Patents

Literature

1567 results about "Volute" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

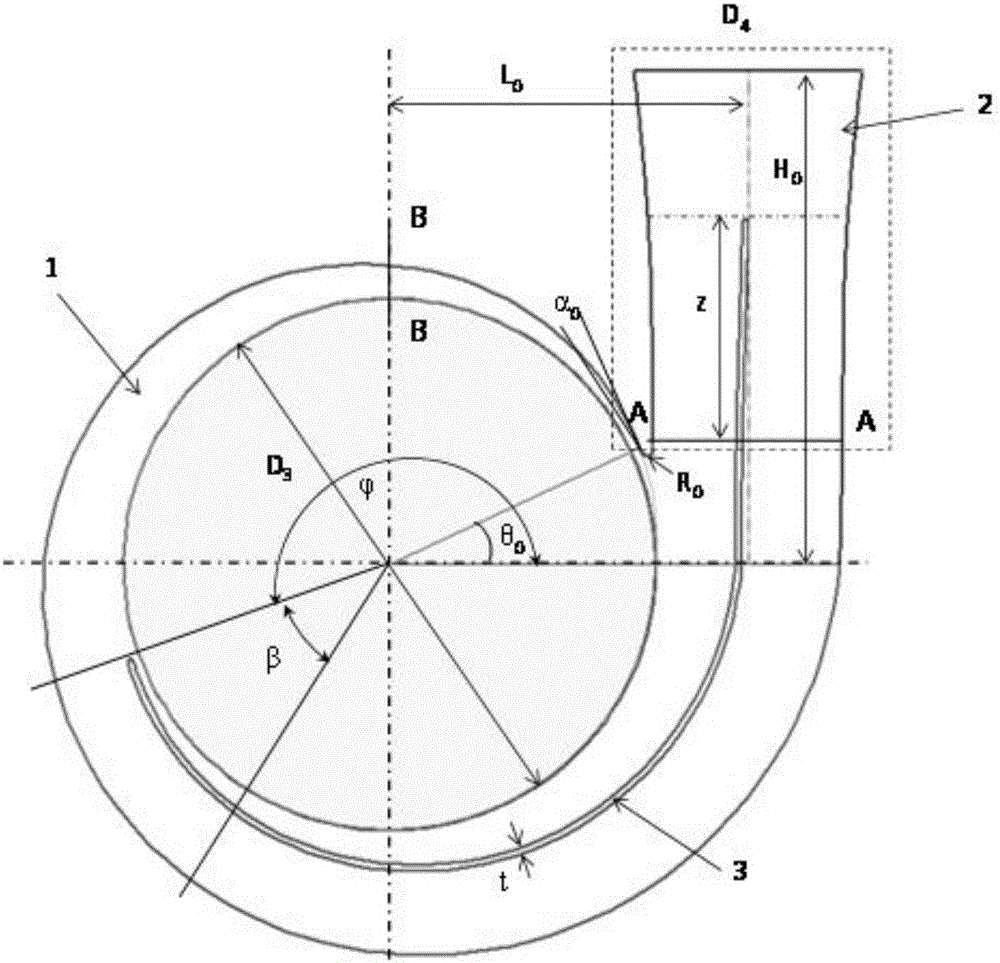

A volute is a curved funnel that increases in area as it approaches the discharge port. The volute of a centrifugal pump is the casing that receives the fluid being pumped by the impeller, maintaining the velocity of the fluid through to the diffuser. As liquid exits the impeller it has high kinetic energy and the volute directs this flow through to the discharge. As the fluid travels along the volute it is joined by more and more fluid exiting the impeller but, as the cross sectional area of the volute increases, the velocity is maintained if the pump is running close to the design point. If the pump has a low flow rate then the velocity will decrease across the volute leading to a pressure rise causing a cross thrust across the impeller that we see as vibration. If the pump flow is higher than design the velocity will INCREASE across the volute and the pressure will decrease according to the first law of thermodynamics. This will cause a side thrust in the opposite direction to that caused by low flow but the result is the same - vibration with resultant short bearing and seal life.

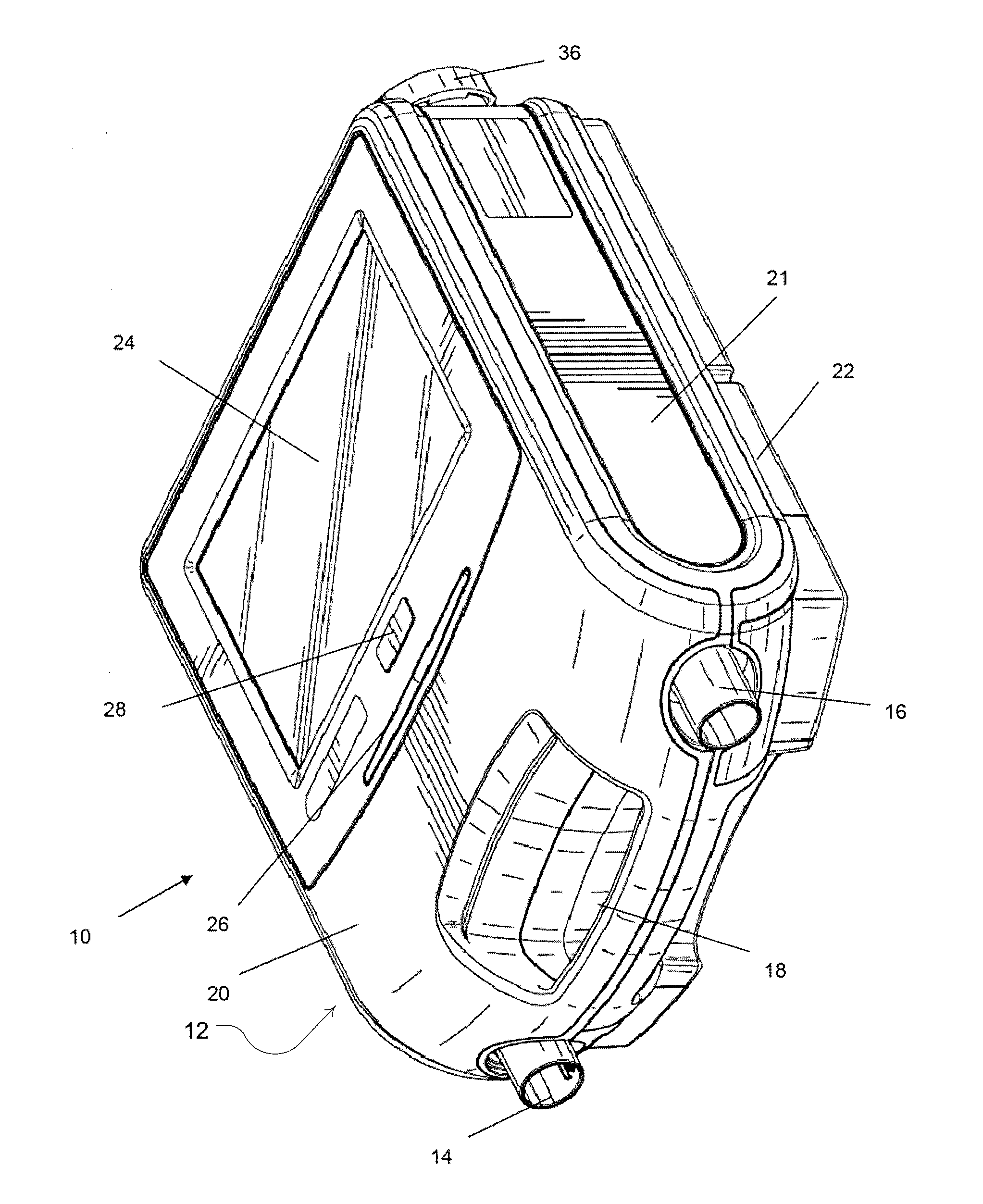

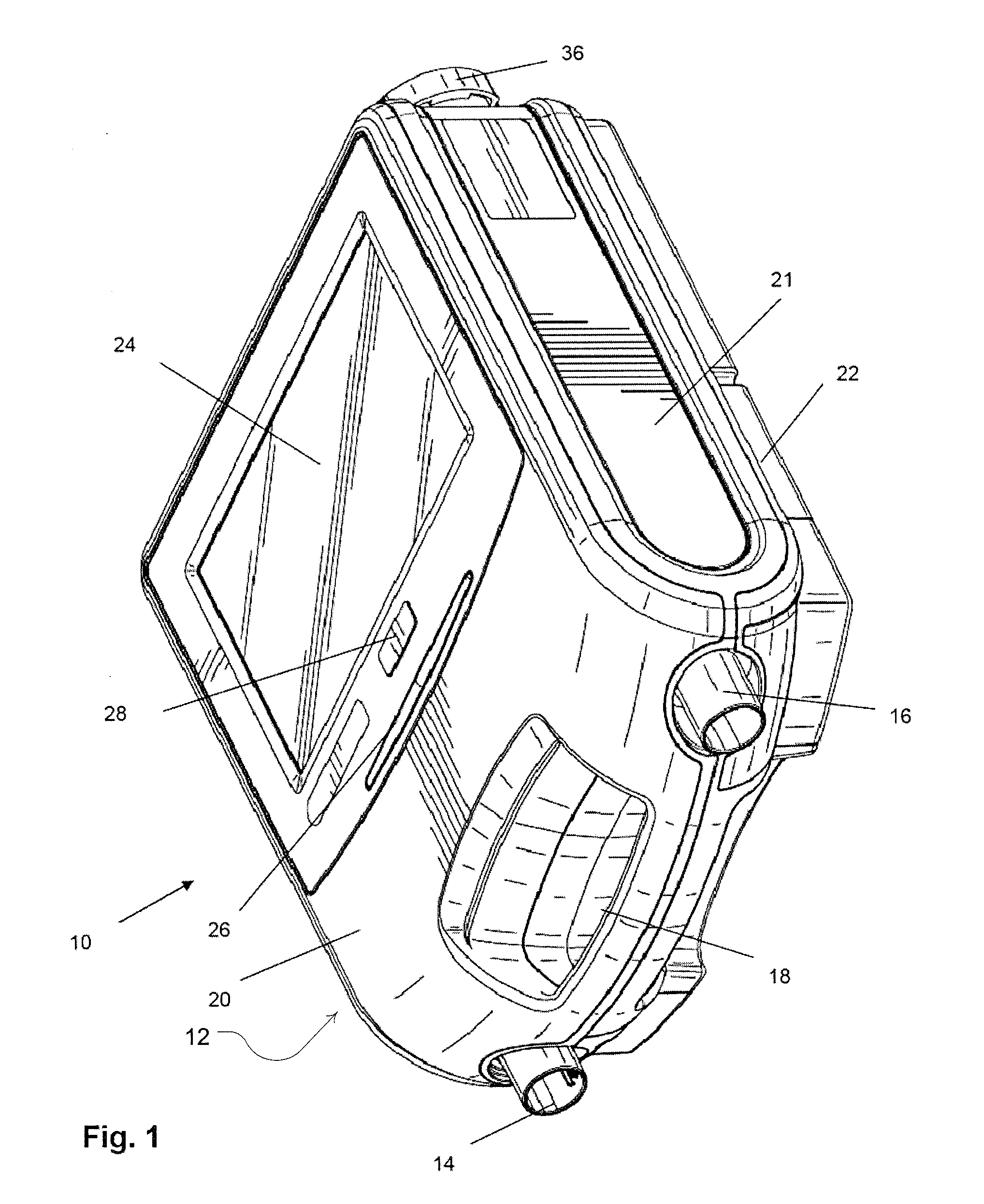

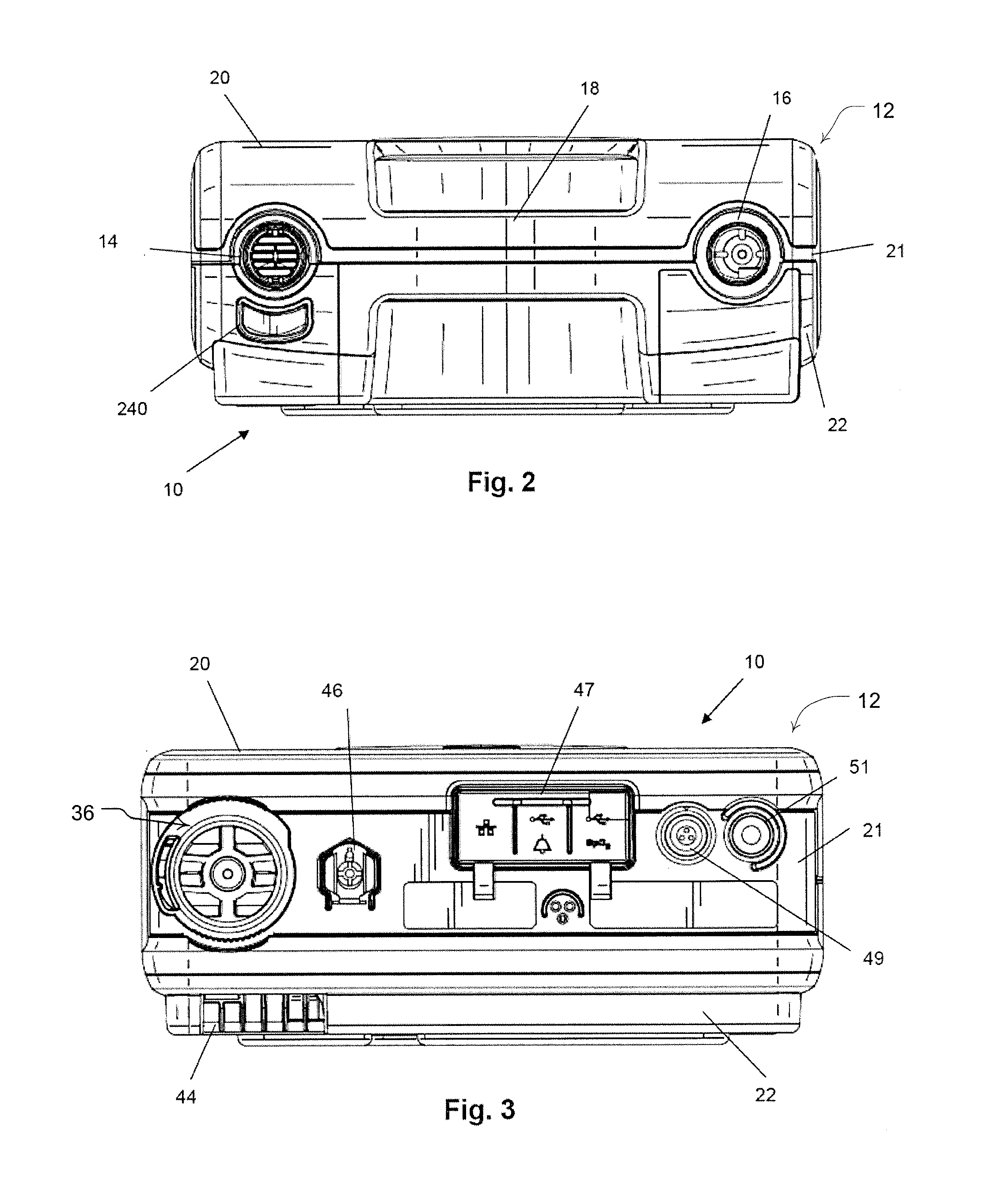

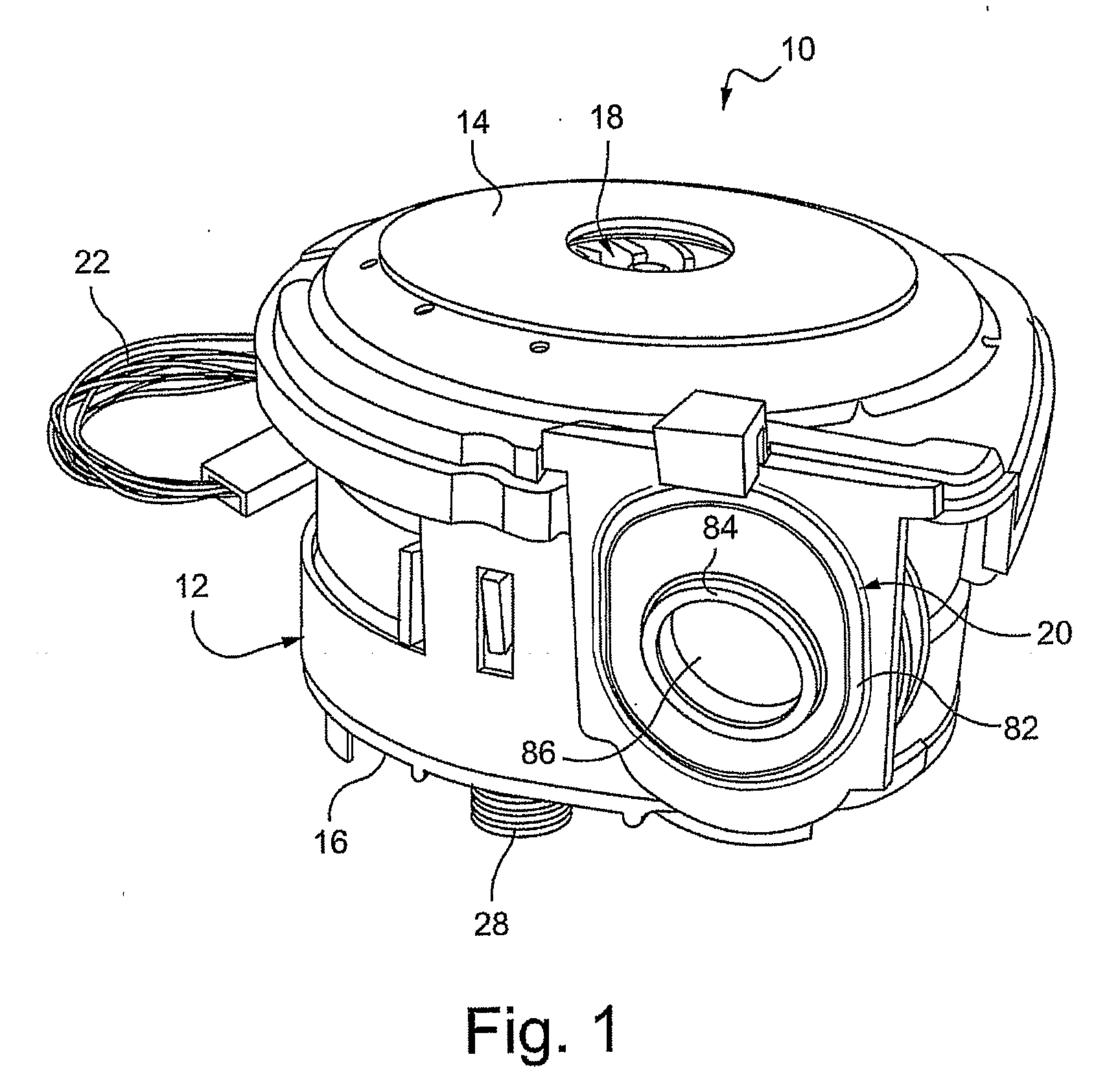

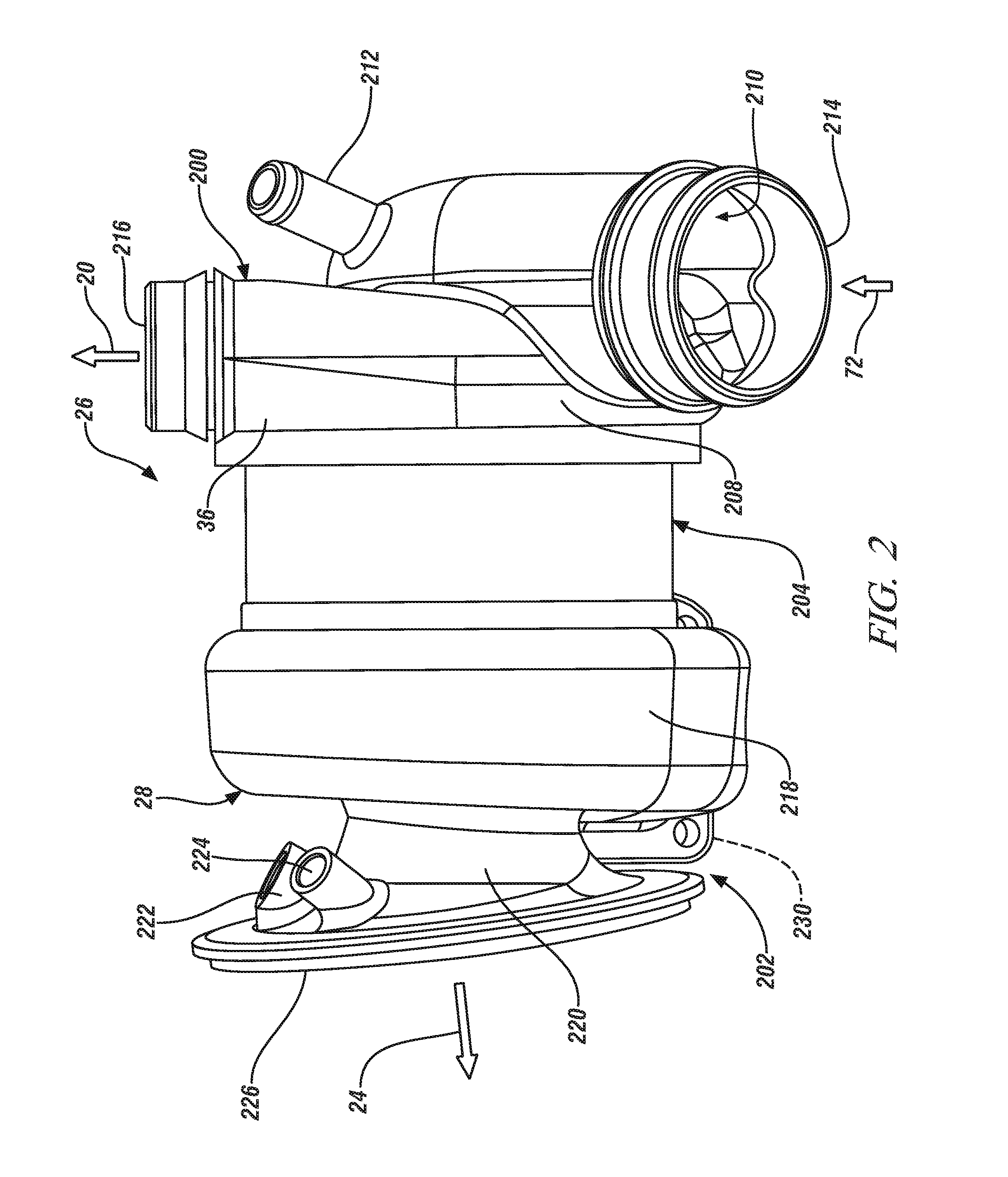

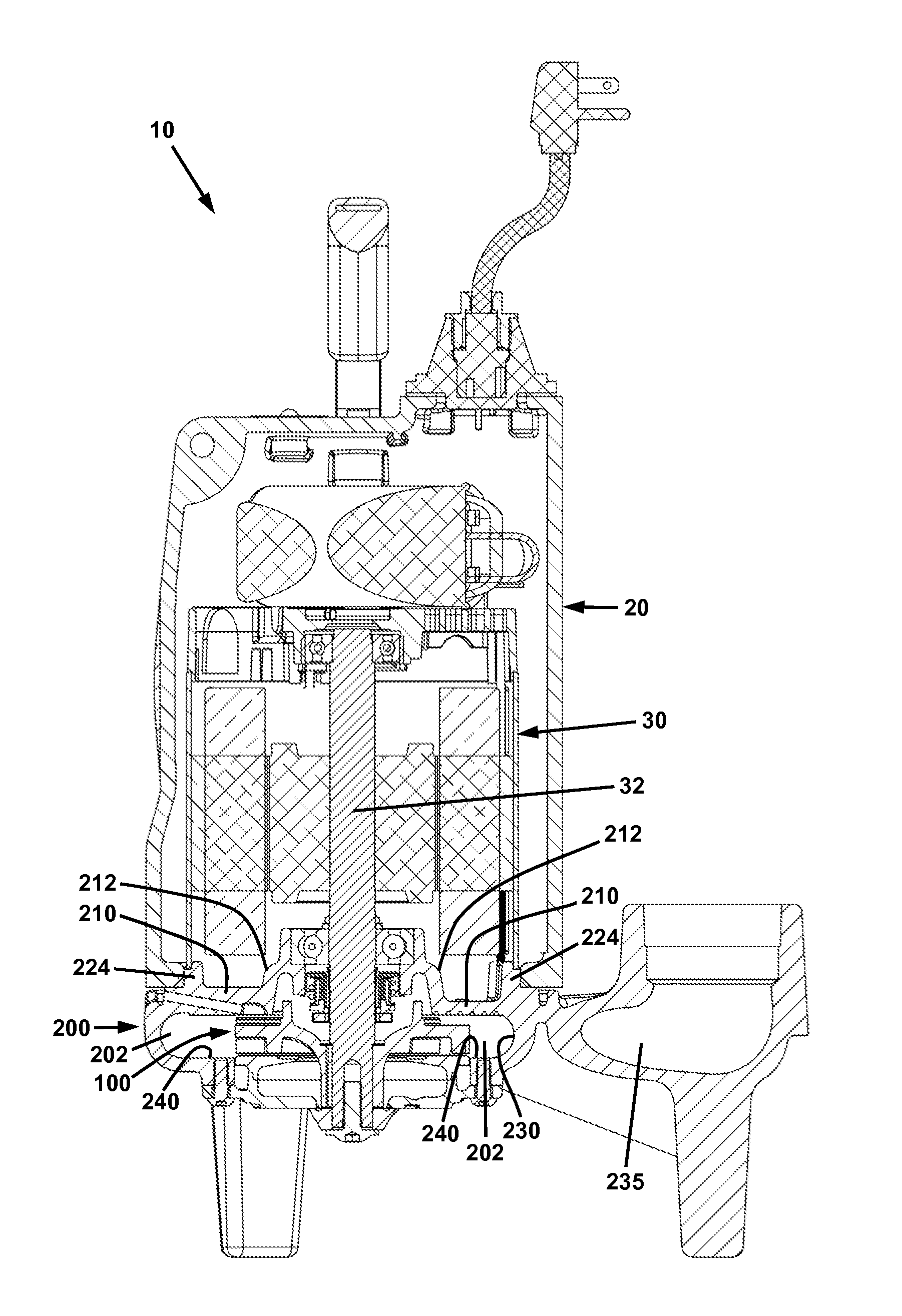

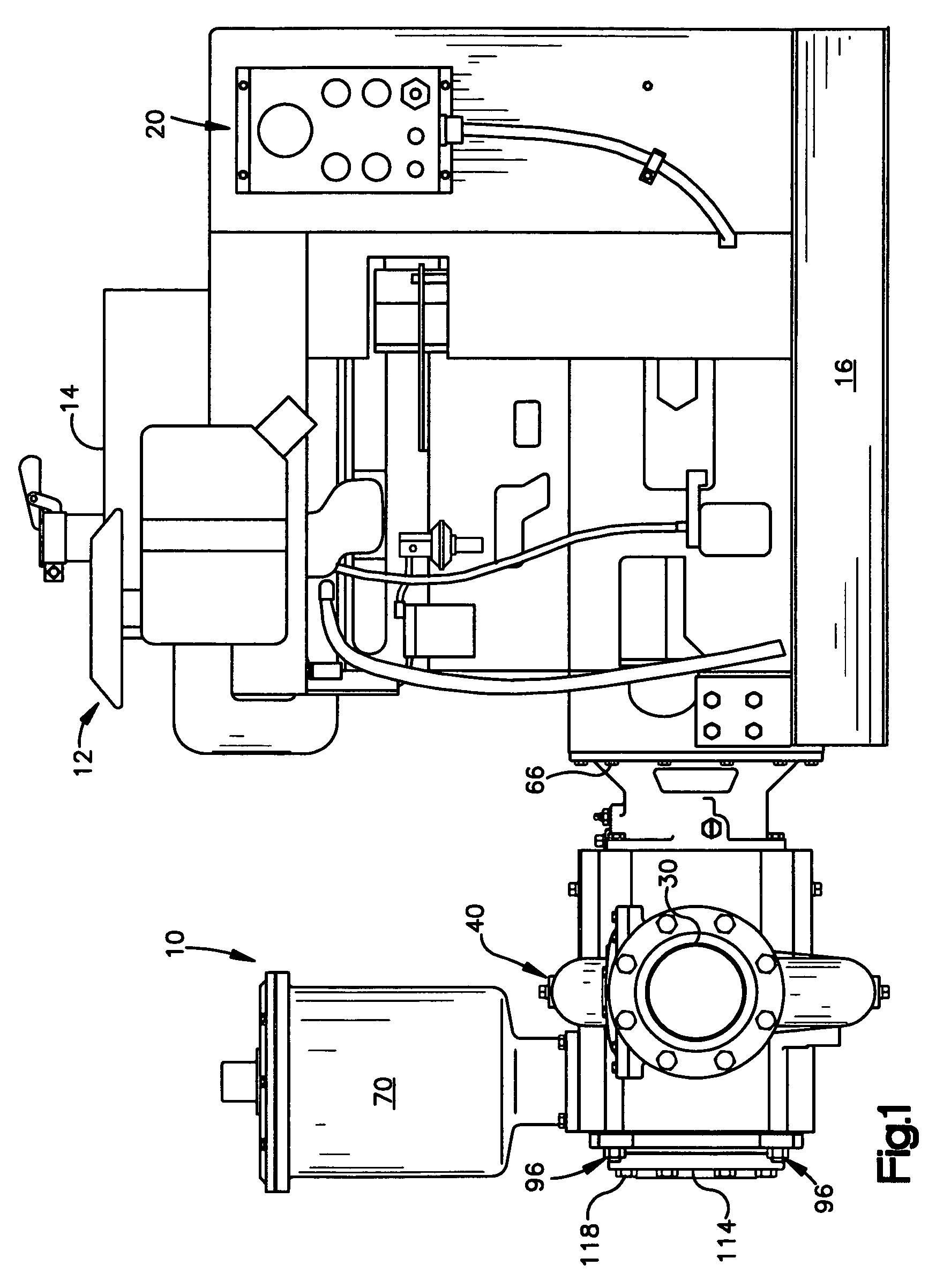

Ventilator apparatus and method

ActiveUS20130263854A1Less mechanically complexRespiratorsOperating means/releasing devices for valvesMedicineBreathing gas

