Patents

Literature

602results about How to "Increase wind pressure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

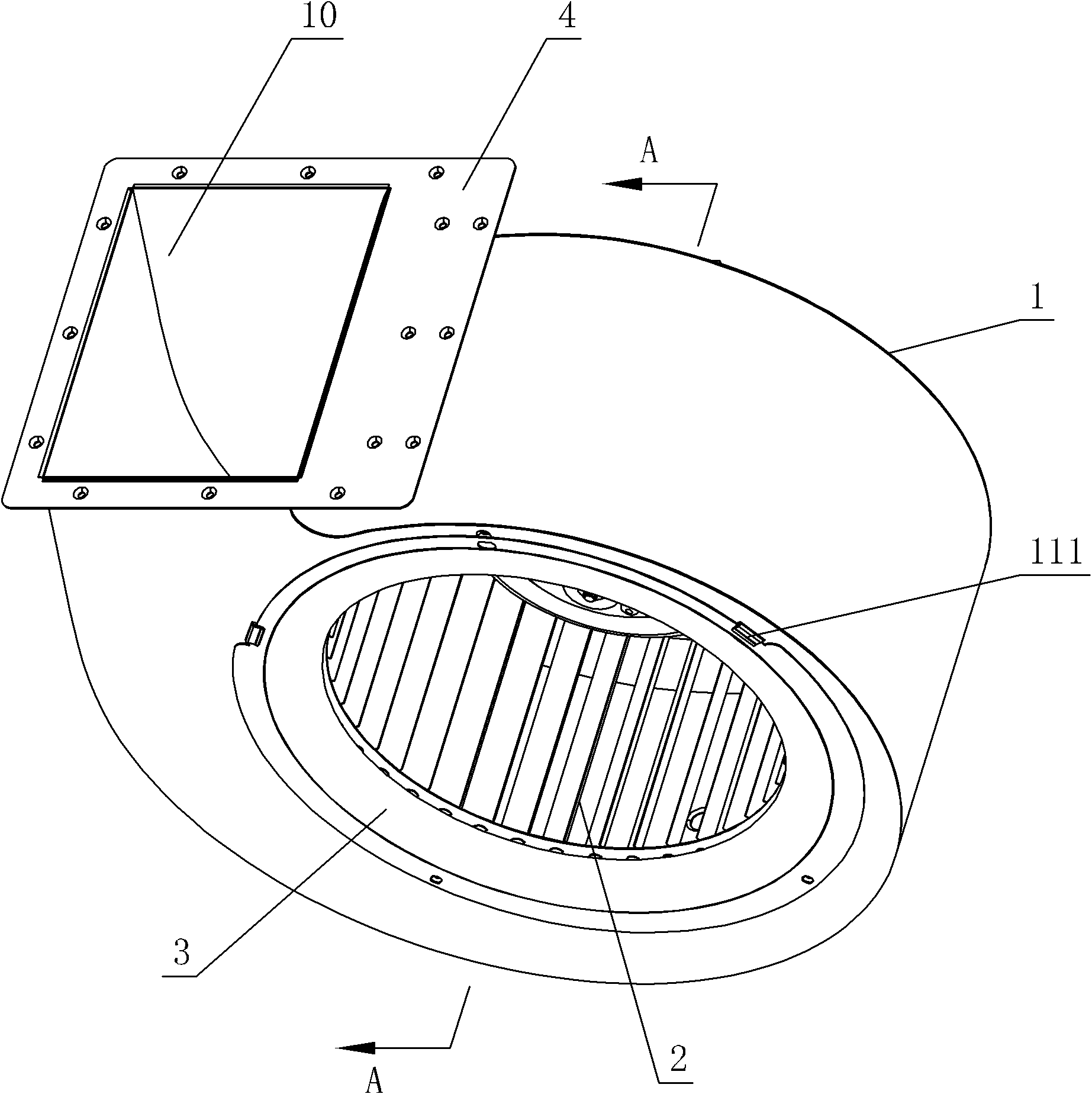

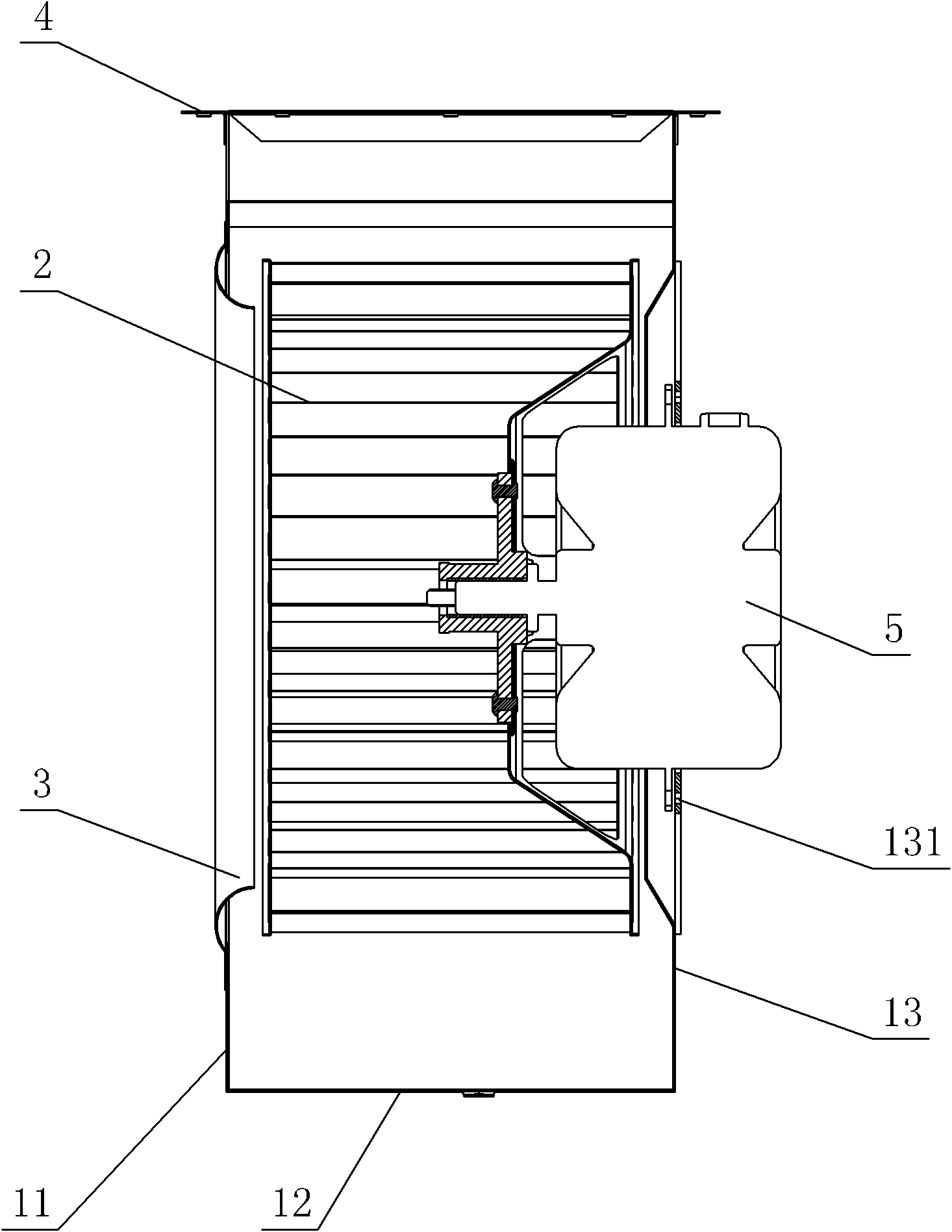

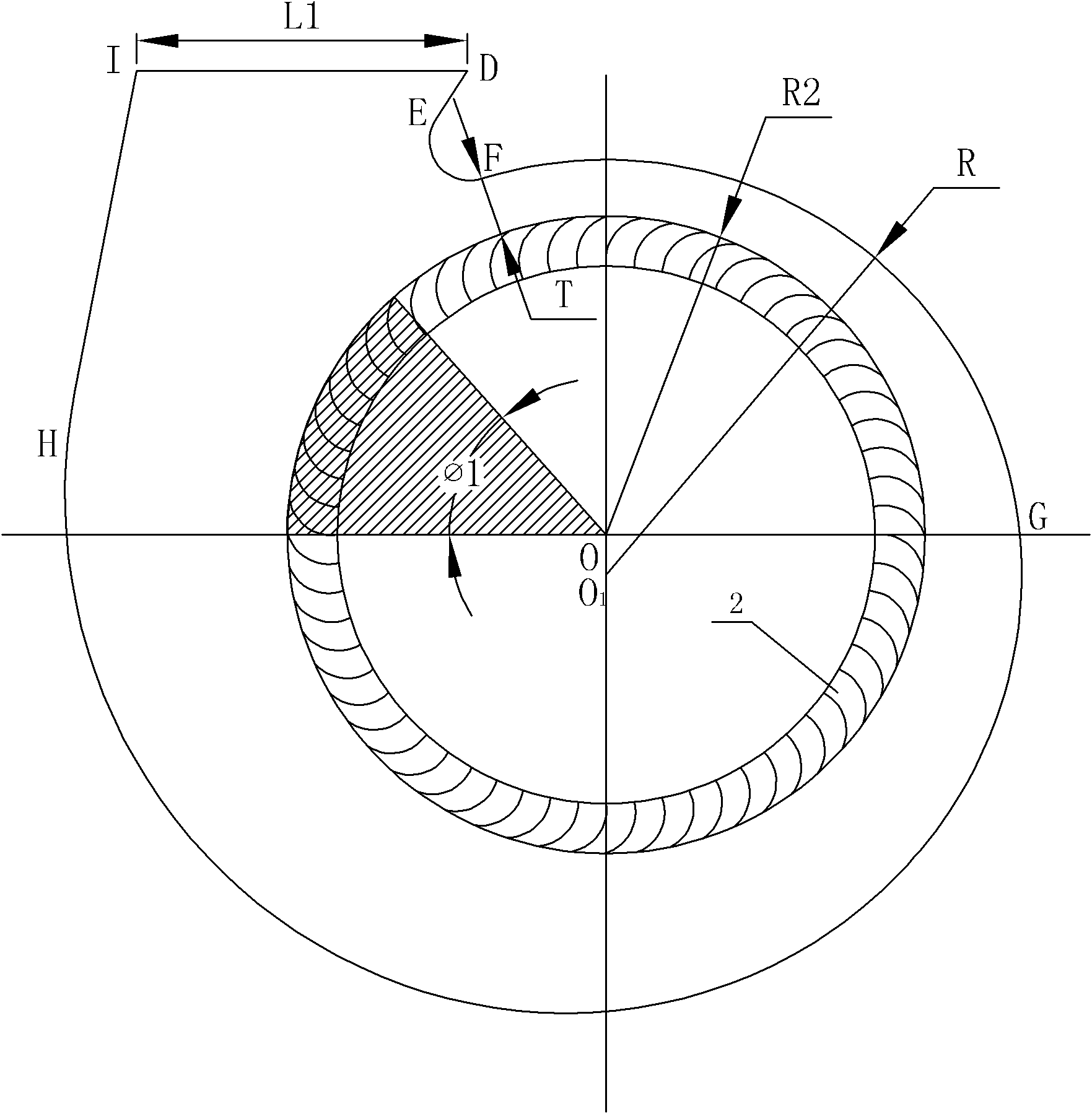

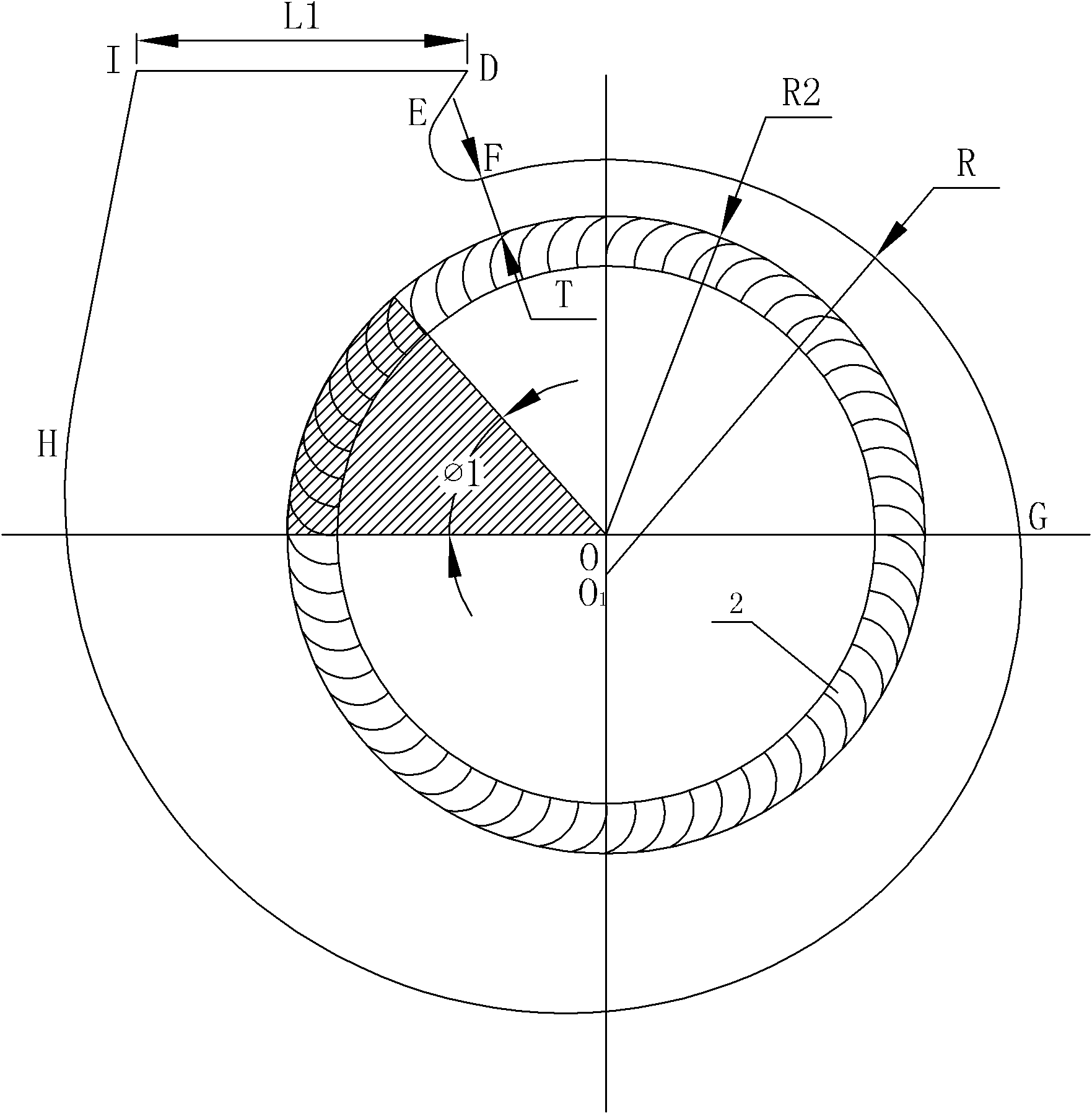

Centrfugal fan for oil and smoke exhaust machine and method for manufacturing volute profile line thereof

The invention relates to a centrifugal fan for an oil and smoke exhaust machine and a method for manufacturing a volute profile line thereof. The centrifugal fan comprises a volute, a blade wheel, an air inlet ring and a motor, wherein the volute is provided with an air inlet and an air outlet; the blade wheel is arranged in the volute; the air inlet ring is arranged on the air inlet; the motor drives the blade wheel to rotate; the volute comprises a volute top plate, a volute enclosing plate and a volute base plate; and the volute enclosing plate is connected between the volute top plate and the volute base plate. The centrifugal fan is characterized in that the outline of the inner side face of the volute enclosing plate is the volute profile line, and the volute profile line is formed by the smooth transitional connection of a first straight line DE, a first arc line EF, a second arc line FG, a spiral line GH and a second straight line HI. According to the invention, after considering problems in the prior art and aiming at the characteristics of large impellor size and small volute size of the centrifugal fan for the oil and smoke exhaust machine, a design method of the volute profile line of the centrifugal fan is presented, thereby making great contribution to improving the air rate, air pressure and efficiency of the centrifugal fan for the oil and smoke exhaust machine and reducing the pneumatic noises.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG

