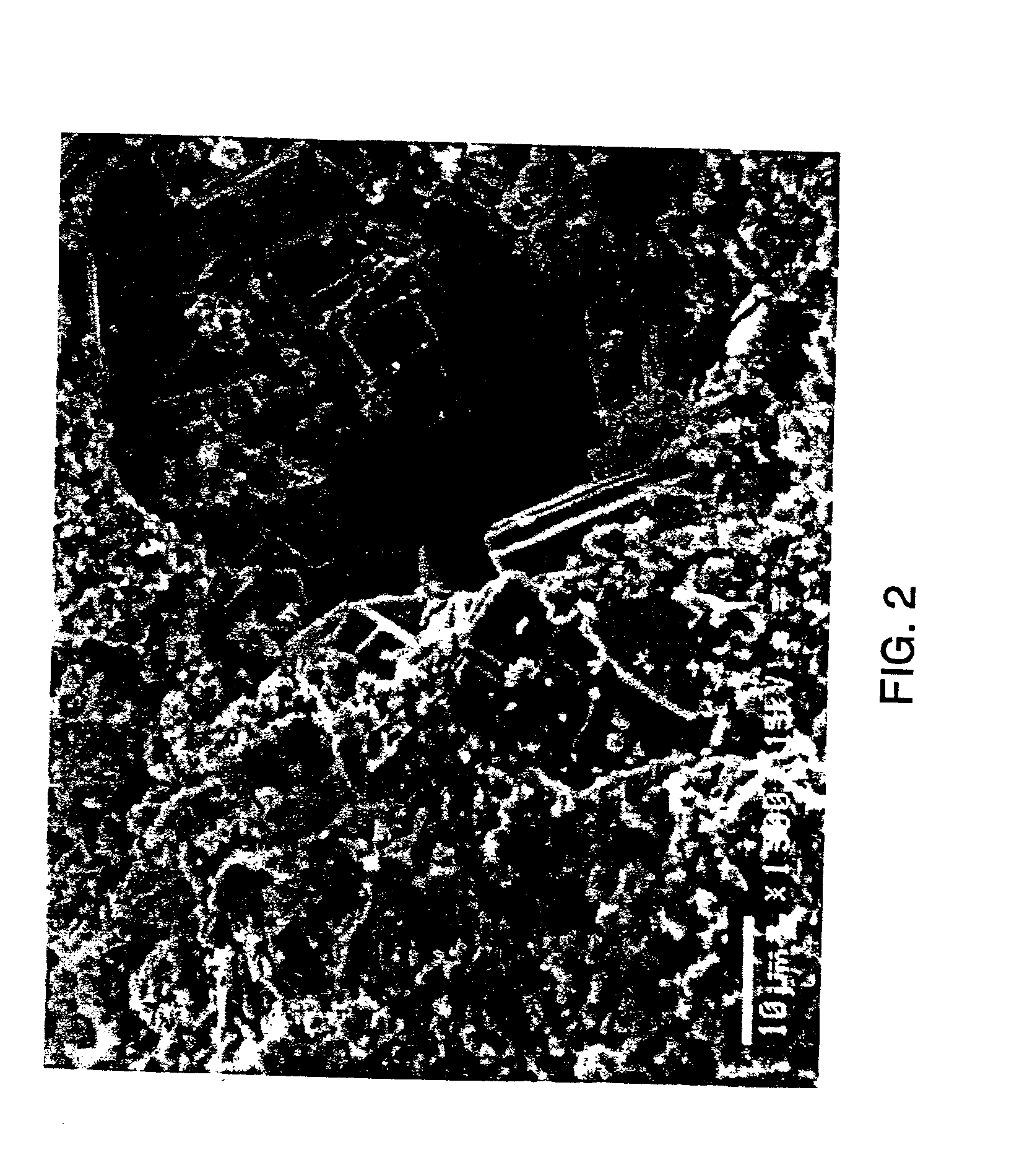

Sintered polycrystalline gallium nitride and its production

InactiveUS6861130B2Flat surfaceReadily apparentPressurized chemical processNitrogen-metal/silicon/boron binary compoundsApparent densityHardness

Polycrystalline gallium nitride (GaN) characterized by having the atomic fraction of gallium ranging from between about 49% to 55%, an apparent density of between about 5.5 and 6.1 g / cm3, and a Vickers hardness of above about 1 GPa. Polycrystalline GaN can be made by hot isostatic pressing (HIPing) at a temperature ranging from about 1150° C. to 1300° C. and a pressure ranging from between about 1 and 10 Kbar. Alternatively, polycrystalline GaN can be made by high pressure / high temperature (HP / HT) sintering at a temperature ranging from about 1200° to 1800° C. and a pressure ranging from about 5 to 80 Kbar.

Owner:SLT TECH

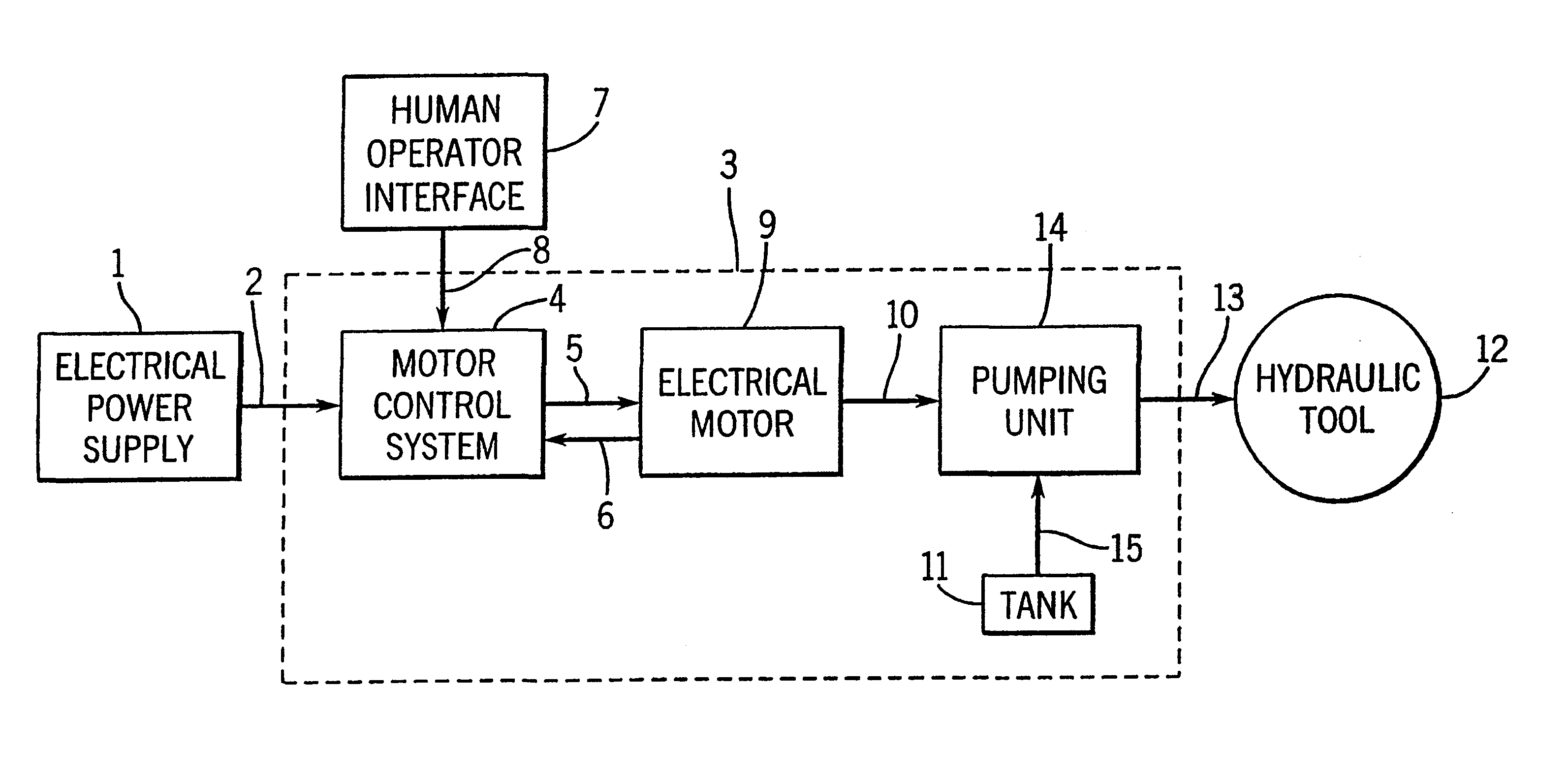

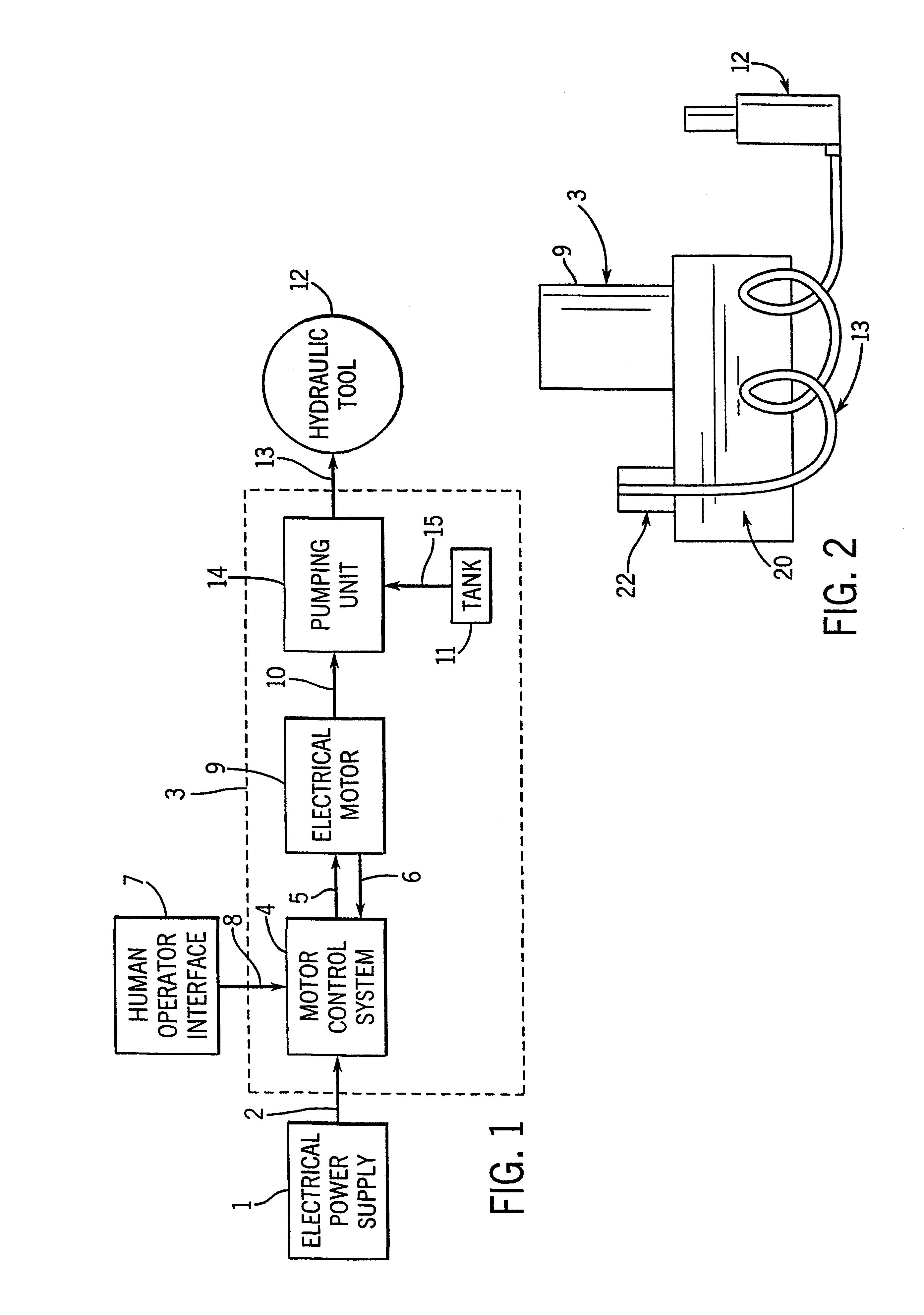

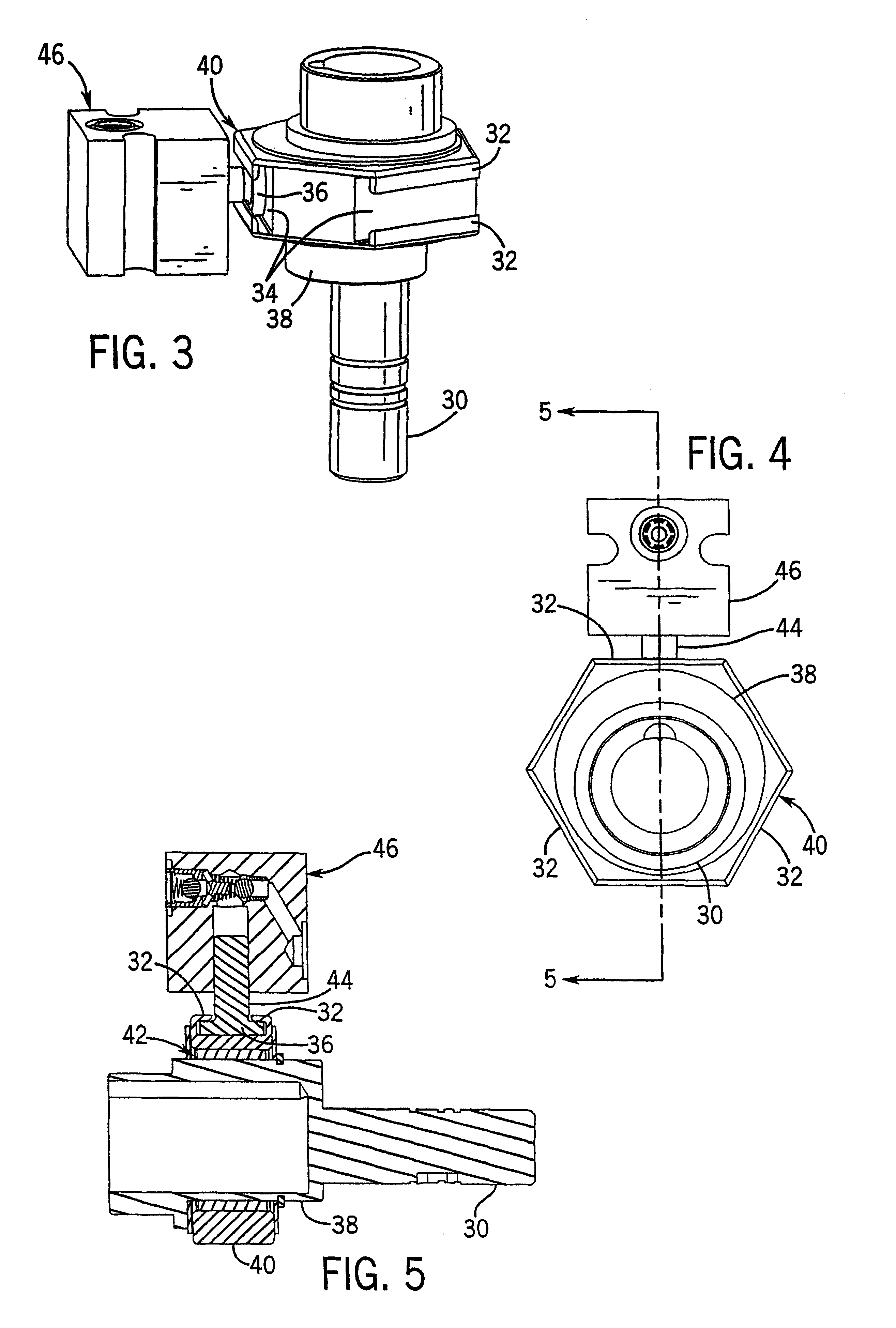

Variable speed hydraulic pump

InactiveUS6863502B2Increase flow rateMaximize flowFlexible member pumpsMotor parameterMotor speedHydraulic pump

The invention provides a variable speed hydraulic pump designed to operate at a maximum horsepower throughout its pressure range by adjusting motor speed according to motor load parameters. In particular, the variable speed hydraulic pump includes a hydraulic pump unit coupled to a variable speed electric motor by a drive unit and to a hydraulic fluid tank for pressurizing and pumping hydraulic fluid when operated by the motor. A motor controller is electrically connected to the motor to supply drive signals to the motor based on electrical characteristics of the drive signals which are dependent on the load exerted on the motor. Suction from the load is provided by both the main pump and a bidirectional supercharging pump by reversing the direction of the motor and shifting a 4 / 3 valve to connect the main pump inlet to the load and its outlet to tank. In addition, the controller reduces the motor speed at the maximum rated pressure to just maintain the pressure, to reduce the amount of fluid pumped through the maximum pressure relief valve.

Owner:ENERPAC TOOL GRP CORP

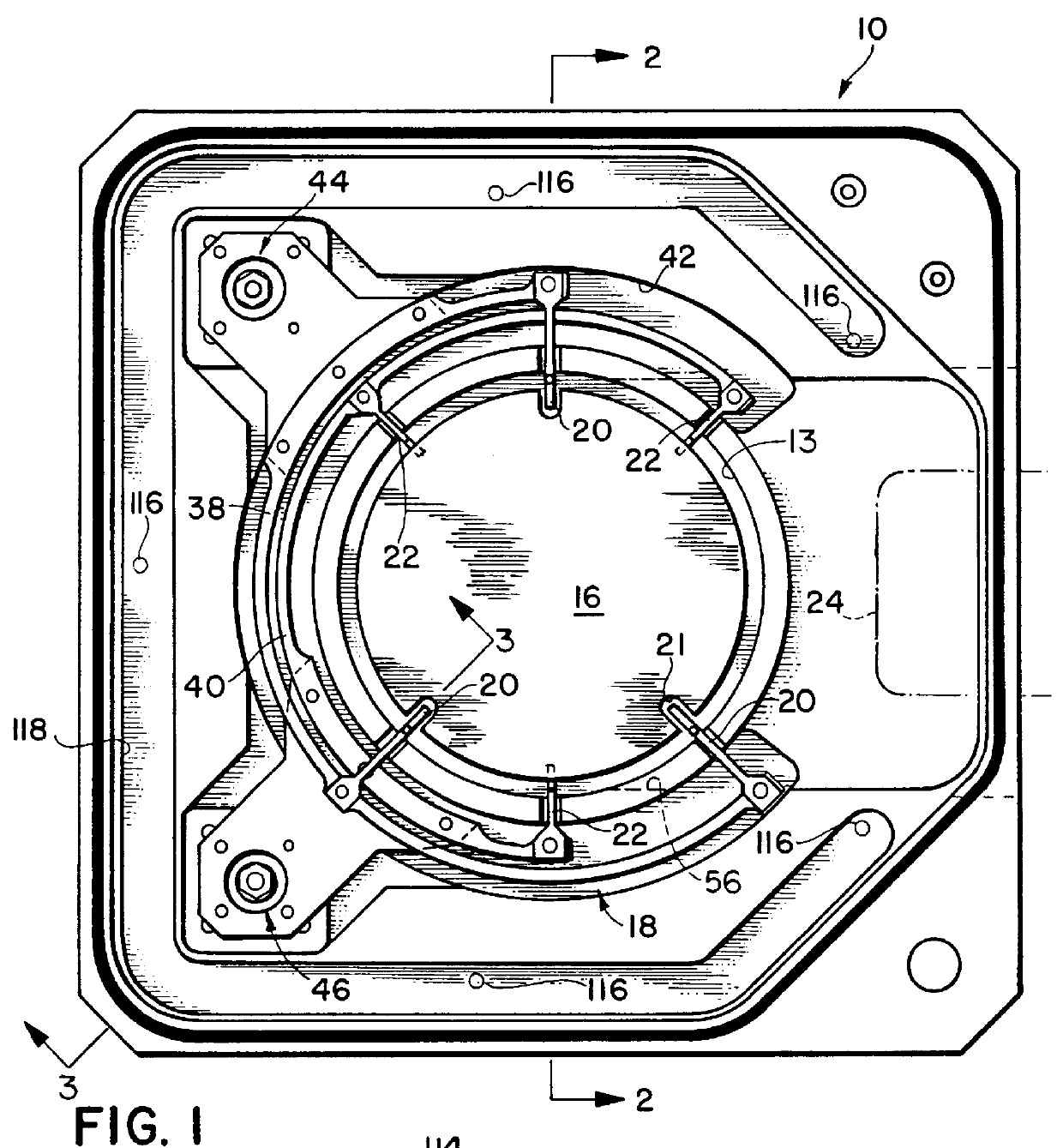

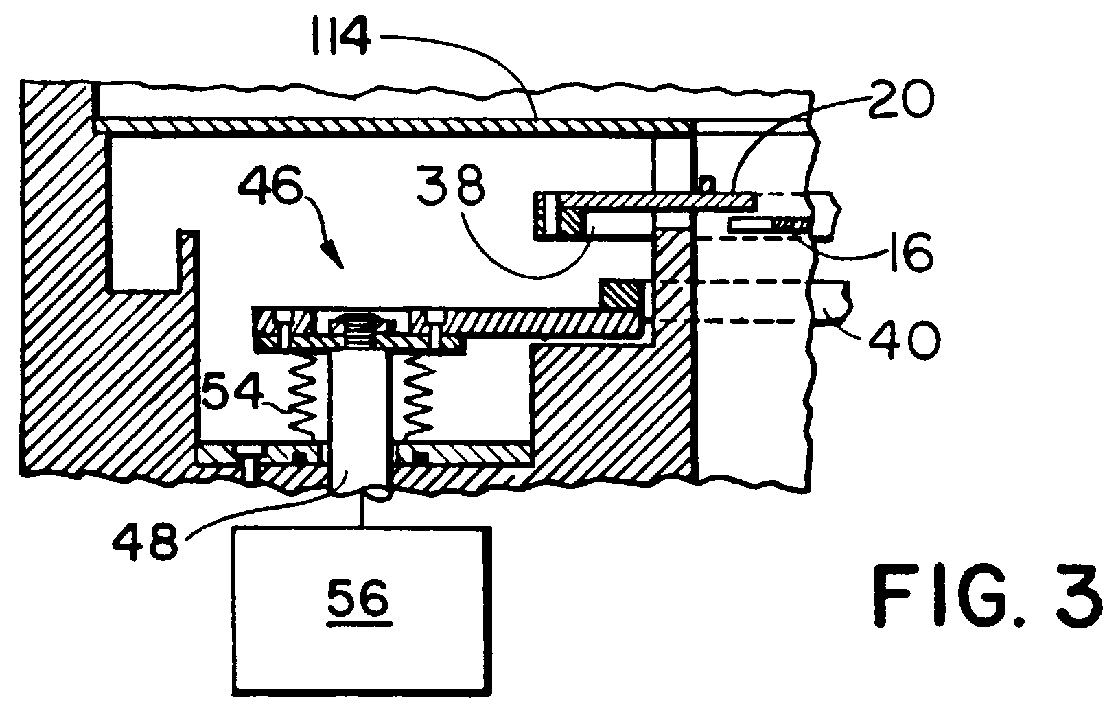

Process for PECVD of silicon oxide using TEOS decomposition

InactiveUSRE36623E1Eliminate depositsAvoid failureElectric discharge tubesPretreated surfacesHigh rateSilicon oxide