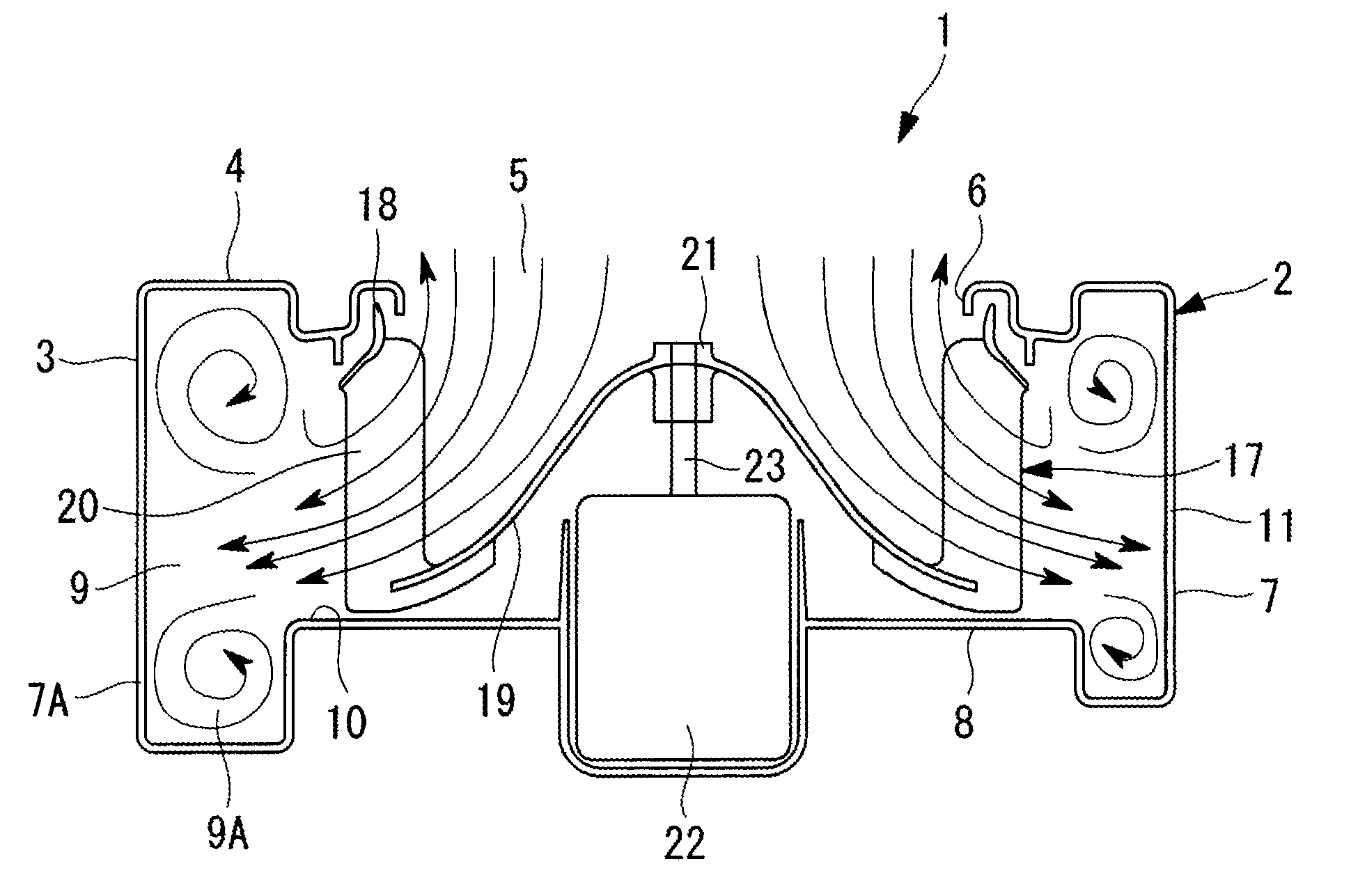

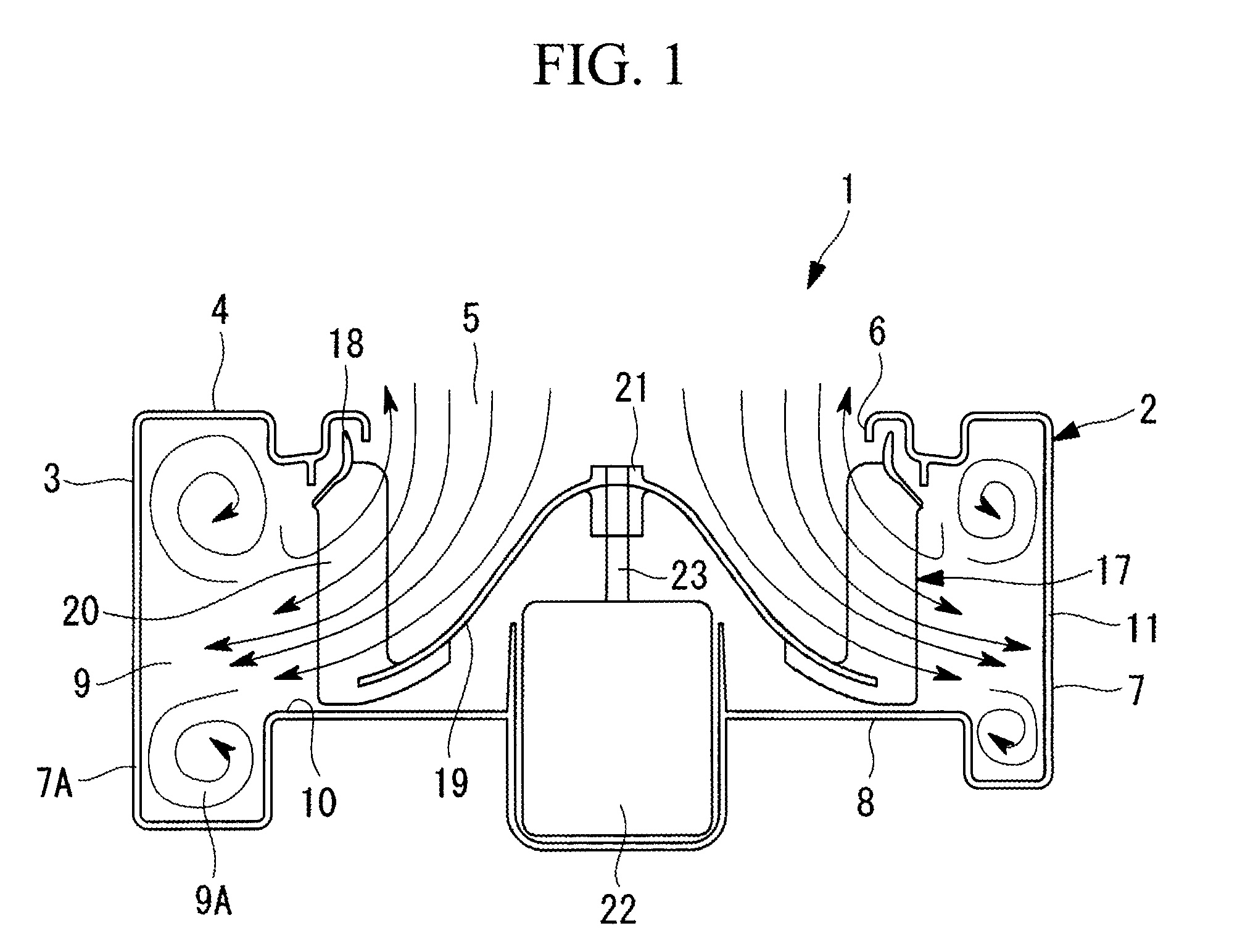

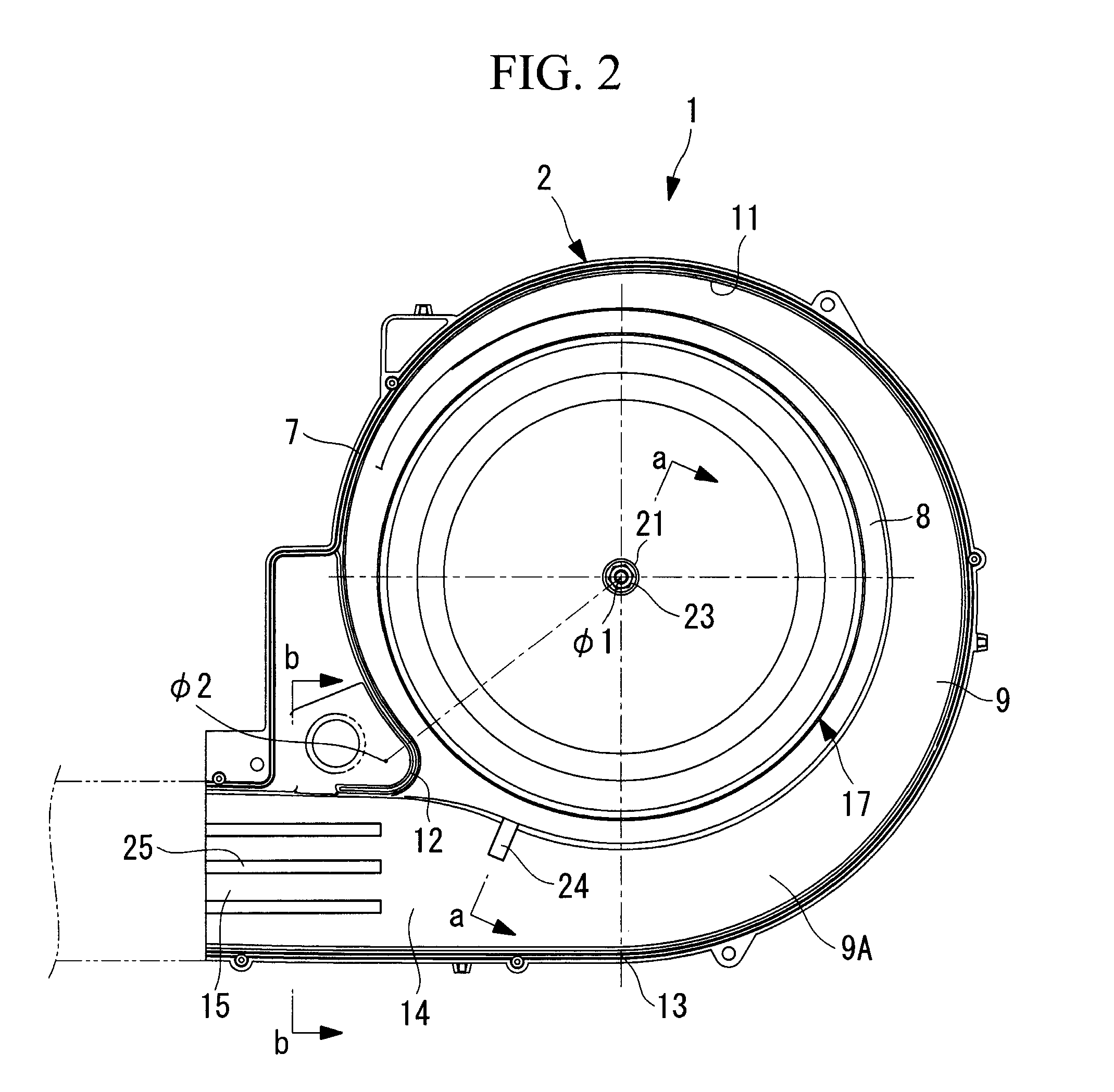

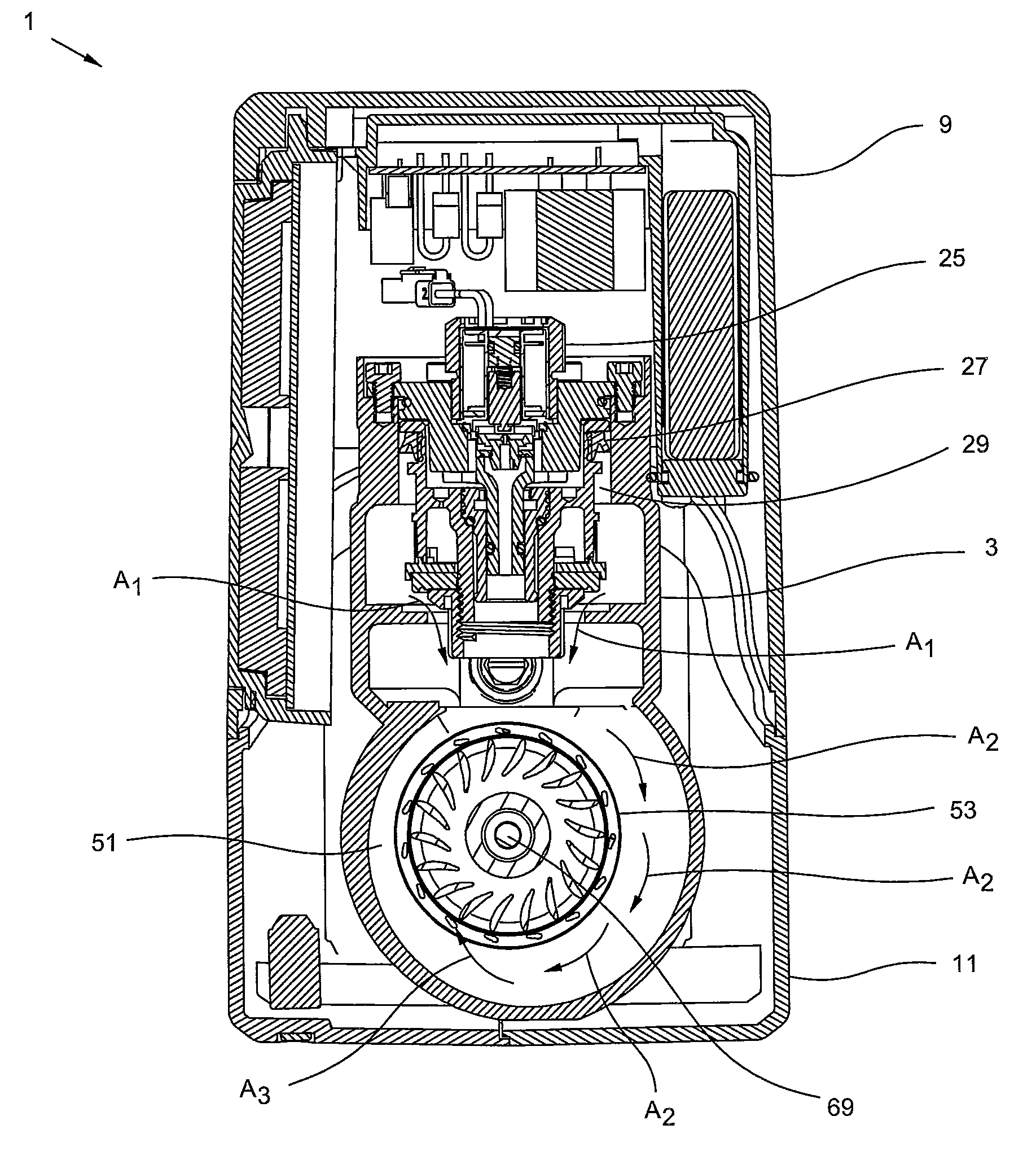

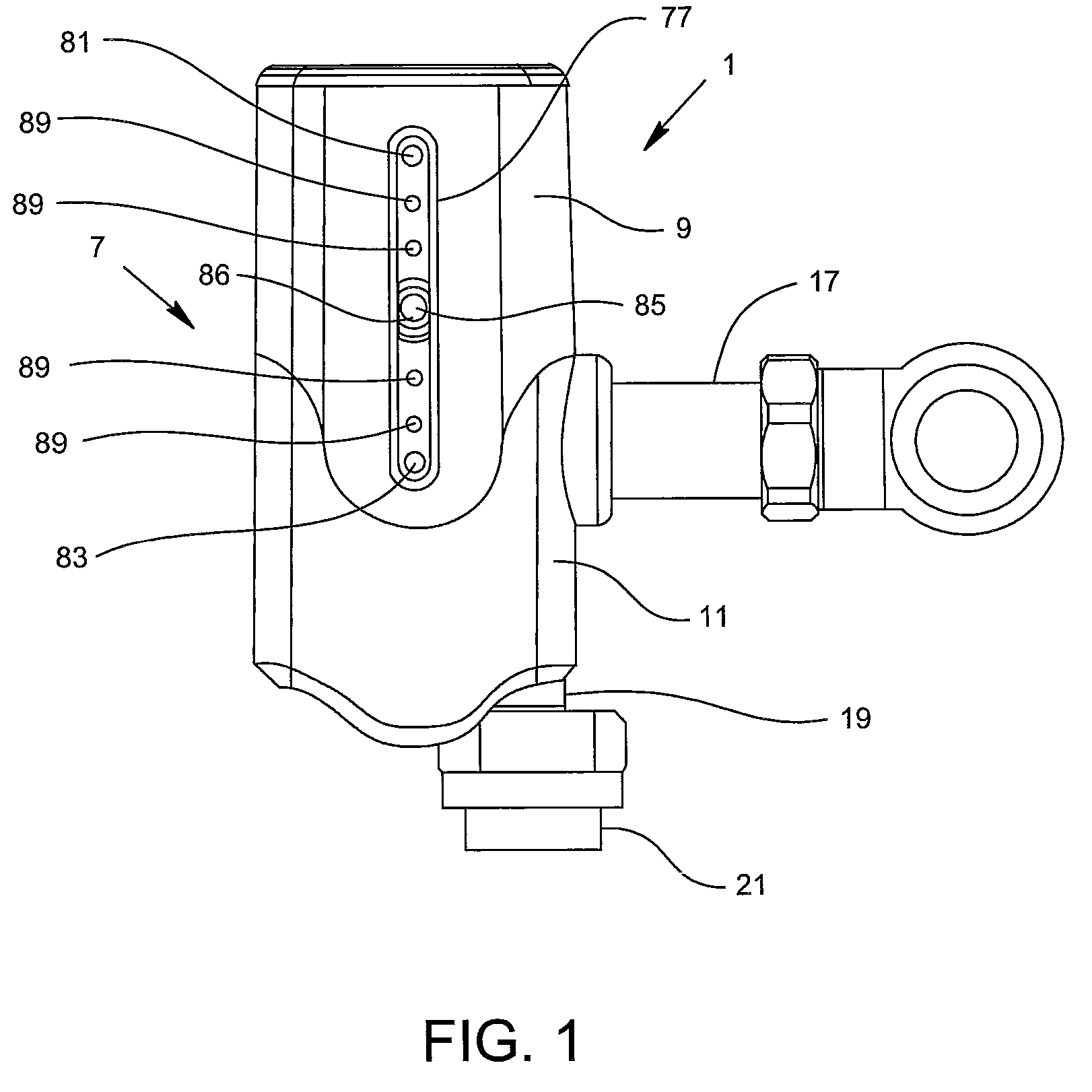

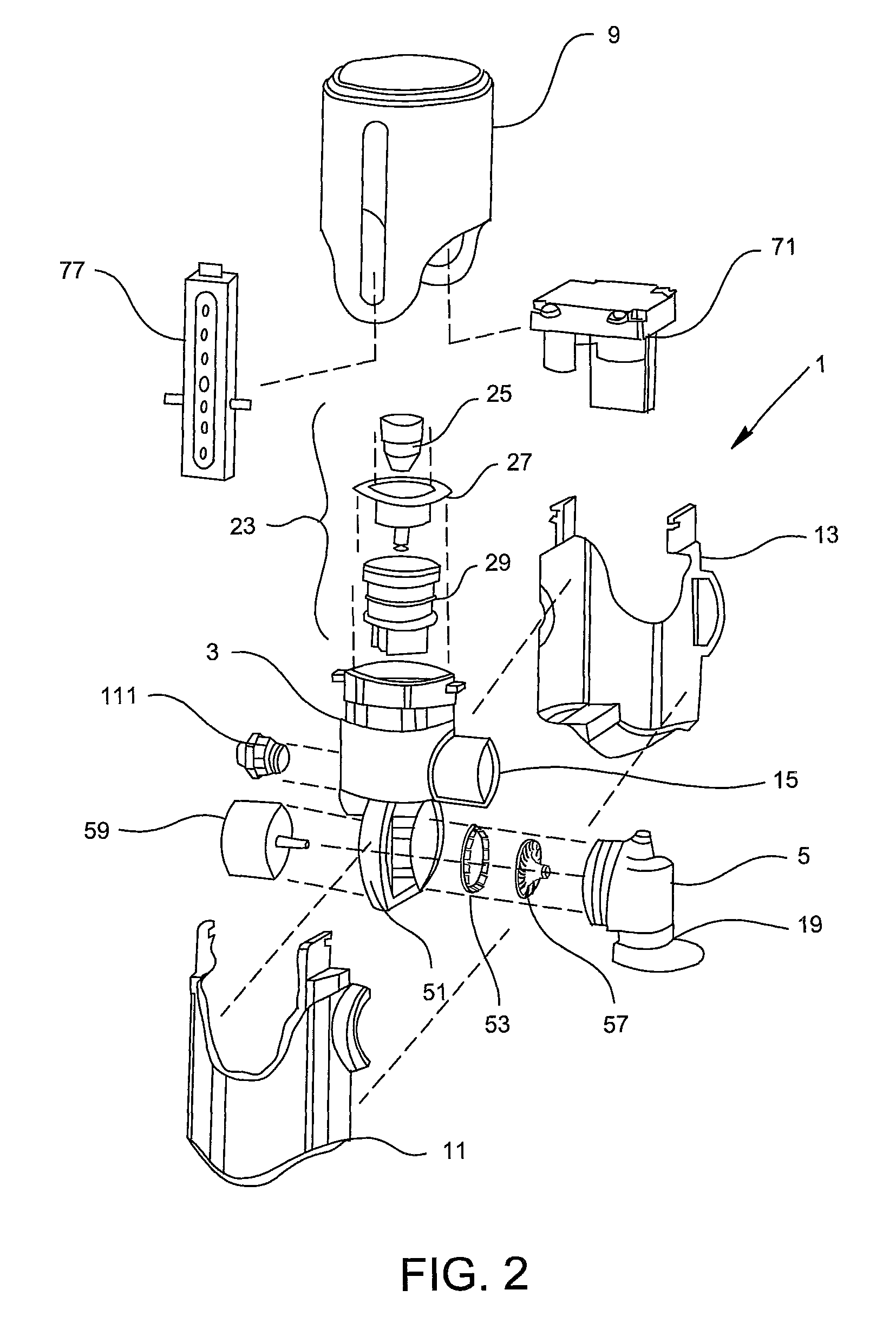

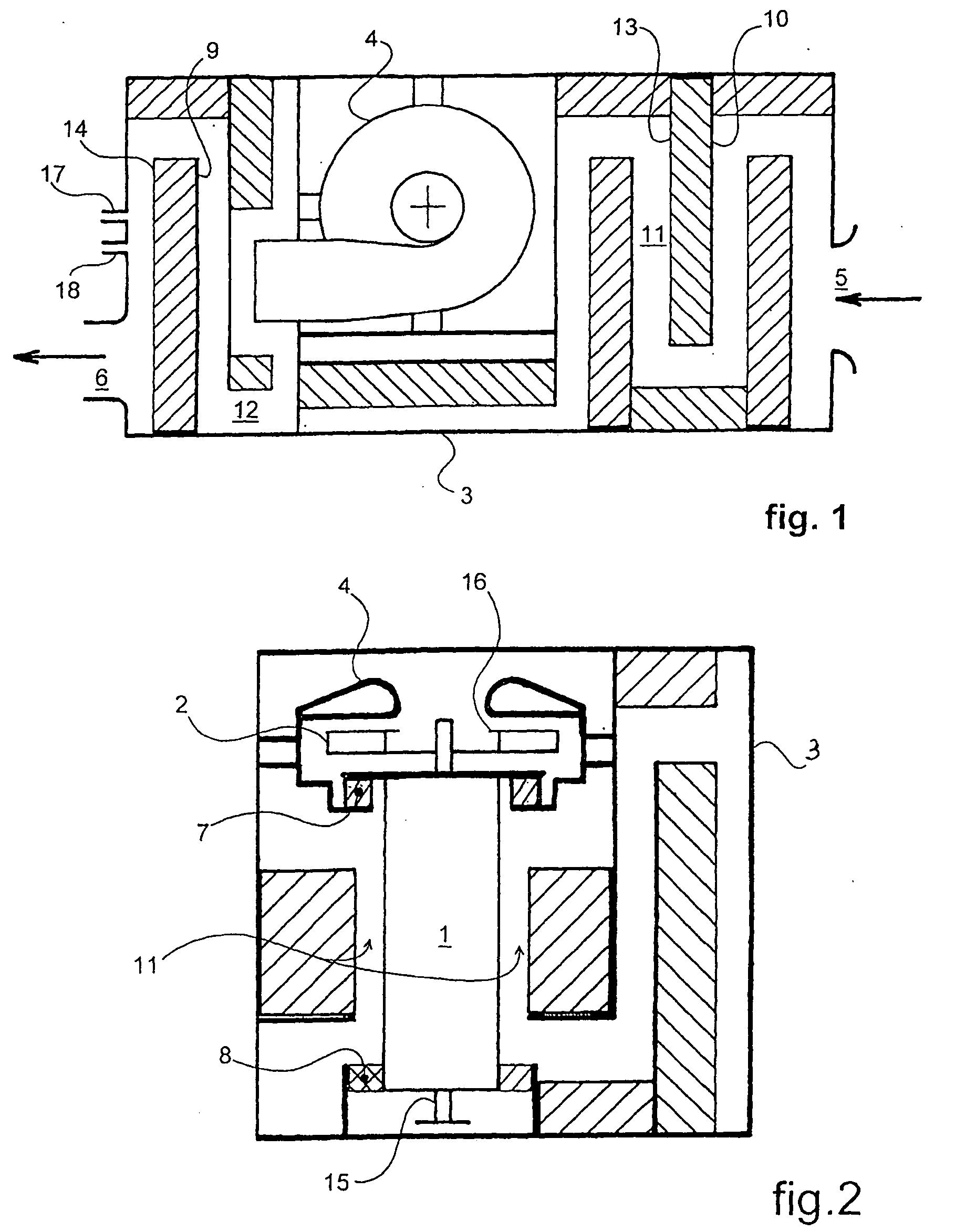

A respiratory treatment apparatus configured to provide a flow of breathable gas to a patient, including a breathable air outlet, an outside air inlet, and an pneumatic block module, wherein the pneumatic block module includes: a volute assembly including an inlet air passage, a mount for a blower and an outlet air passage; the blower being mounted in the mount such that an impeller of the blower is in a flow passage connecting the inlet air passage and the outlet air passage; a casing enclosing the volute assembly, wherein air passages within the casing connect air ports on the volute assembly, wherein the inlet air passage of the volute assembly is in fluid communication with the outside air inlet and the outlet air passage of the volute assembly is in fluid communication with the air outlet.

Owner:RESMED PARIS

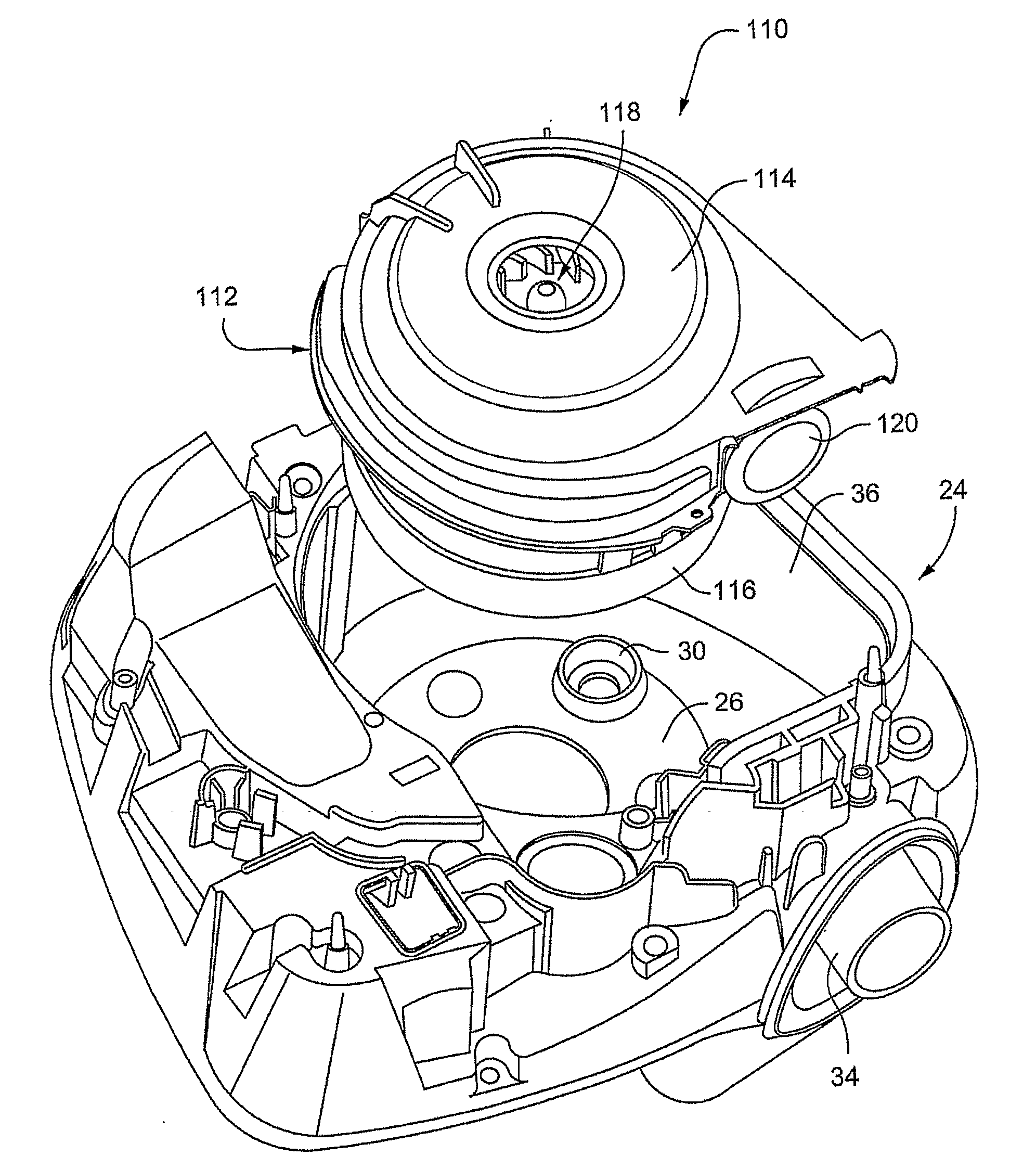

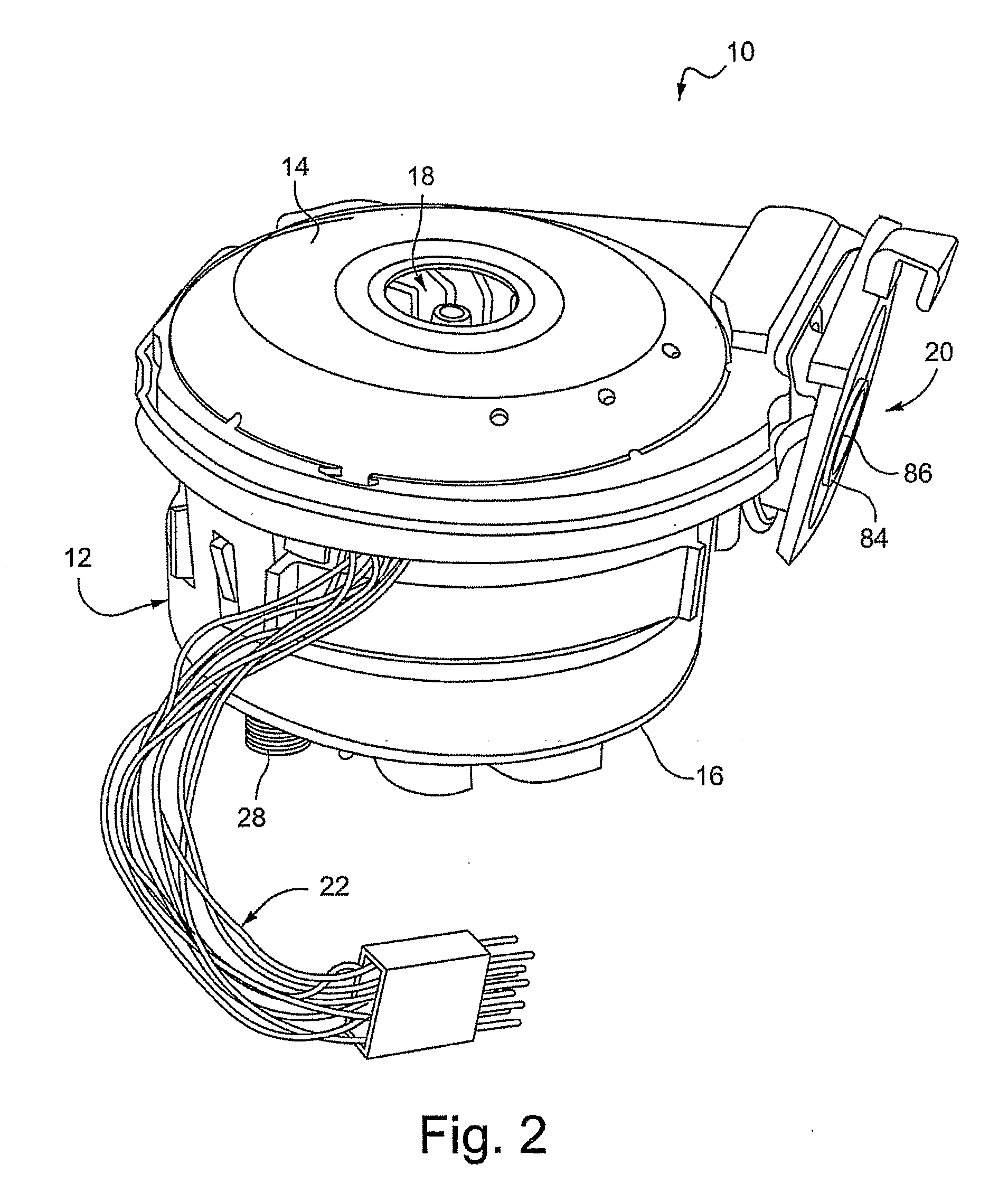

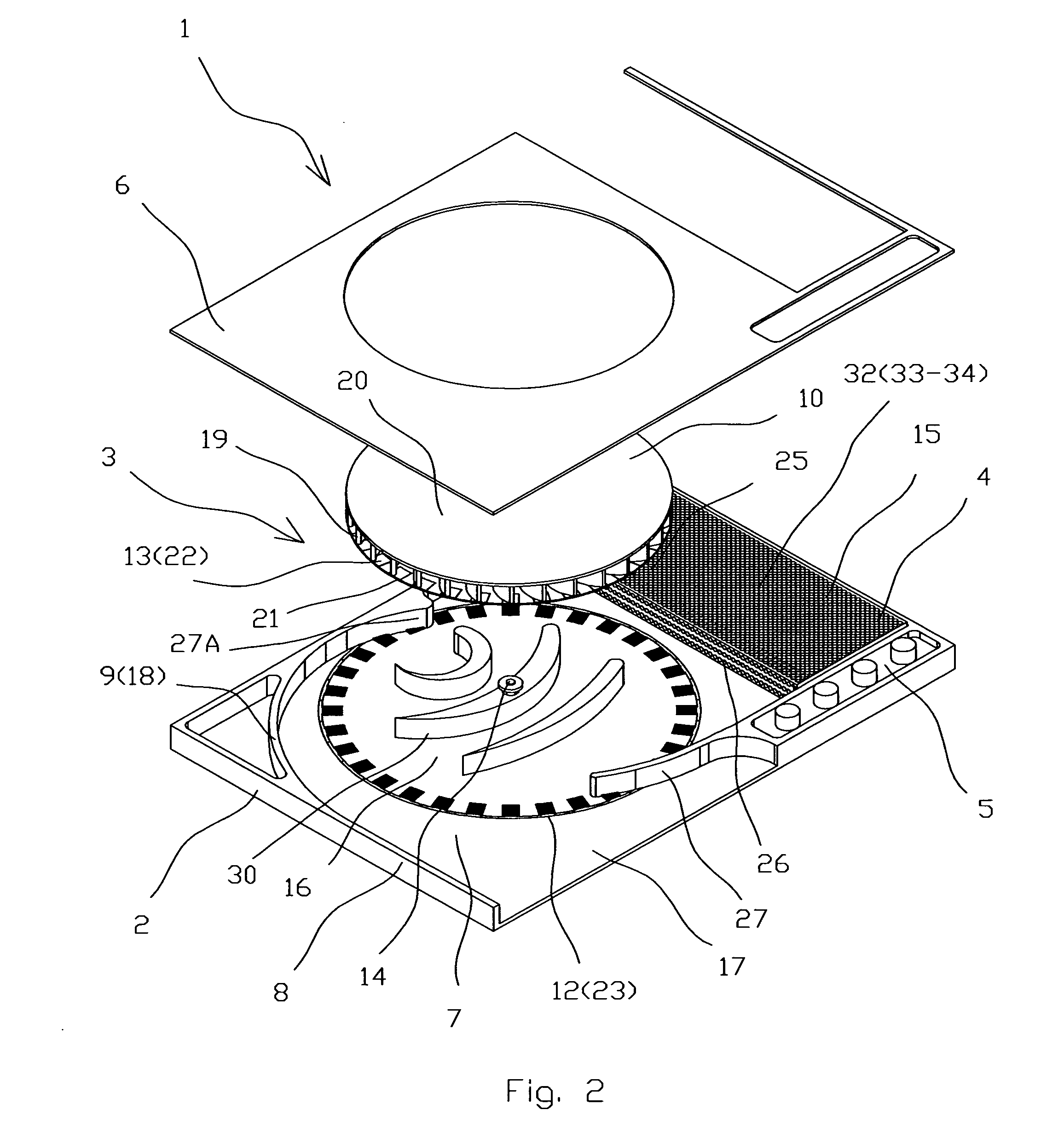

Single or multiple stage blower and nested volute(s) and or impeller(s) thereof

ActiveUS20090301485A1Faster pressure response timeImprove reliabilityPropellersBlade accessoriesImpellerMultiple stages

An impeller includes a top shroud, a bottom shroud, and a plurality of vanes extending from the top shroud to the bottom shroud. The top and bottom shrouds are generally planar, and a lower edge of each vane tapers from an outer edge of the bottom shroud to a transverse tip edge thereof.

