Oil-refining chemical production balancing system

A balancing system, refining and chemical technology, applied in the petroleum industry, hydrocarbon oil cracking, refining hydrocarbon oil, etc., can solve the problems of production managers unable to accurately understand the production situation of oil refining production units, command lag, and the lack of measurement methods in refineries.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

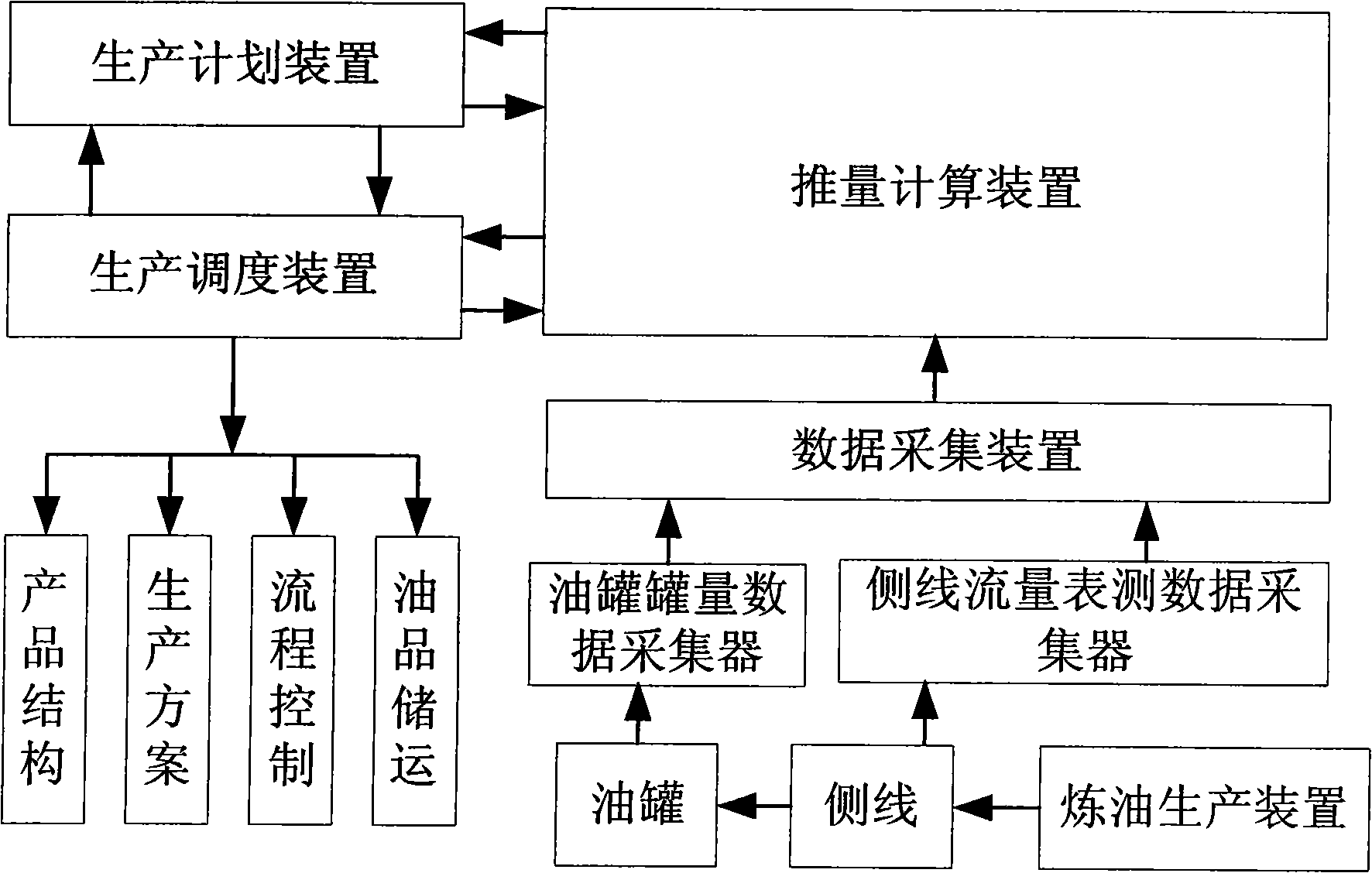

[0021] The oil refining and chemical production balance system of the present invention will be further described below in conjunction with the accompanying drawings of the description.

