Heat dissipation device which is pre-built with an air vent structure

a technology of air vents and heat dissipation devices, which is applied in the direction of basic electric elements, semiconductor devices, lighting and heating apparatus, etc., can solve the problems of low cost of dissipation devices, slow heat conduction rate, and low operation speed, and achieve the effect of beautiful appearan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

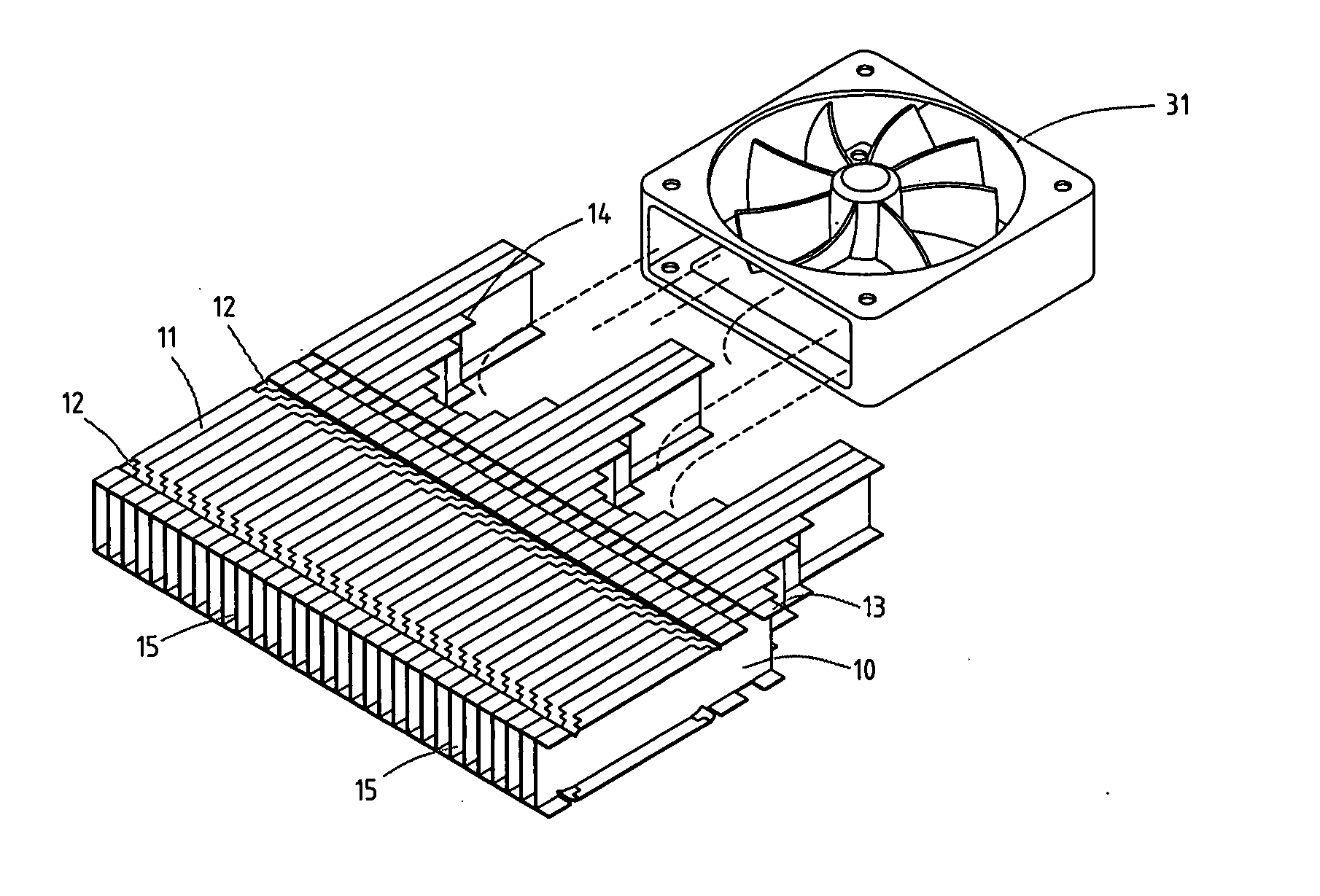

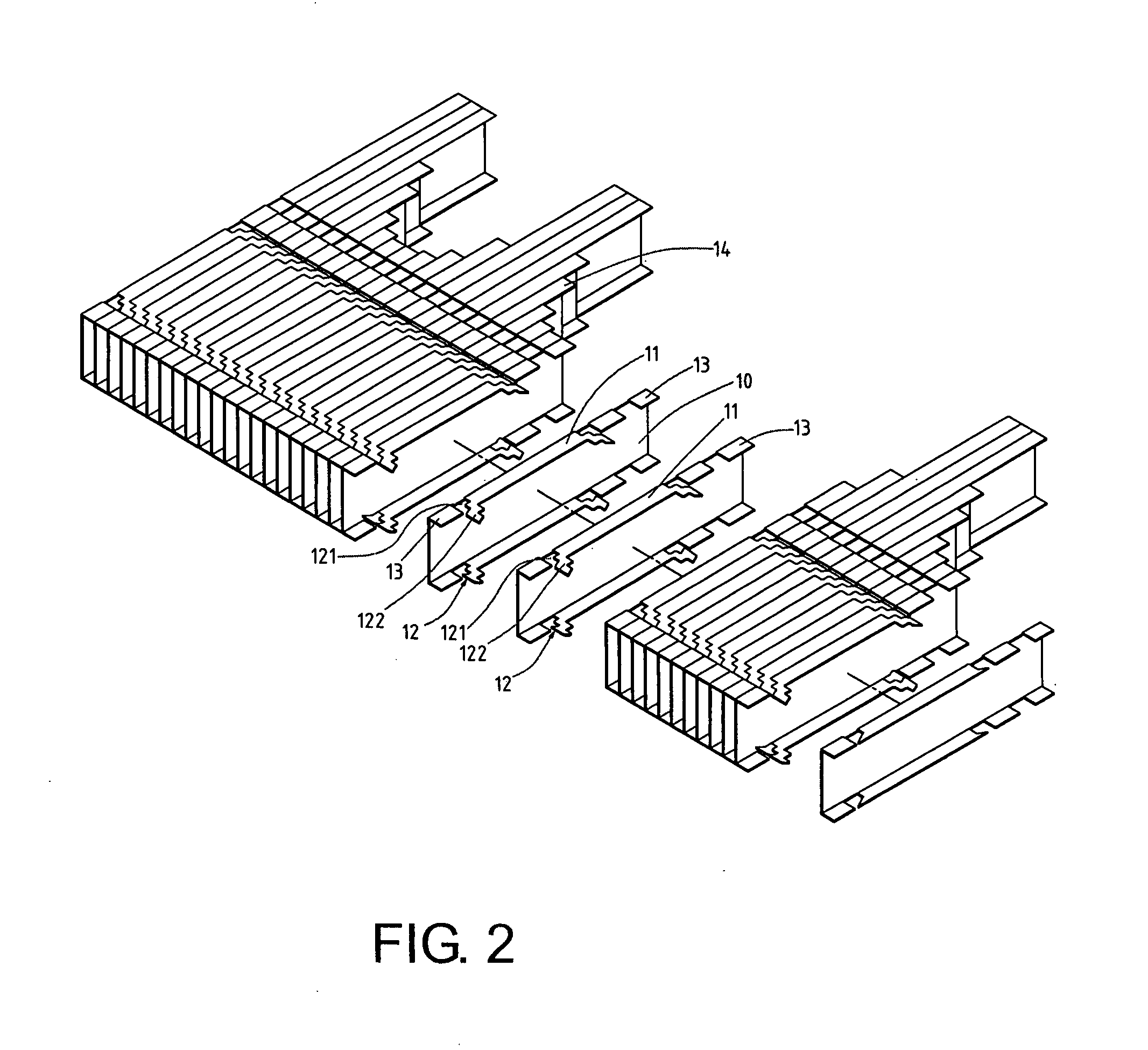

[0019]Referring to FIG. 2, it shows an exploded view of a preferred embodiment of the present invention, wherein a cooling fin 10 is a thin plate formed by punching, a top and bottom rim of the cooling fin 10 are bended horizontally with heat transmission wings 11, and each heat transmission wing 11 is provided with a locking part 12 constituted by a locking slot 121 and a locking hook 122, with the locking slot 121 being extended forward with the locking hook 122. A bended part of the locking hook 122 is formed with an inverted hook, such that the cooling fins 10 can be assembled forward and backward into a cooling fin set, without dropping off. When the cooling fins 10 are formed by punching, a length of each piece can be configured in advance, meaning that upon punching, a fin of different length can be formed by extending respectively from a left and right side of the locking part 12, allowing each cooling fin 10 to be formed with an extension section 13 of different length. Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com