Patents

Literature

691 results about "Hydrogen consumption" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

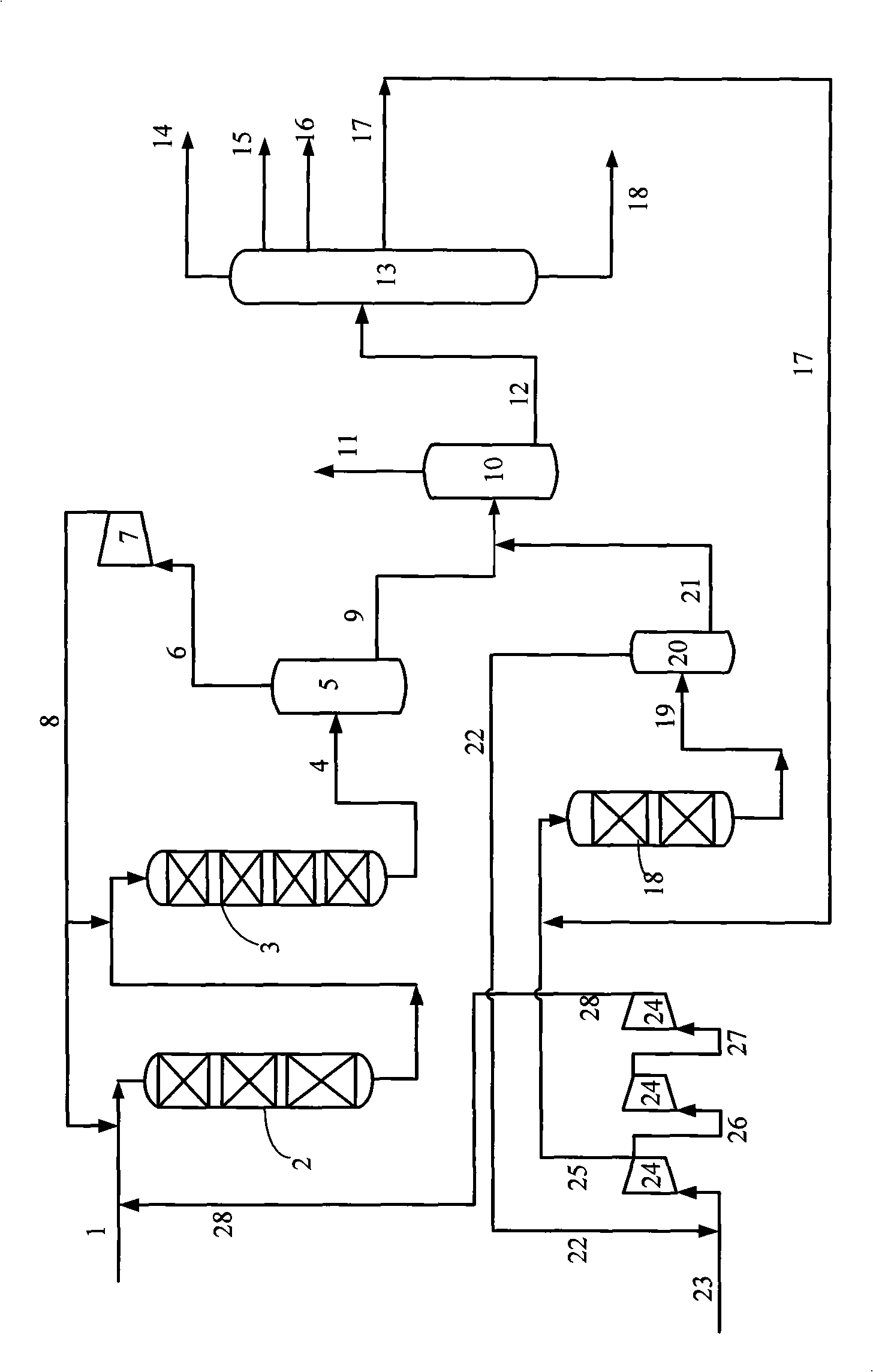

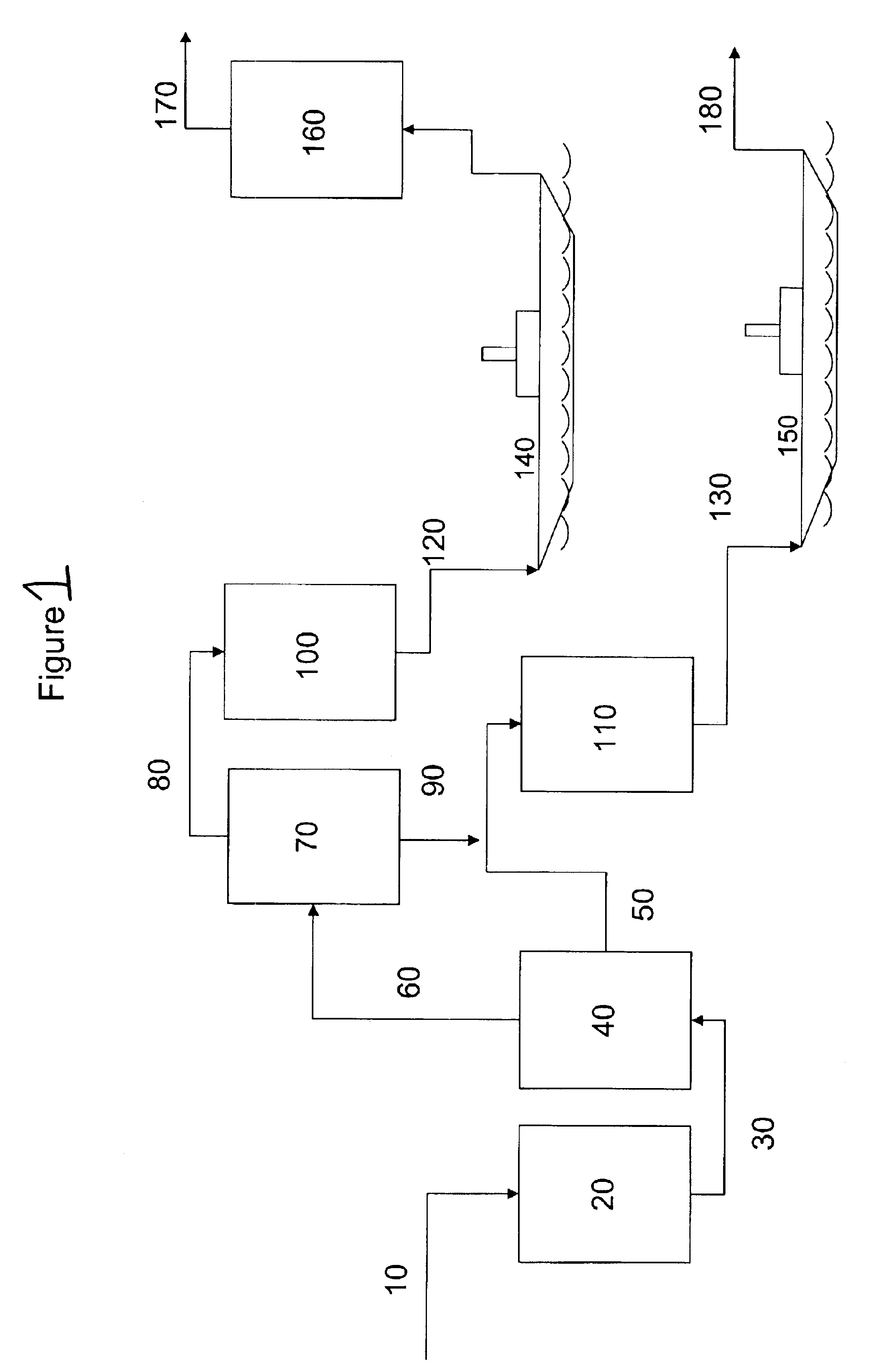

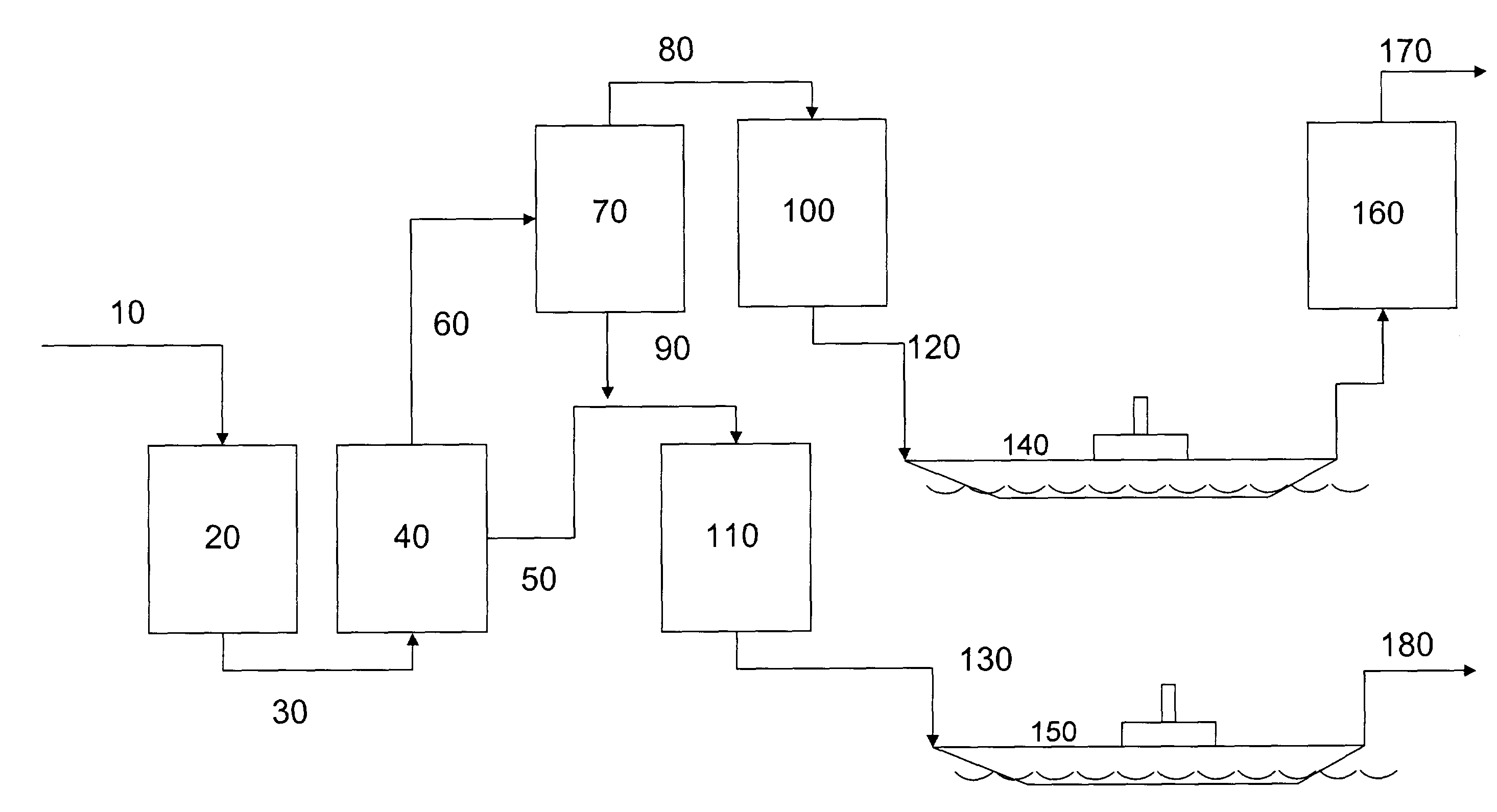

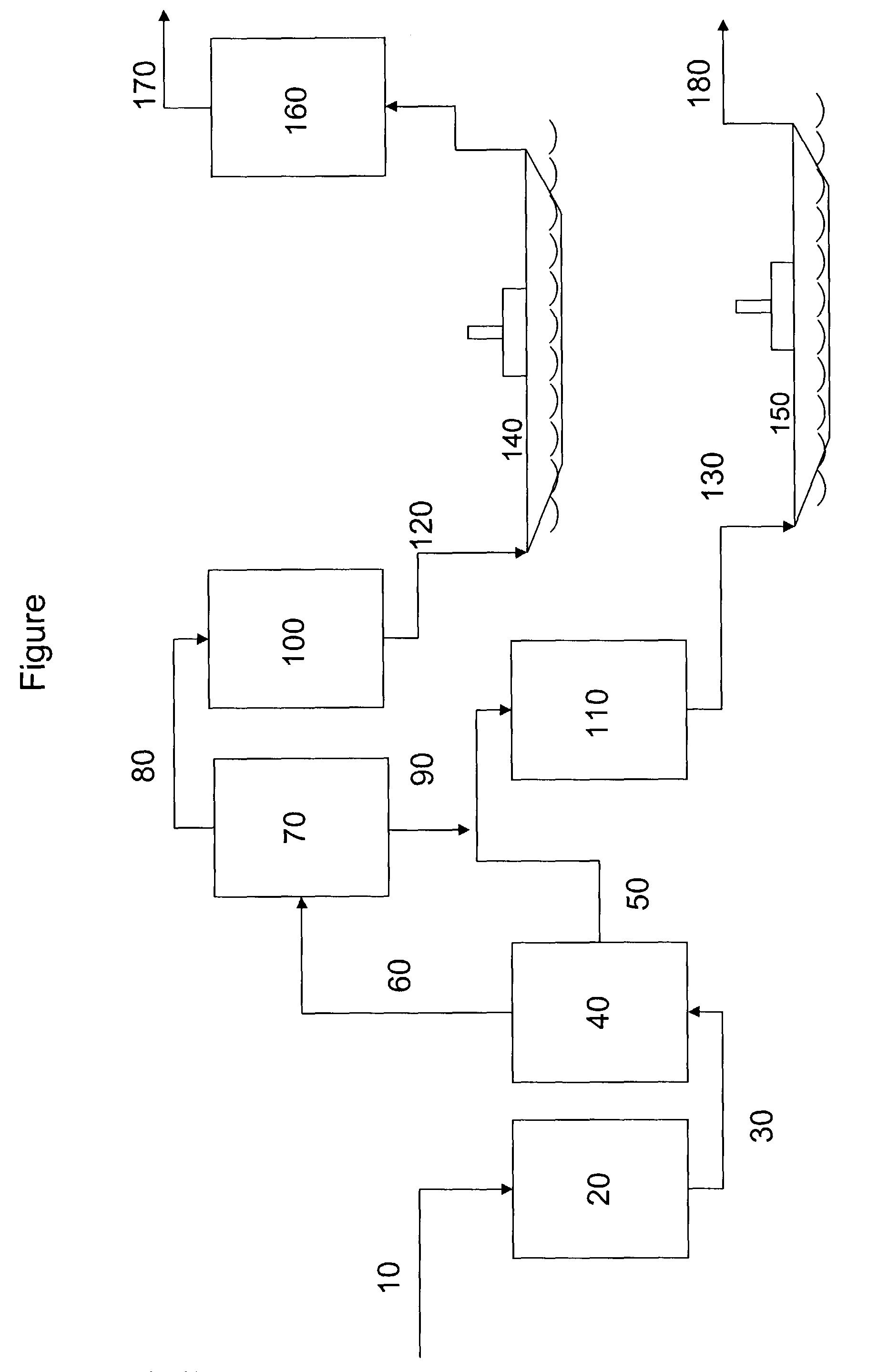

Production of Diesel Fuel from Renewable Feedstocks with Reduced Hydrogen Consumption

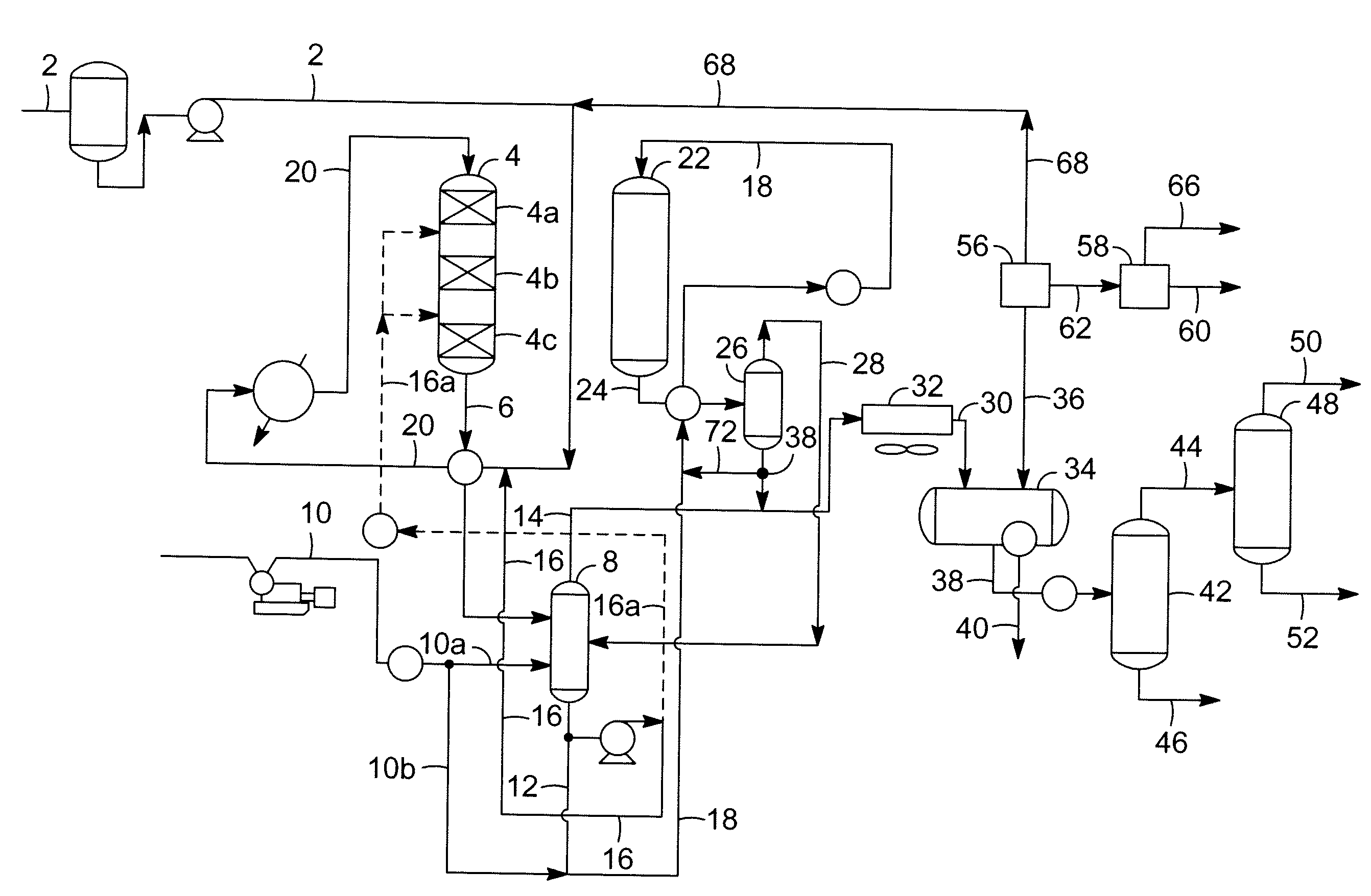

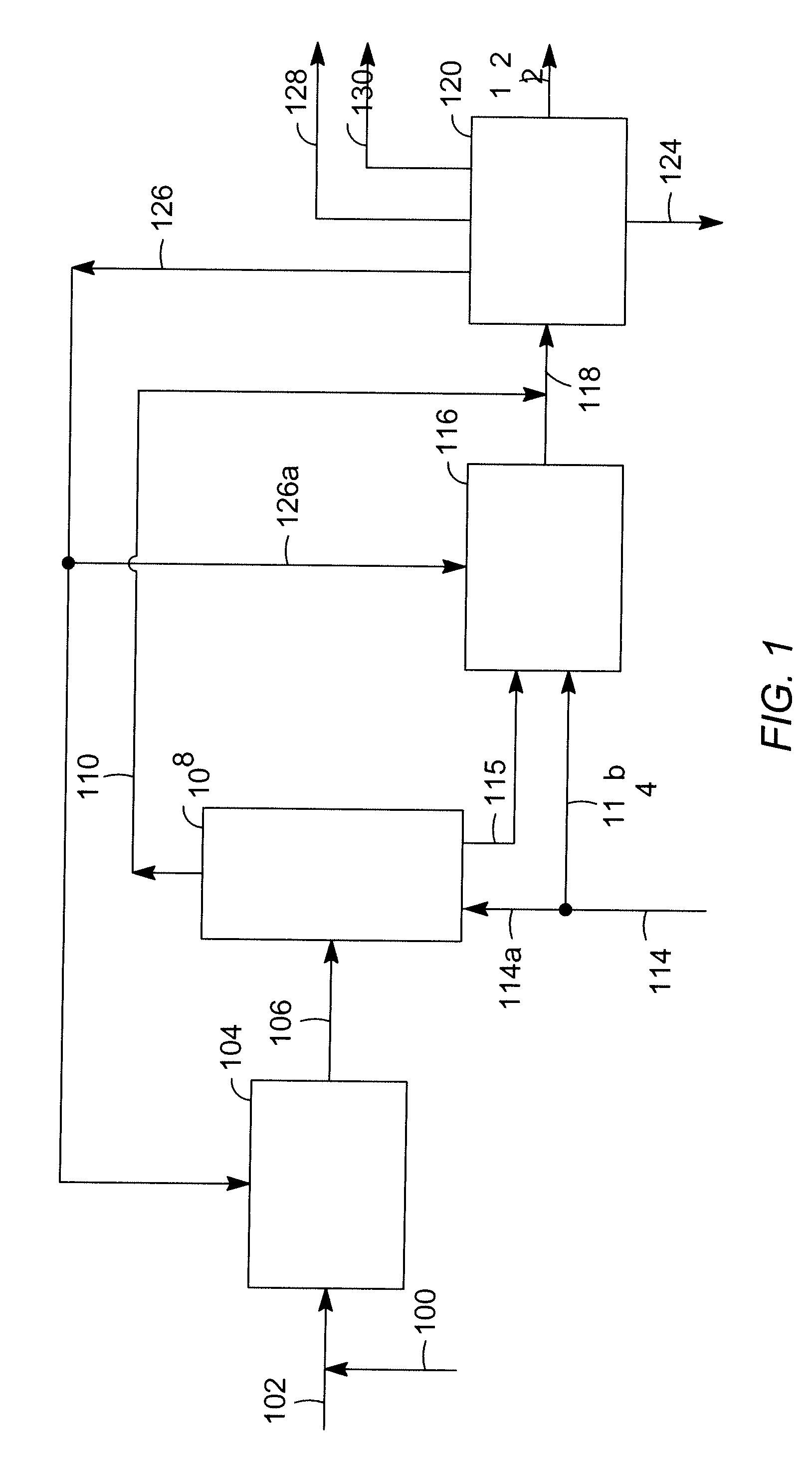

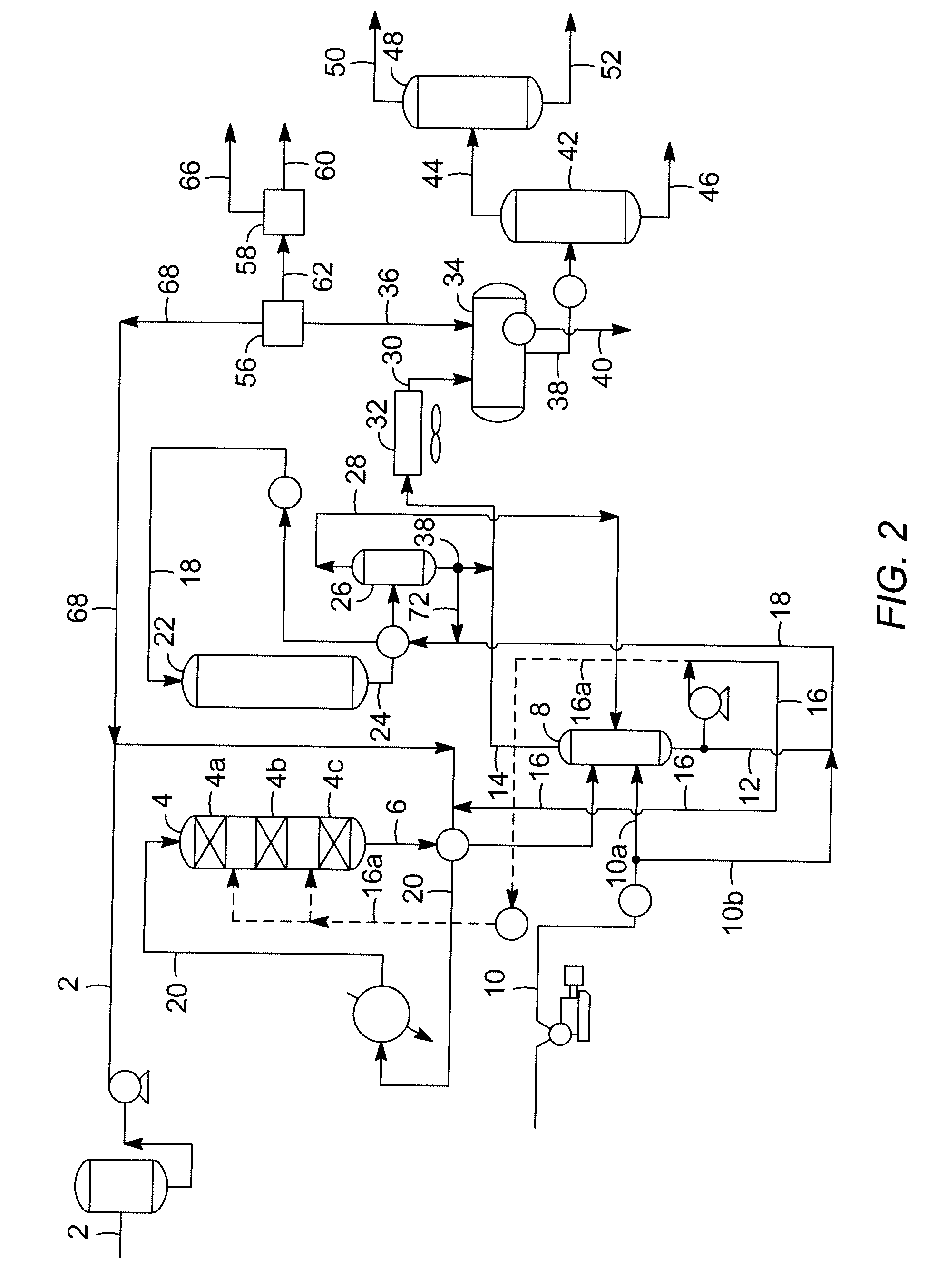

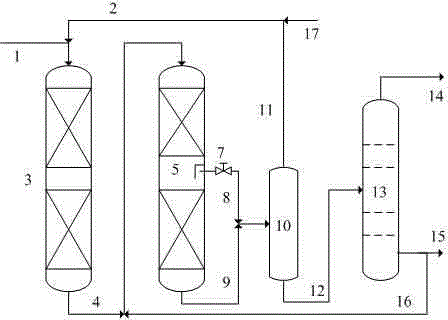

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel. Water is added to the deoxygenation reaction to drive carbon monoxide and water to react to form hydrogen and carbon dioxide. The hydrogen is then consumed by the reactions. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties.