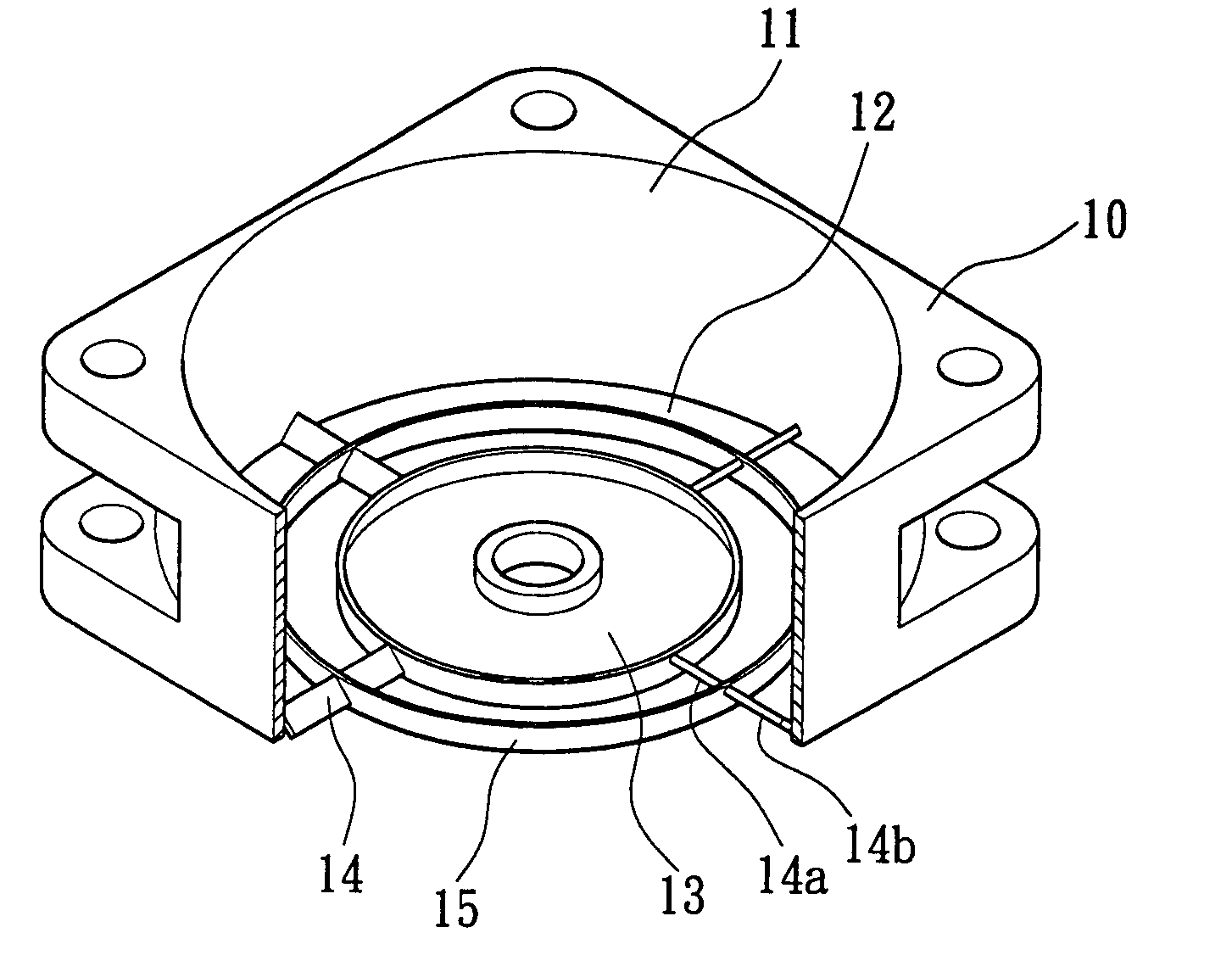

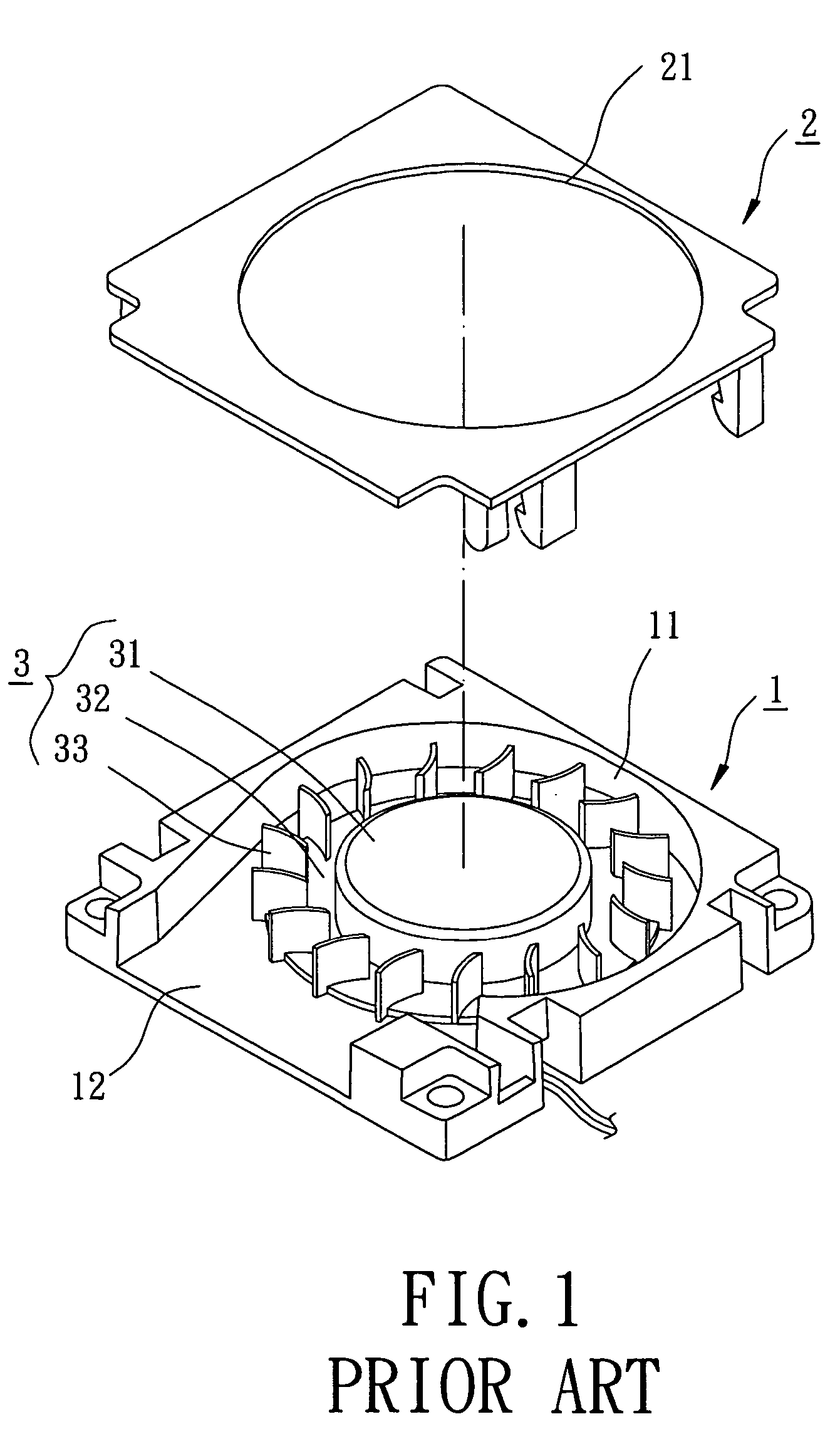

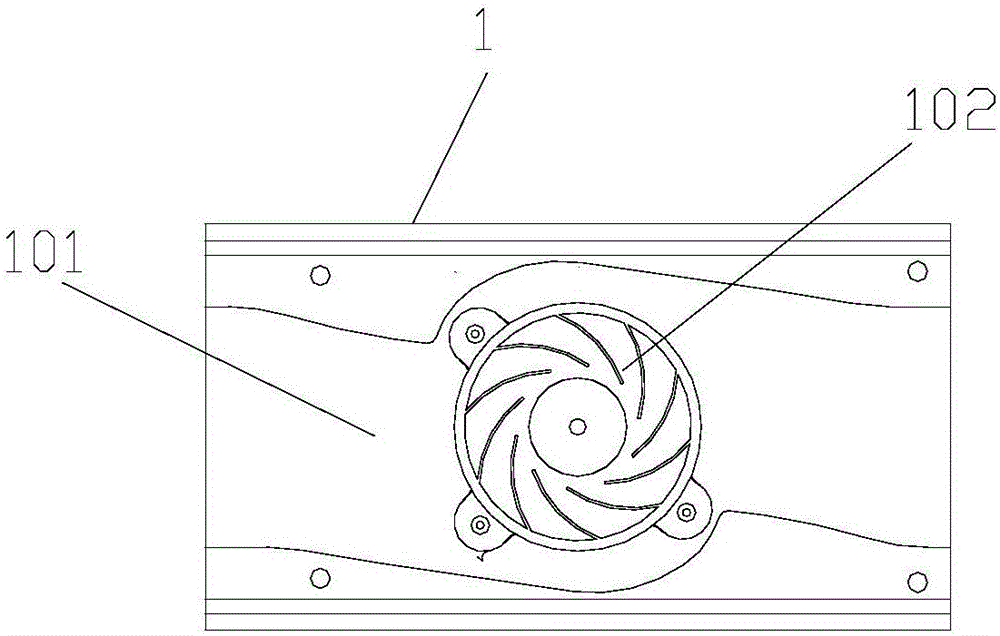

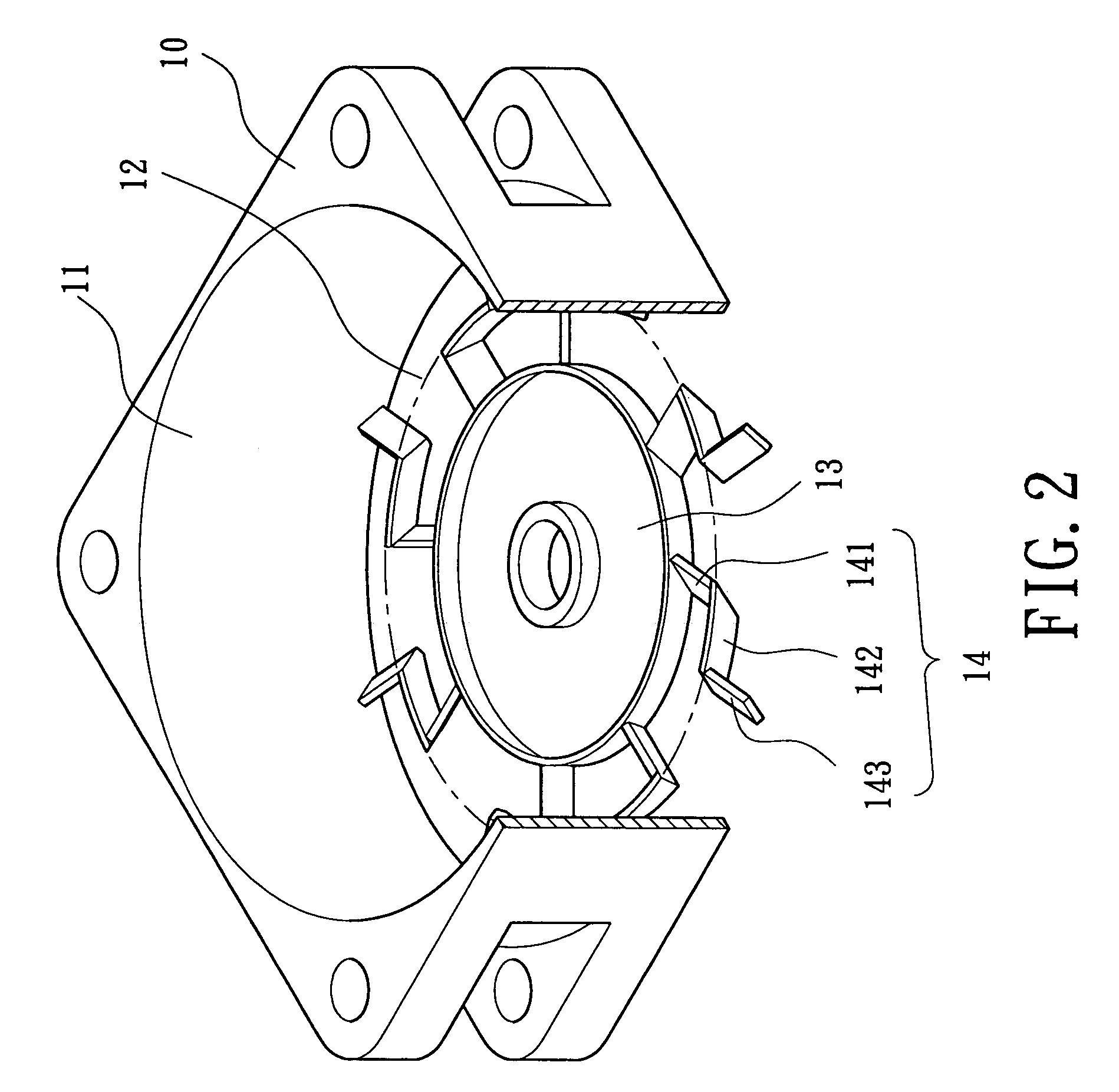

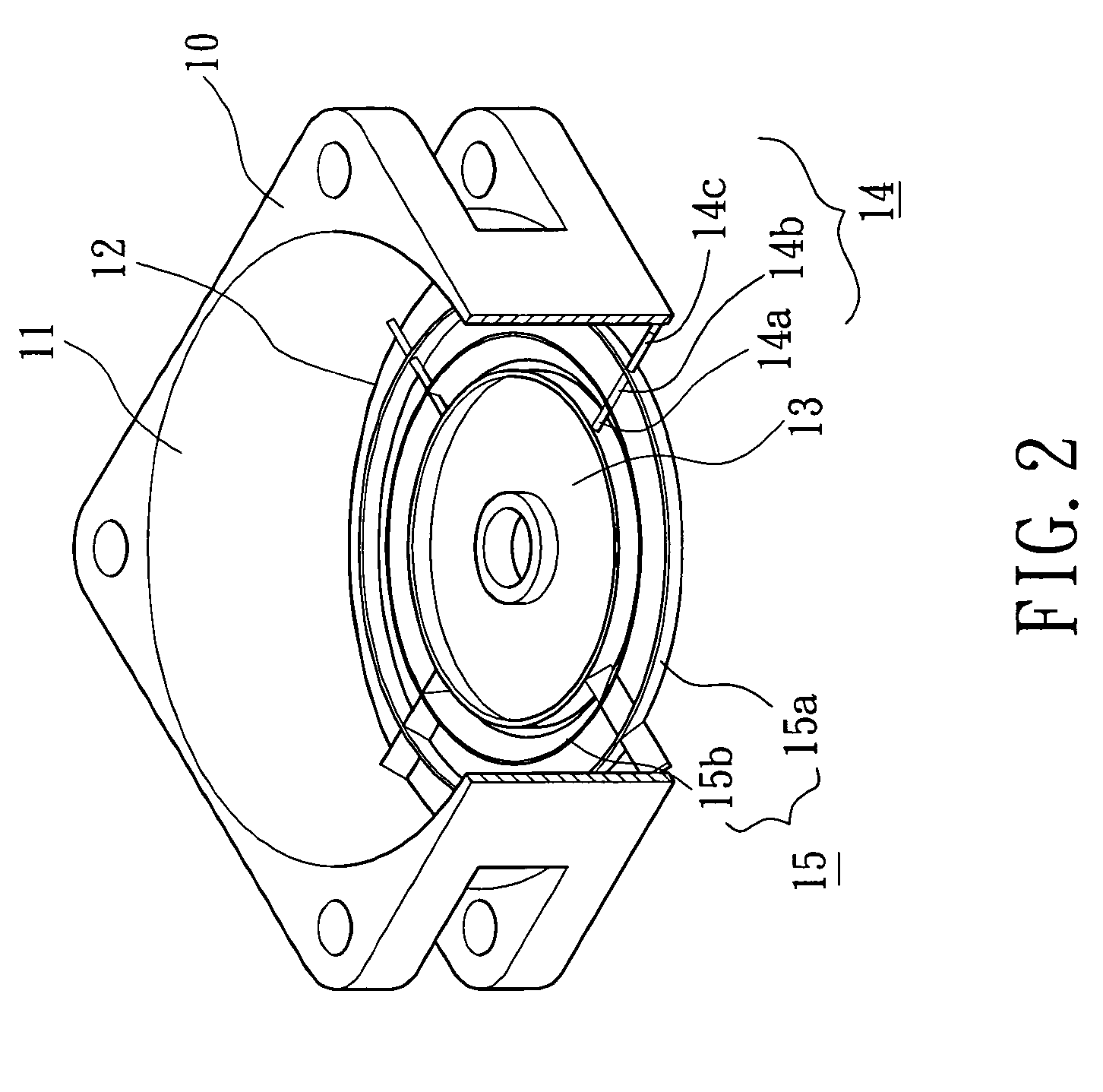

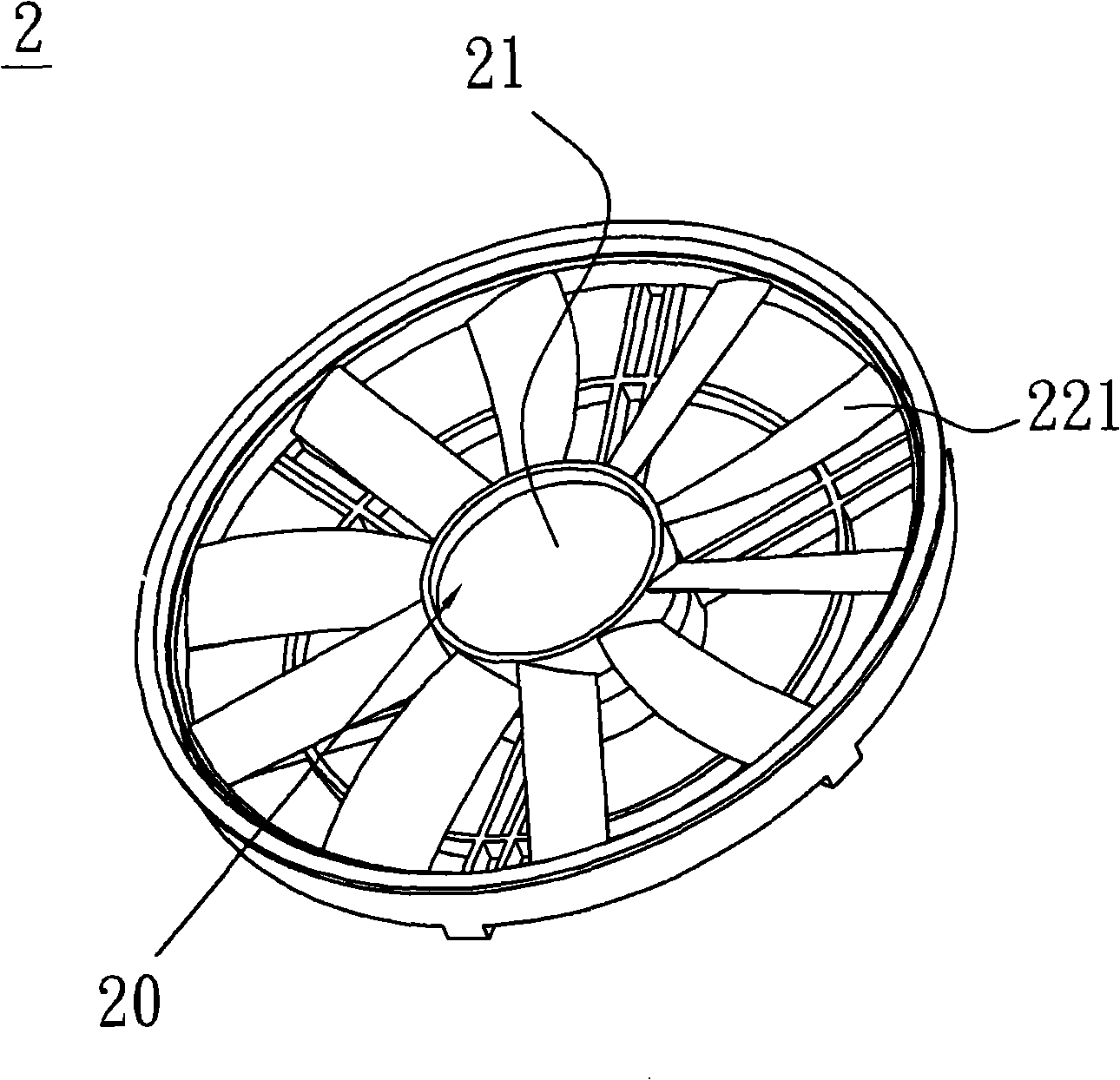

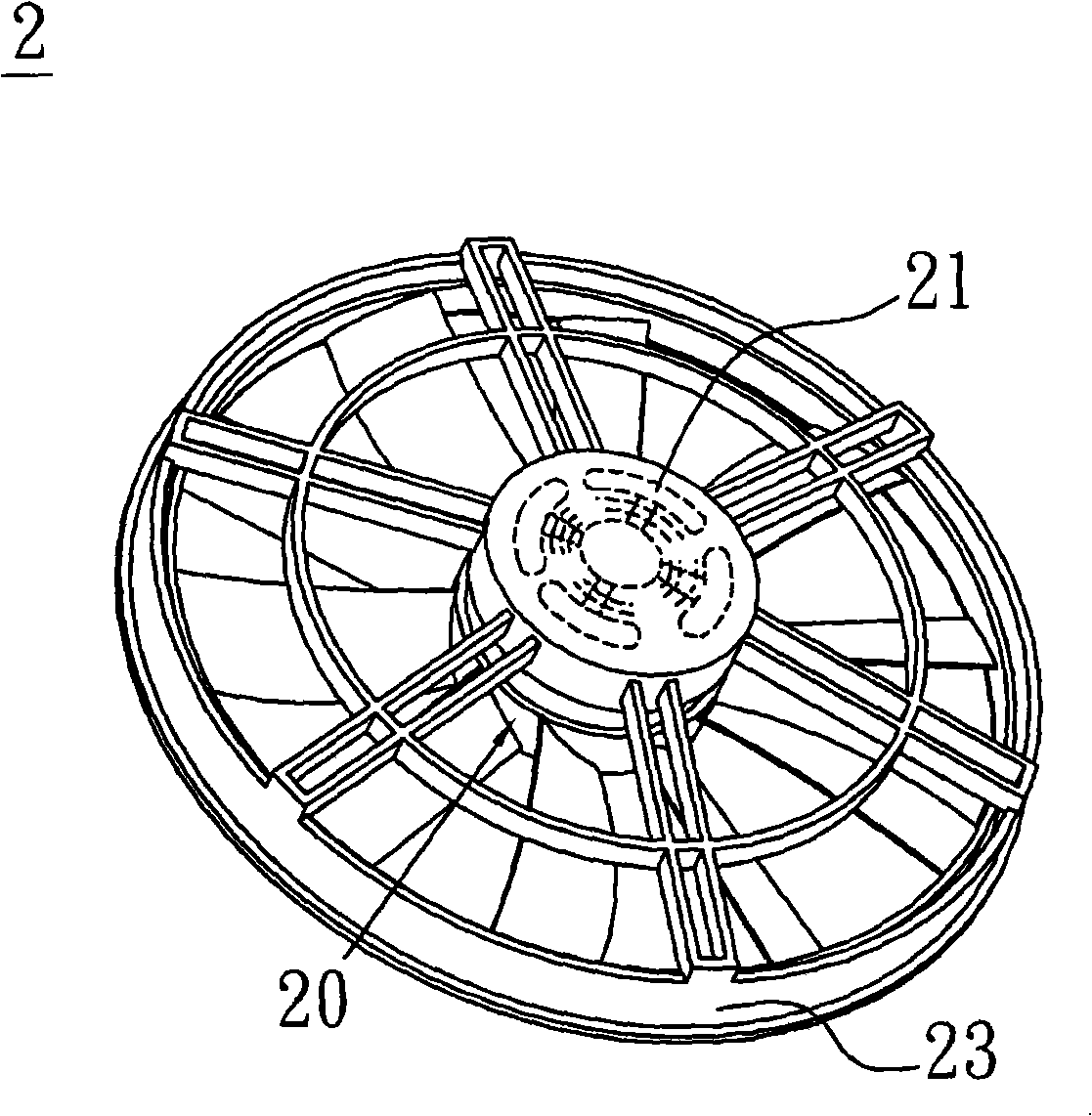

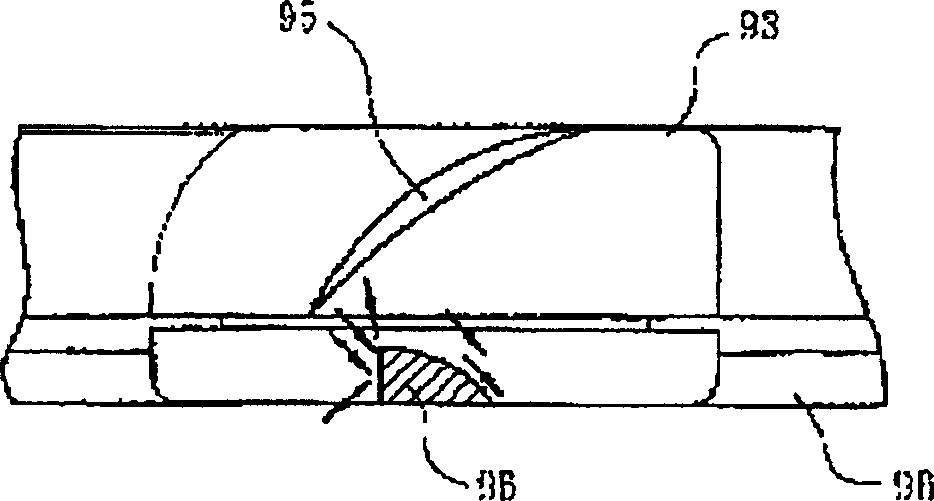

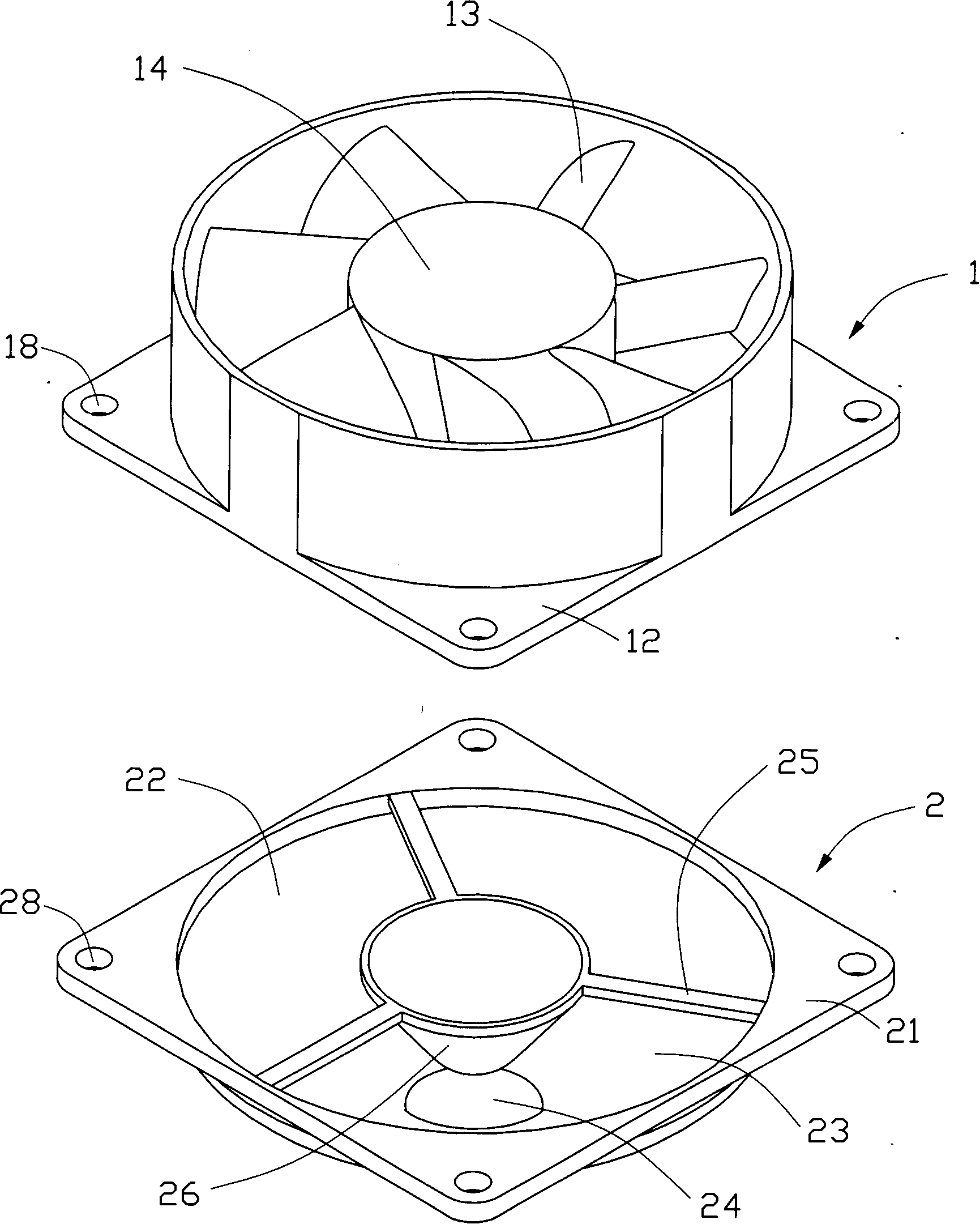

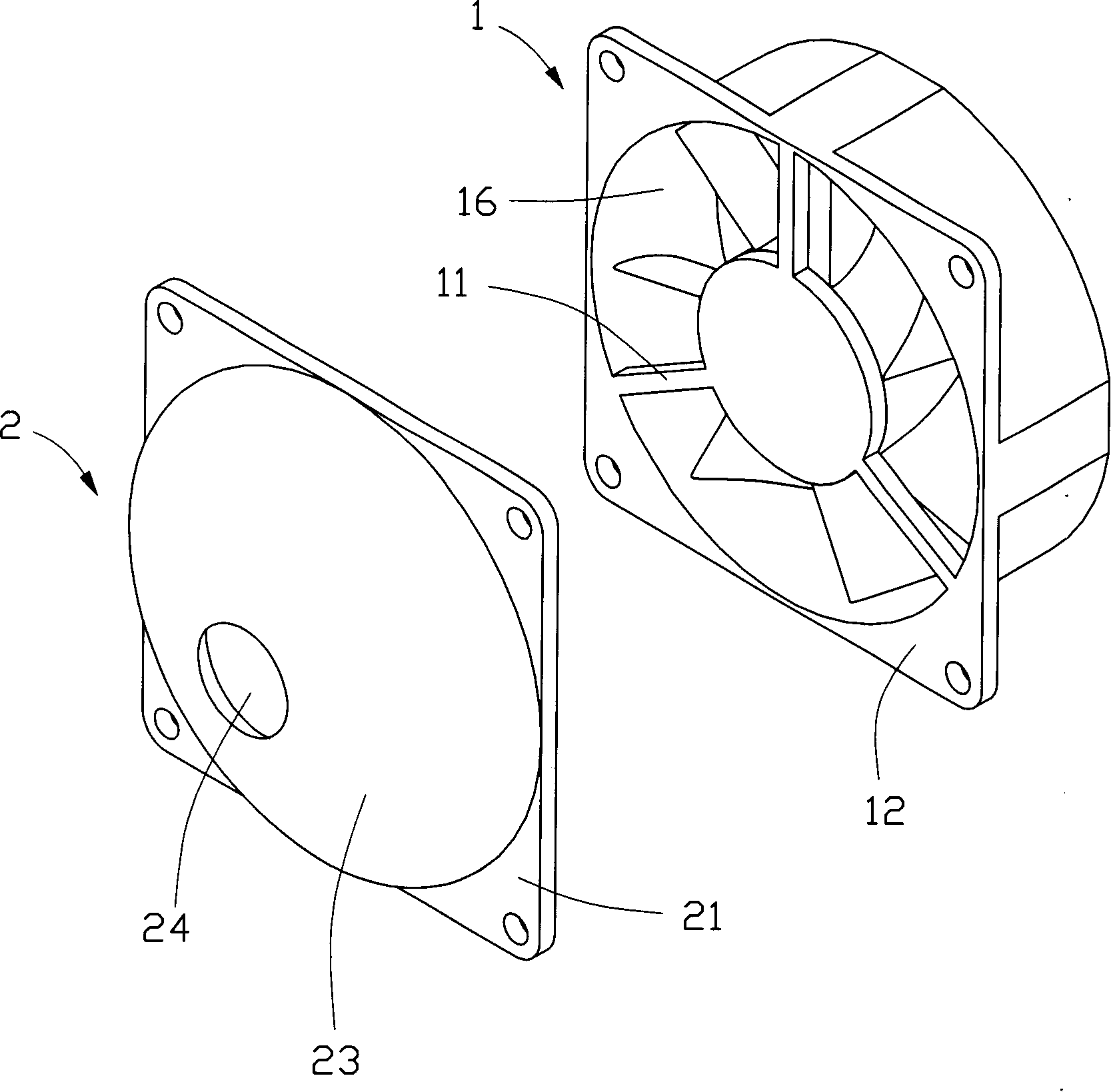

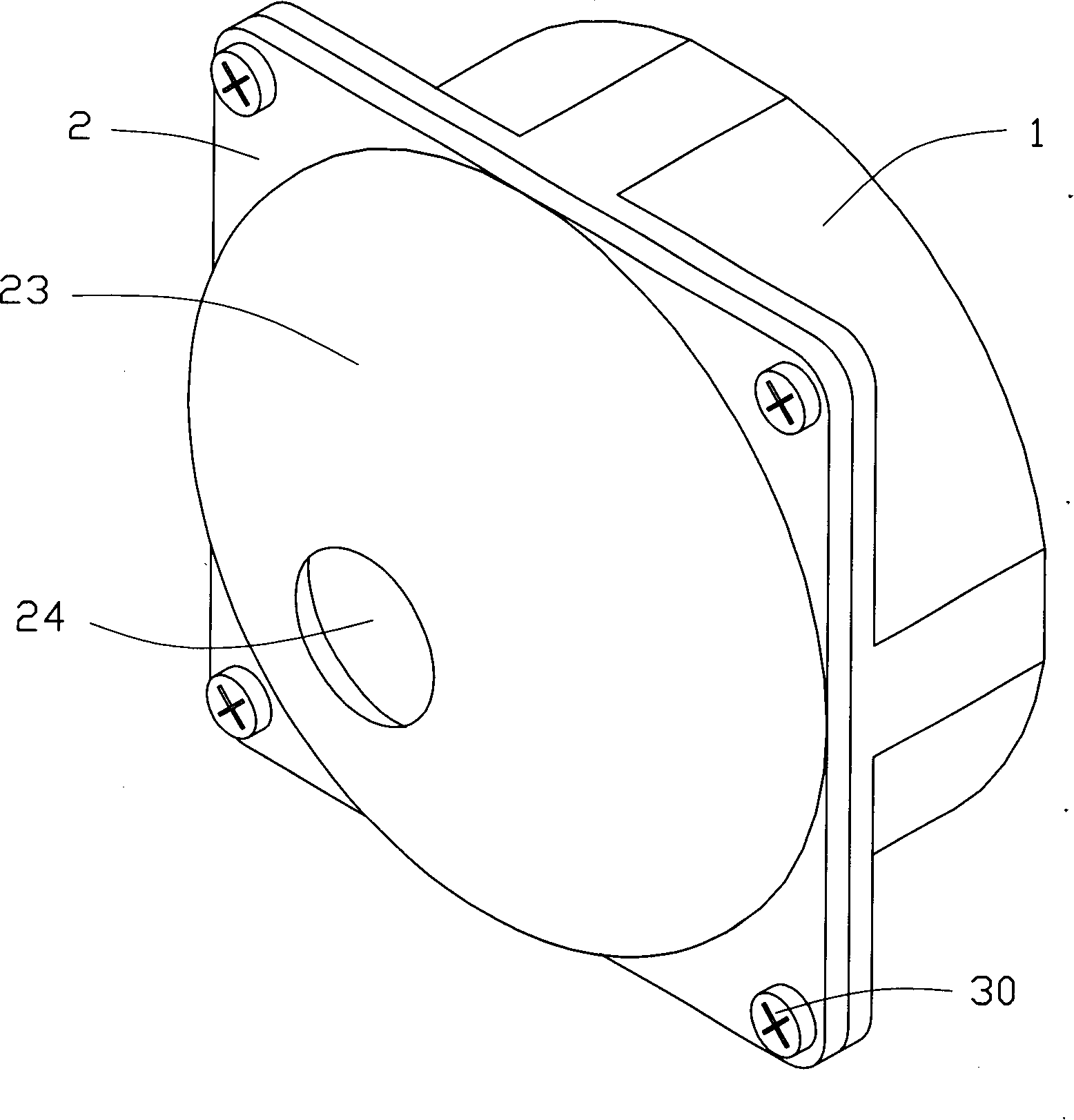

Airflow guiding structure for a heat-dissipating fan

A heat-dissipating fan includes a casing having an air outlet, a base mounted in the air outlet, an impeller being mounted on the base and having a plurality of blades, a plurality of ribs each extending between the base and the casing along a radial direction of the base, and at least one guiding ring fixedly mounted to the ribs. The guiding ring has an axial length that is longer than a width of the guiding ring in the radial direction. The guiding ring guides and divides airflow passing through the air outlet when the impeller is turning.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

