Patents

Literature

4366 results about "Material flow" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Material flow is the description of the transportation of raw materials, pre-fabricates, parts, components, integrated objects and final products as a flow of entities. The term applies mainly to advanced modeling of supply chain management.

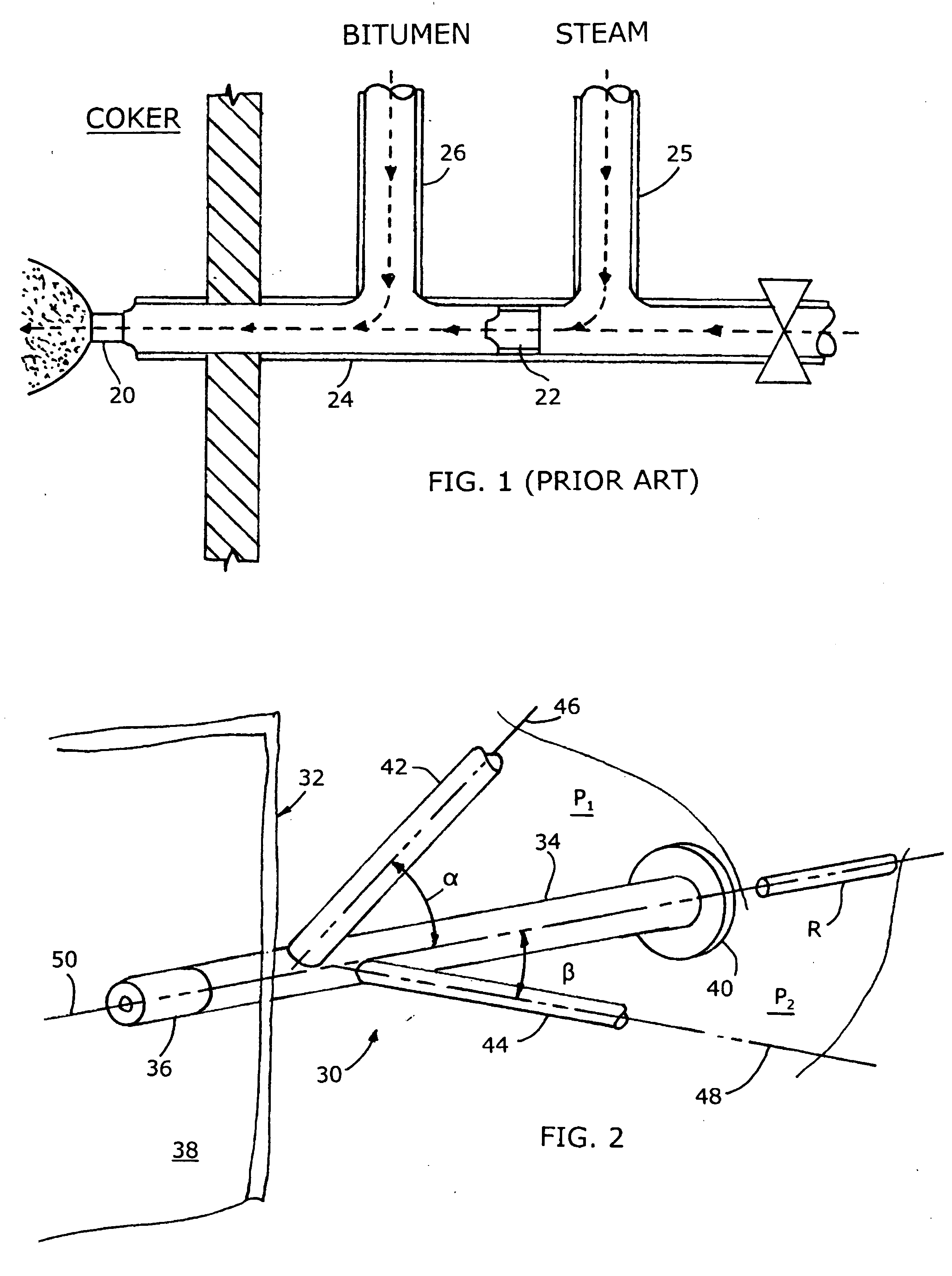

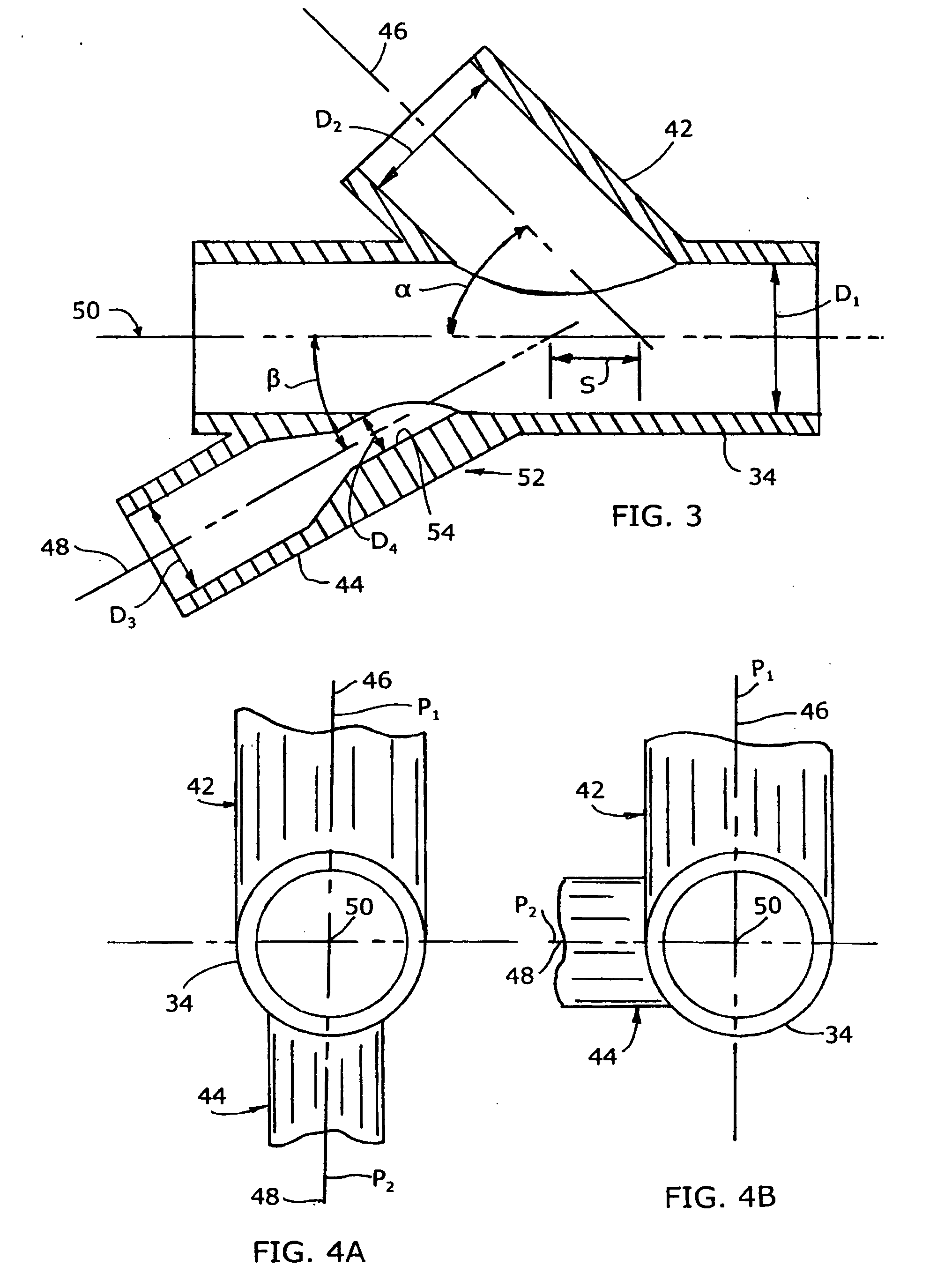

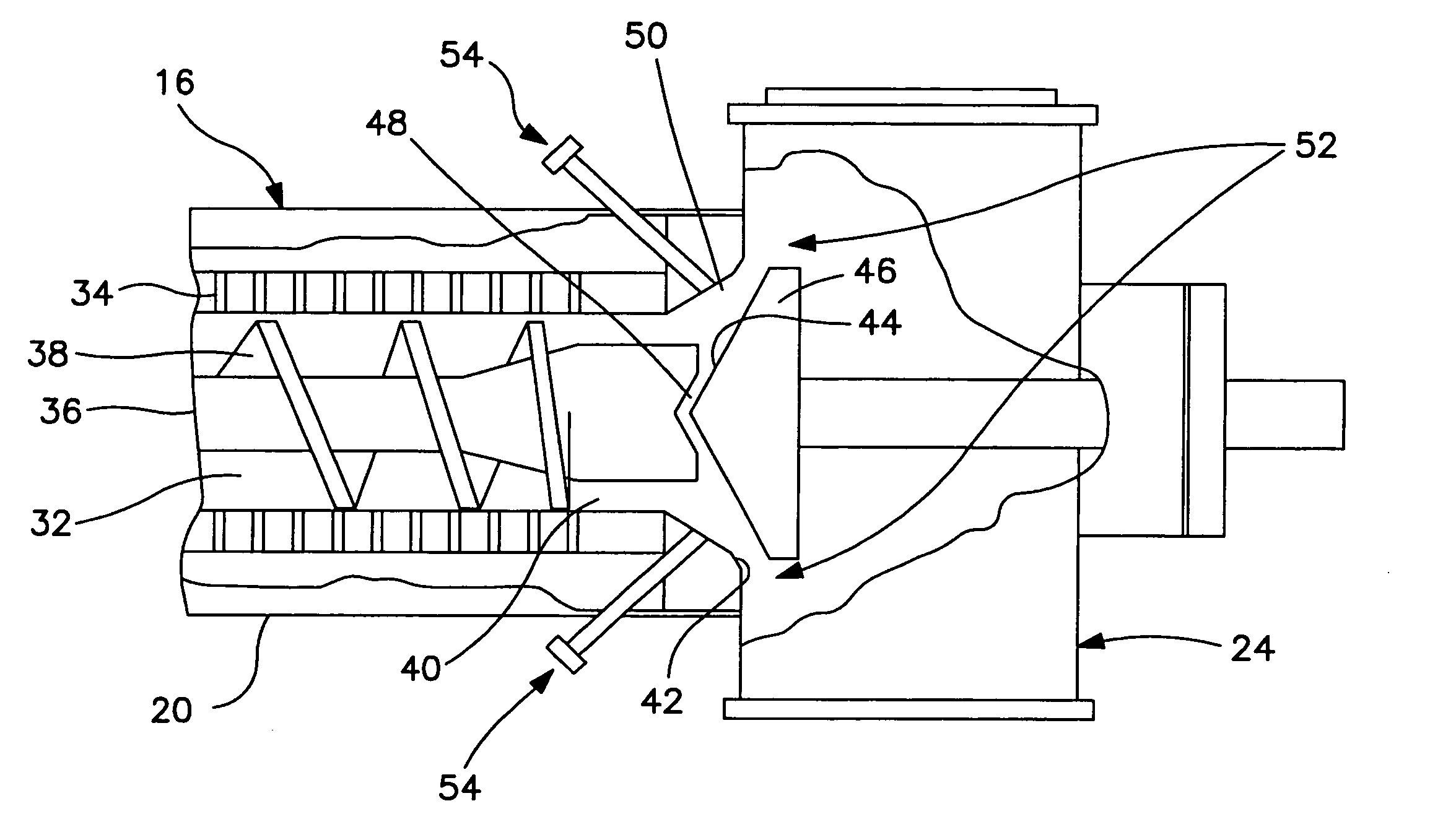

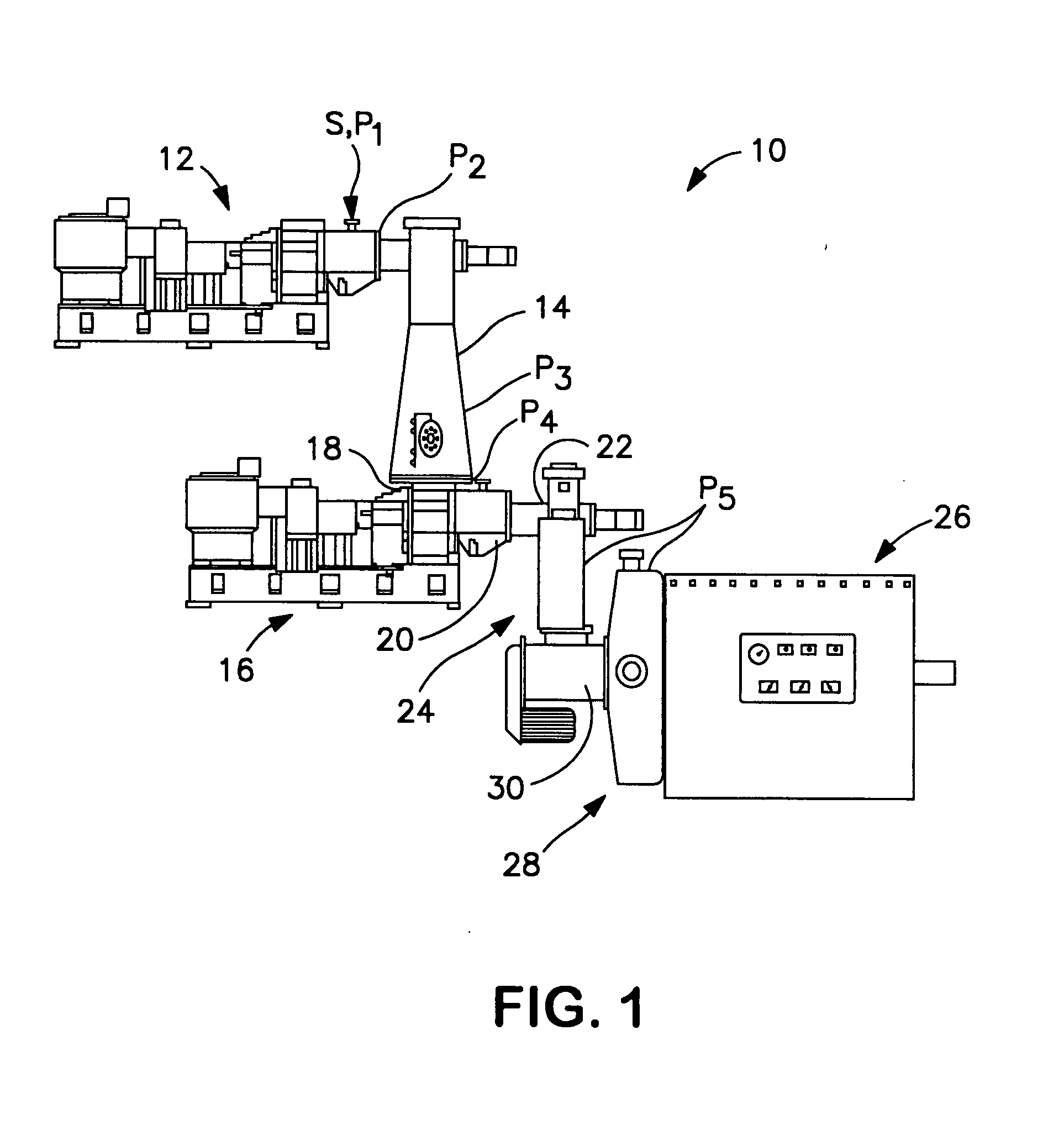

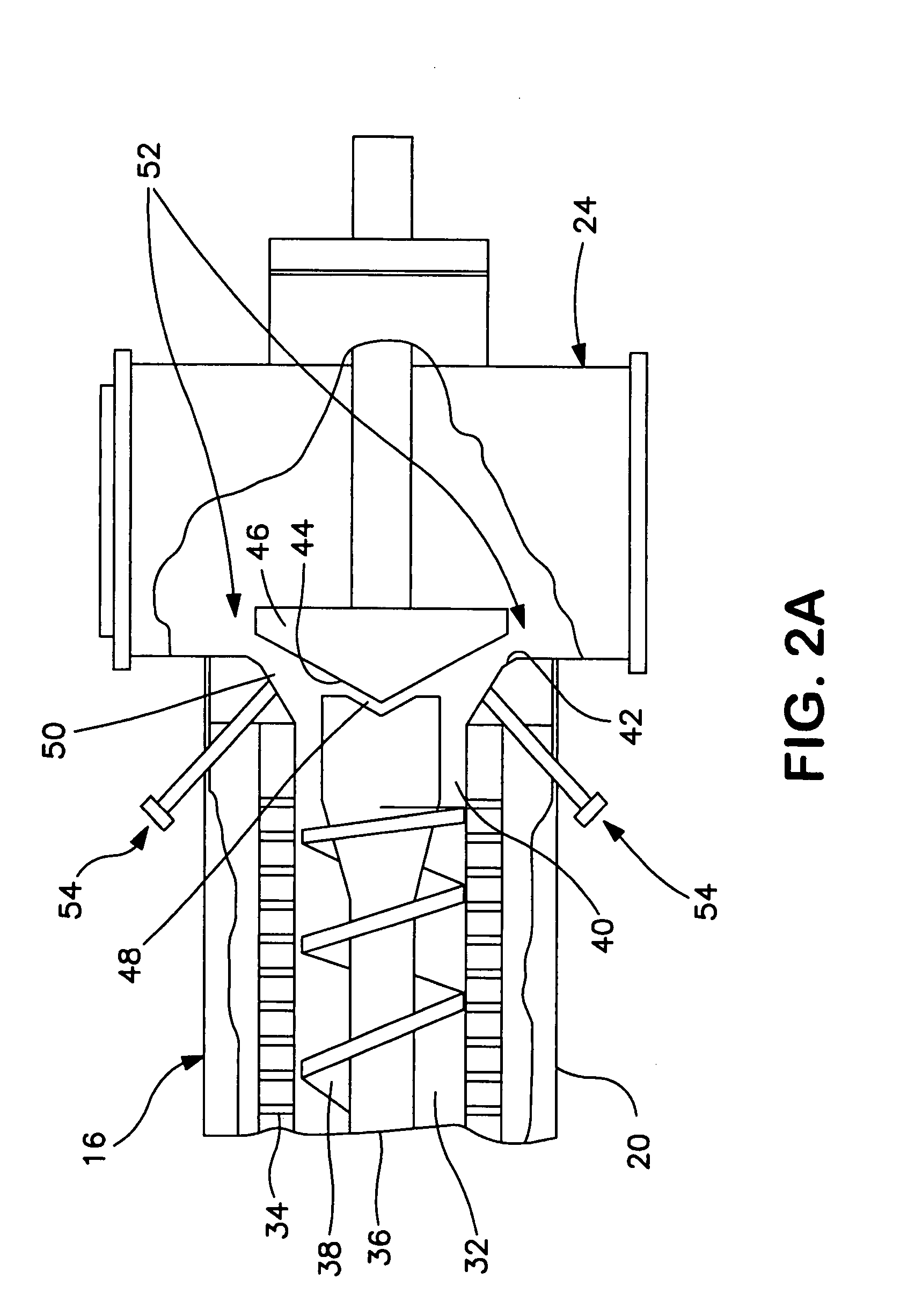

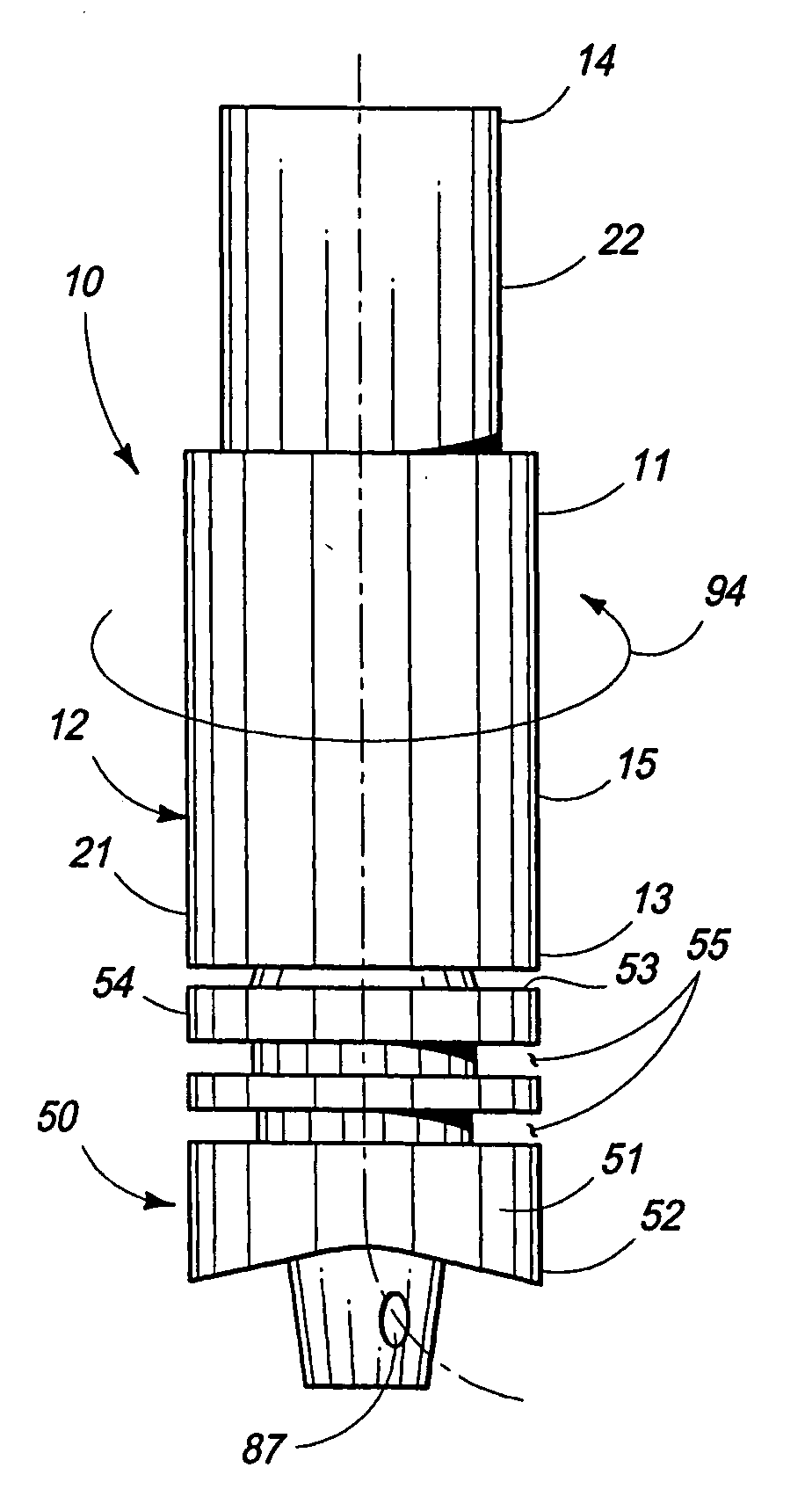

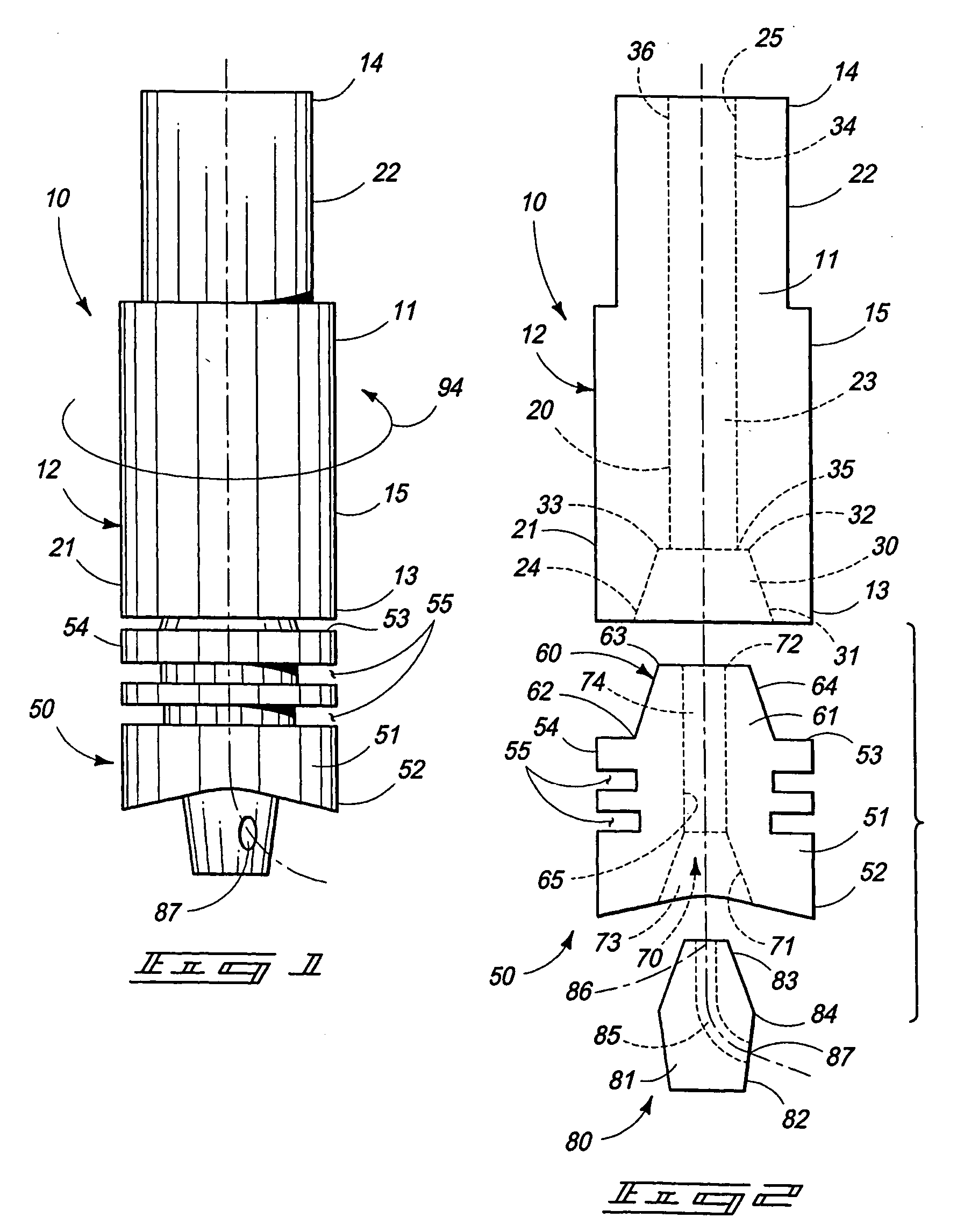

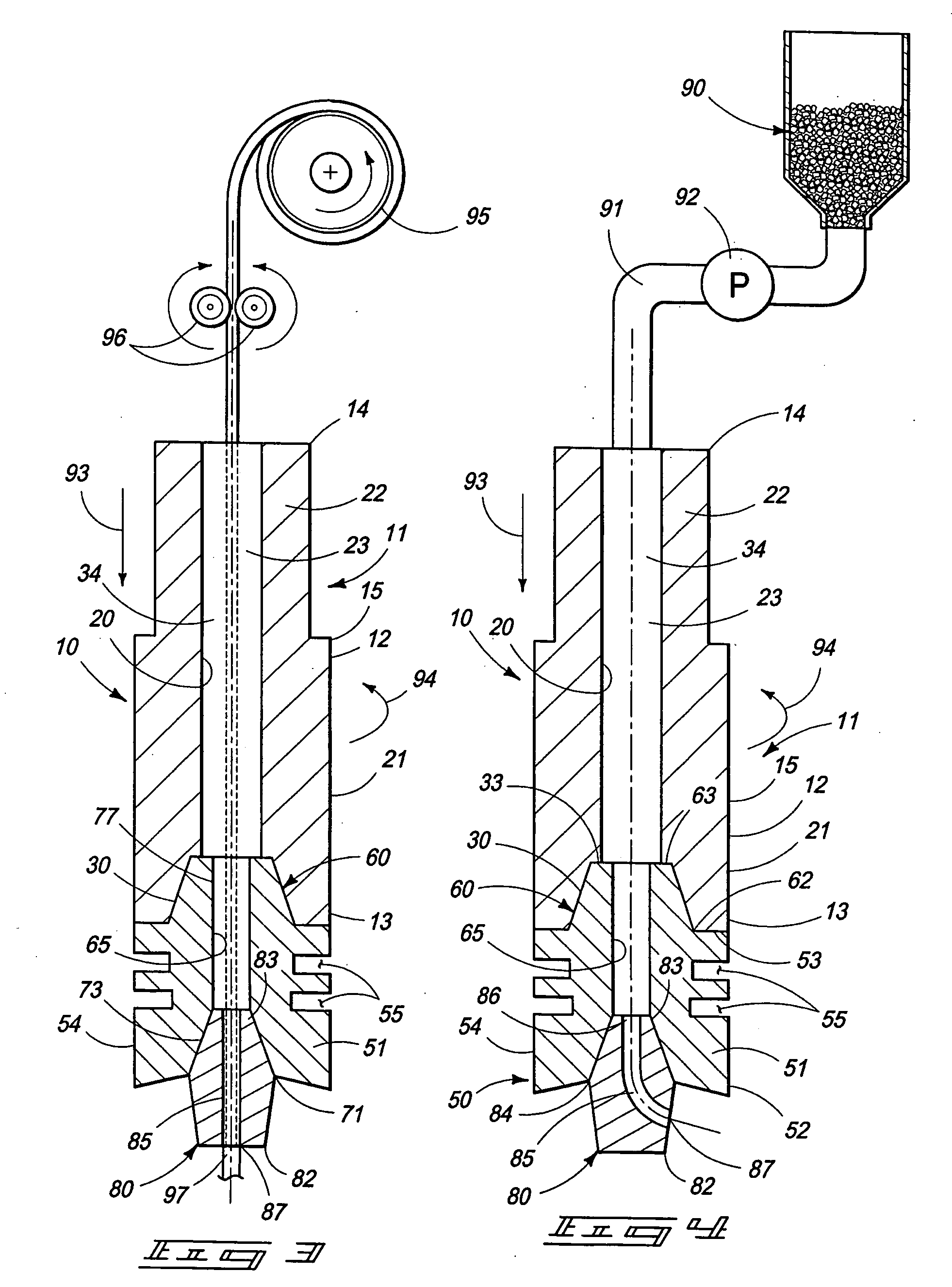

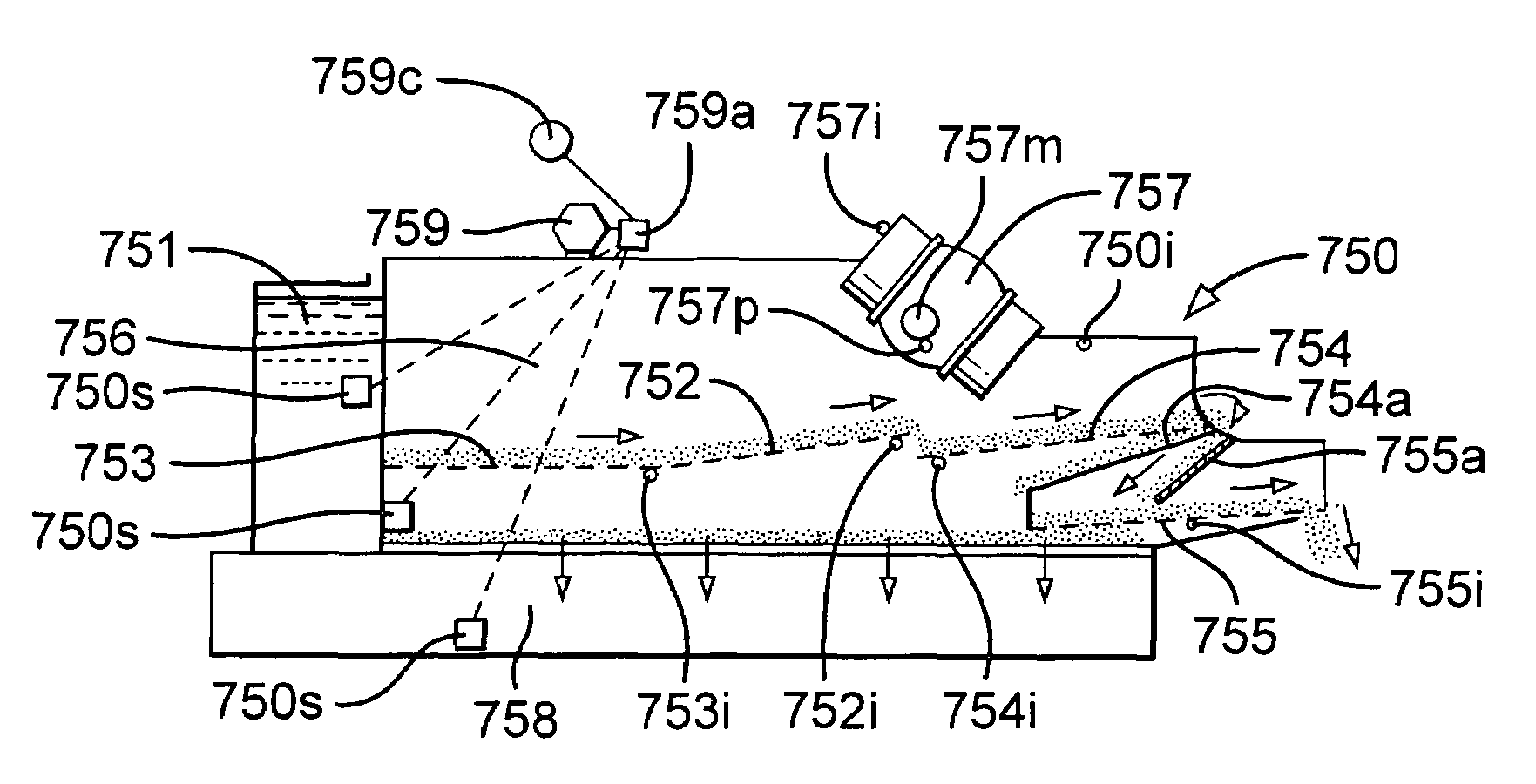

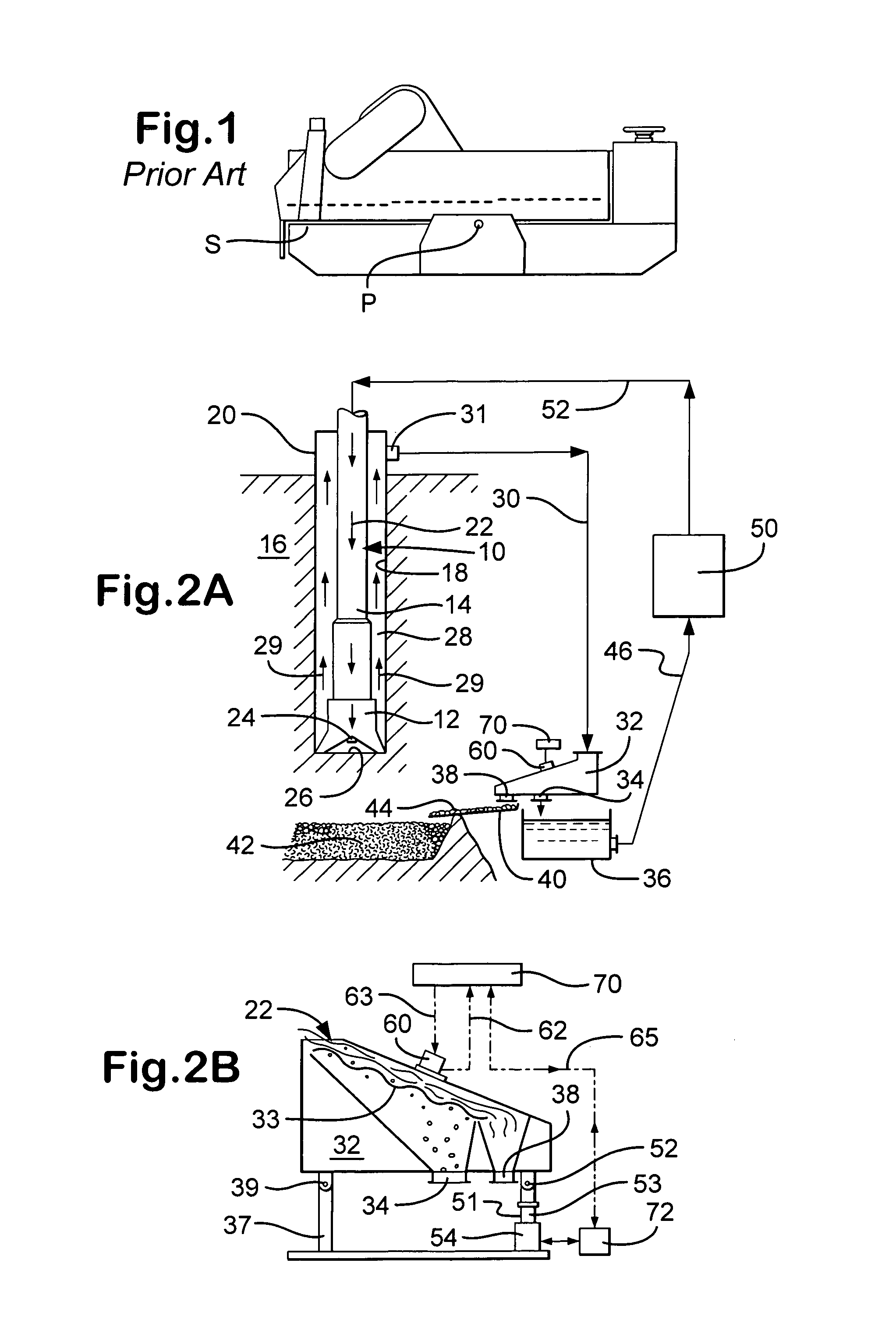

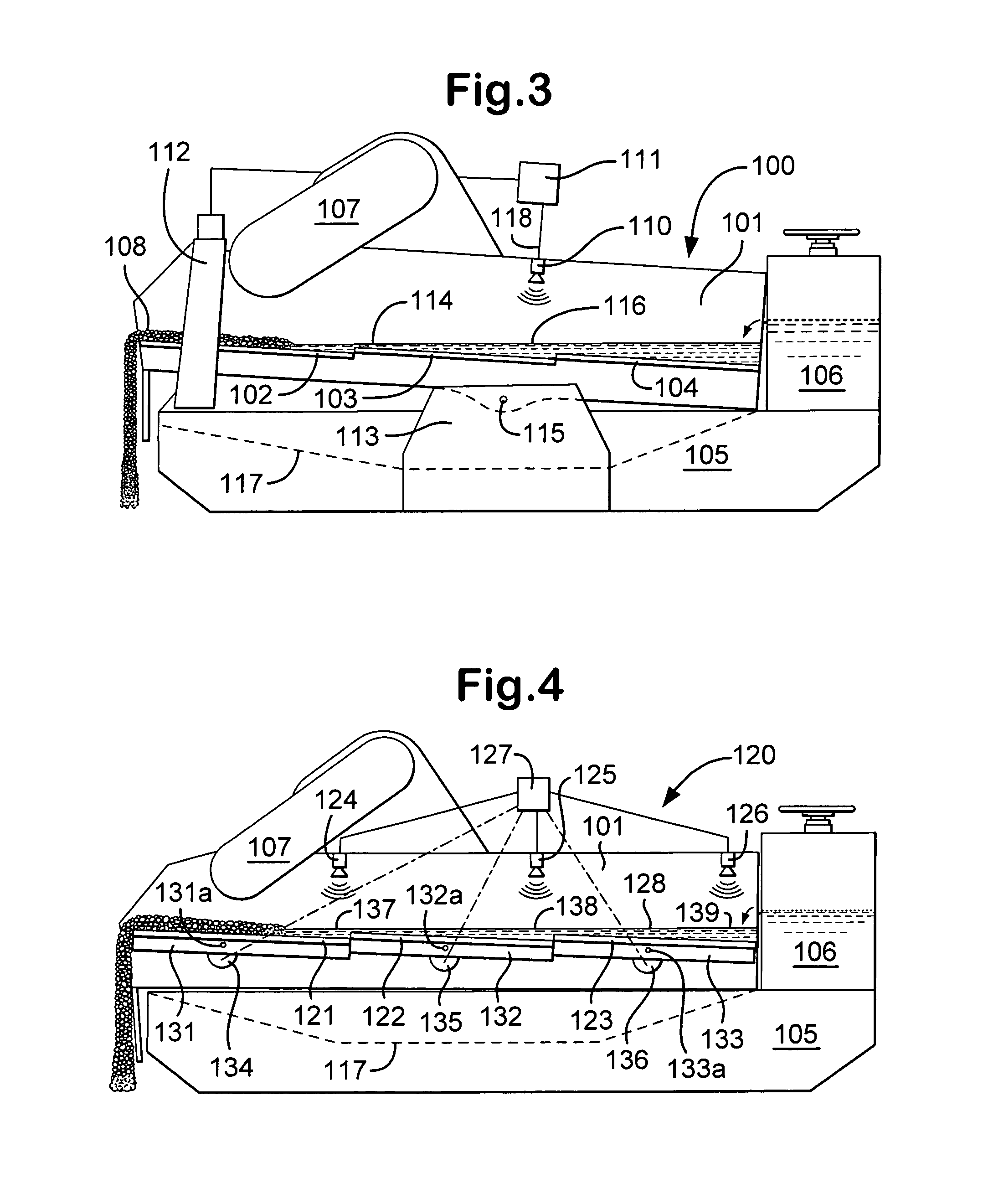

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS7140558B2Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