Owner:UOP LLC

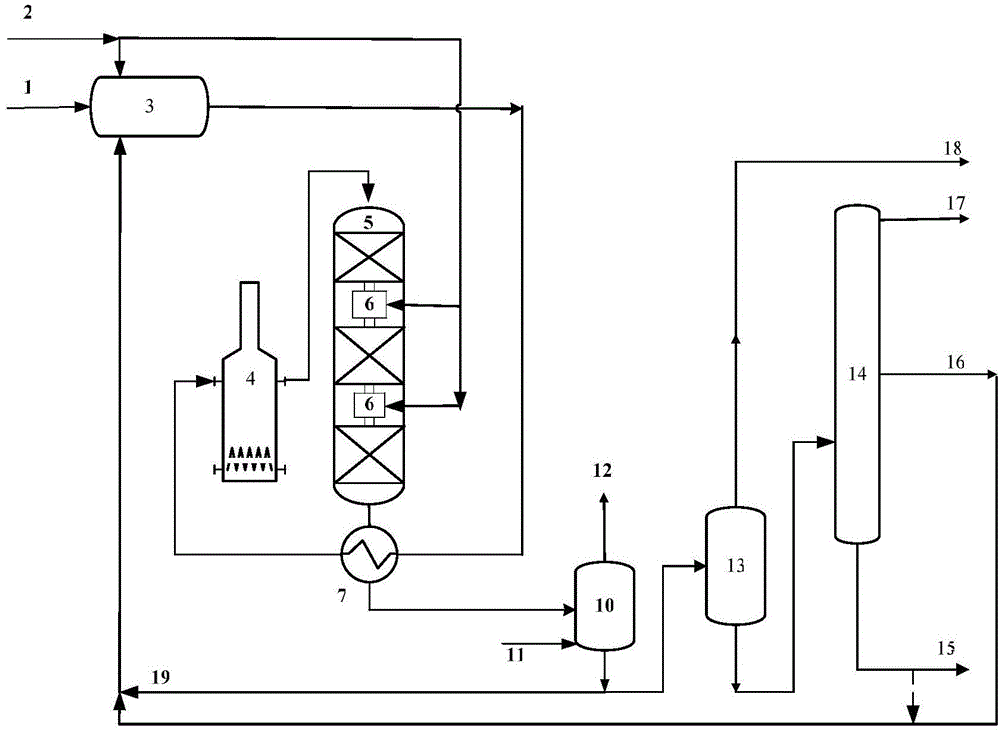

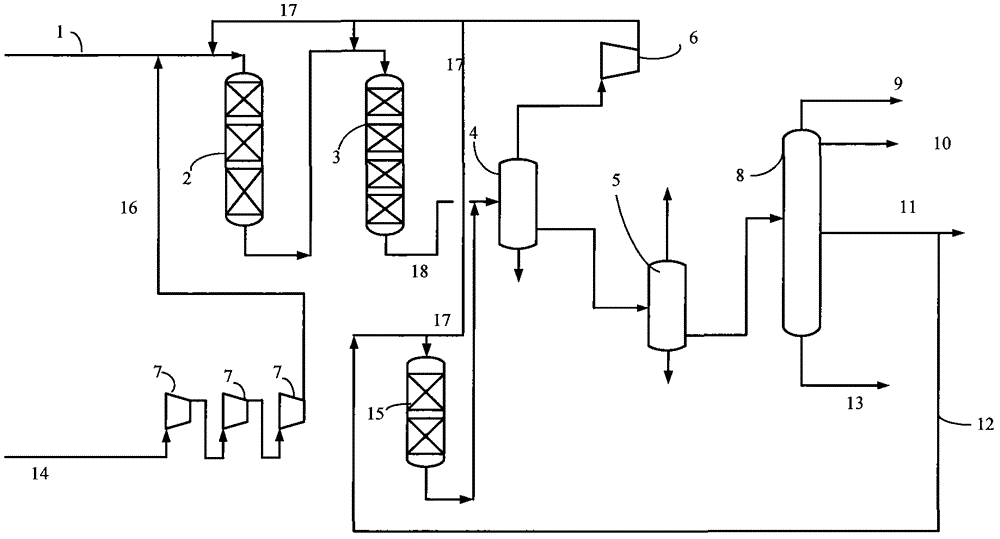

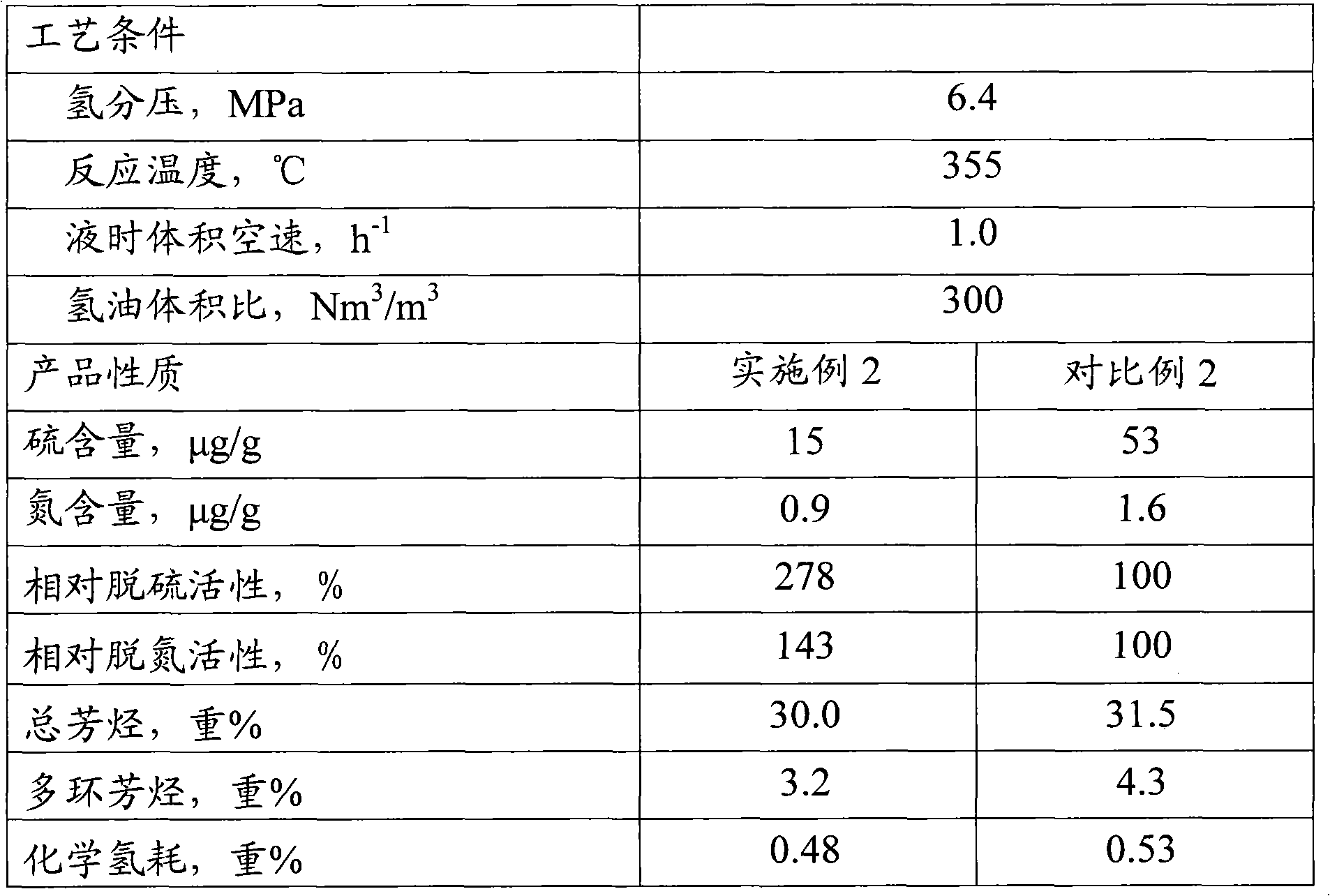

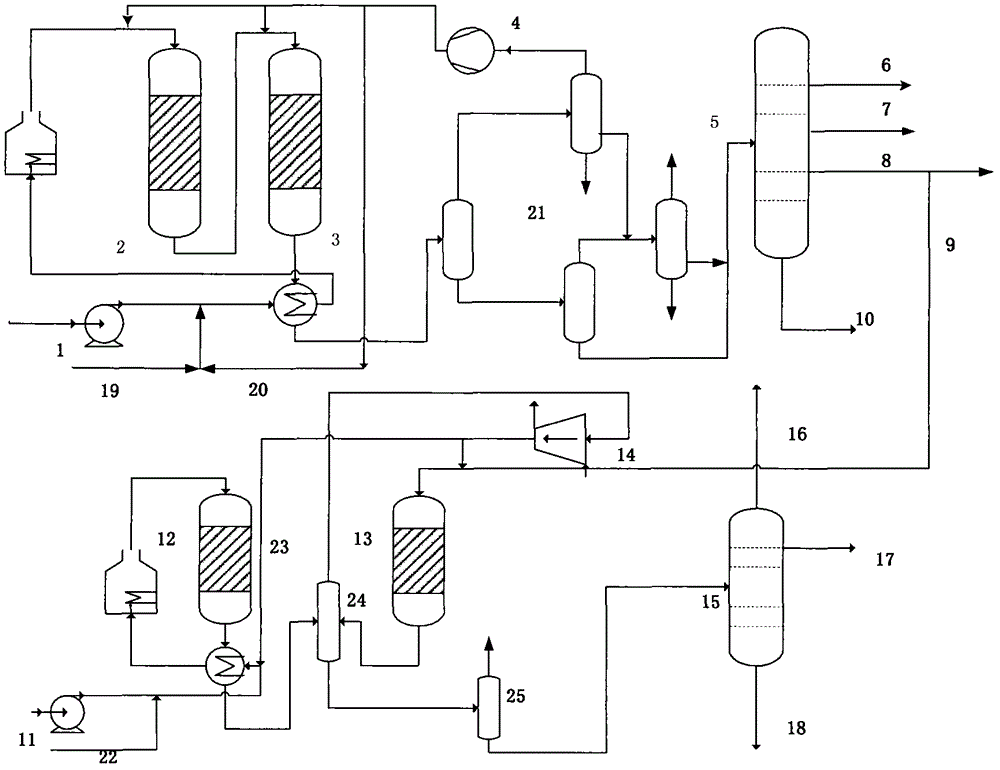

Catalytic cracking diesel fuel hydroconversion method

ActiveCN104611029AReduce hydrogenationHigh yieldTreatment with hydrotreatment processesHydrocarbon oils treatment productsNaphthaPtru catalyst

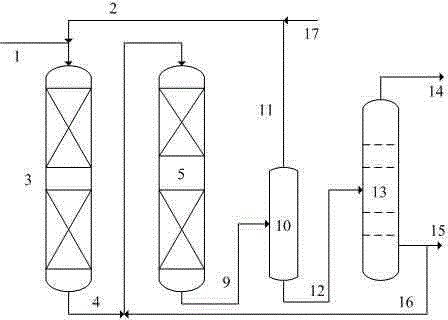

The present invention discloses a catalytic cracking diesel fuel hydroconversion method. According to the method, catalytic diesel fuel and hydrogen are mixed and then enter a hydrorefining reactor to carry out a hydrorefining reaction; the hydrorefining reaction effluent directly enters a hydrocracking reactor and then is subjected to a contact reaction with the grading catalyst bed layer inside the hydrocracking reactor, wherein at least two cracking catalyst bed layers are arranged inside the hydrocracking reactor, and the hydrogenation activity of the hydrocracking catalyst presents the decrease tendency according to the reaction material flowing direction; and the hydrocracking reaction effluent is subjected to separation and fractionation to obtain the naphtha and the diesel fuel. With the method of the present invention, the diesel fuel hydrocracking effect can be ensured while the excessive hydrogenation and the secondary cracking of the naphtha can be reduced and the chemical hydrogen consumption can be reduced so as to increase the octane number and the liquid yield of the naphtha.

Owner:CHINA PETROLEUM & CHEM CORP +1

Production of diesel fuel from renewable feedstocks with reduced hydrogen consumption

A process has been developed for producing diesel boiling range fuel from renewable feedstocks such as plant and animal fats and oils. The process involves treating a renewable feedstock by hydrogenating and deoxygenating to provide a hydrocarbon fraction useful as a diesel boiling range fuel. Water is added to the deoxygenation reaction to drive carbon monoxide and water to react to form hydrogen and carbon dioxide. The hydrogen is then consumed by the reactions. If desired, the hydrocarbon fraction can be isomerized to improve cold flow properties.

