Energy-saving and environment-friendly flue gas desulfurization equipment

An energy-saving and environmental protection, desulfurization equipment technology, applied in the direction of gas treatment, dispersed particle filtration, transportation and packaging, etc., to achieve the effect of improving desulfurization efficiency, improving passing efficiency, and reducing dust adhesion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

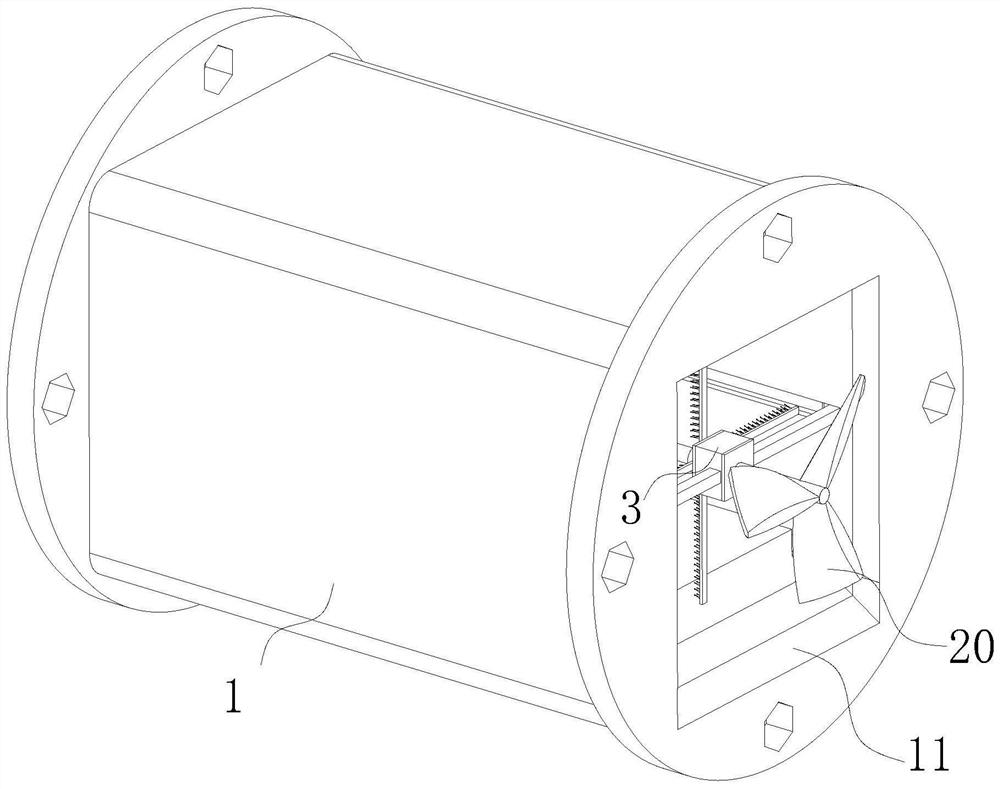

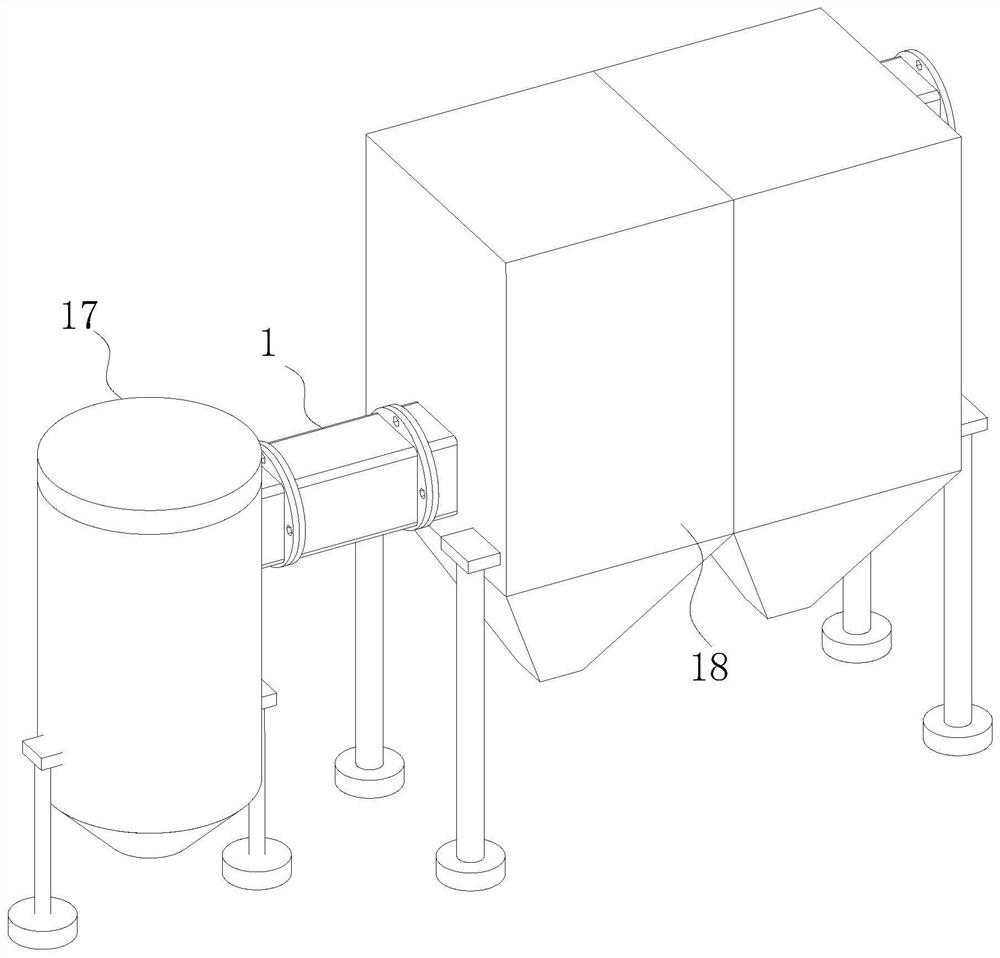

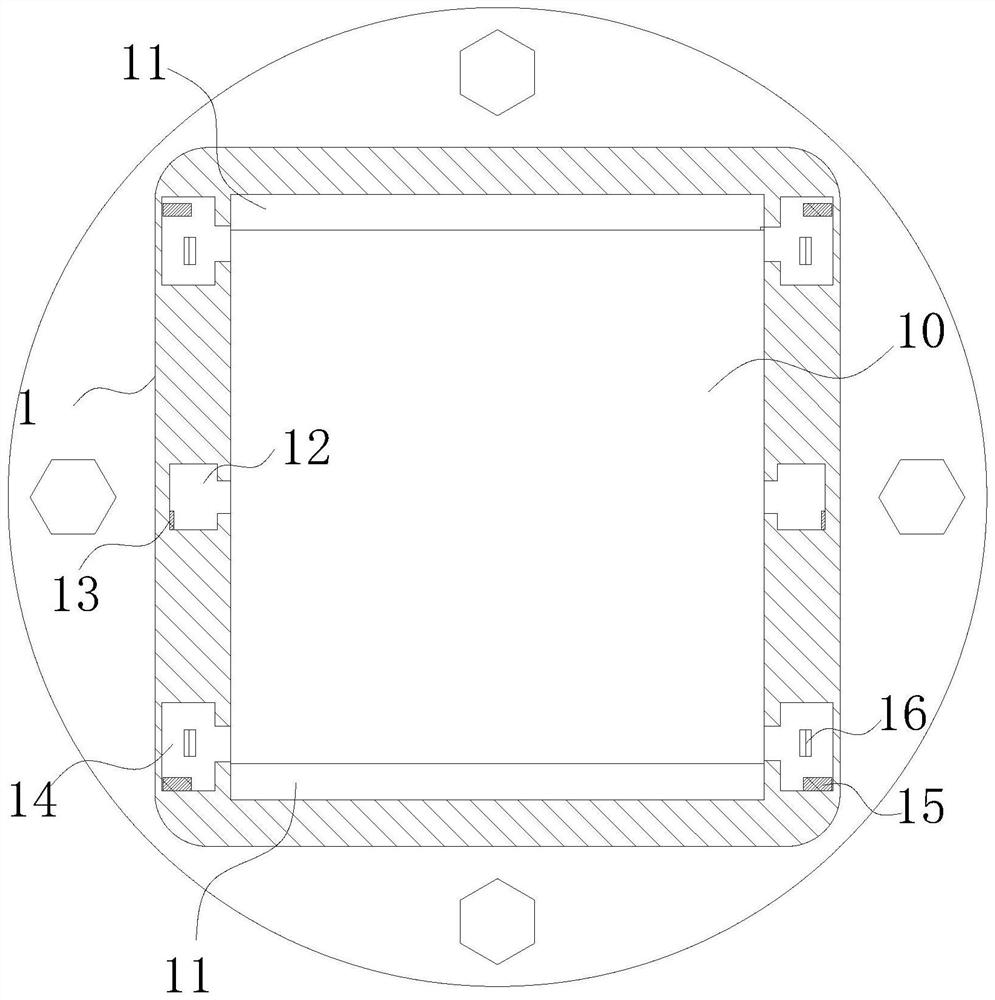

[0039] see Figure 1-15 , the present invention provides a technical solution: comprising a self-scraping communication pipe 1 connected between the exhaust port of the absorption tower 17 and the air inlet of the bag filter 18;

[0040] The self-scraping connecting pipe 1 is provided with a scraper part driven by hot air pressure and a stirring part driven by the scraper part;

[0041] The scraper part includes two symmetrically arranged and foldable scraper boards 4 , the outer wall of the scraper board 4 is slidingly connected with the inner wall of the ventilation channel 10 of the self-scraping communication pipe 1 , and the two scraper boards 4 are arranged in the absorption tower 17 The side of the exhaust port of the self-scraping connecting pipe 1 will be covered, and when the air pressure in the absorption tower 17 increases, the hot air will drive the two scraping plates 4 to the bag filter in a closed state through the rotating sliding part. 18 slides on one side ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com