Patents

Literature

76results about "Hydrocarbon oils treatment control/regulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

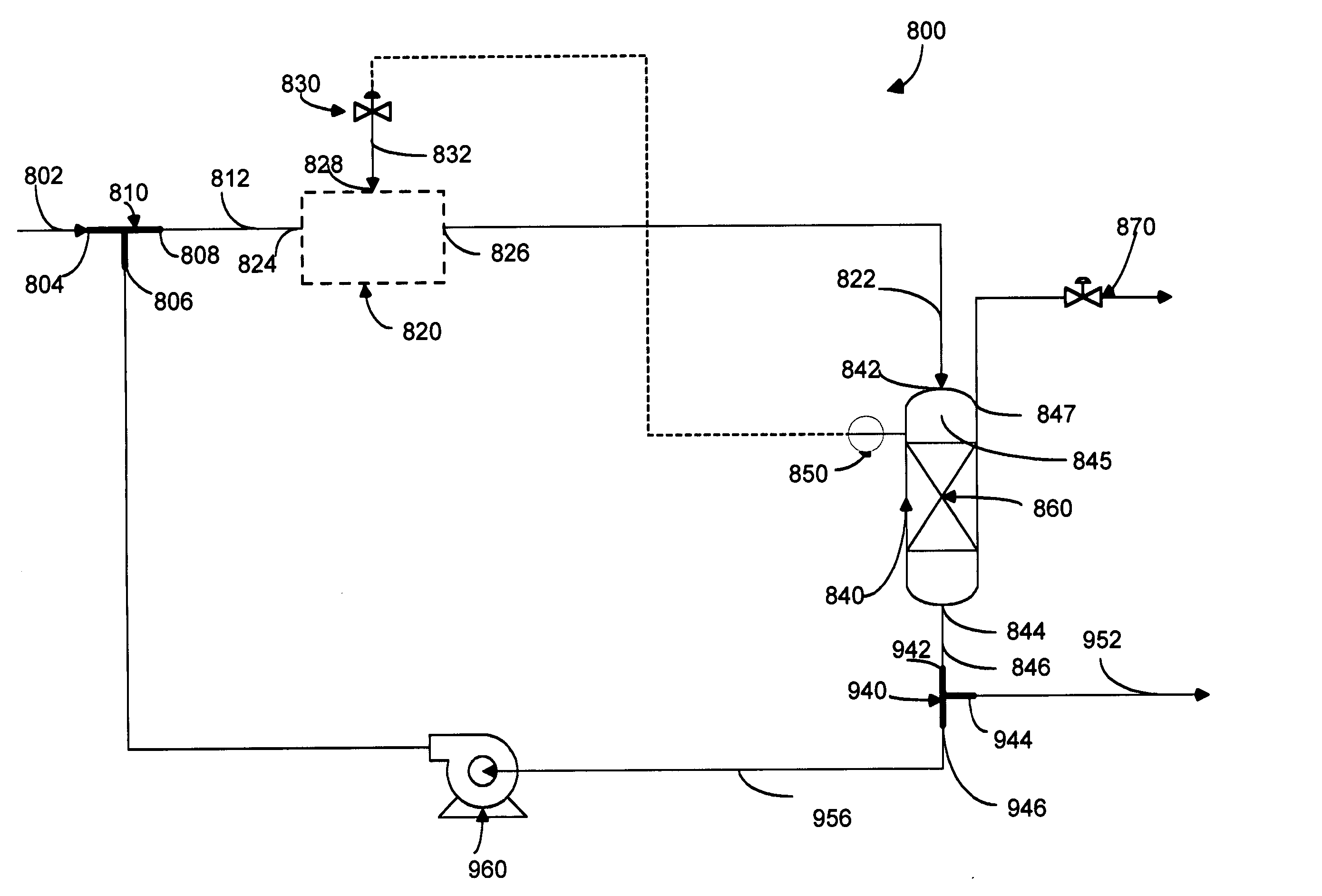

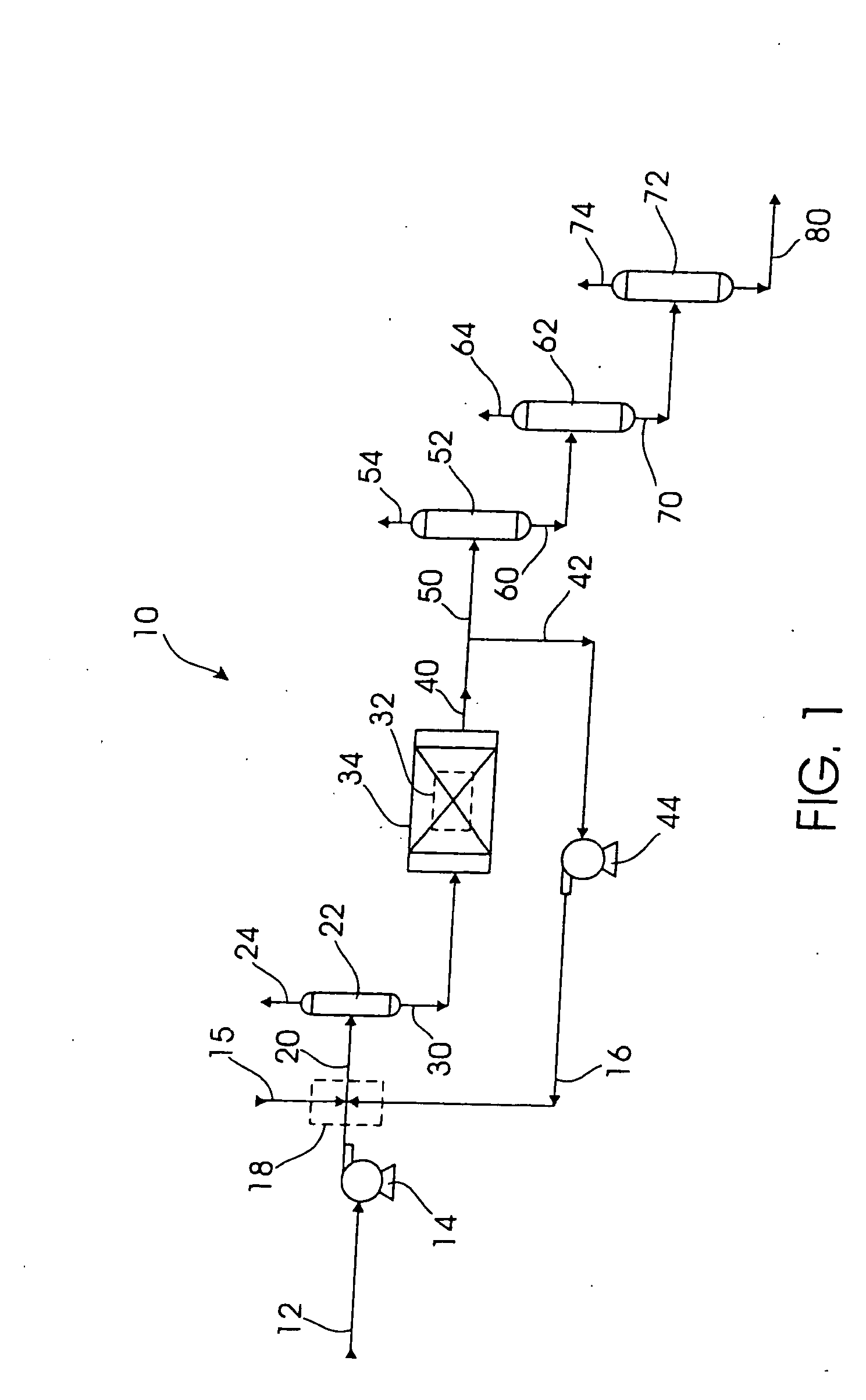

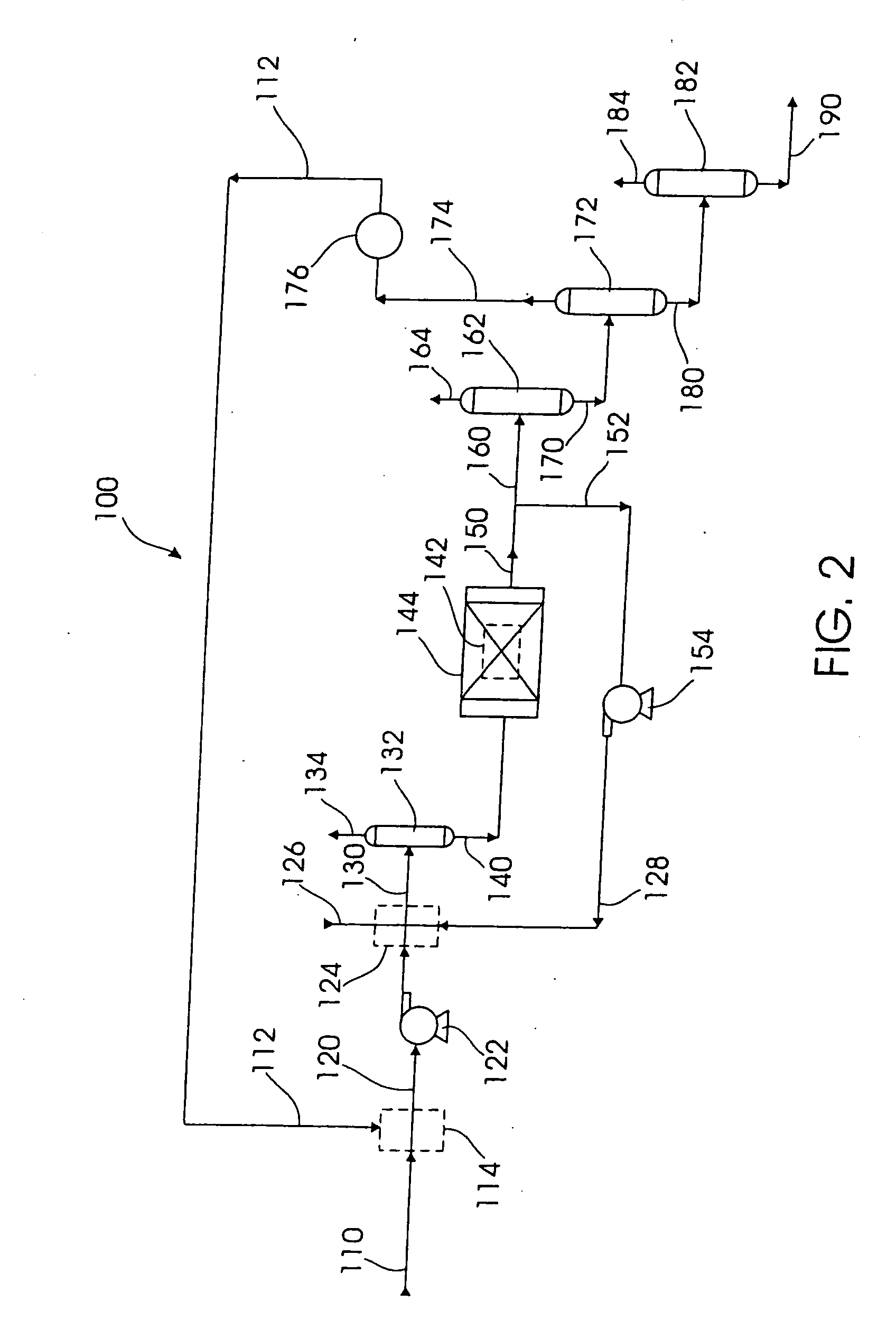

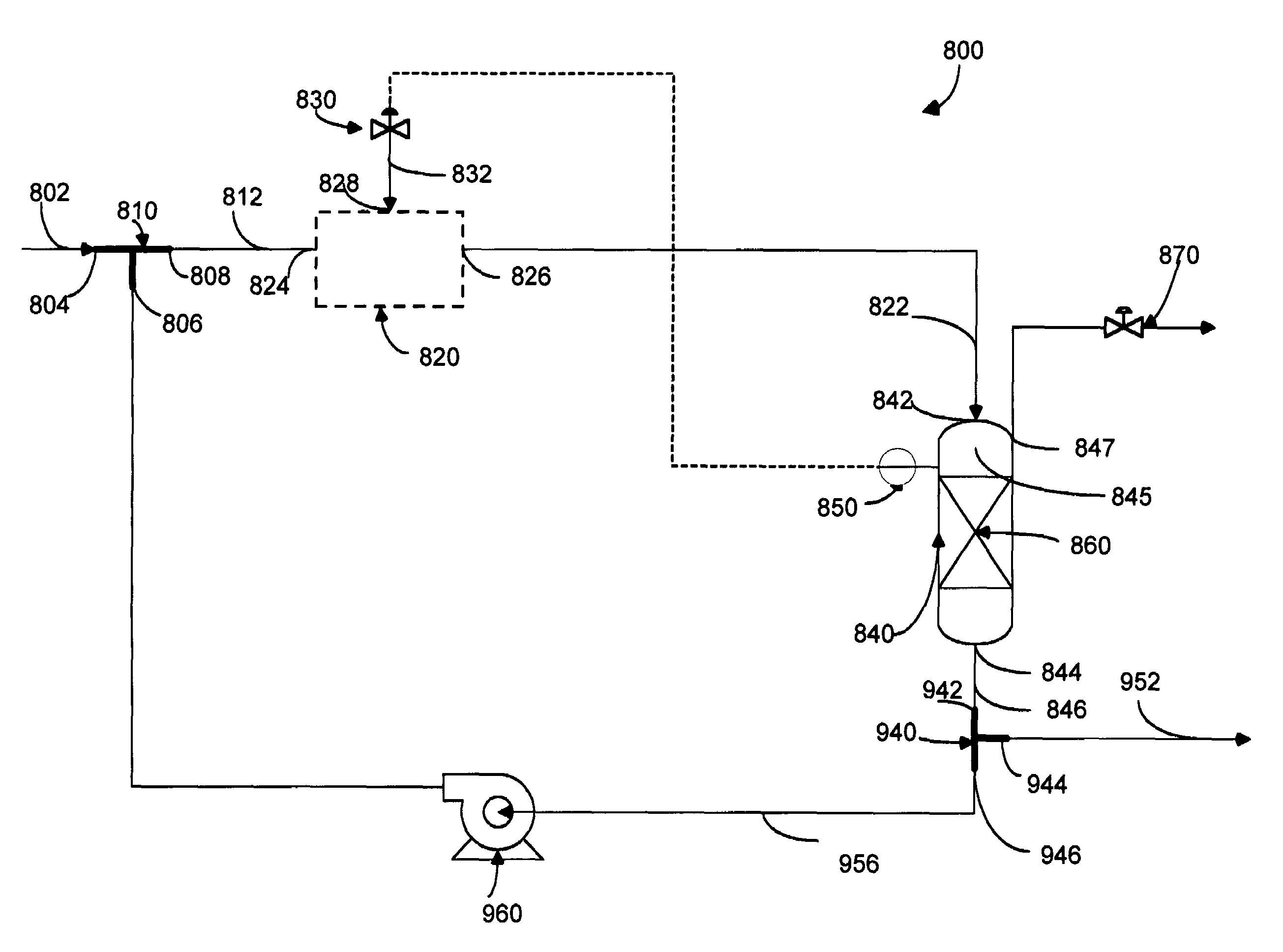

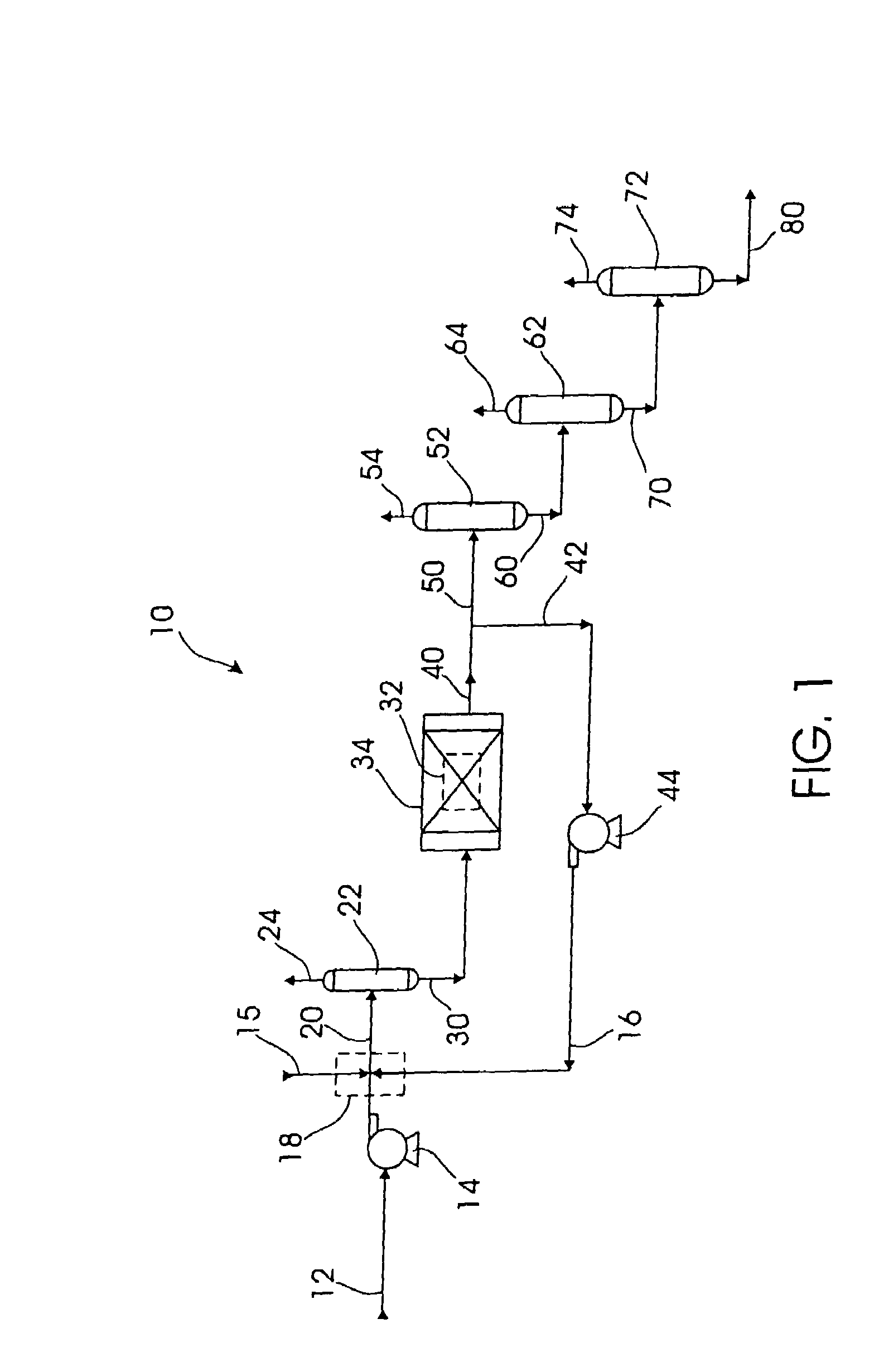

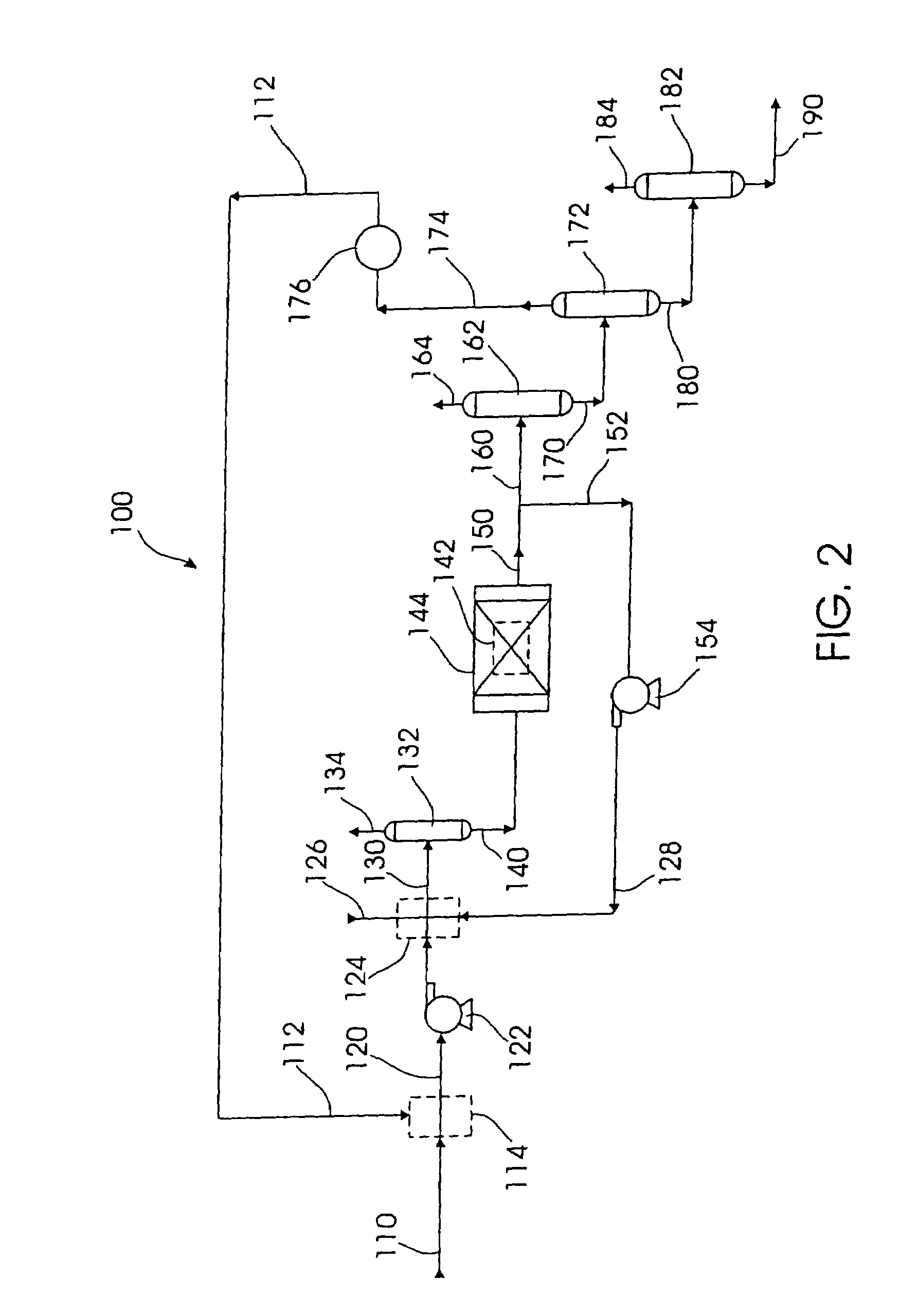

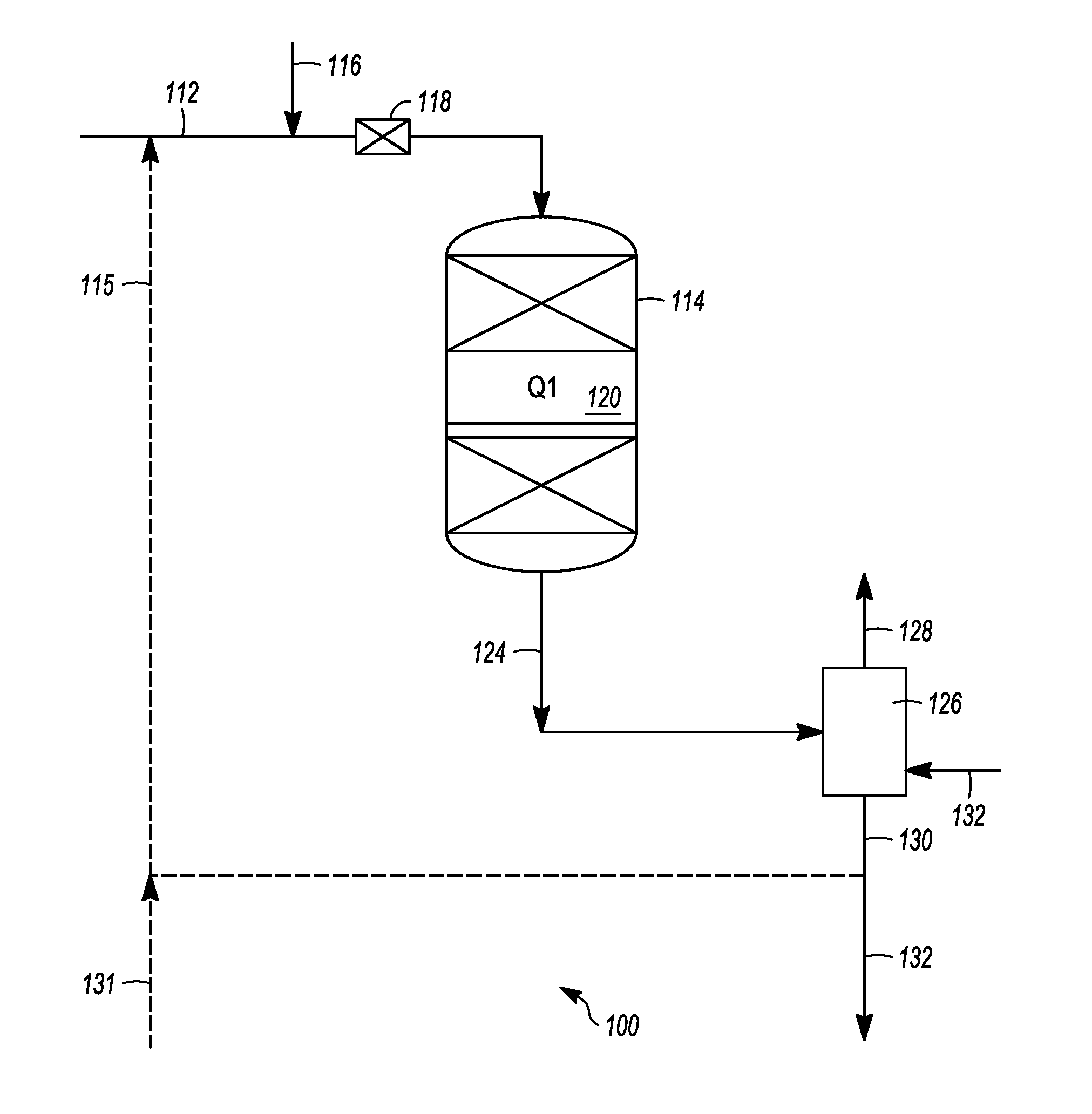

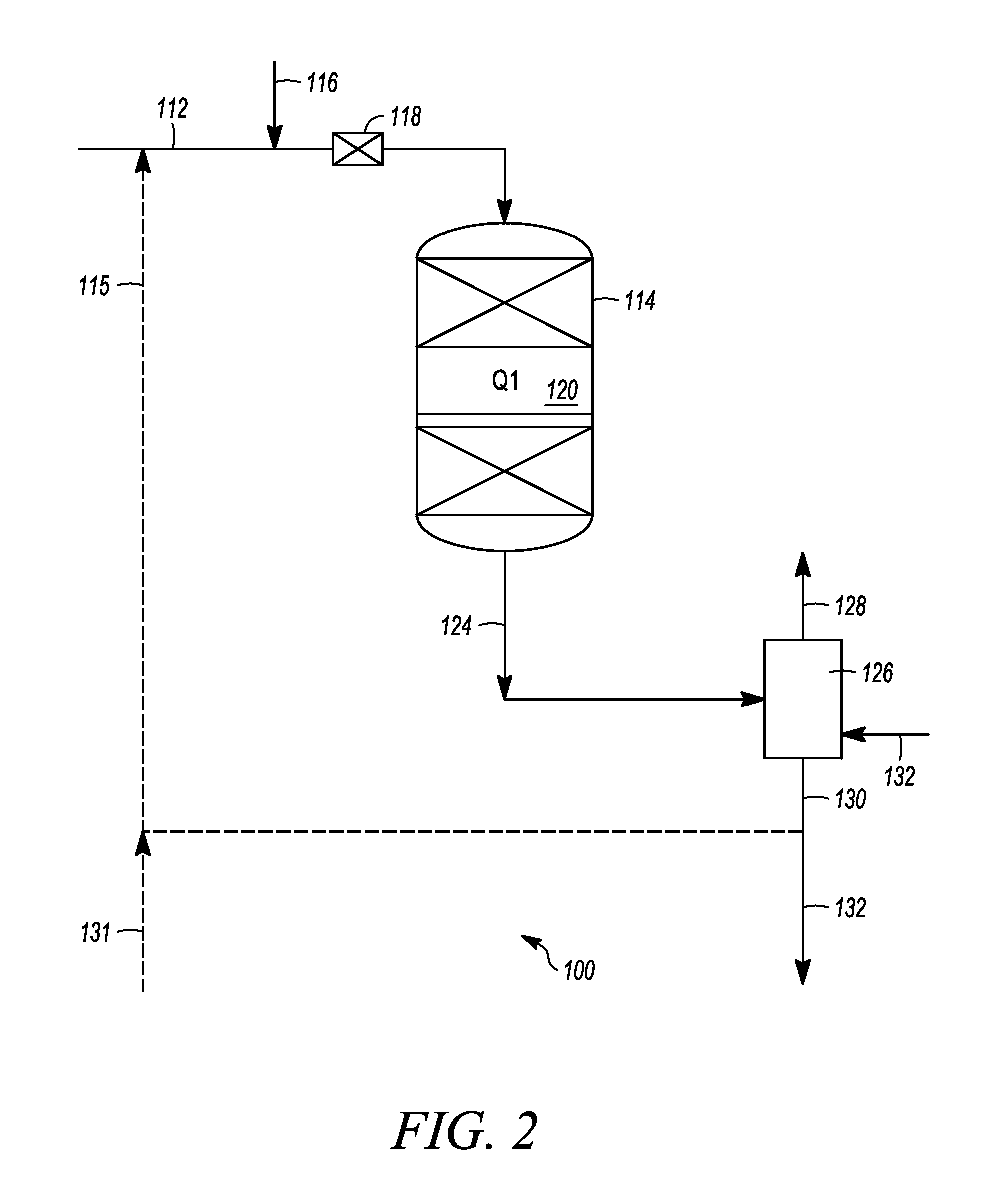

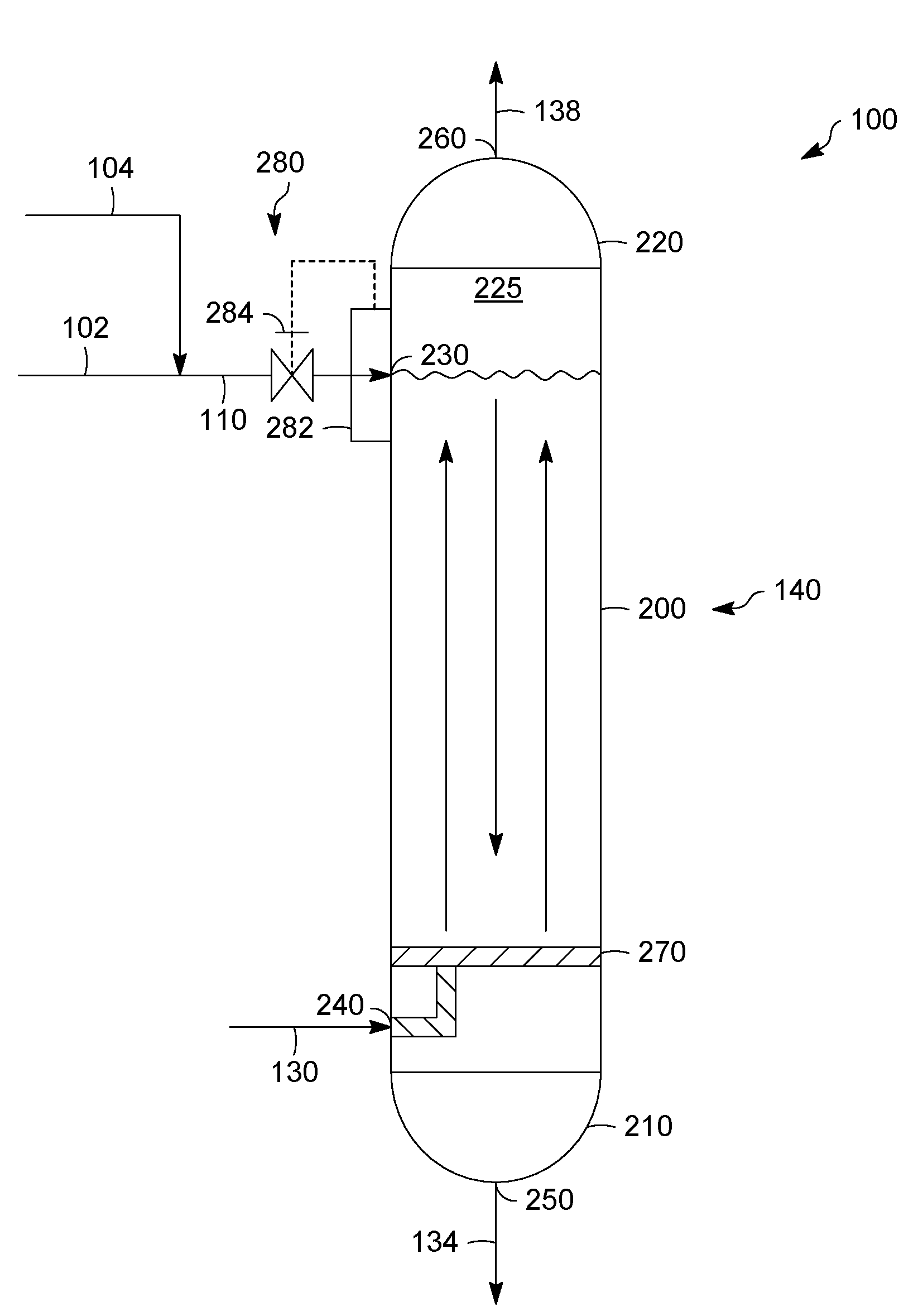

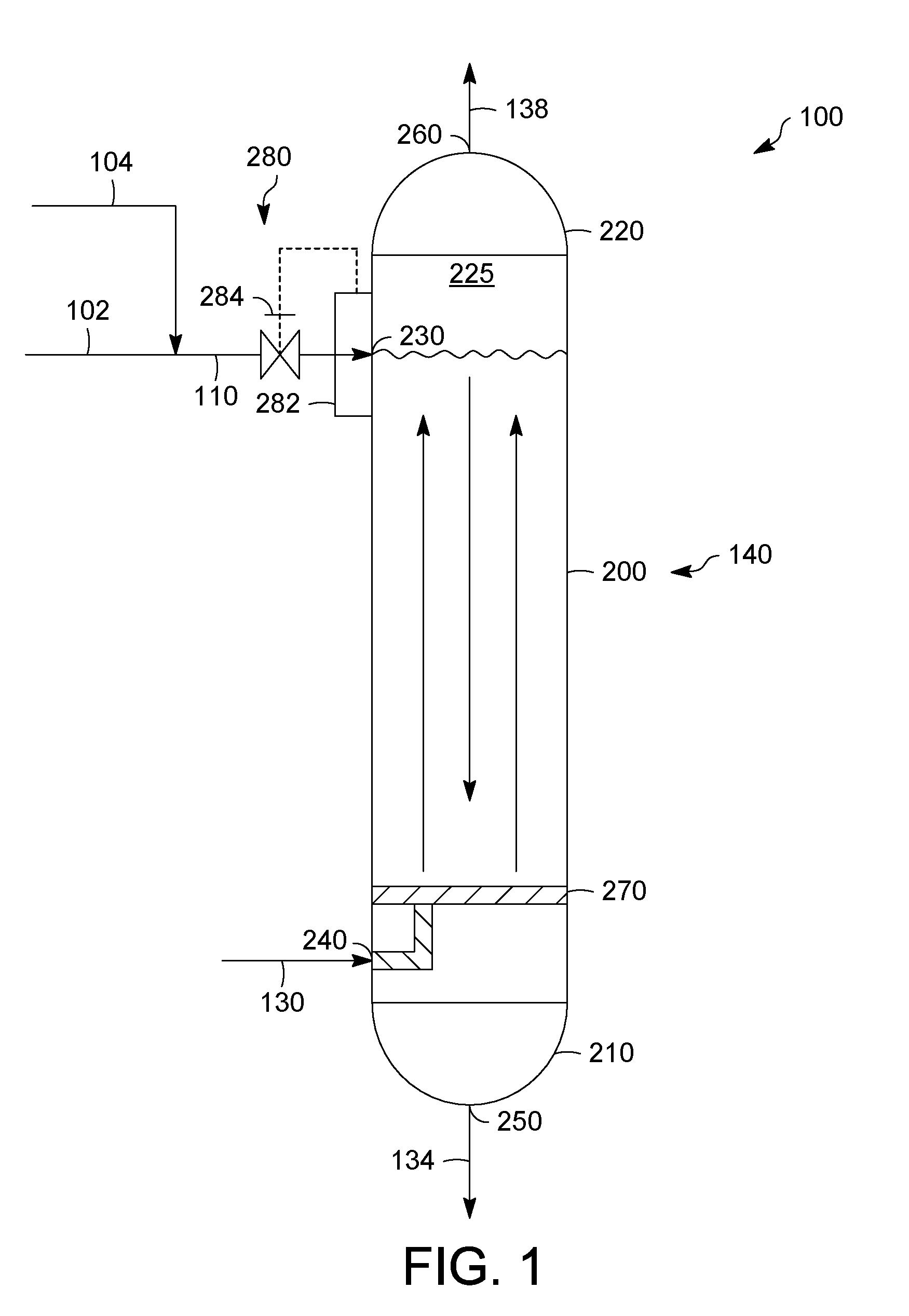

