Mill for drying and pulverizing high-moisture and high-viscosity material and application method thereof

A grinding and main machine technology, applied in grain processing, spray evaporation, evaporator accessories, etc., can solve the problem of not being able to effectively solve the problem of high-humidity and high-viscosity materials hanging on the wall, and achieve good economical results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

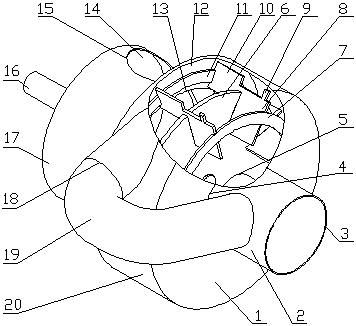

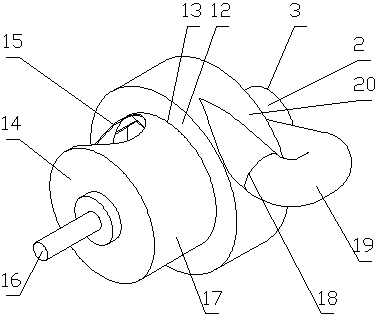

[0048] Example 1: A Yunjie mill host, see figure 1 with figure 2 , Is composed of a shell, a rotor, and an internal circulation tube 19, the shell is composed of a feed tube 2, a front cover 1, a cylinder 20, a middle cover 12, a discharge tube 17 and a rear cover 14. The feed tube 2 Inlet 3 is the main machine entrance of Yunjie Mill. There is an inlet 4 on the front cover 1, an inner circulation pipe interface 18 on the cylinder body 20, an outlet 13 on the middle cover 12, a Yunjie mill outlet 15 on the discharge pipe 17, and a back cover 14 has a drive shaft hole, the rear cover drive shaft hole is provided with a sealing device, the outlet of the feed pipe 2 is connected with the inlet 4 on the front cover 1, the front cover 1 is set at the front end of the cylinder 20, and the middle cover 12 is set At the rear end of the cylinder 20, the front end of the discharge pipe 17 is connected with the outlet 13 on the middle cover 12, and the rear cover 14 is arranged at the rea...

Embodiment 2

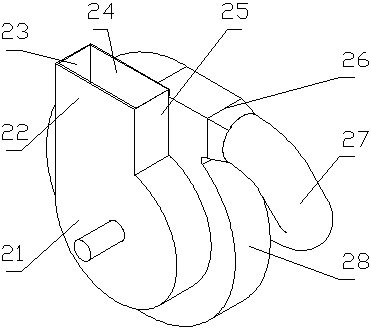

[0049] Example 2: The second Yunjie mill host, see image 3 , Consists of a shell, a rotor and an internal circulation tube. The shell is composed of a feed tube, a front cover, a cylinder 28, a middle cover, a discharge tube and a rear cover 21. The inlet of the feed tube is the Yunjie mill inlet , The front cover has an inlet, the cylinder 28 is a volute, the cylinder has an inner circulation pipe interface 26, the middle cover has an outlet, and the discharge pipe has a Yunjie mill outlet, which extends from the middle cover The middle plate 24, the rear plate 22 extending from the rear cover along the cloud, the enclosure plate A23 and the enclosure plate B25 which are arranged between the middle plate and the rear plate to connect with the opening on the discharge pipe, and the rear cover is provided with a drive shaft hole to enter The outlet of the material pipe is connected with the inlet on the front cover, the front cover is arranged at the front end of the cylinder 28...

Embodiment 3

[0050] Example 3: The third Yunjie mill host, see attached Figure 4 , Consists of a shell, a rotor and an internal circulation pipe 33. The shell is composed of a front cover 35, a cylinder 30, a middle cover, a discharge pipe and a rear cover. The front cover has an inlet, and the inlet on the front cover is Yunjie Mill The main engine inlet 36, the cylinder 30 has an inner circulation pipe interface 32 and an inner circulation pipe outlet interface 34, an outlet on the middle cover, a Yunjie mill host outlet 31 on the discharge pipe, a drive shaft hole on the back cover, and a front cover 35 is arranged at the front end of the cylinder body 30, the middle cover is arranged at the rear end of the cylinder body 30, the front end of the discharge pipe is connected with the outlet on the middle cover, and the rear cover is arranged at the rear end of the discharge pipe; the rotor consists of a disc 37, The drive shaft 39, the grinding blades 38 and the grading blades are composed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com