Patents

Literature

39results about How to "Forward rotation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

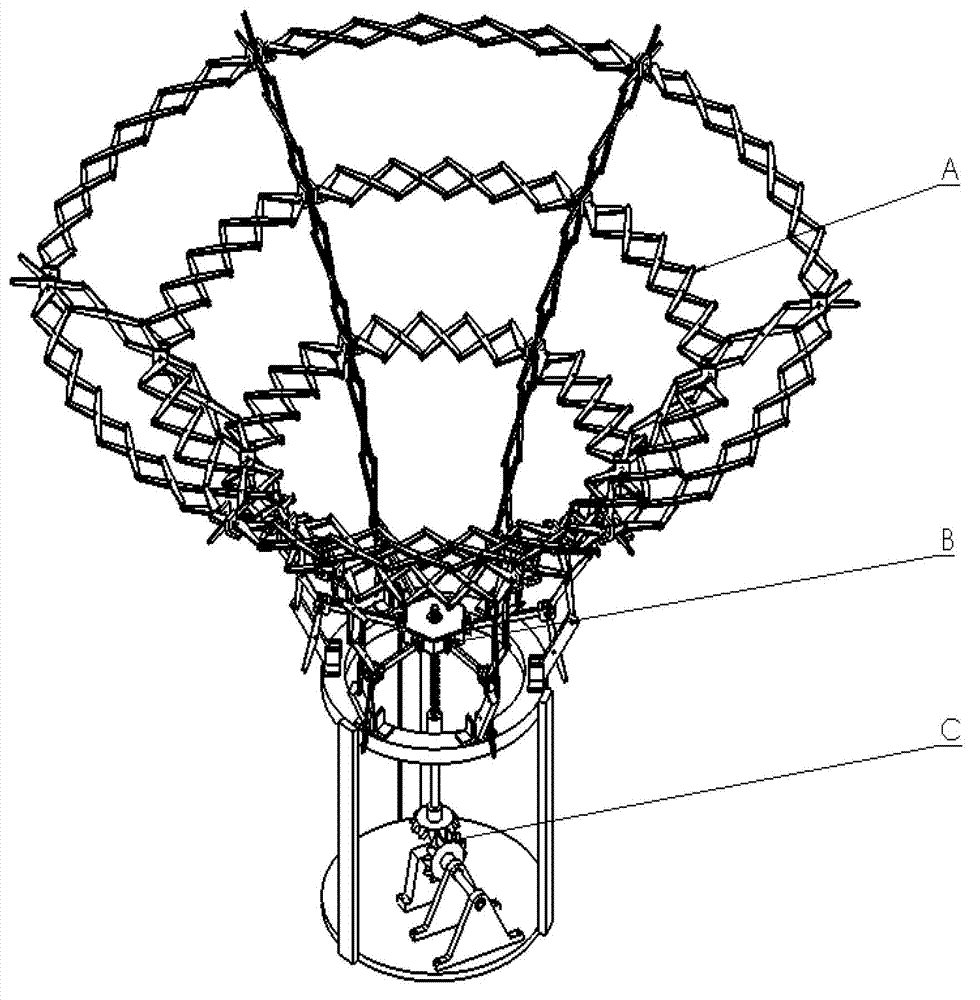

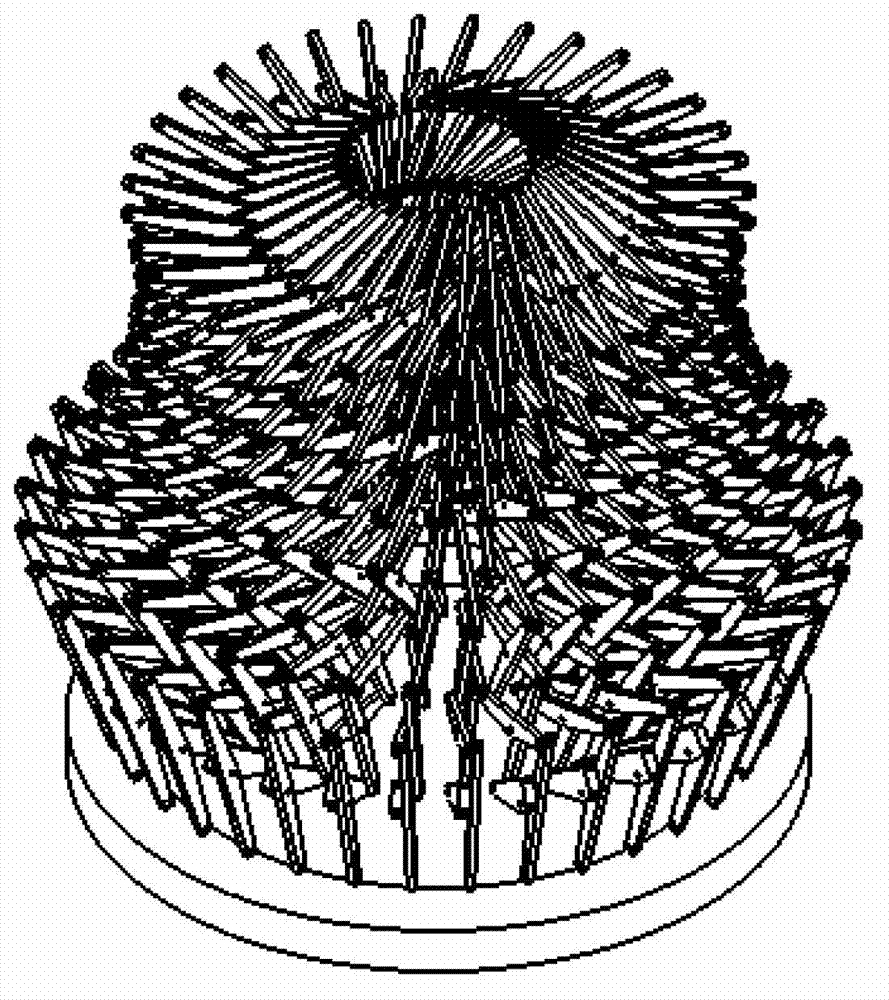

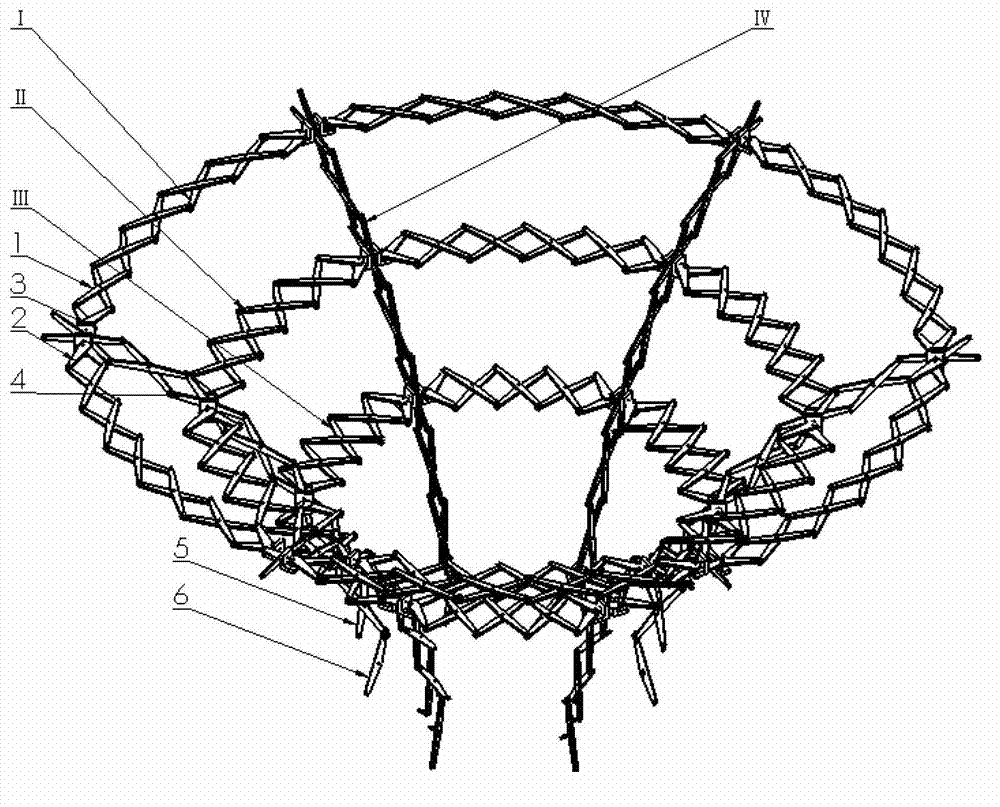

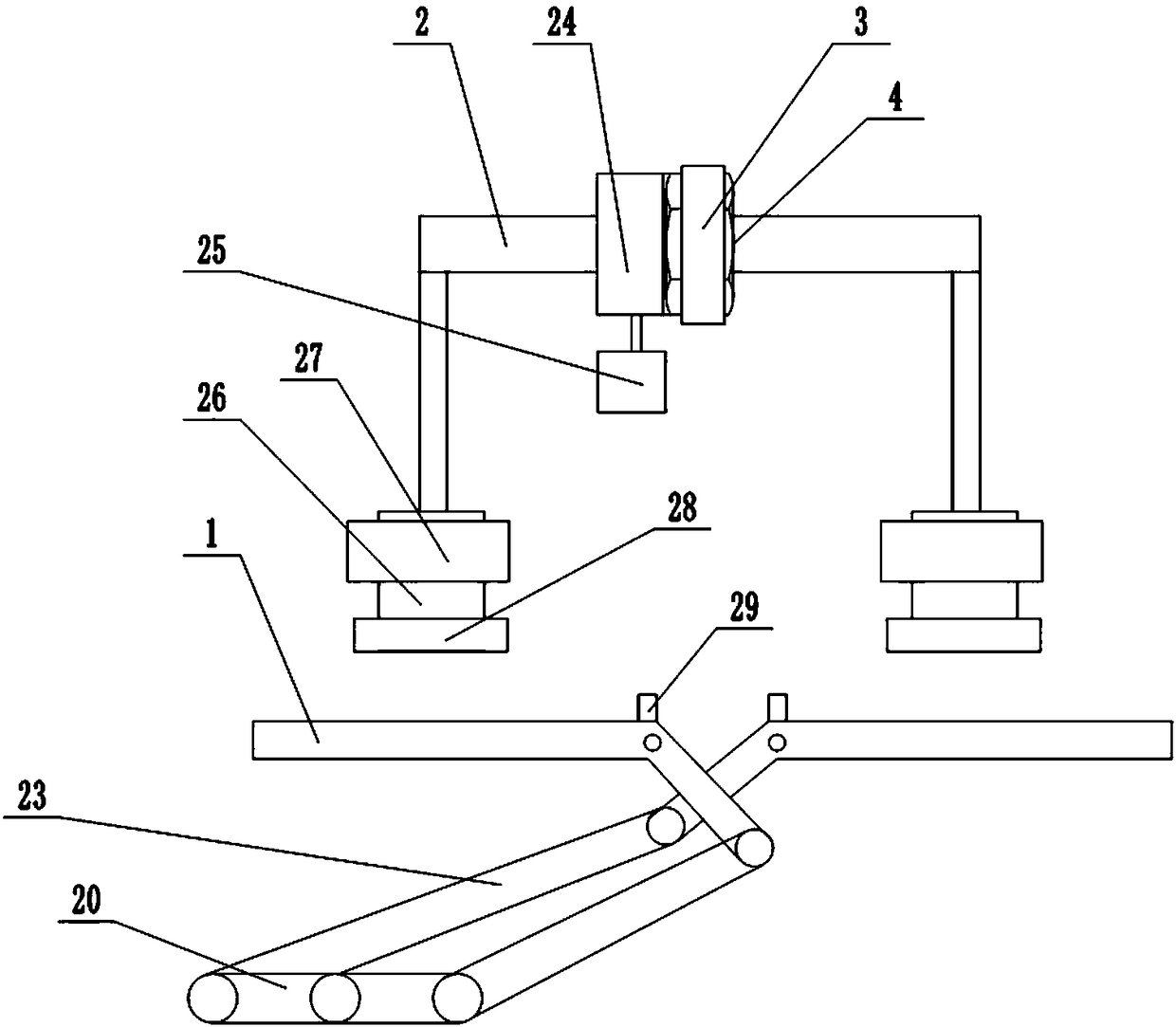

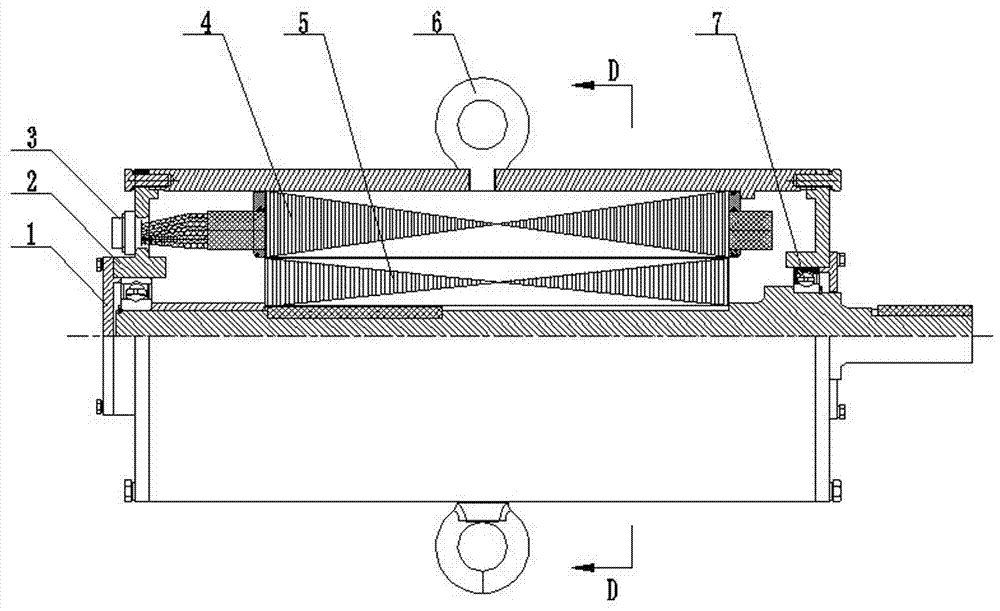

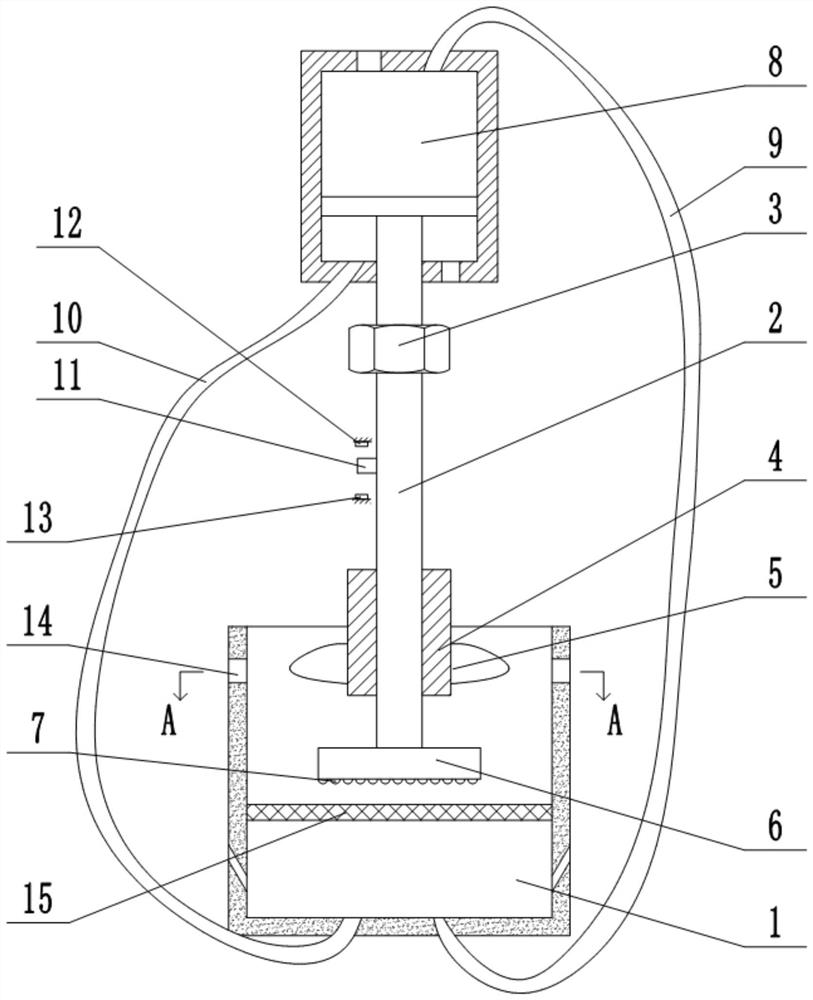

Scalable novel deformed lamp

ActiveCN103090232AForward rotationAchieve reversalSpecial ornamental structuresElectric lightingCouplingDrive motor

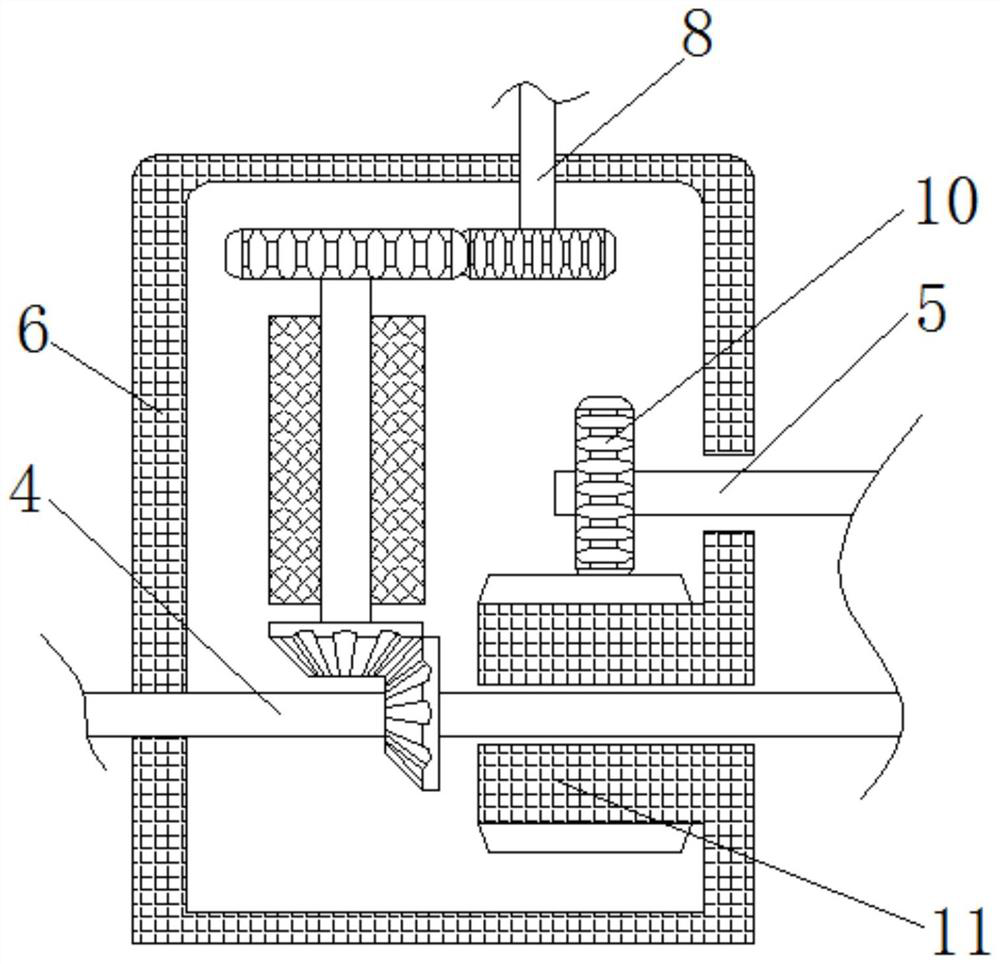

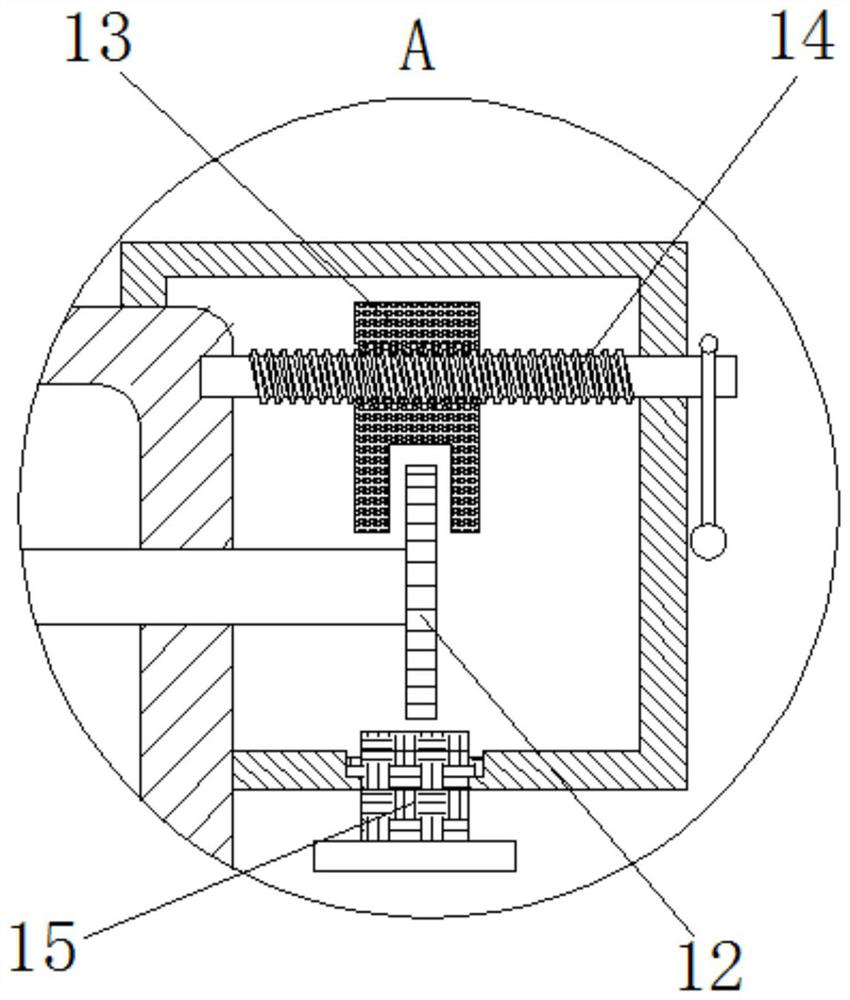

The invention provides a scalable novel deformed lamp which comprises a rod group part A, a drive part B and a motive power input part C, wherein the rod group part A is connected with the drive part B through a revolute pair formed by a rod (6) and a support rod (8). A rod (5) and the rod (6) on a rod group (IV) of the rod group part A are respectively connected with a rod (7) and the connections form a parallelogram. The shape of the parallelogram is the same with shapes of the other parallelograms formed on the rod group (IV), the rod (7) and the vertical direction form an included angle, and the shape of the whole lamp can be adjusted through the included angle. The drive part B and the motive power input part C are connected with a coupler (14) through a lead screw. The rod group part A of the lamp is a dimensional circular arc camber, a main body of the lamp is formed by the camber, and a bulb of the lamp can be positioned on each rod piece. Scale deformation of the lamp is divided into two conditions of contraction and unfolding, degrees of the contraction and the unfolding are controlled by time of positive and negative rotating of a drive motor, and the overall shape of the lamp is flowerlike.