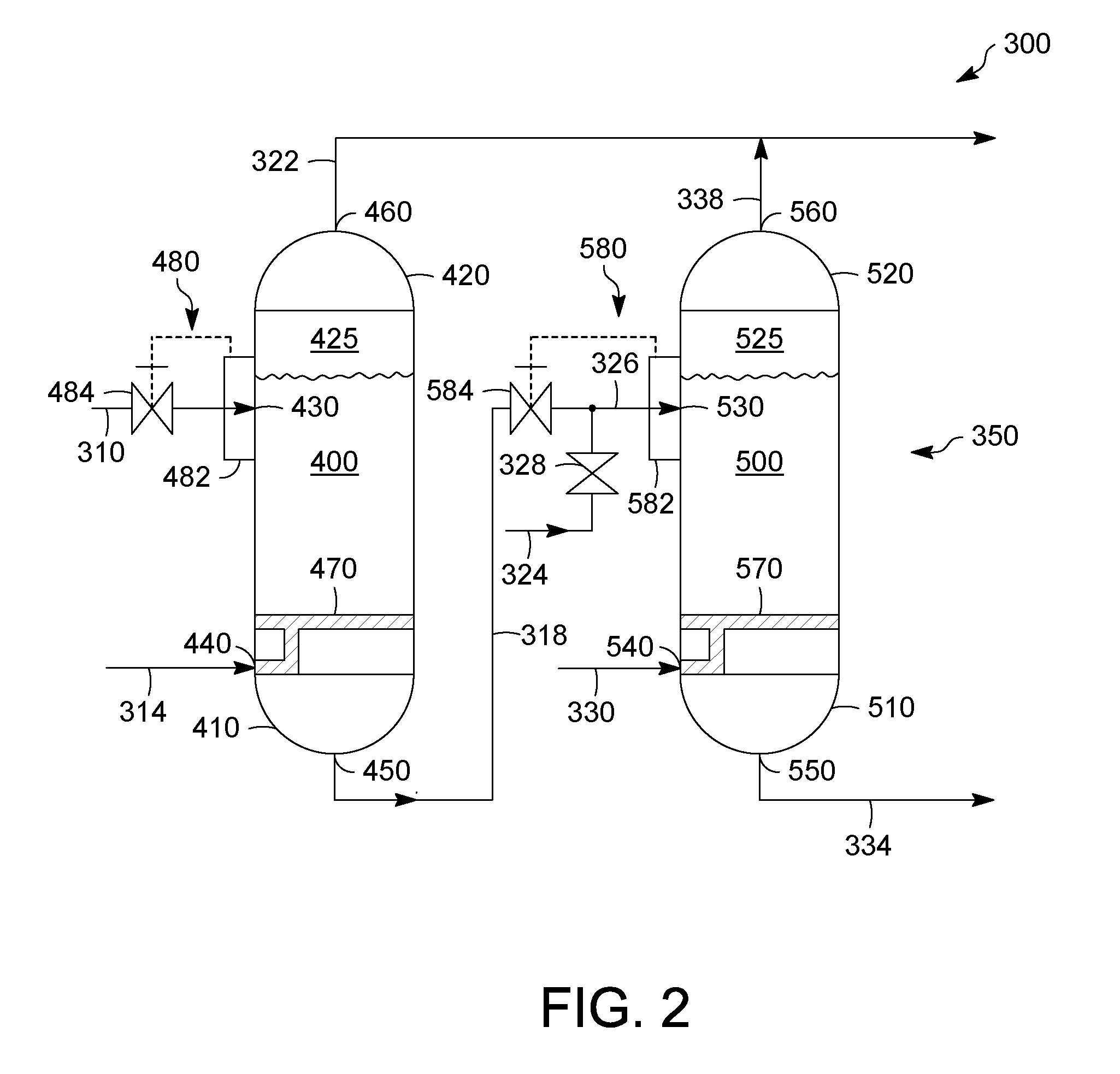

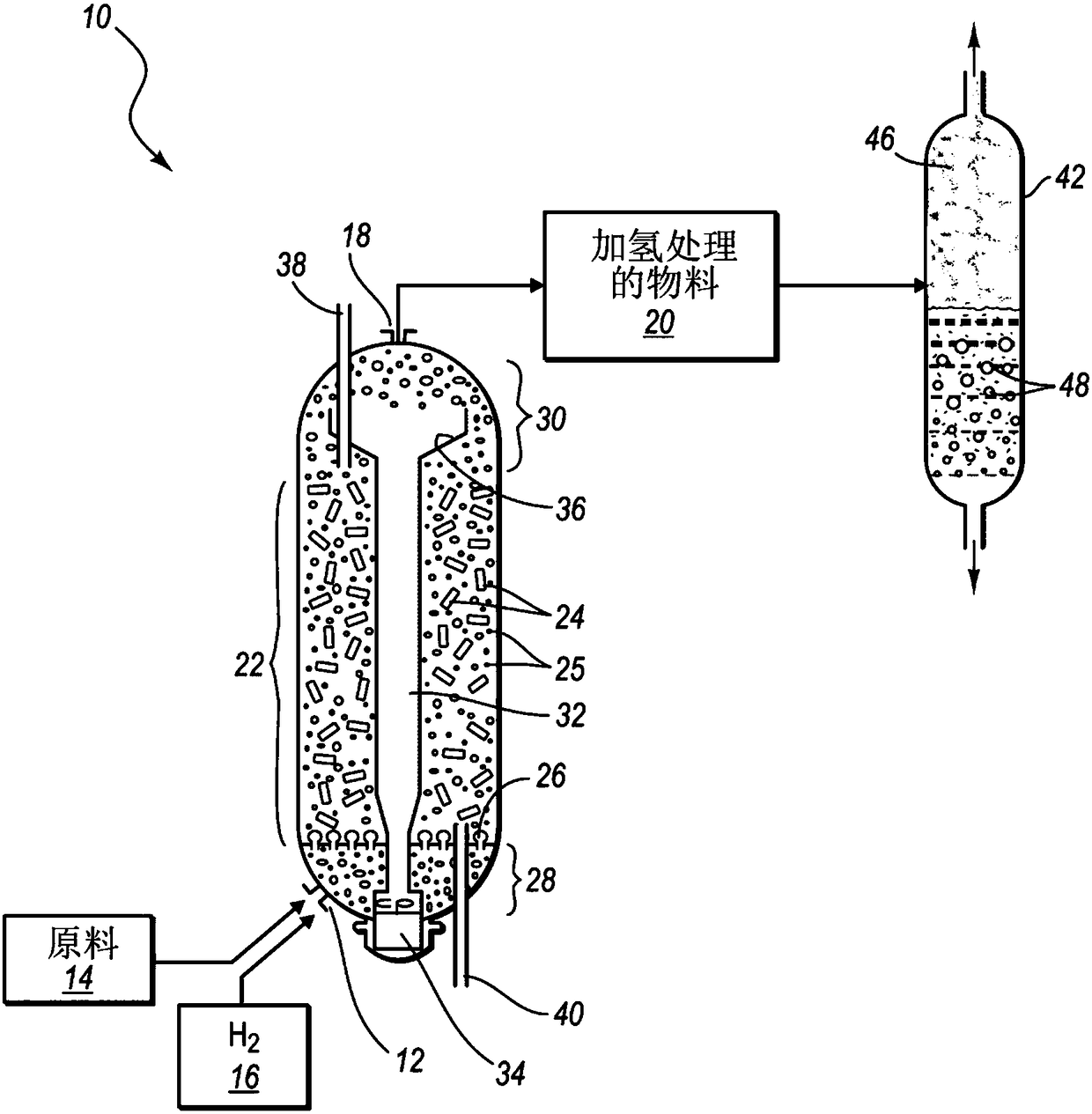

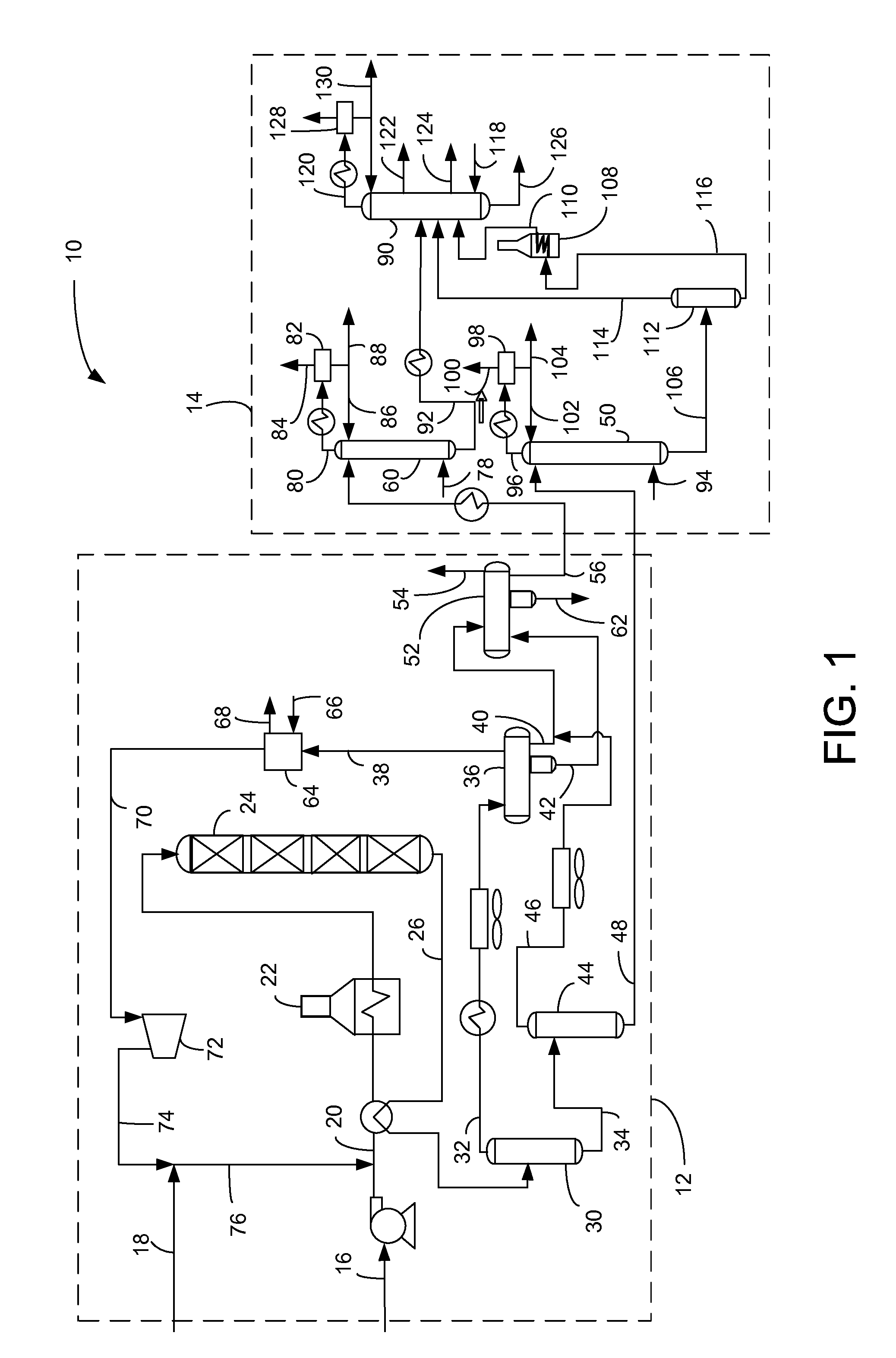

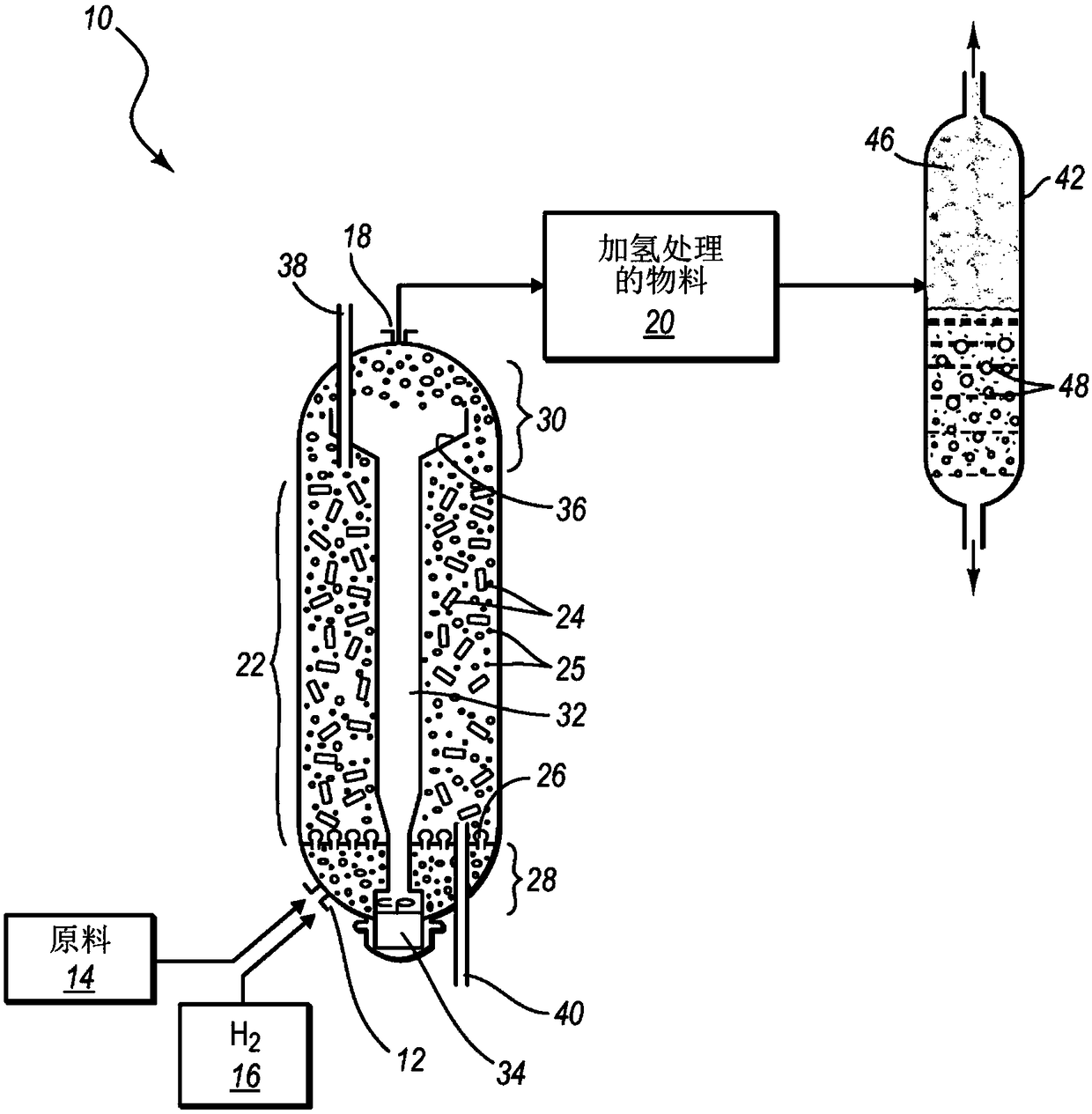

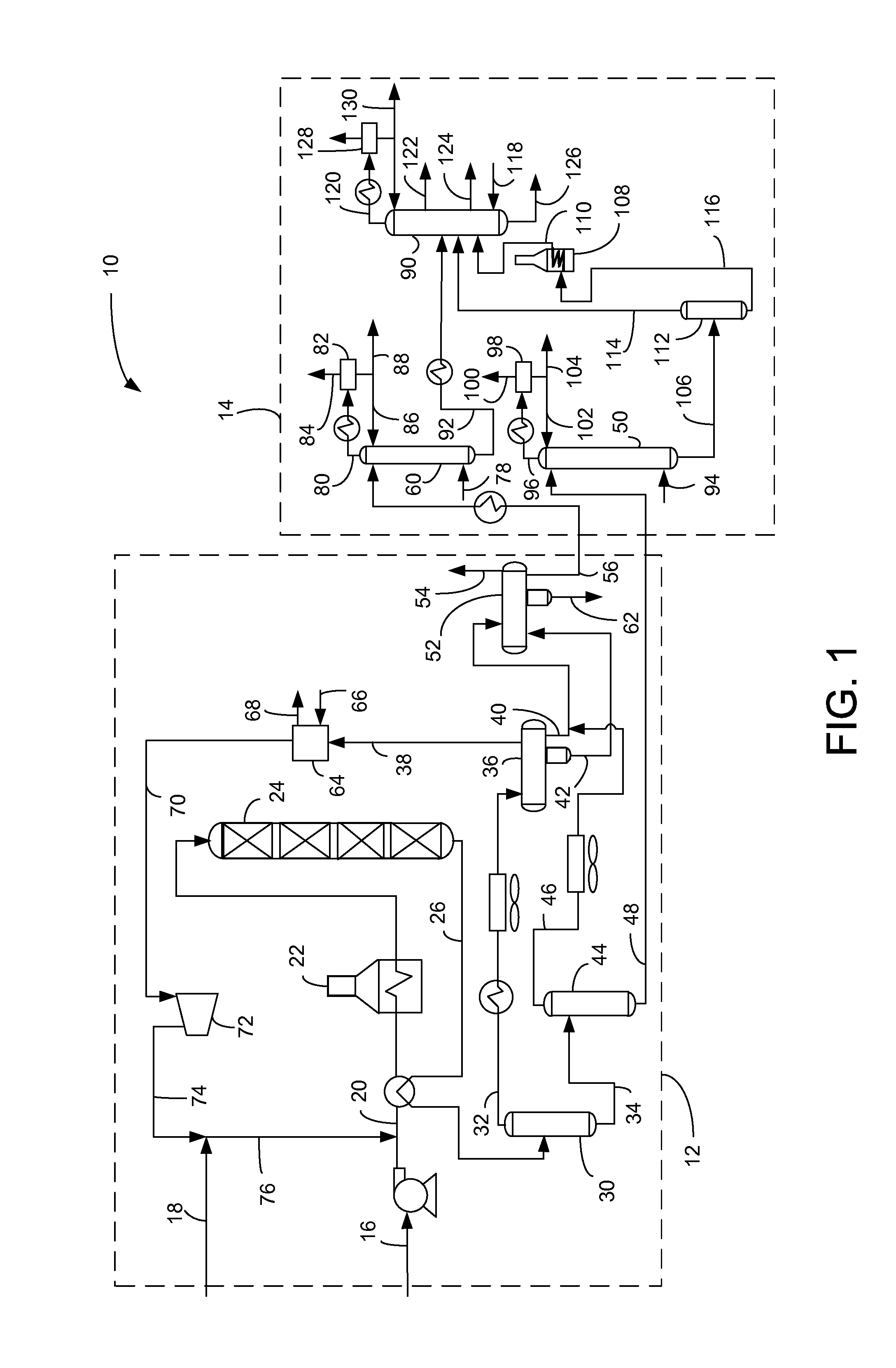

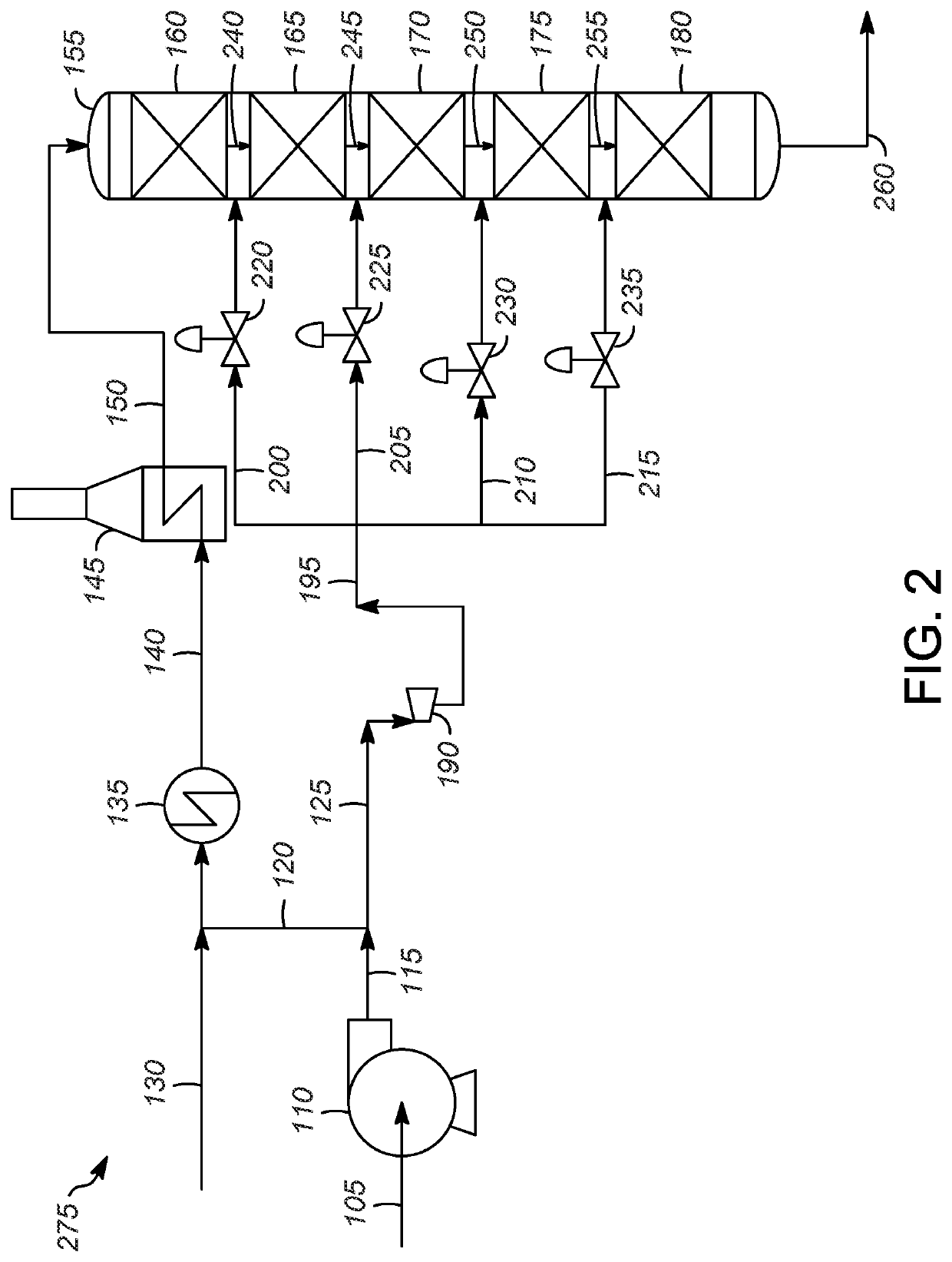

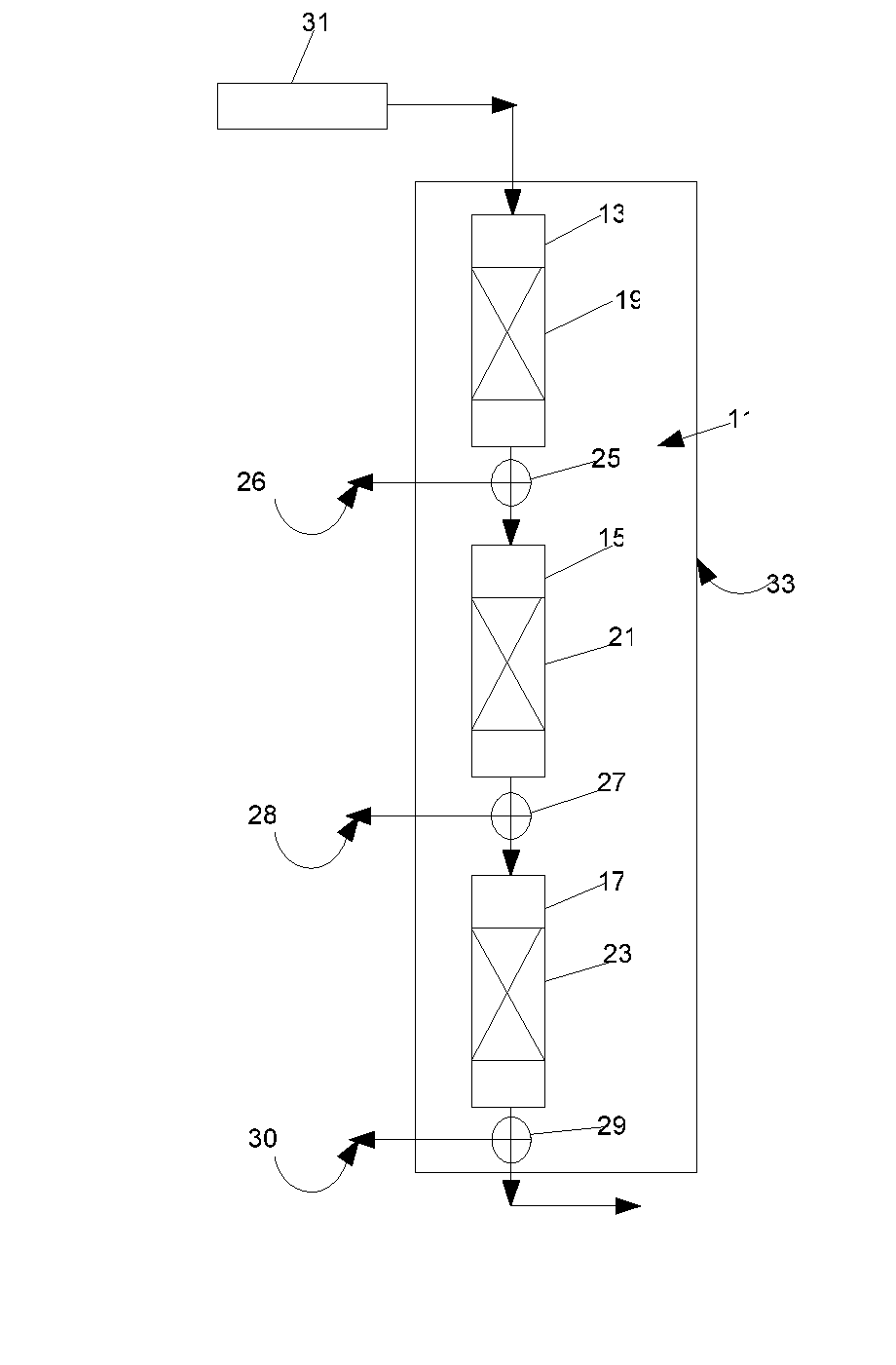

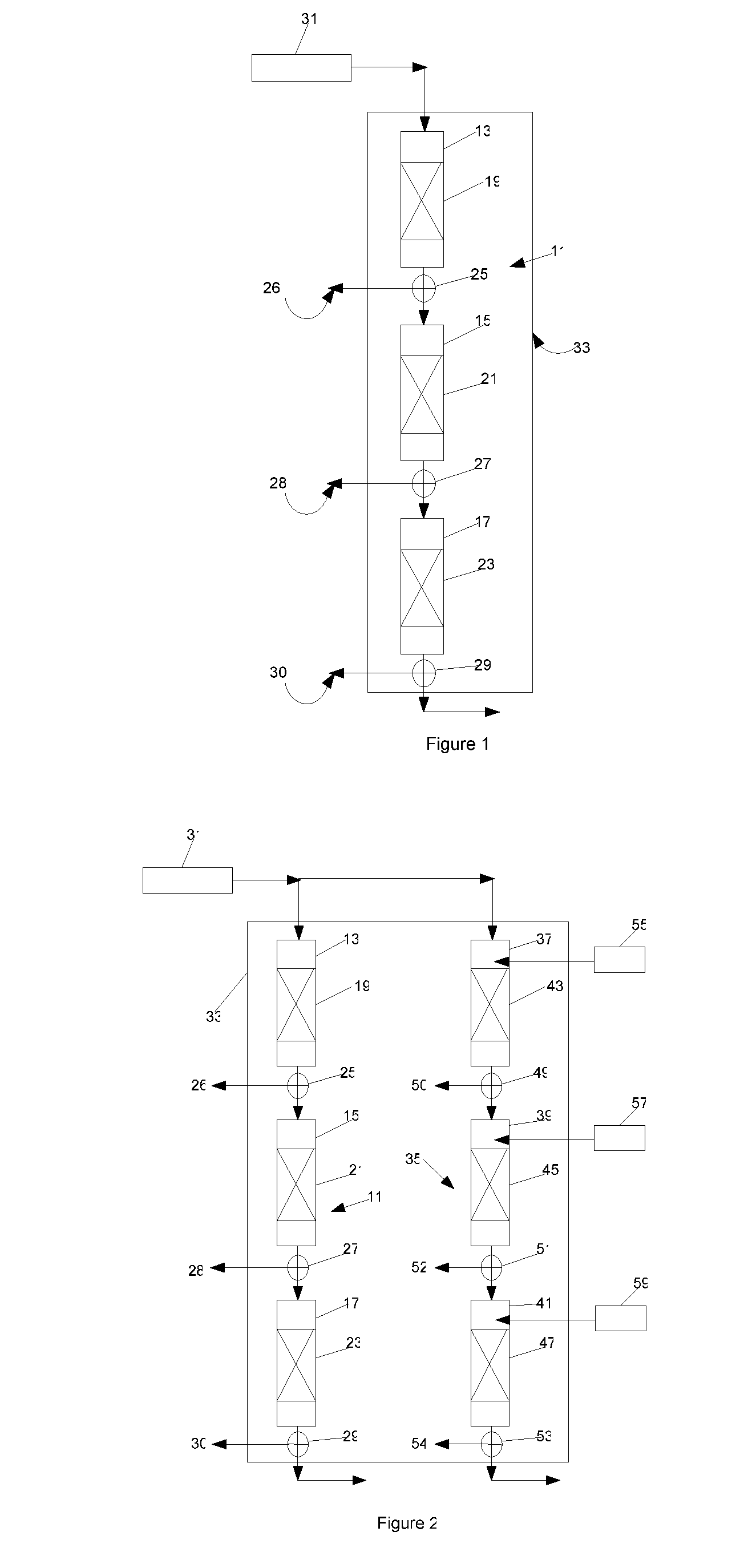

Control system method and apparatus for two phase hydroprocessing

InactiveUS20060144756A1Eliminate needHydrogen solubility is “Physical/chemical process catalystsHydrocarbon oils treatment control/regulationSolubilityHydrogen