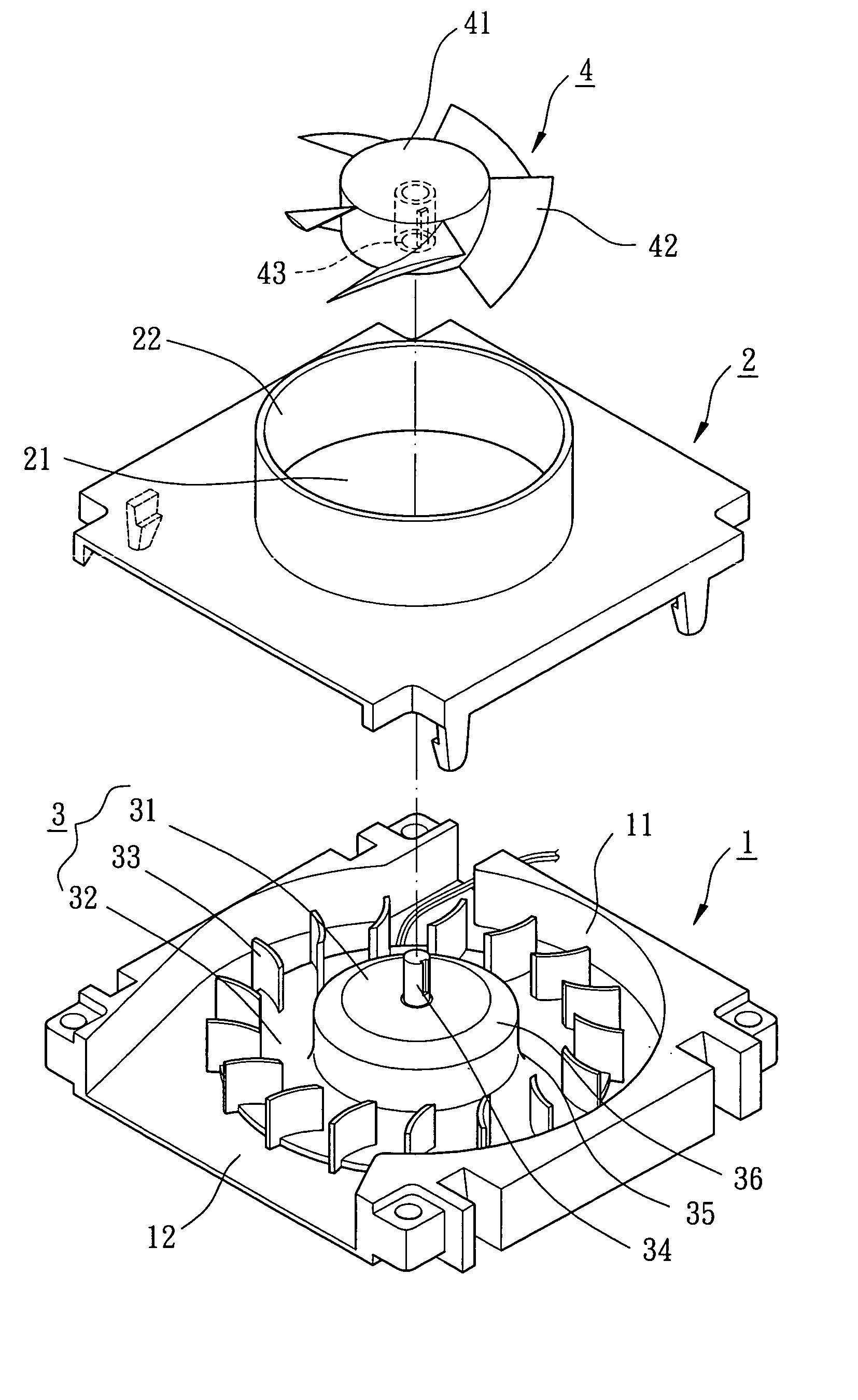

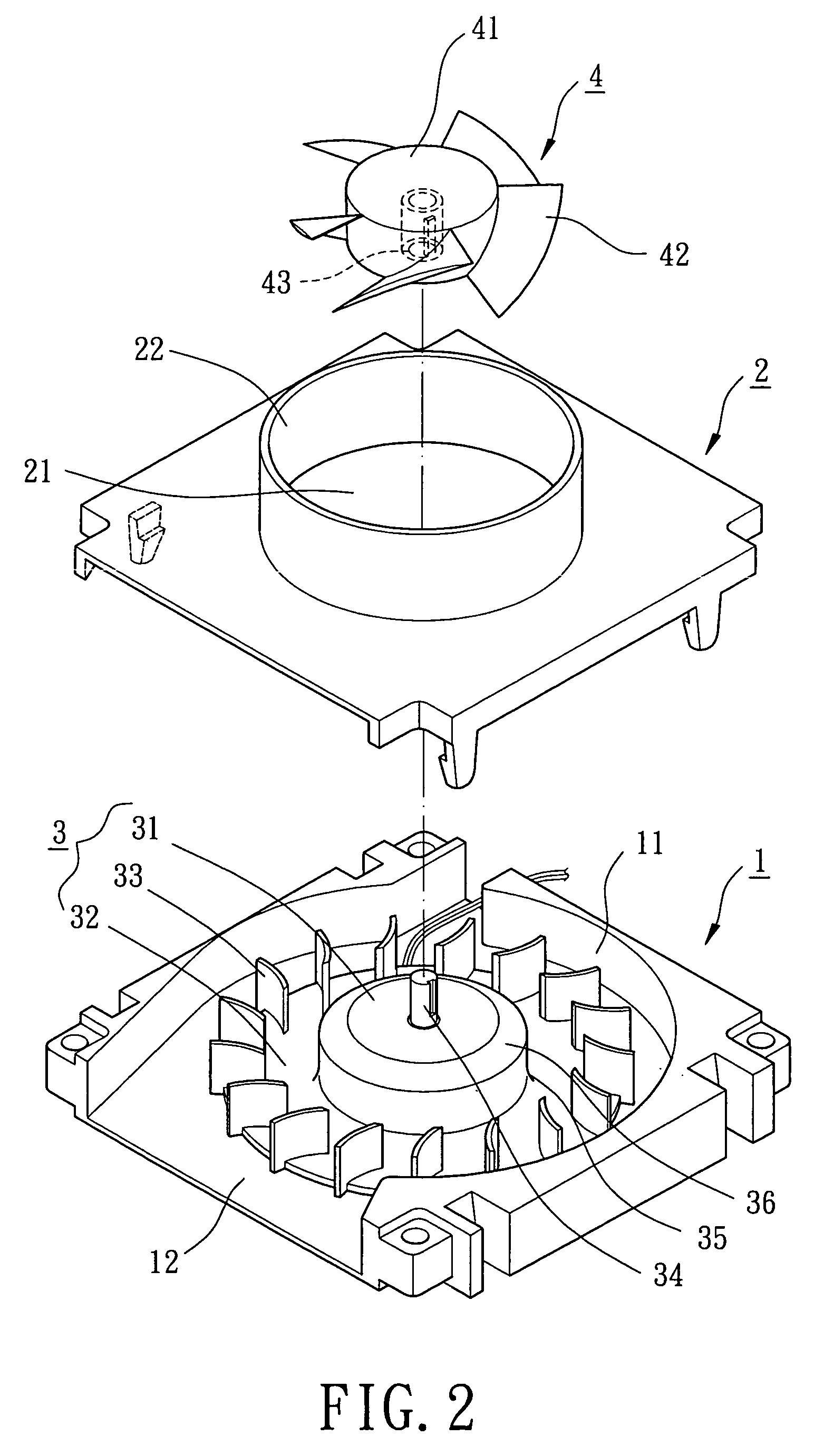

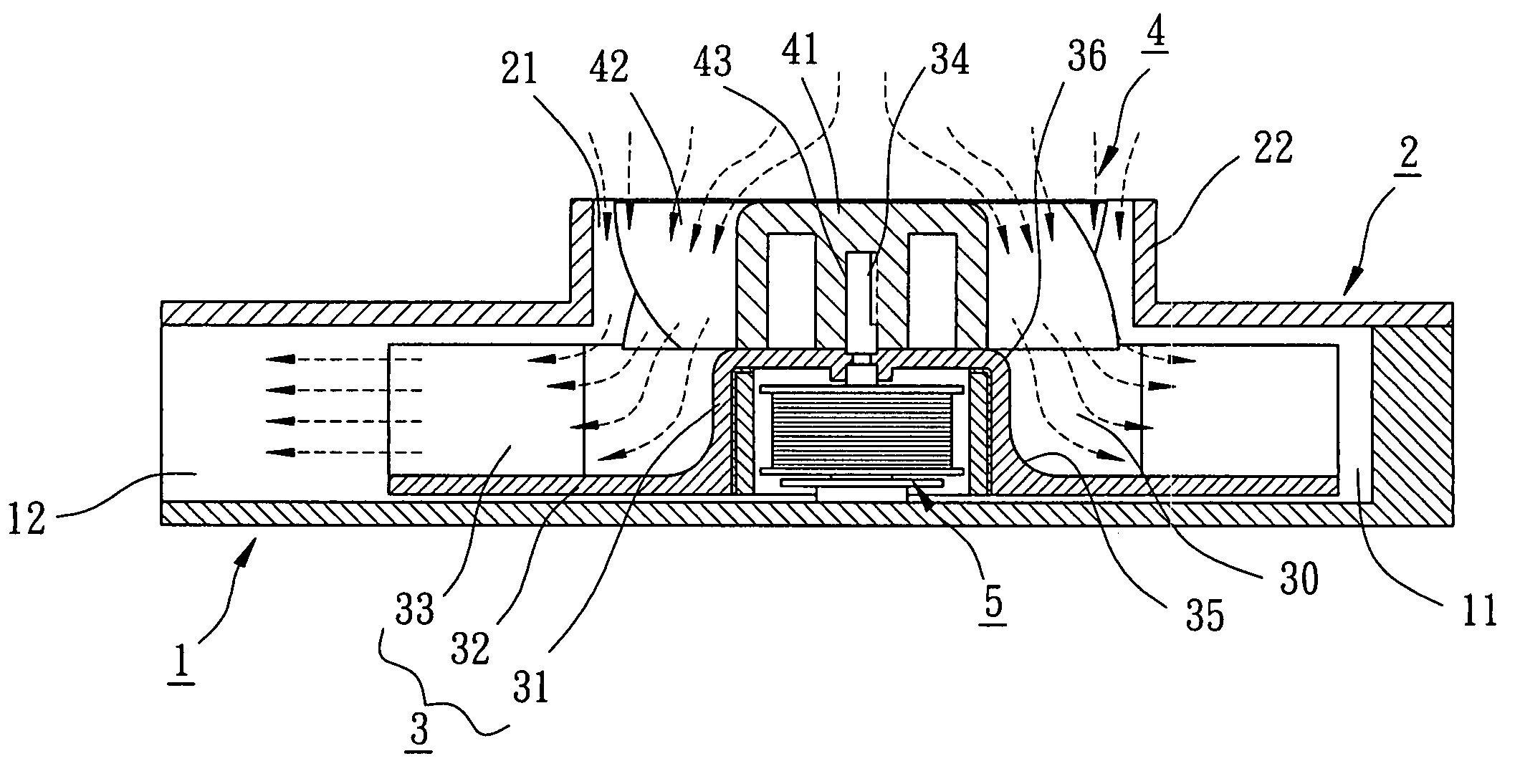

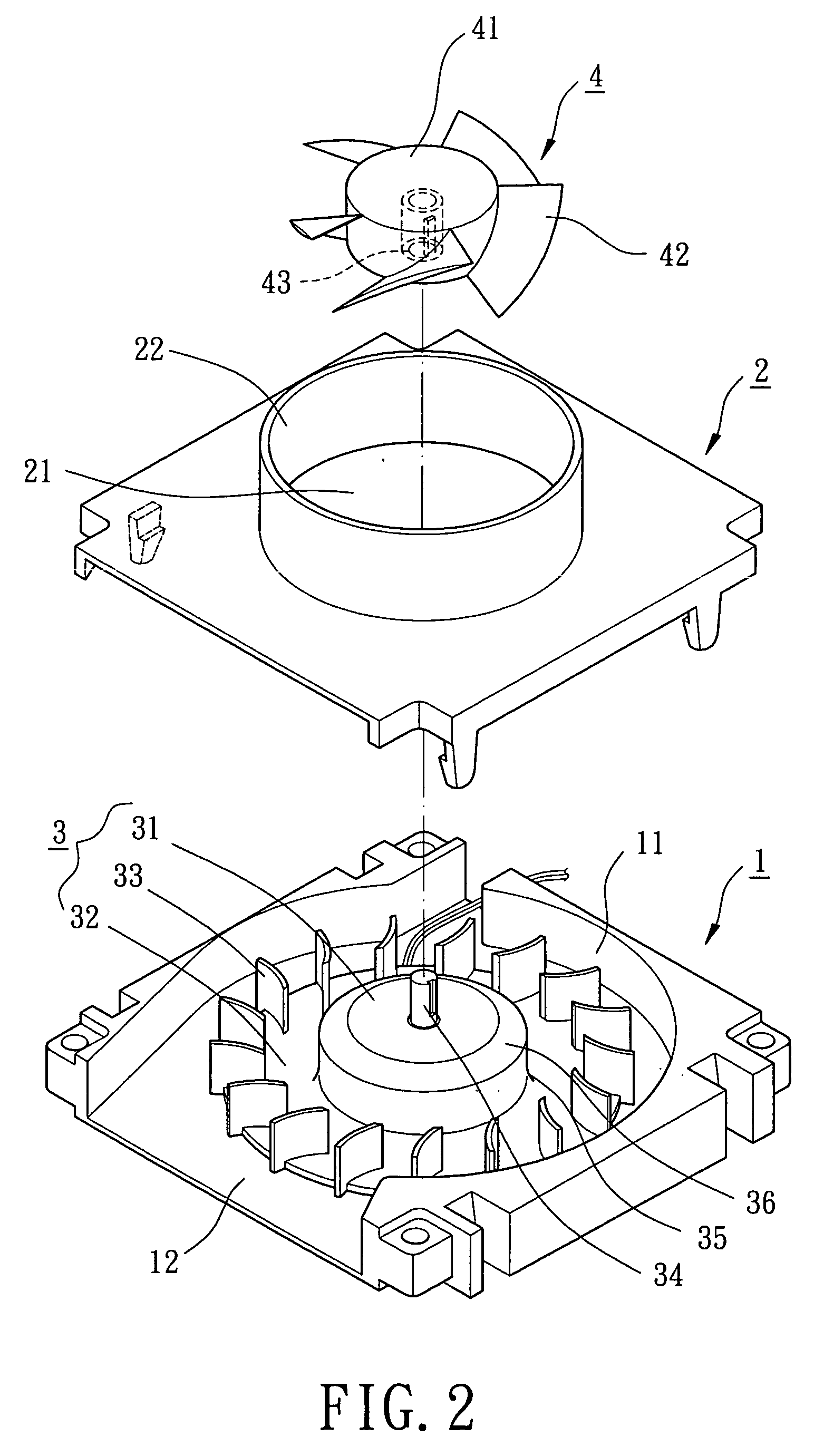

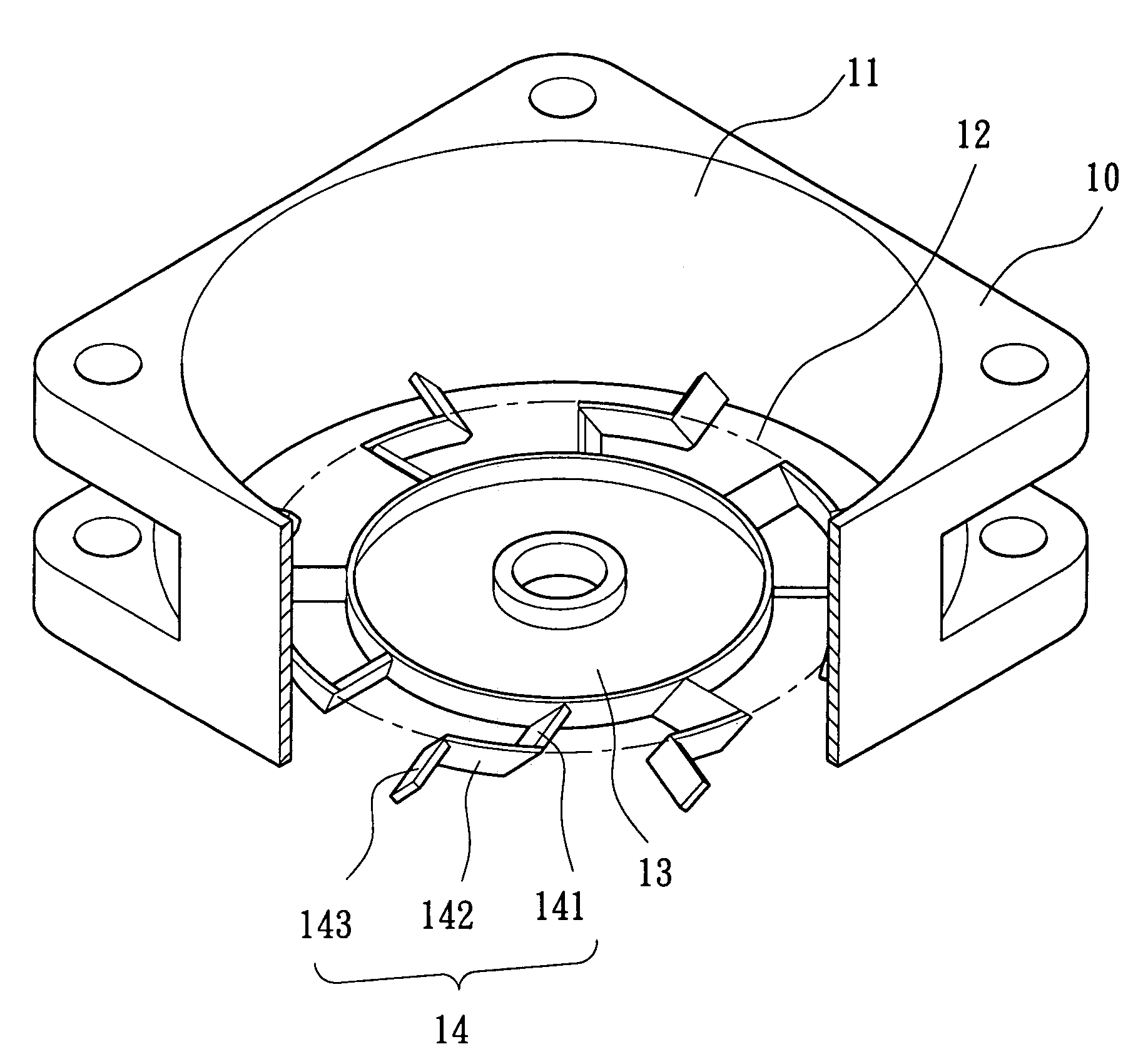

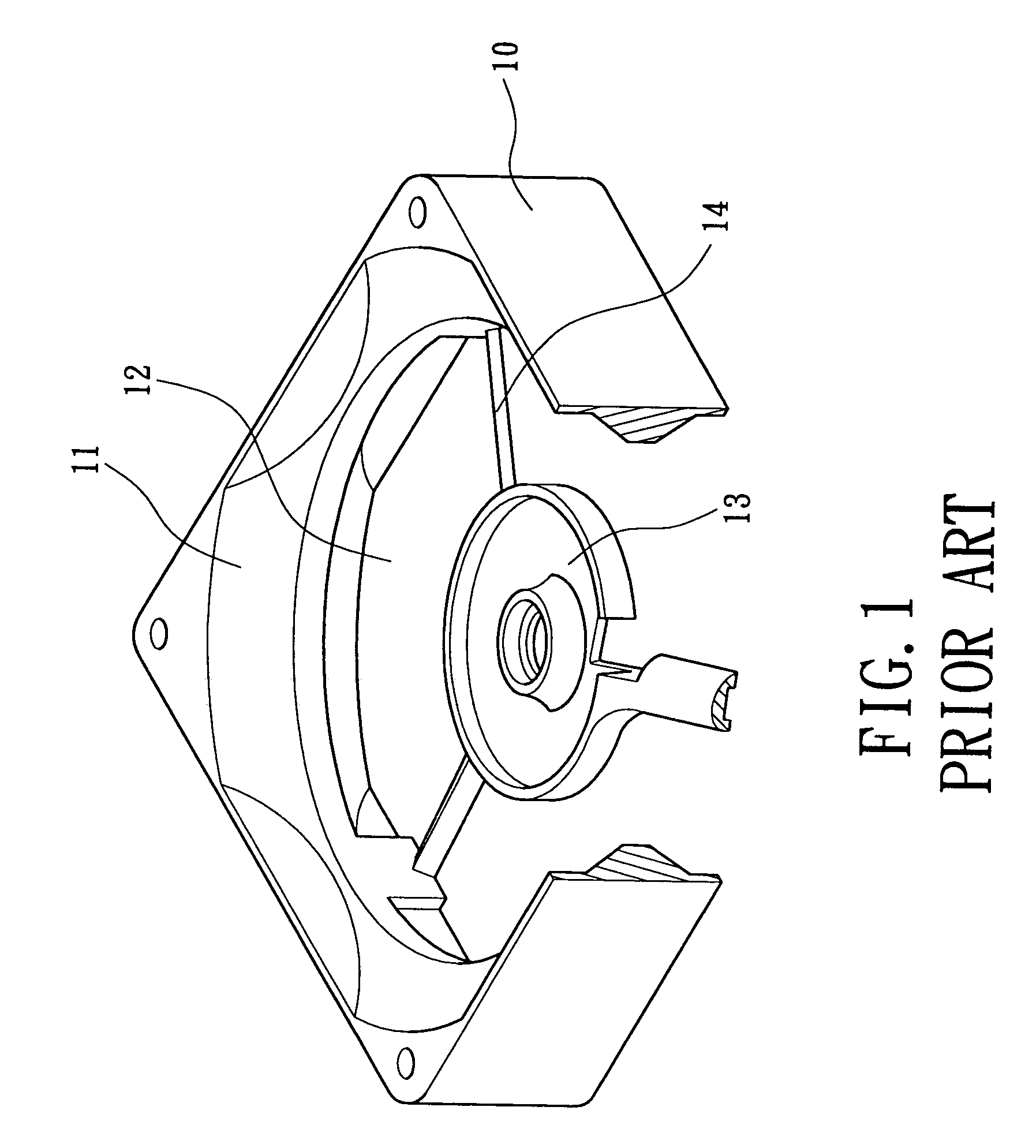

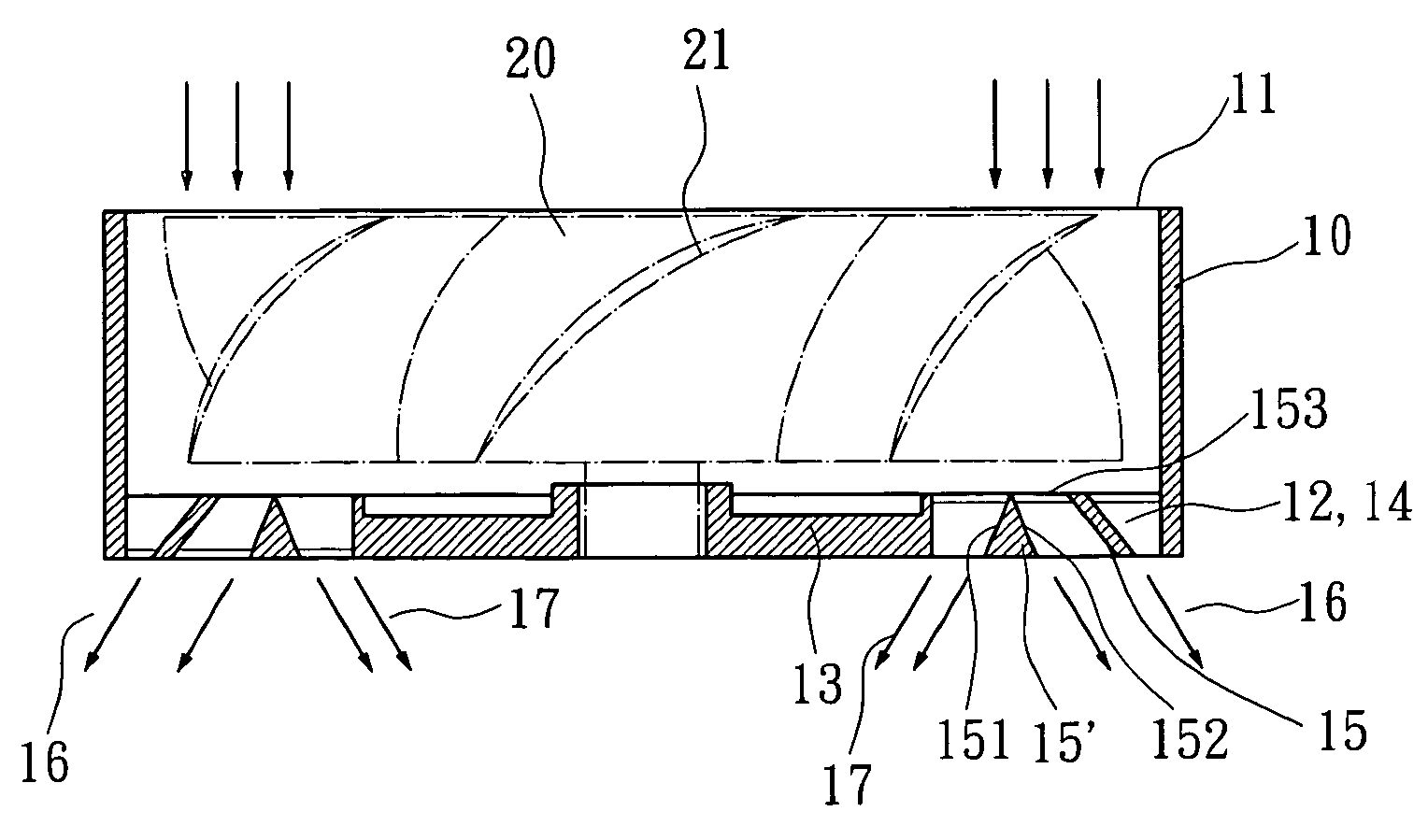

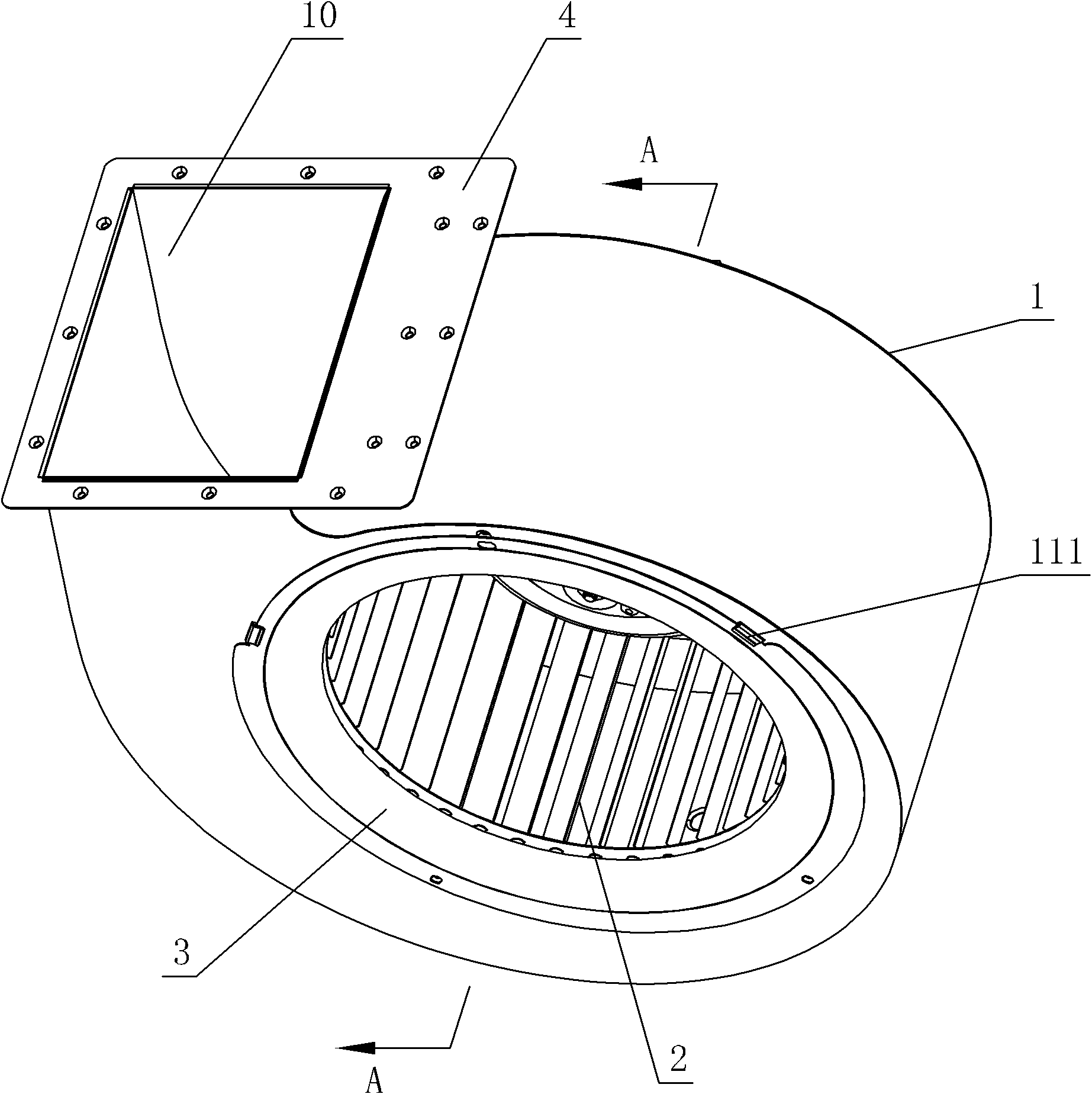

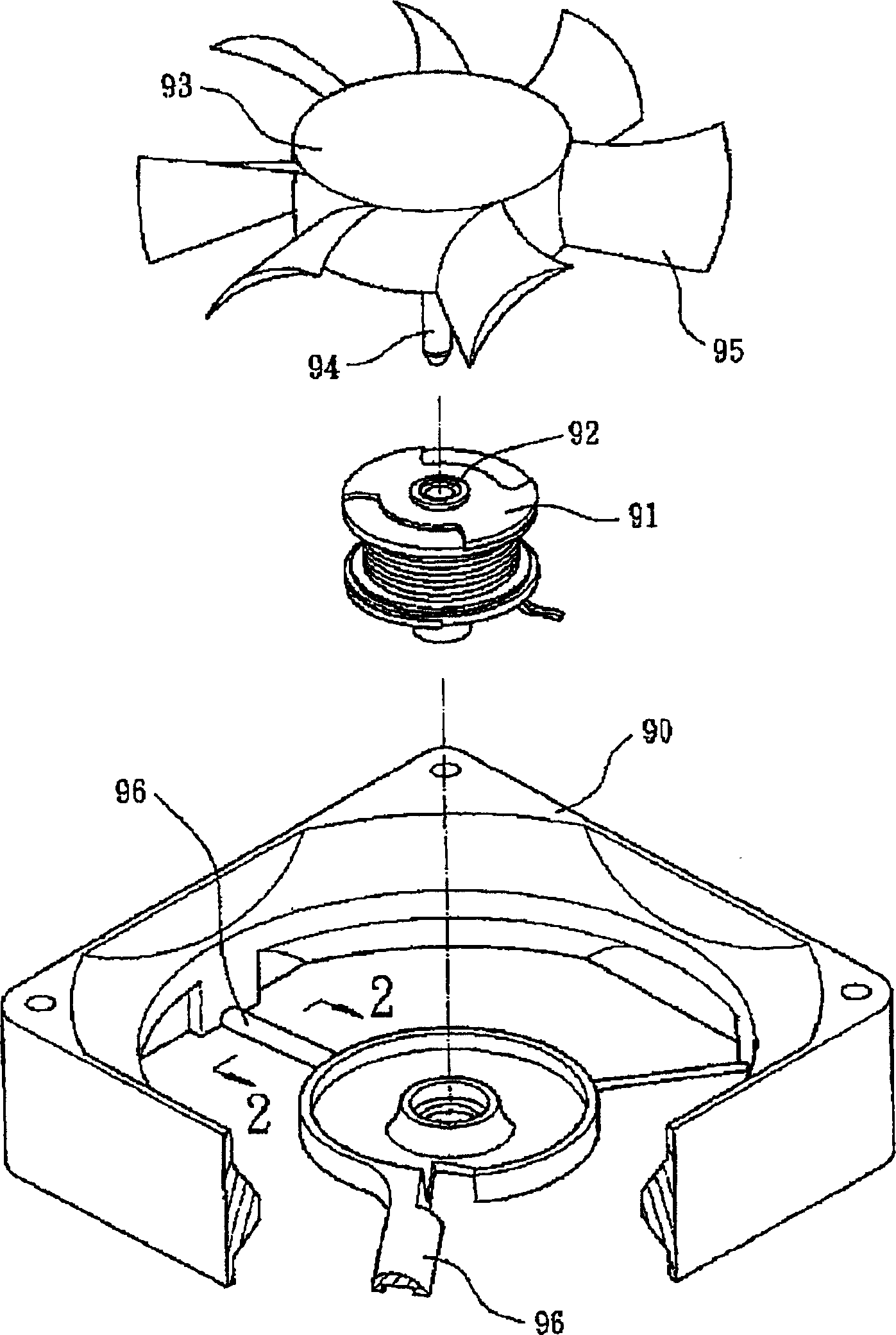

Radial-flow heat-dissipating fan with increased inlet airflow

InactiveUS7134839B2Increasing inlet airflowIncrease wind pressurePropellersRotary propellersImpellerEngineering

A radial-flow heat-dissipating fan includes a casing and a cover mounted to a side of the casing. The casing includes a compartment and a side air outlet, and the cover includes an air inlet. A primary fan wheel is rotatably mounted in the compartment and the primary fan wheel includes a hub and a plurality of radial-flow blades surrounding the hub. An auxiliary fan wheel is mounted in the air inlet of the cover and includes a plurality of axial-flow blades. An airflow transition area is defined between a circumference of the hub of the primary fan wheel, the radial-flow blades, and the axial-flow blades. The axial-flow blades increase axial inlet airflow via the air inlet, with the airflow transition area changing a direction of the axial inlet airflow into centrifugal airflow that is outputted via the side air outlet by the radial-flow blades.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

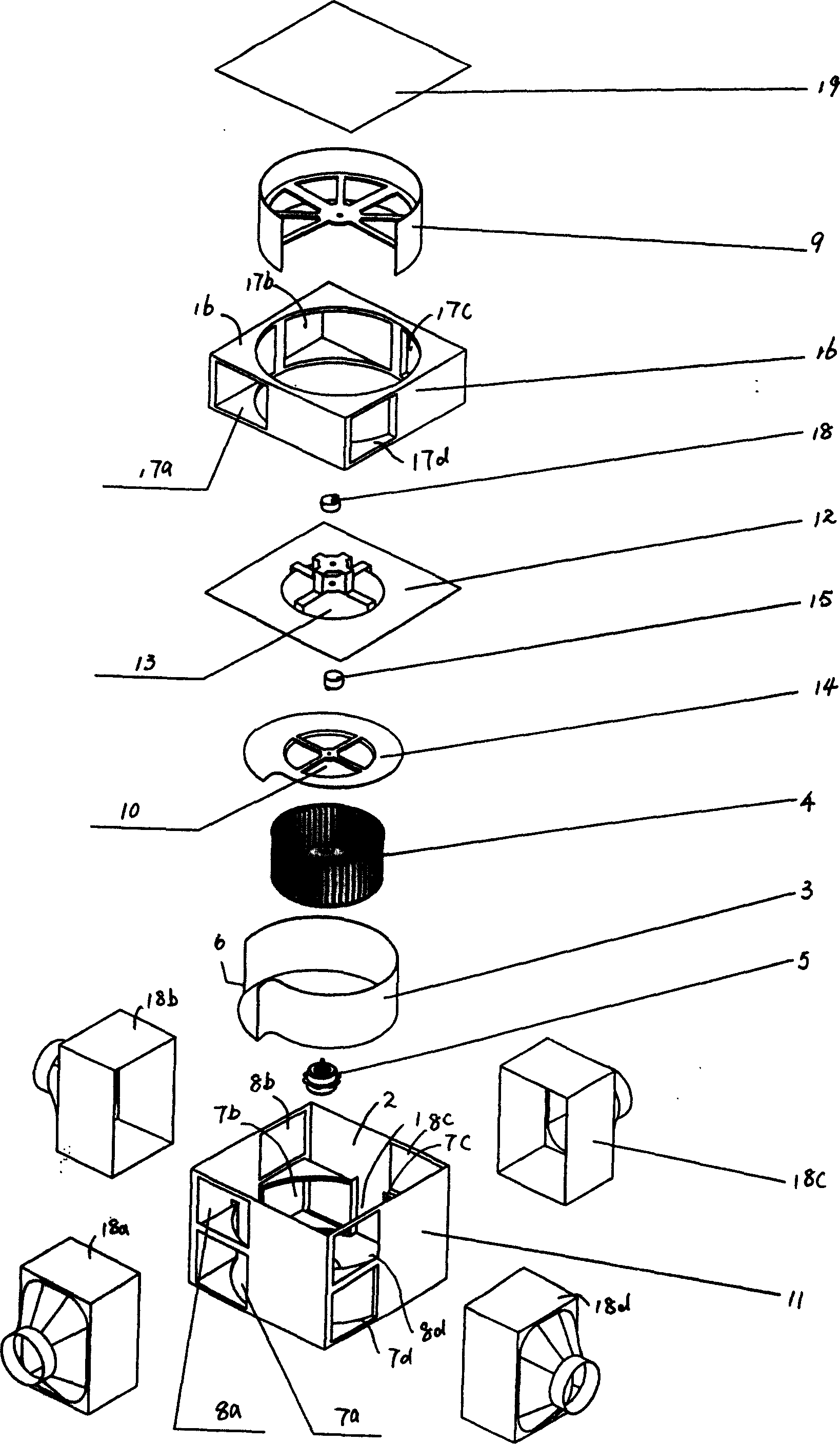

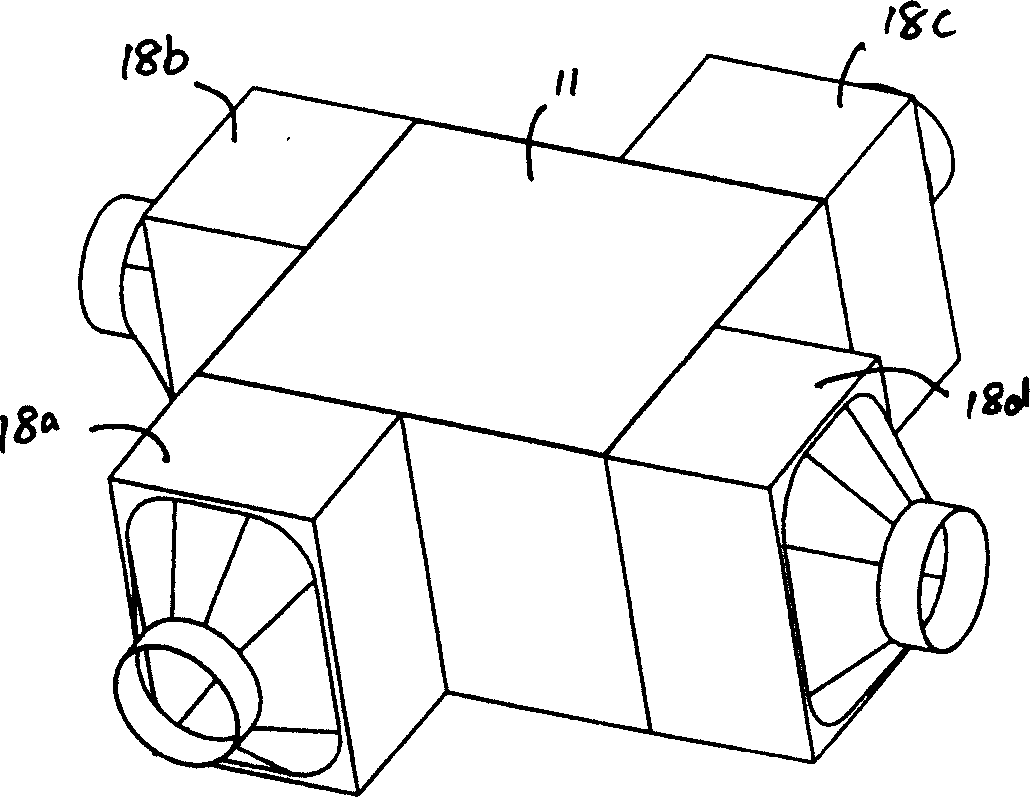

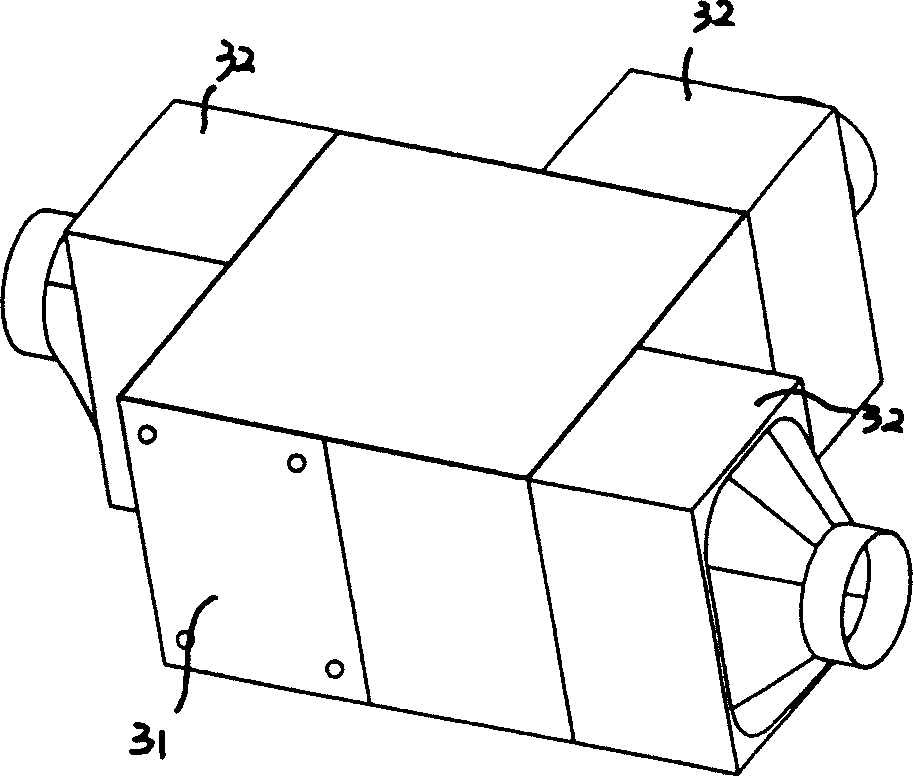

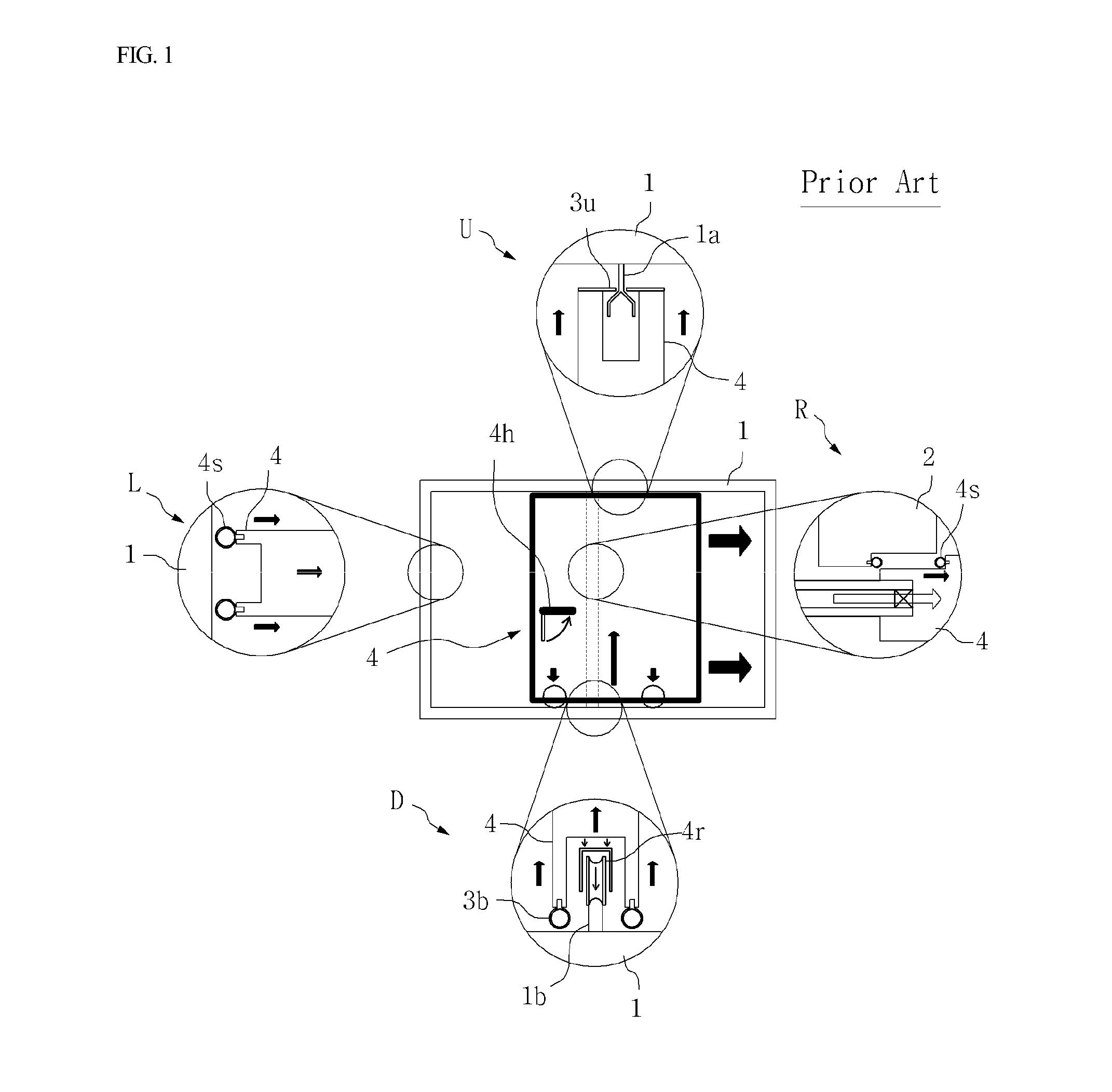

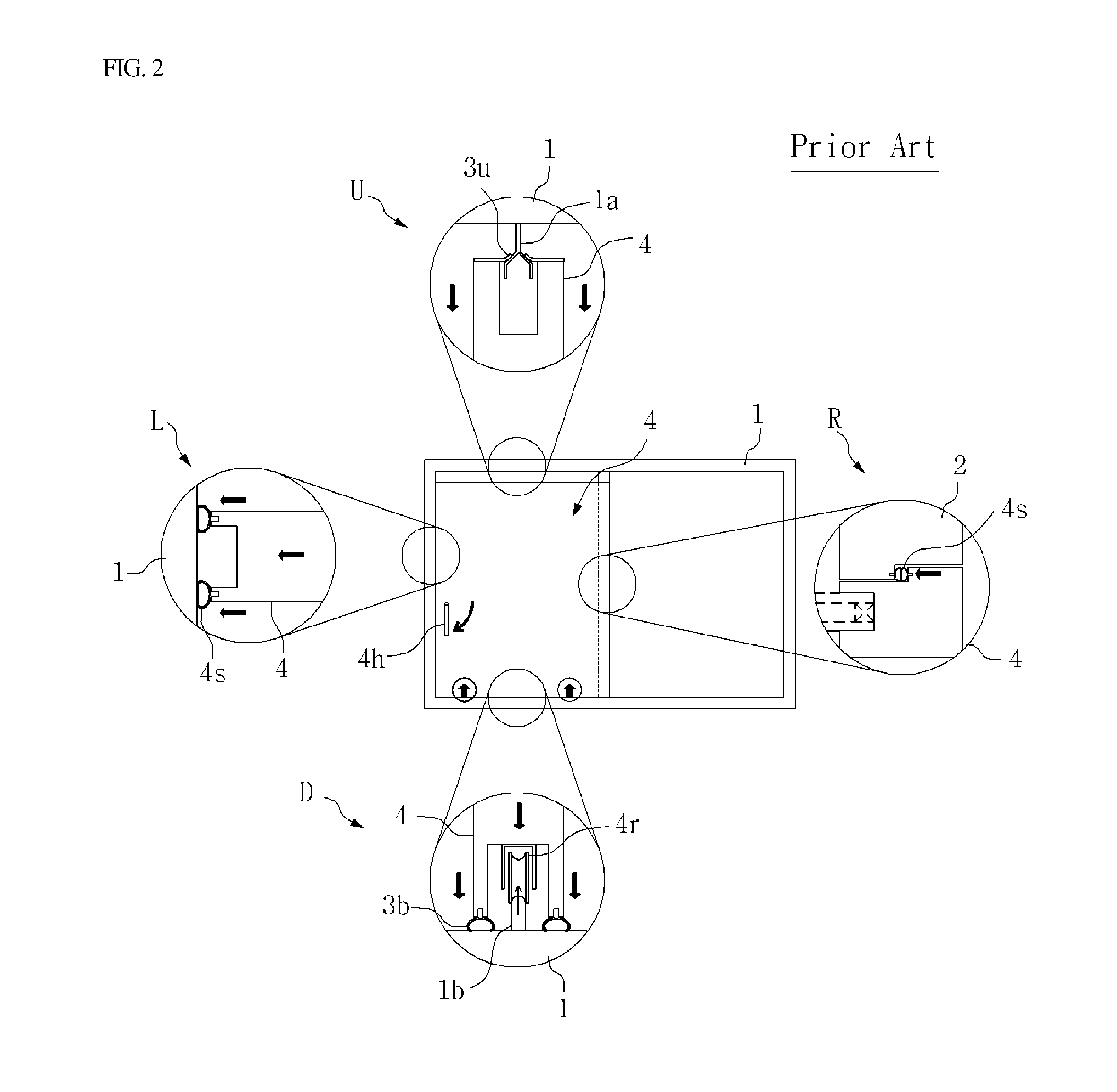

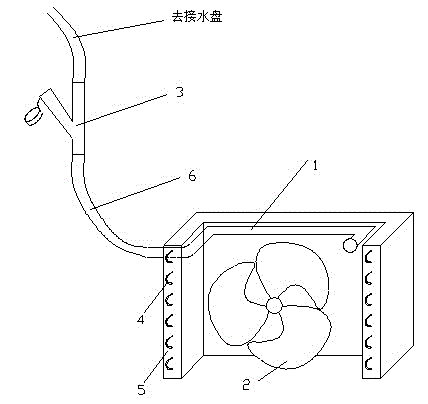

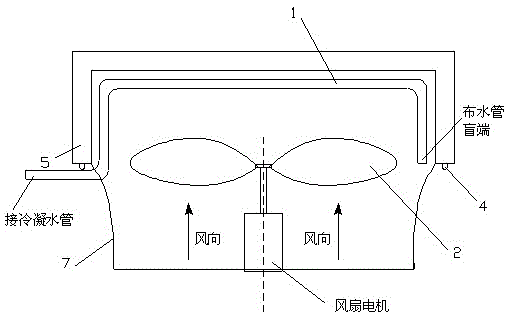

Air exchanger

ActiveCN1715797AIncrease wind pressureLarge ventilationLighting and heating apparatusPump installationsFresh airAir exchange

The air exchanger includes air exhaust cavity, air sucking cavity and volute rotating driving mechanism. The air exhaust cavity is provided with volute, eccentric blower and motor, as well as exhaust port to outdoor and one or several exhaust ports to indoor. The air sucking cavity has air sucking port to the outdoor paired with the exhaust port to outdoor and air sucking ports to the indoor paired with the exhaust ports to indoor ,as well as air door for opening and closing the air sucking ports, and is communicated with the inlet port to the volute. The present invention can exhaust stagnant air from indoor and suck in fresh air from outdoor without altering the rotation direction of blower, has high wind pressure, great air exchange amount and high speed, and can realize the air exchange control to single or several rooms.

Owner:顾建军

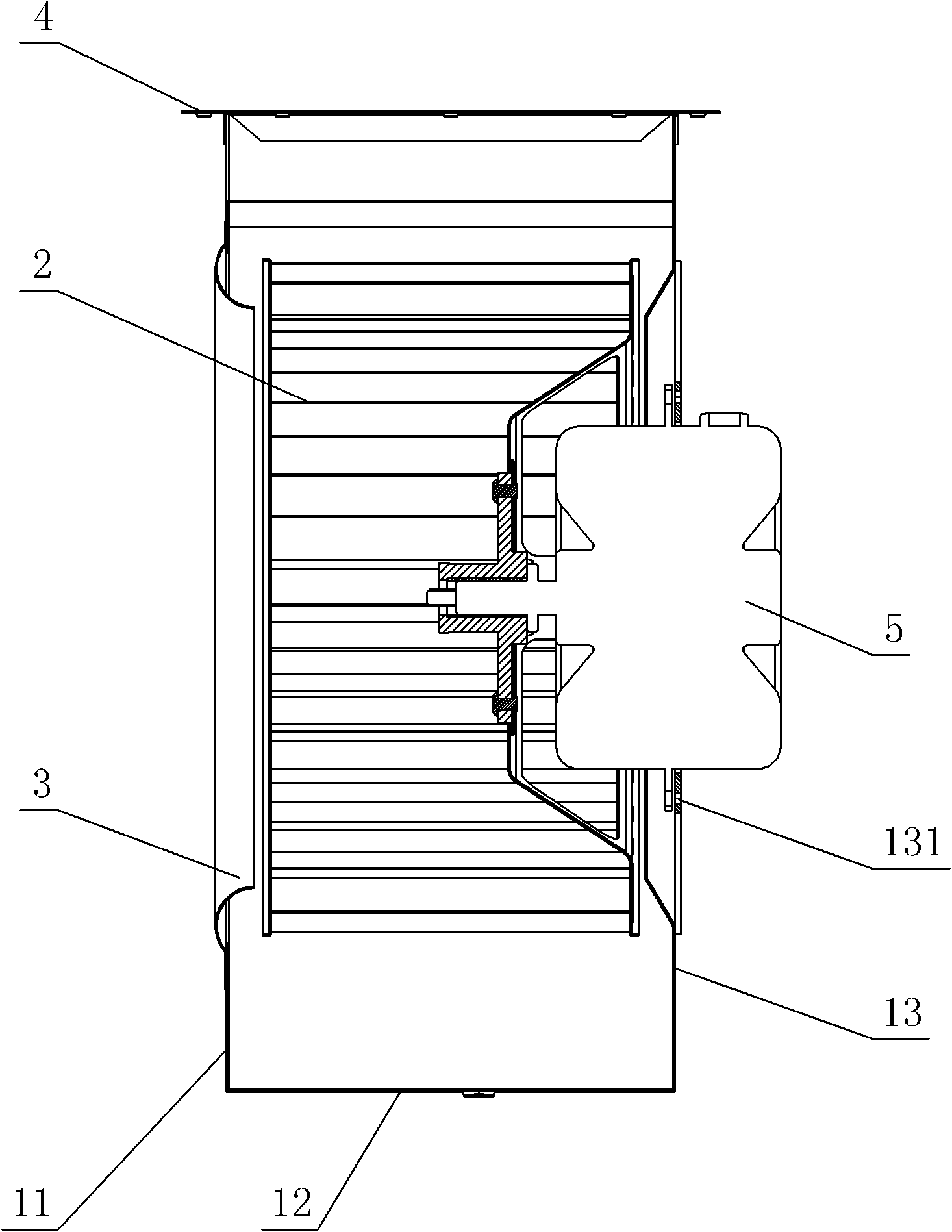

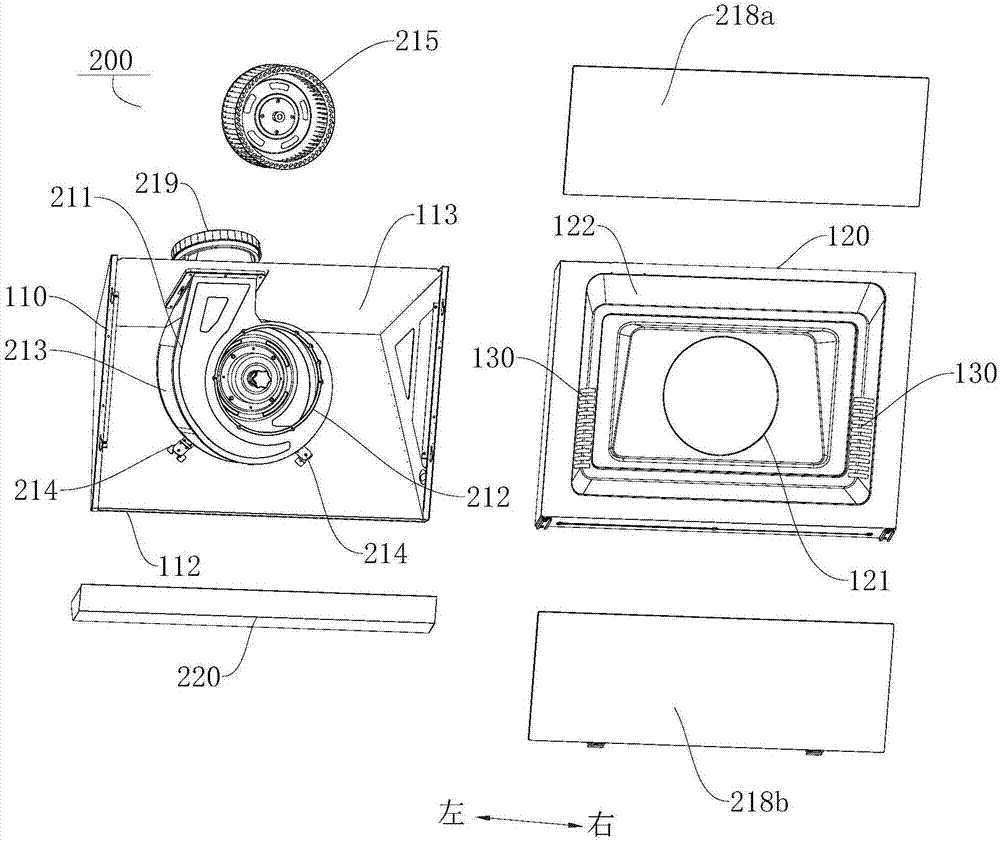

Spiral case of blower fan in apparatus with inlet air from two sides for sucking oil fume