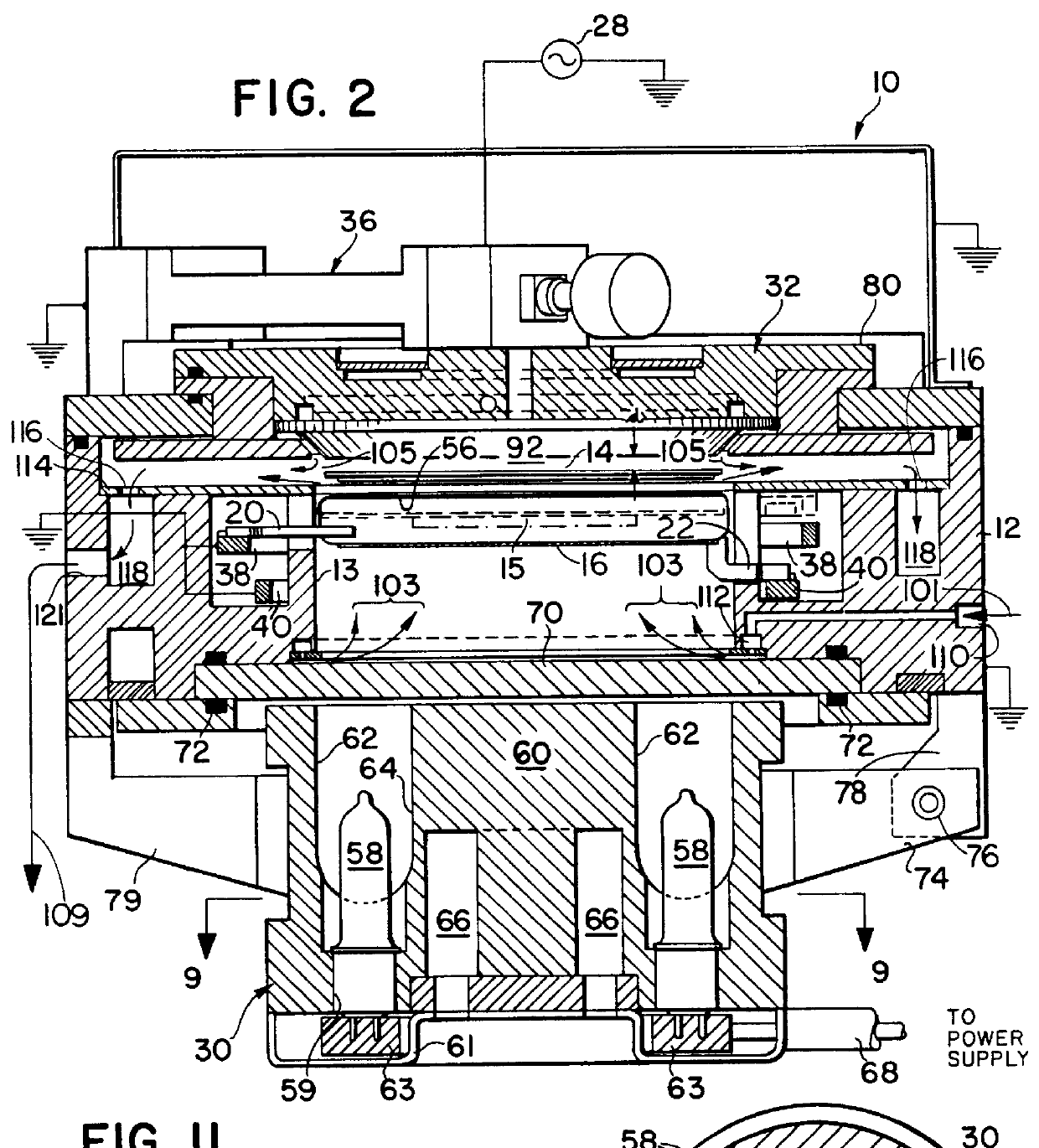

A high pressure, high throughput, single wafer, semiconductor processing reactor is disclosed which is capable of thermal CVD, plasma-enhanced CVD, plasma-assisted etchback, plasma self-cleaning, and deposition topography modification by sputtering, either separately or as part of in-situ multiple step processing. The reactor includes cooperating arrays of interdigitated susceptor and wafer support fingers which collectively remove the wafer from a robot transfer blade and position the wafer with variable, controlled, close parallel spacing between the wafer and the chamber gas inlet manifold, then return the wafer to the blade. A combined RF / gas feed-through device protects against process gas leaks and applies RF energy to the gas inlet manifold without internal breakdown or deposition of the gas. The gas inlet manifold is adapted for providing uniform gas flow over the wafer. Temperature-controlled internal and external manifold surfaces suppress condensation, premature reactions and decomposition and deposition on the external surface. The reactor also incorporates a uniform radial pumping gas system which enables uniform reactant gas flow across the wafer and directs purge gas flow downwardly and upwardly toward the periphery of the wafer for sweeping exhaust gases radially away from the wafer to prevent deposition outside the wafer and keep the chamber clean. The reactor provides uniform processing over a wide range of pressures including very high pressures. A low temperature CVD process for forming a highly conformal layer of silicon dioxide is also disclosed. The process uses very high chamber pressure and low temperature, and TEOS and ozone reactants. The low temperature CVD silicon dioxide deposition step is particularly useful for planarizing underlying stepped dielectric layers, either alone or in conjunction with a subsequent isotropic etch. A preferred in-situ multiple-step process for forming a planarized silicon dioxide layer uses (1) high rate silicon dioxide deposition at a low temperature and high pressure followed by (2) the deposition of the conformal silicon dioxide layer also at high pressure and low temperature, followed by (3) a high rate isotropic etch, preferably at low temperature and high pressure in the sane reactor used for the two oxide deposition steps. Various combinations of the steps are disclosed for different applications, as is a preferred reactor self-cleaning step.

Owner:APPLIED MATERIALS INC

High pressure high non-reactive diluent gas content high plasma ion density plasma oxide etch process

InactiveUS6238588B1Increase pressureHigh strengthElectric discharge tubesDecorative surface effectsHigh plasmaOxygen

The invention is embodied in a method of processing a semiconductor workpiece in a plasma reactor chamber, including supplying a polymer and etchant precursor gas containing at least carbon and fluorine into the chamber at a first flow rate sufficient of itself to maintain a gas pressure in the chamber in a low pressure range below about 20 mT, supplying a relatively non-reactive gas into the chamber at second flow rate sufficient about one half or more of the total gas flow rate into the chamber, in combination with the first flow rate of the precursor gas, to maintain the gas pressure in the chamber in a high pressure range above 20 mT, and applying plasma source power into the chamber to form a high ion density plasma having an ion density in excess of 1010 ions per cubic centimeter. In one application of the invention, the workpiece includes an oxygen-containing overlayer to be etched by the process and a non-oxygen-containing underlayer to be protected from etching, the precursor gas dissociating in the plasma into fluorine-containing etchant species which etch the oxygen-containing layer and carbon-containing polymer species which accumulate on the non-oxygen-containing underlayer. Alternatively, the high pressure range may be defined as a pressure at which the skin depth of the inductive field exceeds {fraction (1 / 10)} of the gap between the inductive antenna and the workpiece.