Owner:BEIJING JIAOTONG UNIV

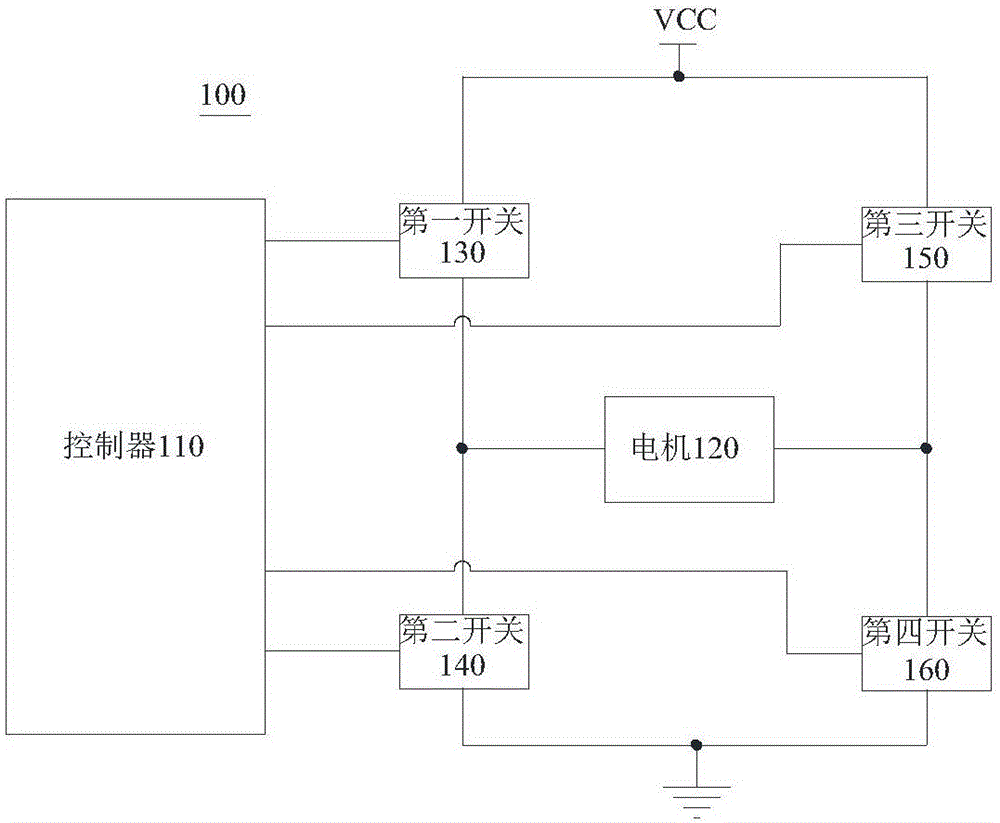

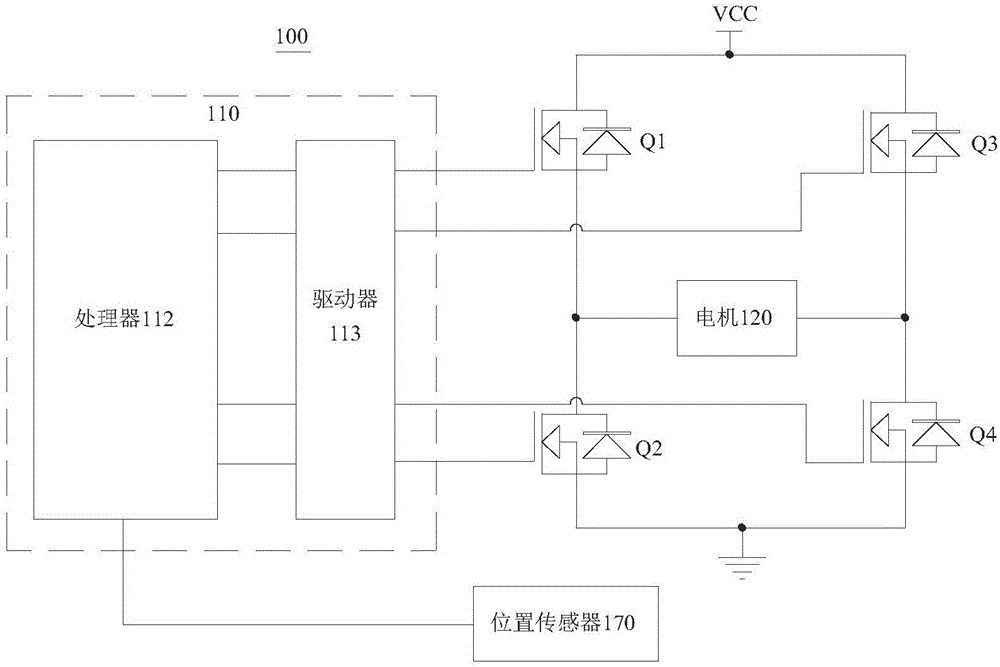

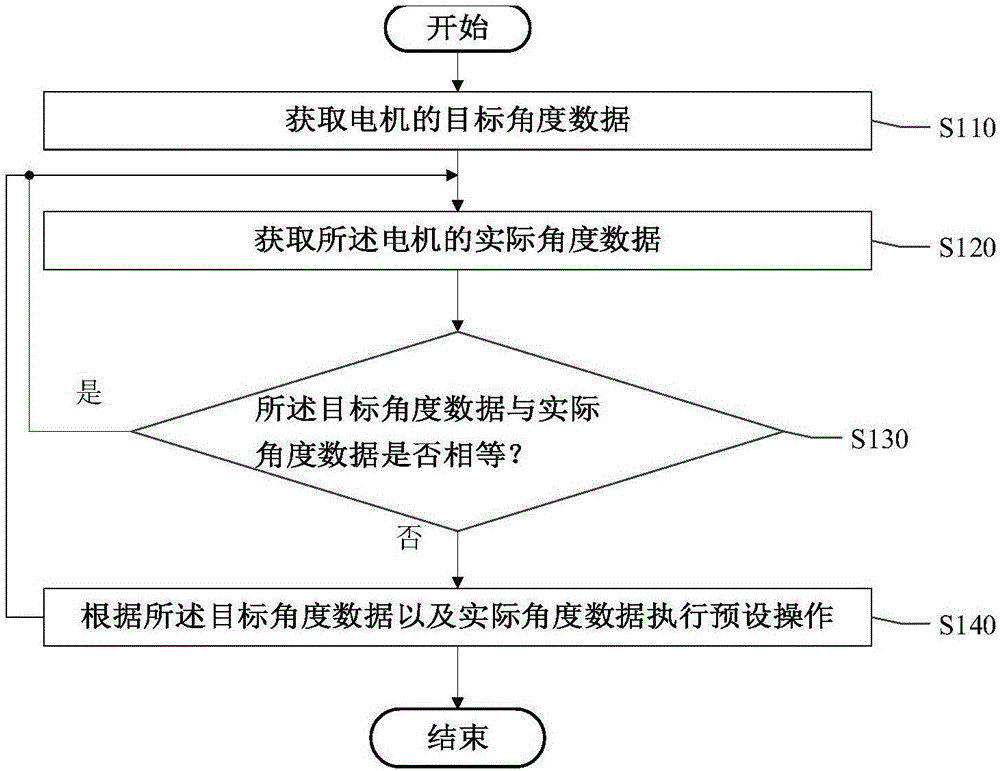

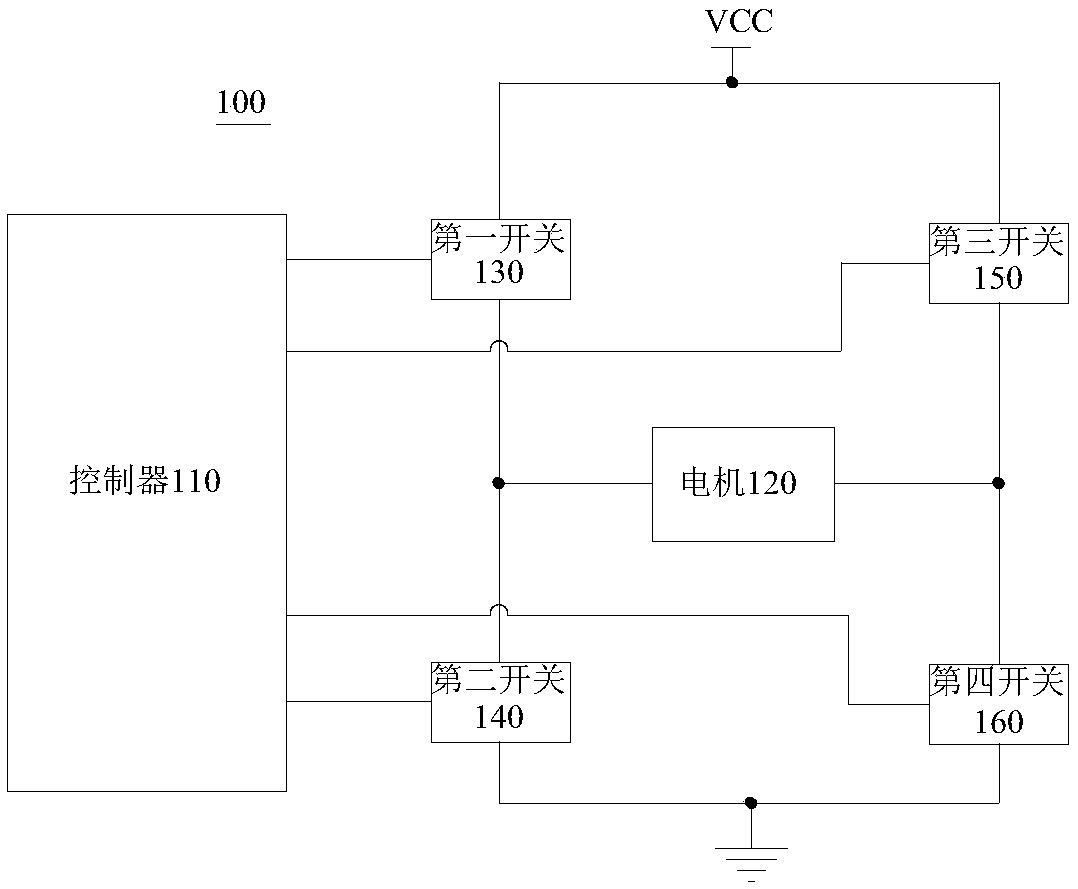

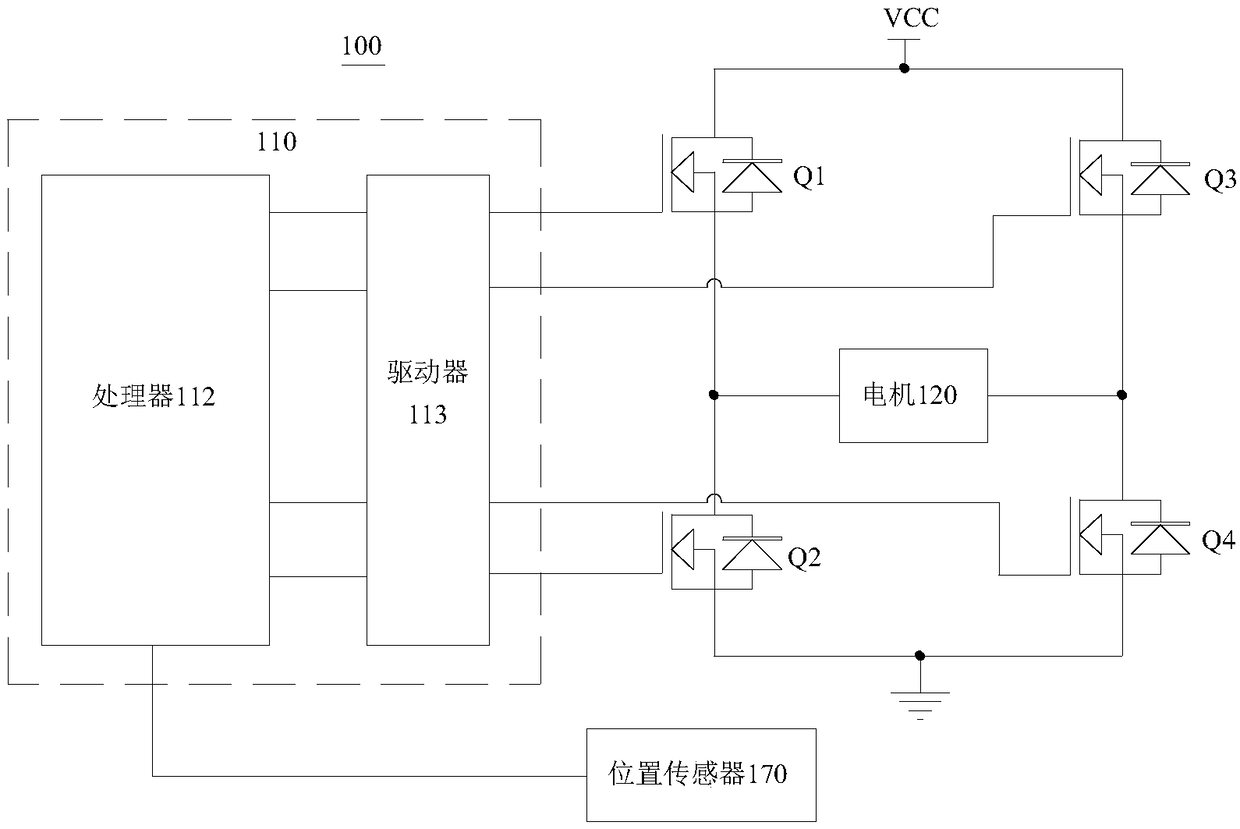

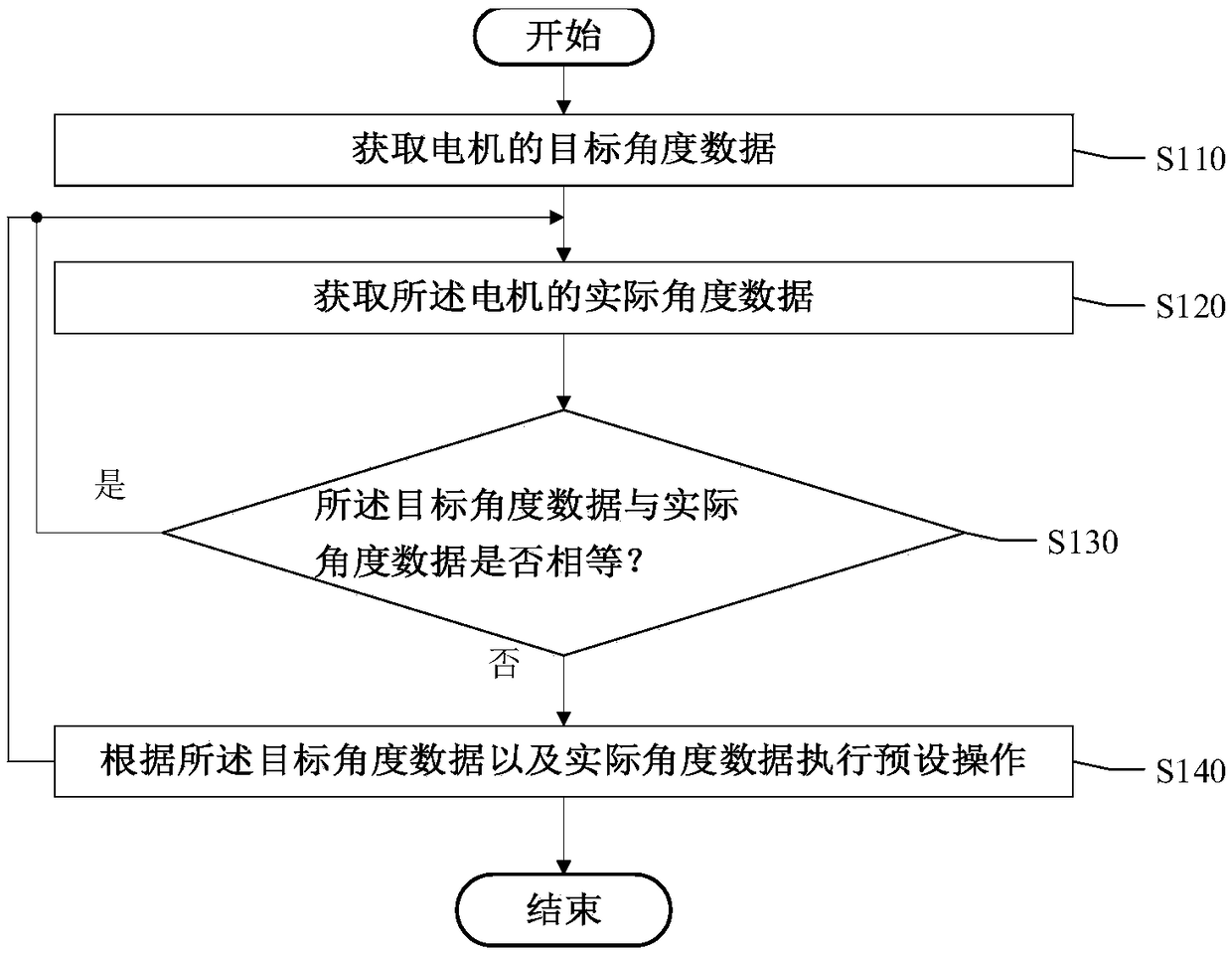

Motor angle control method, motor angle control system and unmanned aerial vehicle

ActiveCN106385209AForward rotationAchieve reversalDC motor rotation controlControl systemUncrewed vehicle

A motor angle control method provided by an embodiment of the invention comprises the following steps: a controller acquires the target angle data of a motor and the actual angle data of the motor; the controller judges whether the target angle data and the actual angle data are equal; and if the target angle data and the actual angle data are not equal, the controller processes the target angle data and the actual angle data, and switches on a first path coupled to the motor to make the motor rotate forwardly or switches on a second path coupled to the motor to make the motor rotate reversely according to the processing result. According to the motor angle control method, a motor angle control system and an unmanned aerial vehicle provided by the embodiments of the invention, the first path or the second path coupled to the motor can be controlled according to the values of the target angle data and the actual angle data of the motor so as to realize forward or reverse rotation of the motor. Compared with the existing motor angle control method, the control process is simple, and the precision of motor control is improved.

Owner:ZEROTECH (SHENZHEN) INTELLIGENCE ROBOT CO LTD

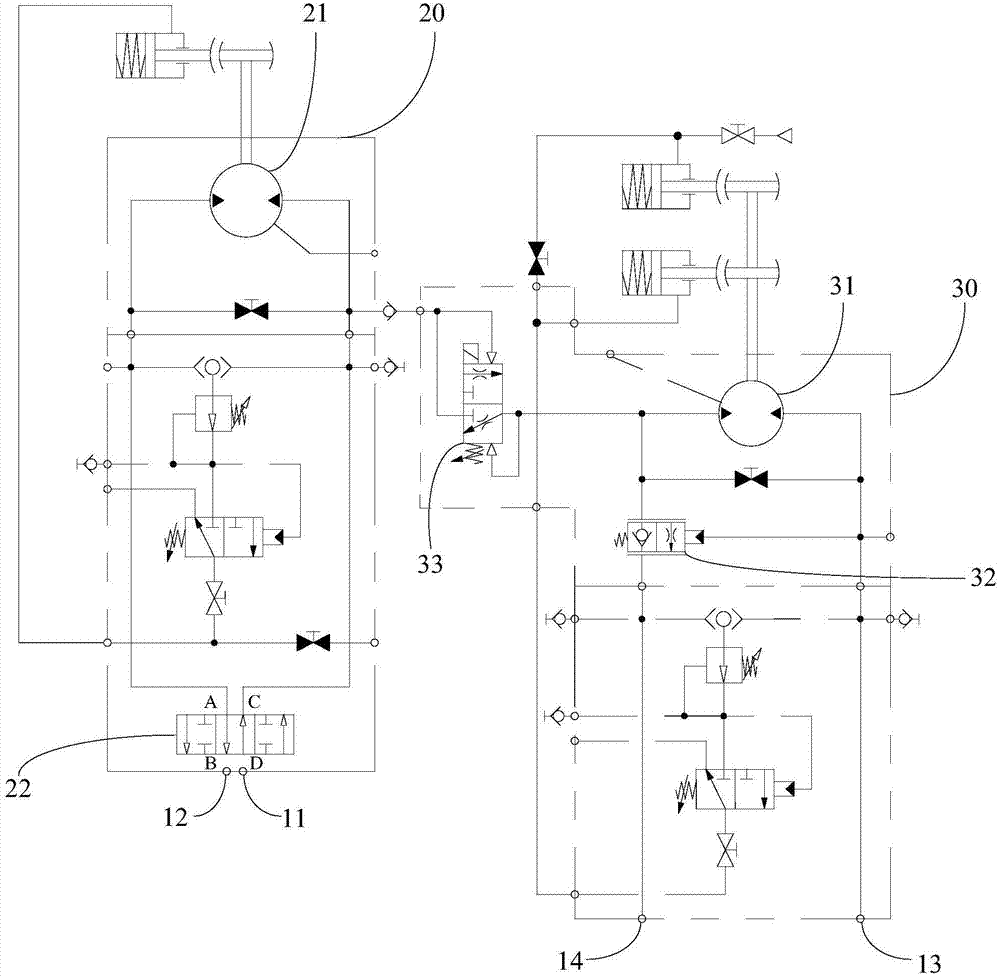

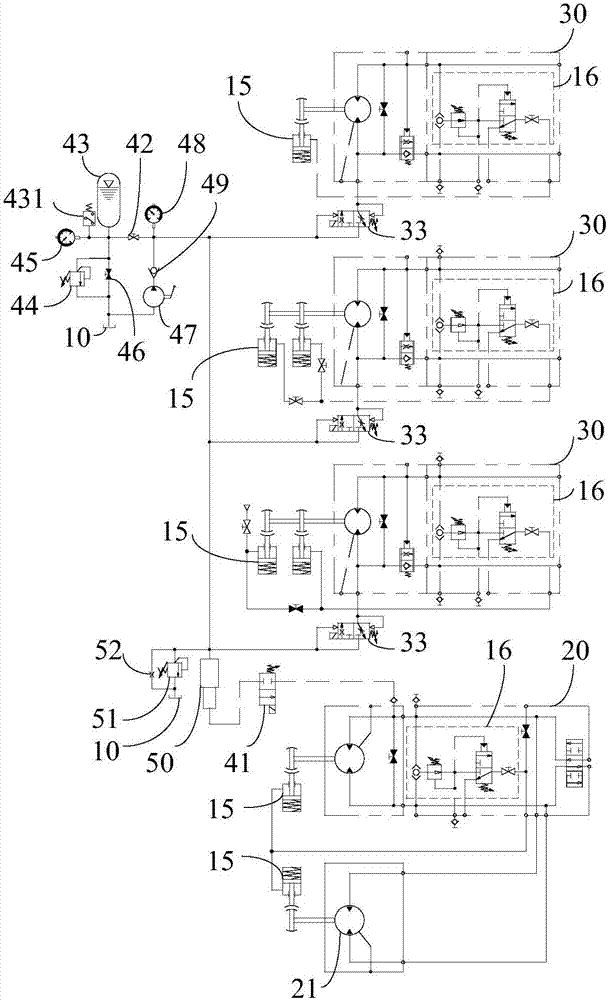

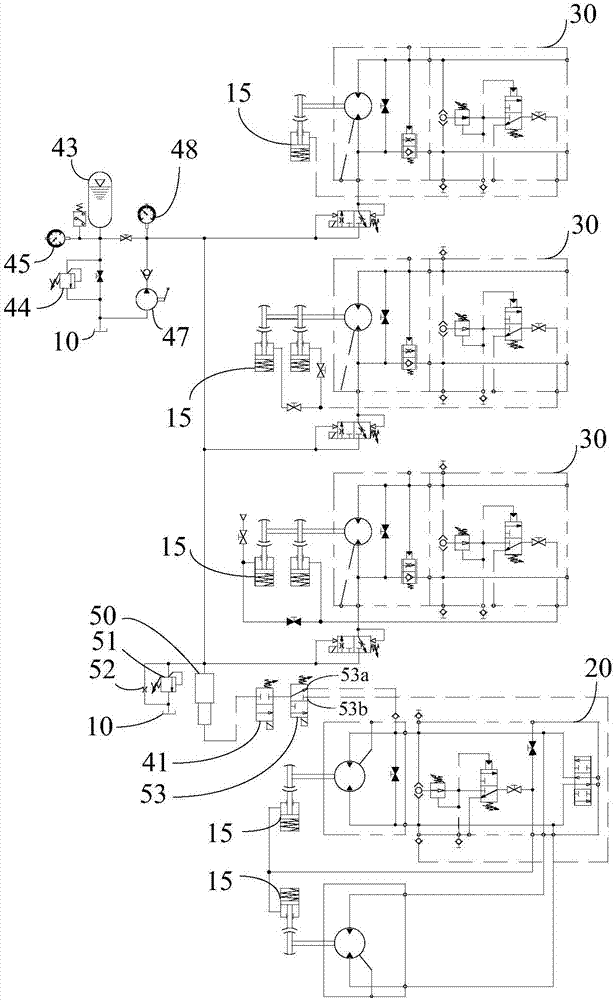

Hydraulic control system of crane

ActiveCN107117534AForward rotationAchieve reversalServomotor componentsServomotorsHydraulic motorControl system

The invention discloses a hydraulic control system of a crane, and belongs to the field of hydraulic control. The hydraulic control system comprises a rotation valve set and a winch valve set; the rotation valve set comprises a rotation hydraulic motor used for driving the crane to rotate and a first control valve, the winch valve set comprises a winch hydraulic motor, a second control valve and a reset control valve, a second oil port of the winch hydraulic motor is communicated with a first oil port of the reset control valve, a second oil port of the reset control valve is communicated with a first oil port or second oil port of the rotation hydraulic motor, the winch hydraulic motor is used for driving a main ascending mechanism, an auxiliary ascending mechanism or amplitude variation mechanism of the crane so as to enable hydraulic oil in a pipeline of the winch valve set to be pressed into the rotation hydraulic motor under the pressure effect, so that the rotation hydraulic motor is driven to rotate, a rotating table is driven to be reset, meanwhile, the rotation hydraulic motor rotates, heavy objects or lifting arms gradually descend under the gravity effect, and resetting is finished.