This invention discloses a fan turbine casing inletting wind from two sides including a front cover plate, a back cover plate and a circular middle shell connecting the two, a front air-inlet and a back air-inlet are set on them separately, and the projection of the center of the front one on the plane where the back cover places is coincident with that of the back one characterizing that a curved panel projecting downward is connected between the down edges of the two plates to shield the middle shell, so smoke can be led to the front and back air-inlets smoothly.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

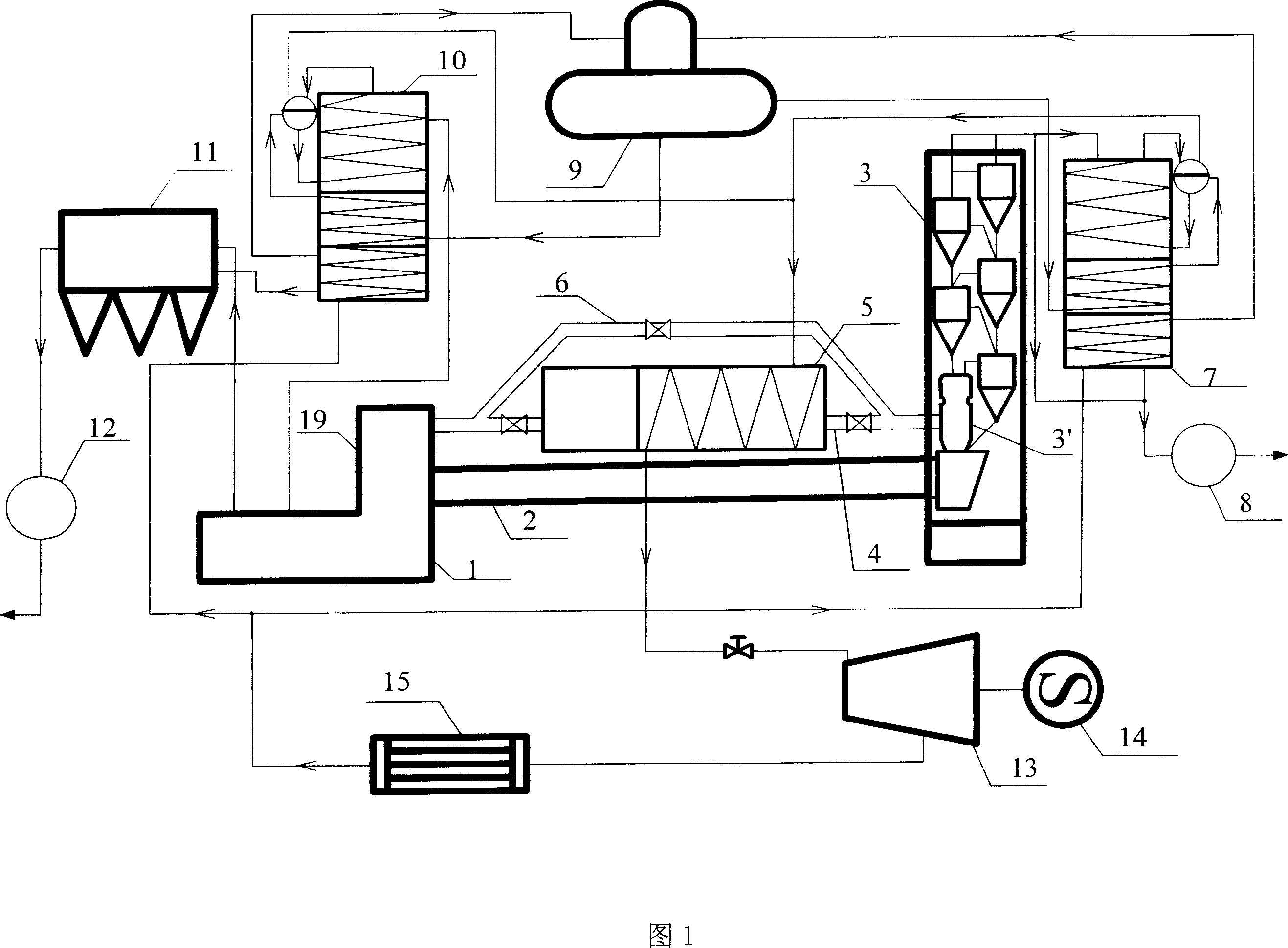

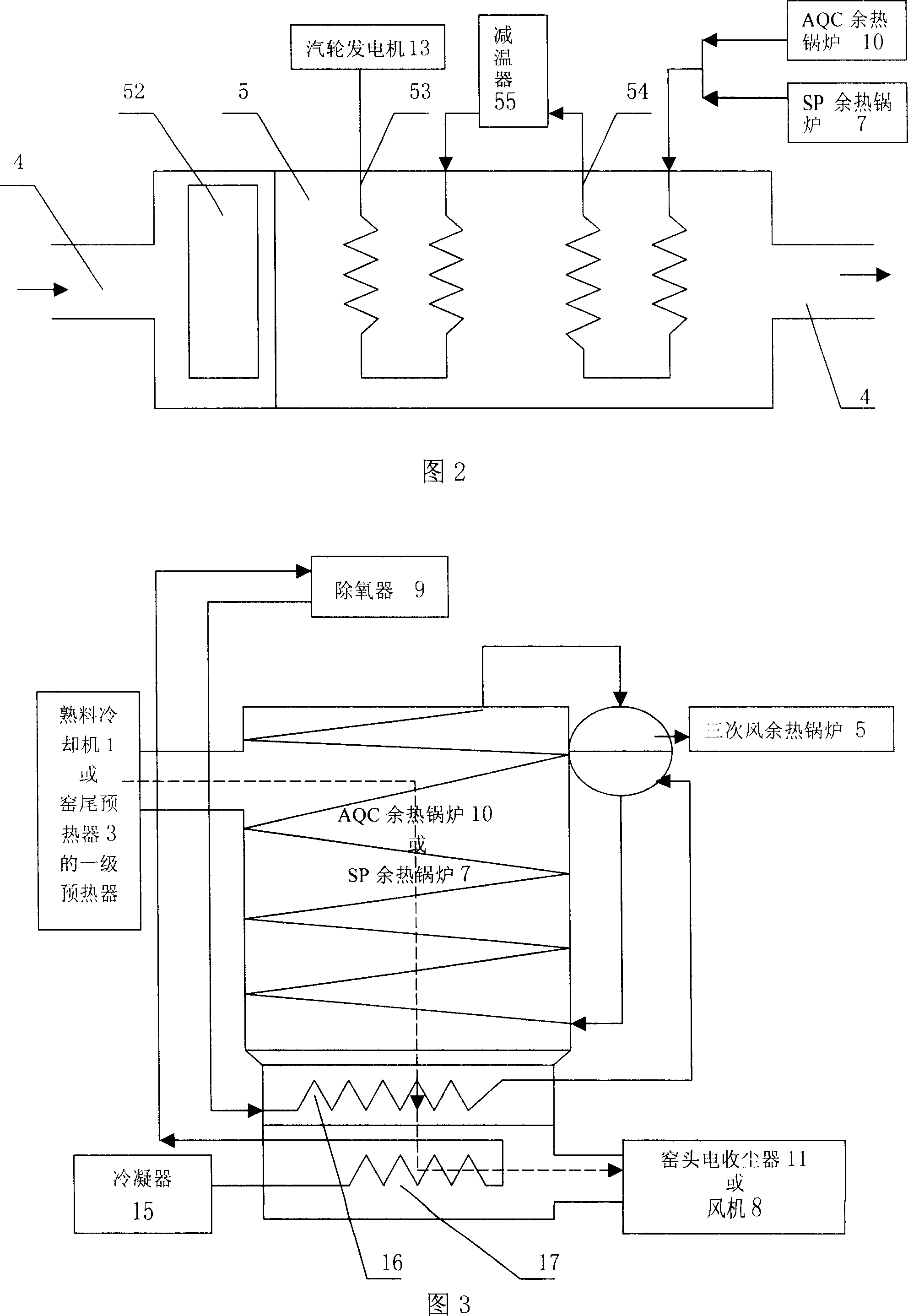

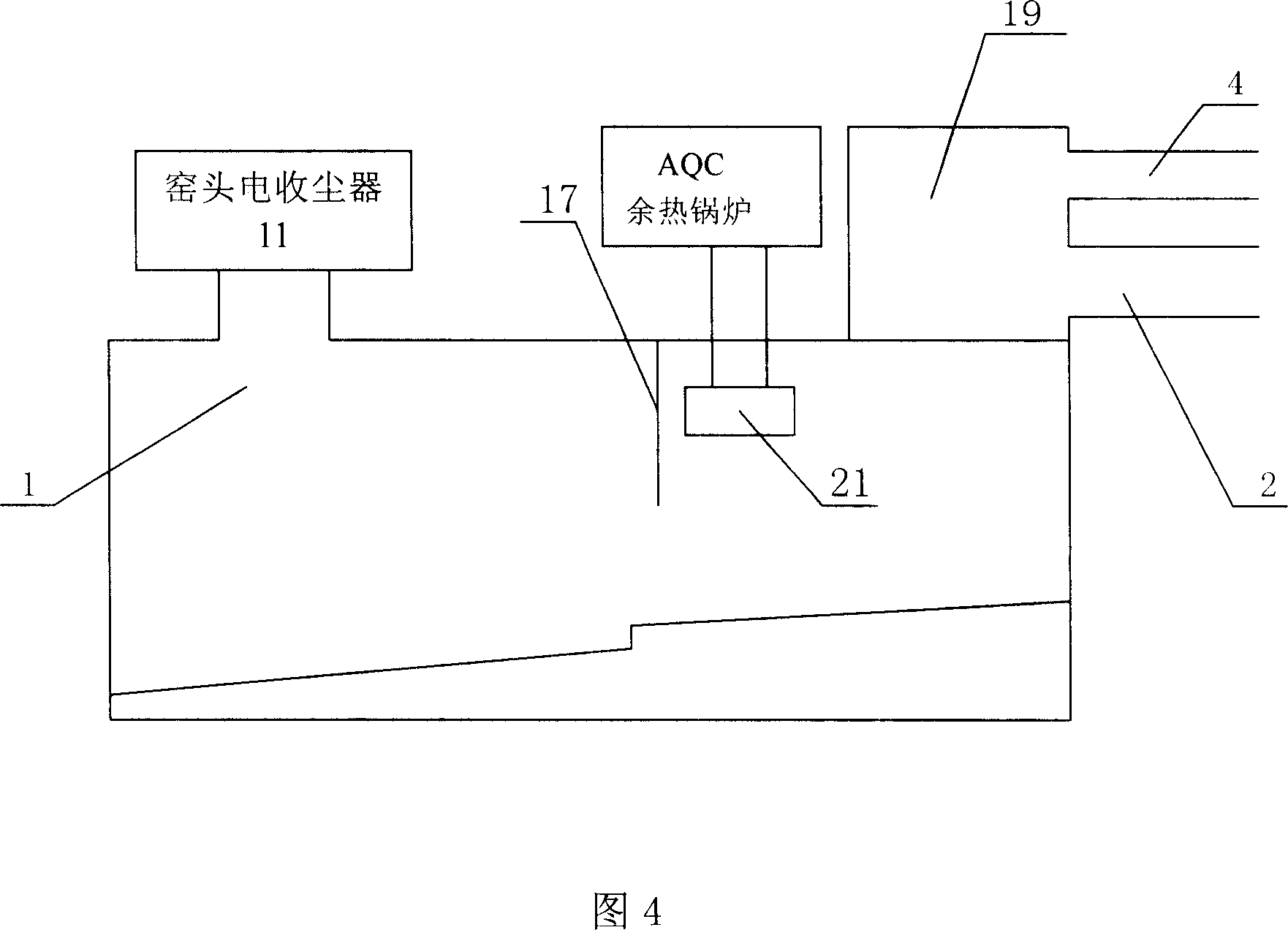

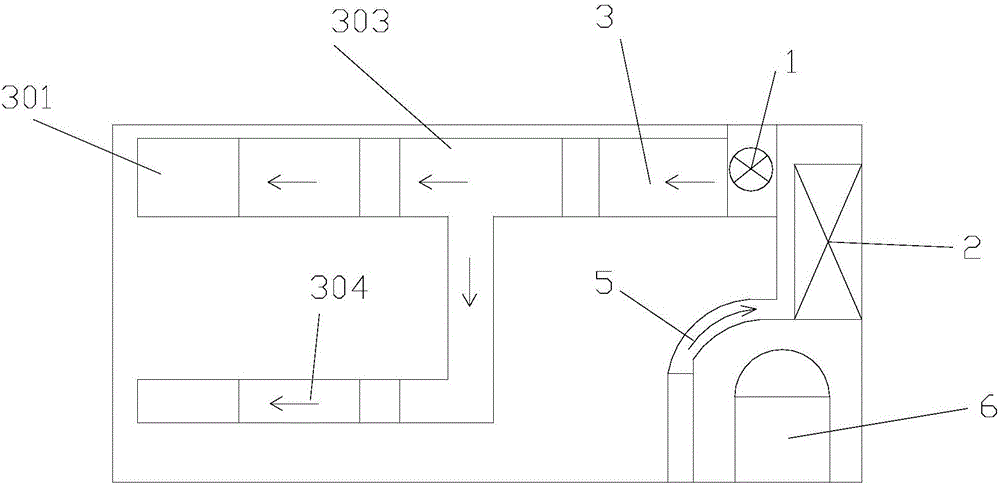

Residual heat generating system used for new type nonaqueous cement production line

ActiveCN101013002AMeet production needsIncrease profitIncreasing energy efficiencyClinker productionDeaeratorSuperheated steam

The invention discloses an abundant generating system used in dry cement product line, comprising a grog cooler, a AQC abundant heat boiler, a cement rotary furnace, a head frame of cement rotary furnace, a third-stage wind tube, a cement preheating device, a cement predissociation furnace, a SP abundant heat boiler, a fan, a deaerator, a condenser, and a generator of turbine. The third-stage wind tube is between the head frame and the predissociation furnace. The head frame is communicated with the grog cooler. The invention is characterized in that third-stage wind tube is arranged with a third-stage wind abundant-heat boiler with bypass wind channels; the medium inlet of the third-stage wind abundant-heat boiler via the tube is connected with the AQC abundant-heat boiler and the SP abundant-heat boiler, while the medium outlet is connected with the turbine generator. The invention can completely absorb the abundant heat of product line, to supply overheated steam to the generator, while the electricity generation is higher than 40kwh.

Owner:BEIJING LIULIHE CEMENT +1

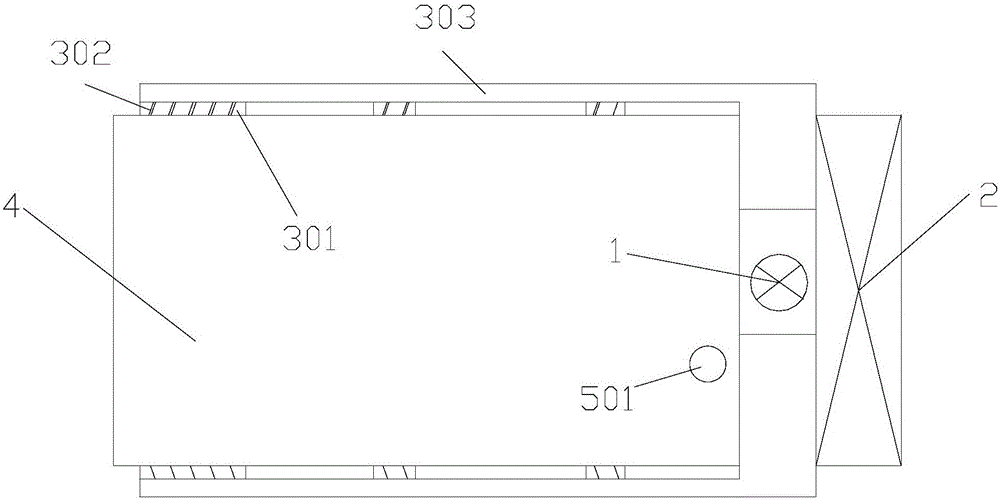

Air duct system of horizontal type freezer and freezer

InactiveCN106225389AImprove cooling efficiencyIncrease wind pressureLighting and heating apparatusDomestic refrigeratorsCold airEngineering

The invention discloses an air duct system of a horizontal type freezer and the freezer. The air duct system comprises an evaporator, a fan assembly, inlet air ducts, a return air duct, wherein the evaporator is located in an evaporator cavity; the evaporator cavity is located at one end of a box body in the length direction; the fan assembly is located above the evaporator; one end of each inlet air duct and one end of the return air duct respectively communicate with the upper part and the lower part of the evaporator cavity; the fan assembly is a centrifugal fan assembly with a volute structure; the inlet air ducts comprise two groups of inlet air ducts respectively arranged on two sides of a compartment; each group of inlet air ducts consist of a main inlet air duct and an auxiliary inlet air duct which are arranged in the vertical direction side by side; the main inlet air ducts and the auxiliary inlet air ducts extend to the other end of the box body in the length direction; and a plurality of air inlets communicating with the compartment are formed in the main inlet air ducts and the auxiliary inlet air ducts. The air duct system has the advantages that cold air is supplied to one end, away from the evaporator, of the horizontal type freezer through the inlet air ducts, and the refrigeration efficiency of the freezer is improved.

Owner:CHANGHONG MEILING CO LTD

Radial-flow heat-dissipating fan with increased inlet airflow

InactiveUS20050265832A1Increasing inlet airflowIncrease wind pressurePropellersPump componentsImpellerEngineering

A radial-flow heat-dissipating fan includes a casing and a cover mounted to a side of the casing. The casing includes a compartment and a side air outlet, and the cover includes an air inlet. A primary fan wheel is rotatably mounted in the compartment and the primary fan wheel includes a hub and a plurality of radial-flow blades surrounding the hub. An auxiliary fan wheel is mounted in the air inlet of the cover and includes a plurality of axial-flow blades. An airflow transition area is defined between a circumference of the hub of the primary fan wheel, the radial-flow blades, and the axial-flow blades. The axial-flow blades increase axial inlet airflow via the air inlet, with the airflow transition area changing a direction of the axial inlet airflow into centrifugal airflow that is outputted via the side air outlet by the radial-flow blades.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

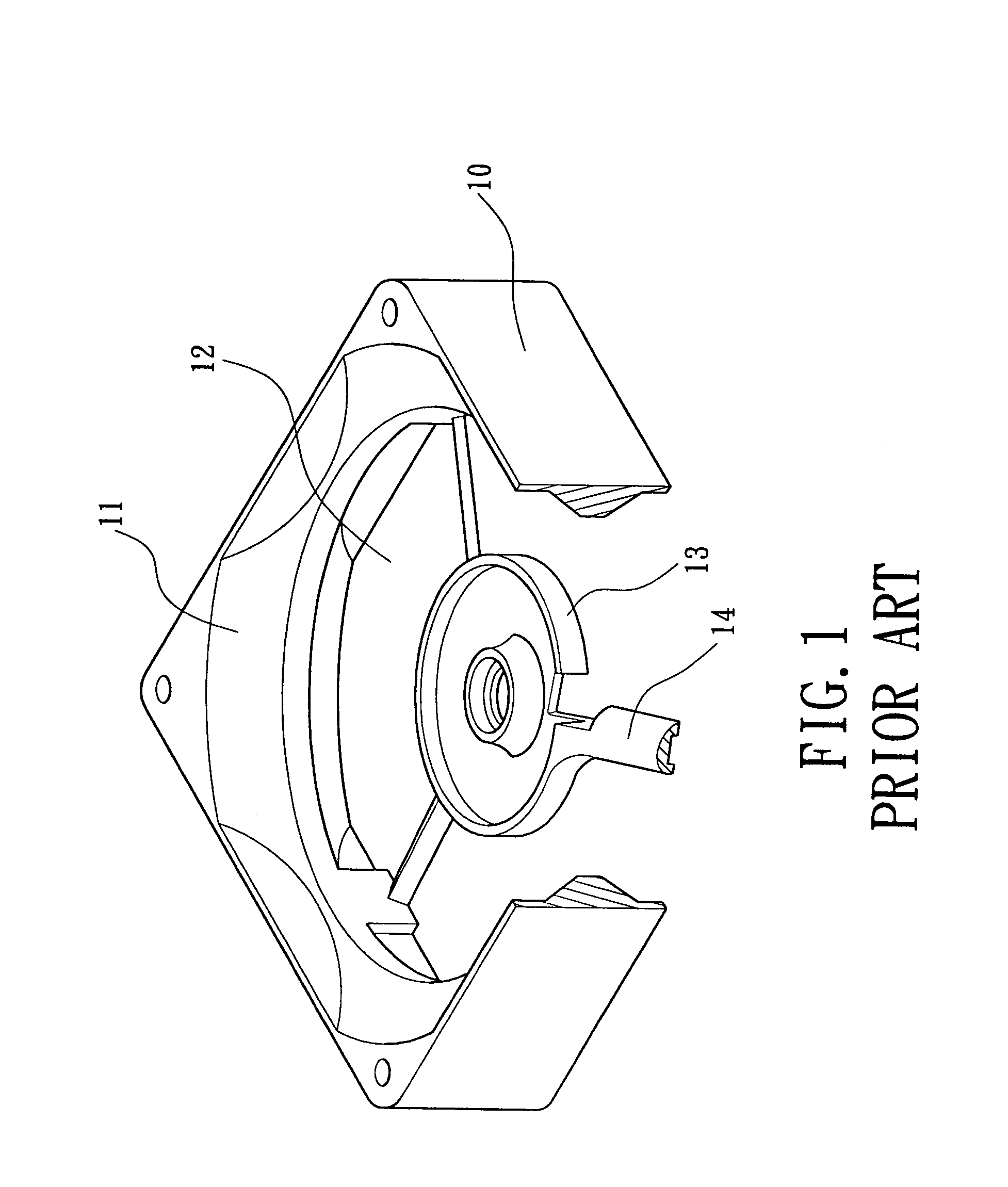

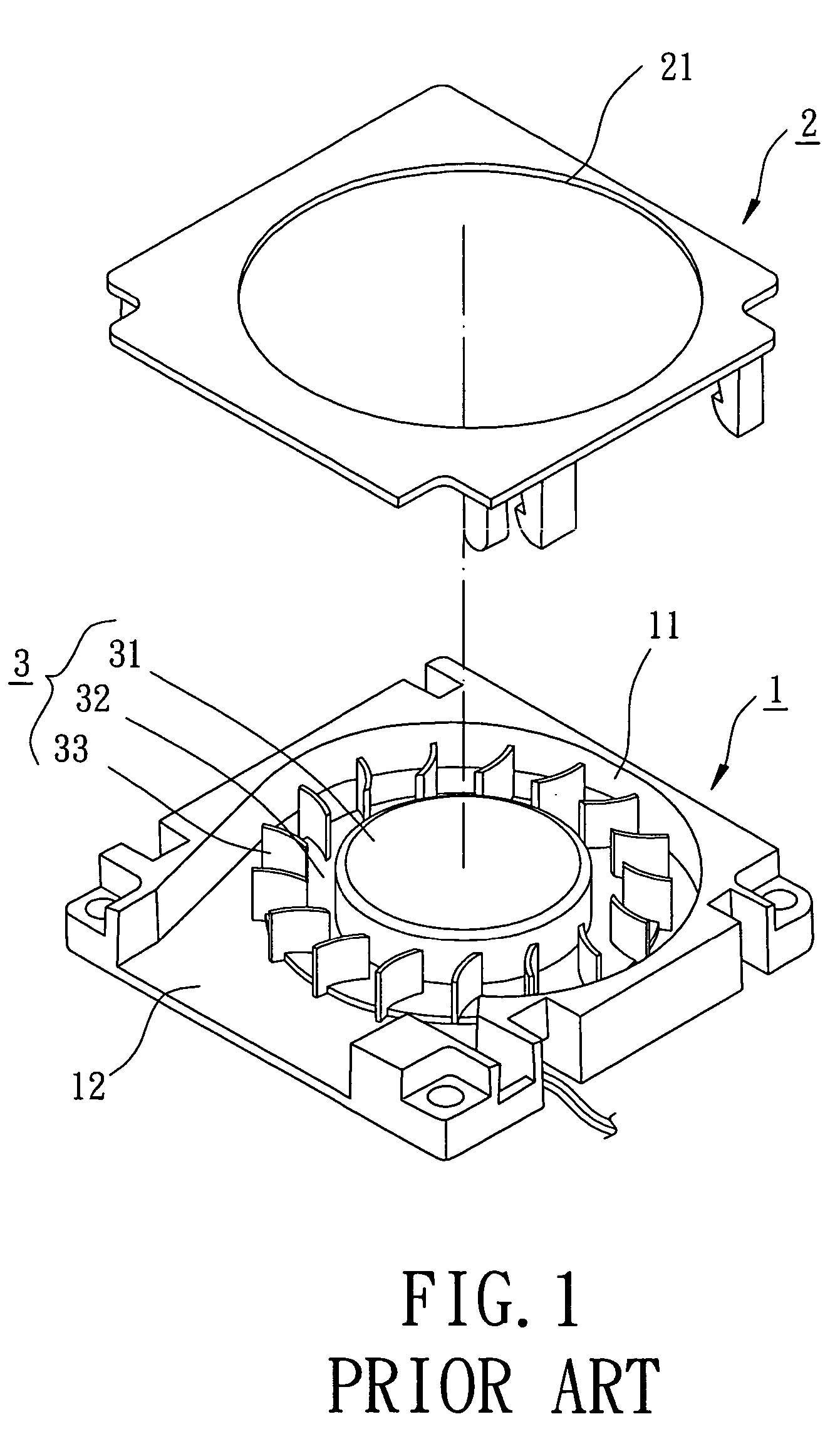

Airflow guiding structure for a heat-dissipating fan

InactiveUS6899521B2Increase wind pressureReduce wind noisePump componentsReaction enginesImpellerEngineering

A heat-dissipating fan includes a casing having an air outlet, a base mounted in the air outlet, and a plurality of ribs each mounted between the base and the casing. An impeller is mounted on the base and includes a plurality of blades. Each rib includes in sequence at least a first radial guiding portion, a first circumferential guiding portion, and a second radial guiding portion. Each of the first radial guiding portion and the second radial guiding portion extends in a direction having an inclining angle with an axial direction of the air outlet. The first radial guiding portion, the first circumferential guiding portion, and the second radial guiding portion guide airflow passing through the air outlet and increase wind pressure of the airflow when the impeller is turning.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

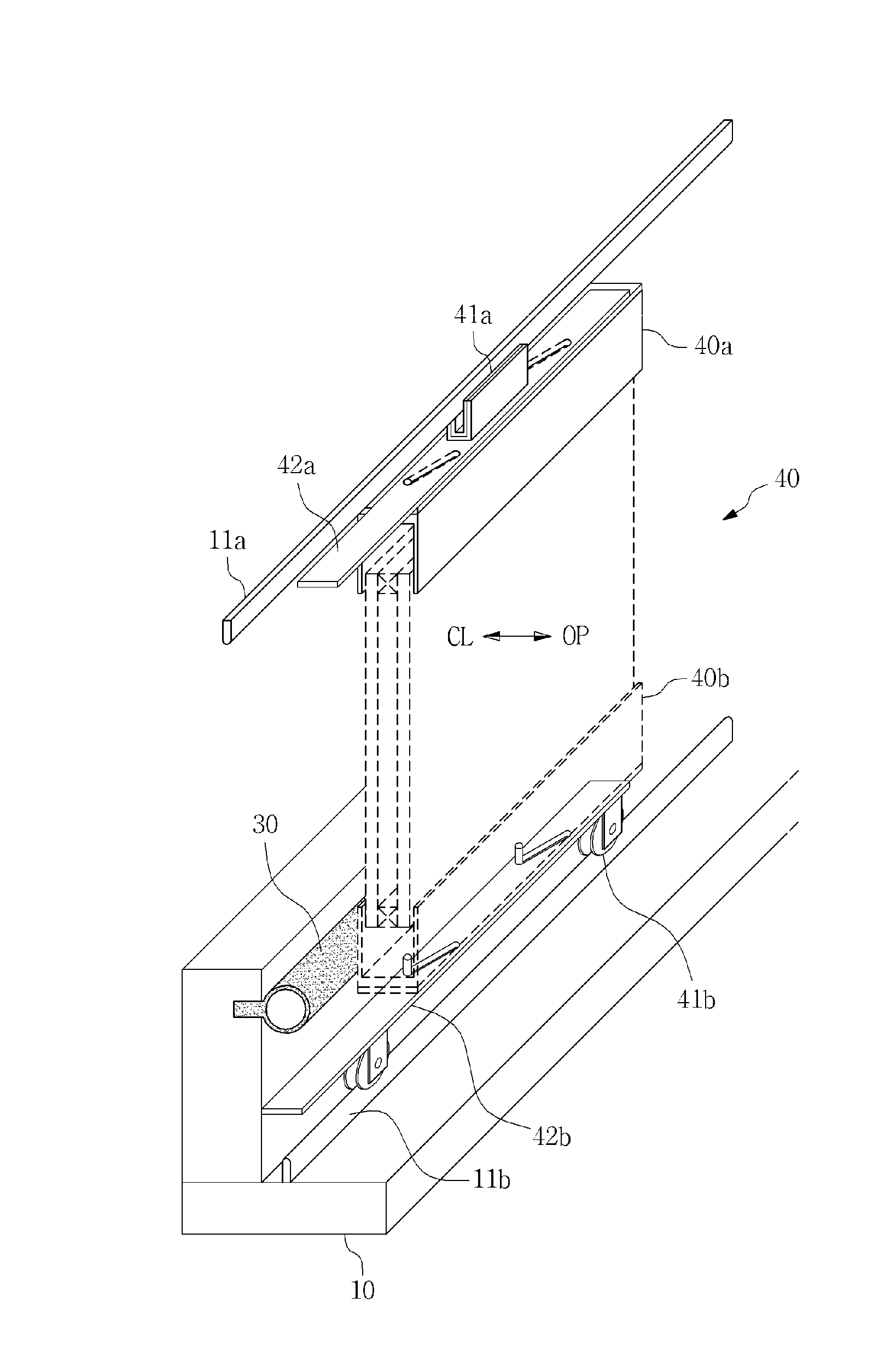

Moving window installation structure of sliding window system having aluminum alloy sash structure

ActiveUS20150052819A1Heat insulation function can be improvedDew condensation can be minimizedNoise insulation doors/windowsSealing arrangementsSash windowSlide window

The present invention relates to a moving window installation structure of a sliding window system. More specifically, the present invention relates to a moving window installation structure of a sliding window system which is configured to prevent a vertical reaction force from being applied between a rail and a roller for supporting the weight of a moving window that constitutes a sliding window having an aluminum alloy sash structure such that the moving window can be smoothly moved in a direction perpendicular to the longitudinal direction of the rail and the sliding mobility of a large-sized window having a heavy weight can be improved, and to improve a profile cross-section structure of a window installation frame provided with a sliding window such that heat insulation can be remarkably improved and wind pressure resistance against wind pressure can be enhanced.