Owner:RESMED LTD

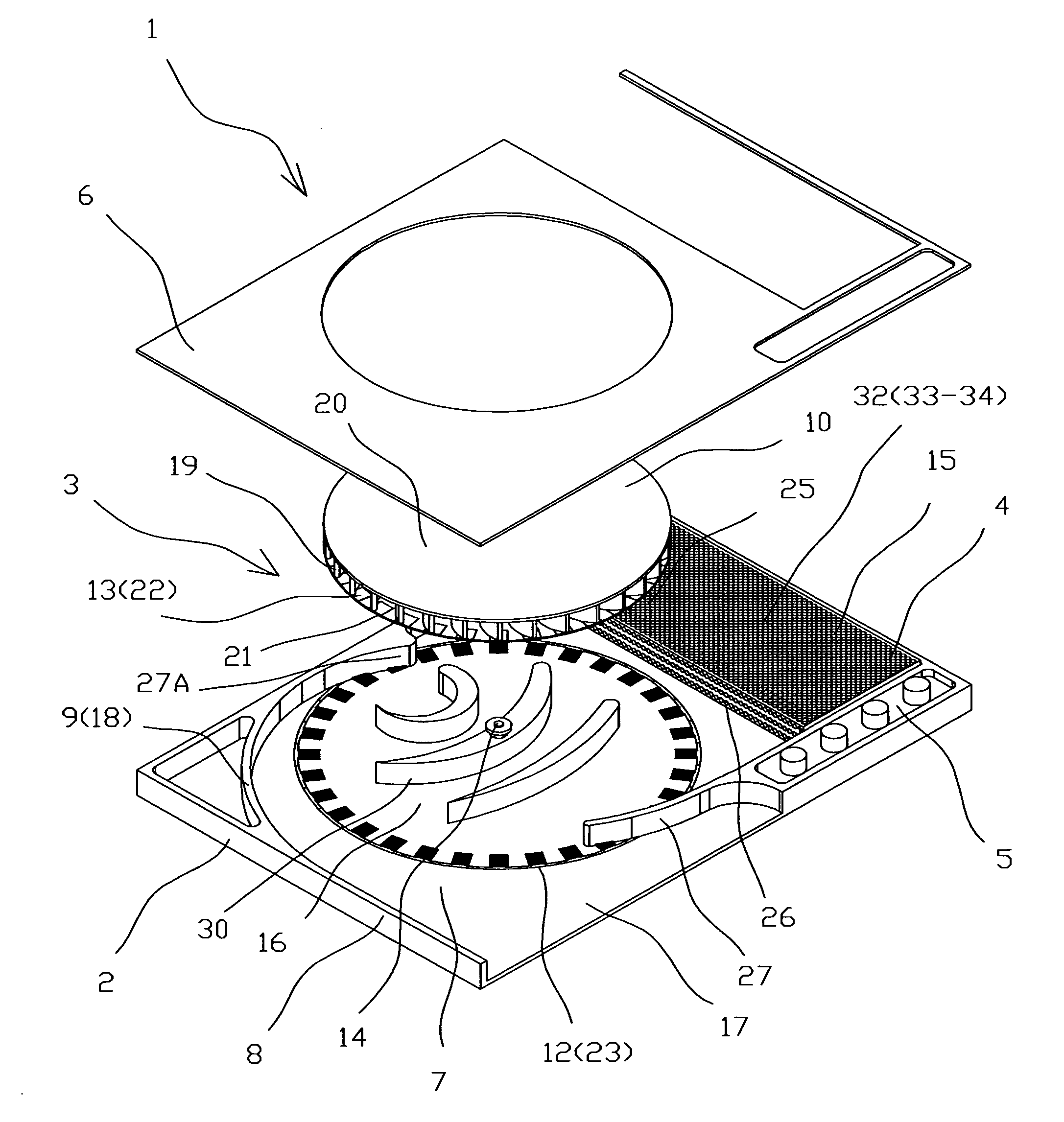

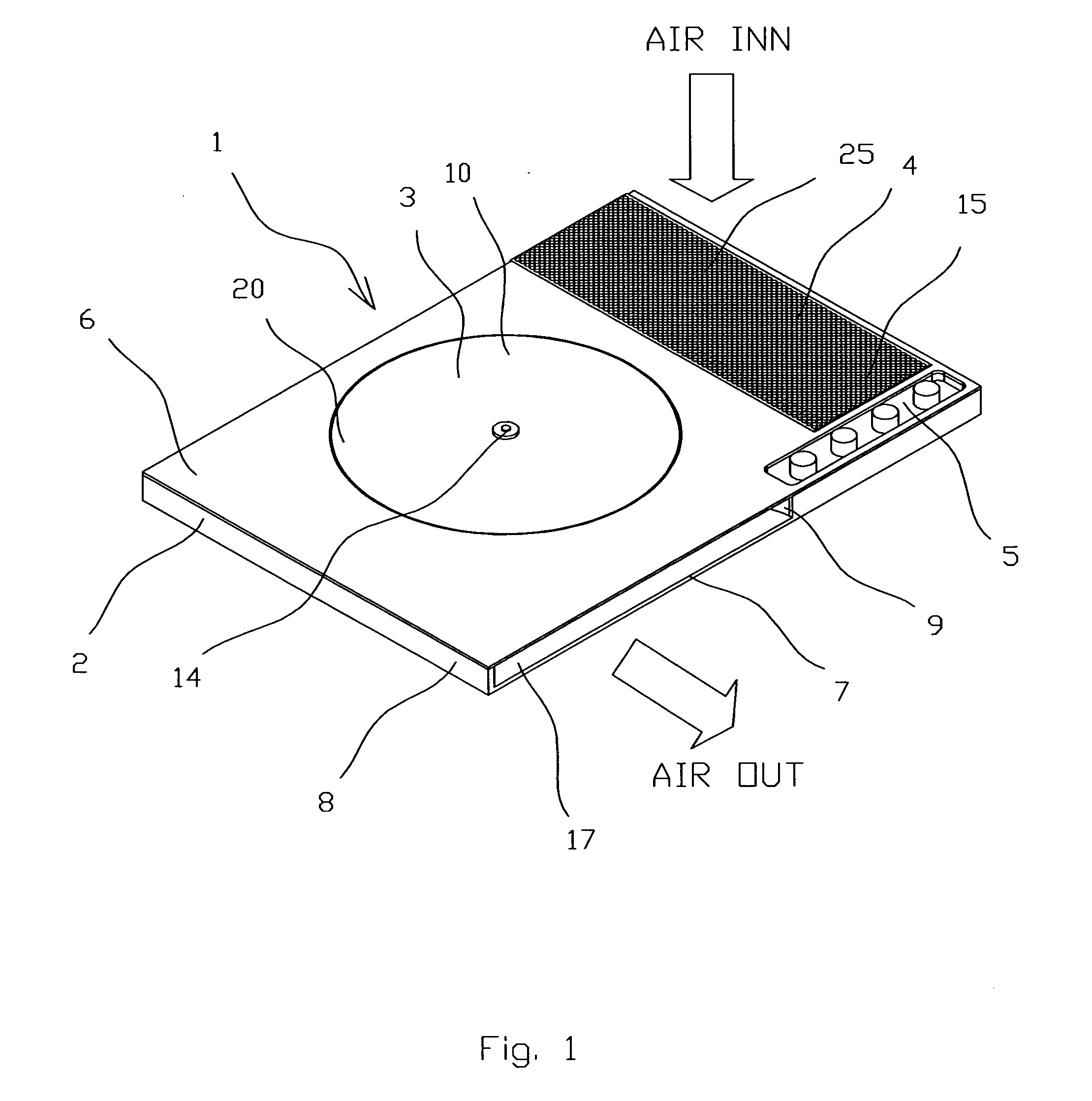

Thin air processing device for heat ventilation air conditioning system

A thin air processing device suitable for wall mounting comprises a housing and located inside a crossflow blower, an air processing unit and a controller unit. The housing comprises a cover plate, a base and side parts. The blower comprises a casing, an impeller, an electric drive with a flat stator and a magnetized rotor, and an axle fixed perpendicularly to the base. The casing comprises an inlet, a central part and an outlet and integrated with the housing thus a volute shape of the casing formed by side parts. The impeller comprises circumferential arrayed magnetic means thus serving as the magnetized rotor. The flat stator comprises circumferential arrayed coils with magnetic axes coincide with a plane of the flat stator and integrated with the housing. The air processing unit located at the inlet of the casing and comprises an intake and an outtake openings.

Owner:INDAL DESIGN LAB

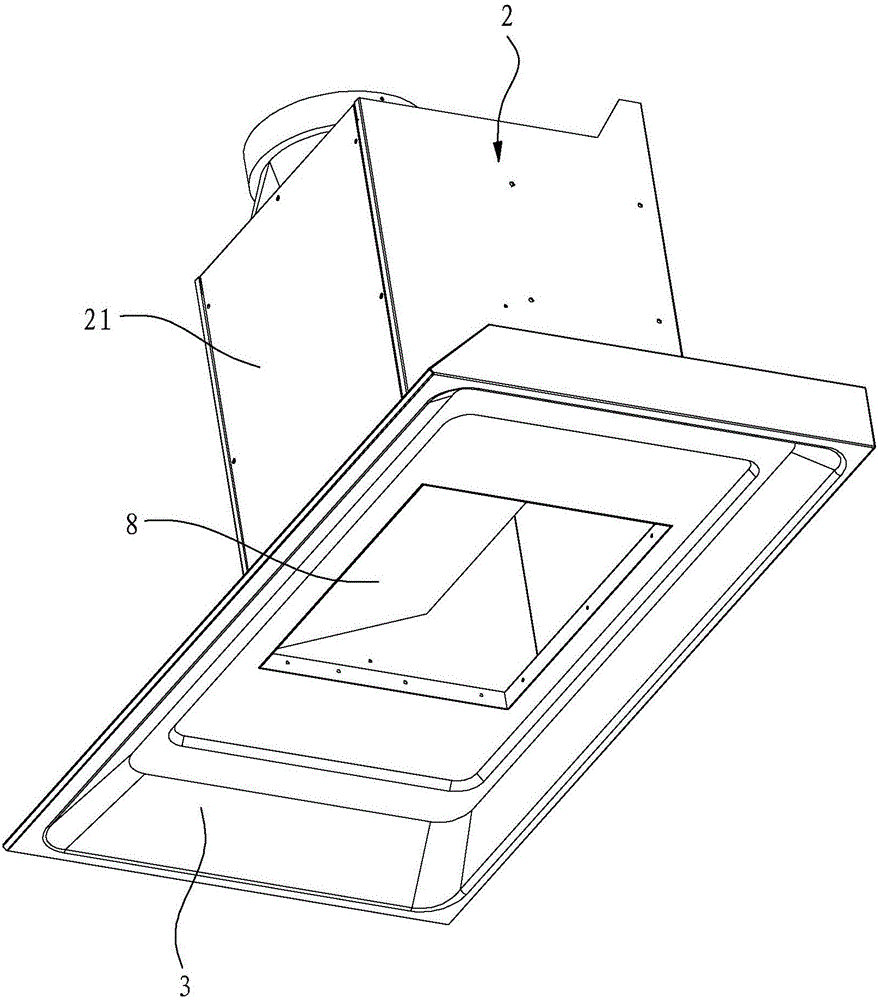

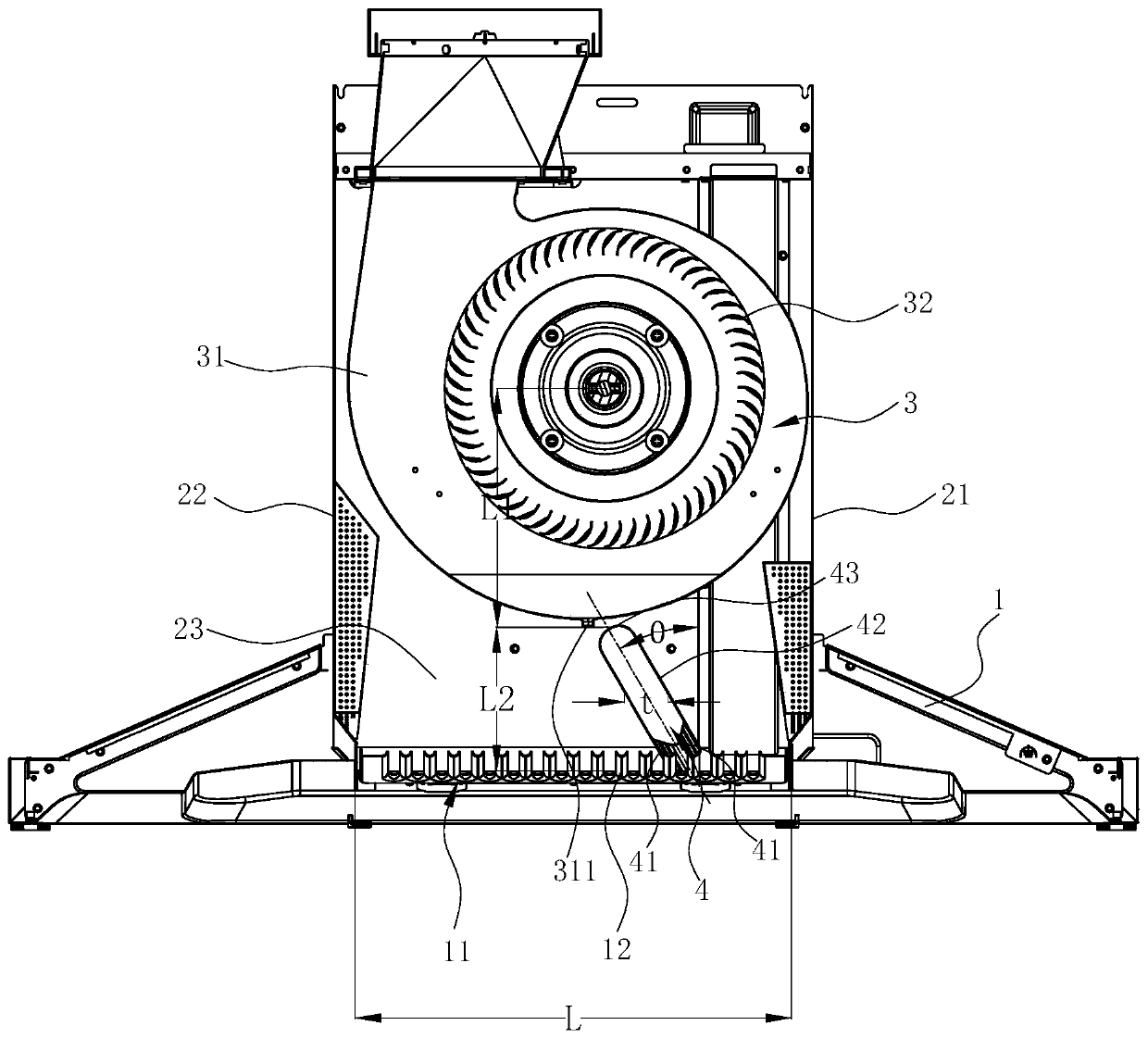

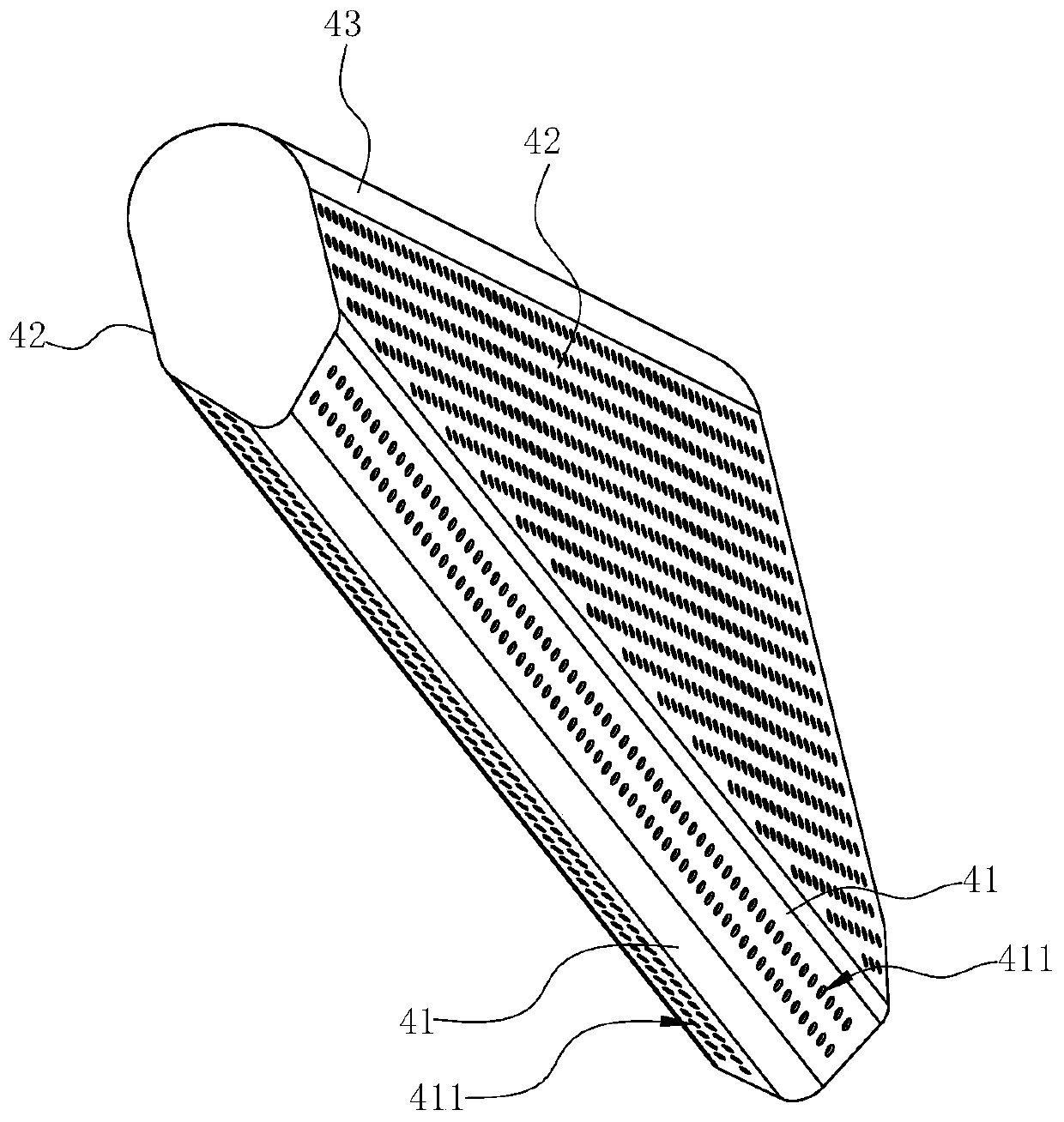

Spiral case of blower fan in apparatus with inlet air from two sides for sucking oil fume

This invention discloses a fan turbine casing inletting wind from two sides including a front cover plate, a back cover plate and a circular middle shell connecting the two, a front air-inlet and a back air-inlet are set on them separately, and the projection of the center of the front one on the plane where the back cover places is coincident with that of the back one characterizing that a curved panel projecting downward is connected between the down edges of the two plates to shield the middle shell, so smoke can be led to the front and back air-inlets smoothly.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Multi-blade centrifugal fan and air conditioner employing the same

InactiveUS20120211205A1Deviation can be suppressedSuppress instabilityEngine manufacturePump componentsImpellerCentrifugal fan

In a multi-blade centrifugal fan in which an impeller is provided in a scroll casing in a freely rotatable manner, the scroll casing is provided with an axially expanded portion that forms an air channel at a bottom surface thereof which is expanded in a rotation-axis direction at a radially outer side of an annular flange portion which supports the impeller; and is provided, in a region of an outlet between a tongue portion and a spiral-end portion of the scroll casing in the axially expanded portion, with a protrusion that protrudes radially outward from a radially inner side surface by a predetermined amount so as to directly face an airflow in a circumferential direction.

Owner:MITSUBISHI HEAVY IND LTD

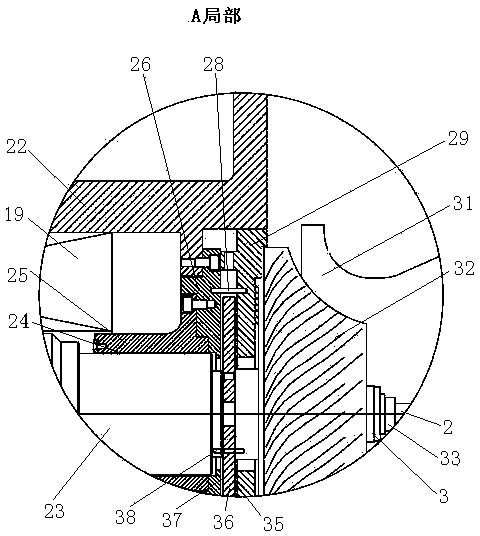

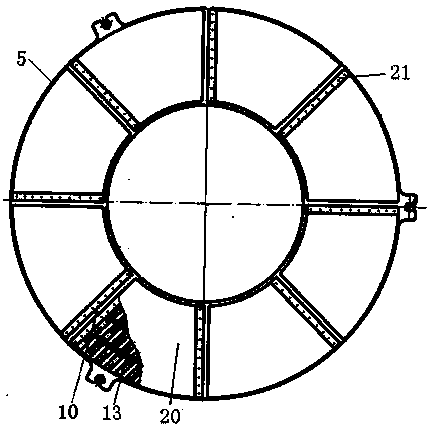

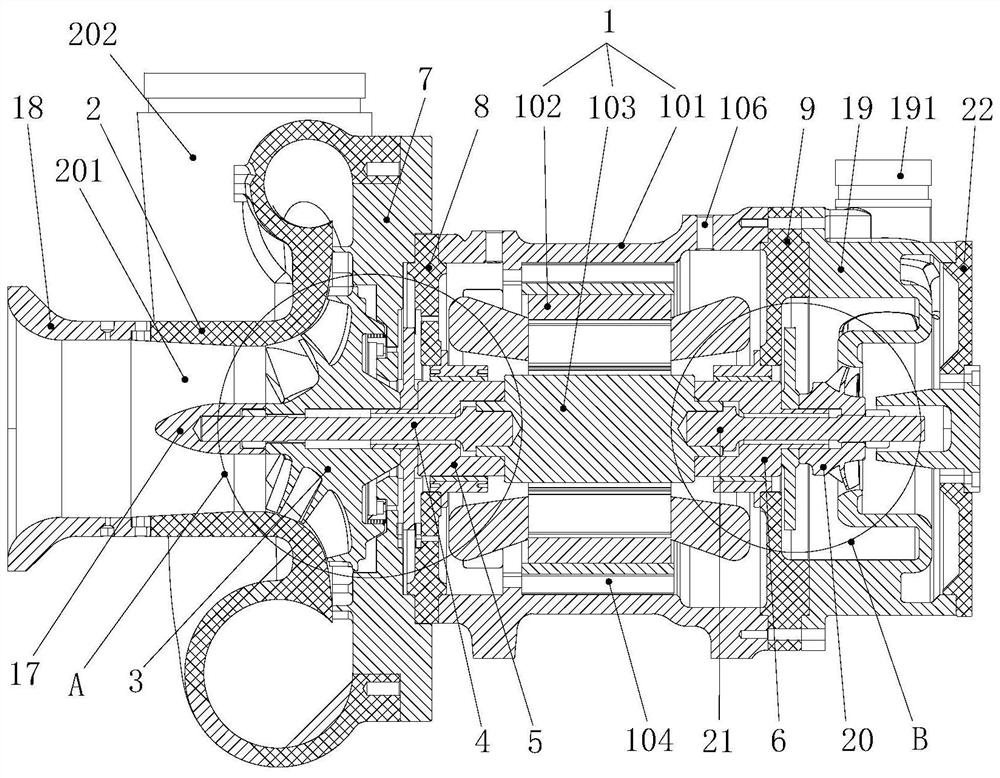

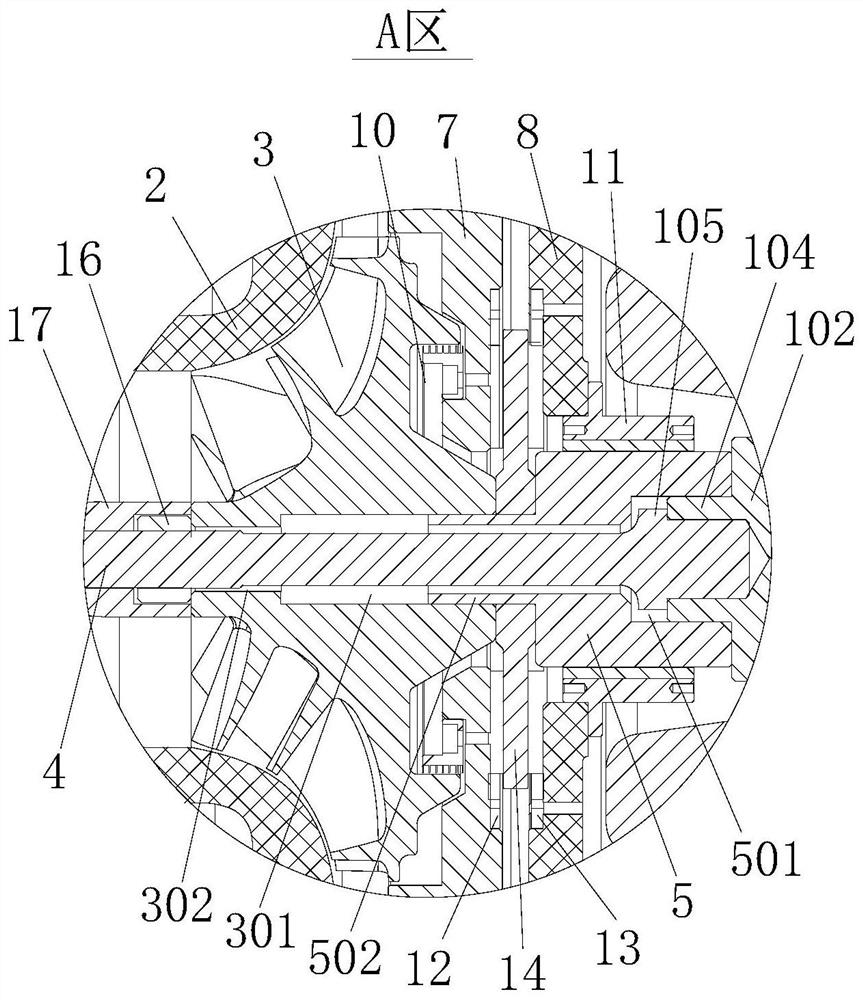

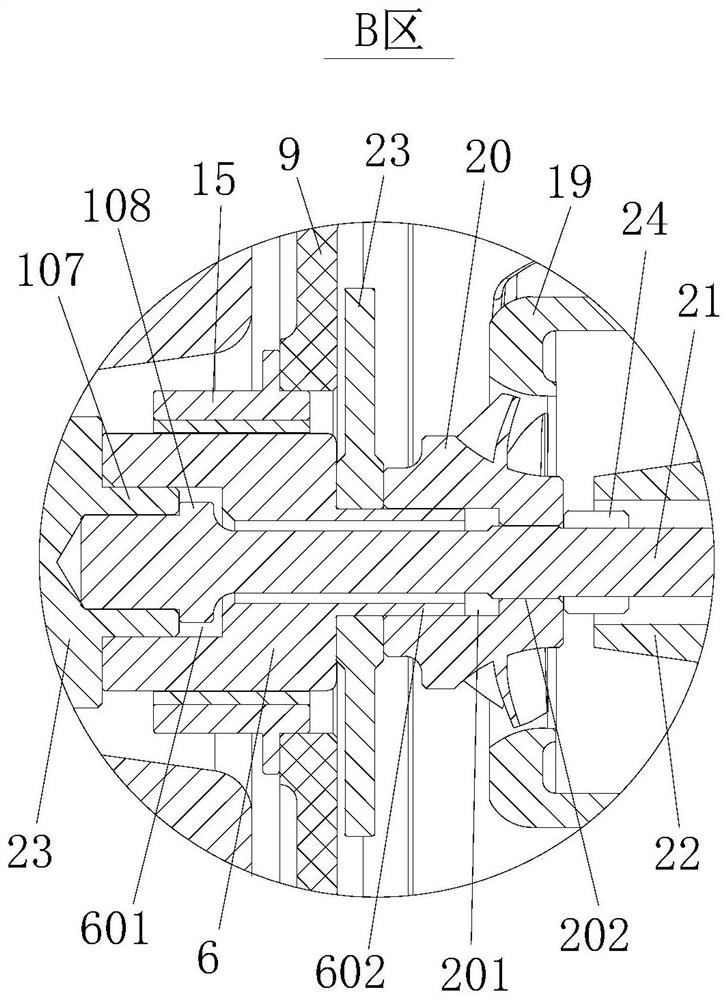

Air suspension centrifugal blower

ActiveCN104179712AImprove efficiencyImprove high-speed stabilityPump componentsPumpsThrust bearingElectric machinery

Owner:SHIJIAZHUANG KINGSTON BEARING TECH

Double-air-inlet centrifugal fan

InactiveCN104196761AOvercome problems caused by uneven outlet velocity distributionReduce rotational noisePump componentsPumpsAir volumeElectric machinery

The invention provides a double-air-inlet centrifugal fan which comprises a volute, double-air-inlet impellers and a motor. The double-air-inlet impellers are arranged on a rotating shaft of the motor and are arranged in the volute. The volute comprises a front cover plate, a rear cover plate and a volute coaming arranged between the front cover plate and the rear cover plate. The positions, aligned with the double-air-inlet impellers, of the front cover plate and the rear cover plate are provided with a front air-inlet channel and a rear air-inlet channel respectively. The volute coaming is provided with an air outlet channel. The position, corresponding to the air outlet channel, of the volute is provided with a volute tongue. The volute tongue comprises a volute tongue curved face, and the volute tongue curved face is located on one side of the air outlet channel and is an inwards-concave and asymmetric curved face. According to the double-air-inlet centrifugal fan, the inwards-concave and asymmetric curved face is adopted for the volute tongue curved face, on one hand, rotating noise can be reduced, on the other hand, a deep tongue form is adopted for the volute tongue contour line close to an impeller front end ring and an impeller rear end ring, a shallow tongue form is adopted for the volute tongue contour line close to an impeller middle disc, so that the problem caused by uneven outlet speed distribution of the impellers can be avoided, and thus air volume and air pressure are increased, and efficiency are improved easily.

Owner:GUANGDONG HISENSE HOME APPLIANCES CO LTD

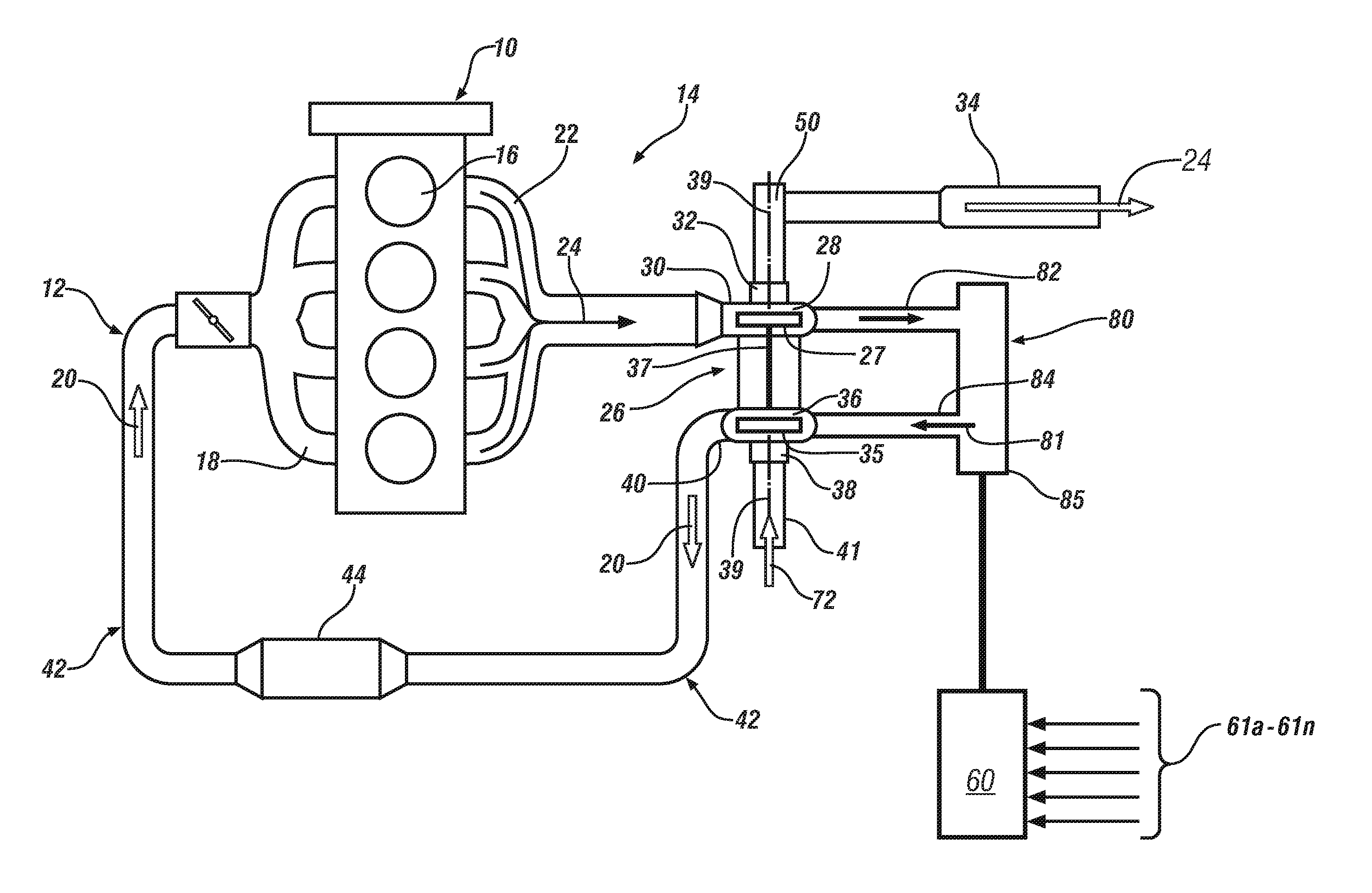

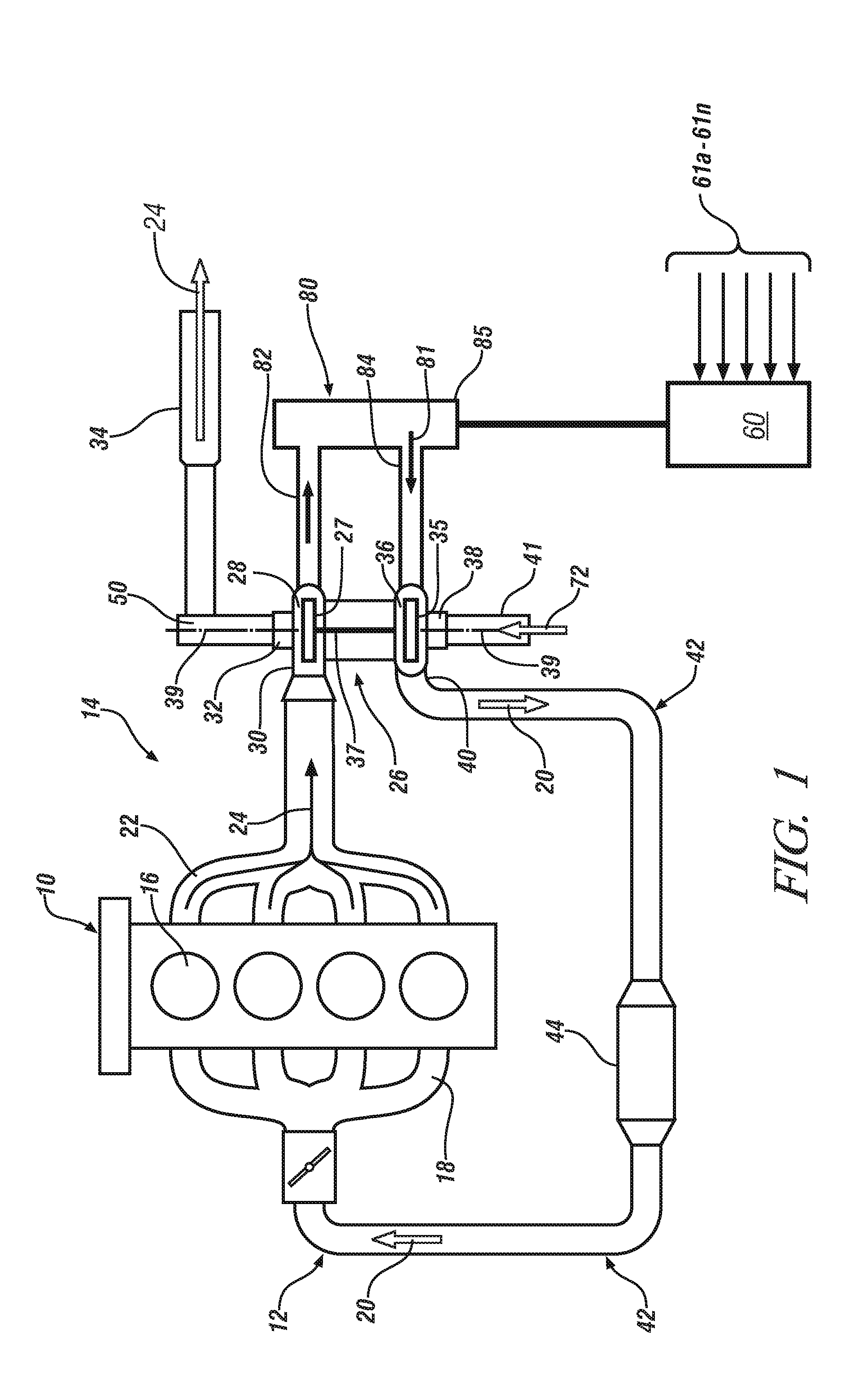

Turbine housing and method for directing exhaust

InactiveUS20120312011A1Internal combustion piston enginesNon-fuel substance addition to fuelImpellerTurbine wheel

In one exemplary embodiment of the invention, a turbine housing for a forced induction system of an internal combustion engine is provided, the turbine housing including a turbine inlet passage in fluid communication with a turbine volute configured to house a turbine wheel, the turbine inlet passage configured to direct an exhaust gas flow from an exhaust manifold to the turbine wheel. The housing also includes a turbine outlet passage in fluid communication with the turbine volute, the turbine outlet passage configured to direct the exhaust gas flow to a catalytic converter coupled to the turbine outlet passage, wherein the turbine outlet passage comprises a cone shaped passage.