Owner:WUHAN MARINE MACHINERY PLANT

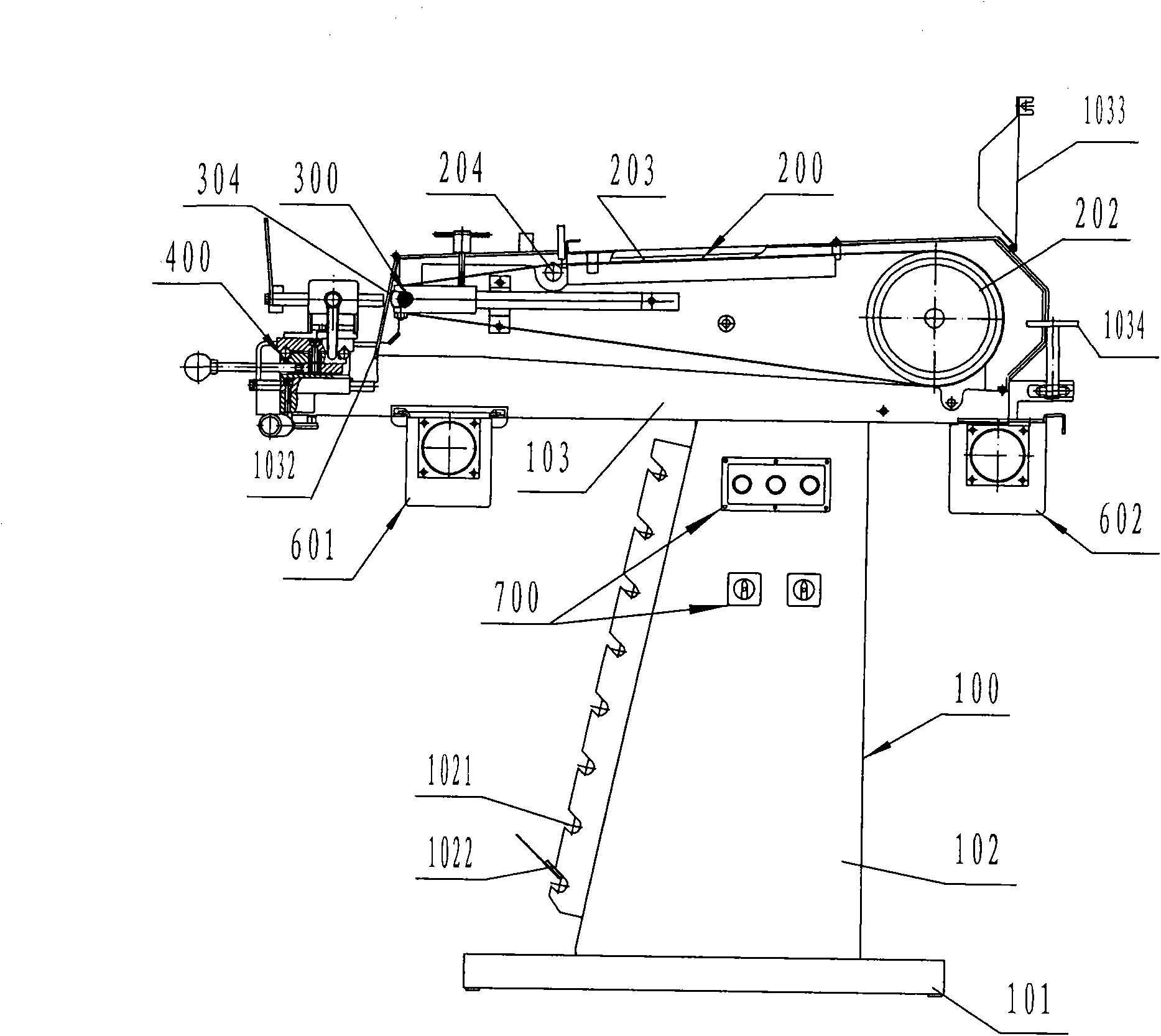

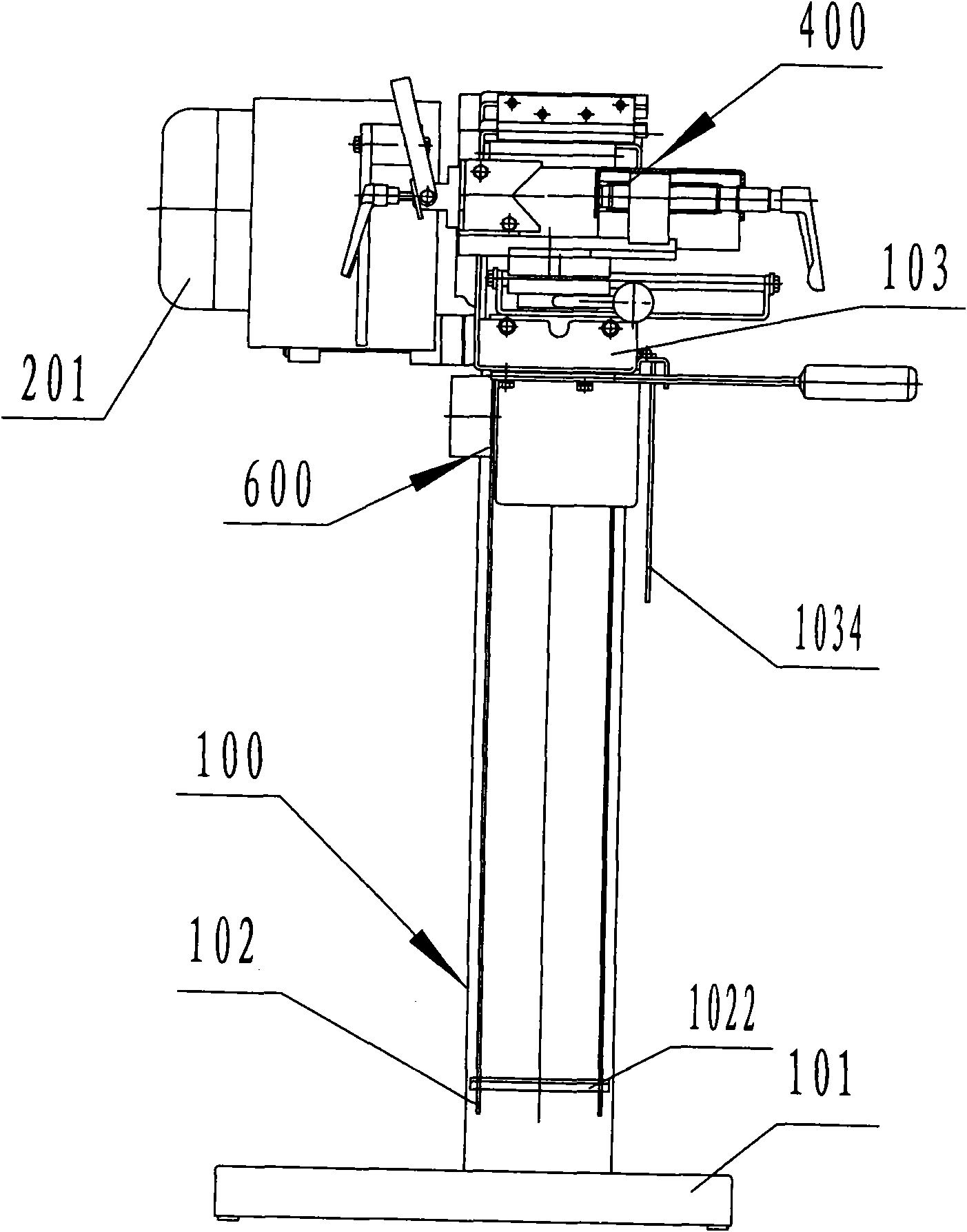

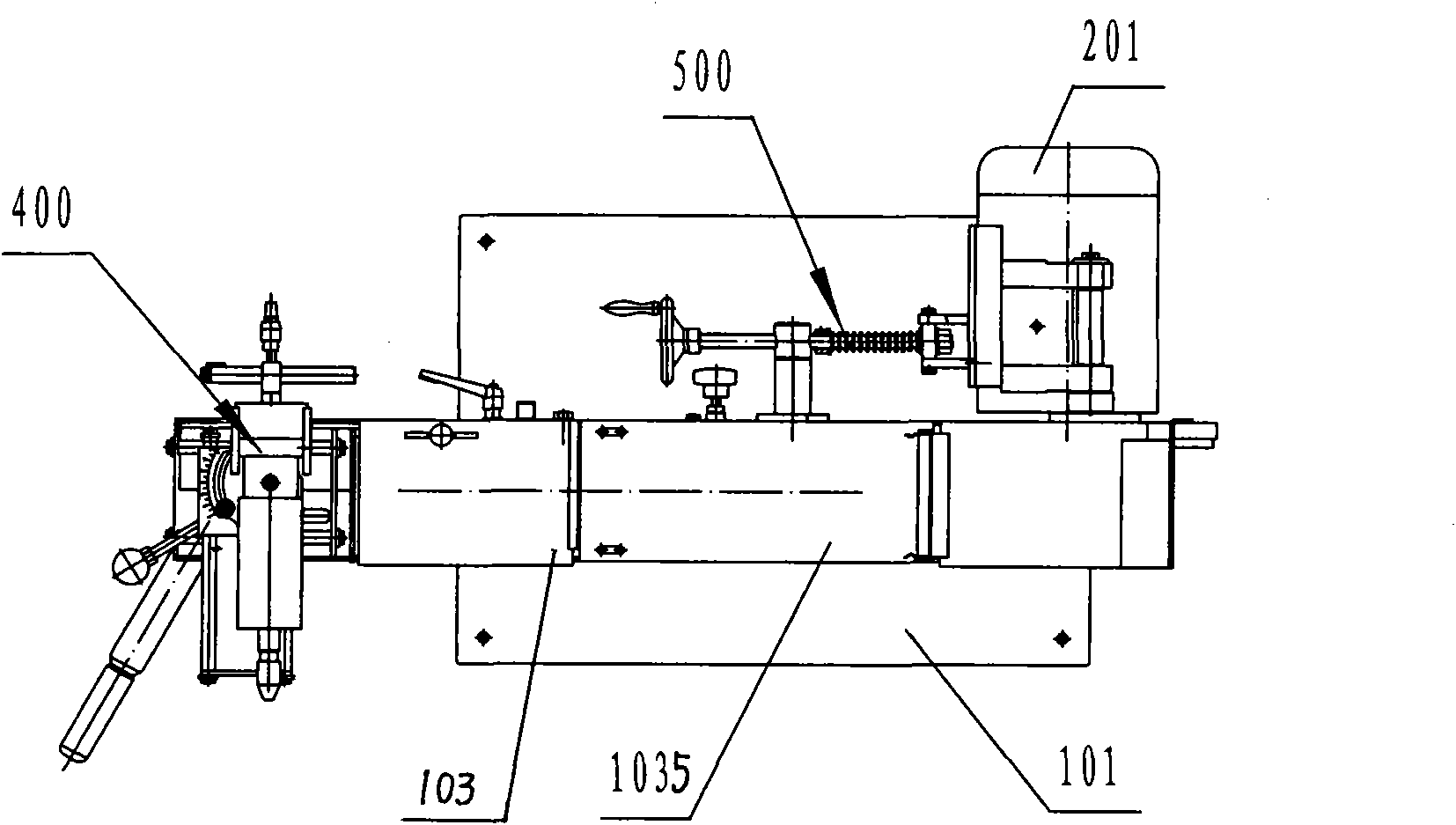

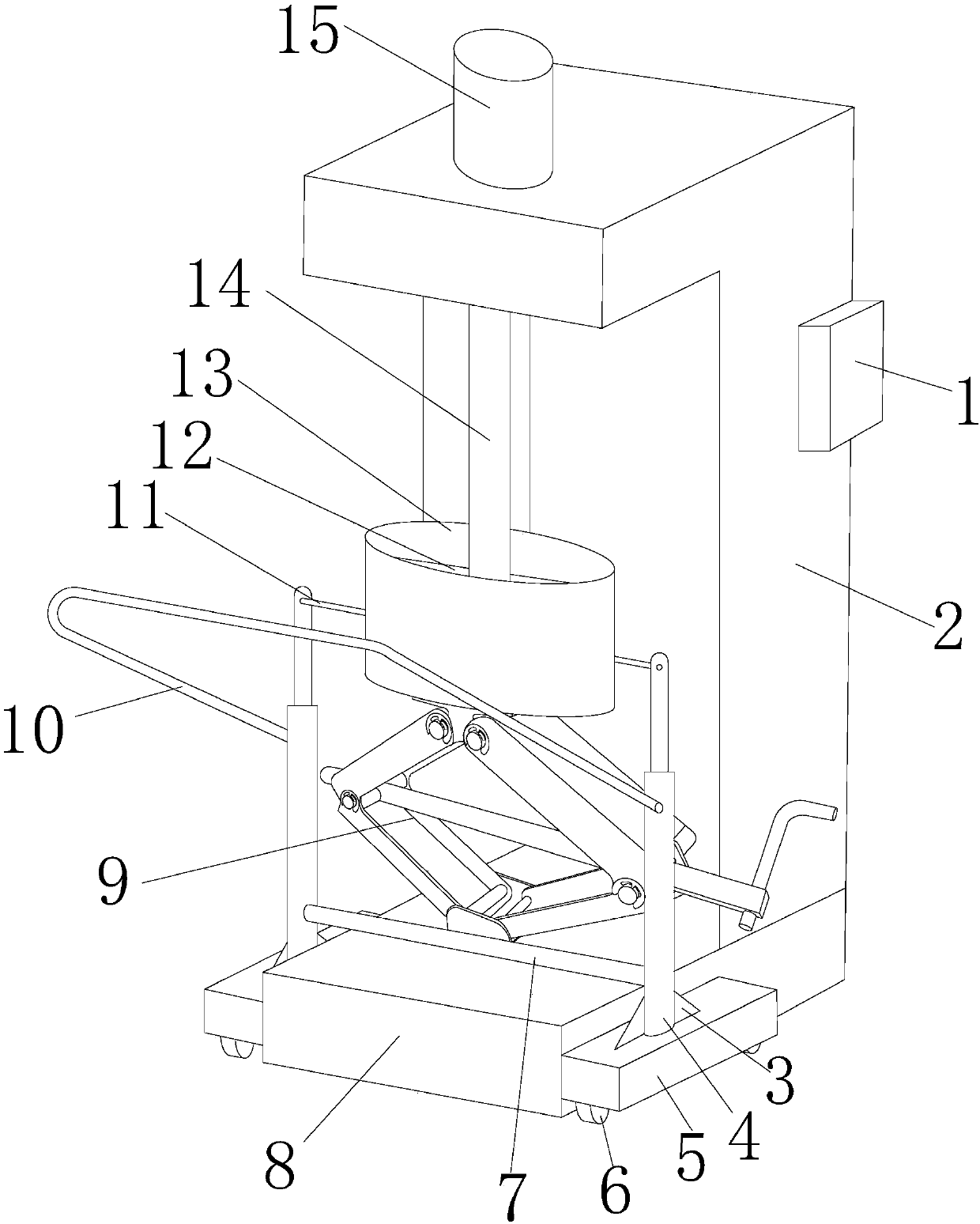

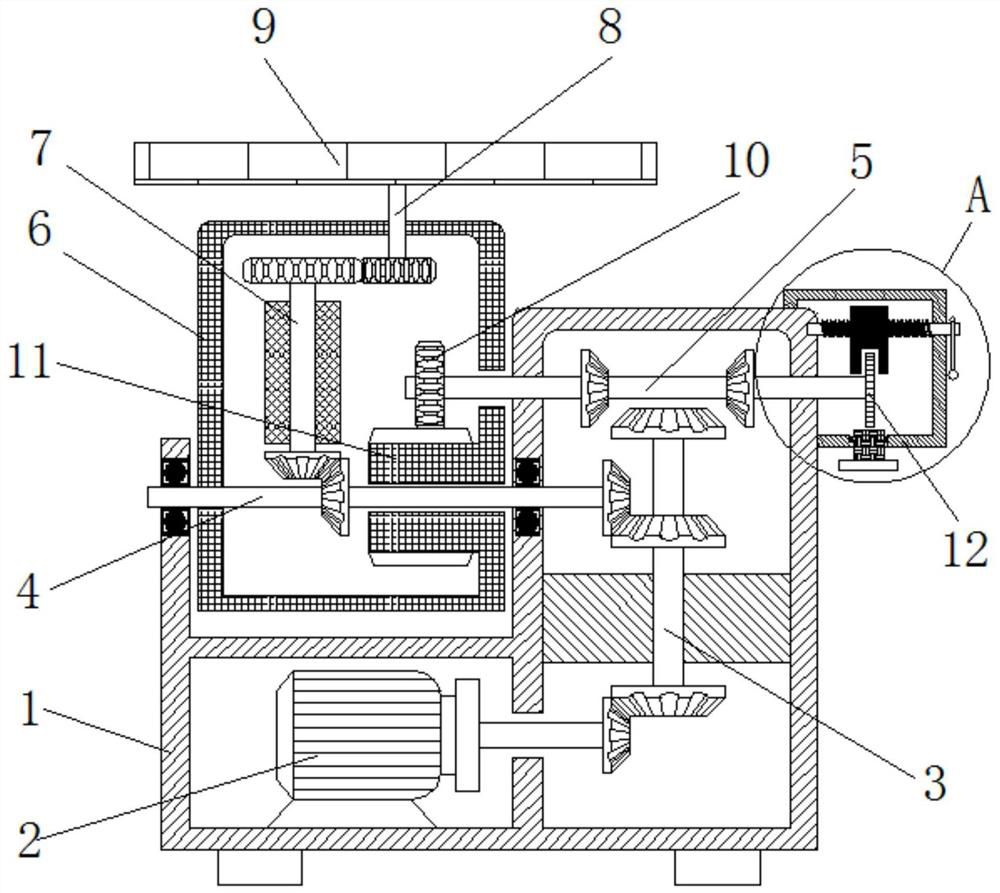

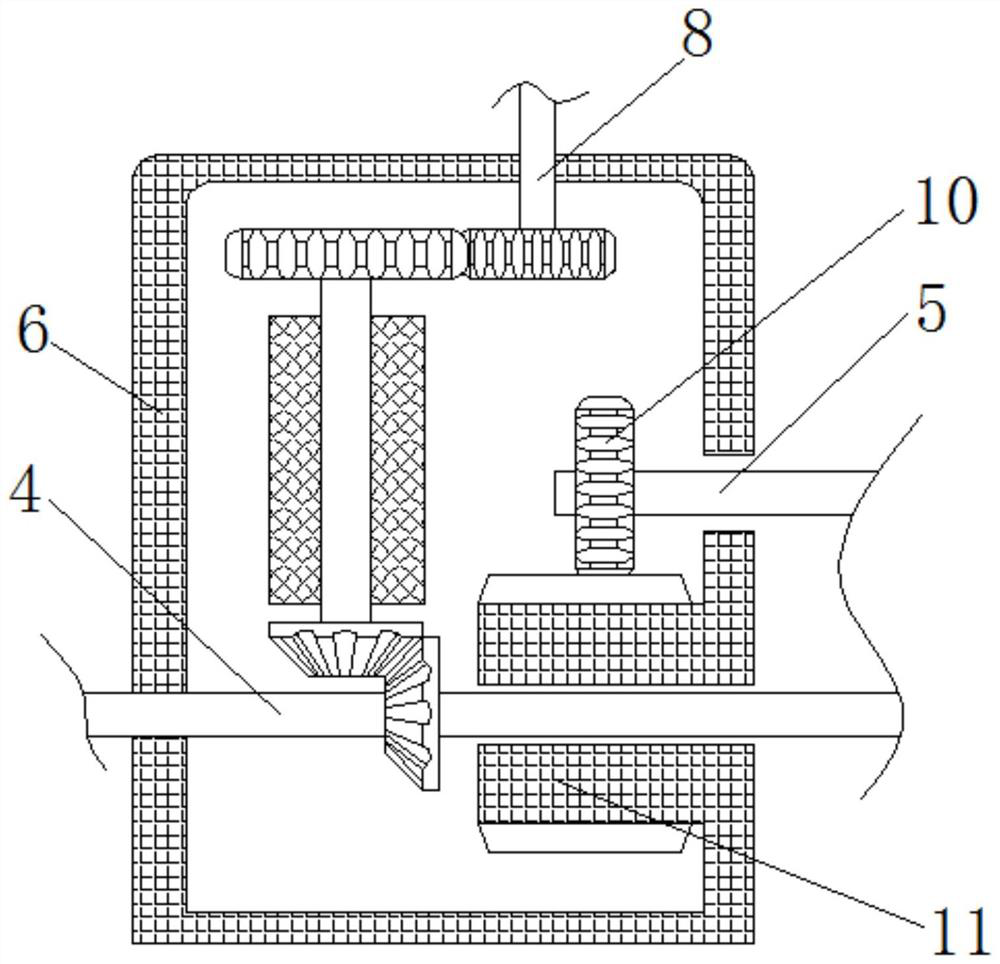

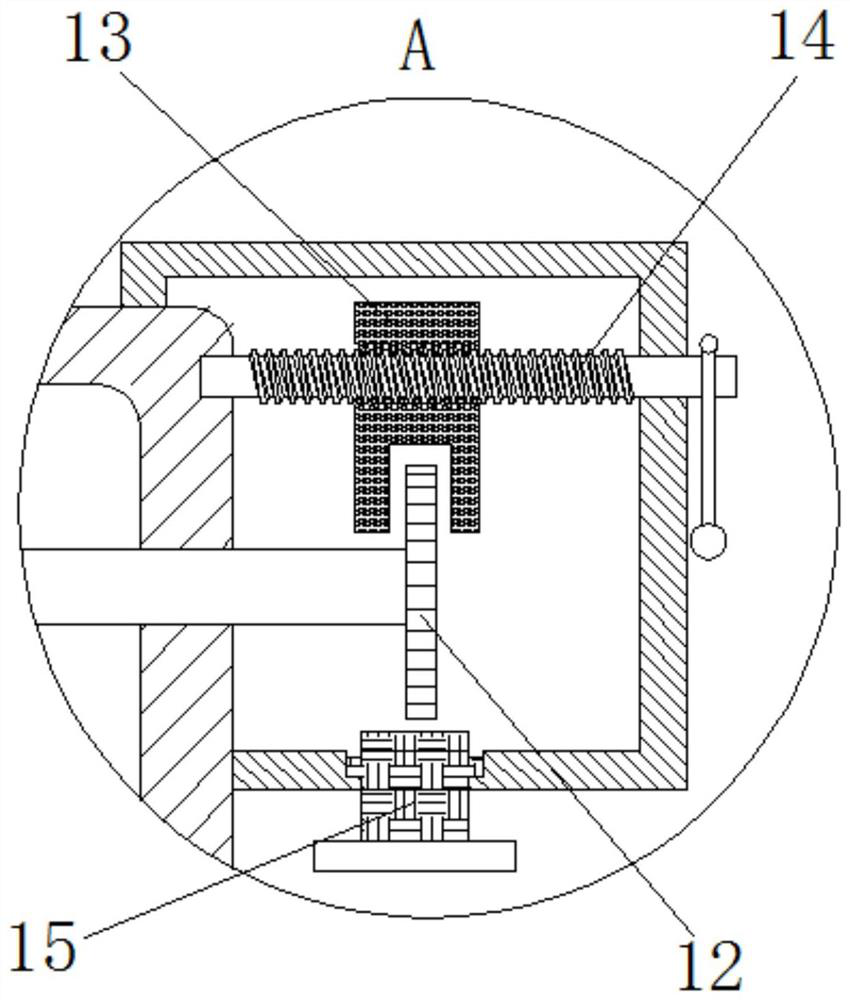

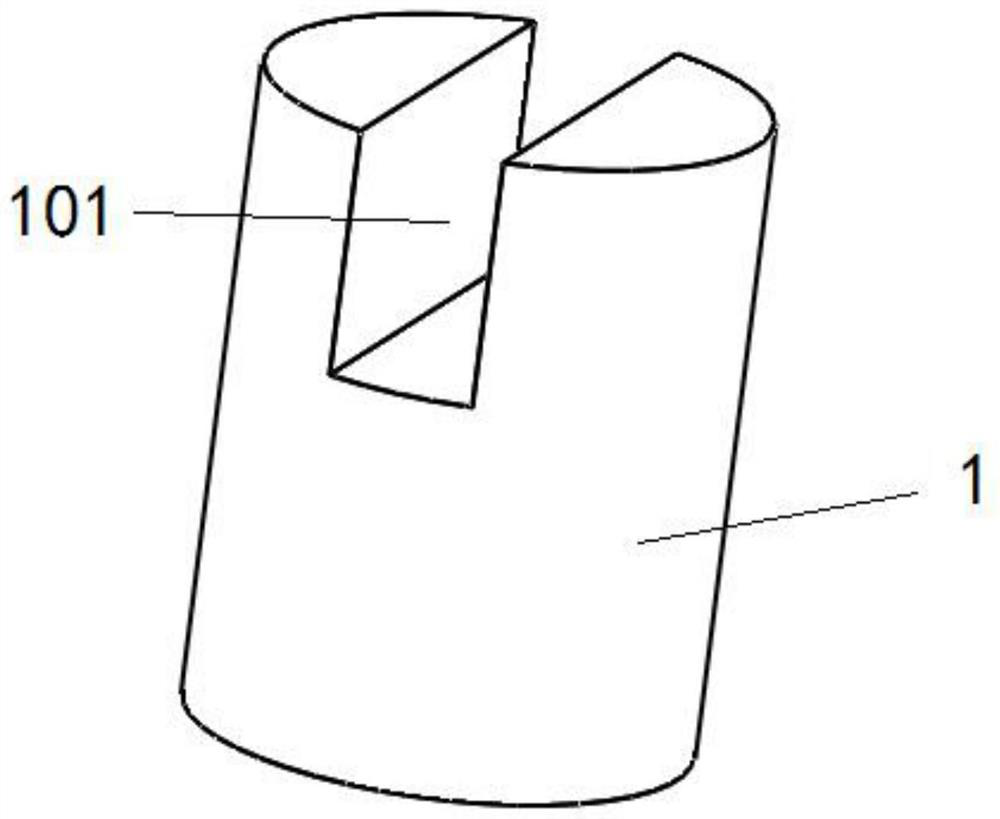

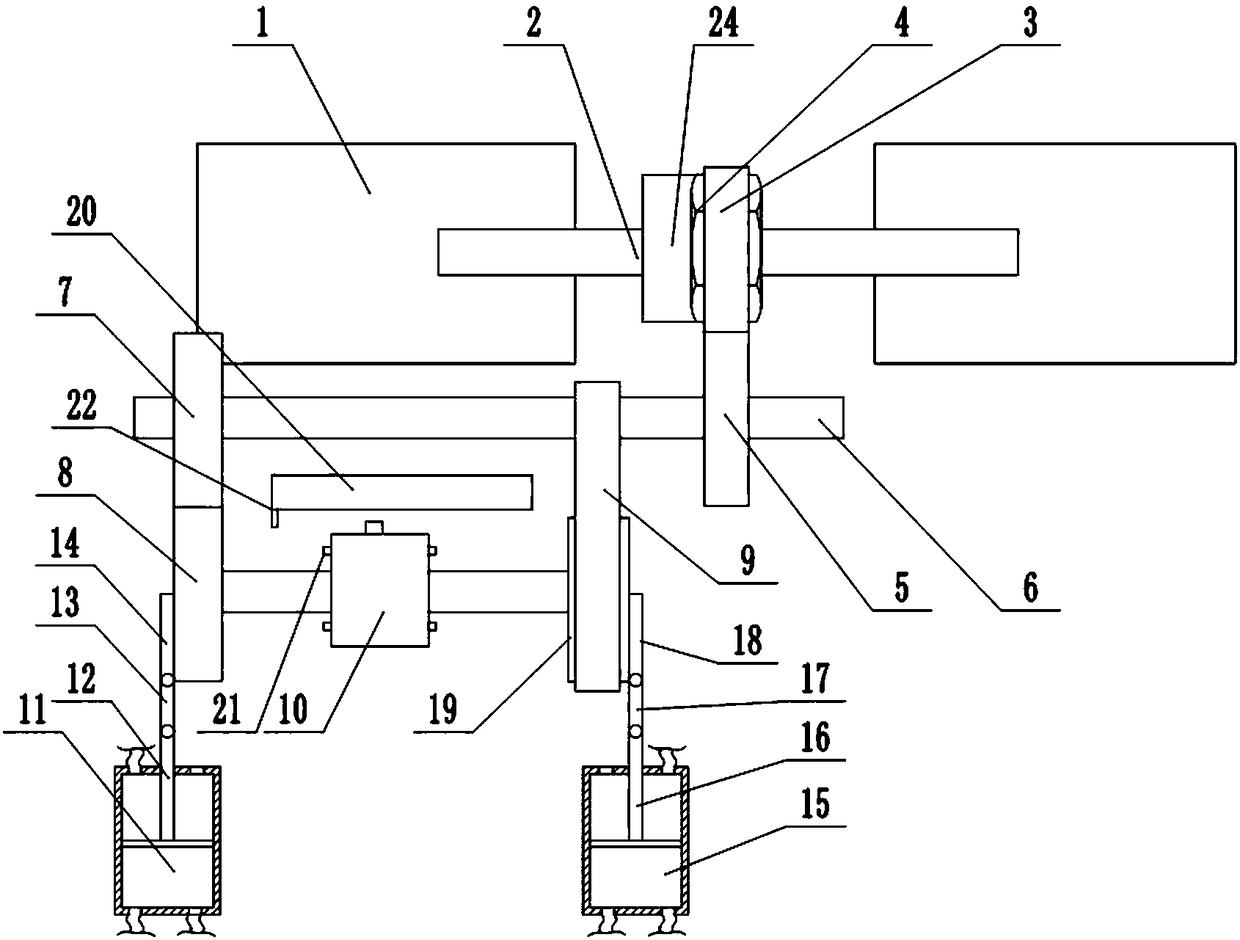

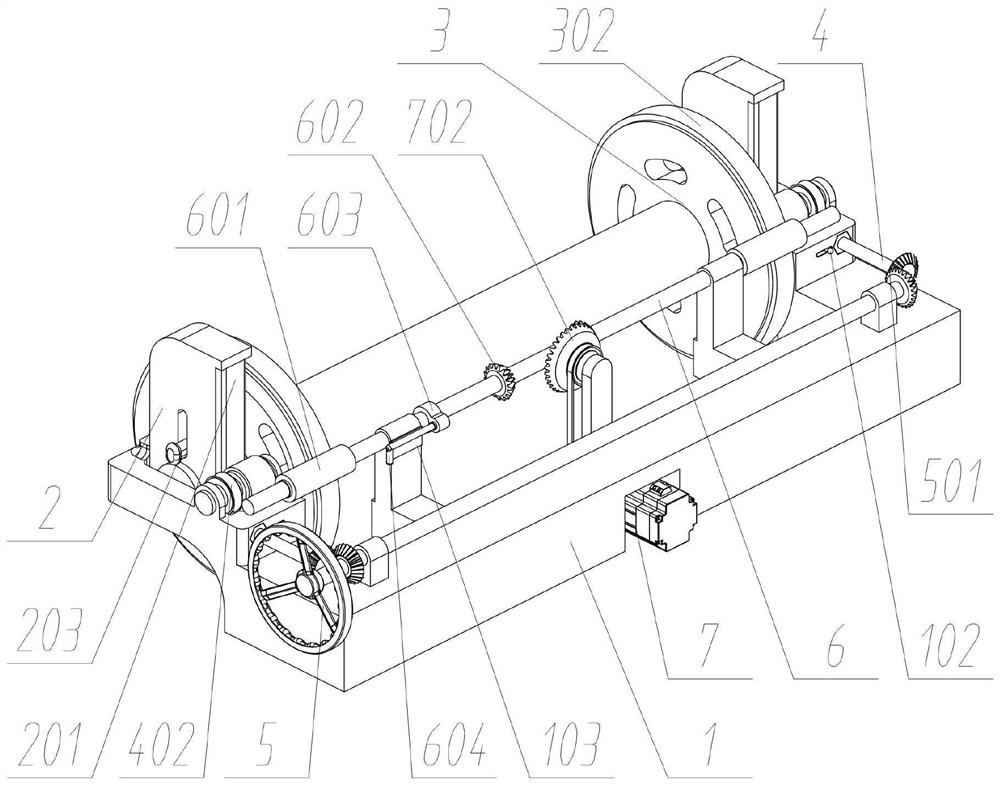

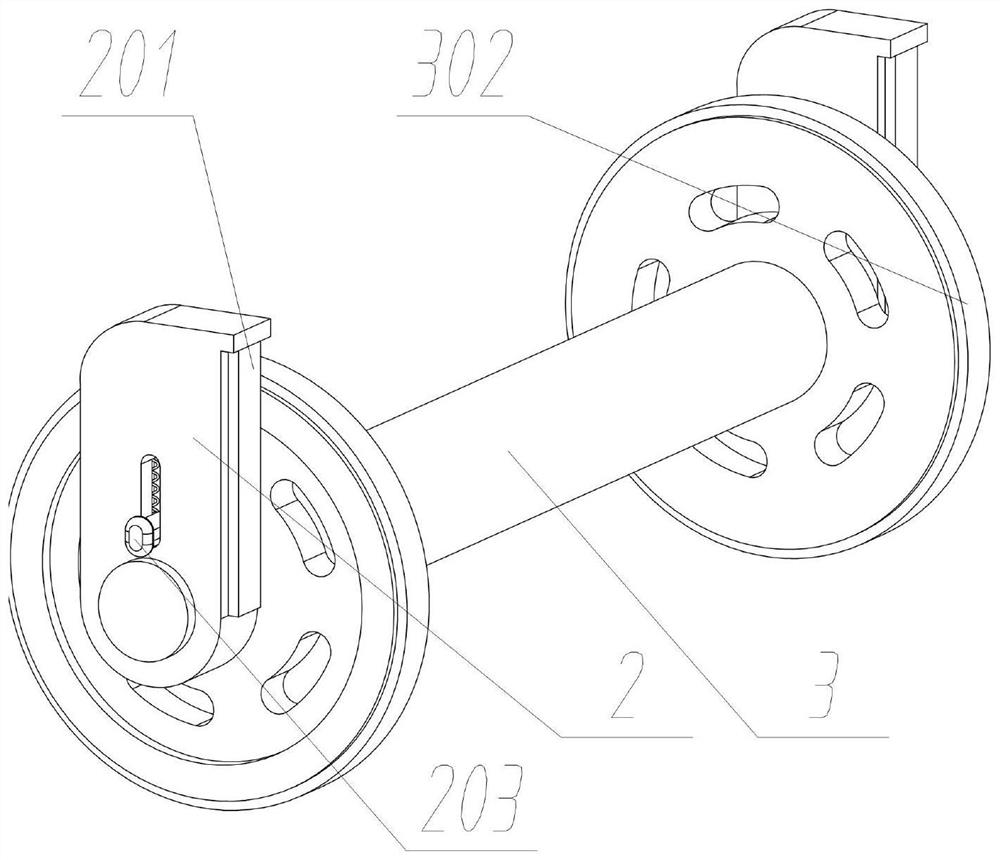

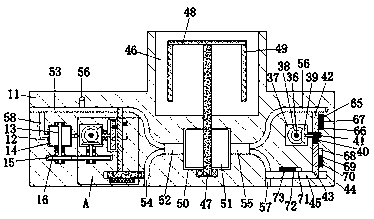

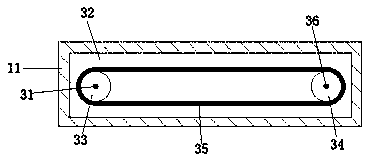

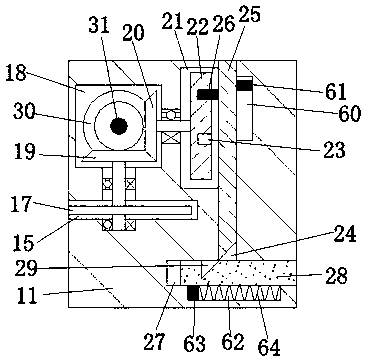

Small multifunction belt sander

The invention discloses a small multifunction belt sander which comprises a sander body portion, a power portion, a roll shaft adjusting mechanism, a workpiece clamping mechanism, a sanding belt tensioning mechanism, a dedusting device and an electrical control system. A roll shaft in the roll shaft adjusting mechanism is arranged at one end of a roll shaft frame through a pair of bearings and a pair of adjusting screw assemblies, and the other end of the roll shaft frame is in a floating connection with a box; an adjusting bolt is arranged at the outer end of the inner side of the roll shaft frame, and the outer end is close to the roll shaft; two locking handles are vertically arranged at intervals, and inner ends of the two locking handles and a semicircle shaft fixed on the inner side of the middle of the roll shaft frame form a thread connection; and a zero line is marked on one side surface of the roll shaft frame to be matched with a vertical ruler on the box to be adjusted for using. According to the small multifunction belt sander, arc-shaped surfaces with various radians and angles can be ground at the end of a round metal tube or a rod in a molding mode, plate type metal workpiece plane can be ground, metal workpiece chamfering deburring processing is performed, the operation is convenient, fast, safe and environment-friendly, the positioning adjustment and grinding accuracies are high, labor intensity is low, working efficiencies are high, and the service life is long.

Owner:莱州鑫岳机械股份有限公司

Energy-saving and environment-friendly flue gas desulfurization equipment

PendingCN114247284AReduce damageImprove desulfurization efficiencyGas treatmentDispersed particle filtrationFlue gasFlue-gas desulfurization

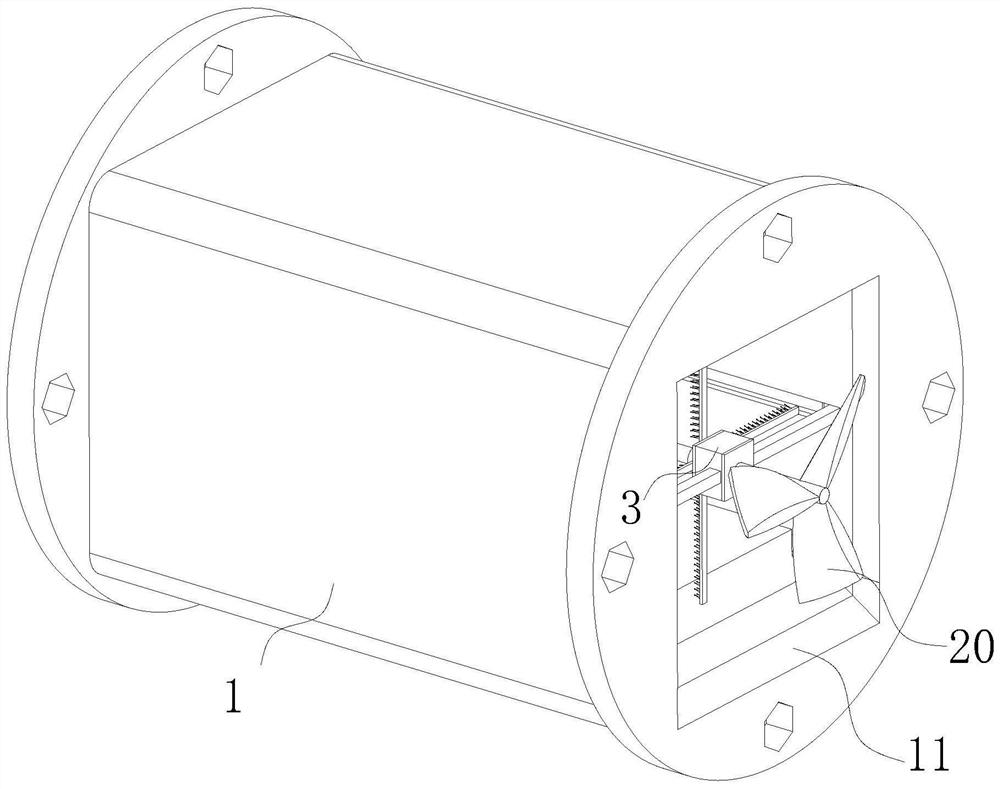

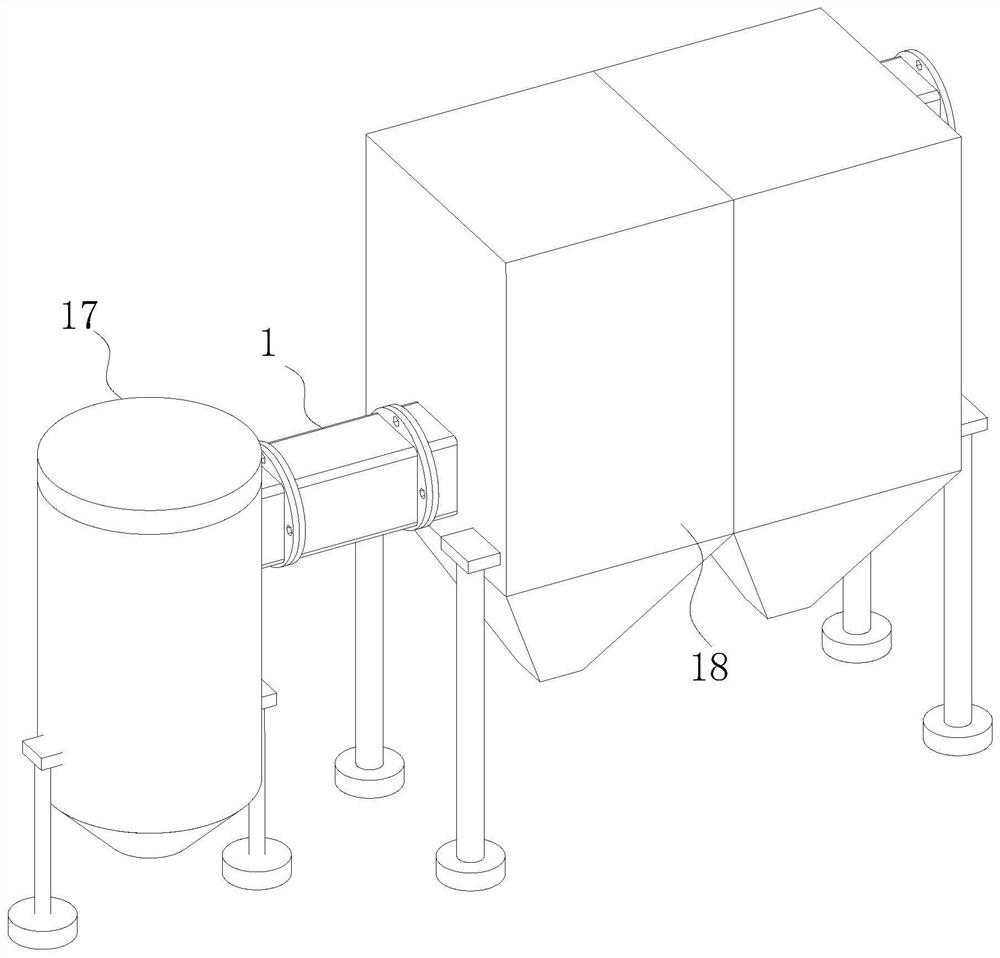

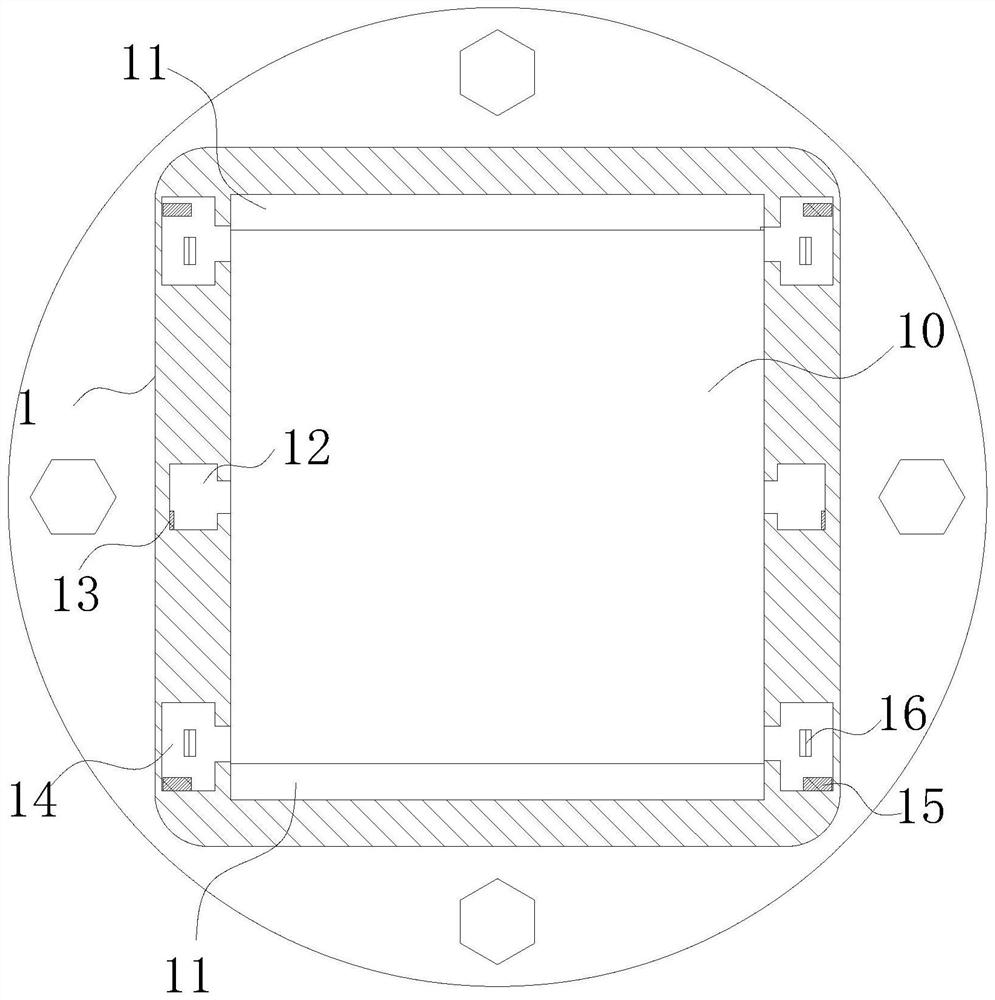

The invention discloses energy-saving and environment-friendly flue gas desulfurization equipment in the technical field of flue gas desulfurization, which comprises a self-scraping communicating pipe communicated between an exhaust port of an absorption tower and an air inlet of a bag-type dust collector, and a scraper part driven by hot air pressure and a flow stirring part driven by the scraper part are arranged in the self-scraping communicating pipe. The scraper part comprises two wall scraping plates which are symmetrically arranged and can be turned and closed, the outer side walls of the wall scraping plates are in sliding connection with the inner wall of the ventilation channel of the self-scraping communicating pipe, and the two wall scraping plates are arranged on one side of the exhaust port of the absorption tower and cover the ventilation channel in the self-scraping communicating pipe; the flow stirring part comprises a suction fan blade and a reverse blowing fan blade which are rotationally mounted at the axial lead position of the ventilation channel; flue gas in the ventilation channel integrally passes in a pulse airflow mode, self-cleaning of the interior of the ventilation channel is achieved in the airflow passing process, the desulfurization efficiency in the absorption tower and the dust removal efficiency in the bag-type dust remover are reversely improved, heat energy of the flue gas is utilized, and more energy conservation and environmental protection are achieved.