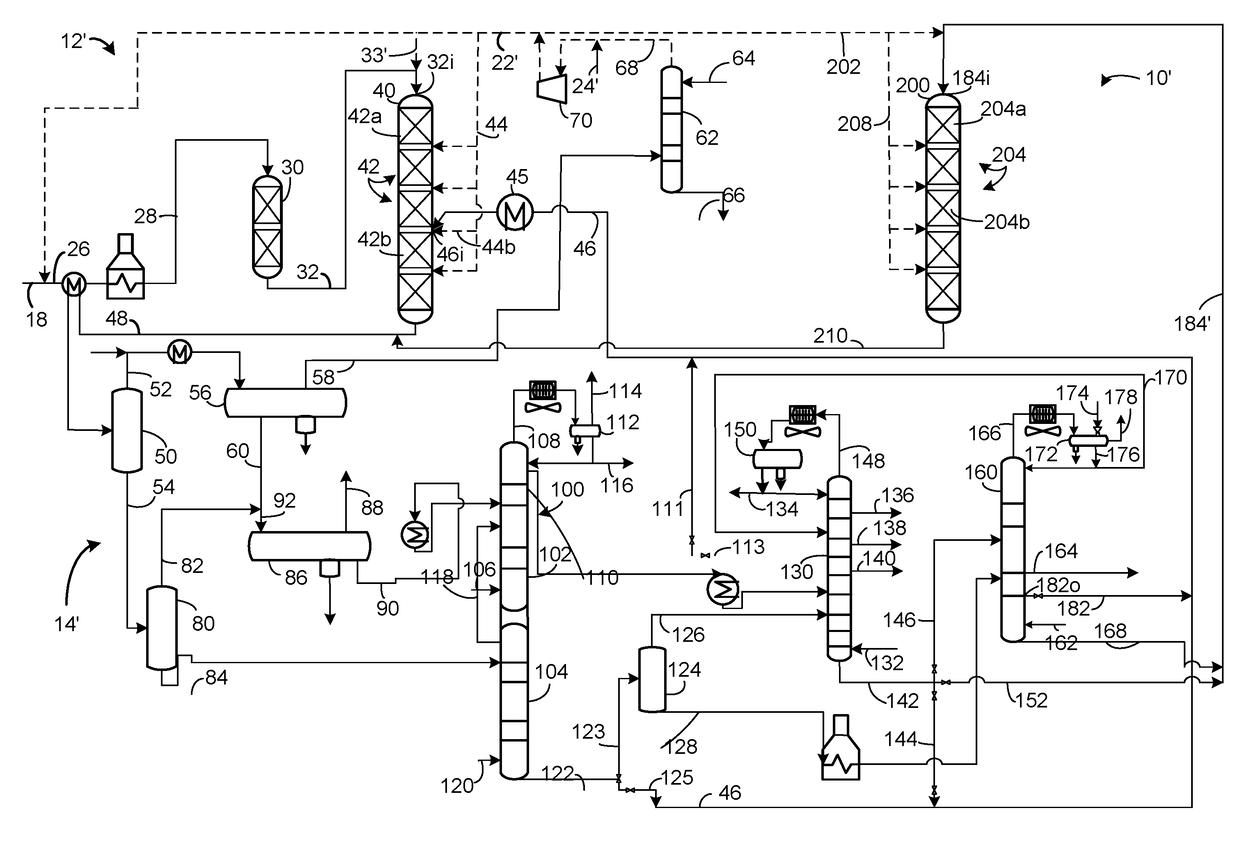

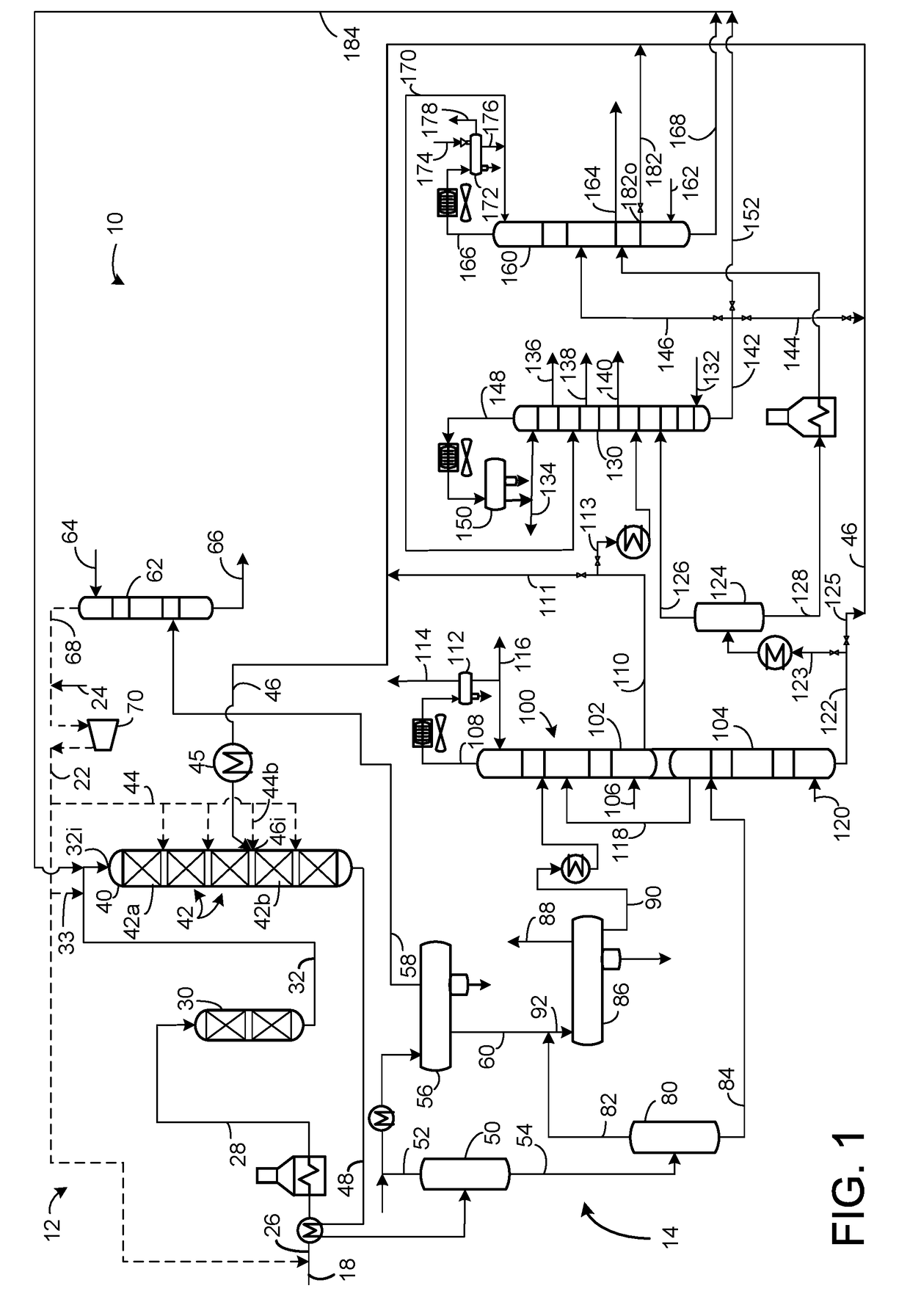

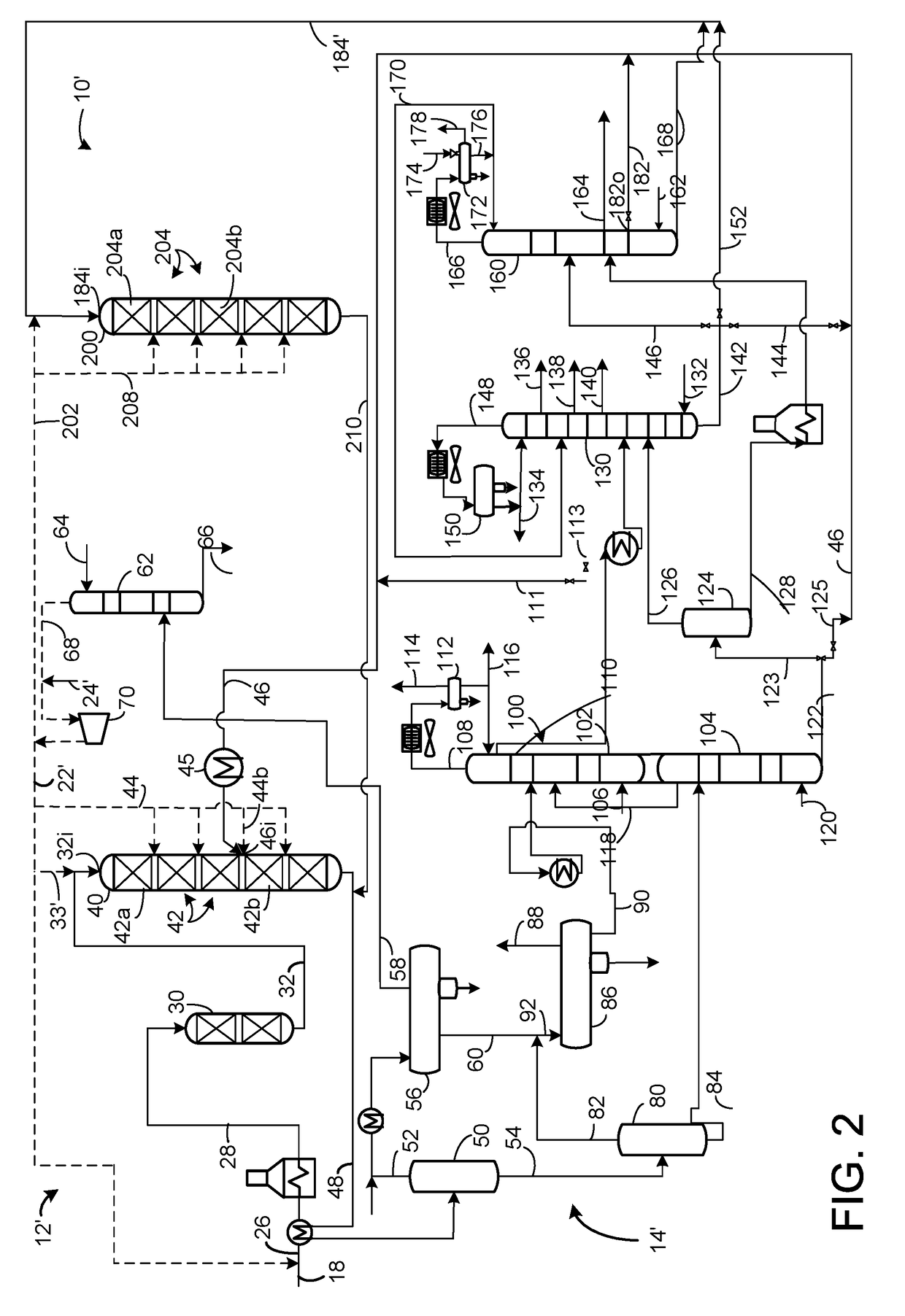

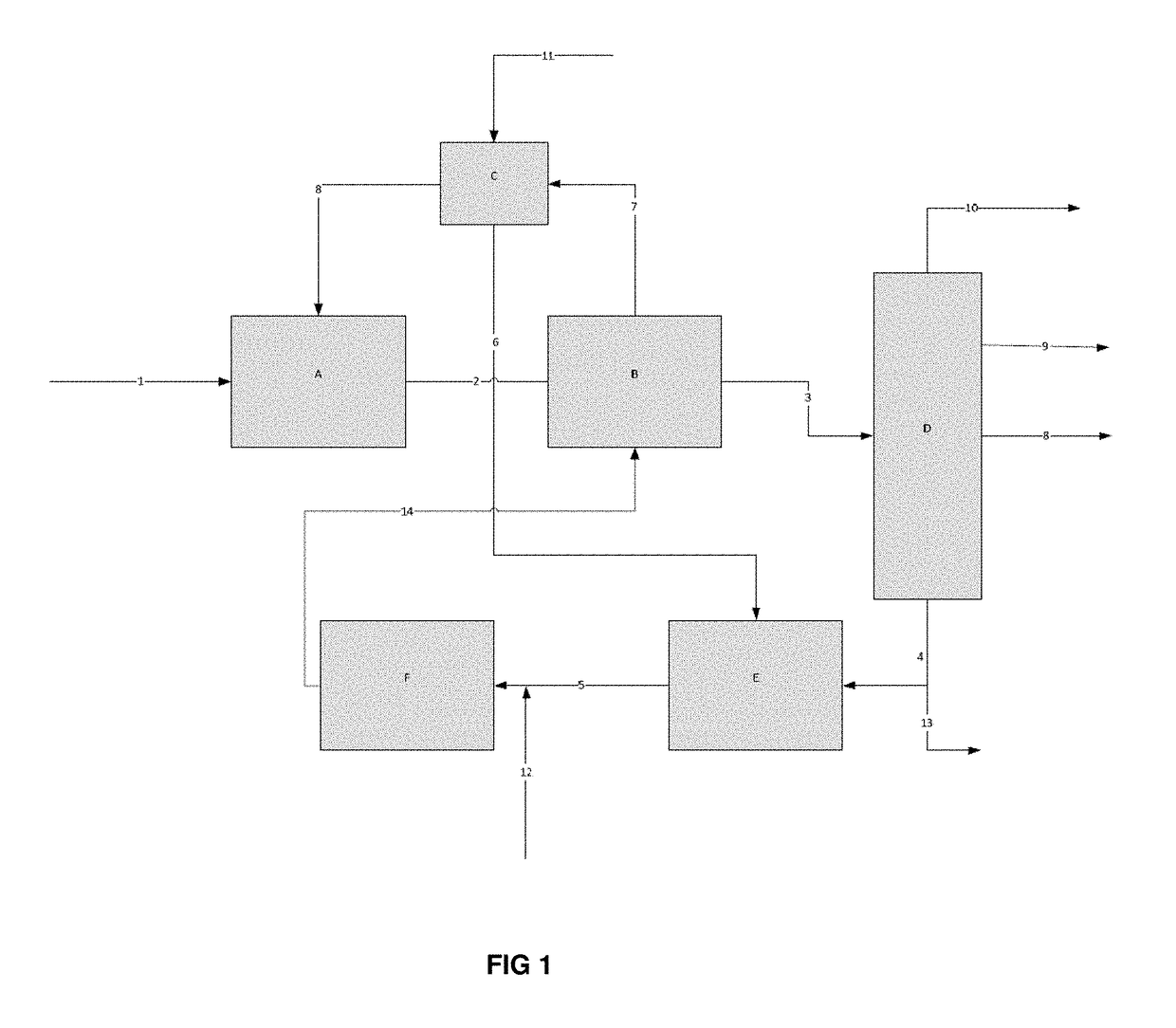

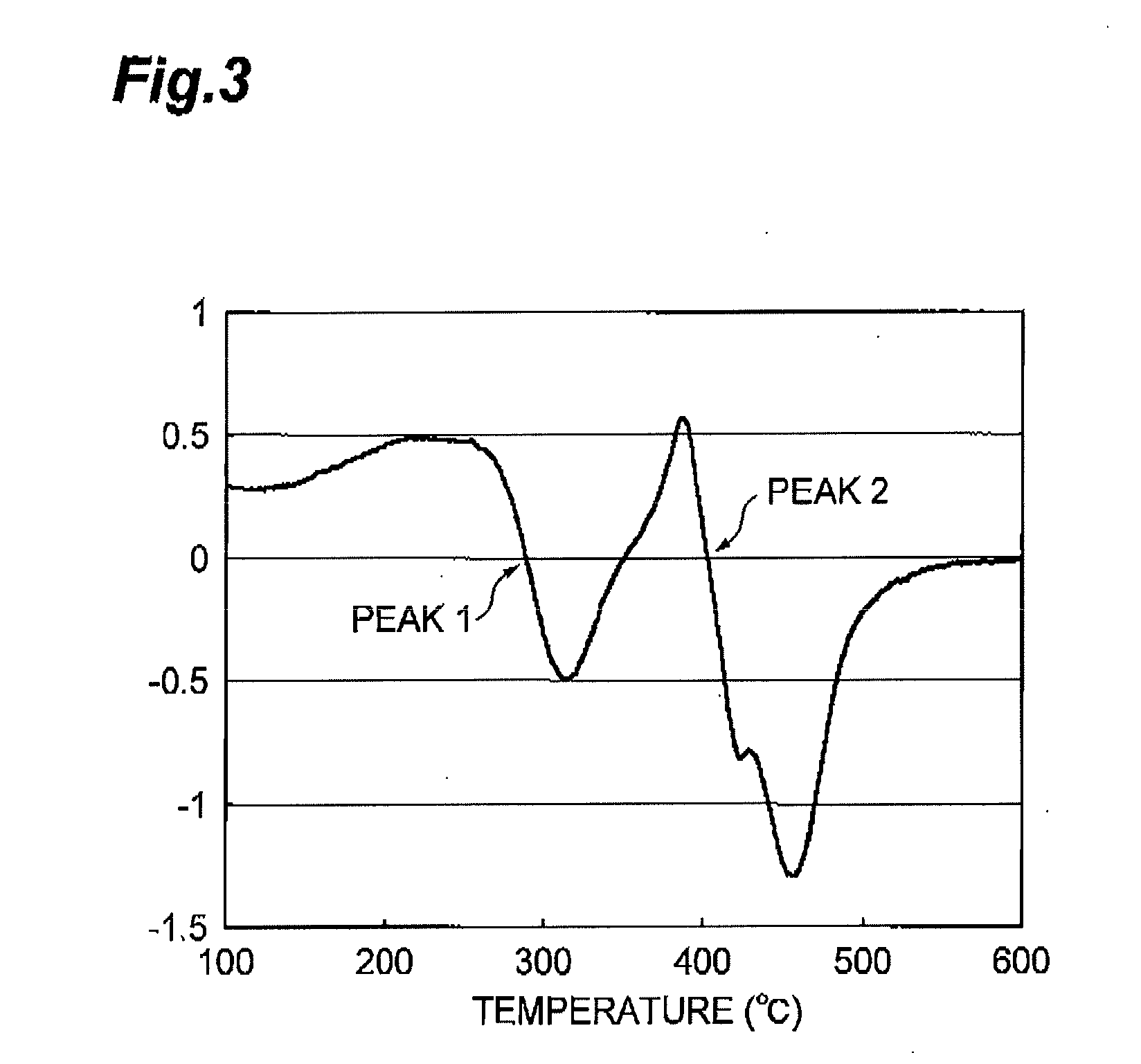

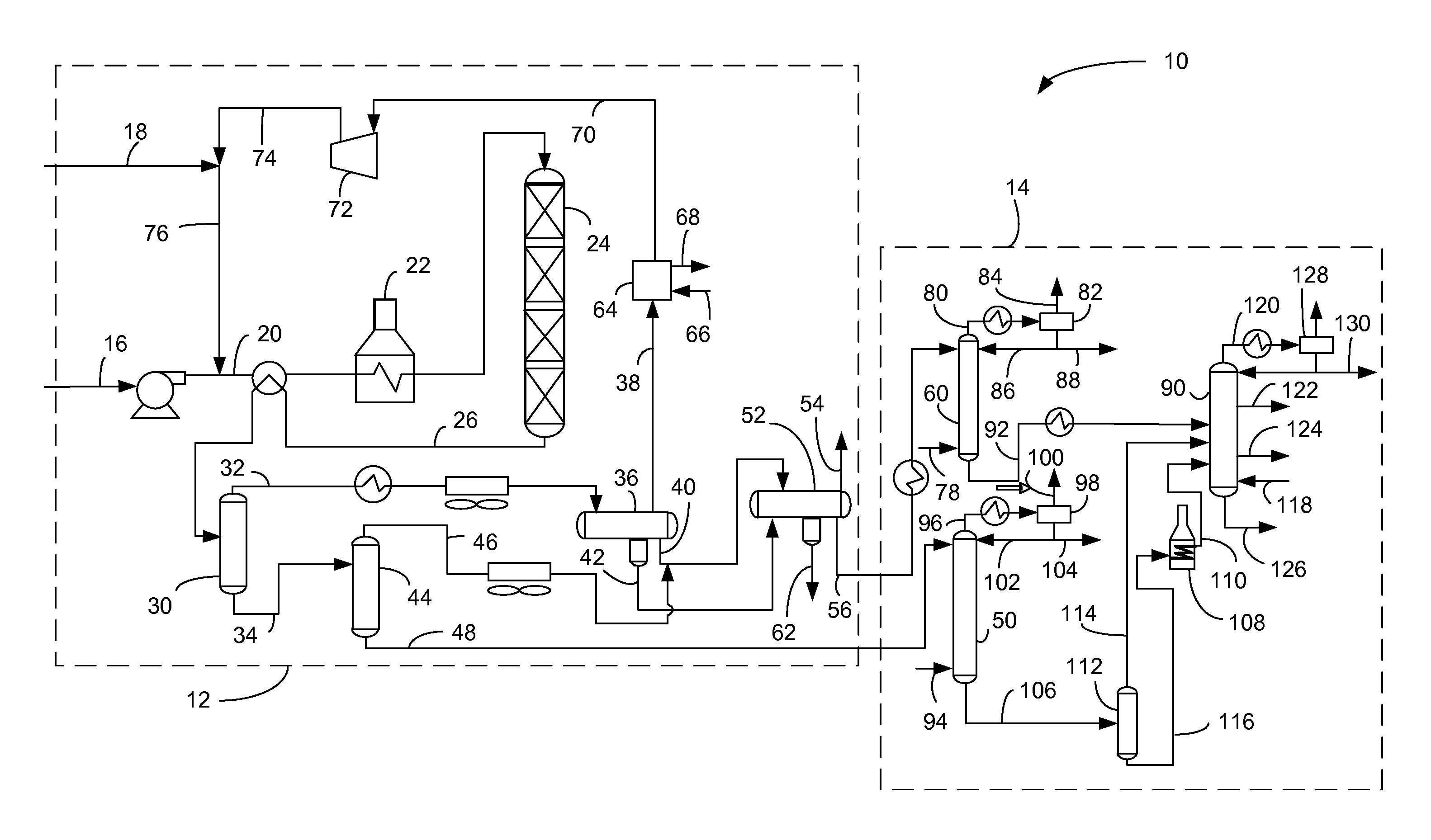

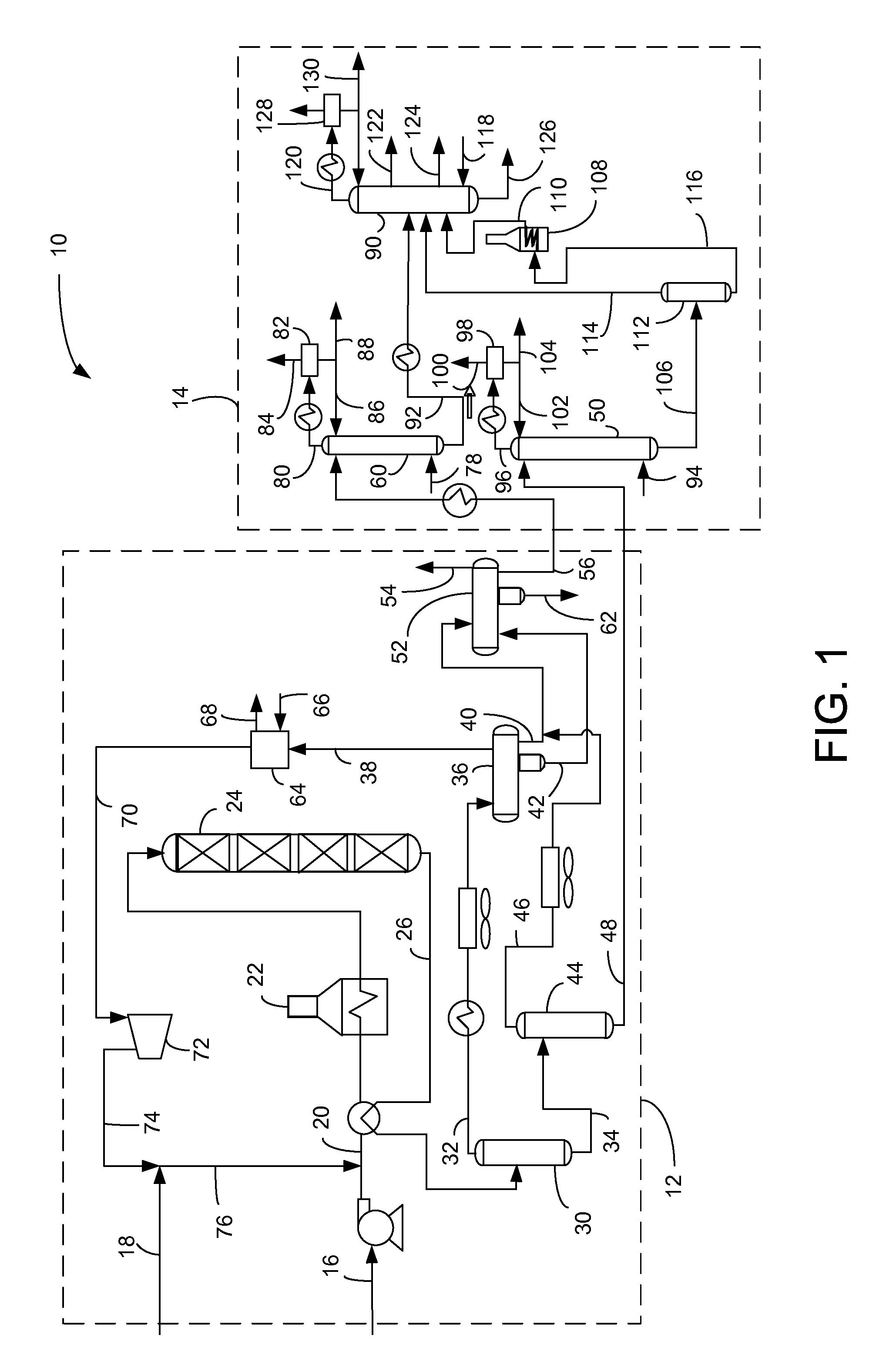

A continuous liquid phase hydroprocessing process, apparatus and process control systems, where the need to circulate hydrogen gas through the catalyst is eliminated. By mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is high relative to the oil feed, all of the hydrogen required in the hydroprocessing reactions may be available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required; therefore, the large trickle bed reactors can be replaced by much smaller tubular reactors. The amount of hydrogen added to the reactor can be used to control the liquid level in the reactor or the pressure in the reactor.

Owner:EI DU PONT DE NEMOURS & CO

Control system method and apparatus for two phase hydroprocessing

InactiveUS7569136B2Hydrogen solubility is “Eliminate needPhysical/chemical process catalystsHydrocarbon oils treatment control/regulationSolubilityHydrogen

A continuous liquid phase hydroprocessing process, apparatus and process control systems, where the need to circulate hydrogen gas through the catalyst is eliminated. By mixing and / or flashing the hydrogen and the oil to be treated in the presence of a solvent or diluent in which the hydrogen solubility is high relative to the oil feed, all of the hydrogen required in the hydroprocessing reactions may be available in solution. The oil / diluent / hydrogen solution can then be fed to a plug flow reactor packed with catalyst where the oil and hydrogen react. No additional hydrogen is required; therefore, the large trickle bed reactors can be replaced by much smaller tubular reactors. The amount of hydrogen added to the reactor can be used to control the liquid level in the reactor or the pressure in the reactor.

Owner:EI DU PONT DE NEMOURS & CO

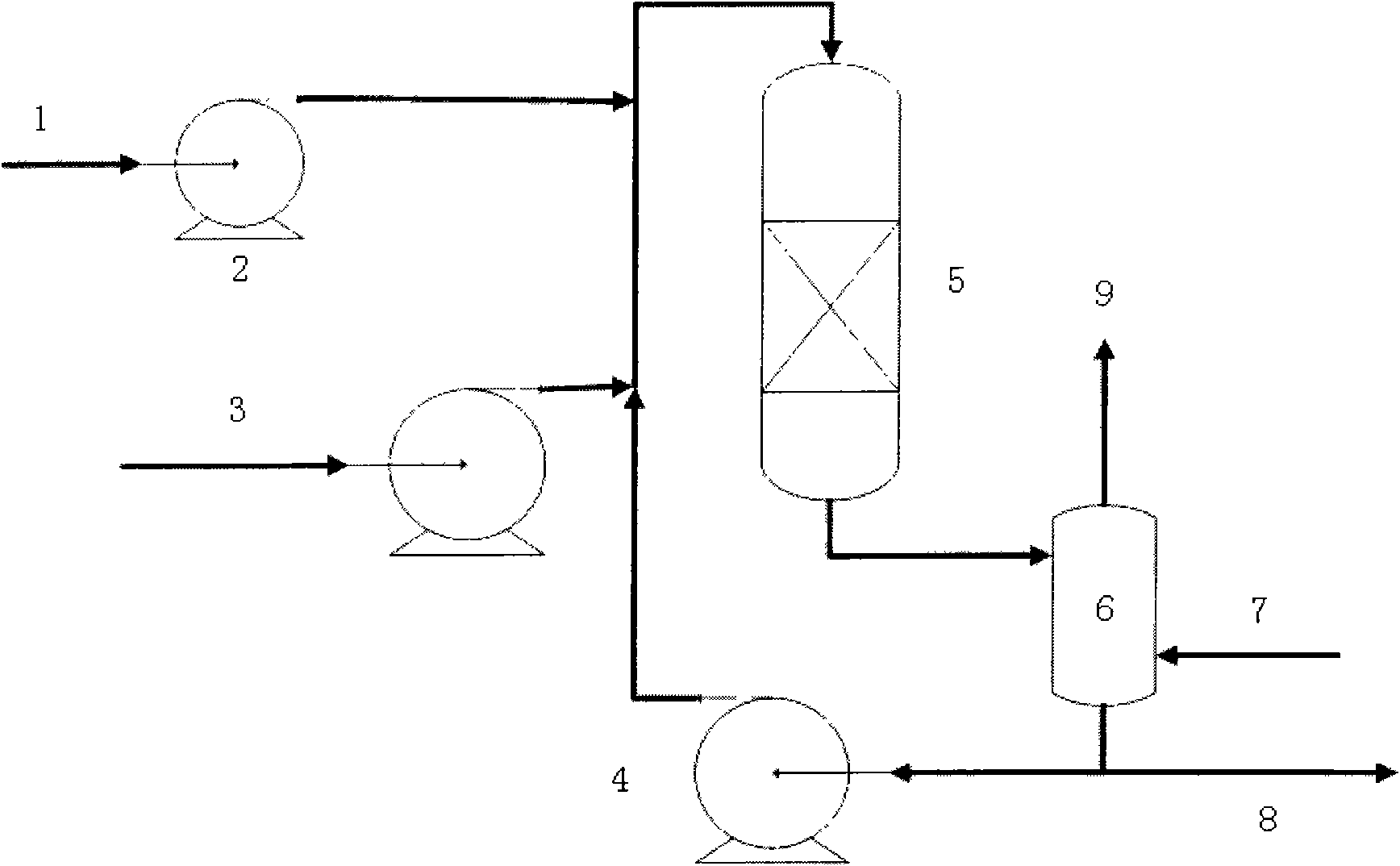

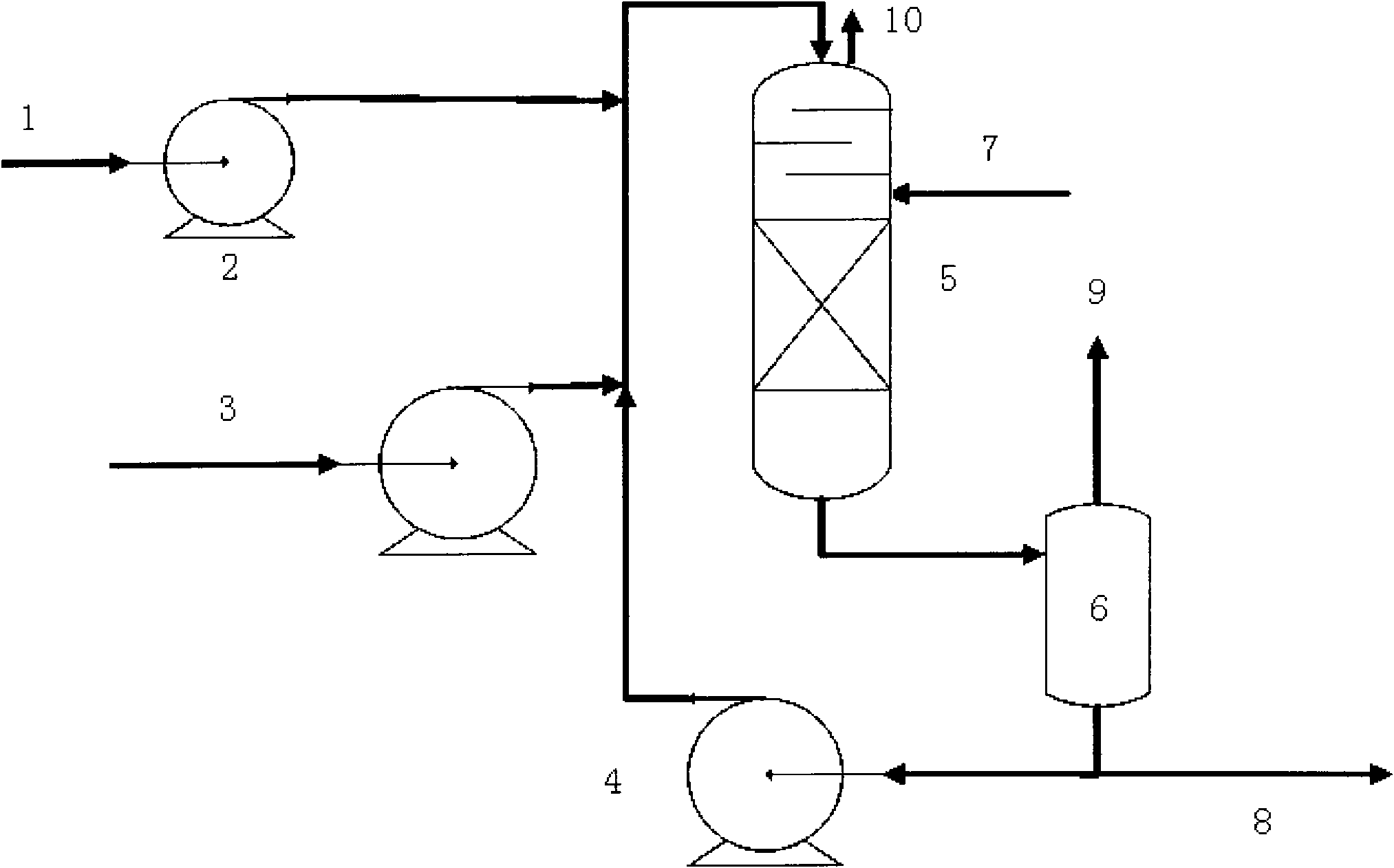

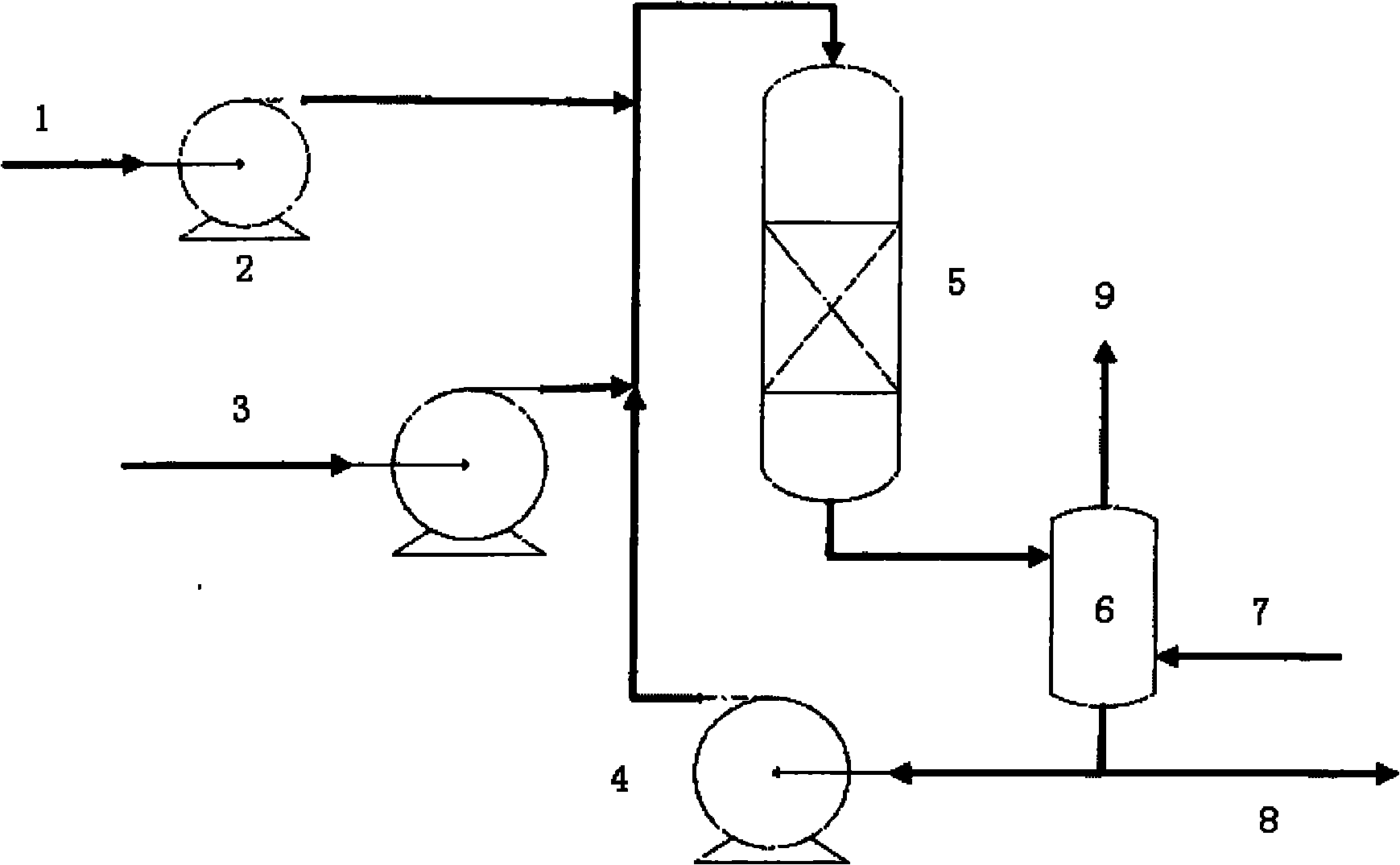

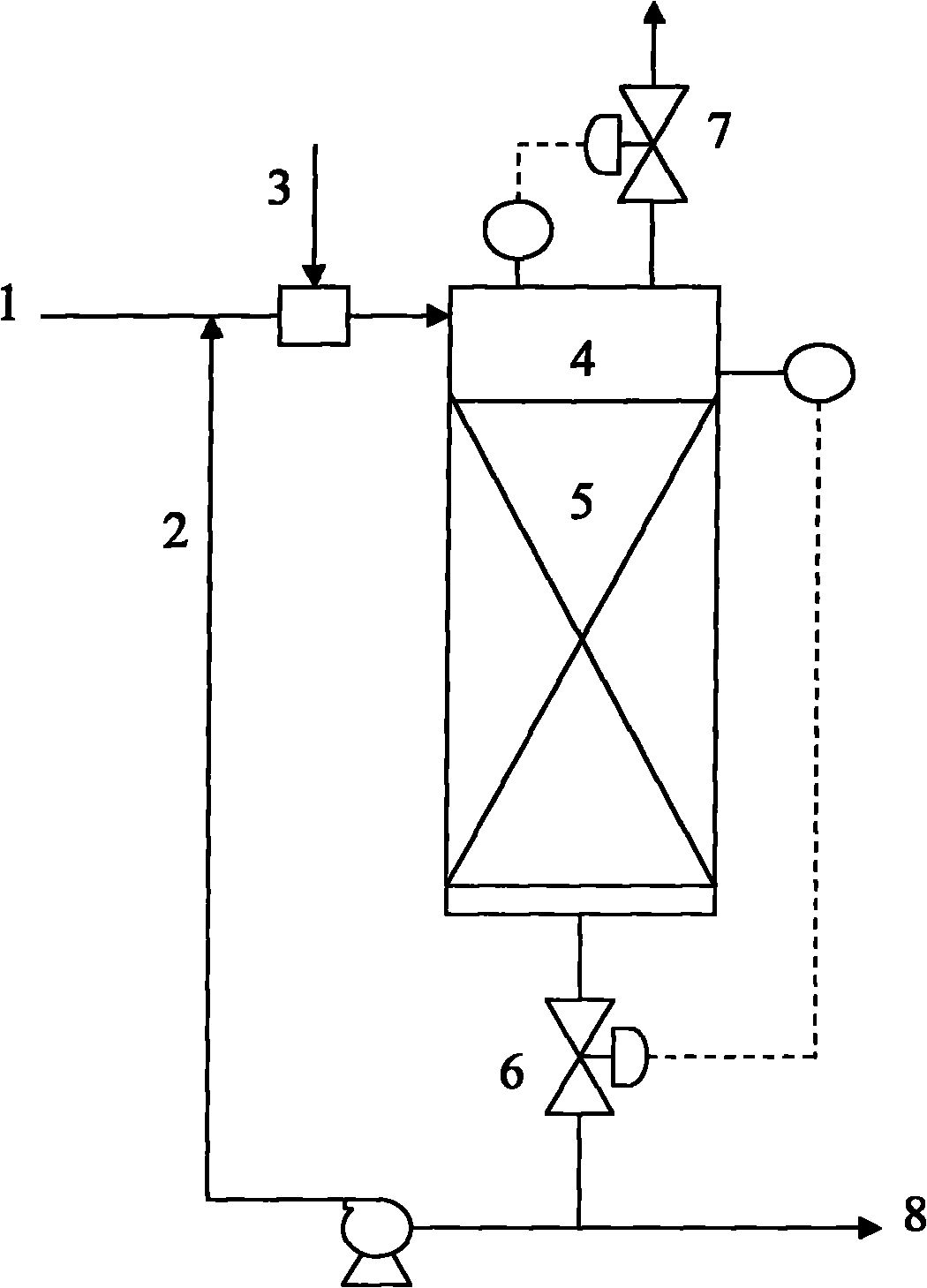

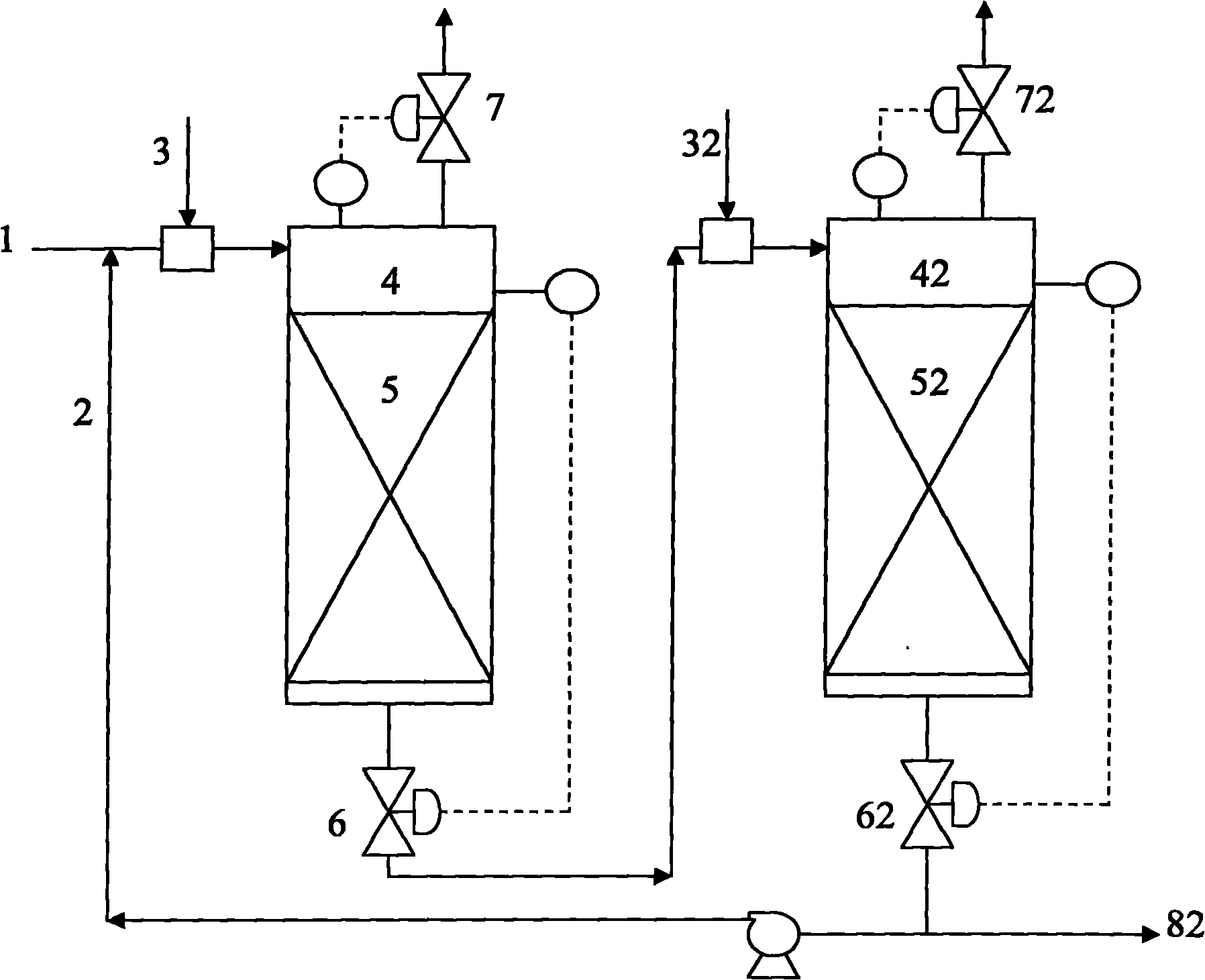

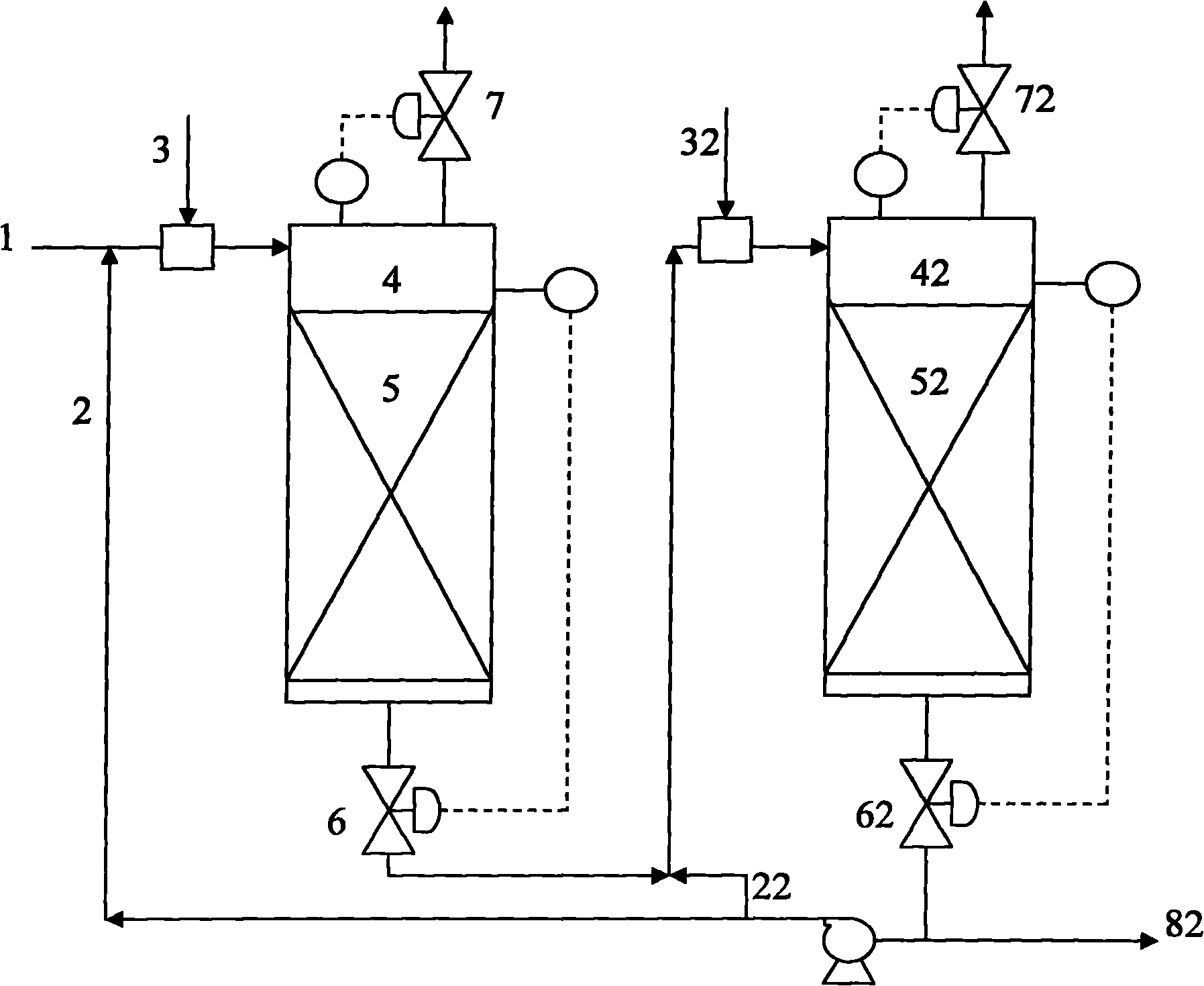

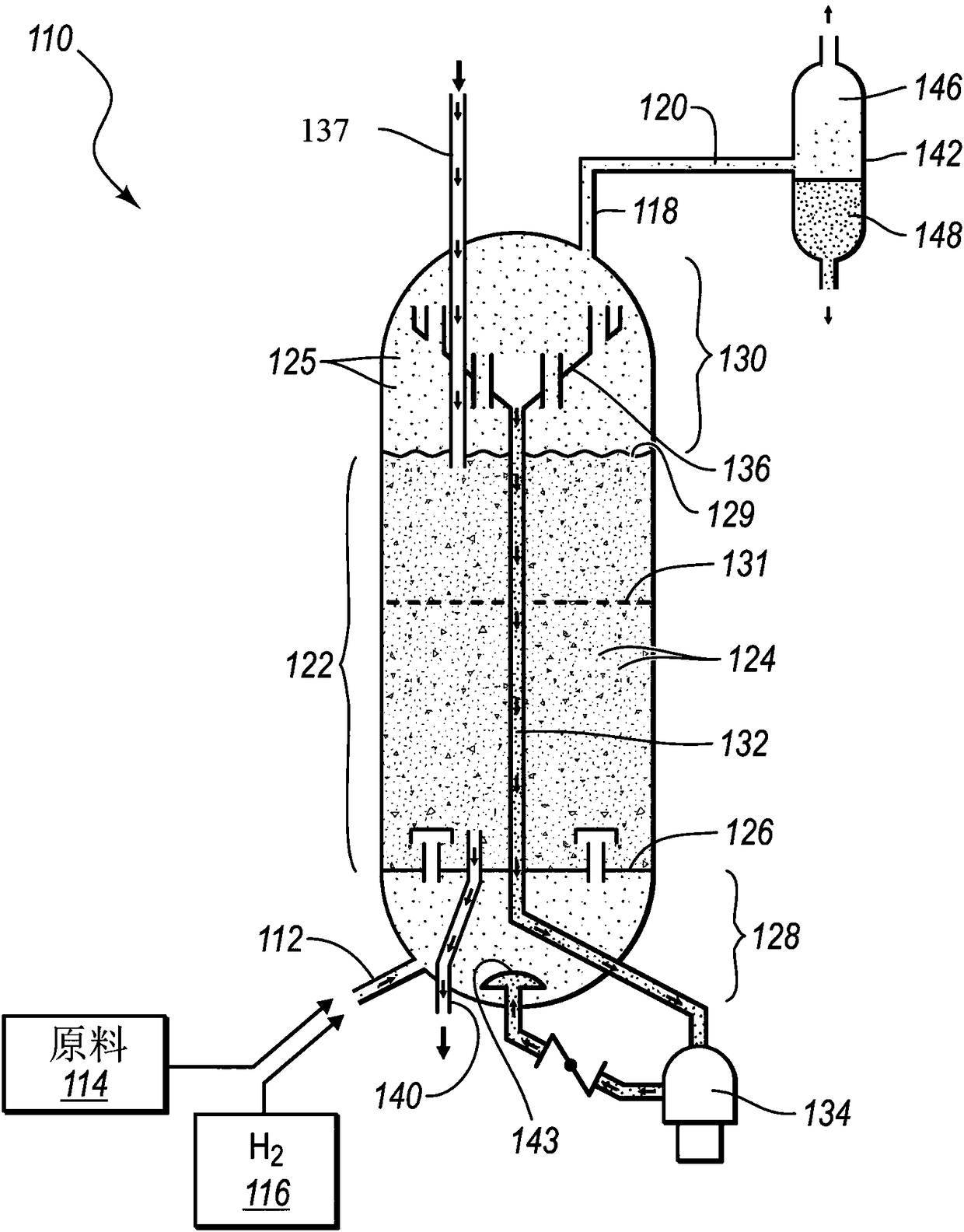

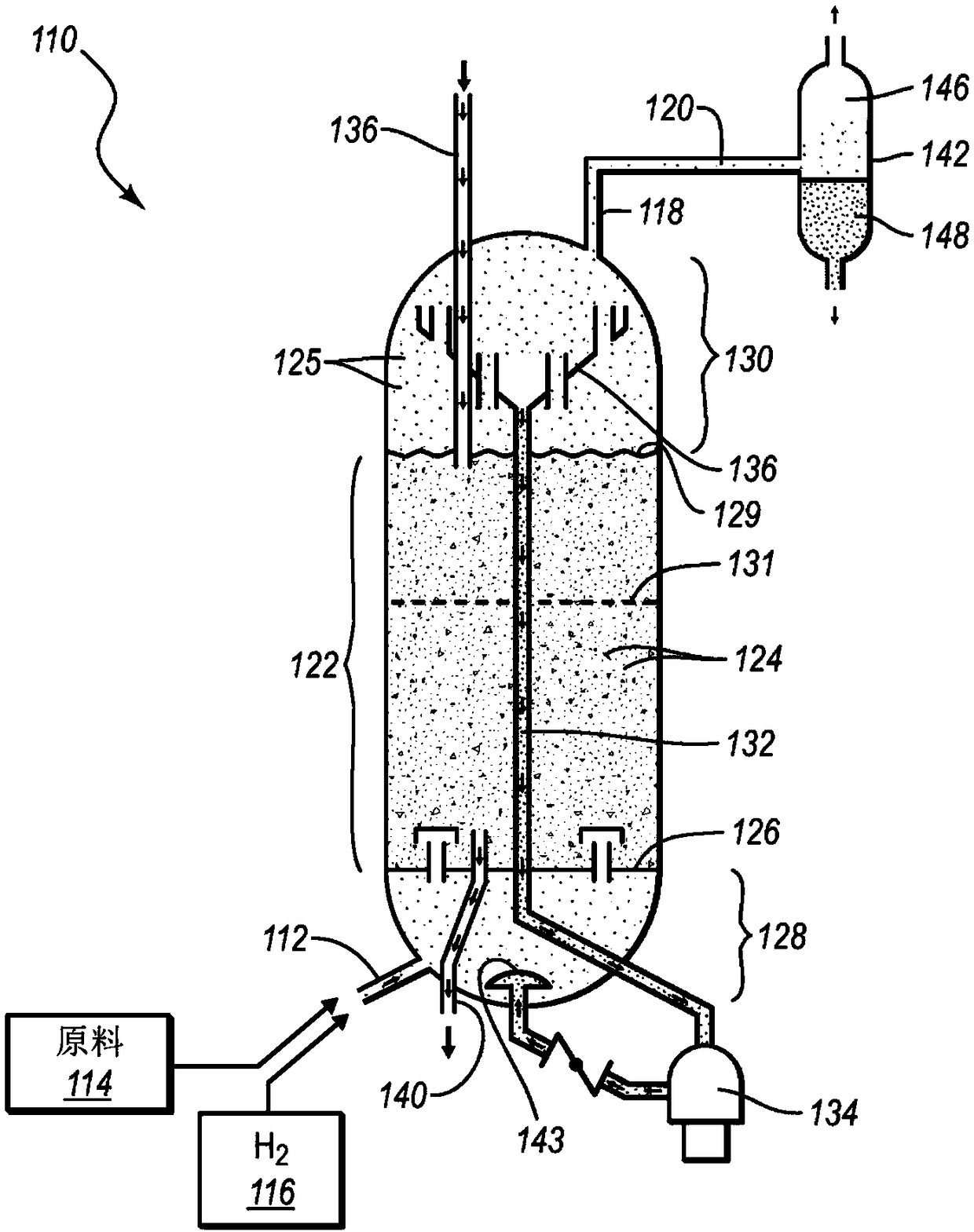

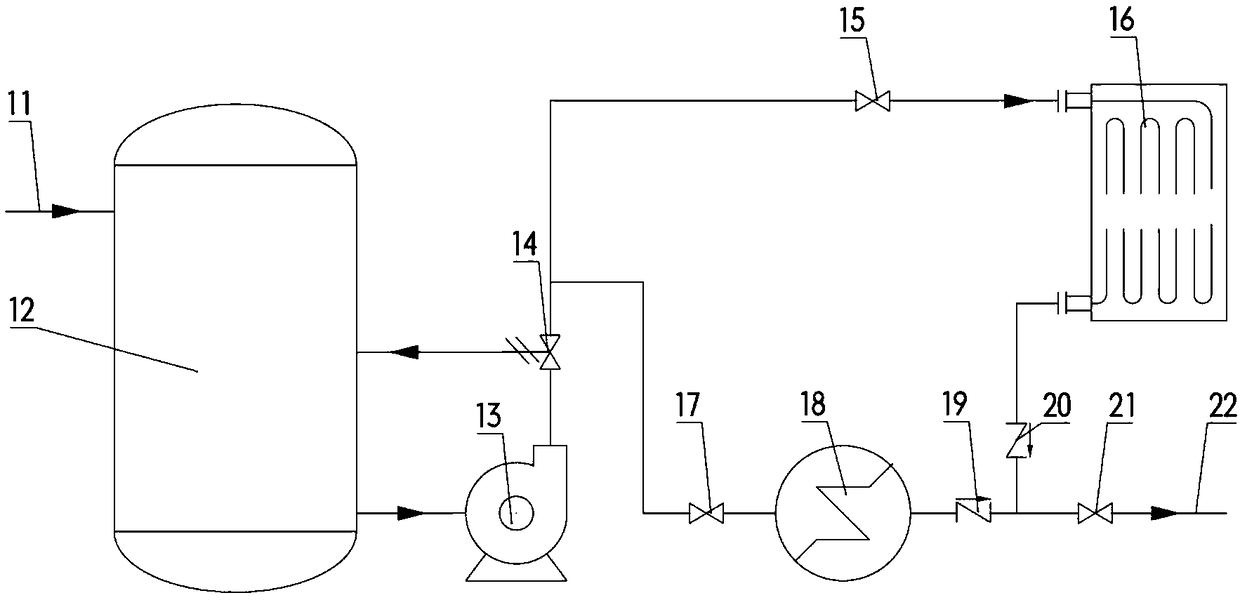

Method of liquid phase circulation hydrotreatment and reaction system

ActiveCN101787305AMaintain active stabilityEliminate the effect of wetting factorHydrocarbon oils treatment control/regulationLiquid productGas phase