Owner:GM GLOBAL TECH OPERATIONS LLC

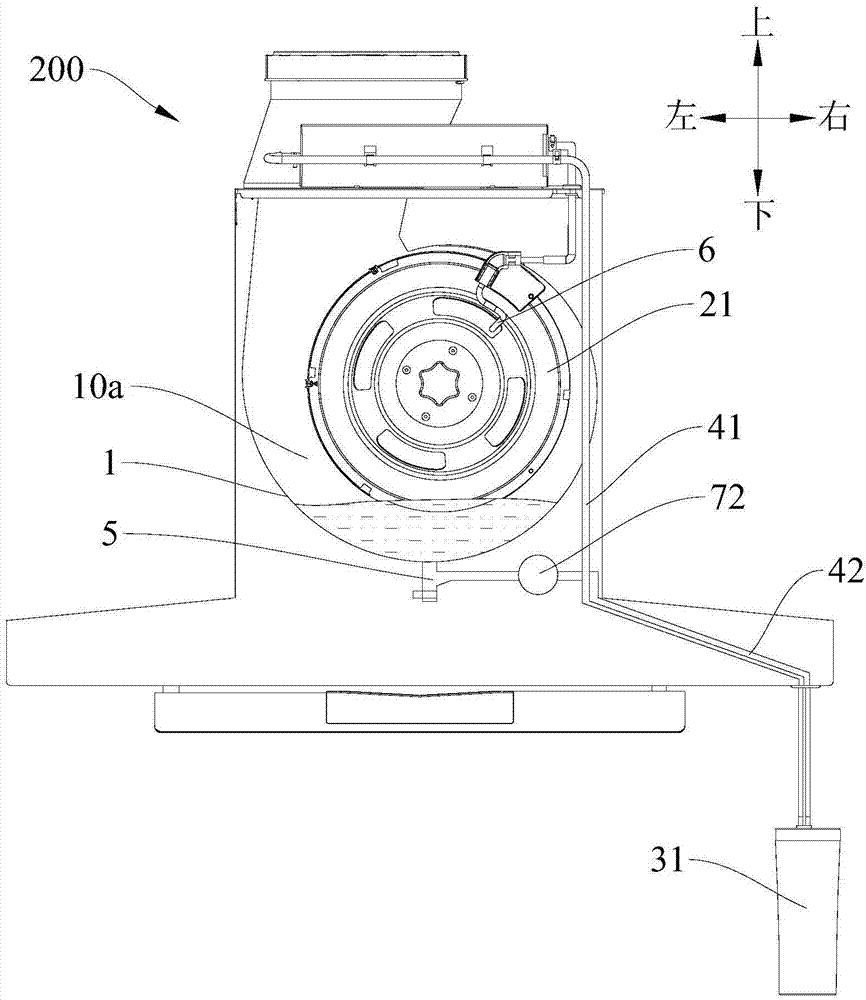

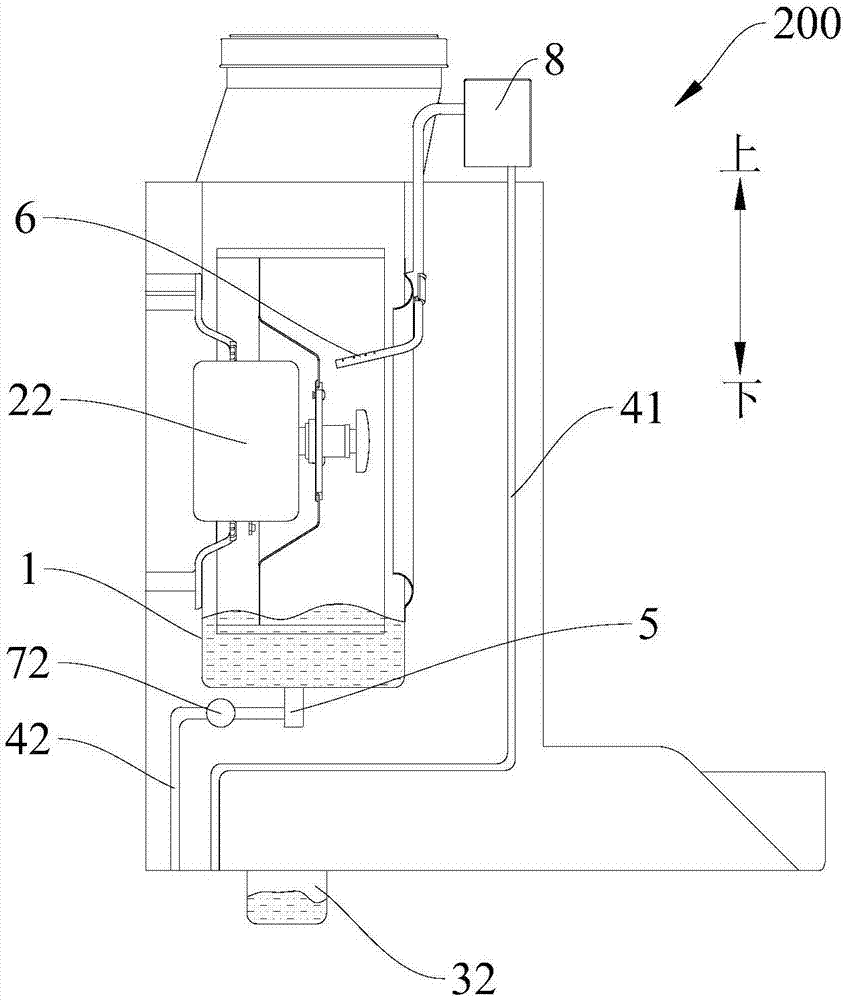

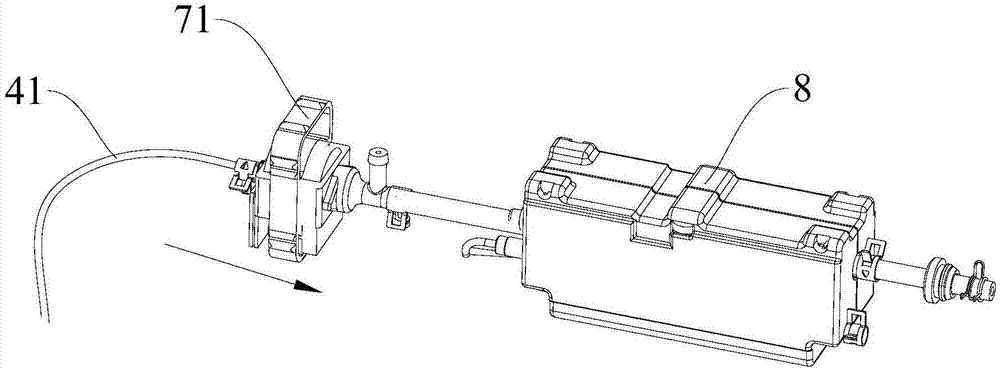

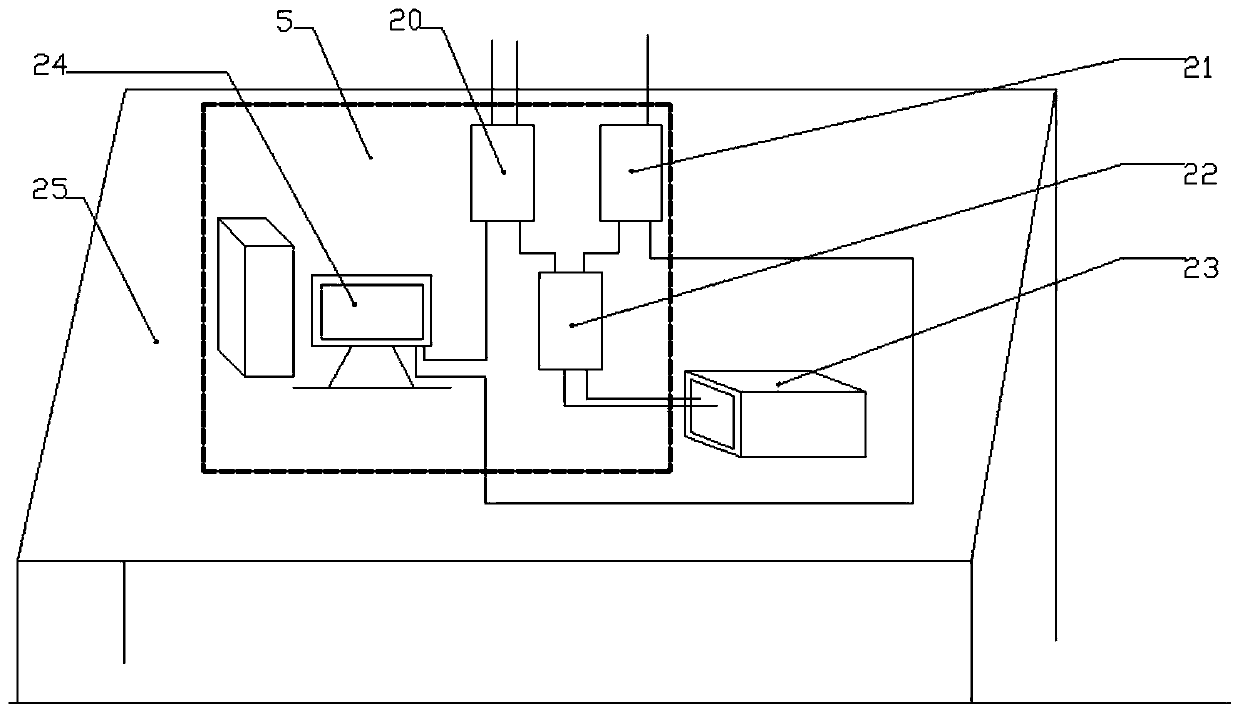

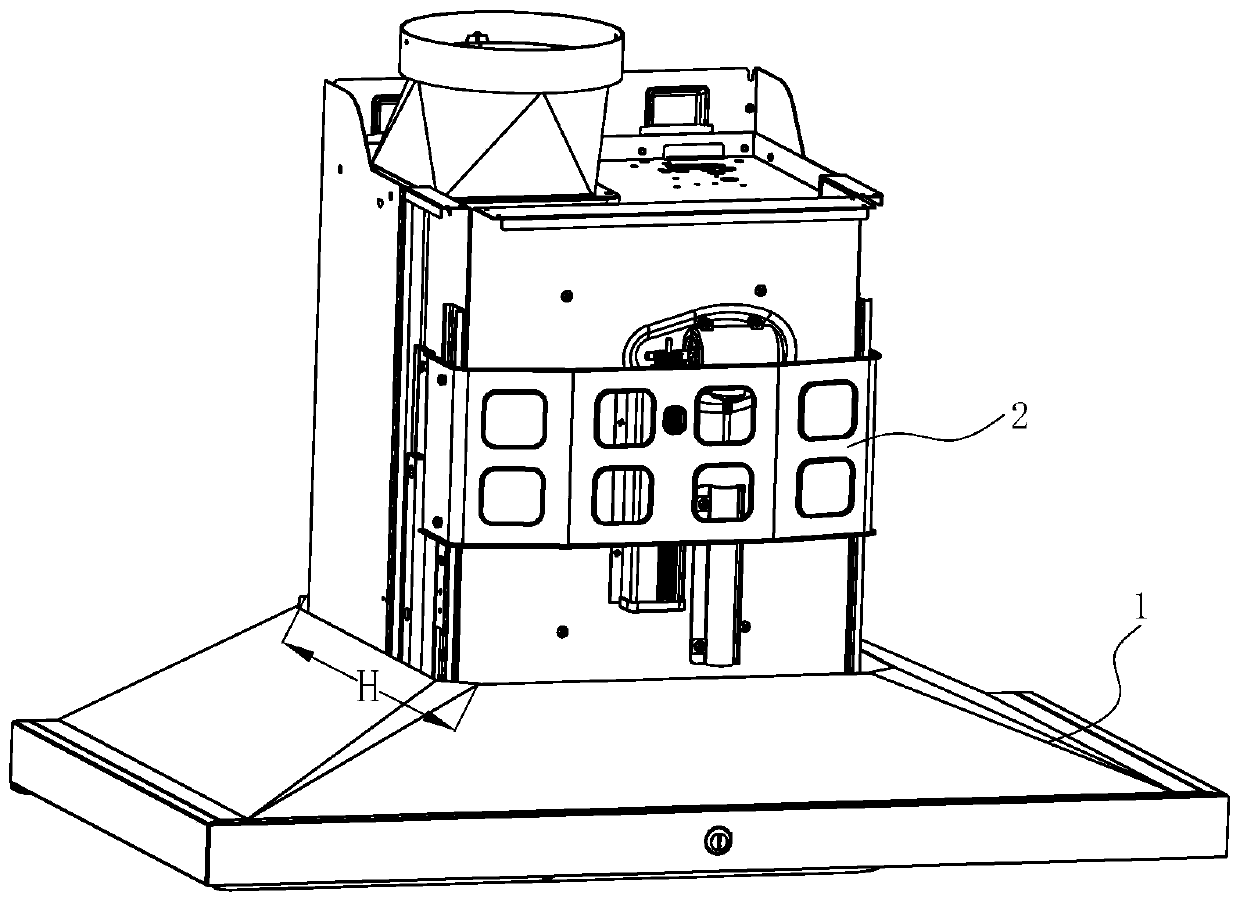

Cleaning device of extractor hood, control method of extractor hood and extractor hood

ActiveCN107355835AGuaranteed performanceAvoid repeated disassembly and assemblyDomestic stoves or rangesLighting and heating apparatusControl valvesDrain tube

The invention discloses a cleaning device of an extractor hood, a control method of the extractor hood and the extractor hood. The cleaning device of the extractor hood comprises a volute, a wind wheel, a water containing box, an oil containing cup, a water inlet pipeline, a water drain pipeline, an oil drain pipeline and a control valve. The water inlet pipeline is used for inletting fluid into a mounting cavity, the water drain pipeline is used for draining the fluid in the mounting cavity, and the control valve is used for controlling on and off states of the water inlet pipeline and the water drain pipeline. The control valve has a first state, a second state and a third state; when the control valve is in the first state, both the water inlet pipeline and the water drain pipeline are disconnected; when the control valve is in the second state, the water inlet pipeline is connected, and the water drain pipeline is disconnected; and when the control valve is in the third state, the water inlet pipeline is disconnected, and the water drain pipeline is connected. According to the cleaning device of the extractor hood, under the premise of guaranteeing normal operation of the extractor hood, the extractor hood can be effectively cleaned.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

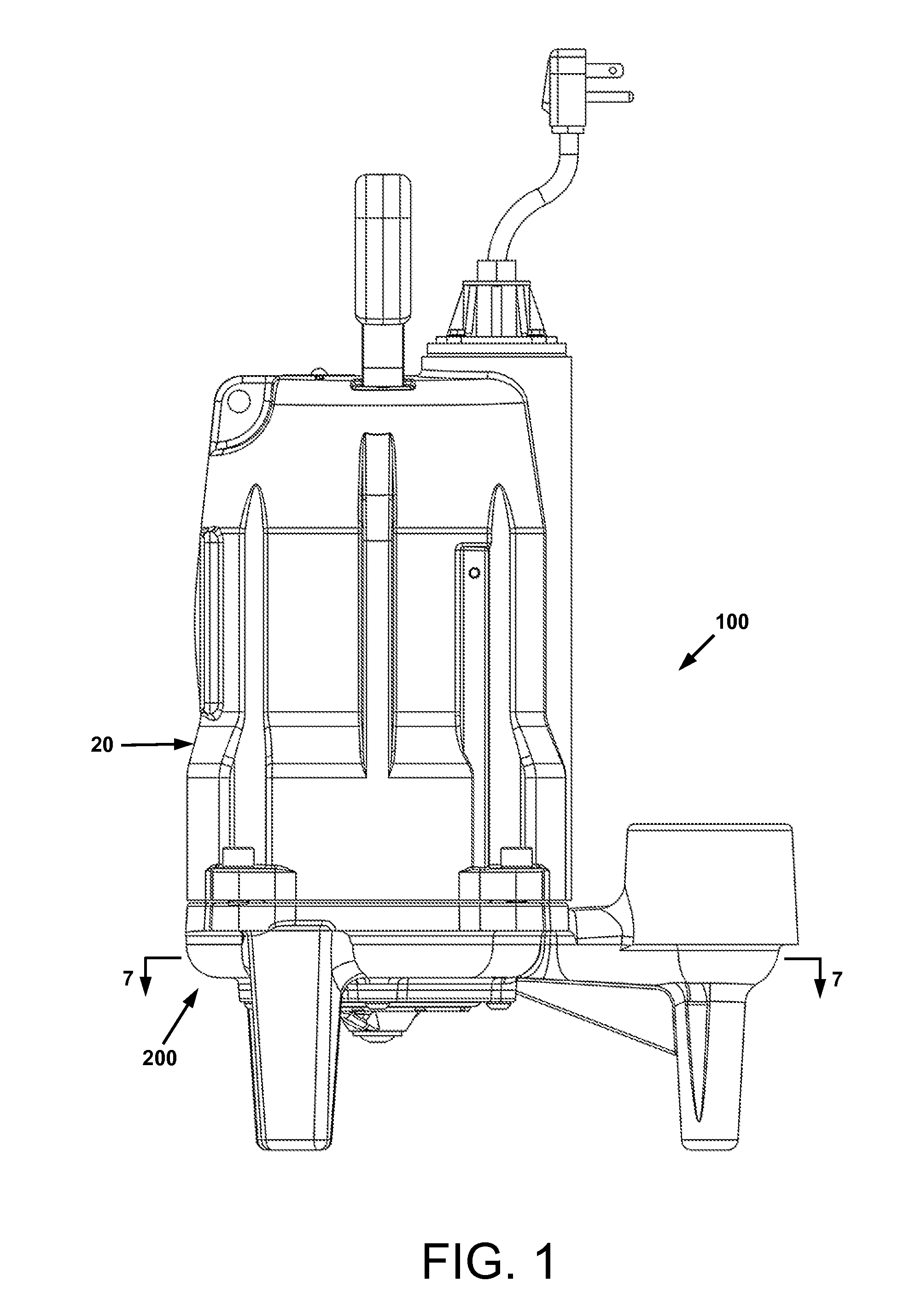

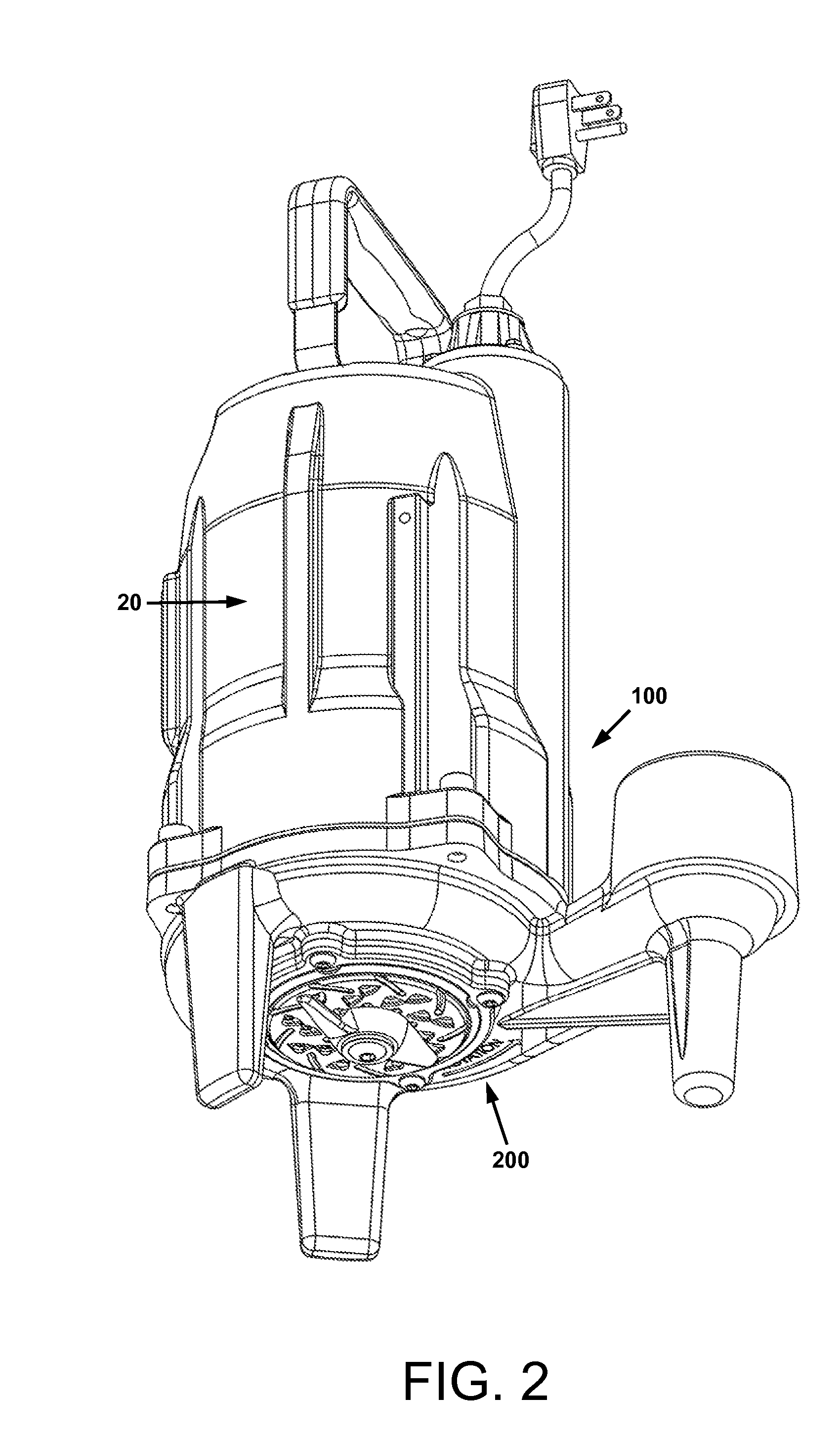

Liquid pump

ActiveUS20140199165A1Prevent damage to the sealProlong lifeSpecific fluid pumpsPump componentsImpellerLeading edge

A pump for pumping liquids containing entrained solids. The pump is comprised of a volute surrounding an impeller comprising vanes that are self-cleaning. The outer surfaces of the vanes are coplanar and define a first plane and have a leading edge. The volute is comprised of a planar mating surface defining a second plane parallel to the first plane of the rotary impeller. The planar mating surface is proximate to the outer surfaces of the vanes and is comprised of a plurality of channels extending radially from the inner perimeter to the outer perimeter thereof. Each channel includes a forward edge in the direction of impeller rotation. The channels are oriented such that when the impeller is rotated within the volute, for any vane, the leading edge of the vane traverses each channel progressively from the inner end of the channel to the outer end of the channel.

Owner:LIBERTY PUMPS

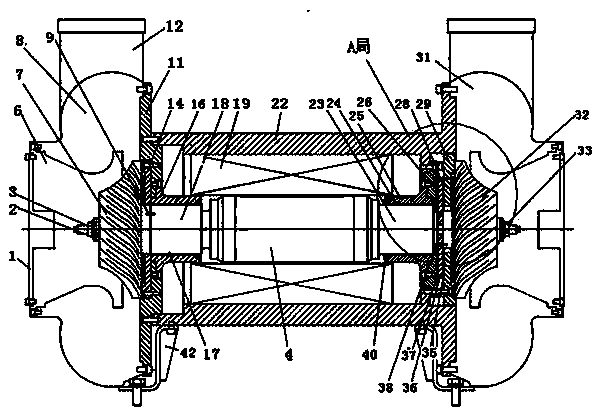

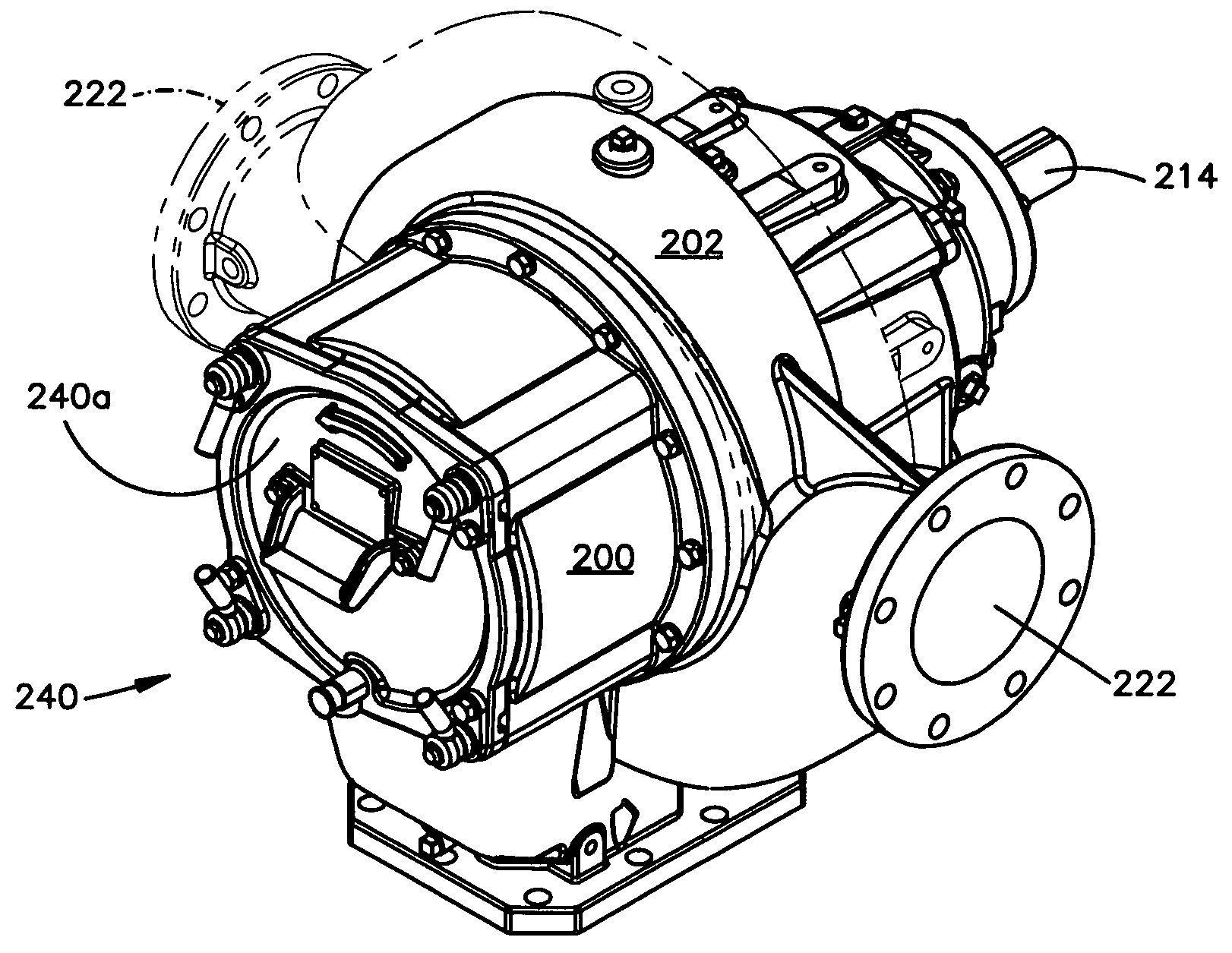

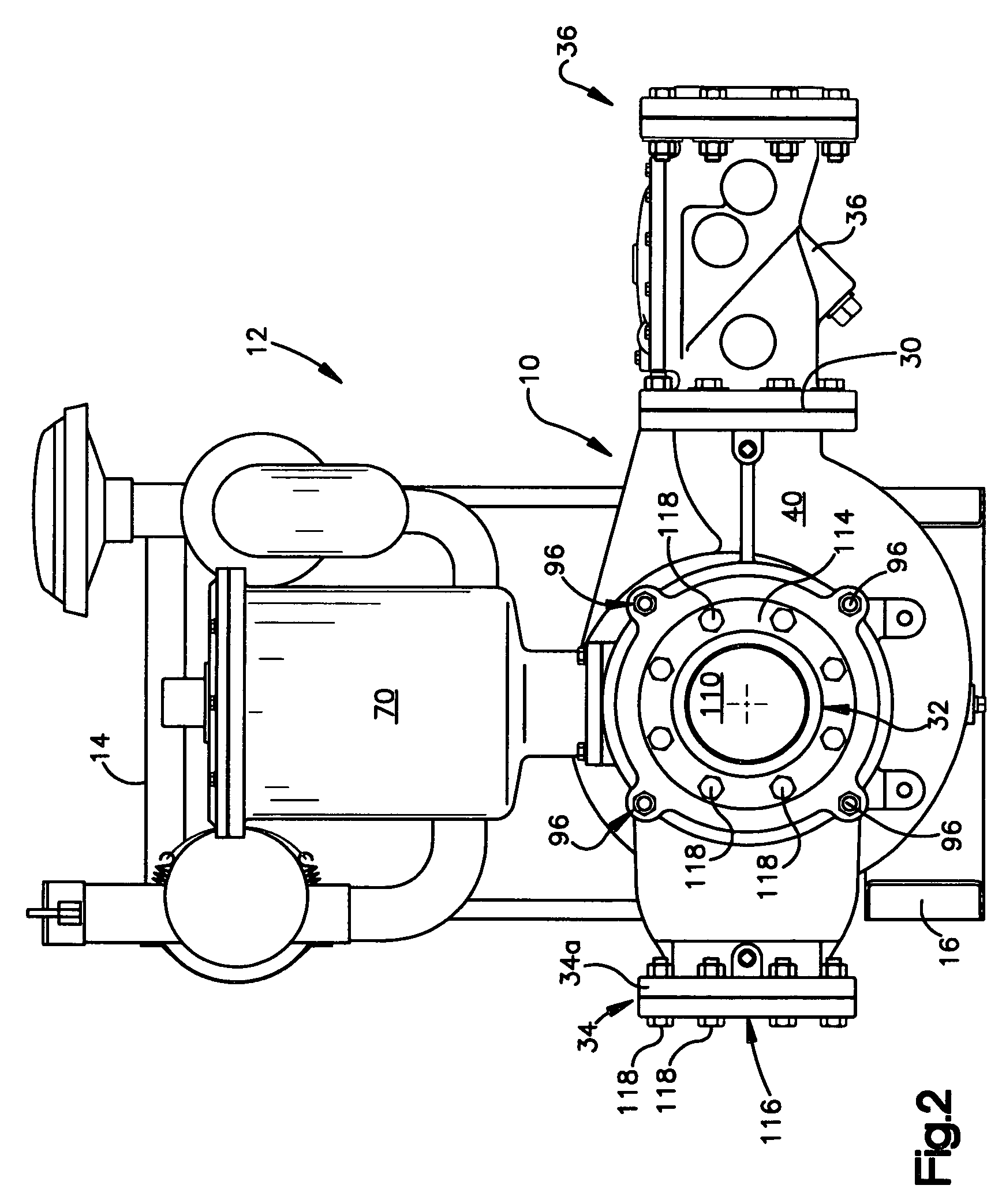

Centrifugal pump with multiple inlets

A centrifugal pump assembly that includes an inlet housing that defines a inlet chamber and at least one inlet port in fluid communication with the inlet chamber. A volute forming part of the assembly defines an outlet port. An impeller is mounted for rotation at least partially within the volute and operative upon rotation to convey fluid from the inlet port to the outlet port. The inlet housing defines mounting structure by which the inlet housing can be secured to the volute in any one of a plurality of positions with respect to the volute so that the spatial relationship between the inlet port and the outlet port can be changed by changing the relative position of the inlet housing with respect to the volute. The inlet housing also mounts a pump insert which may be either a dedicated clean-out assembly or structure defining an axial inlet port. The inlet housing defines a mounting flange that includes a plurality of symmetrically spaced apertures and the volute includes structure that is engageable with the flange and includes a plurality of symmetrically spaced bores that are alignable with the apertures formed in the mounting flange in several relative positions. The inlet housing may also be fitted with a aperture in an inlet housing wall for defining a radial inlet port communicating directly with the inlet chamber. Alternately, the inlet housing can include a passage for communicating a spaced inlet port with the inlet chamber. The passage may be jogged. The passage should be such to make the radial inlet and the radial outlet share a common plane, perpendicular to the axis of the impeller shaft. The impeller may form part of a rotating assembly which includes a mounting structure that enables the volute to be secured to the rotating assembly in any one of several positions.