Owner:UOP LLC

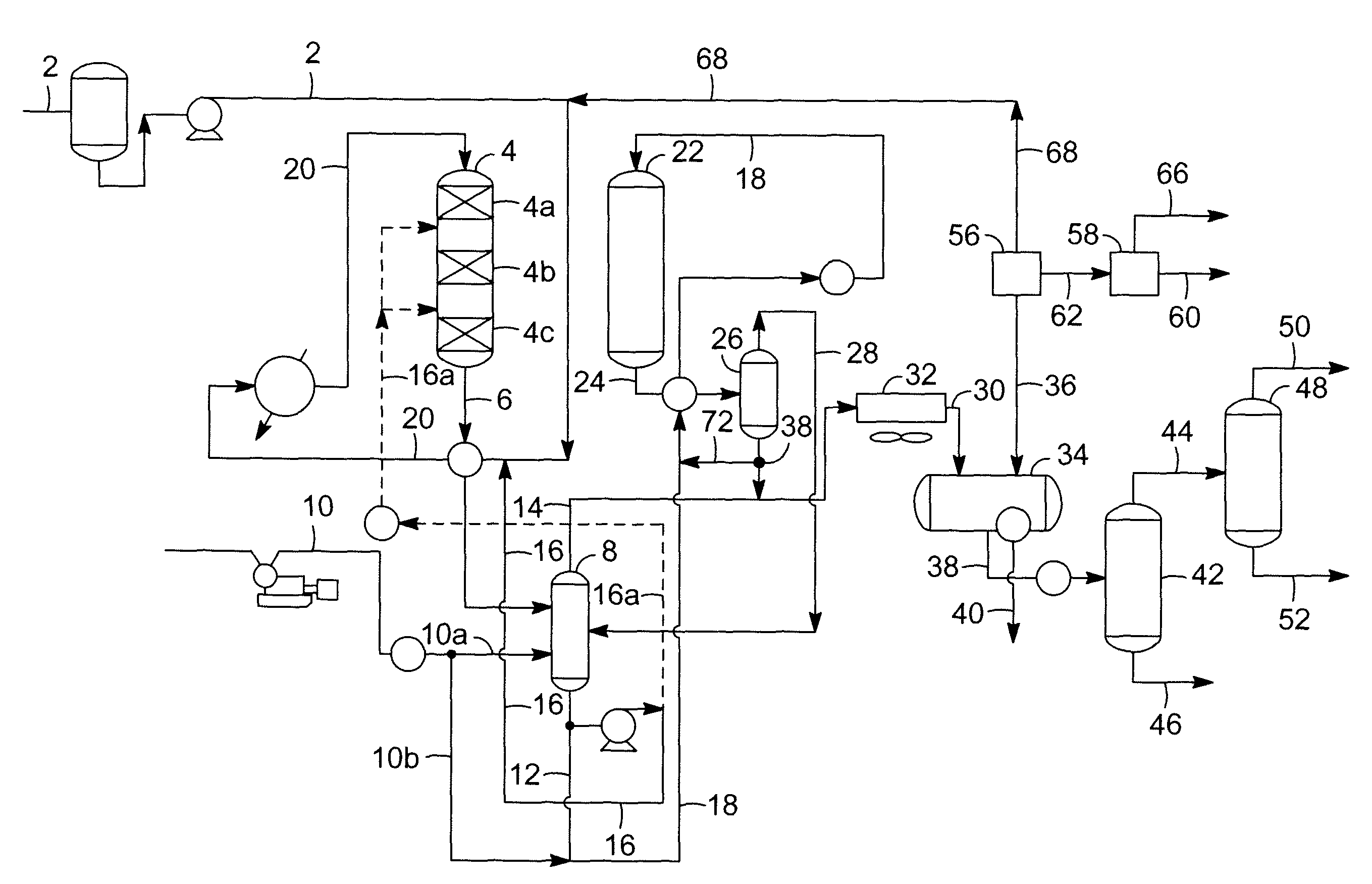

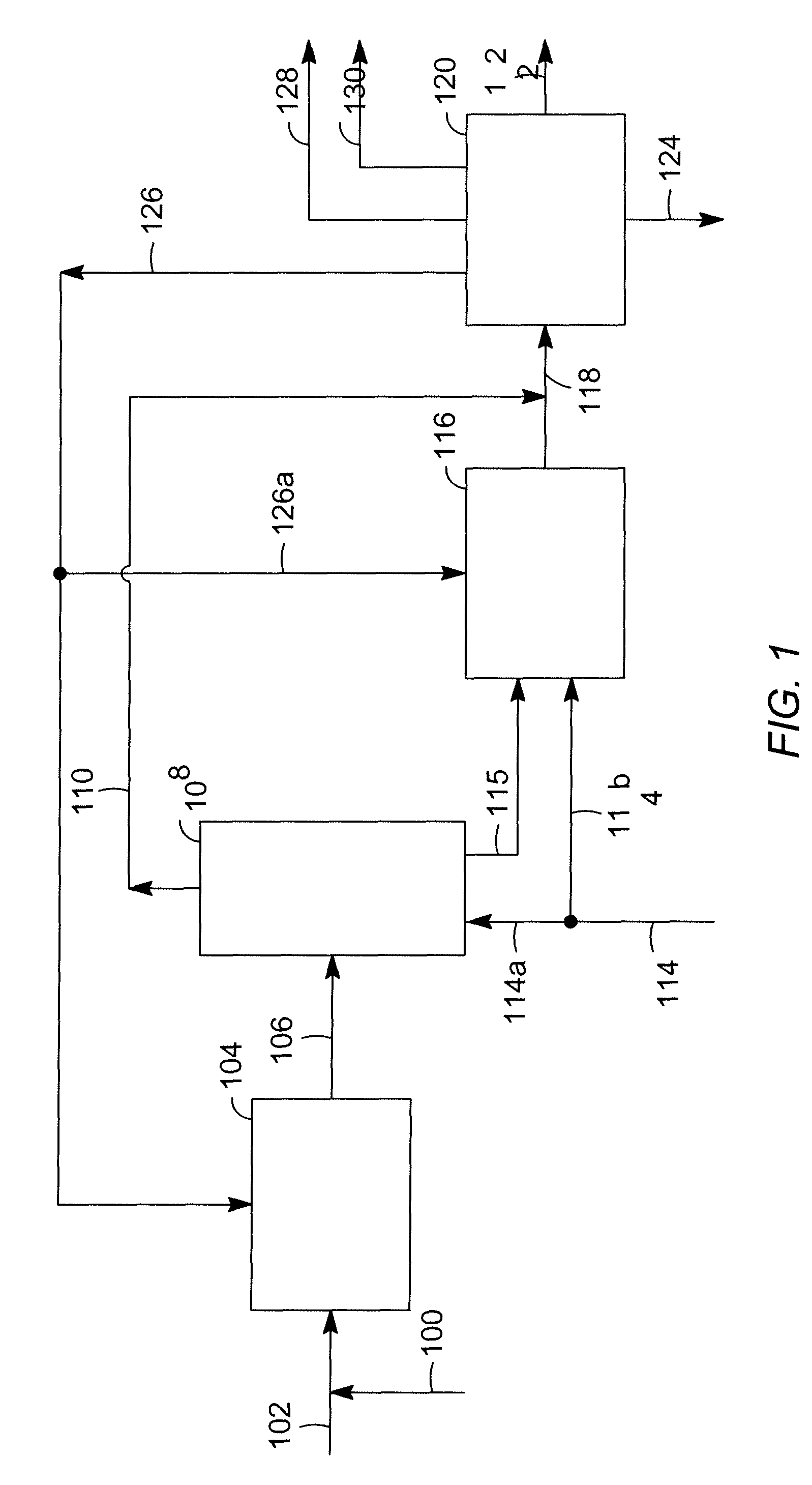

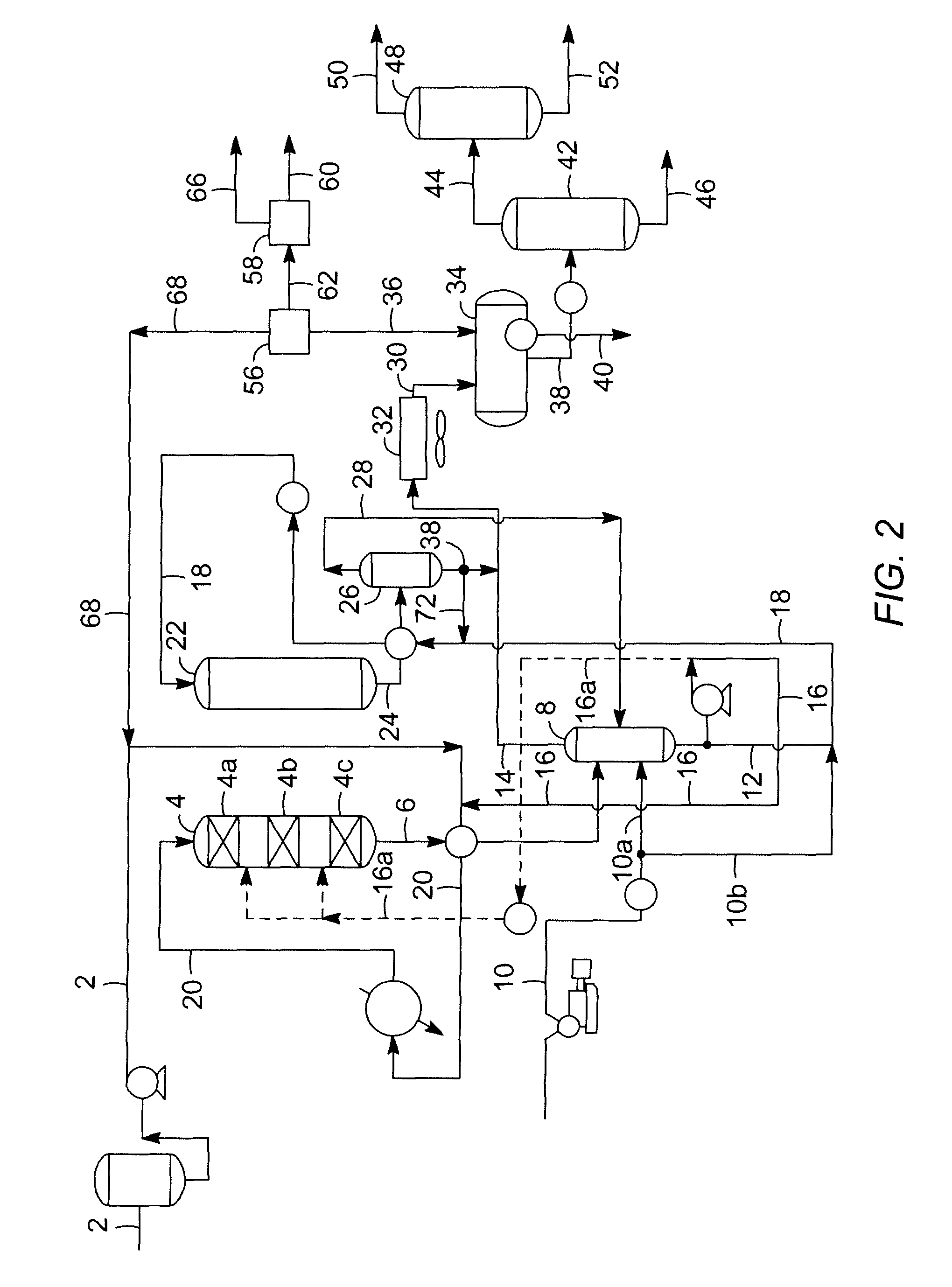

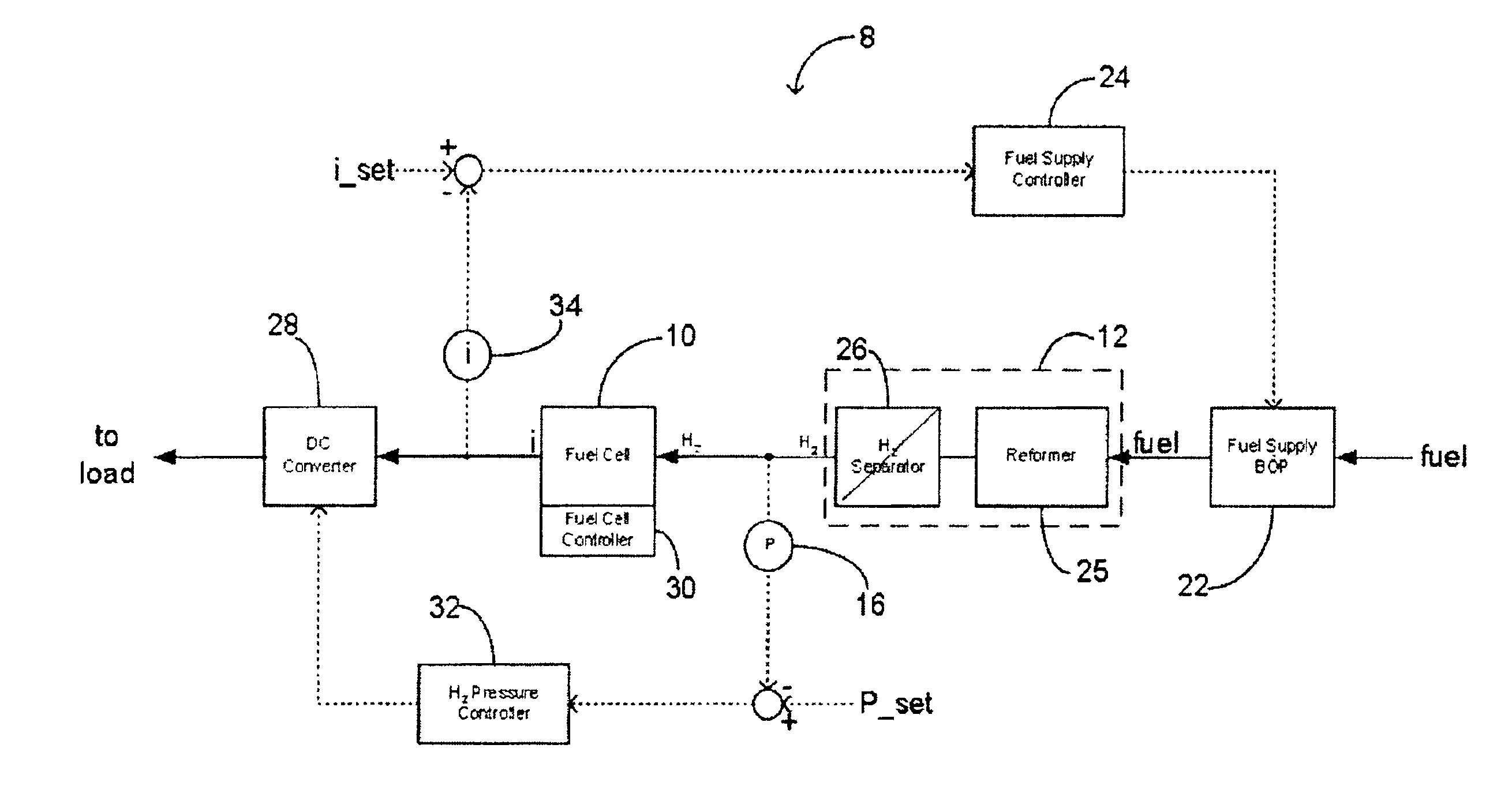

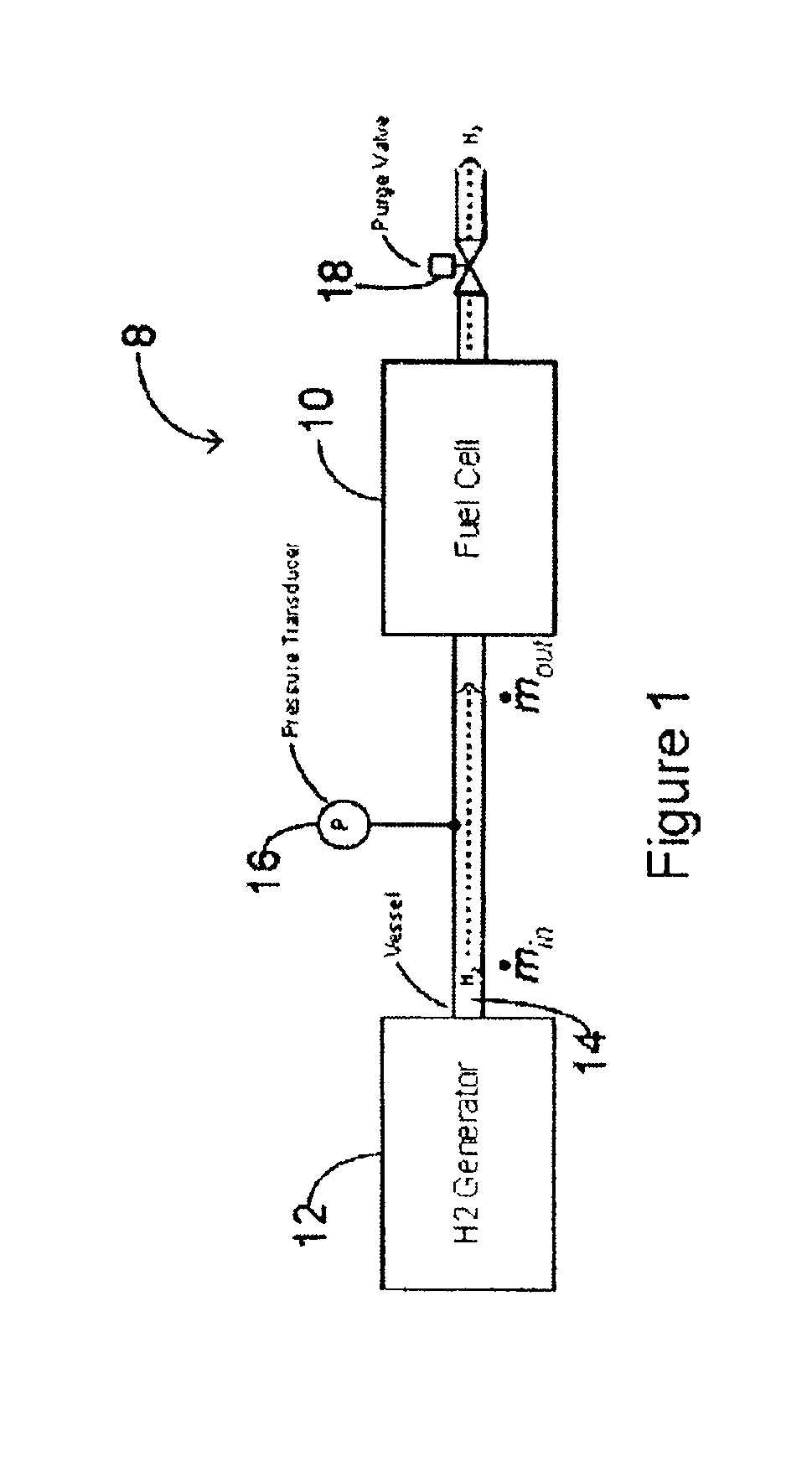

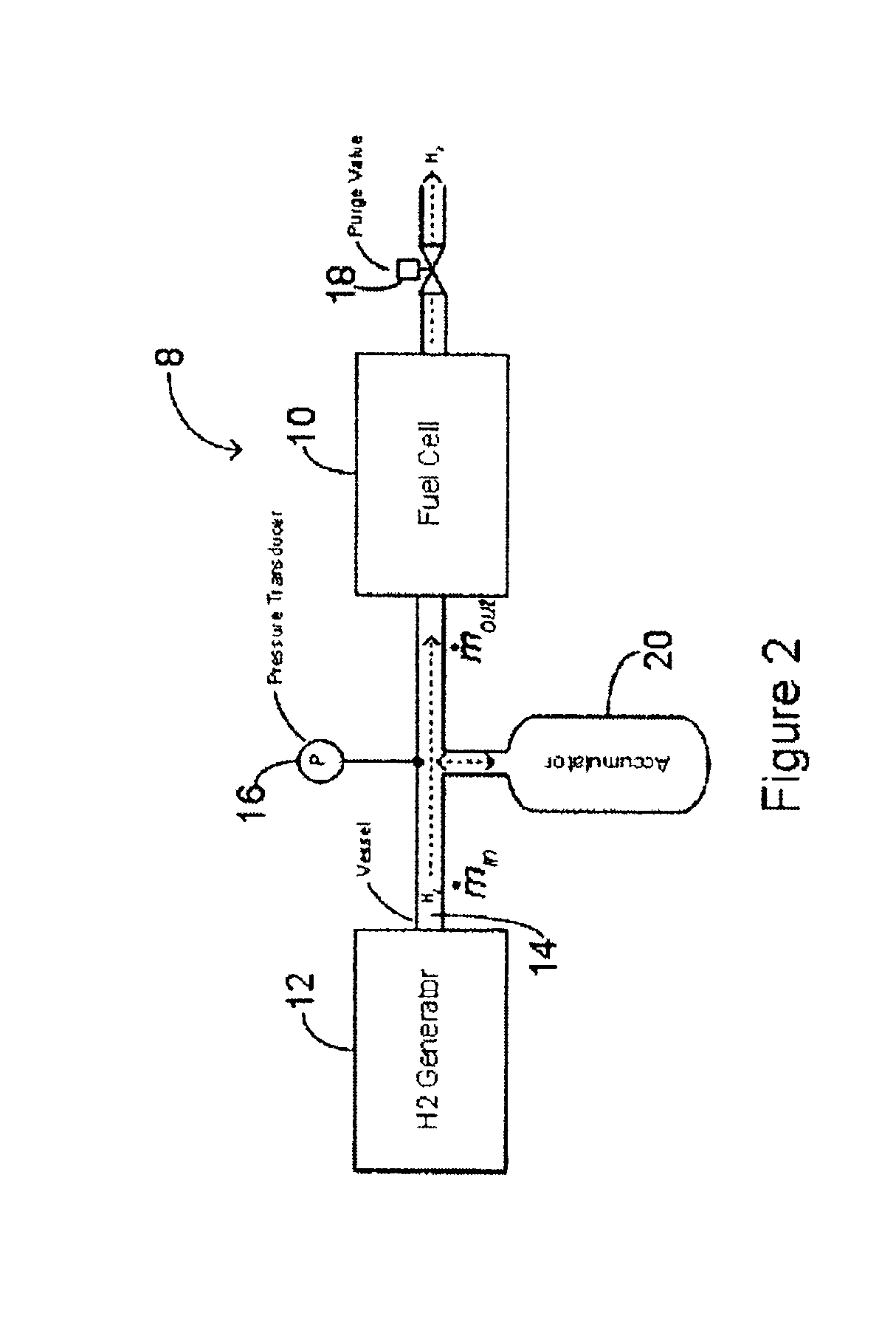

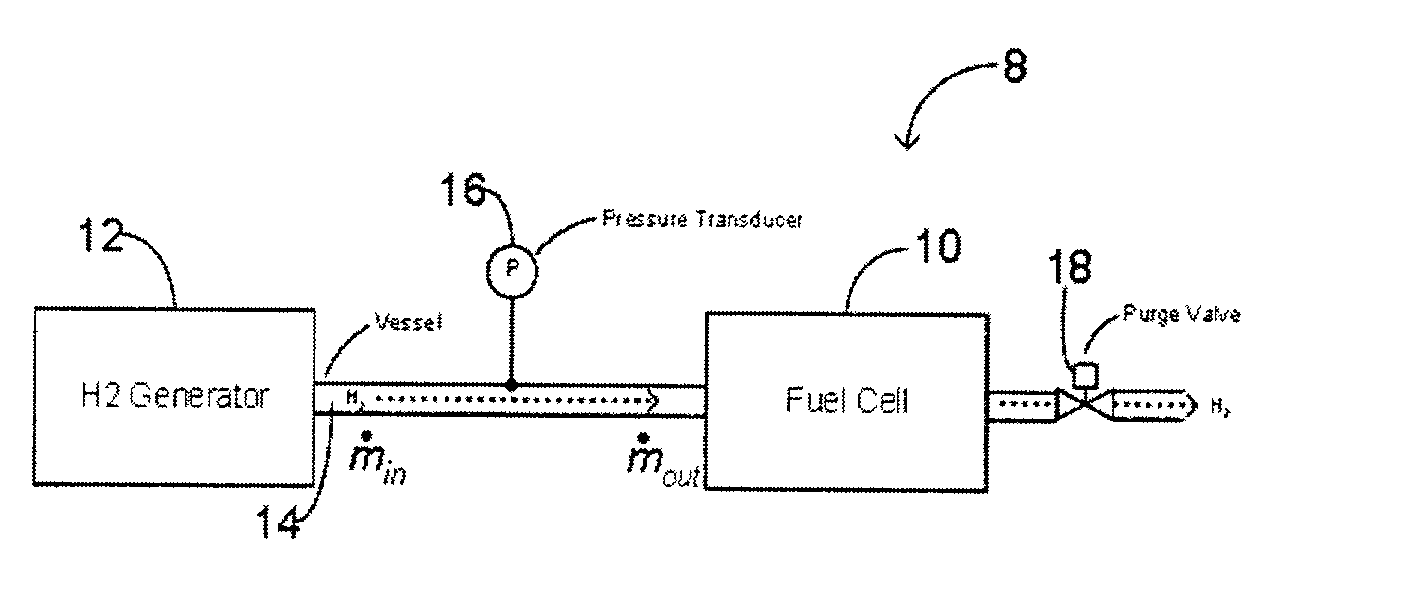

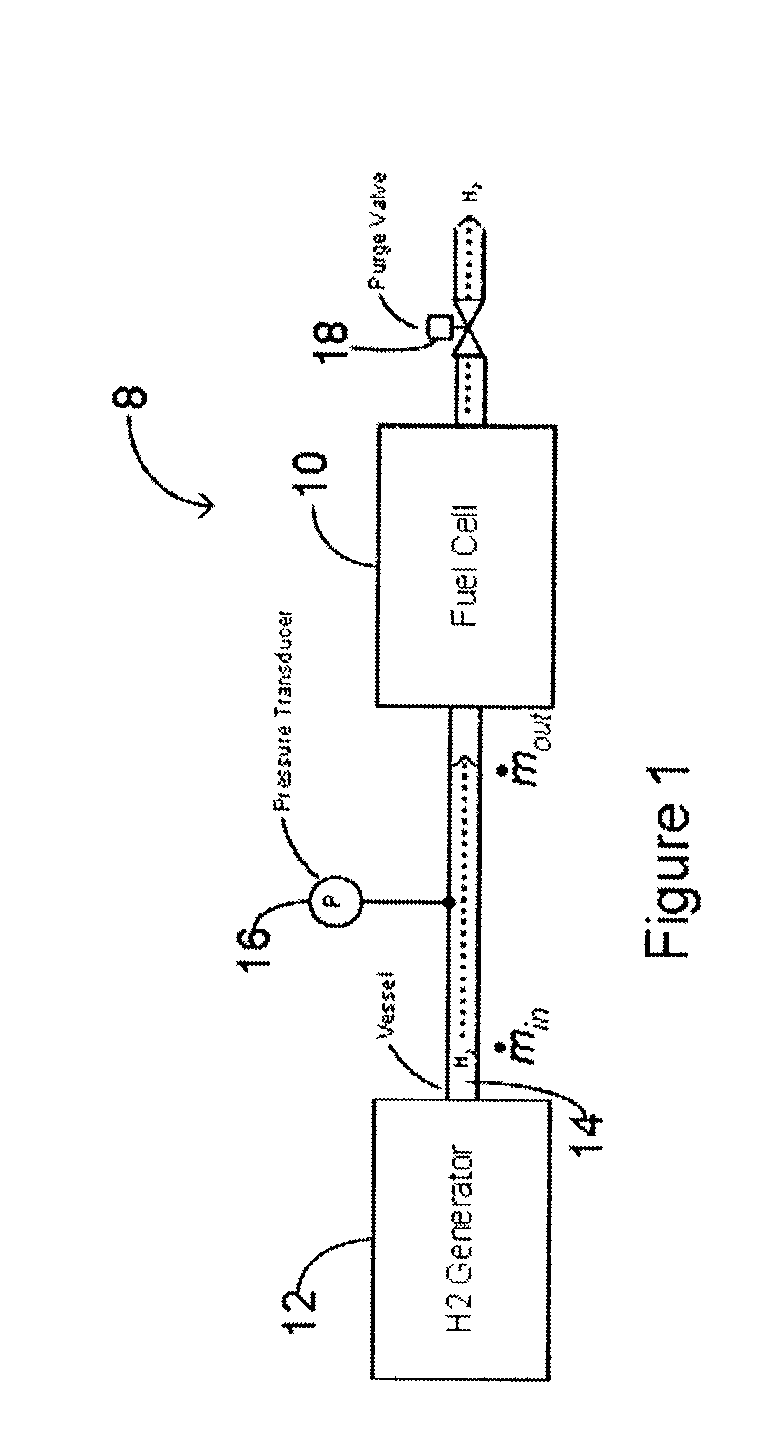

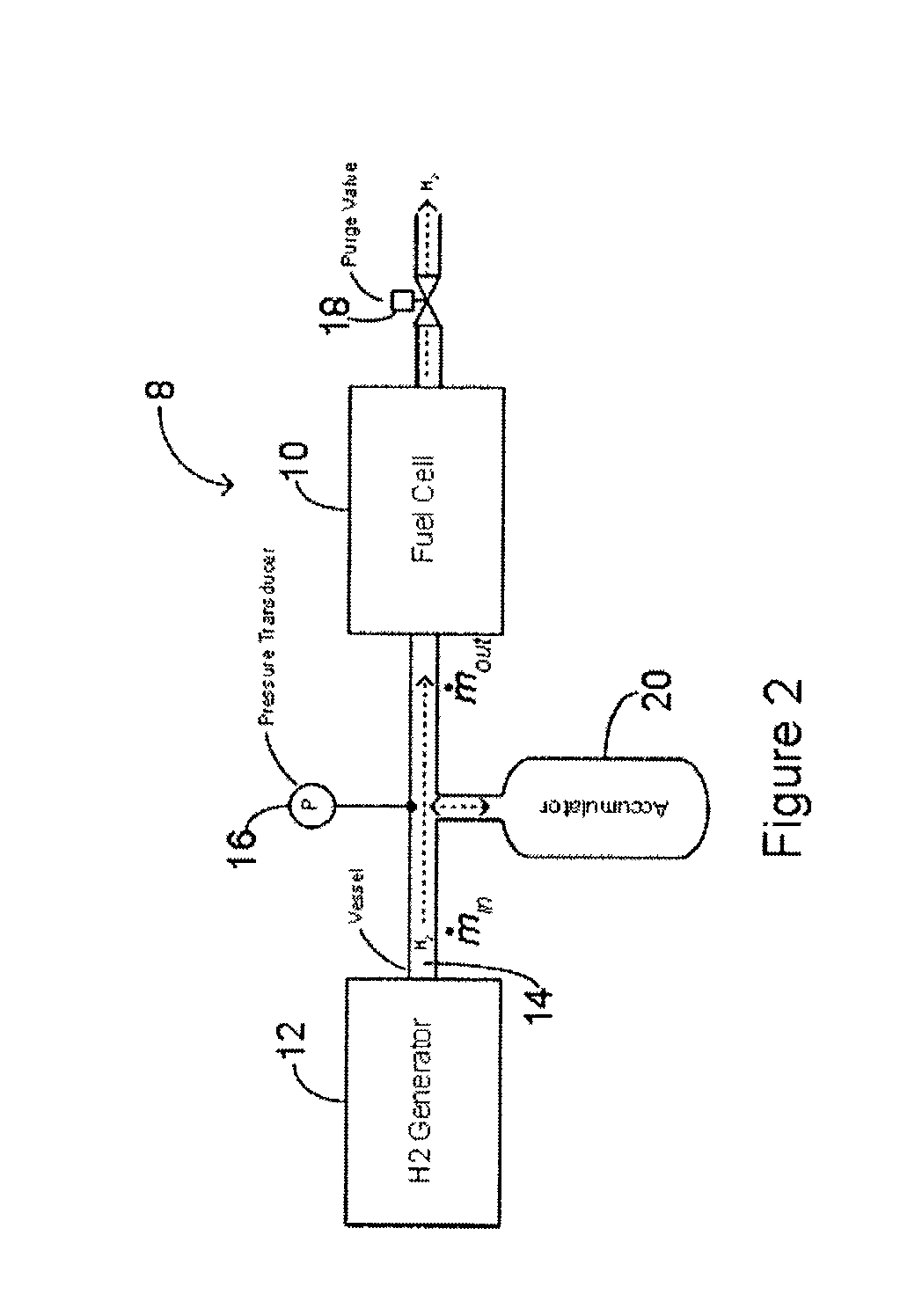

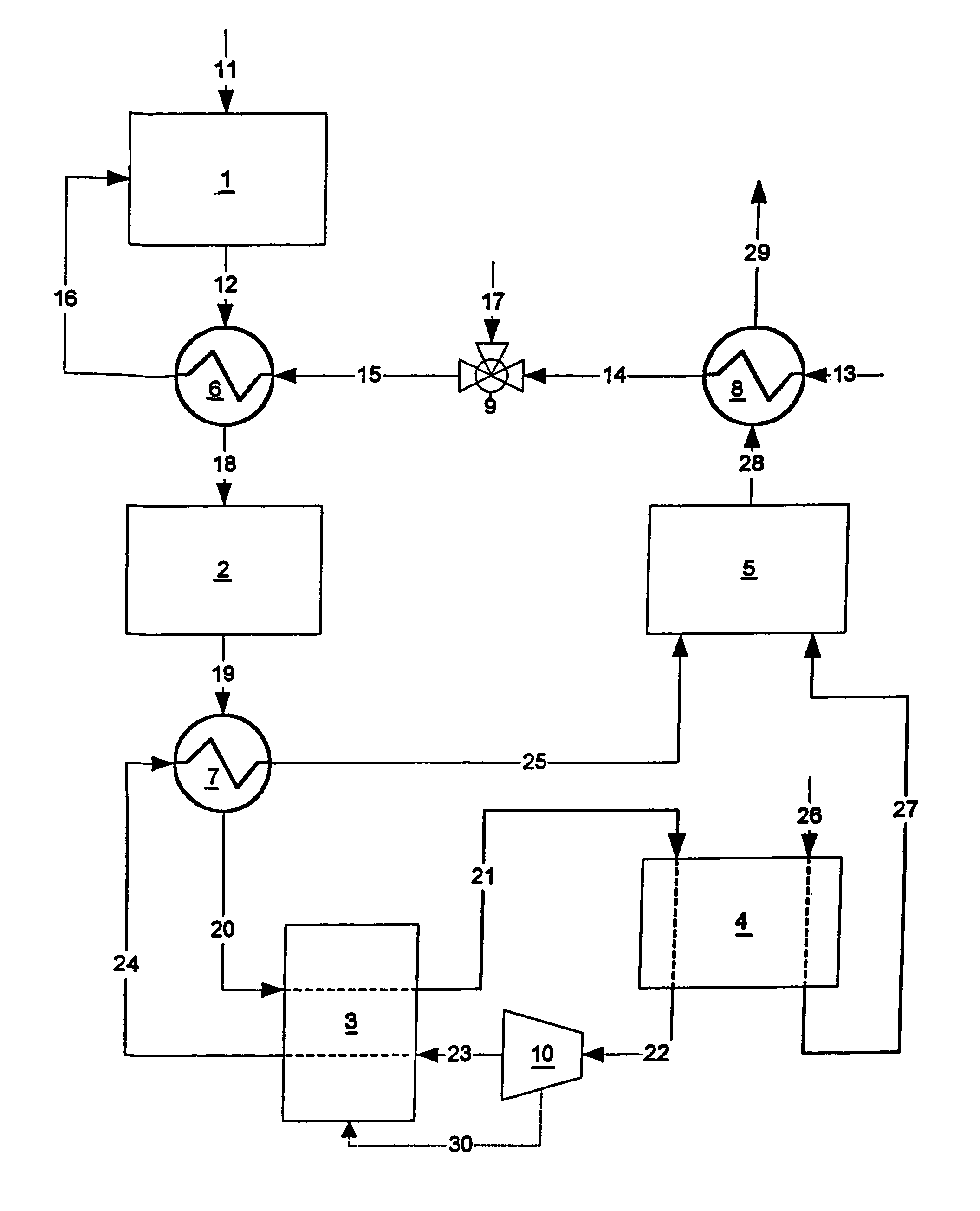

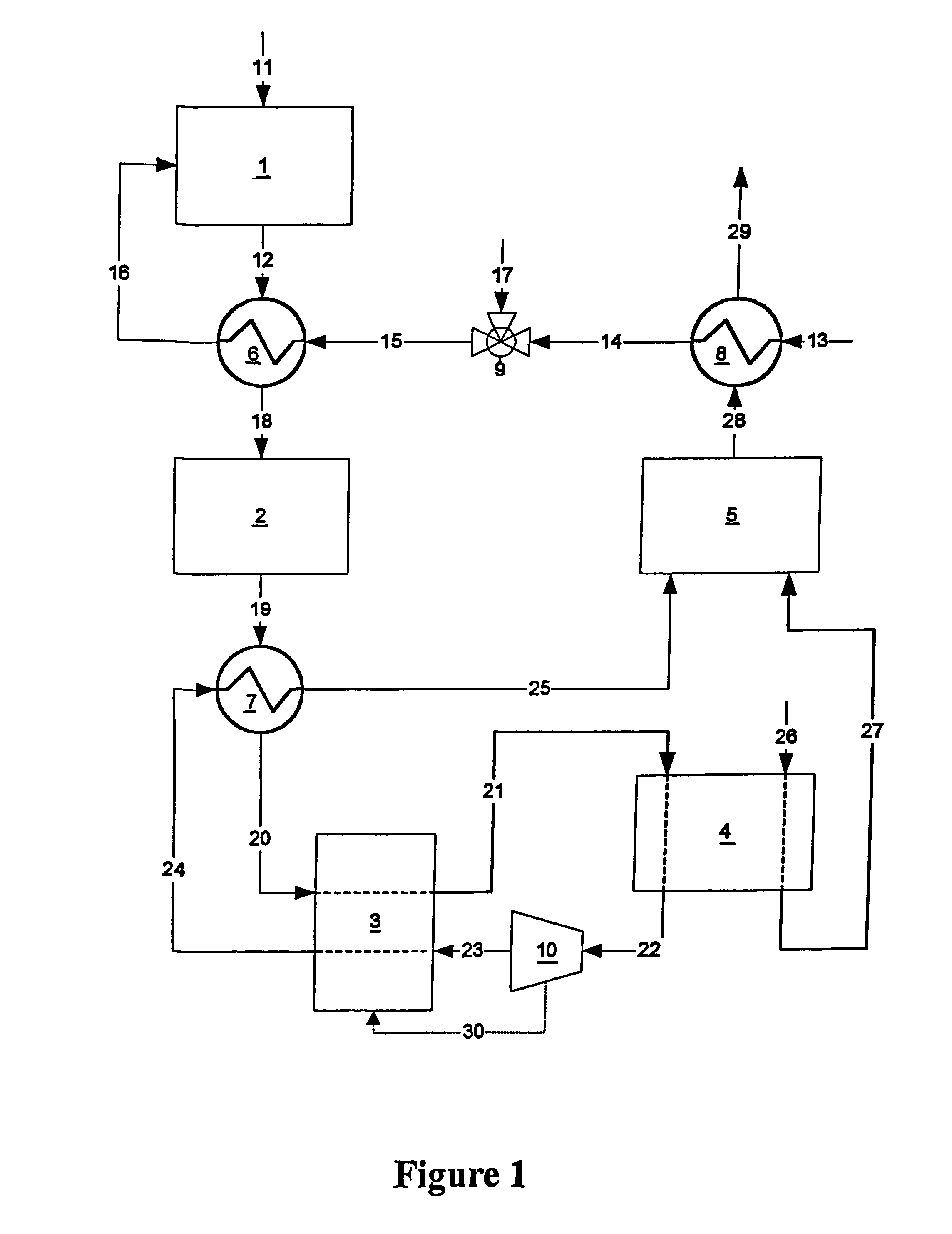

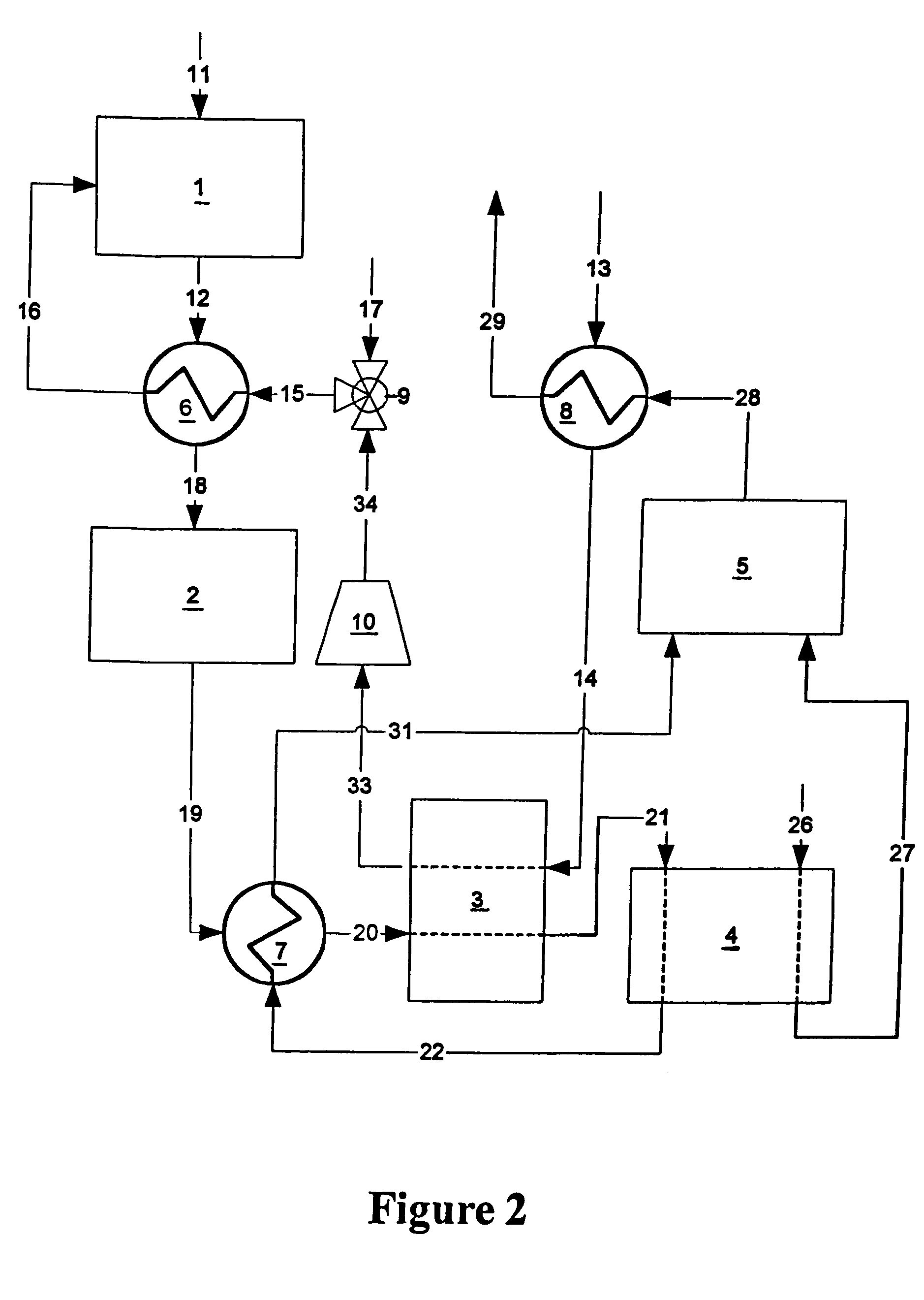

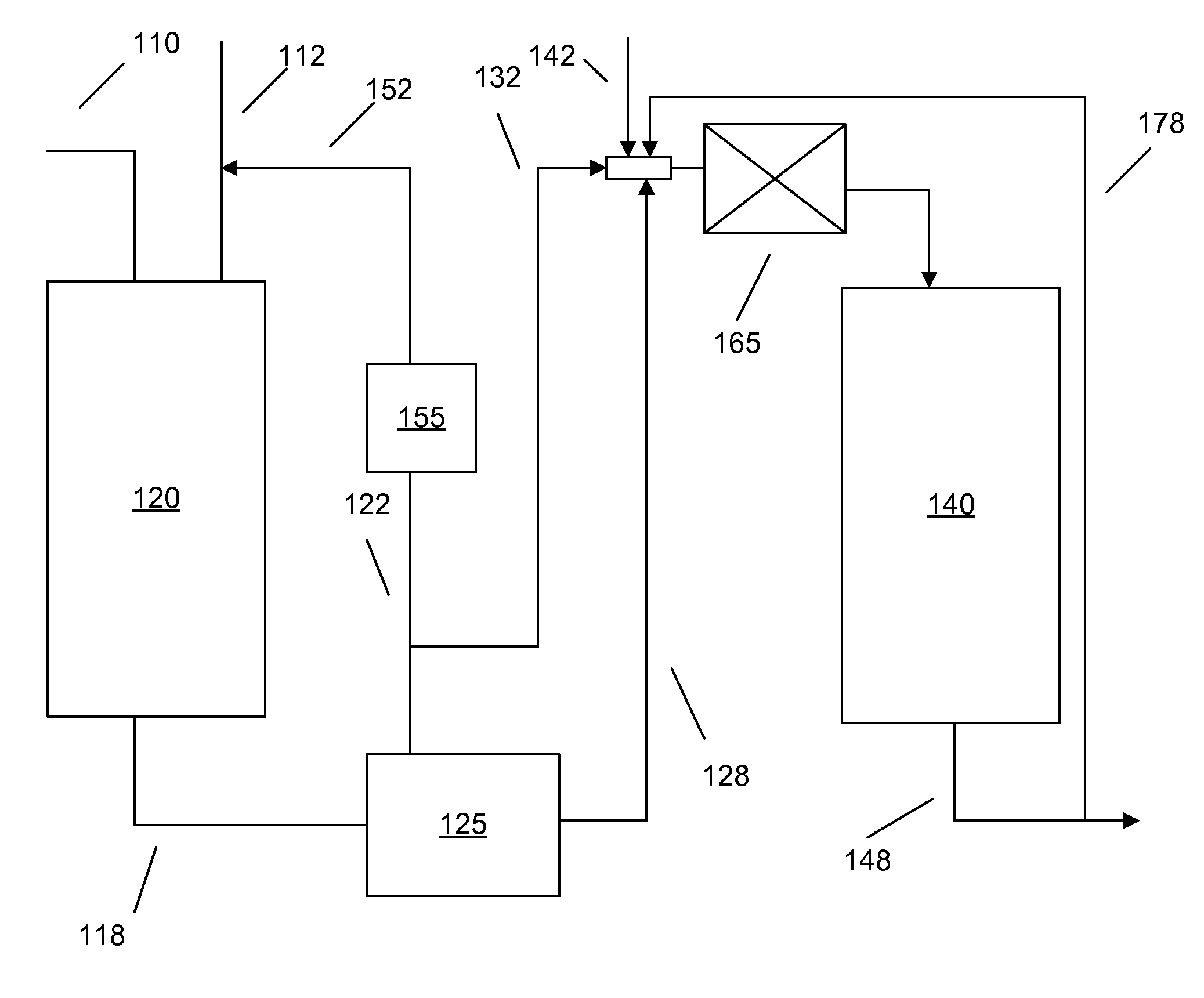

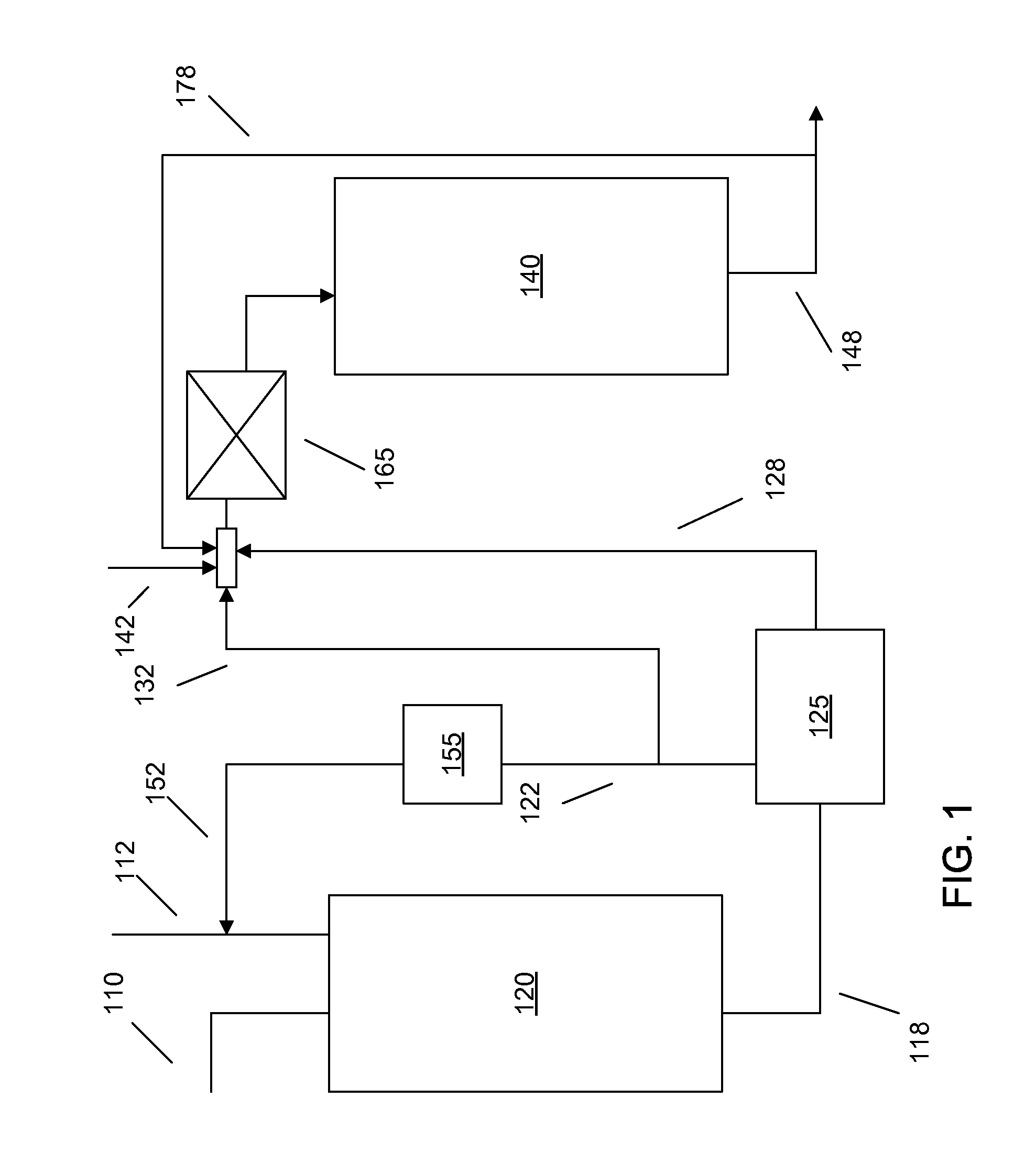

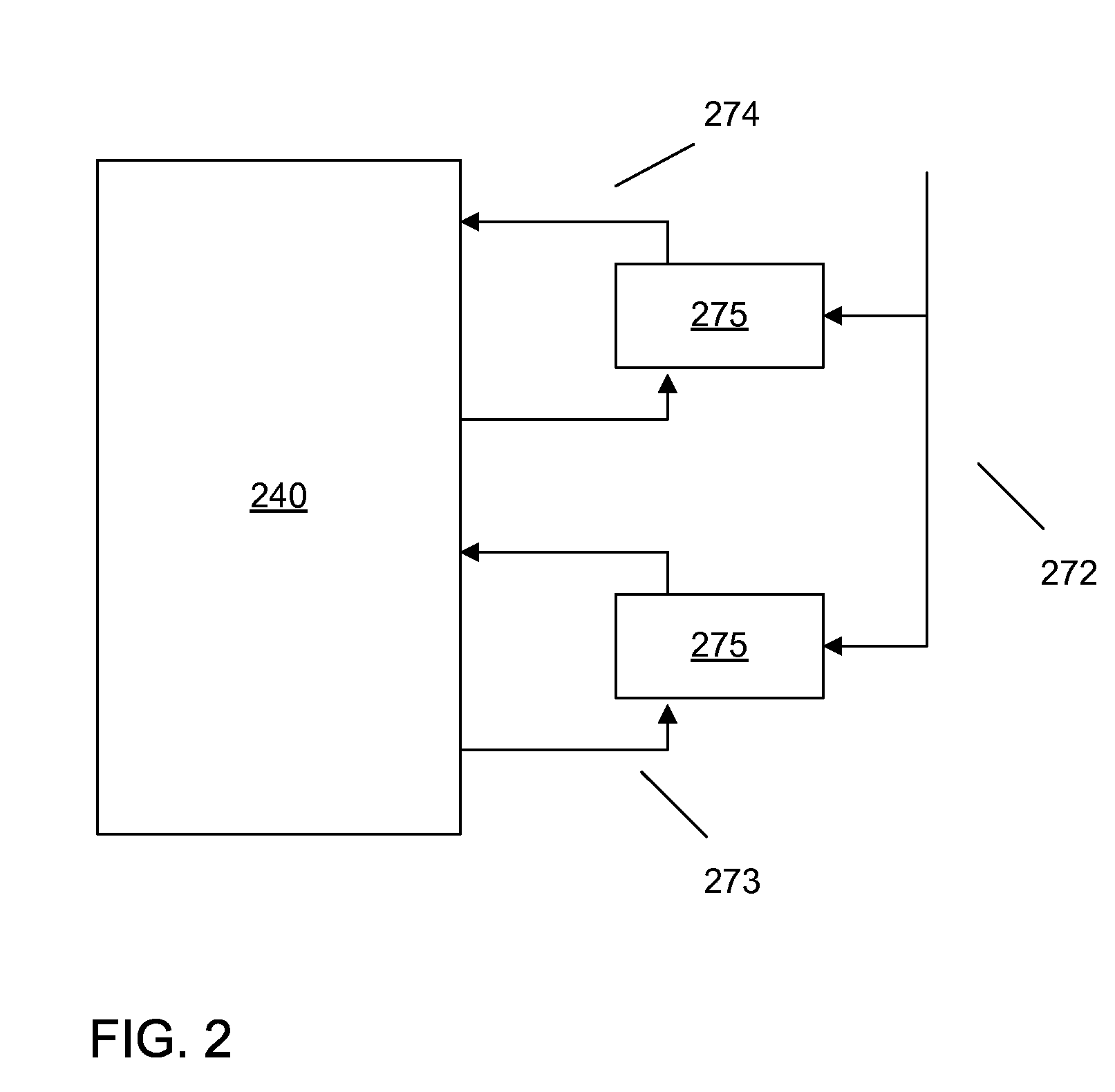

Method and system for controlling the operation of a hydrogen generator and a fuel cell

InactiveUS6893755B2Batteries circuit arrangementsReactant parameters controlThermodynamicsHydrogen pressure

This application relates to a method and system for controlling the supply of fuel to a dead-ended hydrogen fuel cell. The invention may be utilized, for example, to more efficiently integrate the operation of a hydrogen fuel cell and a hydrogen generator, such as a reformer coupled with a hydrogen separation unit. The invention ensures that the production and consumption of hydrogen are effectively balanced to avoid negative feed line pressure fluctuations. The fuel supply control subsystem and hydrogen consumption control subsystems are, however, “decoupled” and hence independently operable. The invention may include an accumulator disposed in a flow path between the hydrogen generator and the fuel cell for storing hydrogen under pressure. The accumulator is sufficiently large in volume such that the pressure of hydrogen in the flow path does not deviate substantially from a target pressure, even during the waste purging sessions. The system enables the use of low-cost pressure transducers in place of mass flow meters. In one aspect of the invention raffinate flow from the hydrogen separator can be controllably adjusted to regulate the temperature or other operating parameters of the reformer.

Owner:CELLEX POWER PRODS

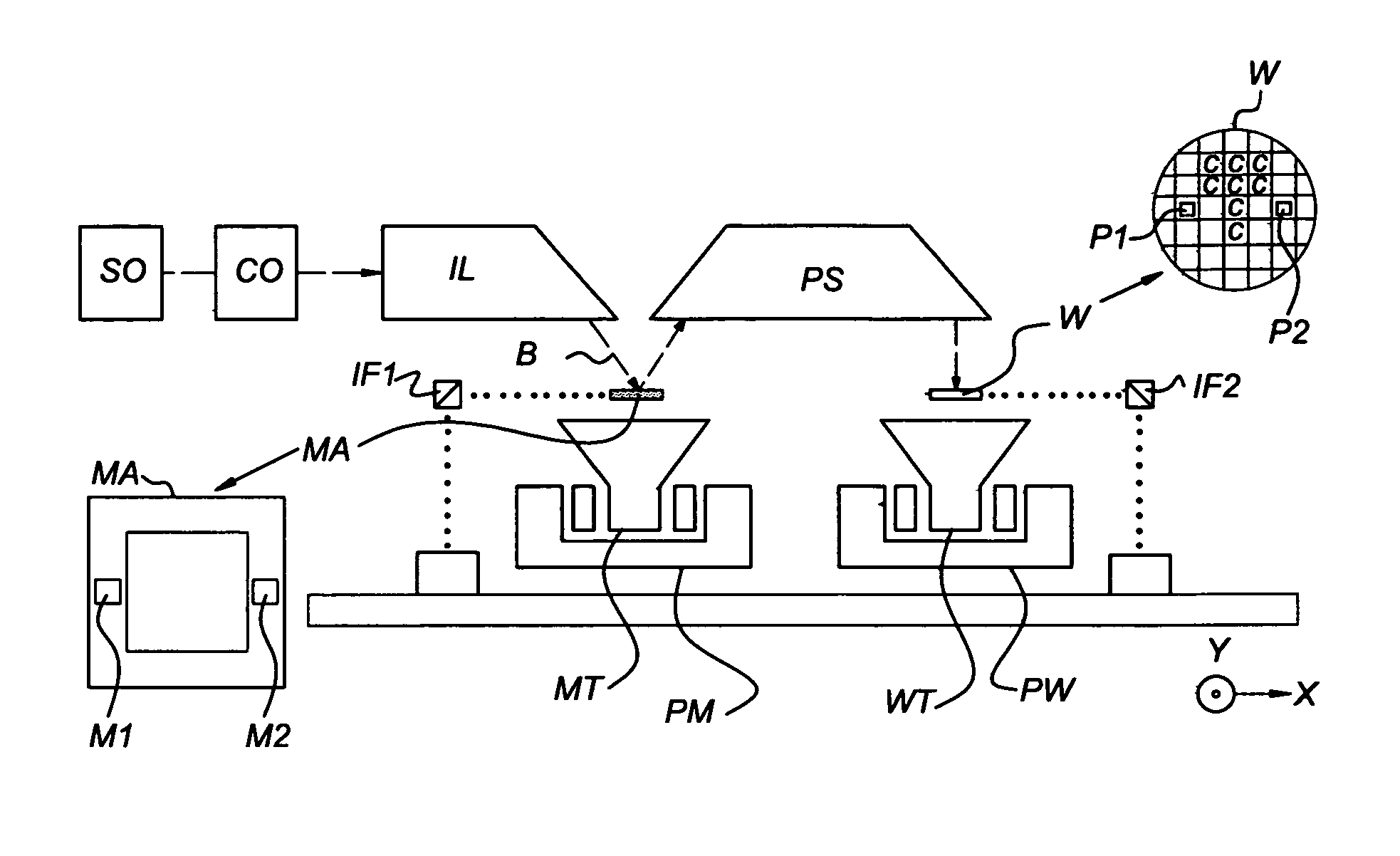

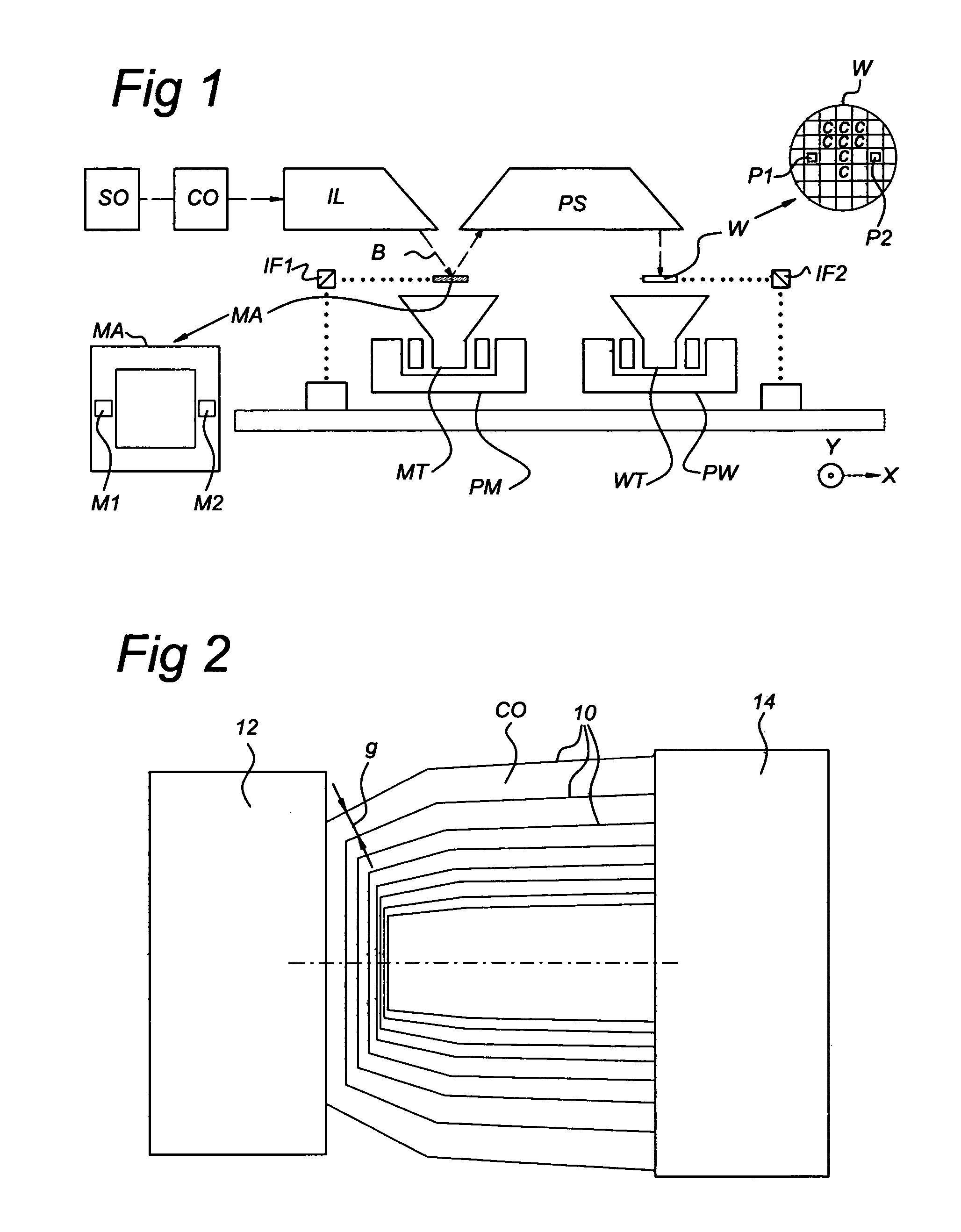

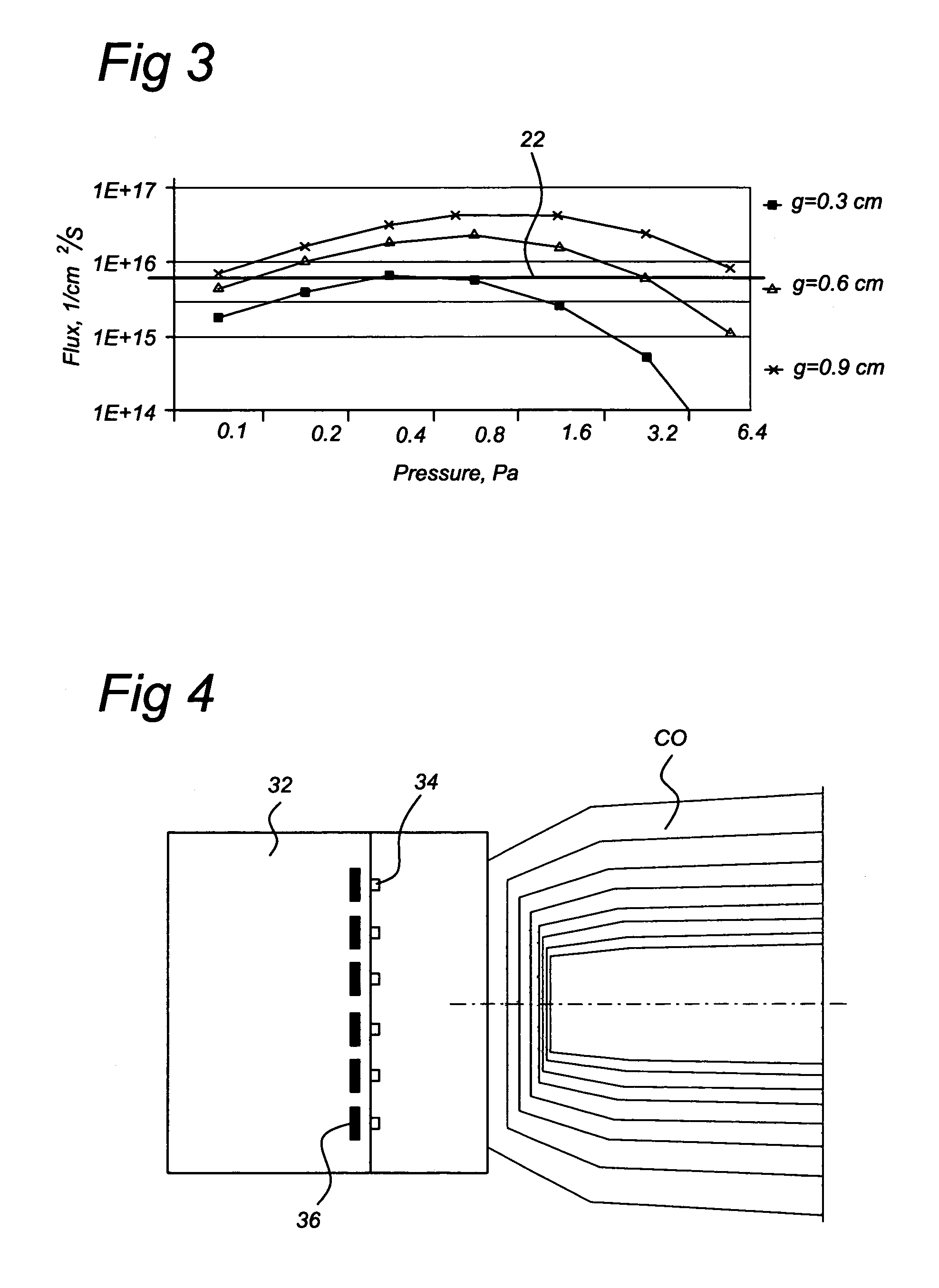

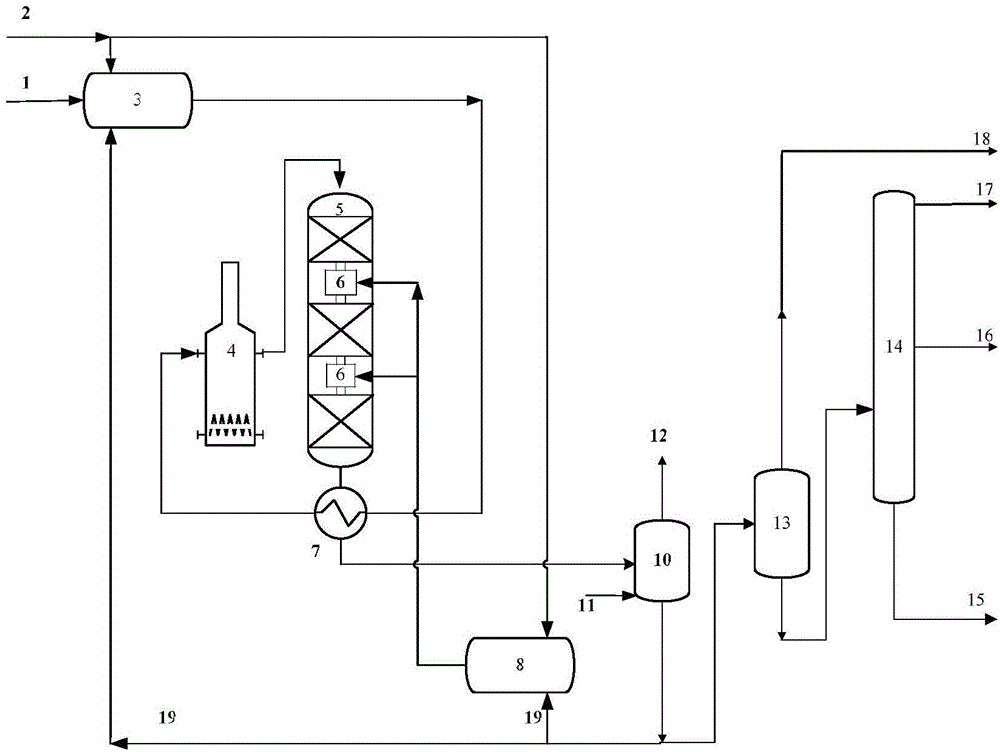