Owner:APPLIED MATERIALS INC

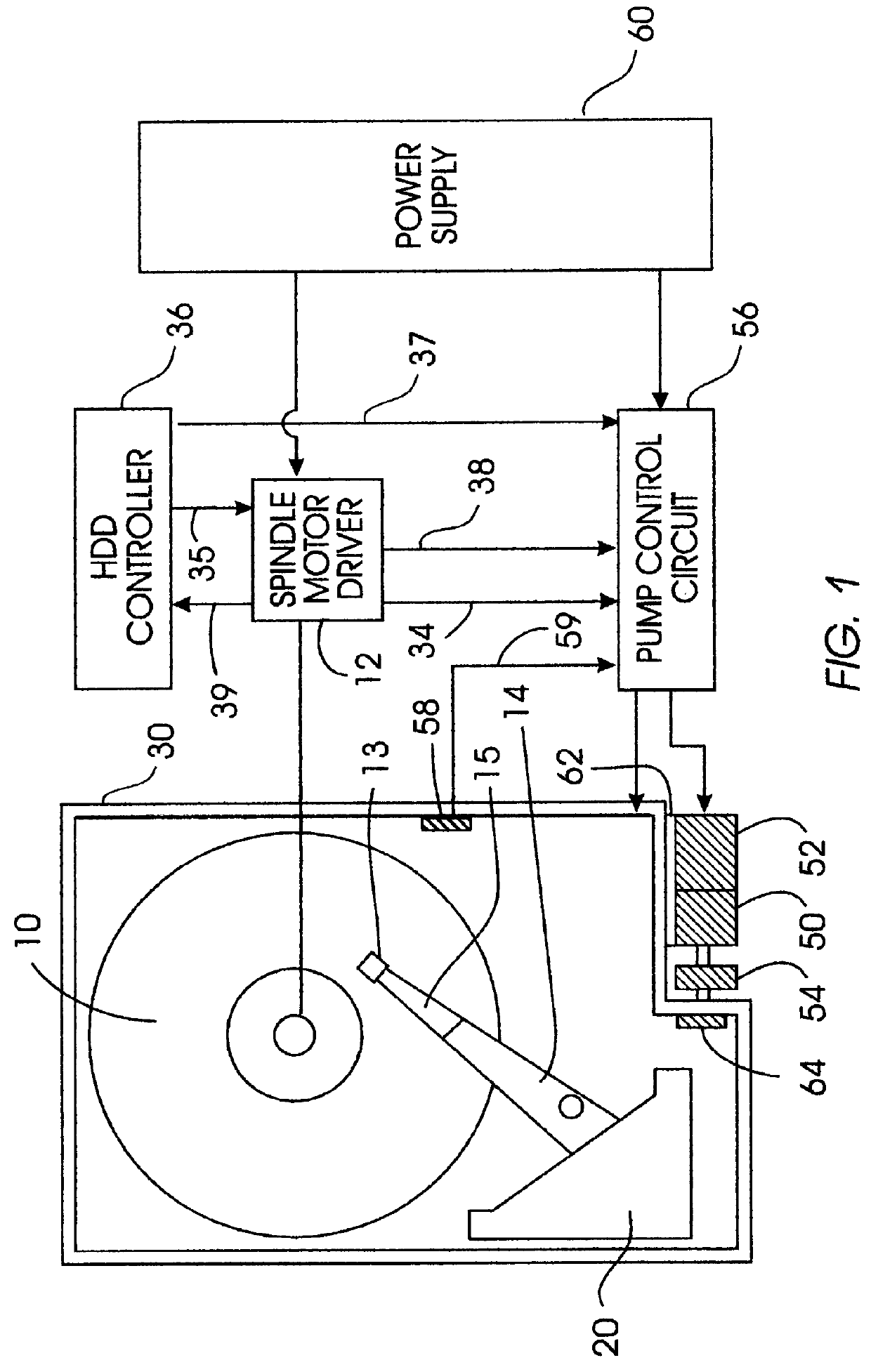

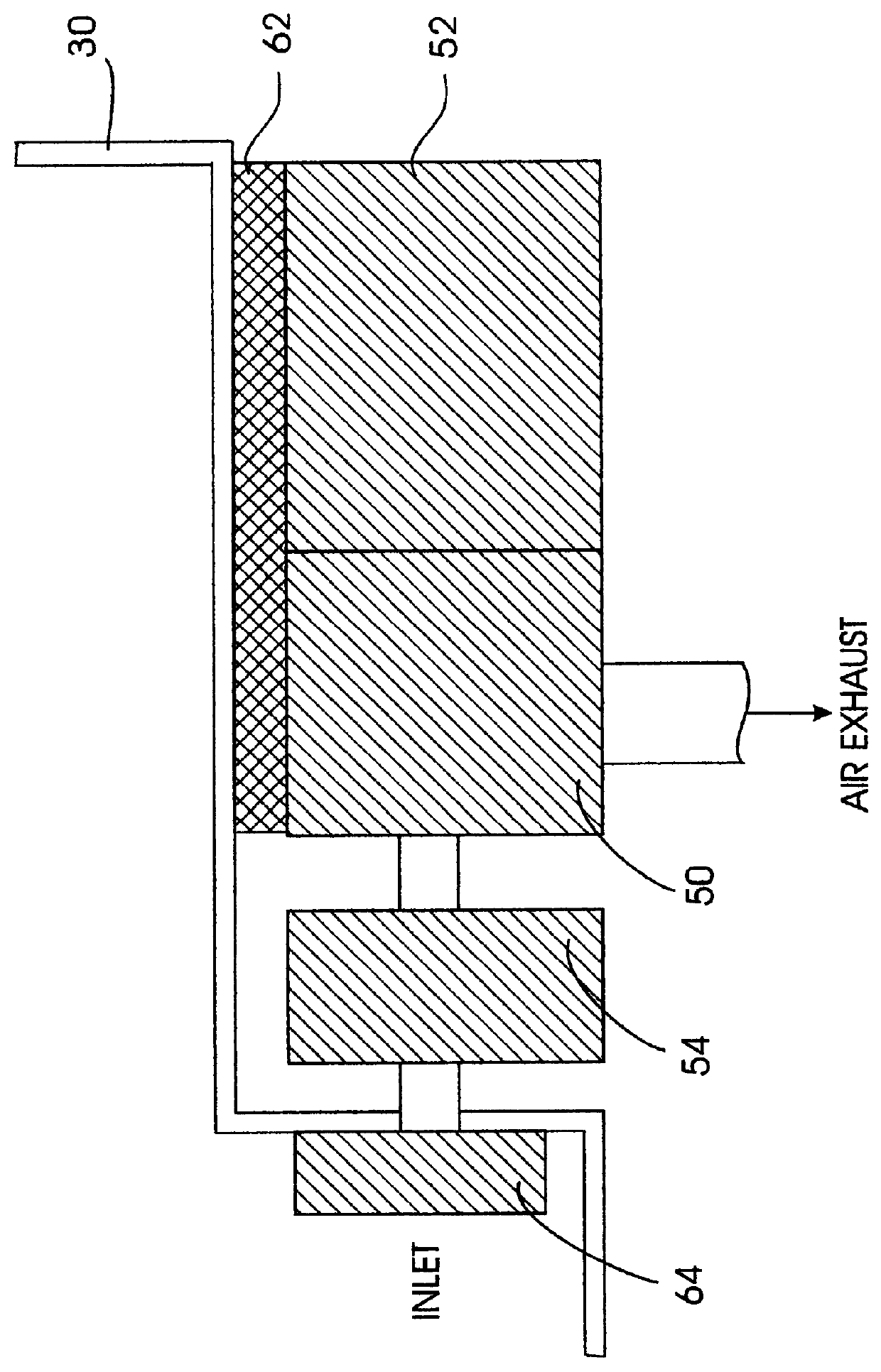

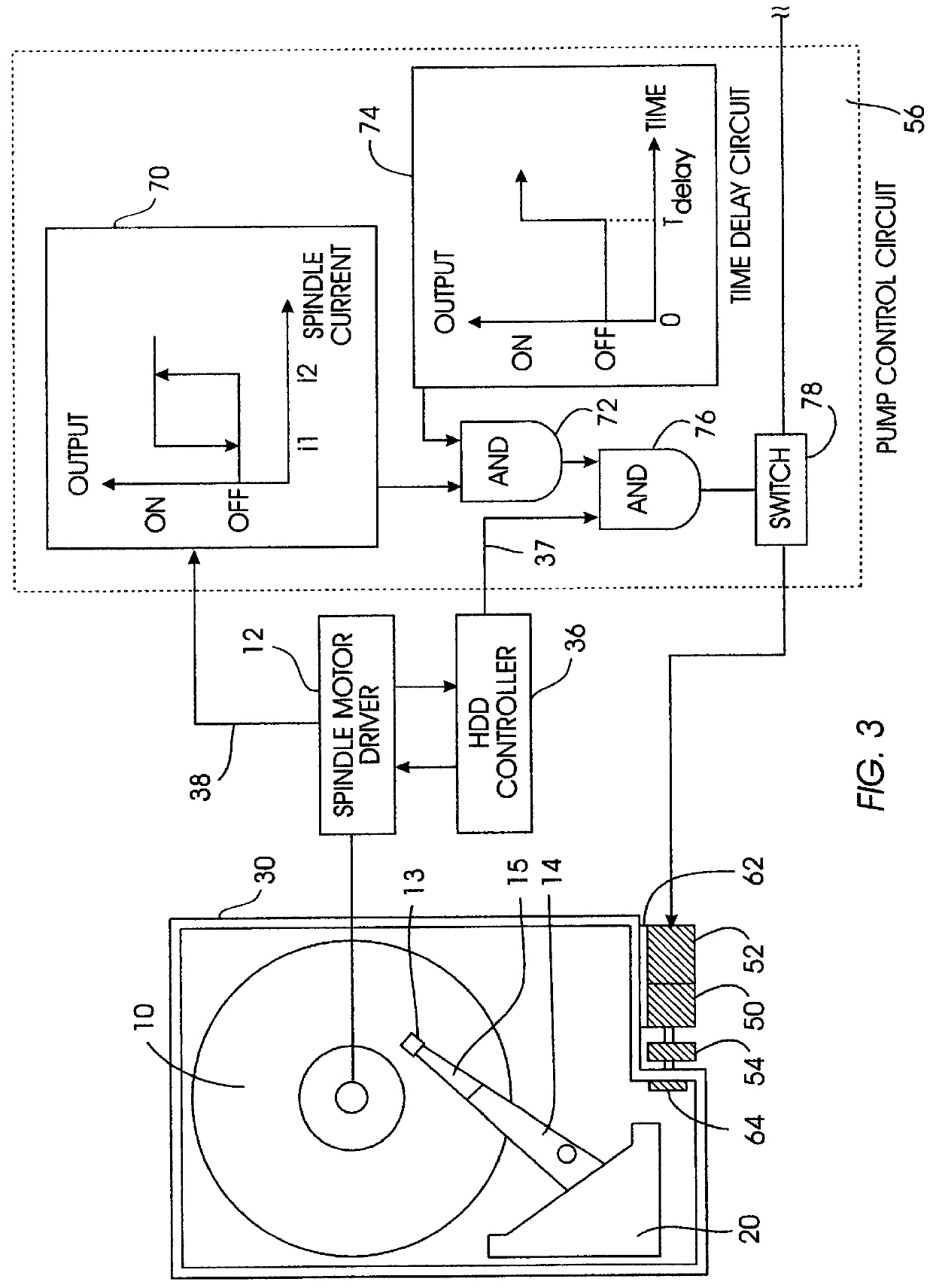

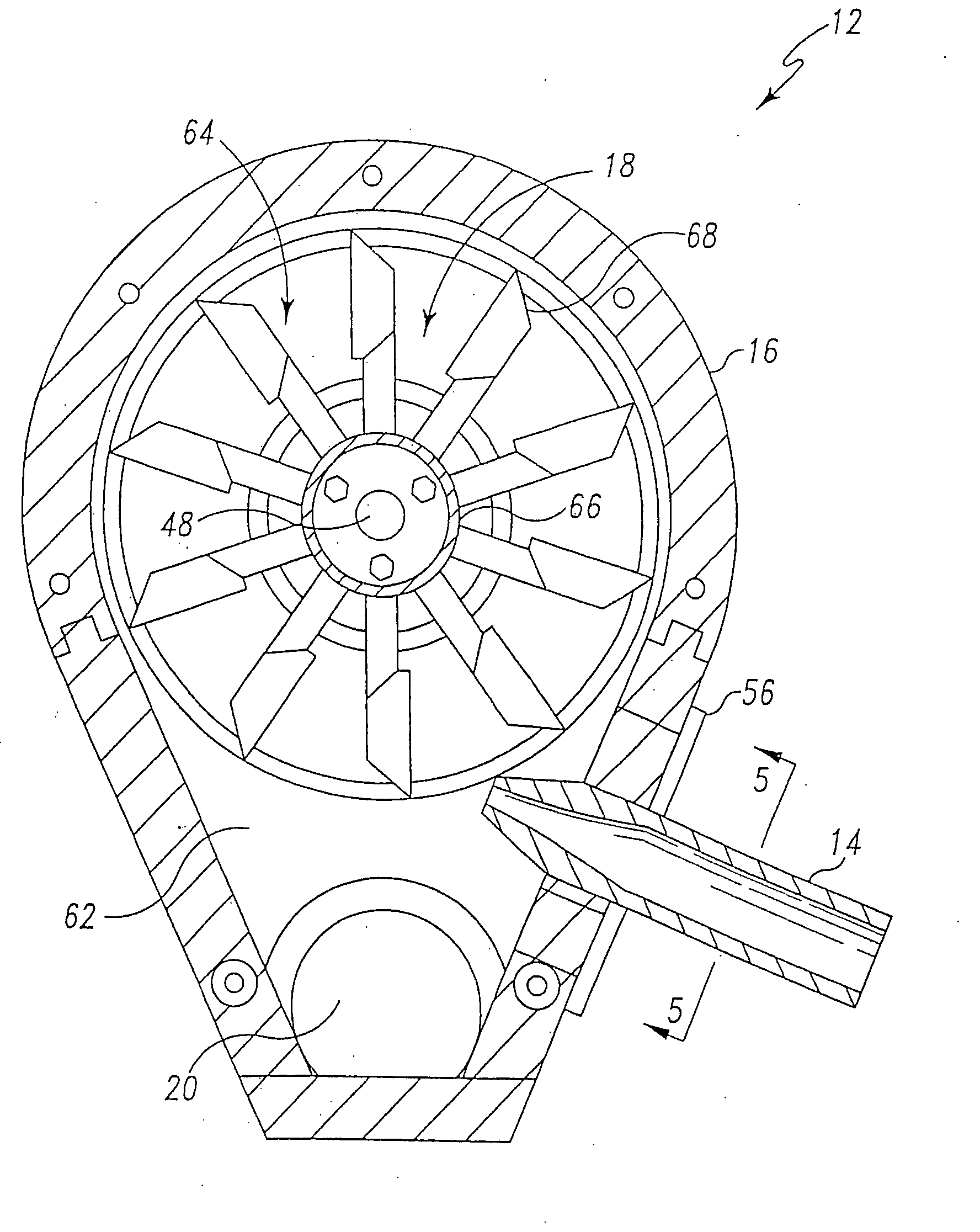

Disk drive with controlled reduced internal pressure

InactiveUS6144178AReduce internal pressureIncrease speedDC motor speed/torque controlElectrical testingInternal pressureElectric machine

A rigid magnetic recording disk drive includes a vacuum pump attached to the disk drive housing for removing air from within the housing so that the disk drive is operated at a reduced internal gas pressure. The pump motor is controlled by control circuitry that receives an input signal representative of the pressure within the housing to enable the pressure to be maintained within a predetermined reduced pressure range. Because spindle motor current has been directly correlated with internal pressure, a signal representative of the spindle motor current is used as the input to the pump control circuitry. The pump control circuitry also prevents the pump from turning on until the spindle motor has reached its stable operating speed, and from turning on when the disk drive is reading or writing data. Because of the reduced internal pressure the disk drive operates at a significantly higher disk RPM with only a minimal increase in power consumption and without any increase in track misregistration.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Miniature hydro-power generation system

InactiveUS20080136191A1High speedShorten speedGeneral water supply conservationGas turbine plantsEngineeringKinetic energy

A miniature hydro-power generation system includes an outer housing and an inner housing. The outer housing may receive a flow of liquid flowing in a first direction at a predetermined range of pressure. The flow of liquid may be decreased by a predetermined amount of pressure and increased by a predetermined amount of velocity and channeled to a hydro-generator included in the inner housing with an inlet nozzle. The flow of liquid may be channeled with the inlet nozzle to flow in a second direction that is substantially perpendicular to the first direction. Upon transfer of kinetic energy in the flow of liquid to the hydro-generator, the inner housing may rotate in the second direction. The flow of liquid may then be channeled back to the first direction and out of the housing with an outlet nozzle. The outlet nozzle configured to increase the pressure and decrease the velocity of the flow of liquid to minimized non-laminar flow characteristics.

Owner:ACCESS BUSINESS GRP INT LLC

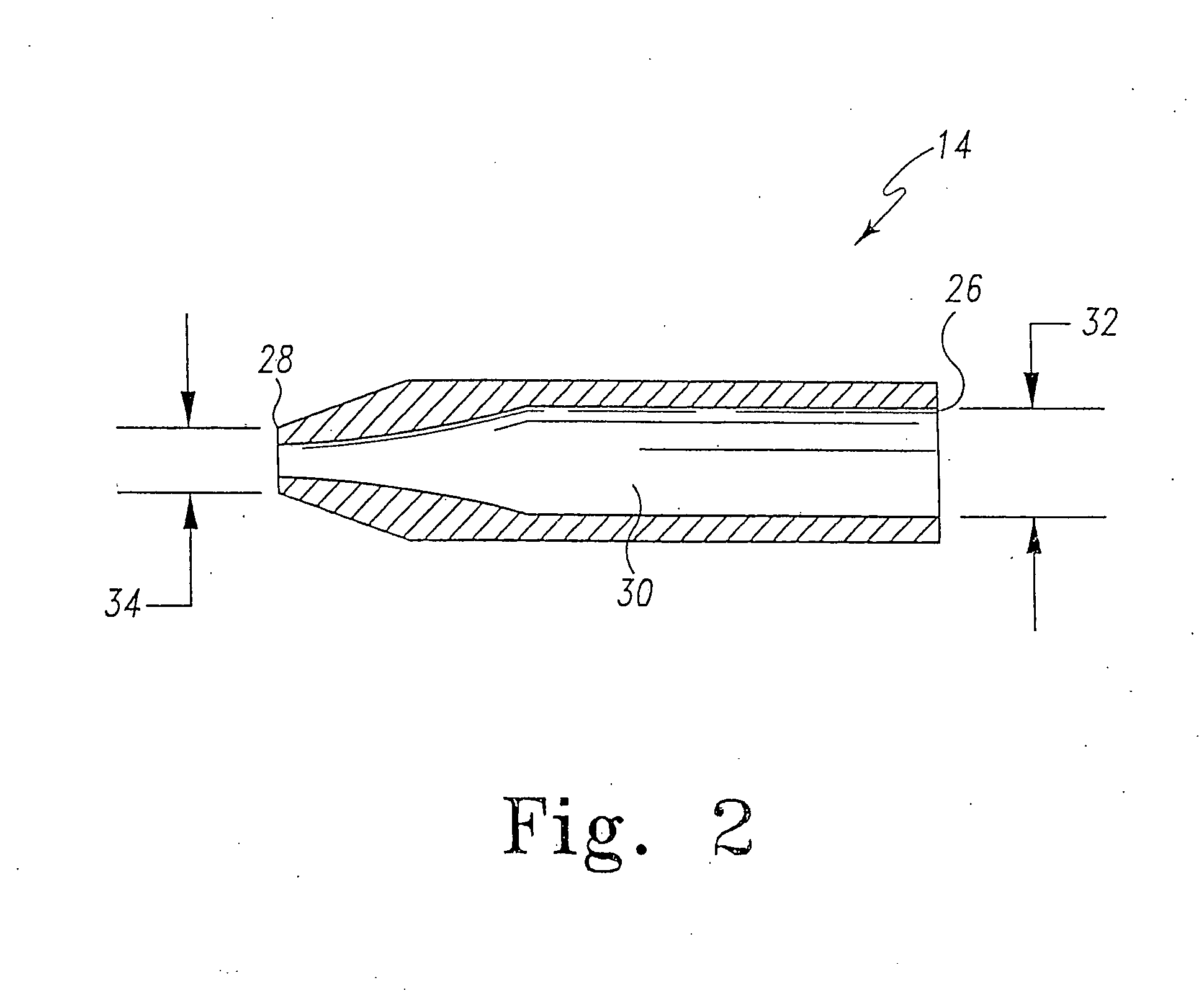

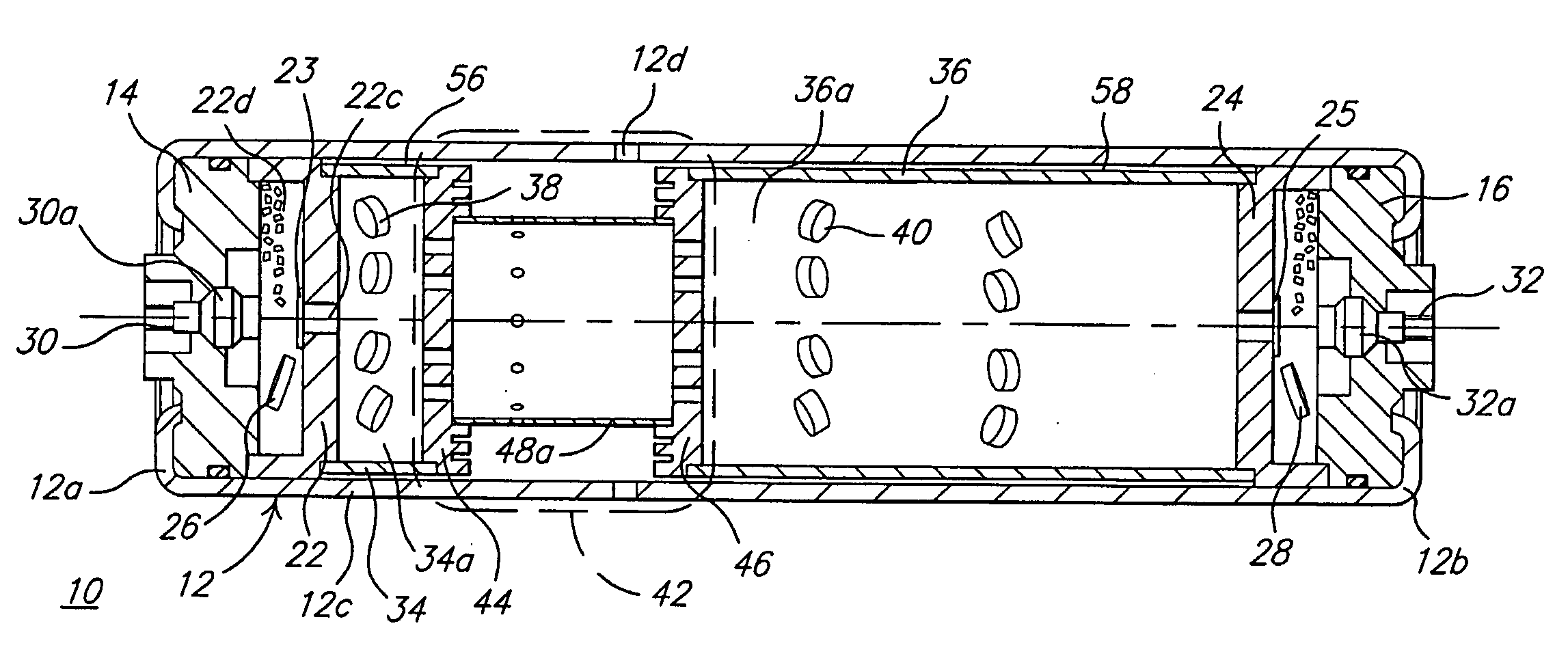

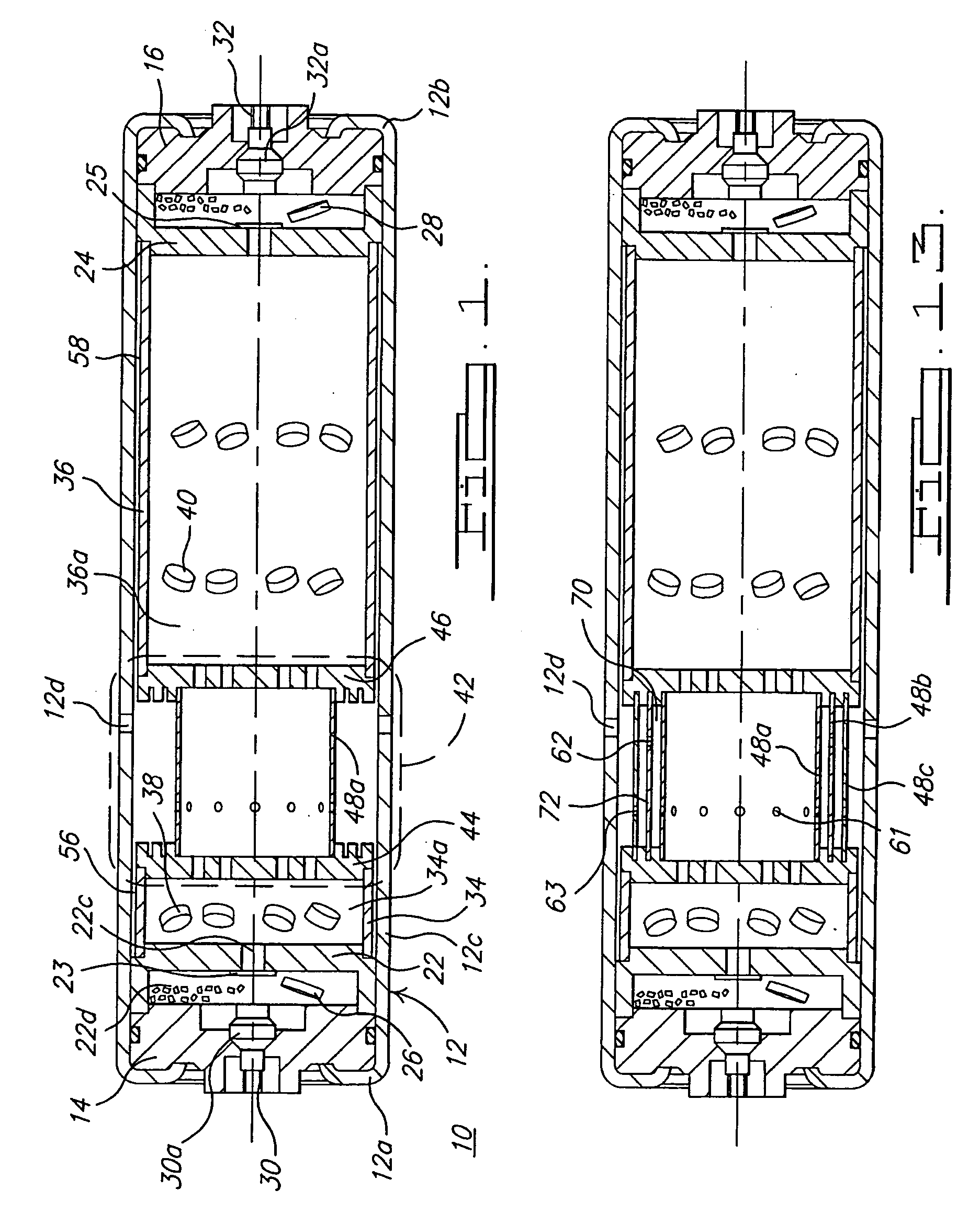

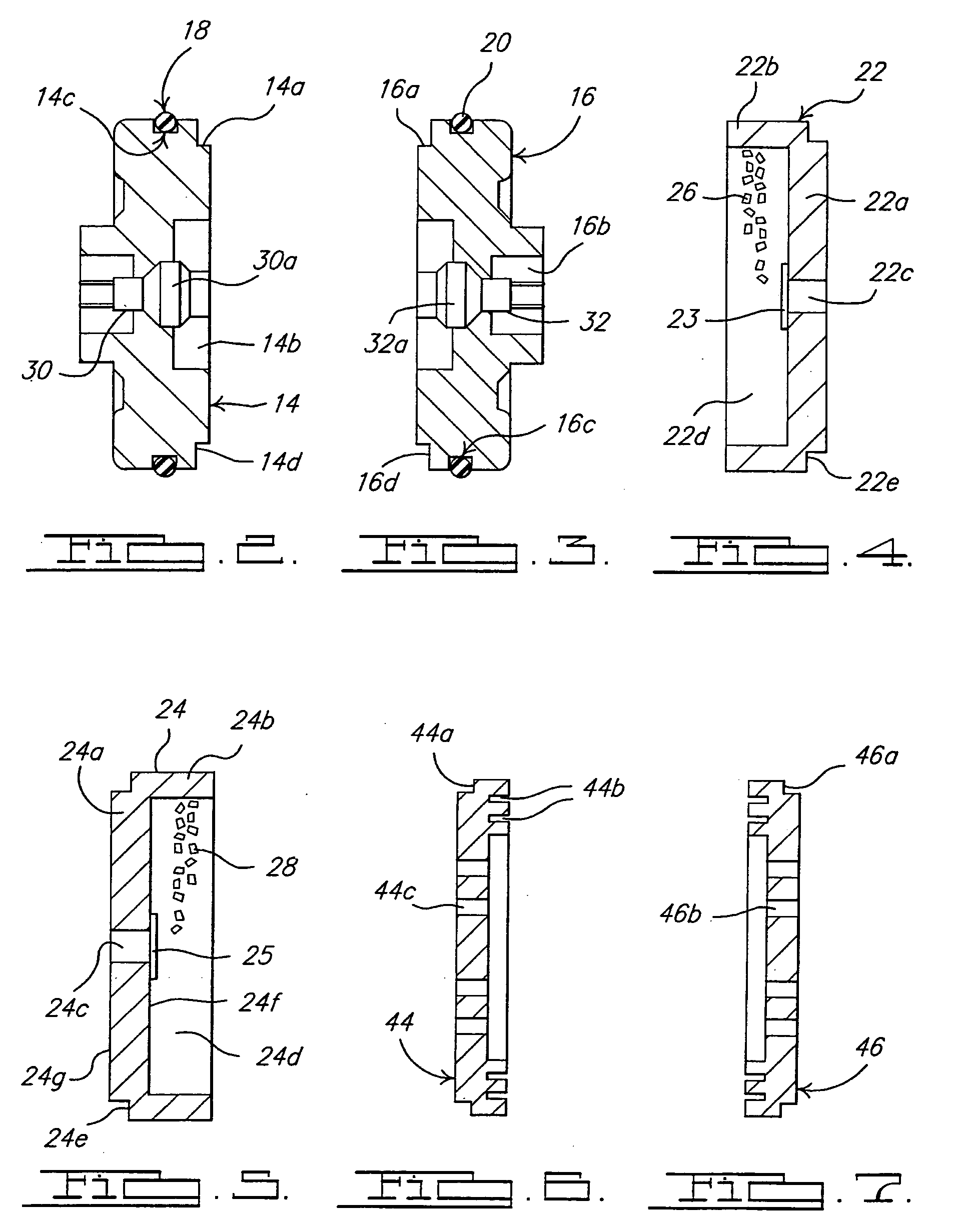

Gas generating system

InactiveUS20060005734A1Pedestrian/occupant safety arrangementPressure gas generationParticulatesCombustion chamber

A gas generating system (10) including a baffle system (42) for modifying the temperature and pressure of a gas generated by the system, and to remove particulates from the gas. The gas generating system includes a first combustion chamber (34a), a second combustion chamber (36a), and the baffle system (42) adjacent both the first and second combustion chambers so as to enable fluid communication with the combustion chambers upon activation of the gas generating system. In another aspect of the present invention, a baffle system (42) is provided including a first end plate (44) having an opening (44b) formed therein for enabling fluid communication with a first fluid source (34a), a second end plate (46) having an opening (46b) formed therein for enabling fluid communication with a second fluid source (36a), and a sequence of baffle elements (48) extending between the first and second end plates. A first baffle element (48a) of the sequence of baffle elements defines a chamber (60) for receiving therein a fluid through the openings in the first and second end plates. Each additional baffle element in the sequence of baffle elements is spaced outwardly apart from a preceding baffle element in the sequence of baffle elements. In another aspect of the invention, a method is provided for producing, in a gas generating system, a gas having a pressure within a predetermined pressure range and a temperature within a predetermined temperature range. In another aspect of the present invention, a vehicle occupant protection system is provided.