Owner:GORMAN RUPP COMPANY THE

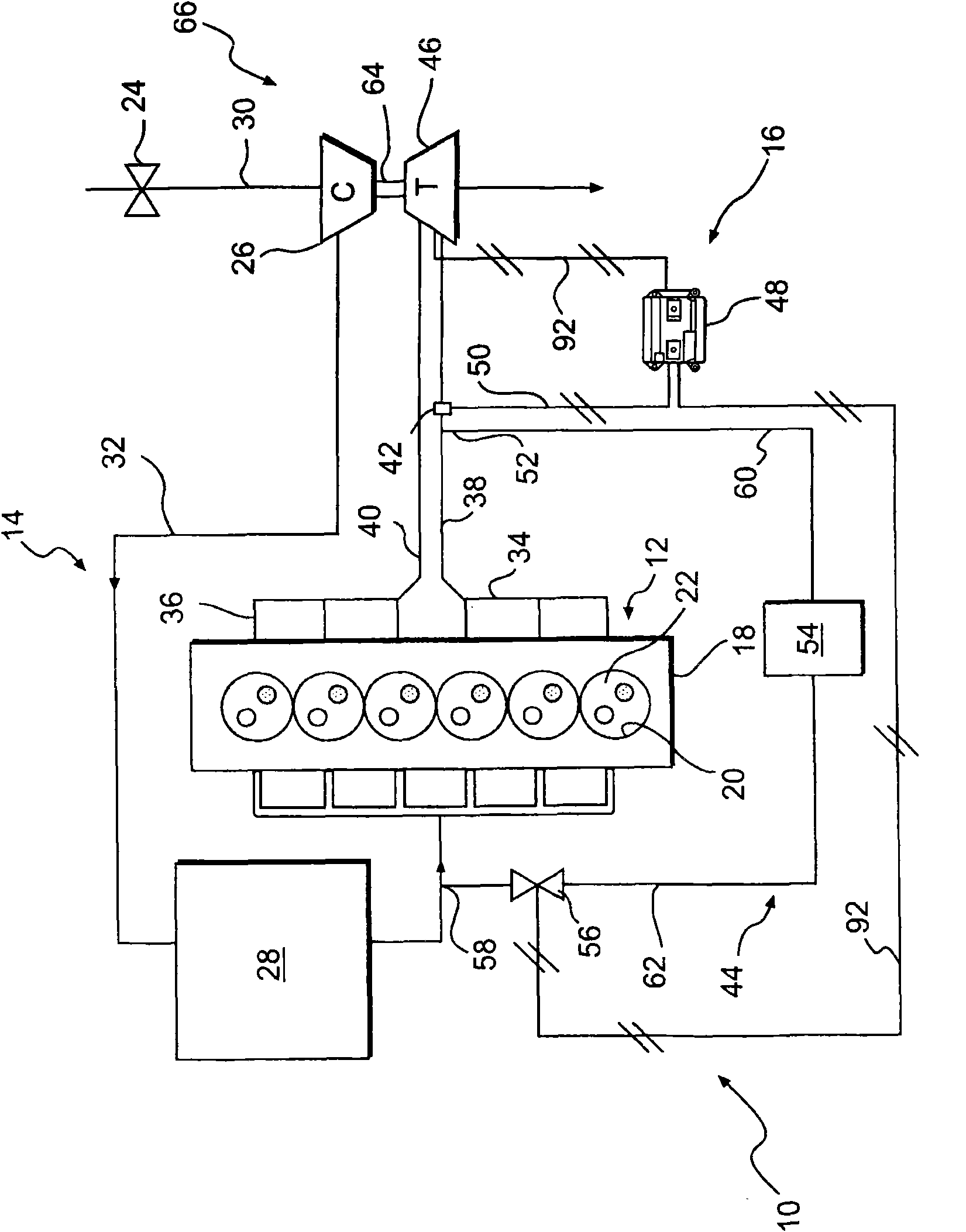

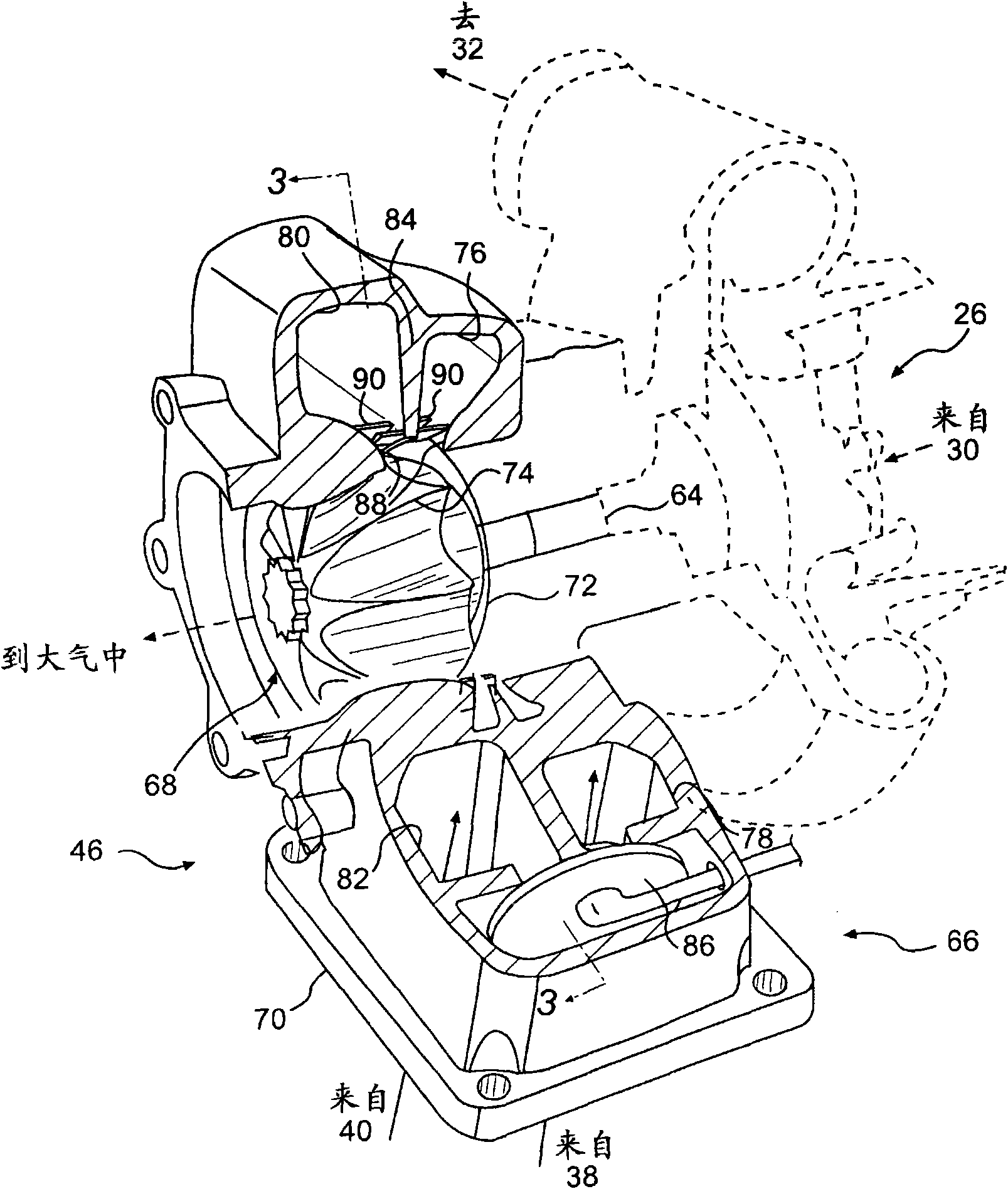

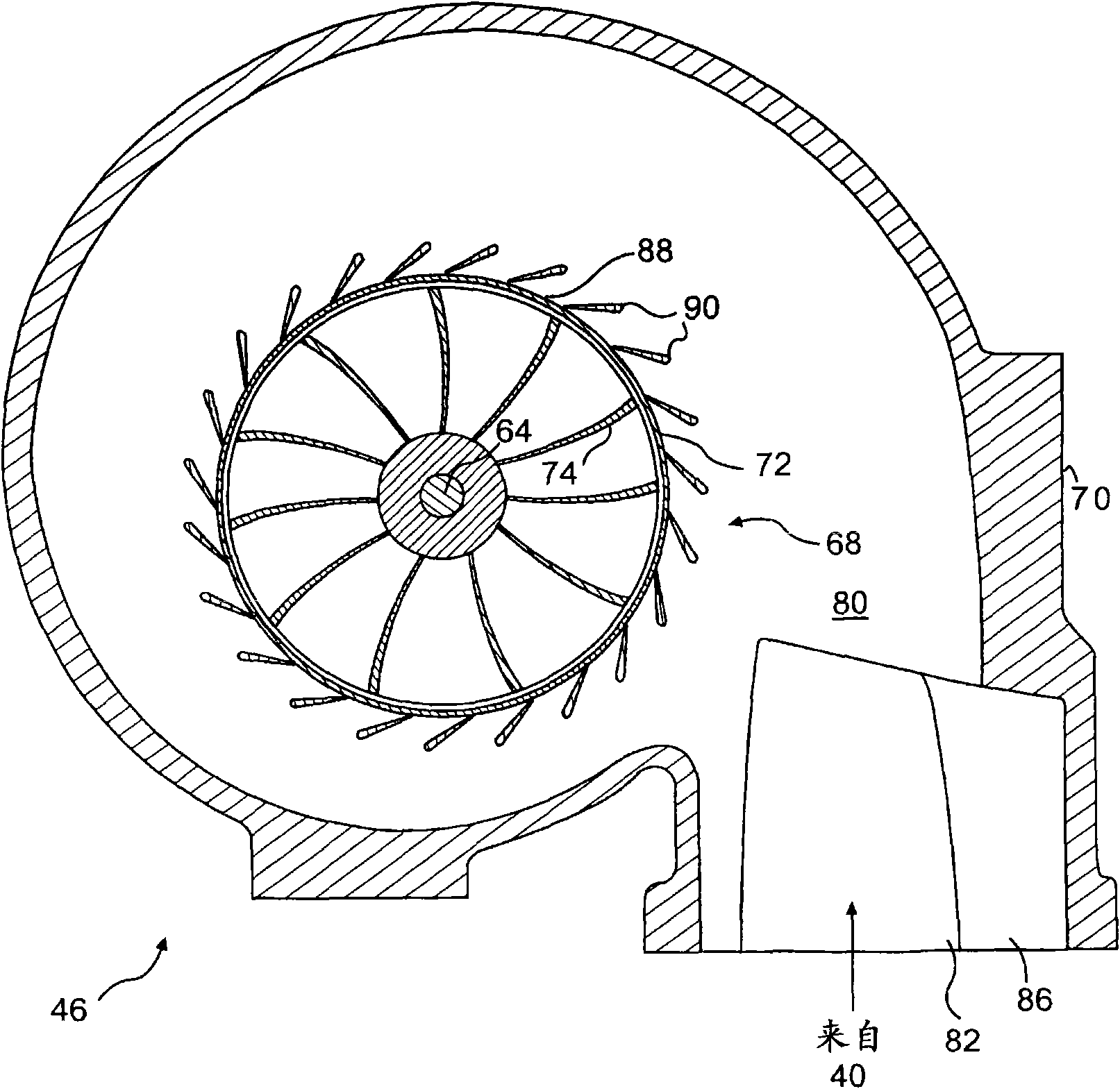

Exhaust gas turbocharger with 2 inflow channels connected by a valve

InactiveCN101688447AIncreased power output/power outputImprove efficiencyInternal combustion piston enginesExhaust apparatusTurbine wheelMechanics

A turbocharger (66) is provided having a turbine wheel (68) and a housing (70) configured to at least partially enclose the turbine wheel. The housing may have a first turbine volute (76) including afirst inlet (78) and a second turbine volute (80) having a second inlet (82). The first and second volutes may be configured to communicate a first and a second fluid flow with the turbine wheel. Thehousing may also have a wall member (84) axially separating the first and second turbine volutes. In addition, the housing may have a valve (86) configured to selectively allow fluid in the first inlet to communicate with fluid in the second inlet.

Owner:CATERPILLAR INC

Flush valve hydrogenerator

ActiveUS8698333B2Efficient power generationHydro energy generationMachines/enginesDynamoPlumbing fixture

A power generating device for use with a plumbing fixture includes: a volute configured to receive water from a water supply pipe; a stator having a plurality of blades positioned around a circumference thereof positioned within the volute; a rotor positioned within the stator; and a generator coupled to the rotor. The volute directs substantially all of the water received from the water supply pipe in a circumferential direction through the plurality of blades of the stator to the rotor, thereby causing the rotor to rotate.

Owner:ZURN INDS

Double-volute hydraulic design method based on RSM model

InactiveCN106570263AReduce design difficultyShorten the design and development cycleGeometric CADPump componentsEngineeringDesign methods

The invention discloses a double-volute hydraulic design method based on an RSM model. The design method comprises the steps of 1) solving double-volute initial hydraulic geometric parameters based on a velocity coefficient method; 2) performing optimization solving on double-volute key geometric parameters by adopting an RSM-based adaptive sequence algorithm; 3) performing parameterization automatic modeling based on a CATIA macroprogram, and outputting to obtain a three-dimensional double-volute model; 4) by adopting a GridPro script file to output a grid file used for numerical value calculation; 5) automatically completing grid loading and boundary condition setting based on a CFX CCL language drive program to complete calculation of related data, and outputting a calculation result; 6) repeatedly executing the steps 3) to 5) to obtain a double-volute scheme with the minimum total pressure loss coefficient; and 7) taking the data obtained in the steps 1) to 6) as the double-volute design parameters to manufacture a double-volute centrifugal pump. By adoption of the double-volute hydraulic design method, the double-volute hydraulic optimization design can be realized.

Owner:ZHEJIANG COLLEGE OF ZHEJIANG UNIV OF TECHOLOGY

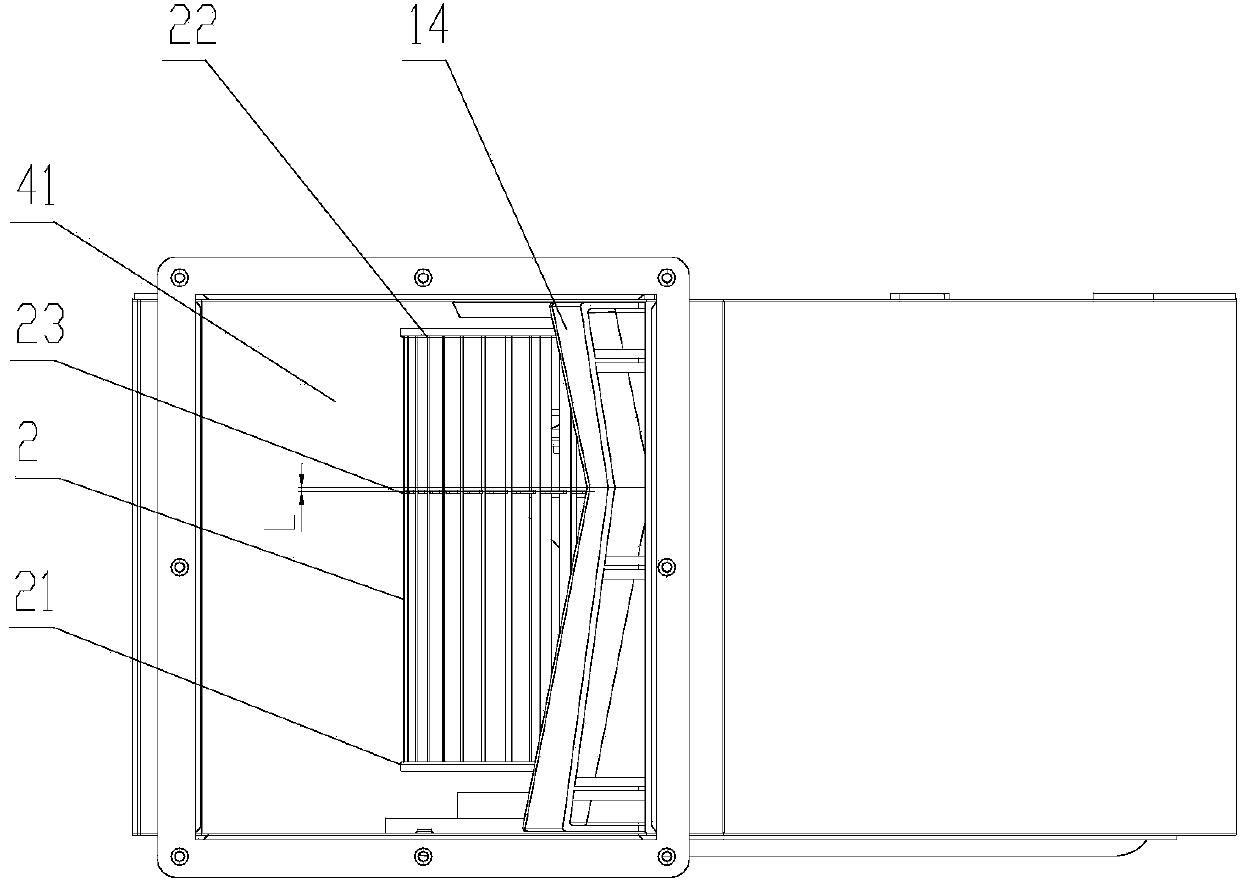

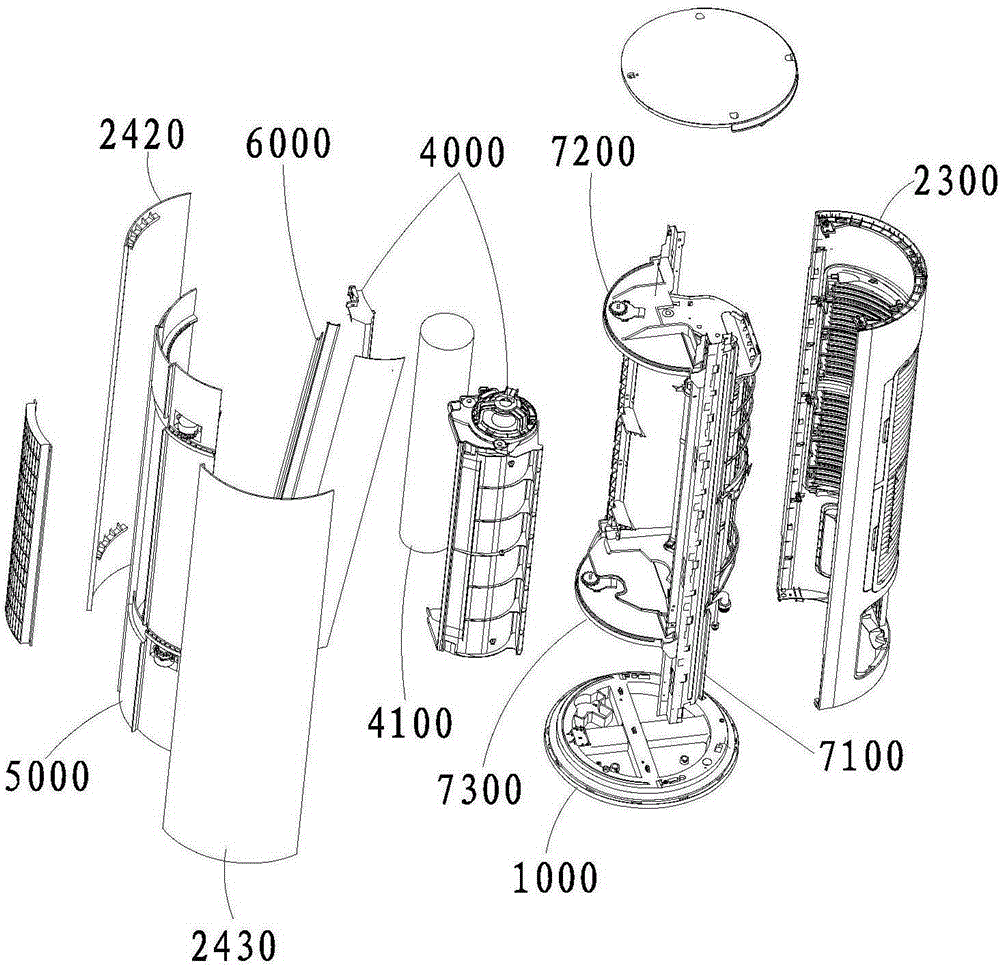

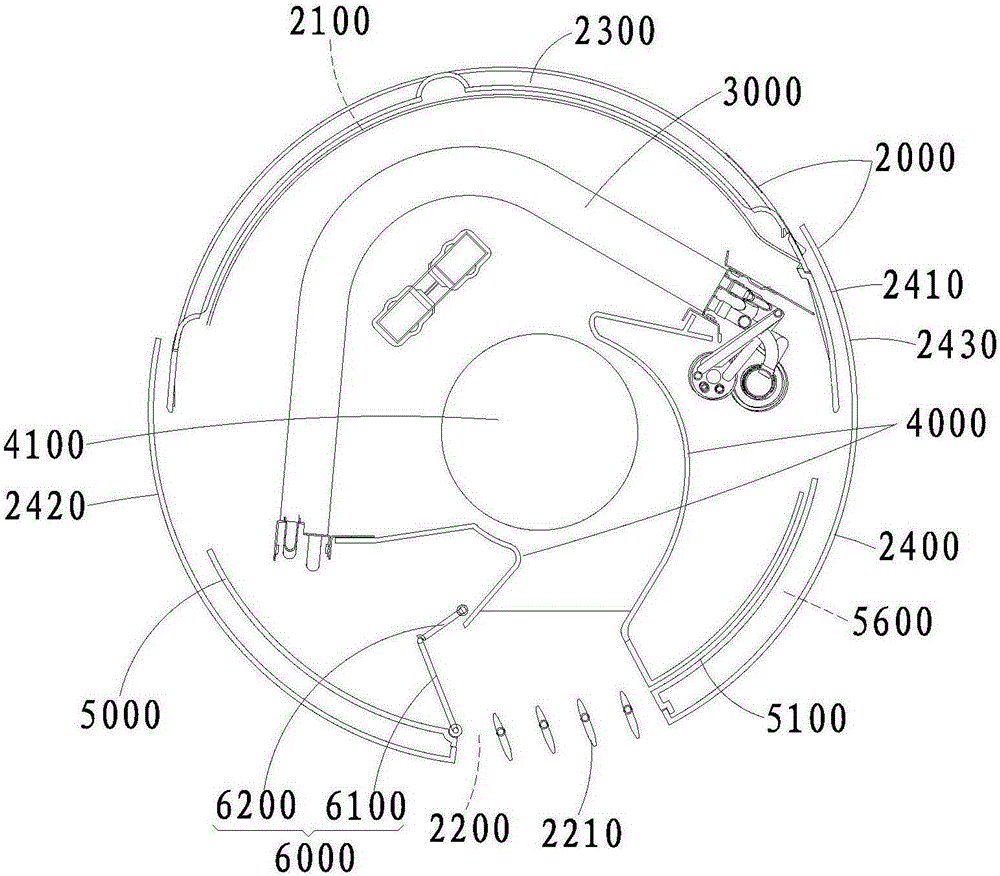

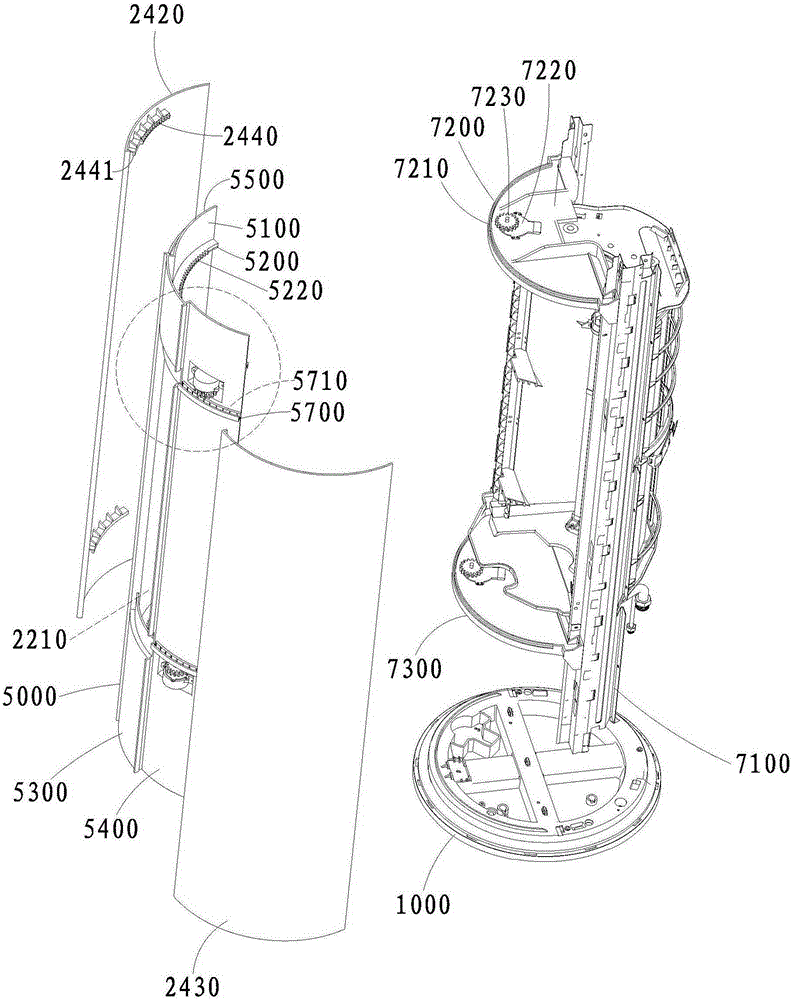

Vertical indoor unit

ActiveCN105180282ALarge sweeping angleLighting and heating apparatusAir conditioning systemsWaste managementEvaporator

The invention discloses a vertical indoor unit. A vertical air conditioner comprises a shell arranged on a body fixing seat. The shell is provided with an air inlet and an air outlet. The air outlet is in a longitudinally-extending strip shape. An evaporator, a volute and volute tongue assembly and an air outlet frame are sequentially arranged between the air inlet and the air outlet. A longitudinally-extending cross-flow wind wheel is arranged in the volute and volute tongue assembly. The air outlet frame is connected between the volute and volute tongue assembly and the air outlet. An air channel communicated with the air inlet and the air outlet is formed by the air outlet frame and the volute and volute tongue assembly. The evaporator, the volute and volute tongue assembly and the position of the body fixing seat are fixed. A drive device is arranged in the shell and drives the air outlet frame to do reciprocating rotation around a longitudinally-extending rotating axis. The vertical air conditioner further comprises a movable door device used for exposing out of the air outlet and sealing the air outlet. The effect that the swing air guide coverage area is larger is achieved.

Owner:WUHU MATY AIR CONDITIONING EQUIP CO LTD

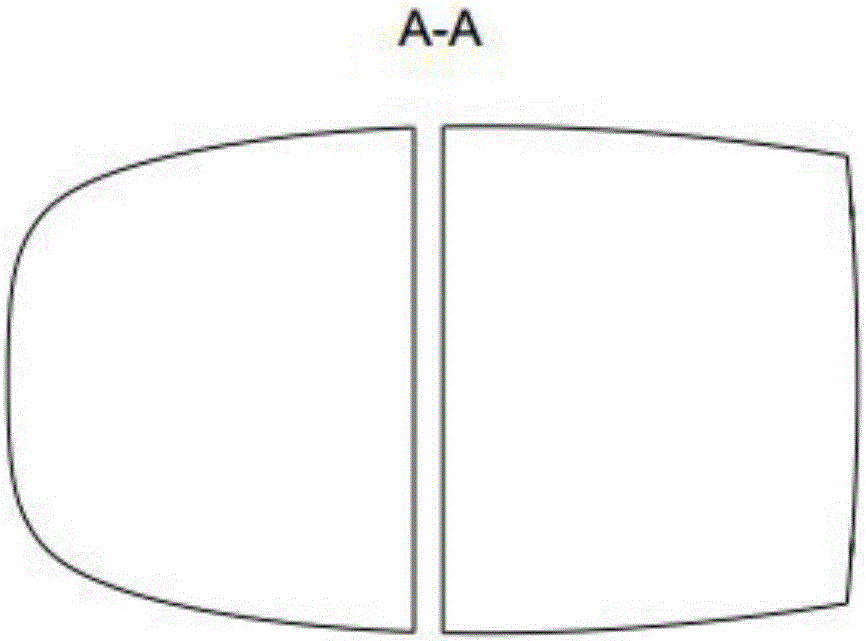

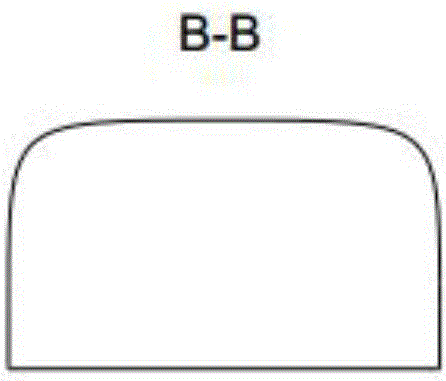

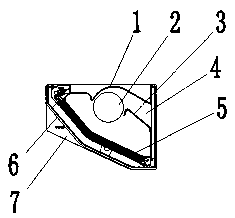

Indoor unit of air conditioner with vertical air channel

InactiveCN103017264ACompact structureReduce volumeLighting and heating apparatusAir conditioning systemsEngineeringHeating effect

An indoor unit of an air conditioner with a vertical air channel comprises a vertically arranged volute, a tubular air wheel, a volute tongue, a heat exchanger and an indoor unit air outlet formed between the volute and the volute tongue, wherein the shape of the cross section of an indoor unit air channel system takes a right triangle-like structure or a trapezoid-like structure; the indoor unit air channel system consists of the volute, the tubular air wheel, the volute tongue and the heat exchanger; the outlet edge of the indoor unit air outlet is a right-angled edge of the triangle or the trapezoid; the back surface of the volute is another right-angled edge of the triangle or the trapezoid; the heat exchanger is a transversely bent structure or a straight piece structure; and the outer edges of the heat exchanger are the inclined edges of the triangle or the inclined edges and the short straight edge of the trapezoid. The indoor unit has a compact and simple structure and a smaller size, can be mounted in a hiding manner or can be mounted obviously through being matched with a casing, and can be mounted against a wall by one surface or can be mounted against a corner, so that the mounting application range is wide, the refrigeration and heating utilization rate of the air conditioner is higher, the heating effect of the air conditioner is better, and the indoor unit is maintained and repaired more conveniently.

Owner:李力游

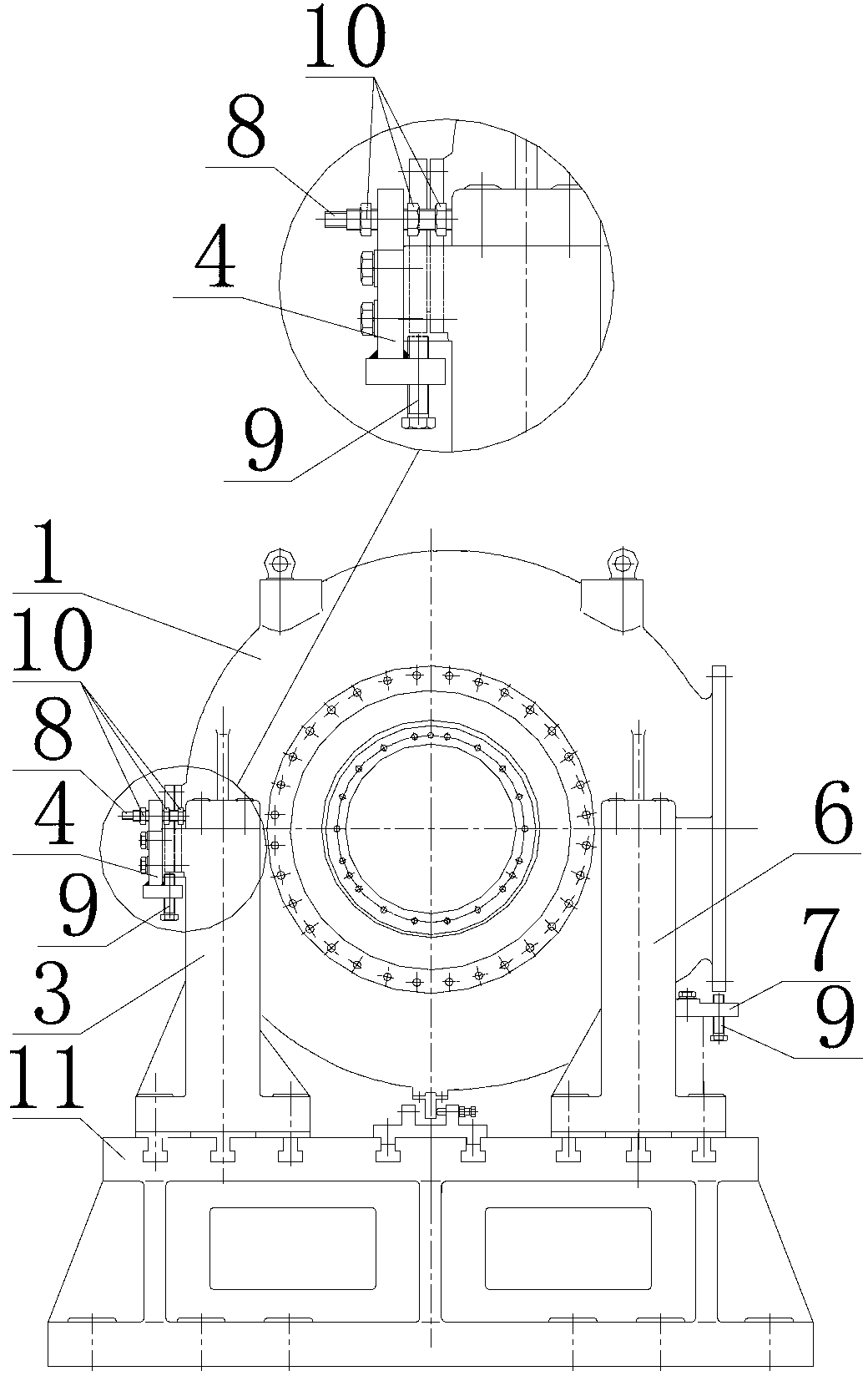

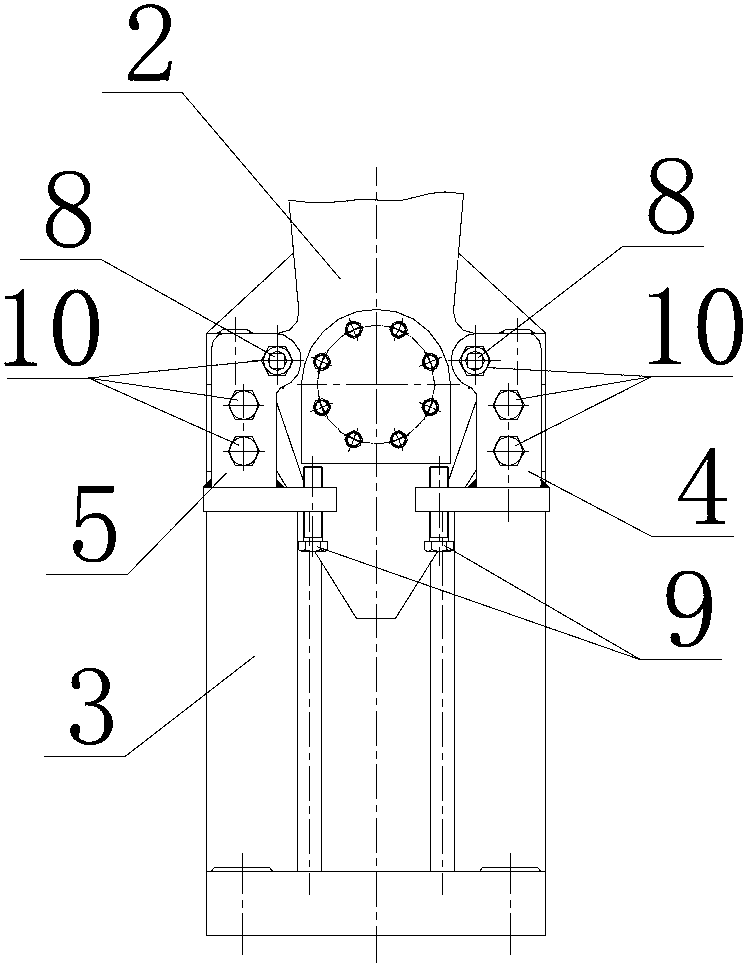

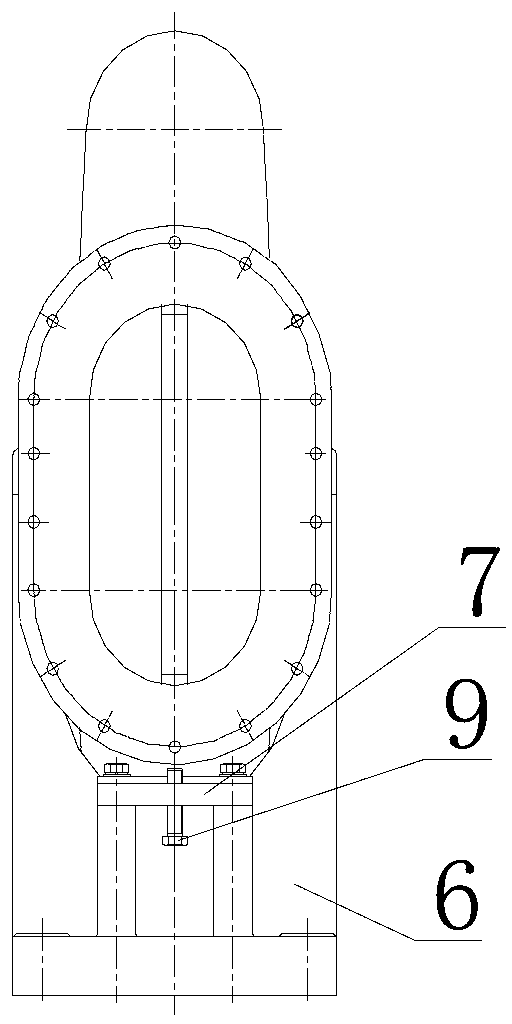

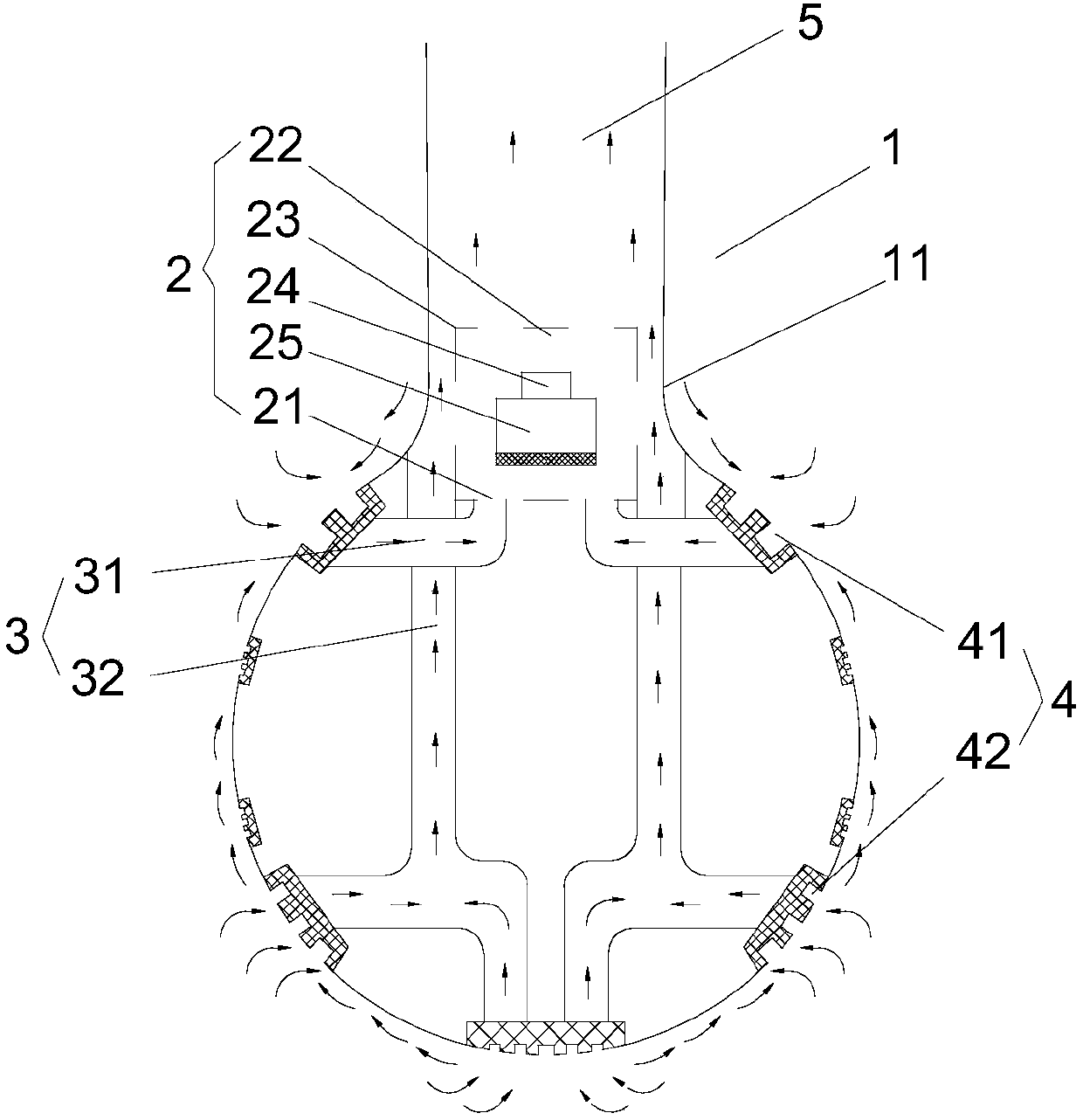

Coaxiality adjusting device and coaxiality adjusting method

ActiveCN103292676AReduce volumeSimple structureMachine part testingEngine testingAir compressorEngineering