Radical cleaning arrangement for a lithographic apparatus

ActiveUS7462850B2Easy to handleRestore reflectivityRadiation pyrometryPhotomechanical apparatusEngineeringHydrogen consumption

A cleaning arrangement is configured to clean an EUV optic of an EUV lithographic apparatus. The partial radical pressure ranges between 0.1-10 Pa. The cleaning arrangement can be configured inside a cleaning cocoon of the lithographic apparatus for offline cleaning. It can also be configured at particular positions inside the apparatus to clean nearby optics during production. In the pressure range of 0.1-10 Pa the penetration of atomic hydrogen into the optical devices is high, while the recombination to molecular hydrogen and hydrogen consumption is limited.

Owner:ASML NETHERLANDS BV

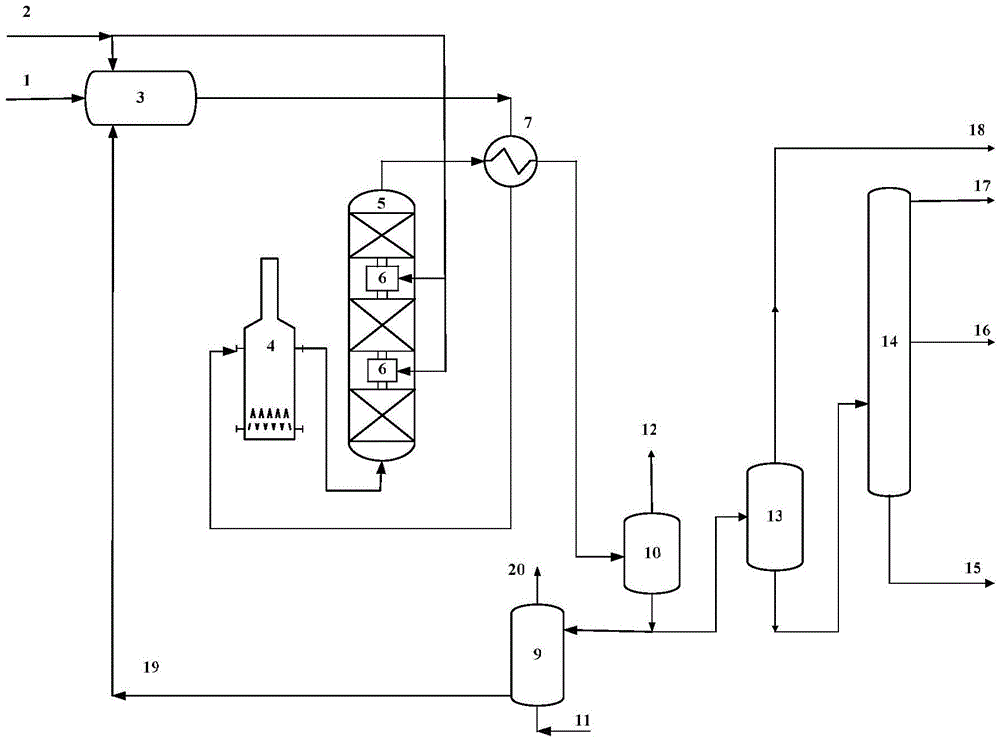

Method for hydrotreatment of continuous liquid-phase wax oil

ActiveCN104560132ALow investment costLow operating costHydrocarbon oils treatment productsRefining to eliminate hetero atomsWaxSulfur

The invention relates to a method for hydrotreatment of continuous liquid-phase wax oil. Wax oil raw oil, an effluent from a reactor and hydrogen are mixed in mixers to form a mixture, hydrogen can be dissolved in hydrocarbon oil in a form of bubbles by virtue of hydrogen distributors arranged inside the mixers, the amount of hydrogen is higher than the saturated solubility of liquid or the total hydrogen consumption, a plurality of bed layers are arranged in the reactor, the mixers are arranged among the bed layers, the mixture and fresh hydrogen or a mixture of hydrogen and partial reaction products are mixed again, a partial effluent from the reactor is partially circulated and a partial effluent is subjected to cooling, separating and fractional distillation to obtain the product. By the method, the problems that reaction process is difficult to process due to the limitation on the solubility of hydrogen in the hydrocarbon oil and the chemical hydrogen consumption is relatively high are solved and the adaptability of raw oil is expanded and furthermore, under the condition of relatively low circulation ratio, low-sulfur refined wax oil can be produced to provide high-quality feedstock for catalytic cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