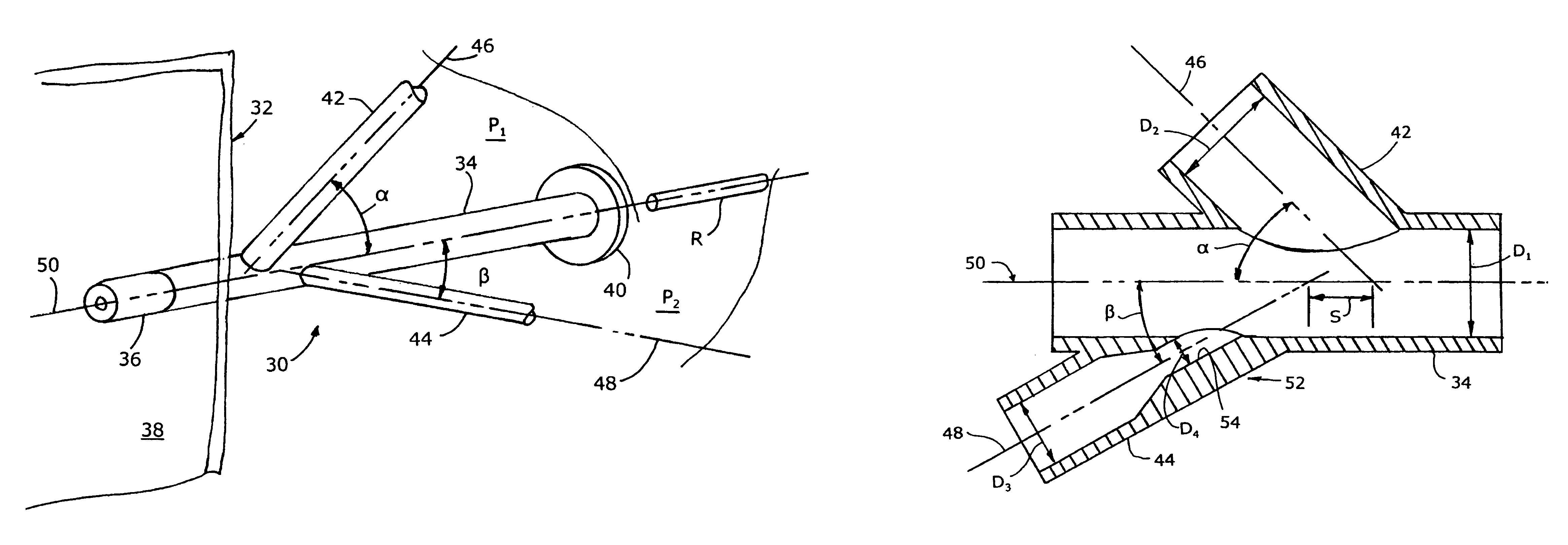

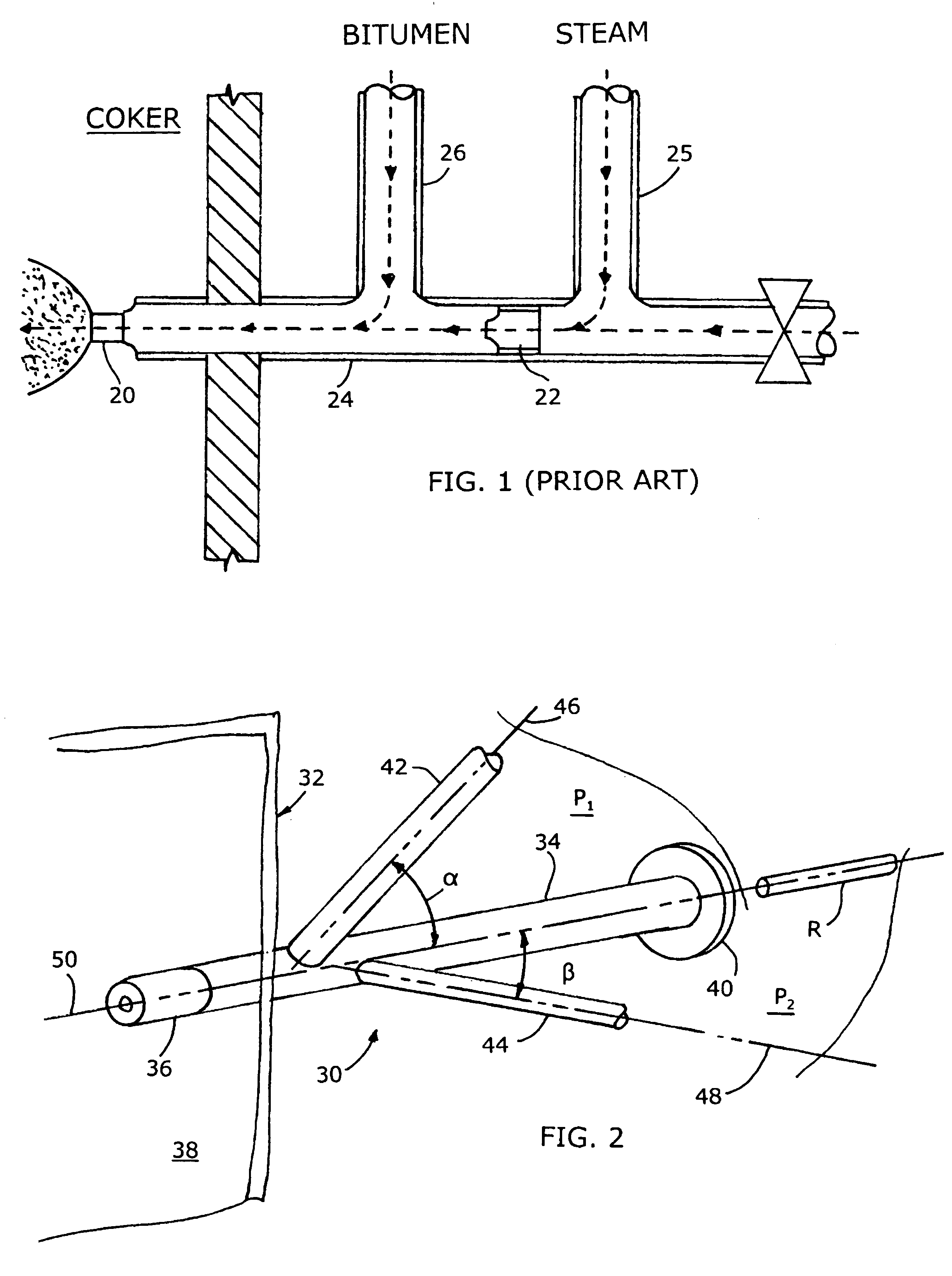

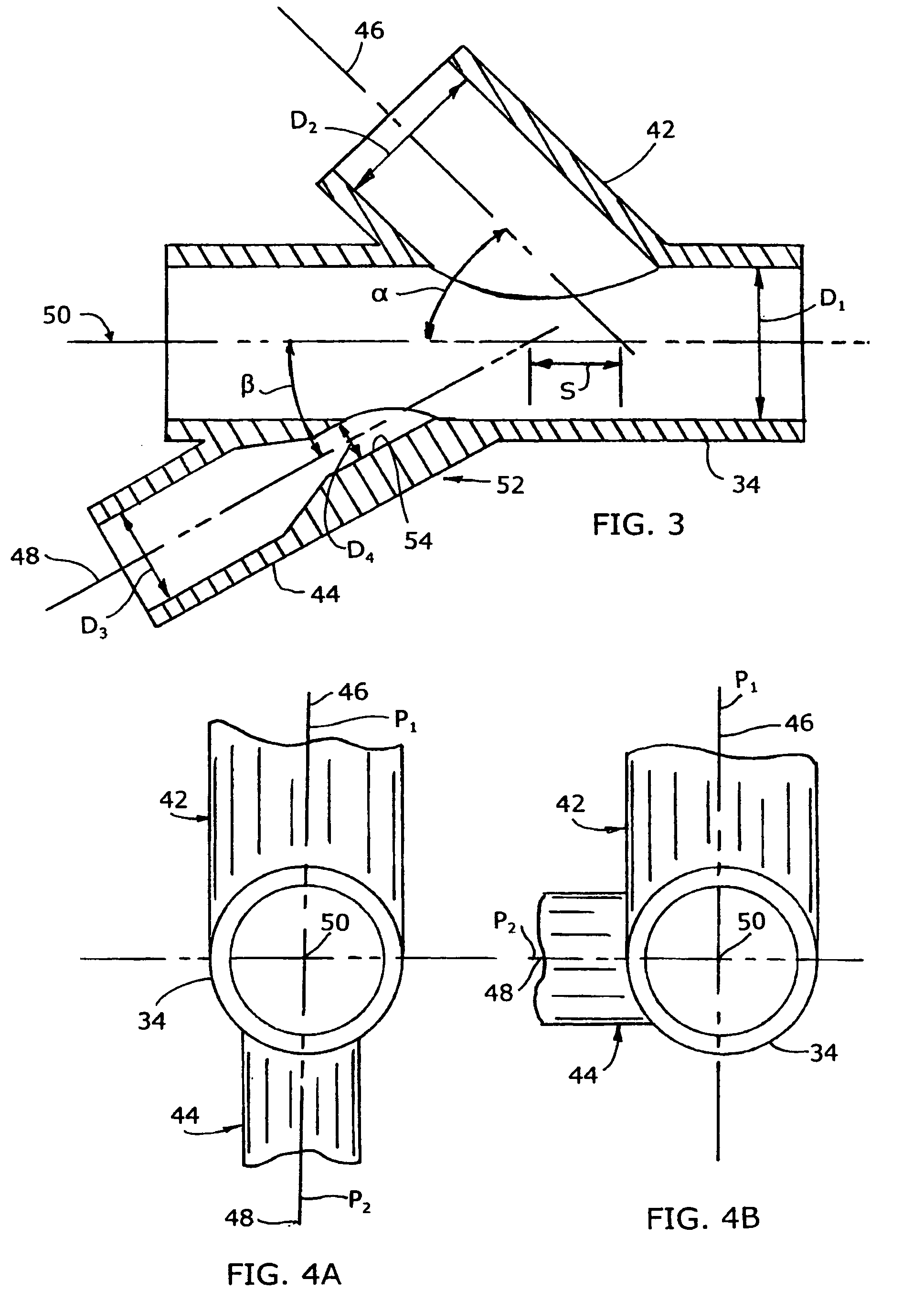

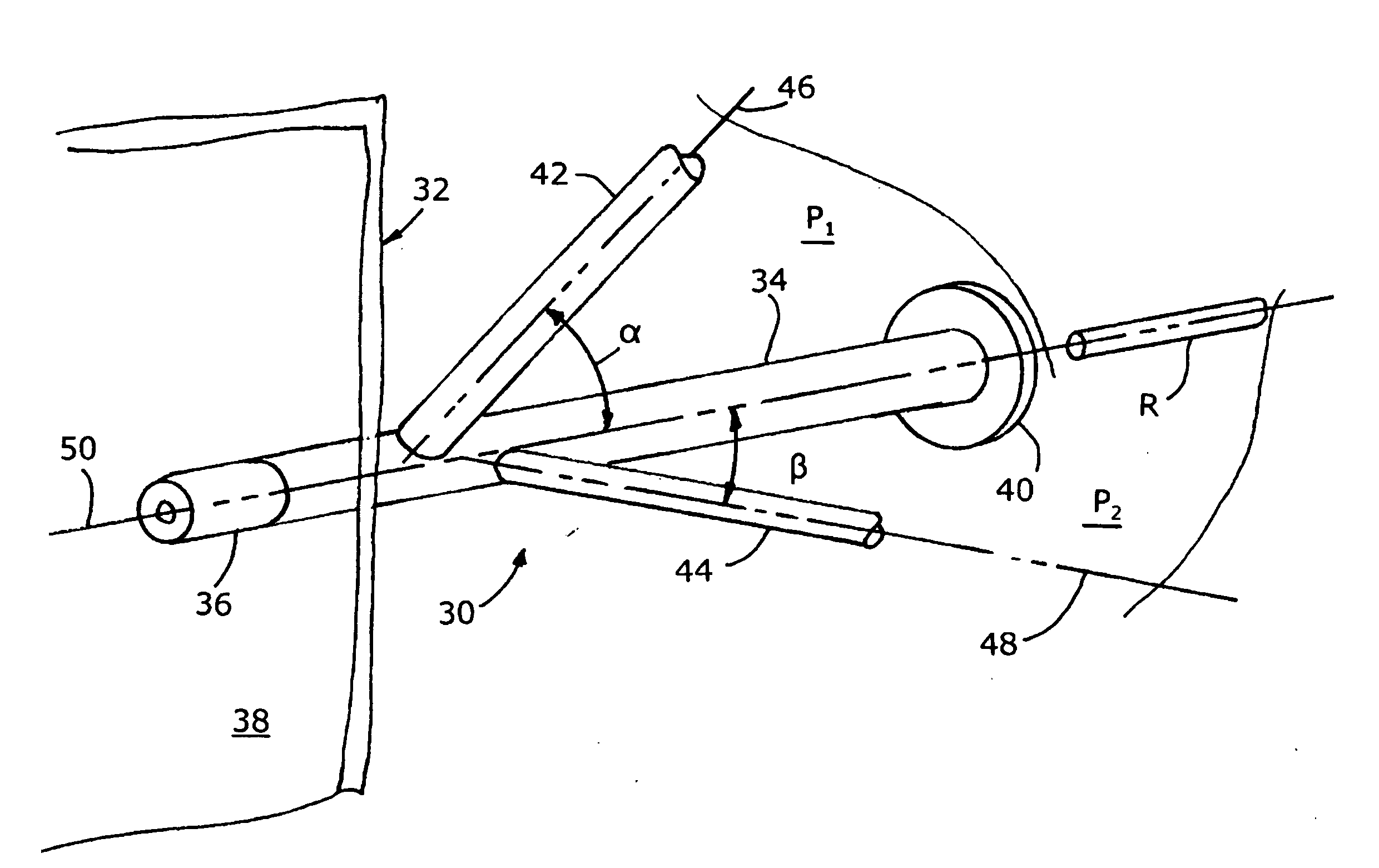

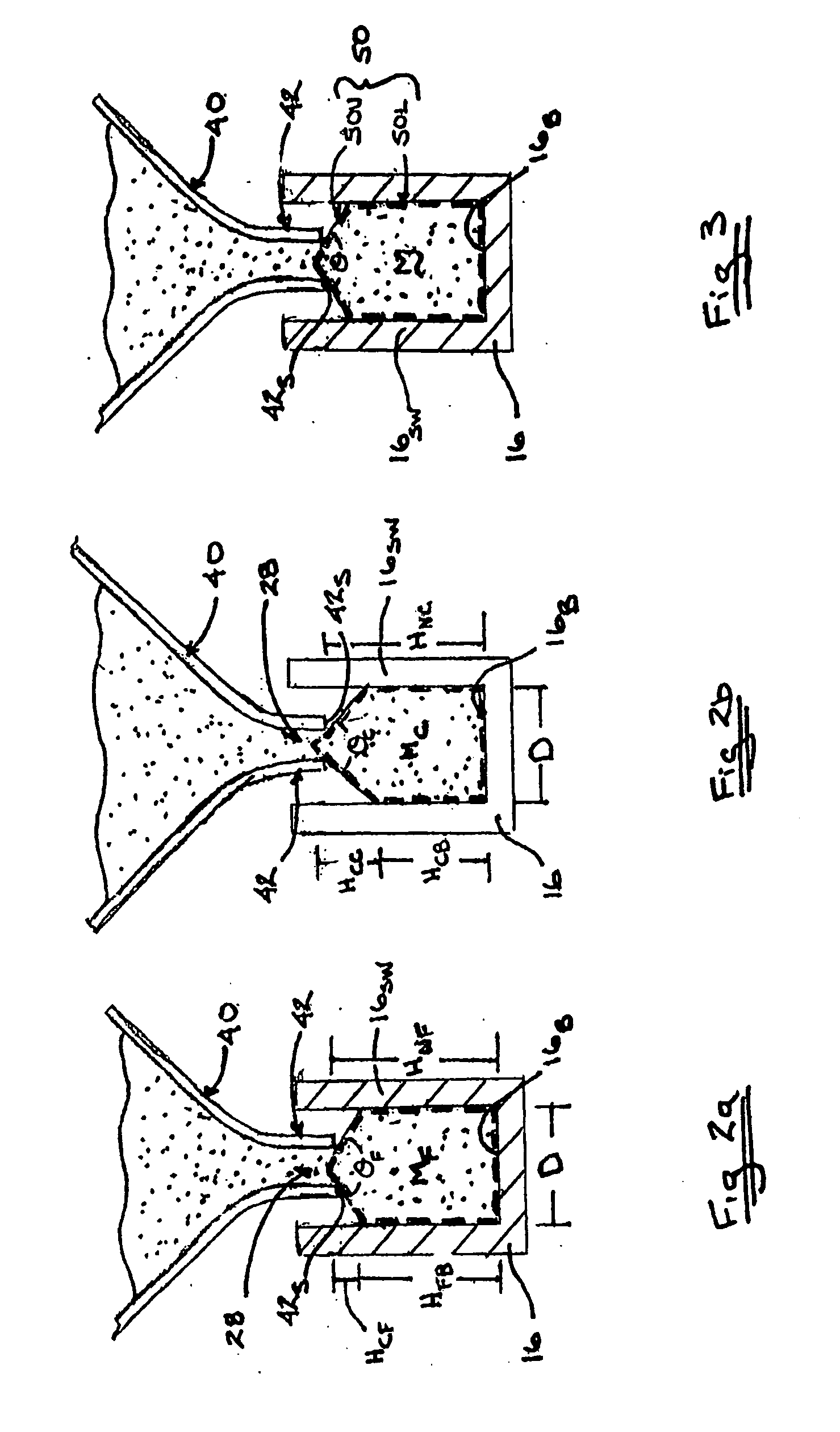

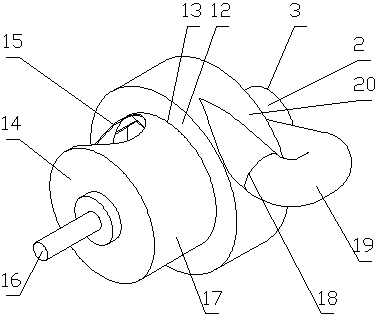

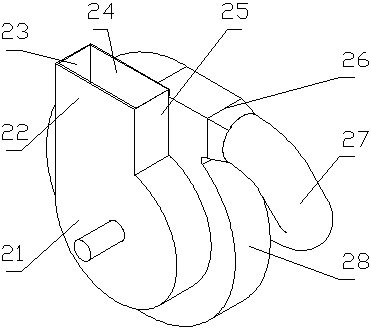

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned upstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

Mixing arrangement for atomizing nozzle in multi-phase flow

ActiveUS20050001062A1Smooth transitionEasy to processCharging-discharging device combinationsFlow mixersAcute angleShortest distance

The invention relates to an improved mixing arrangement for, primarily, moving bitumen in steam from sources of such bitumen and steam to a reactor or coker for further processing of the bitumen into petroleum products. The invention provides a main conduit connected to an atomizing nozzle mounted in a wall of the reactor and first and second conduits for flowing bitumen and steam respectively into the main conduit. The first conduit is angled relative to the main conduit at an acute angle of about 45° and the second conduit is angled relative to the main conduit at an acute angle of about 30°. The second conduit is positioned downstream of the first conduit by a short distance of about 23 mm and may be angled radially relative to the first conduit by any angle, although a 90° angle is preferred. A flow accelerating nozzle is located in the second conduit adjacent the entrance therefrom into the main conduit. The arrangement of the invention improves the flow characteristics of 2-phase material flowing to the atomizing nozzle, reducing pulsations in the main conduit and improving the resulting atomization of the bitumen in the reactor.