The invention discloses a method of liquid phase circulation hydrotreatment. A part of liquid product after hydrotreatment circulates and is mixed with raw material to form liquid phase material, the hydrogen is mixed in the liquid phase material, the mixing volume of the hydrogen is increased by below 20 times of the dissolved hydrogen volume of a reaction system under the reaction condition based on the chemical hydrogen consumption in the reaction process, the liquid phase material mixed with the hydrogen enters the upper part of a reactor, the upper part of the reactor is provided with a gas phase space and an exhaust system which is communicated with the gas phase space, the pressure and the liquid level in the reactor are controlled by controlling the displacement of the exhaust system, the liquid phase material dissolved with the hydrogen enters a hydrogenation catalyst bed at the lower part of the reactor for hydrotreatment reaction, a part of the liquid phase reaction productis discharged from the reaction system, and the other part circulates and is mixed with the raw material. The method can ensure good reaction effect and leads the liquid phase circulation hydrotreatment to be stably controlled and operated.

Owner:CHINA PETROLEUM & CHEM CORP +1

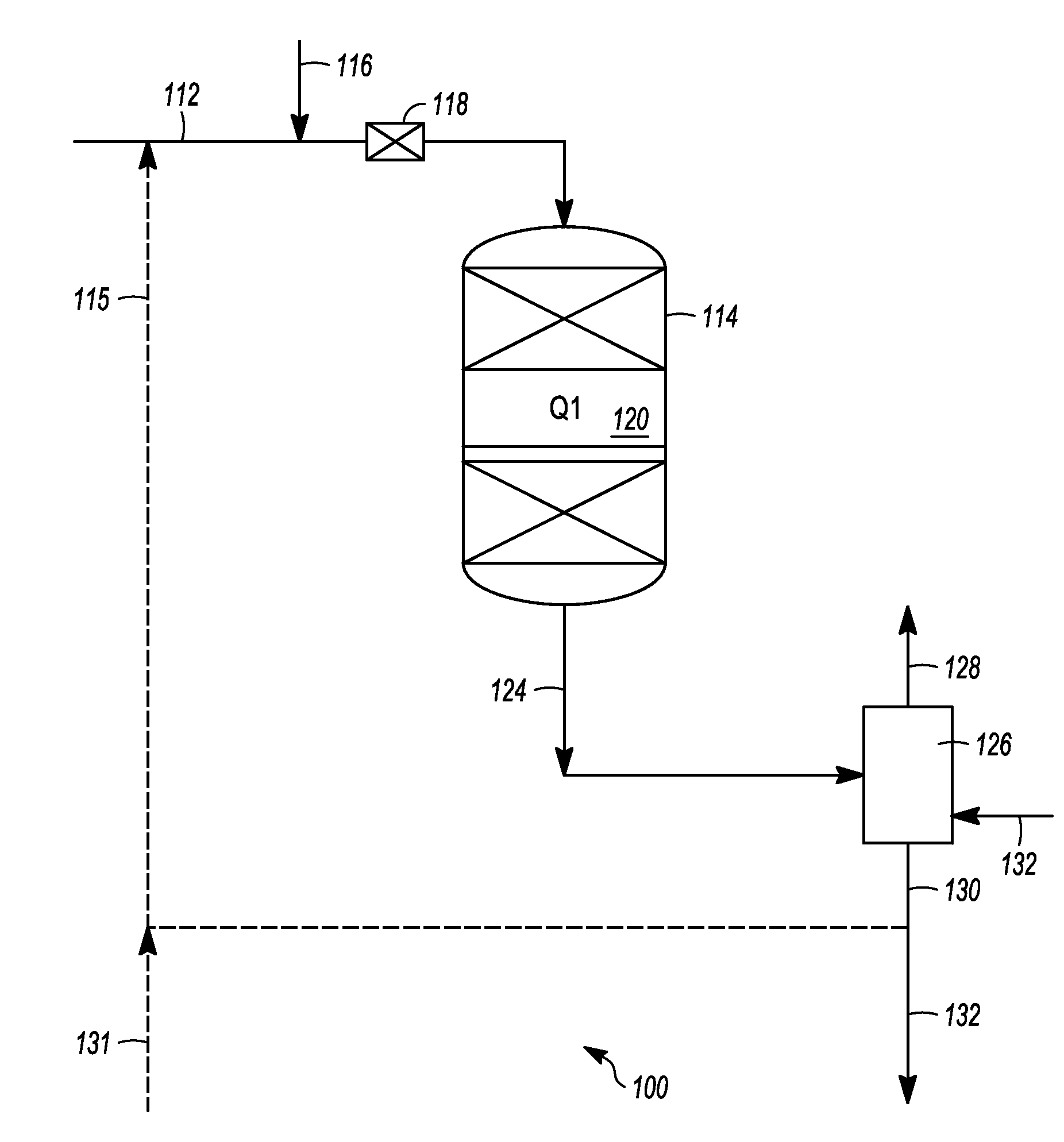

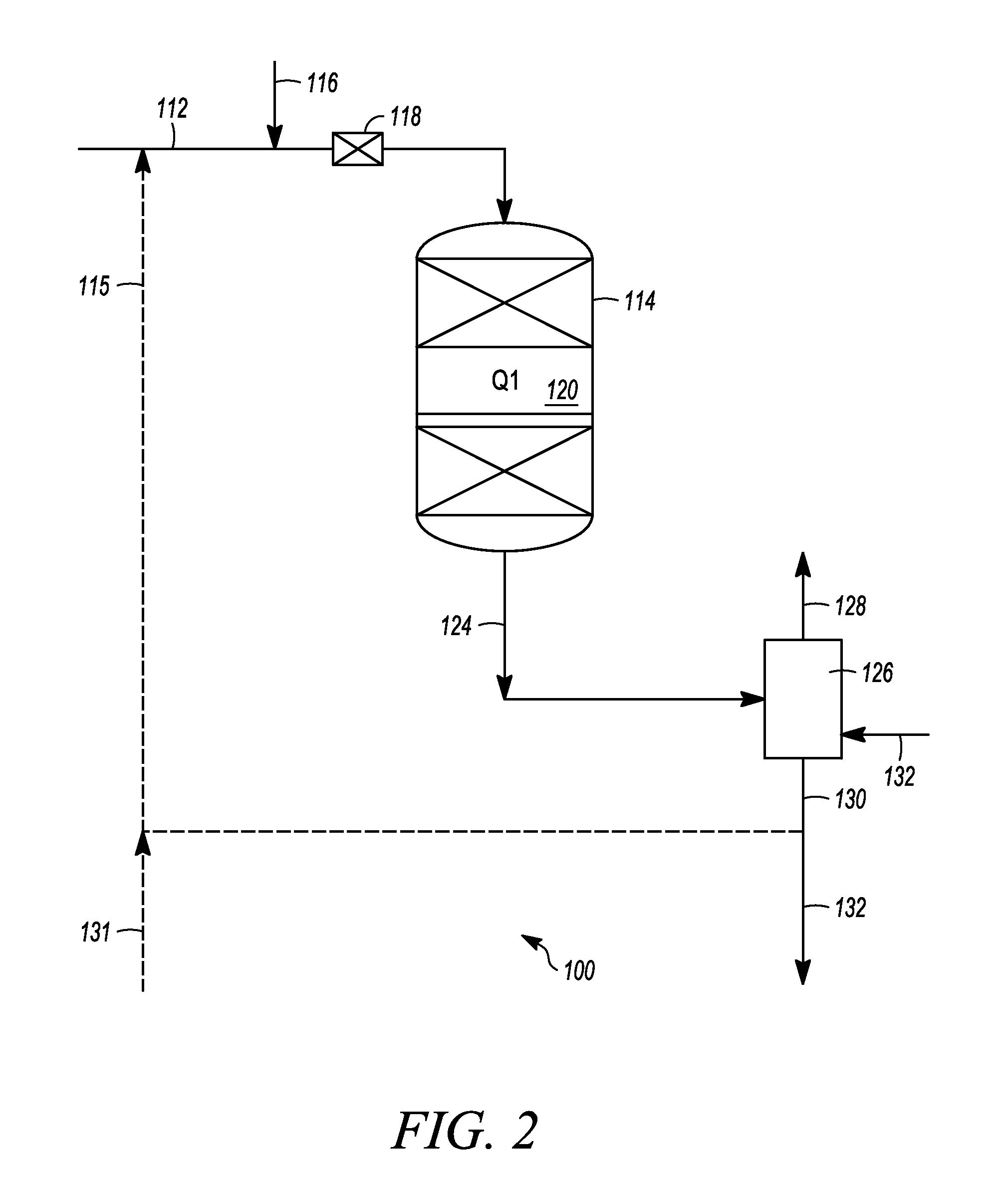

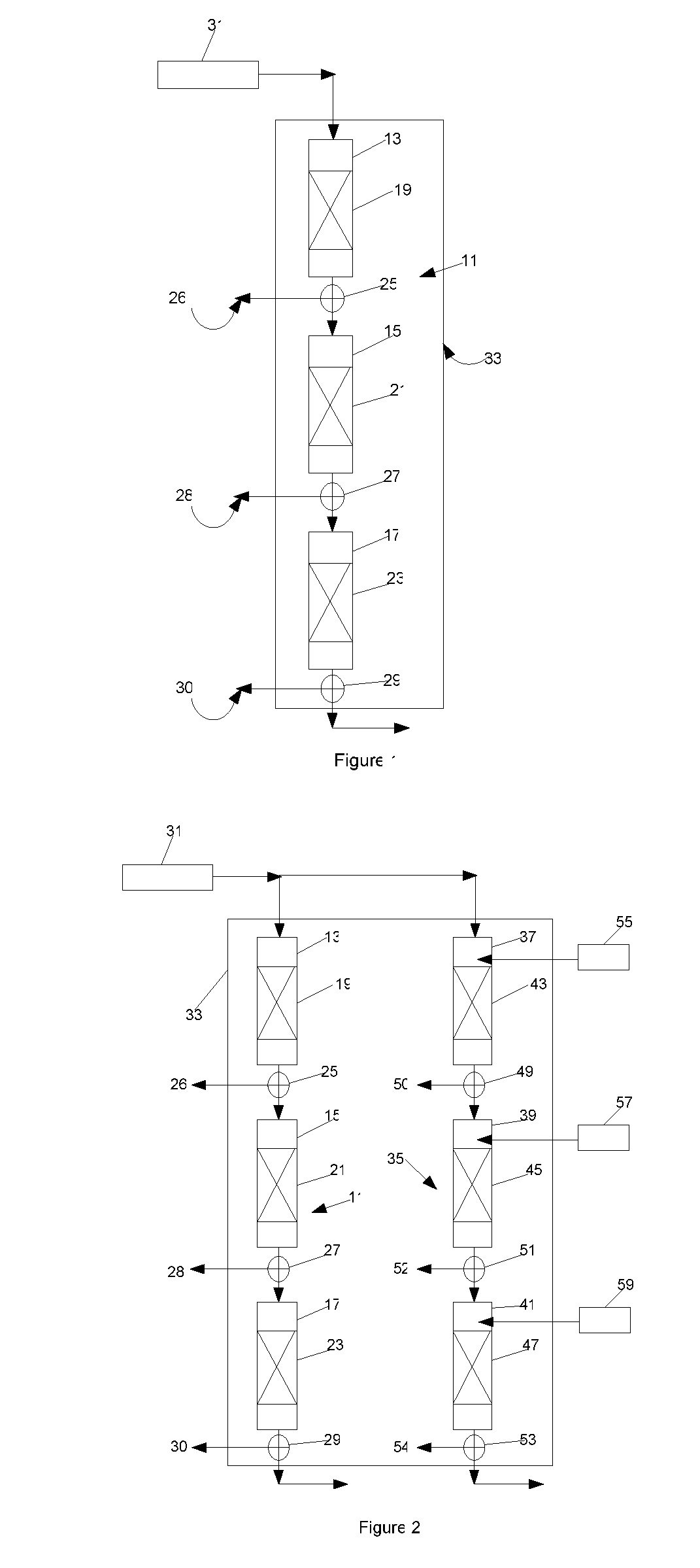

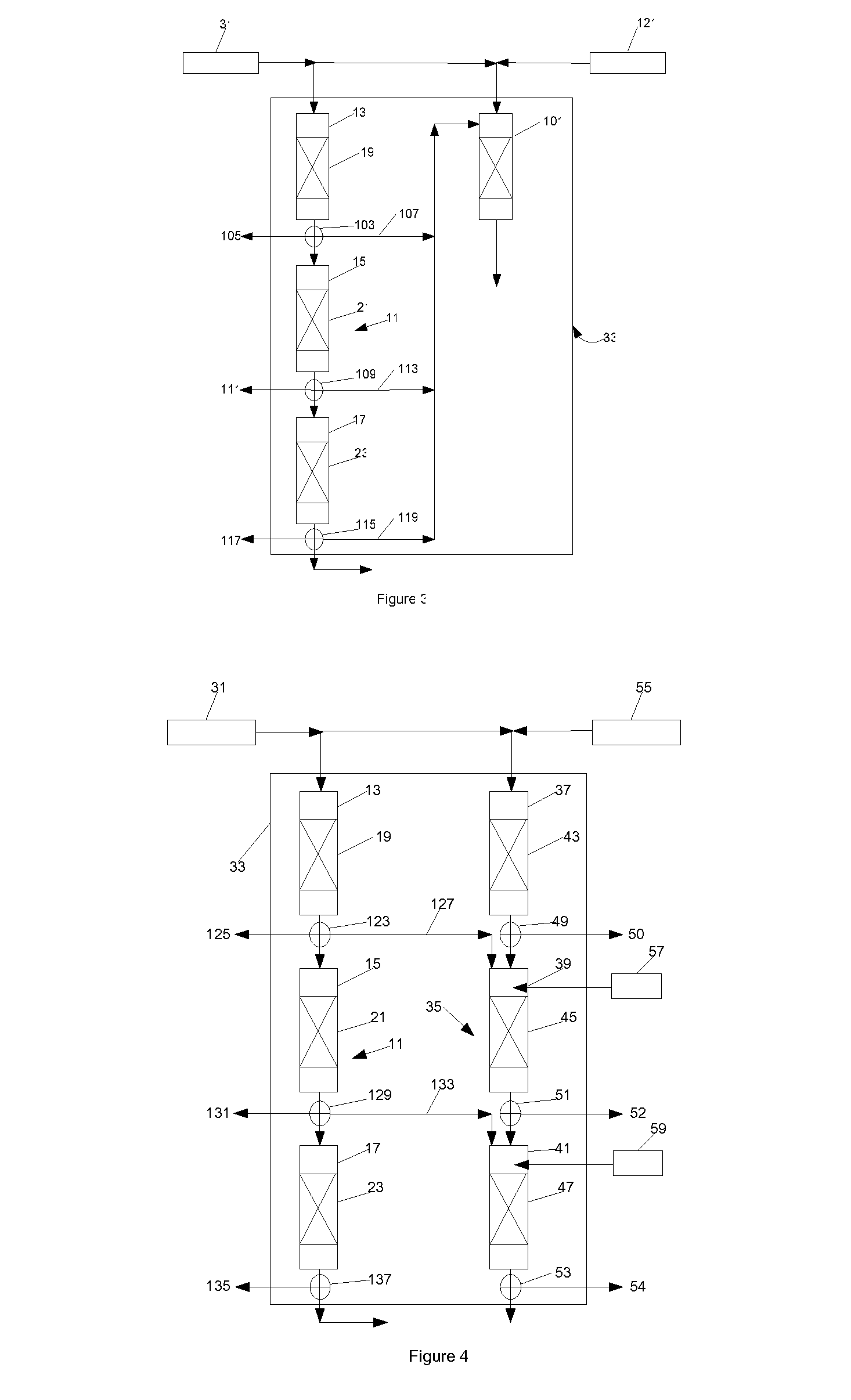

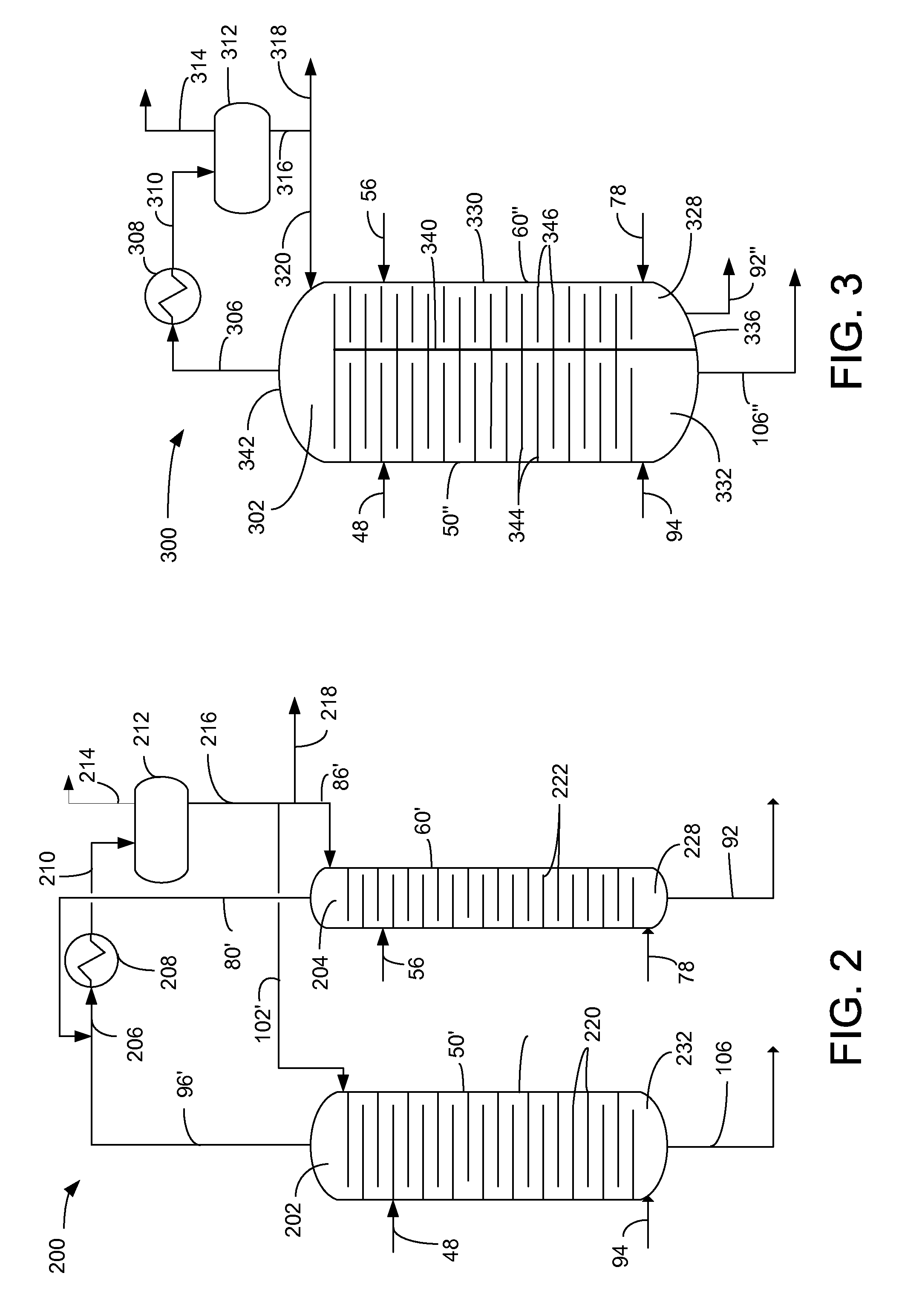

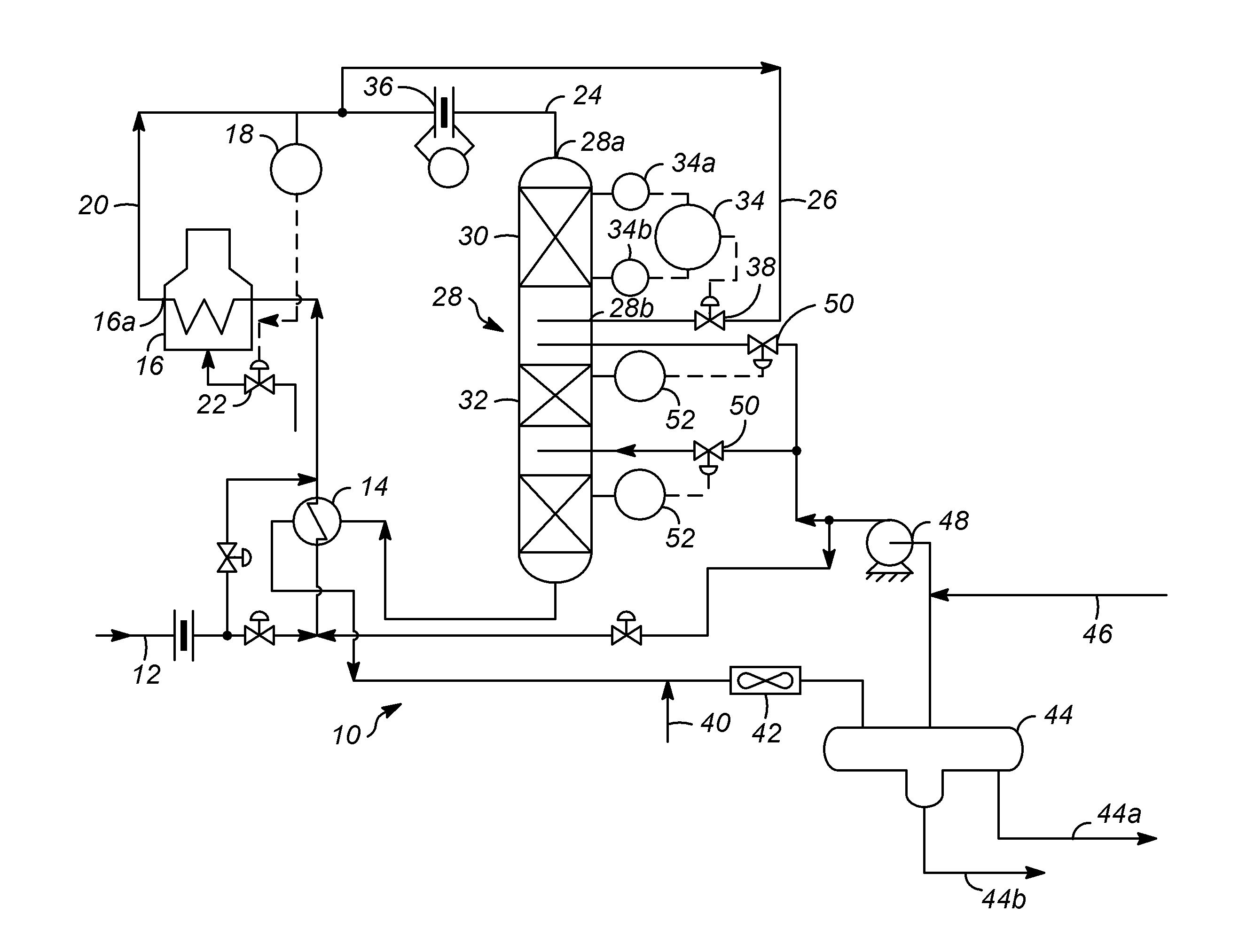

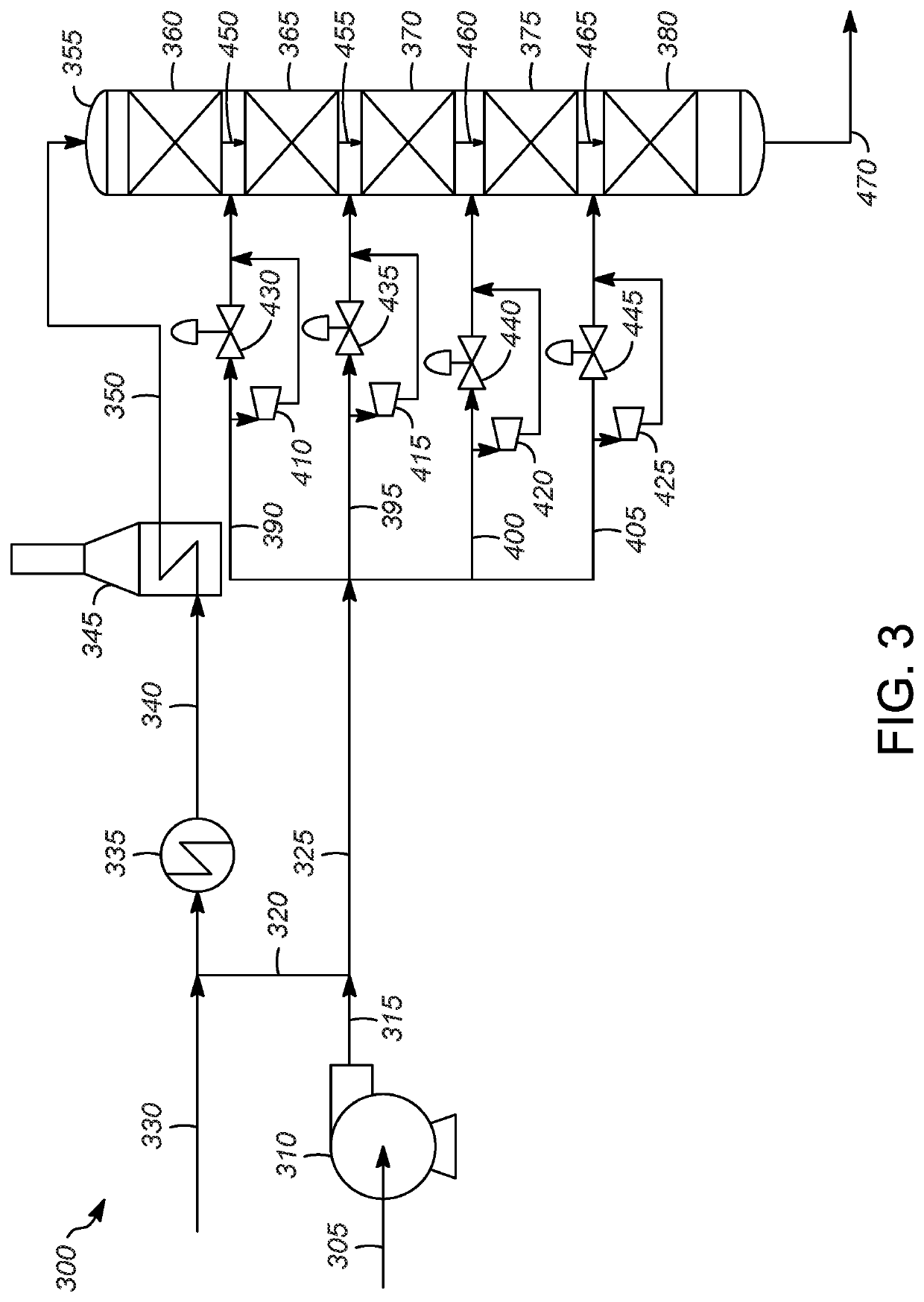

Liquid Phase Hydroprocessing With Temperature Management

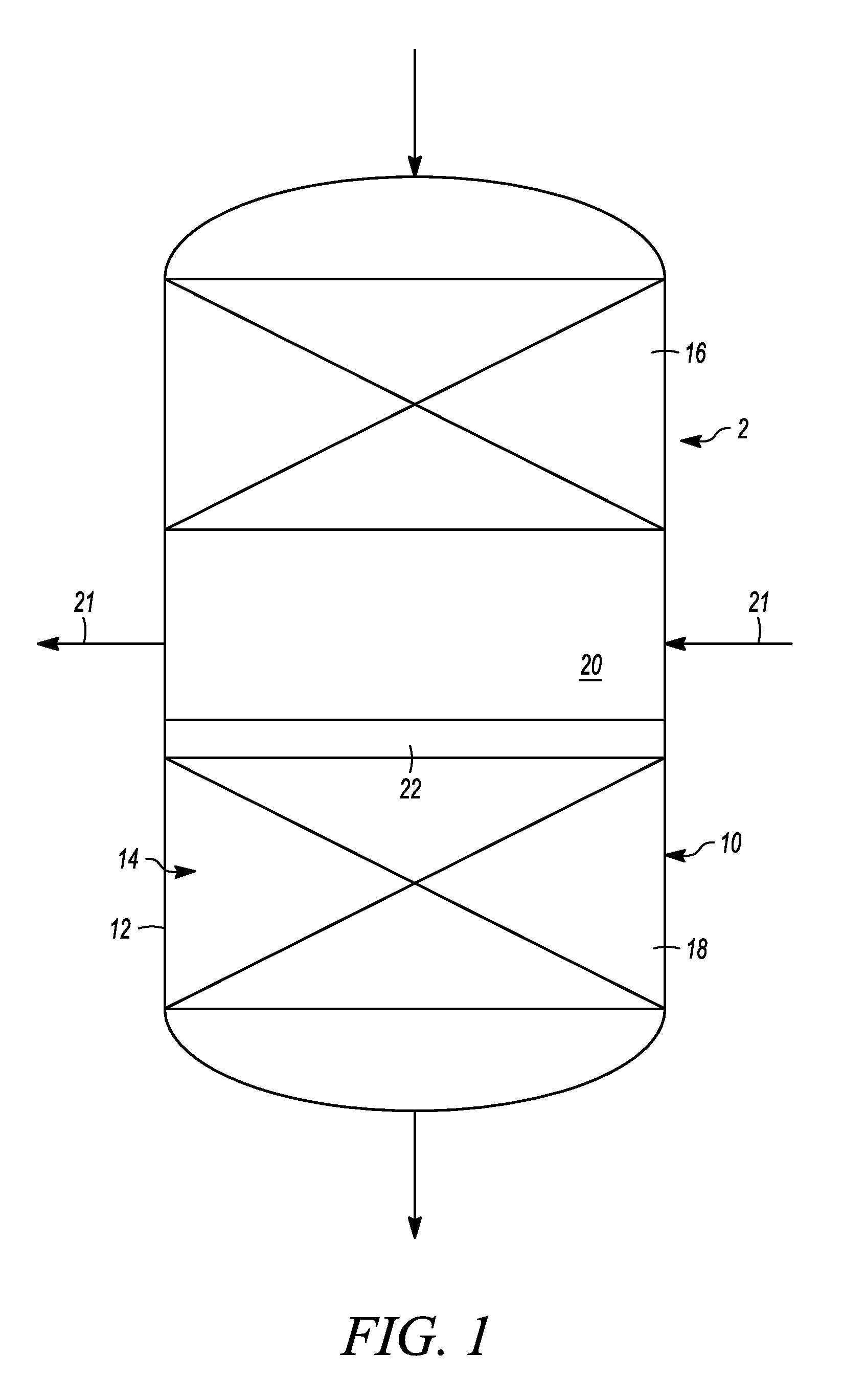

ActiveUS20090326289A1Efficient managementUndue complexityTreatment with plural serial cracking stages onlyMolecular sieve catalystsProcess engineeringOperating temperature range

A method of hydroprocessing hydrocarbons is provided using a substantially liquid-phase reactor having first and second catalyst beds with a heat transfer section positioned therebetween. The first and second catalyst beds and the heat transfer section are combined within the same reactor vessel. Each catalyst bed having an inlet temperature and an exit temperature and having a hydroprocessing catalyst therein with a maximum operating temperature range. The method hydroprocesses the hydrocarbons and removes sufficient heat from the hydrocarbons using the heat transfer section so that the exit temperature of the hydrocarbons existing the first catalyst bed is substantially maintained below the maximum operating temperature range of the hydroprocessing catalysts in the first bed and, at the same time, also providing the hydrocarbons to the second catalyst bed at the inlet temperature so that the exit temperature of the hydrocarbons at the exit of the second catalyst bed also does not exceed the maximum operating temperature range of the hydroprocessing catalyst in the second bed.

Owner:UOP LLC

Method and reaction system for liquid phase cycling hydrotreatment

ActiveCN101993721AMaintain active stabilityImprove effective utilizationHydrocarbon oils treatment control/regulationTreatment with hydrotreatment processesGas phaseControl system

The invention discloses a method and a reaction system for liquid phase cycling hydrotreatment. In the method, part of a liquid phase product after the hydrotreatment is mixed with fresh raw oil in a cycling mode to form a liquid phase material; hydrogen is mixed into the liquid phase material; the hydrogen mixed amount is 1 to 20 times that of the dissolved hydrogen which makes the reaction system saturated under a reaction condition; the liquid phase material mixed and dissolved with the hydrogen is put into a reactor; a hydrogenation catalyst bed is arranged in the reactor and is immersed in the liquid phase material; the upper part of the reactor is provided with a gas phase space; a pressure control system communicated with the gas phase space is arranged on the reactor and controls the pressure in the reactor by controlling the gas exhaust quantity; and the liquid phase material dissolved with the hydrogen is put into the hydrogenation catalyst bed of the reactor to perform hydrogenation reaction. Compared with the prior art, the method ensures that the liquid phase cycling hydrotreatment can be controlled and operated stably, and obtain an ideal reaction effect.