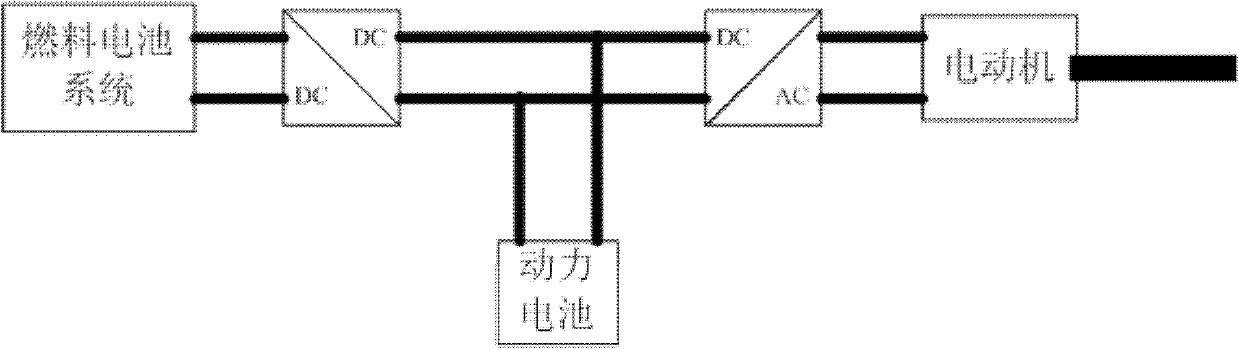

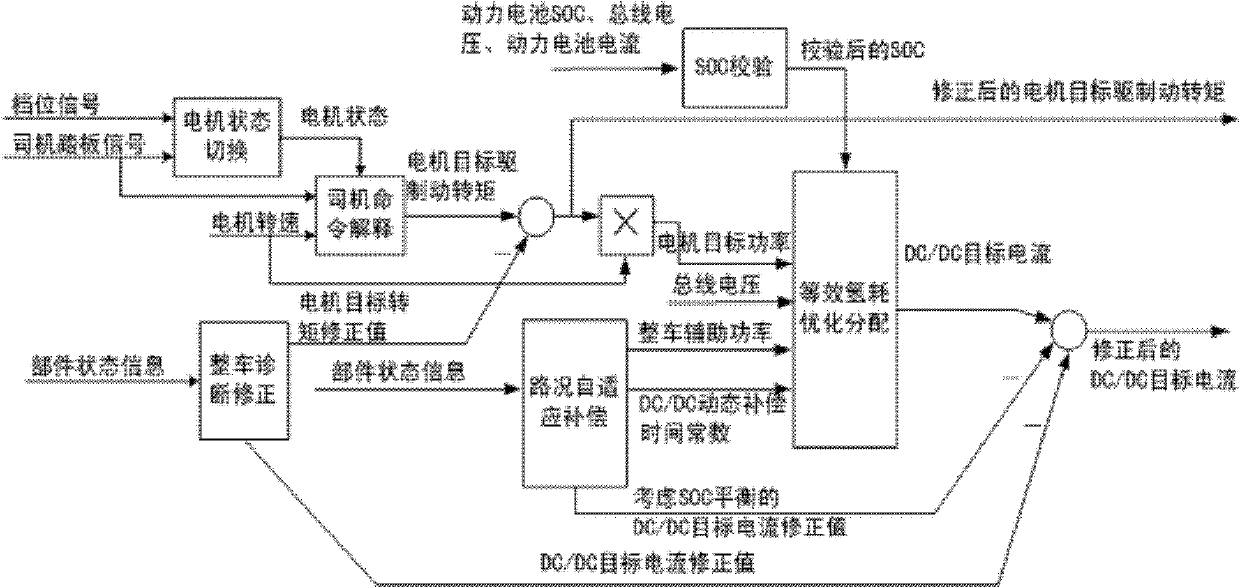

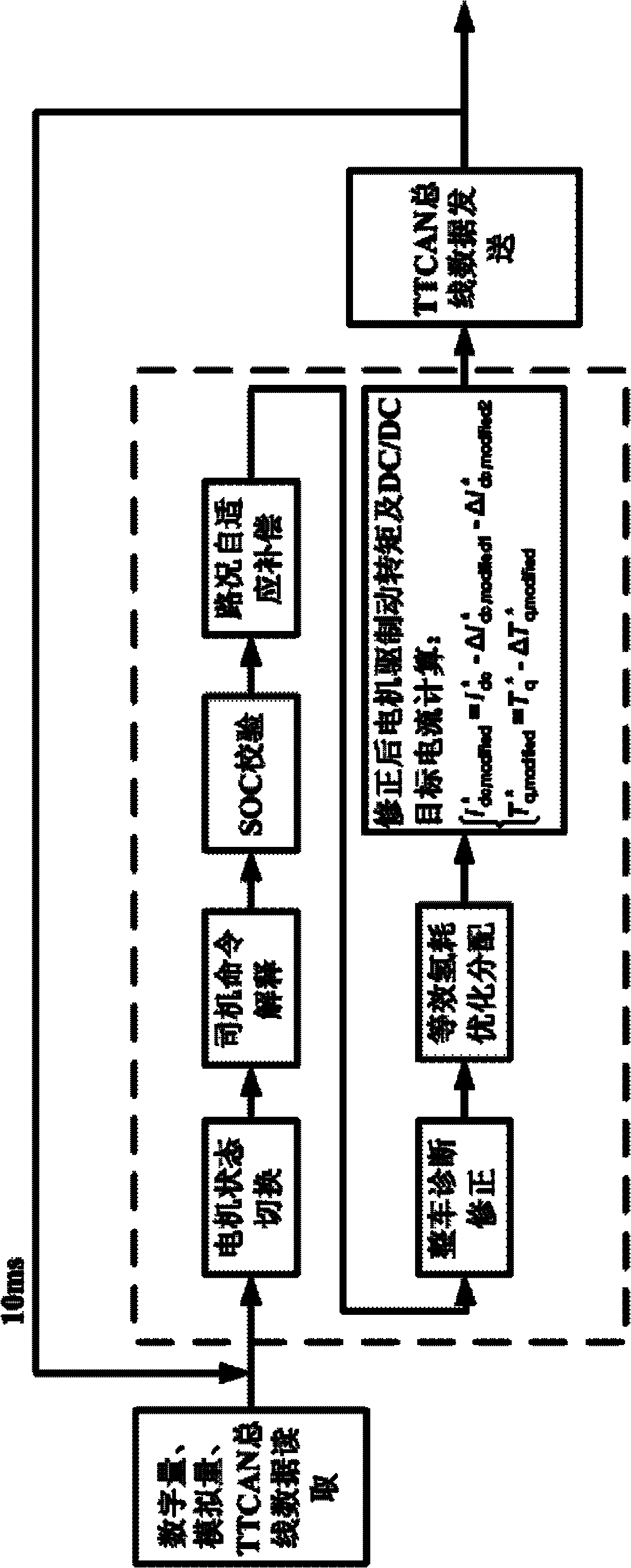

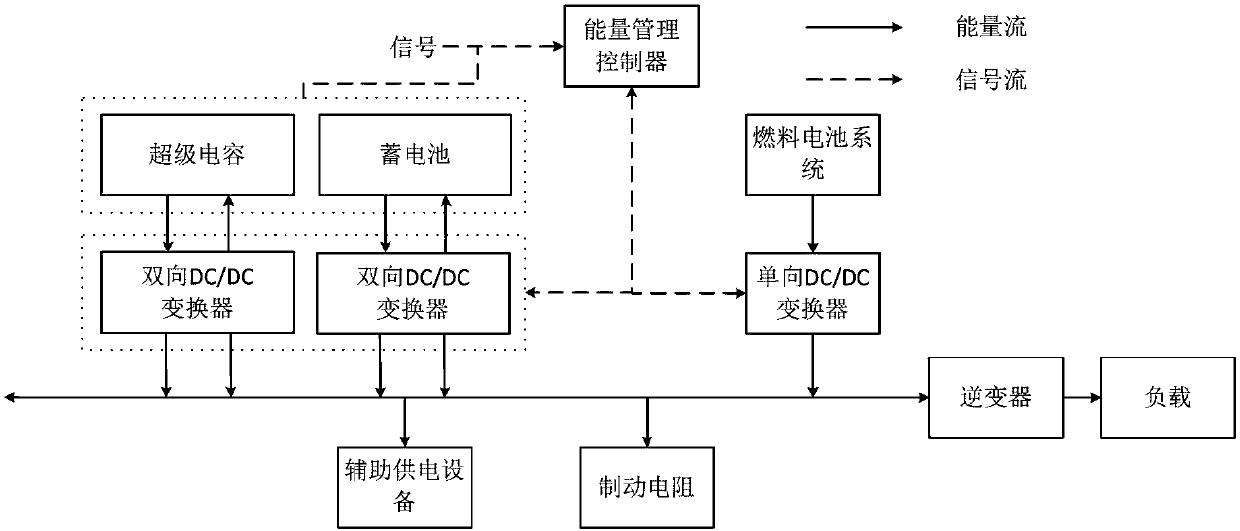

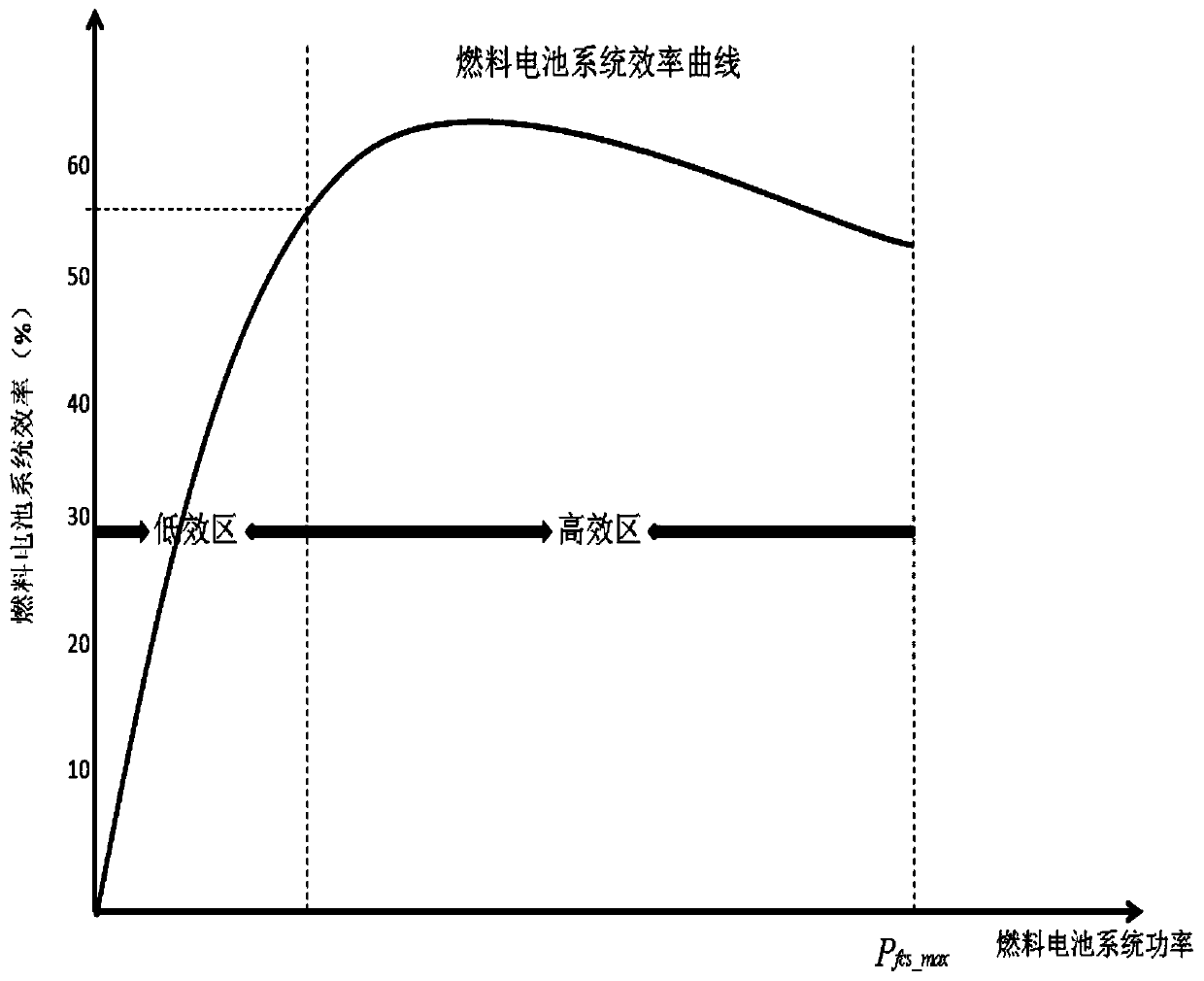

Control method of fuel cell hybrid vehicle

ActiveCN102167036ASolving Energy Management ProblemsExtended service lifeHybrid vehiclesData processing managementArea networkElectrical battery

The invention relates to a control method of a fuel cell hybrid vehicle, which comprises the following steps: a vehicle controller is internally provided with a motor status switching module, a driver order explaining module, a power cell charged status verifying module, a road condition self-adaption compensating module, a vehicle diagnosis correcting module and an equivalent hydrogen consumption optimal distributing module; the vehicle controller reads a gear signal, a pedal signal and TTCAN (triggered controller area network) bus data; the motor status switching module switches the motor status; the driver order explaining module confirms a motor target torque; the power cell charged status verifying module verifies a SOC (system on chip) value, TTCAN bus voltage and power cell current; the road condition self-adaption compensating module computes the auxiliary power and the DC (direct current) / DC dynamic compensation time constant of the vehicle; the vehicle diagnosis correcting module corrects the motor target torque and the DC / DC target current; the equivalent hydrogen consumption optimal distributing module optimally distributes the vehicle target power between the power cell and the fuel cell; and the modified motor target torque and the DC / DC target current are transmitted to a motor controller and a DC / DC controller so as to control the output power of the motor andthe fuel cell.

Owner:TSINGHUA UNIV

Process for hydrogenating modifying faulty gasoline

ActiveCN1597865ASimple processEasy to operateTreatment with hydrotreatment processesOrganic sulfide compoundIsomerization

The invention provides a process method for making hydrodesulfation and alkene reduction on the bad gasoline, like all-fractional FCC gasoline, etc. Under the conditions of hydrogen gas existence and temperature gradually rising, to contact with three catalysts forms three reaction regions. The first reaction region has lower temperature and uses hydrofining catalyst and mainly eliminates di-alkene in the gasoline; the second reaction region has higher temperature and uses selective hydrodesulfation catalyst and mainly eliminates organic sulfide and some alkenes; the third reaction region has the highest temperature, uses gasoline modifying catalyst and makes the modifying reactions including aromatization, isomerization and benzene alkylation, increasing octane number of gasoline and improving product quality. It has the advantages of simple flow, being easy to operate, fully using reaction heat, prolonging the operating cycle of catalyst, high liquid yield, low hydrogen consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

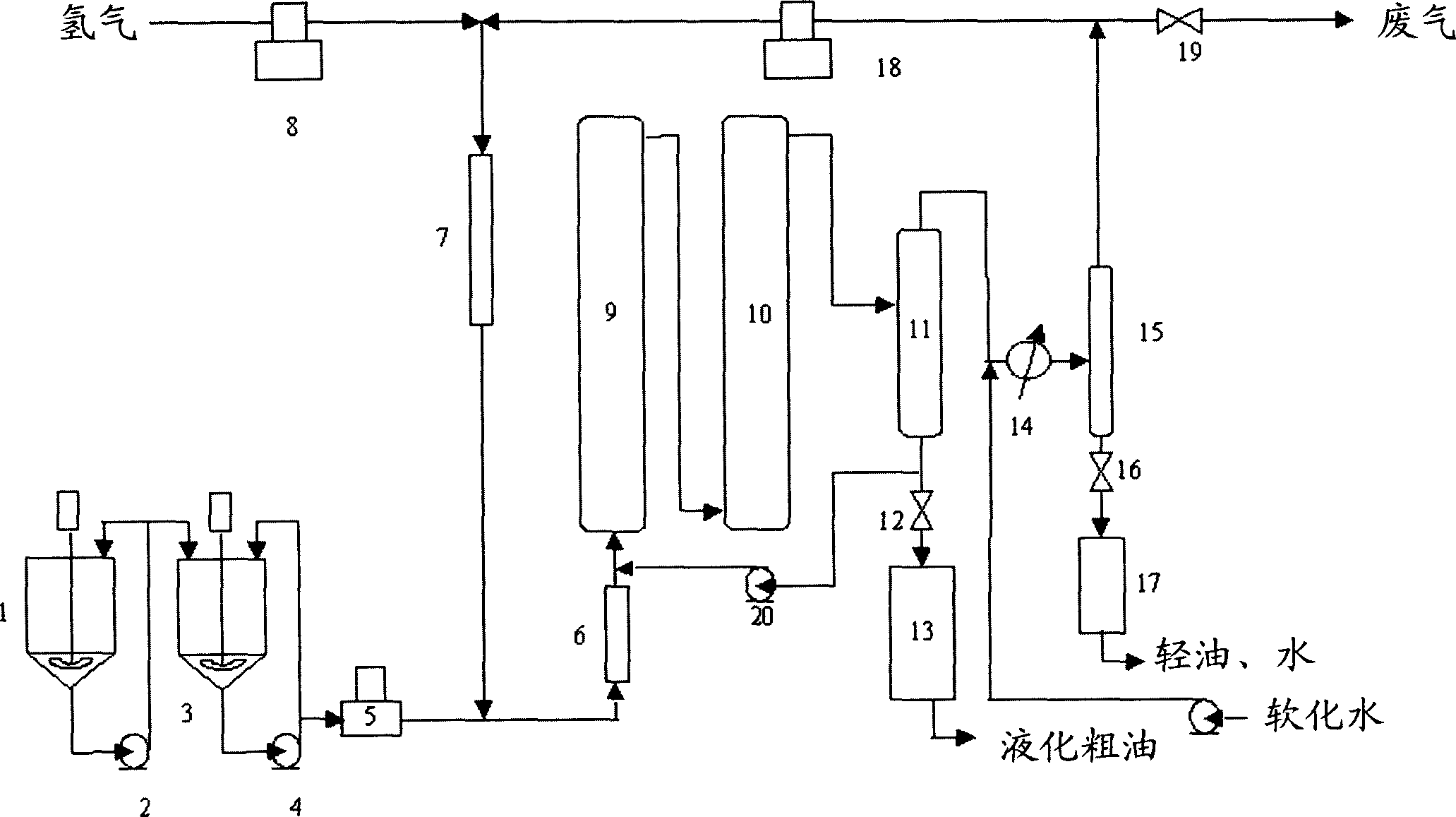

Method of directly liquifying coal

ActiveCN1869159AHigh yieldAvoid secondary decompositionLiquid hydrocarbon mixture productionCoal dustPre treatment

The invention relates to a coal direct liquefaction method. It includes the following steps: mixing coal slurry which is made up of coal dust, hydrogenation cycle solvent, and iron catalyst with freshness or cycle hydrogen; reacting by the first and second reactor; sending the product from the second reactor to high temperature separator to separate; the weight flow ratio of the recycle and freshness materials is 2-20. The method can reduce hydrogen consumption and gas yield.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

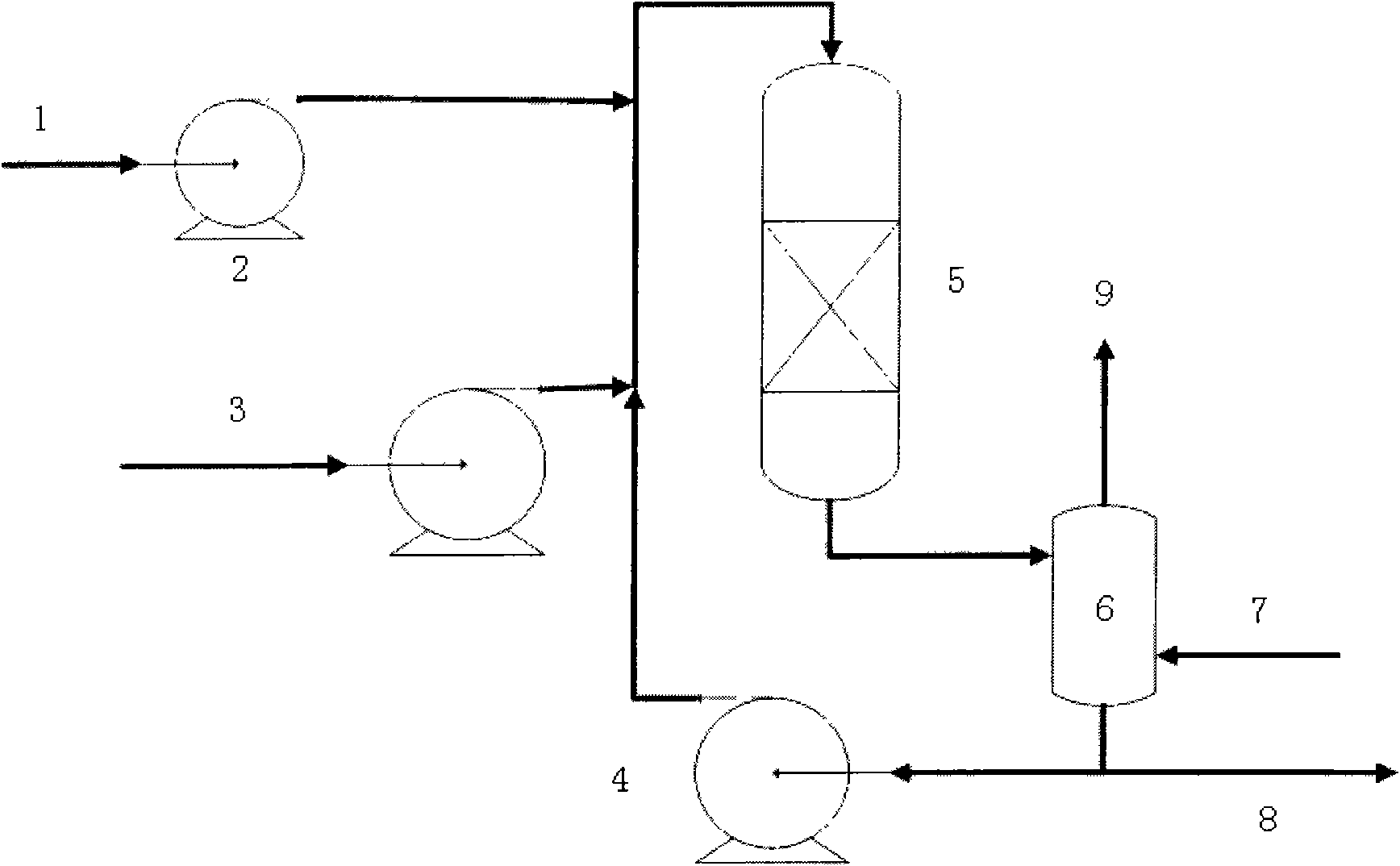

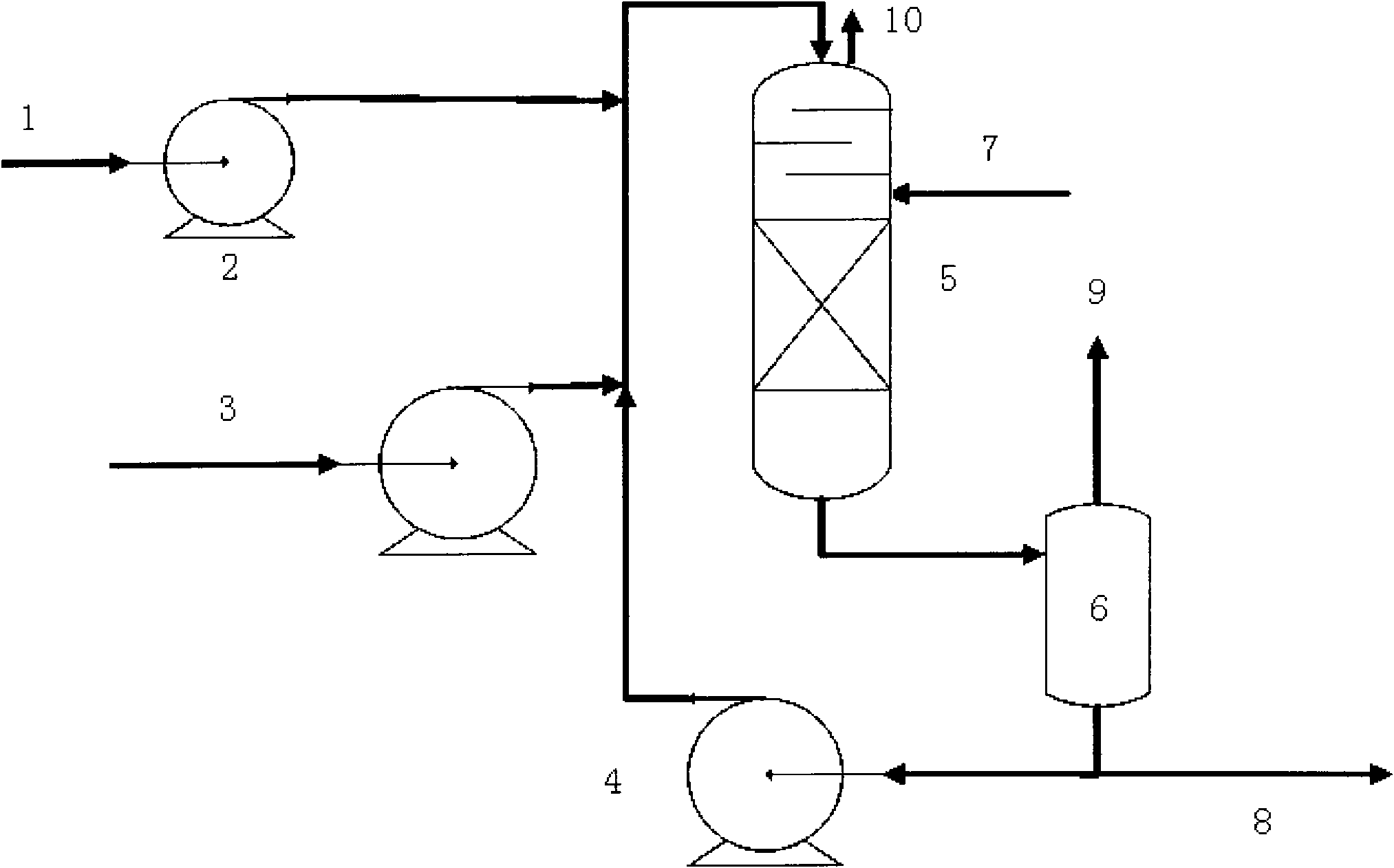

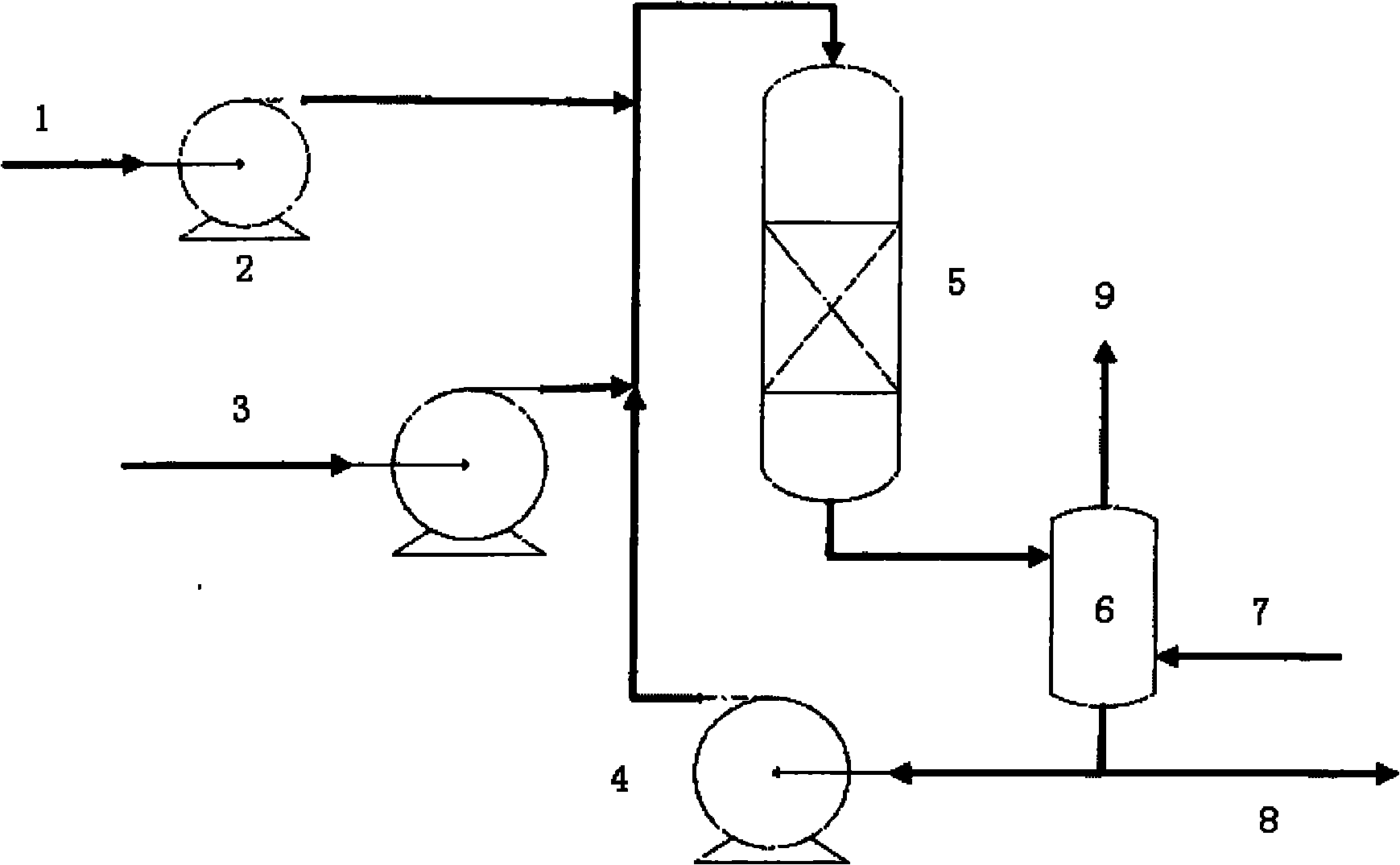

Method of liquid phase circulation hydrotreatment and reaction system

ActiveCN101787305AMaintain active stabilityEliminate the effect of wetting factorHydrocarbon oils treatment control/regulationLiquid productGas phase

The invention discloses a method of liquid phase circulation hydrotreatment. A part of liquid product after hydrotreatment circulates and is mixed with raw material to form liquid phase material, the hydrogen is mixed in the liquid phase material, the mixing volume of the hydrogen is increased by below 20 times of the dissolved hydrogen volume of a reaction system under the reaction condition based on the chemical hydrogen consumption in the reaction process, the liquid phase material mixed with the hydrogen enters the upper part of a reactor, the upper part of the reactor is provided with a gas phase space and an exhaust system which is communicated with the gas phase space, the pressure and the liquid level in the reactor are controlled by controlling the displacement of the exhaust system, the liquid phase material dissolved with the hydrogen enters a hydrogenation catalyst bed at the lower part of the reactor for hydrotreatment reaction, a part of the liquid phase reaction productis discharged from the reaction system, and the other part circulates and is mixed with the raw material. The method can ensure good reaction effect and leads the liquid phase circulation hydrotreatment to be stably controlled and operated.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking method for producing chemical materials to maximum with low cost

ActiveCN101684415AReduce hydrogen consumptionLow investment costHydrocarbon oil crackingNaphthaFractionation

The invention relates to a hydrocracking method for producing chemical materials to the maximum with low cost, comprising the following steps: mixing raw oil and hydrogen gas , entering a first reaction area, sequentially contacting with hydrofining catalyst and hydrocracking catalyst, reacting under the pressure of 6.0-16.0 MPa; carrying out oil-gas separation and fractionation on the reaction products thereof to obtain liquefied gas, light naphtha fractions, heavy naphtha fractions, middle fractions and tail oil fractions; mixing the middle fractions and the hydrogen gas and enteringa second reaction area, contacting with the hydrocracking catalyst under the pressure of 1.0-5.5 MPa to react; and carrying out oil-gas separation on the reaction products thereof and entering a fractionation system . By adopting the method, heavy raw materials such as vacuum gas oil, coking gas oil and the like are treated to obtain more than 98 weight percent chemical materials. In the invention, themiddle fractions are wholly converted into the chemical materials in the low pressure condition, and low hydrogen consumption, low investment cost and low operation cost are realized.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and system for controlling the operation of a hydrogen generator and a fuel cell

InactiveUS20040080297A1Low costBatteries circuit arrangementsReactant parameters controlHydrogen fuel cellTransducer

This application relates to a method and system for controlling the supply of fuel to a dead-ended hydrogen fuel cell. The invention may be utilized, for example, to more efficiently integrate the operation of a hydrogen fuel cell and a hydrogen generator, such as a reformer coupled with a hydrogen separation unit. The invention ensures that the production and consumption of hydrogen are effectively balanced to avoid negative feed line pressure fluctuations. The fuel supply control subsystem and hydrogen consumption control subsystems are, however, "decoupled" and hence independently operable. The invention may include an accumulator disposed in a flow path between the hydrogen generator and the fuel cell for storing hydrogen under pressure. The accumulator is sufficiently large in volume such that the pressure of hydrogen in the flow path does not deviate substantially from a target pressure, even during the waste purging sessions. The system enables the use of low-cost pressure transducers in place of mass flow meters. In one aspect of the invention raffinate flow from the hydrogen separator can be controllably adjusted to regulate the temperature or other operating parameters of the reformer.