Owner:FILOBE

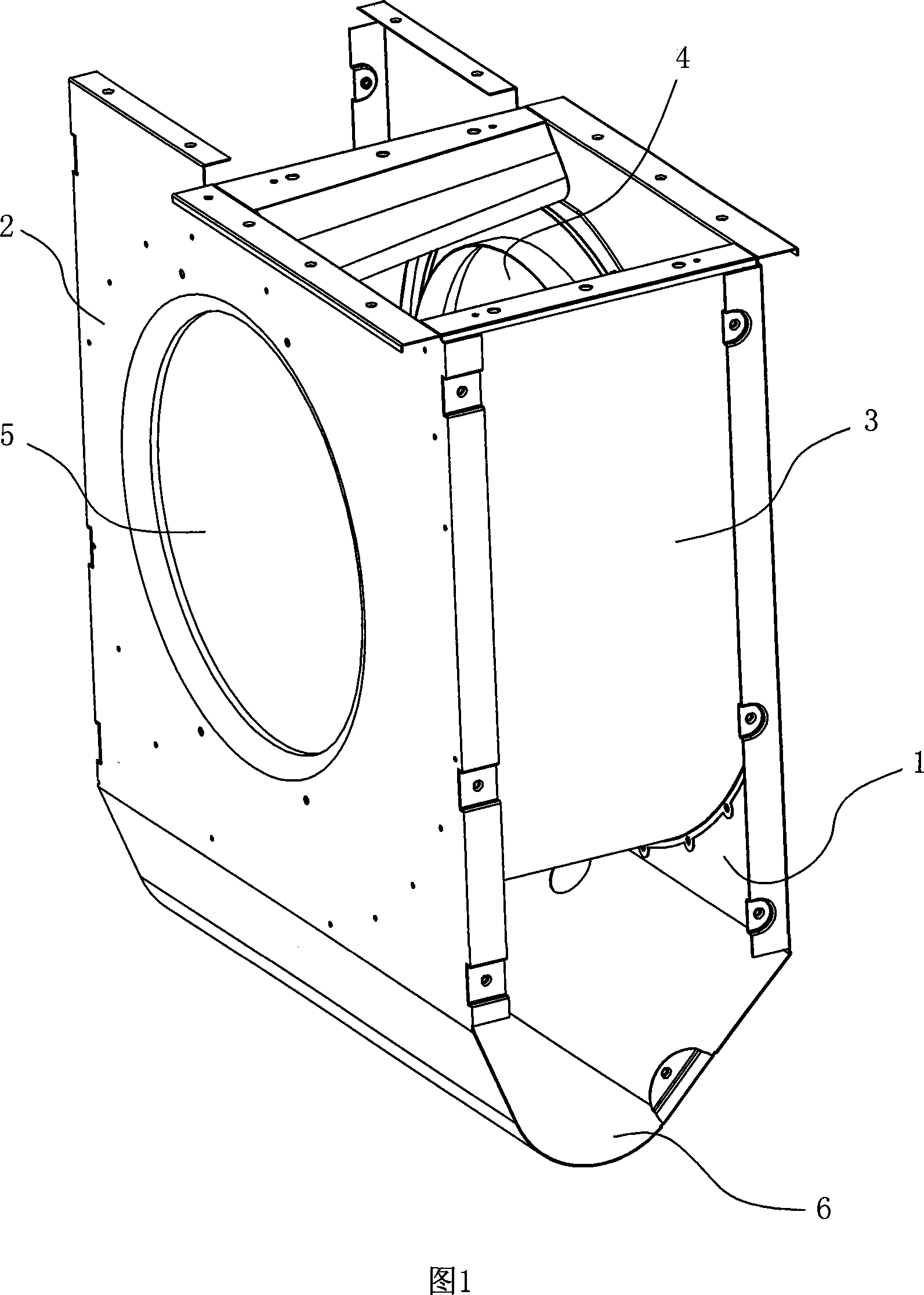

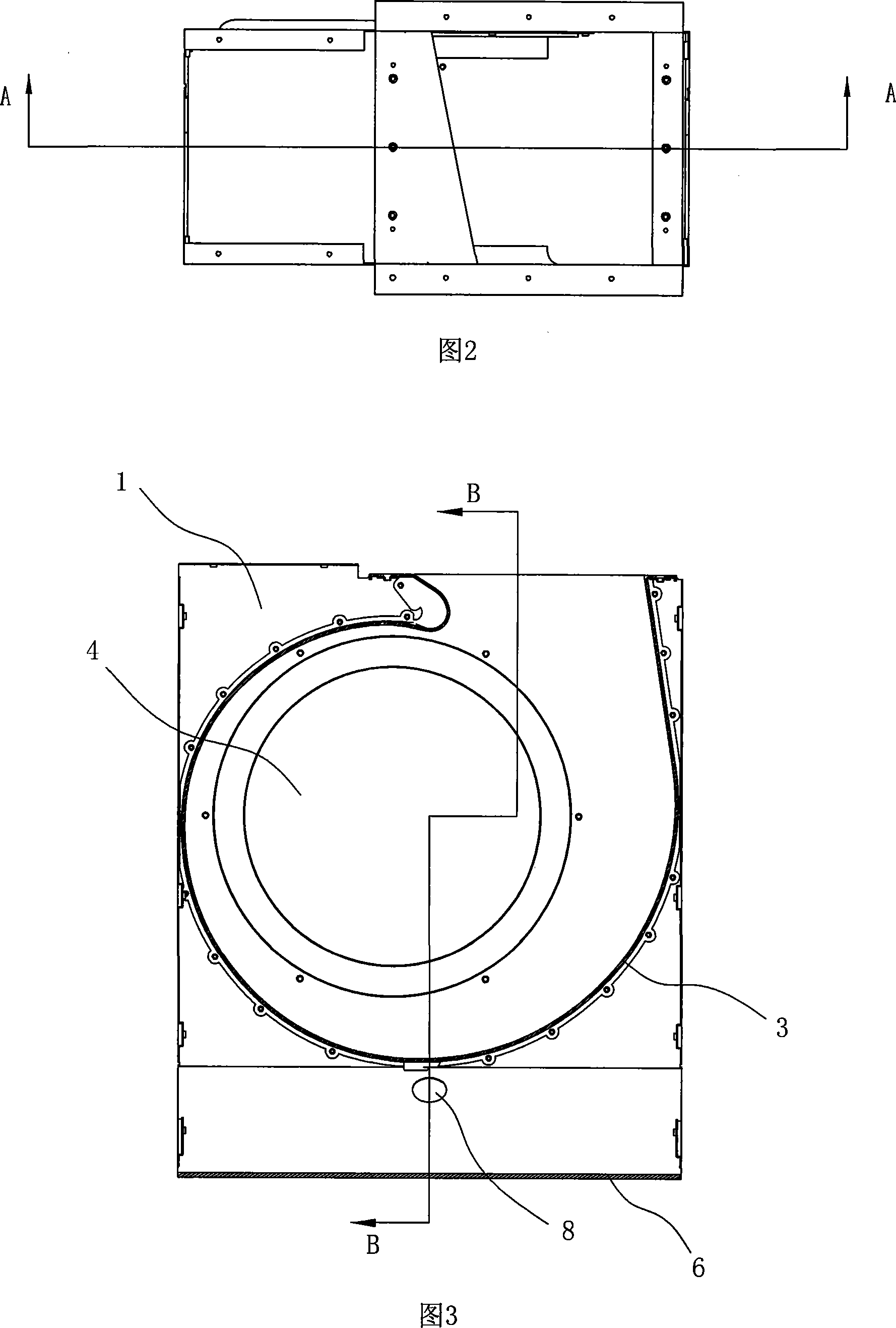

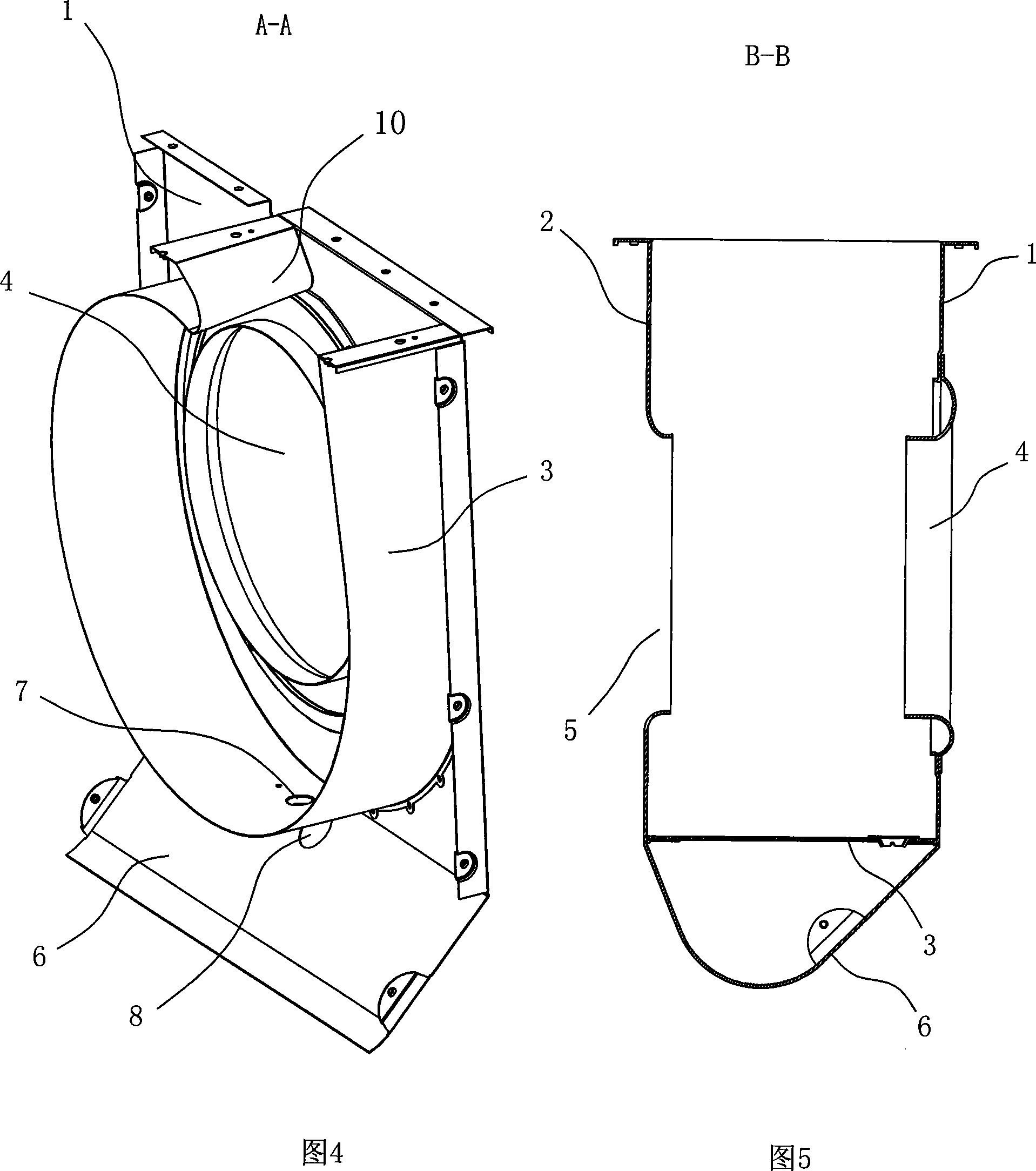

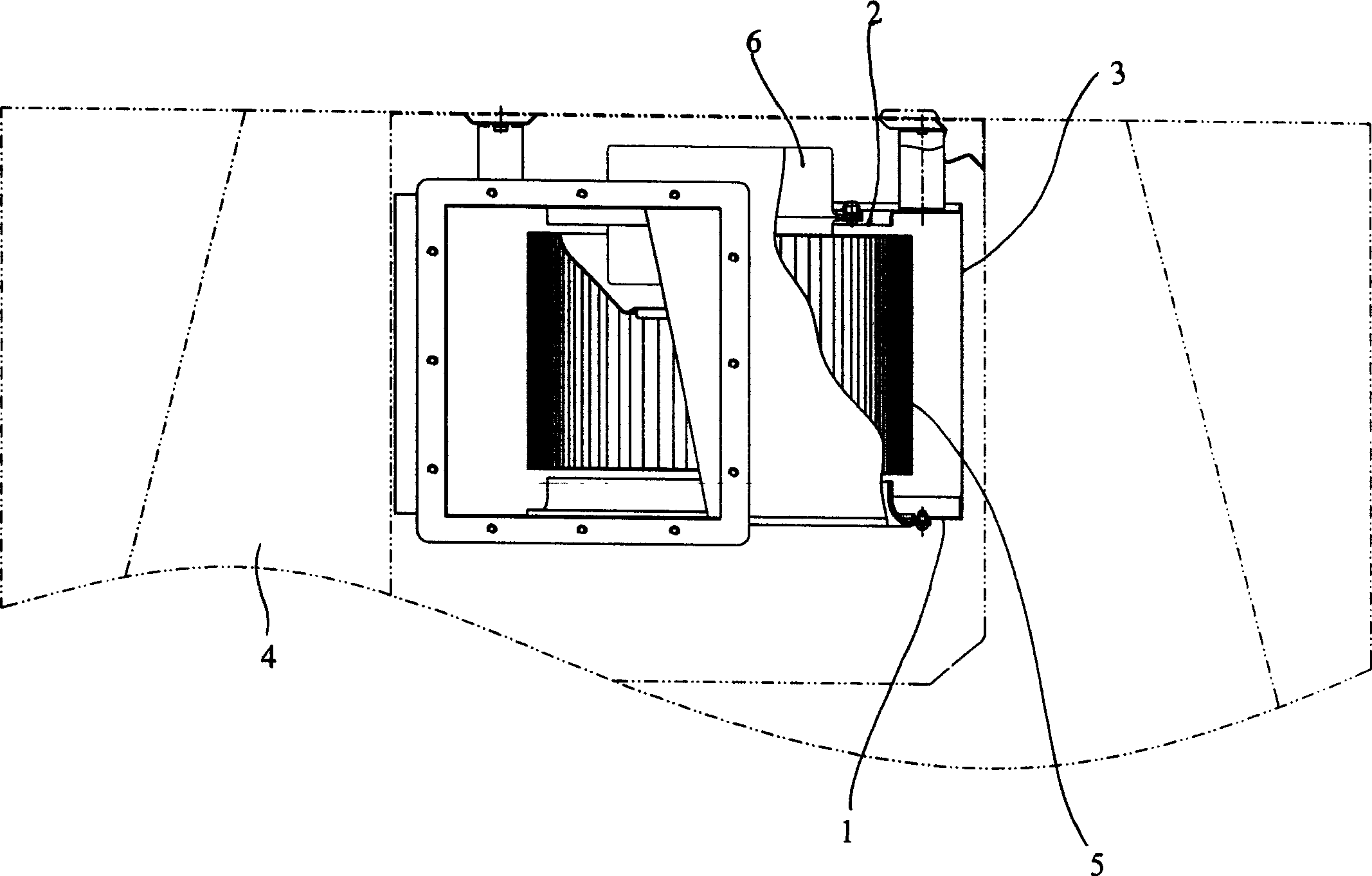

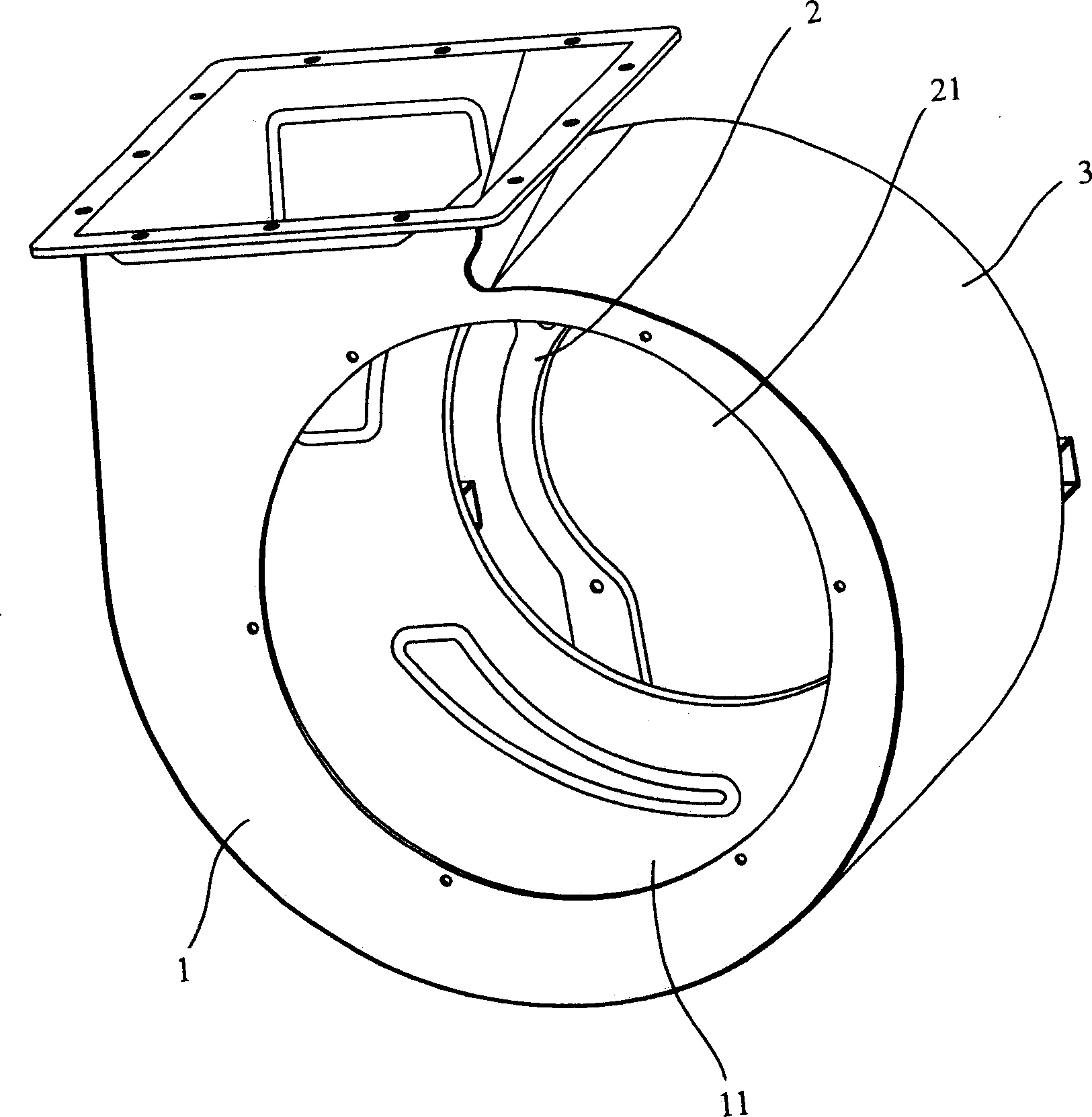

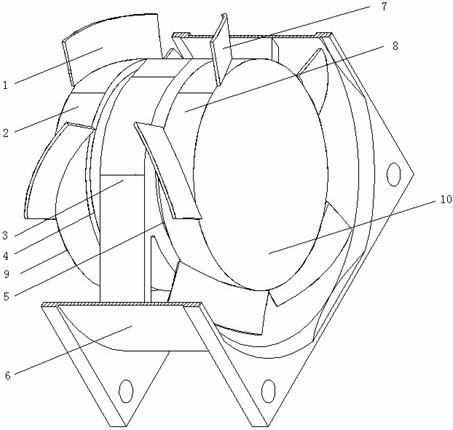

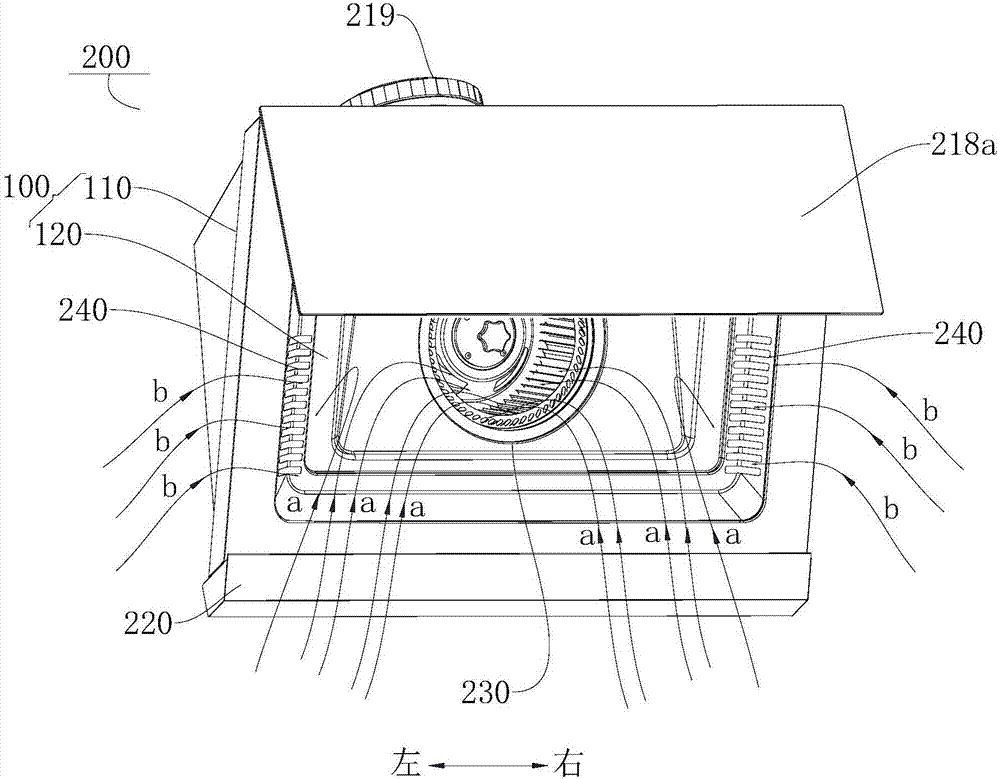

Fan volute structure with air inlets on double sides for European-style smoke exhaust ventilator

ActiveCN1844758AAvoid separationTotal noise reductionDomestic stoves or rangesLighting and heating apparatusAgricultural engineeringFront cover

The invention discloses a wind engine volute of Europe-type kitchen ventilator, which can adsorb wind via two surfaces. Wherein, the front and back cover plates (1, 2) are both mounted with wind inlets (11, 21); the edge of front cover plate (1) is formed by a straight line (AB), several arcs (BC, CD, DE, EF, FG, GH) and straight lines (HJ, JA); the edge of back cover plate (2) is formed by a straight line (A'B'), several arcs (B'C, C'D', D'E', E'F', F'G, G'H'), and a straight line (H'A'); the ratio between the radius of edge (FG) at the volute tongue of front cover plate (1) and the edge radius of edge (G'H') at the volute tongue of back cover plate (2) is 7.3-18.5. Compared to present technique, the invention can generate a new noise source at the volute tongue, which is reverse to other noise, to be eliminated some.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

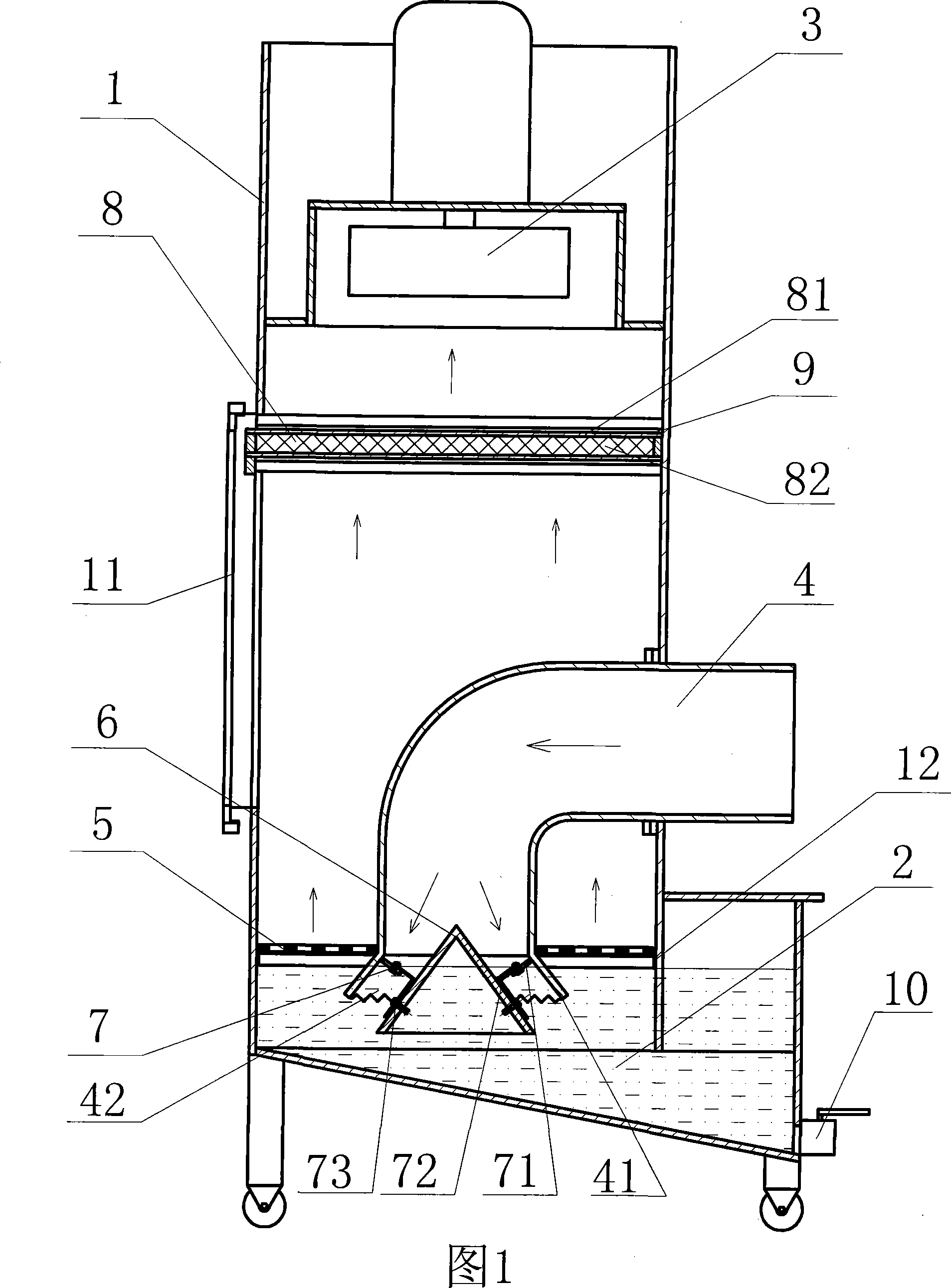

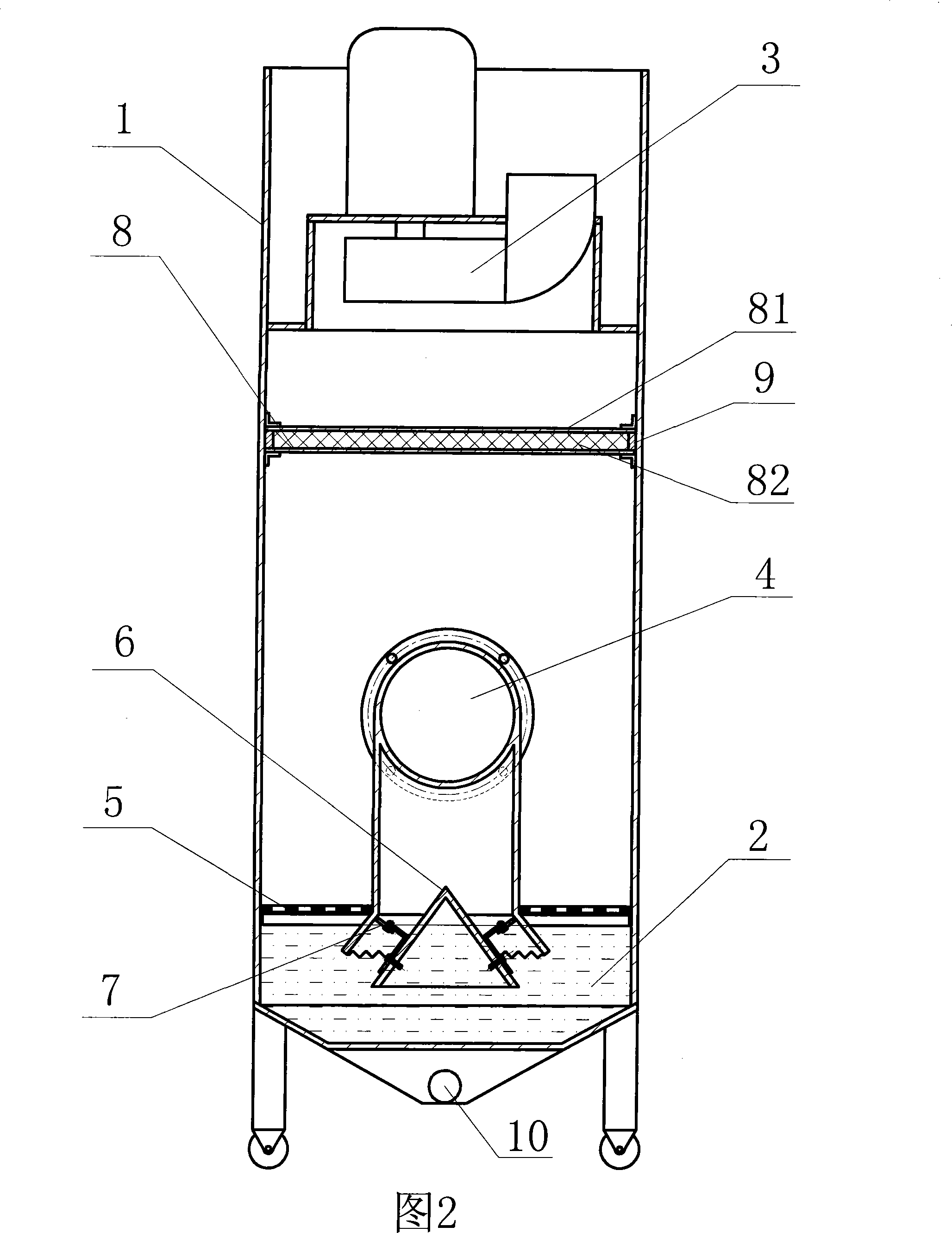

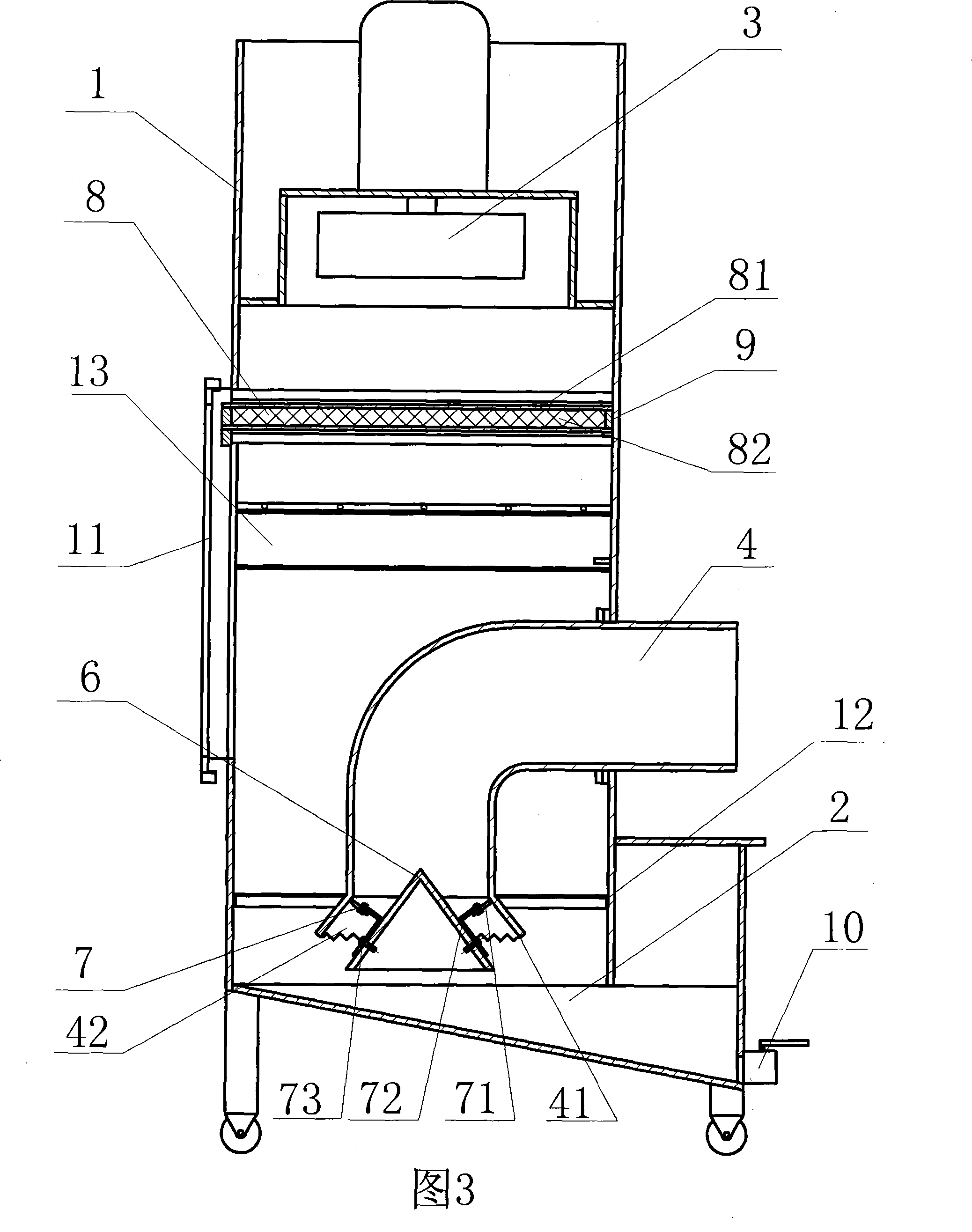

Bubble wet processing dust container

InactiveCN101229465AExtended stayFully mixedCombination devicesUsing liquid separation agentProduct gasPerforated metal

The invention discloses a water medium filtering and dust removing bubble wet dust collector, which comprises a tank body (1), a water tank (2) arranged under the tank body (1), an ejector positioned over the tank body, a drain pipe (10) positioned below the water tank, a door (11) arranged at the side of the tank body, a filter plate (8) in the tank body, a pumping elbow (4) fixed on the water tank, a bell mouth (41) at the outlet end thereof, a layer of perforated metal sheet (5) arranged close to the working water surface and supported by a bar bearer (12) in the tank body. The bell mouth (41) enters into the water through the perforated metal sheet (5); the middle most of the lower part of the bell mouth (41) is provided with a pyramidal guide wind bucket (6) which is suspended at the inner side of the bell mouth (41) through a duct regulating thread slipping (7), thereby ensuring the outer side of the guide wind bucket (6) and the inner side of the bell mouth form an annular exhaust passage (42), size of which can be adjusted. The invention has simple structure and generates bubble through the guide wind bucket, thereby ensuring the pumped dust gas can fully enter into the water to be filtered and saving energy.

Owner:江门市蓬江区永兴盛五金设备有限公司

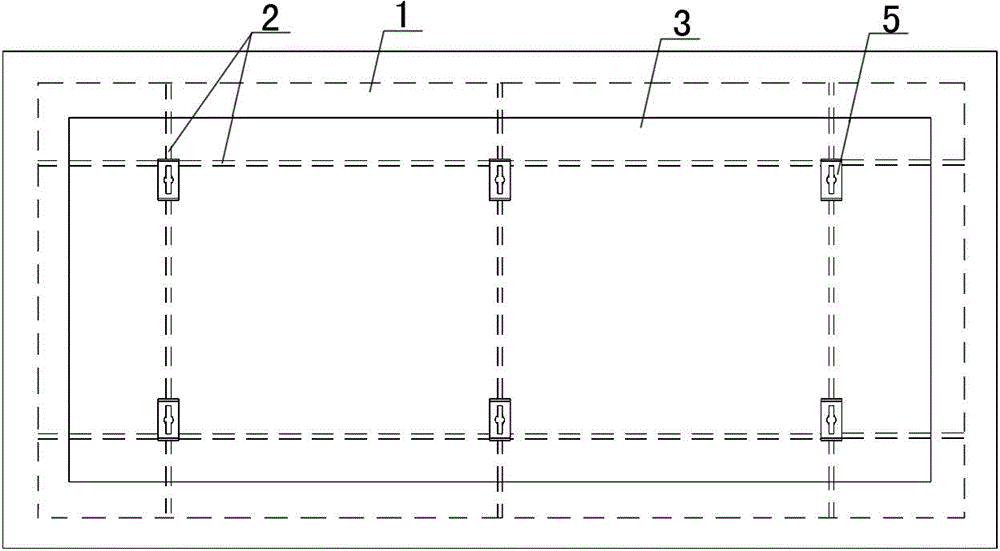

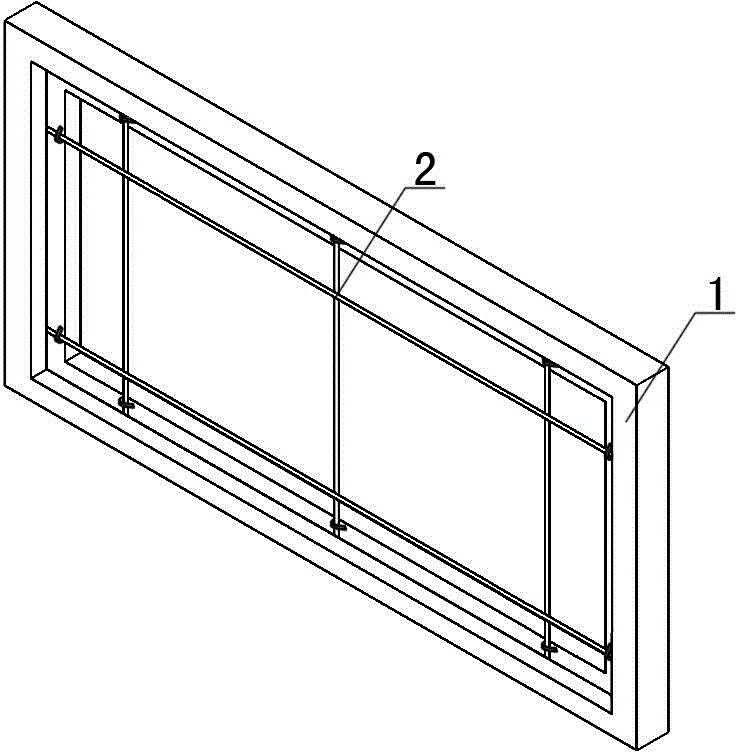

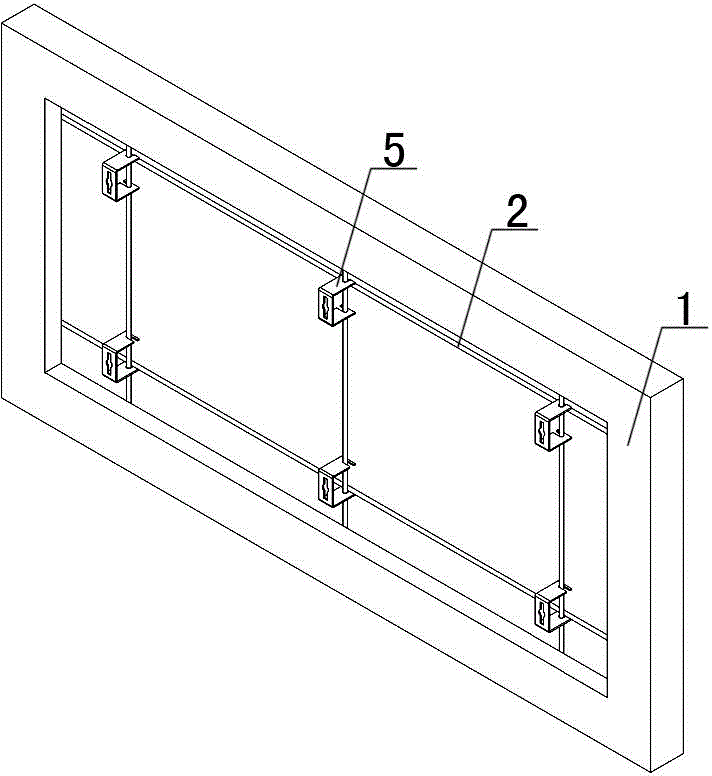

Non-dismantling die cast-in-place lightweight thermal insulation wall formboard, thermal insulation wall and construction method thereof

ActiveCN104674985AReduce the amount of constructionFast constructionWallsThermal insulationDie casting

Disclosed are a non-dismantling die cast-in-place lightweight thermal insulation wall formboard, a thermal insulation wall and a construction method thereof. The formboard comprises an inner formboard unit, an outer formboard unit and opposite-drawing connectors connecting the formboard units; the inner formboard unit comprises a formboard frame, steel bar grid frames connected between inner circles of the formboard frame, steel bar clamps connected to the cross points of the steel bars of the steel bar grid frames and a formboard core filling the inner side of the formboard frame; the inner formboard unit and the outer formboard unit are the same in structure and are connected at two ends of the opposite-drawing connector symmetrically; the steel bar clamps of the inner formboard unit and outer formboard unit are corresponded horizontally and are connected through the opposite-drawing connectors. The thermal insulation wall is simple in structure, by means of the double-layer wall formboard, the wall thickness consistence is guaranteed, the strength performance requirements are met, the thermal insulation wall is convenient to construct, the matching bar, core column and tie beam arrangement procedures are omitted, construction cost is lowered, constructing efficiency is improved, and the formboard can widely applied to wall construction.