Owner:CHINA PETROLEUM & CHEM CORP +2

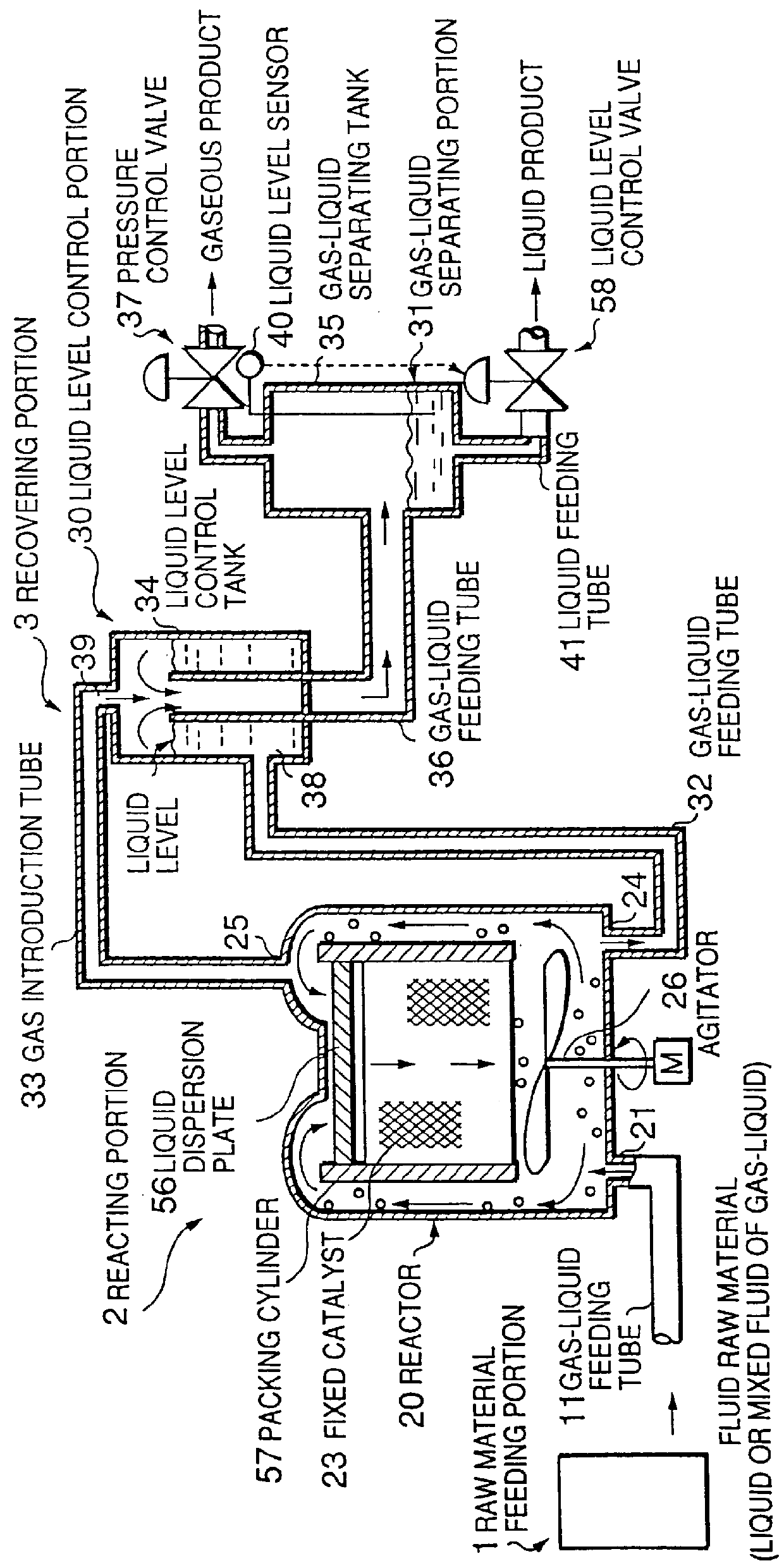

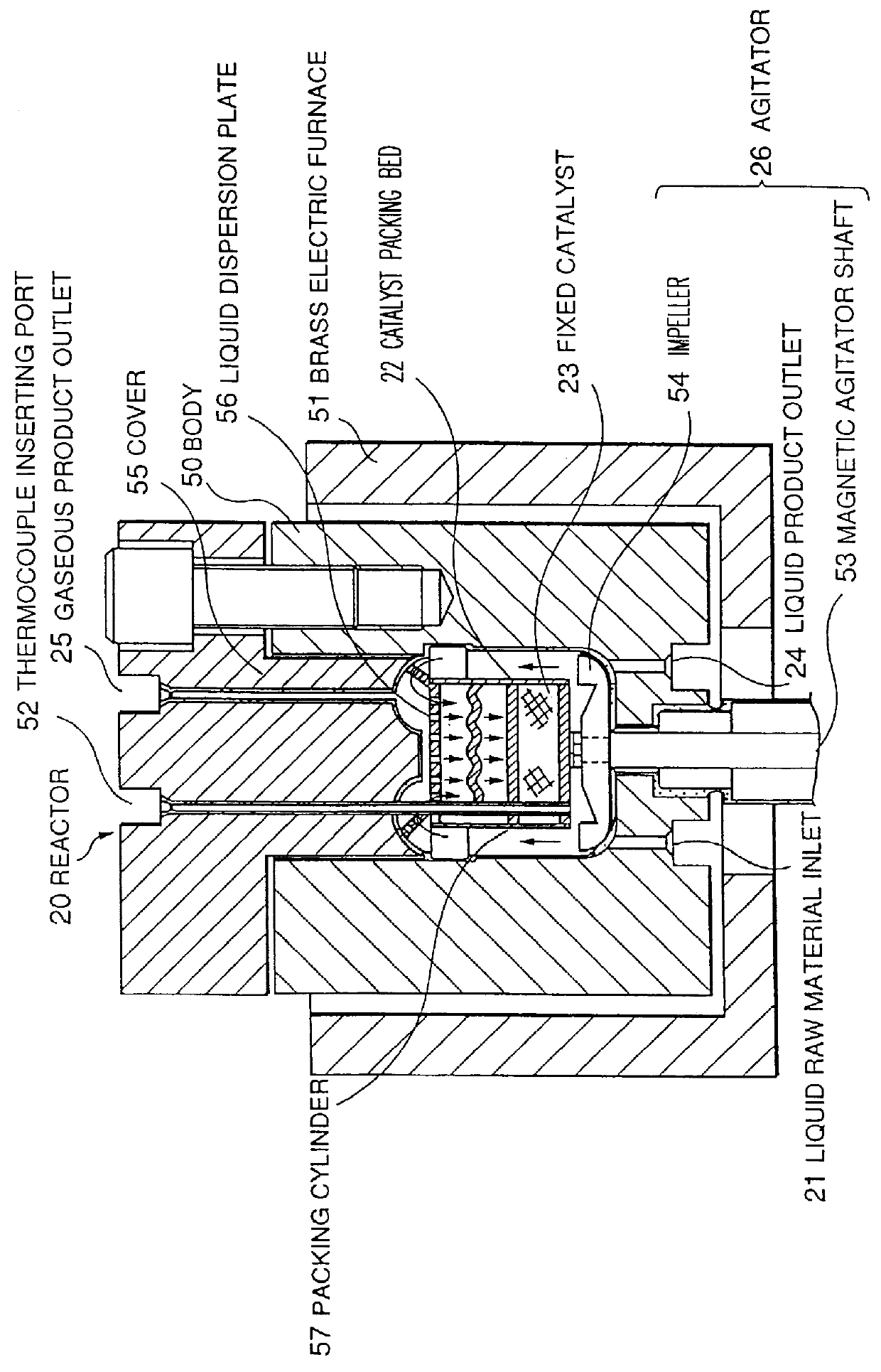

Apparatus for evaluating a solid catalyst and evaluation method using the apparatus

InactiveUS6086832AAccurate estimateIncrease rangeChemical analysis using catalysisPressurized chemical processLiquid productLaboratory scale

An apparatus for evaluating a solid catalyst which can enlarge a range of an applied fluid used for an evaluation of a performance of the solid catalyst and can accurately evaluate the performance of the solid catalyst on a laboratory scale and a method of evaluating a solid catalyst using the apparatus are provided. There are disclosed an apparatus of evaluating a solid catalyst, wherein a raw material feeding portion has a function capable of continuously feeding a liquid raw material or a mixed raw material consisting of a gas and a liquid, wherein a reactor in a reacting portion has an inlet for a fluid raw material and reaction product outlets for discharging a reaction product while separating it into a liquid product and a gaseous product, and wherein a recovering portion has reaction product inlets connected to each of the reaction product outlets of the reactor and has a liquid level control portion for keeping a liquid level within the reactor constant, and a method of evaluating a solid catalyst using the apparatus.

Owner:IDEMITSU KOSAN CO LTD

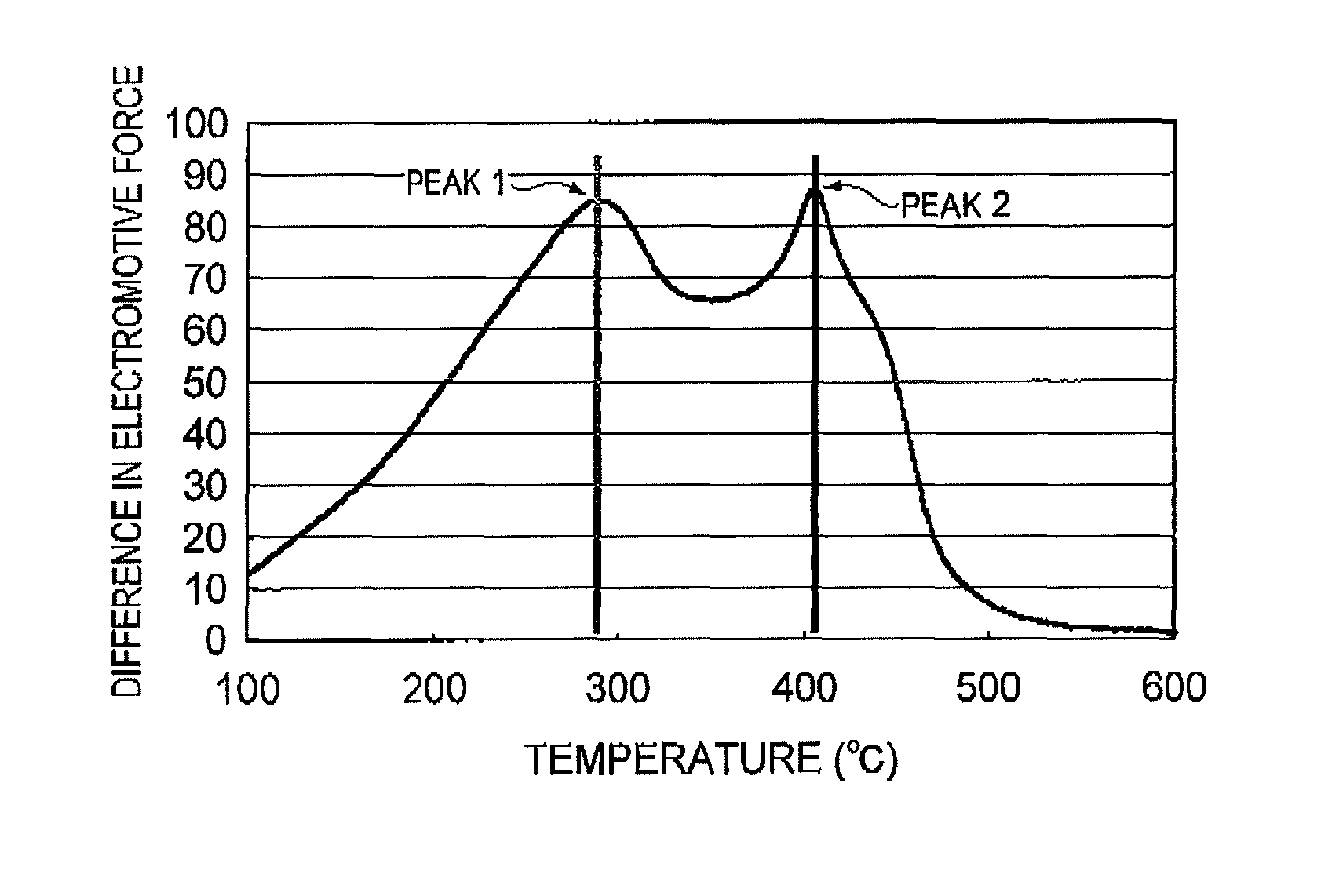

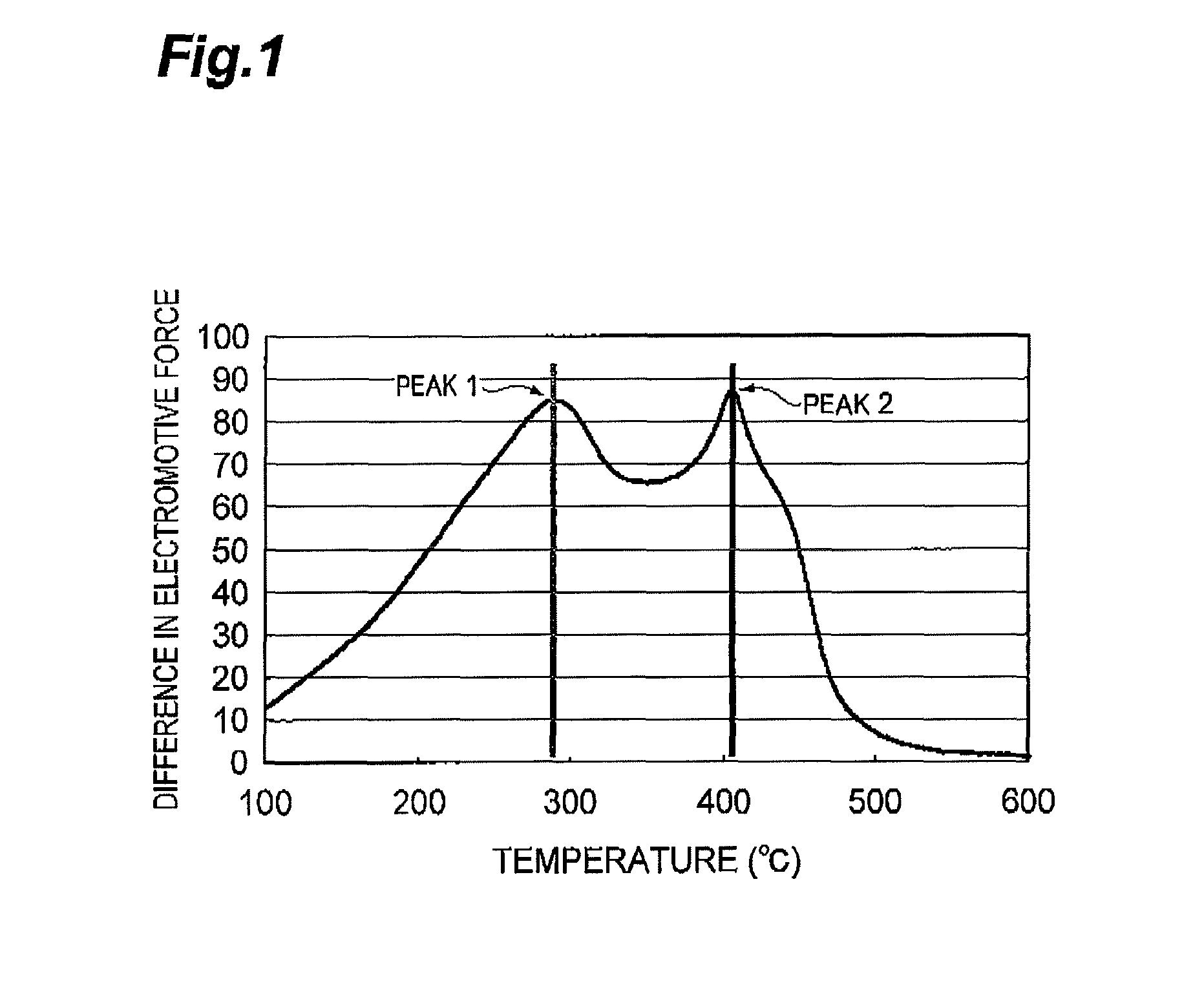

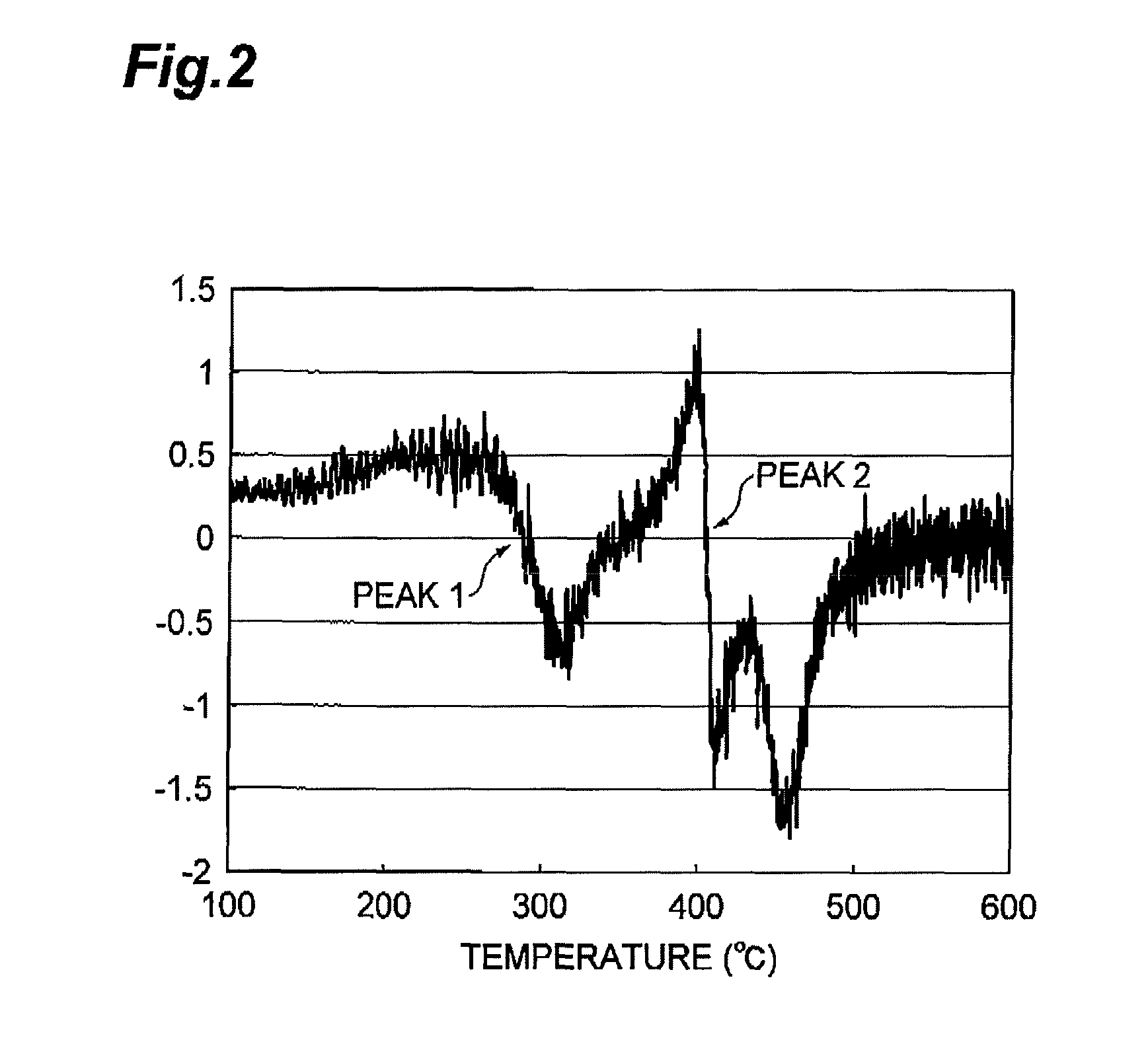

Process for producing regenerated hydrotreating catalyst and process for producing petrochemical product

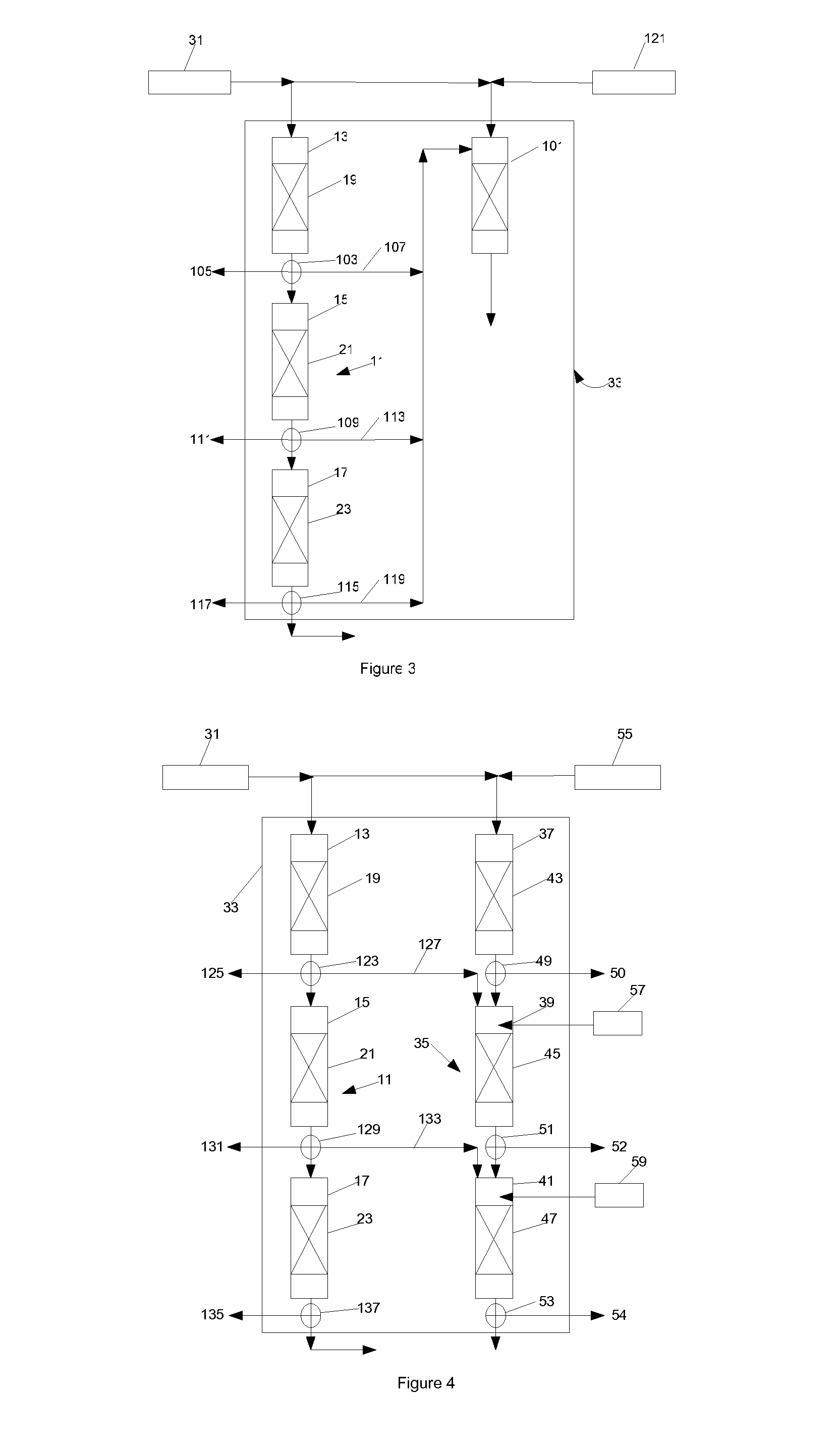

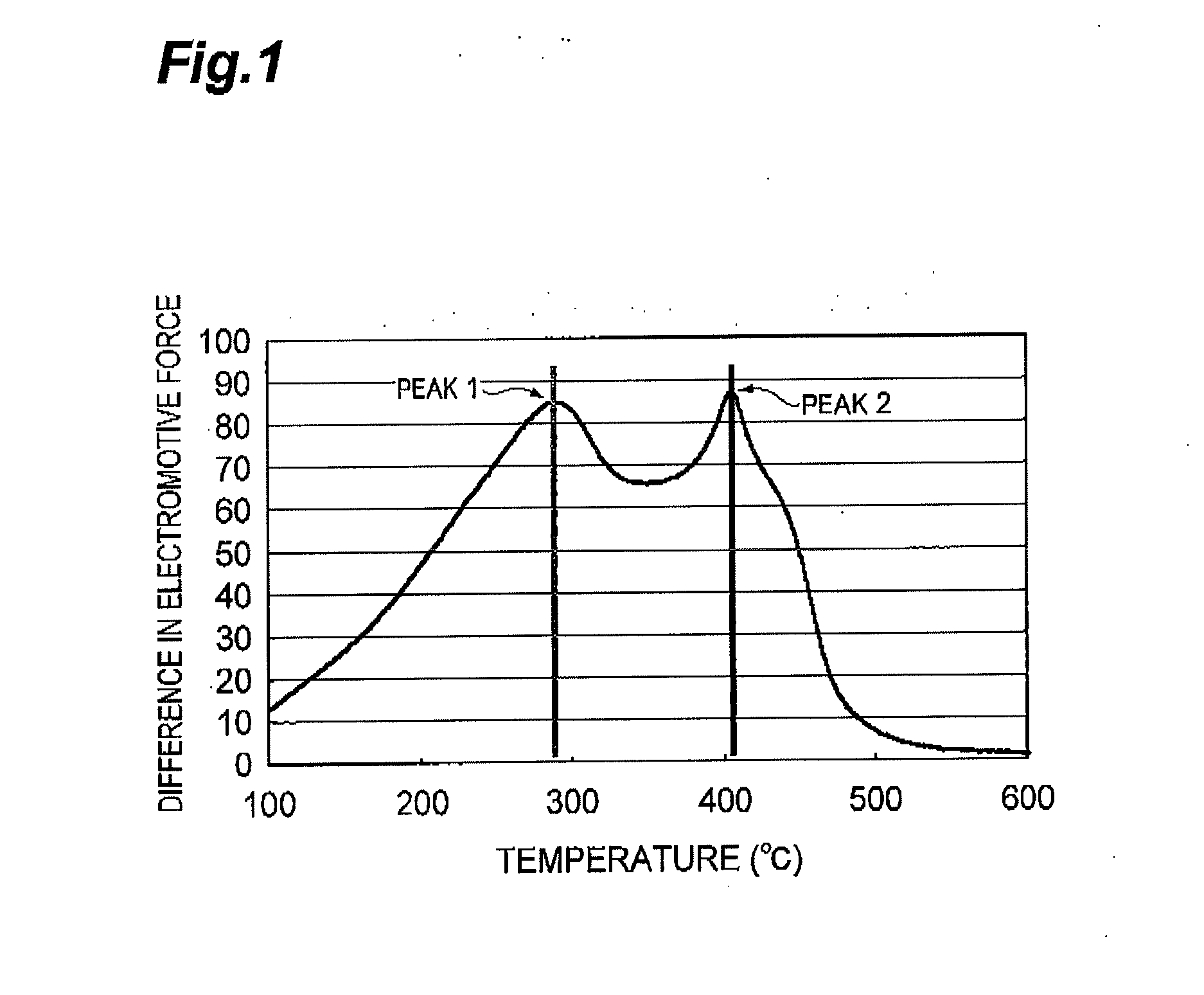

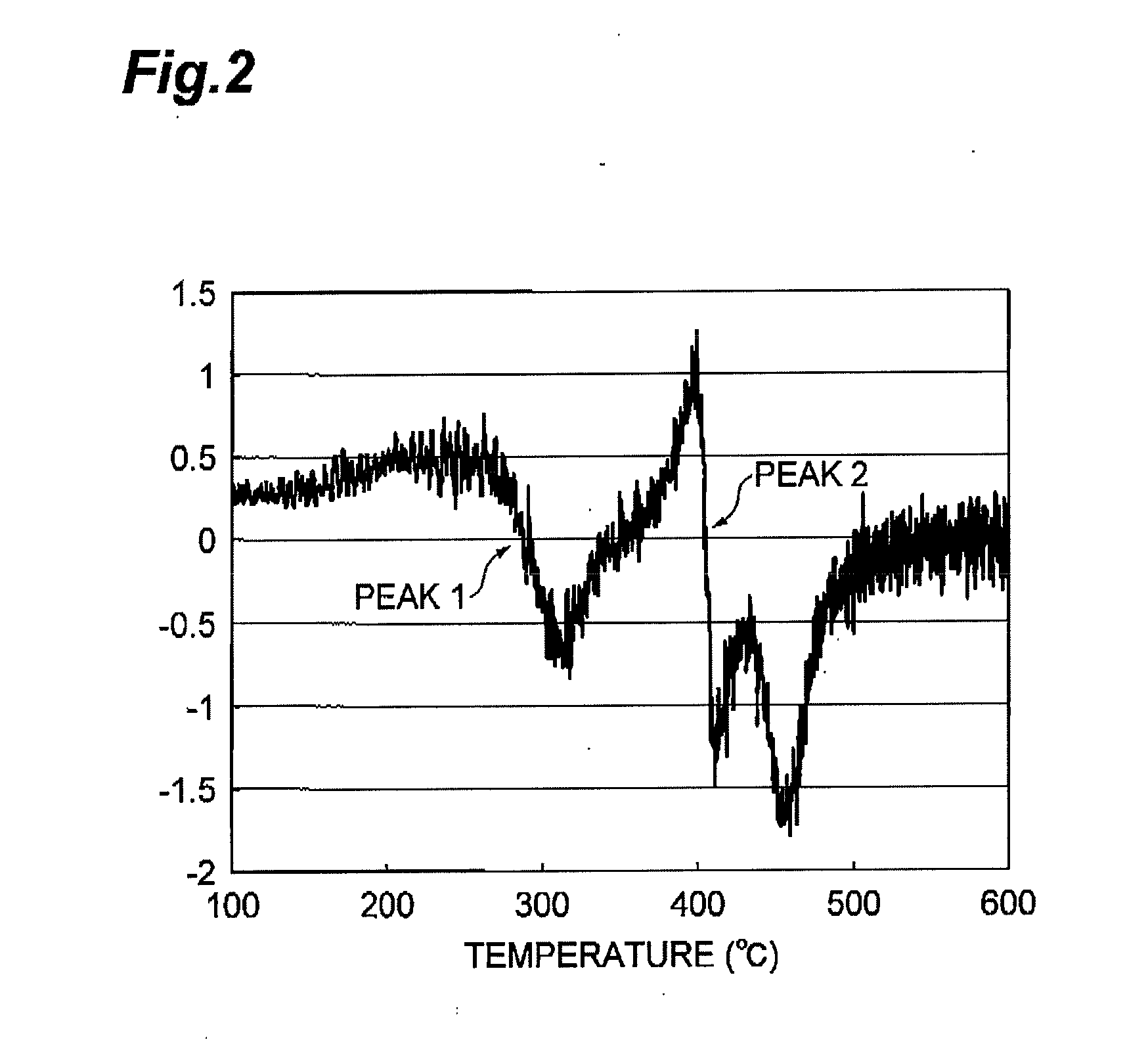

InactiveUS8722558B2Easy to produceSolve the lack of activityCoke ovensTreatment with hydrotreatment processesPetrochemicalElectromotive force

Provided is a process for producing a regenerated hydrotreating catalyst by regenerating a spent hydrotreating catalyst in a prescribed temperature range, wherein the prescribed temperature range is a temperature range of T1−30° C. or more and T2+30° C. or less, as determined by subjecting the spent hydrotreating catalyst to a differential thermal analysis, converting a differential heat in a measuring temperature range of 100° C. or more and 600° C. or less to a difference in electromotive force, differentiating the converted value twice by temperature to provide a smallest extreme value and a second smallest extreme value, and representing a temperature corresponding to the extreme value on the lower-temperature side as T1 and a temperature corresponding to the extreme value on the higher-temperature side as T2.