Owner:CELLEX POWER PRODS

Carbon monoxide adsorption for carbon monoxide clean-up in a fuel cell system

InactiveUS6964692B2Eliminate useReduce carbon monoxide contentThermal non-catalytic crackingCombination devicesSorbentHydrogen fuel cell

An apparatus removes carbon monoxide (CO) from a hydrogen-rich gas stream in a hydrogen fuel cell system. CO fouls costly catalytic particles in the membrane electrode assemblies of proton exchange membrane (PEM) fuel cells. A vessel houses a carbon monoxide adsorbent. The vessel may be a rotating pressure swing adsorber. A water gas shift reactor is upstream of the rotating pressure swing adsorber. The water gas shift reactor may include a second adsorbent adapted to adsorb carbon monoxide at low temperatures and to desorb carbon monoxide at high temperatures. The apparatus advantageously eliminates the use of a preferential oxidation (PROX) reactor, by providing an apparatus which incorporates CO adsorption in the place of the PROX reactor. This cleans up carbon monoxide without hydrogen consumption and the concomitant, undesirable excess low grade heat generation. The present invention reduces start-up duration, and improves overall fuel processor efficiency during normal operation.

Owner:GM GLOBAL TECH OPERATIONS LLC

Production of stable olefinic fischer tropsch fuels with minimum hydrogen consumption

The present invention relates to a stable, low sulfur, olefinic distillate fuel blend component derived from a Fischer-Tropsch process and a process for producing this stable, low sulfur, olefinic distillate fuel blend component. The stable, low sulfur, olefinic distillate fuel comprises olefins in an amount of 2 to 80 weight percent, non-olefins in an amount of 20 to 98 weight percent wherein the non-olefins are predominantly paraffins, oxygenates in an amount of less than 1 weight percent, and sulfur in an amount of less than 10 ppm by weight. A distillate fuel comprising the above blend component forms less than 5 ppm peroxides after storage at 60° C. for four weeks.

Owner:CHEVROU USA INC

Liquid phase distillate dewaxing

Hydrocarbon feeds can be hydrotreated in a continuous gas-phase environment and then dewaxed in a liquid-continuous reactor. The liquid-continuous reactor can advantageously be operated in a manner that avoids the need for a hydrogen recycle loop. A contaminant gas can be added to the hydrogen input for the liquid-continuous reactor to modify the hydrogen consumption in the reactor.

Owner:EXXON RES & ENG CO

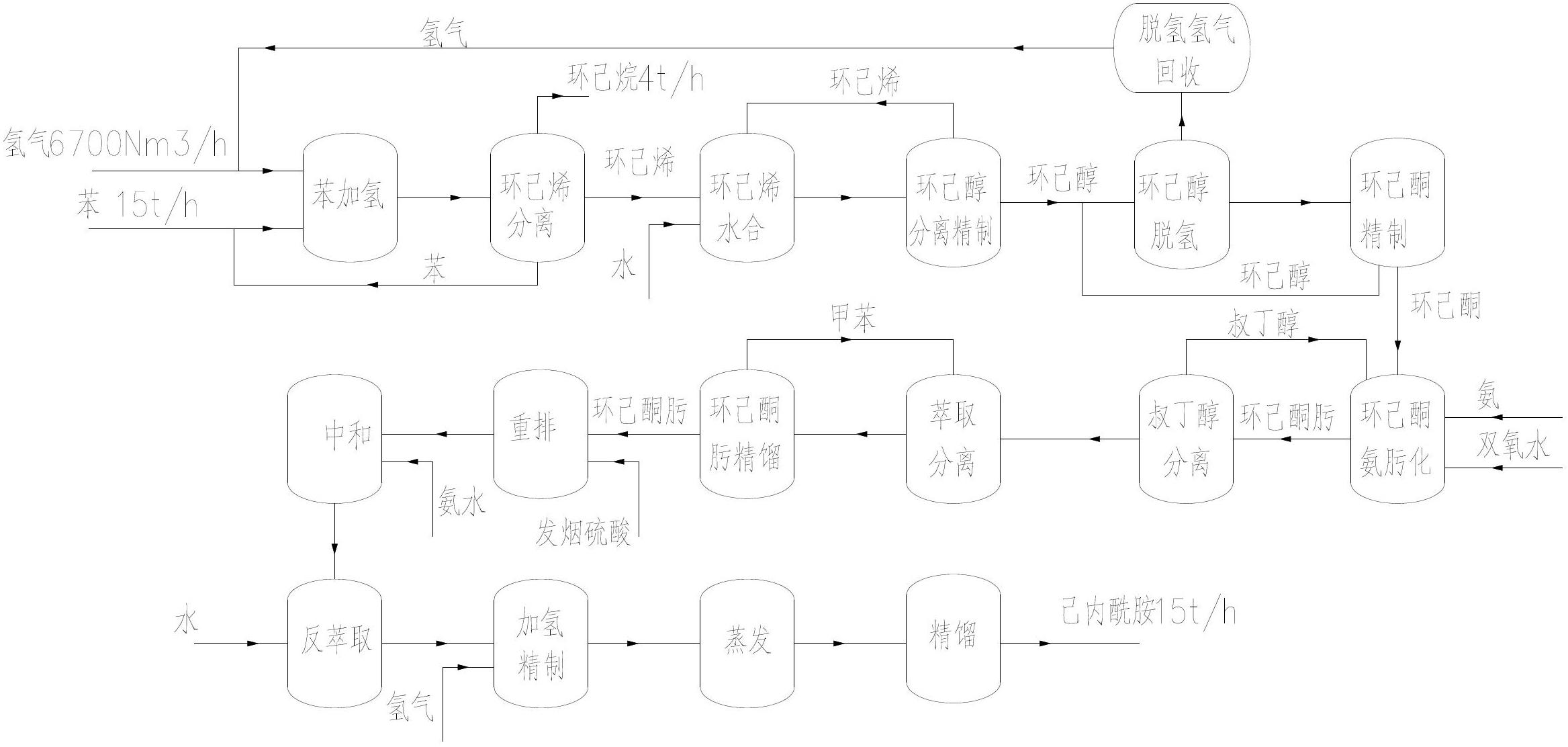

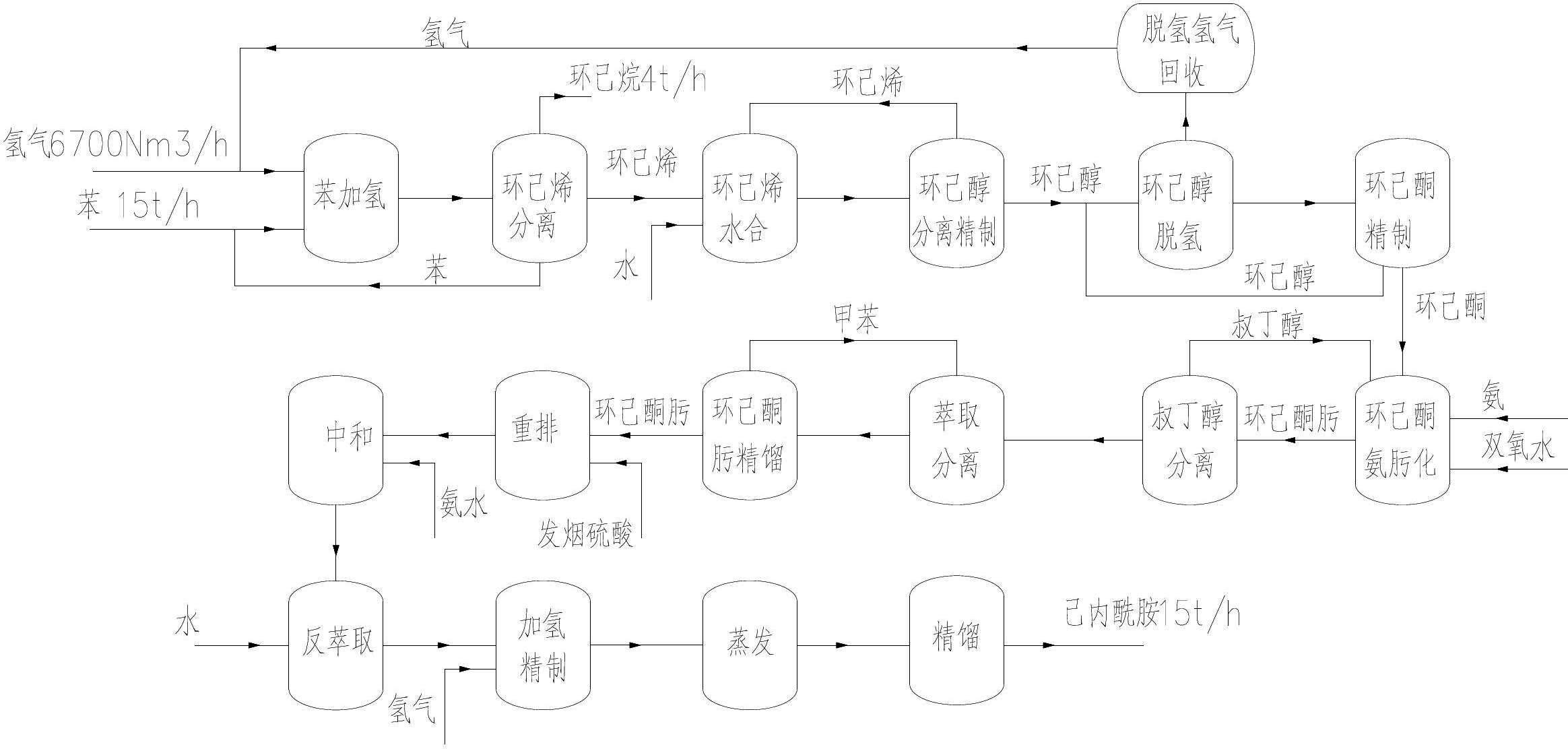

Method for producing caprolactam by taking high-purity benzene as raw material

ActiveCN102675176AAvoid it happening againQuality improvementLactams preparationHydration reactionCyclohexene

The invention provides a method for producing caprolactam by taking high-purity benzene as a raw material, and the method comprises the following steps of: A. preparing cyclohexene from the raw material benzene through hydrogenation; B. separating and purifying cyclohexene; C. carrying out hydration on the cyclohexene for preparing cyclohexanol; D. separating and purifying cyclohexanol; E. carrying out dehydrogenation on cyclohexanol for preparaing cyclohexanone; F. refining cyclohexanone; G. carrying out oximation on cyclohexanone so as to prepare cyclohexanone-oxime; H. refining cyclohexanone-oxime; I. carrying out rearrangement on refined cyclohexanone-oxime so as to prepare caprolactam; and J. refining caprolactam, wherein the high-purity benzene is adopted as a raw material, so that the purity of benzene is more than 99.95%, the sulphur content is less than 5ppm, and the methylbenzene is not more than 100ppm. The method has the beneficial effects that the high-purity benzene is adopted as a raw material, so that the impurity is less, and the product quality is high; the raw material is high in comprehensive utilization rate and low in hydrogen consumption; and the mass of the raw material and intermediate products generated in all the steps of reaction can be strictly controlled, so that the direct commercial value of the intermediate products is fully exerted, and the optimal quality of the product caprolactam can be reached.

Owner:CHINA TIANCHEN ENG +3

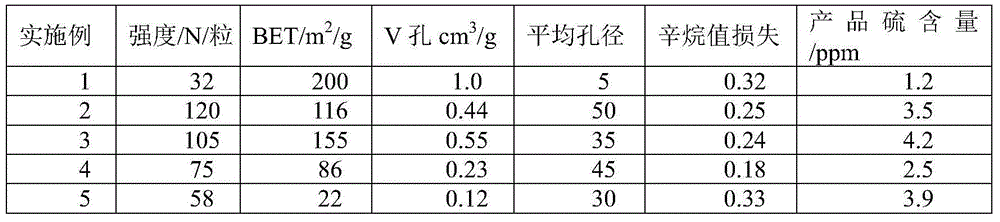

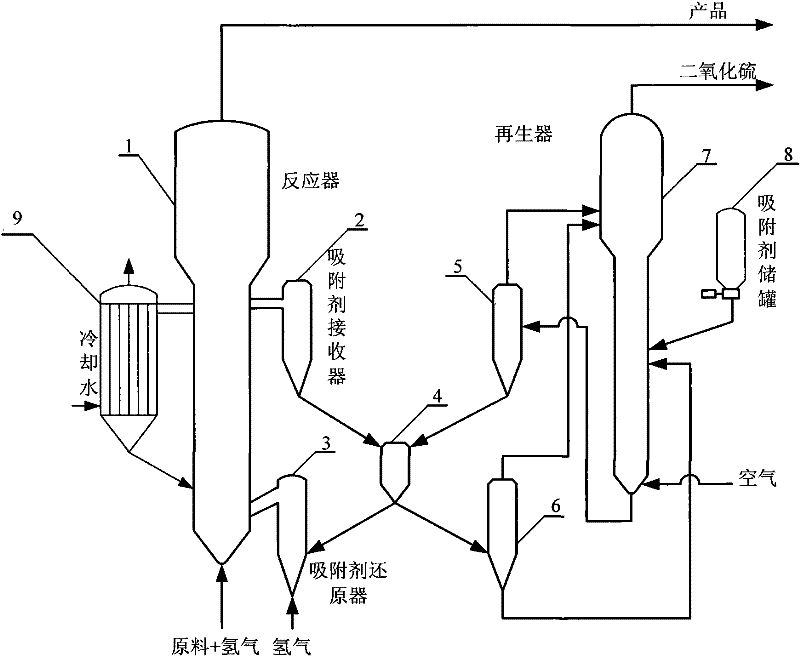

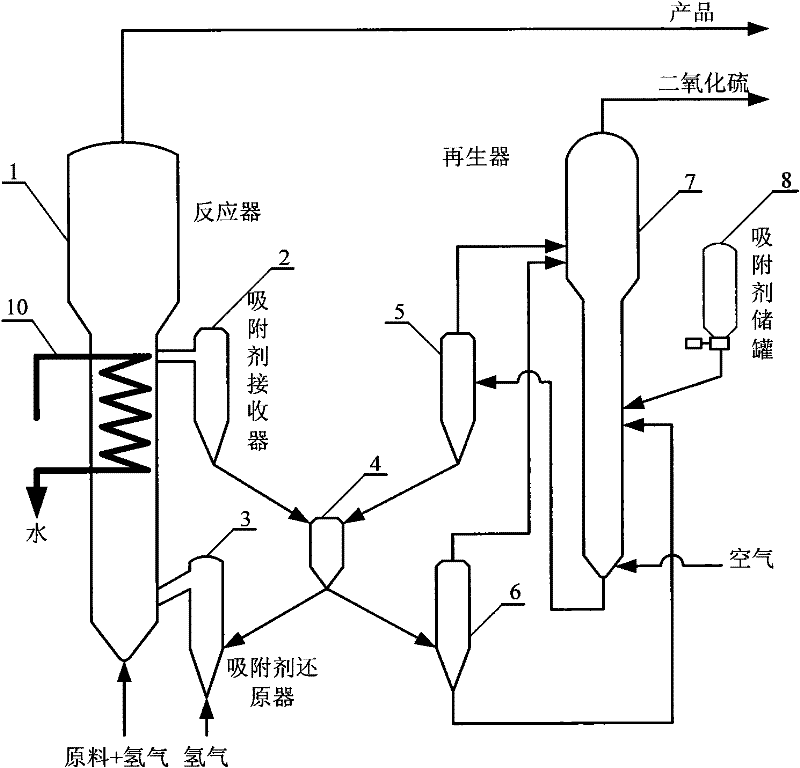

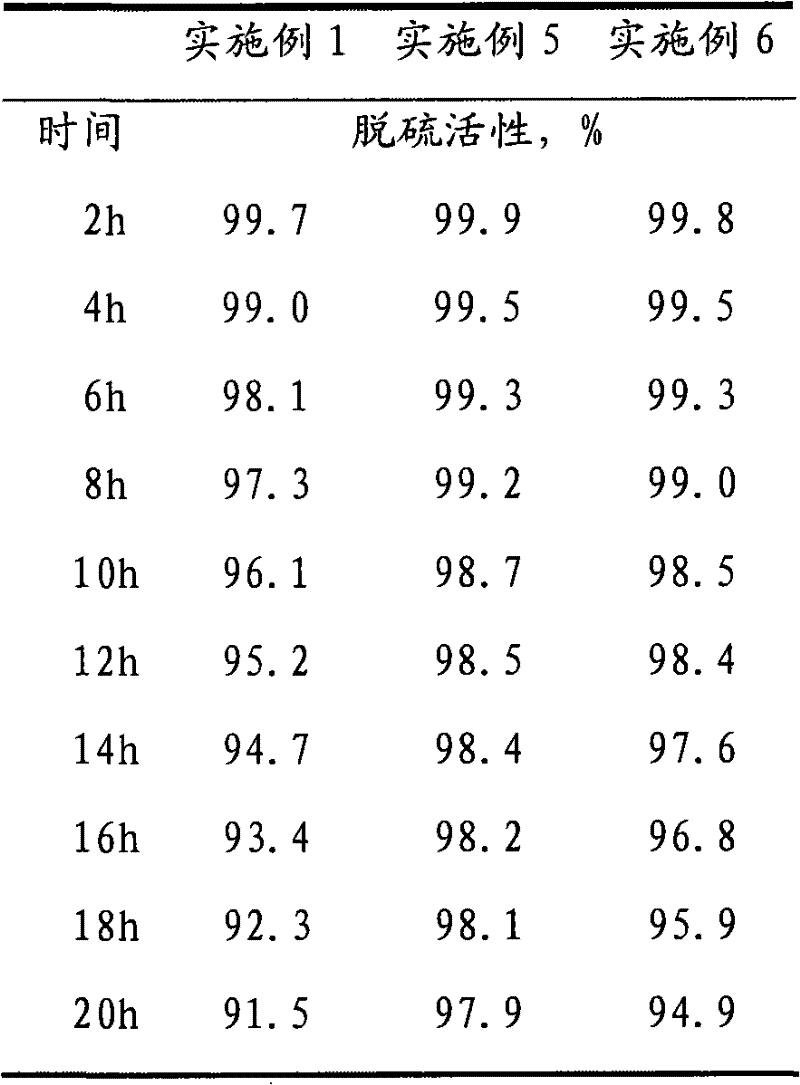

Fuel oil deep-adsorption desulfurizationn catalyst, preparation method and application thereof

ActiveCN104056632ALarge specific surface areaReduce hydrogen consumptionOther chemical processesMetal/metal-oxides/metal-hydroxide catalystsPtru catalystSorbent

The invention discloses a fuel oil deep-adsorption desulfurizationn catalyst. The desulfurizationn catalyst is characterized by consisting of an active component, a sulfur adsorbent and an adhesion agent, wherein the active component refers to one or more of Ni, Co, Cu, W and Mo oxides; the sulfur adsorbent refers to at least one of Mg, Ca, Zn, Ce, Fe, Mn and Ti oxides; the mass percent content of the active component is 2wt%-50wt%, the mass percent content of the sulfur adsorbent is 20wt%-90wt%, and the mass percent content of the rest components is the adhesion agent. The adhesion agent is one or a mixture of more than one of aluminium oxide, pseudo-boehmite, kaolin, imvite, bentonite, Yunmeng soil, kieselguhr, silica sol, silica gel and expanded perlite. The catalyst has the advantages of high specific surface area, moderate reaction, high intensity and low hydrogen consumption.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

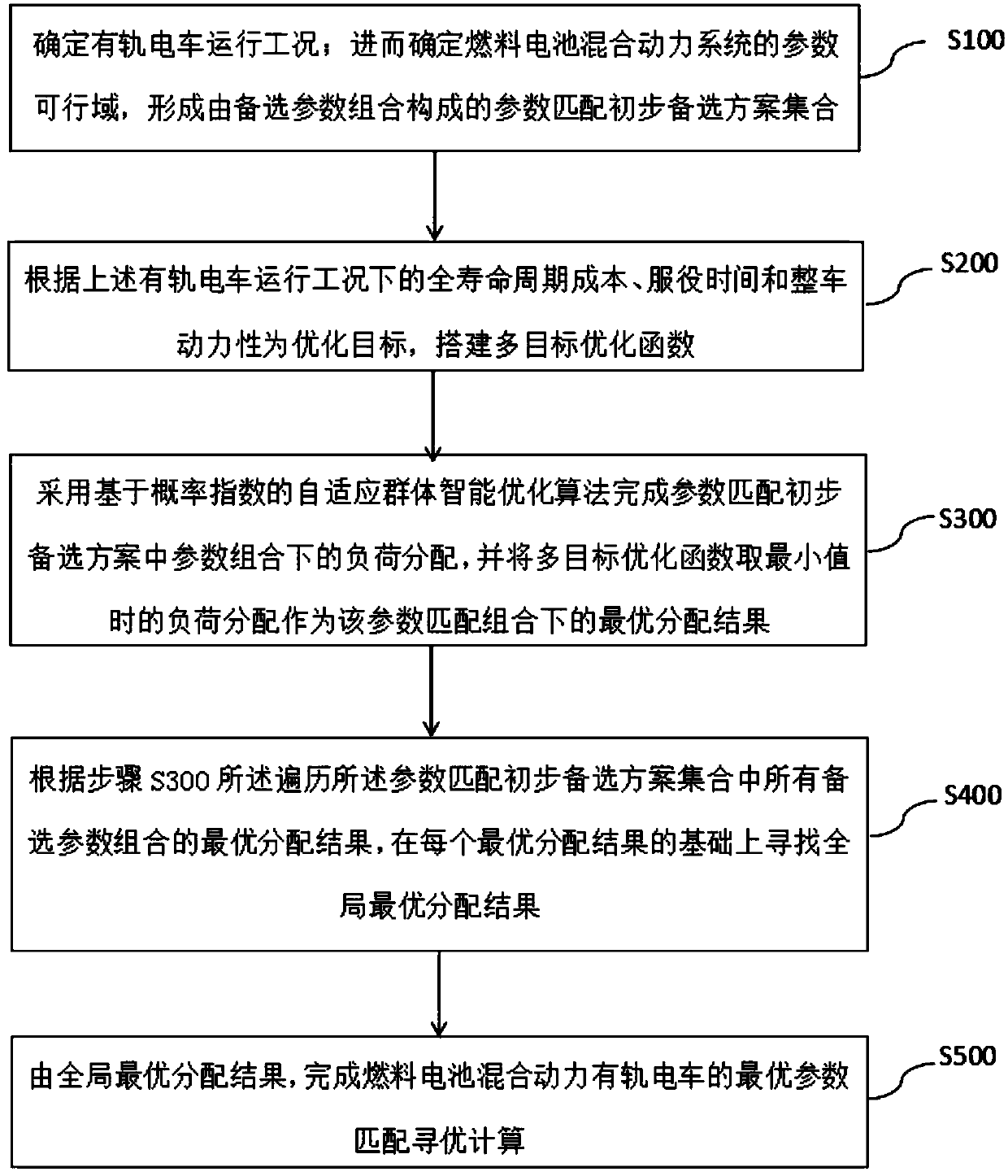

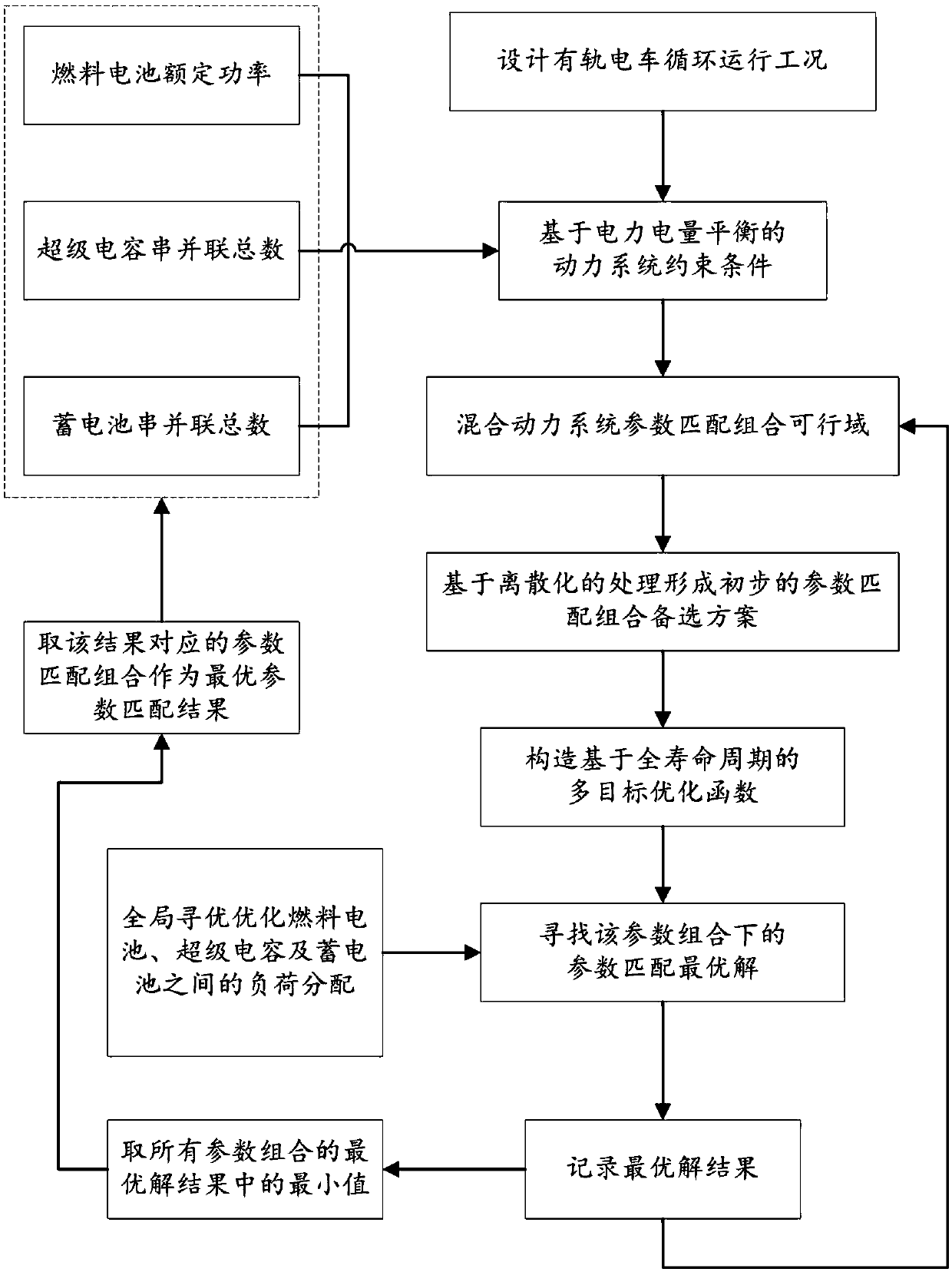

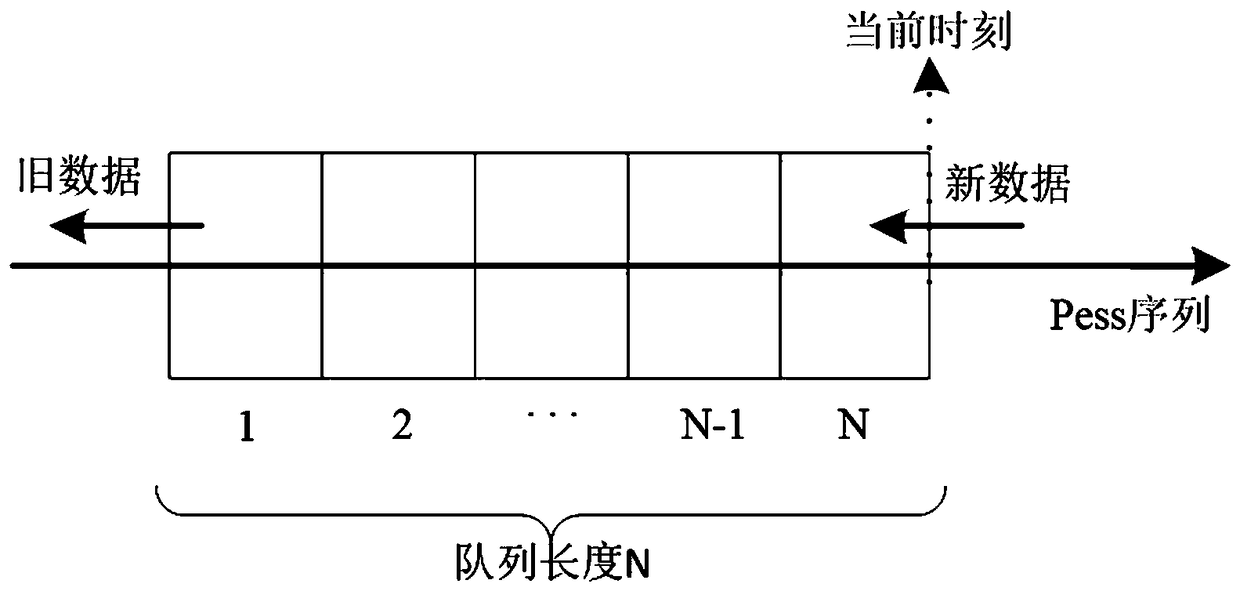

Parameter matching joint optimization method of fuel cell hybrid tramcar

ActiveCN107618519AIncrease output powerReduce unnecessary redundancyElectric locomotivesVehicular energy storagePower performanceSelf adaptive

The invention discloses a parameter matching joint optimization method of a fuel cell hybrid tramcar. The method includes: according to operation needs and target route conditions, designing tramcar power system indexes and tramcar operation conditions and determining the parameter feasible region of a fuel cell hybrid power system to form a preliminary parameter matching alternative scheme; usingwhole life cycle cost, service time and the power performance of the whole tramcar as the optimization targets to build a multi-target optimization function, using the self-adaptation swarm intelligent optimization algorithm based on probability indexes to complete load allocation under optional parameter combination, and using the load allocation when the value of the multi-target optimization function is minimum as the optimal allocation result under the parameter matching combination; traversing all alternative parameter combinations, and searching for the global optimum on the basis of the individual optimum to complete the optimal parameter matching optimization calculation of the fuel cell hybrid tramcar. By the method, hydrogen consumption can be reduced effectively, the efficiencyof the whole tramcar can be increased, and optimal economical efficiency during operation can be achieved.