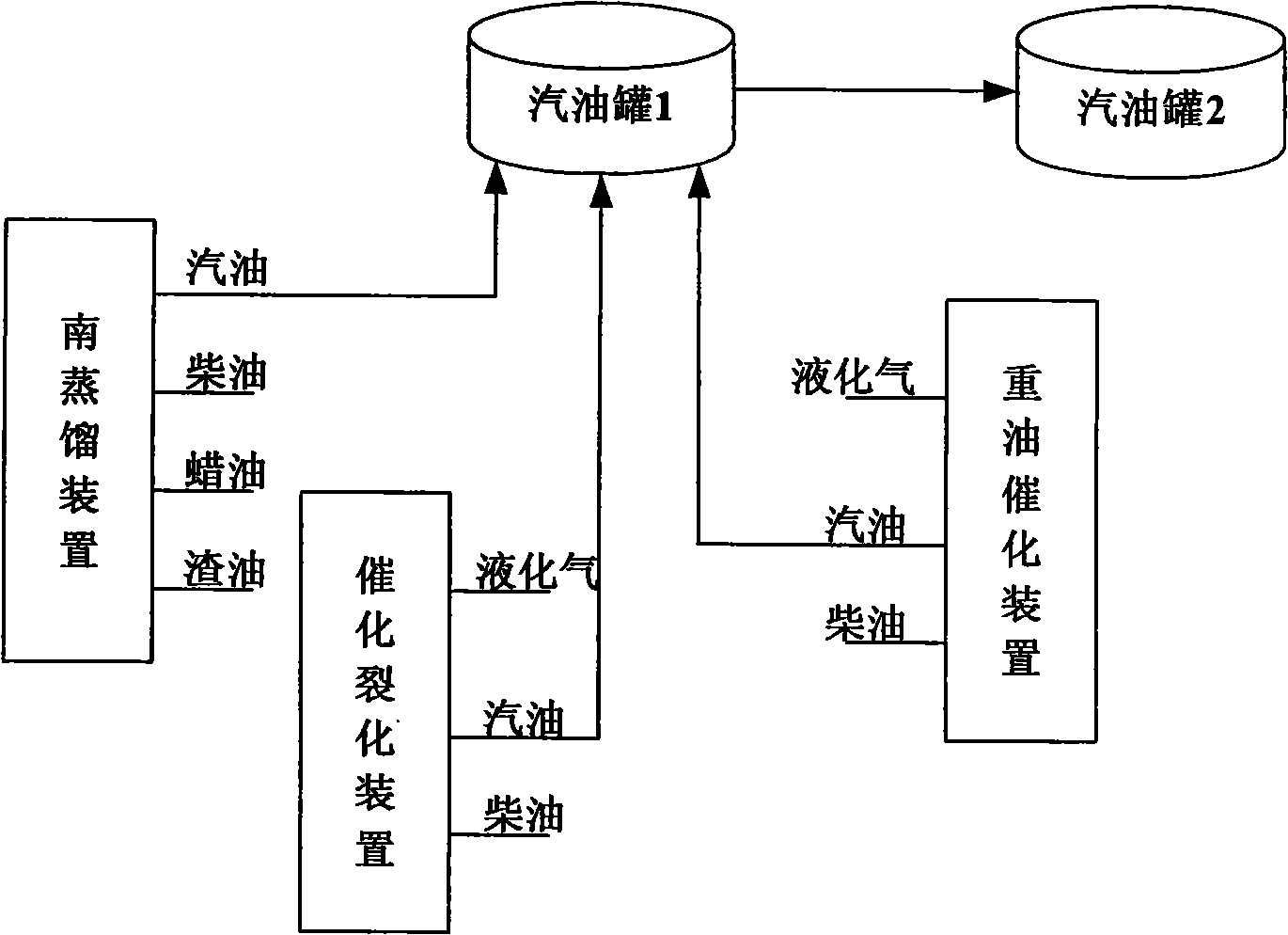

[0022] Oil refining enterprises use crude oil and natural gas as the main raw materials to produce fuel, lubricating oil, paraffin and other products to meet the needs of the society and at the same time seek the maximum economic benefits of the enterprise. The oil refining process is a continuous production with a large scale, consisting of many complex interrelated unit operation devices. The unit devices are connected to each other by material flow, energy flow and equipment to form different refining and chemical process flows. In order to facilitate the understanding of the following, some related terms in refining and chemical industry are introduced first:

[0023] Oil refining production unit: The equipment combination of oil refining enterprises to produce gasoline, diesel oil, keros...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com