Owner:JX NIPPON OIL & ENERGY CORP

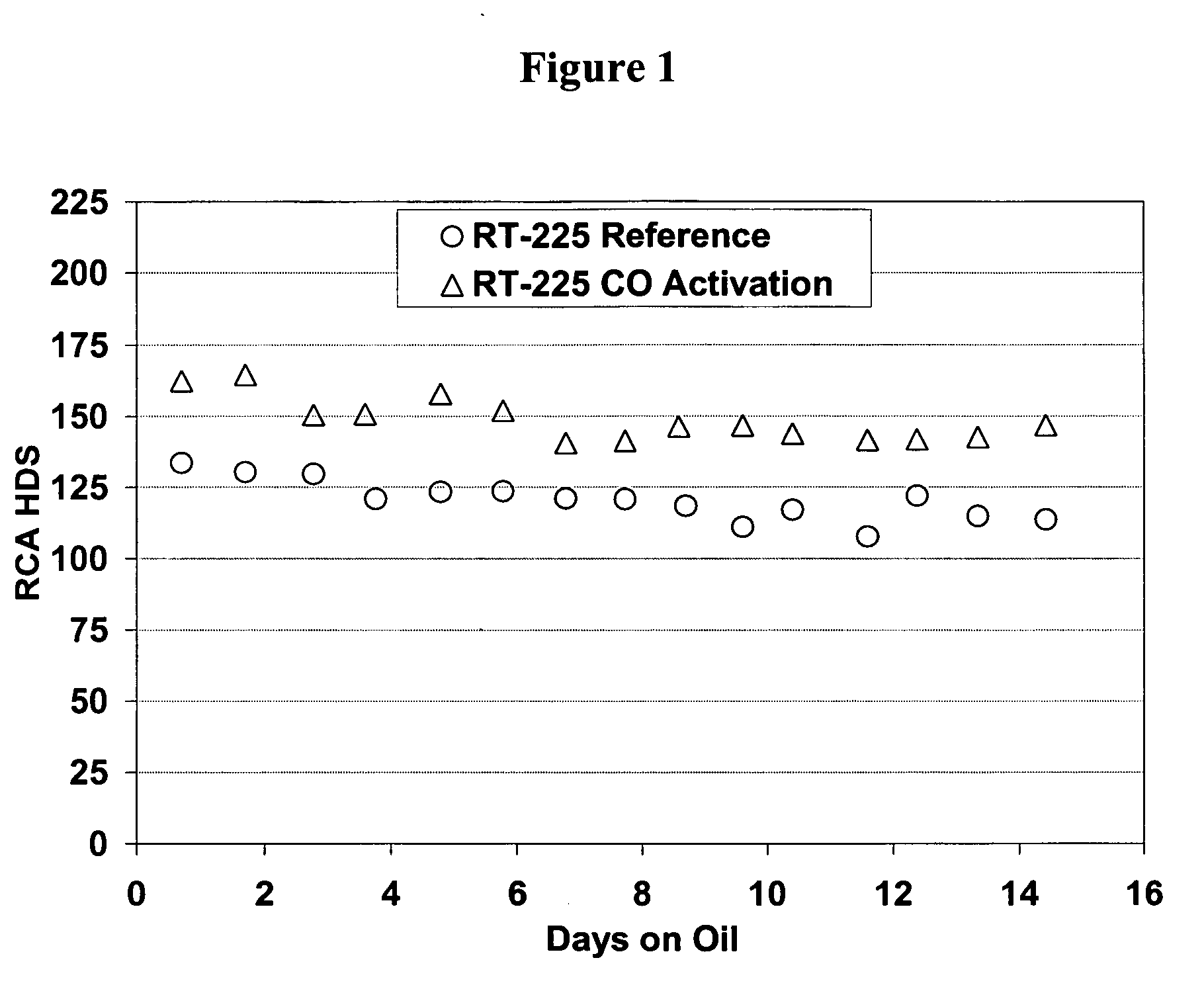

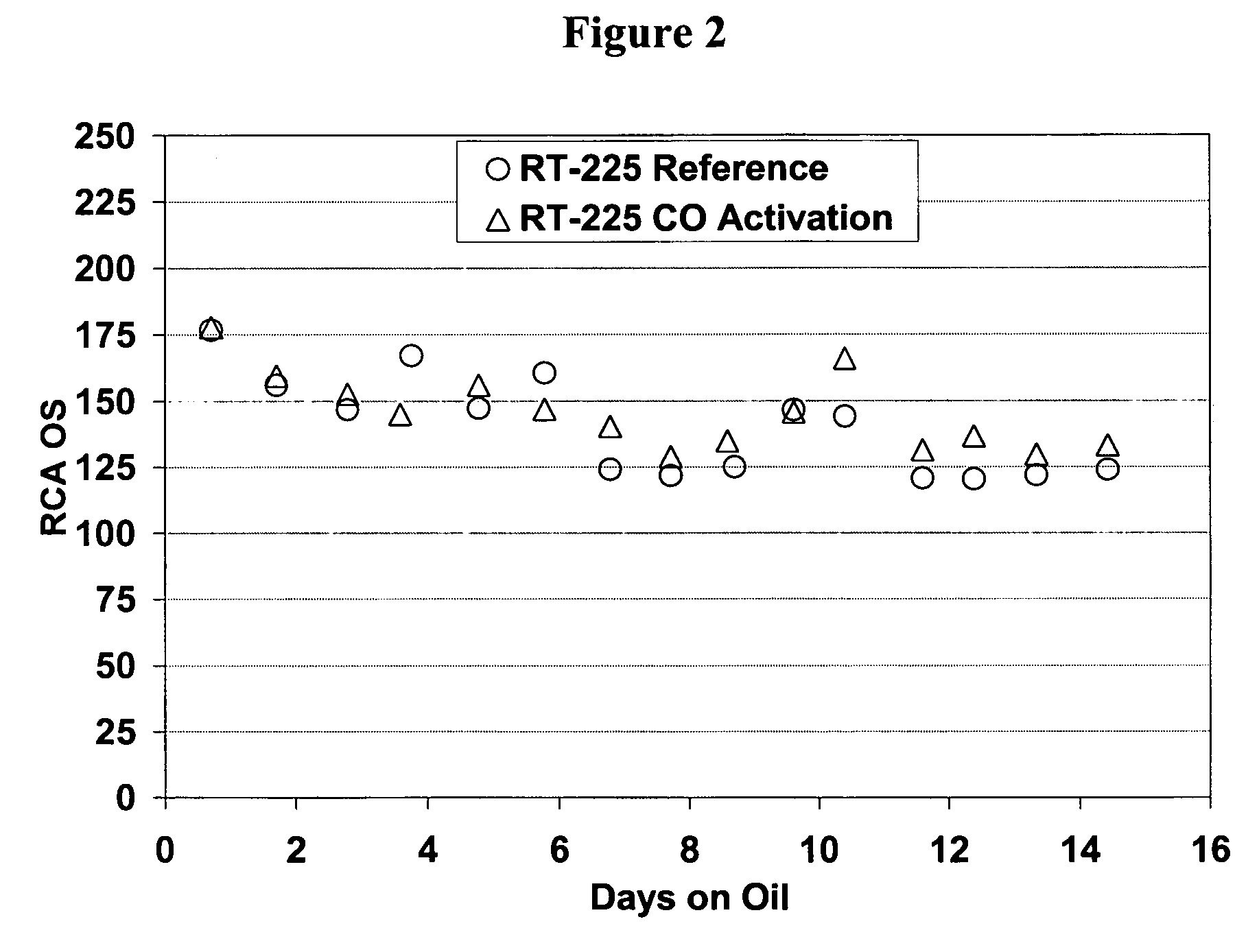

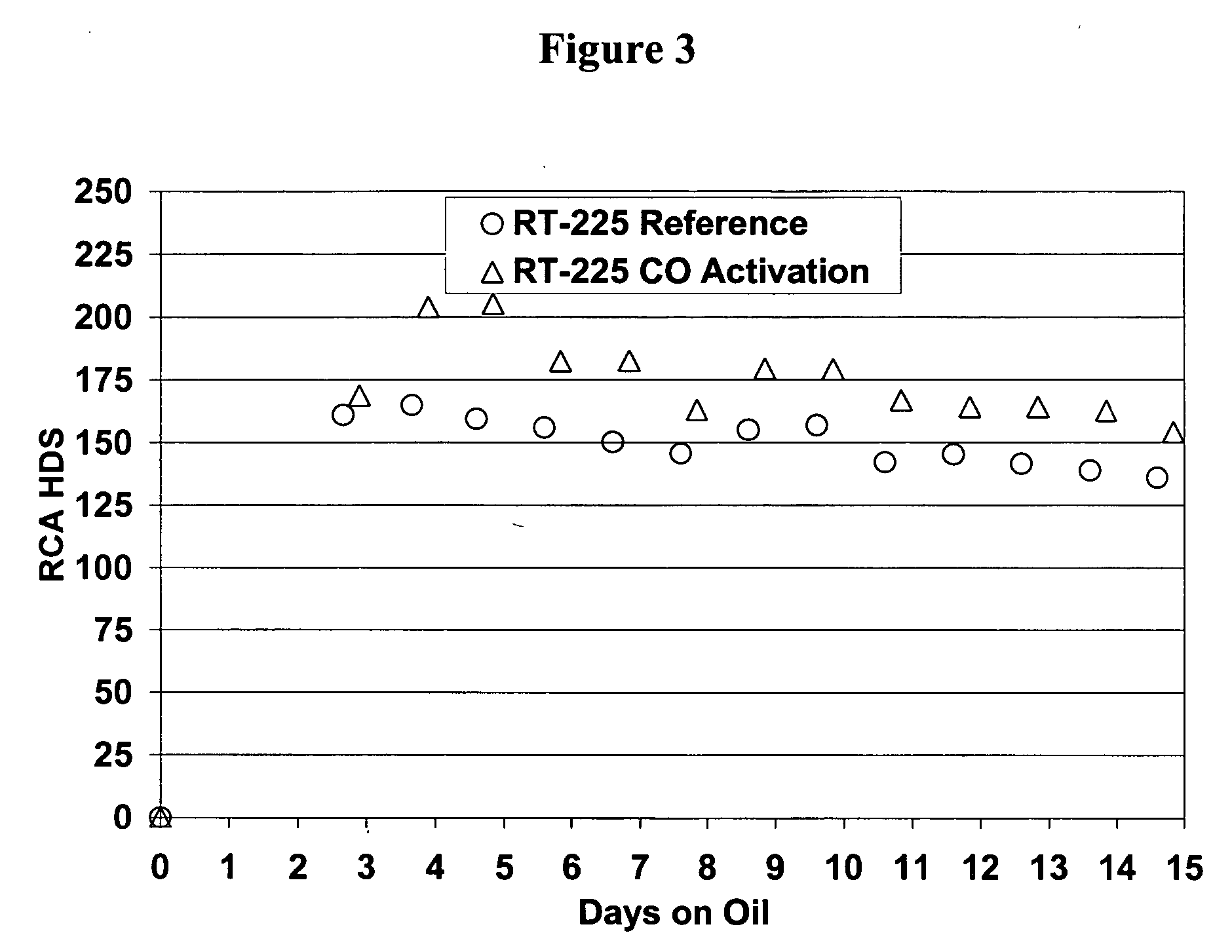

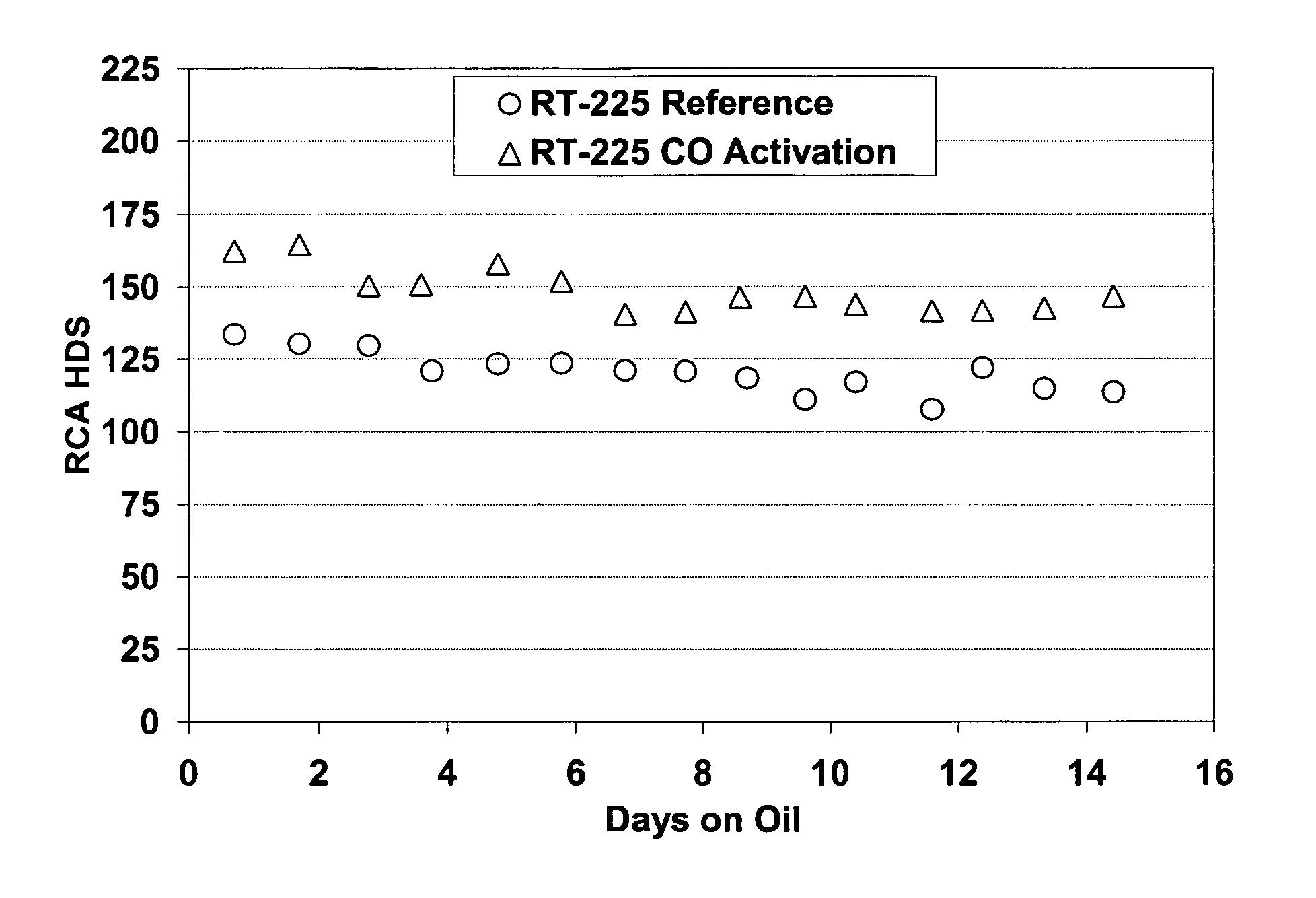

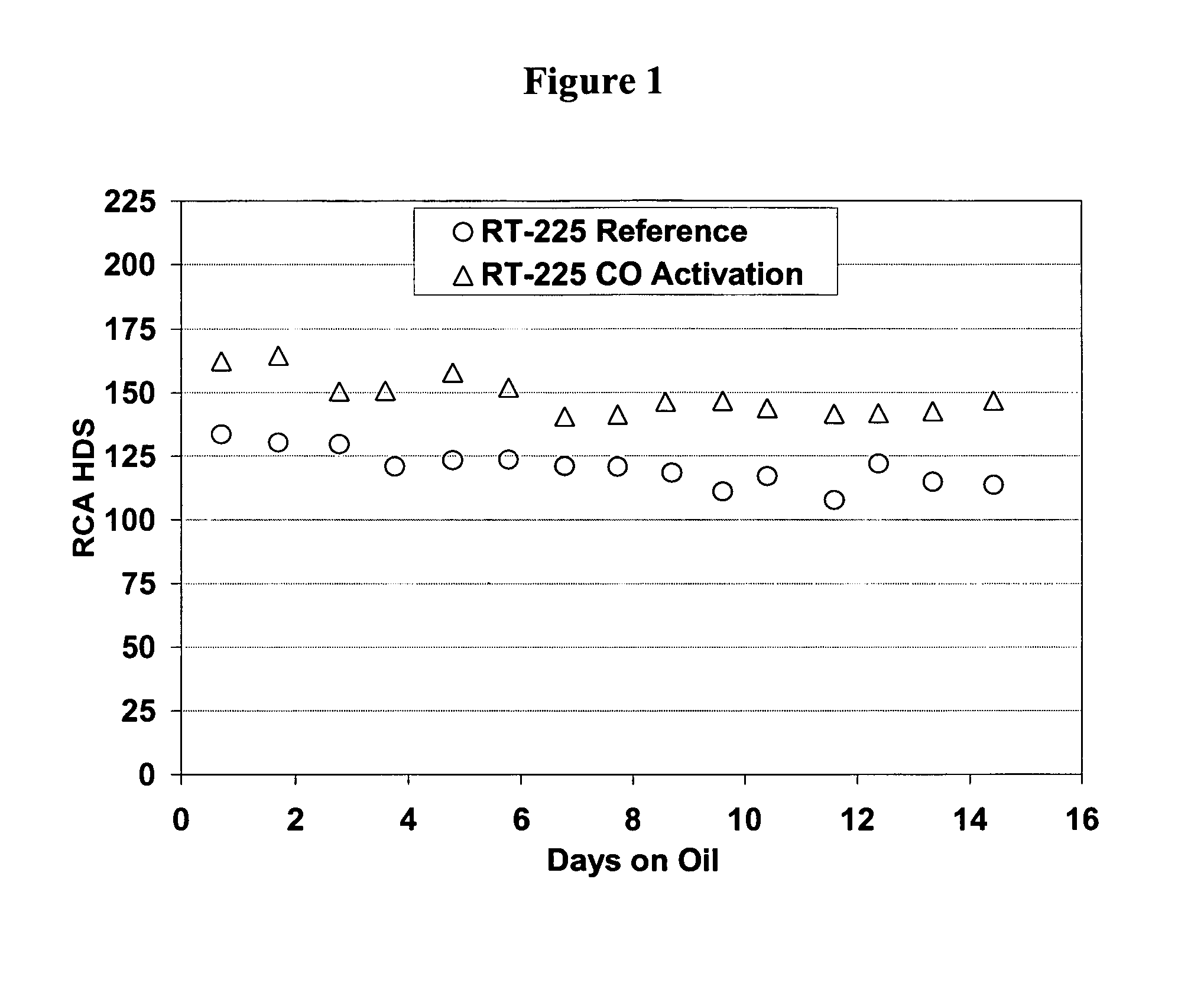

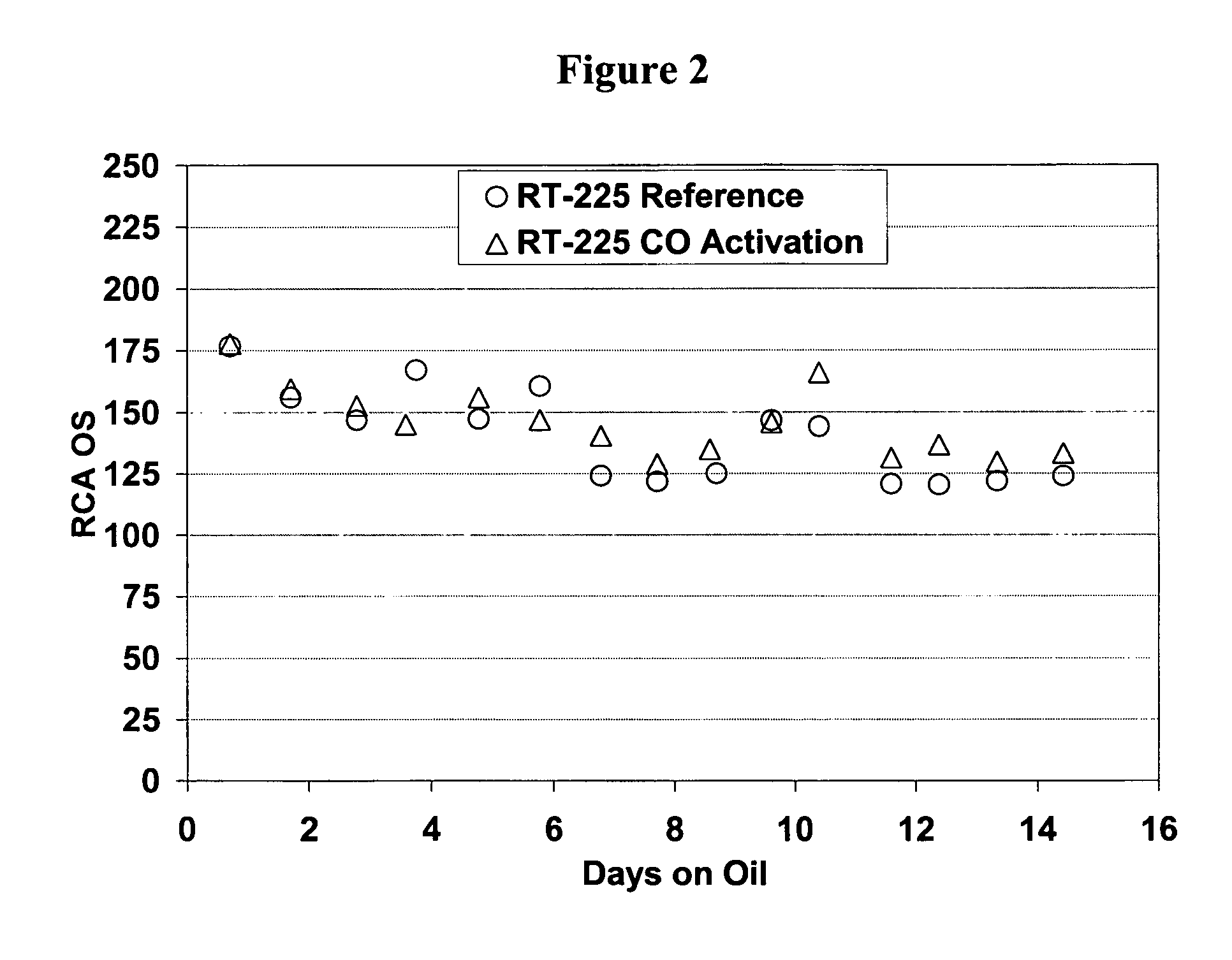

Activating hydroprocessing catalysts using carbon monoxide and use of catalysts for hydroprocessing

ActiveUS20060231464A1Hydrotreatment operations starting-upHydrocarbon oils treatment control/regulationOrganic chemistryCo treatments

This invention relates to a process for activating a hydroprocessing catalyst and the use of activated catalyst for hydroprocessing. More particularly, hydroprocessing catalysts are activated in the presence of carbon monoxide. The catalysts that have been activated by CO treatment have improved activity.

Owner:EXXON RES & ENG CO

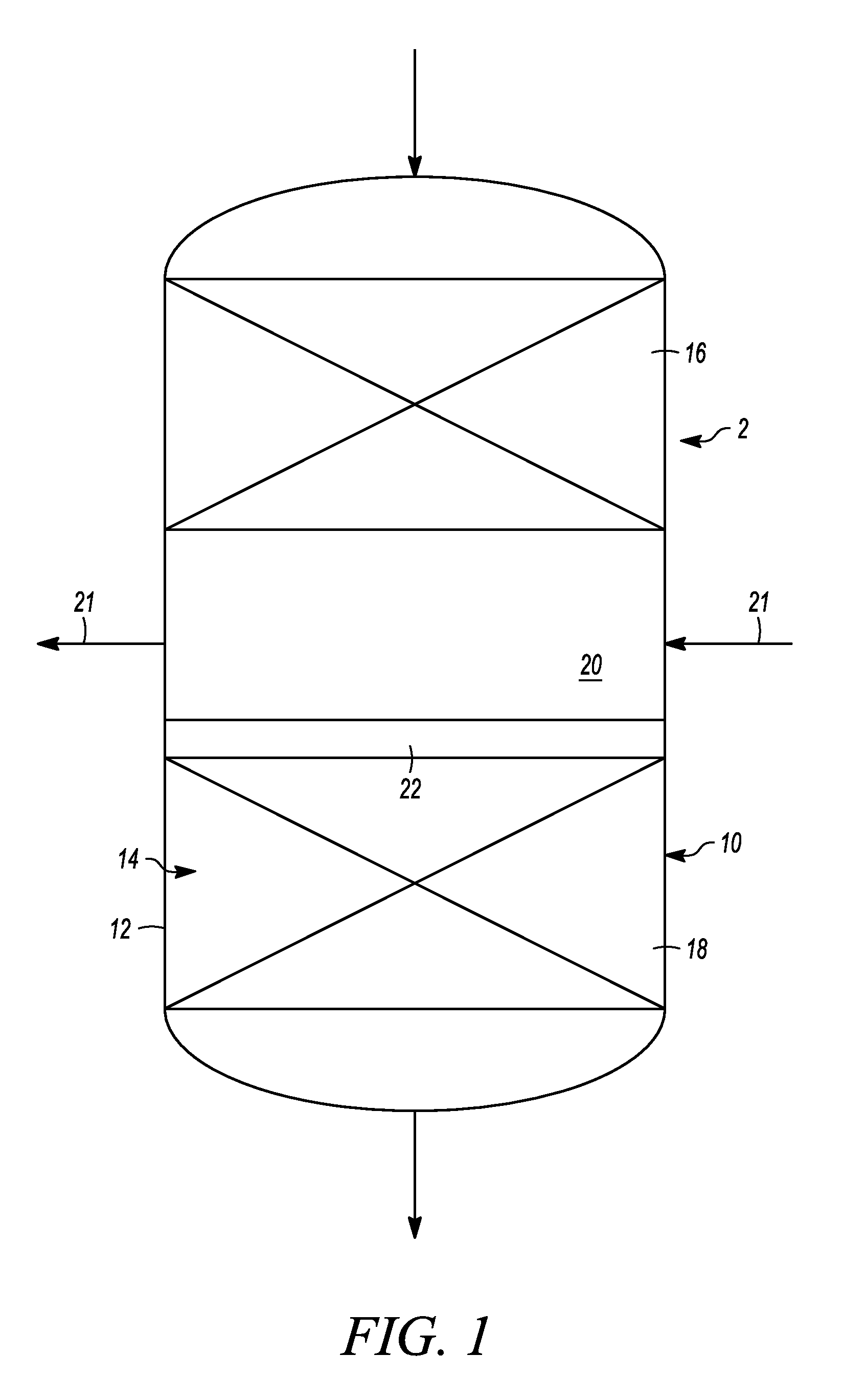

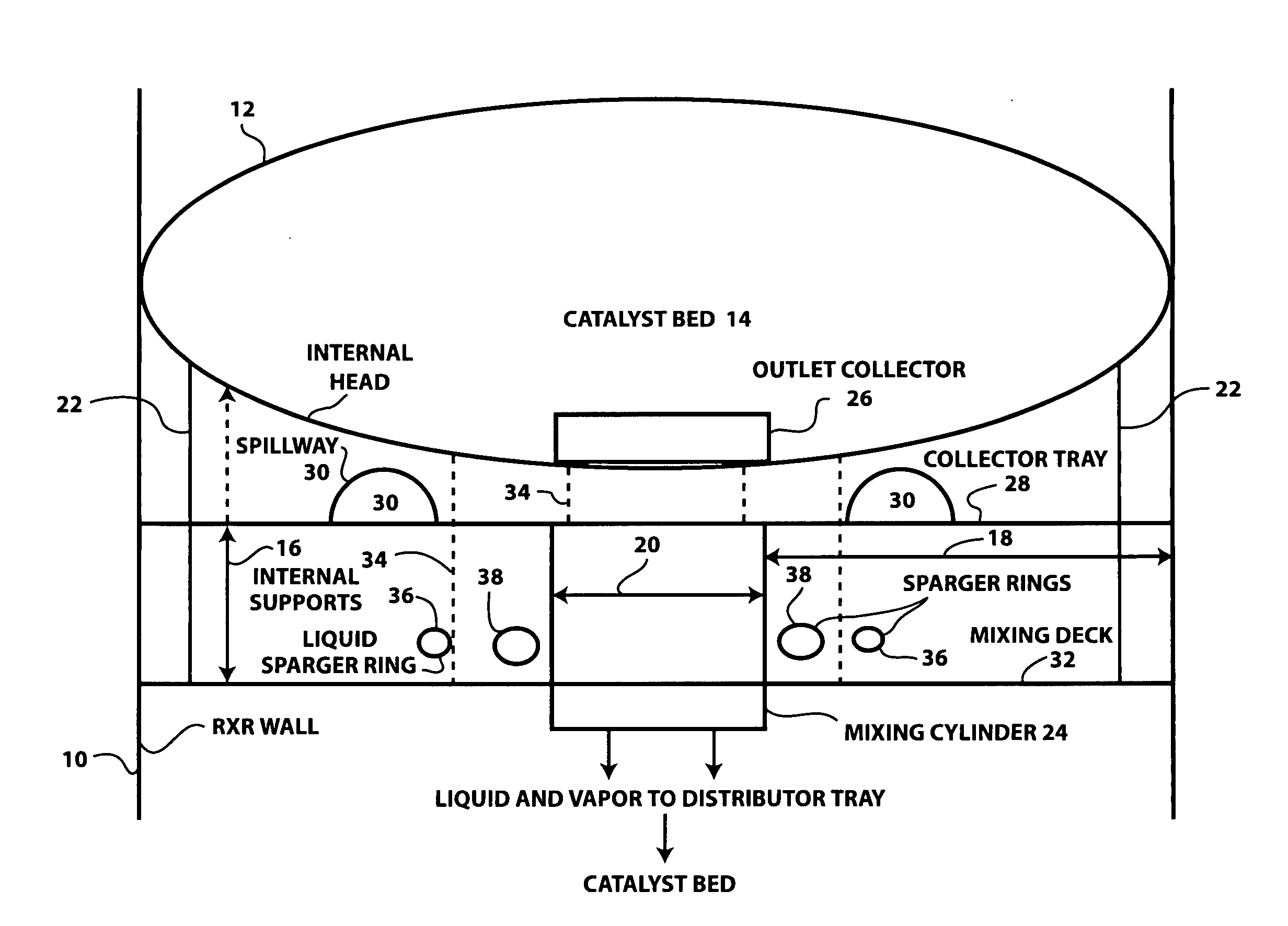

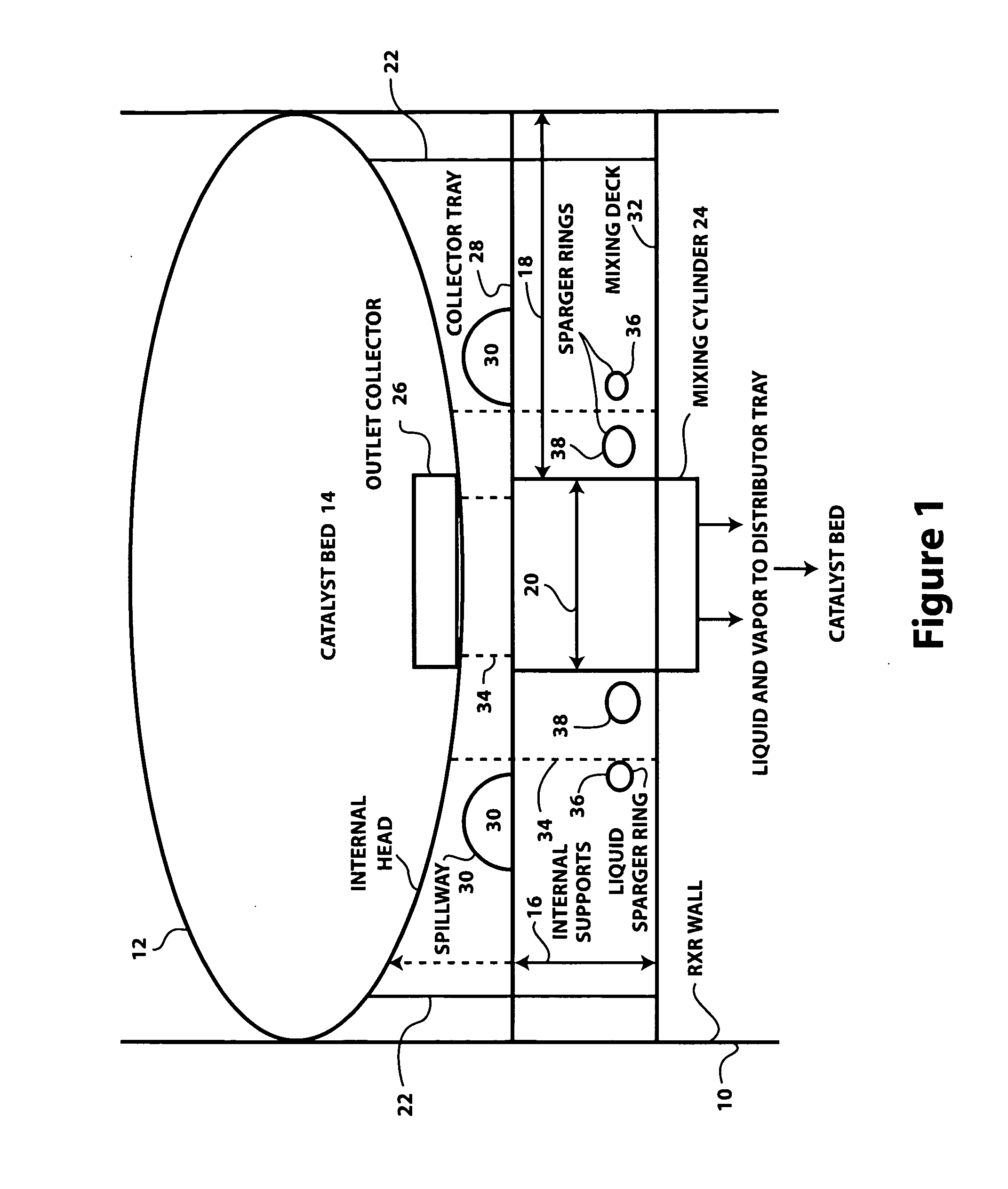

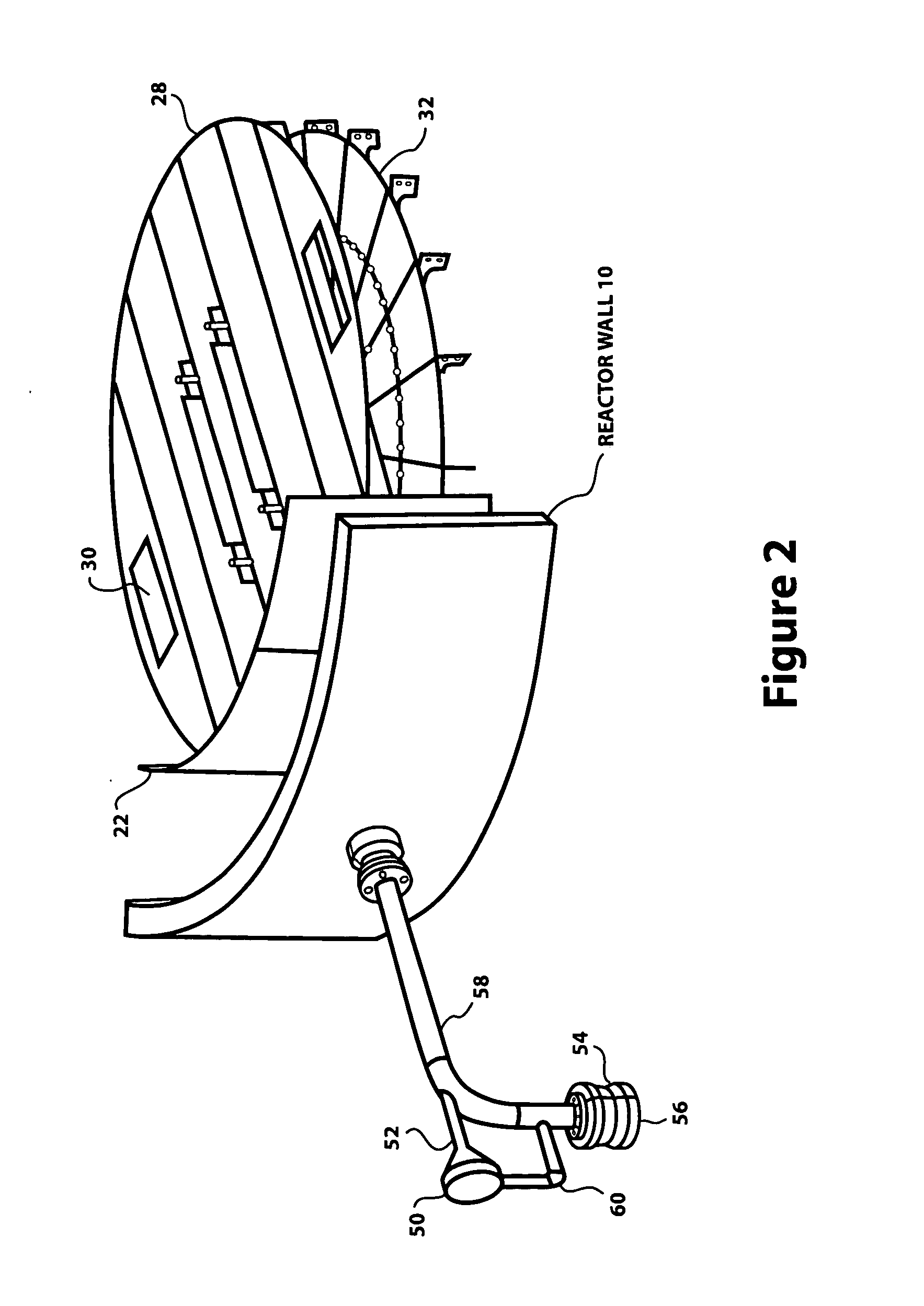

Dual gas-liquid spargers for catalytic processing units

InactiveUS20070248510A1Obstruct passageFlow mixersHydrocarbon oils treatment control/regulationTemperature controlChemical physics

This invention relates to a quenching device for temperature control in catalytic processes. More particularly, the quenching device includes gas and liquid spargers for interbed temperature control in an interbed mixing zone in a catalytic reactor. The quenching device includes a first injector for injecting a first quenching fluid into an outer mixing zone and a second injector for injecting a second quenching fluid into an inner mixing zone. The quenching fluids include both gaseous and liquid quenching fluids.

Owner:EXXON RES & ENG CO

Liquid phase hydroprocessing with temperature management

ActiveUS8008534B2Efficient managementUndue complexityTreatment with plural serial cracking stages onlyMolecular sieve catalystsProcess engineeringOperating temperature range

A method of hydroprocessing hydrocarbons is provided using a substantially liquid-phase reactor having first and second catalyst beds with a heat transfer section positioned therebetween. The first and second catalyst beds and the heat transfer section are combined within the same reactor vessel. Each catalyst bed having an inlet temperature and an exit temperature and having a hydroprocessing catalyst therein with a maximum operating temperature range. The method hydroprocesses the hydrocarbons and removes sufficient heat from the hydrocarbons using the heat transfer section so that the exit temperature of the hydrocarbons existing the first catalyst bed is substantially maintained below the maximum operating temperature range of the hydroprocessing catalysts in the first bed and, at the same time, also providing the hydrocarbons to the second catalyst bed at the inlet temperature so that the exit temperature of the hydrocarbons at the exit of the second catalyst bed also does not exceed the maximum operating temperature range of the hydroprocessing catalyst in the second bed.

Owner:UOP LLC

System and process for reacting a petroleum fraction

InactiveUS20090314686A1Facilitate converting pitchLow hydrogen purityHydrocarbon oils treatment control/regulationCatalytic naphtha reformingDistillates petroleumHydrogen

In one exemplary embodiment, a system for reacting a first feed can include a petroleum fraction having at least about 90%, by volume, with a boiling point of at least about 300° C. The system can include a bubble column reactor. The bubble column reactor, in turn, can include a first inlet for the first feed and a second inlet for a second feed including a gas rich in hydrogen. In addition, the petroleum fraction may be in counter-current flow with respect to the gas rich in hydrogen inside the bubble column reactor.

Owner:UOP LLC

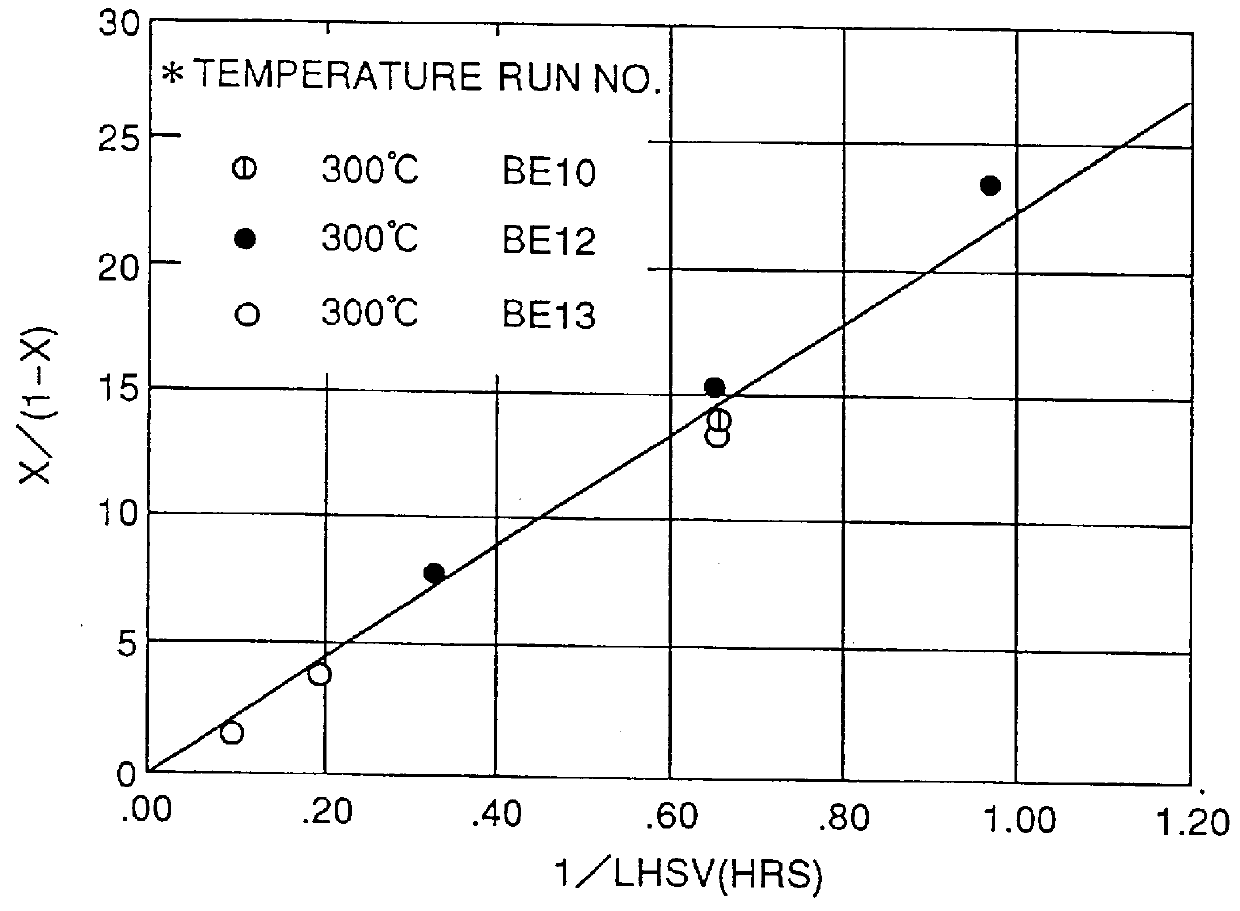

High throughput development method for catalytic hydroprocessing of dirty feedstocks

InactiveUS20100320121A1Low costIncrease productivitySequential/parallel process reactionsHydrocarbon oils treatment control/regulationHydrogenReactor system

A method for determining a set of operating parameters for a commercial scale plug flow catalytic process and reactor system for hydroprocessing dirty feedstocks, comprises the steps of: feeding selected partial pressures of said feedstock and hydrogen to the inlet the first reactor stage of a first composite multi-stage series-connected laboratory scale plug flow reactor including at least three reactor stages, the catalyst beds of each of said reactor stages including catalyst particles capable of catalyzing the removal by hydrogen of heteroatoms from said heterocyclic molecules; sampling the effluents of each of said reactor stages; measuring the concentration of heterocyclic molecules in said dirty feedstock in the concentrations of heterocyclic molecules and intermediate and final products and by products of the catalytic reaction in the effluents of each of said reactor stages.

Owner:ACCELERGY CORP

Process and apparatus for hydrocracking and hydroisomerizing a hydrocarbon stream

ActiveUS20180002616A1Refining to change hydrocarbon structural skeletonHydrocarbon oils treatment control/regulationQuenchingHydrocarbon

A process and apparatus for quenching a hydrocracked stream to prepare it for hydroisomerization. A fractionated hydroisomerized stream is recycled to quench a hot hydrocracked stream prior to hydroisomerization. Sufficient quenching can inactivate the hydroisomerization catalyst bed. The hydroisomerization catalyst bed can be heated back to hydroisomerization temperature and can actively hydroisomerize again.

Owner:UOP LLC

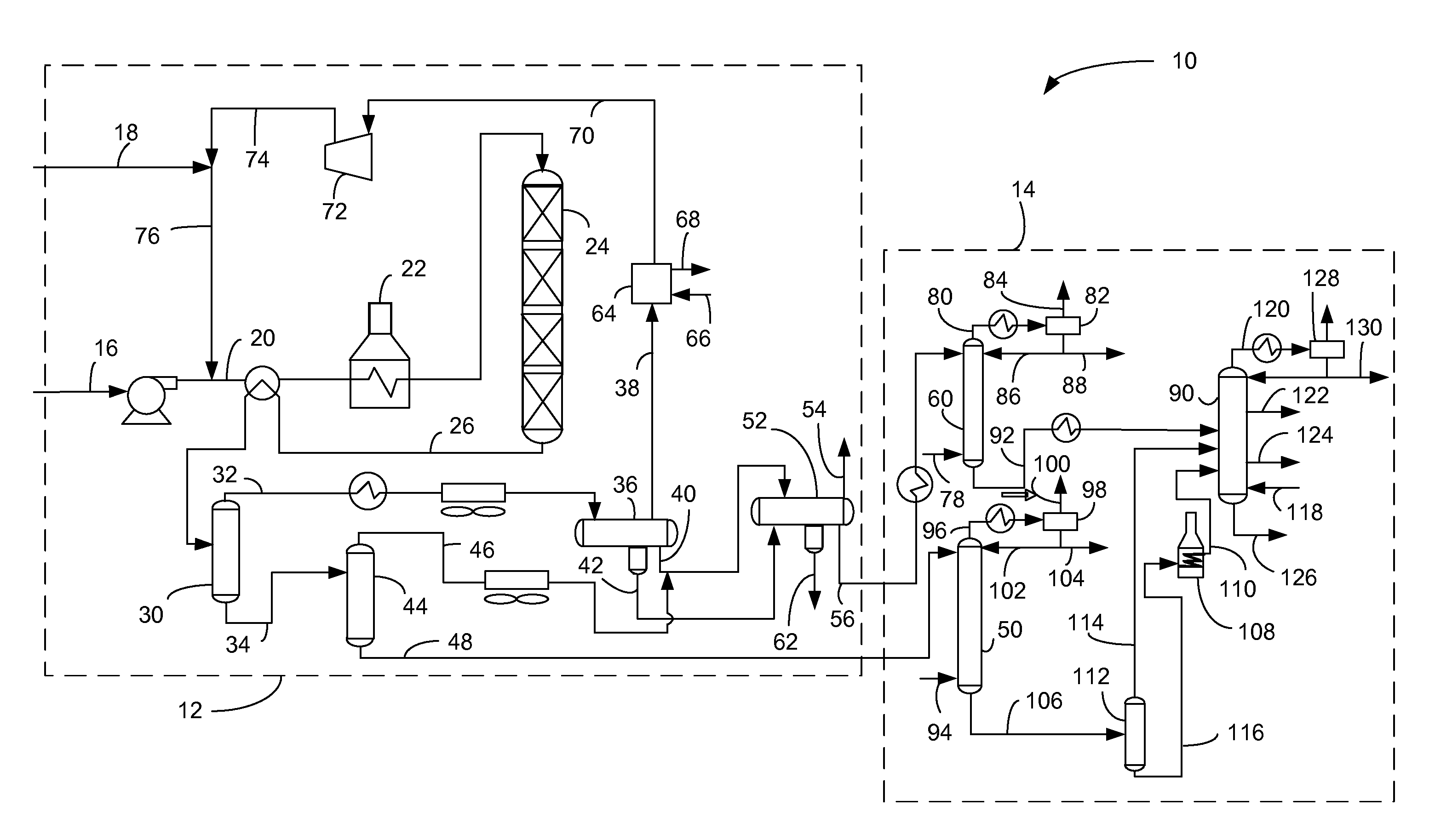

Process integrating two-stage hydrocracking and a hydrotreatment process

ActiveUS20180362864A1Reduce consumptionReduce investmentHydrocarbon oils treatment control/regulationHydrocarbon oil crackingHydrogenBoiling point

A process for hydrocracking hydrocarbon-containing VD feedstocks allowing the improved production of middle distillates: a) hydrocracking of feedstocks in hydrogen and at least one hydrocracking catalyst, b) gas / liquid separation of effluent originating from a) producing a liquid effluent and a gaseous effluent with hydrogen, c) comprising the gaseous effluent before recycling into hydrocracking a), d) fractionation of liquid effluent into at least one effluent of converted hydrocarbon-containing products having boiling points less than 340° C. and an unconverted liquid fraction having a boiling point greater than 340° C., e) hydrocracking unconverted liquid fraction from d), in hydrogen and a hydrocracking catalyst, f) hydrotreating effluent from e) in a mixture with a hydrocarbon-containing gas-oil liquid feedstock having at least 95% by weight of compounds boiling at a boiling point between 150 and 400° C., hydrotreating f) operating in hydrogen and with at least one hydrotreating catalyst.