Owner:新疆金禾山能源科技有限公司

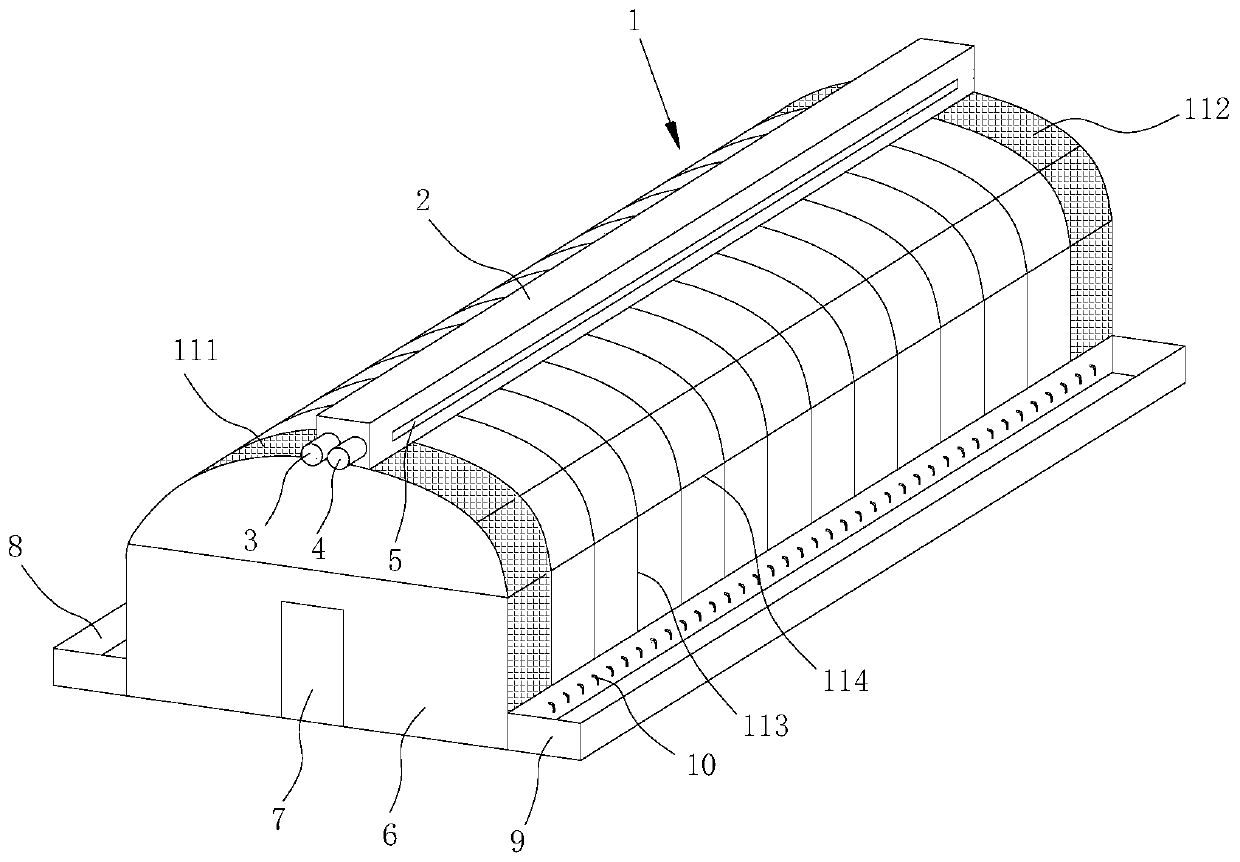

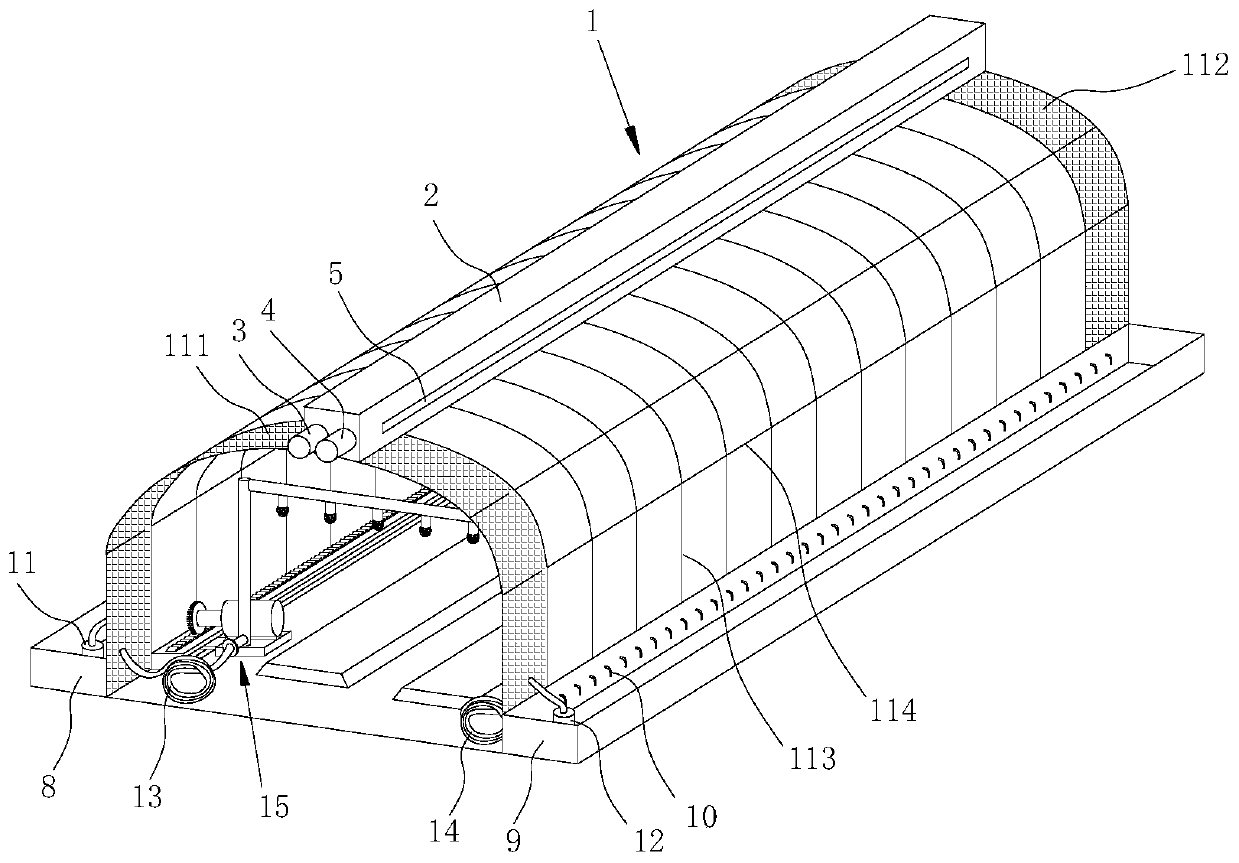

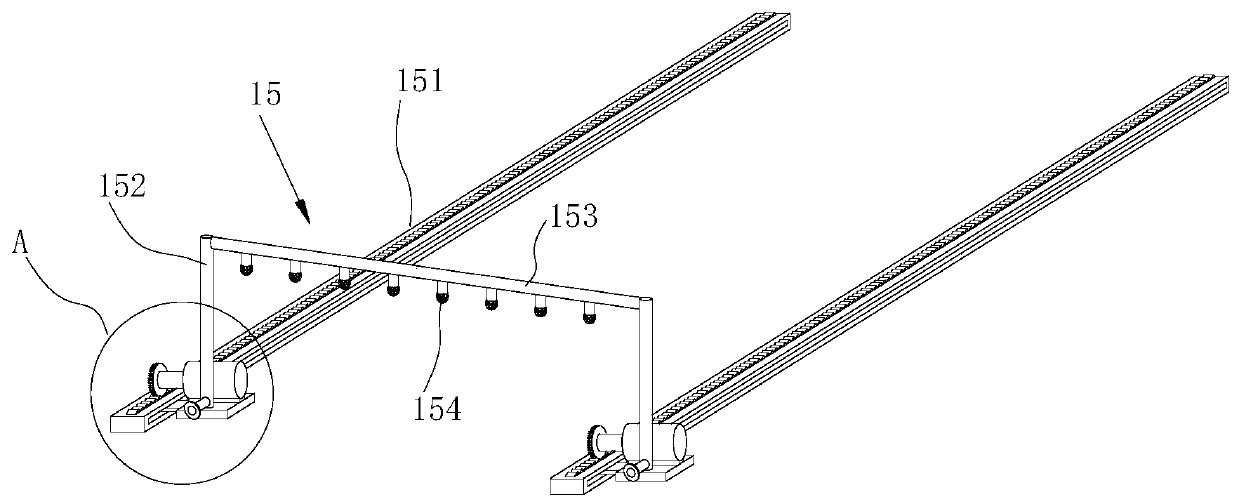

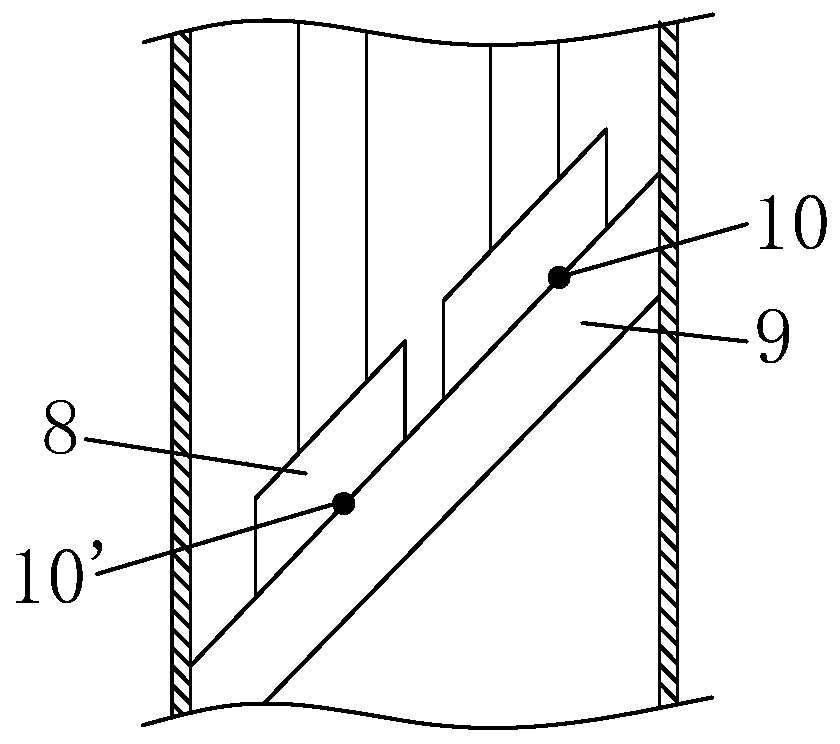

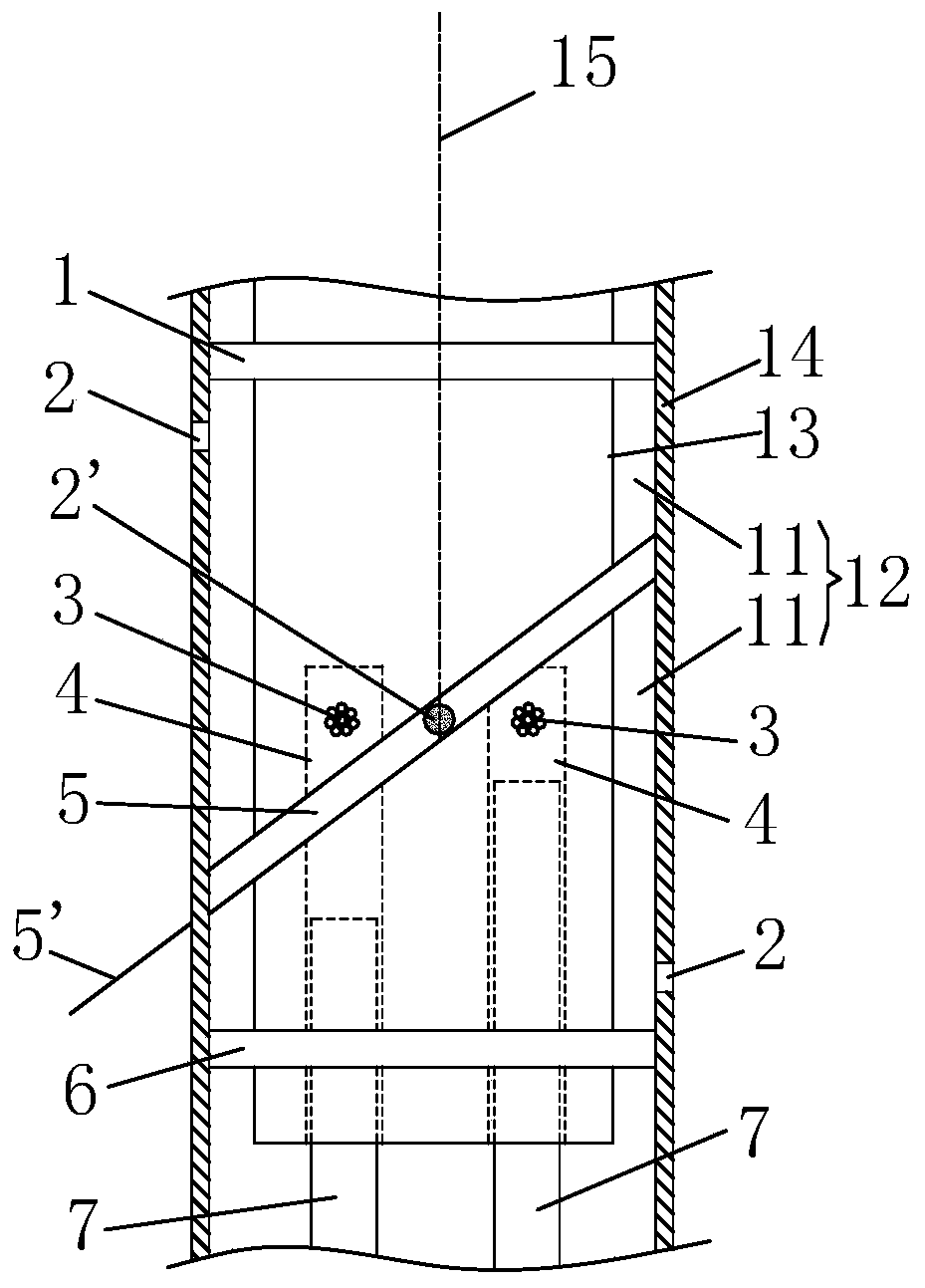

Anti-seismic anti-wind automatic agricultural plastic greenhouse

ActiveCN110521454AImprove wind and earthquake resistanceForward rotationClimate change adaptationGreenhouse cultivationBrickGear wheel

The invention discloses an anti-seismic anti-wind automatic agricultural plastic greenhouse. Arch-shaped steel frames connected through transverse supporting steel strips are arranged between a firstarch-shaped brick and a second arch-shaped brick in a greenhouse frame. A first winding shaft and a second winding shaft are installed in a limiting box fixed to the greenhouse frame. Plastic cloth iswound on the first winding shaft and the second winding shaft. The edges of the plastic cloth are fixedly provided with limiting rings. A first water reservoir and a second water reservoir are arranged at the lower portion of the greenhouse frame. A first water conveying pump is arranged in the first water storage pool. A second water conveying pump is arranged in the second water storage pool. An automatic watering device in the greenhouse frame is composed of a limiting guide rail, a vertical water conveying pipe, a transverse water conveying pipe, watering nozzles, straight rail teeth, a limiting gateway, a limiting slider, a supporting plate, a third electric motor and a transmission gear, and the problems are solved that an existing agricultural plastic greenhouse cannot realize theeffect of automatically winding and unwinding plastic cloth, cannot realize automatic watering, cannot realize water resource conservation, and is poor in anti-seismic anti-wind performance.

Owner:山东利森特农业科技有限公司

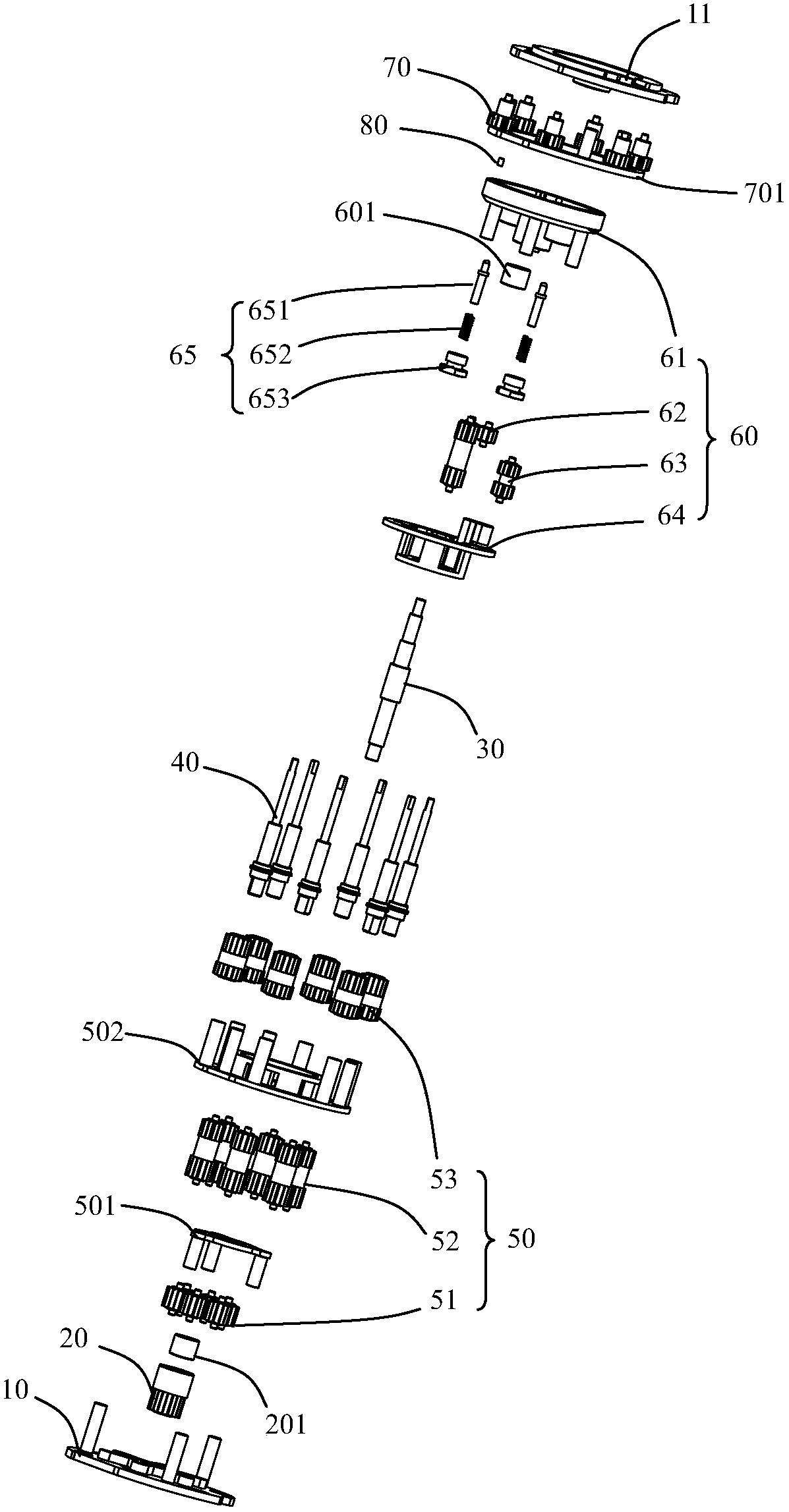

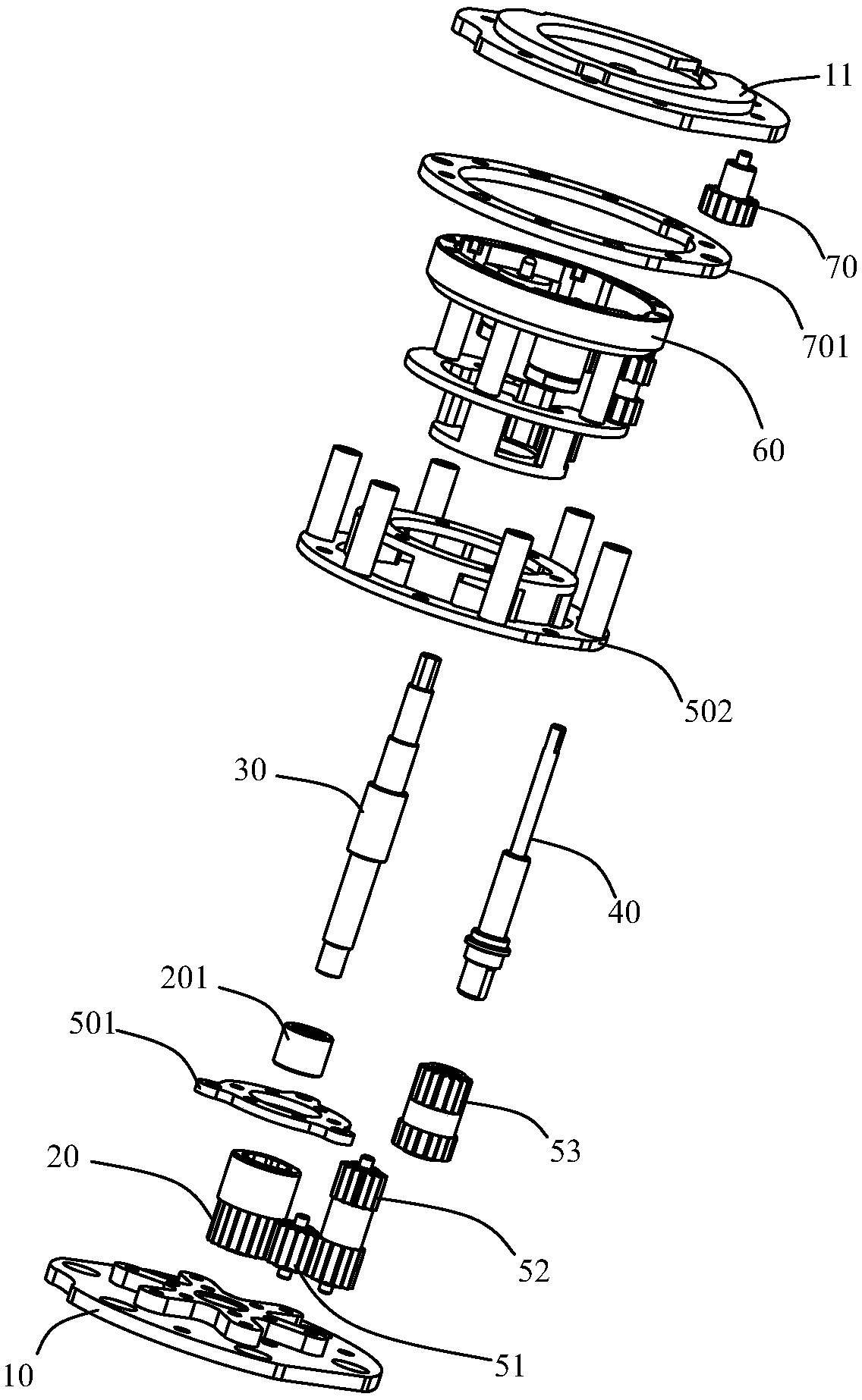

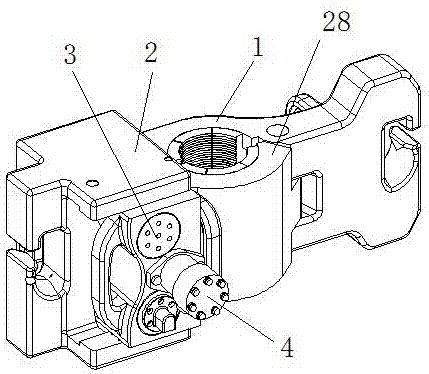

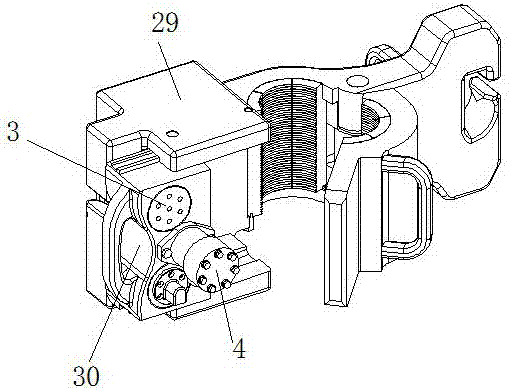

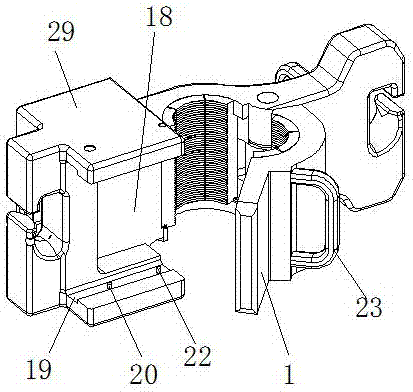

Antenna phase shifter transmission device

PendingCN110364815ALow costCompact structureAntennasElectrical and Electronics engineeringEngineering

Owner:PROSE TECH CO LTD

Rapid stirring device for dental cast raw material for medical stomatology department

InactiveCN107930487AQuality assuranceStir wellShaking/oscillating/vibrating mixersTransportation and packagingEngineeringDental mold

The invention discloses a rapid stirring device for a dental cast raw material for the medical stomatology department. The structure of the device comprises a controller, a body, triangular fasteningblocks, hydraulic rods, a supporting seat, universal wheels, a connecting rod, a pedestal, a jack, a pushing hand rack, a supporting plate, a stirring blade, a stirring container, a stirring rod and afirst motor, the bottom surface of the body is fixedly connected with the top surface of the pedestal, the body and the pedestal form a U-shaped structure, a controller electrically connected with the body is arranged on one side surface of the body, and the first motor is vertically fixed on the top surface of the body. A positive and negative rotation mechanism is arranged in the body of the rapid stirring device for the dental cast raw material for the medical stomatology department, and has a positive and negative stirring function, so the dental cast raw material can be cyclically alternately stirred in a positive and negative direction in the stirring process to achieve a good stirring effect, thereby the raw material is fully stirred, and the quality of a dental cast is guaranteed.

Owner:万文杰

Angle-adjustable rotary commodity exhibition stand

The invention relates to the technical field of electronic commerce, and discloses an angle-adjustable rotary commodity exhibition stand. The stand includes a base, a motor is arranged on the bottom surface of the interior of the base, the right gear of the motor is engaged with a power shaft, the middle section of the power shaft is connected with a center shaft in a meshed mode, the top end of the power shaft is connected with a planet shaft in a meshed mode, the middle section of the center shaft is sleeved with a platform support, the section, in the platform support, of the center shaft is connected with a transmission shaft in a meshed mode, and the right side of the transmission shaft is connected with a platform rotating shaft in a meshed mode. A driving screw rotates to enable a poking piece to poke a brake wheel to drive the planet shaft to move left and right, forward rotation, vacancy and reverse rotation of the planet shaft are achieved, the platform support is driven to rotate around the center shaft, that is, angle adjustment and motor rotation are achieved, the power shaft, the center shaft, the transmission shaft and the platform rotating shaft are sequentially driven to rotate, and the exhibition stand rotates around the axis of the exhibition stand, so the exhibition stand rotates around the free inclined position.