Owner:JOYSON SAFETY SYST ACQUISITION LLC

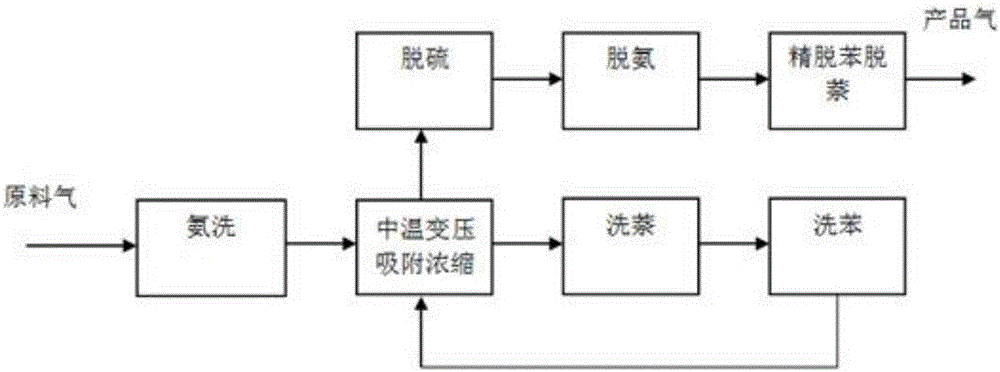

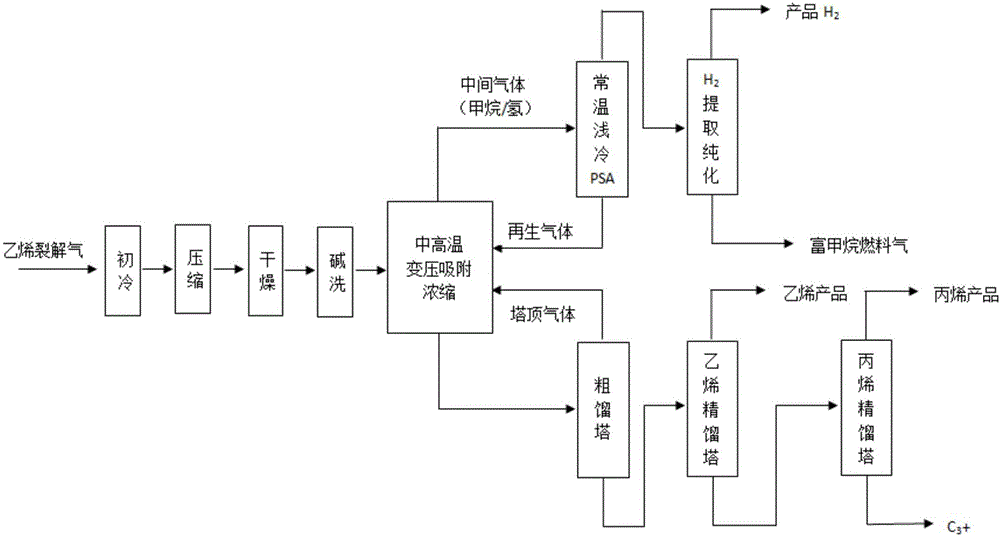

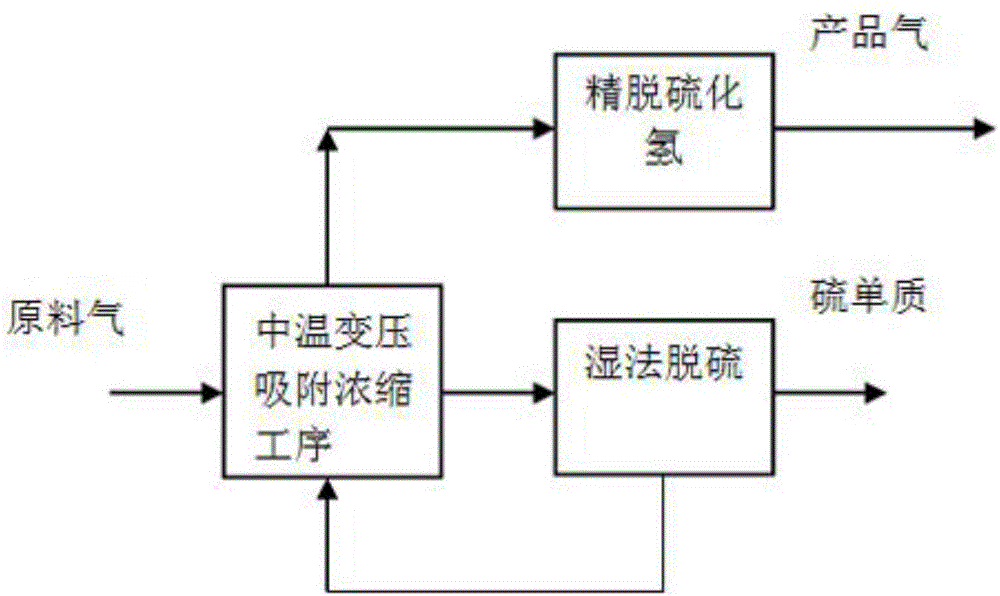

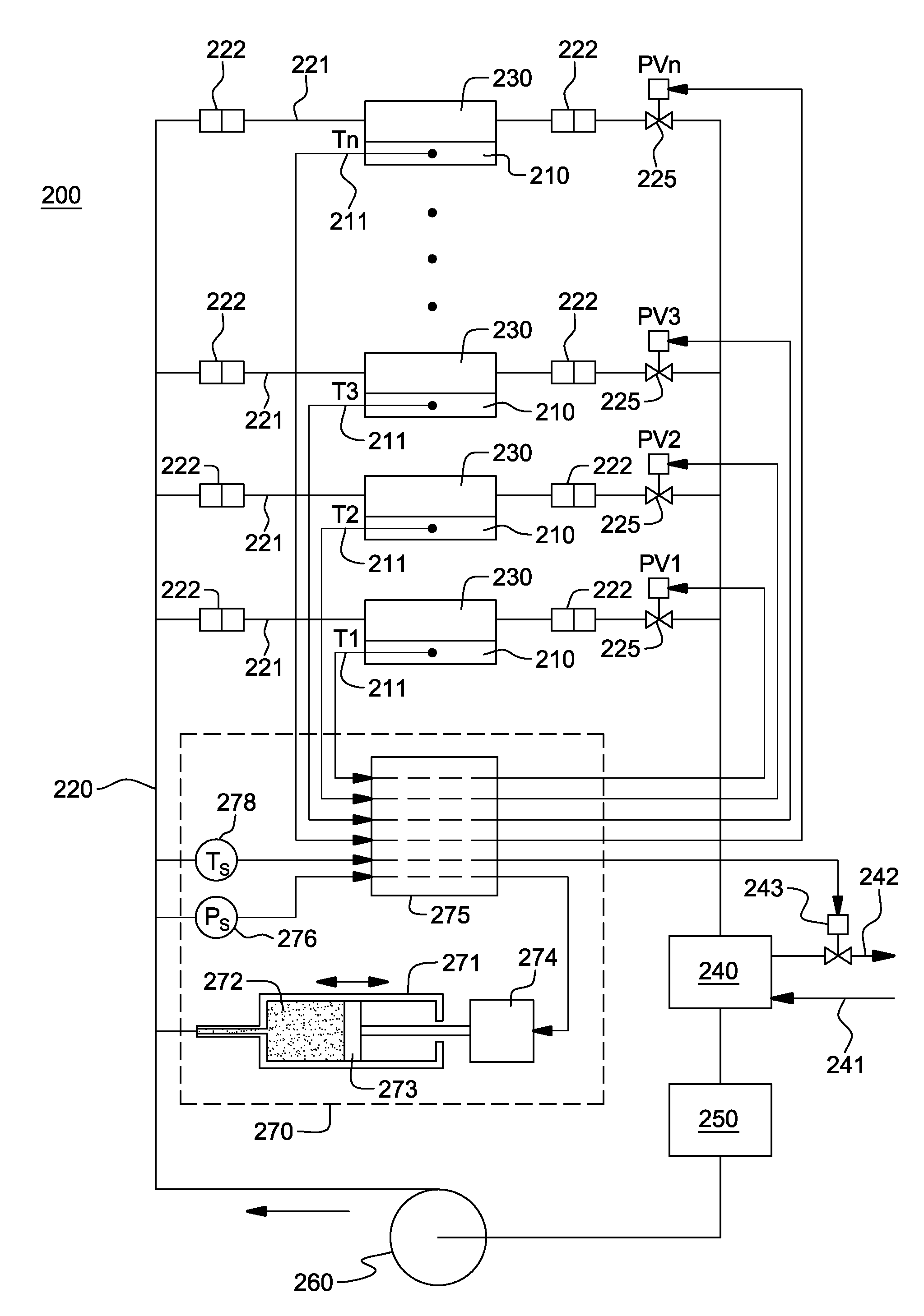

Full-temperature-range pressure swing adsorption gas separation, refinement and purification method

ActiveCN105749699AReduce energy consumptionBroaden the scope of adsorption separation applicationsSolidificationLiquefactionEnergy gradientPurification methods

The invention discloses a full-temperature-range pressure swing adsorption gas separation, refinement and purification method.By means of the difference of the temperatures and pressures of different raw material gases and the difference of the adsorption separation coefficients and physical chemistry properties of all components in the raw material gases in the temperature range of 80-200 DEG C and the pressure range of 0.03-4.0 MPa, the adsorption or desorption regeneration operation of the pressure swing adsorption circulation process is adjusted by coupling all separation methods, the adsorption theory that the pressure or temperature swing adsorption separation process is only limited to the adsorption and desorption regeneration circulation operation through pressure or temperature changes is expanded, and therefore all raw material gases are separated, refined and purified by achieving the energy gradient utilization in the gas separation, refinement and purification process and achieving the circulation operation, where adsorption, desorption and regeneration are easily matched and balanced, in the moderate to low cold and moderate to high temperature pressure swing adsorption separation process, and it is changed that a traditional adsorption method is only limited to the auxiliary effect of refinement and purification, and adsorption becomes the basic separation unit operation just as important as refinement, absorption and extraction separation.

Owner:SICHUAN TECHAIRS

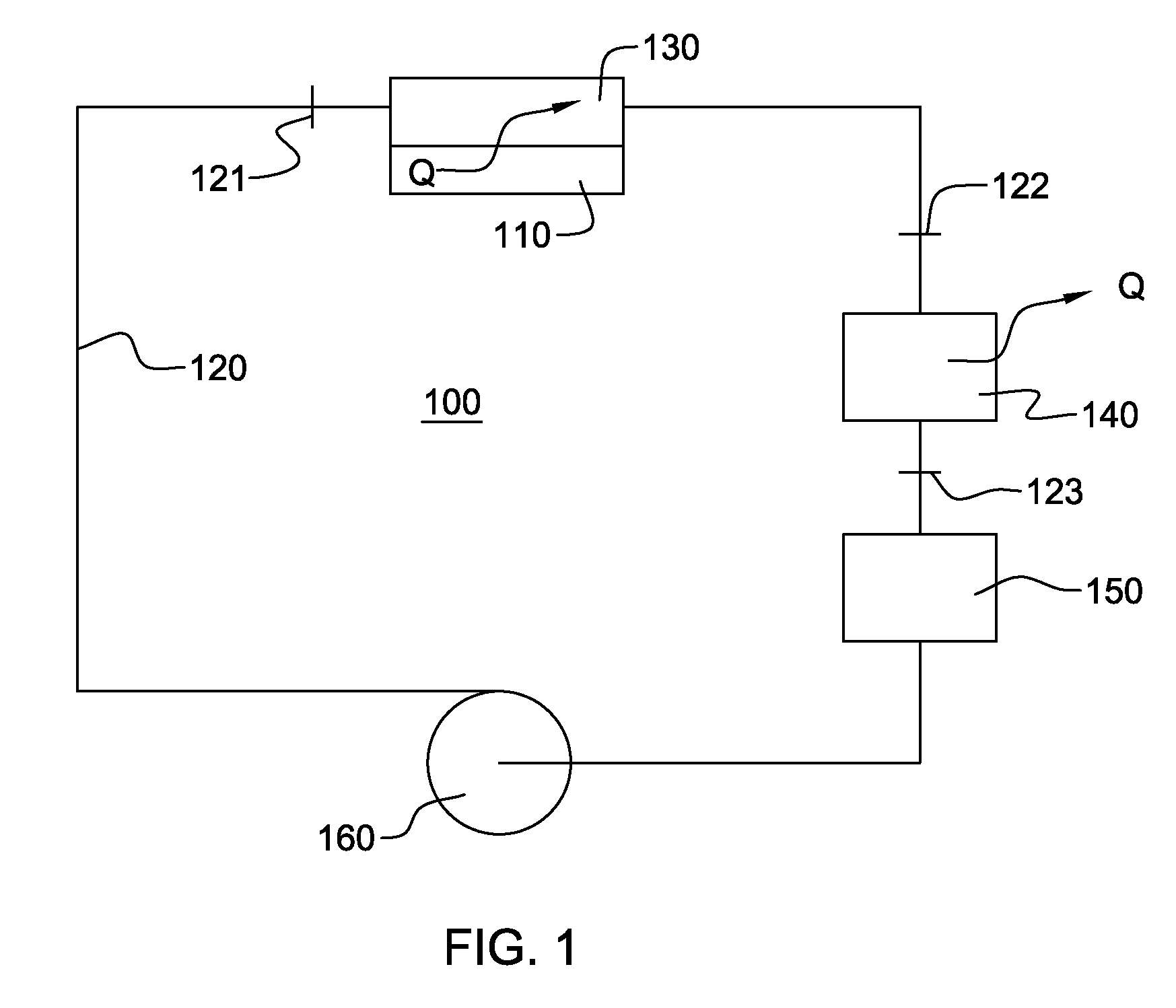

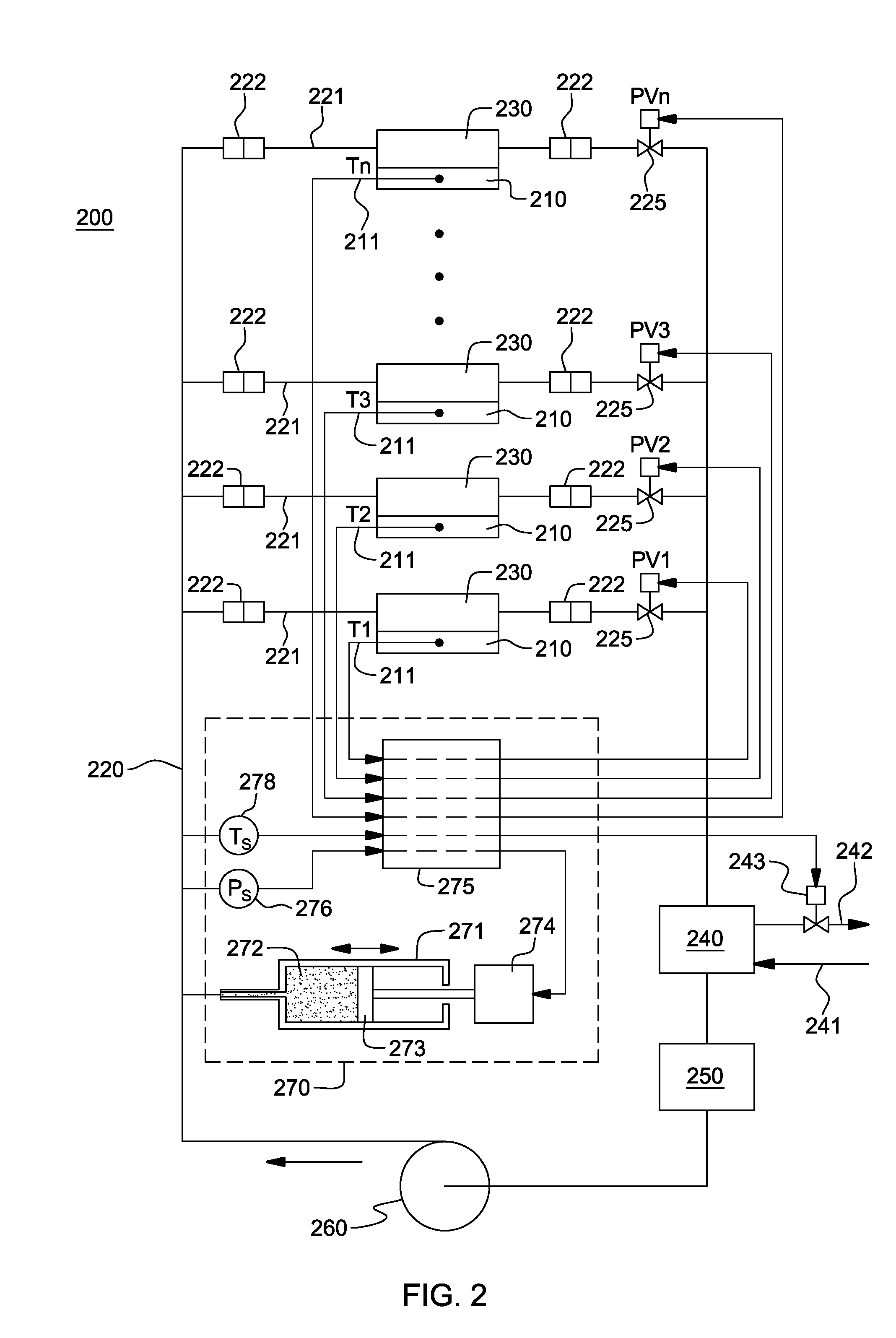

Control of system coolant to facilitate two-phase heat transfer in a multi-evaporator cooling system

ActiveUS20110056225A1Increase the amount of heatingHigh heat densitySpace heating and ventilation safety systemsSpace heating and ventilation control systemsElectronic systemsNuclear engineering

A cooling system and method are provided for facilitating two-phase heat transfer from an electronics system including a plurality of electronic devices to be cooled. The cooling system includes a plurality of evaporators coupled to the electronic devices, and a coolant loop for passing system coolant through the evaporators. The coolant loop includes a plurality of coolant branches coupled in parallel, with each coolant branch being coupled in fluid communication with a respective evaporator. The cooling system further includes a control unit for maintaining pressure of system coolant at a system coolant supply side of the coolant branches within a specific pressure range at or above saturation pressure of the system coolant for a given desired saturation temperature of system coolant into the evaporators to facilitate two-phase heat transfer in the plurality of evaporators from the electronic devices to the system coolant at the given desired saturation temperature.