Owner:INST FR DU PETROLE

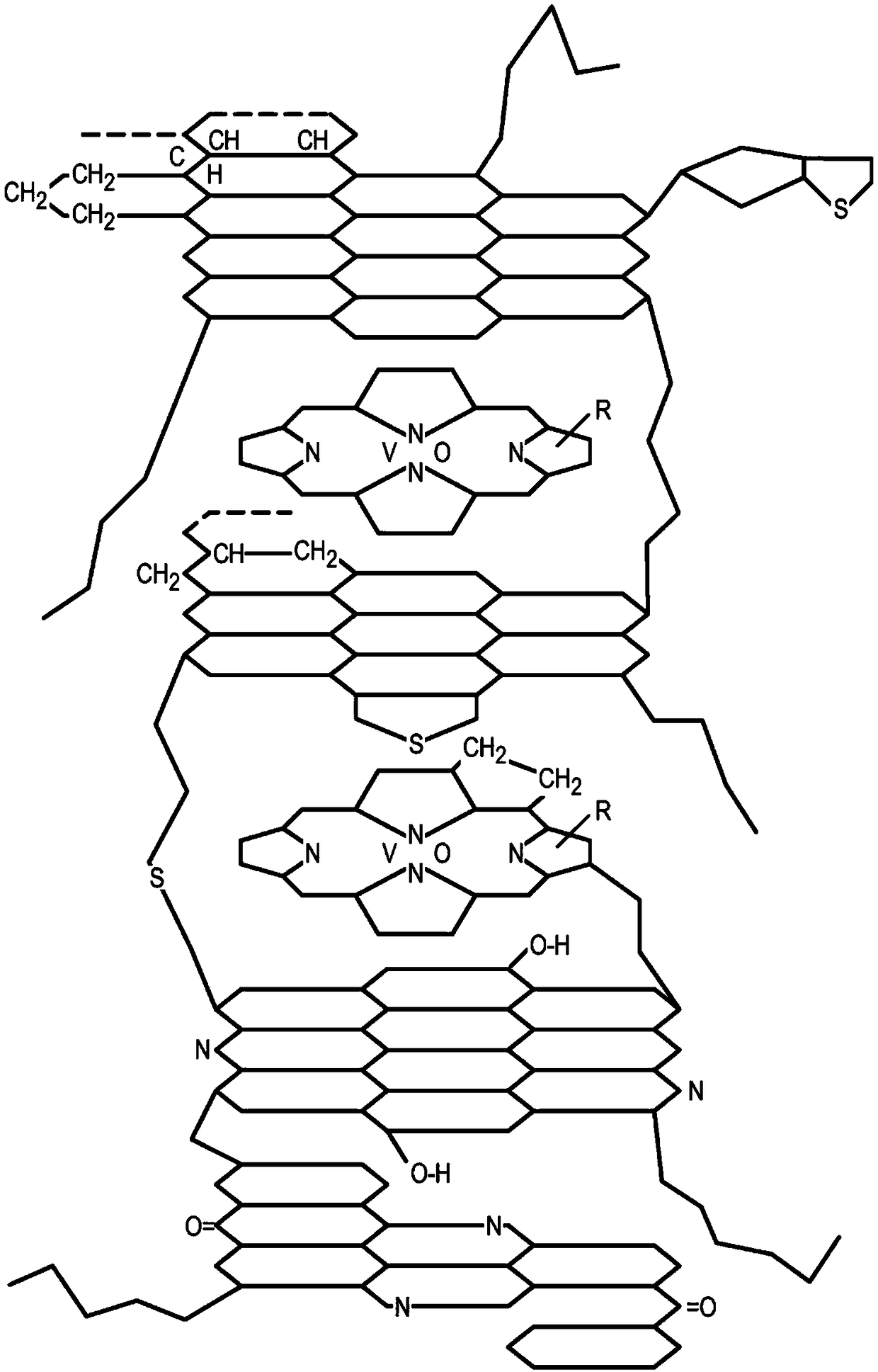

Upgraded ebullated bed reactor with less fouling sediment

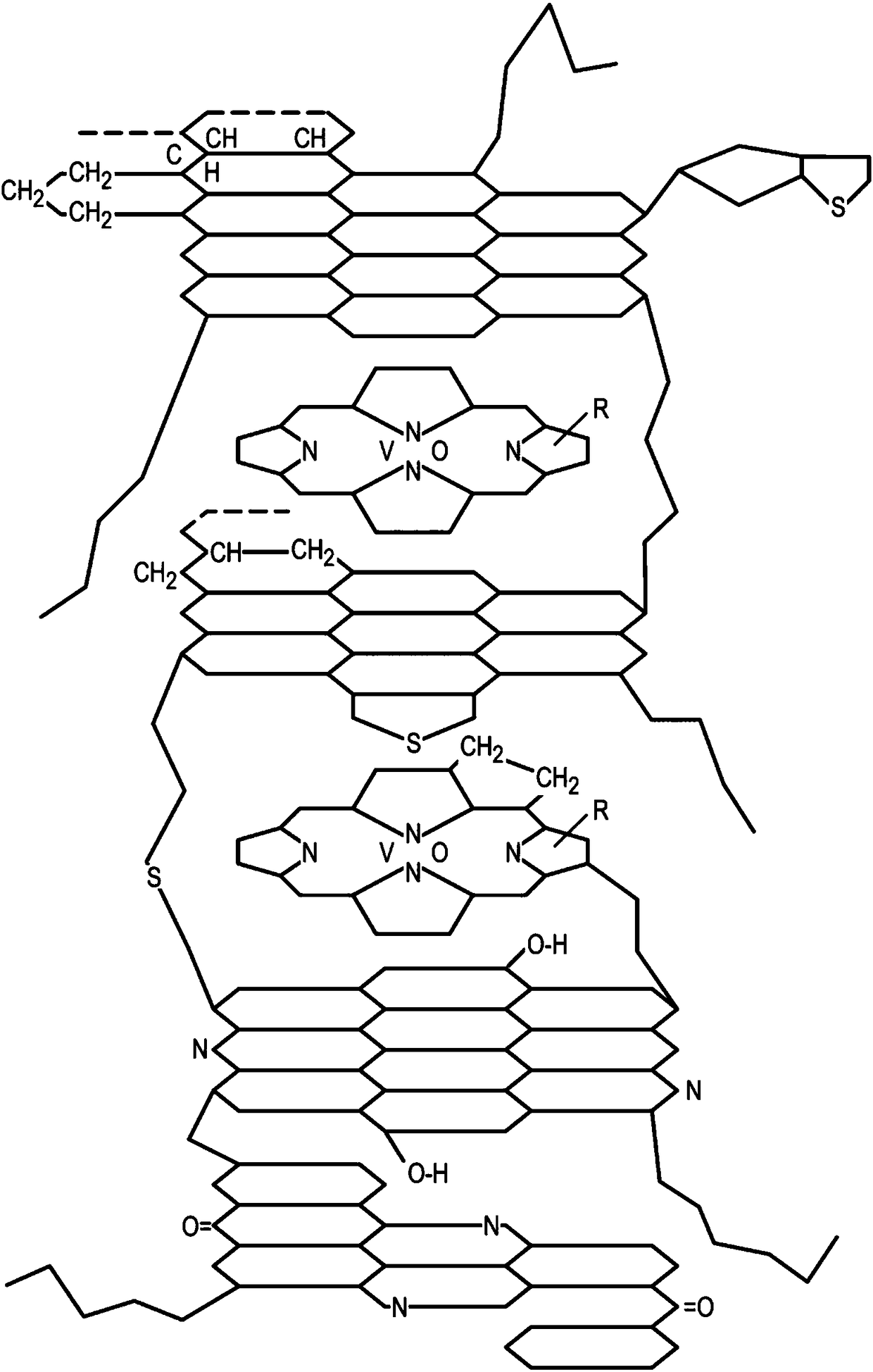

ActiveCN108531215AHydrocarbon oils treatment control/regulationCatalyst activation/preparationPtru catalystEnvironmental engineering

An ebullated bed hydroprocessing system is upgraded using a dual catalyst system that includes a heterogeneous catalyst and dispersed metal sulfide particles to produce less fouling sediment. The dualcatalyst system more effectively converts sediment-forming precursors to produce sediment that is less fouling than sediment produced using only the heterogeneous catalyst and not the dispersed metalsulfide particles. The dual catalyst system provides for a lower rate of equipment fouling for a given sediment production rate and / or concentration. In some cases, sediment production rate and / or concentration can be maintained or increased while equipment fouling is reduced. In some cases, sediment production rate and / or concentration can be increased without increasing equipment fouling.

Owner:HEADWATERS TECH INNOVATION LLC

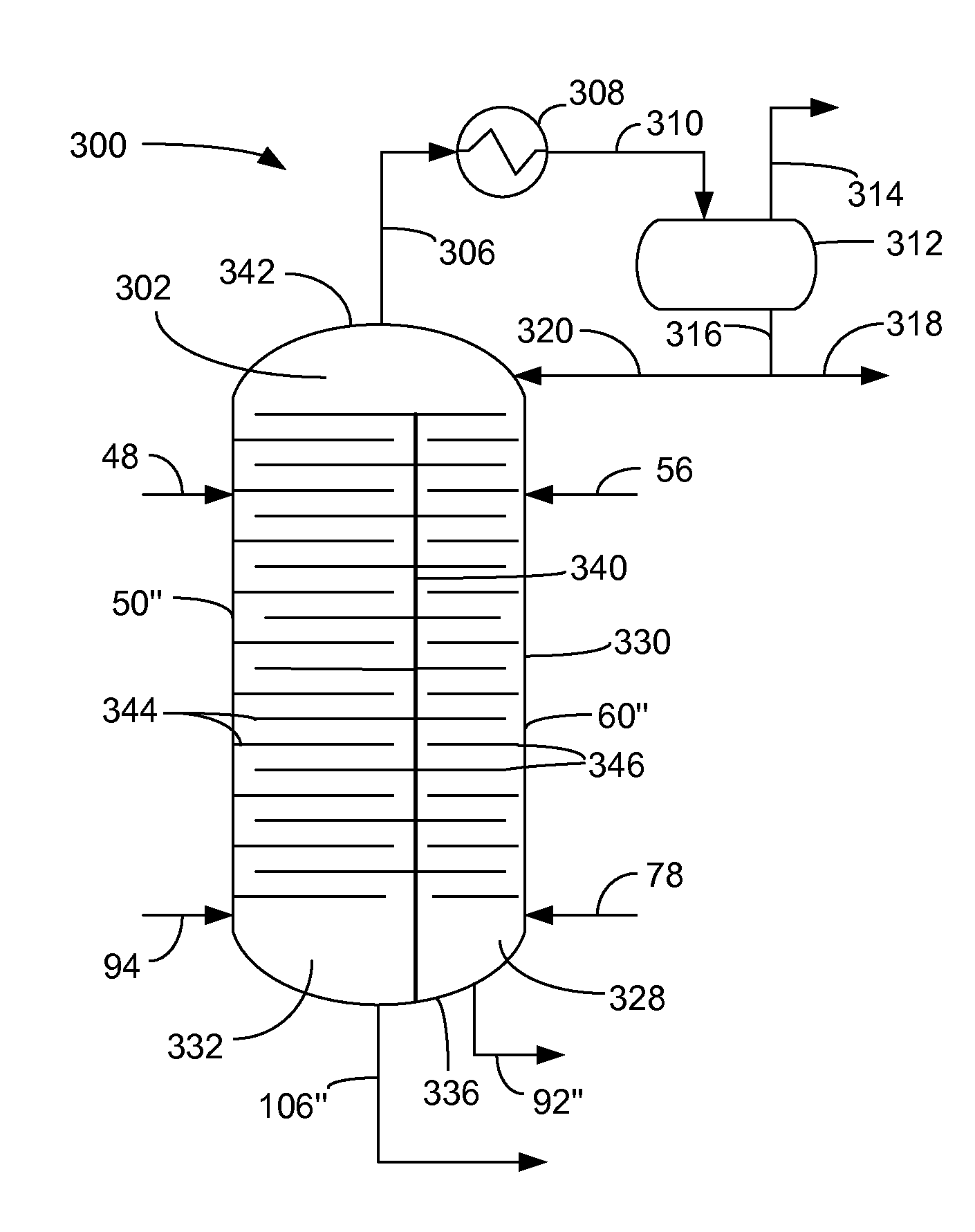

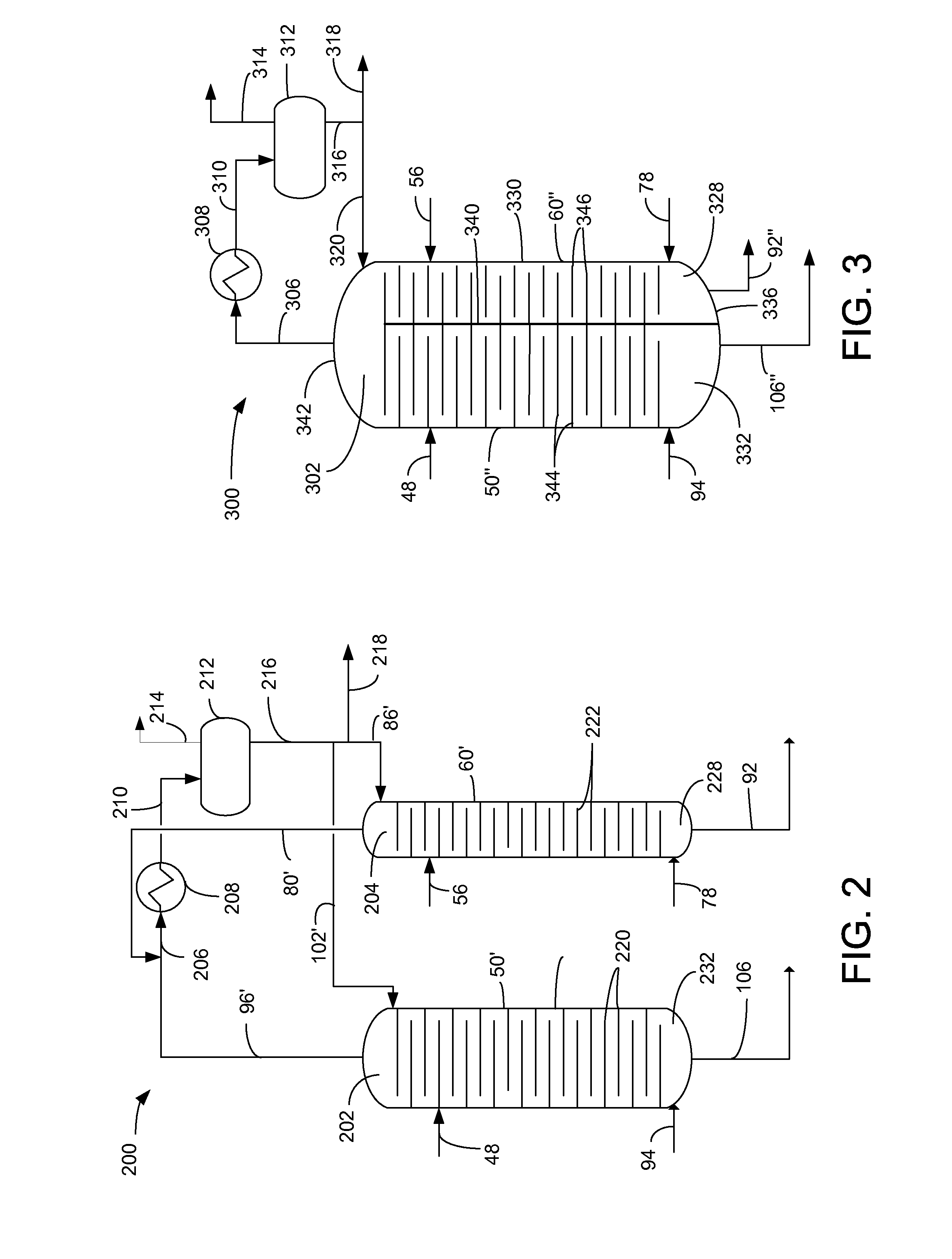

Apparatus for recovering hydroprocessed hydrocarbons with two strippers in one vessel

ActiveUS20130045141A1Hydrocarbon oils treatment control/regulationTreatment with plural parallel refining stagesProcess engineeringHydrocarbon

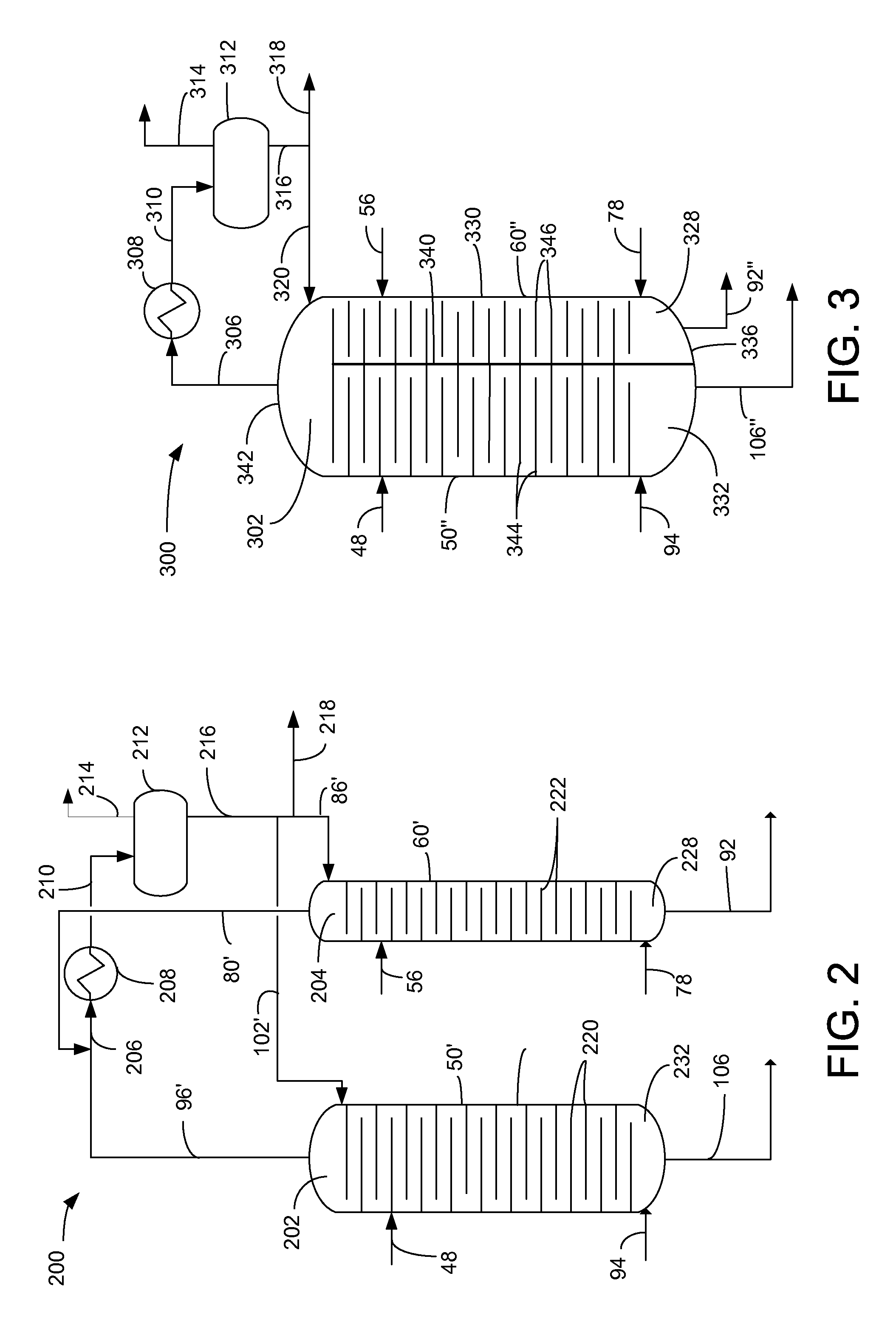

An apparatus is disclosed for recovering hydroprocessing effluent from a hydroprocessing unit utilizing a hot stripper and a cold stripper. The cold stripper and the hot stripper are contained in the same vessel. A barrier prevents material from the hot stripper from entering into the cold stripper.

Owner:UOP LLC

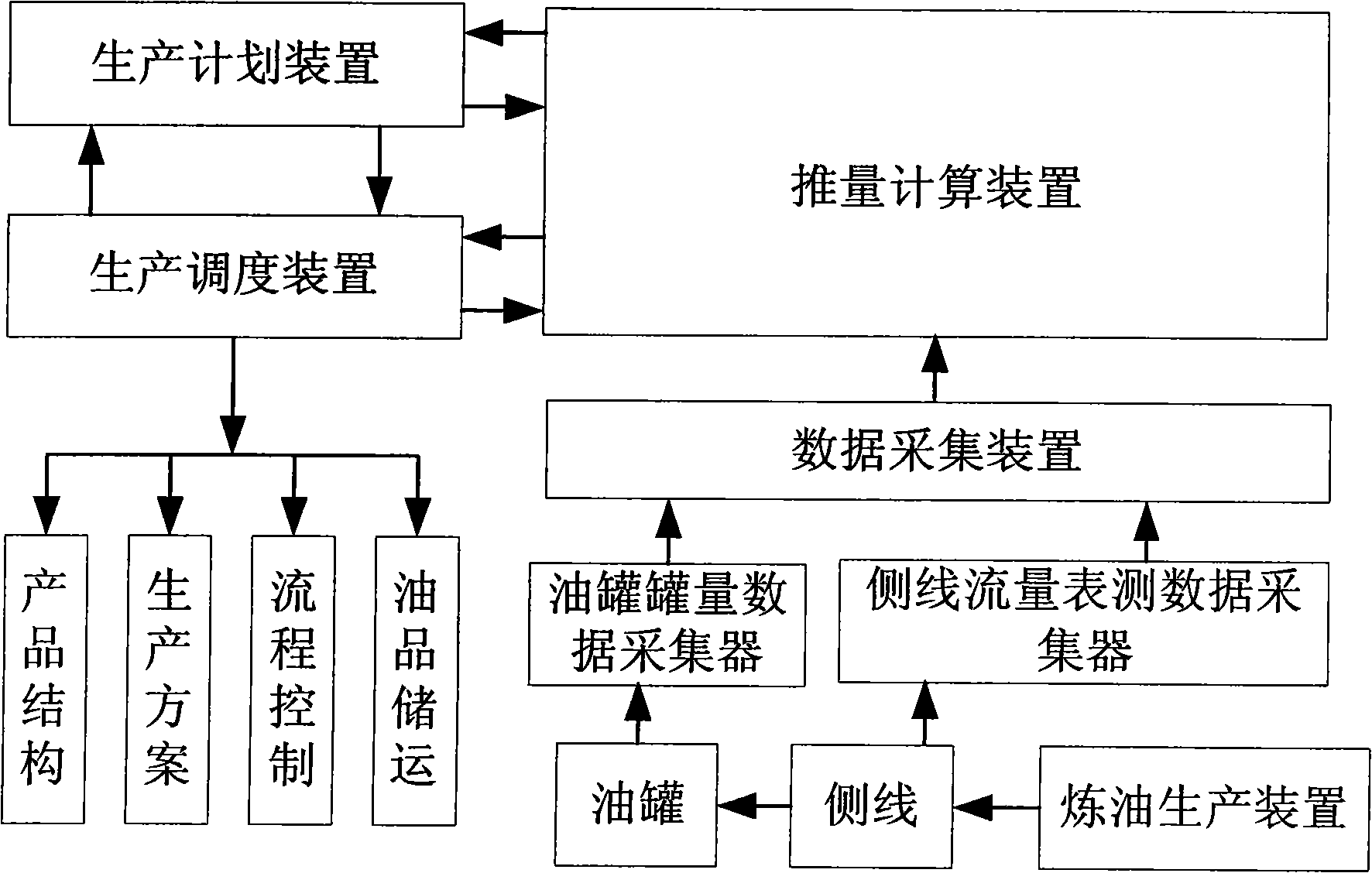

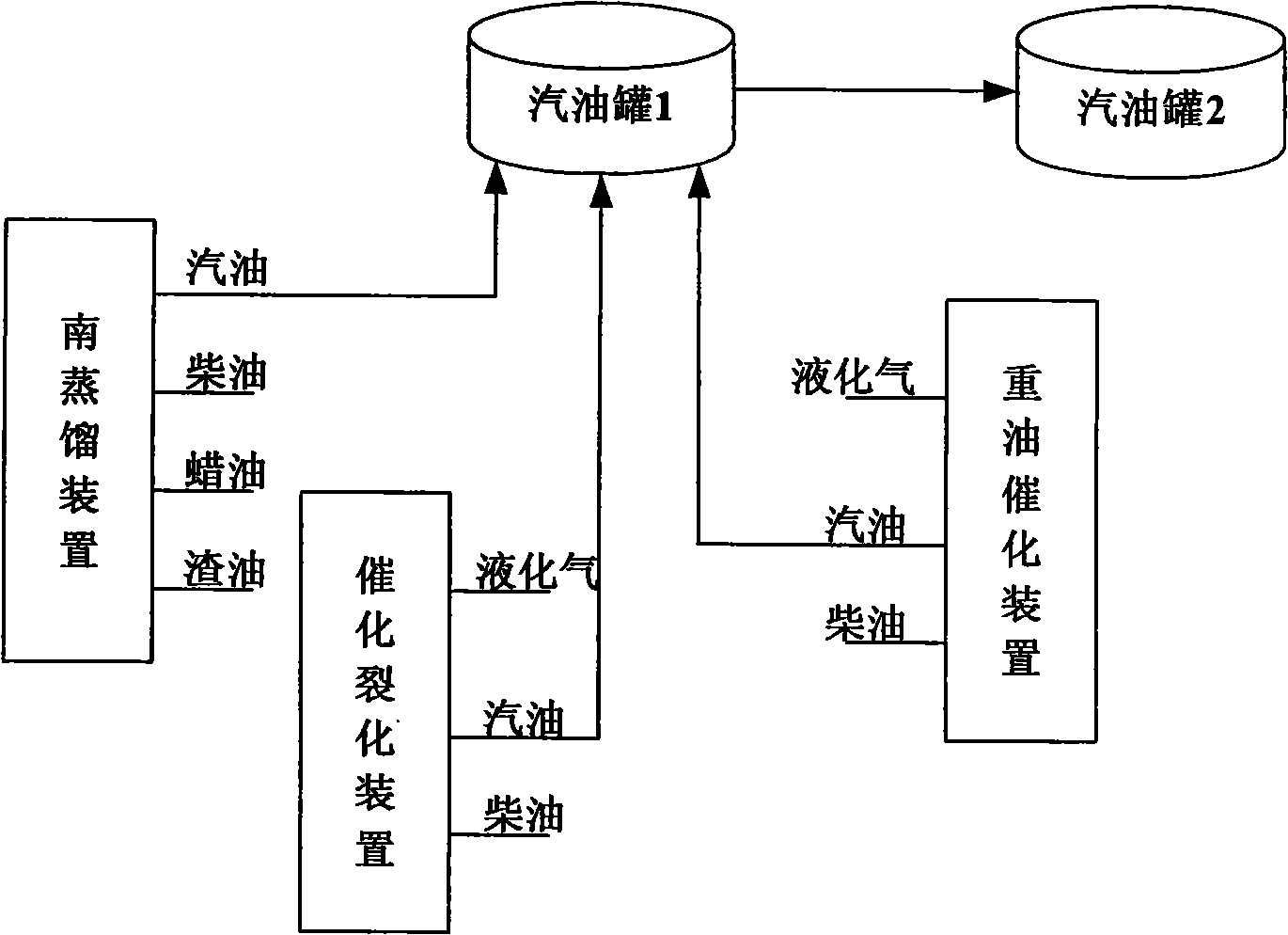

Oil-refining chemical production balancing system

ActiveCN101515170AAccurately understand the production situationHydrocarbon oils treatment control/regulationHydrocarbon oil crackingData acquisitionStreamflow

The invention relates to an oil-refining chemical production balancing system, which comprises an oil-refining production device, an oil tank, a lateral line for connecting the oil-refining production device and the oil tank, and a data acquisition unit for connecting an oil tank volume data acquisition device and a lateral line flow conjecture data acquisition device, wherein the data acquisition unit is connected with an estimation calculating device which can calculate out lateral line flow conjecture data according with oil tank volume data. The oil-refining chemical production balancing system can calculate out the lateral line flow conjecture data which are in consistent with the oil tank volume data and accords with actual situations better through the oil tank volume data, so thata production manager can accurately know the production condition of the oil-refining production device. The oil-refining chemical production balancing system can feed back on-site production information in time and make adjustments according with the actual situation aiming at the production condition of the device.

Owner:石化盈科信息技术有限责任公司

Upgraded ebullated bed reactor with increased production rate of converted products

ActiveCN108699451AHydrocarbon oils treatment control/regulationTreatment with hydrotreatment processesPtru catalystProcess engineering

An ebullated bed hydroprocessing system is upgraded using a dual catalyst system that includes a heterogeneous catalyst and dispersed metal sulfide particles to increase rate of production of converted products. The rate of production is achieved by increasing reactor severity, including increasing the operating temperature and at least one of throughput or conversion. The dual catalyst system permits increased reactor severity and provides increased production of converted products without a significant increase in equipment fouling and / or sediment production. In some cases, the rate of production of conversion products can be achieved while decreasing equipment fouling and / or sediment production.

Owner:HEADWATERS TECH INNOVATION LLC

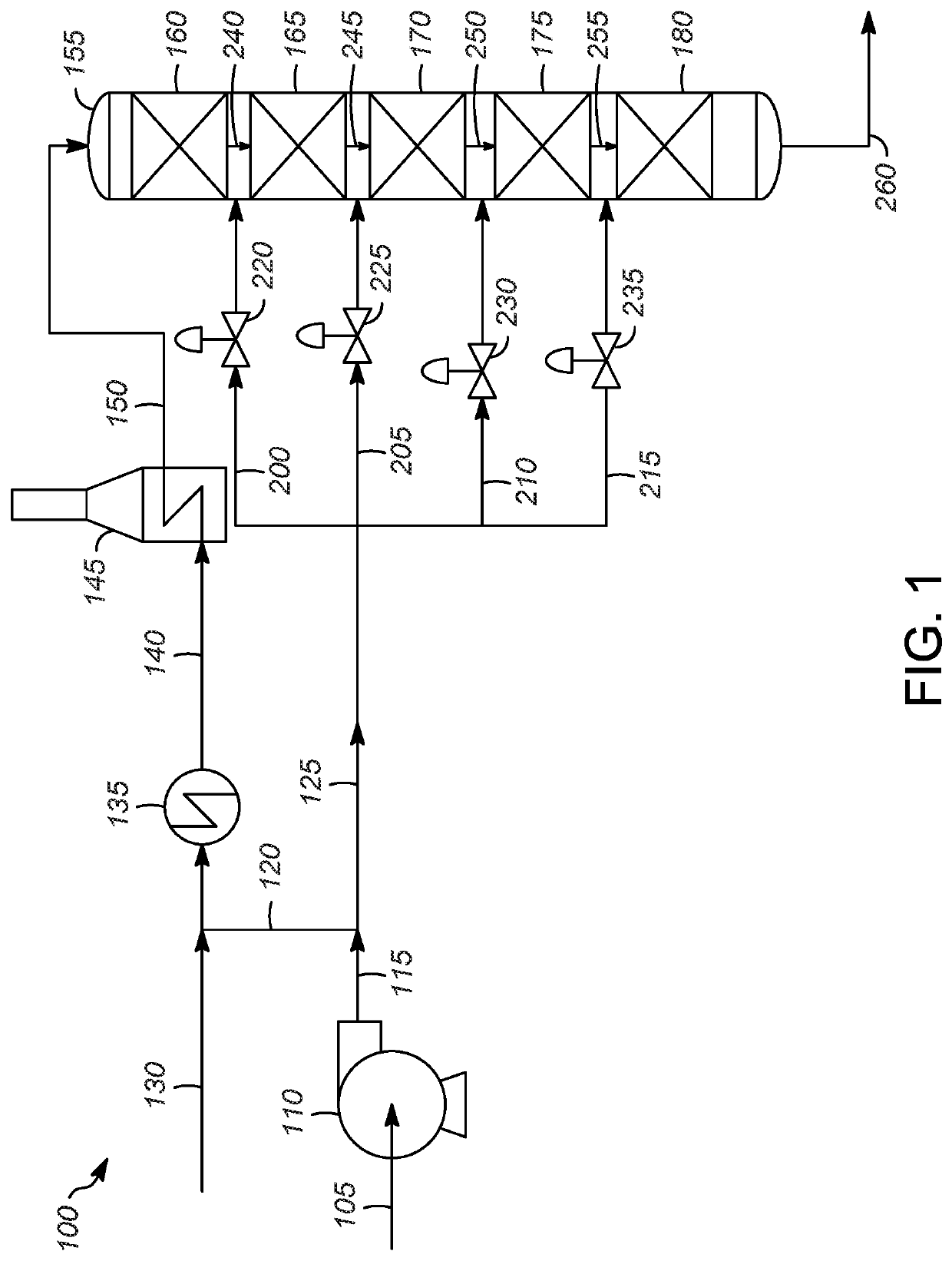

Split feed reactor bed in hydrotreater device

InactiveUS20150073186A1Accurate operationHydrocarbon oils treatment control/regulationHydrocarbon oil crackingTemperature differenceProcess engineering

A hydrotreater reactor device includes a reactor chamber including a first bed and a second bed. A first input is disposed to provide a hydrocarbon stream to the first bed and a second input is disposed to bypass the first bed and provide a hydrocarbon stream to the second bed. A differential temperature controller measures a temperature difference across the first bed. A control valve at the second input adjusts an amount of the hydrocarbon stream admitted through the second input based on the measured temperature difference. A charge heater provides a hydrocarbon stream as an output through a split output line having a first branch connected to the first input and in fluid communication with the first bed, and a second branch connected to the second input and in fluid communication with the second bed. A restrictor downstream of the split controls a pressure drop at the first input.