Owner:北京振利节能环保科技股份有限公司

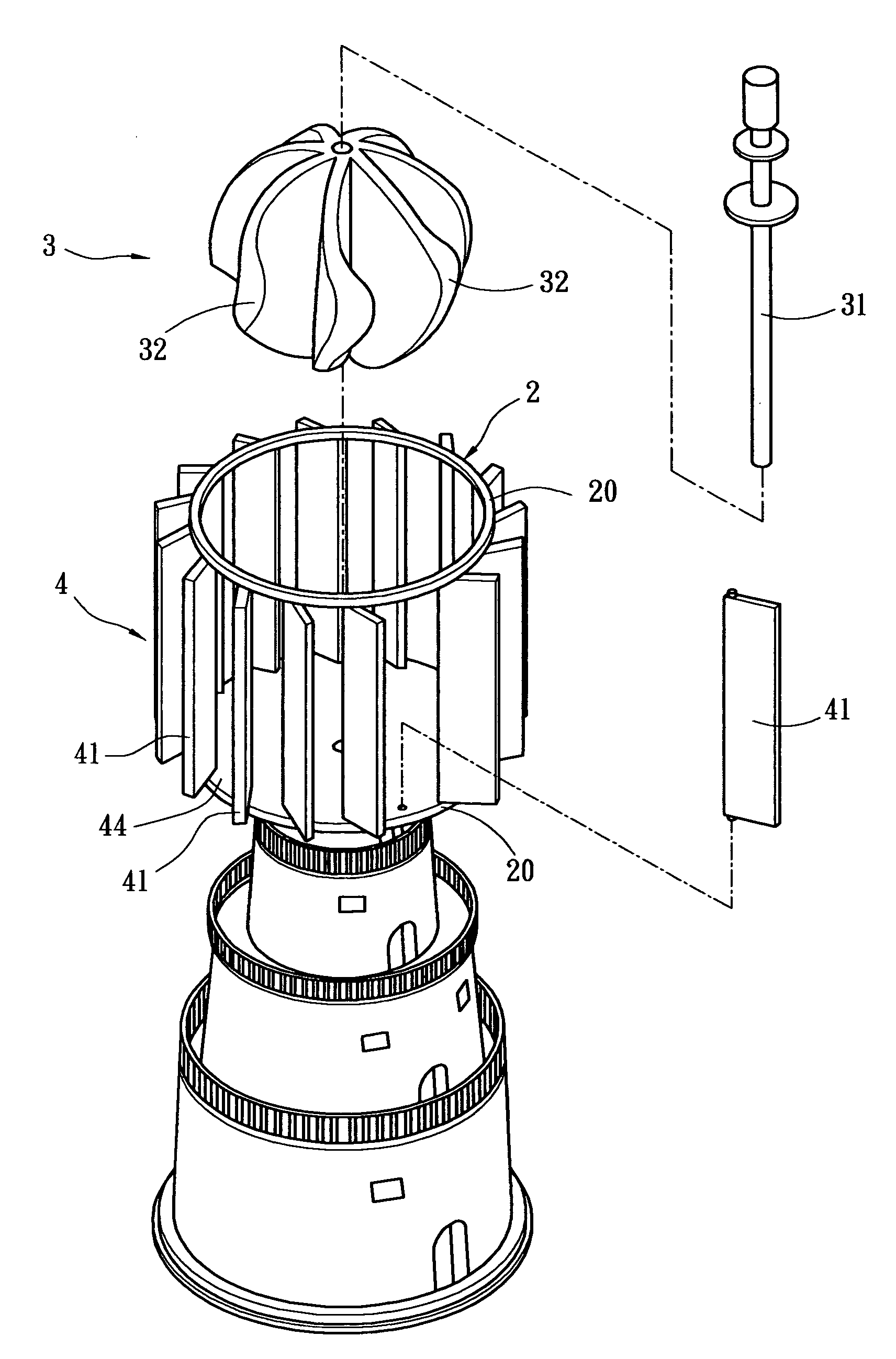

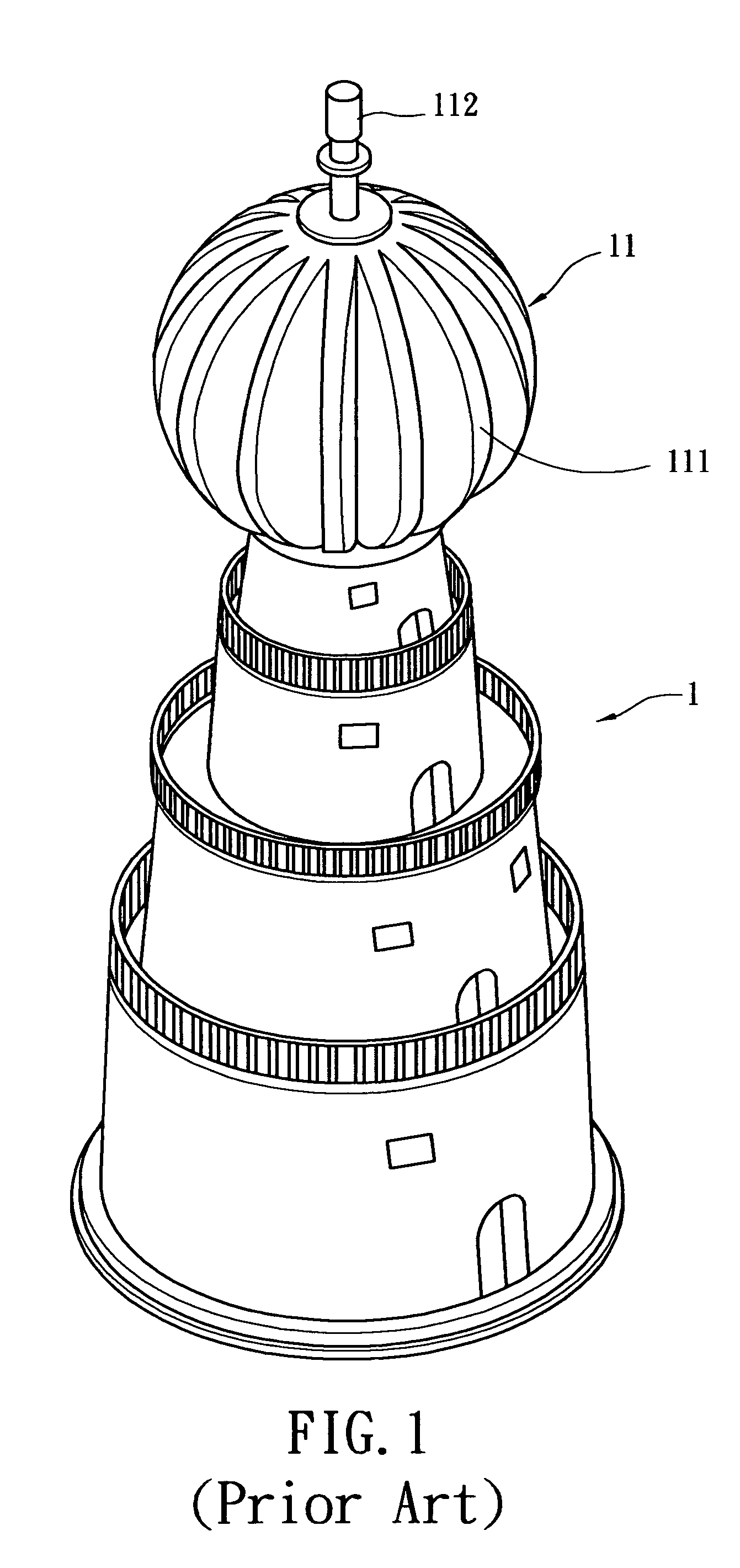

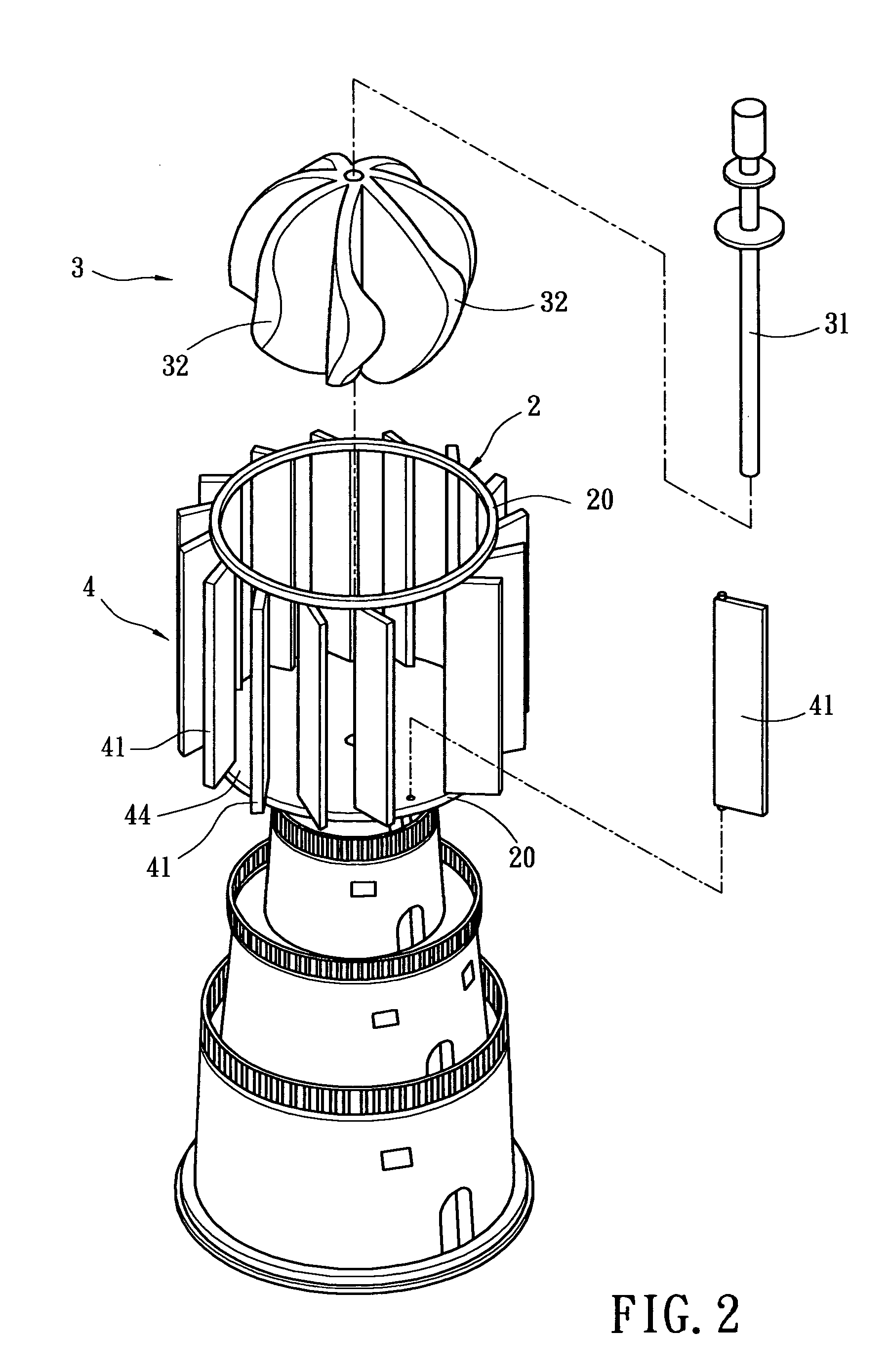

Wind-guidance enhancing apparatus for a fluid power generator

InactiveUS20060076782A1Increase wind pressureEnhance wind capturing angleRenewable energy generationWind motor combinationsImpellerEngineering

A wind-guidance enhancing apparatus for a wind power generator includes a support stage; an impeller stage including at least one blade, and a wind-guidance unit for guiding wind to the impeller stage. The wind-guidance unit includes a plurality of wind-guidance plates having wind-guidance faces, wind-guidance gates, and wind-guidance runners defined between adjacent wind-guidance faces and being shrunk toward the impeller stage. The wind-guidance gate is designed to be movable to adjust the width and flowing direction of outlets of the wind-guidance runners. Moreover, the wind-guidance enhancing apparatus further includes at least one gutter plate and the wind-guidance plates are arranged corresponding to a reference plate to enhance wind capturing angle.

Owner:YEH DON FONG

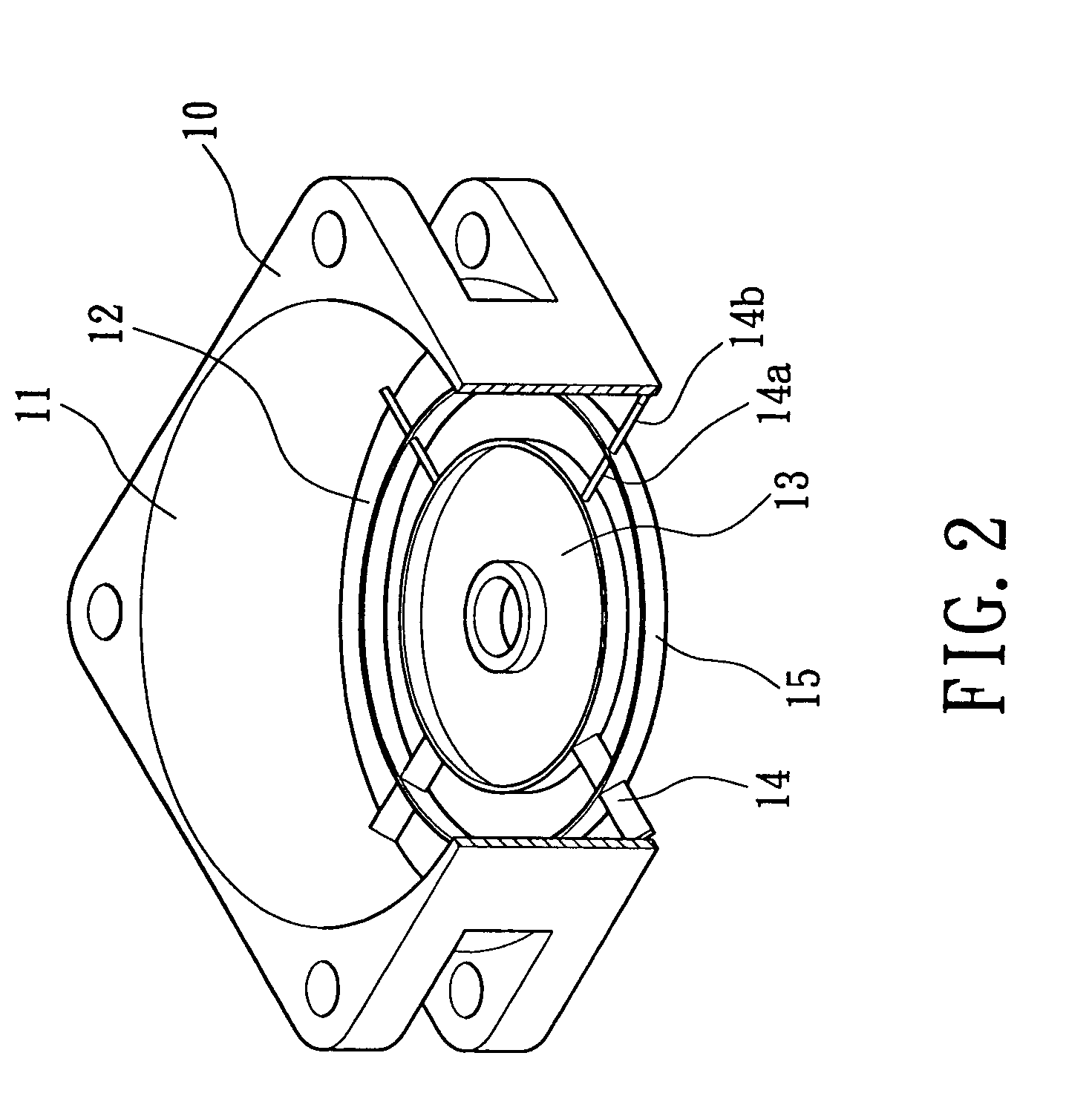

Airflow guiding structure varying in inclinations of air-guiding rings for a heat-dissipating fan

InactiveUS7334988B2Increase wind pressureReduce wind noisePump componentsReaction enginesImpellerEngineering

A heat-dissipating fan includes a casing having an air outlet, a base mounted in the air outlet, an impeller being mounted on the base and having a plurality of blades, a plurality of ribs each extending between the base and the casing along a radial direction of the base, and at least two air-guiding ring fixedly mounted to the ribs. The air-guiding rings vary in inclinations along a longitudinal direction of the casing. The air-guiding ring guides airflow in various directions, and divides airflow passing through the air outlet when the impeller is turning.

Owner:SUNONWEALTH ELECTRIC MACHINE IND

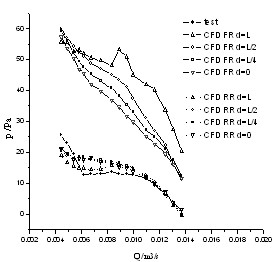

Centrifugal fan for oil and smoke exhaust machine and method for manufacturing volute profile line thereof

InactiveCN102182707BIncrease air volumeIncrease wind pressurePump componentsPumpsImpellerEngineering

The invention relates to a centrfugal fan for an oil and smoke exhaust machine and a method for manufacturing a volute profile line thereof. The centrfugal fan comprises a volute, a blade wheel, an air inlet ring and a motor, wherein the volute is provided with an air inlet and an air outlet; the blade wheel is arranged in the volute; the air inlet ring is arranged on the air inlet; the motor drives the blade wheel to rotate; the volute comprises a volute top plate, a volute enclosing plate and a volute base plate; and the volute enclosing plate is connected between the volute top plate and the volute base plate. The centrfugal fan is characterized in that the outline of the inner side face of the volute enclosing plate is the volute profile line, and the volute profile line is formed by the smooth transitional connection of a first straight line DE, a first arc line EF, a second arc line FG, a spiral line GH and a second straight line HI. According to the invention, after considering problems in the prior art and aiming at the characteristics of large impellor size and small volute size of the centrifugal fan for the oil and smoke exhaust machine, a design method of the volute profile line of the centrifugal fan is presented, thereby making great contribution to improving the air rate, air pressure and efficiency of the centrifugal fan for the oil and smoke exhaust machine and reducing the pneumatic noises.

Owner:FOSHAN SHUNDE MIDEA WASHING APPLIANCES MFG CO LTD

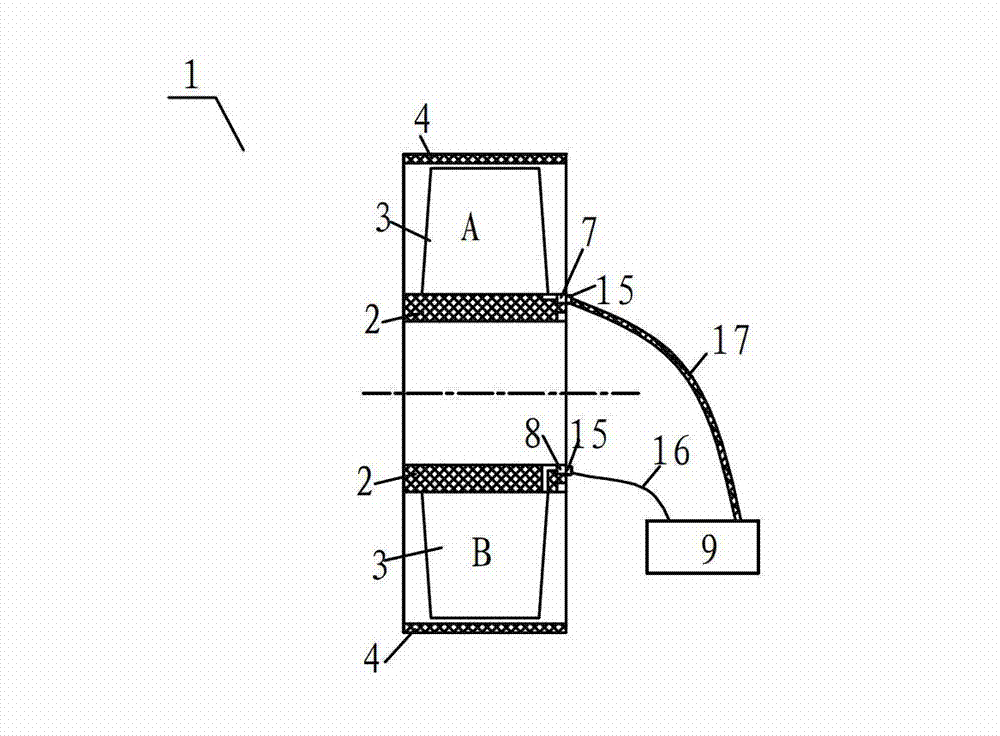

Double-layer reverse axial fan

InactiveCN102052339AIncrease pressure energyIncrease air volumePump componentsPump installationsAir volumeEngineering

The invention discloses a double-layer reverse axial fan, which is characterized in that a motor holder is fixed on a machine case, and a first motor and a second motor are fixed on the motor holder; a first axial fan is fixed on a rotary shaft of the first motor, and comprises a first hub and a first leaf, the first leaf is fixed on the first hub; a second axial fan is fixed on a rotary shaft of the second motor, and comprises a second hub and a second leaf, the second leaf is fixed on the second hub; the rotate speeds of the first axial fan and the second axial fan are same, and the rotation directions of the first axial fan and the second axial fan are reverse; and the installation directions of the first leaf and the second leaf are reverse. The double-layer reverse axial fan has the advantages that under the mutual action of two rotors with the same leaf shape and reverse rotation directions, an original speed deviating from the axial direction is corrected, and the pressure energy of fluid is increased; and the fan is a double-layer fan, and the air quantity and wind pressure are improved by using a back installation method, thereby achieving the purpose of improving the heat dissipation efficiency.

Owner:ZHEJIANG SCI-TECH UNIV

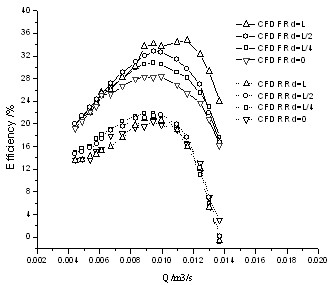

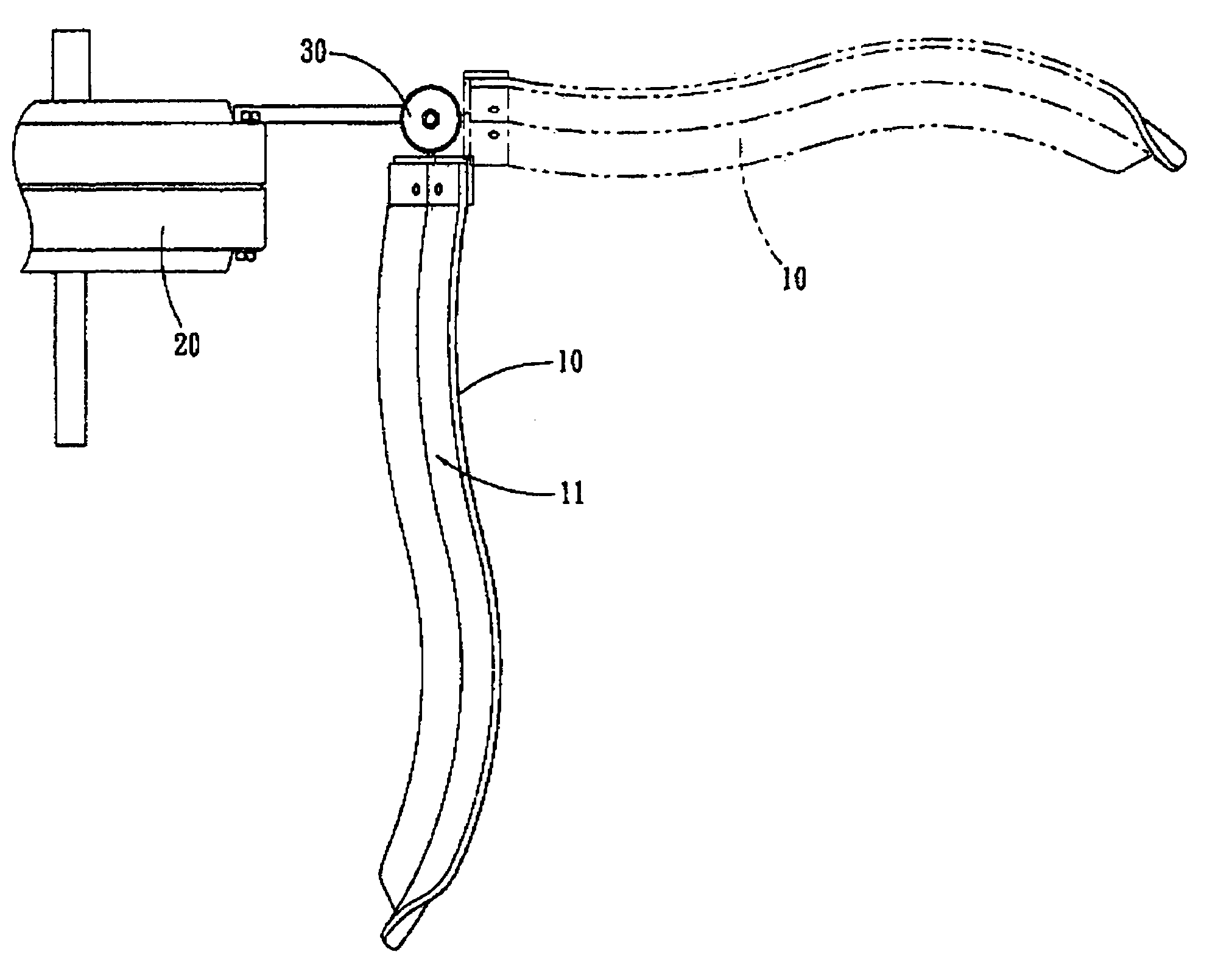

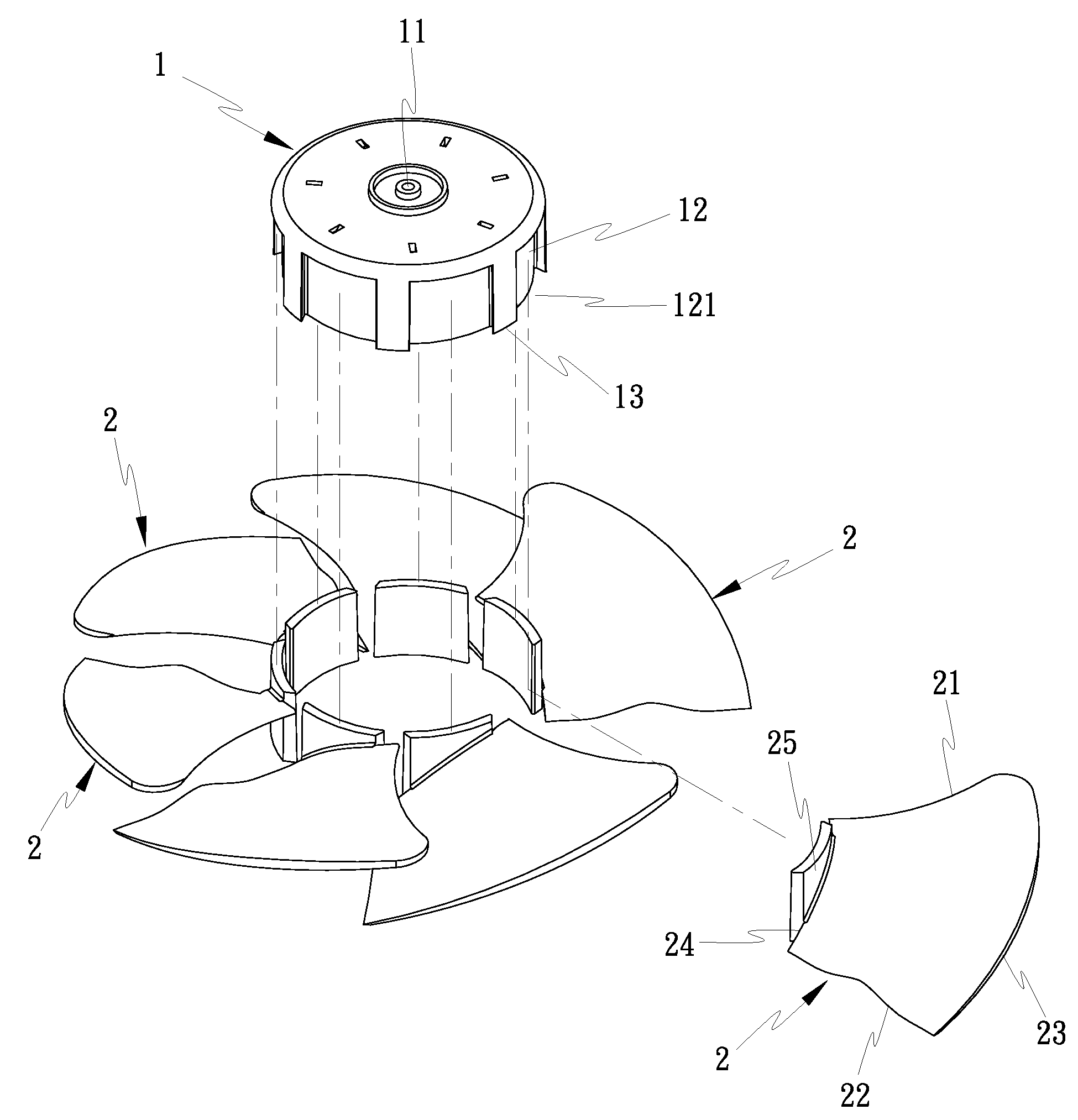

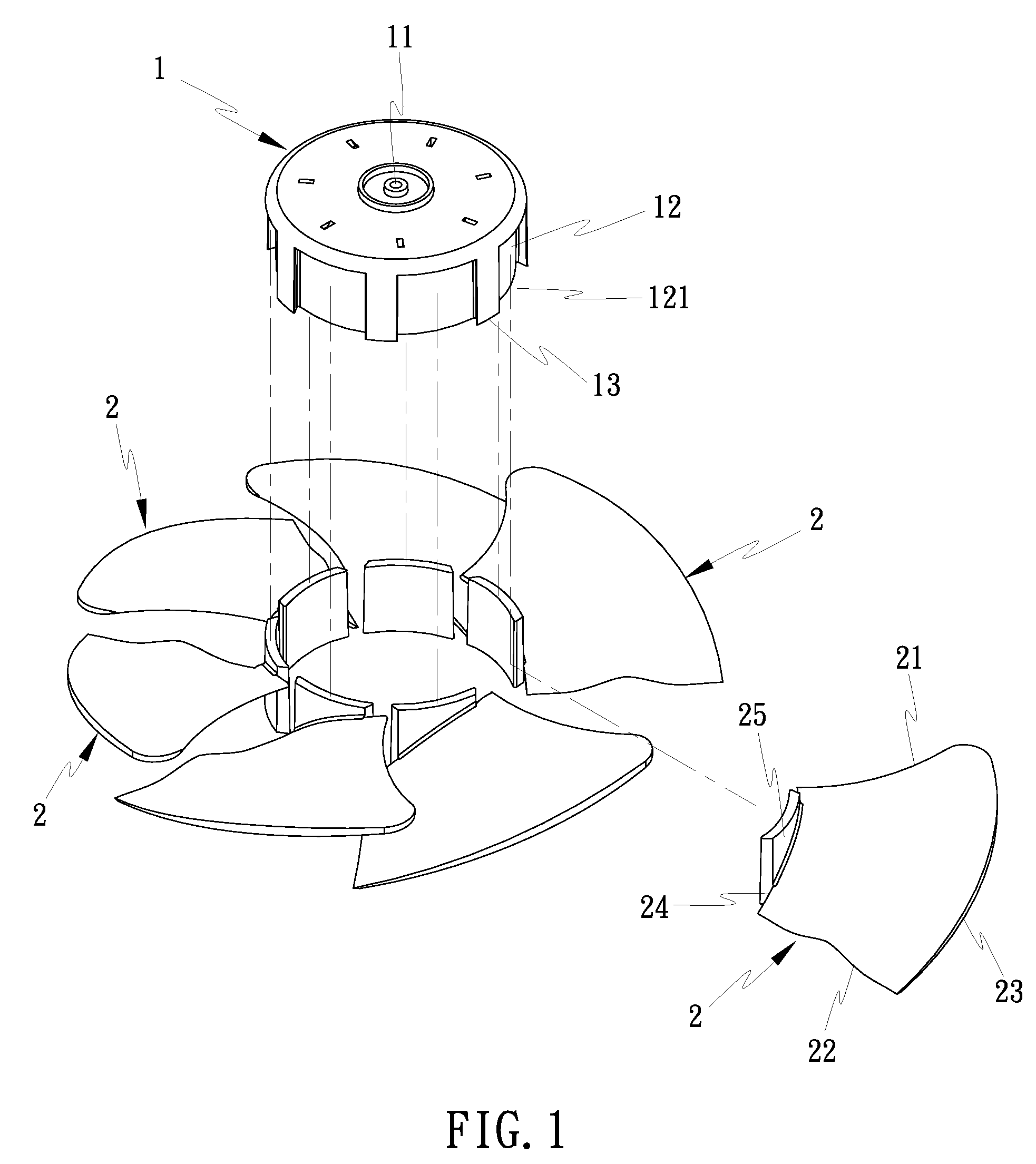

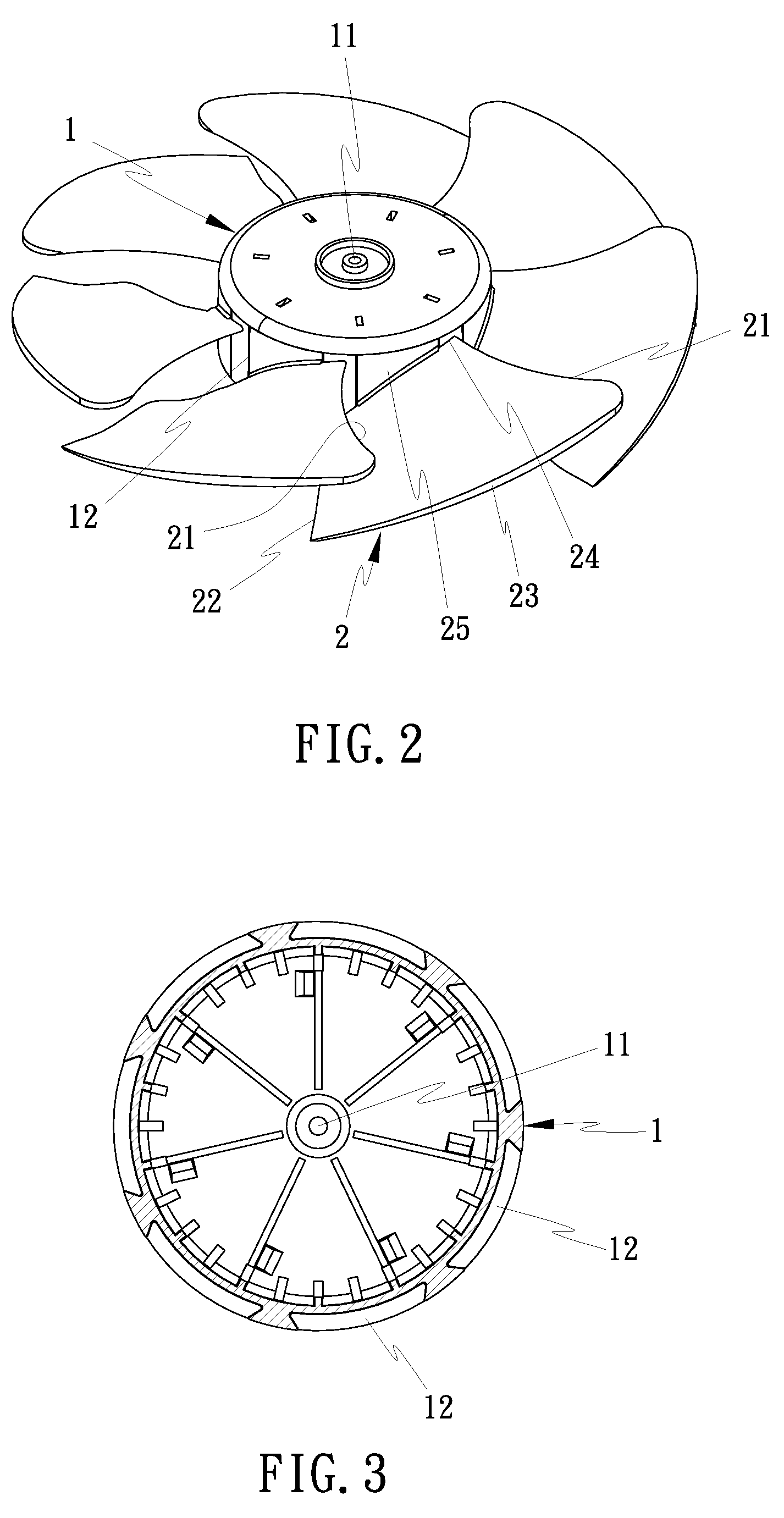

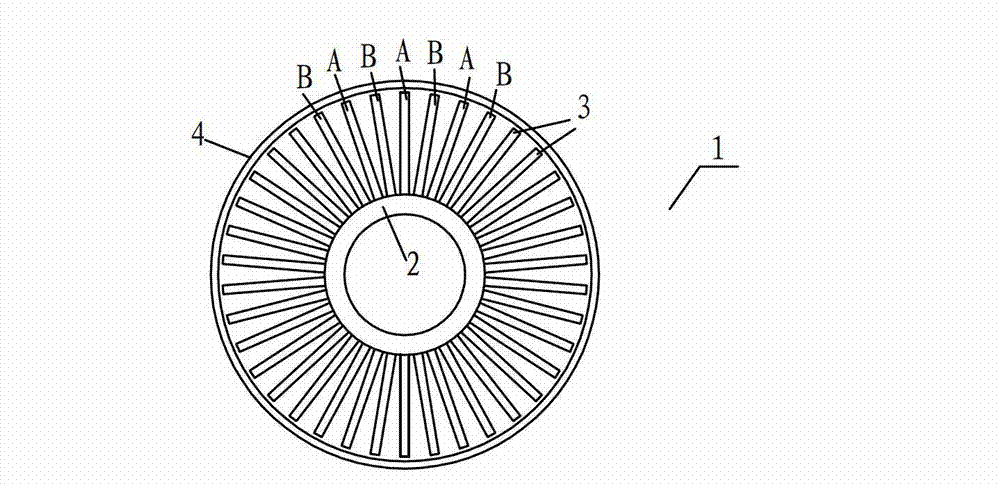

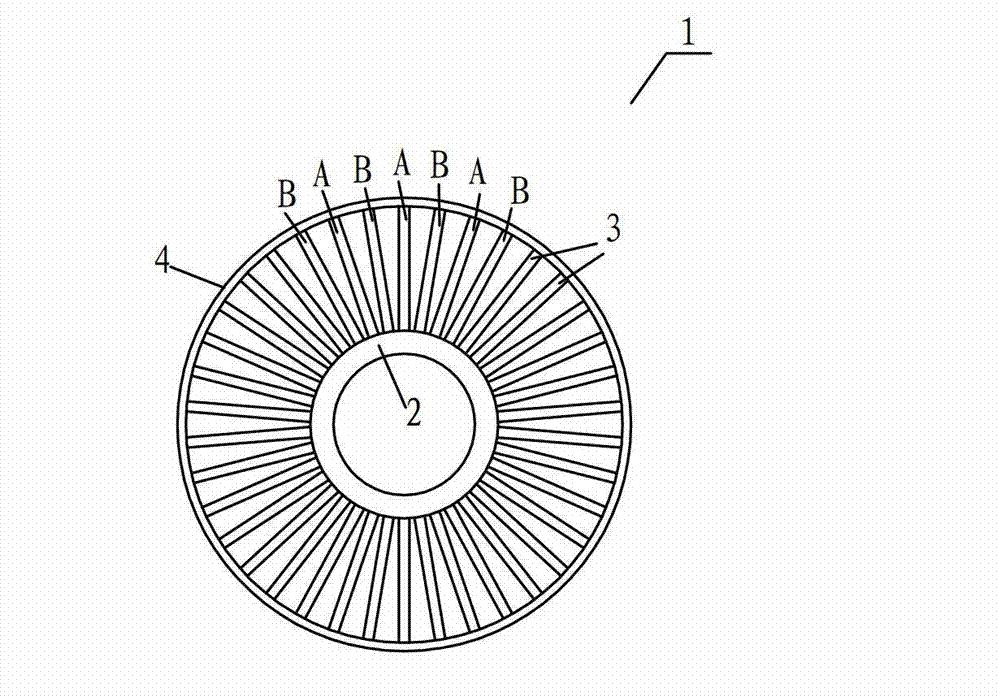

Fan and its impeller

InactiveCN101285484AIncrease air volumeIncrease wind pressurePump componentsPump installationsImpellerAgricultural engineering

The invention discloses a fan. The fan comprises an impeller, a motor and a fan frame. The impeller and the motor are received in the fan frame; the motor is connected with the impeller and drives the impeller to rotate, wherein, the impeller is provided with a hub and odd number of fan blade sets which are annularly arranged on the periphery of the hub; each fan blade set is respectively provided with a plurality of fan blades; and the fan blades in each fan blade set are the same or different with each other.