Owner:LENOVO GLOBAL TECH INT LTD

Body fluid treating filter device

ActiveUS7597806B2Excellent body fluid recovery performanceDialysis systemsCartridge filtersInterior spaceBody fluid

Owner:ASAHI KASEI MEDICAL CO LTD

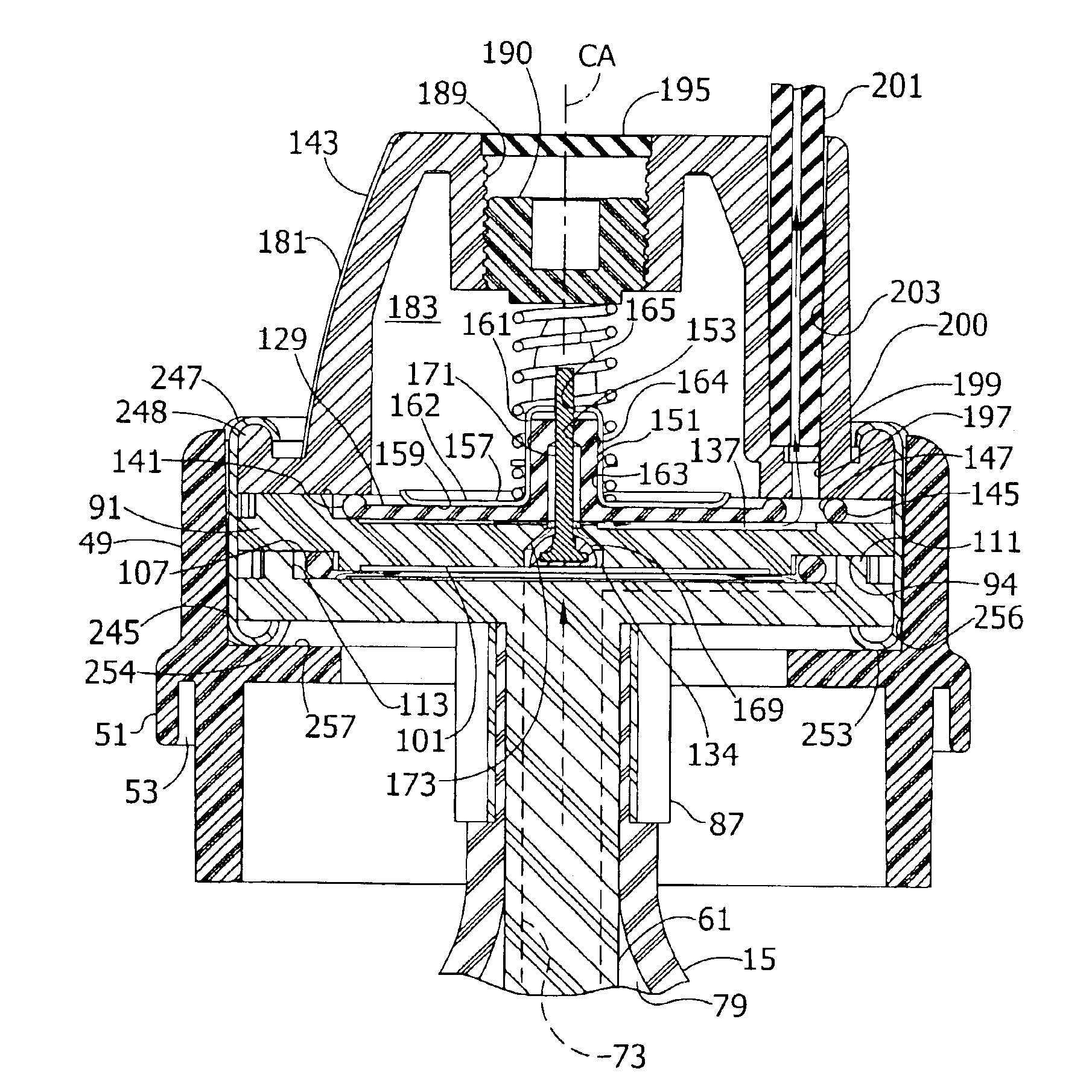

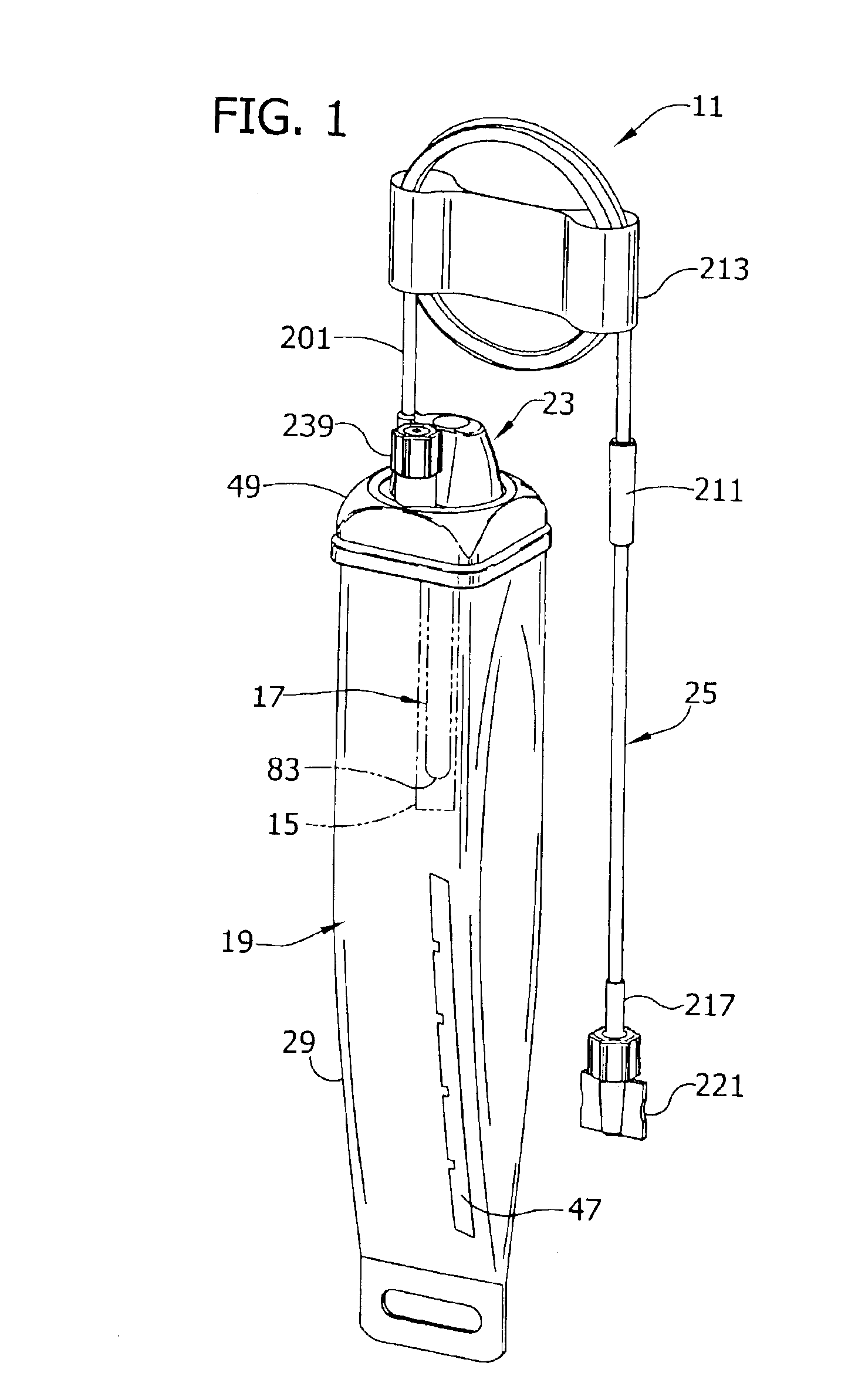

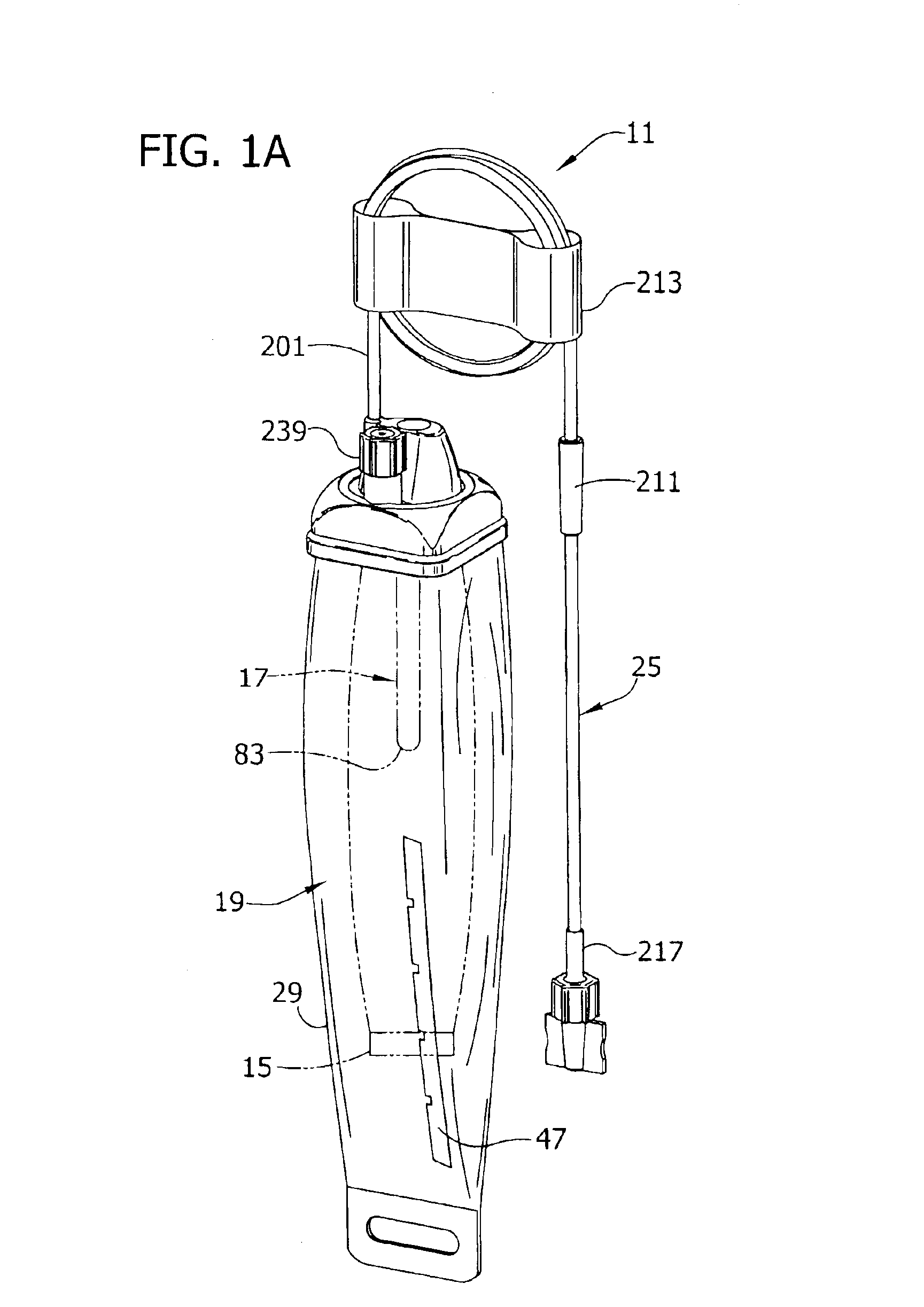

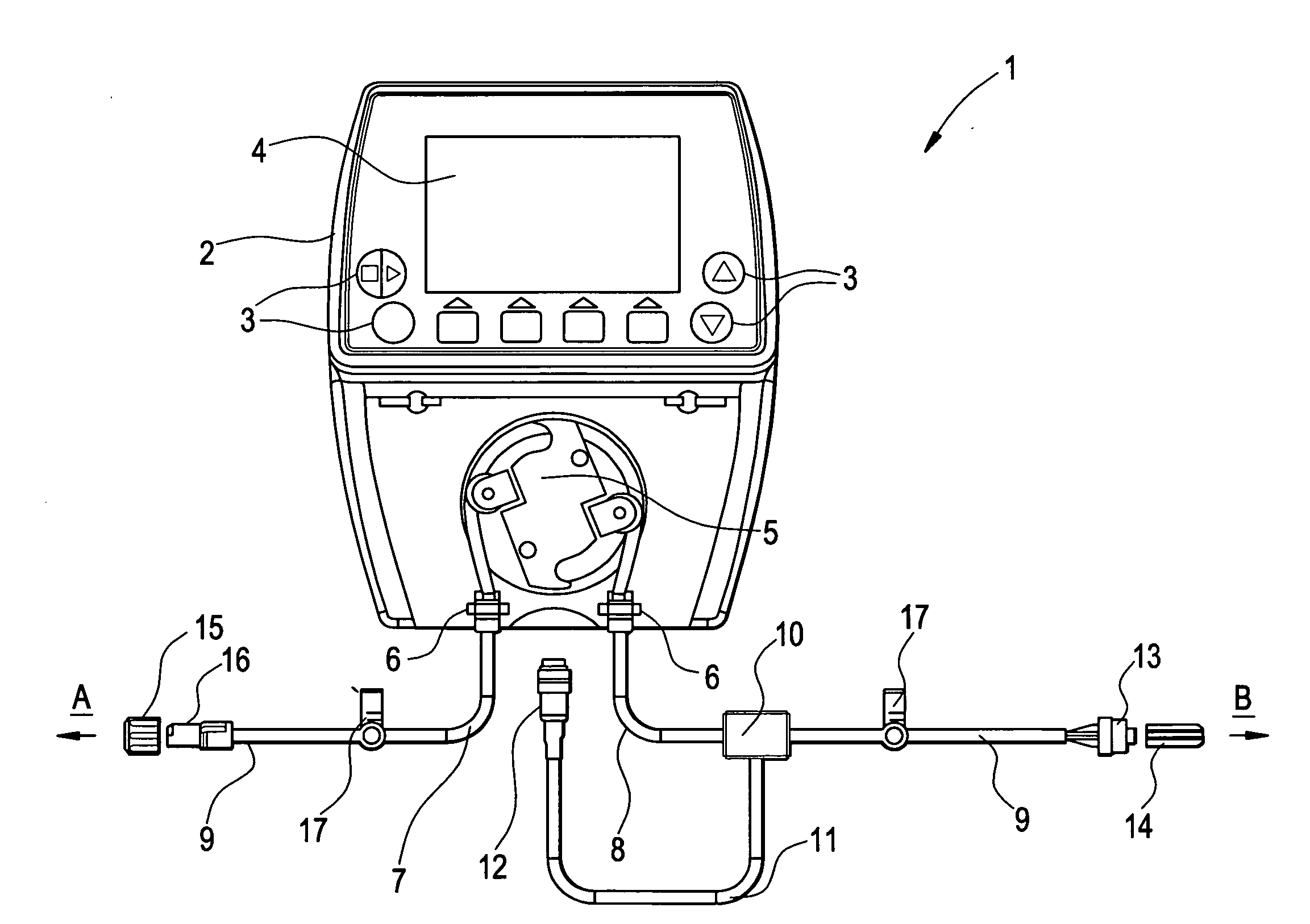

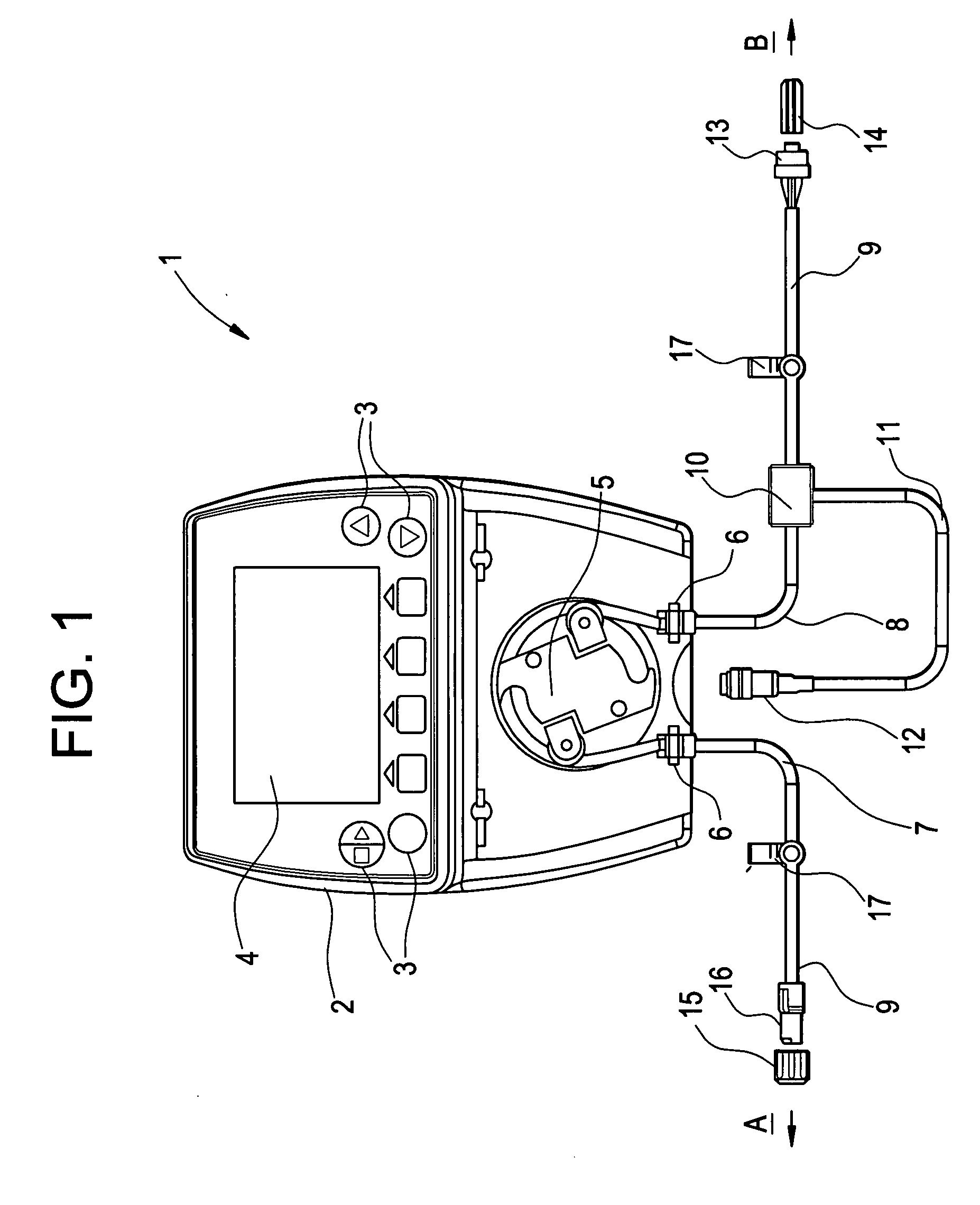

Pressure regulator for infusor

InactiveUS6892755B2Operating means/releasing devices for valvesMedical devicesInfusion setInlet pressure

An improved ambulatory infusion device for dispensing a fluid into a patient includes a flexible bladder enclosure having a first open end a closed second end. The closed second end of the sheath is free to conform to the body of the patient so that the device is comfortable when worn. In other aspects, a pressure regulator of the device is adapted to maintain the outlet pressure within a predetermined range of pressures so that the fluid flow rate is substantially constant during fluid flow. A flow restrictor of the device is formed of flexible tubing.An ambulatory infusion device for dispensing a fluid at a predetermined fluid flow rate includes an elastic bladder having an interior volume for storing the fluid under pressure and an opening for dispensing the fluid. A pressure regulator is in fluid communication with the opening of the bladder and includes an inlet for receiving fluid from the bladder at an inlet pressure and an outlet for discharging the fluid at a predetermined outlet pressure. A valve at the inlet has a hemispheric-shaped head adapted to cooperate with a frustoconic-shaped seat to promote uniform fluid flow therebetween. A movable diaphragm is connected to the valve, and a valve plate opposite a surface of the diaphragm has channels or texture therein. The diaphragm and the valve are movable in response to the fluid pressure acting on the diaphragm surface.