The invention discloses a coaxiality adjusting device which is characterized by comprising a left-side lug or / and a left-front aligning supporting seat, a left-rear aligning supporting seat and a right aligning supporting seat. The left-side lug is fixed to an exhaust volute of an air compressor, the left-front aligning supporting seat and the left-rear aligning supporting seat are arranged on a left support, the right aligning supporting seat is fixed onto a right support, both the left-front aligning supporting seat and the left-rear aligning supporting seat are provided with aligning push-pull rods, aligning ejector rods and nuts, the nuts are fixed onto the aligning push-pull rods, the aligning push-pull rods are fixed onto reserved threaded mounting holes of the left-side lug of the exhaust volute of the air compressor, the aligning ejector rods are respectively arranged on a bottom plate of the left-front aligning supporting seat and a bottom plate of the left-rear aligning supporting seat, and the right aligning supporting seat is provided with an aligning ejector rod which is fixed onto a bottom plate of the right aligning supporting seat. The coaxiality adjusting device has the advantages of small size, simple structure, convenience in use, high efficiency and capability of saving time and labor during coaxiality adjusting operation.

Owner:CHINA AVIATION POWER MACHINE INST

Range hood with axial-flow type wind wheel

ActiveCN107726414AExtended service lifeSimple structureDomestic stoves or rangesLighting and heating apparatusElectric machineryFlue

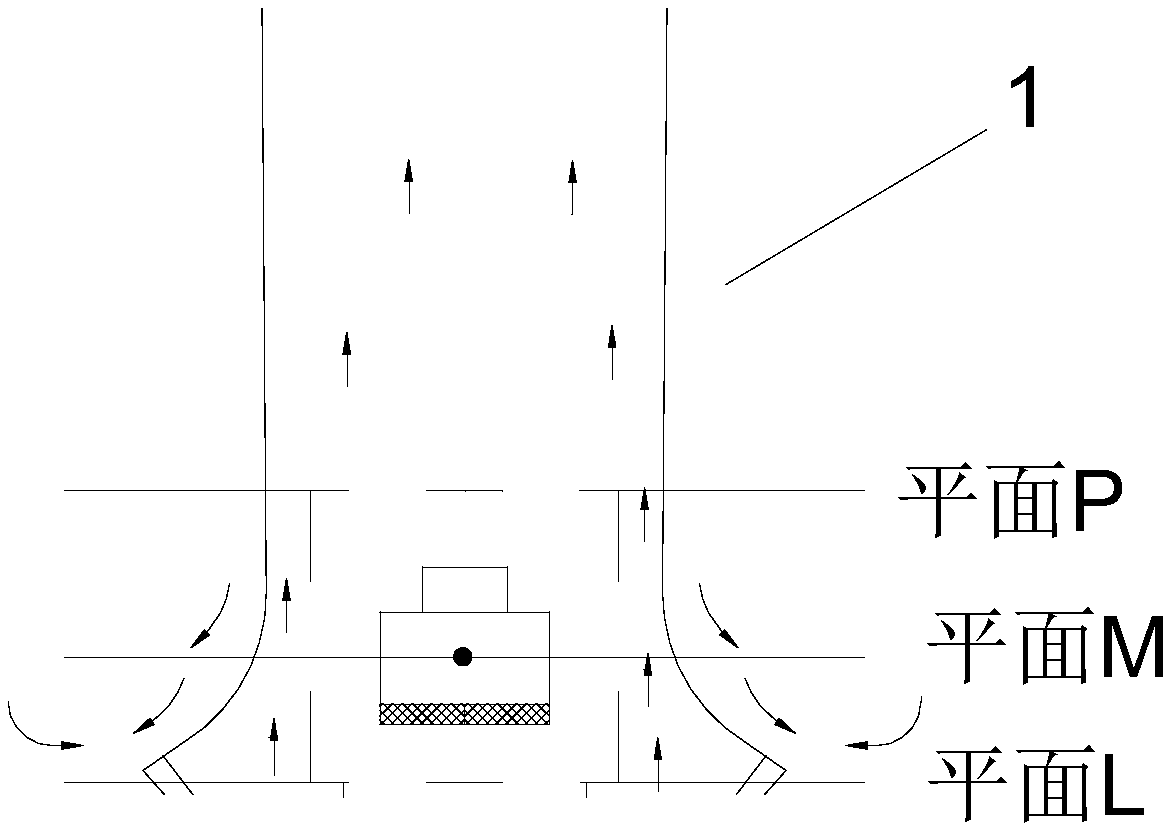

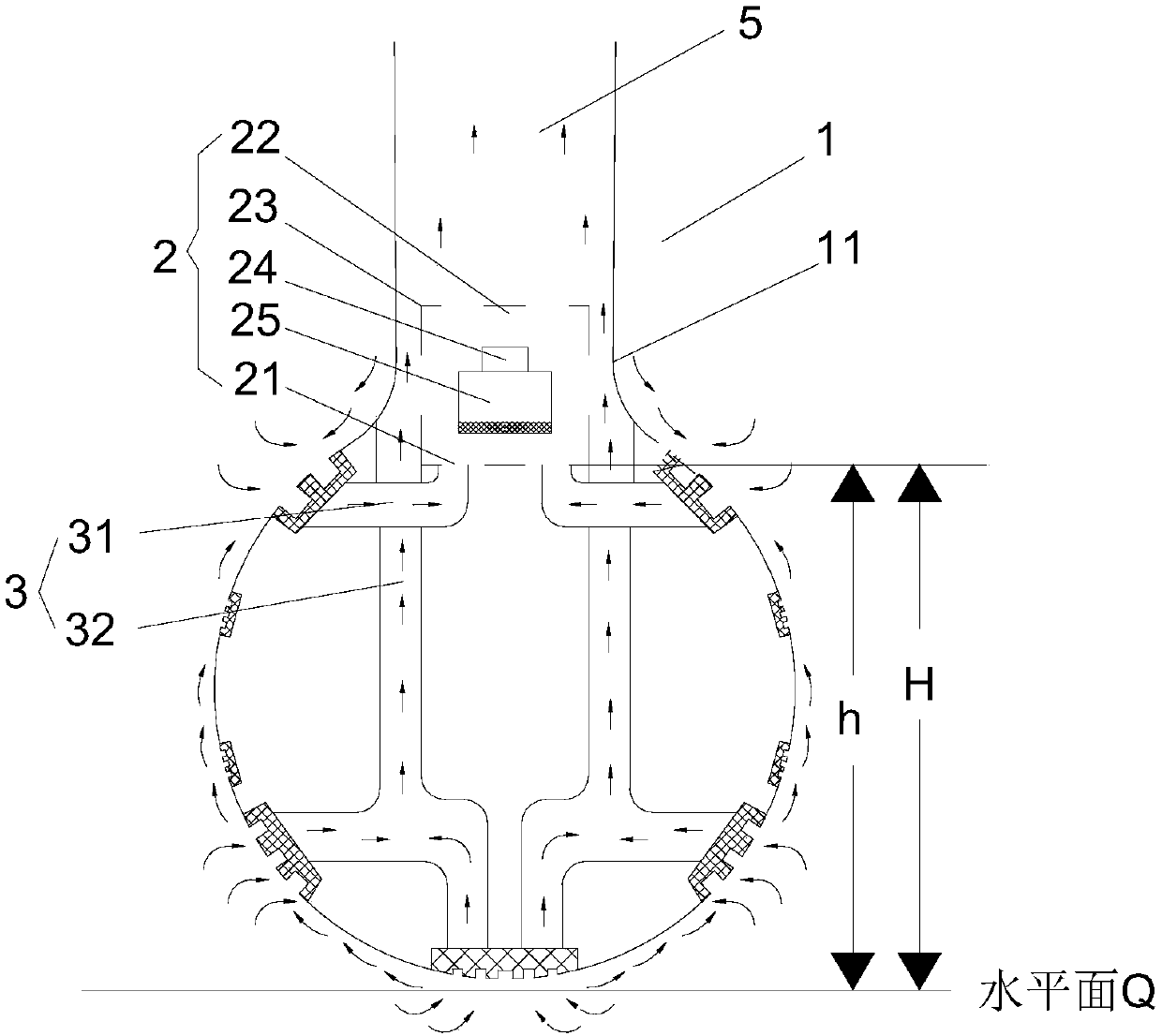

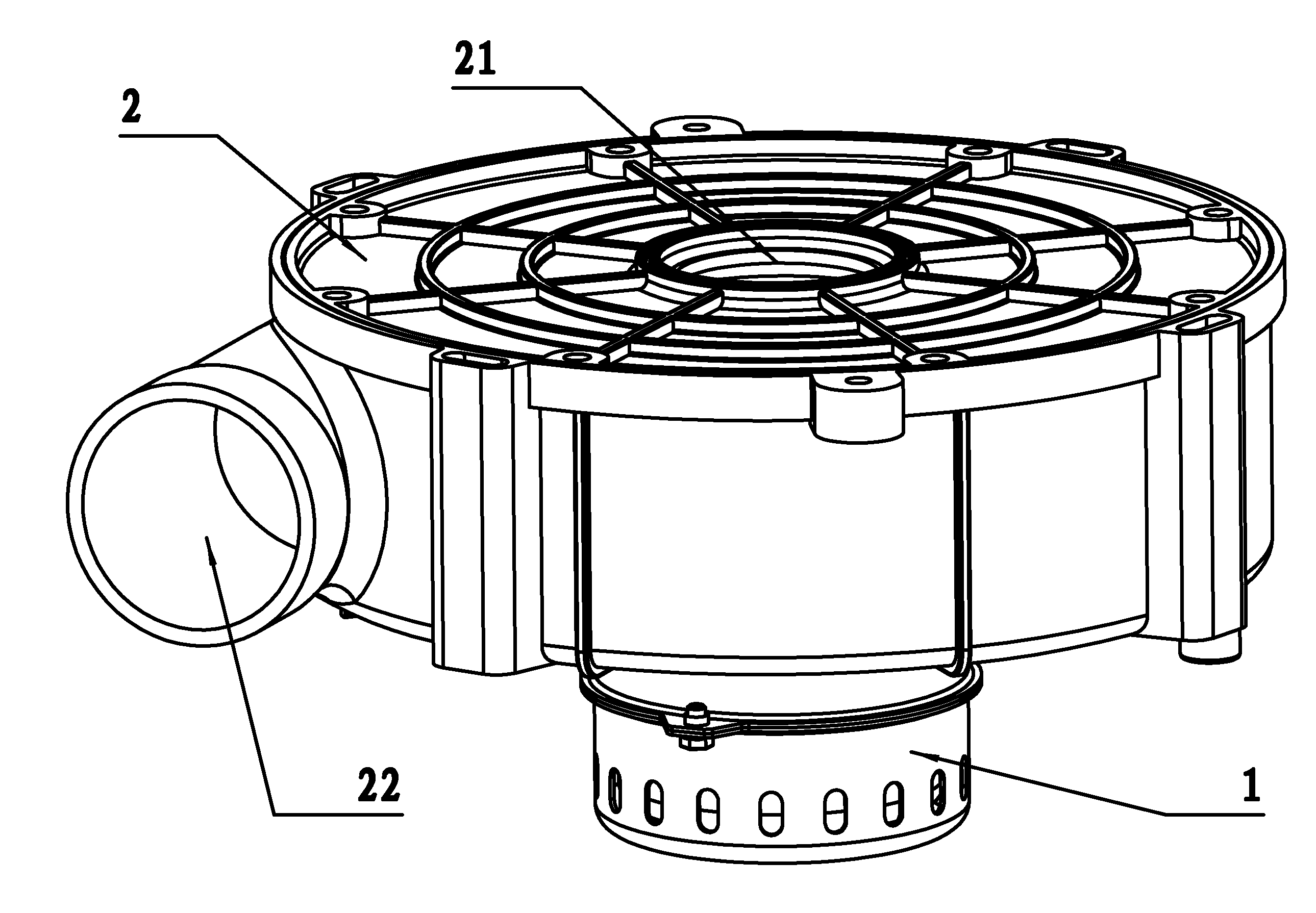

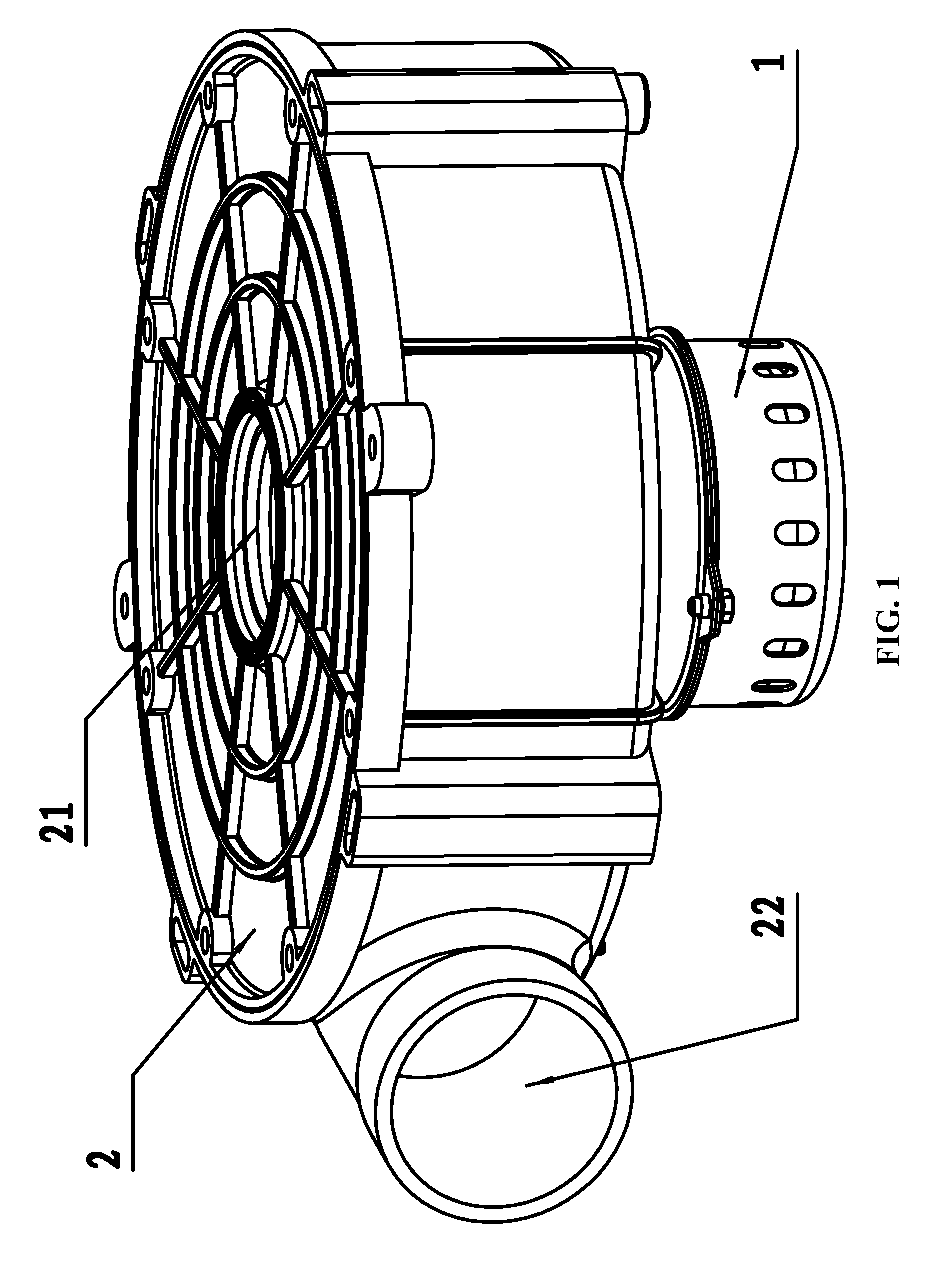

The invention discloses a range hood with an axial-flow type wind wheel. The range hood comprises a range hood main body, wherein an axial-flow type exhaust component is assembled inside the range hood main body; a plane L on which the gas inlet of the exhaust component is arranged is parallel to a plane P on which the a gas outlet is arranged; the exhaust component comprises a volute; the gas outlet and the gas inlet are correspondingly formed in the upper surface and the lower surface of the volute; a motor is assembled inside the volute; blades are rotationally assembled at the rotor end ofthe motor; the plane M of the central points of the blades is parallel to the plane L and the plane P respectively; the gas inlet is communicated with air inlet groups of the range hood main body through an air flue; the gas outlet is communicated with a smoke discharge channel in the top of the range hood main body; a plurality of air inlet groups are arranged; the air inlet groups comprise cleaned air inlet groups and cooking fume air inlet groups. The range hood with the axial-flow type wind wheel is simple in structure and convenient to mount and dismount; meanwhile, according to air dynamic principle, cooking fume is not introduced into the axial-flow type wind wheel but is discharged directly, then the interior of the wind wheel is kept clean, and the service life of the wind wheelis prolonged.

Owner:FOSHAN VIOMI ELECTRICAL TECH +1

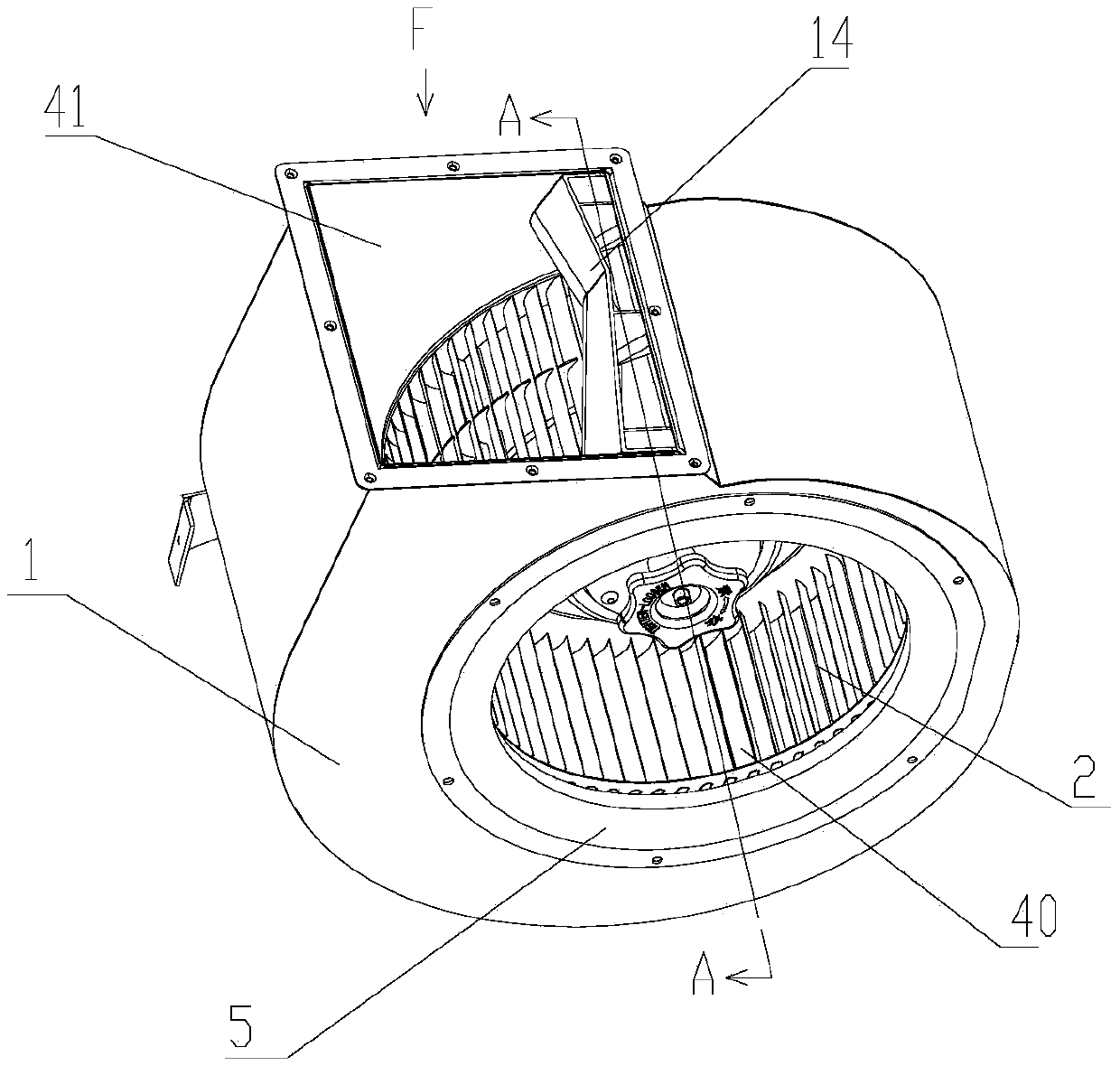

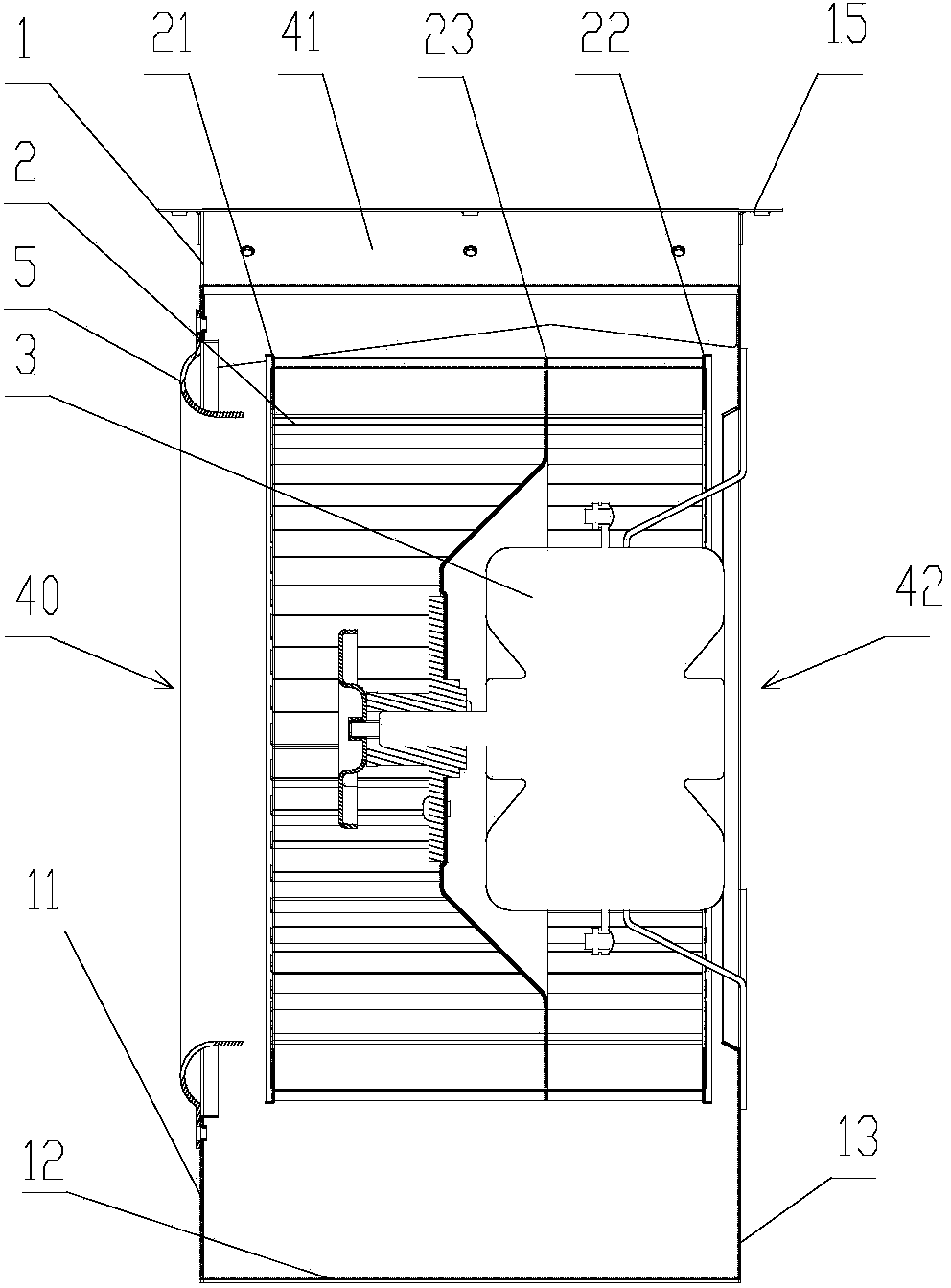

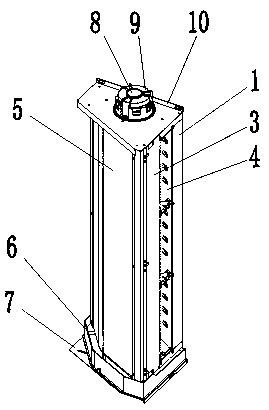

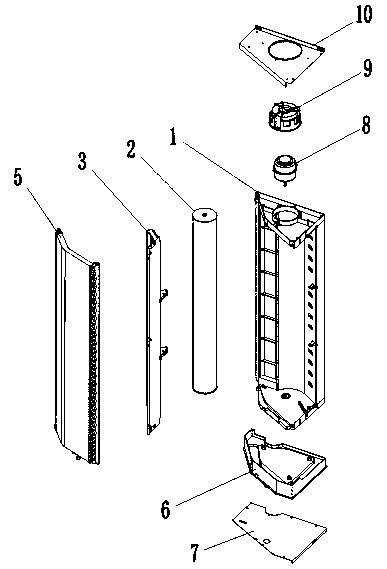

Induced draught fan

ActiveUS20130216377A1Simple structureEasy to installPump componentsEngine componentsEngineeringElectric motor

An induced draught fan, including: a motor, the motor including a shaft; a volute; and a wind wheel. The volute is provided with an air intake and an air outlet. The wind wheel is arranged inside the volute. The top of the volute is provided with a through-hole. The shaft of the motor passes through the through-hole and is connected to the wind wheel. A seal ring is arranged on the volute corresponding to the through-hole. An outer side of the seal ring is provided with an annular groove. The volute is embedded in the annular groove. The middle of the seal ring is provided with a center hole. The middle of the side wall of the center hole is provided with a ring-like convex edge. The shaft passes through the center hole and contacts with the ring-like convex edge.

Owner:ZHONGSHAN BROAD OCEAN

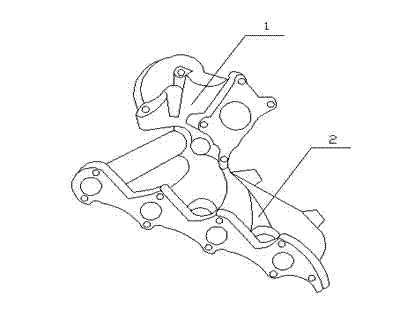

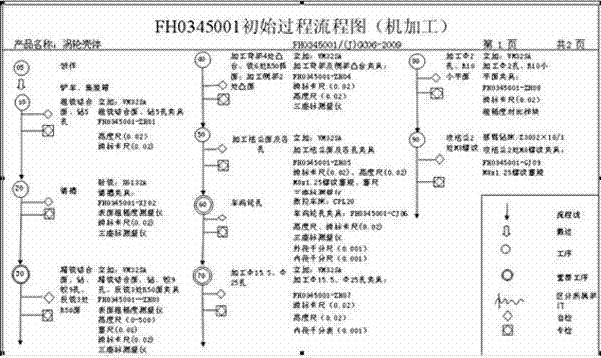

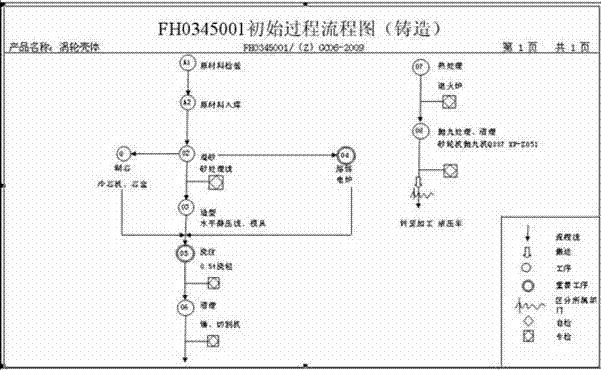

A method for producing an integral volute supercharged exhaust manifold

ActiveCN102269020AHigh sand hardnessHigh repetitionInternal combustion piston enginesFoundry mouldsThermodynamicsEngine power

The invention discloses a method for producing an integral volute pressurization exhaust manifold. The integral volute pressurization exhaust manifold comprises a supercharger turbo shell and an exhaust manifold. The supercharger turbo shell and the exhaust manifold are integrally cast. The integral volute pressurization exhaust manifold is made of an austenitic nodular cast iron QTANi35Si5Cr2 material. According to a product produced by the invention, the supercharger turbo shell and the exhaust manifold are designed into an integral cast; weights of parts are greatly reduced; simultaneously, a flow channel is smooth; and the normal exertion of engine power cannot be influenced by preventing a vortex from locally generated in a gap of combined surfaces in the gas flowing process.

Owner:西峡县内燃机进排气管有限责任公司 +1

Anticorrosive wear-resistant centrifugal pump volute casing

The invention relates to an improved anticorrosive wear-resistant centrifugal pump volute casing, which is characterized in that: a pump casing an all-plastic or plastic-lined pump casing, and a sectioning pump casing is a volute casing which is formed by asymmetrically lateral sectioning and provided with a complete liquid outlet pipe section; an integral wear-resistant inlay is in a shape of a cover or basis which is provided with a liquid outlet hole and not provided with a liquid outlet pipe section and is provided with a through axle hole at the bottom; an involution end surface of a lining in the volute casing does not exceed an involution end surface of the volute casing; and a casting-type hardened combining layer is arranged between the volute casing and the wear-resistant inlay. By adoption of the structure and the lining mode, the lining manufacturing difficulty of ceramics, microcrystal glass and the like which are low in cost and difficult to mold is greatly decreased, the manufacturing cost is reduced, the lining is simple, the two historic difficulties of lining body molding and manufacturing and easiness of crazing of high-brittleness lining body during installation and maintenance are solved with low cost, the comprehensive service life is prolonged by more than one time, the overall cost is higher than that of the original all iron pump casing lining ceramic inlay. The invention creates a precedent that the silicon carbide and microcrystal glass materials which are difficult to mold and machine, high in brittleness and extremely good in abrasive resistance are applied to a wear-resisting lining of a centrifugal pump.