Owner:深圳市艺和展览展示有限公司

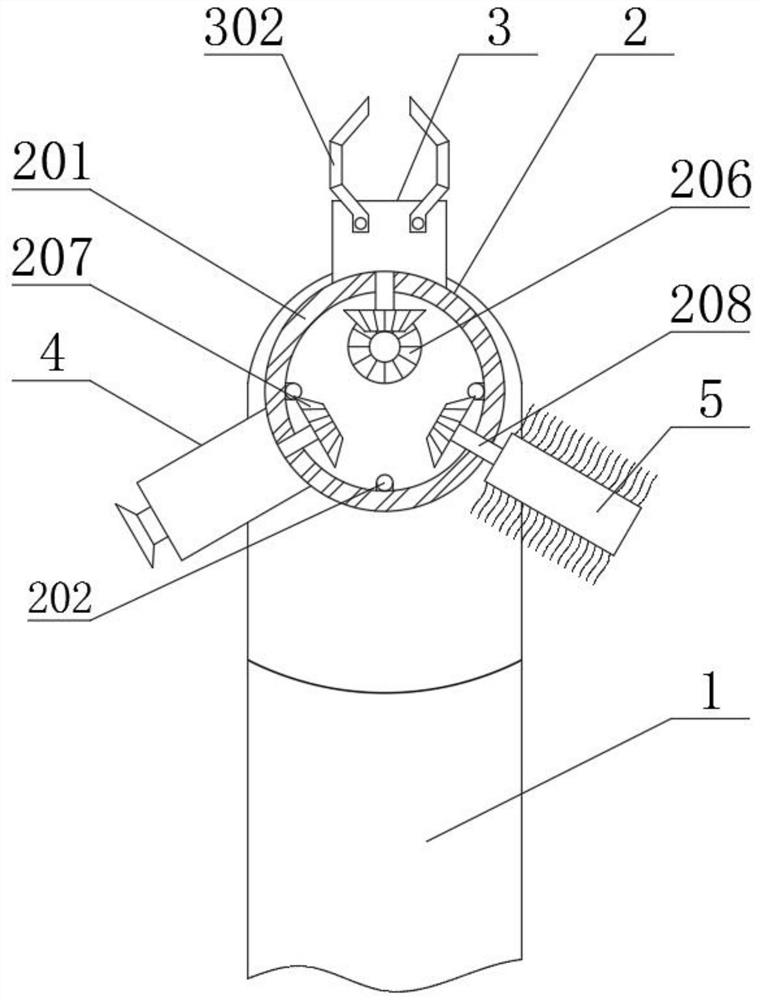

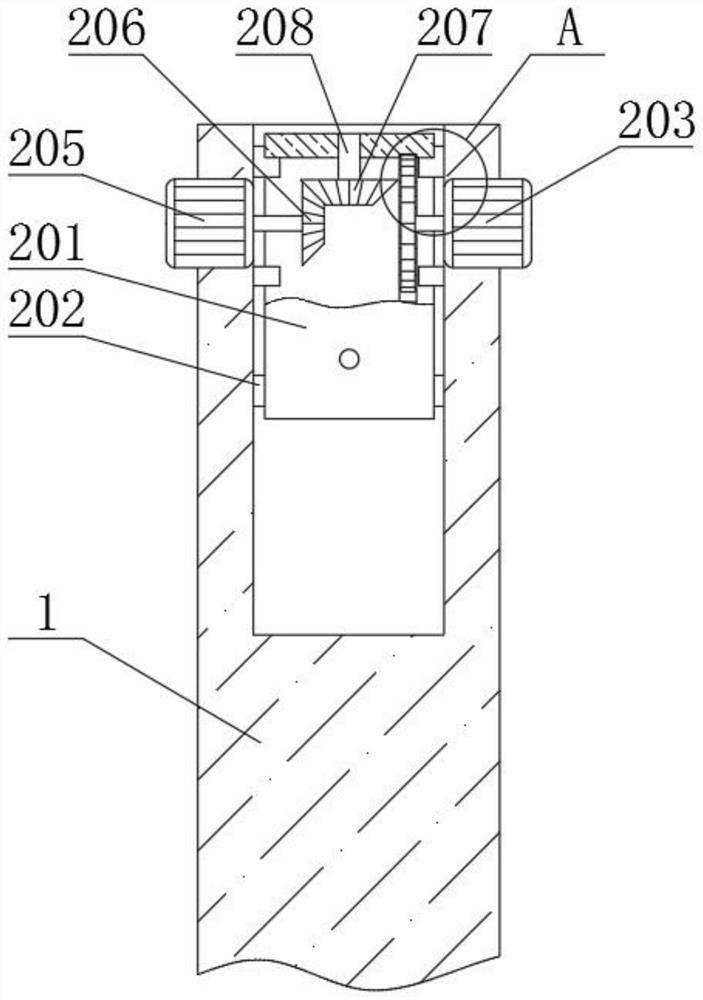

Multifunctional manipulator and using method thereof

The invention discloses a multifunctional manipulator and a using method thereof. The manipulator comprises a manipulator driving arm and a conversion device, wherein the conversion device is arrangedat the top end of the manipulator driving arm, the conversion device comprises a conversion cylinder, an L-shaped positioning block, a conversion motor, a conversion gear, a driving motor, a first driving bevel gear, a second driving bevel gear and a driving rod, and the outer end face of the conversion cylinder is in transmission connection to an object clamping device, an object sucking deviceand a cleaning brush. According to the manipulator, the conversion motor and the conversion gear in the conversion device drive the conversion cylinder to rotate, so that the object clamping device, the object sucking device and the cleaning brush can be separately arranged above the manipulator driving arm, therefore, the manipulator driving arm can realize three operations of clamping, sucking and deashing an object through the object clamping device, the object sucking device and the cleaning brush, and the practicability is improved.

Owner:河北宏龙环保科技有限公司

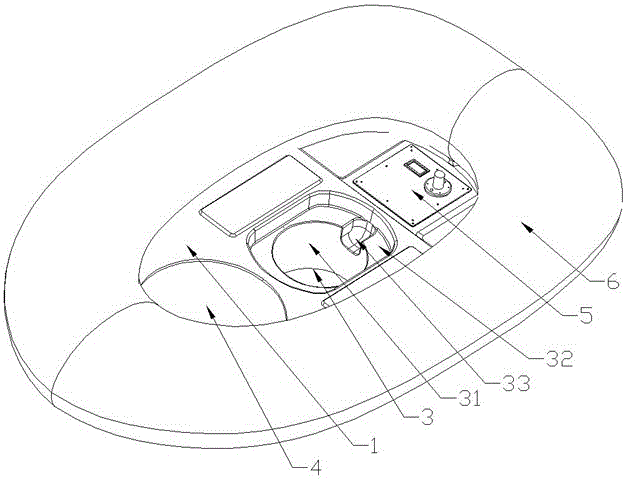

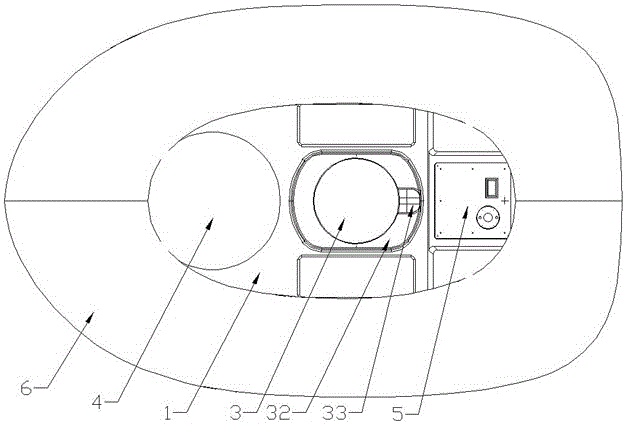

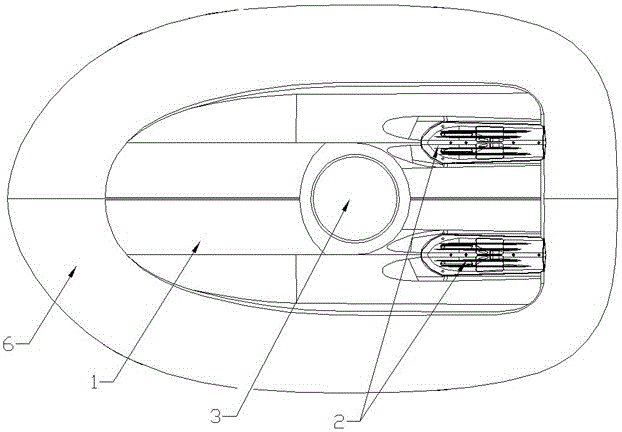

Multifunctional high-speed intelligent modularized platform system surveying and mapping robot

The invention aims at providing a multifunctional high-speed intelligent modularized platform system surveying and mapping robot which is simple in structure, capable of achieving multifunctional operation, safe and high in reliability and ship speed. The robot comprises a ship body, the ship body is driven by two propellers arranged on the two sides of the bottom of the ship body, and the ship body is further provided with a self-righting device, a multifunctional task cabin, an equipment system carrying cabin and a control system cabin; a ship body control system is arranged in the control system cabin and connected with the propellers and the self-righting device, the multifunctional task cabin is arranged at the bottom of the ship body and penetrates through the bottom of the ship body, a modularized functional module is arranged in the multifunctional task cabin a clamped and closely matched mode, an analysis system is arranged in the equipment system carrying cabin, and the functional module is connected with the analysis system. The robot can be applied to the technical field of robots.

Owner:珠海科微智能科技有限公司

Paint brushing device for two faces of cork board

InactiveCN108465614ARealize touch-up paintAchieve dryingLiquid surface applicatorsCoatingsLacquerBrush device

The invention belongs to the field of board processing, and particularly relates to a paint brushing device for two faces of a cork board. The paint brushing device is characterized in that a paint brushing portion, an overturning portion and a driving portion are arranged on a machine frame, the overturning portion is positioned below the paint brushing portion, and comprises a handle which is rotationally connected on the machine frame, first connecting rods are hinged to the two ends of the handle, and overturning plates are hinged to the ends, far away from the handle, of the first connecting rods; the driving portion comprises a first rotating shaft and a second rotating shaft which are rotationally connected to the machine frame; the paint brushing portion comprises a nut which is rotationally connected to the machine frame, a fourth gear meshed with a third gear is arranged on the nut, the nut is in threaded connection with a screw rod, the screw rod is connected to the machineframe in a sliding mode, and sponge brush heads are arranged at the two end portions of the screw rod; and a paint box used for storing paint is fixedly connected to the machine frame, one end of a first piston cylinder and one end of a second piston cylinder each are provided with a paint inlet and a paint outlet, and the other end of the first piston cylinder and the other end of the second piston cylinder each are provided with an air inlet and an air outlet. By adopting the paint brushing device, the requirement for supplementing the paint on the brush heads in a self-operating mode duringpaint brushing of the cork board is met.

Owner:CHONGQING XINNAN WOOD PROCESSING CO LTD

Pneumatic lifting device for hanging basket

The invention discloses a pneumatic lifting device for a hanging basket. The pneumatic lifting device for the hanging basket comprises a blade type pneumatic motor, wherein one end of a rotating shaft of the blade type pneumatic lifting motor is connected with a braking device, and the other end serving as an output end is connected with a hoister through a reduction gear; and a gas hole is formed in the casing of the blade type pneumatic motor, and a gas direction control valve is arranged on the gas hole and mutually communicated with a remote controller. The pneumatic lifting device for the hanging basket is safe in operation, cannot be influenced by vibration, high temperature, electromagnetism, radiation and the like, is applicable to a harsh working condition, and can operate normally under the adverse conditions of flammability, explosive environment, high temperature, vibration, moistness, dust and the like; and further, compressed air is adopted as a power source, so that the operation and maintenance costs are low.

Owner:SHENXI MACHINERY

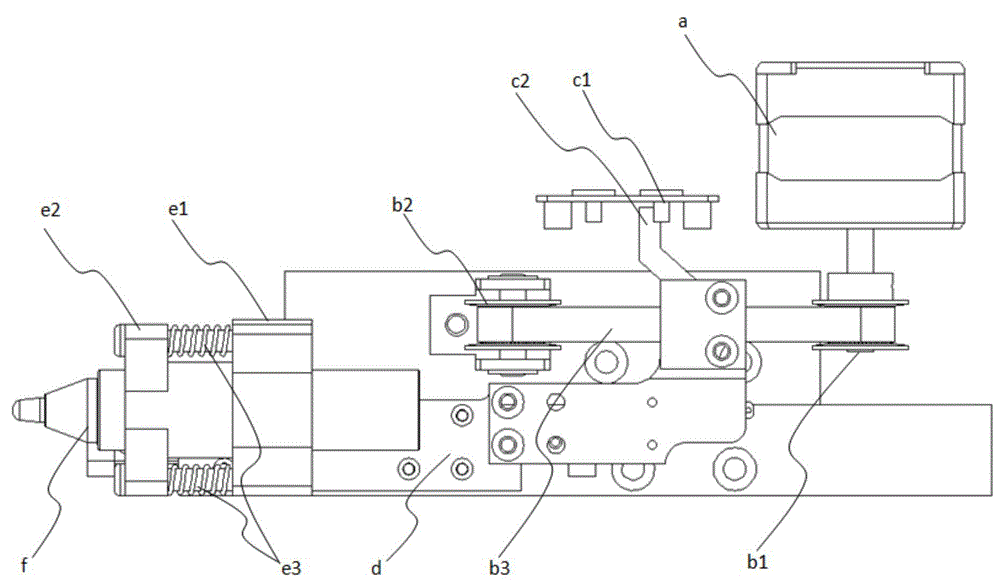

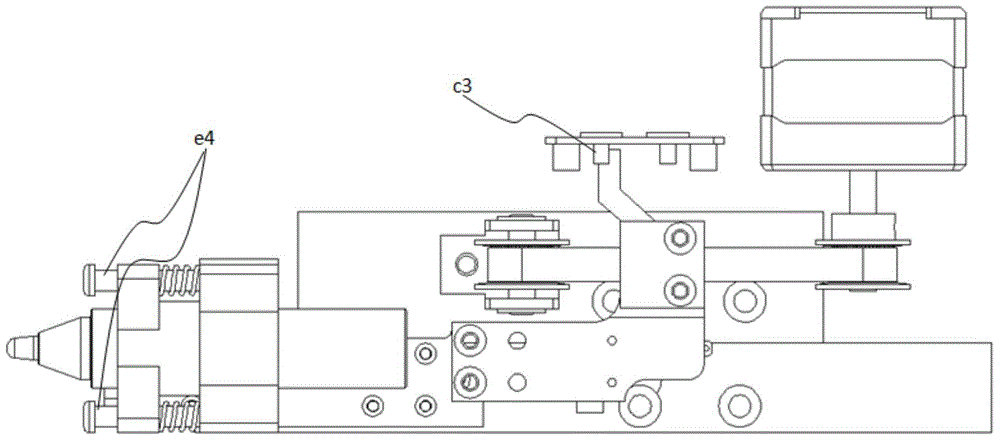

Automatic identifying device

The invention discloses an automatic identifying device. The automatic identifying device comprises an identifying mechanism with an identifying piece (f) and a driving device which drives the identifying mechanism to move back and forth. The identifying mechanism further comprises a fixed base (e1) which is connected with the driving device and a movable base (e2) which is arranged on the fixed base (e1) in a linear back-and-forth moving mode. The identifying piece (f) is mounted on the movable base (e2), and a bias pressure part is mounted between the fixed base (e1) and the movable base (e2). The bias pressure of the bias pressure part acts on the movable base (e2), so that the movable base (e2) is made to have the tendency of moving in the identifying direction. According to the automatic identifying device, the impact of a seal on an object to be sealed in the sealing process can be buffered, so that the problem that the object to be sealed and the seal are damaged due to the fact that a seal mechanism directly and rigidly impacts the object to be sealed is solved; accordingly, the seal is prevented from being abraded, and the sealing quality can also be kept stable for a long time.

Owner:JOINT STARS TECH

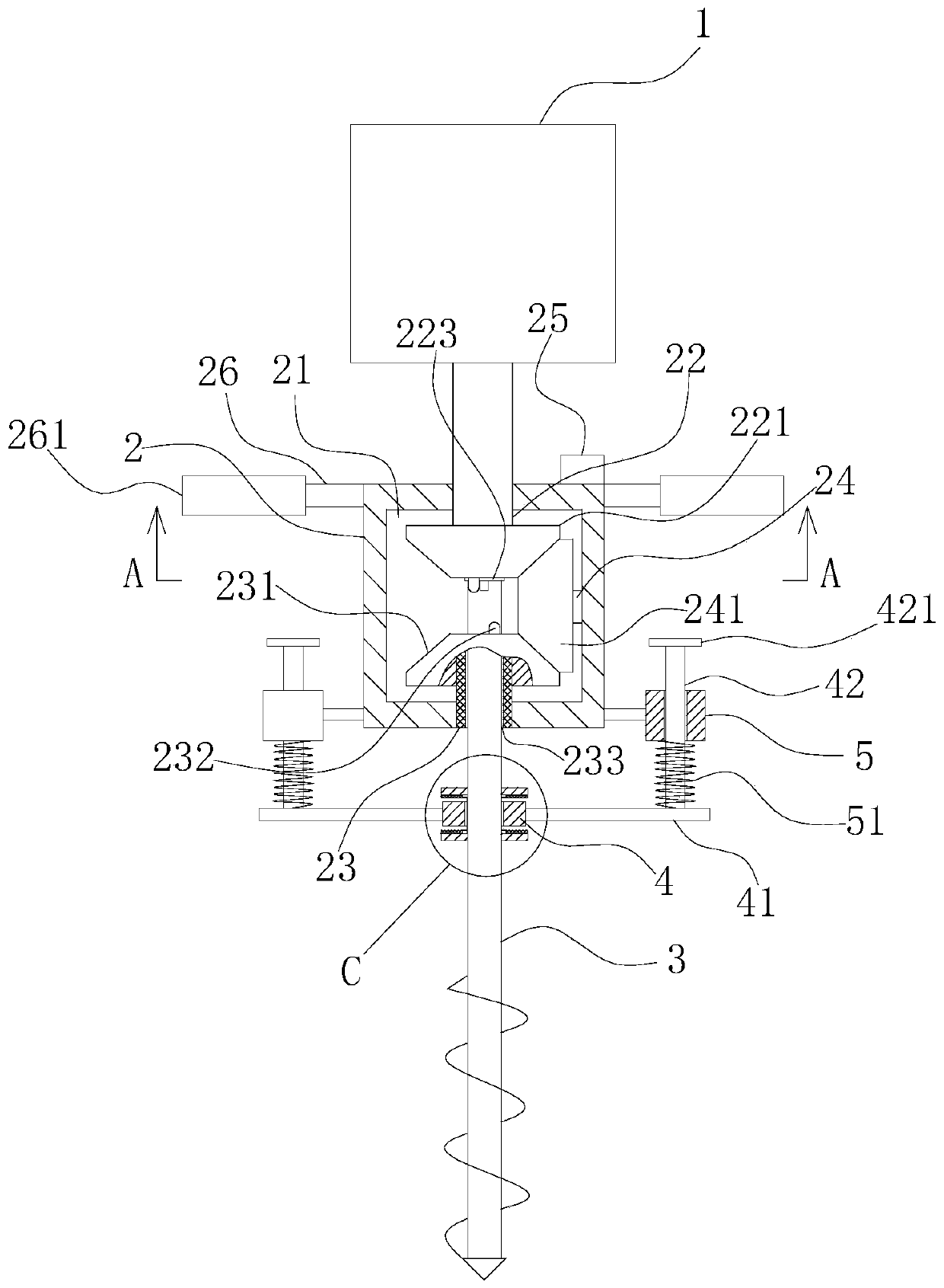

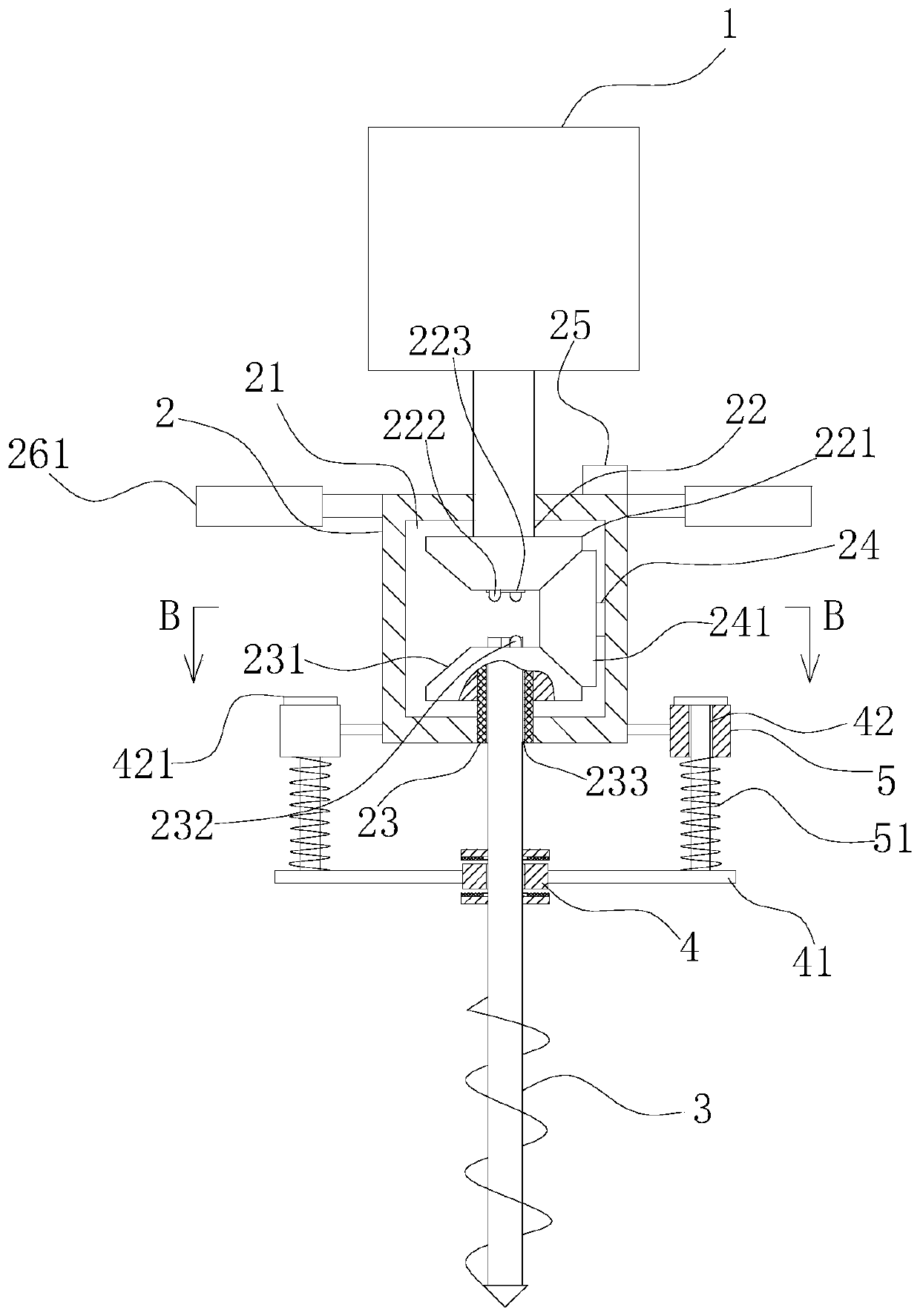

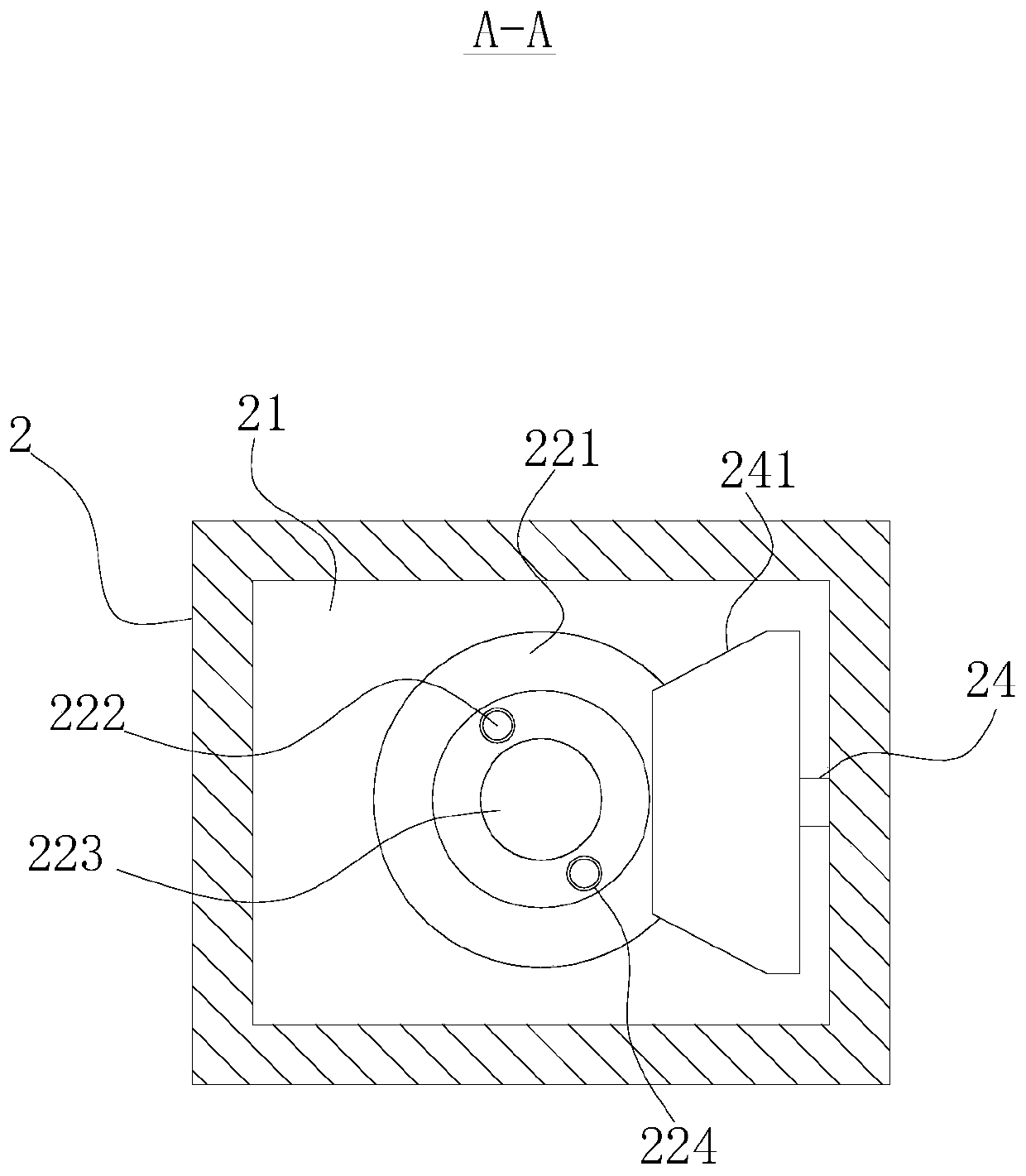

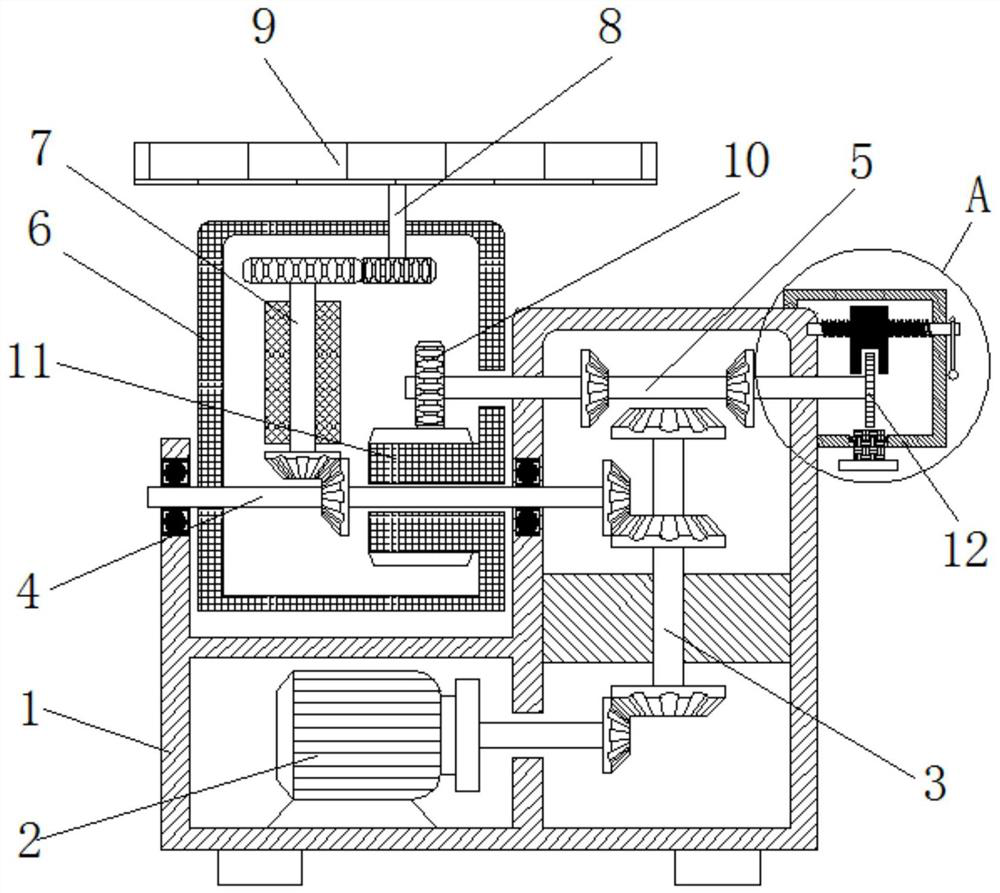

Electric drill capable of quickly adjusting rotating direction of drill rod

InactiveCN110280798AForward rotationAchieve reversalFeeding apparatusBoring/drilling componentsDrill

The invention provides an electric drill capable of quickly adjusting the rotating direction of a drill rod and belongs to the technical field of electric drills. The electric drill comprises a mounting box, a first rotating shaft, a second rotating shaft, a third bevel gear, a motor, a drill rod, a first linking mechanism and a second linking mechanism, wherein the mounting box is internally provided with a mounting cavity; the first rotating shaft is rotationally arranged in the mounting cavity and is fixedly provided with a first bevel gear; the second rotating shaft is fixedly arranged in the mounting cavity; the second rotating shaft is rotationally provided with a second bevel gear; the third bevel gear is rotationally arranged in the mounting cavity; the first bevel gear is in meshed connection with the third bevel gear; the second bevel gear is in meshed connection with the third bevel gear; the first rotating shaft is fixedly connected with an output shaft of the motor; the drill rod is arranged in a first through hole of the second rotating shaft in a sliding manner; the first bevel gear can be in driving connection with the drill rod by the first linking mechanism; the second bevel gear can be in driving connection with the drill rod by the second linking mechanism. The electric drill provided by the invention can realize positive rotation and negative rotation of the drill rod without changing the rotating direction of the output shaft of the motor.