Owner:NAT RES COUNCIL OF CANADA +1

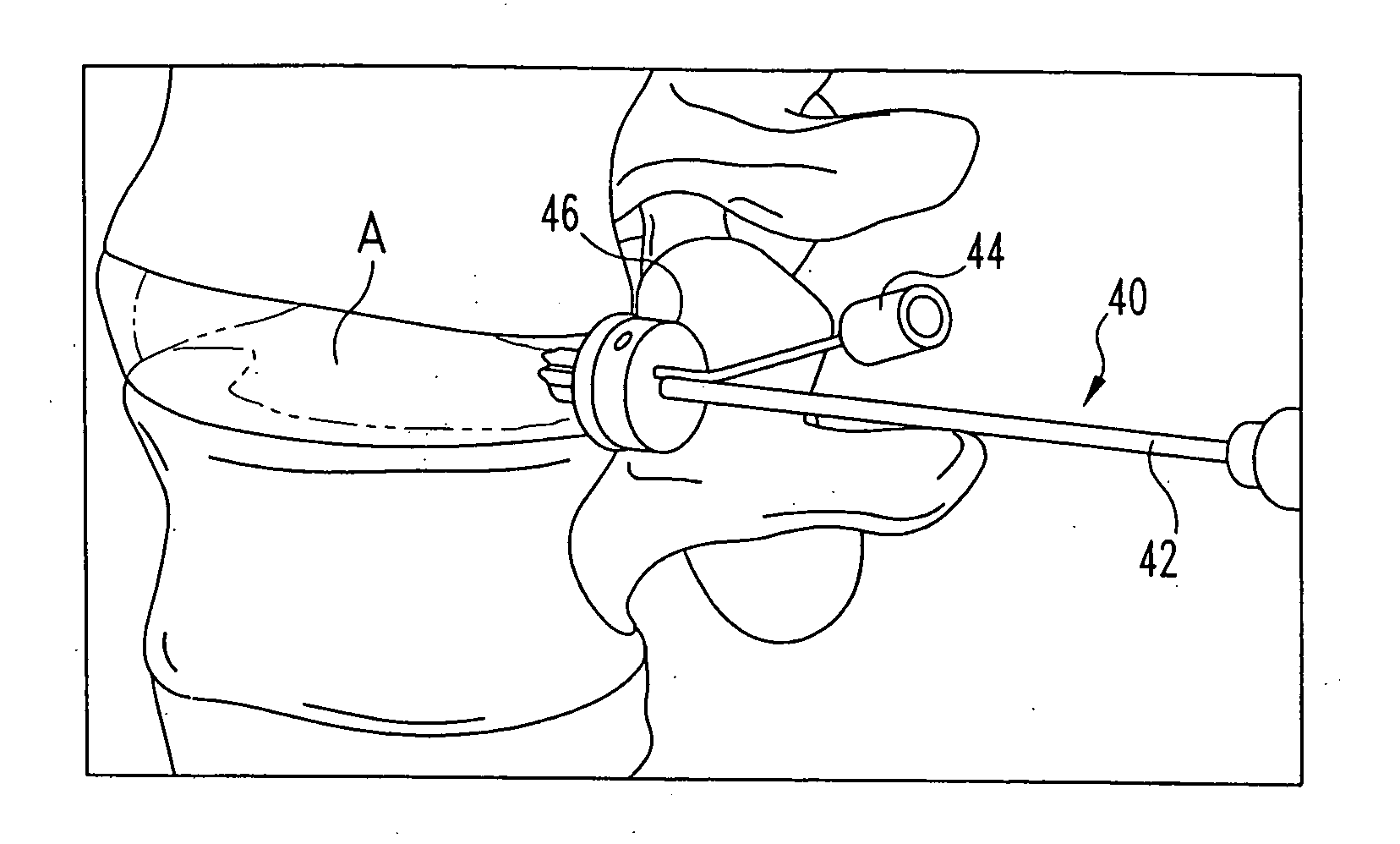

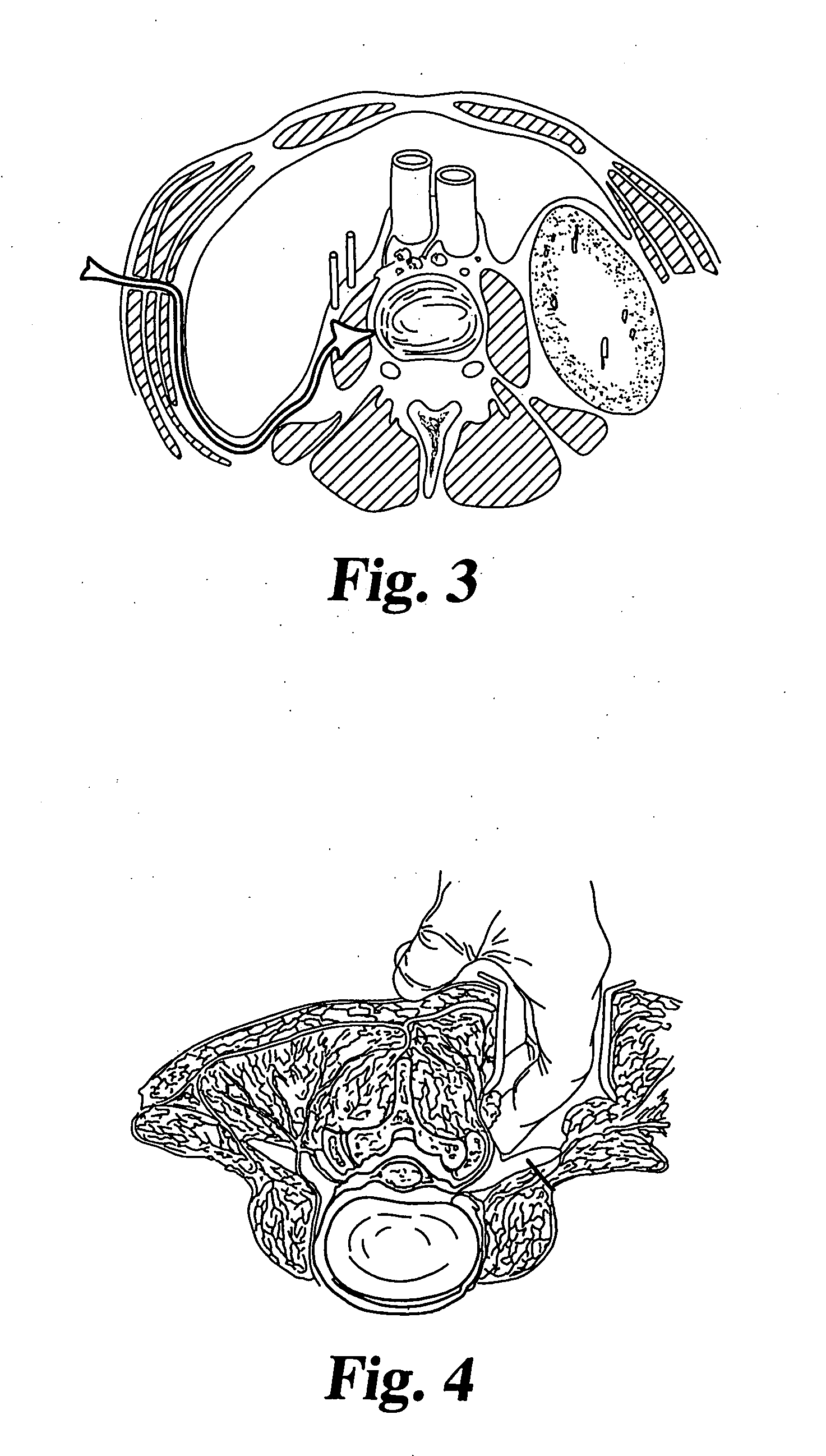

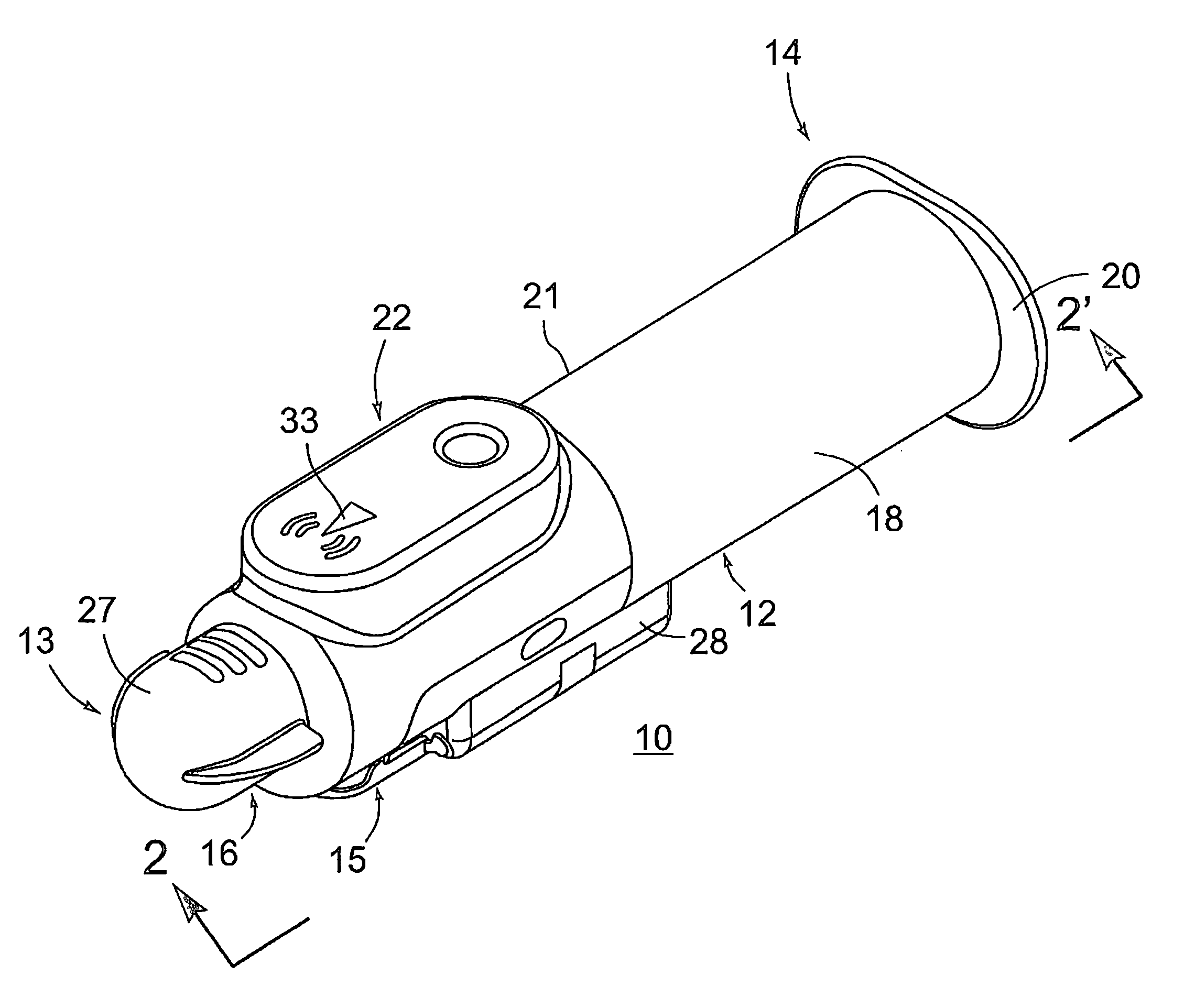

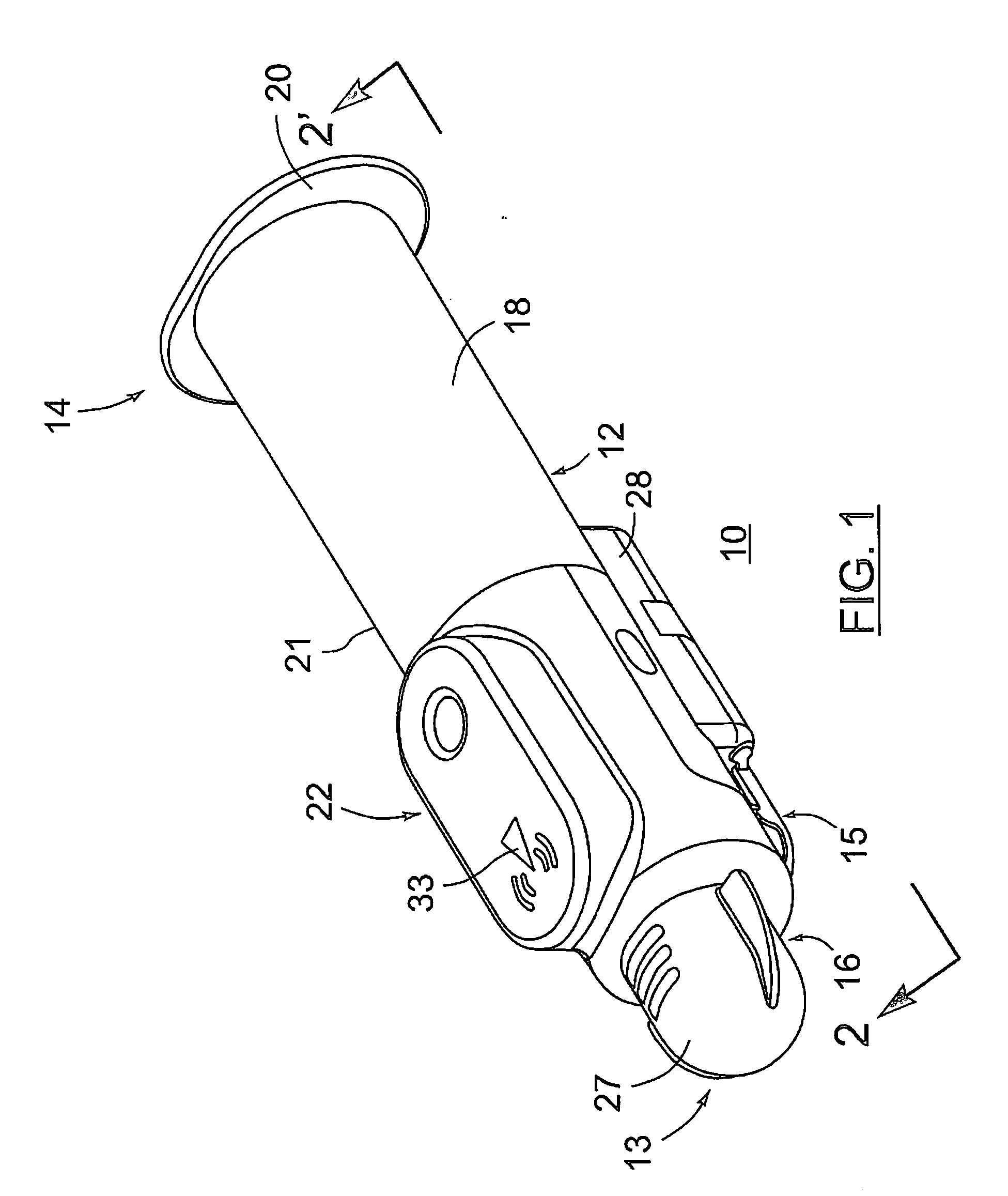

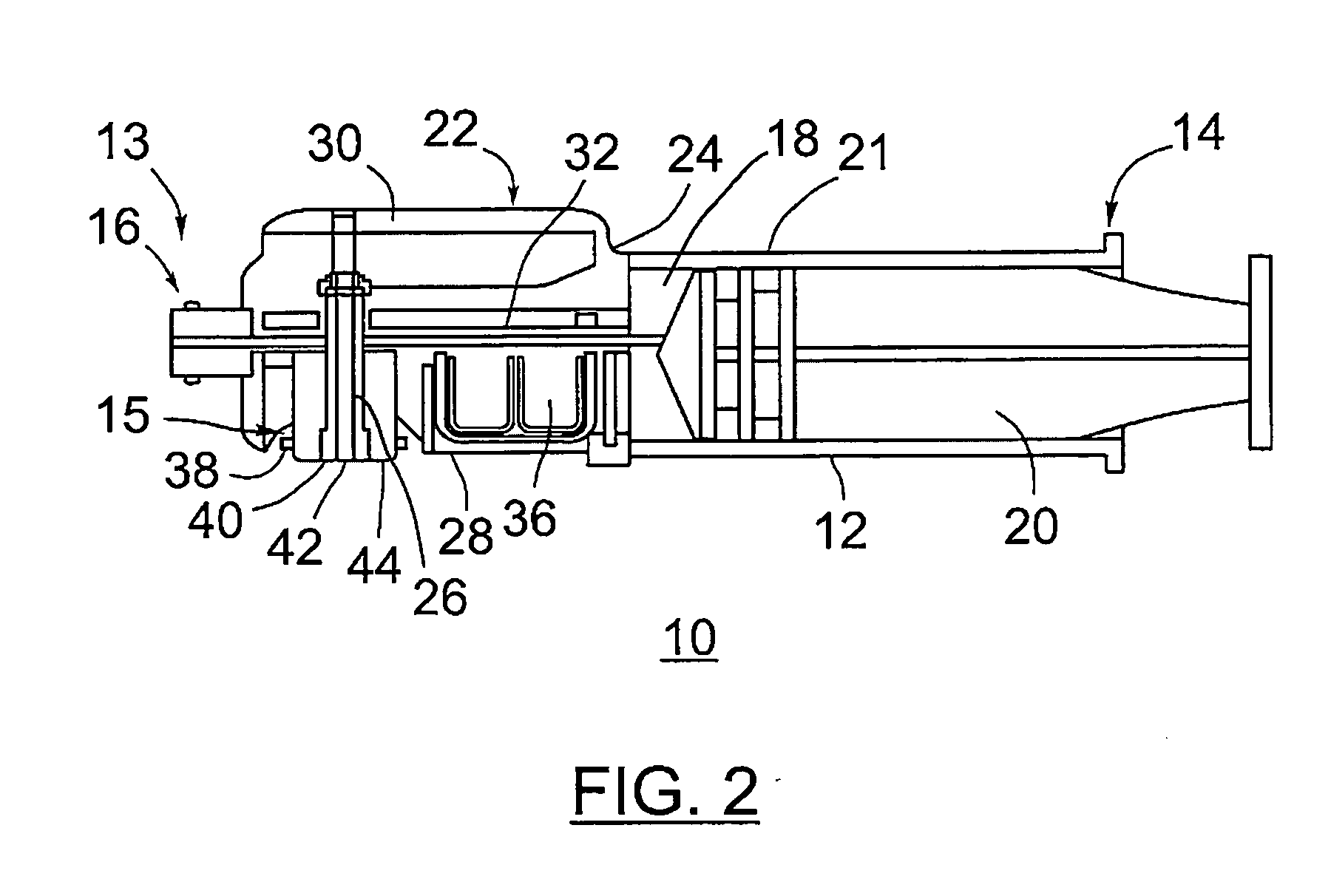

Methods for injecting a curable biomaterial into an intervertebral space

A method for treating a diseased or damaged spinal disc comprises the steps of: (a) providing access to the nucleus pulposus through the annulus; (b) removing at least a portion of the nucleus pulposus to create an intradiscal space; determining the size of the intradiscal space; and (c) sealably introducing under pressure a curable biomaterial through the annulus directly into the intradiscal space. The method may include the additional steps of applying a force to distract the opposing vertebral bodies about the intradiscal space and then removing the distraction force after the biomaterial has cured. The step of determining the size of the intradiscal space may be accomplished by expanding a compliant balloon within the intradiscal space using a contrast medium capable of visualization under fluoroscopy. The curable material is sealably introduced through a vented needle inserted through the opening. The curable biomaterial is introduced until a quantity of the material flows into the vent.

Owner:SPINEWAVE

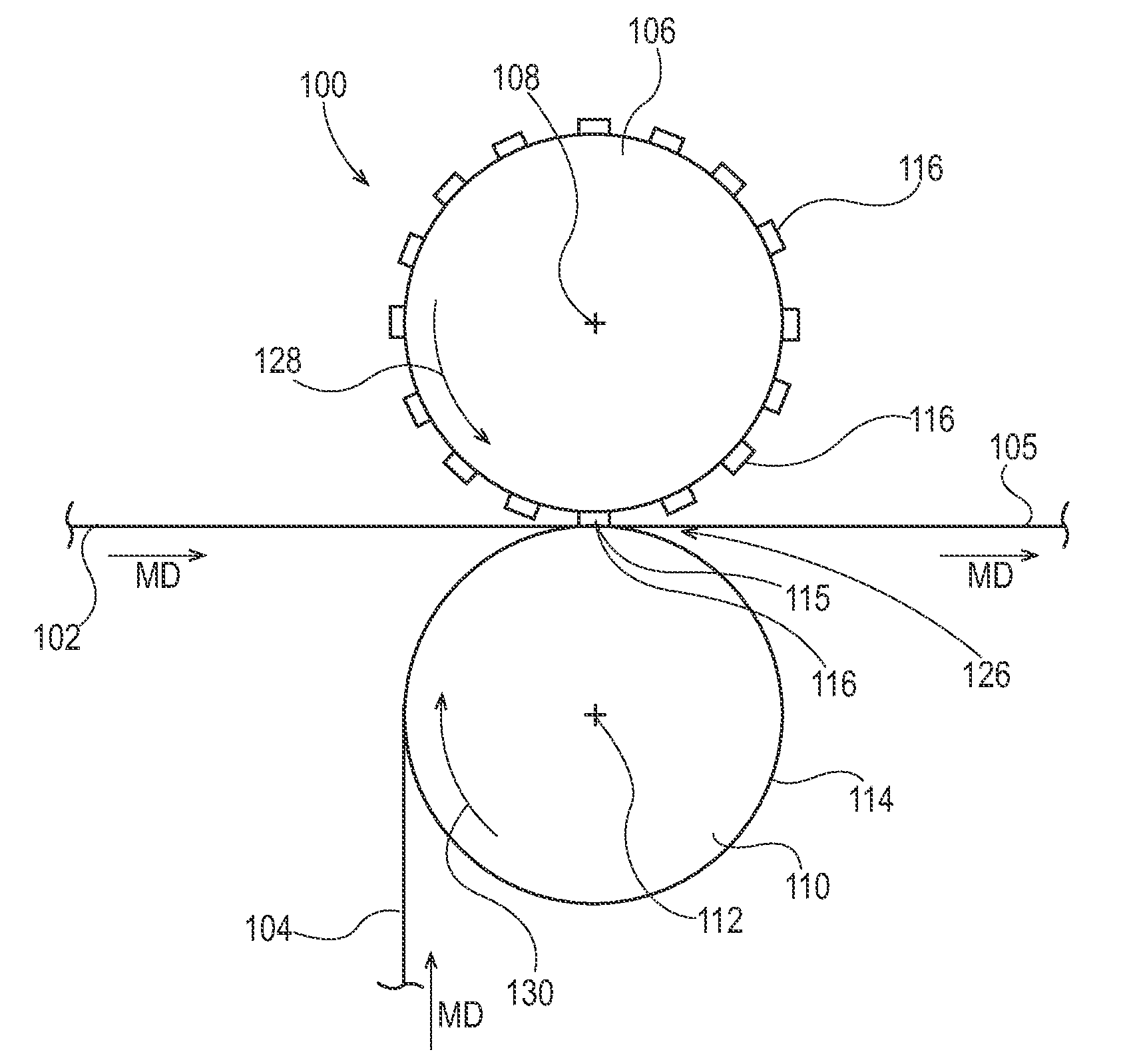

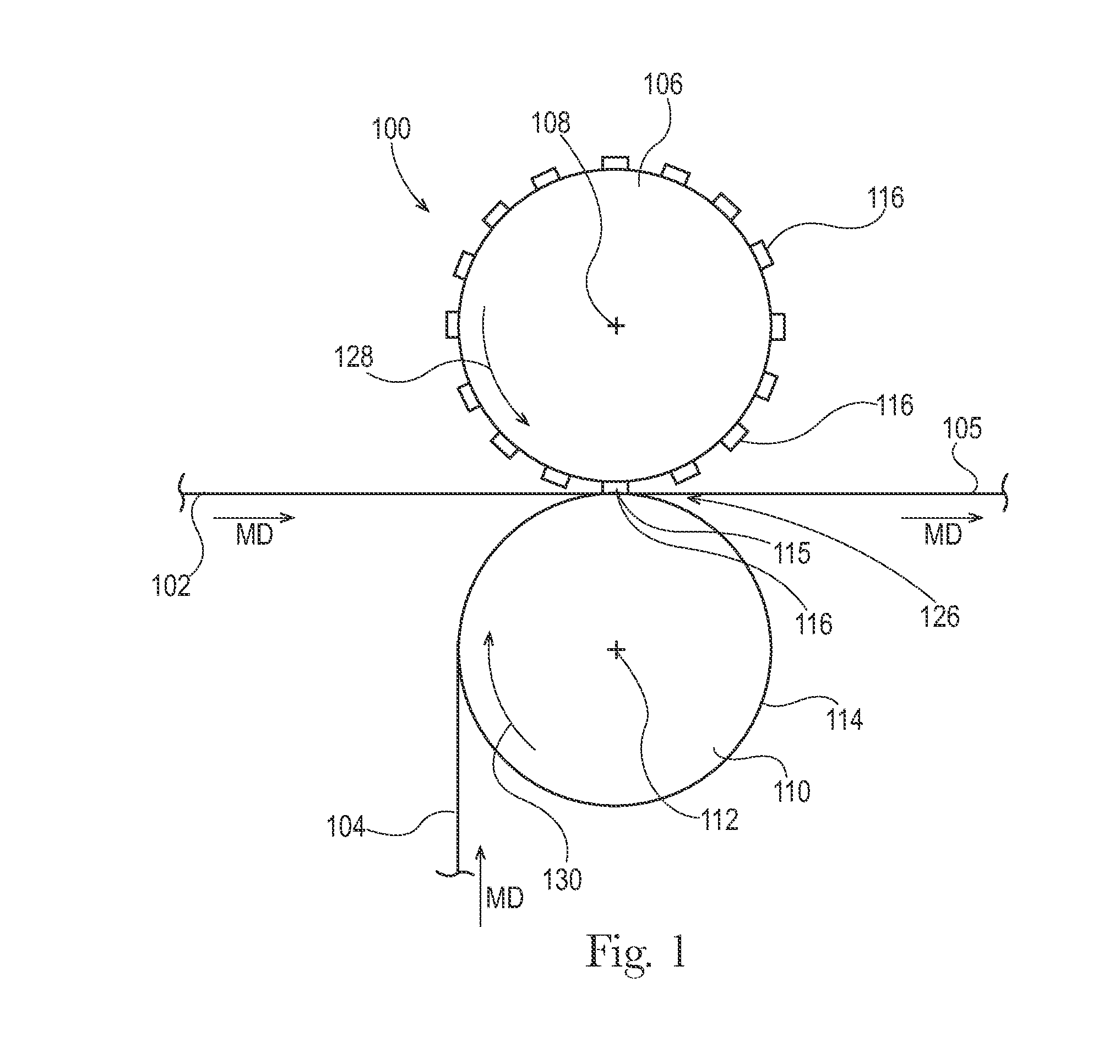

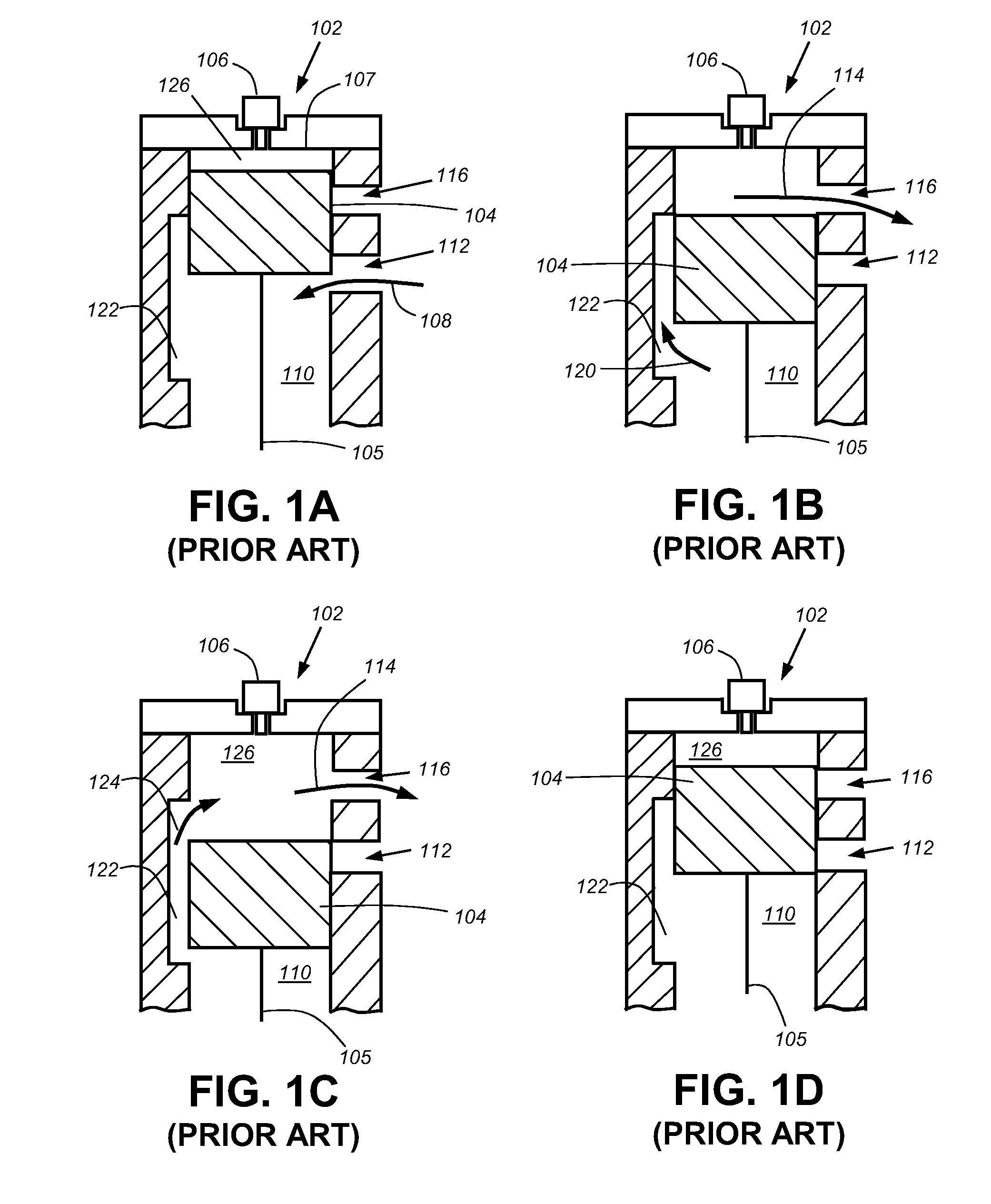

Bonding Apparatus and Method

The present disclosure relates to methods and apparatuses for mechanically bonding substrates together. The apparatuses may include a pattern roll including a pattern element protruding radially outward. The pattern element includes a pattern surface and includes one or more channels adjacent the pattern surface. The pattern roll may be positioned adjacent an anvil roll to define a nip between the pattern surface and the anvil roll, wherein the pattern roll is biased toward the anvil roll to define a nip pressure between pattern surface and the anvil roll. As substrates advance between the pattern roll and anvil roll, the substrates are compressed between the anvil roll and the pattern surface to form a discrete bond region between the first and second substrates. As such, during the bonding process, some yielded substrate material flows from under the pattern surface and into the channel to form a channel grommet region.

Owner:THE PROCTER & GAMBLE COMPANY

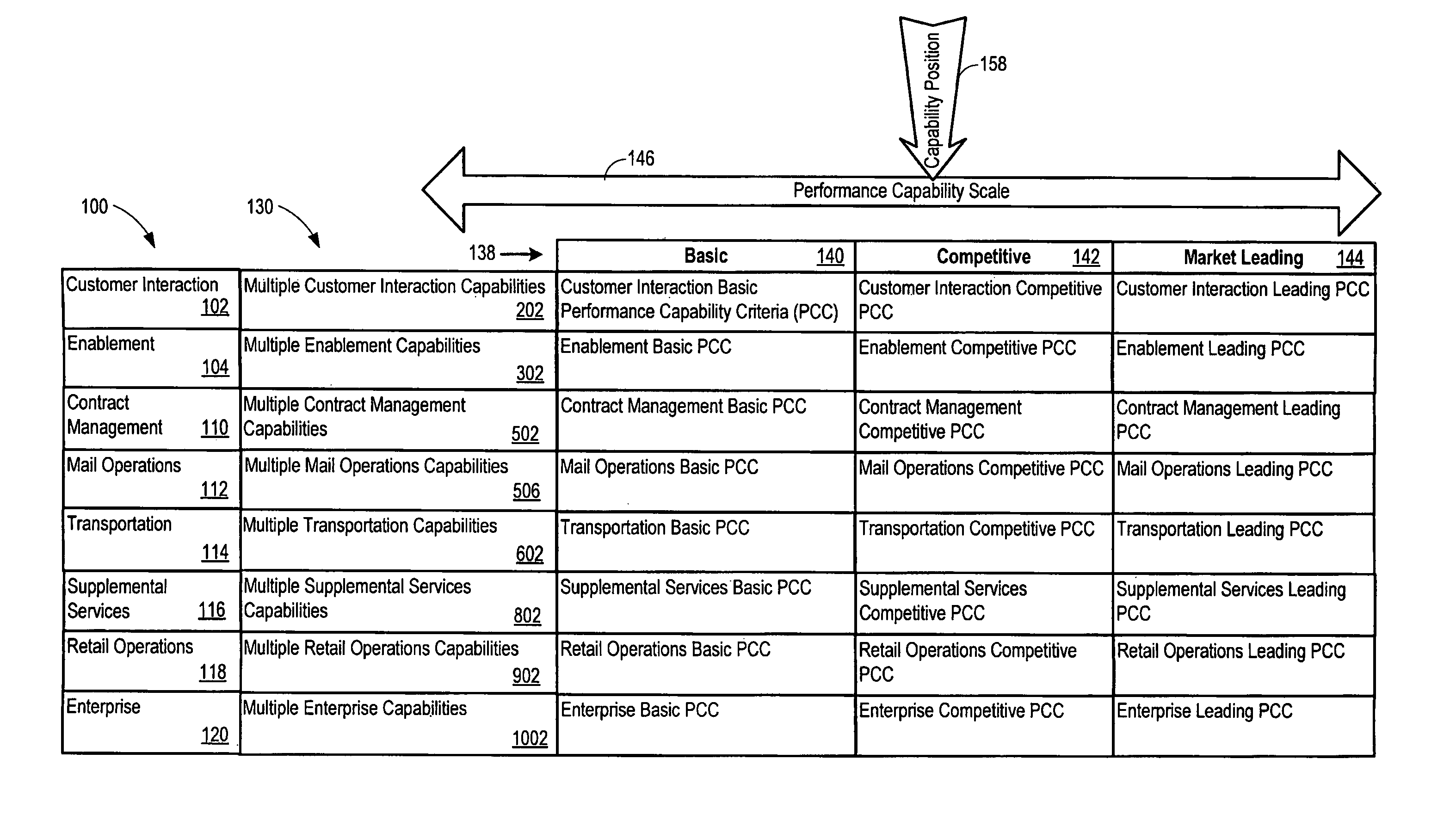

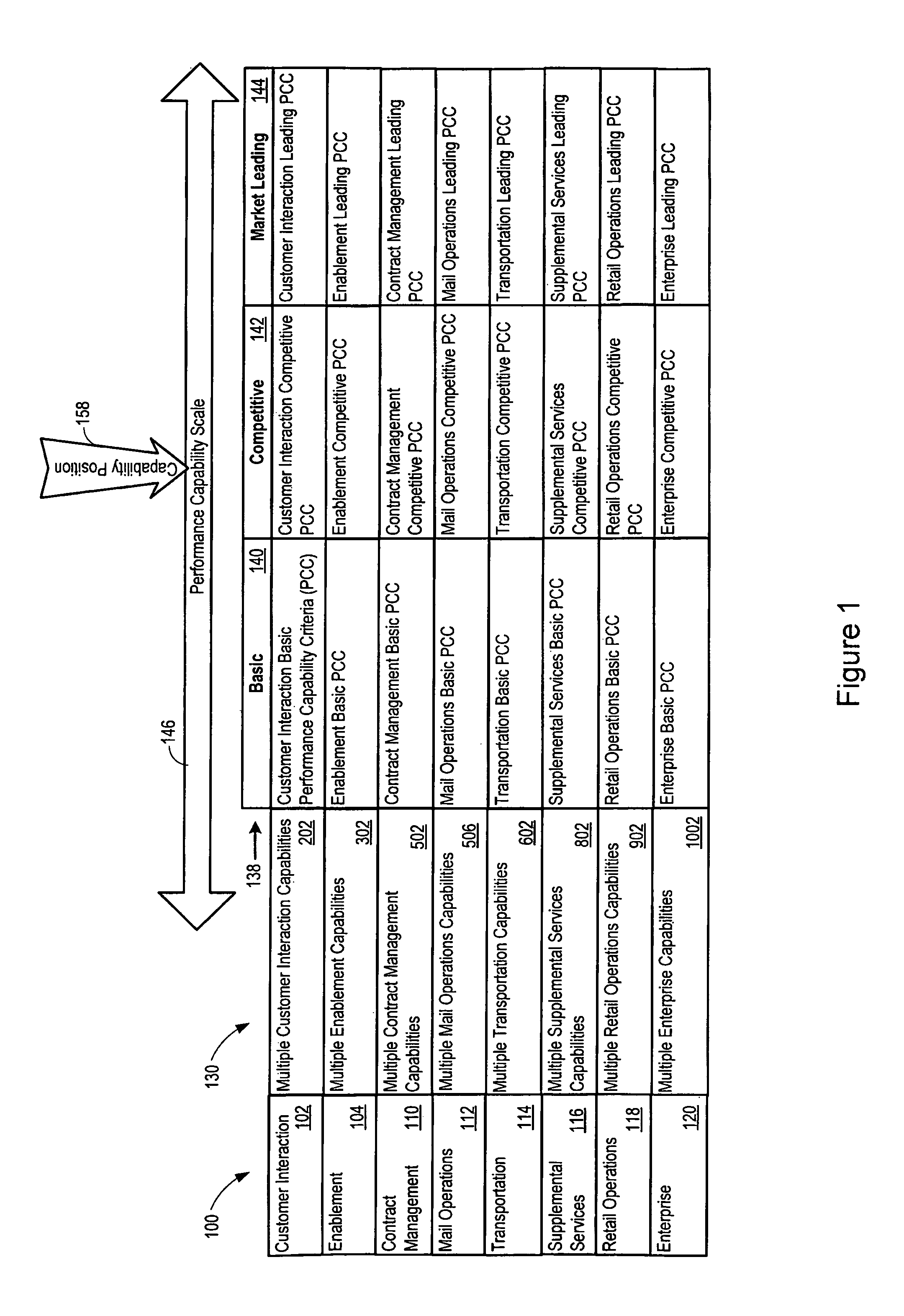

Postal, freight, and logistics industry high performance capability assessment

A high performance capability assessment model helps a postal industry business meet the challenges of the global marketplace. As a result, the postal industry business can achieve the clarity, consistency, and well-defined execution of core processes that reduce inefficiencies and waste that result from unnecessary process complexity and exceptions. In addition, the high performance capability assessment model helps the postal industry business to identify specific areas in which improvements may be made and understand how to make the improvements, and establishes levels of capability along the way to reaching an ultimate capability goal.

Owner:ACCENTURE GLOBAL SERVICES LTD

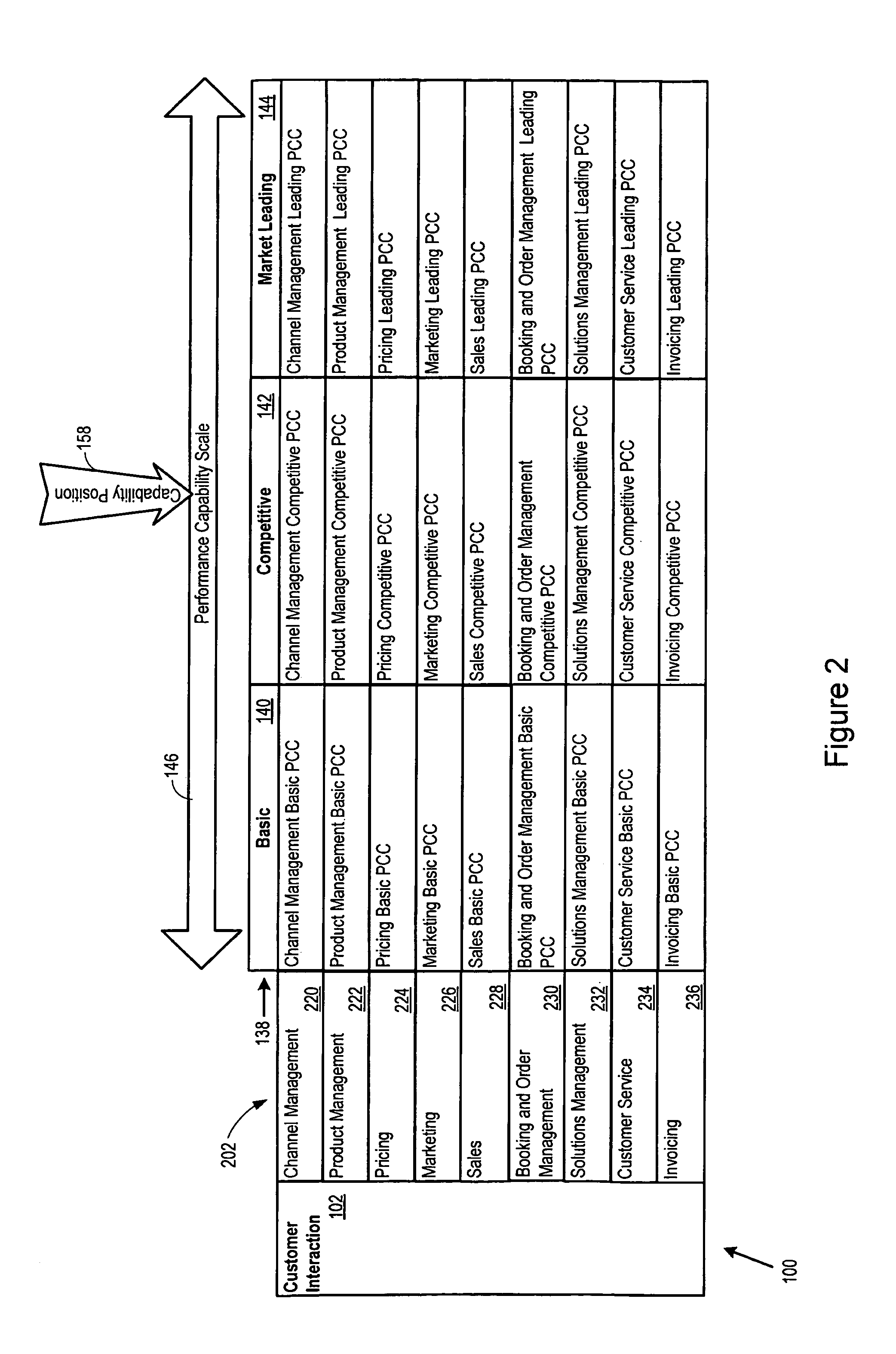

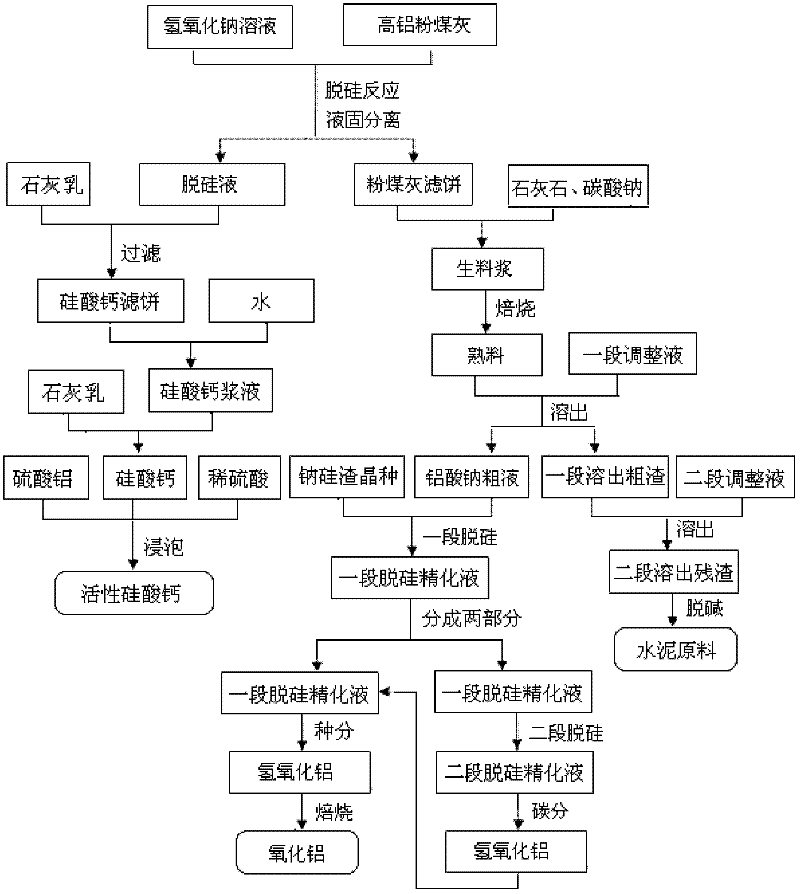

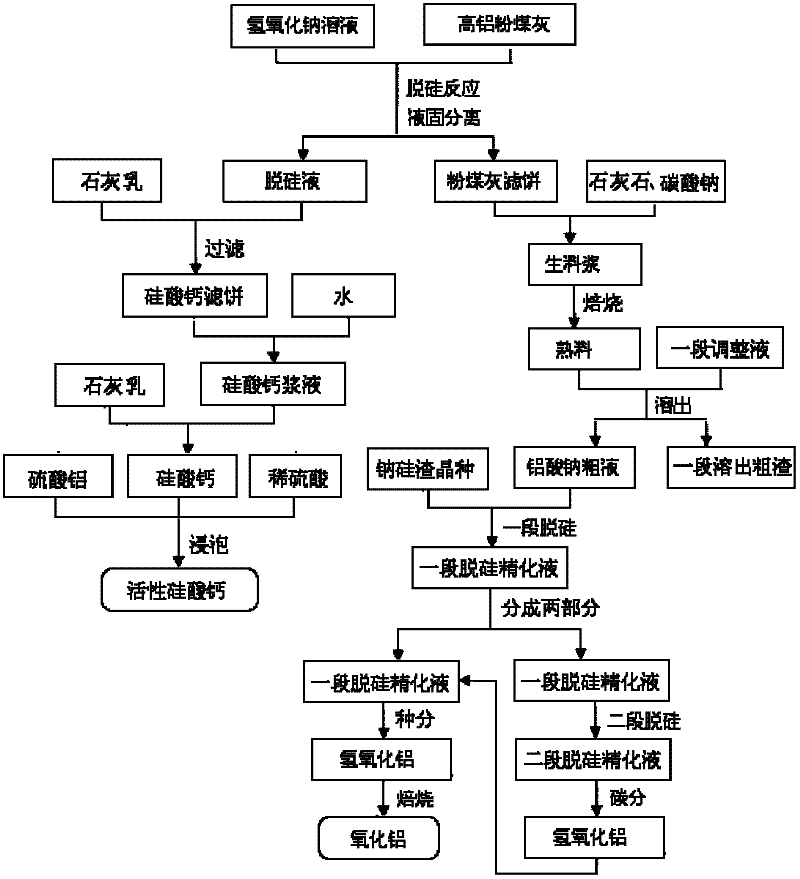

Method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash

ActiveCN102249253AExtraction is effective and cheapIncrease Al-Si RatioAlkaline-earth metal silicatesAluminium oxide/hydroxide preparationCalcium silicateSodium aluminate

The invention provides a method for producing aluminum oxide and co-producing active calcium silicate through high-alumina fly ash. The method comprises the following steps that: the high-alumina fly ash firstly reacts with a sodium hydroxide solution to carry out pre-desilication to obtain a liquid-phase desiliconized solution and a solid-phase desiliconized fly ash; lime cream is added to the liquid-phase desiliconized solution to carry out a causticization reaction, the resulting solid phase is active calcium silicate which is prepared through carrying out filter pressing, flash evaporation and drying to obtain the finished product; limestone and a sodium carbonate solution are added to the desiliconized fly ash to blend qualified raw slurry, then the blend qualified raw slurry is subjected to baking into the clinker, the liquid phase generated from dissolution of the clinker is a crude solution of sodium aluminate; the crude solution of the sodium aluminate is subjected to processes of first-stage deep desilication, second-stage deep desilication, carbonation, seed precipitation, baking and the like to obtain the metallurgical grade aluminum oxide meeting requirements. According to the present invention, the defects in the prior art are overcome; purposes of less material flow and small amount of slaggling are achieved; energy consumption, material consumption and production cost are relative low; extraction rate of the aluminum oxide is high; the calcium silicate with high added value is co-produced; the method provided by the present invention can be widely applicable for the field of chemical engineering.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