Owner:BAXTER INT INC

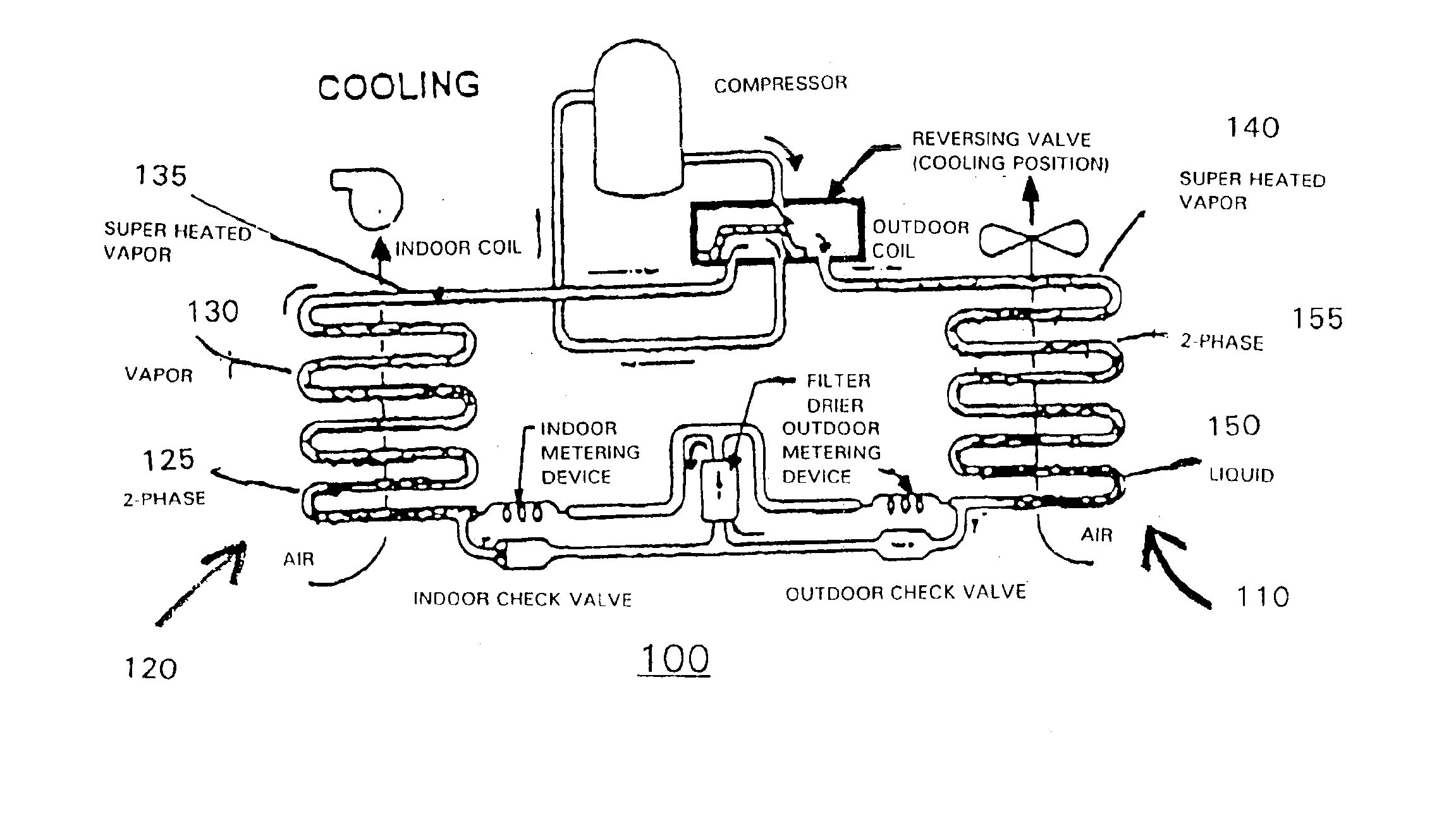

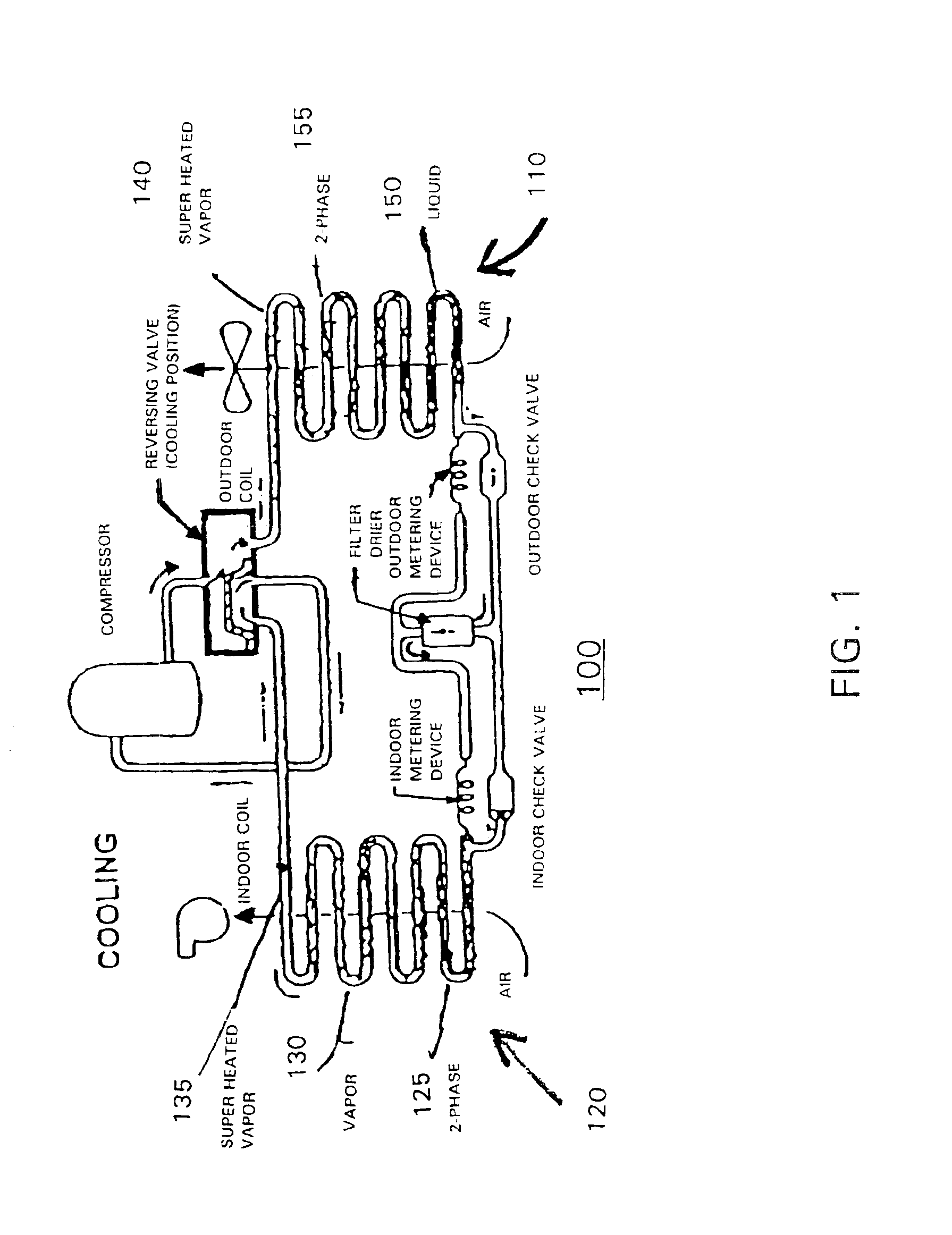

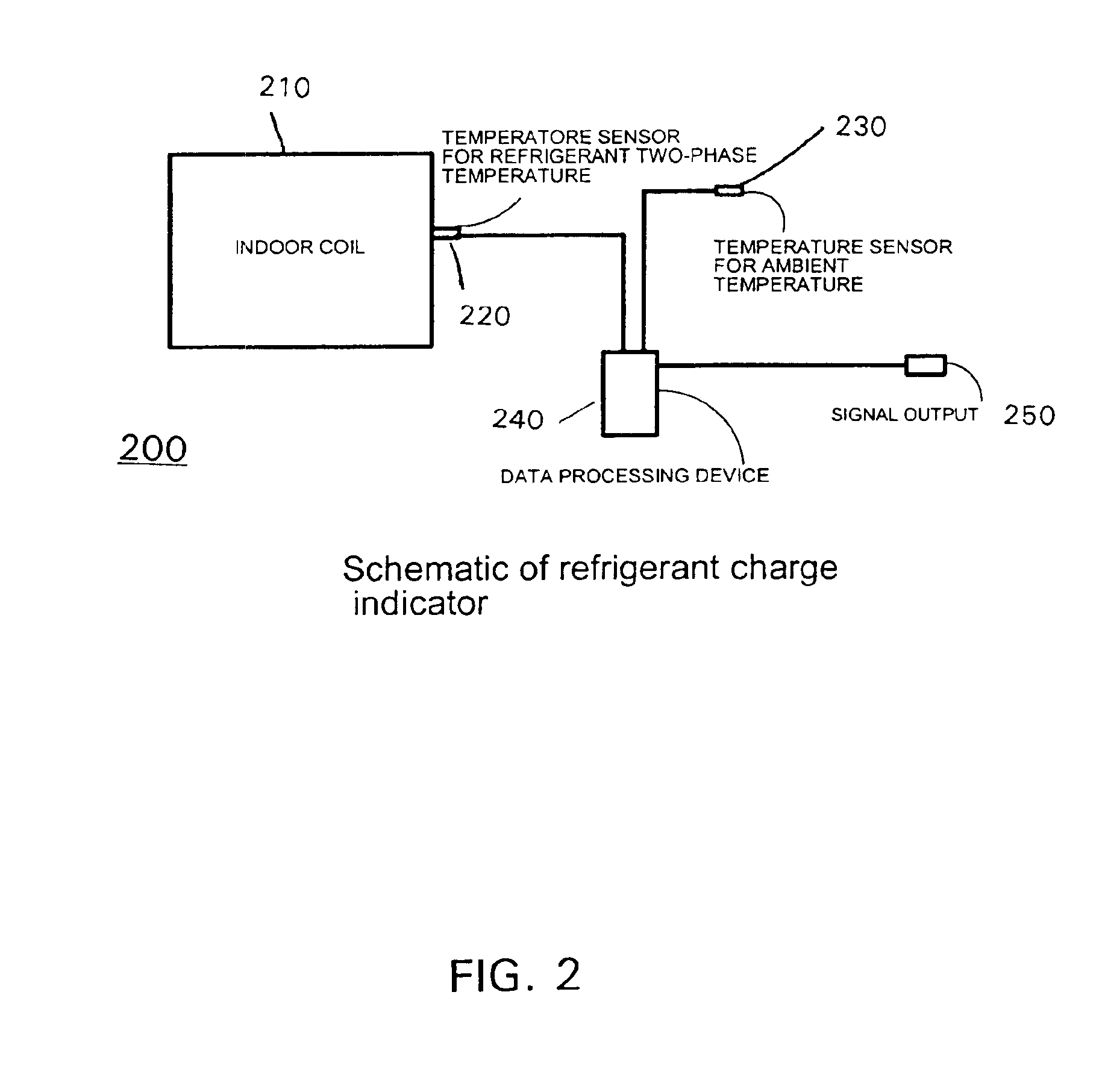

Non-intrusive refrigerant charge indicator

A non-intrusive refrigerant charge level indicator includes a structure for measuring at least one temperature at an outside surface of a two-phase refrigerant line section. The measured temperature can be used to determine the refrigerant charge status of an HVAC system, and can be converted to a pressure of the refrigerant in the line section and compared to a recommended pressure range to determine whether the system is under-charged, properly charged or over-charged. A non-intrusive method for assessing the refrigerant charge level in a system containing a refrigerant fluid includes the step of measuring a temperature at least one outside surface of a two-phase region of a refrigerant containing refrigerant line, wherein the temperature measured can be converted to a refrigerant pressure within the line section.

Owner:UT BATTELLE LLC

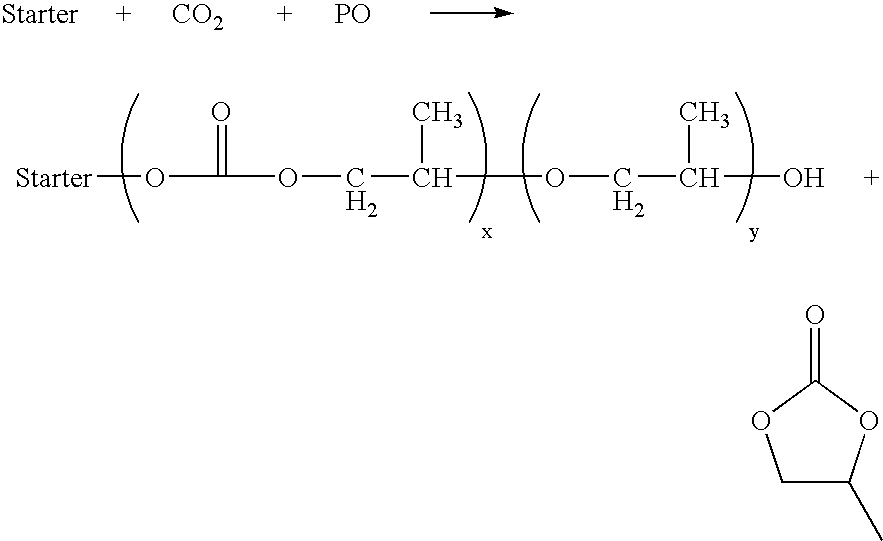

Polyether carbonate polyols made via double metal cyanide (DMC) catalysis

ActiveUS20080021154A1Lower Level RequirementsOrganic chemistryPharmaceutical non-active ingredientsElastomerAdhesive

The present invention relates to a polyether carbonate polyol made by copolymerizing a starter molecule with carbon dioxide, at a pressure ranging from about 10 psia to about 2,000 psia, and an alkylene oxide, at a temperature ranging from about 50° C. to about 190° C. and in the presence of from about 0.001 wt. % to about 0.2 wt. % of a substantially non-crystalline double metal cyanide (DMC) catalyst, wherein the polyol has an incorporated carbon dioxide content of from about 1 wt. % to about 40 wt. %, wherein the ratio of cyclic carbonate by-product to total carbonate is less than about 0.3 and wherein the weight percentages are based on the weight of the polyol. The inventive polyether carbonate polyols may find use in producing polyurethane foams, elastomers, coatings, sealants and adhesives with improved properties.

Owner:COVESTRO LLC

Drainage system for cerebrospinal fluid

ActiveUS20080033400A1The structure is easy to operateImprove accuracyFluid parameterWound drainsControl mannerEngineering

The object of providing a cerebrospinal fluid drainage system 1 which reacts precisely to changes in pressure in the cerebrospinal fluid, with ease of operation, is achieved by the present invention in that a pump 5 is used for draining the cerebrospinal fluid (liquor), wherein operating measured values supplied by sensors act as controlled variable for the operation of the pump. The pressure in the liquor line currently measured by a pressure sensor 10, the liquor pressure in the intracranial cavity being treated, measured intracorporeally by a pressure sensor, and / or the volume of liquor already pumped out, as operating measured value, can, for example, serve as the basis for operational control of the pump of the liquor drainage system. The liquor drainage system according to the invention has the advantage that the liquor is drained not only simply on the basis of the excess pressure in the intracranial cavity being treated, but is actively pumped out of the intracranial cavity in a controlled manner, in particular with constant measurement of the liquor pressure. In this way the pumping capacity can be regulated depending on requirement and the drainage pressure or the liquor pressure kept reliably within a specific pressure range.

Owner:MOLLER MEDICAL

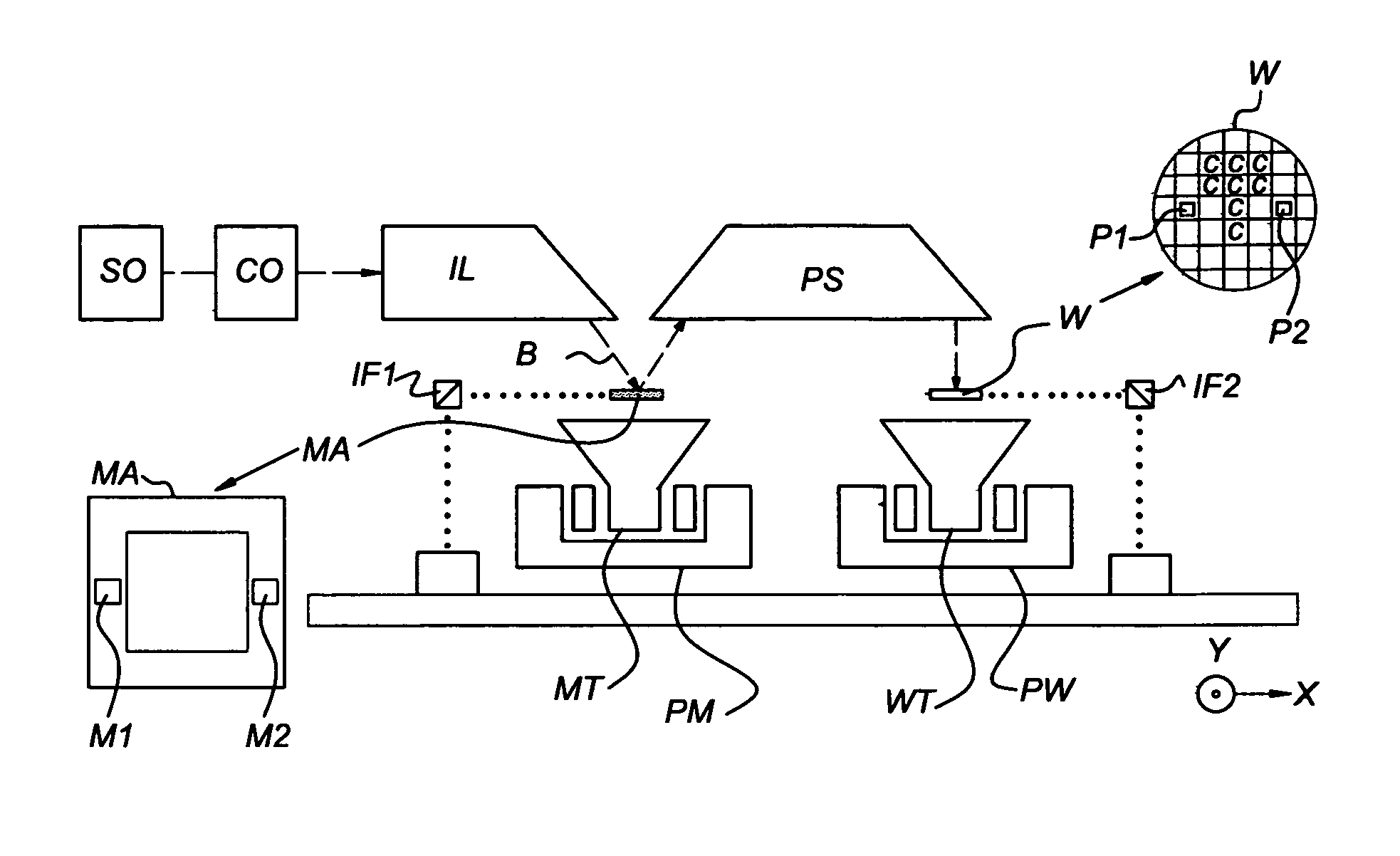

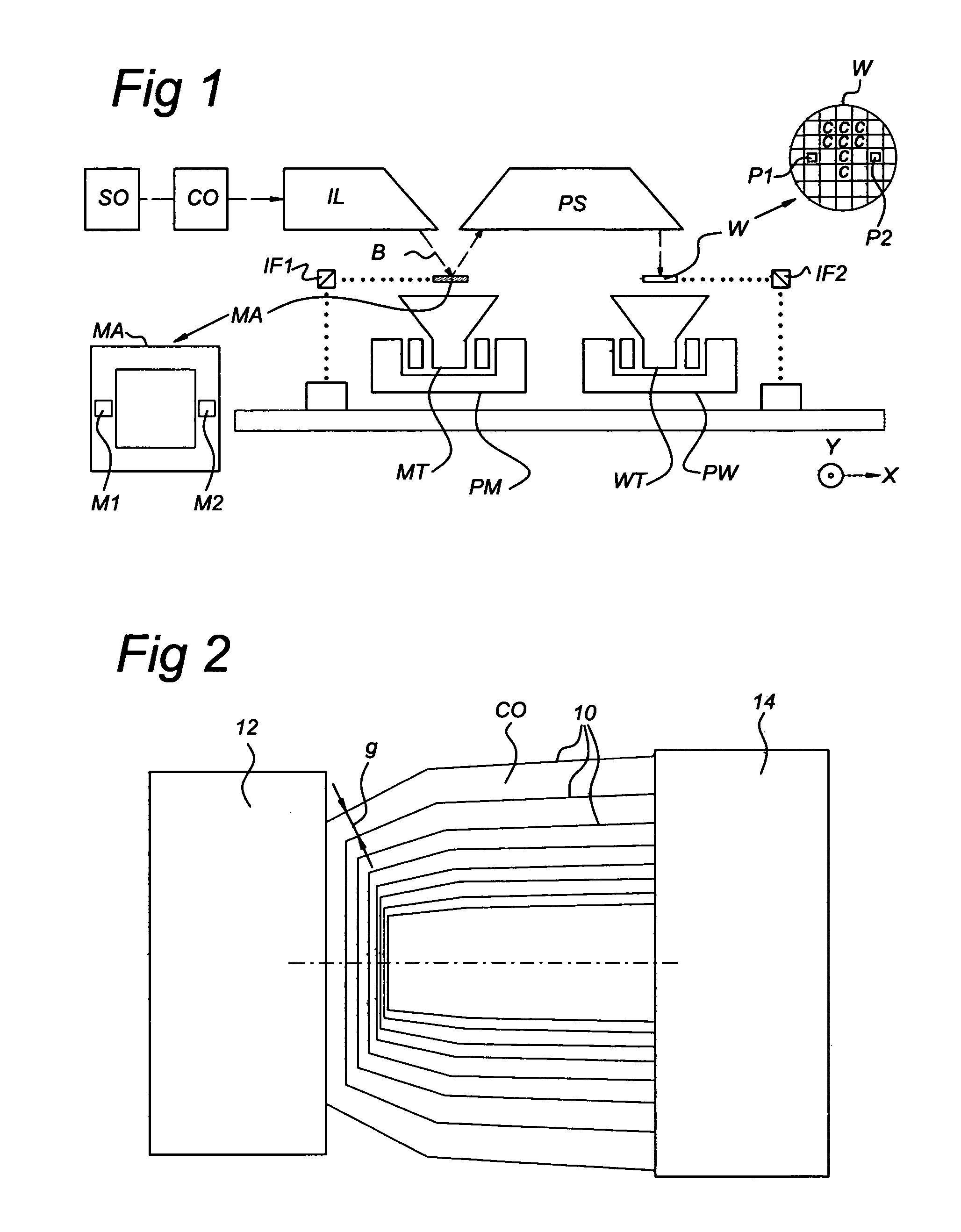

Radical cleaning arrangement for a lithographic apparatus

ActiveUS7462850B2Easy to handleRestore reflectivityRadiation pyrometryPhotomechanical apparatusEngineeringHydrogen consumption

A cleaning arrangement is configured to clean an EUV optic of an EUV lithographic apparatus. The partial radical pressure ranges between 0.1-10 Pa. The cleaning arrangement can be configured inside a cleaning cocoon of the lithographic apparatus for offline cleaning. It can also be configured at particular positions inside the apparatus to clean nearby optics during production. In the pressure range of 0.1-10 Pa the penetration of atomic hydrogen into the optical devices is high, while the recombination to molecular hydrogen and hydrogen consumption is limited.