Owner:ZHEJIANG OCEAN UNIV

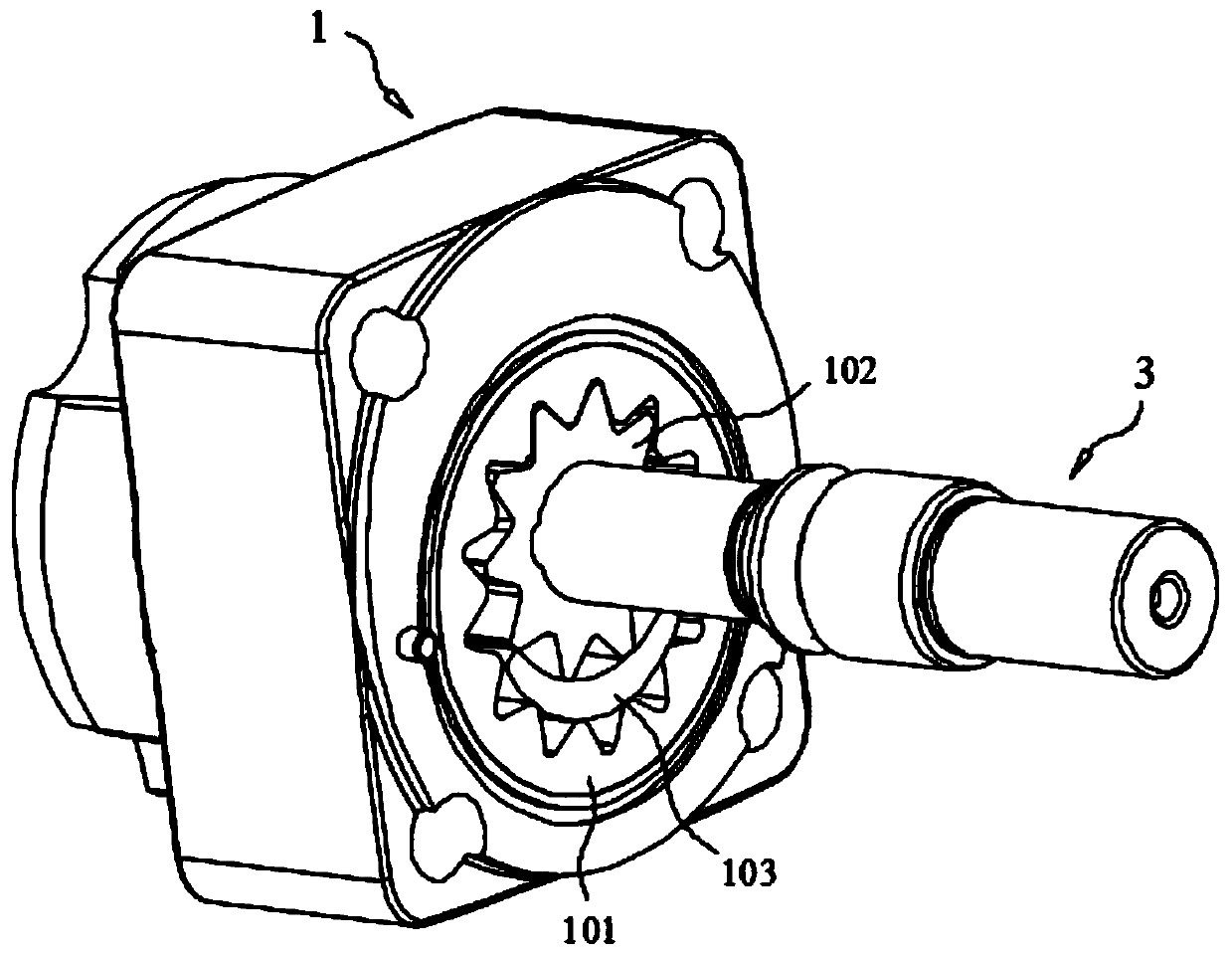

Internal engagement hydraulic motor capable of achieving four-quadrant operation

ActiveCN110107448AImprove sexual functionIncrease the scope of applicationRotary piston pumpsRotary piston liquid enginesHydraulic motorFour quadrants

The invention discloses an internal engagement hydraulic motor capable of achieving four-quadrant operation, and belongs to the technical field of medium delivery. A first pump and a second pump are arranged correspondingly, the two pumps are each internally provided with a symmetrical structure composed of a crescent plate, an inner gear ring, an outer gear and two oil ports, and a special oil drain hole and a special oil drain channel are formed in a rotating shaft correspondingly so that the internal engagement hydraulic motor can achieve four-quadrant operation under a pump mode and a motor mode, and hydraulic oil entering a bearing area along with the rotating shaft can be effectively drained. The internal engagement hydraulic motor is simple in structure, low in manufacturing cost and good in reliability, can effectively achieve four-quadrant operation, is high in functionality and wide in application range, and has good application prospects and popularization value.

Owner:NAVAL UNIV OF ENG PLA

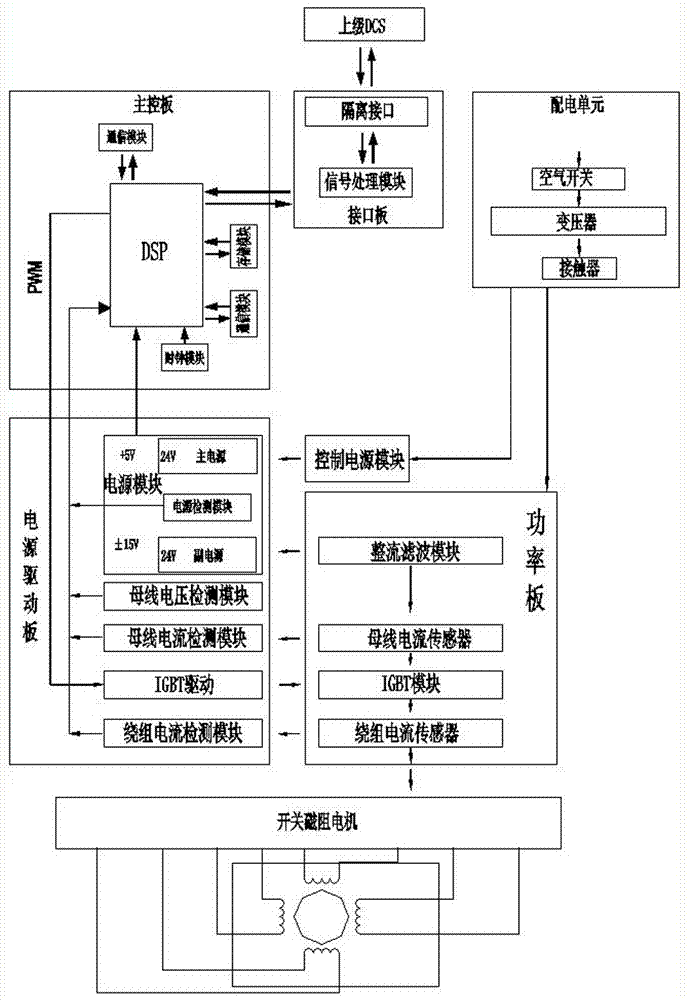

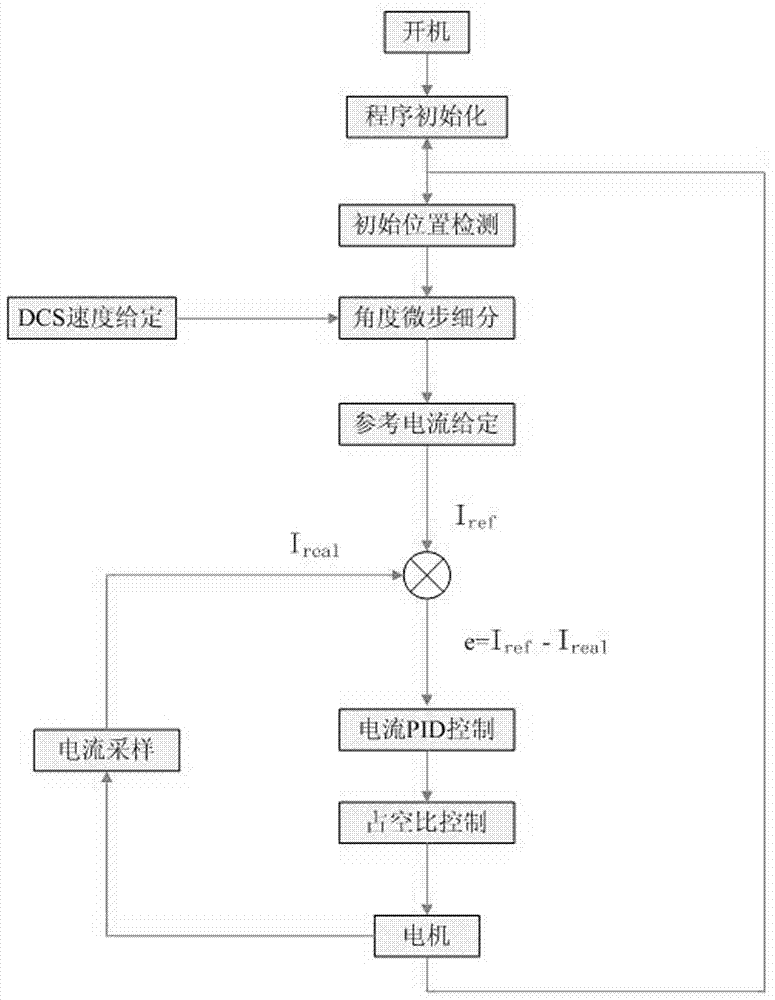

Speed regulating system and speed regulating method for switched reluctance motor

PendingCN107994837ARealize real-time monitoringGuaranteed stabilityAssociation with control/drive circuitsAC motor controlStatorEngineering

The invention discloses a speed regulating system and speed regulating method for a switched reluctance motor. The speed regulating system includes an upper DCS, the switched reluctance motor and a controller, and the controller comprises a main control board, an interface board, a power distribution unit, a power drive board and a power board. The main control board includes a DCS chip. The powerdrive board includes a power supply unit, an IGBT drive module and a winding current detection module. The power board includes an IGBT module and a winding current sensor. The power distribution unit supplies power to the power board. The winding current detection module is used to collect current information of each phase in a stator winding. The IGBT drive module and the winding current detection module are connected with the IGBT module and the winding current sensor respectively. The signal output end of the winding current detection module is connected with a data collection port of theDCS chip, the signal input end of the IGBT drive module is connected with a PWM signal output end of the DCS chip. The speed regulation of the switched reluctance motor can be achieved without installation of a position sensor, and the speed regulating system and speed regulating method for the switched reluctance motor are high in control accuracy and reliability.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

Drill-rod fixed clamp and control method thereof

The invention relates to a drill-rod fixed clamp device for preventing blowout of oil and gas field well drilling, in particular to a drill-rod fixed clamp and a control method thereof. The drill-rod fixed clamp comprises a first fixed clamp assembly and a second fixed clamp assembly, and the first fixed clamp assembly is hinged to one end of the second fixed clamp assembly; one end of the first fixed clamp assembly is fixedly connected with a locking device, and the other end of the first fixed clamp assembly is hinged to the second fixed clamp assembly; one end of the second fixed clamp assembly is hinged to the first fixed clamp assembly, and the other end of the second fixed clamp assembly is a free end; and the locking device comprises a locking device body and a sliding part capable of sliding along the locking device body, and a groove used for placing the free end of the second fixed clamp assembly is formed between the sliding part and the locking device body. According to the drill-rod fixed clamp and the control method thereof, the first fixed clamp assembly and the locking device are fixedly connected, the locking device is arranged to be of a push-pull structure, and locking and unlocking of the second fixed clamp assembly are completed by pushing and pulling the sliding part, so that the fixed clamp assemblies and the locking device are integrated; and one-time hoisting is only needed to complete installation and removal, and installation and removal are both very convenient.

Owner:CHENGDU ZHUOXIN IND

An Angle Adjustable Rotary Commodity Exhibition Stand

The invention relates to the technical field of e-commerce, and discloses an angle-adjustable rotating commodity exhibition stand, which includes a base, a motor is arranged on the inner bottom surface of the base, and a power shaft is meshed with the right gear of the motor, and the power shaft The middle section of the power shaft is meshed with a central shaft, the top of the power shaft is meshed with a planetary shaft, the middle section of the central shaft is sleeved with a platform bracket, and a section of the central shaft is meshed with a transmission shaft in the platform bracket. The right side of the transmission shaft is meshed with a platform rotating shaft. The angle-adjustable rotary commodity booth, through the rotation of the driving screw, makes the paddle to toggle the brake wheel to drive the planetary shaft to move left and right, realize the forward rotation, vacancy and reverse rotation of the planetary shaft, and drive the platform bracket to rotate around the central axis, that is, the angle Adjustment, the motor rotates, which in turn drives the power shaft, the central shaft, the transmission shaft and the platform shaft to rotate, so that the display stand can rotate around its own axis, so that the display stand can rotate at a freely inclined position.

Owner:深圳市艺和展览展示有限公司

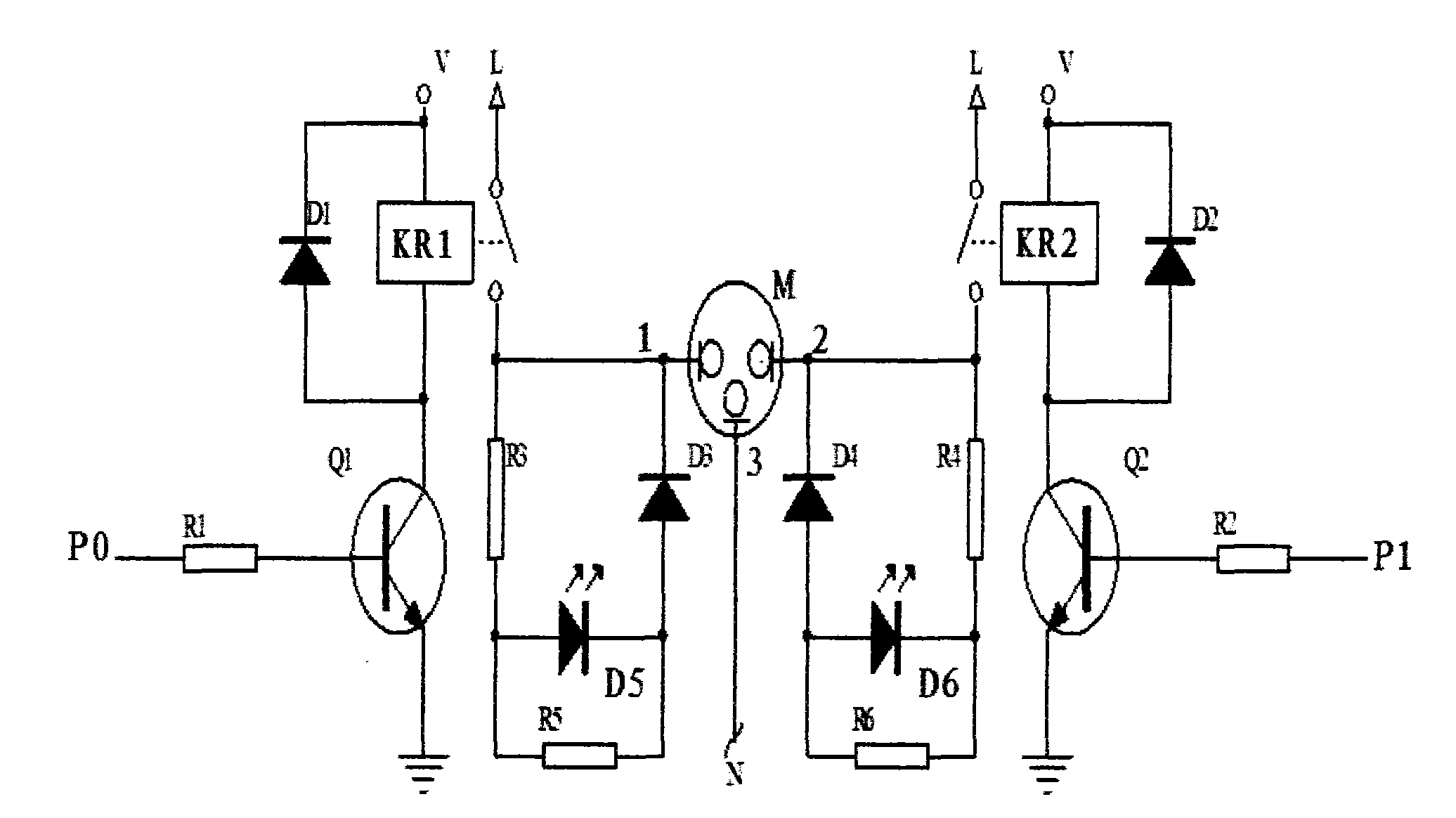

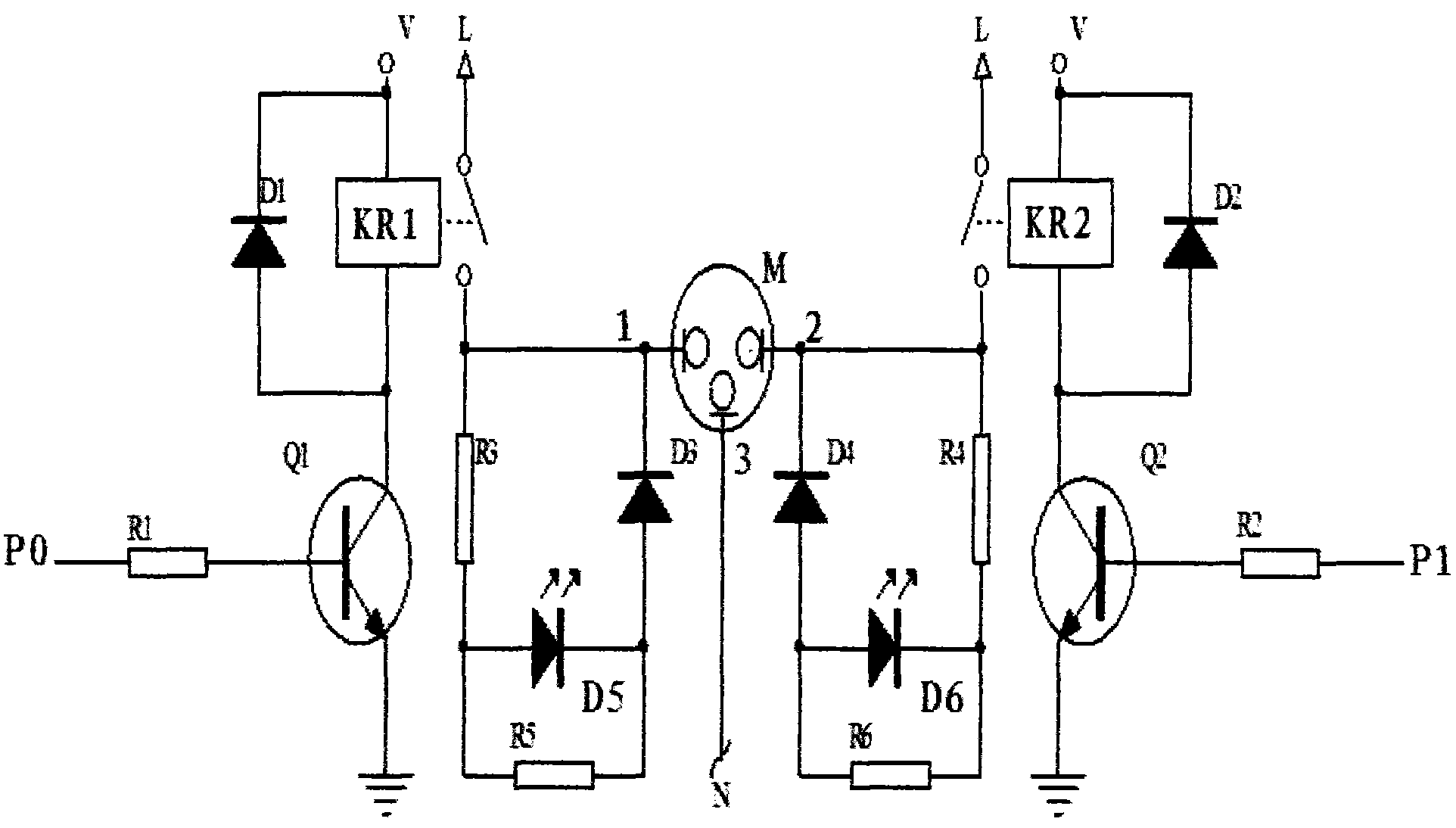

Drive circuit for reducing motor

InactiveCN101976995AForward rotationAchieve reversalPolyphase induction motor starterDriving circuitElectrical and Electronics engineering

The invention discloses a drive circuit for a reducing motor, which comprises the reducing motor M, wherein, a third input terminal of the reducing motor M is connected to a null line N, a first input terminal of the reducing motor M is connected on one end of an output circuit of a trigger KR1, and the other end of the output circuit of the trigger KR1 is connected to a live line L; one end of an input circuit of the trigger KR1 is connected to a power supply V, and the other end thereof is connected to the collecting electrode of a triode Q1; the emitting electrode of the triode Q1 is grounded, and the base electrode thereof is connected on an output terminal P0 of a control chip through a resistor R1; and a second input terminal of the reducing motor M is connected with the same circuit as the first input terminal of the reducing motor M. The drive circuit of the invention can simply and effectively realize positive and reverse rotation functions of the reducing motor.

Owner:SUZHOU HEXINMEI ELECTRONICS SCI & TECH CO LTD

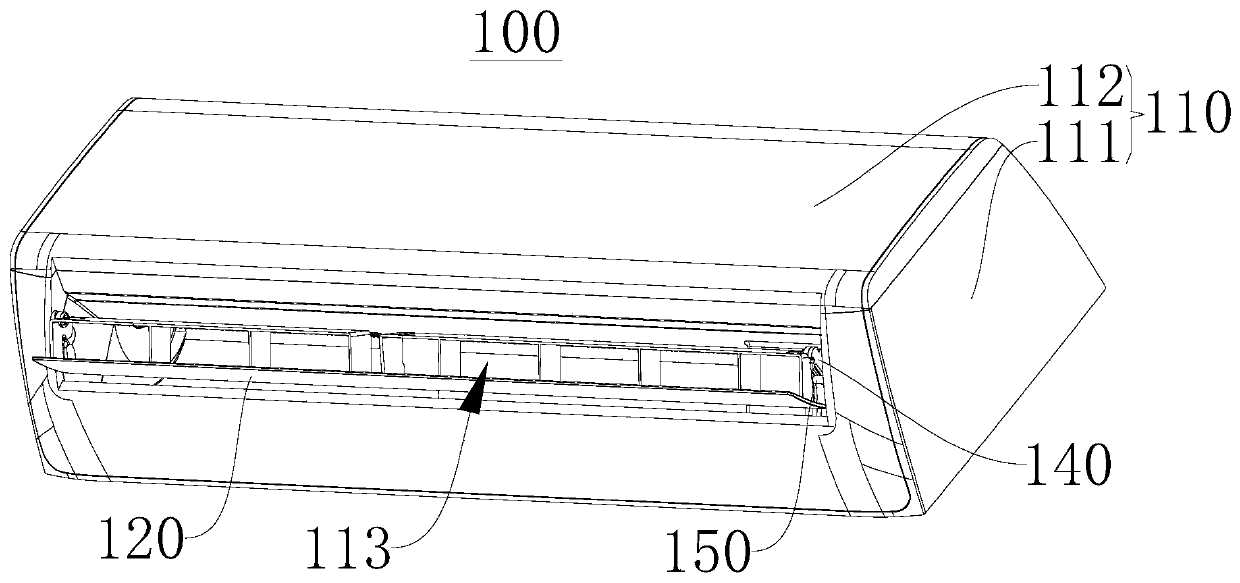

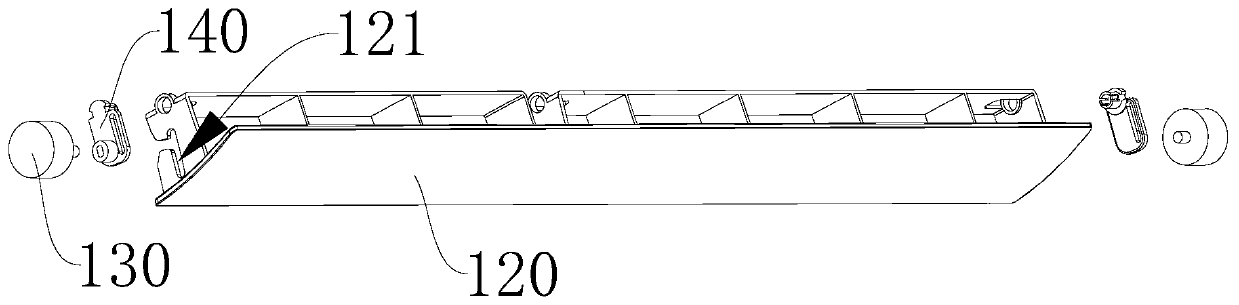

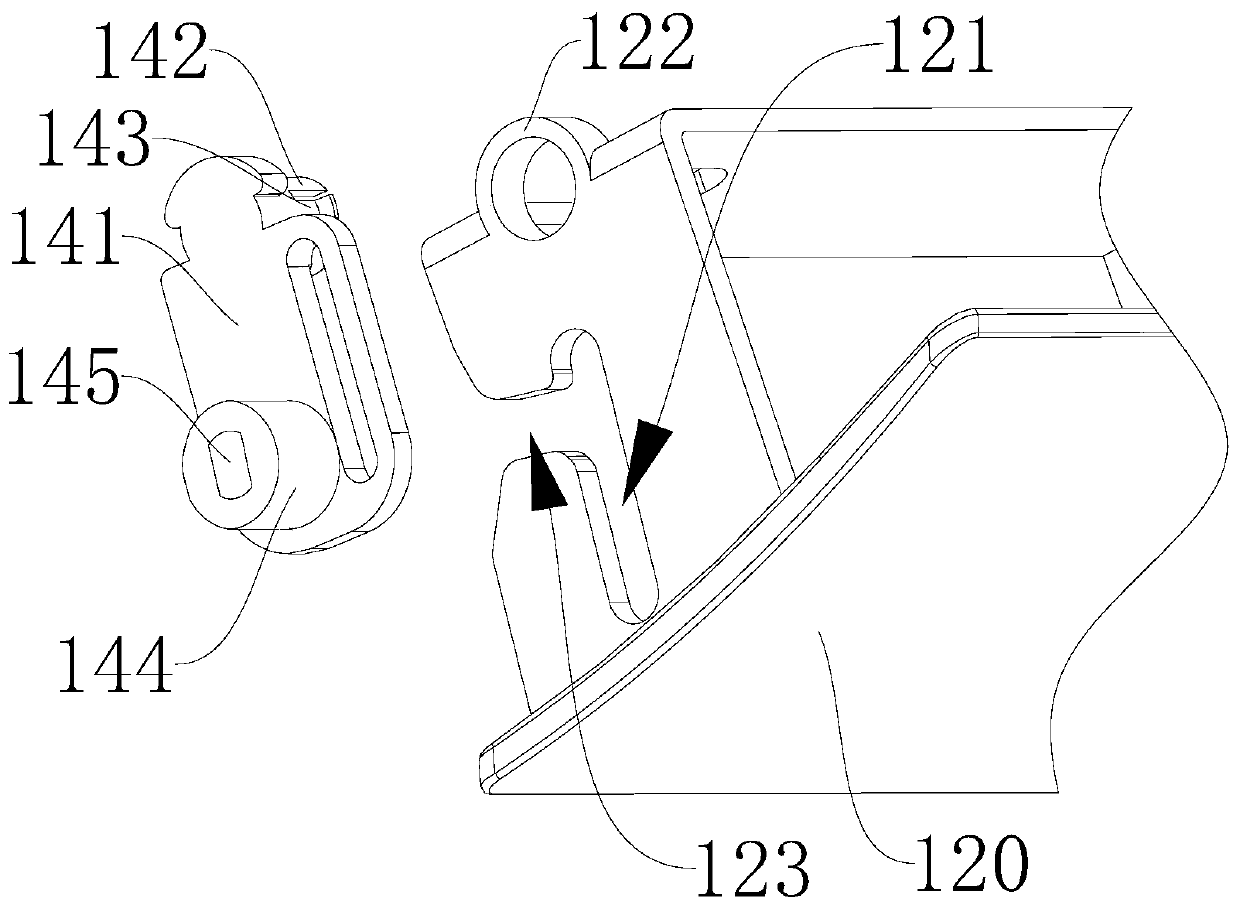

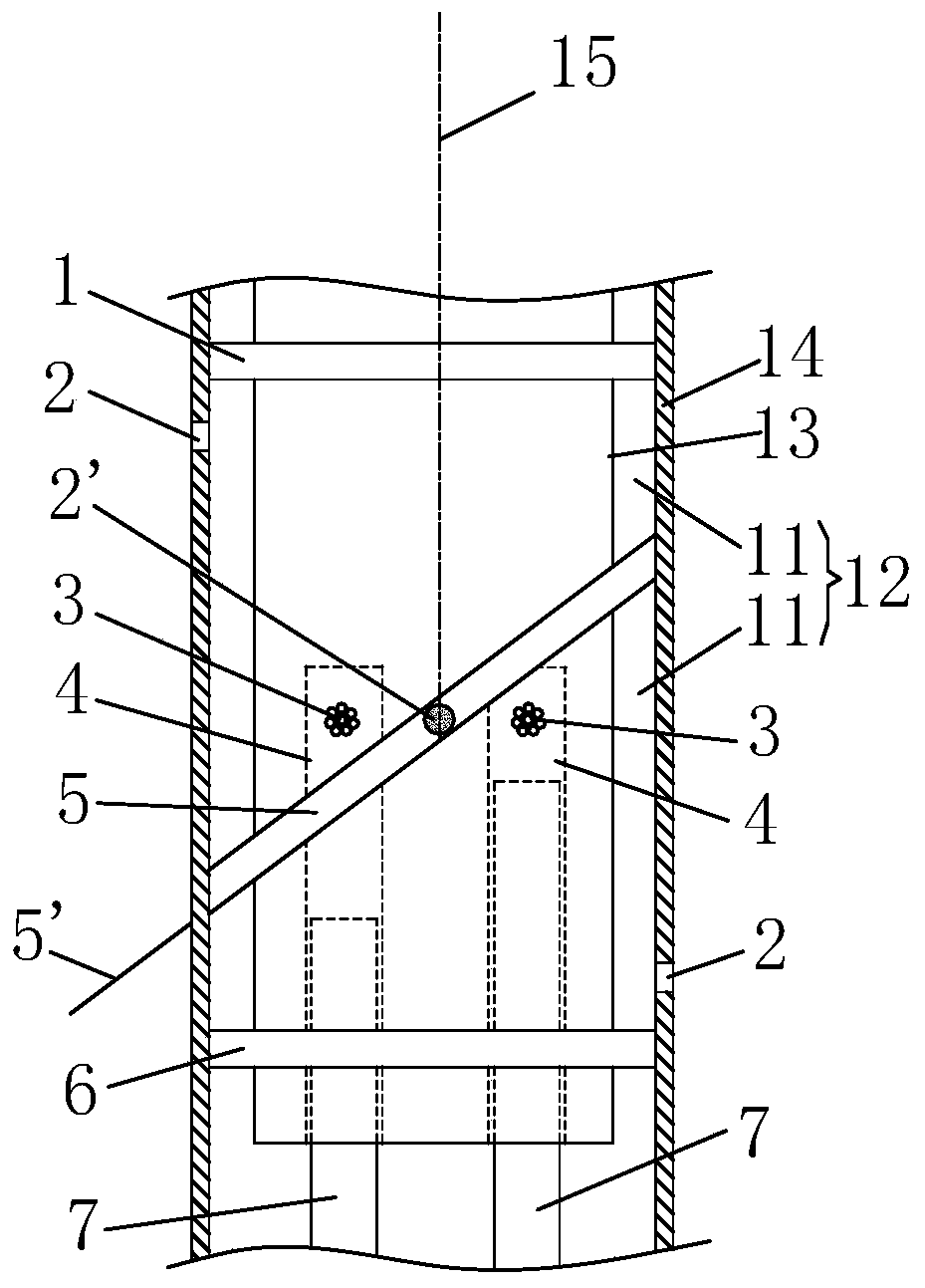

Air guide mechanism and air conditioner

PendingCN110454963AAvoid interferenceForward rotationLighting and heating apparatusAir conditioning systemsDrive motorEngineering