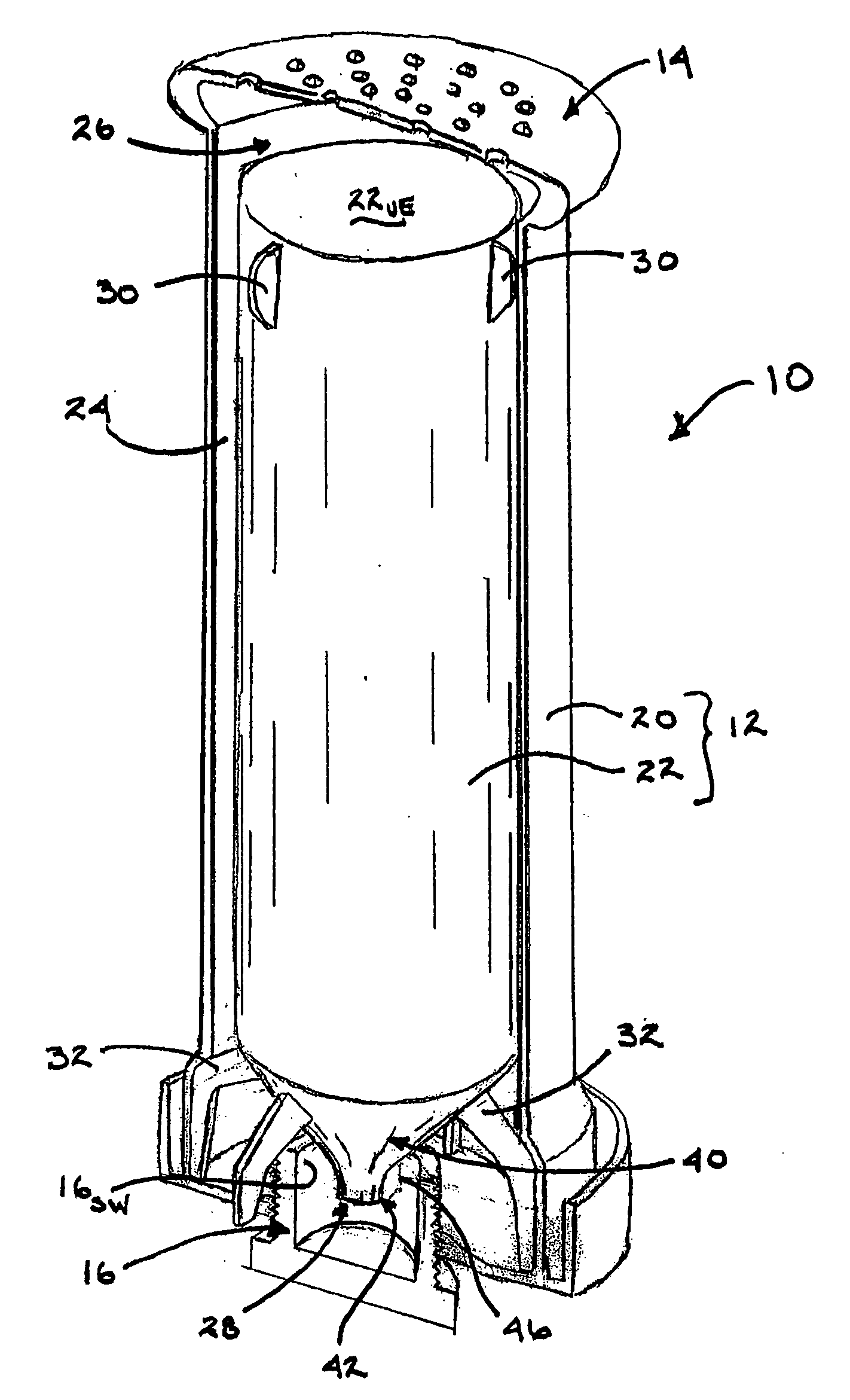

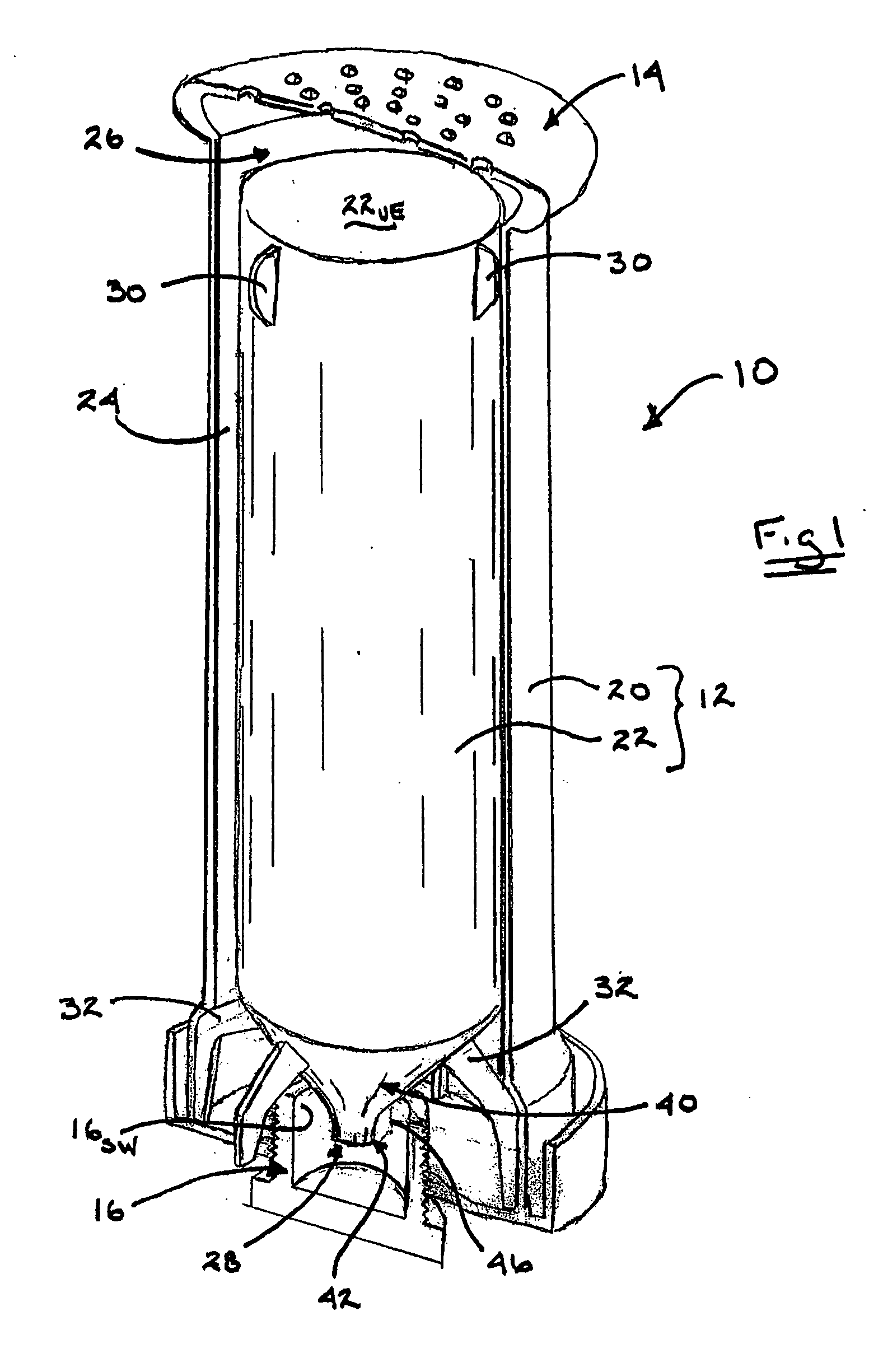

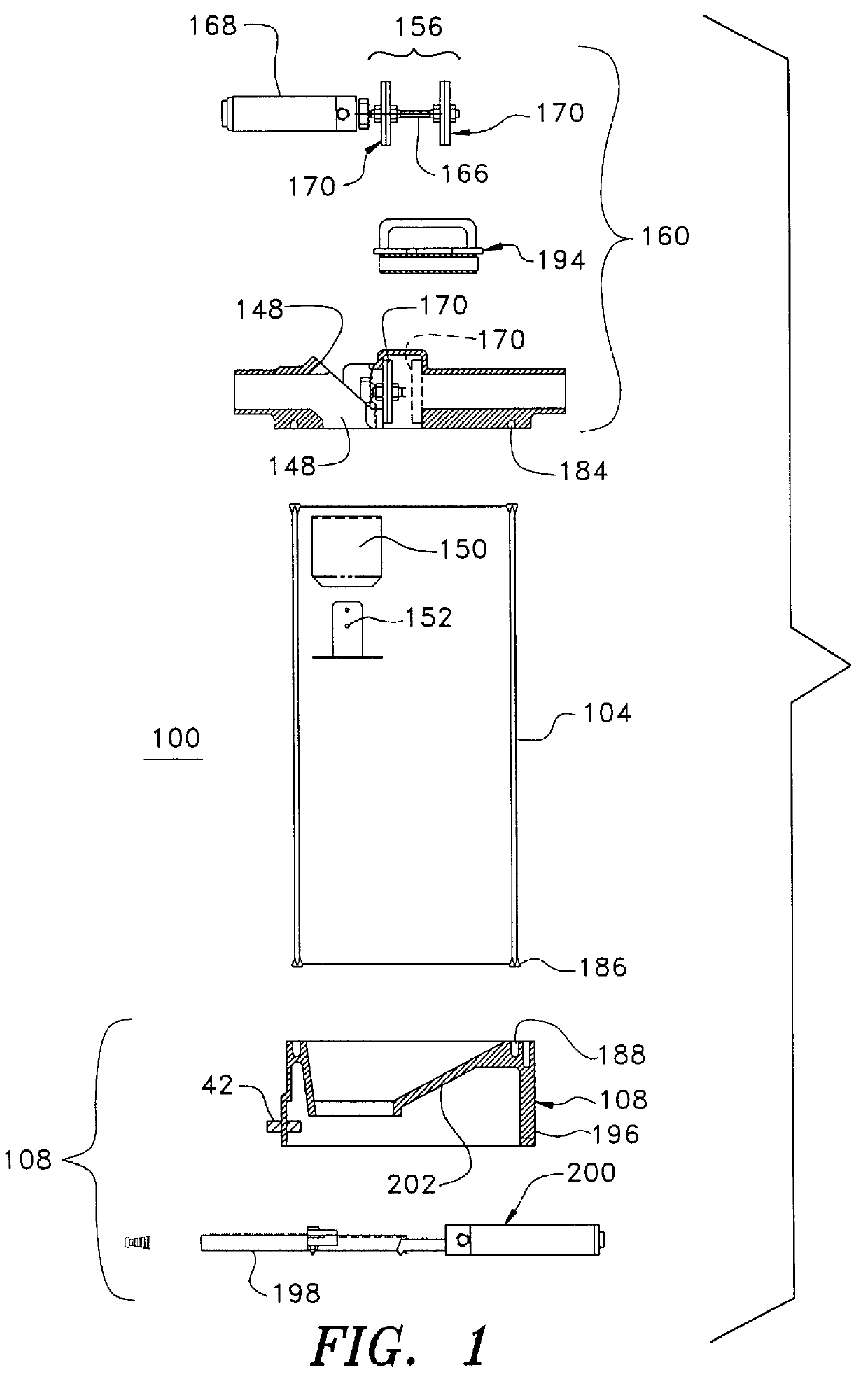

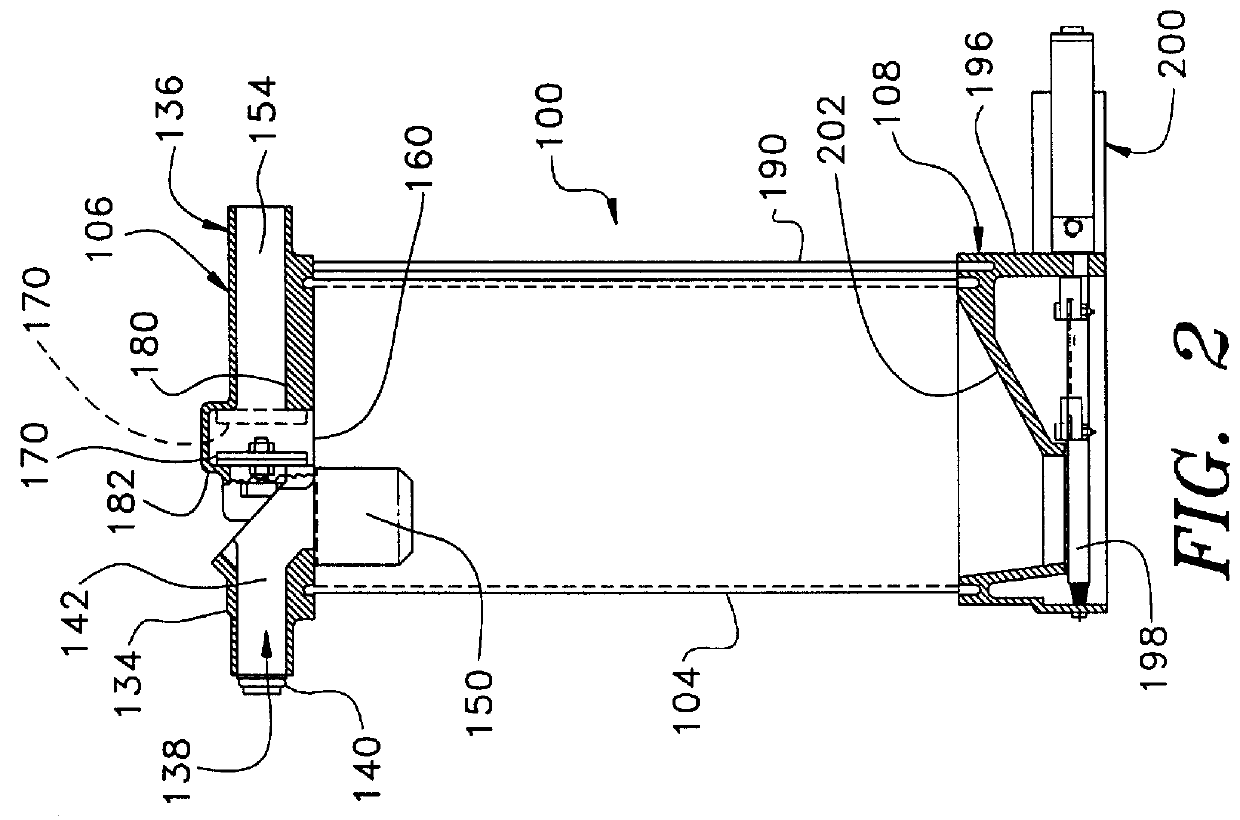

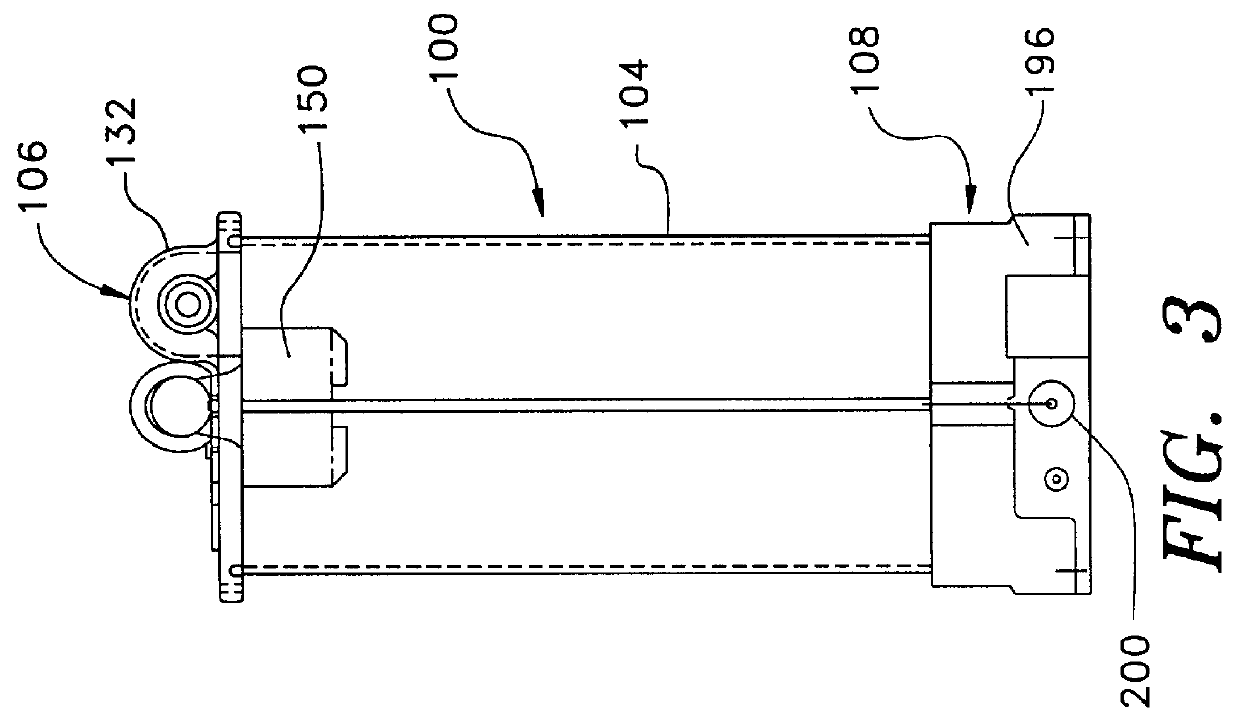

Reconfigurable metered material dispenser

A dispenser is provided for delivering a controlled quantity of a granular material. The dispenser includes a container assembly, a diffuser and a metering cup. The container includes a reservoir which supports a disposable cartridge of granular material. The cartridge is supported in the reservoir so as to define a passageway therebetween. A nozzle is defined for the outflow of material from the cartridge. The diffuser is disposed on one end of the container and includes a plurality of apertures. The metering cup is disposed on the opposite end of the container and has an open end adapted to receive granular material. Adjustment of the axial spacing between the nozzle and metering cup varies the quantity of granular material collected in the cup. The granular material is dispensed by inverting the container to a second orientation, such that material flows out of the metering cup, through the passageway and out of the diffuser. The nozzle may serve as a piercing mechanism for opening the disposable cartridge upon its insertion into the reservoir.

Owner:RESTAURANT TECH

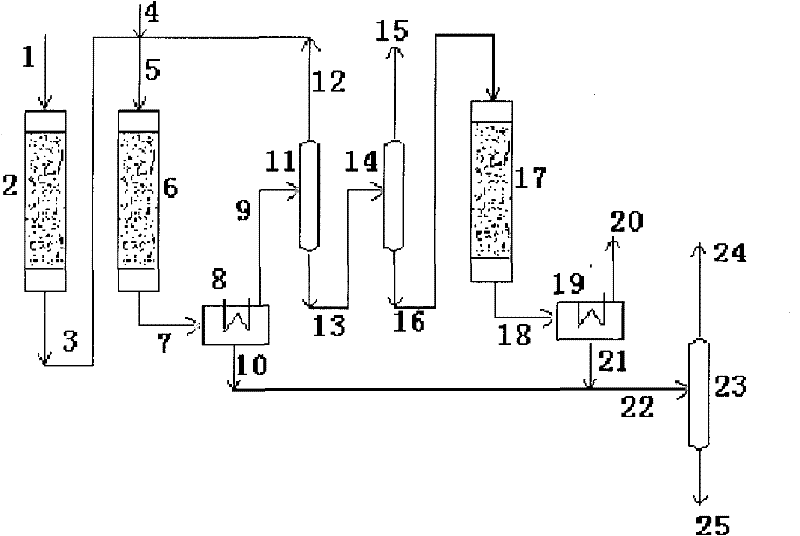

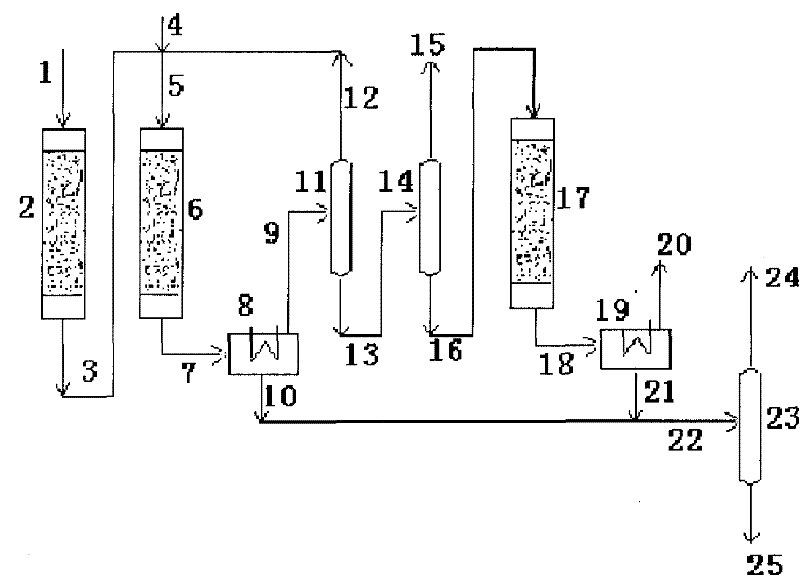

Method for preparing propylene and aromatic hydrocarbon by virtue of conversion of methanol

ActiveCN102190546AHigh yieldHydrocarbon from oxygen organic compoundsEthylene productionLiquid productGas phase

The invention relates to a method for preparing propylene and aromatic hydrocarbon by virtue of conversion of methanol, and the method is mainly used for solving the problem that the methanol is just converted into propylene and the aromatic hydrocarbon can not be co-produced in the prior art. The method comprises the following steps: 1) converting above 80% of methanol into dimethyl ether by virtue of pre-reaction; 2) feeding the generated diamethyl ether and residual methanol into a device for producing propylene from the methanol for reaction so as to obtain a material flow I which mainly comprises the propylene, ethylene and C4, C5, C6 and over-C6 hydrocarbons; 3) after the material flow I is separated, returning the ethylene back to the device for producing the propylene from the methanol for cycling reaction, and feeding C4 and C5 hydrocarbons into an aromatizing device for reaction so as to obtain a material flow II containing aromatic hydrocarbon; and 4) cooling the material flow II, separating a gas-phase product low-carbon hydrocarbons from a liquid-phase product, and separating the liquid product from the material flow I so as to obtain C6 and over-C6 hydrocarbons, mixing, extracting and separating so as to obtain the aromatic hydrocarbon and non-aromatic hydrocarbon. By using the technical scheme, the problem is well solved; and the method can be used in industrialproduction for preparing the ethylene and the aromatic hydrocarbon by virtue of conversion of methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

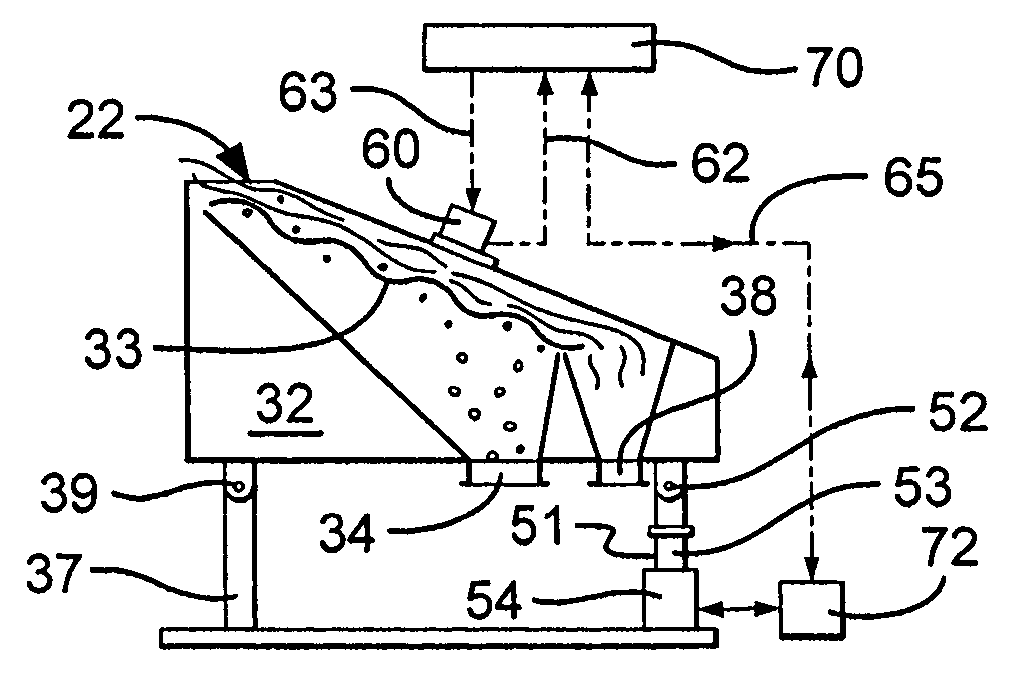

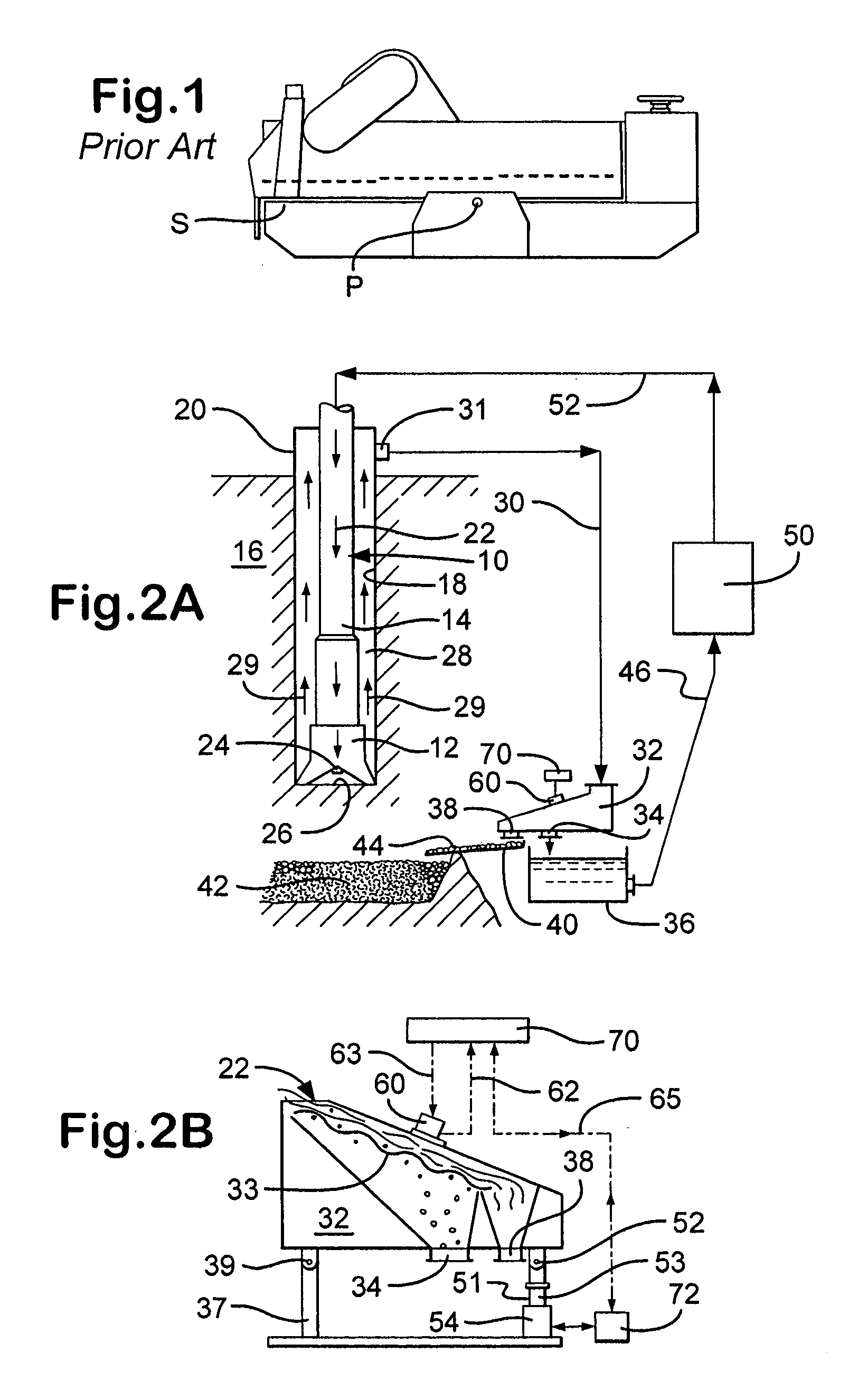

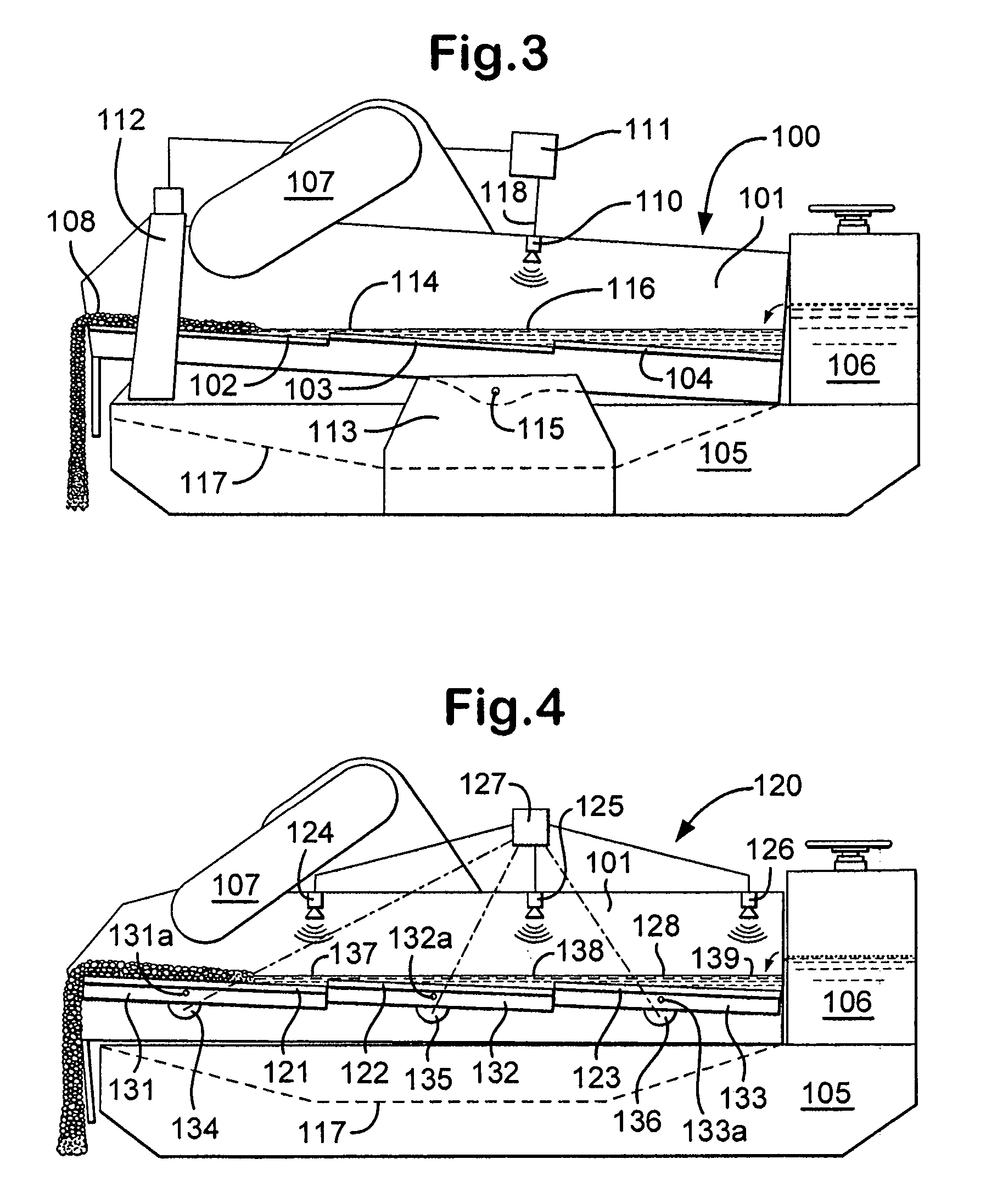

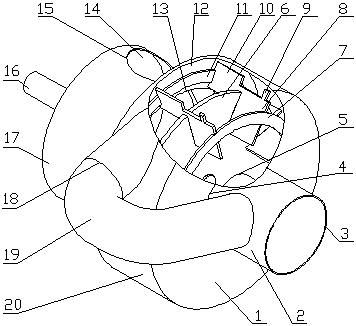

Automatic separator or shaker with electromagnetic vibrator apparatus

InactiveUS20060243643A1Affect effectivenessAffect screening efficiencySievingScreeningMechanical engineeringDrilling fluid

A vibratory separator (in one aspect, a shale shaker) and methods for using it, the separator in certain aspects having a base, a basket movably mounted on the base, screen apparatus on the basket, material flowing onto the screen apparatus for treatment, at least a portion of the screen apparatus not inclined downhill (e.g. said portion horizontal or uphill), electromagnetic vibratory apparatus connected to the basket for vibrating the basket and the screen apparatus, driving apparatus for driving the electromagnetic vibratory apparatus, and control apparatus (on-site and / or remote) for controlling the driving apparatus and the electromagnetic vibratory apparatus; the material, in one aspect, being drilling fluid material with solids therein.