Owner:SOUTHWEST JIAOTONG UNIV

Production of stable olefinic Fischer-Tropsch fuels with minimum hydrogen consumption

Owner:SASOL TEKHNOLODZHI PROPRIEHJTEHRI LTD

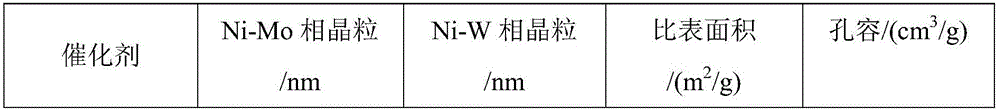

Preparation method of bulk-phase hydrofining catalyst

ActiveCN106513006AExcellent hydrodesulfurization performanceReduce utilizationHeterogenous catalyst chemical elementsMetal/metal-oxides/metal-hydroxide catalystsActive phaseSulfur containing

The invention relates to a preparation method of a bulk-phase hydrofining catalyst. The method comprises steps as follows: an Ni-containing compound and deionized water are mixed and pre-dispersed in an ultrasonic environment, a Mo-containing compound is added, an Ni-Mo fine grain structure is formed by adjusting the ultrasonic frequency and in combination with a surfactant and ammonia water, a W-containing compound and a complexing agent are added for a hydrothermal reaction, spray drying and roasting are performed, and active component powder is obtained; an active component and aluminum hydroxide dry glue are mixed, kneaded and extruded, and the catalyst is obtained through drying and roasting. According to the catalyst prepared with the method, grains of active phases are fine, grains of different active phases are uniformly dispersed, the utilization rate of active metal is high, the catalyst has an excellent pore structure property, the removal efficiency of complicated sulfur-containing compounds in inferior diesel oil is improved, hydrogen consumption is reduced, and the use cost of the catalyst is reduced.

Owner:CNOOC TIANJIN CHEM RES & DESIGN INST +1

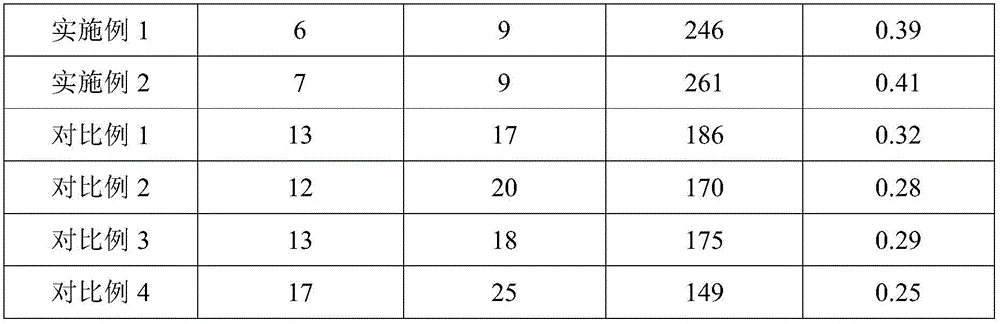

Small-sized coal gasification hydrogen making method

ActiveCN101391746AReduce consumptionReduce production energy consumptionHydrogen separationChemical industryImpurityFine chemical

The invention discloses a mini-type coal-gasifying hydrogen preparation method which comprises the following steps: blind coals are burnt and introduced with steam to prepare water gas; the water gas is processed by electricity to remove tar and then is processed by wet desulphurization so as to lead the content of H<2>S to be less than 200ppm; the water gas is converted to obtain a converted gas mixed by CO<2> and H<2>; VPSA decarbonization is carried out to remove the impurity of H<2>O and CO<2> from the converted gas; PSA purification is carried out to remove all the impurity except hydrogen so as to obtain the hydrogen product. Compared with the mini-type natural-gas hydrogen preparation method, the method has simple process, easily-supplied materials and low energy consumption; the cost of preparing hydrogen can be reduced by 30 to 50 percent and then the investment can be saved by 20 percent. The method can be applicable to industries of petrifaction, metallurgy, food production, electronic, non-ferrous metals processing, steel, fine chemicals and the like, with the hydrogen consumption of 2000 to 50000m<3>n / h.

Owner:SHANGHAI HANXING ENERGY TECH

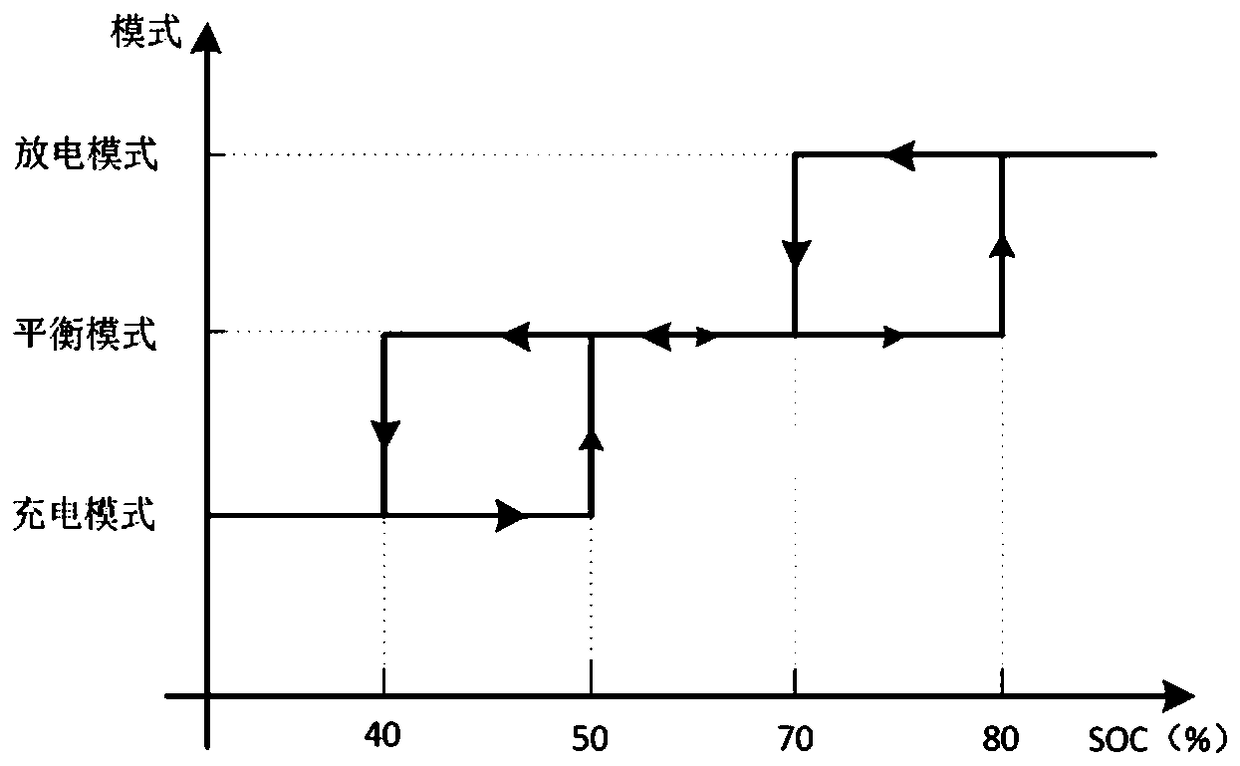

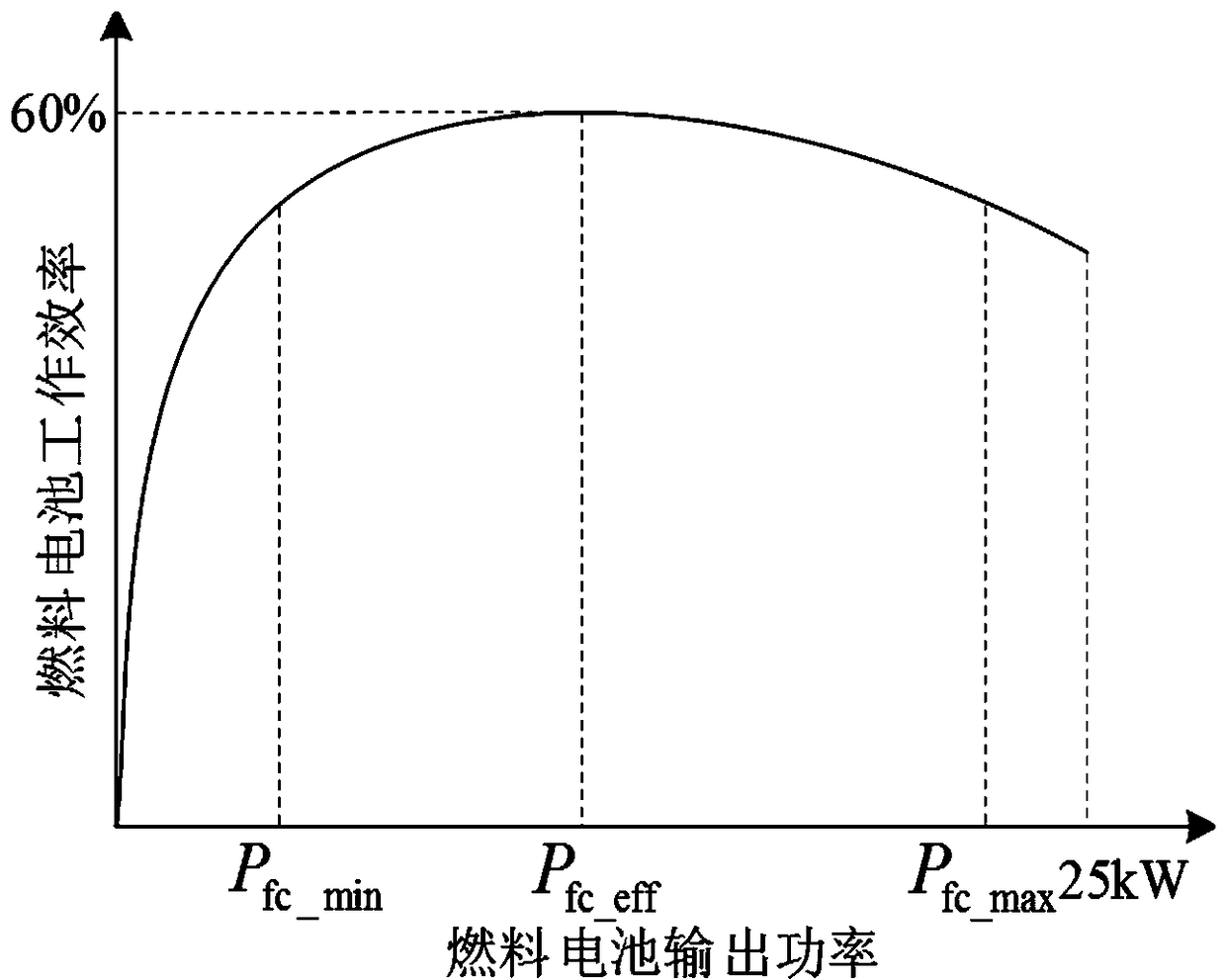

Power distribution method of fuel cell hybrid electric vehicle

ActiveCN108656981AReduce consumptionAvoid switching back and forthVehicular energy storageBattery/fuel cell control arrangementHysteresisCapacitance

The invention provides a power distribution method of a fuel cell hybrid electric vehicle. The power distribution method comprises the steps of distribution of output power of main energy sources andauxiliary energy sources of the vehicle, and distribution of output power among the auxiliary energy sources. The distribution strategy of the output power of the main energy sources and the auxiliaryenergy sources of the vehicle is that load power of the vehicle is distributed to a fuel cell and the auxiliary energy sources, and the power distribution strategy of the auxiliary energy sources isthat the required power of the auxiliary energy sources is distributed to a cell and a super capacitor. Under the condition of a charge-discharge hysteresis loop, modes are divided into the dischargemode, the balance mode and the charge mode. Then under the different cell modes, the distribution method based on rules is set by combining the working efficiency of the fuel cell. According to the demand distribution step of the auxiliary energy sources, the required power of the auxiliary energy sources serves as the sampling value, and the required power of the auxiliary energy sources minus the cell output power is the output power of the super capacitor. The load power is reasonably distributed to the fuel cell, the cell and the super capacitor, and meanwhile the purpose of decreasing ofthe hydrogen consumption quantity is achieved.

Owner:HENAN UNIV OF SCI & TECH

Method for producing super-low sulfur gas oil blending component or super-low sulfur gas oil composition, and super-low sulfur gas oil composition

InactiveUS7938955B2Reduce sulfur contentLow aromatic contentRefining with metalsLiquid carbonaceous fuelsAdverse effectFuel injection

Provided are a method for producing a super-low sulfur gas oil blending component or a super-low sulfur gas oil composition having a sulfur content of less than 5 mass ppm, under relatively mild conditions, without greatly increasing the hydrogen consumption and without remarkably decreasing the aromatic content; and a super-low sulfur gas oil composition having a sulfur content of less than 5 mass ppm which exhibits a high heating value, is excellent in fuel economy and output power, and is free from an adverse effect on a sealing rubber member or the like used in the fuel injection system and thus does not cause the leakage of a fuel. A method for producing a super-low sulfur gas oil blending component or a super-low sulfur gas oil composition having a sulfur content of less than 5 mass ppm is also disclosed.

Owner:JAPAN ENERGY CORP

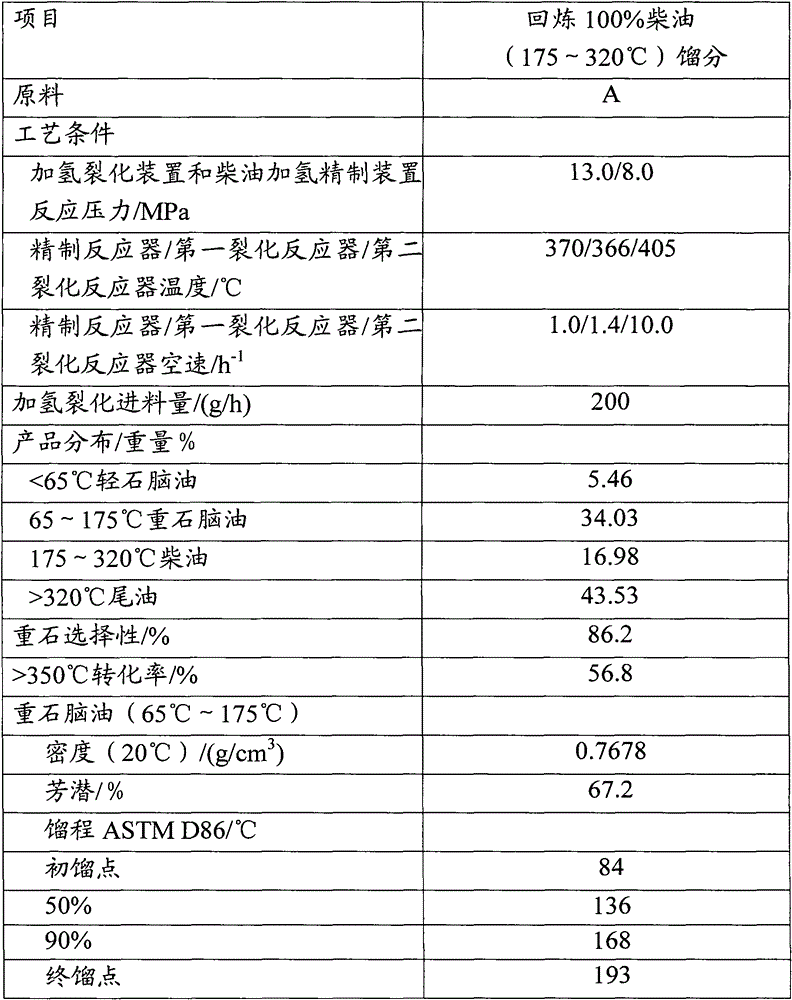

Hydrocracking method for producing chemical materials

ActiveCN103059986AHigh selectivityGood choiceTreatment with hydrotreatment processesNaphthaOrganic chemistry

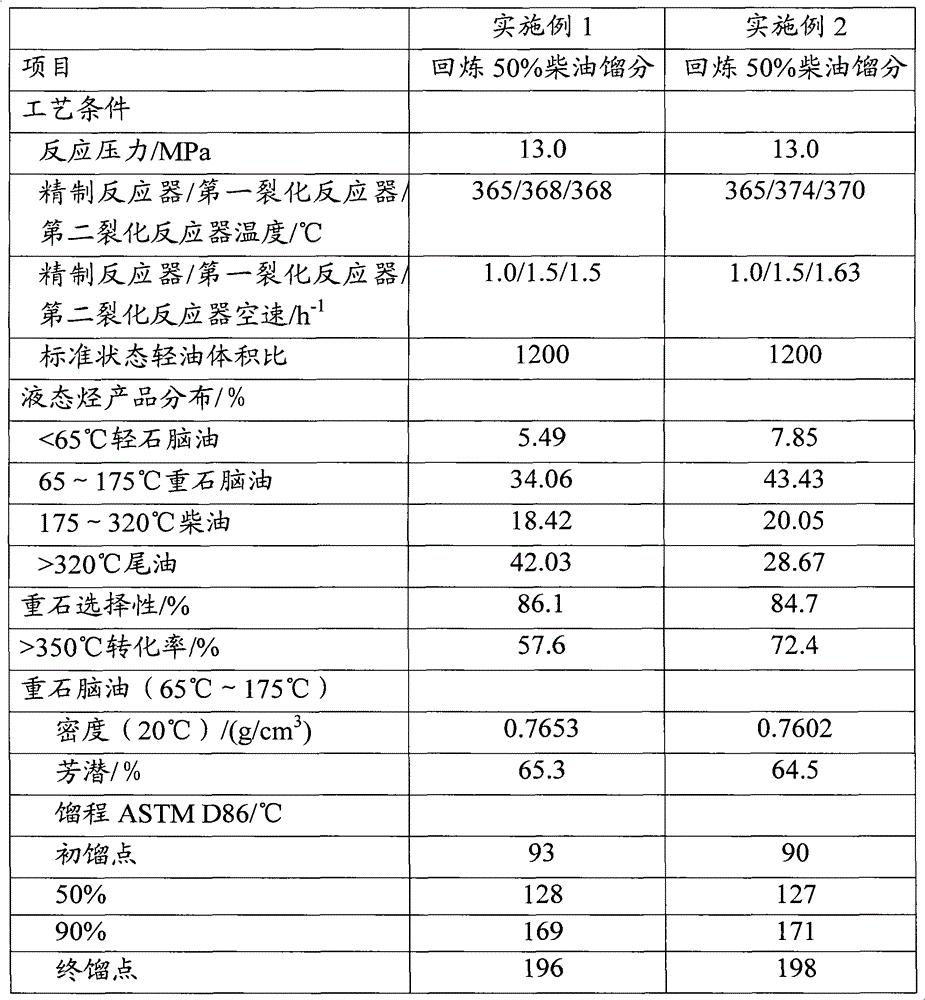

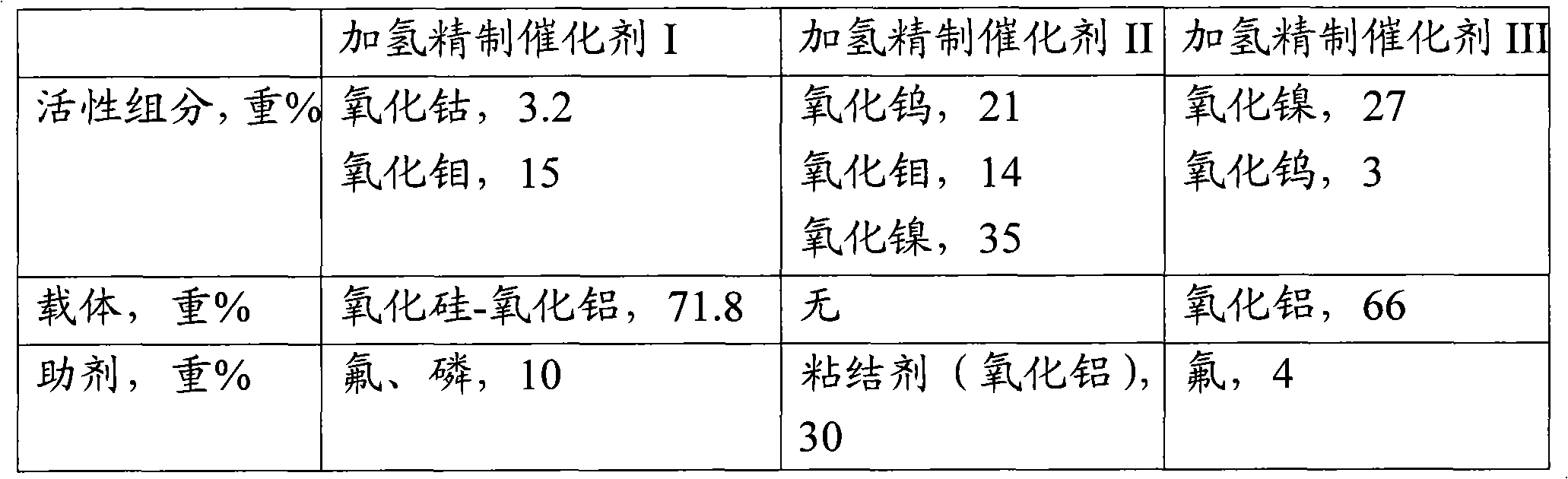

The invention discloses a hydrocracking method for producing chemical materials. The method comprises the steps of: orderly entering material oil and hydrogen into a hydrorefining reactor and a first hydrocracking reactor to react after being mixed; and cooling and separating reactants, and then entering obtained 10-100% of diesel fraction with the temperature of 175-320 DEG C into a second hydrocracking reactor to further react, wherein a hydrocracking catalyst II is a hydrocracking catalyst with low metal content; the metal content of the hydrocracking catalyst II is lower than that of a hydrocracking catalyst I. By adopting the hydrocracking method, the yield and the selectivity of heavy naphtha can be effectively improved; the aromatic latent of the heavy naphtha is improved, and hydrogen consumption is reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrogenation method for producing ultra-low sulfur clean diesel

ActiveCN102051217AHigh densityHigh denitrificationTreatment with hydrotreatment processesMetal/metal-oxides/metal-hydroxide catalystsHydrodesulfurizationSulfur

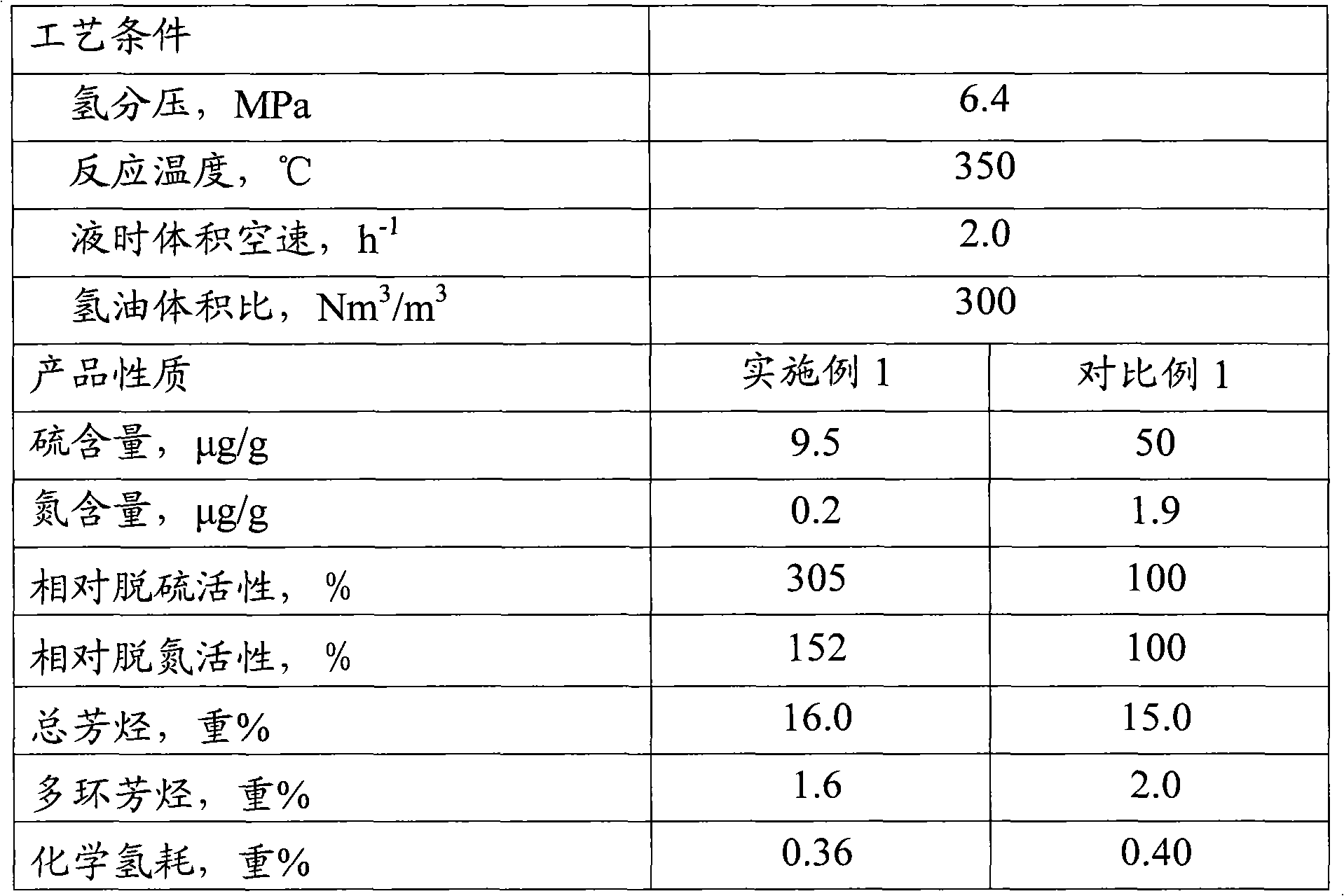

The invention relates to a hydrogenation method for producing ultra-low sulfur clean diesel. The method comprises the following steps: mixing diesel fraction feed oil and hydrogen gas, then transferring the mixture into a reactor to contact with a hydrofining catalyst I and a hydrofining catalyst II to react sequentially, and separating and distilling the reaction outflow to obtain the diesel product, wherein the hydrofining catalyst I is a supported hydrofining catalyst using Co-Mo as the active metal component, and the hydrofining catalyst II is a bulk hydrofining catalyst. By adopting the method provided by the invention to process inferior diesel fractions under mild conditions, the low sulfur or ultra-low sulfur clean diesel product can be obtained. Compared with the prior art, when the hydrodesulphurization depths are same, the chemical hydrogen consumption in the hydrogenation process of the invention is 5wt%-10wt% lower than that of the prior art.

