Spiral case of blower fan in apparatus with inlet air from two sides for sucking oil fume

A range hood and fan technology, applied in the field of component structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

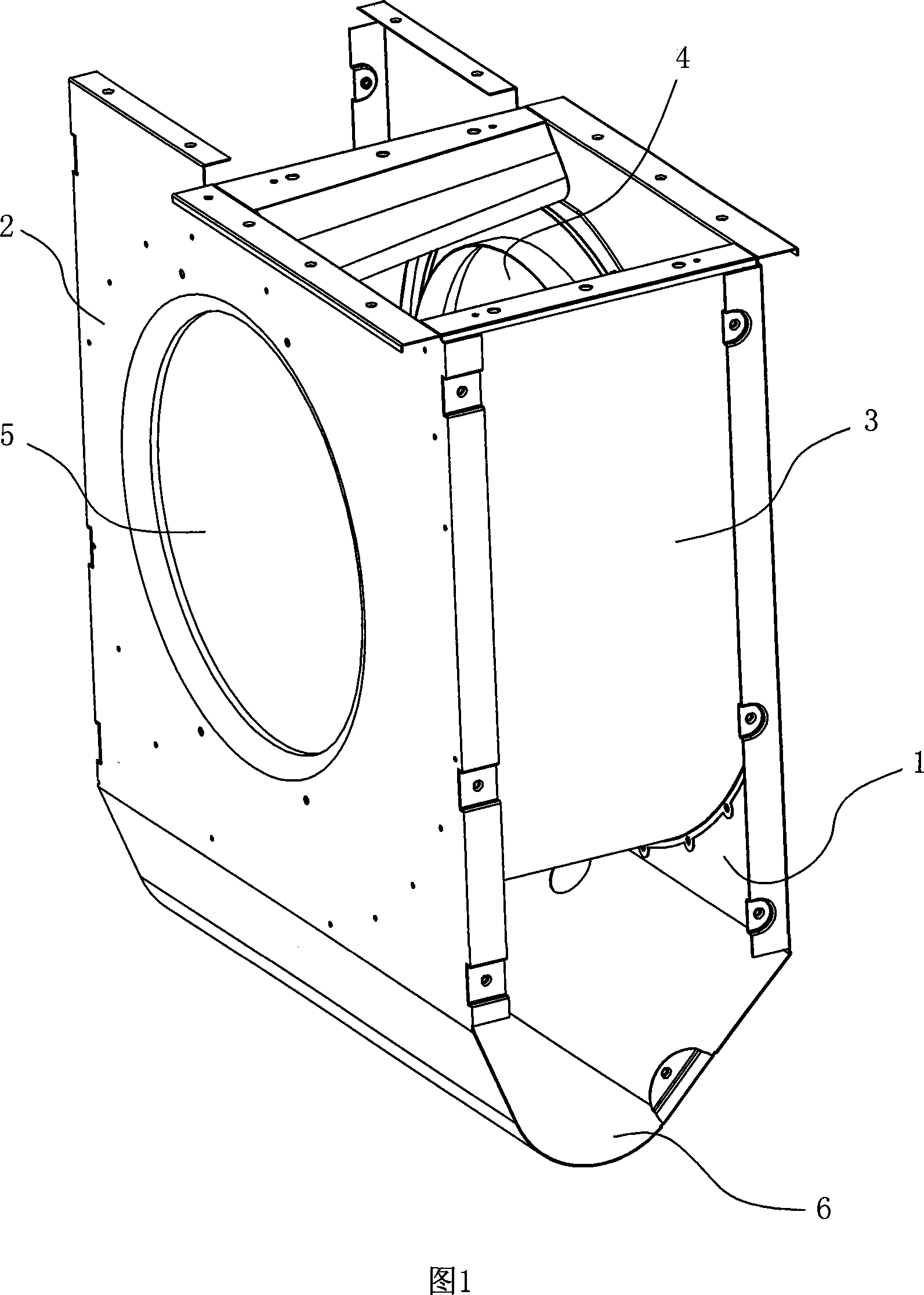

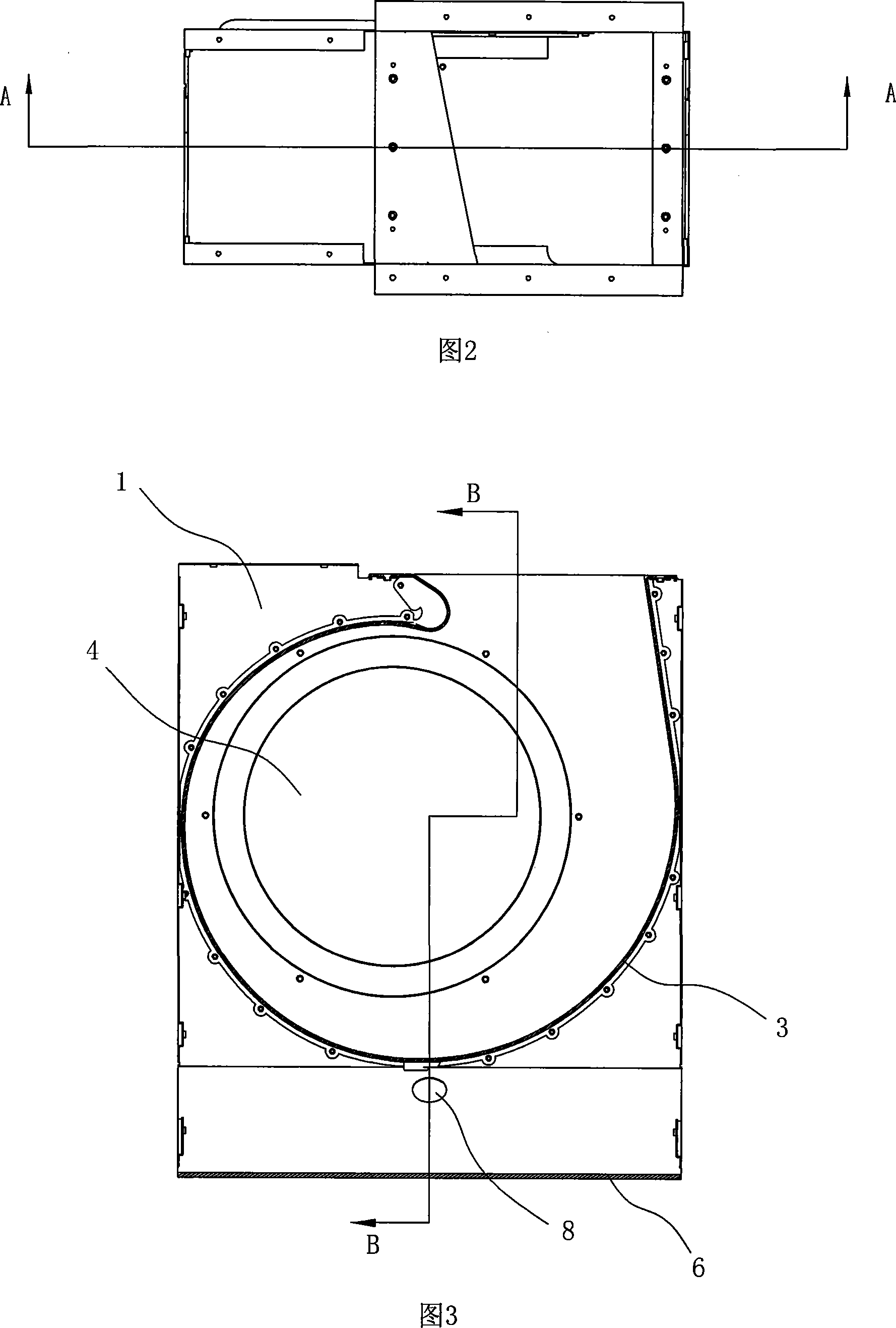

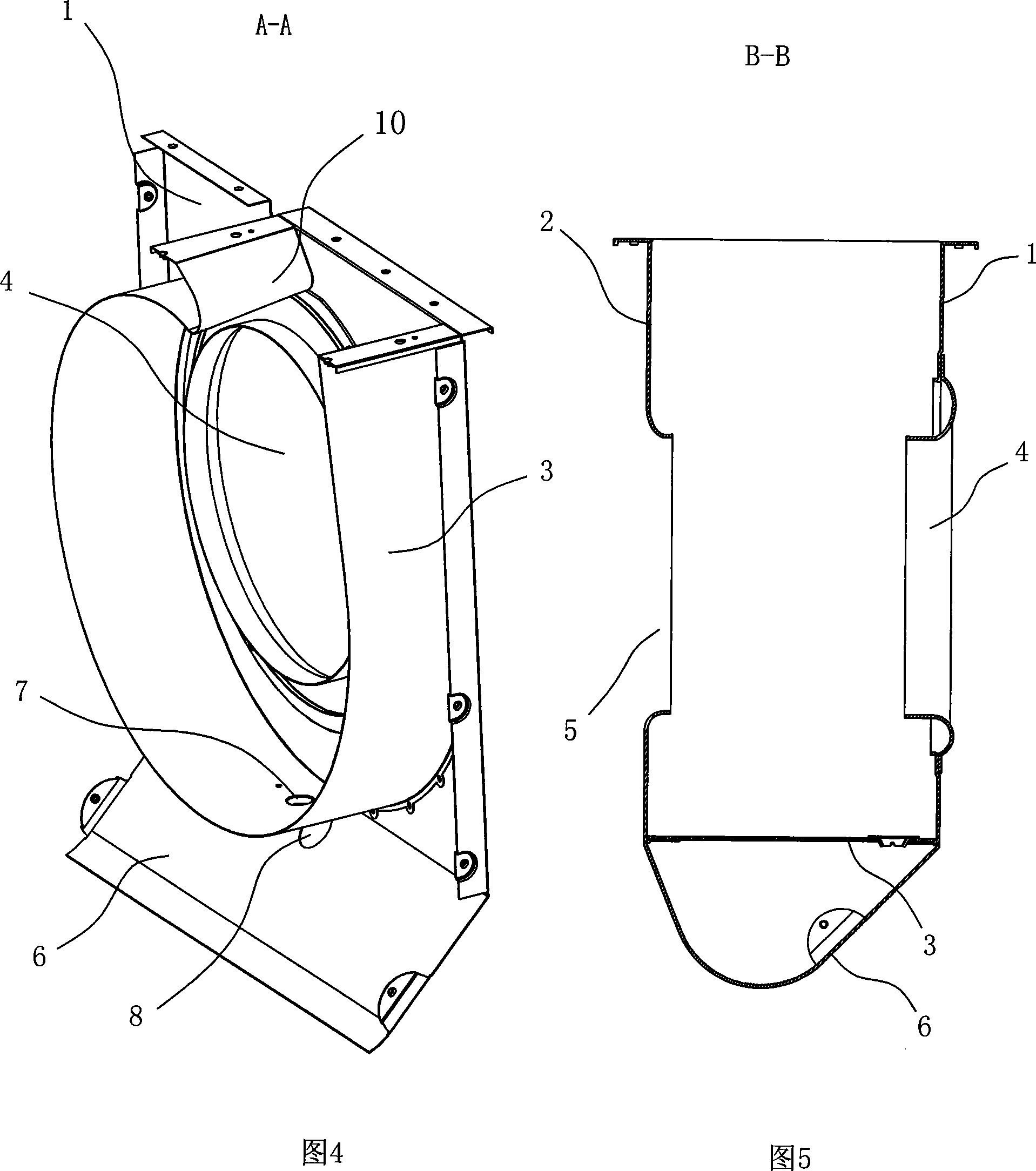

[0031] As shown in Fig. 1 to Fig. 9, it is a preferred embodiment of the present invention. As shown in Figures 1 to 9, the fan volute of the range hood with double-sided air intake in this embodiment has a front cover 1, a rear cover 2 and an annular intermediate casing 3 connecting the two, except for the volute tongue Outside, the middle shell 3 is perpendicular to the front cover 1 and the rear cover 2, and the front cover 1 and the rear cover 2 are respectively opened with the forward air hole 4 and the rear air inlet 5, and the center of the circle of the forward air hole 4 The projection on the plane where the rear cover plate 2 is located coincides with the center of circle of the rear air inlet hole 5 . Between the lower edge of the front cover 1 and the lower edge of the rear cover 2 is connected a downwardly protruding cylindrical ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Angle | aaaaa | aaaaa |

| Angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com