Owner:VARCO I P INC

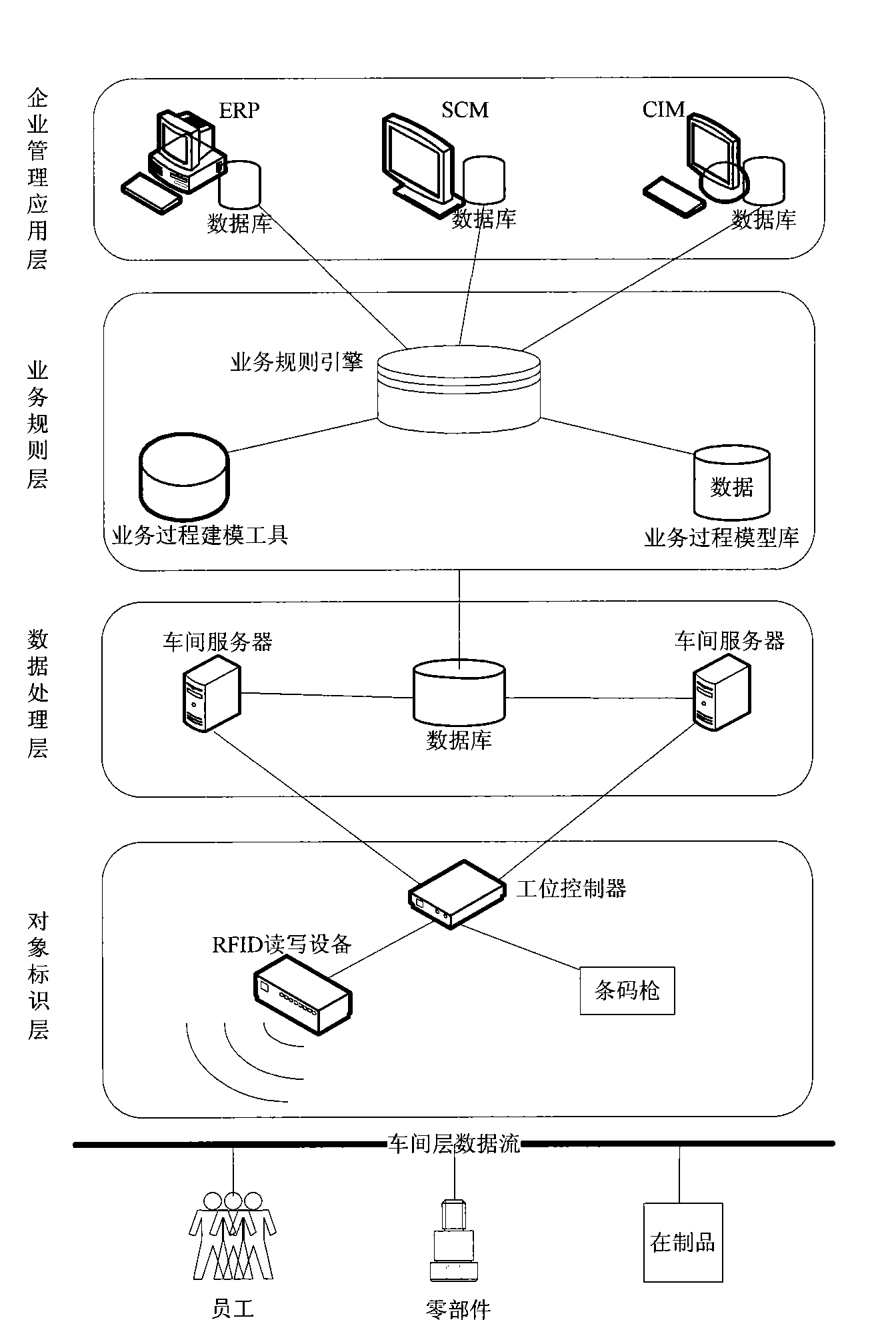

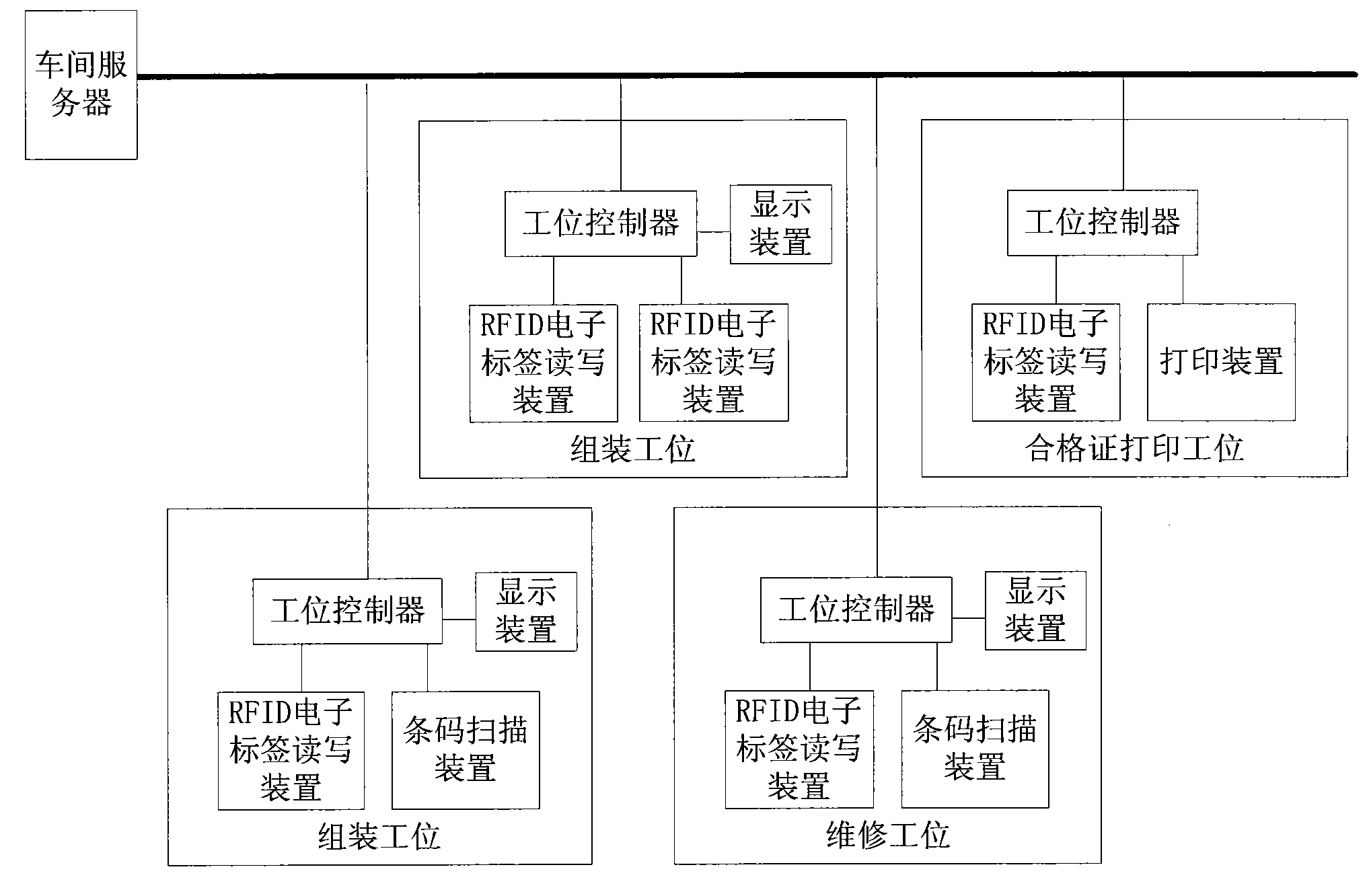

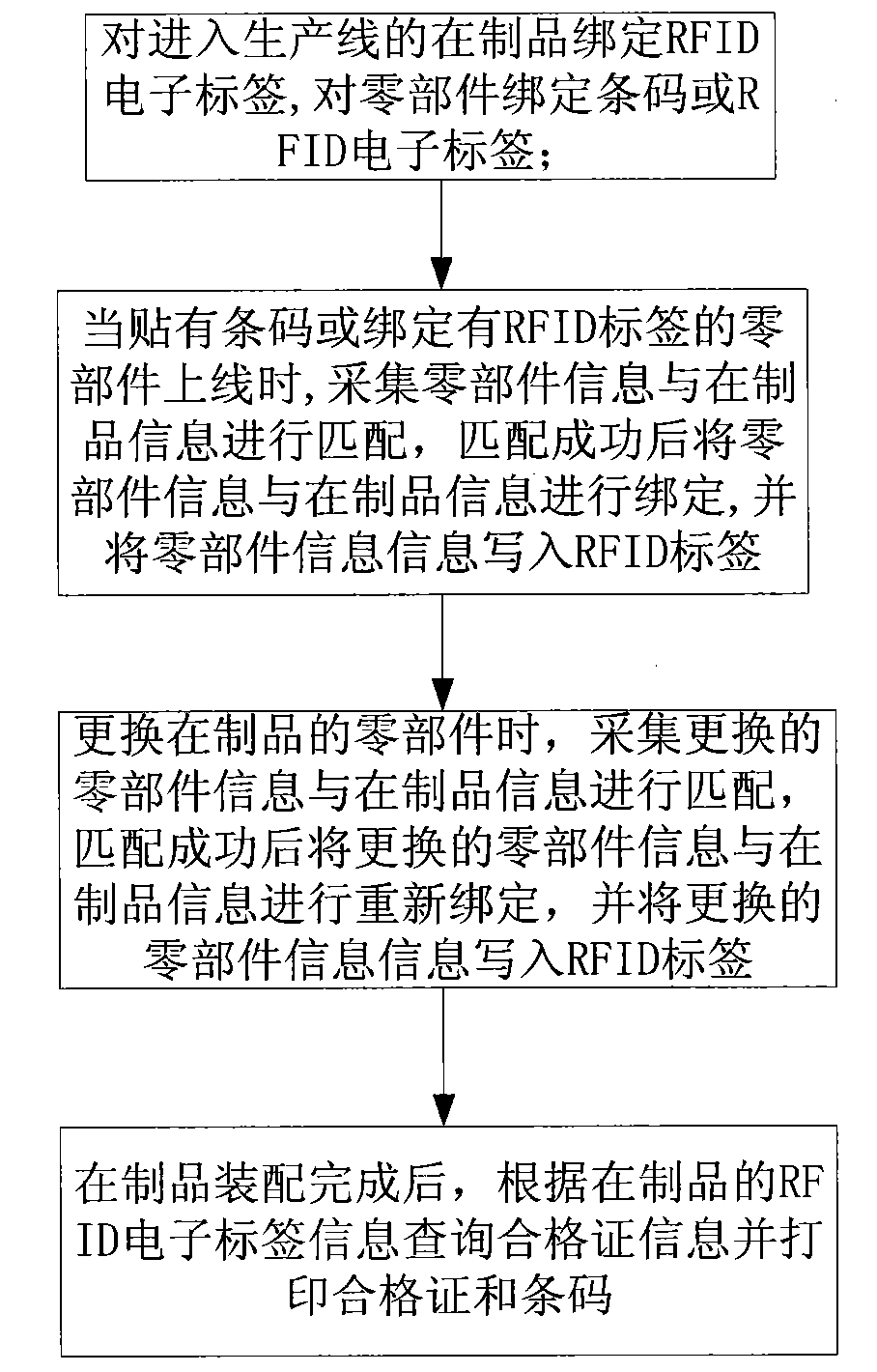

Refinement production system and production method based on RFID and bar code fusion

InactiveCN101655918AEffective cost controlLow costCo-operative working arrangementsRecord carriers used with machinesProduction lineMethods of production

The invention provides a refinement production system and a production method based on RFID and bar code fusion, wherein an RFID electronic tag is bound on the goods in process, the RFID electronic tag or a bar code can be selected randomly to be bound on the components and parts, thus being capable of effectively controlling production cost, being beneficial to carry out real time and effective collection on the information of goods in process and components and parts simultaneously, realizing accurate synchronization of material flow and information flow, and providing a possibility for therealization of refinement production for enterprises. The production method in the invention comprises the following steps: 1) binding the RFID electronic tags on the goods in process which enter a production line, and binding the bar codes or the RFID electronic tags on the components and parts; 2) when the components and parts which are pasted with bar codes or bound with the RFID electronic tags are on the production line, collecting the information of the components and parts to match with the information of the goods in process, and binding the information of components and parts with theinformation of the goods in process after matching successively; and 3) when the products are finally off the line, collecting the RFID electronic tag information which is bound on the goods in process and printing manufacturer certificates and bar codes.

Owner:CHONGQING UNIV

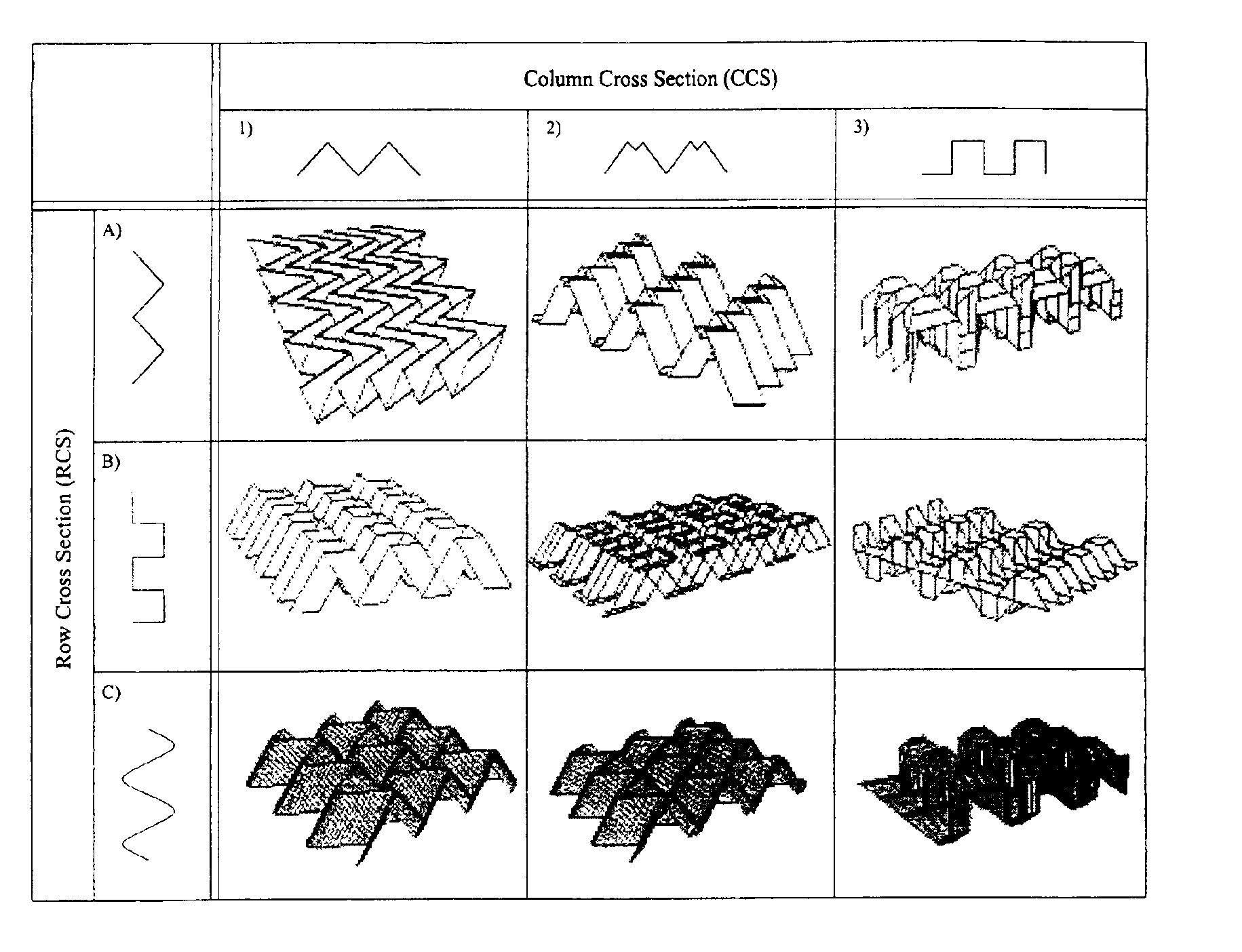

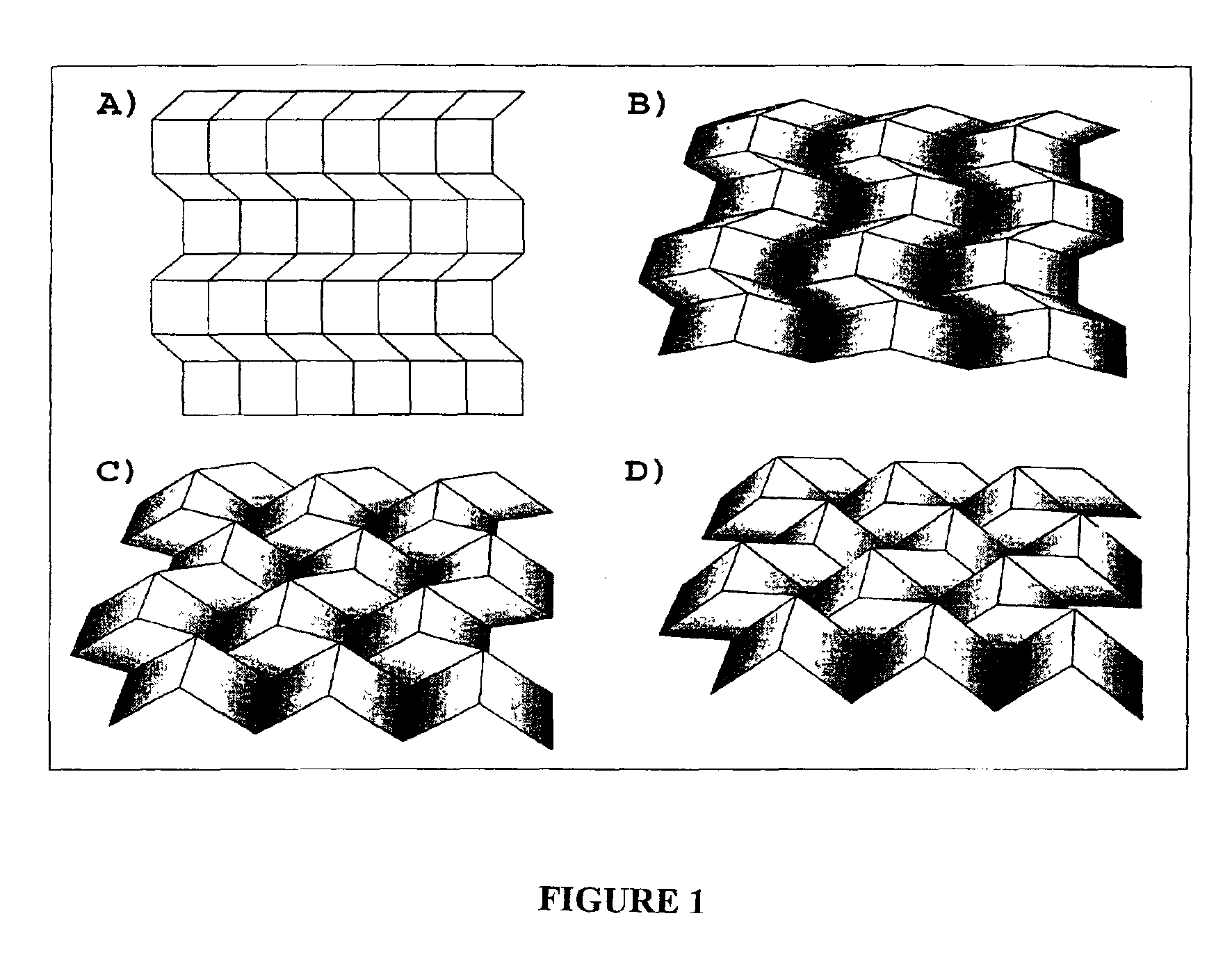

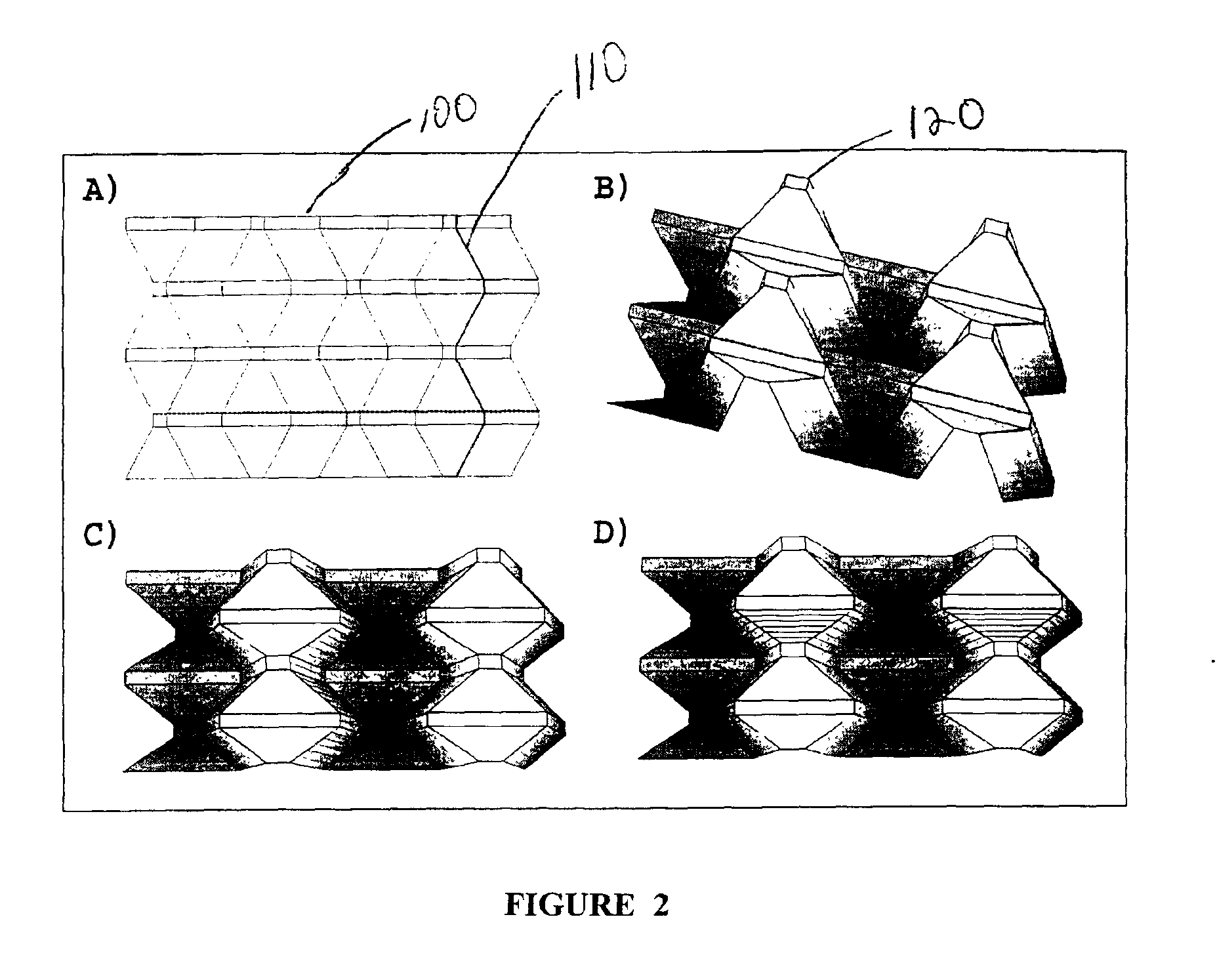

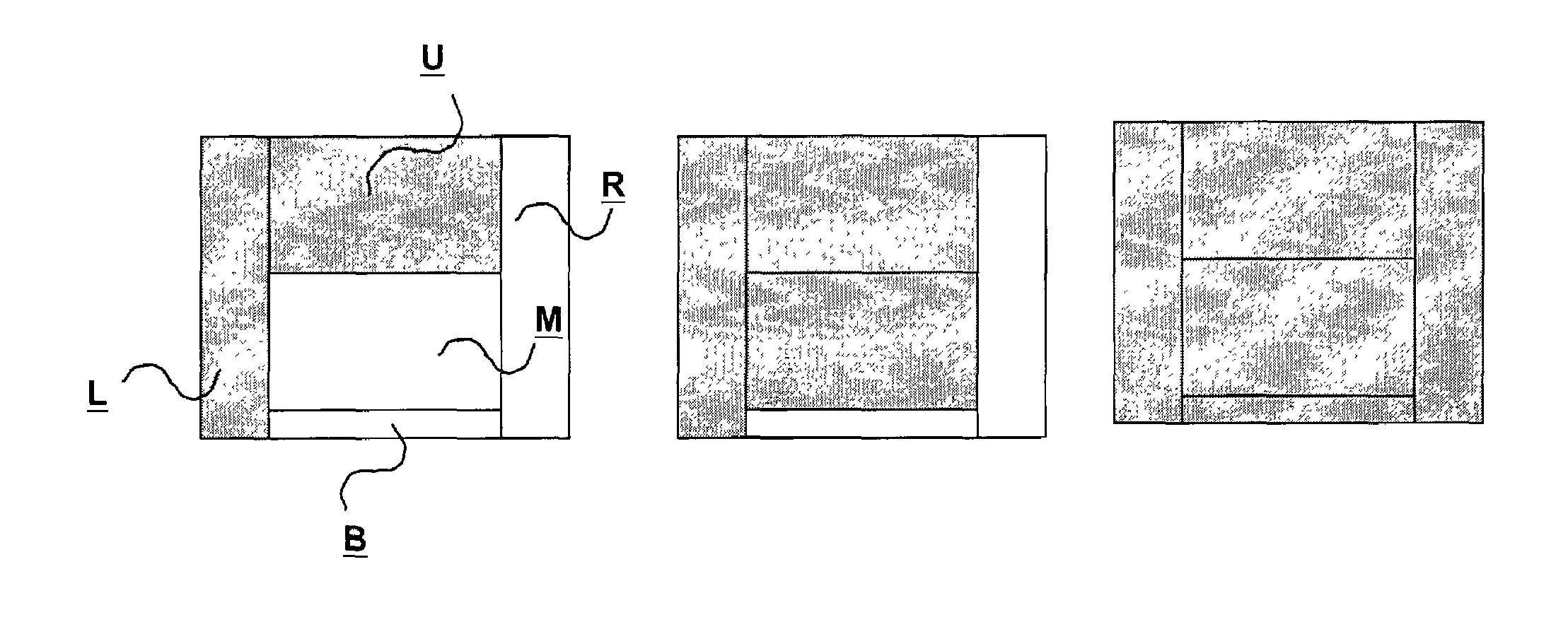

Patterning technology for folded sheet structures

The present invention supplies practical procedures, functions or techniques for folding tessellations. Several tessellation crease pattern techniques, and the three-dimensional folded configuration are given. Additionally several new forming processes, including mathematical methods for describing the material flow are disclosed doubly-periodic folding of materials that name the doubly-periodic folded (DPF) surface, including vertices, edges, and facets, at any stage of the folding. This information is necessary for designing tooling and forming equipment, for analyzing strength and deflections of the DPFs under a variety of conditions, for modeling the physical properties of DPF laminations and composite structures, for understanding the acoustic or other wave absorption / diffusion / reflection characteristics, and for analyzing and optimizing the structure of DPFs in any other physical situation. Fundamental methods and procedures for designing and generating DPF materials include ways for defining the tessellation crease patterns, the folding process, and the three-dimensional folded configuration. The ways are mathematically sound in that they can be extended to a theorem / proof format.

Owner:FOLDSTAR INC

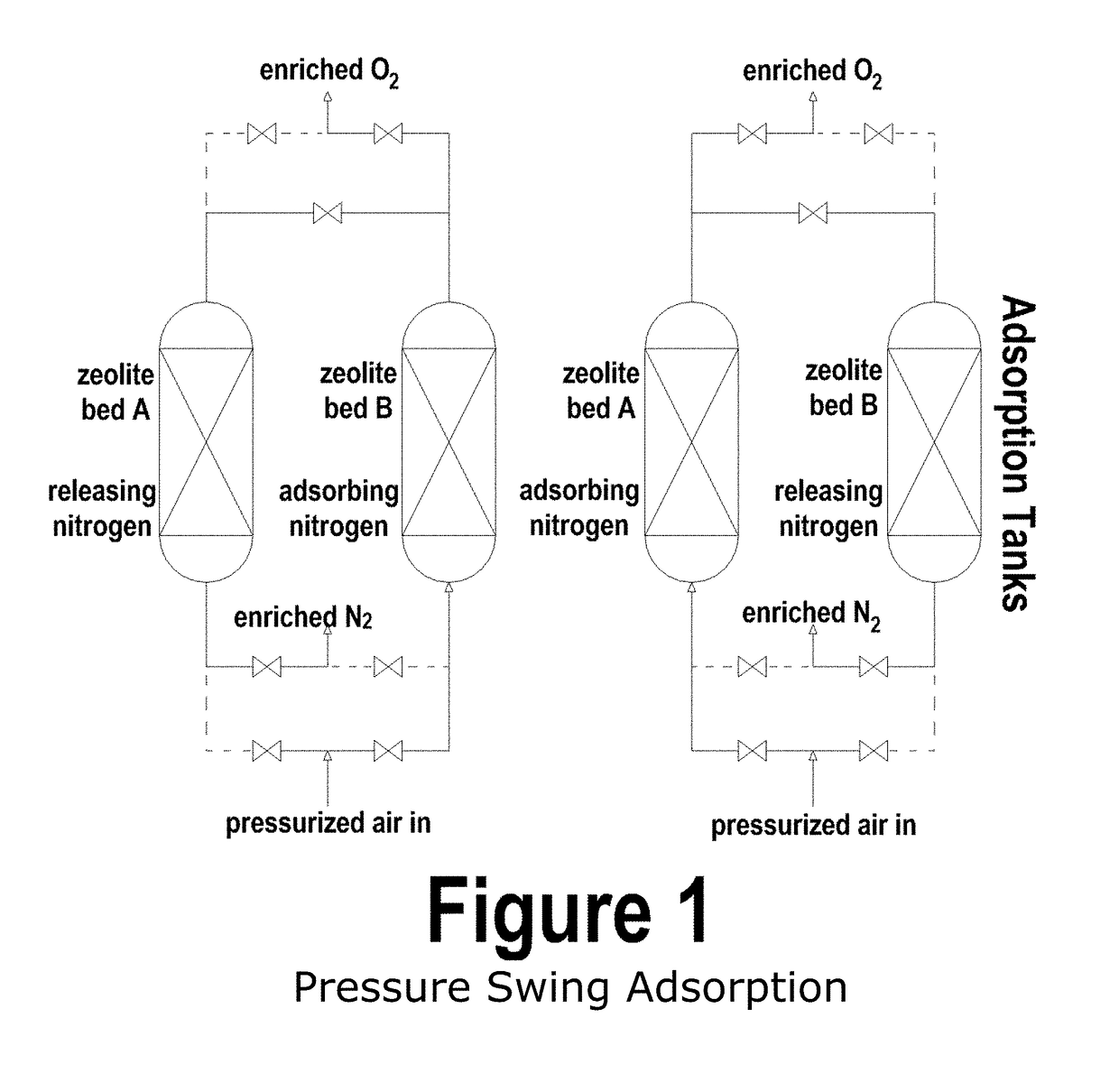

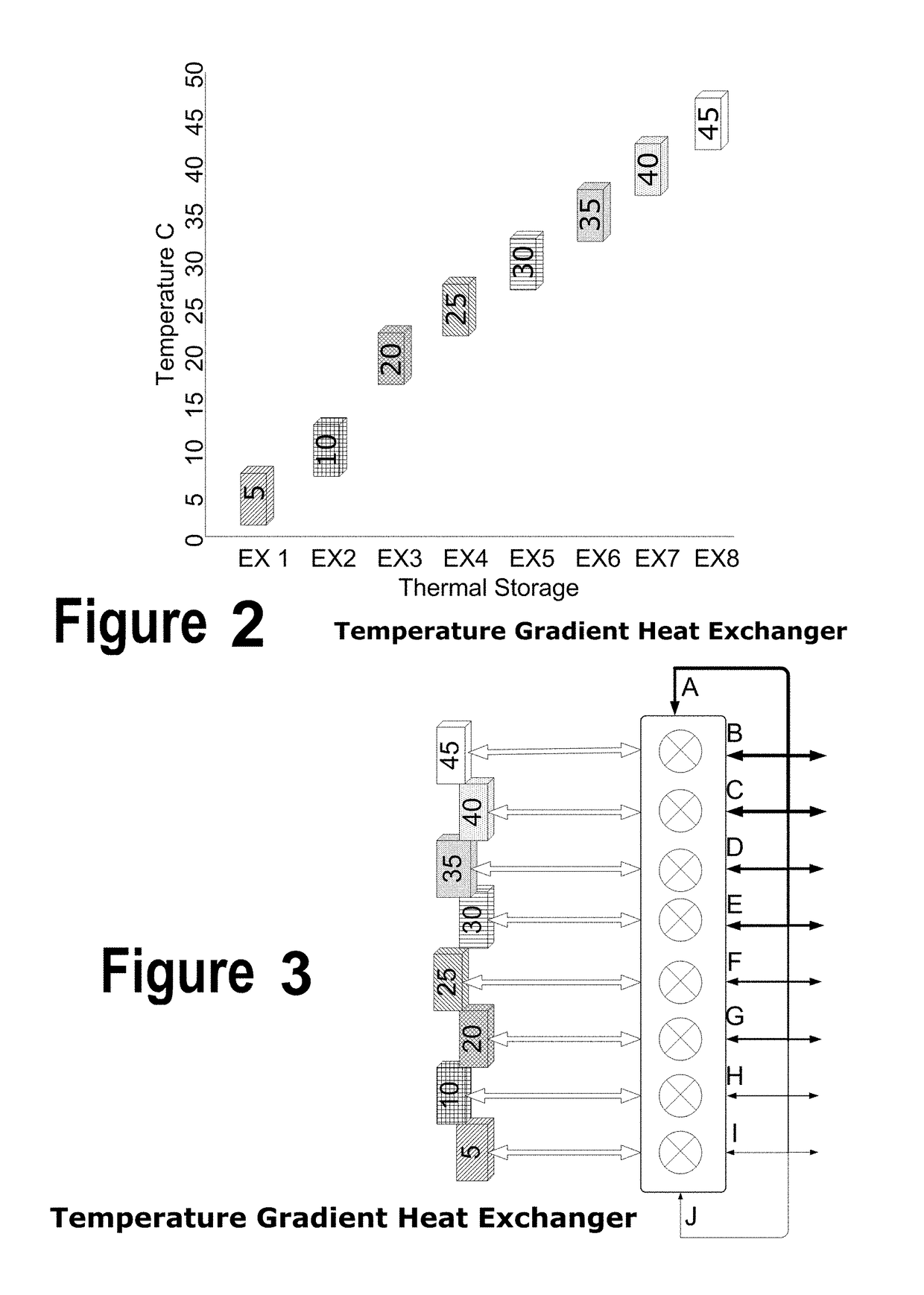

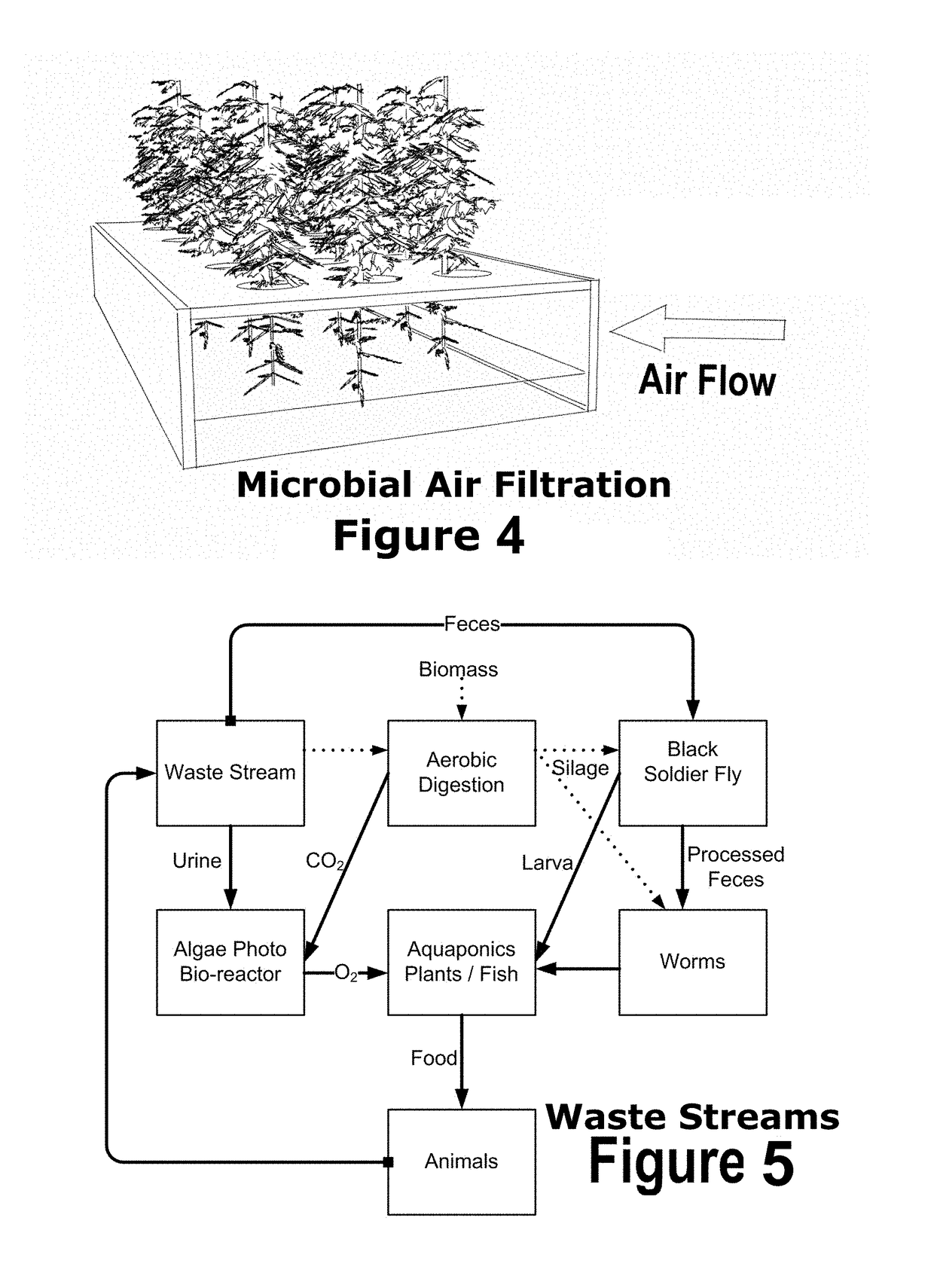

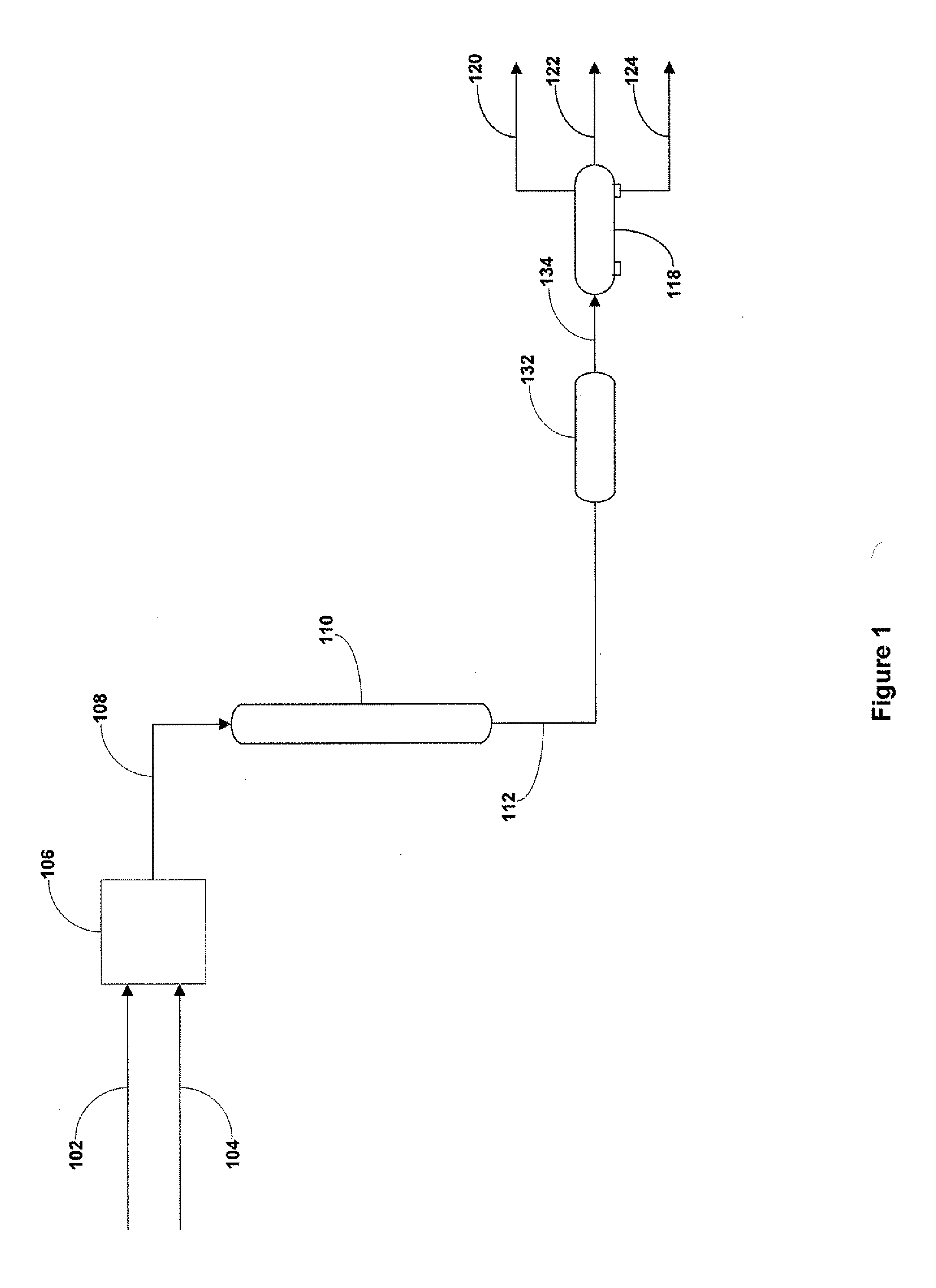

Building system for cascading flows of matter and energy

An engineered ecosystem, moderating eight primary systems—thermal management, atmospheric optimization, radiation controls, hydrological systems, energy systems, material flows, systems management, and built systems—to provide homeostatic regulation of cascading flows of matter and energy.