Owner:DELTA ELECTRONICS INC

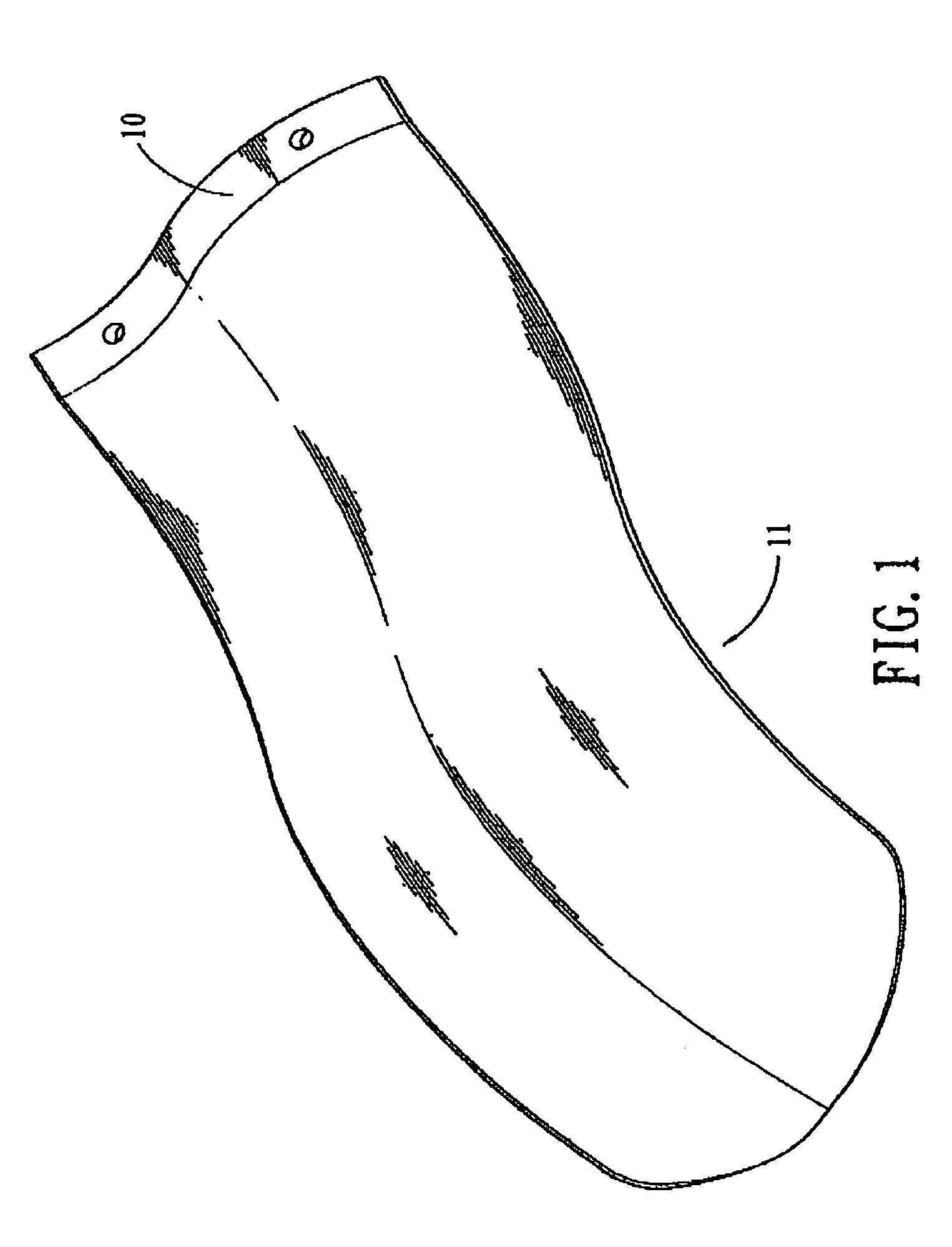

Ceiling fan blade

ActiveUS6991431B2Wind pressure and much windIncrease wind pressurePropellersRotary propellersCeiling fanEngineering

The present invention relates to a ceiling fan blade capable of producing full wind pressure and much wind. The solution of the present invention is to form a front and a rear wind receiving surfaces on the ceiling fan blade. A tangent angle of the rear wind-receiving surface is bigger than that of the front wind-receiving surface. A wavy wind guide surface is formed between the two wind receiving surfaces. The wavy wind guide surface and the two wind receiving surfaces can effectively increase the wind pressure and the wind; in addition, sinuous flow is substantially reduced when the blade is rotating.

Owner:PAN AIR ELECTRIC

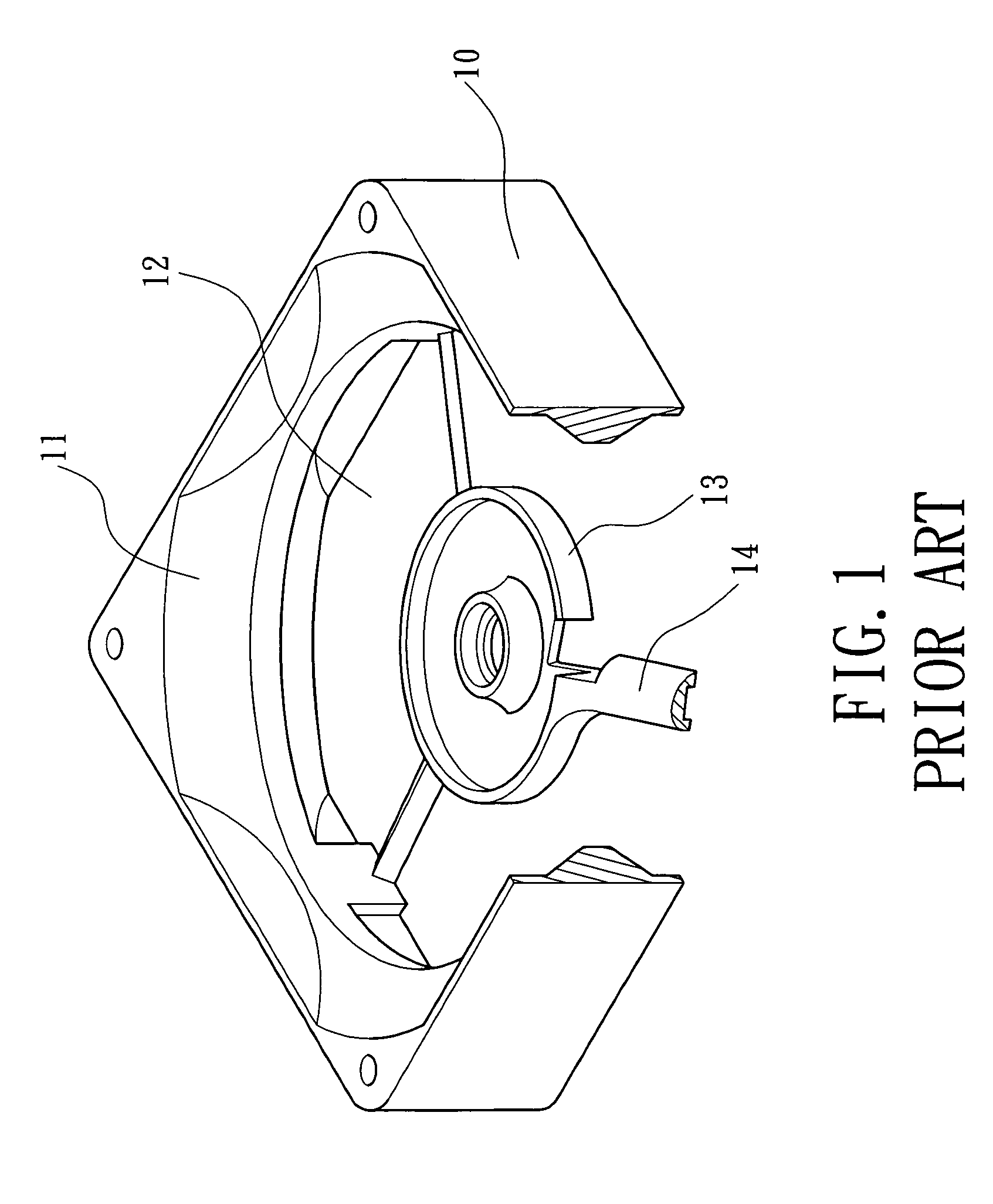

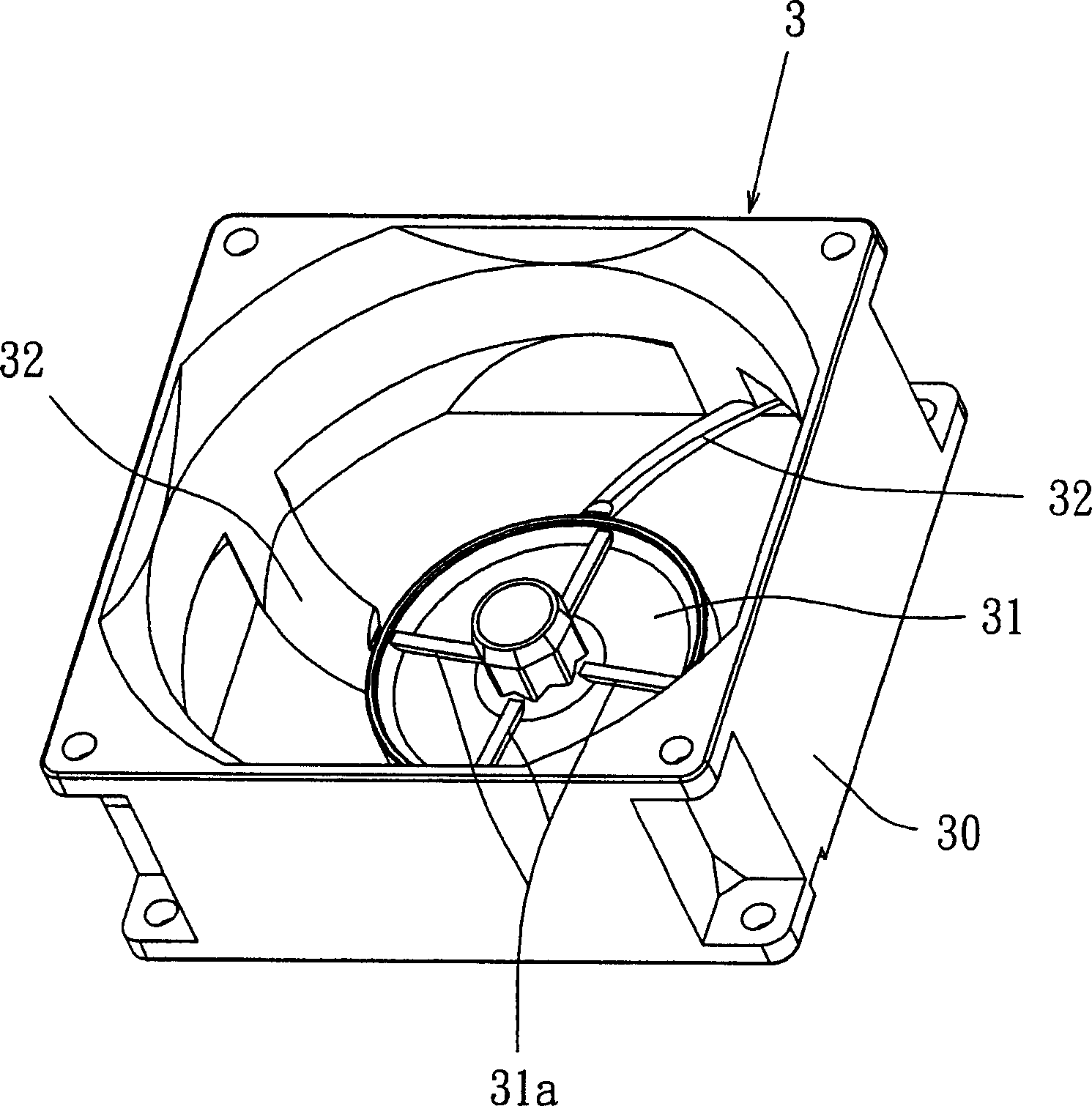

Radiating fan and base of fan frame

InactiveCN1746513AReduce spoiler noiseIncrease wind pressurePump componentsDigital data processing detailsImpellerEngineering

This invention is a heat emission fan and its frame base. The fan comprises a frame, an impeller formed by a wheel hub and motive blades around the hub. The frame base is installed inside the fan frame to support the impeller. Several flow guiders are fixed in between the frame base and the frame. The flow guiders have the first and the second curve surfaces to largely decrease noise and increase wind pressure.

Owner:DELTA ELECTRONICS INC

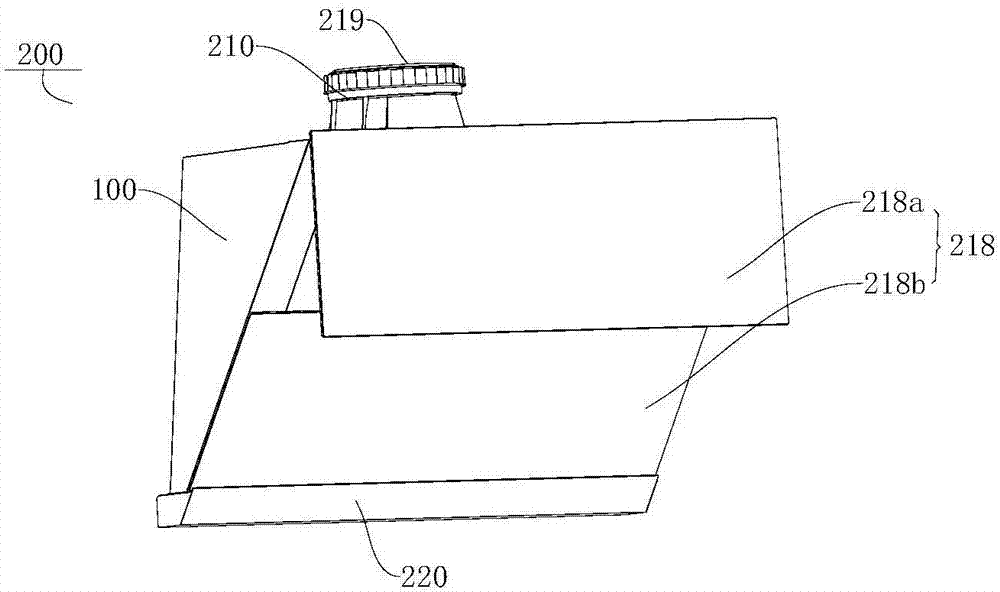

Shell assembly of range hood and range hood

PendingCN106855257AImprove air intake efficiencyImprove the smoke effectDomestic stoves or rangesLighting and heating apparatusAir volumeEngineering

The invention discloses a shell assembly of a range hood and the range hood. The range hood comprises a shell, a partition and a fan assembly, wherein an opening is formed in the front side of the shell; the partition is arranged in the shell, and divides the inside of the shell into a front side cavity and a rear side cavity which are arrayed in the front-to-back direction; a main air inlet is formed in the partition; at least one of the partition and the shell defines an auxiliary air inlet; the auxiliary air inlet is close to the edge of the partition; the air feeding end opening of the fan assembly is formed at the main air inlet and is communicated with the front side cavity; an auxiliary air opening is formed in the fan assembly; the main air inlet and the air feeding end opening define a main air duct; the auxiliary air opening and the auxiliary air inlet define an auxiliary air duct. According to the range hood disclosed by the invention, the shell assembly and the fan assembly are used for defining the main air duct and the auxiliary air duct, so that the lampblack catching capacity of the range hood can be improved, the air feeding efficiency is improved, and the air volume and the air pressure are increased; therefore, the lampblack absorption effect of the range hood can be enhanced.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Combination axial-flow fan

InactiveUS20090155081A1Increase wind pressureLarge capacityPropellersRotary propellersLow noiseElectric machinery

A high-performance low-noise combination axial-flow fan includes a fan hub that has a center connection portion for the connection of a fan motor shaft and a plurality of mounting grooves equiangularly spaced around the periphery, and fan blades each having a wedge block disposed at the inner end for insertion into one mounting groove to secure the respective fan blade to the fan hub so that the fan blades are radially fastened to the fan hub and no gap is seen between each two adjacent fan blades when viewed from the front side.

Owner:TAIWEI FAN TECH

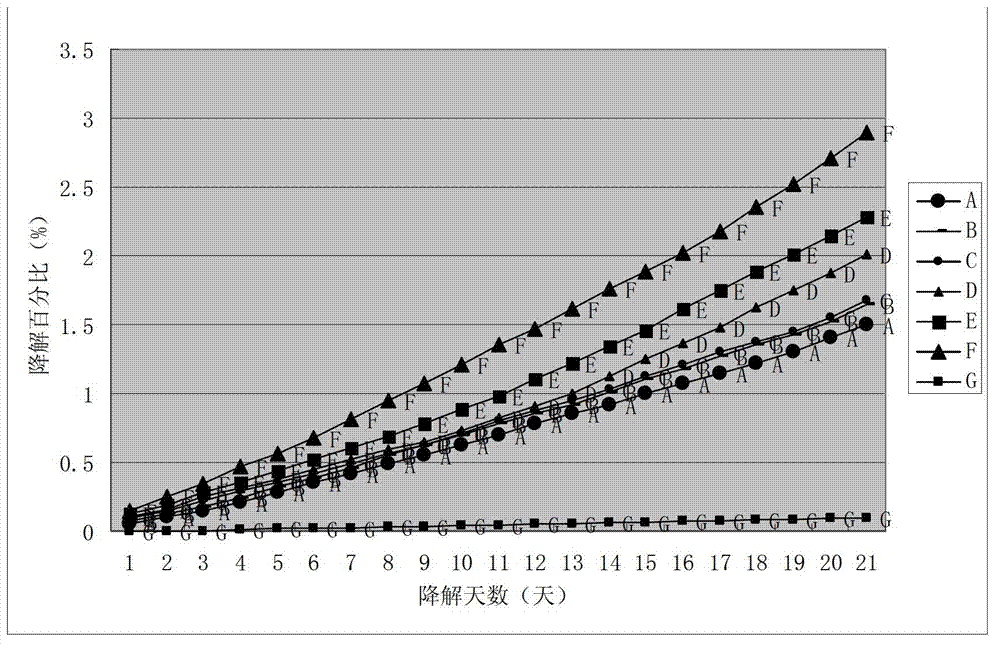

Preparation method of biodegradable regenerated polyester staple fibers

ActiveCN102828276APrevent volatilizationBalanced moistureFilament forming substance formingArtificial filament heat treatmentPolyesterPolymer science

The invention discloses a preparation method of biodegradable regenerated polyester staple fibers, which is characterized by comprising the steps of drying spinning materials by a vacuum drum, mixing with biodegradable master batch dried by a master batch drying system at the feed inlet of a screw extruder; preparing primary fibers after mixing and fusing by the screw extruder and extruding by a spinneret plate; cooling primary fibers by an annular blowing device; successively carrying out winding, falling, bundling and time balancing on the primary fibers in a constant temperature and constant-humidity room; stretching the primary fibers in oil bath and stream respectively; performing curling, relaxation heat setting, cutting and packaging to obtain biodegradable regenerated polyester staple fibers, wherein physical properties and mechanical properties of the biodegradable regenerated polyester staple fibers produced by the method do not change, and therefore, the subsequent processing and usage are not influenced; after being used, the fibers can be decomposed into inert humus, carbon dioxide and water in a microorganism-enriching environments such as refuse landfill or composting site, thereby returning to nature and achieving real biodegradation.

Owner:福建鑫华股份有限公司

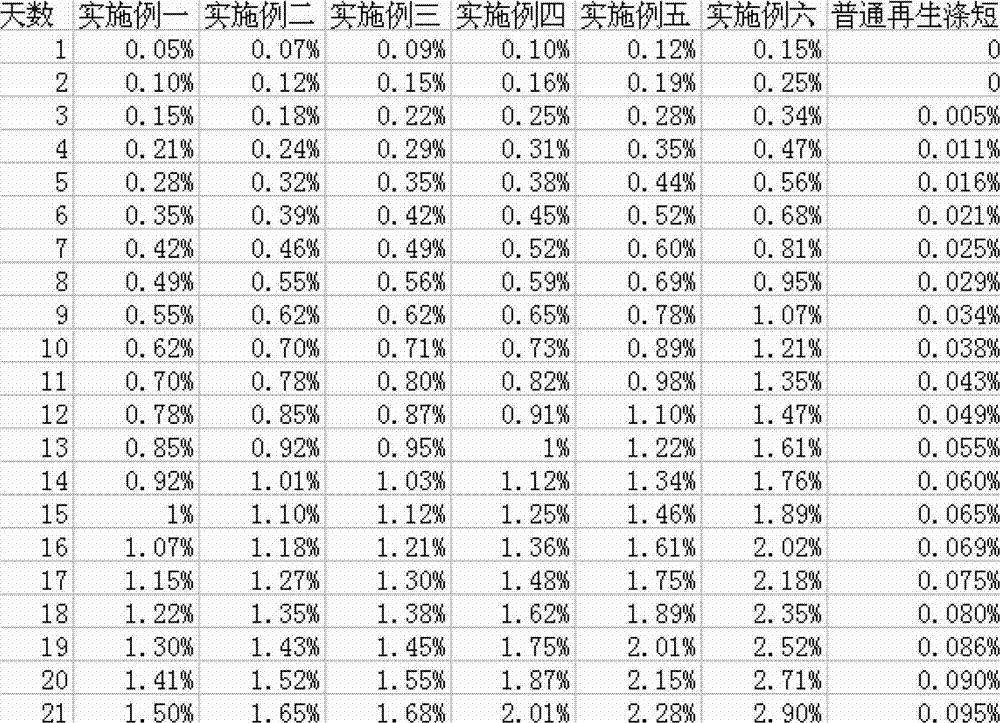

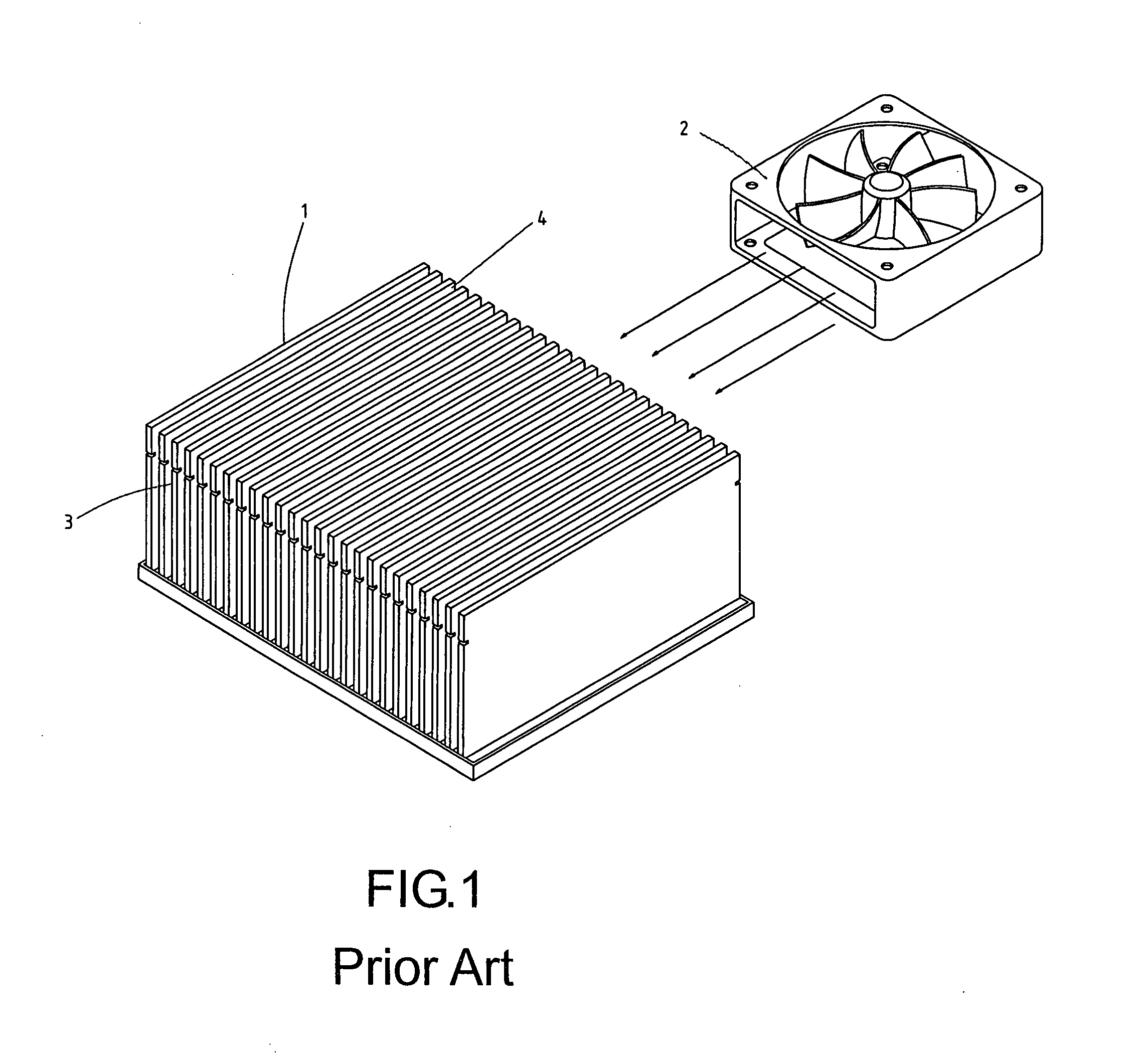

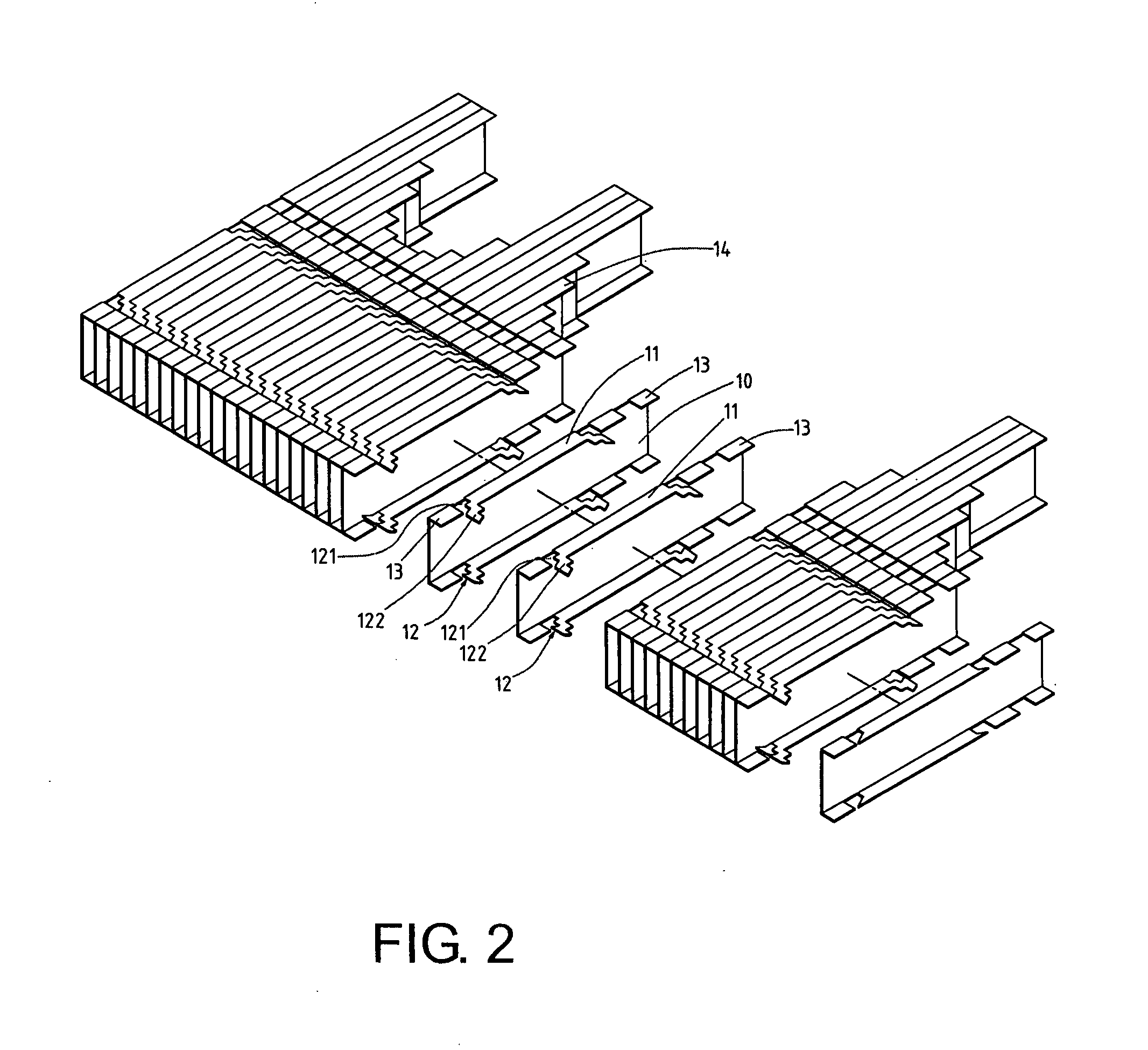

Heat dissipation device which is pre-built with an air vent structure

InactiveUS20110277969A1Beautiful appearanceImprove cooling efficiencySemiconductor/solid-state device detailsSolid-state devicesHeat transmissionEngineering

A heat dissipation device which is pre-built with an air vent structure uses primarily a plurality of cooling fins, which are formed into different lengths, to assemble into the heat dissipation devices of different shapes, for shunning away from other elements inside a computer host. In addition, diversion baffles of a different angle can be arranged and assembled, so as to form air ducts following an angle of wind direction, allowing an air flow to be smoothly guided in by a fan, and to quickly flow into a heat transmission zone in a gap between the cooling fins, such that a heat source can be dissipated more quickly.