Owner:宜兴市宙斯泵业有限公司

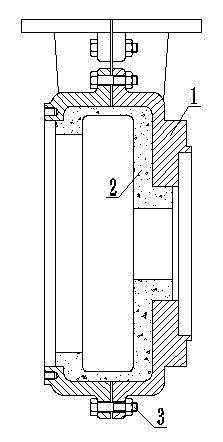

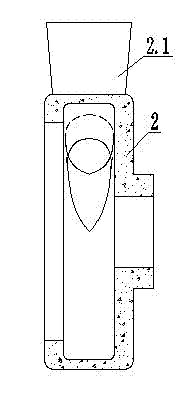

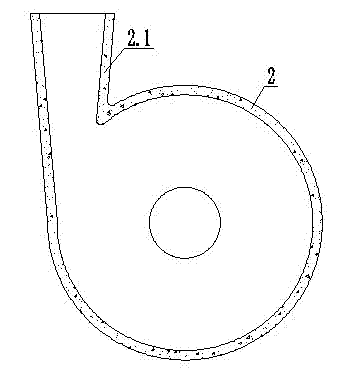

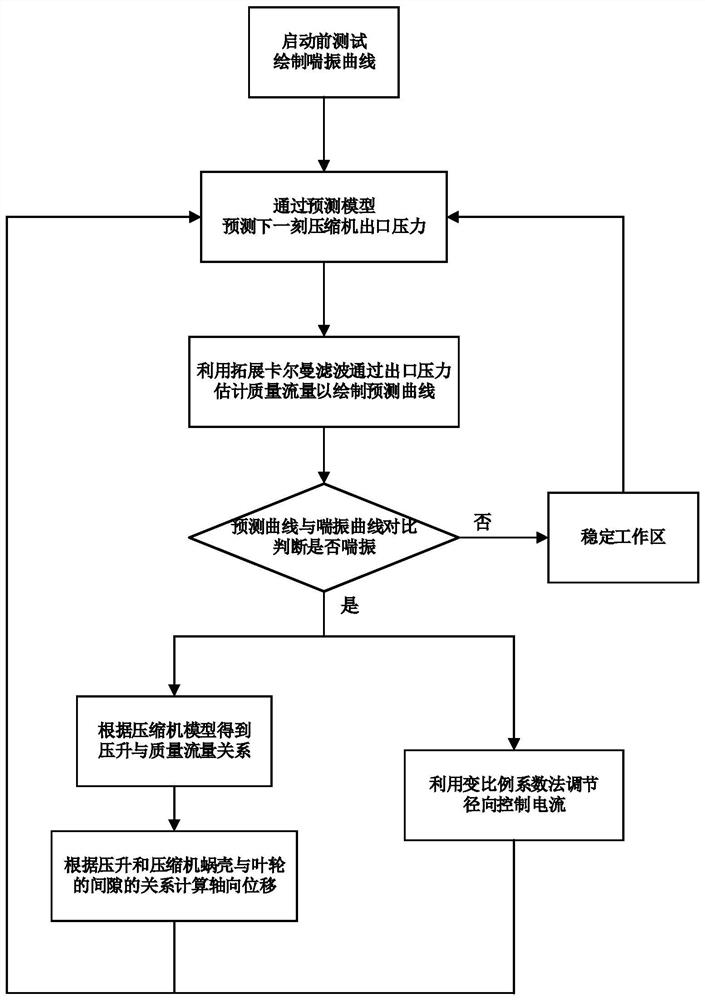

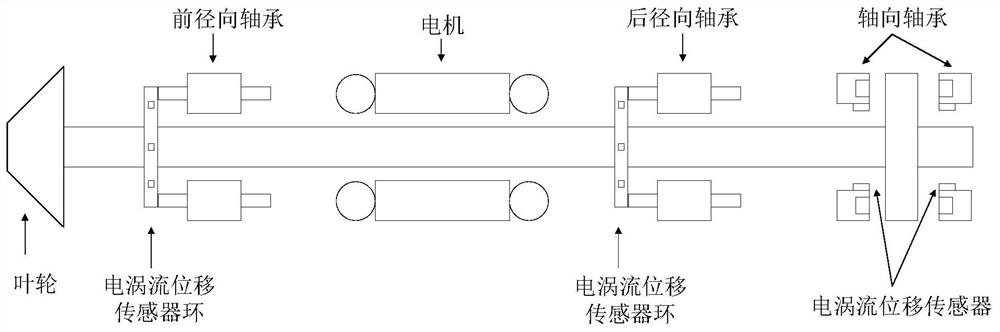

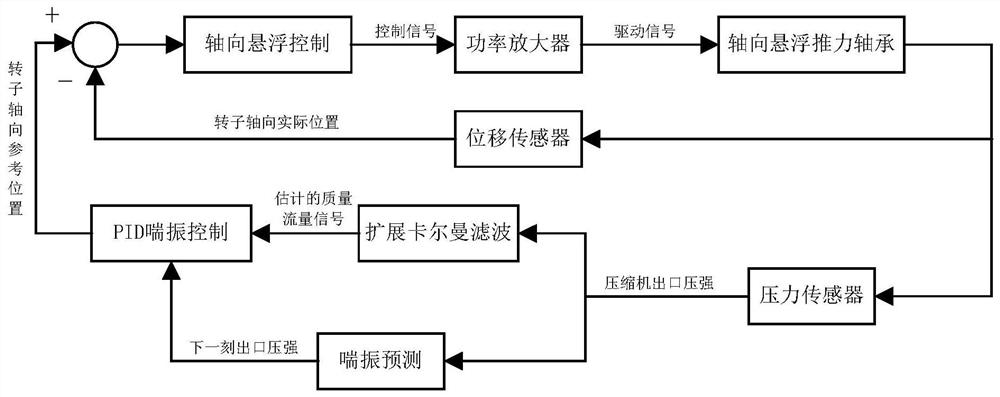

Compressor surge prediction control method based on magnetic suspension axial position control

ActiveCN113339310AEliminate surgePrevent surgeDesign optimisation/simulationPump controlPressure riseMathematical model

The invention provides a compressor surge prediction control method based on magnetic suspension axial position control. The compressor surge prediction control method comprises the steps that a surge curve is drawn by collecting compressor outlet pressure values and flow values at different rotating speeds; a function relation between pressure rise and mass flow is derived by establishing a compressor mathematical model; a compressor outlet pressure prediction model is established to determine the coordinates of an operating point of a compressor at the next moment; and when the coordinates of the operating point intersect with the surge curve, that surge will occur at the next moment is indicated, and the axial direction and the radial direction of a bearing in the compressor need to be adjusted to eliminate surge, namely, the distance between a rotor axial impeller and a volute is adjusted, and the rotor radial control current is increased to eliminate surge. According to the compressor surge prediction control method, whether surge occurs on the magnetic suspension compressor at the next moment or not can be predicted, and then a control strategy is adjusted so that the magnetic suspension compressor can always keep operating close to the right side of a surge line, the surge margin is effectively reduced, and the compressor can effectively avoid surge and can operate at the highest efficiency point.

Owner:NORTHEASTERN UNIV LIAONING

Noise reduction impeller and range hood applying same

ActiveCN106482187AAlienation flow fieldEliminate flow noiseDomestic stoves or rangesLighting and heating apparatusImpellerHigh resistance

The invention discloses a noise reduction impeller and a range hood applying the same. According to the noise reduction impeller, outer rings and / or inner rings of front-side blades of a middle disk are covered with net covers, the inner flow field of air can be alienated by the covers, and the noise reduction effect can be realized. An air inlet of a fan of the range hood is a back air inlet formed in a volute back side plate, a front ventilating port communicating with an air outlet of the fan is formed in a volute front side plate, the front ventilating port and the back air inlet are separated from each other through the middle disk of the noise reduction impeller, and a noise reduction cavity communicating with the front ventilating port is arranged in front of the fan or in front of and below the fan. The range hood adopts a back side air inlet manner, after the noise reduction cavity is arranged on the front side of the fan, the front ventilating port can be prevented from sucking in oil fume from the lower side of an oil fume collecting cover, flow noise caused by air flow turbulence in front-side space of an outer cover of the fan is eliminated, meanwhile, the way through which noise propagates outwards from the front side of the outer cover of the fan can be blocked, and besides, under the condition of high resistance of a common flue, the noise reduction cavity can also realize the pressure relief effect.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

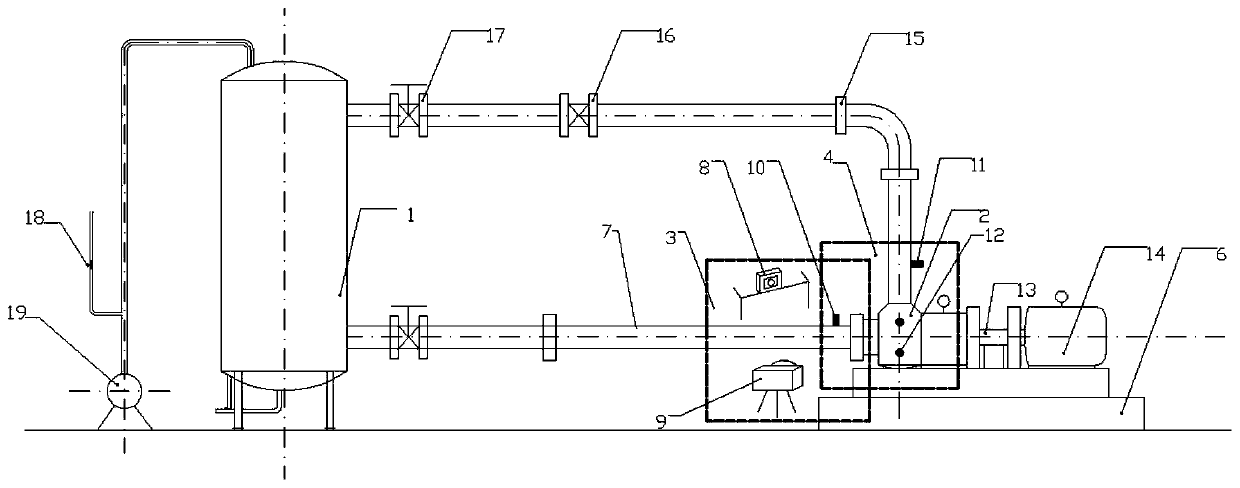

Device and method for testing blade pump backflow vortex cavitation

ActiveCN111306076AEasy to observe newbornEasy to observe developmentPump controlNon-positive displacement fluid enginesEngineeringOrganic glass

The invention provides a device and a method for testing blade pump backflow vortex cavitation. The device and the method are used for testing the backflow vortex cavitation performance and dynamic characteristics of a blade pump under small flow working conditions. According to the device, the blade pump is fixed to a working table; one pressure pulsation sensor is mounted at an organic glass inlet pipe 1*Ds away from an impeller inlet; a plurality of pressure pulsation sensors are correspondingly mounted in the circumferential direction of a volute flow channel every 45 degrees; a pressure pulsation sensor is mounted at a position 2*Ds away from a pump outlet pipe; and a sensor and a collecting card are sequentially connected in series to a computer system provided with signal acquisition and data processing software. According to the testing method, based on the situation that backflow is generated at the pump impeller inlet, the mainstream flow of a pump inlet and the hydraulic performance of the pump inlet can be affected, the internal pressure pulsation information of the pump is collected in real time through the pressure pulsation sensor, and the internal flow condition ofthe pump during backflow vortex cavitation is combined to accurately identify and judge blade pump backflow vortex cavitation.

Owner:JIANGSU UNIV

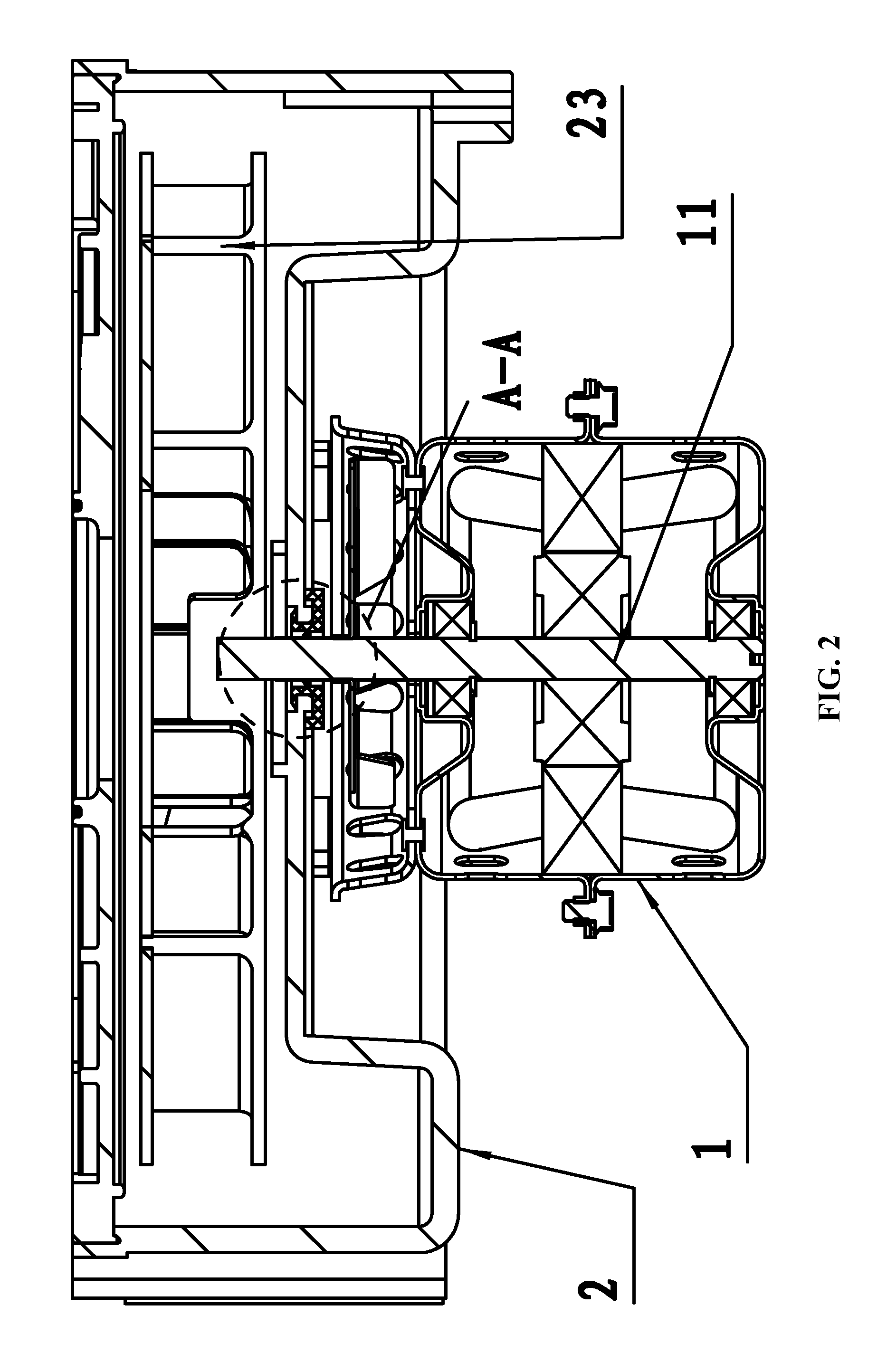

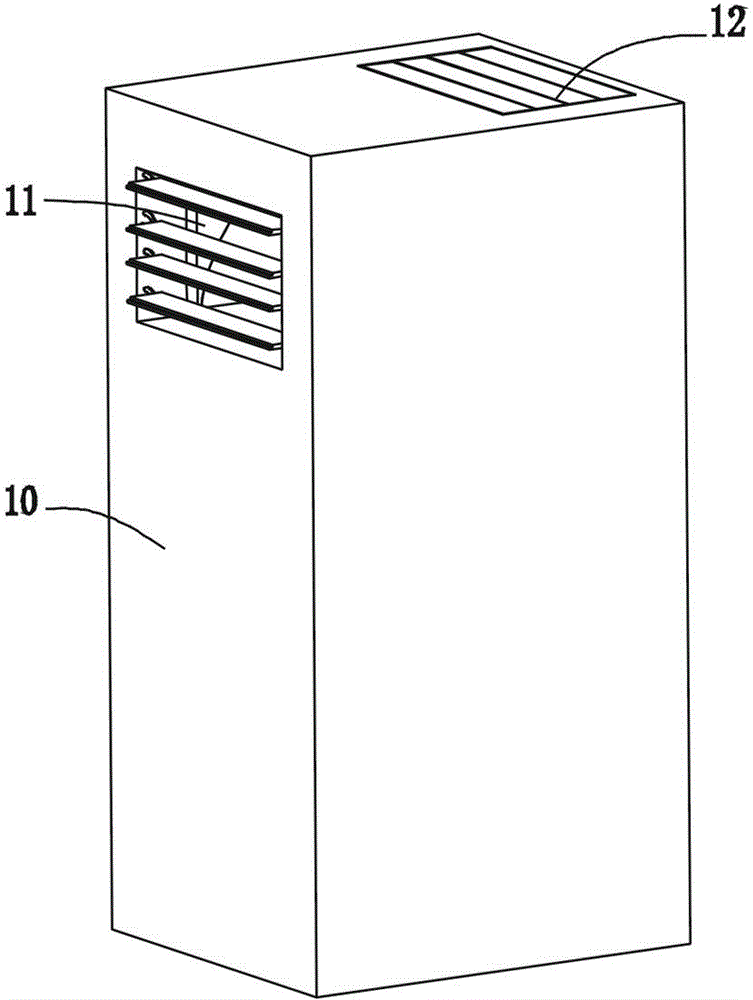

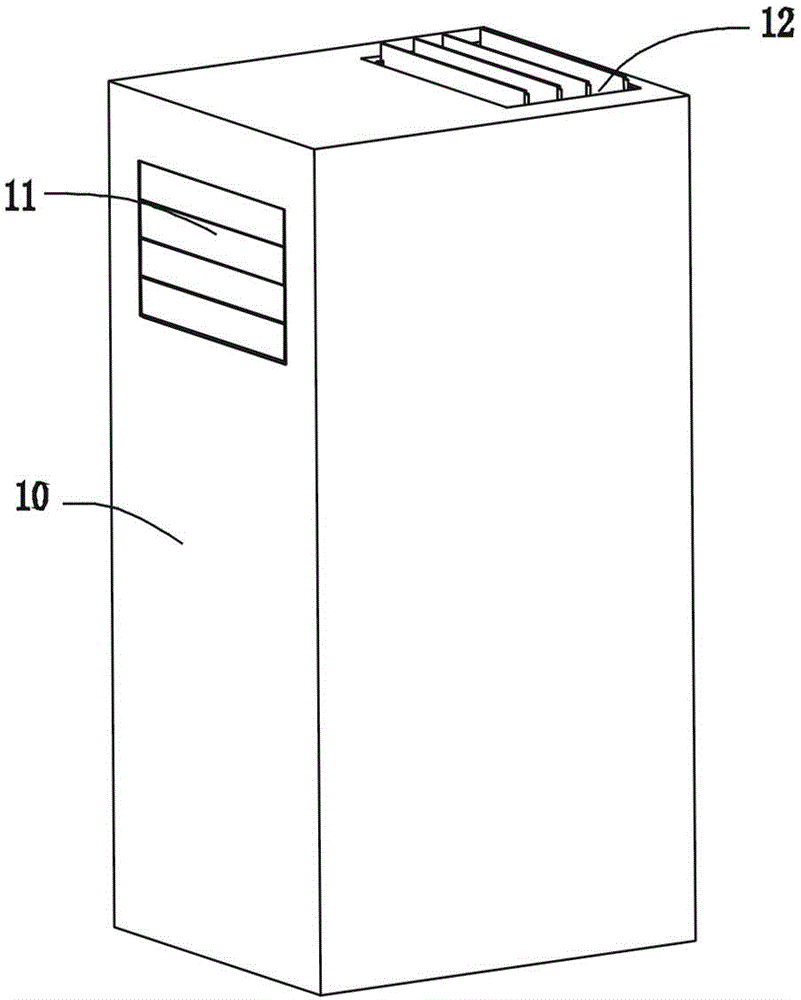

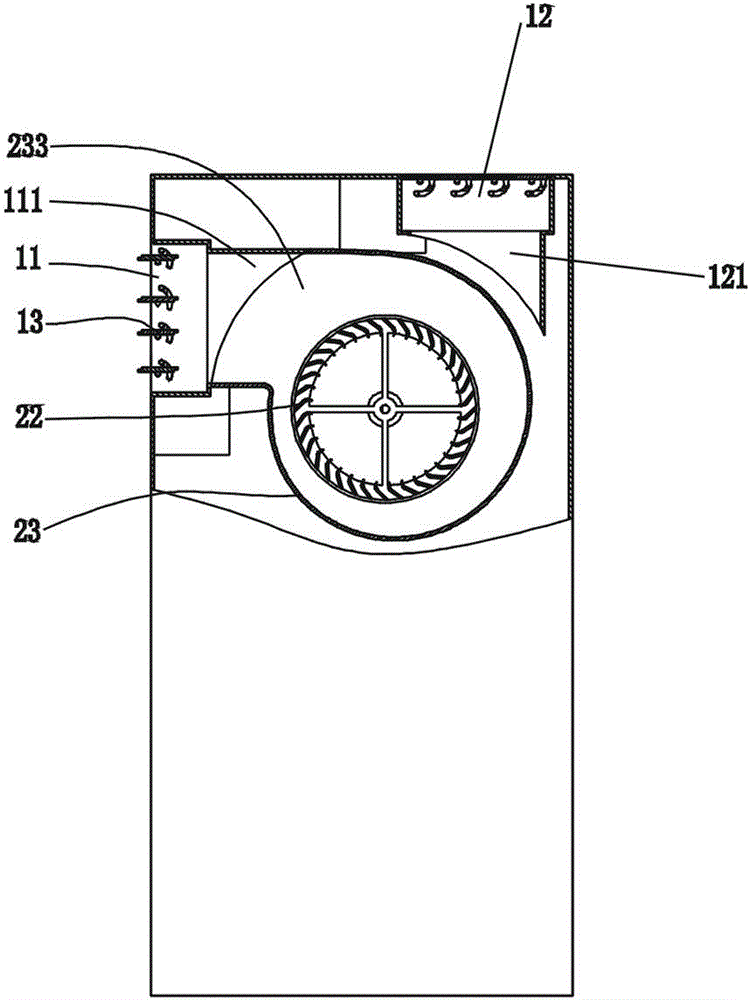

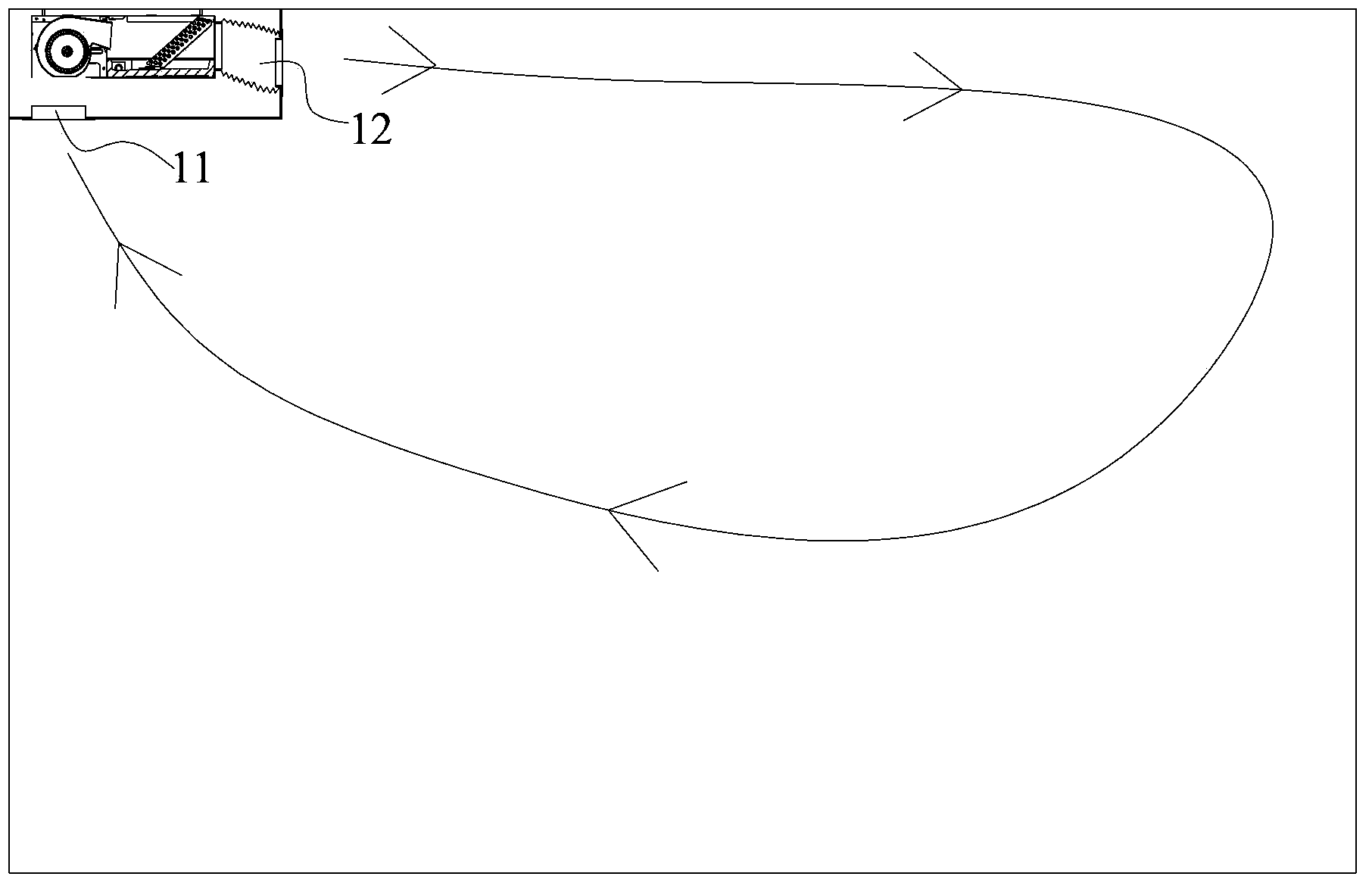

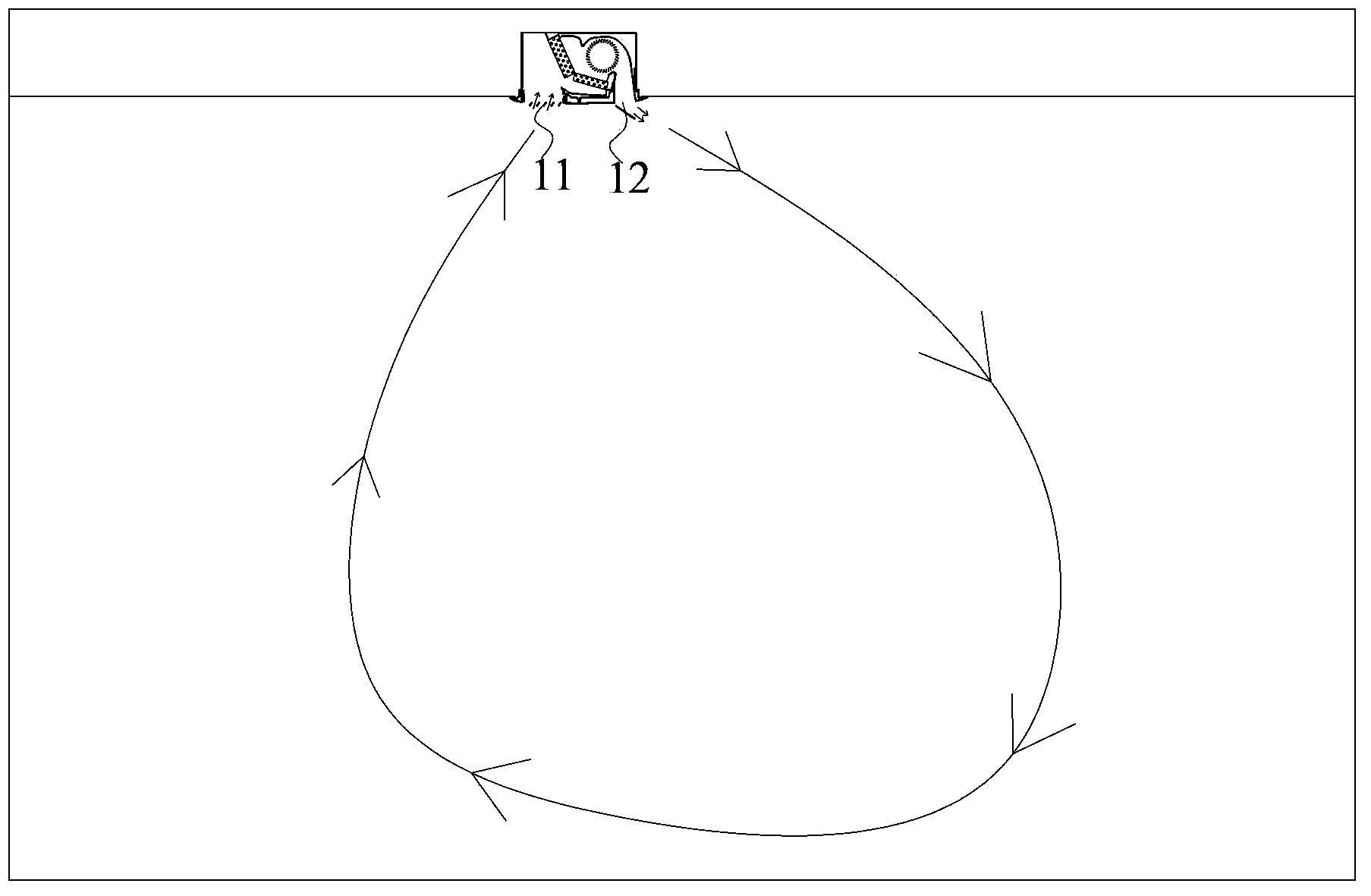

Twin-air-outlet air conditioner with swingable air duct

InactiveCN104422096APracticalSimple structureLighting and heating apparatusAir conditioning systemsEngineeringAir conditioning

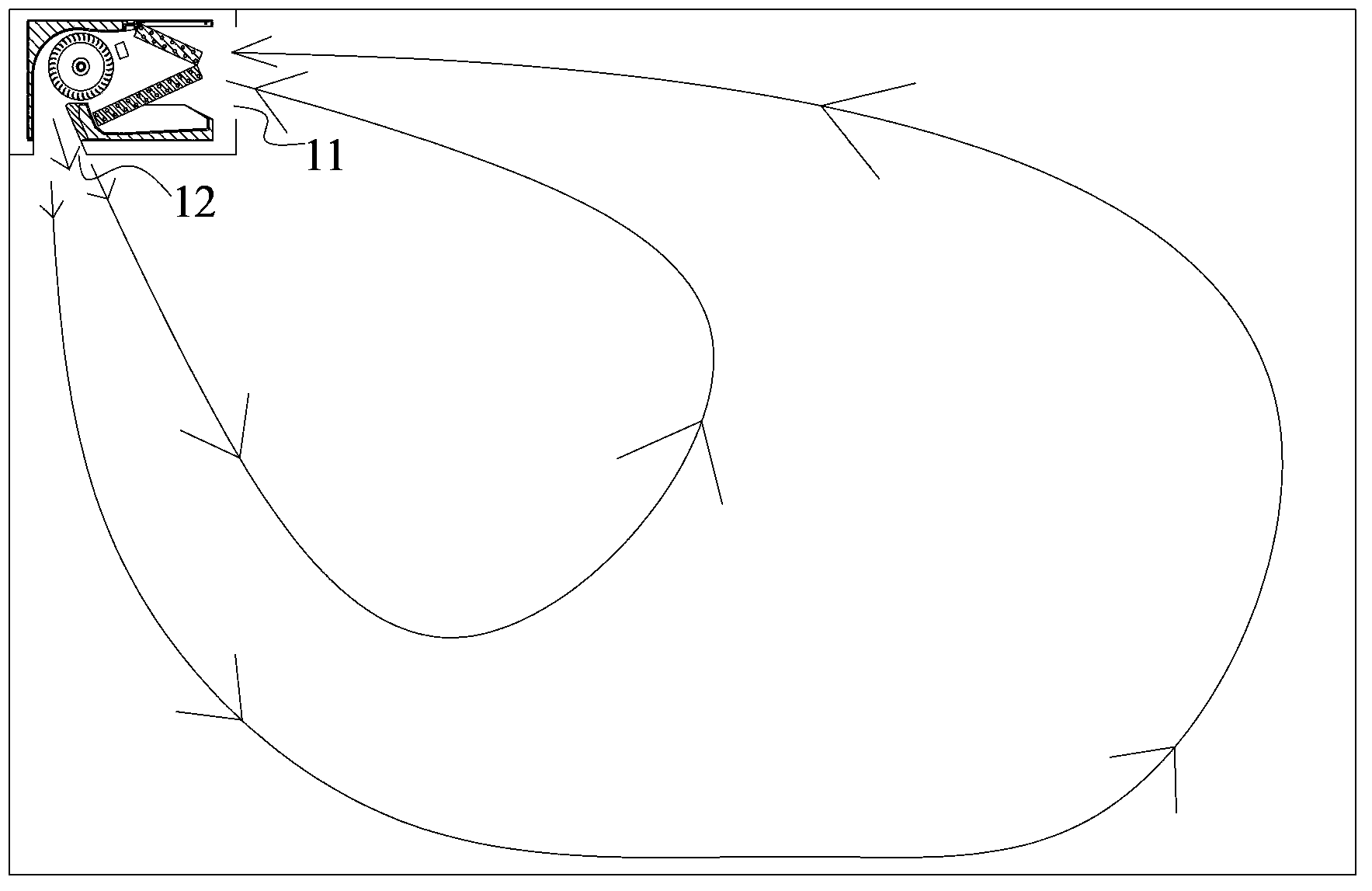

A twin-air-outlet air conditioner with a swingable air duct comprises a body (10) and a front air outlet (11) and a top air outlet (12) thereon. A centrifugal fan component (20) is arranged in the body (10). When air is out from the front side, a volute (23) of the centrifugal fan component (20) rotates and swings to an air outlet thereof and stops after communicated with the front air outlet (11) of the body (10), and the top air outlet (12) is closed at the same time. When the air is out from the top, the volute (23) reversely rotates and swings to the air outlet and stops after communicated with the top air outlet (12) on the body (10), and the front air outlet (11) is closed at this time. The volute (23) swings back and forth between the front air outlet (11) and the top air outlet (12) of the body, and discharges air after communicated with the front air outlet (11) or the top air outlet (12) of the body (10) selectively. The twin-air-outlet air conditioner is simple in structure and convenient to use.