Owner:UOP LLC

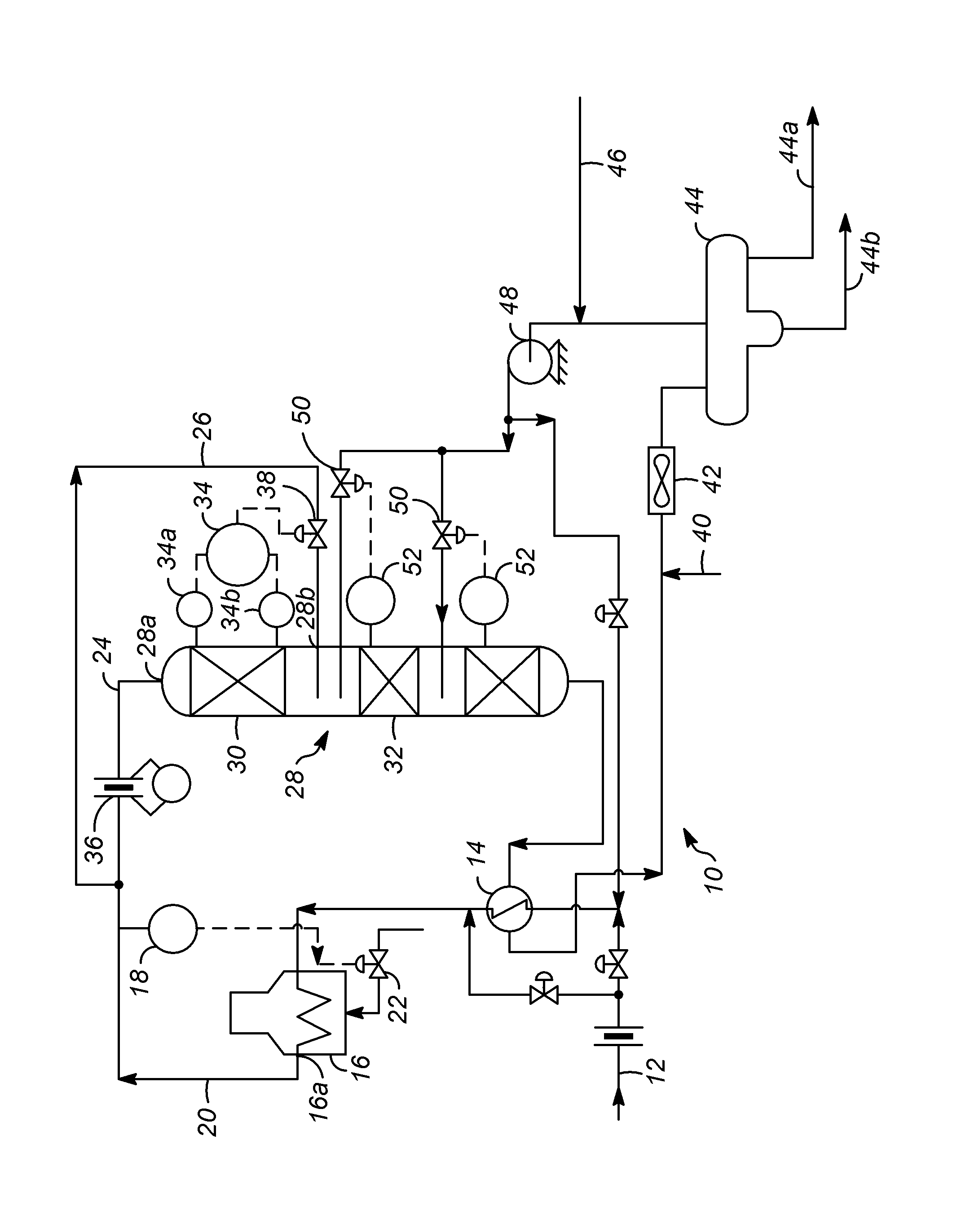

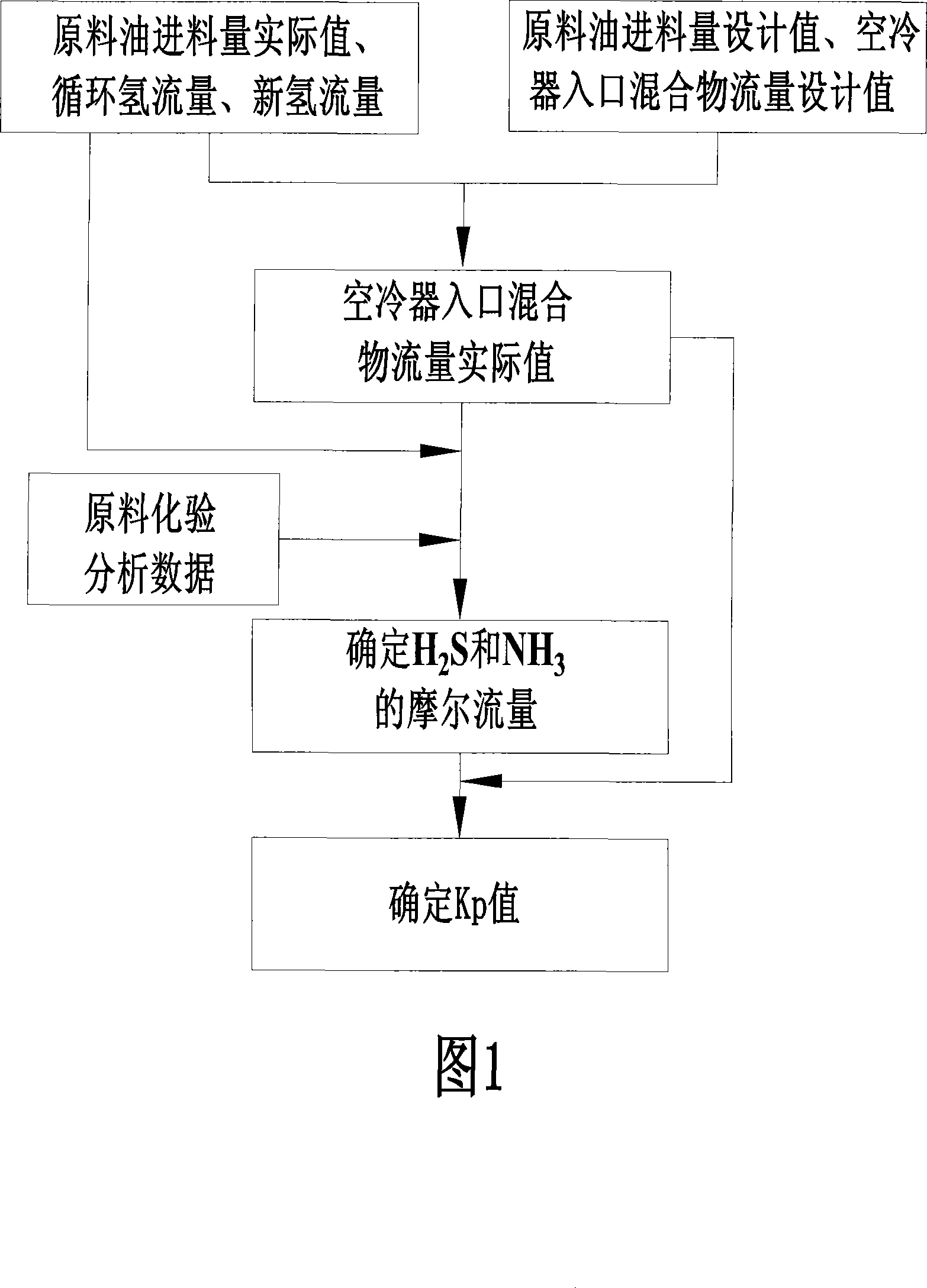

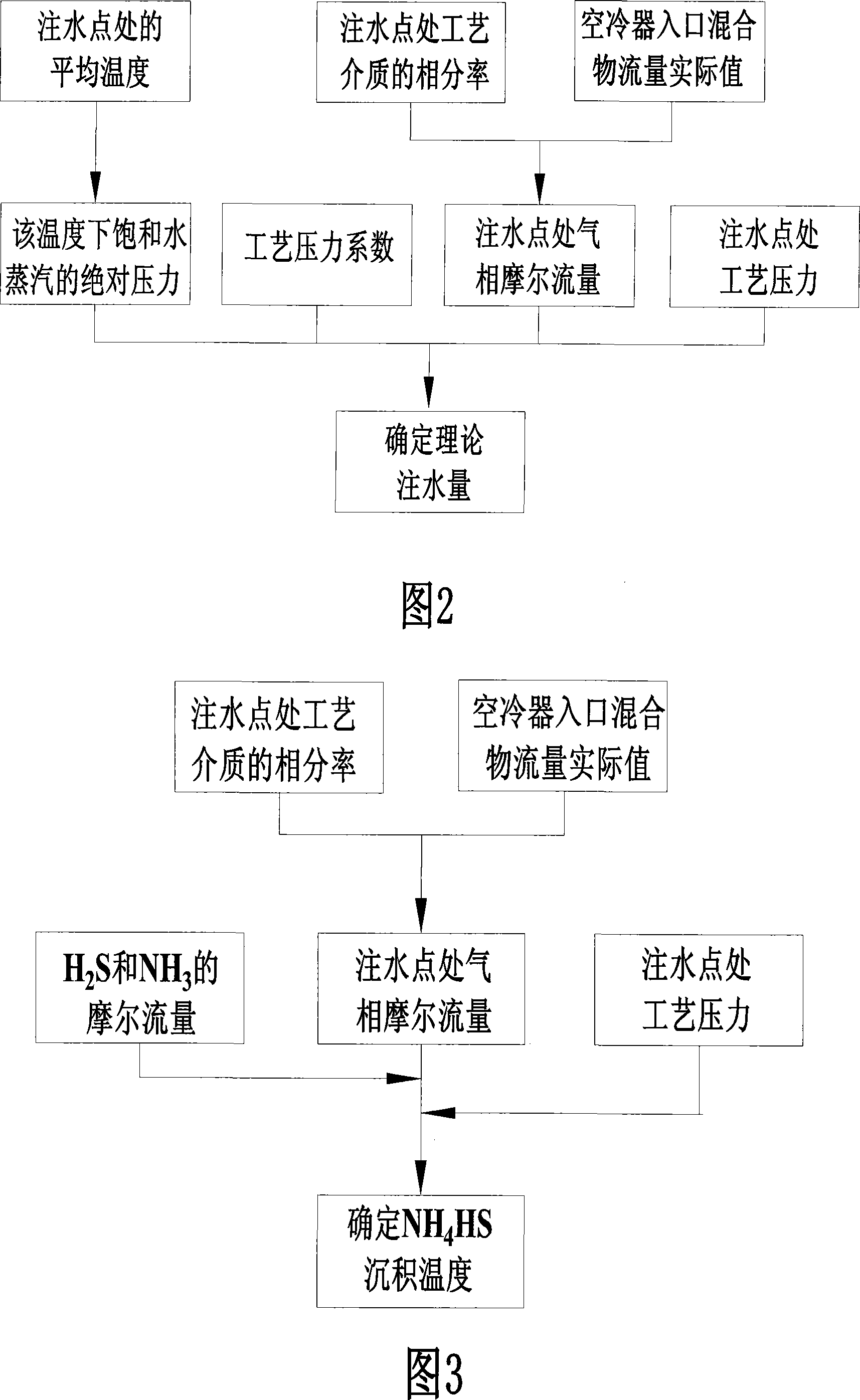

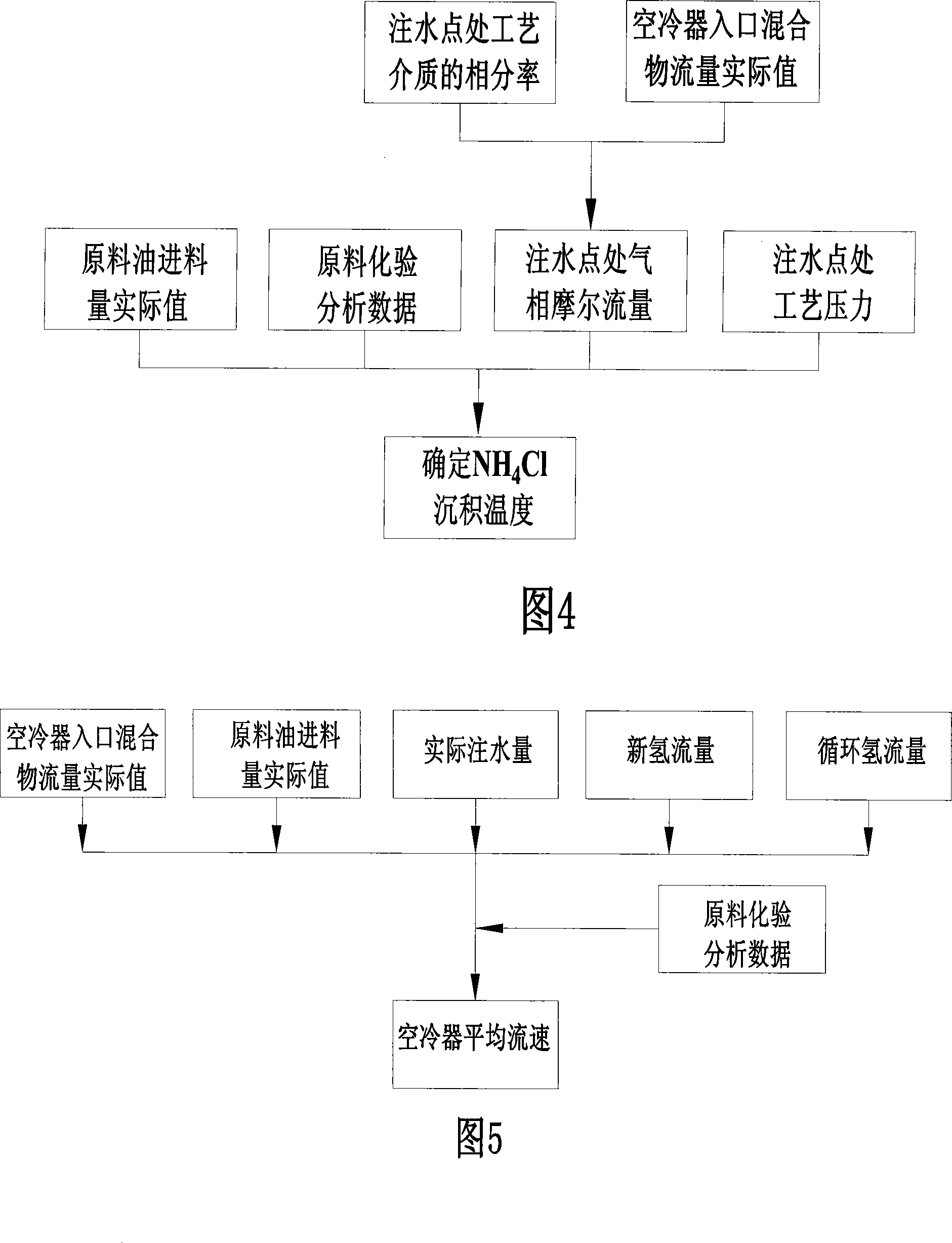

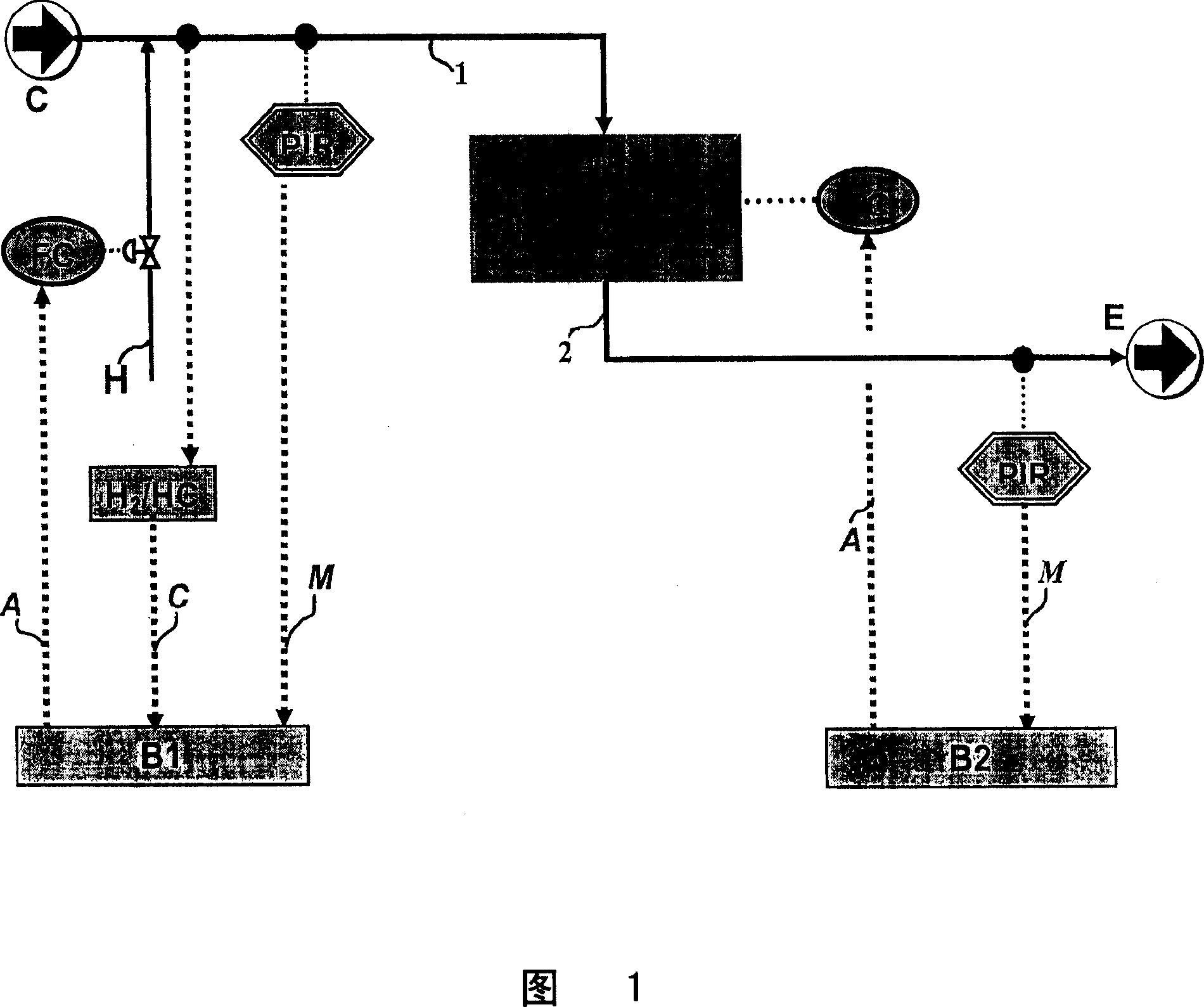

Modeling method for hydrogenation reaction effluent system failure control parameter

ActiveCN101225326AReduce unplanned downtime incidentsHydrocarbon oils treatment control/regulationHydrocarbon oil crackingDeposition temperatureModel method

The invention discloses a modeling method for invalidation control parameter of hydrogenation reaction effluent system; wherein, the invalidation control parameter modeling comprises a KP value, the concentration of NH4HS, the theoretical quantity of water injection, the deposition temperature of NH4HS, the deposition temperature of NH4Cl and the mean velocity of air cooler. The modeling method is characterized in that the operation parameters of hydrogenation reaction effluent system are loaded by the DCS control system data base, the material chemical examination analysis data and the principle flow chart of hydrogenation reaction are combined, the modeling is processed according to the concrete invalidation control parameter in the running of hydrogenation reaction effluent system variable condition, and that the KP value, the concentration of NH4HS, the theoretical quantity of water injection, the deposition temperature of NH4HS, the deposition temperature of NH4Cl and the mean velocity of air cooler are determined. The modeling method for invalidation control parameter of hydrogenation reaction effluent system has the advantages of effective monitor of invalidation control parameter of hydrogenation reaction effluent system for field operators, guarding against unplanned shutdown accident caused by invalidation of hydrogenation reaction effluent system, and long cycle, safety and stable running of hydrogenation reaction effluent system.

Owner:ZHEJIANG SCI-TECH UNIV

Apparatus for recovering hydroprocessed hydrocarbons with two strippers in one vessel

ActiveUS8715596B2Gaseous chemical processesHydrocarbon oils treatment control/regulationProcess engineeringHydrocarbon

An apparatus is disclosed for recovering hydroprocessing effluent from a hydroprocessing unit utilizing a hot stripper and a cold stripper. The cold stripper and the hot stripper are contained in the same vessel. A barrier prevents material from the hot stripper from entering into the cold stripper.

Owner:UOP LLC

Process improvement through the addition of power recovery turbine equipment in existing processes

ActiveUS20200056509A1Hydrocarbon oils treatment control/regulationSingle network parallel feeding arrangementsDC - Direct currentPetrochemical

Power recovery turbines can be used debottlenecking of an existing plant, as well as recover electric power when revamping a plant. A process for recovering energy in a petroleum, petrochemical, or chemical plant is described. A fluid stream having a first control valve thereon is identified. A first power-recovery turbine is installed at the location of the first control valve, and at least a portion of the first fluid stream is directed through the first power-recovery turbine to generate electric power as direct current therefrom. The electric power is then recovered.

Owner:UOP LLC

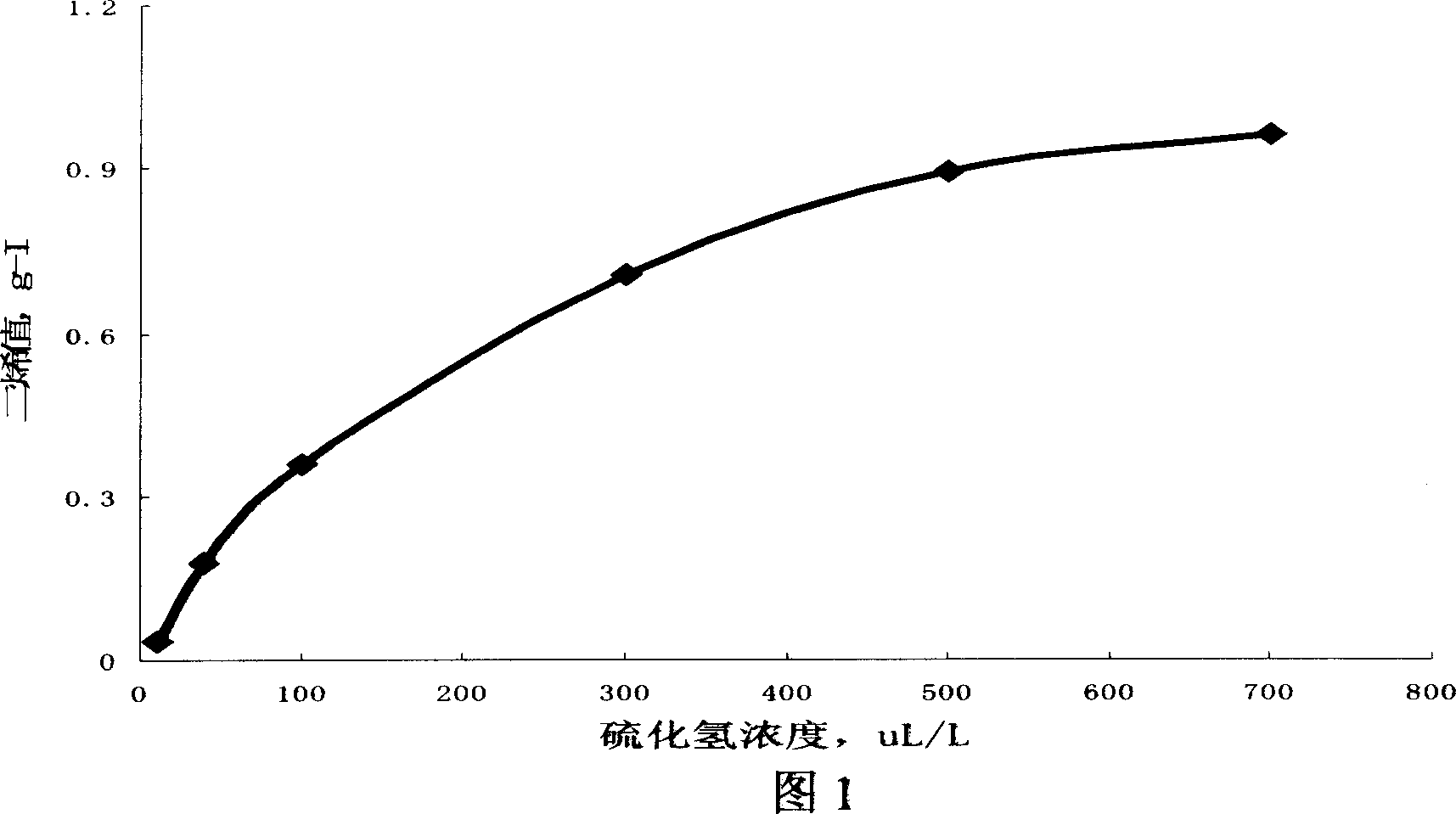

Method for controlling concentration of sulfureted hydrogen in circulating hydrogen of hydrogenation unit

ActiveCN101003747AImprove responsivenessExtend the stable operation periodHydrocarbon oils treatment control/regulationTreatment with hydrogen-generating compoundsSolventChemistry

This invention relates to a method for controlling H2S concentration in circulating H2 in hydrogenation apparatus. The method comprises: continuously or intermittently adding an appropriate amount of alkaline solvent into the water-injection pump inlet of hydrogenation apparatus, neutralizing H2S in circulating H2 when ammonium salt crystal is generated, and further dissolving H2S in water phase to reduce H2S concentration to an appropriate value. The method can reduce H2S concentration in circulating H2, and improve catalyst hydrogenation activity and stability. Besides, the method also has such advantages as low cost and easy operation, and can be used in the process of high-quality clean fuel production from fraction oil by hydrogenation.

Owner:CHINA PETROLEUM & CHEM CORP +1

Activating hydroprocessing catalysts using carbon monoxide and use of catalysts for hydroprocessing

InactiveUS7988848B2Hydrotreatment operations starting-upHydrocarbon oils treatment control/regulationOrganic chemistryChemistry

This invention relates to a process for activating a hydroprocessing catalyst and the use of activated catalyst for hydroprocessing. More particularly, hydroprocessing catalysts are activated in the presence of carbon monoxide. The catalysts that have been activated by CO treatment have improved activity.

Owner:EXXON RES & ENG CO

High throughput clean feed hydroprocessing development method

InactiveUS20100317907A1Low costIncrease productivitySequential/parallel process reactionsHydrocarbon oils treatment control/regulationReactor systemHydrogen

A method for determining a set of operating parameters for a commercial scale plug flow catalytic process and reactor system for hydroprocessing clean feedstocks in the presence of hydrogen, comprises the steps of: supplying a clean hydrocarbon feedstock to the inlet of a composite multistage series-connected laboratory scale plug flow reactor, the stages of said laboratory scale reactor each containing a catalyst suitable for the hydroprocessing of said feedstock; hydrocracking and isomerizing hydrocarbon molecules; sampling and measuring the concentration of reactants and catalytic process products and byproducts in the effluents of each of said reactor stages of said laboratory scale reactor for determining the nature of the catalytic reactions taking place in each such stage.

Owner:ACCELERGY CORP

Process for producing regenerated hydrotreating catalyst and process for producing petrochemical product

InactiveUS20120160738A1Easy to produceSolve the lack of activityCoke ovensTreatment with hydrotreatment processesPetrochemicalElectromotive force

Provided is a process for producing a regenerated hydrotreating catalyst by regenerating a spent hydrotreating catalyst in a prescribed temperature range, wherein the prescribed temperature range is a temperature range of T1−30° C. or more and T2+30° C. or less, as determined by subjecting the spent hydrotreating catalyst to a differential thermal analysis, converting a differential heat in a measuring temperature range of 100° C. or more and 600° C. or less to a difference in electromotive force, differentiating the converted value twice by temperature to provide a smallest extreme value and a second smallest extreme value, and representing a temperature corresponding to the extreme value on the lower-temperature side as T1 and a temperature corresponding to the extreme value on the higher-temperature side as T2.

Owner:JX NIPPON OIL & ENERGY CORP

Apparatus for recovering hydroprocessed hydrocarbons with two strippers and common overhead recovery

ActiveUS20130045142A1Hydrocarbon oils treatment control/regulationTreatment with plural parallel refining stagesEngineeringProcess engineering

Owner:UOP LLC

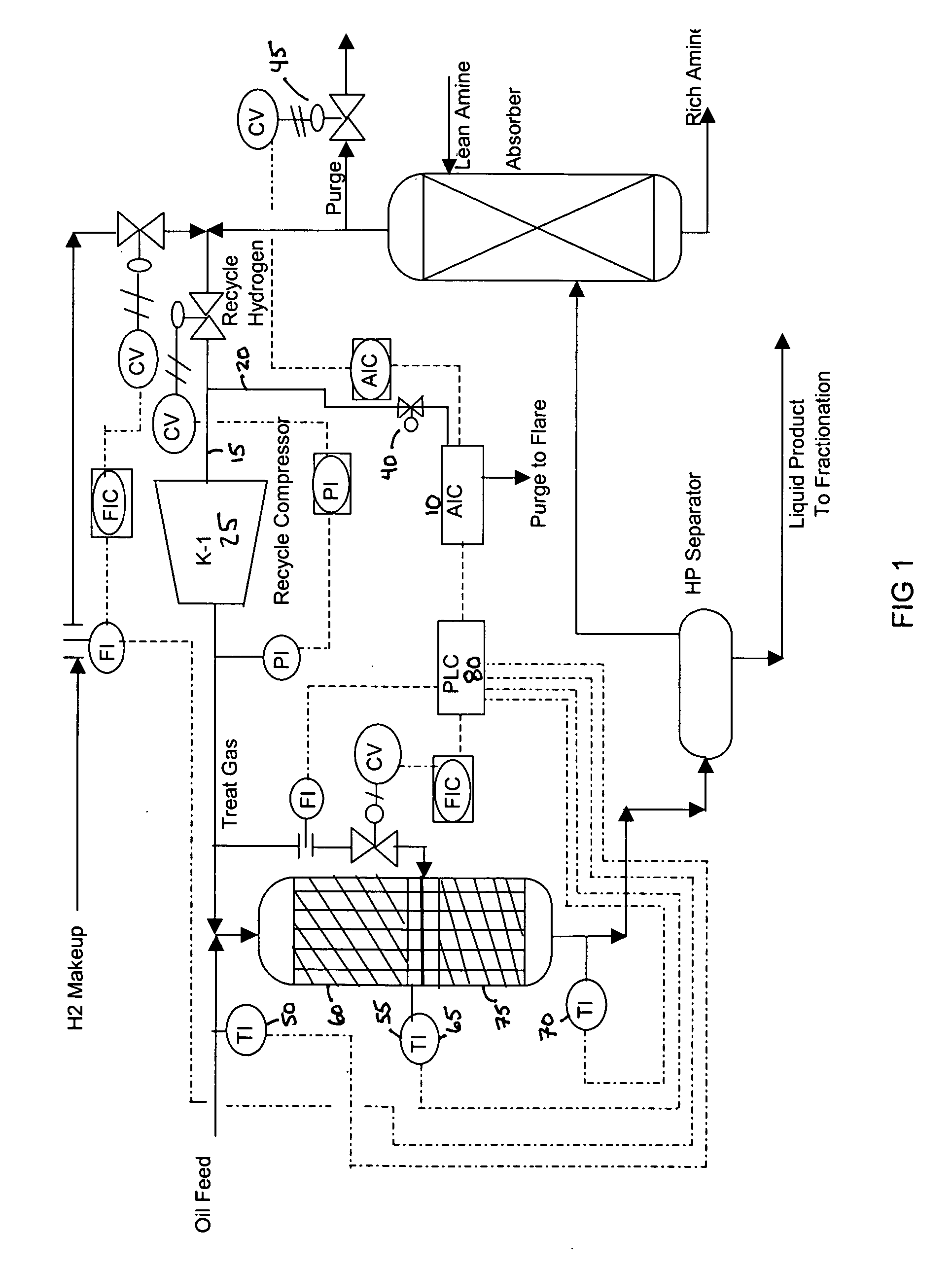

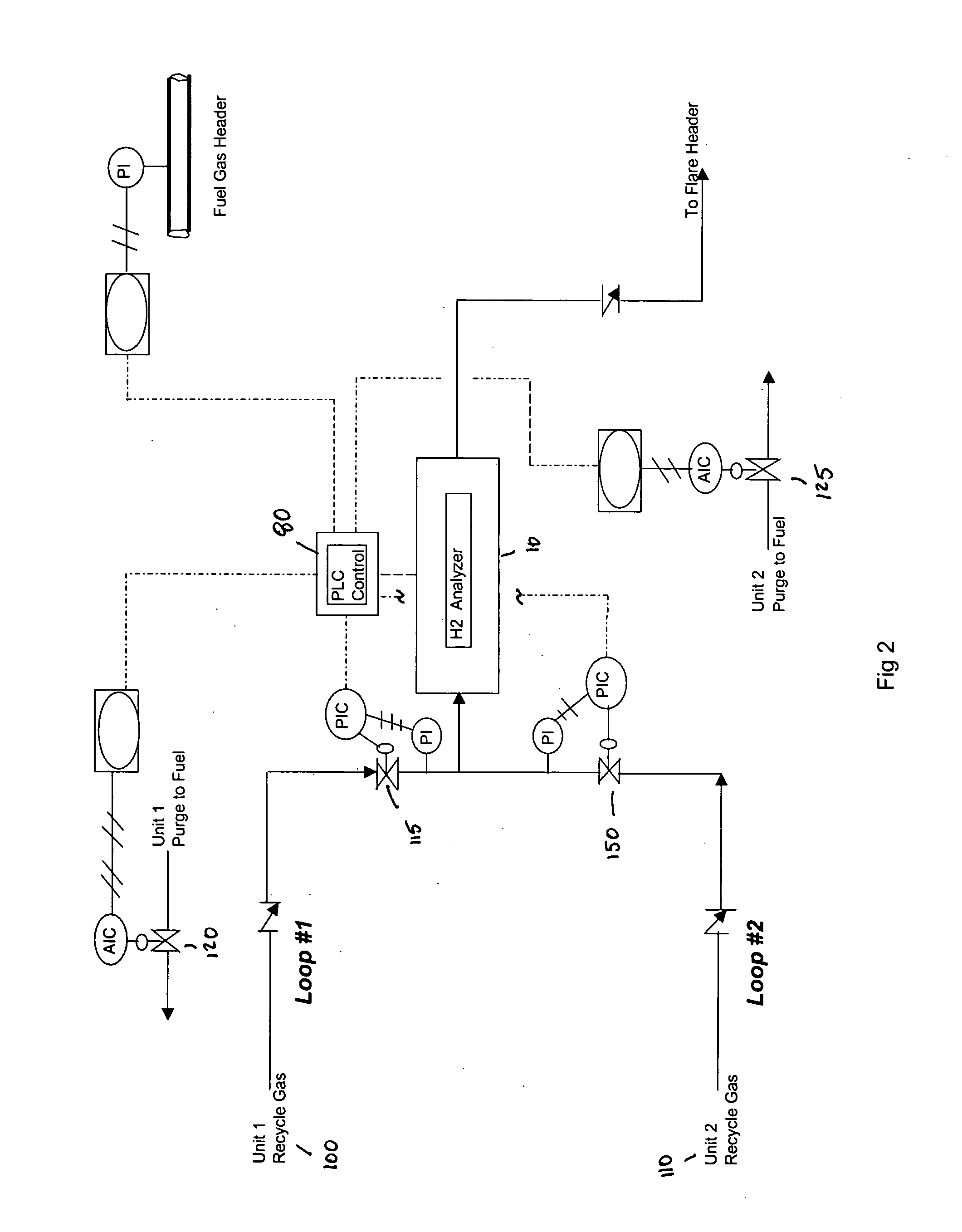

Process for controlling hydrogen partial pressure in single and multiple hydroprocessors

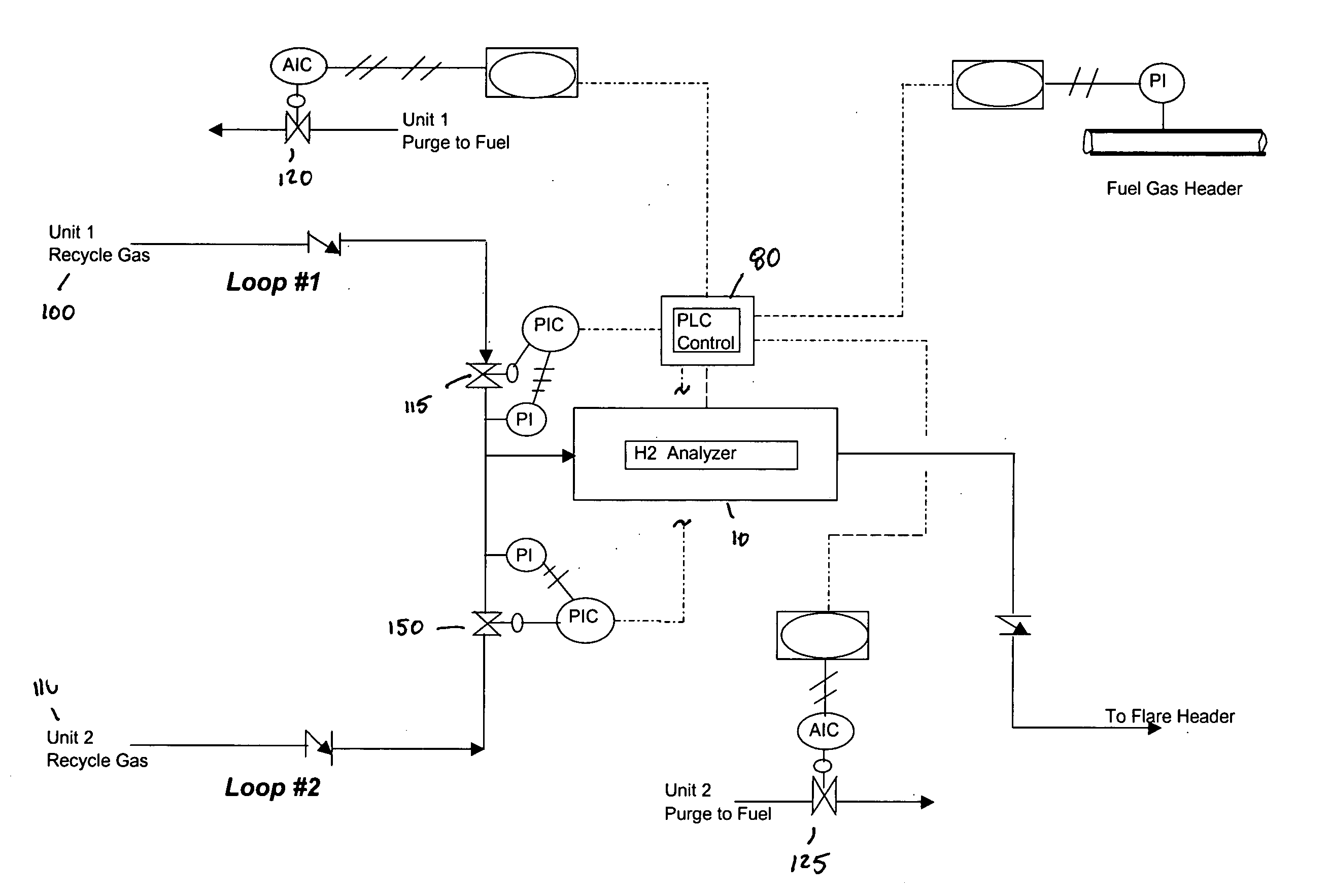

InactiveUS20060040399A1Long catalyst lifePrevent coke formationHydrocarbon oils treatment control/regulationMaterial analysis by optical meansHydrogen purityControl signal

A control scheme for controlling hydrogen partial pressure is provided that generally comprises a hydrogen purity analyzer that measures hydrogen purity on one or more hydroprocessing units. The hydrogen analyzer measures the purity of the treat gas, which is converted into a control signal and is transmitted to the appropriate hydroprocessing unit's purge gas controller. As hydrogen purity decreases in the hydroprocessing unit's recycle stream, the purge gas control valve opens and purges cracked gas contaminants. As hydrogen purity fluctuates, the purge gas control valve will open and close to maintain the desired purity setpoint. A programmable logic controller manages the inputs from the one or more hydroprocessing units and the signals that are transmitted to each unit's purge controller. The programmable logic controller may also be utilized to reactor hydrogen quench systems. The control of hydrogen partial pressure improves catalyst activity, hydrogen usage, and fuel efficiency.

Owner:HURT WILLIAM F

Skid-mounted decompression system

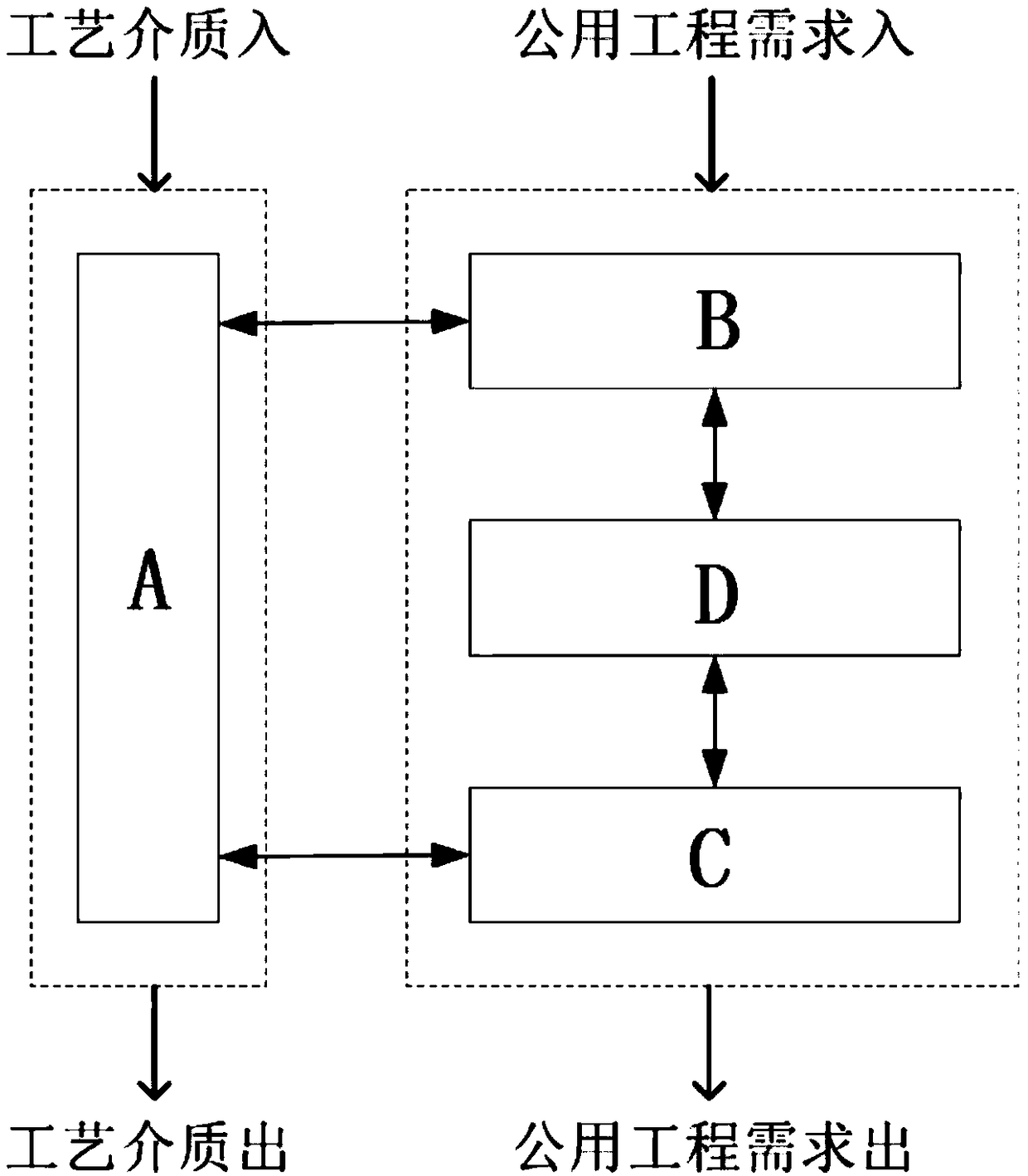

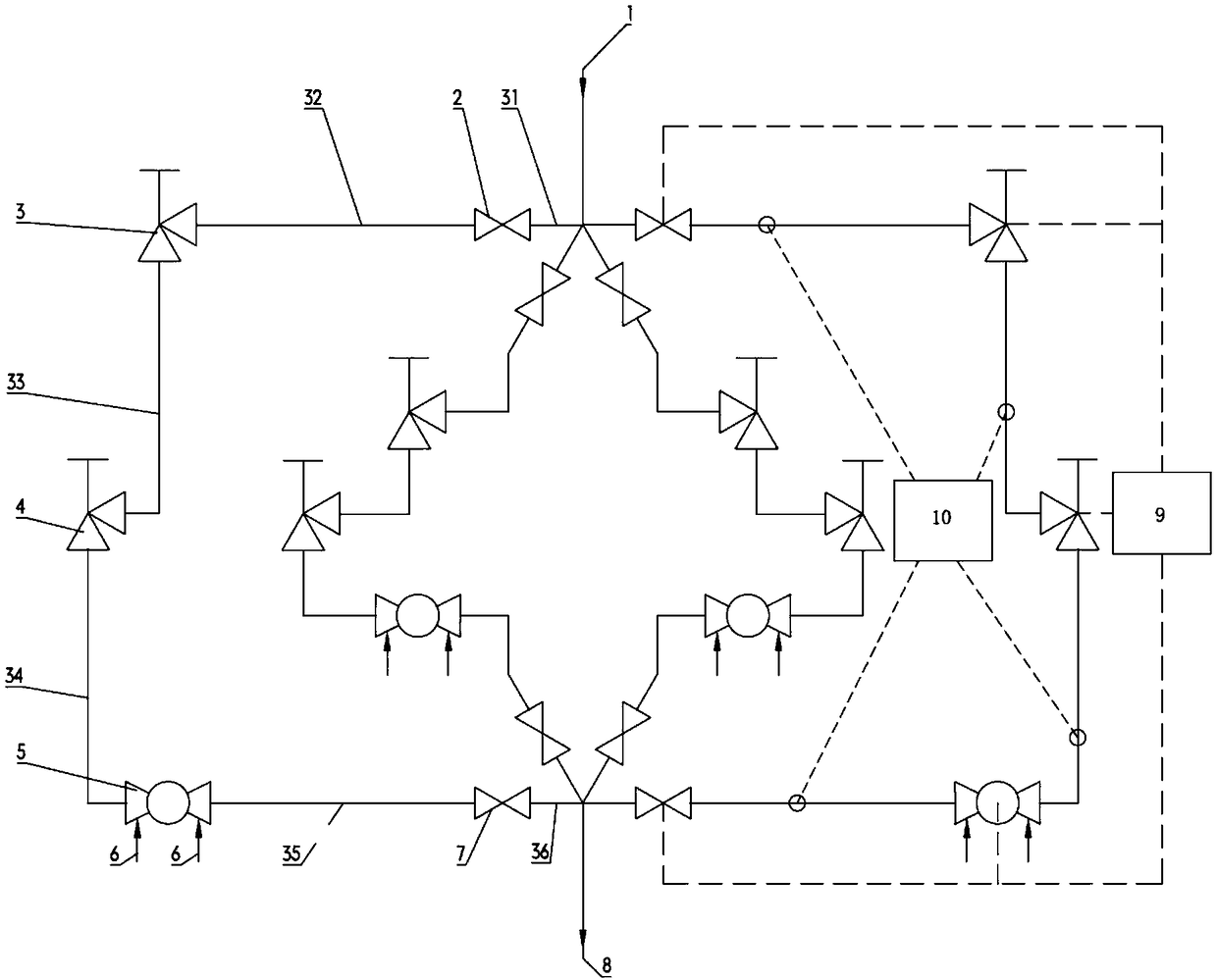

PendingCN108913202AStable and reliable long-term operation schemeReduce crackingHydrocarbon oils treatment control/regulationTreatment with hydrotreatment processesProcess moduleComputer module

The invention belongs to the technical field of coal chemical industry and petrochemical industry equipment, and specifically relates to a skid-mounted decompression system. The system is applied to coal chemical industry and petrochemical industry equipment, wherein the decompression system comprises a main process module, a mechanical control system, a thermodynamic balance system and an intelligent control system. A process medium enters the main process module, then the mechanical control system outputs torques under instructions of the intelligent control system, and opening-closing and opening degree of each valve of the main process module are regulated, so that the decompression of the process medium is realized, and then the process medium flows out from the decompression system.The provided thermodynamic balance scheme can effectively reduce thermal stress of the apparatus in a use process, and reduce risks of valve cracking and clamping stagnation and the like in the main process module. The decompression system is high in automation degree, strong in safety and reliability, and convenient in maintenance.

Owner:BEIJING AEROSPACE PETROCHEM TECH & EQUIP ENG CORP LTD +1

Method for the determination of the conjugated diolefins content of a sample using near infrared spectrum and method for controlling a unit

ActiveCN1990831AHydrocarbon oils treatment control/regulationColor/spectral properties measurementsInfraredGasoline

This invention describes a method for determining the content of conjugated diolefins by means of the measurement of the MAV of a sample of catalytic cracking gasoline or thermal cracking gasoline, from its NIR (near-infrared) spectrum, and the application of said method for monitoring a unit for selective hydrogenation of the cracking gasolines.

Owner:INST FR DU PETROLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com