Owner:MELSHEIMER KEVIN HANS

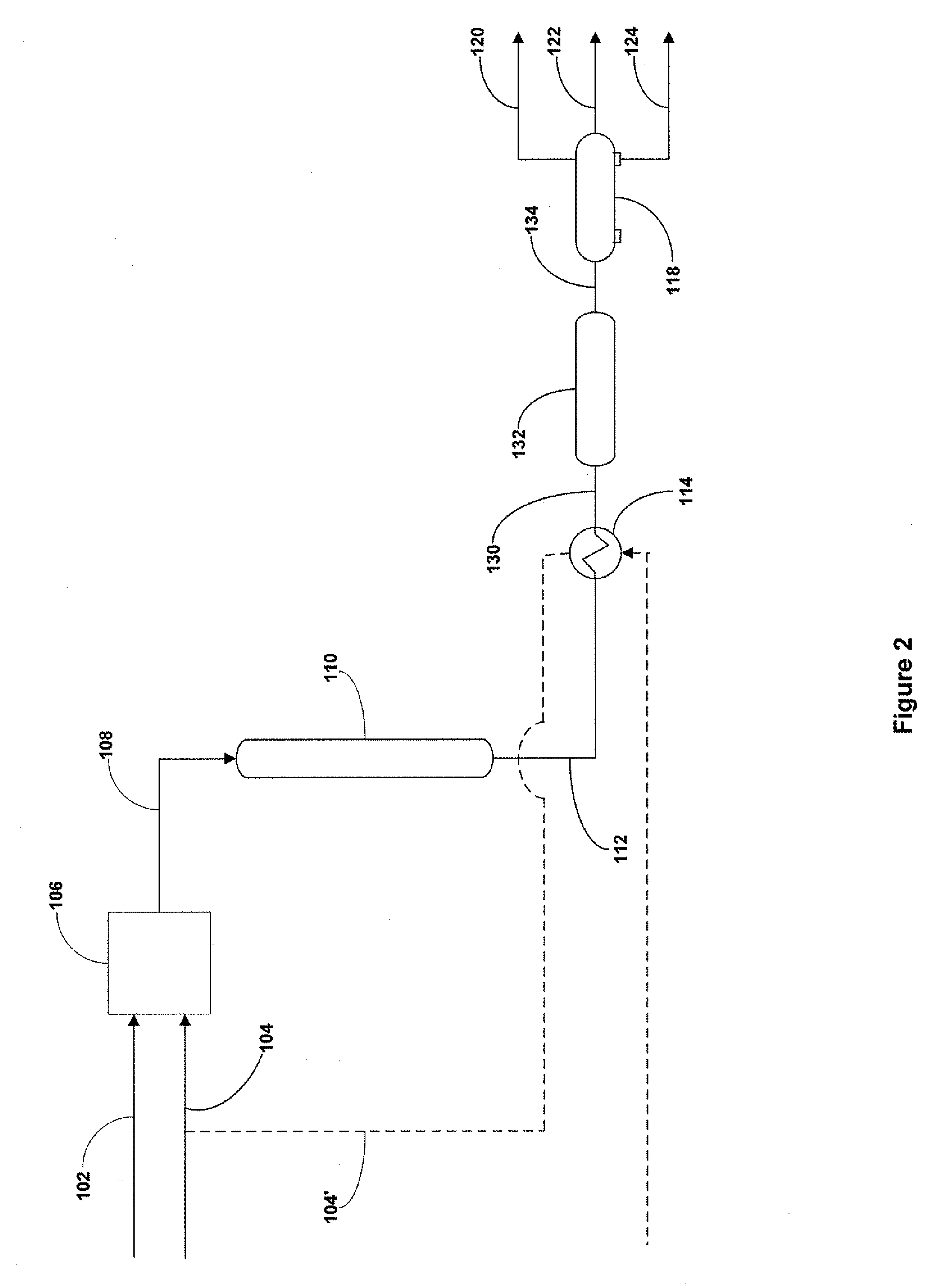

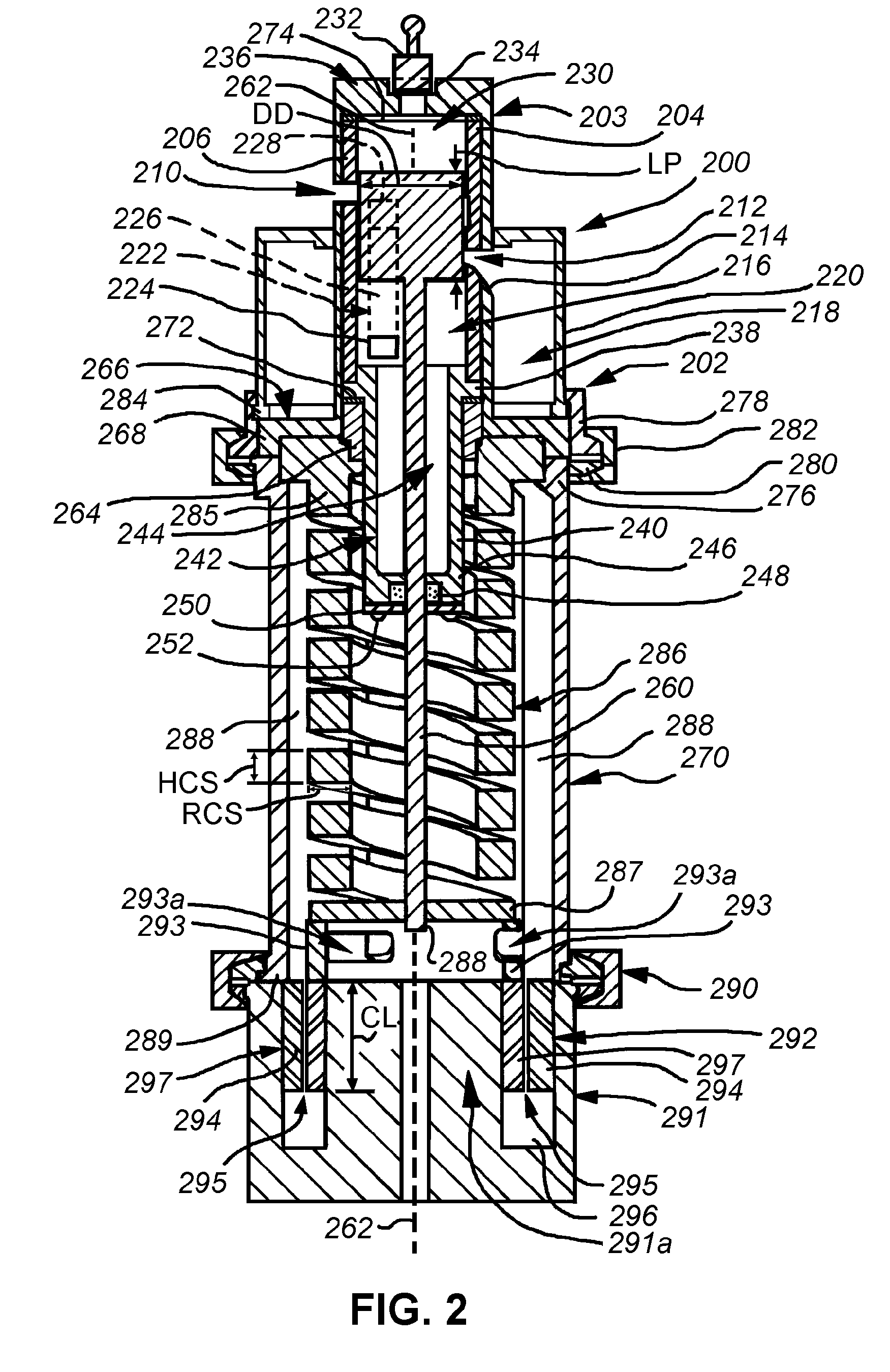

Petroleum Upgrading Process

ActiveUS20120061294A1Reduce dwell timeSizeHydrocarbon oil crackingTreatment with hydrotreatment processesWater flowPetroleum

A method and apparatus for upgrading a petroleum feedstock with supercritical water are provided. The method includes the steps of: (1) heating and pressurizing a petroleum feedstock; (2) heating and pressurizing a water feed to above the supercritical point of water; (3) combining the heated and pressurized petroleum feedstock and the heated and pressurized water feed to produce a combined feed; (4) supplying the combined feed to a hydrothermal reactor to produce a first product stream; (5) supplying the first product stream to a post-treatment process unit to produce a second product stream; and (6) separating the second product stream into a treated and upgraded petroleum stream and a water stream.

Owner:SAUDI ARABIAN OIL CO

Disc refiner with increased gap between fiberizing and fibrillating bands

ActiveUS20070164143A1Minimizing componentSpace minimizationCocoaPulp beating/refining methodsFiberBand pattern

Plate elements, a plate configuration, and associated system for thermomechanical refining of wood chips wherein destructured and partially defibrated chips are fed to a rotating disc primary refiner, where opposed discs each have an inner band pattern of bars and grooves and outer band pattern of bars and grooves, such that substantially complete fiberization (defibration) of the chips is achieved in the inner band and the resulting fibers are fibrillated in the outer band. One embodiment is directed to a pair of opposed co-operating refining plate elements for a flat disc refiner wherein the bars and grooves on each of the inner bands form an inner feed region followed by an outer working region, the bars and groove on each of the outer bands form an inner feed region followed by an outer working region, and the gap and / or material flow area formed when the plates are placed in front of each other increases between the inner working region and the outer feed region.

Owner:ANDRITZ INC

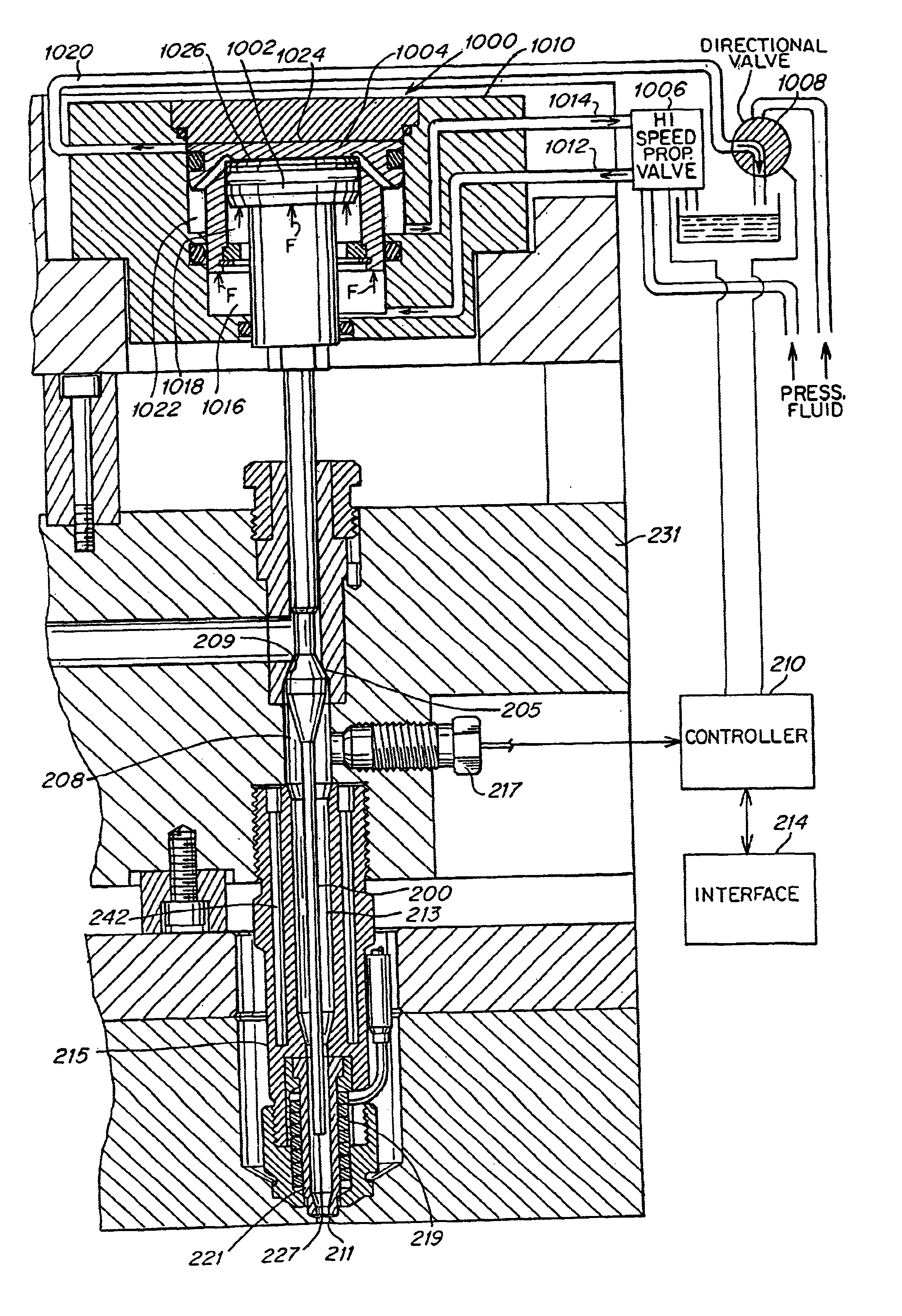

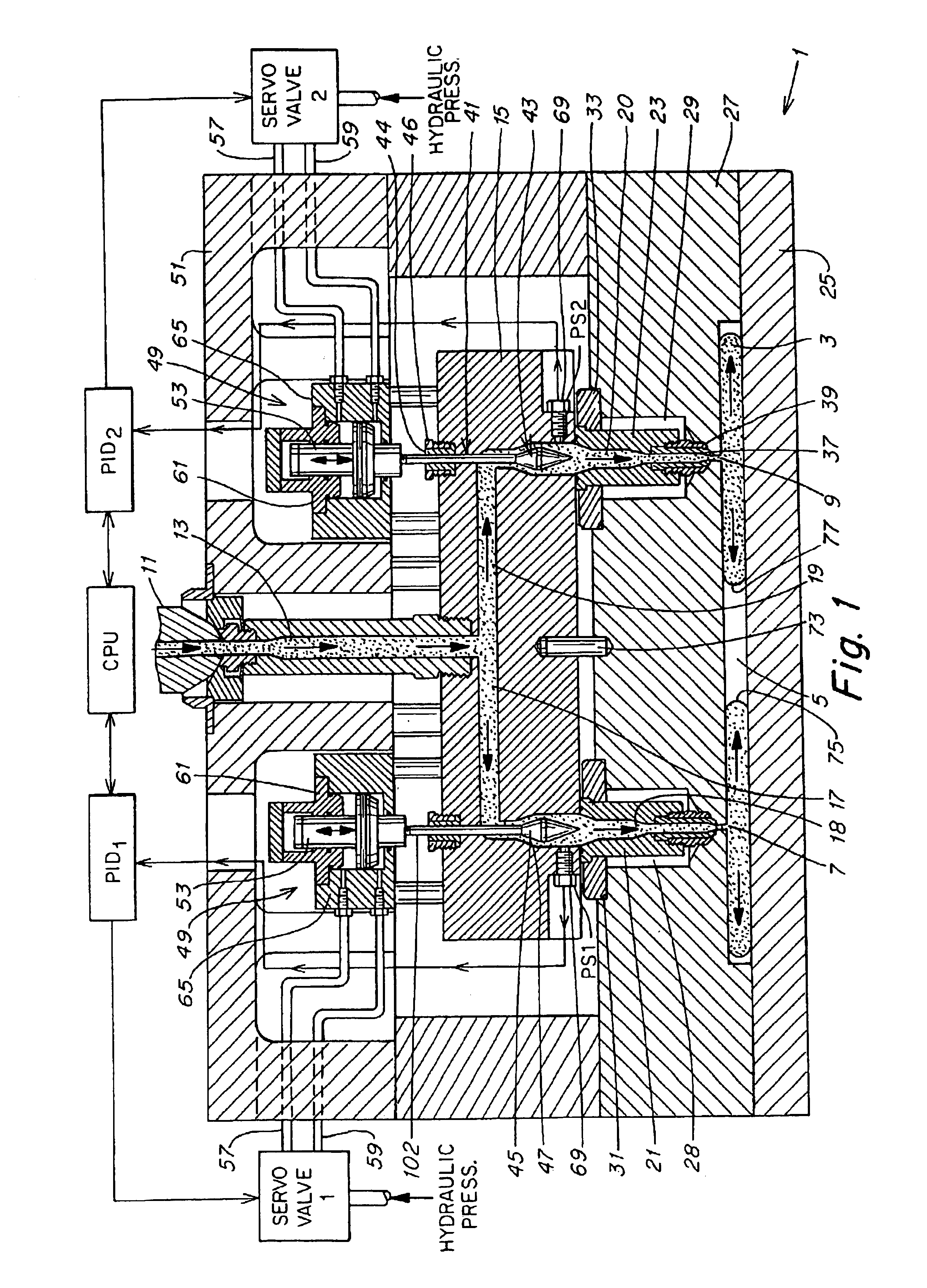

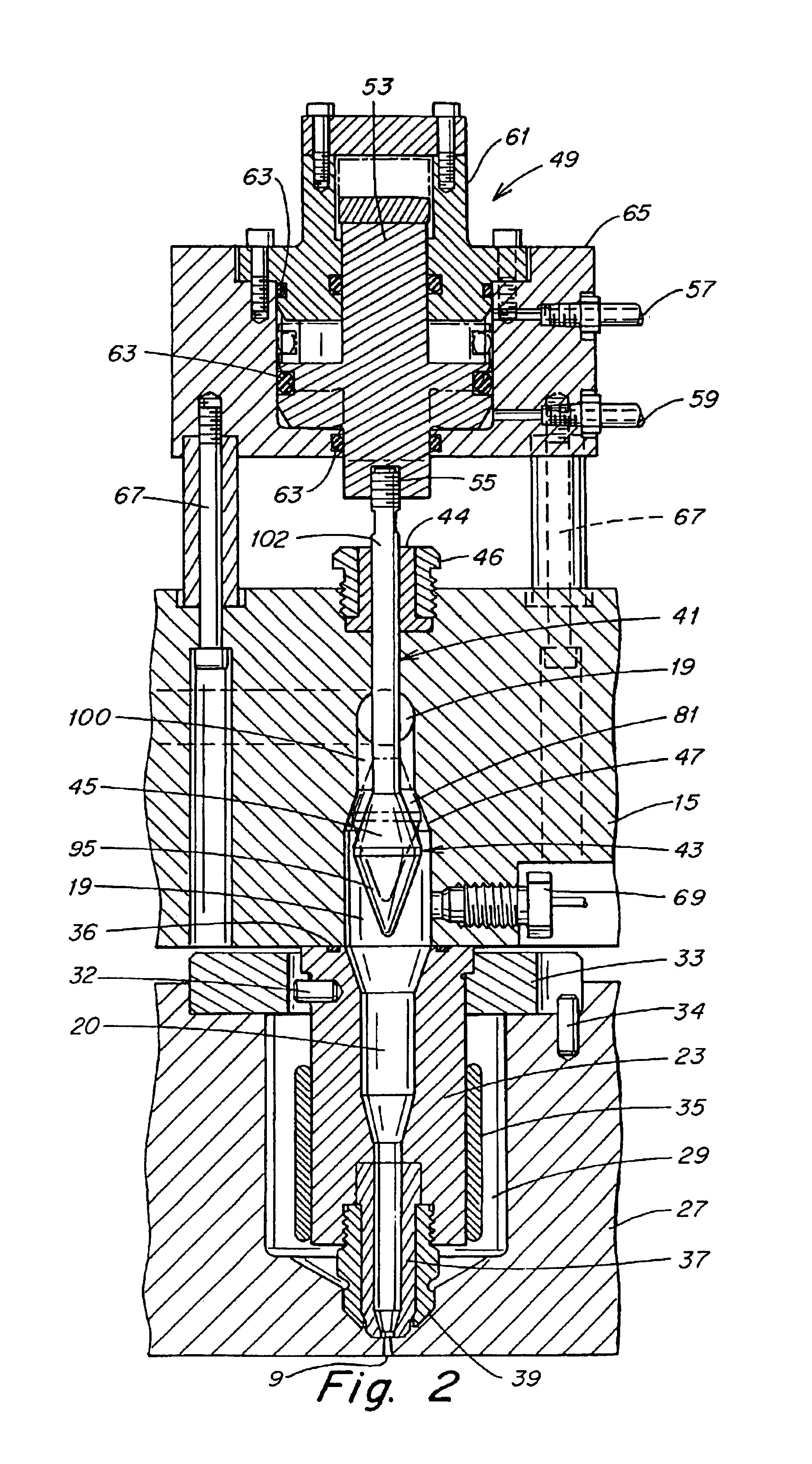

Apparatus for utilizing an actuator for flow control valve gates

Owner:SYNVENTIVE MOLDING SOLUTIONS INC

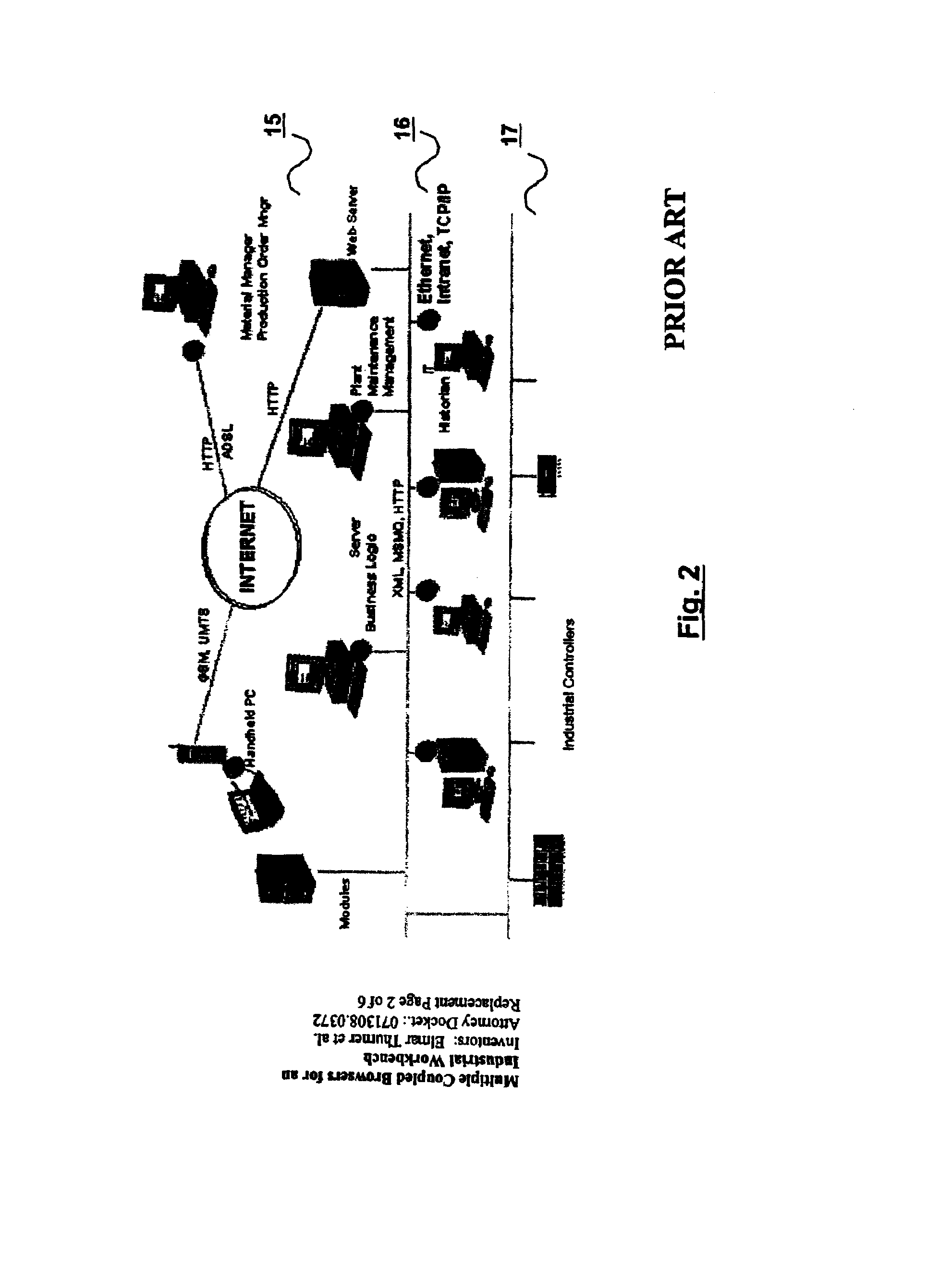

Multiple coupled browsers for an industrial workbench

Multiple Views of an Industrial Plant are graphically displayed and viewed. A graphical user interface displays the views in corresponding panes or windows of the graphical user interface. The views, being graphical representations of systems of the Industrial Plant, are coupled by a coupler according to a predetermined relationship between the underlying systems of the Industrial Plant represented by the coupled views. The coupler automatically refocuses the panes to display different views of the Industrial Plant based on a selection of an object in any of the panes or on a manual refocus of one view and on the predetermined relationship for coupling the views. The Coupled views represent different domains of the Industrial Plant or Industrial Network e.g. real-time monitoring and operation, configuration, debugging, maintenance, scheduling, asset management, documentation, training, simulation, physical construction, material flow monitoring, programming, interconnecting function blocks, performance analysis. The analysis may be provided at different points in time (now, past, predicted future) and with a different spatial focus (parts, whole). Coupling different views greatly reduces handling effort for building and operating Industrial Plants.

Owner:SIEMENS AG

Micro-crack self-repairing microcapsule and preparation method thereof

ActiveCN102702838ARealize automatic curingFill crack voidsAnti-corrosive paintsMicroballoon preparationCyclohexanoneSolvent

The invention discloses a micro-crack self-repairing microcapsule, which comprises a capsule core and a capsule wall, wherein the capsule core comprises the following ingredients in part by weight: 10 to 60 parts of isocyanate derivative, 0.1 to 10 parts of capsule core diluent and 2 to 40 parts of cosolvent; and the capsule wall comprises ingredients with the following mol ratio: urea: formaldehyde solution, prepolymer=1: (1.0-4.0): (2.0-6.0), wherein the prepolymer is formed from the ingredients with the mol ratio: isocyanate derivative: cyclohexanone: chain extender=1: (2.0-5.0): (0.3-3.0). The invention also discloses a micro-crack self-repairing anti-corrosion coating utilizing the capsule. The micro-crack self-repairing microcapsule is free from additionally adding a repairing catalyst or an initiator, can realize completely automatic repairing function, can be widely applied to the protection field of a metal surface coating in a wet environment, and solves the problems that the contact probability between functional filling material flowing into cracks in the intelligent anticorrosion coating and the catalyst or the initiator is small.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