Owner:NENG TYI PRECISION INDS

Guide blade or stator blade, and air treatment device having the same

ActiveCN102728470AReduce power consumptionNo pressure dropExternal electric electrostatic seperatorElectrostatic separation detailsLow noiseAir treatment

The invention relates to a guide blade or a stator blade, and an air treatment device having the guide blade or the stator blade. The guide blade or the stator blade comprises a wheel hub, blades and a wheel cover, wherein the blades are distributed on the wheel hub and / or the wheel cover at certain intervals along the circumferential direction. Structural characteristics of the guide blade or the stator blade are that: the blades comprise a first group of blades and a second groups of blades; the two groups of the blades have conductive properties; the first group of the blades and the second group of the blades are staggeredly distributed and insulated, and are not conducted; the first group of the blades and the second group of the blades are respectively applied with high potential and low potential so as to form a charged high voltage space between the first group of the blades and the second group of the blades, the high voltage space forms a dust removing channel, and the dust removing channel can effectively adsorb dust particles flowing through the dust removing channel. The blade and the device of the present invention have characteristics of simple and reasonable structure, high dust absorption efficiency, low resistance, low power consumption, low noise and no pressure loss. In addition, with the blade and the device of the present invention, air delivery, air pressure and efficiency of a fan can be effectively improved.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD

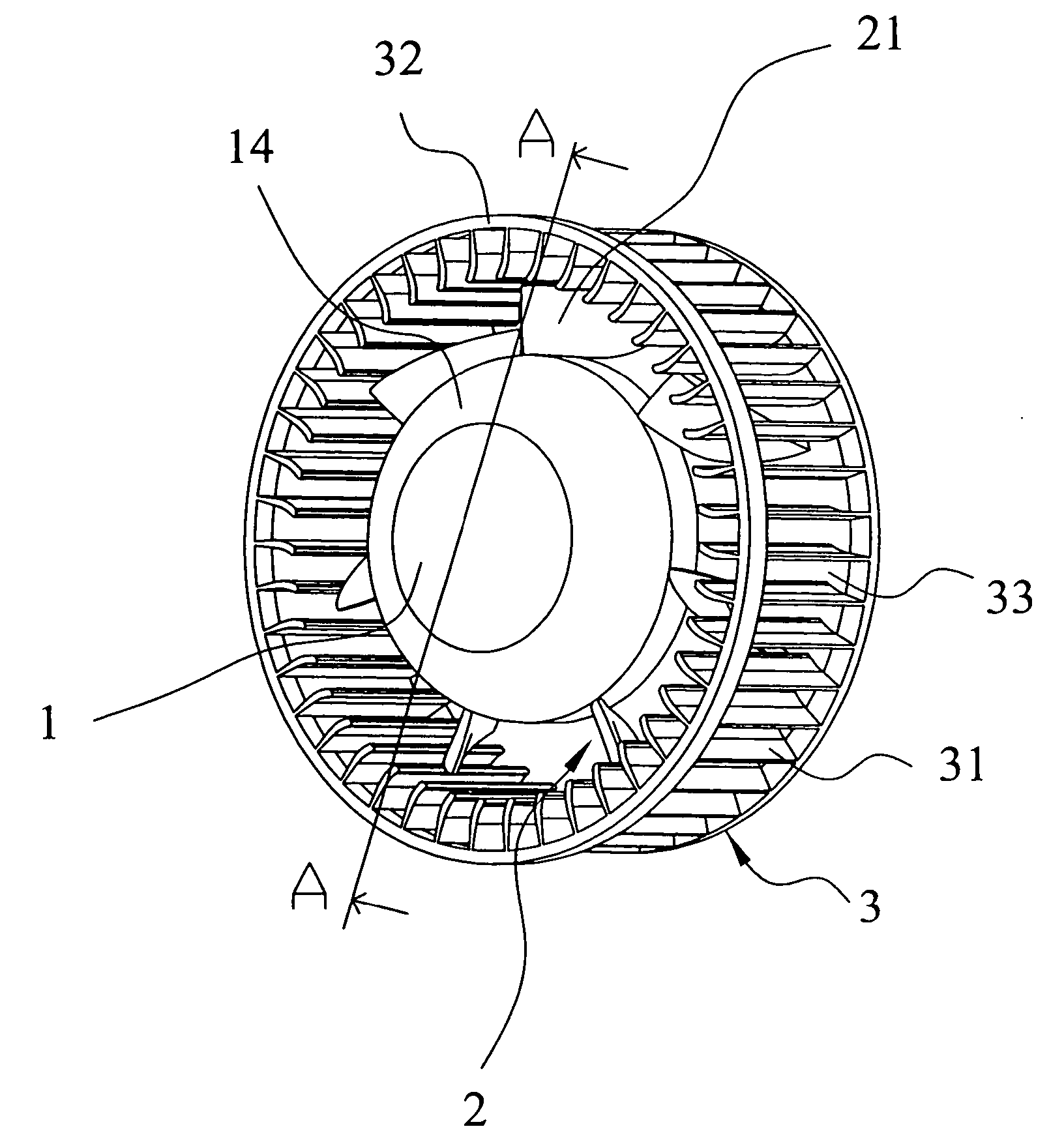

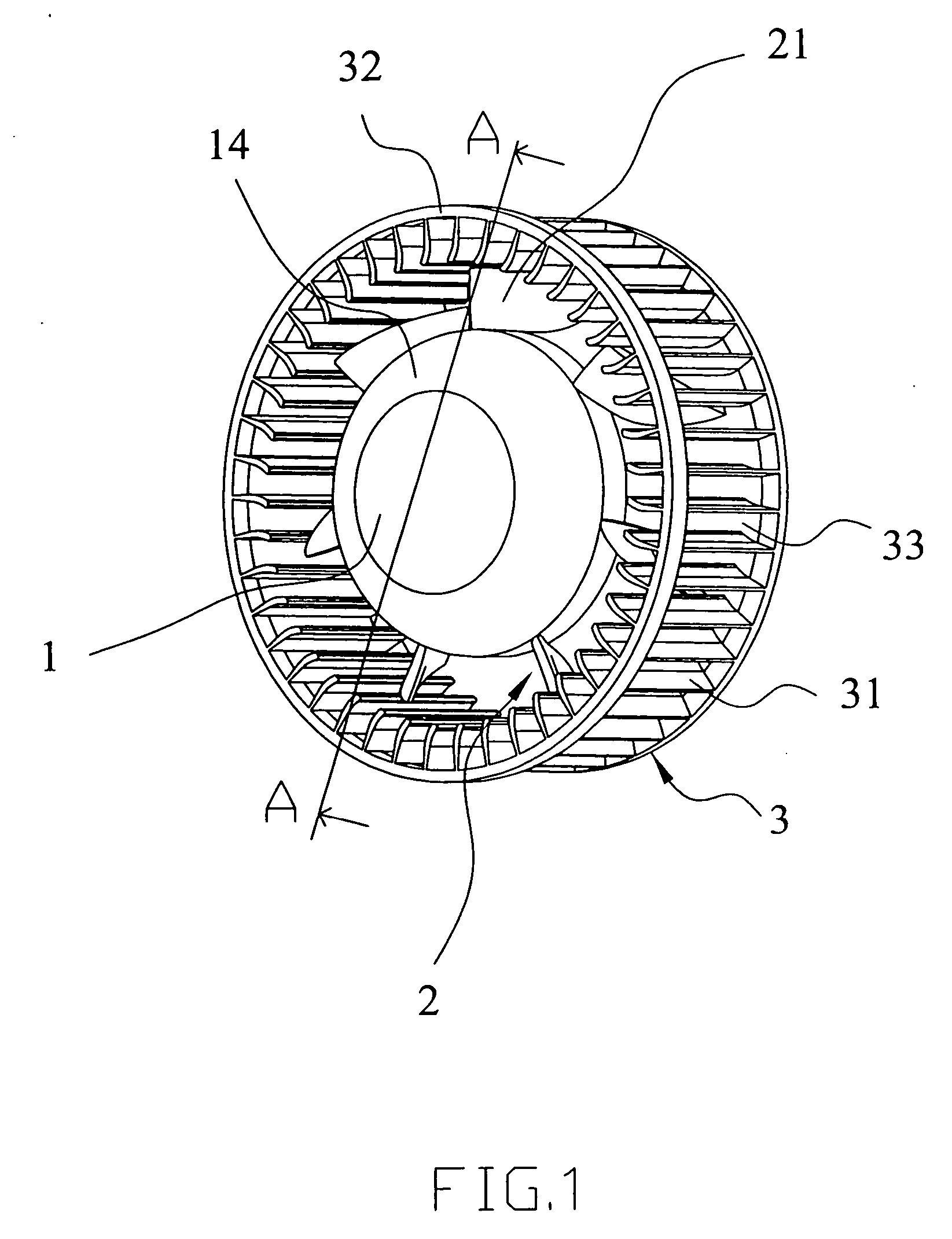

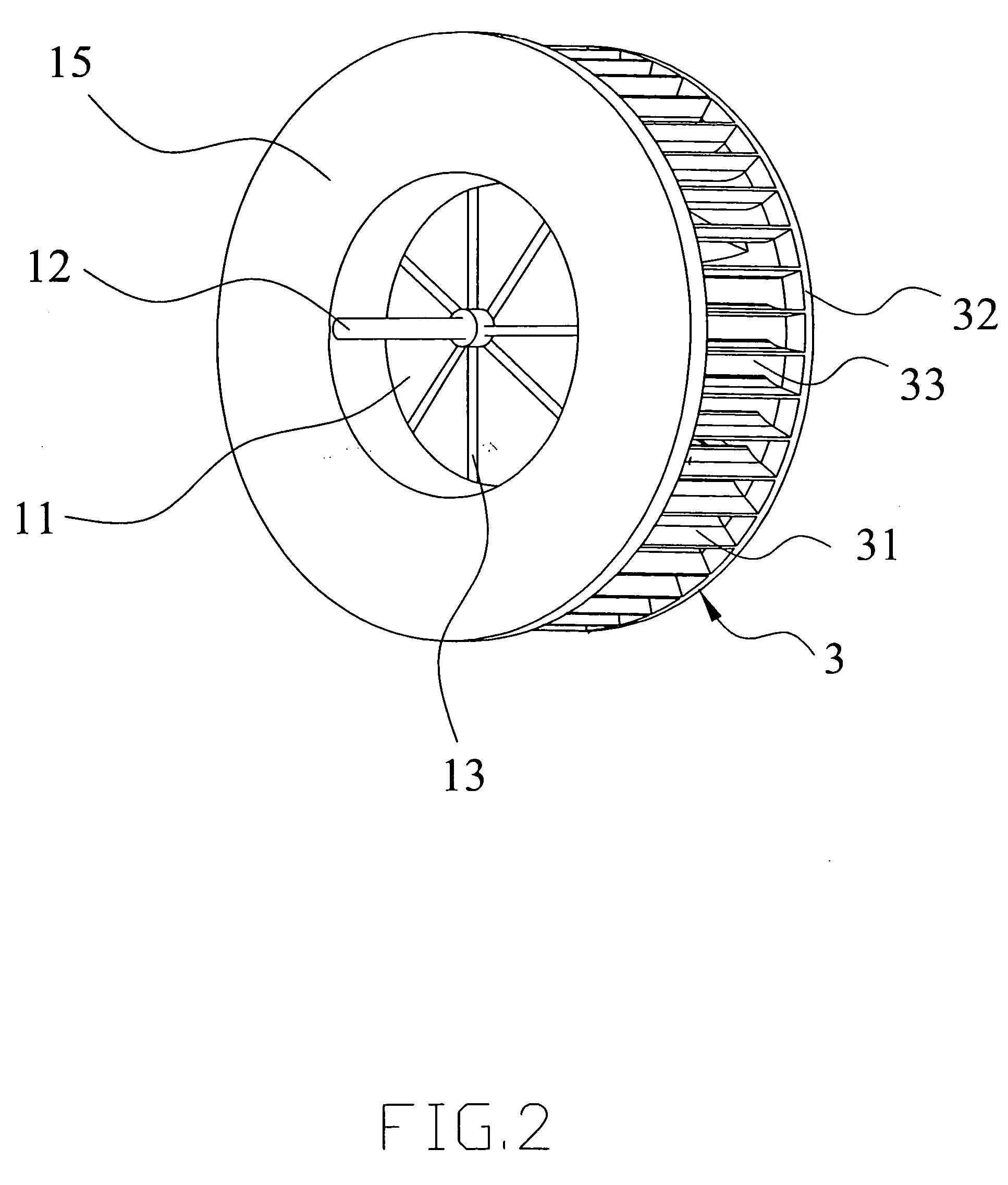

Radial fan having axial fan blade configuration

InactiveUS20060034694A1Improve work efficiencyIncrease wind pressurePropellersRotary propellersEngineeringFan blade

The present invention is a radial fan having an axial fan blade configuration. The present invention comprises a hub; a first set of blades around the hub; and a second set of blades on the extending part. Therein, the hub comprises a hollow at the center, an axle, a guiding part and an extending part. The gaps are each between every two adjacent blades of the second blade set, having the same distance between every two adjacent gaps. The second set of blades comprises a plurality of blades around outside of the first set of blade and a ring connected with the blades. Accordingly, the structure of the blades may increase the wind pressure, reduce the energy loss by the blade rotation and raise the work efficiency of the blades while the noise is lessened and the working current is lowered.

Owner:DATECH TECH CO LTD

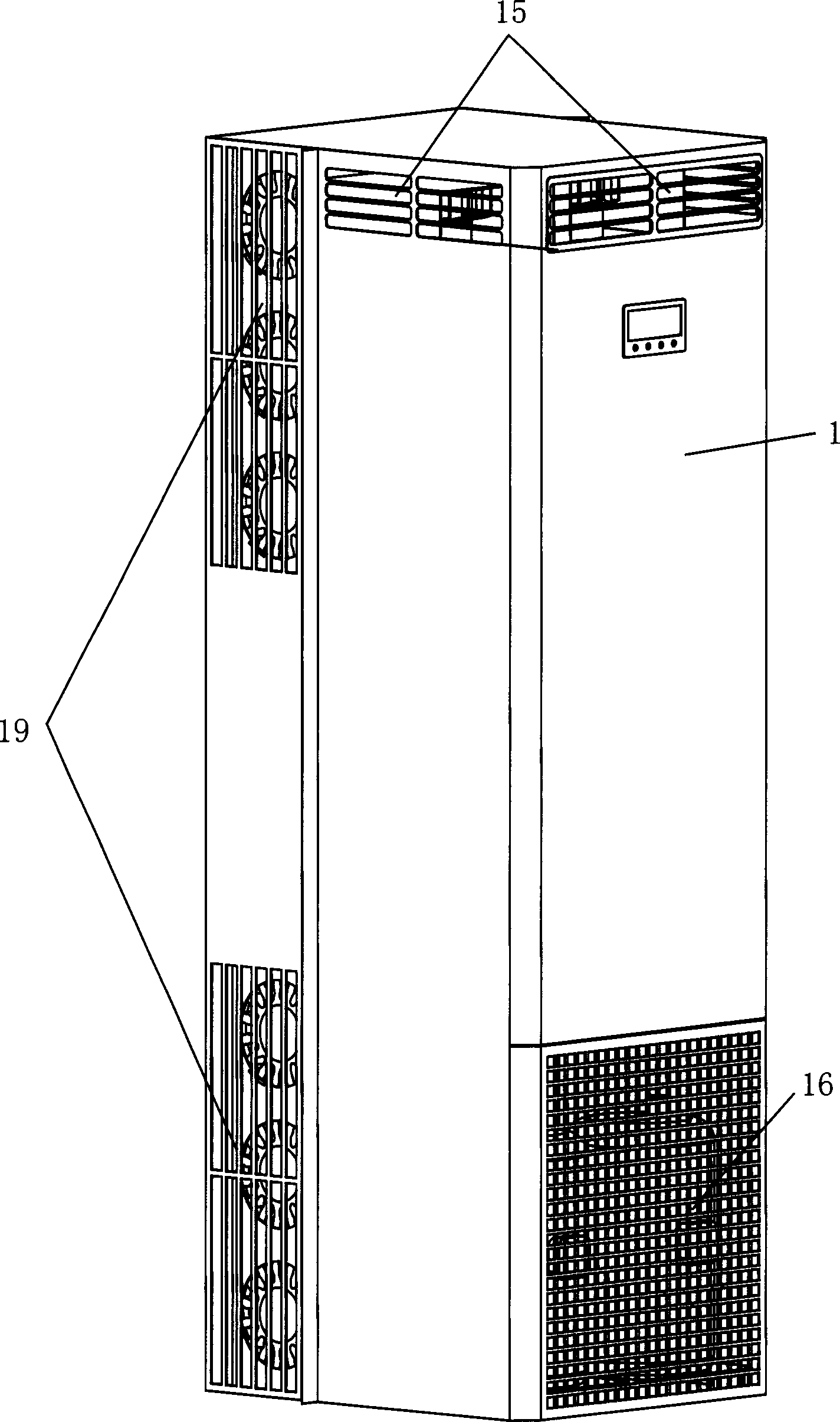

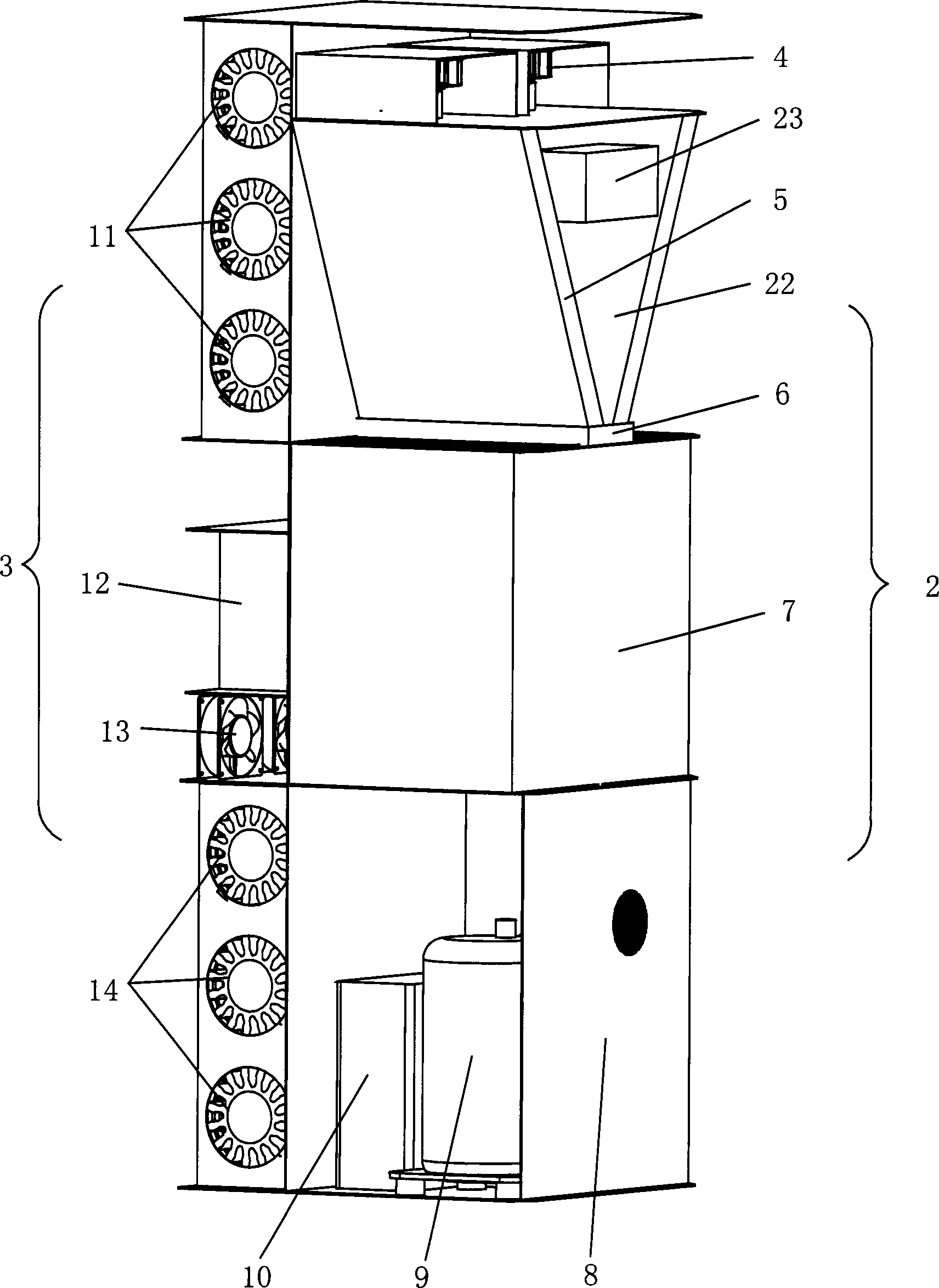

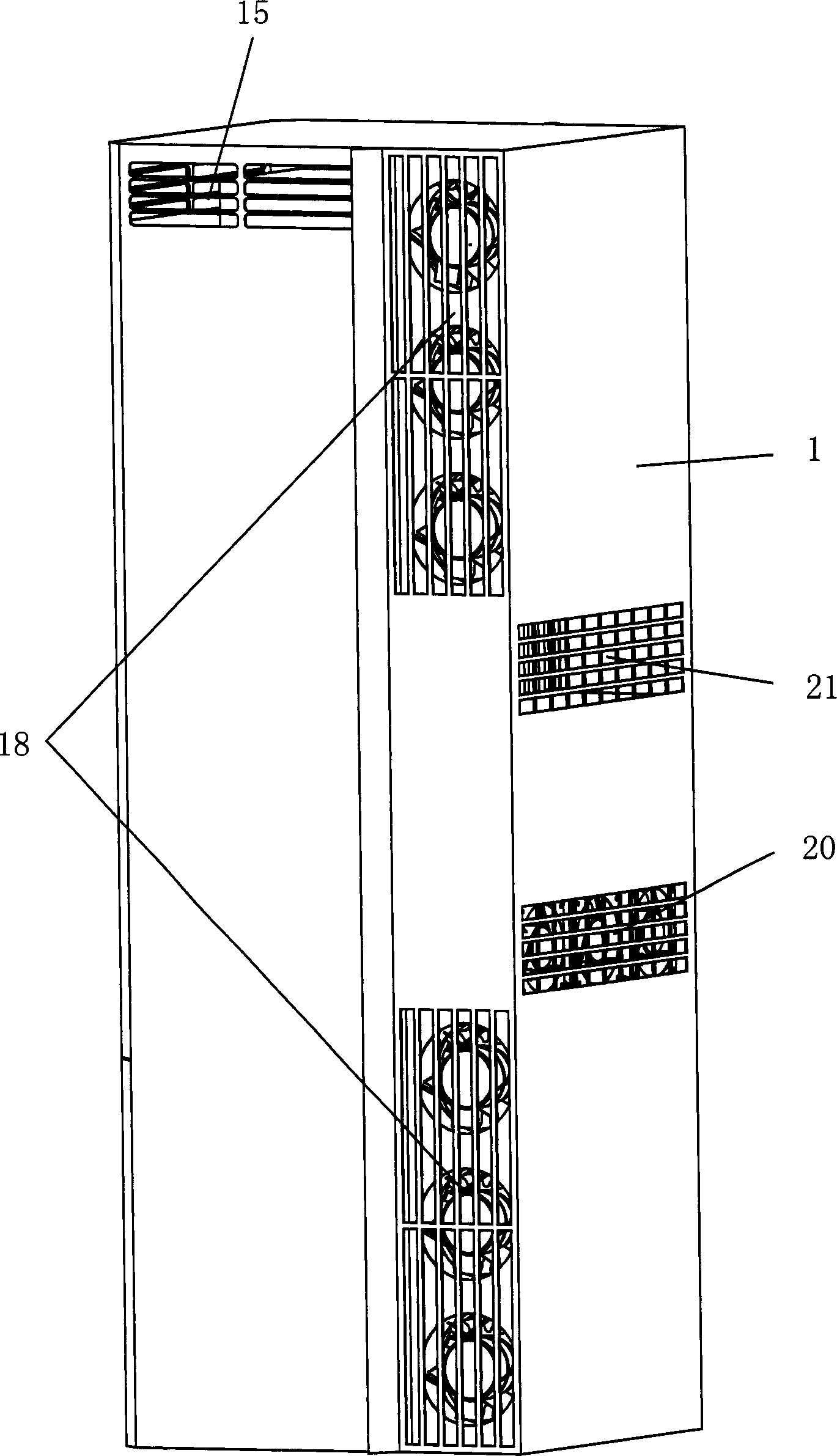

Panel integrated precision air conditioner

InactiveCN1821666ASave spaceNo on-site installation requiredLighting and heating apparatusAir conditioning systemsPlate heat exchangerEngineering

The panel integral precise air conditioner includes one inner unit and one outer unit combined integrally and installed inside the same casing. The inner unit includes inclined disc type blower in the top, evaporator below the blower, water collector in the bottom of the evaporator, air heat exchanger below the water collector, filtering net in the front below the air heat exchanger, and compressor and humidifier behind the filtering net. The outer unit includes the first heat exchanger in the upper part, water tank below the first heat exchanger, axial flow blower below the water tank in the position corresponding to the air heat exchanger, and the second heat exchanger below the axial flow blower. The present invention combines the indoor unit and the outdoor unit integrally, embeds the integral into wall, and has raised refrigerating efficiency, saving in power and convenient installation.

Owner:SUZHOU QUTU THERMAL CONTROL SYST

Blast deflector of fan

InactiveCN1796799AIncrease wind pressureIncrease wind speedPump componentsDigital data processing detailsEngineeringBody region

A flow guide device of fan is prepared as setting an air inlet and an air outlet on hollow flow guide case and setting a guiding body in hollow flow guide case, setting said guiding body at air outlet side to directly face to position of hub for preventing generation of low pressure in guiding body region so as to avoid generation of back flow when said flow guide device is used in coordination with fan.

Owner:FU ZHUN PRECISION IND SHENZHEN +1

Cleaning and energy-saving device for househould air conditioner outer unit condenser

ActiveCN102878624ASimple structureEasy to operateLighting and heating apparatusAir conditioning systemsWater dischargeEvaporation

A cleaning and energy-saving device for a househould air conditioner outer unit condenser comprises a condenser pipe in an air conditioner outer unit, wherein a blowing-type axial flow fan is arranged on the inner side of the condenser pipe, a condensed water distribution pipe is arranged at the upper part of the space between the condenser pipe and a fan, one end of the condensed water distribution pipe is a blind pipe, the other end of the condensed water distribution pipe is connected with an air conditioner condensed water discharge pipe, a three-way pipe is connected onto an indoor pipe section of the condensed water discharge pipe, the condensed water discharge pipe is communicated with a water receiving tray, atomization spray holes which are uniformly distributed are formed in the lower positions of the water distribution pipe, which are close to a condenser pipe side, so that the condensed water is uniformly sprayed onto the heat exchange fins of the condenser pipe, and the gasification latent heat which is generated by water evaporation is utilized for enhancing heat exchange. When the air conditioner normally works, the condensed water can be guided to the water distribution pipe and is sprayed onto the heat exchange fins for enhancing heat exchange; and when the condenser water is cleaned, and a close cover of an opening end of the three-way pipe is opened to be filled with clean water or is connected with tap water, and is matched with the fan for cleaning the condenser pipe. The device has the characteristics of simplicity in structure, convenience in use, low cost and convenience in popularization.

Owner:DONGYING JINYILAI PETROLEUM MACHINERY

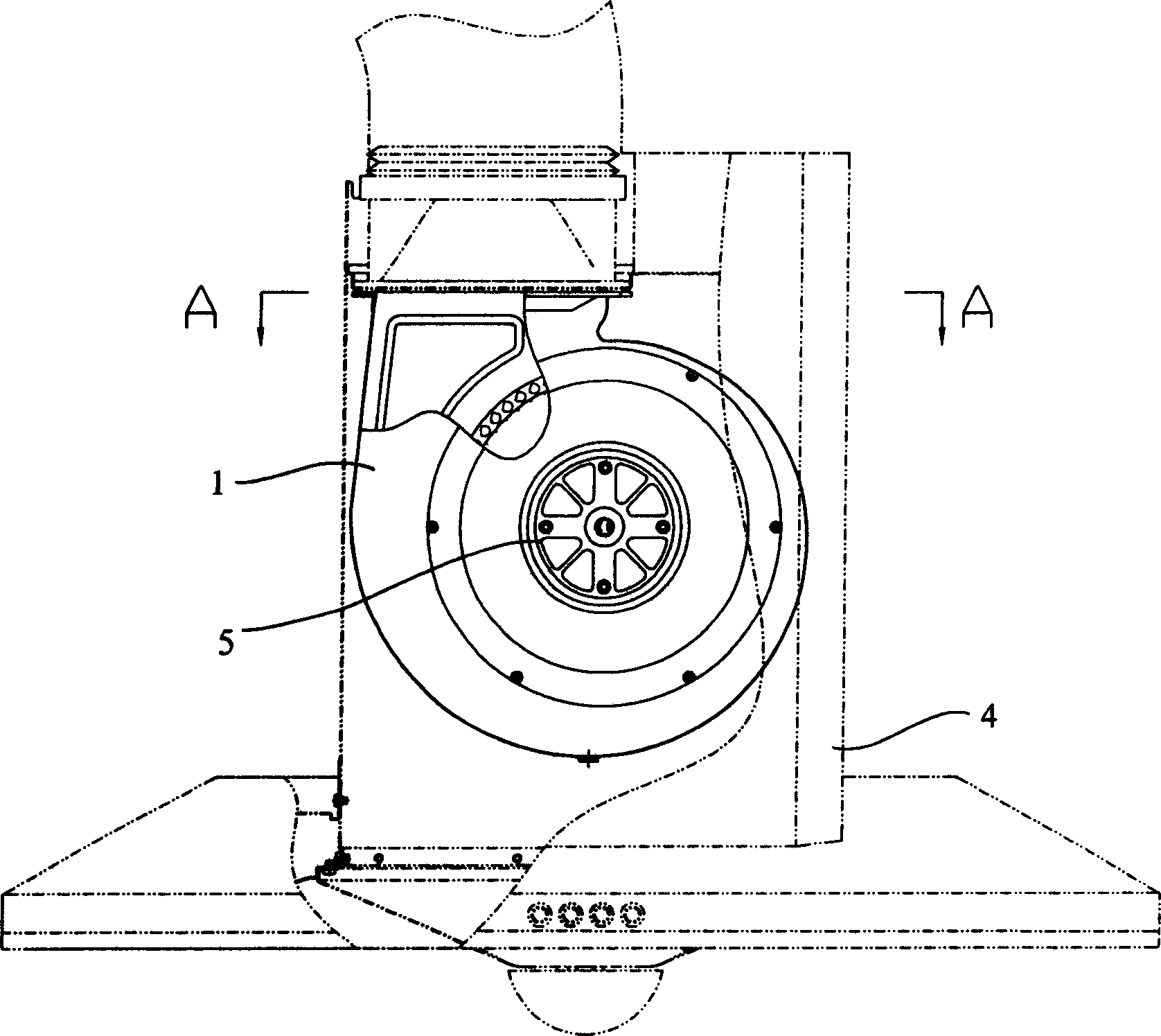

Sheet feeding device and image forming apparatus

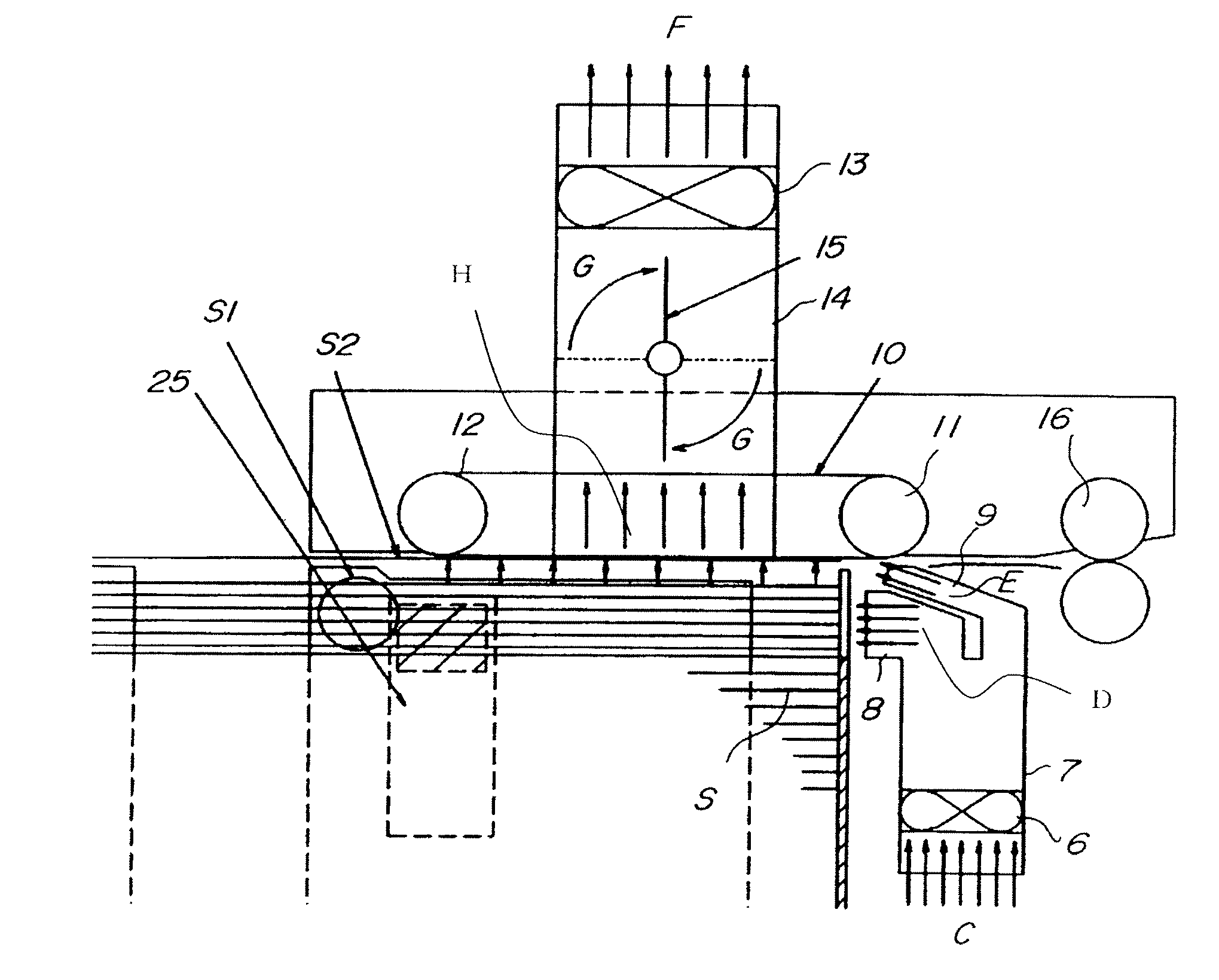

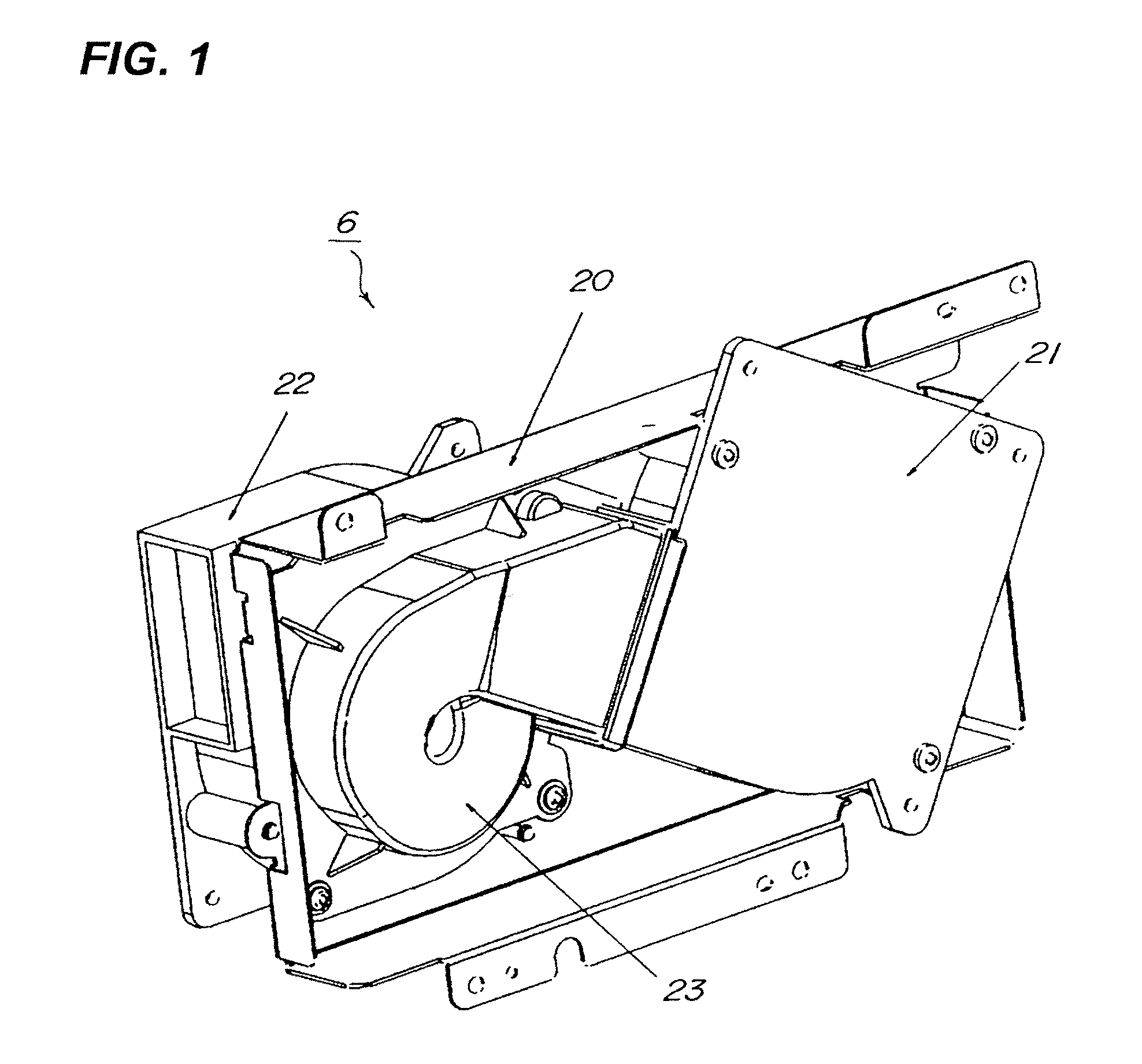

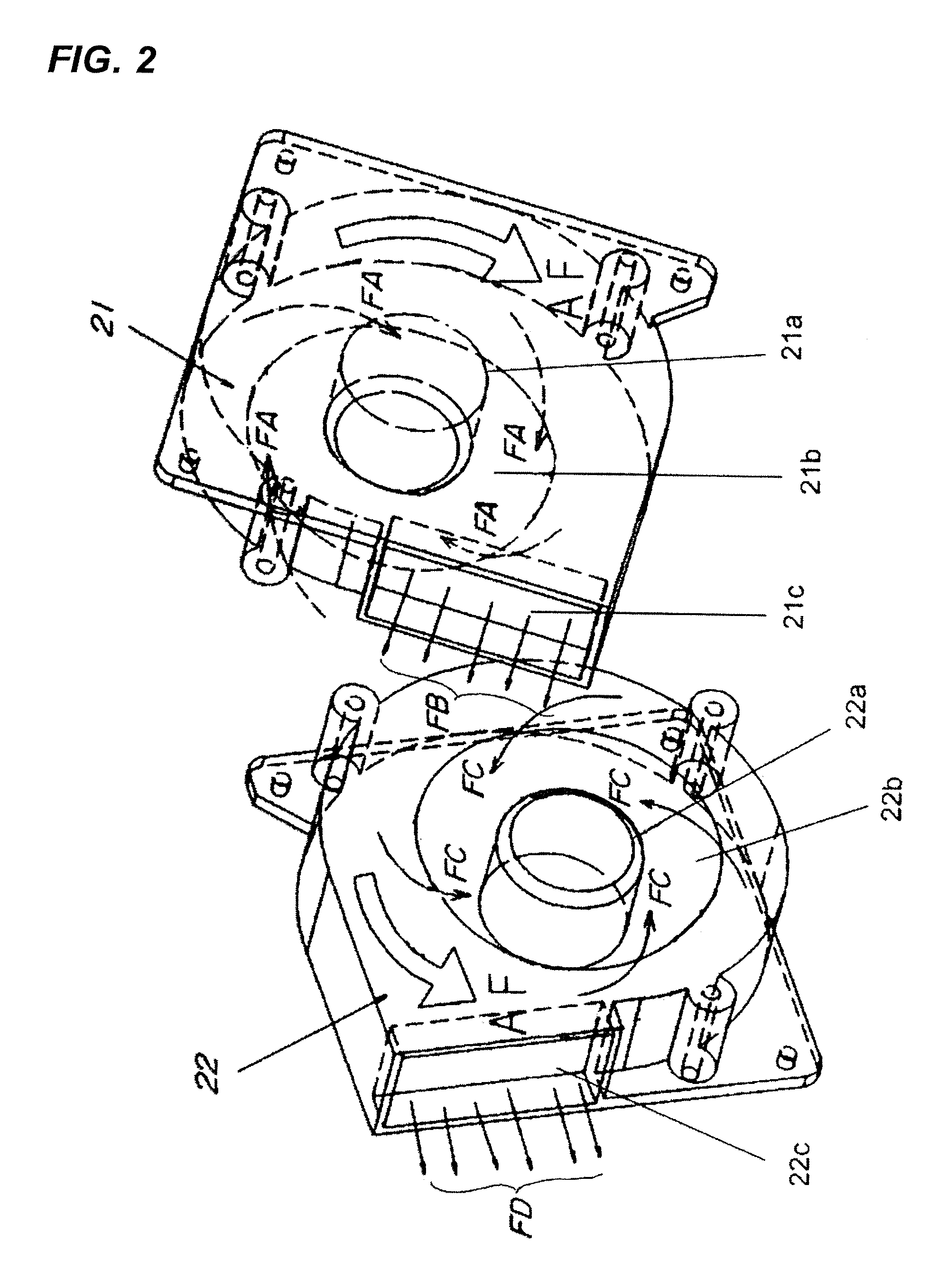

ActiveUS7380781B2Securely looseningAvoid it happening againFunction indicatorsPump installationsEngineeringSpiral flow

A sheet feeding device which blows air to placed sheets, separates and conveys the sheets includes a sheet containing portion which contains the sheets, an air blowing portion which blows air to the sheets contained in the sheet containing portion, and an air supply unit which supplies air to the air blowing portion. The air supply unit is constituted by connecting two or more centrifugal fans, and the air blown out from an upstream side fan in an air flow passage is sucked by an adjacent downstream side fan via a spiral flow passage.

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com