Owner:NINGBO AUX ELECTRIC +1

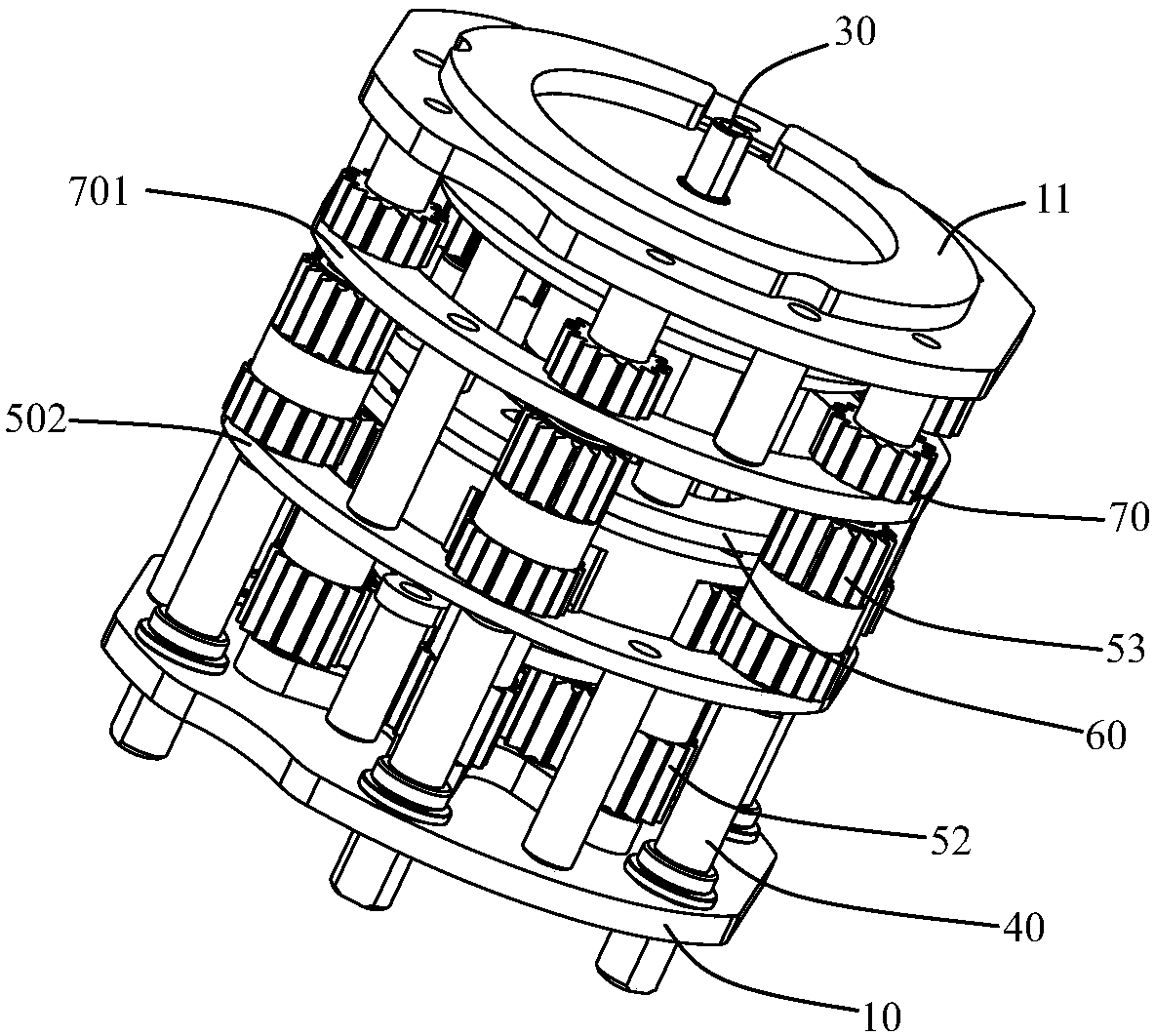

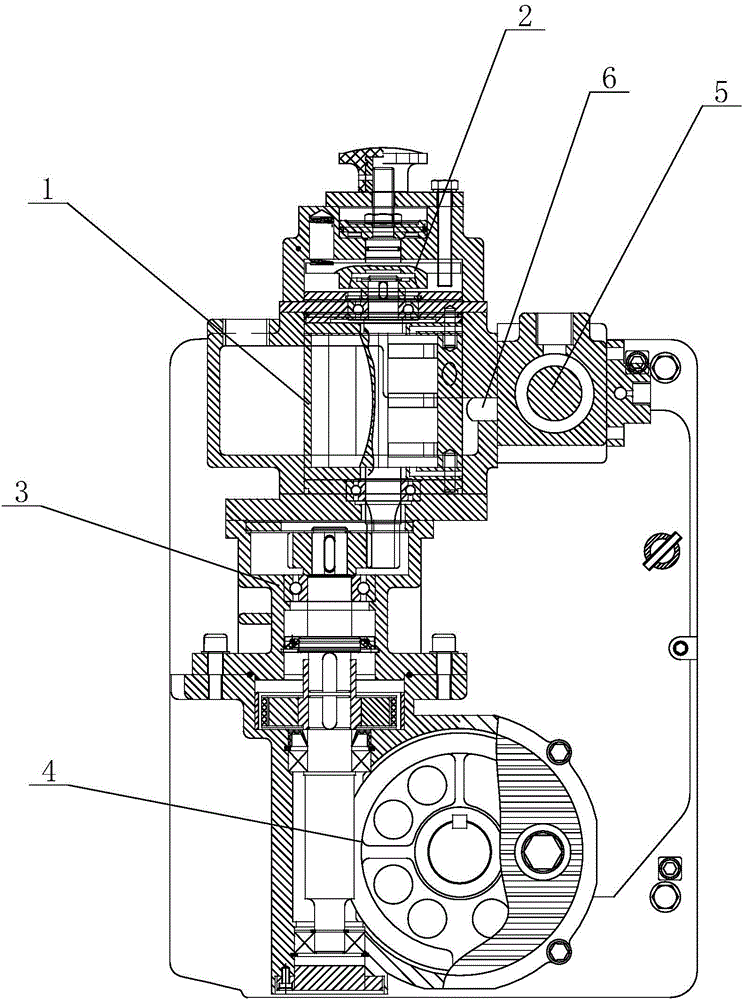

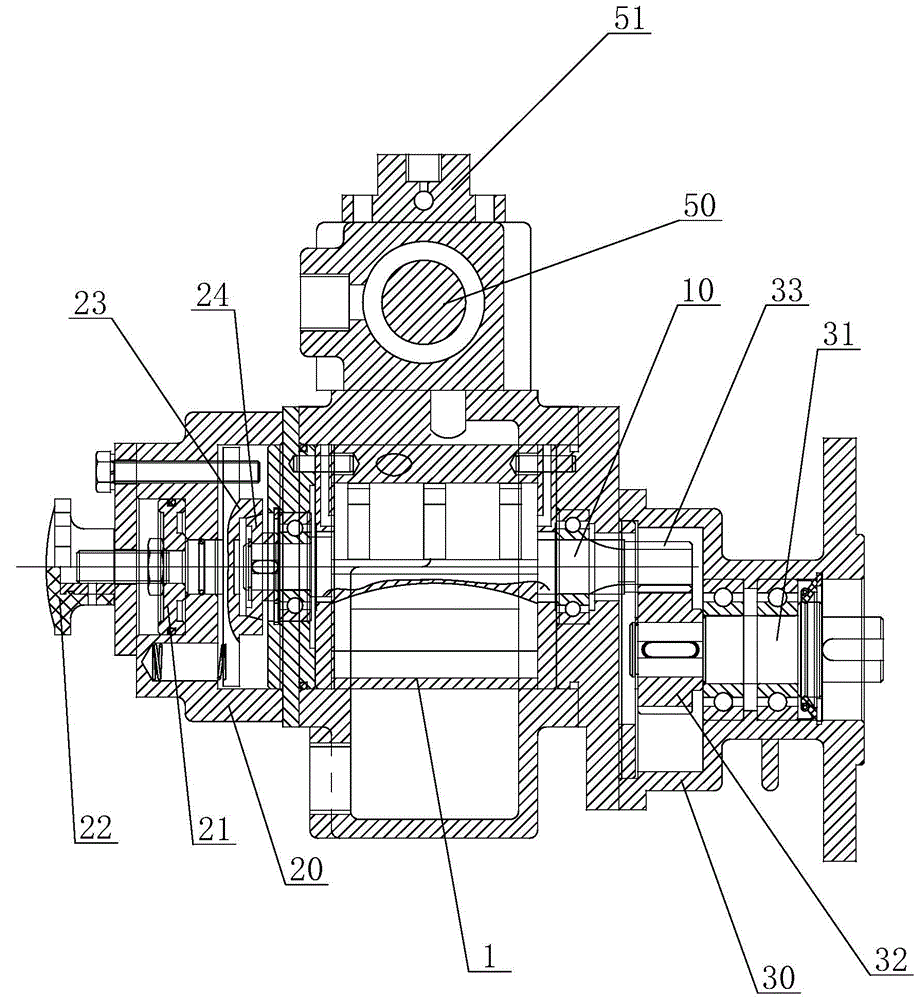

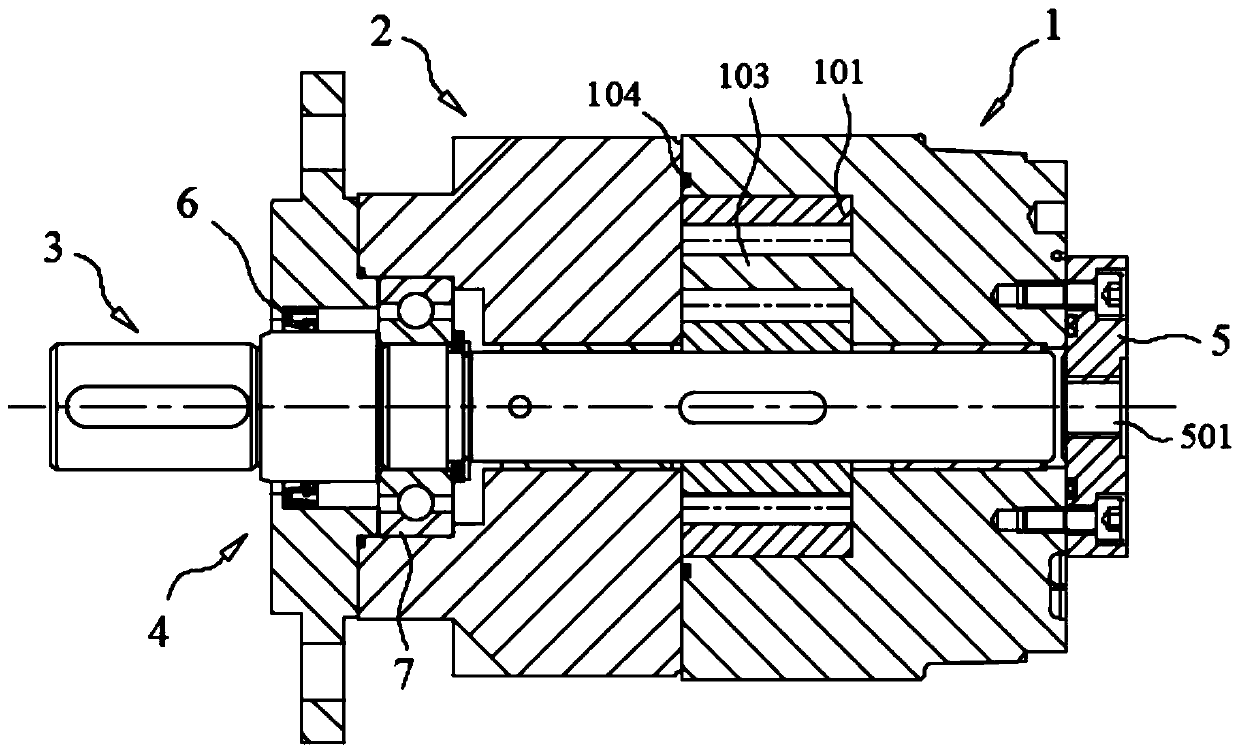

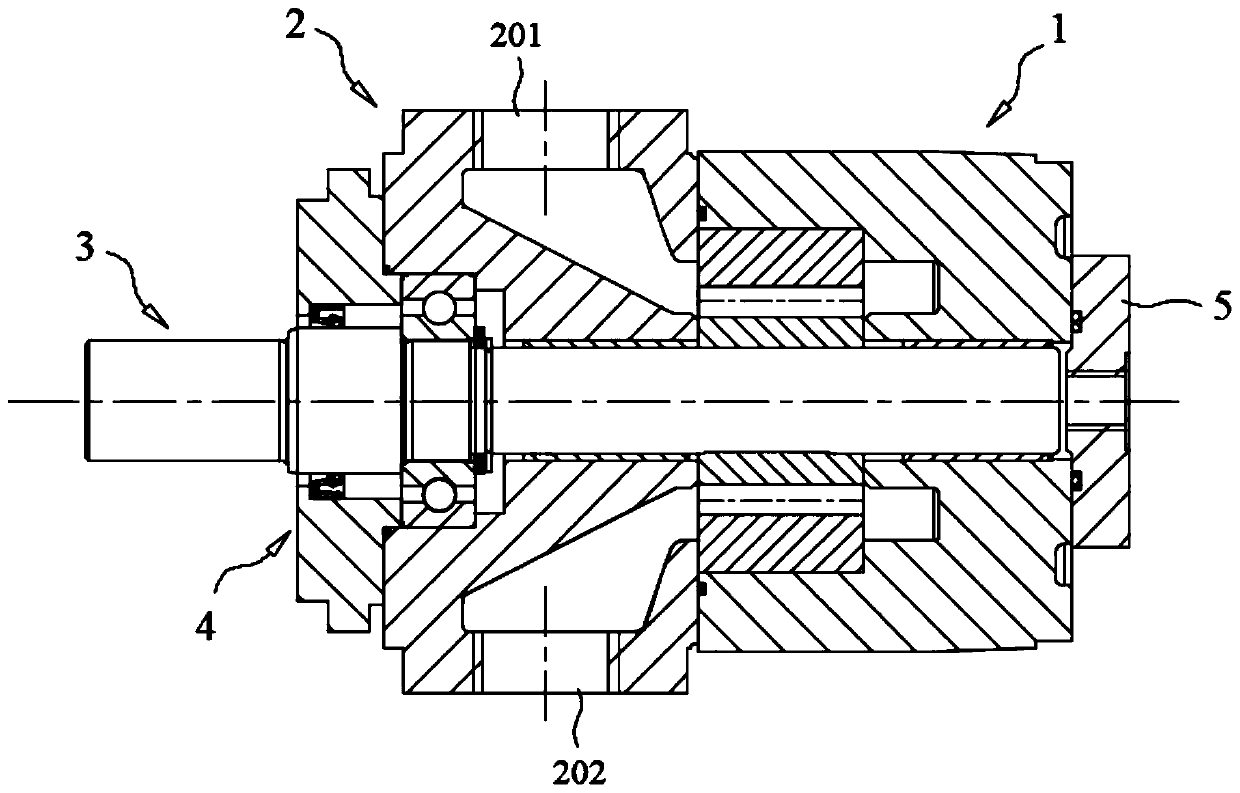

Inclined sealing ring flow distribution mechanism, axial plunger motor and axial plunger pump

PendingCN109989898AForward rotation is conveniently achievedEasy to reversePositive displacement pump componentsEngine componentsEngineeringMechanical engineering

The invention provides an inclined sealing ring flow distribution mechanism, an axial plunger motor and an axial plunger pump. The leakage and heating caused by abrasion of friction pairs in flow distribution of a flow distribution plate, as well as the problem that the flow distribution structure is complex when a one-way valve is used for flow distribution to achieve positive and negative rotation. A first sealing ring (1), a second sealing ring (5) and a third sealing ring (6) are arranged on an inner wall of a shell (14) of an axial plunger moving device at intervals, form a friction pairwith a side wall of a plunger cylinder (13) of the axial plunger moving device; second working medium holes (3) are respectively arranged at the position, corresponding to each plunger cavity (4), ofthe side wall of the plunger cylinder; the second working medium holes are matched with the second sealing ring, so that the plunger cavities (4) alternately communicate with two working medium areas(11) with the rotation of the plunger cylinder; and the sealing switching of working medium in and out of the plunger cavity is achieved. The axial plunger motor and the axial plunger pump comprise the flow distribution mechanism.

Owner:梁德荣

Textile machine with yarn roll reverse rotation driving device

The invention discloses a textile machine with a yarn roll reverse rotation driving device, and relates to the technical field of textile machines. The textile machine aims to solve the problems thatan existing textile machine usually requires manual mounting and dismounting of a yarn roll, and consequently the workload of an operator is large; and the yarn roll is manually inverted after being broken, time and labor are wasted, and the learning cost is high. According to the textile machine, two yarn roll lifting frames are slidably connected to the front portion of a yarn roll support; a yarn roller is rotationally connected between the yarn roll lifting frames; a lifting frame bevel gear is rotationally connected to each of the two sides of the yarn roll support; a lifting frame operation rod is transversely and rotationally connected into the yarn roll support; and a yarn roll transmission rod is slidably connected into the yarn roll support. A yarn roll is mounted and dismountedthrough lifting frame gears, so that the textile machine saves more physical strength and is more user-friendly; and forward rotation and reverse rotation of the yarn roller are realized through a reverse rotation control rod, the rotation direction of a motor does not need to be changed, operation control is simpler, and the learning cost of operators is reduced.