Owner:CHINA PETROLEUM & CHEM CORP +1

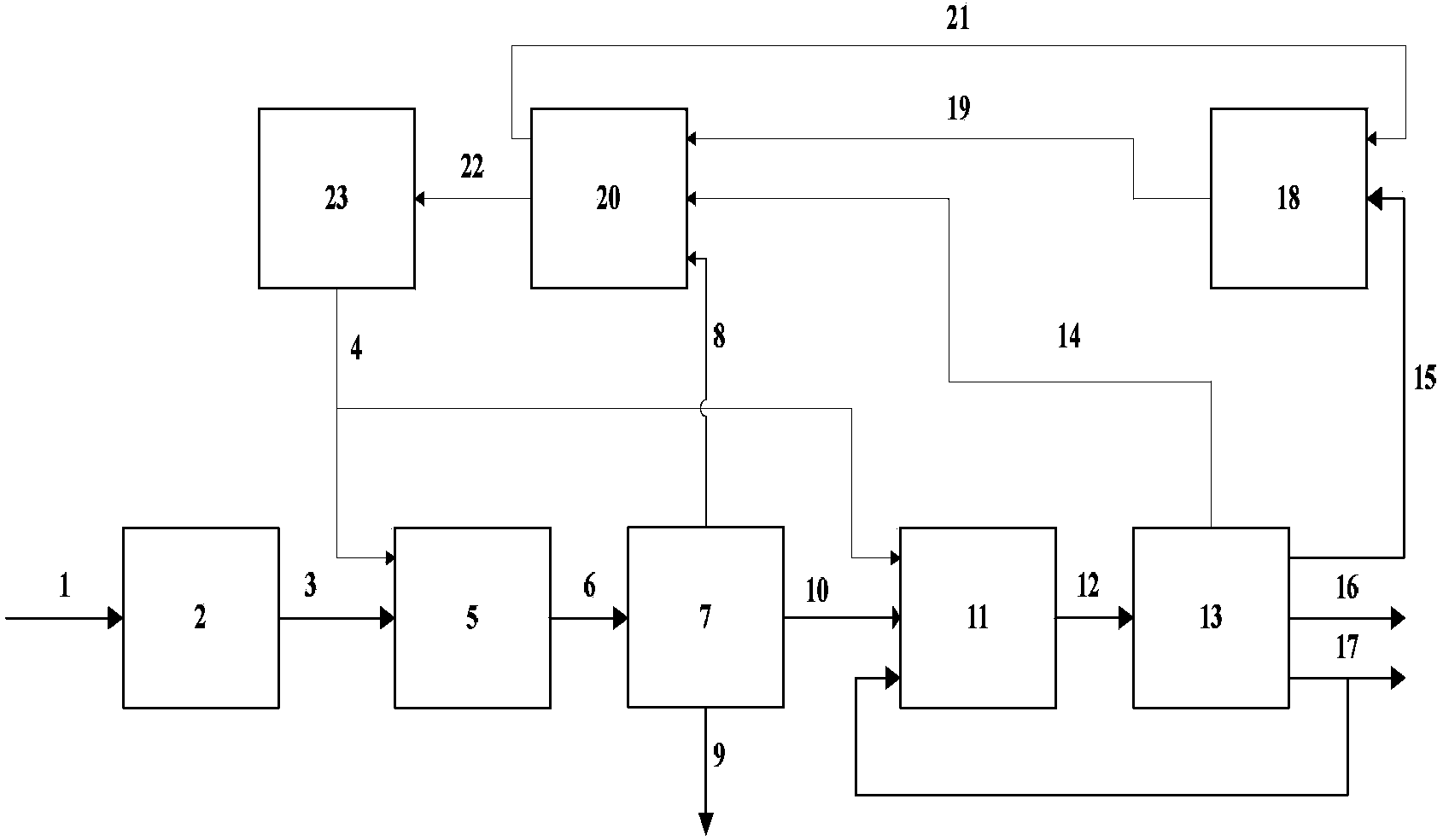

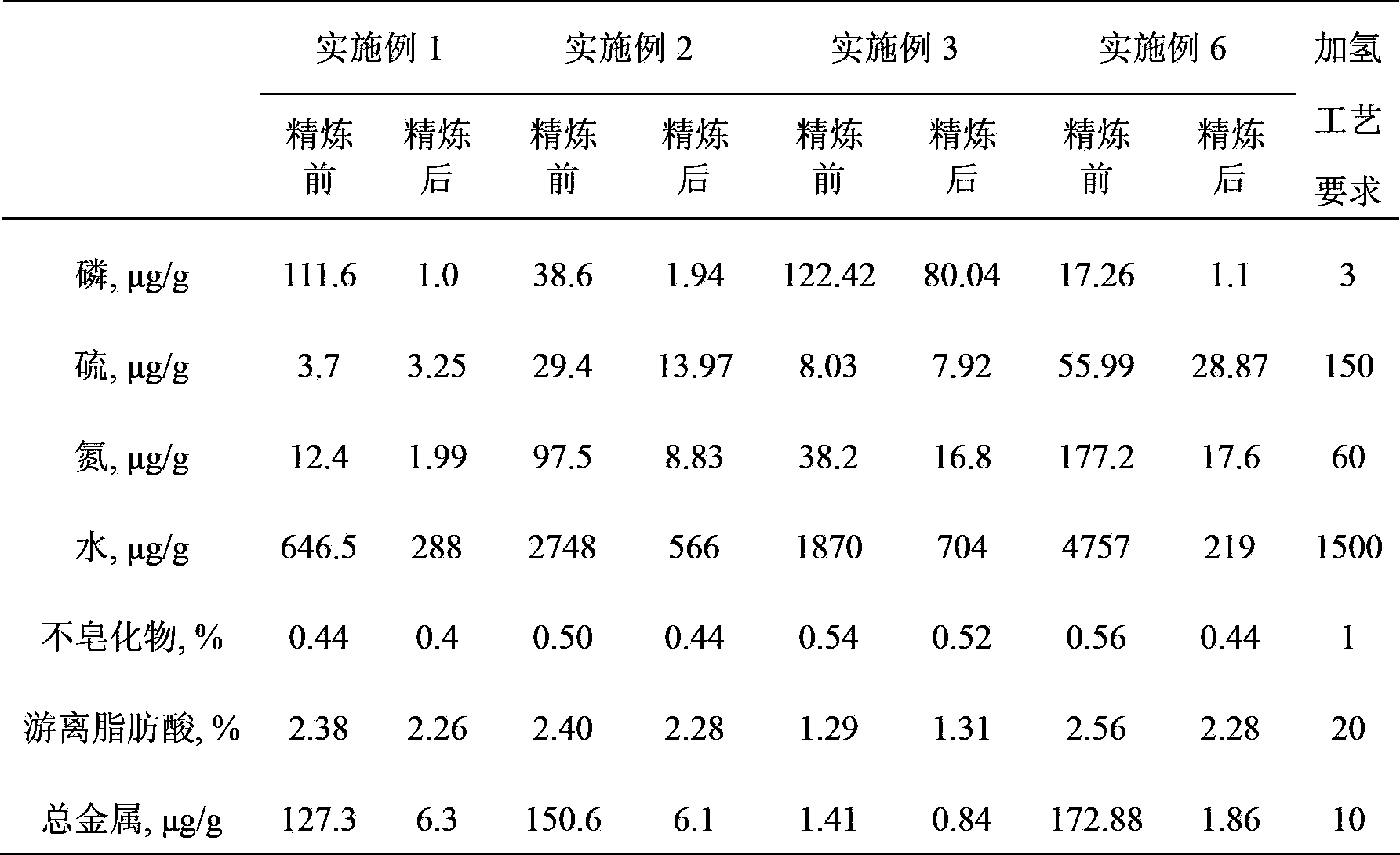

Method for production of diesel oil fraction and aviation fuel fraction by use of animal and plant oils and fats

The invention relates to a method for production of a diesel oil fraction and an aviation fuel fraction by use of animal and plant oils and fats, and the method comprises the following steps: a) performing refining processing on the animal and plant oils and fats; b) performing catalytic hydrogenation and deoxidation to obtain saturated linear alkanes and propane; c) performing hydroisomerization and hydrocracking processing to obtain an alkane material flow with higher branched chain degree; d) separating to obtain liquid hydrocarbons and gaseous hydrocarbons with the boiling point within the boiling point range of diesel oil, aviation fuels and naphtha; e) directly collecting the diesel oil fraction as a product, or cycling in whole or in part to continue isomerization and cracking reaction to increase production of the aviation fuel fraction; and f) mixing propane gaseous hydrocarbon and naphtha for steam reforming hydrogen production reaction, separating and purifying the obtained hydrogen to enter into a circulating hydrogen system; the method is used in the production of the renewable diesel oil and aviation fuels with excellent combustion performance and cold flow performance, and meanwhile efficient utilization of by-products and in-system supplement of hydrogen consumption can be realized.

Owner:PETROCHINA CO LTD

Method for lowering sulfur and olefin content in gasoline

ActiveCN102191080AReduce olefinsReduce sulfur contentHydrocarbon oils treatmentRefining to eliminate hetero atomsFluidized bedSorbent

The invention relates to a method for lowering the sulfur and olefin content in gasoline, which comprises: introducing a preheated gasoline raw material containing more than 35 weight percent of olefin and a hydrogen donor to a fluidized bed reactor to contact the gasoline raw material and the hydrogen donor with an absorber to form desulfurized oil gas and sulfurized absorbent; separating the desulfurized oil gas and sulfurized absorbent; delivering the separated oil gas to a subsequent separation system for product separation; and regenerating and reducing the sulfurized absorbent and returning the sulfurized absorbent to the reactor. The fluidized bed reactor is provided with a heater and / or devices for cooling the reduced absorbent and returning the reduced absorbent to the reactor. When the method is used to process a high-olefin gasoline raw material, deep desulfurization can be realized under a low hydrogen consumption condition, and the olefin content in the gasoline can be lowered considerably.

Owner:CHINA PETROLEUM & CHEM CORP +1

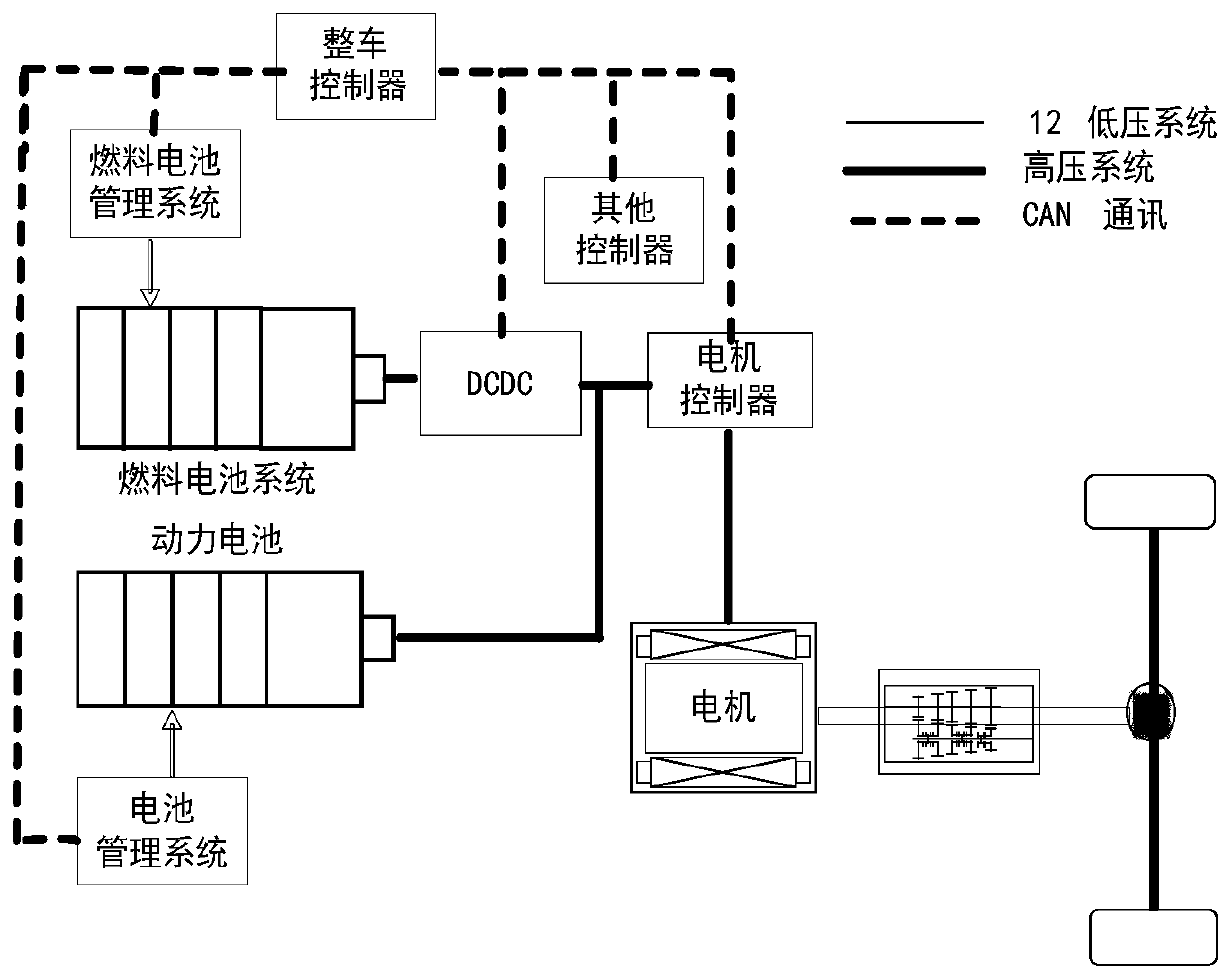

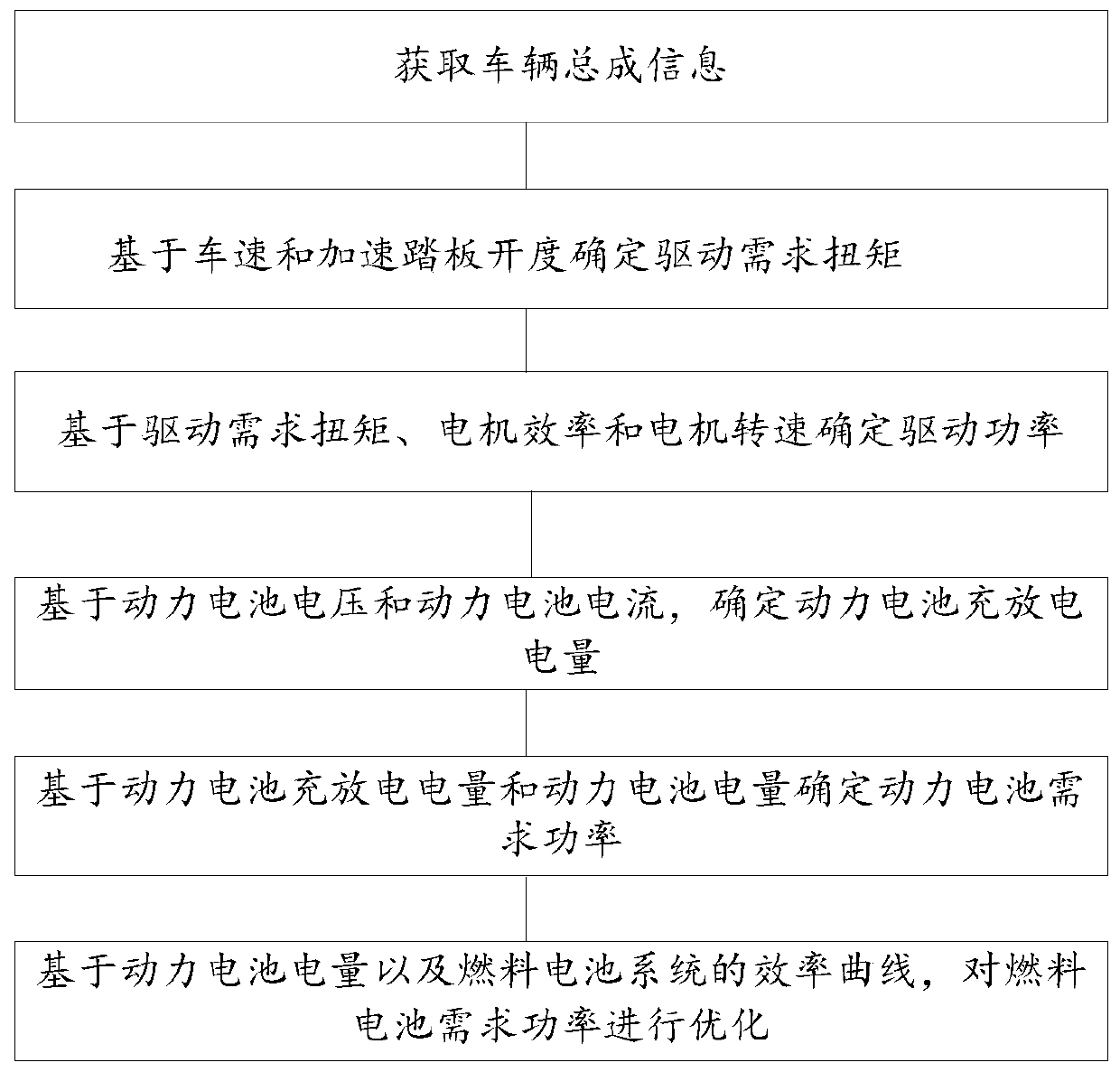

A whole vehicle power distribution control method and system for a fuel cell vehicle

ActiveCN109693578AReduce hydrogen consumption indexImprove efficiencyVehicular energy storageBattery/fuel cell control arrangementPower batteryDistribution control

The invention provides a whole vehicle power distribution control method for a fuel cell vehicle. The whole vehicle power distribution control method comprises the following steps: determining a driving required torque based on a vehicle speed and the accelerator pedal aperture; determining driving power based on the driving required torque, the motor efficiency and a motor rotating speed; based on a power battery voltage and a power battery current, determining the power battery charging and discharging electric quantity; determining a power battery required power based on the power battery charging and discharging electric quantity and the power battery electric quantity; taking a sum value obtained by adding the driving required power and the power battery required power as the fuel battery required power; optimizing the required power of the fuel cell based on the electric quantity of the power battery and the efficiency curve of the fuel cell system. The invention further providesa whole vehicle power distribution control system of the fuel cell vehicle. On the basis of protecting the power battery, the efficiency of the power battery is maximized, and on the basis of protecting the fuel cell system, a hydrogen consumption index of the whole vehicle is reduced to the maximum extent.

Owner:CHINA FIRST AUTOMOBILE

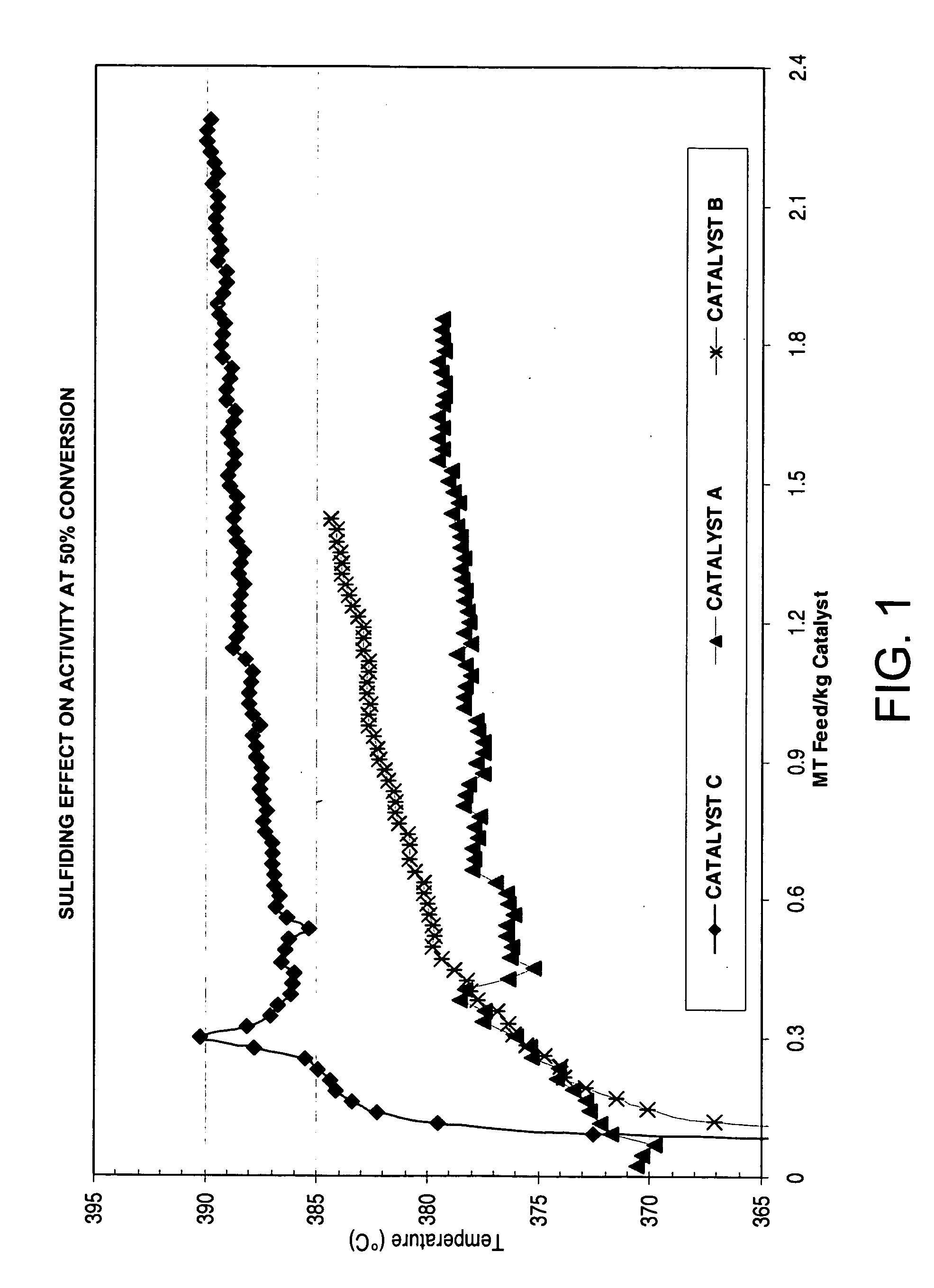

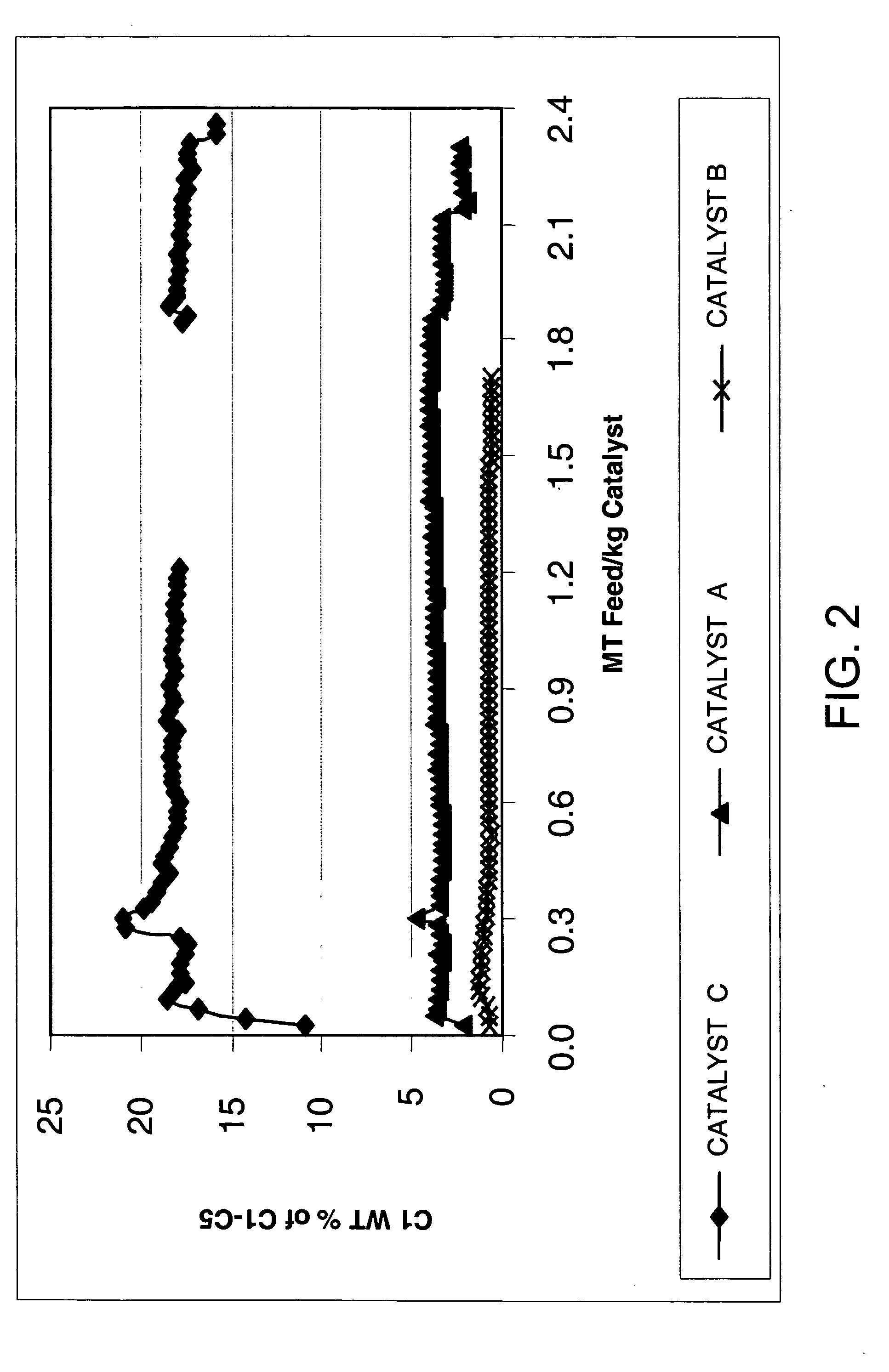

Catalyst treatment useful for aromatics conversion process

A process for preparing a transalkylation catalyst, the catalyst itself, and a transalkylation process for using the catalyst are herein disclosed. The catalyst comprises rhenium metal on a solid-acid support such as mordenite, which has been treated with a sulfur-based agent. Such treatment reduces the amount of methane produced by metal hydrogenolysis in a transalkylation process wherein heavy aromatics like A9+ are reacted with toluene to produce xylenes. Reduced methane production relative to total light ends gas production results in lower hydrogen consumption and lower reactor exotherms.

Owner:UOP LLC

Combined hydrogenation method of producing chemical materials

ActiveCN103059972AHigh yieldHigh selectivityTreatment with hydrotreatment processesNaphthaDiesel fuel

The invention discloses a combined hydrogenation method of producing chemical materials. The method comprises the steps of: mixing hydrocracking material oil with hydrogen, and then entering a mixture into a hydrorefining reactor and a first hydrocracking reactor by adopting a once serial process; further cracking 10-100% diesel fraction with the temperature of 175-320 DEG C in the second hydrocracking reactor which is arranged in a diesel refining unit, wherein the cracked oil is a mixed fraction of naphtha and diesel; and further fractioning the mixed fraction in a fractionating system of the diesel refining device to obtain light naphtha, high-aromatic latent heavy naphtha and the diesel fraction. By adopting the method disclosed by the invention, the hydrocracking device and the diesel refining device are combined to produce the chemical material; and the reaction pressure of the diesel refining device is low and middle pressure, and improvement of the aromatic latent of the heavy naphtha and reduction of hydrogen consumption are facilitated in the second hydrocracking process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com