Owner:SHENZHEN LIANCHUANG TECHNOLOGY GROUP CO LTD

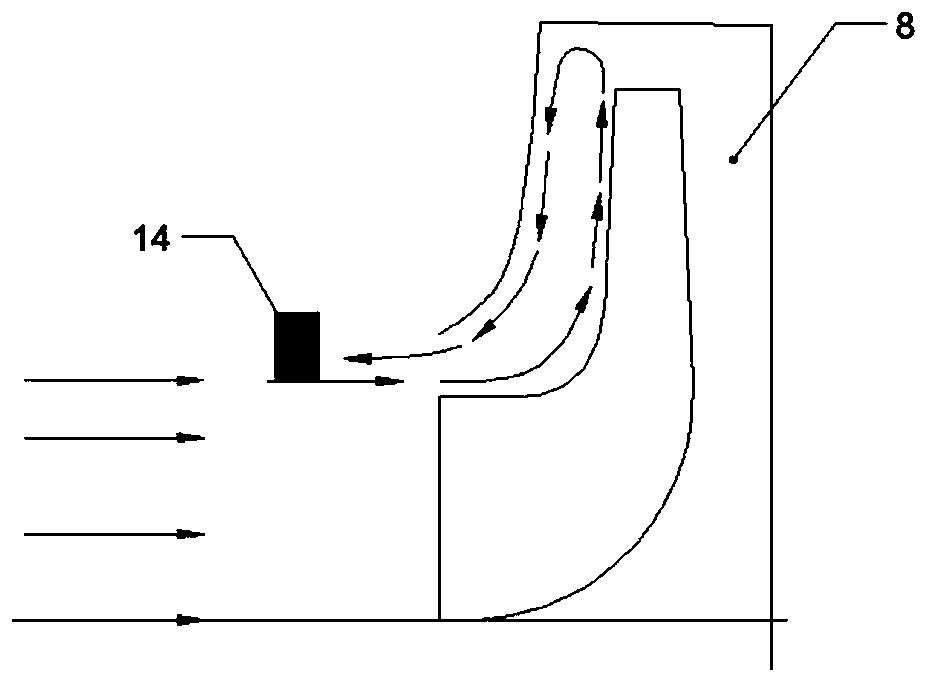

Range hood

ActiveCN110905858AAvoid it happening againReduce local refluxDomestic stoves or rangesPump componentsEngineeringBackflow

The invention discloses a range hood, which comprises a fan frame and a fan system arranged in the fan frame. The fan system comprises a volute and an impeller; a vortex eliminating and noise reducingdevice is arranged in the fan frame; the vortex eliminating and noise reducing device is a cylinder; the vortex eliminating and noise reducing device has windward wall faces located at the bottom, flow guide wall faces located on the side face and an airflow separation wall face located at the top. One ends of the two windward wall faces are connected, and the other ends of the two windward wallfaces extend away from each other; the flow guide wall faces extend upwards in the longitudinal direction from the ends, away from each other, of the windward wall faces; and the airflow separation wall face is connected between the top ends of the two flow guide wall faces. The vortex eliminating and noise reducing device deflects relative to the vertical direction and has an inclination angle theta, and the deflection direction of the vortex eliminating and noise reducing device is opposite to the rotating direction of the impeller. Compared with the prior art, the range hood has the advantages that the deflection of the vortex eliminating and noise reducing device is used for eliminating obvious air inlet vortexes in the fan frame, so that local backflow and vortex kinetic energy loss caused by vortexes are reduced, and noise is reduced.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

Indoor unit of air conditioner

ActiveCN103851694AAdjustable sizeSave ceiling spaceLighting and heating apparatusNoise suppressionEngineeringMechanical engineering

The invention discloses an indoor unit of an air conditioner. The indoor unit of the air conditioner comprises a shell, a heat exchanger and a cross-flow fan, the heat exchanger and the cross-flow fan are mounted in the shell, and the cross-flow fan comprises a cross-flow wind wheel and a volute which are matched with each other; the volute comprises a front volute tongue which is formed into the first lateral surface of a diffusion part of the cross-flow fan and a rear volute which is formed into the second lateral surface of the diffusion part, wherein the second lateral surface is opposite to the first lateral surface, the diffusion part is downward, an air outlet is formed in the lower lateral surface of the shell, and a return air inlet is formed in each of the rear lateral surface and / or upper lateral surface of the shell; the minimum clearance between the front volute tongue and the rear volute is D, and D is more than or equal to 40 millimeters and less than or equal to 75 millimeters. According to the indoor unit of the air conditioner, the air outlet is formed in the lower lateral surface, the return air inlet is formed in each of the rear lateral surface and / or upper lateral surface, so that a room can be partially ceiled, and the air current circulation in the room is improved; and in addition, the minimum clearance D between the front volute tongue and the rear volute is optimized to regulate the size of the air outlet, the air outlet speed is optimized, and the noise is lowered.

Owner:GREE ELECTRIC APPLIANCES INC

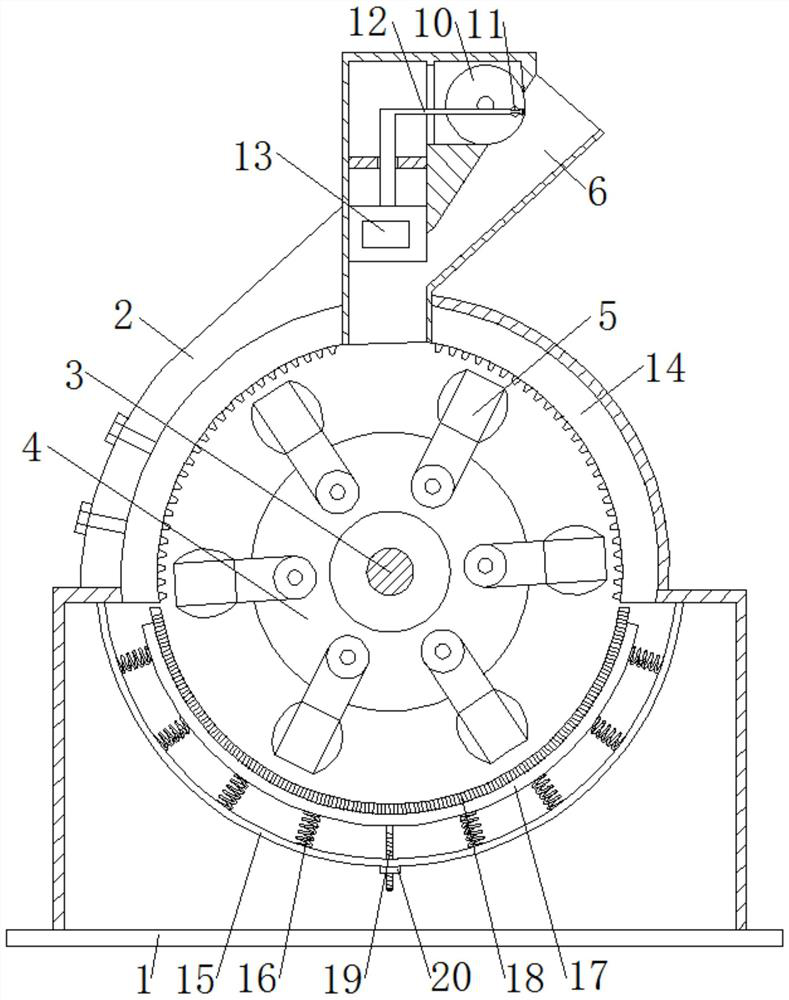

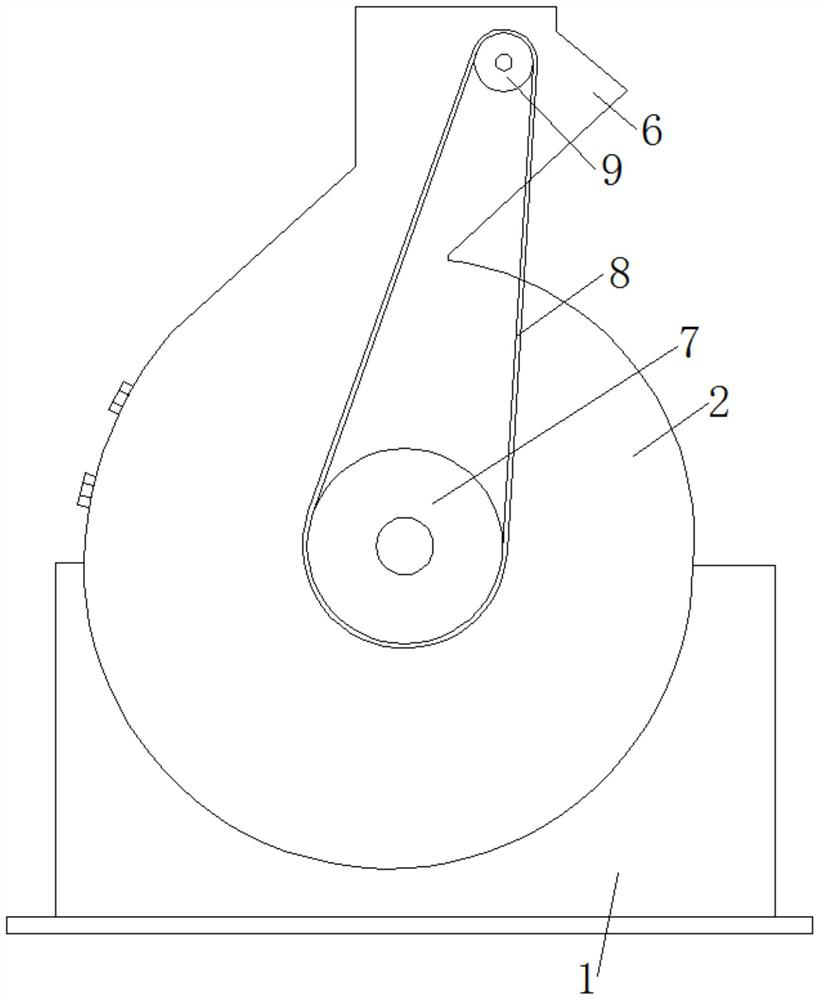

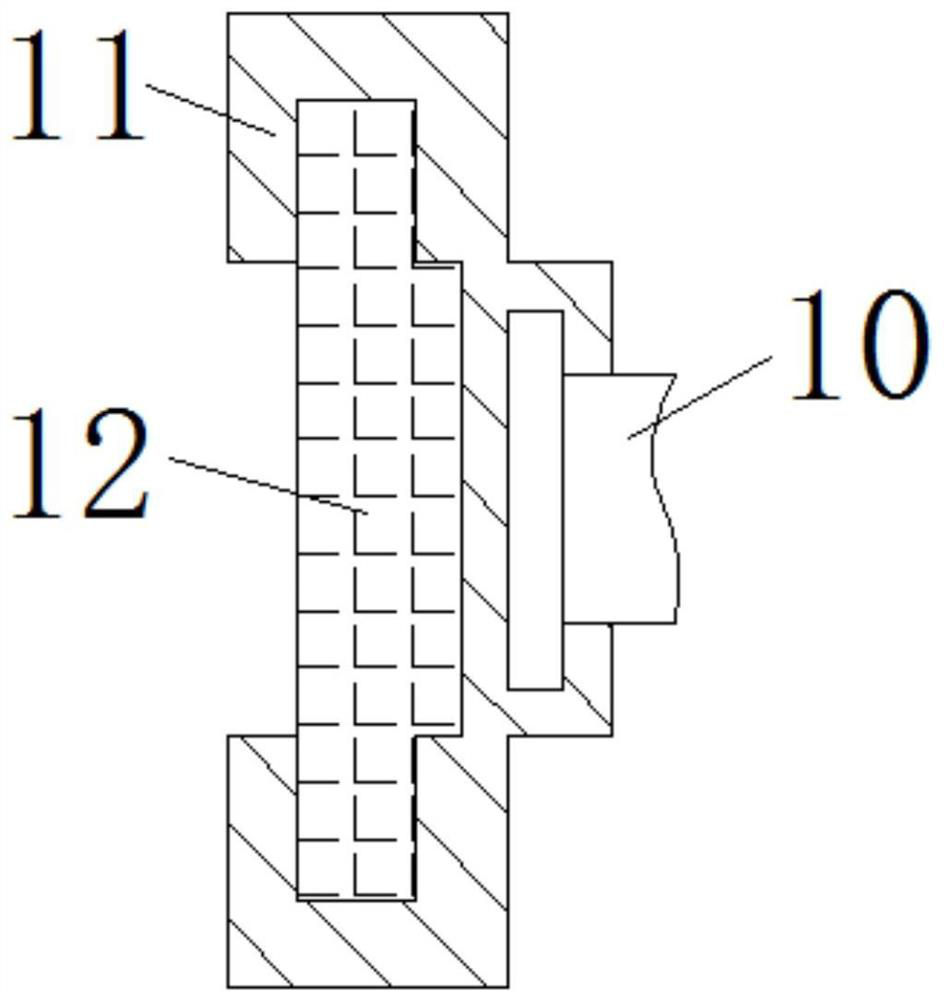

Hammer type crusher capable of improving crushing efficiency

ActiveCN111889192AAvoid damageExtended service lifeGrain treatmentsArchitectural engineeringStructural engineering

The invention relates to the technical field of mineral processing equipment, and discloses a hammer type crusher capable of improving crushing efficiency. The hammer type crusher comprises a base, wherein the upper end of the base is fixedly connected to volute casing; a feeding hole is fixedly connected above the volute casing; and the middle part of the volute casing movable sleeves a transmission shaft. A bracket, a spring and a supporting plate are arranged, so that a hammer head hits against a sieve plate through materials while the hammer head of the crushing hammer re-crushes materialswith greater particle diameters, which drop onto the sieve plate; damages on the sieve plate by the hammer head are reduced by damping, extending and retracting of the spring, so that the sieve plateis protected, and the service life of the sieve plate is prolonged; while part of relatively great particles are pressed along with the sieve plate, the spring rebounds after the crushing hammer rotates through the materials for throwing the materials, so that the materials are directly crushed by the crushing hammer, and therefore, crushing efficiency is improved; and meanwhile, the spring can be arranged, so that the sieve plate is always in a shaking and vibrating state, and therefore, the sieving process can be quickened, and sieving effect can be improved.

Owner:徐州中矿汇弘矿山设备有限公司

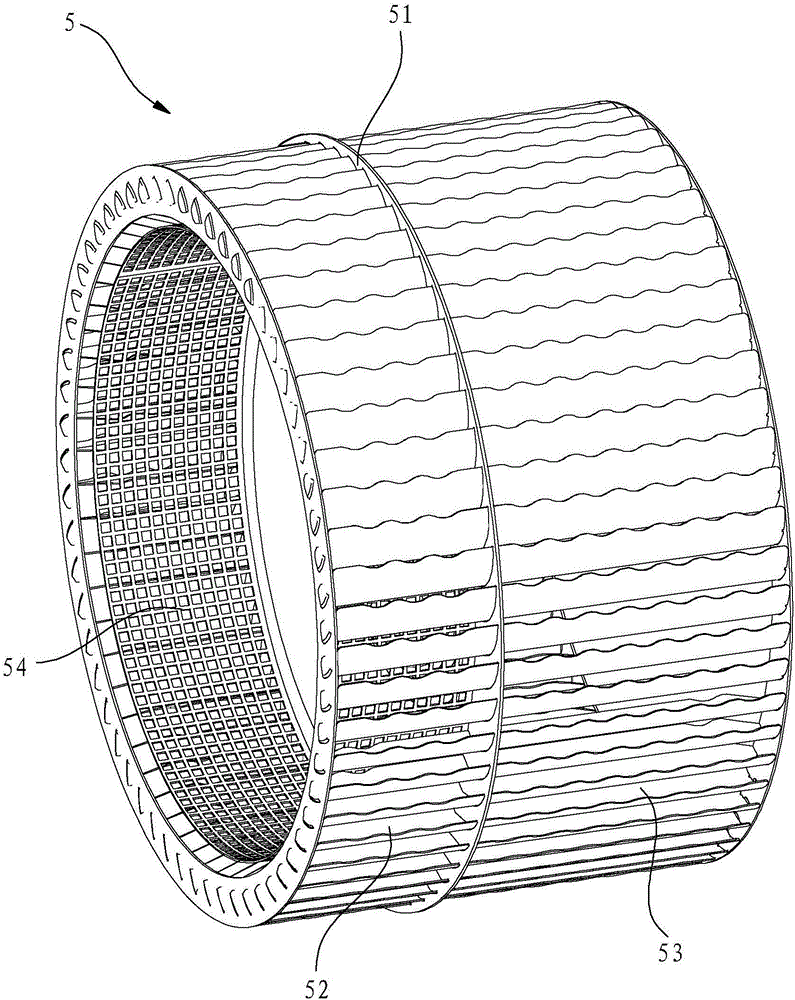

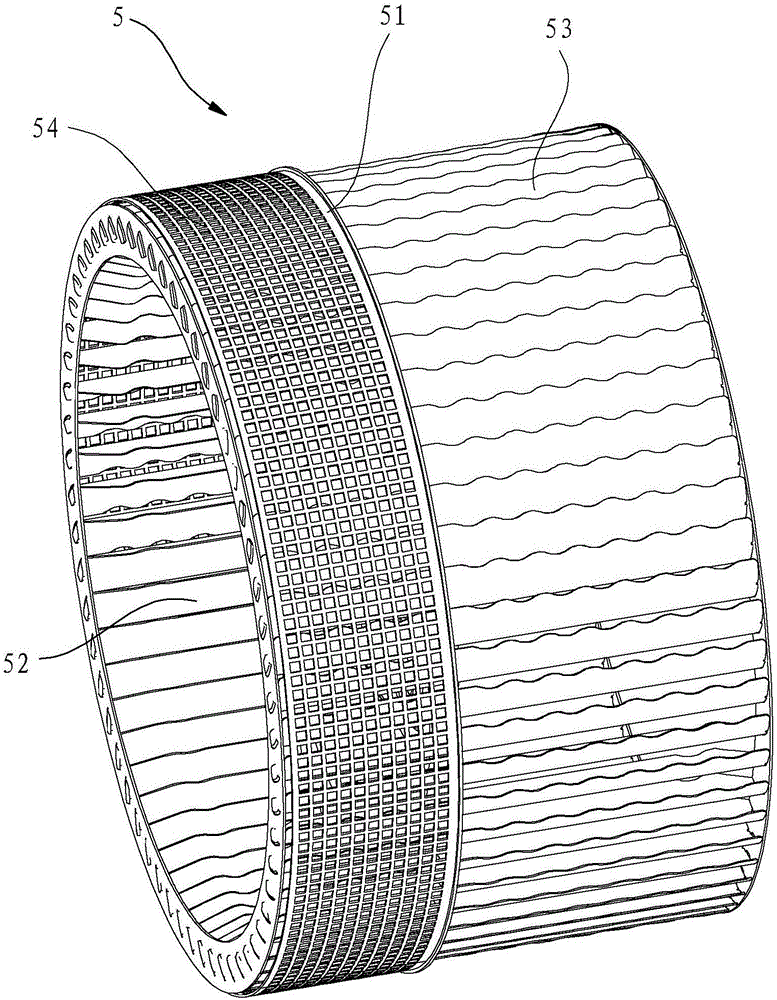

Air suspension centrifugal blower

ActiveCN112228361ALow costImprove variable efficiencyPump componentsPump installationsElectric machineThrust bearing

The invention discloses an air suspension centrifugal blower. The air suspension centrifugal blower comprises a motor, a volute, an impeller, an impeller shaft, bearing rotating shafts, air suspensionradial bearings and air suspension thrust bearings. The front end and the rear end of a motor rotor are rotationally connected with the air suspension radial bearings through the bearing rotating shafts respectively. The bearing rotating shaft located at the front end of the motor is rotationally connected with the air suspension thrust bearing through a thrust disc, PVD coatings are arranged onthe friction faces of the bearing rotating shafts and the thrust disc, the friction coefficient of the PVD coatings is smaller than or equal to 0.1, and the thickness of the PVD coatings ranges from 2micrometers to 8 micrometers. PTFE coatings are arranged on the friction faces of the air suspension radial bearings and the air suspension thrust bearings, the friction coefficient of the PTFE coatings is smaller than or equal to 0.05, and the thickness of the PTFE coatings ranges from 0.02 mm to 0.05 mm. The air suspension centrifugal blower has the advantages of compact structure, high efficiency, long service life, good stability, high start-stop frequency, low motor temperature rise and the like.

Owner:益鑫能源科技(上海)有限公司

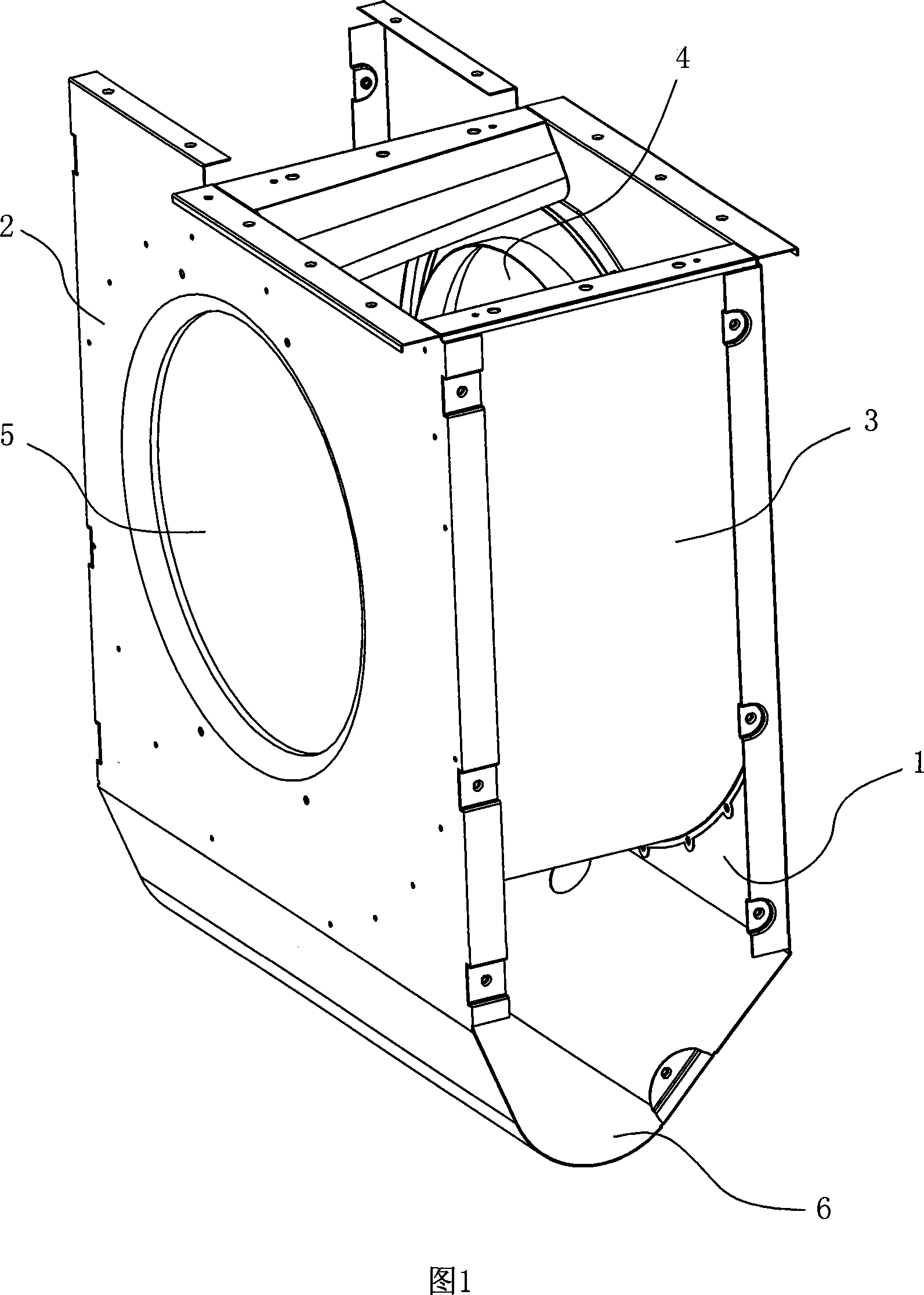

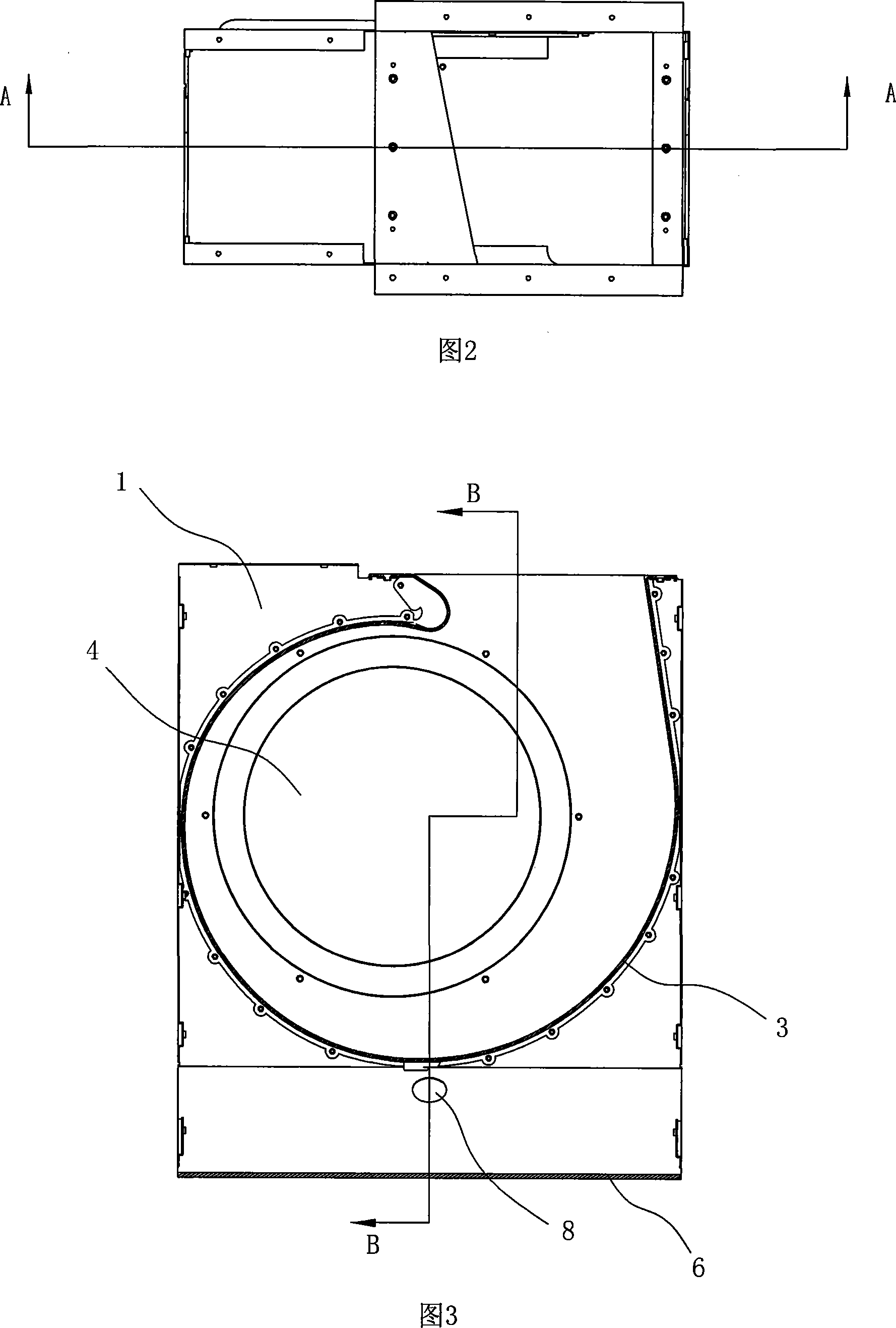

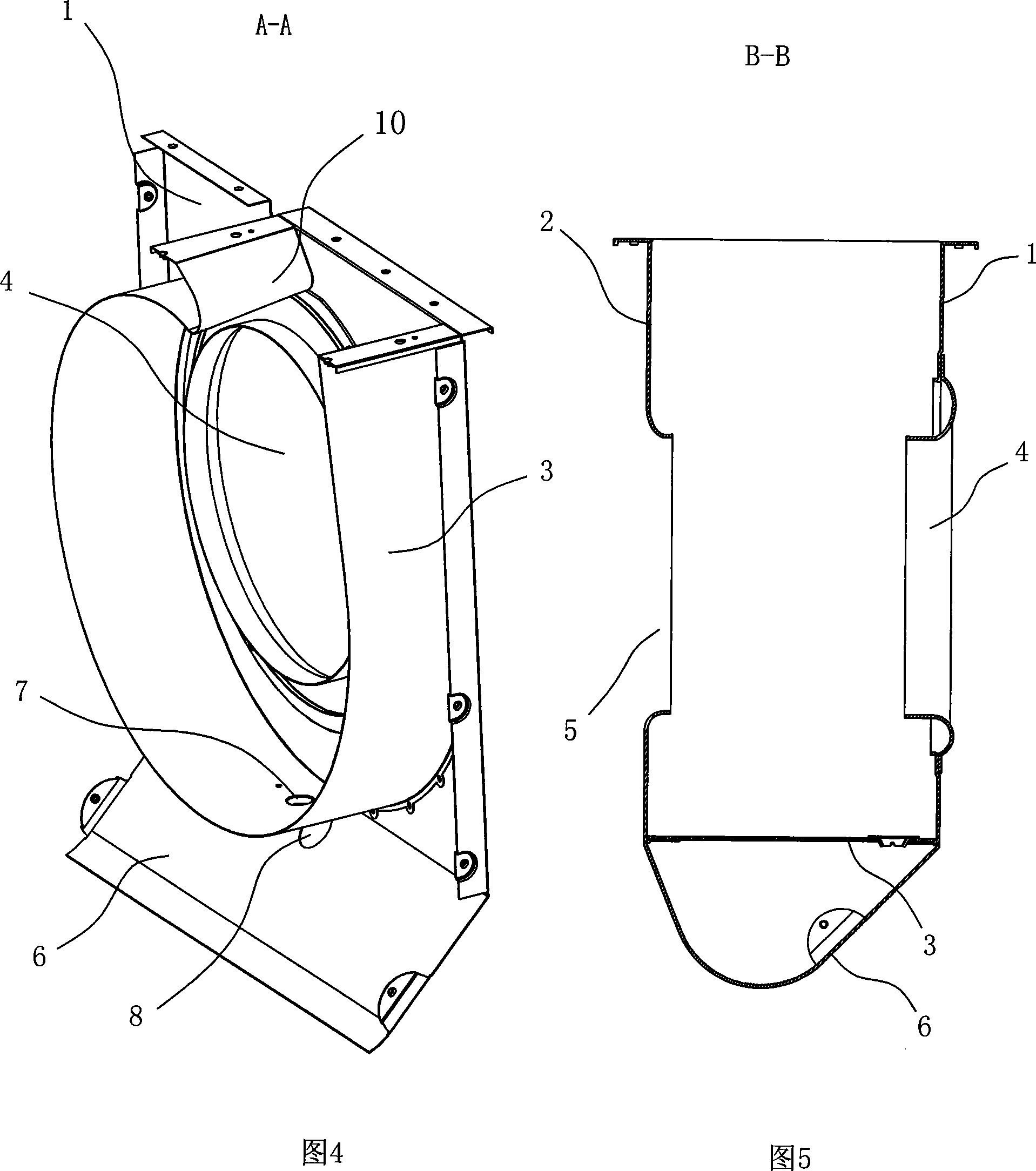

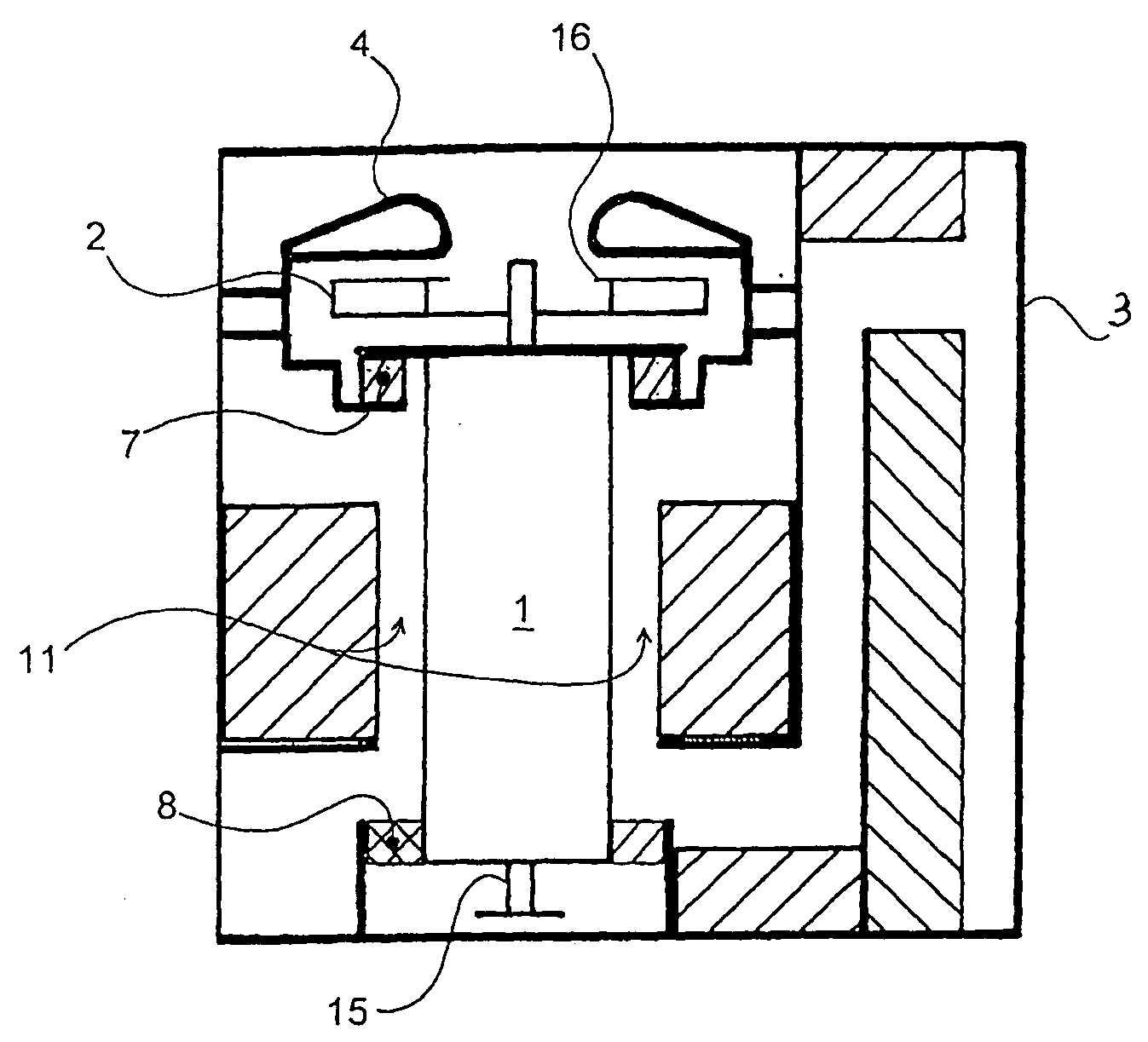

Respiratory Assistance Device

InactiveUS20080257347A1Avoid spreadingReduce the impactRespiratorsPump componentsDriver/operatorEngineering

The high-speed centrifugal ventilation device for assisting a patient respiratory function includes a centrifugal fan which is arranged in a casing box and essentially has a wheel actuated by a driver. The wheel is provided with a volute connected to the casing box in such a way that an integral fixed assembly is formed. An elastic device is interposed between the fixed assembly and the driver provided with the wheel which is driven thereby. A dynamic assembly is formed for avoiding transmission of vibrations generated by the wheel and the driver towards the fixed assembly.

Owner:AIR LIQUIDE MEDICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com