Owner:温州邑品鞋业有限公司

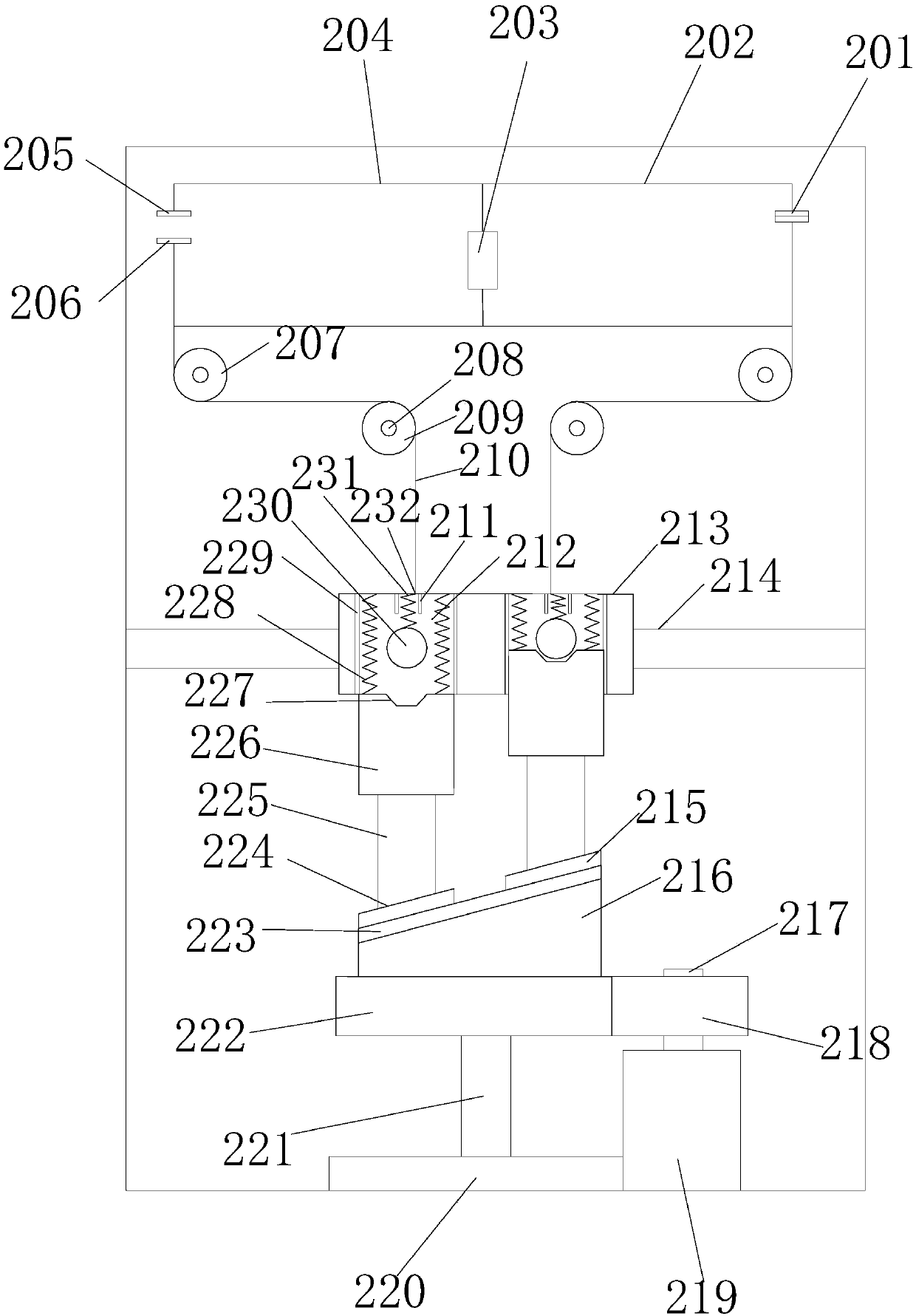

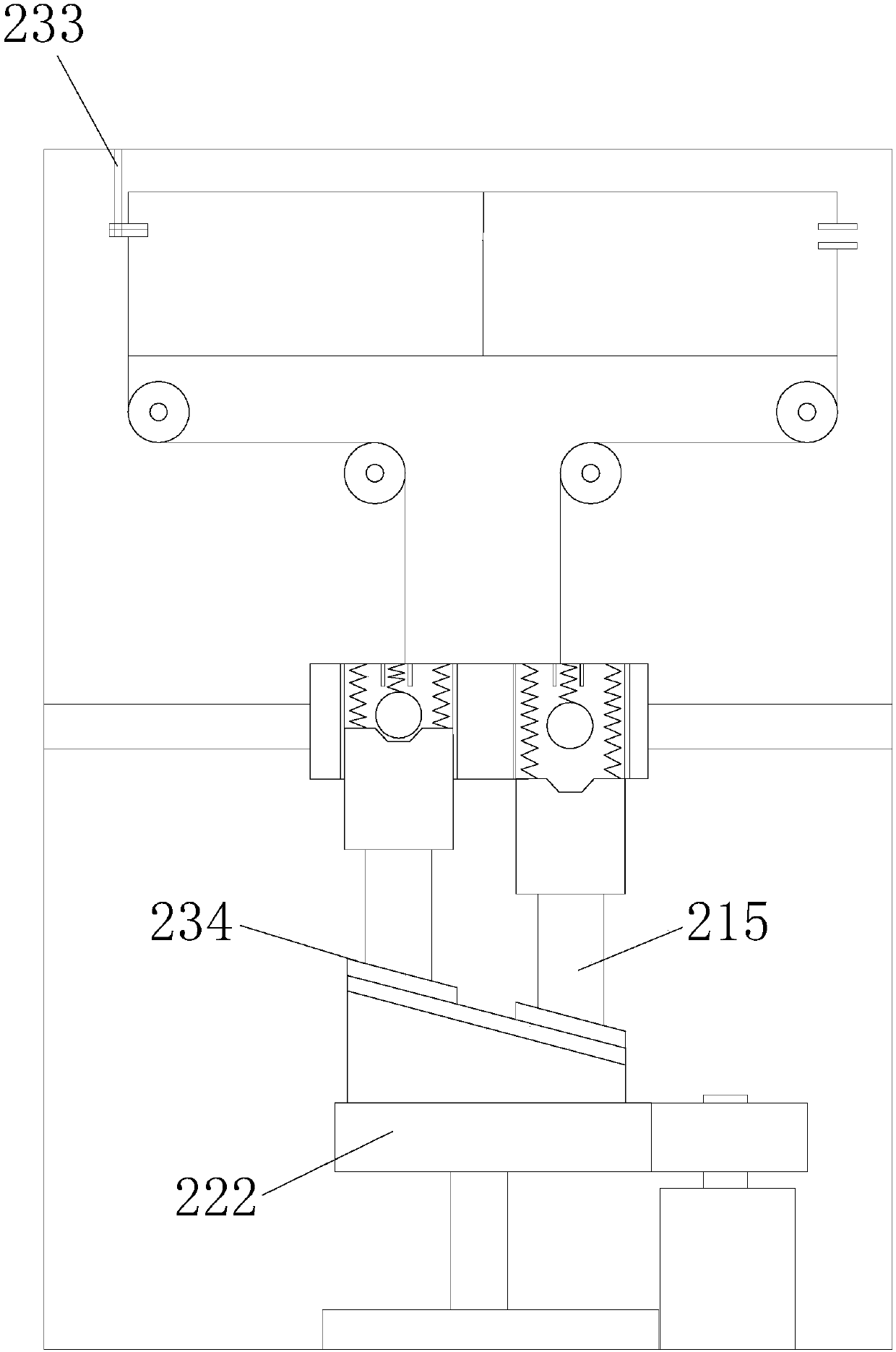

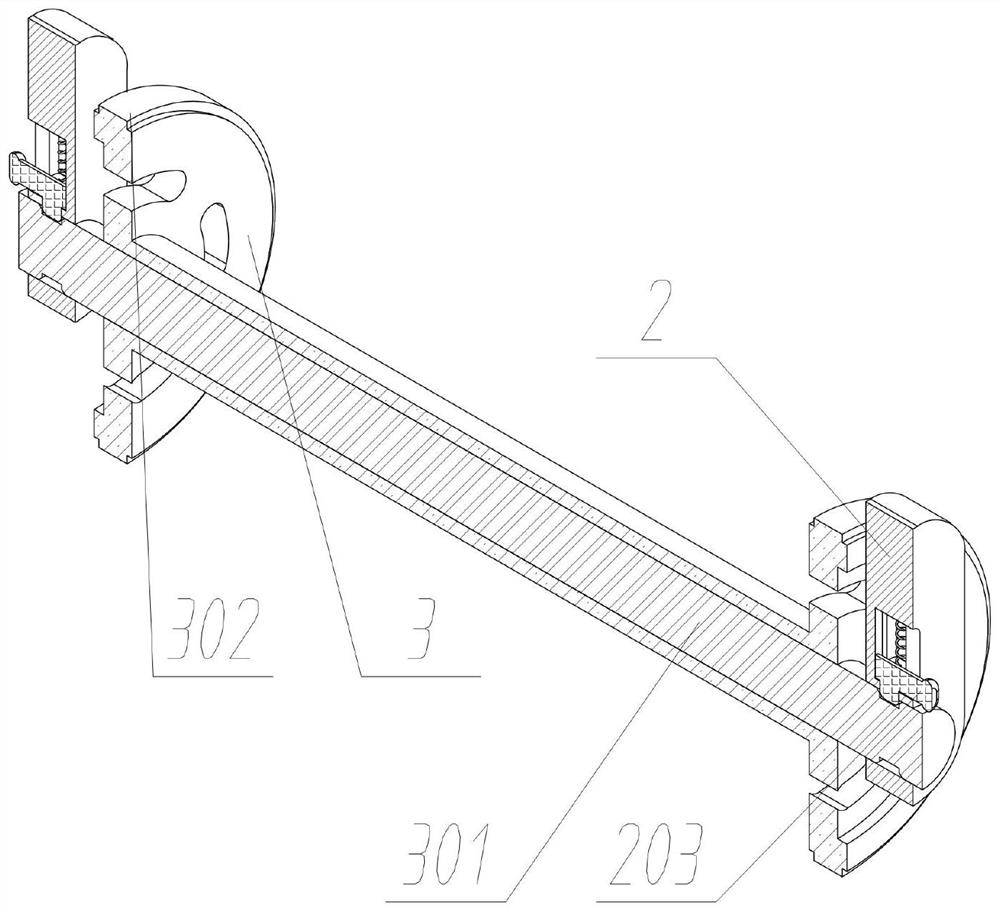

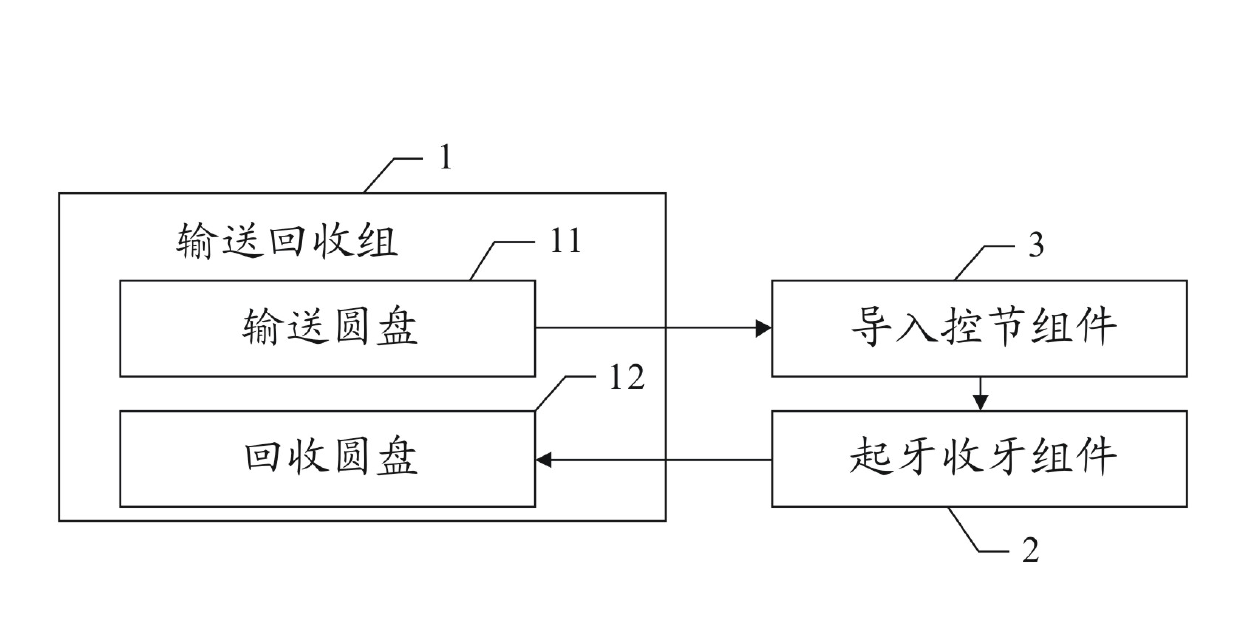

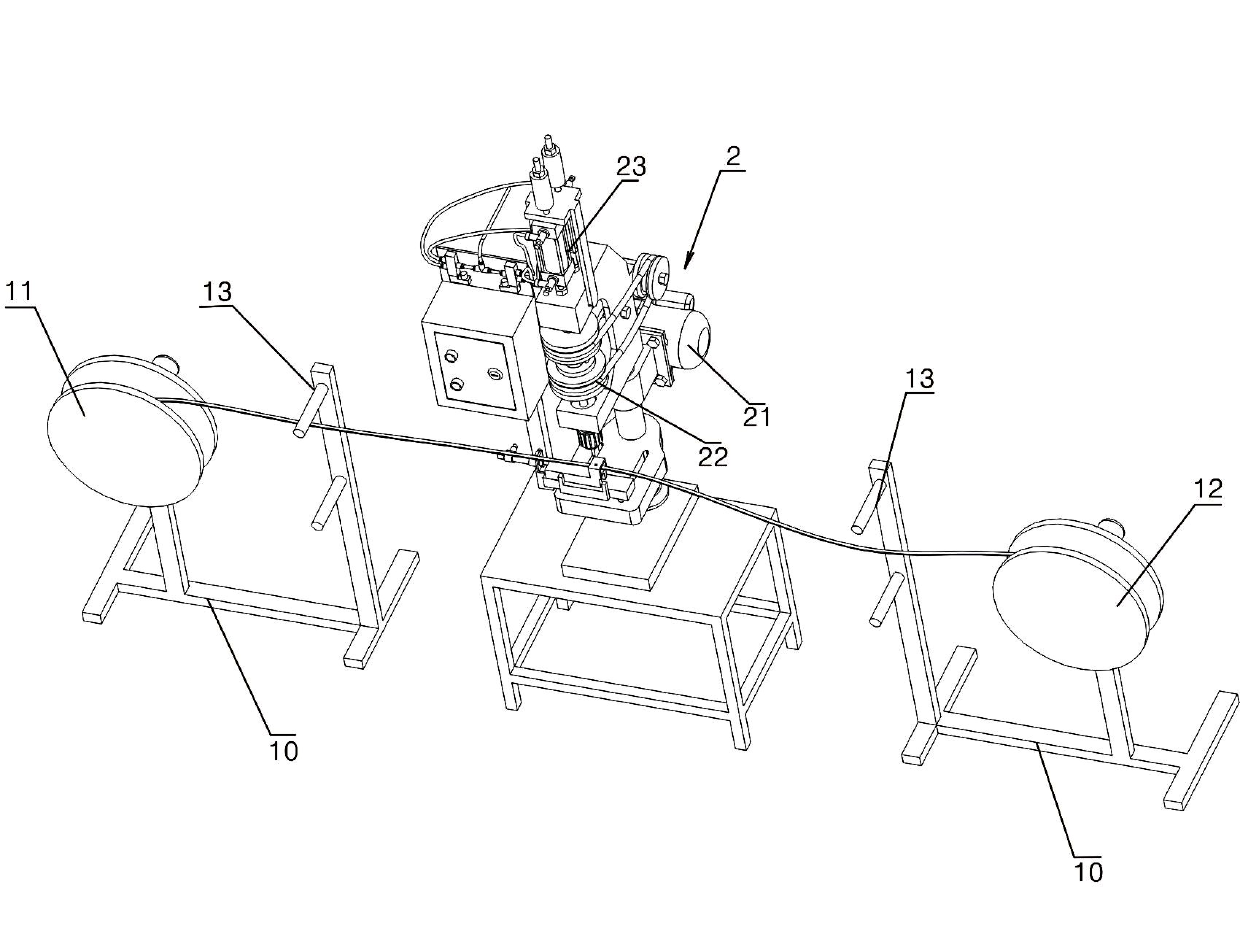

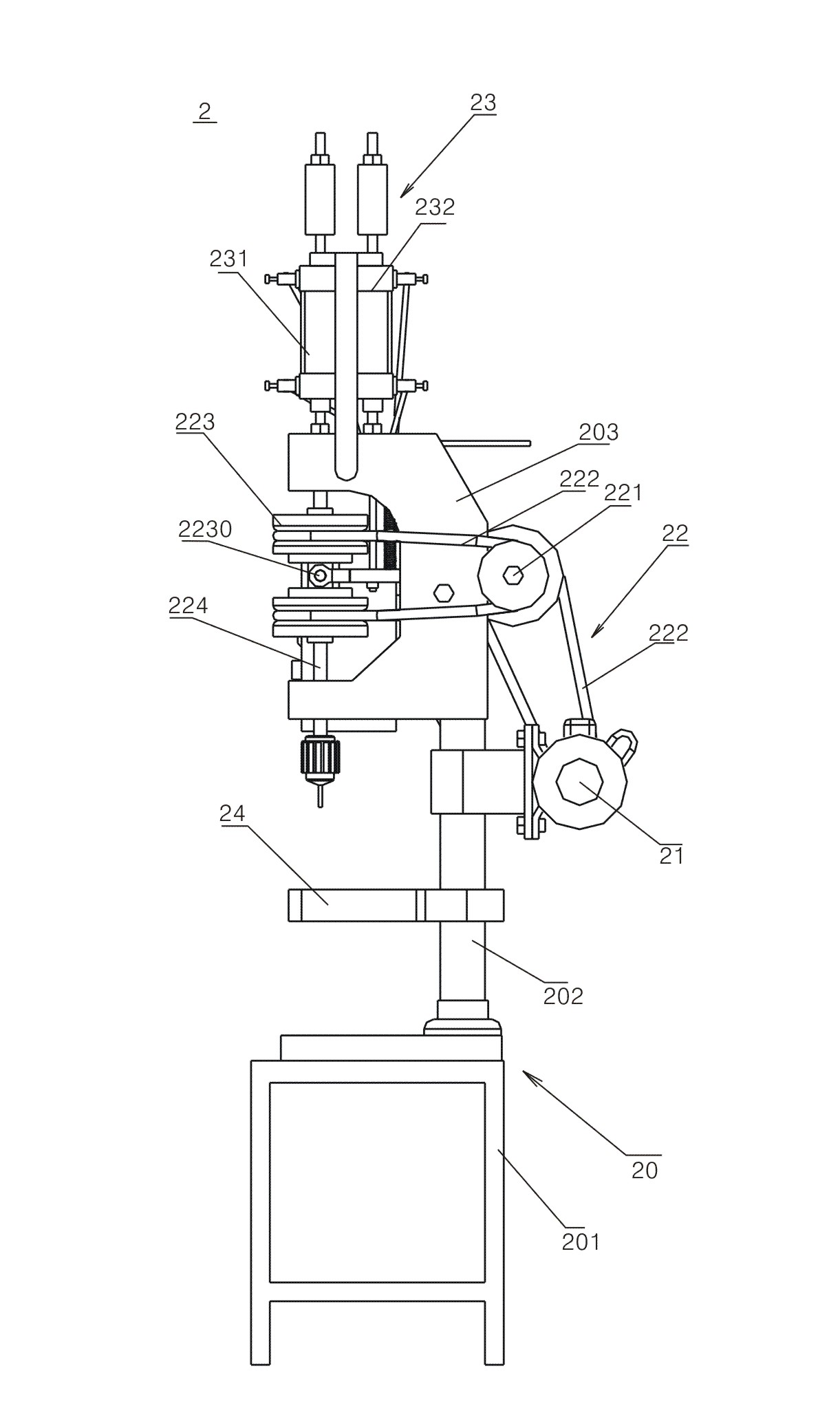

Inner hole toothing device for flexible strips

The invention discloses an inner hole toothing device for flexible strips, which comprises a conveying and recovering component, a toothing and tooth collecting component and a control section introducing component. The conveying and recovering component comprises a conveying disc and a recovering disc, the conveying disc is connected to the control section introducing component, the recovering disc is connected to the toothing and tooth collecting component, the toothing and tooth collecting component comprises a motor, a double-rotation-direction transmission portion and a control portion, the double-rotation-direction transmission portion is respectively connected with the motor and the control portion, the motor transmits power to the double-rotation-direction transmission portion, and the control portion controls the double-rotation-direction transmission portion to reciprocate and / or rotate synchronously. The inner hole toothing device for flexible strips can applied to conveying, toothing, recovering and the like of all-dimensional operations for fittings of the flexible strips fixed on machine tools, is accurate in recovering and conveying and can rotate forwardly or reversely without stress control, and quality of processed products are improved.

Owner:SHANTOU NANHA ELECTRICAL

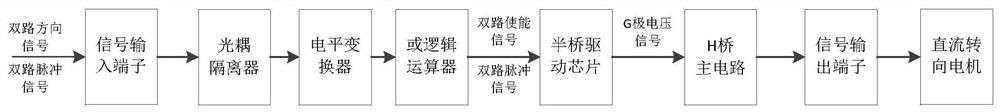

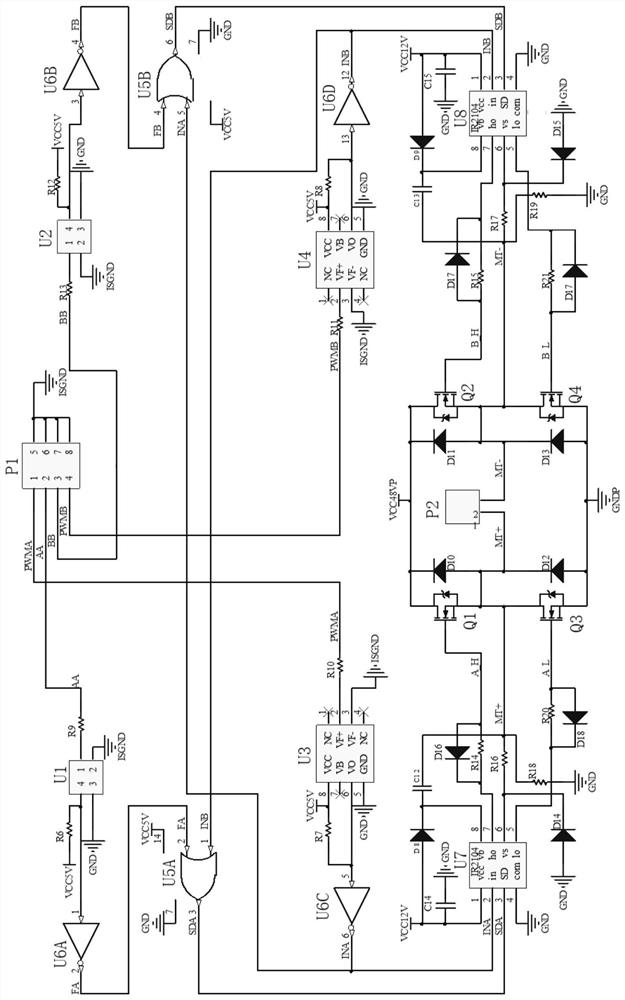

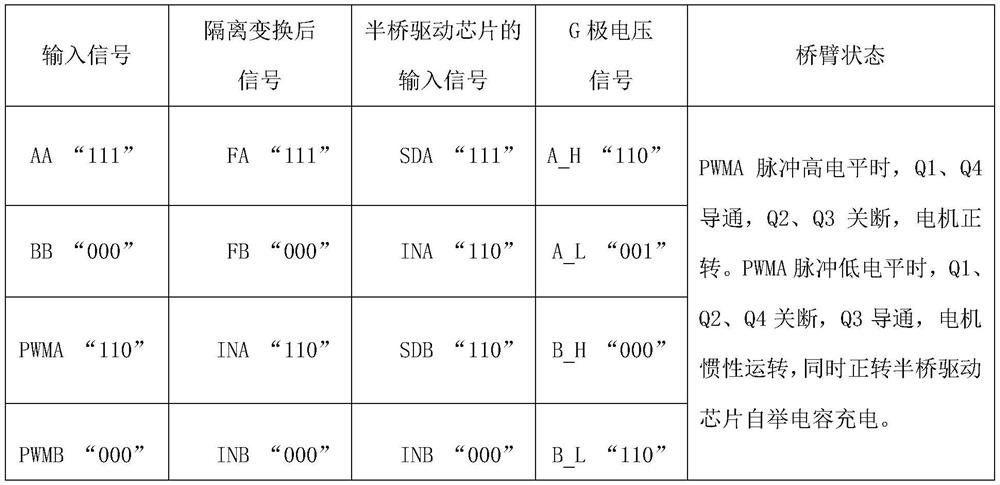

Bi-directional double-pulse driver for DC steering motor in vehicle steering-by-wire system

ActiveCN112896303BForward rotationGuaranteed charging functionElectrical steeringControl engineeringElectric machinery

The invention discloses a bidirectional double-pulse driver for a DC steering motor of a vehicle steering system by wire, which receives a forward and reverse direction signal and a forward and reverse pulse signal, and sequentially performs optocoupler isolation and NOT gate level conversion on each signal; OR logic operation is performed on the converted forward direction signal and reverse pulse signal to generate a forward enable signal; OR logic operation is performed on the transformed reverse direction signal and forward pulse signal to generate a reverse enable signal; The forward enable signal and the transformed forward pulse signal are the input of the forward half-bridge drive chip; the reverse enable signal and the transformed reverse pulse signal are used as the input of the reverse half-bridge drive chip; the forward half-bridge The output of the bridge driver chip and the reverse half-bridge driver chip controls the H-bridge main circuit. The present invention adopts the combined configuration of dual-channel pulse signals and dual-channel direction signals to realize the driving of the DC steering motor, which can reduce system energy consumption and improve the tracking precision of wire-controlled steering.

Owner:WUHAN UNIV OF SCI & TECH

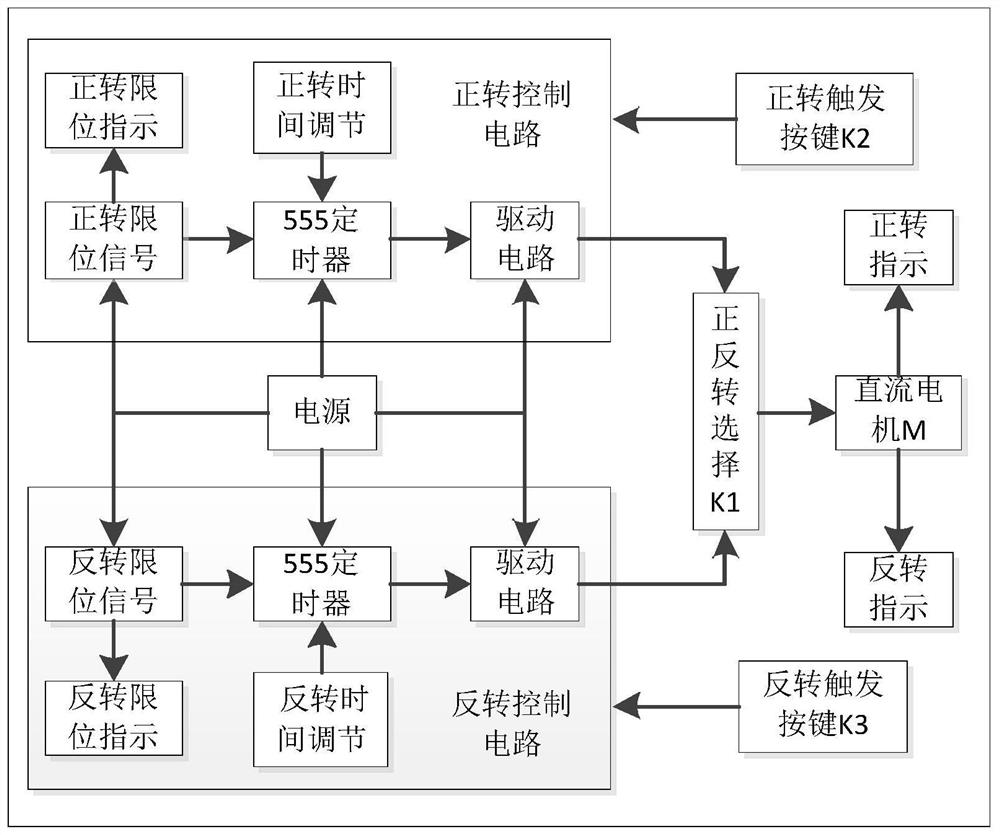

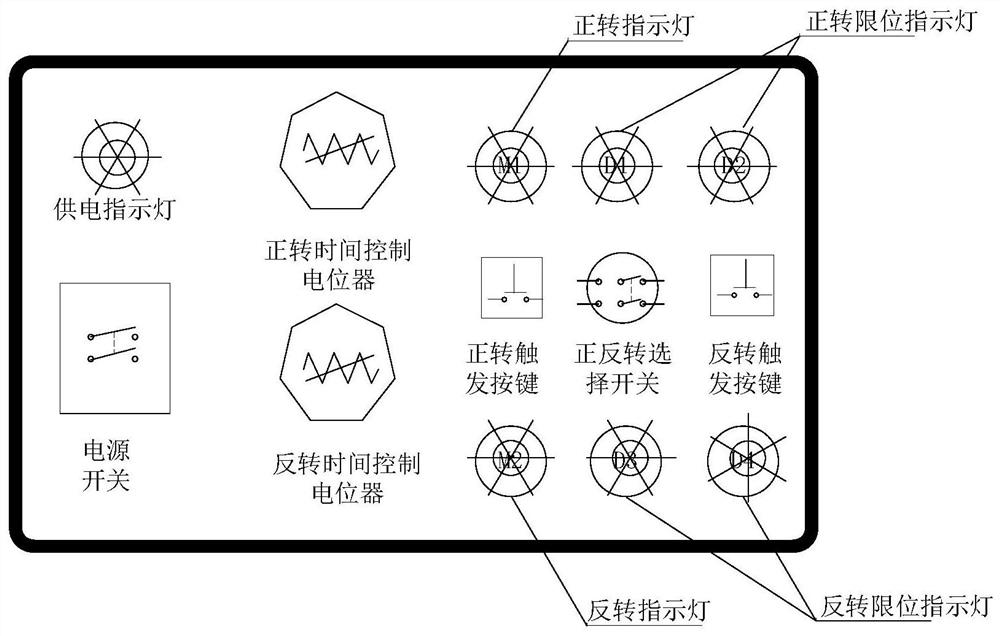

Motor forward and reverse rotation control system with dual-protection function

PendingCN112532125AForward rotationImplementation timeEmergency protective circuit arrangementsDC motor rotation controlControl systemControl engineering

The invention provides a motor forward and reverse rotation control system with a dual protection function. The system comprises a starting control circuit, an operation control circuit and a power supply; the starting control circuit comprises a starting selection module, and the operation control circuit comprises a forward rotation control circuit and a reverse rotation control circuit which are connected with the starting selection module. According to the invention, the forward rotation and reverse rotation time control is achieved through the 555 timer, under the condition that the limiting switch is abnormal, power supply of the motor can be cut off after the forward rotation and reverse rotation time of the motor exceeds the set longest time, and the effect of dual protection of the motor is achieved. The delay time of the 555 timer can be adjusted through a resistor, so that the forward and reverse rotation time of the motor can be adjusted; software control is not needed, andmotor forward and reverse rotation control with dual protection and adjustable time can be achieved only through a simple classic hardware circuit.

Owner:GUIZHOU AEROSPACE ELECTRONICS TECH CO LTD

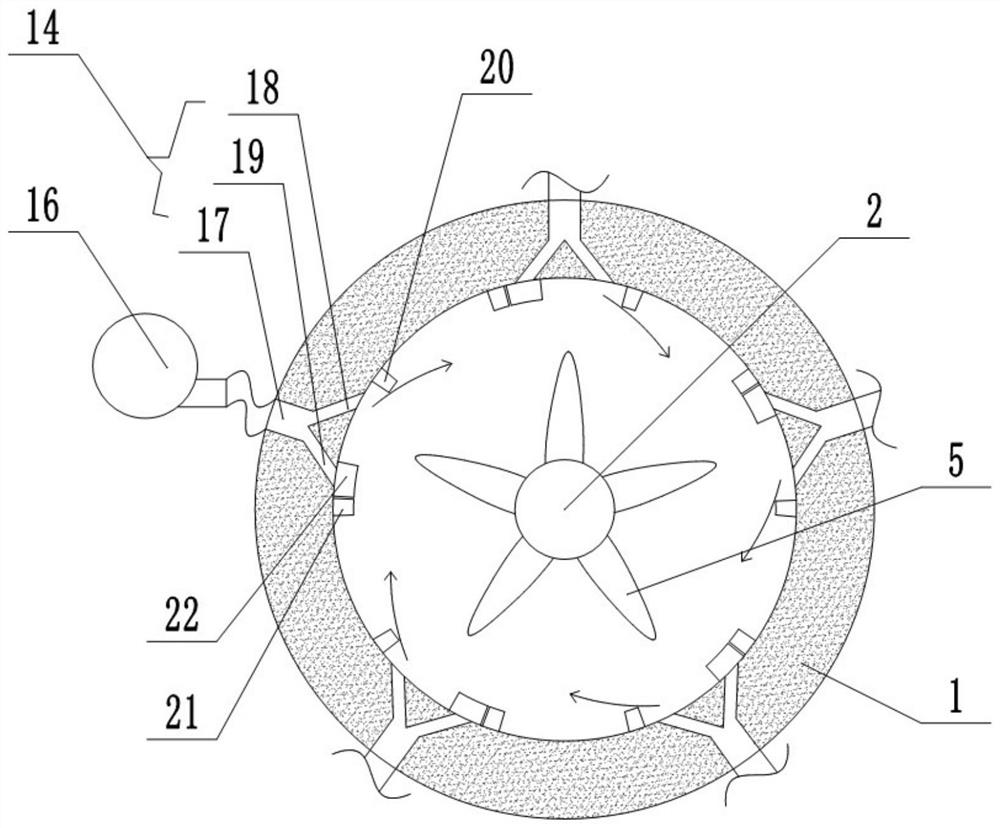

Turbine device

InactiveCN109158012ASimple structureEasy to operateRotary stirring mixersTransportation and packagingTurbine blade

The invention discloses a turbine device. The turbine device comprises a first device body, a control device arranged in the first device body, and a stirring device arranged in the first device body,wherein the control device comprises a first turbine cavity arranged in the first device body; a first rotating shaft is rotationally arranged in the first turbine cavity; a first turbine blade is fixedly arranged on the first rotating shaft in an array manner; a first transmission cavity is arranged on the inner wall of the lower side of the first turbine cavity; the lower end of the first rotating shaft extends into the first transmission cavity and is fixedly connected with a first straight gear; a second straight gear is meshed with the right end of the first straight gear; and a second transmission cavity is formed in the upper side of the second straight gear and in the inner wall of the upper side of the first transmission cavity. The turbine device takes a turbine as power to perform stirring, meanwhile can realize automatic switching of positive and negative rotation, realizes positive and negative rotation stirring, and ensures uniform stirring.

Owner:童钟益

Motor angle control method, system and unmanned aerial vehicle

ActiveCN106385209BForward rotationAchieve reversalDC motor rotation controlControl systemUncrewed vehicle

A motor angle control method provided by an embodiment of the invention comprises the following steps: a controller acquires the target angle data of a motor and the actual angle data of the motor; the controller judges whether the target angle data and the actual angle data are equal; and if the target angle data and the actual angle data are not equal, the controller processes the target angle data and the actual angle data, and switches on a first path coupled to the motor to make the motor rotate forwardly or switches on a second path coupled to the motor to make the motor rotate reversely according to the processing result. According to the motor angle control method, a motor angle control system and an unmanned aerial vehicle provided by the embodiments of the invention, the first path or the second path coupled to the motor can be controlled according to the values of the target angle data and the actual angle data of the motor so as to realize forward or reverse rotation of the motor. Compared with the existing motor angle control method, the control process is simple, and the precision of motor control is improved.

Owner:ZEROTECH (SHENZHEN) INTELLIGENCE ROBOT CO LTD

Seed Peanut Shelling Device

ActiveCN108634332BReduce speedPrevent crushingHuskingHullingAgricultural engineeringElectric heating

The invention belongs to the field of agricultural processing and specifically discloses a peanut shelling device capable of reserving seeds for planting. The peanut shelling device comprises a machine frame, wherein a bucket body is arranged on the machine frame; an electric heating plate is fixedly connected in the bucket body; mesh wires of the electric heating plate are composed of electric heating wires; a hitting rod is arranged on the machine frame; a spline-connected spline housing, a thread-connected nut, a fixedly connected bulge, a fixedly connected blade and a fixedly connected press plate are arranged on the hitting rod sequentially from top to bottom; a plurality of Y-shaped channels are arranged along the circumferential direction in a position where the side wall of the bucket body is flush with the blade; a blower is fixedly connected with the machine frame; the blower communicates with an air inlet channel; both a first air outlet channel and a second air outlet channel communicate with the inside of the bucket body; a stop block is connected between a first electric magnet and a second electric magnet in a sliding mode on the inner wall of the bucket body; and one side of the stop block, opposite to one sides of the first electric magnet and the second electric magnet, is opposite in polarity to the sides of the first electric magnet and the second electric magnet. By adopting the scheme of the peanut shelling device capable of reserving seeds for planting, the problem of low efficiency of shelling by manual work is solved.

Owner:贵州务川八爷农场有限公司

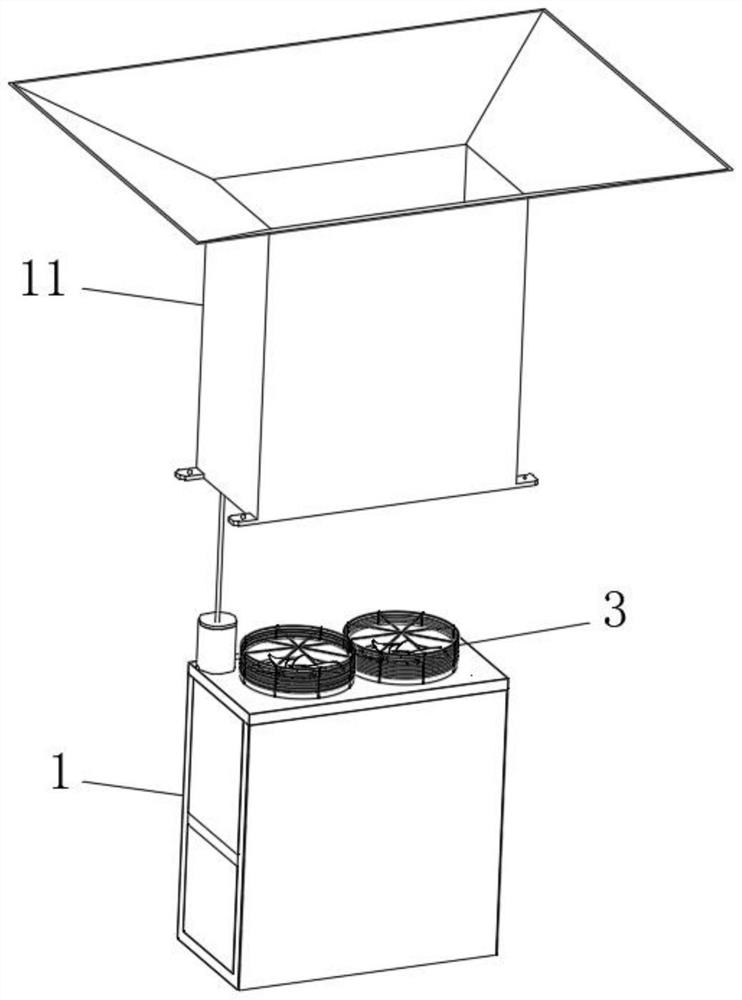

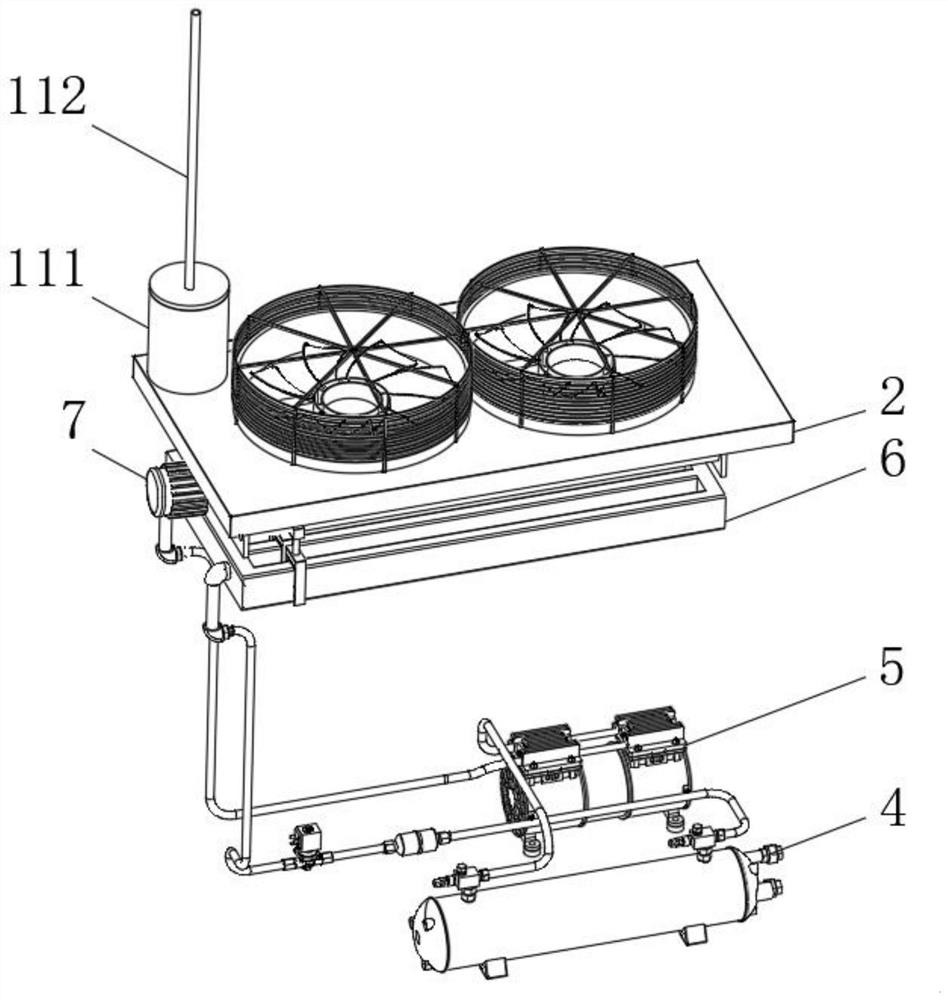

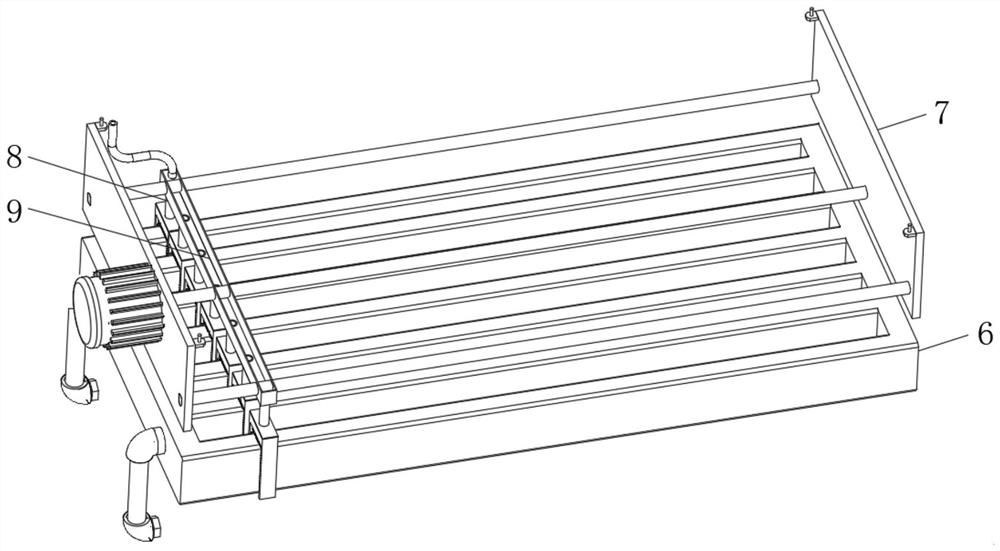

Industrial water chilling unit

InactiveCN112161417AReach wetImprove cooling effectGeneral water supply conservationEvaporators/condensersProcess engineeringIndustrial water

The invention relates to the technical field of water chilling units, in particular to an industrial water chilling unit. The industrial water chilling unit comprises a base unit lower shell, a unit upper shell is arranged at the upper end of the unit lower shell, a condensing fan is arranged in the unit upper shell, an evaporator is arranged at the bottom in the unit lower shell, a compressor isarranged at the position, close to the rear side of the evaporator, of the bottom of the interior of the unit lower shell, a condenser is arranged under the condensing fan in the unit lower shell, anautomatic cleaning mechanism is installed on the outer surface of the lower end of the unit lower shell, a detaching mechanism is arranged between the condenser and the automatic cleaning mechanism, and a dust brushing mechanism is arranged at the lower end of the automatic cleaning mechanism. According to the industrial water chilling unit, the purposes of saving energy, protecting the environment and reducing energy consumption of the industrial water chilling unit can be achieved.

Owner:陈喜林

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com