Owner:ASML NETHERLANDS BV

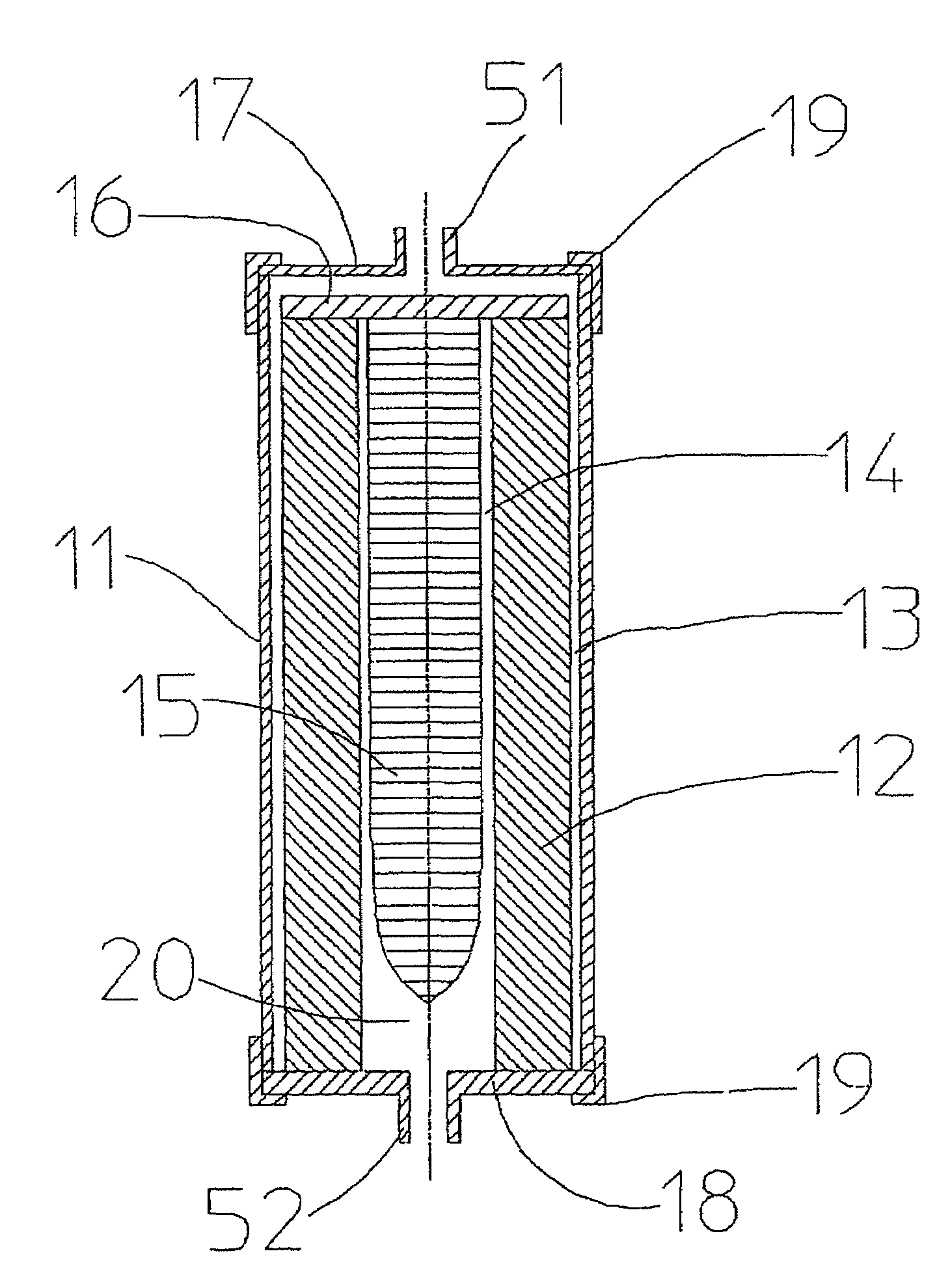

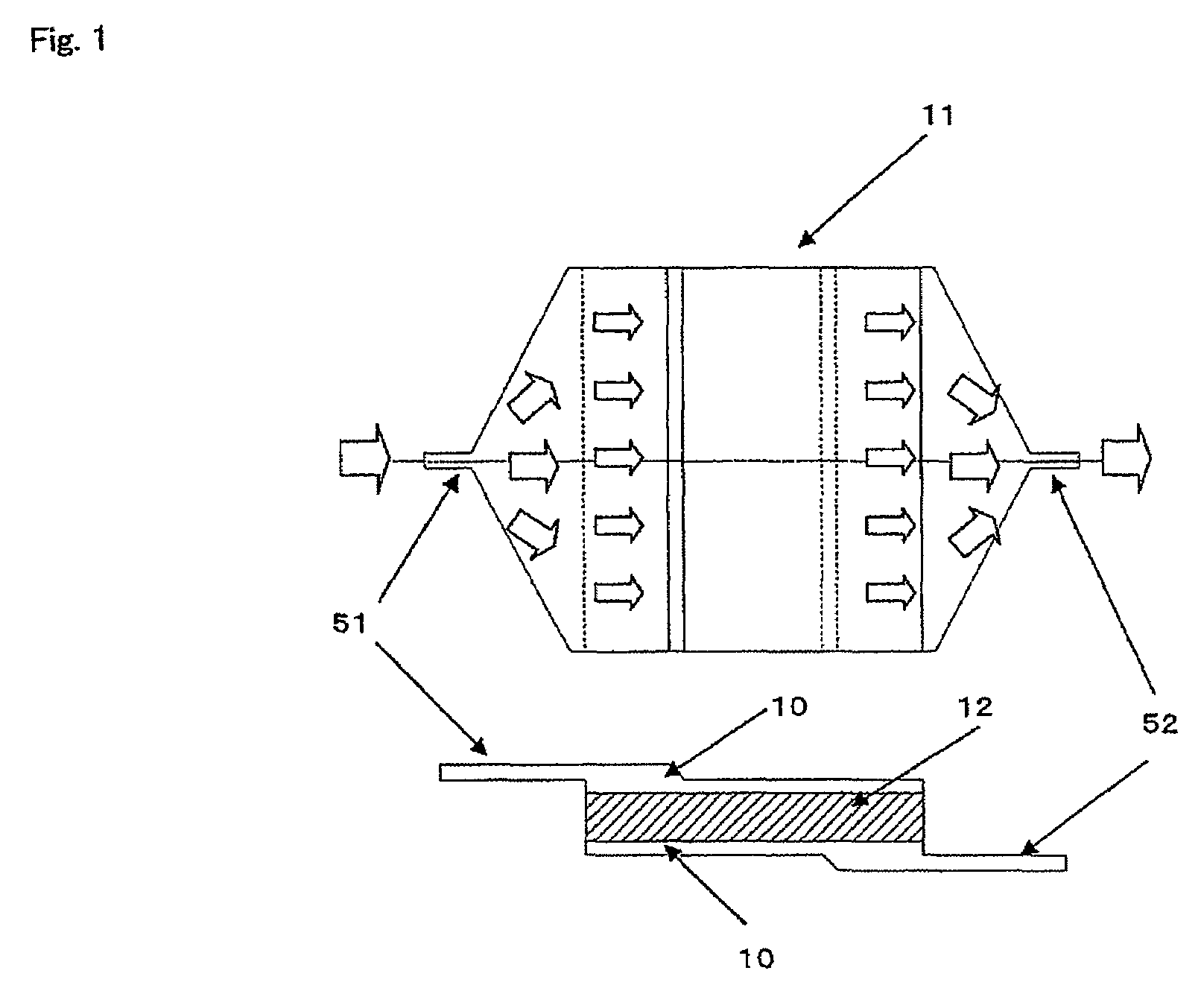

Body fluid treating filter device

ActiveUS20090078636A1Excellent body fluid recovery performanceDialysis systemsFiltration separationInterior spaceBody fluid

A body fluid treating filter device capable of maintaining its treating pressure within a clinically safe pressure range even if body fluid treatment is performed over a long period and having excellent property for recovering a body fluid after the body fluid treatment is completed. A body fluid treating cylindrical filter layer is stored in a cylindrical container having two body fluid flow ports. The cylindrical filter layer is disposed so that the inner space of a container can be divided into two parts by making its both end parts fluid-tight and fixing at least one of these both end parts to the inner wall surface of the container. One of the inner spaces of the container divided by the cylindrical filter layer is allowed to communicate with the first body fluid flow port and the other of the inner spaces of the container divided by the cylindrical filter layer is allowed to communicate with the second body fluid flow port. The body fluid treating cylindrical filter device is characterized in that a bar-like flow passage resistant member extending along the center axis is installed in the hollow part of the cylindrical filter layer, and a spacer layer for flowing the body fluid of 0.7 to 3.5 mm in thickness is formed between the outer peripheral surface of the cylindrical filter layer and the container and between the inner peripheral surface of the cylindrical filter layer and the flow passage resistance member.

Owner:ASAHI KASEI MEDICAL CO LTD

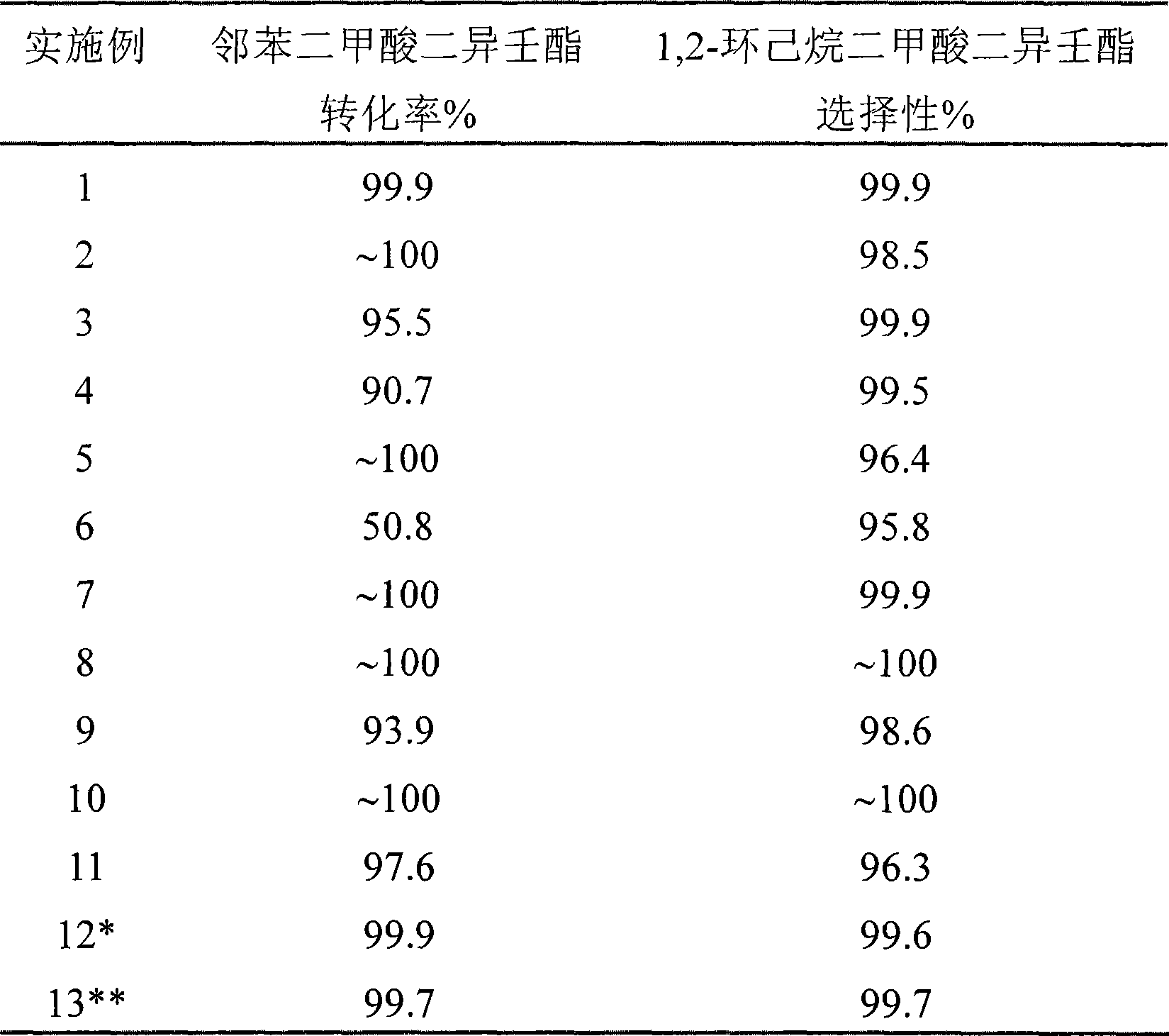

Method for preparing 1,2-cyclohexane cyclohexanedimethanol dibasic ester

ActiveCN101417950AHigh selectivityLow reaction pressureOrganic compound preparationCarboxylic acid esters preparationReaction temperatureDibasic ester

The invention relates to a method for preparing 1, 2-cyclohexanedicarboxylic acid ester of binary, comprising a reaction system composed by binary phthalate ester, hydrogen and a catalyst; the reaction temperature ranges from 100 to 250 DEG C; the reaction pressure ranges from 3.0 to 12.0 Mpa; the molar ratio of H2 and X ranges from 50 to 450; the liquid space velocity of binary phthalate ester ranges from 0.1 to 2.5 h<-1>; the catalyst uses Al2O3, ZrO2, TiO2 or SiO2-Al2O3 as vehicle, and load active component can be Ru, Pt, Pd, Rh, Fe, Co, Ni and Cu; the binary phthalate ester is diisonynol phthalate, diisooctyl phthalate or dibutyl phthalate; the product 1, 2-cyclohexanedicarboxylic acid ester of binary is 1, 2-cyclohexane diisononyl dimethyl ester, 1, 2-cyclohexane diisooctyl dimethyl ester or 1, 2-cyclohexane dibutyl dimethyl ester.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