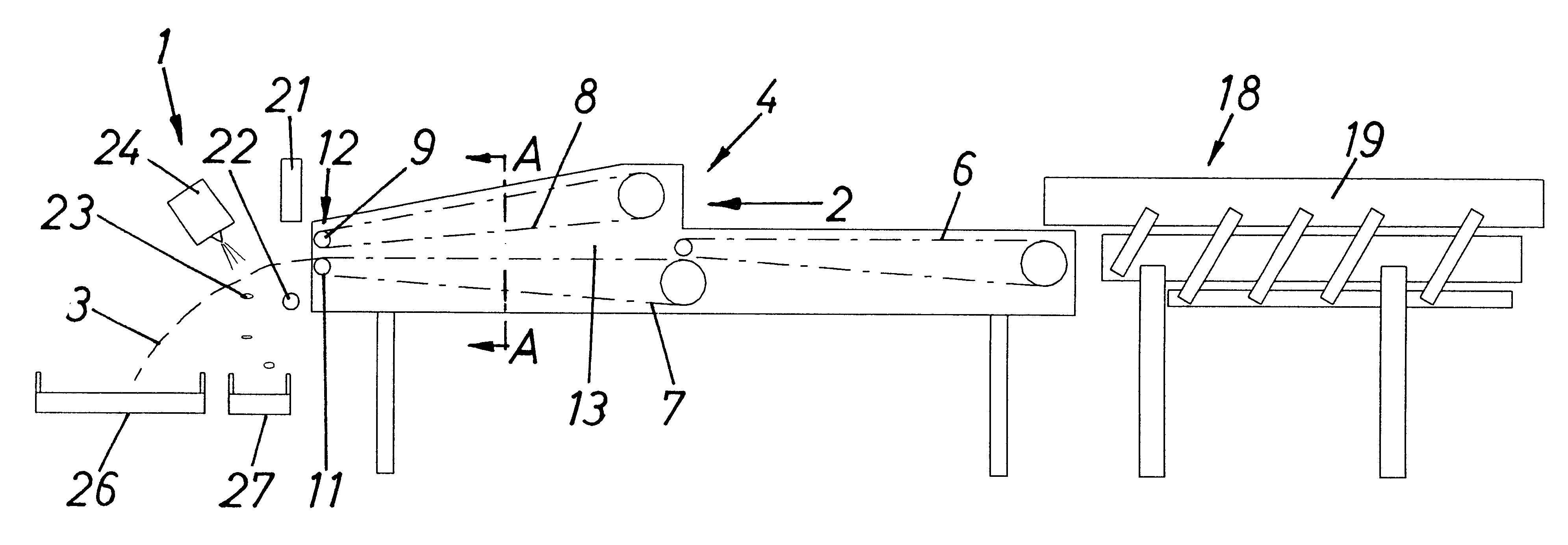

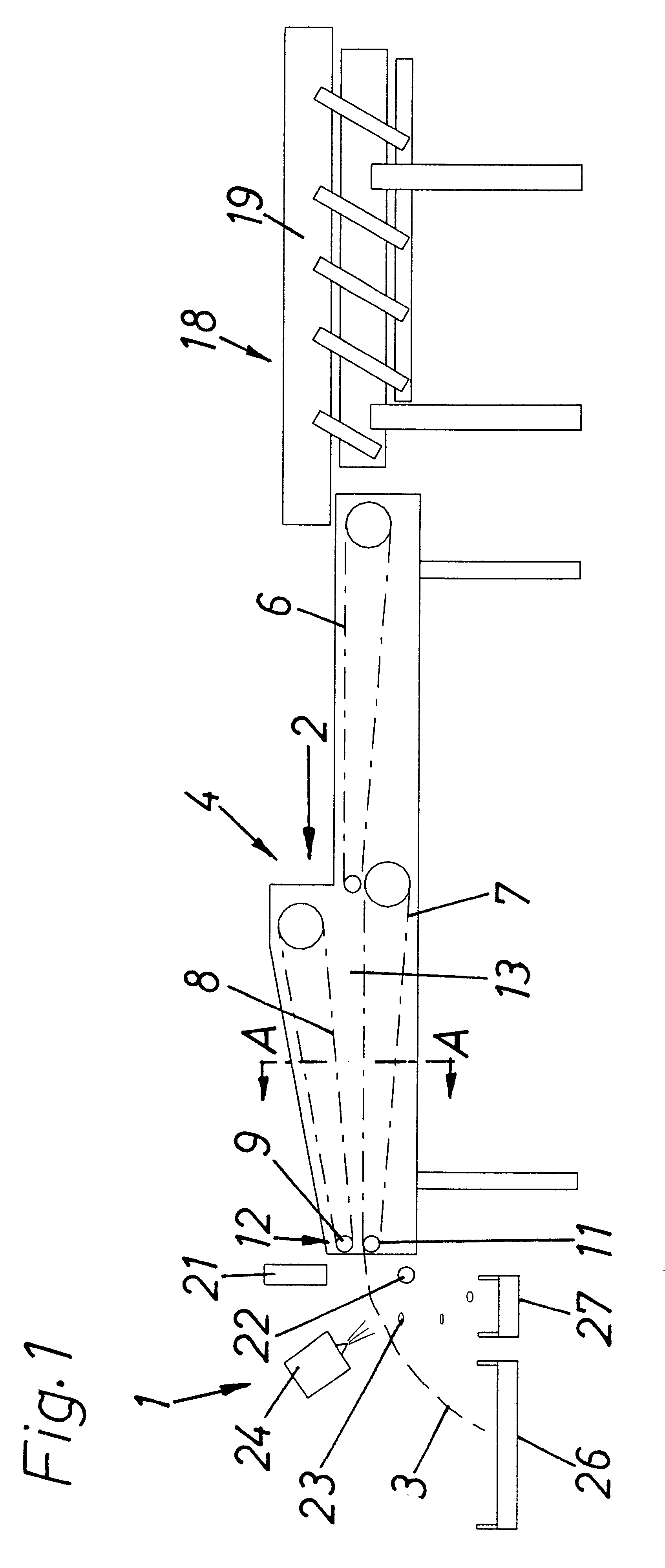

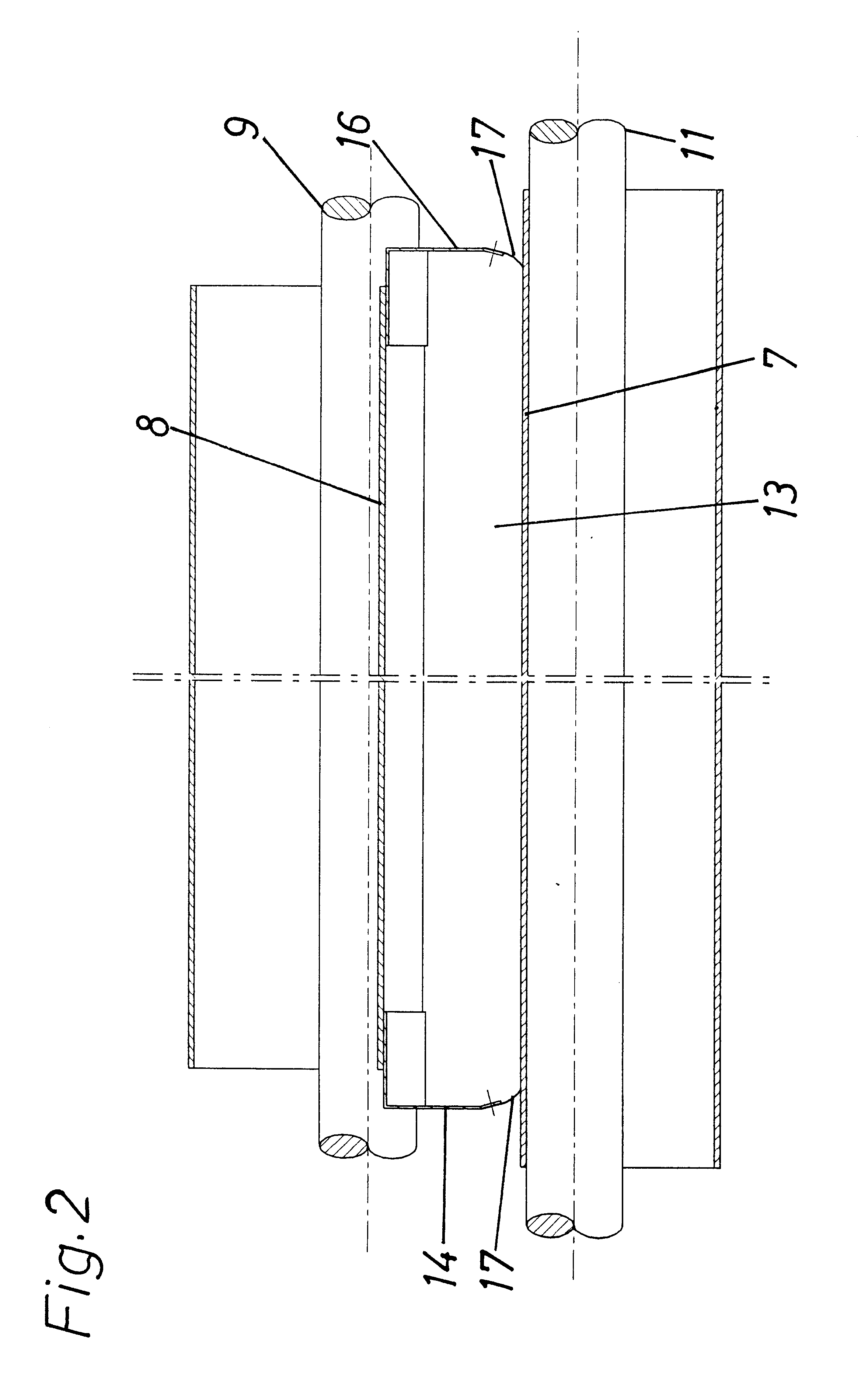

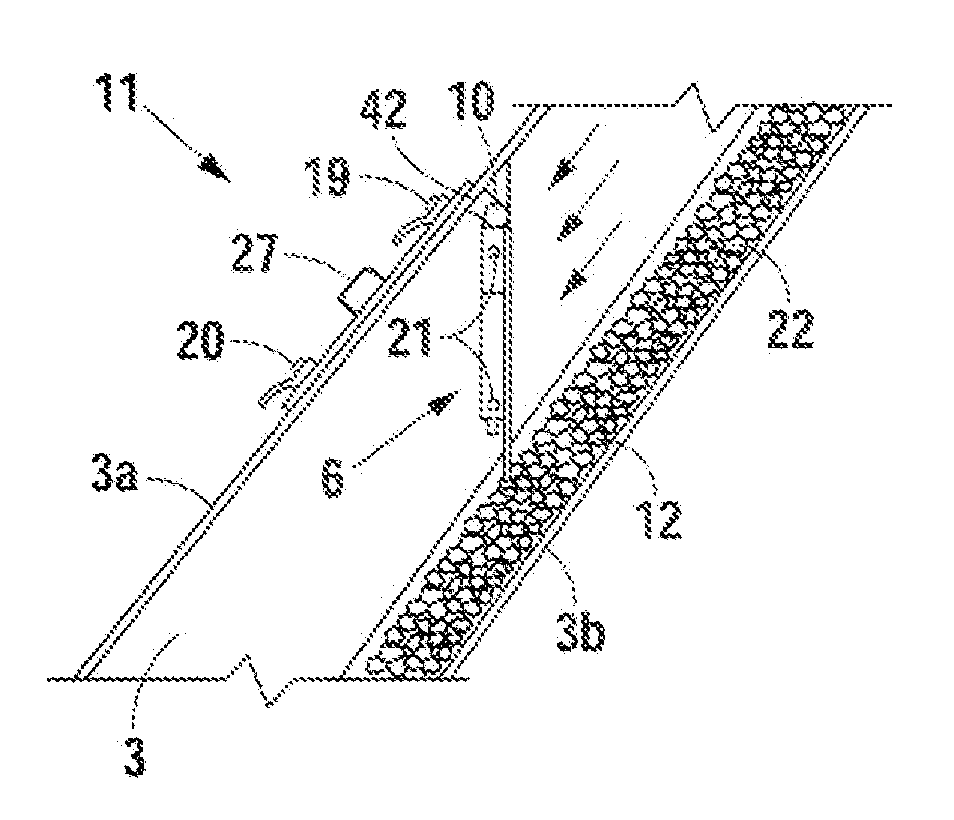

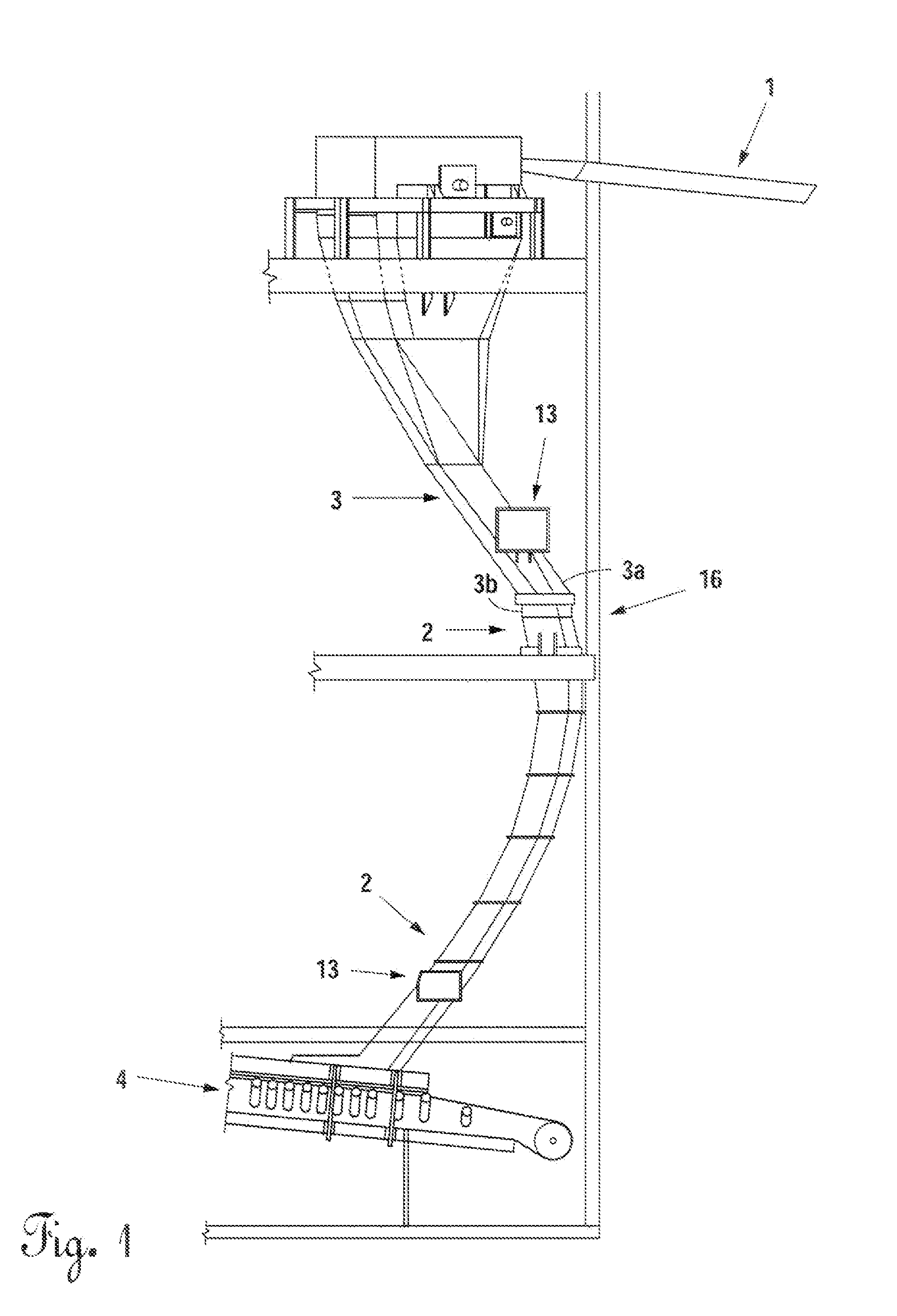

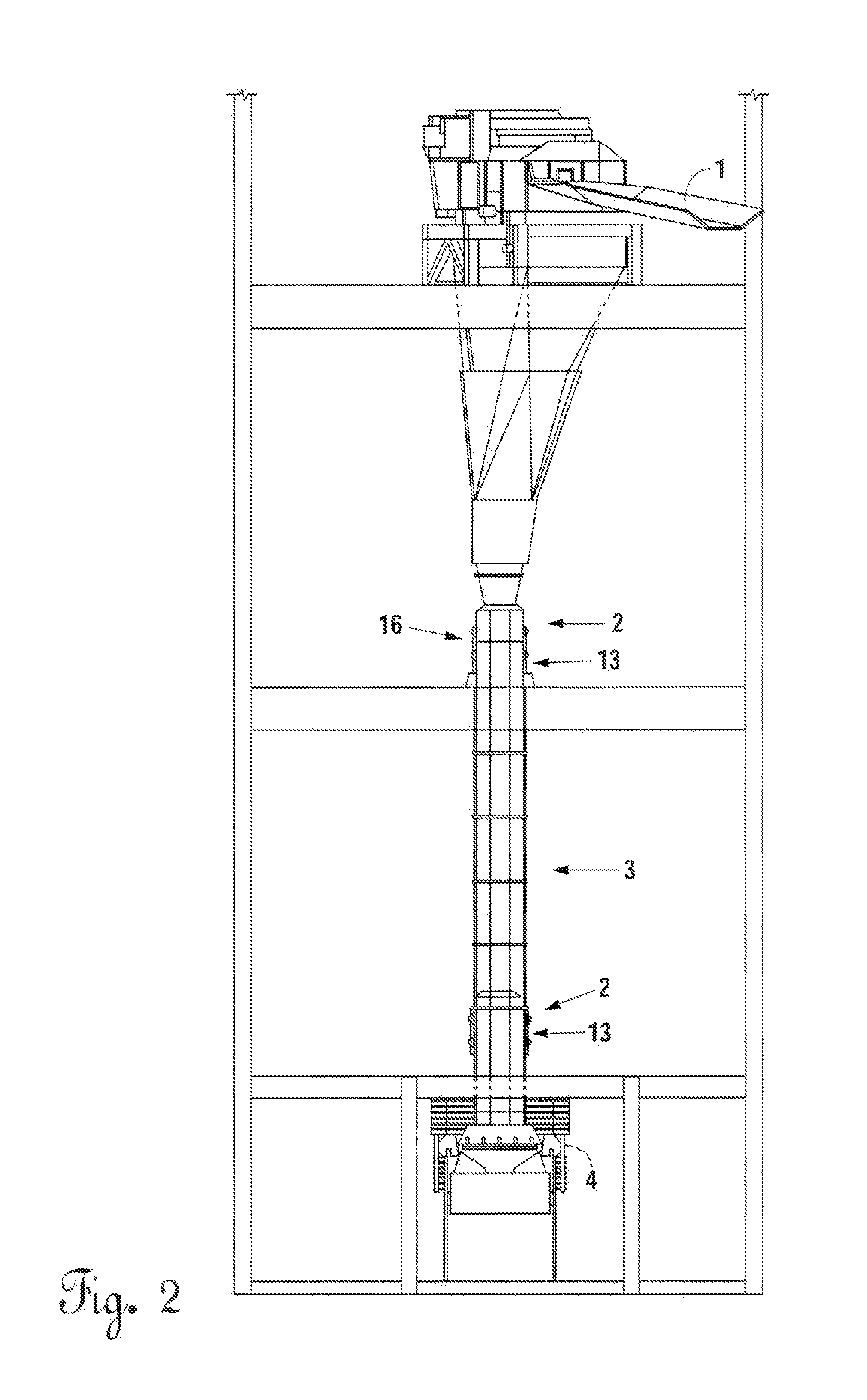

Apparatus for converting a continuously supplied material flow into a single layer

InactiveUS6332543B1Reliably flowIncrease ratingsThrowing machinesTobacco preparationEngineeringStreamflow

There is provided an apparatus which can simplify, expedite and enhance the segregation of undesirable particles from desirable particles in a multiple-layer flow wherein the desirable and undesirable particles are randomly intermixed with each other. This is accomplished by a stepwise reduction of the thickness of the flow to thus locate all or nearly all undesirable particles at or close to the exposed sides of the resulting relatively thin flow so that the undesirable particles can be readily detected and segregated from the thin flow. The stepwise reduction of thickness of the original flow is effected by a cascade of successive accelerating conveyors including a first conveyor which receives successive increments of the original flow from a vibratory trough, and a faster second conveyor which receives successive increments of the accelerated flow from the first conveyor and cooperates with an overhead conveyor to define a channel for advancement of the repeatedly accelerated original flow into the range of instrumentalities for detection and segregation of undesirable particles.

Owner:BEST & CO

Material forming tool and method for forming a material

Owner:BATTELLE ENERGY ALLIANCE LLC

Mill for drying and pulverizing high-moisture and high-viscosity material and application method thereof

ActiveCN107694135ASolve the problem of hanging on the wallSolve the problem of dry millingEvaporator accessoriesGrain treatmentsImpellerEngineering

The invention provides a Yunjie mill. The Yunjie mill adopts a Yunjie mill main engine composed of a shell body, a rotor with a powder mill and a grading function and an inner circulating pipe, so that materials are pulverized and dried at the same time in a high-speed circulating flowing process in an inner circulating channel composed of an inner circulating pipe, a pulverizing impeller, a spacebetween the pulverizing impeller and an inner wall of a barrel body and the like; a wall remaining problem of the inner circulating channel is solved by utilizing an impact effect of a high-speed material flow; the wall remaining problem of an outer circulating channel is solved by controlling the moisture content of materials, discharged by the main engine, through a grading impeller; the defects of equipment in the inventive patent 2015110139212 are overcome and a method and a product of the inventive patent 2015110139212 are economically realized; the invention provides an application method of the Yunjie mill, so that the drying and pulverizing problem of high-moisture and high-viscosity materials including vegetable materials, meat, liquid materials and the like is solved; a solutionwith good economical efficiency is provided for processing feed and preparing a medicine which takes a volatile component as a functional component.

Owner:KUNMING TEKANG TECH CO LTD

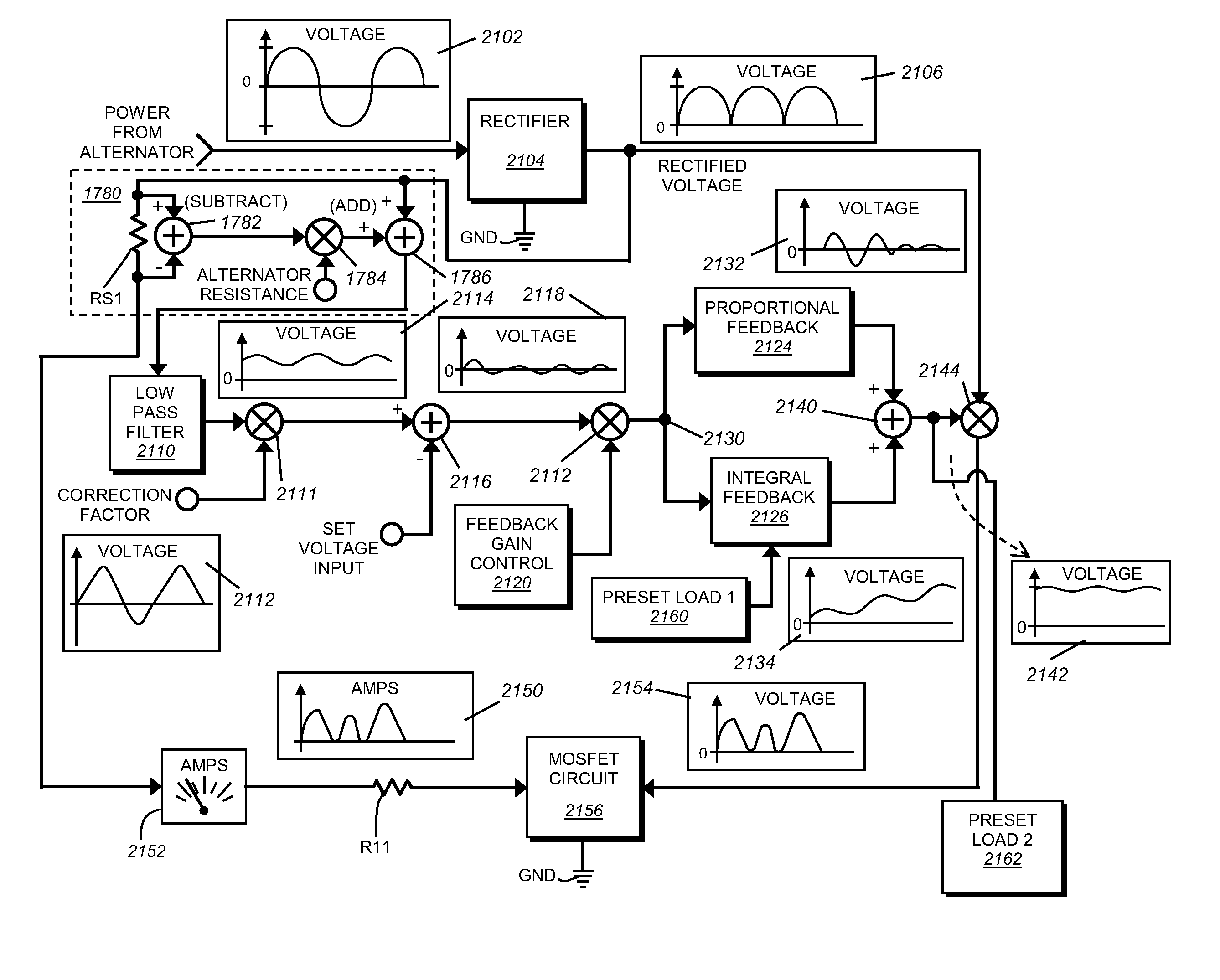

System and method for controlling a power generating system

InactiveUS20070158945A1Improve clarityMachines/enginesMechanical energy handlingPeak valueElectric power

This invention overcomes the disadvantages of the prior art by providing a power generating system particularly suitable for field use in remote locations, which is fuel-efficient, relatively quiet, tolerant of dust, capable of operating on low-grade logistics and diesel-like fuels and capable of generating between 500 W and 2 KW of continuous electrical power. This generating system employs a two-cycle MICE generator having a piston that operates within a cylinder, and an interconnected, axially moving piston shaft that oscillates an alternator coil within a magnetic core. The piston shaft is attached to, and resisted by, the free end of a strong spring with a second, opposing end fixed to the MICE casing. To control operation of the MICE generator a clipper circuit is employed with a set threshold to resolve peaks and an adjustable harshness for applying load to the coil based upon an amps / volt harshness setting. The engine can also be controlled dynamically throughout the cycle using the added feedback from the proportional and integral elements of a PID controller in conjunction with an energy dissipating and / or storing circuit to load the coil. The dynamic control can be based on a switching power supply implementation. Various engine operating parameters can be derived from coil voltage, current and resistance, and used to control and / or monitor the engine's performance.

Owner:AERODYNE RES

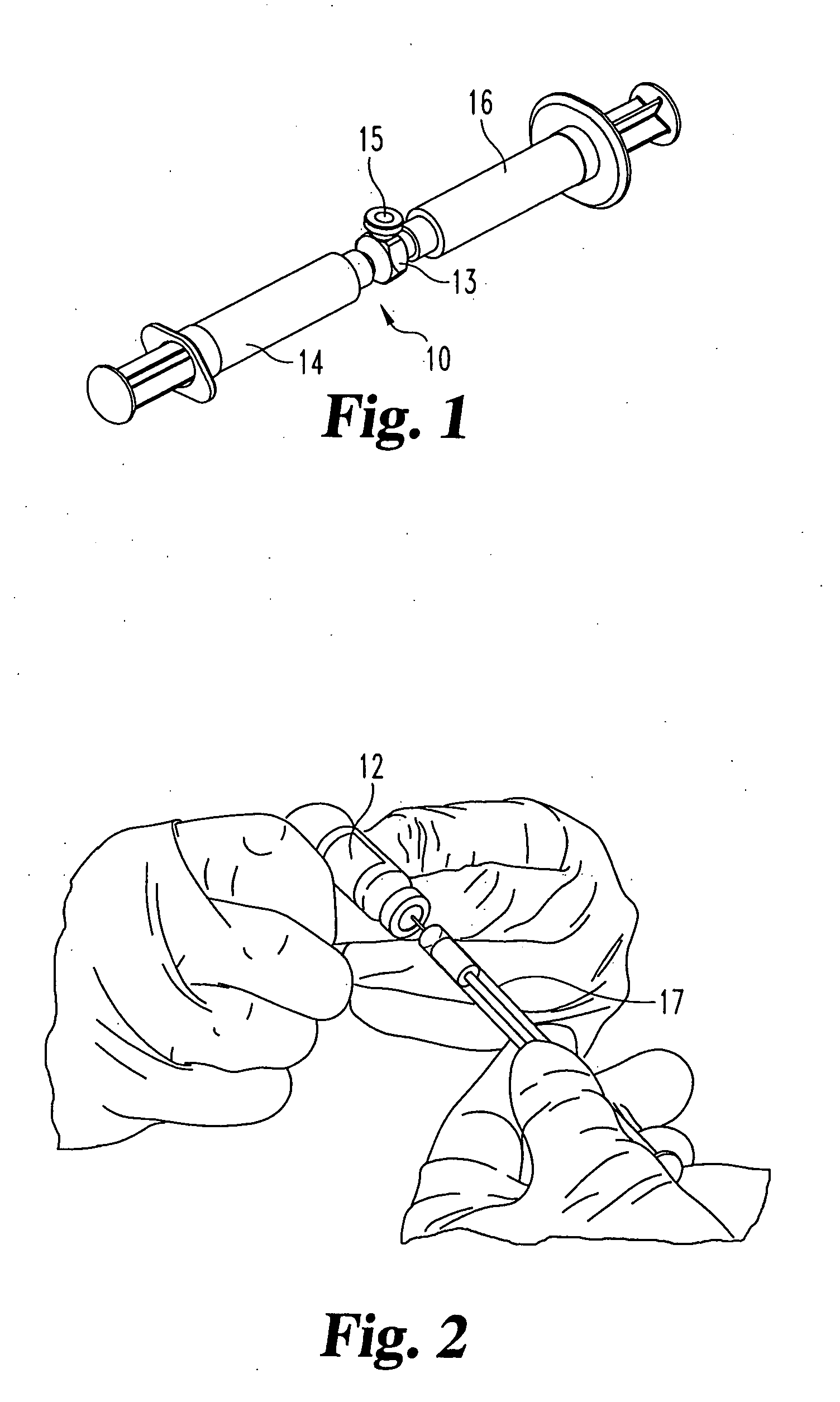

Material dispenser with a control valve

A syringe comprising a chamber and material transfer portion with a cavity in communication with an inlet portion and an outlet portion. The inlet portion includes an inlet valve means for controlling material flow therethrough, and the material transfer portion includes a control valve operable between a first position to control the inflow of material from the inlet portion to the material container portion, and a second position to control the flow of material from the chamber to the outlet portion, and the outlet portion includes a releasable lock means for allowing discharge the material through the outlet portion.

Owner:VASOGEN IRELAND LTD

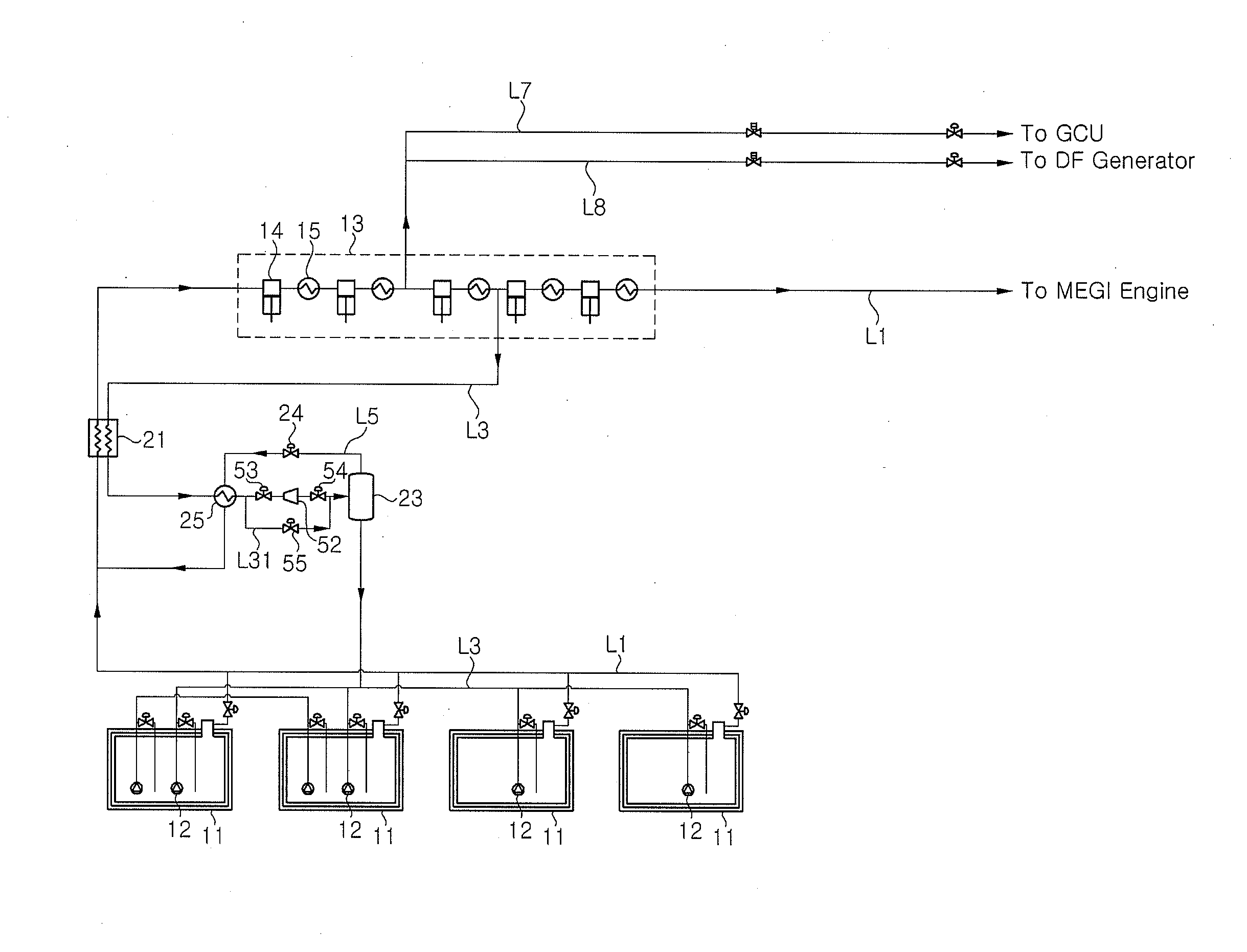

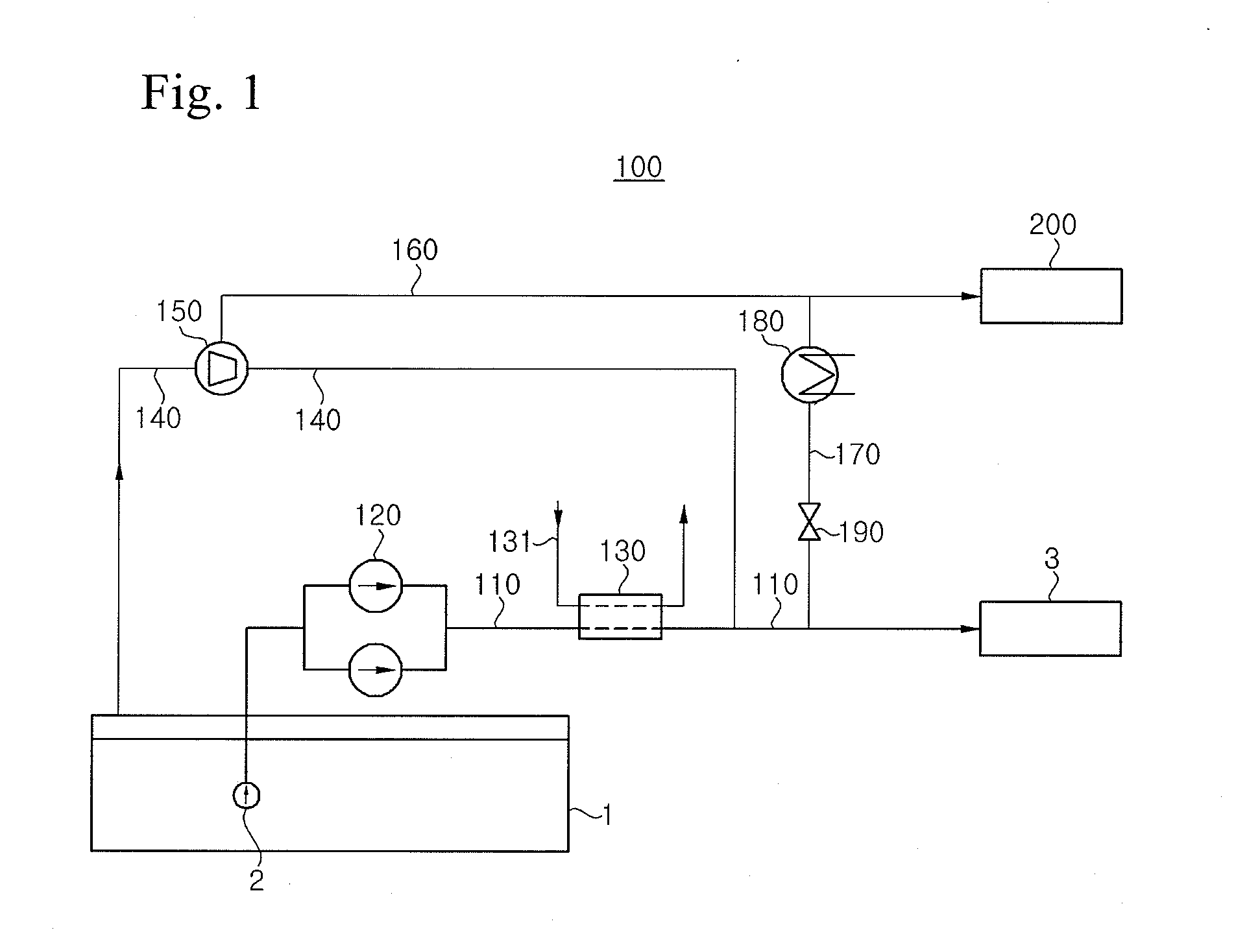

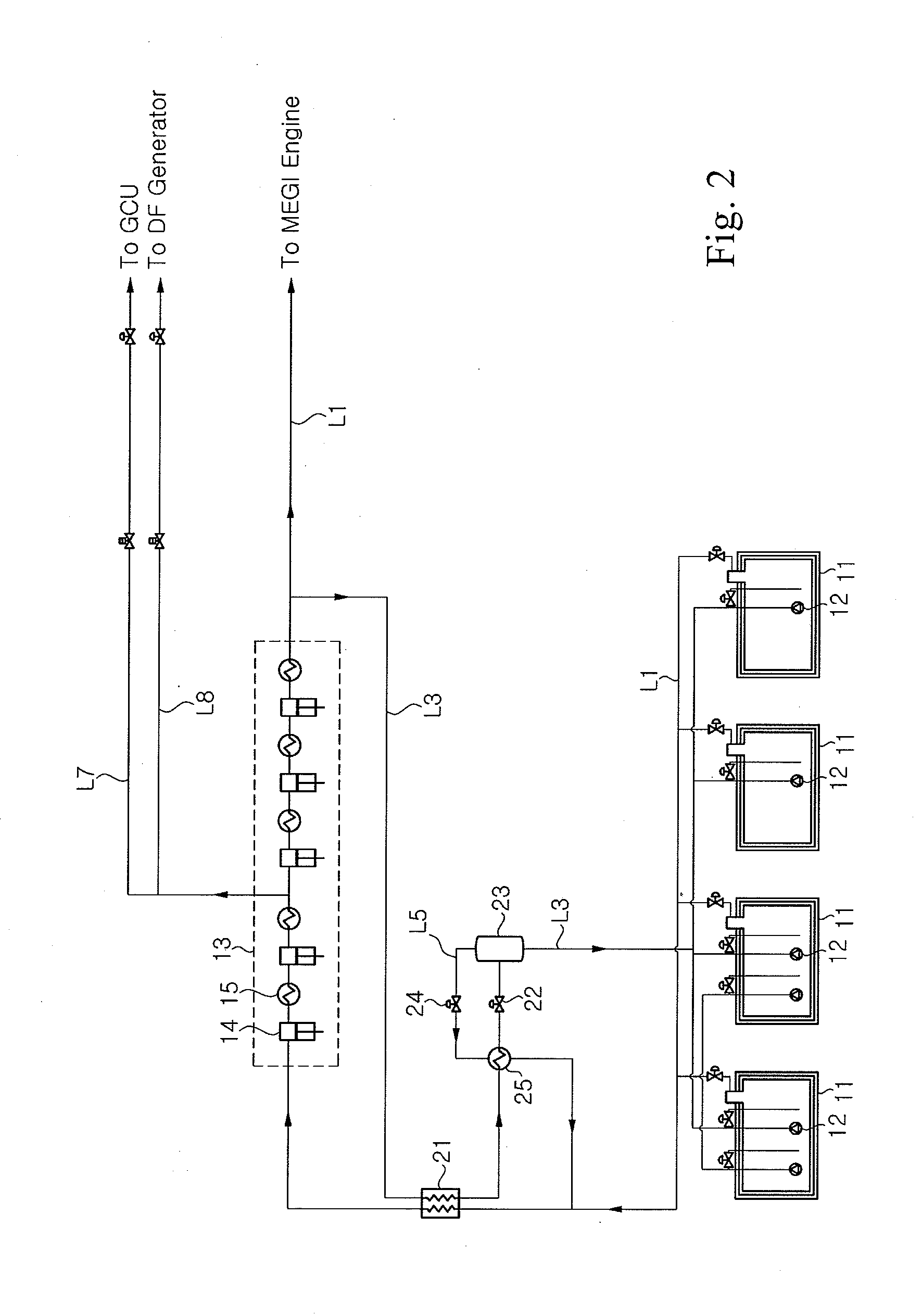

Liquefied gas treatment system for vessel

InactiveUS20140290279A1Save energy consumptionLower initial installation costsSolidificationLiquefactionProcess engineeringRefrigerant

A liquefied gas treatment system includes: a first stream of boil-off gas, which is generated from the liquefied natural gas in the cargo tank and is discharged from the cargo tank; a second stream of the boil-off gas, which is supplied as fuel to the engine in the first stream; and a third stream of the boil-off gas, which is not supplied to the engine in the first stream. The first stream is compressed in a compressor and is then branched into the second stream and the third stream. The third stream is liquefied by exchanging heat with the first stream in a heat exchanger, so that the boil-off gas is treated without employing a reliquefaction apparatus using a separate refrigerant.

Owner:DAEWOO SHIPBUILDING & MARINE ENG CO LTD

Automatic separator or shaker with electromagnetic vibrator apparatus

InactiveUS7571817B2Affect effectivenessAffect efficiencySievingScreeningEngineeringMechanical engineering

A vibratory separator (in one aspect, a shale shaker) and methods for using it, the separator in certain aspects having a base, a basket movably mounted on the base, screen apparatus on the basket, material flowing onto the screen apparatus for treatment, at least a portion of the screen apparatus not inclined downhill (e.g. said portion horizontal or uphill), electromagnetic vibratory apparatus connected to the basket for vibrating the basket and the screen apparatus, driving apparatus for driving the electromagnetic vibratory apparatus, and control apparatus (on-site and / or remote) for controlling the driving apparatus and the electromagnetic vibratory apparatus; the material, in one aspect, being drilling fluid material with solids therein.

Owner:VARCO I P INC

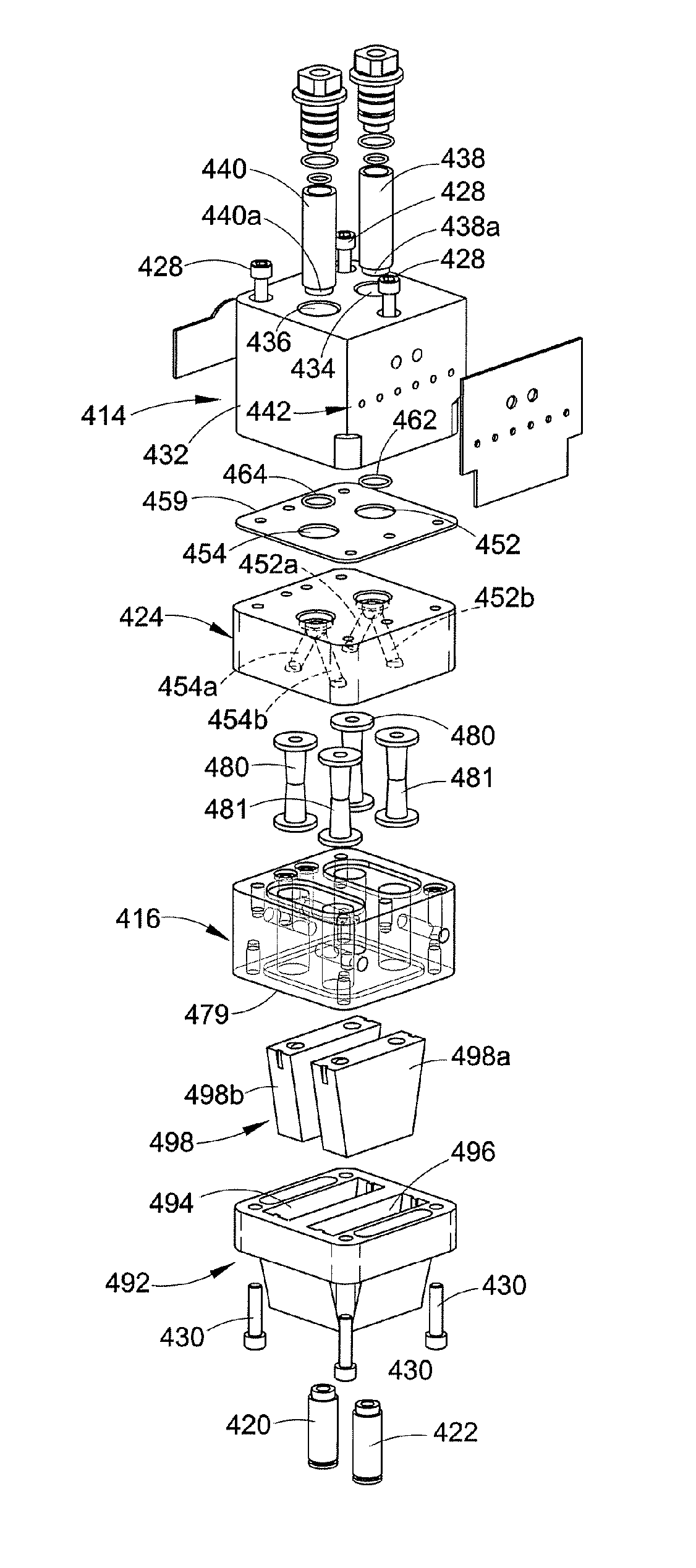

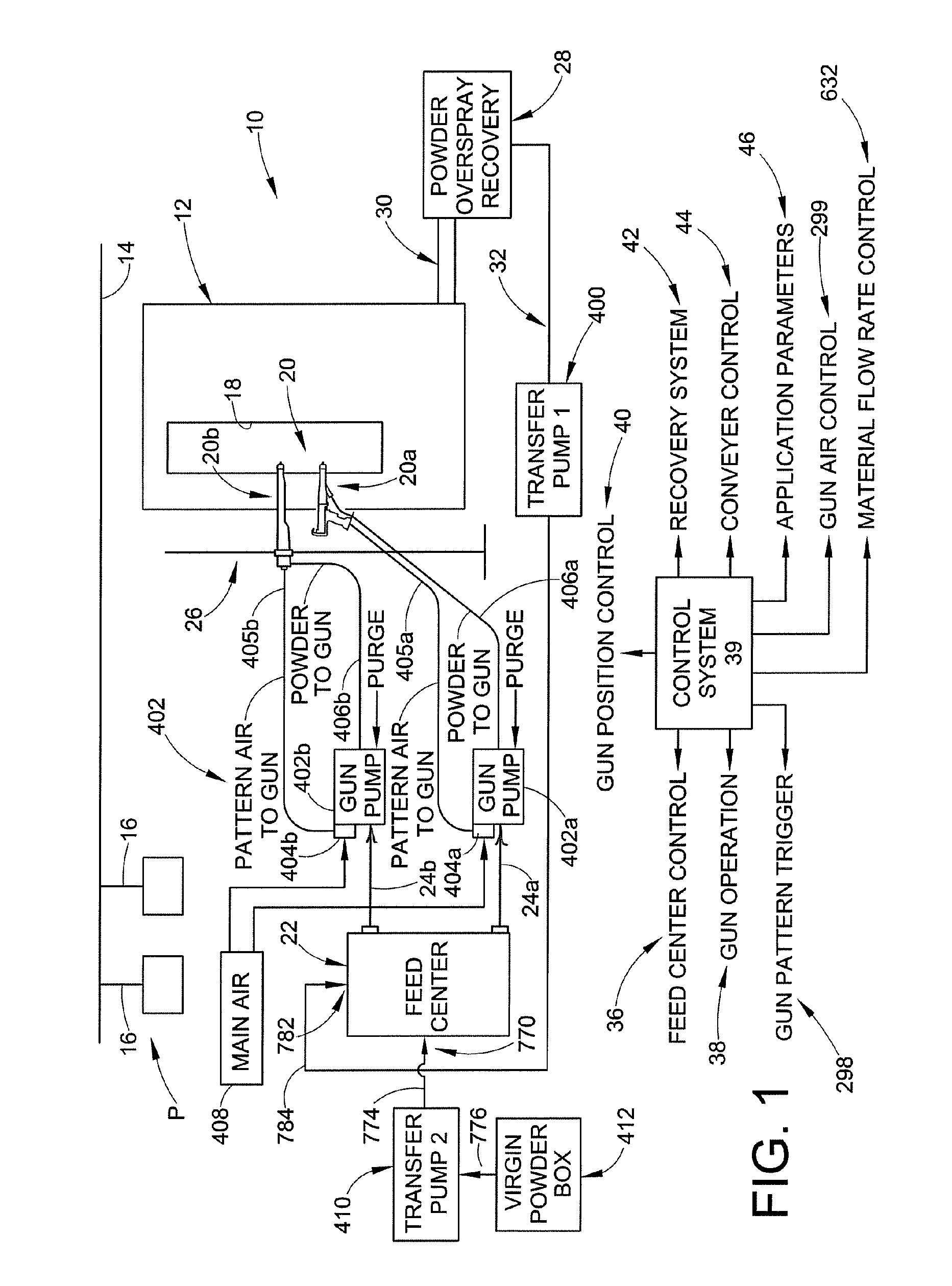

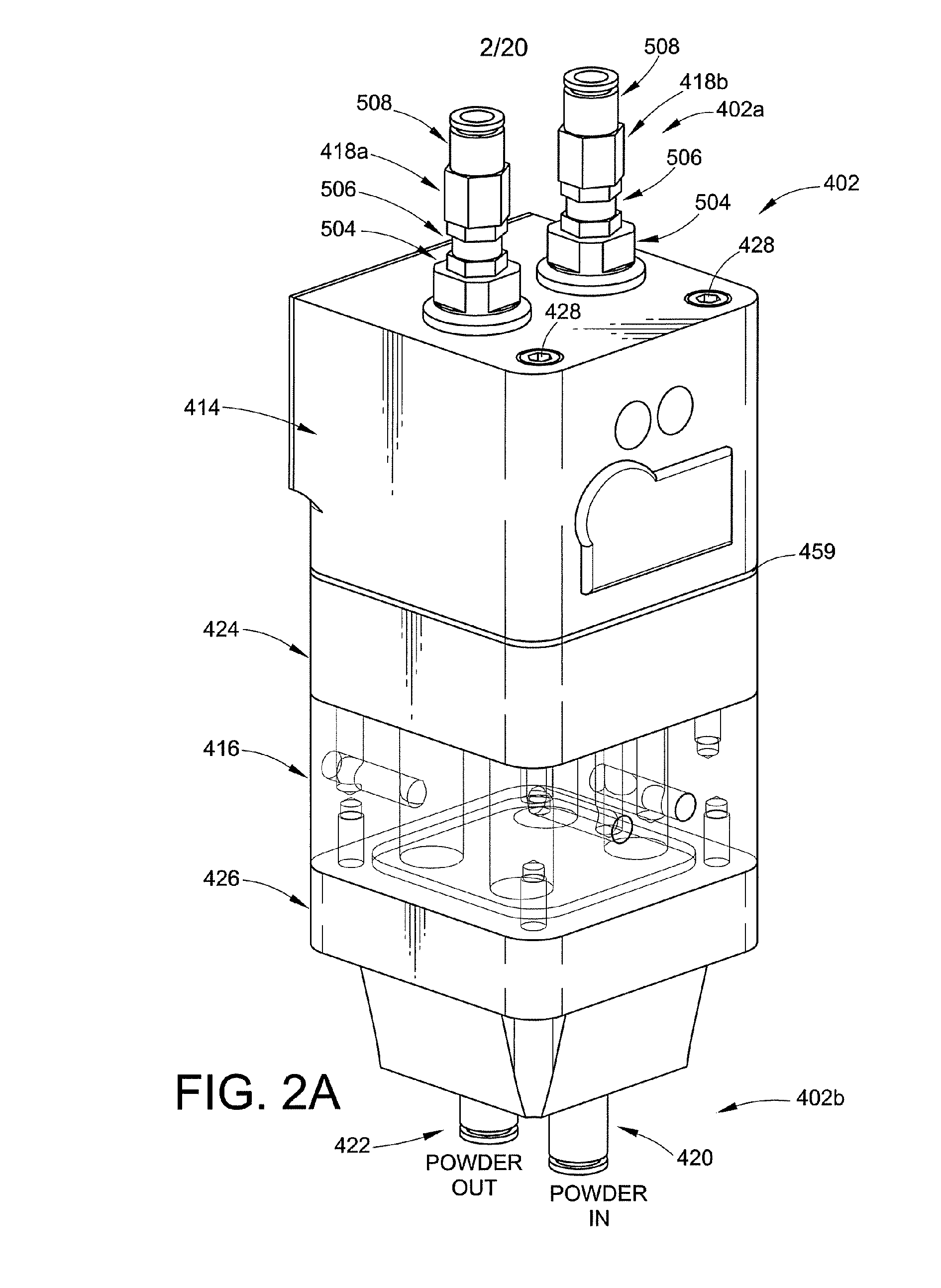

Dense phase pump for dry particulate material

InactiveUS20050158187A1Improve cleanabilityImprove serviceabilityLiquid surface applicatorsPositive displacement pump componentsCycle ratePump chamber

A dense phase pump for particulate material includes a pump chamber wherein material flows into the pump chamber under negative pressure and flows out of the pump chamber under positive pressure. A plurality of pinch valves are provided to control flow of material into and out of the pump chamber. The pinch valves are operated independent of each other and of the pump cycle rate. A modular design of the pump is provided.

Owner:NORDSON CORP

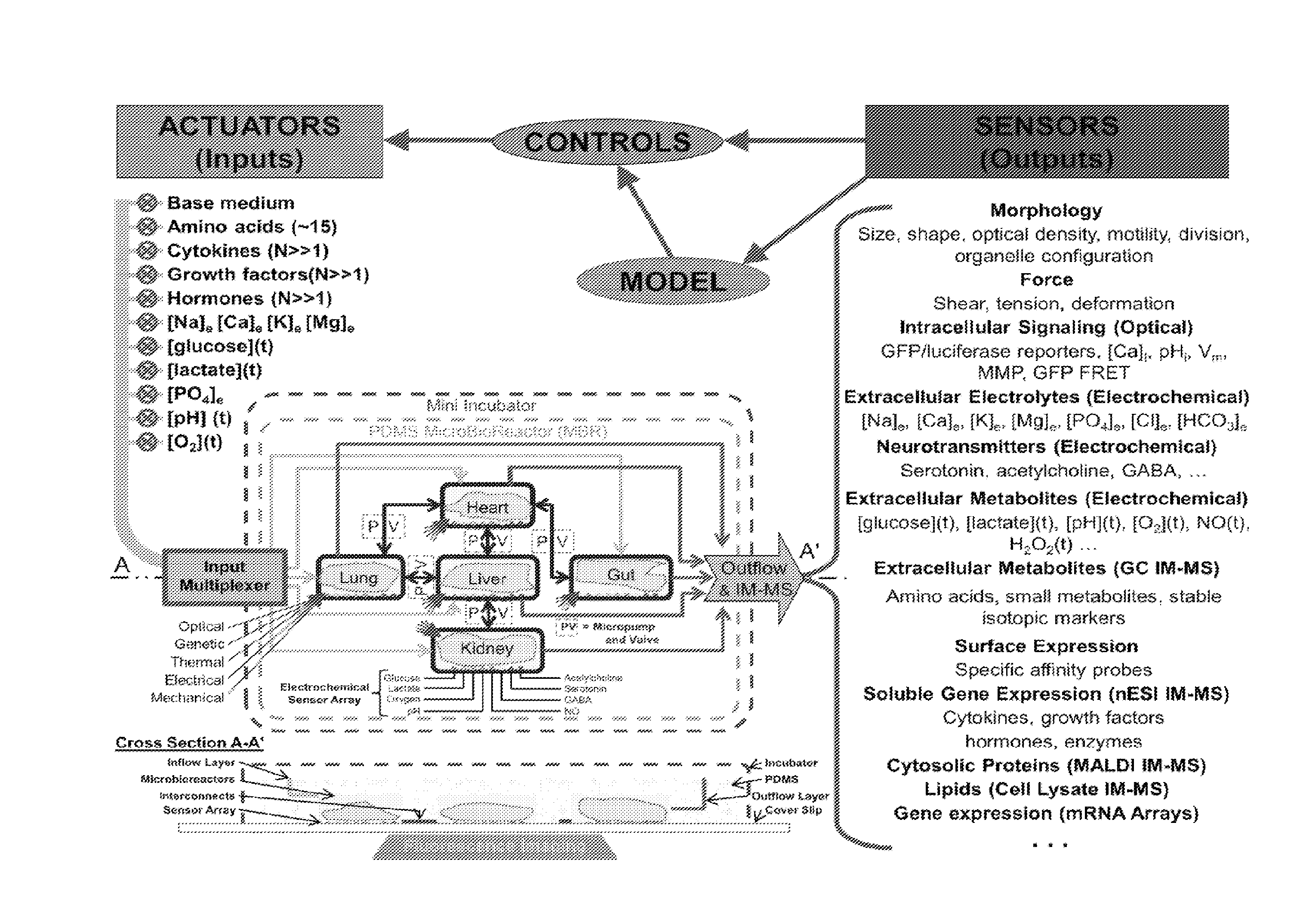

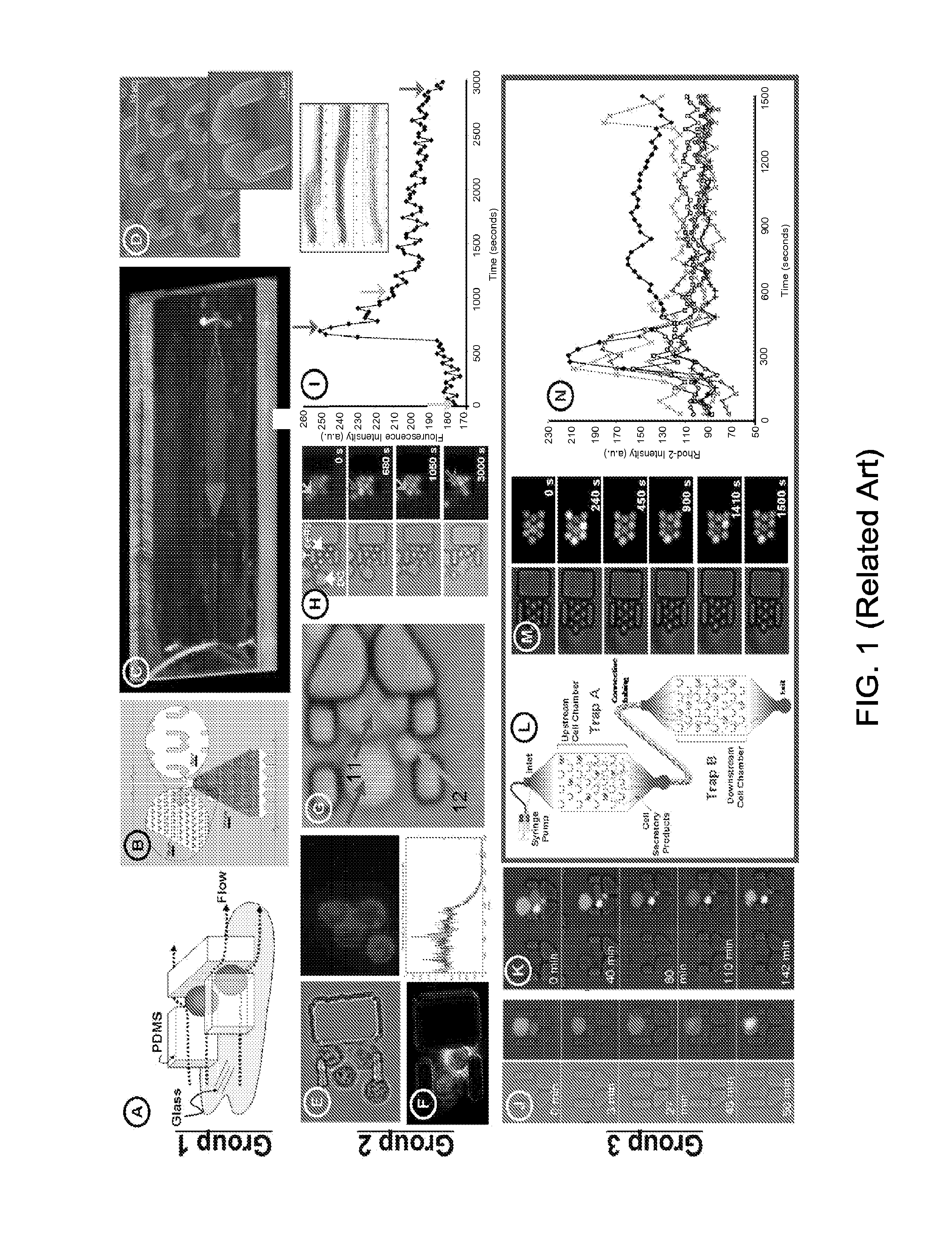

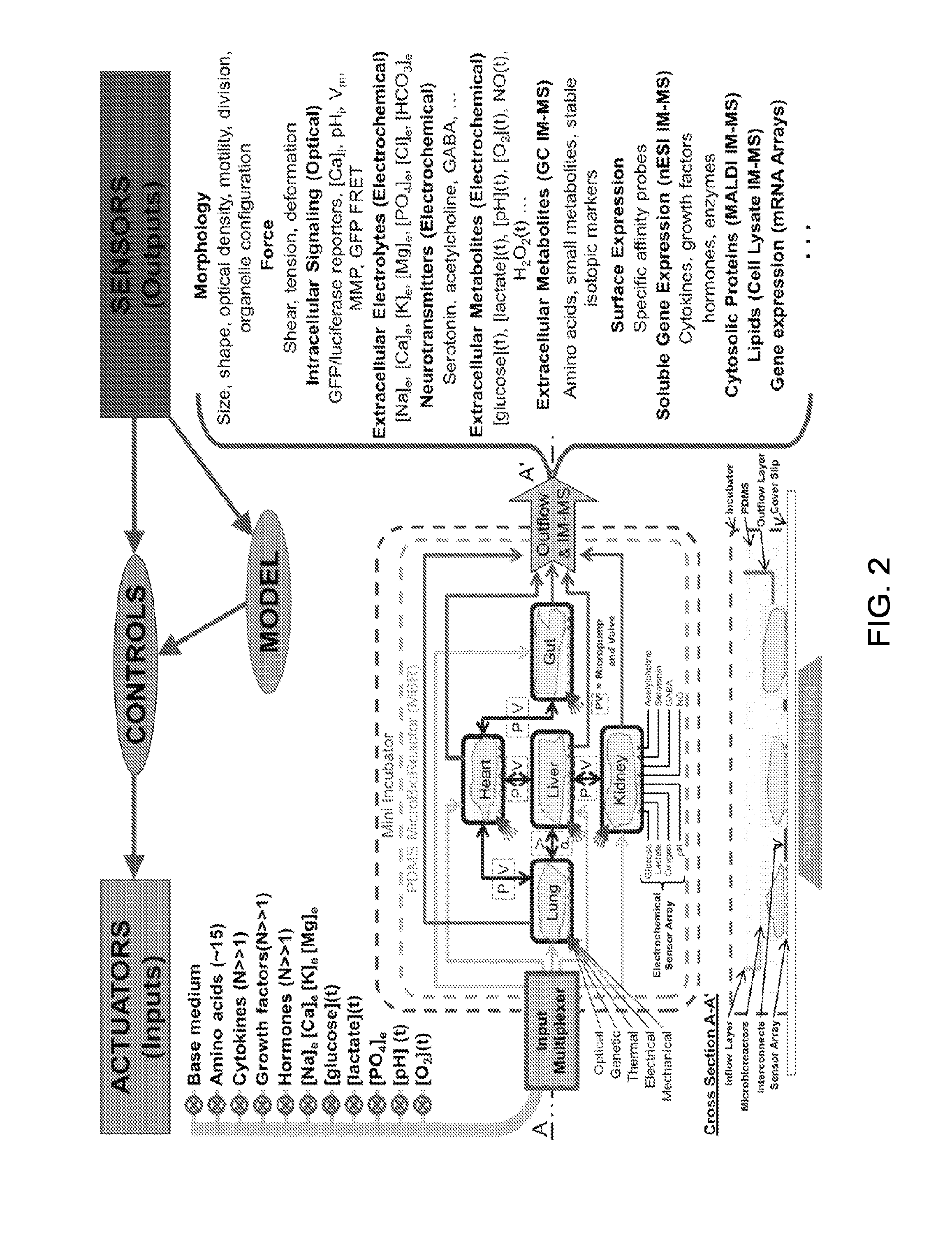

Integrated organ-on-chip systems and applications of the same

ActiveUS20140356849A1Maintain performanceBiochemistry apparatusDead animal preservationMicrofluidicsEngineering

In one aspect of the invention, an integrated bio-object microfluidics chip includes a fluidic network having a plurality of inlets for providing a plurality of fluids, a plurality of outlets, a bio-object chamber for accommodating at least one bio-object, a plurality of fluidic switches, and one or more pumps, coupled to each other such that at least one fluidic switch operably and selectively receives one fluid from a corresponding inlet and routes the received fluid, through the one or more pumps, to the bio-object chamber so as to perfuse the at least one bio-object therein, and one of the downstream fluidic switches selectively delivers an effluent of the at least one bio-object responsive to the perfusion to a predetermined outlet destination, or to the at least one fluidic switch for recirculation.

Owner:VANDERBILT UNIV

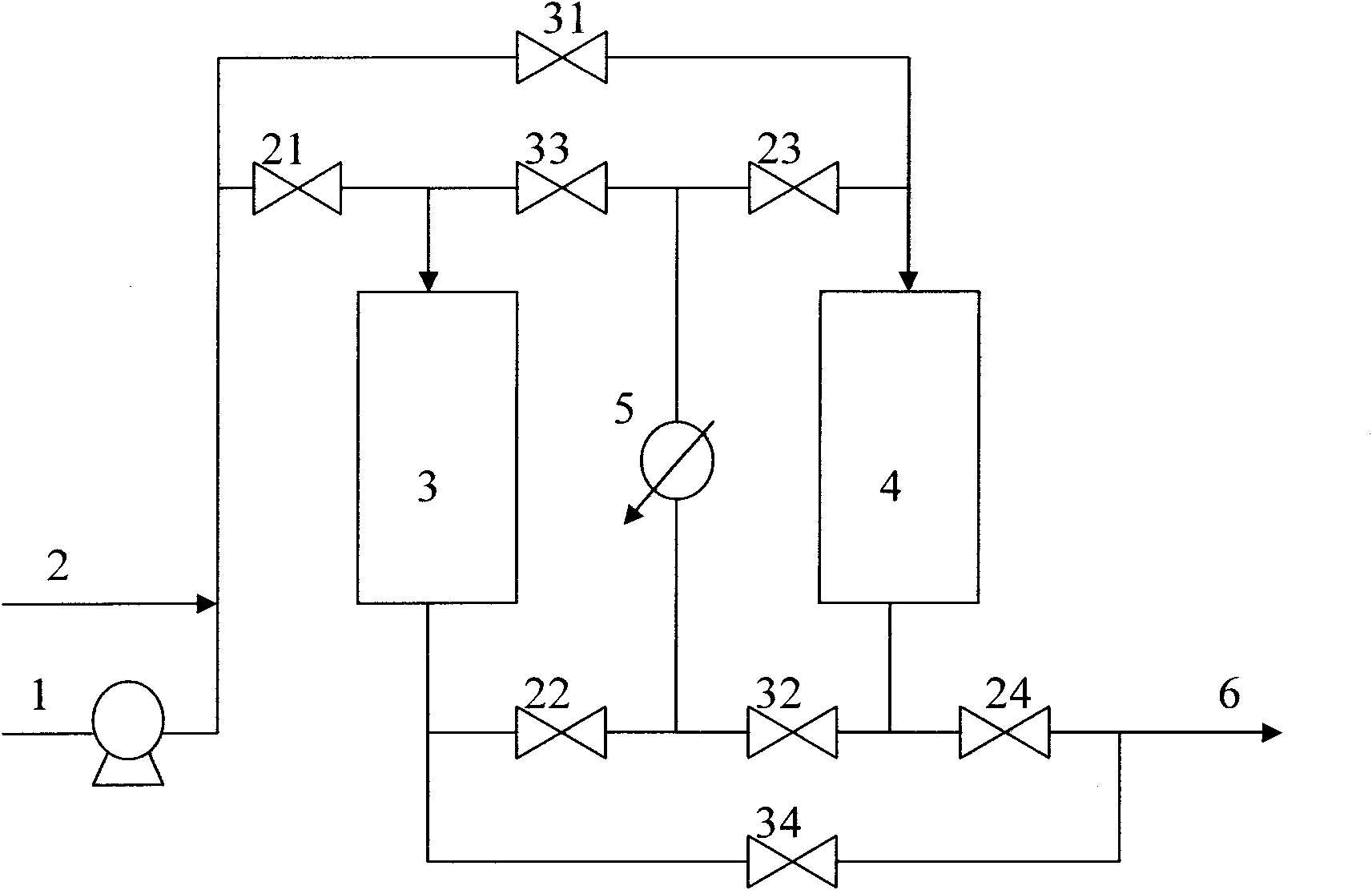

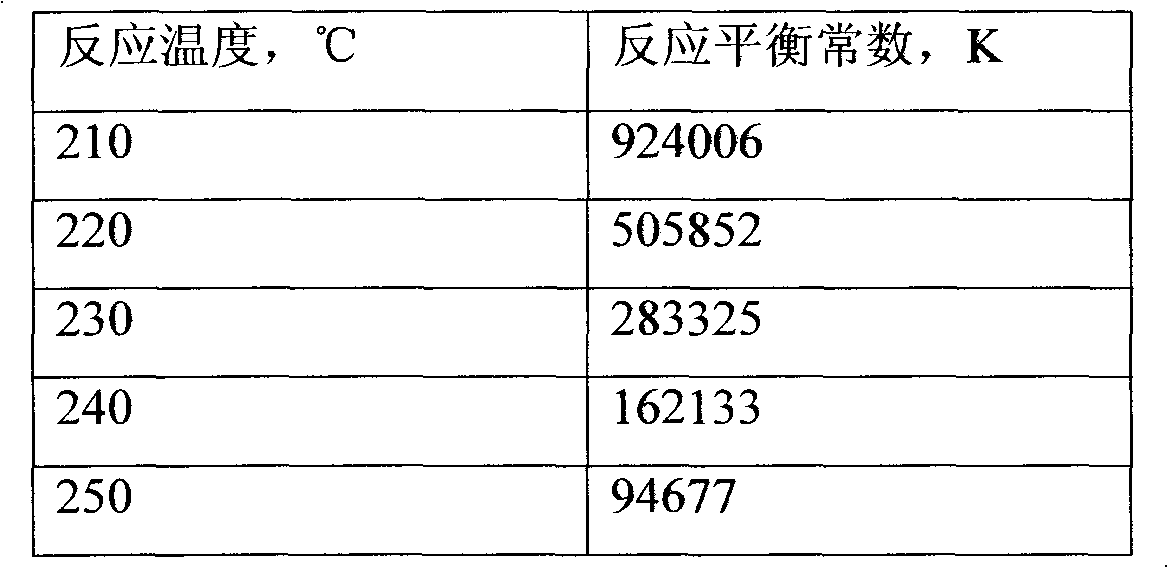

Method of hydrogenating liquefied petroleum gas to prepare ethylene cracking feed

ActiveCN102311787AEffective temperature controlTemperature controlLiquid hydrocarbon mixtures productionTreatment with hydrotreatment processesHydrogenAlkene

The invention discloses a method of hydrogenating liquefied petroleum gas to prepare ethylene cracking feed, which is provided with two reaction sections. Reaction material cooling operation is carried out between the two reaction sections, the mixture of C4 fraction raw material and hydrogen is cooled after passing through the first reaction section, then enters the second reaction section, non-precious metal hydrofining catalysts are arranged in the two reaction sections, and a reaction material flow switching device is arranged between an inlet and an outlet of the two reaction sections to change the sequence of the reaction material flow entering the two reaction sections. The method disclosed by the invention solves the problem that the olefin content does not reach the standard due to thermodynamic control factors, simultaneously the catalysts are entirely fully utilized, and the operating cycle can be prolonged.

Owner:CHINA PETROLEUM & CHEM CORP +1

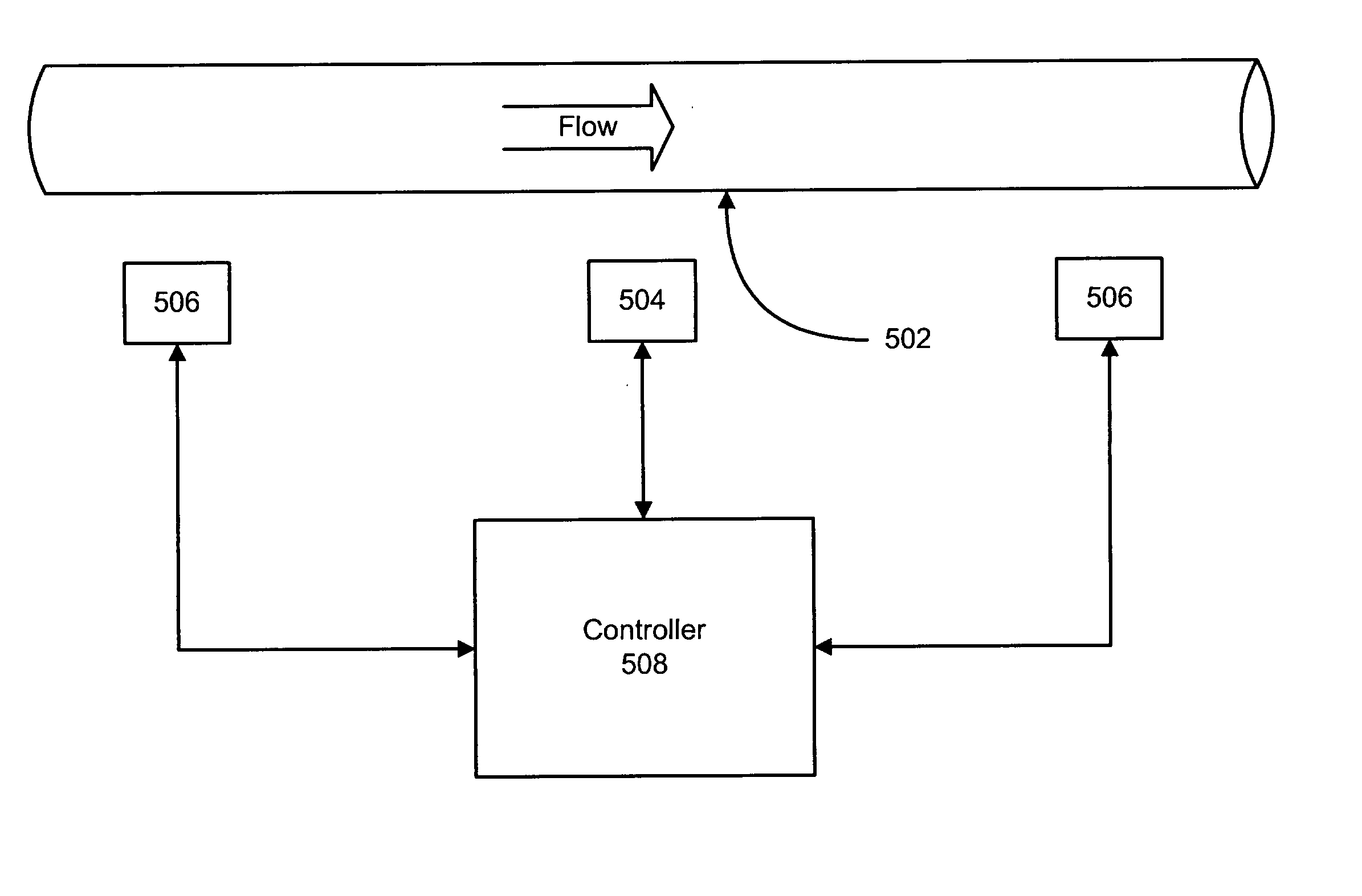

Method and Apparatus for Determining Flow Pressure Using Density Information

ActiveUS20080034893A1Guaranteed corrective effectTesting/calibration apparatusFluid pressure measurementEnvironmental geologyMaterial flow

Owner:MICRO MOTION INC

Apparatus and Method for Passive Dust Control in a Transfer Chute

InactiveUS20120090956A1Minimize air flowReduce dust emissionsLoading/unloadingConveyor partsTransfer systemDust control

A dust control apparatus and method for a bulk material handling transfer system having a chute comprising a pathway there through for handling varying volumes of bulk material flowing through the chute using gravity flow. A self-adjusting air restrictor gate is mounted in the chute for engaging the upper surface of flowing bulk material through the chute for restricting the air pathway during material volume flow variations to reduce dust emissions. The gate member contacts the upper surface of flowing bulk material and moves up and down in response to the flow of bulk material through the chute to restrict the flow of air to reduce dust. A counterweight mechanism and a damper helps maintain controlled contact of the air restrictor gate with the upper surface of bulk material flowing through the chute.

Owner:BROBST STEVEN HAYS

Vacuum loading system

Apparatus and methods for providing granular material to a loading hopper preparatory to processing, provide an at least partially transparent receptacle for receiving material prior to processing machinery supplied by the hopper with the receptacle having a top, a valve for selectably connecting the receptacle to vacuum or to ambient air, vacuum drawn in the receptacle, a conduit connecting the receptacle to a supply of granular material, a valve selectably permitting material flow from the receptacle into the hopper and control temporally adjustably closing the first valve and opening the second valve responsively to visually detected presence of a suitable amount of material in the receptacle.

Owner:MAGUIRE STEPHEN B

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com