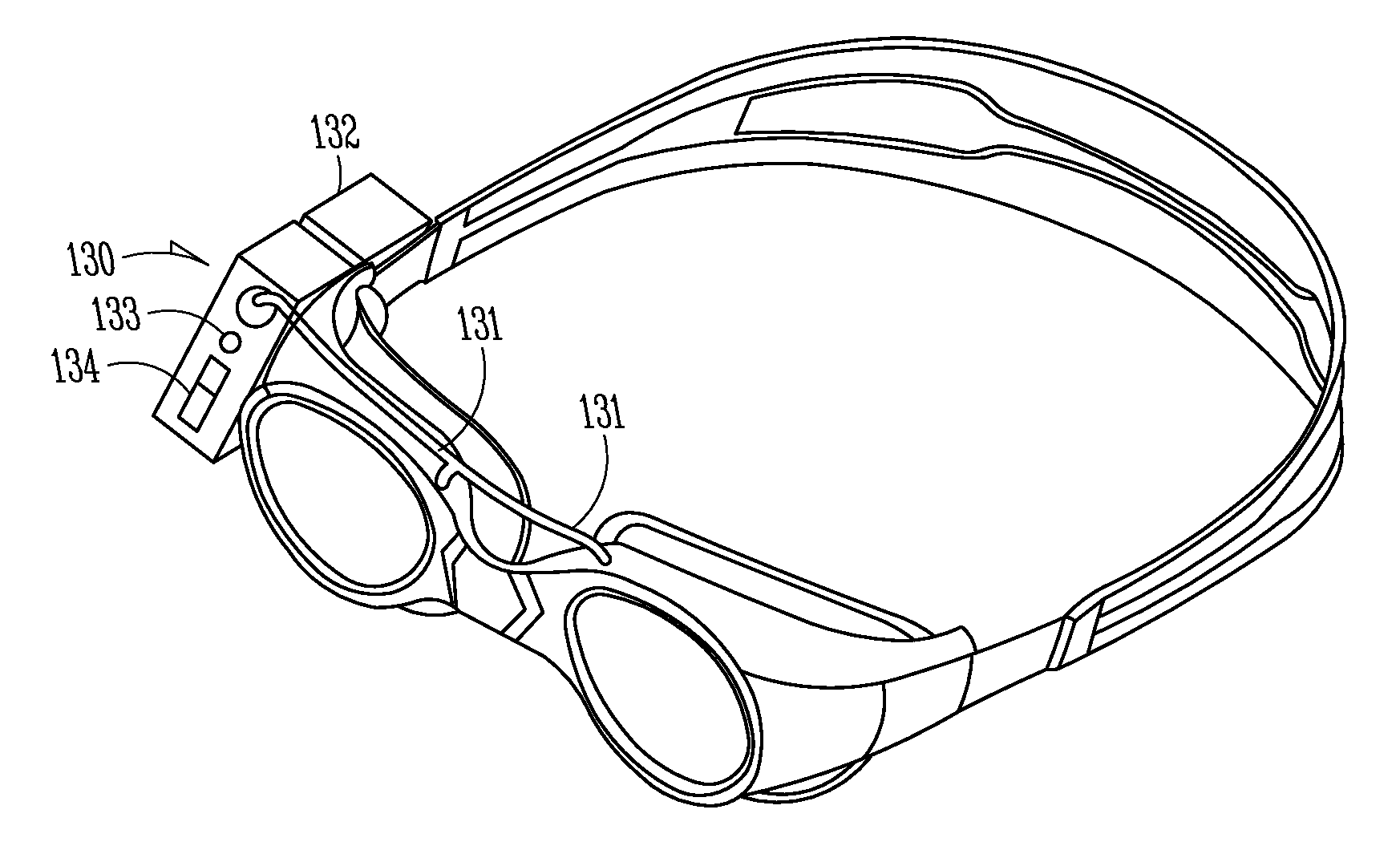

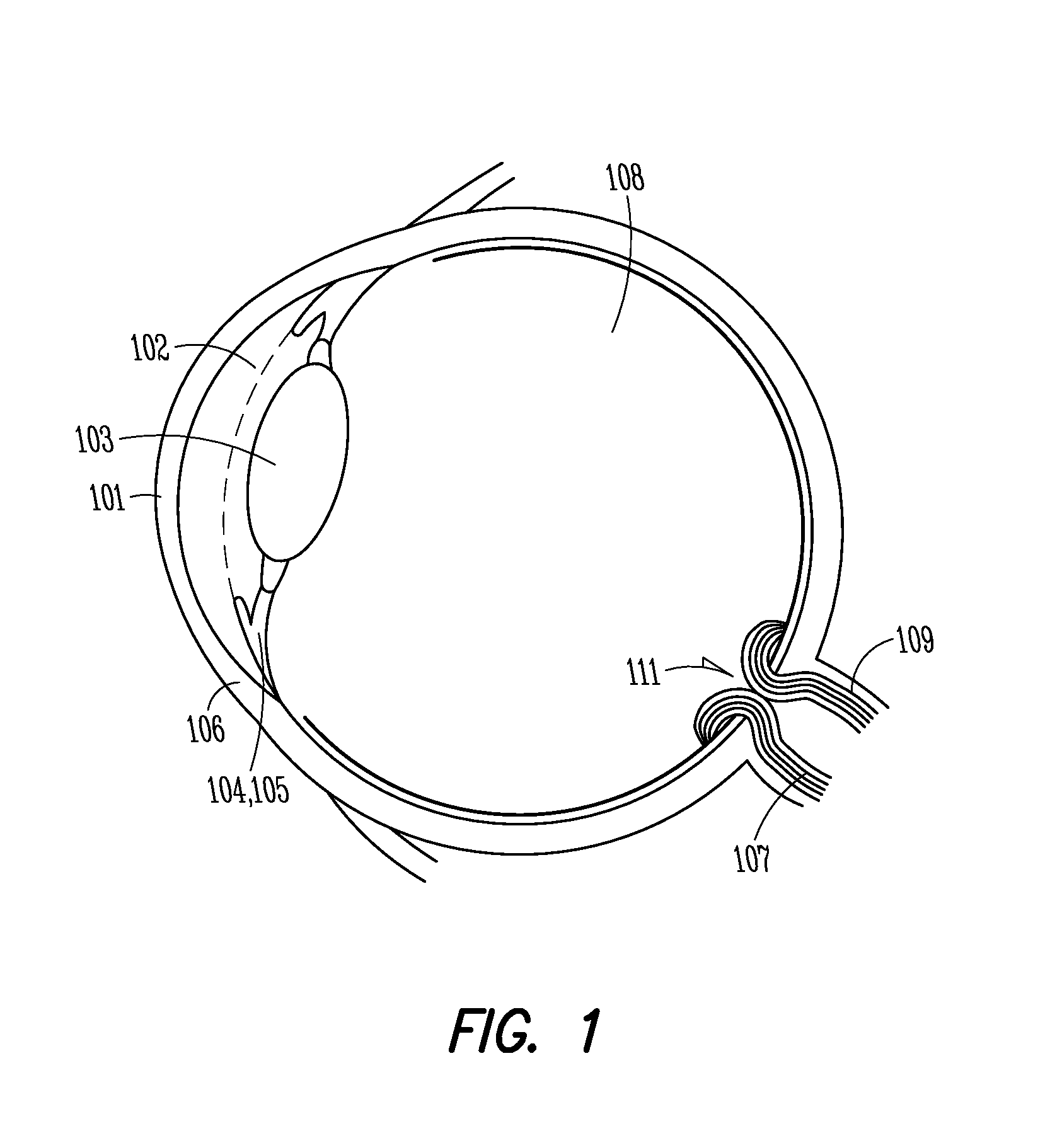

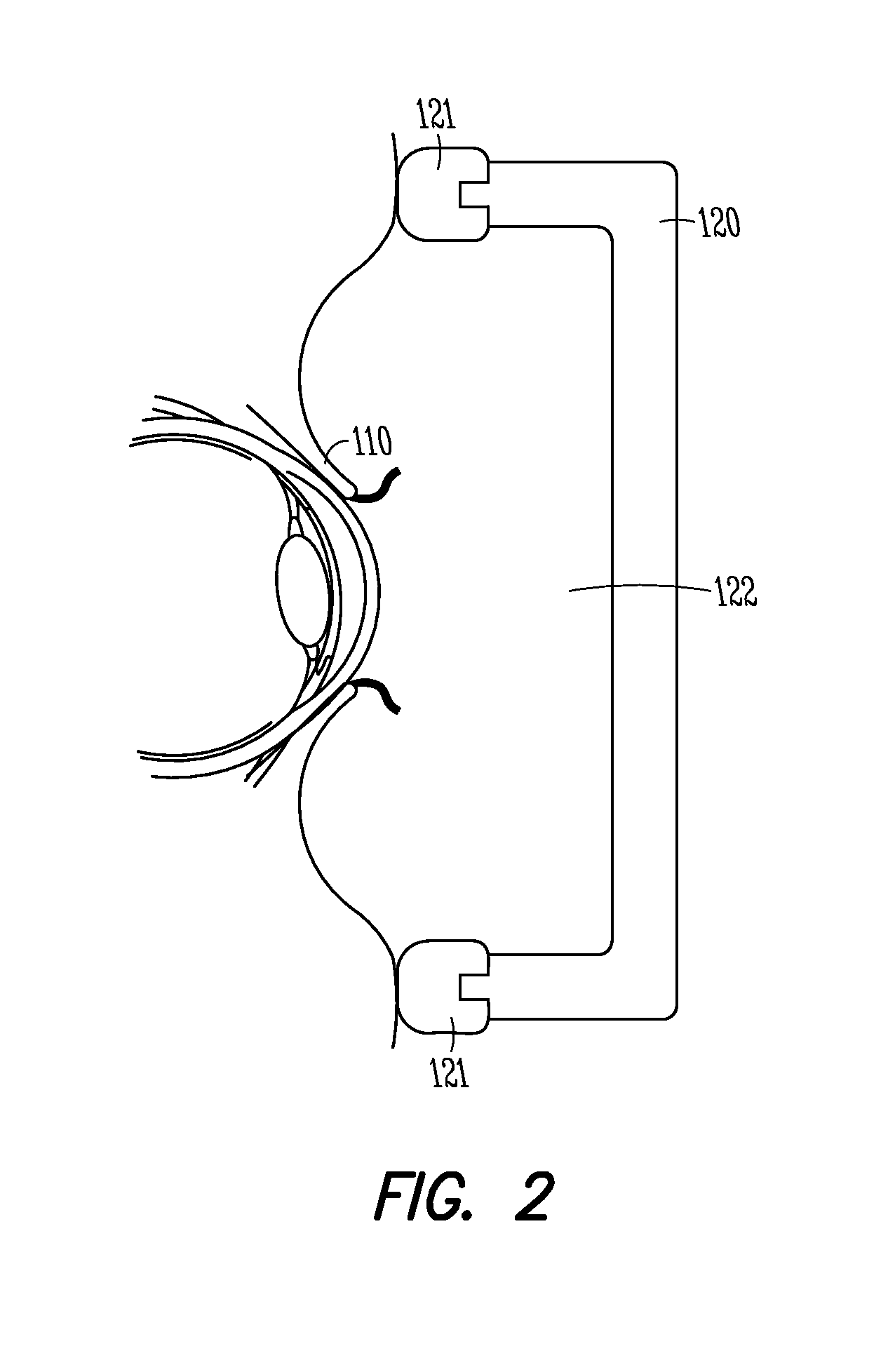

Intraocular pressure modification

ActiveUS20130238015A1Easy to createMinimize timeGogglesNon-surgical orthopedic devicesIIH - Idiopathic intracranial hypertensionHigh intraocular pressure

Assemblies and methods for modifying an intraocular pressure of a patient's one or both eyes are disclosed. The assemblies and methods can be used to treat, inhibit, or prevent ocular conditions such as glaucoma, high intraocular pressure, optic disc edema, idiopathic intracranial hypertension, zero-gravity induced papilledema, and other optic pressure related conditions. An assembly can include a goggle including at least one cavity, a pump in fluid communication with the at least one cavity, and a control mechanism. The control mechanism can be operatively coupled to the pump and can maintain a target pressure or target pressure range in the at least one cavity, which, when the assembly is worn by a patient, is the area between a patient's eye(s) and wall surfaces of the goggle. Controlling the pressure over the outer surfaces of the patient's eye(s) can drive a desired change in the intraocular pressure of the eye(s).

Owner:BERDAHL JOHN

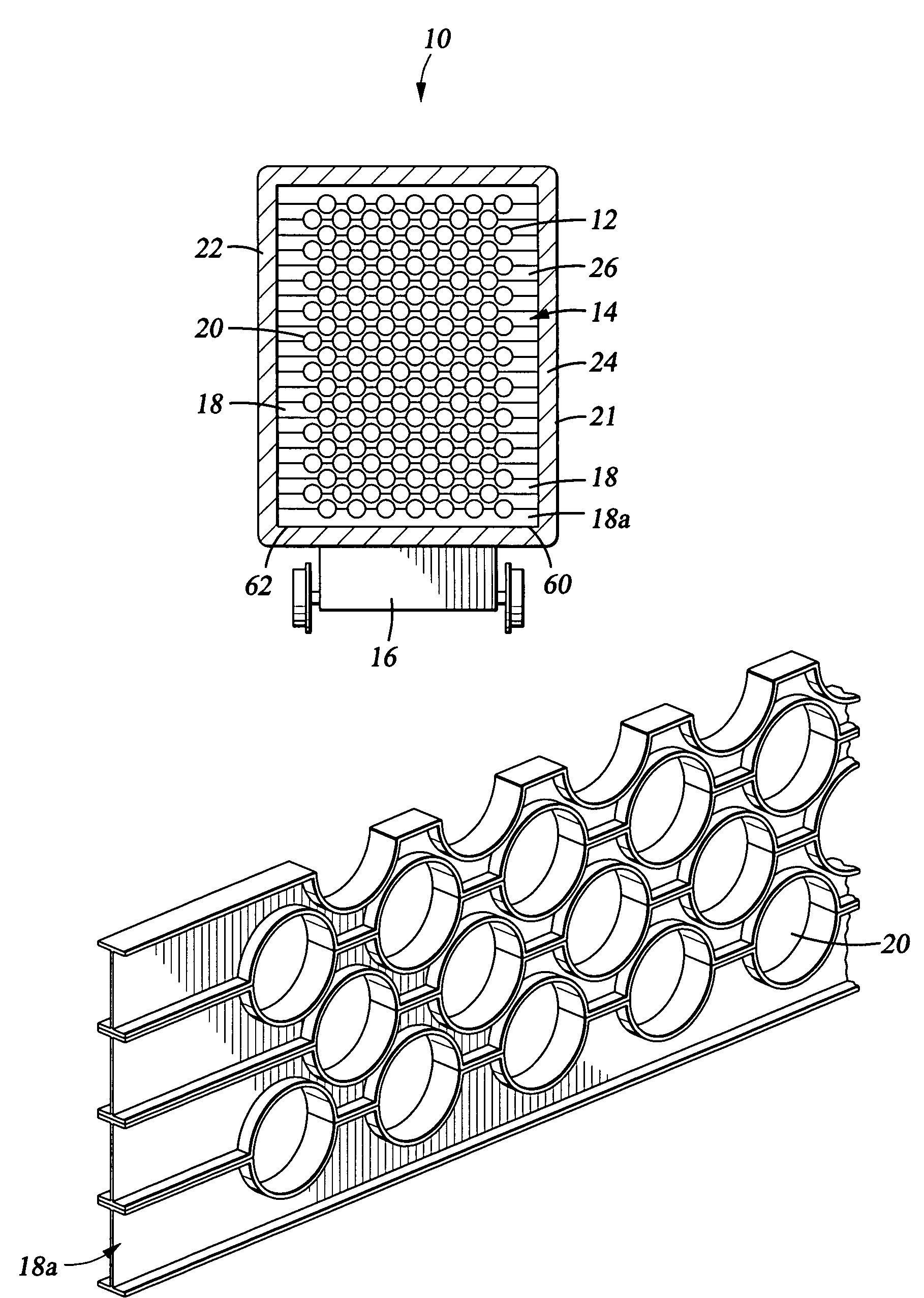

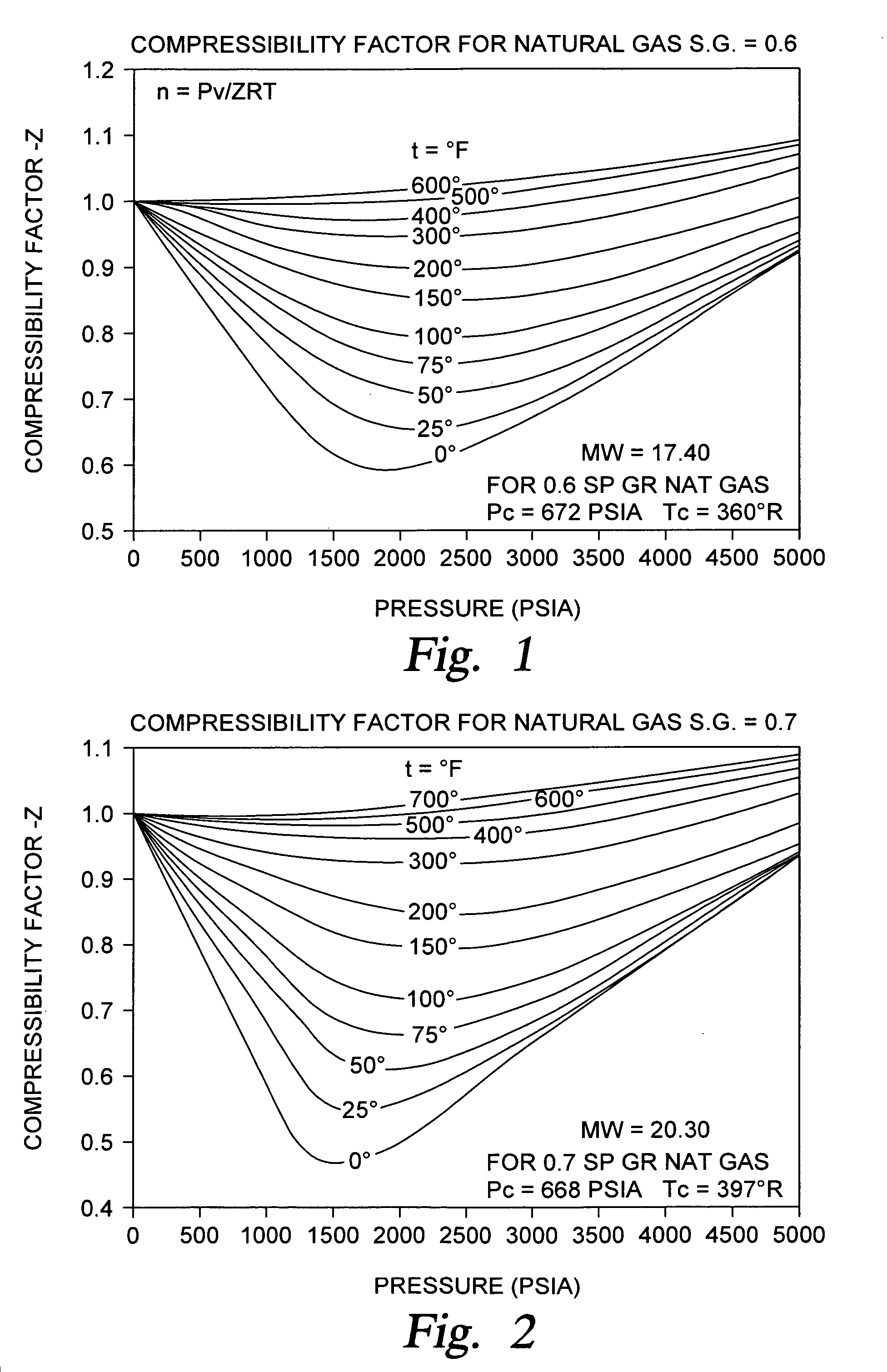

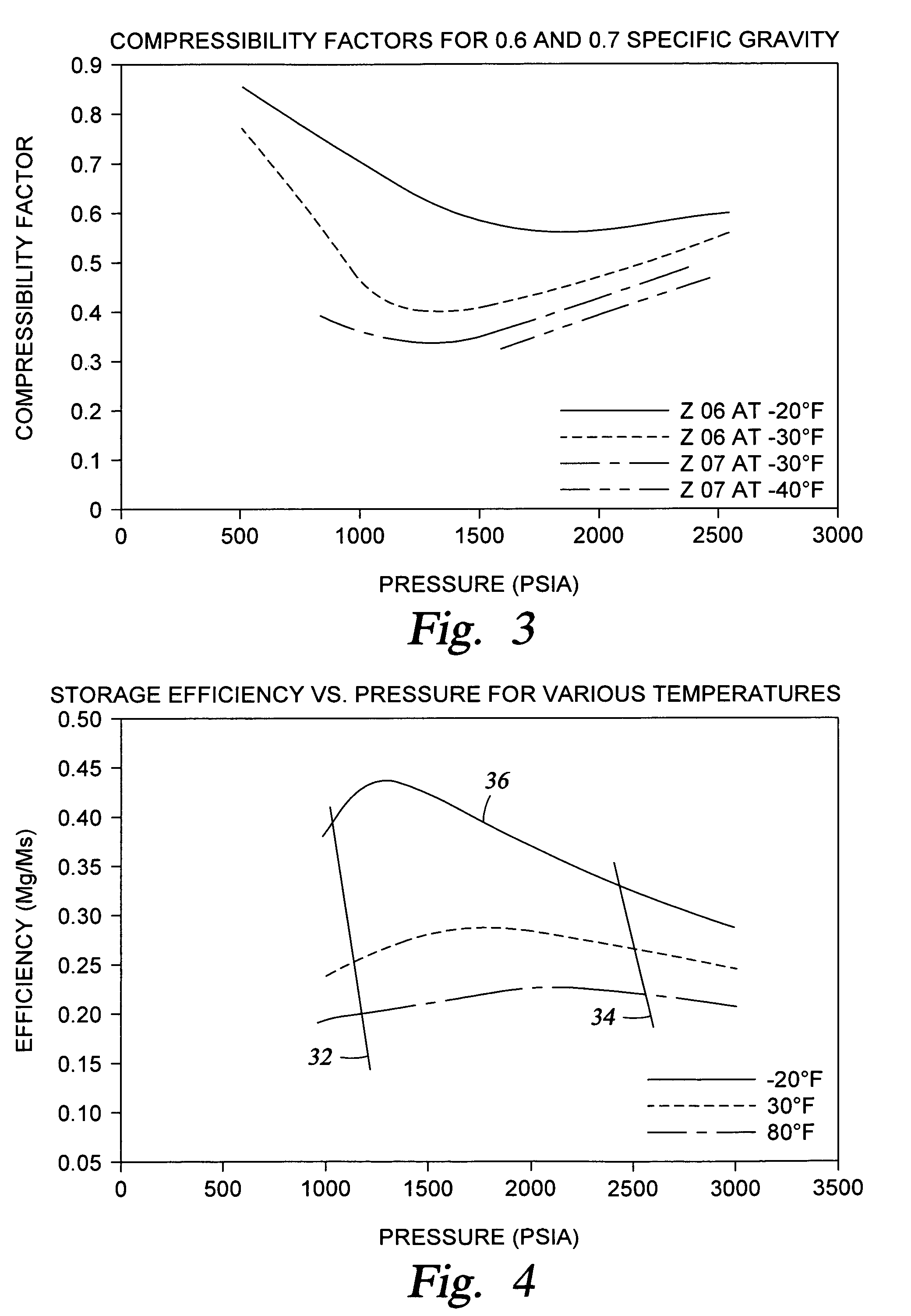

Modular system for storing gas cylinders

InactiveUS6994104B2High procedureIncrease profitabilitySolidificationLiquefactionSystems designGas cylinder

The methods and apparatus for transporting compressed gas includes a gas storage system having a plurality of pipes connected by a manifold whereby the gas storage system is designed to operate in the range of the optimum compressibility factor for a given composition of gas. The pipe for the gas storage system is preferably large diameter pipe made of a high strength material whereby a low temperature is selected which can be withstood by the material of the pipe. Knowing the compressibility factor of the gas, the temperature, and the diameter of the pipe, the wall thickness of the pipe is calculated for the pressure range of the gas at the selected temperature. The gas storage system may either be modular or be part of the structure of a vehicle for transporting the gas. The gas storage system further includes enclosing the pipes in an enclosure having a nitrogen atmosphere. A displacement fluid may be used to offload the gas from the gas storage system. A vehicle with the gas storage system designed for a particular composition gas produced at a given location is used to transport gas from that producing location to a receiving station miles from the producing location.

Owner:ENERSEA TRANSPORT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com